Patents

Literature

101 results about "Treatment design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

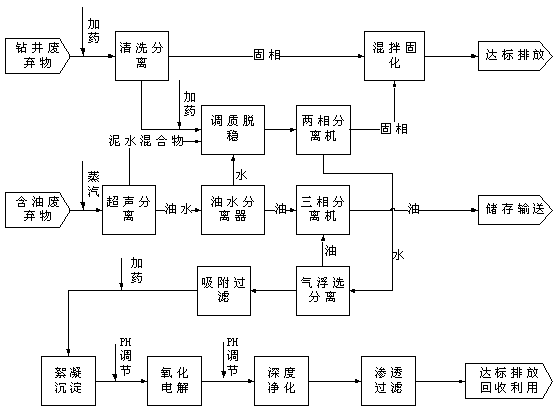

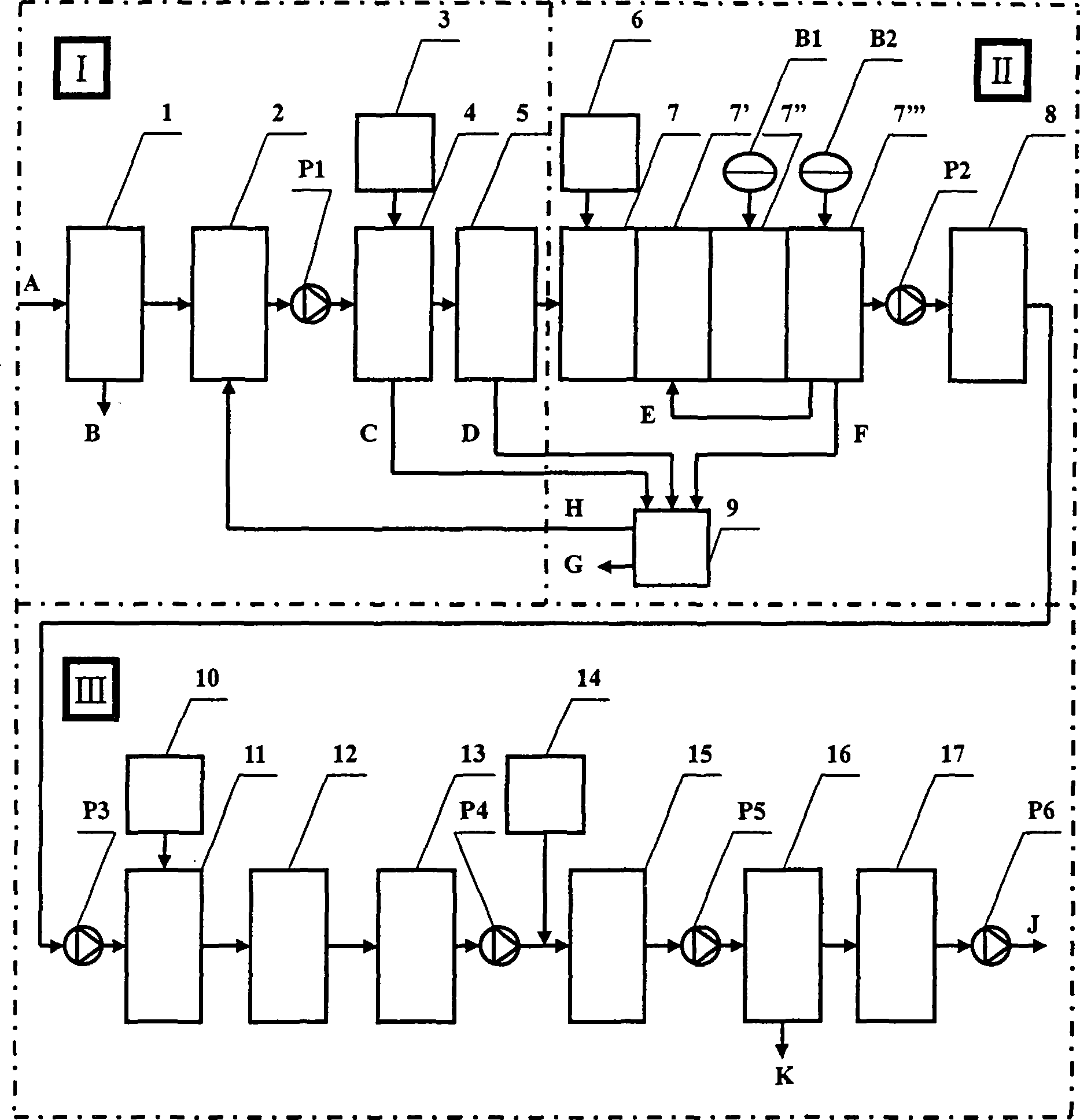

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

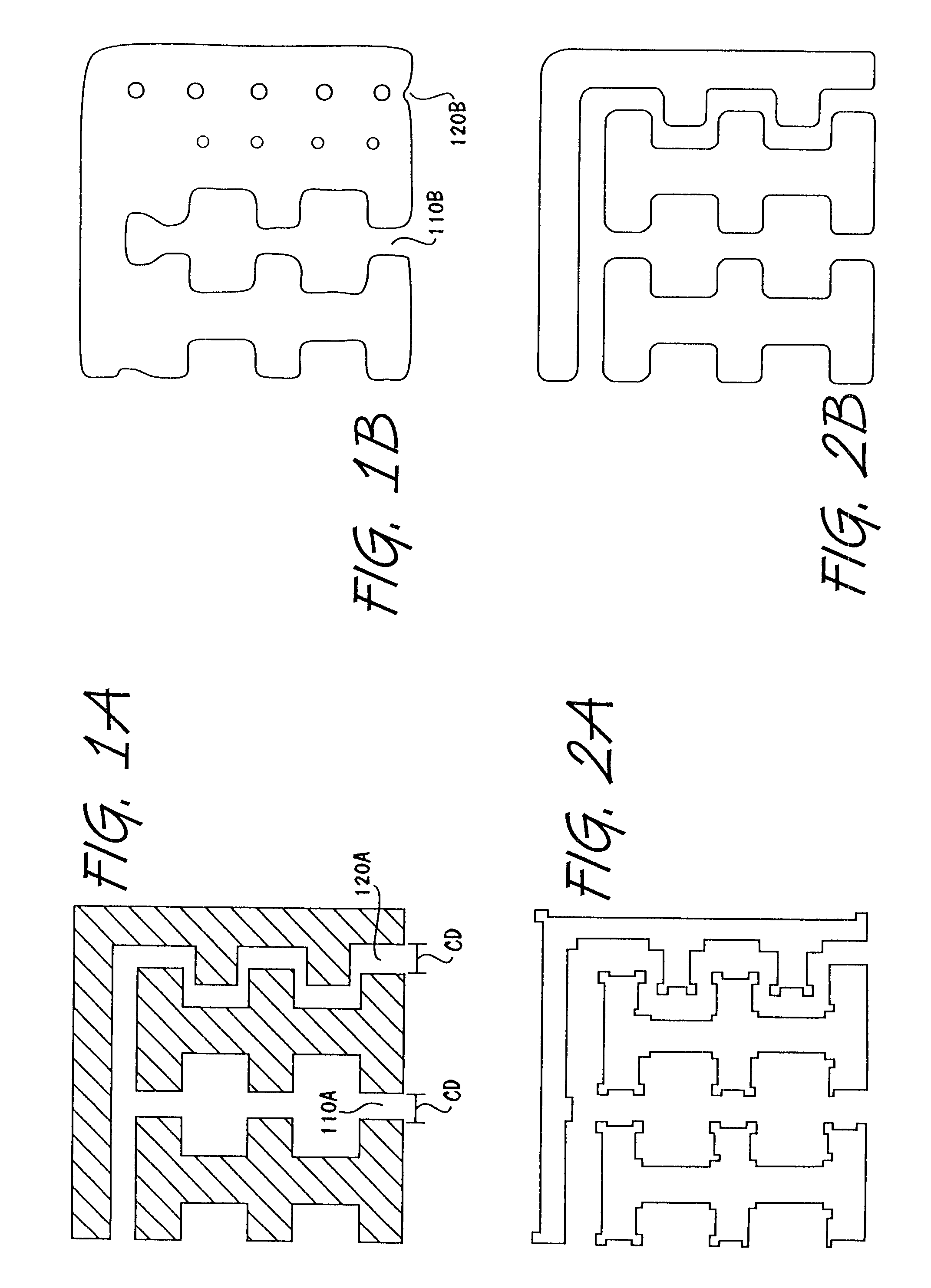

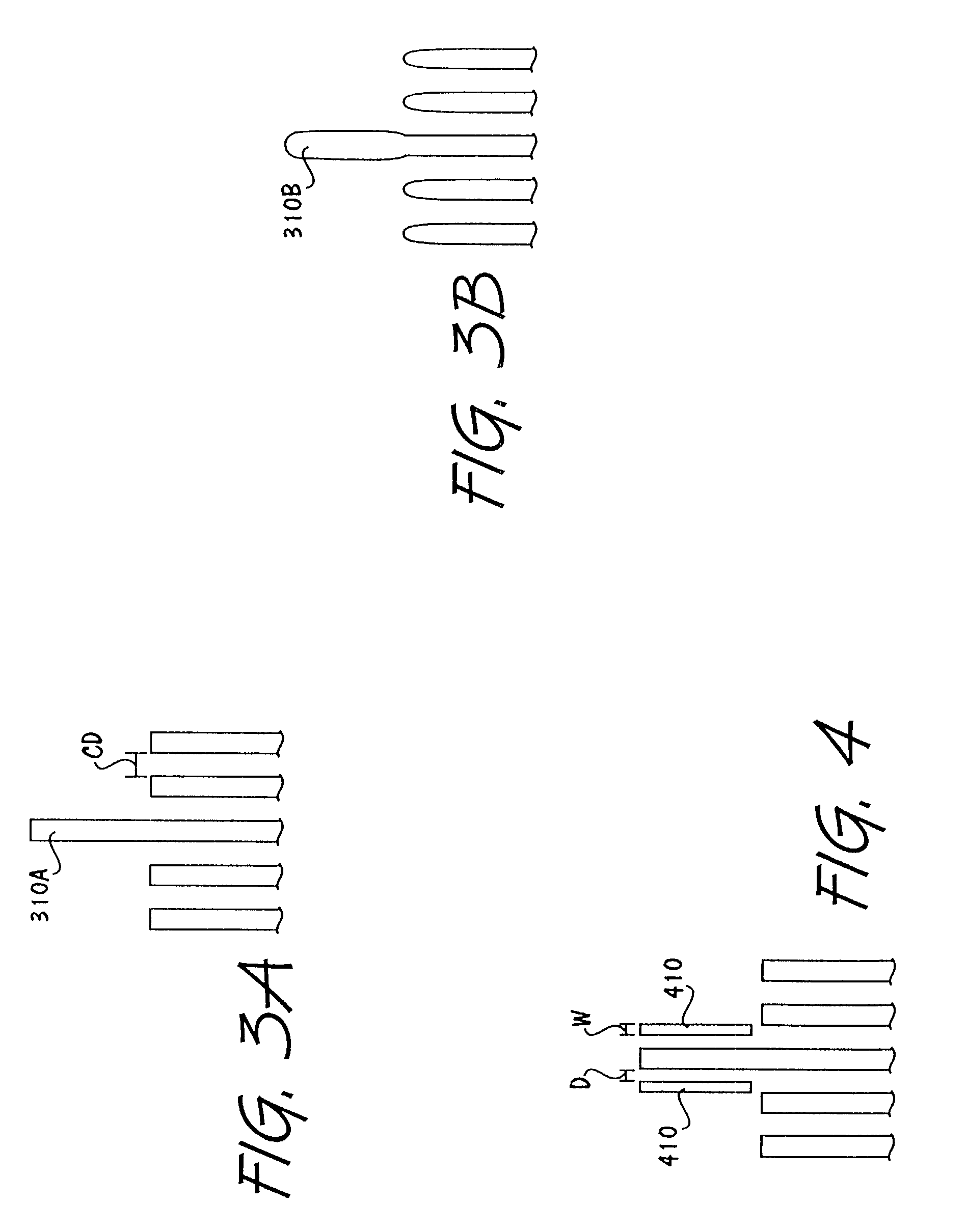

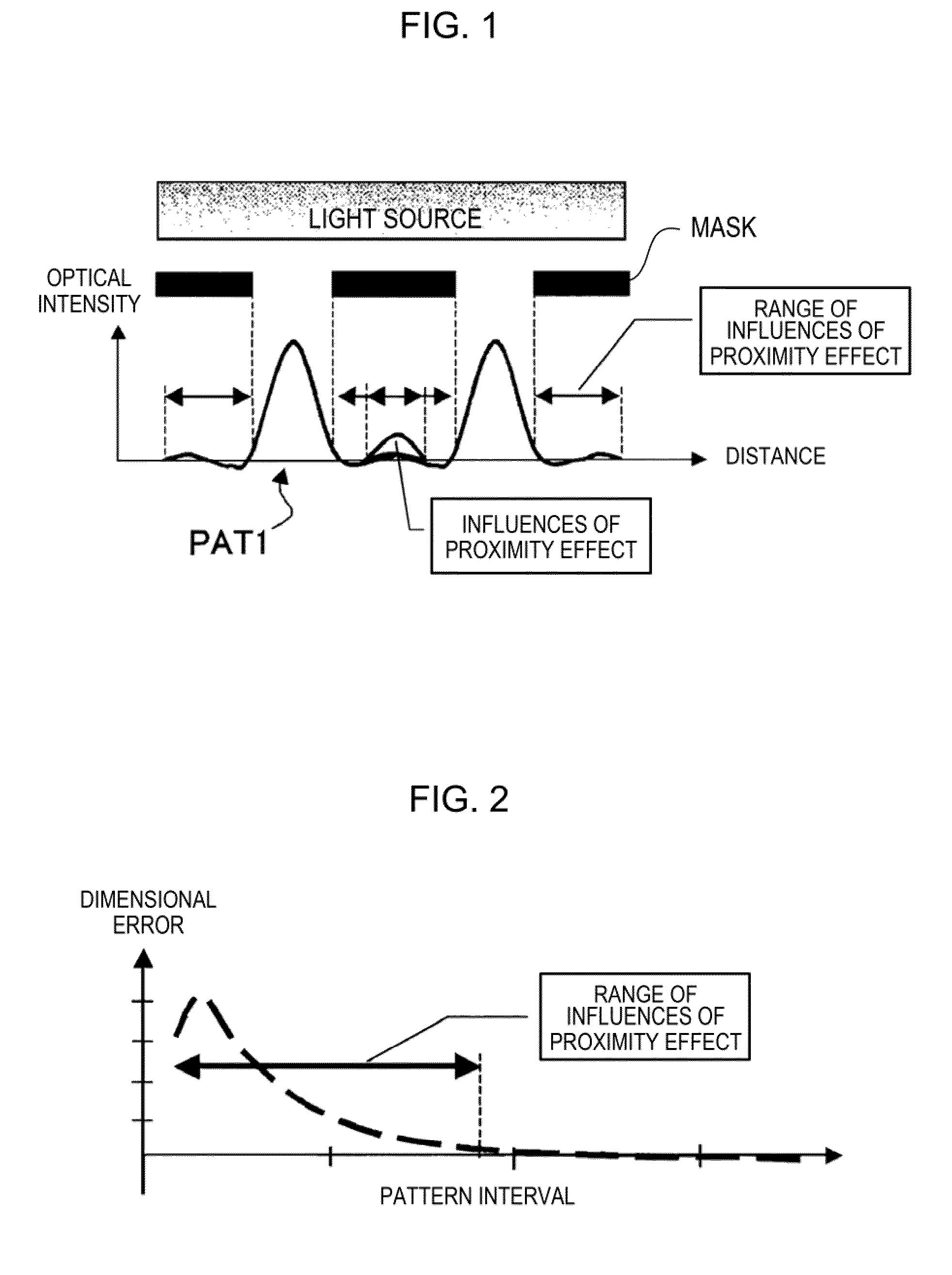

Mixed-mode optical proximity correction

InactiveUS7024655B2Photomechanical exposure apparatusMicrolithography exposure apparatusTreatment designEngineering

A mask is prepared by processing design data with various combinations of rule-based and model-based optical proximity correction. In one embodiment, the design data is first processed with a set of optical proximity correction rules to produce a rule-corrected design. The rule-corrected design is examined to identify a set of features to process with model-based optical proximity correction. Then, the set of features are processed with the model-based optical proximity correction.

Owner:COBB NICOLAS B

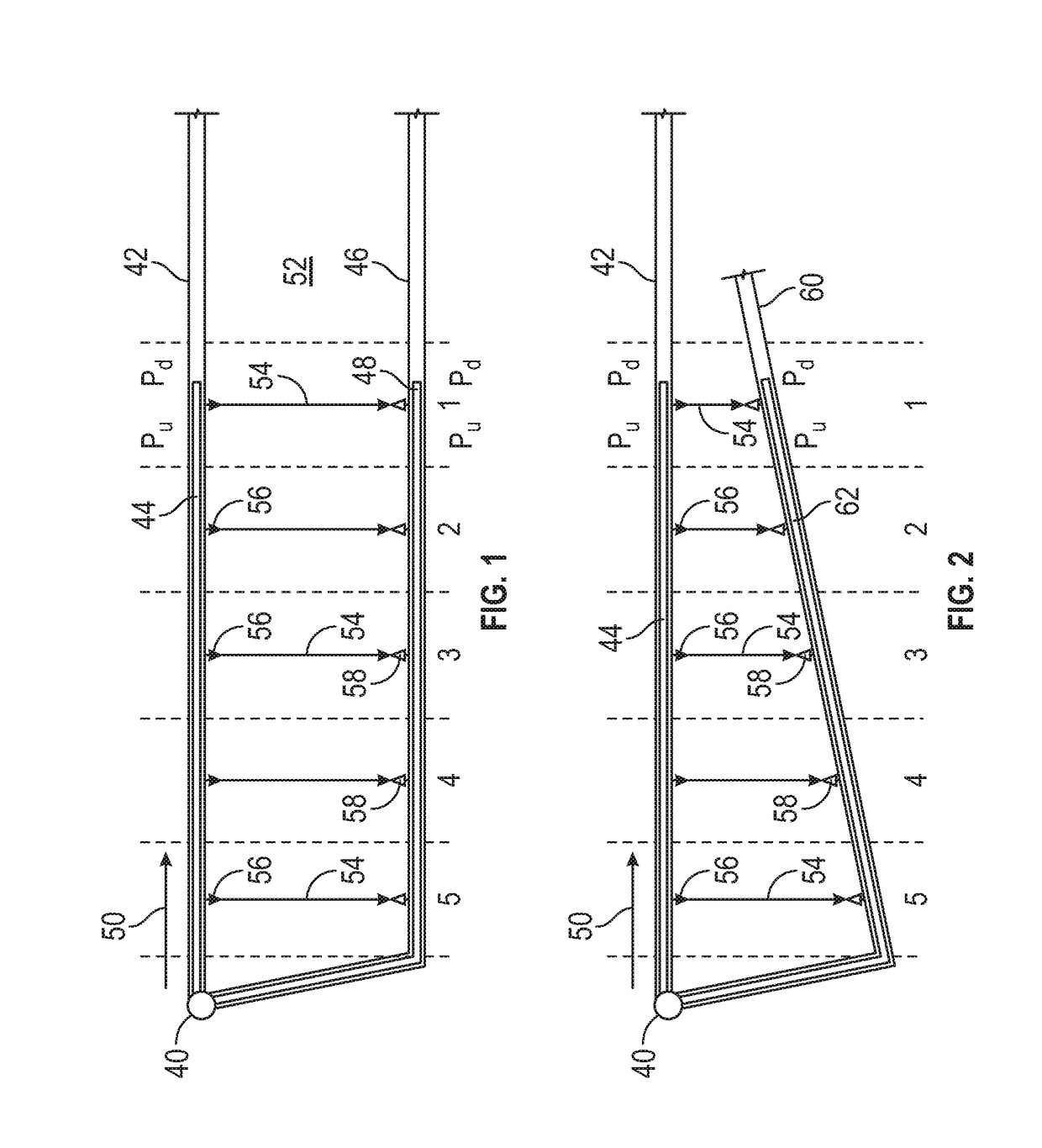

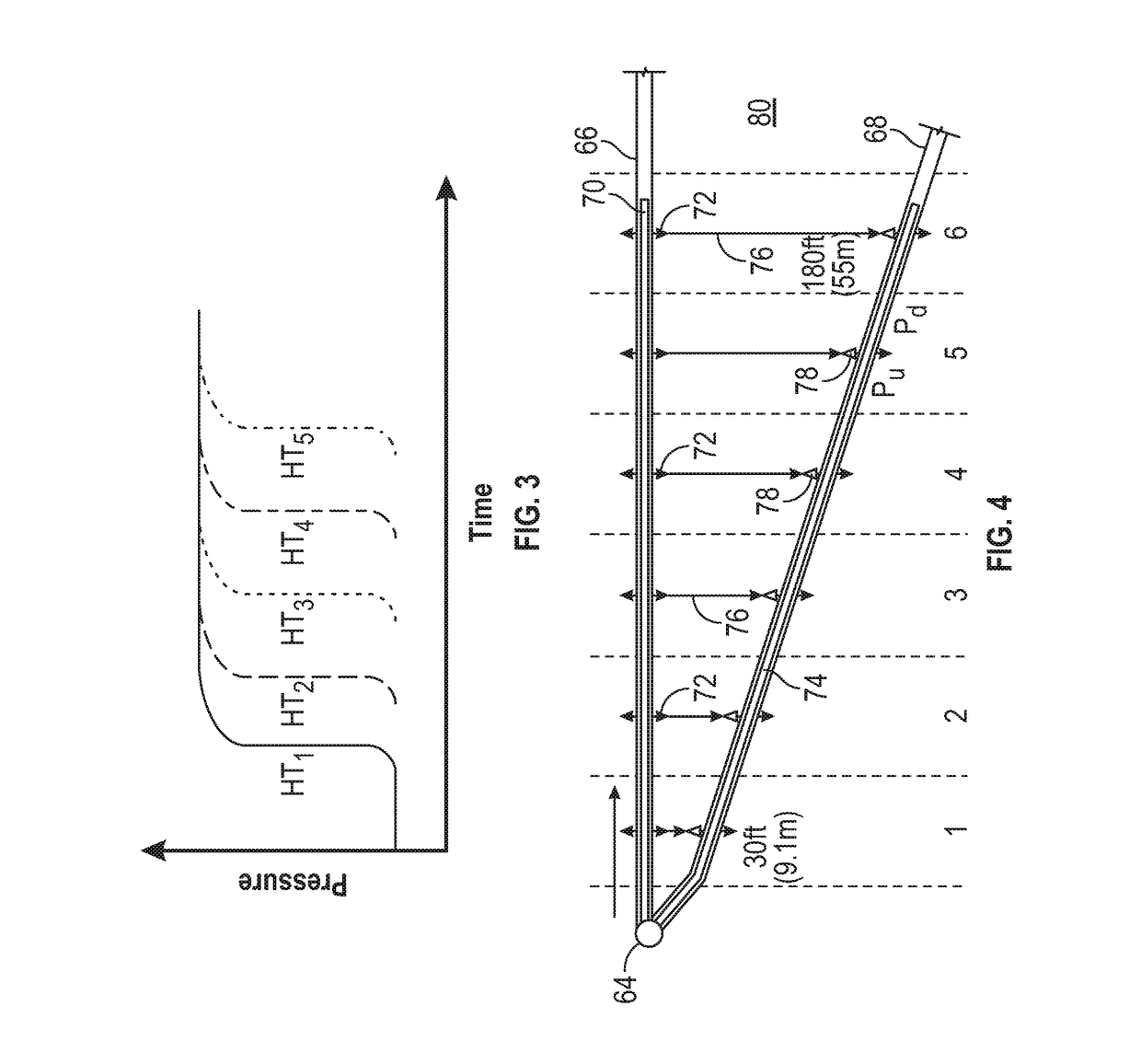

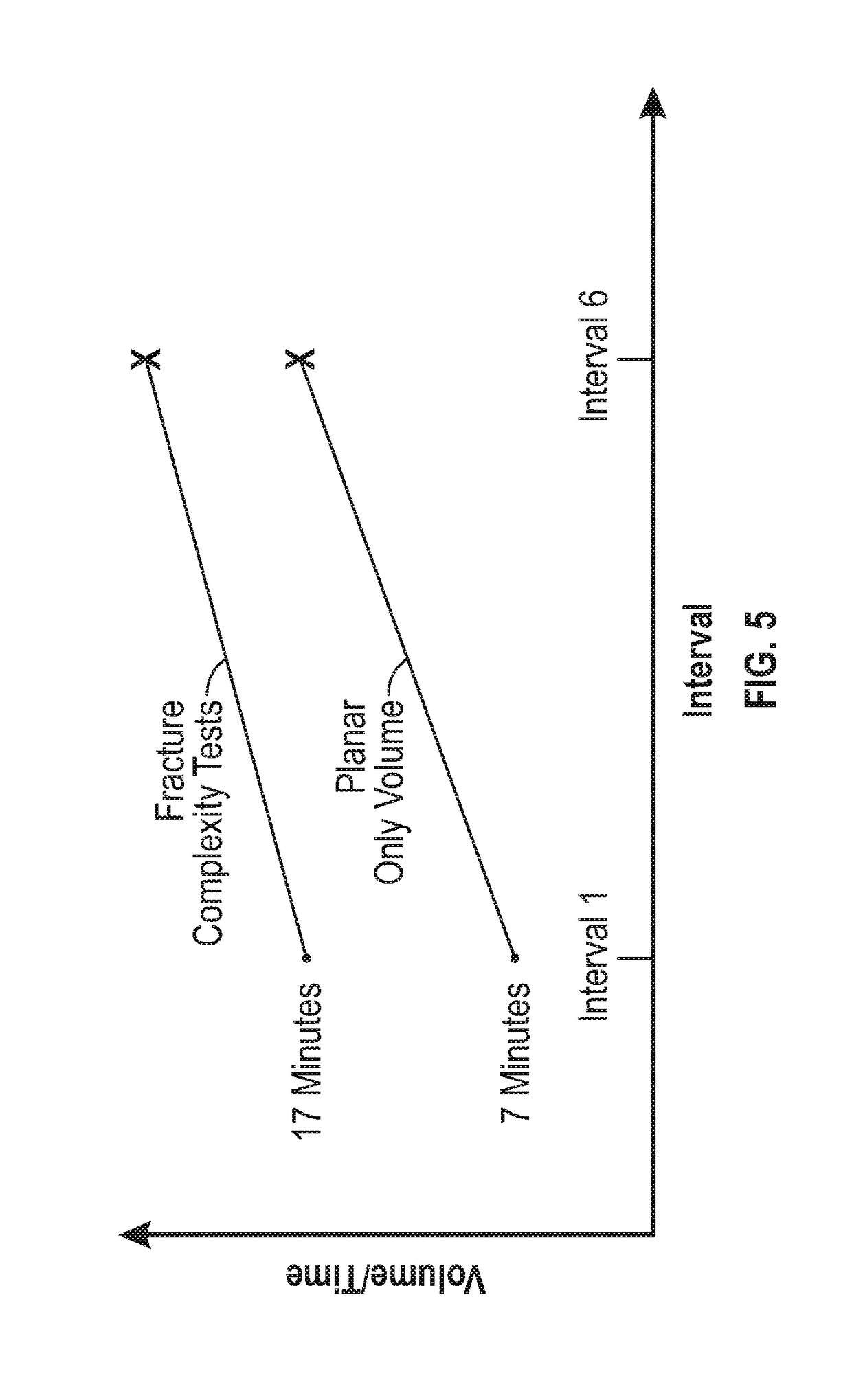

Evaluating far field fracture complexity and optimizing fracture design in multi-well pad development

A method for evaluating and optimizing complex fractures, in one non-limiting example far-field complex fractures, in subterranean shale reservoirs significantly simplifies how to generate far-field fractures and their treatment designs to increase or optimize complexity. The process gives information on how much complexity is generated for a given reservoir versus distance from the wellbore under known fracturing parameters, such as rate, volume and viscosity. The method allows the evaluation of the performance of diversion materials and processes by determining the amount of fracture volume generated off of primary fractures, including far-field secondary fracture volumes. The methodology utilizes fracture hit times, volumes, pressures and similar parameters from injecting fracturing fluid from a first primary lateral wellbore to create fractures and record fracture hit times, pressures and volumes from a diagnostic lateral wellbore in the same interval.

Owner:BAKER HUGHES INC

Method and apparatus for treating and recycling carbonized wastewater

ActiveCN101428945ASolve processing problemsImprove biochemical propertiesFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processSludgeTreatment design

The invention relates to a coking waste water treatment reuse method and a device thereof. The method comprises the following process steps: 1. strengthening pretreatment; 2. biological treatment; and 3. reuse water treatment. The structure of the method is as follows: electrochemical equipment at the strengthening pretreatment step is connected with a water outlet of an air float and a water inlet of biological treatment; and a water outlet pipe of an MBR water outlet tank at the biological and sludge treatment step is connected in serial with an ozone contact tower, an active carbon filter tower and an RO at the reuse water treatment step. The method has the advantages of providing a novel combination process for the coking waste water, effectively combining the technologies of de-oiling, biochemistry, electrochemistry and membrane, improving the biodegradability of difficultly degraded pollutants by utilizing the electrochemical strengthening pretreatment, strengthening the biochemical treatment by MBR, reasonably designing the reuse treatment of ozone-active carbon-RO, solving the problem of the difficult treatment of coking waste water and achieving the aim of the reuse of the coking waste water.

