Preparation method of hyperbranched polymer-modified nano-silicon dioxide hybrid material

A technology of nano-silica and hyperbranched polymers, which is applied in the coating and other directions, can solve the problems of insignificant anti-oxidation resistance, low mercapto group introduction, and limited addition, and achieve good transparency, simple synthesis process, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

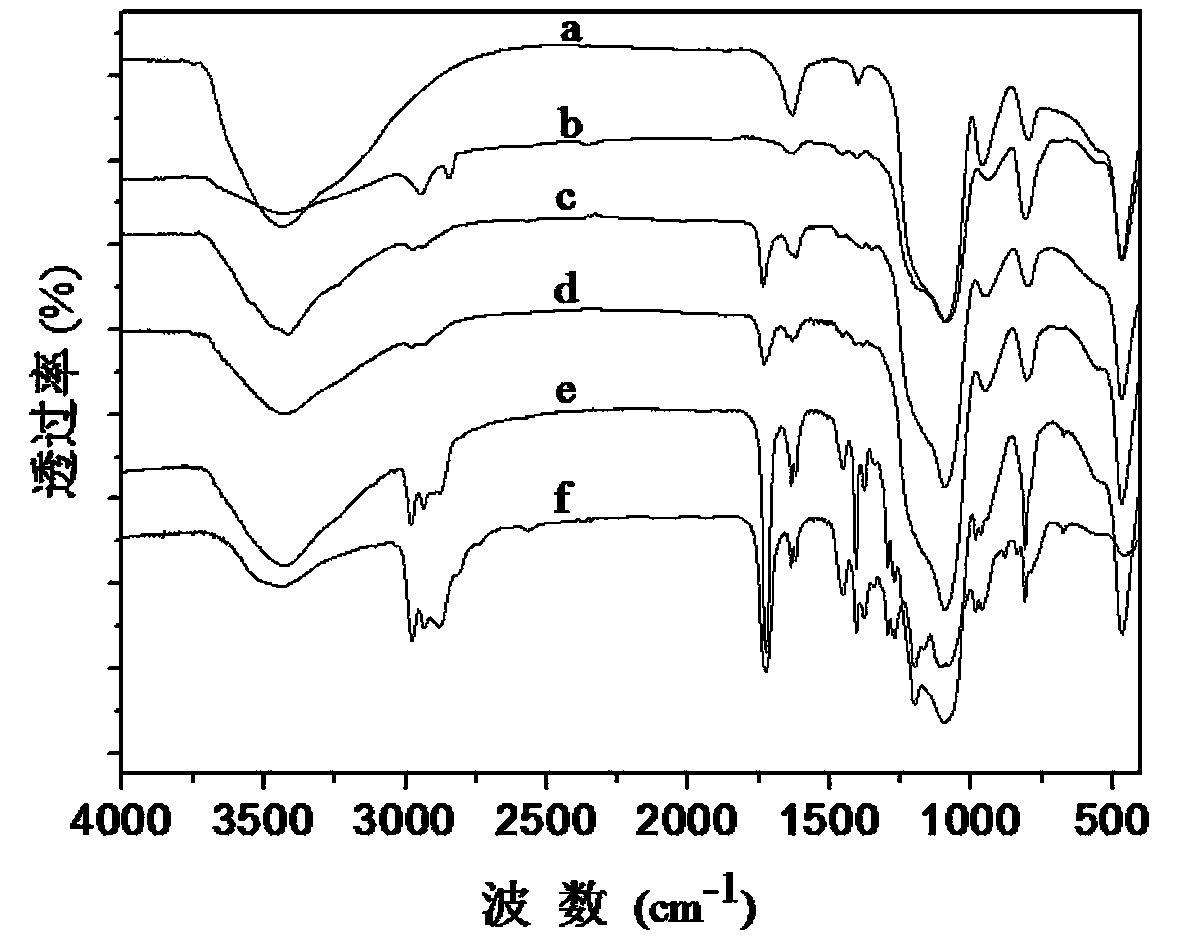

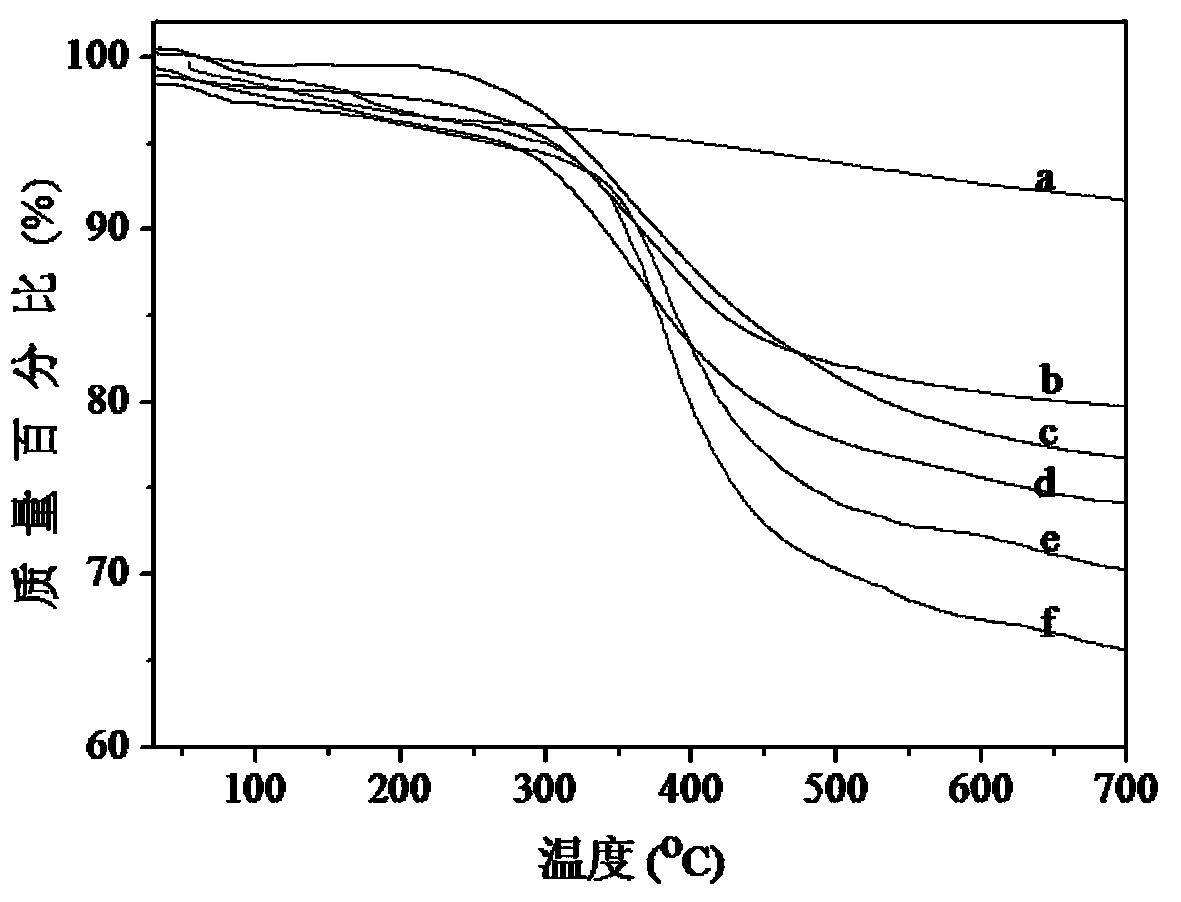

[0029] a) Add 5g of nano-silica and 30mL of toluene into a 250mL four-neck flask equipped with a thermometer, agitator, and a condenser tube. After ultrasonically dispersing for 1 hour, add 5mL of water, 5mL of absolute ethanol and 100g of γ- The mixed solution composed of mercaptopropyltrimethoxysilane (KH590), the pH of the system is adjusted to 6 with acetic acid, the grafting reaction is carried out at 50°C for 10 hours, the product is filtered, washed and dried to obtain the modified nano-silica with mercapto groups on the surface , that is, the first generation of modified nano-silica.

[0030] b) Take 5g of the first-generation modified nano-silica and 30mL of toluene, ultrasonically disperse it in a 250mL four-necked bottle for 1 hour, add 50g of trimethylolpropane triacrylate and 0.05g of benzophenone, and React for 8 hours, filter, wash, and dry to obtain modified nano-silica whose surface is acrylate, that is, the second-generation modified nano-silica.

[0031] c)...

Embodiment 2

