Patents

Literature

220 results about "Complex fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

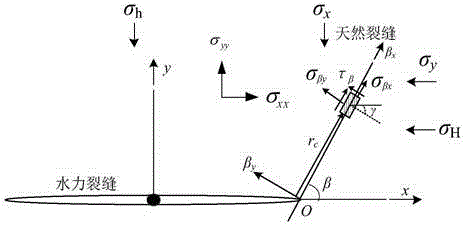

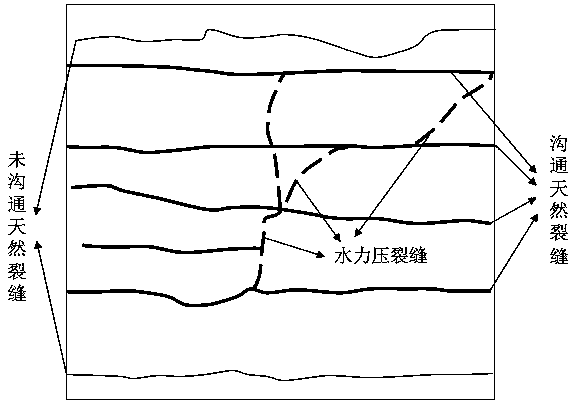

Simulating method of forming process of unconventional oil and gas reservoir hydraulic fracturing complex fracture net

ActiveCN107545113AAccurate guidanceThe process is convenient and fastFluid removalSpecial data processing applicationsHydraulic fracturingUnconventional oil

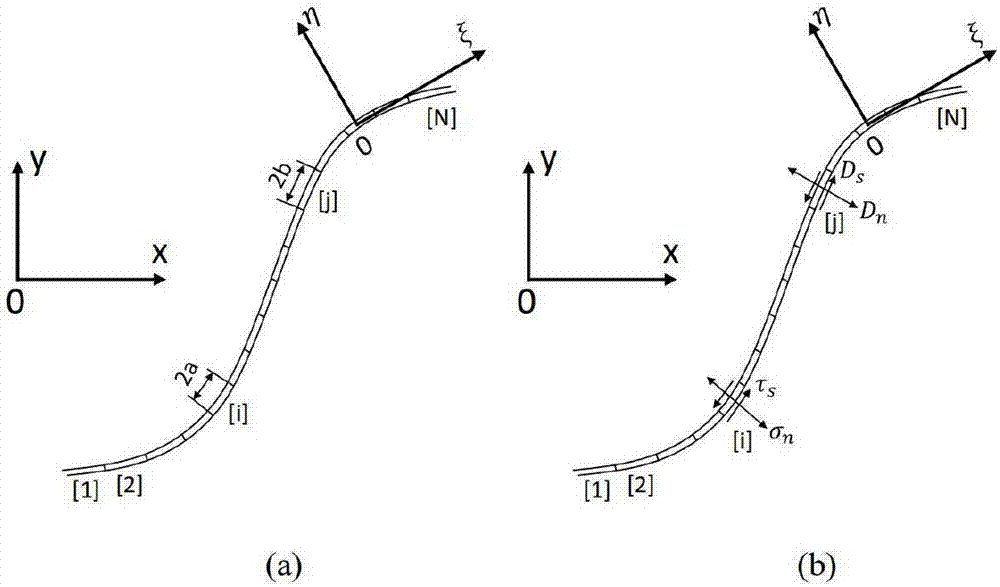

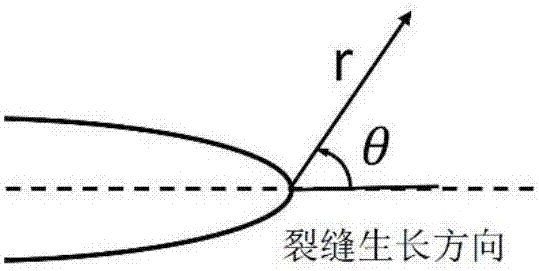

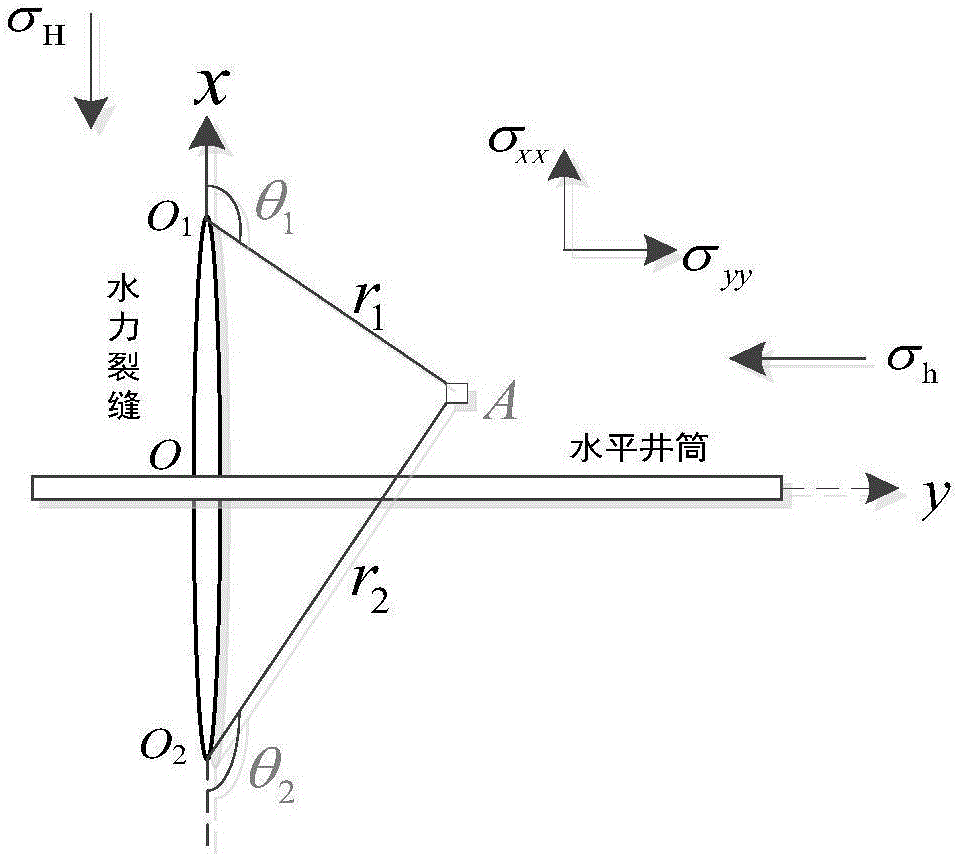

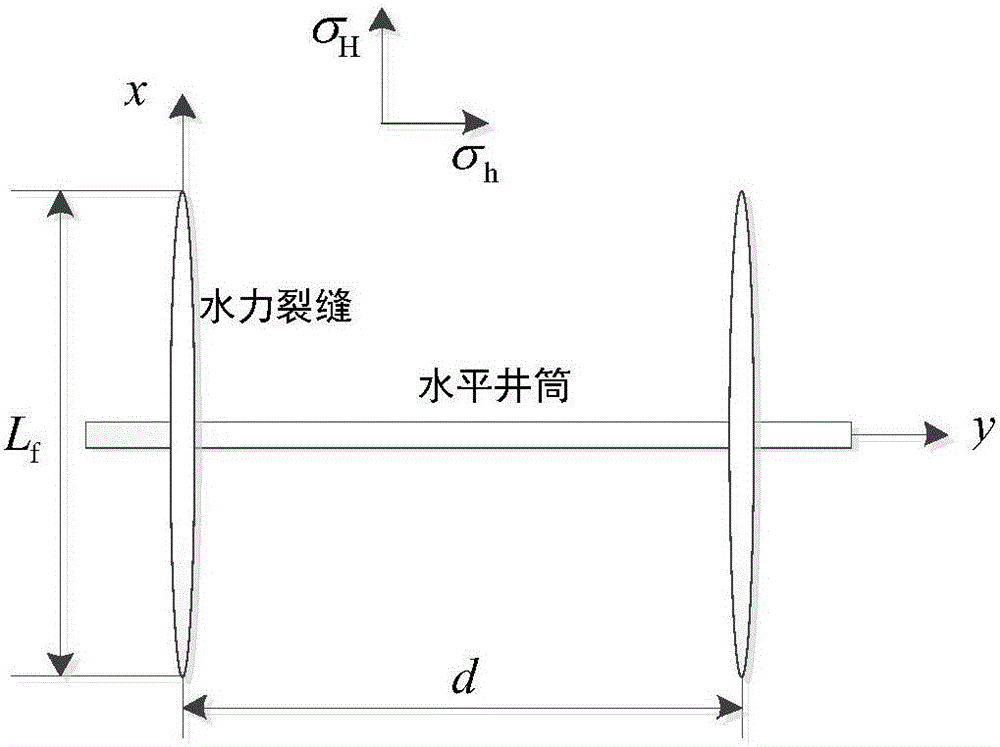

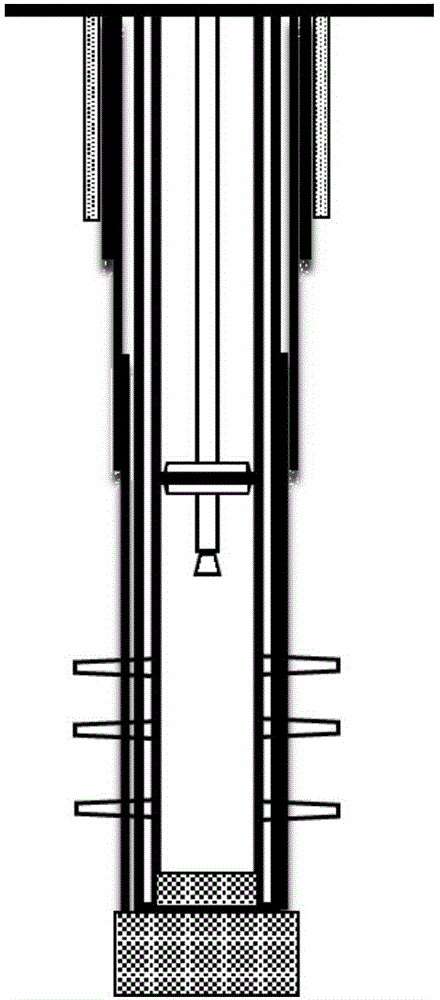

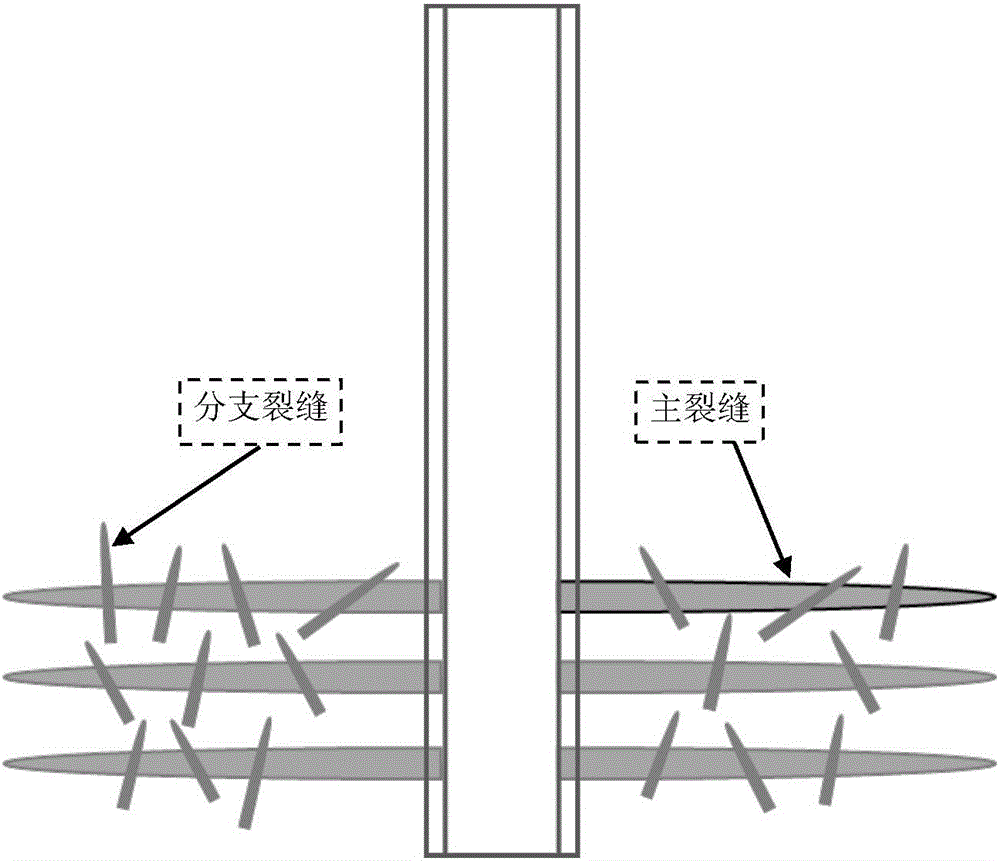

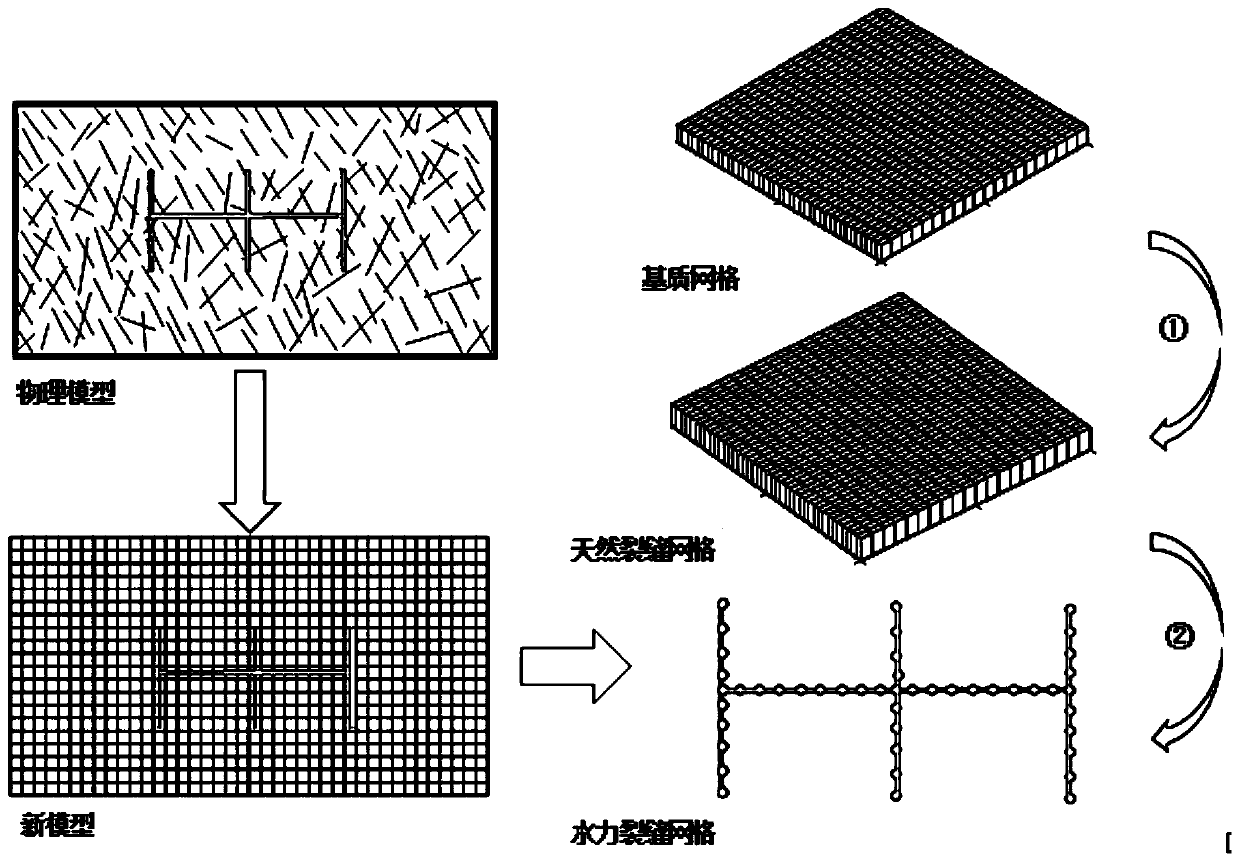

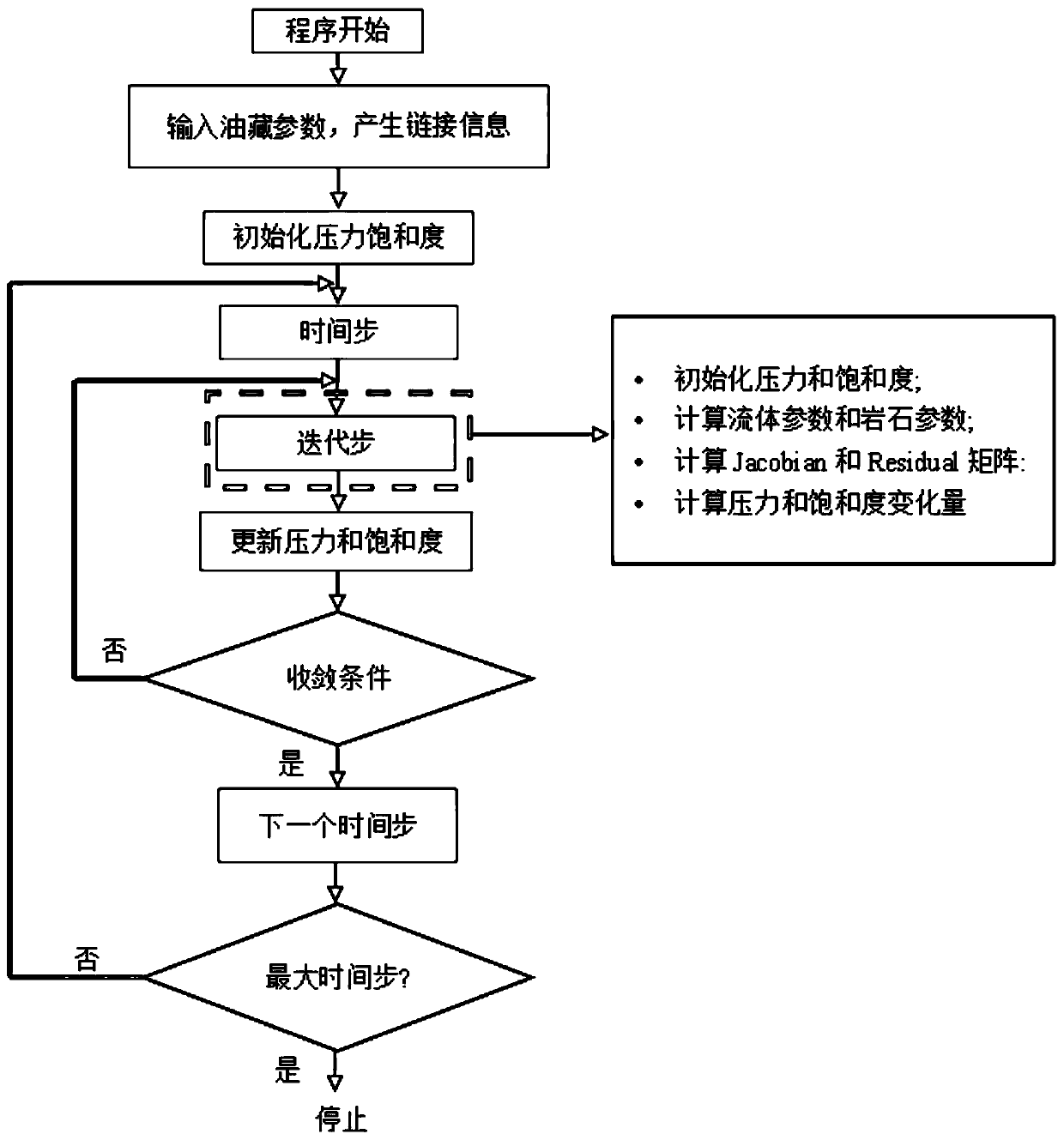

The invention discloses a simulating method of the forming process of an unconventional oil and gas reservoir hydraulic fracturing complex fracture net. The method includes the steps of a, reestablishing natural fracture distribution, estimating the properties of natural fractures, obtaining rock mechanical information and stratum stress information of a stratum from log data or a geological model, and obtaining a data file related to the well factory construction process; b, inputting the obtained parameters in an established natural fractured reservoir fracturing model coupling a well cylinder, fractures and the stratum; c, conducting numerical value solving on the model to obtain after-fracturing information such as fracture forms, opening degree distribution and pressure intensity distribution; d, analyzing the fracturing effect through a model calculating result, and making a preparation for numerical value simulation of the later-period production process. The fractured reservoirfracturing numerical value simulating method coupling the well cylinder flowing, the fracture deformation expanding, the multi-state natural fractures and the flowing of fluid in the fractures can quantitatively analyze the form of the unconventional reservoir segmented volume fracture net and is an effectively means for evaluating and optimizing the fracturing scheme.

Owner:SOUTHWEST PETROLEUM UNIV

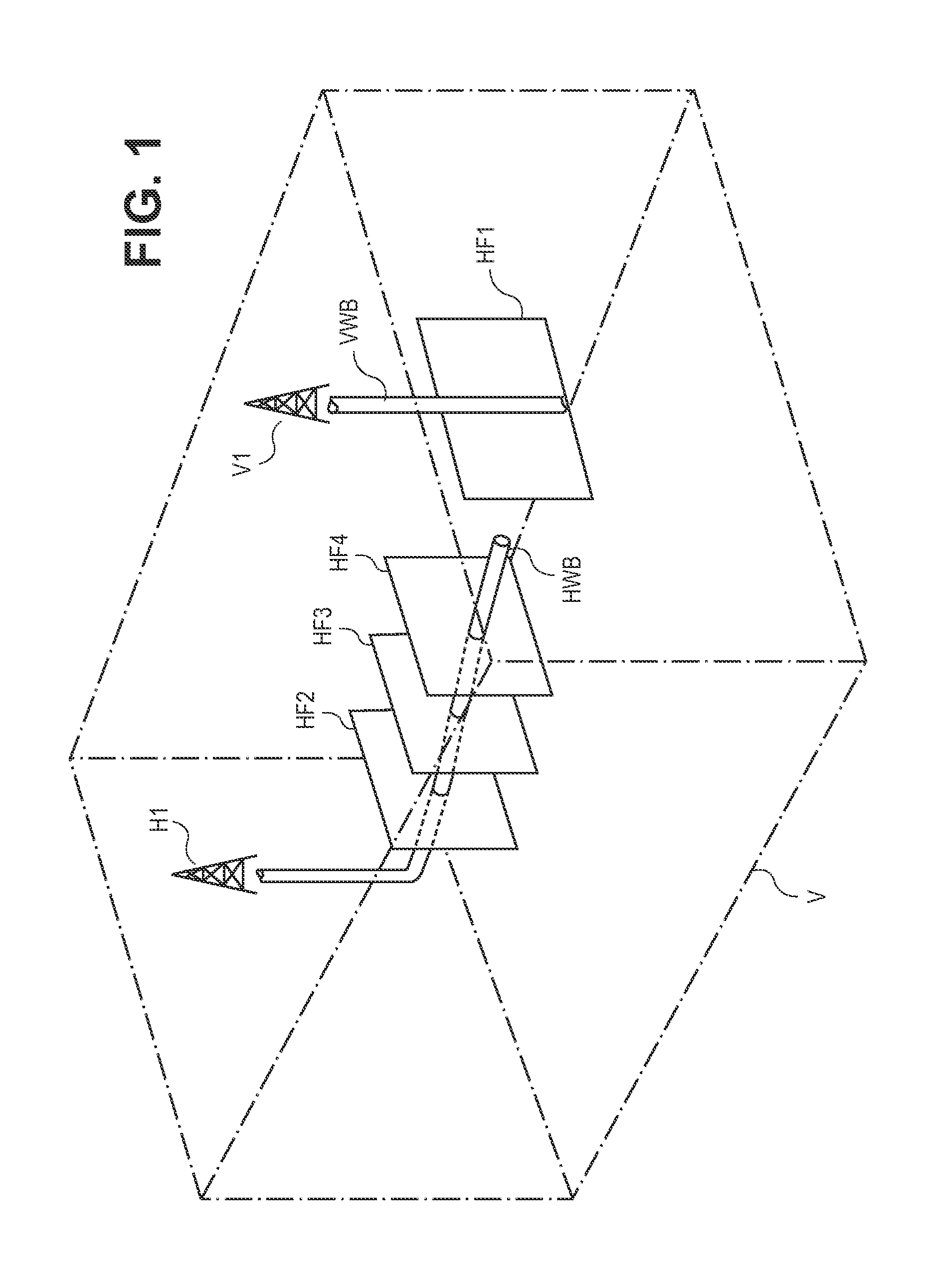

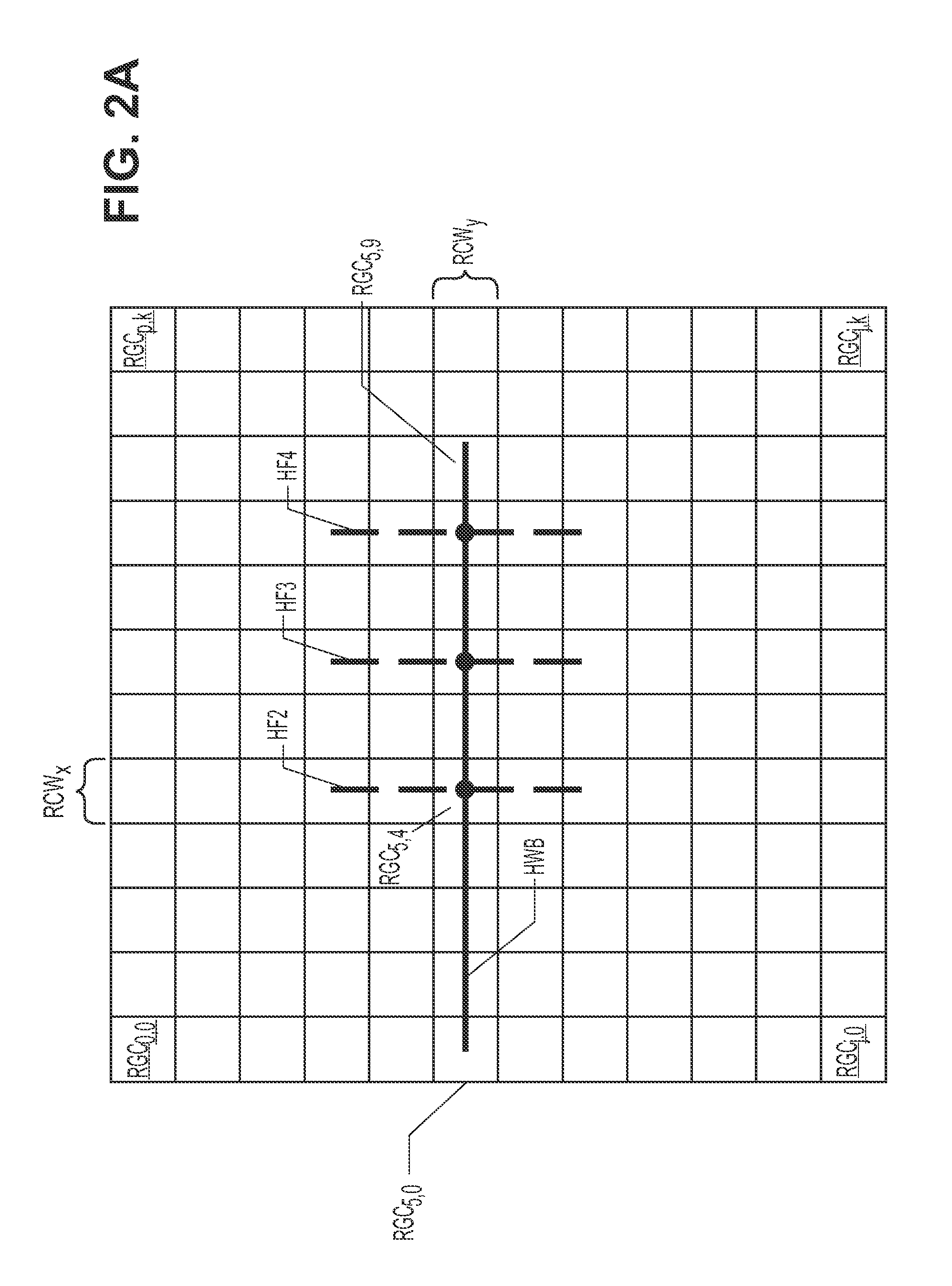

Automated generation of local grid refinement at hydraulic fractures for simulation of tight gas reservoirs

