Patents

Literature

89 results about "Glass fiber reinforced polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

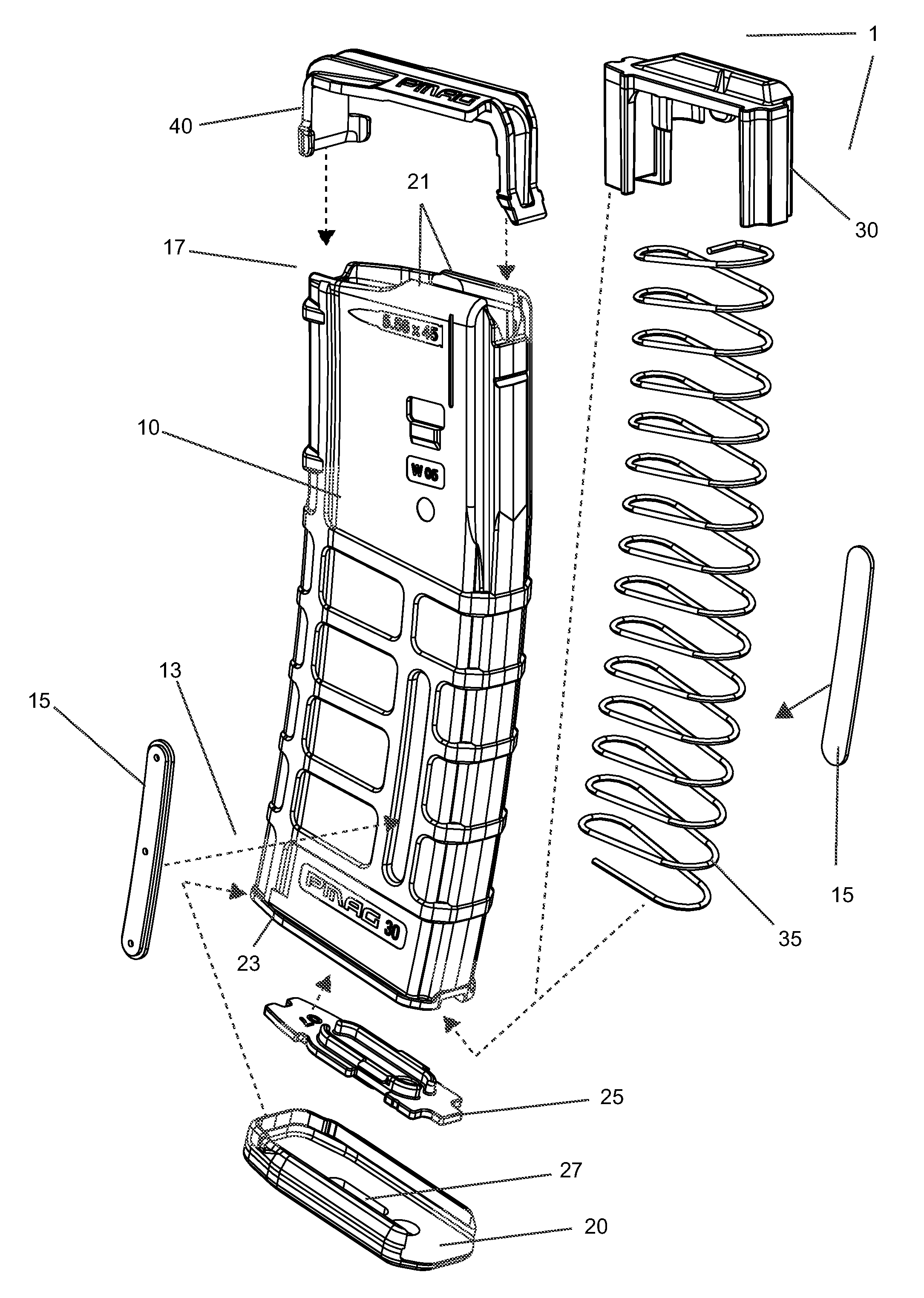

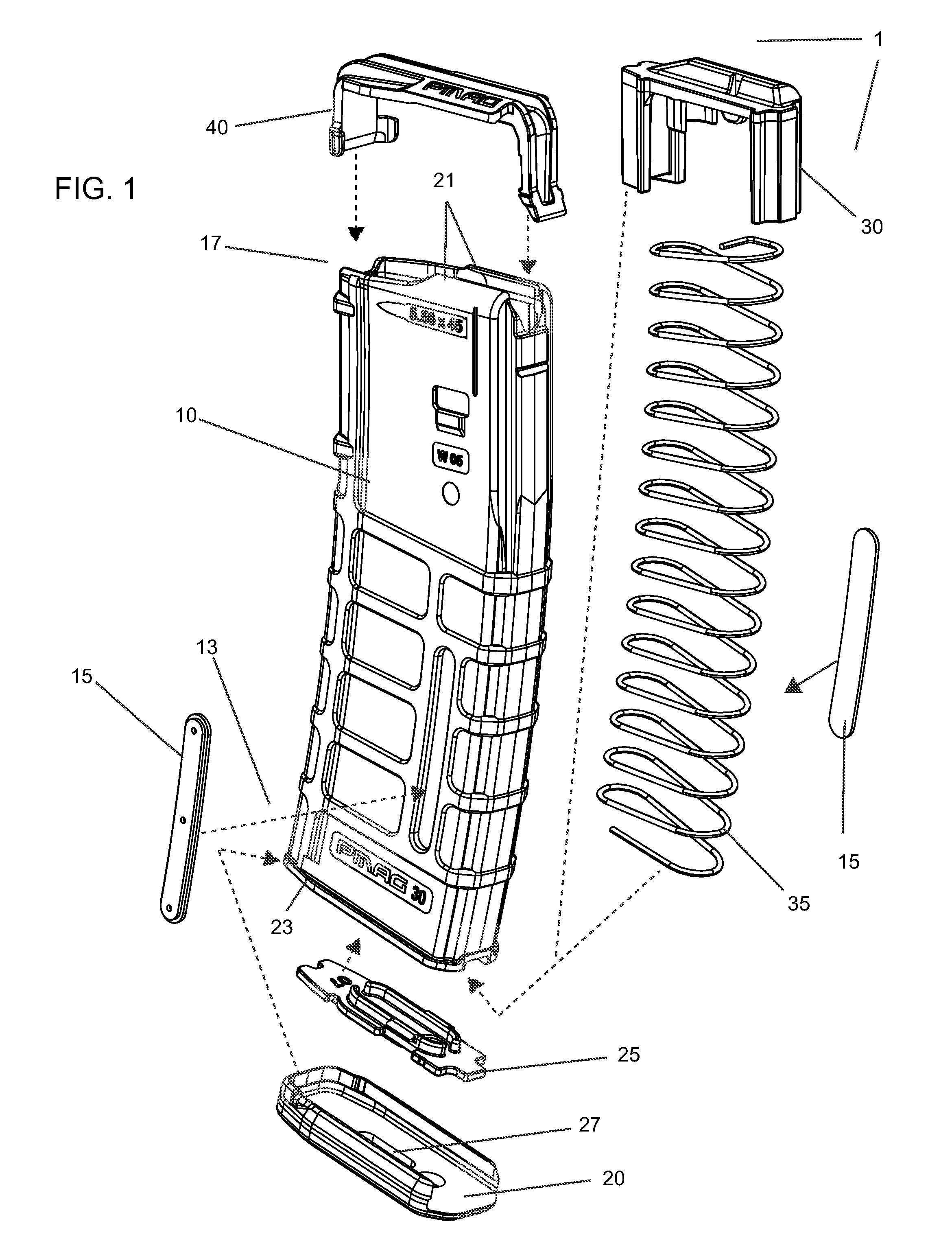

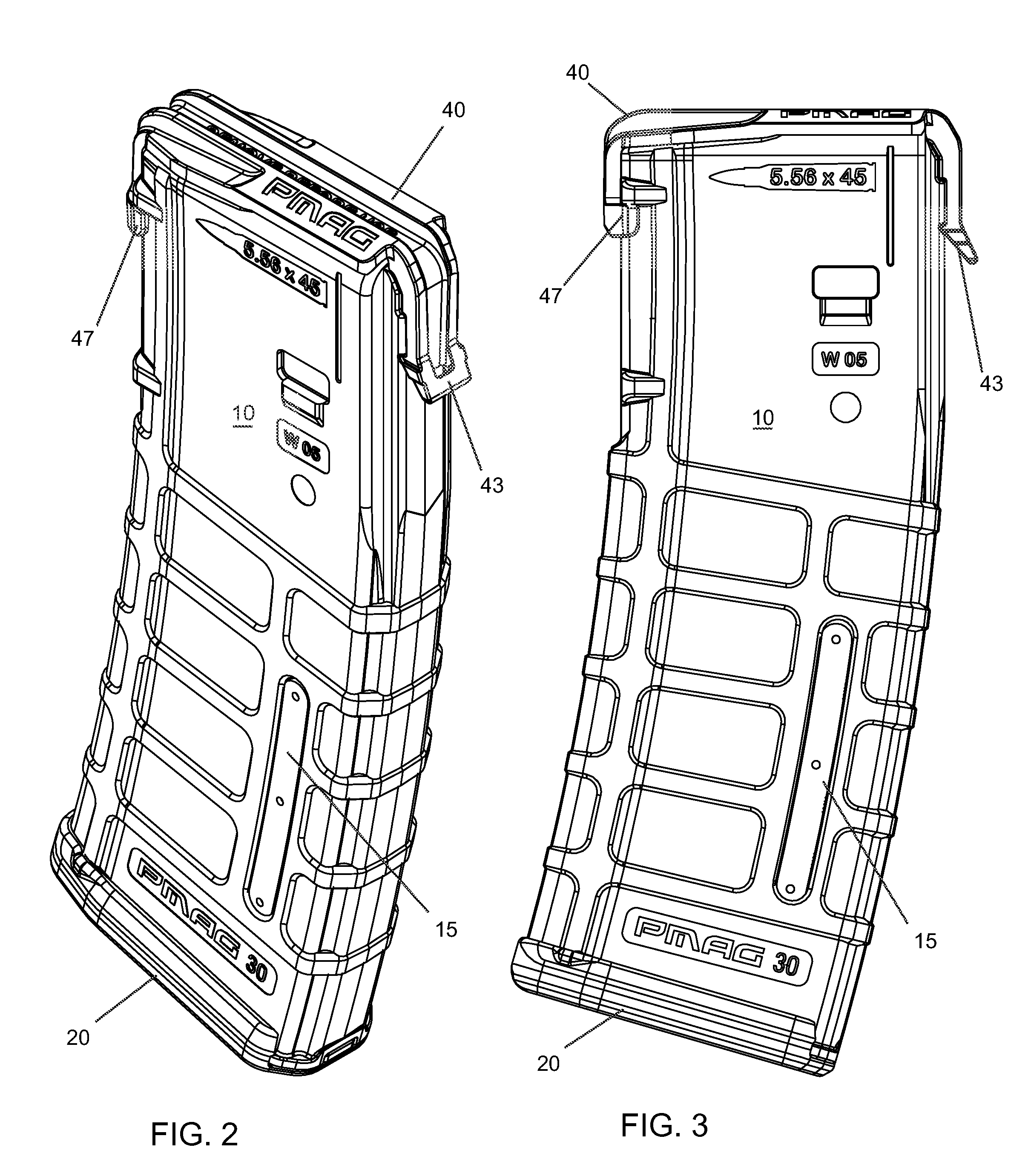

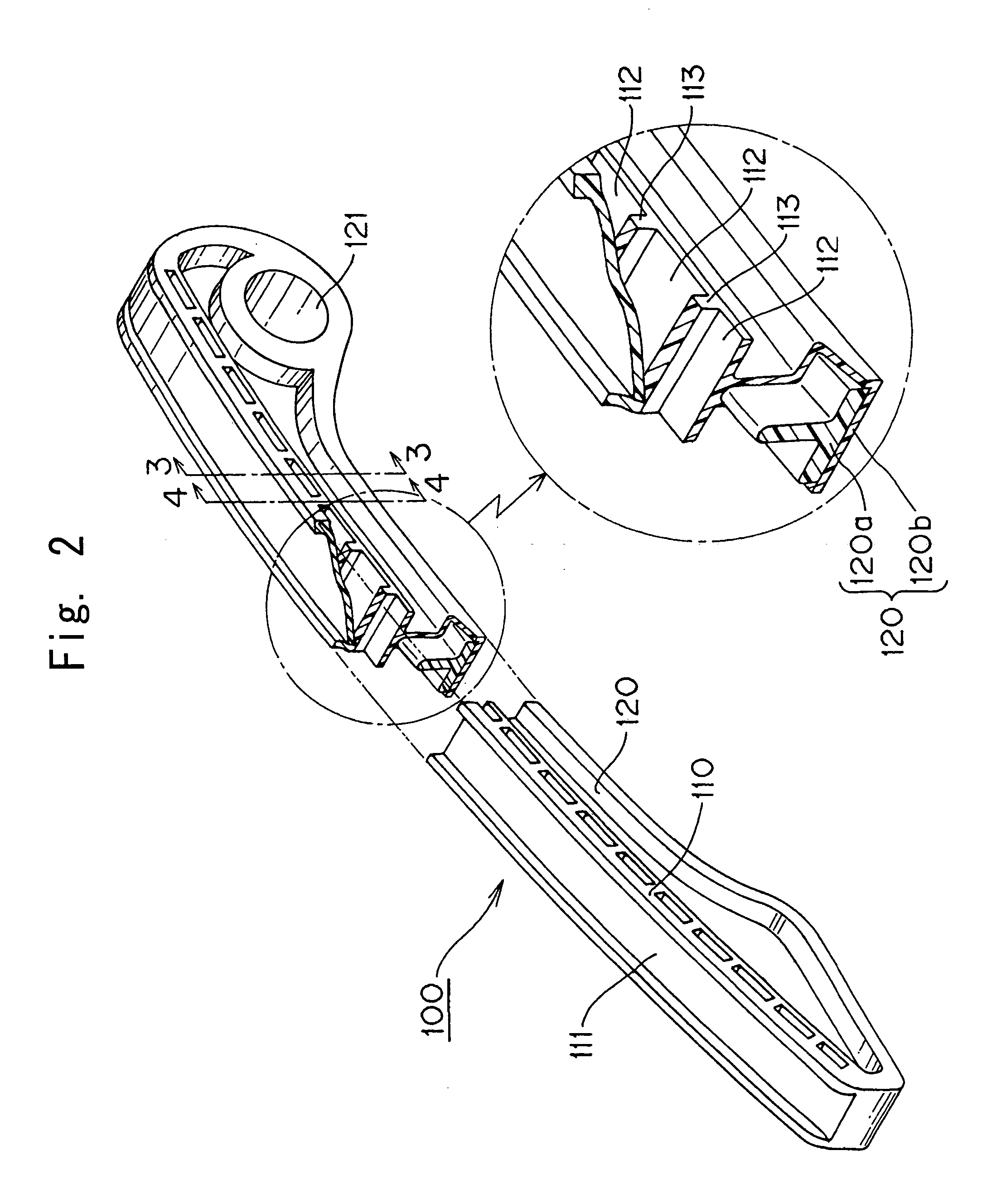

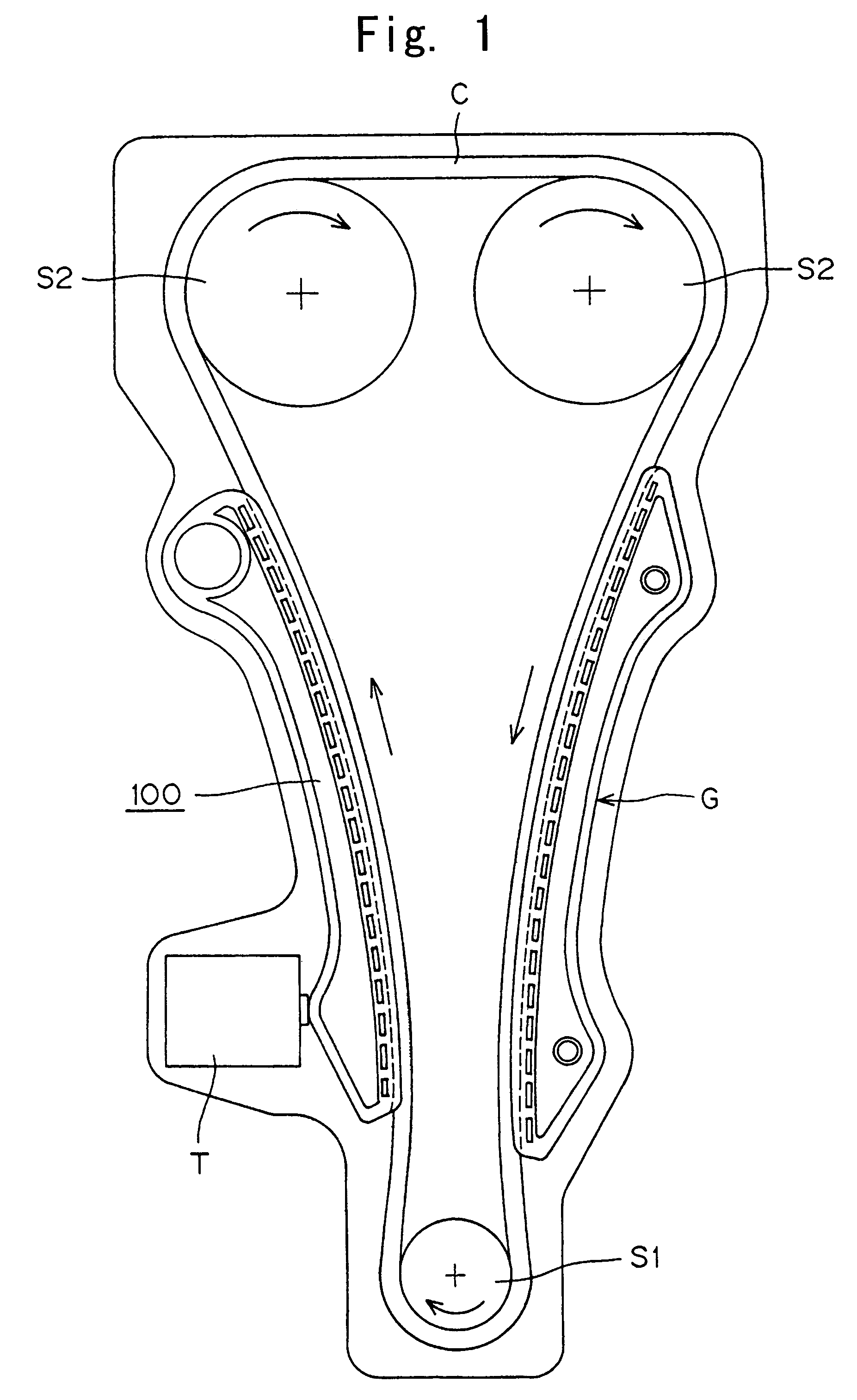

Ammunition Magazine

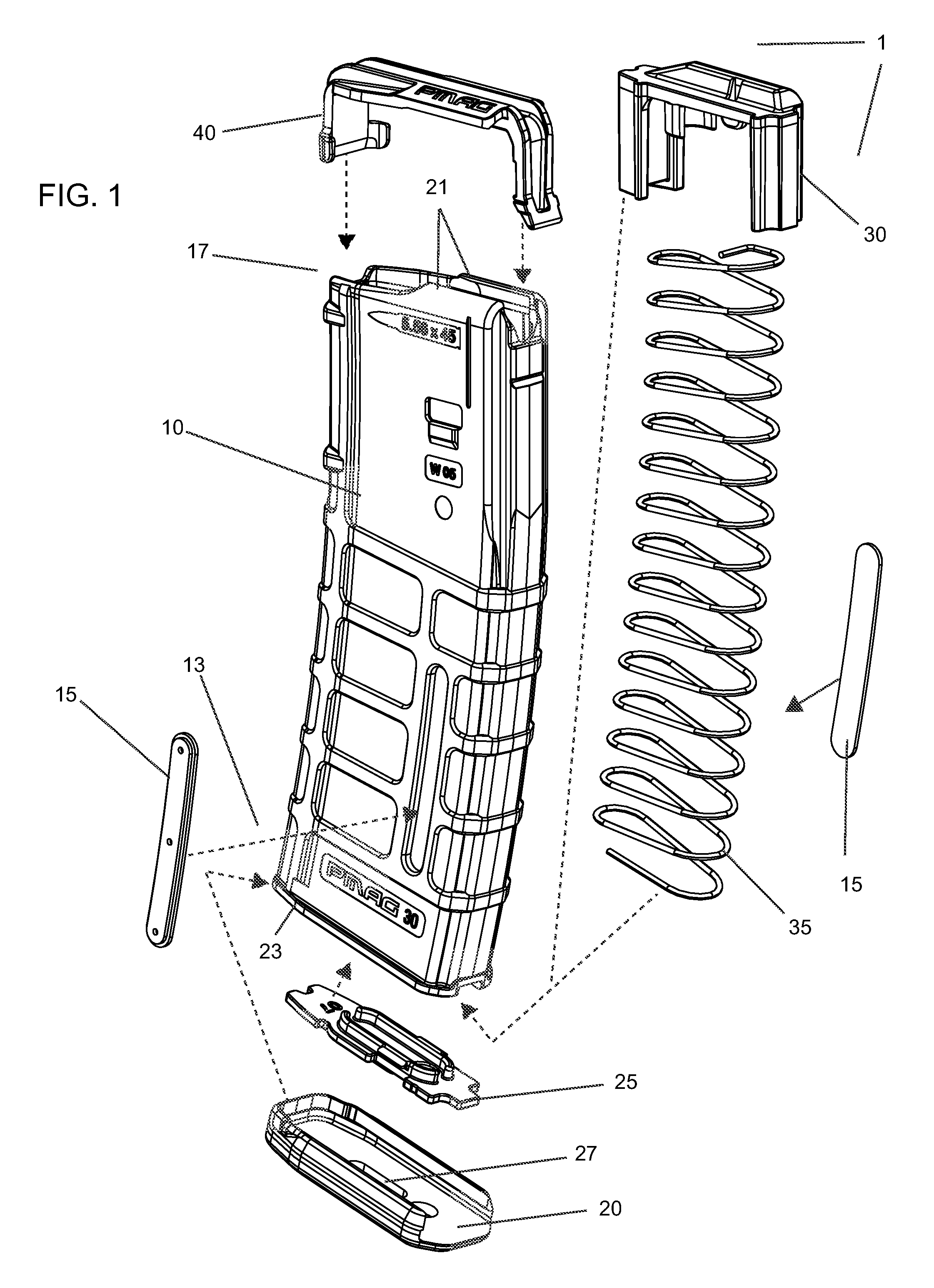

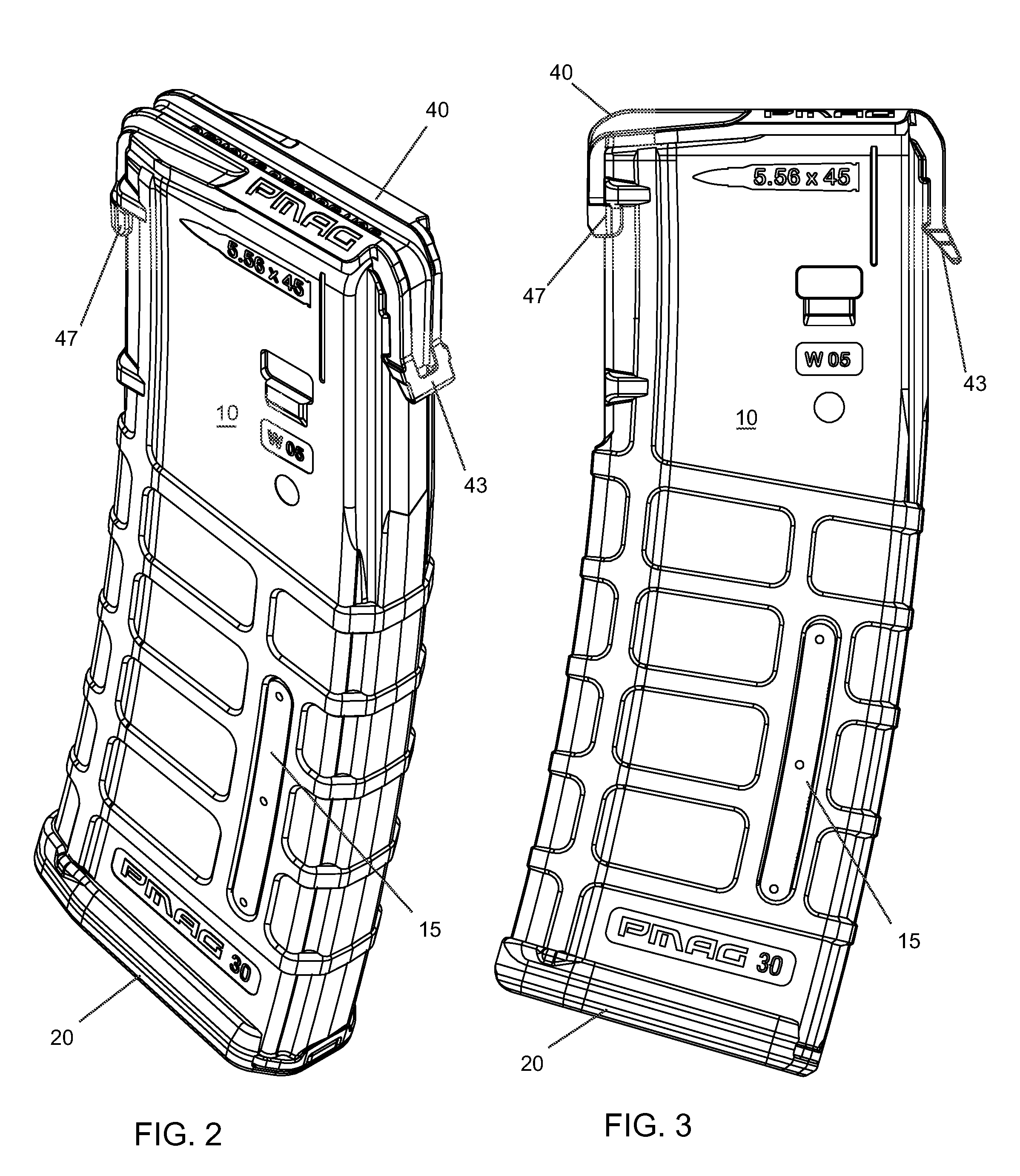

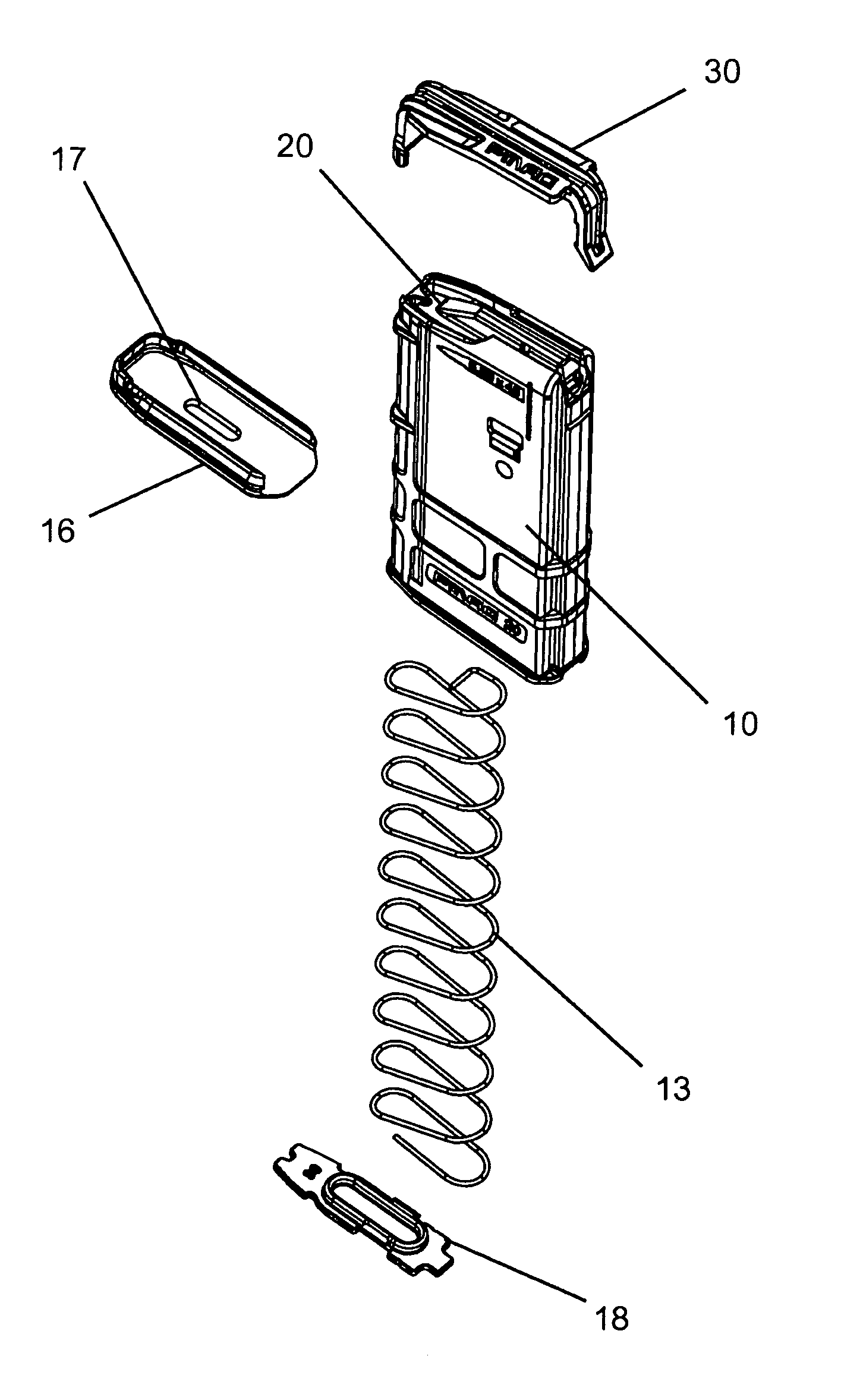

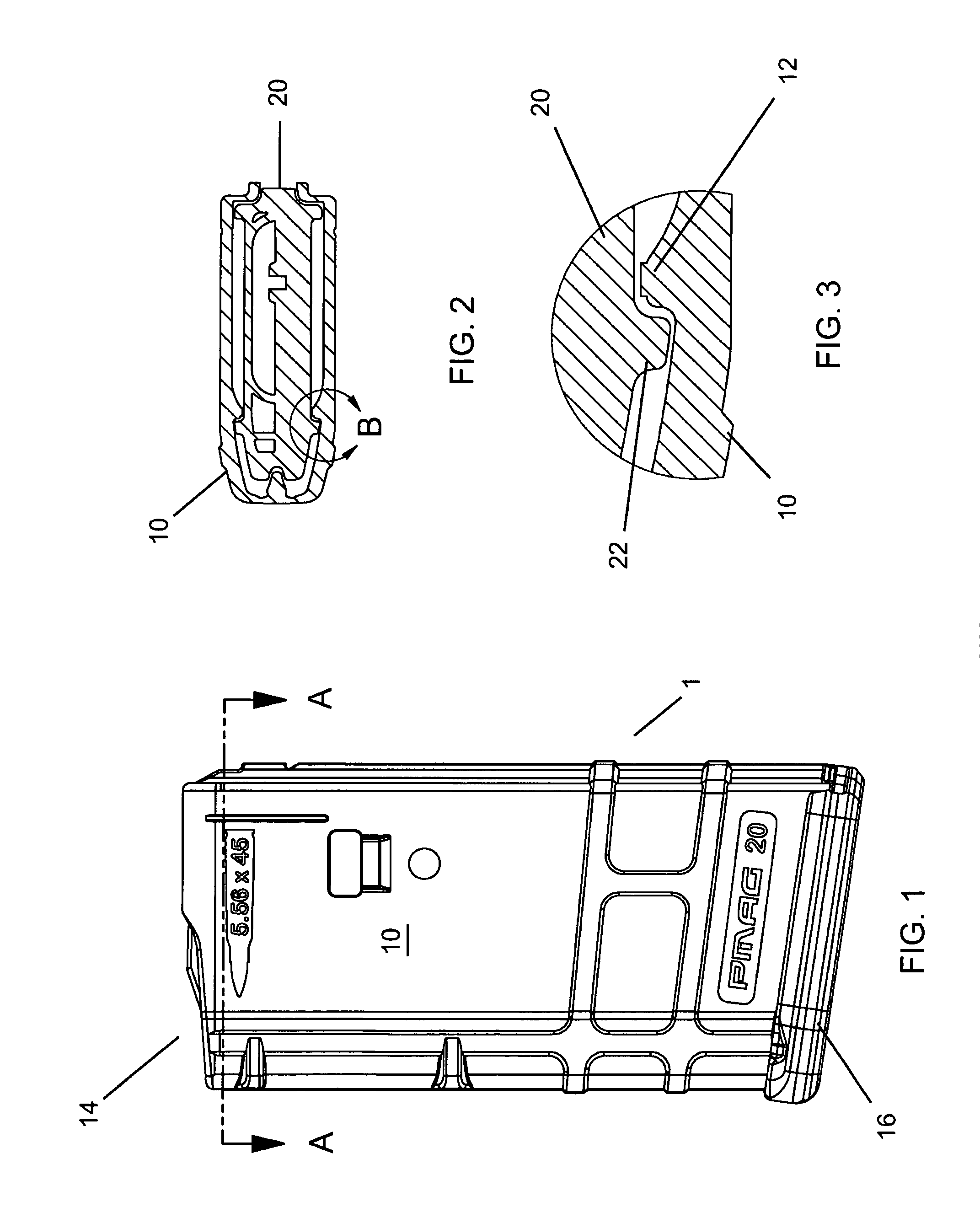

ActiveUS20100251590A1Stable follower follower pathStable follower and follower pathAmmunition loadingGlass fiber reinforced polymerEngineering

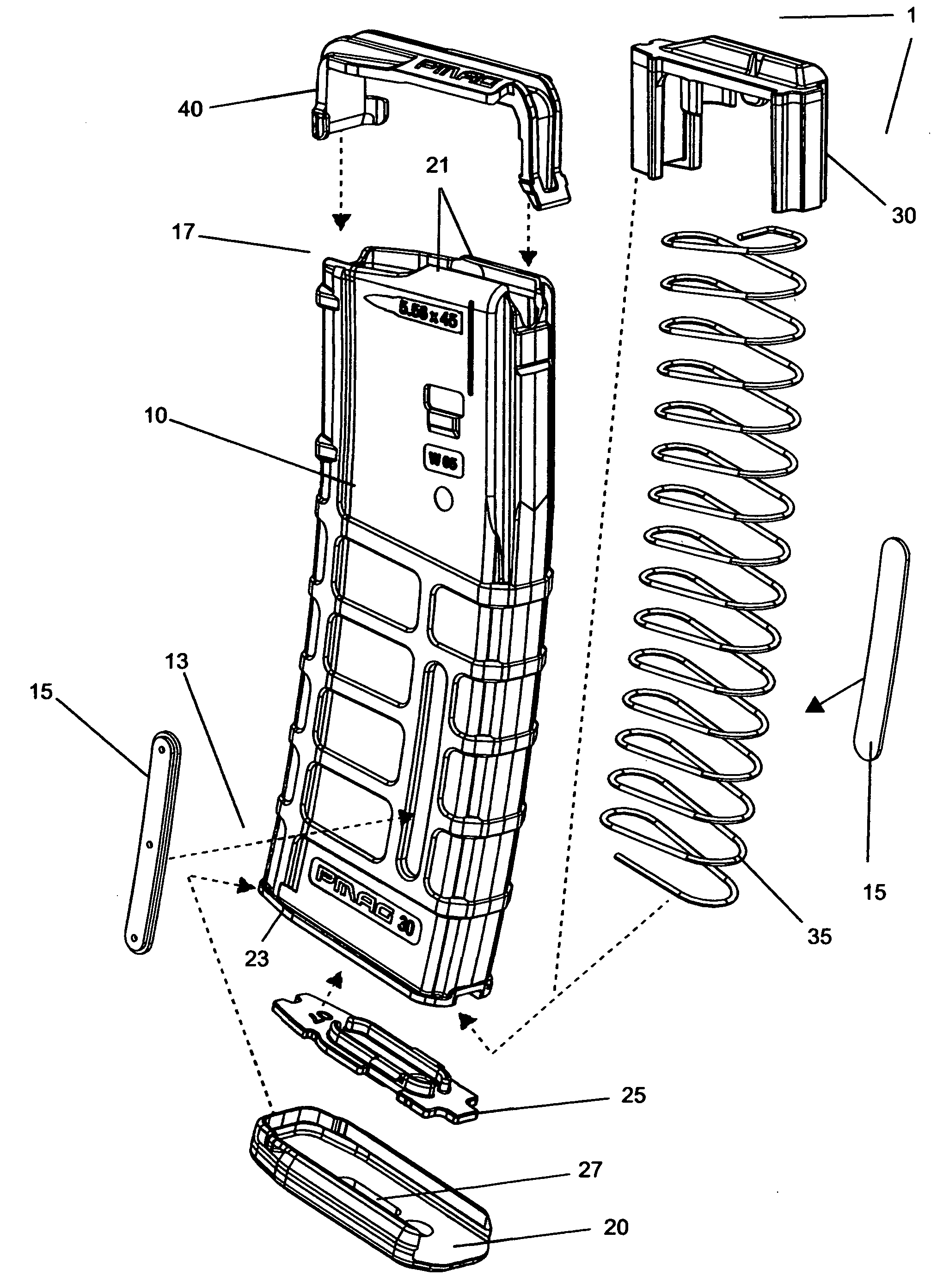

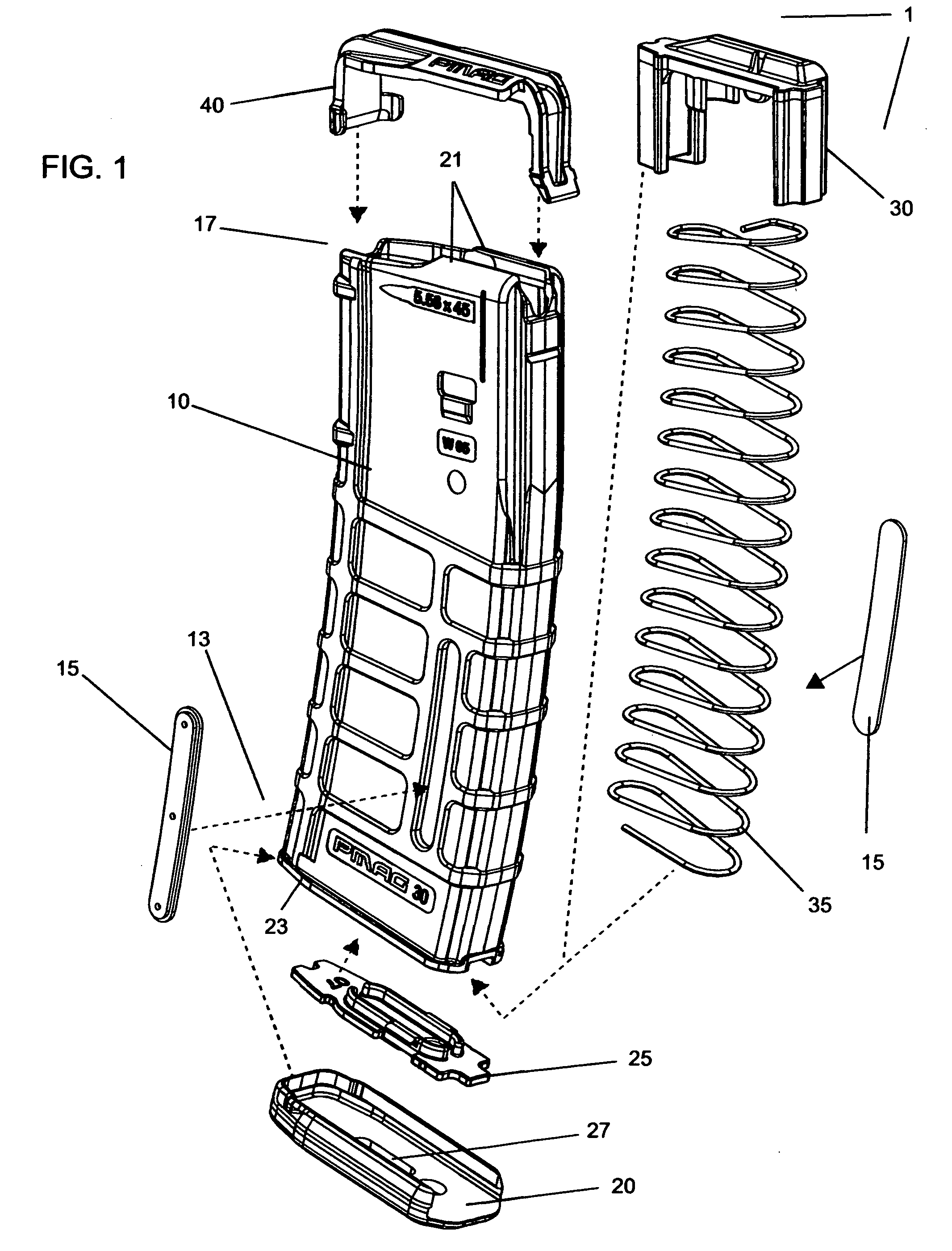

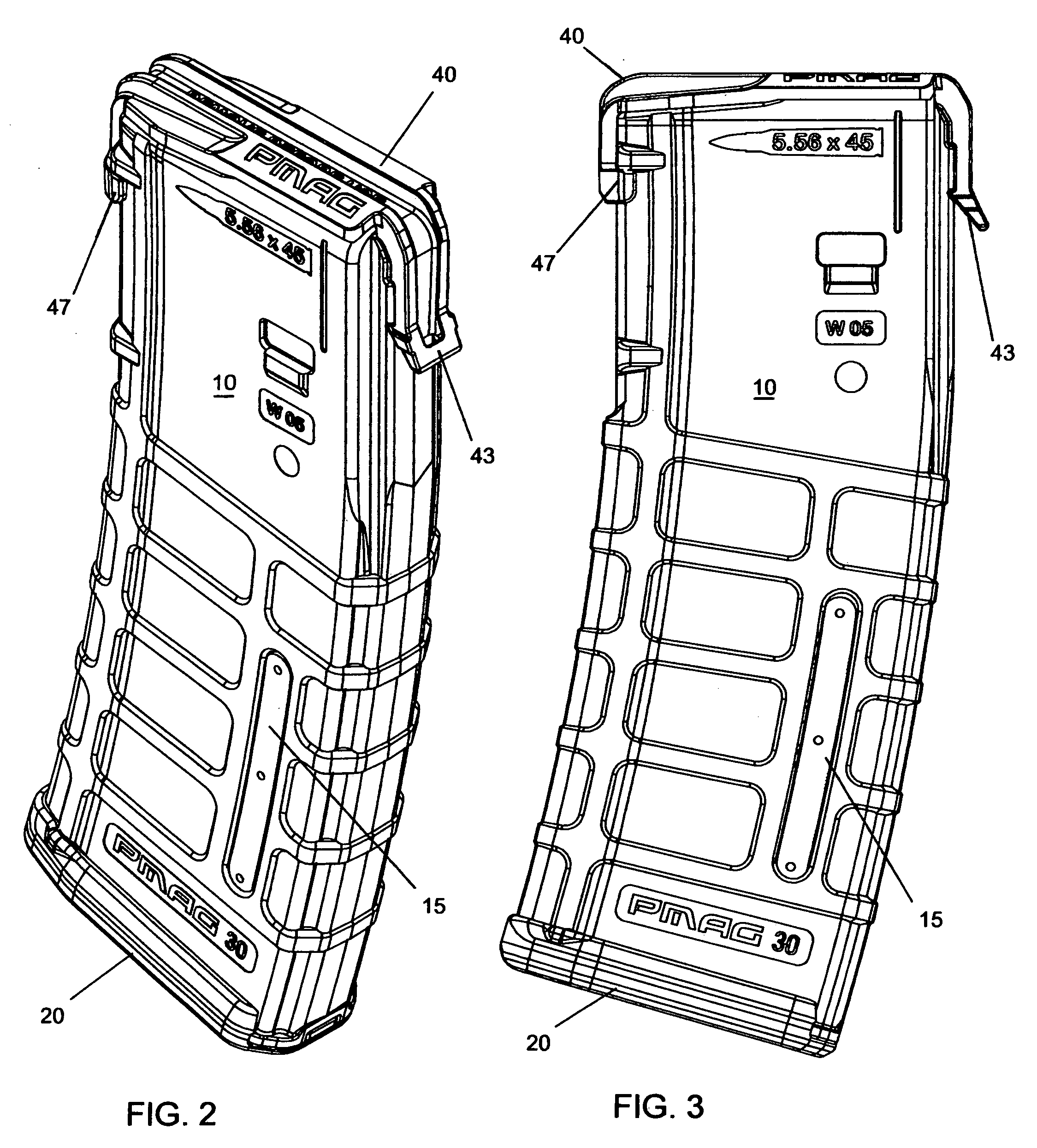

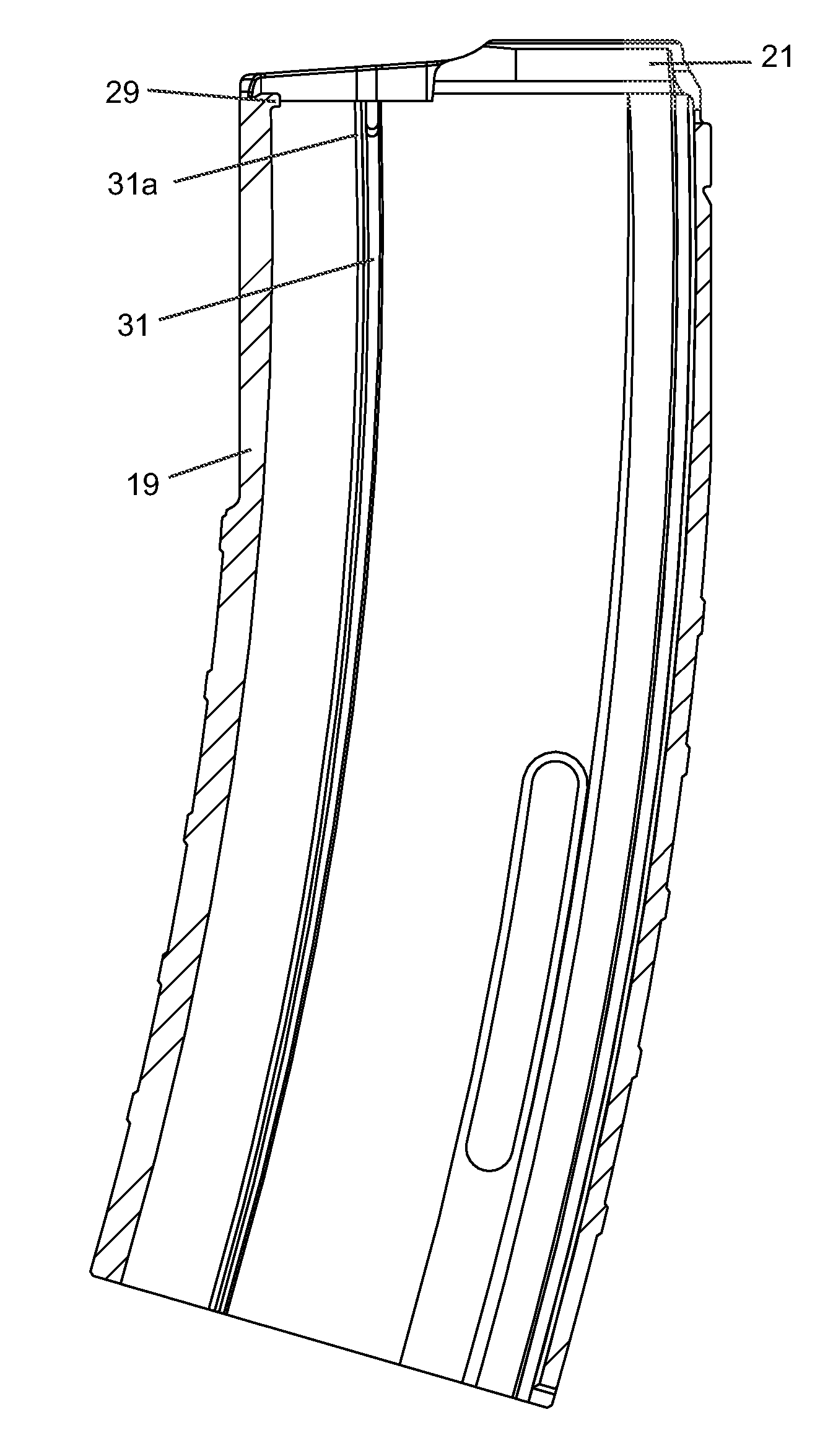

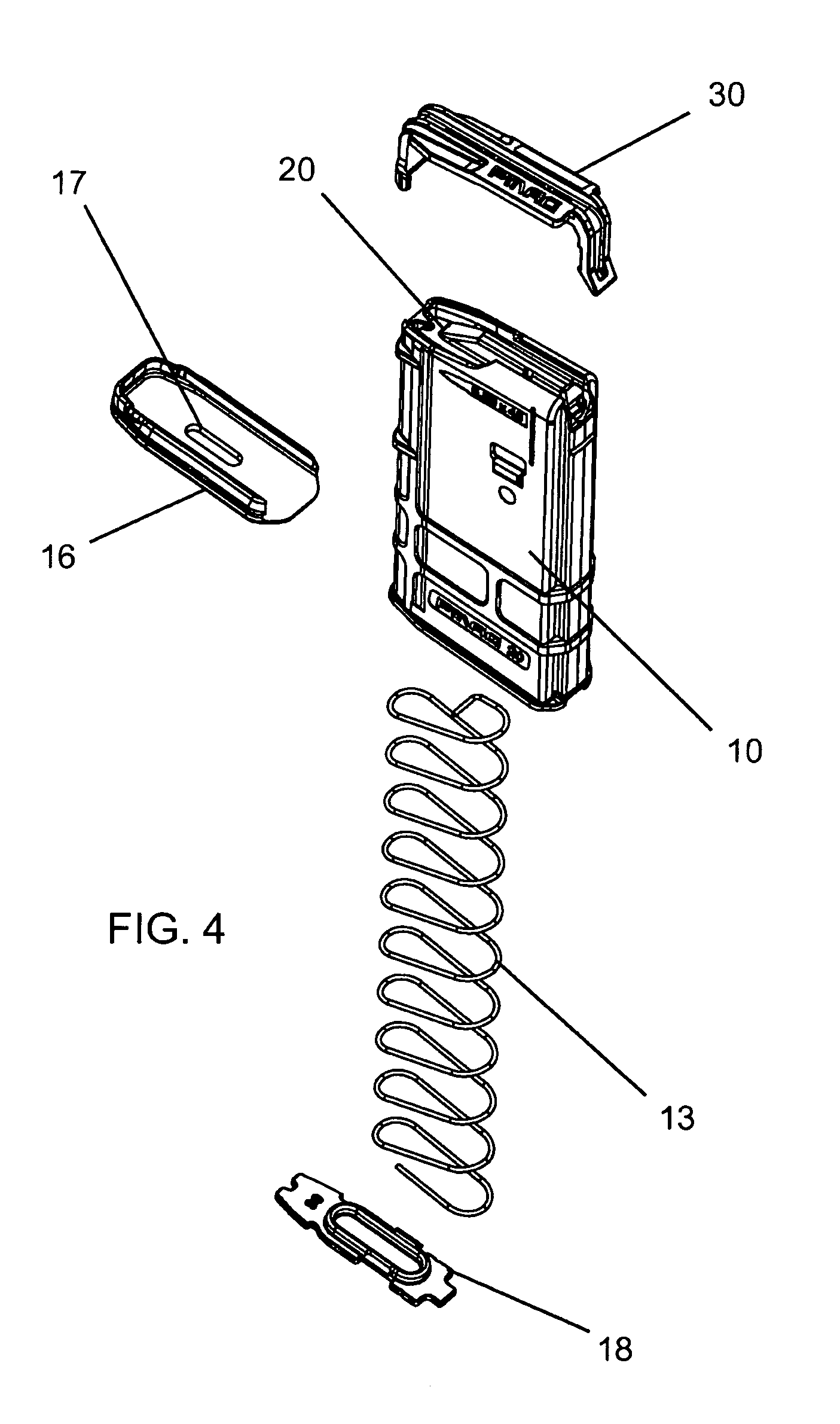

The present invention is an ammunition magazine, preferably made of a glass fiber reinforced polymer, utilizing a structurally enhancing ridge, angular guide rails and a follower made to interface with said guide rails to reduce wobble. The preferred embodiment also features a protective cover that distributes forces from the spring to more structurally sound areas of the magazine, thus reducing feed end splay, and an ammunition indication system comprised of at least one window and a noticeable marker on the follower spring. The follower and magazine casing are also designed to interface to prevent the follower from popping out of the feed end and the floor plate of the magazine utilizes a locking plate and sliding relationship between the floor plate, locking plate and magazine to secure the floor plate onto the magazine casing. The cover features built in tools for, among other things, unloading and disassembling the magazine.

Owner:MAGPUL INDUSTRIES

Ammunition magazine

ActiveUS8069601B1Stable follower and follower pathAmmunition loadingGlass fiber reinforced polymerEngineering