Owner:上海缘脉环境科技有限公司

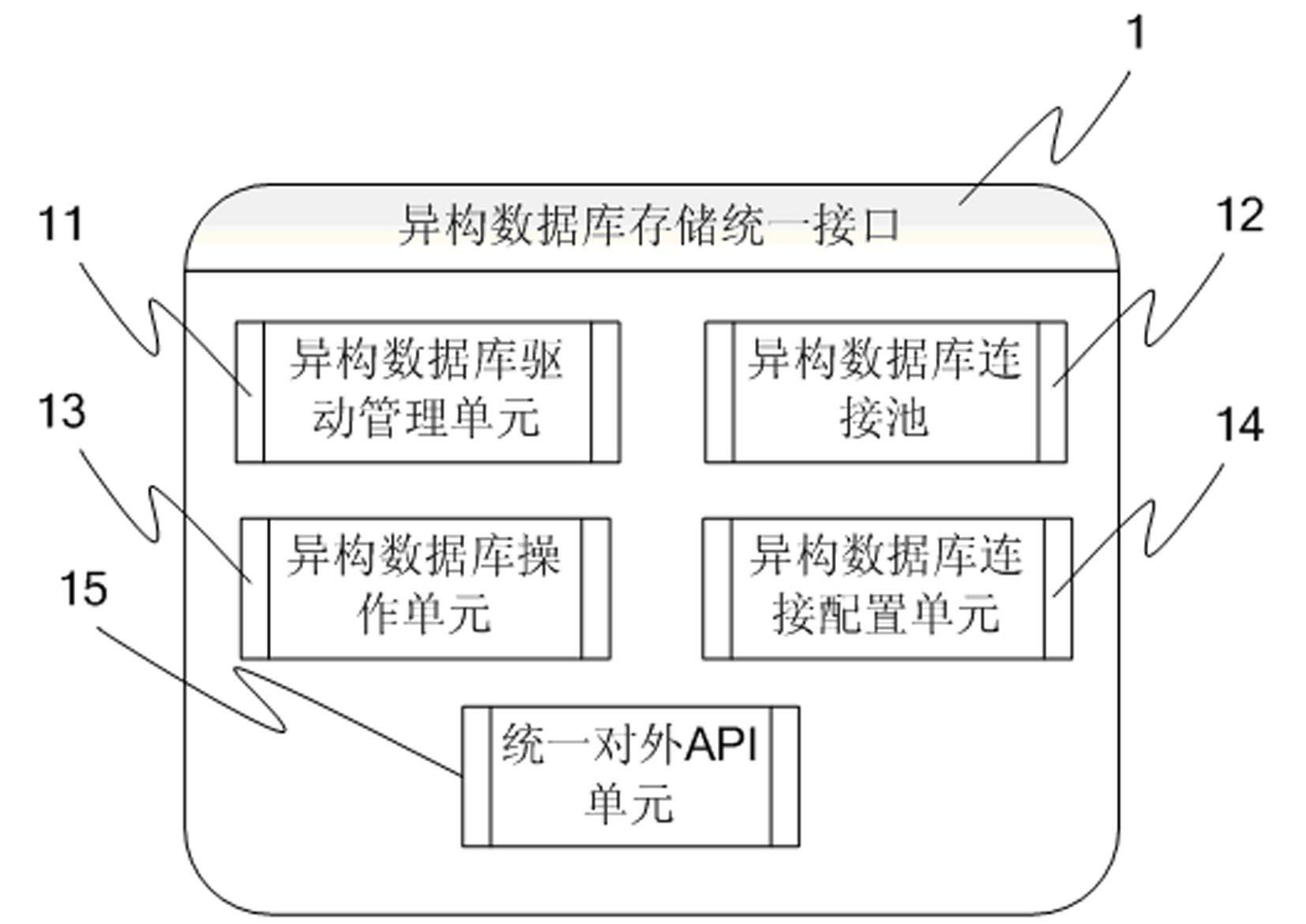

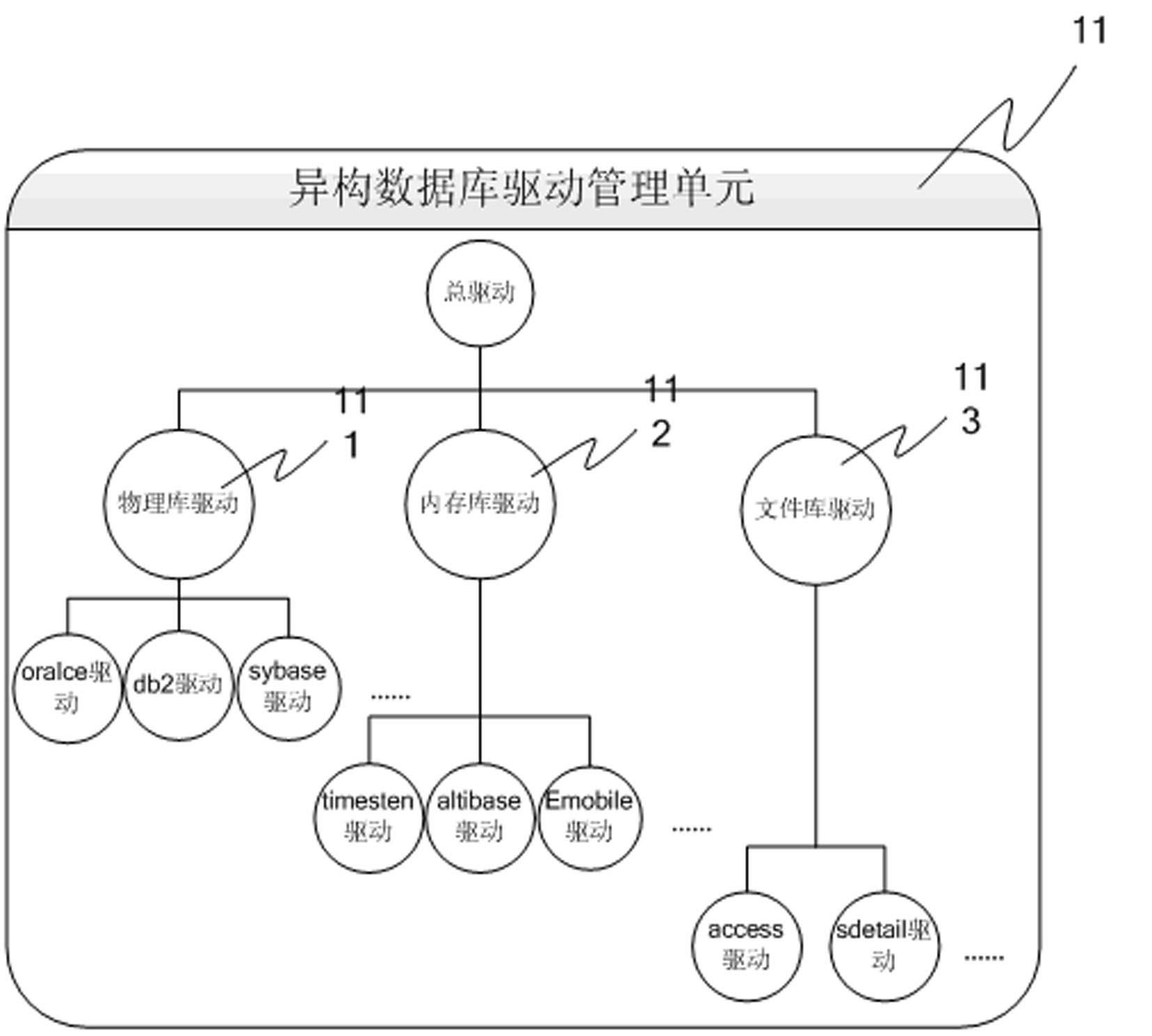

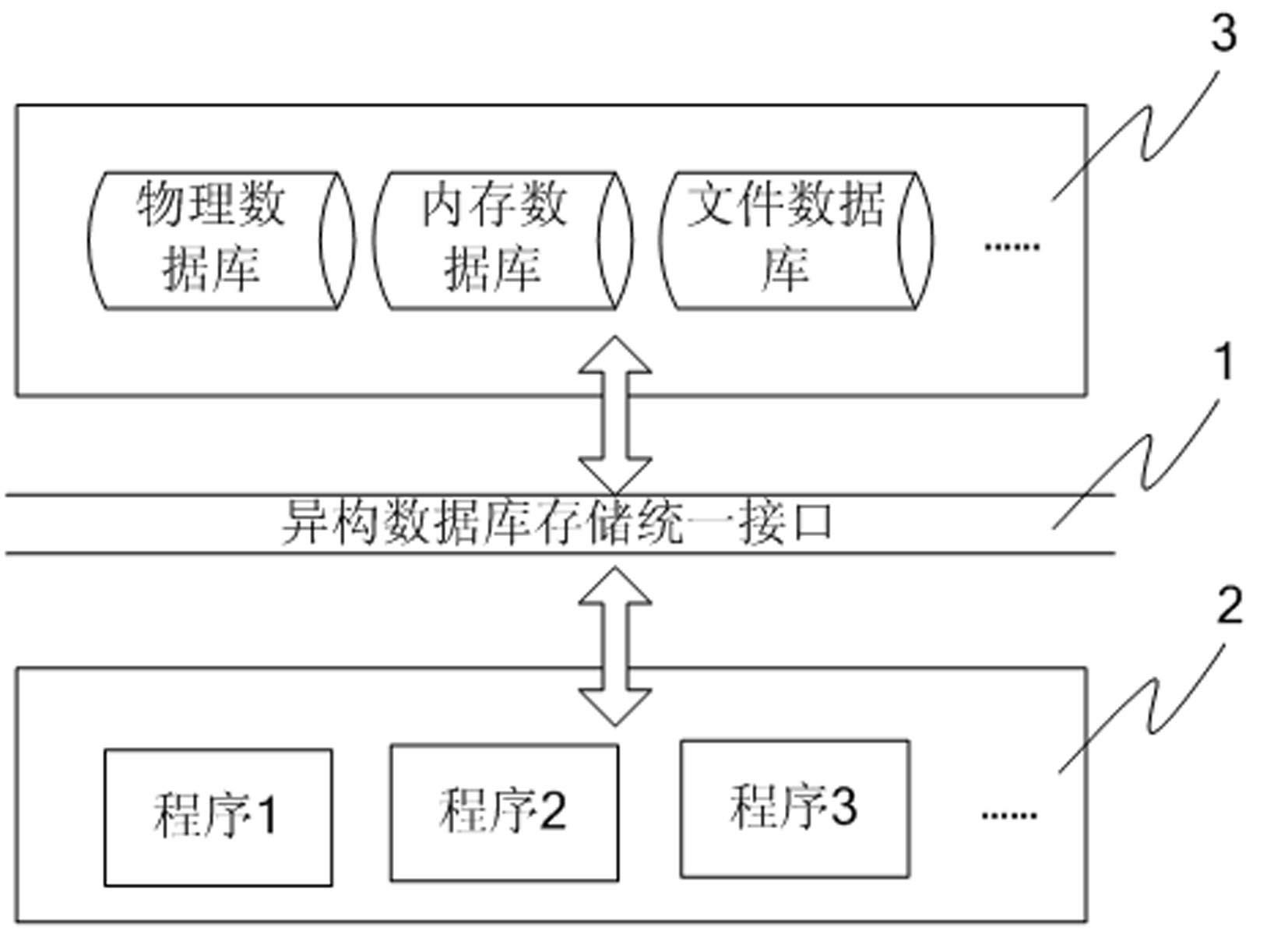

Heterogeneous database storage unified interface and database access method

InactiveCN102314375AAchieve portingImplement changesMultiprogramming arrangementsSpecial data processing applicationsManagement unitTreatment design

The invention relates to a heterogeneous database storage unified interface and a database access method by using the same. The interface mainly comprises a heterogeneous database drive management unit, a heterogeneous database connection pool, a heterogeneous database operation unit, a heterogeneous database connection configuration unit and a unified external API (Application Program Interface) unit. Through the heterogeneous database storage unified interface, a plurality of application processes can simultaneously access databases with different structures without modifying the databases and / or programs or knowing the kinds of the databases, so that the design of an application program can completely independent of different database treatment designs to achieve the aim that program design is irrelevant with the databases; and the operation APIs of all the databases are same, therefore, application codes are simplified, the maintenance is convenient, data transplanting and changing are realized.

Owner:北京思特奇信息技术股份有限公司

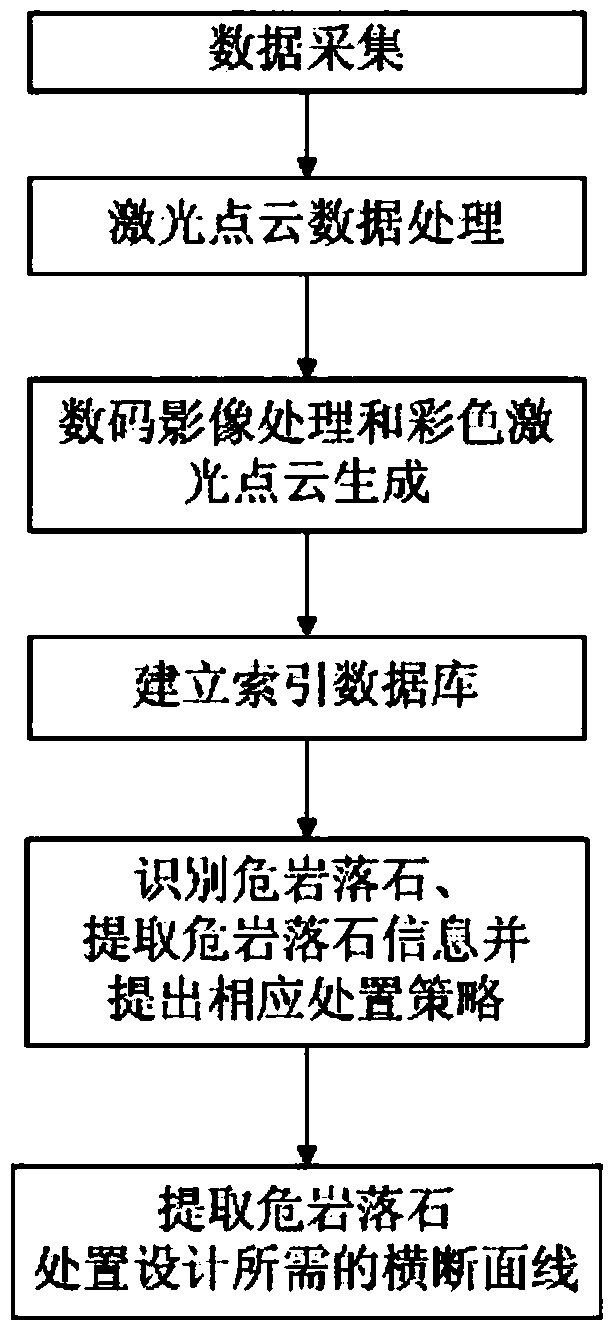

Three-dimensional investigation method for dangerous falling rock based on air-borne laser radar

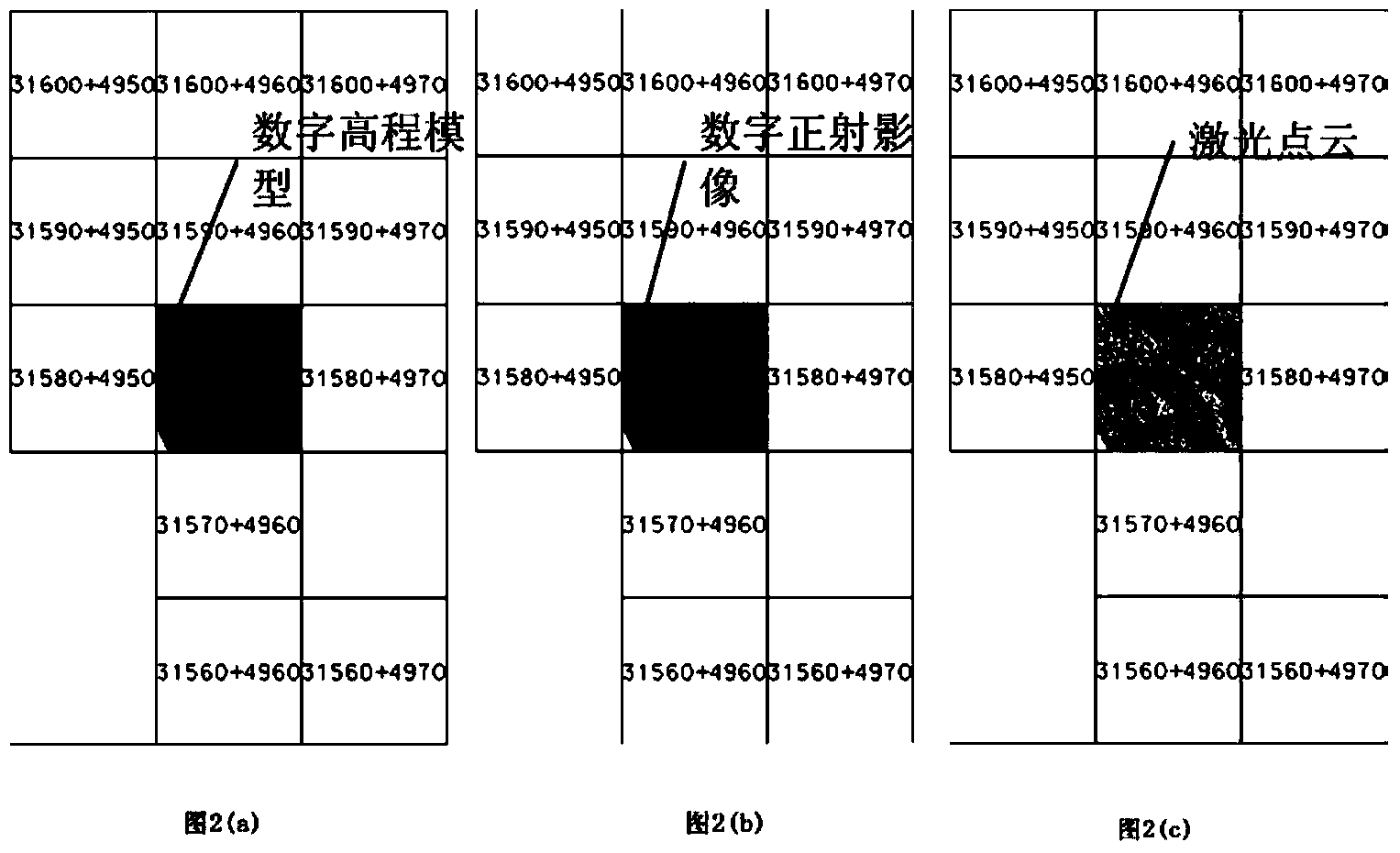

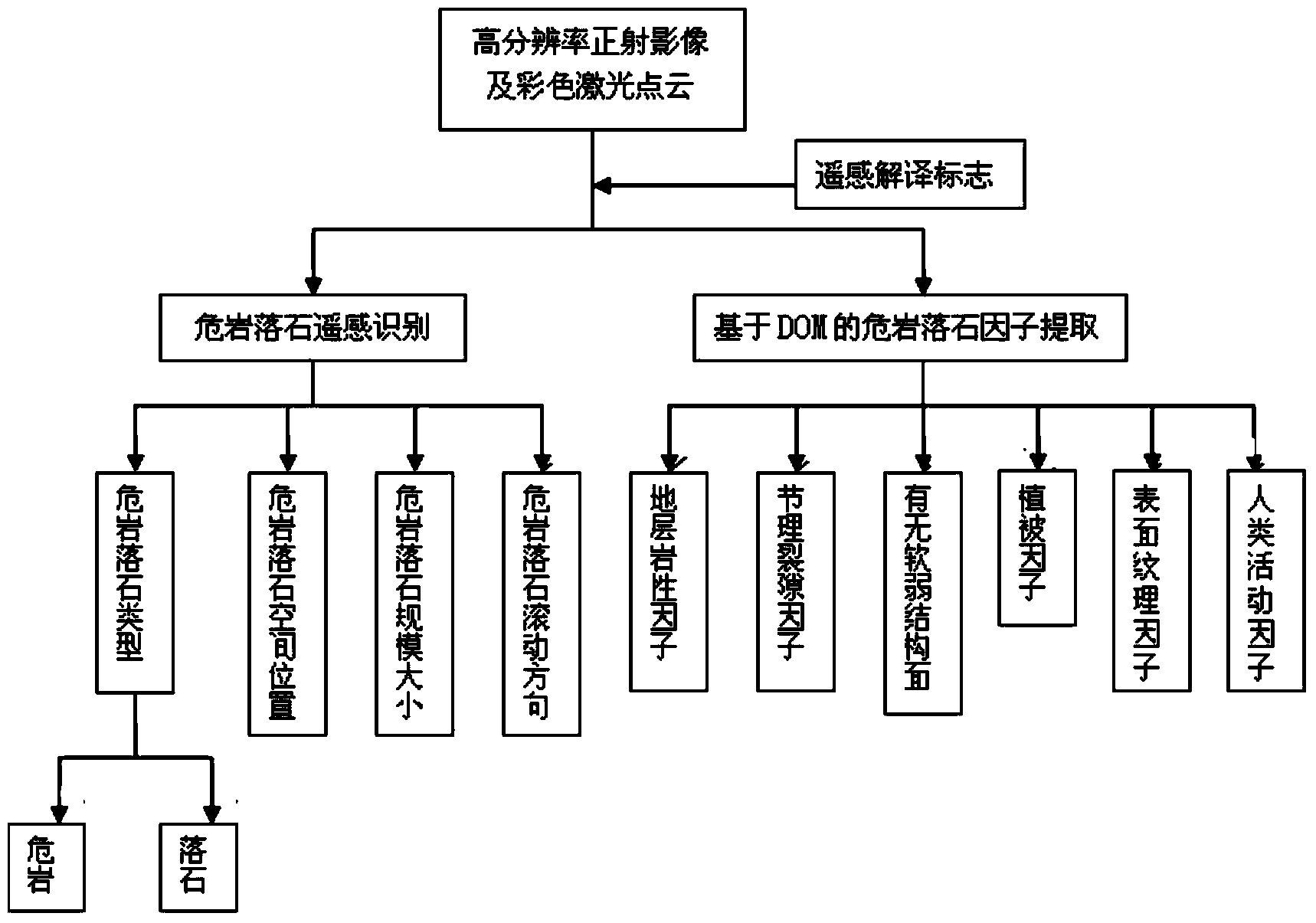

ActiveCN103529455AEasy to handleAccurately determineElectromagnetic wave reradiationSpecial data processing applicationsPoint cloudInvestigation methods

The invention discloses a three-dimensional investigation method for a dangerous falling rock based on an air-borne laser radar. Original laser point cloud data and original video image data which cover an engineering zone and the initial exterior orientation elements of the original video image data are collected and processed to generate a DEM (Digital Elevation Model), a DOM (Digital Orthophoto Map) and a color laser point cloud. An index database is generated, the dangerous falling rock is recognized by information in the index database, the information factors of the dangerous falling rock are extracted to classify the hazard rate of the dangerous falling rock and provide a treatment strategy, and cross section lines required by a treatment design are extracted. The high-precision color laser point cloud, the high-precision DEM and the high-precision DOM are established by the advanced space-to-land observation technology based on the air-borne laser radar, the information extraction, quantitative analysis and risk evaluation of the dangerous falling rock are realized, and a novel method for surveying mountain hazards based on the air-borne laser radar technology is created.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

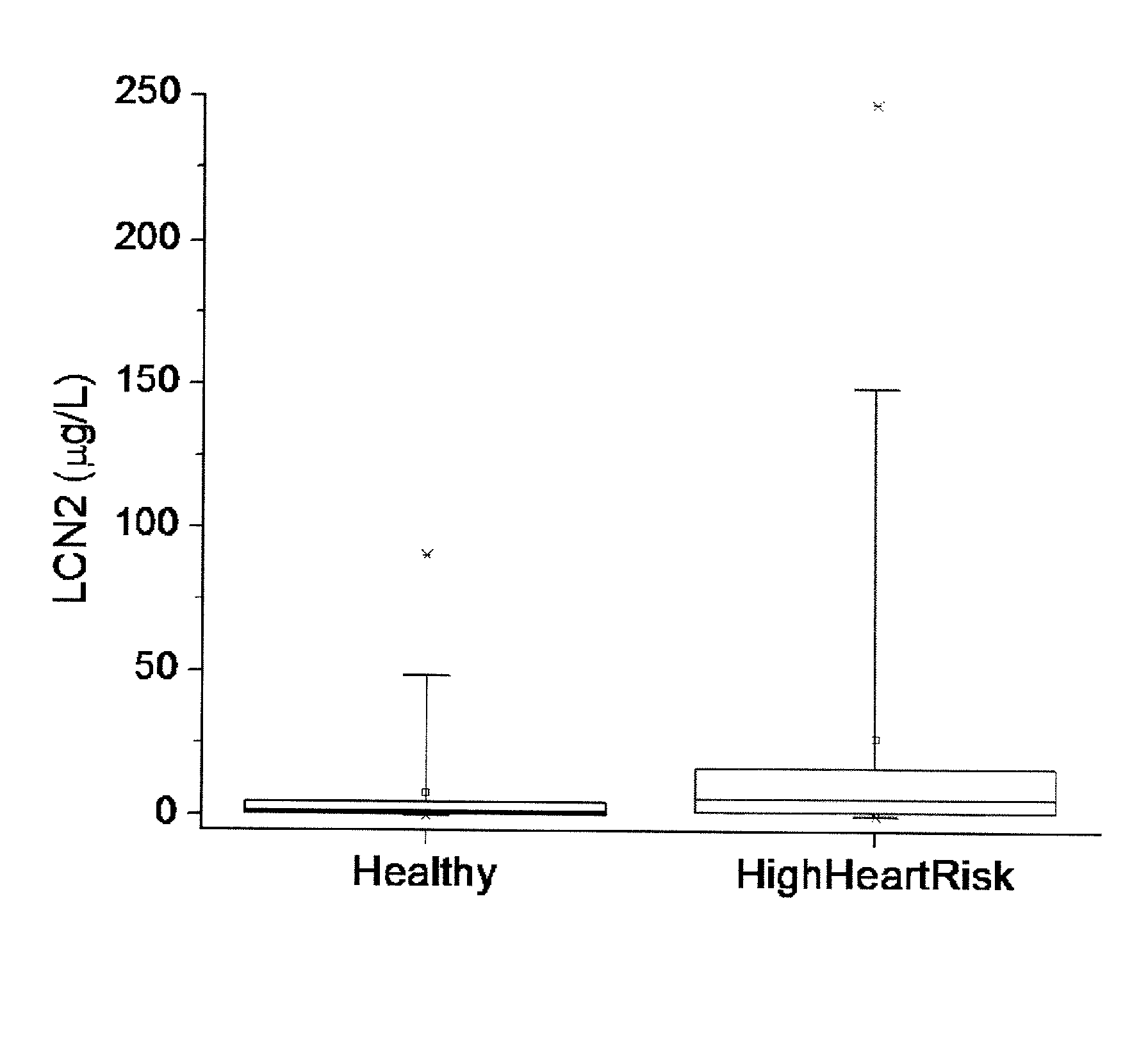

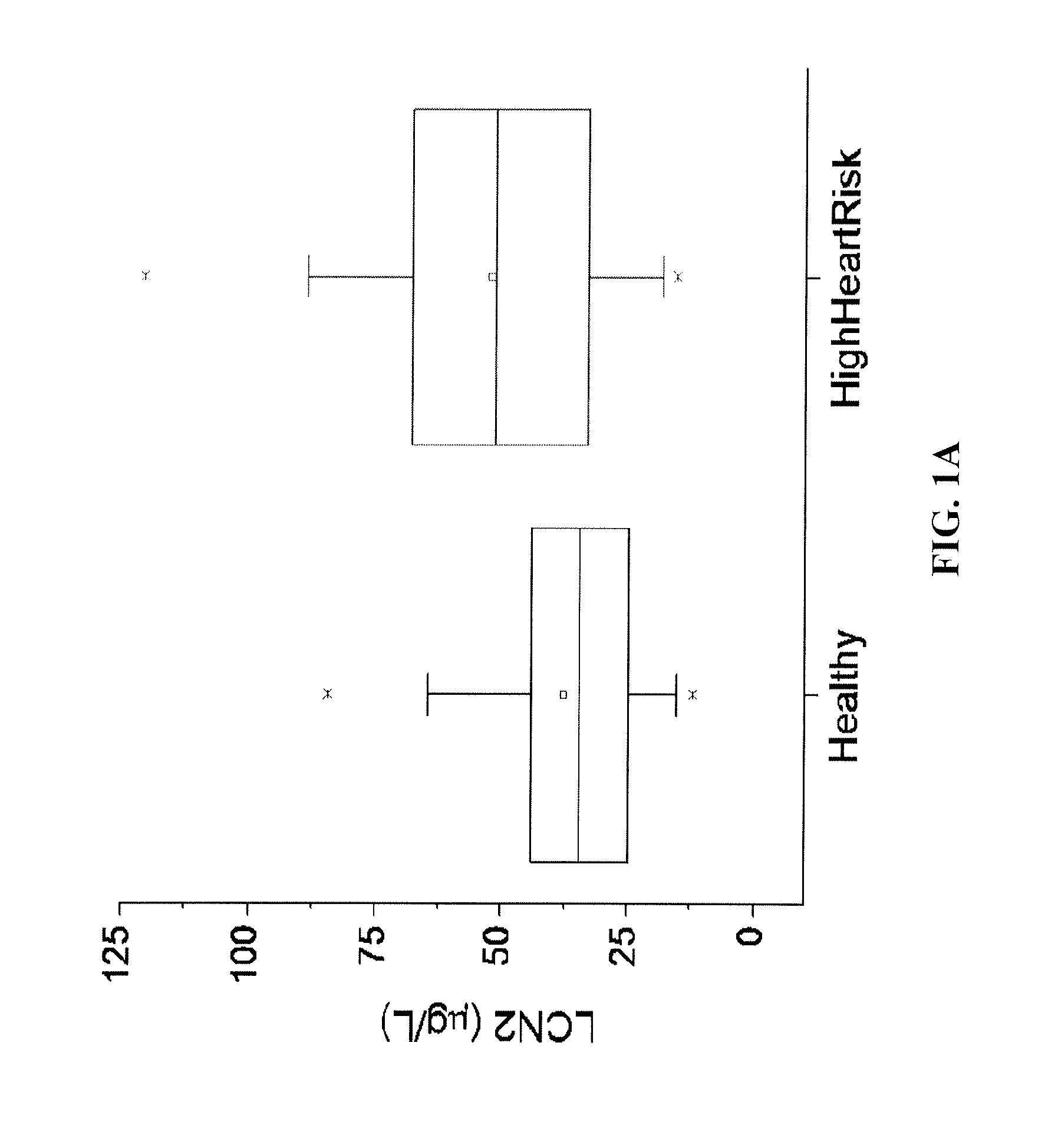

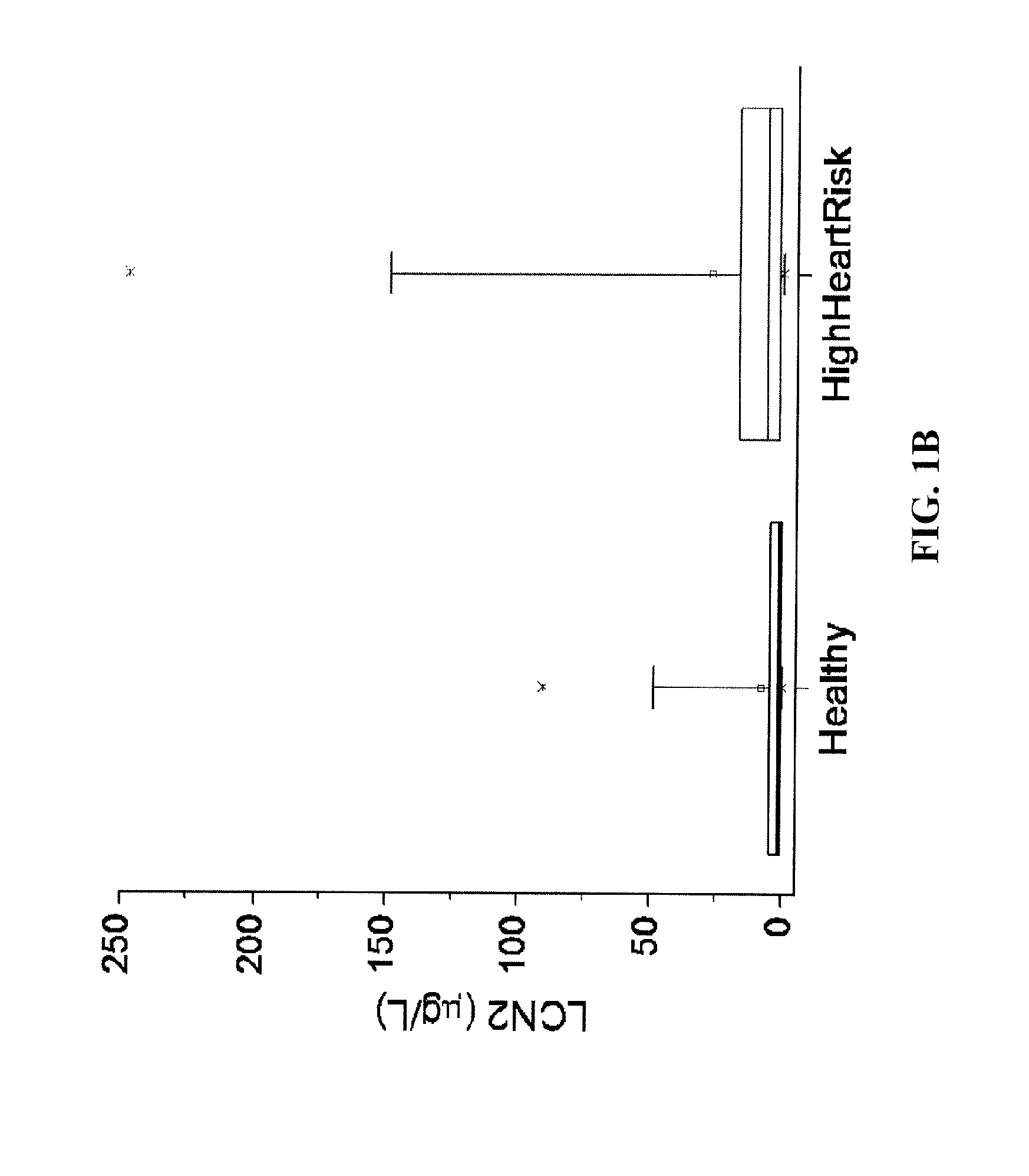

Lipocalin-2 As A Prognostic and Diagnostic Marker For Heart And Stroke Risks

ActiveUS20090274709A1Easy to adaptPeptide/protein ingredientsMicrobiological testing/measurementCvd riskBlood plasma

Methods and apparatus are disclosed for the measurement of lipocalin-2 in body fluids (including but not limited to blood, serum, plasma, urine, saliva, tear, etc.) by an assay such as an immunoassay or an immunotest for (1) the prediction of risk of future cardiovascular diseases; and (2) the determination of the likelihood that certain individuals will benefit to a greater or lesser extent from the use of certain treatments designed to prevent and / or treat cardiovascular diseases.

