Patents

Literature

137 results about "Fracture conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracture conductivity, defined as fracture permeability times width k f w, is a measure of how easily fluids flow through a fracture.

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS20050059558A1Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

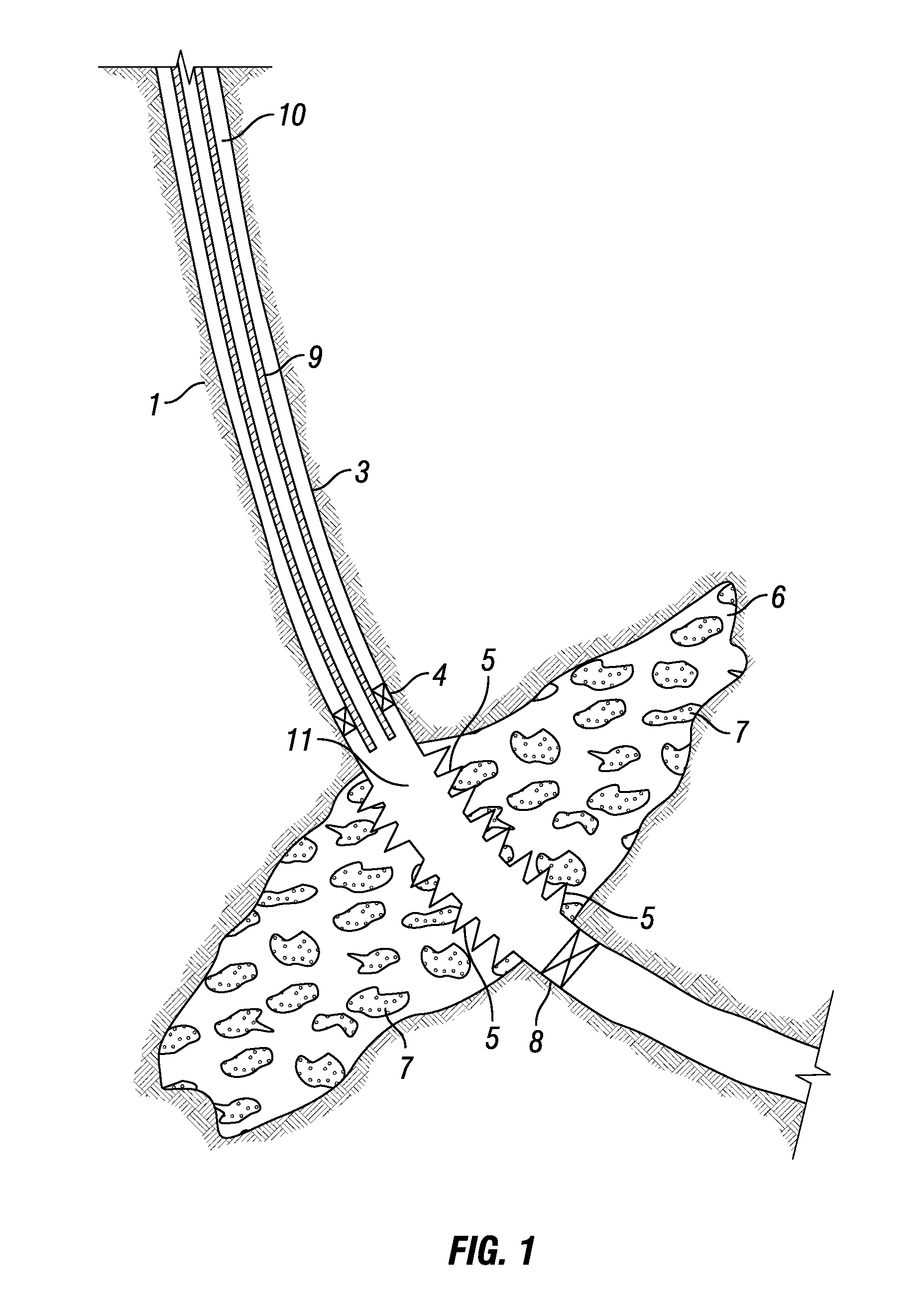

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS7178596B2Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

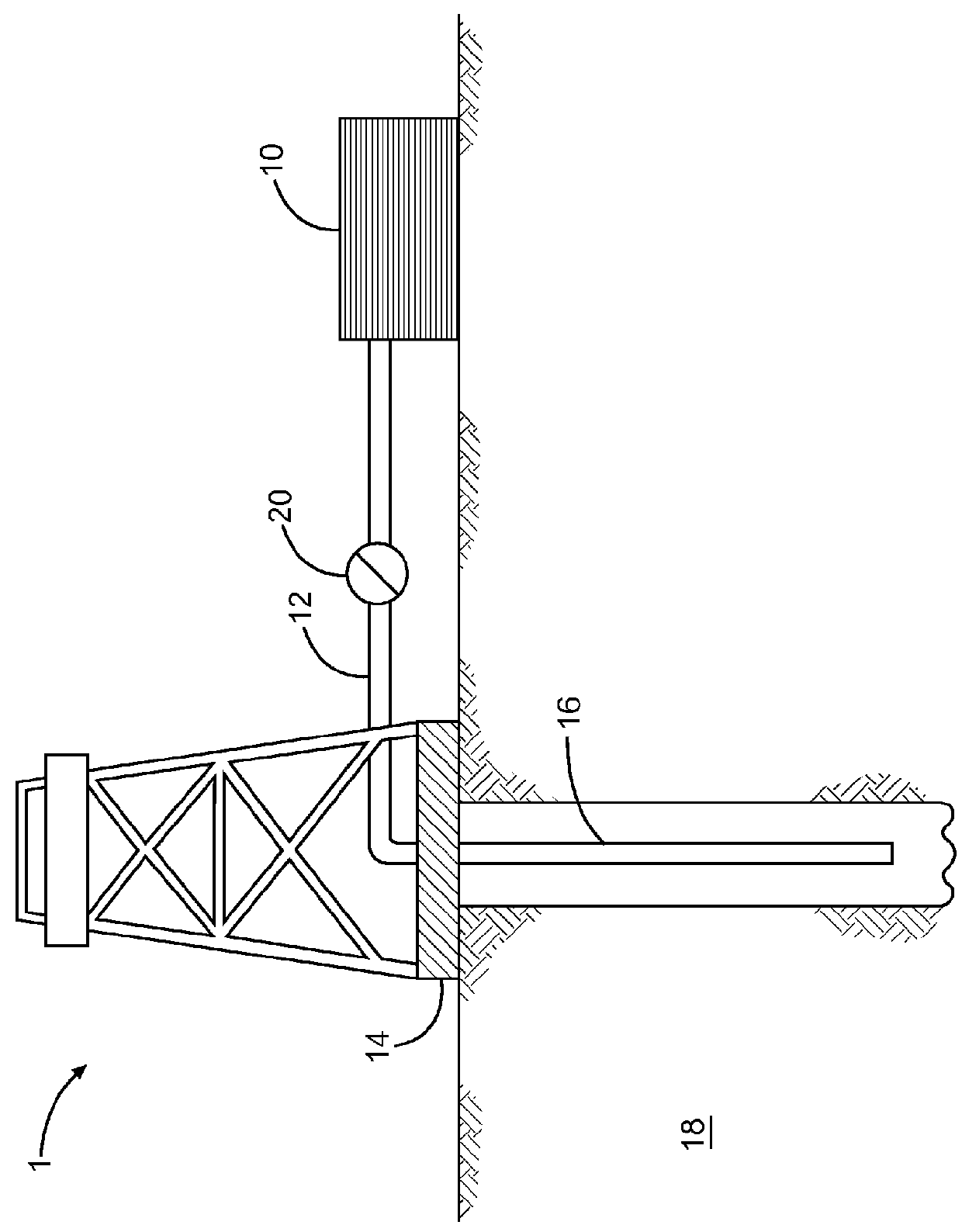

Method and apparatus for deliberate fluid removal by capillary imbibition

InactiveUS6283212B1Increase the lengthRateFluid removalDrilling compositionCapillary pressureWell stimulation

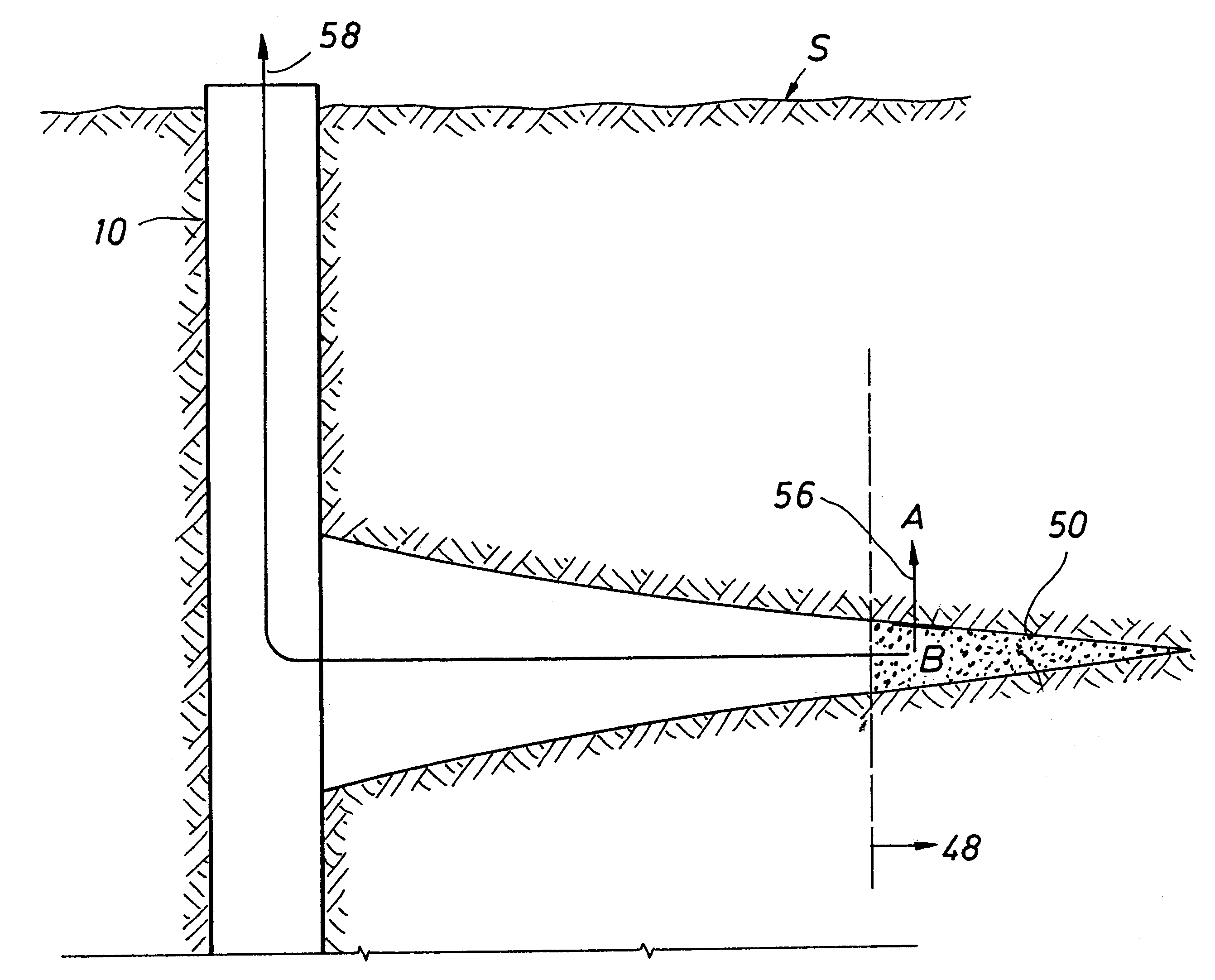

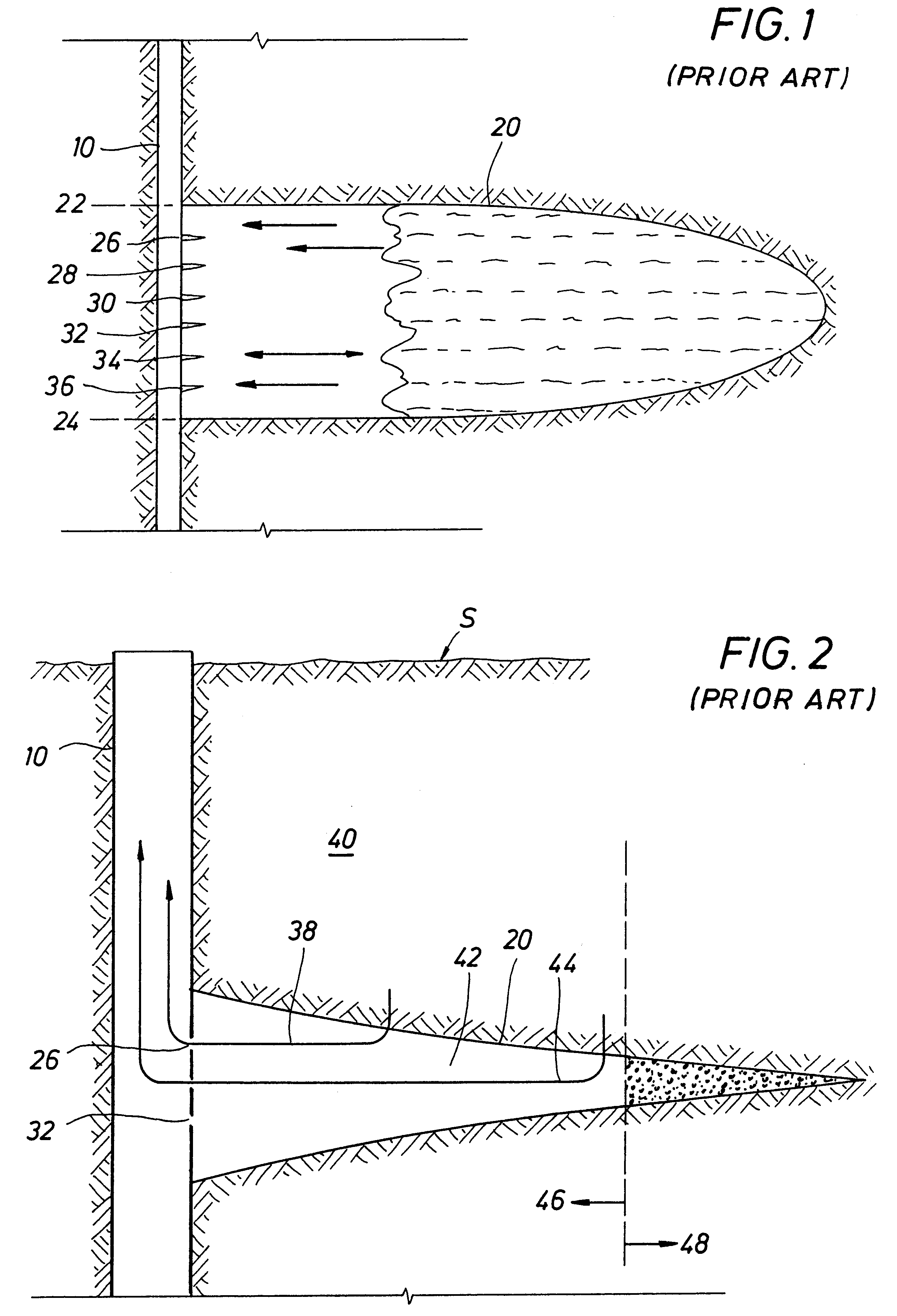

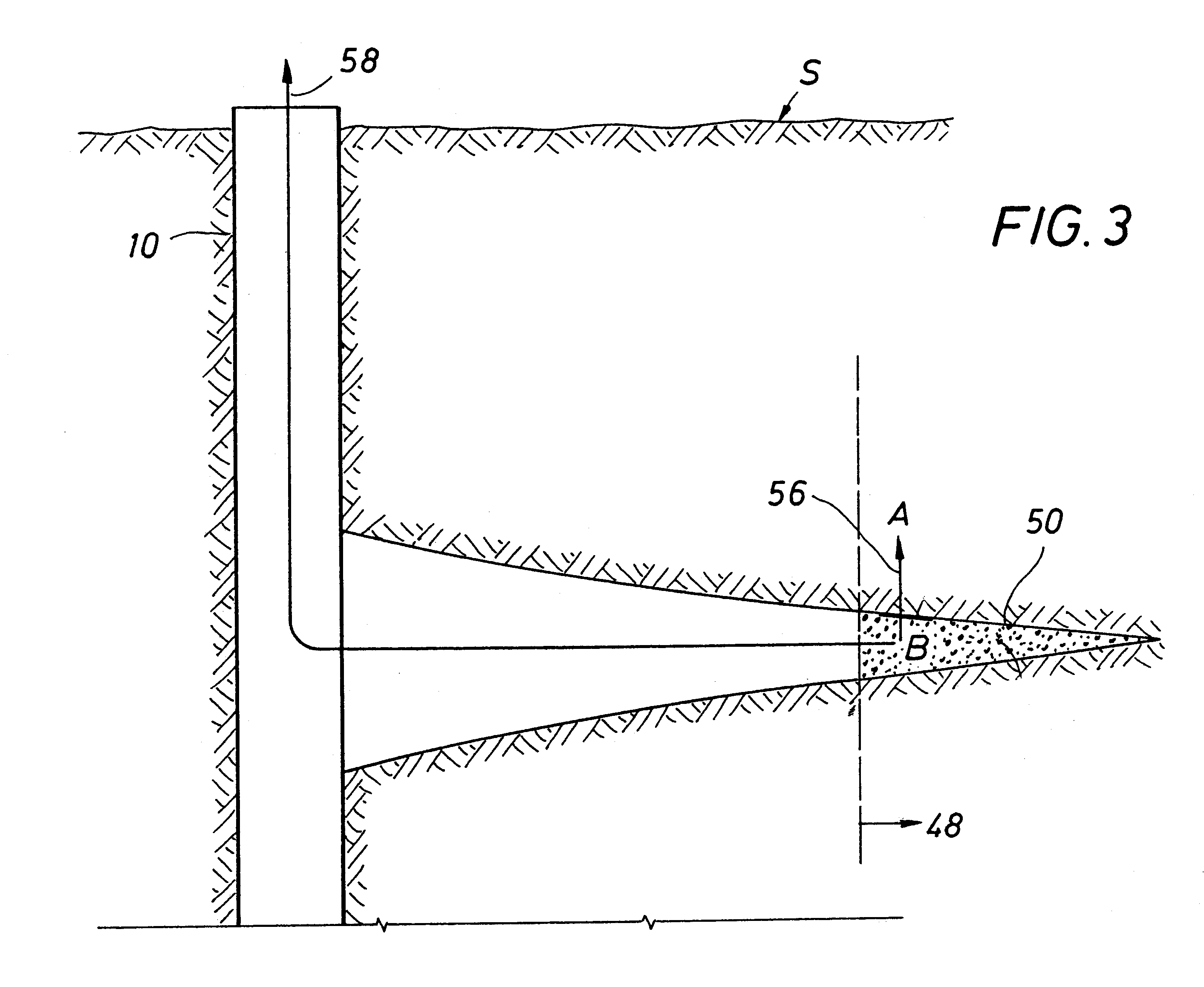

The present Invention relates to hydrocarbon well stimulation, and more particularly to methods and compositions to remove (or more generally to transfer) fluid introduced into the subsurface. For instance, preferred methods involve creating then exploiting a capillary pressure gradient at the fracture face to induce fluid flow from the fracture into the formation thereby increasing effective fracture length, and then improving fracture conductivity.

Owner:SCHLUMBERGER TECH CORP

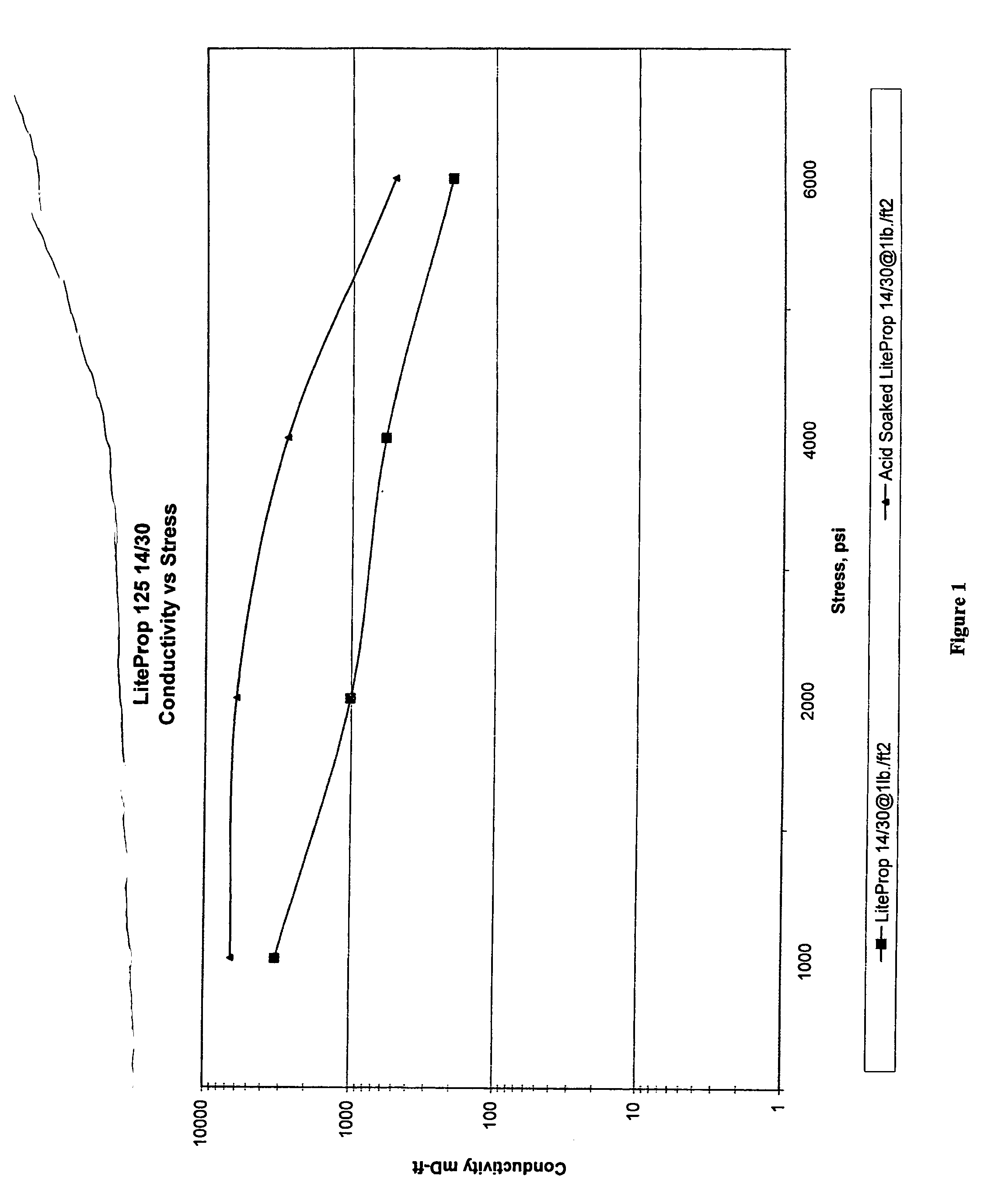

Well treating composition containing relatively lightweight proppant and acid

InactiveUS20060073980A1Satisfied with placementImprove productivityFluid removalFlushingParticulatesAcid fracturing

A well treating composition contains an aqueous acid and at least one relatively lightweight proppant, preferably having an apparent specific gravity (ASG) less than or equal to 2.45. The acid fracturing composition may used to acid fracture a hydrocarbon reservoir within a subterranean formation of an oil or gas well. The composition may further be used to stimulate the production of hydrocarbons. The proportion of relatively lightweight proppant to acid in the composition is such that the dimensional fracture conductivity (CfD) is in excess of 1.0. The aqueous acid typically has an ASG substantially equal to the ASG of the relatively lightweight particulate. As such, the relatively lightweight particulate is suspended in the aqueous acid.