The present invention is an ammunition magazine, preferably made of a glass fiber reinforced polymer, utilizing a structurally enhancing ridge, angular guide rails and a follower made to interface with said guide rails to reduce wobble. The preferred embodiment also features a protective cover that distributes forces from the spring to more structurally sound areas of the magazine, thus reducing feed end splay, and an ammunition indication system comprised of at least one window and a noticeable marker on the follower spring. The follower and magazine casing are also designed to interface to prevent the follower from popping out of the feed end and the floor plate of the magazine utilizes a locking plate and sliding relationship between the floor plate, locking plate and magazine to secure the floor plate onto the magazine casing. The cover features built in tools for, among other things, unloading and disassembling the magazine.

Owner:MAGPUL INDUSTRIES

Ammunition magazine

ActiveUS20110005113A1Solve large capacityStable follower and follower pathAmmunition loadingGlass fiber reinforced polymerEngineering

The present invention is an ammunition magazine, preferably made of a glass fiber reinforced polymer, utilizing a structurally enhancing ridge, angular guide rails and a follower made to interface with said guide rails to reduce wobble. The preferred embodiment also features a protective cover that distributes forces from the spring to more structurally sound areas of the magazine, thus reducing feed end splay, and may include an ammunition indication system comprised of at least one window and a noticeable marker on the follower spring. The follower and magazine casing are also designed to interface to prevent the follower from popping out of the feed end and the floor plate of the magazine utilizes a locking plate and sliding relationship between the floor plate, locking plate and magazine to secure the floor plate onto the magazine casing.

