Flexible roof photovoltaic tile and preparation method thereof

A photovoltaic tile and flexible technology, applied in photovoltaic power generation, roofs using tiles/slate tiles, and roofs using flat/curved panels, etc., can solve the problems of easily damaged roof waterproof and thermal insulation layer, heavy photovoltaic tile weight, and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

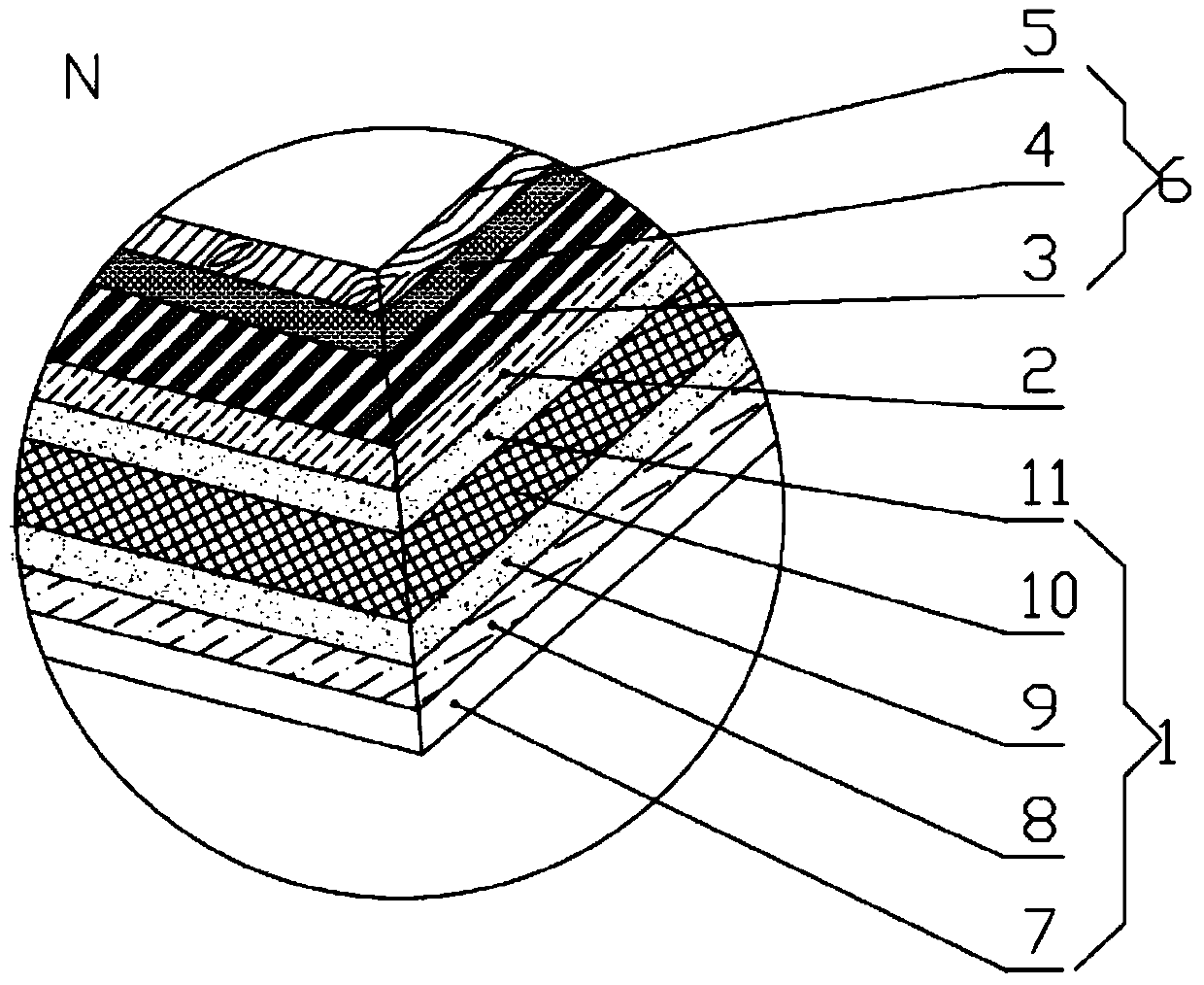

[0034] like figure 1 and figure 2 As shown, a flexible photovoltaic tile includes a roof flexible substrate 1 and a photovoltaic decorative layer 6 bonded by an adhesive 2, and the roof flexible substrate 1 is a glass fiber reinforced flame-retardant polymer cement mortar sheet, which is specifically It is a layered structure, from bottom to top: isolation layer 7, adhesive layer 8, lower flame retardant polymer cement mortar layer 9, high toughness glass fiber reinforced flame retardant non-woven fabric base 10 and upper flame retardant polymer cement Mortar layer 11, the five-layer structure is consolidated into one. The adhesive 2 is Sika's single-component high-modulus polyurethane sealing adhesive, and the high-tough glass fiber reinforced flame-retardant non-woven fabric adopts Anfang flame-retardant fiber. The adhesive layer 8 is composed of asphalt self-adhesive, with a thickness of 0.2mm; the isolation layer 7 is kraft paper, adhered to the sticky surface of the ad...

Embodiment 2

[0037] The back adhesive layer 8 of the present invention is made of polyacrylic self-adhesive, with a thickness of 1.0 mm; the high-toughness glass fiber reinforced flame-retardant non-woven fabric adopts 4080 fibers; the isolation layer 7 is a polyester film, adhered to On the sticky surface of the adhesive layer 8; the upper flame-retardant polymer modified cement mortar layer 11 and the lower flame-retardant polymer modified cement mortar layer 9 are composed of the following raw materials in parts by weight: 17 parts of ordinary silicon 425 cement , 45 parts of quartz sand, 23 parts of propionic acid emulsion, 25 parts of water, 8 parts of composite flame retardant; the flexible thin film battery assembly 3 is copper indium potassium selenium thin film solar cell; the coating layer 5 is coated by fluorocarbon coating The thickness is 70um, and the film layer 4 is an ethylene-tetrafluoroethylene copolymer (ETFE) film; others are the same as in Example 1.

Embodiment 3

[0039] The back glue layer 8 of the present invention is made of butyl rubber self-adhesive, with a thickness of 0.5mm; the upper flame-retardant polymer modified cement mortar layer 11 and the lower flame-retardant polymer modified cement mortar layer 9 are composed of the following The composition of raw materials in parts by weight: 15 parts of ordinary silicon 425 cement, 42 parts of quartz sand, 20 parts of propionic acid emulsion, 20 parts of water, 6 parts of composite flame retardant; the flexible thin film battery module 3 is a cadmium telluride thin film solar cell; The paint layer 5 is made of fluorocarbon paint, with a thickness of 70um, and the film layer 4 is an ethylene-tetrafluoroethylene copolymer (ETFE) film, and the others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com