Owner:BAKER HUGHES INC

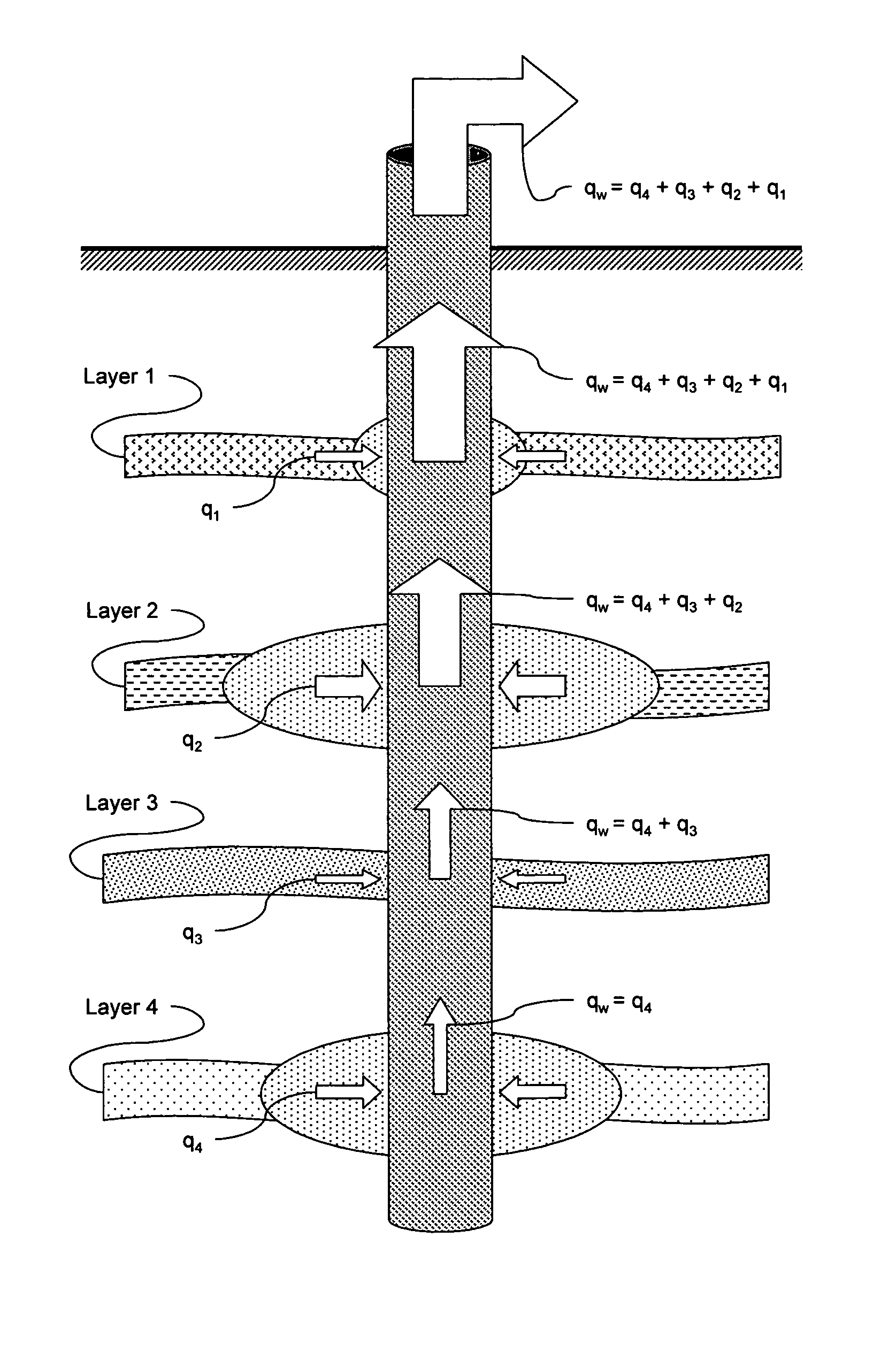

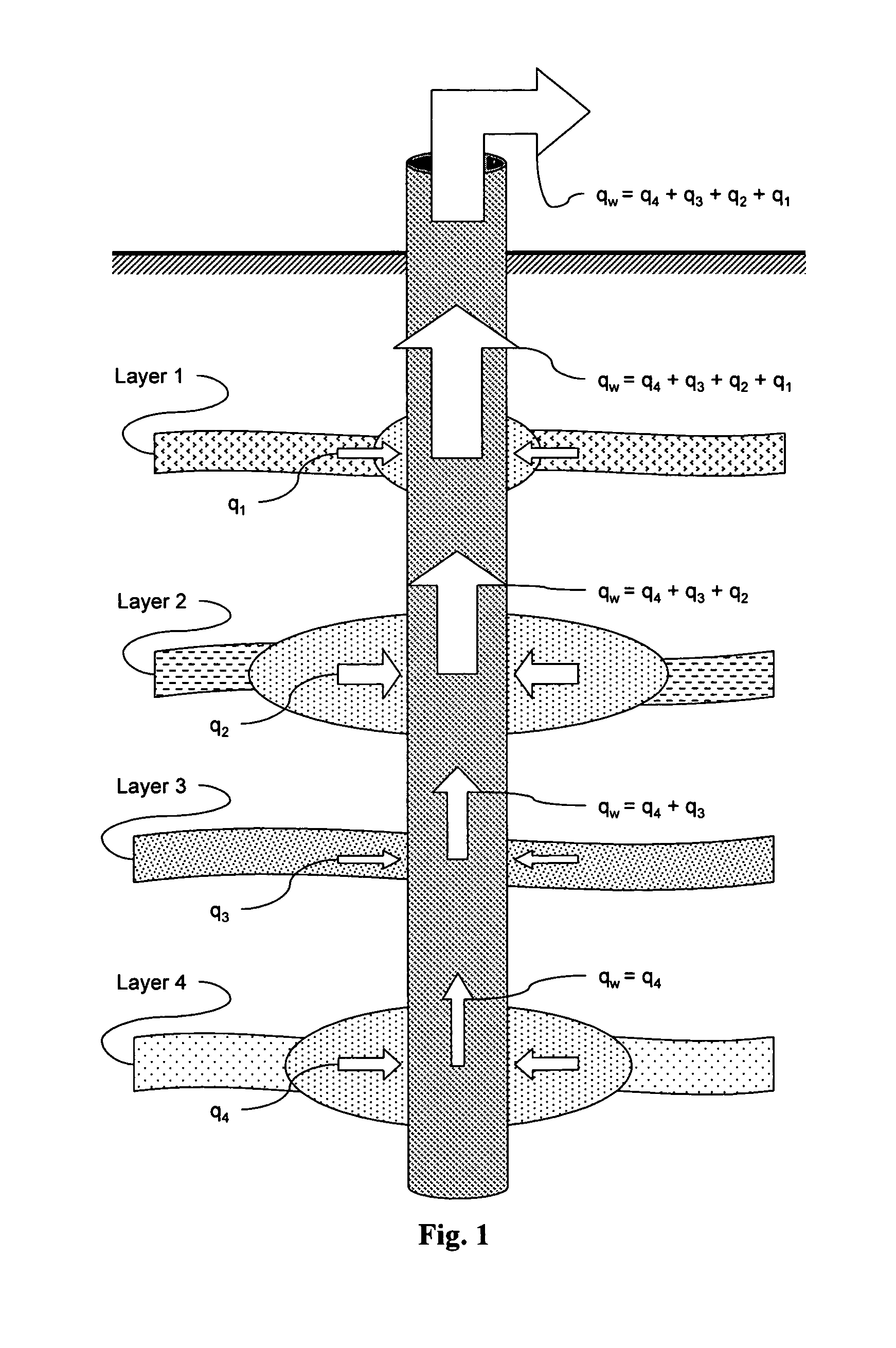

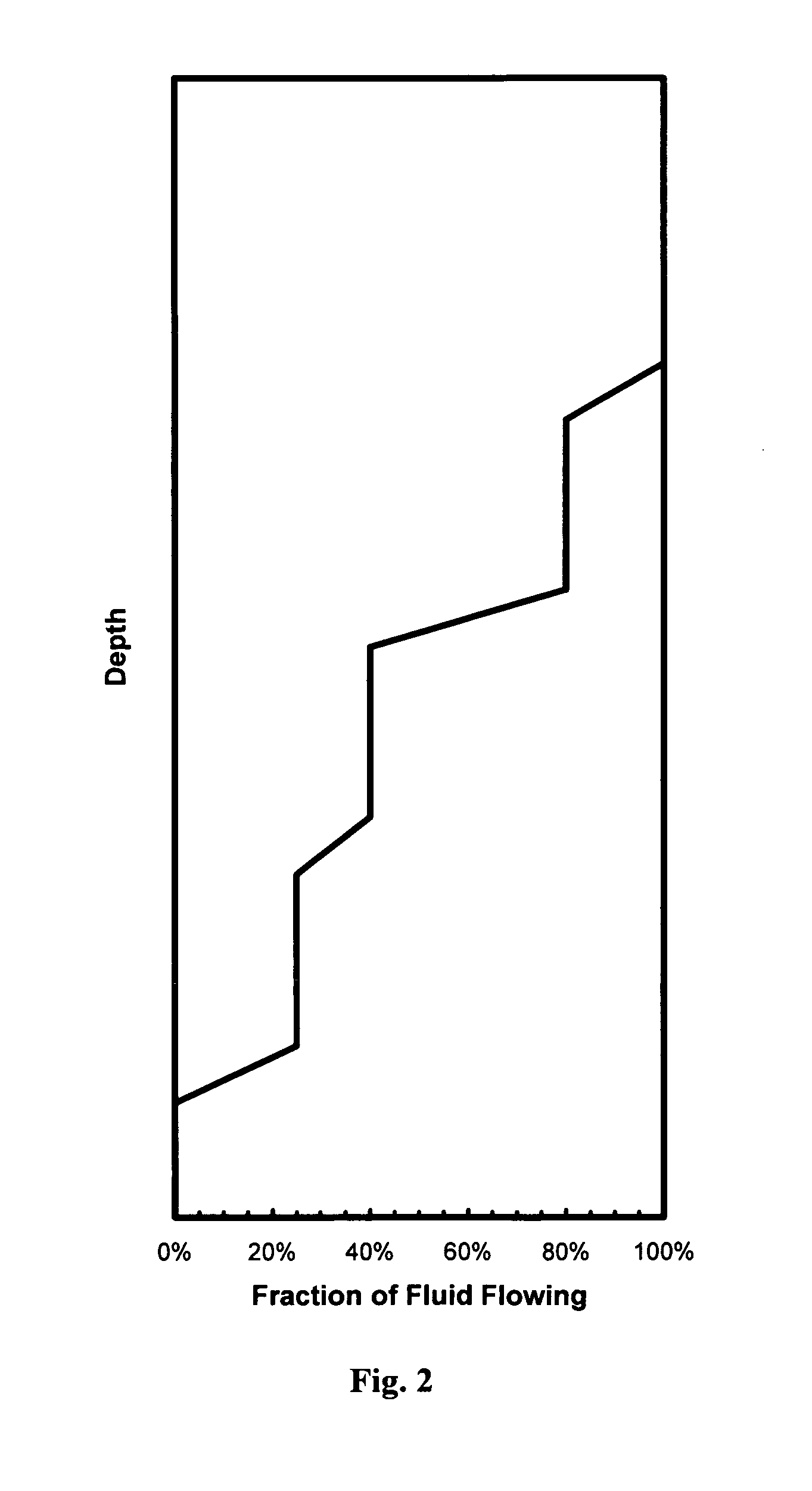

Method for characterizing and forecasting performance of wells in multilayer reservoirs having commingled production

InactiveUS7369979B1Electric/magnetic detection for well-loggingFluid removalSkin factorPredictive methods

A method for forecasting performance for and characterizing the properties of a multilayer low permeability gas reservoir. The method includes a coupled well / reservoir predictive model that accounts for pressure drop between layers, allowing accurate, rigorous, and rapid forecasting of reservoir performance. The method provides estimates of individual layer properties such as in-situ permeability, skin factor, fracture half-length, fracture conductivity, drainage area, etc. by simultaneously history matching production data and production log data using the coupled well / reservoir predictive model.

Owner:SPIVEY JOHN PAUL

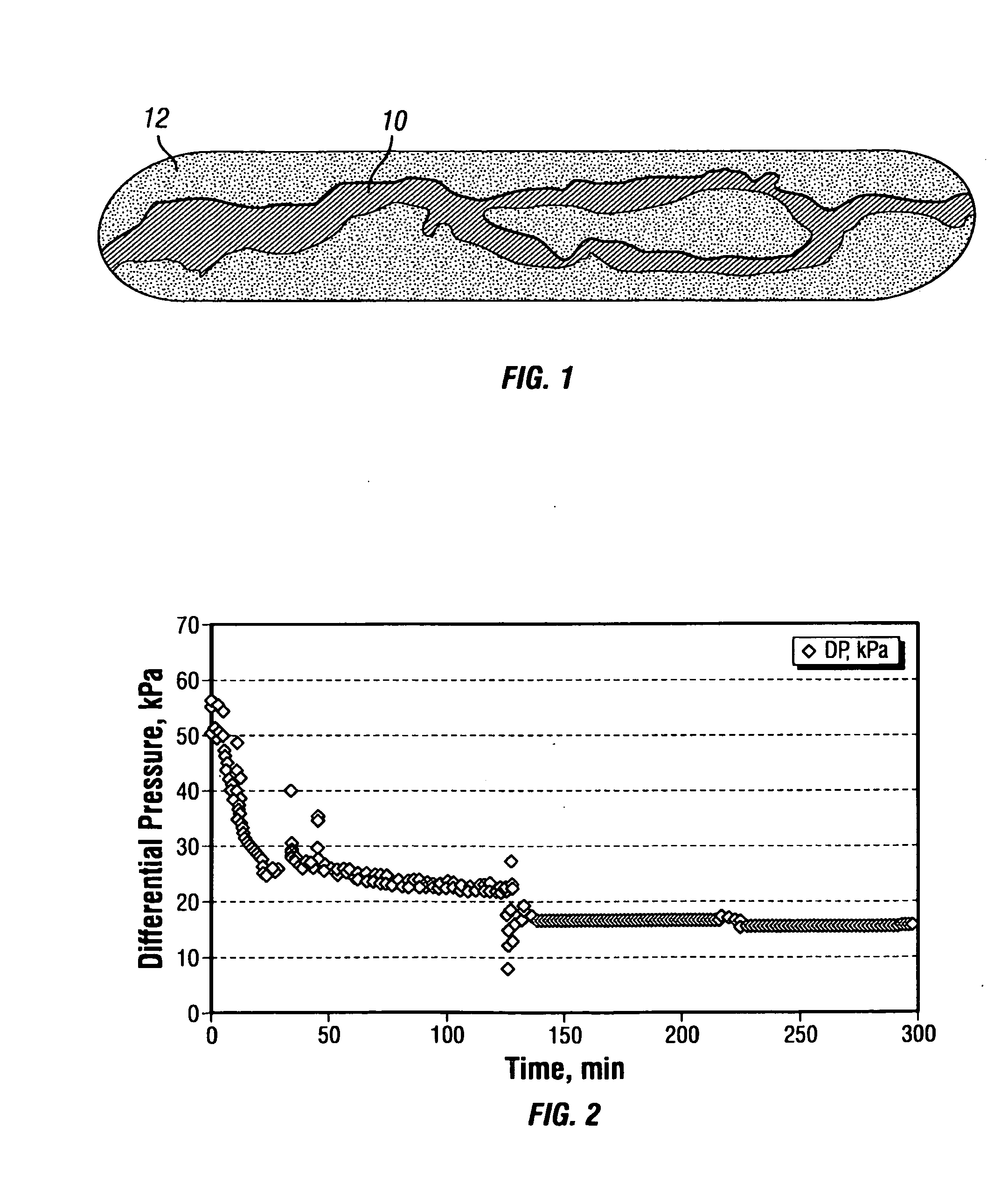

Proppant placement

InactiveUS20130161003A1Induce and enhance non-uniformityImprove conductivityFluid removalDrilling compositionFlocculationEngineering

Embodiments of hydraulic fracturing methods disclosed herein use fine mesh proppant. In one embodiment the method is used to fracture a low permeability formation. In one embodiment the method uses flocculation to improve conductivity of a fracture. In one embodiment fluid flow through the fine mesh proppant in the fracture creates a network of connected channels to improve the fracture conductivity.

Owner:SCHLUMBERGER TECH CORP

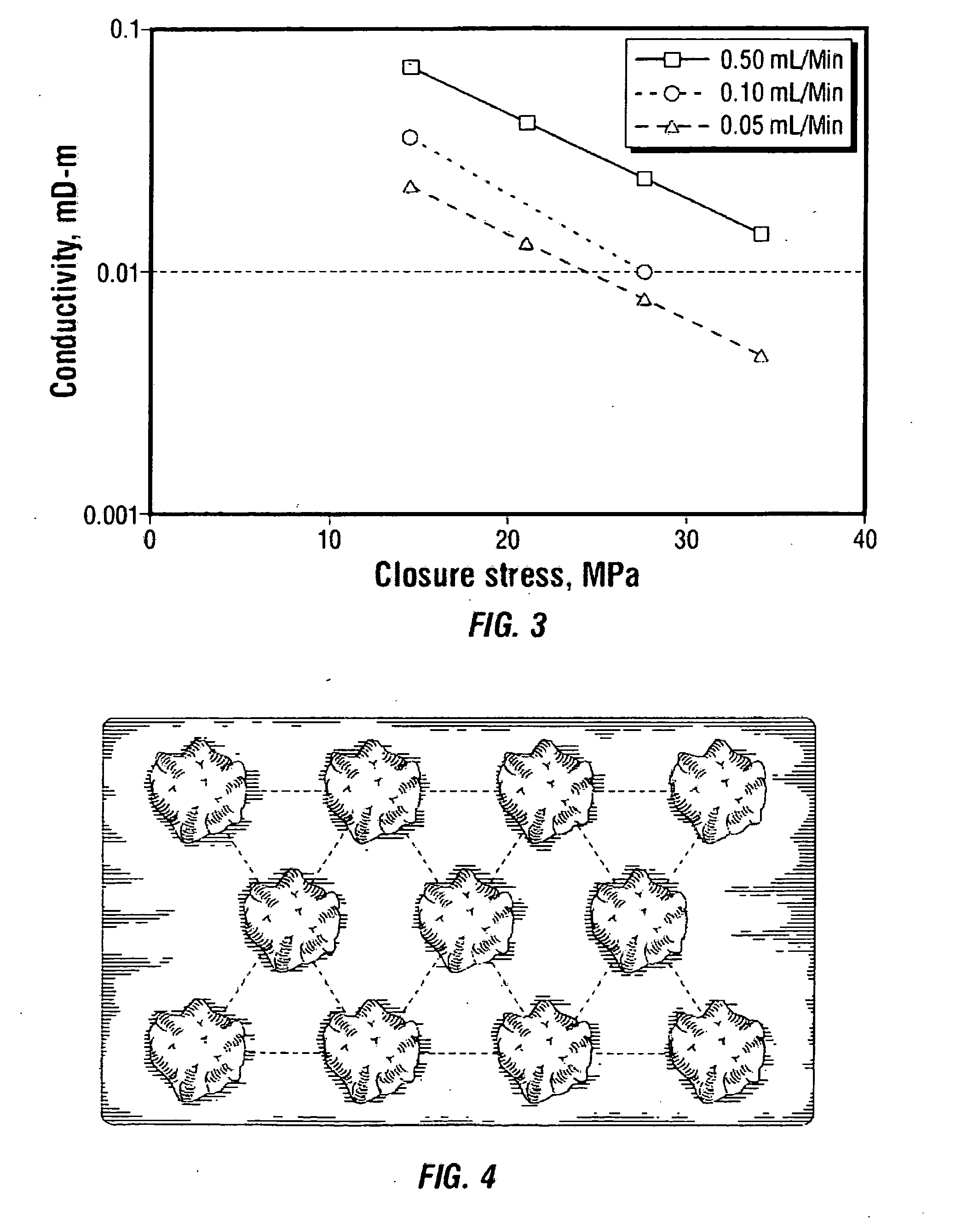

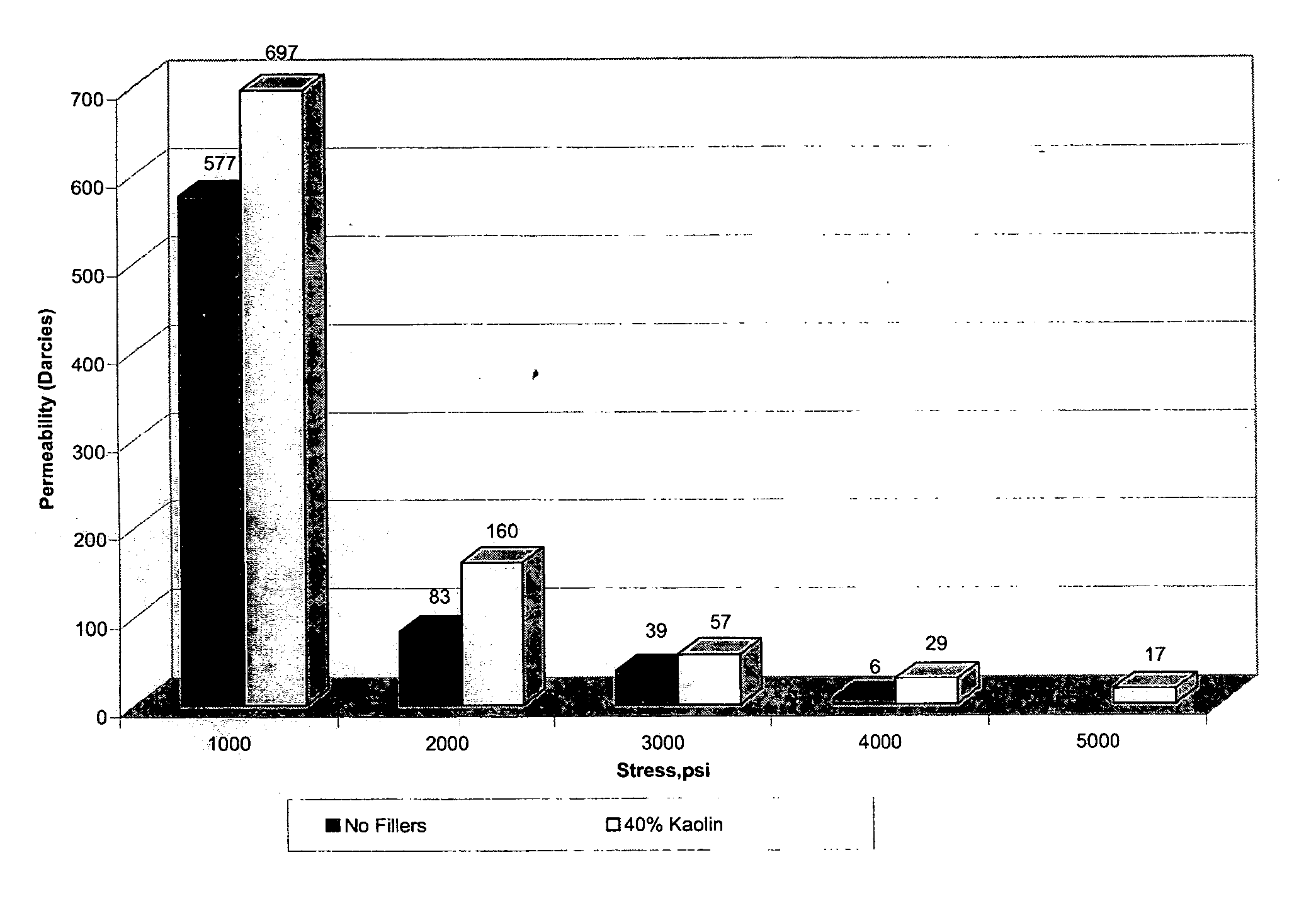

Method of fracturing using lightweight polyamide particulates

Lightweight polyamide particulates may be used in treatment of subterranean formations, including hydraulic fracturing and sand control methods, such as gravel packing. The polyamide particulates typically have an apparent specific gravity (ASG) between from about 1.05 to about 2.0 and are stable at temperatures up to 500° C. The polyamide particulates may be used in combination with a filler which further serves to increase the strength and temperature stability of the resulting composite. Fracture conductivity may be increased by the placement of the low density polyamide particulates as a partial monolayer.