Owner:R&C BIOGENIUS +1

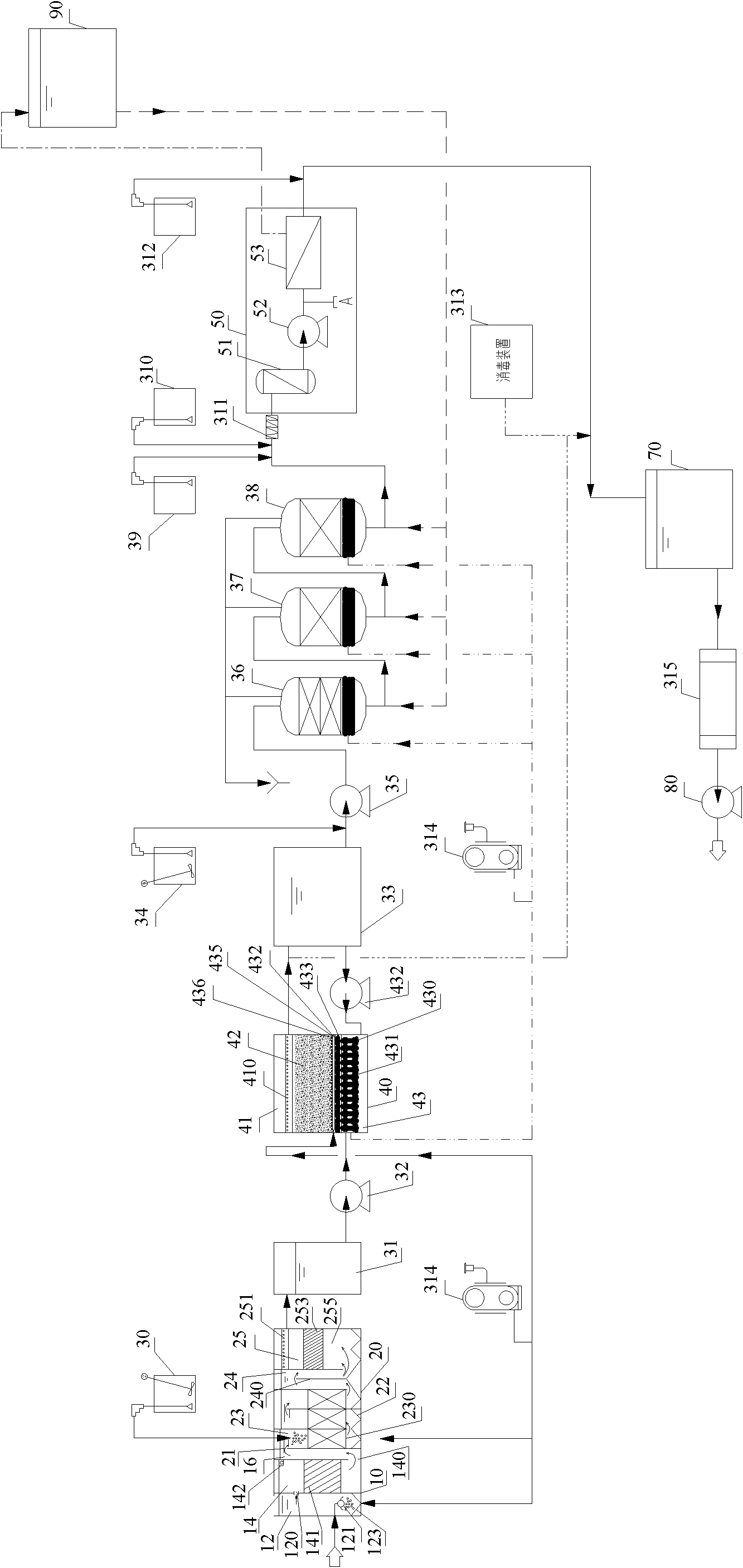

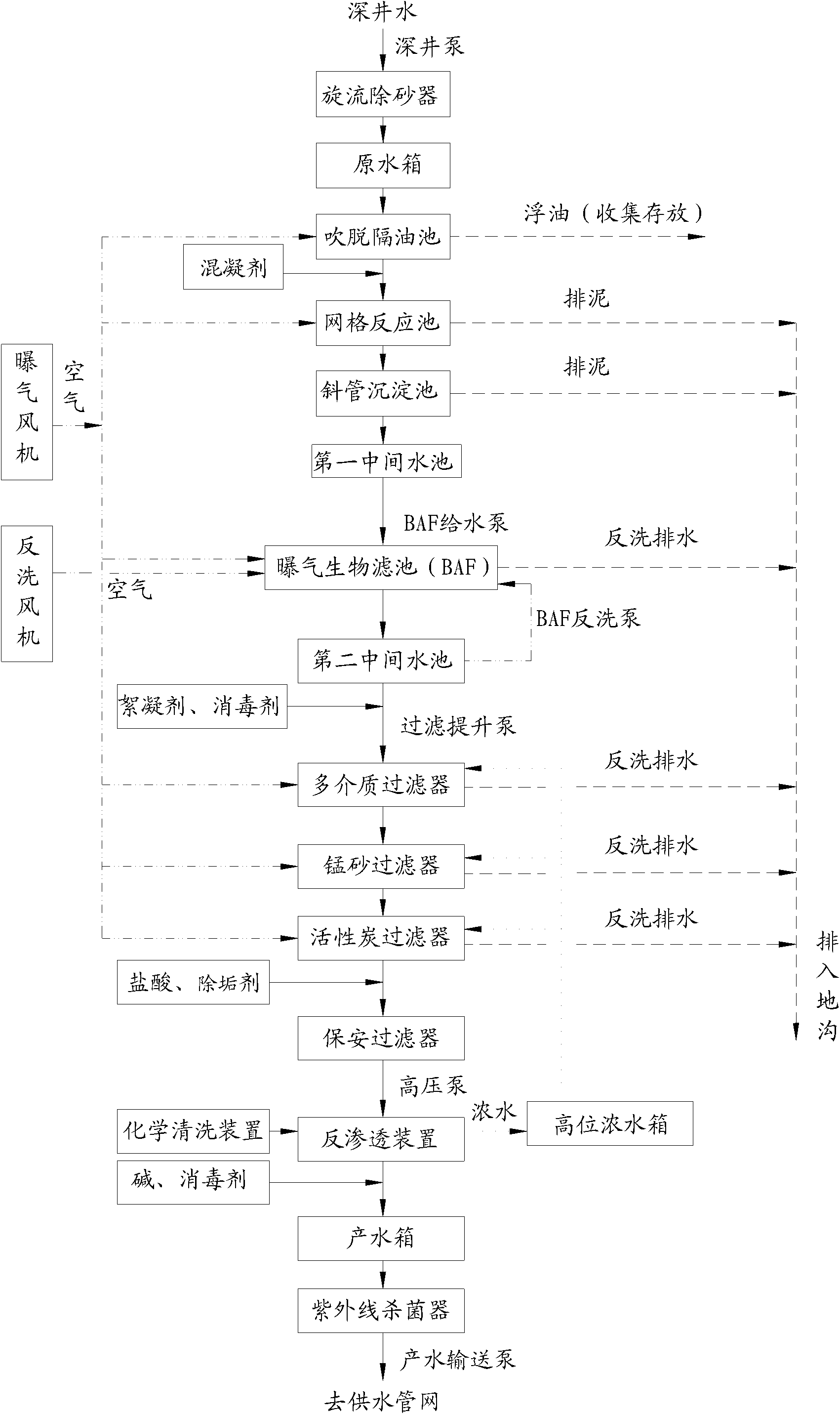

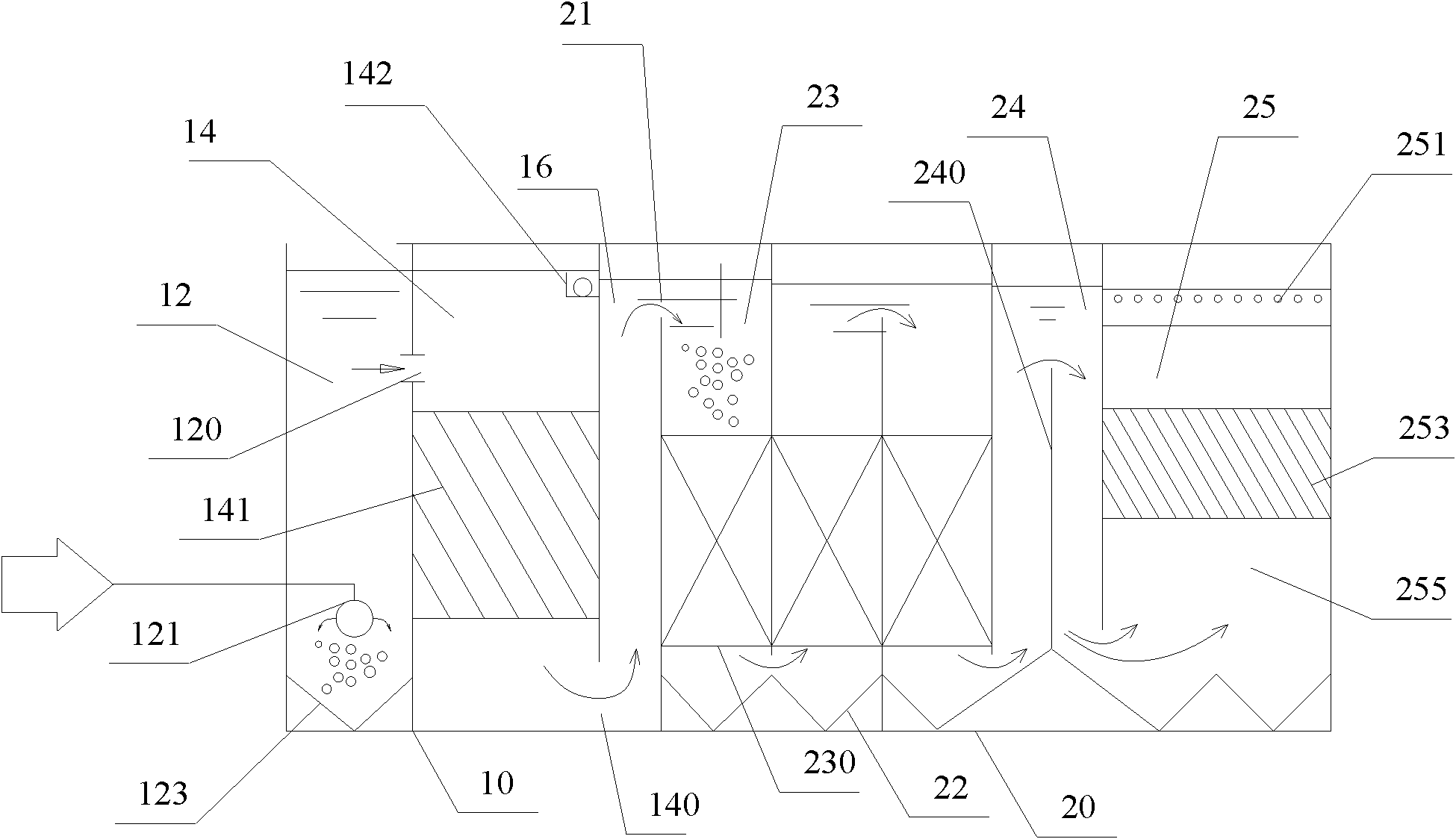

Purification system for micro-polluted raw water and purification method thereof

InactiveCN102557350AImprove recycling ratesStrong shock adaptabilityWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisPurification methodsActivated carbon filtration

The invention relates to a purification system for micro-polluted raw water, comprising a stripping oil separation tank, a coagulating sedimentation tank, a coagulating chemical dosing device, a first middle water tank, a water feeding pump, a biological aerated filter, a second middle water tank, a coagulating chemical dosing unit, a filtering lift pump, a multi-media filter, a manganese sand filter, an active carbon filter, an acid dosing device, a scale inhibitor dosing device, a mixer, a reverse osmosis device, an alkali dosing device, a disinfection device and an ultraviolet sterilization device. The purification system for micro-polluted raw water disclosed by the invention has the following advantages that: main pollutants are especially removed at first, and then a reverse osmosis technology is used as a safety guarantee; the reverse osmosis pre-treatment is designed adequately, and the operation of the system is safe and stable, so that the occurrence frequency of pollution and blockage phenomena is greatly decreased, chemical cleaning period is greatly prolonged, and the recycling rate of water is up to 75%; and the purification system is suitable for the occasions of treating the drinking water of municipal administration, villages, industrial enterprises and mine fields or for the occasions of reusing the reclaimed water which needs advanced treatment. The invention further refers to a purification method of the purification system for micro-polluted raw water.

Owner:HEFEI DEAN WATER TREATMENT EQUIP

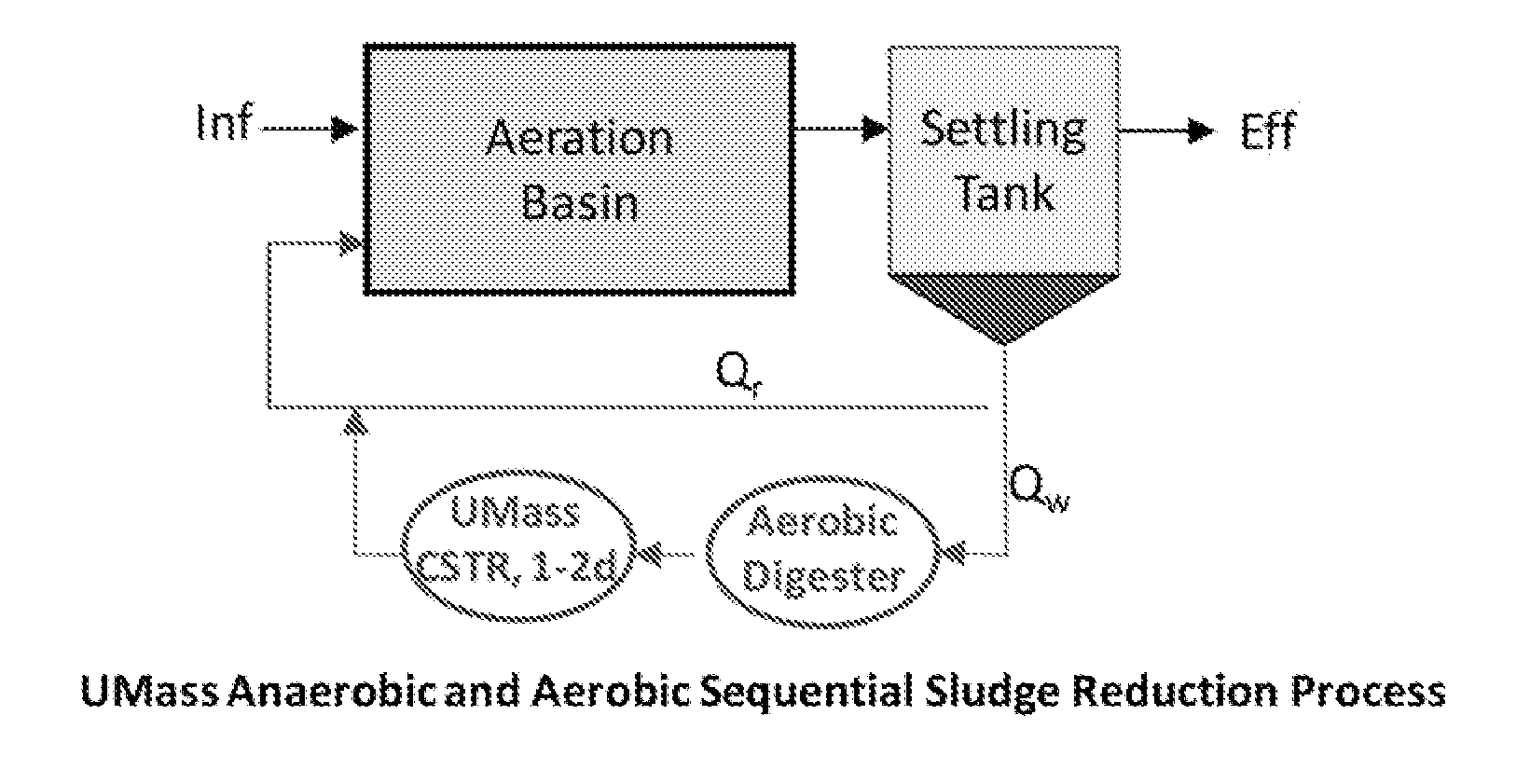

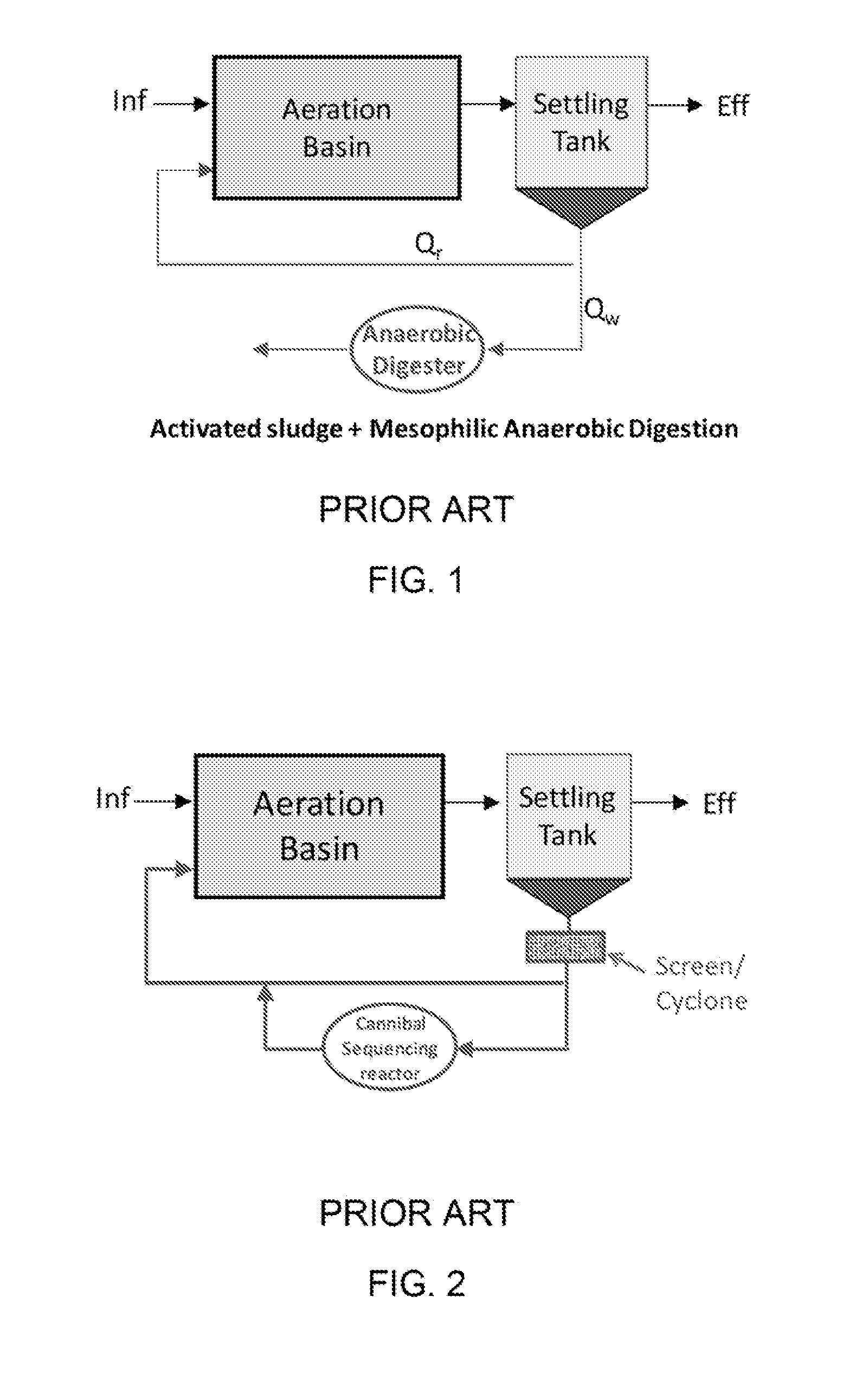

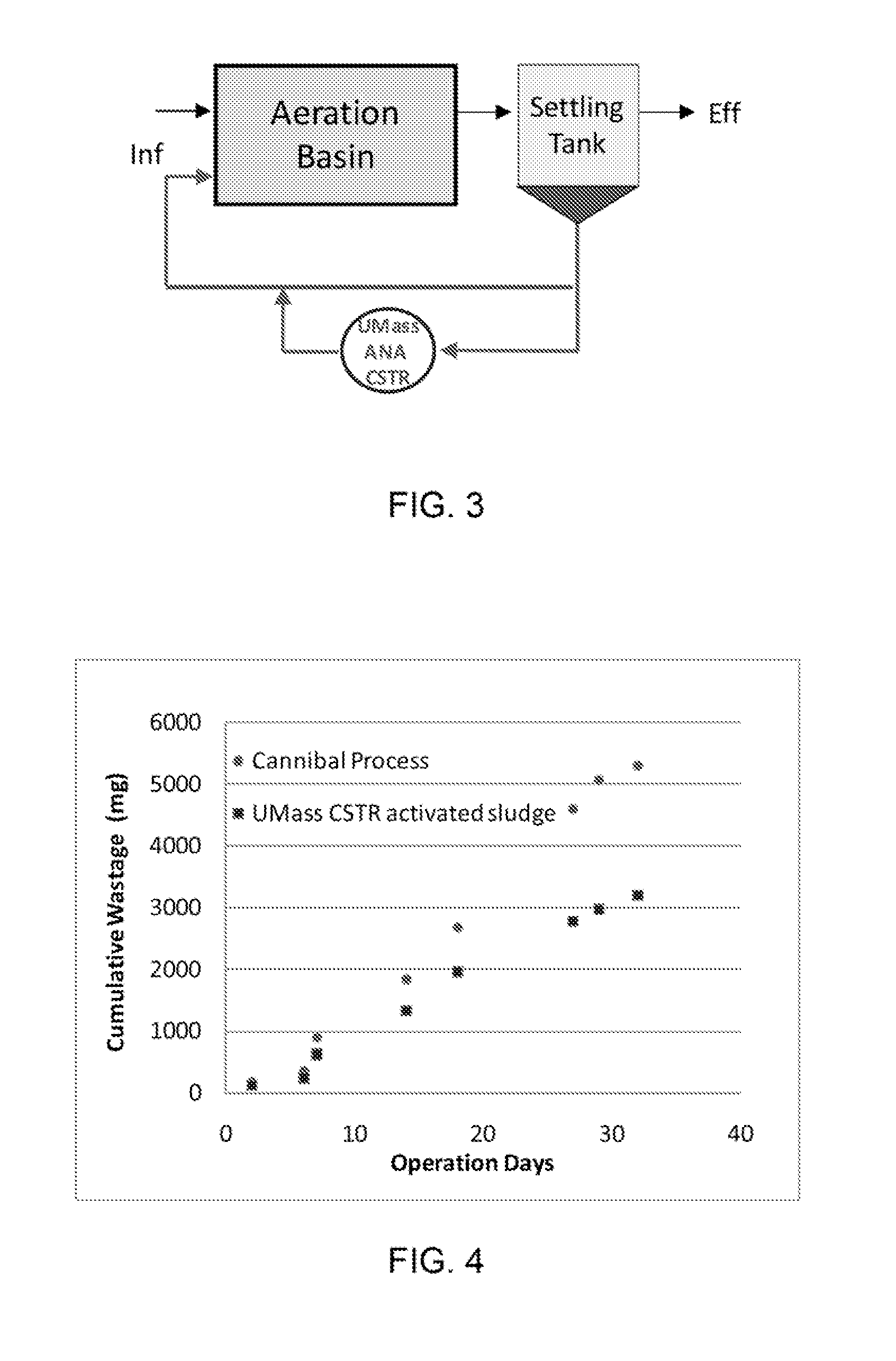

Method to reduce sludge generation in wastewater treatment systems

ActiveUS20120152812A1Reduce phosphorus contentReduce nitrogen contentSludge treatment by thermal conditioningWater/sewage treatment with mechanical oscillationsSludgeReactor design

The systems and methods described provide for reducing sludge generation, and thus sludge wasting and handling, by including an anaerobic completely stirred tank reactor (CSTR) as a bioreactor in a side-stream. The CSTR provides a significant simplification of side-stream treatment design, enhanced sludge minimization, and enhanced removal of nitrogen and phosphorous without the need to add organic carbon. The described systems and methods provide generation of biogas including both hydrogen and methane from the activated sludge system. The described systems and methods avoid complex reactor designs for nutrient removal.