Owner:MAGPUL INDUSTRIES

Drive shaft for a surgical reamer

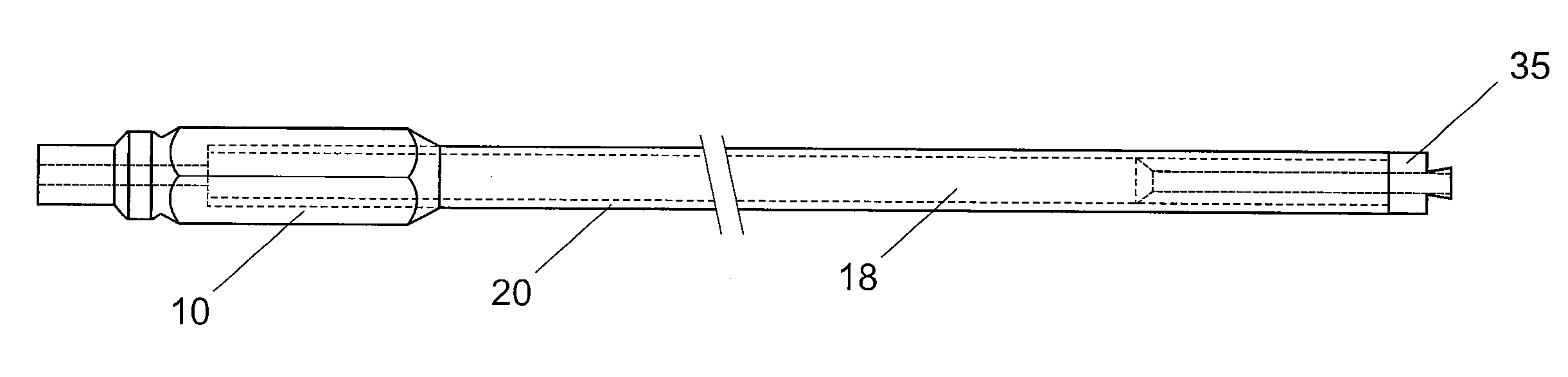

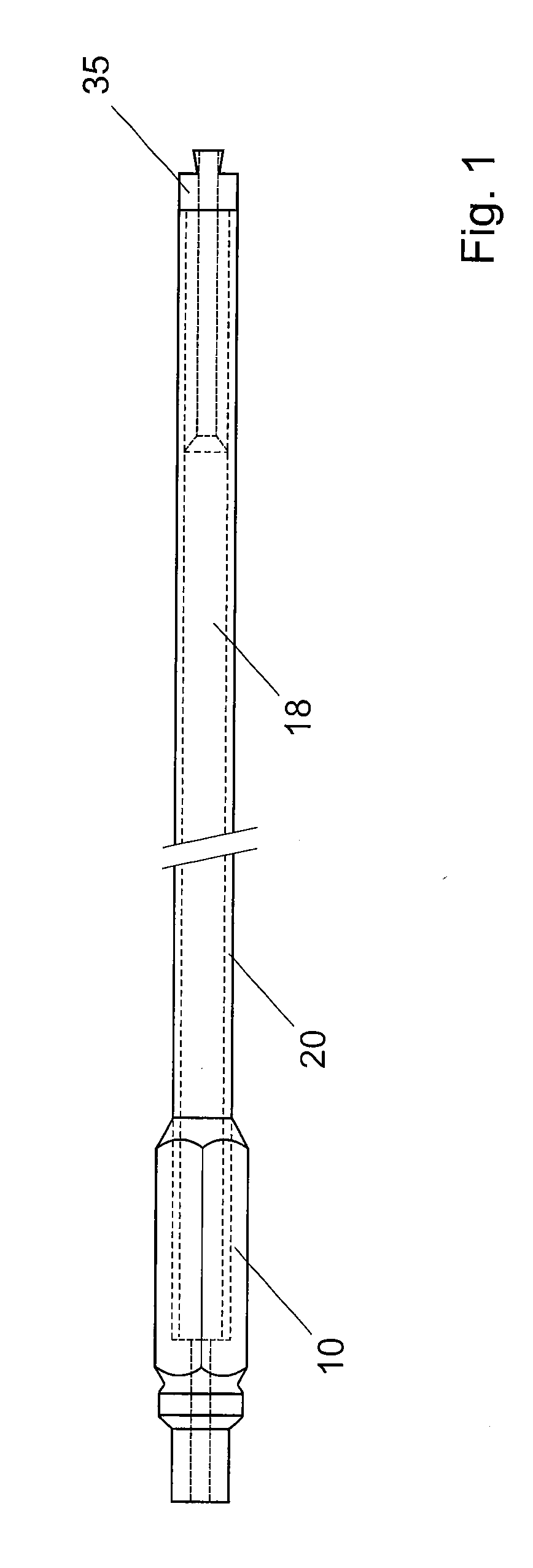

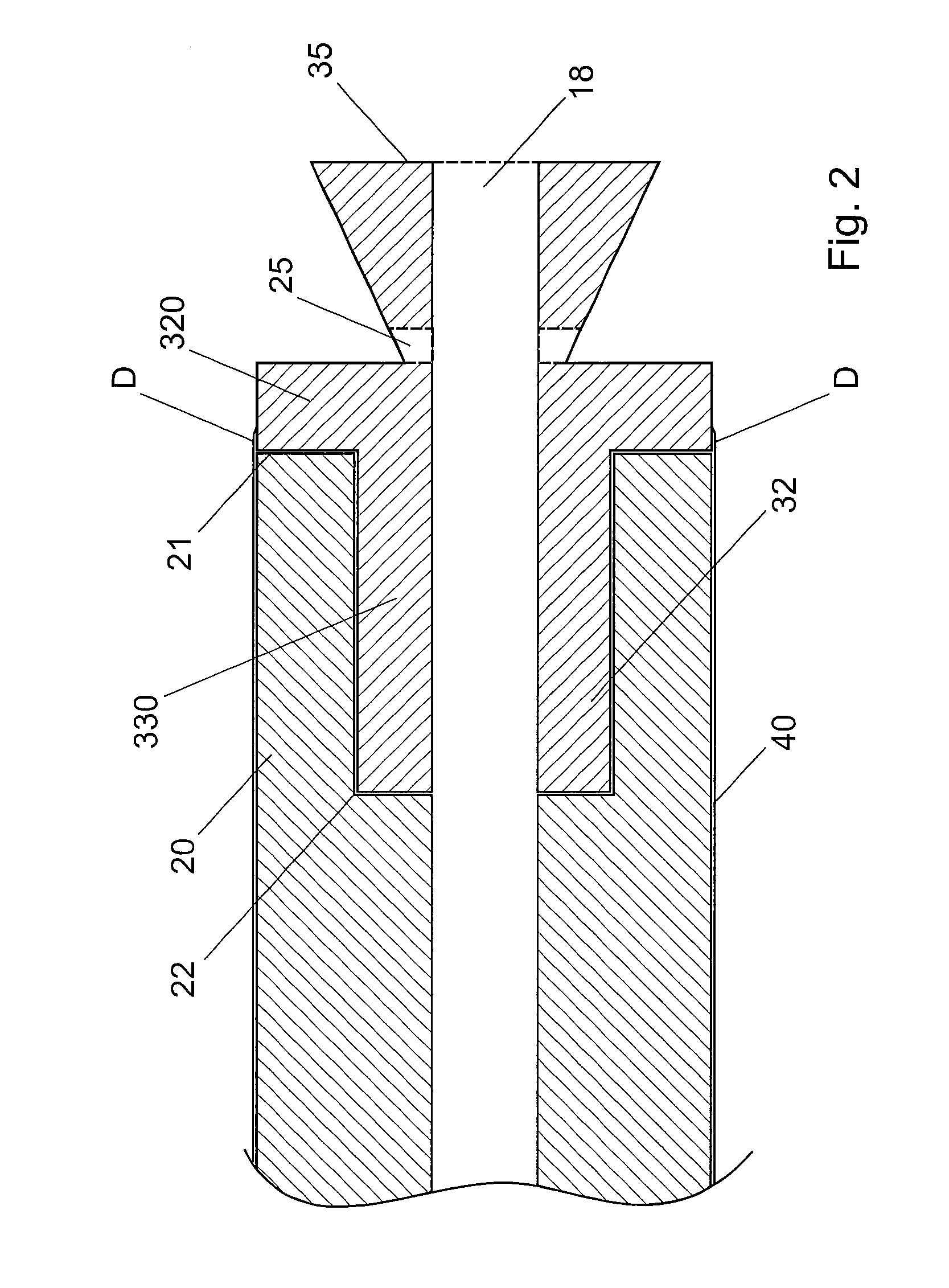

InactiveUS20120253348A1Lighter and less-expensiveDifficulty costThread cutting auxillary apparatusSurgeryGlass fiber reinforced polymerCoupling

Drive shaft for interchangeable reaming heads intended for surgical use, in particular a reaming head used prior to the positioning of an intramedullary nail in the femur or in a long bone. The shaft has a rod (20) made from composite material, e.g. carbon and / or glass fiber reinforced polymer, and a connection element (35) for the coupling of an interchangeable reaming head. One portion (32) of said connection element (35) is inserted into a cavity in the first end (21) of said rod (20). The inventive shaft has a constant diameter, a smooth external surface and a low cost such that it can be disposed of after use.

Owner:CHIRMAT

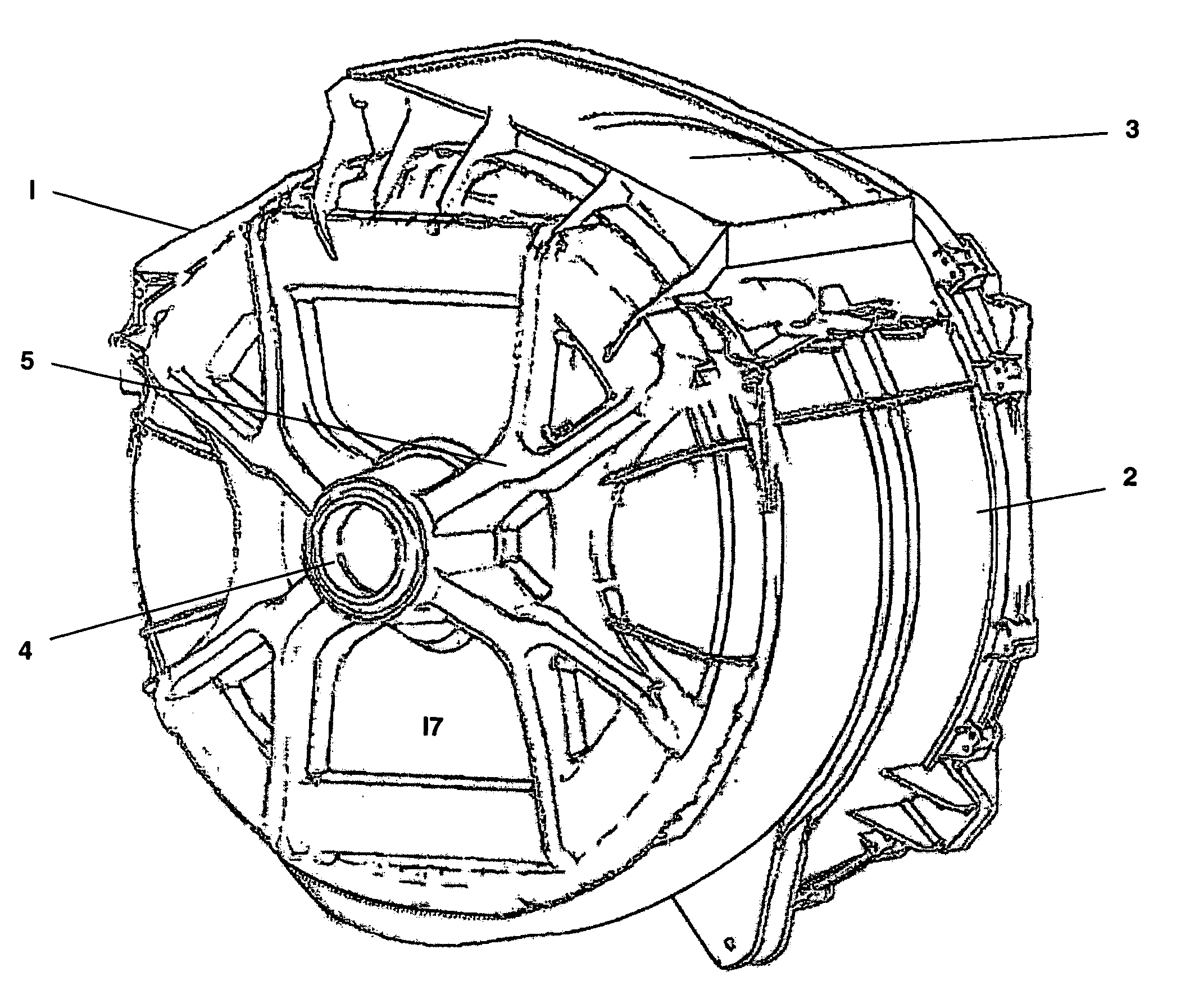

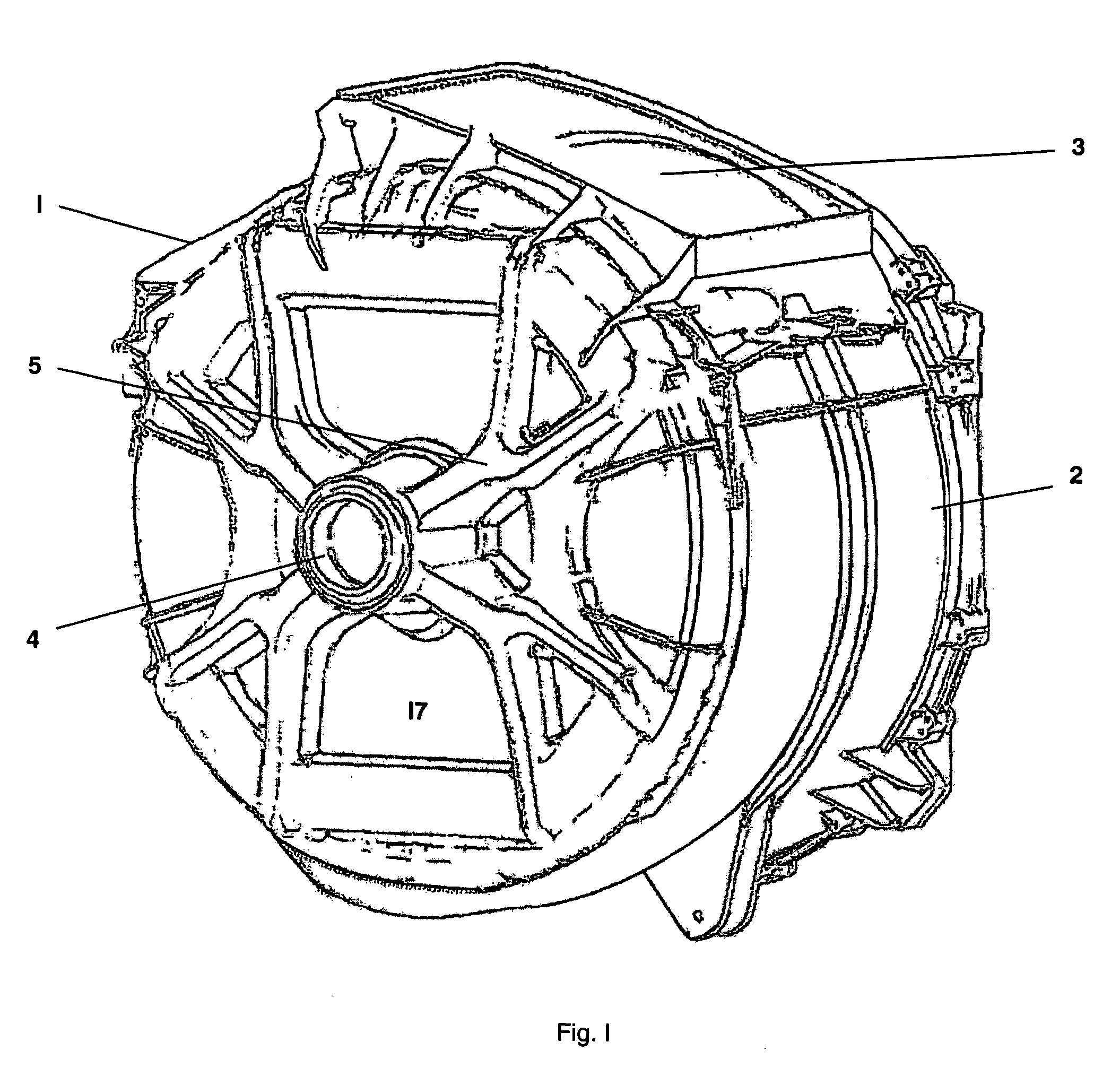

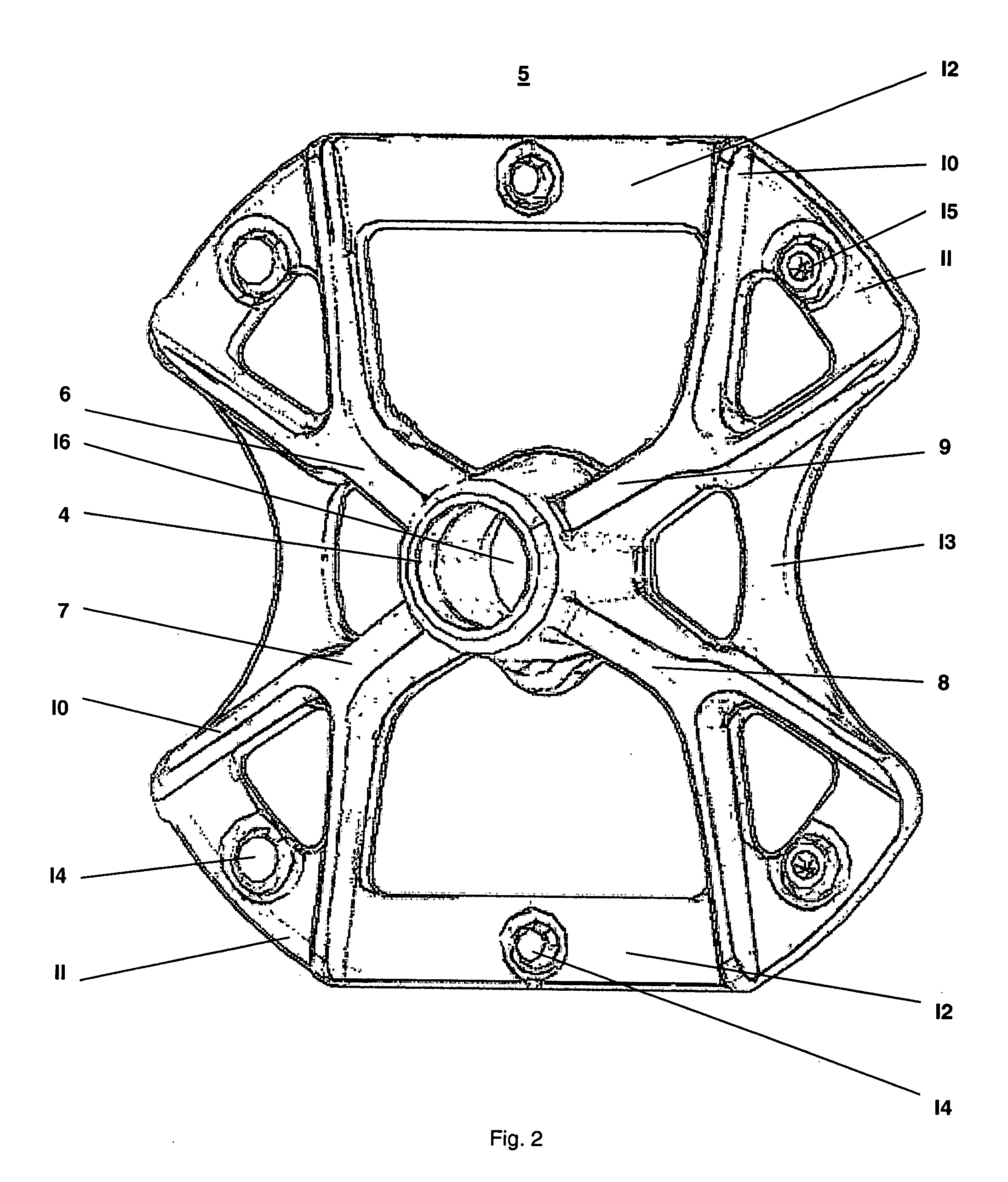

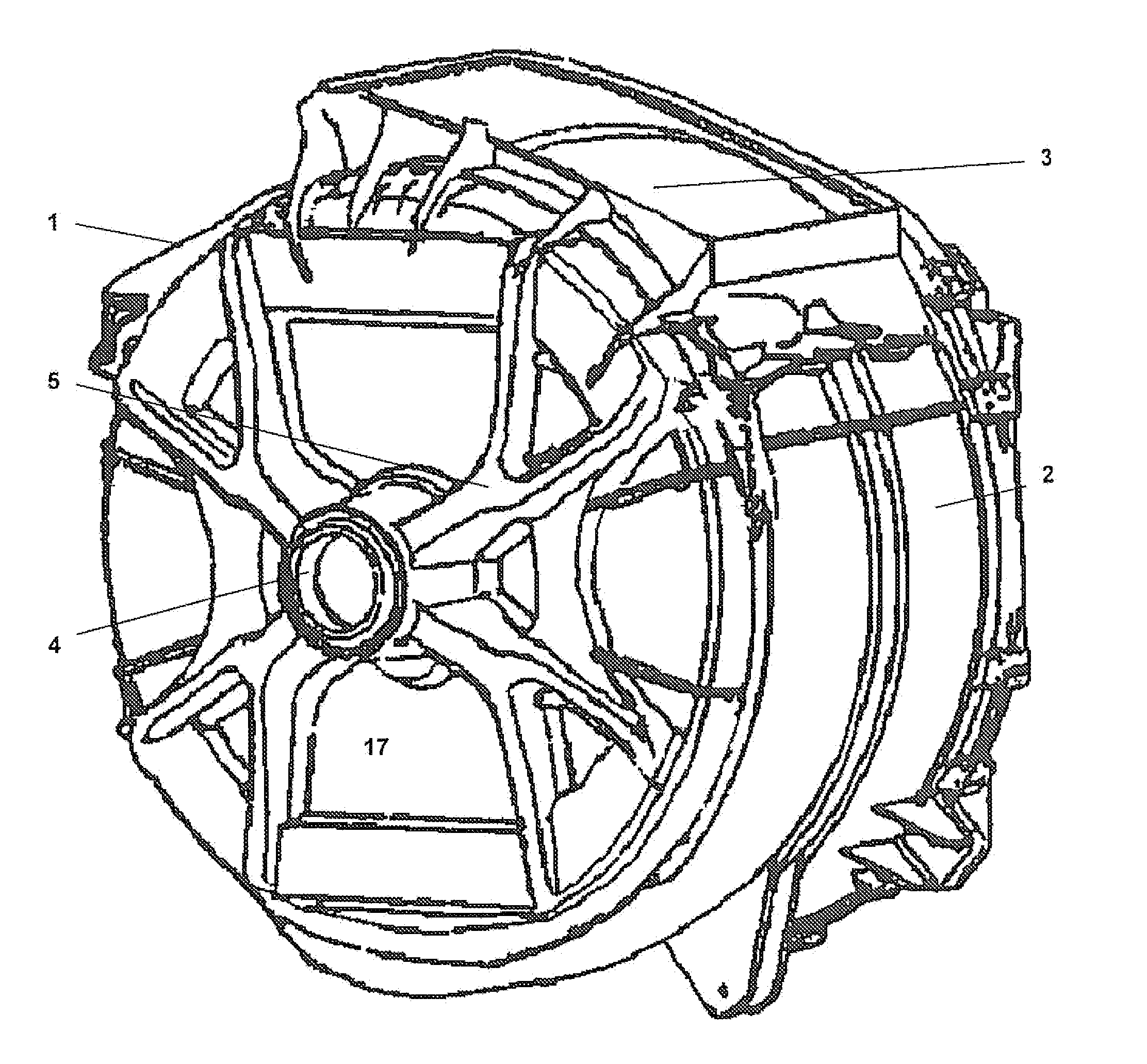

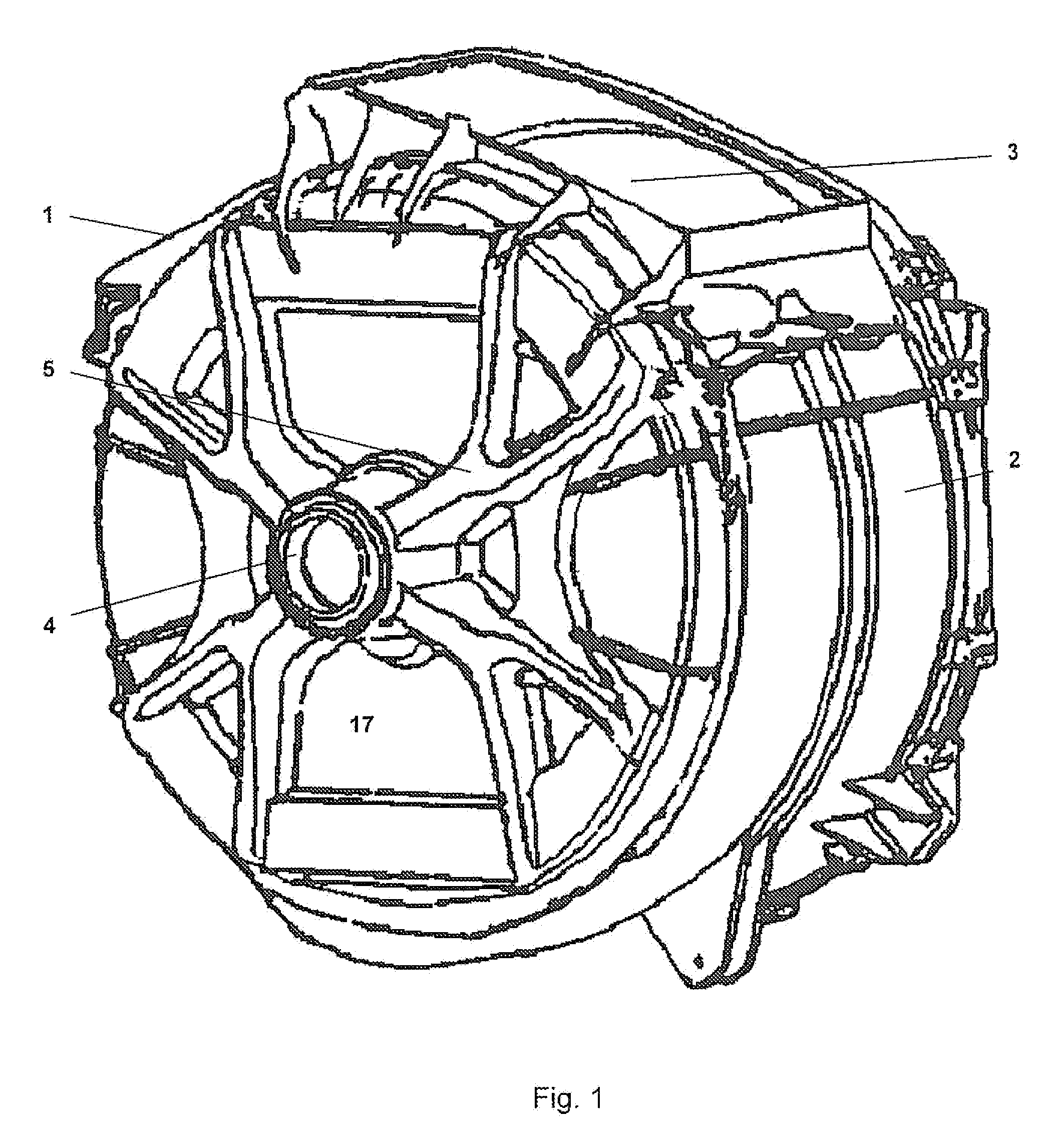

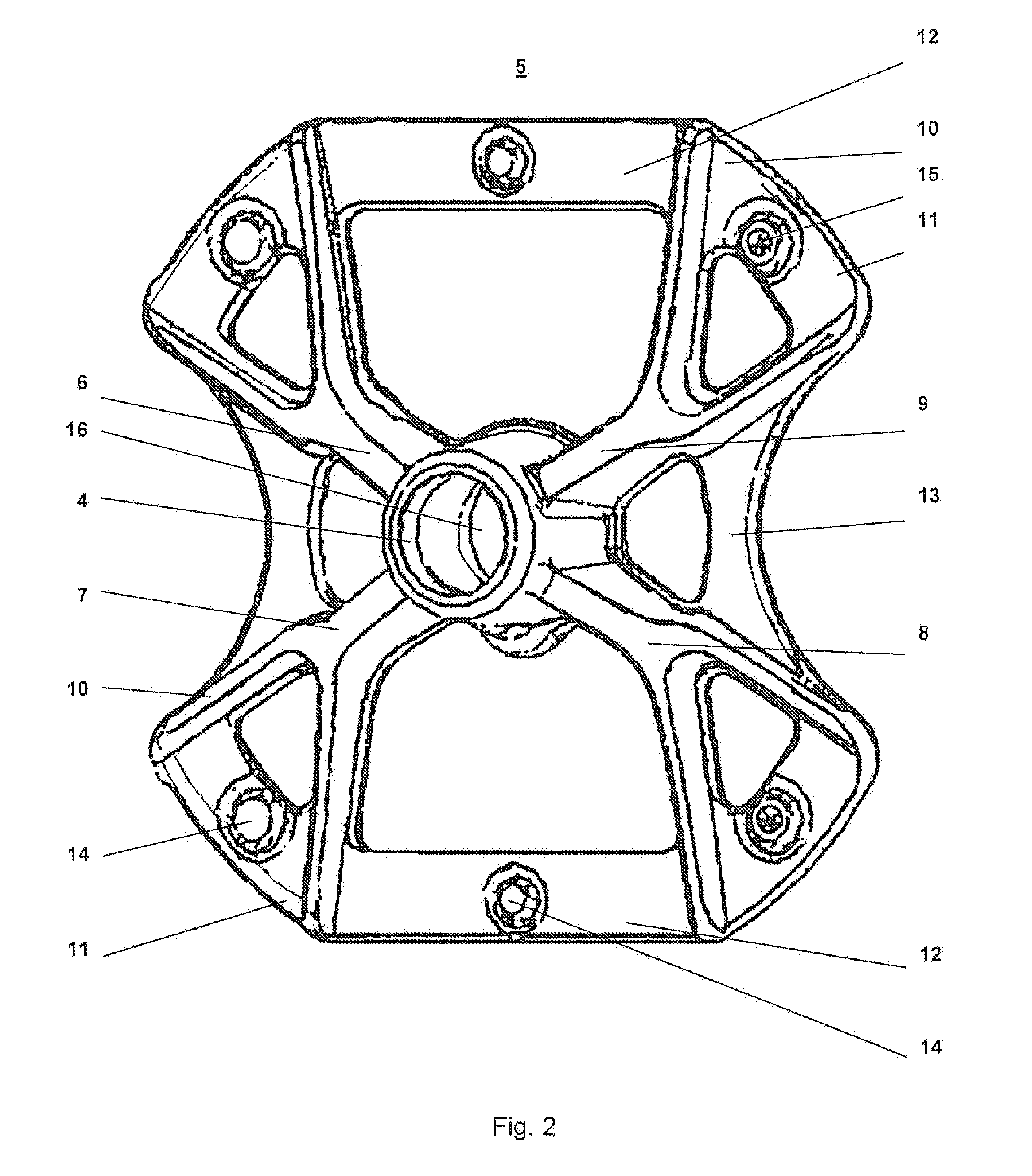

Aggregate for a washing machine with a plastic sudsing container

InactiveUS20050092034A1Safely dissipatedHigh strengthWringing machinesOther washing machinesGlass fiber reinforced polymerEngineering

An aggregate for a washing machine provided with a substantially hollow cylindrical suds container of fiberglass reinforced polymeric material and consisting of two end walls and a shell, a hollow cylindrical washing drum disposed in the suds container for rotation on a shaft about a non-vertical axis, and a unitary support structure embedded substantially completely in one of the end walls and with a bearing support adapted to receive the shaft and at least one arm extending radially from the bearing support.

