Patents

Literature

11901 results about "Oil well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil well is a boring in the Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released along with the oil. A well that is designed to produce only gas may be termed a gas well.

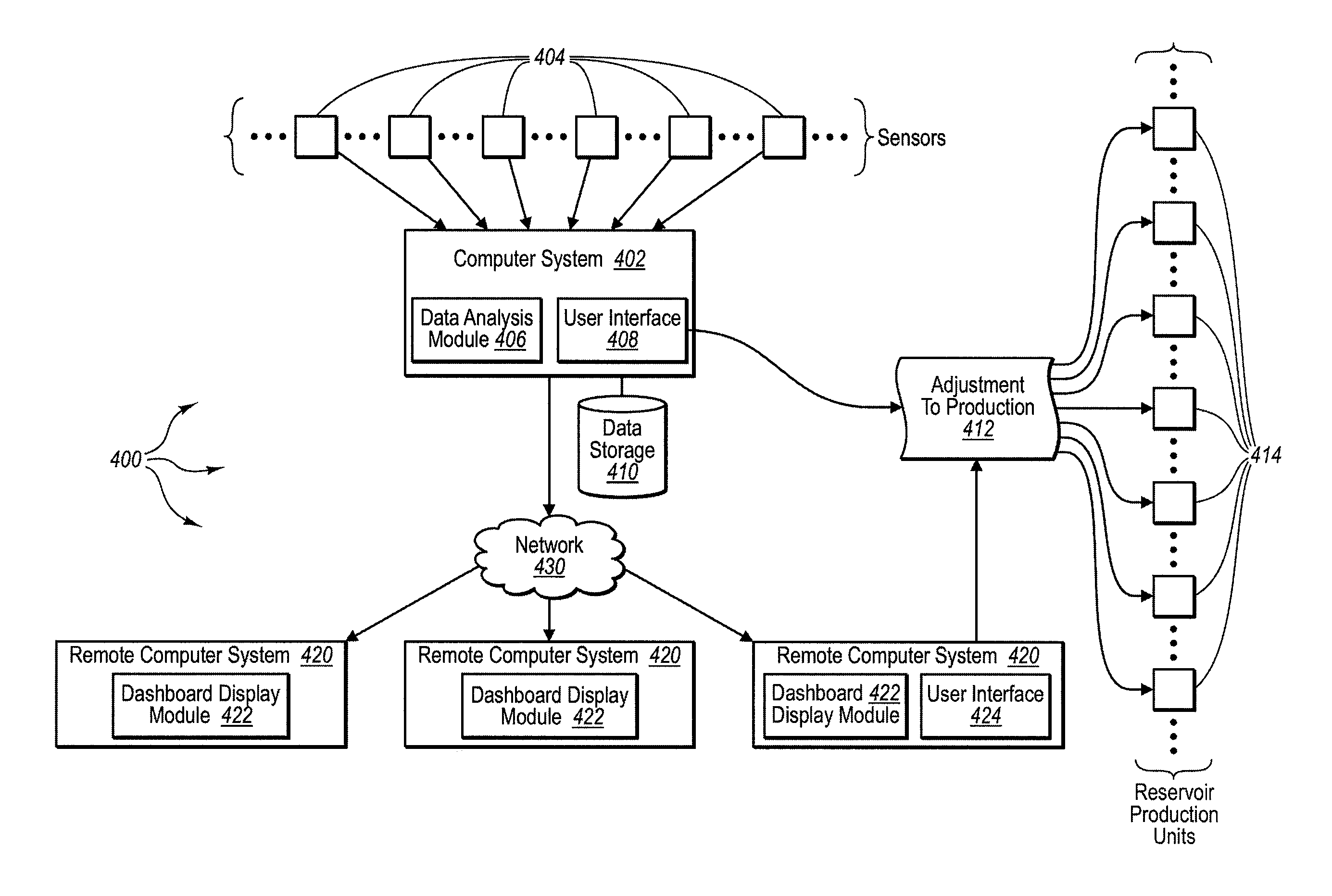

Integrated reservoir optimization

InactiveUS20050149307A1Maximize productionMaximizing value of propertyElectric/magnetic detection for well-loggingSurveyHigh rateAcquisition time

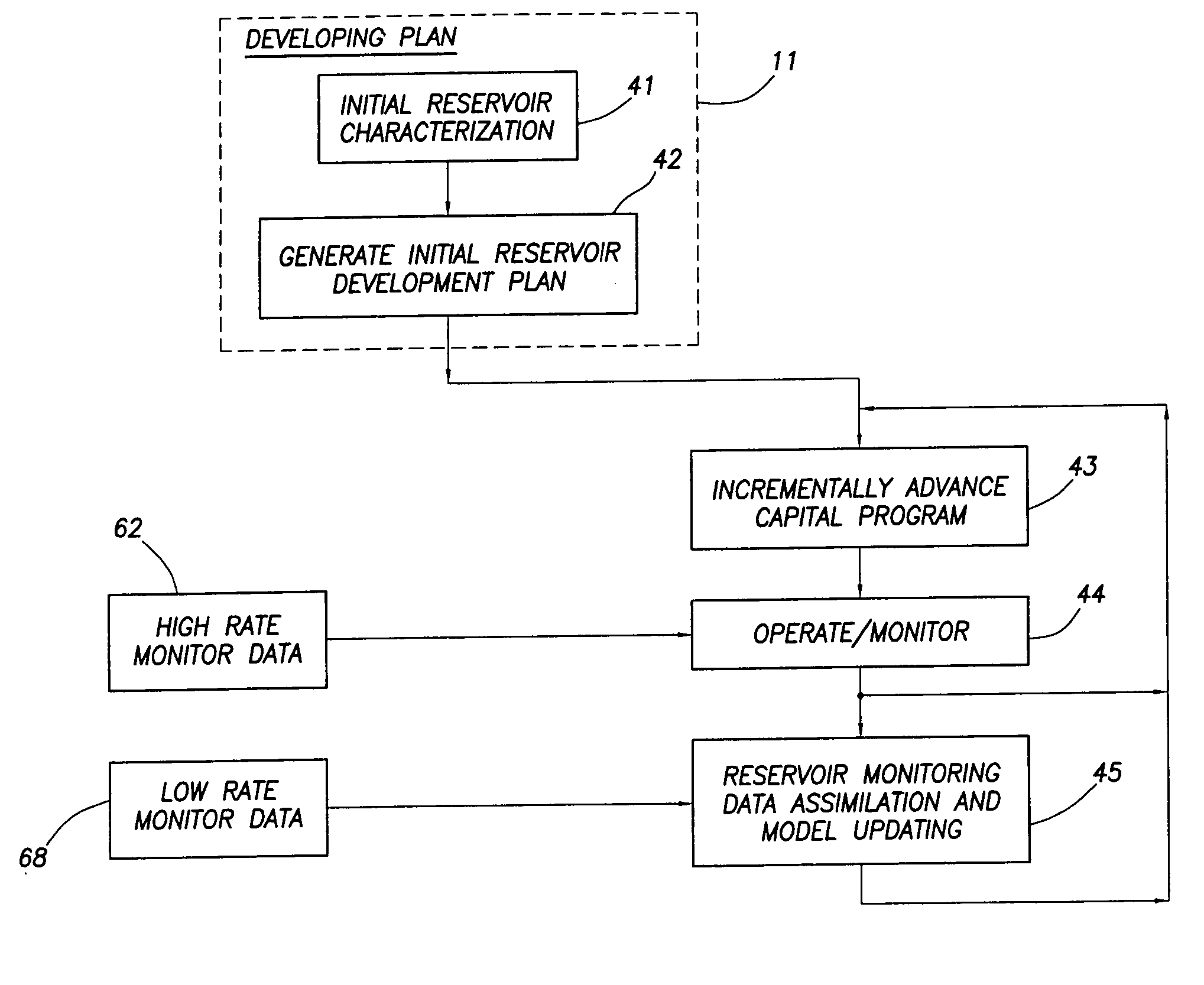

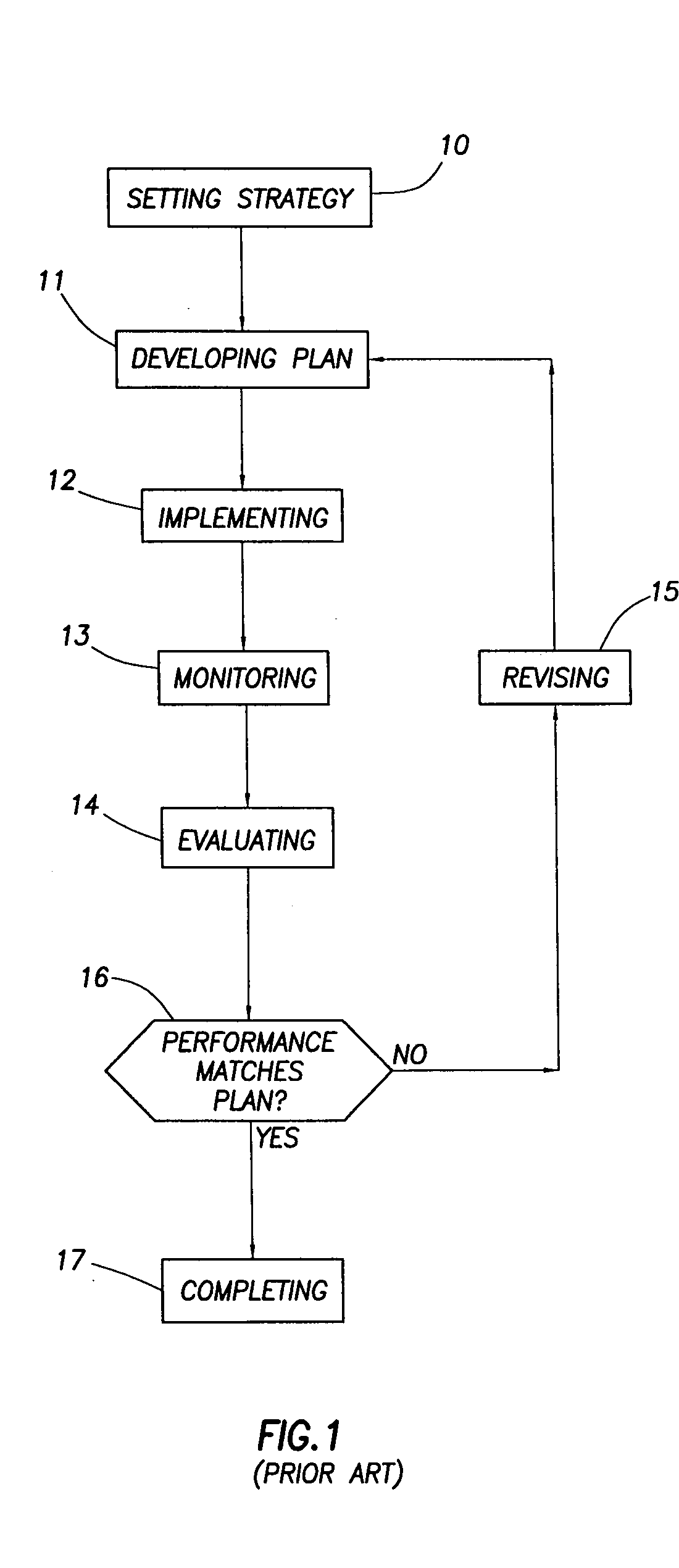

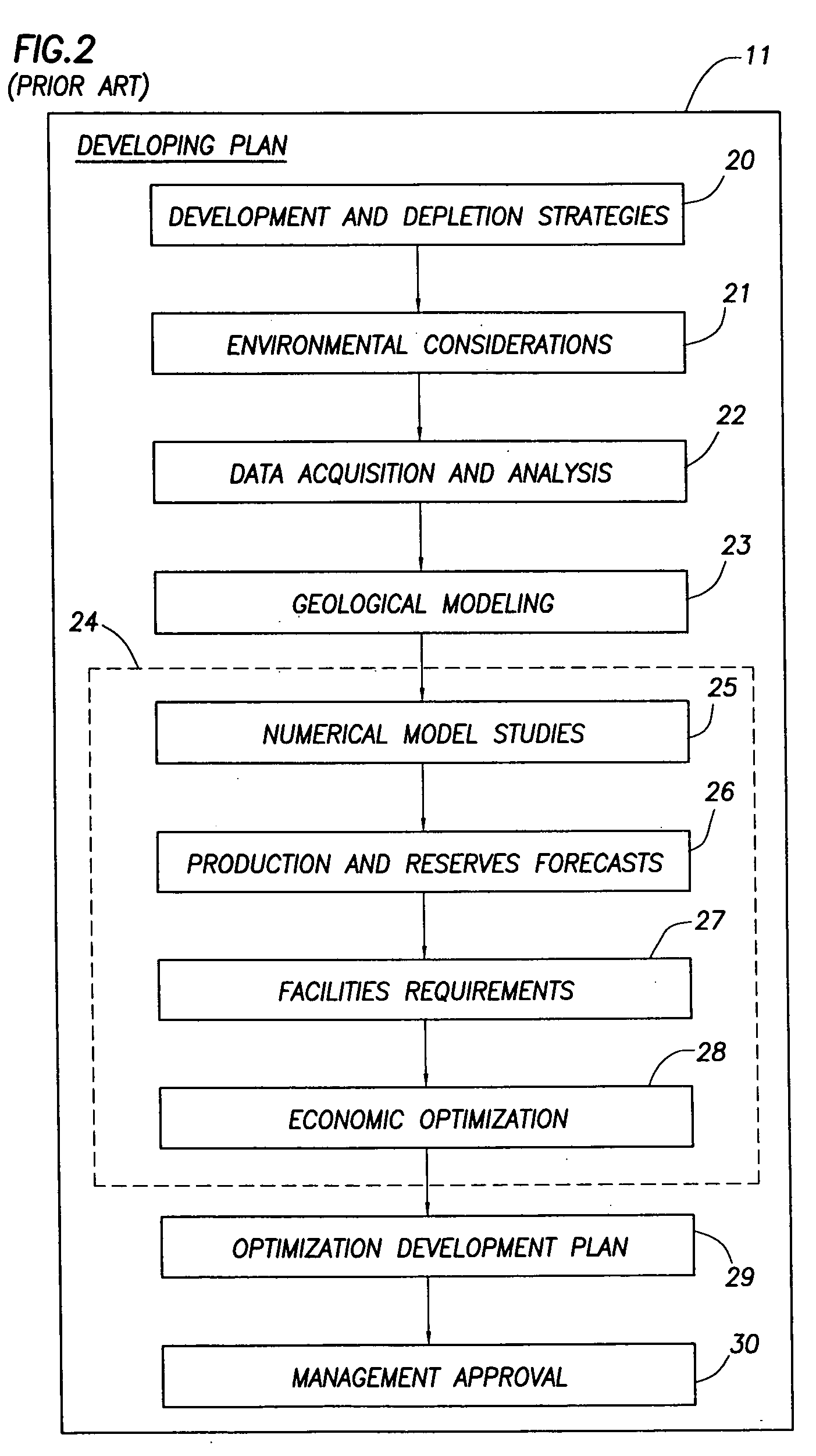

A method of managing a fluid or gas reservoir is disclosed which assimilates diverse data having different acquisition time scales and spatial scales of coverage for iteratively producing a reservoir development plan that is used for optimizing an overall performance of a reservoir. The method includes: (a) generating an initial reservoir characterization, (b) from the initial reservoir characterization, generating an initial reservoir development plan, (c) when the reservoir development plan is generated, incrementally advancing and generating a capital spending program, (d) when the capital spending program is generated, monitoring a performance of the reservoir by acquiring high rate monitor data from a first set of data measurements taken in the reservoir and using the high rate monitor data to perform well-regional and field-reservoir evaluations, (e) further monitoring the performance of the reservoir by acquiring low rate monitor data from a second set of data measurements taken in the reservoir, (f) assimilating together the high rate monitor data and the low rate monitor data, (g) from the high rate monitor data and the low rate monitor data, determining when it is necessary to update the initial reservoir development plan to produce a newly updated reservoir development plan, (h) when necessary, updating the initial reservoir development plan to produce the newly updated reservoir development plan, and (i) when the newly updated reservoir development plan is produced, repeating steps (c) through (h). A detailed disclosure is provided herein relating to the step (a) for generating the initial reservoir characterization and the step (b) for generating the initial reservoir development plan.

Owner:SCHLUMBERGER TECH CORP

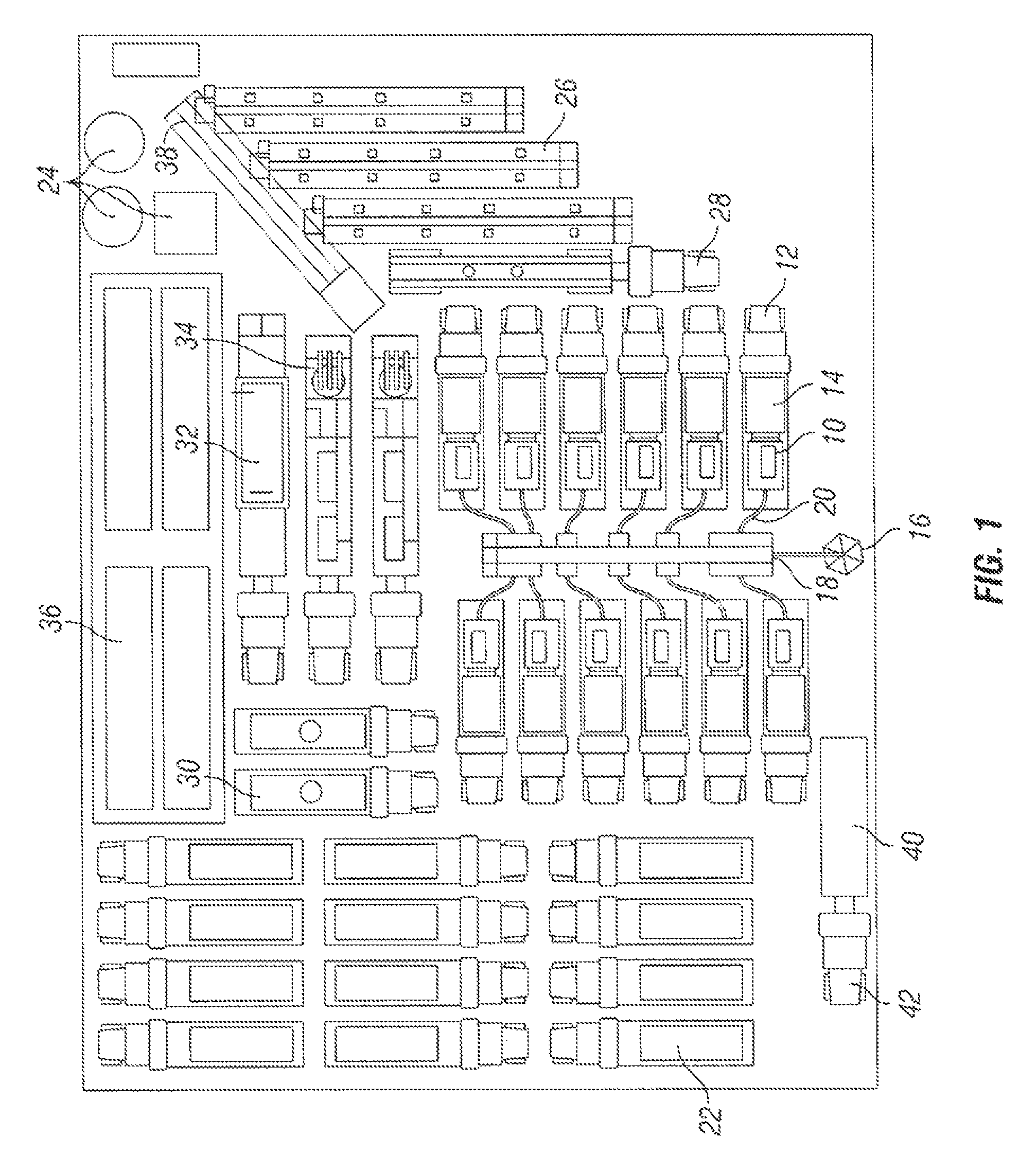

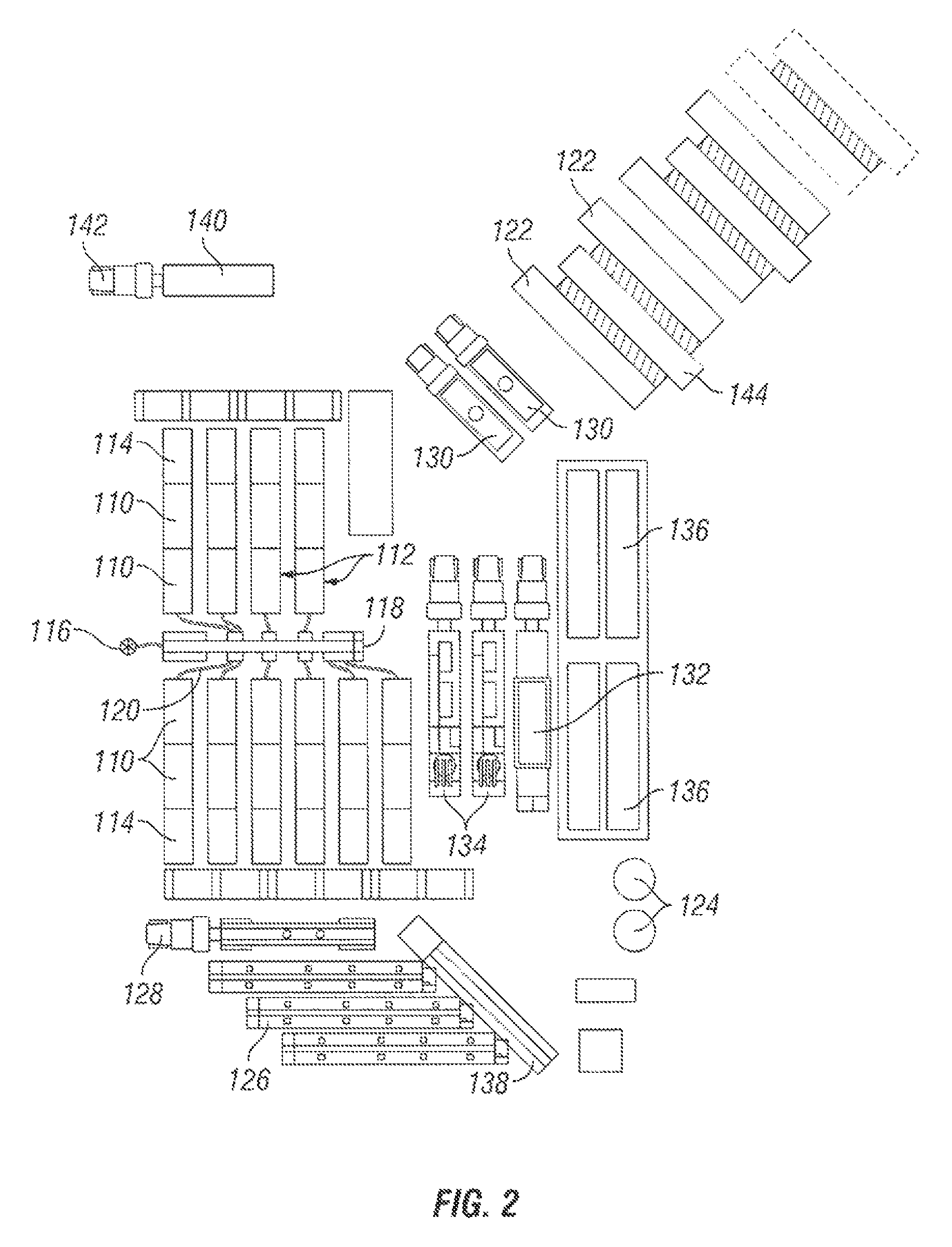

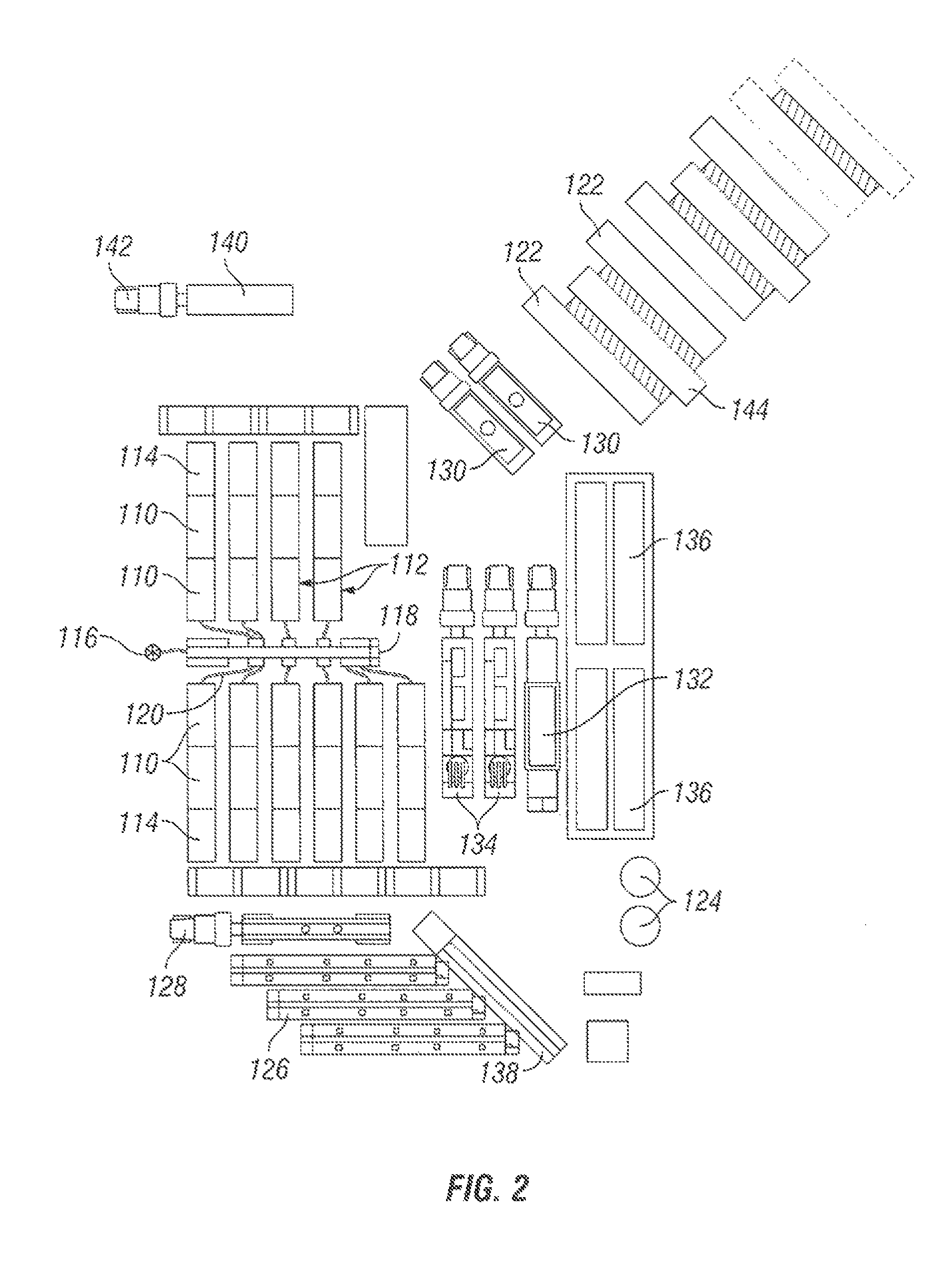

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of pumps powered by electric induction motors and fluidly connected to the well, the pumps configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the, and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

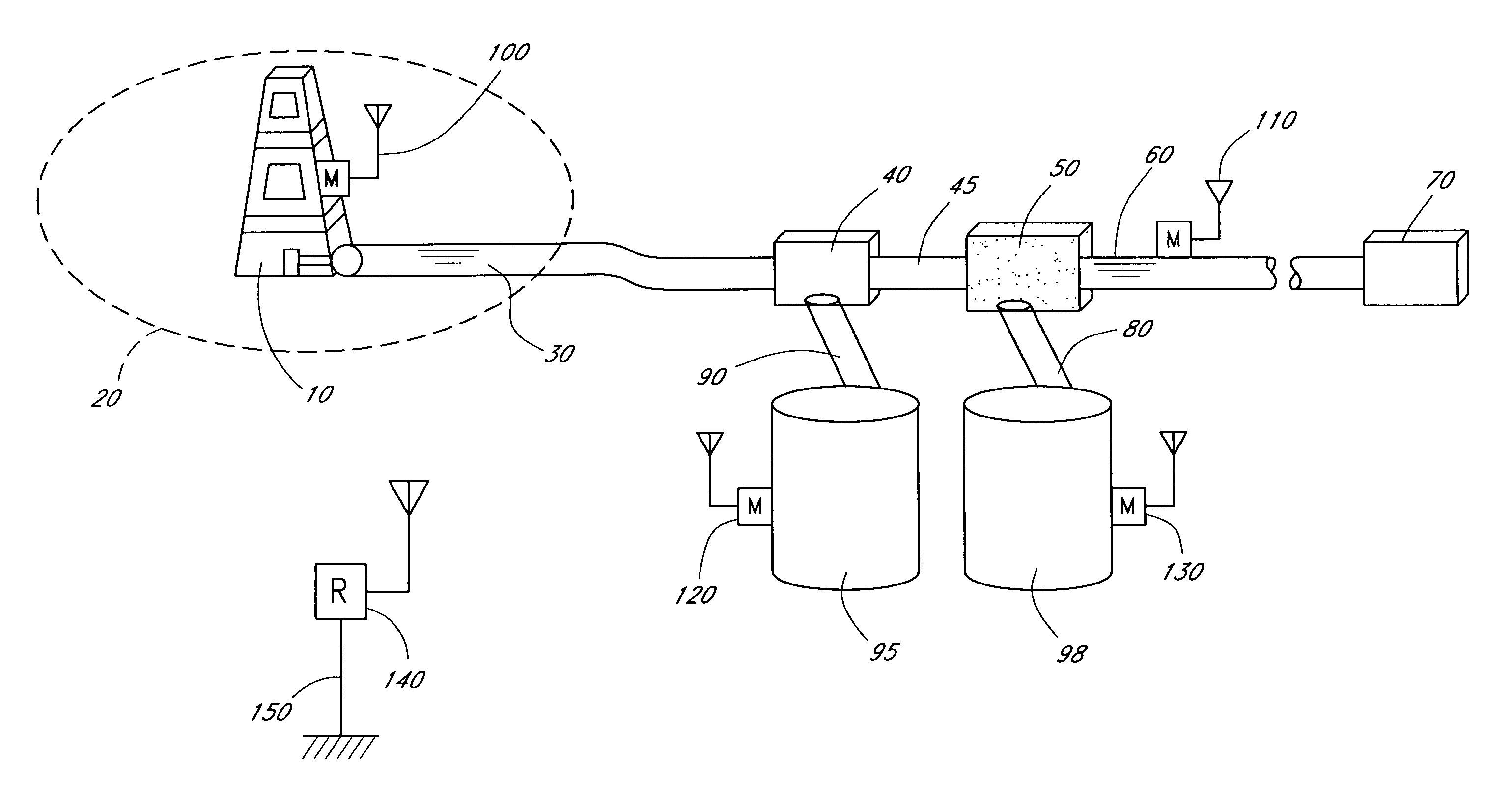

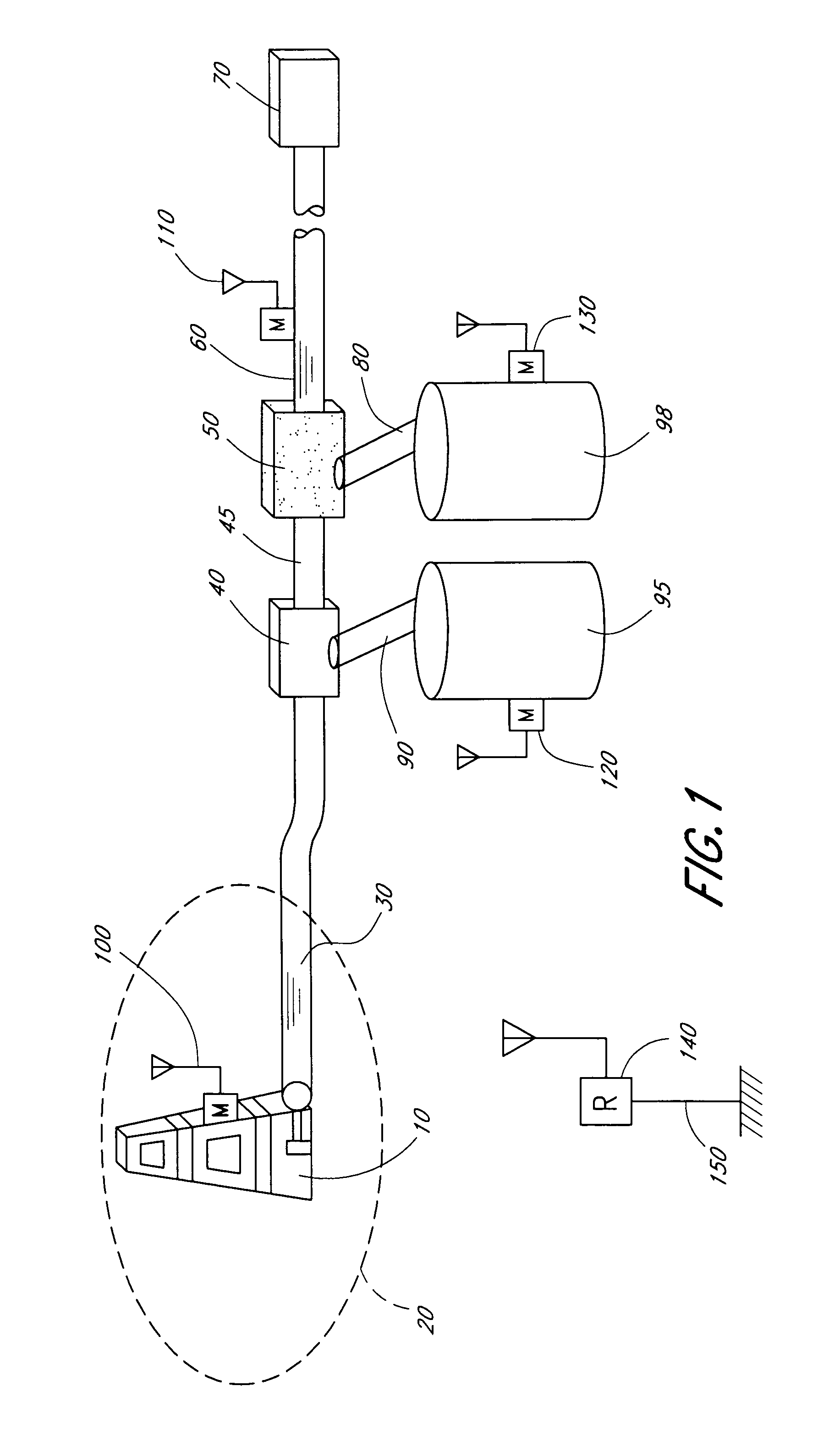

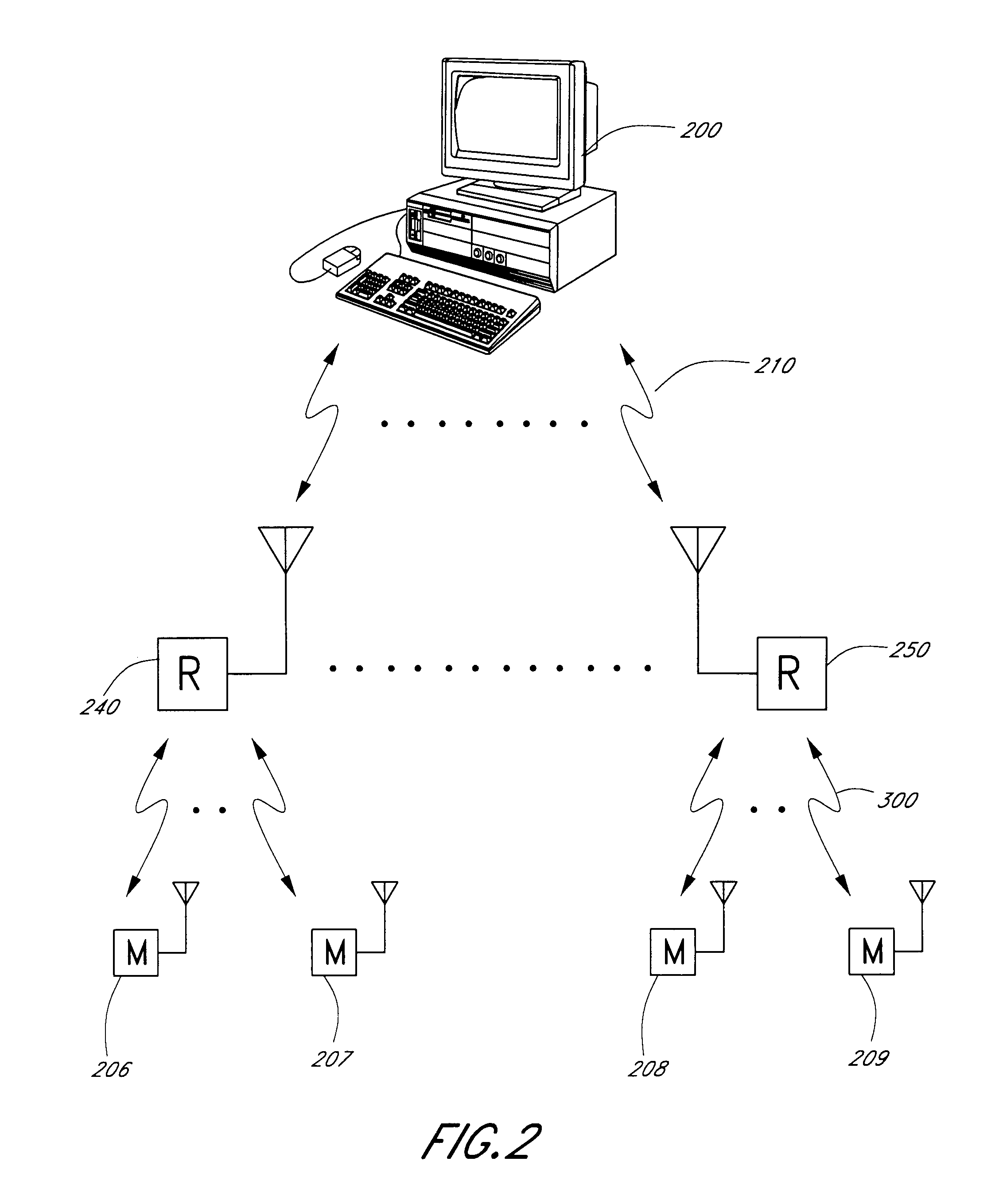

Gas/oil well monitoring system

A system for monitoring a gas / oil well is provided with a monitoring unit, a relay unit and a host interface. A monitoring unit collects data regarding the status of the gas / oil well and wirelessly transmits that data to a relay unit. The relay unit, in turn, connects to a host interface using cellular communications and transmits the data. The monitoring unit can transmit information on demand or after an alarm condition is sensed. In either case, the monitoring unit is normally in a sleep mode. The relay unit can request information from the monitoring unit or respond to a wake up transmission sent to it from either the host interface or monitoring unit. The host interface receives data from the relay unit and then informs an end user of that data.

