Patents

Literature

976results about How to "High grafting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

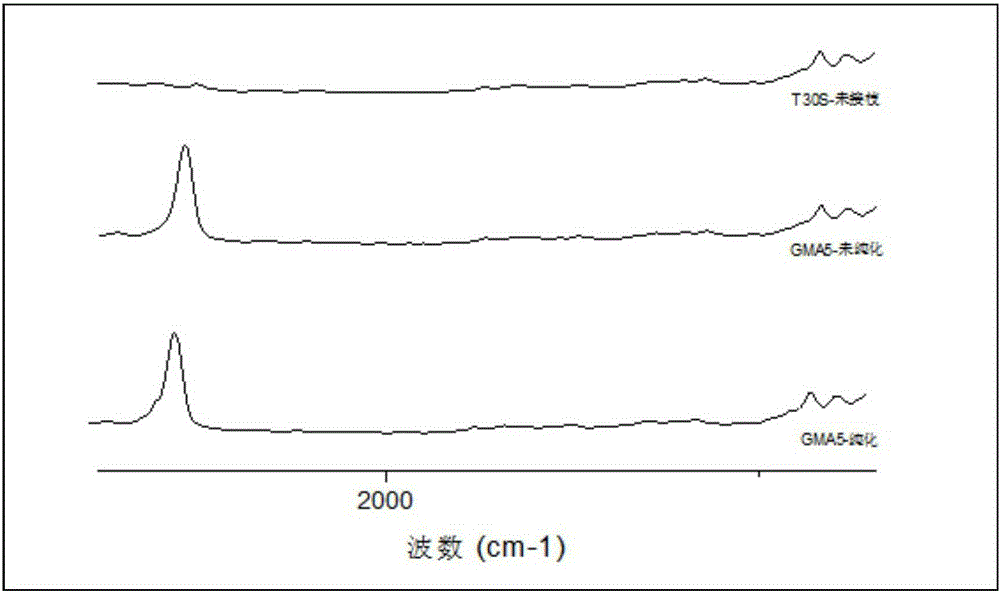

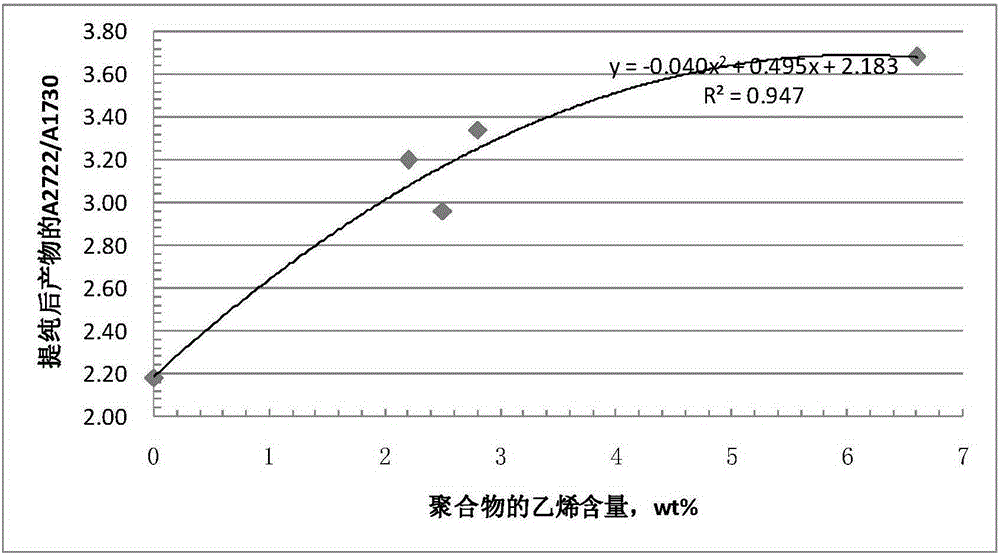

Grafting modification method for solution-polymerized styrene-butadiene rubber with low gel rate

The invention relates to a preparation method of polar solution-polymerized styrene-butadiene rubber with low gel rate. The method involves grafting polar monomers on solution-polymerized styrene-butadiene rubber by means of free radical solution method, so as to change the polarity and further improve the interface bonding force of styrene-butadiene rubber and carbon black or white carbon black, so that the wet-skid resistance, wear resistance and dynamic mechanical property of vulcanized rubber are improved and the rolling resistance is reduced. The polar monomers used comprise maleic anhydride, acrylic acid, acrylamide, N-vinyl pyrrolidone and the like. The grafting rate of modified styrene-butadiene rubber is 1-5% and the gel rate is 1-3%; and the rubber polarity changes obviously.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Polar monomer graft-modified amorphous poly-alpha-olefin and preparation method thereof

