Patents

Literature

154 results about "Undecylenic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

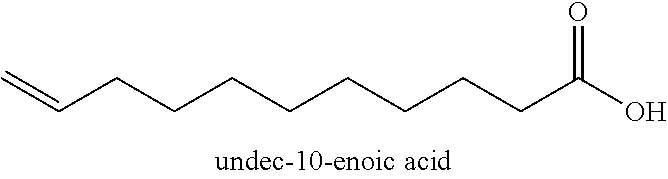

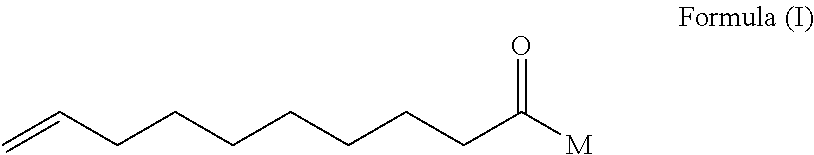

Undecylenic acid is an organic compound with the formula CH₂=CH(CH₂)₈CO₂H. It is an unsaturated fatty acid. It is a colorless oil. Undecylenic acid is mainly used for the production of Nylon-11 and in the treatment of fungal infections of the skin, but it is also a precursor in the manufacture of many pharmaceuticals, personal hygiene products, cosmetics, and perfumes. Salts and esters of undecylenic acid are known as undecylenates.

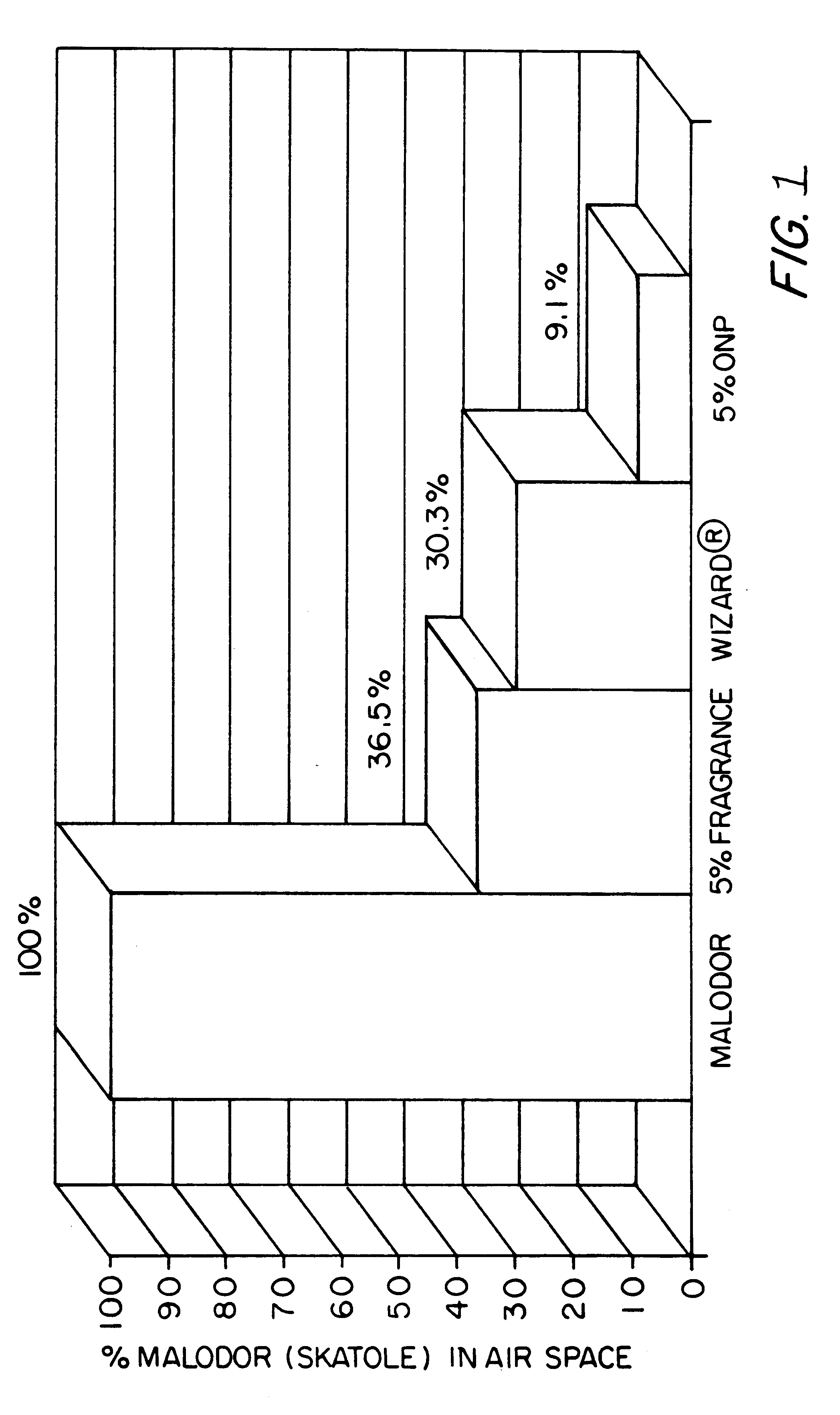

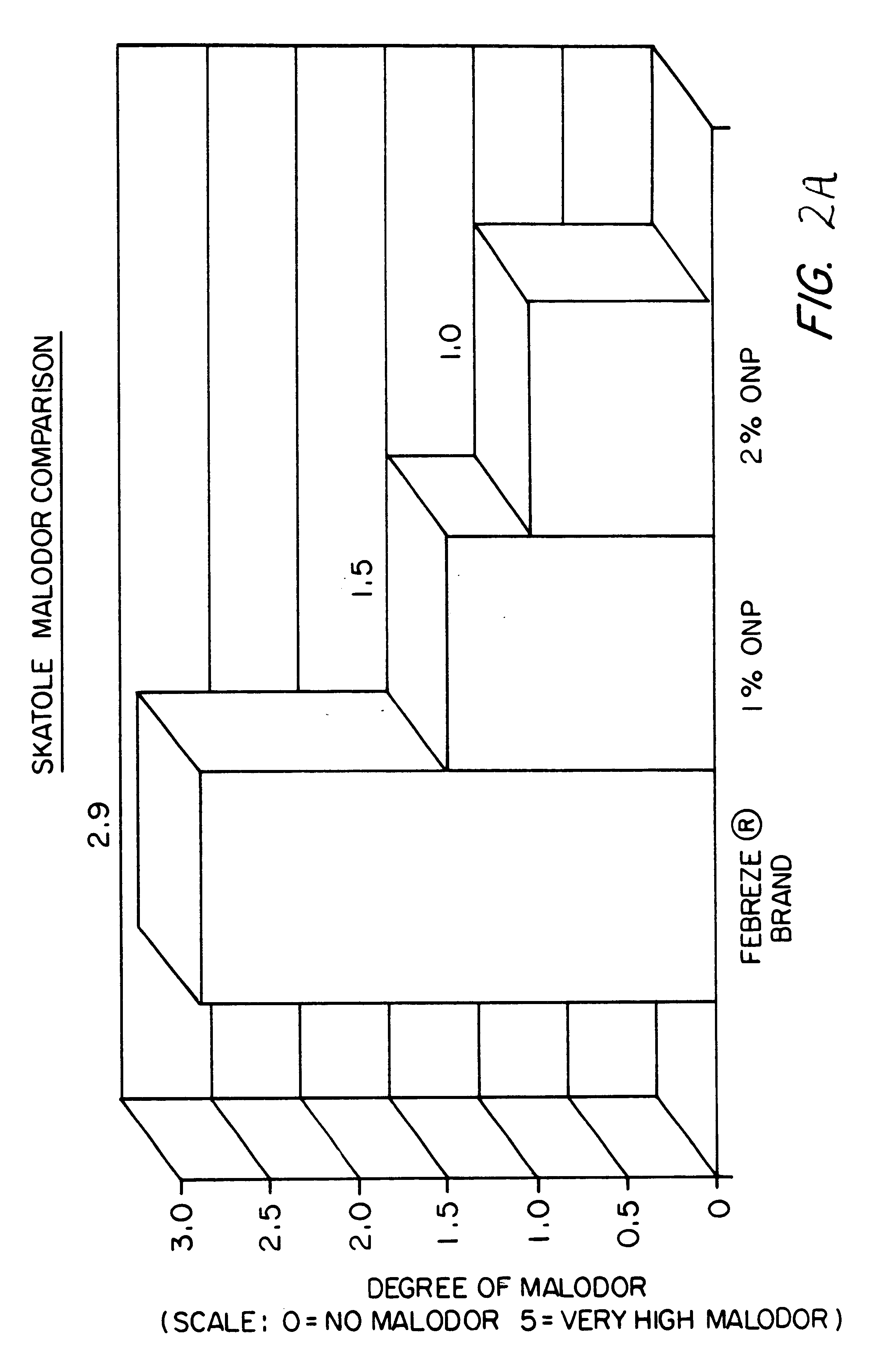

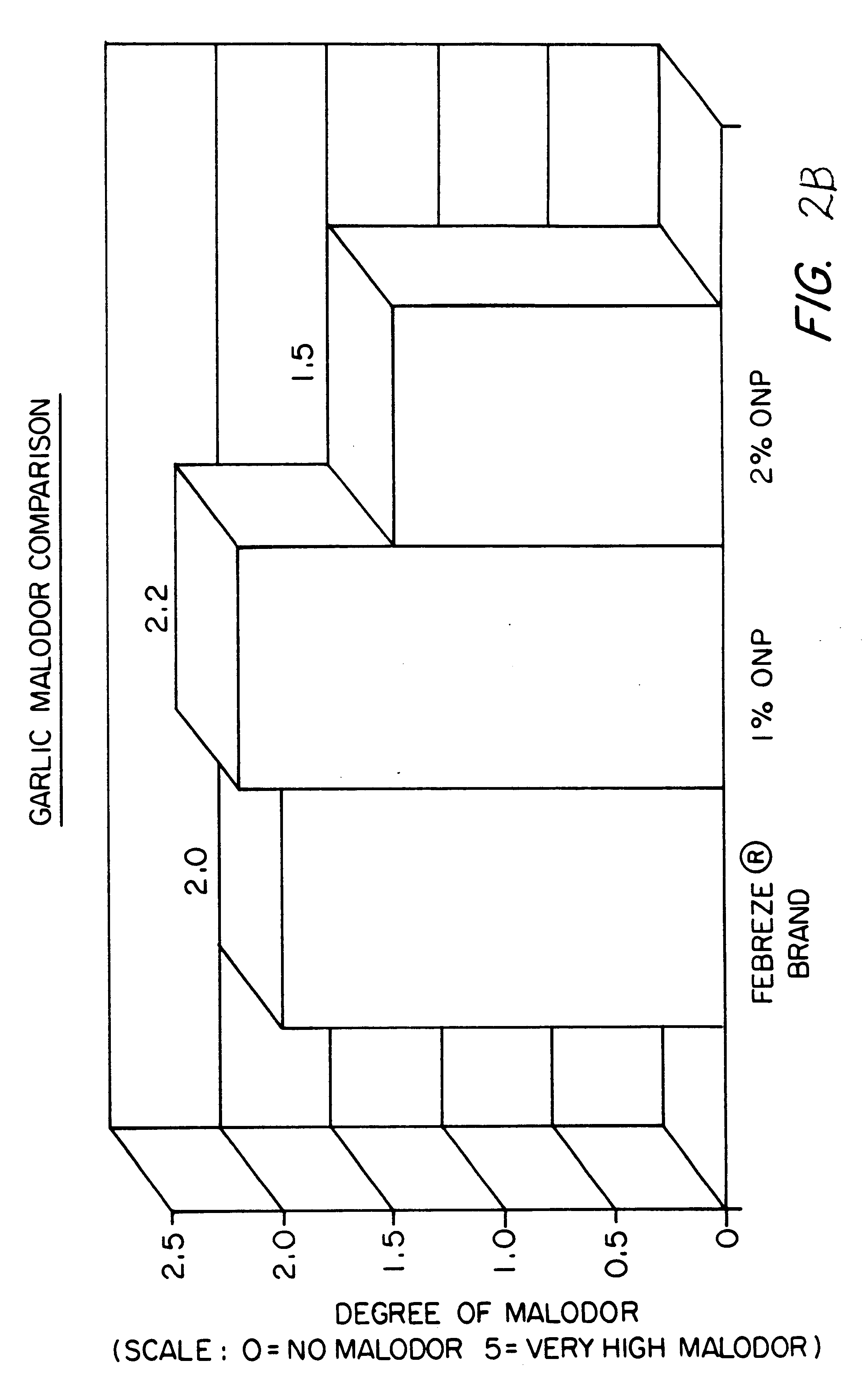

Fragrance and flavor compositions containing odor neutralizing agents

InactiveUS6495097B1Reduces undesirable scavengingFacilitated releaseCosmetic preparationsToilet preparationsFood flavorUndecenoic acid

A composition and a method of use for reducing malsensory agents comprising a component selected from the group consisting of fragrances, flavors, unfragranced carriers and mixtures thereof, with undecylenic acid and / or a derivative thereof, in an amount effective to reduce the malsensory agents and allow release of the component from the composition.