ActiveUS20130073268A1Reasonable computational complexityLow costComputation using non-denominational number representationDesign optimisation/simulationHorizontal wellsHydraulic fracturing

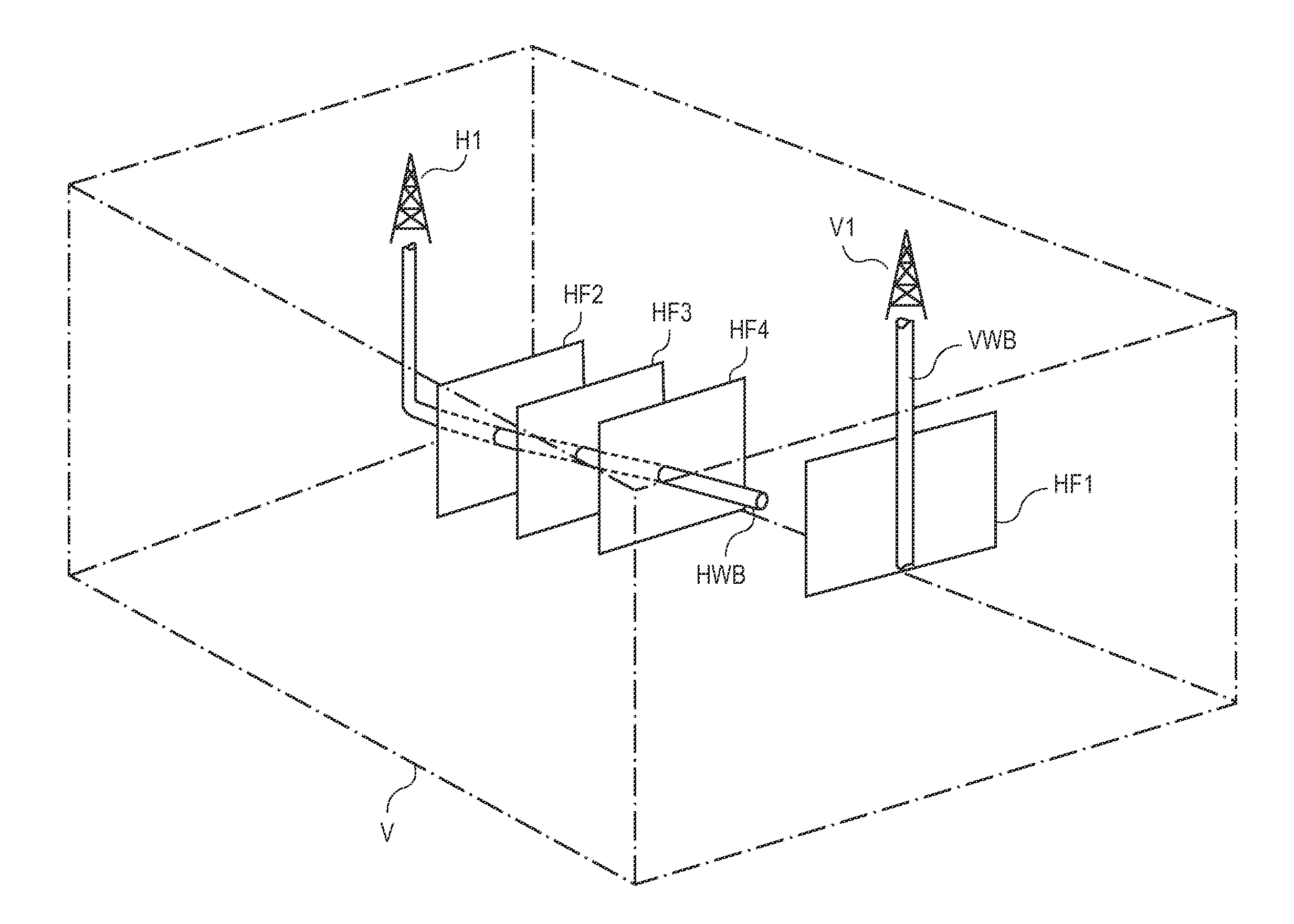

A computer system and method of automatically generating a Local Grid Refinement (LGR) gridded model of a gas reservoir. A geologic file includes information identifying the locations of one or more wells according to root grid cells within a volume of the earth to be modeled. User inputs specify the number of hydraulic fractures from each well, and such parameters as the fracture length, etc. User inputs also specify the number of “splits” of the root grid cells containing hydraulic fractures; those root grid cells are then split into finer resolution grid cells of increasing width within the root grid cells containing the fractures. For horizontal wells, user inputs indicate the number of splits of root grid cells containing the lateral portions of the wellbore. Non-orthogonal and complex fractures are processed by a“nested” LGR approach. Geologic properties are assigned to each grid cell, with a tensorial adjustment included for non-orthogonal fractures, and the resulting model is available for simulation.

Owner:BP CORP NORTH AMERICA INC

Propping Complex Fracture Networks in Tight Formations

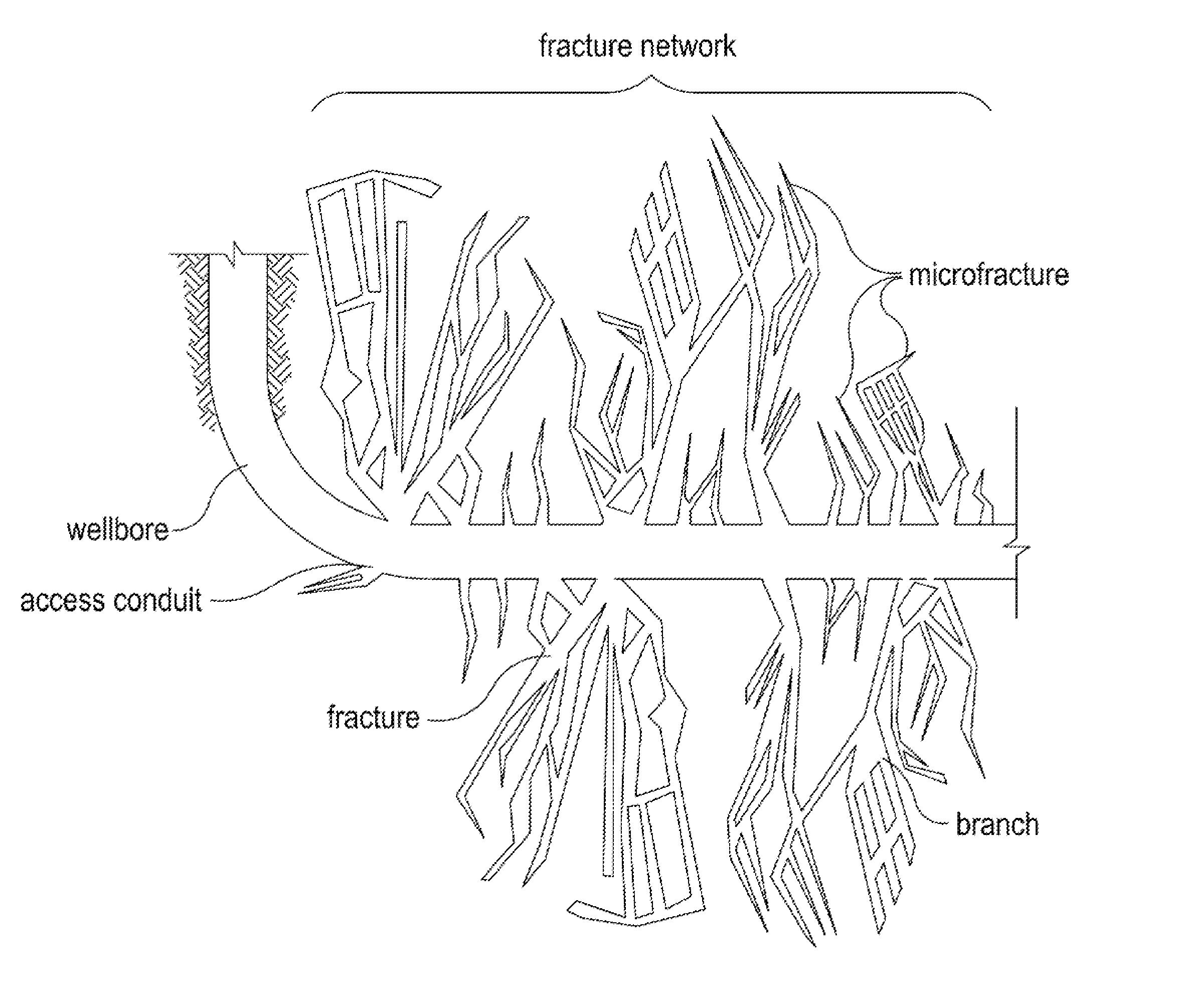

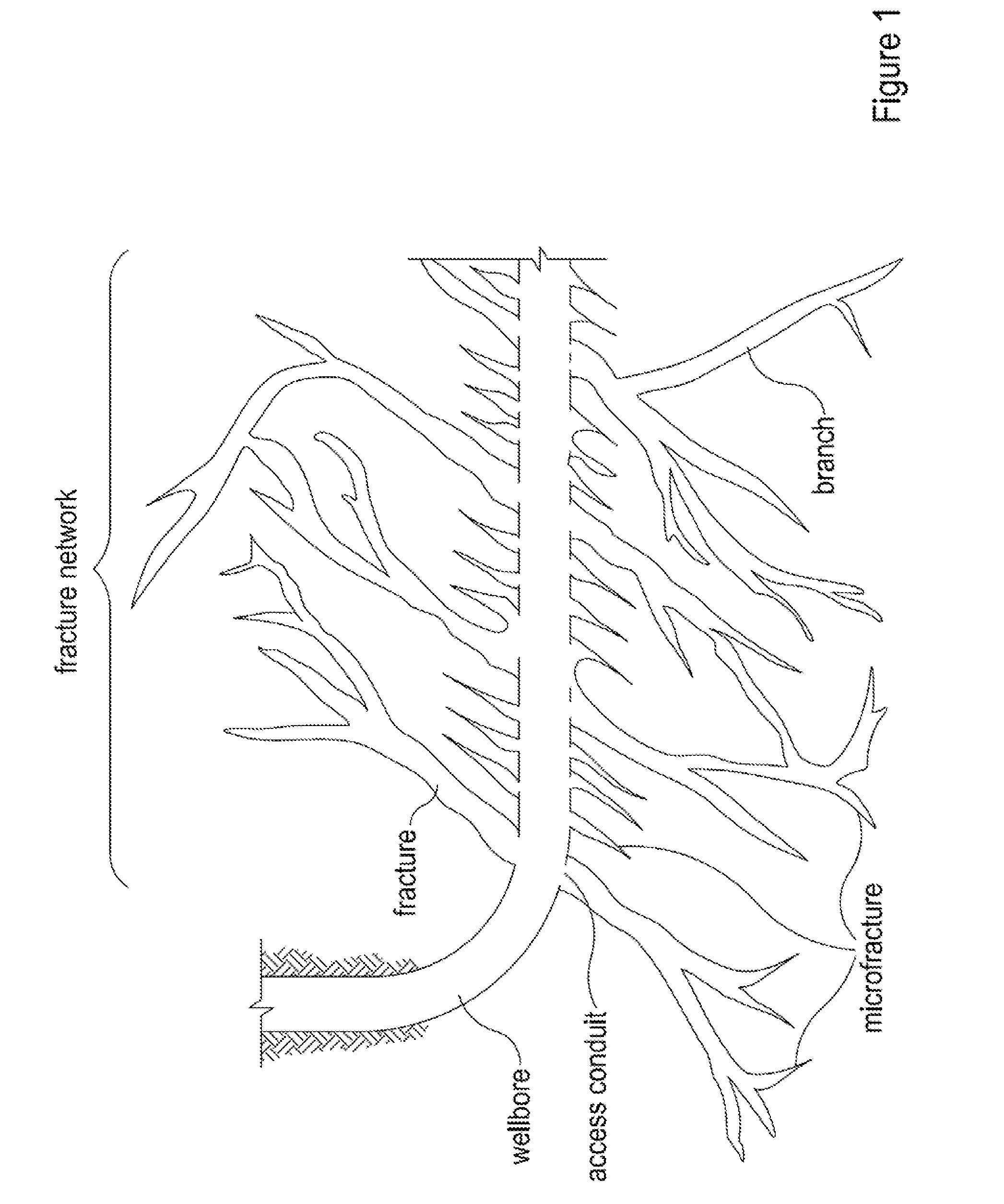

Generally, methods for propping complex fracture networks in tight subterranean formations may involve introducing a first treatment fluid comprising a first base fluid and a first propping agent having a mean particulate size distribution ranging from about 0.5 microns to about 20 microns into a fracture network in a subterranean formation; and then introducing a second treatment fluid comprising a second base fluid and a second propping agent having a mean particulate size distribution greater than about 35 microns into the fracture network.

Owner:HALLIBURTON ENERGY SERVICES INC

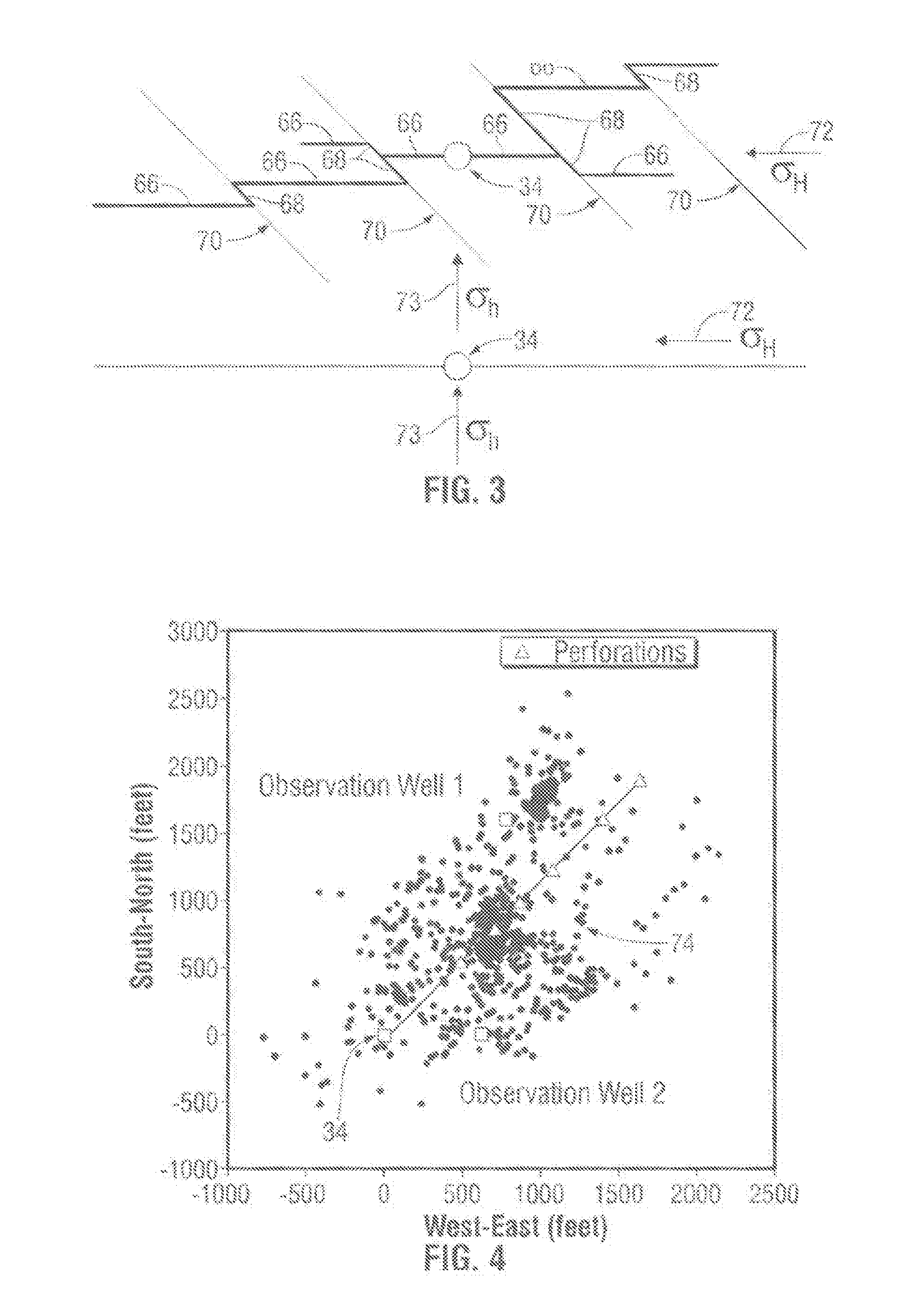

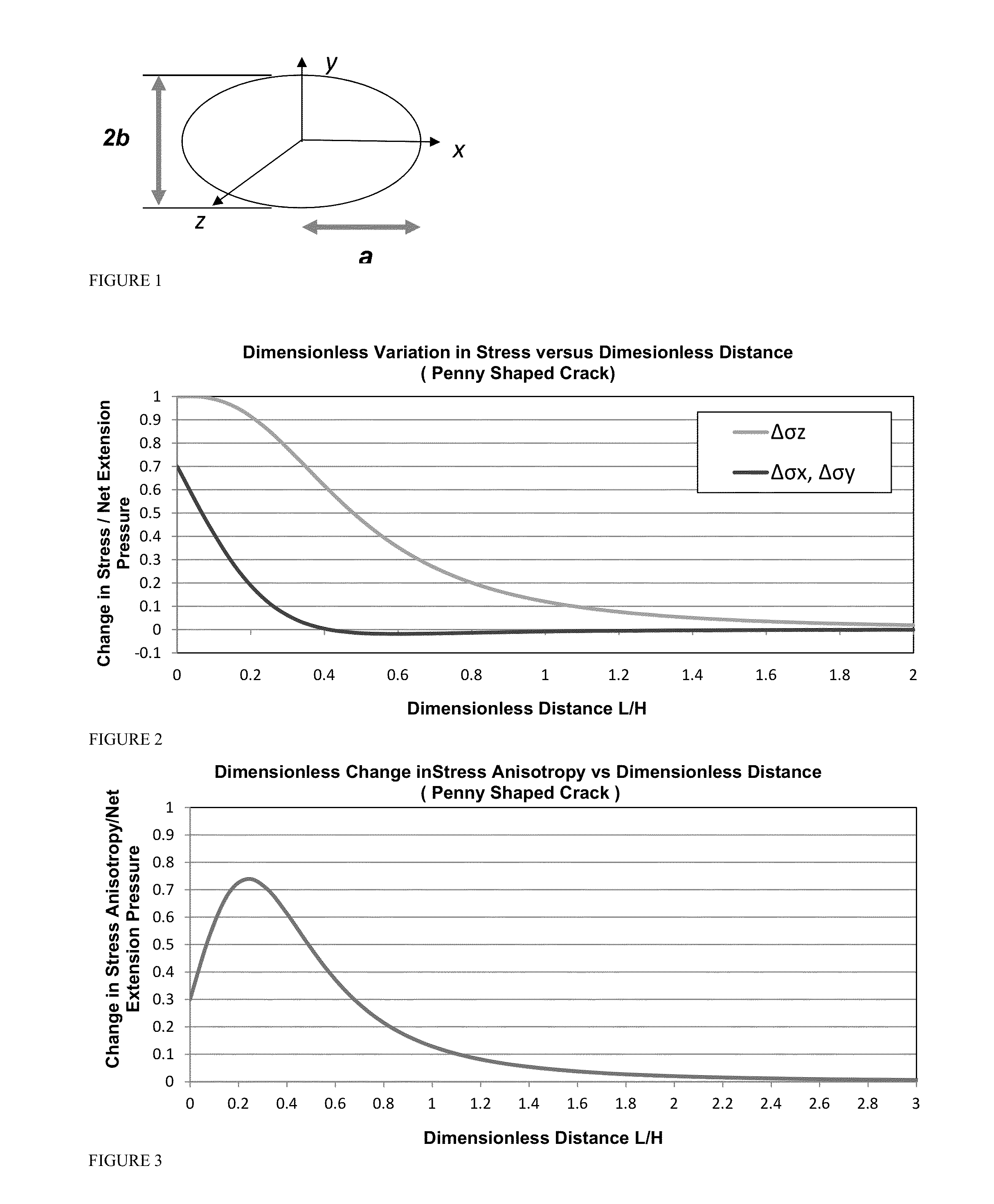

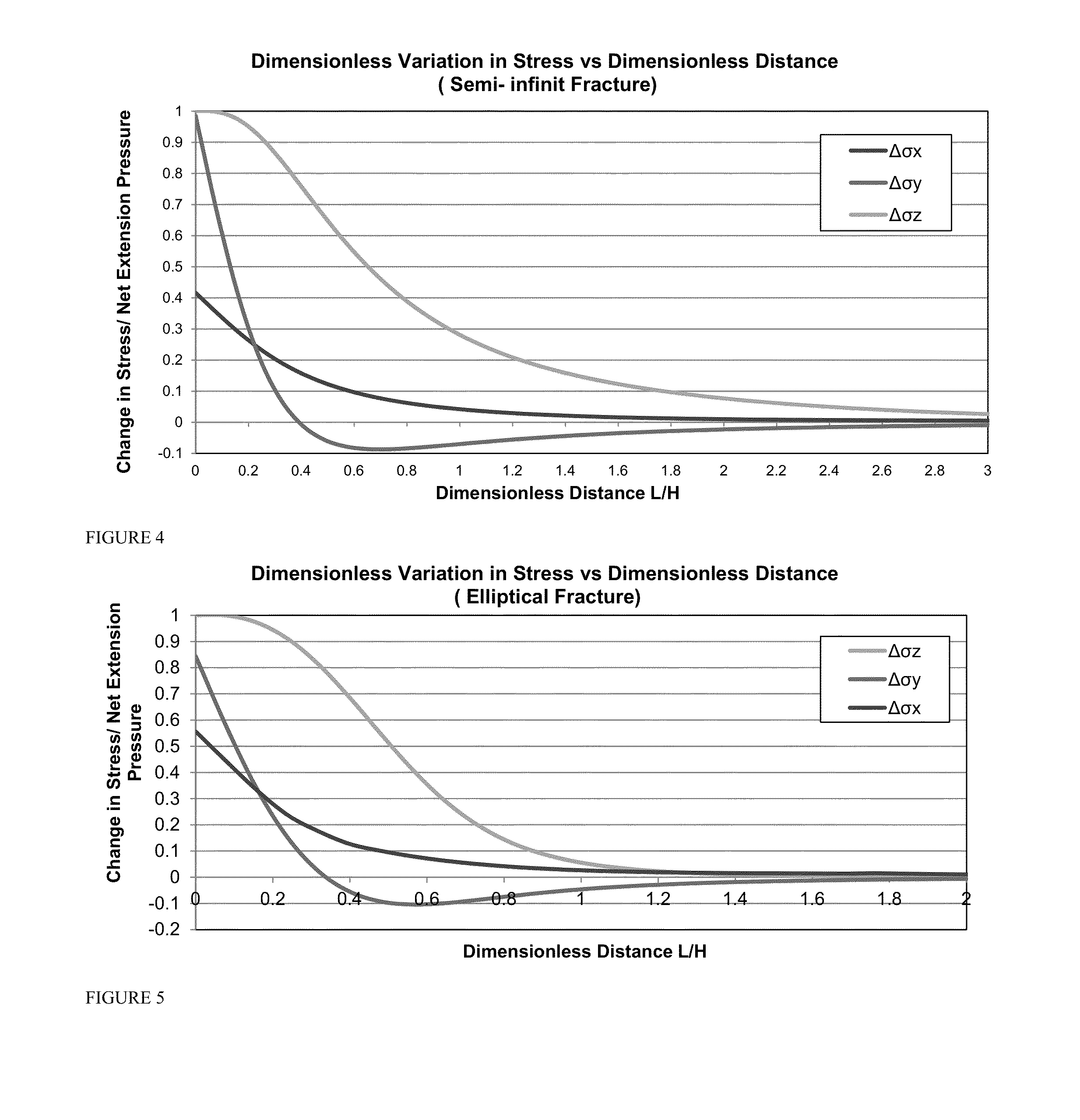

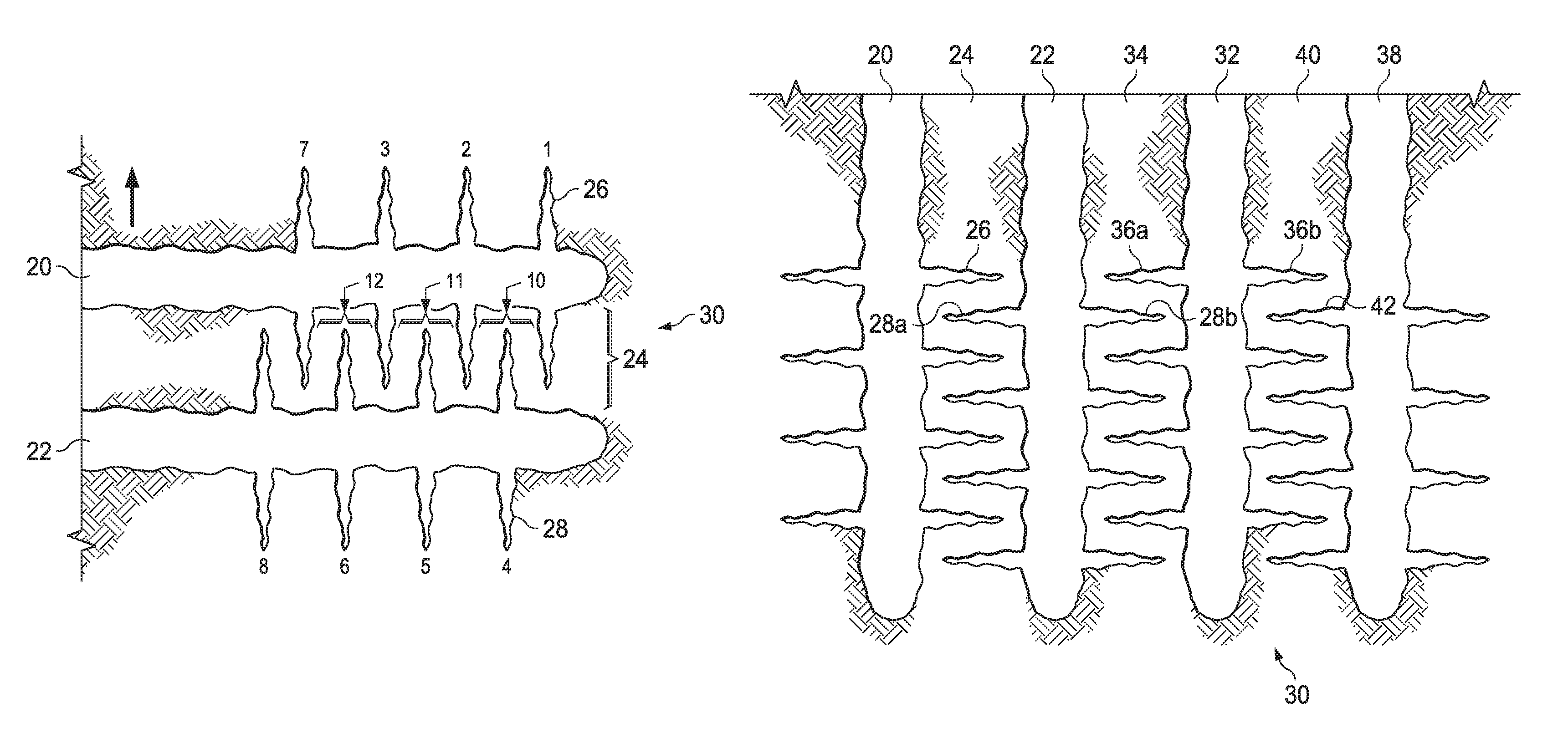

Evaluating far field fracture complexity and optimizing fracture design in multi-well pad development

