Non-welding buckling restraining support with inspection windows

A technology of buckling constraints and observation windows, which is applied to building components, earthquake resistance, etc., can solve the problems of self-heaviness and poor corrosion resistance, and achieve the effect of solving poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

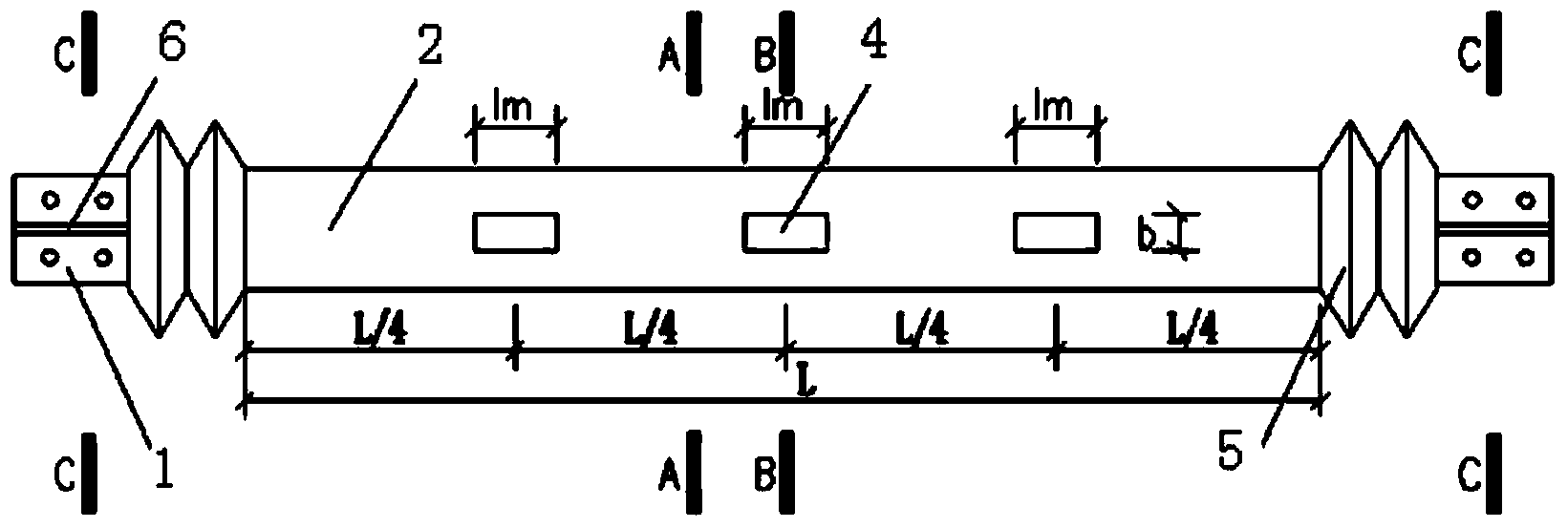

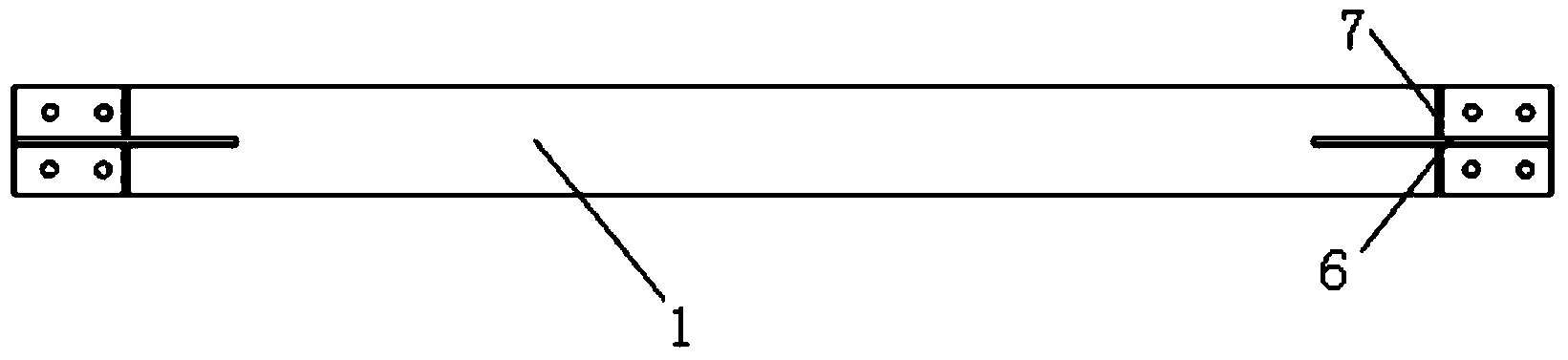

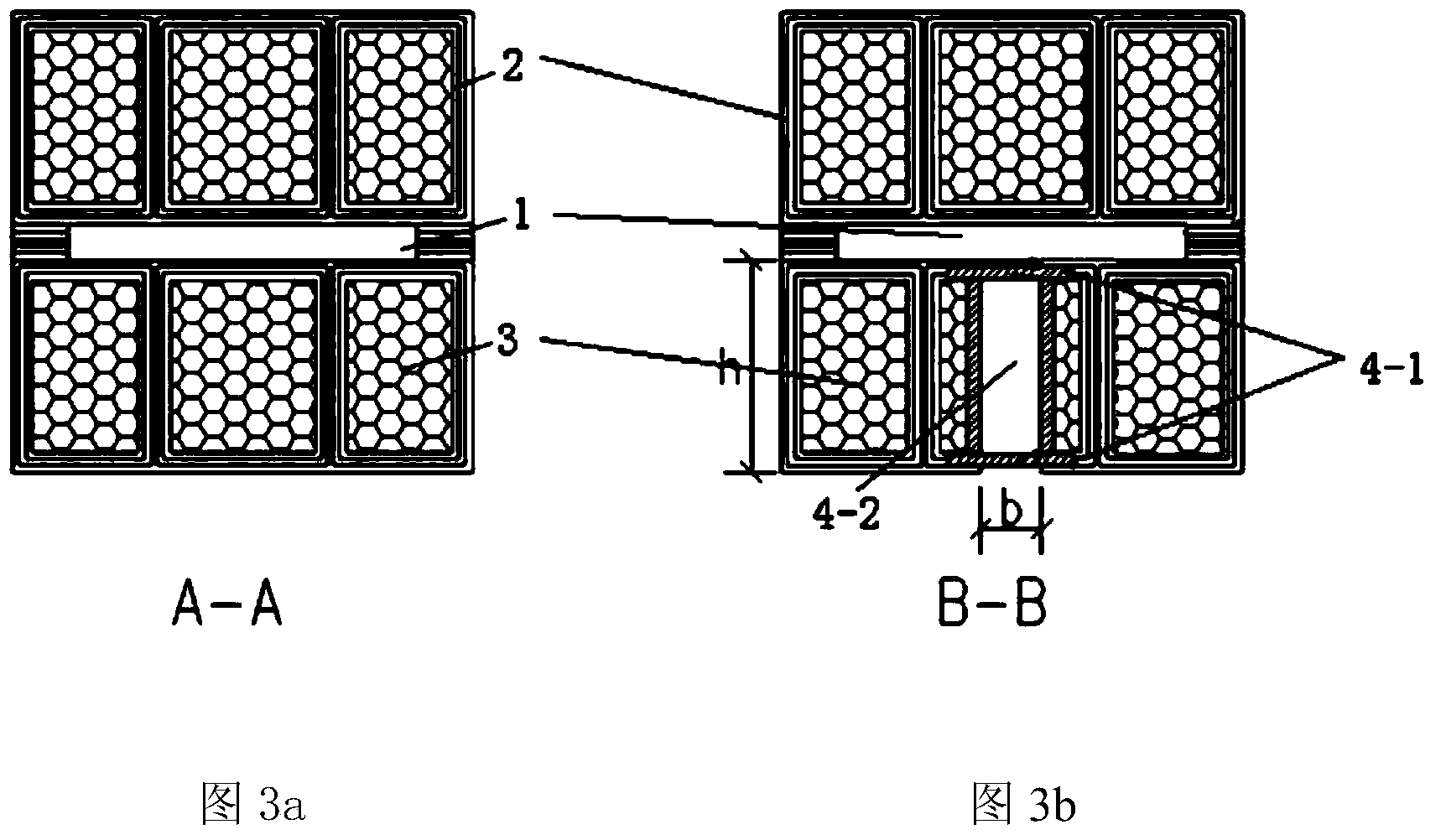

[0026] A buckling restraint support without welding and with an observation window, comprising an inner core steel core 1 and a peripheral restraint unit, the inner core steel core 1 is a "one"-shaped steel plate, the outer restraint unit includes an energy dissipation section, and the energy dissipation section shaft To the transition section at both ends and the installation section outside the two transition sections, the energy dissipation section is a ribbed GFRP rectangular tube 2, and the tube is filled with molding foam 3 during molding, and the GFRP ribs in the tube are evenly arranged perpendicular to the inner core steel core 1. On the axis of the energy dissipation section, a plurality of observation windows 4 are arranged perpendicular to the inner core steel core 1, the conversion section is a GFRP expansion joint 5, and the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com