Owner:GIVAUDAN SA

Compositions for Regulation of Hair Growth

InactiveUS20080254055A1Reduce frequencyImprove shaving efficiencyBiocideCosmetic preparationsPersonal carePhytic acid

Personal care composition comprising at least one hair growth regulating compound selected from the group consisting of glyceryl dilaurate, apigenin, tetrahydrocurcumin, oleanolic acid, azelaic acid, sulforaphane, canavanine, pyridoxal 5-phosphate, phytic acid, tannic acid, grape seed extract, NG-nitro-L-arginine-methyl ester, benzamidine, sodium butyrate, betulinic acid, polyornithine, polyarginine, fisetin, jasmonates, methyl-jasmonate, cis-jasmone, caffeic acid phenethyl ester, delphinidin, ethyl abietate, esculetin, sorbic acid methyl ester, canaline, N-formyl-methionine, N-formyl-alanine, taurine, palmitoyl carnitine, undecanol, undecylenic acid, rutin, fusidic acid, phenyl pyruvic acid, L-isoleucine, phenyl glycine, silibinin, silymarin, L-ascorbic acid-6-palmitate, N-undecylenoyl-L-phenylalanine, and salts, derivatives and mixtures of any of the foregoing; and a dermatologically-acceptable carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Topical antifungal treatment

A topical mycological treatment composition for medical, veterinarian, or dental use contains as active ingredients clotrimazole, ketoconazole, micanazole, nystatin, tolnaftate, propionic acid, sodium propionate, undecelynic acid, and zinc undecelynate. These ingredients are contained in a natural cream base, and the base may also contain an anti-inflammatory agent and an antibacterial agent.

Owner:AYON COVARRUBIAS BLAS

Topical steroid spray with botanic seed oils

A pharmaceutical topical spray composition of corticosteroid, an alcohol, a propellant, and botanic seed oils having a blend of black raspberry seed oil, black cumin seed oil, and red raspberry seed oil prepared according to a cold press method. A method for treating an inflammatory skin condition using the administration to the skin of a mammal of the pharmaceutical composition. The pharmaceutical composition is effective in the treatment of inflammatory skin conditions without the need for zinc pyrithione, undecylenic acid, or a detergent.

Owner:CUTICEUTICALS

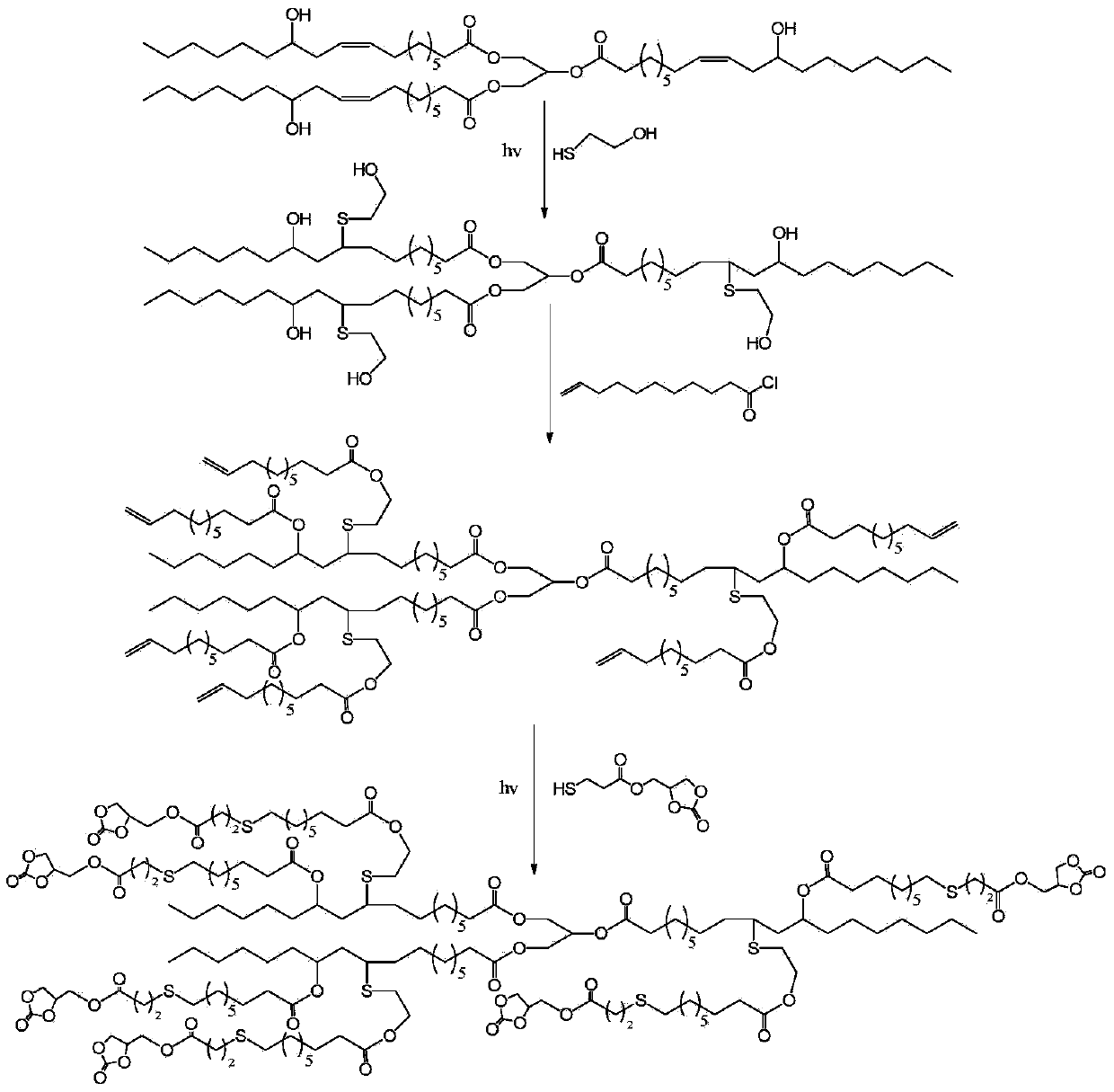

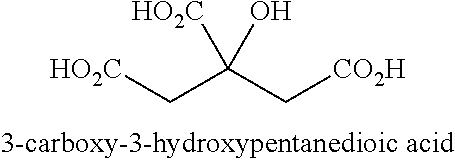

Preparation method of castor-oil base branched polybasic cyclic carbonate and non-isocyanate polyurethane thereof

ActiveCN105367790ALow viscosityHigh reactivityOrganic chemistryPolyurea/polyurethane coatingsRadiation reactionHigh pressure

The present invention discloses a preparation method of castor-oil base branched polybasic cyclic carbonate and non-isocyanate polyurethane thereof. The method is as below: raw materials of 10-undecylenic acid modified castor-oil base branched polyenoid prepolymer and thiol cyclic carbonate and a solvent chloroform are subjected to UV radiation reaction in the presence of a photoinitiator for 6-15 h to obtain a castor-oil base polybasic branched cyclic carbonate prepolymer; and the prepolymer further reacts with an amino compound to prepare the castor-oil base non-isocyanate polyurethane. The preparation of the cyclic carbonate does not require high temperature, high pressure or catalyst, and can well control the graft number of cyclic carbonate groups in the vegetable oil; and the prepared cyclic carbonate has branched structure and lower viscosity, and has long space group from a vegetable oil connection point, so that the cyclic carbonate group at the end has very high reactivity. The castor-oil base polyurethane material has the advantages of biodegradability and high content of renewable carbon, and can be used as renewable polyurethane resin for paint.

Owner:JIANGXI SCI & TECH NORMAL UNIV

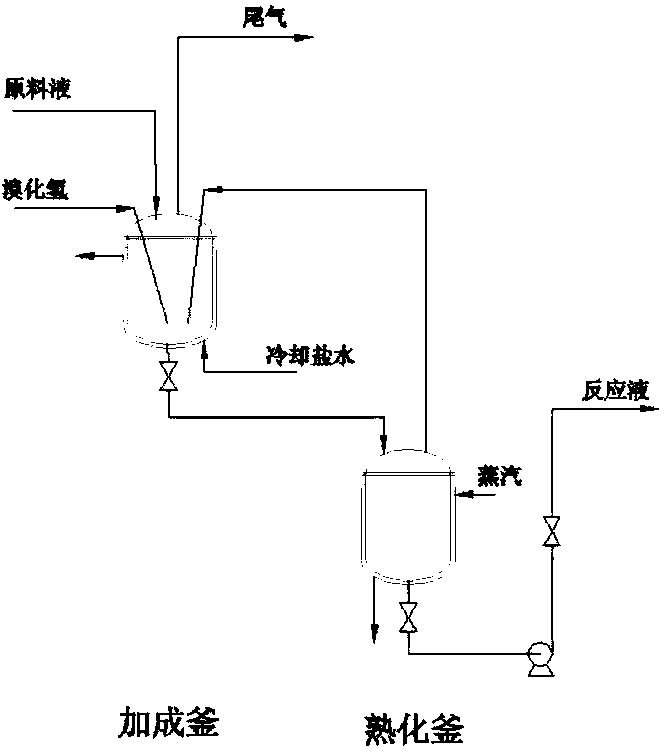

Method for preparing 11-aminoundecanoic acid by utilizing 10-undecenoic acid

ActiveCN103804209AIncrease profitSolve the problem that the reaction temperature is difficult to controlOrganic compound preparationAmino-carboxyl compound preparationBenzeneColneleic acid

The invention relates to a process for producing nylon 11 resin by utilizing castor oil, in particular to a method for preparing 11-aminoundecanoic acid by utilizing 10-undecenoic acid. The method comprises the following steps: proportioning 10-undecenoic acid, methylbenzene and benzene to prepare a raw material solution, and generating 11-bromoundecanoic acid by virtue of the additive reaction of the raw material solution with hydrogen bromide in a double-kettle reaction device in the presence of catalyst; ammonolyzing the 11-bromoundecanoic acid by virtue of three different processing ways without the crystallization; adding a phase-transfer catalyst in the ammonolysis reaction to accelerate the ammonolysis reaction; carrying out vacuum filtering after the ammonolysis reaction is completed, wherein a filter cake is a 11-aminoundecanoic acid crude product; adding the crude product into the deionized water, dissolving the crude product by heating the crude product, cooling and crystallizing the crude product, and filtering the crude product to obtain the refined 11-aminoundecanoic acid product.

Owner:江苏东鼎化学科技有限公司

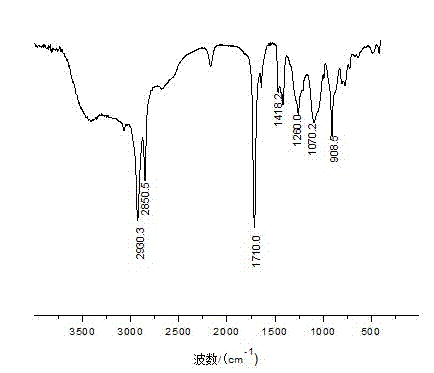

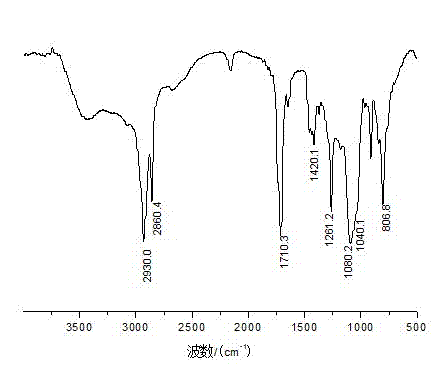

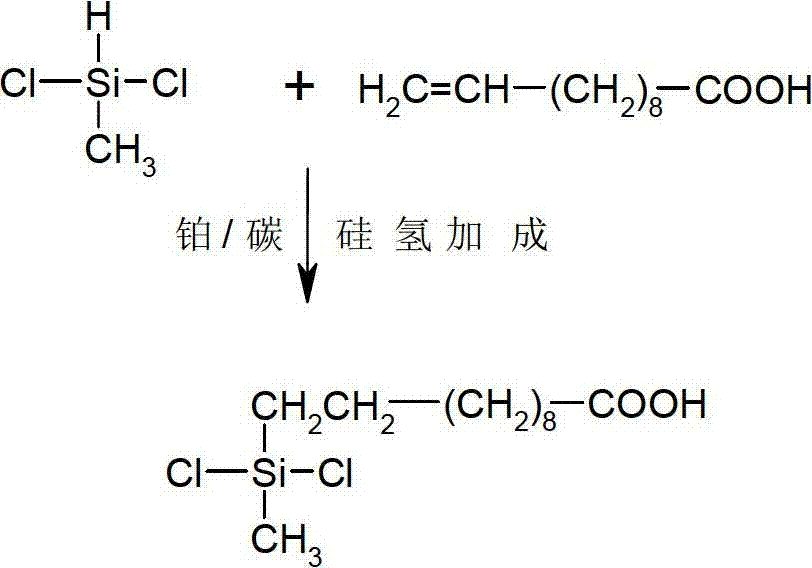

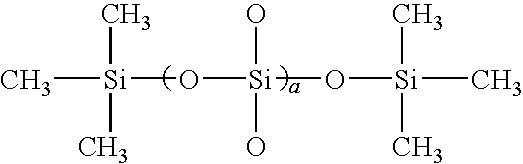

Preparation method of carboxyl silicone oil

InactiveCN102731787AThe synthesis process is simpleRaw materials are easy to getFibre treatmentSilanesHydrosilylation