Owner:OLEUMTECH CORP

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

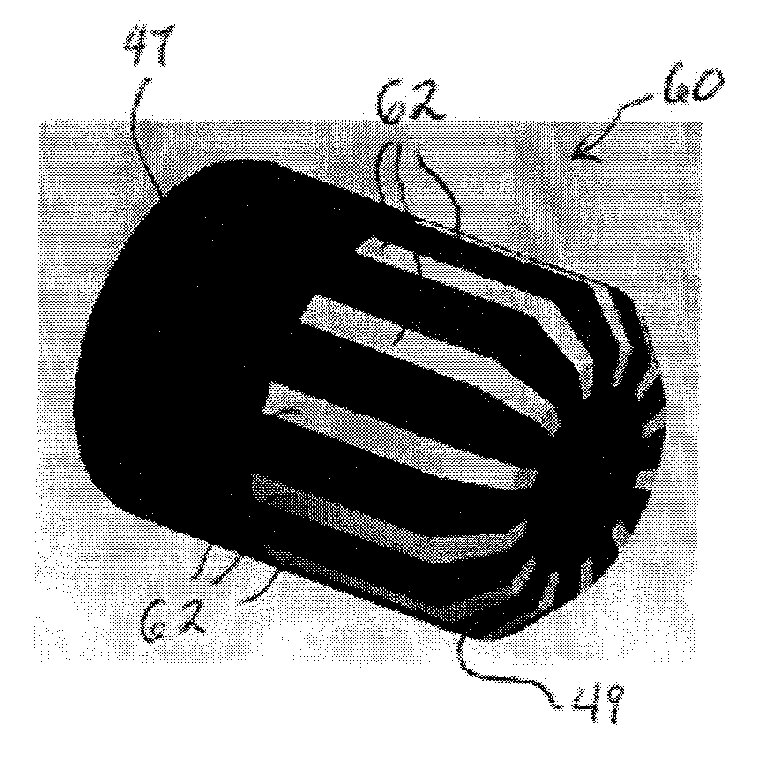

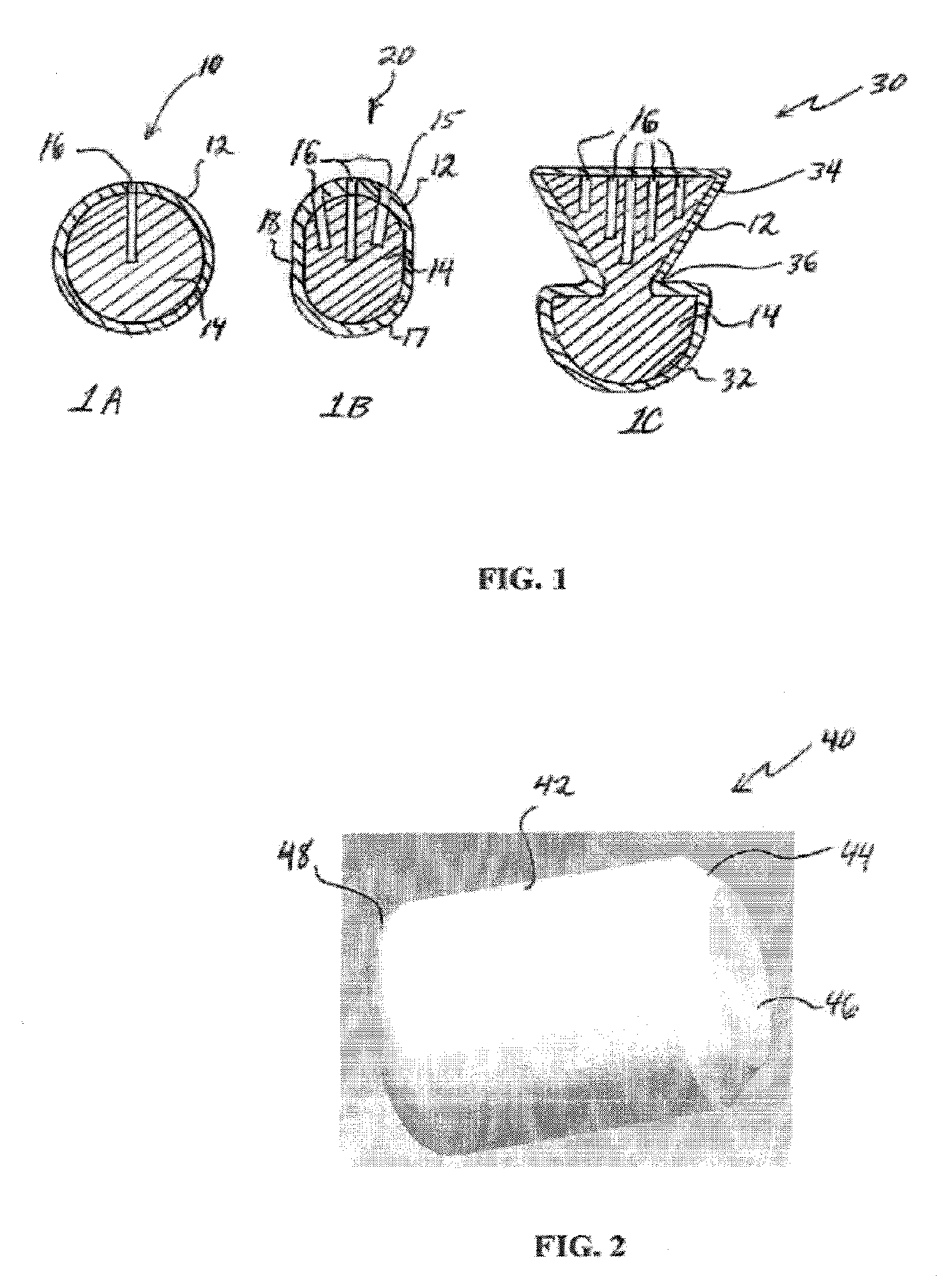

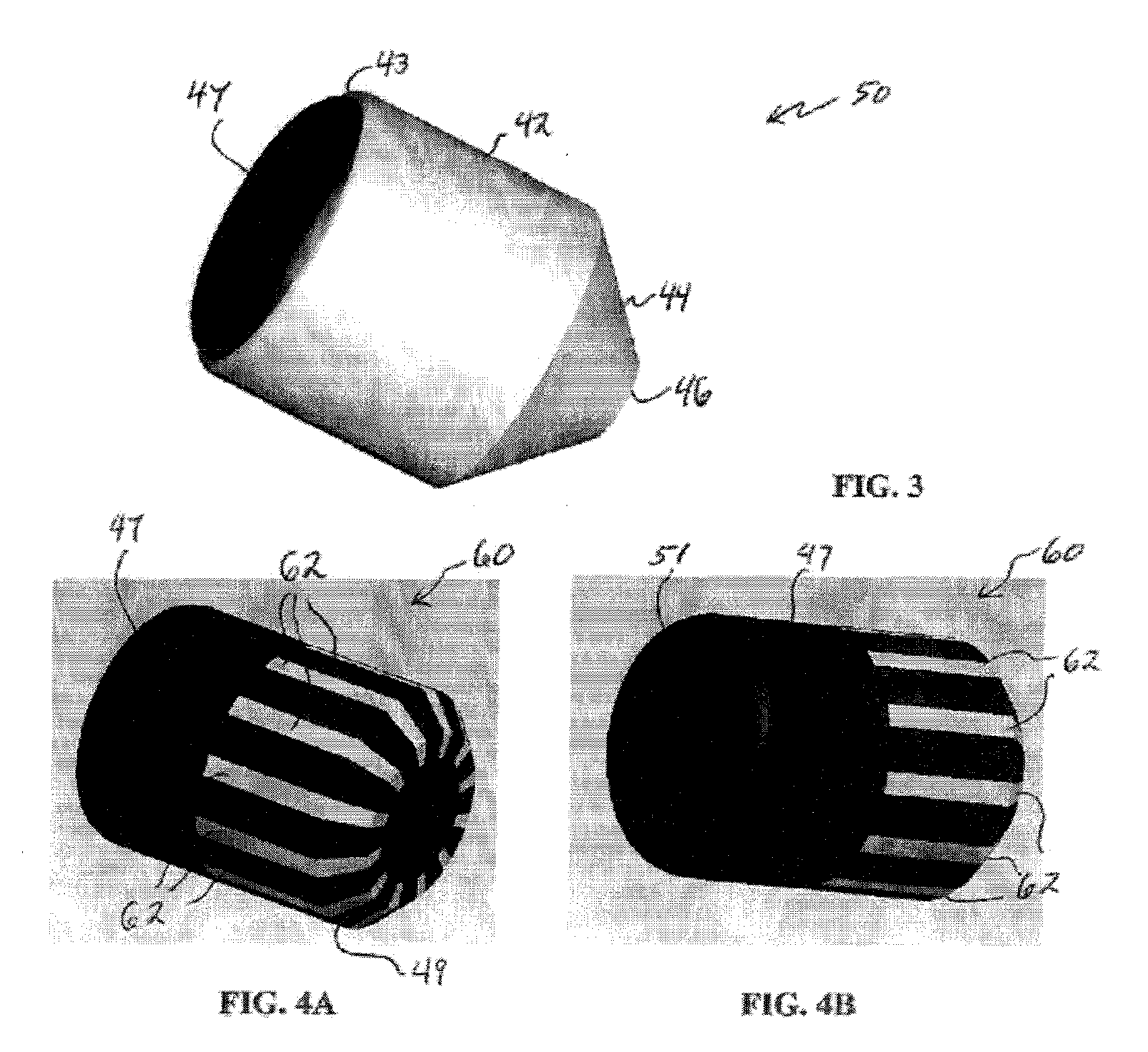

Well Operating Elements Comprising a Soluble Component and Methods of Use

Well operating elements are described, one embodiment comprising a first component that is substantially non-dissolvable when exposed to a selected wellbore environment and a second component that is soluble in the selected wellbore environment and whose rate and / or location of dissolution is at least partially controlled by structure of the first component. A second embodiment includes the component that is soluble in the selected wellbore environment, and one or more exposure holes or passages in the soluble component to control its solubility. The second embodiment may or may not include a substantially non-dissolvable component. Methods of using the well operating elements in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

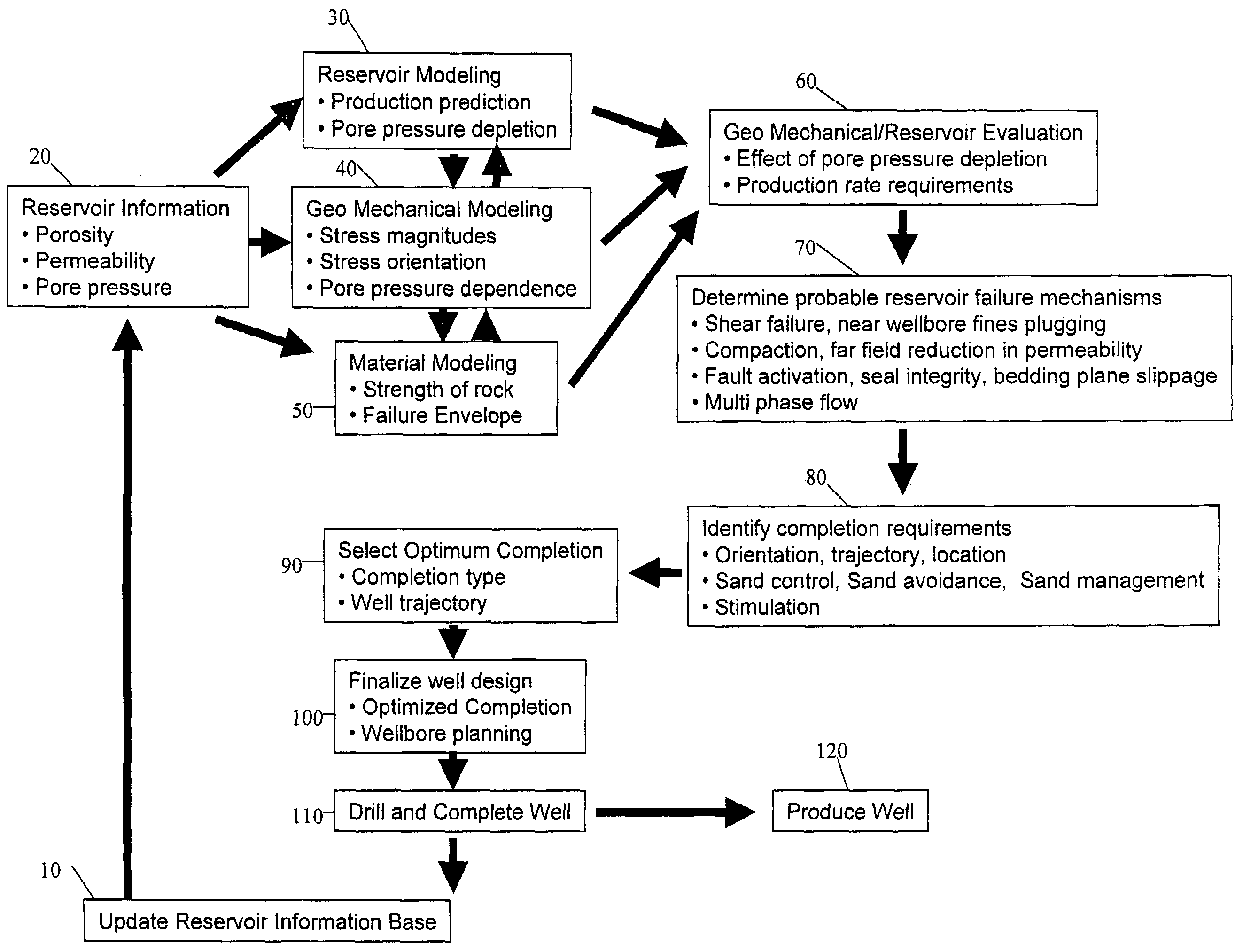

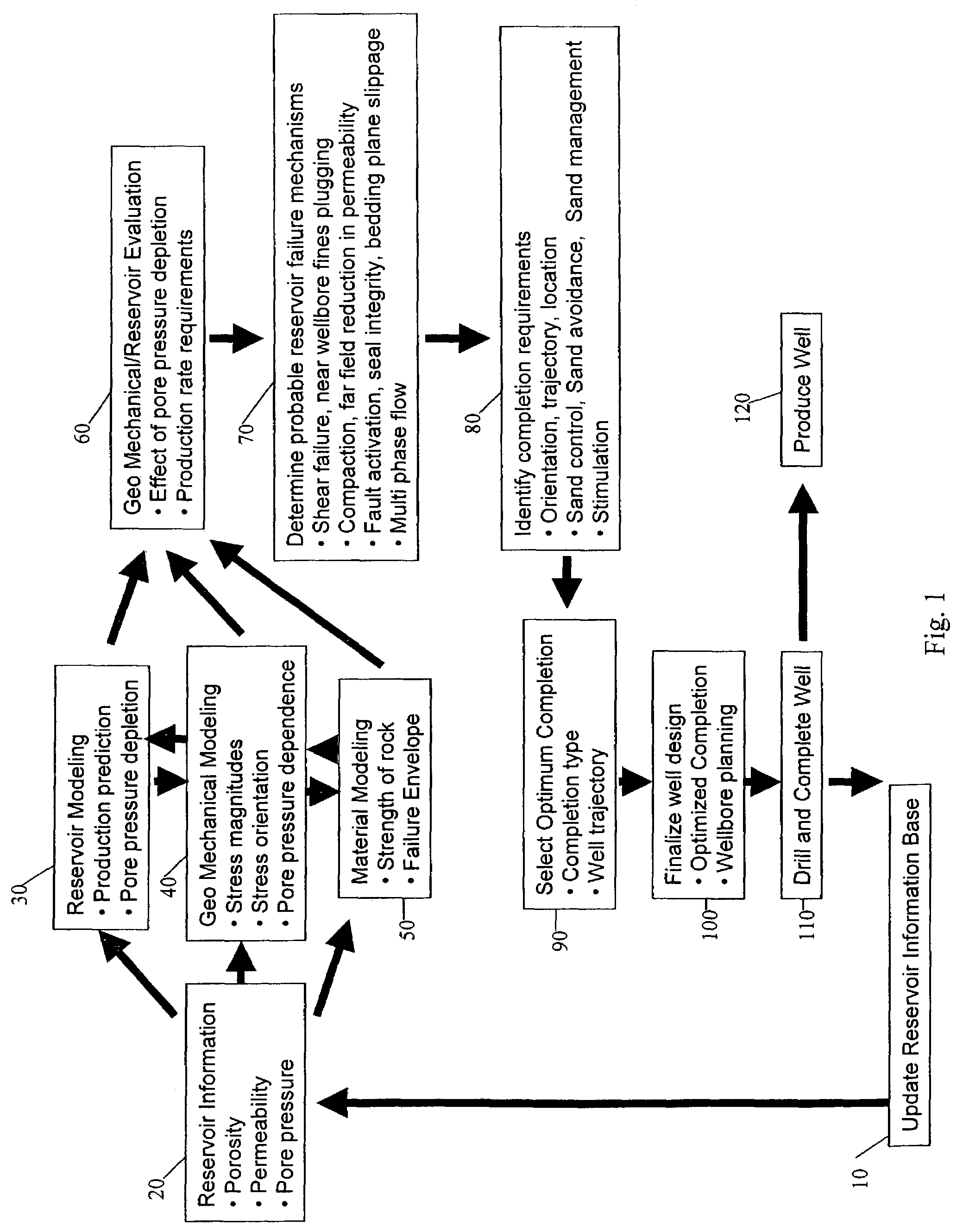

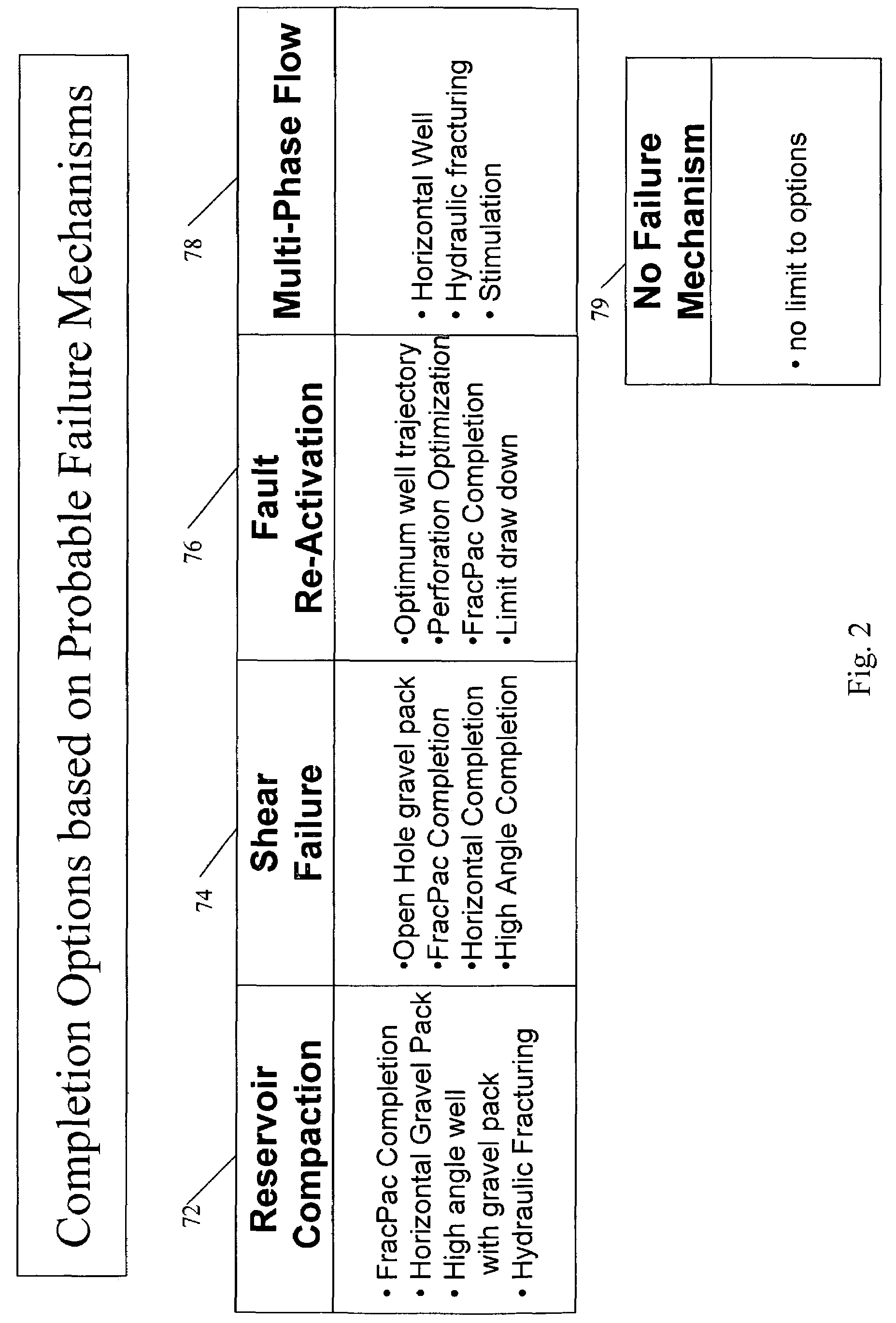

System and process for optimal selection of hydrocarbon well completion type and design

ActiveUS7181380B2Electric/magnetic detection for well-loggingSurveyUltimate tensile strengthFailure mechanism

A process to determine optimal completion type and design prior to drilling of a hydrocarbon producing well utilizing information from hydrocarbon recovery modeling such as reservoir, geo-mechanical, and material modeling over the production life of the well. An embodiment of the process includes obtaining information regarding pore pressure depletion, stress magnitudes and orientations, and strength of rock formation from hydrocarbon recovery modeling to determine optimum well completion design including the selection of a completion type, trajectory, and location. Additionally, the process may also consider probable failure mechanisms and identified completion requirements, and their corresponding effect on completion options.

Owner:GEOMECHANICS INT +1

Method for determining the extent of recovery of materials injected into oil wells during oil and gas exploration and production

Disclosed is a method of determining the extent of recovery of materials injected into a oil well comprising the steps of: a) preparing a material to be injected into an oil well; b) admixing therewith a chemical tracer compound at a predetermined concentration; c) injecting the admixture into an oil well; d) recovering from the oil well a production fluid; e) analyzing the production fluid for the concentration of the chemical tracer present in the production fluid; and f) calculating the amount of admixture recovered from the oil well using the concentration of the chemical tracer present in the production fluid as a basis for the calculation. Fluorinated benzoic acids are disclosed as a preferred tracer.