Owner:MIELE & CIE KG

Ammunition magazine

ActiveUS20110302816A1Stable follower and follower pathAmmunition loadingGlass fiber reinforced polymerClassical mechanics

The present invention is an ammunition magazine, preferably made of a glass fiber reinforced polymer, utilizing a structurally enhancing ridge, angular guide rails and a follower made to interface with said guide rails to reduce wobble. The preferred embodiment also features a protective cover that distributes forces from the spring to more structurally sound areas of the magazine, thus reducing feed end splay, and an ammunition indication system comprised of at least one window and a noticeable marker on the follower spring. The follower and magazine casing are also designed to interface to prevent the follower from popping out of the feed end and the floor plate of the magazine utilizes a locking plate and sliding relationship between the floor plate, locking plate and magazine to secure the floor plate onto the magazine casing. The cover features built in tools for, among other things, unloading and disassembling the magazine.

Owner:MAGPUL INDUSTRIES

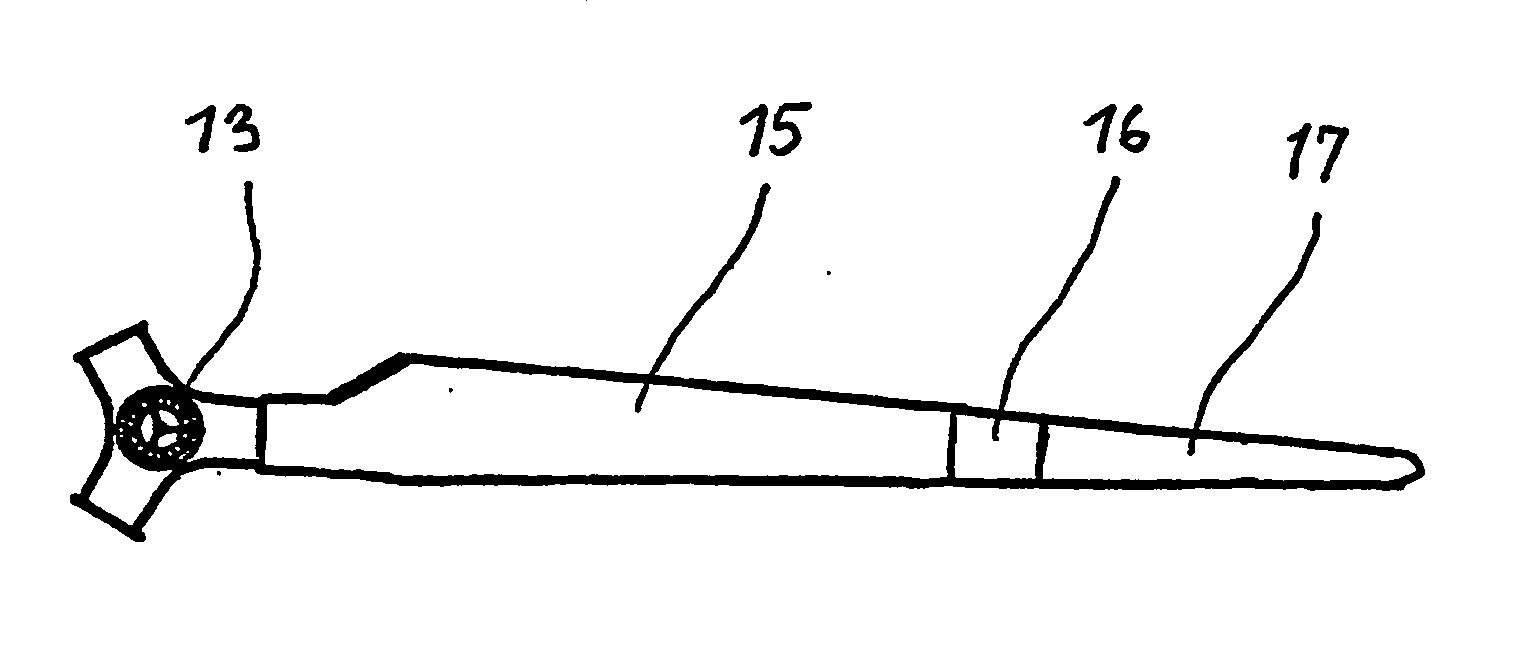

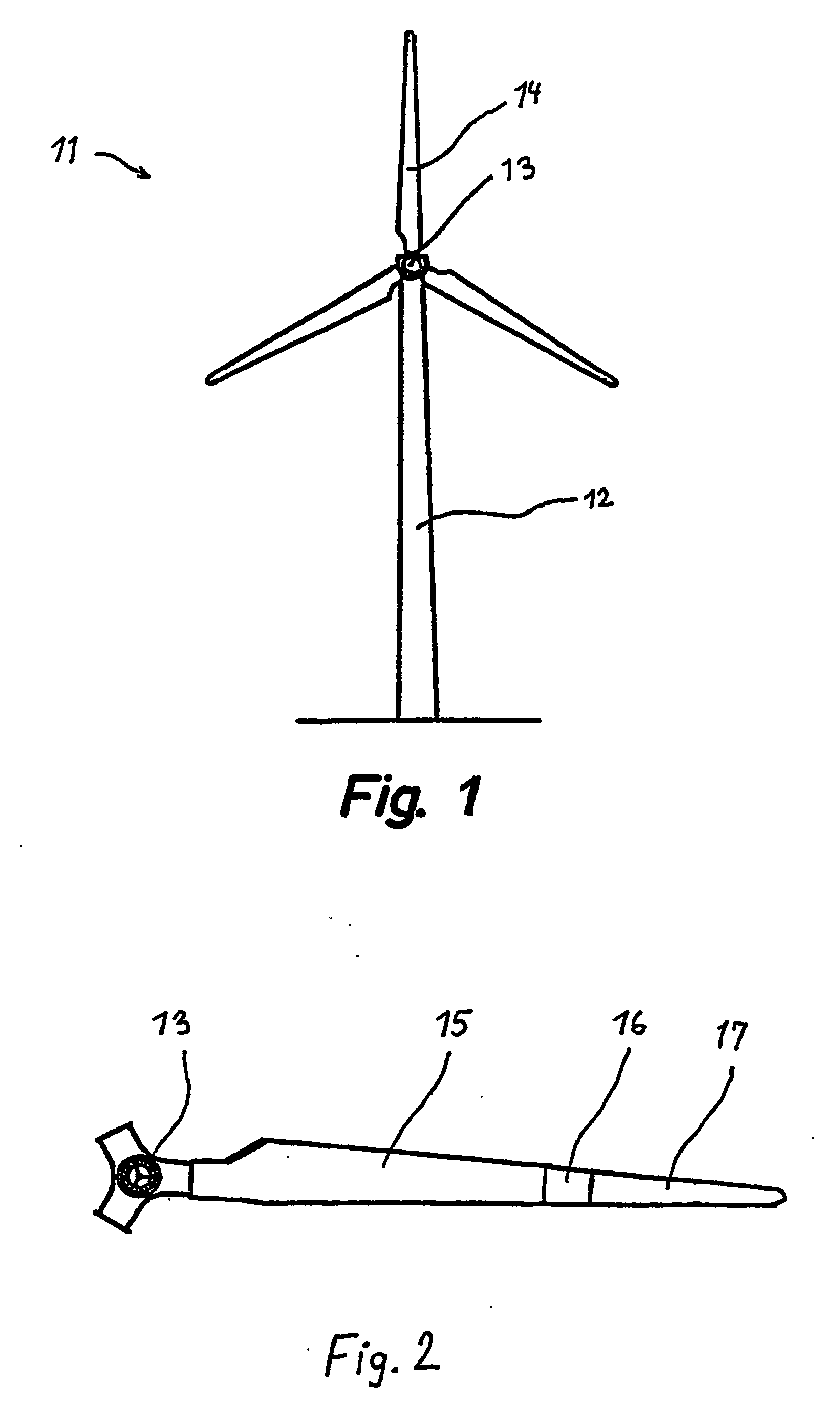

Wind turbine blade with carbon fibre tip

InactiveUS20050180853A1Increase stiffnessLow production costPropellersPump componentsGlass fiber reinforced polymerCarbon fibers

Owner:LM GLASSFIBER

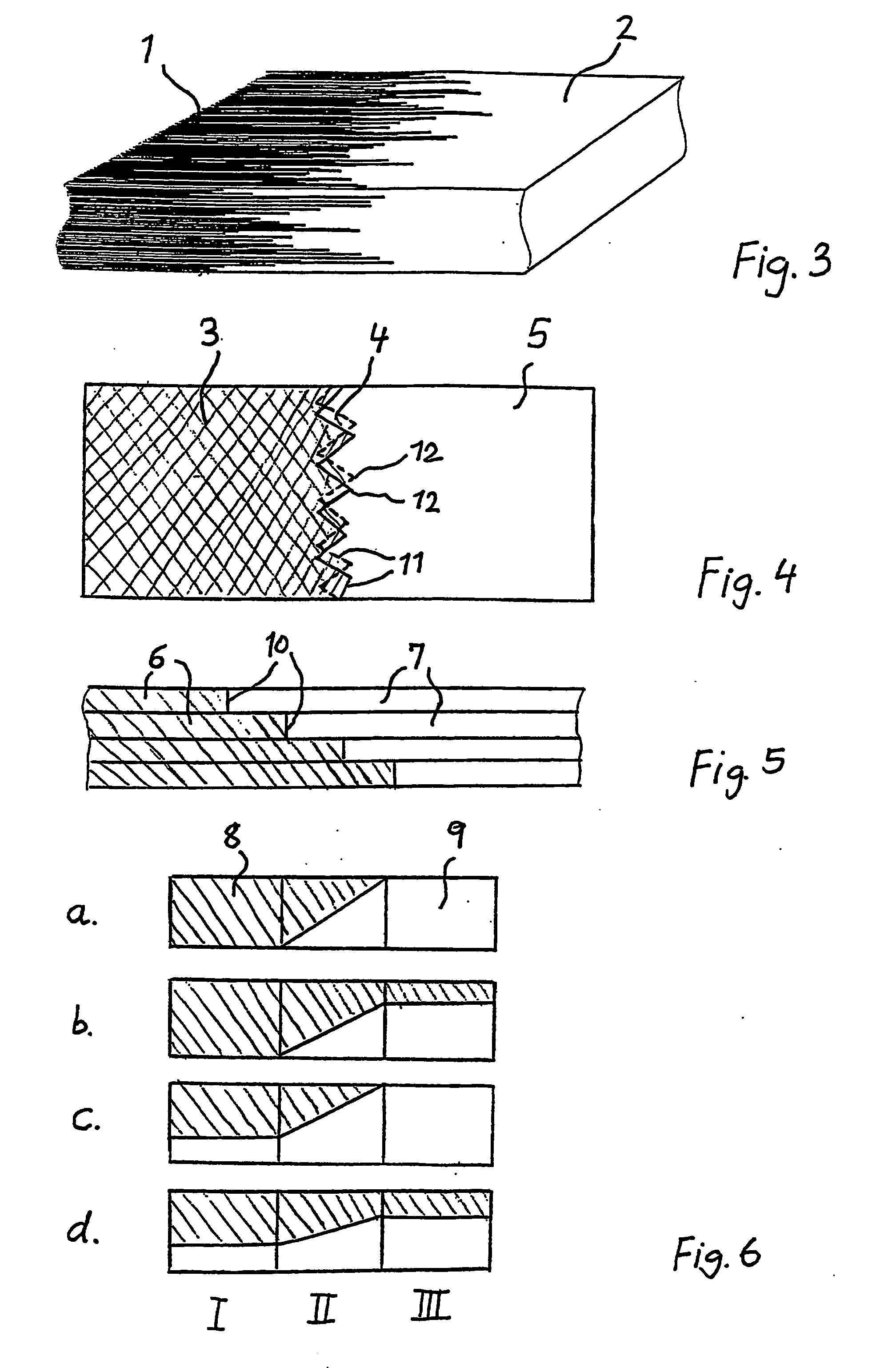

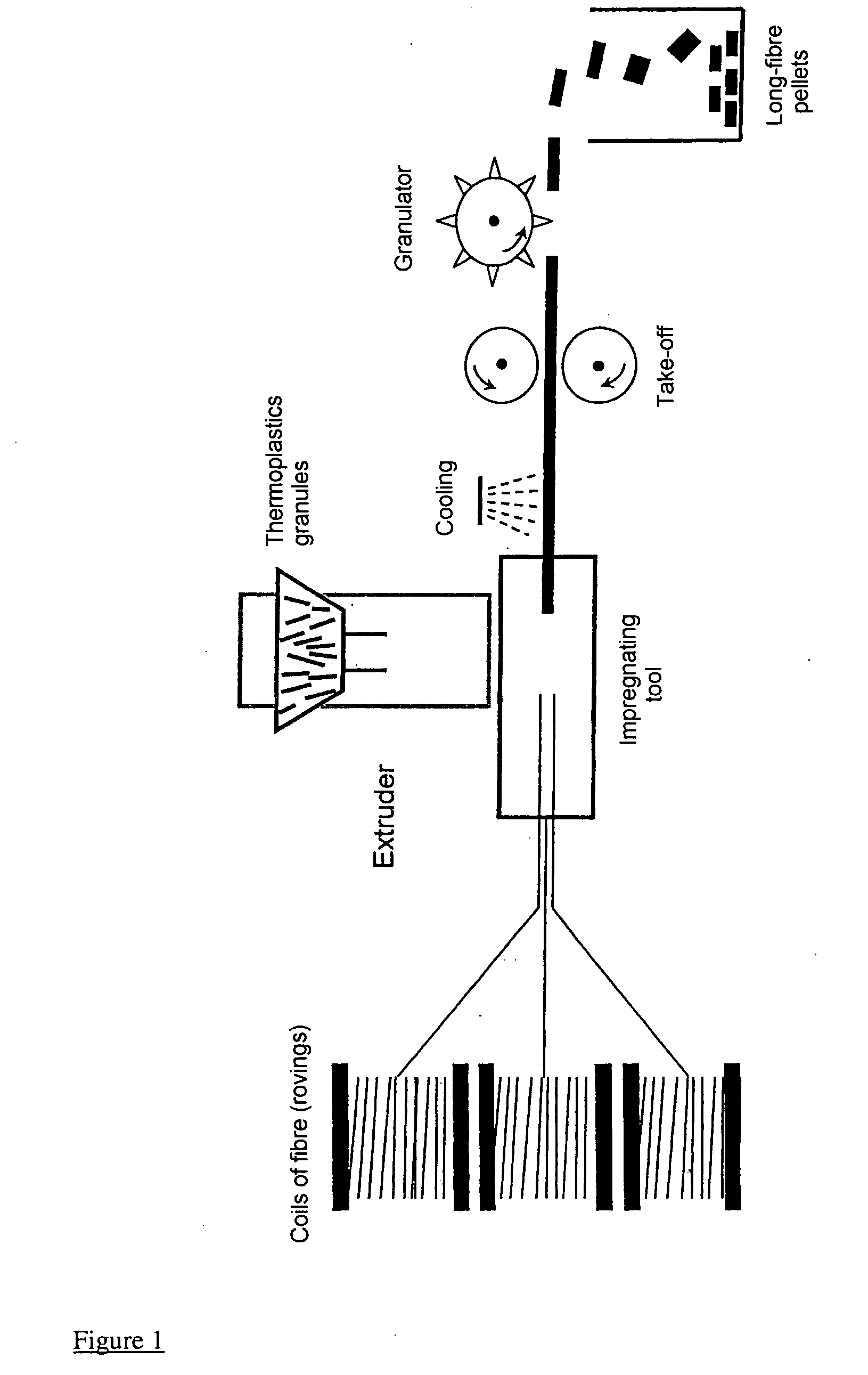

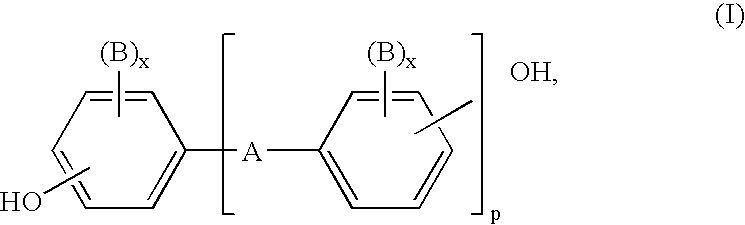

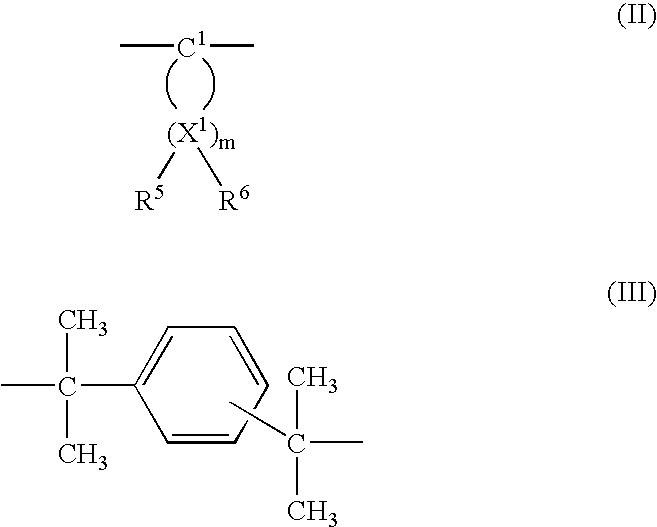

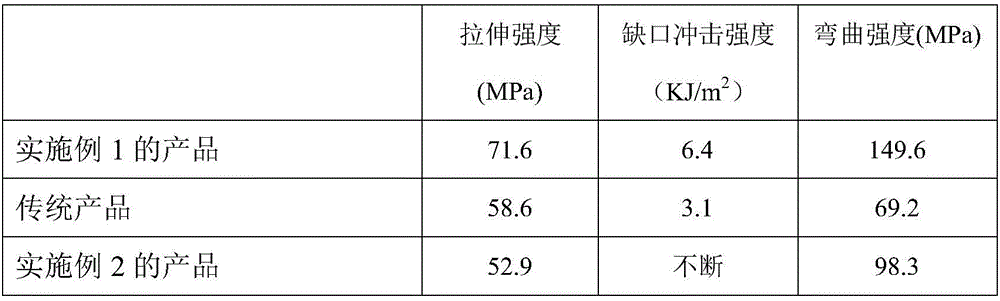

Glass-fiber-reinforced polymer compositions

InactiveUS20060094813A1Improve mechanical propertiesSpecial tyresCoatingsPolyesterGlass fiber reinforced polymer

A thermoplastic molding composition that contains long glass fibers is disclosed. The composition contain a) at least one polymer selected from the group consisting of polyamides, polycarbonates, polyester carbonates, graft polymers and copolymers, b) a terpolymer of styrene, acrylonitrile and maleic anhydride and c) long glass fibers, the diameter of the fiber filament being from 7 to 25 μm. The composition features improved mechanical properties.

Owner:BAYER MATERIALSCIENCE AG +1

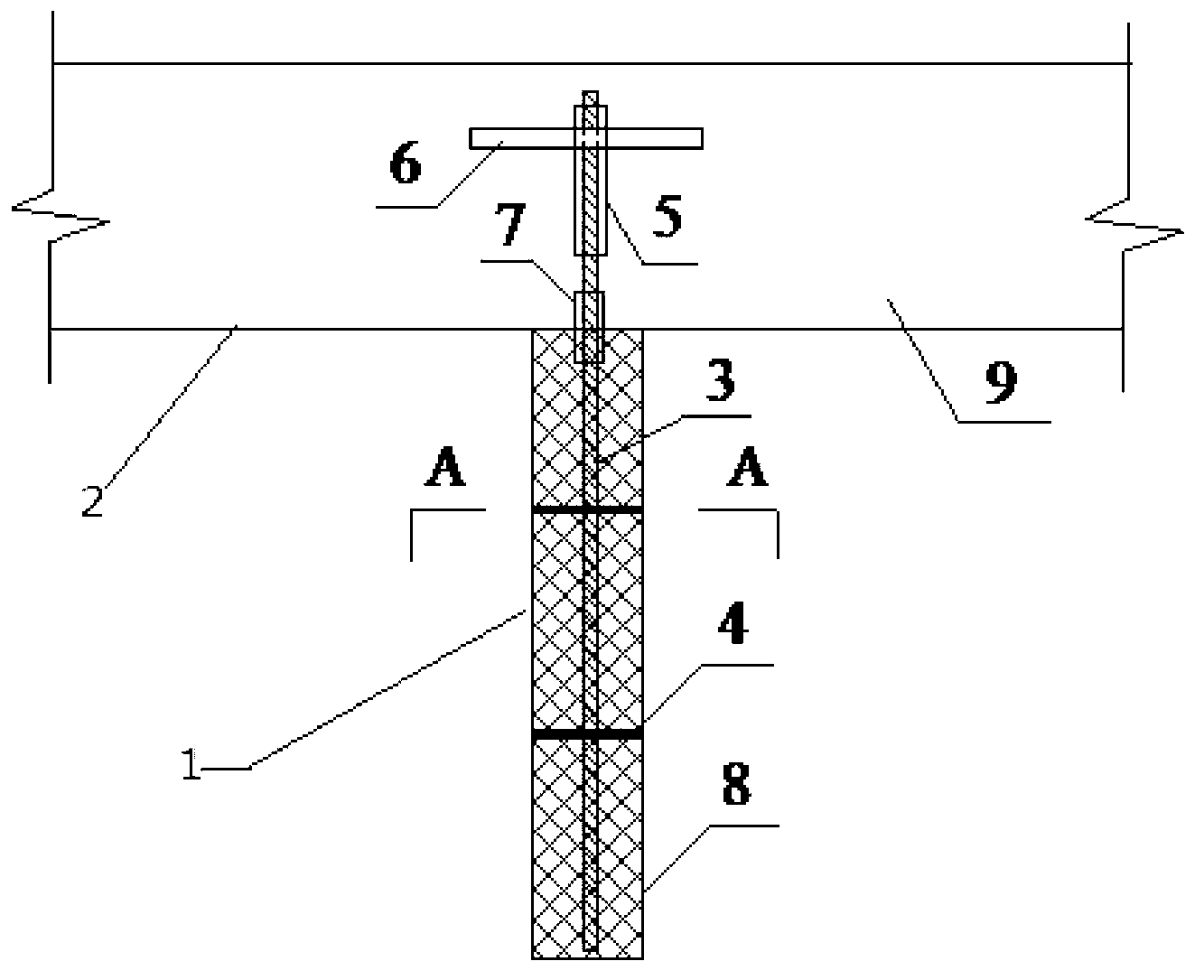

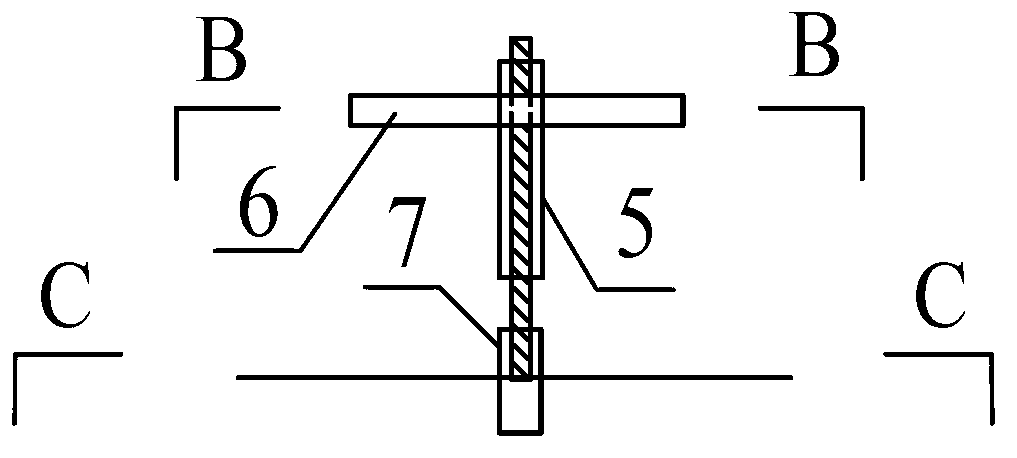

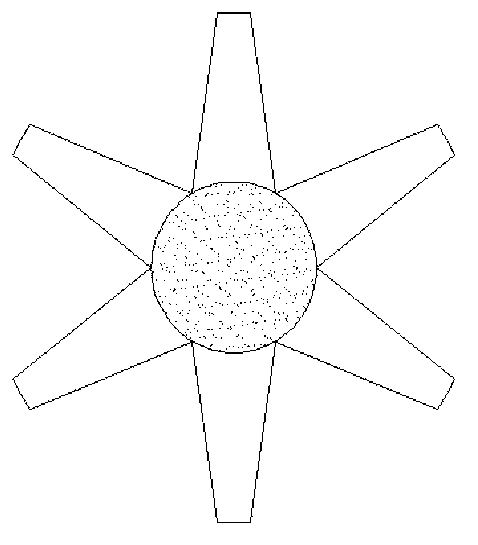

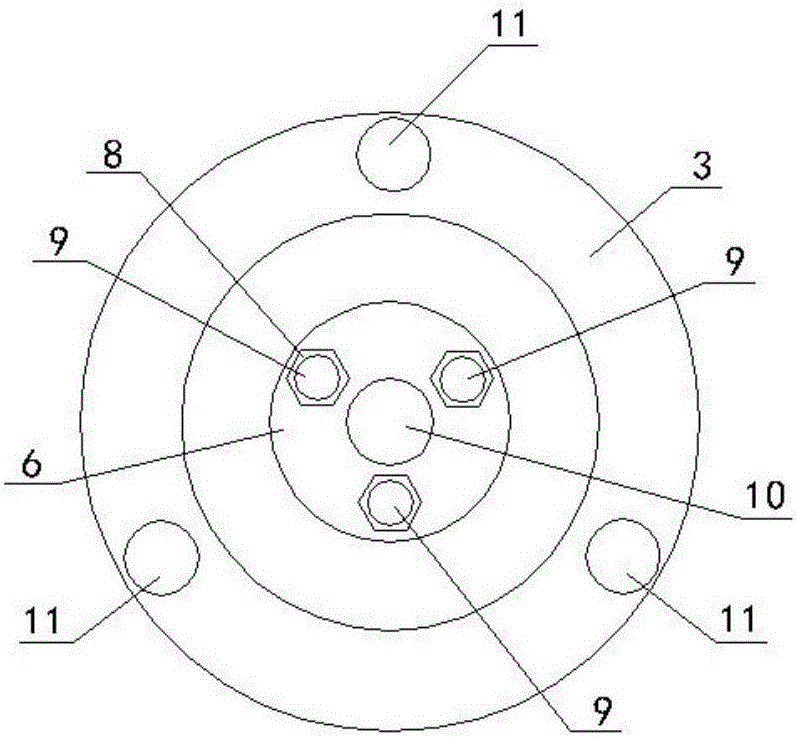

Shield end socket reinforcing system of scree soil layer advance large pipe roof and construction method thereof

ActiveCN104806267AReduce engineering riskReduce the impactUnderground chambersTunnel liningGlass fiber reinforced polymerPolyvinyl chloride

The invention relates to a shield end socket reinforcing system of a scree soil layer advance large pipe roof and a construction method thereof. When a stratum where a shield enters and exits a hole is reinforced in a common soil layer, ground high-pressure spiral spraying or ground PVC (polyvinyl chloride) grouting reinforcement is often adopted, and the reinforcing effect of a scree soil layer is difficult to control. The shield end socket reinforcing system of the scree soil layer advance large pipe roof comprises glass fiber reinforced polymer rebar fender posts which are constructed around a shield well, wherein pipe roof guide walls are constructed among the posts and are located above an arch of a shield tunnel; longitudinal pipe roof guide steel pipes are pre-buried in the glass fiber reinforced polymer rebar fender posts and the pipe roof guide walls above the arch of the shield tunnel; the pipe roof guide steel pipes cover within the range of the arch of the shield tunnel in an equal interval; a big pipe roof is arranged from the pipe roof guide steel pipes to the stratum and is a slip casting steel flower pipe. According to the invention, the single reinforcing mode such as common full-fracture surface ground spiral spraying or ground PVC slip casting can be changed, the construction is convenient, the investment is saved, the influence of the end socket reinforcement to the ground is greatly reduced, and the whole reliability of the shield during entering or exiting the hole is increased.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