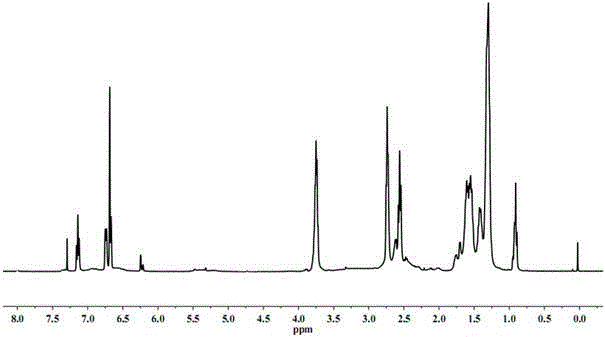

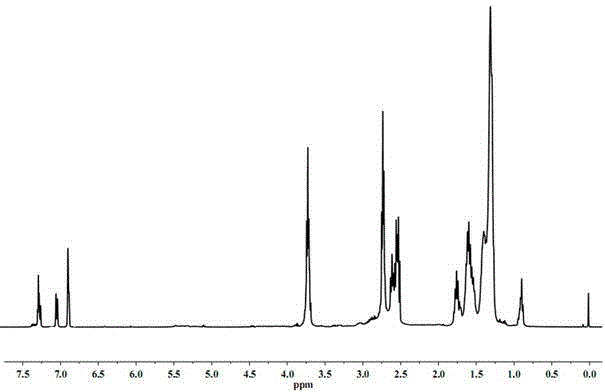

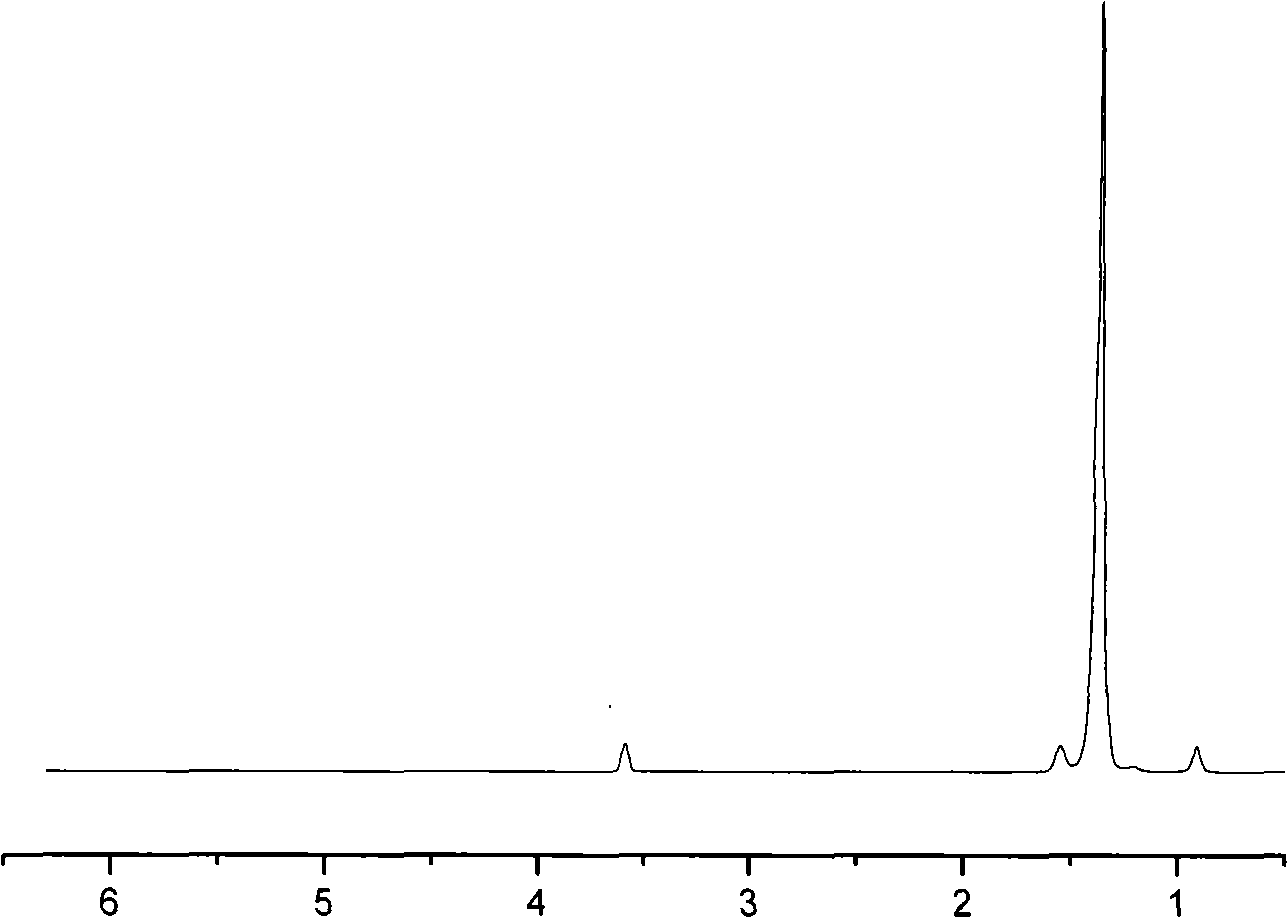

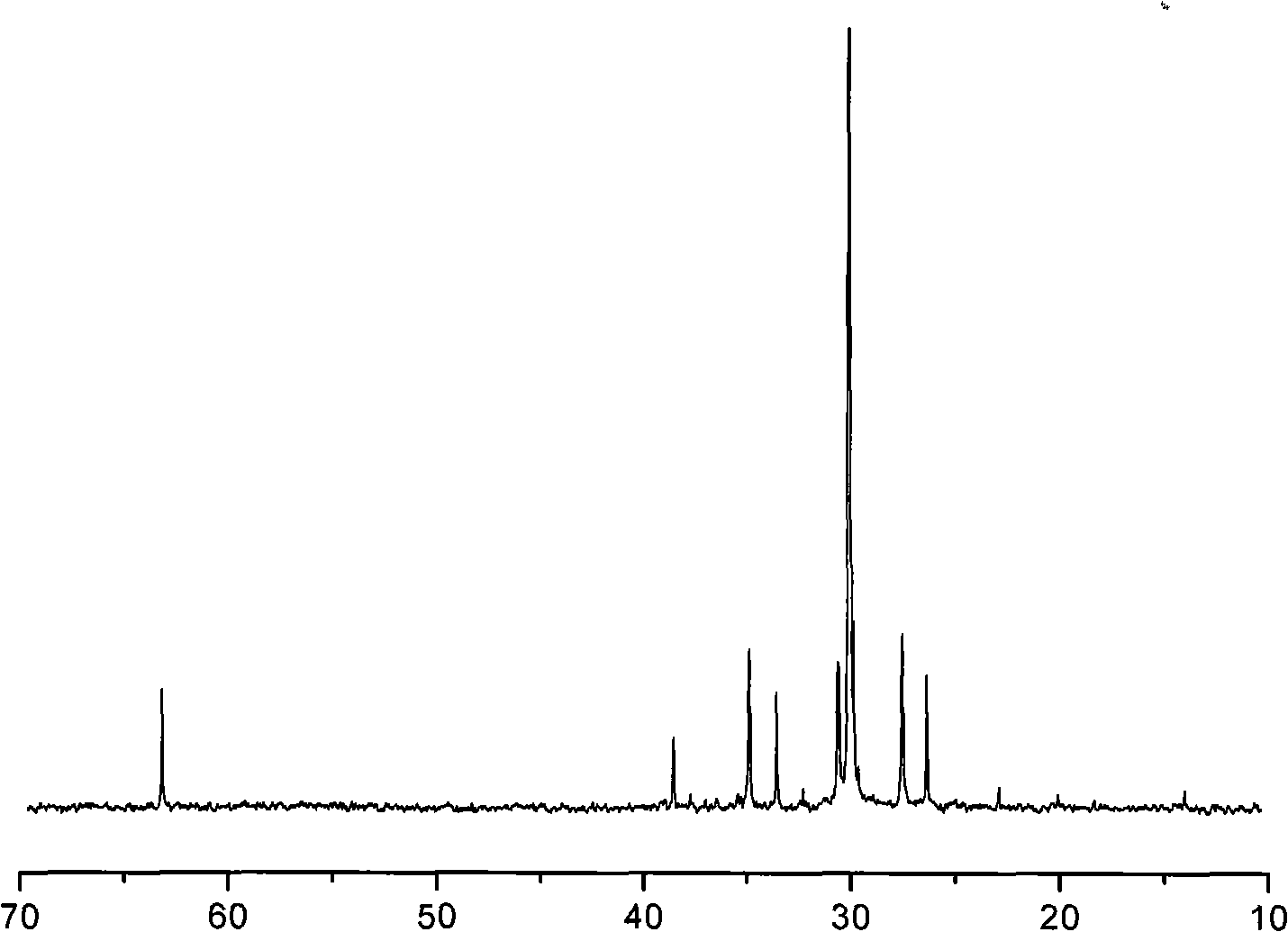

The invention discloses a preparation method of carboxyl silicone oil. Undecylenic acid and methyl hydrogen dichlorosilane are taken as raw materials to be subjected to direct hydrosilylation in the presence of a platinum / carbon catalyst to obtain 11-carboxyl undecyl methyl dichlorosilane; and the carboxyl silane monomer 11-carboxyl undecyl methyl dichlorosilane and dimethyldichlorosilane are subjected to co-hydrolysis and equilibrium polycondensation to obtain 11-carboxyl undecyl methyl silicone oil. The preparation method has the following advantages: the preparation process of carboxyl silicone oil is simplified by adopting the method for preparing the carboxyl silane monomer by one step through the direct addition reaction; the raw materials adopted for synthesis are industrial raw materials and are suitable for industrial large-scale production; and after being prepared into emulsion and compounded with amino silicone oil emulsion, the prepared carboxyl silicone oil can provide very good softness and full hand feel when being applied to textile finishing.

Owner:SUZHOU UNIV

Water-based fracturing fluid thickening agent and synthetic method thereof

ActiveCN105062455AImprove solubilityNo pollution in the processDrilling compositionWater basedMethacrylate

The invention belongs to the field of chemical engineering, and particularly relates to a water-based fracturing fluid thickening agent and a synthetic method thereof. The thickening agent comprises substances in parts by weight as follows: acrylamide, methacrylamide, undecylenic acid, 2-acrylamide-2-methylpropane sulfonate, methacryloyloxyethyl trimethyl ammonium chloride, dodecafluoroheptyl methacrylate, vinyl pyrrolidone, modified corn starch, an initiator and water. The synthetic method of the thickening agent comprises steps as follows: various co-monomers and modified starch are prepared in deionized water in proportion; the PH value and the temperature of the solution are adjusted; high-purity nitrogen is fed for oxygen removal; the compound initiator is added to initiate a reaction. The thickening agent is a multifunctional high-molecular polymer which is easily soluble, free of pollution and damage, good in sand carrying property and particularly good in temperature resistance and anti-shearing sand carrying property. The thickening agent has main characteristics of wide use temperature range as well as high temperature resistance and shearing resistance, has characteristics that the thickening agent is high in sand carrying property, free of residues, causes no damage to reservoir and the like, and can be used as an excellent substitute for guanidine gum.