Owner:CORE LAB LP

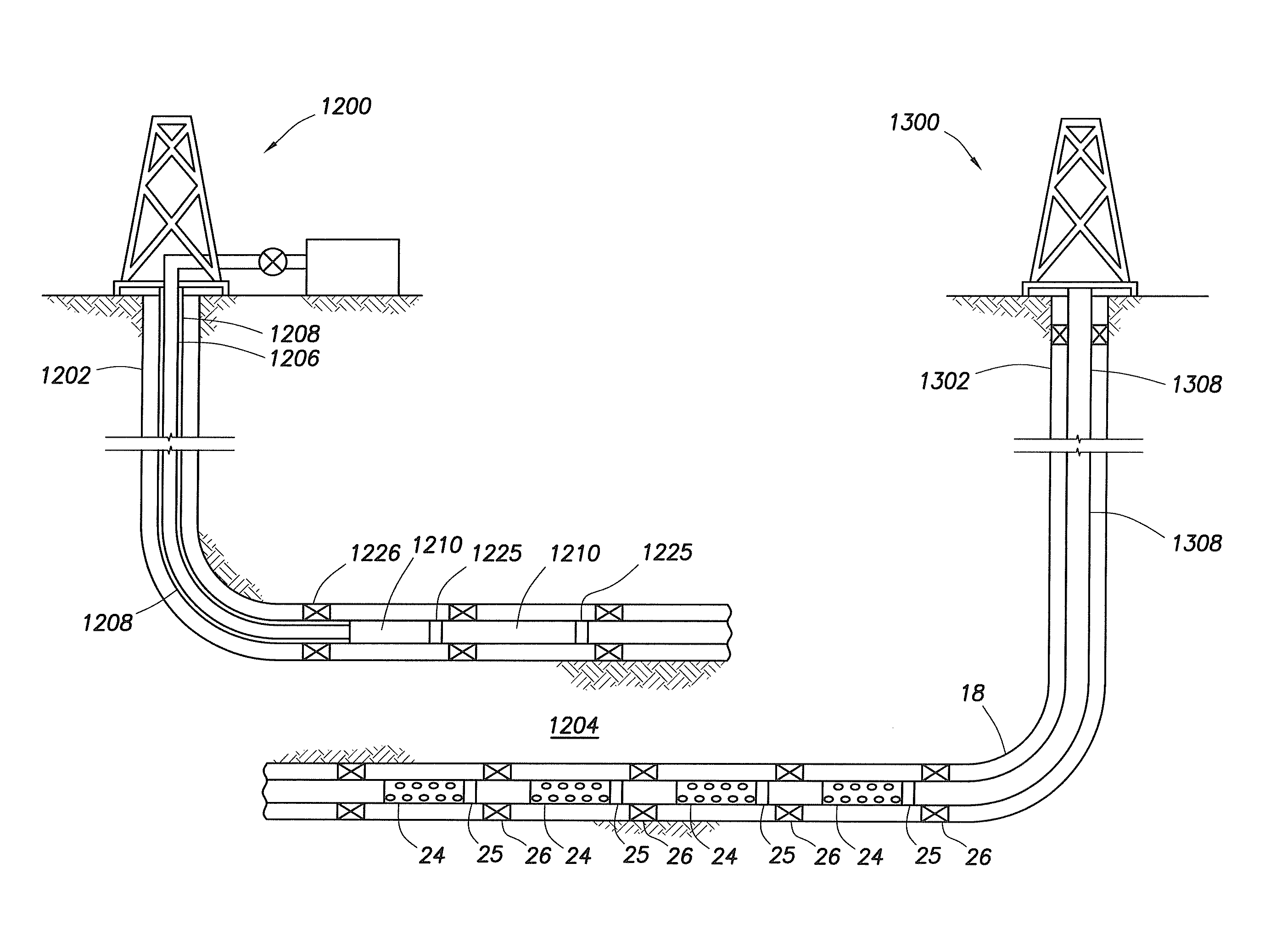

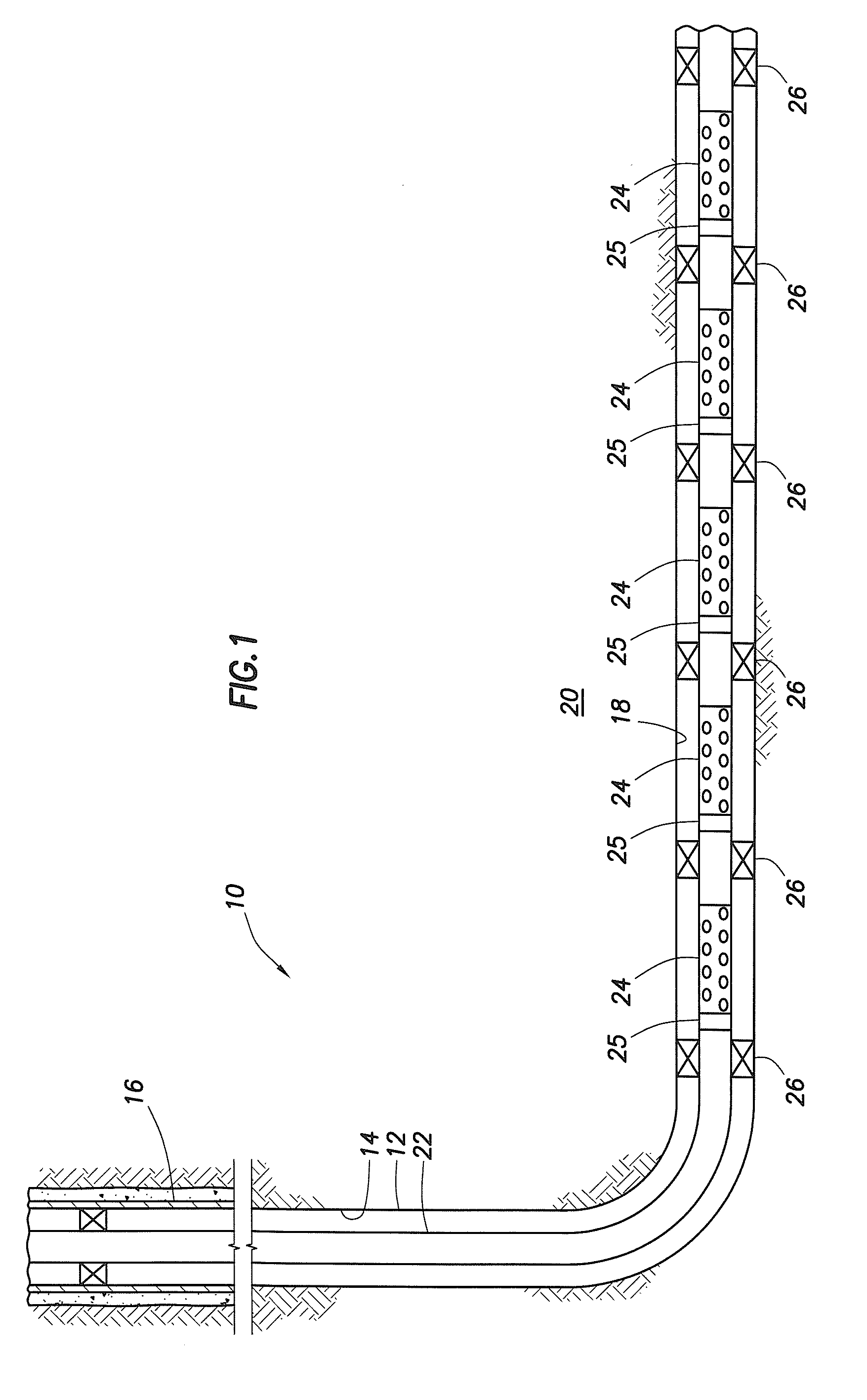

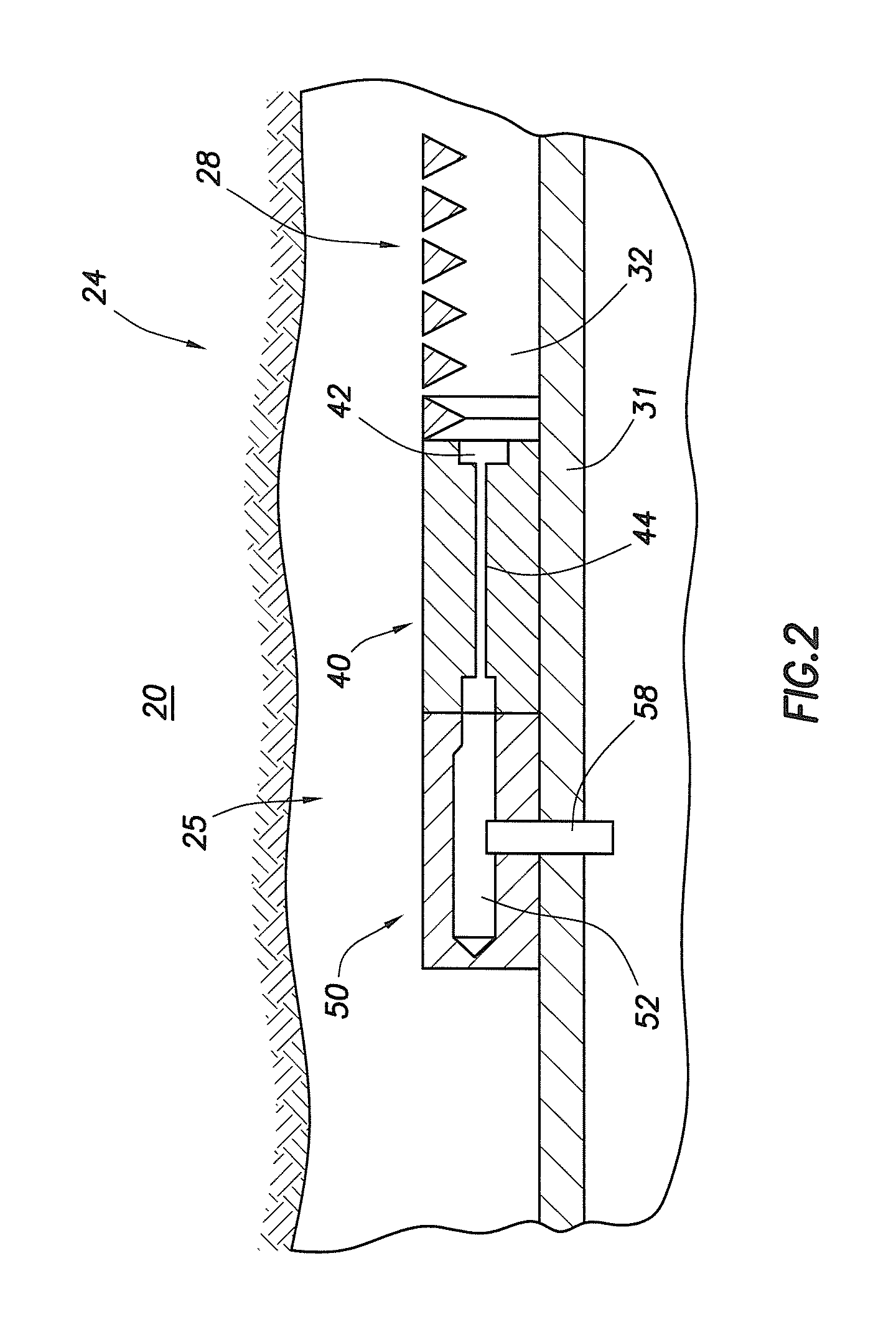

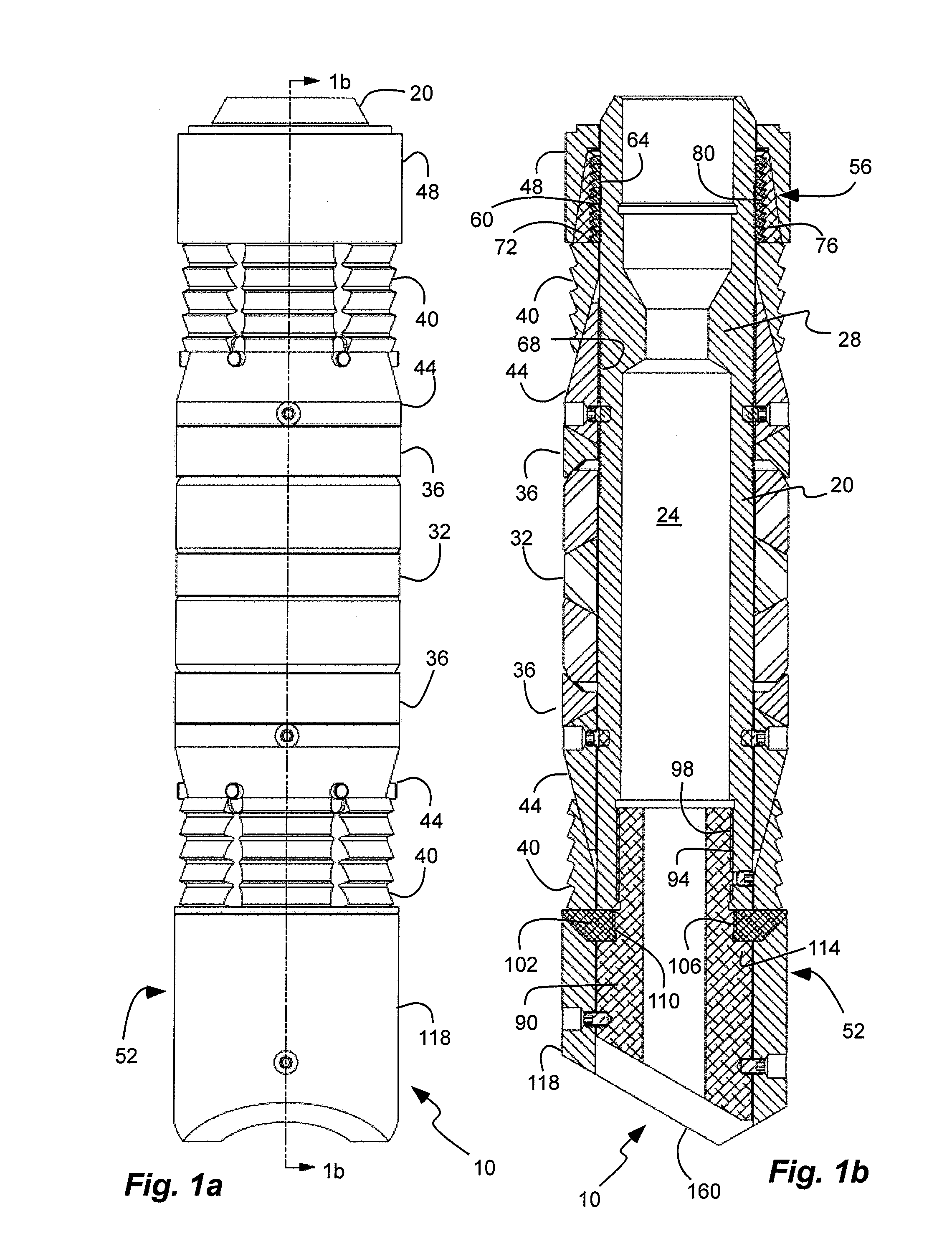

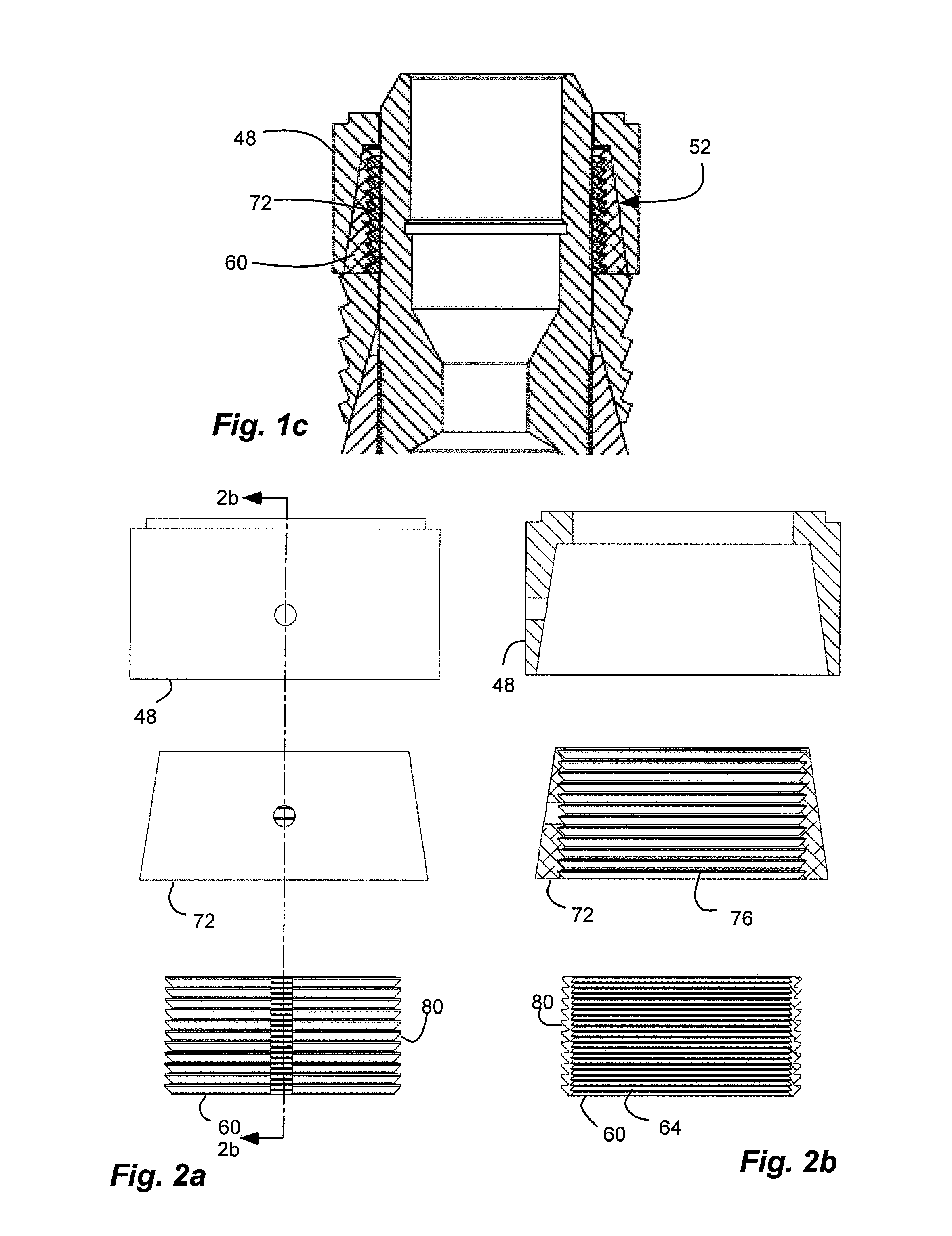

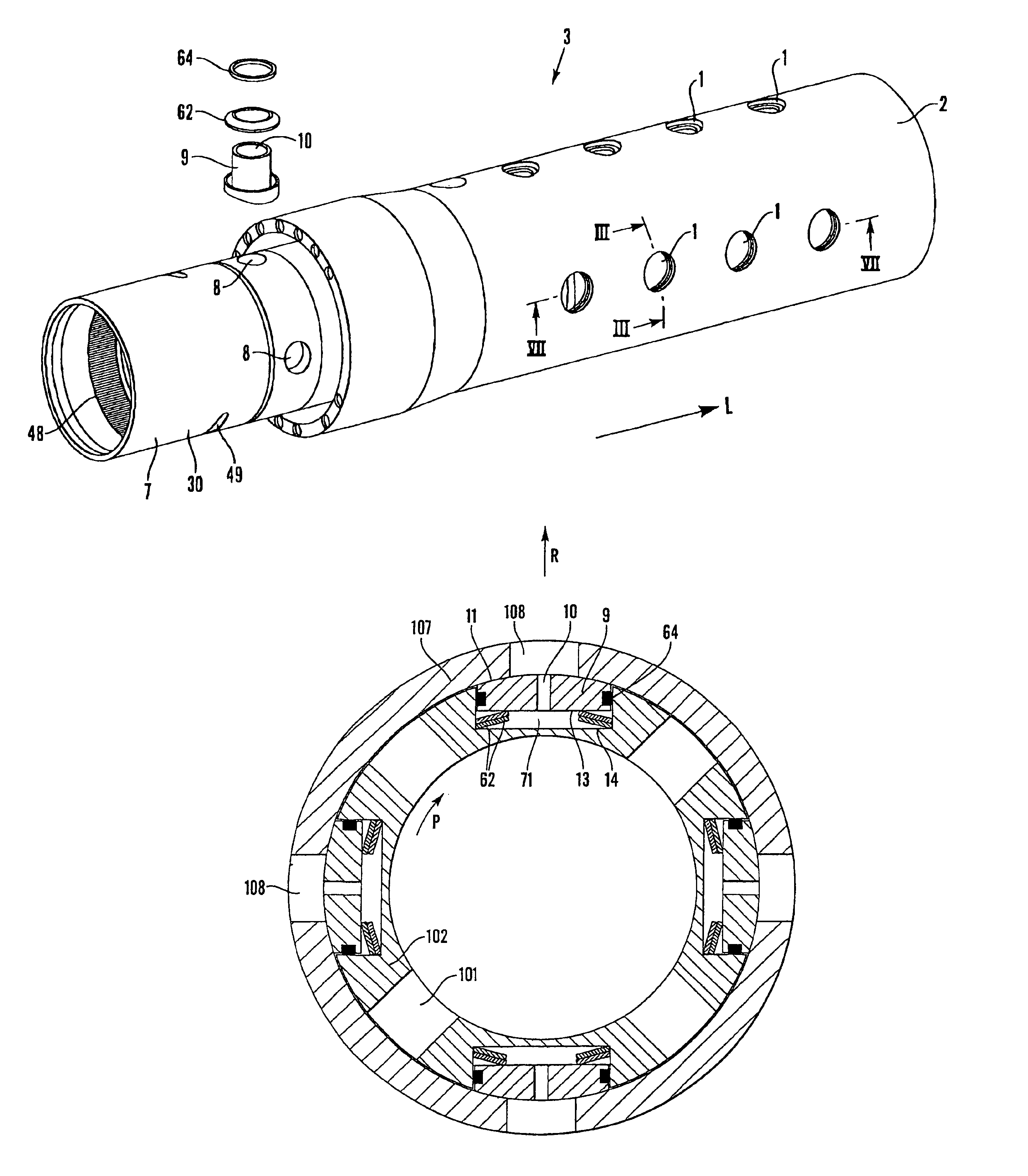

Method and apparatus for autonomous downhole fluid selection with pathway dependent resistance system

An apparatus is described for controlling flow of fluid in a tubular positioned in a wellbore extending through a subterranean formation. A flow control system is placed in fluid communication with a main tubular. The flow control system has a flow ratio control system and a pathway dependent resistance system. The flow ratio control system has a first and second passageway, the production fluid flowing into the passageways with the ratio of fluid flow through the passageways related to the characteristic of the fluid flow. The pathway dependent resistance system includes a vortex chamber with a first and second inlet and an outlet, the first inlet of the pathway dependent resistance system in fluid communication with the first passageway of the fluid ratio control system and the second inlet in fluid communication with the second passageway of the fluid ratio control system. The first inlet is positioned to direct fluid into the vortex chamber such that it flows primarily tangentially into the vortex chamber, and the second inlet is positioned to direct fluid such that it flows primarily radially into the vortex chamber. Undesired fluids, such as natural gas or water, in an oil well, are directed, based on their relative characteristic, into the vortex primarily tangentially, thereby restricting fluid flow when the undesired fluid is present as a component of the production fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

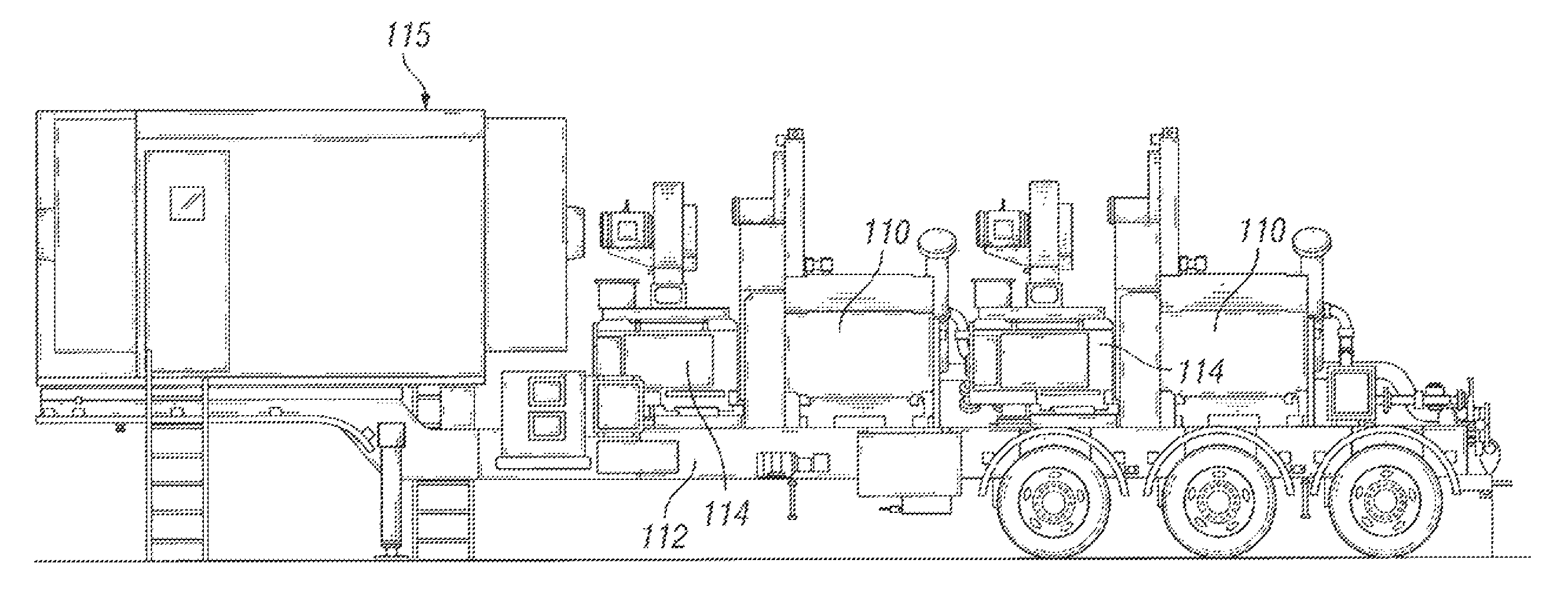

System for Pumping Hydraulic Fracturing Fluid Using Electric Pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

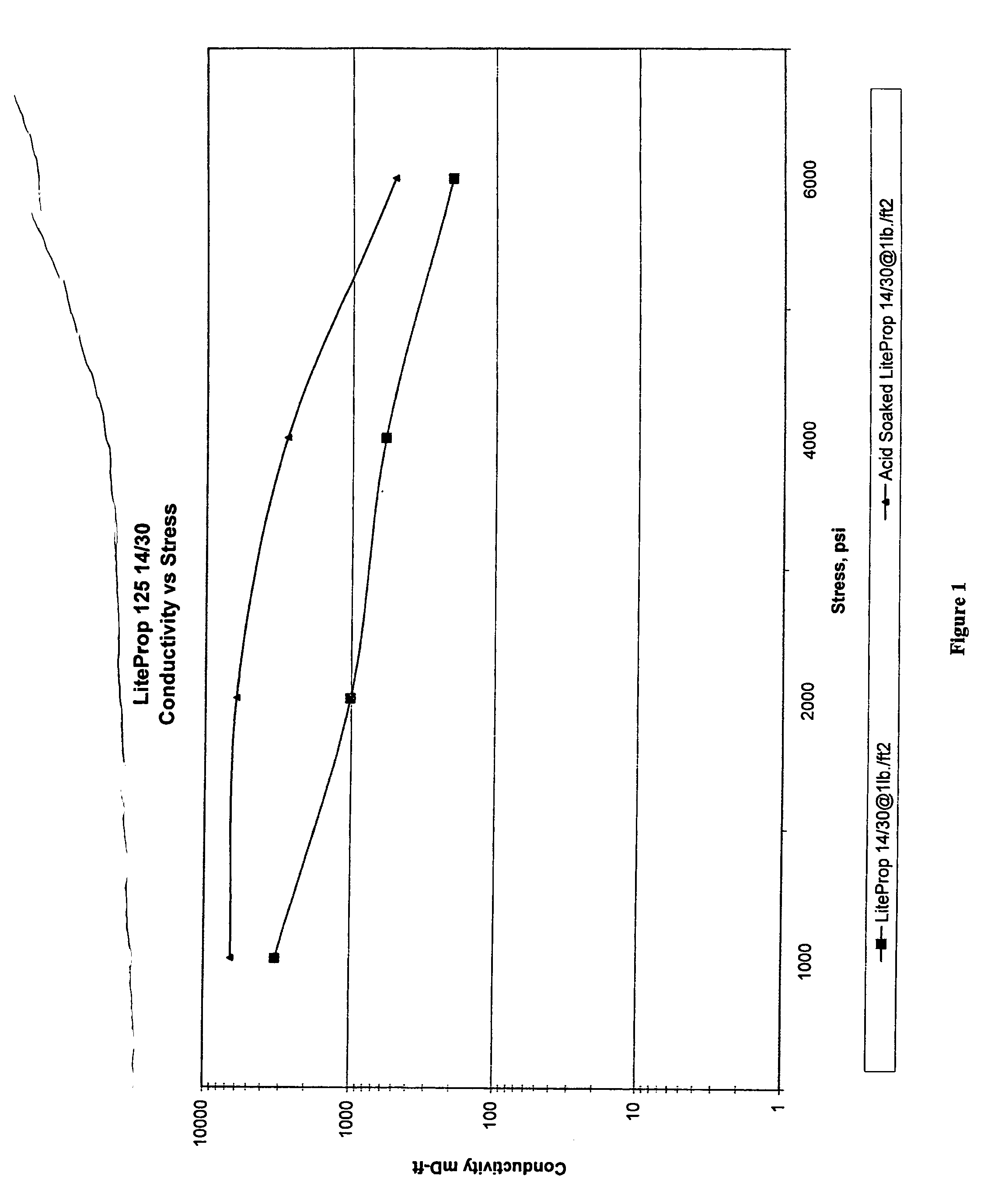

Well treating composition containing relatively lightweight proppant and acid

InactiveUS20060073980A1Satisfied with placementImprove productivityFluid removalFlushingParticulatesAcid fracturing

A well treating composition contains an aqueous acid and at least one relatively lightweight proppant, preferably having an apparent specific gravity (ASG) less than or equal to 2.45. The acid fracturing composition may used to acid fracture a hydrocarbon reservoir within a subterranean formation of an oil or gas well. The composition may further be used to stimulate the production of hydrocarbons. The proportion of relatively lightweight proppant to acid in the composition is such that the dimensional fracture conductivity (CfD) is in excess of 1.0. The aqueous acid typically has an ASG substantially equal to the ASG of the relatively lightweight particulate. As such, the relatively lightweight particulate is suspended in the aqueous acid.

Owner:BAKER HUGHES INC

Cementing compositions and application of such compositions to cementing oil wells or the like

InactiveUS6874578B1Improve mechanical propertiesReduce penetrationFluid removalDrilling compositionPolymer sciencePortland cement

Method of well cementing with a foamed slurry having a very low water content. When based on ordinary cement, the solid fraction of the slurry includes (by volume) 20-35% Portland cement, 35-65% particles ranging from 200 μm to 600 μm, and 5% to 25% of fine particles in the range 0.5 μm to 5 μm and the water content is less than 50% by volume. When based on micro-cement, the solid fraction includes (by volume) 50-75% micro-cement, 15-40% fine particles in the range 0.5 μm to 5 μm, and 0-20% particles in the rang 3 nanometers to 60 nanometers and the water content is less than 72% by volume.

Owner:SCHLUMBERGER TECH CORP

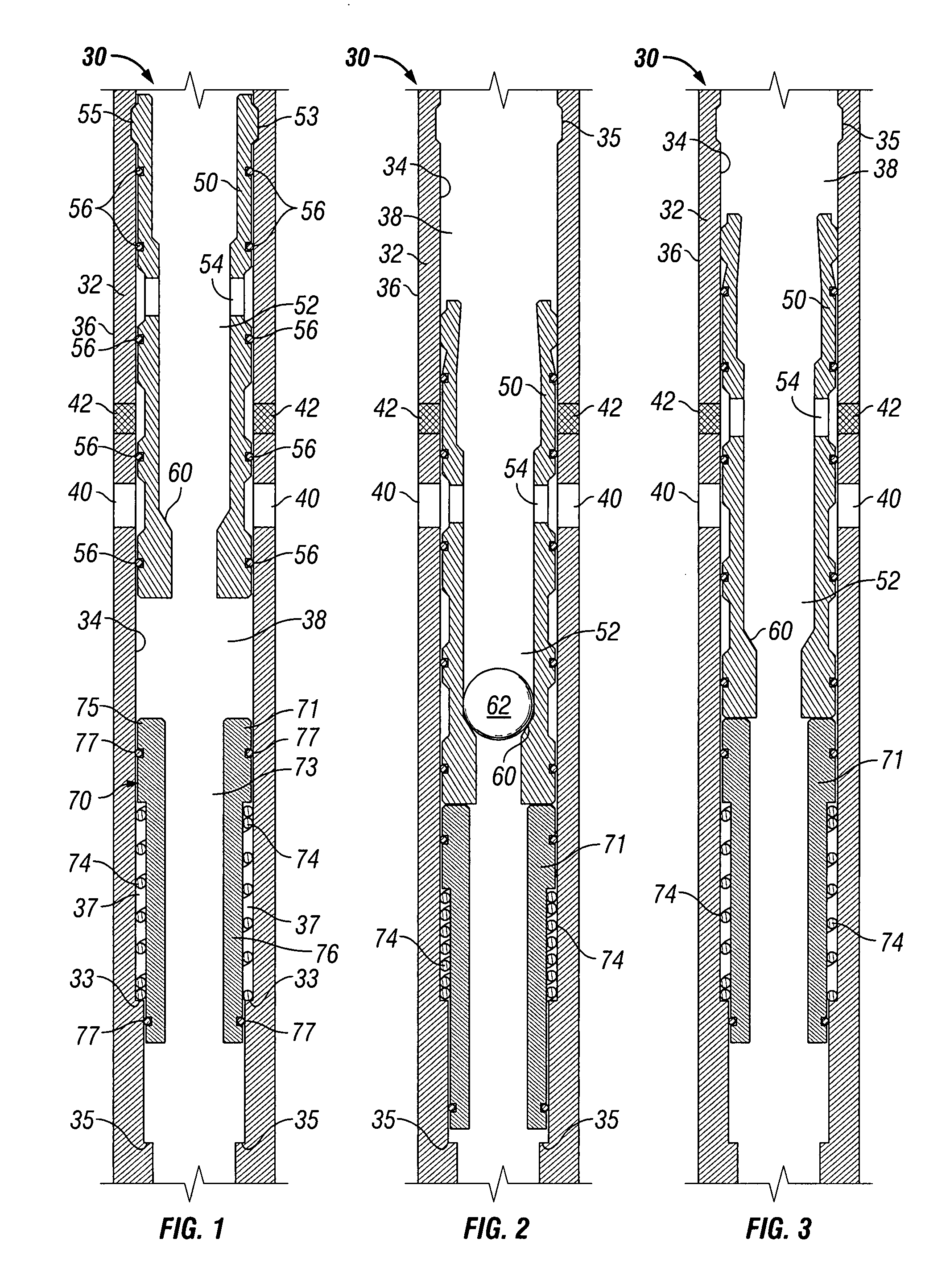

Means for creating field configurable bridge, fracture or soluble insert plugs

InactiveUS8267177B1Improves drill out performanceFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

A plug for a pipe in an oil or gas well includes a packer, a slip ring and a cone disposable on a mandrel and pressed between an upper push sleeve and a lower anvil on the mandrel. The plug can be field configurable with a frac plug kit, a bridge plug kit and a soluble insert plug kit. A pair of concentric locking rings is disposed between the push sleeve and the mandrel with an outer annular cone with an outer conical shape tapered upwardly and inwardly.

Owner:BEAR CLAW TECH LLC

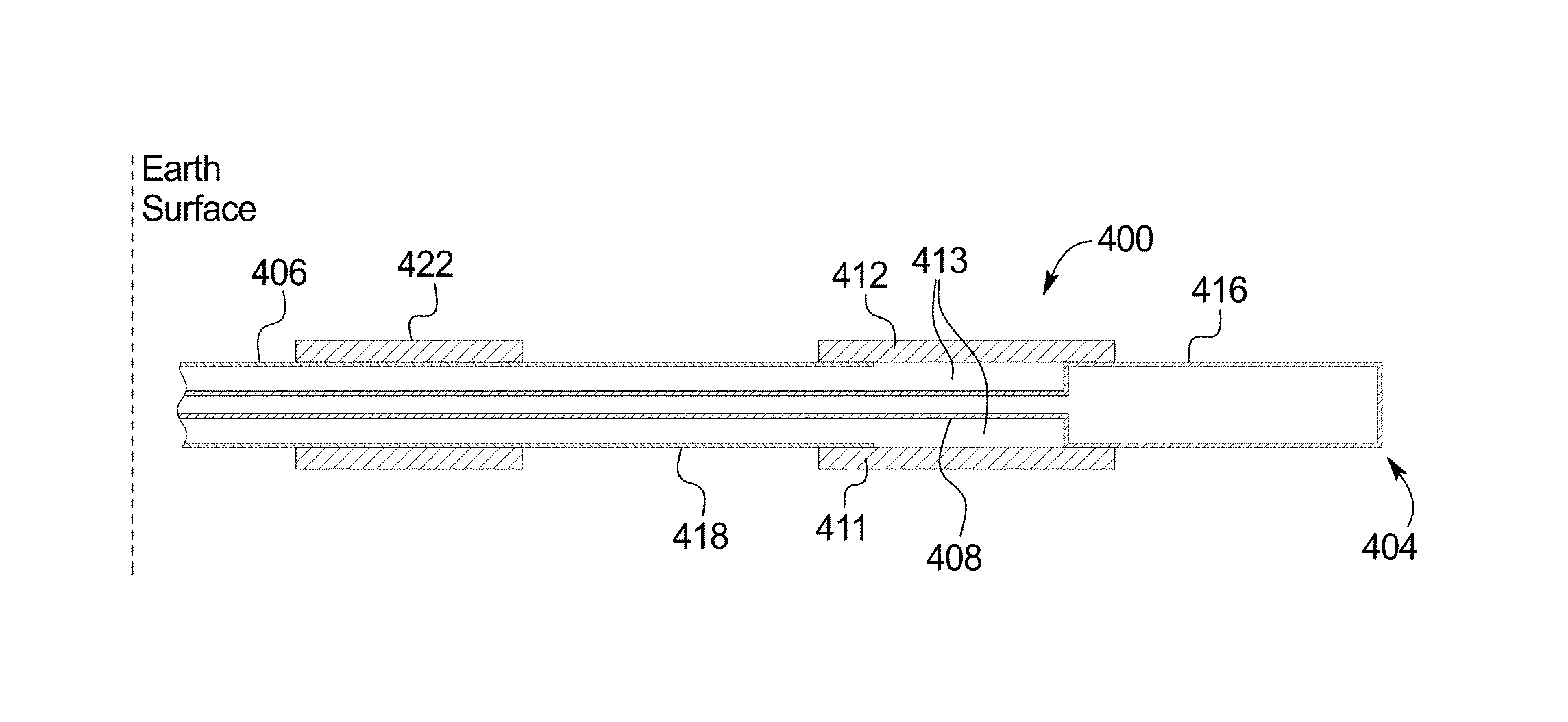

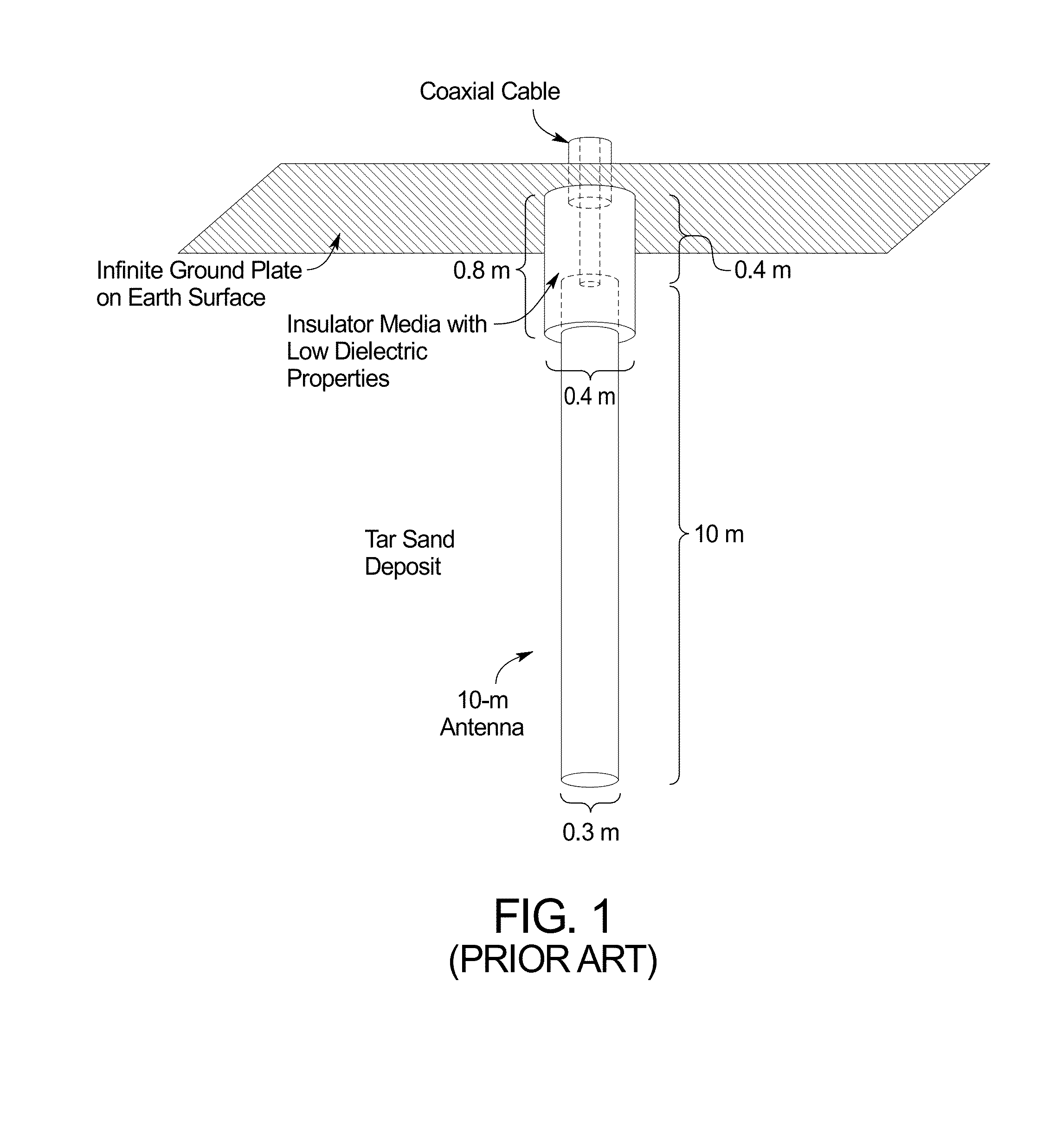

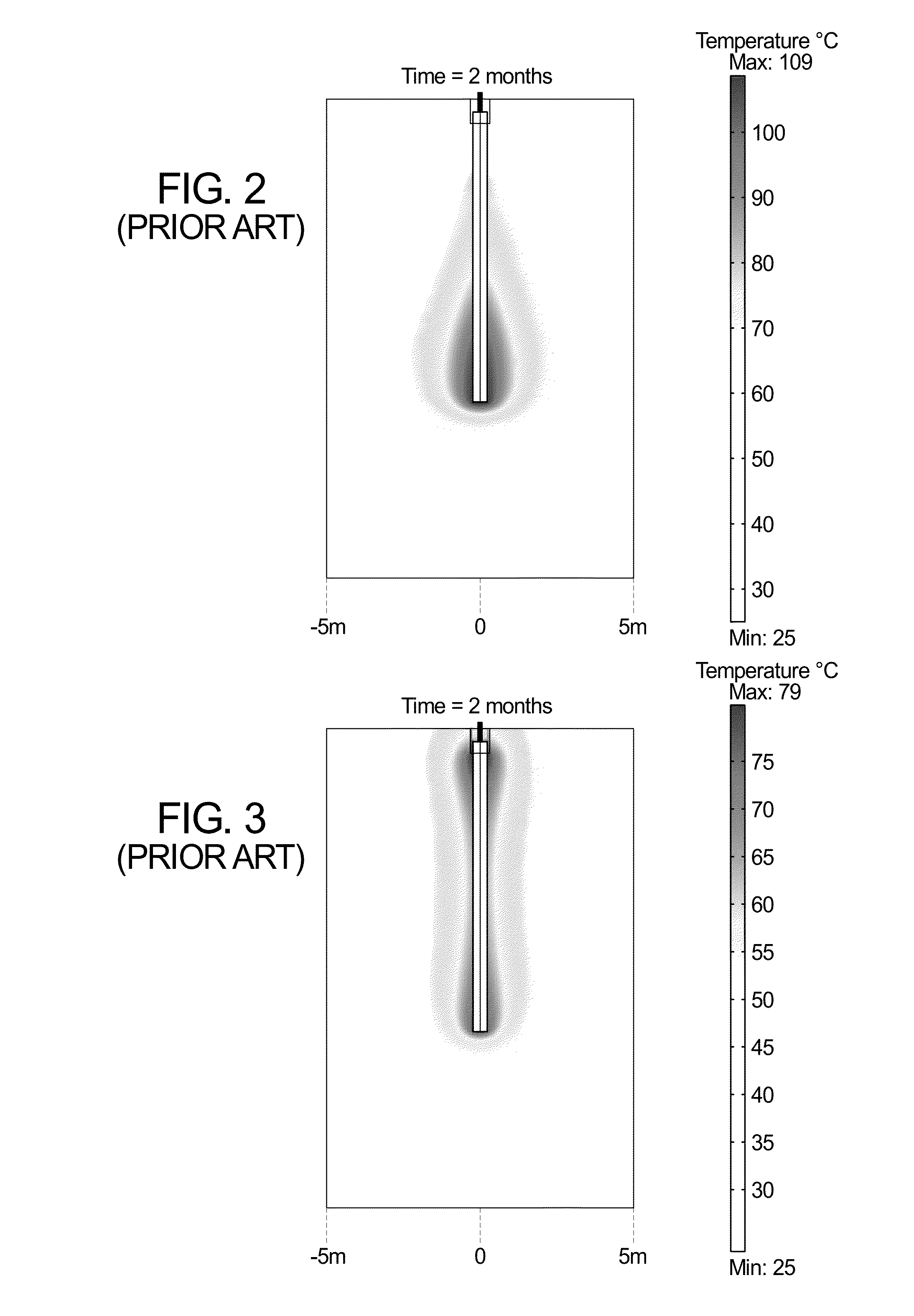

Stimulating production from oil wells using an RF dipole antenna

ActiveUS20140152312A1Reduced effectivenessLow thermal conductivityFluid removalDetection using electromagnetic wavesRf fieldElectrical conductor

A system emplaced in a subsurface formation configured to produce radio frequency (RF) fields for recovery of thermally responsive constituents includes coaxially disposed inner and outer conductors connected at an earth surface to an RF power source. The inner and outer conductors form a coaxial transmission line proximate said earth surface and a dipole antenna proximate said formation. The inner conductor protrudes from the outer conductor from a junction exposing a gap between the conductors to a deeper position within the formation. The RF power source is configured to deliver, via the conductors, RF fields to the formation. The system also includes at least one choke structure attached to said outer conductor at a distance at least ¼ wavelength above said junction. The choke structure is configured to confine a majority of said RF fields in a volume of said formation situated adjacent to said antenna.