Owner:UNIV OF MASSACHUSETTS

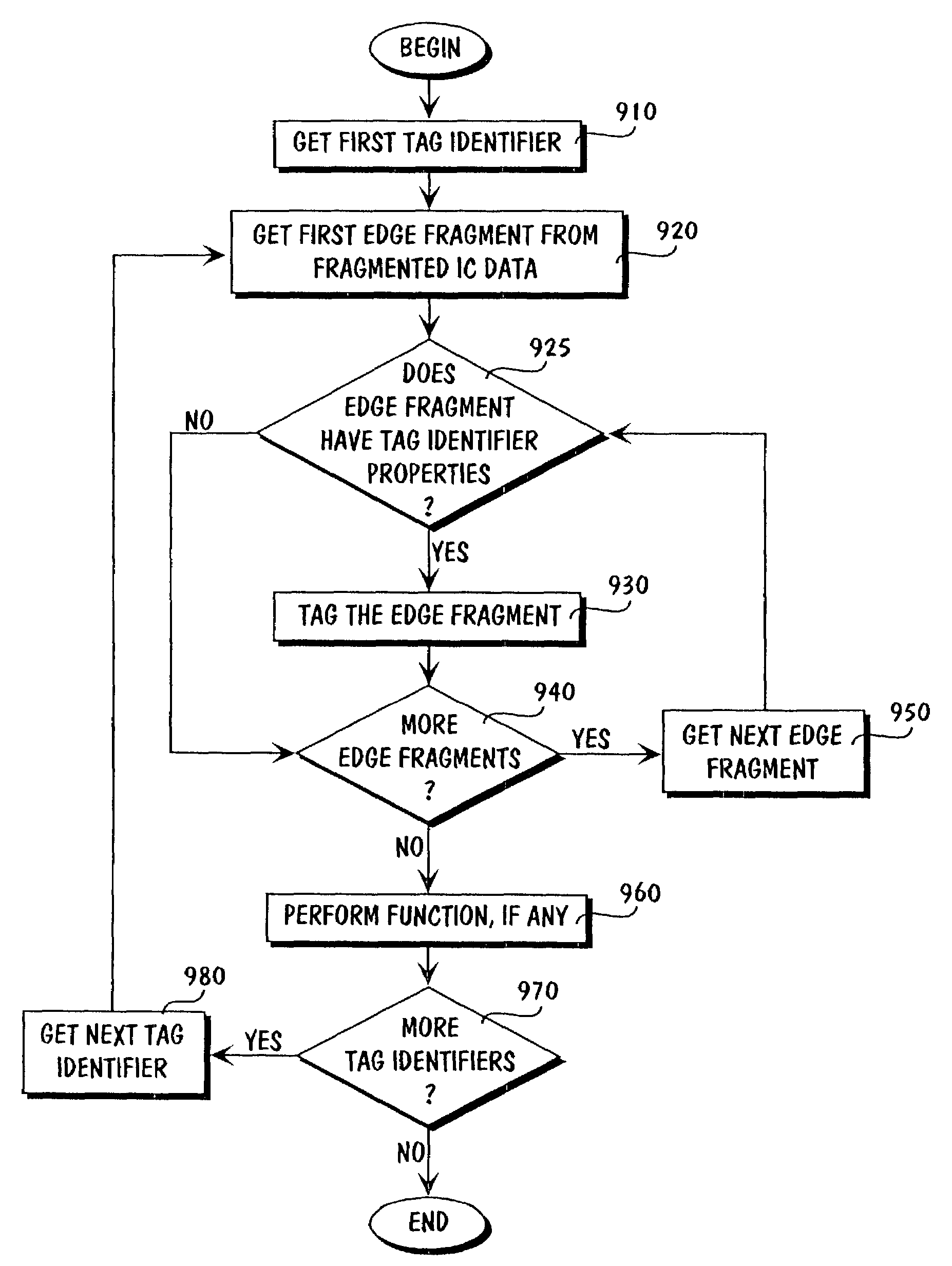

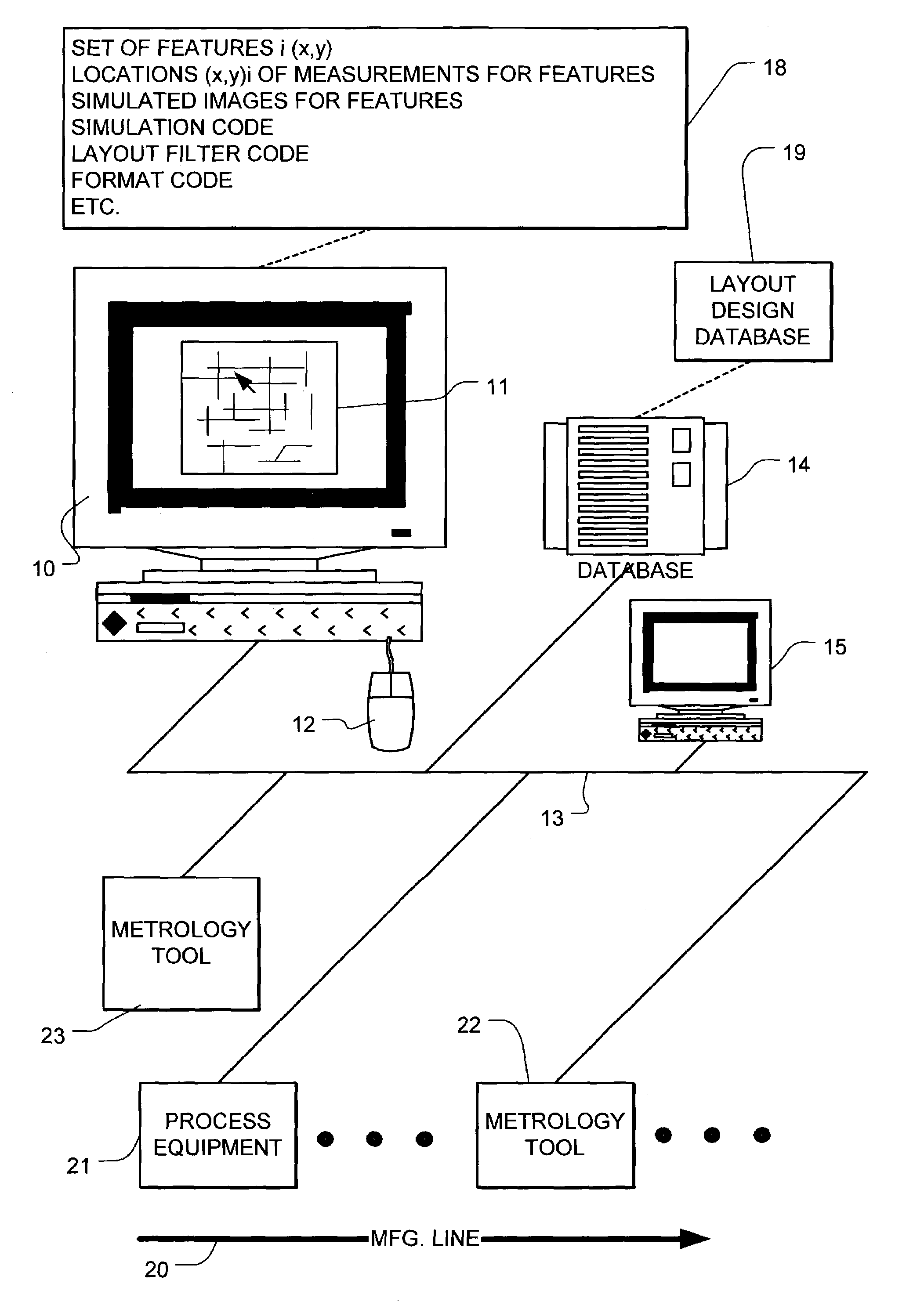

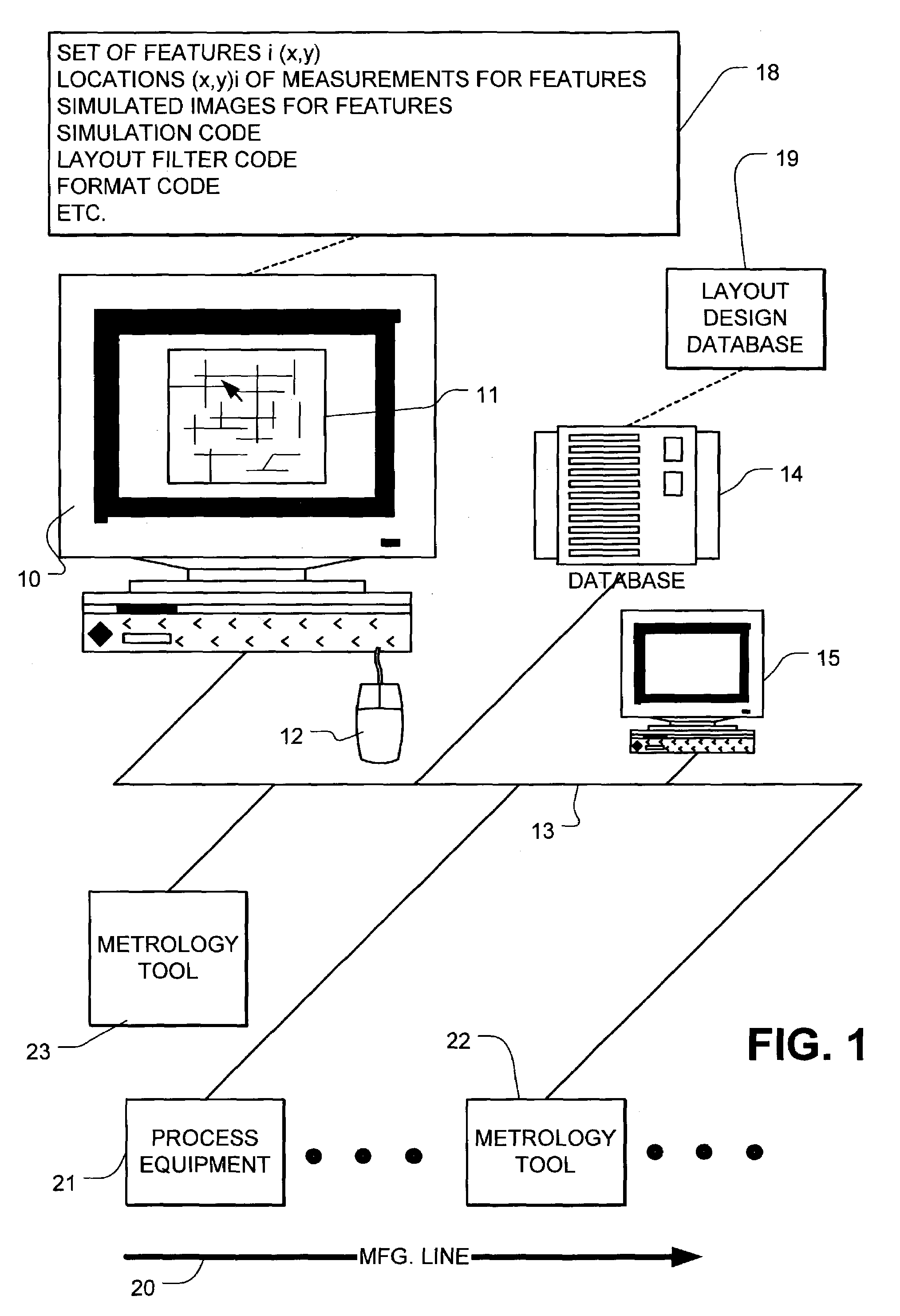

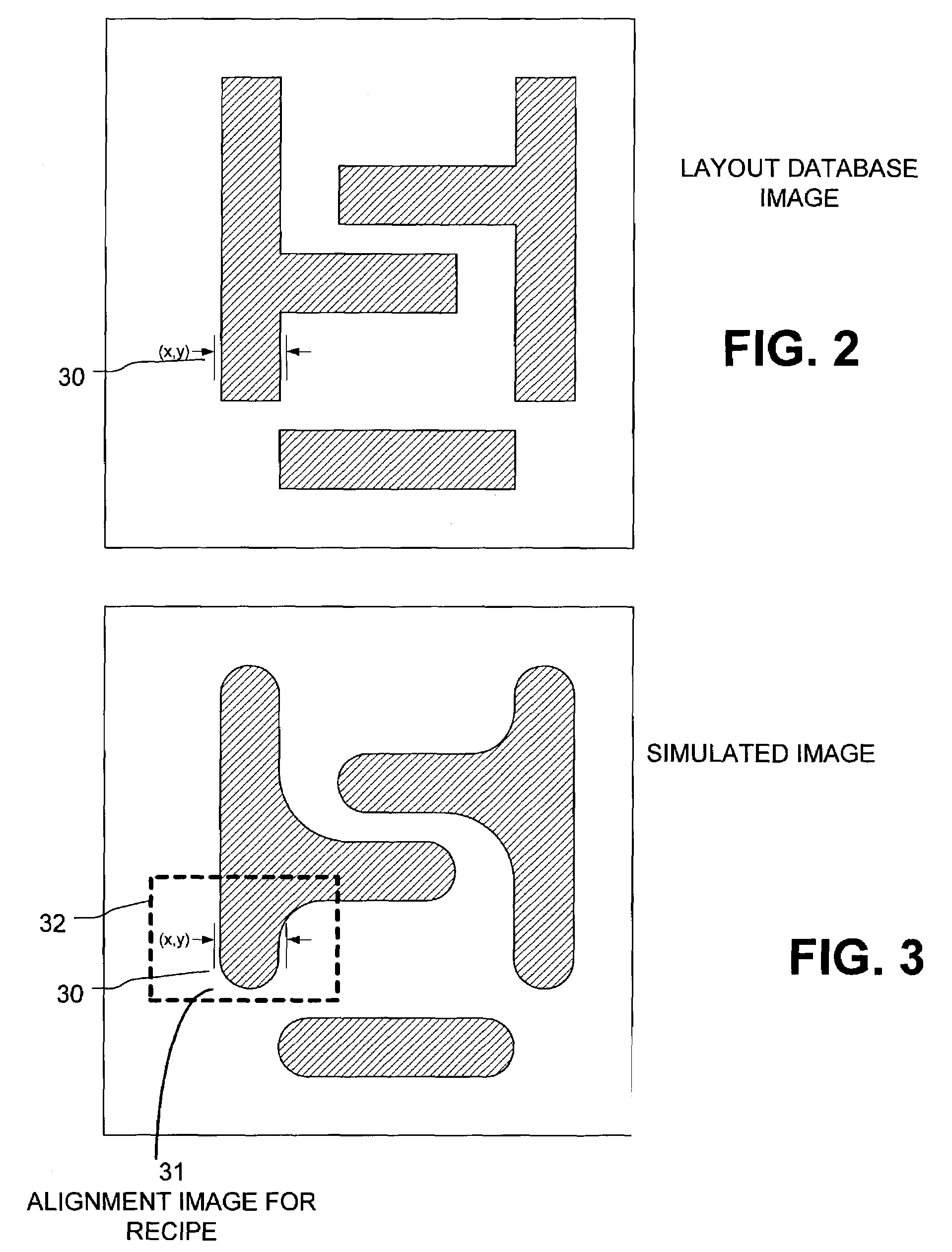

Automated creation of metrology recipes

ActiveUS7457736B2Improve accuracyImprove throughputSemiconductor/solid-state device testing/measurementAnalogue computers for electric apparatusMetrologyTreatment design

An automated metrology recipe set up process is described for a manufacturing process, in which patterns to be formed on a device are defined using a design database. The design database is processed to produce a simulated image of a feature for use in a metrology tool for a measurement of the feature. The simulated image is supplied to the metrology tool, where it is used as a basis for alignment of the tool for the measurement. Other recipe data is combined with the simulated image to provide a fully automated metrology set up process.

Owner:SYNOPSYS INC

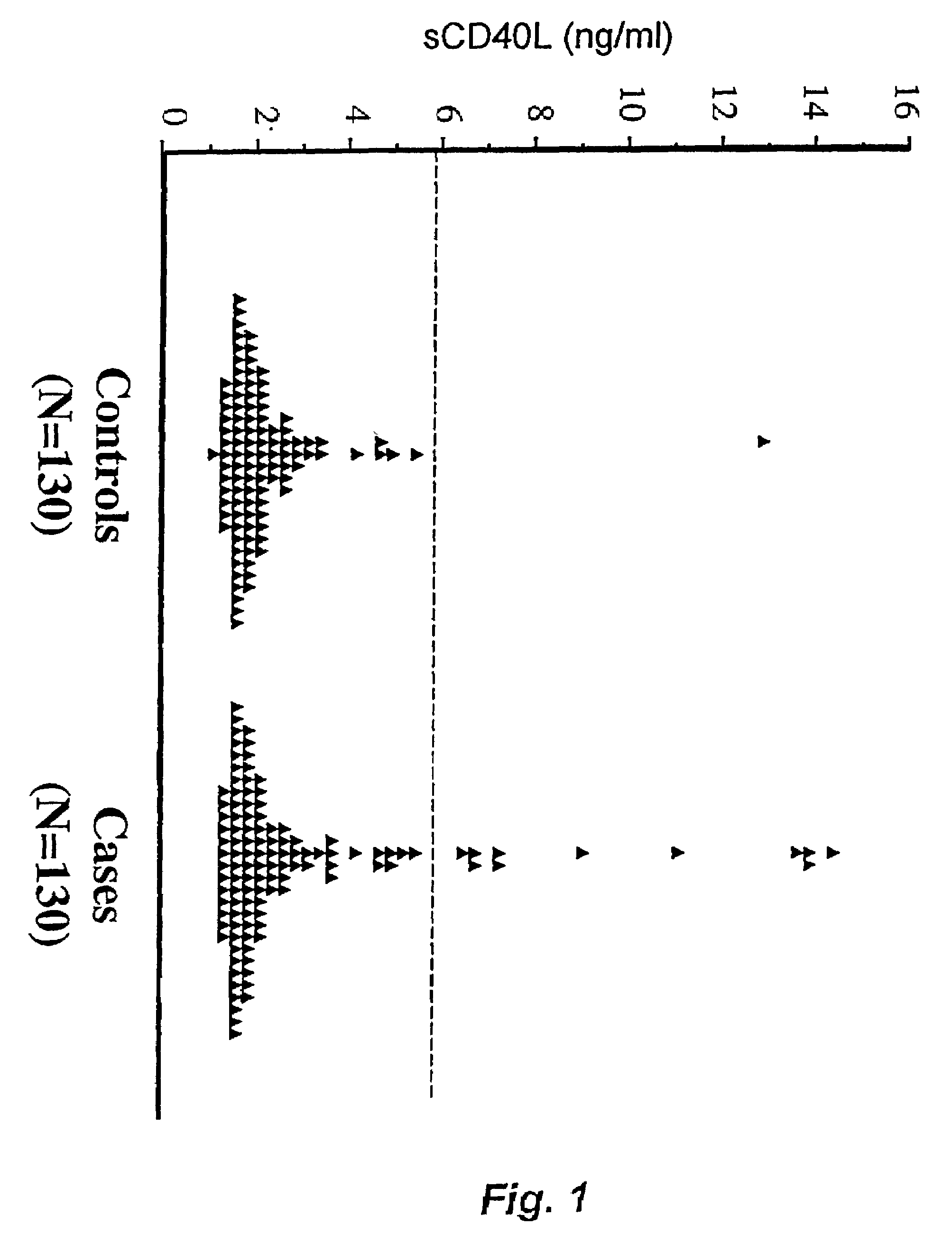

Soluble CD40L(CD154) as a prognostic marker of atherosclerotic diseases

InactiveUS7189518B2Prevent cardiovascular disorderReduce riskBiocidePeptide/protein ingredientsDiagnostic testSoluble cd40l

This invention involves the new use of a diagnostic test to determine the risk of atherosclerotic diseases such as myocardial infarction and stroke, particularly among individuals with no signs or symptoms of current disease and among nonsmokers. Further, this invention involves the new use of a diagnostic test to assist physicians in determining which individuals at risk will preferentially benefit from certain treatments designed either to prevent first or recurrent myocardial infarctions and strokes, or to treat acute and chronic cardiovascular disorders. Methods for treatment also are described.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

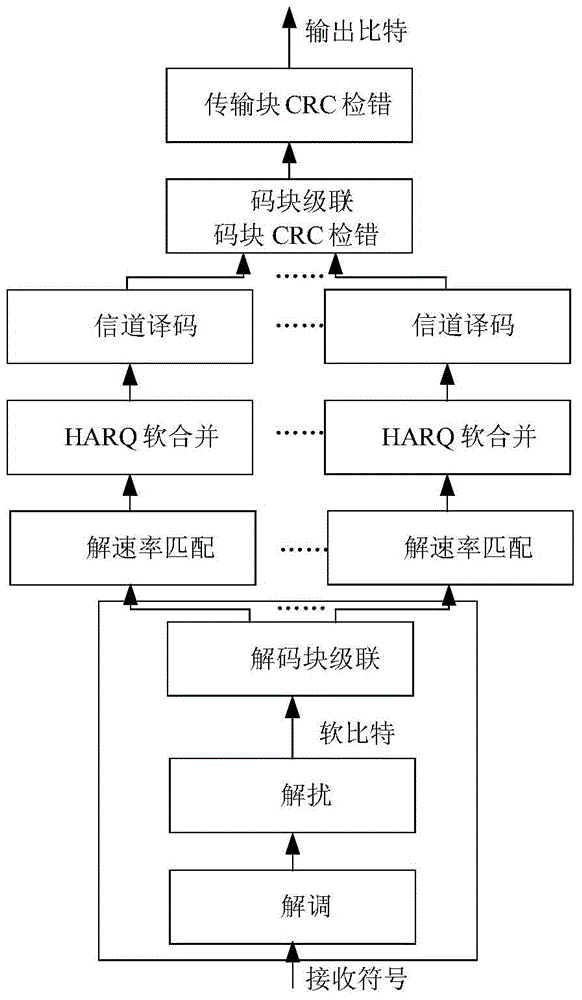

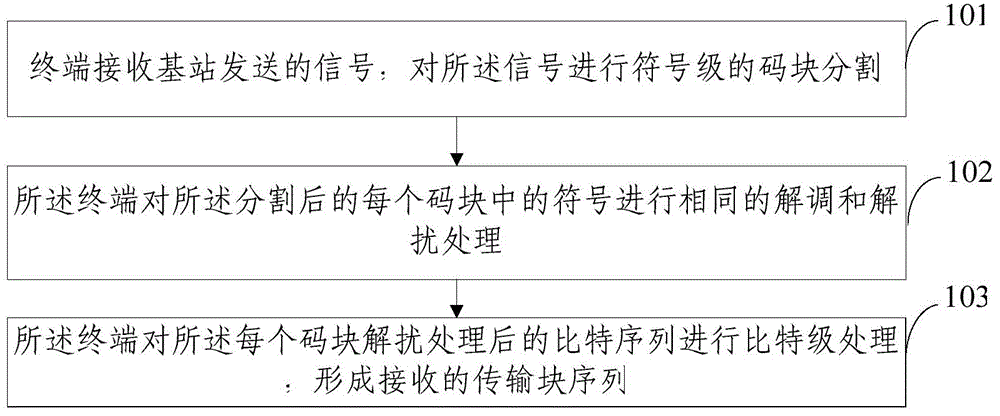

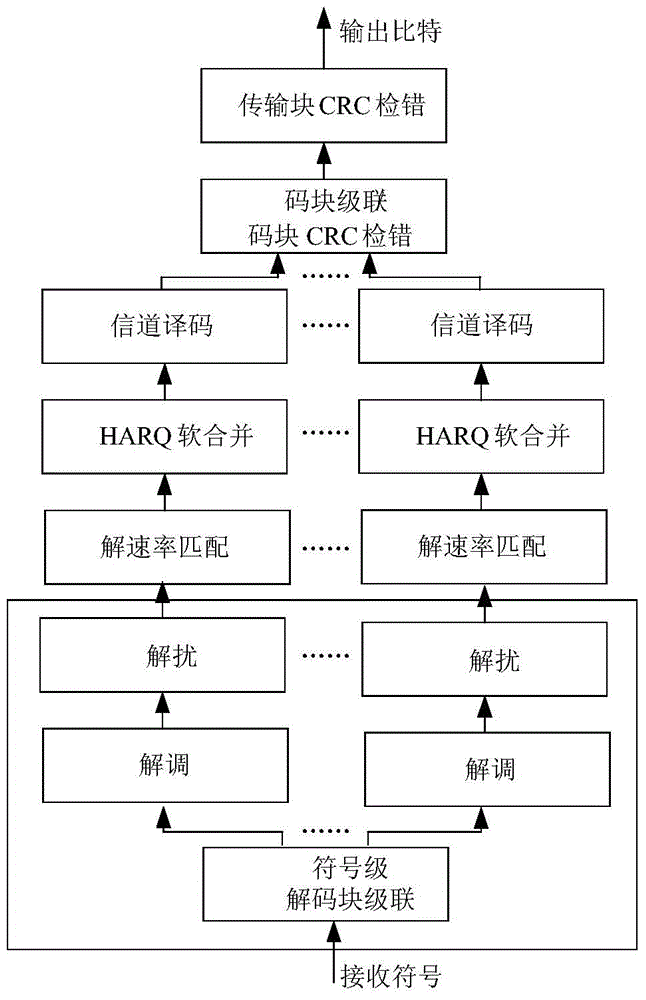

Code block receiving and processing method and device

The invention discloses a code block receiving and processing method and device. The method comprises the following steps that: a terminal receives a signal sent by a base station; the terminal performs symbol level code block division of the signal; the terminal performs same demodulation and descrambling treatments of a divided symbol in each code block; and the terminal performs bit-level treatments of a descrambled bit sequence of each code block, such that a received transmission block sequence is formed. According to the method disclosed by the invention, the demodulation and descrambling treatments based on the code block level are combined with treatments based on the code block, such as bit-level rate de-matching and channel decoding; therefore, the treatment capacity of a system is simplified and reduced; and the method is also suitable for parallel treatment design in a hardware environment.

Owner:POTEVIO INFORMATION TECH

Personalized airway stent manufacturing technology

InactiveCN105748179AReduce hyperplasiaStentsAdditive manufacturing apparatusManufacturing technologyAirway structure

The invention discloses a personalized airway stent manufacturing technology.A personalized airway stent is manufactured by utilizing a CT image to reestablish an airway stenosis model of a patient, expanding the stenosis of the airway model in three-dimensional numerical model reestablishment software by 20%-40% and then outwards expanding the wall face of the outmost side of the processed airway model by 10% to form the outer wall of the stent.A three-dimensional numerical model of the personalized airway stent is designed through the processing.Finally, the personalized airway stent model is imported into a 3D printer, and silicone and other medical biological materials are injected to manufacture the personalized stent conforming to the airway structure of the patient.Three-dimensional modeling is performed according to airway stenosis of different patients, the personalized airway stents are designed, and the shortcomings and defects that existing commercial airway stents difficultly fit the airways of the patients and granulation tissue proliferation is easily caused are overcome.

Owner:CHANGZHOU UNIV

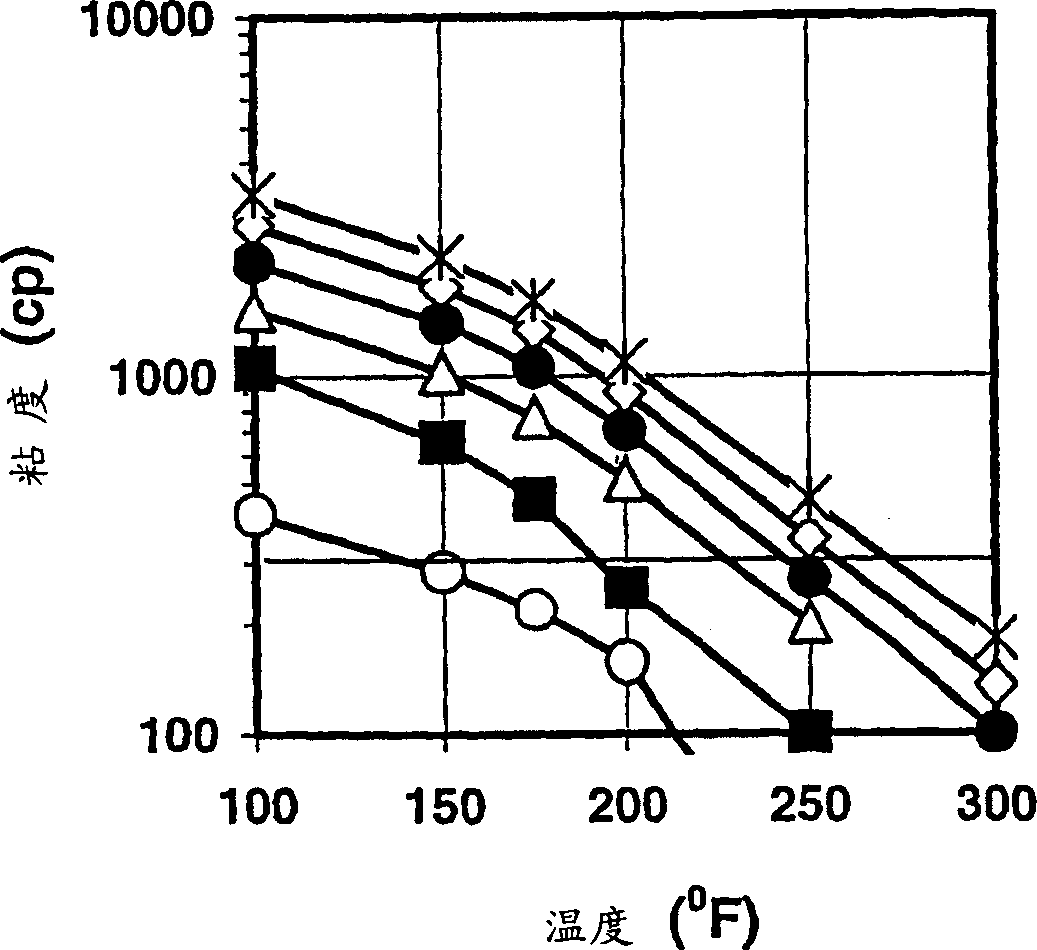

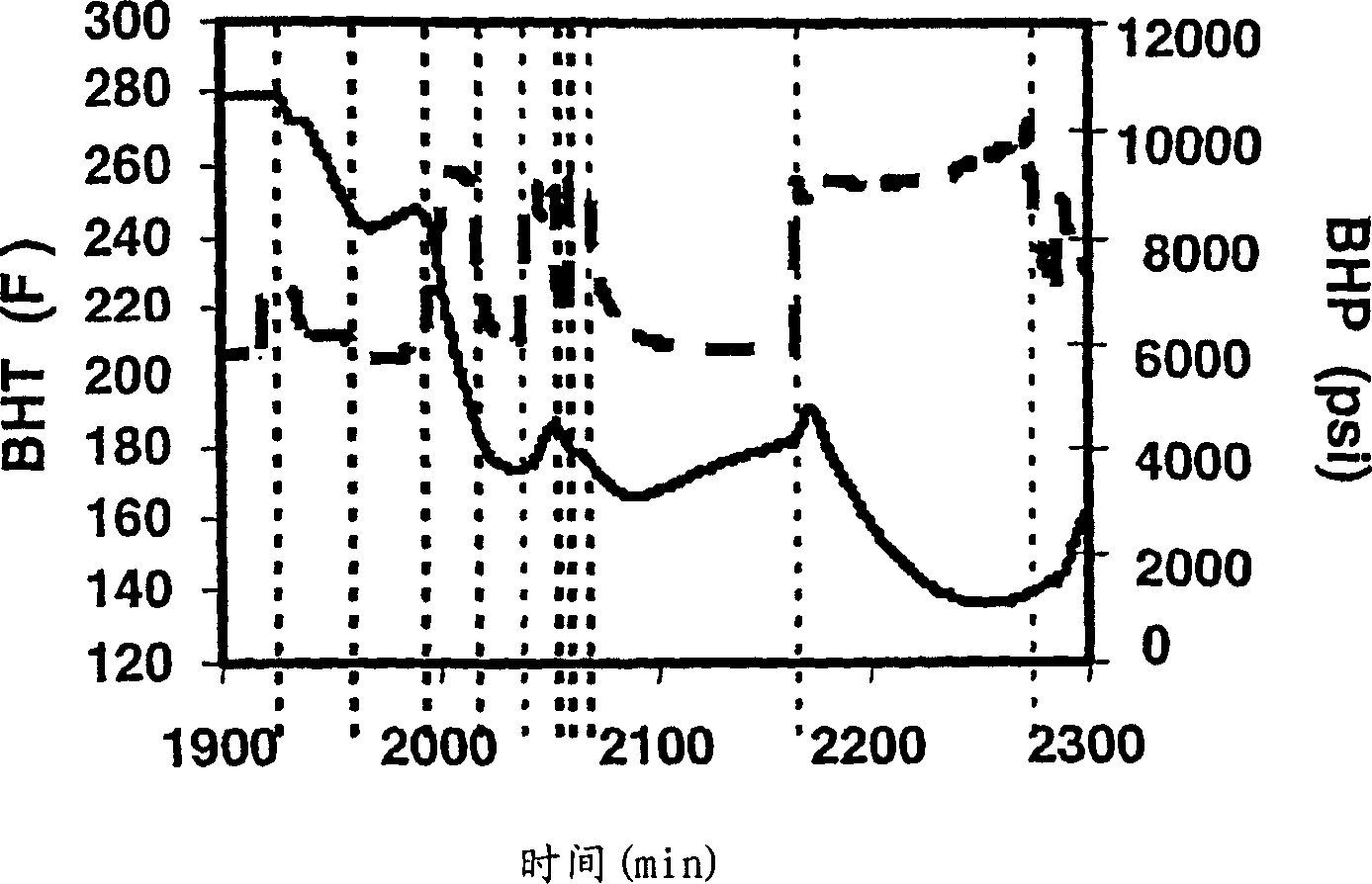

Hydraulic fracturing method

InactiveCN1729346AControl geometryFluid removalDrilling compositionTreatment designHydraulic fracturing

The present invention relates to a method of designing a hydraulic fracturing treatment in a subterranean reservoir comprising the steps of: a) quantifying reservoir parameters including bottom hole temperature and formation permeability, b) estimating formation stress due to treatment fluid injection Temporary changes in temperature, and c) designing the fluid best suited to said temporary temperature.

