Patents

Literature

293 results about "Trapped air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

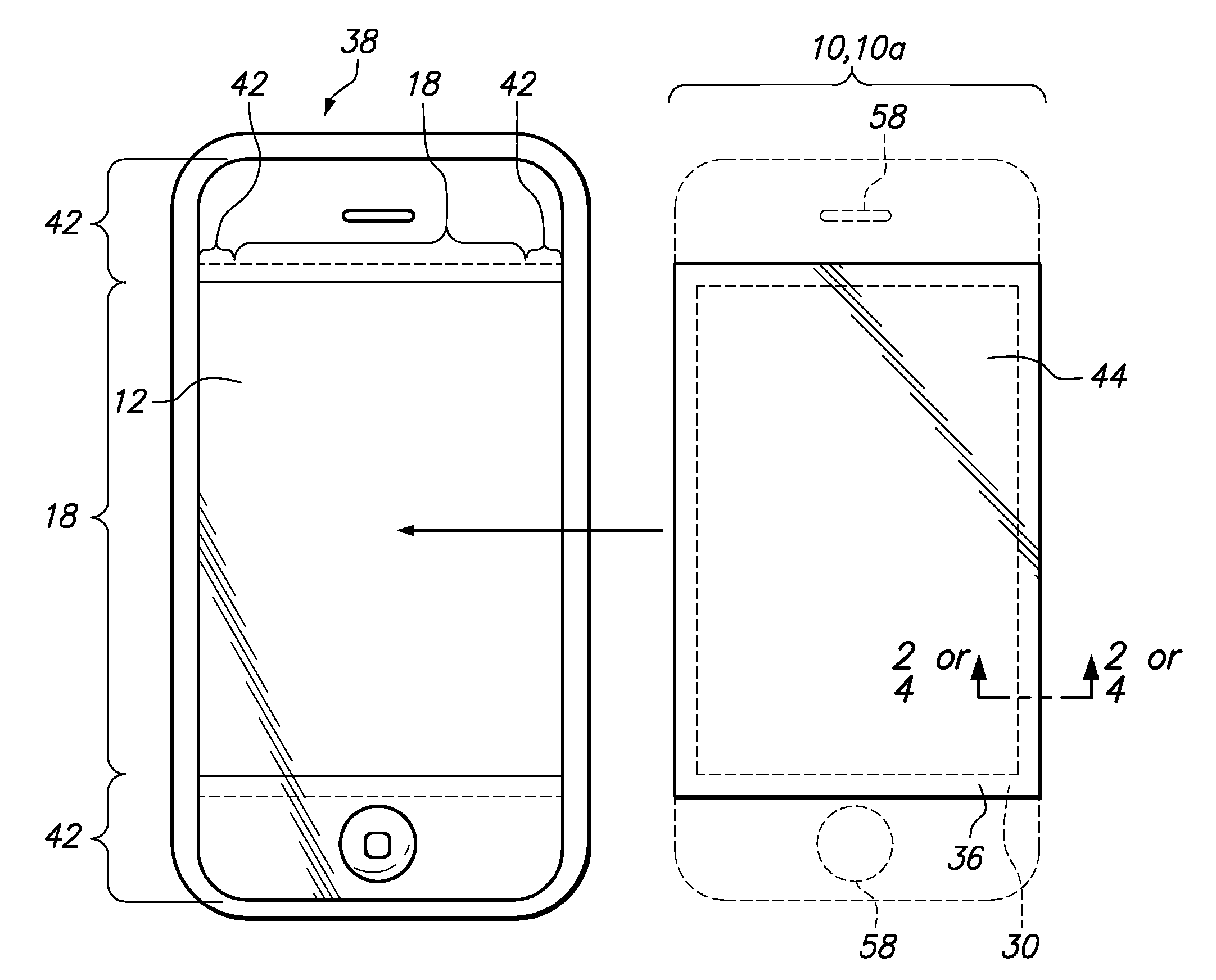

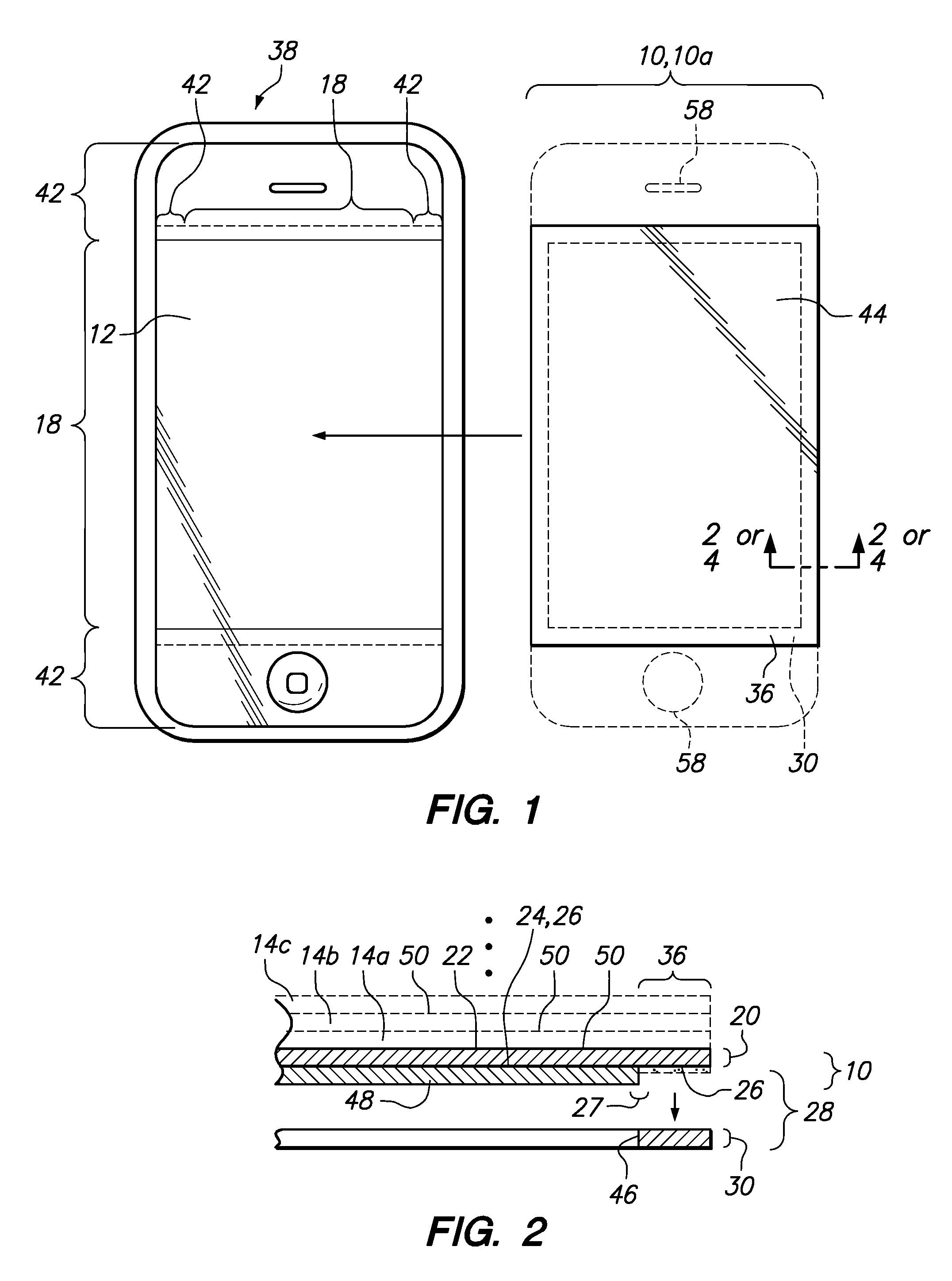

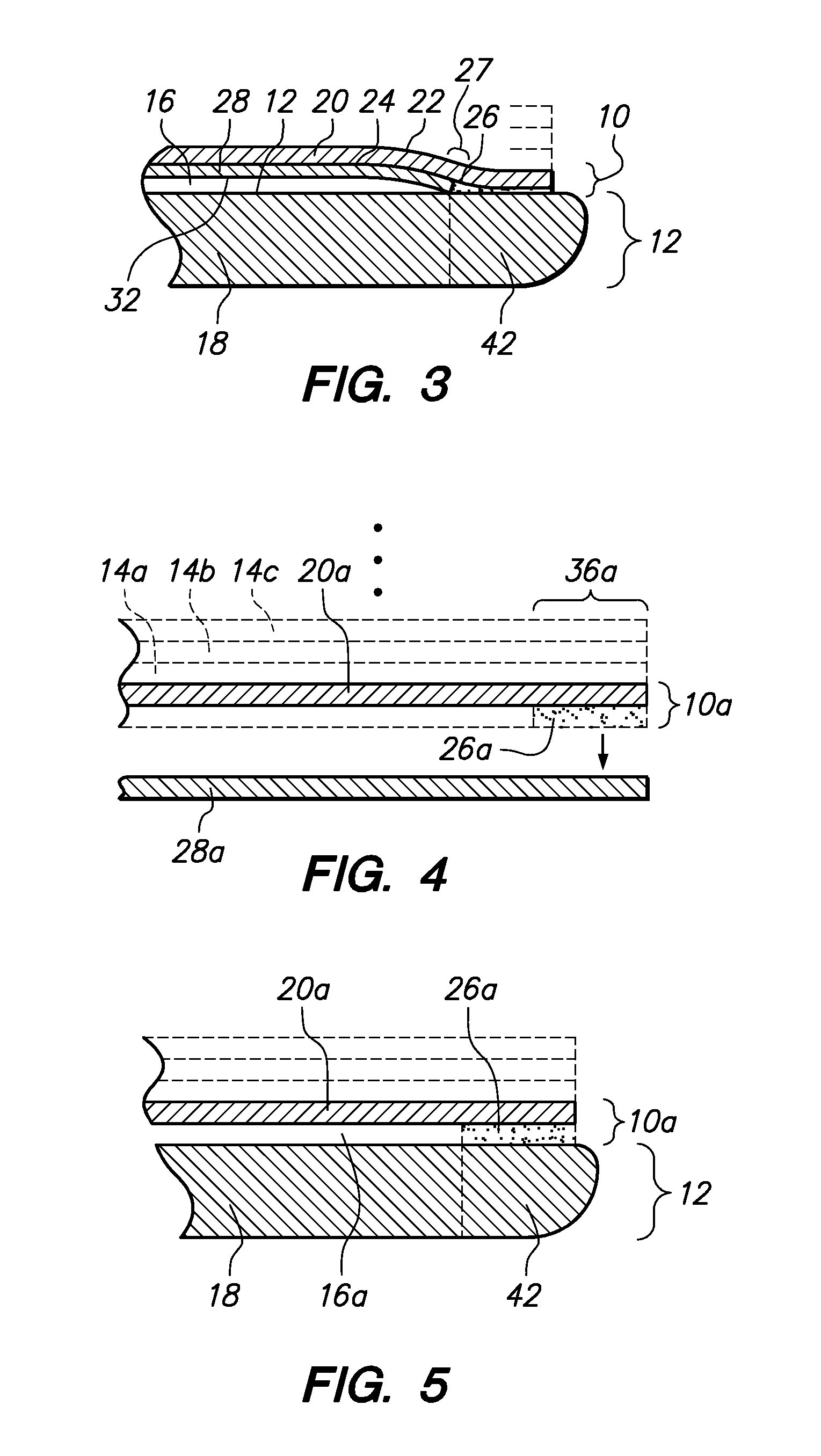

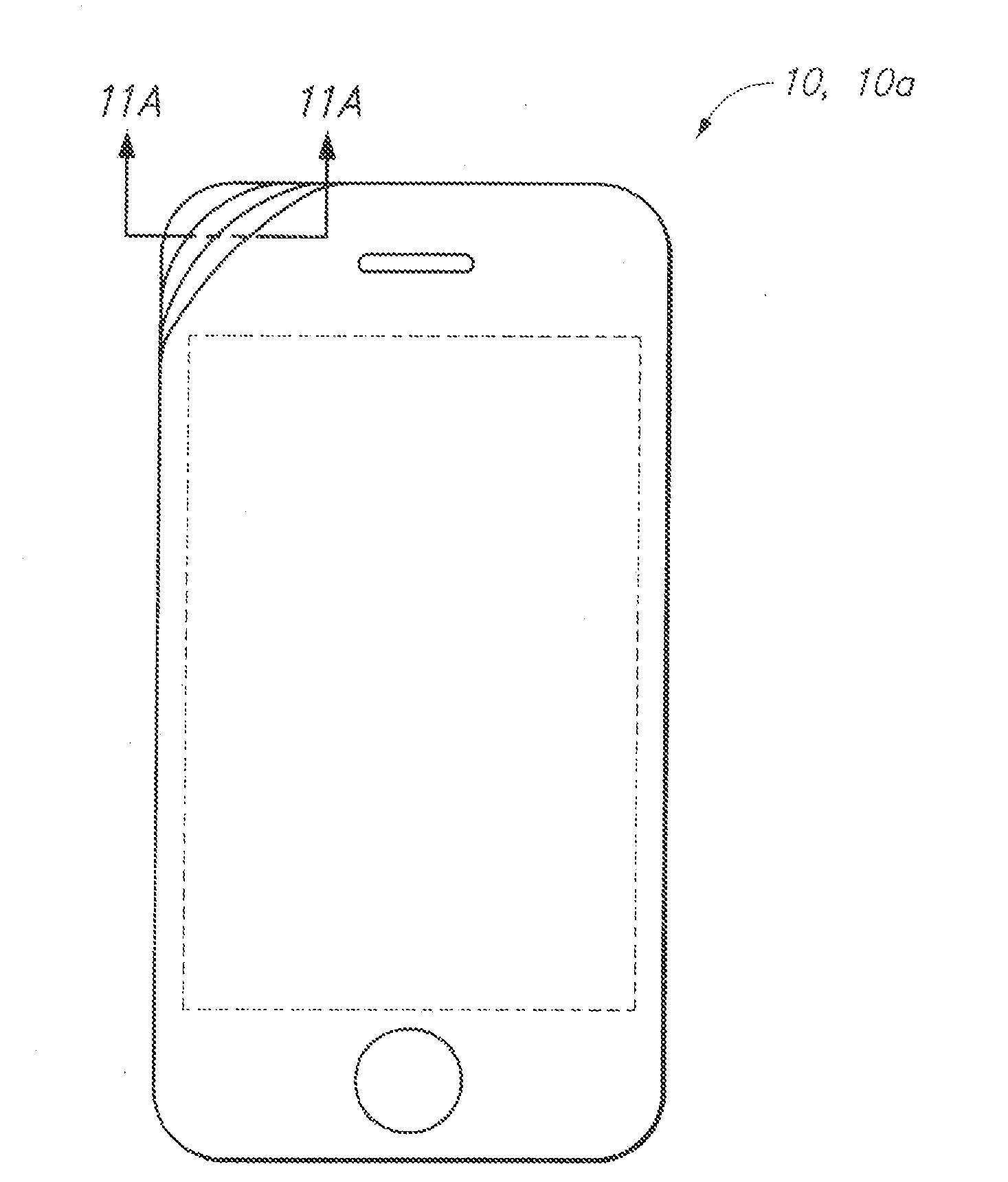

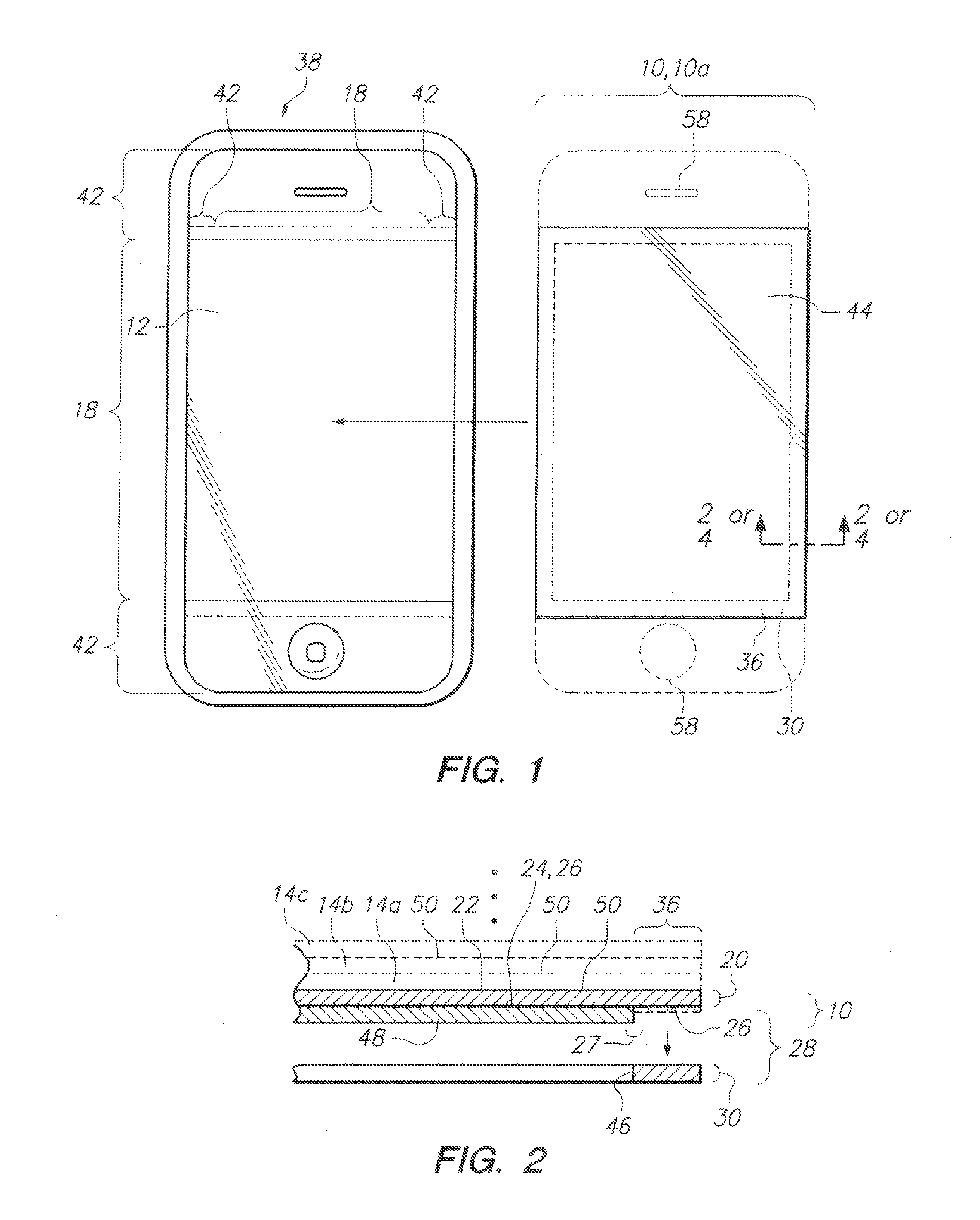

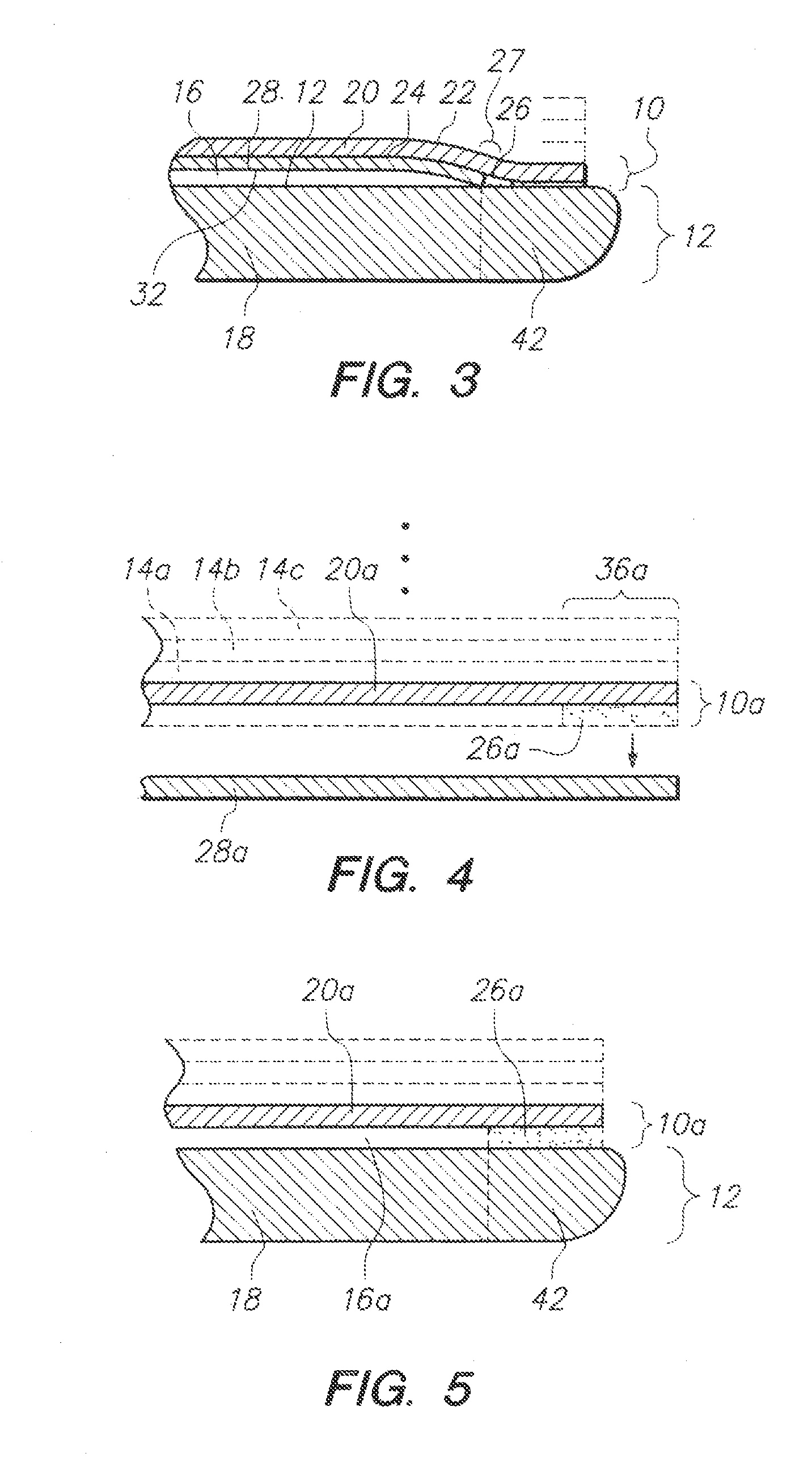

Touch Screen Shield

ActiveUS20110279383A1Promote formationStay flexibleLamination ancillary operationsProtective equipmentEngineeringTouchscreen

A shield that is attachable to a touch sensitive screen is disclosed. The shield may be attached to the touch sensitive screen only at its outer peripheral portion. An air gap is enclosed between the shield and the touch sensitive screen to form a planar air bearing. The shield preferably does not touch the active area of the touch sensitive screen when the user is not touching the shield but only viewing the touch sensitive screen through the shield. This mitigates unwanted optical artifacts such as trapped air bubbles, Newton rings and chromatic interference while maintaining the sensitivity of the touch sensitive screen.

Owner:RACING OPTICS

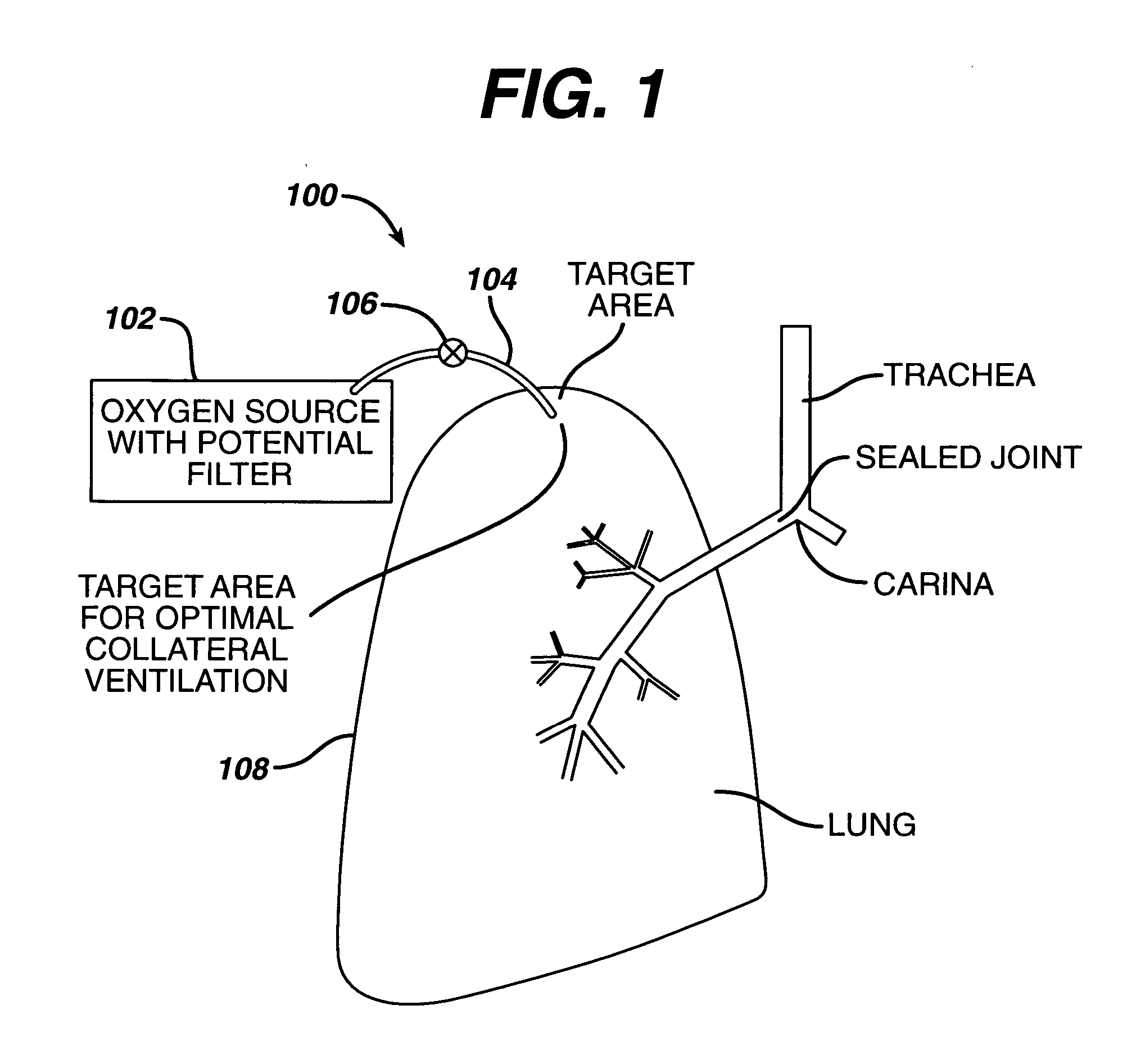

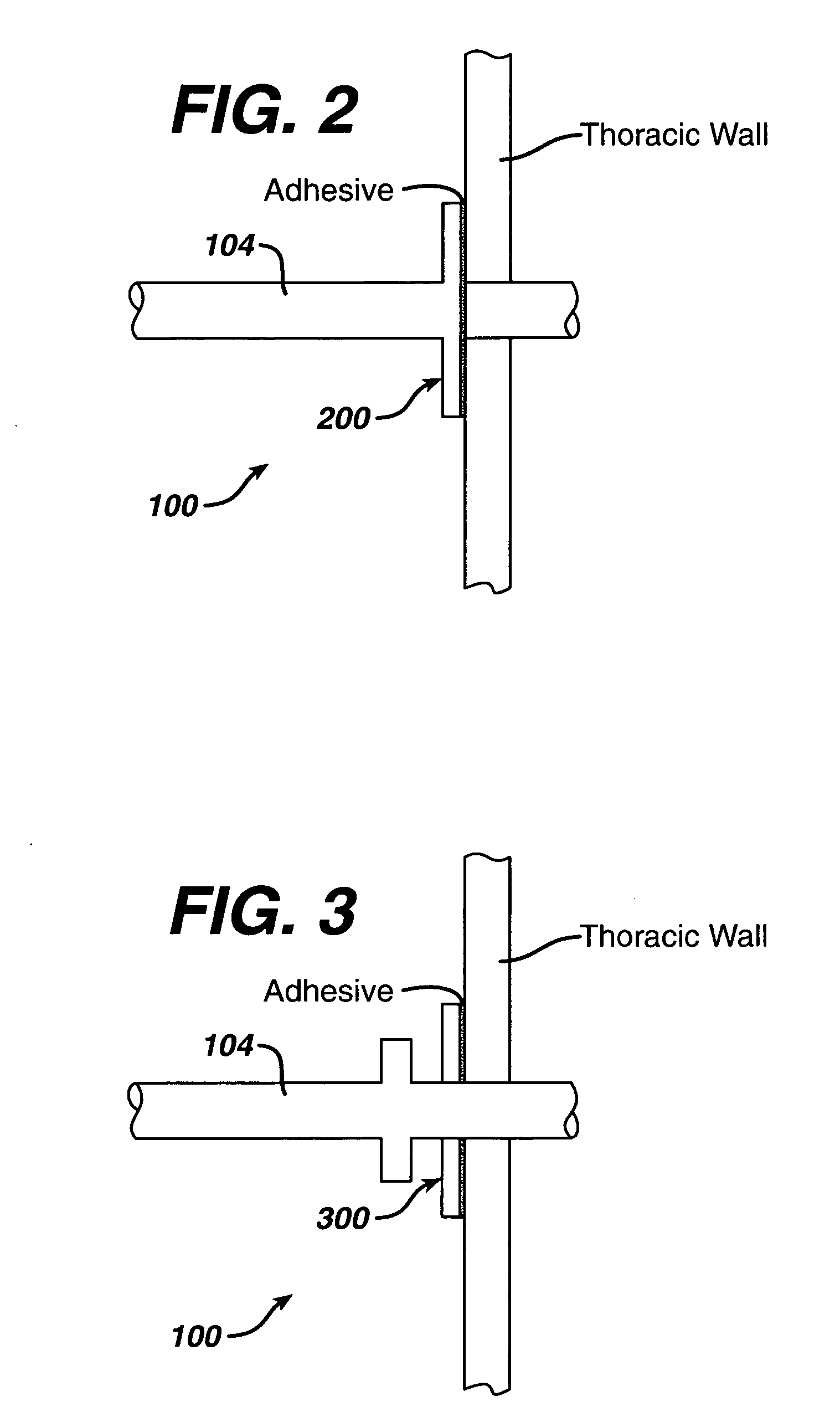

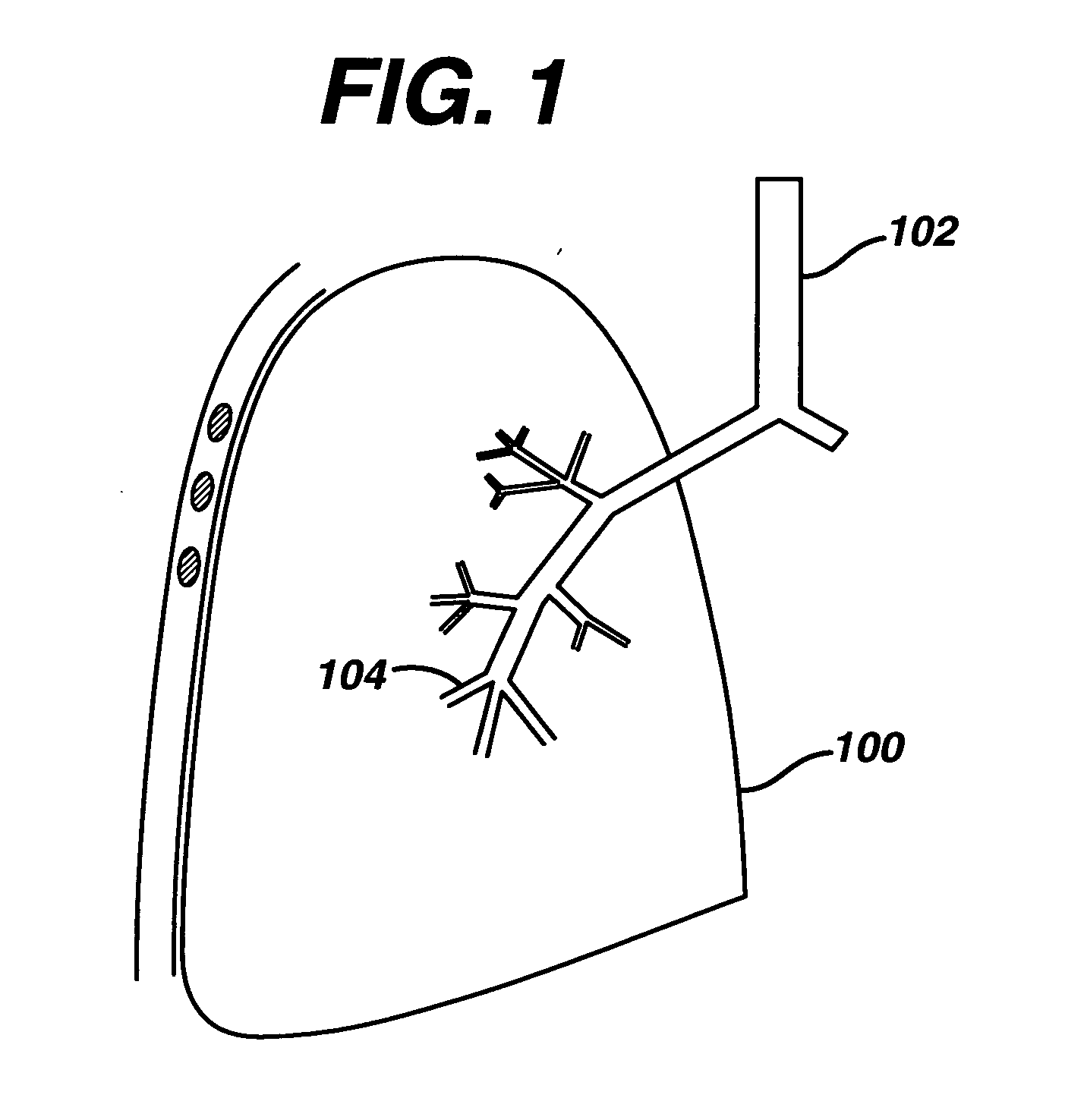

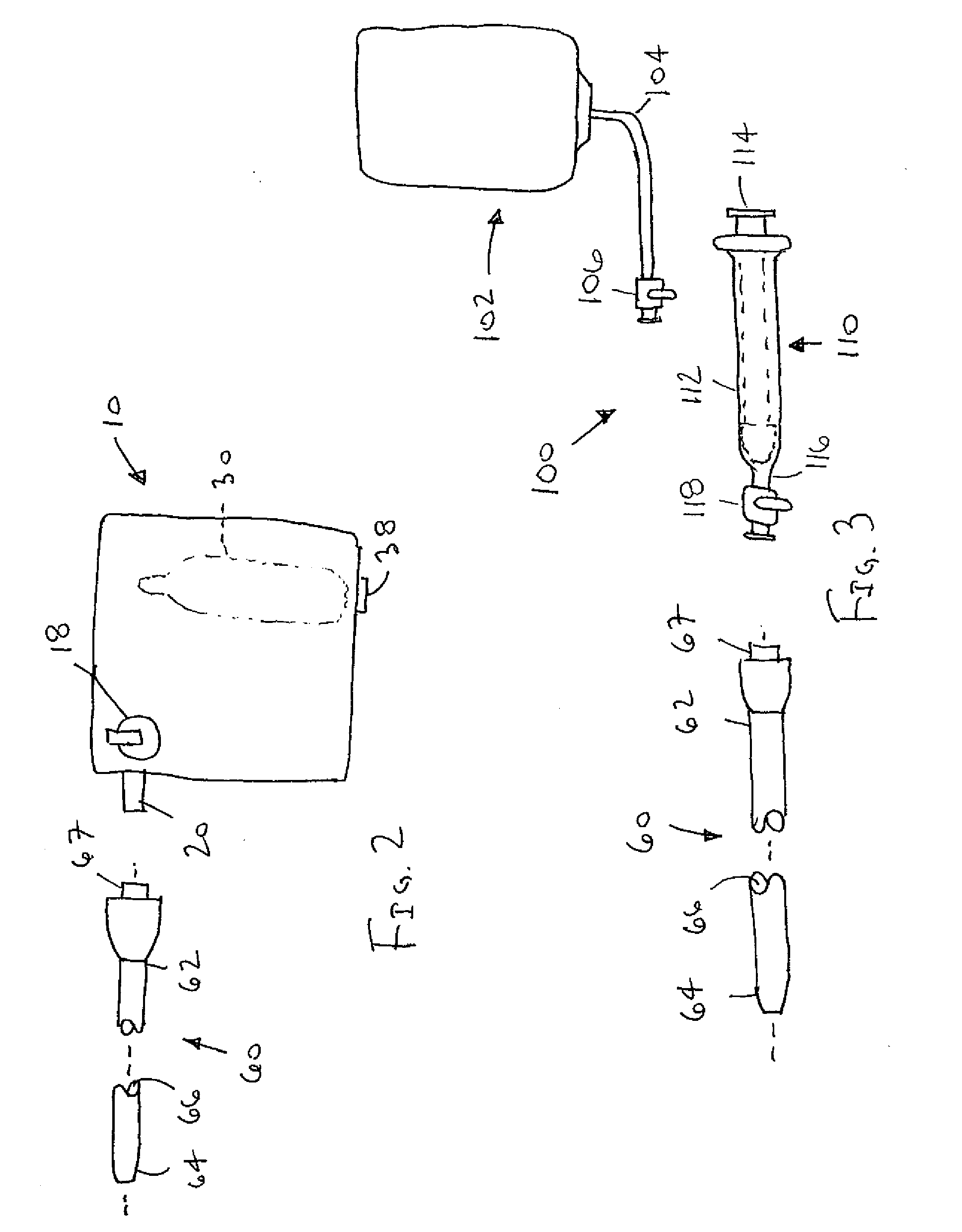

Methods and devices to accelerate wound healing in thoracic anastomosis applications

