Slow blocking remover for deep part of oil and water well

A plugging agent, oil-water well technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of short effective period of production increase, secondary precipitation, ineffectiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: The weight percent of each component of the oil-water well deep retarding plugging removal agent is:

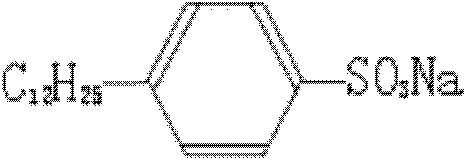

[0050] 1. Sodium dodecylbenzenesulfonate (industrial product): 1.5%;

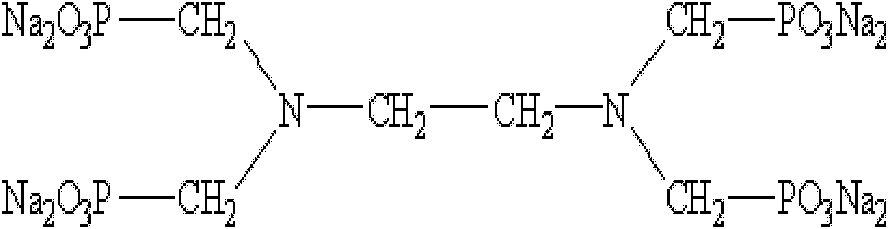

[0051] 2. Sodium ethylenediamine tetramethylene phosphonate (industrial product): 5.5%;

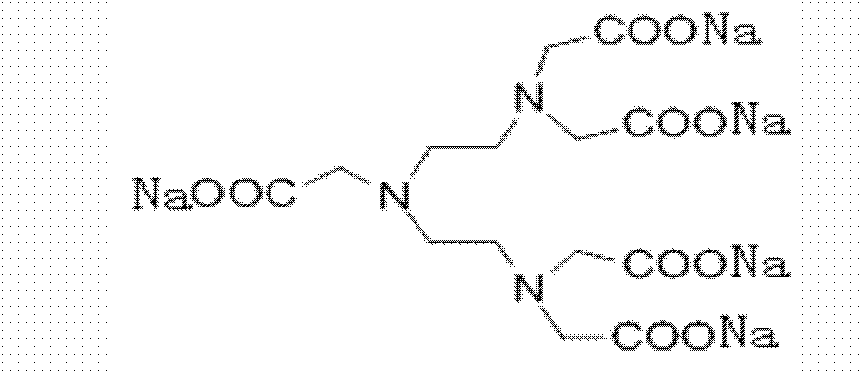

[0052] 3. Sodium diethylenetriaminepentaacetate (industrial product): 25.5%;

[0053] 4. Methanesulfonic acid (industrial product): 15.5%;

[0054] 5. Sodium acetate (industrial product): 0.5%;

[0055] 6. Water: 51.5%.

[0056] Preparation method: first, add sodium dodecylbenzenesulfonate, sodium ethylenediaminetetramethylene phosphonate, and sodium diethylenetriaminepentaacetate into a steel reaction kettle with a capacity of 1000 liters according to the above ratio, and put them under normal temperature Stir well. Secondly, under continuous stirring, first add 10% of the water that needs to be added and continue to stir for 30 minutes, then add methanesulfonic acid and sodium acetate in se...

Embodiment 2

[0058] Embodiment 2: The weight percent of each component of the oil-water well deep retarding plugging removal agent is:

[0059] 1. Sodium dodecylbenzenesulfonate (industrial product): 1.7%;

[0060] 2. Sodium ethylenediamine tetramethylene phosphonate (industrial product): 6.1%;

[0061] 3. Sodium diethylenetriaminepentaacetate (industrial product): 23.5%;

[0062] 4. Methanesulfonic acid (industrial product): 16.2%;

[0063] 5. Sodium acetate (industrial product): 0.6%;

[0064] 6. Water: 51.9%.

[0065] The daily oil production of the second oil well (YD5-8) was 0.27t / d before the plugging removal measures, and the daily oil production was 1.42t / d after the measures, with a daily increase of 1.15t / d.

Embodiment 3

[0066] Embodiment 3: The weight percent of each component of the slow-speed plugging removal agent in the deep part of the water injection well is:

[0067] 1. Sodium dodecylbenzenesulfonate (industrial product): 1.85%;

[0068] 2. Sodium ethylenediamine tetramethylene phosphonate (industrial product): 6.8%;

[0069] 3. Sodium diethylenetriaminepentaacetate (industrial product): 22.0%;

[0070] 4. Methanesulfonic acid (industrial product): 16.8%;

[0071] 5. Sodium acetate (industrial product): 0.8%;

[0072] 6. Water: 51.75%.

[0073] The water injection pressure of the first water injection well (D91-41) was 18MPa before the plugging removal measures, and the water injection pressure decreased to 14.6MPa under the condition of constant injection volume, which is 18.9% lower than the injection pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com