Owner:PYROPHASE INC

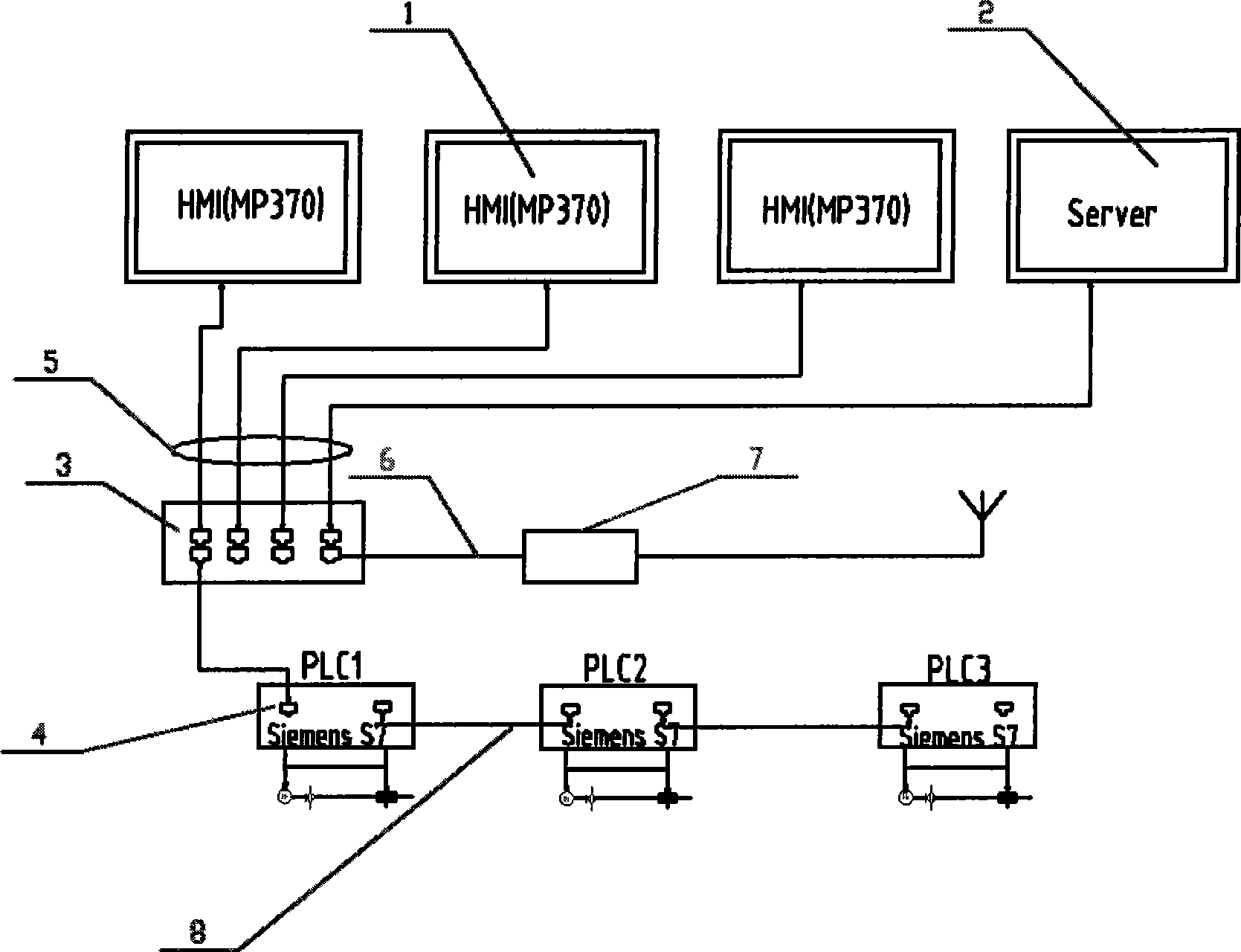

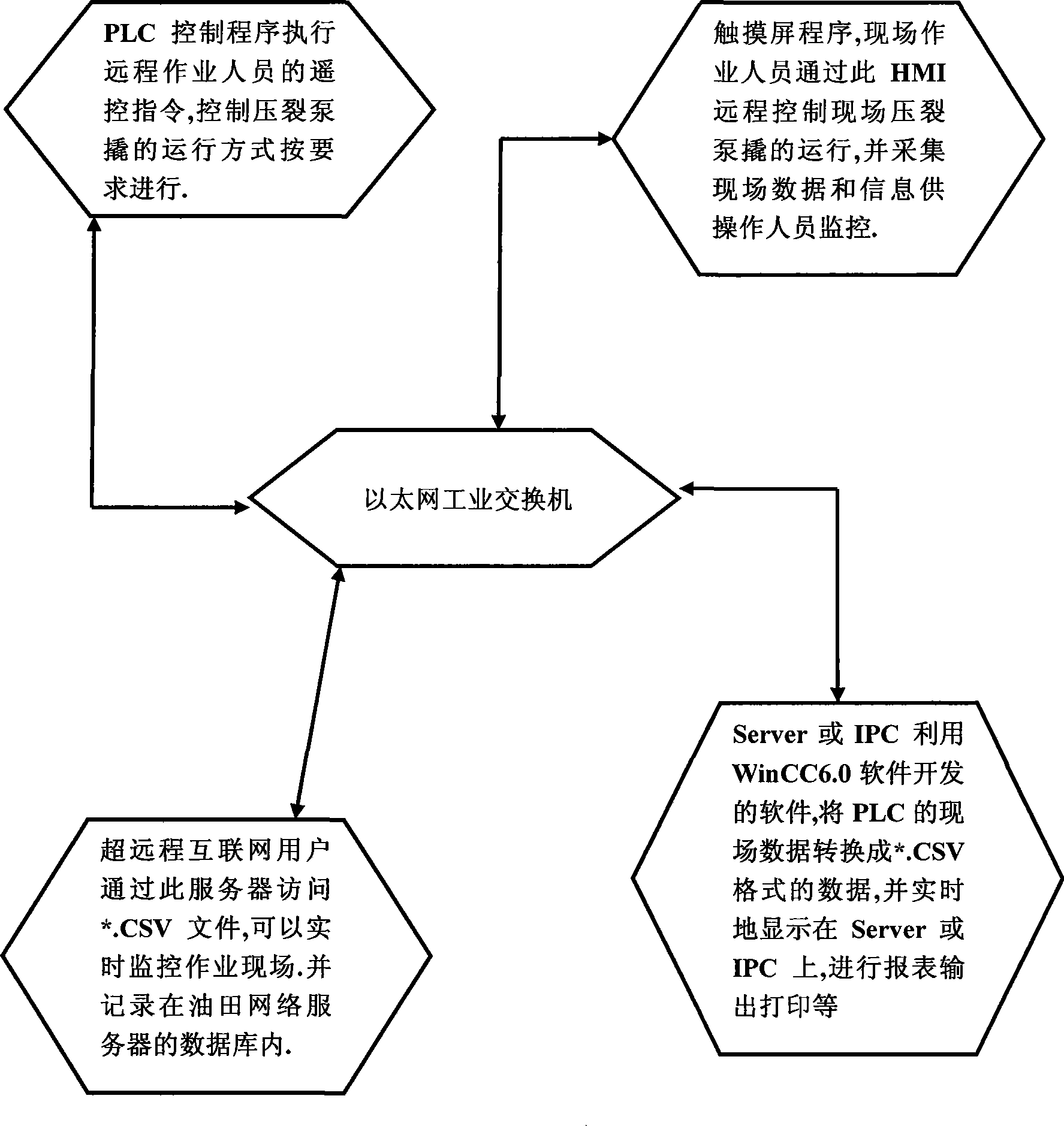

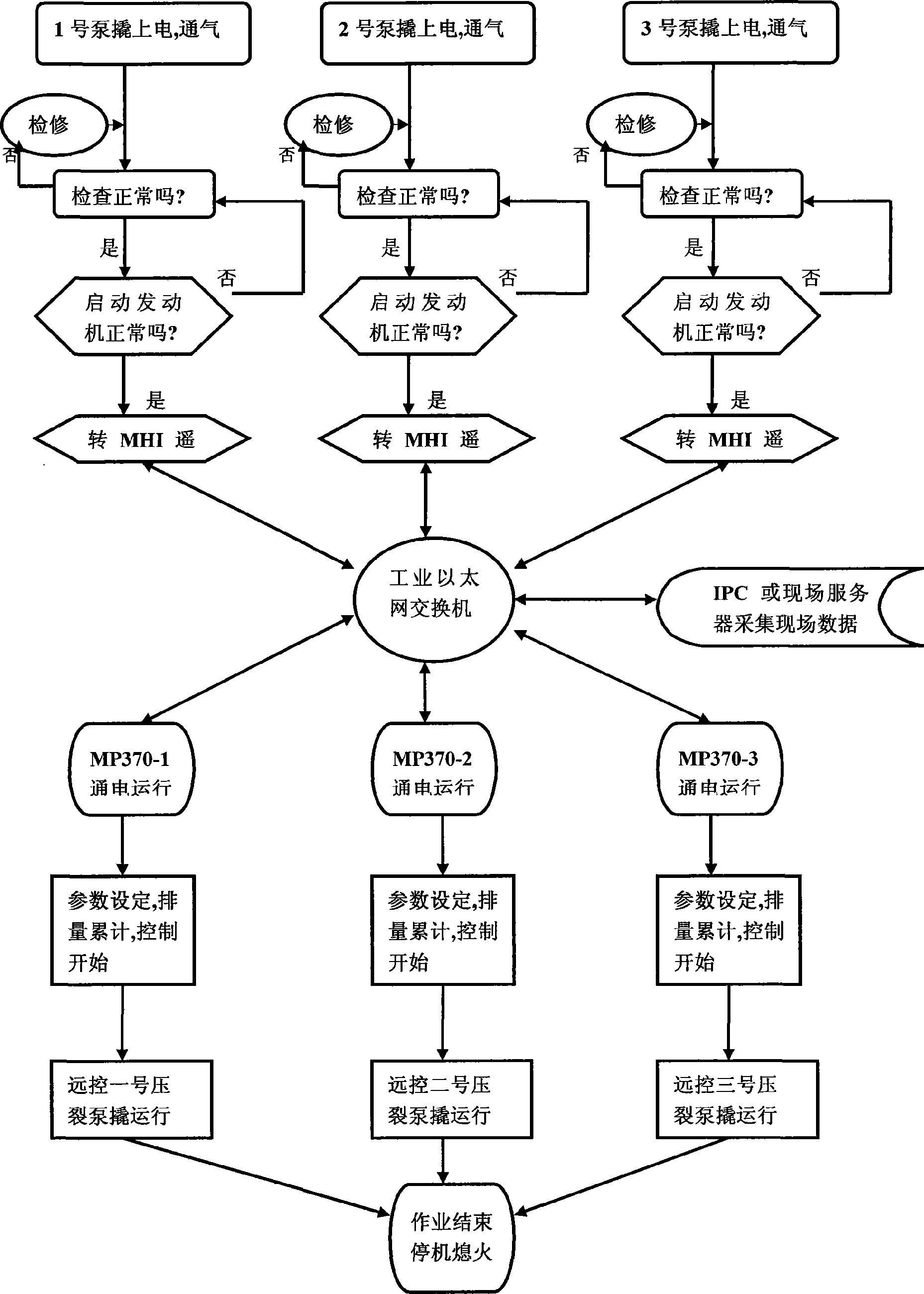

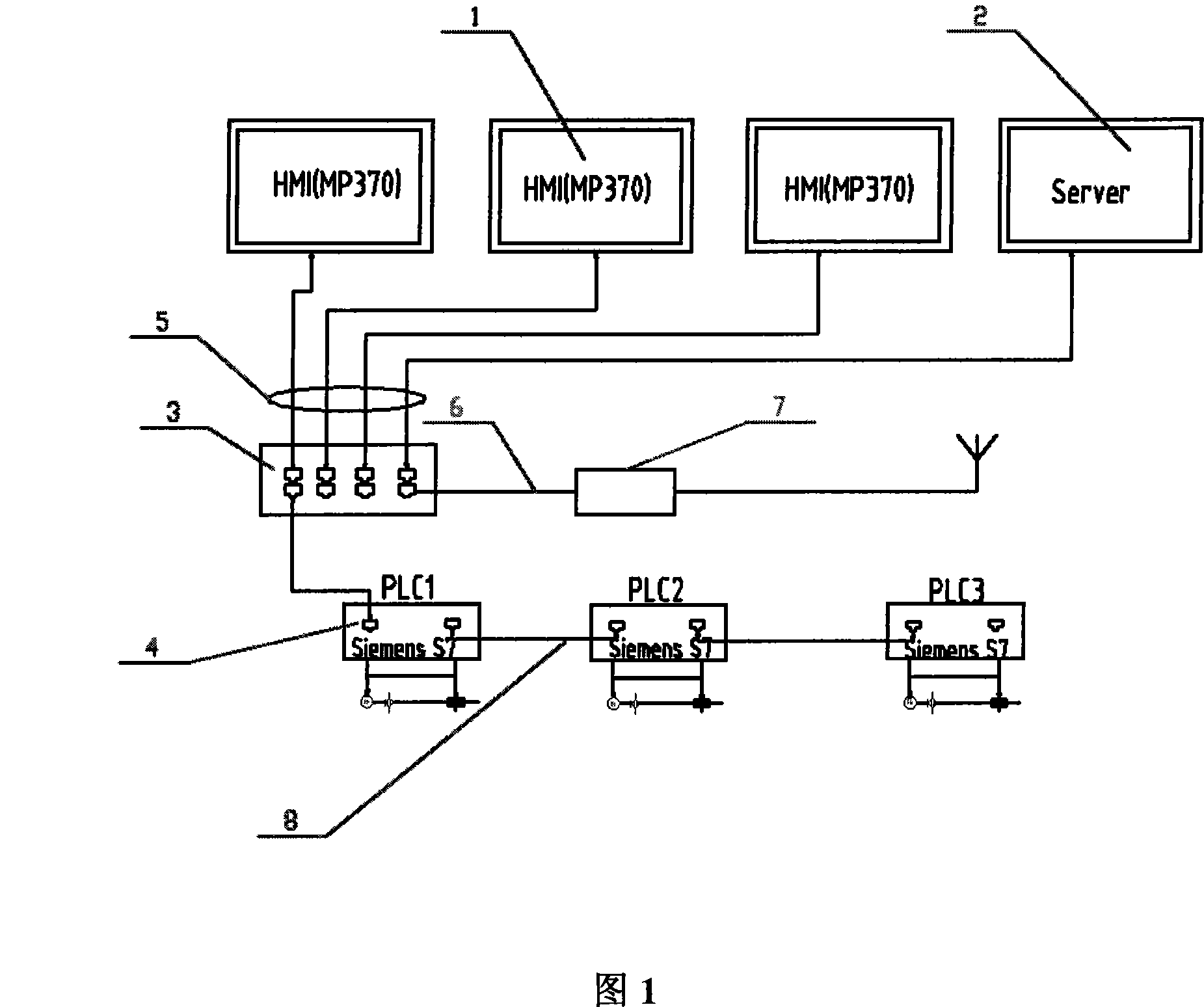

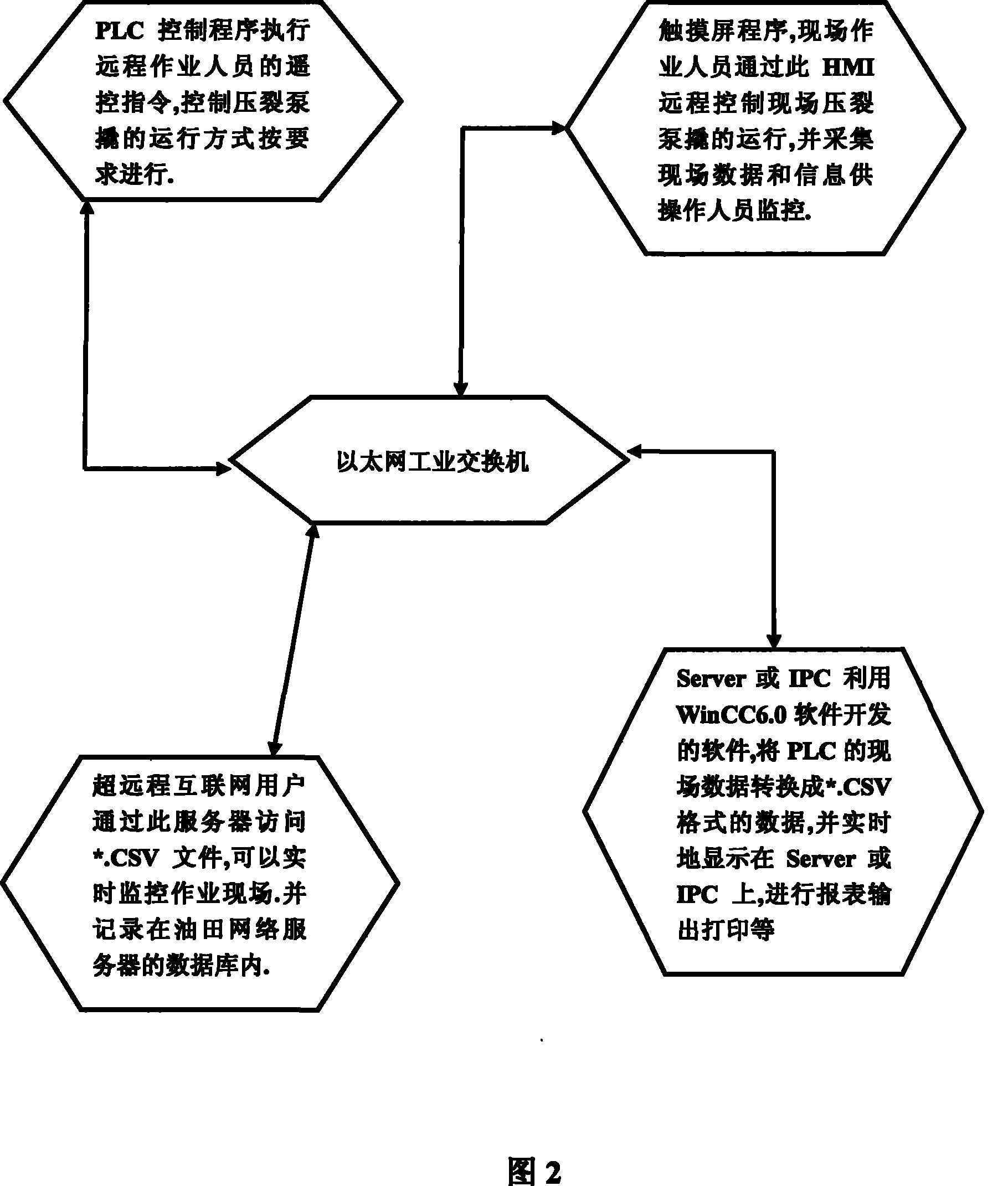

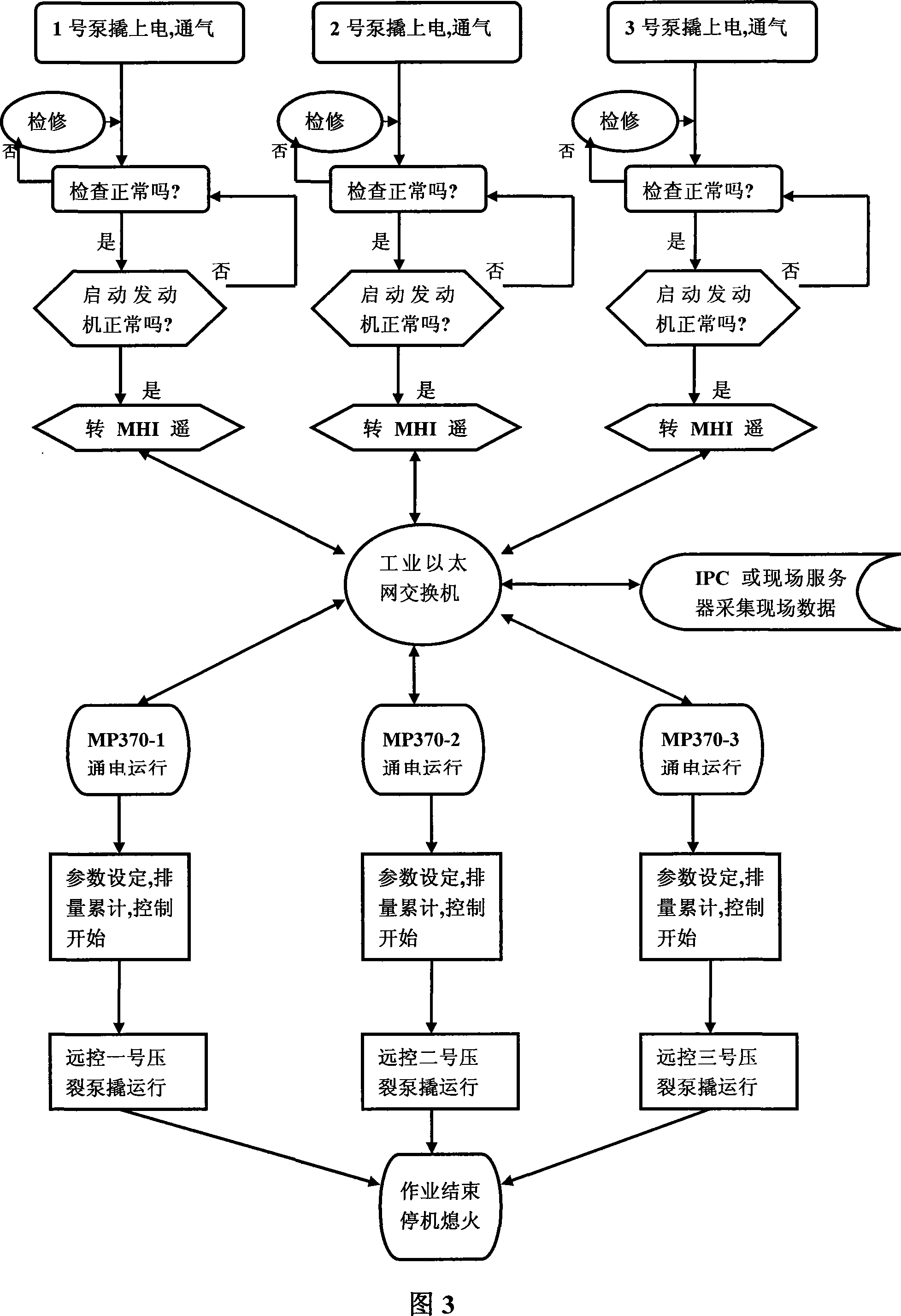

Oil field fracturing pumping remote automatic control system

ActiveCN101414171AMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

The invention discloses a remote automatic control system of a fracturing pump skid used in an oil field. The system is used for remote automatic control of a well service pump skid and a truck-mounted skid used in the oil field; the remote automatic control system consists of a field control system which consists of Siemens S7-315 series PLCs which are taken as a core, a Siemens MP370 which is taken as a remote control human-machine interface, and Ethernet which is taken as a transmission media; the system can achieve remote control functions such as start, stop and emergency stop of an engine, gear shifting, braking, turning back to a neutral position and idle speed of a gearbox and the like, and the system can modify field running parameters in a remote manner, thus realizing bidirectional transmission between the pump skid and the human-machine interface (HMI); the Ethernet is taken for communication so that the pump skid can transmit the field data to a remote controller or a server at the speed of 100MB / S; an industrial exchanger is taken to connect the devices such as the PLC, the HMI and the like to achieve more group controls; the exchanger can convert the field data into the data formats such as a standard *.CSV format and the like, and directly transmit the data to the server for data processing.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

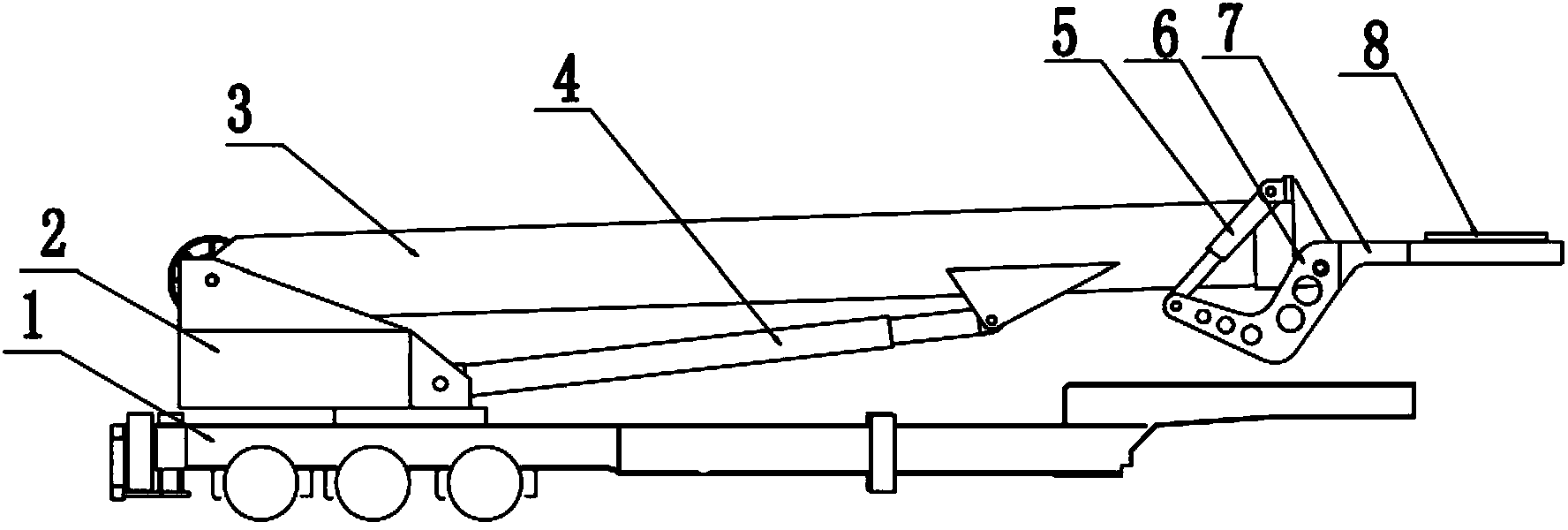

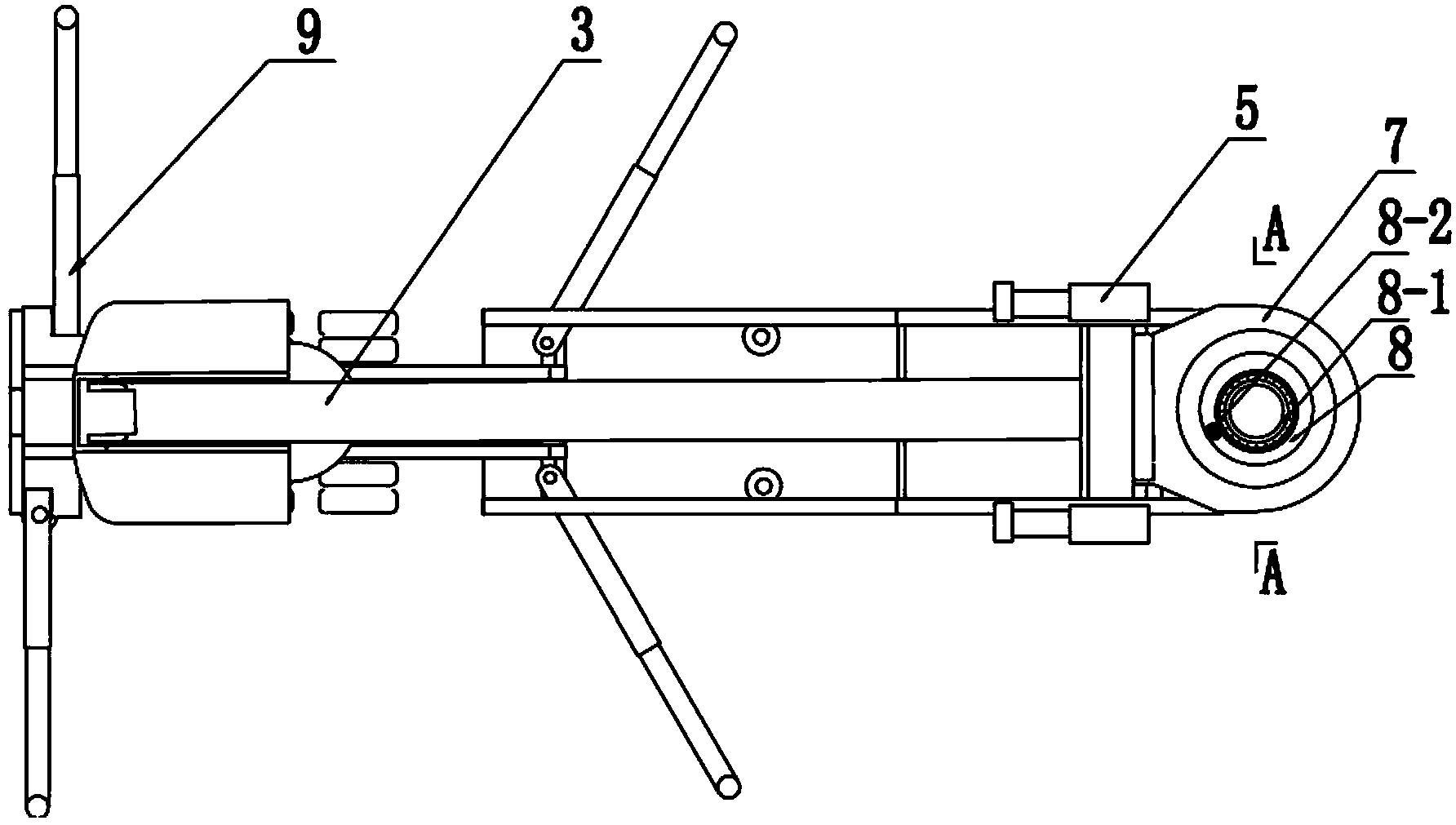

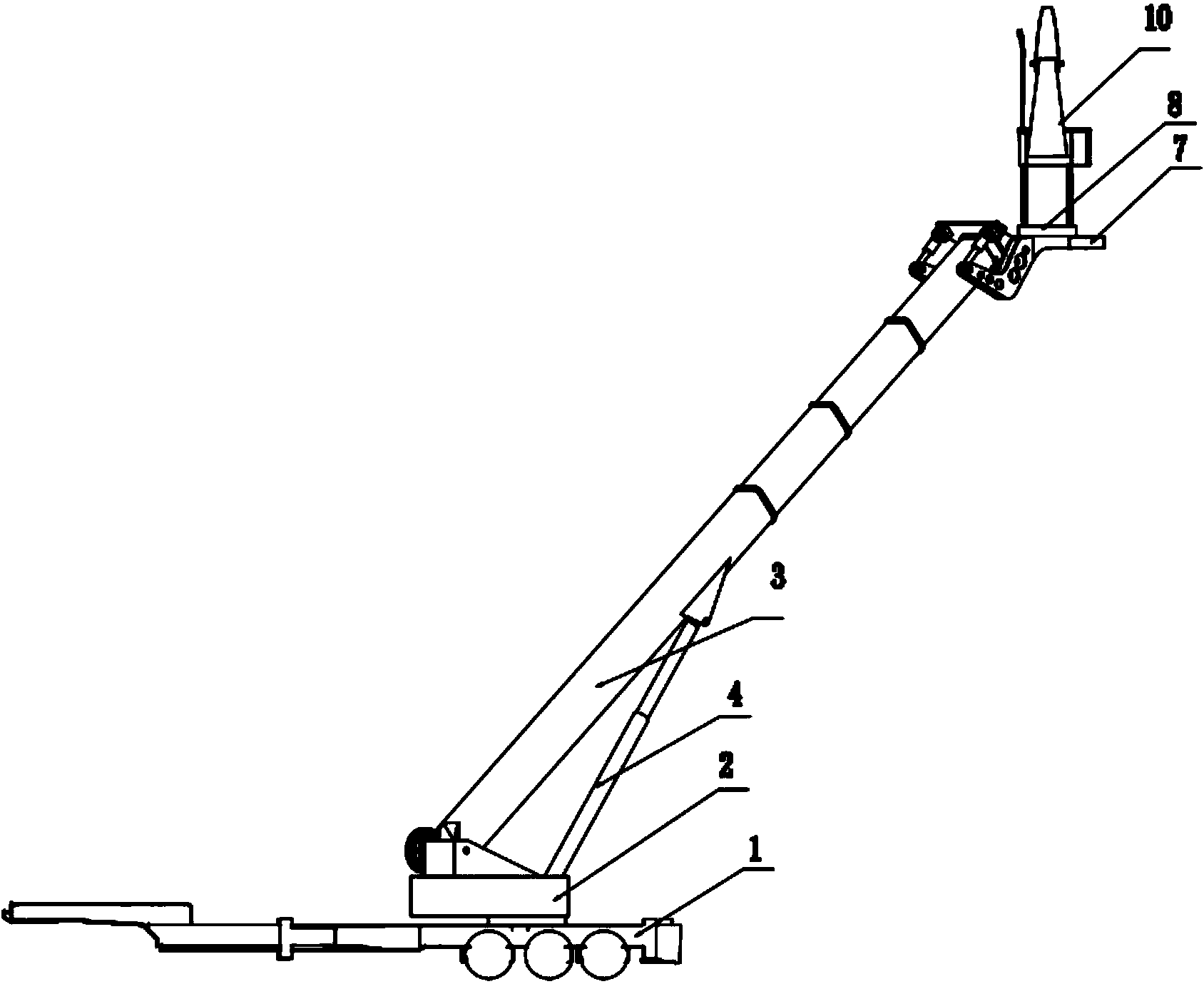

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Remote, automatic control system for oil field fracturing pumping