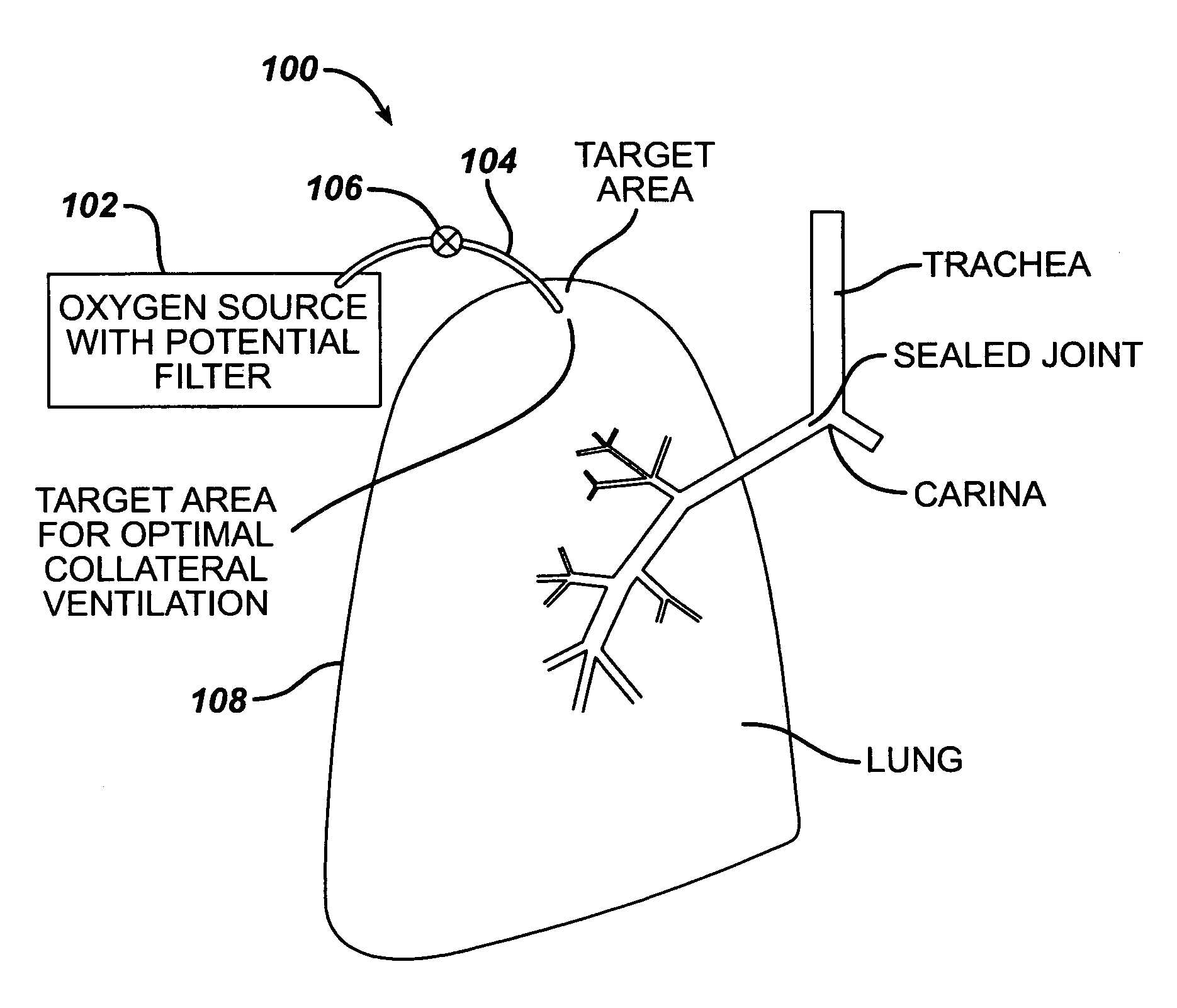

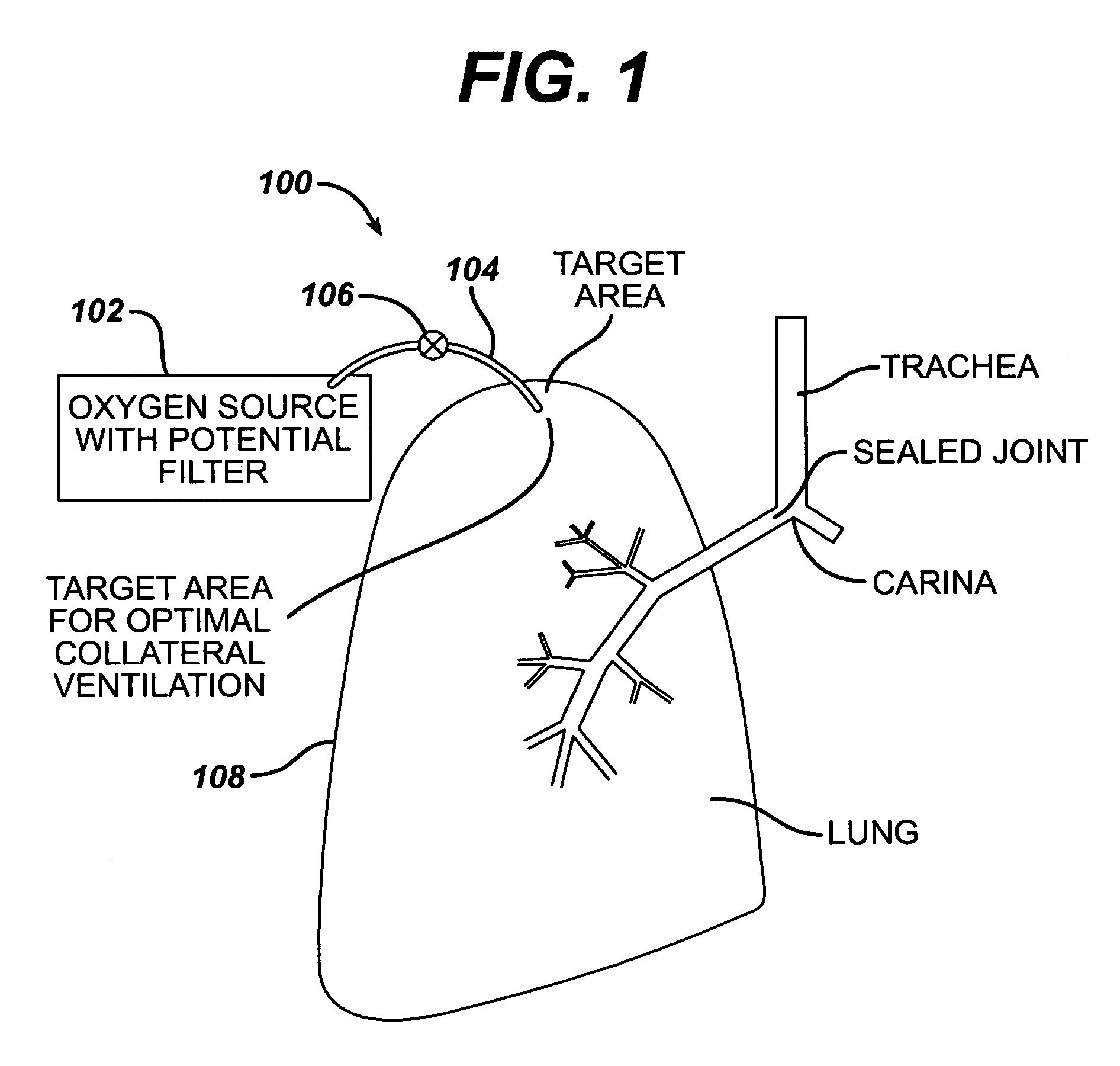

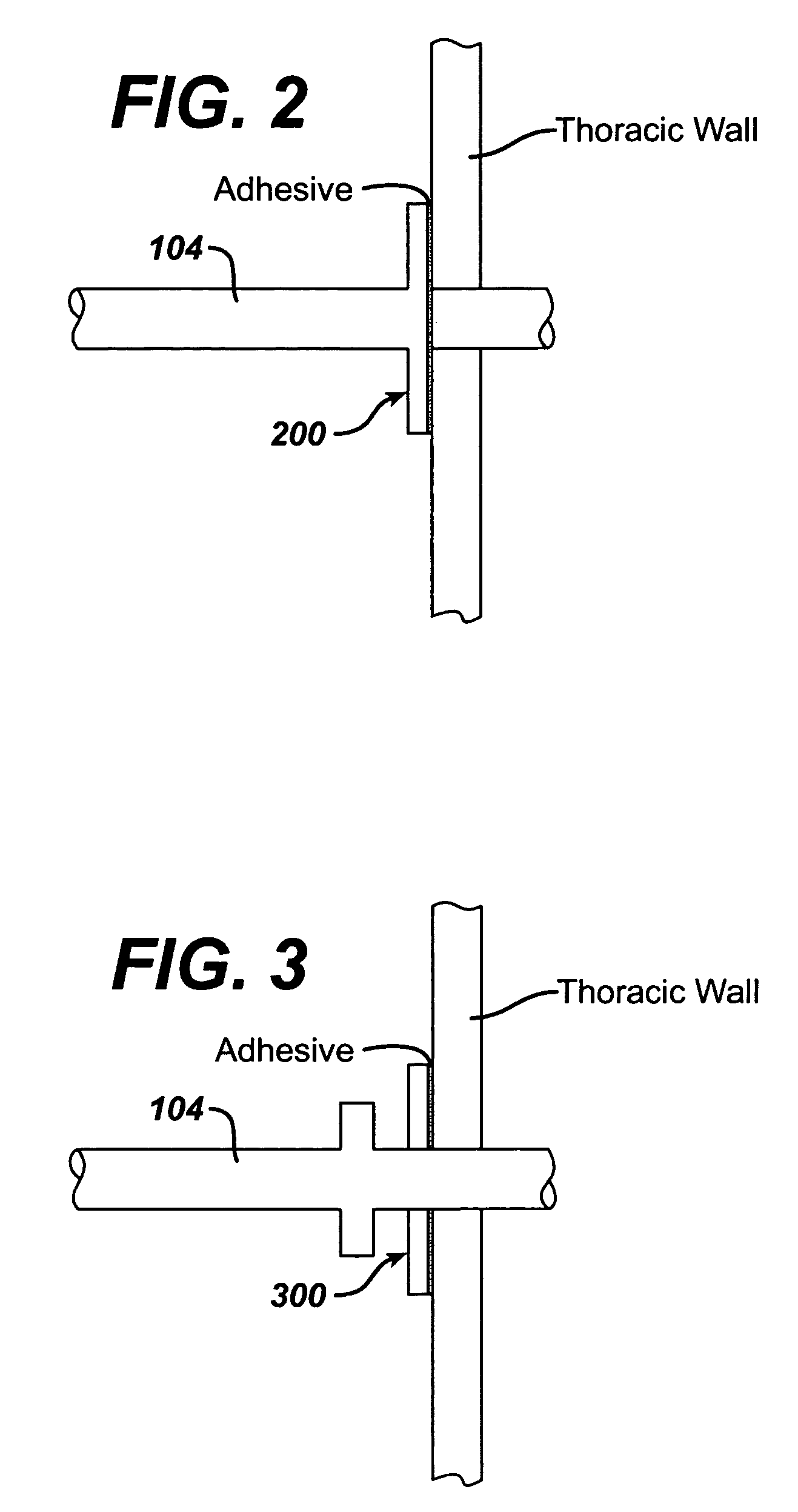

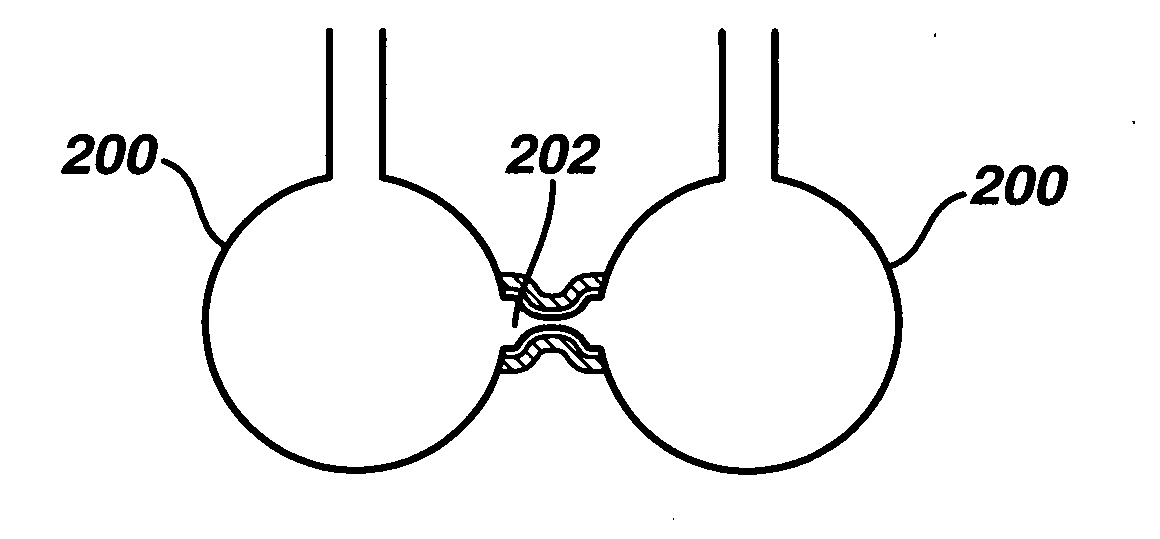

InactiveUS20050025816A1Increase expiratory flowOvercome disadvantagesRespiratorsElectrotherapyStapling procedureObstructive Pulmonary Diseases

A long term oxygen therapy system having an oxygen supply directly linked with a patient's lung or lungs may be utilized to more efficiently treat hypoxia caused by chronic obstructive pulmonary disease such as emphysema and chronic bronchitis. The system includes an oxygen source, one or more valves and fluid carrying conduits. The fluid carrying conduits link the oxygen source to diseased sites within the patient's lungs. A collateral ventilation bypass trap system directly linked with a patient's lung or lungs may be utilized to increase the expiratory flow from the diseased lung or lungs, thereby treating another aspect of chronic obstructive pulmonary disease. The system includes a trap, a filter / one-way valve and an air carrying conduit. In various embodiments, the system may be intrathoracic, extrathoracic or a combination thereof. A pulmonary decompression device may also be utilized to remove trapped air in the lung or lungs, thereby reducing the volume of diseased lung tissue. A lung reduction device may passively decompress the lung or lungs. In order for the system to be effective, an airtight seal between the parietal and visceral pleurae is required. Chemical pleurodesis is utilized for creating the seal and various devices and / or drugs, agents and / or compounds may be utilized to accelerate wound healing in thoracic anastomosis applications.

Owner:PORTAERO

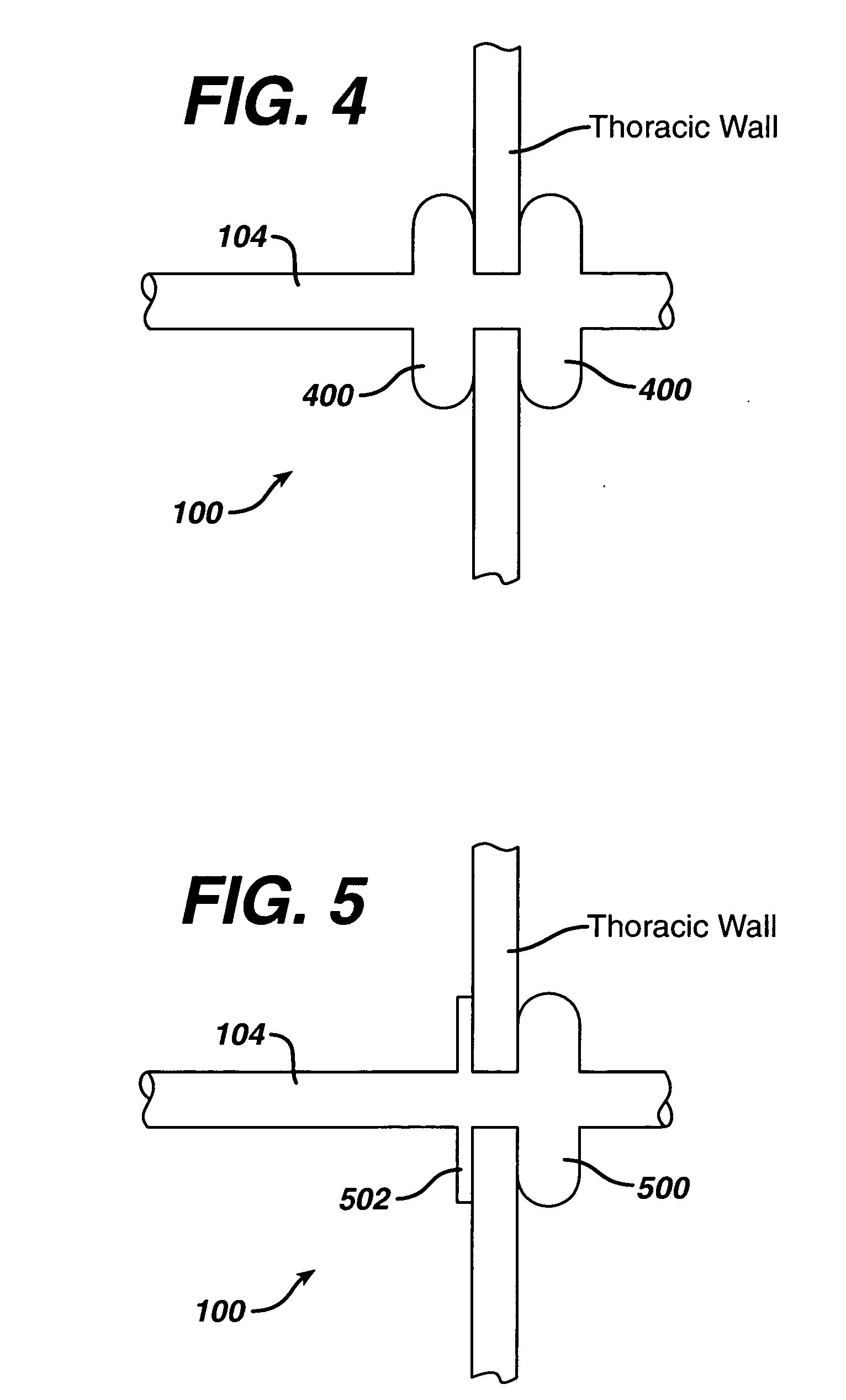

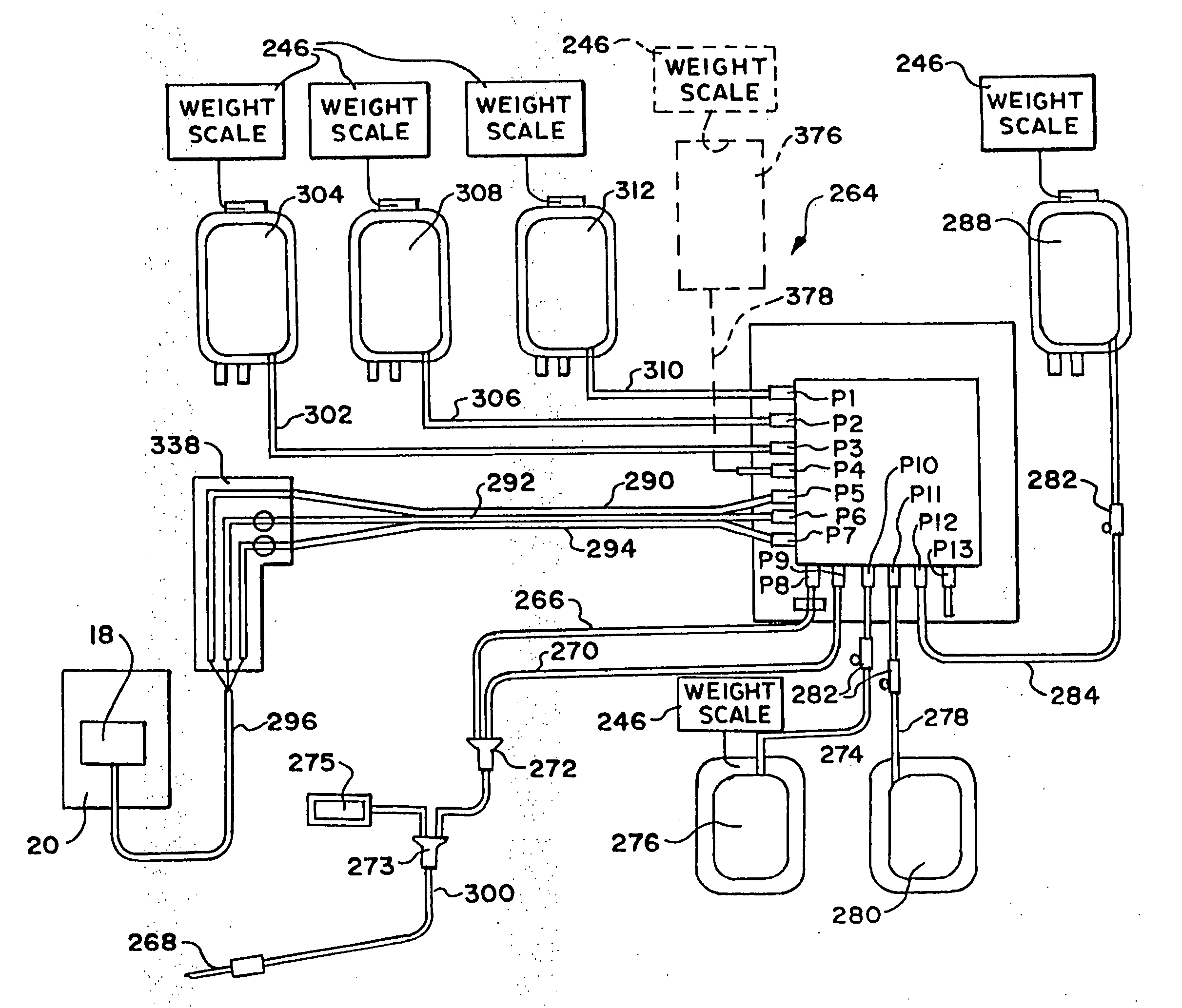

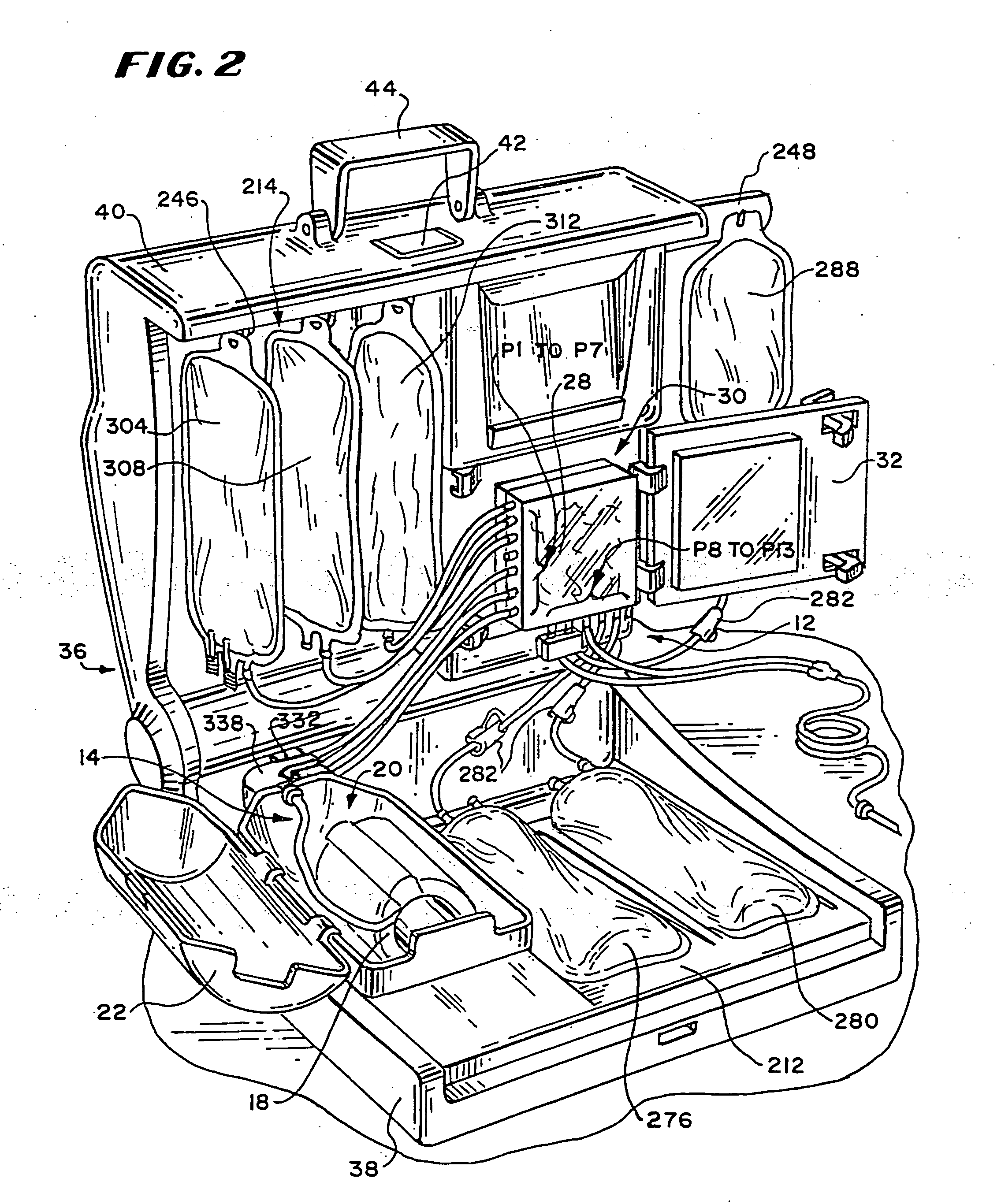

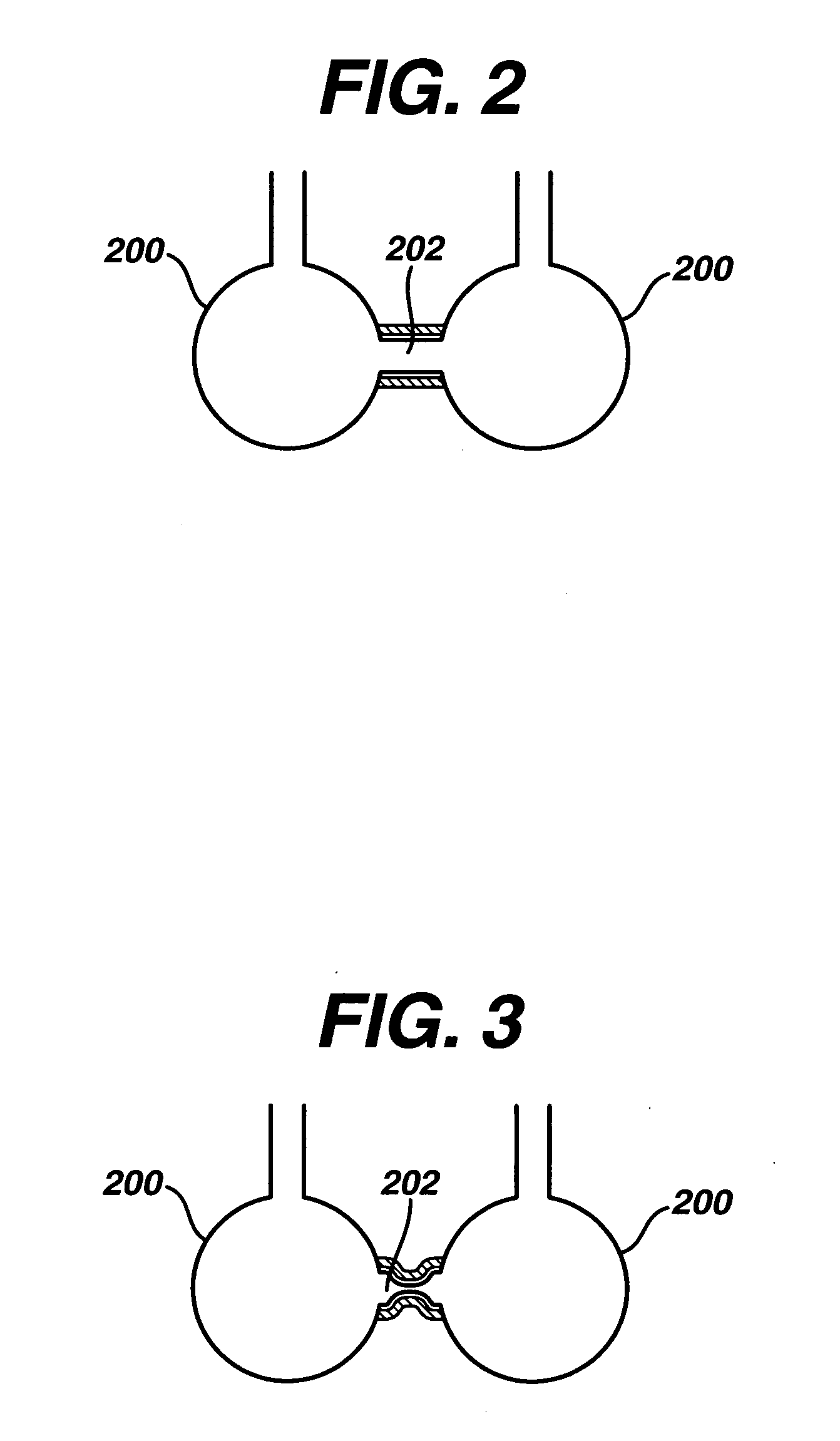

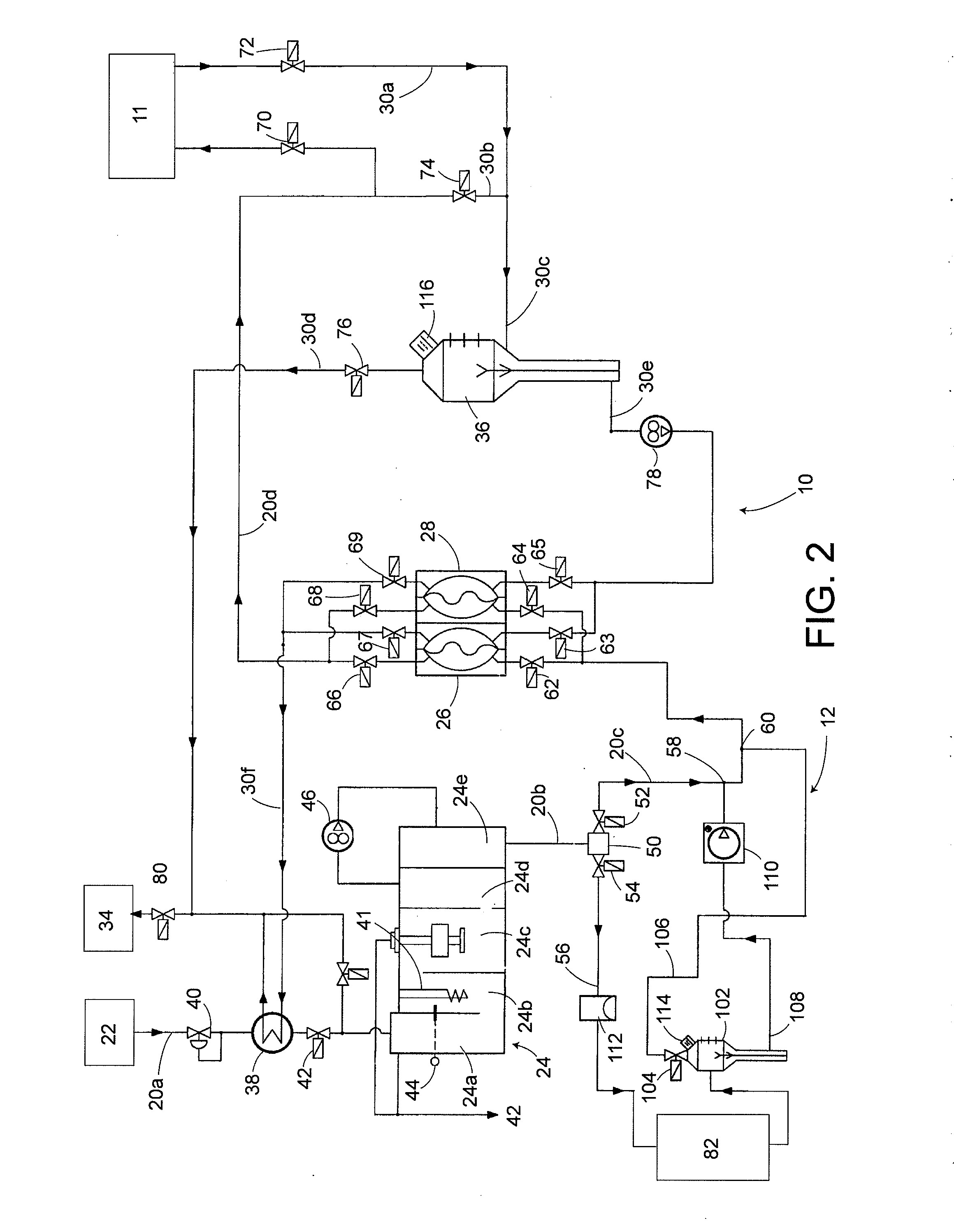

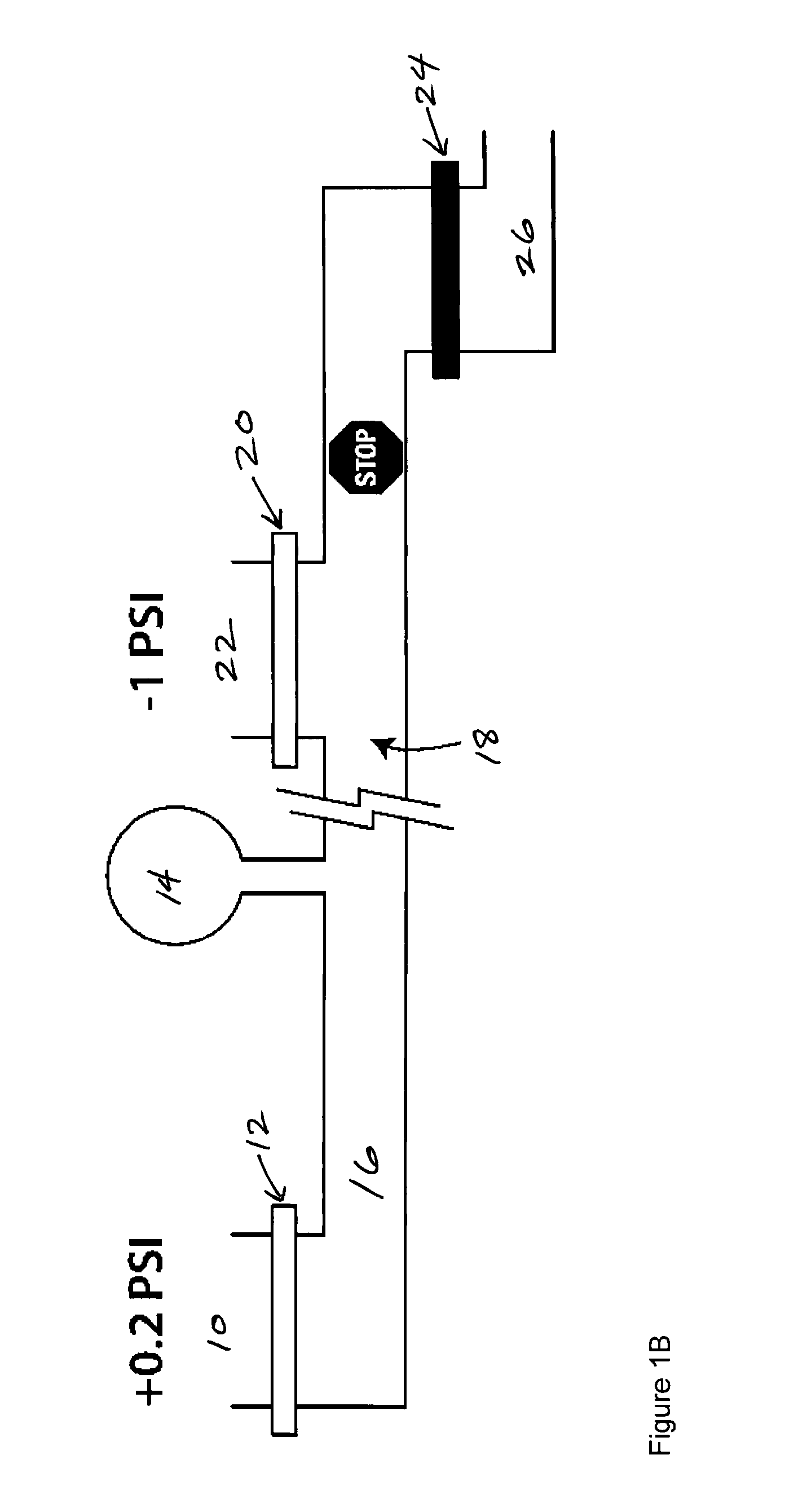

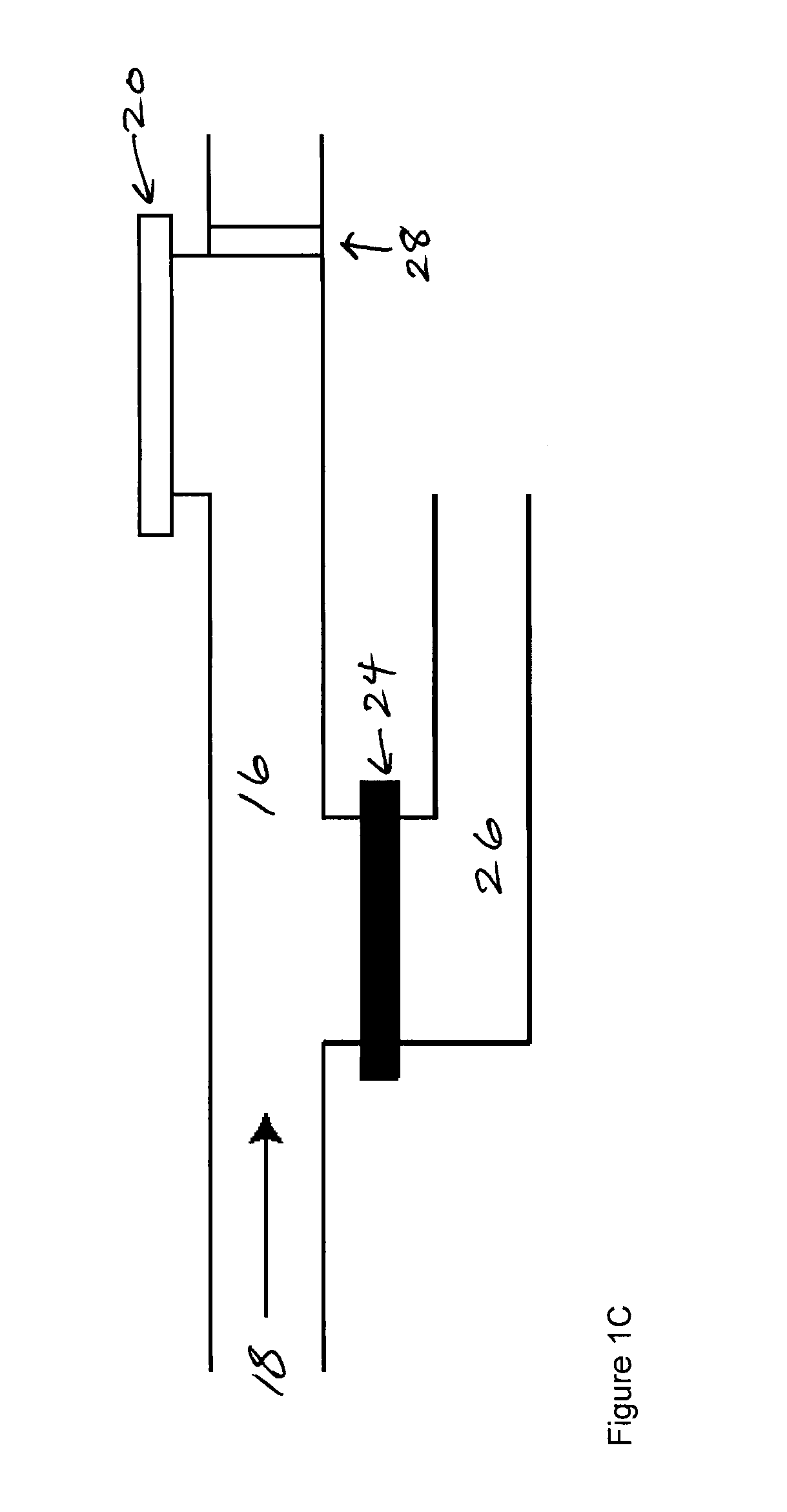

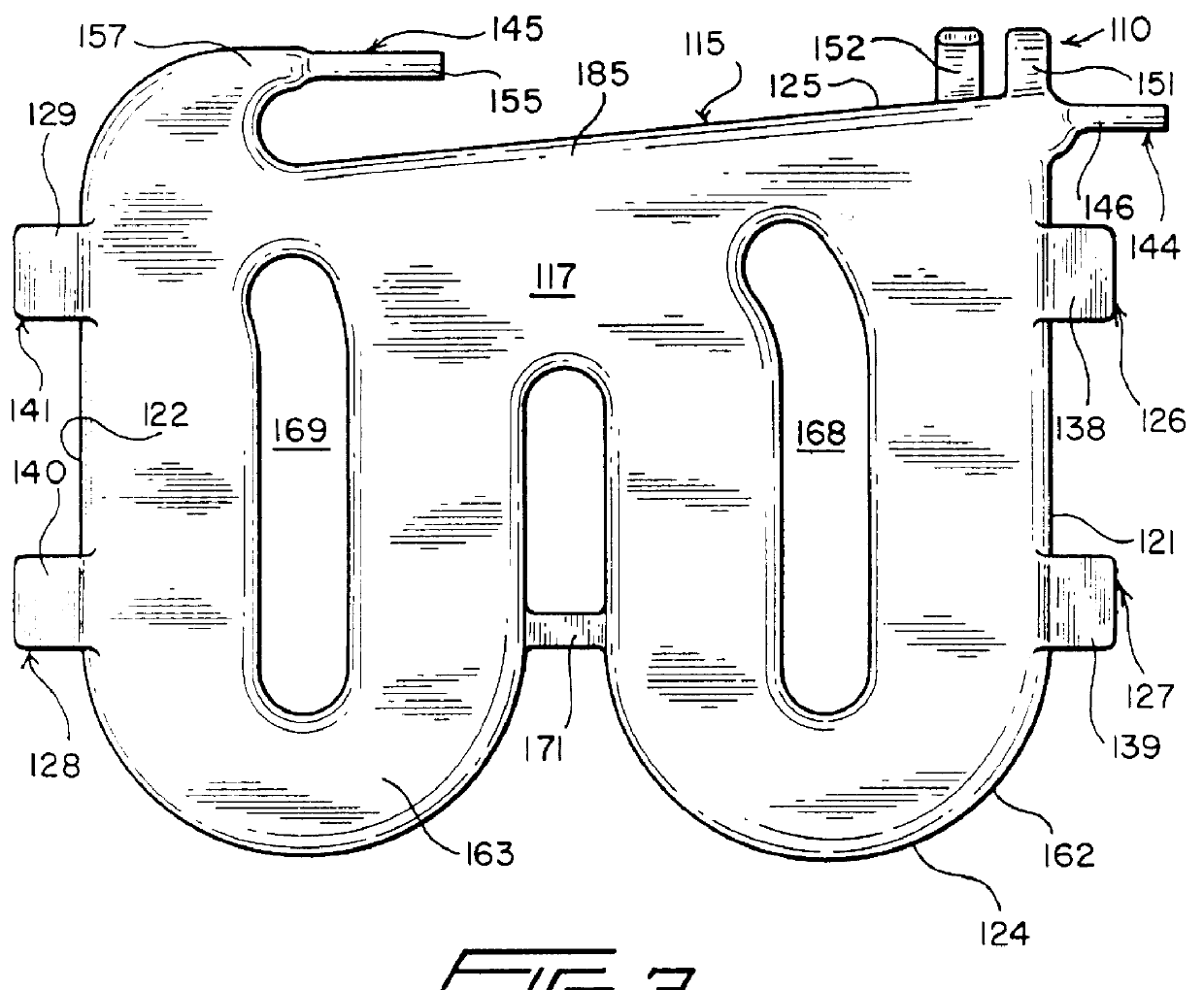

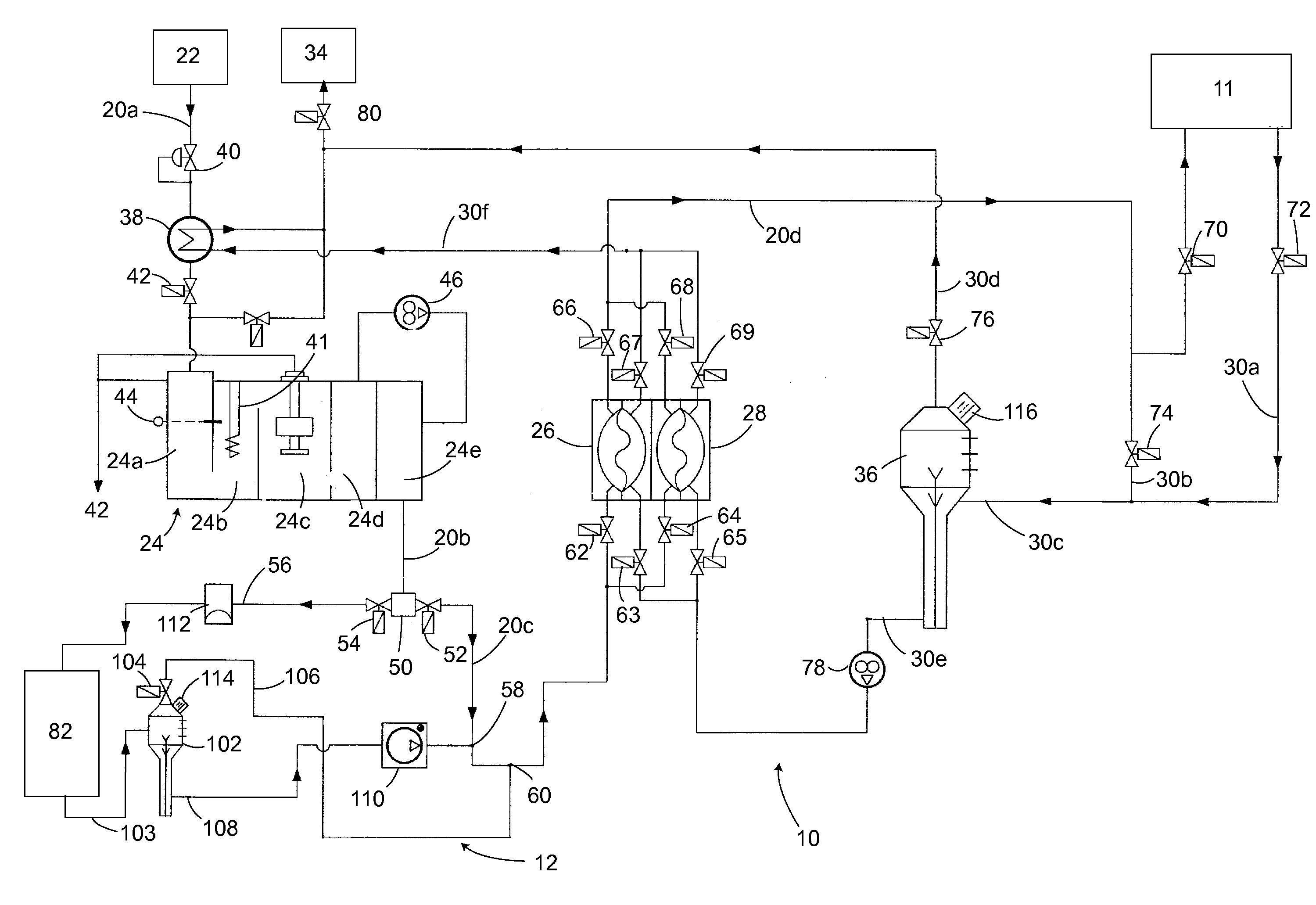

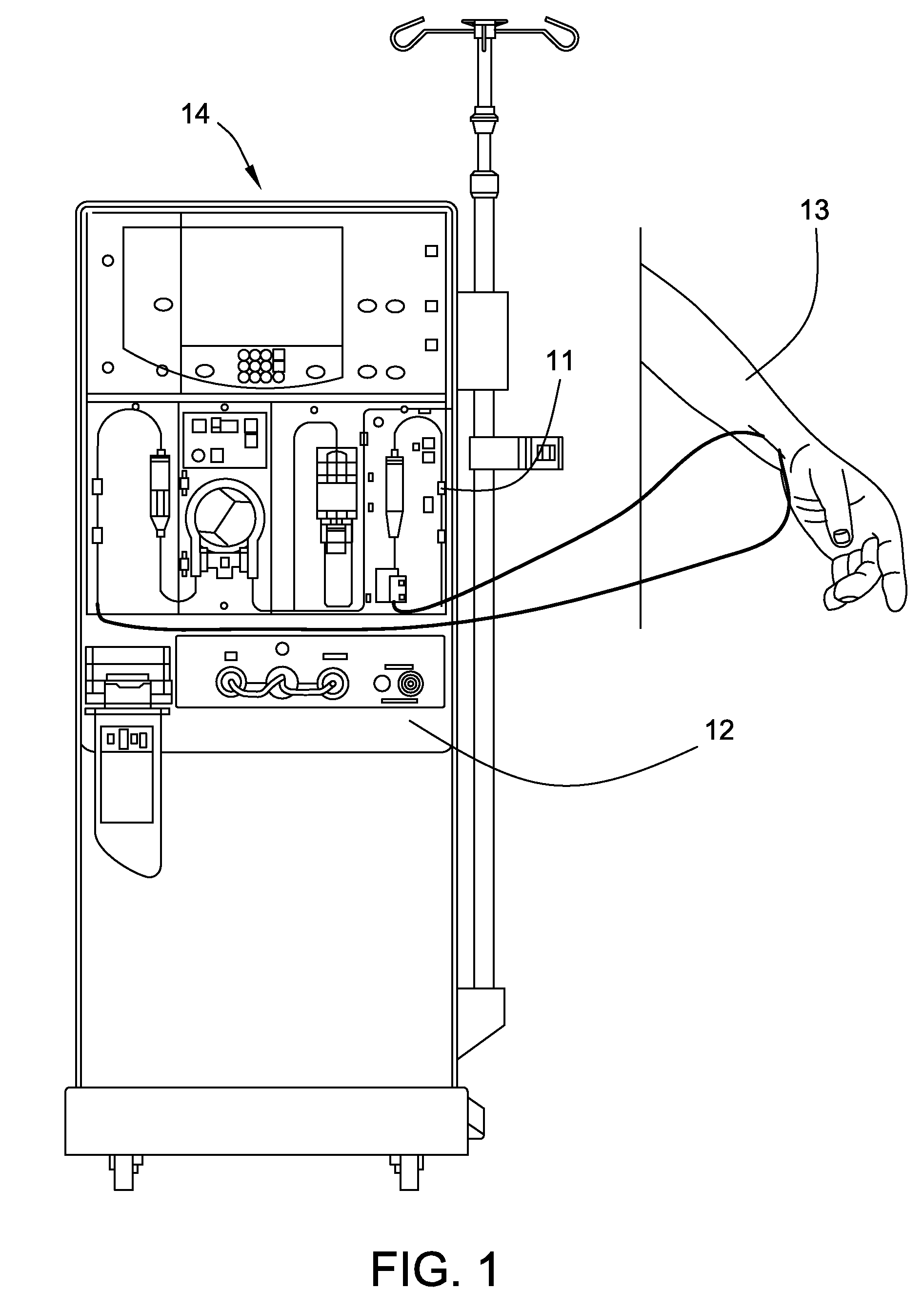

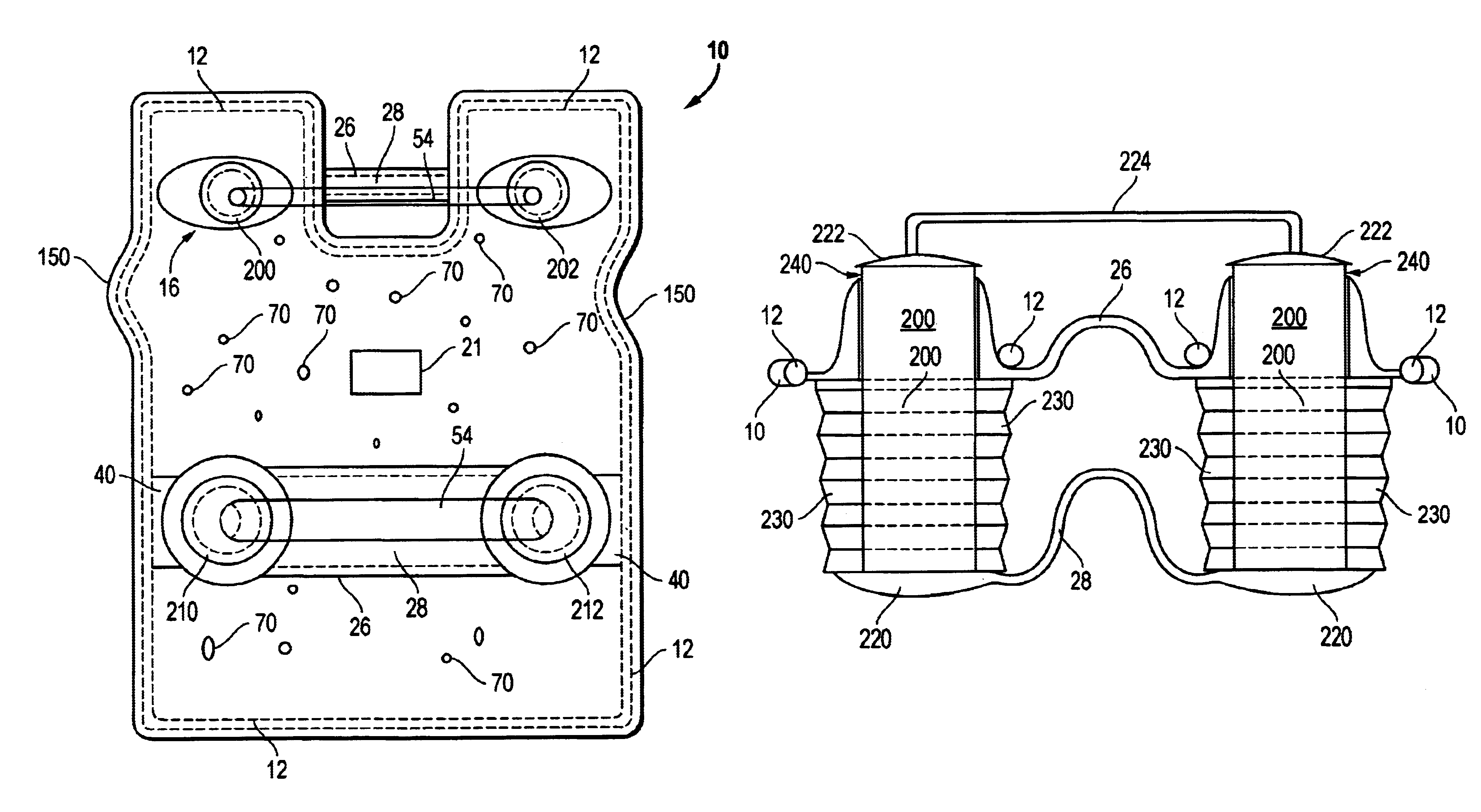

Blood processing systems with fluid flow cassette with a pressure actuated pump chamber and in-line air trap