Owner:BAKER HUGHES INC

Method of using lightweight polyamides in hydraulic fracturing and sand control operations

ActiveUS20070209795A1Enhancing fracture conductivityImprove stabilityFluid removalFlushingParticulatesPolyamide

Lightweight polyamide particulates may be used in treatment of subterranean formations, including hydraulic fracturing and sand control methods, such as gravel packing. The polyamide particulates typically have an apparent specific gravity (ASG) between from about 1.05 to about 2.0 and are stable at temperatures up to 500° C. The polyamide particulates may be used in combination with a filler which further serves to increase the strength and temperature stability of the resulting composite. Fracture conductivity may be increased by the placement of the low density polyamide particulates as a partial monolayer.

Owner:BAKER HUGHES INC

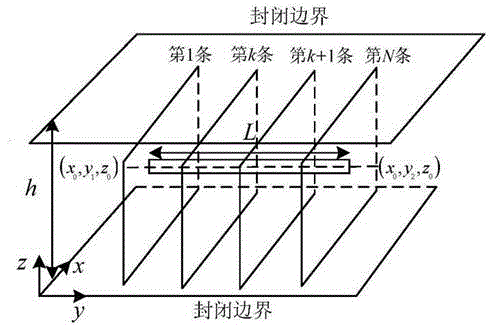

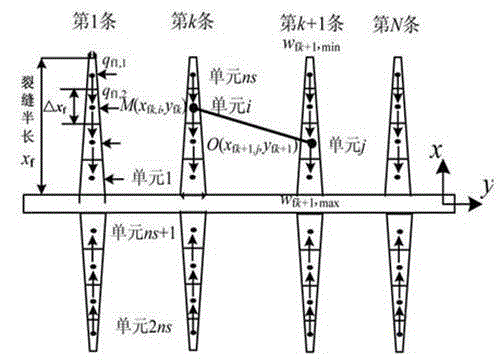

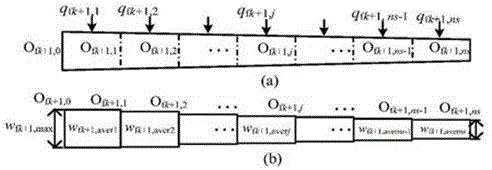

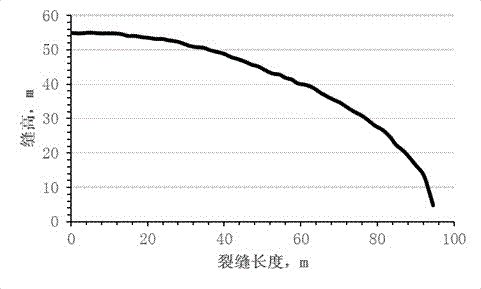

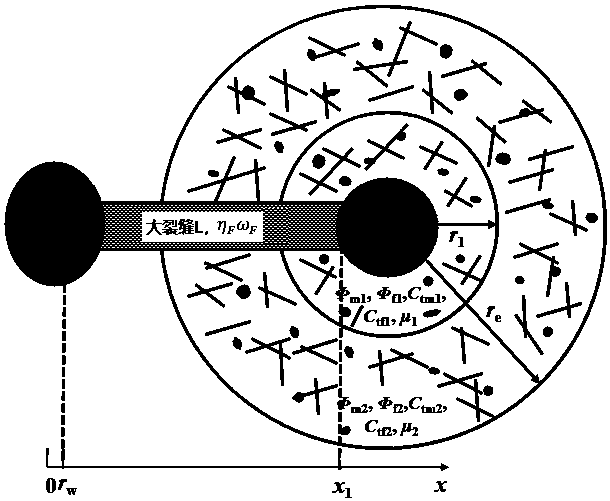

Method for optimizing fracture conductivity of tight gas-reservoir fractured horizontal well

ActiveCN104594872AAchieve Quantitative OptimizationImprove effectivenessFluid removalSpecial data processing applicationsSurface conductivityWellbore

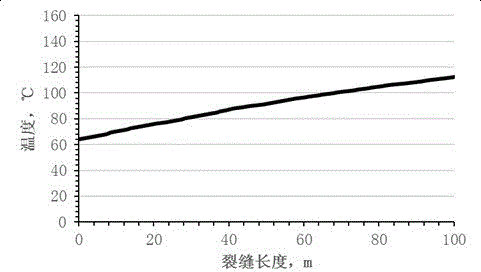

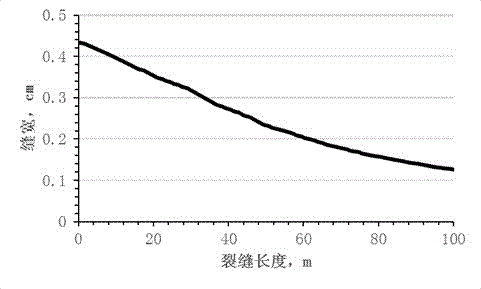

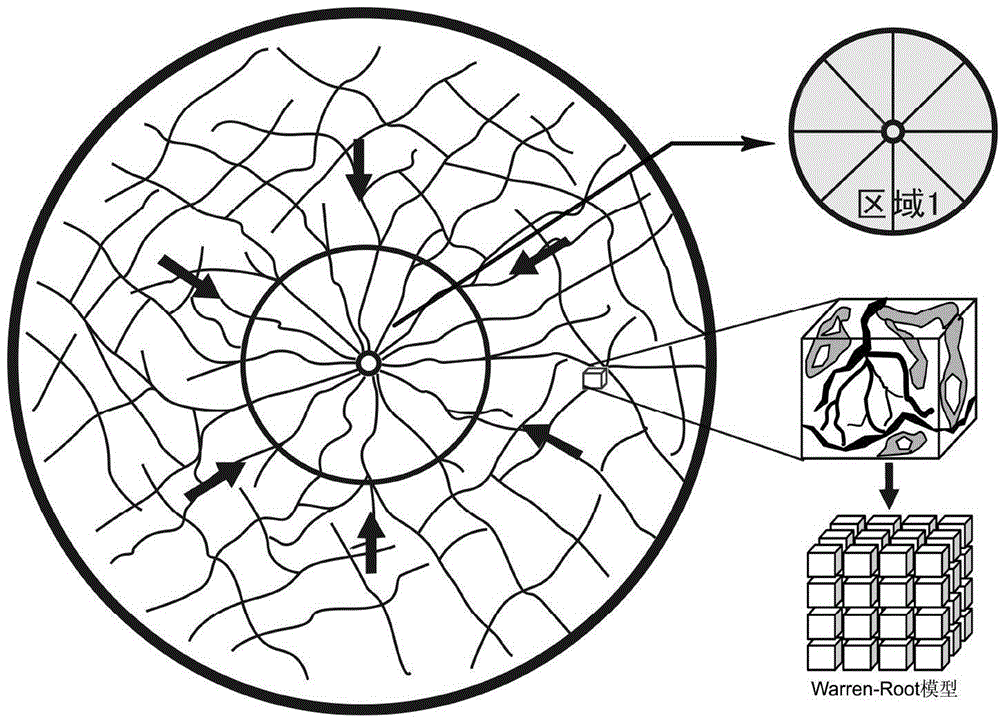

The invention relates to fracturing reformation in the field of oil-gas field development, in particular to a method for optimizing fracture conductivity of a tight gas-reservoir fractured horizontal well. The method mainly comprises the following steps of (1) collecting basic parameters of a reservoir, fluid property and a horizontal well shaft; (2) collecting basic parameters of fractures of the fractured horizontal well; (3) evenly dividing each fracture of the fractured horizontal well into line congruence with equal length along the fracture length direction; (4) building a reservoir permeability model for a tight gas-reservoir fractured horizontal well fracture system; (5) building a flowing decompression model of gas in the fractures; (6) building a flowing model of coupled gas in the reservoir permeability and the fractures, and forming a yield calculation model of the tight gas-reservoir fractured horizontal well; (7) optimizing the fracture conductivity of the tight gas reservoir fractured horizontal well. By utilization of the method for optimizing the fracture conductivity of the tight gas-reservoir fractured horizontal well provided by the invention, the shortages of the prior art can be conquered, and the problem of optimizing non-constant fracture conductivity of the fractured horizontal well along the fracture length direction is effectively solved, so that reasonable basis is provided for the optimization design of reservoir reformation, and the reservoir reformation effect is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Method of enhancing fracture conductivity

The method disclosed herein includes the introduction of proppant-free stage and a proppant laden stage into the wellbore and / or subterranean formation. The method increases the effective fracture width and enhances fracture conductivity within the formation. Either the proppant-free stage or the proppant laden stage contains a breaker. The other stage contains a viscosifying polymer or viscoelastic surfactant to which the breaker has affinity. The proppant-free stage may be introduced prior to introduction of the proppant laden stage into the wellbore and / or formation. Alternatively, the proppant laden stage may be introduced into the wellbore and / or formation prior to introduction of the proppant-free stage.

Owner:BAKER HUGHES INC

Method of Enhancing Fracture Conductivity

The method disclosed herein includes the introduction of proppant-free stage and a proppant laden stage into the wellbore and / or subterranean formation. The method increases the effective fracture width and enhances fracture conductivity within the formation. Either the proppant-free stage or the proppant laden stage contains a breaker. At least one of the proppant-free stage or proppant laden stage contains a viscosifying agent to which the breaker has affinity. The viscosifying agent may be a superabsorbent, a viscosifying polymer (other than a superabsorbent) or a viscoelastic surfactant. The breaker has greater affinity for the viscosifying agent not present in the same stage as the breaker. Either the proppant-free stage or the proppant laden stage may be foamed.

Owner:BAKER HUGHES INC

Methods for enhancing propped fracture conductivity

ActiveUS20160053160A1Increasing and maintaining fracture conductivityImprove conductivityDrilling rodsFluid removalViscosityFracture conductivity

Various embodiments disclosed relate to methods of treating a subterranean formations that provide enhanced fracture conductivity over other methods. In various embodiments, the present invention provides a method of treating a subterranean formation. The method can include obtaining or providing a composition including a tackifies. The composition can have a viscosity less than about 20 cP. The method can include placing the composition in a subterranean formation downhole. The method can also include fracturing the subterranean formation with the composition.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of enhancing fracture conductivity

The method disclosed herein includes the introduction of proppant-free stage and a proppant laden stage into the wellbore and / or subterranean formation. The method increases the effective fracture width and enhances fracture conductivity within the formation. Either the proppant-free stage or the proppant laden stage contains a breaker. The other stage contains a viscosifying polymer or viscoelastic surfactant to which the breaker has affinity. The proppant-free stage may be introduced prior to introduction of the proppant laden stage into the wellbore and / or formation. Alternatively, the proppant laden stage may be introduced into the wellbore and / or formation prior to introduction of the proppant-free stage.

Owner:BAKER HUGHES INC

Method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution

ActiveCN106522935AImprove the transformation effectThe distribution of diversion capacity is conducive to real evaluationConstructionsFluid removalAcid fracturingAcid etching

The invention discloses a method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution. The method comprises the steps that an acid fracturing simulator FracproPT is adopted for simulating the down-hole acid fracturing fracture extending and acid etching process during acid fracturing, and fracture width distribution, fracture height distribution, temperature distribution and acid liquor mass concentration distribution data in the hydraulic fracture length direction are obtained; in the hydraulic fracture length direction, fracture width, fracture height and temperature data of total 10 feature points with the acid liquor mass concentration being 100%, 90%, 80%, 70%, 60%, 50%, 40%, 30%, 20%, 10% of the initial mass concentration are selected; acid injection displacement of the oil field site scale is converted into acid injection displacement of the laboratory scale; according to the acid liquor mass concentration data of the 10 feature points, acid liquor used for an experiment is prepared; and the acid etching process is simulated, the conductivity under the condition of reservoir closed pressure is tested experimentally, and a distribution diagram of the acid etching fracture conductivity in the fracture length direction under the reservoir condition is drawn. The method is reliable in principle and simple and convenient to operate and has wide market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

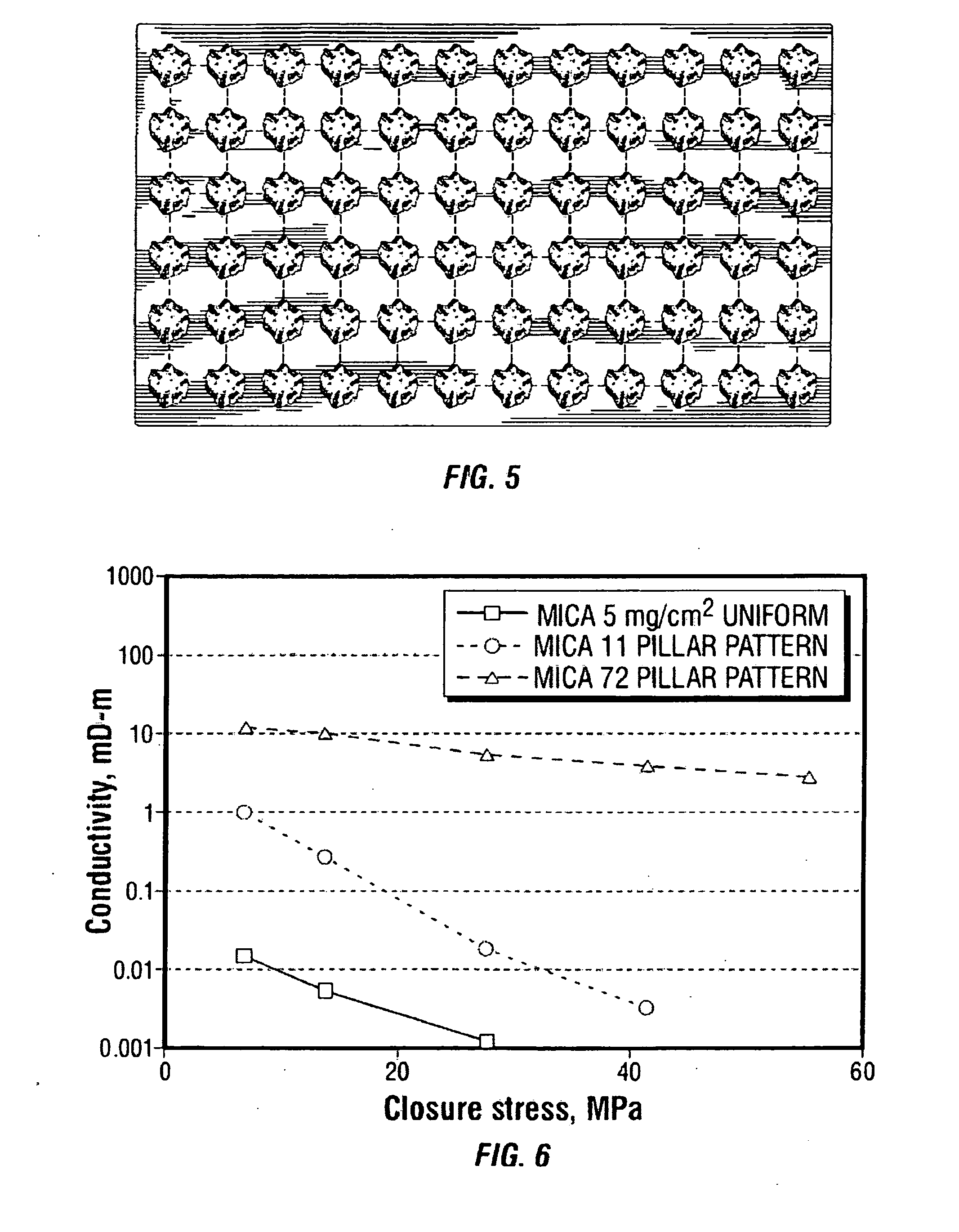

Methods of Enhancing Fracture Conductivity of Subterranean Formations Propped with Cement Pillars

InactiveUS20140144635A1Enhancing fracture conductivityFluid removalDrilling compositionAcid fracturingCement slurry

Methods of treating a subterranean formation having at least one fracture including providing a cement slurry comprising an expandable cementitious material and a breakable foamed carrier fluid, wherein the expandable cementitious material is capable of consolidating to form a plurality of expandable cementitious material aggregates and wherein the breakable foamed carrier fluid is capable of coating and isolating the expandable cementitious material aggregates; introducing the cement slurry into the fracture; curing the expandable cementitious material aggregates so as to form a cement pillar within the fracture in the subterranean formation, wherein the curing of the expandable cementitious material aggregates expands the expandable cementitious material aggregates such that at least one microfracture is created within the fracture; breaking the breakable foamed carrier fluid; removing the broken breakable foamed carrier fluid from the subterranean formation; and acid-fracturing the at least one fracture in the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

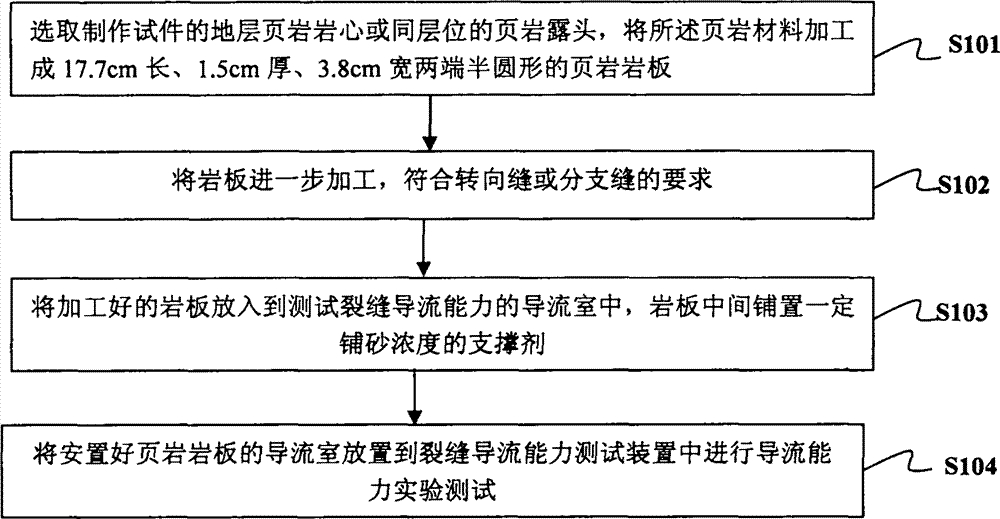

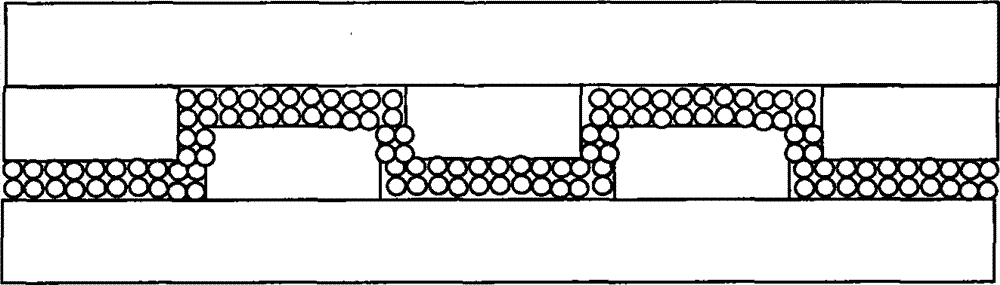

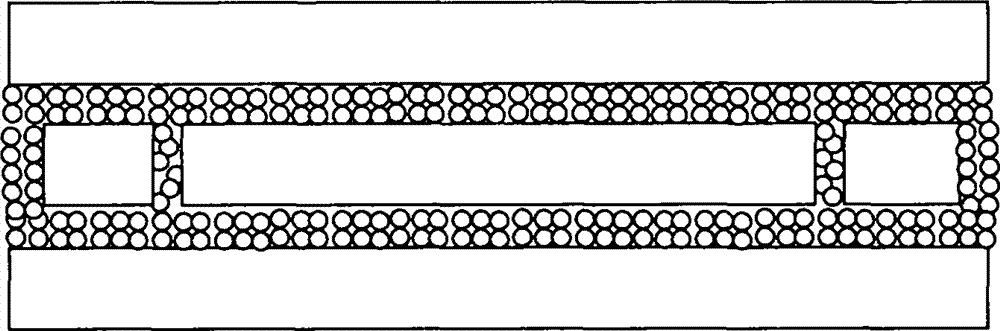

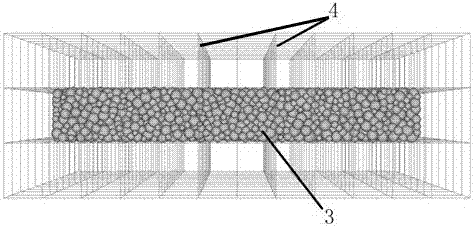

Shale gas reservoir complex fracture conductivity simulation experiment method

The invention provides a shale gas reservoir complex fracture conductivity simulation experiment method. The method comprises the following steps that (a) a stratum shale core or a peer position shale outcrop for manufacturing a test piece is selected, and shale materials are processed into a shale slab, wherein the length of the shale slab is 17.7 cm, the thickness of the shale slab is 1.5 cm, the width of the shale slab is 3.8 cm, and the two ends of the shale slab are in a semicircular shape; (b) the shale slab is further processed to meet the requirement of turning fractures or branch fractures; (c) the processed shale slab is put in a conducting room for testing the fracture conductivity, and a propping agent with the certain sanding concentration is laid in the middle of the shale slab; (d) the conducting room with the propping agent and the shale slab well arranged is put in a fracture conductivity testing device to conduct a conductivity experiment test. For fractured fragile shale with complex fractures, the shale gas reservoir complex fracture conductivity simulation experiment method can be used for studying the conductivity of the turning fractures and the branch fractures formed through fracturing of shale gas reservoirs and evaluating the influence on the fracture conductivity by the fracture steering degree and the branch fracture form.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method for evaluating volume transformation capacity of vertical well of fractured tight oil reservoir