Owner:SCHLUMBERGER TECH LTD BV

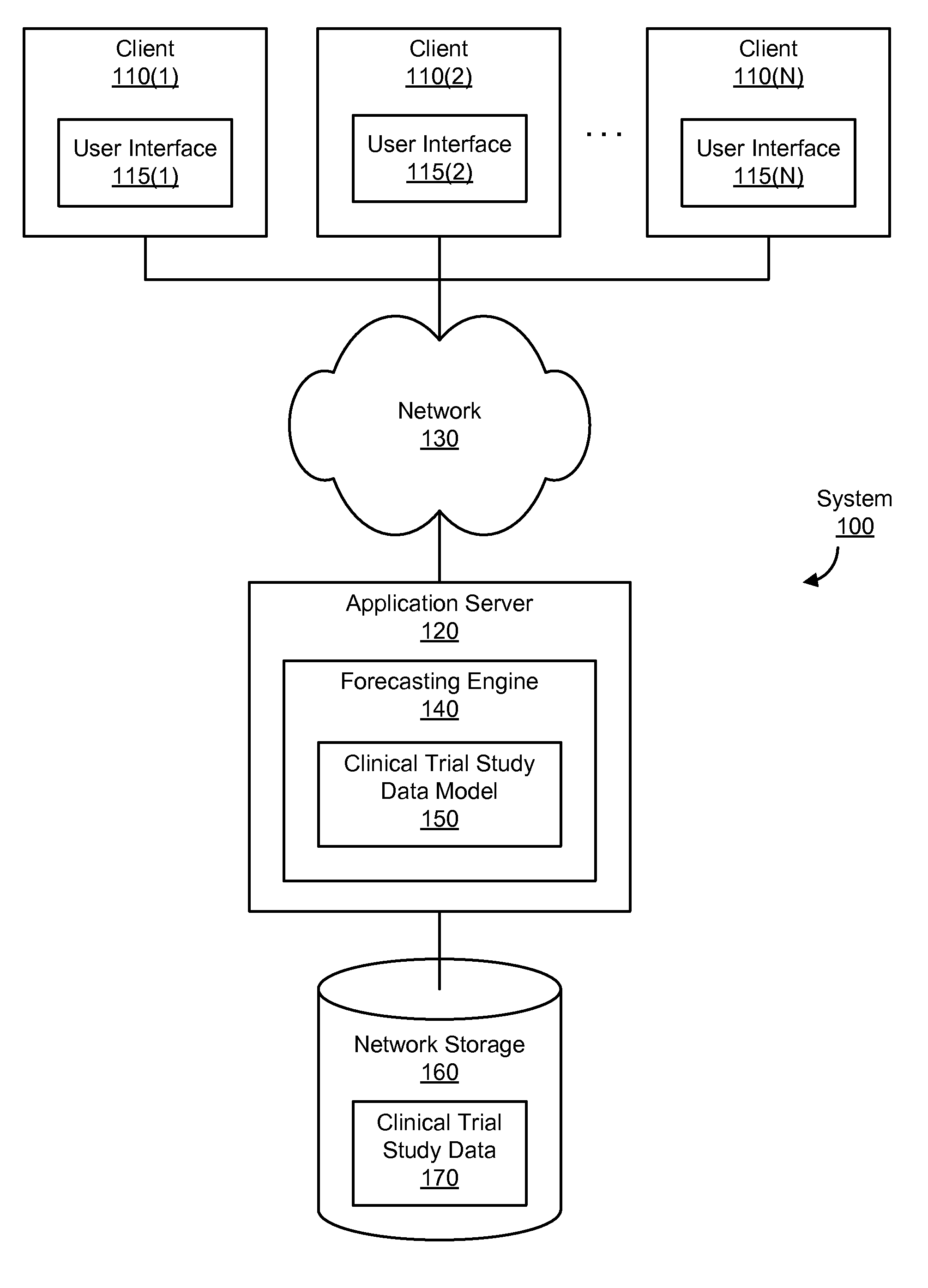

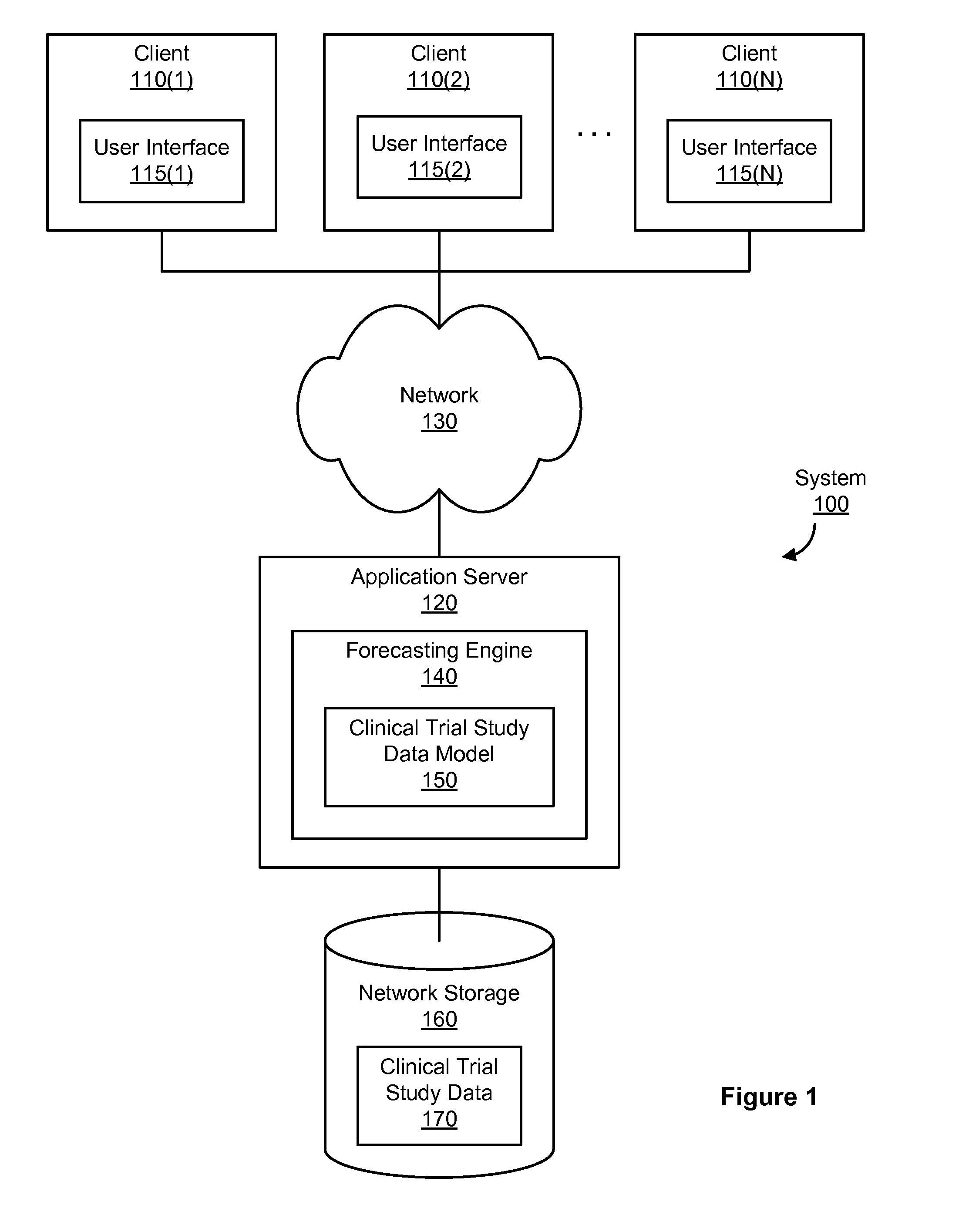

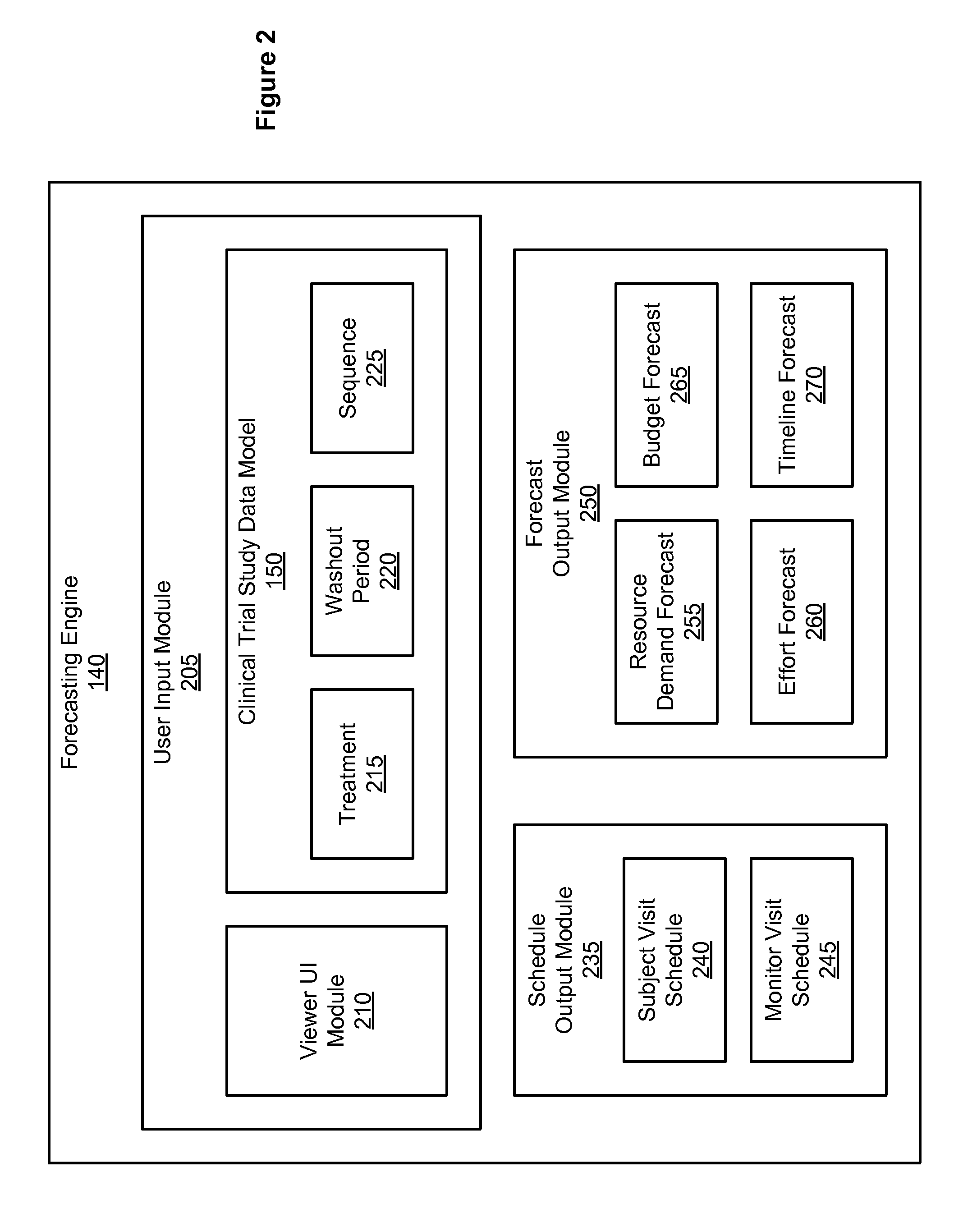

Framework for Modeling a Clinical Trial Study Using a Cross-Over Treatment Design

ActiveUS20140330572A1Data processing applicationsComputer-assisted medical data acquisitionTreatment designClinical trial

The present disclosure provides for modeling a clinical trial study, which may implement a cross-over design. A plurality of treatments is generated for a clinical trial study, based on a first subset of operational parameters. A plurality of sequences is also generated for the clinical trial study, based on a second subset of the operational parameters. Each sequence of the plurality of sequences comprises a combination of ones of the plurality of treatments. A plurality of subject groups is assigned to the plurality of sequences, where one subject group of the plurality of subject groups is respectively assigned to one sequence of the plurality of sequences. The one sequence is administered to subjects of the one subject group during the clinical trial study.

Owner:ORACLE INT CORP

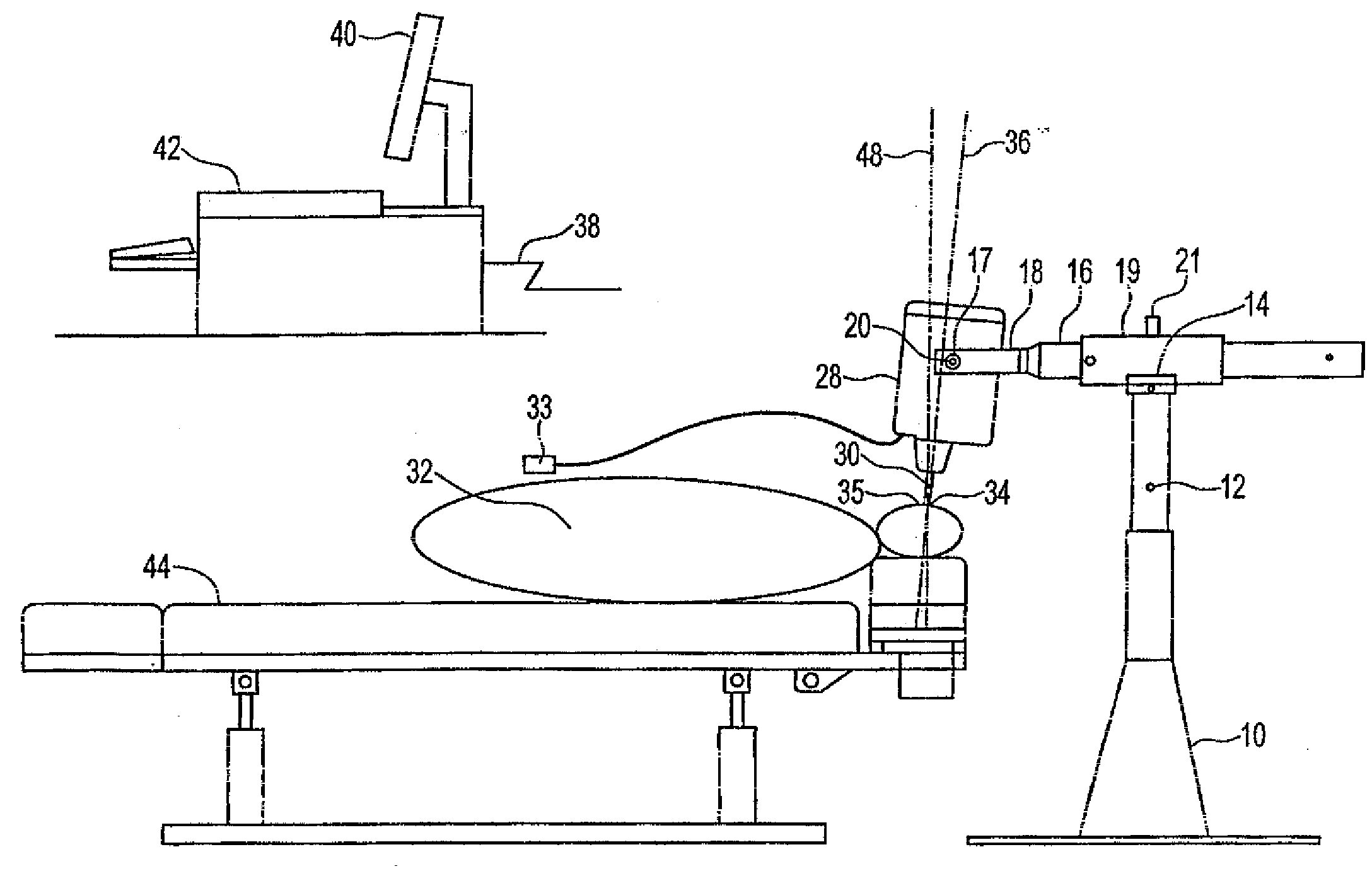

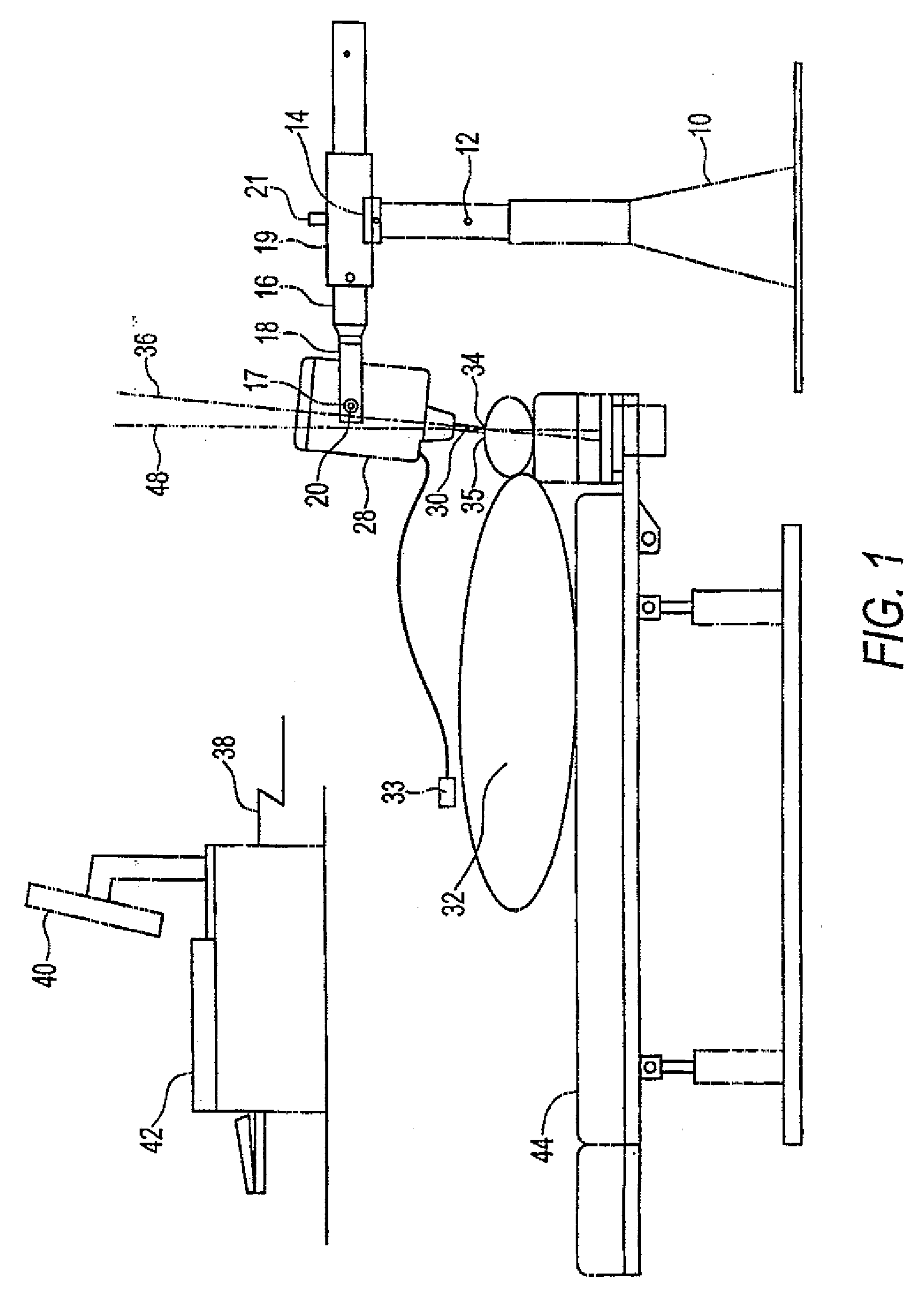

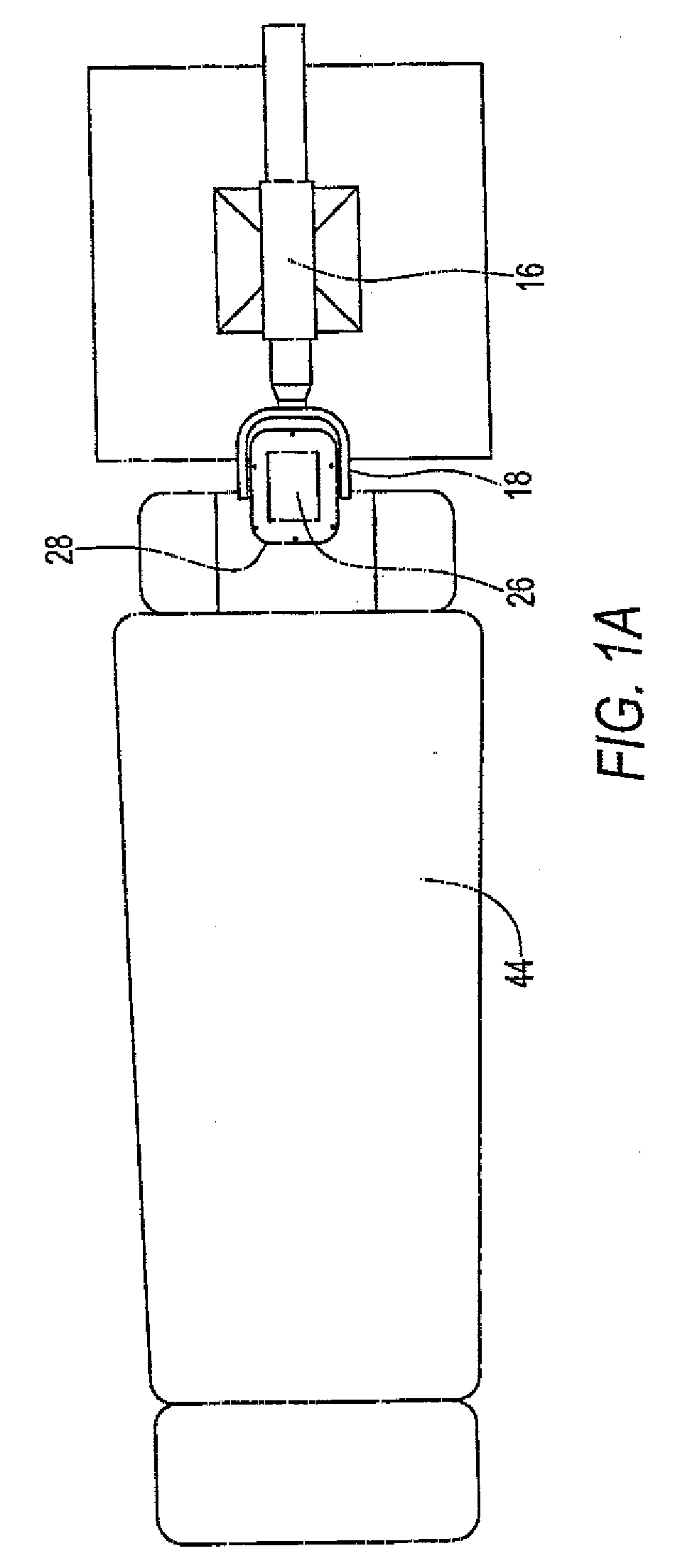

Spinal and Upper Cervical Impulse Treatment and Device

ActiveUS20080312724A1Improve accuracySuperior of applying forceElectrotherapyDiagnosticsSpinal columnData validation

The current invention is a spinal and upper cervical impulse treatment device and controller, which delivers multiple impulses of variable frequency and variable force in a linear direction, as well as rotational forces, for patient treatment. Known chiropractic impulse devices are all hand held devices. In contrast, the spinal and upper cervical impulse treatment device is mounted on a fixed stand and armature, allowing reliable positioning and directional alignment in three dimensions. Fixed mounting also facilitates ease of use. A safety coupling is incorporated to avoid patient injury due to excessive force on the treatment site in the fixed mounting scenario Smooth sinusoidal waveforms are a preferred waveform for impulse delivery and sine waves are generated digitally in the apparatus. Data validation is used to ensure correct directional alignment prior to device activation Patient safety and consistency in treatment protocols are considered in the spinal and upper cervical impulse treatment design

Owner:KHAN ASLAM

Site mixing and blow-filling method of solidified dredged mud

InactiveCN104532817AAdvantages of in-situ mix blow-fill methodLow costIn situ soil foundationSoil preservationTreatment designResource utilization

The invention discloses a site mixing and blow-filling method of solidified dredged mud. The method comprises the steps of: (1) site mixing and blow-filling of the solidified dredged mud; (2) site solidification of the dredged mud; and (3) detection of the solidified dredged mud. The step (1) further comprises analysis of the soil texture of the dredged mud, selection of a curing agent, determination of a mixing ratio of the curing agent to the dredged mud, mixing of the curing agent and the dredged mud, reinforcing design of the solidified dredged mud and determination of the shear strength index, the modulus of compressibility of the solidified dredged mud and the thickness of a reinforced soil layer to achieve characteristic values of the bearing capacity of foundation soil and allowing deformation values of the foundation treatment design, and determination of the maintenance time of finished products. The step (2) is to finish the reinforcement of a shallow-layer soft soil foundation through mixing and solidifying the curing agent and the dredged mud. The site mixing and blow-filling method of the solidified dredged mud can achieve the purposes of guarantee of the construction days, reduction of the project cost, reasonable resource utilization and environmental protection.