ActiveCN101414171BMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

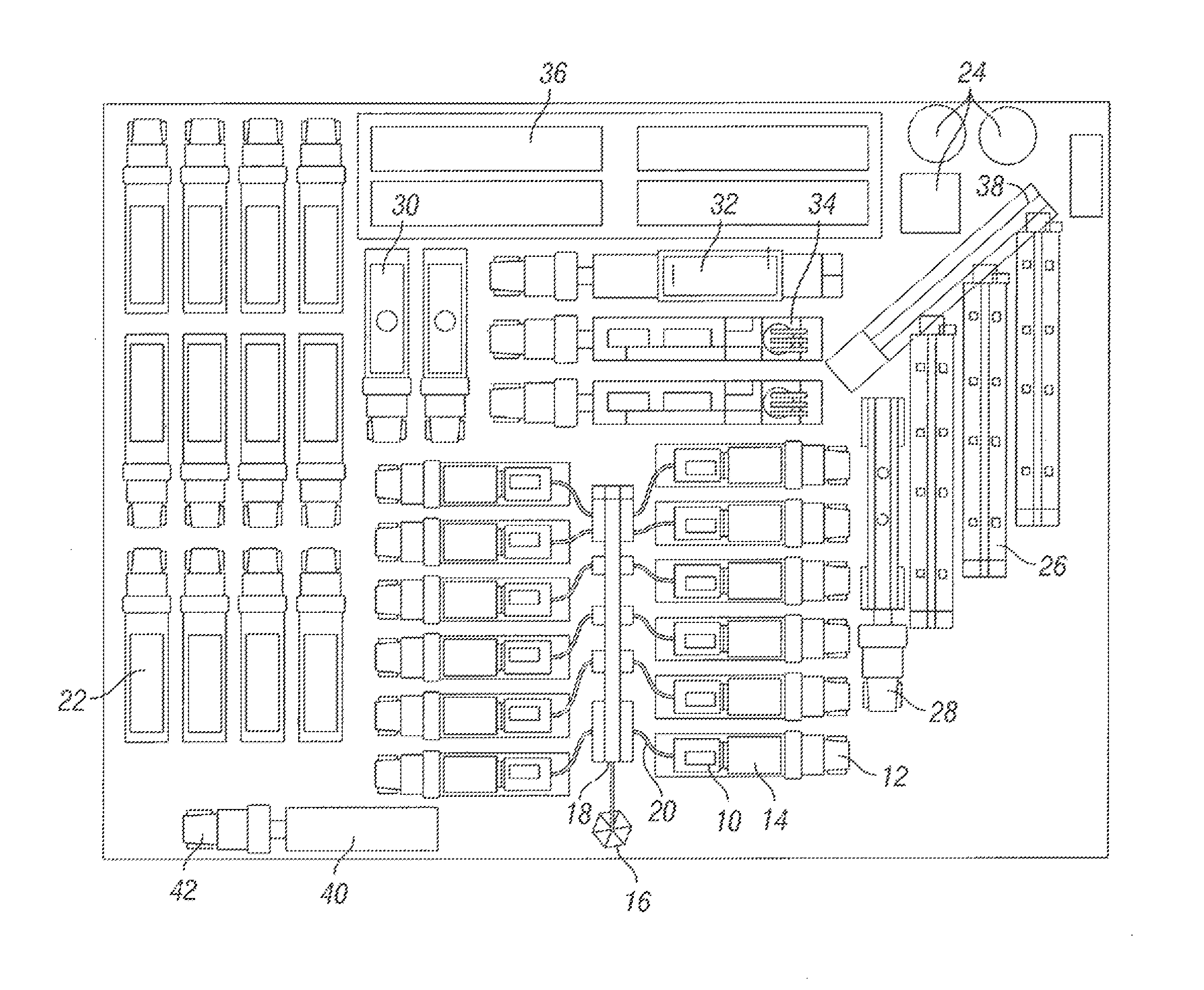

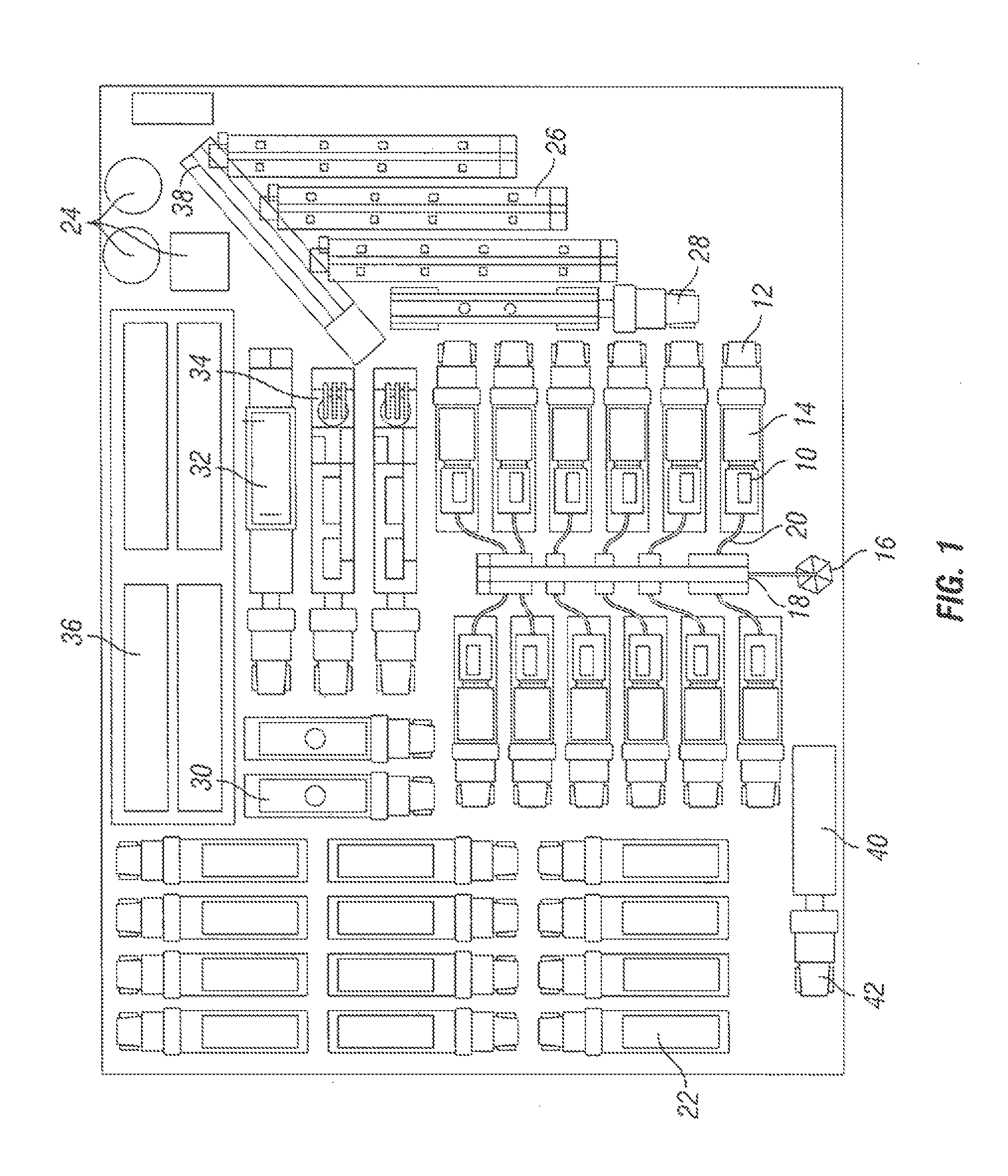

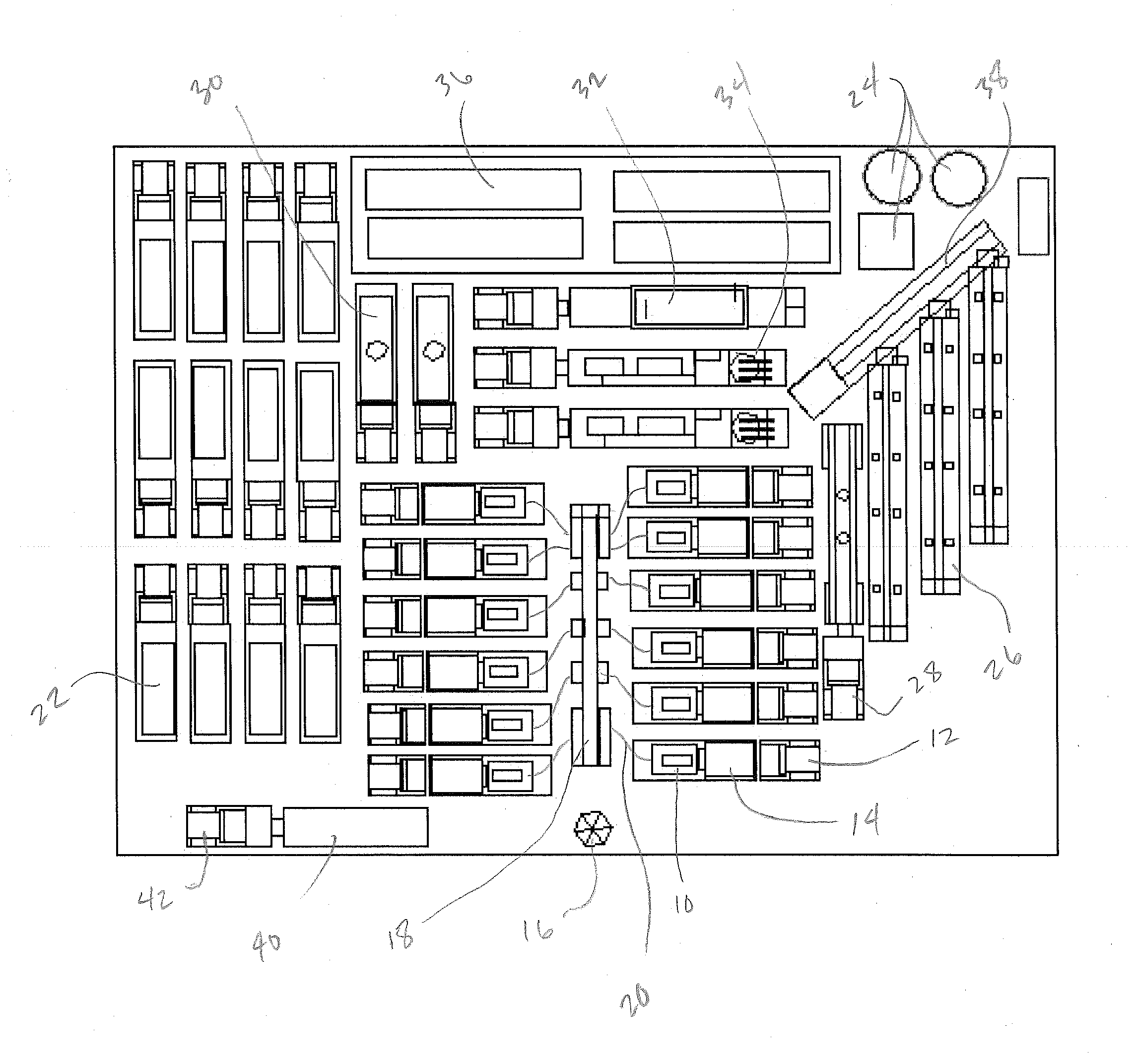

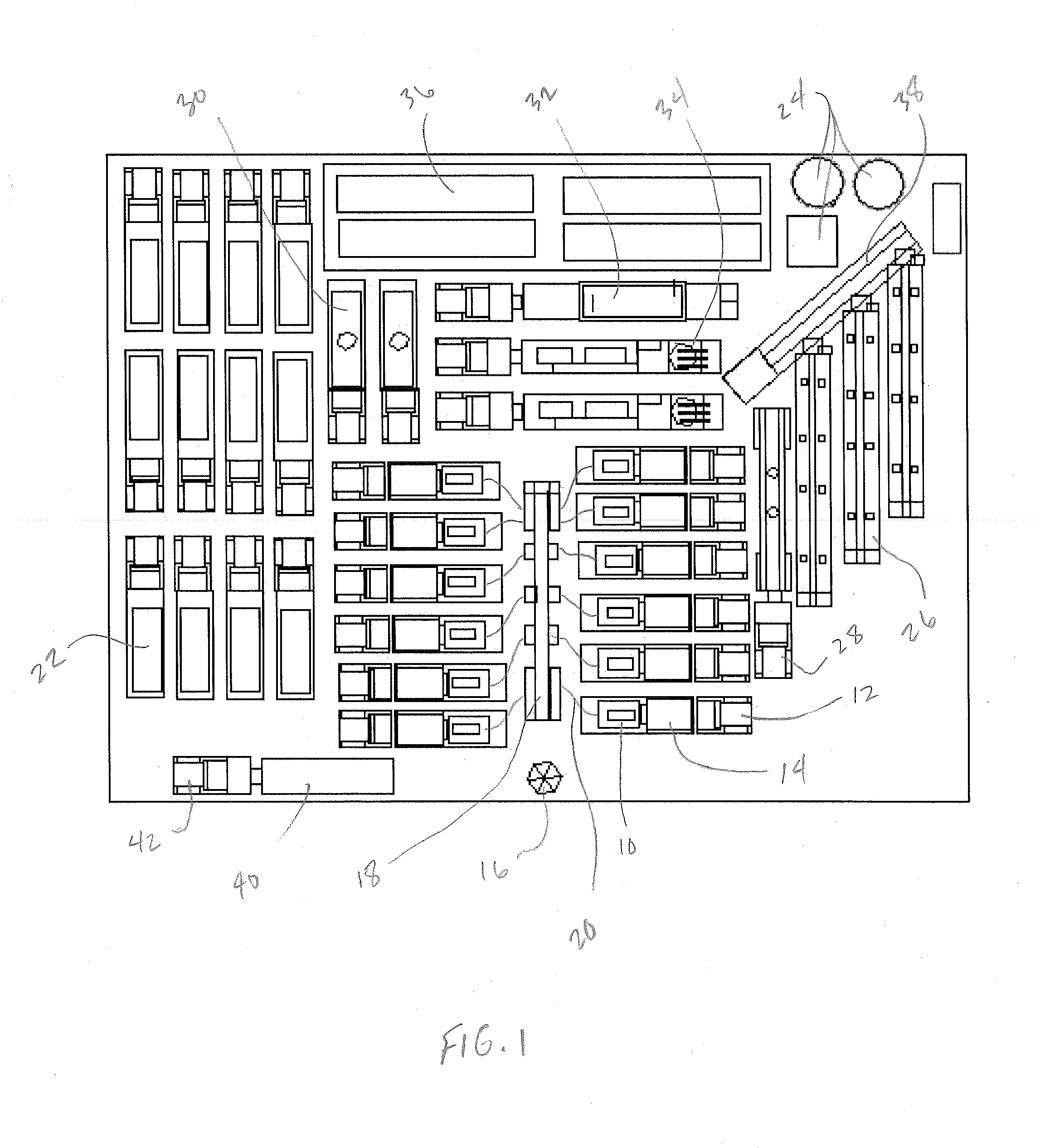

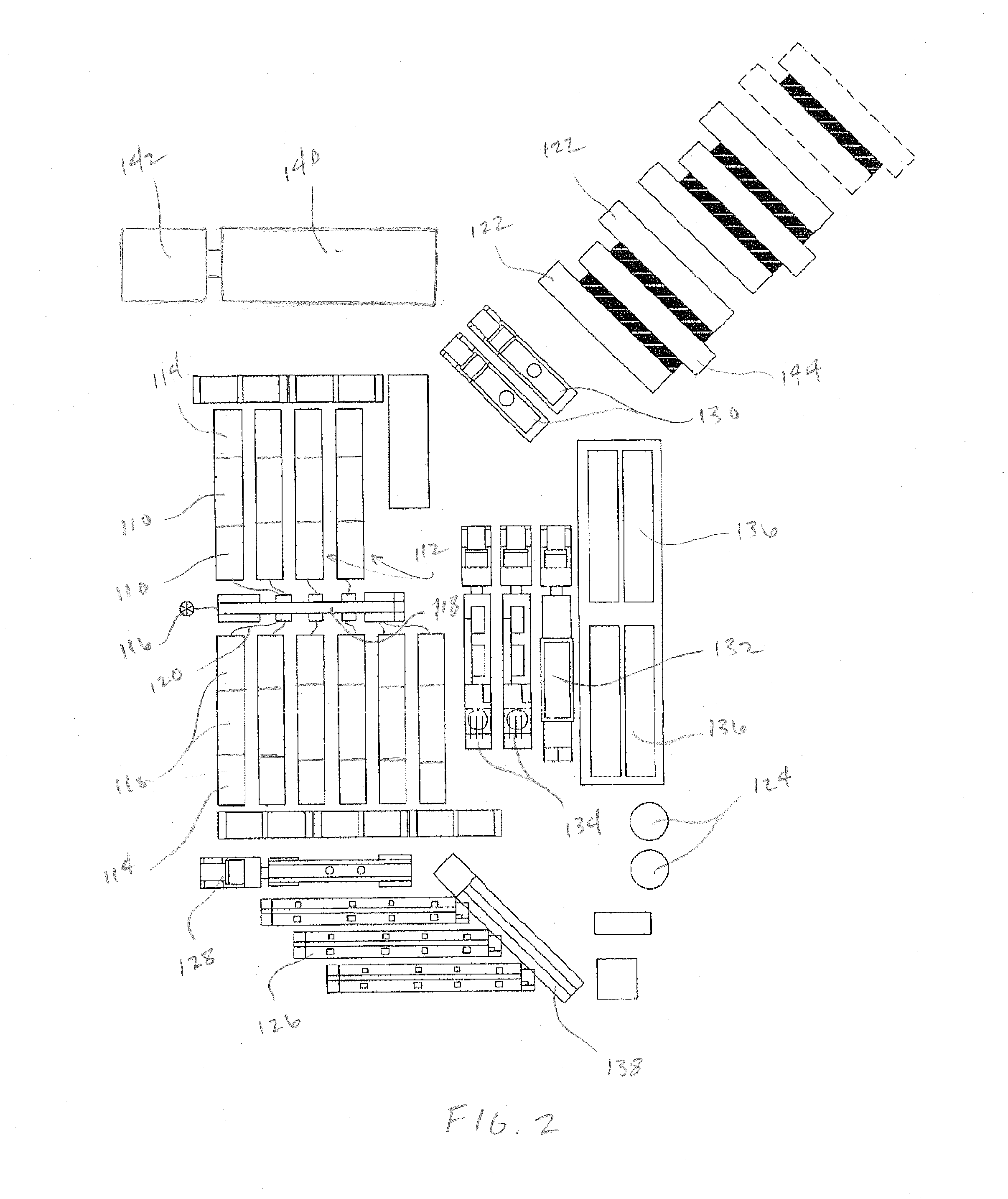

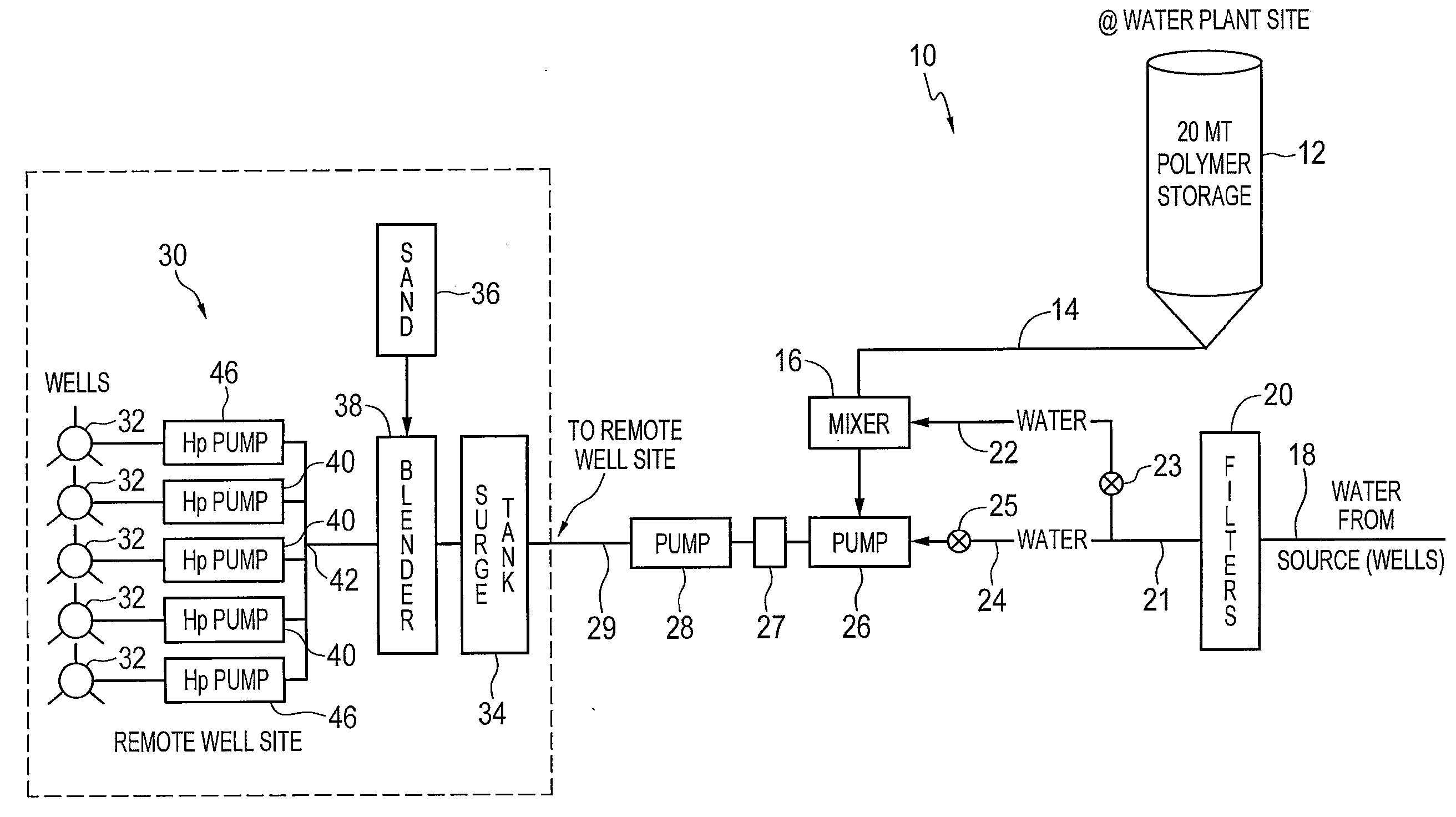

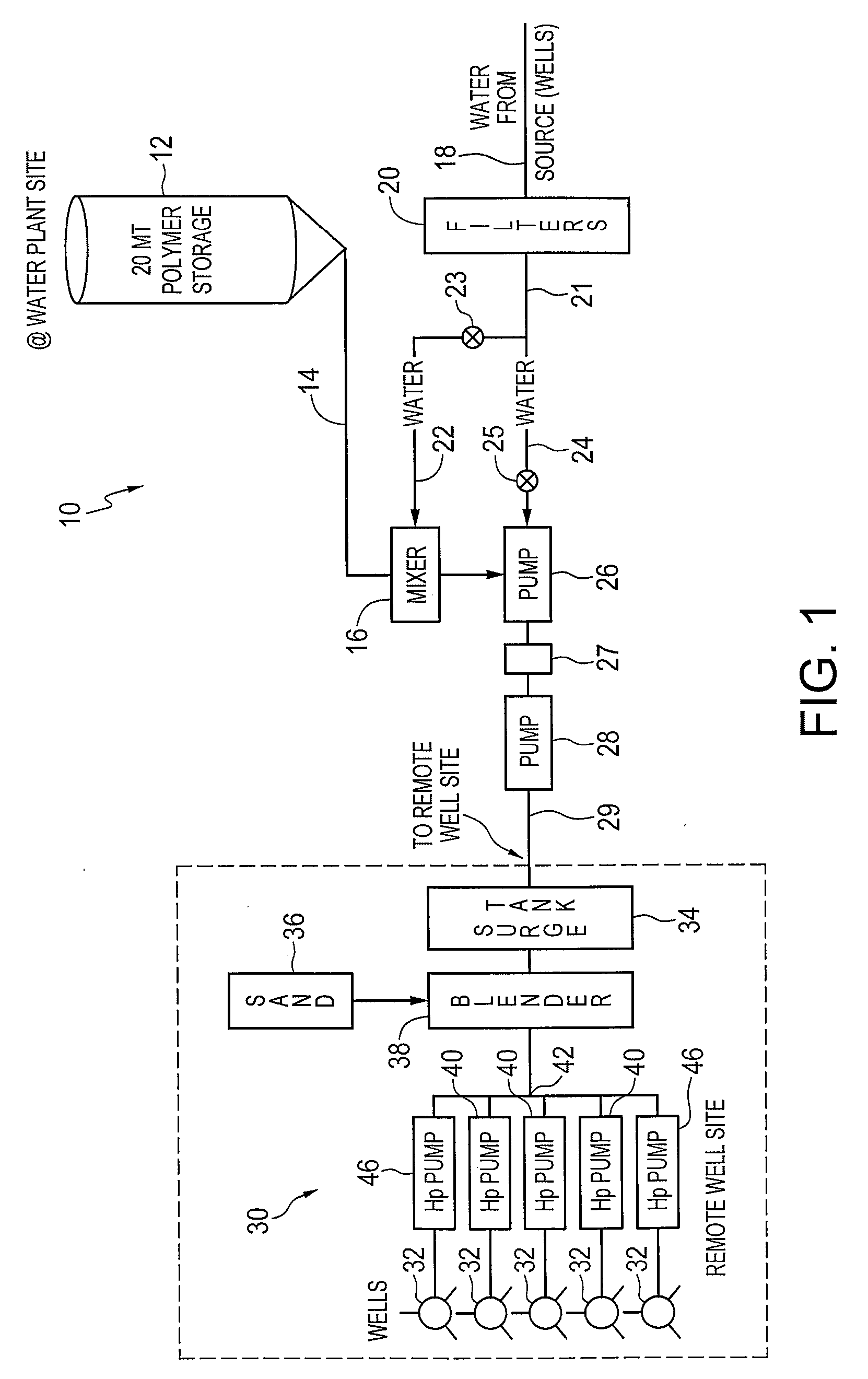

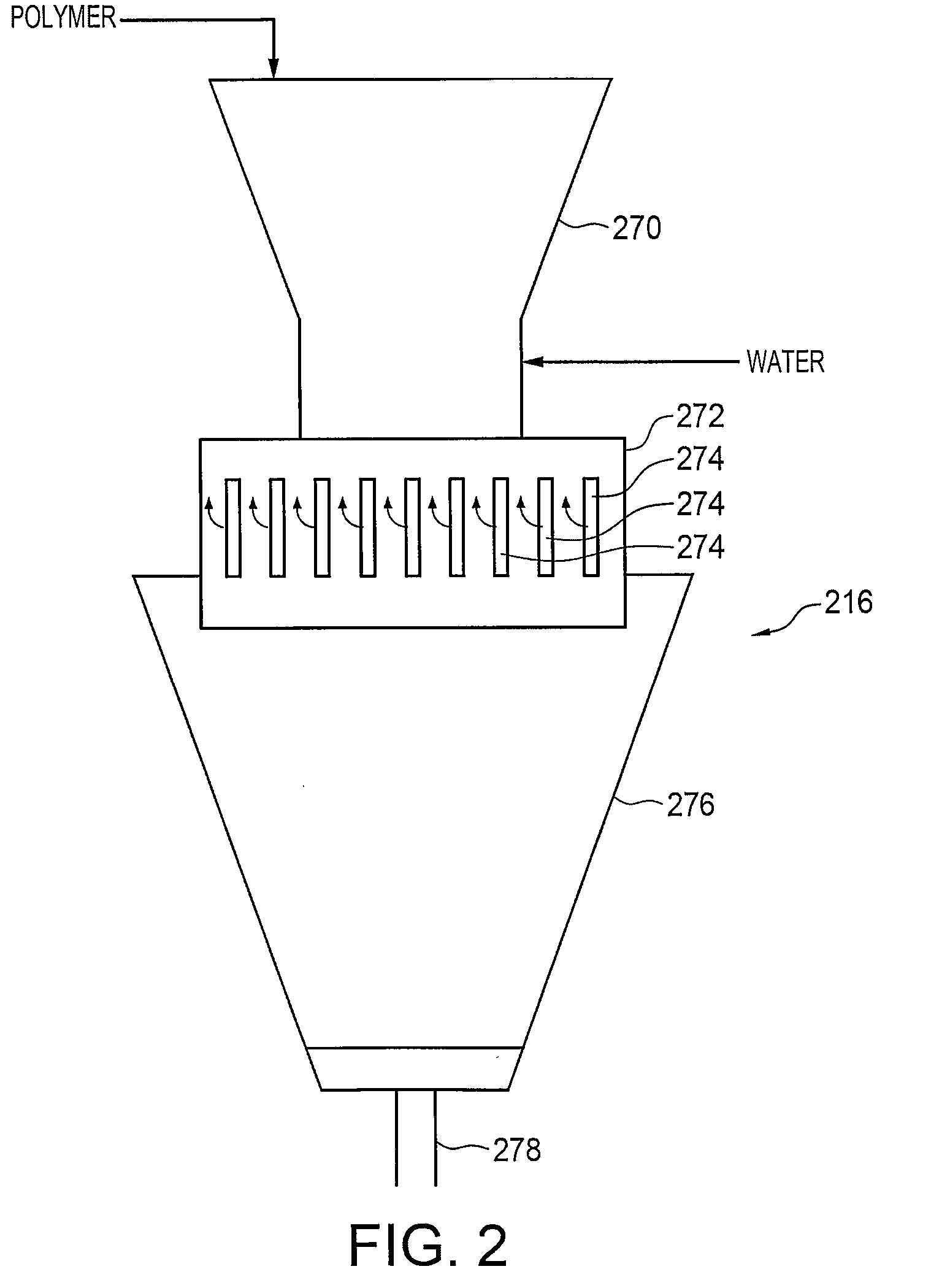

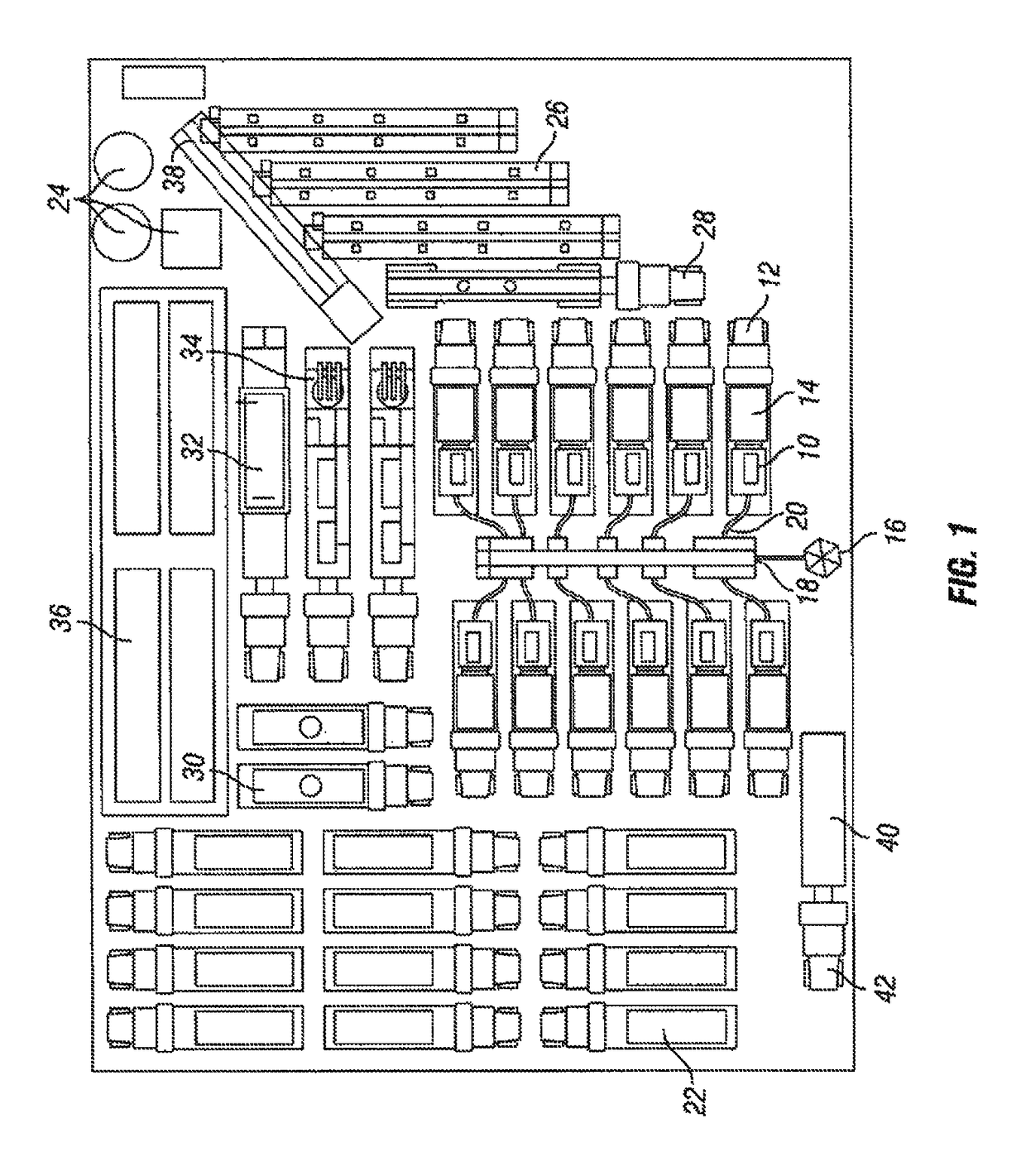

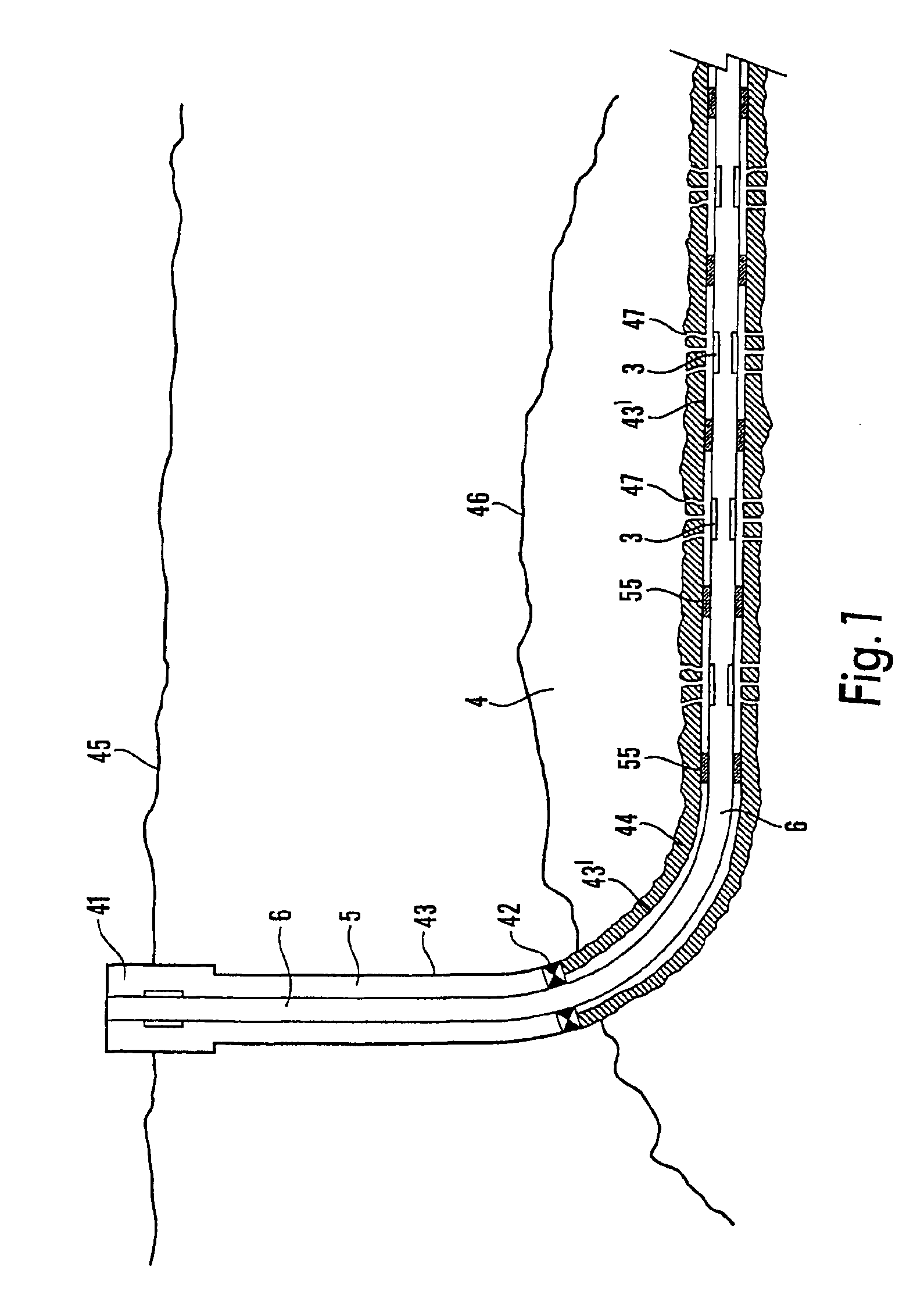

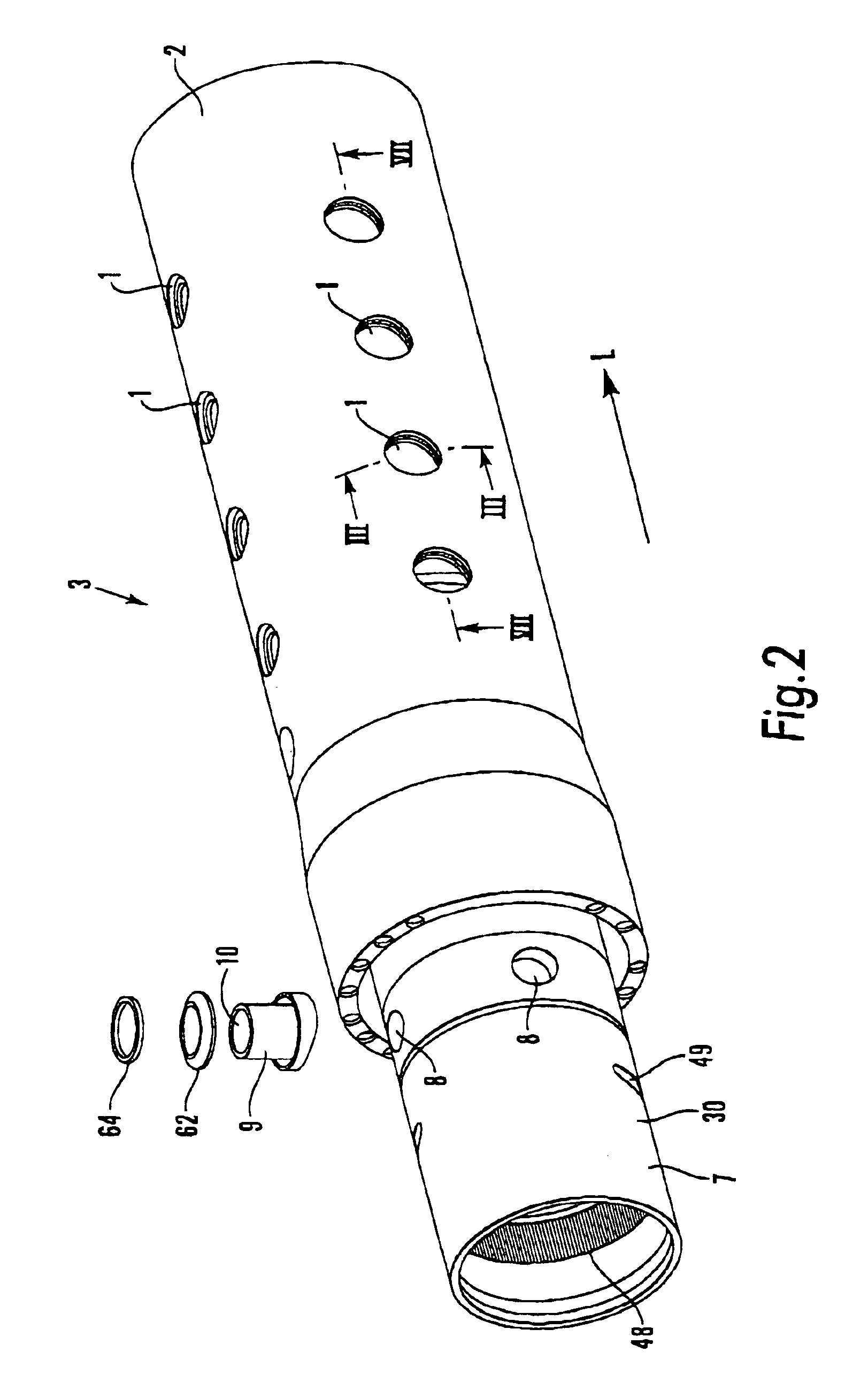

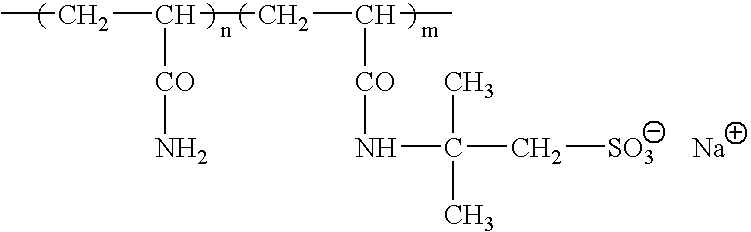

Process and process line for the preparation of hydraulic fracturing fluid

InactiveUS20100132949A1Drilling rodsTransportation and packagingFracturing fluidHydraulic fracturing

A process and process line is provided for preparing a friction-reduced hydraulic fracturing fluid at a central location which can be readily transported to an oil or gas well in a formation at a well site, comprising: preparing a mixture of polymer and water at the central location by shearing the polymer in the water in a high shear environment to create the friction-reduced hydraulic fracturing fluid; pumping the friction-reduced hydraulic fracturing fluid through a series of pumps and pipelines to the well site; and injecting the hydraulic fracturing fluid into the oil or gas well at a pressure sufficient to cause fracturing of the formation.