InactiveCN104695928AEasy to addSimple and clear reflectionFluid removalDesign optimisation/simulationGeomorphologyMathematical model

Owner:OIL & GAS SURVEY CGS

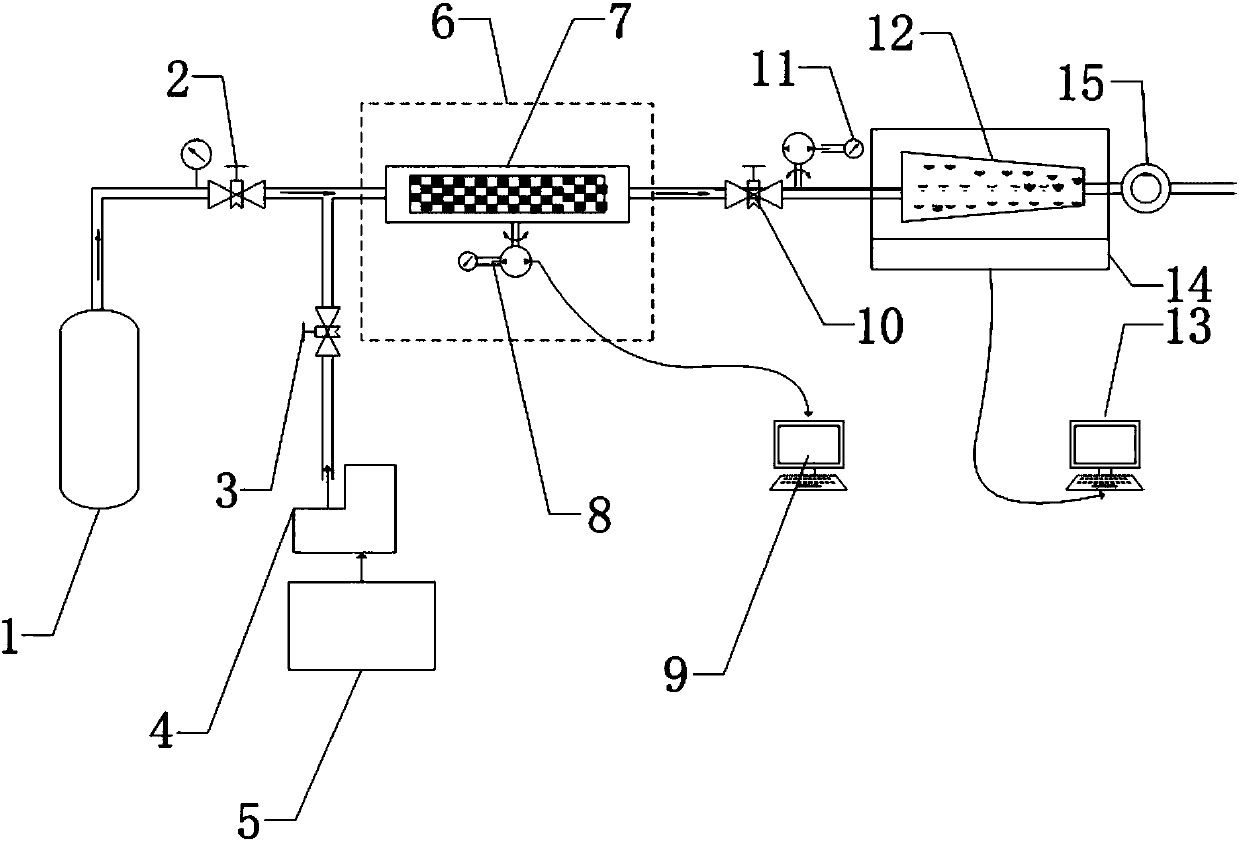

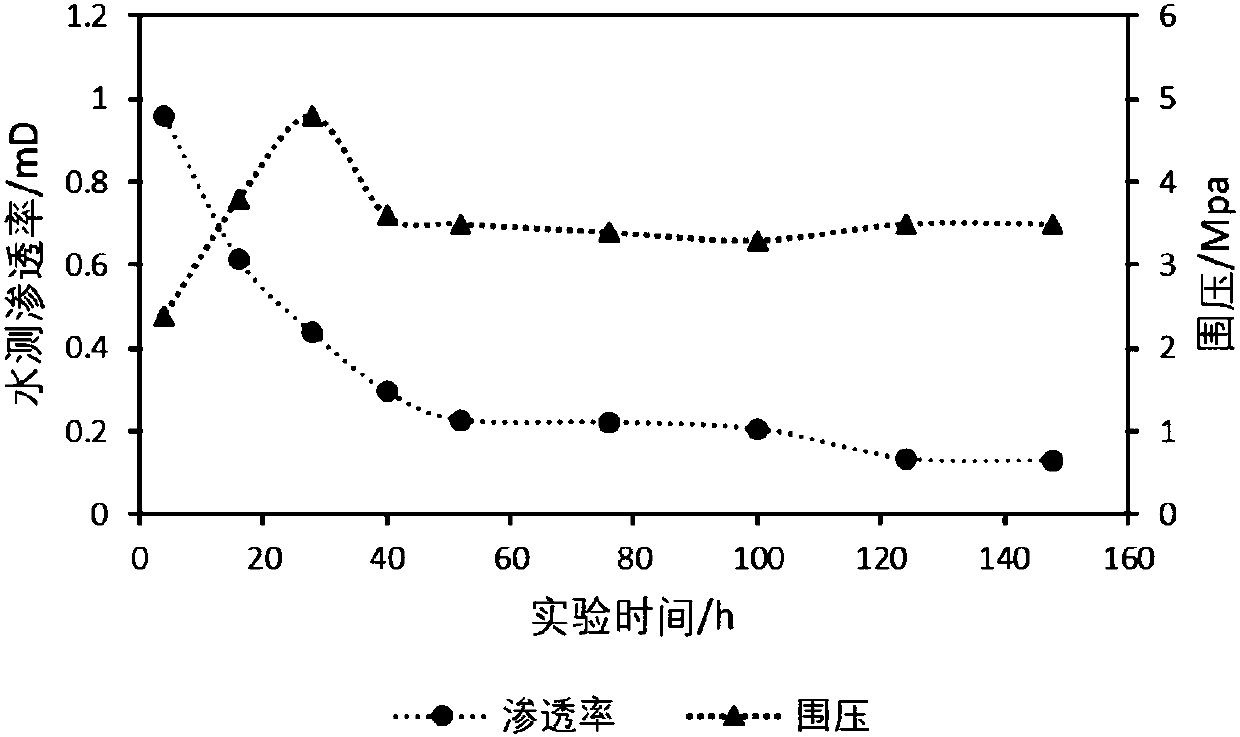

Fractured shale gas-water two-phase flow fracture conductivity evaluation device and method

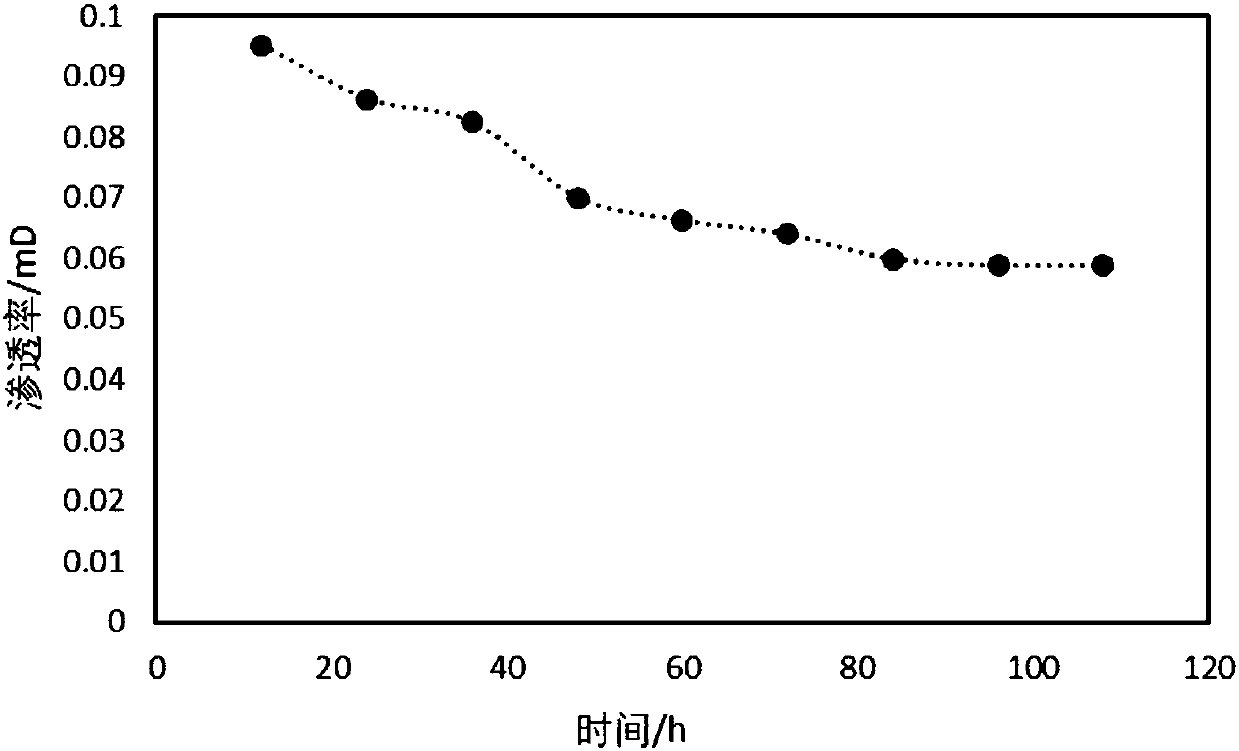

Belonging to the technical field of oil and gas exploitation, the invention provides a fractured shale gas-water two-phase flow fracture conductivity evaluation device and method. The device consistsof a seepage system, an injection system, a data acquisition and processing system and a triaxial core holder. Specifically, the seepage system is divided into a water injection stage and a gas flooding stage. The method includes: firstly using the device to determine the initial permeability and initial mass of a shale sample; conducting water injection to the shale sample for water invasion experiment and ending water injection when core effluent water flow becomes stable; adding a dryer, then conducting gas flooding on the shale sample, collecting the gas flooding zone outflow water phase fracturing fluid, and ending gas flooding until a flowmeter measures stable gas output. The device and method provided by the invention measure that the permeability of the shale sample at the water injection stage and gas flooding stage varies with time, and explore the influence of water phase fracturing fluid invasion on shale fracture conductivity and the seepage law. The device and method canaccurately determine the seepage law of shale gas in microfractures, and the operation is simple.

Owner:UNIV OF SCI & TECH BEIJING

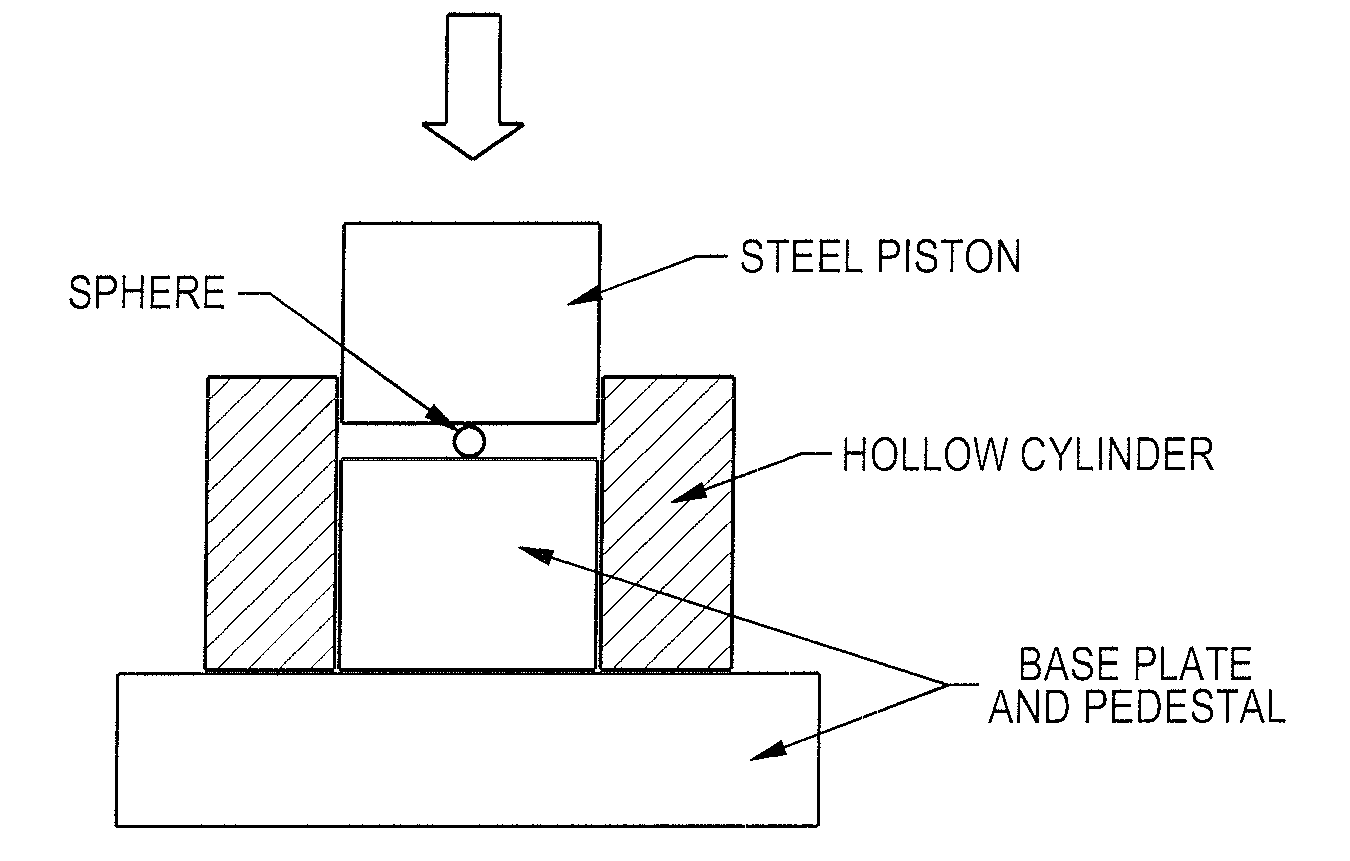

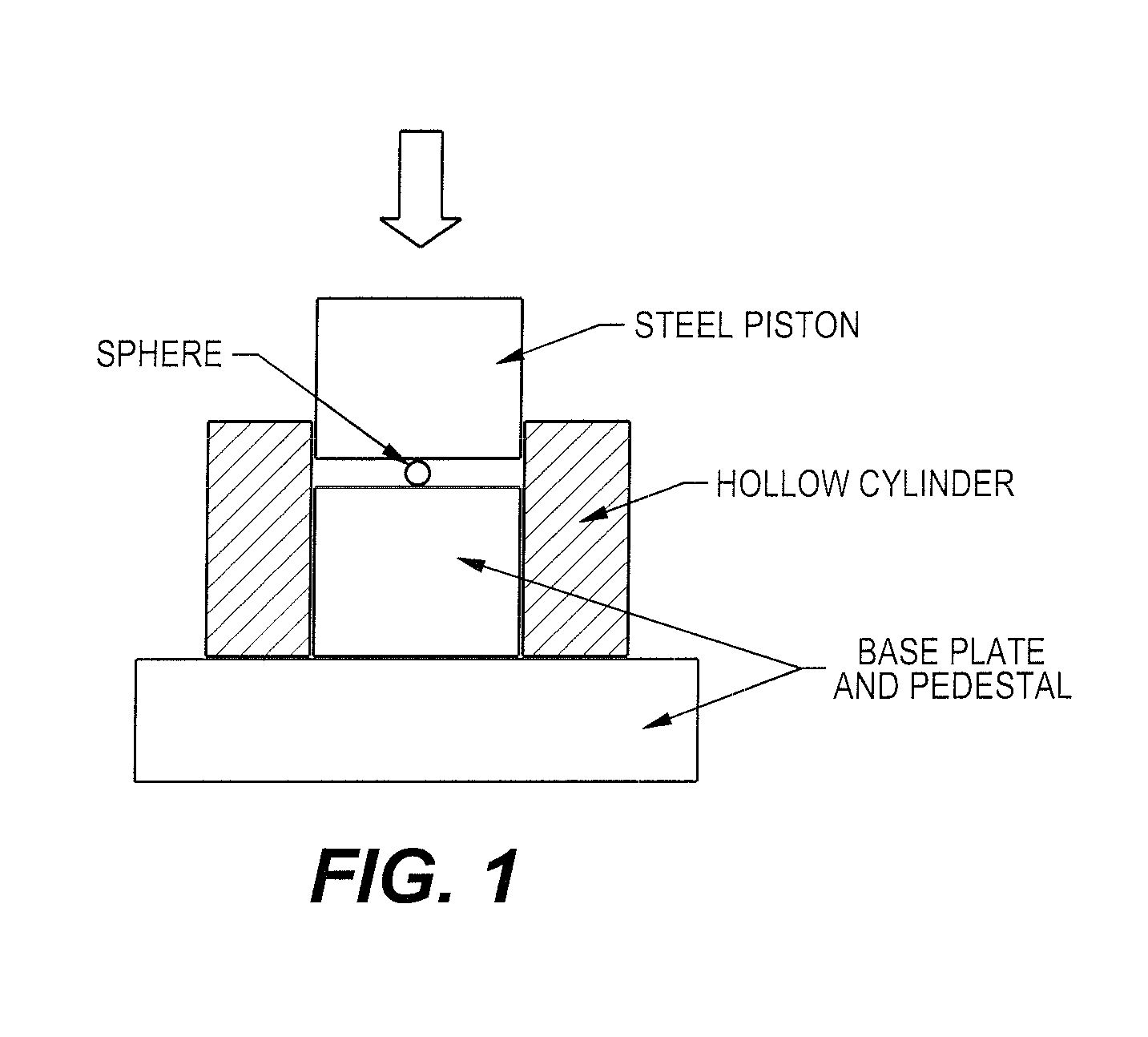

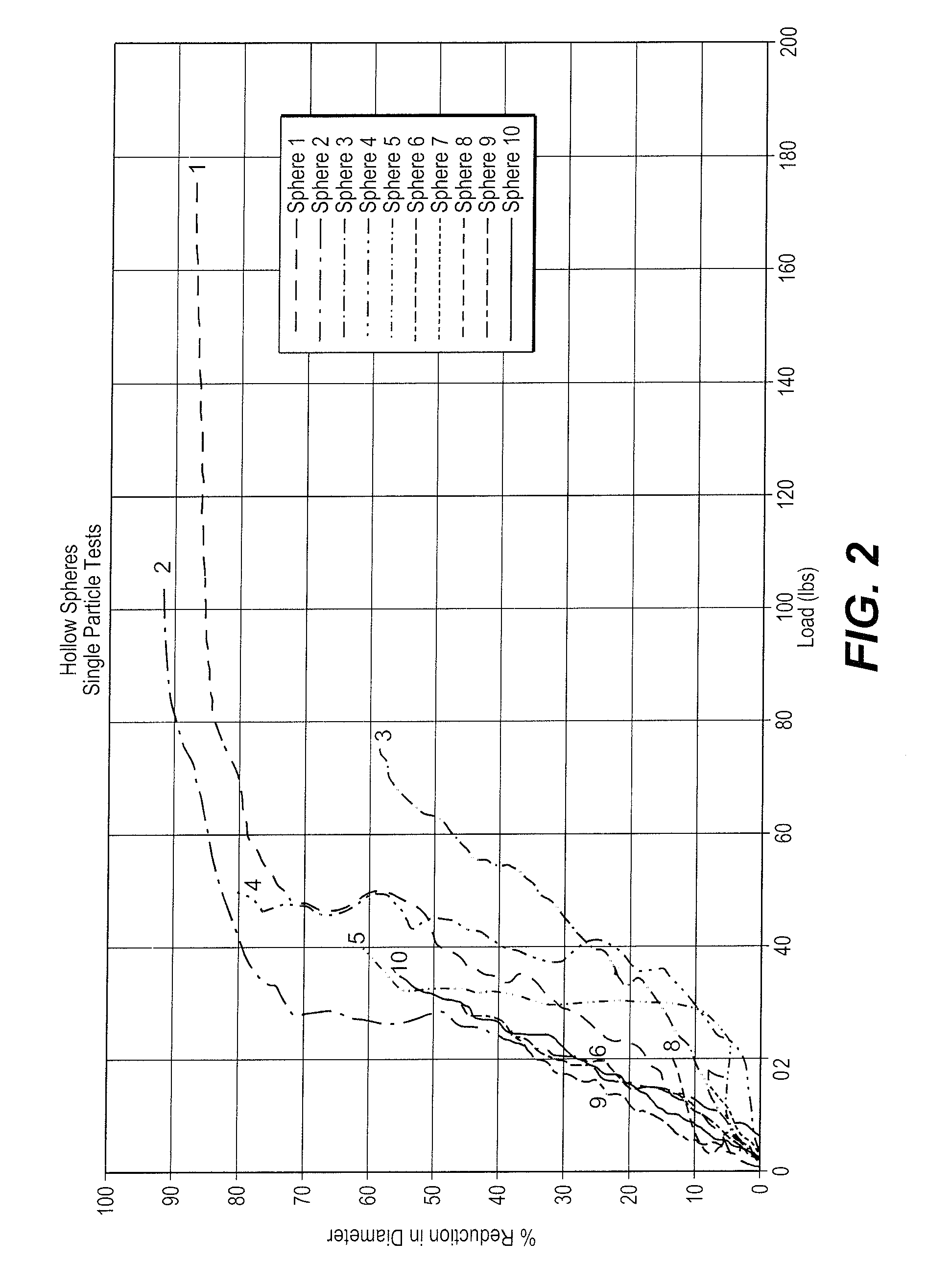

Well Treating Agents of Metallic Spheres and Methods of Using the Same

InactiveUS20080179057A1Good anti-corrosion propertiesPrevent intrusionFluid removalFlushingThick wallMetal

Hollow non-porous metallic spheres may be used in treatment of subterranean formations, including hydraulic fracturing and sand control methods, such as gravel packing. The spheres typically having a diameter ranging from about 4 mesh to about 100 mesh. When employed in deep water environments having high closure stresses, the spheres have a thicker wall and are characterized by the higher ASG, typically between 2.5 to about 4.0. The ASG of the spheres, when less harsh environments are encountered, is generally ultra lightweight (ULW) with an ASG less than or equal to 2.0. Fracture conductivity may be increased by the placement of the hollow non-porous metallic spheres as a partial monolayer.

