Thermosetting epoxy asphalt material and preparation method thereof

An epoxy asphalt material and technology of epoxy asphalt, applied in building insulation materials, building components, buildings, etc., can solve the problems of poor compatibility and quality reduction of modified asphalt, and achieve good low-temperature crack resistance and good fatigue resistance Effects of performance and expansion of types of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

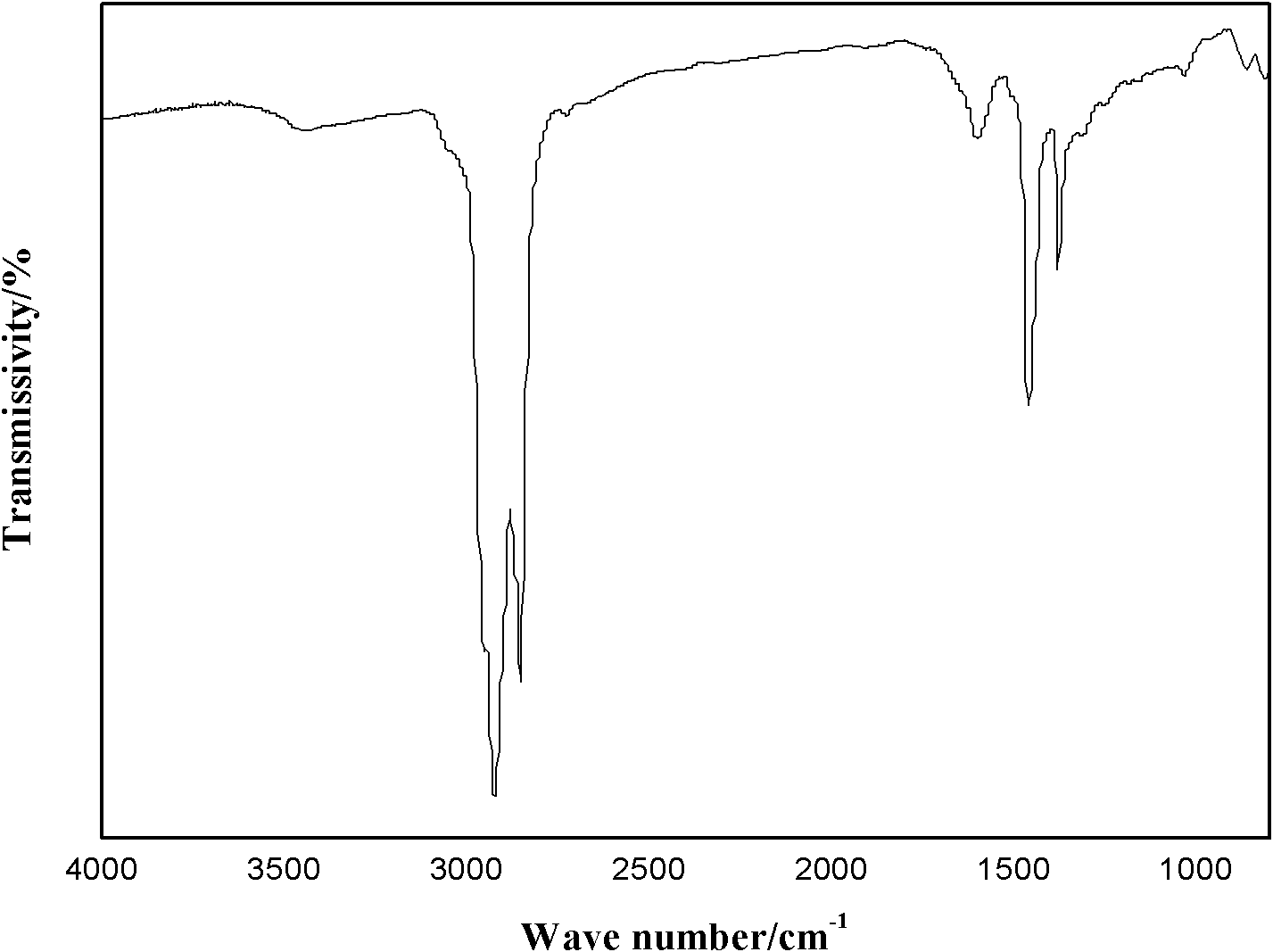

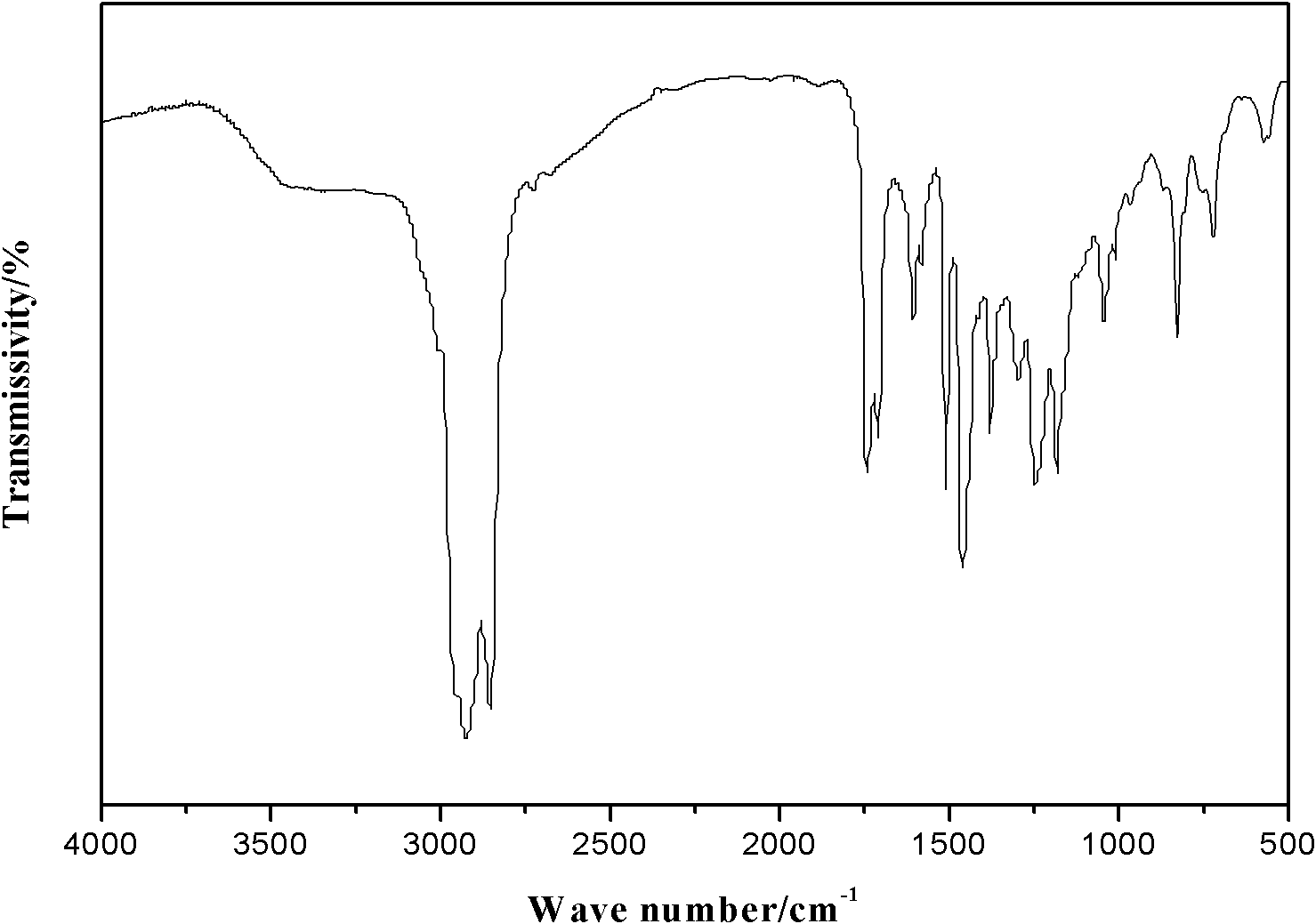

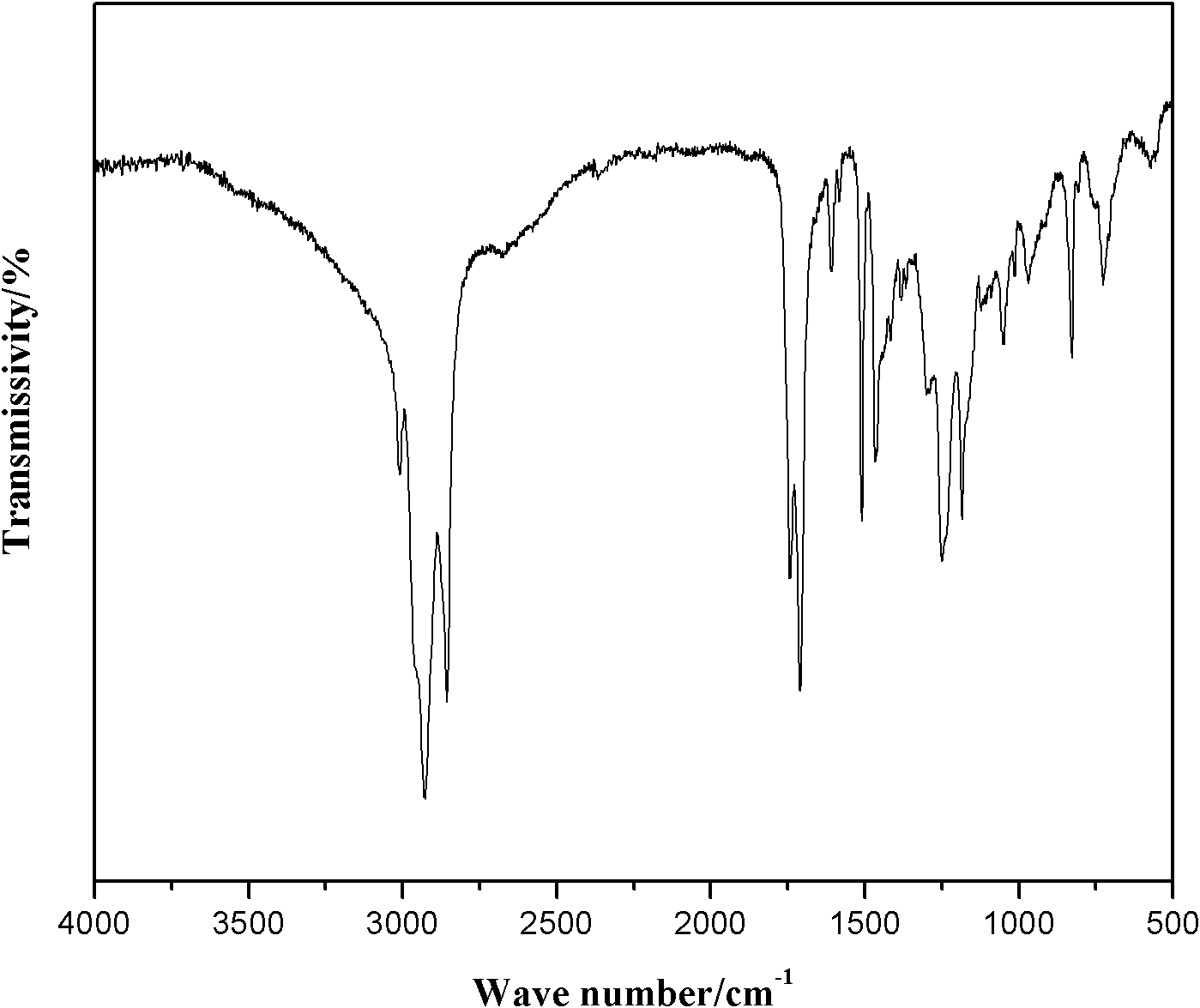

Image

Examples

Embodiment 1

[0052] 1. The preparation method of oleyl chloride thermosetting epoxy asphalt compatibilizer, which includes the following steps:

[0053] 1) Preparation of oleyl chloride: In a 500 mL three-necked flask equipped with a constant temperature oil bath, a stirring device, and a reflux device, add 126 grams of oleic acid, 21 grams of phosphorus trichloride, and 140 grams of chloroform. The temperature is raised to 50°C for reaction 4. After hours, the lower layer precipitate was separated, and the solvent (trichloromethane) was evaporated to obtain 134 g of oleyl chloride.