The invention discloses a polar monomer graft-modified amorphous poly-alpha-olefin and a preparation method thereof. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared by carrying out grafting reaction on amorphous poly-alpha-olefin, a peroxide initiator, a polar monomer and an auxiliary grafting agent under molten or dissolved conditions. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared from the following raw materials: 100 parts of amorphous poly-alpha-olefin, peroxide initiator accounting for 0.1-1 wt% of the amorphous poly-alpha-olefin, polar monomer accounting for 0.5-10 wt% of the amorphous poly-alpha-olefin, auxiliary grafting agent accounting for 0.1-5 wt% of the amorphous poly-alpha-olefin, solvent accounting for 0-300 wt% of the amorphous poly-alpha-olefin, and antioxidant accounting for 0.05-2 wt% of the amorphous poly-alpha-olefin. The amorphous poly-alpha-olefin has the characteristics of high grafting ratio, light color, high polarity, favorable flowability, favorable storage capability and no risk in moisture crosslinking.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

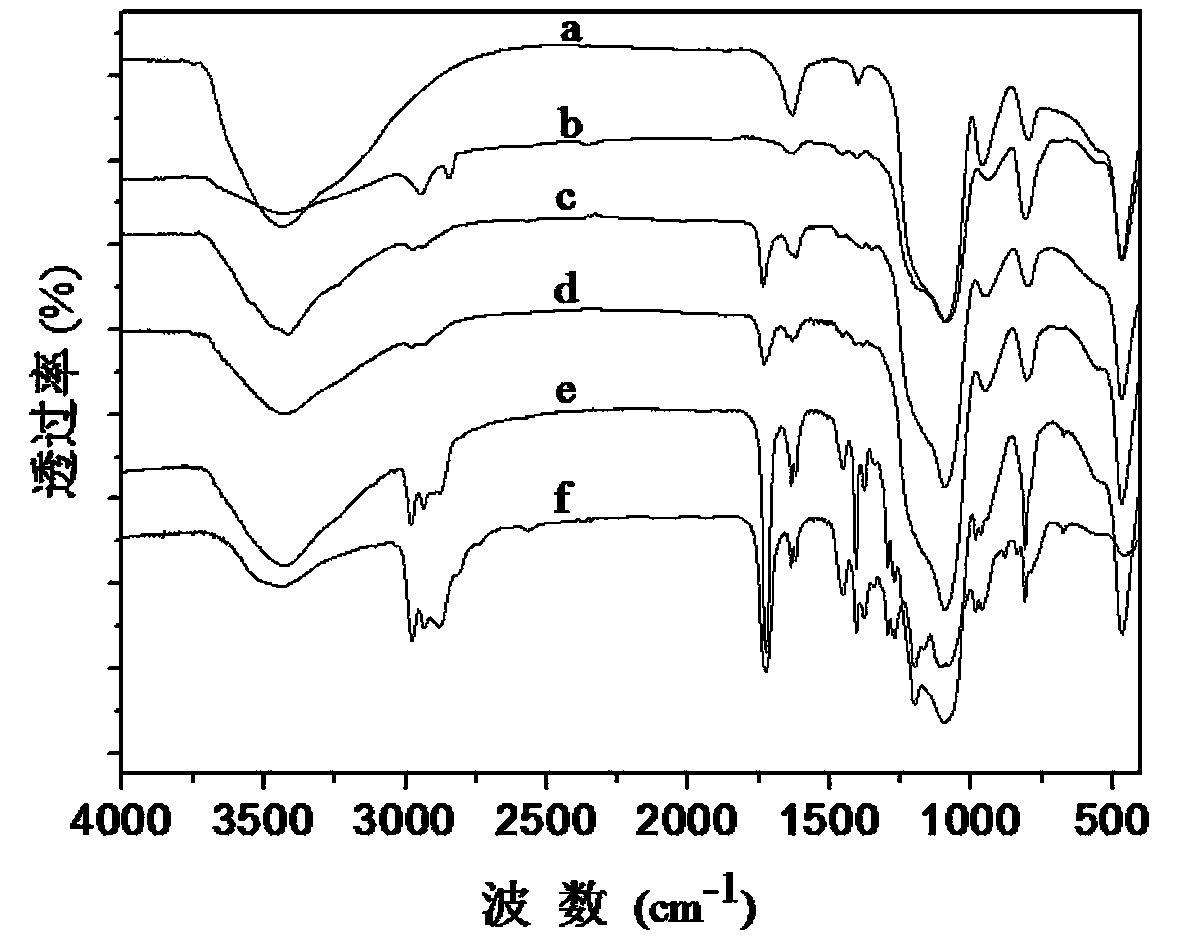

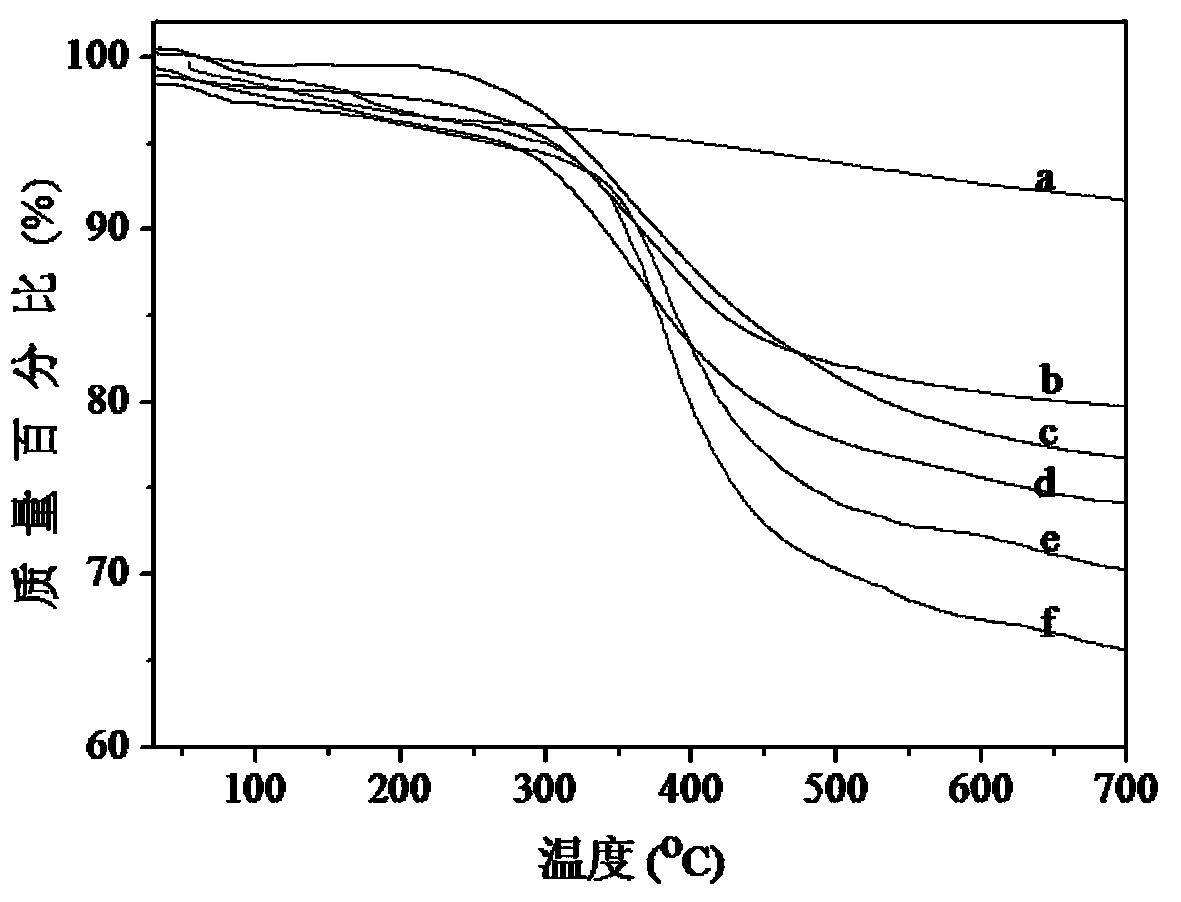

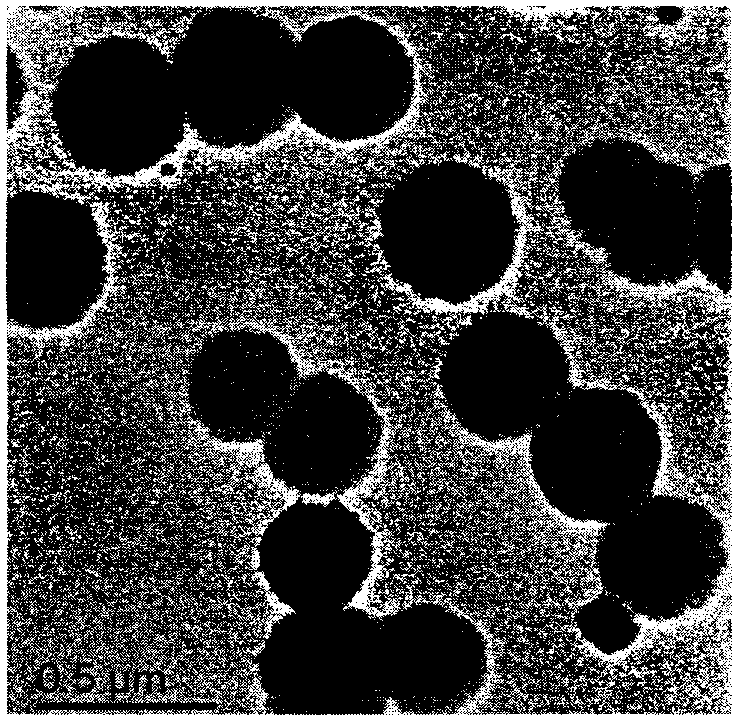

Preparation method of hyperbranched polymer-modified nano-silicon dioxide hybrid material