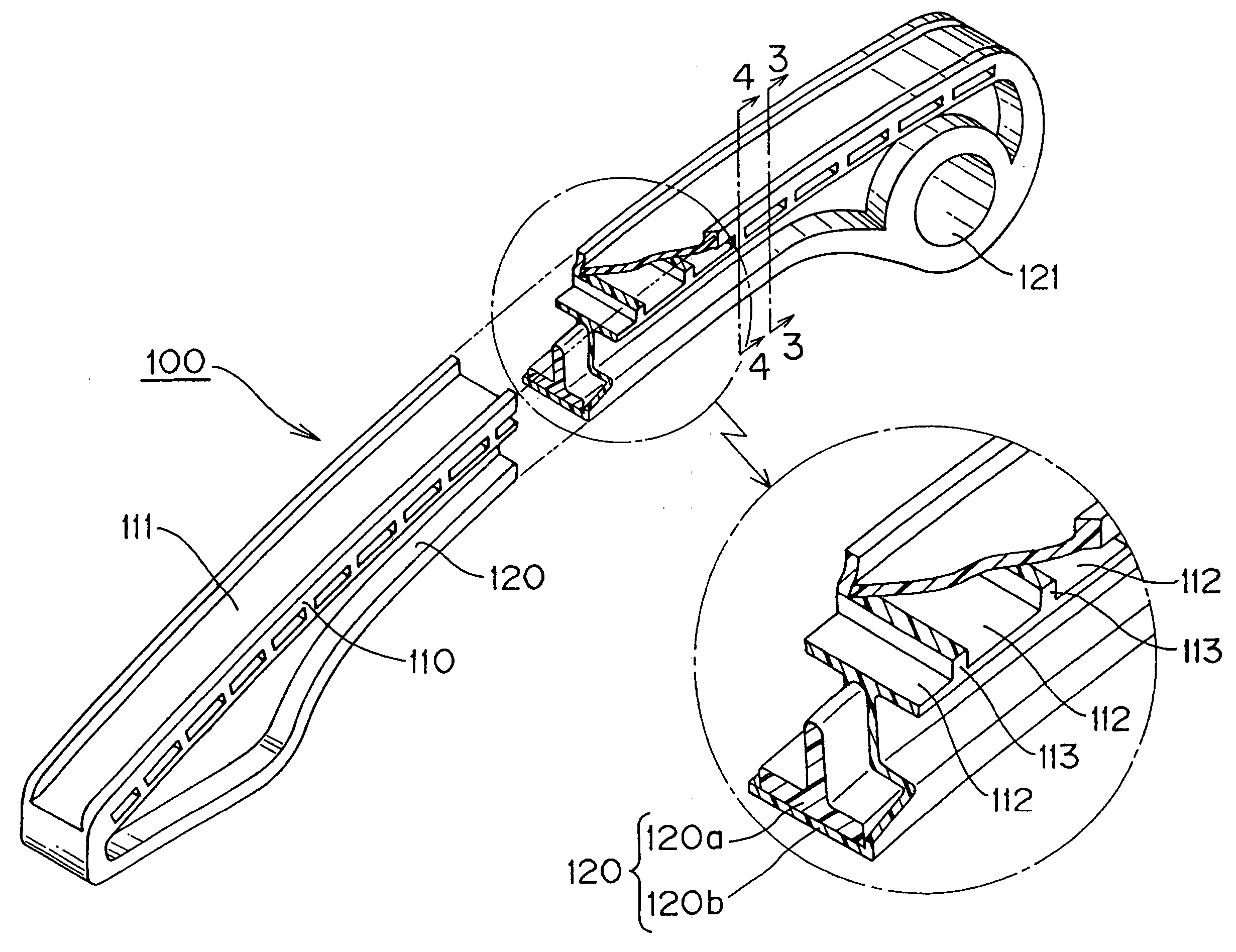

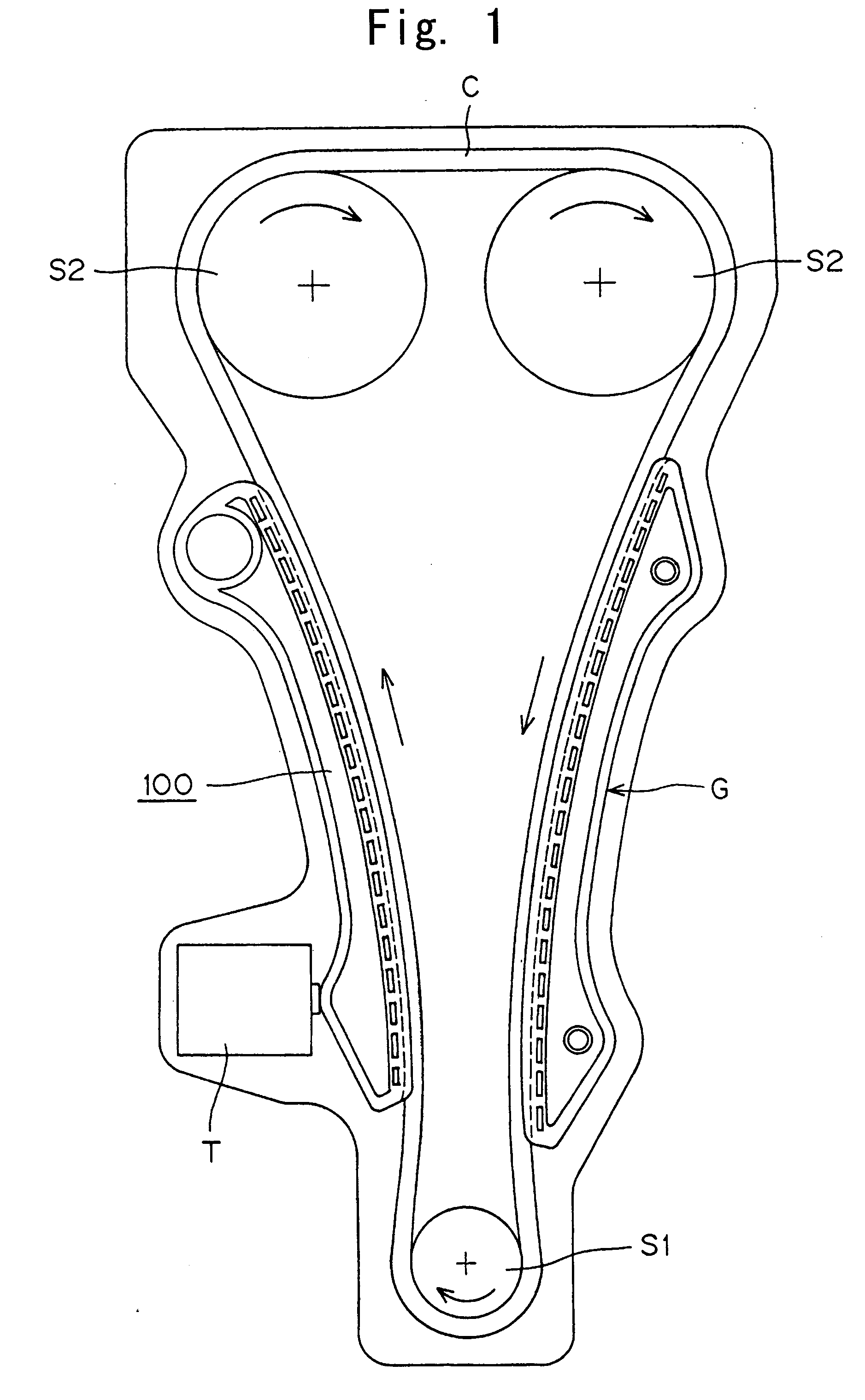

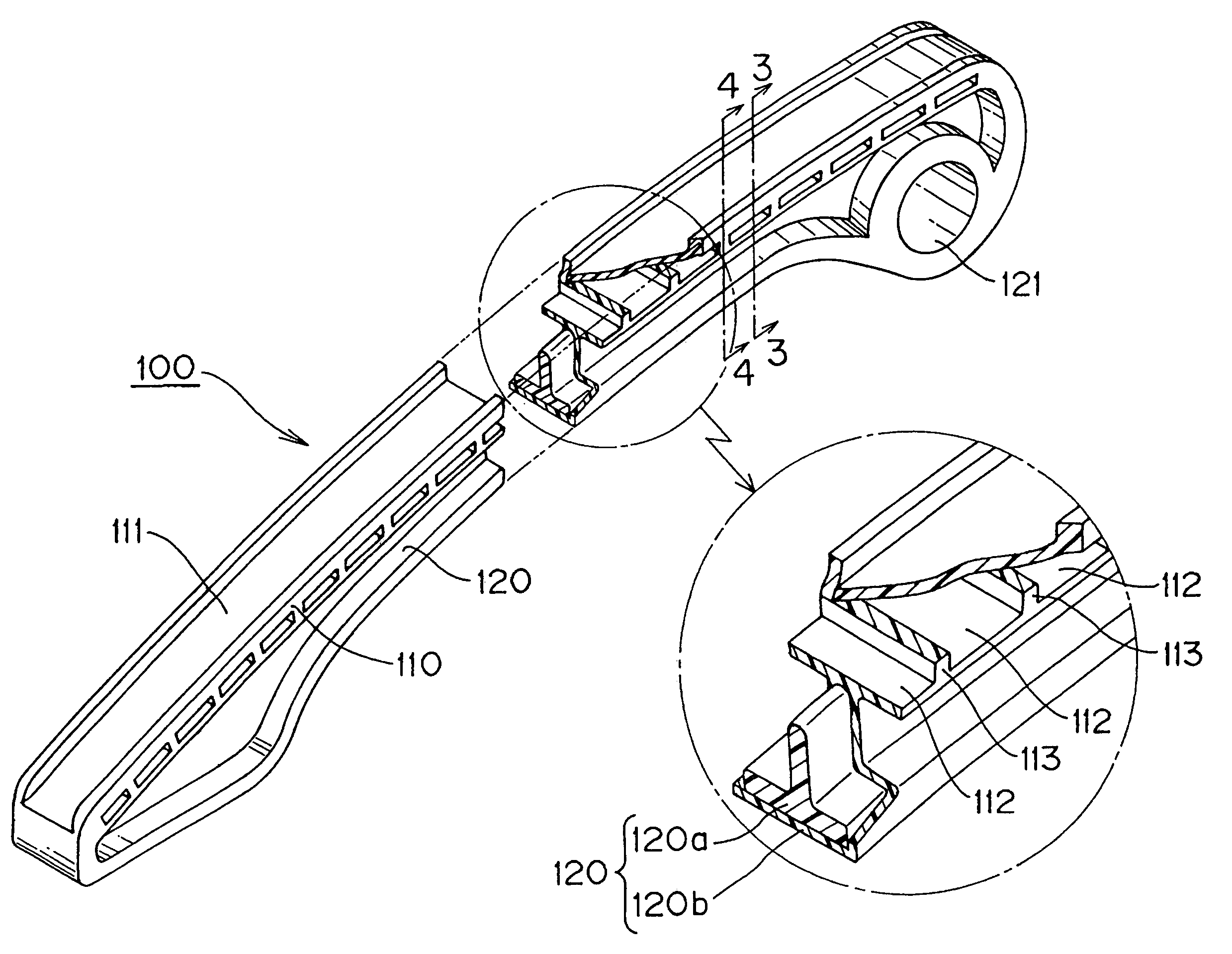

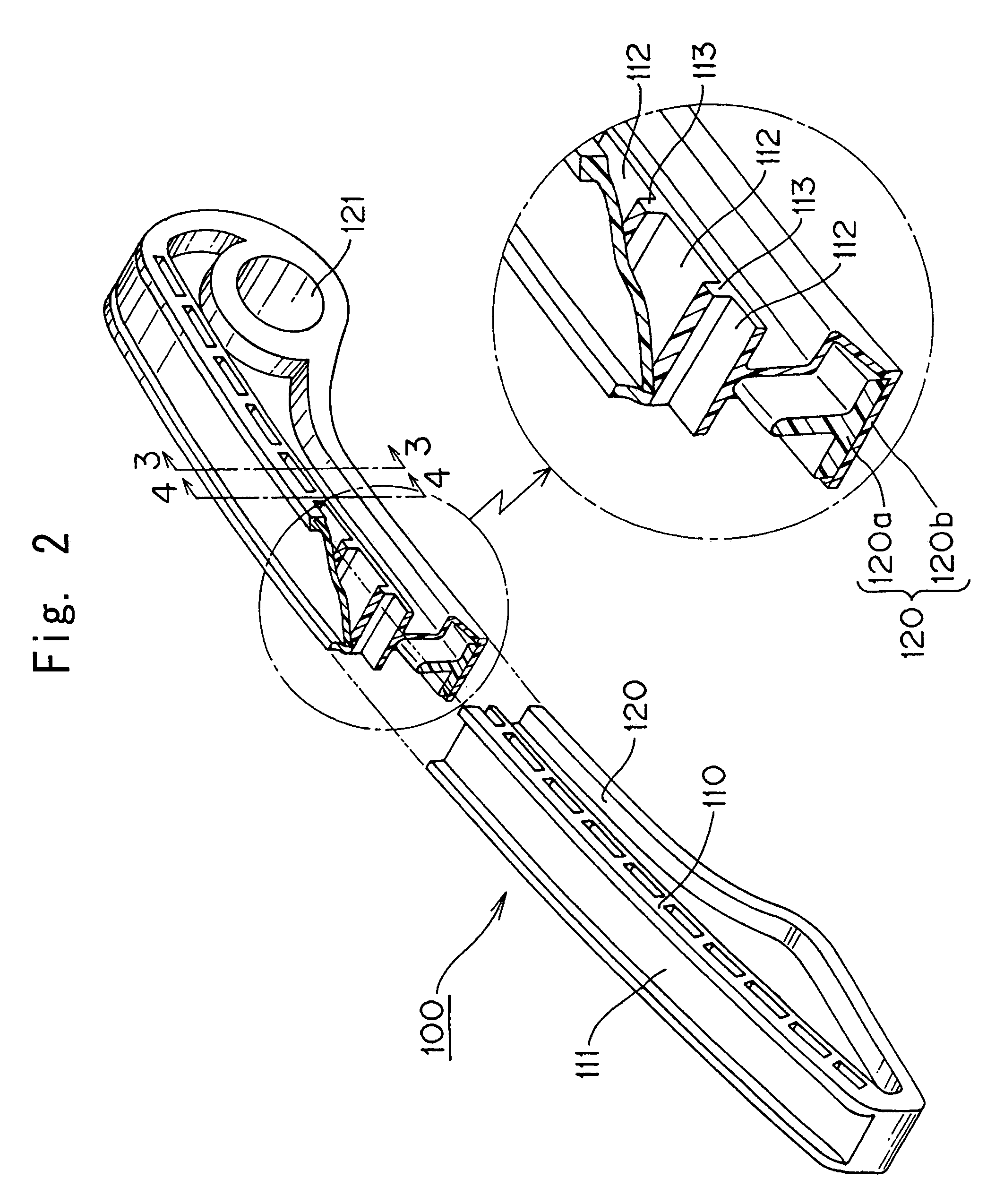

Guide for transmission device

InactiveUS20050107196A1Reduction in guide strengthDeterioration of supportGearingGearing detailsGlass fiber reinforced polymerPolymer resin

In a guide for a transmission chain, a slide rail elongated in the direction of travel of the chain, and having a front surface for sliding engagement with the chain, is supported by a rail support which extends perpendicularly from the back side of the slide rail. The guide is formed by sandwich molding and comprises a glass fiber-reinforced polymer resin forming a core of the rail support, and a wear-resistant polymer resin forming both the slide rail, and a skin layer on the rail support, the skin layer of the rail support being unitary with the slide rail. A plurality of hollow, heat-dissipating, cavities extend inwardly from both sides of the slide rail in directions transverse to the direction of elongation of the slide rail.

Owner:I & P +1

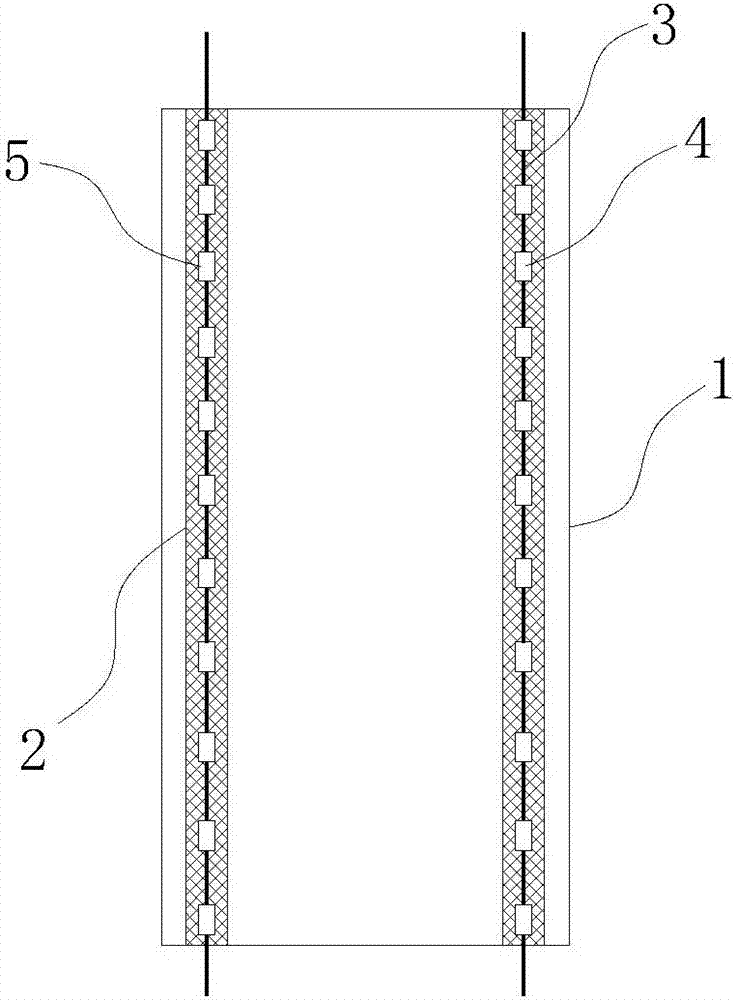

Double-channel Brillouin optical fiber cable sensor

InactiveCN102023061AReal-time online monitoringForce measurement by measuring optical property variationThermometers using physical/chemical changesGlass fiber reinforced polymerMonitoring temperature

The invention provides a double-channel Brillouin optical fiber cable sensor capable of monitoring temperature and pressure at the same time. The sensor comprises two parallel Brillouin optical fibers, wherein one optical fiber is a tight optical fiber, the other optical fiber is a loose optical fiber, the tight optical fiber is used for measuring pressure, and the loose optical fiber is used for measuring temperature; and a reinforcing wire is clamped between the two optical fibers, a macromolecular material (glass fiber reinforced polymer, GFRP) is wrapped outside the two optical fibers, and an optical cable (8mm*4mm) with square section is formed. The sensor can be arranged on an oil well, a mine, a tunnel, a dam, a bridge, a road or a cable, and realizes real-time online monitoring of distributed temperature and pressure.

Owner:林茂

Aggregate for a washing machine with a plastic sudsing container

InactiveUS20070289341A1Safely dissipatedHigh strengthWringing machinesOther washing machinesGlass fiber reinforced polymerEngineering

An aggregate for a washing machine provided with a substantially hollow cylindrical suds container of fiberglass reinforced polymeric material and consisting of two end walls and a shell, a hollow cylindrical washing drum disposed in the suds container for rotation on a shaft about a non-vertical axis, and a unitary support structure embedded substantially completely in one of the end walls and with a bearing support adapted to receive the shaft and at least one arm extending radially from the bearing support.

Owner:MIELE & CO KG

Guide for transmission device

InactiveUS7329196B2Reduced strengthDeterioration of supportGearingGearing detailsGlass fiber reinforced polymerPolymer resin

In a guide for a transmission chain, a slide rail elongated in the direction of travel of the chain, and having a front surface for sliding engagement with the chain, is supported by a rail support which extends perpendicularly from the back side of the slide rail. The guide is formed by sandwich molding and comprises a glass fiber-reinforced polymer resin forming a core of the rail support, and a wear-resistant polymer resin forming both the slide rail, and a skin layer on the rail support, the skin layer of the rail support being unitary with the slide rail. A plurality of hollow, heat-dissipating, cavities extend inwardly from both sides of the slide rail in directions transverse to the direction of elongation of the slide rail.

Owner:I&P CO LTD +1

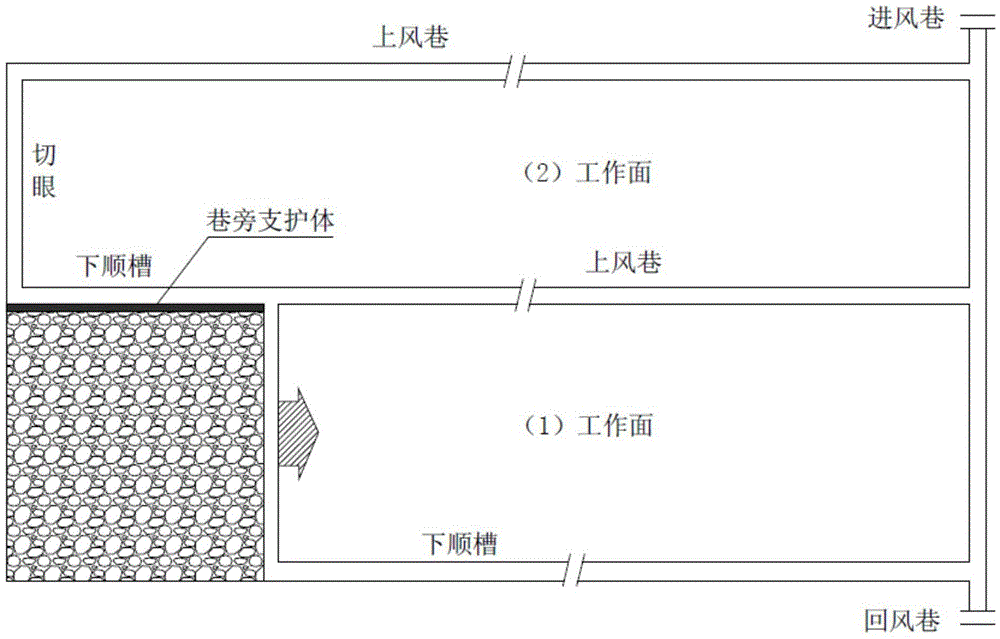

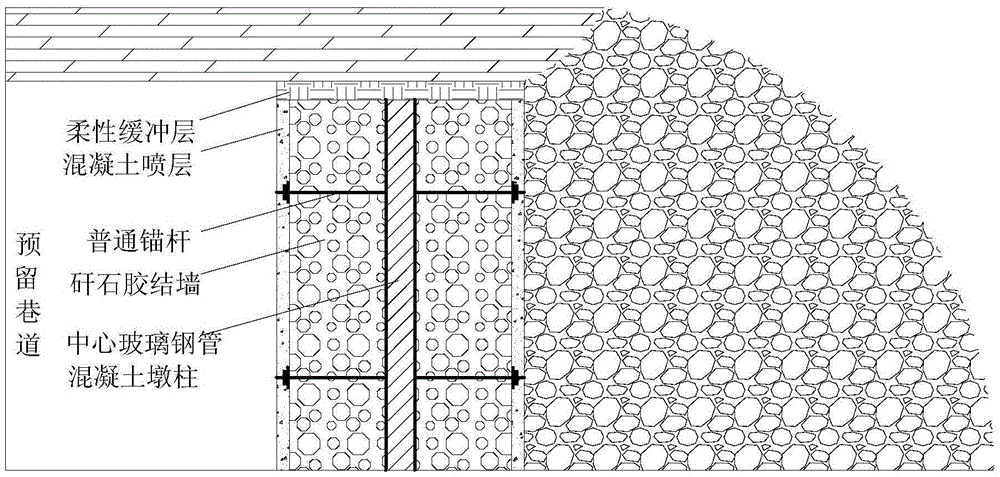

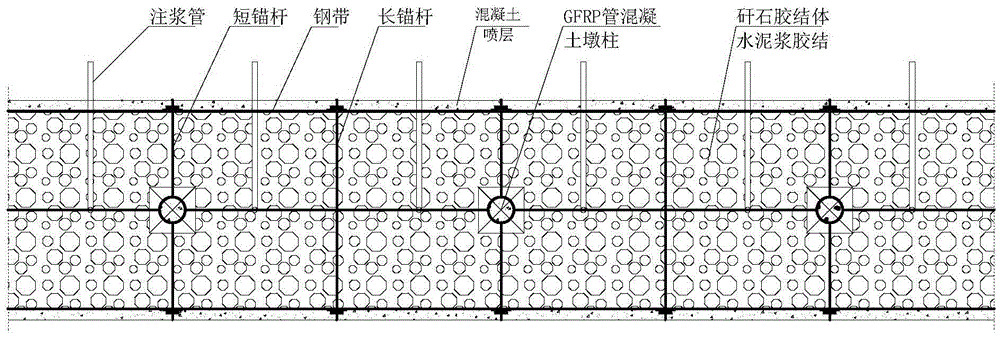

Gob-side entry retaining method for GFRP (Glass Fiber Reinforced Polymer) tube concrete pier stud and gangue concrete wall

InactiveCN105569726ASimple structureImprove stabilityMaterial fill-upGlass fiber reinforced polymerStructural engineering

The invention discloses a gob-side entry retaining method for a GFRP (Glass Fiber Reinforced Polymer) tube concrete pier stud and a gangue concrete wall. A roadside supporting body which takes the GFRP tube concrete pier stud as a center framework and a gangue cement wall body as an auxiliary protection is finally formed by constructing a roadside supporting space which takes the GFRP tube concrete pier stud as the center, filling the roadside supporting space with the gangue wall body, spraying concrete onto the two sides of the gangue wall body for sealing, and injecting rapid hardening cement paste into the gangue wall body for cementing. The roadside supporting body is simple in structure, high in stability, and suitable for roadside supporting of a great depth and thick coal seam during gob-side entry retaining.

Owner:SHANDONG SHENBO ROADWAY SUPPORTING TECH CO LTD

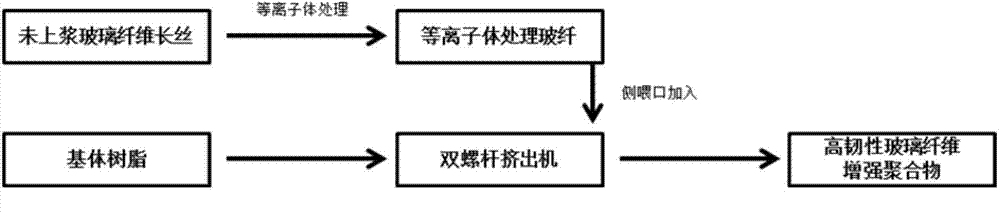

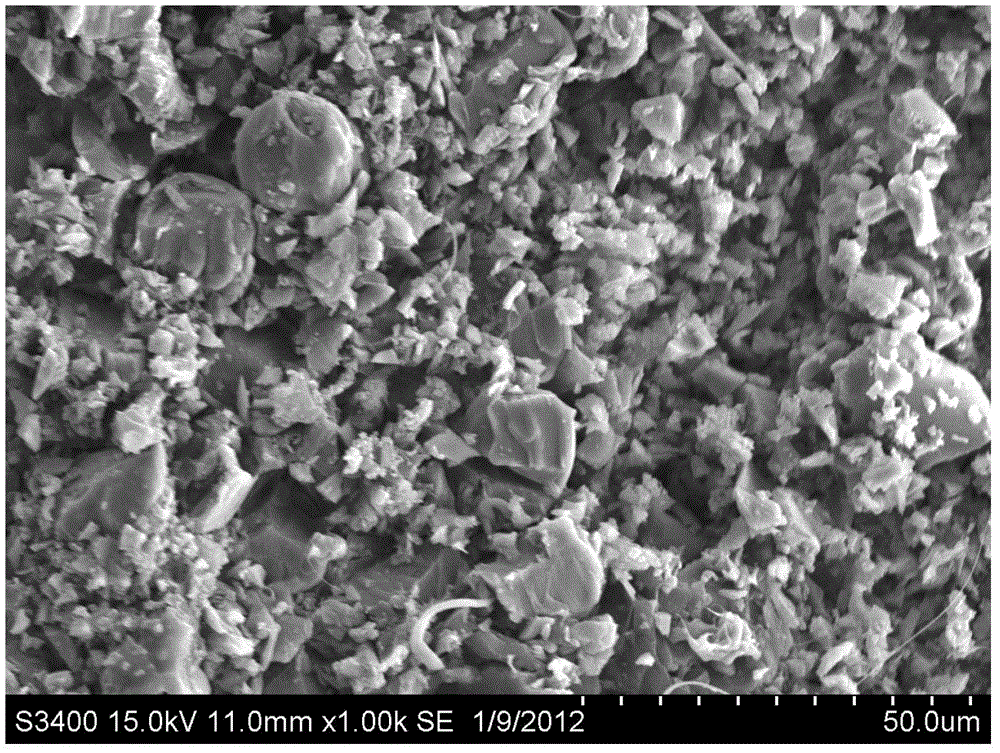

High-toughness glass fiber reinforced polymer alloy and preparation method thereof

ActiveCN104845288AReduce processing costsImprove wettabilityGlass fiber reinforced polymerDispersity

The invention relates to high-toughness glass fiber reinforced polymer alloy and a preparation method thereof. The alloy comprises components of, by weight, 40 parts to 95 parts of matrix resin, 5 parts to 50 parts of plasma processed glass fiber, 1 part to 10 parts of flexibilizers, 0.1 part to 5 parts of coupling agents, 0.1 part to 1 part of antioxidants and 0.1 part to 1 part of lubricants. According to the preparation method, glass fibers which are not sized are subjected to plasma processing, and accordingly, the roughness and active groups on glass fiber surfaces are increased, and the wettability of the flexibilizer to the glass fibers and the dispersity of the glass fibers in polymers are increased; by the use of the coupling agents, the wettability of the flexibilizer to the glass fibers and the fiber and polymer bonding performance are further improved, and accordingly, the strength of the glass fiber enhancement material is improved greatly, and the glass fiber enhancement polymer alloy material toughness is improved.