InactiveUS20050234385A1Straightforward and accurate control functionFluid parameterOther blood circulation devicesPump chamberEngineering

A blood processing system comprises a processing chamber to process blood and a fluid flow cassette that communicates with the processing chamber. The cassette comprises a body, a pump chamber formed in the body, and a flexible diaphragm on the pump chamber responsive to an applied fluid pressures for flexure toward and away from the pump chamber to pump fluid through the pump chamber. The cassette also includes a flow path formed, at least in part, in the body to couple the pump chamber in fluid flow communication with the processing chamber, to convey fluid pumped by the pump chamber into the processing chamber. The cassette also includes an in line cavity formed in the body and located in the flow path to trap air to prevent entry of air into the processing chamber.

Owner:FENWAL

Touch screen shield

ActiveUS20120188743A1Reduce scratchesPromote formationMechanical working/deformationMagnetic/electric field screeningEngineeringTouchscreen

A shield that is attachable to a touch sensitive screen is disclosed. The shield may be attached to the touch sensitive screen only at its outer peripheral portion. An air gap is enclosed between the shield and the touch sensitive screen to form a planar air bearing. The shield preferably does not touch the active area of the touch sensitive screen when the user is not touching the shield but only viewing the touch sensitive screen through the shield. This mitigates unwanted optical artifacts such as trapped air bubbles, Newton rings and chromatic interference while maintaining the sensitivity of the touch sensitive screen.

Owner:RACING OPTICS

Lung reduction system

InactiveUS7252086B2Speed up the flowLower the volumeTracheal tubesBronchiLung tissueIntensive care medicine

A pulmonary decompression device may be utilized to remove trapped air in the lung or lungs, thereby reducing the volume of diseased lung tissue. A lung reduction device may passively decompress the lung or lungs. In order for the system to be effective, an airtight seal between the parietal and visceral pleurae is required. Chemical pleurodesis is utilized for creating the seal.

Owner:PORTAERO

Methods and devices for controlling collateral ventilation

InactiveUS20060118126A1Improve efficiencyReduce riskRespiratorsBronchoscopesCollateral ventilationAnesthesia

Chemical lung volume reduction may be utilized to control collateral ventilation so that trapped air in diseased lungs can be removed. The chemical or therapeutic agent may be locally delivered to the site or sites of highest collateral ventilation utilizing any number of methods including bronchoscopic delivery.

Owner:RESPIRA

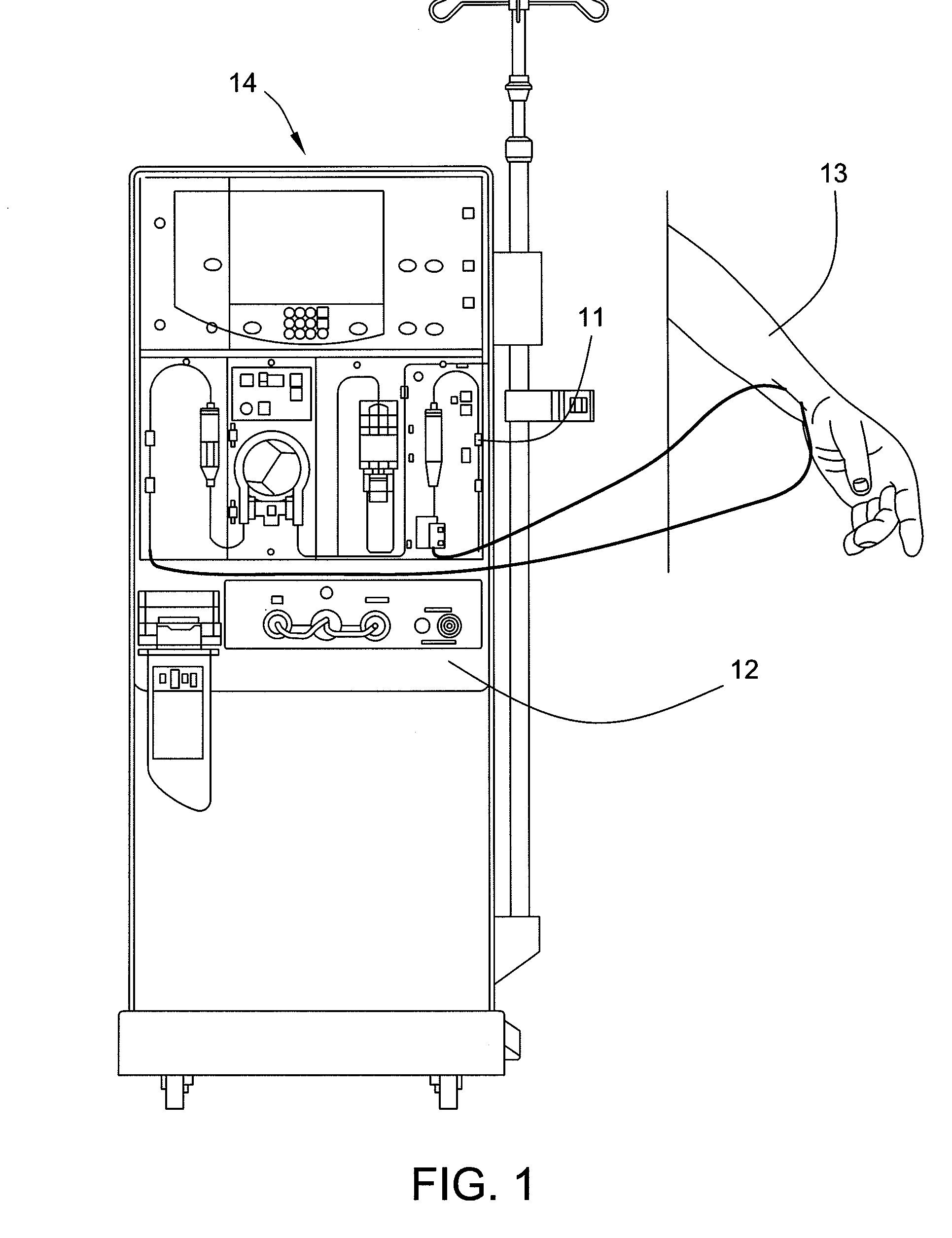

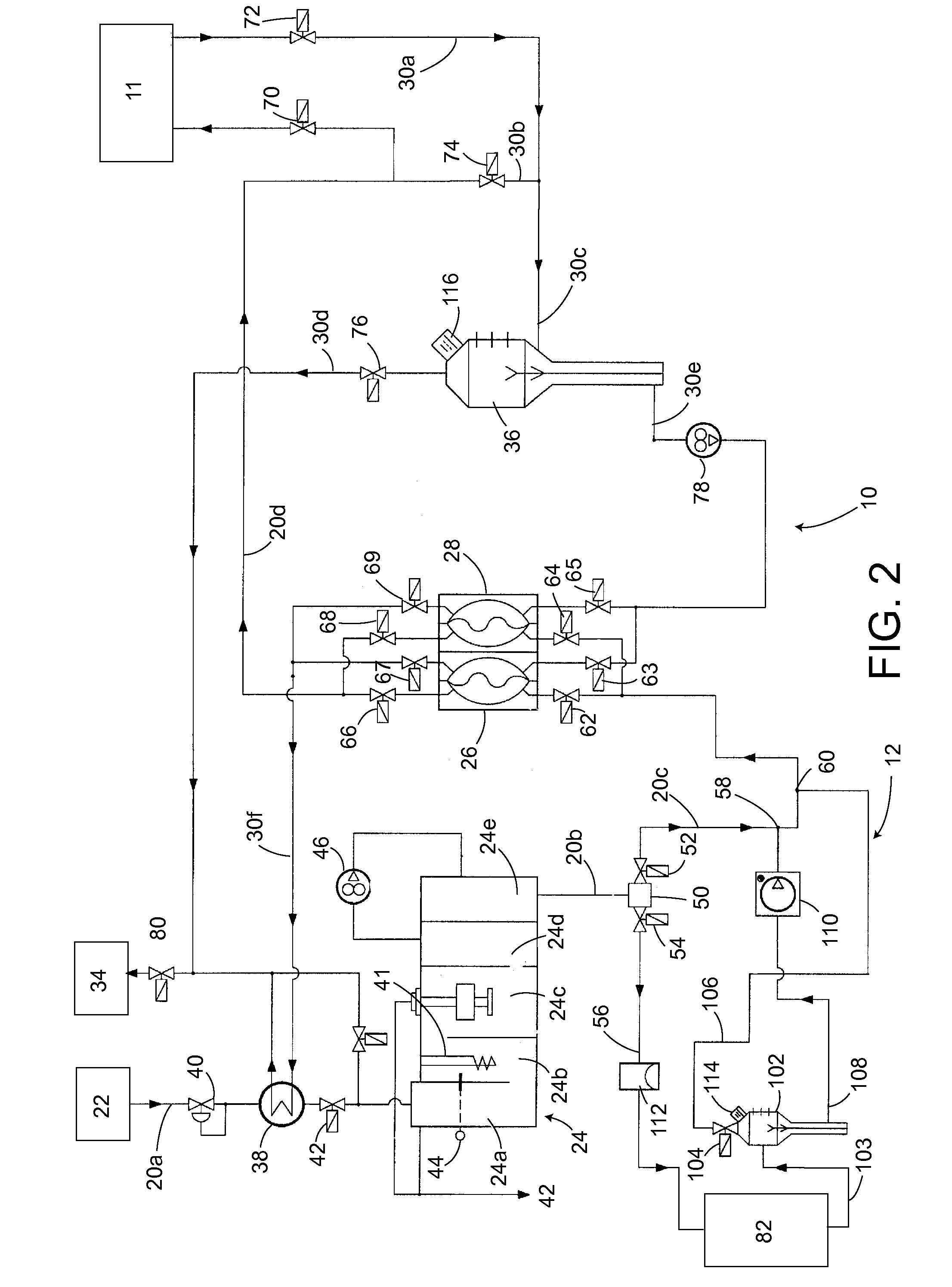

Method for removing gases from a container having a powdered concentrate for use in hemodialysis

ActiveUS20110120946A1Easy to pressurizeLiquid degasificationSolvent extractionHaemodialysis machineProduct gas

An apparatus and a method for filling a container containing a dry powdered salt concentrate for use in dialysis with purified fluid and removing the trapped air or gases generated during the filling of the container, while maintaining the required fluid level in the container and without the need for evacuating gases from the container prior to filling.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Blood collection and measurement apparatus

InactiveUS20060228258A1Material analysis by optical meansLaboratory glasswaresBlood collectionMeasuring instrument

Some embodiments of the invention provide one apparatus that is suitable for both the collection and measurement of a blood sample. Once a blood sample is drawn into such an apparatus the blood sample can be analyzed, without having to transfer any portion of the blood sample into another vessel. Also, in some very specific embodiments, the apparatus is provided with an optical chamber that is specifically designed to reduce the average attenuation of electromagnetic radiation (EMR) due to scattering of EMR by the red blood cells in a blood sample, without having to hemolyze the red blood cells by using sound waves or by adding reagents to the blood sample. Moreover, as a result of the time saved by using a single apparatus for blood sample collection and measurement, the addition of an anticoagulant is not required to prevent clotting. Moreover, in such embodiments the optical chamber is designed to spread blood into a thin film, thereby reducing the incidences of trapped air bubbles in the collected blood sample in the optical chamber. Instead air bubbles are easily pushed through the optical chamber and guided out of the apparatus through a vent. Optionally, at least one biosensor may be provided within a second flow path in the apparatus.

Owner:CHROMEDX

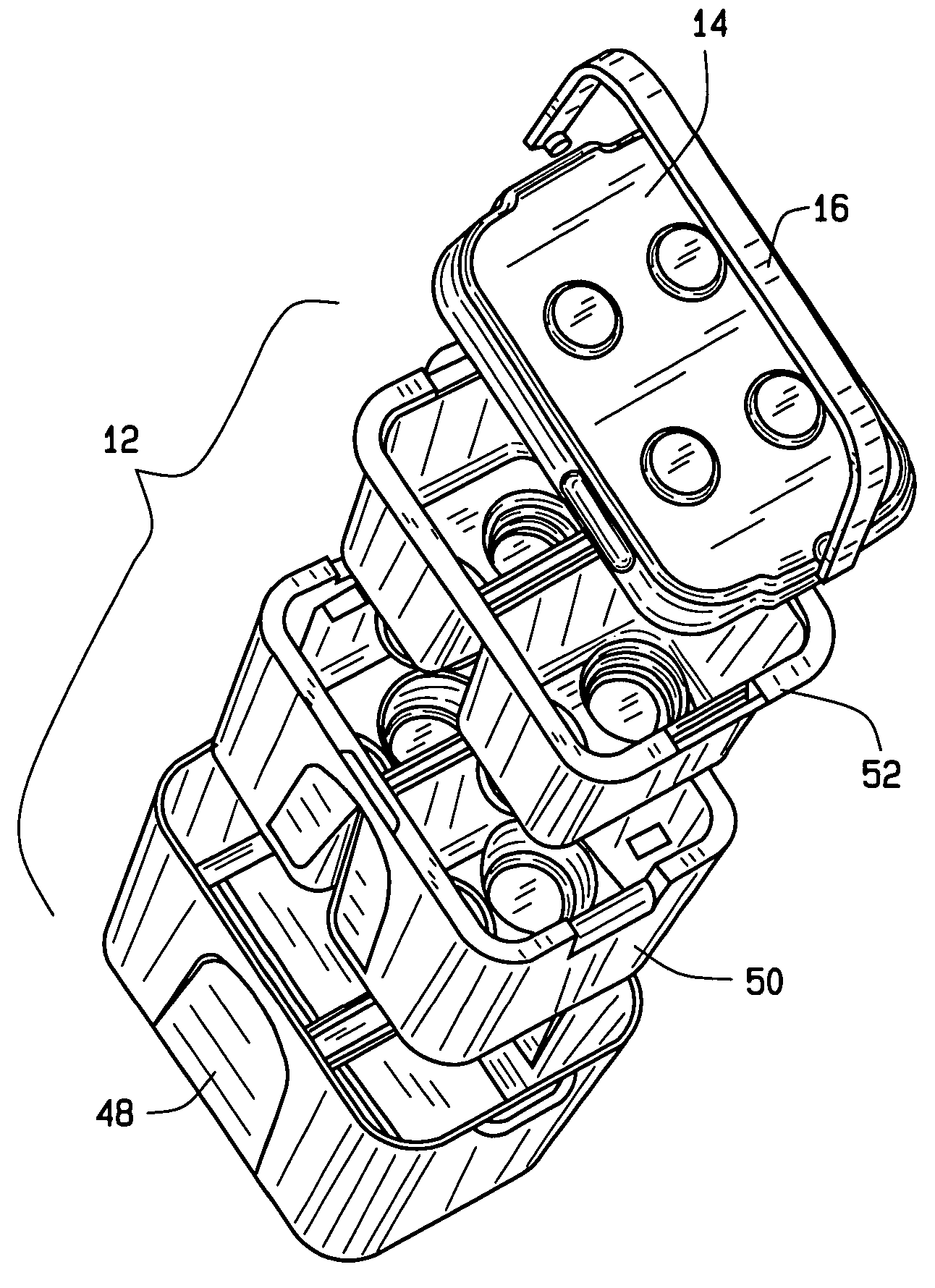

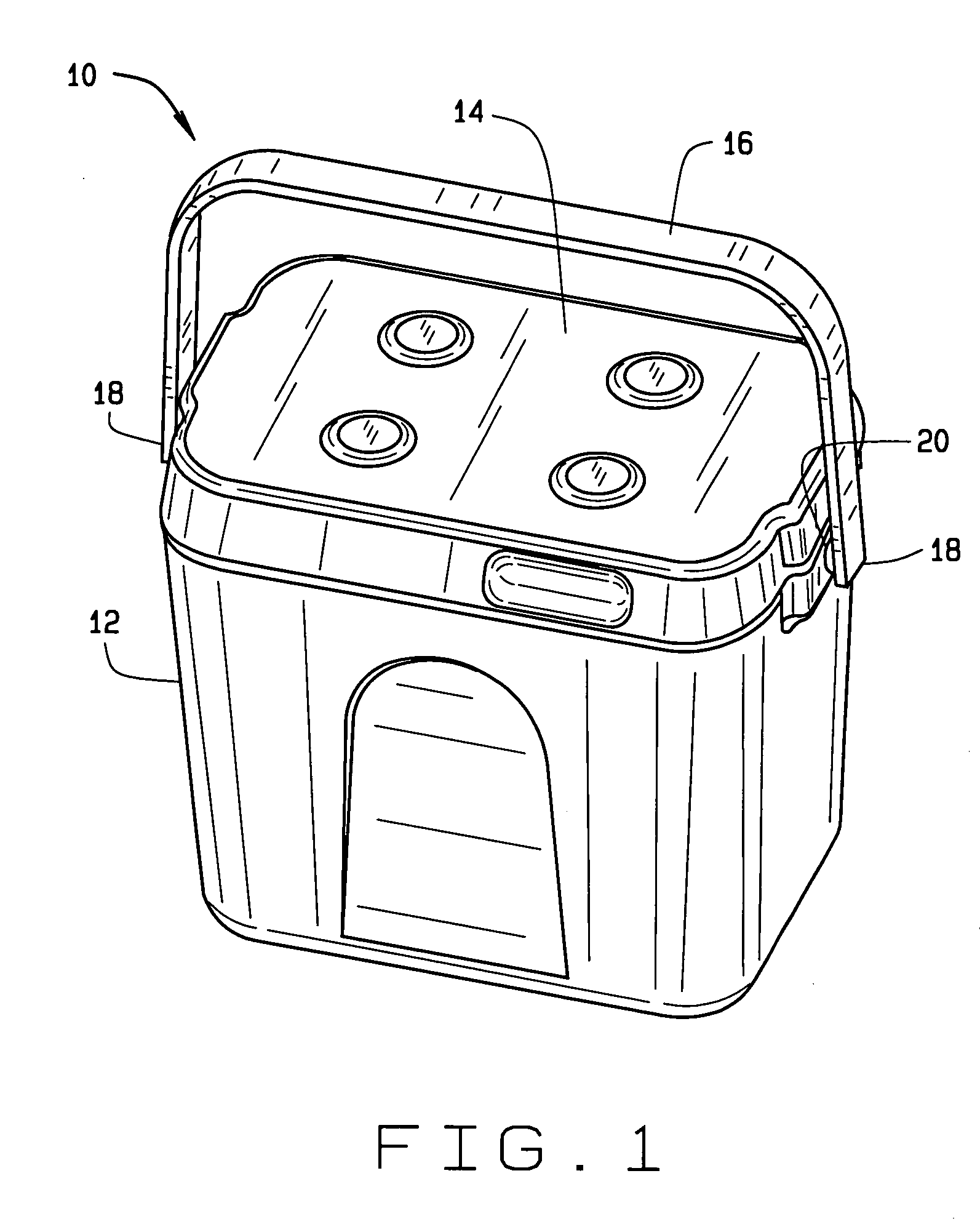

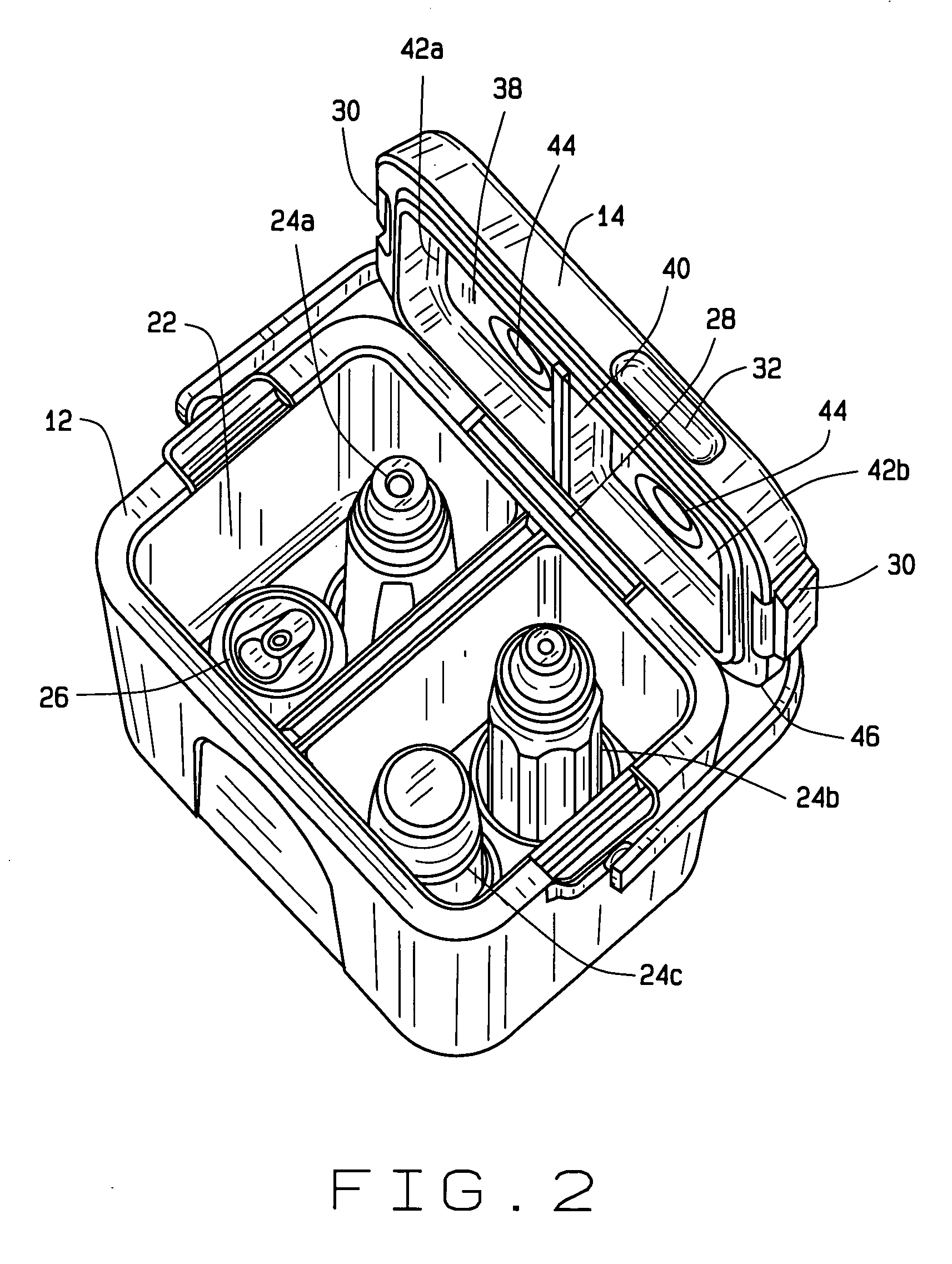

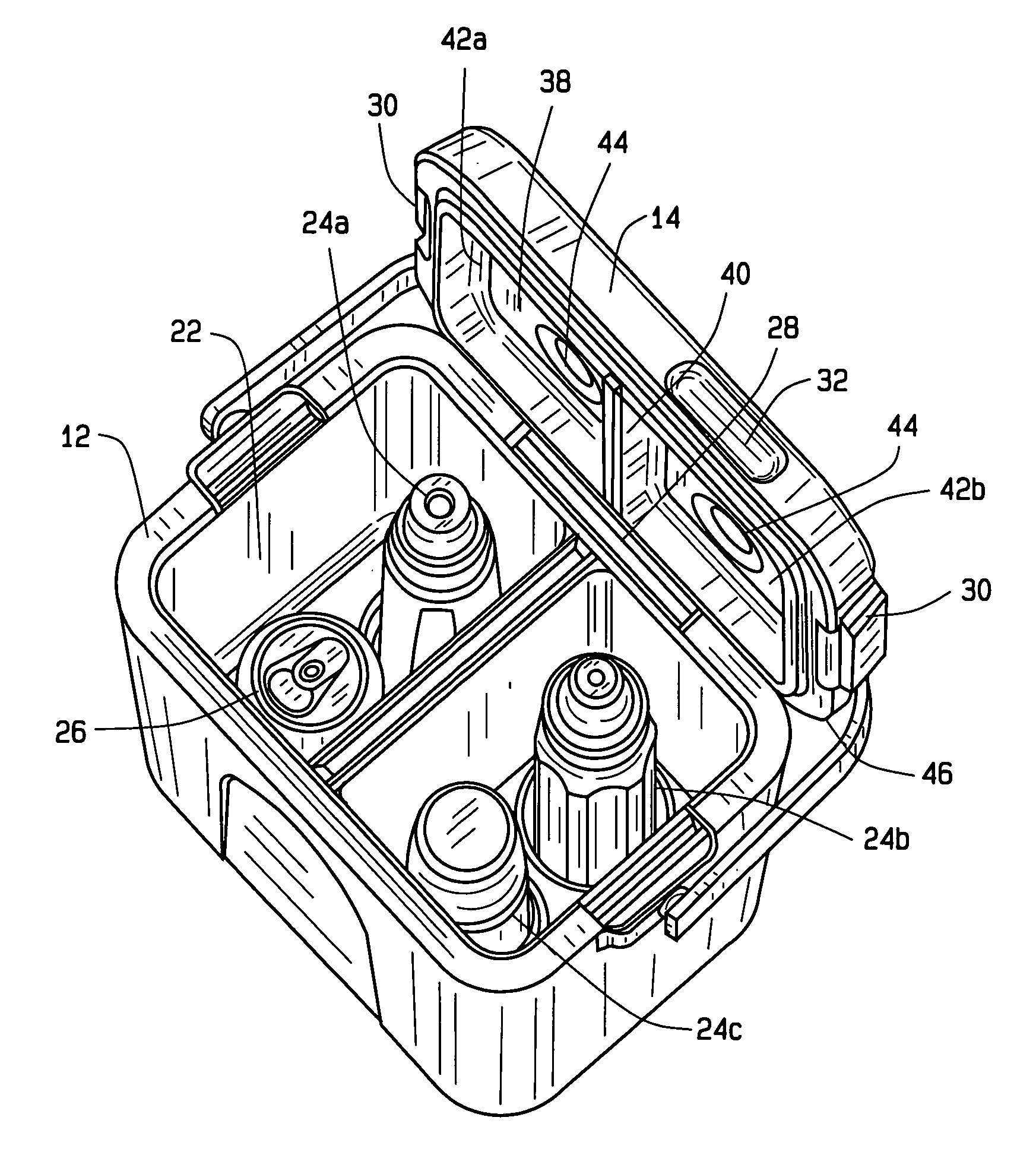

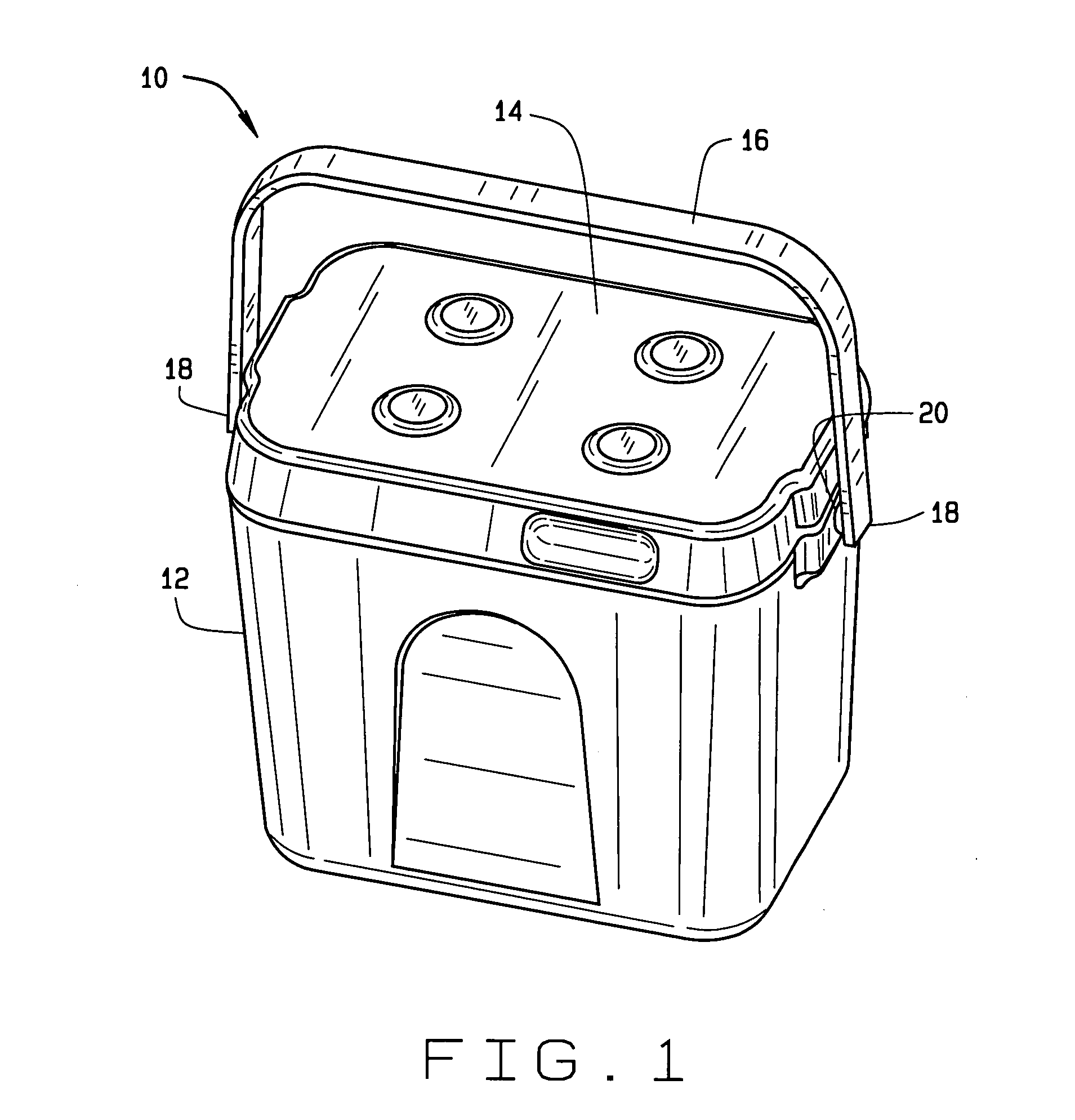

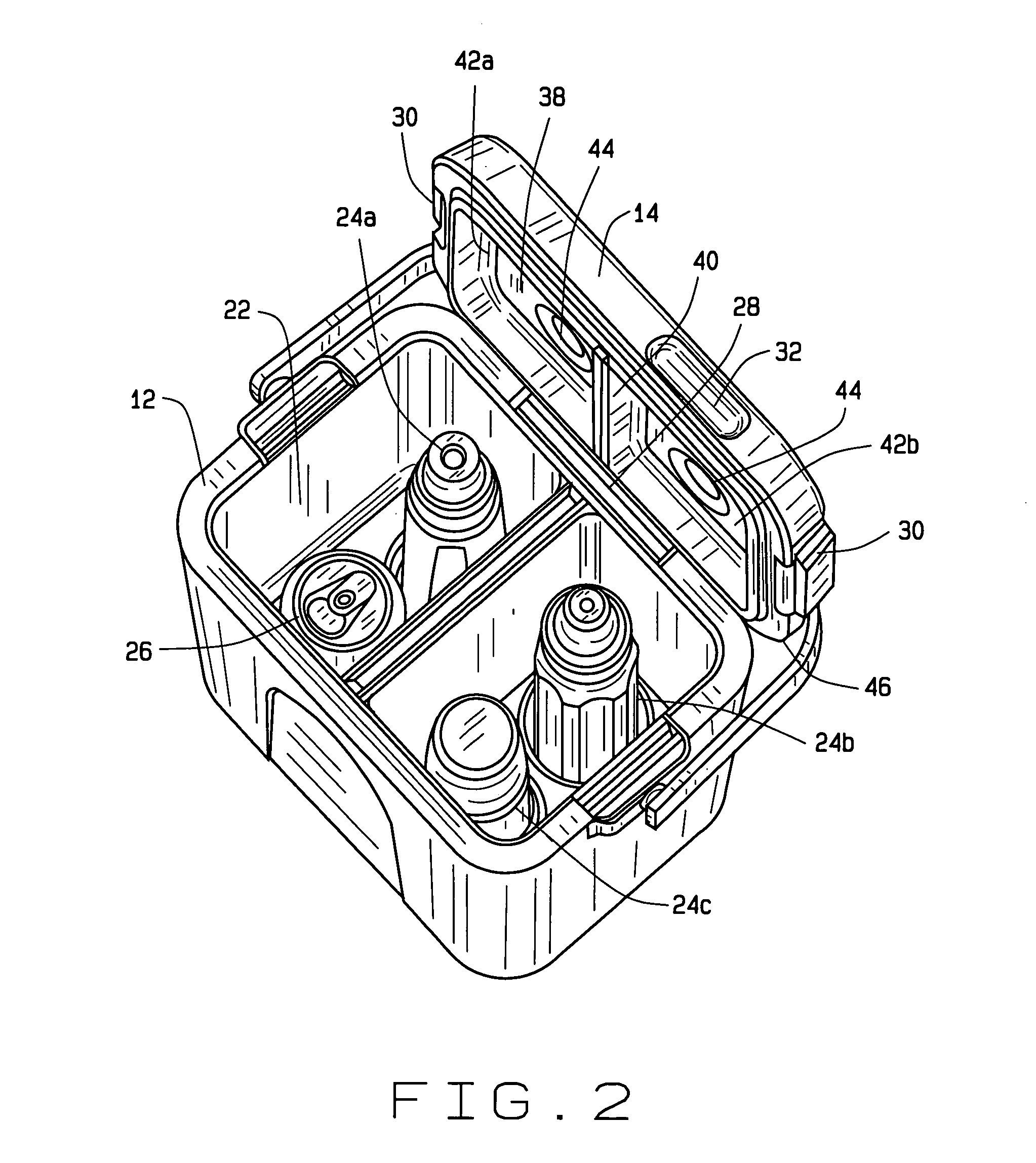

Insulated storage container having a removable liner

InactiveUS20050109776A1Secure retentionDomestic cooling apparatusLighting and heating apparatusCouplingEngineering

The present invention comprises an insulated container having a liner fitted therein. The liner is removable, reusable, and washable. The insulated container also has an insulated partition defining a pair of thermally isolated compartments to maintain different temperatures in each compartment. To secure the liner in place, a latch is provided, and to vent trapped air, the liner includes a channel. The liner is also configured to shed water when inverted in a washing machine so that the liner can be easily sterilized. An additional unique feature of this invention is that the liner also includes coupling cavities configured to accept various bottles and cans to prevent the bottle or can from tipping over inside the insulated container.