Owner:YANTAI RUNXING ENVIRONMENTAL PROTECTION TECH DEV

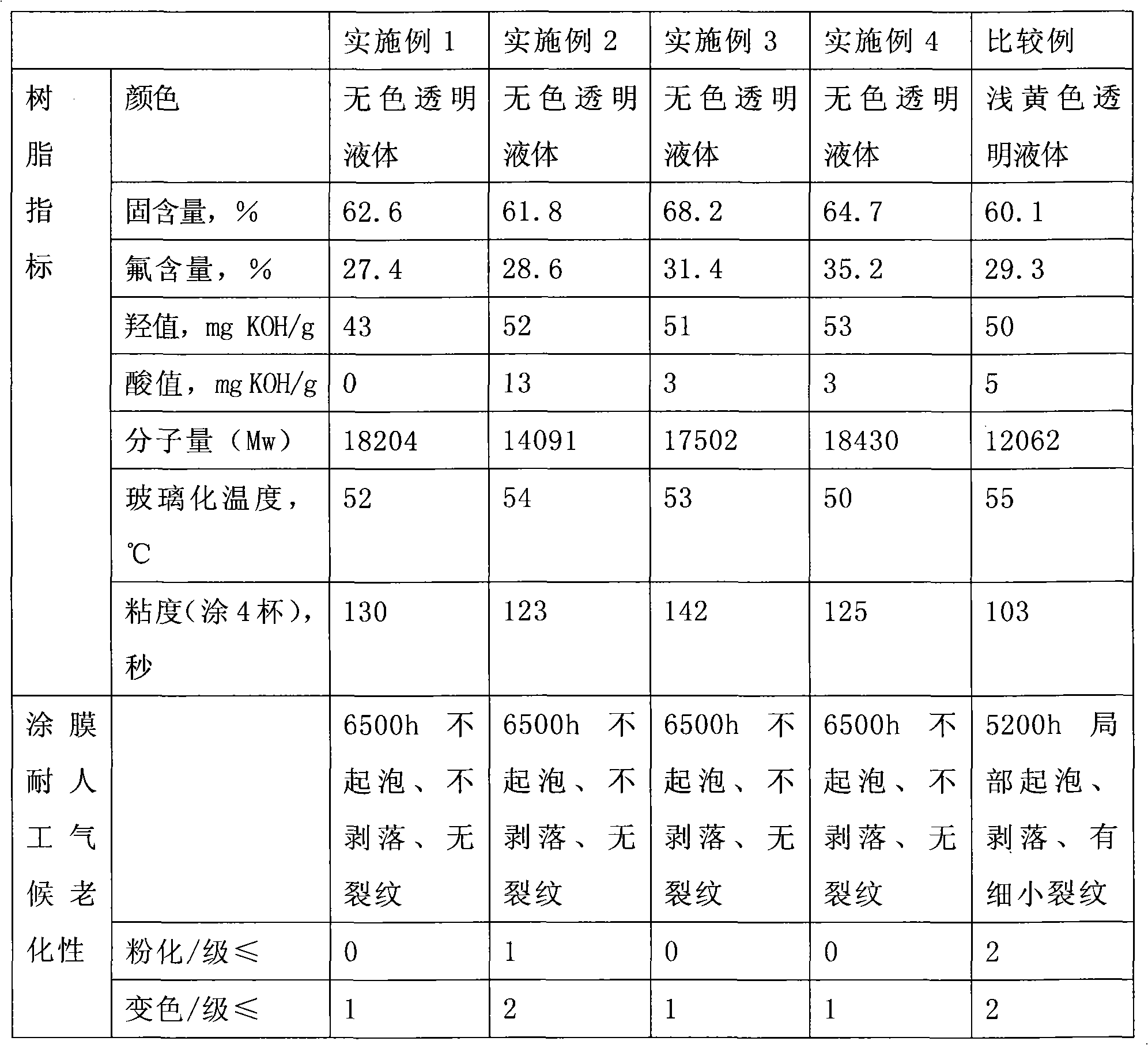

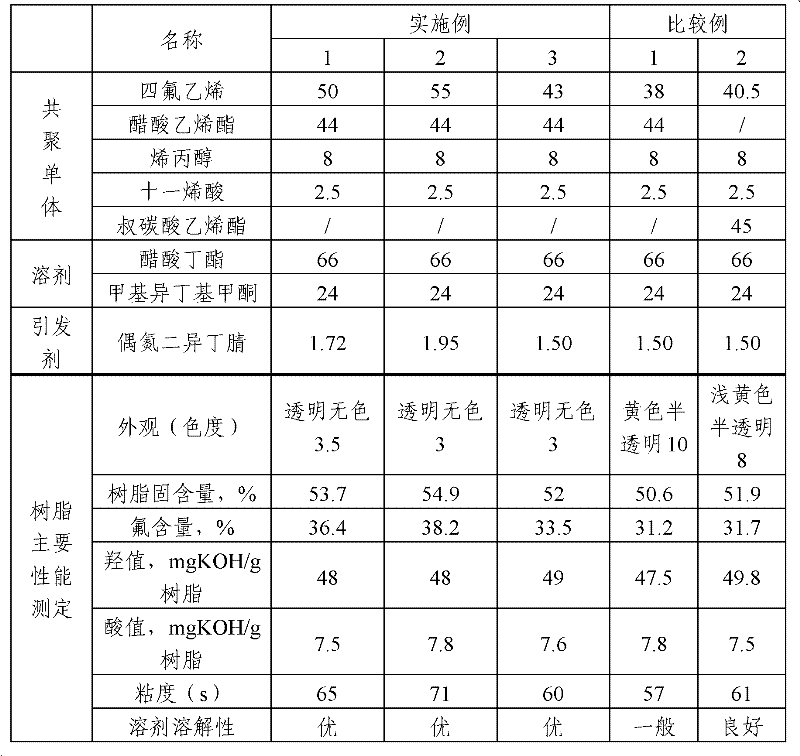

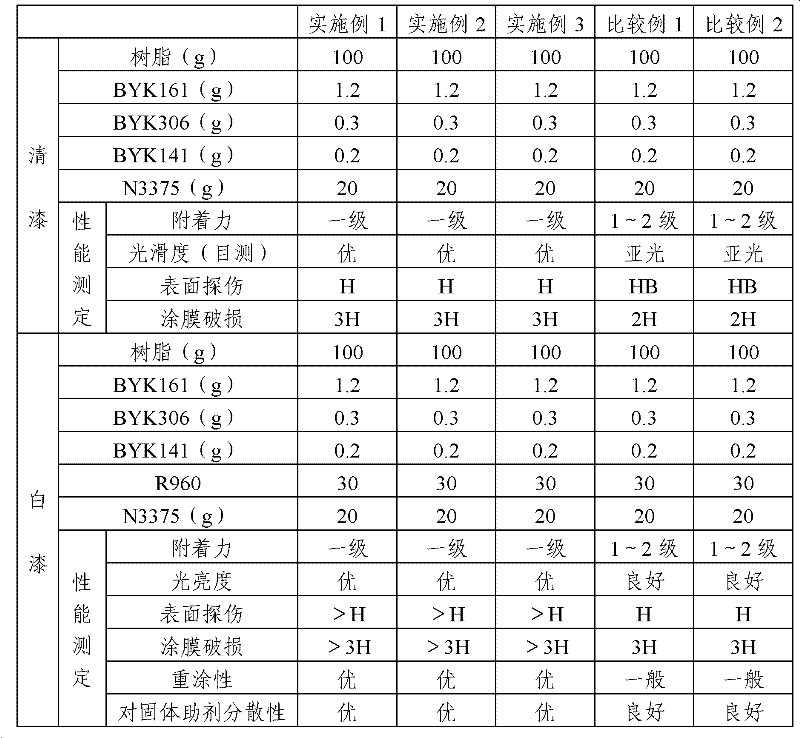

Normal temperature cured type tetrafluoroethylene fluorocarbon coating resin and preparation thereof

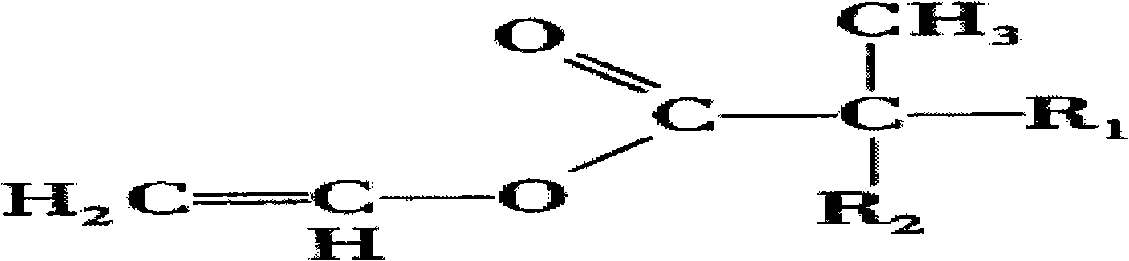

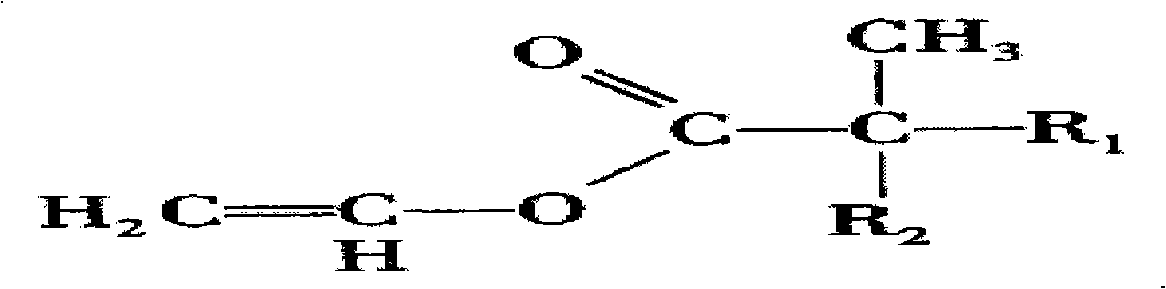

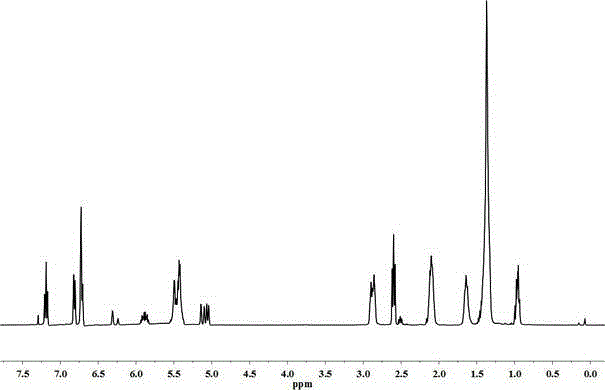

The invention relates to a fluorocarbon coating resin, in particular to a room temperature cured tetrafluoroethylene series fluorocarbon coating resin which is synthesized by solution polymerization with tetrafluoroethylene monomer and vinyl ester of tertiary carboxylic acid as the main comonomers; the matching of raw materials is as follows: 25 percent to 40 percent of tetrafluoroethylene, 25 percent to 35 percent of vinyl ester of tertiary carboxylic acid, 5 percent to 8 percent of hydroxyalkyl olefine aether, 25 percent to 35 percent of organic solvent and 0.5 percent to 1 percent of evocating agent; the R<1> and R<2> of the vinyl ester of tertiary carboxylic acid are alkyl groups and the total number of carbon atoms is 5 to 9. The preparation method of the room temperature cured tetrafluoroethylene fluorocarbon coating resin comprises the steps of: adding the vinyl ester of tertiary carboxylic acid, hydroxyalkyl olefine aether, undecylenic acid and organic solvent into a dissolving tank, opening the valve of tetrafluoroethylene monomer tank when the temperature reduces to minus 20 to minus 5 DEG C, adding tetrafluoroethylene monomer and raising the temperature of a polymerizing pot by a control system for copolymerization. Due to the alternating copolymerization of the tetrafluoroethylene and the vinyl ester of tertiary carboxylic acid, the room temperature cured tetrafluoroethylene series fluorocarbon coating resin of the invention greatly improves weather resisting property of coatings and prolongs the service life of coatings.