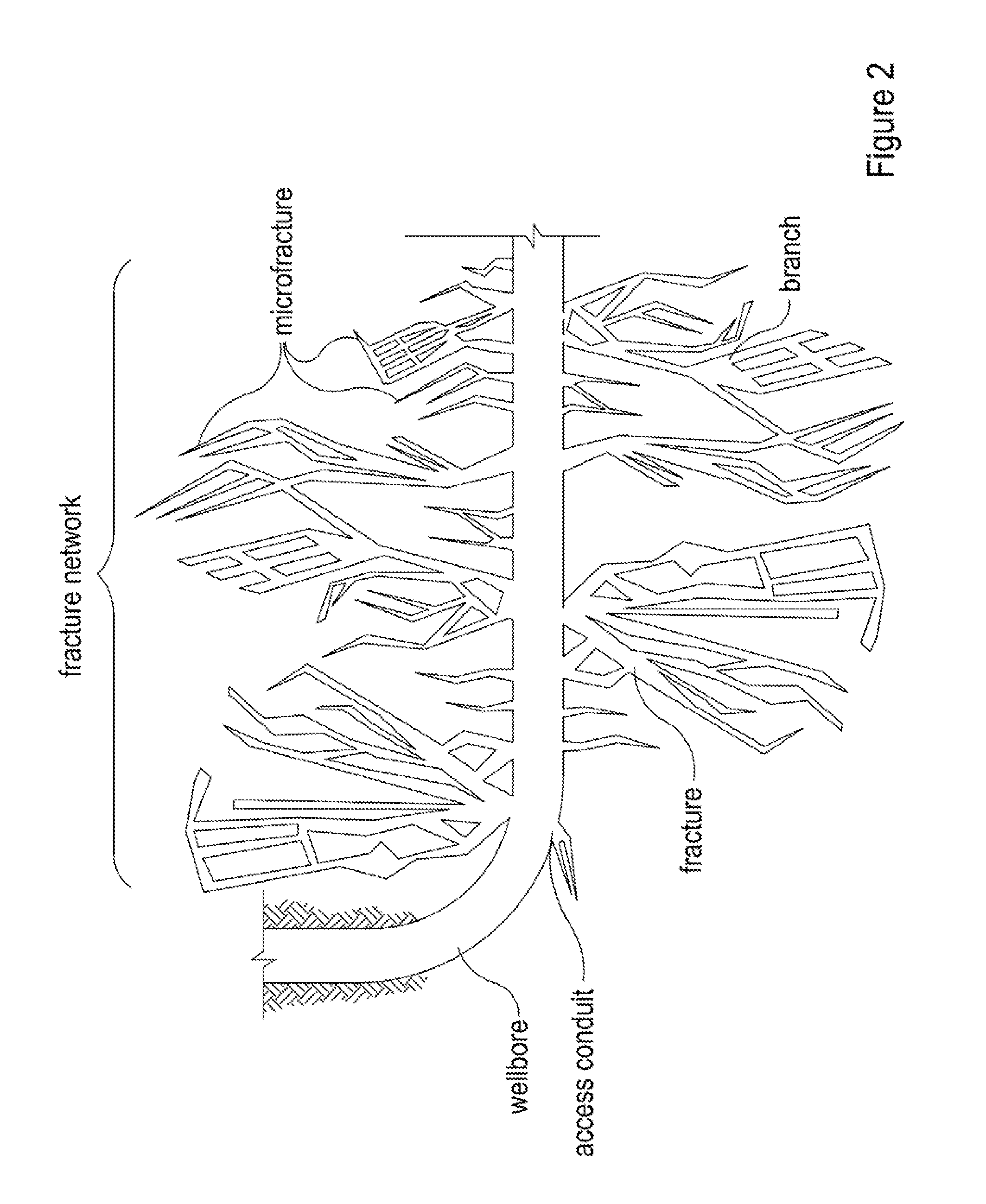

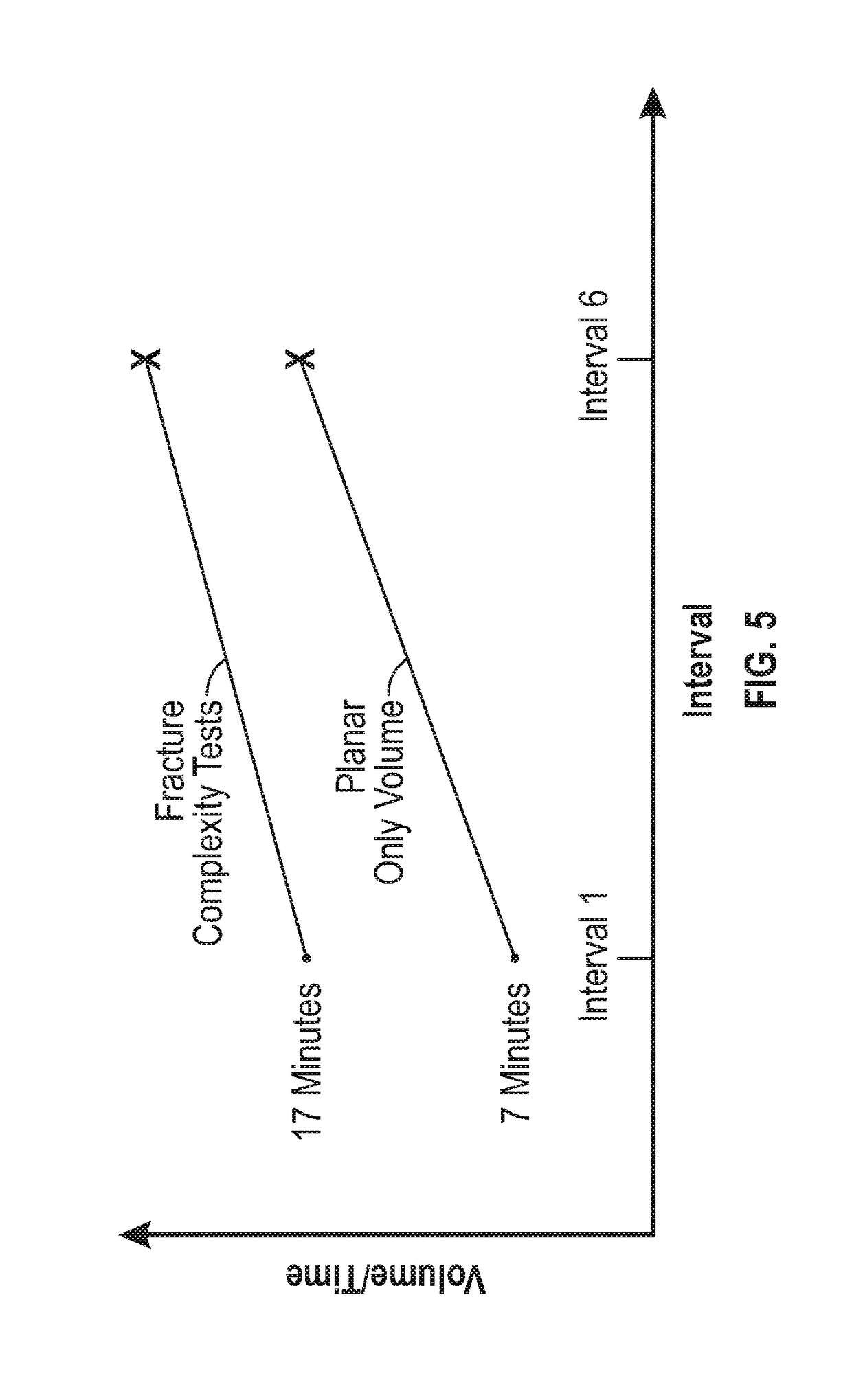

A method for evaluating and optimizing complex fractures, in one non-limiting example far-field complex fractures, in subterranean shale reservoirs significantly simplifies how to generate far-field fractures and their treatment designs to increase or optimize complexity. The process gives information on how much complexity is generated for a given reservoir versus distance from the wellbore under known fracturing parameters, such as rate, volume and viscosity. The method allows the evaluation of the performance of diversion materials and processes by determining the amount of fracture volume generated off of primary fractures, including far-field secondary fracture volumes. The methodology utilizes fracture hit times, volumes, pressures and similar parameters from injecting fracturing fluid from a first primary lateral wellbore to create fractures and record fracture hit times, pressures and volumes from a diagnostic lateral wellbore in the same interval.

Owner:BAKER HUGHES INC

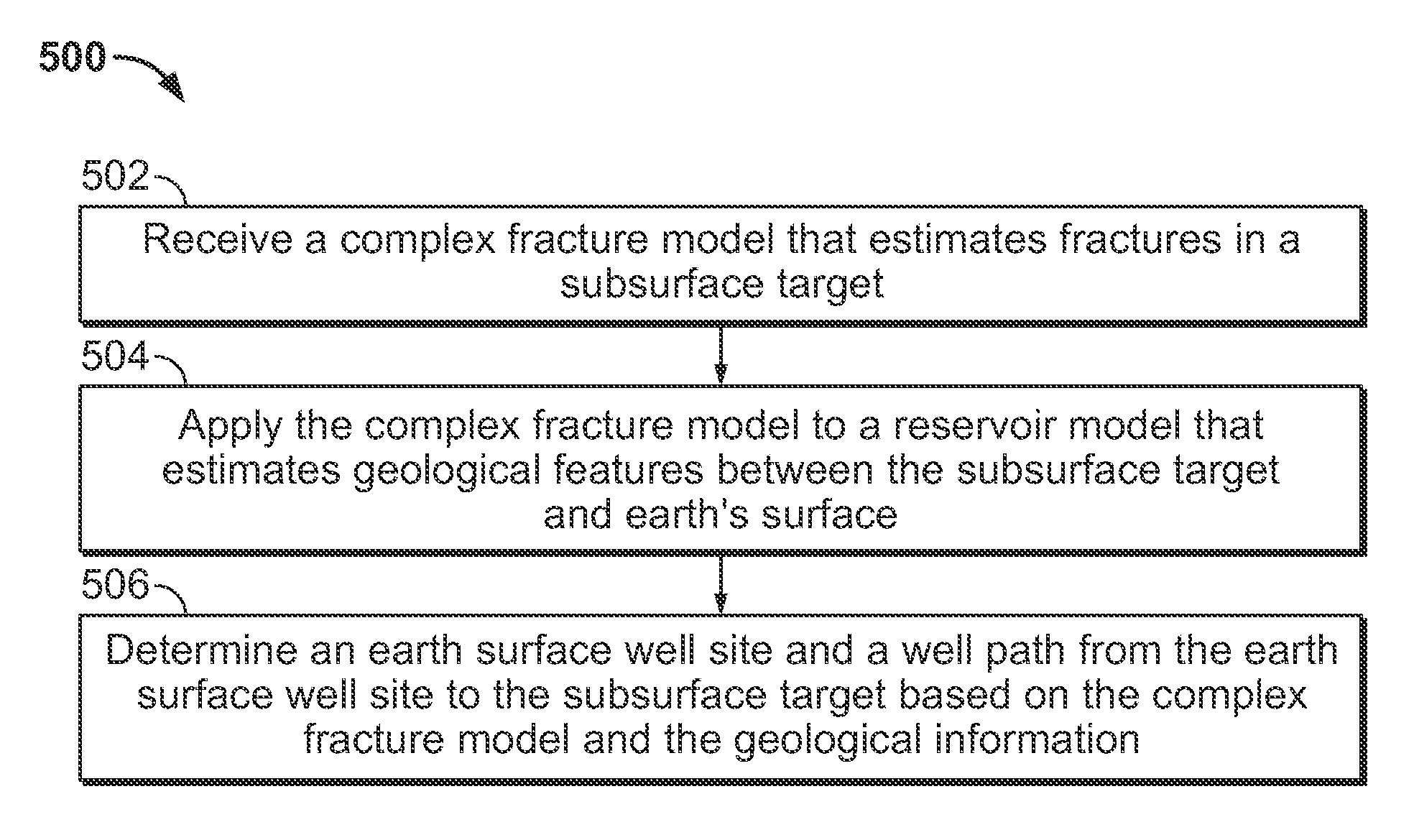

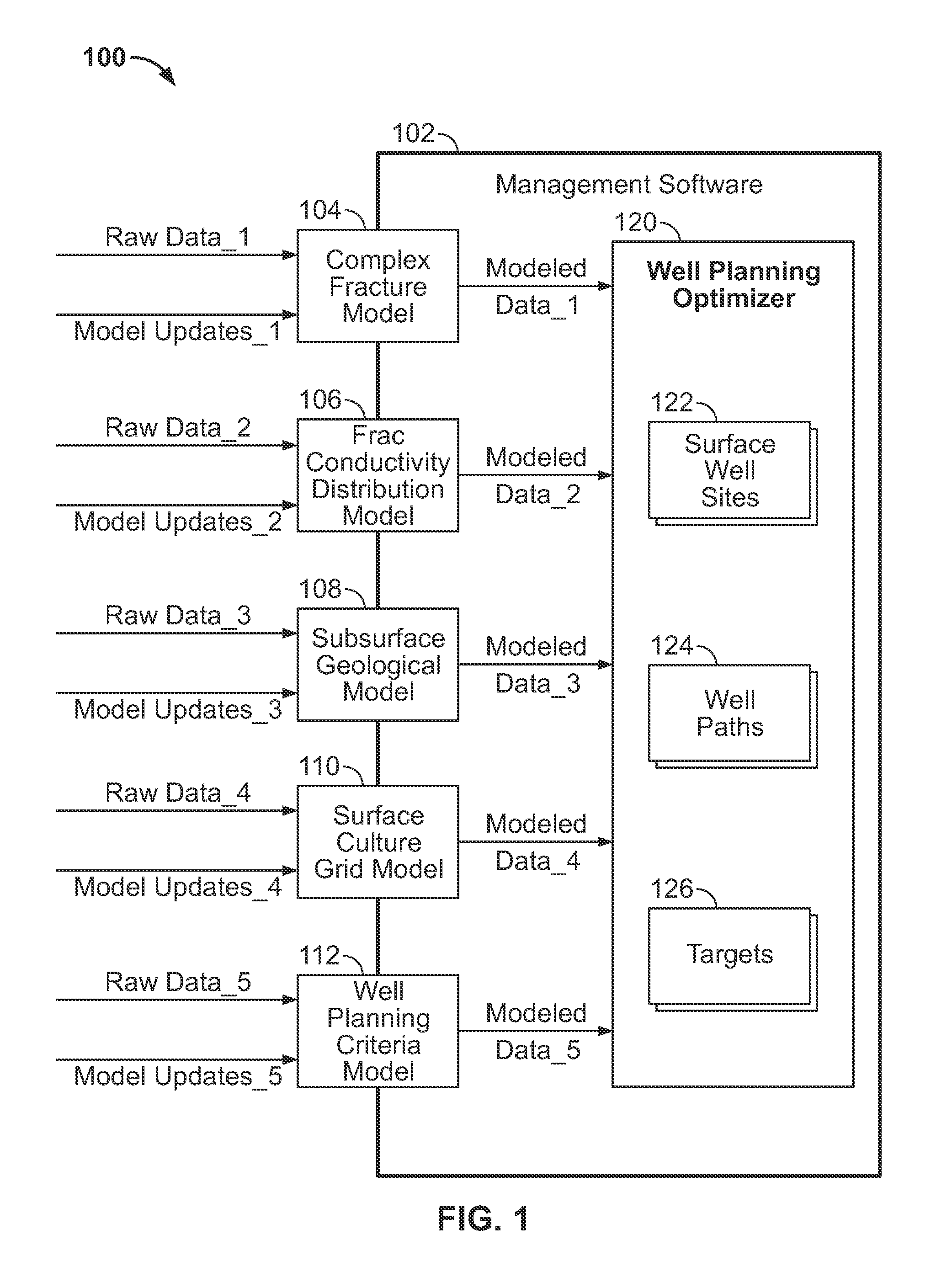

Methods and systems for well planning based on a complex fracture model

Optimizing well planning scenarios. At least some of the illustrating embodiments include: receiving, by a computer system, a complex fracture model that estimates fractures in a subsurface target; applying the complex fracture model to a reservoir model that estimates geological features between the subsurface target and earth's surface; and determining an earth surface well site and a well path from the earth surface well site to the subsurface target based on the complex fracture model and the geological in formation, wherein the earth surface well site is offset from the subsurface target.

Owner:LANDMARK GRAPHICS

Method for computing unsteady state output of shale gas reservoir complex fracture network

ActiveCN108518212ASimple calculationCalculation of non-steady-state output is simpleSurveyData processing applicationsPorous mediumNetwork model

The invention belongs to the technical field of mineral resources, and particularly relates to a method for computing unsteady state output of a shale gas reservoir complex fracture network. The method comprises the following steps that S1, basic parameters of shale gas reservoir strata and shale gas are collected, and a shale substrate porous media capillary tube permeability model is established; S2, shale gas reservoir microseism fracture imaging data is collected, a box method is applied to acquire fractal dimensions, a two-dimensional discrete fracture network model is established, and animproved cubic law is adopted to calculate the complex fracture network permeability; S3, it is considered that a shale gas reservoir fracturing horizontal well outer region is a substrate area infiltration area and a shale gas reservoir fracturing horizontal well inner region is a complex fracture network area flow area, and a shale gas reservoir fracturing horizontal well steady-state productivity model is established; according to a shale gas pressure propagation radius equation and a shale gas reservoir material balance equation, a continuous quasi-steady method is applied to establish ashale gas reservoir fracturing horizontal well unsteady state model. The method for the computing unsteady state output of the shale gas reservoir complex fracture network has the advantages that theconsideration factors are close to the actual conditions of strata, and computed results are more accurate.

Owner:SOUTHWEST PETROLEUM UNIV

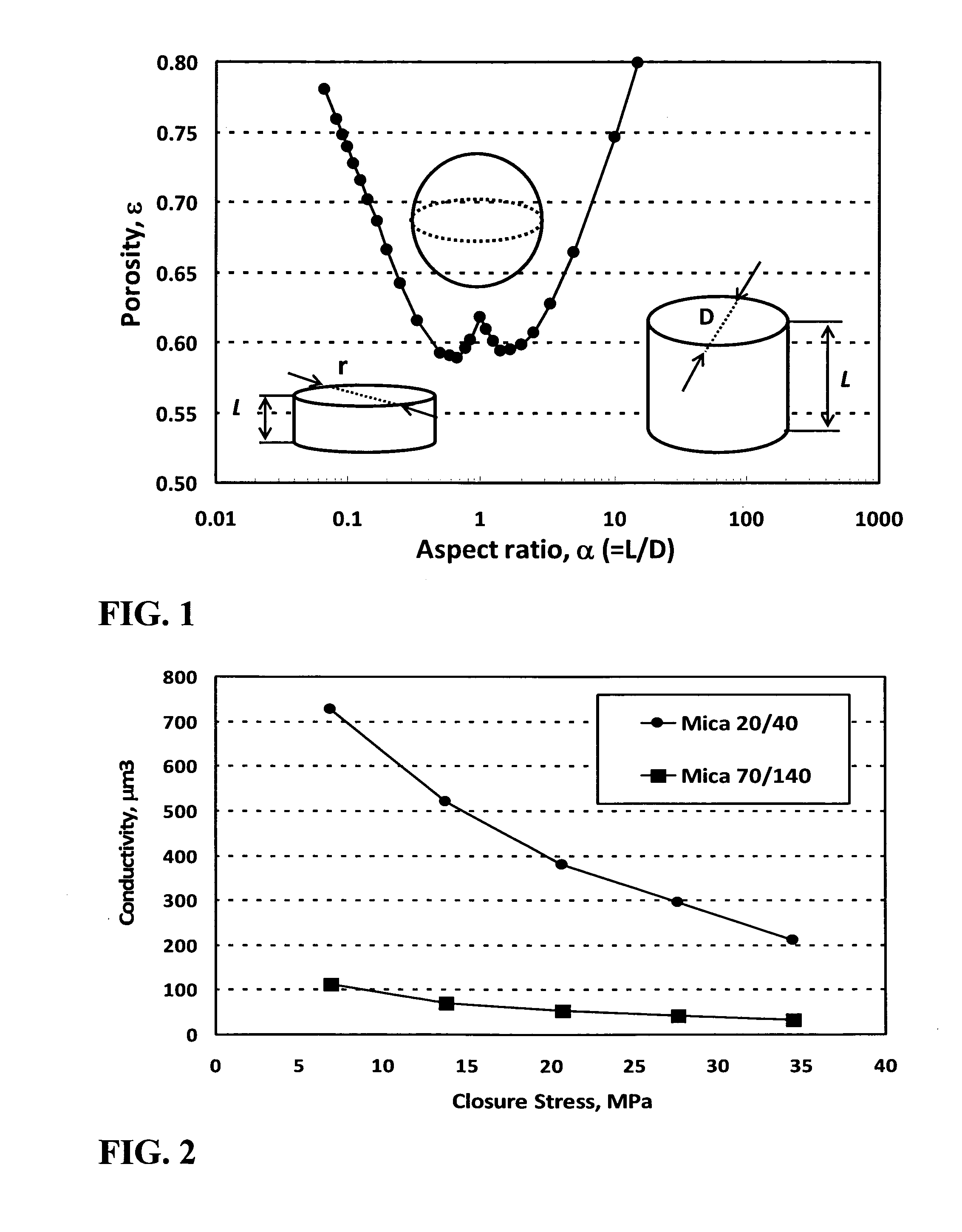

Hydraulic Fracturing Proppants

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

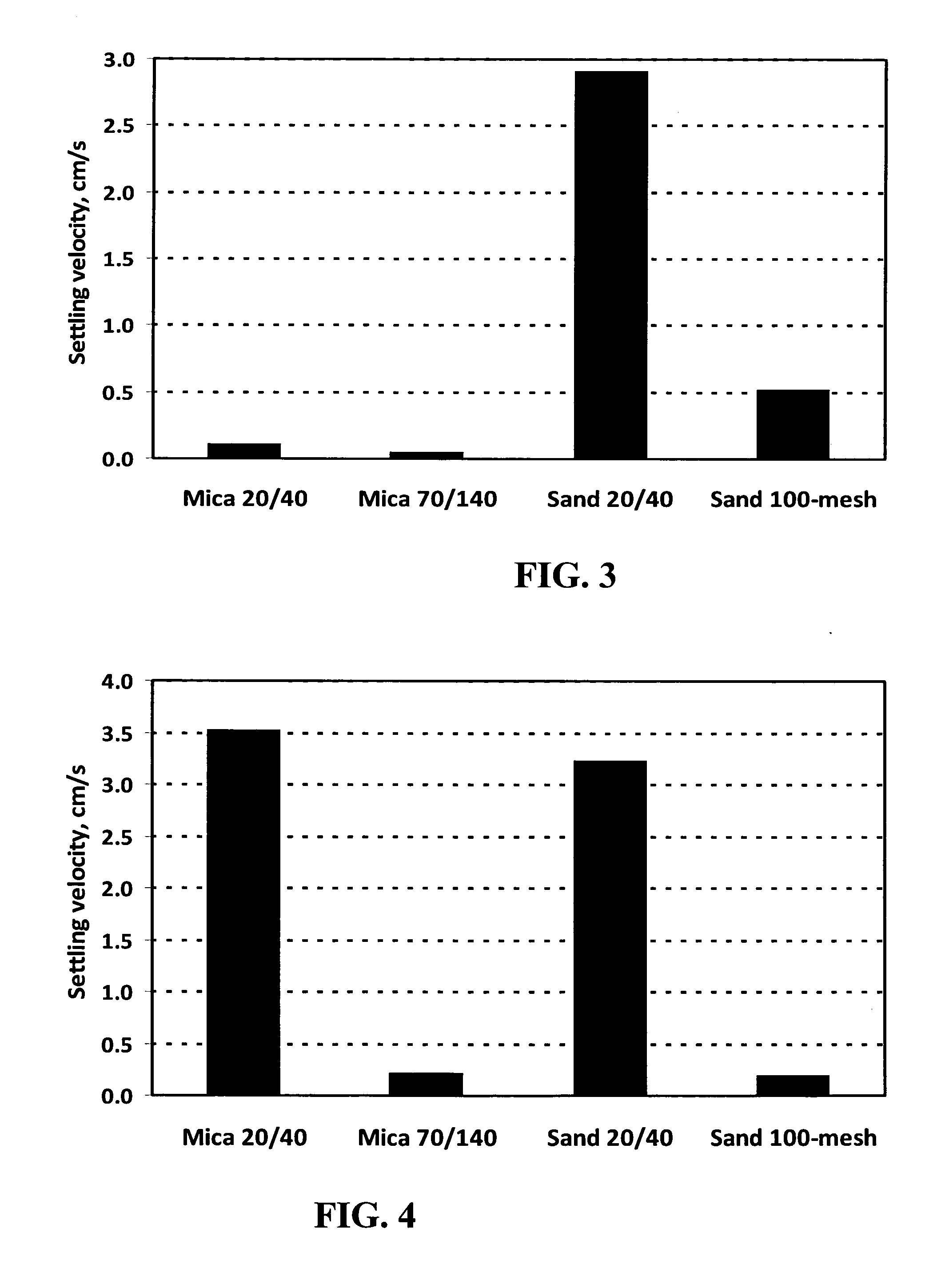

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

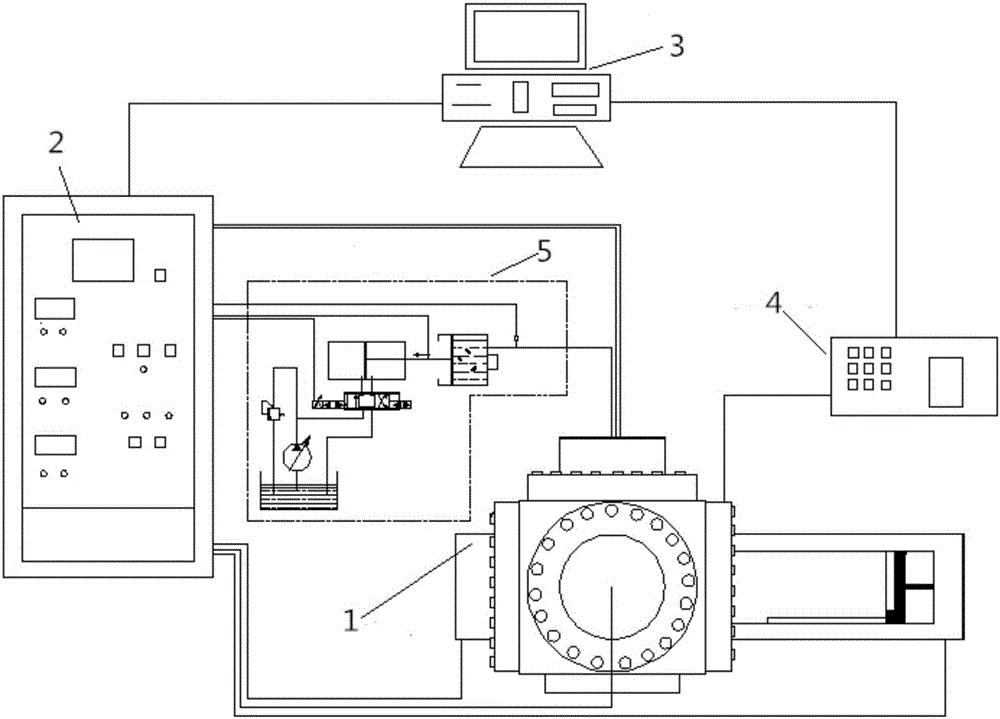

Observable experiment equipment for simulating propping agent migration in complex fracture network

