A low-permeability reservoir water injection well pretreatment agent and preparation method thereof

A pretreatment agent, a technology for water injection wells, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems such as the inability to effectively reduce pressure and increase injection, cannot be used at the same time, low construction efficiency, etc., achieve anti-swelling and The effect of removing solid phase blockage, improving construction efficiency and reducing water injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

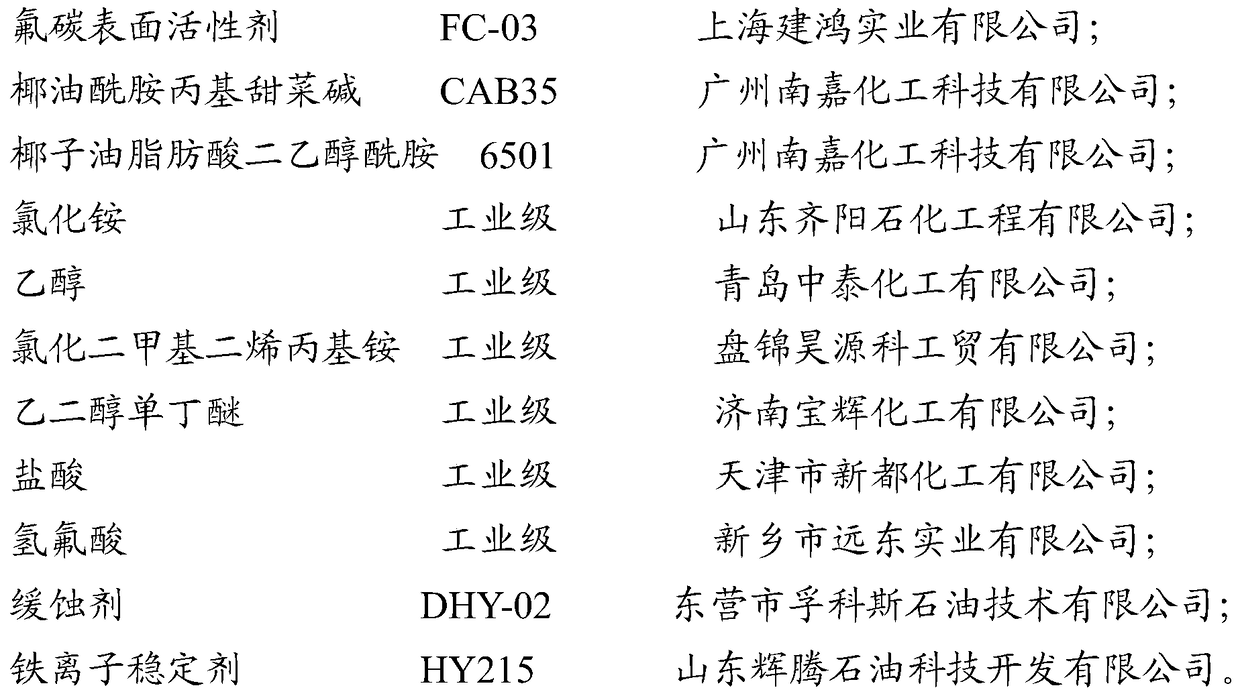

[0039] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned low-permeability oil reservoir water injection well pretreatment agent, including: according to the mass percentage of each component in the low-permeability oil reservoir water injection well pretreatment agent, Mix surfactant, ammonium chloride, ethanol, small molecule cationic polymer, ethylene glycol monobutyl ether, hydrochloric acid, hydrofluoric acid, corrosion inhibitor, iron ion stabilizer and water to obtain low permeability reservoir water injection well pretreatment agent. It can be seen that the method is simple and easy to operate, which is conducive to improving construction efficiency.

[0040] Preferably, in order to improve the preparation efficiency of the pretreatment agent and reduce the preparation time, the method includes: according to the mass percentage content of each component in the pretreatment agent for water injection wells...

Embodiment 1

[0051] This embodiment provides a low-permeability oil reservoir water injection well pretreatment agent, including the following components in mass percentage: 0.6% surfactant, 2% ammonium chloride, 5% ethanol, dimethyl diene chloride Propyl ammonium 2%, ethylene glycol monobutyl ether 1%, hydrochloric acid 12%, hydrofluoric acid 1%, corrosion inhibitor 2%, iron ion stabilizer 2%, and the balance is water. Wherein, the surfactant comprises the following components in mass percentage: 85% of fluorocarbon surfactant, 3% of cocamidopropyl betaine, and 12% of coconut oil fatty acid diethanolamide.

[0052] The preparation method of this pretreatment agent is as follows:

[0053] Preparation of the first solution: According to the mass percentage of each component in the pretreatment agent, add ammonium chloride and part of water into the stirring tank, stir until the ammonium chloride is completely dissolved in the water, and prepare the first solution.

[0054] Prepare the seco...

Embodiment 2

[0057] This embodiment provides a low-permeability reservoir water injection well pretreatment agent, including the following components in mass percentage: fluorocarbon surfactant 0.8%, ammonium chloride 1%, ethanol 2%, dimethyl chloride 4% of diallyl ammonium, 5% of ethylene glycol monobutyl ether, 10% of hydrochloric acid, 3% of hydrofluoric acid, 2% of corrosion inhibitor, 1% of iron ion stabilizer, and the balance is water. Wherein, the surfactant includes the following components in mass percentage: 93% of fluorocarbon surfactant, 7% of coconut oil fatty acid diethanolamide.

[0058] The preparation method of this pretreatment agent is as follows:

[0059] Preparation of the first solution: According to the mass percentage of each component in the pretreatment agent, add ammonium chloride and part of water into the stirring tank, stir until the ammonium chloride is completely dissolved in the water, and prepare the first solution.

[0060] Preparation of the second solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com