Owner:CAMP JR WILLIAM P

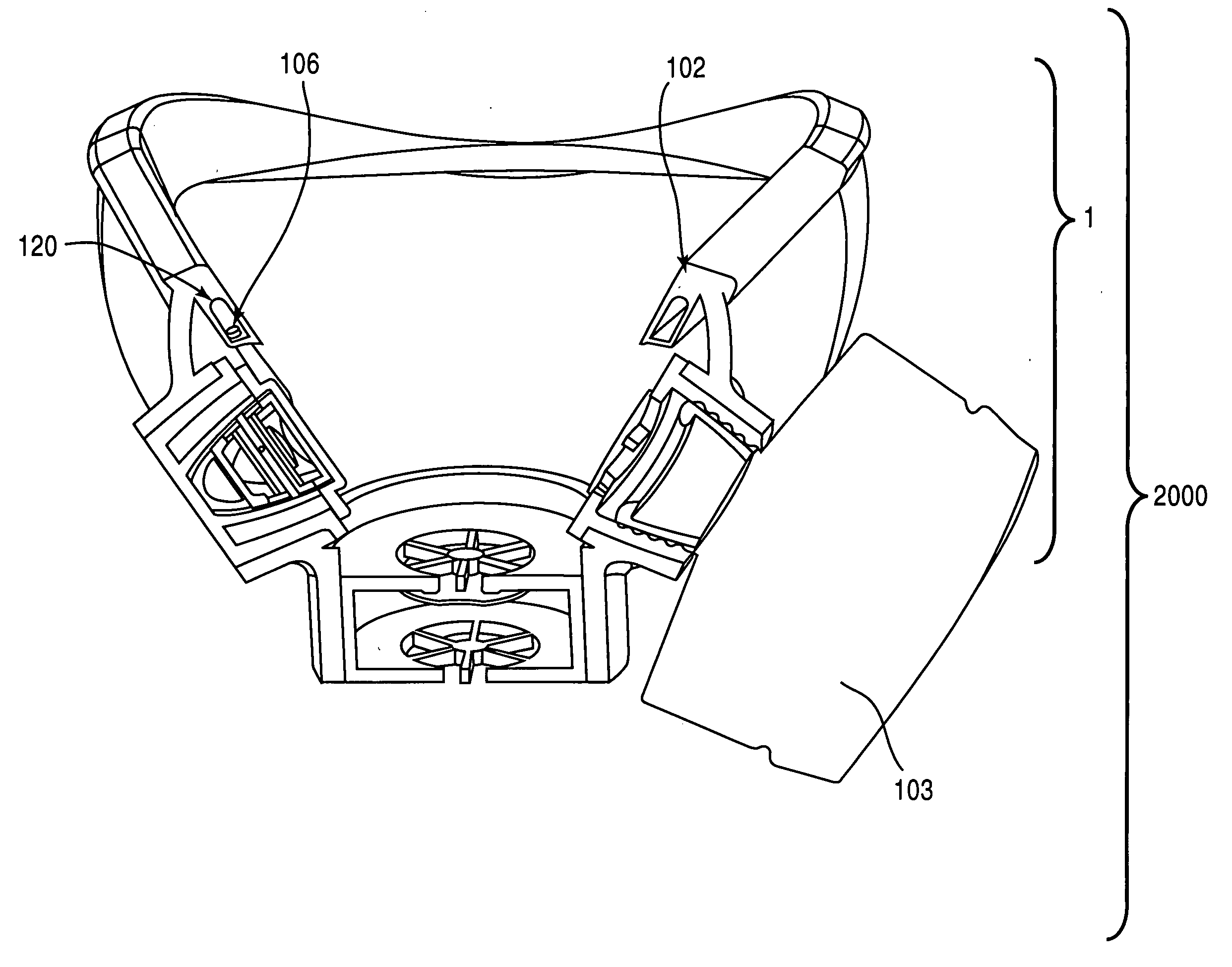

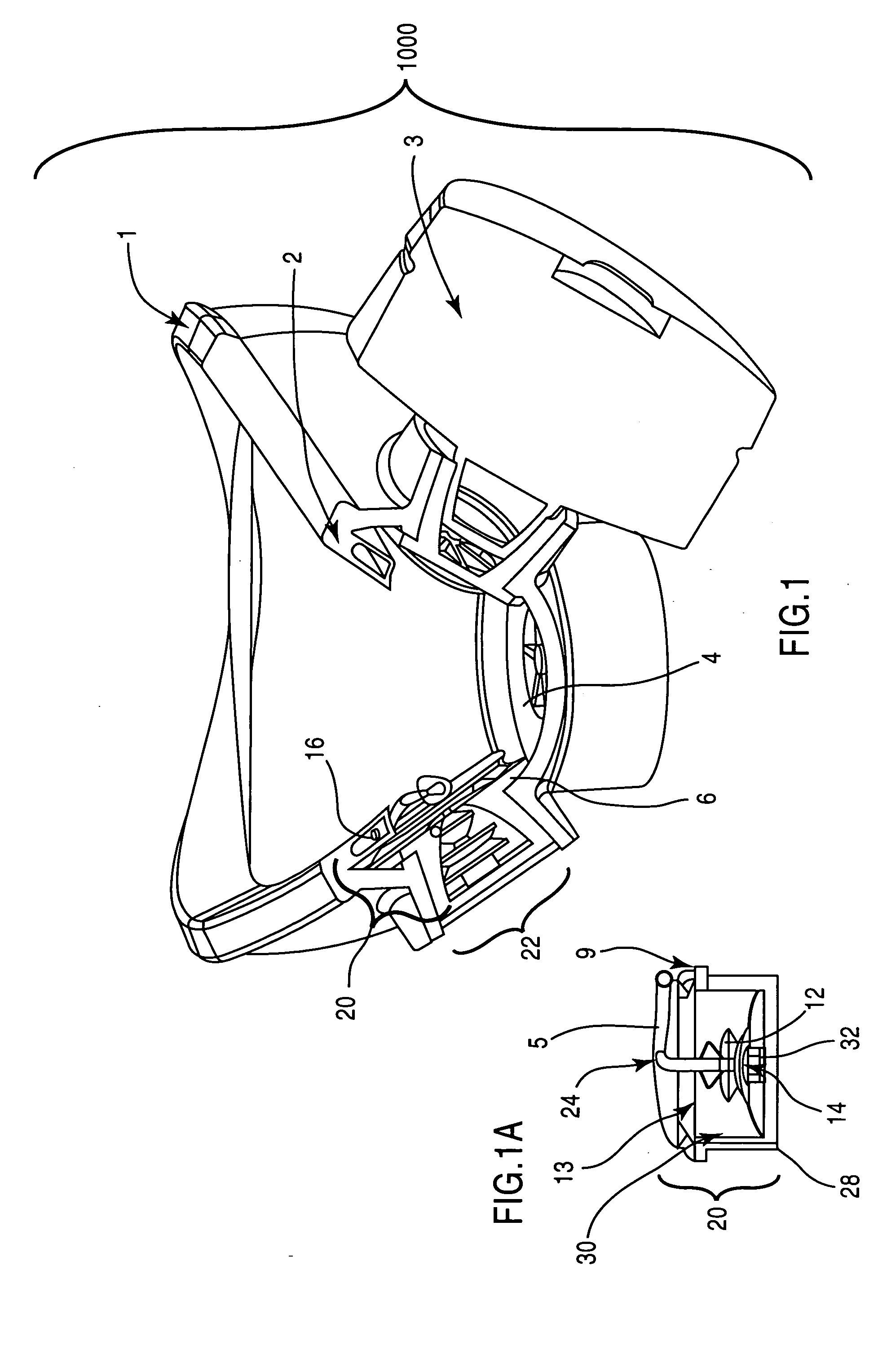

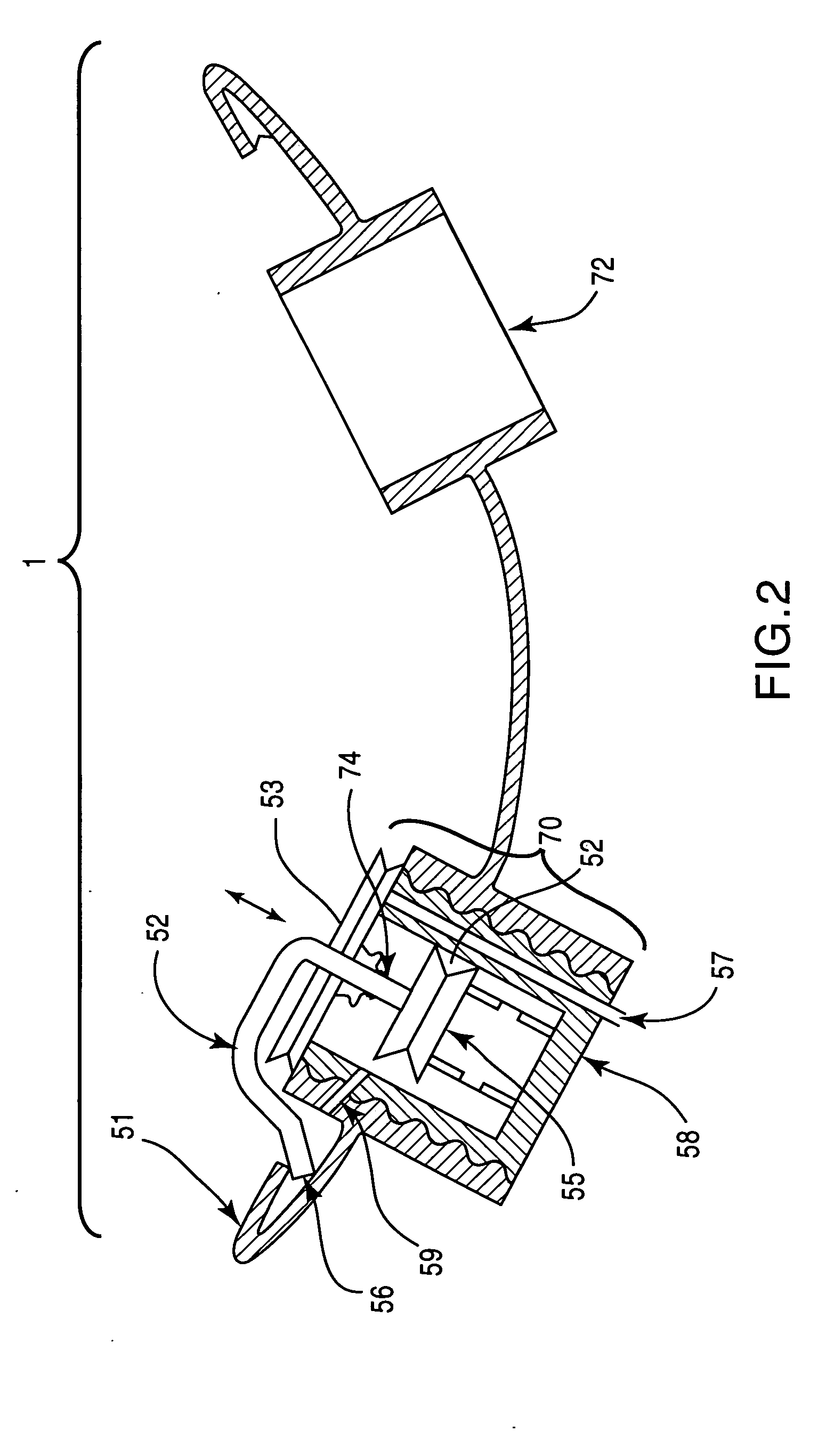

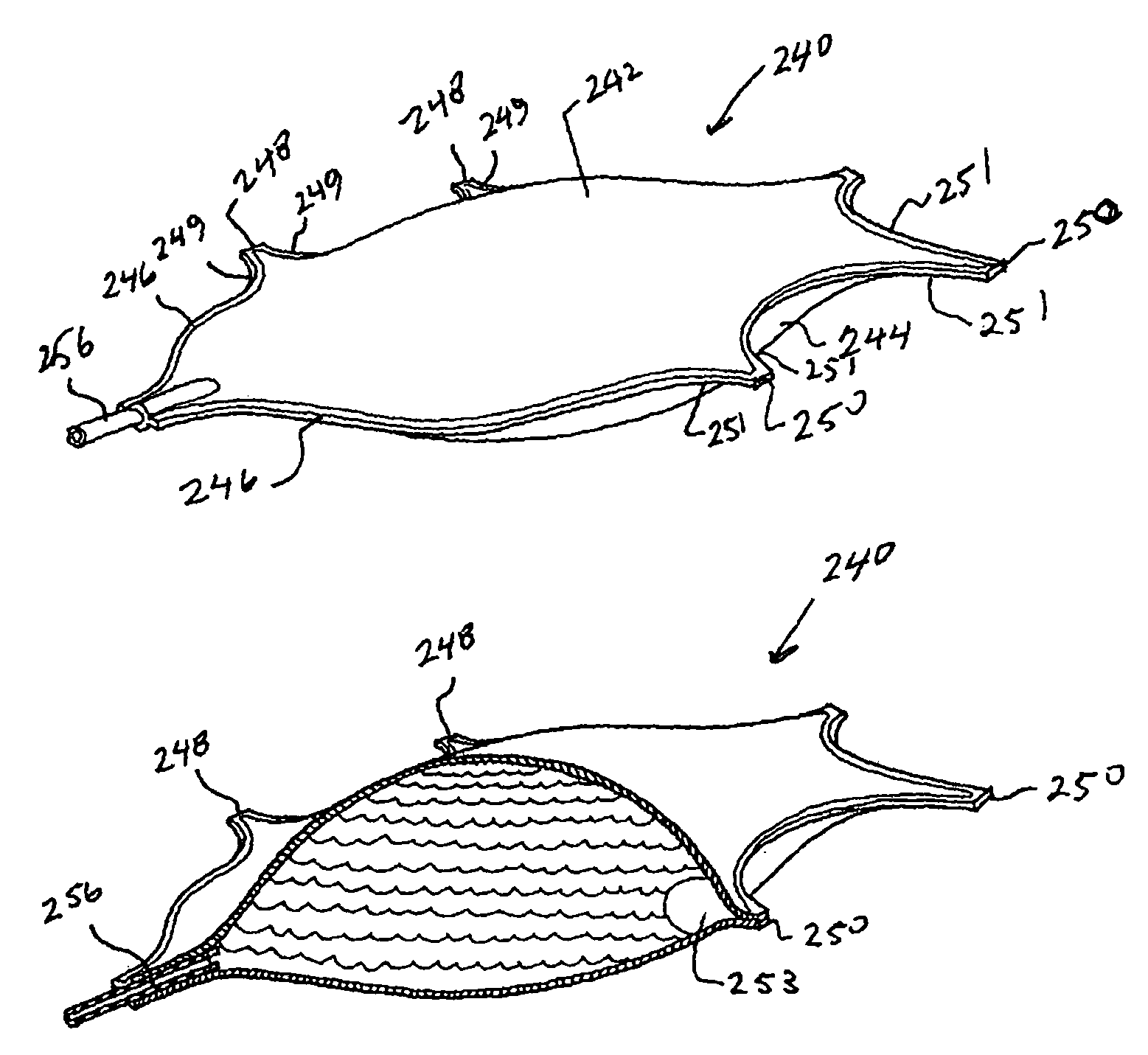

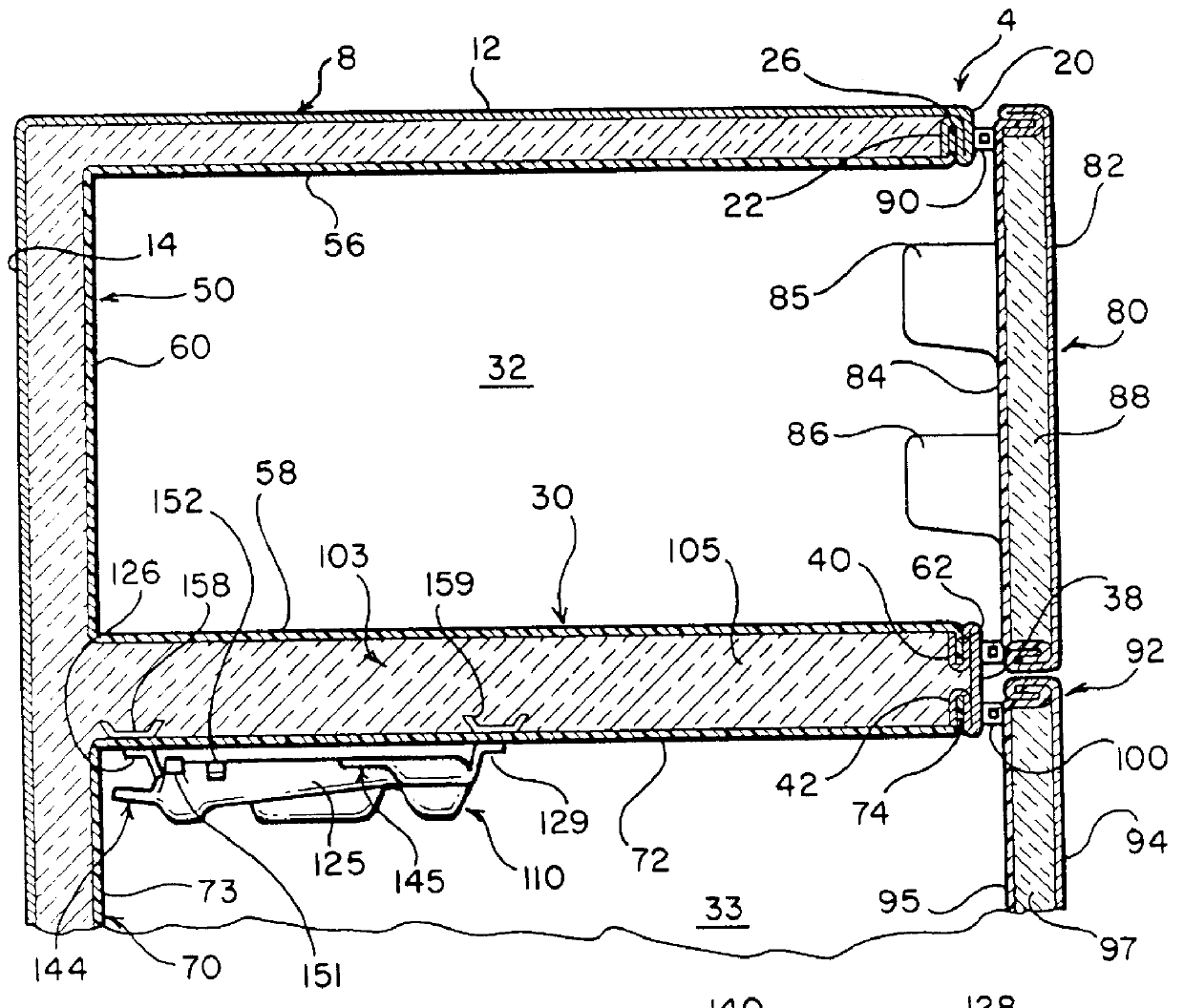

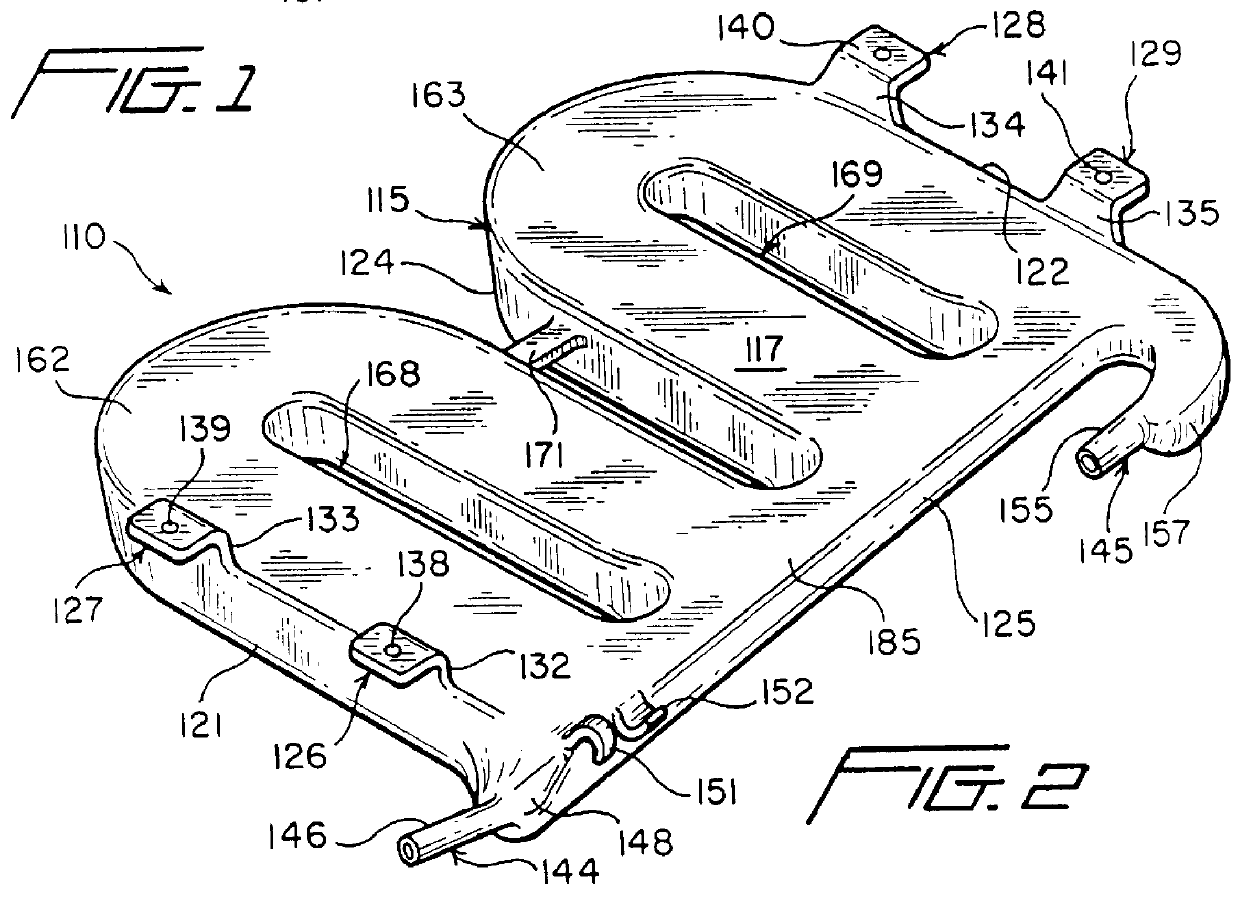

Pneumatic sealing system for protection masks

A pneumatic sealing system for a gas mask, which seals the mask to the face of the user by using a pump that employs air from inside the gas mask to variably inflate a mask seal during the breathing cycle. A double diaphragm pump, which has a driving diaphragm and a driven diaphragm, is connected to the inflatable mask seal via a hose duct. The double diaphragm pump is driven by the pressure difference inside the gas mask. During inhalation, the driving diaphragm fills with ambient air and the driven diaphragm fills with filtered air. During exhalation, the driving diaphragm and the driven diaphragm compress, releasing and trapping air in the mask seal.

Owner:BRANCH BANKING & TRUST +1

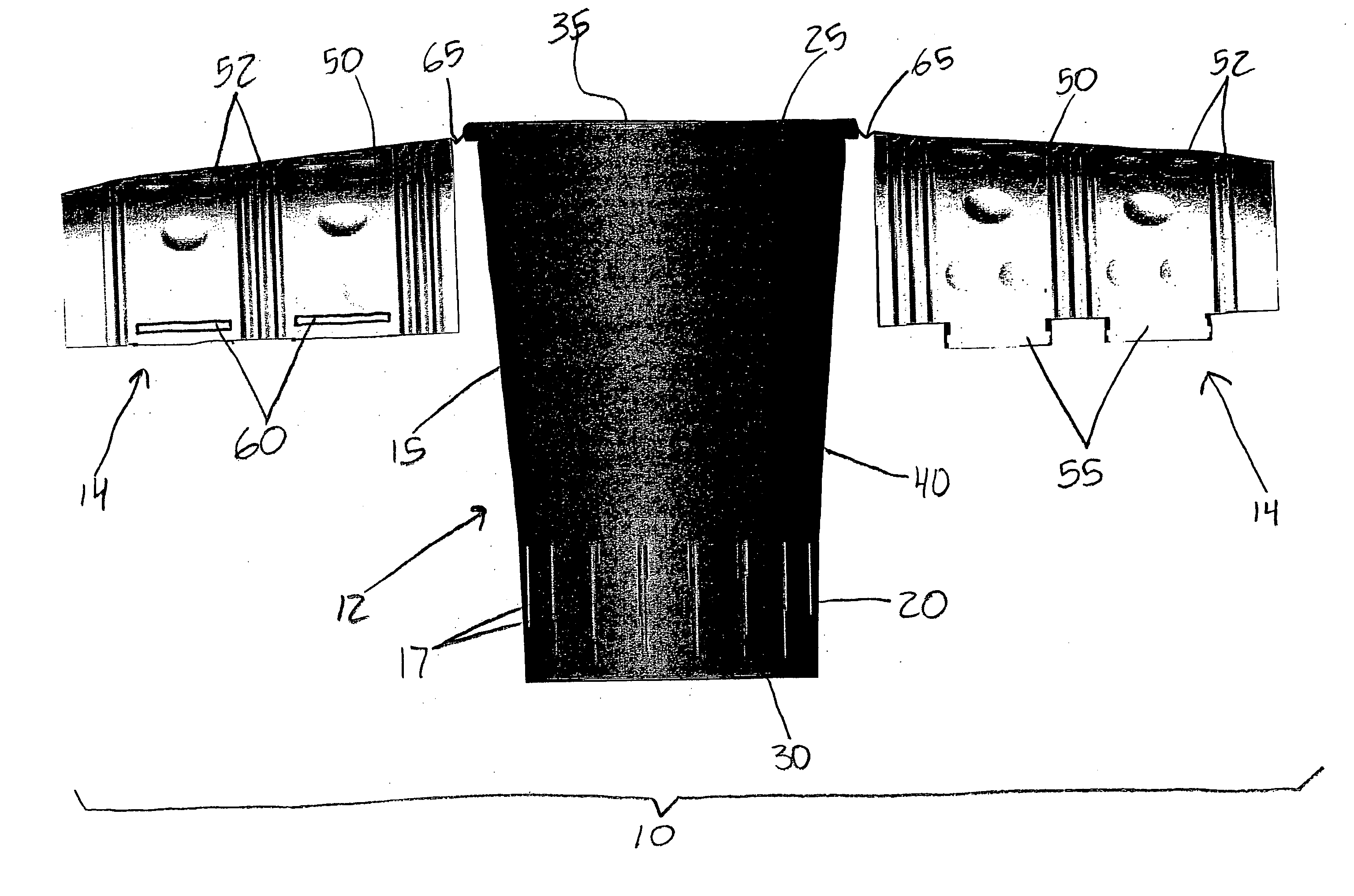

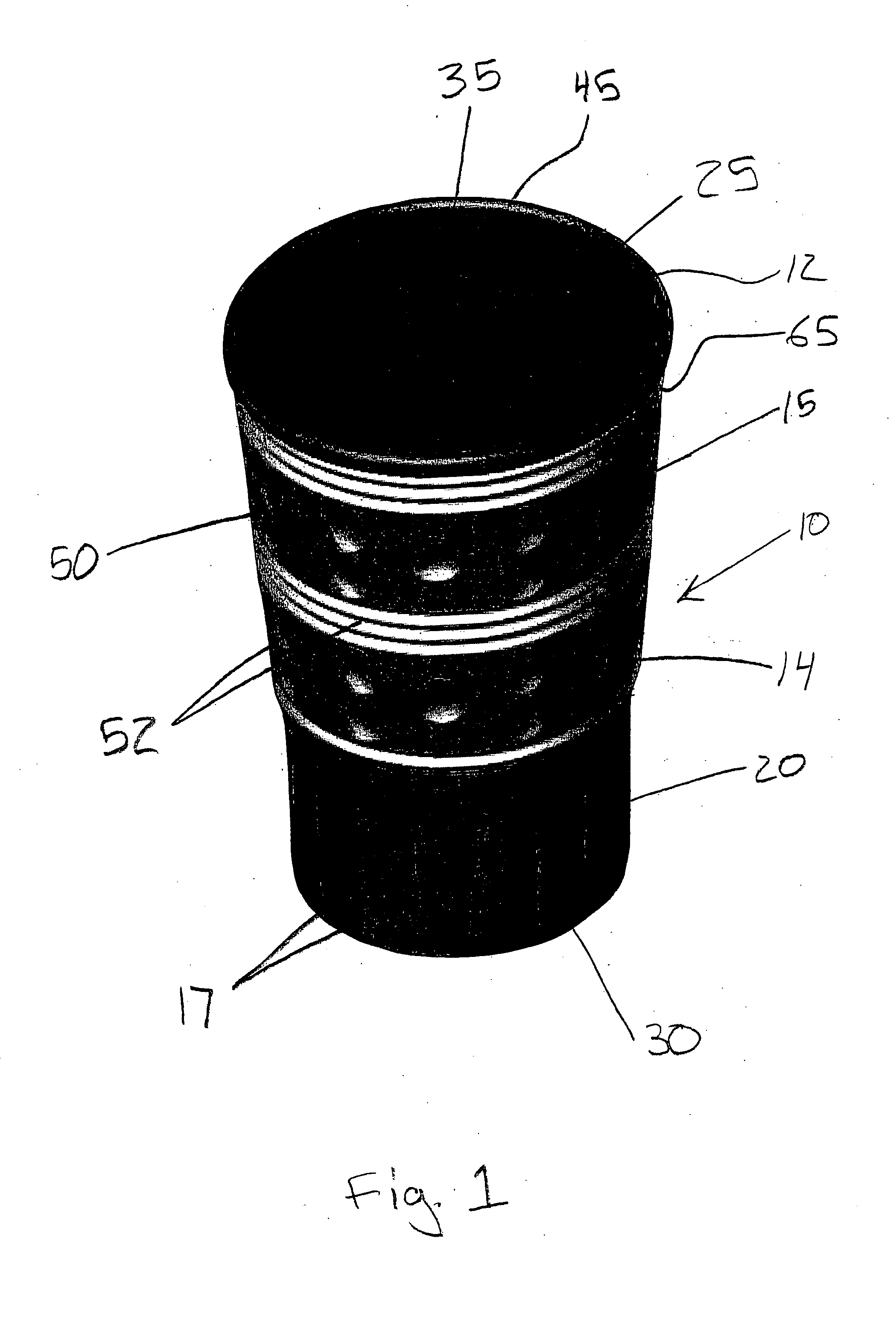

Unitary double walled container and method for making

InactiveUS20050040218A1SturdyEven insulationDomestic cooling apparatusLighting and heating apparatusDouble walledBuilding construction

A single-piece seamless construction container formed from a thermoformable material, the container including a vessel, at least one wing, and at least one hinge coupling the wing to the vessel. The wings comprise a patterned surface, although only the vessel, or the wings and the vessel may also be configured to include a patterned surface. The wings are configured to wrap about the container with the patterned surface serving to trap air between an outer surface of the vessel and an inner surface of the wing. The trapped air and the wing forms an insulative air gap between a surface of the container and the wing. The container may be nestably stacked in a wing open or wing closed position.

Owner:HINCHEY TIMOTHY J +1

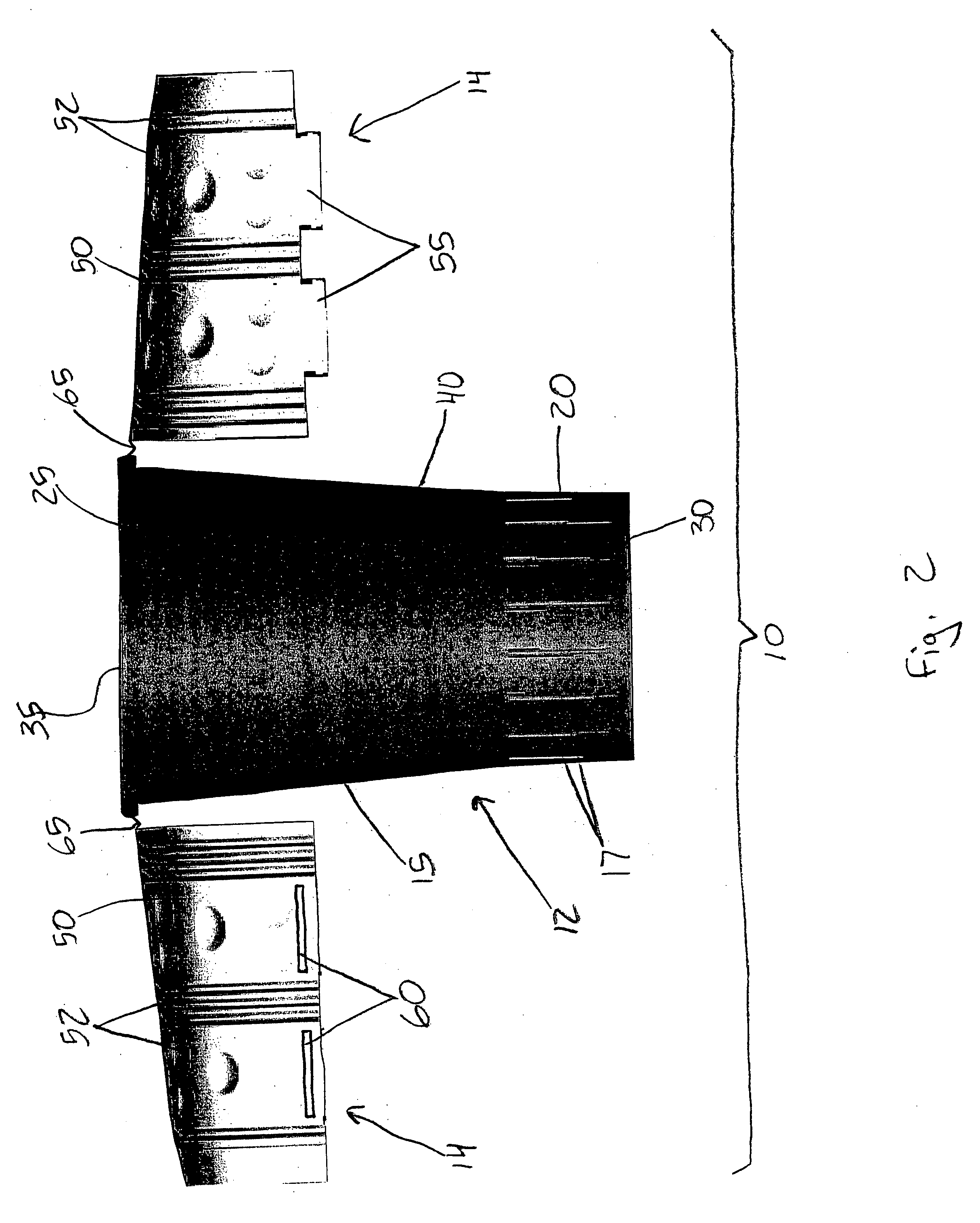

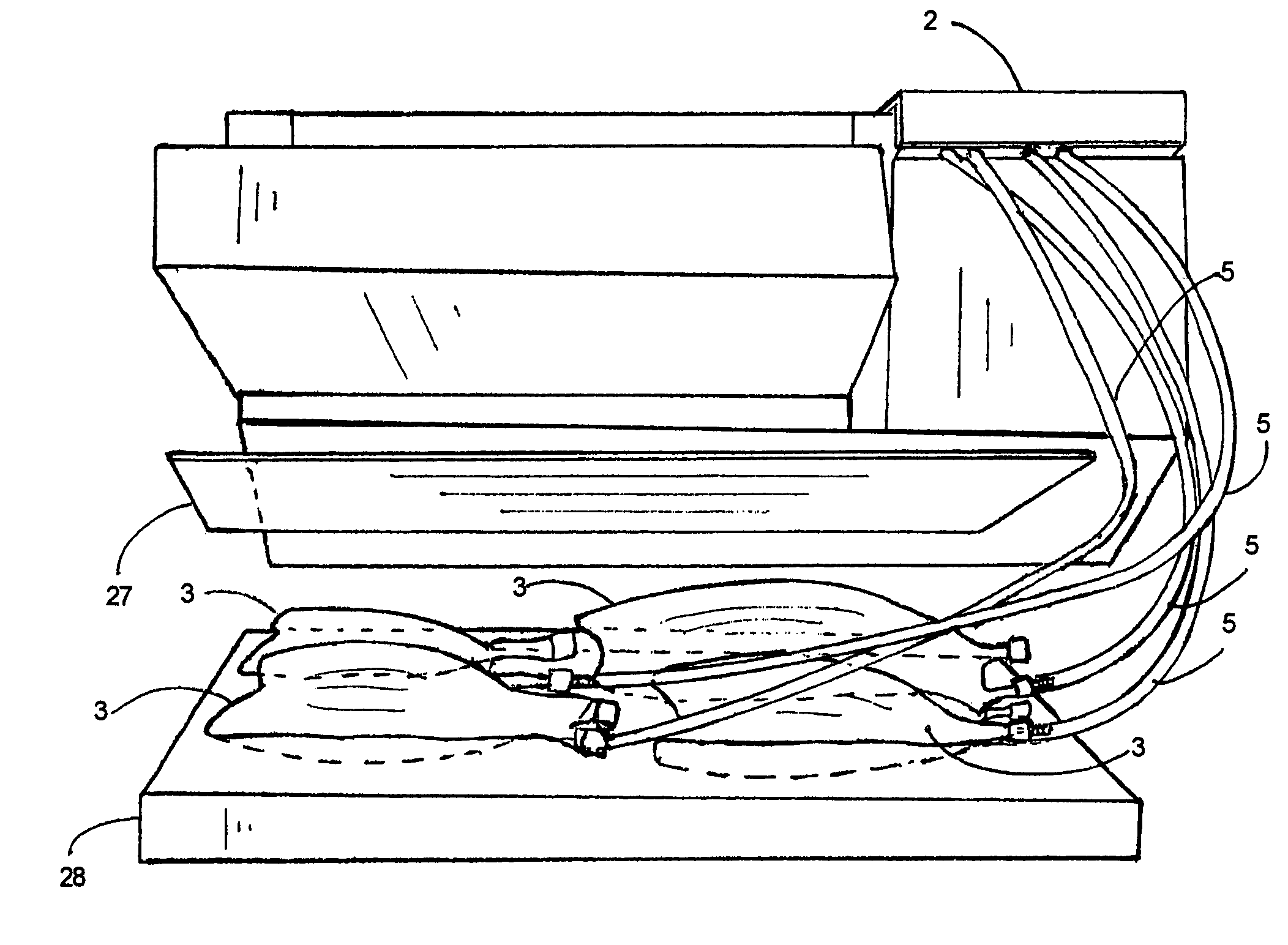

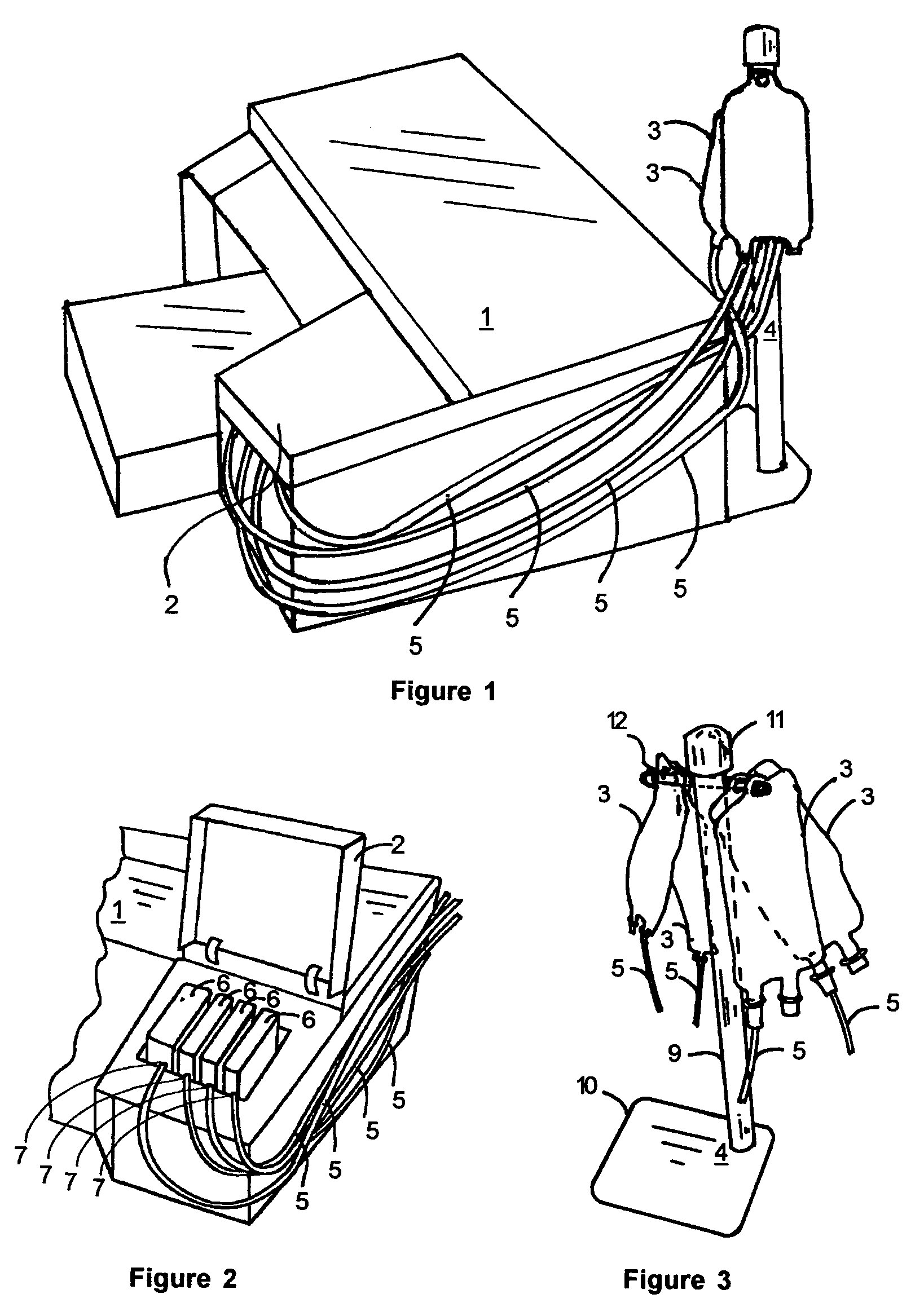

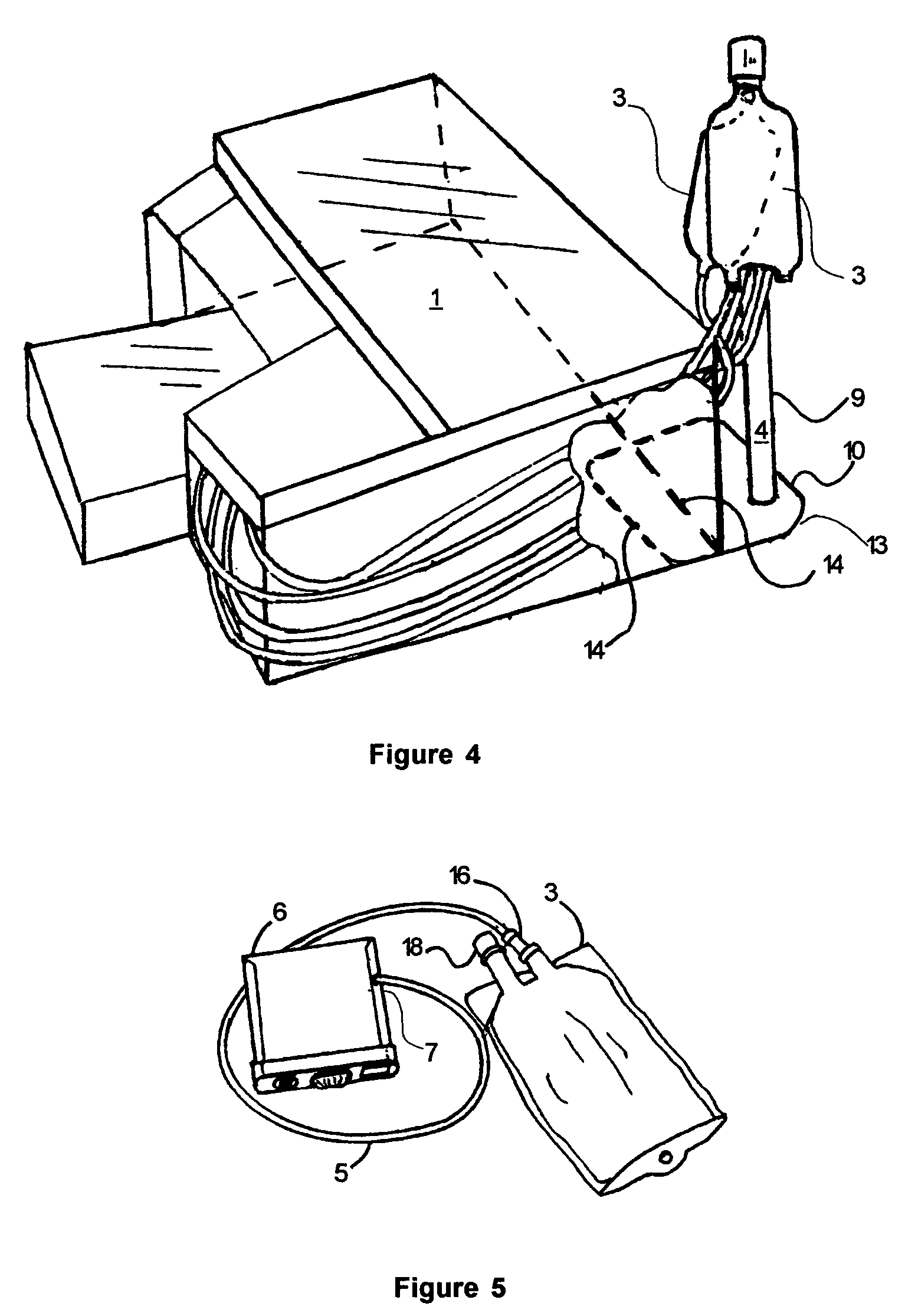

Expanded ink supply system for ink jet printers

The invention provides an expanded ink supply system for inkjet printers. The expanded ink supply system fluidically supplies an ink cartridge, which is intermittently fluidically connected to an array of movable printheads. Described are various means for creating the necessary pressure to force the ink from the expanded supply to a print cartridge. In one described embodiment, the ink supply is in the form of a bag, placed at a level higher than the ink cartridge, thereby utilizing gravity to force the liquid ink via tubing into the ink cartridge's inner part fill port or alternatively, the cartridge's pump channel. Also described are steps to attach a fitting in the cartridge's inner part fill port or pump channel and steps for releasing trapped air from the ink supply system.

