Axial bearing arrangement in a hermetic compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

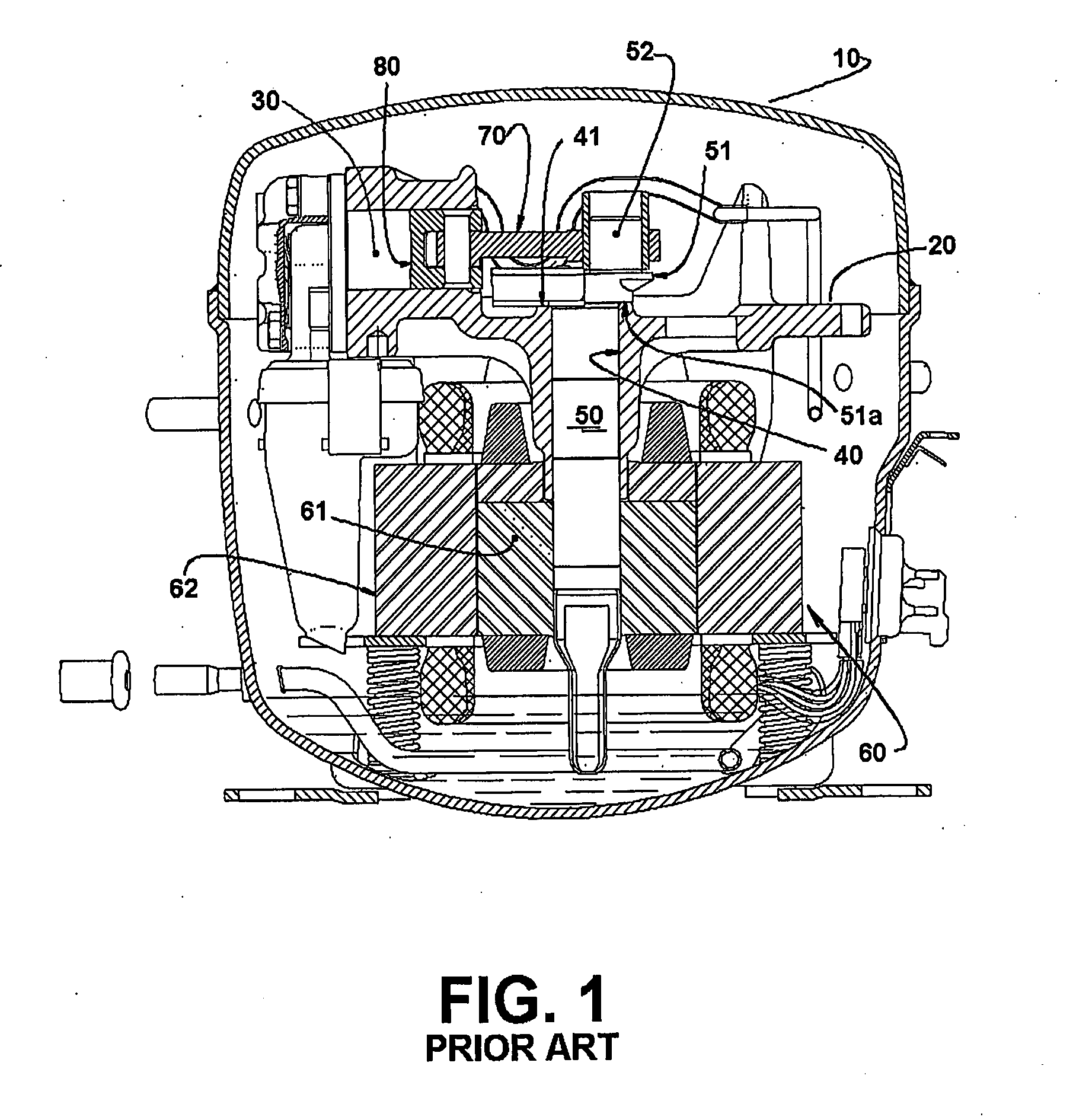

[0024]FIG. 1 illustrates, in a simplified way, a reciprocating hermetic compressor comprising a shell 10 within which is appropriately suspended a cylinder block 20, defining a cylinder 30 and incorporating a radial vertically disposed bearing hub 40 rotatively supporting a vertical crankshaft 50, having a first end portion projecting outwardly from the radial bearing hub 40 so as to secure a rotor 61 of an electric motor 60, whose stator 62 is secured under a cylinder block 20. The crankshaft 50 further presents a second end portion projecting outwardly from the radial bearing hub 40 and incorporating a peripheral flange 51, whose lower face defines an axial bearing annular surface 51a and an eccentric portion 52 to which is mounted the larger eye of a connecting rod 70, whose smaller eye is mounted to a piston 80 reciprocating inside the cylinder 30.

[0025] In this type of prior art construction, the axial bearing annular surface 51a is seated on an upper annular face 41 of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com