Owner:GUANGDONG KUMHO SUNNY POLYMER MATERIAL

Carbon nanometer tube modified resin/glass fiber composite reinforcement material and preparation method thereof

The invention relates to a carbon nanometer tube modified resin / glass fiber composite reinforcement material which consists of 70-80 percent of two types of continuous glass fibers and 20-30 percent of modified resin base material; the modified resin base material is carbon nanometer tube modified resin; and the resin is epoxy resin or carbamate modified vinyl ester resin. A preparation method comprises the preparation processes of: preparing and forming through a pultrusion process after the two types of continuous glass fibers are glued with the modified resin base material, unidirectionally winding the continuous glass fibers by using winding equipment before solidification and forming threads on the surface of the reinforcement material; and fully dipping surface fibers of the reinforcement material through secondary glue dipping to obtain the carbon nanometer tube modified resin / glass fiber composite reinforcement material. The obtained modified GFRP (Glass Fiber Reinforced Polymer) reinforcement material has the beneficial effects that the ultimate tensile strength and the ultimate elongation rate are improved, and particularly, the elastic modulus and the cutting strength are improved.

Owner:HOHAI UNIV

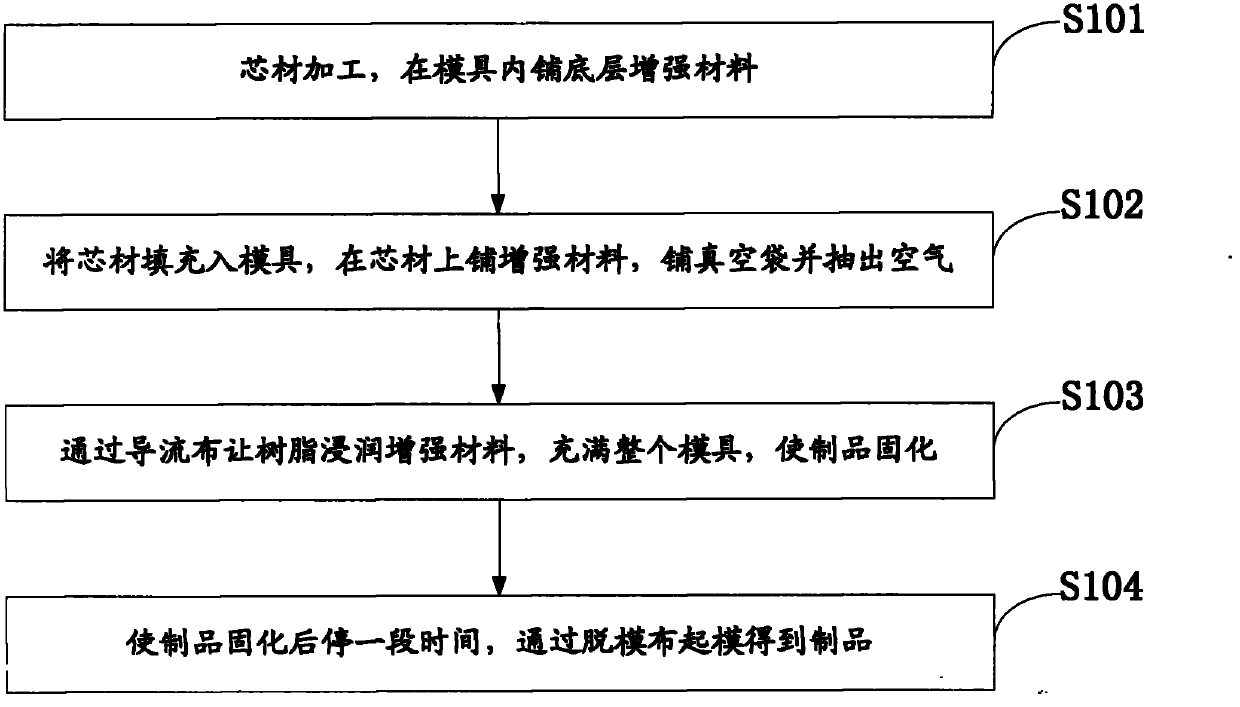

Manufacturing method of maintenance-free steel-composite material buckling restrained brace

InactiveCN103273663AMaintenance-free withMaintenance hasShock proofingGlass fiber reinforced polymerBuckling-restrained brace

The invention discloses a manufacturing method of a maintenance-free steel-composite material buckling restrained brace. The method comprises the following steps of: manufacturing core material, and packaging the core material by reinforcing material; filling the core material into a mould; laying a vacuum bag and extracting air; leading resin into mould; and curing the product to obtain the finished product. The whole brace component is molded into a whole for one time by vacuum infusion; the condition that the axial force is mainly born by an inner core stress unit by a telescopic joint structure during the support work is guaranteed; and a support inner core steel core is packaged by glass fiber reinforced polymer (GFRP) composite material on the whole, so that the brace has the characteristic of corrosion resistance. By adopting a GFRP rectangular tube filling-free restraint yield section structure form, the buckling restrained brace has the characteristic of being light in weight.

Owner:NANJING UNIV OF TECH

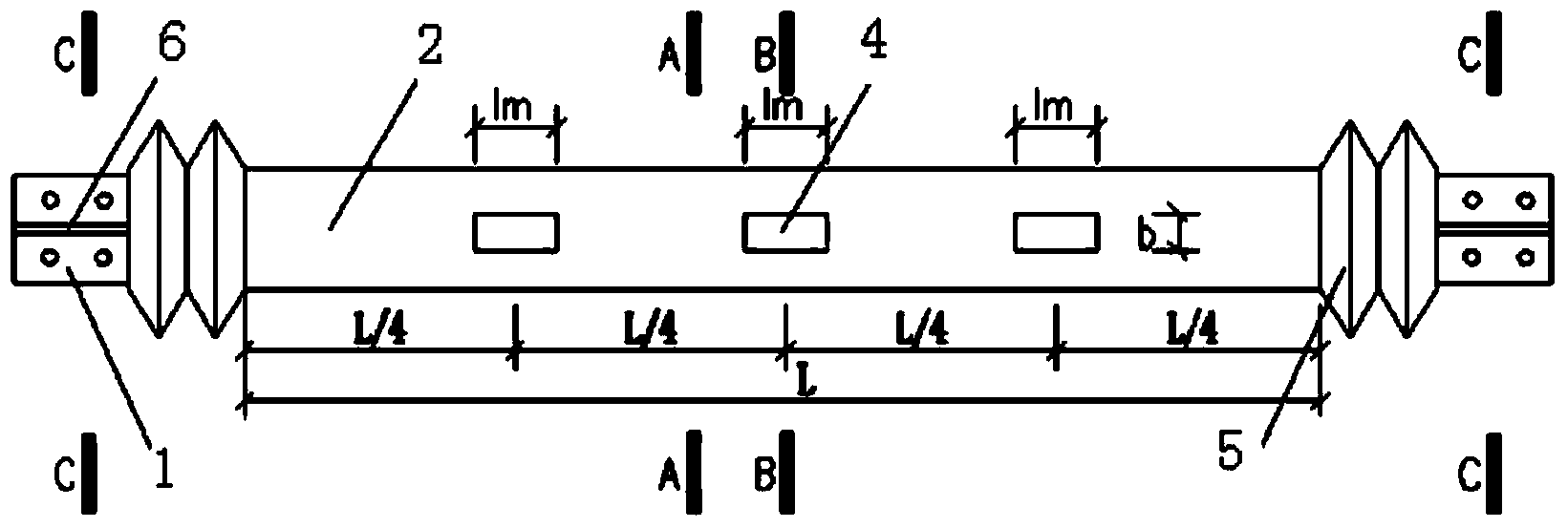

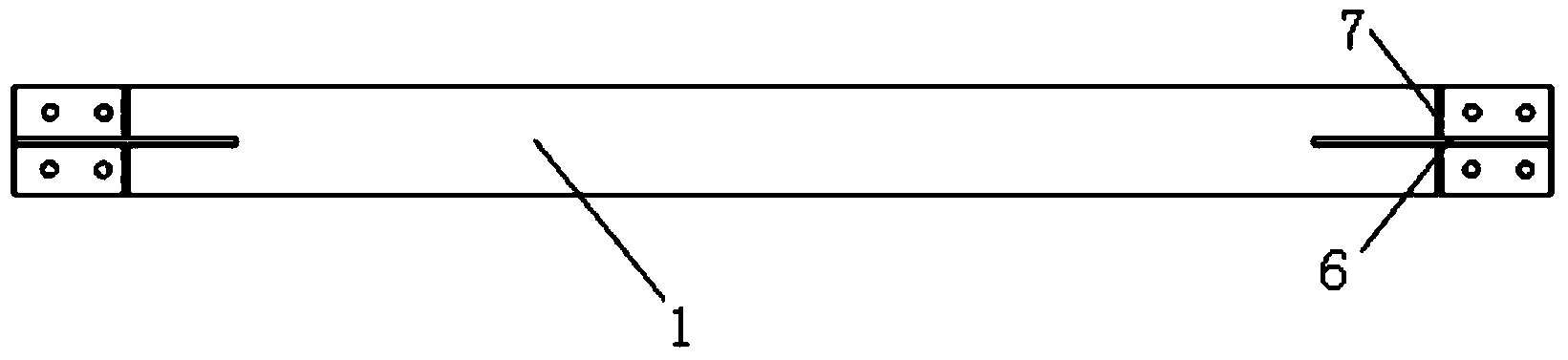

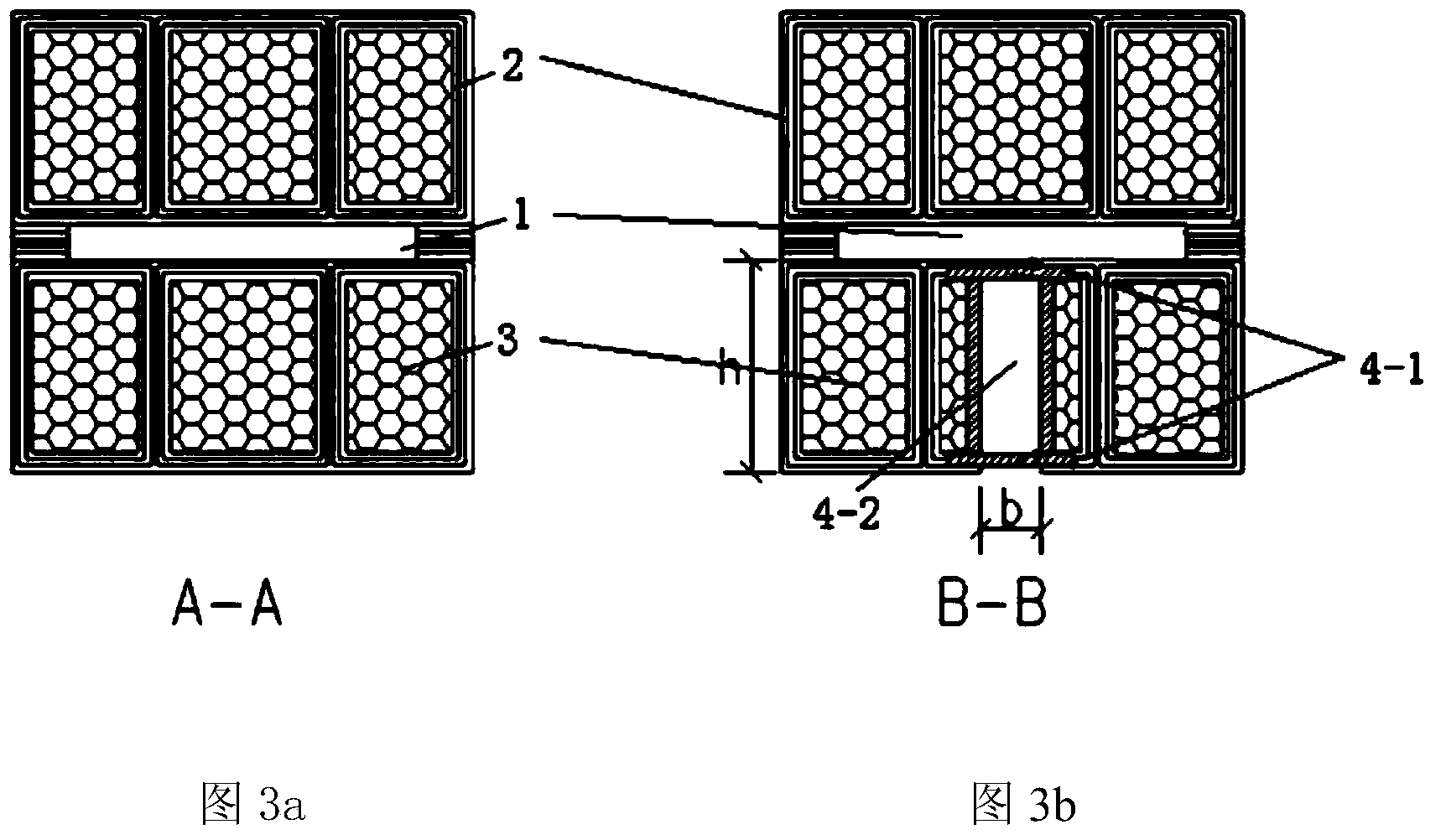

Non-welding buckling restraining support with inspection windows

ActiveCN103469923AImprove corrosion resistanceSolve problems such as self-importanceShock proofingGlass fiber reinforced polymerChinese characters

The invention provides a non-welding buckling restraining support with inspection windows. The non-welding buckling restraining support with the inspection windows comprises an inner core steel core and a peripheric restraining unit. The inner core steel core is a Chinese character Yi shaped steel plate, the peripheric restraining unit comprises an energy dissipation section, the energy dissipation section is in axial direction to transition sections on two ends and mounting sections on the outer sides of the transition sections, the energy dissipation section is an GFRP (glass fiber reinforced polymer) rectangular tube with ribs, the GFRP rectangular tube is filled with contoured foam when contoured, and a GFRP rib in the tube is arranged vertical to the inner core steel core. A plurality of inspection windows are arranged, vertical to the inner core steel core, on an axis of the energy dissipation section , the transition sections are GFRP expansion joints, the mounting sections are GFRP ribbed stiffeners vertical to the inner core steel core and forming a cross shape with the inner core steel core, and polyurethane foam is wrapped by glass fiber cloth to be injected resin in vacuum to solidify to form the whole supporting member in integrity. The non-welding buckling restraining support with the inspection windows is reasonable in structure, light in self weight, anti-corrosion, and free of maintenance and welding, can monitor deformation of inner core in real time via the inspection windows to judge whether having buckling or not so as to have anticipation judgment on supporting conditions.

Owner:NANJING UNIV OF TECH

Method for improving shear strength of nonmetal anti-floating anchor

ActiveCN103306283AIncreased shear strengthReduce adverse effectsBulkheads/pilesGlass fiber reinforced polymerEconomic benefits

The invention belongs to the technical field of anti-floating anchors of building construction, and relates to a method for improving the shear strength of an interface of an inner anchorage section and an outer anchorage section of a nonmetal anti-floating anchor. According to the method, a steel arm is additionally mounted on an anchor body, at the inner anchorage section and the outer anchorage section, of the nonmetal anti-floating anchor, is a seamless steel pipe, and is tightly connected with the anchor and a bottom plate of a building (structure) at the outer anchorage section, tightly connected with the anchor and mortar at the inner anchorage section, and tightly bonded on the outer side of a GFRP (Glass Fiber Reinforced Polymer) anchor; since the rigidity of the seamless steel pipe is higher, the defect of lower transverse shear strength of the GFRP anchor is overcome; the steel arm can provide the sufficient transverse shear strength under the action of horizontal load; and therefore, the purpose of limiting the transverse shear deformation of the GFRP anchor is achieved. The method is simple to operate, low in cost, high in reliability, and good in economic benefit, and has prominent substantial characteristics and significant progress, required devices are simple and easy to obtain, and the mounting and construction are convenient.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

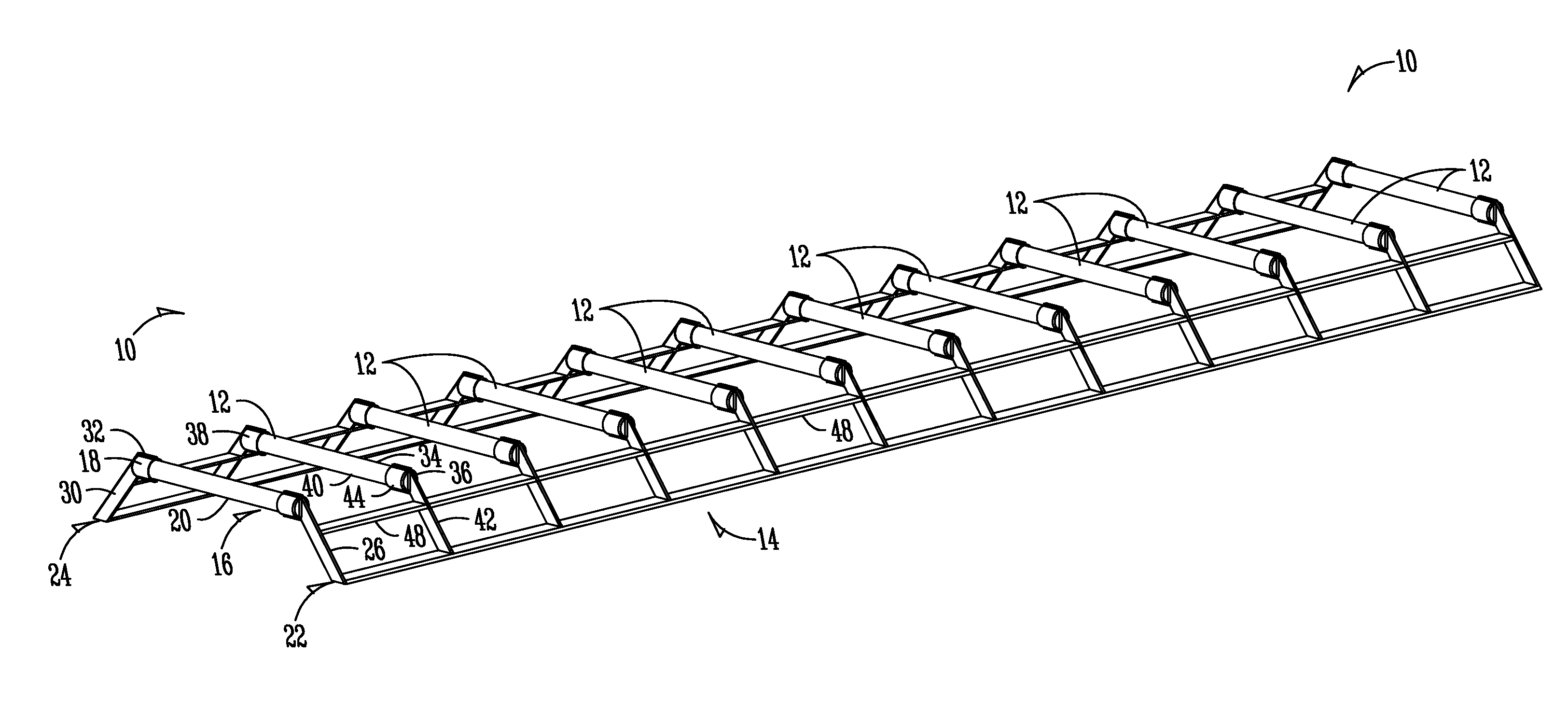

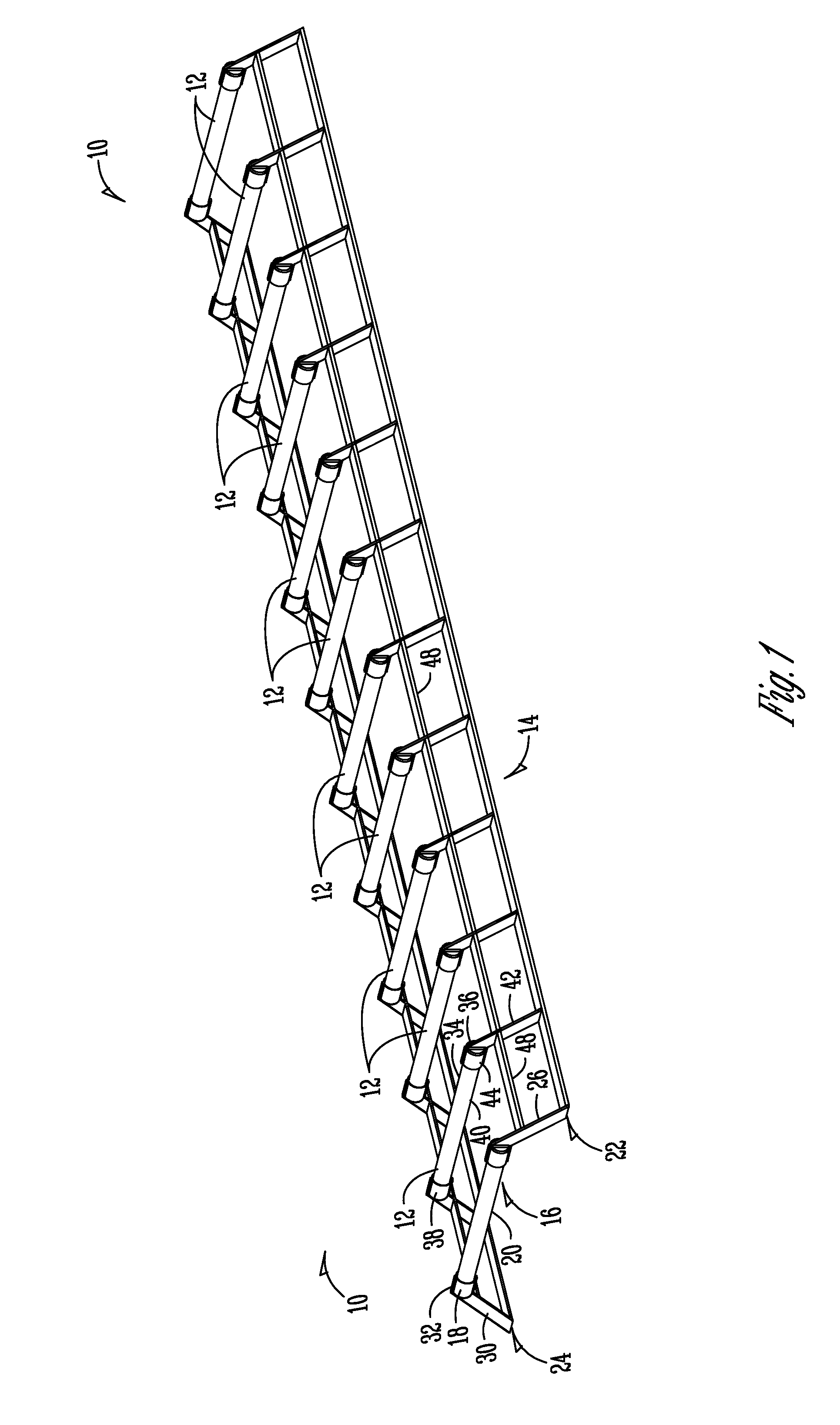

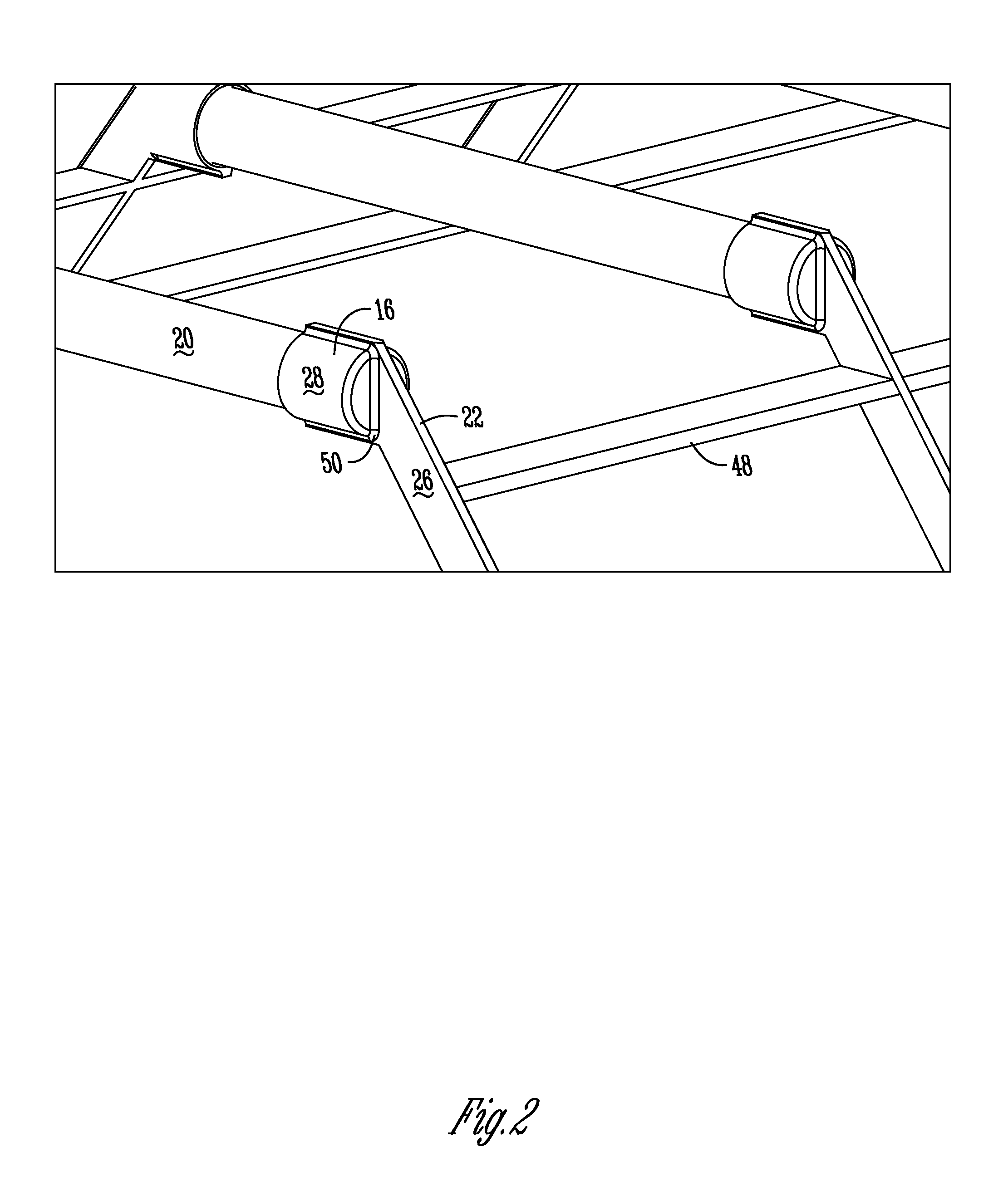

Road basket and method of making same

InactiveUS20140270949A1Increase holdingsCompromising durabilityPaving reinforcementsSingle unit pavingsGlass fiber reinforced polymerBraced frame

An improved road basket including a non-metallic dowel, a first support frame including a first support frame first leg and a first support frame first cup moldably secured to the dowel first end, and a second support frame including a second support frame first leg and a second support frame first cup moldably secured to the dowel second end. Multiple dowels can be secured in similar fashion to additional leg members. Preferably, the first support frame first leg and a first support frame second leg are connected by a base frame member. In addition, the first support frame first leg and the first support frame second leg may be connected by an intermediate frame member. The frame may be constructed of a single piece. The dowel is preferably made from fiberglass or glass fiber reinforced polymer and the frame is preferably high density polyethylene.