Owner:OVINTIV CANADA ULC

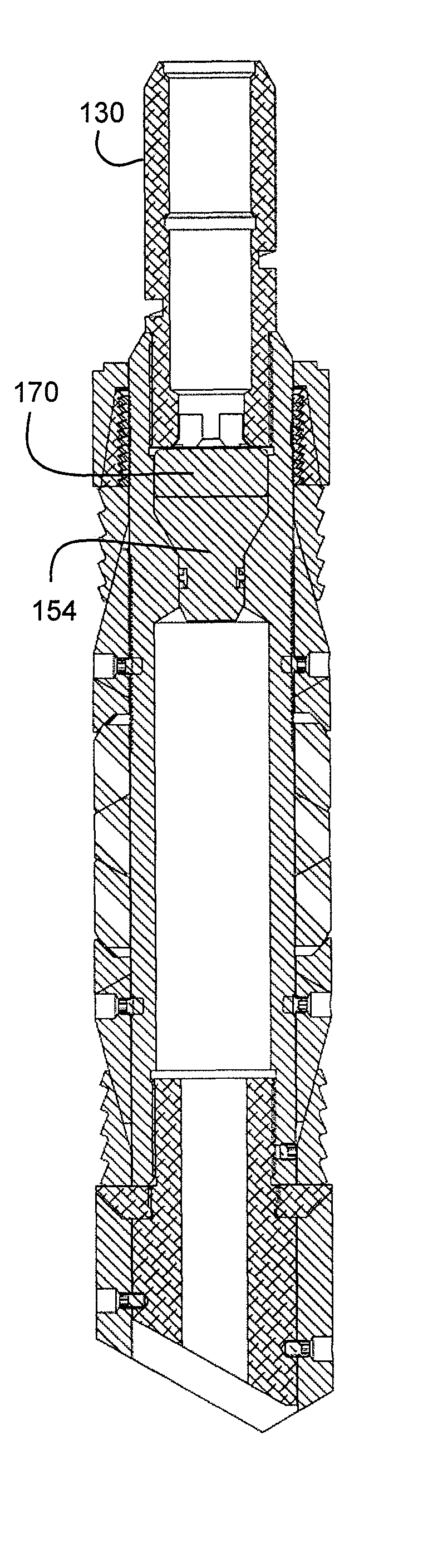

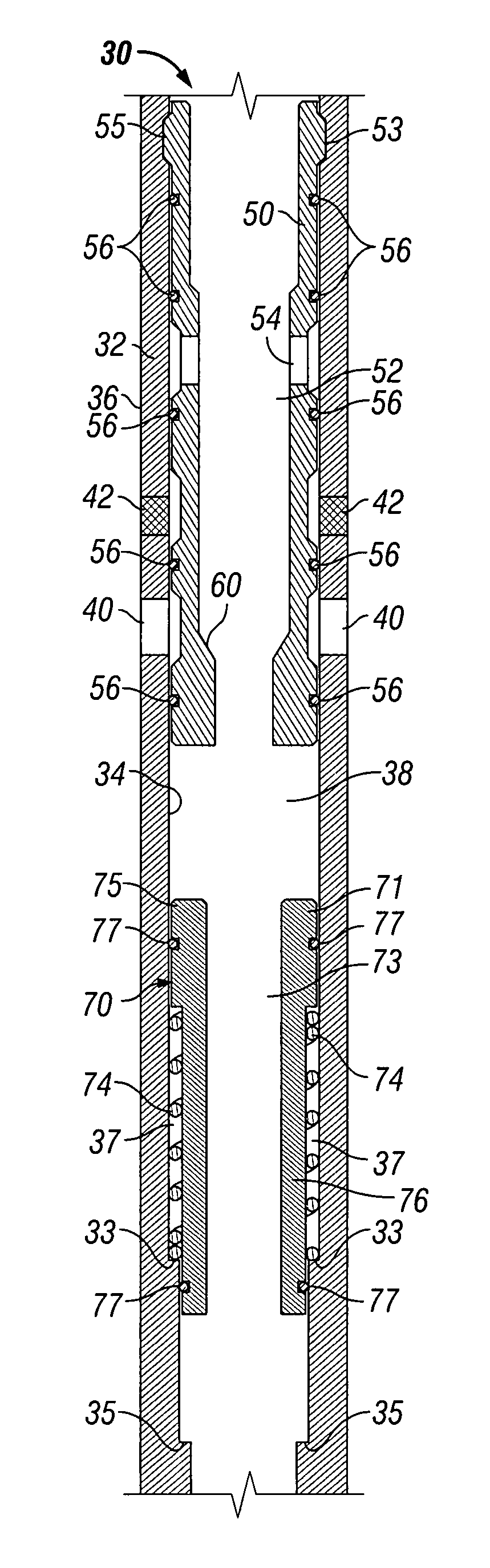

Interventionless multi-position frac tool

Fracturing tools for use in oil and gas wells are disclosed. The fracturing tools have a run-in position and two operational positions. A sleeve disposed in the bore of the fracturing tool comprises a sleeve port alignable with a first port in the housing of the frac tool, i.e., the first operational position, during fracturing operations. A second port having a restriction member is disposed in the housing and is closed by the sleeve during fracturing operations. After fracturing operations are completed, a return member in the frac tool moves the sleeve from the first operational position to a second operational position for production operations. In this second operational position, the first port is closed and the sleeve port is aligned with the second port. Movement of the sleeve from the first operational position to the second operational position is performed without the need for an additional well intervention step.

Owner:BAKER HUGHES INC

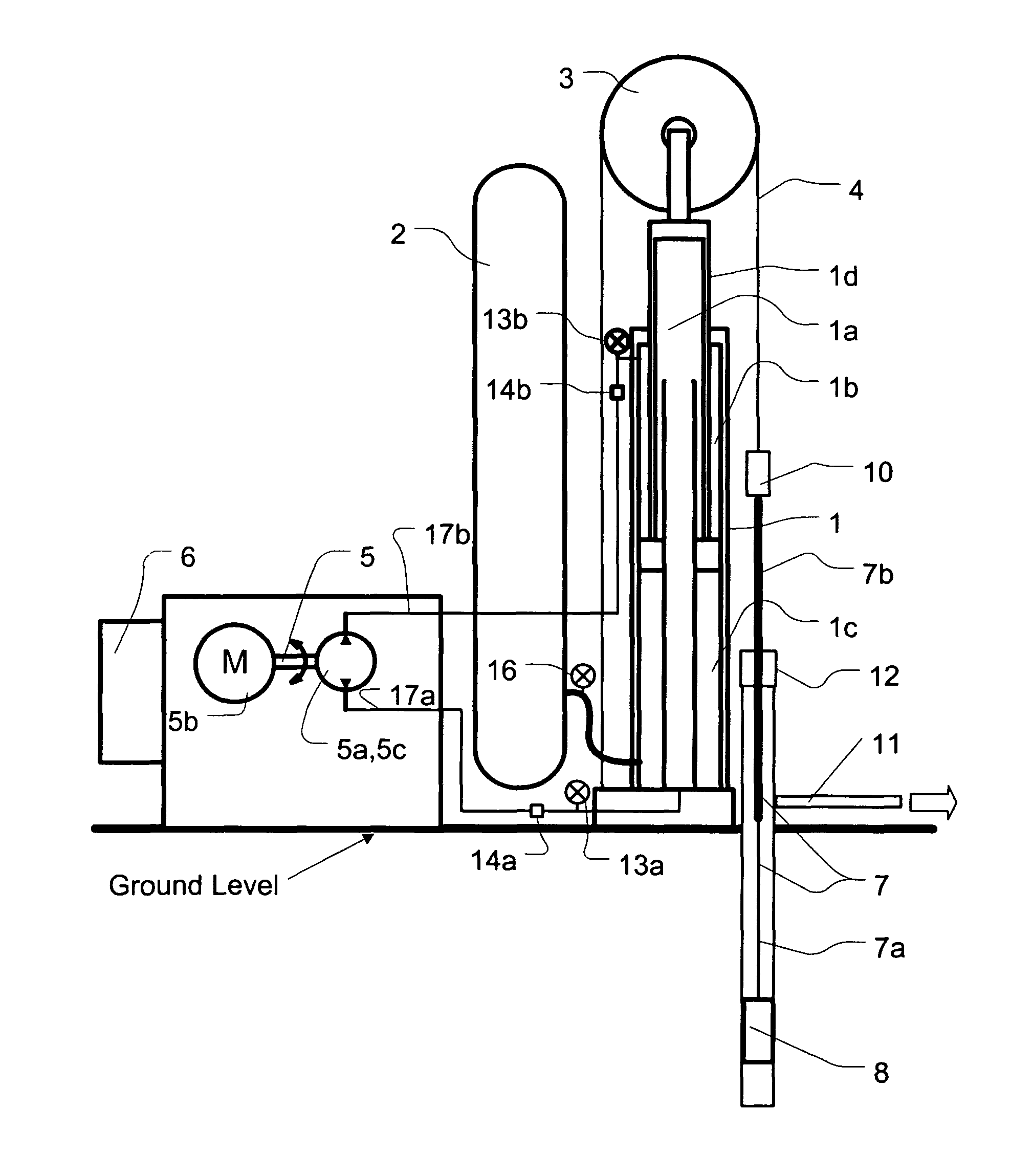

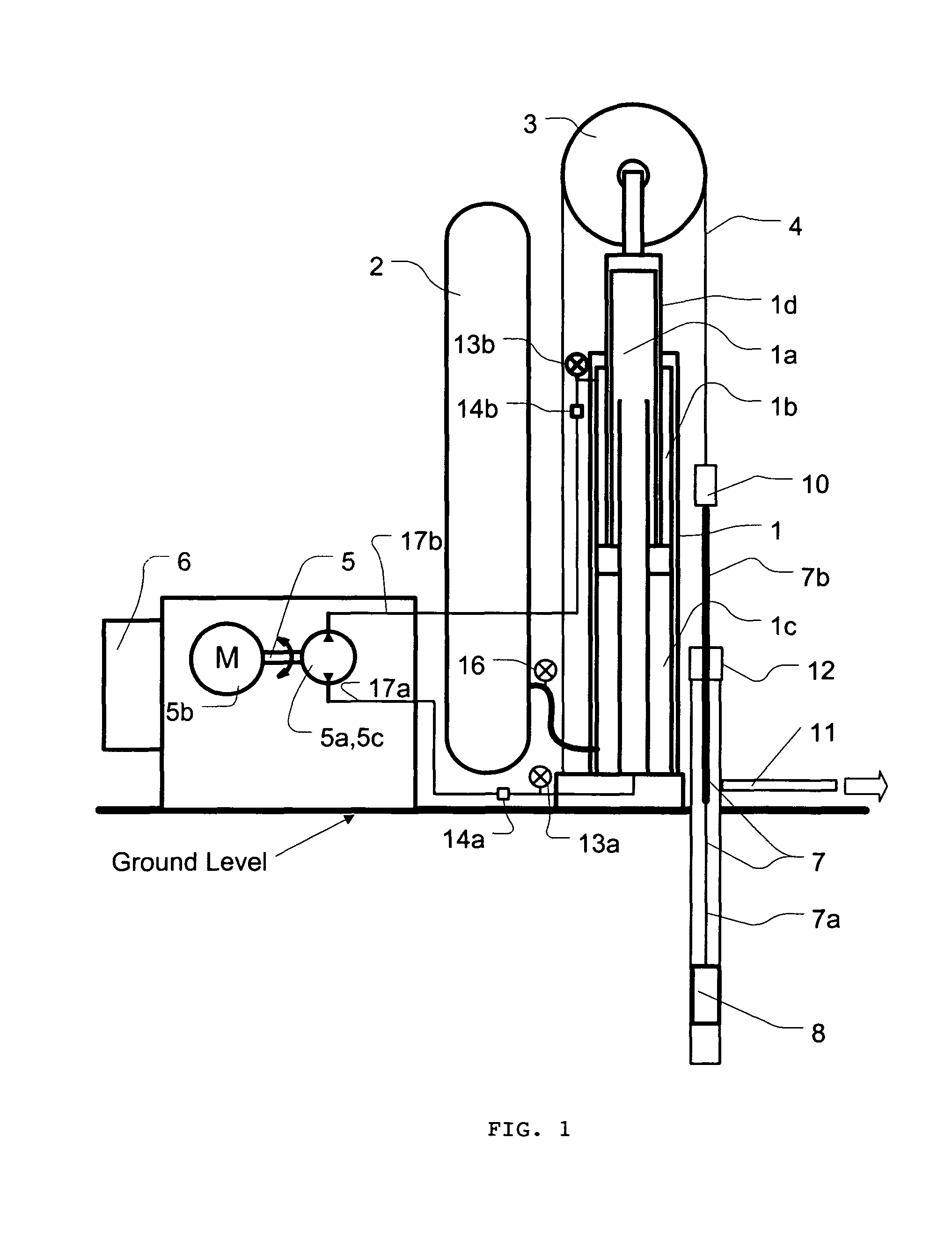

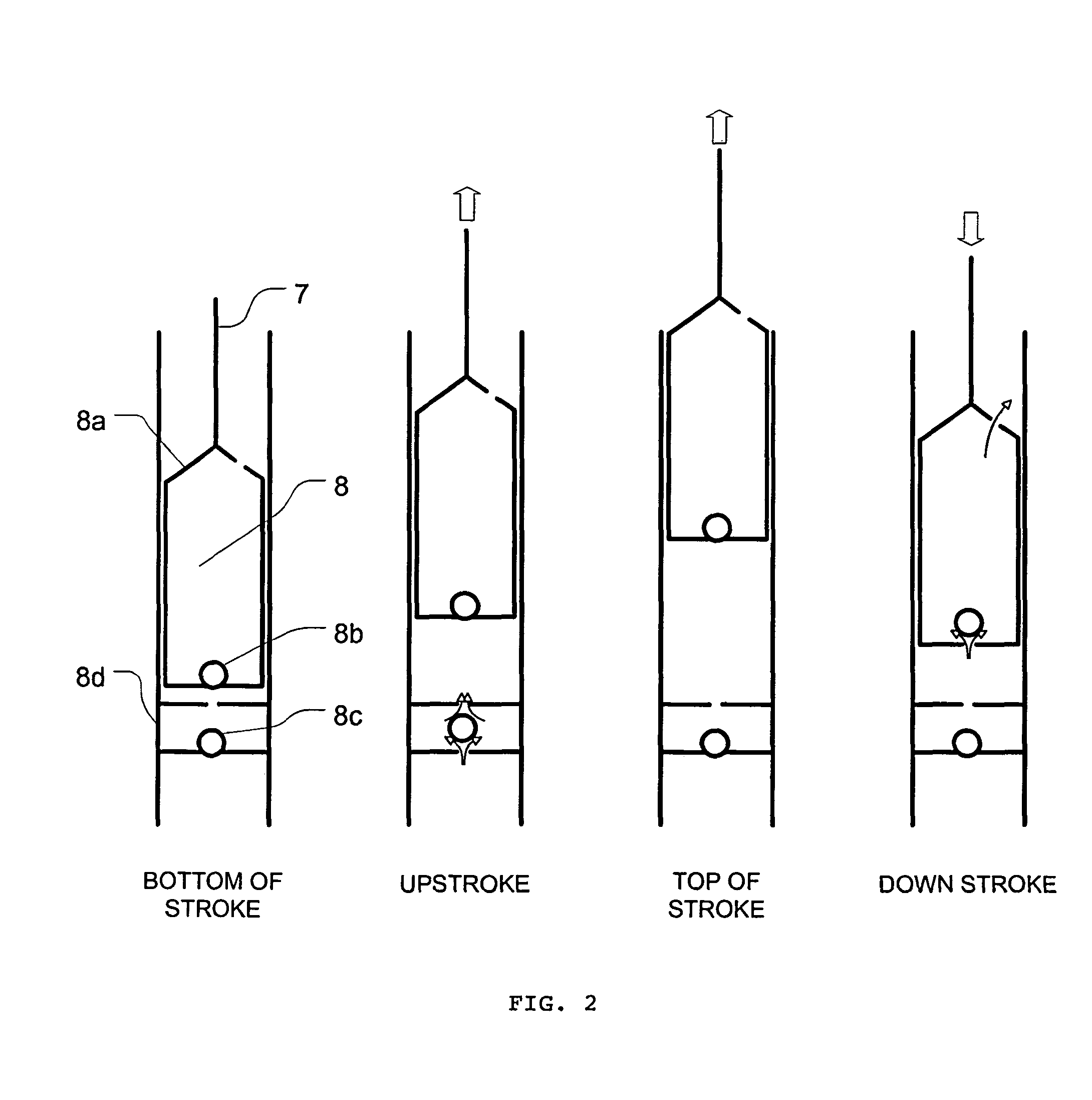

Adaptive control of an oil or gas well surface-mounted hydraulic pumping system and method

ActiveUS8851860B1Increase production capacityIncreased durabilityFluid parameterFlexible member pumpsControl systemSurface mounting

The disclosed invention provides intelligent adaptive control for optimization of production output, energy efficiency and safety of a linear reciprocating long stroke hydraulic lift system, for use at the surface of oil and gas wells to extract fluids or gas after free flowing stopped due to natural decline of reservoir pressure.The hydraulic pump and its adaptive control system introduced in this invention are capable of optimizing its production capacity by varying multiple operating parameters, including its stroking length and speed characteristics continuously and instantaneously at any point. Merits and benefits of this invention include significant increase in production efficiency, improved durability and longevity of the pumping equipment, significant power consumption savings and an ability to adapt effectively to changing well conditions.

Owner:DYNAPUMP INC +1

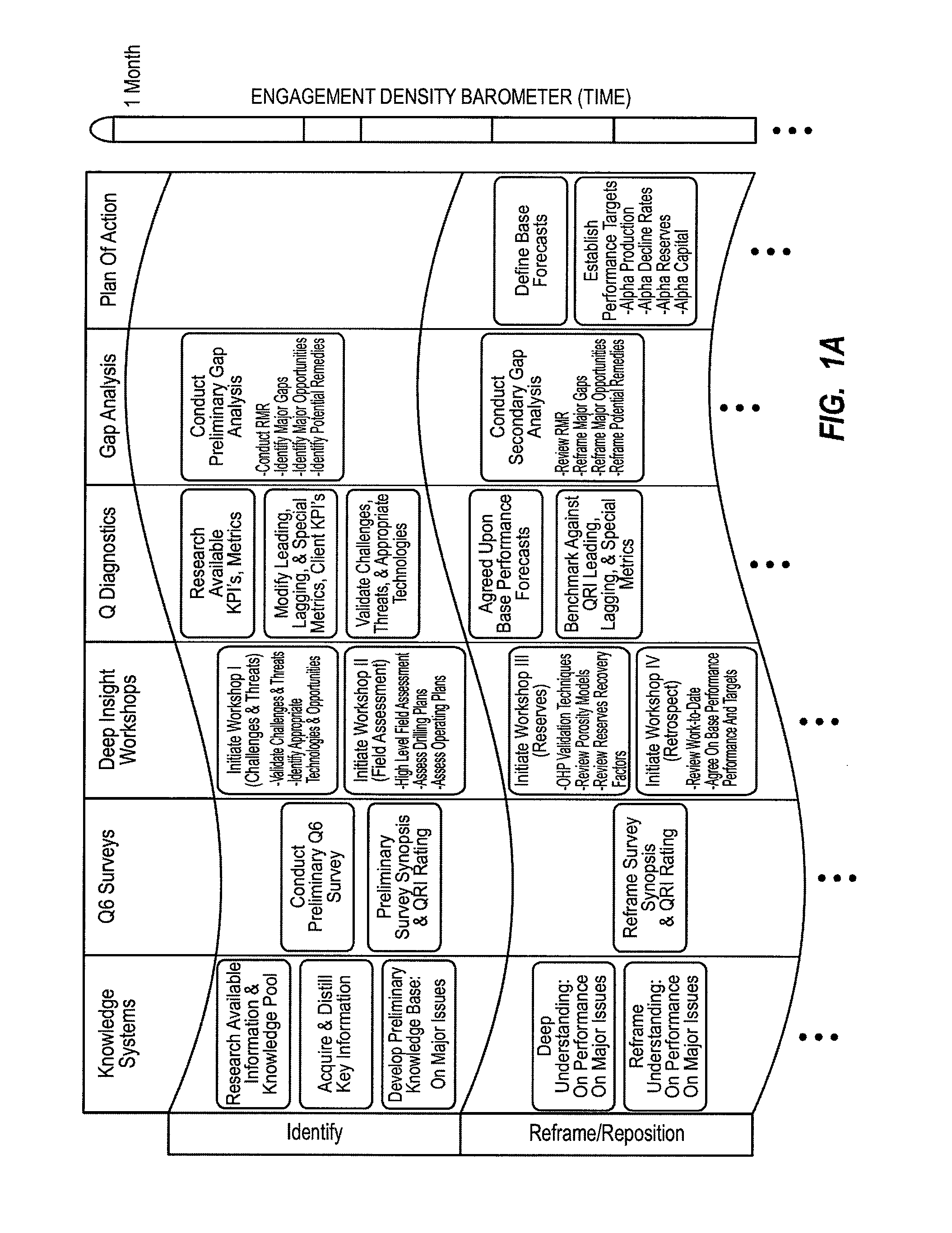

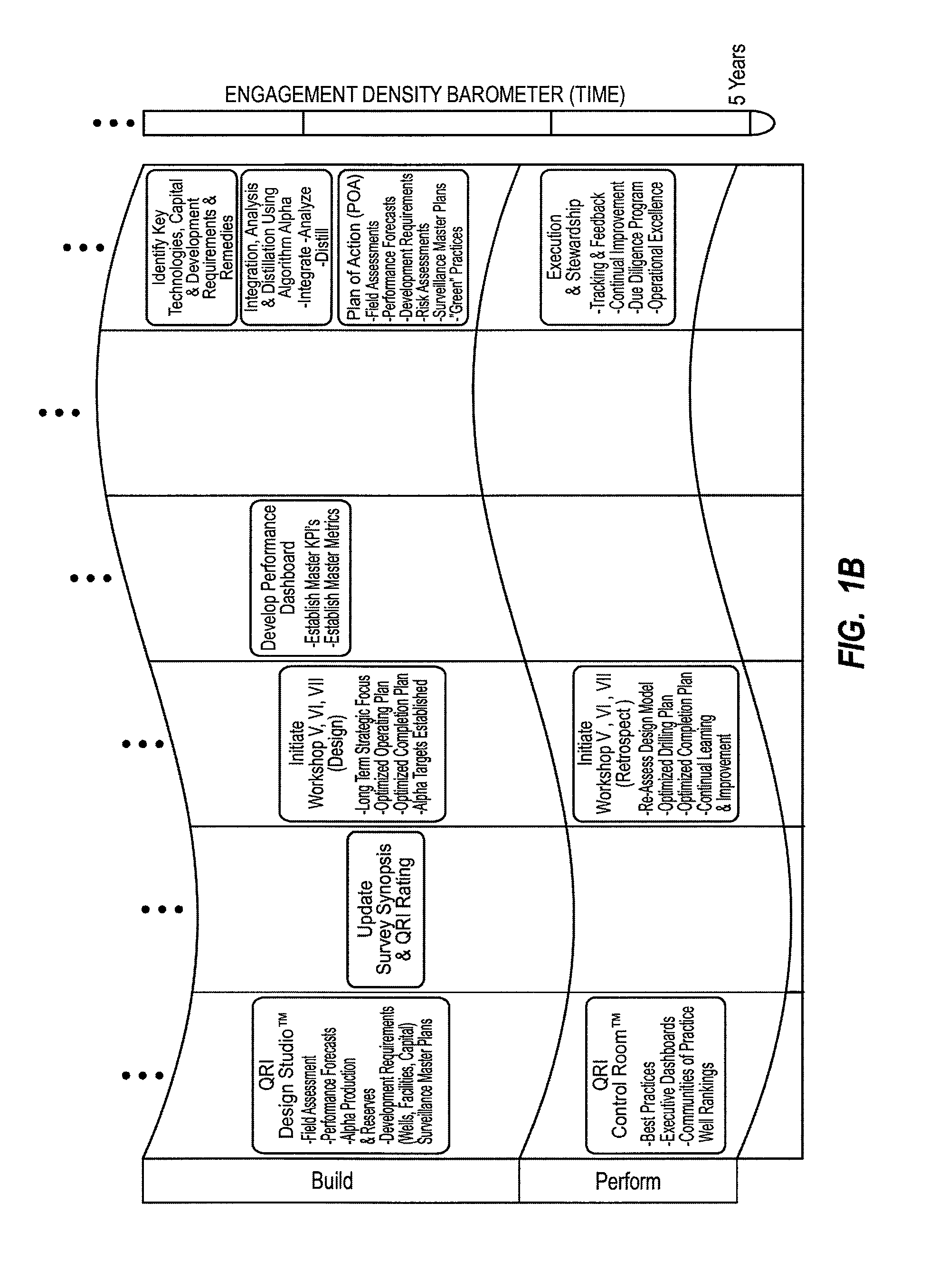

Method for dynamically assessing petroleum reservoir competency and increasing production and recovery through asymmetric analysis of performance metrics

InactiveUS7963327B1Increase short-term production rate and long-term recoveryAccurate assessmentElectric/magnetic detection for well-loggingSurveyProcess engineeringPetroleum reservoir

Methods for accurately assessing the condition of a petroleum reservoir and designing and implementing a plan of action to increase production and recovery of petroleum from the reservoir. Information is gathered using a unique set of metrics and information gathering techniques and analyzed in a targeted fashion by properly weighting the data in the context of the particular reservoir and goals of the producer. A reservoir rating is generated using asymmetric analysis of metrics and then used to formulate a plan of action. Production architecture (e.g., number, location and manner of constructing oil and injector wells) is then constructed according to the plan of action. Reservoir performance can be continuously monitored and used to verify production and recovery goals and / or provide triggers or alarms to alter production equipment.