Owner:AKERMALM PER G

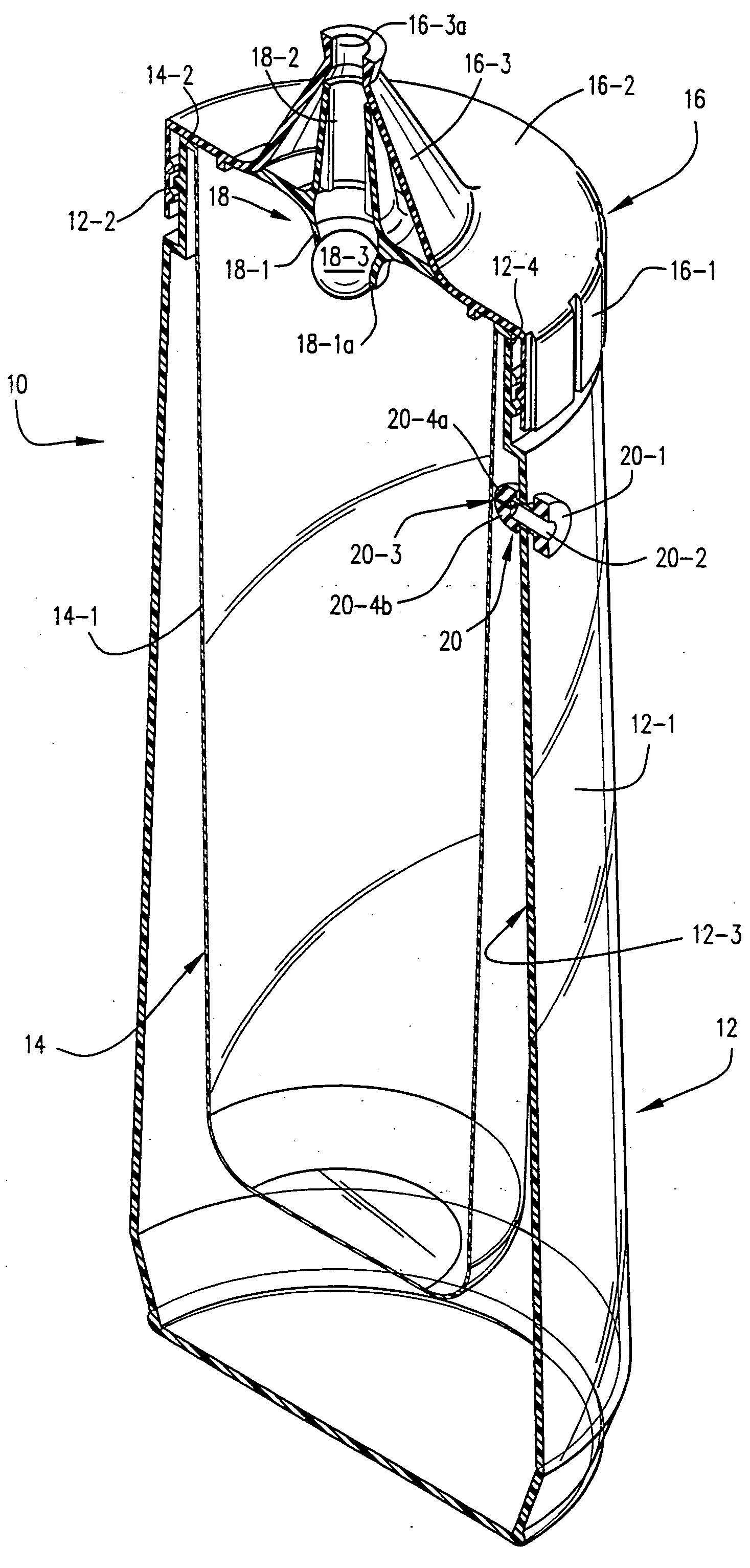

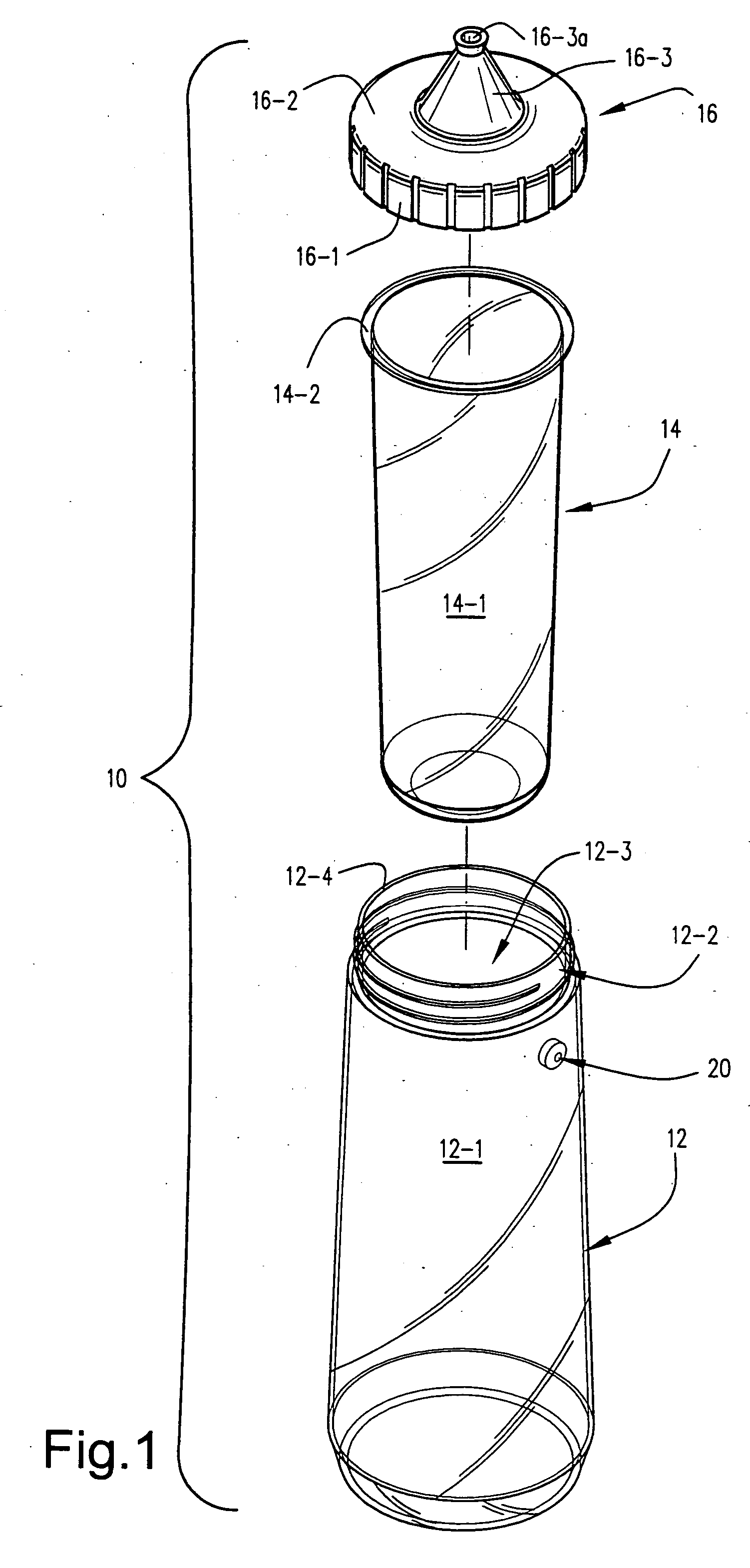

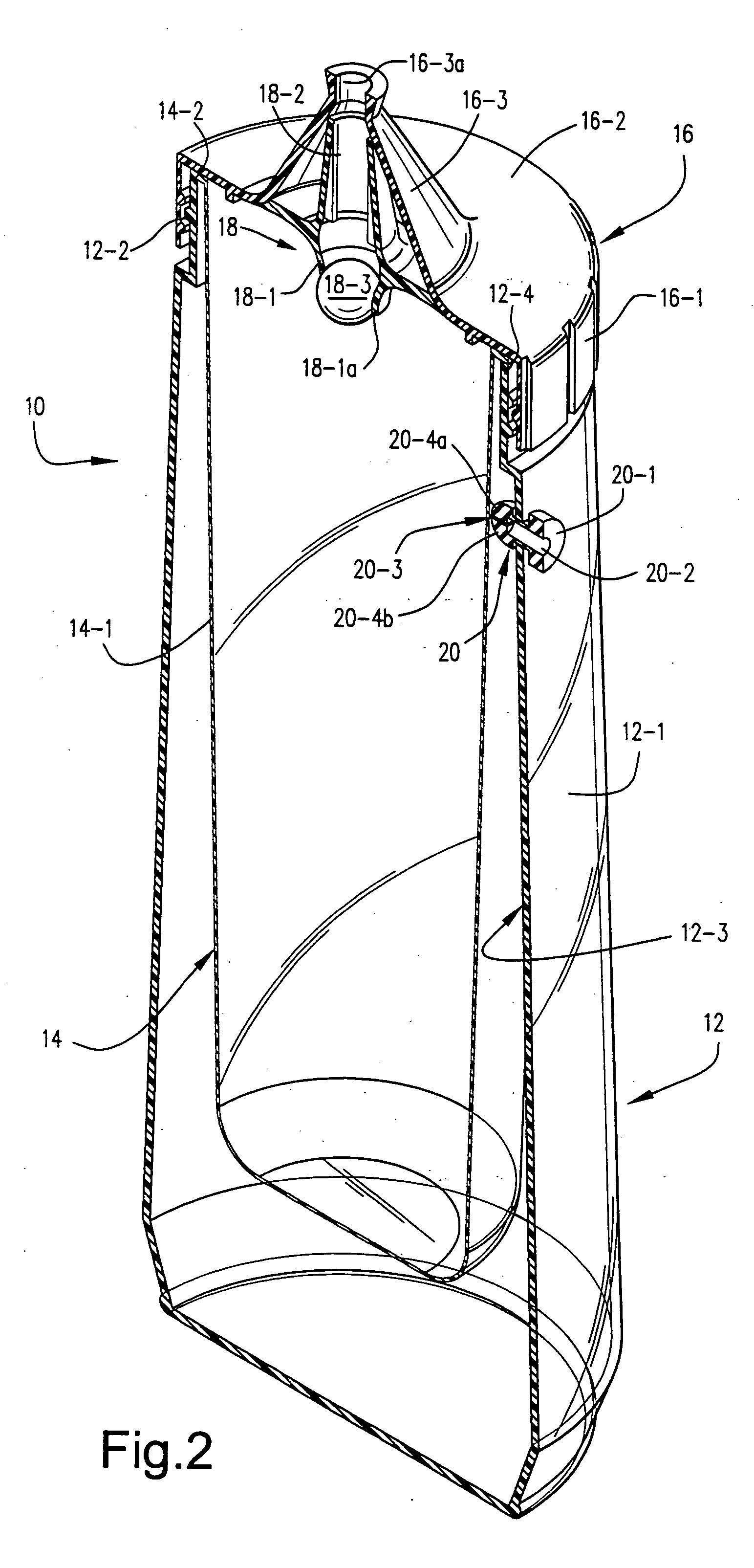

Containers and methods for the on-demand dispensing of flowable materials

InactiveUS20050029285A1Avoid introducingOpening closed containersBottle/container closureInterior spaceInlet valve

Containers and methods are disclosed whereby portions of an available stand-by supply of flowable material within a container may be dispensed substantially immediately on-demand. Preferably, the containers include an open-ended container shell having a resilient, shape-retaining side wall defining an interior space, a liner positioned within the interior space of the container shell, and a cap closing the open-ended container shell to seal the liner against leakage of flowable material. The liner has a flaccid liner body for containing a flowable material to be dispensed. The cap has a discharge opening to allow an amount of flowable material to be discharged therethrough from the liner body. Importantly, the container includes a valve system which includes one-way discharge and inlet valves. The one-way discharge valve allows only flowable material to be discharged from the liner via the discharge opening, but prevents ambient air from being introduced into the liner when the discharge of flowable material is finished. The one-way inlet valve serves to trap air within the interior space of the container shell in response to a collapsing force applied against the side wall of the container shell which, in turn, allows ambient air to enter the interior space when such collapsing force is removed.

Owner:PBM PLASTICS

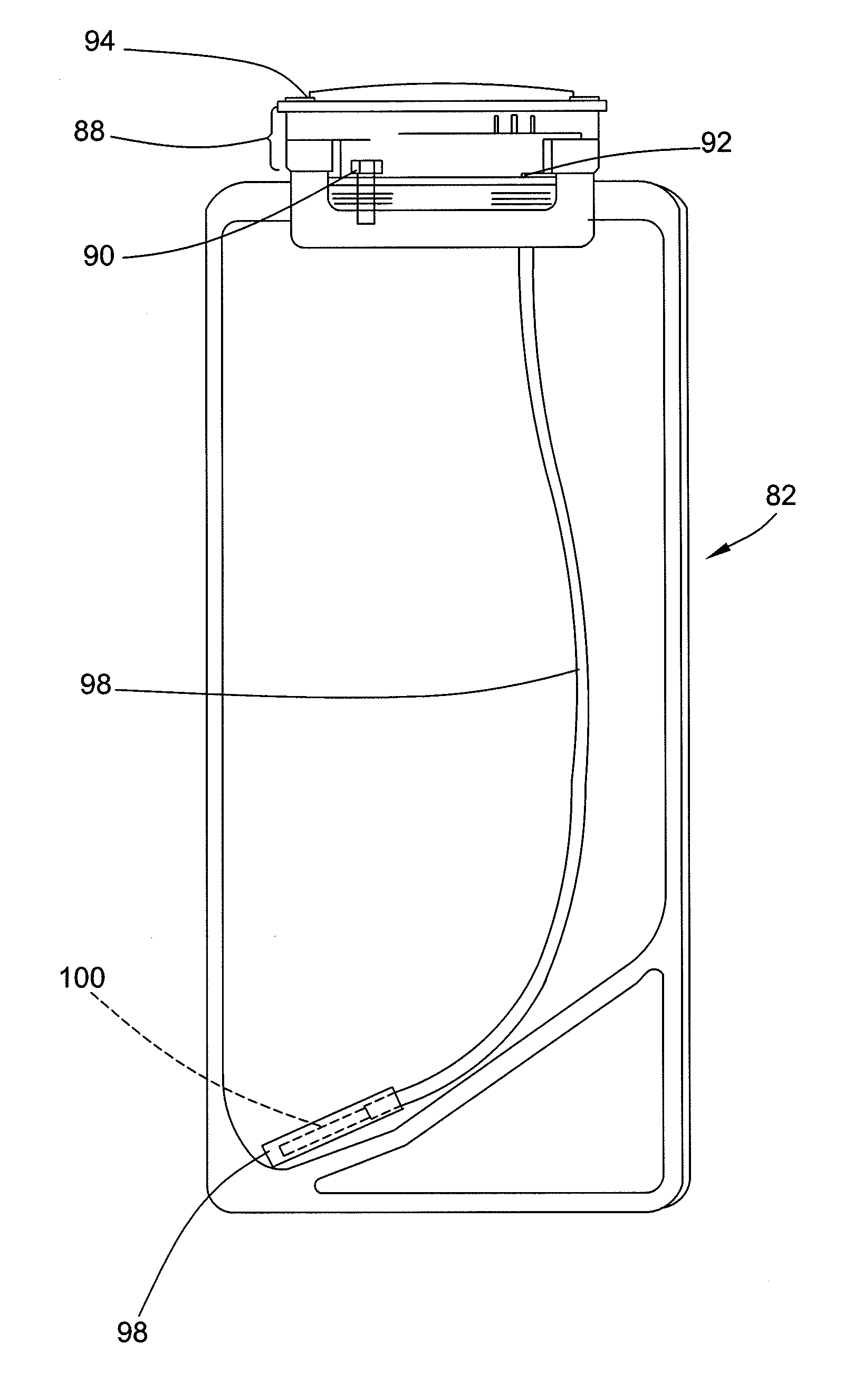

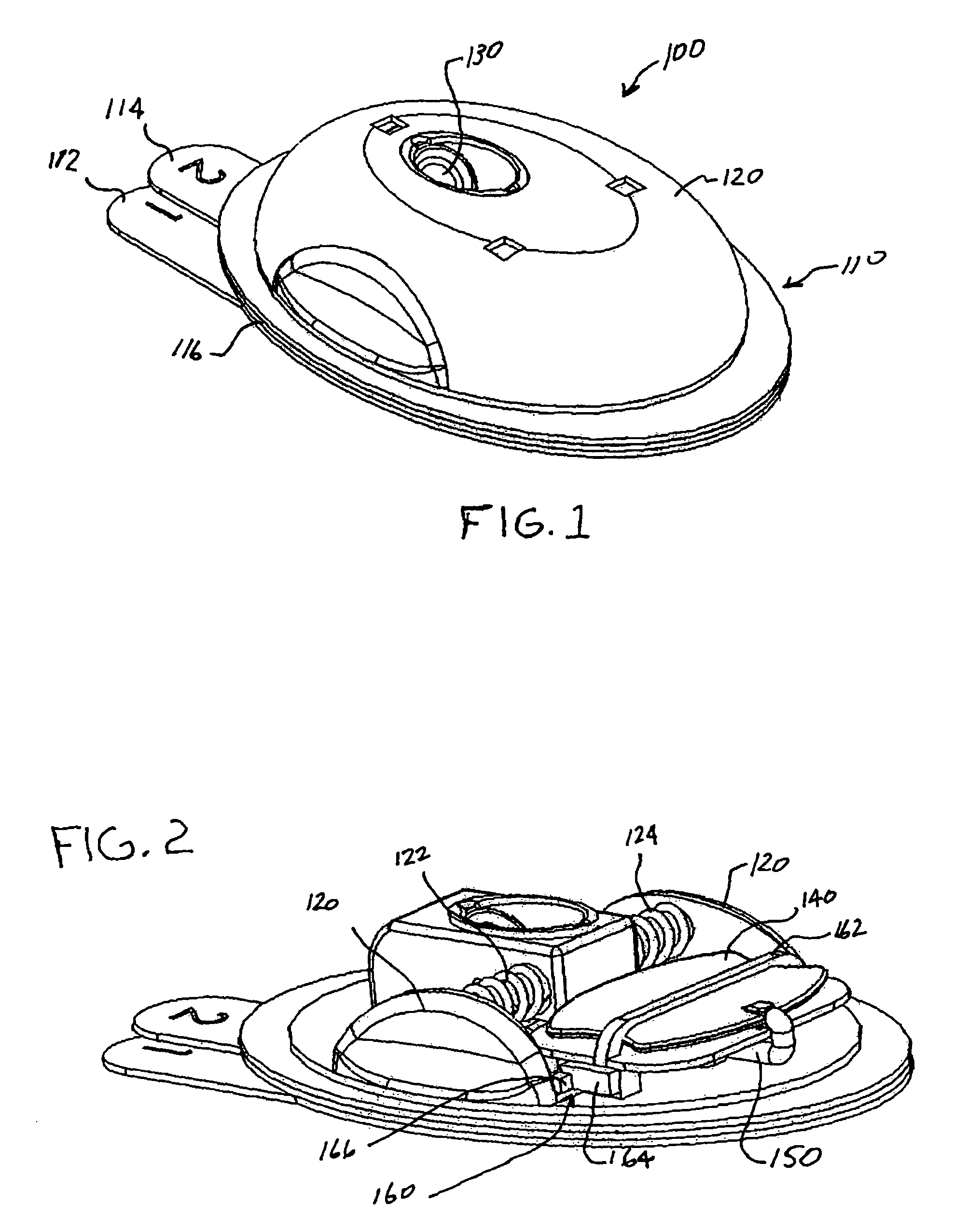

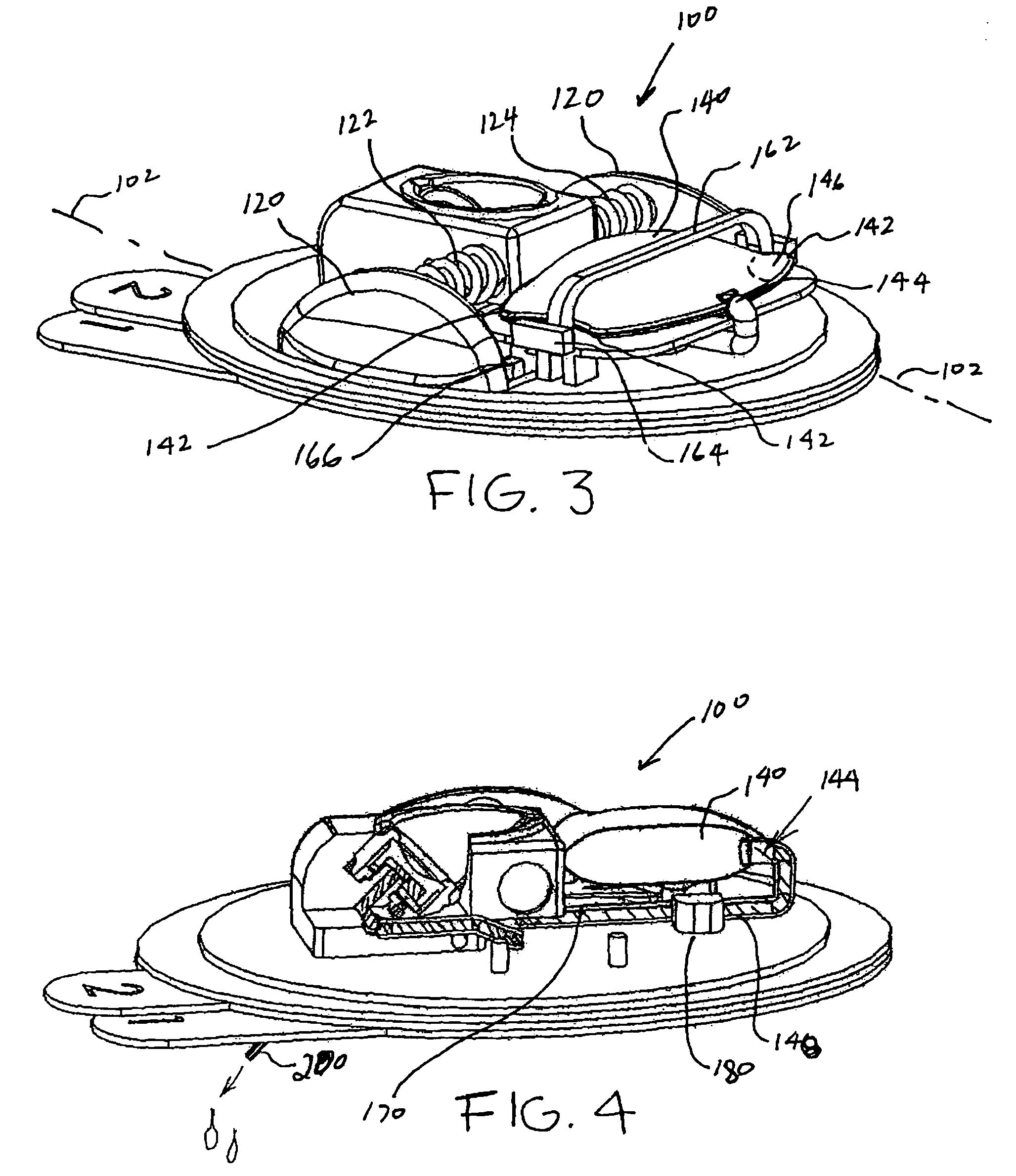

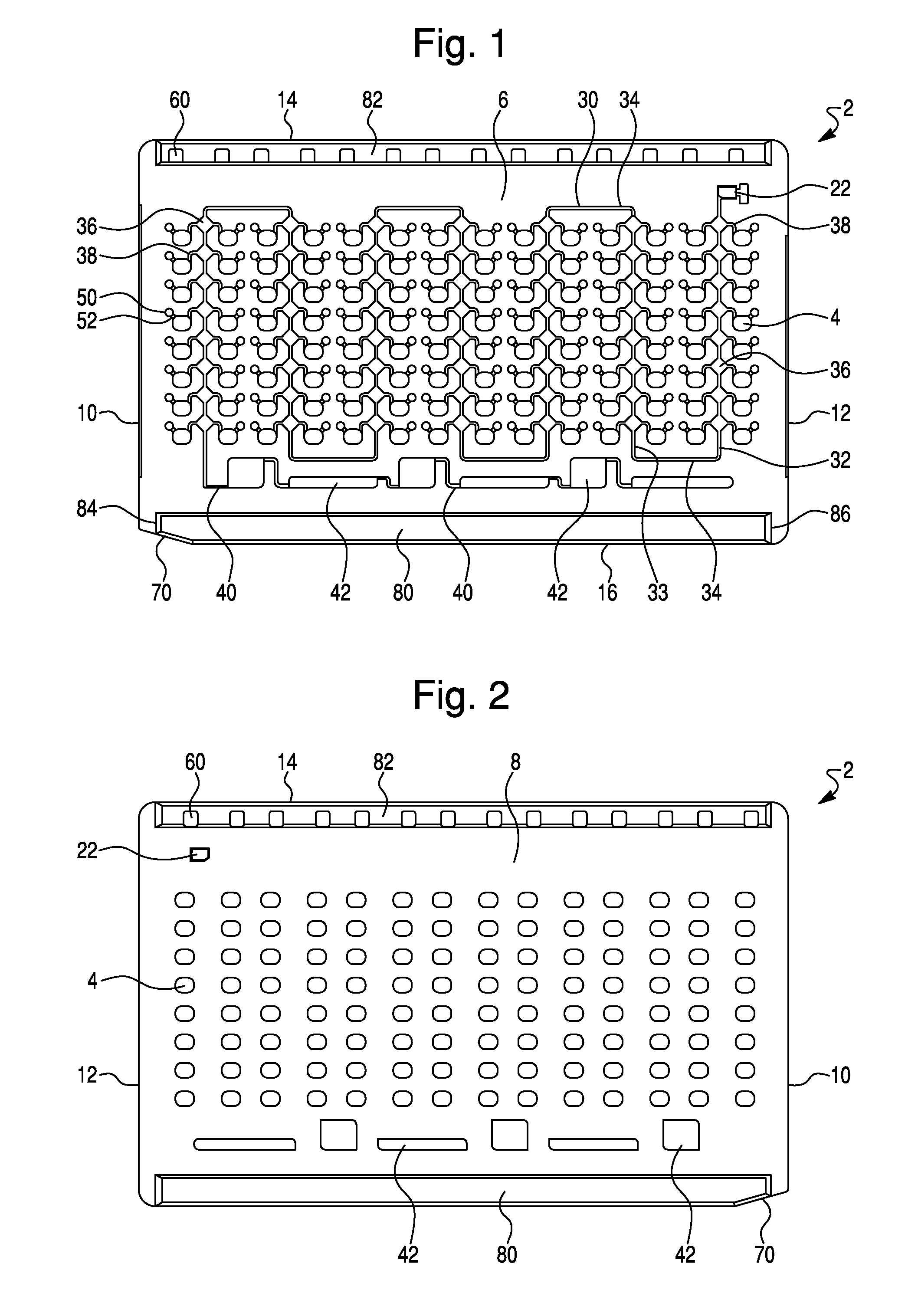

Disposable infusion device with air trapping collapsible reservoir

A wearable infusion device delivers a liquid medicant to a patient. The infusion device comprises a reservoir arranged to contain a liquid medicant to be delivered beneath a patient's skin. The reservoir has an outlet through which the medicant flows and a shape that forms at least one pocket that traps air isolated from the outlet. The infusion device further includes a conduit communicating with the outlet of the reservoir, and a pump that causes the medicant to flow from the reservoir into the conduit.

Owner:CALIBRA MEDICAL

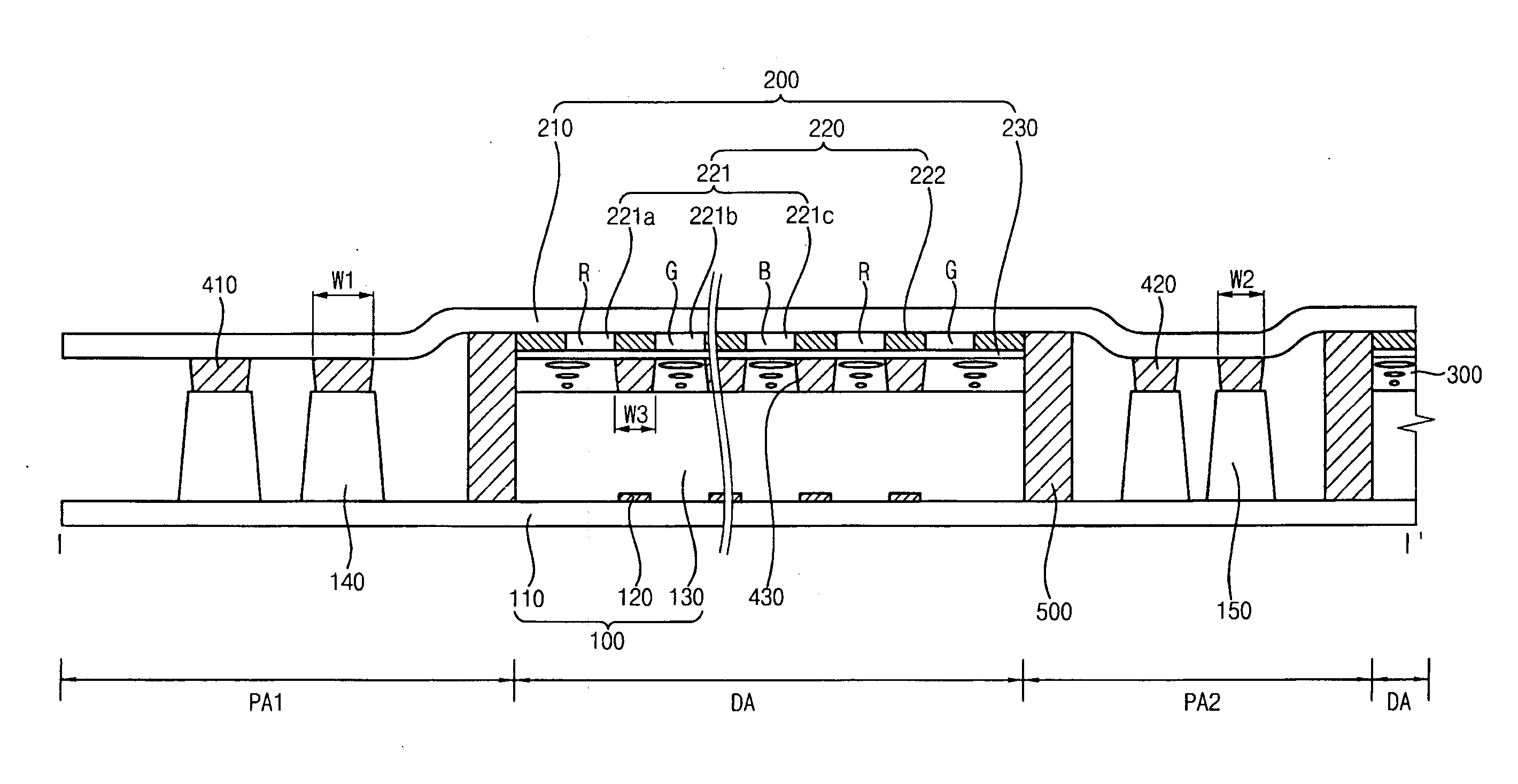

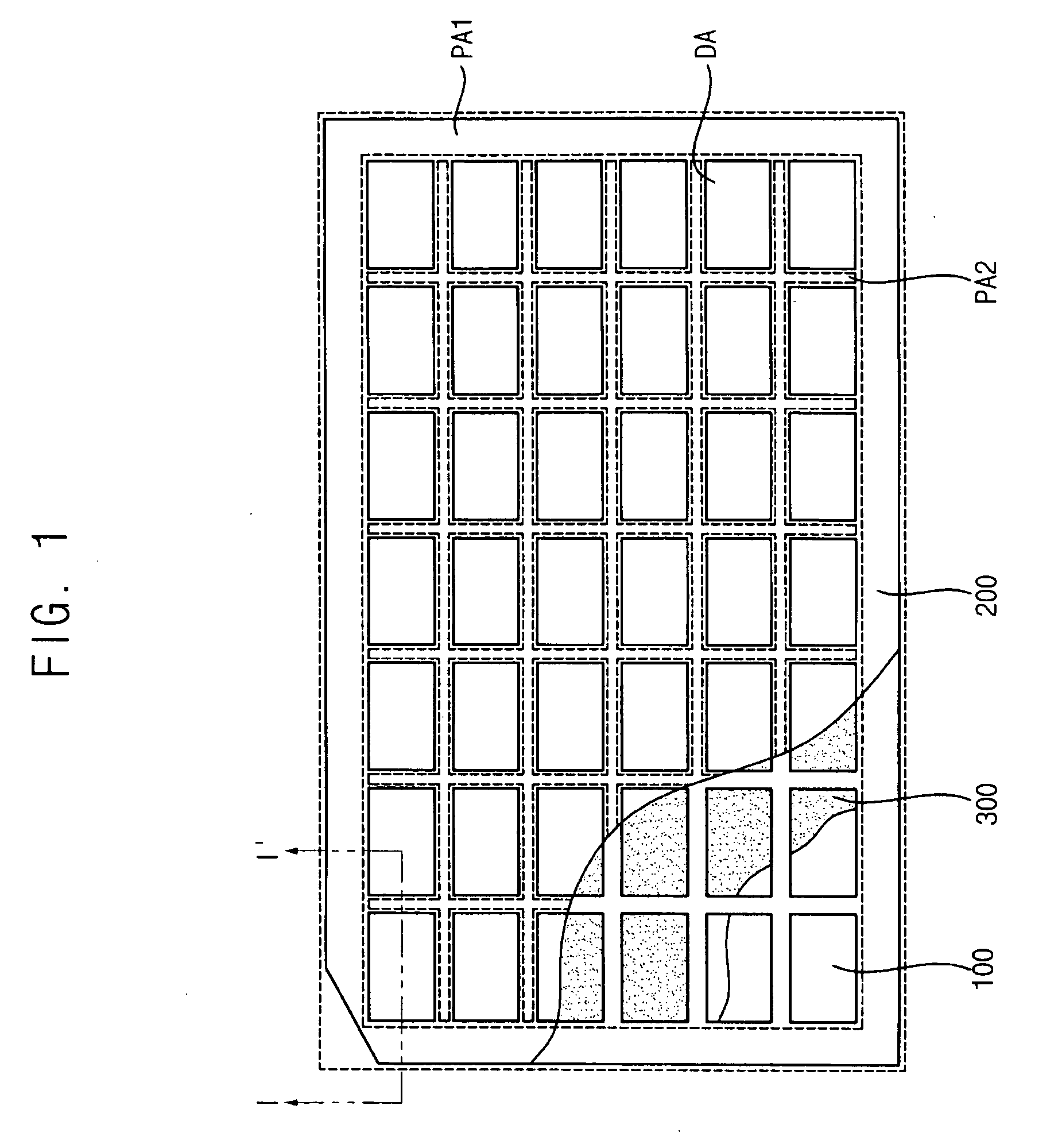

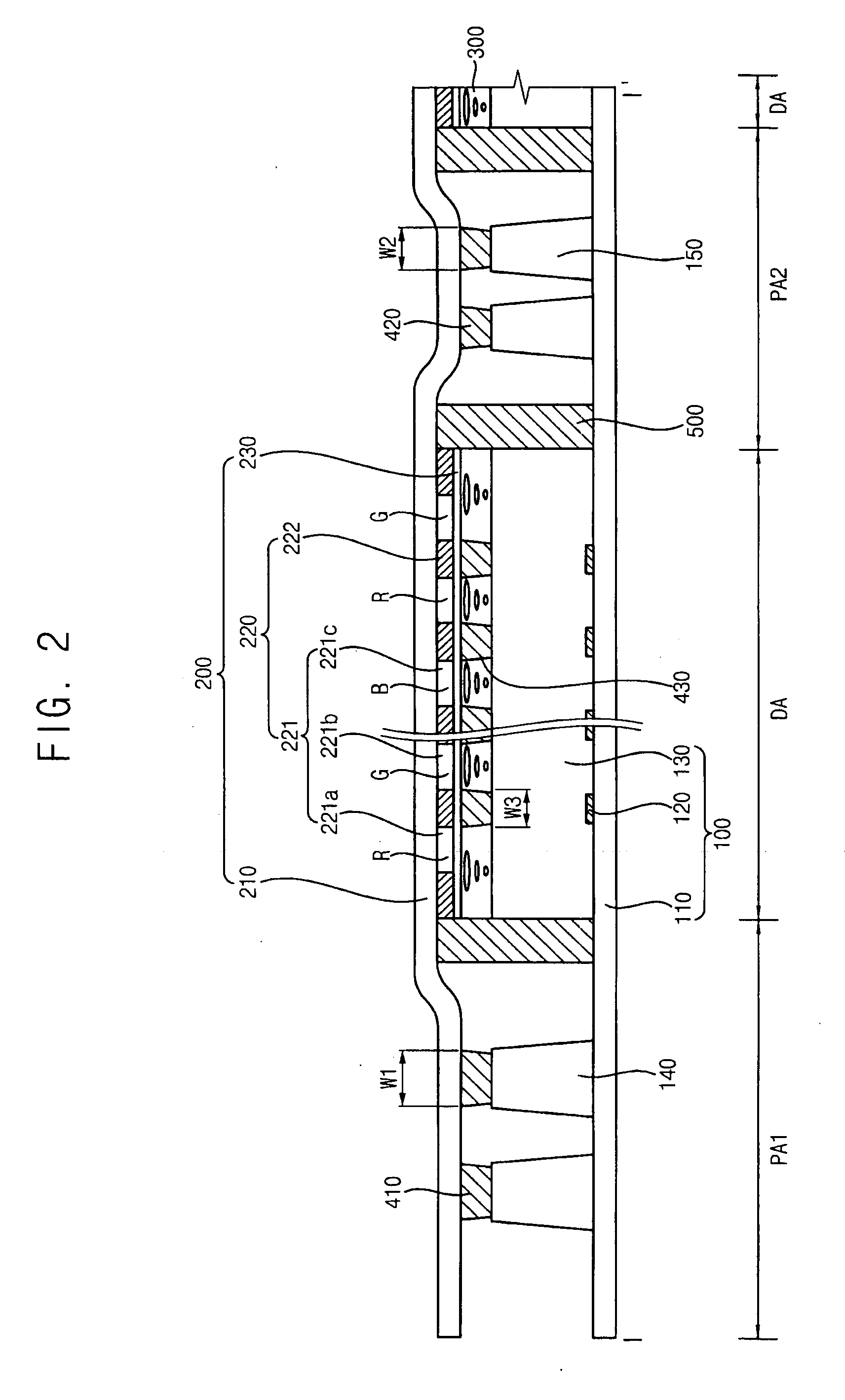

Liquid crystal display apparatus

ActiveUS20060152668A1Improve display characteristicsBreakwatersQuaysLiquid-crystal displayEngineering

A liquid crystal display (LCD) apparatus is divided into a display area on which an image is displayed and a non-display area surrounding the display area. The LCD apparatus includes an organic insulating layer partially formed in the non-display area. A portion of the organic insulating layer is not formed, obtaining a vent space through which to exhaust air trapped when a first substrate is combined with a second substrate of the liquid crystal display apparatus. The LCD apparatus may rapidly and easily exhaust the trapped air from the display area and uniformly maintain the cell gap between the first and second substrates, improving display quality of the LCD apparatus.

