Preparation method of carboxyl silicone oil

A carboxyl silicone oil and solvent technology, which is applied in the field of carboxyl silicone oil preparation, can solve the problems of cumbersome and complicated carboxyl silicone oil processes, and achieve the effects of facilitating popularization and application, simplifying the preparation process, and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

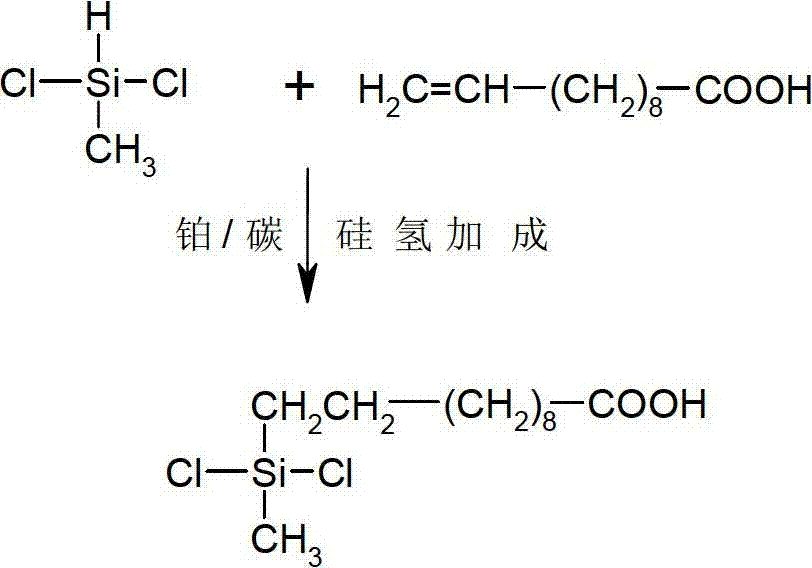

[0027] 1, Preparation of 11-carboxyundecylmethyldichlorosilane

[0028] (1) Hydrosilylation: Add 100g of undecylenic acid and 200g of toluene to a three-necked flask equipped with a magnetic stirrer, a thermometer, a reflux condenser and a nitrogen protection device, raise the temperature to 100~102°C, and add 0.15g of city For a platinum / carbon catalyst with a platinum content of 5%, start to add 63.5 g of methyldichlorohydrosilane dropwise, and finish adding within 1 hour. After dripping, keep warm for 3 hours. After the catalyst was removed by filtration, the filtrate was rotary evaporated to remove toluene to obtain light yellow and transparent 11-carboxyundecylmethyldichlorosilane. In this step, 11-carboxyundecylmethyldichlorosilane is synthesized by the direct hydrosilylation reaction of undecylenic acid and methylhydrogen dichlorosilane, and its reaction formula is as follows:

[0029]

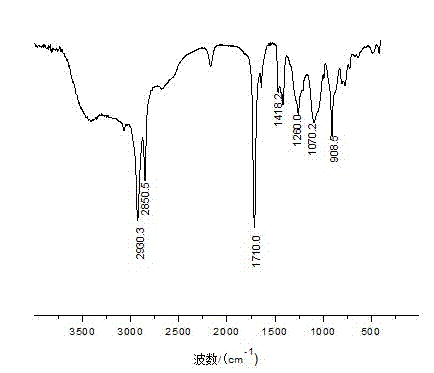

[0030] See attached figure 1 , it is the infrared spectrogram of the 11-carbo...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of carboxyl silicone oil, and its step comprises:

[0048] (1) Hydrosilylation: In a three-necked flask equipped with a magnetic stirrer, thermometer, reflux condenser and nitrogen protection device, add 80 g of undecylenic acid and 150 g of benzotrifluoride, raise the temperature to 103~105 ° C, add 0.1 g of a commercially available platinum / carbon catalyst with a platinum content of 5%, start to add 58.0 g of methyldichlorohydrosilane dropwise, and finish adding within 1 h. After dripping, keep warm for 4 hours. After removing the catalyst by filtration, the filtrate was rotary evaporated to remove benzotrifluoride to obtain transparent 11-carboxyundecylmethyldichlorosilane.

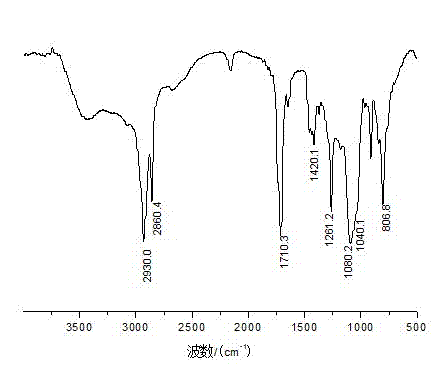

[0049] (2) Co-hydrolysis: Add 60g of distilled water into the three-necked flask, stir at room temperature and start to drop the monomer mixture formed by 45g of 11-carboxyundecylmethyldichlorosilane and 40g of dimethyldichlorosilane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com