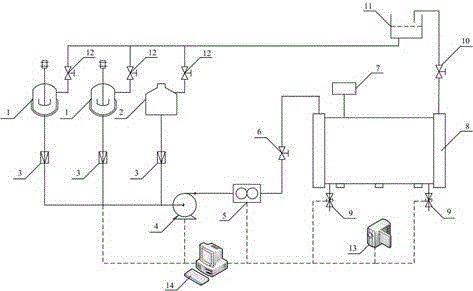

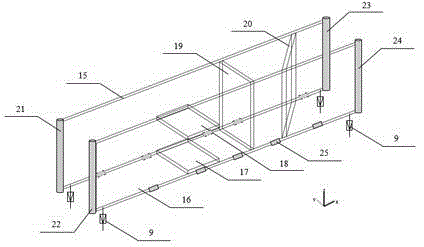

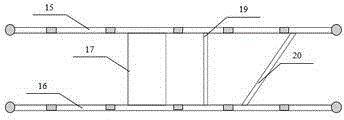

ActiveCN104533404AAccurately reflectReliable principleFluid removalSimulatorsControl systemData acquisition

The invention discloses observable experiment equipment for simulating propping agent migration in a complex fracture network. The observable experiment equipment comprises a fluid supply and sand mixing system, a pump casting system, a pipeline conveyance system, an observable fracture network system, a circulating fluid processing system, a data acquisition system and a control system, wherein the outlet of the fluid supply and sand mixing system is connected with the inlet of the pump casting system through the pipeline conveyance system, the outlet of the pump casting system is connected with the inlet of the observable fracture network system through the pipeline conveyance system, the outlet of the observable fracture network system is connected with the inlet of the circulating fluid processing system through the pipeline conveyance system, and the outlet of the circulating fluid processing system is connected with the inlet of the pump casting system through the pipeline conveyance system so that the data acquisition system for acquiring data is connected with the control system. According to the observable experiment equipment, the propping agent migration rule in the complex fracture network can be truly simulated so that the flow mechanism of the sliminess water fracturing propping agent is explored.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

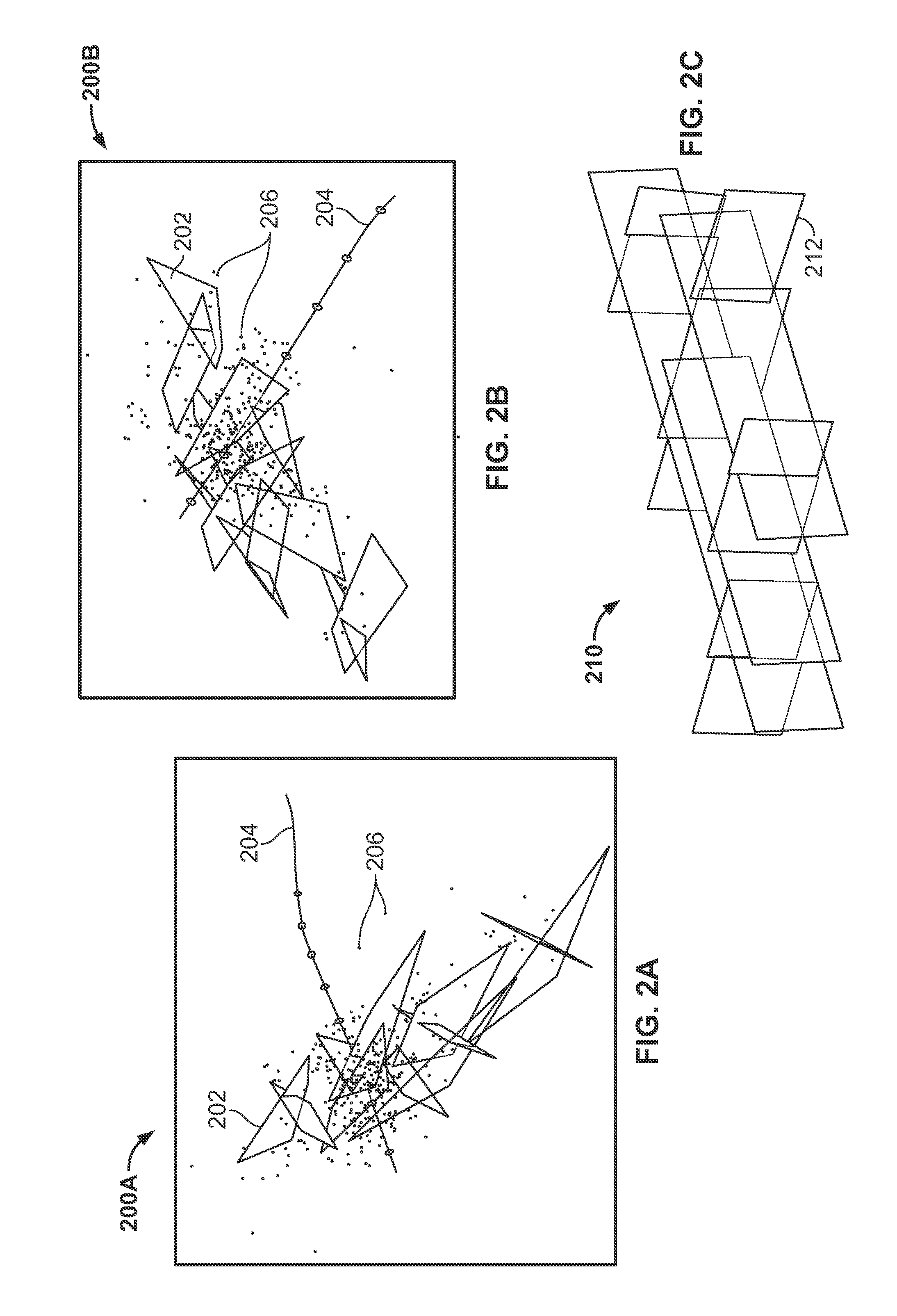

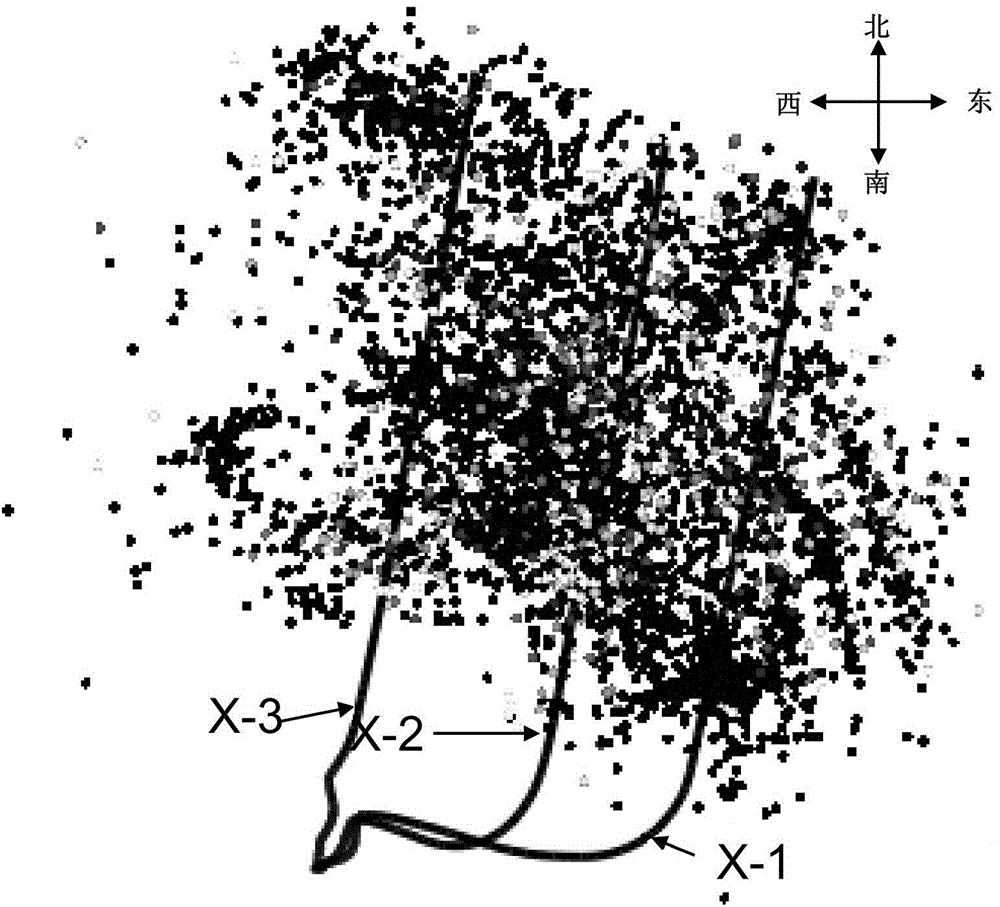

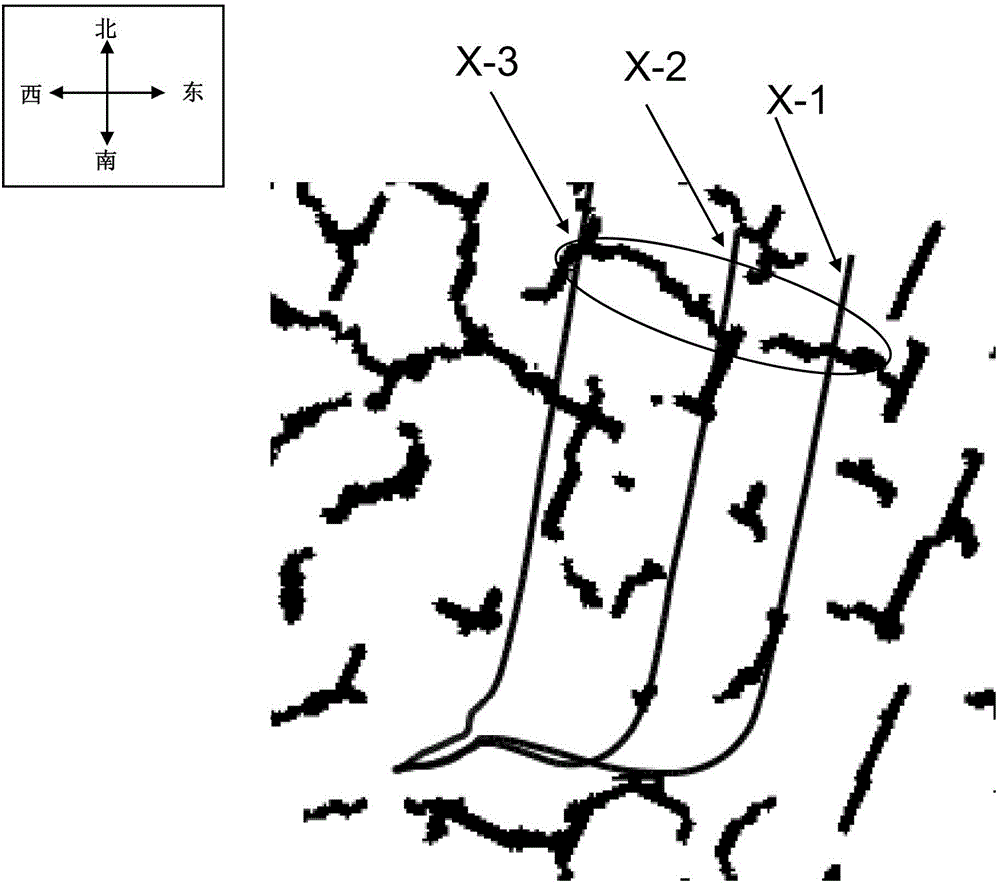

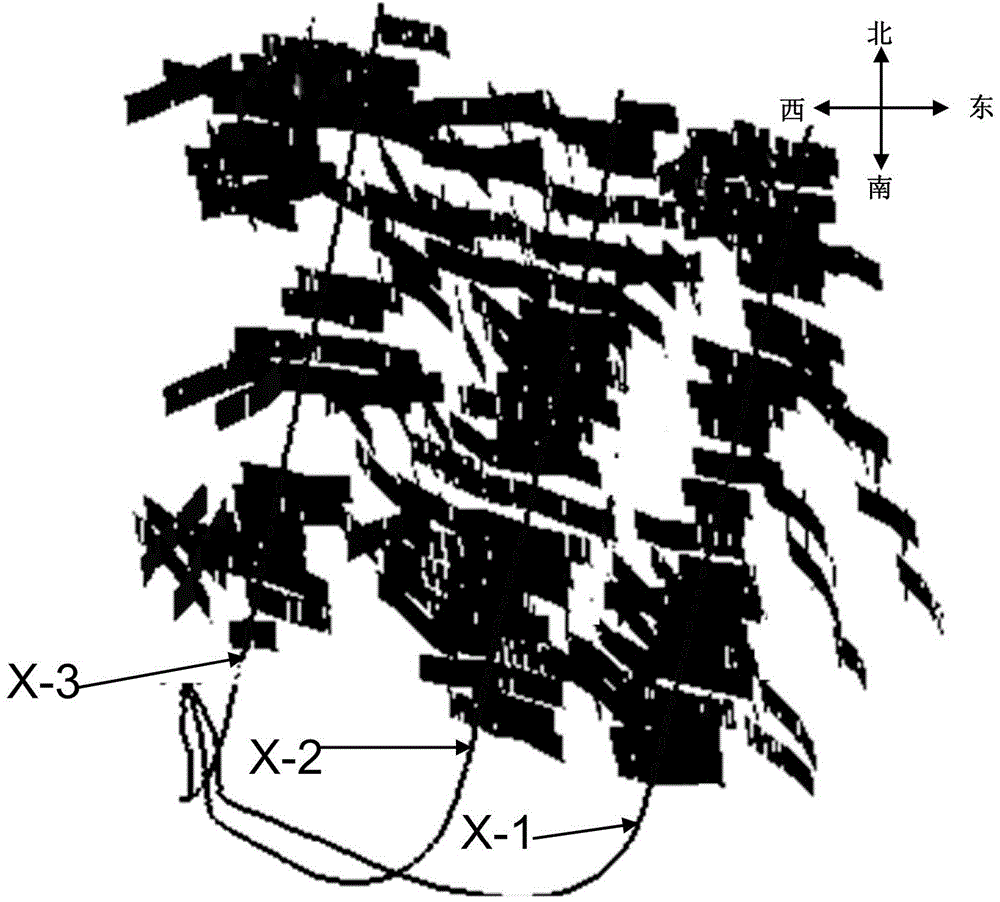

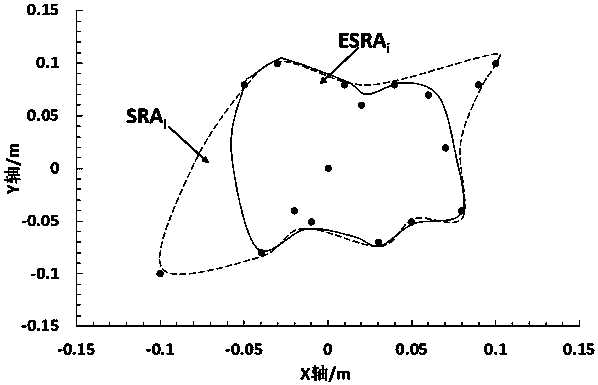

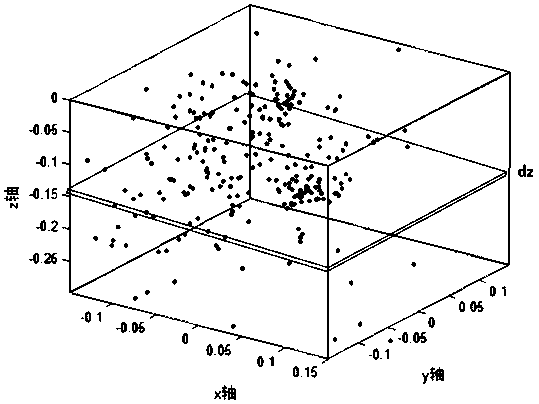

Shale gas reservoir fracture modeling method based on microseism monitoring data

ActiveCN104459775AMeticulous and effective characterizationSeismic signal processingHydraulic fracturingShale gas

The invention provides a shale gas reservoir fracture modeling method based on microseism monitoring data. The method comprises the steps that major fractures of a shale gas reservoir subjected to hydraulic fracturing are modeled to obtain a major fracture model by the adoption of a deterministic modeling method according to the time attribute of microseism event points in the microseism monitoring data in combination with original natural fracture information of the shale gas reservoir; on the basis of the major fracture model and within the effective reconstruction volume range for hydraulic fracturing, constraint conditions of space and geometrical parameters for accompanying fracture simulation in the hydraulic fracturing process are determined according to the density attribute of distribution of the microseism event points in the microseism monitoring data in combination with at least one of the direction attribute, the energy magnitude and the opening degree of the microseism event points, and accompanying fractures of the shale gas reservoir subjected to hydraulic fracturing are modeled by the adoption of a stochastic modeling method to obtain a shale gas reservoir facture basic model. By means of the shale gas reservoir fracture modeling method based on the microseism monitoring data, a complex fracture system of the shale gas reservoir can be depicted meticulously and effectively, and the actual fracture characteristics of the shale gas reservoir subjected to hydraulic fracturing can be reflected.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

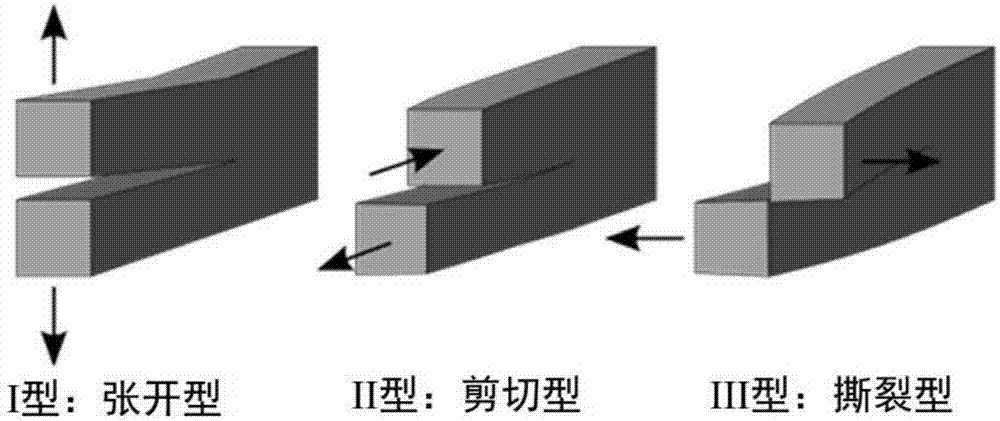

Volume alternating fracturing method of horizontal well in experimental shale reservoir

The invention discloses a volume alternating fracturing method of a horizontal well in an experimental shale reservoir. The method comprises the following steps: collecting the stratum parameter, the natural fracture parameter and the hydraulic fracture basic parameter of a reservoir; establishing stretching, shearing and pass through failure criterions of a natural fracture when a hydraulic fracture and the natural fracture are interacted, and quantitatively analyzing the influence on the natural fracture failure by a horizontal principal stress difference; establishing a hydraulic fracture induced stress calculation model, and computing the influence on the induced stress of a middle perforation cluster fracture elongated area by gaps among different perforation cluster fractures and fracture extended lengths; optimally selecting a shale reservoir horizontal well volume fracturing perforation cluster gap and perforation cluster extended lengths at the two ends, so as to promote a middle perforation cluster hydraulic fracturing fracture to be extended and interactively produce stretching, shearing and pass through failure modes with the natural fracture at the same time to form a complex fracture. According to the method, induced stress field produced through the extension of the hydraulic fracture, perforation gaps within the same fracturing section and the extended fracture lengths are organically combined, and the horizontal well volume fracturing technology is properly perfected.

Owner:SOUTHWEST PETROLEUM UNIV

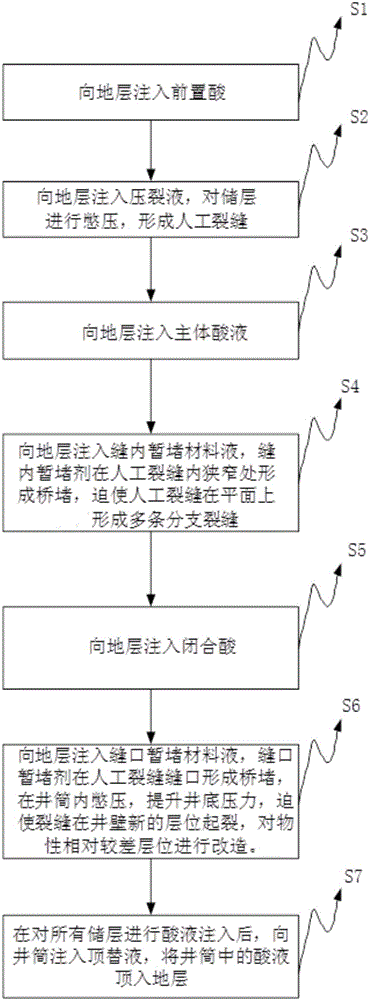

Multi-stage temporary plugging depth network acid fracturing method

The invention discloses a multi-stage temporary plugging depth network acid fracturing method, and belongs to the technical field of oil and gas well production increment and improvement. The method comprises the steps that bridge plugging is formed in an artificial fracture through fracture interior temporary plugging material liquid, the artificial fracture is forced to form multiple branch fractures, and main acid is used for etching the fracture; bridge plugging is formed in an artificial fracture opening through fracture opening temporary plugging material liquid, the fracture is forced to be cracked at the new position of a well wall, and interlayer steering is achieved. The multi-stage temporary plugging depth network acid fracturing method has the advantages of being simple in technology, convenient to operate and the like, a complex fracture network is formed in different permeability zones in carbonatite multi-layer, thick-layer or horizontal well long well sections through the principle of combining fluid power self serching and manual control, the oil and gas region communication probability is increased, the oil and gas percolating resistance is reduced, the single-well yield is improved, and a carbonate reservoir is efficiently and economically developed.

Owner:SOUTHWEST PETROLEUM UNIV +2

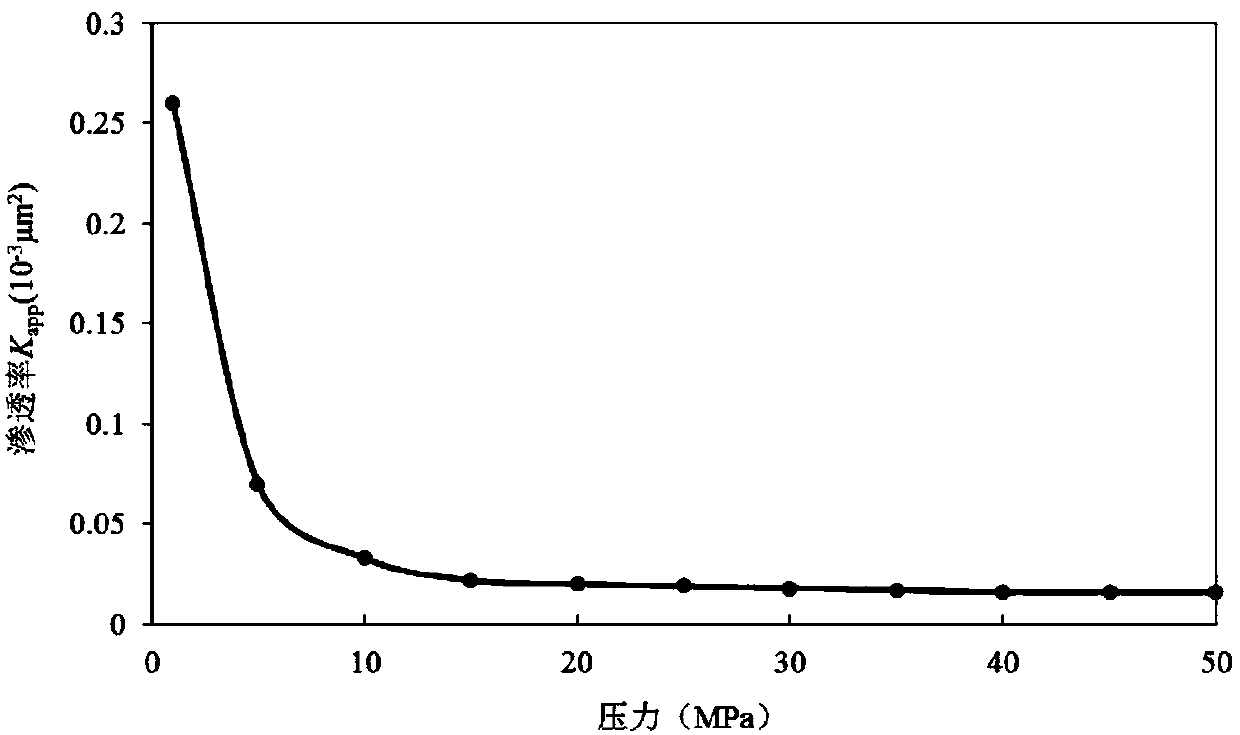

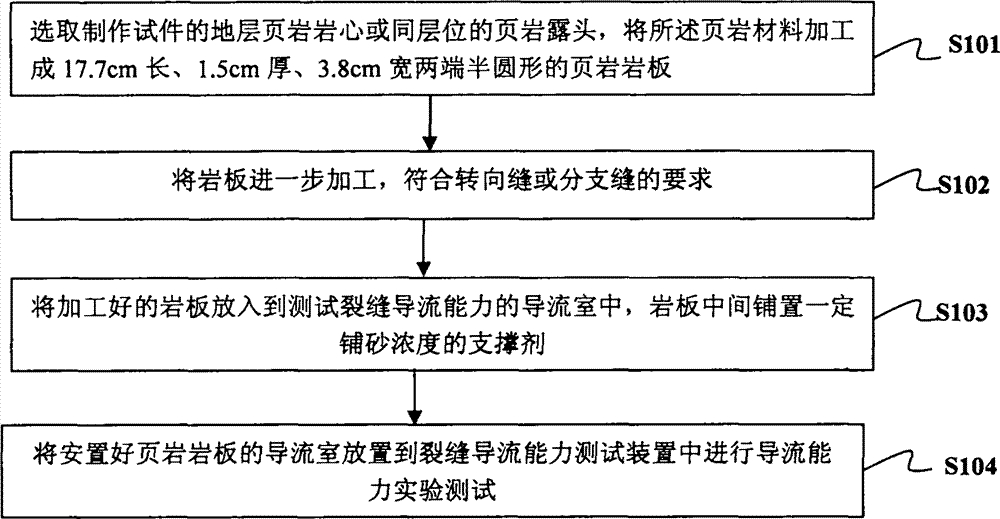

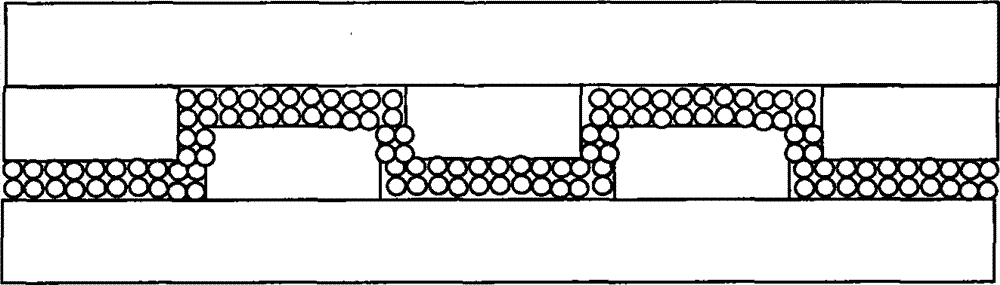

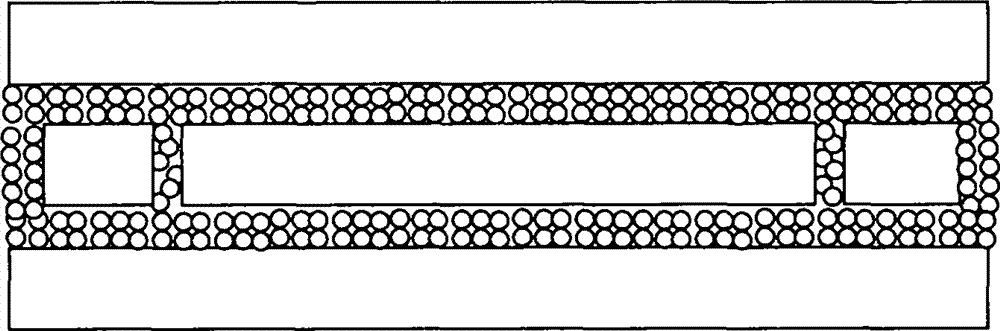

Shale gas reservoir complex fracture conductivity simulation experiment method

The invention provides a shale gas reservoir complex fracture conductivity simulation experiment method. The method comprises the following steps that (a) a stratum shale core or a peer position shale outcrop for manufacturing a test piece is selected, and shale materials are processed into a shale slab, wherein the length of the shale slab is 17.7 cm, the thickness of the shale slab is 1.5 cm, the width of the shale slab is 3.8 cm, and the two ends of the shale slab are in a semicircular shape; (b) the shale slab is further processed to meet the requirement of turning fractures or branch fractures; (c) the processed shale slab is put in a conducting room for testing the fracture conductivity, and a propping agent with the certain sanding concentration is laid in the middle of the shale slab; (d) the conducting room with the propping agent and the shale slab well arranged is put in a fracture conductivity testing device to conduct a conductivity experiment test. For fractured fragile shale with complex fractures, the shale gas reservoir complex fracture conductivity simulation experiment method can be used for studying the conductivity of the turning fractures and the branch fractures formed through fracturing of shale gas reservoirs and evaluating the influence on the fracture conductivity by the fracture steering degree and the branch fracture form.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Recognition and interpreting evaluation method for shale reservoir fractured fractures