Owner:QRI GROUP

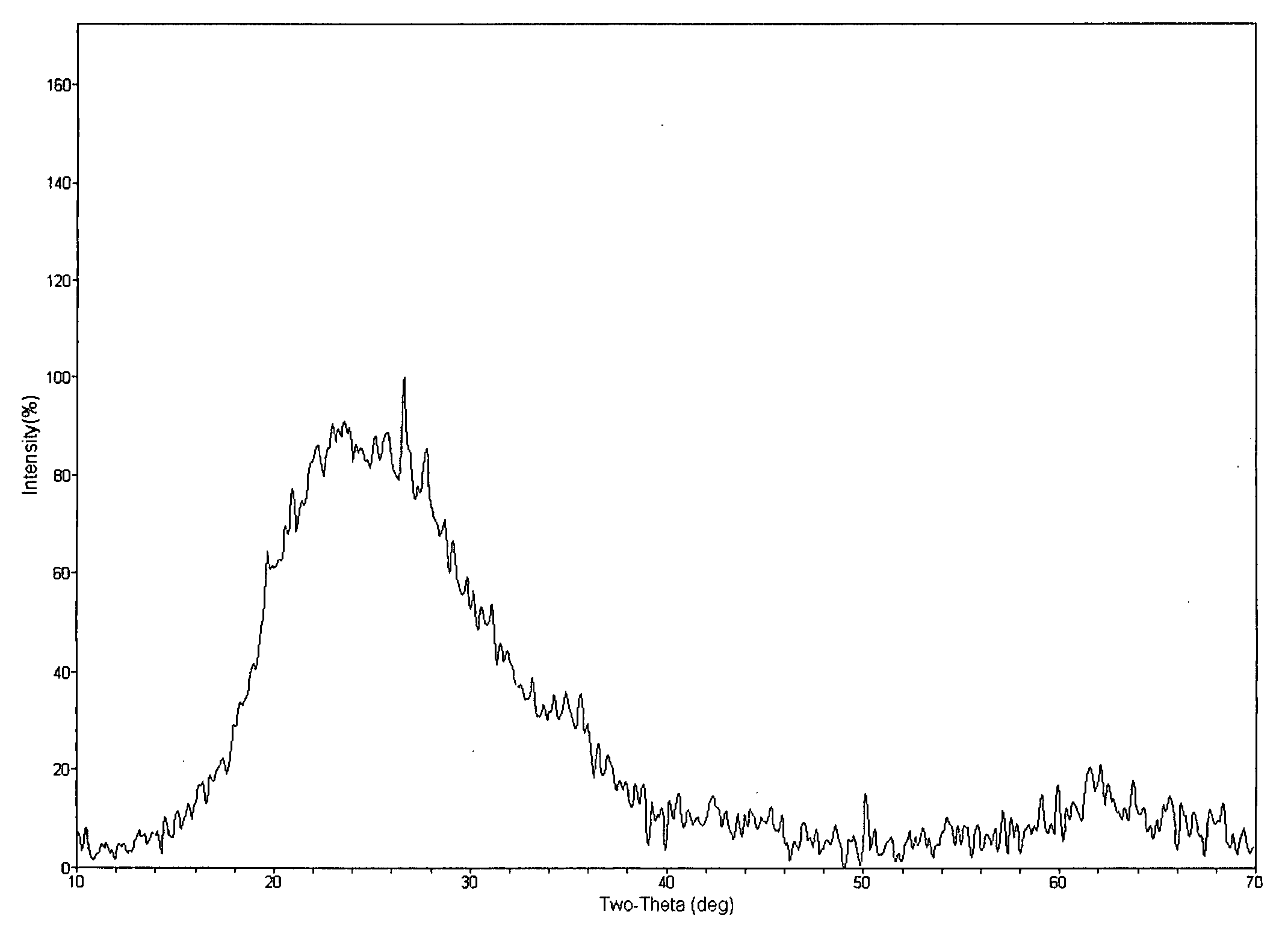

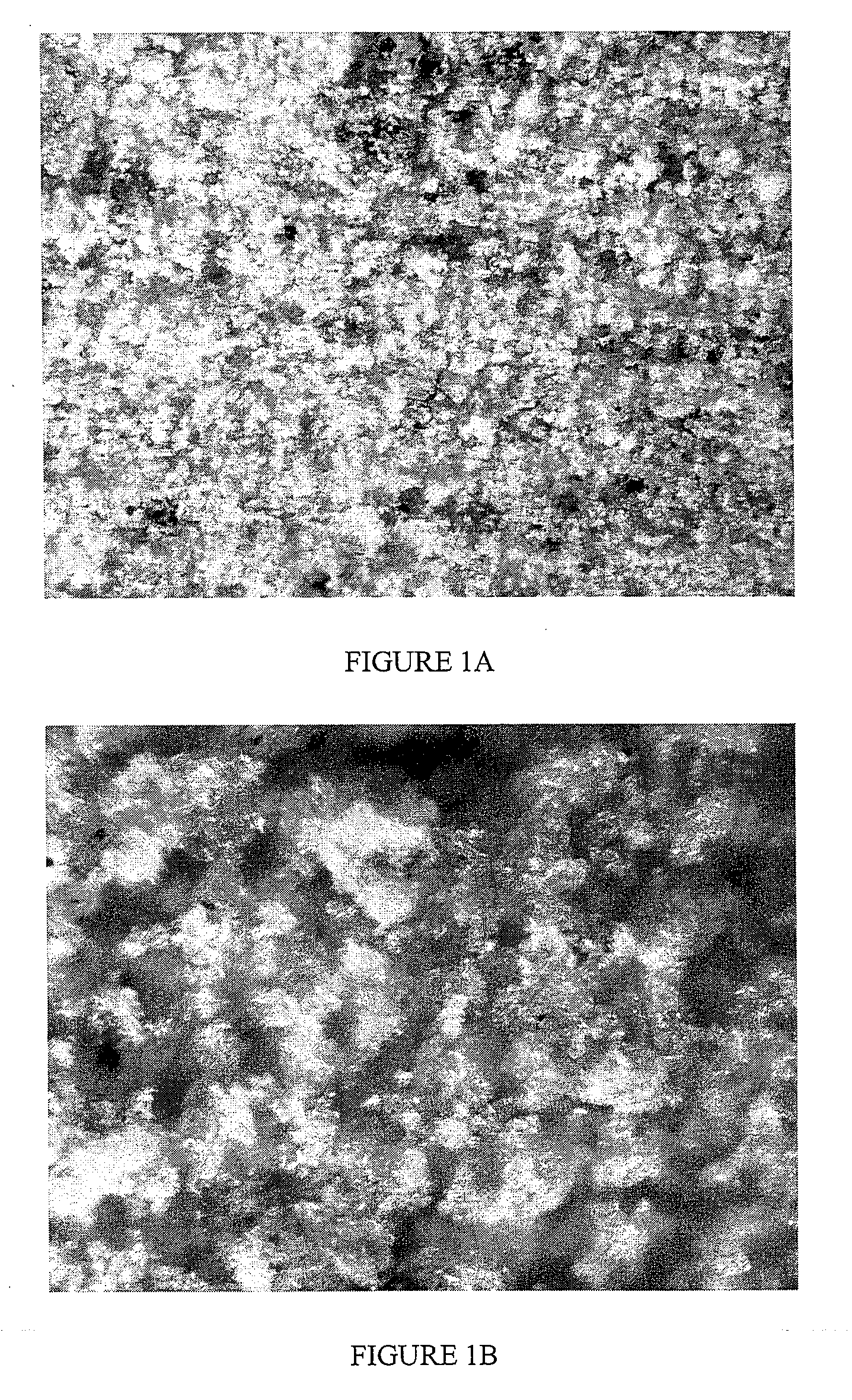

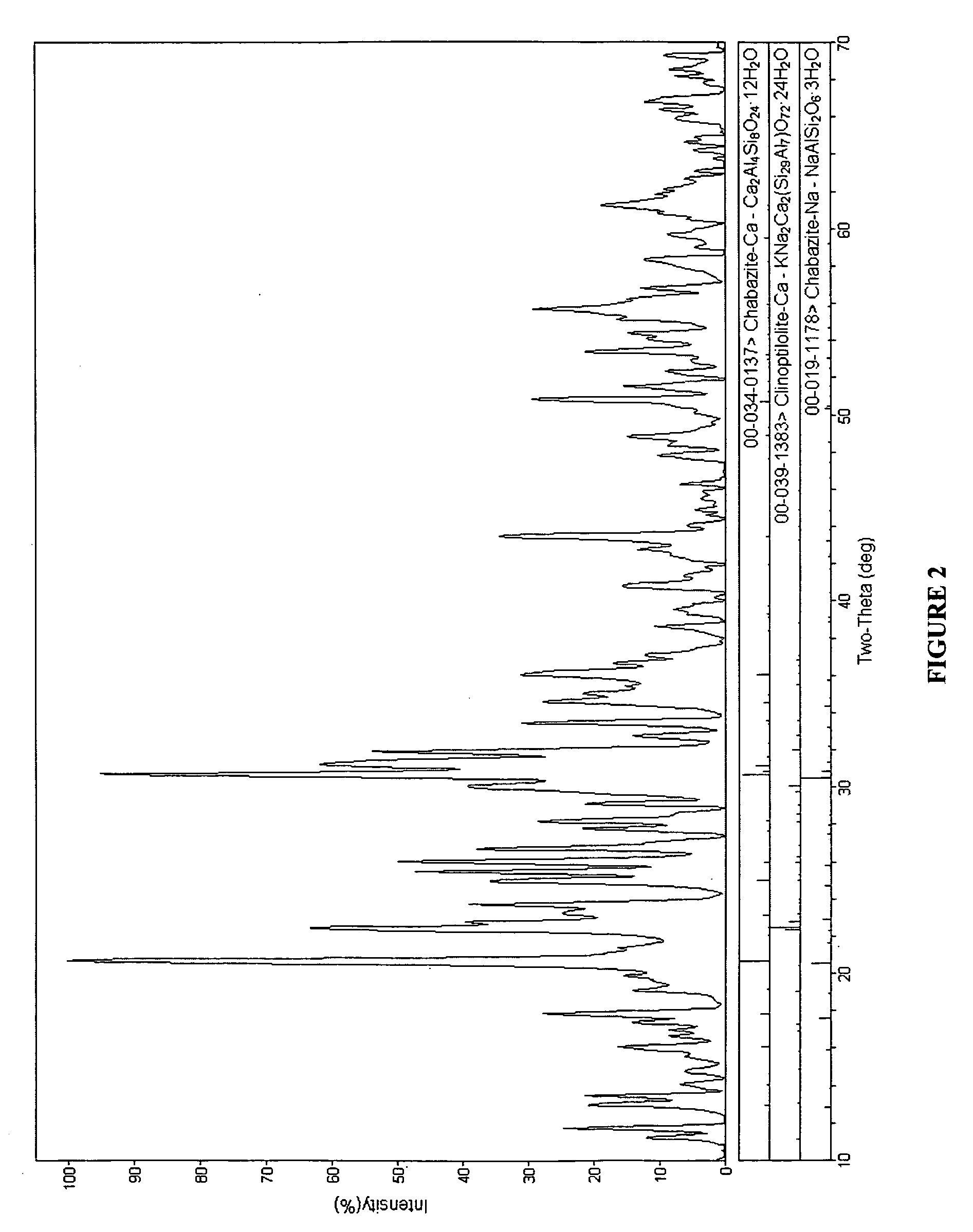

Pumice containing compositions for cementing a well

ActiveUS20090105099A1Reduce carbon dioxide emissionsReduce CO<subSolid waste managementFlushingWell cementingOil well

A cement composition comprises fine pumice particles, for use in cementing subterranean wells, and oil and gas wells in particular. The pumice containing cement blends feature enhanced compressive strength, and favourable compressive strength to Young's Modulus ratios. Lightweight cement blends containing pumice, and their use in cementing oil and gas wells are also described.

Owner:SANJEL ENERGY SERVICES INC

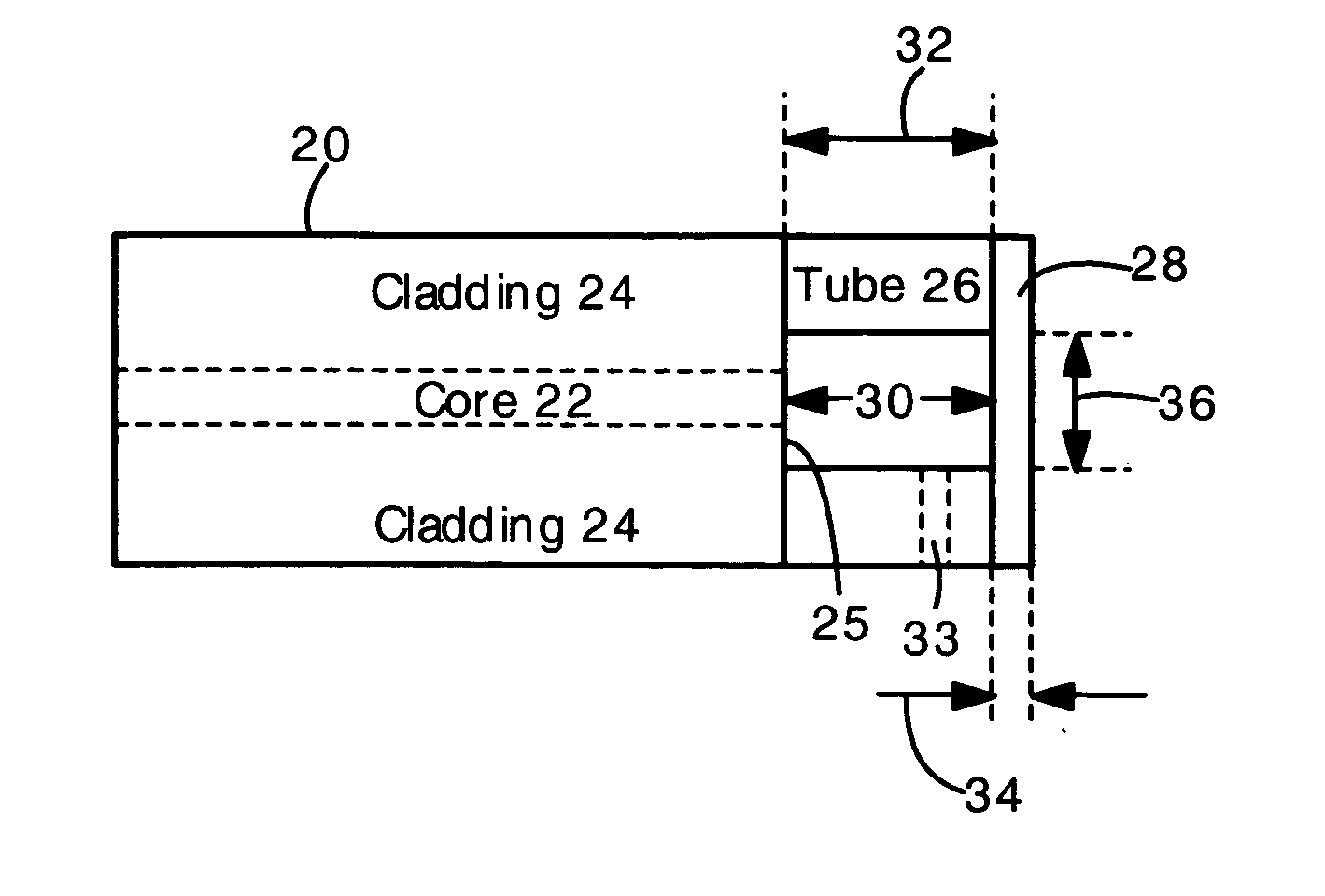

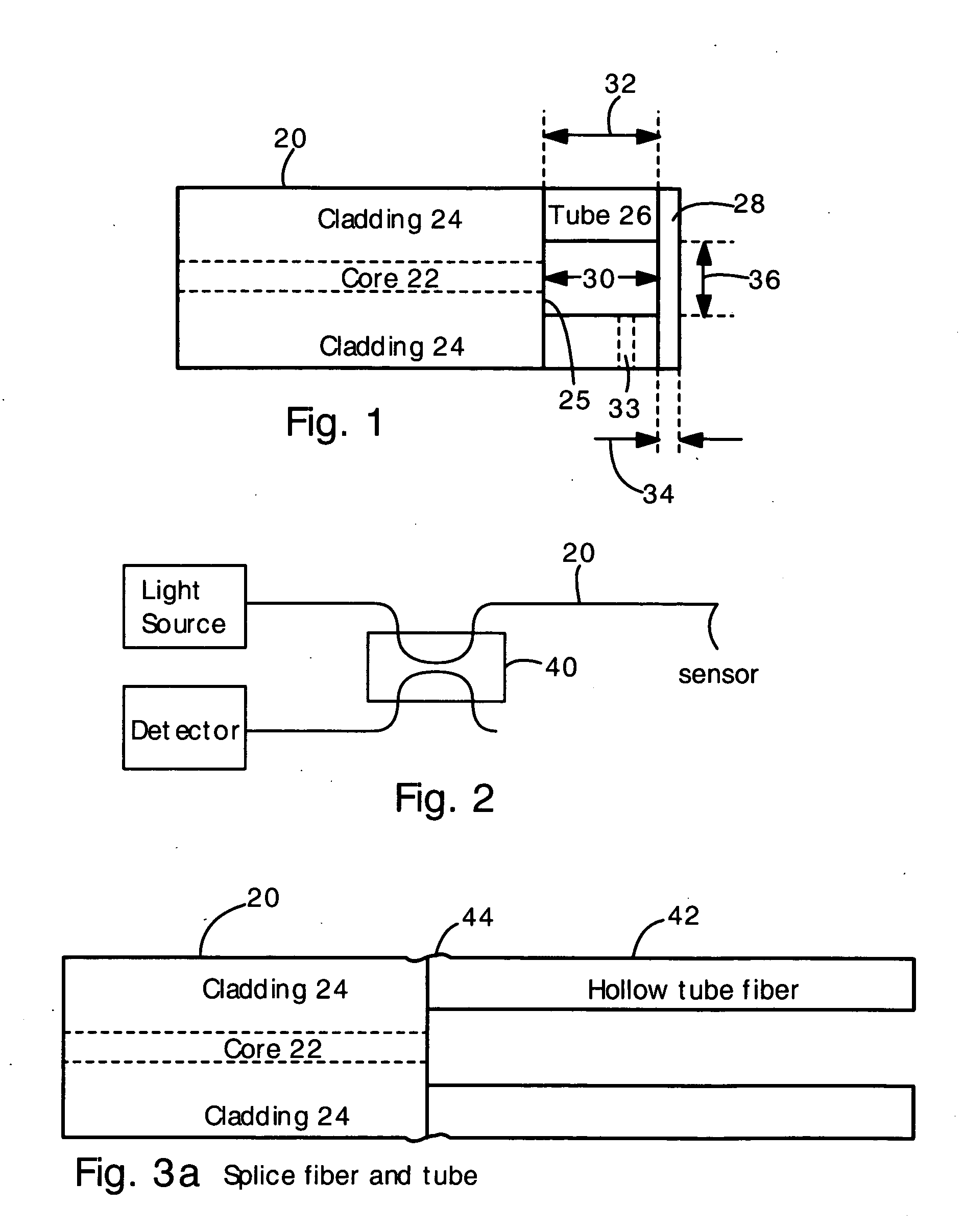

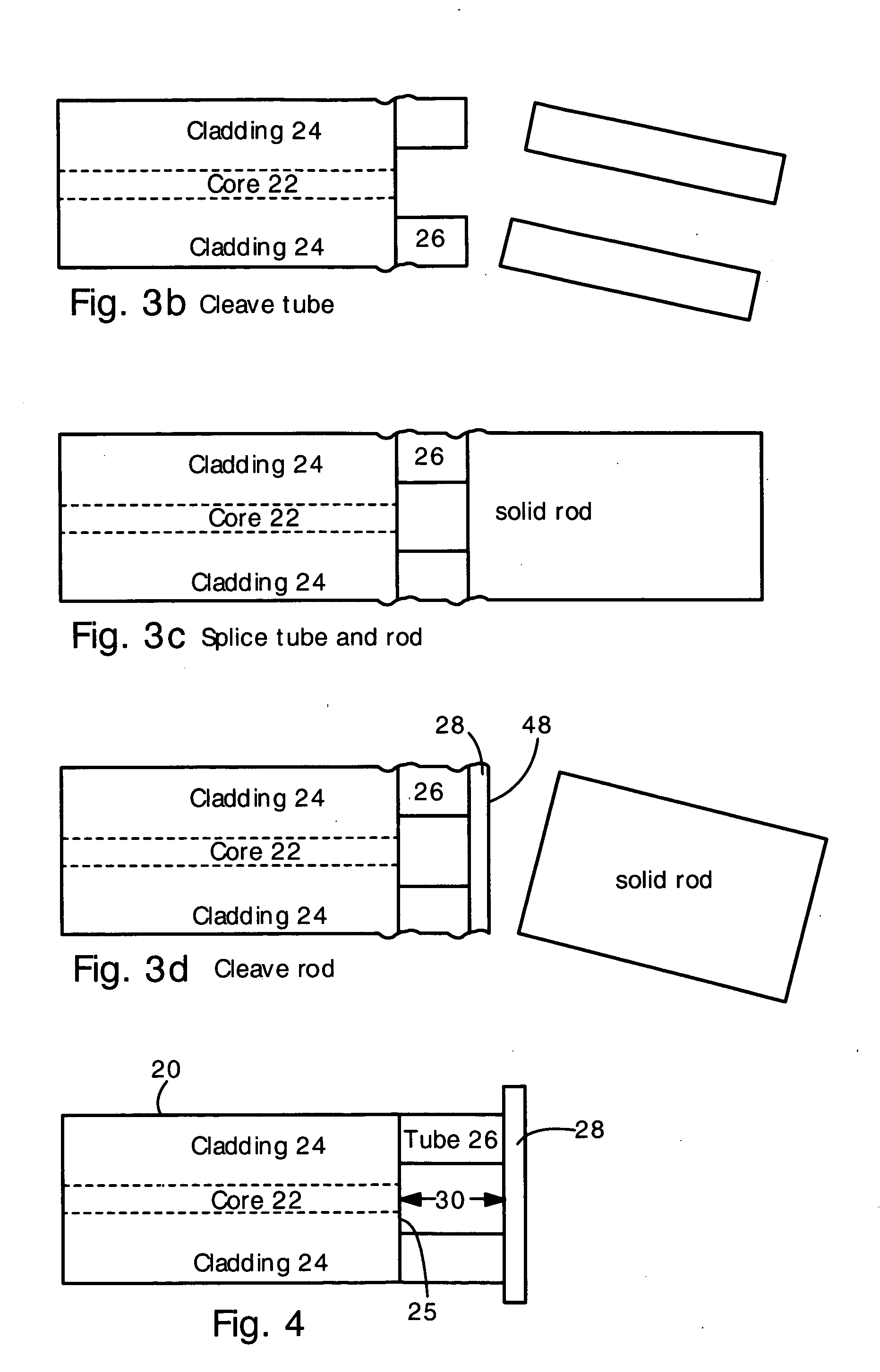

Optical fiber pressure and acceleration sensor fabricated on a fiber endface

InactiveUS20050062979A1Subsonic/sonic/ultrasonic wave measurementFluid pressure measurement by electric/magnetic elementsJet engineClassical mechanics

A fiber optic sensor has a hollow tube bonded to the endface of an optical fiber, and a diaphragm bonded to the hollow tube. The fiber endface and diaphragm comprise an etalon cavity. The length of the etalon cavity changes when applied pressure or acceleration flexes the diaphragm. The entire structure can be made of fused silica. The fiber, tube, and diaphragm can be bonded with a fusion splice. The present sensor is particularly well suited for measuring pressure or acceleration in high temperature, high pressure and corrosive environments (e.g., oil well downholes and jet engines). The present sensors are also suitable for use in biological and medical applications.

Owner:VIRGINIA TECH INTPROP INC

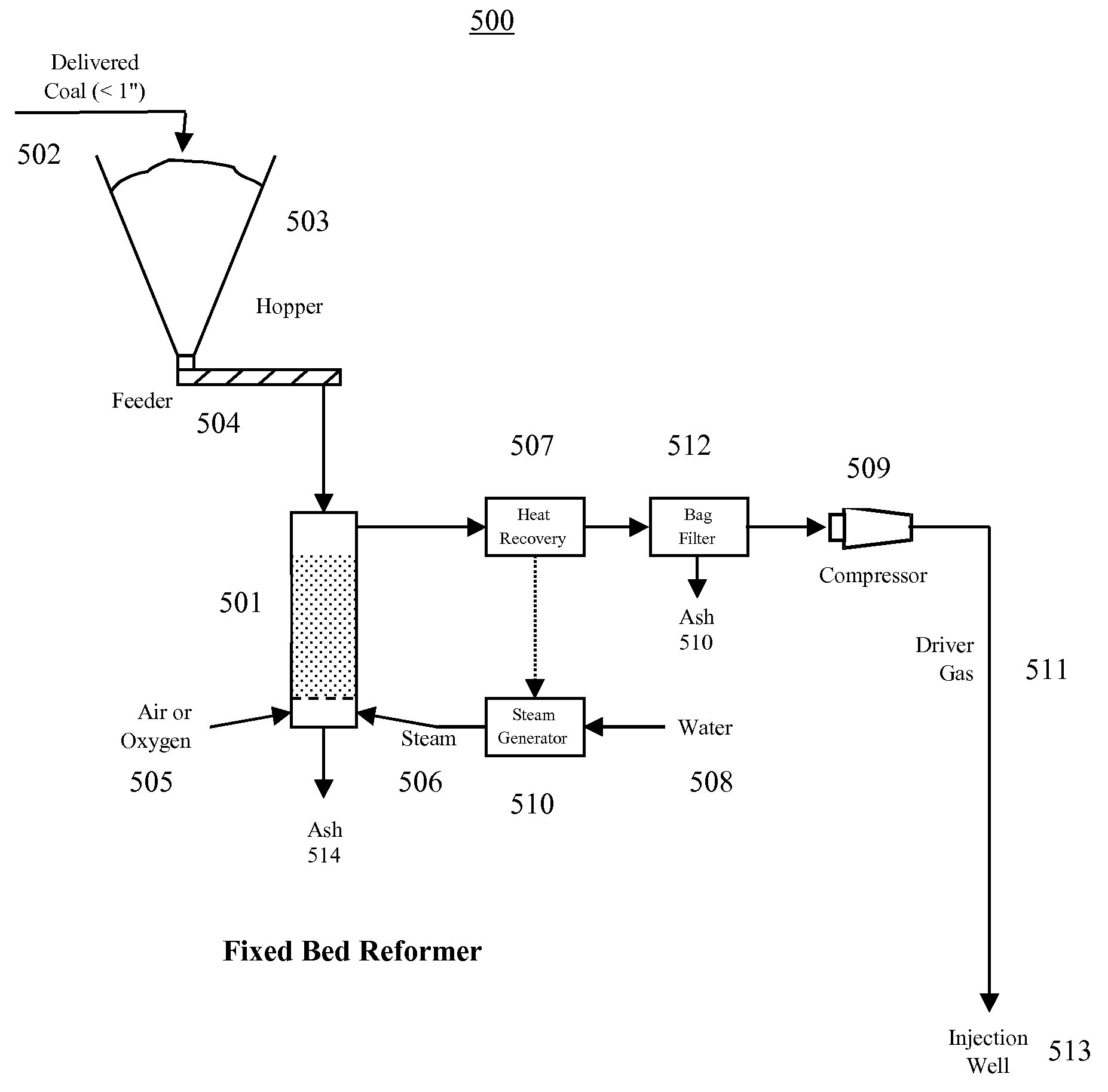

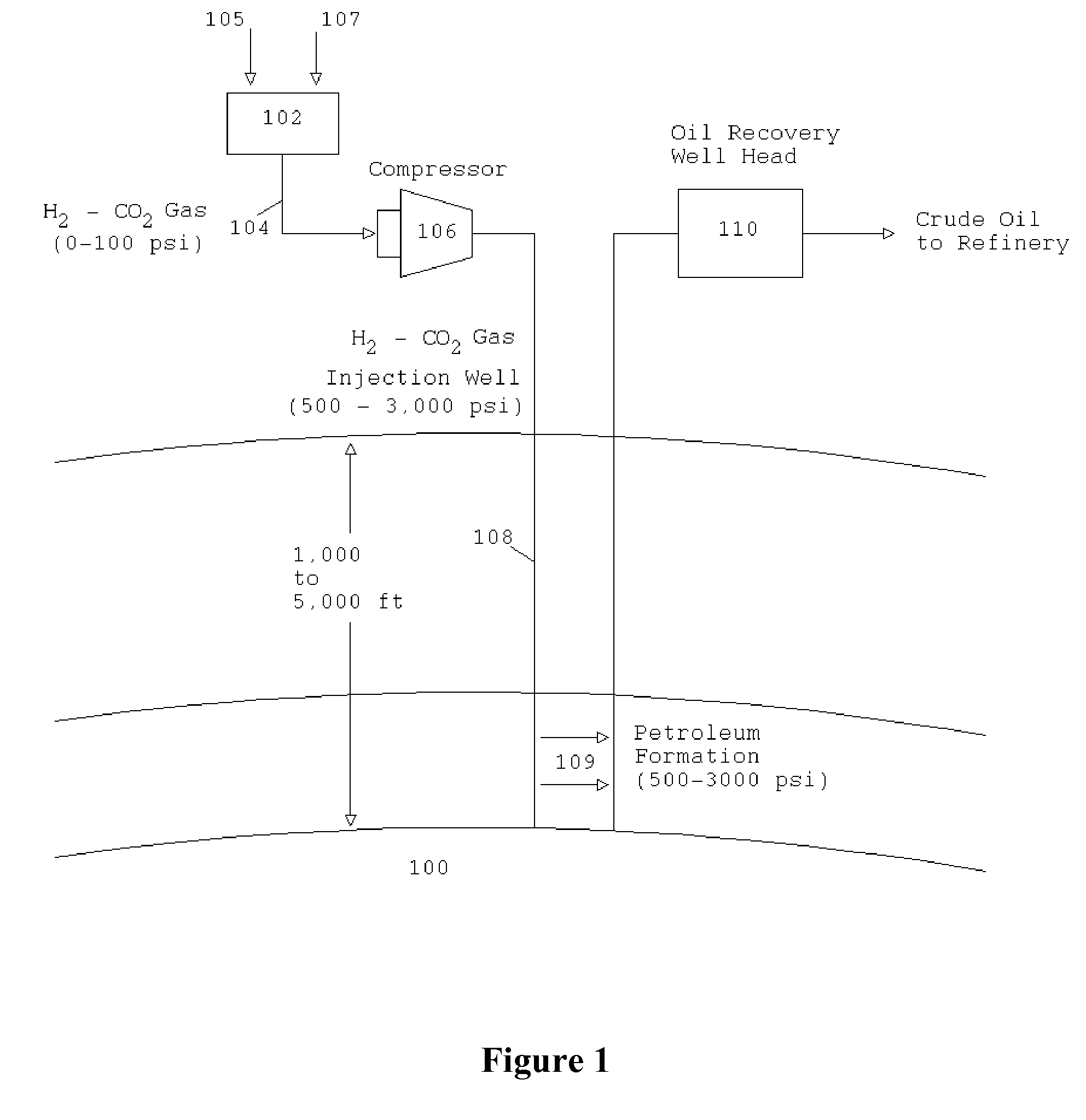

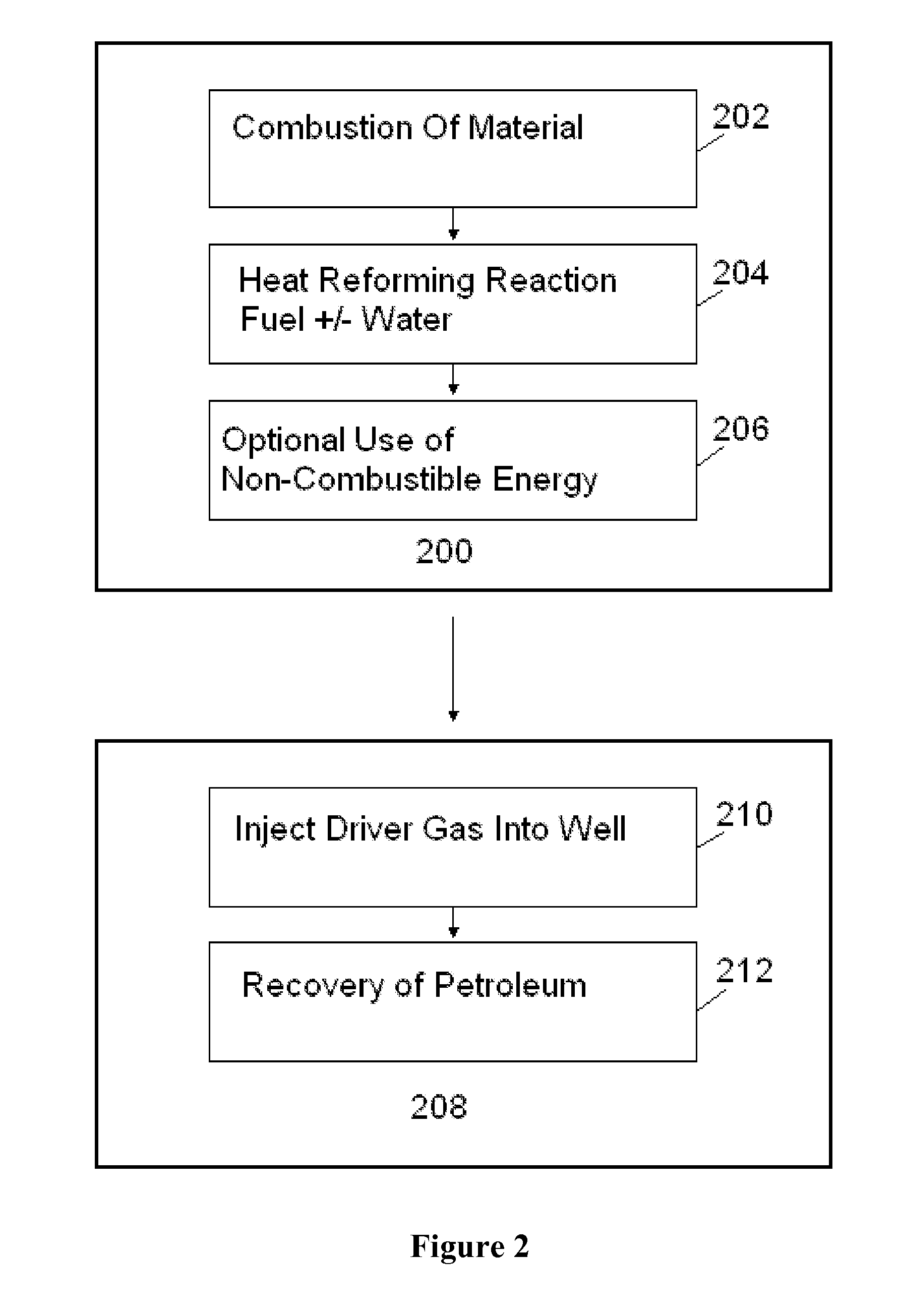

Apparatus, methods, and systems for extracting petroleum using a portable coal reformer

InactiveUS7654330B2Highly economicalVast supplyDrilling rodsHydrogen separation using solid contactPetroleumCoal

Apparatus, methods, and systems for extracting oil or natural gas from a well using a portable coal reformer. In one example, the method may include reforming coal by reaction with water to generate driver gas (comprising carbon dioxide and hydrogen gas), and injecting the driver gas into the well. The driver gas reduces the viscosity and pressurizes the oil to help extract the oil from the oil well. The coal reforming operation may include combusting coal or other combustible material with ambient oxygen to release energy, and heating coal and water with the energy released to a temperature above that required for the coal reforming reaction to proceed, thereby reforming coal and water into driver gas. The driver gas may be purified by filtering out particles and sulfur before injecting into the well. A portion of the hydrogen gas may be separated from the driver gas and used to generate electrical power.