Owner:JINAN HUALIN CHEM

Preparation method of cardanol-base polyalcohols and polyurethanes thereof

The invention discloses a preparation method of two cardanol-base polyalcohols and polyurethanes thereof, which comprises the following steps: (1) directly carrying out sulfhydryl-alkene addition reaction on cardanol side chain unsaturated double bond and sulfhydryl monoalcohol under the irradiation of ultraviolet light to prepare the side chain cardanol-base polyalcohol with controllable hydroxyl number; (2) reacting hendecene acyl chloride and phenolic hydroxyl group of cardanol to prepare 10-undecylenic acid modified cardanol, reacting with sulfhydryl monoalcohol to prepare 10-undecylenic acid modified cardanol-base polyalcohol with controllable hydroxyl number; and (3) reacting the cardanol-base polyalcohol and 10-undecylenic acid modified cardanol-base polyalcohol with diisocyanate to prepare the cardanol-base polyurethanes. The method has the advantages of low cost, no environmental pollution and the like, and is renewable and biodegradable; and the generated polyurethane resin can be used as a resin for paints and adhesives.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

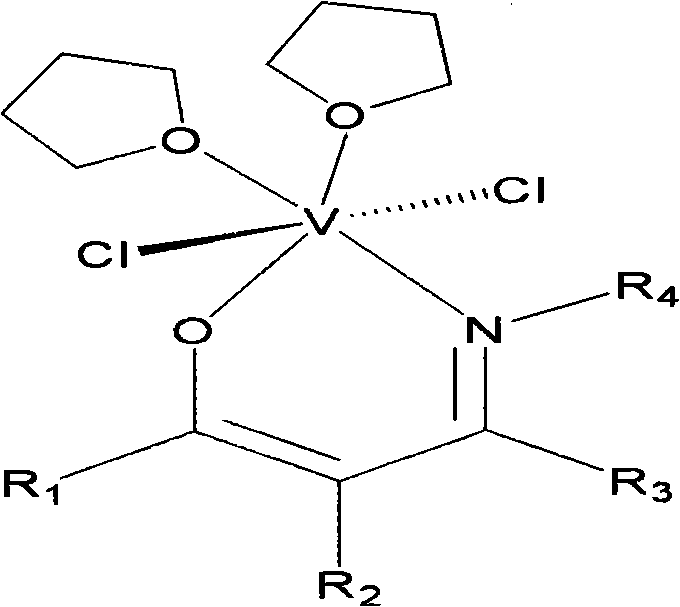

Application and usage of vanadium series catalyst of one-class bidentate N, O coordination

The invention provides an application and a usage of vanadium series catalyst of one-class bidentate N, O coordination. From the angle of preventing functional monomer from poisoning catalyst, the invention selects the vanadium series olefinic polymerization catalyst of one-class bidentate N, O coordination to realize the copolymerization of ethylene and polar monomer under the action of cocatalyst and promoter after different protecting agents pretreat the polar monomer. Through adjusting copolymerization conditions, the invention obtains a series of functional polyolefine with controllable comonomer insertion rate and molecular weight. Especially, the invention realizes the copolymerization between ethylene and 10-hendecene-1-alcohol, between ethylene and 5-hexene-1-alcohol, between ethylene and 3-butylene-1-alcohol or between ethylene and 10-methyl undecylenate.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Malodor neutralizing compositions comprising undecylenic acid or citric acid

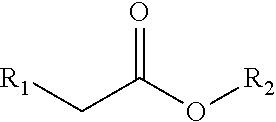

Compositions comprising undecylenic acid or citric acid and certain esters are effective for reducing malodors. The esters are in the molecular weight range of between 150-200 when the acid is undecylenic acid and in the range of between 130-230 when the acid is citric acid. These compositions can be used in perfumed products, household products and personal care products.

Owner:ROBERTET INC

Water-soluble anti-dandruff compounds and compositions thereof

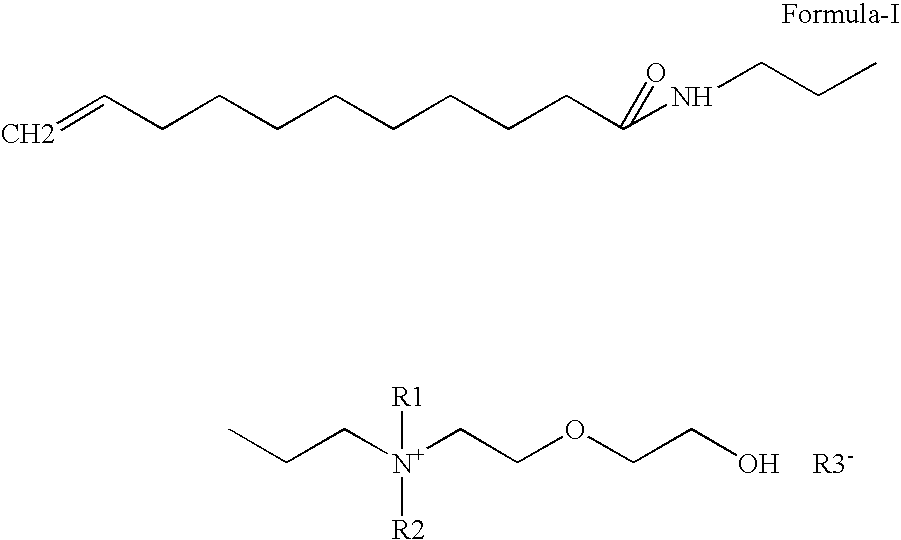

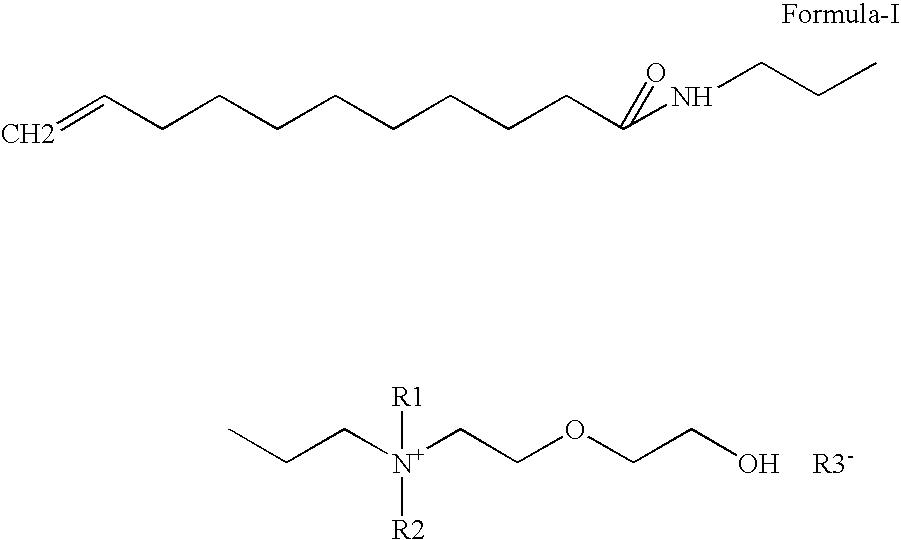

InactiveUS20060182696A1More anti-dandruff activityGood water solubilityCosmetic preparationsCationic surface-active compoundsPersonal careWater dispersible

Water-soluble and water dispersible undecylenic amido propyl dimethyl hydroxyl ethoxy ethyl ammonium undecylenate compounds of formula I having anti-dandruff, preservative and sunscreen activity wherein R1, R2 are from C1-C6 carbon atoms, R3 is undecylenic acid, amino group is selected from dimethyl amino propyl amine. Personal care compositions comprising compounds of formula I

Owner:GALAXY SURFACTANTS

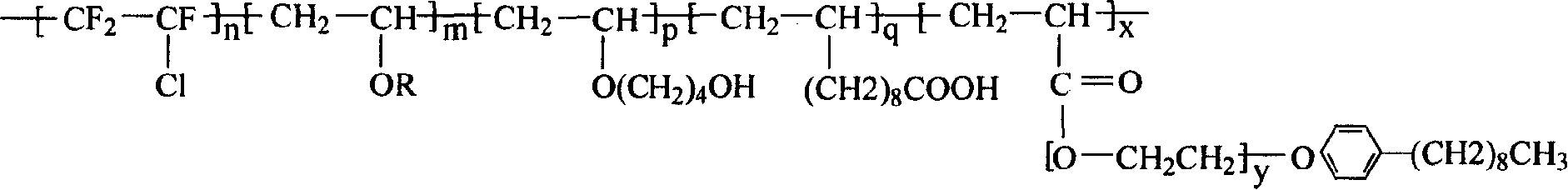

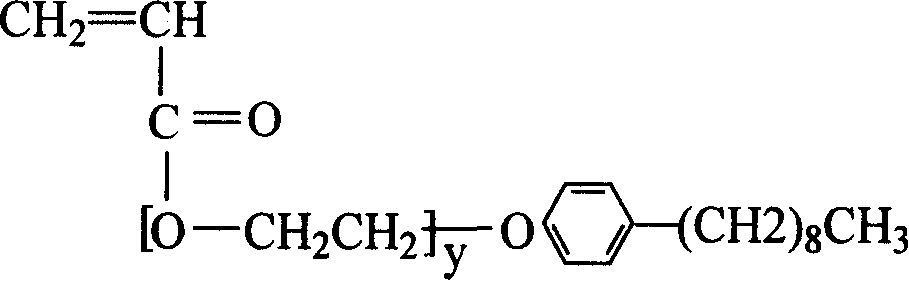

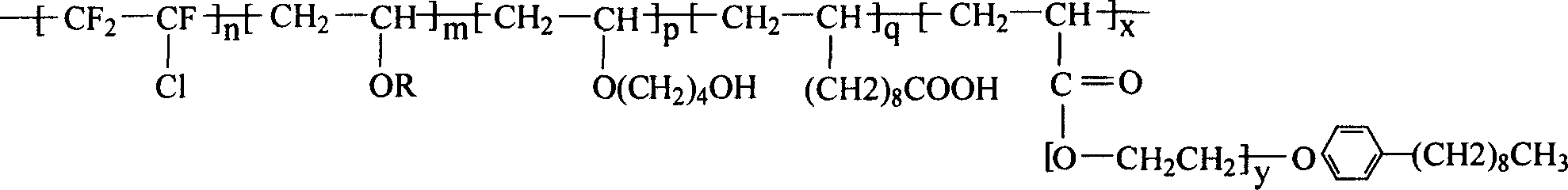

Preparation method and application of water-based fluoropolymer emulsion

The present invention relates to preparation process of water thinned fluoric polymer emulsion for paint. The preparation process is one emulsion copolymerization process with trifluorochloro ethylene, alkyl vinyl ether or vinyl acetate, hydroxyl butyl vinyl ether, undecylenic acid and polyoxyethylene acrylate as monomers, non-ionic emulsifier NP and anionic ammonium perfluoro octoate as composite emulsifier, and composition of ammonium persulfate or potassium persulfate and sodium bisulfite as redox initiation system. The polymerization may be completed in room temperature and is simple, and the product has excellent chemical stability, mechanical stability and mechanical performance. The emulsion has relatively high fluorine content, so that the prepared paint has excellent corrosion resistance, weather resistance and antifouling performance.

Owner:TONGJI UNIV

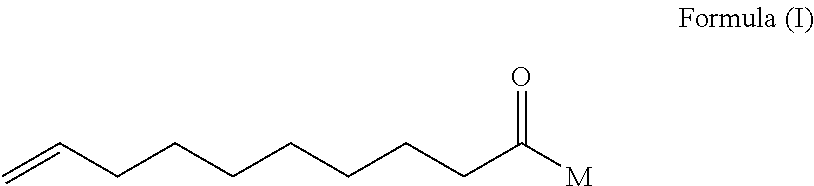

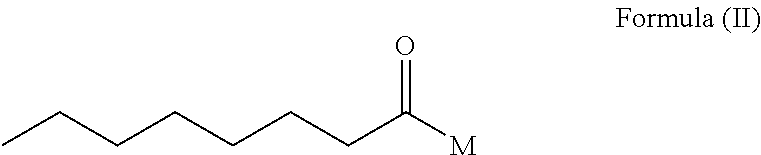

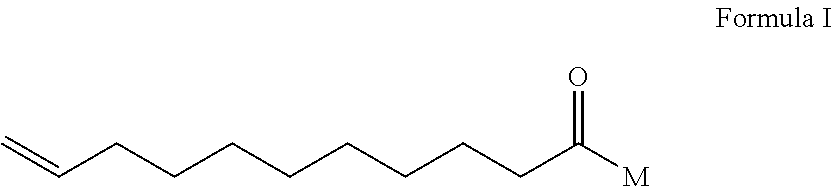

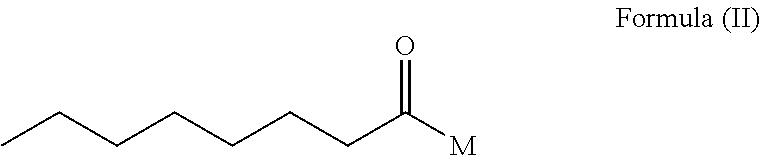

Antimicrobial preservative compositions for personal care products

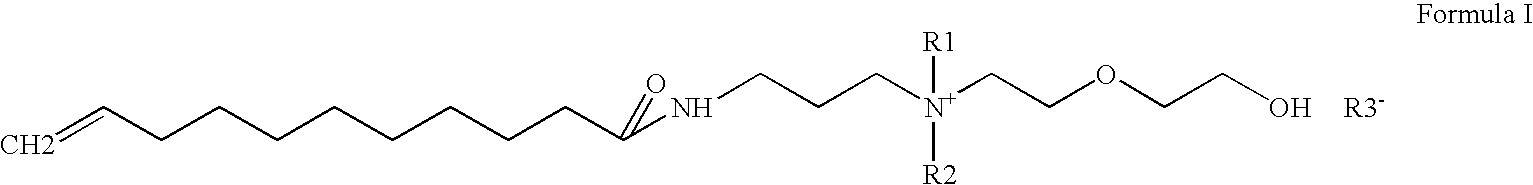

InactiveUS20130101530A1Enhanced anti-fungalImprove antibacterial propertiesBiocideCosmetic preparationsOctanoic AcidsAlcohol

A personal product antimicrobial preservative composition for preservation of topical personal care formulations is provided comprising [A] one or more undecylenic acid derivatives depicted by Formula (I),[B] one or more octanoic acid derivatives depicted by Formula (II),and [C] 2-phenoxy ethanol or 2-ethyl hexyl glyceryl ether or mixture of these two ‘liquid alcohol ethers’; wherein, each of the two components [A] and [B] is present in the range of 5 to 20% by weight and together [A] and [B] constitute 10 to 30% by weight and the ‘liquid alcohol ether’, component [C], is present 70 to 90% by weight of the total preservative composition. A method for preserving personal care product from microbial attack is provided containing an aqueous phase comprising three component composition from about 0.5 to 2.5% by weight of the total personal care formulation.