ActiveCN106988739ARealize numerical representationReduce manufacturing costFluid removalCognitionHydraulic fracturing

The invention discloses a recognition and interpreting evaluation method for shale reservoir fractured fractures. The recognition and interpreting evaluation method mainly comprises the steps of hydraulic fracture dynamic recognition of a shale reservoir under different stratum prestress conditions, three-dimensional natural fracture and hydraulic fracture network reconstruction and fracture network recognition and interpretation based on microseismic monitoring. The recognition and interpreting evaluation method achieves complex fracture network distribution form cognition and evaluation on the basis of hydraulic fractured fracture dynamic recognition and fracture comprehensive correction of microseismic monitoring interpretation to guide a fracture optimally designed fracture-microseism integrated fracture network prediction and evaluation technology and has important production significance for optimizing fracture construction parameters such as the fracture construction scale, the discharge capacity and the sand adding quality, reducing production cost and improving the fracture improvement effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

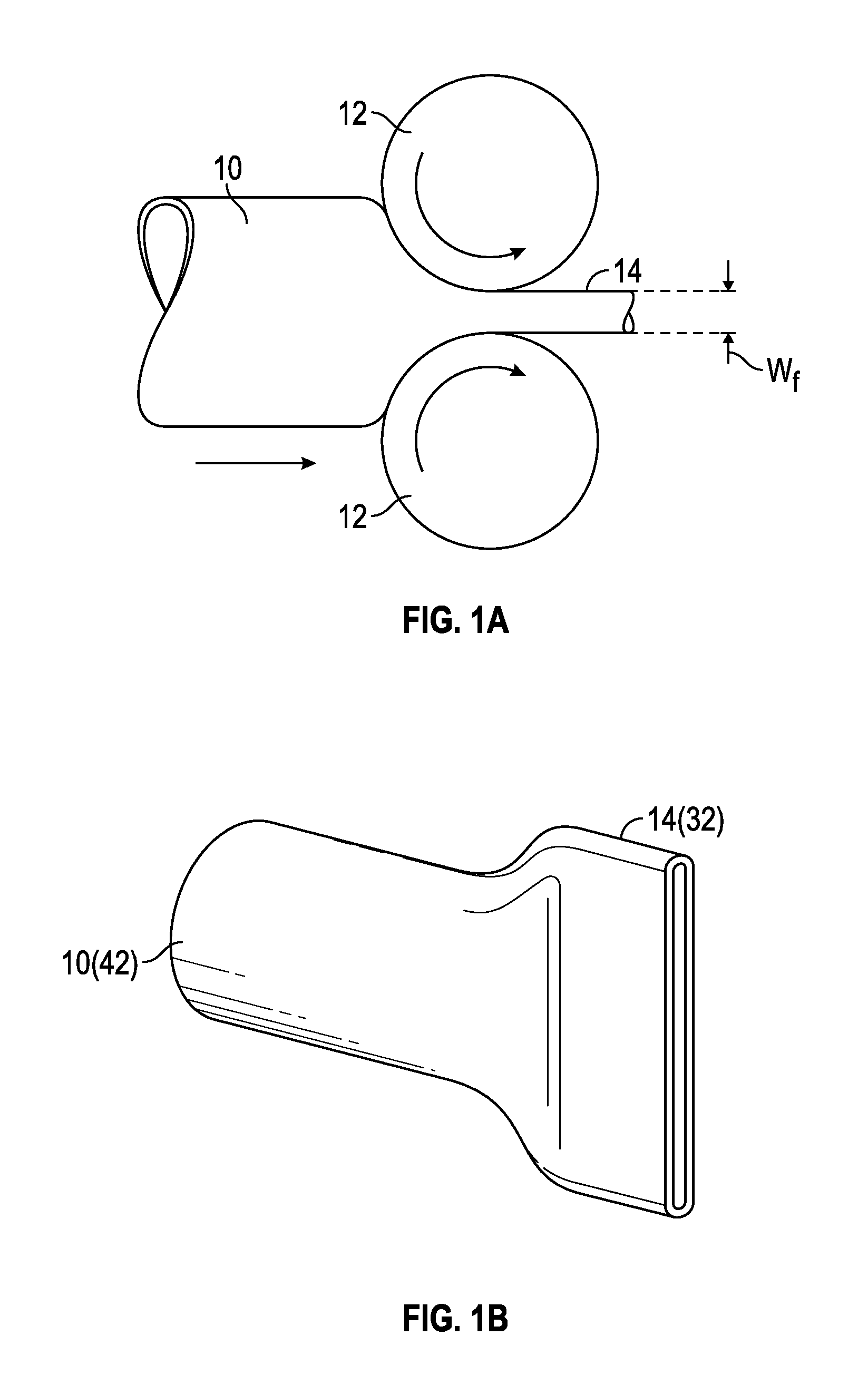

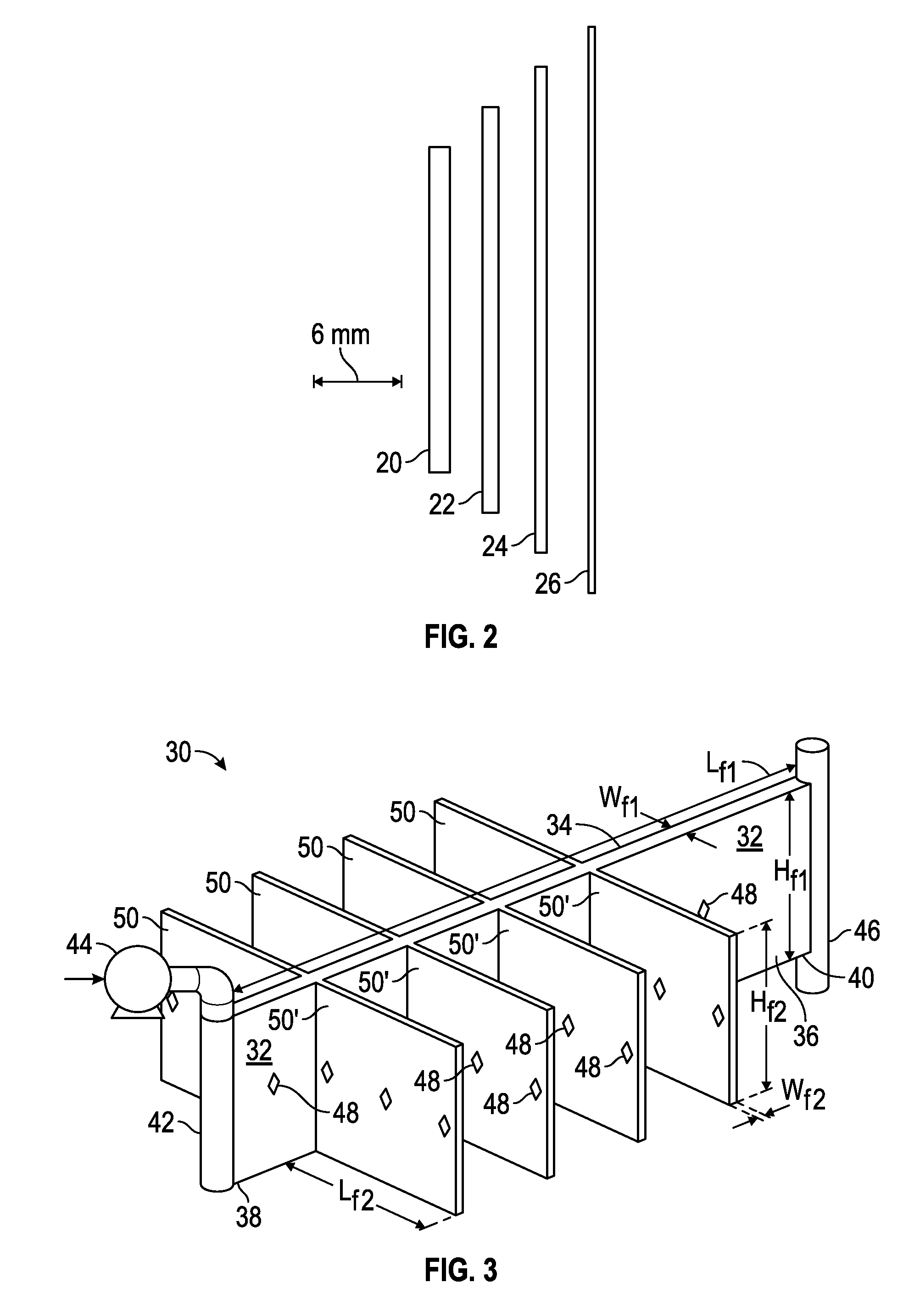

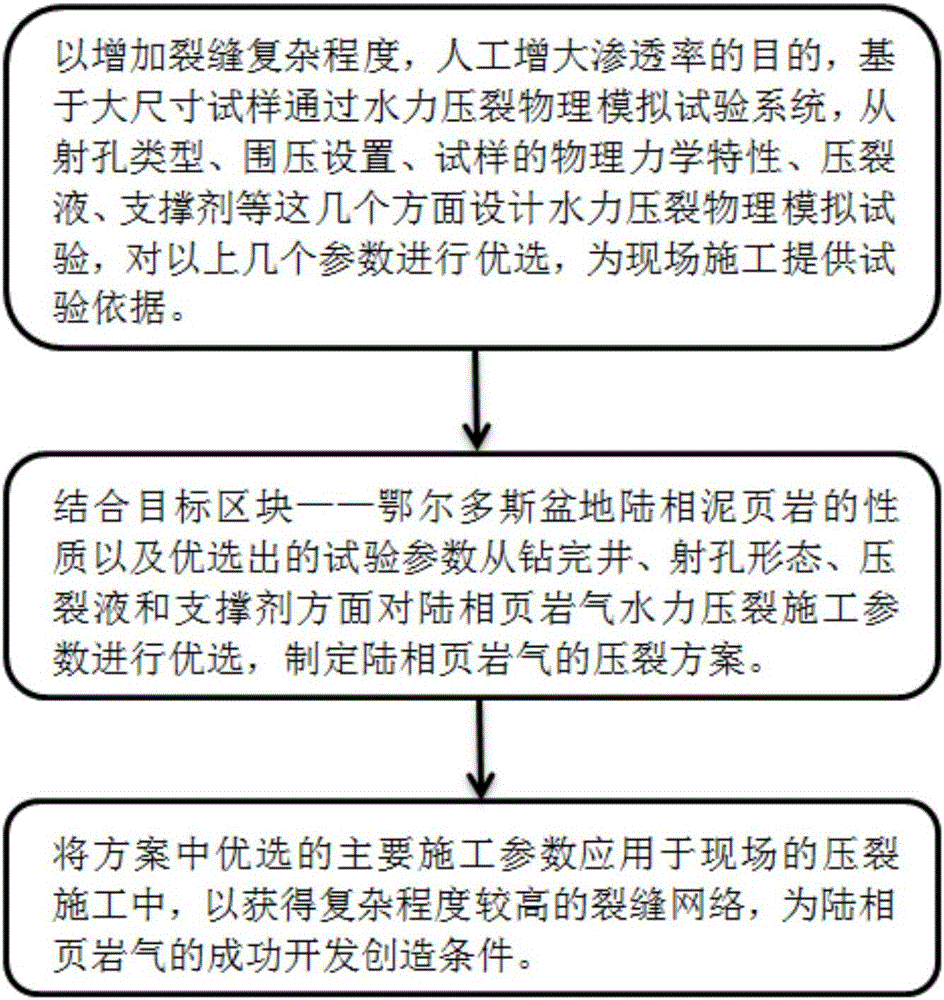

Shale fracture flow simulation apparatus

An apparatus having conduits, flattened tubing or pipes of varying widths, heights and / or lengths may simulate a network of fractures that may be used to experimentally evaluate the flow of treatment fluids (e.g. fracturing fluids) within narrow, shale-type fractures. The tubing or pipes each have an interior space with a height and a width, and in one non-limiting embodiment the ratio of height / width is at least 10. The conduits may be constructed of flattened tubing or constructed from components designed and engineered to have the correct height / width ratio. The apparatus may be used to empirically develop diversion principles, more precise numeric models and the parameter relationships that control fluid diversion, secondary fracture initiation and the development of complex fracture networks.

Owner:BAKER HUGHES INC

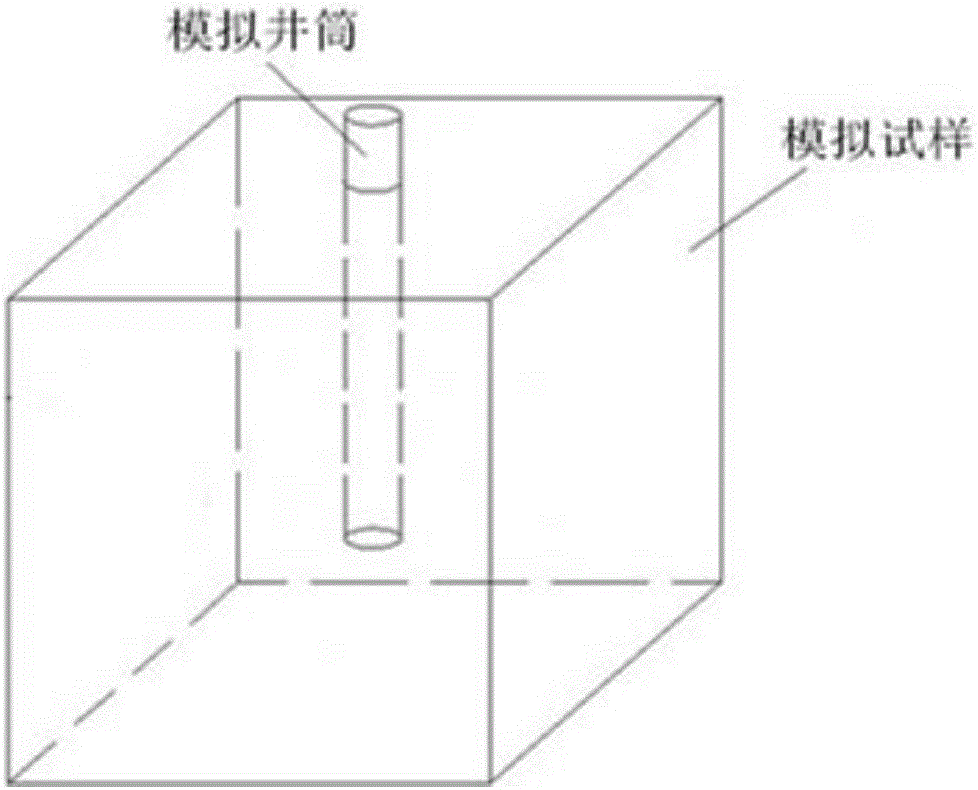

Terrestrial facies shale gas fracture network fracture parameter optimizing method

The invention discloses a terrestrial facies shale gas fracture network fracture parameter optimizing method comprising the following steps: S1, based on a large size sample, using a hydraulic fracturing physics simulation test system to design an indoor shale gas hydraulic fracturing physics simulation test, and optimizing indoor shale gas hydraulic fracturing physics simulation test parameters; S2, according to the indoor shale gas hydraulic fracturing physics simulation test optimized test parameters, combining with target block field fracturing construction conditions, optimizing terrestrial facies shale gas hydraulic fracturing construction parameters, and making a terrestrial facies shale gas fracturing scheme; S3, analyzing the difference between field fracturing construction conditions and laboratory conditions, and applying the parameter optimized result in the field fracturing construction, thus obtaining a complex fracture network. The method combines parameter optimizing test under laboratory conditions with field construction parameter optimization, thus adding crack complex level in the terrestrial facies shale gas fracturing process, artificially increasing permeability, and obtaining a more complex fracture network closer to reality.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

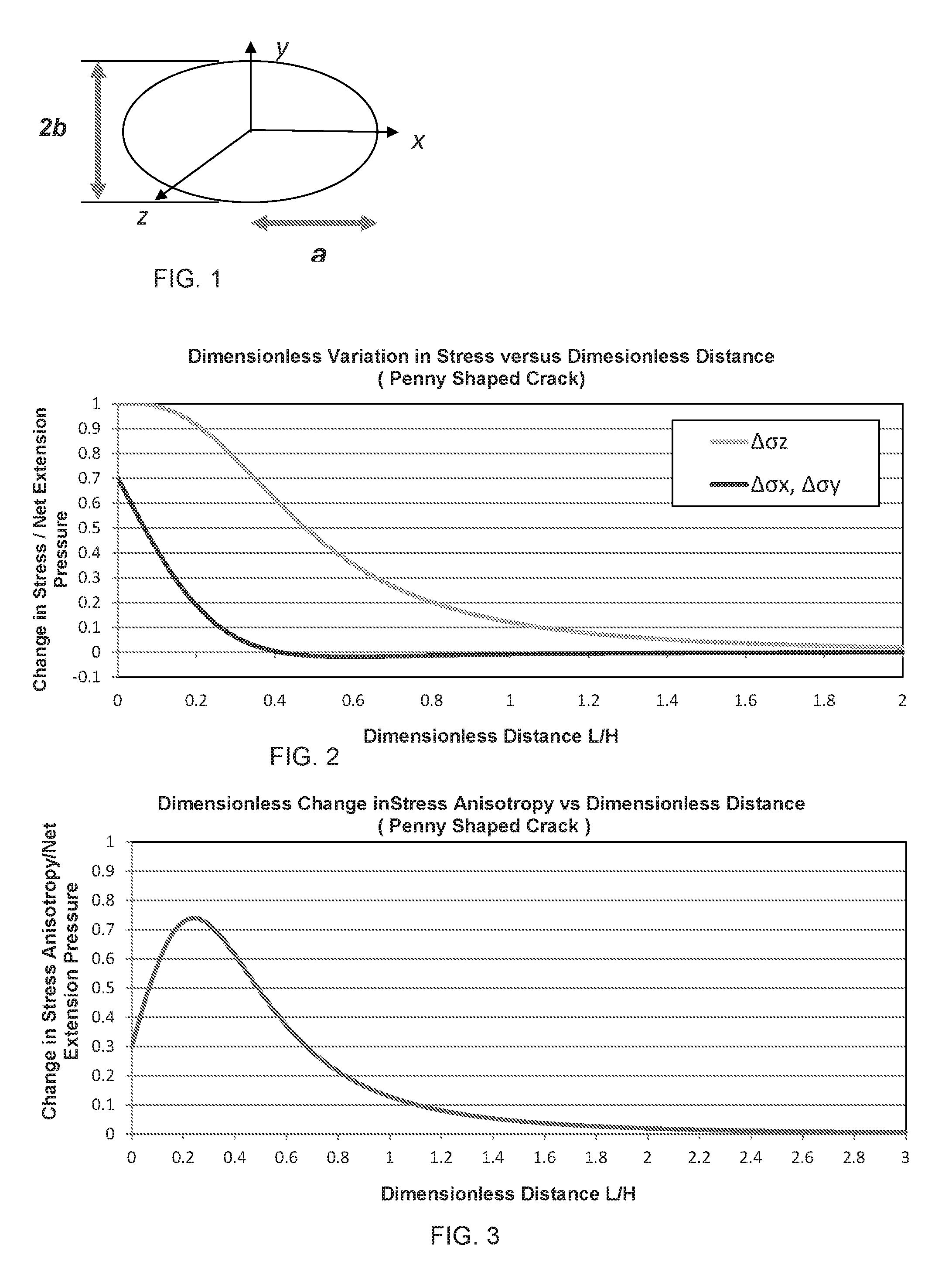

Method for increasing fracture area

ActiveUS20130140020A1Convenient treatmentIncrease the lengthSurveyFluid removalMining engineeringHydraulic fracturing