Owner:HEADY TIMOTHY P +1

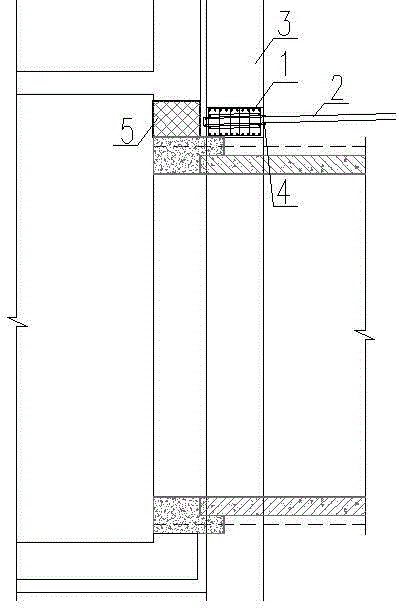

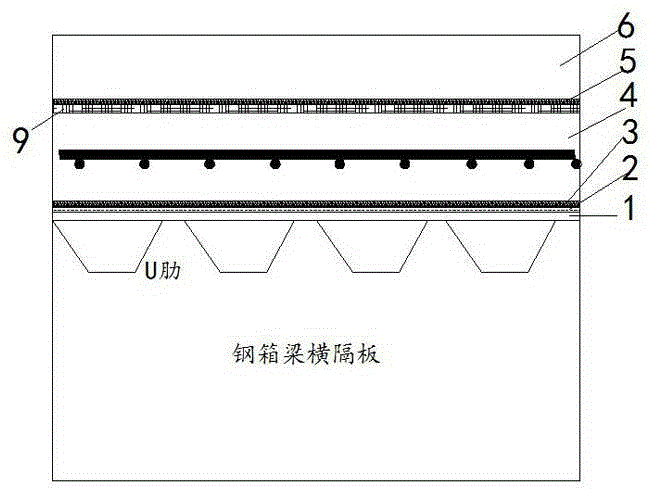

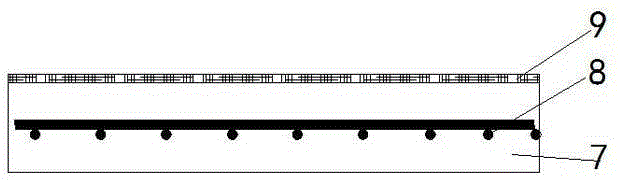

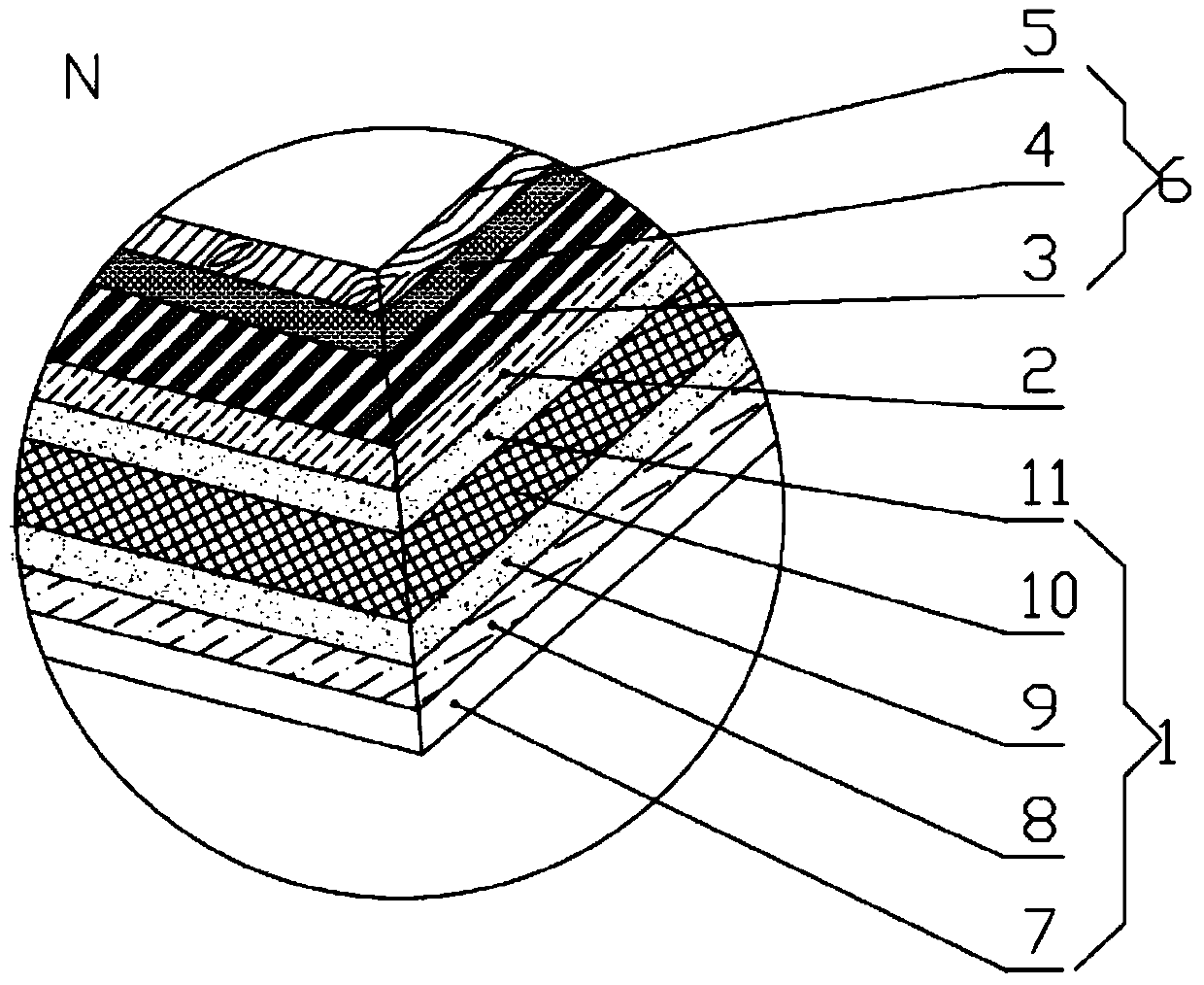

Anti-knocking steel box beam bridge deck paving structure and paving method

ActiveCN105401519AHigh strengthImprove toughnessBridge structural detailsBridge erection/assemblyGlass fiber reinforced polymerBridge engineering

The invention provides an anti-knocking steel box beam bridge deck paving structure and a paving method and belongs to the technical field of traffic transportation and the field of protection of bridge engineering. In the structure, the upper layer is an asphalt concrete wearing layer and the lower layer is a GFRP (Glass Fiber Reinforced Polymer)-composite concrete anti-knocking pavement layer, namely, a waterproof layer (2) is arranged on a steel box beam orthotropic bridge deck slab (1); a lower adhesive layer (3) is arranged on the waterproof layer (2); the GFRP-composite concrete anti-knocking pavement layer (4) is arranged on the lower adhesive layer (3); an upper adhesive layer (5) is arranged on the GFRP-composite concrete anti-knocking pavement layer (4); the asphalt concrete wearing layer (6) is arranged on the upper adhesive layer (5). The paving method comprises the following steps: (a) derusting a steel bridge deck by sandblasting; (b) performing anticorrosive coating on the steel bridge deck slab, and arranging the waterproof layer in a sprinkling way; (c) forming the lower adhesive layer on the waterproof layer in a coating mode; (d) strapping a GFRP glass fiber reinforced bar net, and then pouring high-strength high-toughness light composite concrete; (e) carrying out vibrating and maintaining, and afterwards adhering a GFRP glass fiber reinforced sheet on the upper surface of the concrete layer; (f) laying coarse sand on a contact surface between the GFRP sheet and the asphalt pavement layer, and arranging the upper adhesive layer in a sprinkling way; and (g) laying the asphalt concrete wearing layer.

Owner:ZHONGBEI UNIV

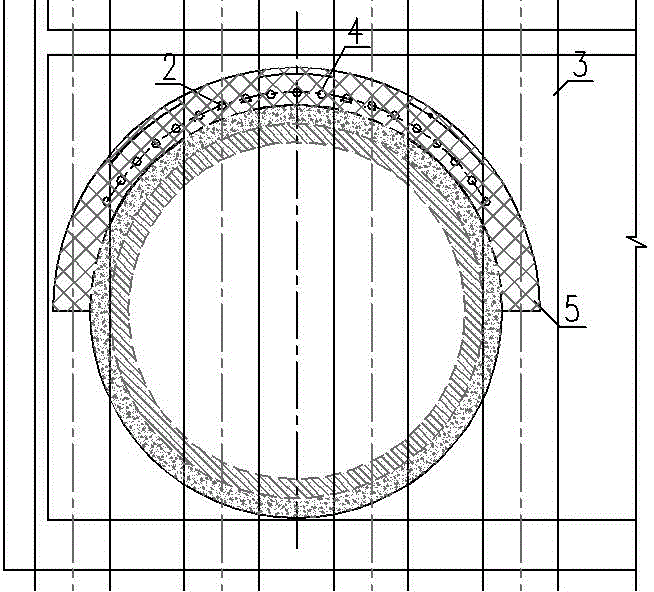

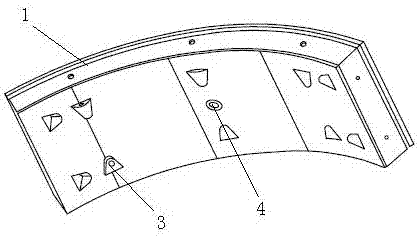

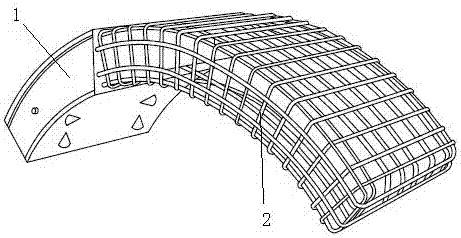

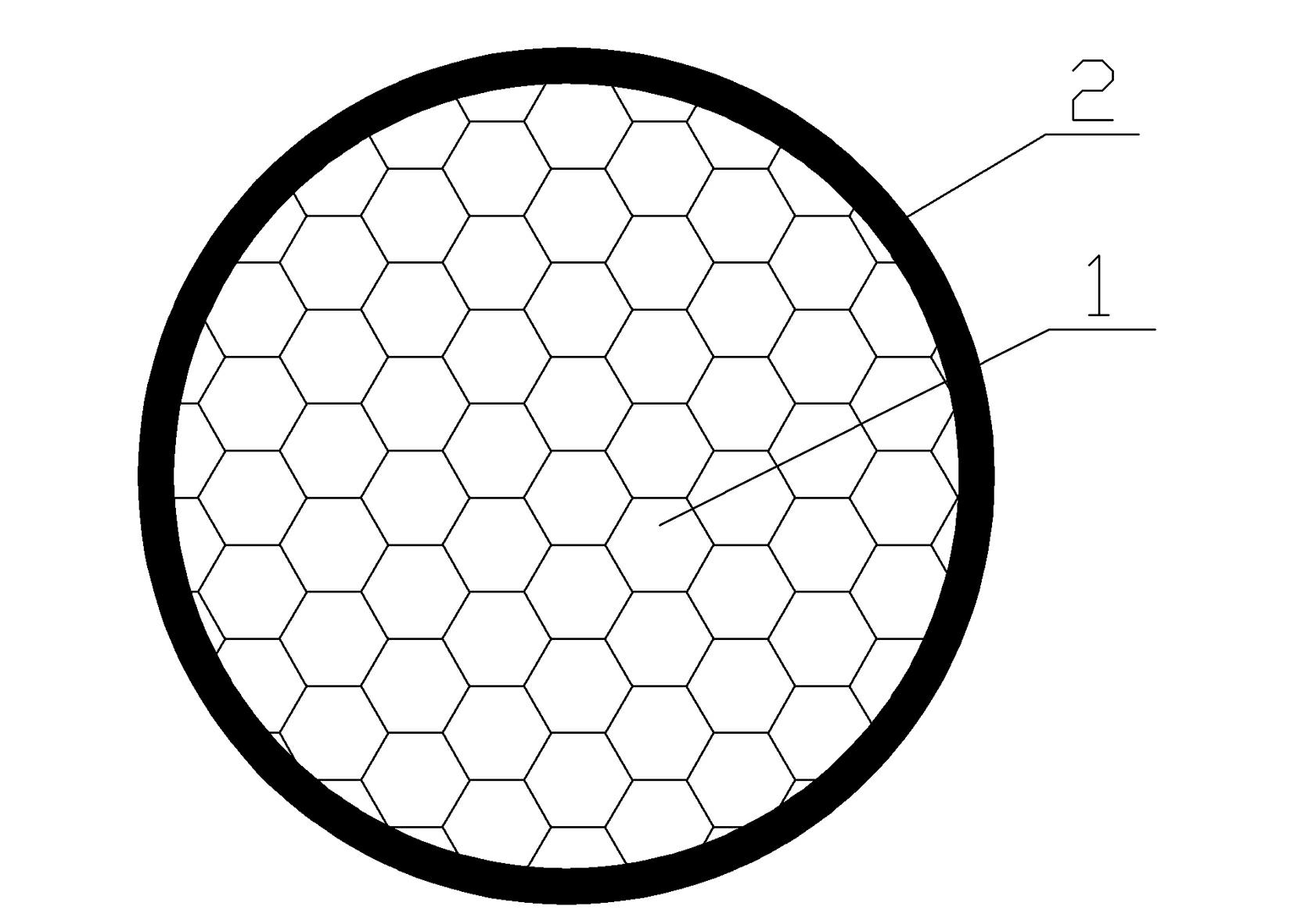

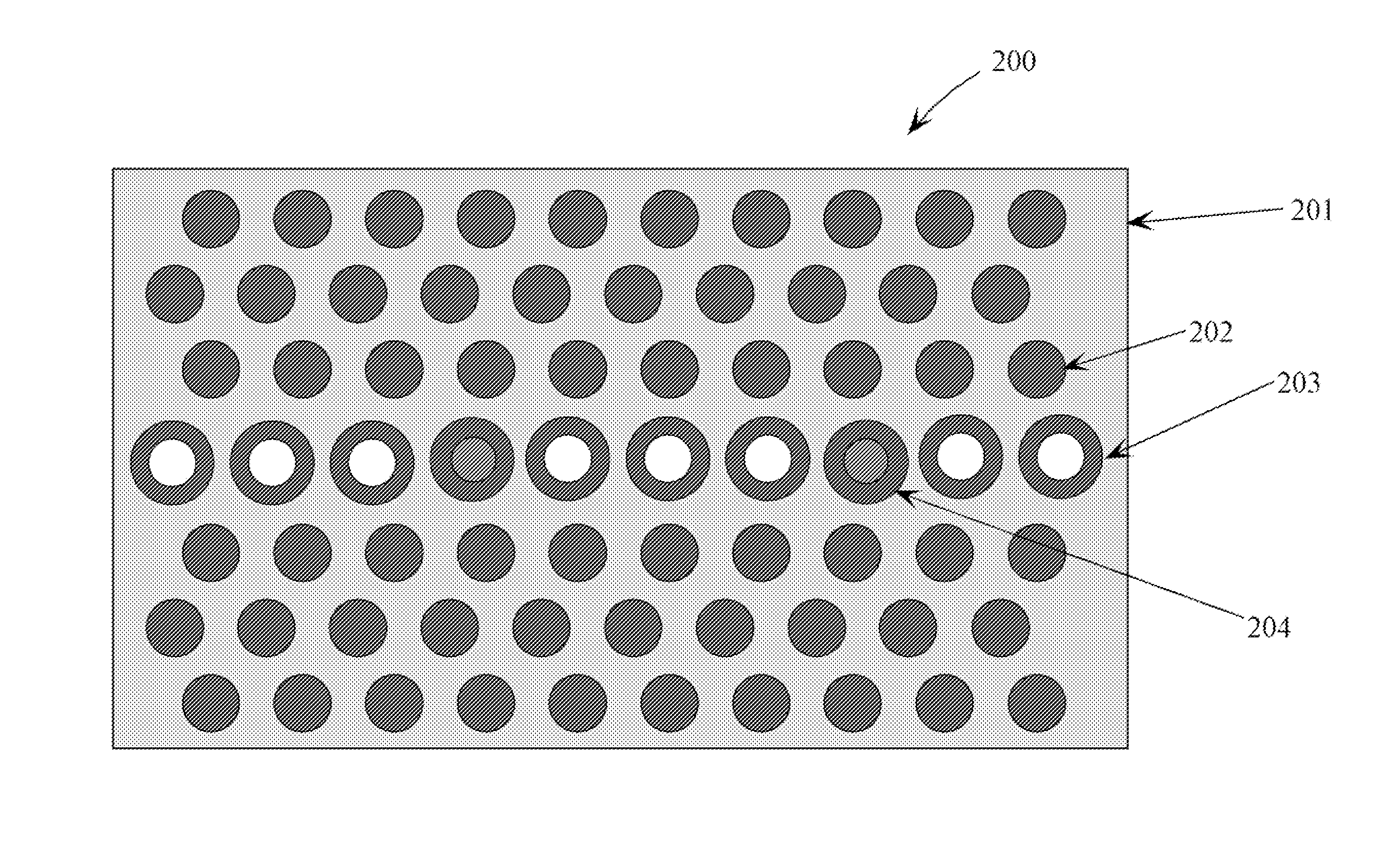

Glass fiber-reinforced polymer concrete segment of shield tunnel lining and manufacturing method of glass fiber reinforced concrete segment

PendingCN107246272AExtended service lifeImprove construction progressUnderground chambersCeramic shaping apparatusGlass fiber reinforced polymerPolymer science

The invention discloses a shield tunnel lining glass fiber reinforced concrete segment and a manufacturing method thereof, which relate to the technical field of tunnel construction. It includes concrete and fiberglass cages. Concrete is poured in the fiberglass cages. Connection holes and hoisting holes are provided on the concrete surface. Rectangular fiberglass reinforcement, rectangular fiberglass reinforcement with curvature, fiberglass reinforcement with curvature, Rectangular fiberglass reinforcement is used as the main fiberglass reinforcement to weave into the main body of the fiberglass cage. Triangular fiberglass reinforcement and square fiberglass reinforcement are supported between the main bodies. The short glass fiber bars are fixed, and the connection between the glass fiber bars is fixed as a whole by the glass fiber bars for binding. The invention has high strength, light weight, low cost, oxygen resistance and corrosion resistance, greatly improves the service life of the segments, and improves the construction progress of the construction method.

Owner:SHANDONG TAIAN SAFETY GFRP TECH

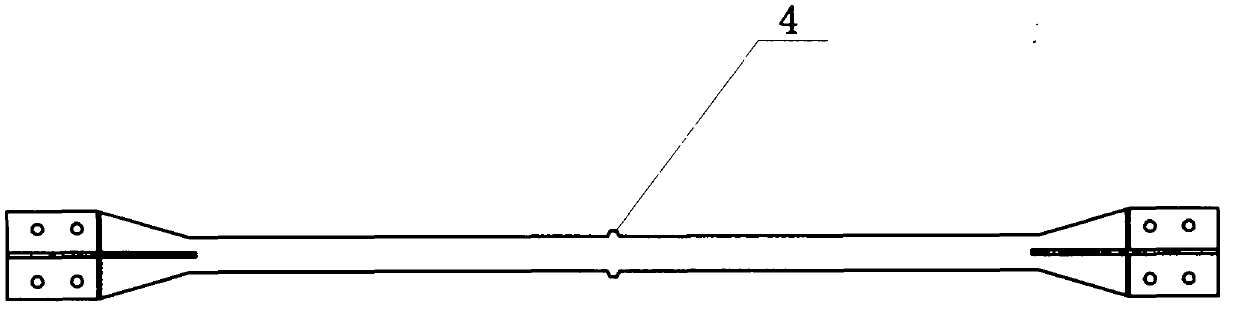

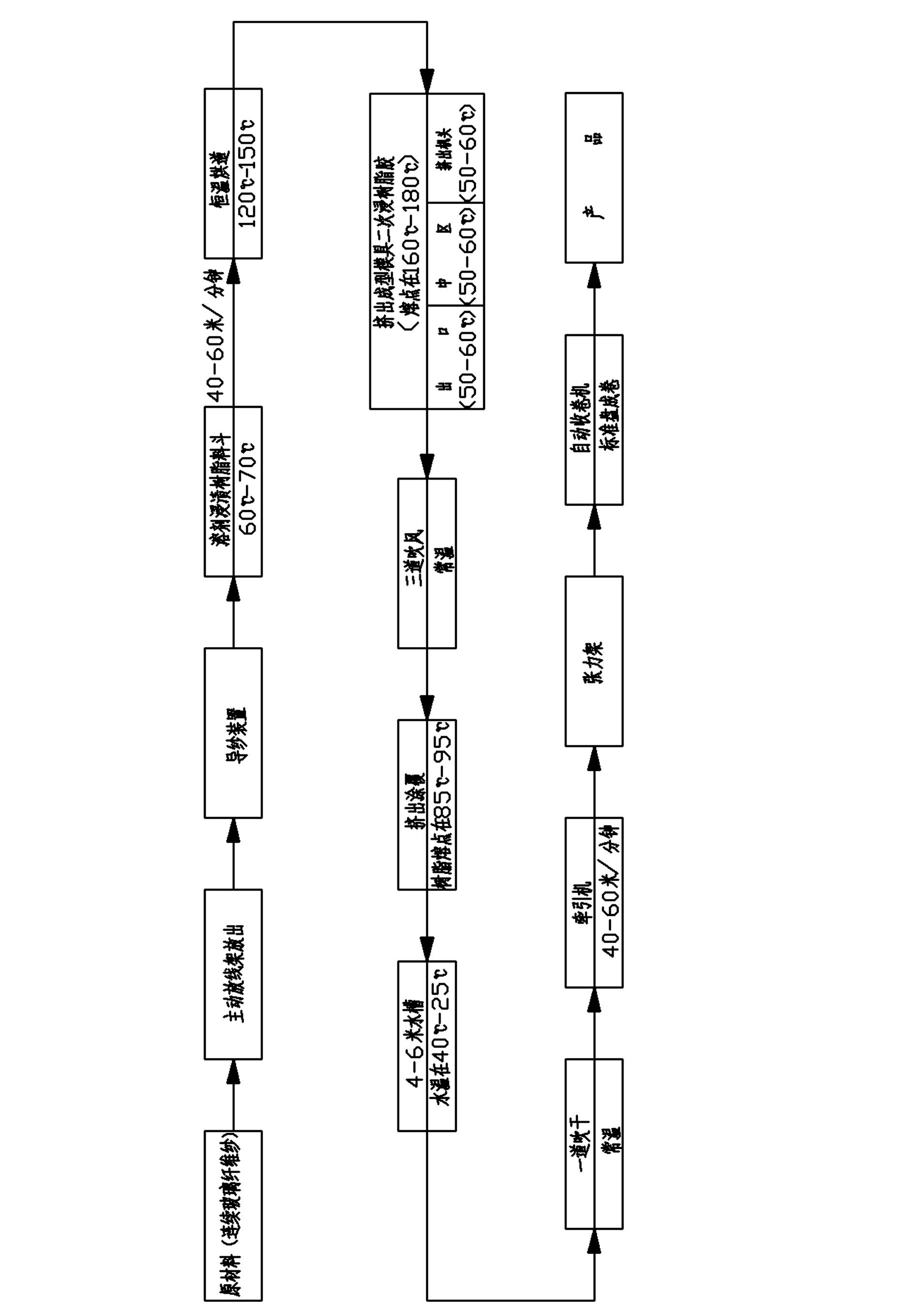

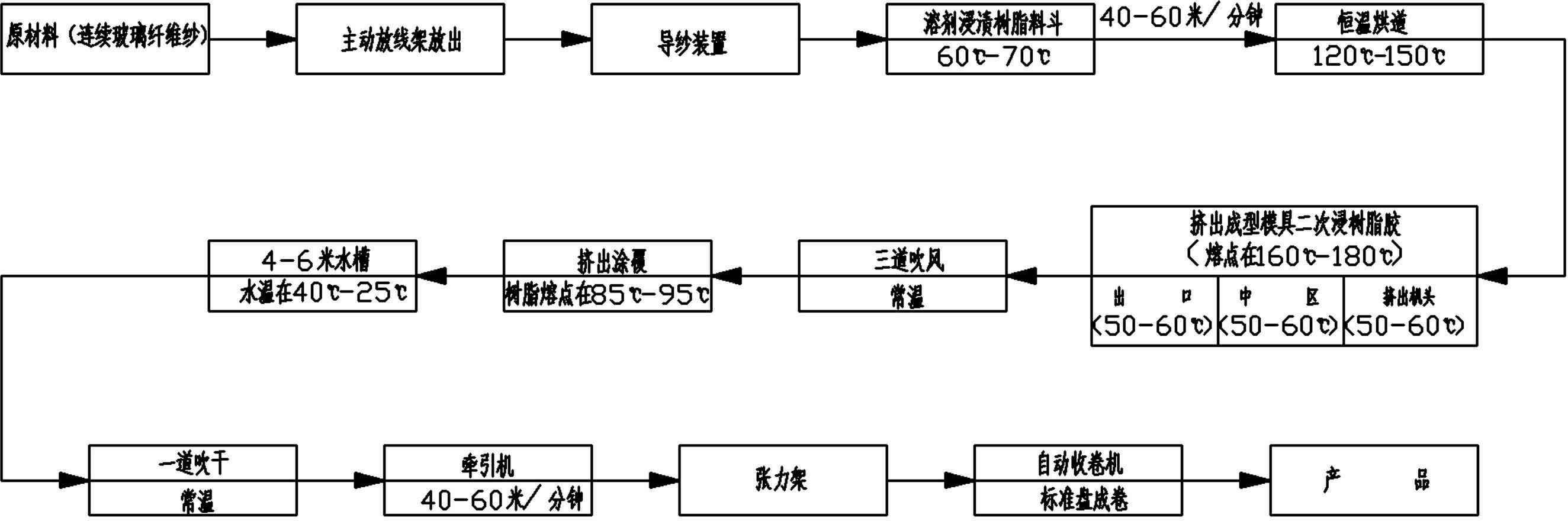

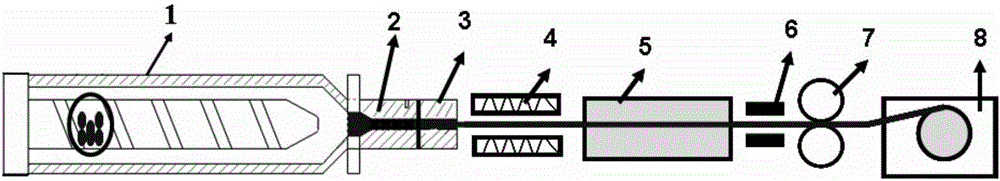

Reinforcement for thermoplastic GFRP (Glass Fiber Reinforced Polymer) butterfly cable and production process of reinforcement

InactiveCN102608718AIncrease production speedGood value for moneyFibre mechanical structuresGlass fiber reinforced polymerThermoplastic

The invention discloses a reinforcement for a thermoplastic GFRP (Glass Fiber Reinforced Polymer) butterfly cable and a production process of the reinforcement. The reinforcement for the thermoplastic GFRP butterfly cable is characterized by comprising a reinforcement body, wherein the reinforcement body is a round rod formed by adhering glass fiber and thermoplastic resin, and a plastic-coated layer is coated on the surface of the reinforcement layer. The production process of the thermoplastic GFRP butterfly cable comprises the steps of: letting the glass fiber out, guiding in and forming, processing the surface, drying in a drying tunnel, secondarily dipping resin adhesive, cooling for forming, air-cooling to room temperature, coating the plastic-coated layer, water-cooling in a water trough, mold-stripping and then blowing, dragging, rolling a tension tower, winding on a rolling rack and completing all production processes of the reinforcement so that the reinforcement of the thermoplastic GFRP butterfly cable is obtained. The reinforcement has the advantages of minimum bending radius of not more than 10D(material diameter), tensile strength of not less than 1100Mpa, elongation at break of not more than 4 percent, tensile modulus of not less than 50Gpa, high production speed, low use cost and high cost performance.