[0054] 2) Add 40 grams of epoxy resin E-51 and 80 grams of acetone into a 250 mL three-necked flask, stir to fully dissolve the epoxy resin in the acetone, heat up to 35°C, and add 7 grams of 5wt% NaOH aqueous solution dropwise to complete the addition. Then, it was reacted at 35°C for 1.5 hours to obtain a hydrolyzed epoxy resin. Take 134 grams of oleoyl chloride and the hydrolyzed epoxy resin (40 grams) obtaine...

Embodiment 2

[0067] 1. The preparation method of oleyl chloride thermosetting epoxy asphalt compatibilizer, which includes the following steps:

[0068] 1) Preparation of oleyl chloride: In a 500mL three-necked flask equipped with a constant temperature oil bath, a stirring device, and a reflux device, add 100 grams of stearic acid, 17 grams of phosphorus trichloride, and 120 grams of chloroform, and heat to 50°C for reaction After 5 hours, the lower layer precipitate was separated, and the solvent (trichloromethane) was evaporated to obtain oleyl chloride.

[0069] 2) Add 100 grams of epoxy resin E-44 and 200 grams of acetone into a 500 mL three-necked flask, stir to fully dissolve the epoxy resin in the acetone, raise the temperature to 35°C, dropwise add 20 grams of 5wt% NaOH aqueous solution, and add to complete Then, it was reacted at 35°C for 1.5 hours to obtain a hydrolyzed epoxy resin. Take 298 grams of oleyl chloride and the hydrolyzed epoxy resin obtained in this step, 300 grams of t...

Embodiment 3

[0073] 1. The preparation method of oleyl chloride thermosetting epoxy asphalt compatibilizer, which includes the following steps:

[0074] 1) Preparation of oleyl chloride: In a 500mL three-necked flask equipped with a constant temperature oil bath, a stirring device, and a reflux device, add 100 grams of undecylenic acid, 17 grams of dimethyl sulfoxide, and 120 grams of toluene, and heat to 60°C for reaction After 4 hours, the lower layer precipitate was separated, and the solvent (toluene) was evaporated to obtain oleyl chloride.

[0075] 2) Add 100 grams of epoxy resin E-42 and 380 grams of acetone into a 500 mL three-necked flask, stir to fully dissolve the epoxy resin in the acetone, raise the temperature to 35°C, dropwise add 20 grams of 8wt% NaOH aqueous solution, and add dropwise to complete Then, it was reacted at 35°C for 1.0 hour to obtain a hydrolyzed epoxy resin. Take 298 grams of oleoyl chloride and the hydrolyzed epoxy resin obtained in this step, 353 grams of tolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com