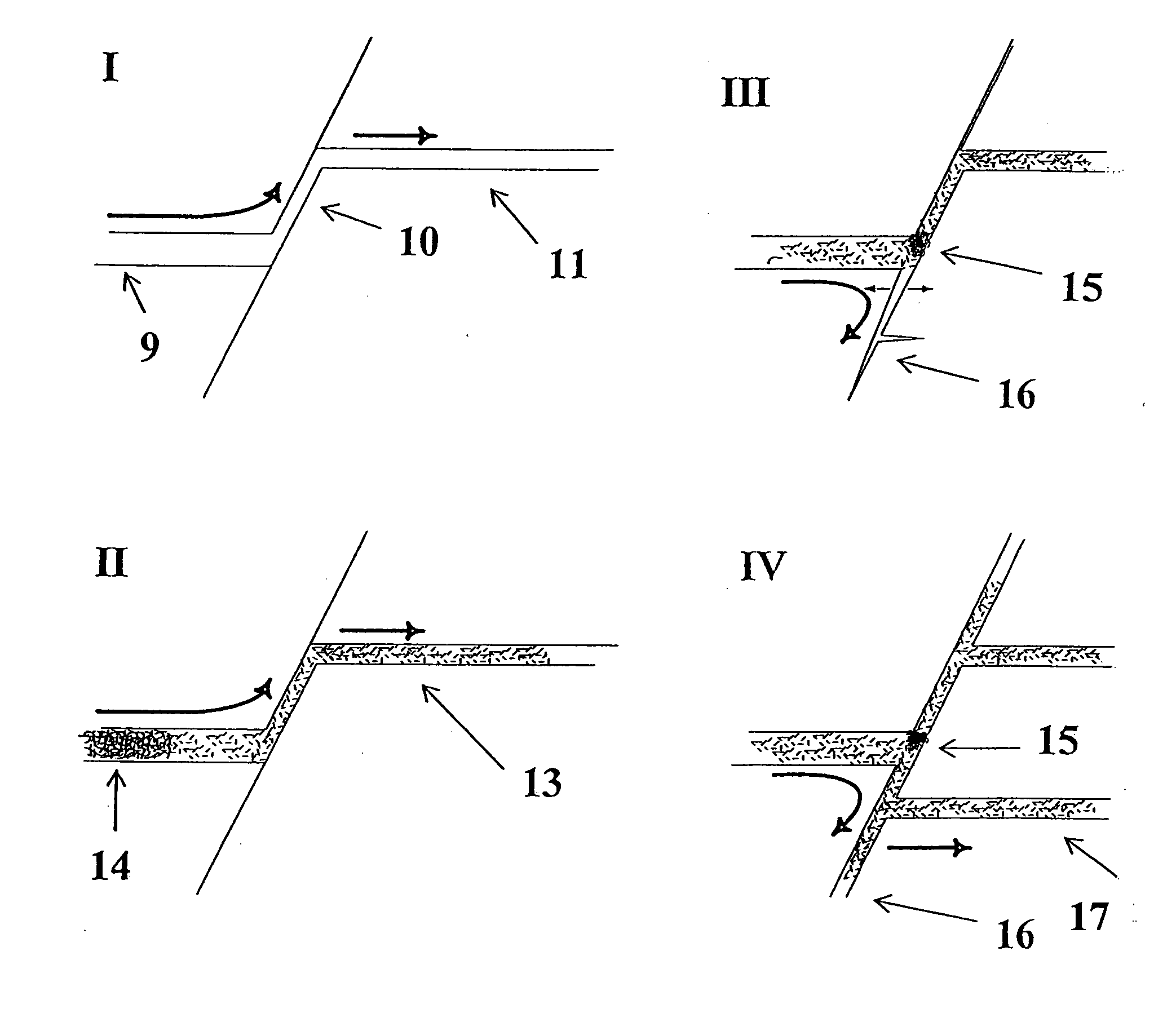

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

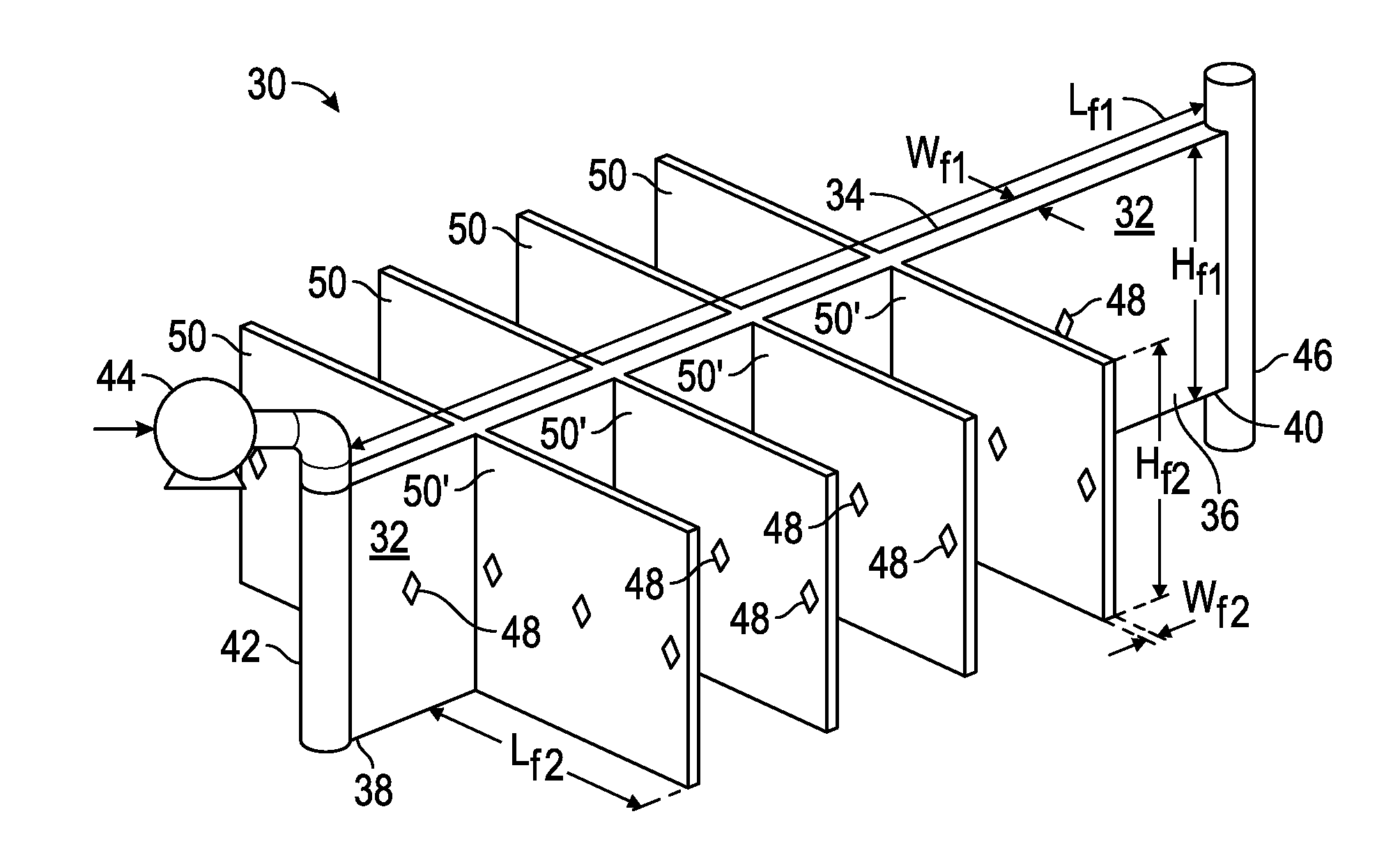

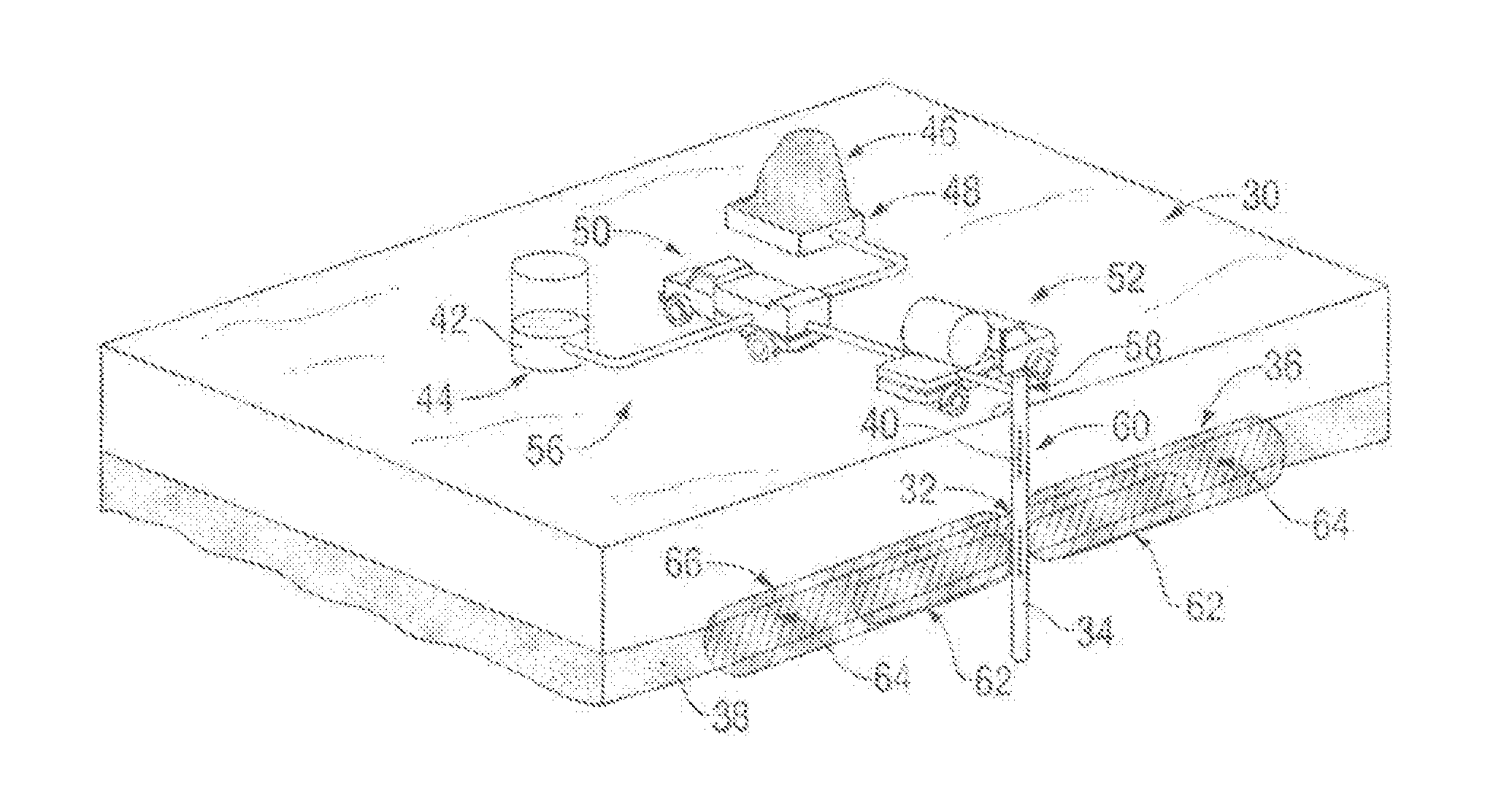

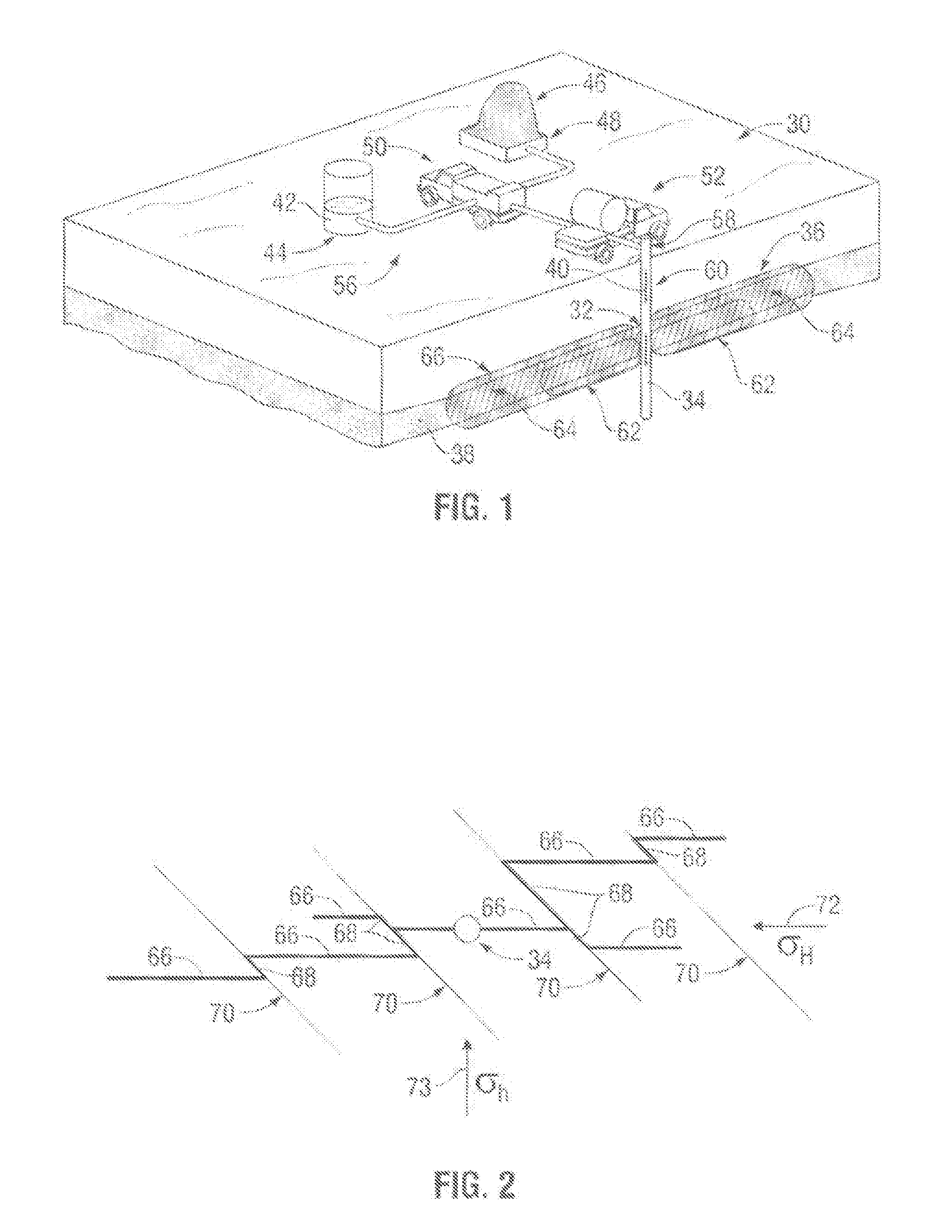

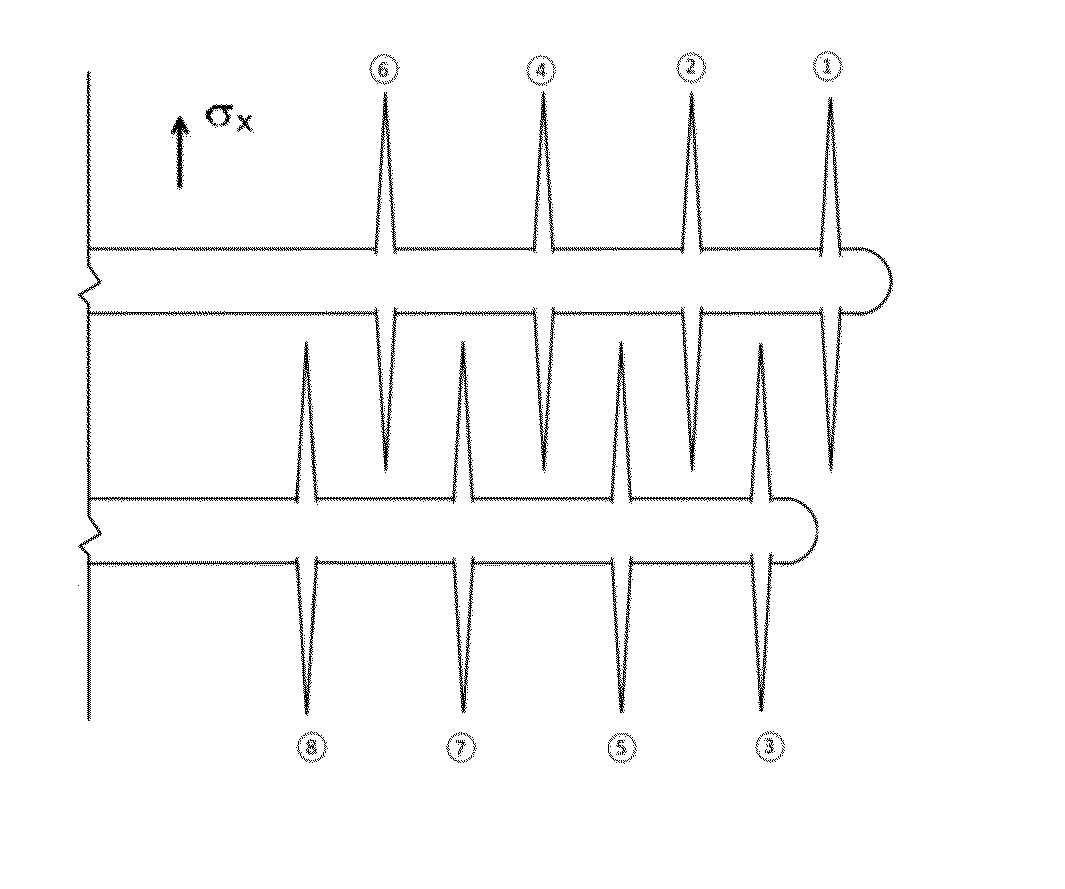

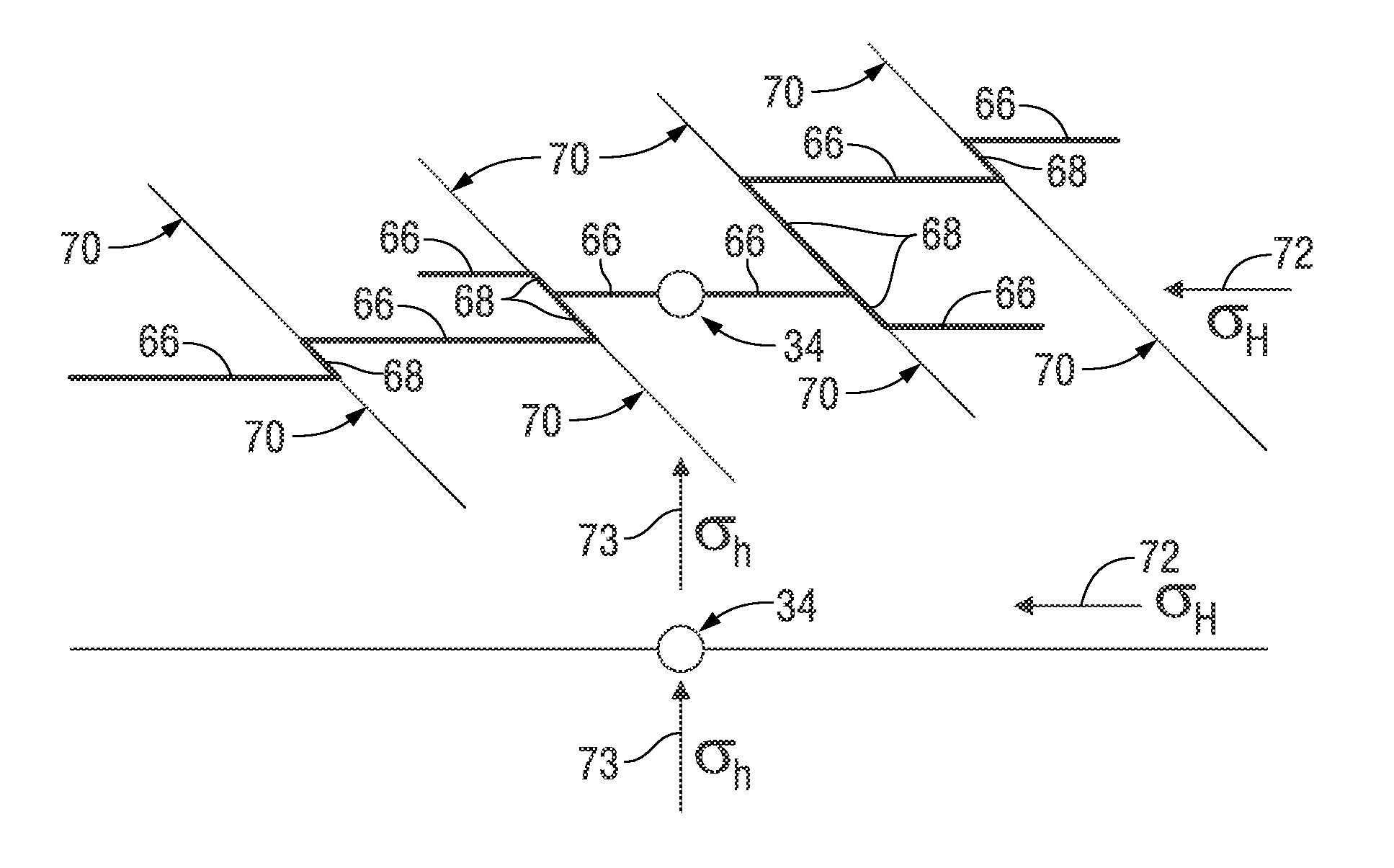

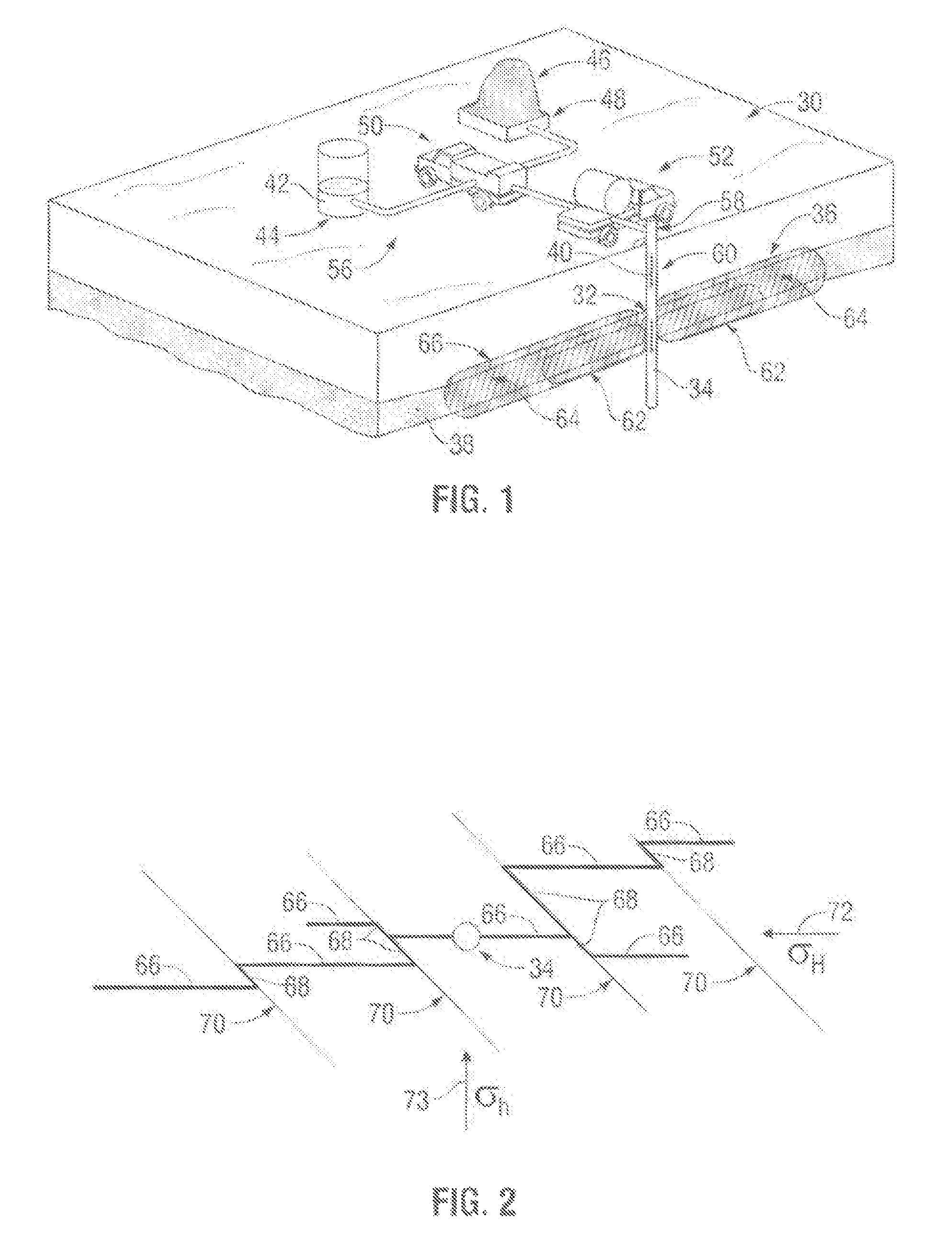

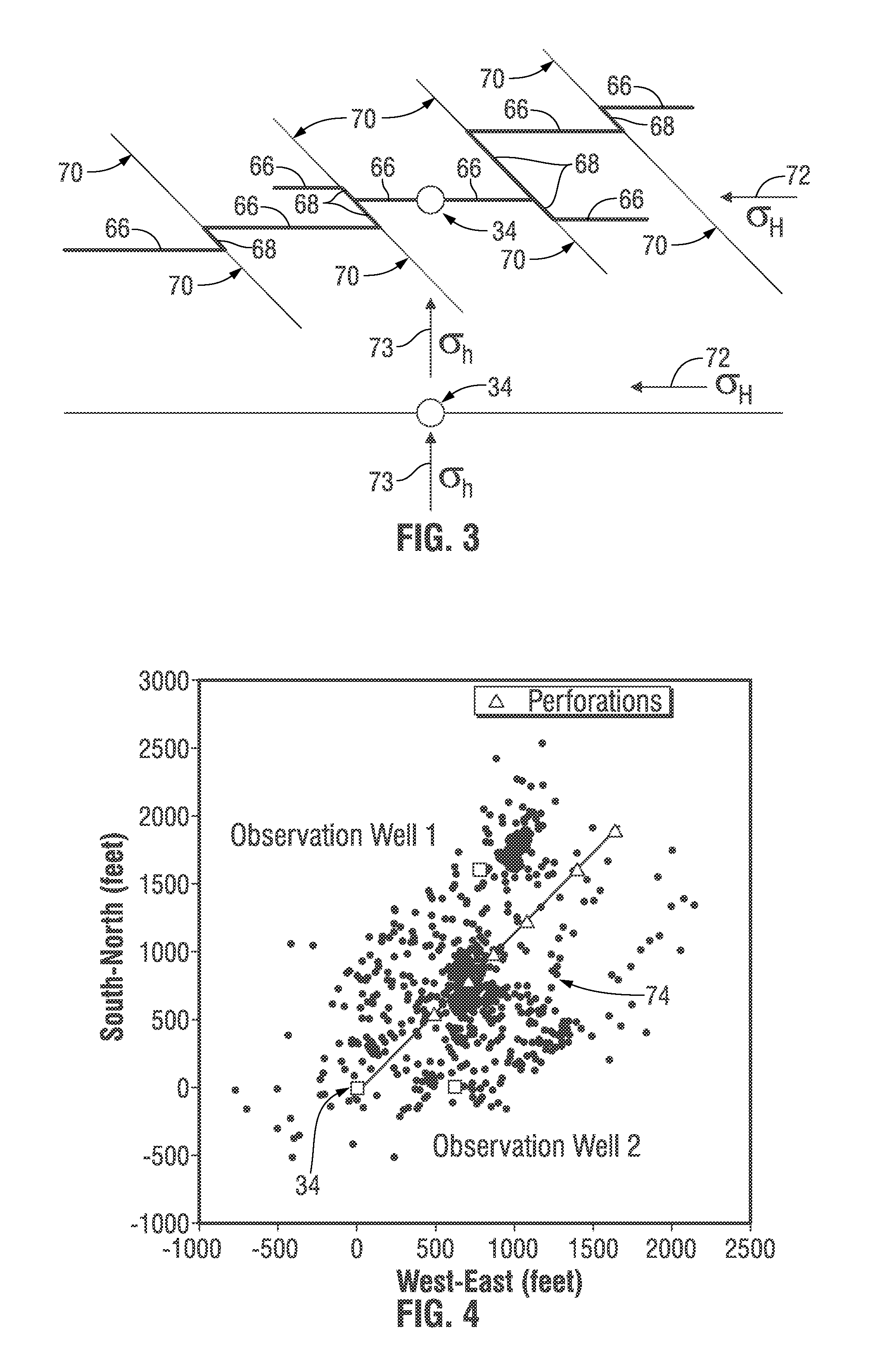

Methods and Devices for Hydraulic Fracturing Design and Optimization: A Modification to Zipper Frac

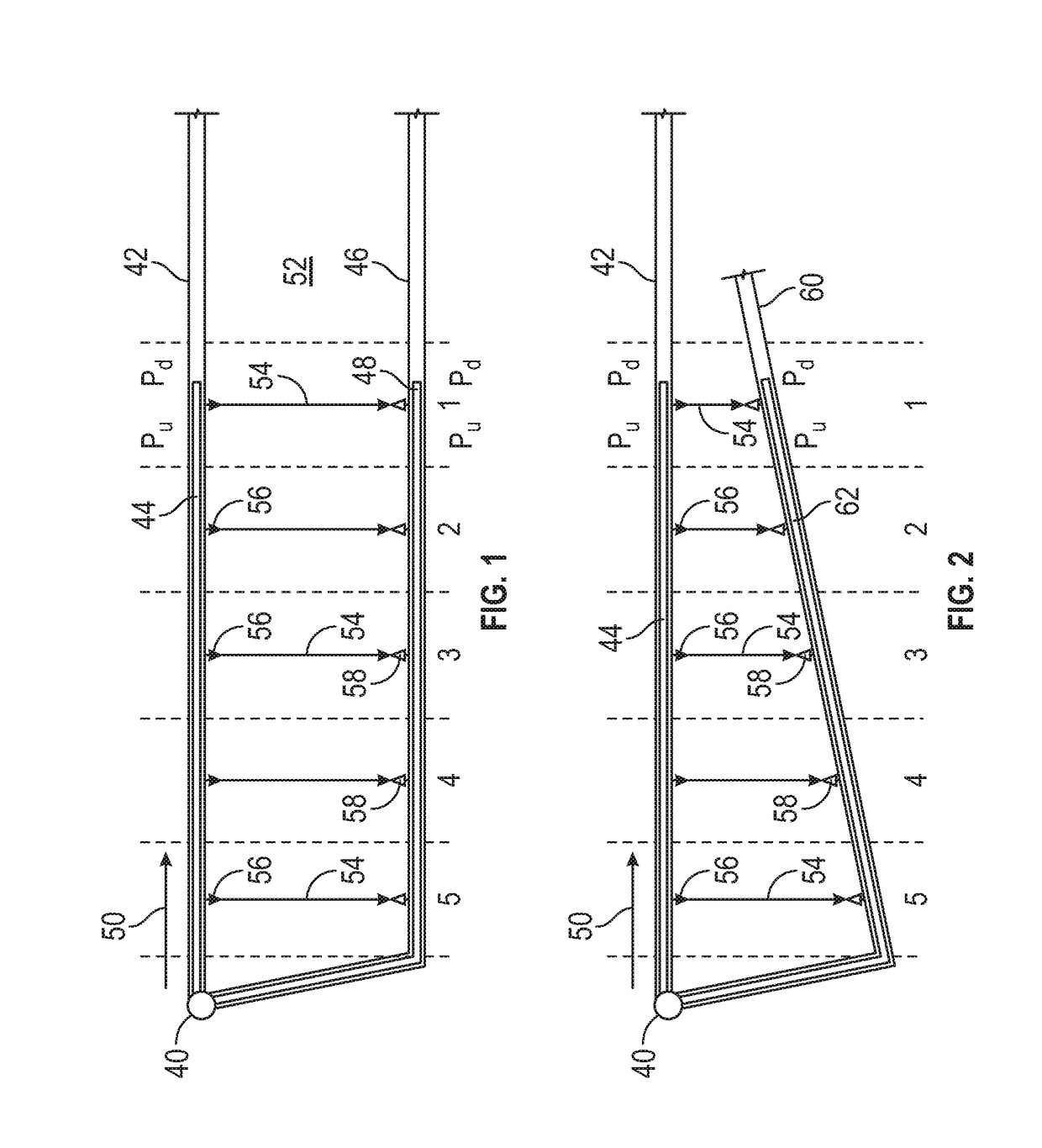

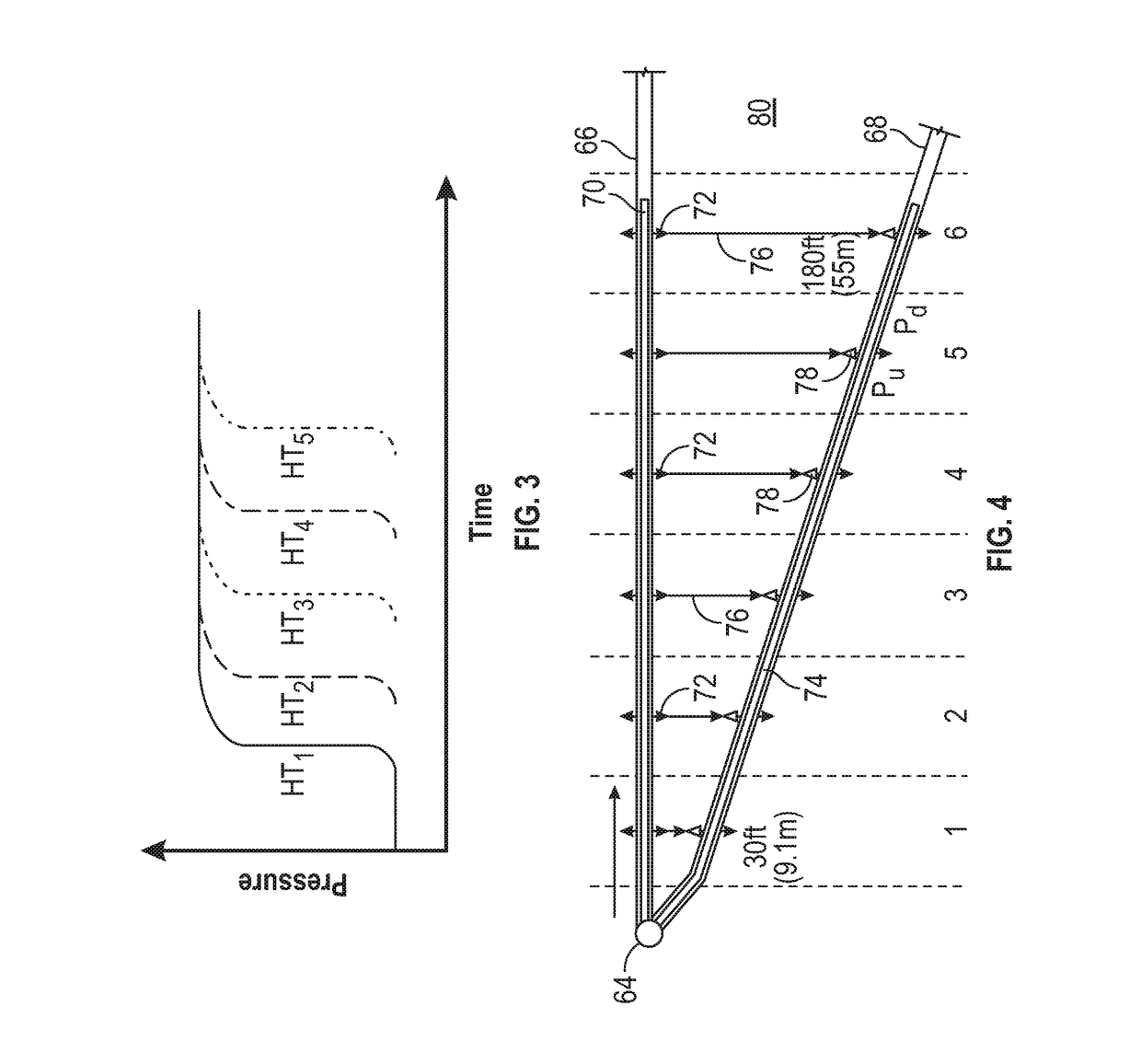

ActiveUS20140048270A1Enhancing far field complexityIncrease productionFluid removalHydraulic fracturingWellbore

The present invention provides a method of optimizing the placement of fractures along deviated wellbores by identifying at least two parallel lateral wellbores in a subterranean formation comprising at least a first wellbore and a second wellbore; introducing a first fracture and a second fracture in the first wellbore; introducing a third fracture in the second wellbore between the first fracture and the second fracture, wherein the third fracture extends to an intermediate area between the first two fractures and alters the stress field in that region; and forming one or more complex fractures extending from the first fracture, the second fracture, the third fracture or a combination thereof to form a complex fracture network.