Owner:BAKER HUGHES INC

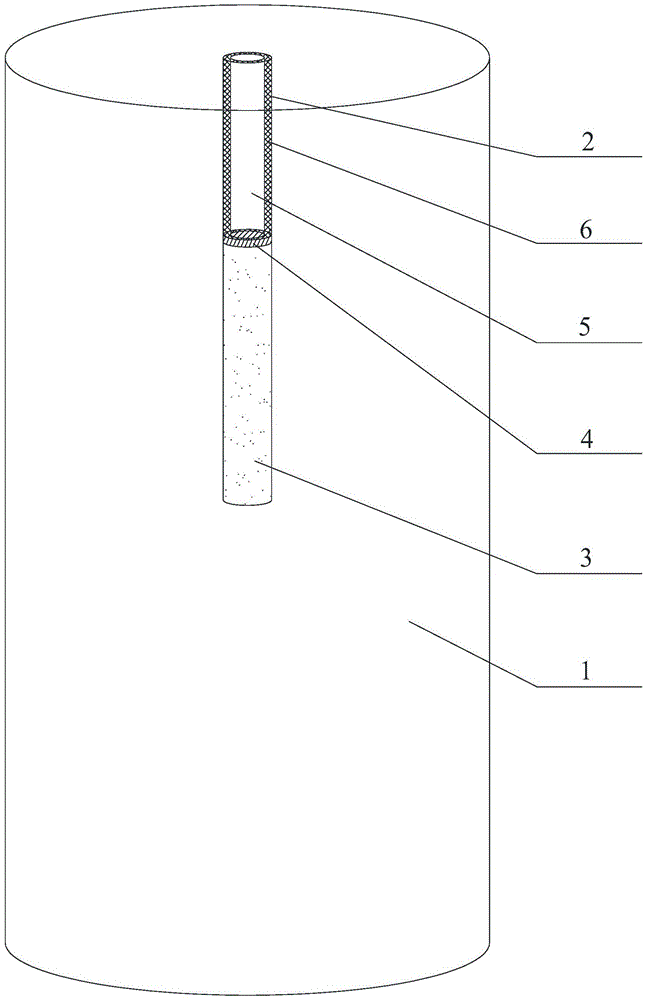

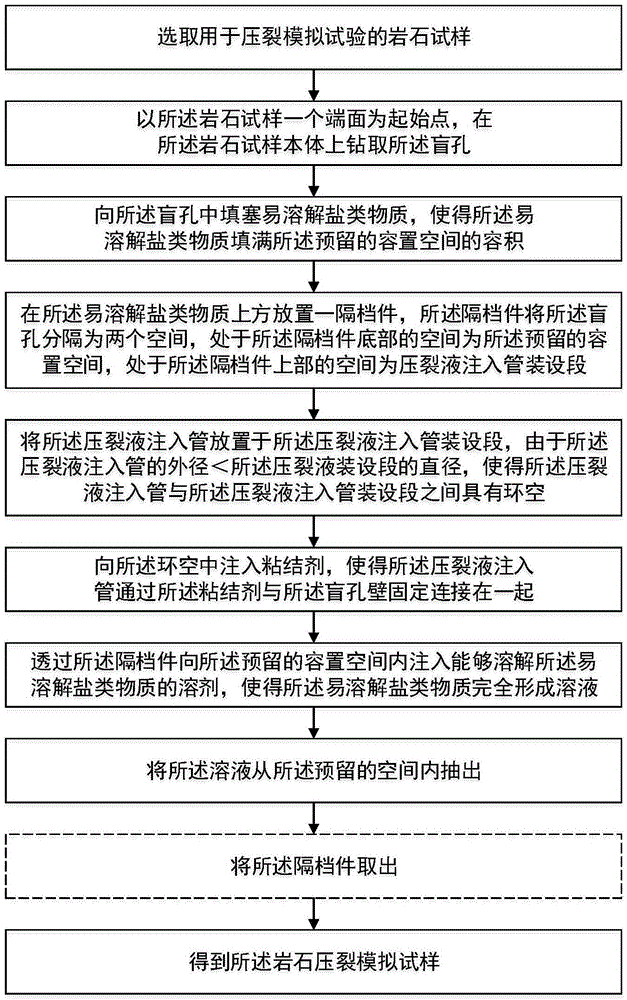

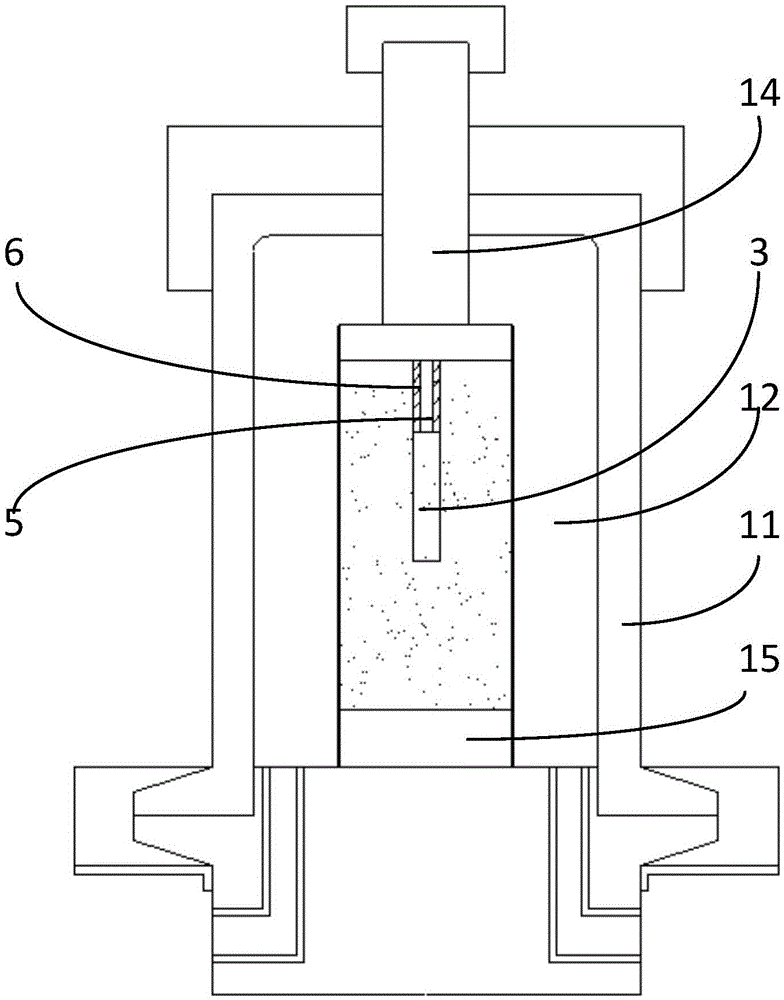

Rock fracture simulation sample and preparation method thereof, as well as simulation test device and simulation test method

ActiveCN105628506APreparing sample for investigationMaterial strength using tensile/compressive forcesTriaxial shear testFracturing fluid

The invention discloses a rock fracture simulation sample and a preparation method thereof, as well as a simulation test device and a simulation test method and belongs to the technical field of rock simulation tests. The simulation sample comprises a body and a fracturing fluid injection pipe, wherein a blind hole is formed by taking one end surface of the body as a start point; the fracturing fluid injection pipe is fixedly connected with the wall of the blind hole; an accommodating space is reserved between the bottommost end of the fracturing fluid injection pipe and the bottommost end of the blind hole. The simulation sample can be prepared by the preparation method. The simulation test device comprises a triaxial test apparatus, wherein the triaxial test apparatus comprises a triaxial chamber, an upper pressing head, a lower pressing head, a confining pressure oil injection mechanism, a fracturing liquid injection pump and the rock fracture simulation sample. The simulation test method is realized on the basis of the simulation test device. According to the simulation test method, vivid complex fracture seams can be formed in a rock sample, and a fracture conductivity test is performed on the basis of the fracture seams, so that the obtained rock gas pool deliverability evaluation is relatively approximate to actual evaluation data, so as to guide actual work more objectively.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Methods of Enhancing Fracture Conductivity of Subterranean Formations Propped with Cement Packs

Methods of treating a subterranean formation including providing a wellbore in a subterranean formation having at least one fracture; providing an expandable cementitious material; introducing the expandable cementitious material into the at least one fracture in the subterranean formation; curing the expandable cementitious material so as to form a cement pack, wherein the curing of the expandable cementitious material expands the expandable cementitious material such that at least one microfracture is created within the at least one fracture in the subterranean formation; and acid-fracturing the at least one fracture in the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

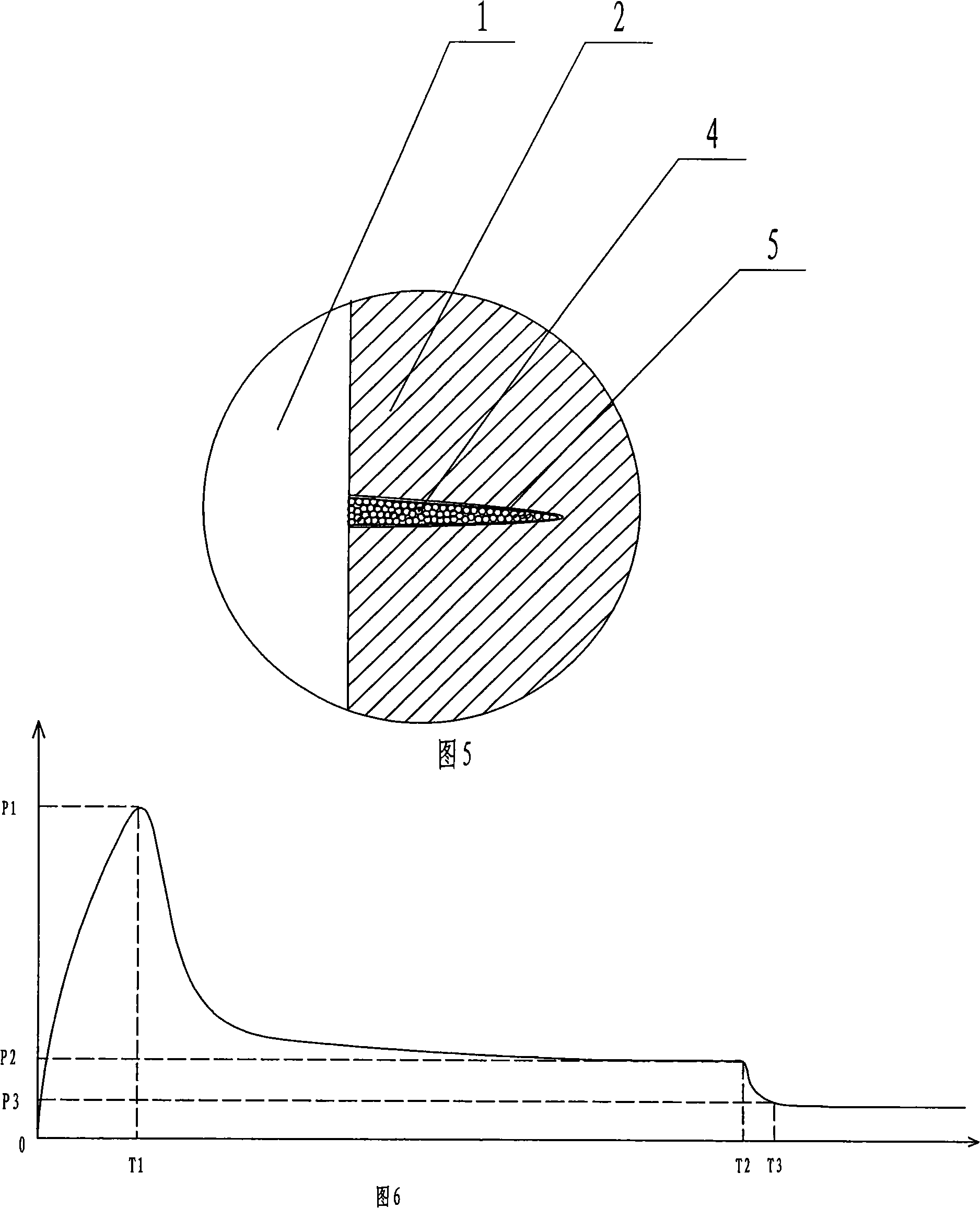

Fracturing process for removing breakdown fluid contamination

The invention relates to a mining technology for the petroleum, natural gas and the coal seam gas, in particular to a compression fracture process which avoids the fracturing fluid pollution and solves the problem that the fracture conductivity is reduced caused by the dense filter cake formed on the surface of the strata fracture by the thickener added in the fracturing fluid applied in all the compression fracture constructions found in the prior art. The construction steps include that the pad fluid is injected into the oil gas storage strata; the sand-laden fluid is injected continuously when the oil gas storage strata generates fractures; subsequently, the displacement fluid is injected; then the pump on the ground is stopped; 60 minutes later after the fracture closing time T3 and the pressure is lower than the fracture closing pressure P3, the oxidant solution such as the chlorine dioxide result solution, the potassium permanganate, the hydrogen peroxide solution or the persulphate which can degrade the polymers is injected into the fractures as the fracturing post pad fluid; finally, the displacement fluid is injected to extrude all the compression fracture post pad fluid to the strata fractures. The compression fracture process can radically avoid the pollution block of the fracturing fluid, exert the potential of the fracturing technology and increase the yield.

Owner:郝东 +1

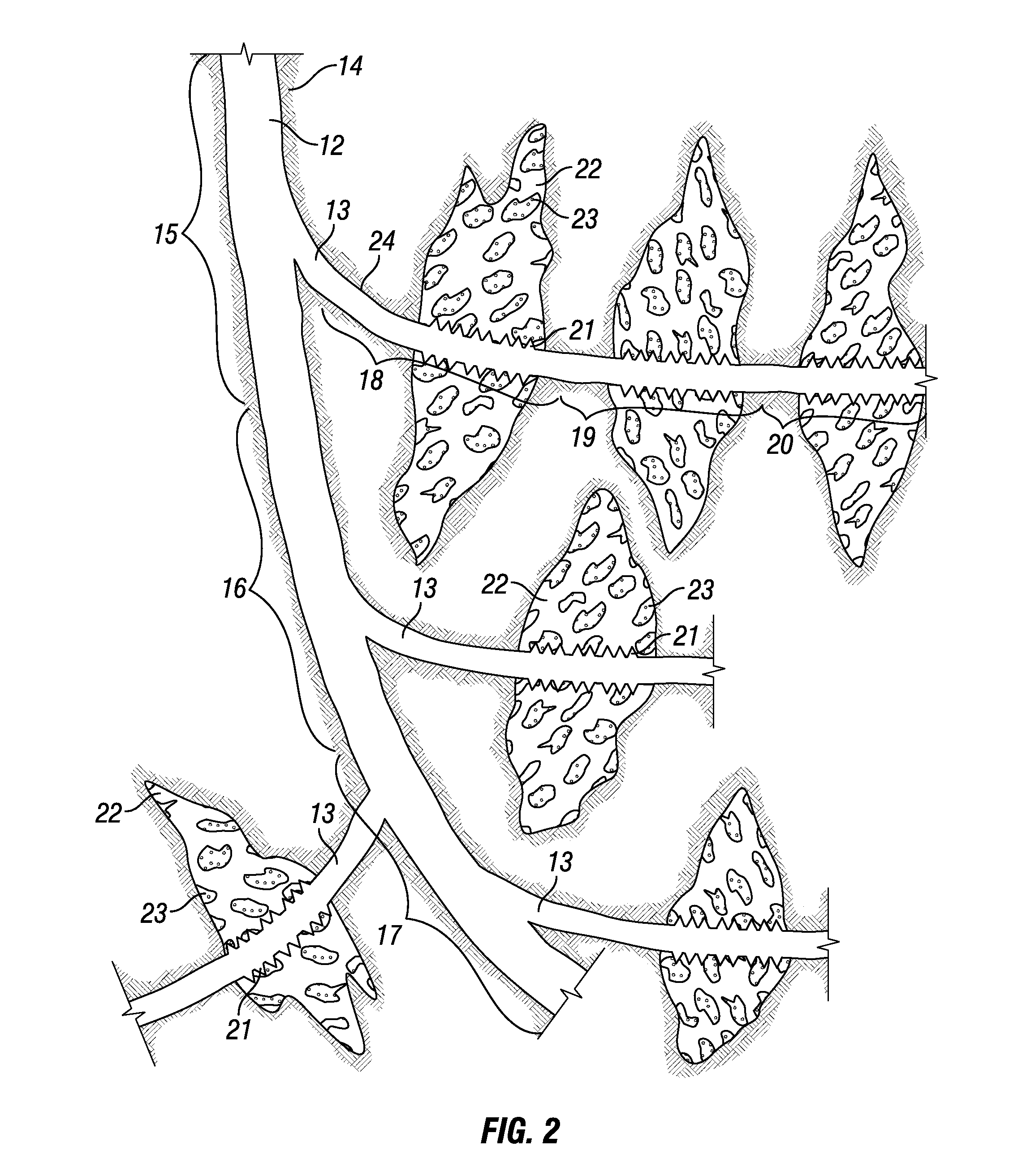

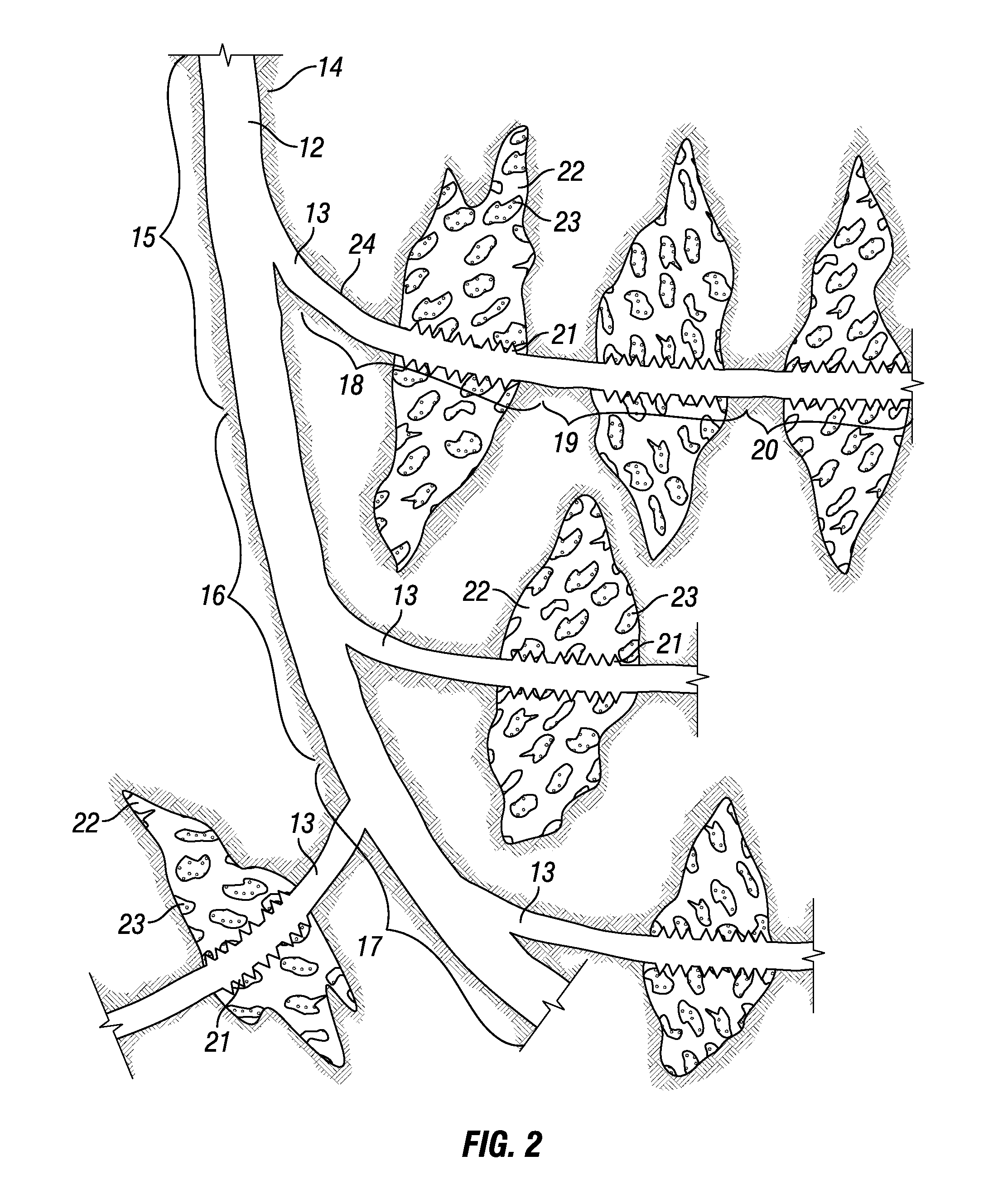

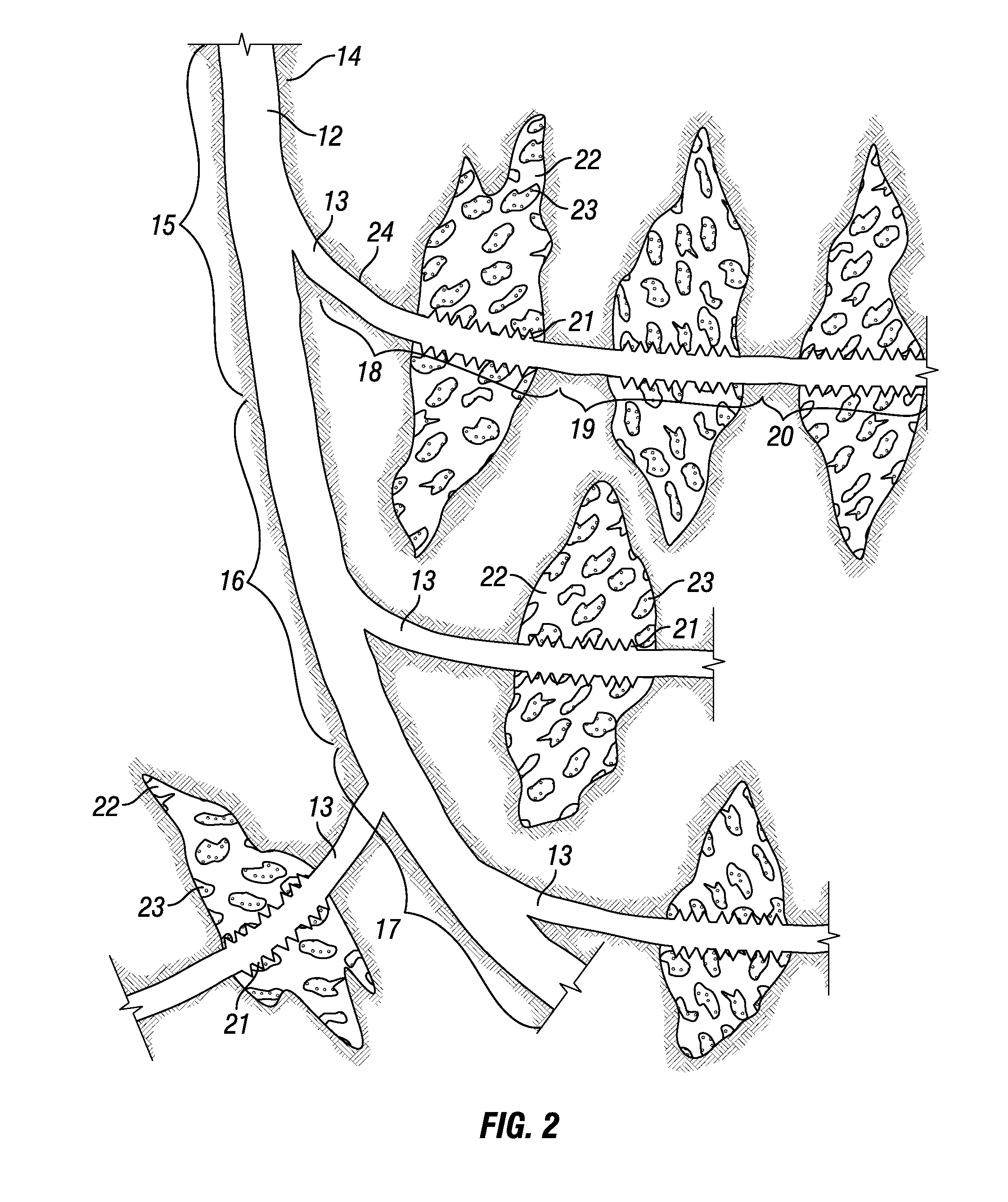

Methods of Enhancing the Fracture Conductivity of Multiple Interval Fractures in Subterranean Formations Propped with Cement Packs