Owner:SAMSUNG DISPLAY CO LTD

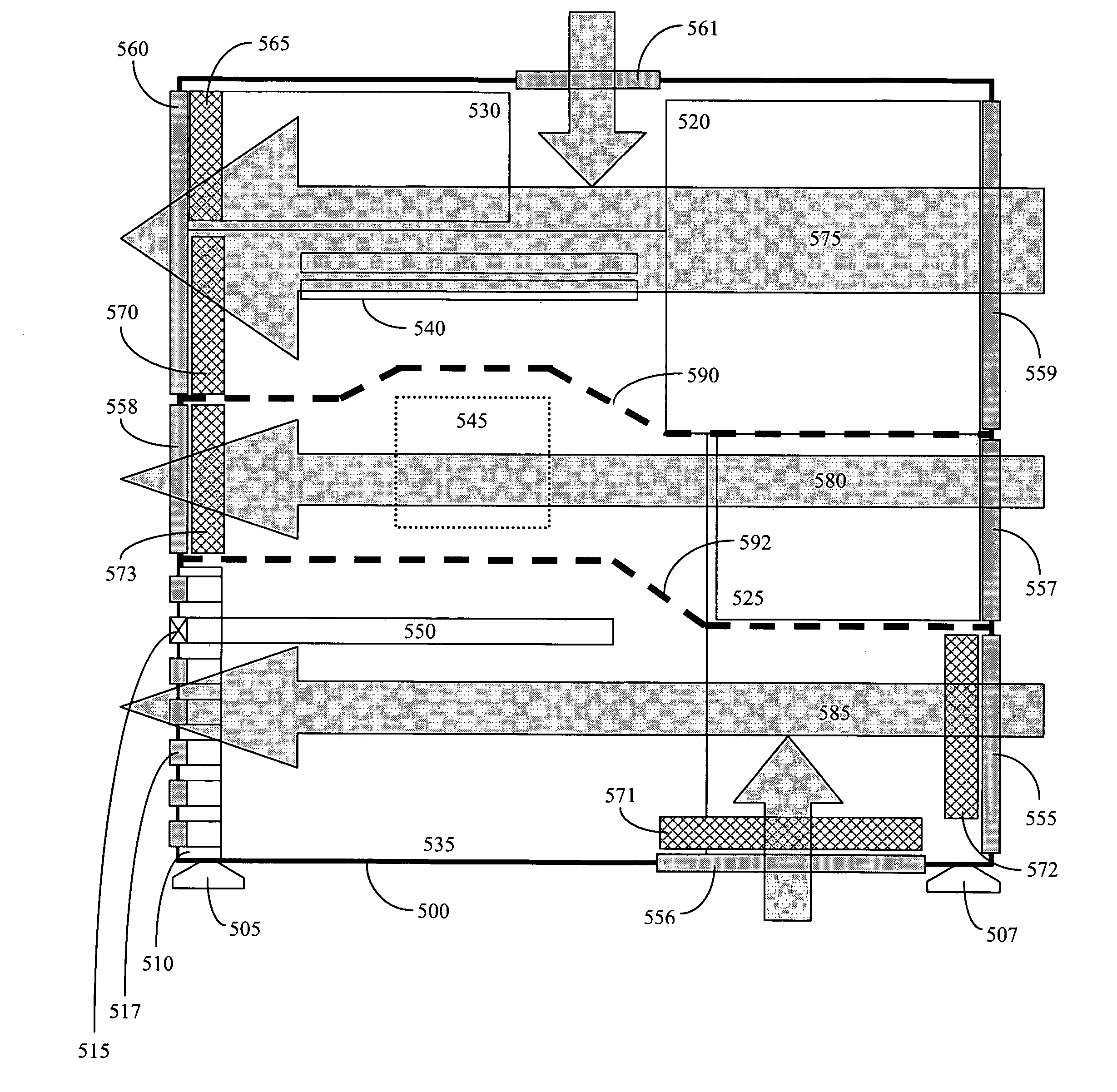

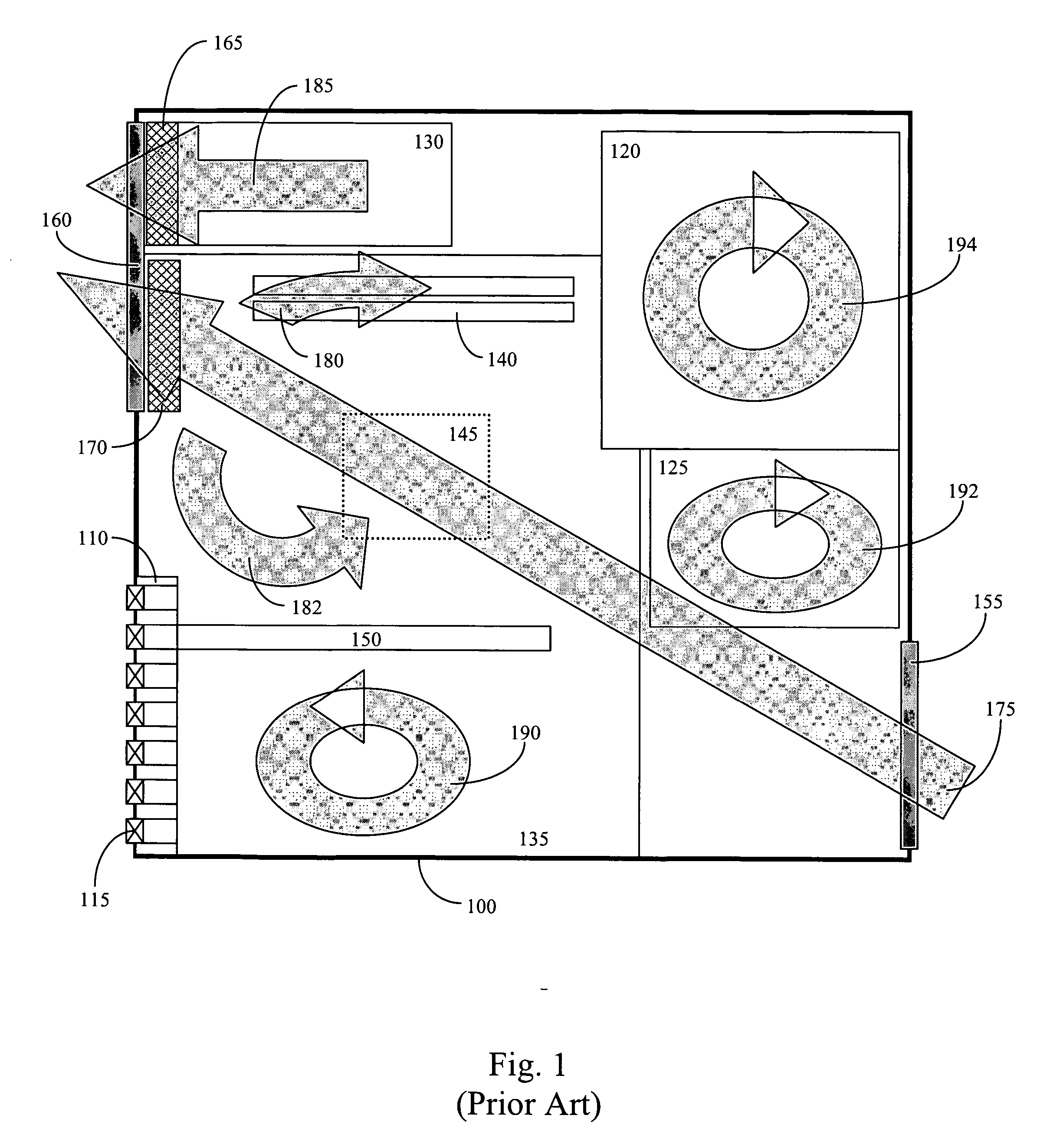

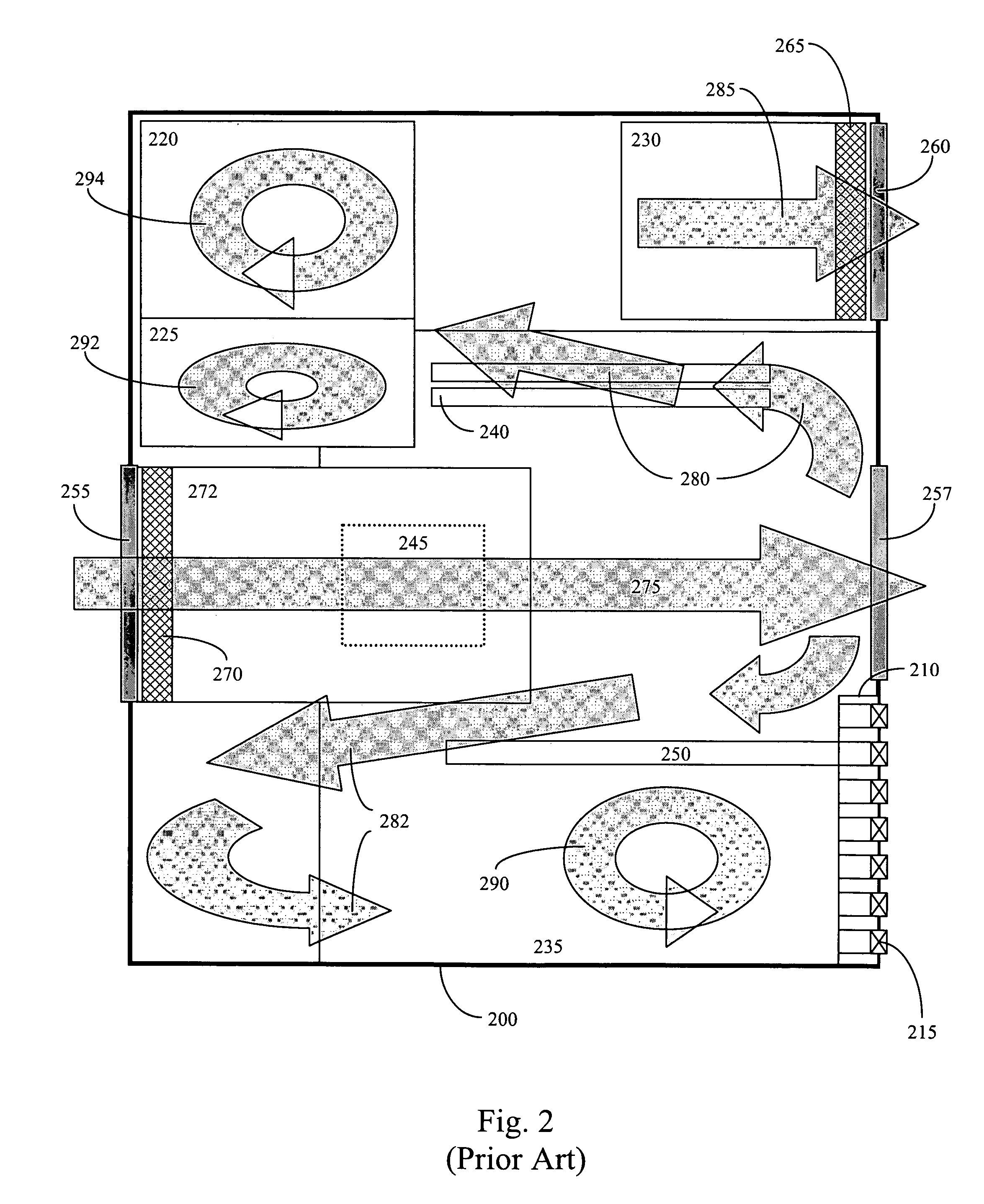

Computer chassis for improved airflow and heat transfer from computer system components

ActiveUS20070133167A1Improve cooling effectReduce generationDigital data processing detailsCooling/ventilation/heating modificationsEngineeringElectrical and Electronics engineering

The present invention pertains to a computer chassis with improved airflow to reduce the occurrence of trapped air pockets and increase heat transfer from components within the chassis. The computer chassis includes a plurality of chambers, wherein each of the chambers is separated by a partition. The partitions are operable to reduce the occurrence of trapped air pockets and increase heat transfer from components of the chassis by causing air to flow through each of the chambers. The computer chassis further includes at least two air vents, wherein each of the chambers is coupled to at least one of the at least two air vents through which air enters the chamber, and wherein each of the chambers is coupled to at least one of the at least two air vents through which air exits the chamber.

Owner:NVIDIA CORP

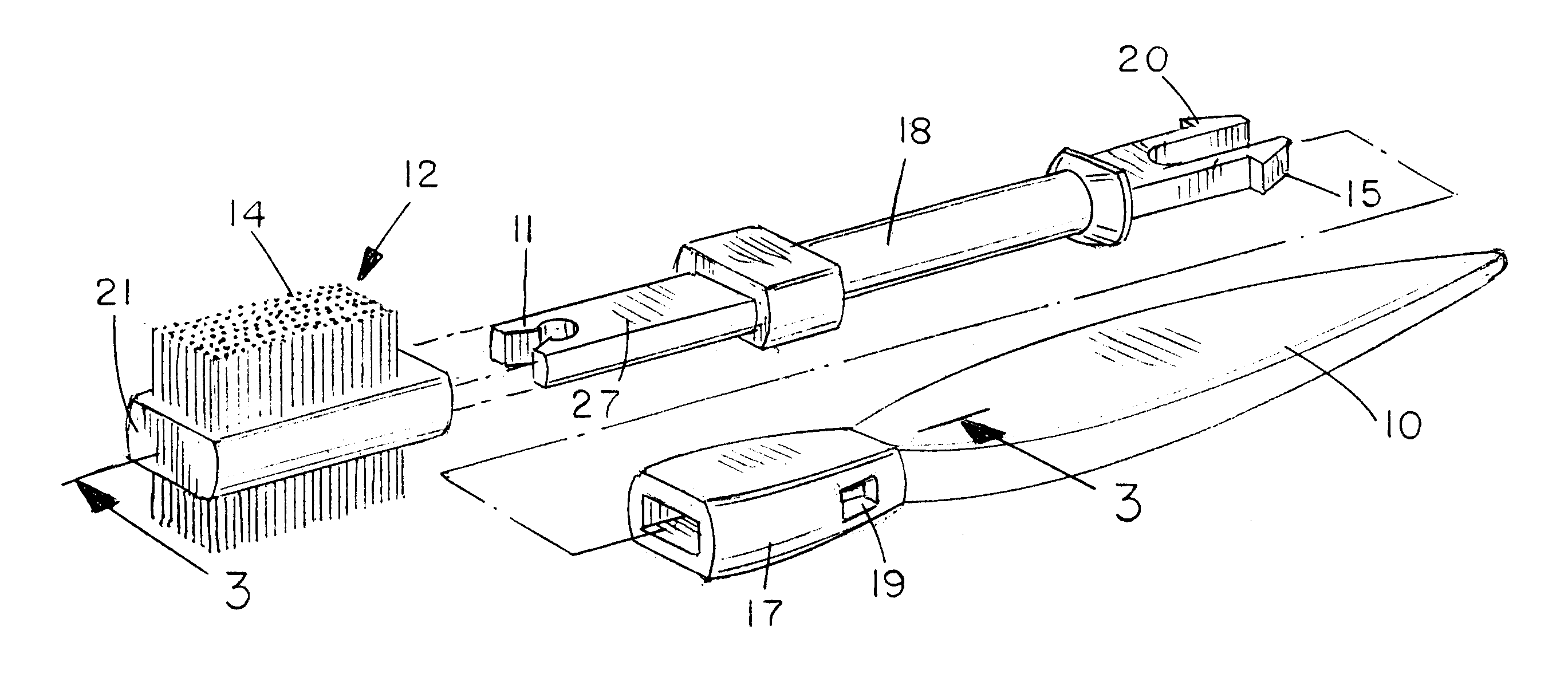

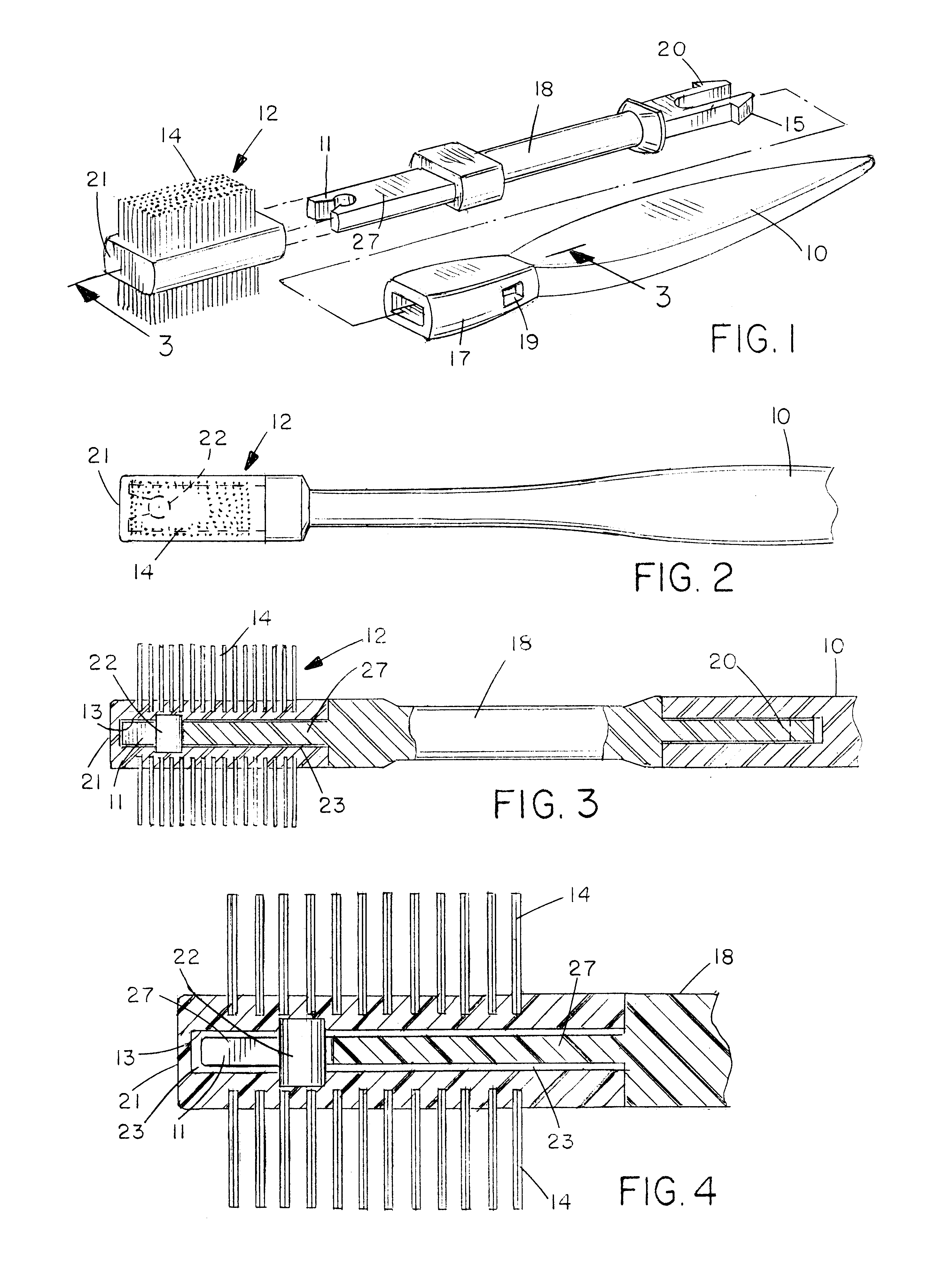

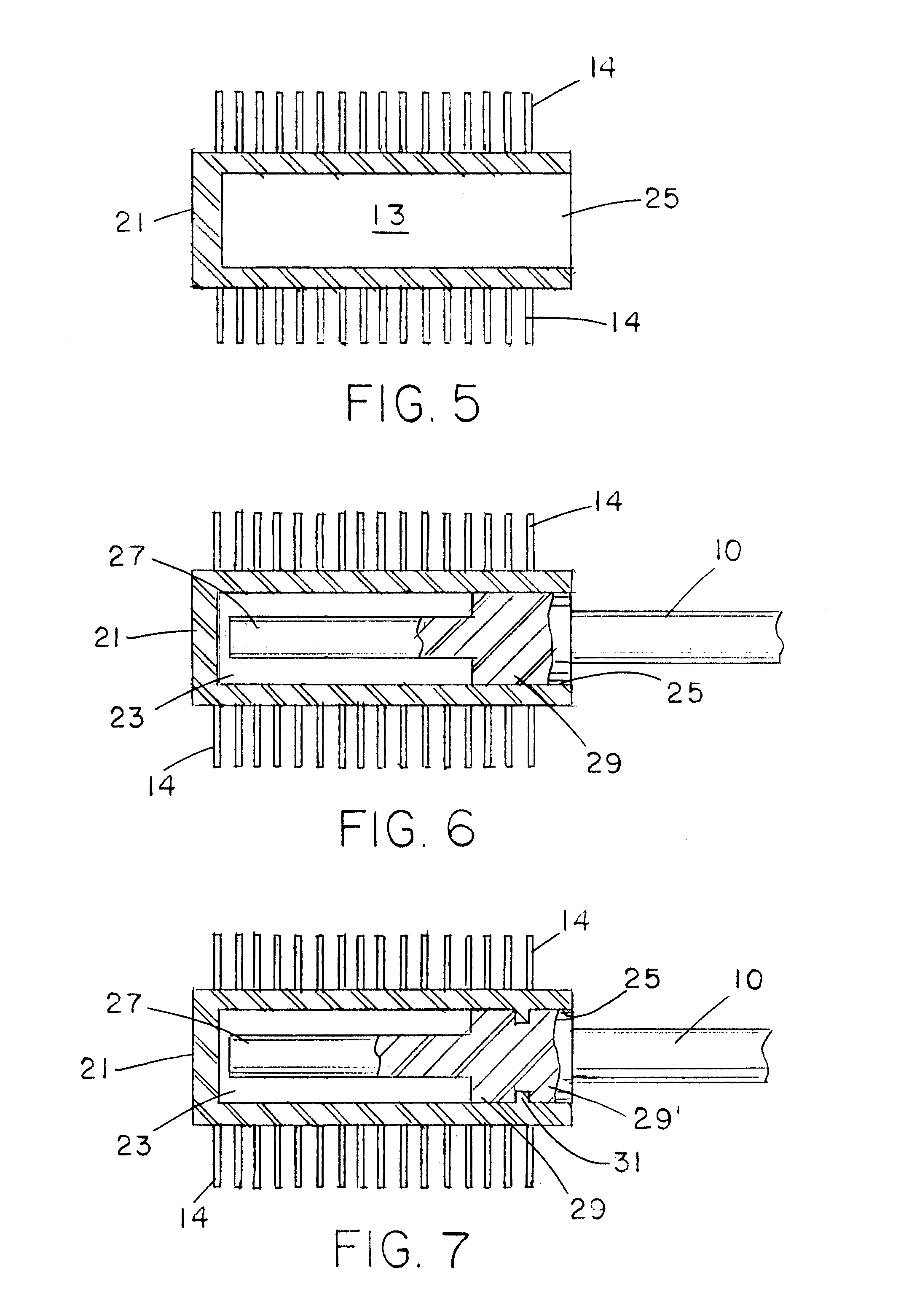

"Air cushion effect" soft oral care brush

InactiveUS6671919B2Reduce the degree of impactUsed easily and comfortably and effectivelyCarpet cleanersBrush bodiesMassageEngineering

Owner:DAVIS COLIN G

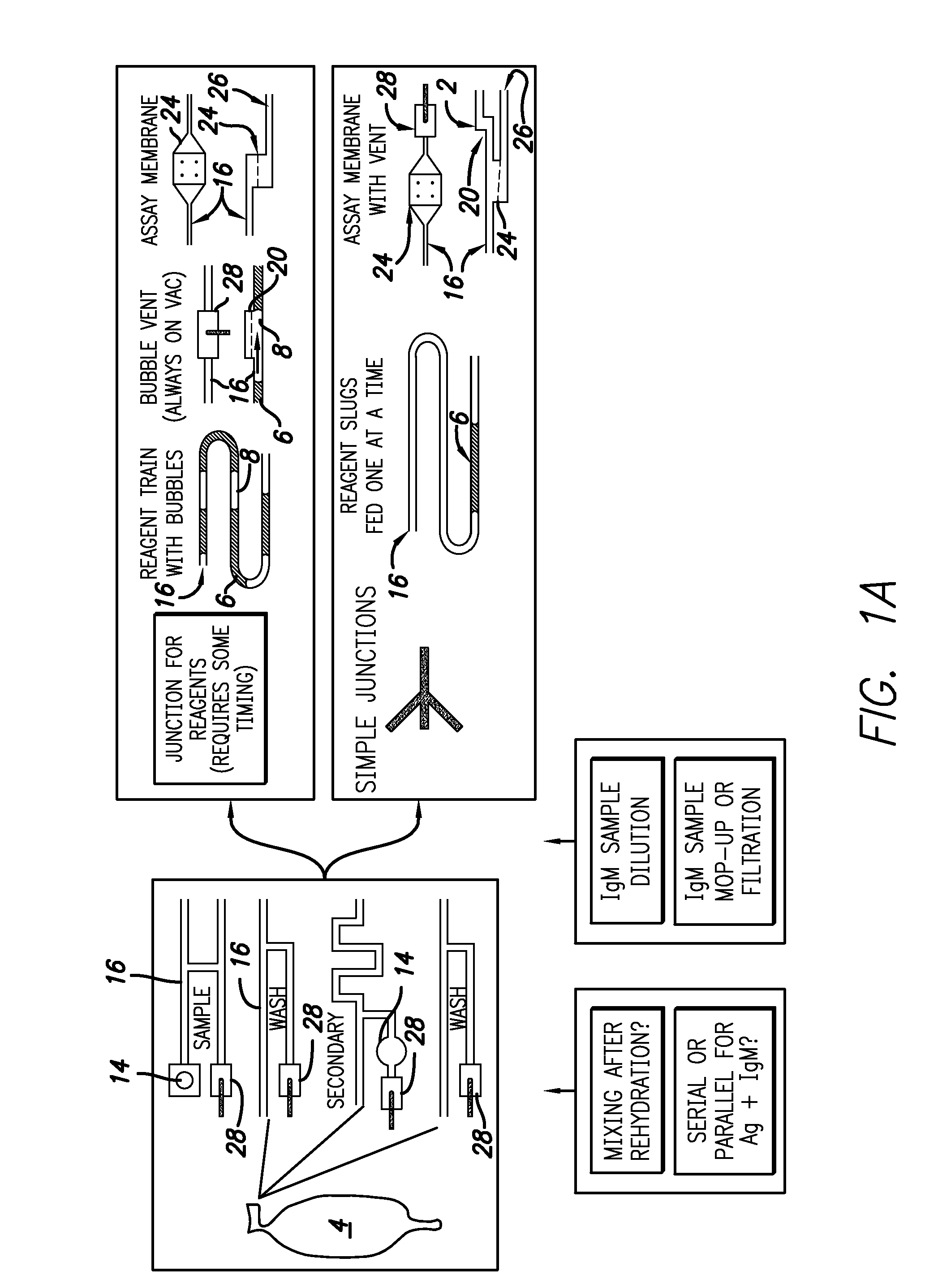

Microfluidic systems incorporating flow-through membranes

InactiveUS20110151479A1Rapid and accurate and controlled mannerReduce deliverySamplingComponent separationPorous membraneHigh surface area

Disclosed is a flow-through membrane assay that takes advantage of a high surface area and rapid transport while allowing individual control over flow rates and times for each step of a multi-step assay. A microfluidic card features channels in communication with a porous membrane, channels on either side of membrane to allow transverse flow across the membrane, capturing a labeled target from the sample by flowing the sample across the membrane, or capturing a target from the sample followed by flowing a reagent containing a label that binds to the target. Fluid can be pushed or pulled through the assay membrane by external control. Air near the membrane is managed by diverting air between fluids to a channel upstream of the assay membrane, venting air between fluids through a hydrophobic membrane upstream of the assay membrane, and / or by venting trapped air through a hydrophobic membrane downstream of the assay membrane.

Owner:UNIV OF WASHINGTON

Refrigerator water tank

A water tank having a body portion that slopes away, in multiple directions, from an outlet thereof is adapted to be mounted within a refrigerator cabinet in a substantially horizontal plane. The water tank is preferably integrally molded with multiple, parallel-arranged flow paths and with a plurality of upstanding tabs for use in mounting the water tank horizontally in a fresh food compartment of a refrigerator cabinet. The inlet and outlet areas of the tank are designed to minimize the potential for trapping air within the tank. In addition, the tank is formed with integrally molded clips for use in attaching a water tube to the tank. When used in a top mount refrigerator, the tank is particularly adapted to be mounted at a rear underside portion of a fresh food liner that forms part of a mullion divider assembly so as to be generally out of visual sight of the consumer, while being in direct heat exchange relationship with cooling air within the compartment.

Owner:MAYTAG

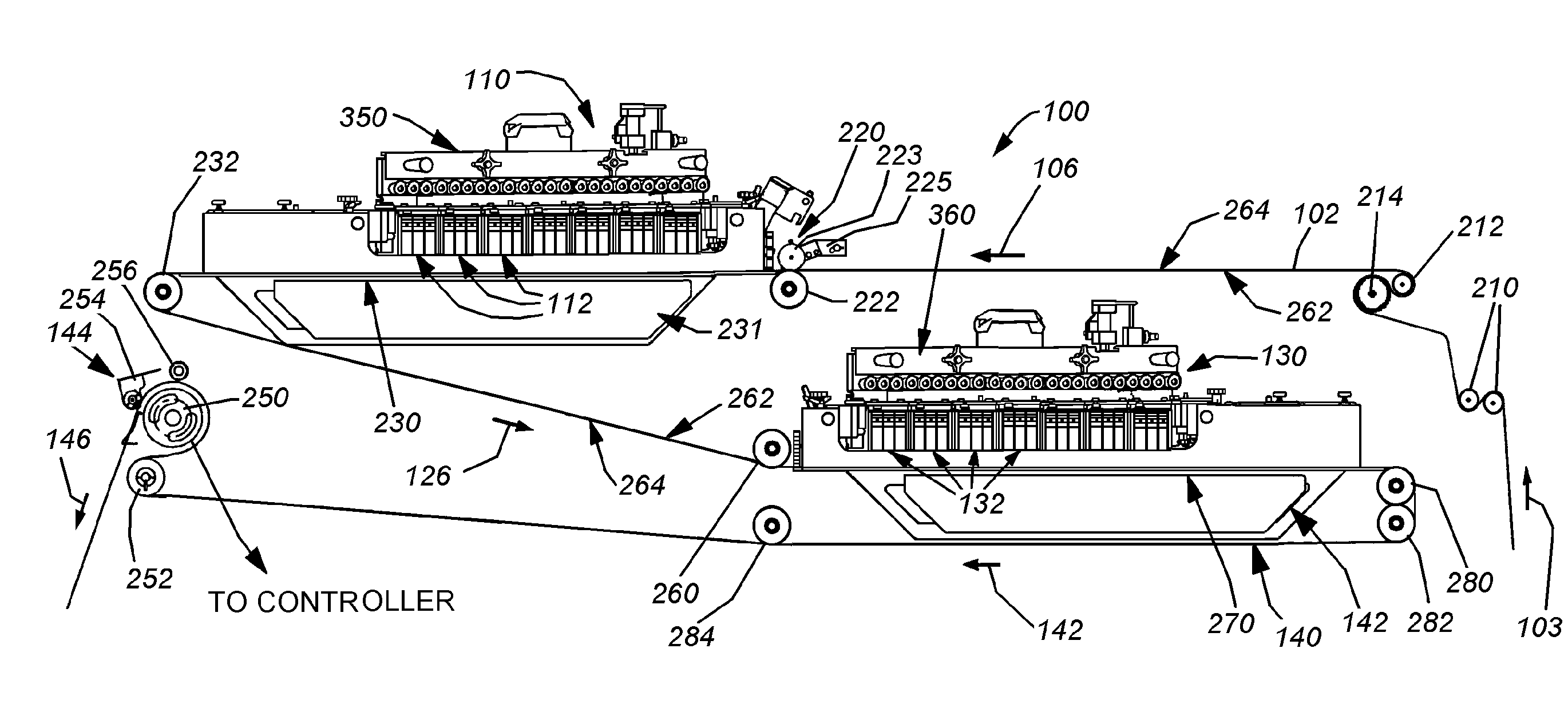

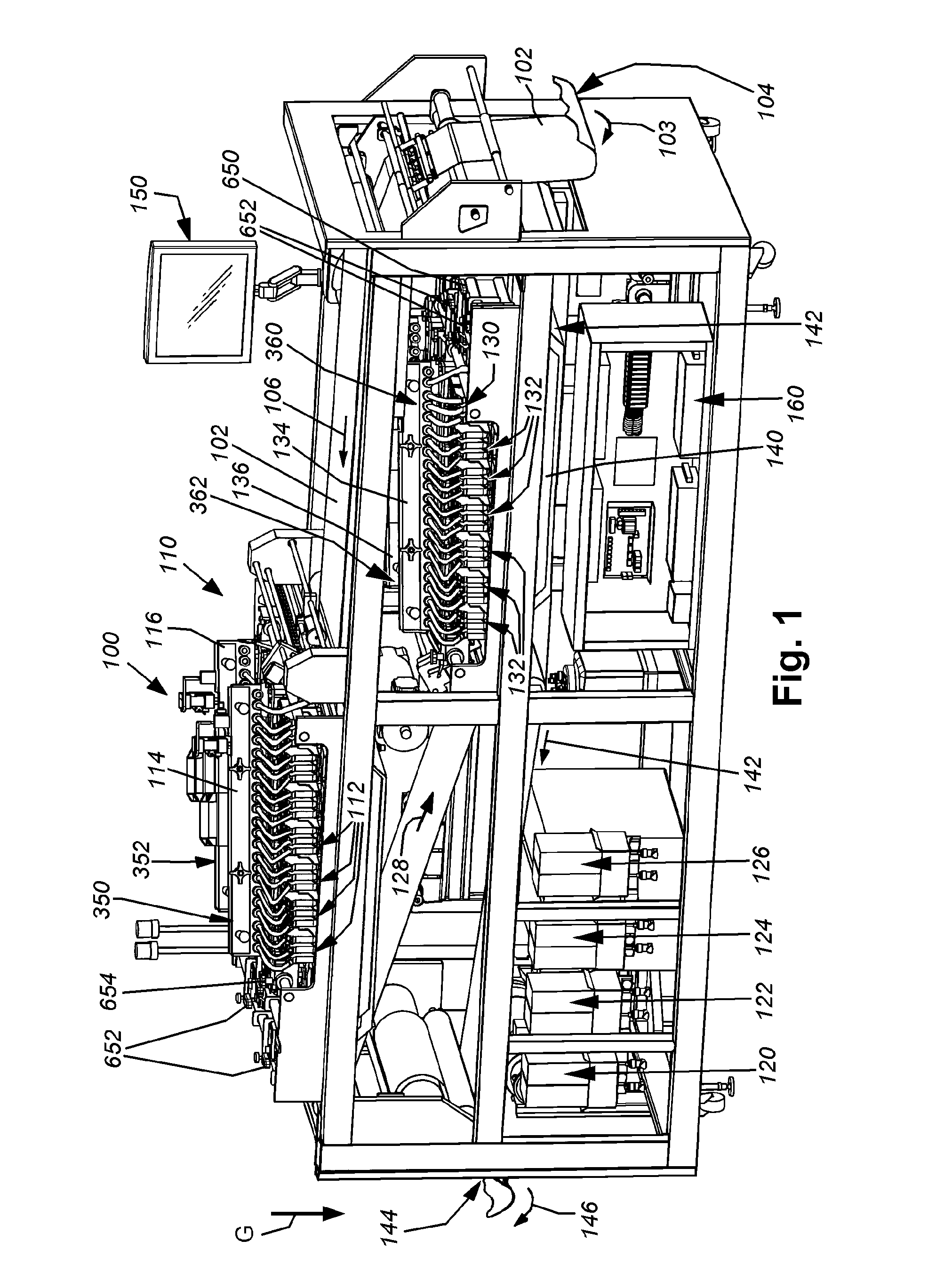

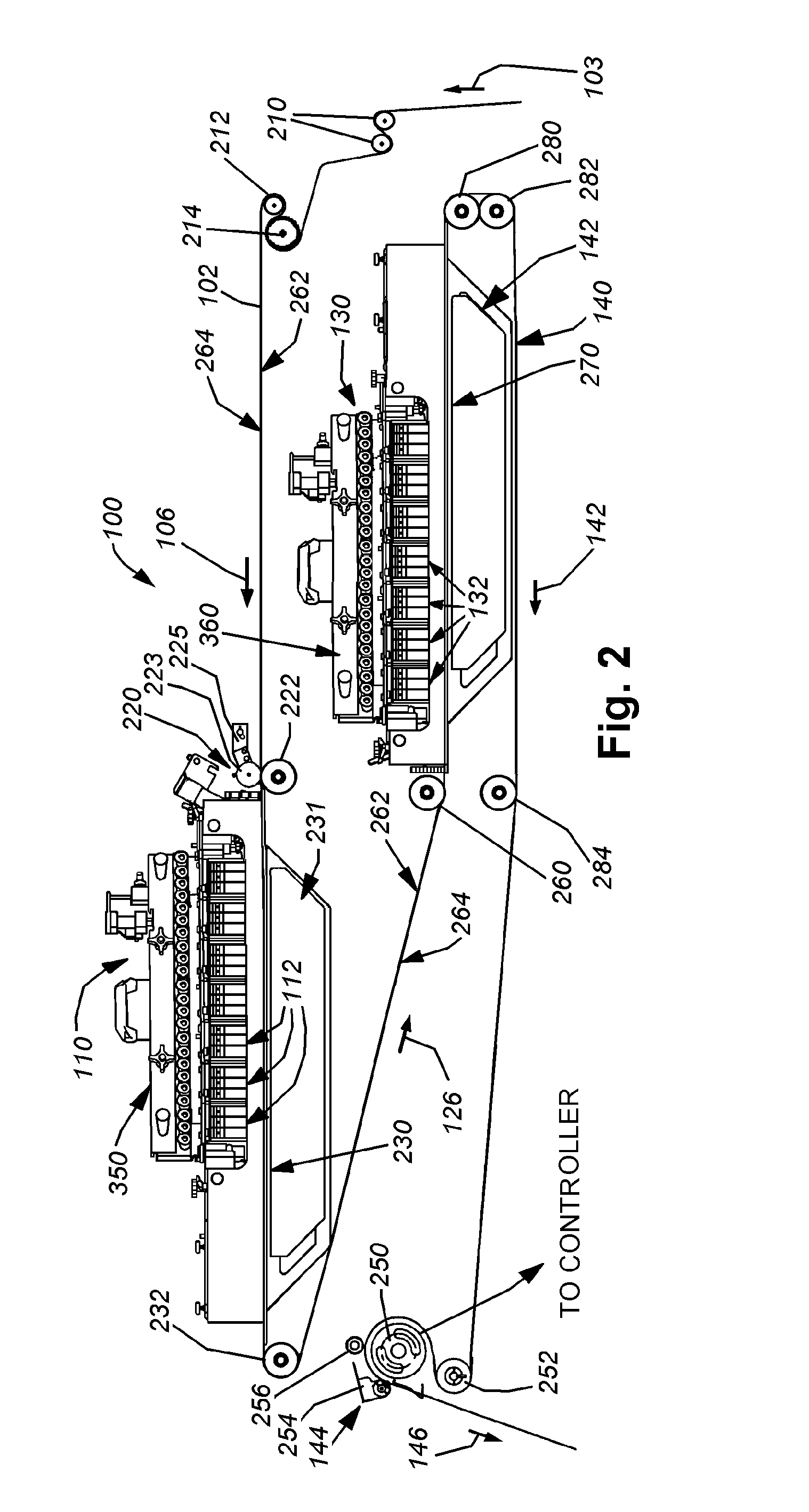

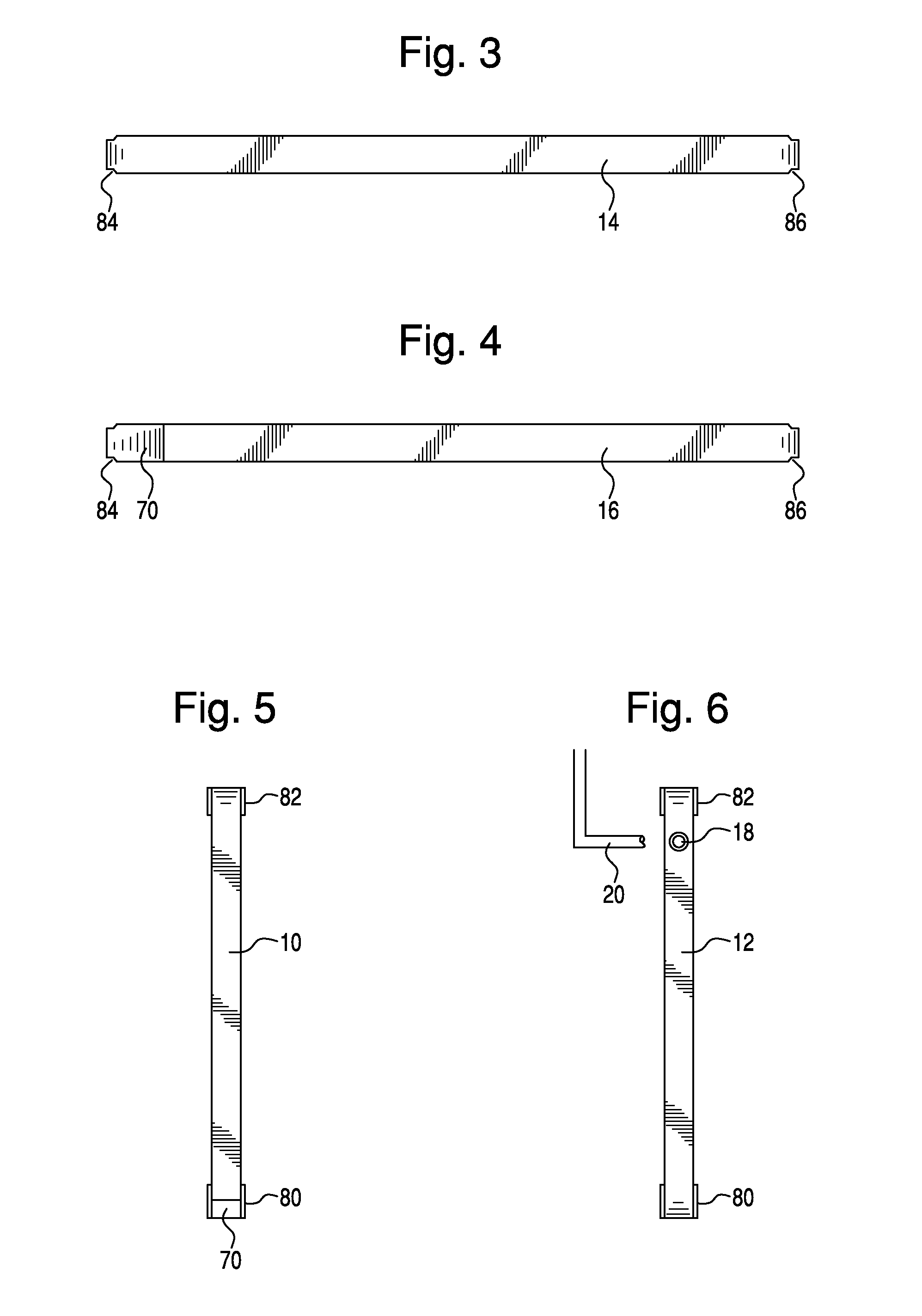

System and method for printing a continuous web employing a plurality of interleaved ink-jet pens fed by a bulk ink source

InactiveUS20090027449A1Improve flatnessEnough timeInking apparatusSpacing mechanismsSufficient timeCoupling

This invention provides a system and method for printing continuous web and feeding ink to printing pens (or cartridges) that employs an array of interleaved ink-jet pens that are arranged to receive bulk ink through a manifold. The manifold and pens are mounted on a fixed array suspended over the web feed path. The manifold includes a plurality of self-sealing quick-disconnect couplings that each serve a discrete ink-jet pen. The pens lay down ink in a registered manner across the full width of the web. The pens are organized into two parallel, multi-pen arrays that are each diagonally oriented with respect to the feed direction. The feed path allows for duplex printing with a second web-side's array located on a lower level of the device, generally beneath the first-side's array. Duplex printing is facilitated due to its inherent length of the feed path. The printed part of the web is free of contact over predetermined lengths that ensure sufficient time for the drying of ink. Each pen is interconnected with a connection to a respective manifold that maintains a vacuum so as to prevent seepage of ink from the pen nozzles. The vacuum is maintained by a draw pump, while ink is continuously provided to the manifold via a float switch in a pressure regulator. The regulator is fed by a bulk ink supply using a feed pump. A check-valve standpipe on each manifold assists in removing any trapped air from the system, thus assisting in maintaining the vacuum.

Owner:ROLL SYST

Method for removing gases from a container having a powdered concentrate for use in hemodialysis

ActiveUS20110120302A1Easy to pressurizeLiquid degasificationDispersed particle filtrationHaemodialysis machineEngineering

An apparatus and a method for filling a container containing a dry powdered salt concentrate for use in dialysis with purified fluid and removing the trapped air or gases generated during the filling of the container, while maintaining the required fluid level in the container and without the need for evacuating gases from the container prior to filling.