Owner:TEXAS TECH UNIV SYST

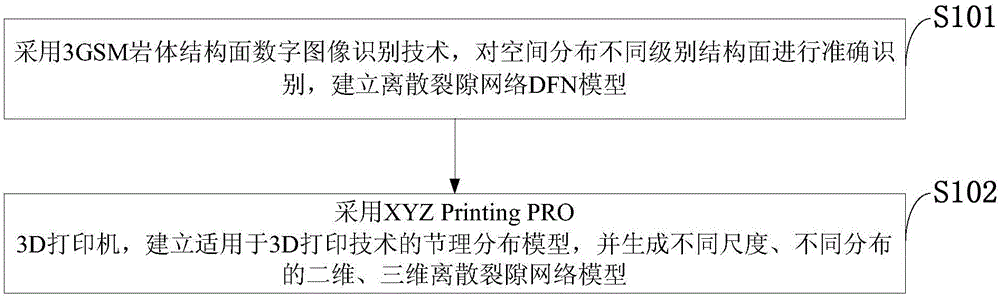

Complex fractured rock mass physical model manufactured based on 3D printing productionand modeling method

InactiveCN106447776ALow costSmall scaleDetails involving processing stepsAdditive manufacturing apparatusModel reconstructionPhysical model

The invention discloses a complex fractured rock mass physical model manufactured based on 3D printing production and a modeling method. By using 3D printing, a complex fractured network model entity is reconstructed and a model suitable for an indoor analog simulation experiment is established; the complex fractured rock mass physical model comprises a discrete fracture network DFN model and an entity discrete joint network DFN model. Based on the 3D printing, the complex fractured network model entity can be reconstructed and the model suitable for the indoor analog simulation experiment is established, and an effective method can be provided for an indoor laboratory research on complex fractured rock mass mechanical behaviors. A reliable and effective method is provided for the rock mechanical test field by adopting fractured rock mass model reconstruction and fractured network entity model construction through the 3D printing; with the help of the 3D printing technology, the problems that modeling is difficult to conduct and the cost is high in the current complex fractured rock mass physical model indoor experiment can be effectively solved.

Owner:UNIV OF SCI & TECH BEIJING

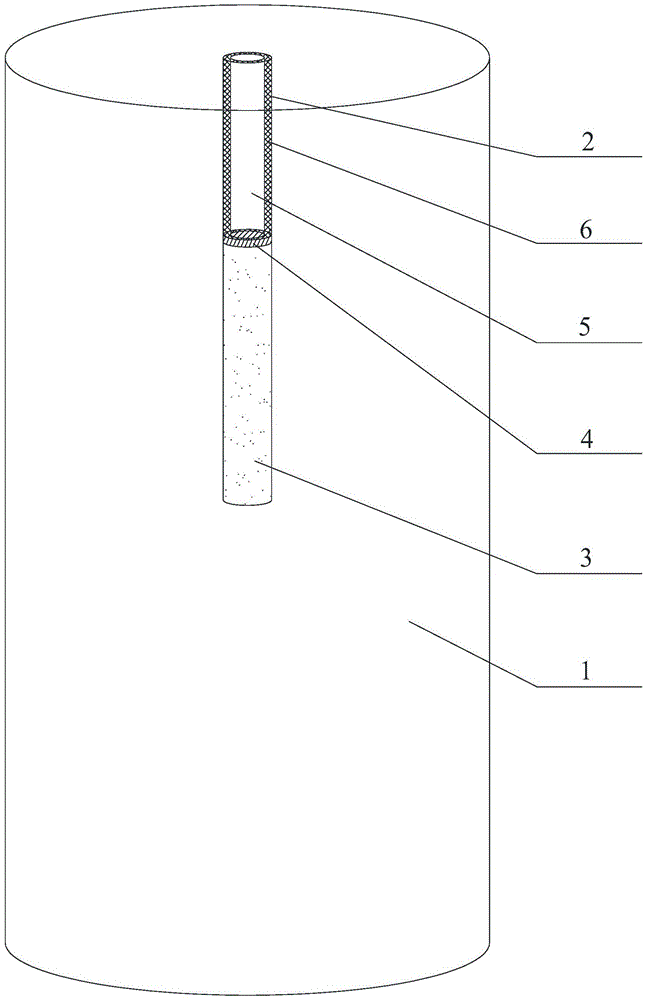

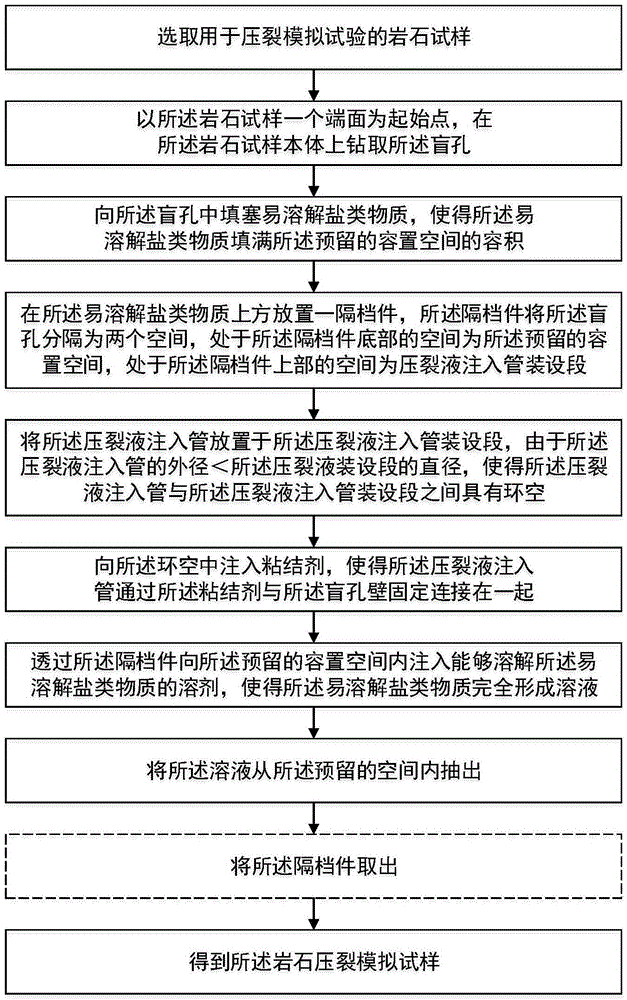

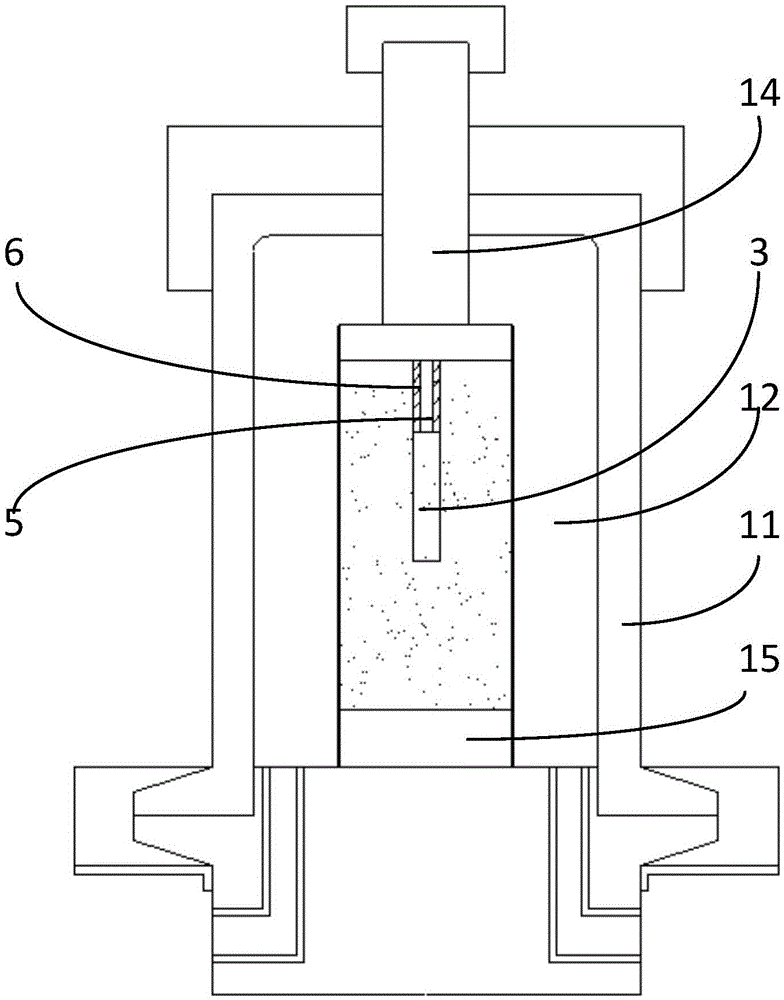

Rock fracture simulation sample and preparation method thereof, as well as simulation test device and simulation test method

ActiveCN105628506APreparing sample for investigationMaterial strength using tensile/compressive forcesTriaxial shear testFracturing fluid

The invention discloses a rock fracture simulation sample and a preparation method thereof, as well as a simulation test device and a simulation test method and belongs to the technical field of rock simulation tests. The simulation sample comprises a body and a fracturing fluid injection pipe, wherein a blind hole is formed by taking one end surface of the body as a start point; the fracturing fluid injection pipe is fixedly connected with the wall of the blind hole; an accommodating space is reserved between the bottommost end of the fracturing fluid injection pipe and the bottommost end of the blind hole. The simulation sample can be prepared by the preparation method. The simulation test device comprises a triaxial test apparatus, wherein the triaxial test apparatus comprises a triaxial chamber, an upper pressing head, a lower pressing head, a confining pressure oil injection mechanism, a fracturing liquid injection pump and the rock fracture simulation sample. The simulation test method is realized on the basis of the simulation test device. According to the simulation test method, vivid complex fracture seams can be formed in a rock sample, and a fracture conductivity test is performed on the basis of the fracture seams, so that the obtained rock gas pool deliverability evaluation is relatively approximate to actual evaluation data, so as to guide actual work more objectively.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

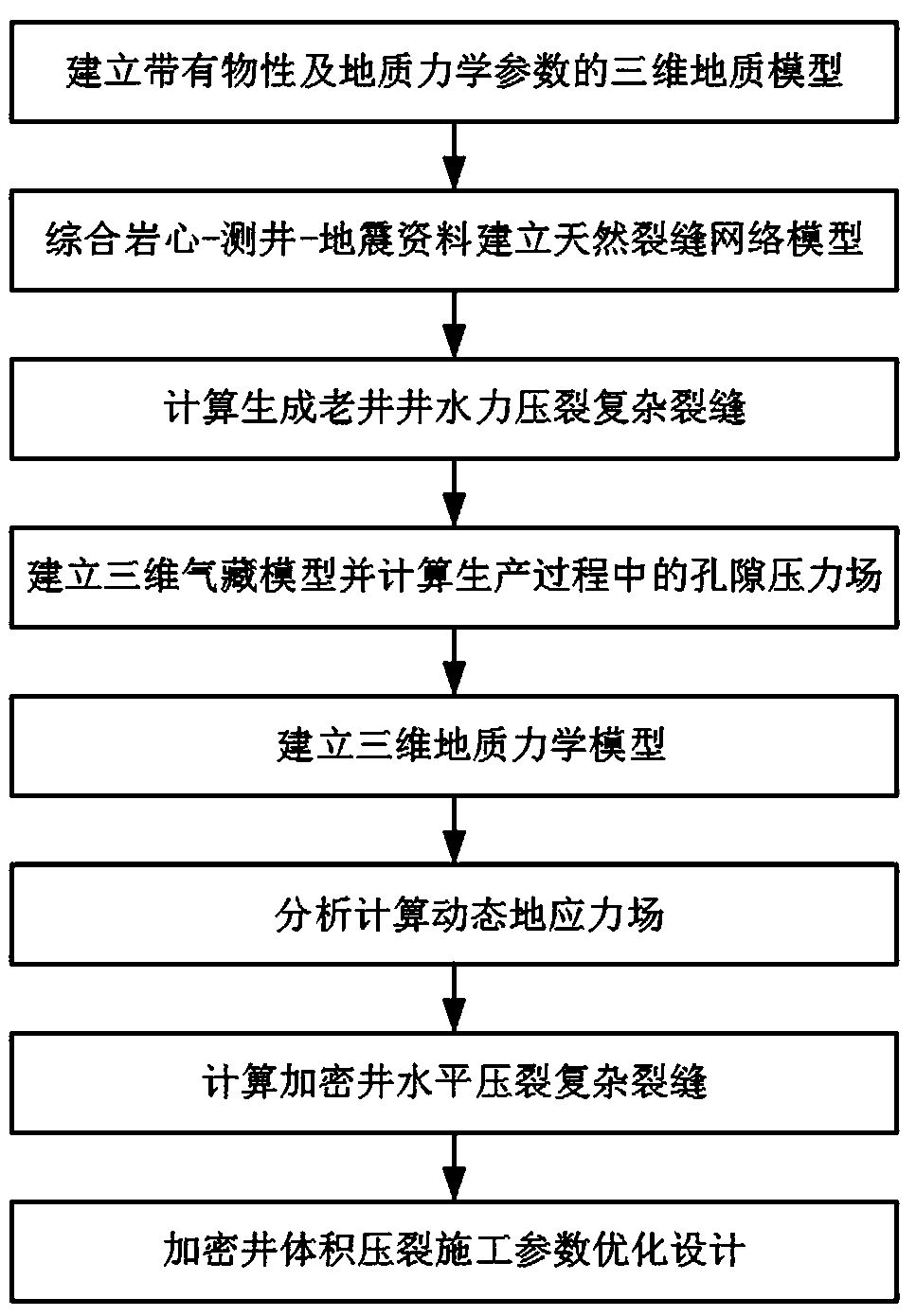

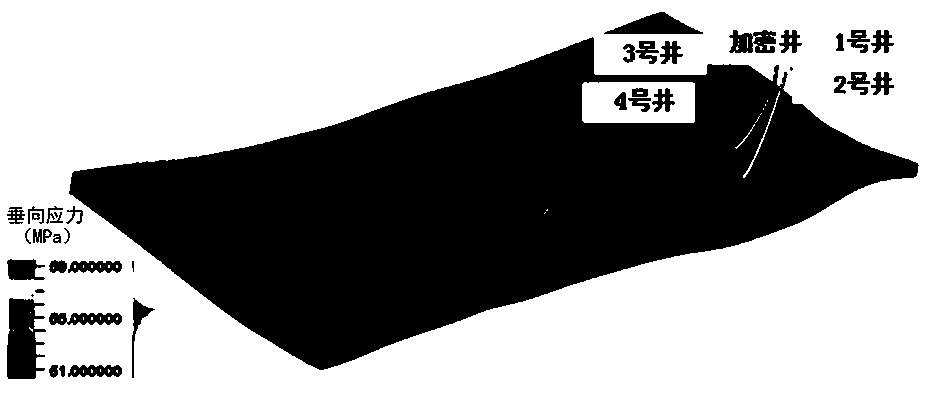

Volume fracturing construction parameter optimization design method for unconventional oil and gas reservoir infill well

ActiveCN110704888ASimple designOvercome the problem of being unable to respond to the dynamic change of the in-situ stress field during the long-term exploitation of shale reservoirsGeometric CADFluid removalRock coreWell logging

The invention discloses a volume fracturing construction parameter optimization design method for an unconventional oil and gas reservoir infill well. The optimization design method comprises the following steps: S1, establishing a three-dimensional geologic model with physical and geomechanical parameters; S2, establishing a natural fracture network model by integrating rock core-logging-seismicdata; S3, generating an old well hydraulic fracturing complex fracture based on the natural fracture model; S4, establishing a three-dimensional shale gas reservoir seepage model; s5, establishing a three-dimensional geomechanical model; s6, analyzing and calculating a dynamic crustal stress field; s7, establishing an infill well horizontal fracturing complex fracture numerical model based on theold well complex fracture and the dynamic crustal stress calculation result; and S8, optimally designing volume fracturing construction parameters of the infill well. The method has the beneficial effects that the influence of the long-term exploitation process of the shale reservoir with natural fracture development on the volume fracturing of the infill well can be accurately reflected, the fracturing construction parameters of the infill well are optimally designed, the fracturing effect is effectively improved, and the single-well productivity is increased.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

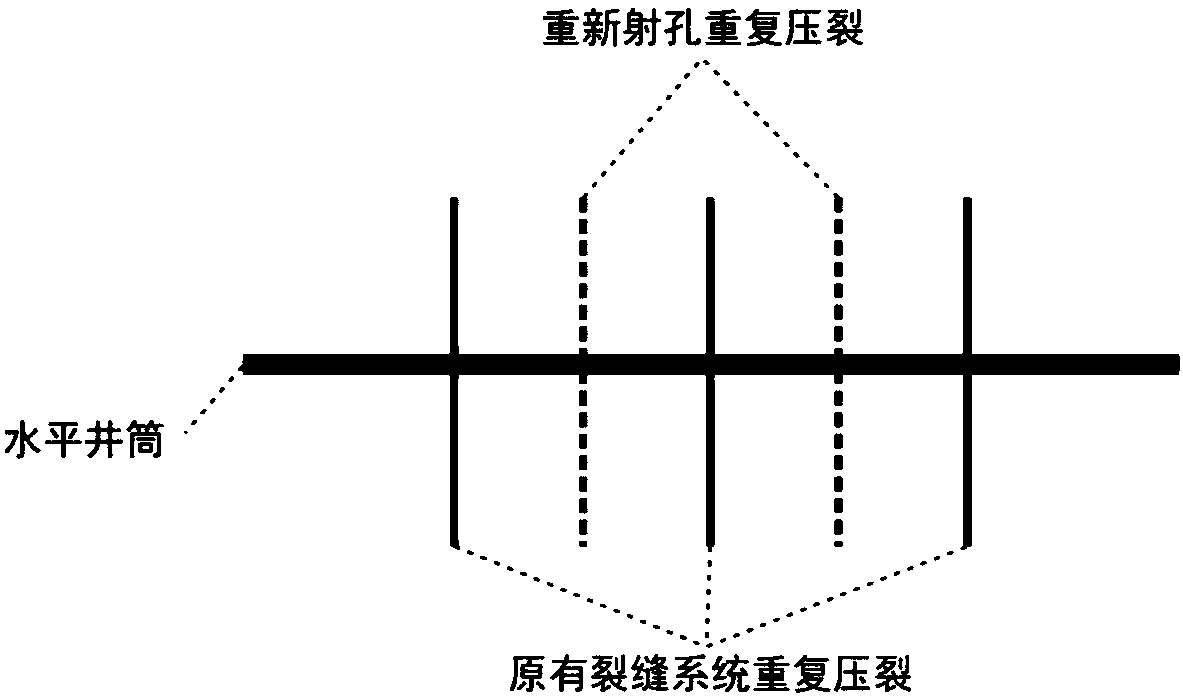

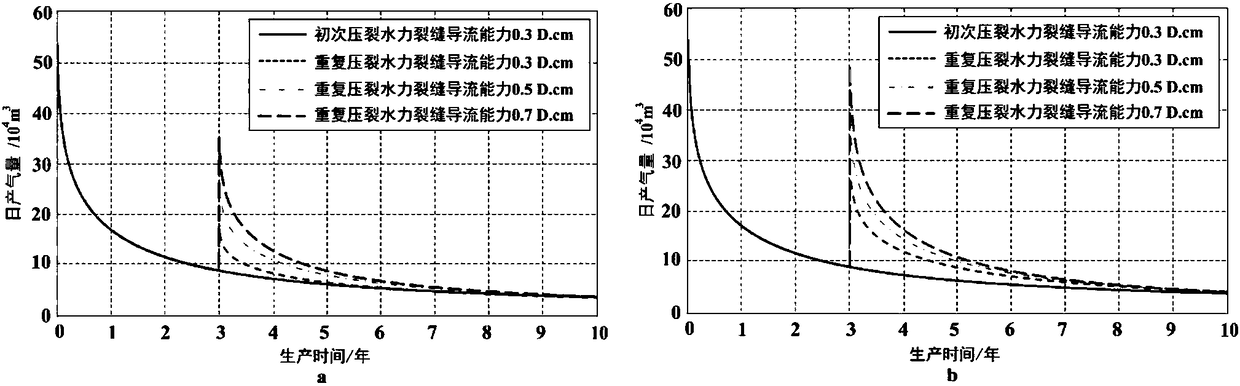

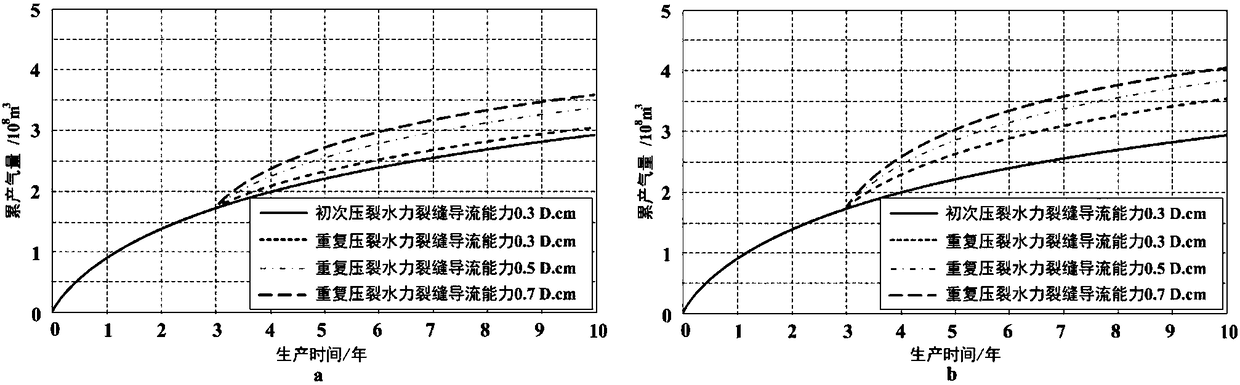

Optimization design method for hydraulic fracture parameters of repeated fracturing of shale gas horizontal wells

The invention belongs to the technical field of unconventional oil and gas production increasing and transformation, and particularly relates to an optimization design method for hydraulic fracture parameters of repeated fracturing of shale gas horizontal wells. The optimization design method comprises the following steps that (a) a numerical model for predicting the productivity of repeated fracturing of the shale gas wells is established; (b) the established numerical model for capacity prediction is numerically solved and integrally coupled; (c) based on the established numerical model forpredicting the productivity of repeated fracturing , the production of the shale gas wells after repeated fracturing under the different hydraulic fracture parameters is simulated by considering two modes of repeated fracturing and re-perforating repeated fracturing of an original fracture system; and (d) a simulation result of the shale gas horizontal well production is evaluated and analyzed, the optimal hydraulic fracture parameters of the corresponding repeated fracturing mode are obtained. The optimization design method can consider the complex fracture morphology and flow behavior of a shale reservoir, simulate the hydraulic fracture parameters to influence the productivity of the shale gas wells under different repeated fracturing modes, and guide the optimization design of the hydraulic fracture parameters for repeated fracturing of the shale reservoir.