Methods of treating a wellbore in a subterranean formation having a top portion and a bottom portion, and a middle portion therebetween. The method includes providing a jetting fluid; providing a cement slurry; and providing a breakable gel fluid. Then introducing the jetting fluid into the bottom portion of the wellbore to create or enhance a bottom portion fracture; introducing the jetting fluid into the top portion of the wellbore to create or enhance a top portion fracture; introducing the cement slurry into the top portion fracture; introducing the cement slurry into the bottom portion fracture; and introducing the breakable gel fluid into the wellbore so as to prevent the expandable cementitious material from migrating out of the top portion fracture and bottom portion fracture. The expandable cementitious material is cured so as to form a cement pack, the breakable gel fluid is broken and removed from the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Energy complementing and fracturing stimulation integrated repeated transformation method of dense oil reservoir old well

ActiveCN105927198AAchieve production increaseIncrease the volume of the transformationCleaning apparatusFluid removalWaxSoil science

Owner:PETROCHINA CO LTD

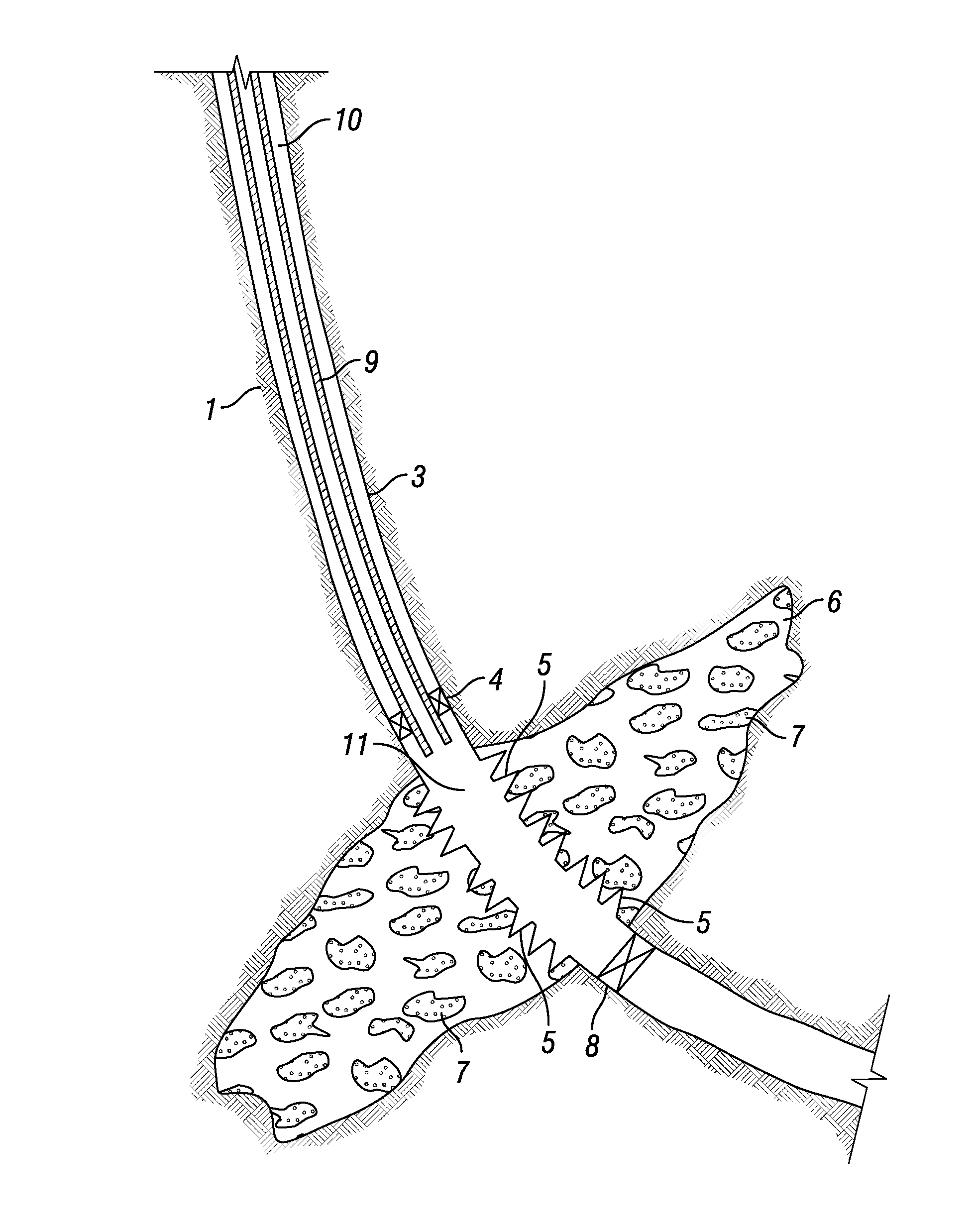

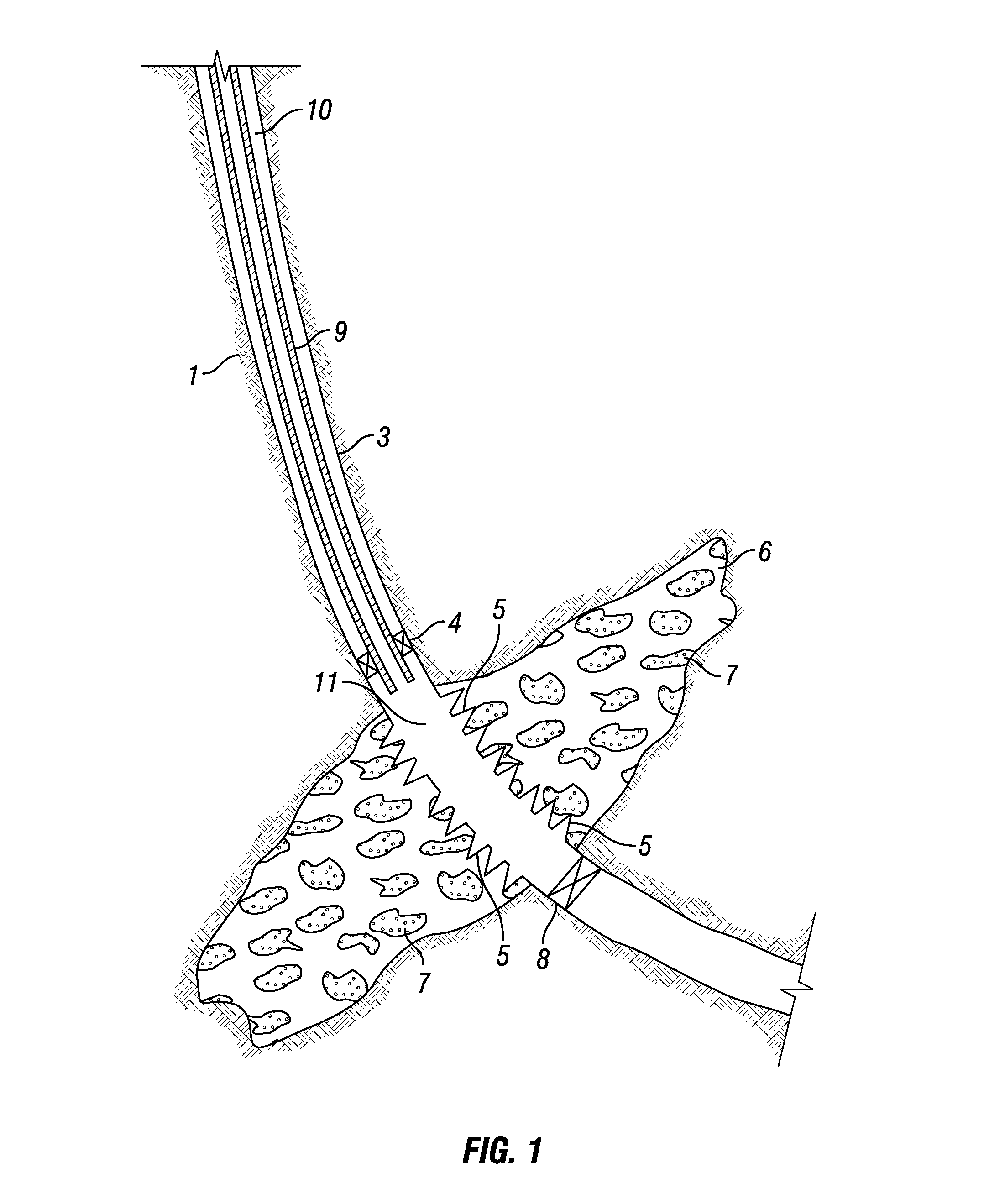

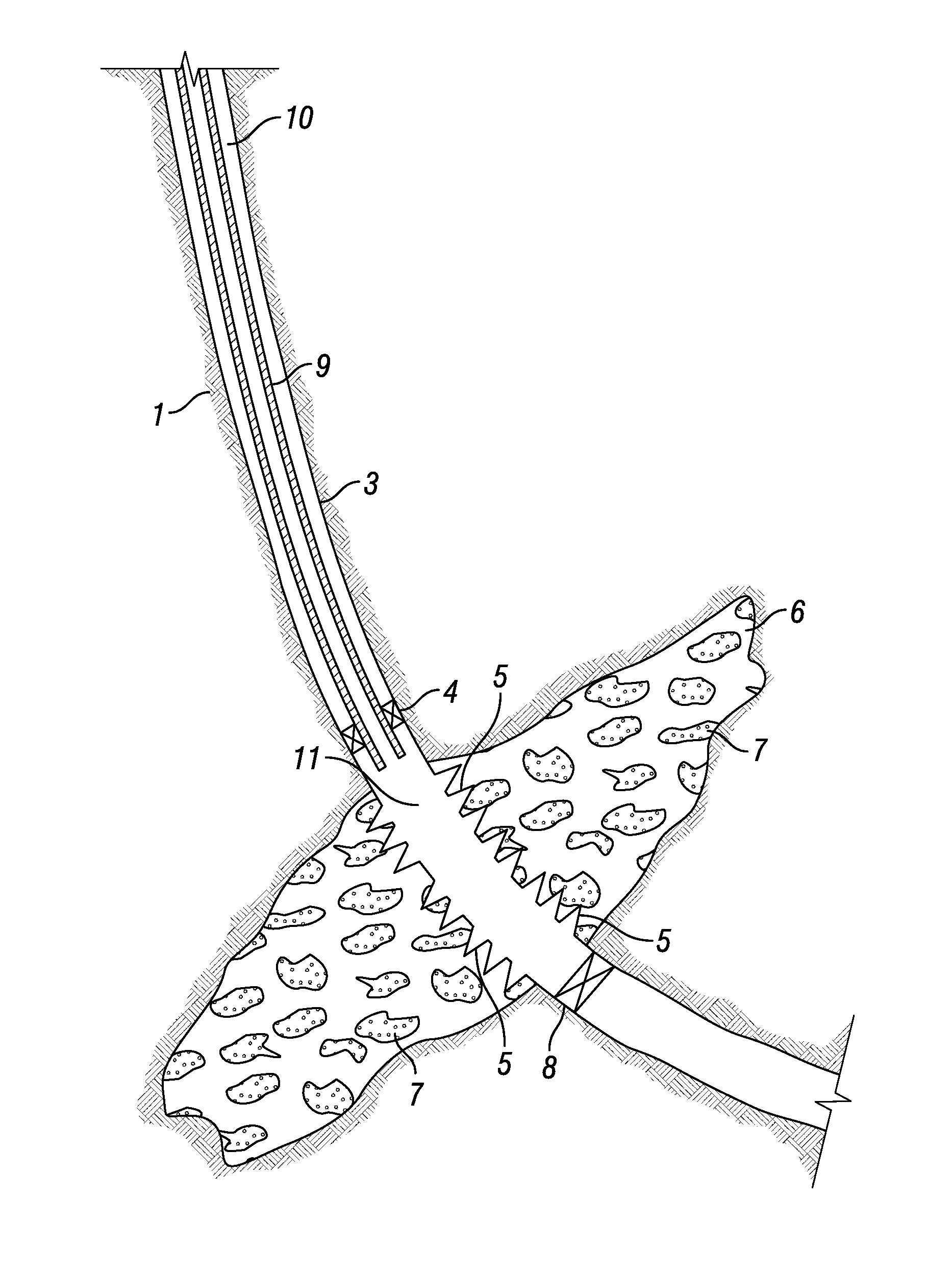

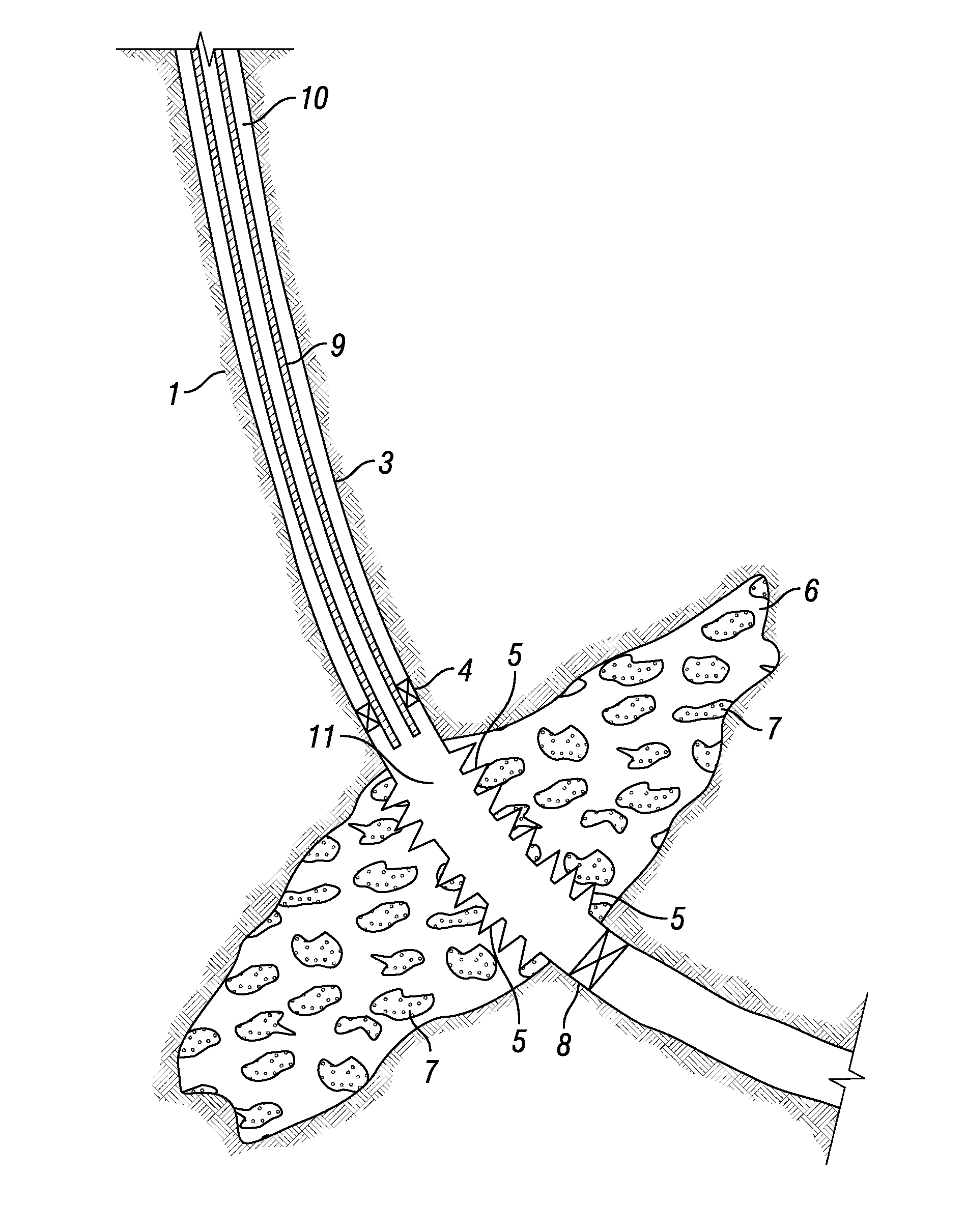

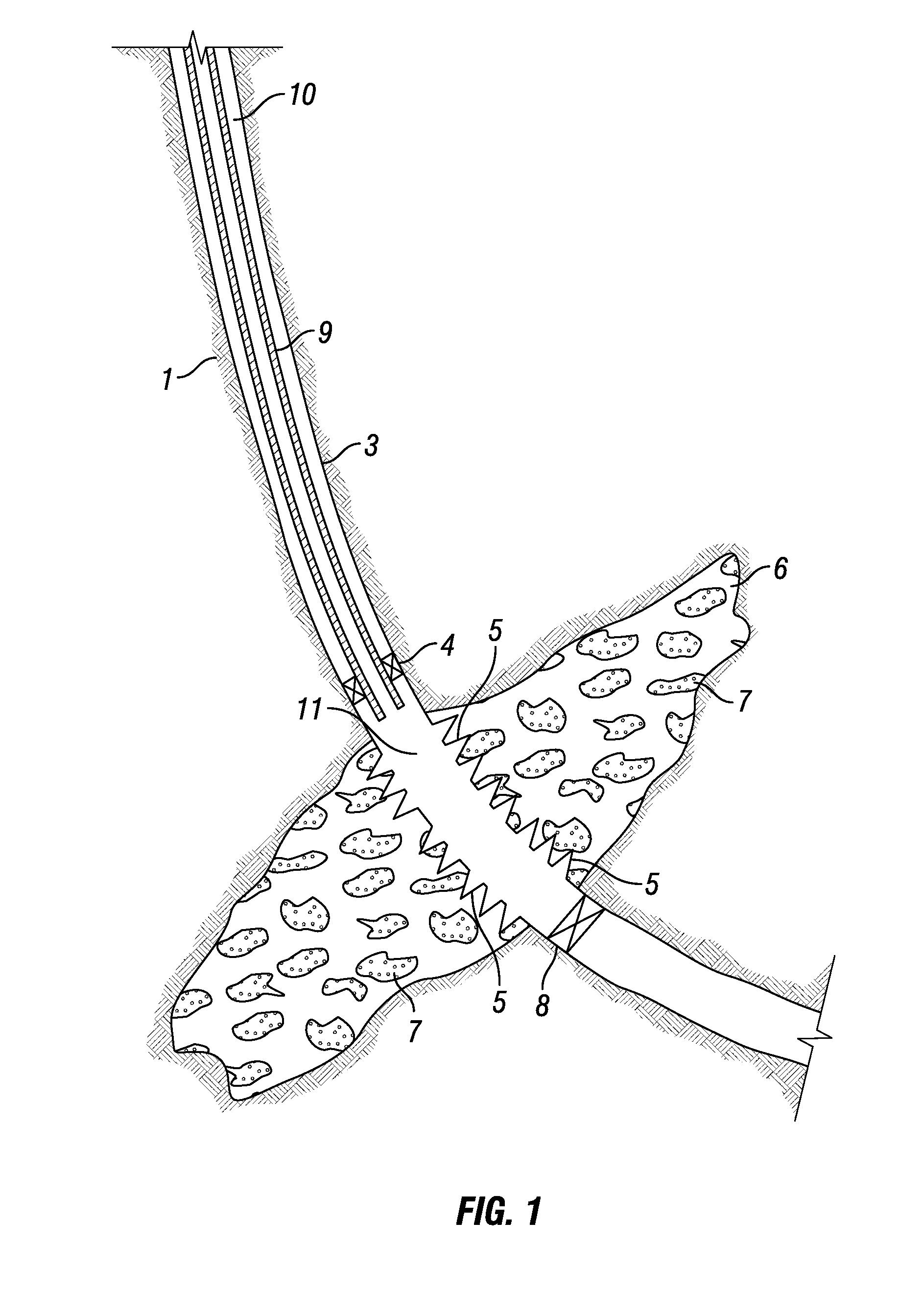

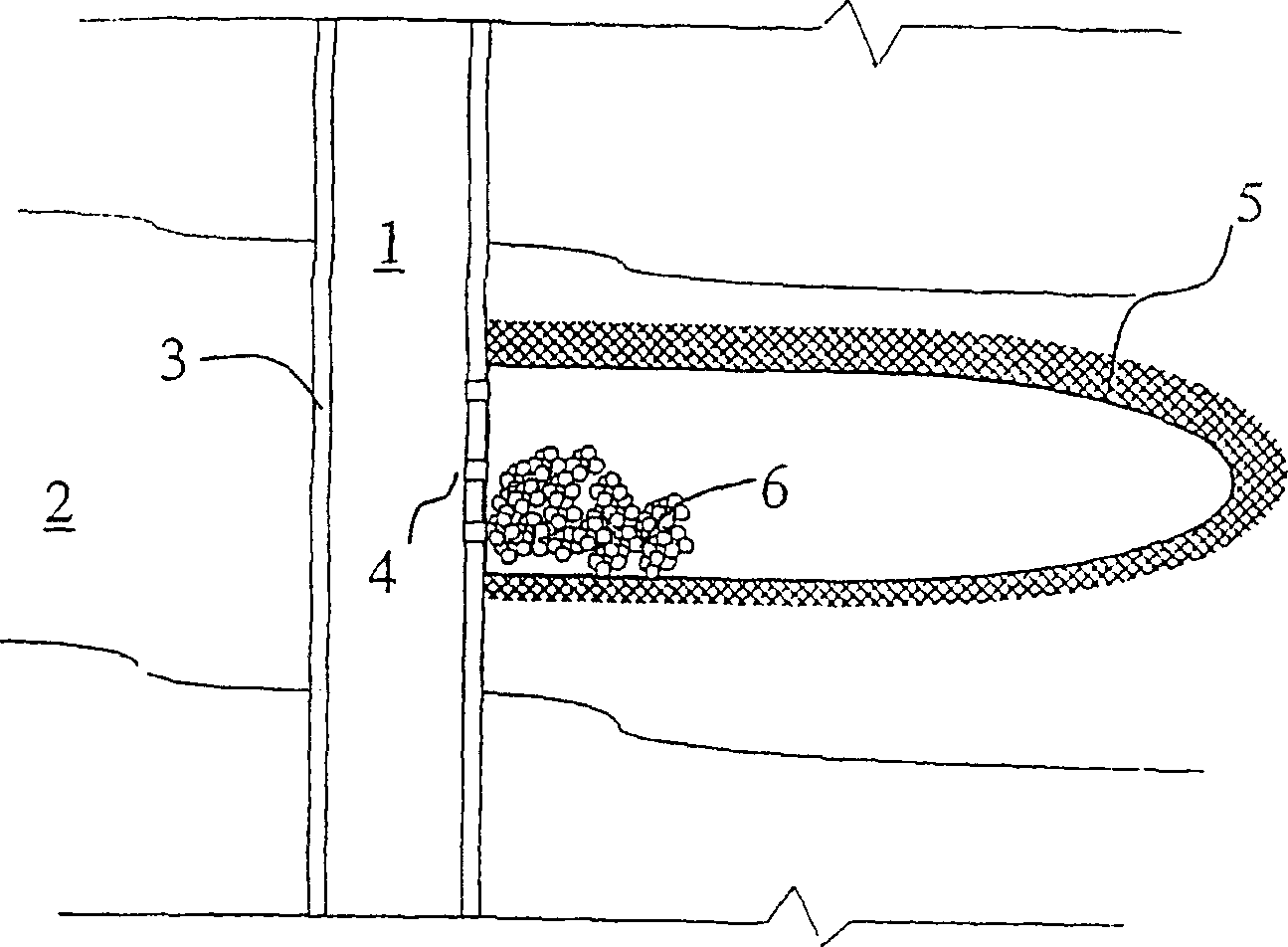

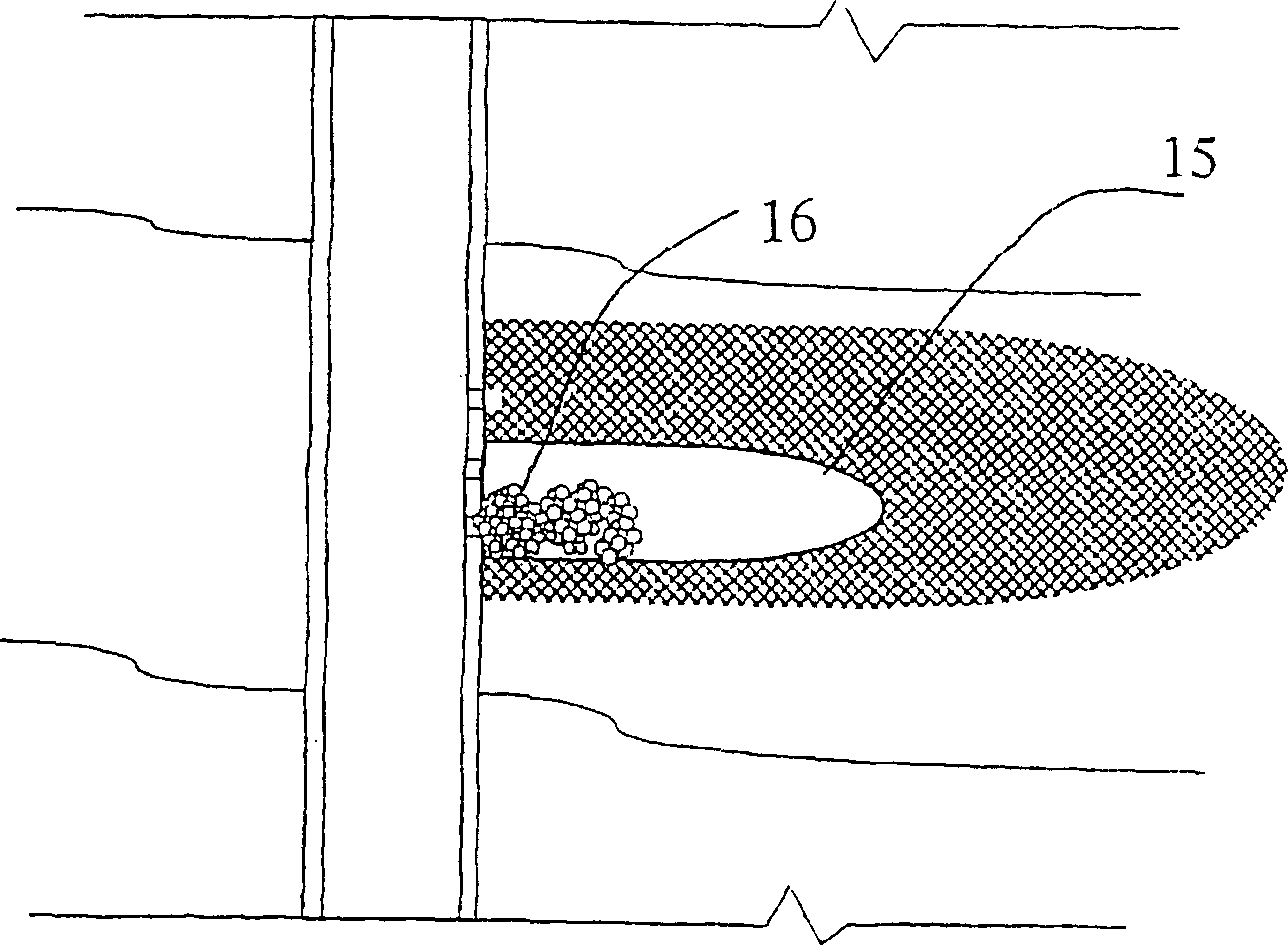

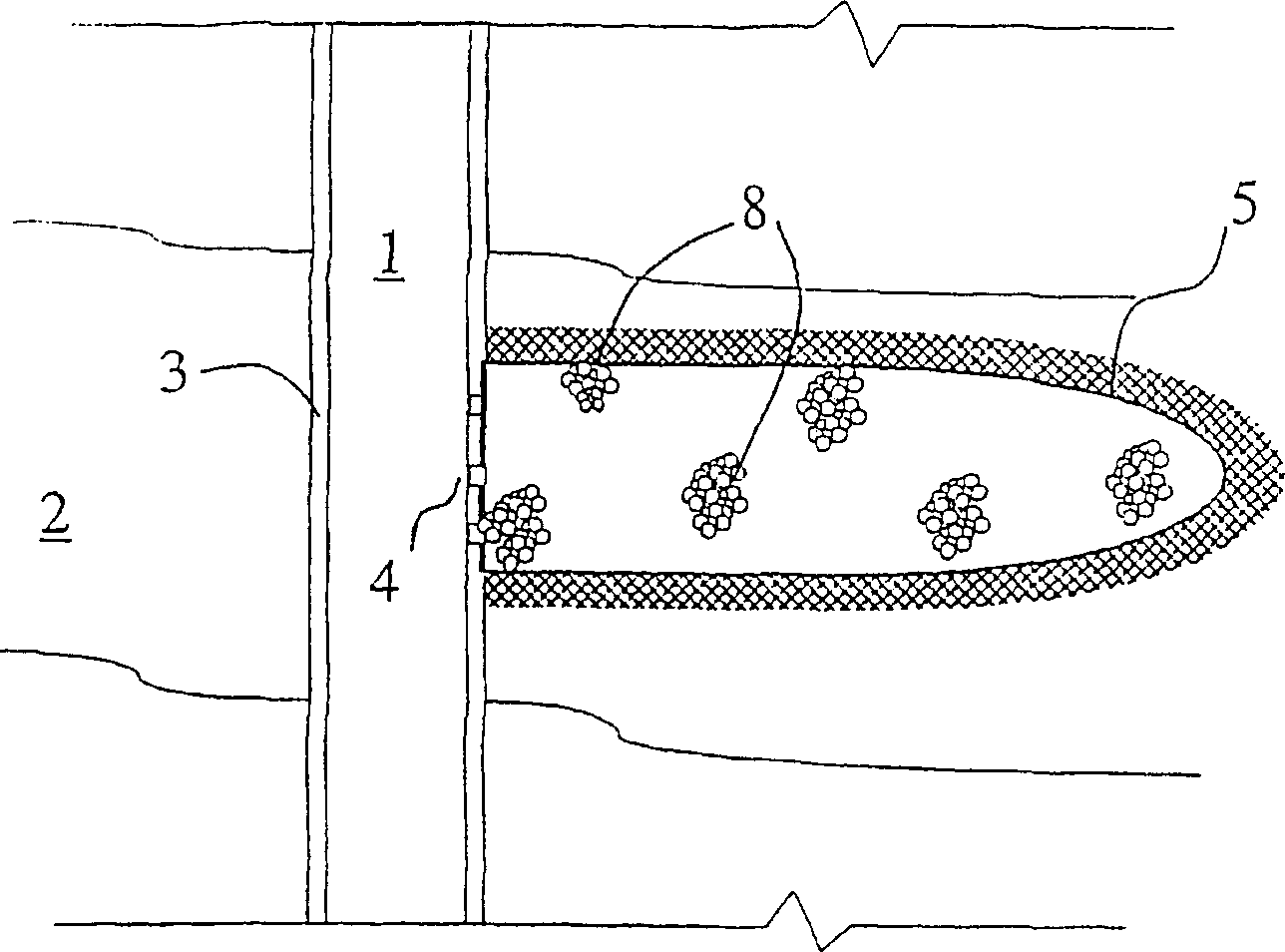

Method of hydraulic fracture of subterranean formation

InactiveCN1671945AEffectively increase productionPromote production increaseFluid removalFracturing fluidWellbore

This invention relates generally to the art of hydraulic fracturing in subterranean formations and more particularly to a method and means for optimizing fracture conductivity. According to the present invention, the well productivity is increased by sequentially injecting into the wellbore alternate stages of fracturing fluids having a contrast in their ability to transport propping agents to improve proppant placement, or having a contrast in the amount of transported propping agents.

