Rock fracture simulation sample and preparation method thereof, as well as simulation test device and simulation test method

A technology for simulating samples and simulating tests, which is applied in the preparation of test samples, measuring devices, and the use of stable tension/pressure to test the strength of materials, etc., which can solve the problems of less sensitive evaluation of shale fracture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

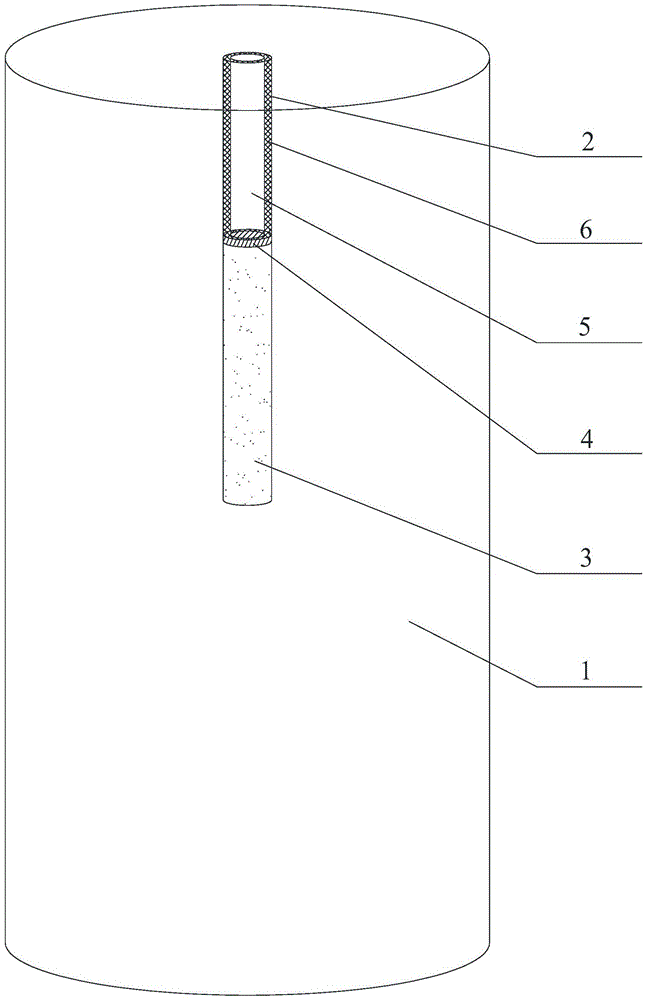

[0050] See attached figure 1 , The rock fracturing simulation sample provided by the first embodiment of the present invention includes a body 1, a fracturing fluid injection tube 5, a blind hole 2 is provided with an end surface of the body 1 as a starting point, and the fracturing fluid injection tube 5 is fixedly connected to the blind hole 2 On the wall of the hole 2, an accommodation space 3 is reserved between the bottom end of the fracturing fluid injection pipe 5 and the bottom end of the blind hole 2.

[0051] The rock fracturing simulation sample provided by the first embodiment of the present invention includes a body 1, a fracturing fluid injection tube 5, a blind hole 2 is provided with an end surface of the body 1 as a starting point, and the fracturing fluid injection tube 5 is fixedly connected to the blind hole 2 On the wall, an accommodation space 3 is reserved between the bottom end of the fracturing fluid injection pipe 5 and the bottom end of the blind hole 2....