[0043] a) Add 3g of nano-silica and 30mL of xylene into a 250mL four-neck flask equipped with a thermometer, agitator, and a condenser tube. After ultrasonic dispersion for 1 hour, add 7mL of water, 4mL of absolute ethanol and 100g of γ under stirring. -Mixed solution composed of mercaptopropyltriethoxysilane (KH580), the pH of the system is adjusted to 5 with acetic acid, the grafting reaction is carried out at 50°C for 8 hours, the product is filtered, washed and dried to obtain the modified nano-dioxide Silicon, the first generation of modified nano-silica.

[0044] b) Take 3g of the first-generation modified nano-silica and 30mL of xylene, ultrasonically disperse it in a 250mL four-necked bottle for 1 hour, add 30g of pentaerythritol tetraacrylate and 0.05g of 2-hydroxy-2-methyl-1-benzene Base-1-acetone, react under ultraviolet light for 8 hours, filter, wash, and dry to obtain modified nano-silica with acrylate surface, that is, the second-generation modified nano-silica....

Embodiment 3

[0049] a) Add 4g of nano-silica and 15mL of isopropanol into a 250mL four-neck flask equipped with a thermometer, a stirrer, and a condenser tube. After ultrasonic dispersion for 1.5 hours, add 5mL of water, 5mL of absolute ethanol and 180g of γ-mercaptopropyltrimethoxysilane (KH590) mixed solution, adjusted the pH of the system to 5.5 with acetic acid, grafted at 50°C for 8 hours, filtered the product, washed, and dried to obtain a modified nanometer with mercapto groups on the surface. Silicon oxide is the first generation of modified nano-silica.

[0050] b) Take 3g of the first-generation modified nano-silica and 20mL of toluene, ultrasonically disperse it in a 250mL four-necked bottle for 0.5h, add 80g of 1,6-hexanediol diacrylate and 0.1g of 1-hydroxycyclohexylbenzene base ketone, reacted for 10 h under ultraviolet light irradiation, filtered, washed and dried to obtain modified nano-silica with acrylate surface, that is, the second-generation modified nano-silica.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com