Owner:SCHLUMBERGER TECH LTD BV

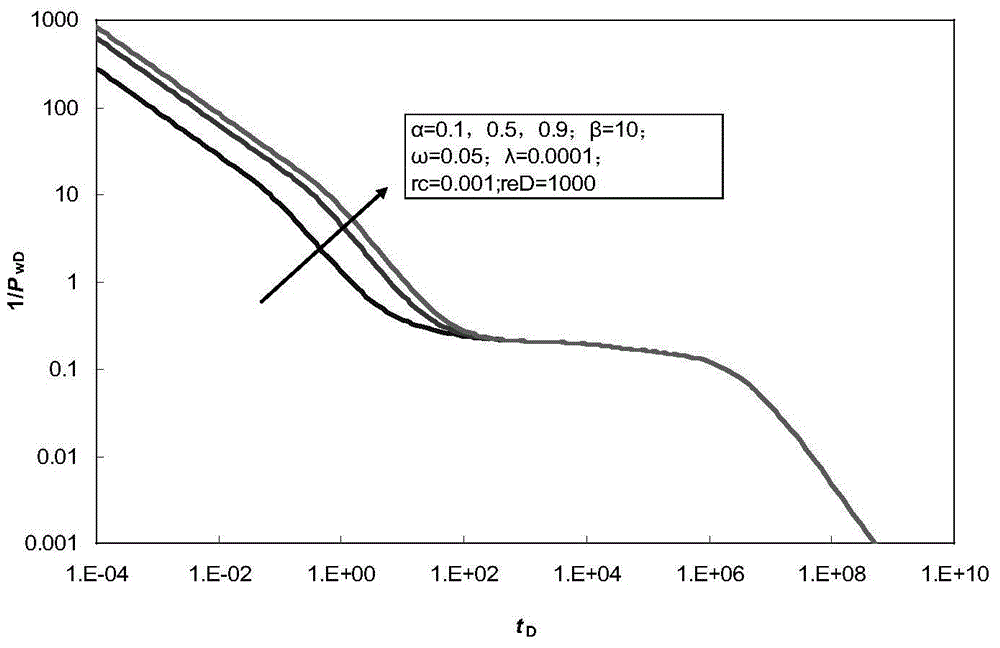

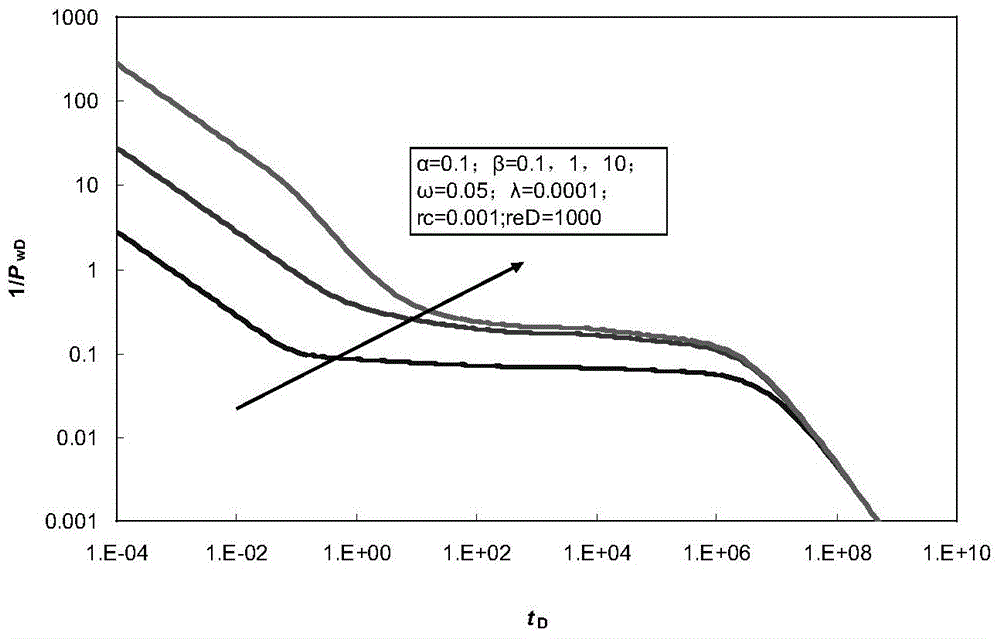

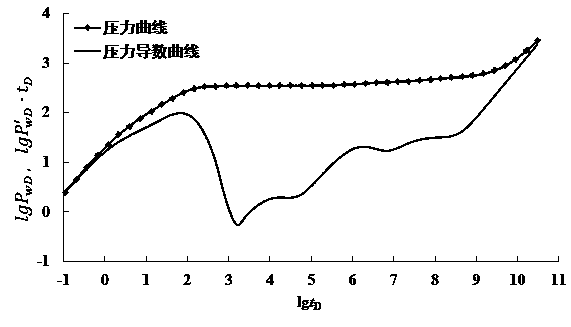

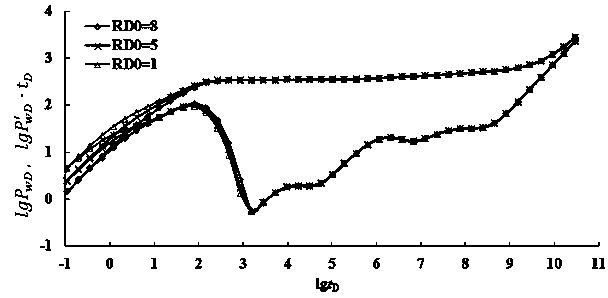

Well testing interpretation model for analyzing fracture-cave series mode double-hole composite reservoir

ActiveCN111581786AReduce utilizationReduce excavationDesign optimisation/simulationCAD numerical modellingBottom hole pressureMathematical model

The invention relates to a well testing interpretation model for analyzing a fracture-cave series mode double-hole composite reservoir, which comprises the following steps of: 1, establishing a corresponding physical model according to reservoir characteristics of a certain type of oil reservoir; 2, establishing a mathematical model, wherein the mathematical model is used for describing a physicalmodel; 3, solving the mathematical model to obtain a real space bottom hole pressure solution; and 4, drawing a real space well testing theoretical curve by utilizing a real space well bottom pressure solution, analyzing the well testing theoretical curve, performing curve fitting on theoretical pressure data and actually measured pressure recovery data to obtain a fitting result, and obtaining interpretation parameters which comprise fracture conductivity, fracture length, karst cave volume and karst cave storage capacity ratio. By solving the well testing mathematical model of the fracture-cavity series mode, the well bottom pressure solution of the fracture-cavity series mode is obtained, the typical well testing curve is drawn, the stratum parameters are obtained, the well testing interpretation method of the fracture-cavity series mode double-hole composite reservoir is determined, and the fracture-cavity type oil reservoir is accurately evaluated and effectively developed.

