An insensitive energetic metal-organic framework and its preparation method

A metal-organic framework and sensitive technology, which is applied in the composition of metal-organic compounds containing nitration, offensive equipment, explosives, etc., can solve the problems of inorganic salts easy to absorb moisture, human health damage, etc., and achieve excellent fluidity and product quality High and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of Ligand HABTNA Suspension

[0026] Take 10ml of deionized water and place it in a 50ml round bottom flask, suspend 0.211g (1mmol) of HABTNA in the deionized water and stir vigorously for 30 minutes to make it a uniform ligand suspension for later use.

[0027] Step 2: Configuration of cesium carbonate solution

[0028] Weigh 1.629g (0.5mmol) of cesium carbonate in a 25ml beaker, add 10ml of deionized water to form a 0.1mol / L cesium carbonate solution, and fully stir it until it becomes a clear cesium carbonate solution for later use.

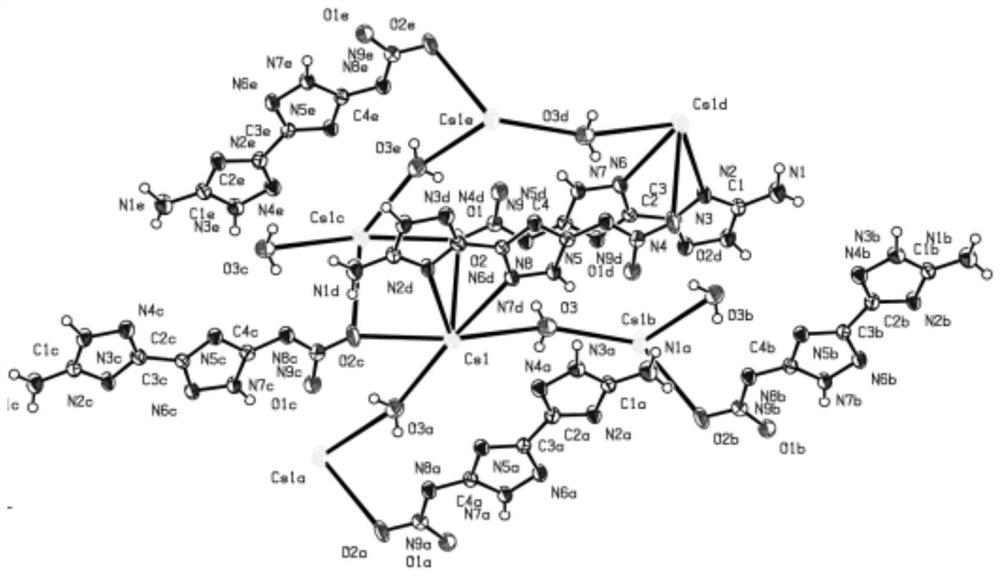

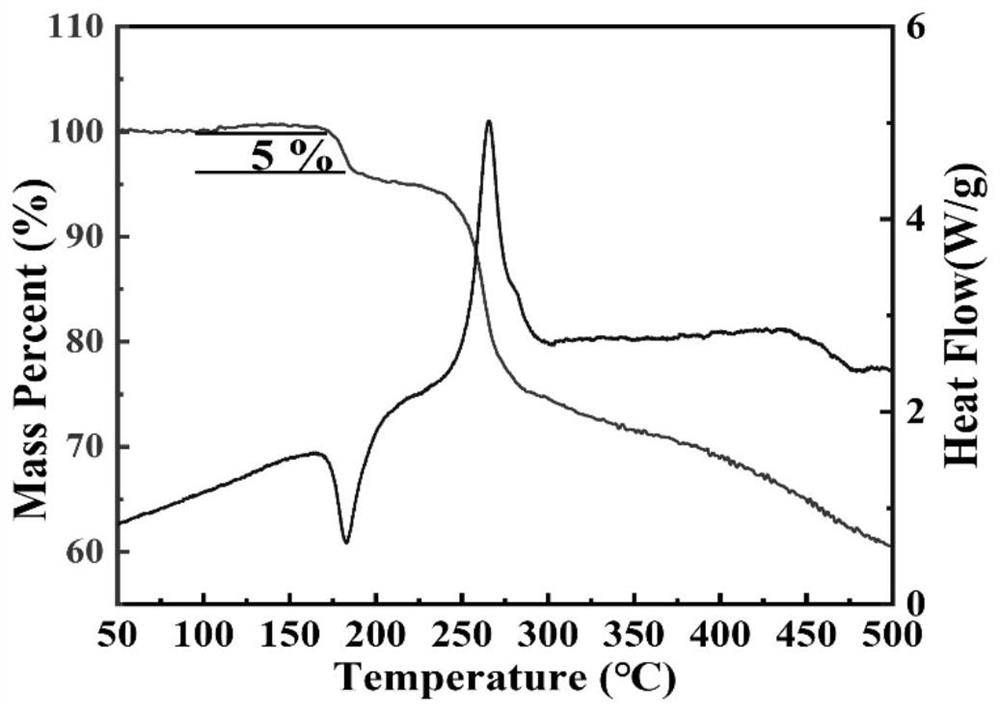

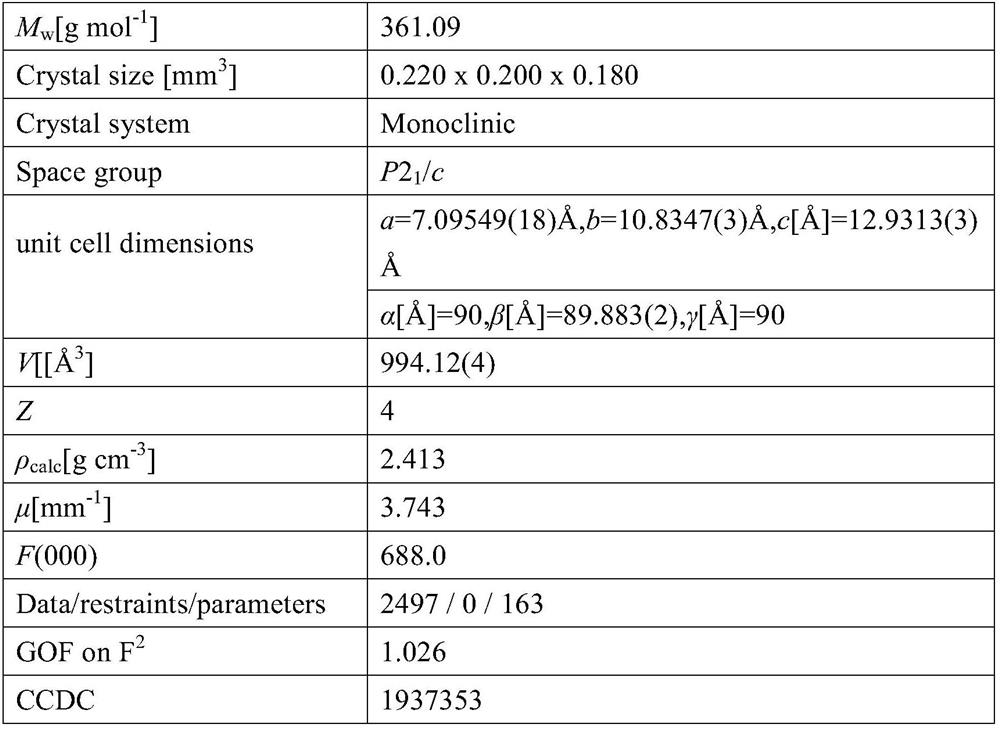

[0029] Step 3: Energetic metal-organic framework [Cs(ABTNA)H 2 O] n preparation of

[0030] After heating the ligand suspension prepared in the above step 1 to 80°C, slowly add the 0.1 mol / L cesium carbonate solution prepared in step 2 into the ligand suspension, and keep the reaction temperature for 30 minutes after the addition is completed. Then cool naturally, filter and dry the resulting product crystals to ...

Embodiment 2

[0032] Step 1: Preparation of Ligand HABTNA Suspension

[0033] Take 10ml of deionized water and place it in a 50ml round bottom flask, suspend 0.211g (1mmol) of HABTNA in the deionized water and stir vigorously for 30 minutes to make it a uniform ligand suspension for later use.