Owner:SHANGHAI MARITIME UNIVERSITY

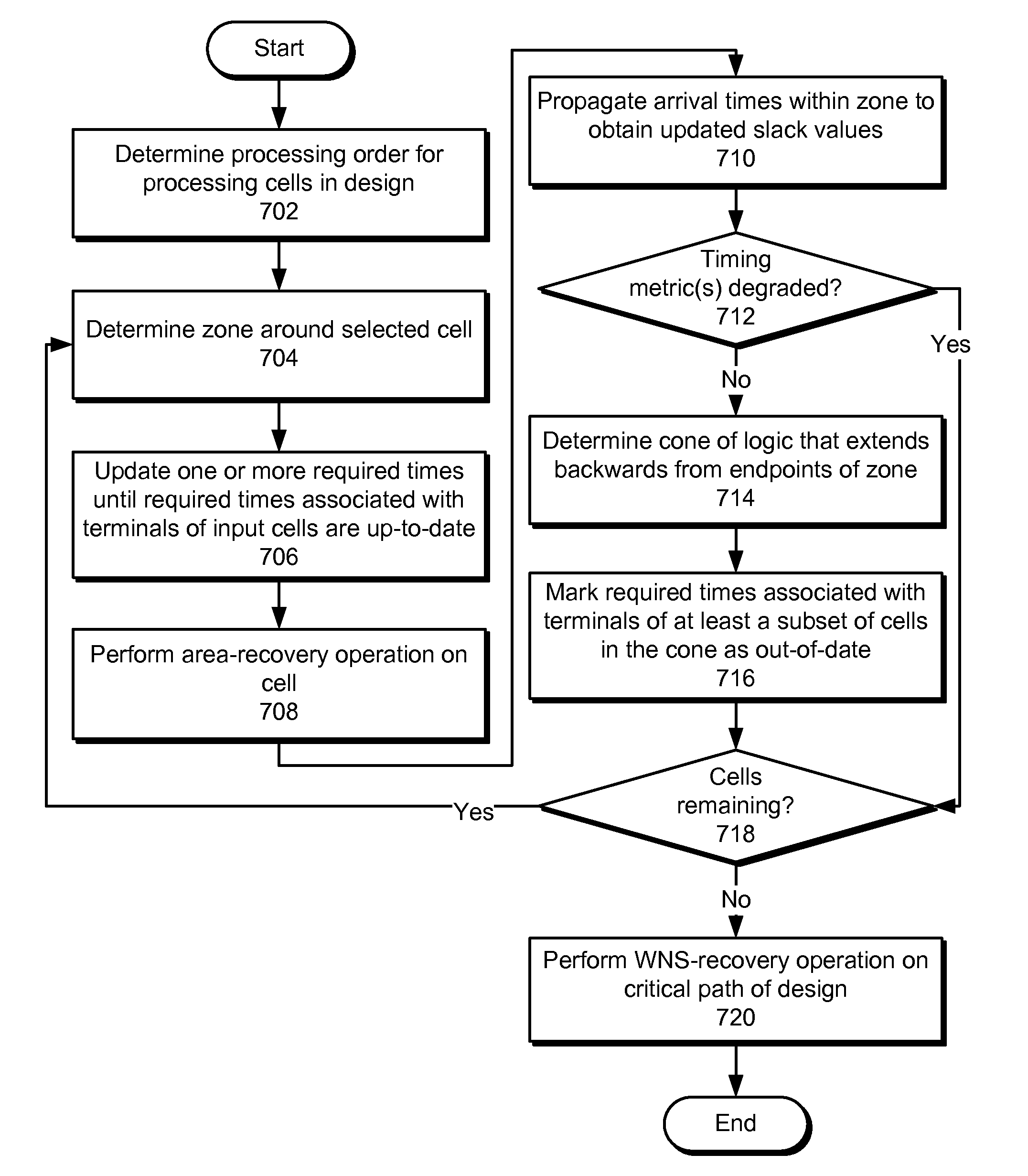

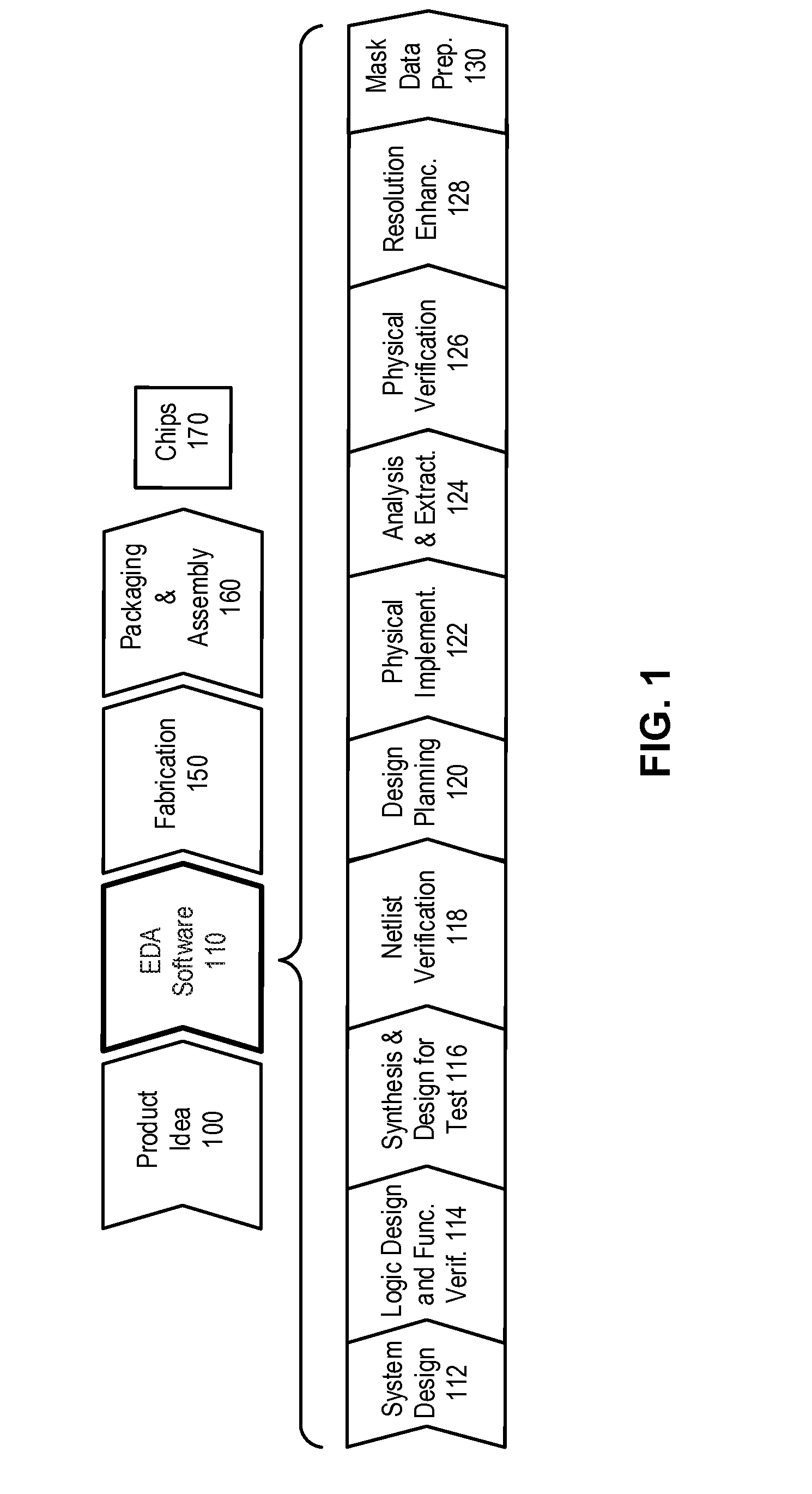

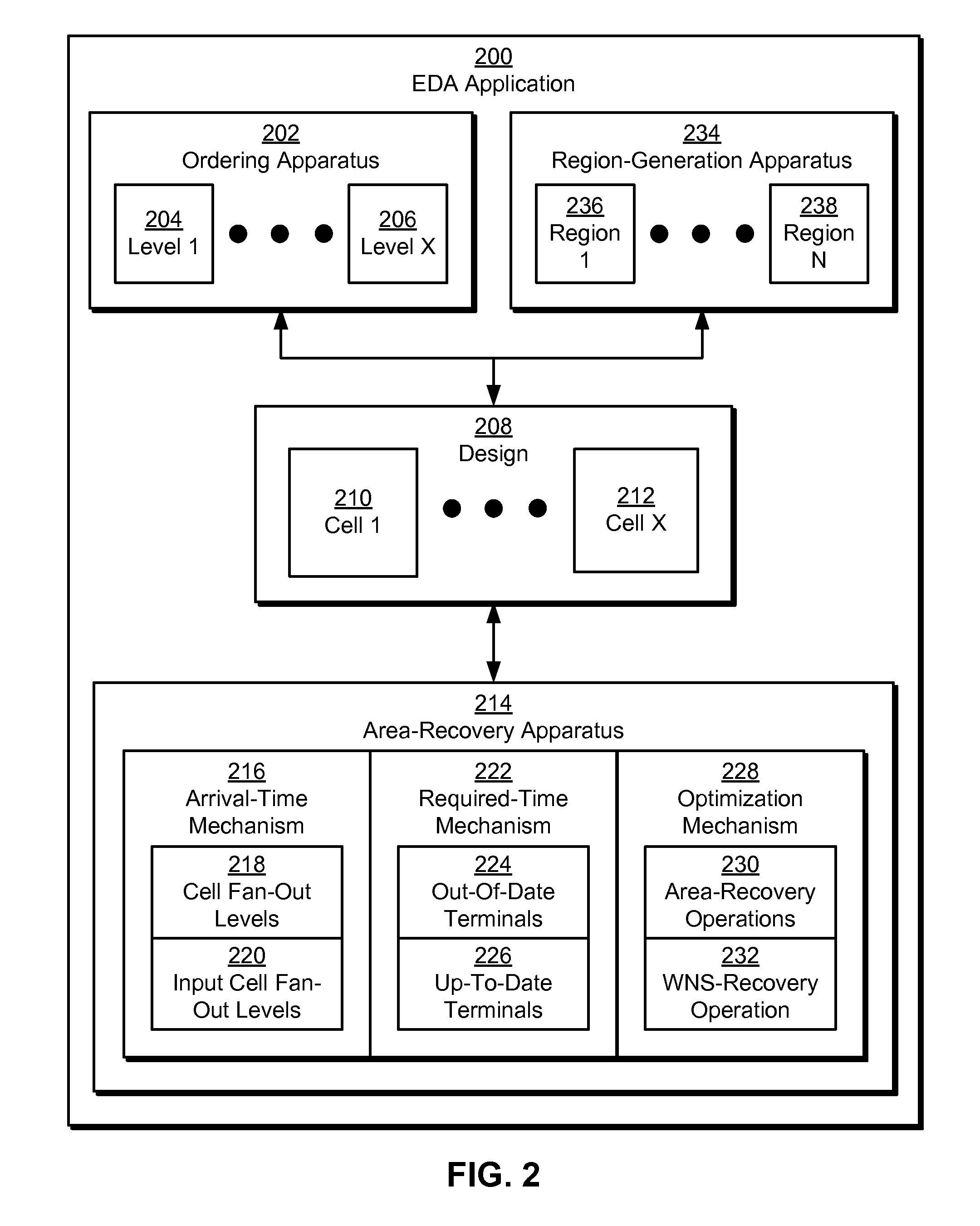

Zone-based area recovery in electronic design automation

ActiveUS20110191731A1Improve efficiencyComputer aided designSoftware simulation/interpretation/emulationAlgorithmTreatment design

Some embodiments provide a system that facilitates the creation of a design in an electronic design automation (EDA) application. During operation, the system determines a processing order for processing a set of cells in the design. In some embodiments, the processing order can be a reverse-levelized processing order. Next, the system may select a cell for performing area recovery according to the processing order. The system may then tentatively perform an area-recovery operation on the selected cell. Next, the system may determine a zone around the selected cell. Next, the system may propagate arrival times within the zone to obtain updated slack values at endpoints of the zone. The system may compute one or more timing metrics at the endpoints. If the updated slack values do not degrade the timing metric(s) at the endpoints, the system may accept the area-recovery operation of the selected cell.

Owner:SYNOPSYS INC

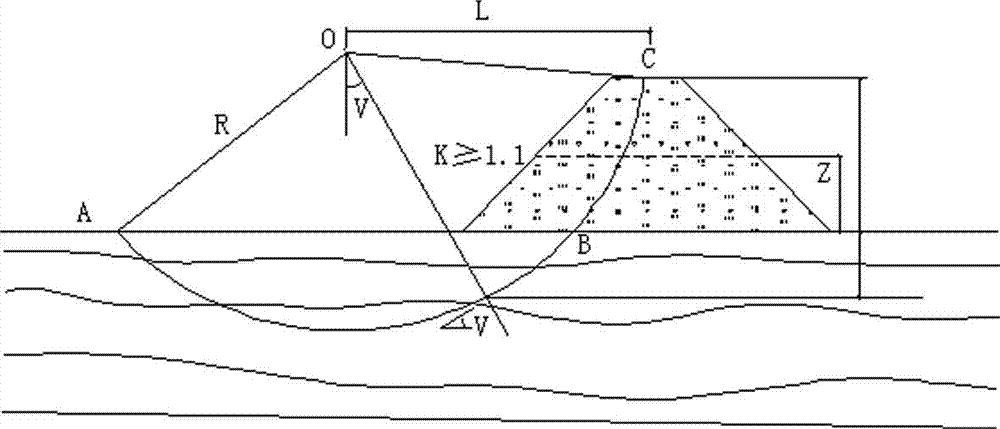

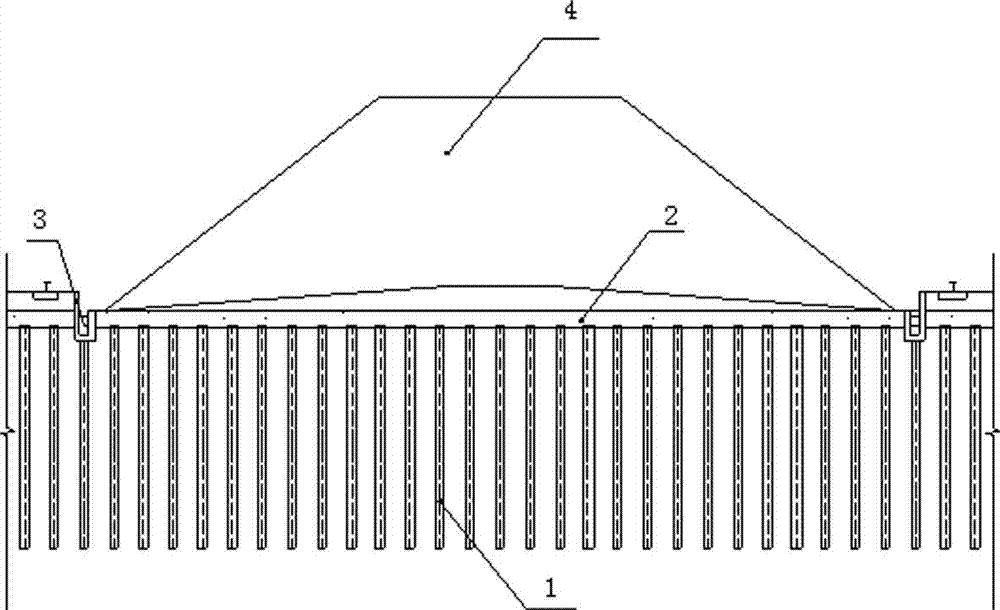

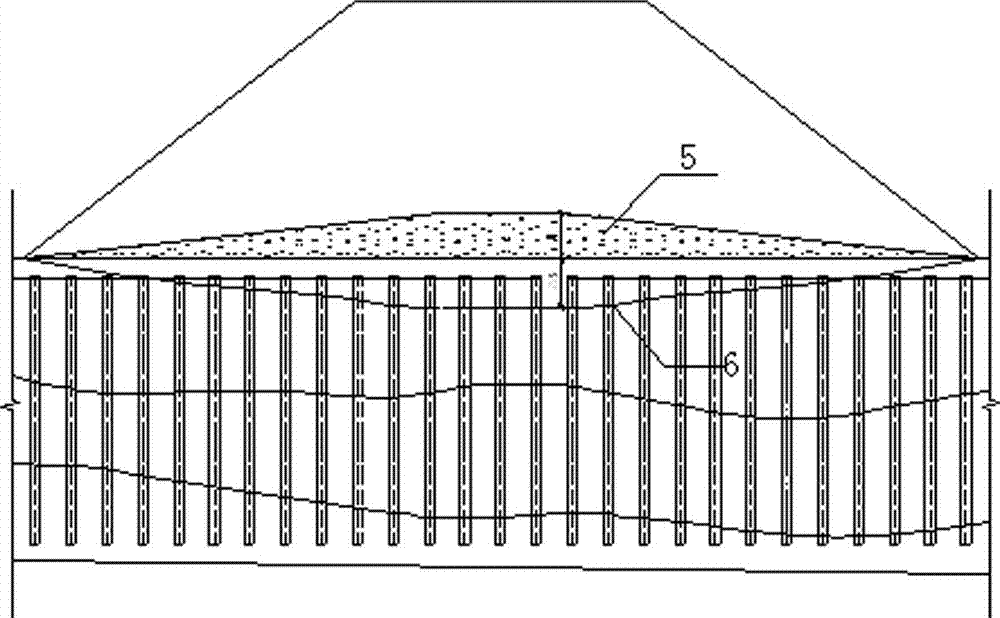

Large-area deep soft foundation preloading comprehensive treatment method combined with production and operation management

ActiveCN102877456ALarge storage capacityReduce wasteSoil preservationManagement processTreatment design

The invention discloses a large-area deep soft foundation preloading comprehensive treatment method combined with production and operation management. The method comprises the following steps of: (1) performing foundation treatment design calculation; (2) designing a drainage system scheme; (3) arranging a monitoring system; (4) arranging a sandstone pre-arched camber according to theoretical sedimentation deformation; and (5) formulating relevant management processes. The method has the advantages that sandstone piles (wells) or plastic drainage plates and the like can be arranged in foundation soil through a scientific material storage management system by fully using abundant stored materials serving as a convenient condition in a raw material storage yard and are used as drainage channels to fulfill the aims of gradually draining water from a foundation and solidifying and compacting the foundation, improving the intensity of the foundation soil and finally meeting the requirement of designing the maximum stocked material load. By the method, the manufacturing cost of foundation treatment engineering can be greatly reduced, the maximum material storage capacity of the raw material storage yard can be realized within the shortest time through strict and scientific material storage management, and the waste of raw materials can be reduced to the greatest extent at the same time; and production and operation time is greatly shortened, and great economic benefits are brought.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

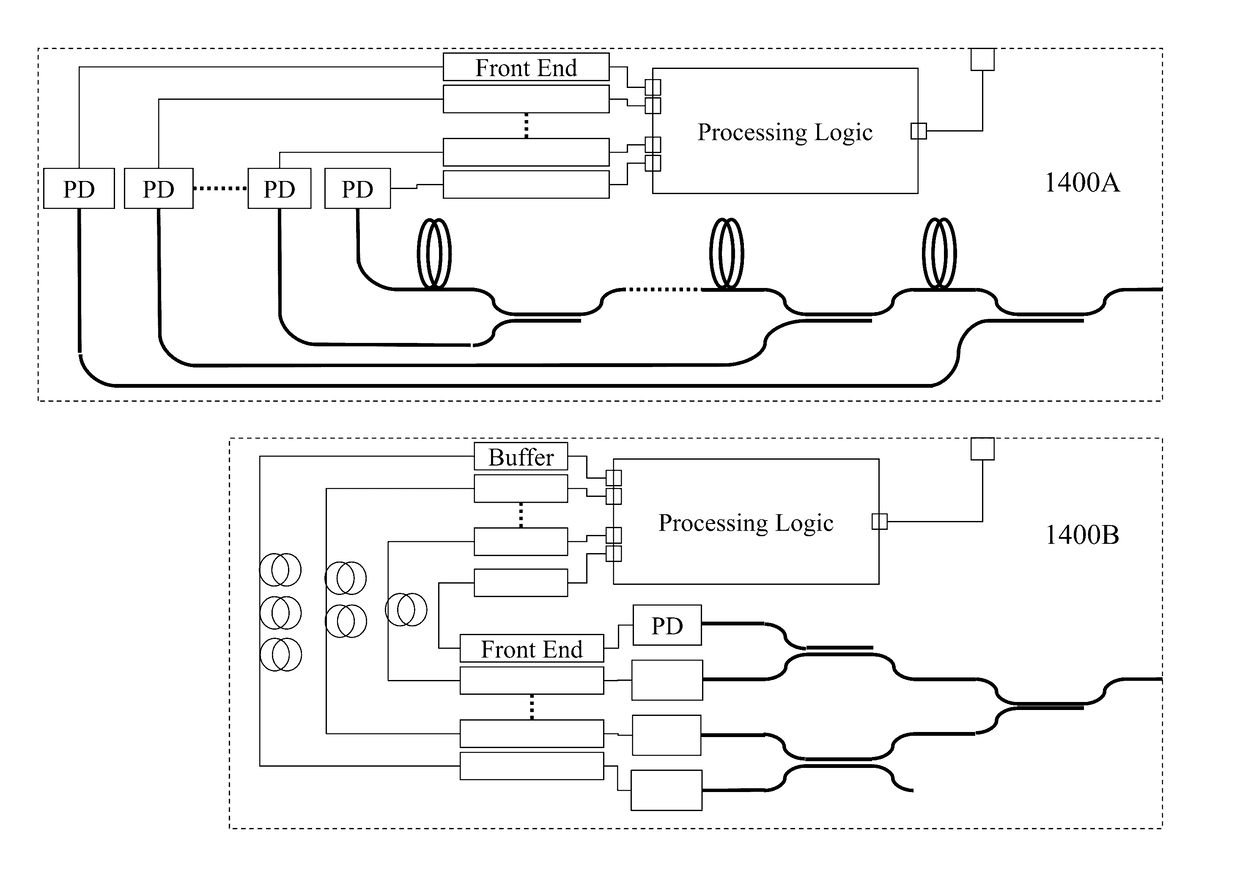

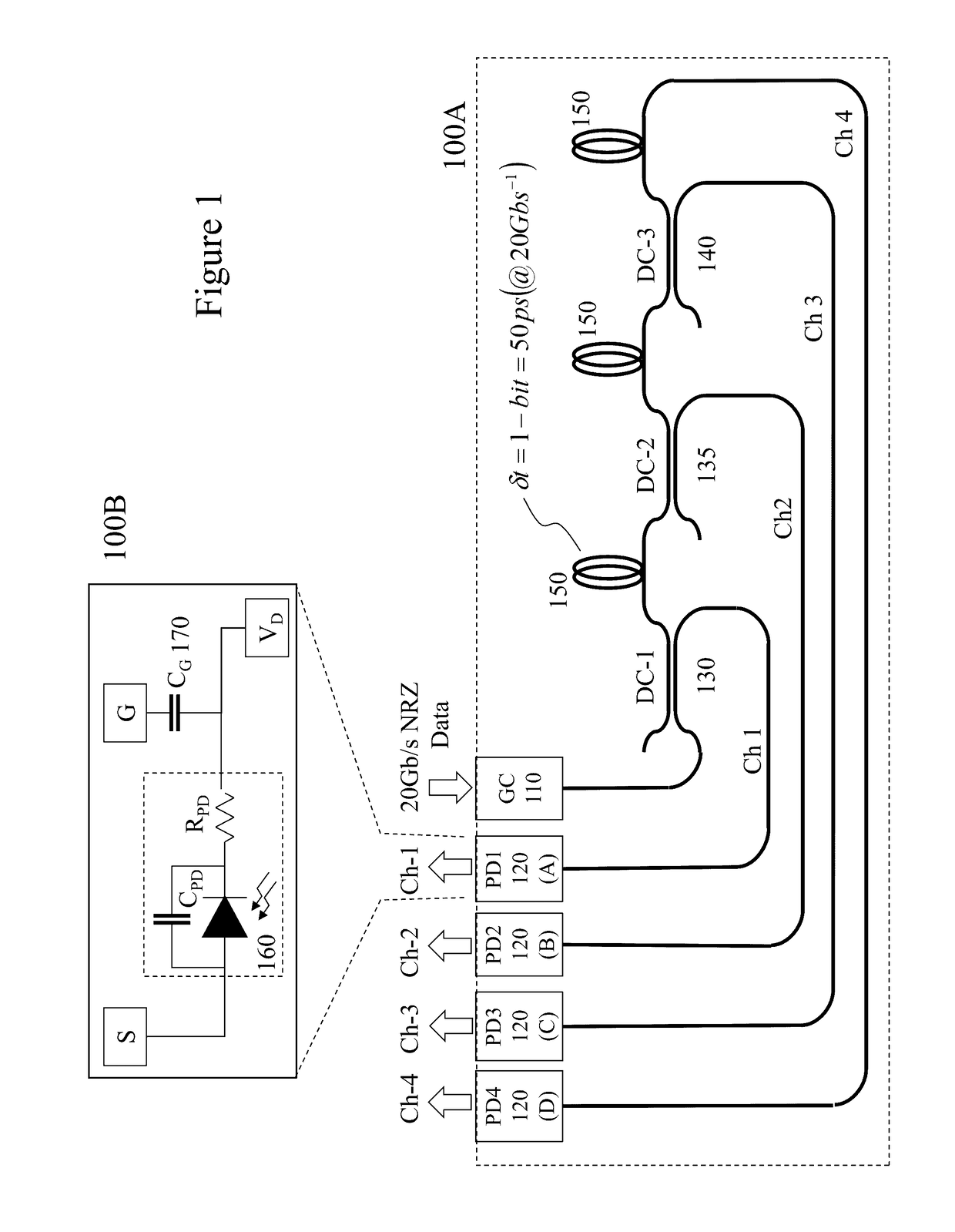

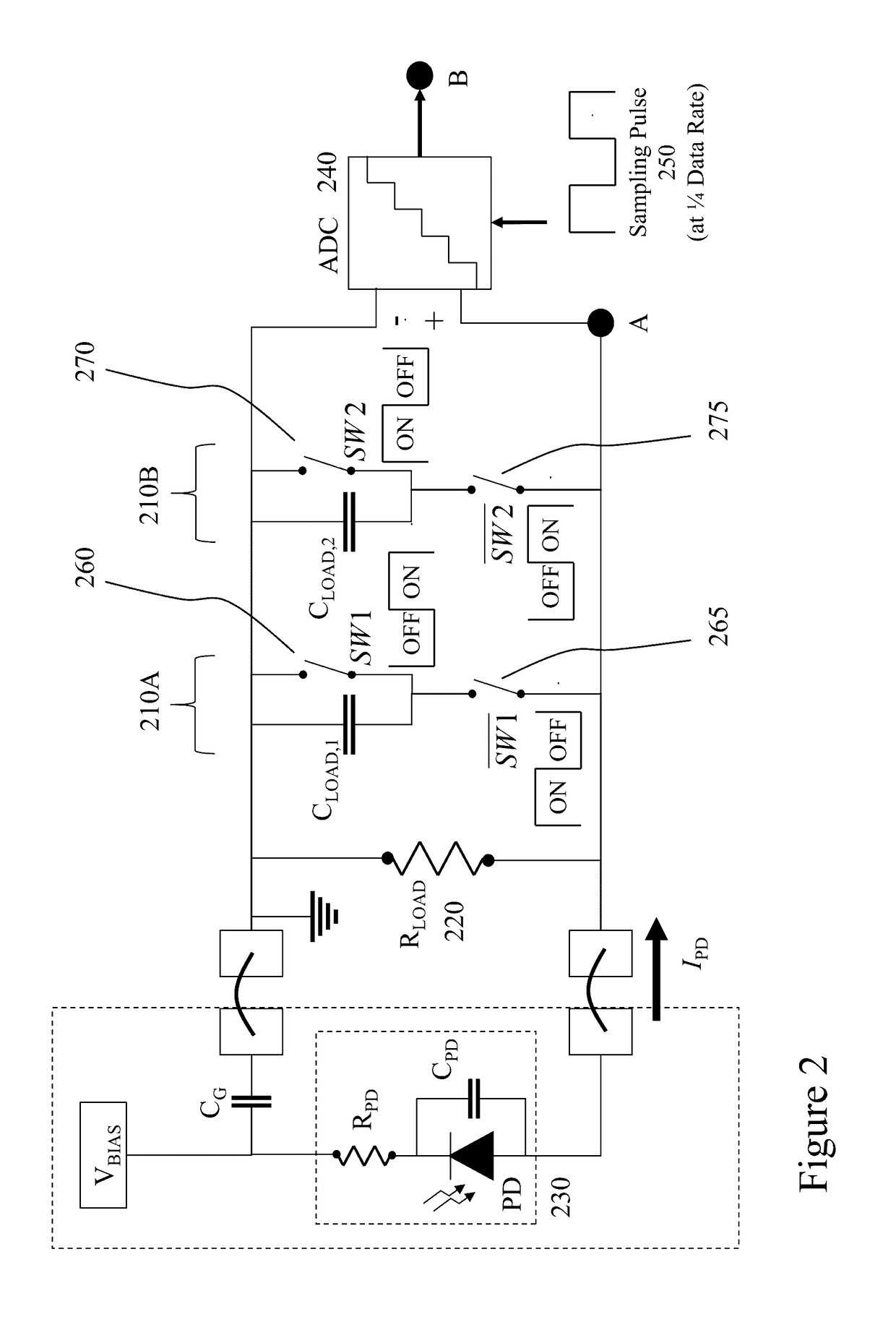

Time sampled photodetector devices and methods

Photonic integration has primarily sought to exploit optical parallelism through wavelength division multiplexing whilst in many instances “brute-force” time division multiplexing offers benefits through reduced complexity and cost. However, photoreceivers are primarily the same now for operation at 10 Gb / s, 20 Gb / s, 40 Gb / s and above as 20 or 25 years ago and exploit the same optical detection—amplification—logic processing design. However, high speed low cost electronics ca be leveraged in conjunction with optical time sampling and logic to provide a new design paradigm. An incoming XGbs−1 optical data stream is sampled and processed by N photodetectors each operating at (X / N)Gbs−1 rather than the current direct XGbs−1 front-end of the prior art. Flexibility for the designer in establishing N within optical layer constraints, electronics capabilities etc. allows for further cost—power—complexity—performance tradeoffs to be established in different systems such that high capacity TDM links can exploit direct CMOS integrated optoelectronic front-ends.

Owner:TRANSFERT PLUS S E C +1

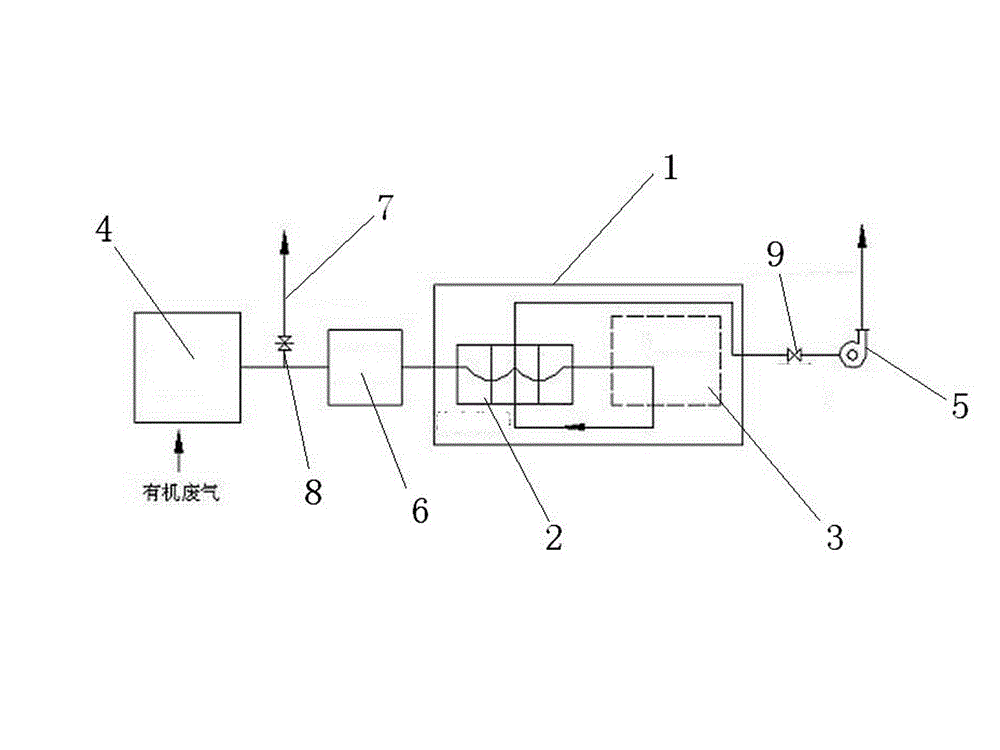

Waste gas catalytic combustion purification device

InactiveCN105546556AWell-thought-out designEfficient purificationIncinerator apparatusTreatment designExhaust fumes

The invention discloses a waste gas catalytic combustion purification device. The waste gas catalytic combustion purification device comprises a purification body, and a heat exchanger and a catalyst chamber are arranged in the body; and organic waste gas passes through a pretreatment device to be input to the purification body through an air pipe, and the waste gas sequentially passes through the heat exchanger and the catalyst chamber and is finally exhausted through a draught fan. According to the organic waste gas purification device, the waste gas is heated and is converted into harmless and inodorous carbon dioxide and water through catalytic combustion, the initiation temperature is low, energy is saved, the purification rate is high, operation is convenient, the occupied area is small, the organic waste gas can be rapidly and effectively purified, waste gas treatment design is well-planned, the waste gas can be purified and filtered layer by layer, and the effect is good.

Owner:朱振新

Quick strengthening method for dredger fill foundation with curing agents and dredger fill mixed in pipeline

The invention discloses a rapid reinforcement method of dredging fill foundation by mixing curing agent and dredging fill pipeline, which comprises: step 1, determining the mixing ratio of curing agent and dredging fill soil, mixing and filling on site; step 2, strengthening the foundation ; Step 3, inspection of solidified dredger fill foundation; wherein, step 1 includes: carry out soil quality analysis to dredger fill; select curing agent type; determine the mixing ratio of curing agent and dredger fill; : Determine the shear strength index, compressive modulus and thickness of the reinforced soil layer of the solidified dredger fill to meet the requirements of the characteristic value of the foundation bearing capacity and the allowable deformation value of the foundation treatment design; Reinforcement; determine curing conditions and curing time. The on-site mixed dredging method for solidified dredged fill provided by the present invention can greatly reduce the construction period, reduce the process of silt consolidation and foundation reinforcement in conventional dredged fill foundation treatment, save engineering cost, rationally utilize resources and protect the environment .