Owner:FRESENIUS MEDICAL CARE HLDG INC

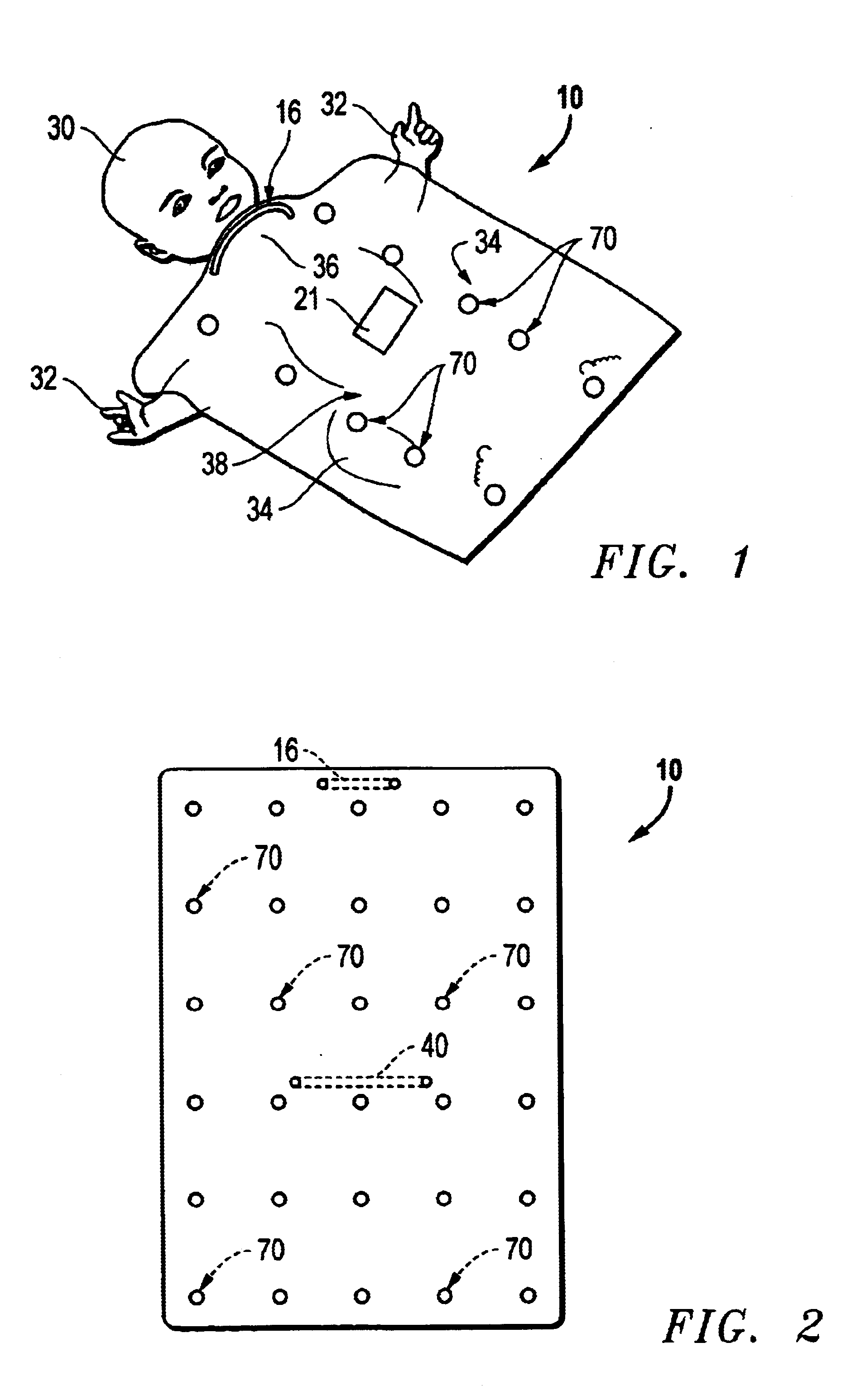

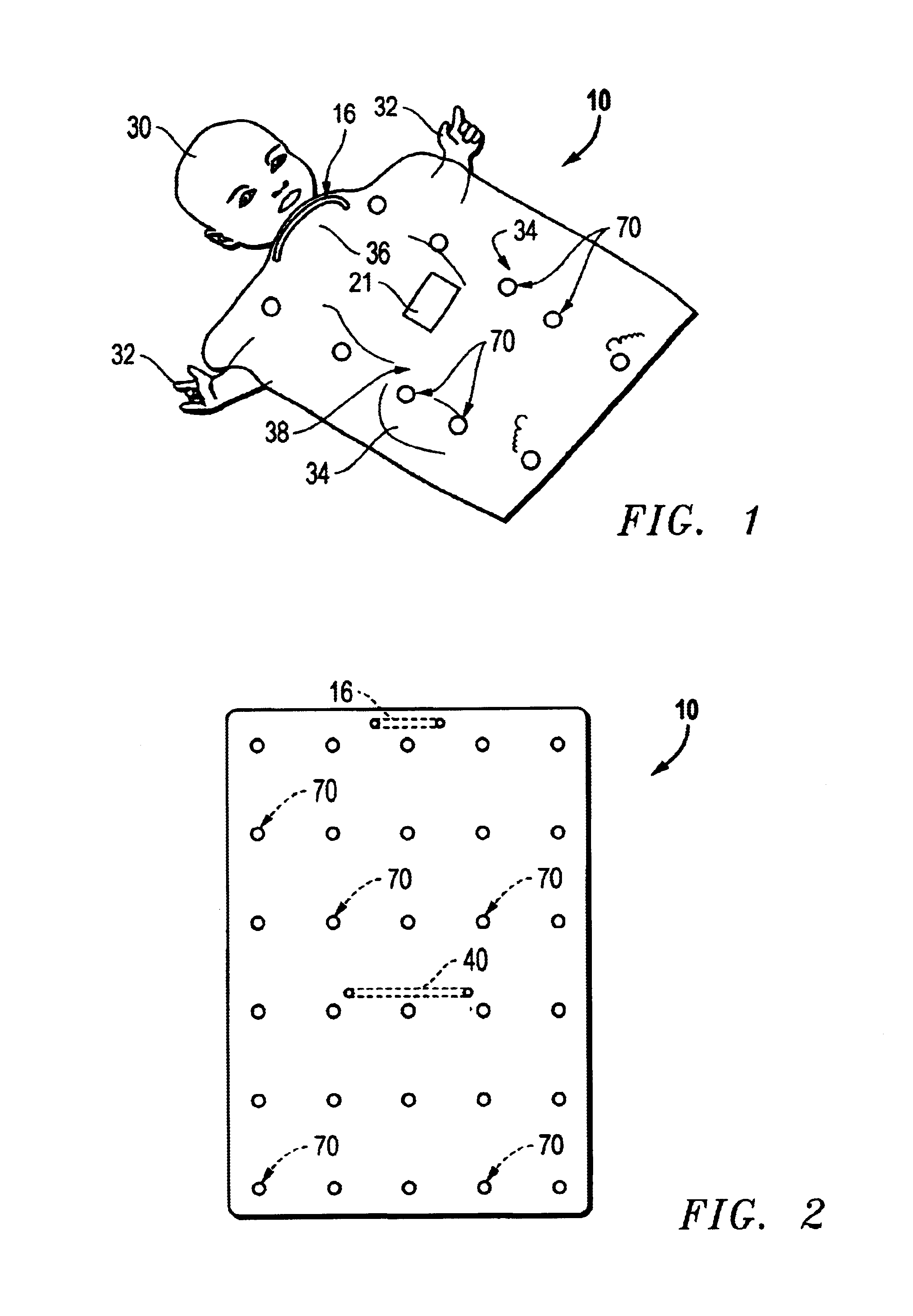

Ventilated blanket

A blanket providing enhanced ventilation to a person lying underneath the blanket. The blanket includes a sheet of material having a plurality of spaced apertures. Each aperture includes an opening allowing the passage of air through the blanket. The blanket may also include a reinforcing section embedded within a perimeter of the sheet of material. The reinforcing section may be a tube containing trapped air. In addition, the blanket may include supports connected to a collar section. The supports allow the blanket to be raised a specified distance above the person lying under the blanket. When the person releases the blanket, the blanket returns to its original position, lying over the person.

Owner:LI HONGBIAO

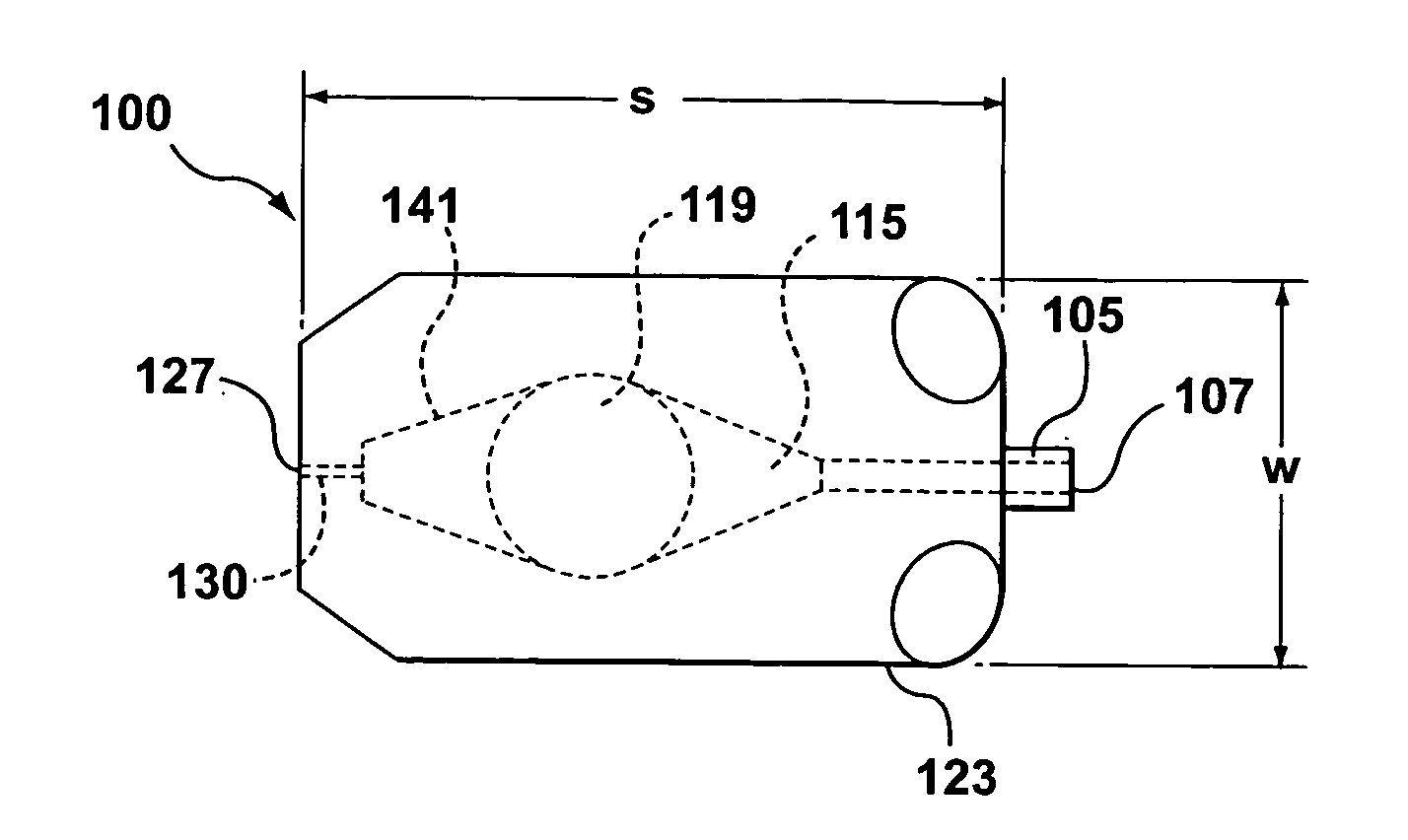

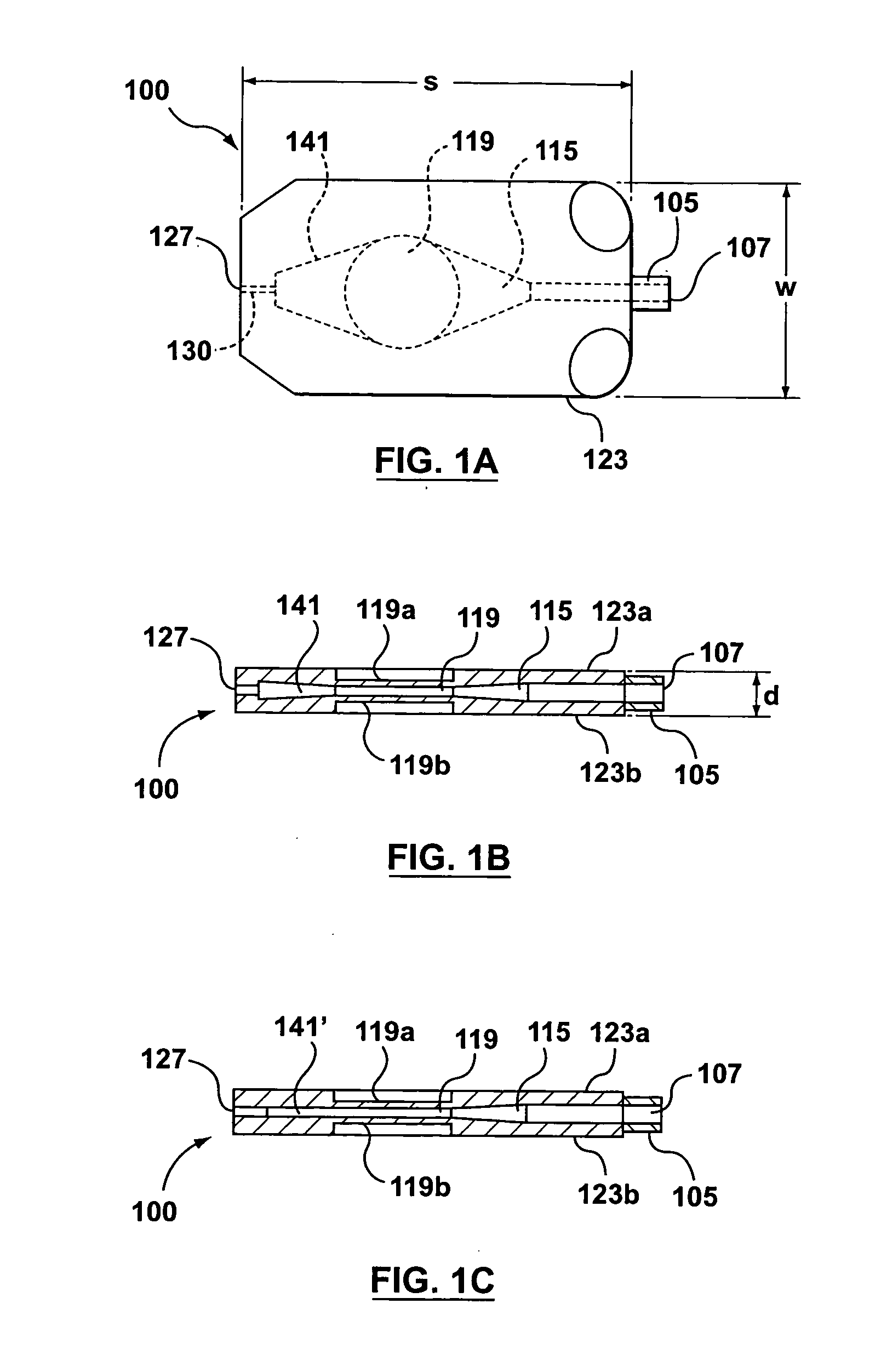

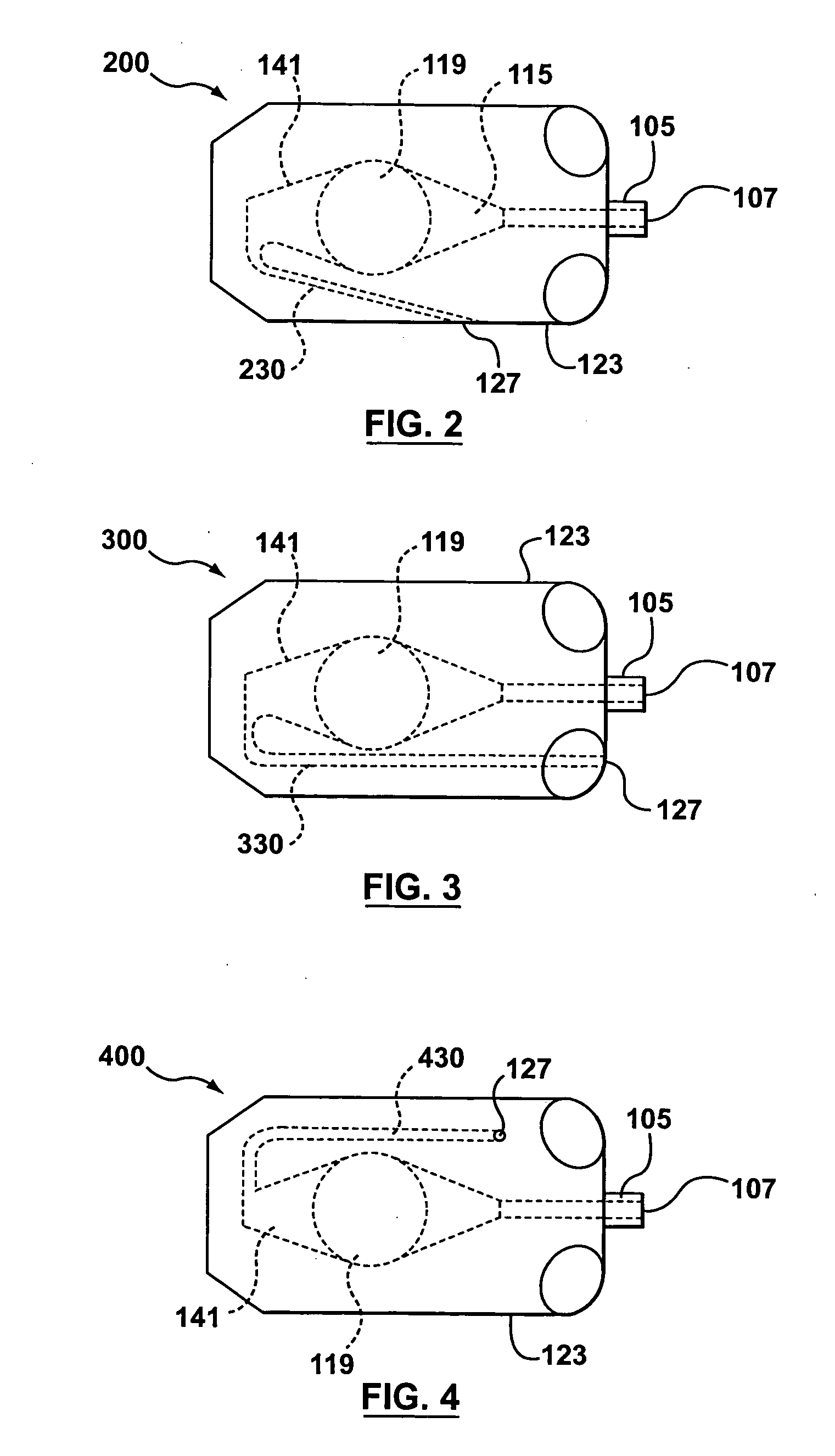

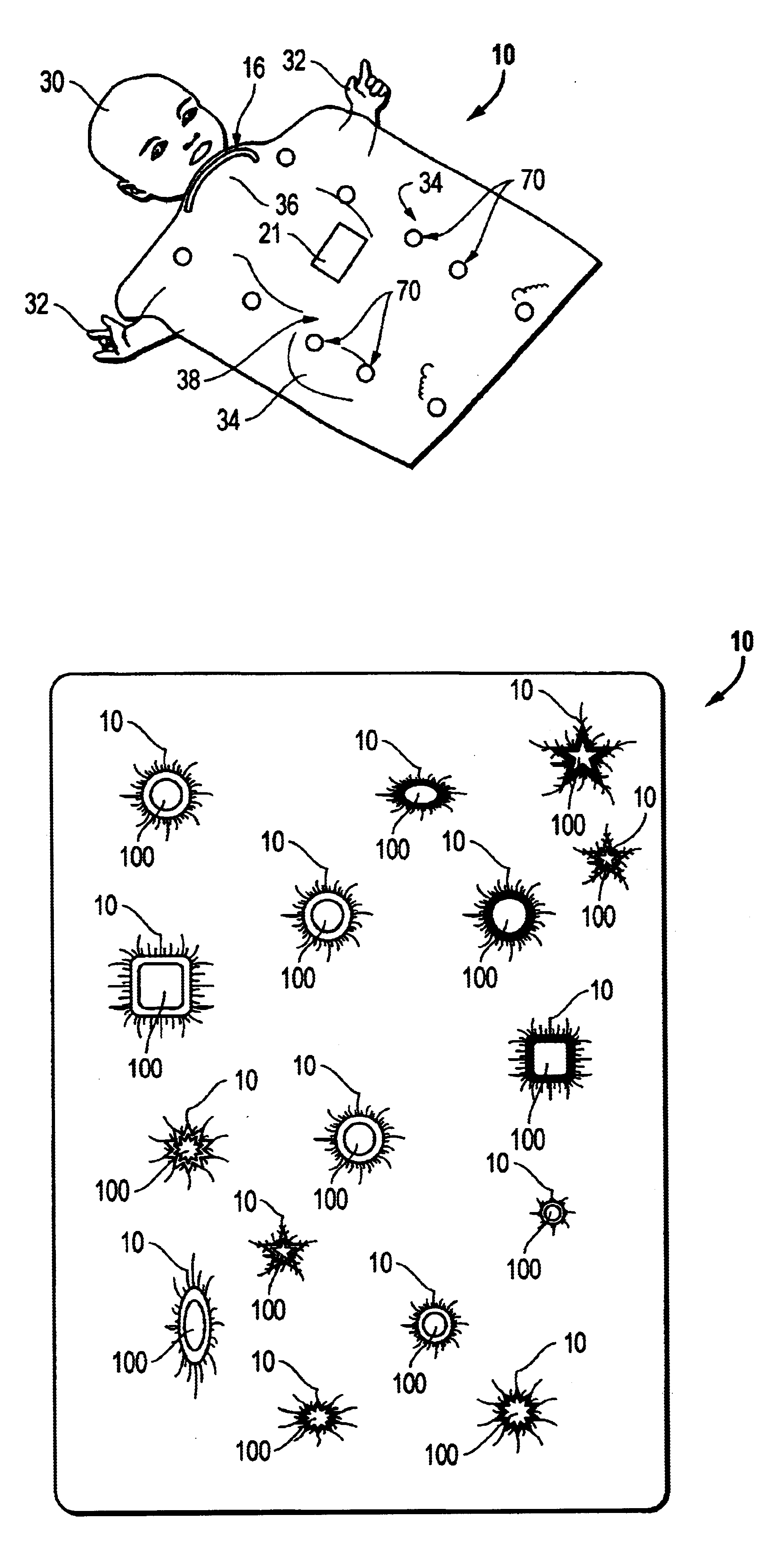

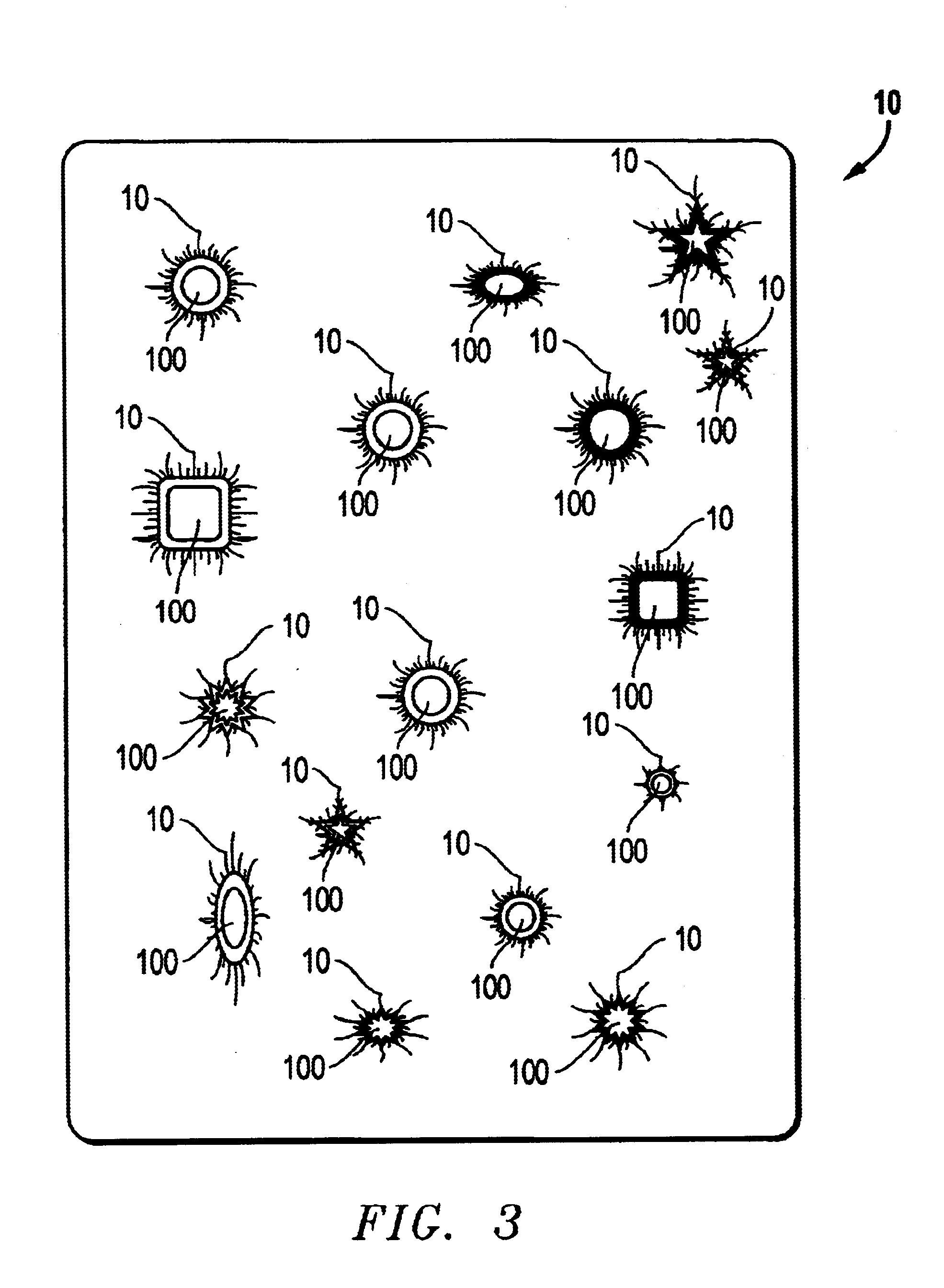

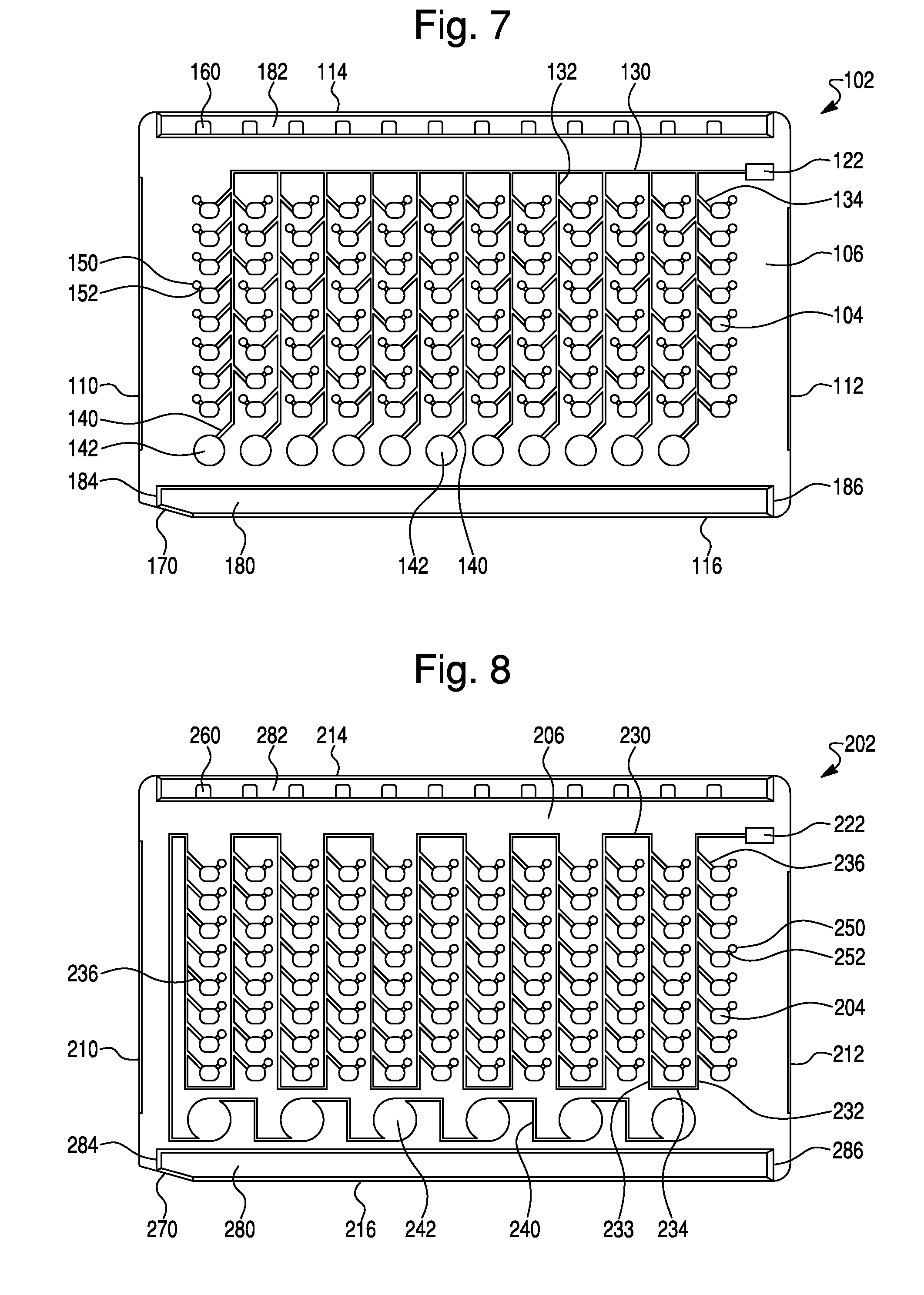

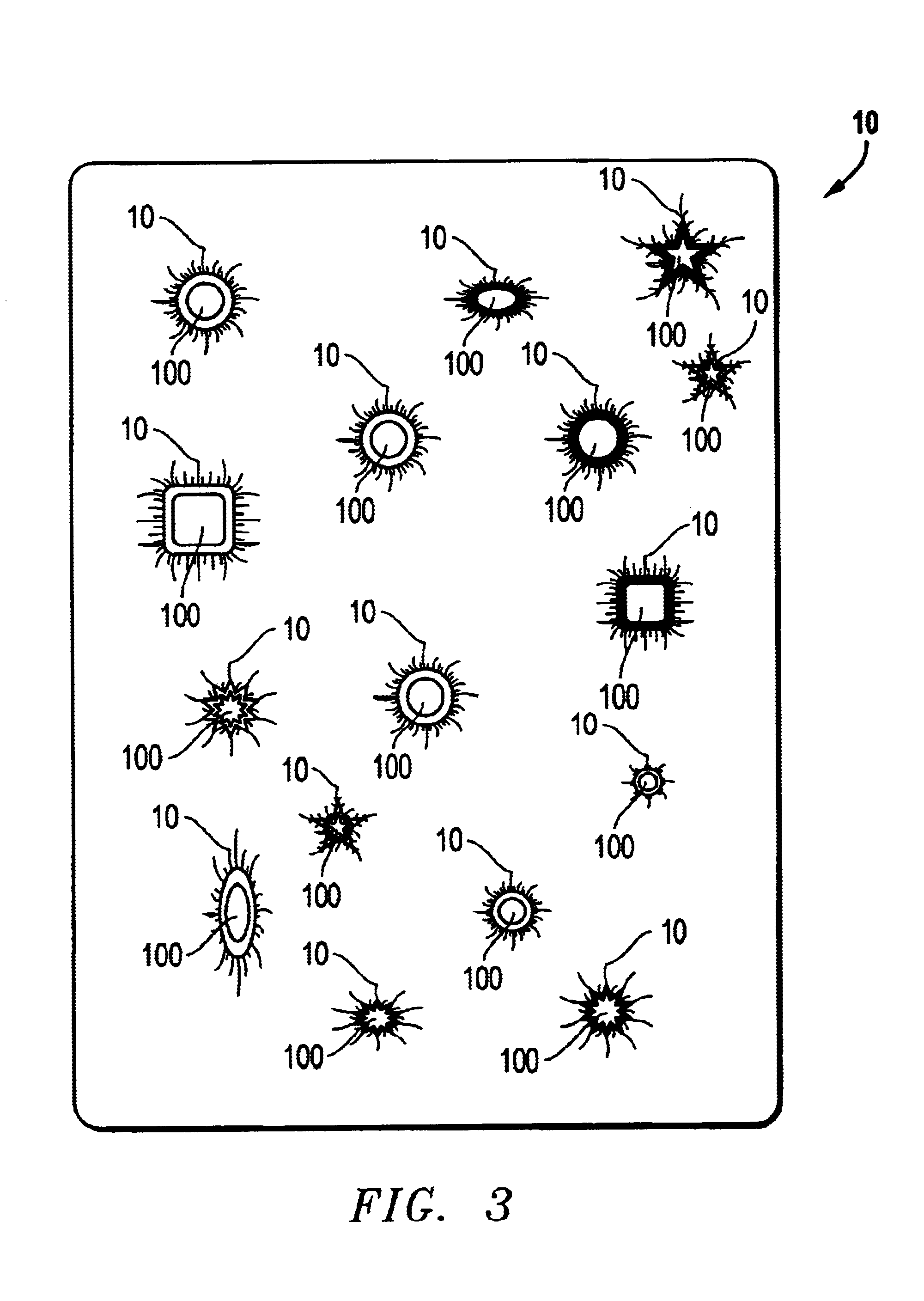

Sample Test Cards

ActiveUS20120088263A1Reduce and prevent well-to-well contaminationReduce Potential ContaminationBioreactor/fermenter combinationsBiological substance pretreatmentsTest sampleEngineering

The present invention is directed to sample test cards having an increased sample well capacity for analyzing biological or other test samples. In one embodiment, the sample test cards of the present invention comprise one or more fluid over-flow reservoirs, wherein the over-flow reservoirs are operatively connected to a distribution channel by a fluid over-flow channel. In another embodiment, the sample test cards may comprise a plurality of flow reservoirs operable to trap air thereby reducing and / or preventing well-to-well contamination. The test card of this invention may comprise from 80 to 140 individual sample wells, for example, in a test card sample test cards of the present invention have a generally rectangular shape sample test card having dimensions of from about 90 to about 95 mm in width, from about 55 to about 60 mm in height and from about 4 to about 5 mm in thickness.

Owner:BIOMERIEUX INC

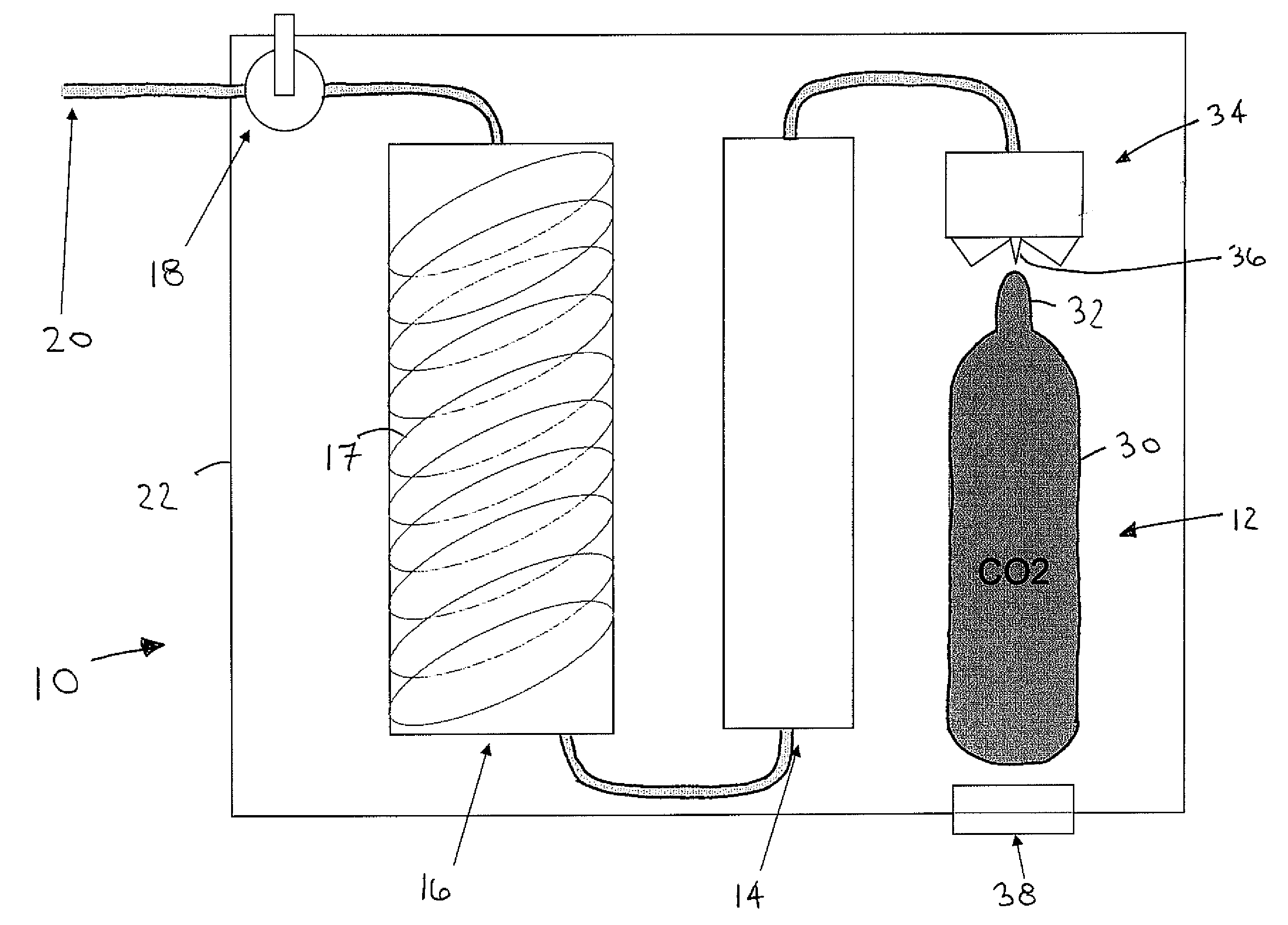

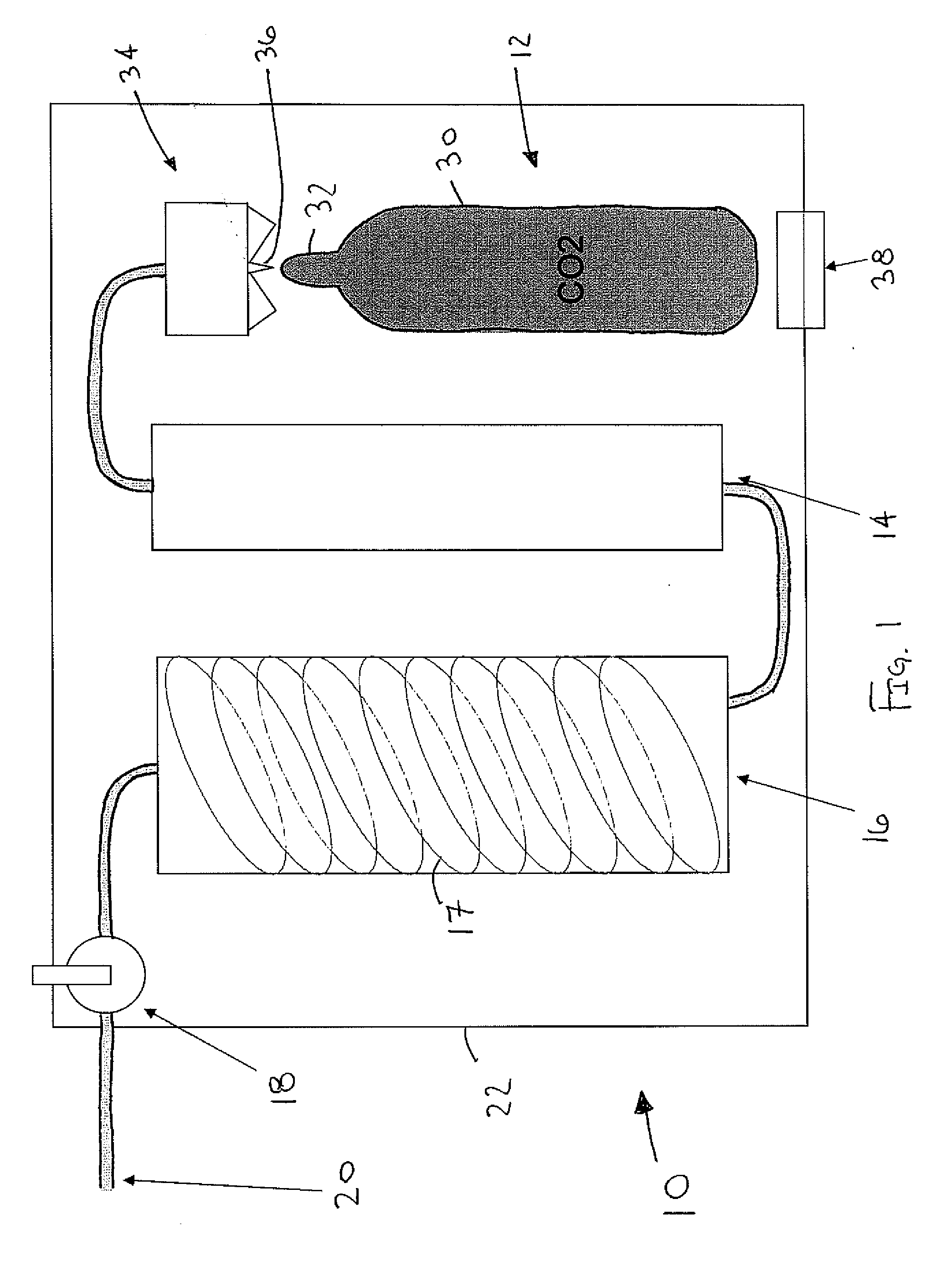

Apparatus and methods for flushing medical devices

Apparatus and methods for flushing medical devices are provided. In one embodiment, a flushing apparatus includes a container of carbon dioxide, a filter, a heat exchanger and an actuator for controlling delivery of carbon dioxide from the apparatus. In another embodiment, the flushing apparatus may be a syringe and a reservoir. During use, a medical device may be connected to the flushing apparatus, and carbon dioxide may be delivered from the apparatus into one or more lumens of the medical device to flush the device with carbon dioxide, e.g., to remove trapped air within the medical device. The medical device is then removed from the apparatus and delivered into a patient's body.

Owner:DADOURIAN DANIEL G

Blanket having extendable supports

A blanket providing enhanced ventilation and preventing a person from inadvertently removing the blanket from the person's body. The blanket includes a sheet of material having a reinforcing section embedded within a perimeter of the sheet of material. The reinforcing section may be a tube containing trapped air. In addition, the blanket may include supports connected to a collar section. The supports allow the blanket to be raised a specified distance above the person lying under the blanket. When the person releases the blanket, the blanket returns to its original position, lying over the person. The blanket may also includes several apertures allowing air to pass through the blanket.

Owner:LI HONGBIAO

Insulated storage container having a removable liner

InactiveUS8061547B2Secure retentionDomestic cooling apparatusLighting and heating apparatusEngineeringBottle

The present invention comprises an insulated container having a liner fitted therein. The liner is removable, reusable, and washable. The insulated container also has an insulated partition defining a pair of thermally isolated compartments to maintain different temperatures in each compartment. To secure the liner in place, a latch is provided, and to vent trapped air, the liner includes a channel. The liner is also configured to shed water when inverted in a washing machine so that the liner can be easily sterilized. An additional unique feature of this invention is that the liner also includes coupling cavities configured to accept various bottles and cans to prevent the bottle or can from tipping over inside the insulated container.

