Energy efficient building environmental control apparatus and method

a technology of environmental control and building construction, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of ever increasing energy consumption concerns, and achieve the effect of improving the energy performance of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

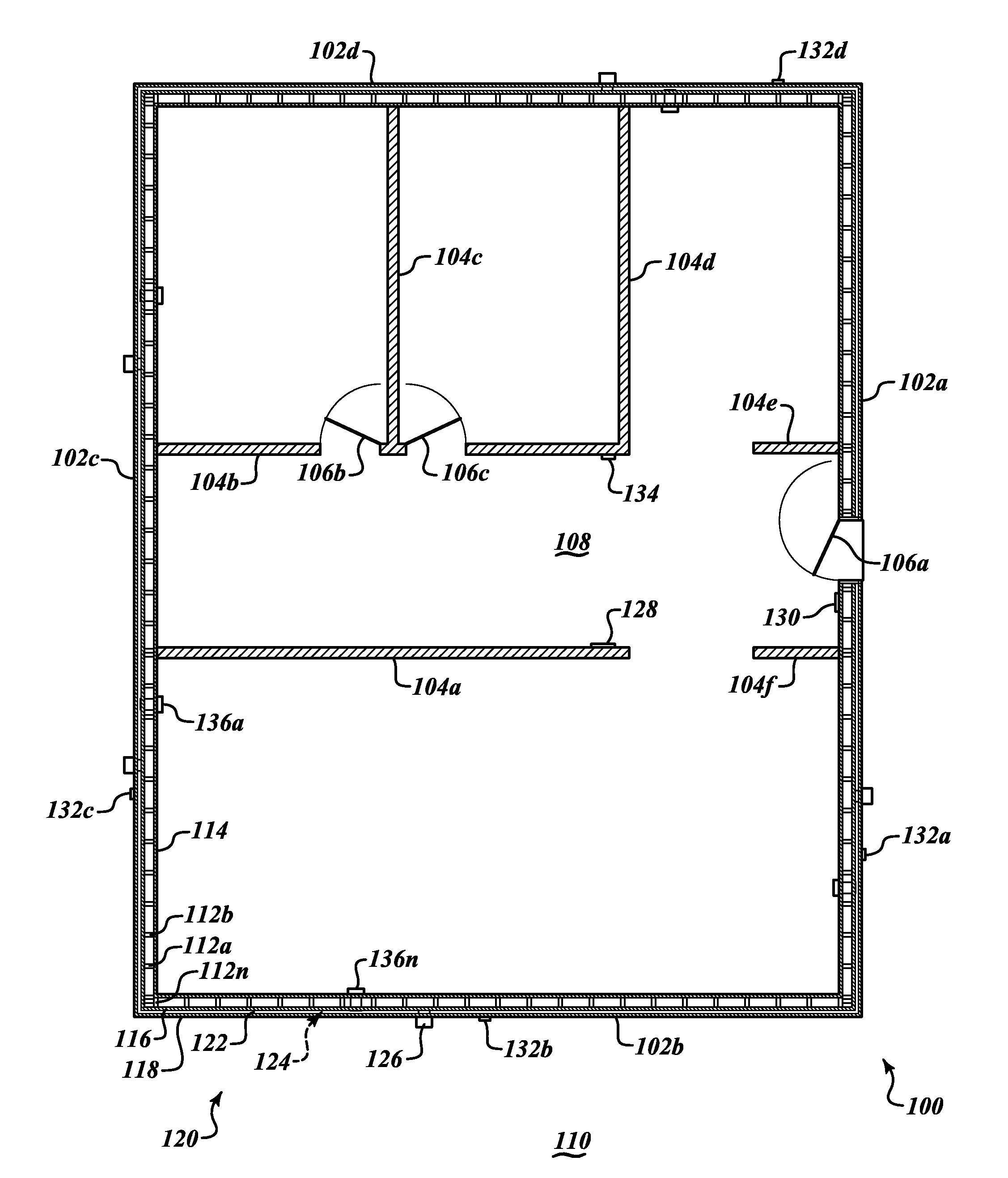

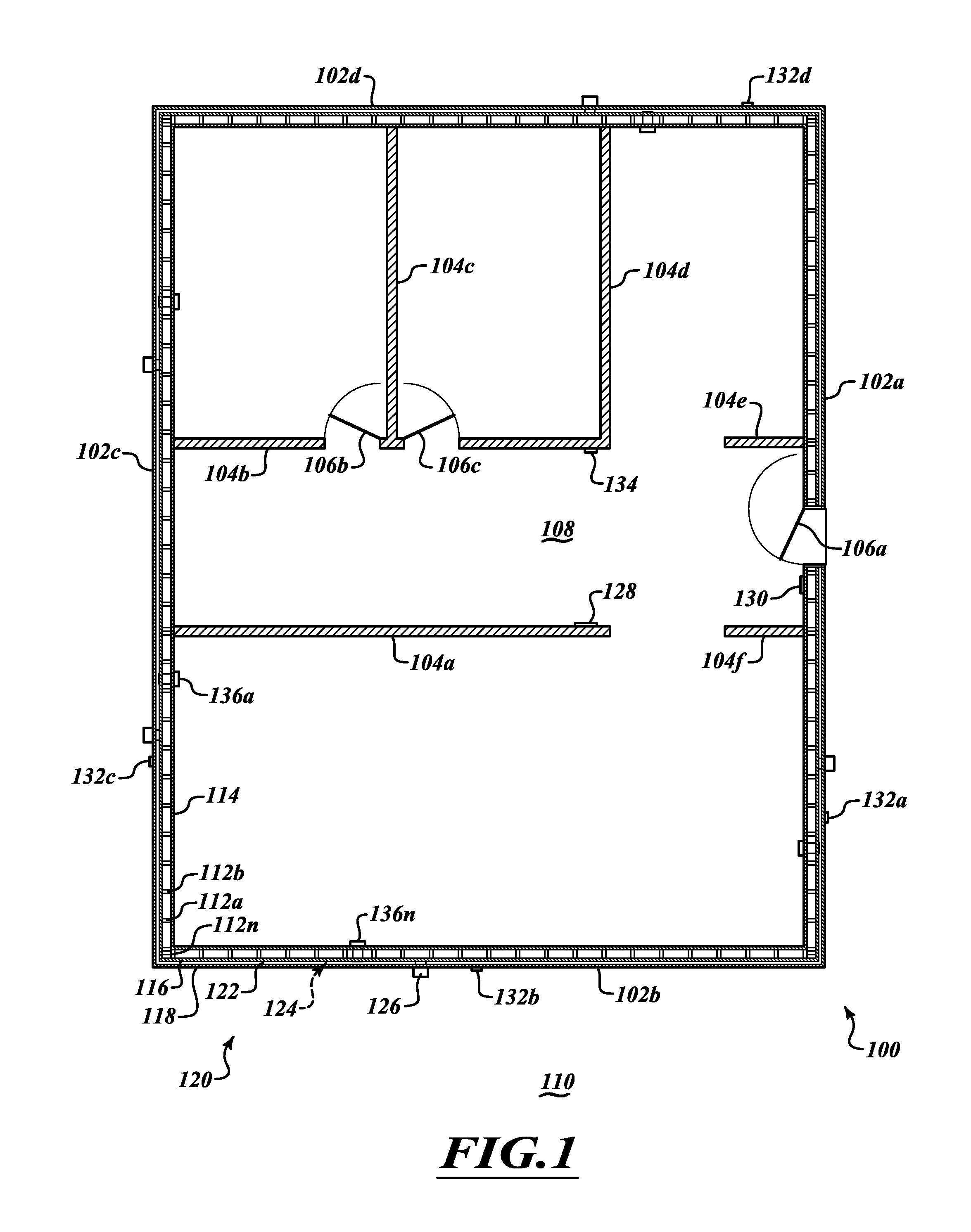

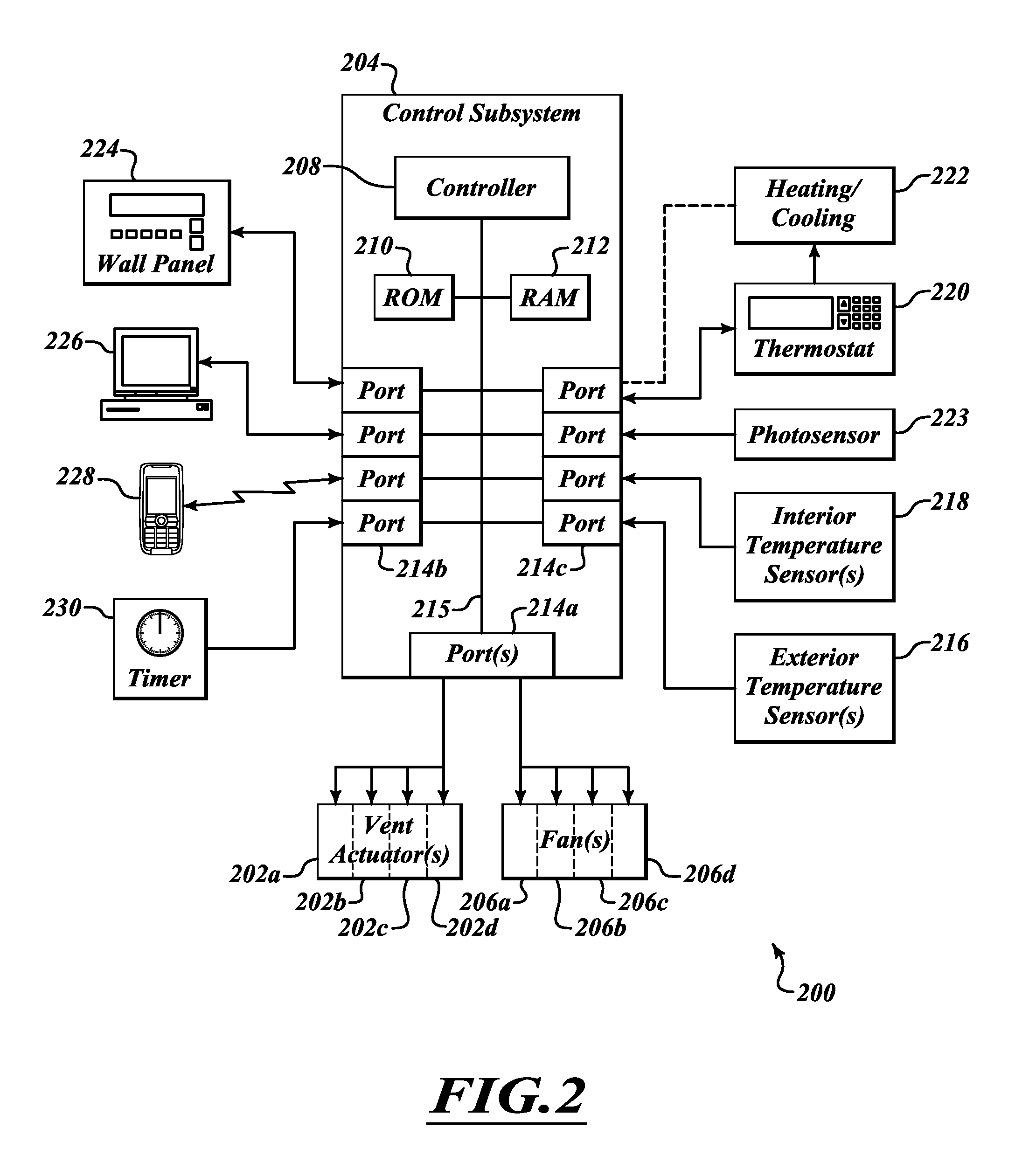

Image

Examples

examples

[0070]In a first example, an exterior wall may include steel studs having a depth of 3½ inches, and spaced 16 inches on center. The interior sheathing may be drywall of ½ inch thick with an associated thermal resistance or R value of approximately 0.45. The intermediate sheathing may be DensGlass® sheathing with an R value of approximately 0.56. The exterior wall may include fiberglass batting between the interior sheathing and the intermediate sheathing, having an associated R value of approximately 13. The wall wire lath may provide an air gap of approximately ⅜ inches with an R value of approximately 1.7 for heating and an estimated R value of from approximately 3 to approximately 4 for cooling. The exterior most sheathing may take the form of an approximately 1 inches layer of stucco containing an expanded perlite and having an associated R value of approximately 1. When determining thermal resistance, there is an air film associated with each surface / air interface which air fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com