Embodiment 2

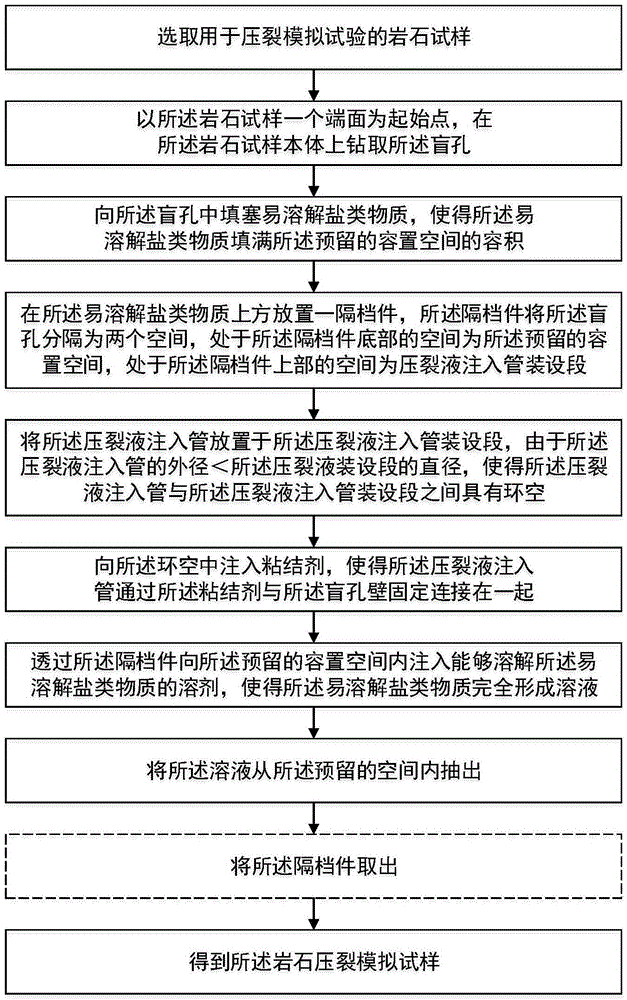

[0055] See attached figure 2 The method for preparing a rock fracturing simulation sample provided in the second embodiment of the present invention includes the following steps:

[0056] Step 101: Select rock samples for fracturing simulation test;

[0057] Step 102: Drill a blind hole in the rock sample body with one end face of the rock sample as a starting point;

[0058] Step 103: Fill the blind holes with easily soluble salt substances so that the easily soluble salt substances fill up the volume of the reserved accommodating space;

[0059] Step 104: Place a barrier above the easily soluble salt substances, the barrier divides the blind hole into two spaces, and the space at the bottom of the barrier is the reserved accommodation space, which is the space above the barrier Installation section for fracturing fluid injection pipe;

[0060] Step 105: Place the fracturing fluid injection pipe in the fracturing fluid injection pipe installation section. Since the outer diameter of ...

Embodiment 3

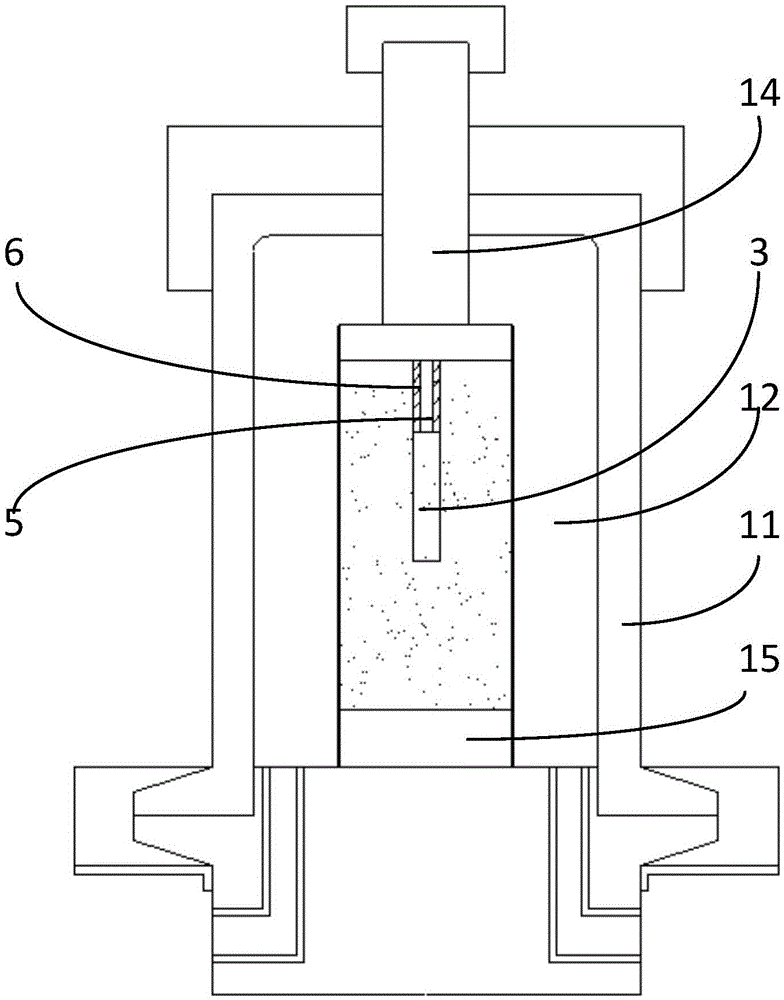

[0075] See attached image 3 , The rock fracturing simulation test device provided by the third embodiment of the present invention includes image 3 The triaxial testing machine shown includes a triaxial chamber 11, an upper pressure head 14, a lower pressure head 15, a confining pressure oil injection system (not labeled in the figure), and a fracturing fluid injection pump (in the figure) Not shown), the rock fracturing simulation sample provided in the first embodiment of the present invention, the rock fracturing simulation sample is installed between the upper indenter 14 and the lower indenter 15, and the upper indenter 14 is provided with a through hole ( (Not shown in the figure), a fracturing fluid injection pump (not shown in the figure) communicates with the fracturing fluid injection pipe 5 through a through hole (not shown in the figure).

[0076] On the basis of the rock fracturing simulation sample provided in the first embodiment of the present invention, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com