Owner:刘文白

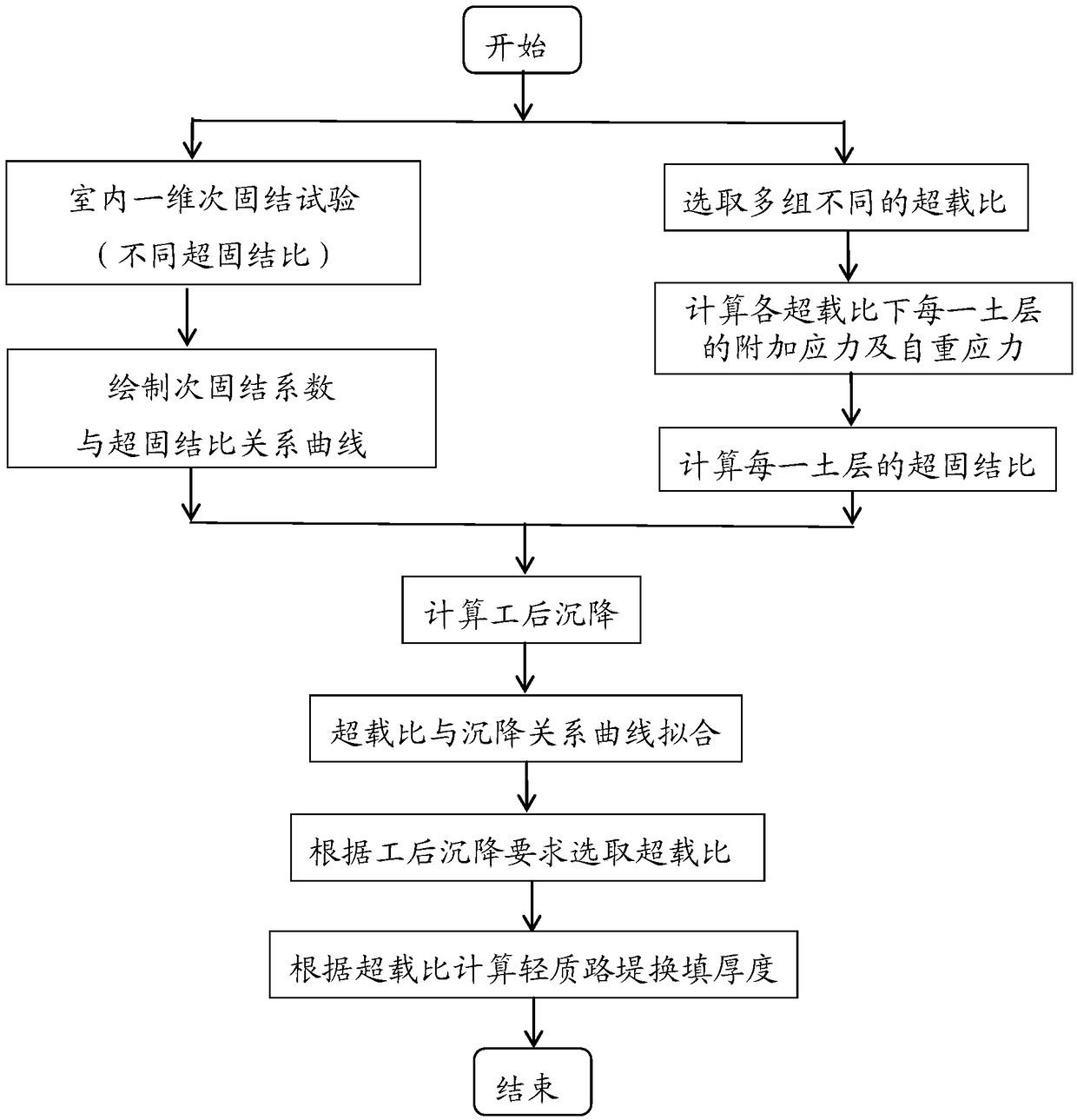

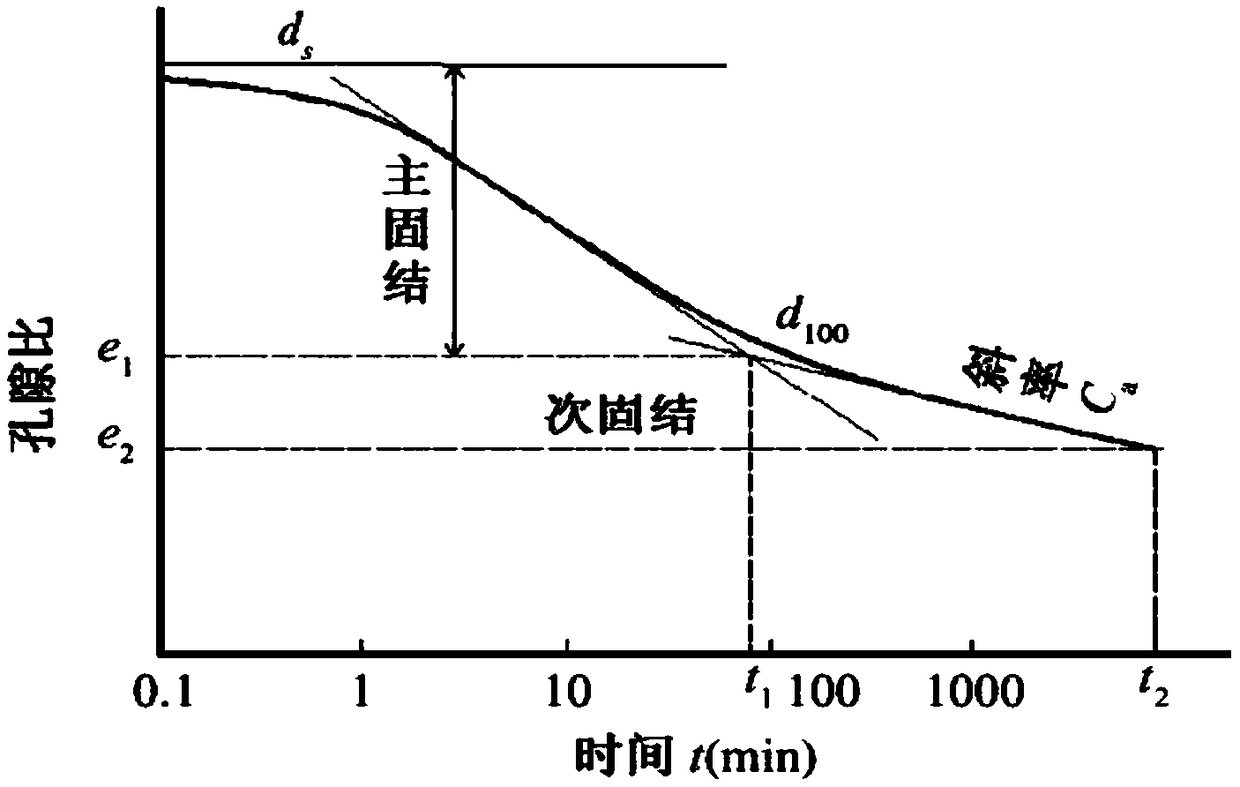

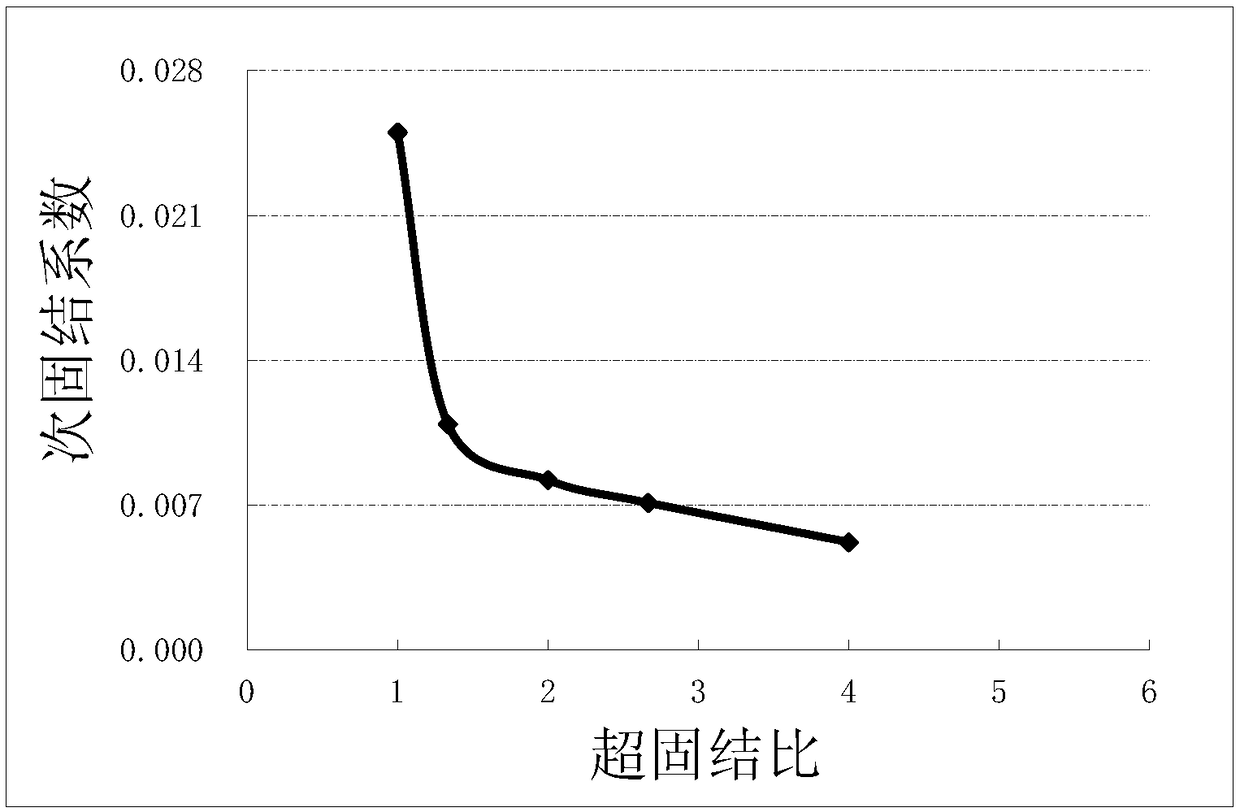

Method for achieving soft soil foundation treatment by controlling secondary consolidation settlement

ActiveCN108797558AAccurate estimateControl post-construction settlementSoil preservationTreatment designSoft clay

The invention discloses a method for achieving soft soil foundation treatment by controlling secondary consolidation settlement. Drainage consolidation and preloading method treatment is carried out on a soft soil foundation, and after the pre-pressing stage is met, unloading and backfilling of an ultra-light material EPS and filling of the pavement structure are carried out; before foundation treatment design, geological prospecting is carried out, meanwhile, undisturbed samples are taken, series conventional secondary consolidation testing and overconsolidated soil secondary consolidation testing are carried out, and series parameters or curved required for design are obtained; and during foundation treatment design, besides conventional stability and total settlement calculation is carried out, secondary consolidation settlement calculation is also carried out, and according to the requirement of specific engineering for foundation post-construction settlement, the thickness of thebackfilled ultra-light material is designed. By means of the method, soft clay can be converted into overconsolidated soil, and therefore the secondary consolidation coefficient of soft soil is reduced, the secondary consolidation settlement of the soft soil layer is reduced, and the aim of controlling post-construction settlement of structures is achieved.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

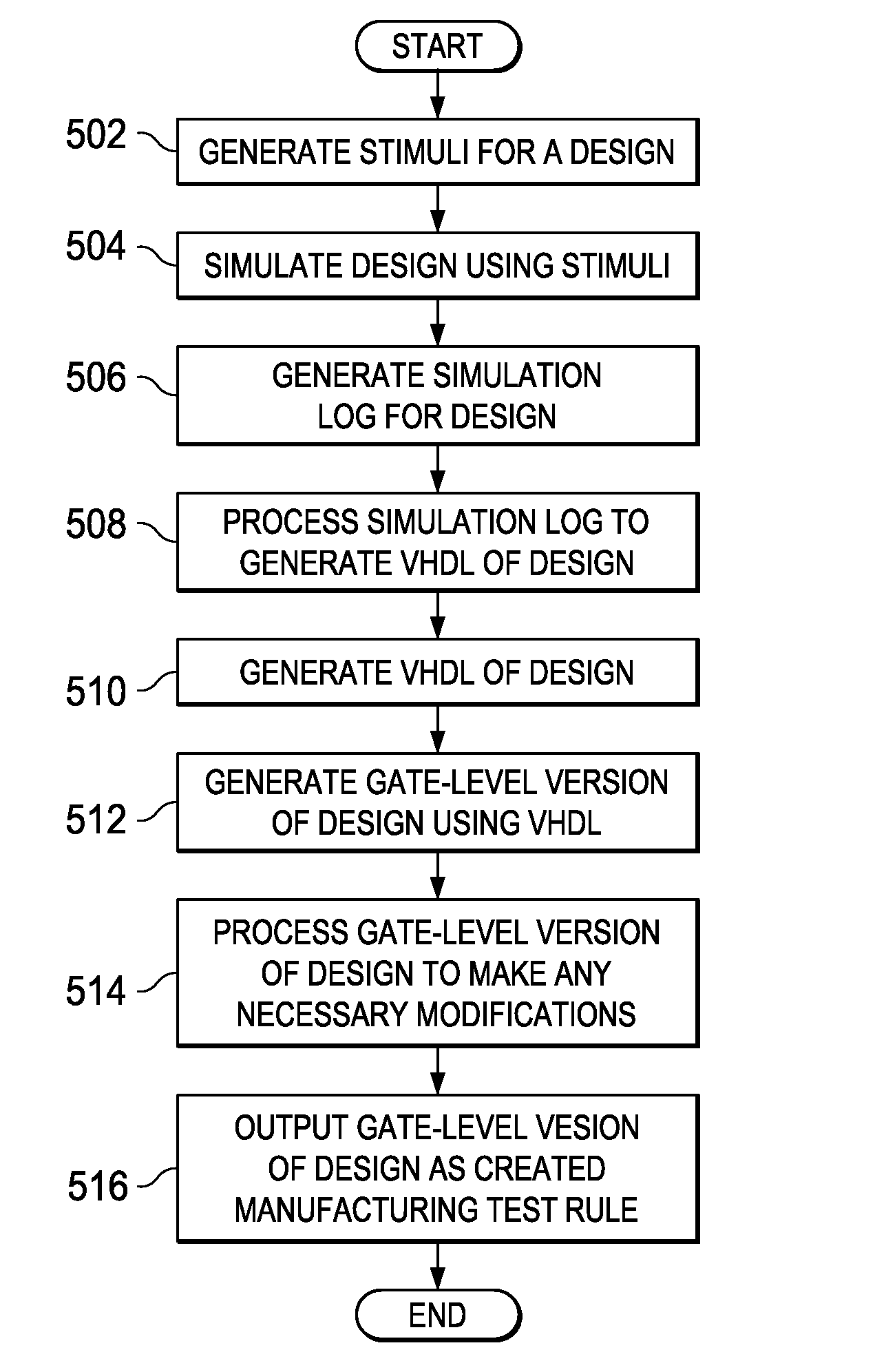

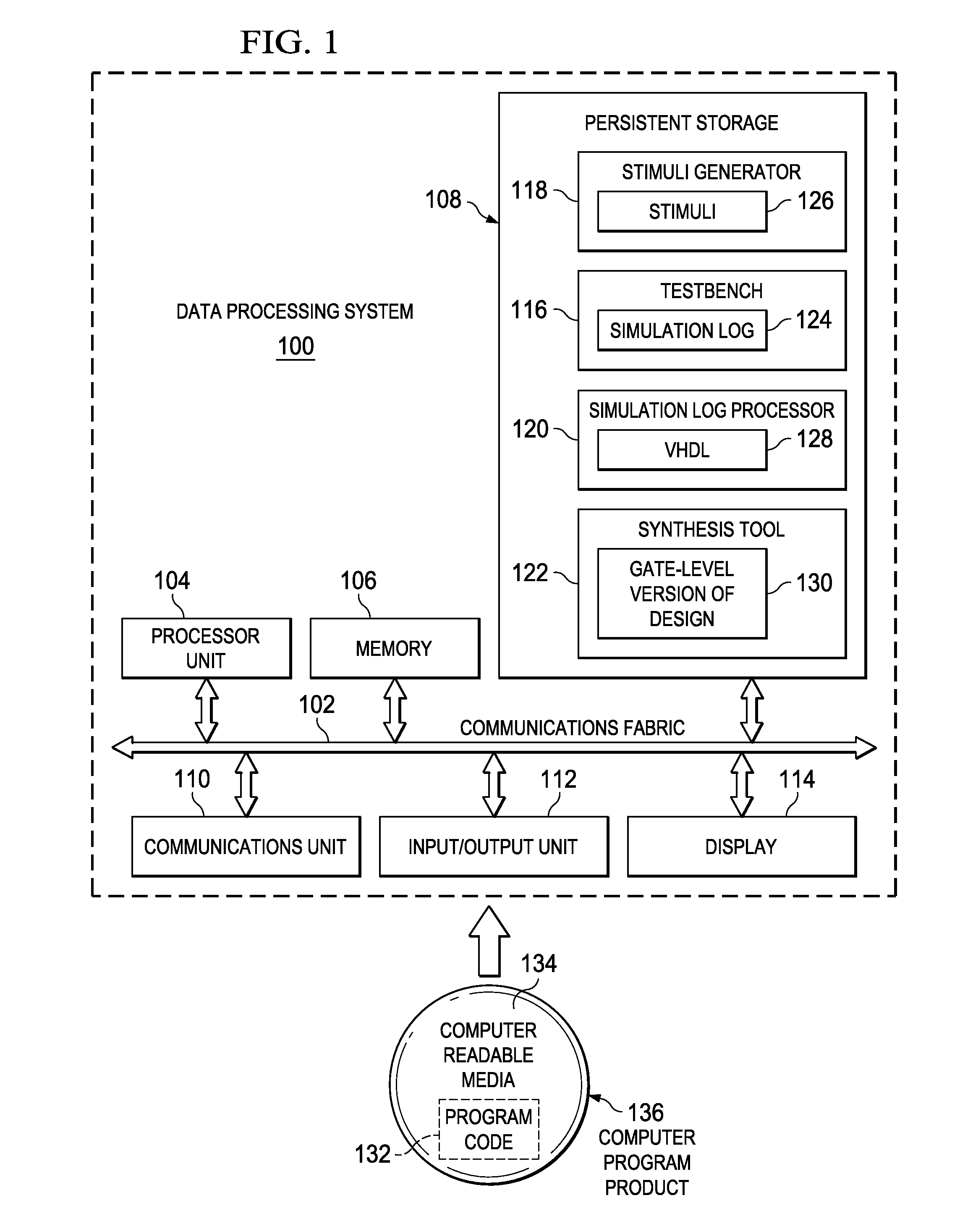

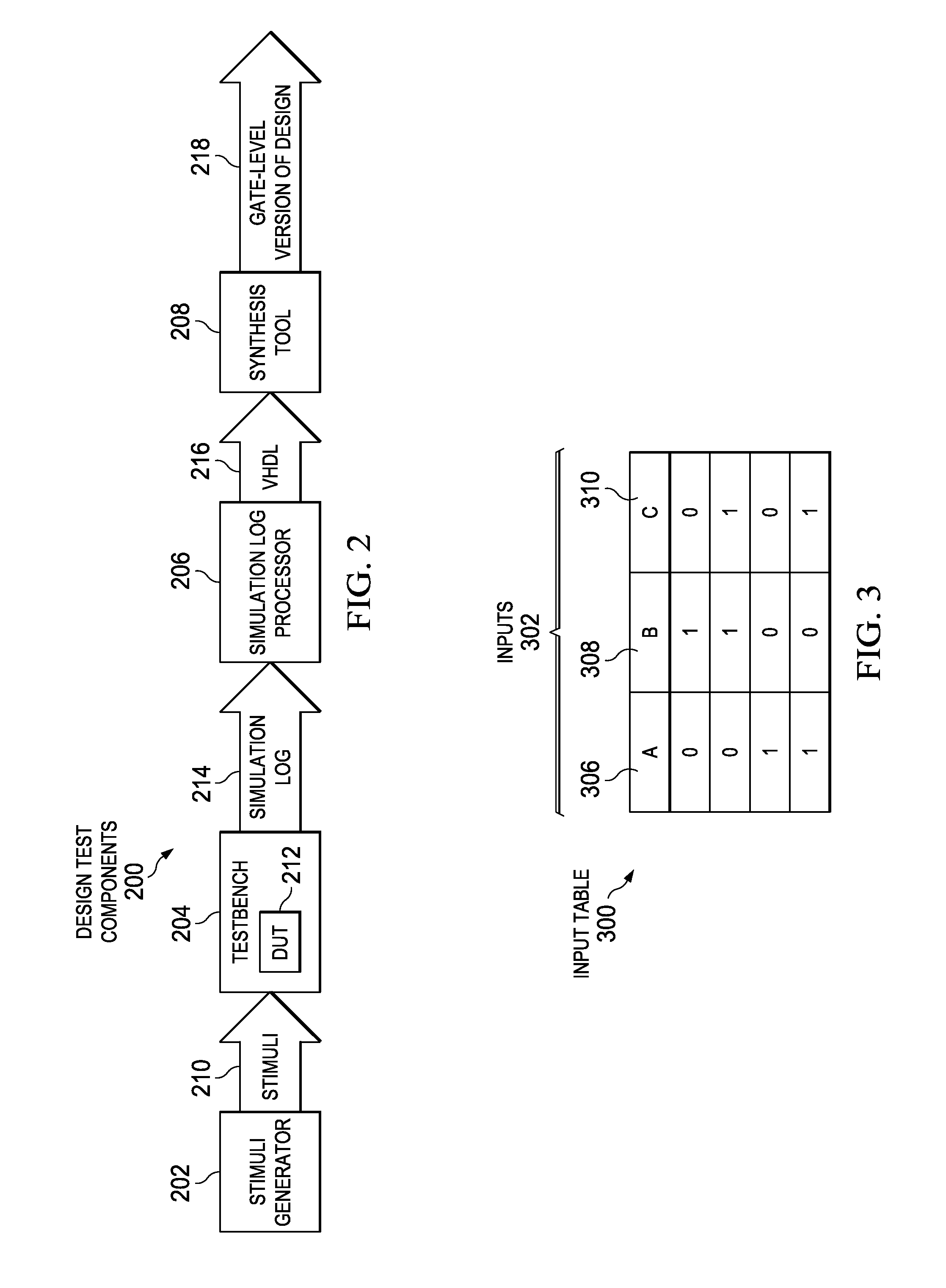

Automatically creating manufacturing test rules pertaining to an electronic component

A system for creating manufacturing test rules. Stimuli for an electronic design are generated automatically by a stimuli generator. The stimuli generator takes into account certain limitations of the design when automatically generating the manufacturing test rules. The design is tested by a testbench using the stimuli. A simulation log for the design is generated by the testbench. The simulation log is then processed by a simulation log processor. An HDL representation of the design is generated by the simulation log processor using the processed simulation log. A gate-level version of the design is generated by a synthesis tool using the HDL representation of the design. The gate-level version of the design is further processed by the synthesis tool to make any necessary modifications. Then, the gate-level version of the design is outputted as the final manufacturing test rule. Thus, creating manufacturing test rules can be completely automated.

Owner:MENTOR GRAPHICS CORP

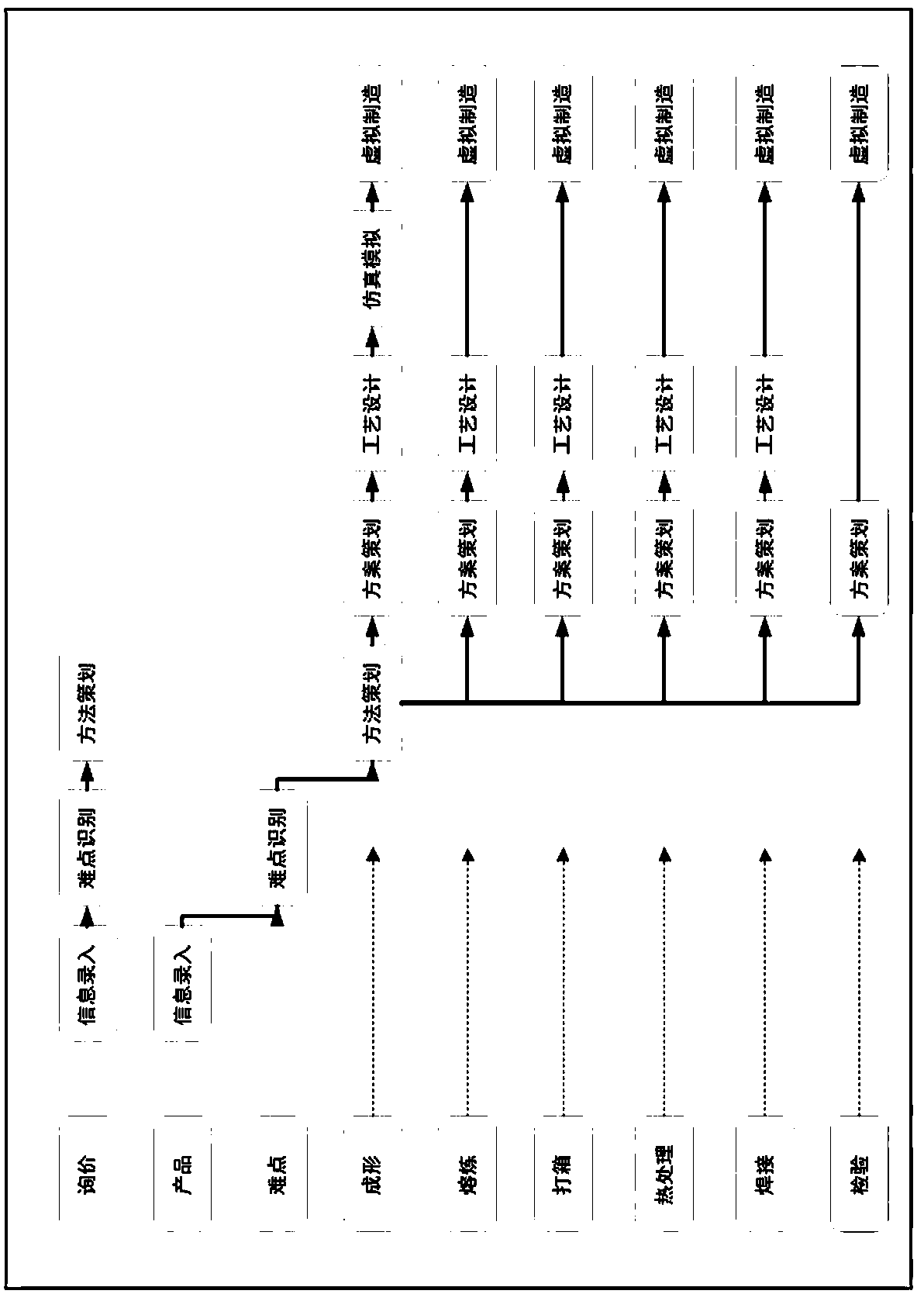

System platform and method of realizing whole process virtual manufacturing of cast iron product in cloud

InactiveCN108492019ARealize full life cycle management and controlReduce manufacturing costBuying/selling/leasing transactionsResourcesTreatment designUser input

The invention discloses a system platform for realizing whole process virtual manufacturing of a cast iron product in cloud in the field of virtual manufacturing. The system platform comprises the following function units: a product information module, an inquiry module and a process module, wherein a user inputs product information to the system platform, and the products are divided to two categories of inquiry products and order products; an inquiry product enters the inquiry module, in the inquiry module, the inquiry product is subjected to difficult point recognition, method planning andquotation, and the inquiry product is finally converted to an order product; and an order product which needs process treatment directly enters the process module, a process treatment design is carried out on the product, and a design scheme for the product is formed. Whole-process management and control during a whole life cycle from input, analysis, inquiry, quotation, design, manufacturing to warehouse-out for a cast iron product can be realized, virtual manufacturing of the product is also realized, production check on the product in an virtual environment is carried out, the whole production cost is thus reduced, and the system platform and the method can be used in cast iron product manufacturing.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

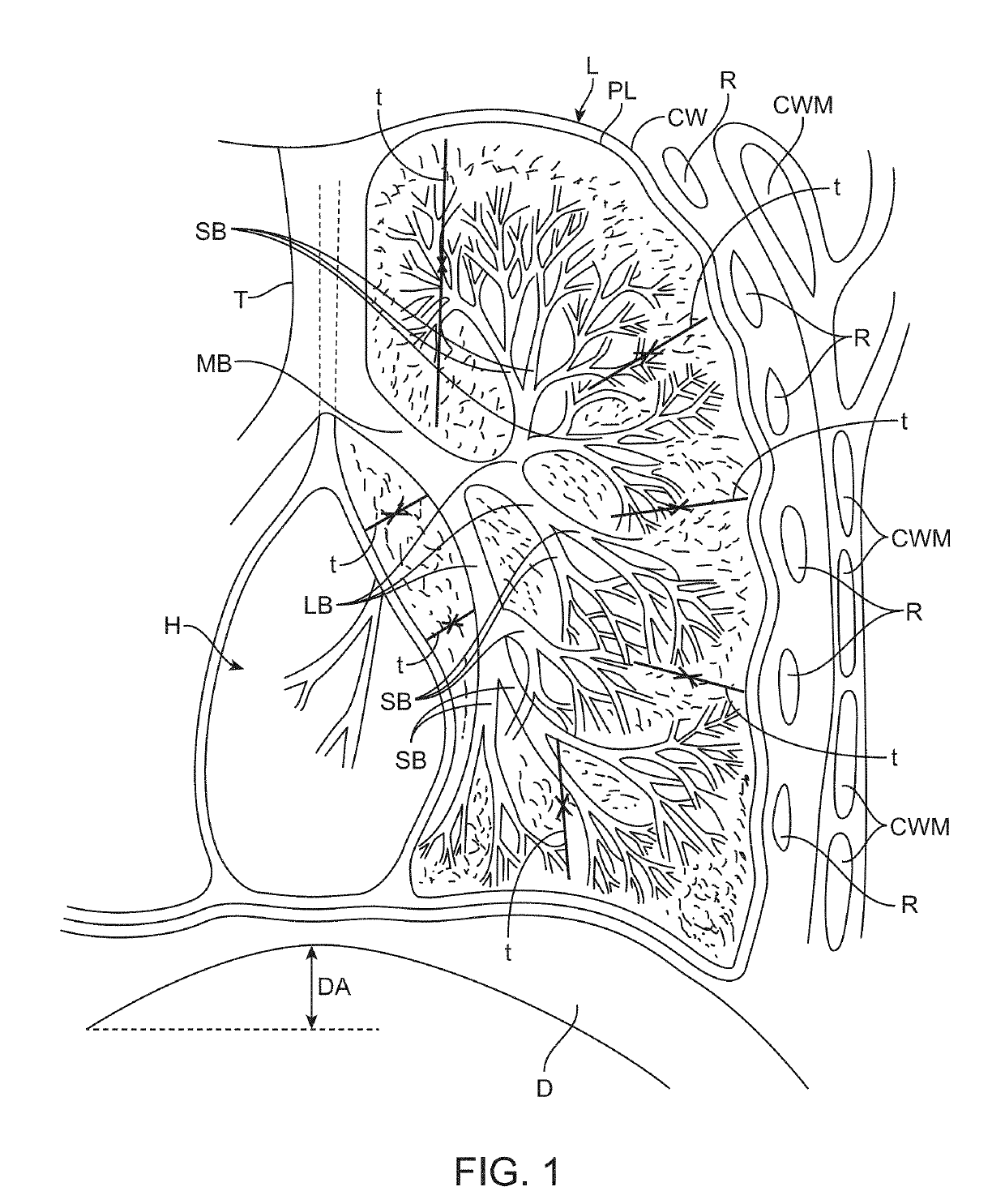

Devices, treatments and methods to restore tissue elastic recoil

Pulmonary treatment devices, systems and methods of use are provided which take into account the vast tissue damage of advanced COPD sufferers and provide treatments designed specifically to treat the particularly compromised lung tissues that are present in these patients. These treatments reduce trapped air volume, tension lung tissue and enhance lung elastic recoil. A variety of embodiments are provided, including pulmonary treatment devices that move portions of lung tissue around a rotational axis into a torqued configuration, anchoring such tissue in place for improved breathing mechanics.