Owner:GALAXY SURFACTANTS

Process and device for the anti-odor treatment of air

The photocatalytic action of titanium dioxide and the anti-odor activity of undecylenic acid or its compounds are combined in an atmospheric scrubbing or renewal system. The invention consists in placing a filter impregnated with these two substances and exposed to a natural or artificial source of ultraviolet radiation in the path of the air.

Owner:ELF ATOCHEM SA

Method for preparing polytetrafluoroethylene resin for coating

ActiveCN102174139AUniform alternating reactionConstant polymerization rateCoatingsSolubilityGas phase

The invention provides a method for preparing polytetrafluoroethylene resin for coating. Gas phase tetrafluoroethylene, vinyl acetate, undecylenic acid and allyl alcohol are taken as polymerization monomers for performing polymerization, an initiating agent is continuously added in the whole polymerization process, and polymerization is performed under an isothermal isobaric condition. The methodfor preparing the polytetrafluoroethylene resin for coating provided by the invention can promote the vinyl acetate and the tetrafluoroethylene to uniformly and alternately react, thereby preparing the polytetrafluoroethylene resin for coating with good solubility, high fluorine content and resistance to chemical corrosion; the prepared resin is colorless and transparent and is improved from matte gloss to high gloss to fully embody the color of the coated film; and performance loss of the resin caused by introduction of exogenous impurities is eliminated, the coated film has recoatability, and the workability is greatly improved. The polymerization process is stable and can meet the requirements of industry scalization.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Elastic tie-plate for high-speed railway and fabrication method thereof

InactiveCN103897226AIncrease elasticityHigh mechanical strengthRail fastenersDimethyl siloxaneAbsorption effect

The invention discloses an elastic tie-plate for a high-speed railway. The elastic tie-plate is prepared from the following raw materials in parts by weight: 80-100 parts of natural rubber, 40-60 parts of cis-butadiene rubber, 20-30 parts of methyl silicone rubber, 20-30 parts of poly dimethyl siloxane, 15-18 parts of high styrene, 8-10 parts of dilauryl thiodipropionate, 8-10 parts of undecylenic acid, 7-9 parts of active magnesium oxide, 1-3 parts of dispersive lubricant, 5-7 parts of calcium sulfate whiskers, 10-30 parts of ceramic fibers, 10-13 parts of microcrystalline wax, 30-40 parts of cashew nut husk oil, 35-45 parts of carbon black, 3-5 parts of hollow microspheres, 3-6 parts of shell powder, 10-15 parts of modified Rectorite, 20-30 parts of red mud, 6-8 parts of coumarone resin, 2-4 parts of curing agent, 3-6 parts of accelerator, 0.8-1.5 parts of anti-aging agent and 2-4 parts of triethylenediamine. The elastic tie-plate disclosed by the invention has the advantages of excellent mechanical strength, oil resistance, anti-aging performance, cold resistance and durability, good shock absorption effect and impact resistance and stable performance. The production process of the elastic tie-plate is easily controlled.

Owner:安徽金科橡塑制品有限公司

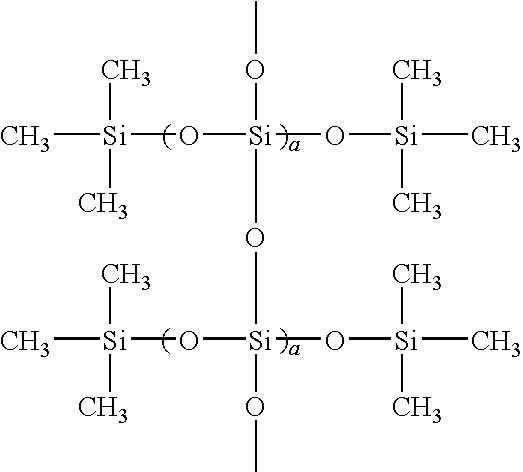

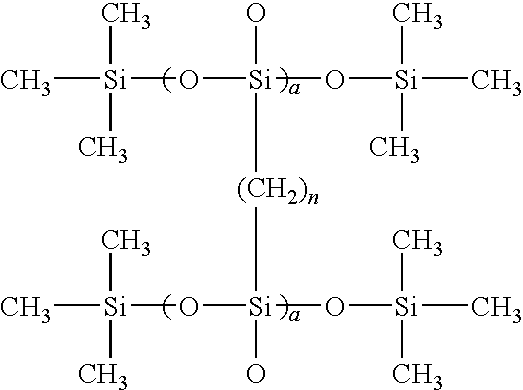

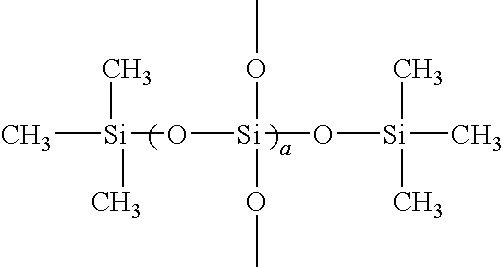

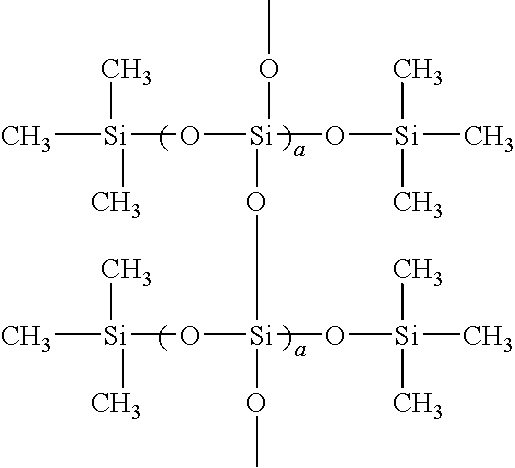

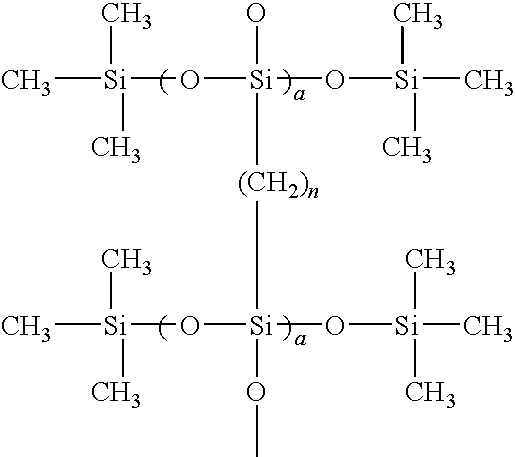

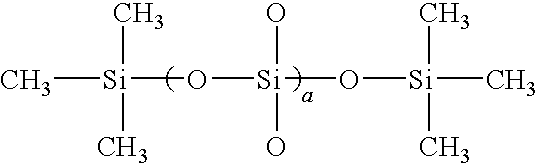

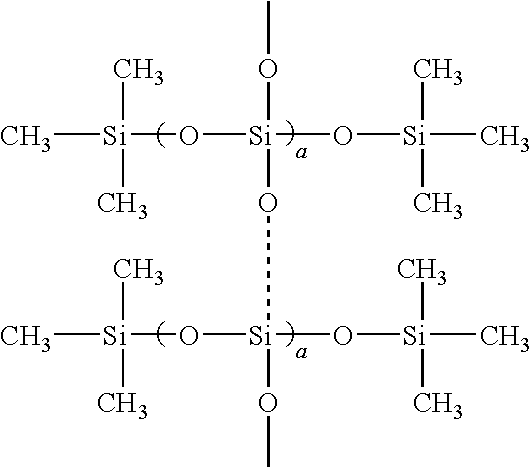

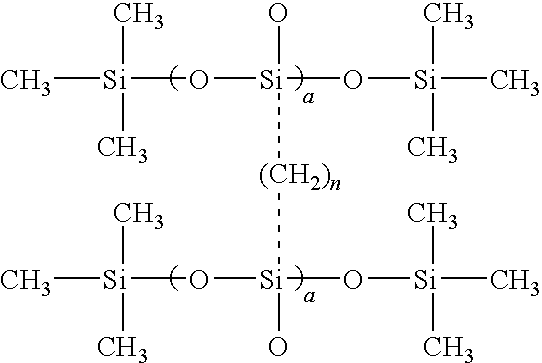

Multifunctional linear silicone resin polymers

InactiveUS7723443B1Efficient responseGood skin feelCosmetic preparationsHair cosmeticsPersonal careSolubility

The present invention relates to a series of crosslinked silicone polymers that by virtue of the nature of the crosslinking undecylenic acid ester based crosslinker, have unique solubility and properties. These include improved tolerance for oily materials and improved skin feel. These polymers find use in personal care applications like pigmented products. In the personal care arena, solid products that do not experience syneresis are important. Syneresis is a condition that exists in a solid product that causes a liquid that is incompatible to ooze out, which is cosmetically unacceptable.

Owner:SILTECH

Process for preparing undecylenic acid by scission of castor oil

InactiveCN101289383AAvoid physical and mental harmConstant responseOrganic compound preparationCarbonyl compound preparation by oxidationBenzoyl peroxideWater vapor

The invention relates to an engineering plastic process for producing nylon-11 by caster oil and particularly relates to a method for cracking the caster oil to produce undecylenic acid, which belongs to the process flow and solves the existing problems of lead pollution and easy coking in the technology that the caster oil is cracked by the technique of cauldron-typed lead melter. The method is as follows: the caster oil and a catalyst of benzoyl peroxide solution are mixed and preheated to 150-200 DEG C, the quality proportion of which is 1000:3-7:1100-1300 with over heated water vapor of 500-600 DEG C, which enters into a loading tube from the mouth of the loading tube, enters into the top of the cracking stove body from the outlet of the loading tube, and enters into a reacting space along a screw panel; the cracking stove body at the upper part of a tower-typed cracking stove is heated to 500-600 DEG C by an electric heater to crack to produce undecylenic acid and heptaldehyde products. The engineering plastic process for producing nylon-11 by caster oil has the advantages of permanent reaction, strongly continuous operability, ,which is suitable for the production of industrialized settings and can improve the operating environment, can overcome the hurt to body and spirit of the operator by the lead pollution, and has low possibilities of coking, high yield and simple setting producing technologies.

Owner:山西宏远科技股份有限公司

Crosslinked silicone polymers

InactiveUS7632488B1Good oil solubilityImproved film forming propertyCosmetic preparationsHair cosmeticsPersonal careSolubility

The present invention relates to a series of crosslinked silicone polymers that by virtue of the nature of the dimol alcohol undecylenic acid ester based crosslinker, have unique solubility and properties. These include improved tolerance for oily materials and improved skin feel. These polymers find use in personal care applications like pigmented products. In the personal care arena, solid products that do not experience syneresis are important. Syneresis is a condition that exists in a solid product that causes a liquid that is incompatible to ooze out, which is cosmetically unacceptable.