Owner:CAMP JR WILLIAM P

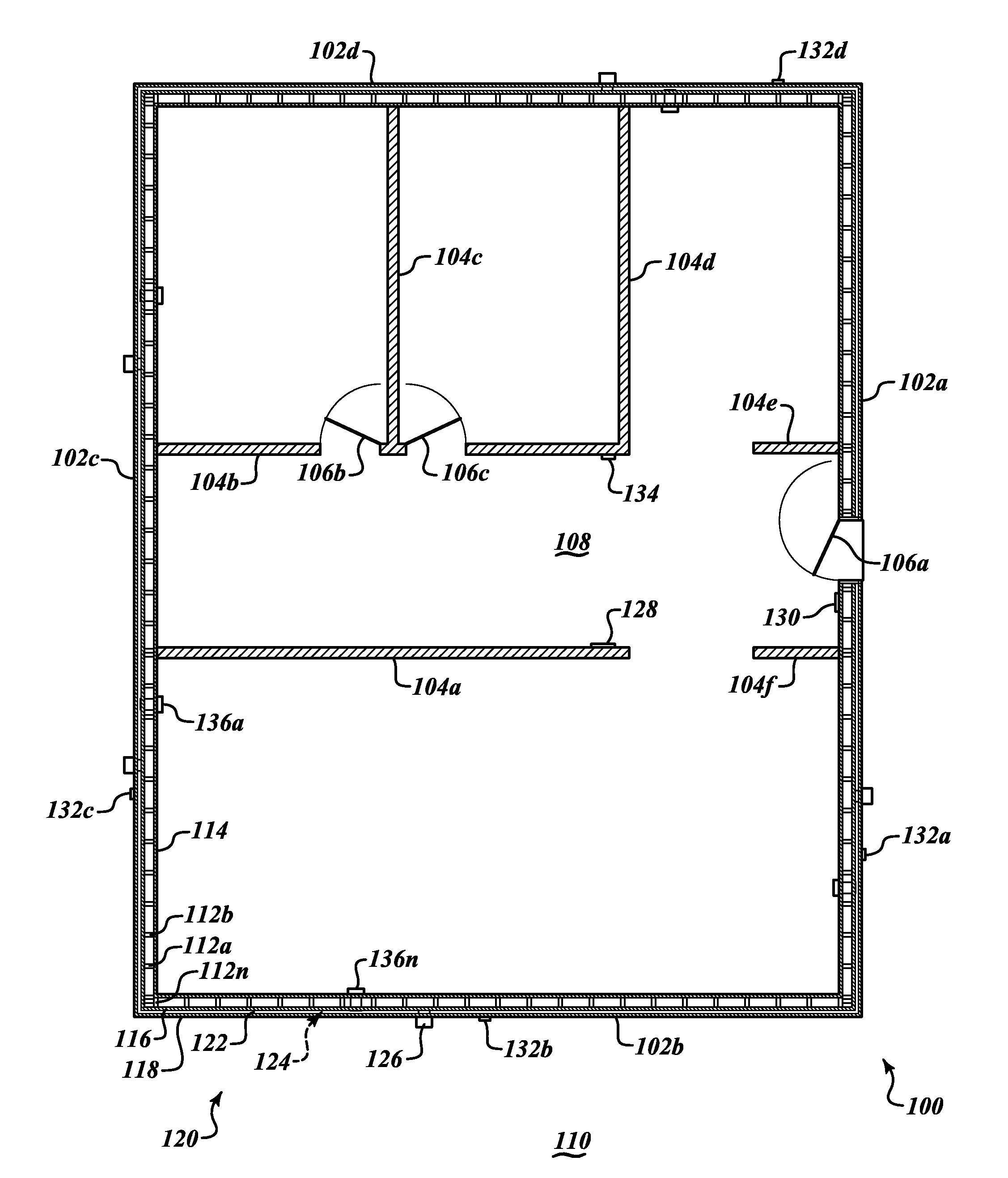

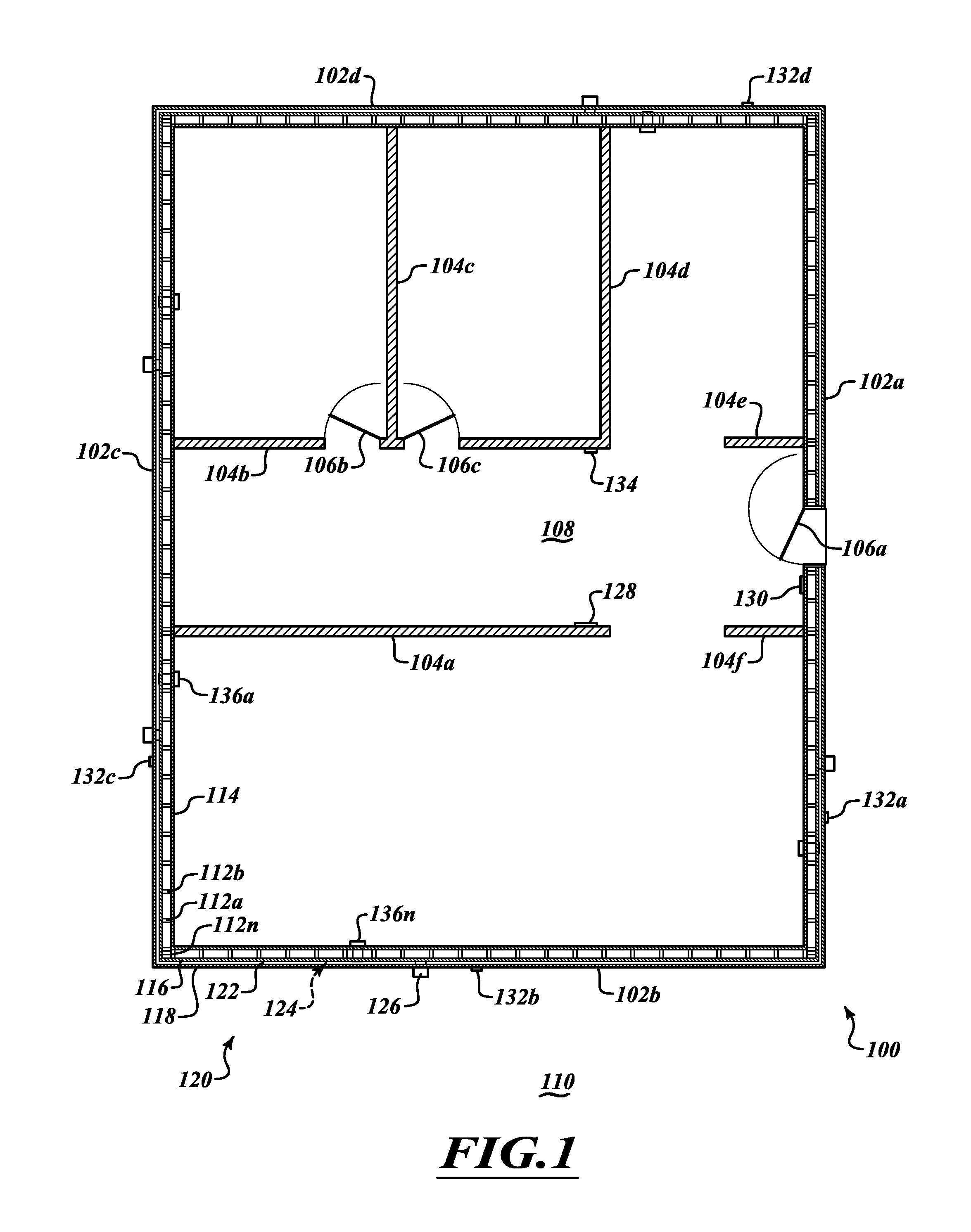

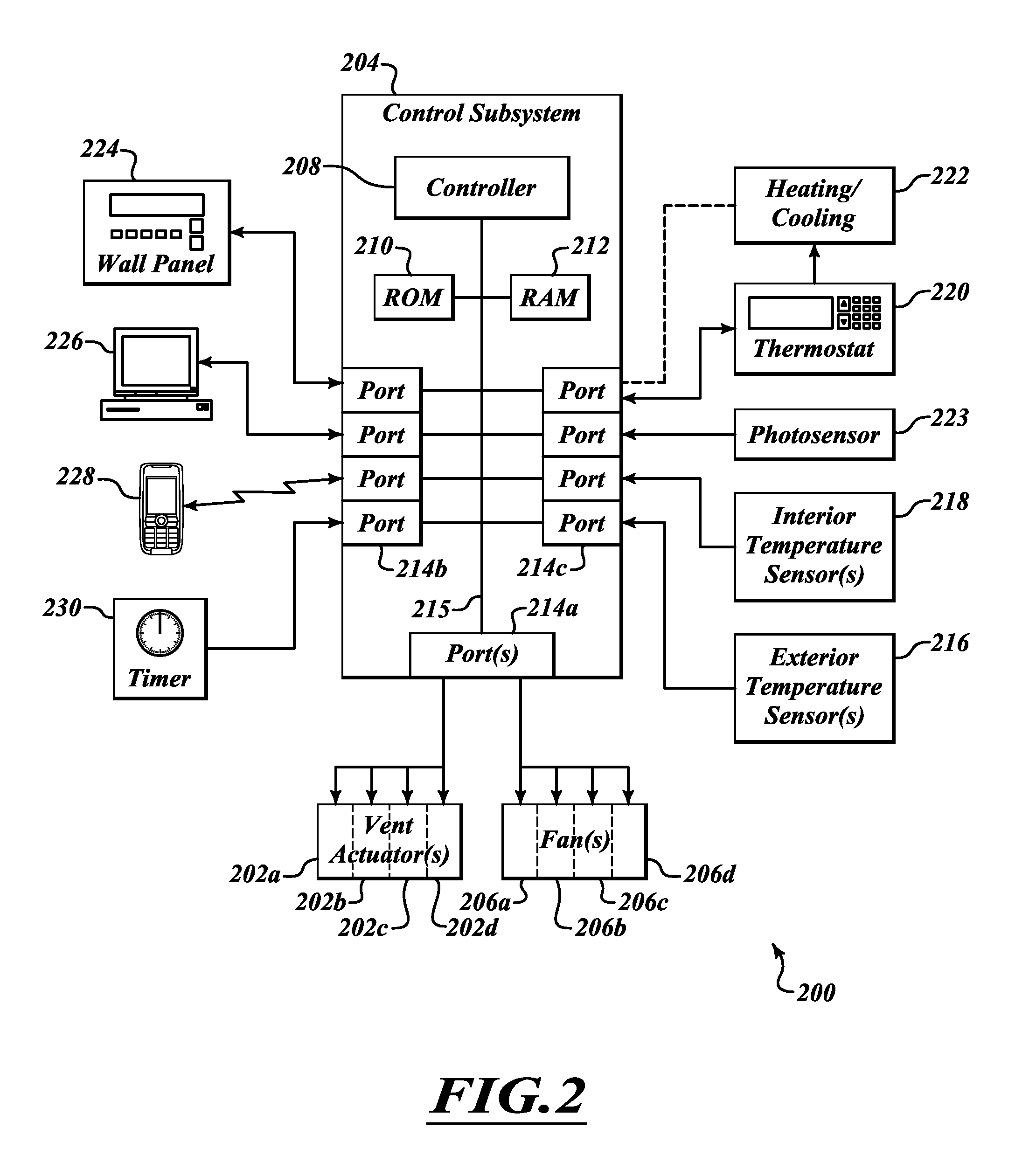

Energy efficient building environmental control apparatus and method

InactiveUS20120028563A1Improve energy performanceDucting arrangementsMechanical apparatusGlass fiberAir cycle

A building includes exterior walls that form spaces which are selectively vented under control of a control system. Vents are operated to retain trapped air or exhaust trapped air to improve the energy performance of the building. Vents with selectively operable dampers may be located proximate a top of a wall or wall section of wall. Vents may also be located proximate a bottom of a wall or wall section to allow drainage of liquid and circulation of air. Various specific wall constructions provide for an air gap between layers of exterior sheathing of the exterior wall. The air gap may be in addition to a space between interior and exterior sheathing, which space may include a thermal insulation material (e.g., fiberglass batting).

Owner:SACKS INDAL

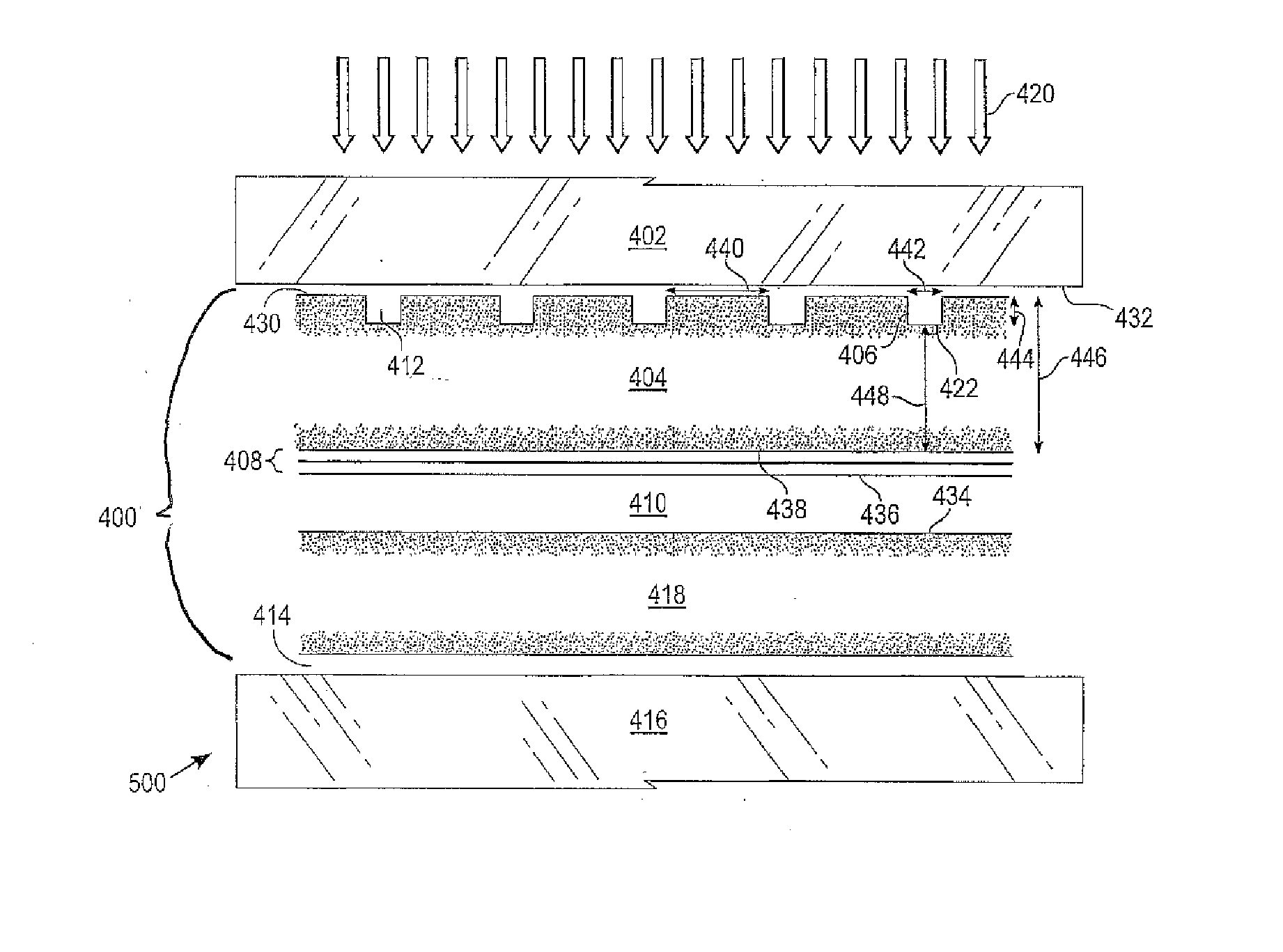

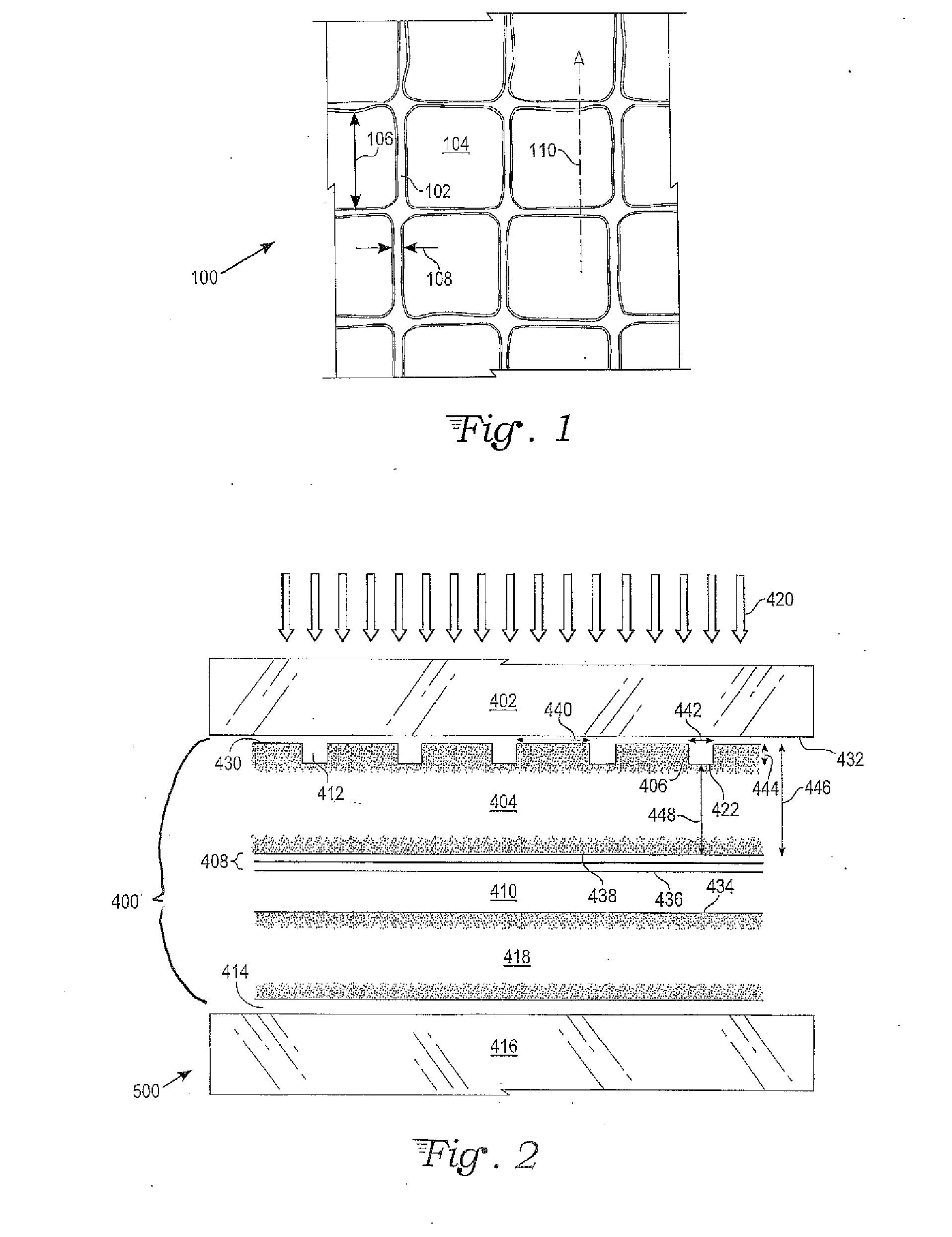

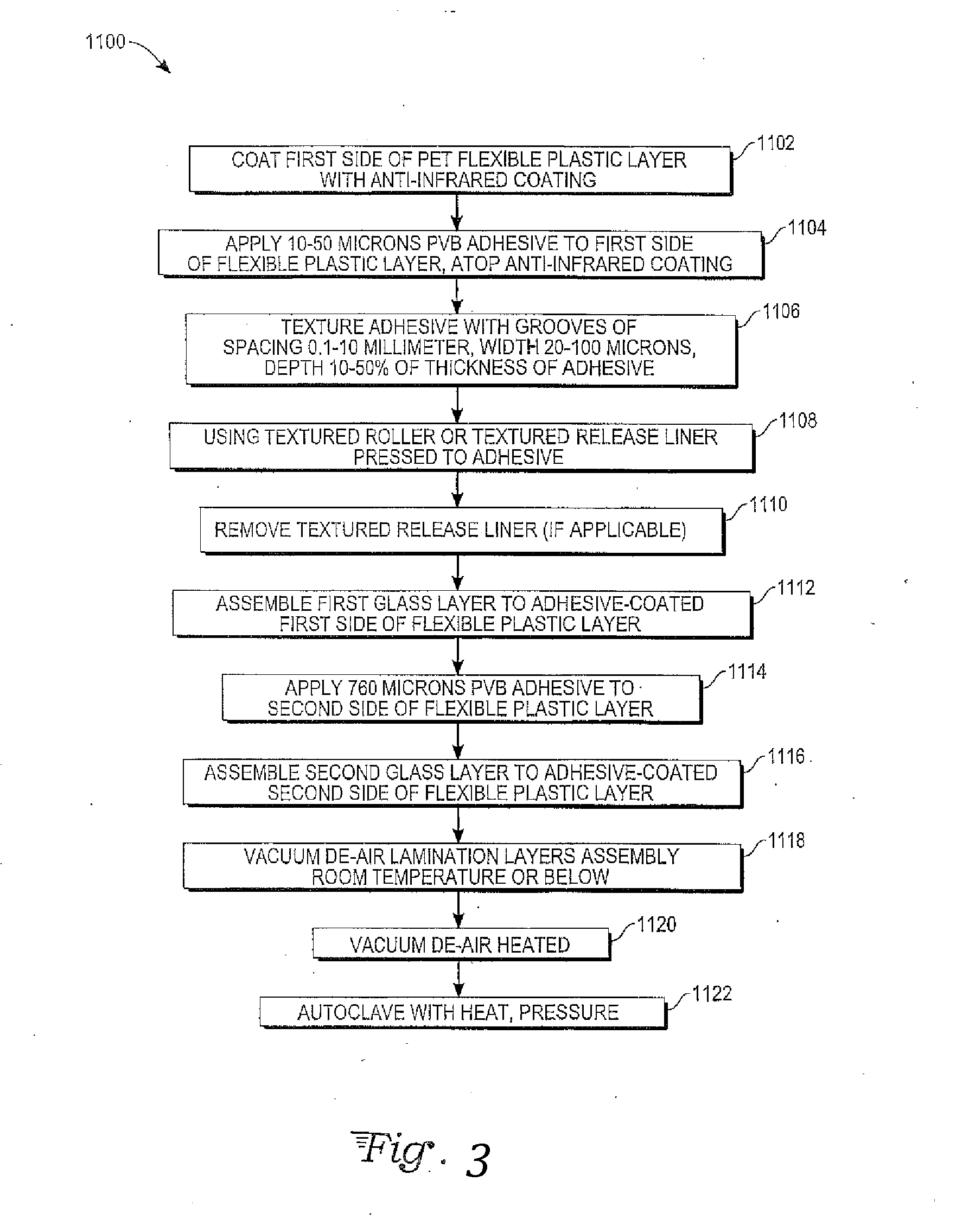

Glass Laminate Using Textured Adhesive

A method for laminating glass, a laminate assembly, and an adhesive-coated plastic material used in a laminate assembly. Specifically an adhesive, once applied to a plastic layer is grooved or textured to allow formerly trapped air to escape from between layers of a laminate assembly during a laminate process. This can allow for the adhesive layer to be thinner, while still providing for a final product that is relatively air bubble-free and optically pleasing or substantially free of optical defects caused by waviness of the plastic layer between two PVB sheets and / or wrinkles of the plastic sheet.

Owner:SOUTHWALL TECH INC

Packaging systems and methods for cold chain shipments

A packaging system for cold chain shipment may include a container having interior surface portions, a plurality of cellulose sheets disposed along the interior surface portions and defining a space configured to receive an item for cold chain shipment, and a cold source disposed within the space and configured to cool the container for cold chain shipment. The packaging system may further include a plurality of cellulose sheets, wherein adjacent sheets of the plurality of cellulose sheets define a plurality of pockets configured to trap air, and wherein the plurality of cellulose sheets are configured to insulate the space.

Owner:LIFE TECH CORP

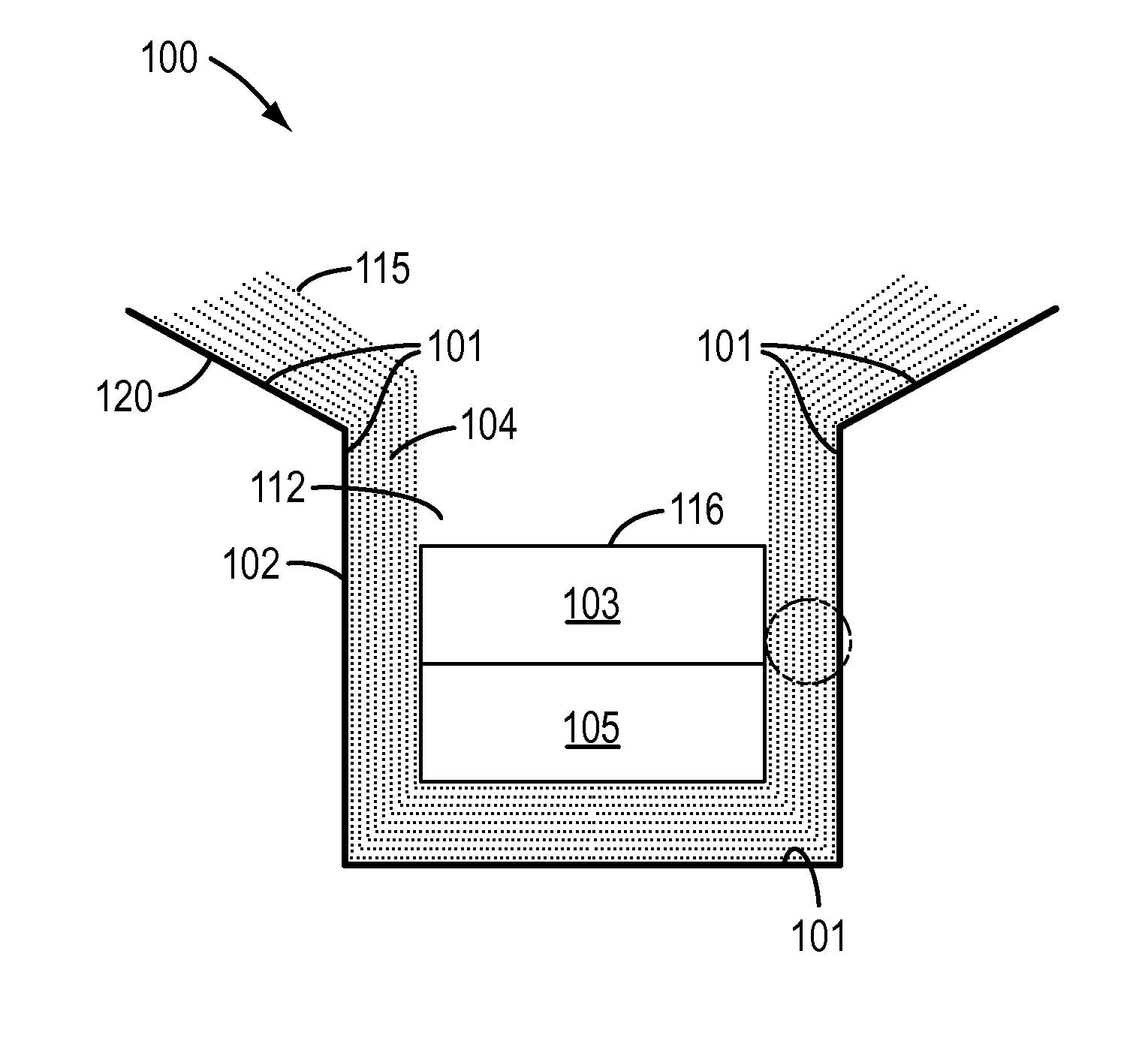

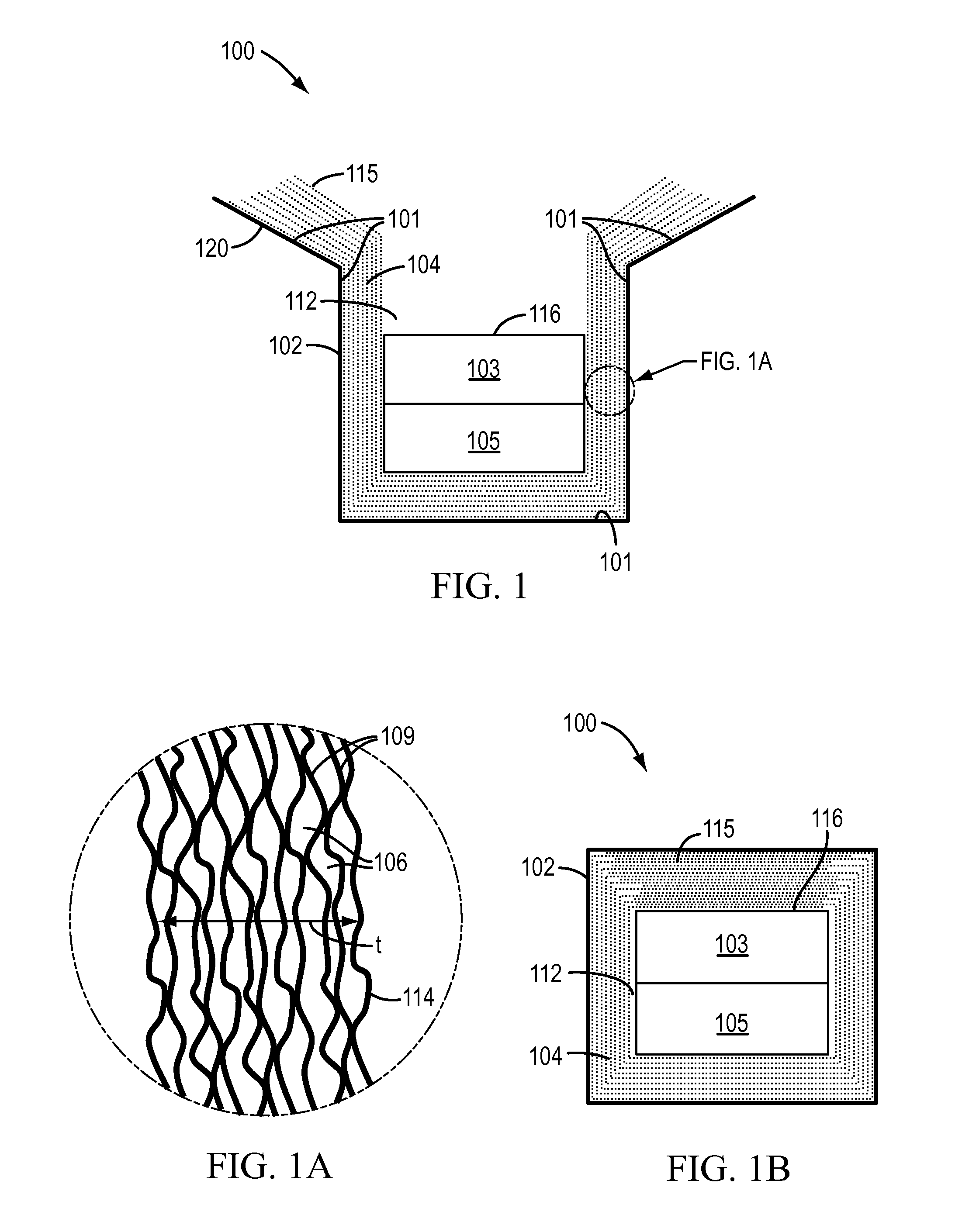

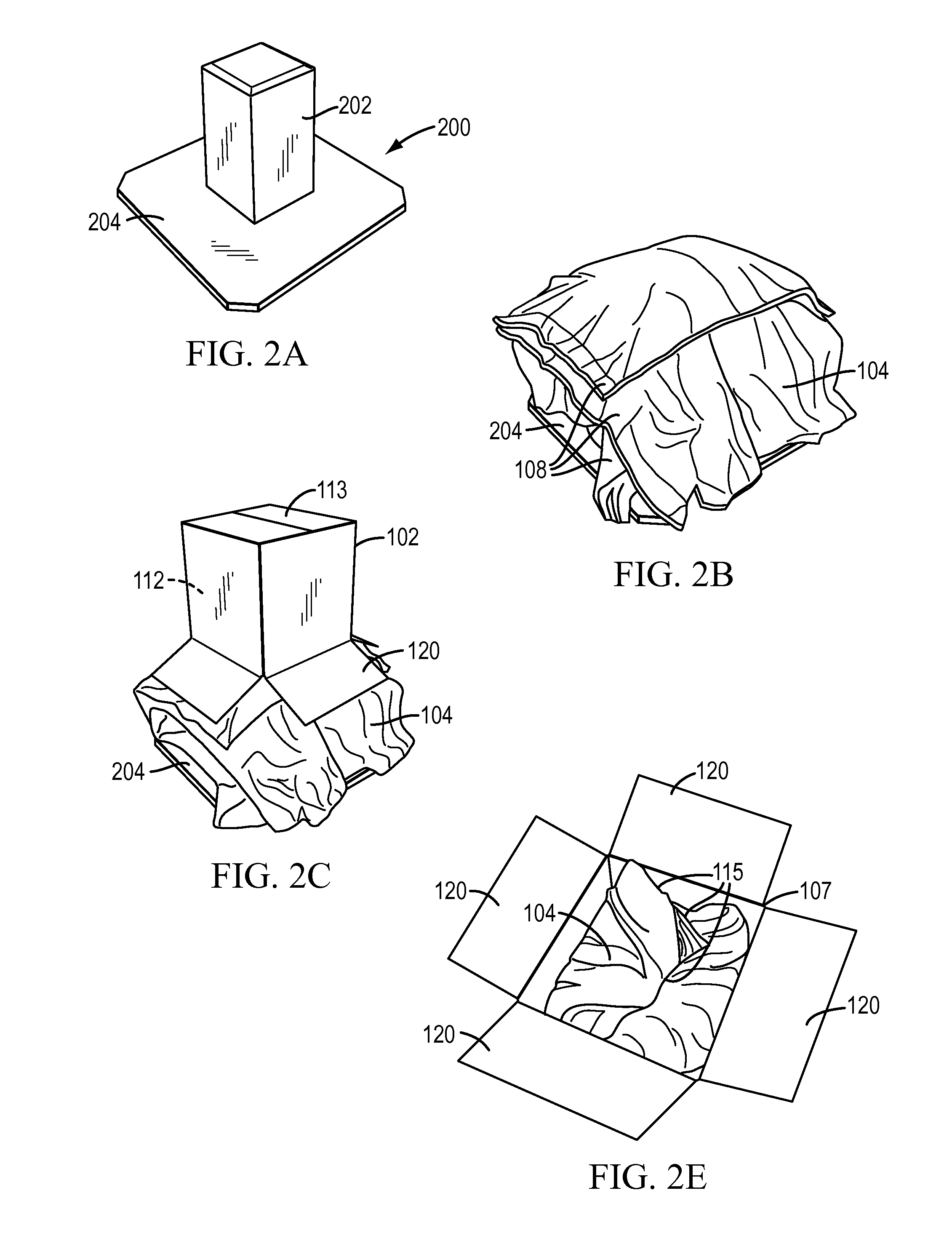

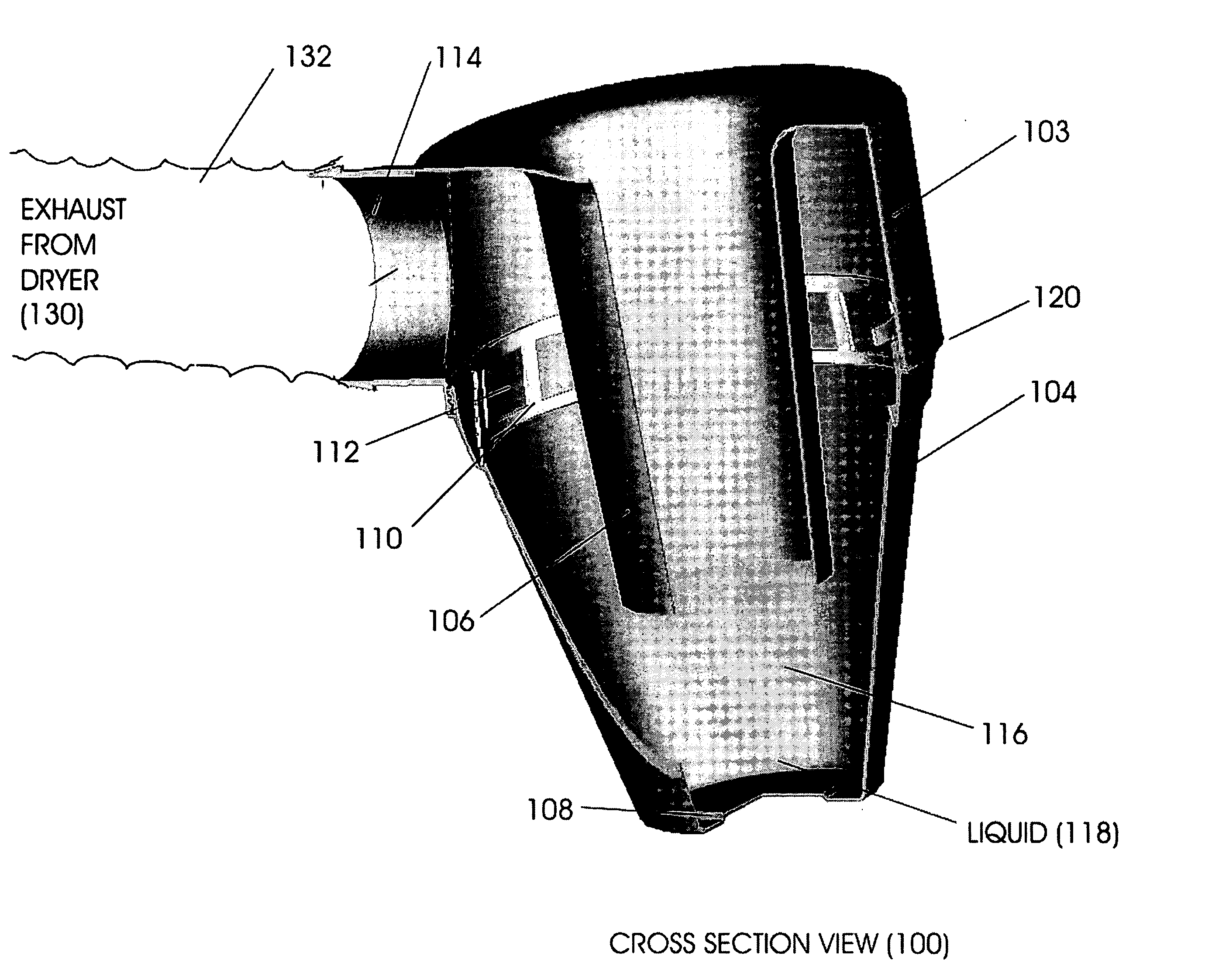

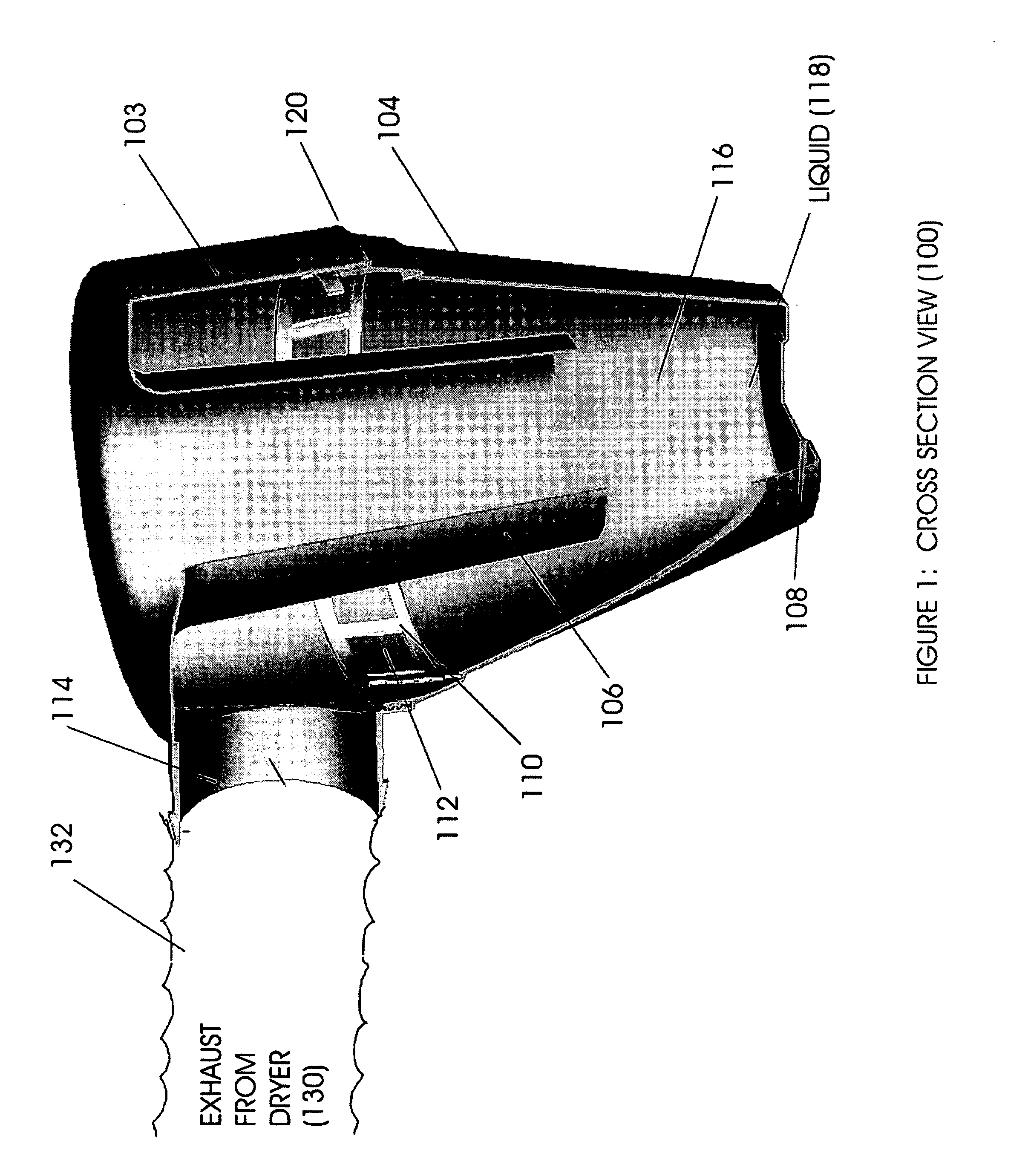

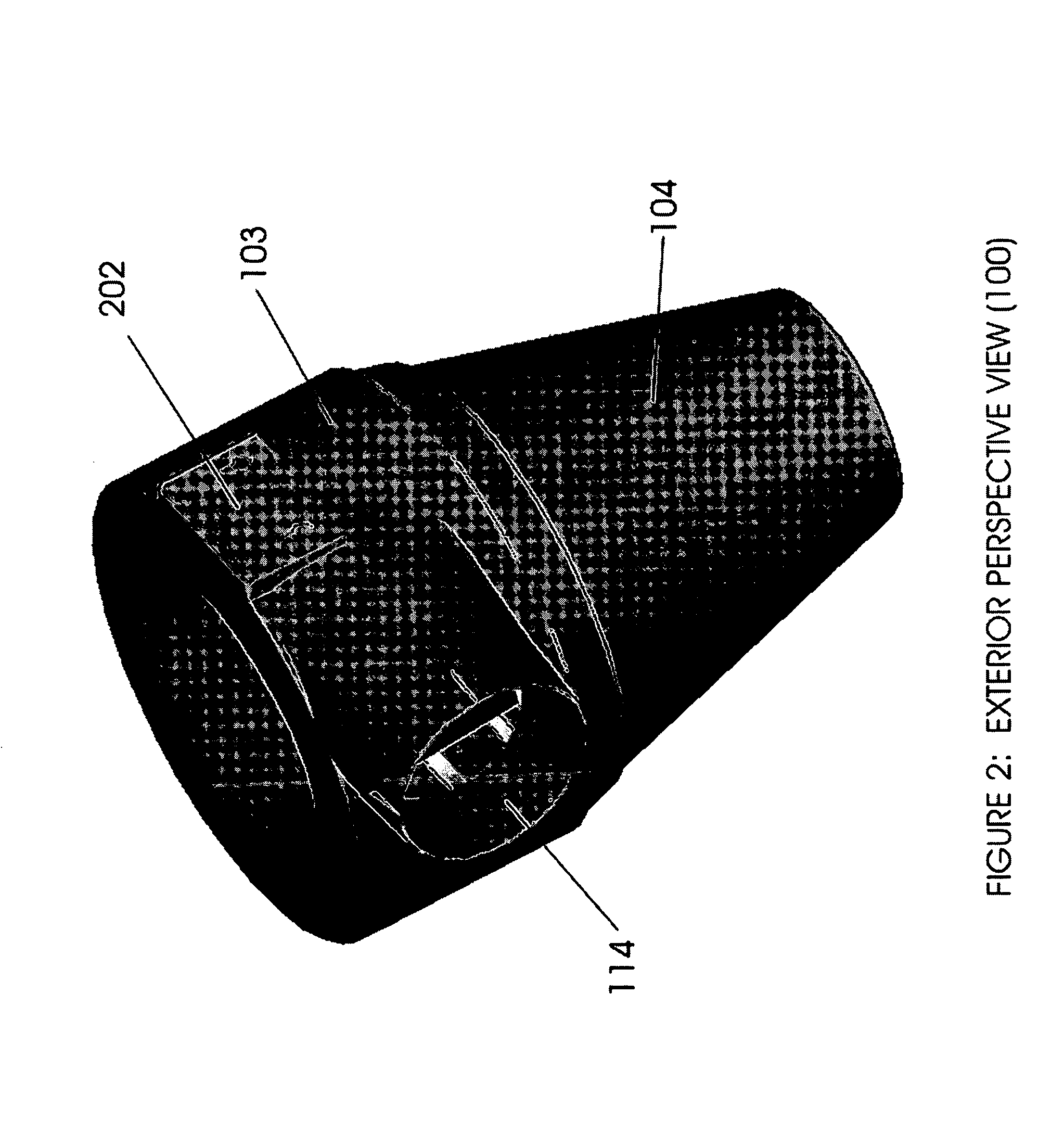

Centrifugal lint trap

InactiveUS20050252022A1Improve efficiencyIncrease back pressureDrying gas arrangementsDrying machines with non-progressive movementsEngineeringCentrifugal force

A lint trap for trapping air particles includes an air inlet for allowing the air particles to enter the lint trap and a base having a tapered gradient for increasing the velocity of the air particles and containment by centrifugal force. The air inlet is connected to a dryer.

Owner:TYAU WARREN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com