Owner:南通科鼎复合材料科技有限公司

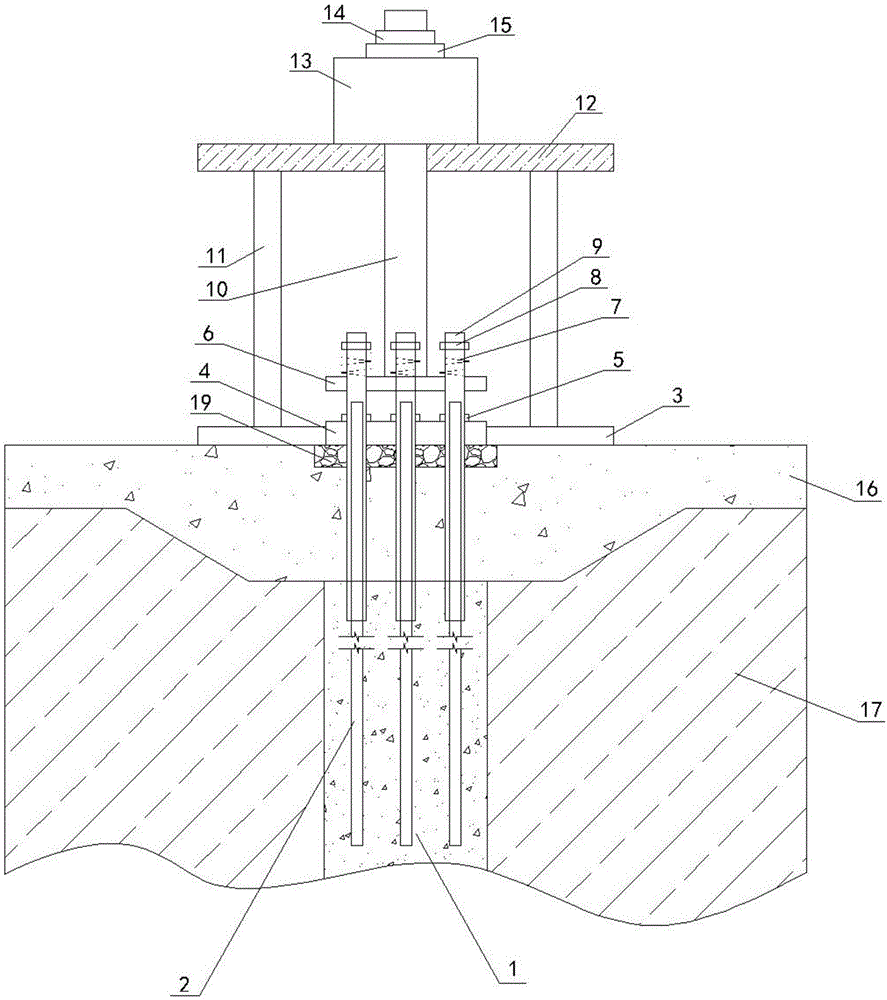

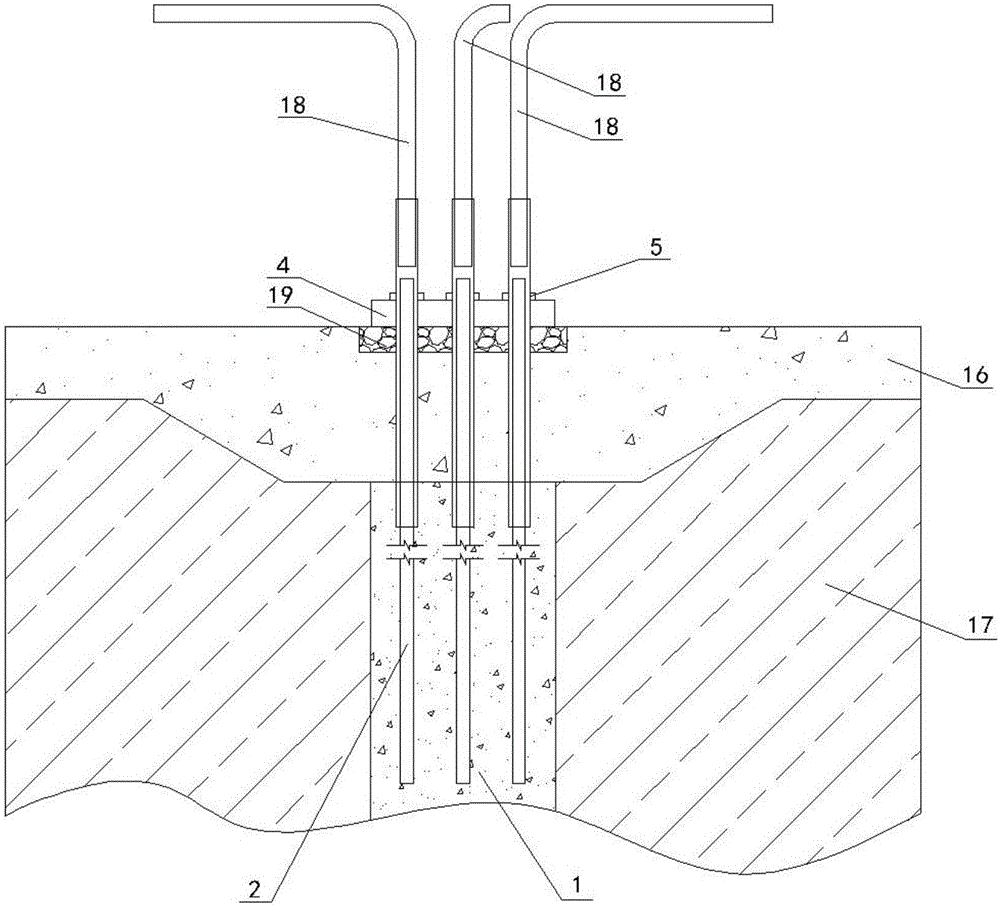

Glass fiber reinforced polymer rebar prestressed anti-floating anchor stock and construction method thereof

ActiveCN106193615AImprove use reliabilityAvoid force unevennessBuilding reinforcementsBuilding material handlingEpoxyGlass fiber reinforced polymer

The invention discloses a glass fiber reinforced polymer rebar prestressed anti-floating anchor stock and a construction method thereof. The glass fiber reinforced polymer rebar prestressed anti-floating anchor stock is characterized in that steel sleeves are arranged; the bottom sleeve ends of the steel sleeves penetrate through the a bottom plate cushion layer and penetrate into a rock foundation layer; the lower section of an anchor stock body is anchored in the rock foundation layer; the upper section of each anchor stock body is sleeved with the corresponding steel sleeve and is fixedly combined with the corresponding steel sleeve through filled epoxy resin; the anchor stock bodies are glass fiber reinforced polymer(GRRP) anchor stocks; a lower bearing plate is arranged on the bottom plate cushion layer; the steel sleeves are sleeved with the lower bearing plate through through hole sliding sleeves; lock nut with the lower bearing plate as the locking end face are arranged on the steel sleeves; and a prestress applying mechanism is arranged on the steel sleeves and used for implementing prestress applying on the anchor stock bodies through force transfer of the steel sleeves. Shear failure to the anchor stock during prestress applying can be avoided, and effective connection of the anchor stock and a bottom plate rebar is ensured, and the anchoring and supporting effects on the anti-floating anchor stock are ensured.

Owner:ANHUI WATER RESOURCES DEV

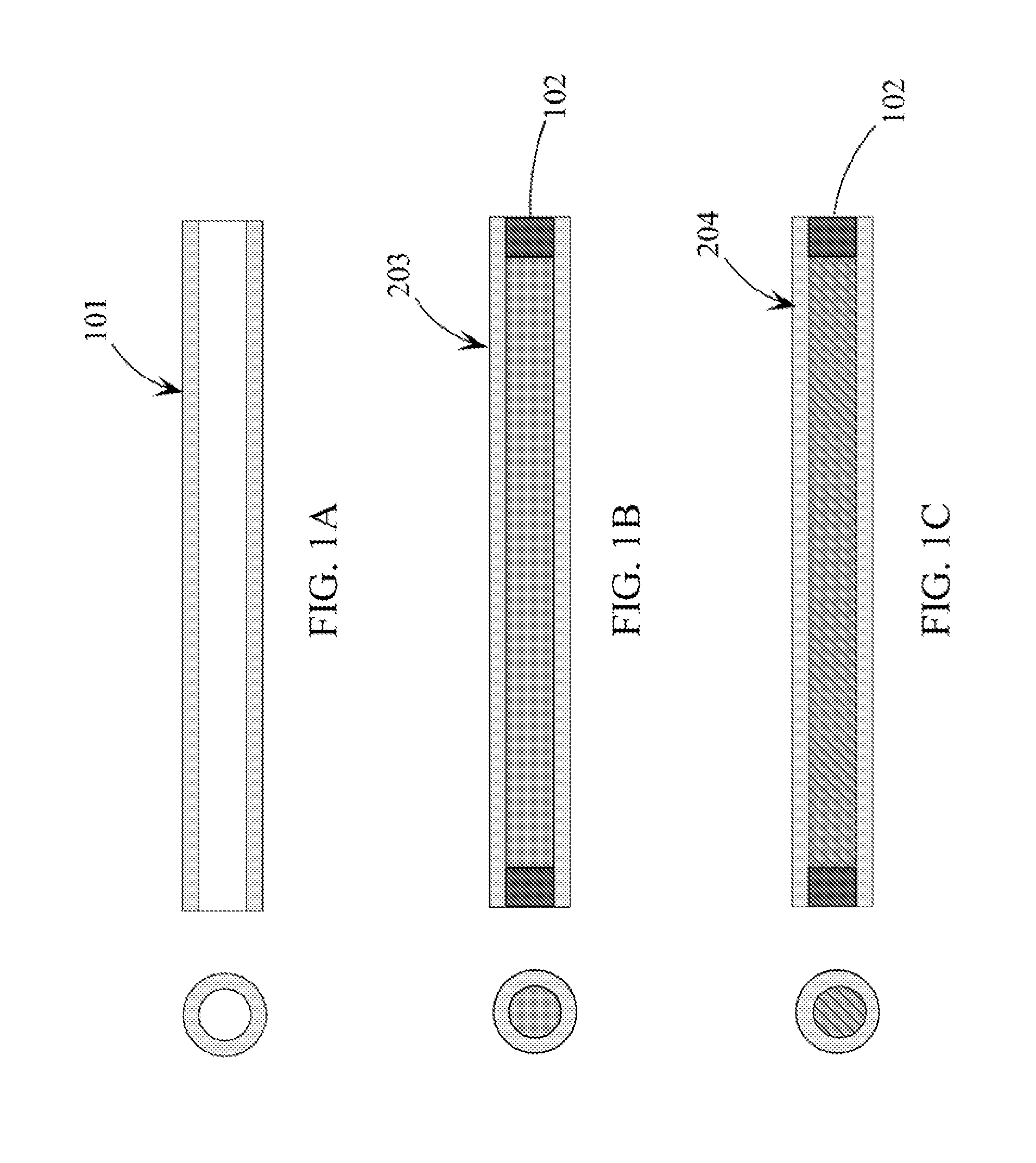

Self-healing material

InactiveUS20150159316A1Extended service lifeFibre typesSynthetic resin layered productsGlass fiber reinforced polymerResin embedding

A glass fiber-reinforced polymer composite includes a polymer matrix, a plurality of glass fibers embedded within the polymer matrix, a first hollow glass fiber containing a resin embedded within the polymer matrix, a second hollow glass fiber containing a catalyst suitable for curing the resin embedded within the polymer matrix. When damage occurs to such a composite, the glass fibers containing the resin and the catalyst are ruptured, resulting in their mixing together so that the resin is cured for repairing the ruptured location.

Owner:PEN

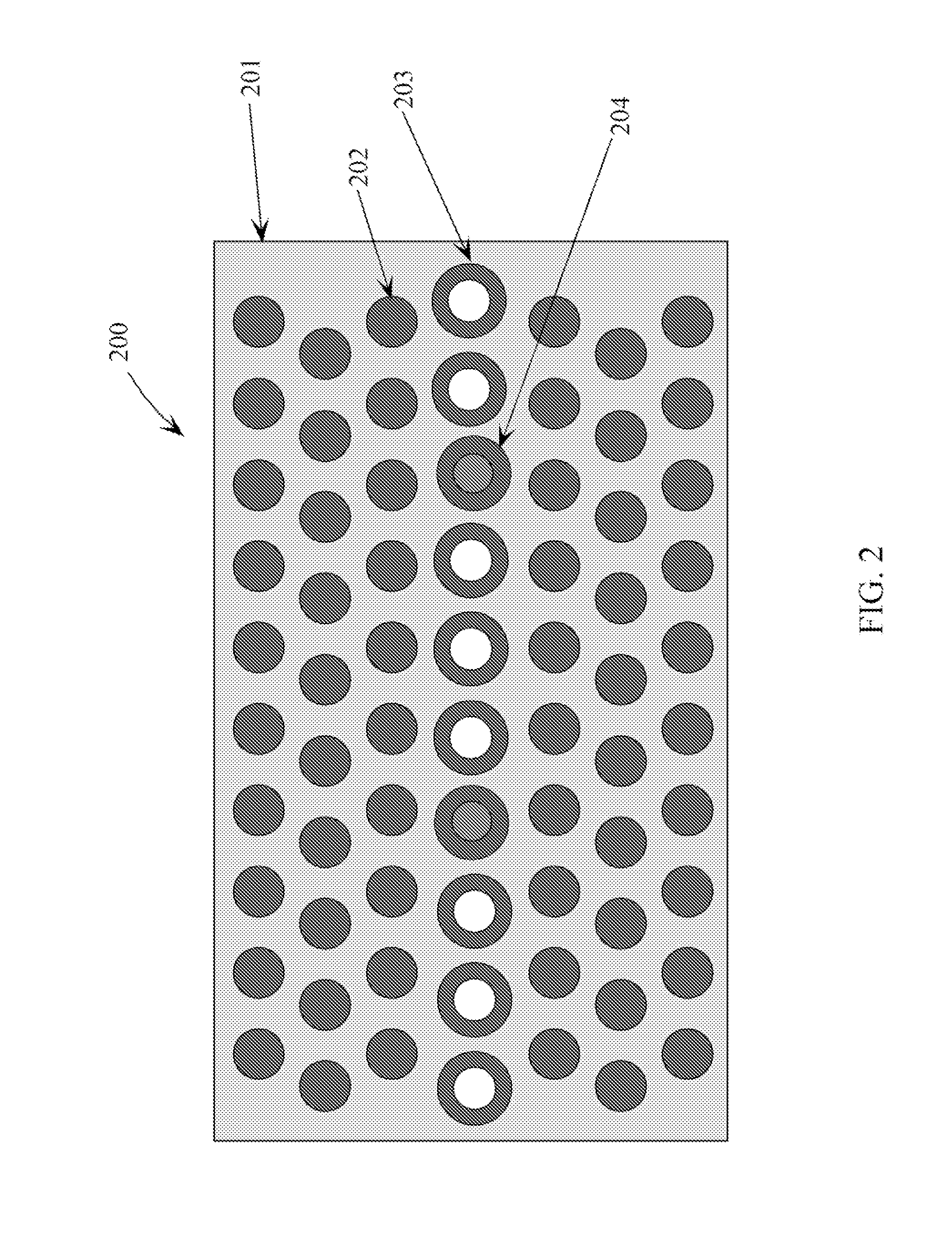

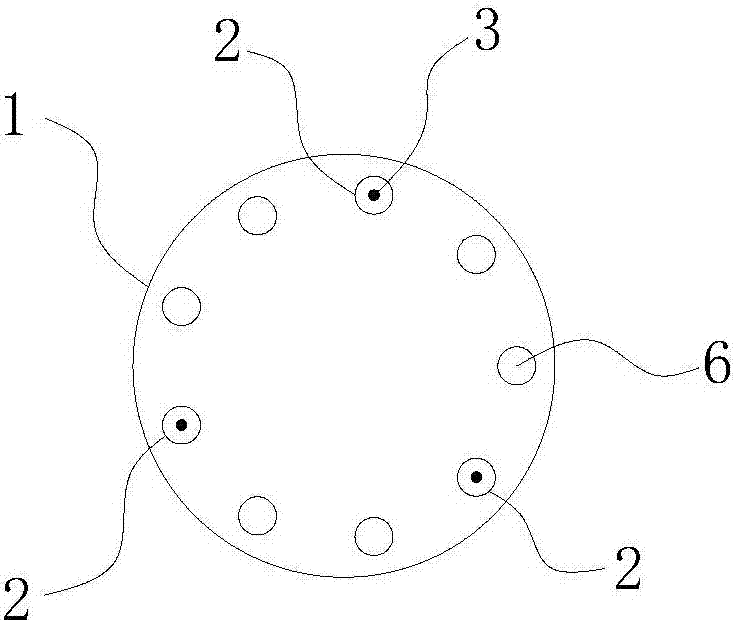

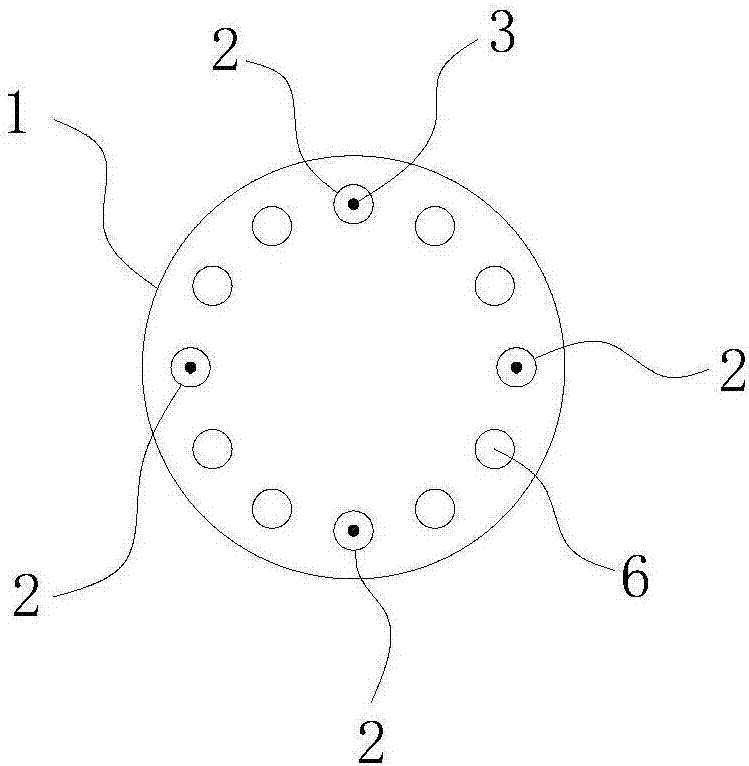

Glass fiber-reinforced polymer concrete pile containing optical fibers

PendingCN107130598AFacilitate real-time monitoring of flexural capacityFacilitates real-time monitoring of integrityFoundation testingBulkheads/pilesGlass fiber reinforced polymerEngineering

The invention relates to a glass fiber-reinforced polymer concrete pile containing optical fibers. The glass fiber-reinforced polymer concrete pile comprises a pile body and glass fiber-reinforced polymers located in the pile body to form a longitudinal main polymer of the pile body; an optical fiber arranged in the length direction of the corresponding glass fiber-reinforced polymer and a plurality of strain sensors and / or sonic wave sensors arranged along the length direction of the corresponding glass fiber-reinforced polymer at intervals are arranged in each glass fiber-reinforced polymer; and a detecting signal of the strain sensors and a detecting signal of the sonic wave sensors are outputted by the corresponding optical fiber. After the glass fiber-reinforced polymer concrete pile disclosed by the invention is used as a building foundation, even the glass fiber-reinforced polymer concrete pile is under a concealed condition, the situations whether the glass fiber-reinforced polymer concrete pile is complete or not or the stress is changed or not can also be detected in a real-time manner; strain data of the pile body is transmitted to a signal acquiring module through the optical fibers by the strain sensors, so that the situation whether the stress of the concrete pile is changed or not can be achieved; the wave velocity of sonic waves broadcasted in the pile body is transmitted to the signal acquiring module by the sonic wave sensors, so that the wave velocity distribution of the sonic waves in the pile body can be achieved; and through the changes of the wave velocity, the situation whether the pile body is complete or not can be judged, and according to the wave velocity distribution, the length of the pile body can also be achieved.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

In-situ micro-glass-fiber reinforced polymer based 3D printing consumables as well as preparation method and equipment thereof

InactiveCN106633713ASmall sizeImprove mechanical propertiesAdditive manufacturing apparatusGlass fiber reinforced polymerPolymer science

The invention discloses in-situ micro-glass-fiber reinforced polymer based 3D printing consumables as well as a preparation method and equipment thereof. Phosphate glass-ceramic and a polymer matrix are composited, so that the mechanical property of the FDM (frequency-division multiplexing) polymer based 3D printing consumables can be remarkably improved and nozzles cannot be blocked during printing; a static mixer is used for further mixing, the size of the phosphate glass-ceramic in a product is reduced, the mechanical property of a material is greatly improved through further extension by a traction device, and the contradiction between reinforcement of the 3D printing consumables and blockage of the nozzles is solved. The 3D printing consumables are prepared from the widely-sourced material, can realize continuous production easily and are low in cost and good in use effect; the preparation method is simple, and large-scale preparation is facilitated.

Owner:贵州一当科技有限公司

Flexible roof photovoltaic tile and preparation method thereof

ActiveCN103441168ALarge choiceGood photovoltaic output characteristicsRoof covering using slabs/sheetsRoof covering using tiles/slatesGlass fiber reinforced polymerAdhesive

The invention discloses a flexible roof photovoltaic tile. The flexible roof photovoltaic tile comprises a flexible roof tile substrate and a photovoltaic decorative layer, wherein the flexible roof tile substrate adheres to the photovoltaic decorative layer through adhesives, a glass fiber reinforced polymer cement mortar sheet serves as the flexible roof tile substrate, is of a layered structure, and comprises an isolation layer, a back glue layer, a lower polymer cement mortar layer, a high-tenacity glass fiber reinforced non-woven fabric base and an upper polymer cement mortar layer in sequence from bottom to top, and the structures of the five layers are combined into a whole in a solidification mode. Sika single-component high-modulus polyurethane sealing adhesives serve as the adhesives. The photovoltaic decorative layer comprises a flexible thin-film battery assembly, a film layer and a coating layer in sequence from bottom to top. The flexible roof photovoltaic tile is a photovoltaic building material which is light in load borne by a roof, safe, reliable, free of heating through fire in the construction process, easy and convenient to construct and low in comprehensive cost, saves energy, protects the environment, and integrates the function of water resistance, the function of fire resistance, the function of decoration and the function of photovoltaic power generation.

Owner:嘉兴如运建筑科技有限公司

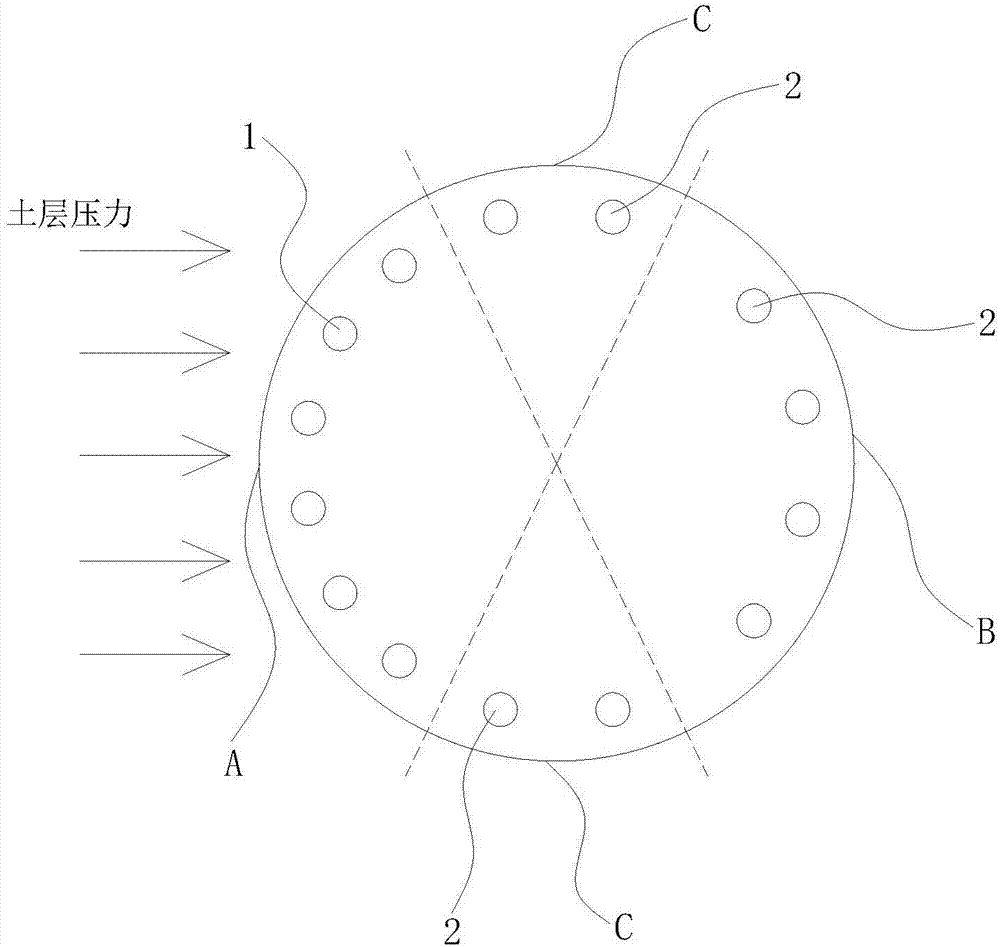

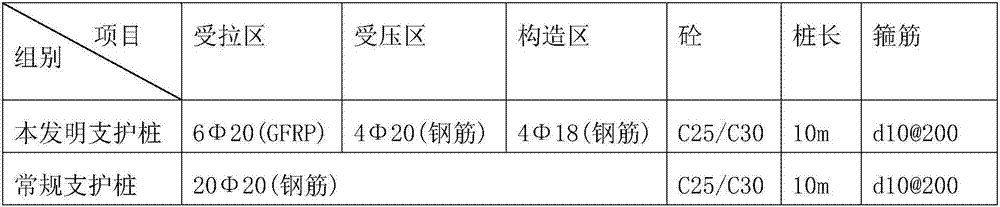

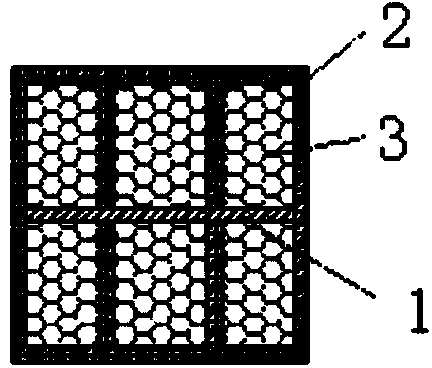

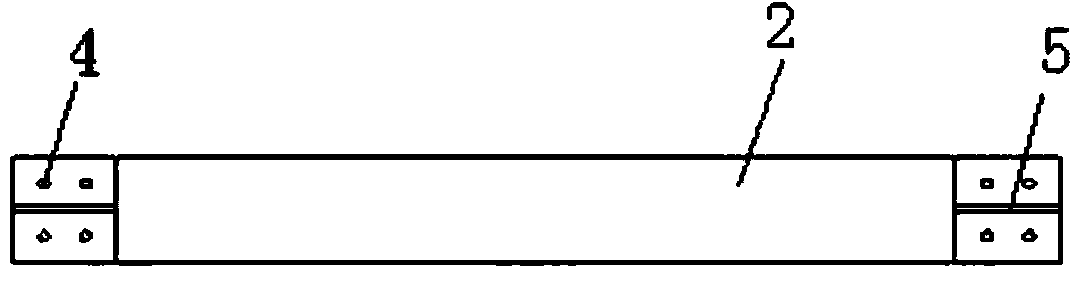

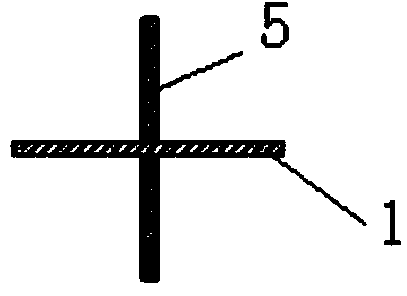

Non-symmetric composite reinforced concrete pouring supporting pile

InactiveCN107130589AReduce usageImprove corrosion resistanceExcavationsBulkheads/pilesGlass fiber reinforced polymerReinforced concrete

The invention relates to a non-symmetric composite reinforced concrete pouring supporting pile. The non-symmetric composite reinforced concrete pouring supporting pile comprises a tensile region and a compression zone, wherein the side surface of the tensile region is close to a soil layer; the side surface of the compression zone is away from the soil layer; reinforcement in the tensile region is formed by glass fiber-reinforced polymers arranged along a supporting pile in a circumferential direction at intervals or the glass fiber-reinforced polymers and steel bars alternately arranged along the supporting pile in a circumferential direction at intervals; the reinforcement in the compression zone is formed by steel bars arranged along the supporting pile in a circumferential direction at intervals; and the axial directions of the glass fiber-reinforced polymers and the steel bars are parallel to that of the supporting pile. According to the non-symmetric composite reinforced concrete pouring supporting pile disclosed by the invention, the usage quantity of the steel bars is greatly reduced through the reinforcement manner, so that steel materials are saved, and the non-symmetric composite reinforced concrete pouring supporting pile is energy-saving and environmentally-friendly; and besides, the corrosion resistance of the supporting pile is strengthened by the glass fiber-reinforced polymers, and the supporting pile is especially suitable for a seaside ground environment with a high content of chloride ions. According to the non-symmetric composite reinforced concrete pouring supporting pile disclosed by the invention, the utilization ratio of reinforcement materials is maximized, and particularly the adopted glass fiber-reinforced polymers are low in cost, so that the construction cost of the supporting pile is effectively reduced; and in addition, compared with the steel bars, the glass fiber-reinforced polymers are lighter, easier to transport, easier to hoist during production and manufacturing, and more convenient and quicker.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

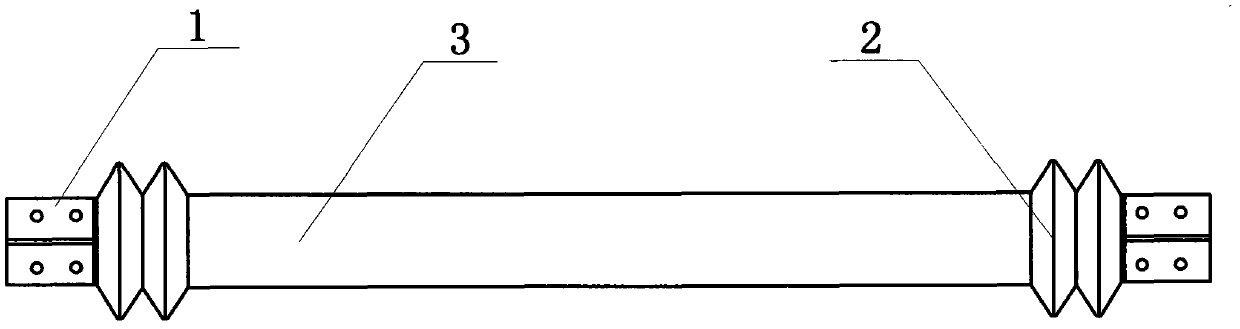

Anti-buckling low yield point steel-composite energy dissipation brace

ActiveCN103437450AStrong designabilityImprove carrying capacityShock proofingGlass fiber reinforced polymerCarrying capacity

The invention discloses an anti-buckling low yield point steel-composite energy dissipation brace, comprising an inner core stress unit which is integrally sealed and coated by a peripheral composite constraint unit, wherein the inner core stress unit is a low yield point steel kernel steel core; the peripheral composite constraint unit is formed by a ribbed glass fiber reinforced polymer (GFRP) pipe, and contoured foams in the pipe; GFRP rib plates inside the pipe are evenly distributed; the kernel steel core and the peripheral composite constraint unit are integrally molded at one time in a vacuum importing manner; screw holes are formed in connecting parts at two ends of the kernel steel core; GFRP stiffening ribs vertical to the kernel steel core are respectively arranged at two ends of the kernel steel core. According to the anti-buckling low yield point steel-composite energy dissipation brace, the GFRP rib plates directly contact the inner core stress unit of the brace; external energy dissipated by the inner core stress unit is constrained by a composite, so that the brace is free of buckling; the carrying capacity of the brace is improved. The brace is integrally molded once in the vacuum importing manner, is corrosion-resistant, low in full-life maintenance cost, light in weight, high in strength, convenient to transport, install and construct, strong in designability, convenient to mold, and quick to produce in batch, and can be flexibly designed according to the requirements.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com