Owner:SILTECH

Antifungal serum

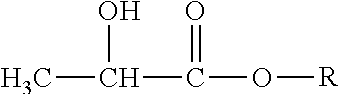

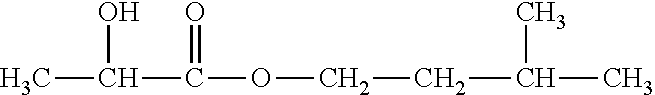

ActiveUS20140011871A1Low recurrence rateIncrease chanceBiocidePharmaceutical delivery mechanismEpitheliumMatrix nail

The subject invention is based upon the discovery that an antifungal agent can be delivered through the fingernail or the toenail of an infected human to treat onychomycosis by dissolving or dispersing the antifungal agent in a solvent system which is comprised of a combination of an alkyl lactate and Simmondsia chinesis seed oil. In accordance with this invention the antifungal agent is absorbed by and incorporated into the nail matrix by diffusing through the epithelium of the nail bed to reach the nail bed hyperkeratosis. The antifungal agent additionally penetrates into the ventral surface of the nail plate. The subject invention more specifically discloses an antifungal serum which is comprised of (1) an alkyl lactate, such as isoamyl lactate, (2) Simmondsia chinesis seed oil, and (3) an antifungal agent, such as tolnaftate or undecylenic acid.

Owner:LUNAM LABS

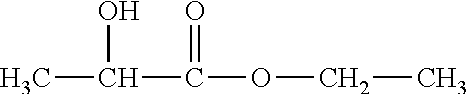

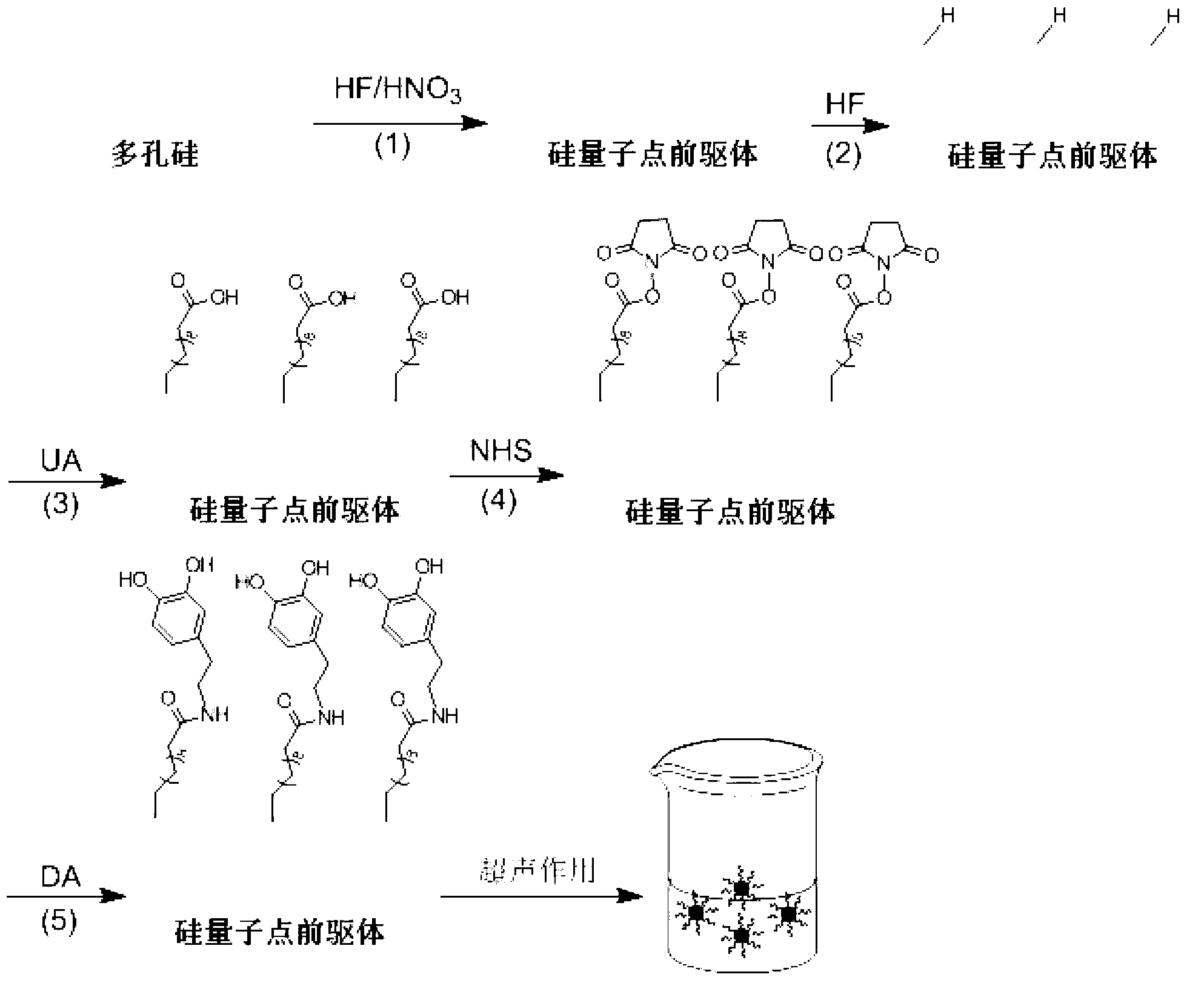

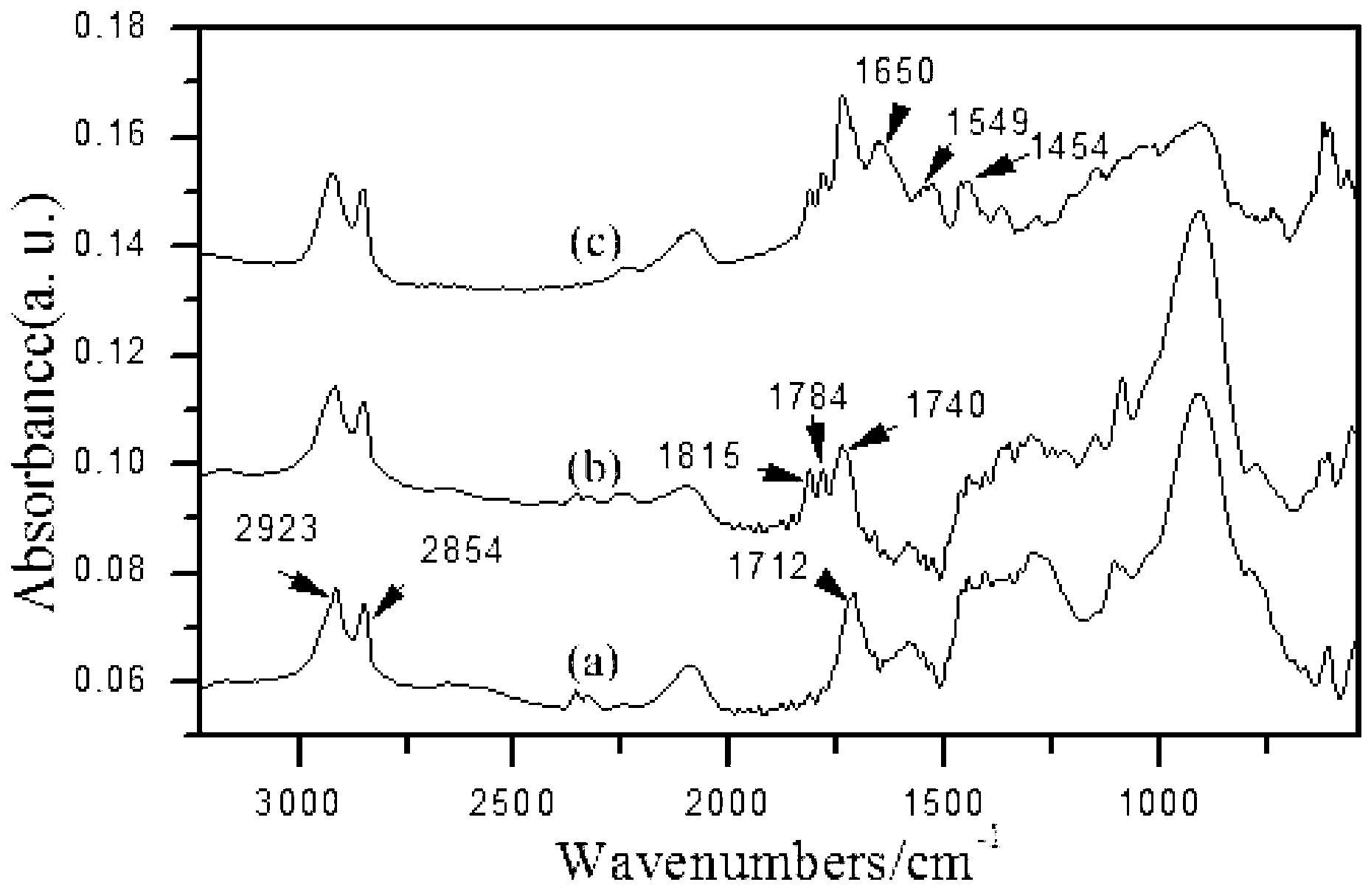

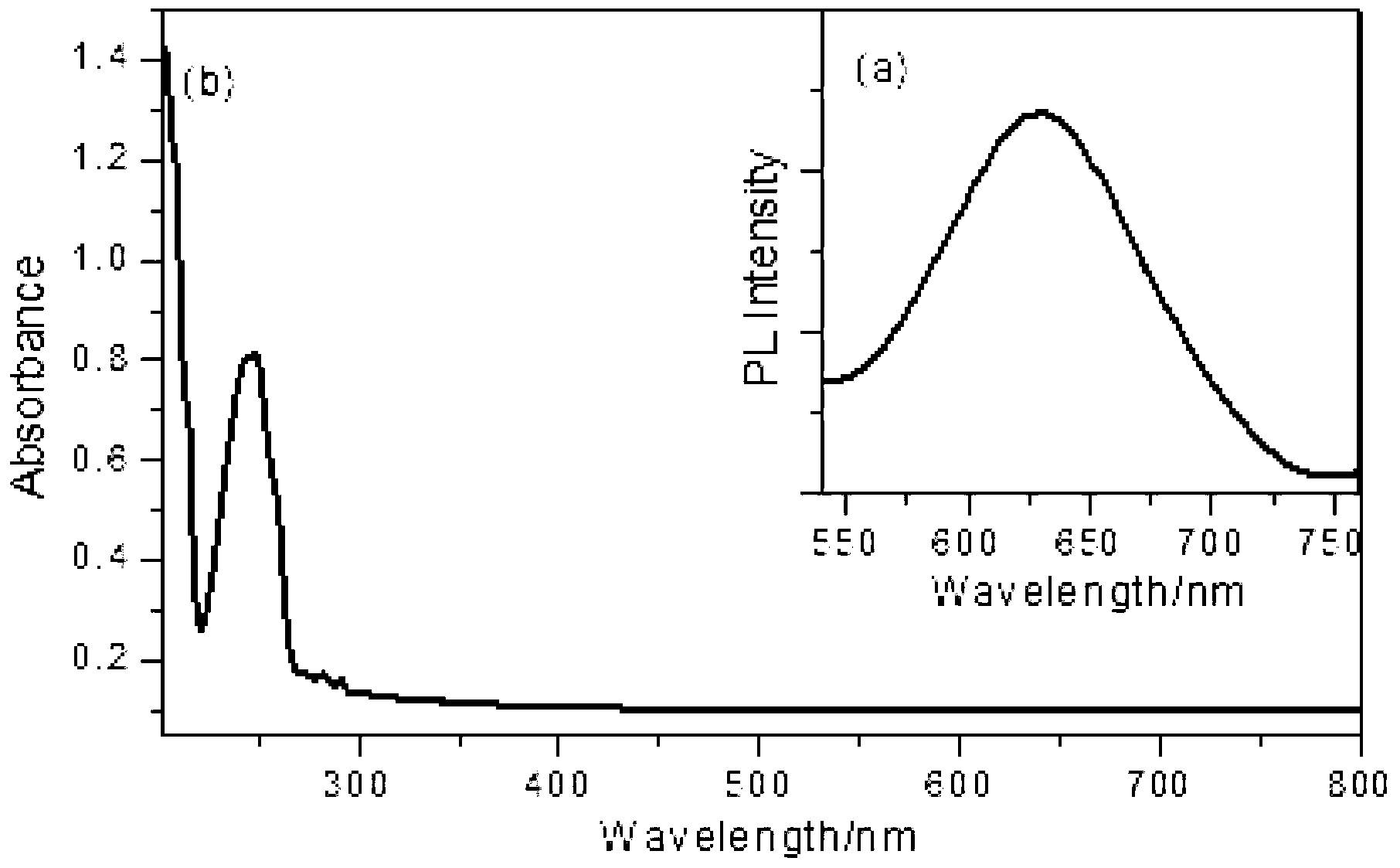

Preparation and application for silicon quantum dots

InactiveCN103232845ASave raw materialsRealization of fluorescent labeling of silicon quantum dotsNanoopticsBiological testingEtchingFluorescence