Owner:PIONEER ENERGY

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS7392844B2Well remediationIncrease stimulationConstructionsCleaning apparatusMETHYL SOYATEFluid system

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a fatty acid ester, such as methyl soyate. The fluid system may further contain a lactic acid ester, such as ethyl lactate, and / or a nonionic surfactant. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES INC

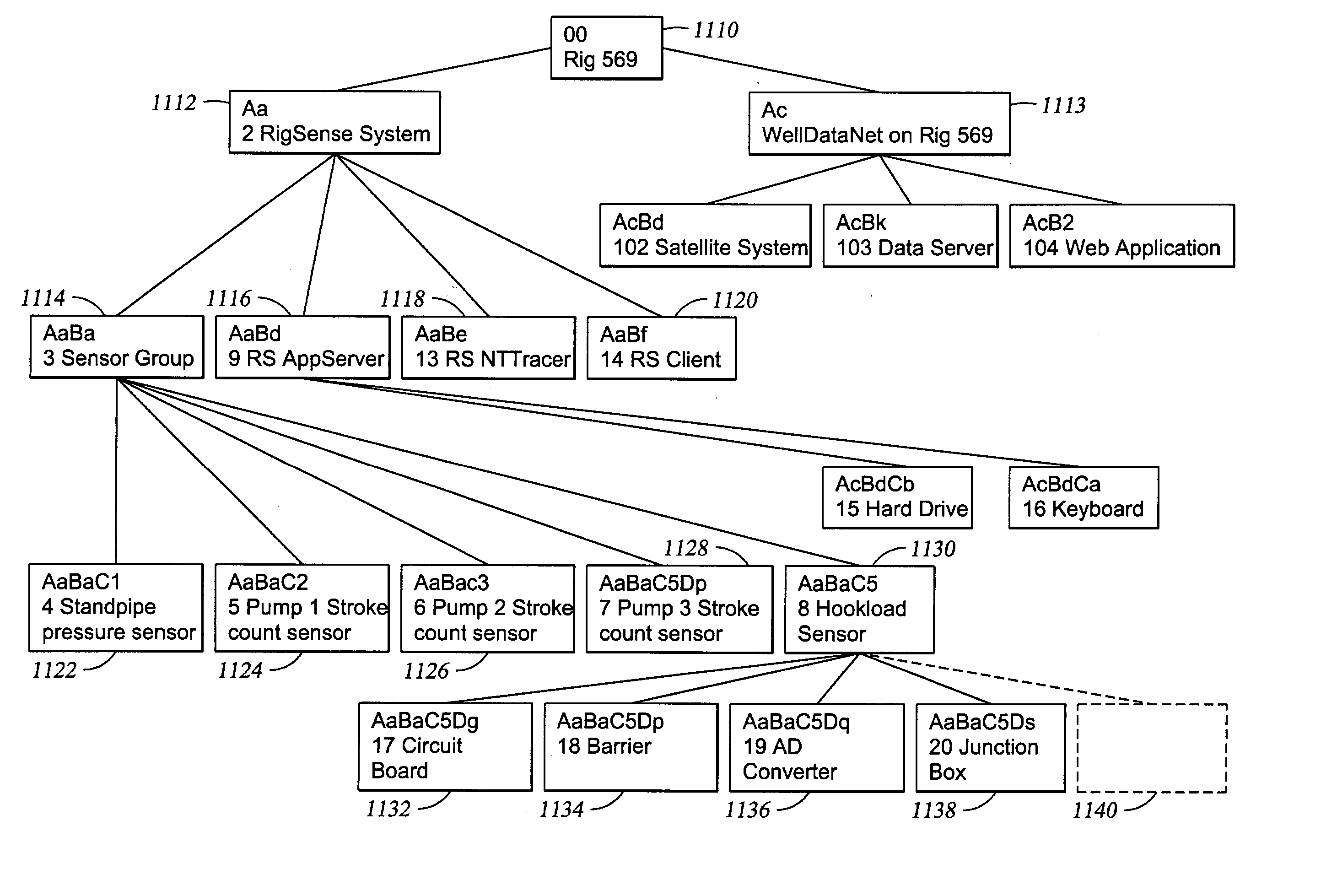

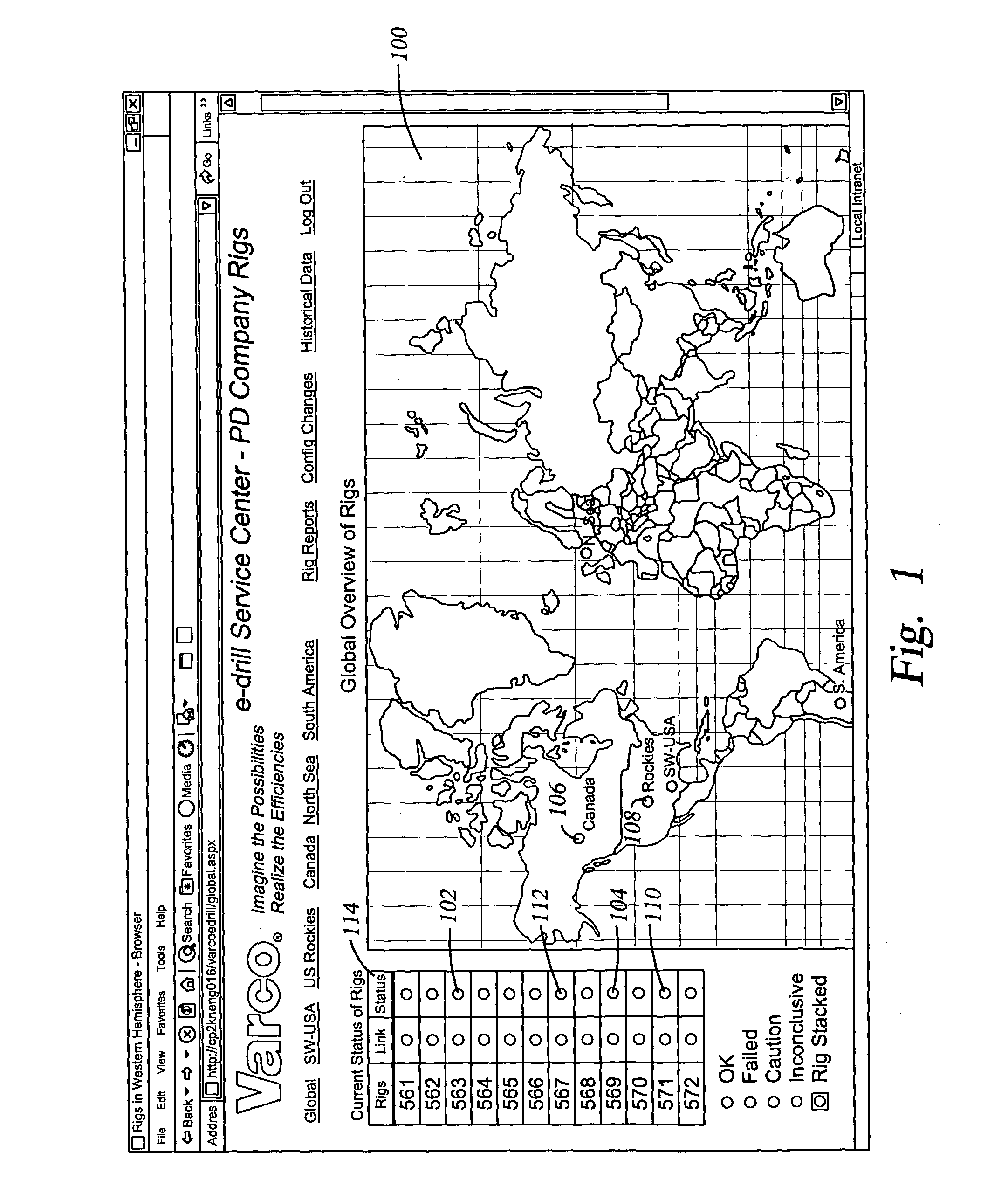

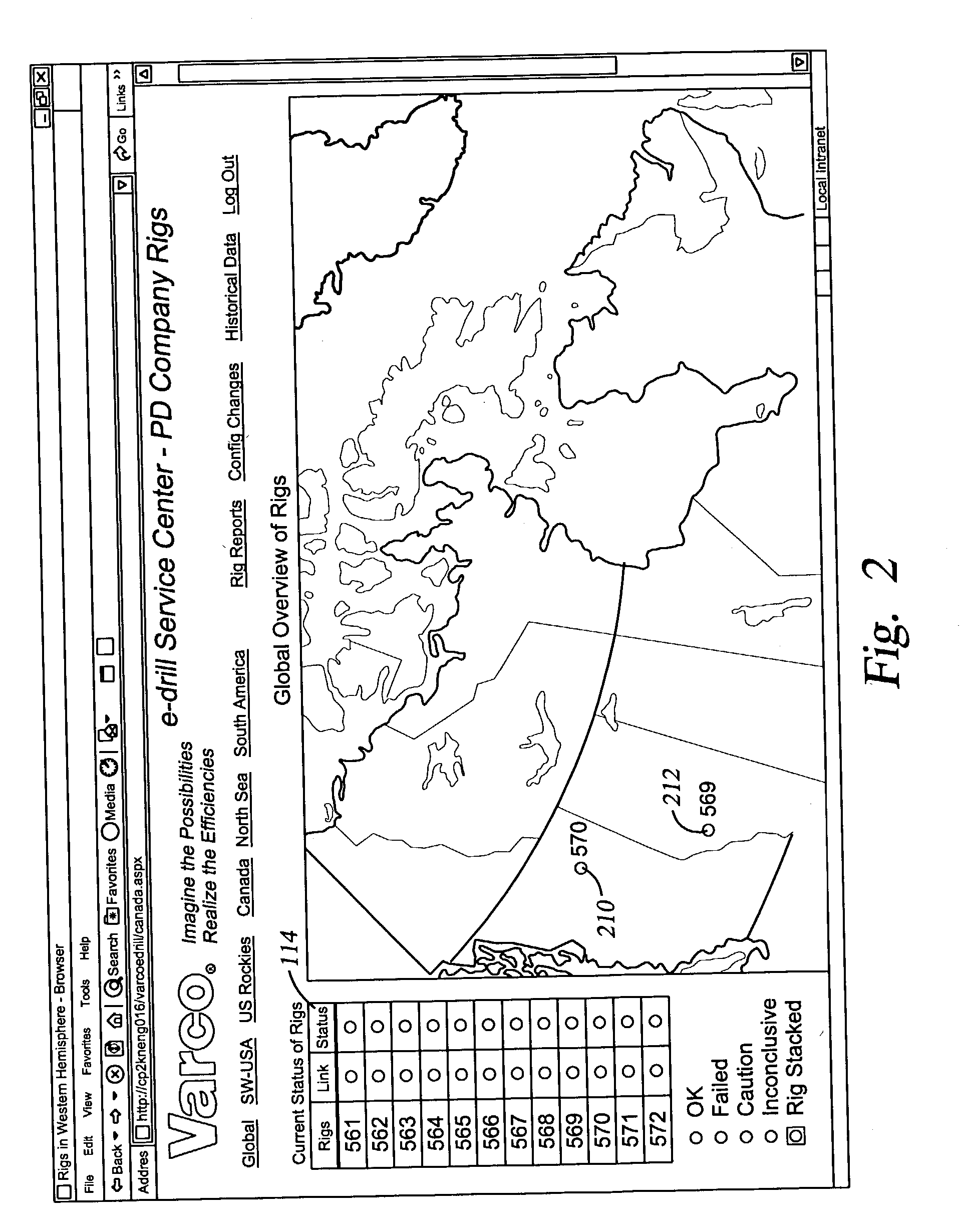

Method and apparatus for dynamic checking and reporting system health

InactiveUS20040088115A1Rapid visual affirmationElectric/magnetic detection for well-loggingResourcesHealth checkRemote analysis

The present invention provides a method and apparatus for remotely analyzing and affirmatively notifying appropriate personnel of problems and events associated with an oil recovery system-comprising hundreds of oil rigs over a vast geographic area. The results of selected Health Checks, which are run on each oilrig, are reported to a central server. The central server populates a data base for the oil recovery system, displays a red / yellow / green color coded electronic notification and status for an entire oil recovery system and affirmatively alerts appropriate personnel of actions required to address events associated with an oilrig in an oil recovery system. The diagnostics run at each oilrig are configurable at the individual rig. The present invention provides a dynamic oilrig status reporting protocol that enables population and display of a tree node structure representing an entire oil recovery system status on a single screen at a top level. Detailed information is available by drilling down in to other screens, enabling rapid visual evaluation of a system Health Check.

Owner:VARCO I P INC

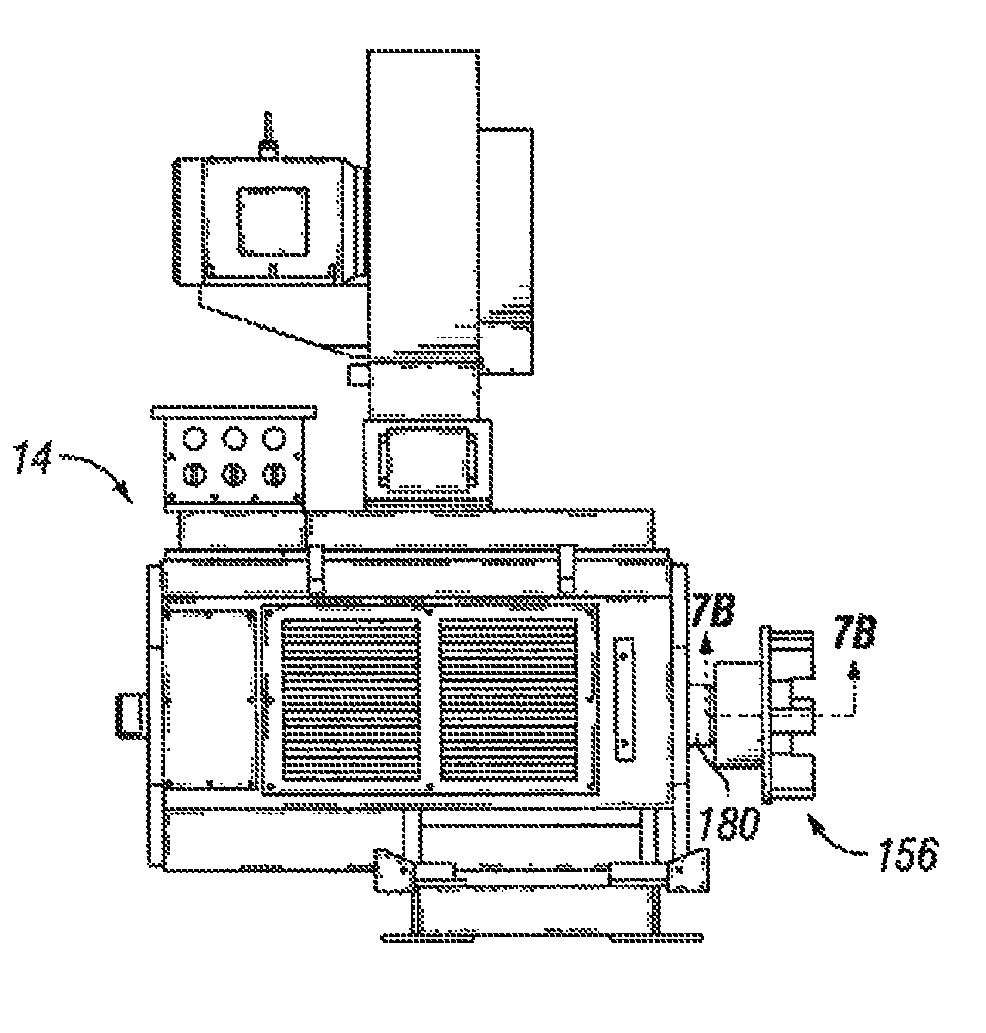

Torsional coupling for electric hydraulic fracturing fluid pumps

A system for hydraulically fracturing an underground formation in an oil or gas well, including a pump for pumping hydraulic fracturing fluid into the wellbore, the pump having a pump shaft, and an electric motor with a motor shaft mechanically attached to the pump to drive the pump. The system further includes a torsional coupling connecting the motor shaft to the pump shaft. The torsional coupling includes a motor component fixedly attached to the motor shaft and having motor coupling claws extending outwardly away from the motor shaft, and a pump component fixedly attached to the pump shaft of the pump and having pump coupling claws extending outwardly away from the pump shaft. The motor coupling claws engage with the pump coupling claws so that when the motor shaft and motor component rotate, such rotation causes the pump component and the pump shaft to rotate, thereby driving the pump.

Owner:US WELL SERVICS LLC

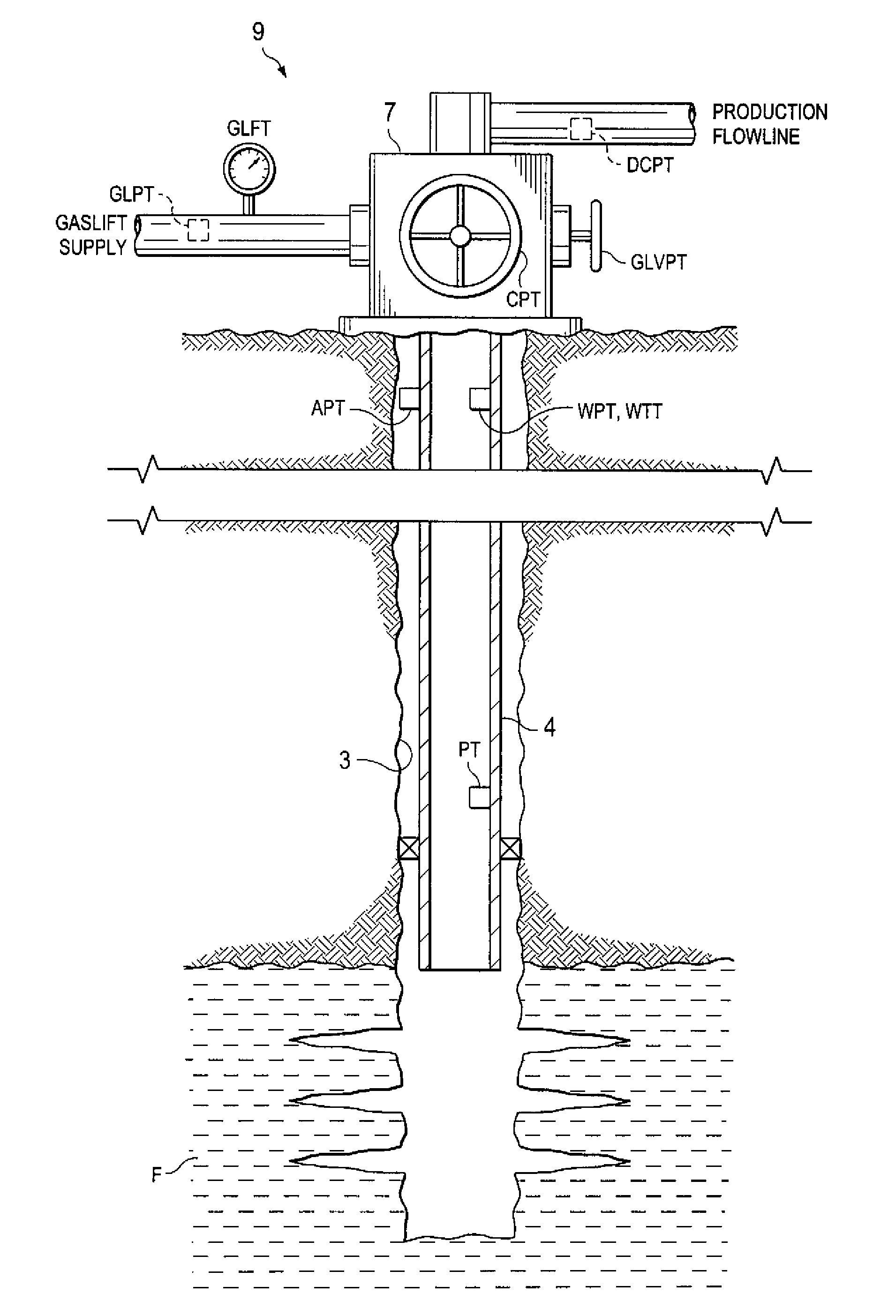

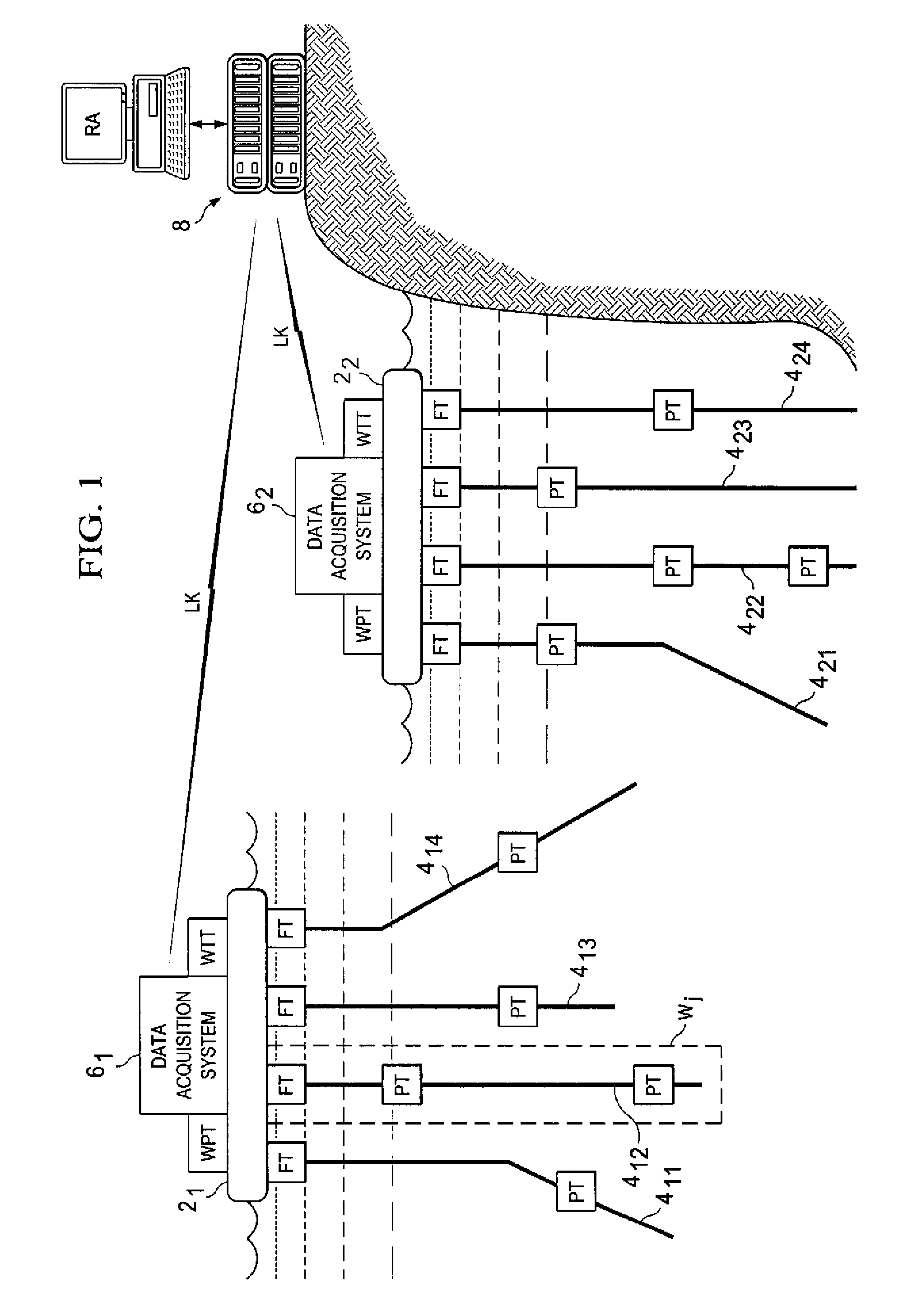

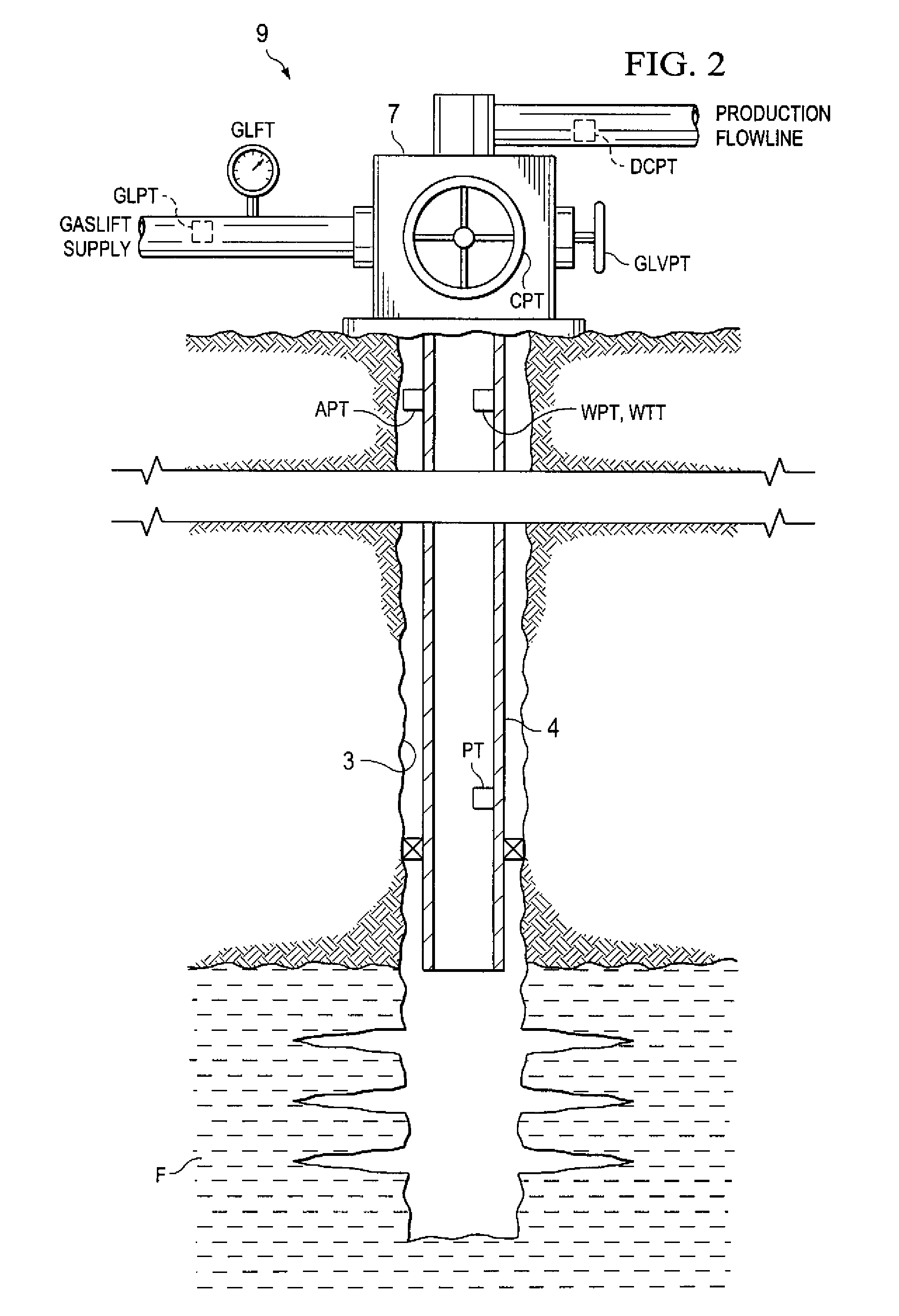

Managing flow testing and the results thereof for hydrocarbon wells

ActiveUS20100023269A1Good estimateElectric/magnetic detection for well-loggingSurveyWell testComputerized system

Automated monitoring and management of well tests of hydrocarbon wells in a production field. Routing of the output of a well to a flow meter, separated from the output from other wells in the field, is detected by a computer system such as a server. Measurement data including the flow as measured by the flow meter, and also other measurements such as temperatures and pressures contemporaneous with the flow meter measurements, are acquired by the computer system; a stable period is identified, over which the flow test measurement data are considered valid. Upon completion of a specified duration or upon a change in the flow environment, the computer system notifies the user of the completion of the flow test. The flow test results can be used to modify predictive well models, with the modification dependent on validation by the user. The system can also plan and schedule future flow tests.

Owner:BP EXPLORATION OPERATING CO LTD

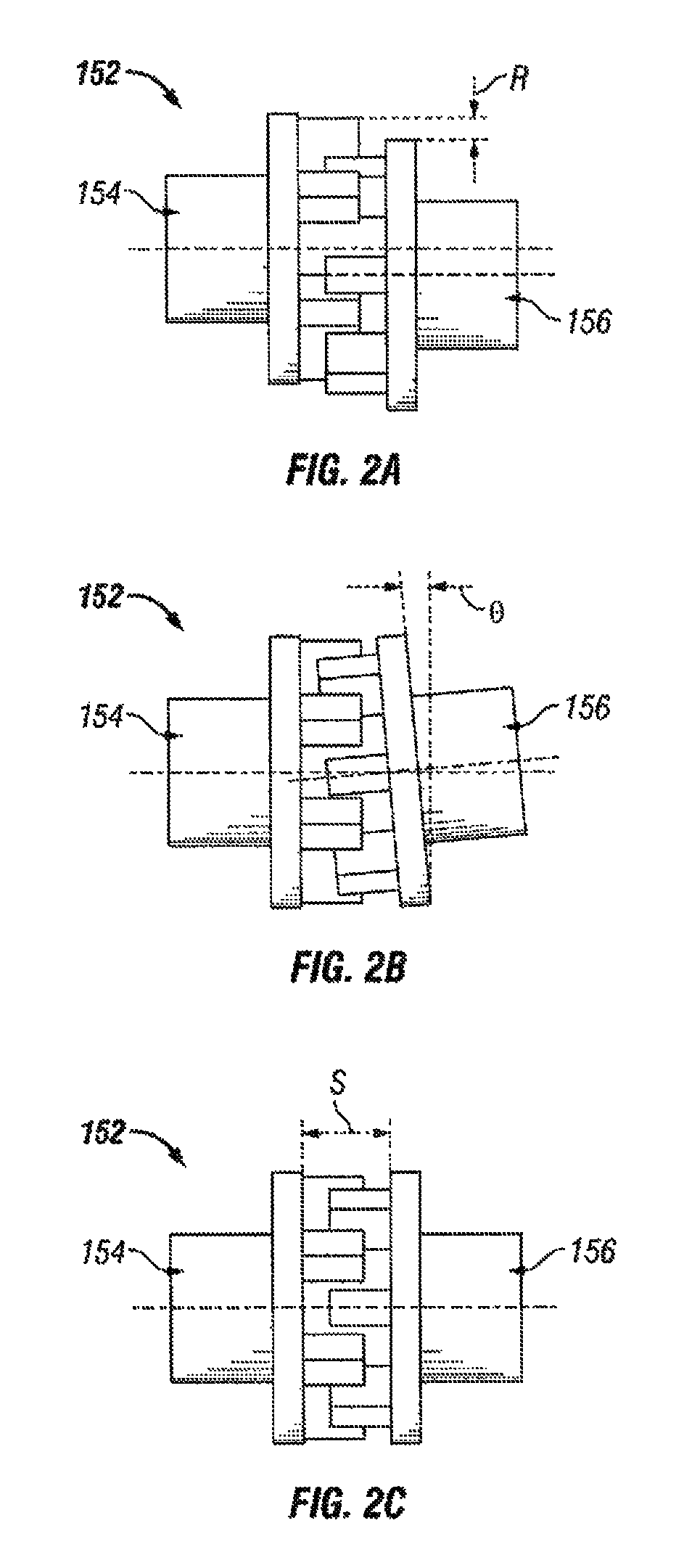

Sleeve valve for controlling fluid flow between a hydrocarbon reservoir and tubing in a well and method for the assembly of a sleeve valve

A sleeve valve for fluid flow between a hydrocarbon reservoir and a well includes a first sleeve and a second sleeve which are relatively movable between a first position in which at least one opening in the first sleeve is aligned or misaligned with at least one opening in the second sleeve in order to admit or shut off the fluid flow. The first sleeve is provided with a radially movable sealing element that has a sealing surface adapted to rest against the second sleeve around the second sleeve opening, and at least one tension element presses the sealing element with its sealing surface against the second sleeve. A method for the assembly of such a sleeve valve includes a sealing element and a tension element placed in the outer sleeve opening and a clamping tool is adapted to the opening in the sealing element and moved outwards together with the sealing element until the sealing element is flush with the inner surface of the outer sleeve. Thereafter, the inner sleeve is inserted into the outer sleeve and the sealing element is allowed to rest against the inner sleeve and the clamping tool is removed.

Owner:WELL INNOVATION ENG

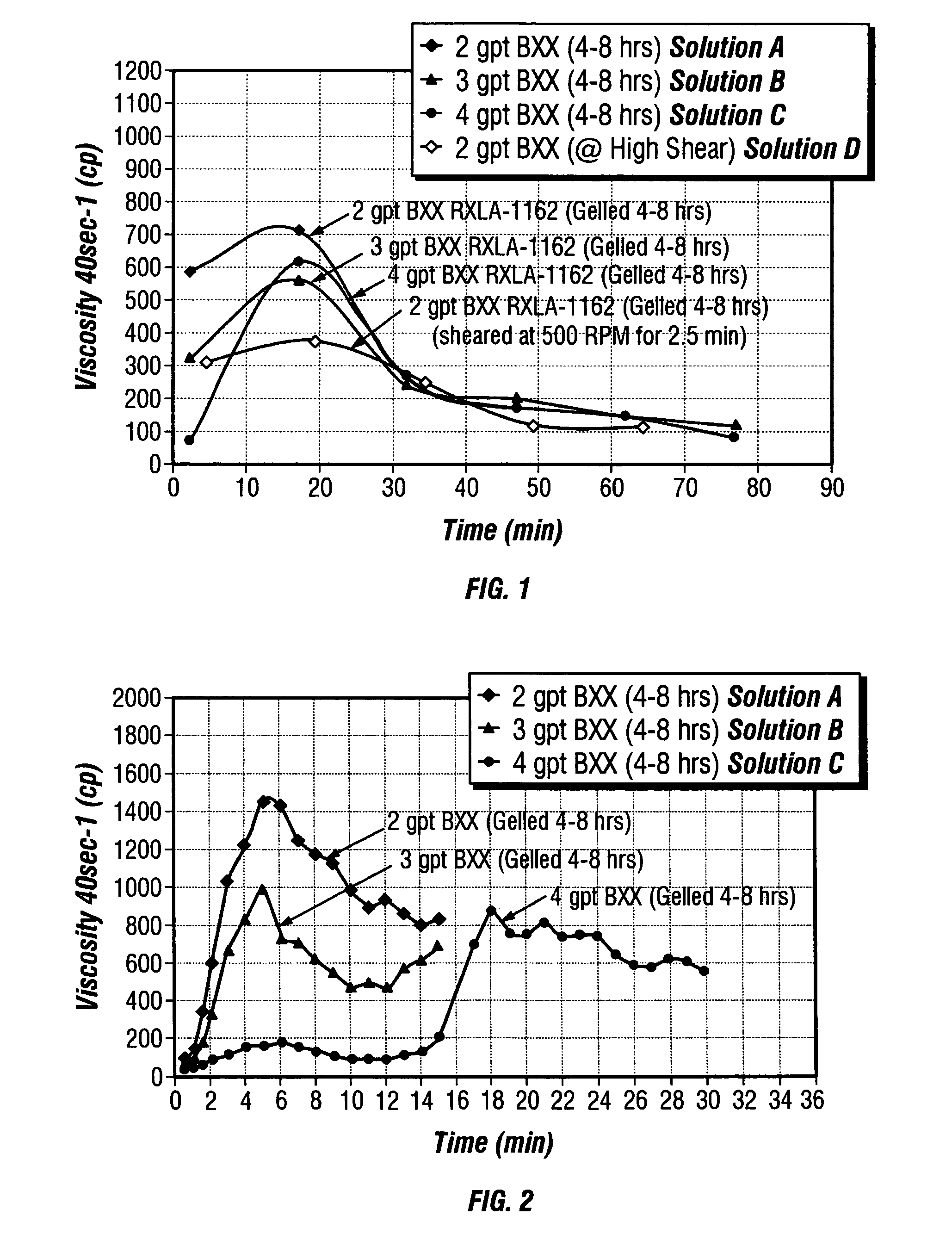

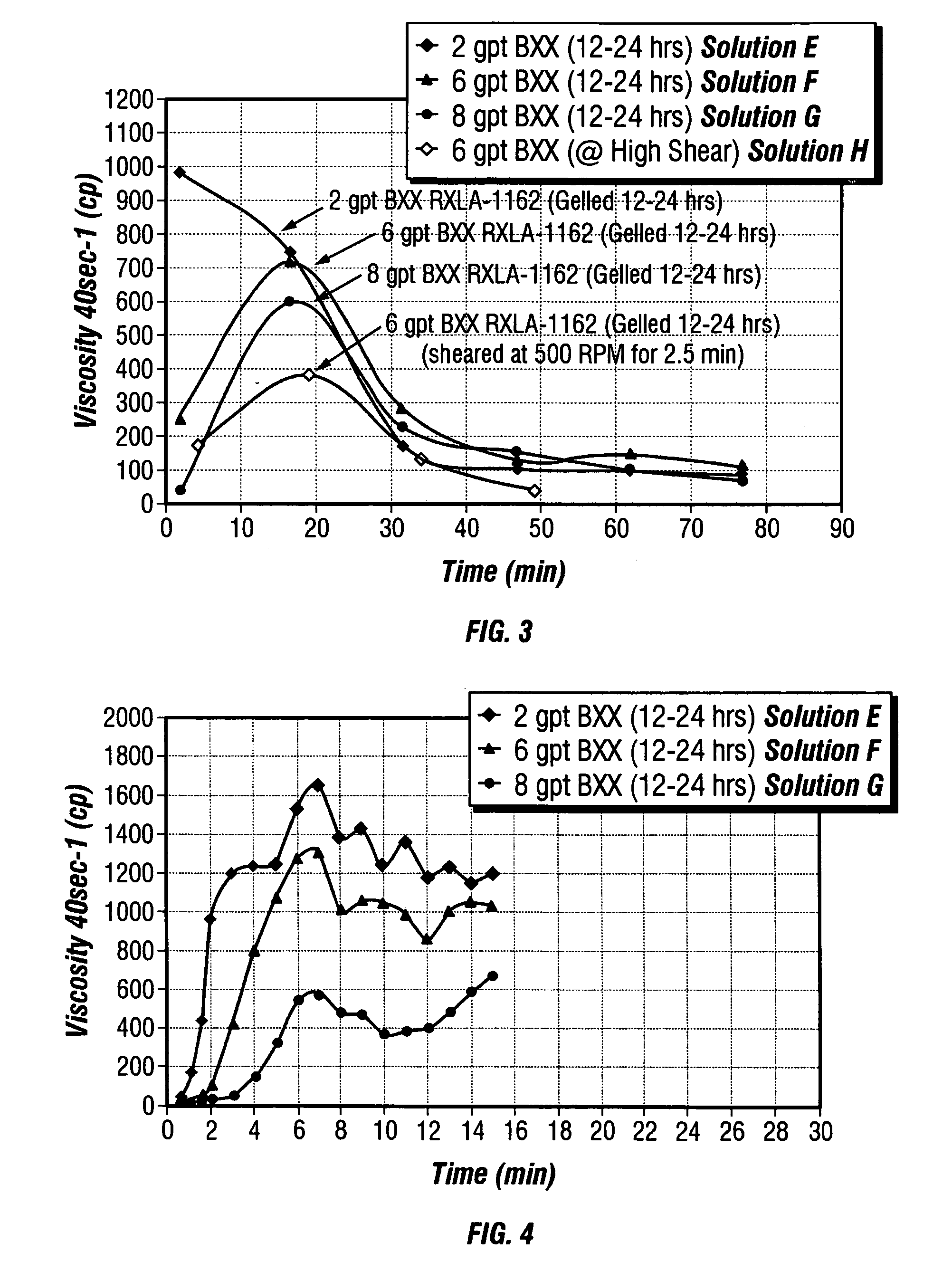

Well treatment method using fluid containing lactic acid or salt thereof

Fluids comprising an aqueous acid, synthetic polymer, metal crosslinking agent and lactic acid or a salt thereof have particular applicability in fracturing subterranean formations of an oil or gas well. The lactic acid acts as a delaying agent. As a result, crosslinking of the synthetic polymer and metal crosslinking agent typically occurs at a temperature of 100° F. or higher.

Owner:BAKER HUGHES INC

Method for determining the extent of recovery of materials injected into oil wells or subsurface formations during oil and gas exploration and production

Disclosed is a method of determining the extent of recovery of materials injected into oil wells or subsurface formations. The method includes injection of one or more tracers into an oil well or into a formation. Included in the method are the steps of introducing a material of interest into the oil well or into the subsurface formation associated with the bore of the oil well; introducing a tracer into the oil well or into the subsurface formation associated with the bore of the oil well; recovering from the oil well a production fluid, analyzing the production fluid for a concentration of the chemical tracer present in the production fluid; and calculating the amount of material of interest recovered from the oil well using the concentration of the chemical tracer present in the production fluid as a basis for the calculation.

Owner:CORE LAB LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com