Owner:FREE FLOW MEDICAL INC

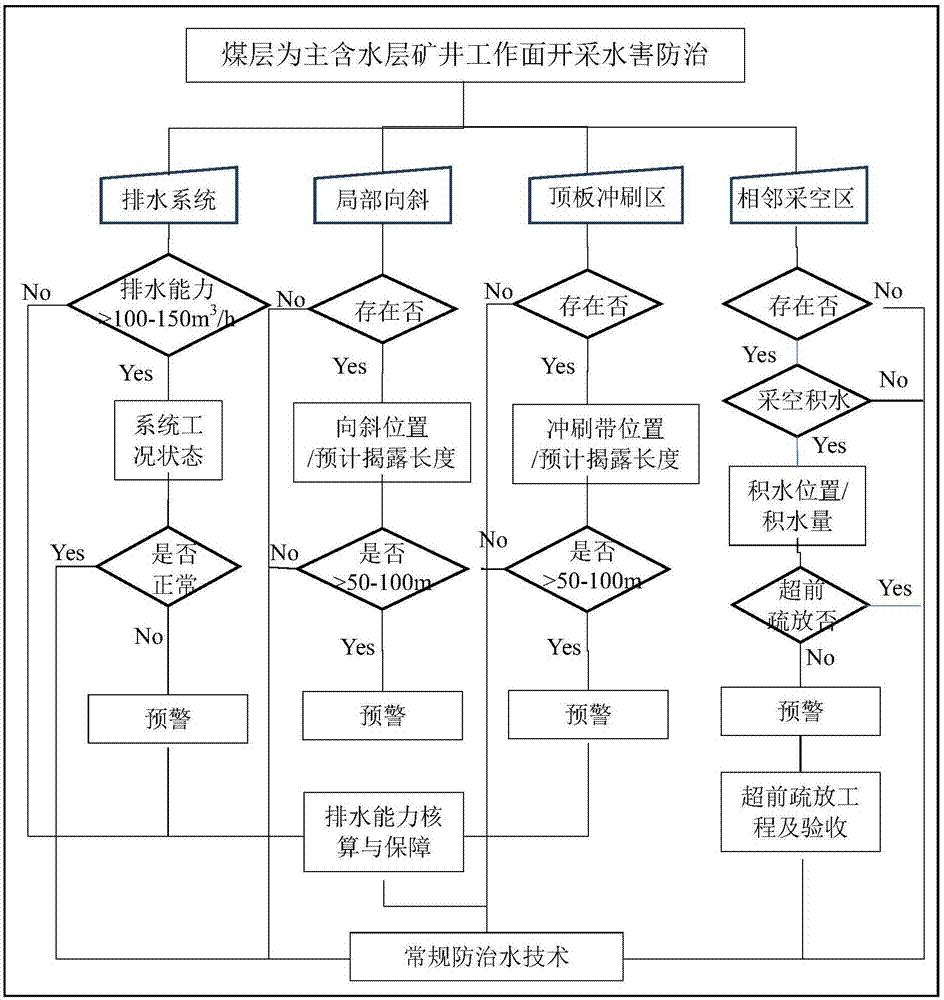

Water disaster prevention and treatment design method for mine taking coal bed as main aquifer

ActiveCN106968707AReduce casualtiesReduce lossesMining devicesDesign optimisation/simulationPondingWater discharge

The invention discloses a water disaster prevention and treatment design method for a mine taking a coal bed as a main aquifer, and the method is applied to coal mine down-hole use. By judging the water discharge amount of a working face water discharging system, whether working face partial syncline exists or not and whether a working face roof scouring zone and adjacent gobs exist or not, check computation and guarantee of the water discharge capacity of a working face and advancing gob ponding drainage are conducted. According to information collecting results of multiple objects and on the basis of corresponding judgment standards, specific water control measures are presented so that early warning of multiple water-inrush types can be provided, the loss caused by mine water disaster hazardous events can be reduced, and even personal casualties caused by the mine water disaster hazardous events can be reduced.

Owner:CHINA UNIV OF MINING & TECH

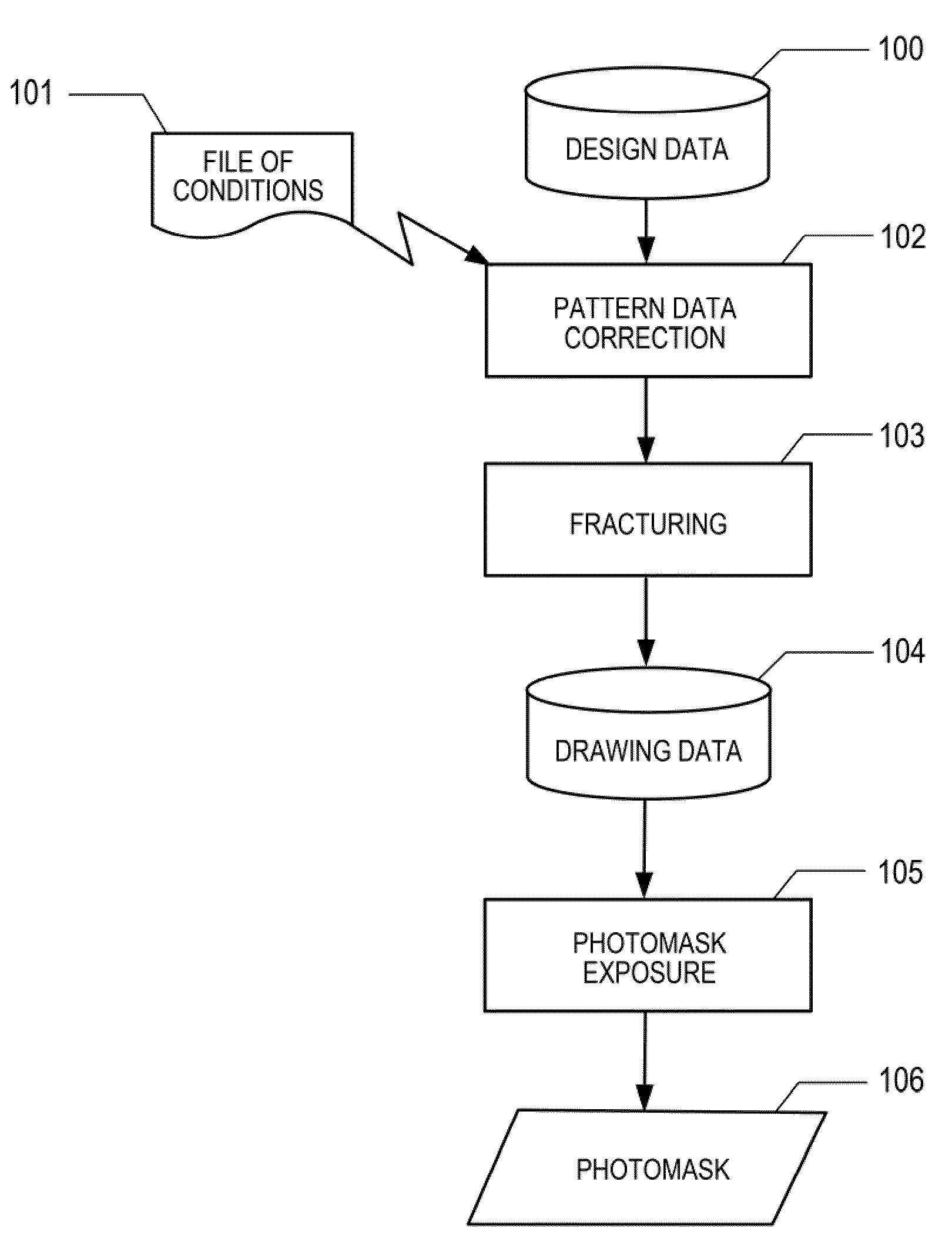

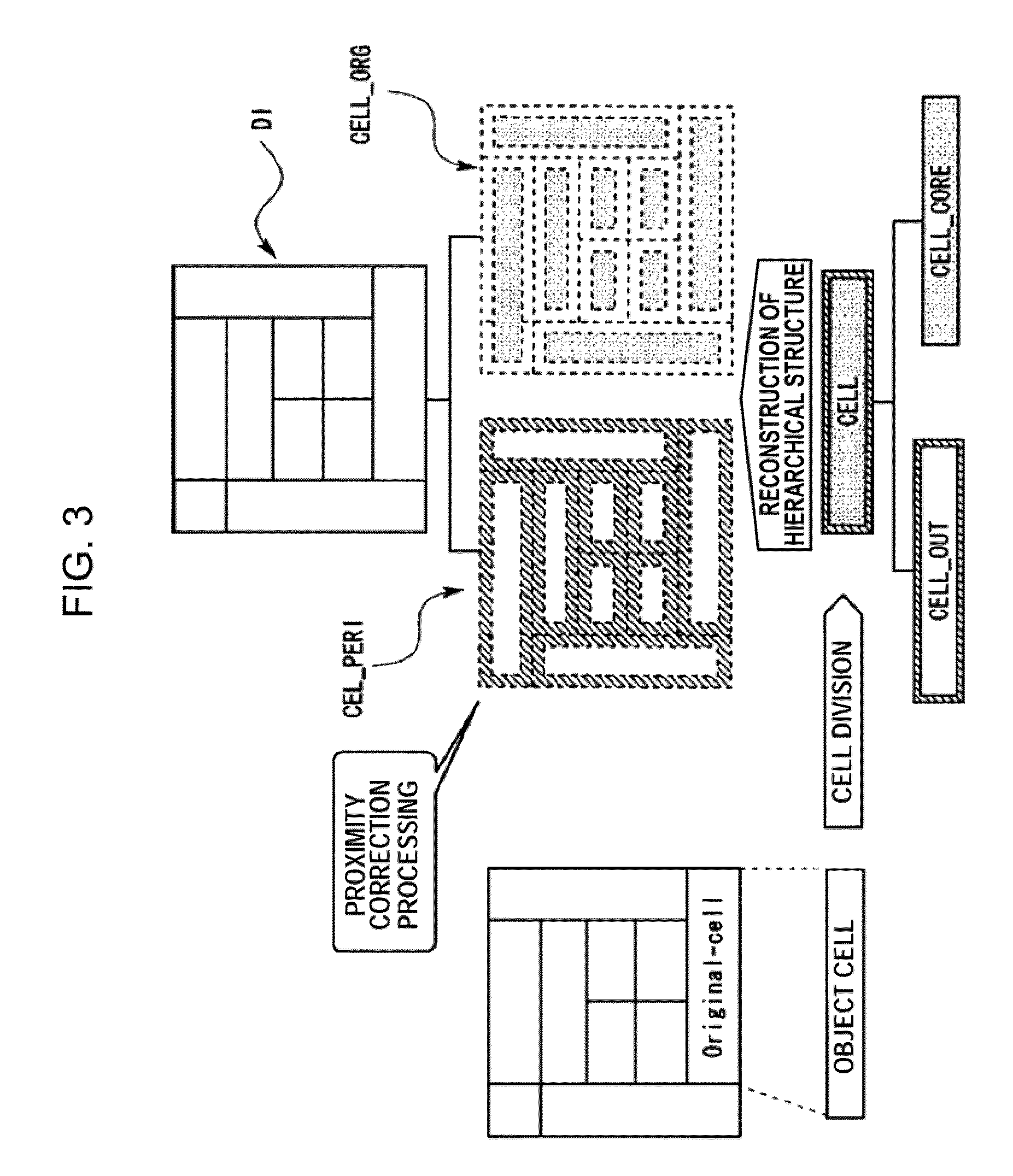

Photomask data processing method, photomask data processing system and manufacturing method

InactiveUS20090228860A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentData processing systemTreatment design

A computer-implemented method, of processing design data to obtain photomask data, includes: selecting, amongst design data, data representing a first cell; selecting a first area in said first cell for which a configuration of a corresponding first pattern is influenced by patterns arranged outward relative to said first cell area; selecting a second area other than said first area in said first cell; constructing a hierarchical structure for said data representing said first cell area that includes said first area and said second area; subjecting the first area to optical proximity correction on the basis of a relationship between the first pattern and the patterns arranged around said first cell area; performing optical proximity correction in said second area on the basis of the first pattern; and synthesizing the corrected first area and the corrected second area, according to the hierarchical structure, to obtain photomask data.

Owner:FUJITSU SEMICON LTD

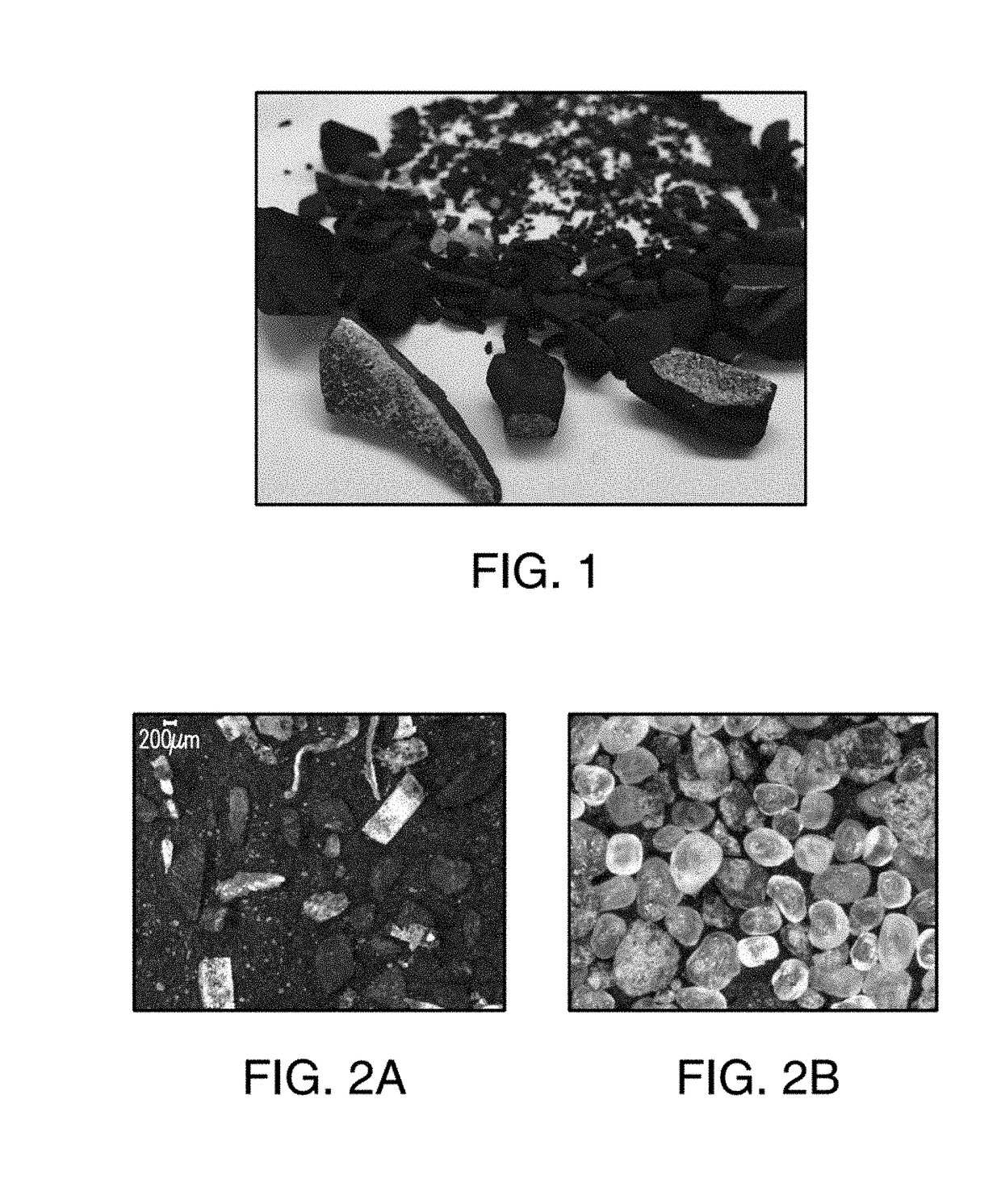

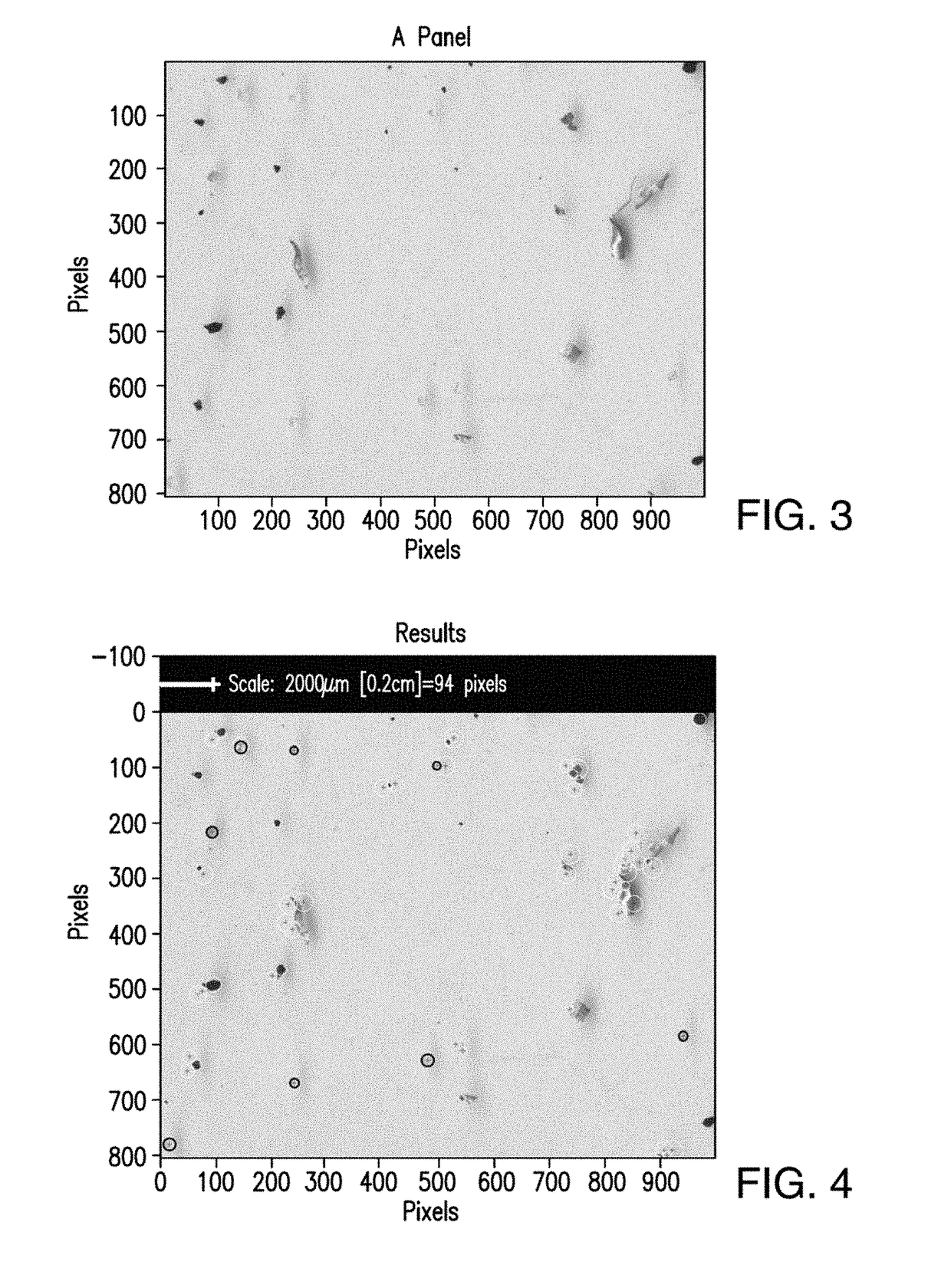

Detection and quantification of proppant for optimized fracture treatment design in in-fill and new wells

ActiveUS20180223641A1Optimized fracture treatment designMaximize productionPreparing sample for investigationFluid removalTreatment designFracture treatments

A system and method for detecting and quantifying proppant for optimized fracture treatment design in in-fill and new wells. Proppant is isolated from drilling fluids and then analyzed to determine whether a formation within the well has been properly stimulated based on the analysis. Placement of an in-fill well may be based upon the determination of whether the well has been properly stimulated.

Owner:GAS TECH INST

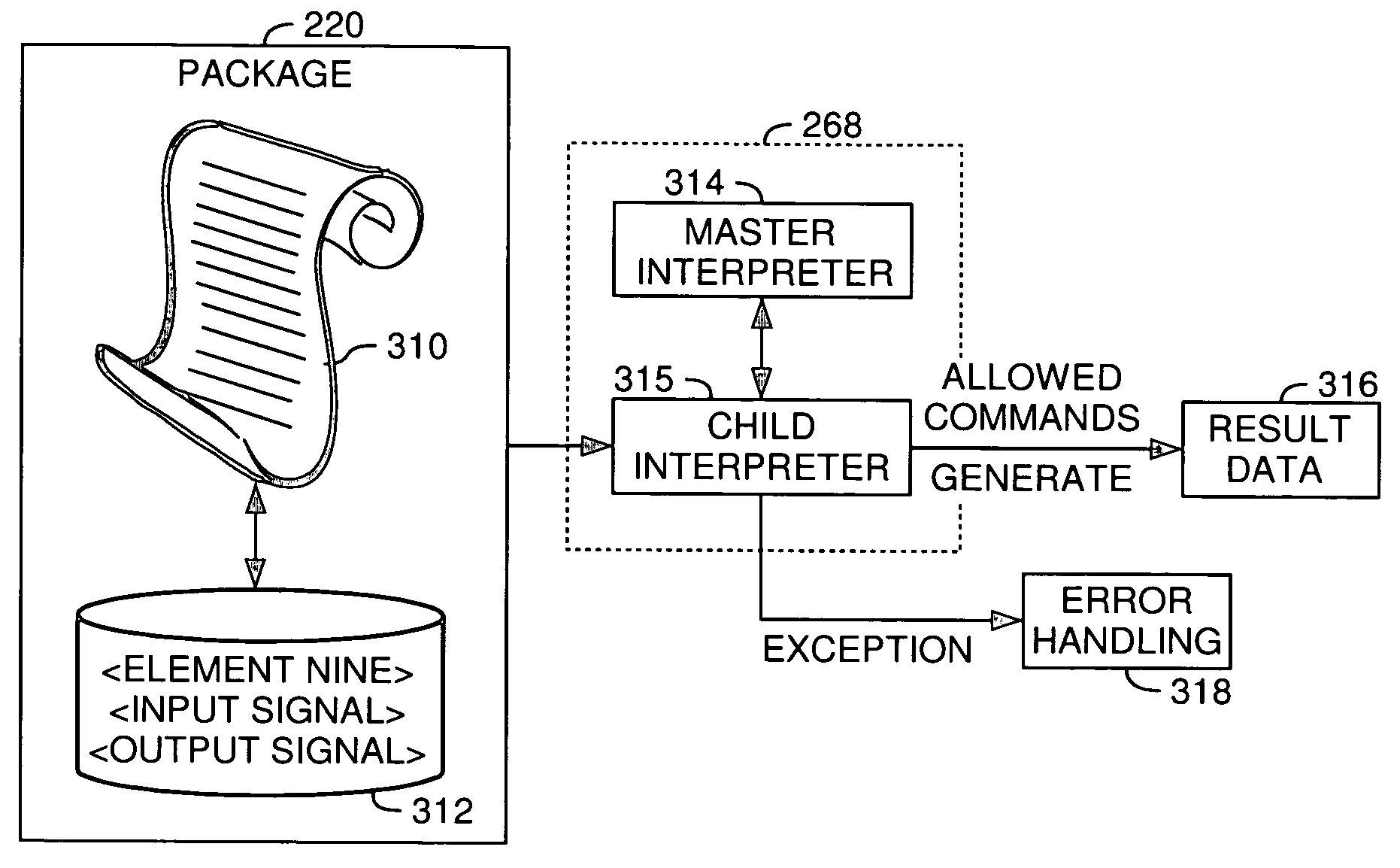

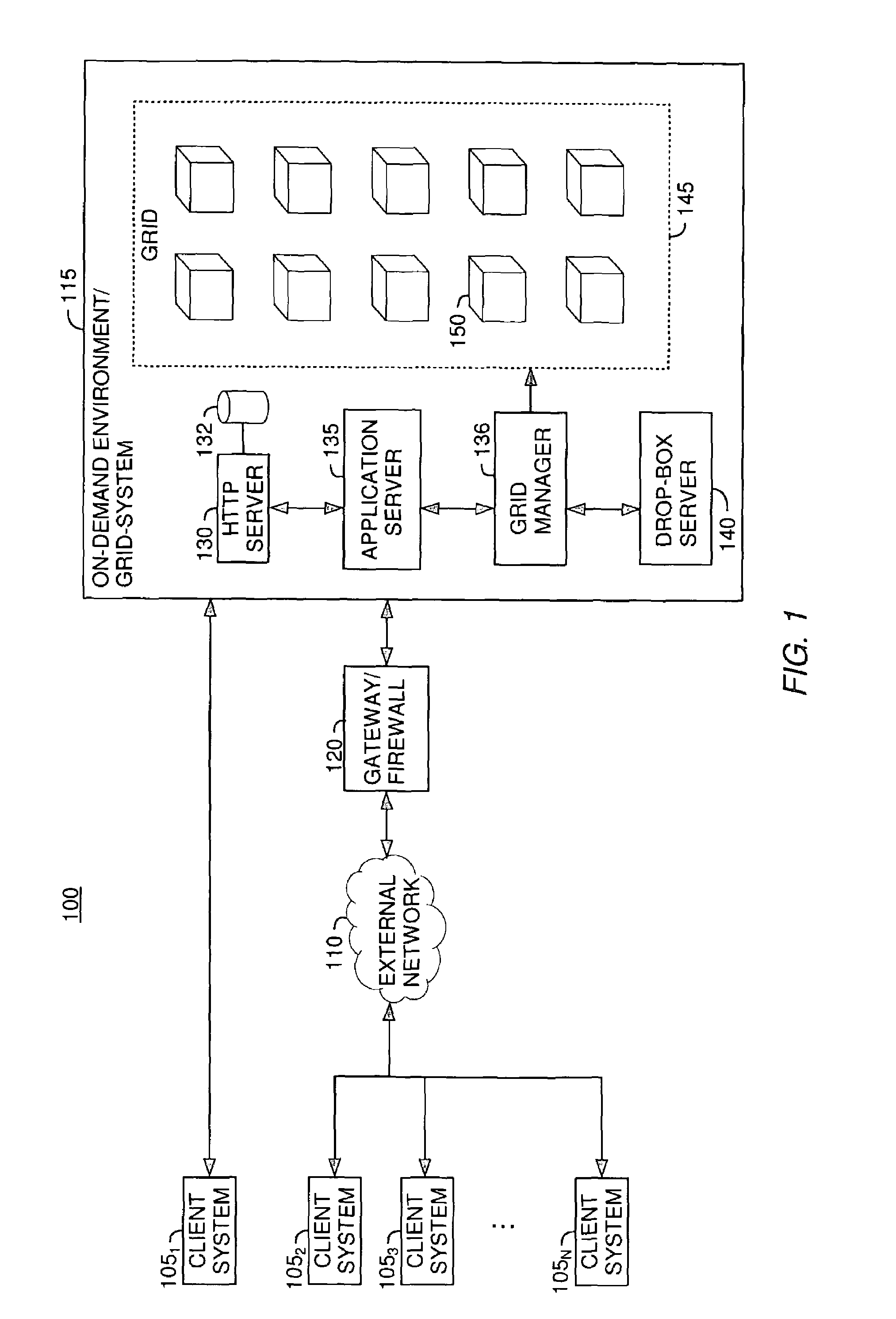

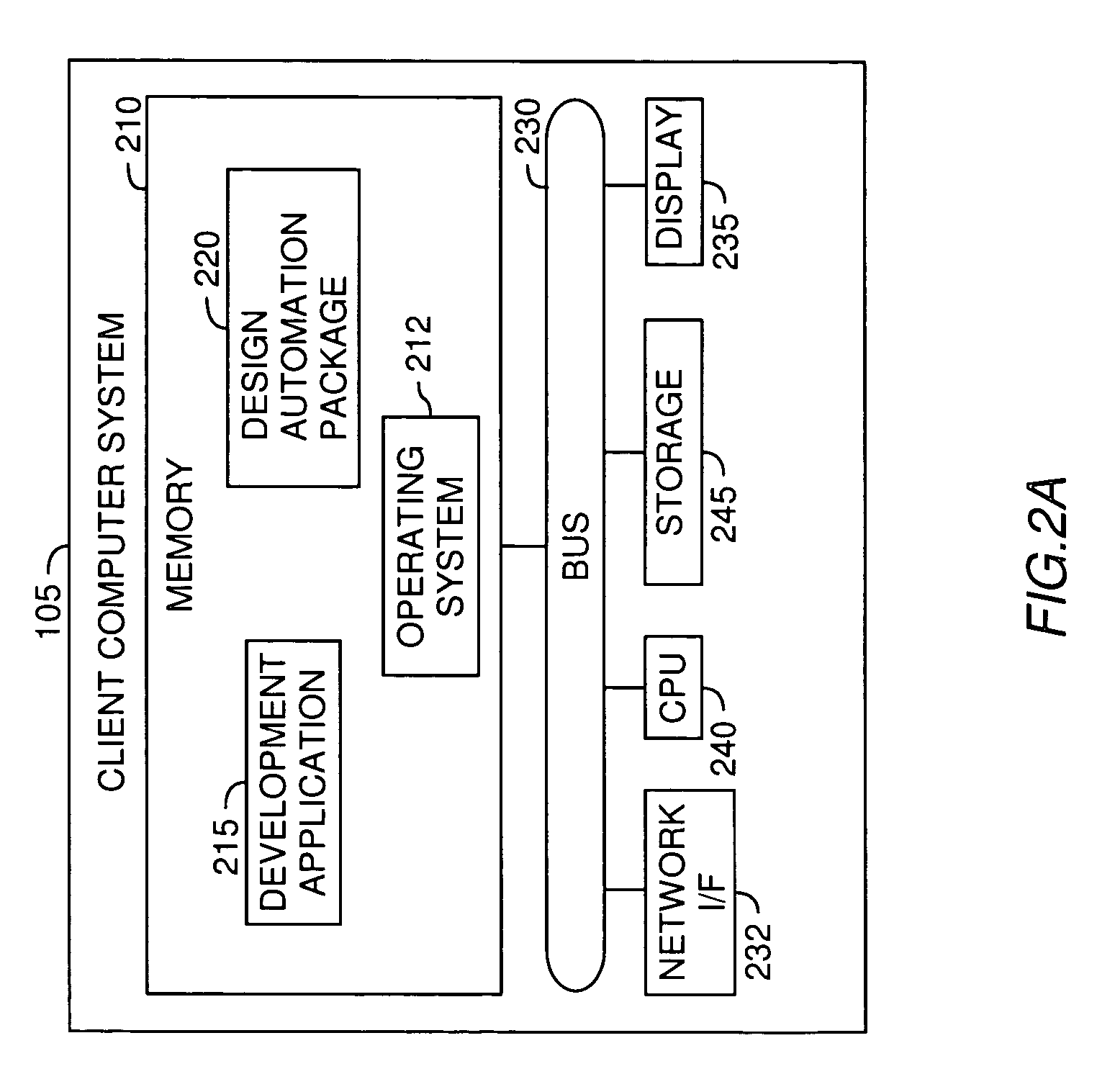

e-Business on-demand for design automation tools

InactiveUS7568006B2Multiple digital computer combinationsSoftware simulation/interpretation/emulationGrid resourcesTreatment design

Methods, apparatus and articles of manufacture are disclosed for a design automation application to evaluate a design automation task using an on-demand computer network. A requesting entity transmits the design automation task, along with a set of data used for testing, to a drop server box provided by the on-demand computer network. The design automation application is configured to process the design automation task and to prevent it from interfering with, or eavesdropping on, other tasks being executed in the on-demand environment and from interfering with the operation of the on-demand environment itself. The design automation application consumes available grid resources to complete the processing task.

Owner:INT BUSINESS MASCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com