Owner:SOUTHWEST PETROLEUM UNIV

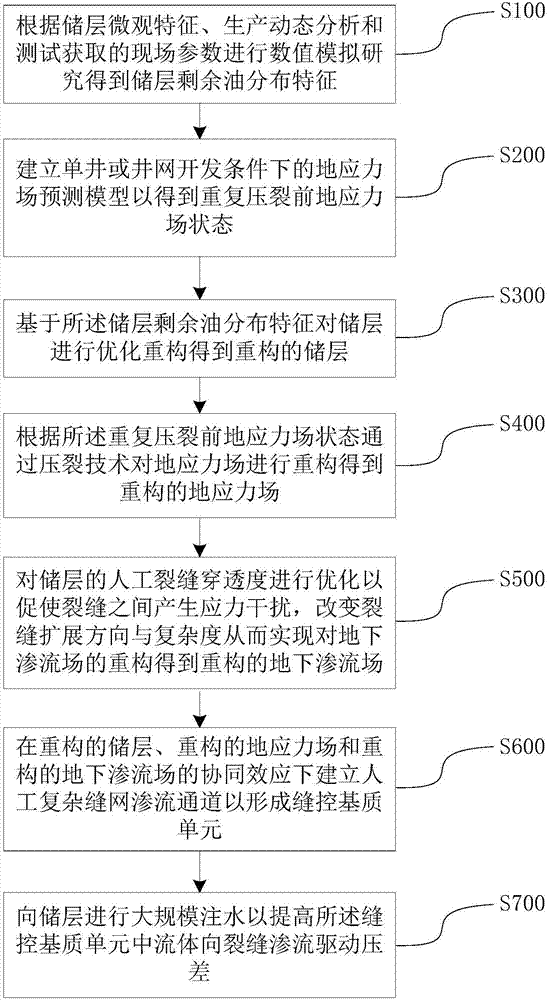

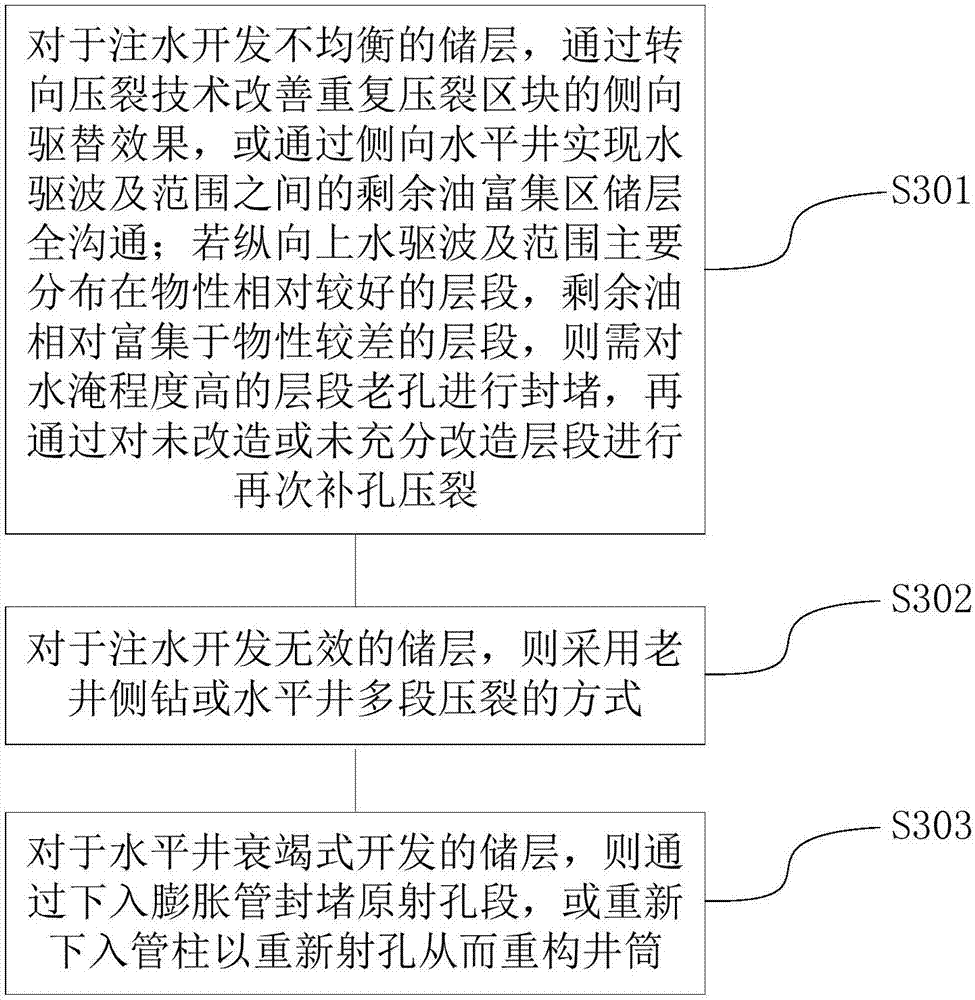

Repeated fracturing method for low-yielding and low-efficiency old oil well

ActiveCN107191169AGood effectImprove driving abilityFluid removalDesign optimisation/simulationRepeated fracturesOil distribution

The invention discloses a repeated fracturing method for a low-yielding and low-efficiency old oil well, and relates to the technical field of repeated fracturing and production-increasing. The method comprises the steps that numerical simulation is conducted to obtain the reservoir remaining oil distribution characteristic according to the reservoir microscopic characteristic, the production performance analysis and the site parameter obtained by testing; a crustal stress field prediction model is established under the development condition of a single well or a well net to obtain the crustal stress field state before repeated fracturing is conducted; a reconstructed reservoir is obtained based on the reservoir remaining oil distribution characteristic; a reconstructed crustal stress field is obtained according to the crustal stress field state before repeated fracturing is conducted; the penetration of artificial fractures of the reservoir is optimized to promote generation of the stress interference between the fractures, and the spreading directions and the complexity of the fractures are changed to obtain a reconstructed underground seepage field; artificial complex fracture net seepage channels are established under the reconstructed reservoir, the reconstructed crustal stress field and the reconstructed underground seepage field to form a fracture control matrix unit; and full-scale water injection is conducted on the reservoir to improve the driving pressure difference of seepage of fluid in the fracture control matrix unit to the fractures.

Owner:PETROCHINA CO LTD

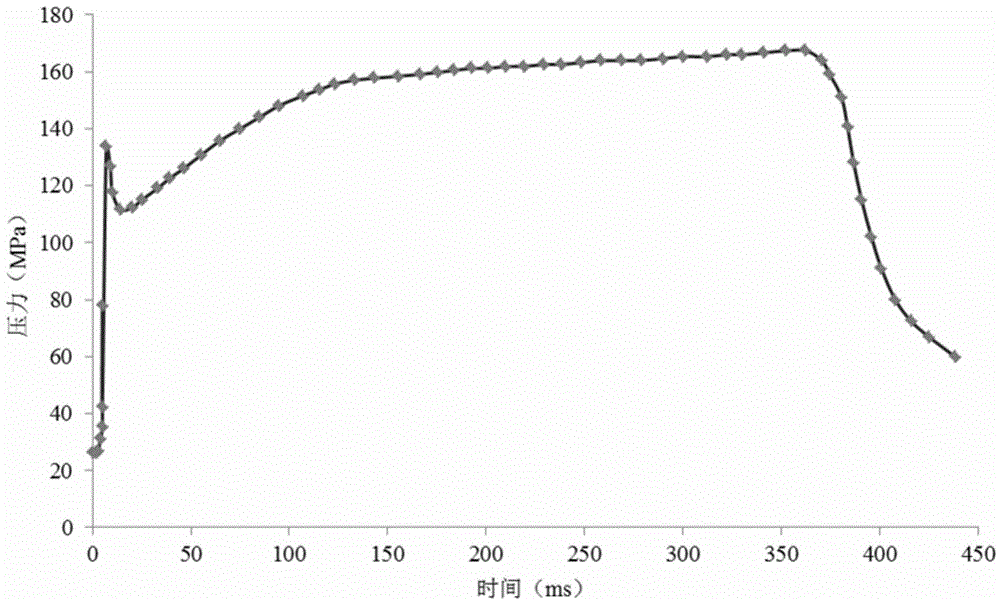

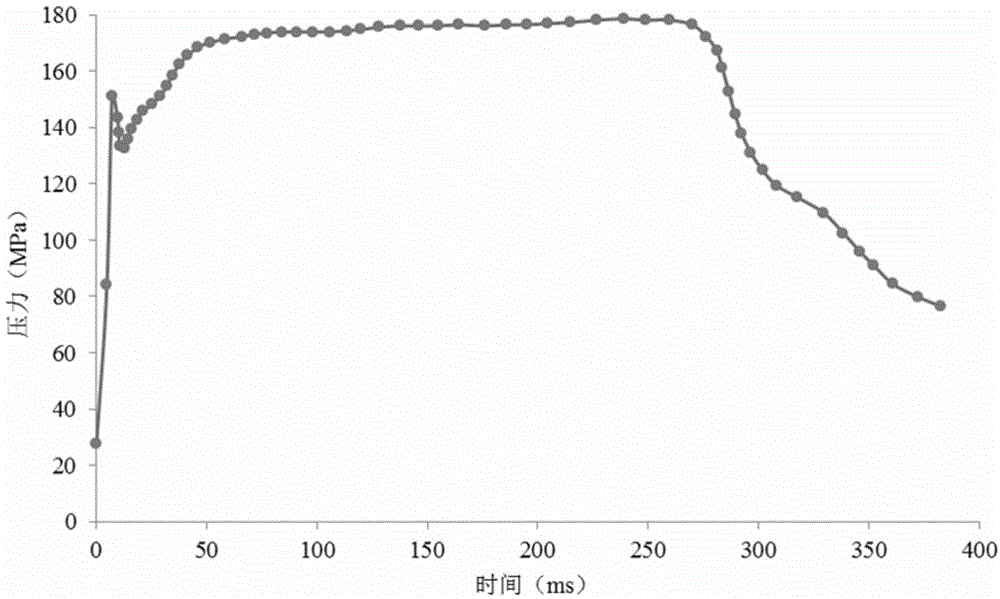

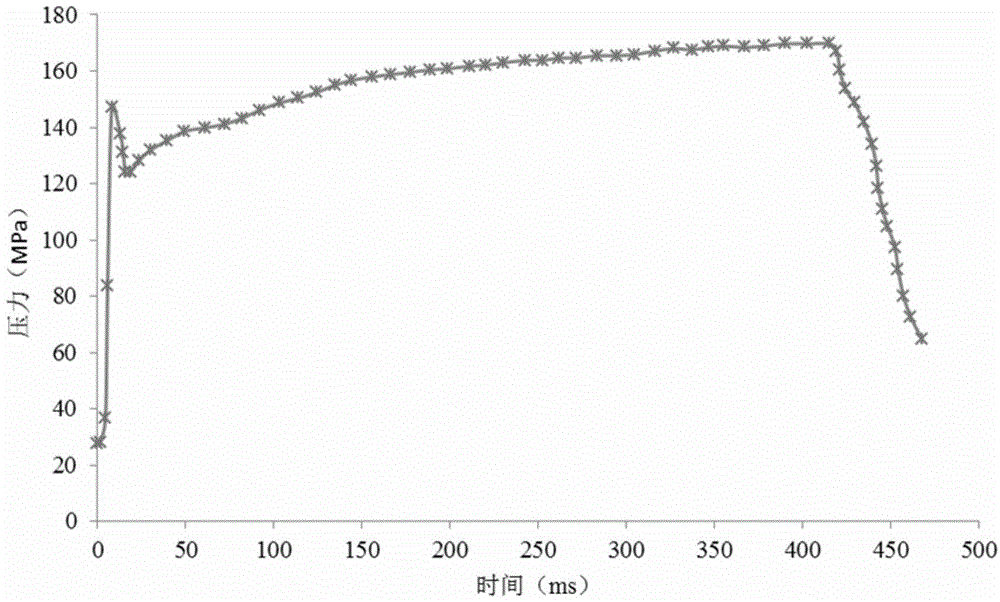

Gunpowder for realizing deep well deep bumming and fracturing

InactiveCN104402659AStable burning rateReduce burning rateExplosivesPtru catalystUltra high pressure

The invention discloses gunpowder for realizing deep well deep bumming and fracturing, the gunpowder includes solid powder and liquid powder; the solid powder comprises a binder, a plasticizer, an oxidizing agent, a metal combustion agent, a high-energy additive, a stabilizer and a catalyst; and the liquid powder comprises an oxidizing agent, a combustion agent, a performance modifier and water. The solid powder of the gunpowder can overcome the restriction of large stress difference coefficient and high fracturing pressure of deep-layer and ultra high pressure formation, a plurality of radial cracks and branched cracks are formed in a broken rock layer, main crack is preliminarily extended, the fracture pressure is reduced to help the liquid powder to continue to fracture the formation, at the same time, the role of ignition of the liquid powder is played, after the solid powder is burn out, the liquid powder continues to maintain a high pressure environment in a wellhole, and effects on the formation for longer time, the main crack length is further extended, the branched cracks are developed, natural cracks are communicated, and a complex fracture network structure is formed in a larger-range purpose layer near the wellbore.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for increasing fracture area

ActiveUS9140109B2Convenient treatmentIncrease the lengthFluid removalShortest distanceReservoir volume

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

Methods and devices for hydraulic fracturing design and optimization: a modification to zipper frac

ActiveUS9394774B2Enhancing far field complexityIncrease productionFluid removalHydraulic fracturingComplex fracture

The present invention provides a method of optimizing the placement of fractures along deviated wellbores by hydraulically fracturing a well to form a complex fracture network of hydraulically connected fractures.

Owner:TEXAS TECH UNIV SYST

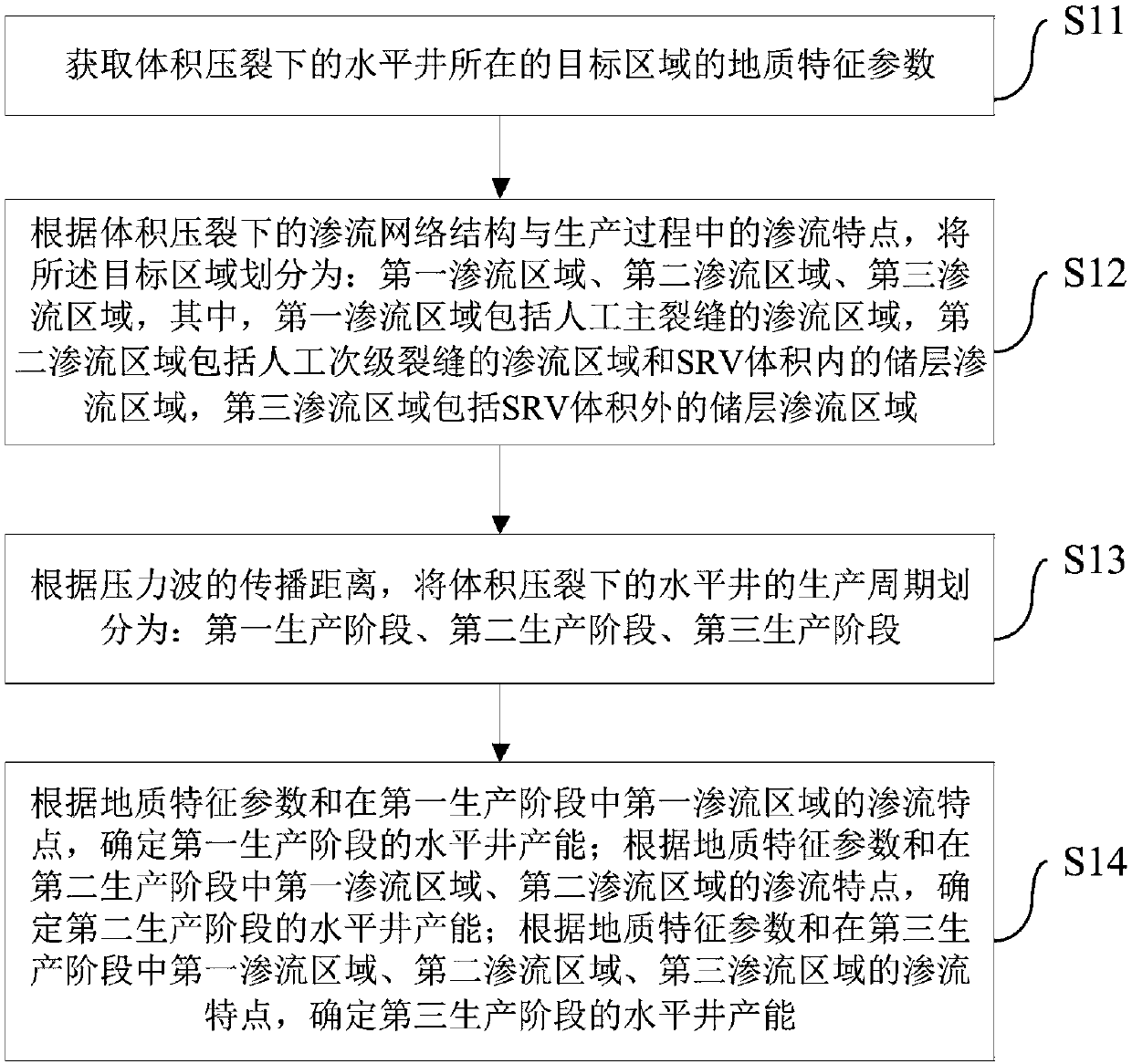

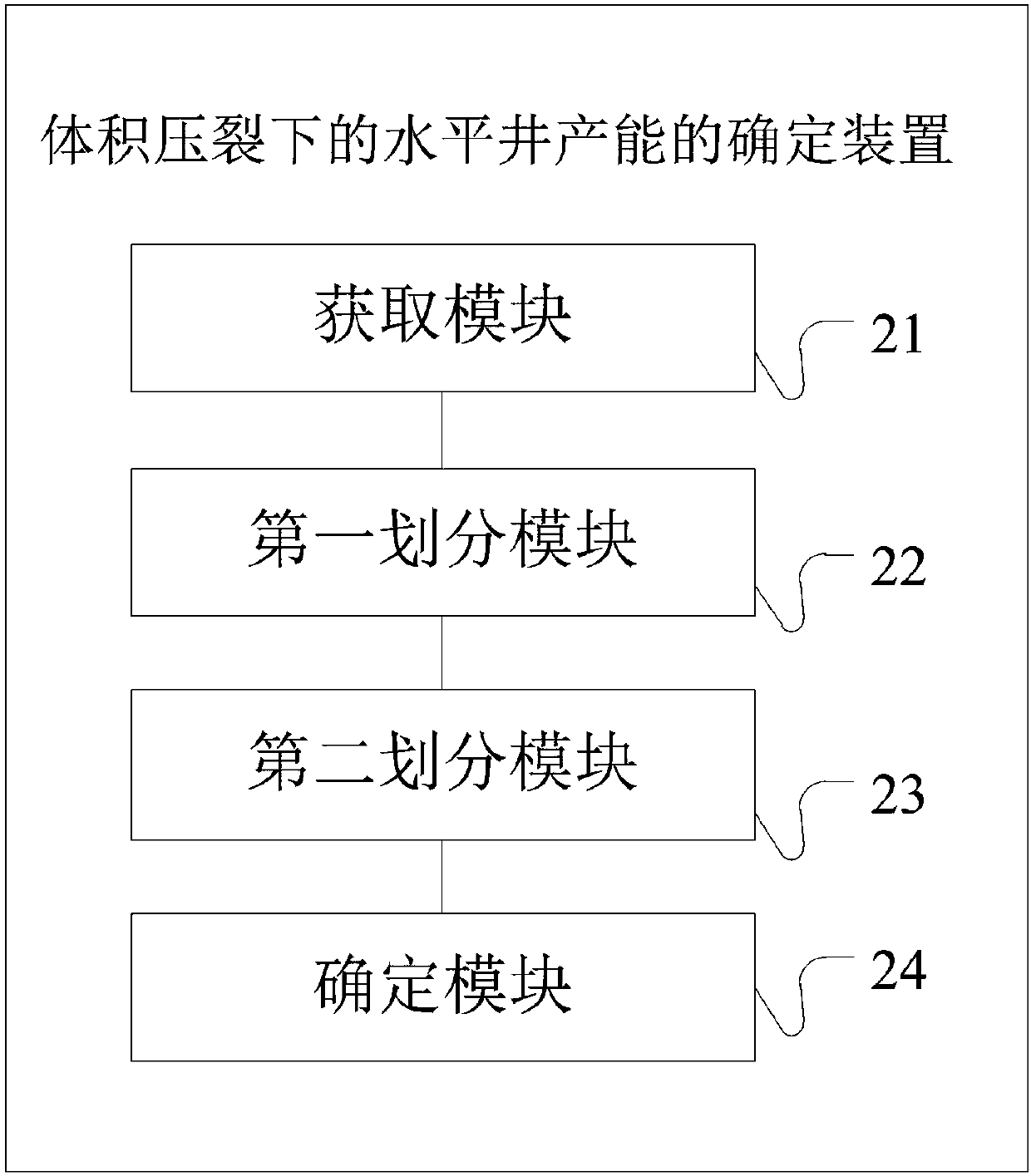

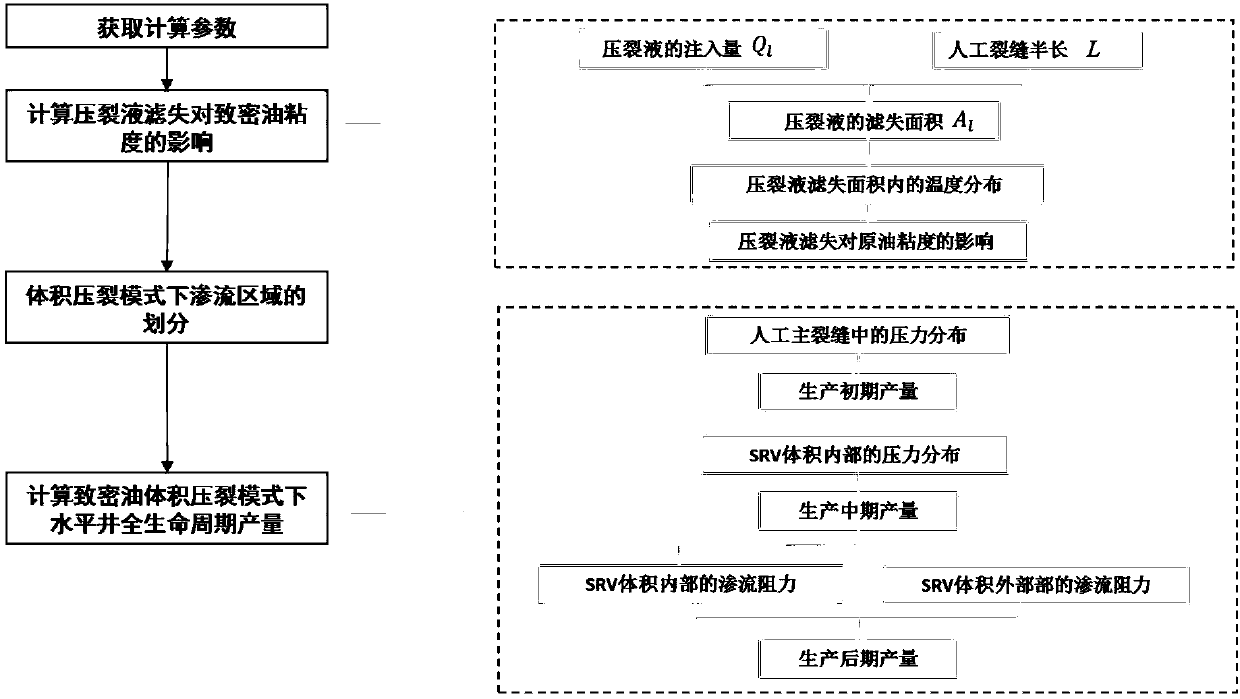

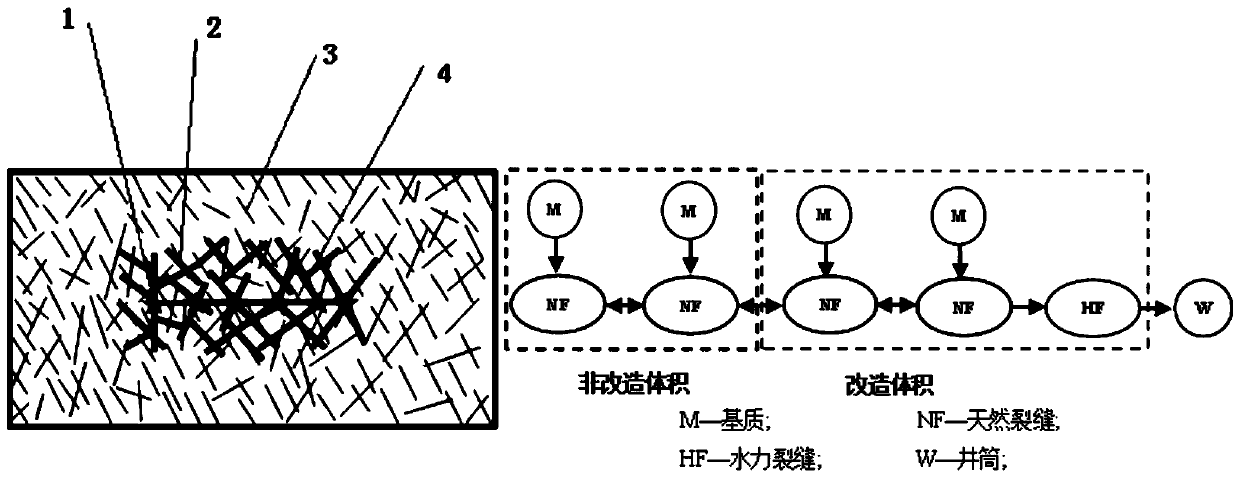

Determination method and device of horizontal well productivity under volume fracturing

ActiveCN108547610AAccurately determineTroubleshoot inaccurate technical issuesFluid removalNetwork structureFeature parameter

The embodiment of the invention provides a determination method and device of the horizontal well productivity under volume fracturing. The determination method comprises the steps that the geologicalcharacteristic parameters of a target area in which a horizontal well is located under volume fracturing are obtained; the target area is divided into a first seepage area, a second seepage area anda third seepage area; a production cycle is divided into a first production stage, a second production stage and a third production stage; the horizontal well productivity of different production stages is determined separately according to the geological characteristic parameters and the seepage characteristics of different seepage areas at different production stages, and according to the scheme, the influence of complex fracture network structures and reservoir pores on seepage under volume fracturing is taken into account, and the target area is divided into the multiple seepage areas according to the specific structural characteristics; and then according to the seepage characteristics of different seepage areas at different production stages, the horizontal well productivity of different production stages is determined separately, so that the technical problem of determining the horizontal well productivity by existing methods is inaccurate is solved.

Owner:PETROCHINA CO LTD

Shale oil complex fracture network discrete fracture continuous medium mixing numerical simulation method

PendingCN111062129AImprove bindingSolve the inability to accurately characterize the stimulated zoneDesign optimisation/simulationCAD numerical modellingMathematical modelClassical mechanics

The invention discloses a shale oil complex fracture network discrete fracture continuous medium mixing numerical simulation method which comprises the following steps: analyzing the fracturing construction condition of a shale oil reservoir, determining the hydraulic fracture property of a fracturing transformation area, and carrying out explicit representation on hydraulic fractures; establishing a seepage mathematical model of the hydraulic fracture-natural fracture and the matrix after hydraulic fracturing transformation; establishing an embedded discrete fracture and continuous medium mixed numerical simulation mathematical model; constructing an embedded discrete fracture and continuous medium model mixed numerical simulation model which comprises a single-phase or oil-water two-phase flow numerical simulation model, and performing solving; and predicting the yield of the tight reservoir under different fracture network transformation conditions by using the model. The conditionthat matrix-natural fracture-hydraulic fracture multi-medium flowing exists in a reservoir can be handled; the problem that an existing commercial numerical simulation method cannot accurately represent the fracturing transformation area is solved, and the calculation result is more objective and accurate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for increasing fracturing volume in tight sandstone reservoir

ActiveCN110761762AIncrease in sizeImprove seepage capacityFluid removalMicro fractureHydraulic fracturing

The invention discloses a method for increasing the fracturing volume in a tight sandstone reservoir. The method includes the steps that (1) micro-fractures are formed in the tight sandstone reservoir; step (2) the micro-fractures are expanded and communicated; step (3) hydraulic fracturing is performed to form main fractures; and step (4) a proppant is turned from temporary blocking to form branch fractures. The method is suitable for fracturing transformation production increase operation of the tight sandstone reservoir with micro-fractures not developed. Through innovative process ideas, first, a large number of radial micro-fractures are artificially generated in a sandstone reservoir with the micro-fractures not developed and a dense matrix, then the main fractures penetrating through the micro-fractures are formed through hydraulic fracturing, and in the extension process, the main fractures are turned for multiple times, so that a complex fracture system is formed, and the fracturing transformation volume is increased and the production increase effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacture method of transparent tunnel model for simulating network containing complex fracture

ActiveCN107976352AAdvanced processing technologyImprove machining accuracyPreparing sample for investigationRock engineeringEngineering

The invention belongs to the field of rock engineering, and relates to a manufacture method of a transparent tunnel model for simulating a network containing a complex fracture. Specific to the shortcomings and defects existing in a current manufacture method of the transparent tunnel model, the invention provides the manufacture method of a high transparent tunnel model which is good in brittleness and easy to form and demold and can be used for easily preparing drill ways with different lengths and controlling the relative position relationship of fractures and a tunnel, an organic glass tube is adopted to simulate the drill ways of the tunnel, a mica sheet is adopted to simulate the fractures existing in rock, and a 3D (three-dimensional) printing technology is adopted to manufacture acomplex fracture model to simulate a complex fracture network in surrounding rock. The method can be used for simulating the transparent tunnel model of which both the excavation phases and the tunnelnumber are different, the fractures which have different shapes, different angles, different numbers and different position relations with the tunnel can be accurately arranged in the surrounding rock, so that the tunnel model can be easily used for observing the mechanical property and fracture law of the underground tunnel, which is subjected to pressing, of jointed rock.

Owner:NORTHEASTERN UNIV

Oil and gas reservoir fracturing sand adding method

The invention provides an oil and gas reservoir fracturing sand adding method, which comprises a fracturing crack forming stage and a sand adding stage. A multi-scale complex crack system is formed inthe fracturing crack forming stage, fracturing fluid with different viscosities and propping agents with different particle sizes are injected in the sand adding stage to adapt to the multi-scale crack system, and the crack system is filled and supported from far to near. According to the method provided by the invention, by optimizing and adjusting the construction parameters and adjusting and controlling the accumulation height of the proppant in the fracture, the effective support of the proppant in the fracture height direction is improved, the filling degree of a multi-scale complex fracture system is improved, the volume fracturing complex fracture sand adding technology is perfected and improved, and finally, the effects of increasing the yield after pressing and stabilizing the yield are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com