[0034] Step 2: Configuration of cesium hydroxide solution

[0035] Weigh 1.499g (1mmol) of cesium hydroxide in a 25ml beaker, add 10ml of deionized water to configure a 0.1mol / L cesium hydroxide solution, and fully stir it until it becomes a clear cesium hydroxide solution spare.

[0036] Step 3: Energetic metal-organic framework [Cs(ABTNA)H 2 O] n preparation of

[0037] After heating the ligand suspension prepared in the above step 1 to 60°C, slowly add the 0.2mol / L cesium hydroxide solution prepared in step 2 into the ligand suspension, and keep the reaction temperature for 60 minutes after the addition is completed , and then cooled naturally, the resulting product crystals were filtered an...

Embodiment 3

[0039] Step 1: Preparation of Ligand HABTNA Suspension

[0040] Take 10ml of deionized water and place it in a 50ml round bottom flask, suspend 0.211g (1mmol) of HABTNA in the deionized water and stir vigorously for 30 minutes to make it a uniform ligand suspension for later use.

[0041] Step 2: Configuration of Cesium Chloride Solution

[0042] Weigh 1.684g (1mmol) of cesium chloride in a 25ml beaker, add 10ml of deionized water to configure a 0.2mol / L cesium chloride solution, and fully stir it until it becomes a clear cesium chloride solution spare.

[0043] Step 3: Energetic metal-organic framework [Cs(ABTNA)H 2 O] n preparation of

[0044] After heating the ligand suspension prepared in the above step 1 to 60°C, slowly add the 0.2mol / L cesium chloride solution prepared in step 2 into the ligand suspension, and keep the reaction temperature for 60 minutes after the addition is completed , and then cooled naturally, the resulting product crystals were filtered and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact sensitivity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com