The invention discloses preparation for silicon quantum dots, and a fluorescence labelling method for dopamine molecules by virtue of the silicon quantum dots, which belong to the field of nanotechnology. The method comprises the following steps of: preparing porous silicon at first, obtaining a silicon quantum dot precursor via chemical etching, and obtaining the silicon quantum dots after ultrasonic treatment, wherein the silicon quantum dot precursor can be reacted with hydrofluoric acid to generate surface Si-H, and then sequentially reacted with undecylenic acid, N-hydroxysuccinimide and dopamine, and finally ultrasonically treated to obtain the dopamine molecules which are fluorescence-labelled by the silicon quantum dots. Compared with the prior art, in the method disclosed by the invention, silicon slices are used as raw materials, and a chemical etching method is adopted, so that fluorescence labelling for the dopamine molecules by the silicon quantum dots can be realized at a low temperature and under the normal pressure; and because a chemical modification reaction is performed on the surface of the silicon quantum dot precursor, separation between the product and reactants can be realized via solvent soaking and washing, thus simplifying the separation operation. The method can also be used for fluorescence labelling for other biomolecules containing primary amine group by the silicon quantum dots.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Air and fabric freshener

ActiveUS20140093471A1Reducing and eliminating malodorEnhanced interactionDeodrantsAdditive ingredientFabric freshener

The present invention relates to a stable, aqueous freshener composition for the reduction or elimination of malodors in air and on fabrics. The composition comprises from about 0.1% to about 3.0% by weight, hydrogen peroxide as a malodor oxidant; an effective level of undecylenic acid (and / or derivative thereof) as a malodor absorber preblended with a fragrance; a surfactant to solubilize the fragrance / malodor absorber blend; an acid based stabilizer in a range from about 0.008% to about 0.60% by weight; an optional pH buffer; and an aqueous carrier. The composition can be delivered via a spray dispenser for treatment of indoor air and fabrics. The composition has a pH of less than about 6 and does not contain ingredients known to soil, stain or damage fabrics. When applied as a fine mist, the composition delivers effective control of a broad range of malodors, while remaining imperceptible on surfaces when dry.

Owner:INNOVASOURCE

External medicament for treating tinea manuum and tinea pedis

InactiveCN107970275AImprove complianceEasy to useSalicyclic acid active ingredientsAntimycoticsDiseaseCuticle

The invention discloses an external medicament for treating tinea manuum and tinea pedis. The external medicament consists of an effervescent tablet A and a gel B, and the main ingredients comprise clove basil oil, cinnamon oil, litsea cubeba oil, eucalyptus oil, a light yellow sophora root extract, salicylic acid, undecylenic acid and the like; and the external medicament has the functions of clearing away heat and toxic materials, killing bacteria, diminishing inflammation, drying dampness and killing insects. The medicament provided by the invention is different from a treatment scheme in the past for treating tinea manuum and tinea pedis only, firstly, the effervescent tablet A is used to quickly kill pathogenic bacteria on the surface of skin to keep the skin clean and environment, and achieve an effect of no recurrence by forcibly killing the bacteria. An epidermal tissue structure of the surface layer infected by diseases, so that a thickened and keratinized skin structure becomes loose to form a channel conducive to smooth penetration of the medicament; on the premise of dredging the channel of medicament penetration, the gel B is used to quickly and thoroughly remove and kill the pathogenic bacteria in the skin; and the combination of the two agents is multi-layered and three-dimensional, achieves both prevention and treatment of symptoms and root causes, and the treatment method is unique and the curative effect is reliable.

Owner:安徽世龙生物医药科技有限公司

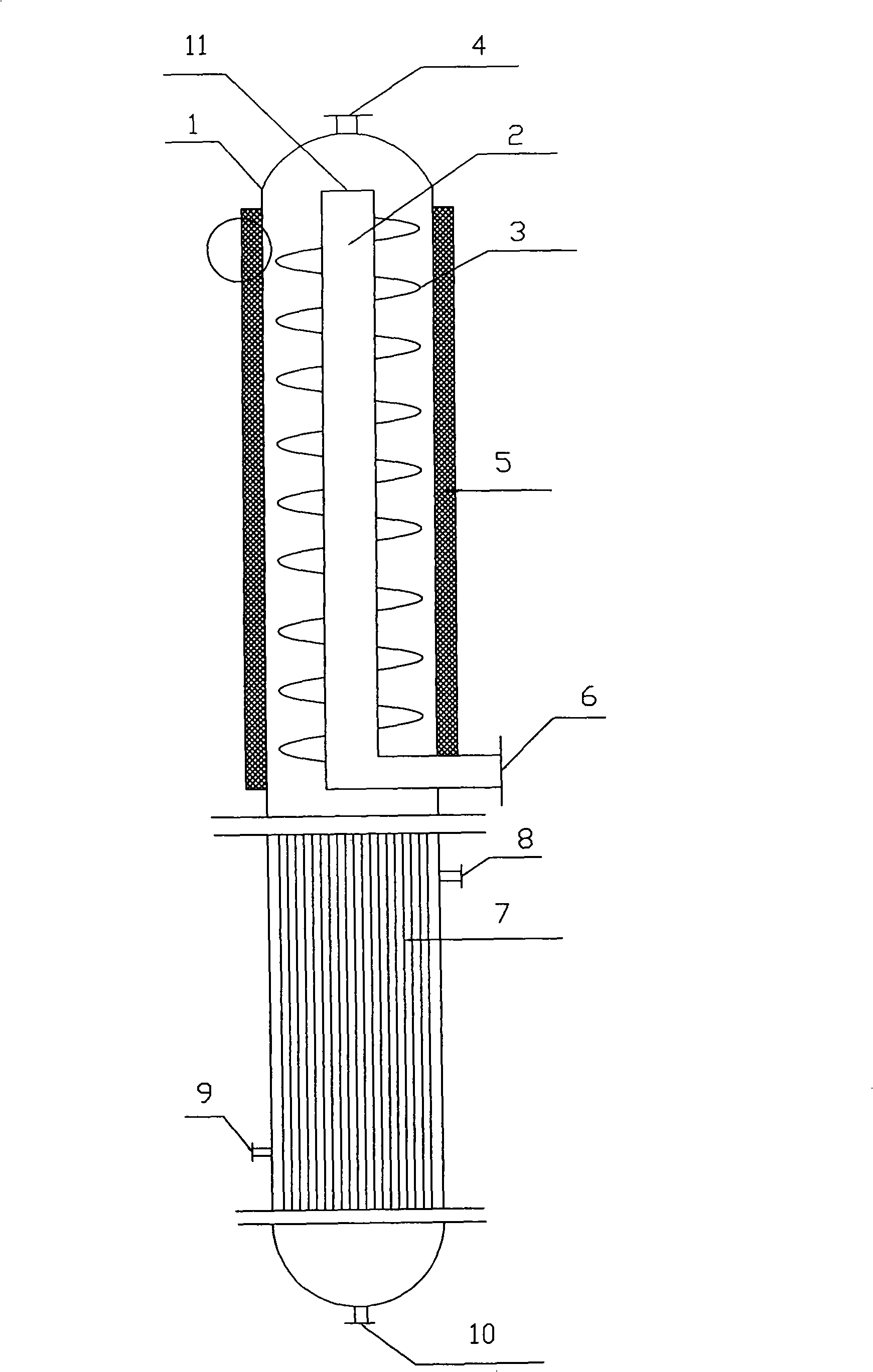

Method for preparing 11-bromo-undecanoic acid by direct freezing crystallization and device therefor

InactiveCN102531879ANot volatileNo lossOrganic compound preparationCarboxylic compound separation/purificationEconomic benefitsColneleic acid

The invention discloses a method for preparing 11-bromo-undecanoic acid by direct freezing crystallization and a device for preparing 11-bromo-undecanoic acid, and relates to a method for preparing the 11-bromo-undecanoic acid. The preparation device comprises a burdening kettle, an addition tower, a crystallization kettle and a filter press, wherein the burdening kettle is connected with the addition tower; the addition tower is connected with the crystallization kettle; the crystallization kettle is connected with the filter press; and the filter press is connected with the top part of the burdening kettle. During work, the preparation method comprises the steps of: mixing undecylenic acid and toluene in a mass ratio of 1:(3-4) at a temperature of -5-0 DEG C in the burdening kettle; allowing the mixed liquid with hydrogen bromide in a mole ratio of 1:1.05 at a temperature of 0-30 DEGC in the addition tower to react so as to generate an addition liquid; putting the addition liquid in the crystallization kettle, carrying out freezing crystallization at a temperature of -4 DEG C to -16 DEG C, a revolving speed of 8 round / min and a vacuum degree of -0.02MPa to -0.03MPa; and filtering crystal in the filter press. The device disclosed by the invention has the advantages of a simple structure, strong continuity and operability and is suitable for industrial production. The preparation method has the advantages of a short process flow, constant reaction, high product purity and good economic benefits.

Owner:山西宏远科技股份有限公司

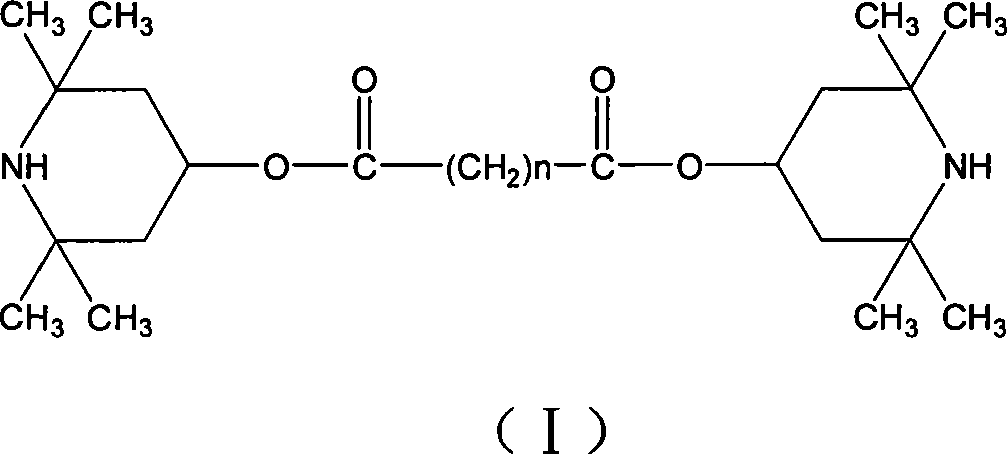

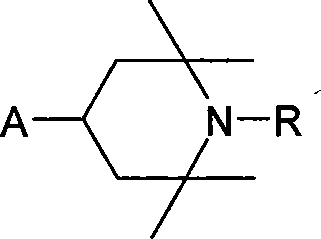

Undecane to pentadecane dicarboxylic acid di(2,2,6,6-tetramethylpiperidinyl)ester and use thereof

The invention relates to the synthesis and the usage of the novel hindered amine light stabilizer undecylenic to pentadecanedioic acid (2, 2, 6, 6-tetramethyl piperidino) diester. The invention utilizes undecylenic acid, dodecanedioic acid, tridecanedioic acid, tetradecanoic acid and pentadecanedioic acid produced through microorganism fermentation paraffinic oil as the raw material, the undecylenic to pentadecanedioic acid diesters are synthesized firstly, then the ester exchange reaction is performed to produce the finished product, secondly, the catalytic agent adopts sodium methoxide, sodium ethoxide or sodium amide which has higher activity, is easy to prepare and segregate, and is suitable for the use in industry, the related reaction condition is bland, the technology is simple, and the invention is easy to realize industrialization. The invention has very good light protection performance, and the addition into lubricating oil hydrogenised base oil can obviously improve the light stability quality. The invention can replace the prior Tinuvin770 sebacic acid (2, 2, 6, 6-tetramethyl piperidino) diester product. The structure formula of the invention is shown in the following (I), wherein, n is equal to 11 or 12 or 13 or 14 or 15.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Multifunctional silicone resin polymers

InactiveUS7790813B2Good skin feelImprove solubilityCosmetic preparationsMake-upPersonal careSolubility

Owner:SILTECH

Antimicrobial Preservative Compositions for Personal Care Products

A personal product antimicrobial preservative composition for preservation of topical personal care formulations is provided and includes [A] one or more undecylenic acid derivatives depicted by Formula (I),[B] one or more octanoic acid derivatives depicted by Formula (II),and [C] 2-phenoxy ethanol or 2-ethyl hexyl glyceryl ether or mixture of these two ‘liquid alcohol ethers’; wherein, each of the two components [A] and [B] is present in the range of 5 to 20% by weight and together [A] and [B] constitute 10 to 30% by weight and the ‘liquid alcohol ether’, component [C], is present 70 to 90% by weight of the total preservative composition. A method for preserving personal care product from microbial attack is provided containing an aqueous phase comprising three component composition from about 0.5 to 2.5% by weight of the total personal care formulation.

Owner:GALAXY SURFACTANTS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com