Owner:NORTHEAST GASOLINEEUM UNIV

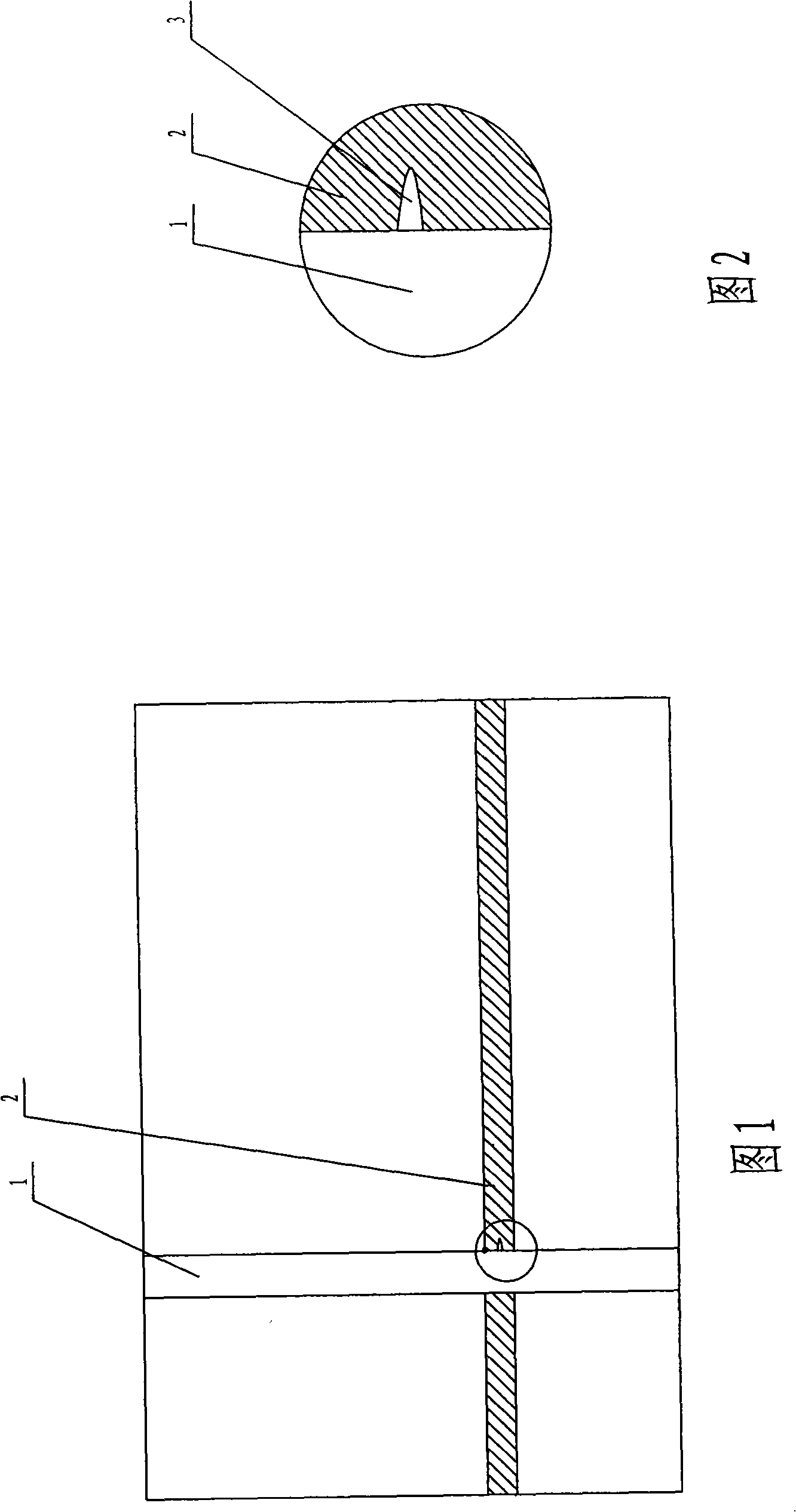

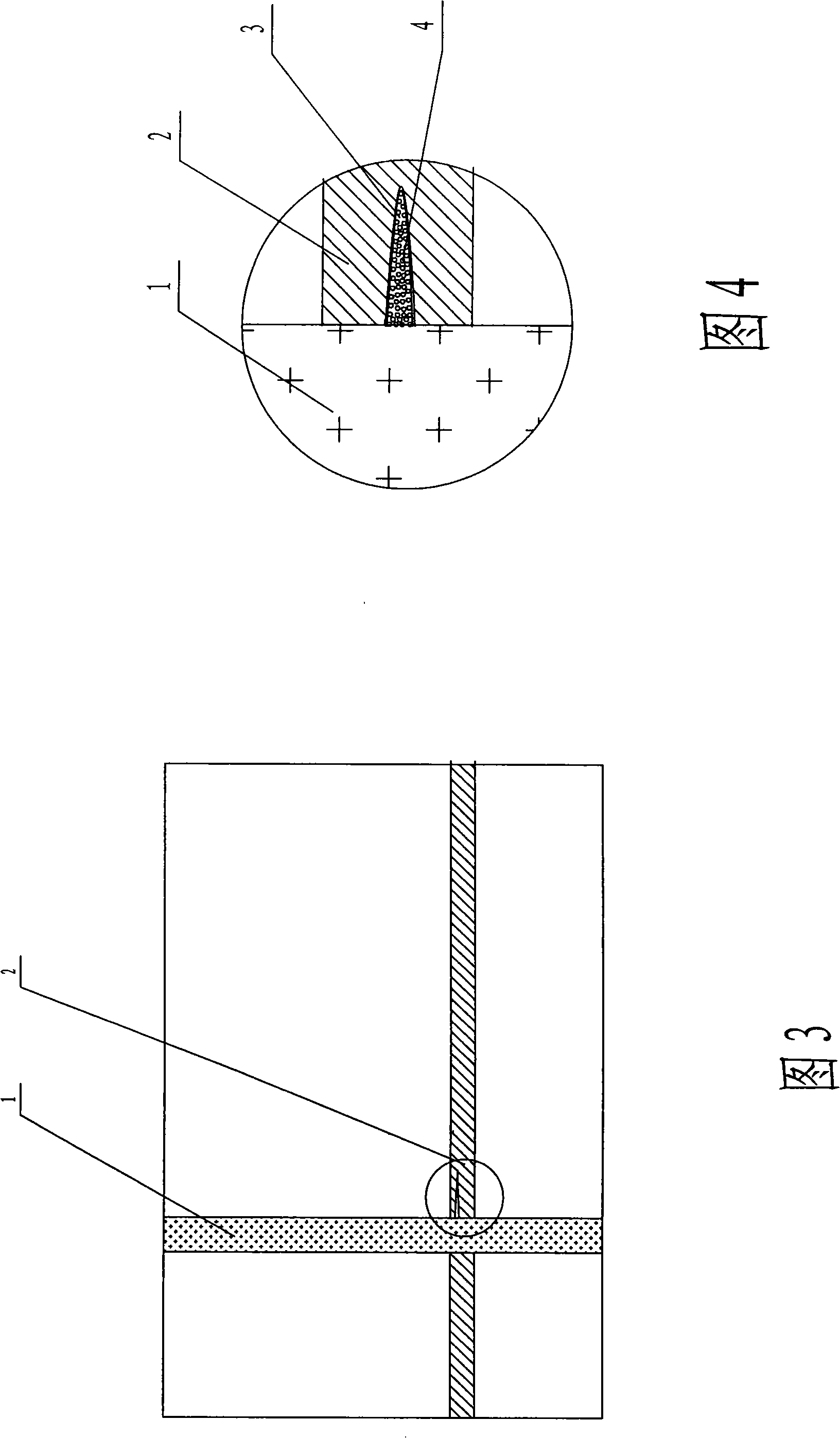

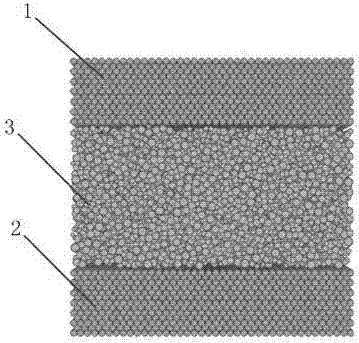

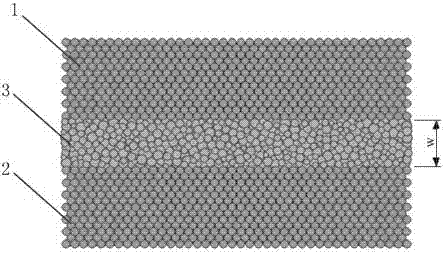

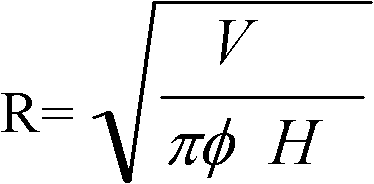

Proppant embedment and fracture conductivity quantitative forecast-based numerical simulation method

ActiveCN107423466AAvoid accuracyAvoid supportData processing applicationsDesign optimisation/simulationPhysical modelEmbedment

The invention discloses a proppant embedment and fracture conductivity quantitative forecast-based numerical simulation method. The method comprises the following steps of: S1, establishing a physical model for reducing the real sizes of proppants; S2, applying closing pressure on the surfaces of an upper rock stratum and a lower rock stratum of the model, wherein the difference between average heights of granules on fracture surfaces of the upper rock stratum and the lower rock stratum is a fracture closing width w; S3, carrying out flow field grid dispersion on a filling layer to ensure that a flow field is wrapped by the proppants, setting viscosity and density of a fluid and pressure of the fluid at two ends of the flow field; S4, calculating a total flow q of the flow field; S5, calculating a permeability and a flow conductivity; and S6, changing physical parameters of the rock stratums or the fluid, and drawing a change curve graph indicating that the conductivity of the proppants with different sanding concentrations changes along with closing stress. The method has the beneficial effects of simulating the real processes of fracture closing, proppant embedment and interaction between granules and fluids, so as to effectively forecast the dynamic change of the flow conductivity.

Owner:SOUTHWEST PETROLEUM UNIV

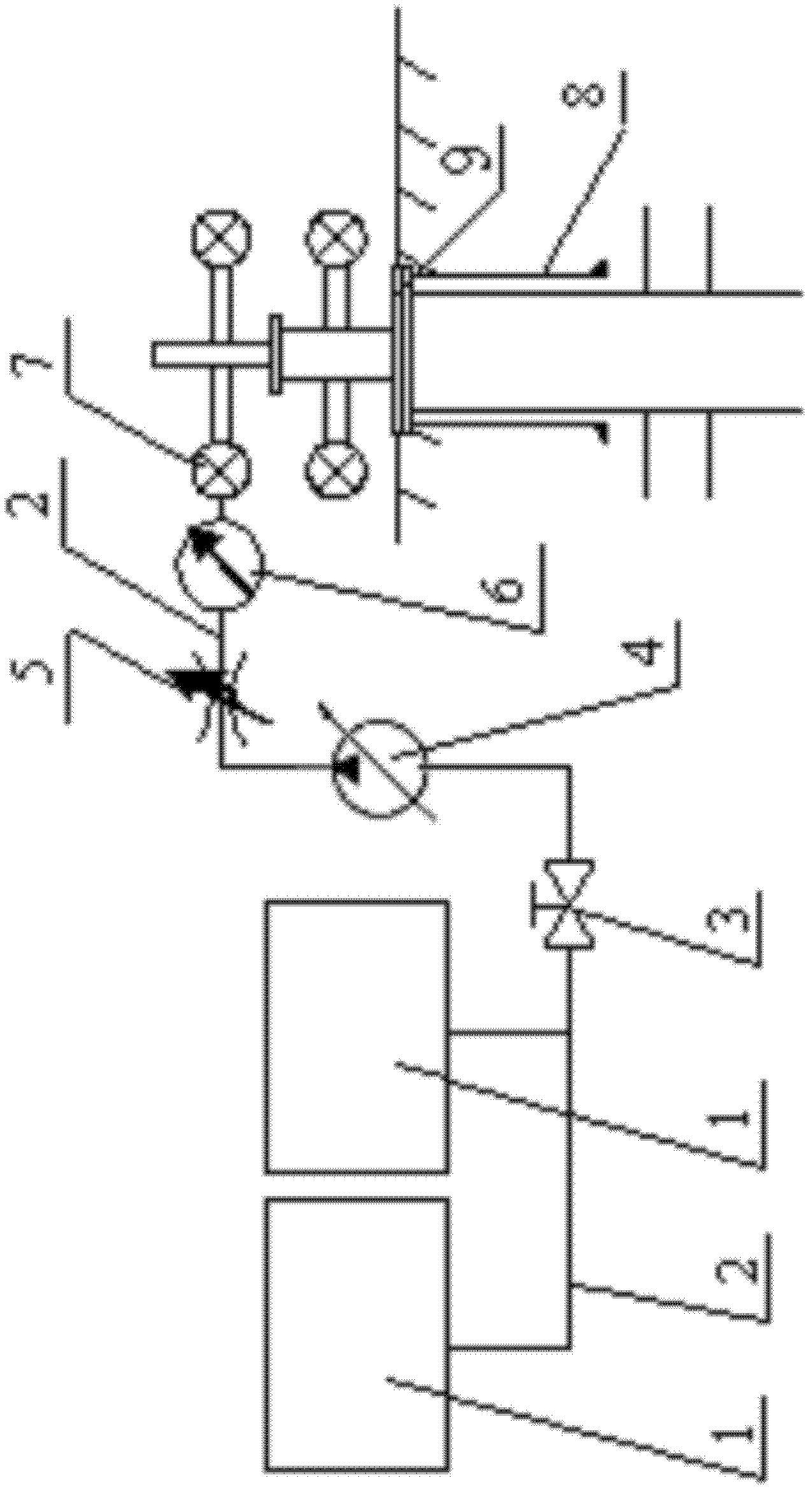

Pressure control injection yield increase method for coalbed methane well

The invention relates to a pressure control injection yield increase method for a coalbed methane well. The radius affected by the pressure of a created fracture after thehydraulic fracture according to the gas production rate, the coal seam thickness and the gas content per ton after the fracture of the coal petrography; the injection solution amount for yield increase is determined; a sleeve can be injected when the sand wash of the borehole operation is 10m far from a coal seam; two bottles of fracturing fluids are connected into an inlet of a plunger pump in parallel; the outlet of the plunger pump is connected with a sleeve valve of a gas collection tree, and a well mouth is provided with a pressure meter; and the accumulated water yield during the production period of a construction well is injected into the coal seam with the maximum pump discharge for filling the volume of the recover part, fluids can be injected by controlling the pressure, 5-20 Mpa injection amount of the fluids is injected in small pump discharge and steady pressure ways according to different pressures, the injection can be stopped when the stratum is saturated and the fluids can not be injected. The well mouth is pressure free in 3-5 days; and when the stratum is saturated and the pressure is not decreased to 5Mpa during the fifth-seventh day, the construction of the well can be finished. The invention has the beneficial effects that the method is suitable for the growth feature of the coal petrography of high order coal, the fracture conductivity is improved, and the generation of coal dust can be controlled.

Owner:PETROCHINA CO LTD

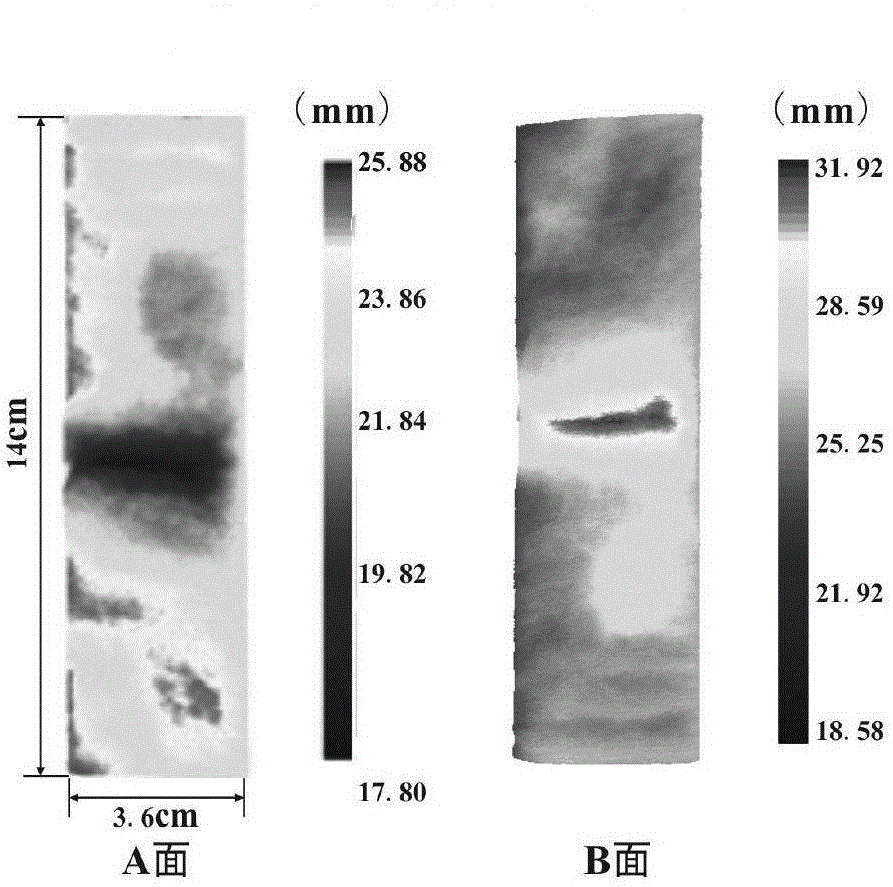

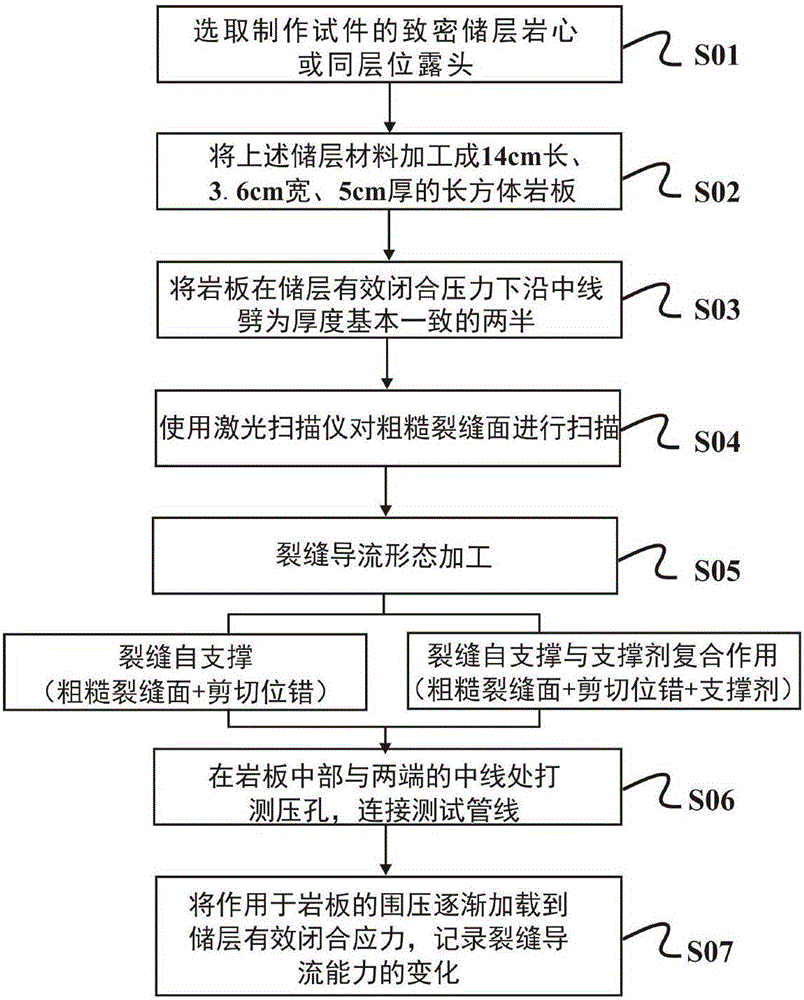

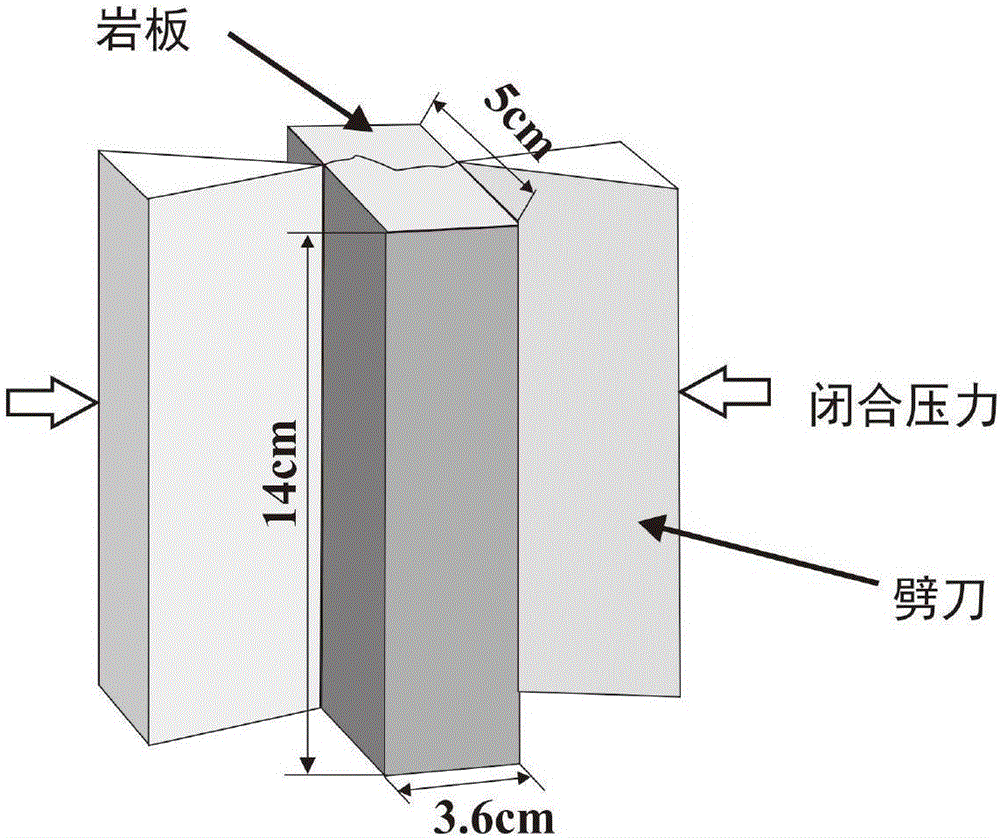

Test method for compact reservoir volume fracture conductivity

ActiveCN106593429AReal simulation of diversion capacityBorehole/well accessoriesGeomorphologyCoupling

The invention discloses a test method for compact reservoir volume fracture conductivity. The test method comprises the following steps that compact reservoir materials used for making a test piece are selected and prepared into a cuboid rock board; the rock board in the first step is divided in half under reservoir closed pressure, a rough fracture face is scanned through a laser scanner, and a scanning fractal result is output; the rock board divided in half is subjected to conducting form processing; a pressure measuring hole, a fluid inlet and a fluid outlet are correspondingly drilled in the positions of the central lines of the middle and the two ends of the rock board, and the rock board is placed in a conducting room; and the confining pressure of the conducting room is increased to reservoir effective closed pressure, and compact reservoir volume fracture conductivity data are obtained and combined with the measured roughness of the fracture face in the second step to conduct analysis. According to the test method, on the one hand, quantitative analysis of the roughness of the fracture coupling face is achieved to enable the roughness of the fracture coupling face to be compared and analyzed with other factors which influence flow conductivity, on the other hand, the fracture conductivity of the rough fracture face in different shear dislocations and different paved-sand concentrations can be simulated more truly.

Owner:SOUTHWEST PETROLEUM UNIV

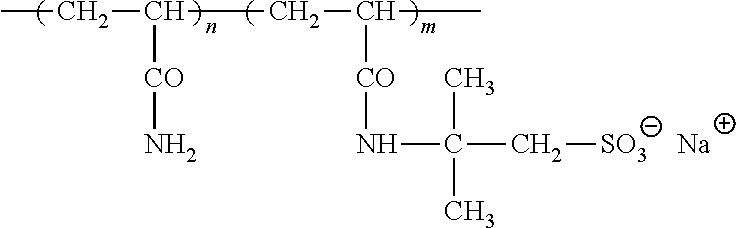

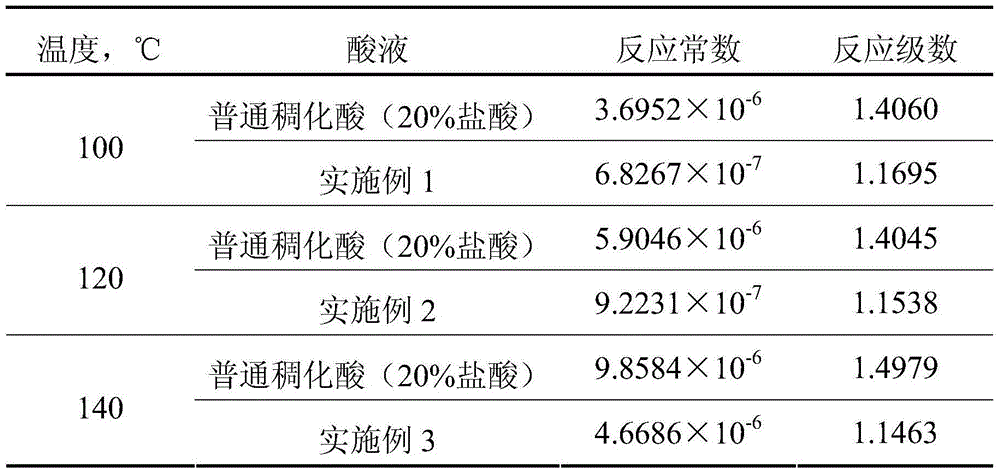

Slow-speed low-friction acid solution system for acid fracturing

InactiveCN104629711AStable high temperature rheological propertiesImprove shear resistanceDrilling compositionStrong acidsAcid strength

Disclosed is a retardant low-friction acid liquid system for acid fracturing. The retardant low-friction acid liquid system for acid fracturing consists of 20-40 parts of emulsified acid and 60-80 parts of thickened acid, the total volume of emulsified acid and thickened acid being 100 parts. The retardant low-friction acid liquid system for acid fracturing has high viscosity, low leak-off, good retardancy, low friction and good discharge capacity under conditions of normal temperature and strong acid, facilitating fracture initiation, and can be used to enlarge the acid fracturing treatment radius and improve acid etched fracturing conductivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com