The invention relates to a preparation method of a hyperbranched polymer-modified nano-silicon dioxide hybrid material. The preparation method comprises the following steps: grafting a mercapto group-containing silane coupling agent to the surface of nano-silicon dioxide, utilizing a surface mercapto group and polyfunctional acrylic ester to perform click reaction to form the modified nano-silicon dioxide with the tail end of the acrylic ester, further performing the click reaction with a polyfunctional mercapto compound to form the modified silicon dioxide with the tail end of the mercapto group, repeating the operation between the polyfunctional acrylic ester and the polyfunctional mercapto compound for multiple times, and forming a hyperbranched polymer on the surface of the silicon dioxide. The hyperbranched polymer-modified nano-silicon dioxide hybrid material prepared by the preparation method provided by the invention has the mercapto group at the tail end and a hyperbranched structure, when the hyperbranched polymer-modified nano-silicon dioxide hybrid material is applied in an ultraviolet curing coating, the heat resistance, the hardness, the wear resistance and other mechanical properties of the coating can be improved, and the hyperbranched polymer-modified nano-silicon dioxide hybrid material can particularly solve the problems of dispersion and migration of the nano-silicon dioxide in the ultraviolet curing coating and the problem of oxygen polymerization inhibition of the ultraviolet curing coating.

Owner:TAIYUAN UNIV OF TECH

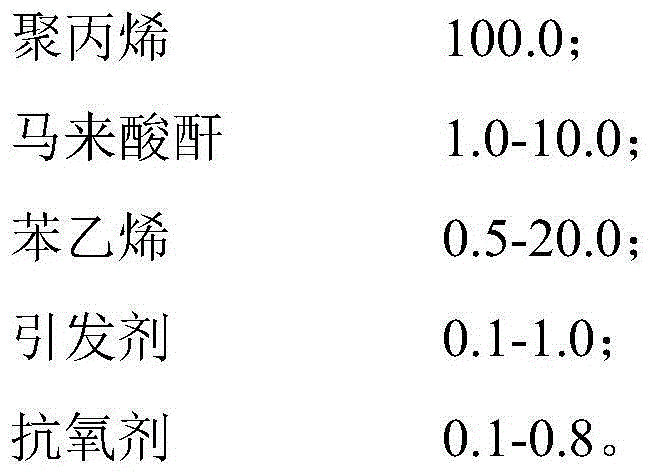

Preparation method of maleic anhydride grafted polypropylene

The invention provides a preparation method of maleic anhydride grafted polypropylene. According to the method, maleic anhydride is grafted to a polypropylene molecular chain through melting free radical grafting reaction. In the melting grafting reaction initiated by a peroxide initiator, the initiator and auxiliary monomer styrene are prepared into a solution, and the solution is continuously metered and input to a plurality of positions of different screw barrel sections of a double-screw extruder. The adopted extruder is the double-screw extruder of which the draw ratio is greater than or equal to 48: 1 or a double-order double-screw extruder. The usage of the maleic anhydride in raw materials is 1.0-10.0 weight percent of that of polypropylene. According to the preparation method, the functional maleic anhydride grafted polypropylene which is high in grafting rate can be obtained, and the molecular weight of the functional maleic anhydride grafted polypropylene is not obviously reduced compared with the molecular weight of the polypropylene in the raw materials.

Owner:EAST CHINA UNIV OF SCI & TECH

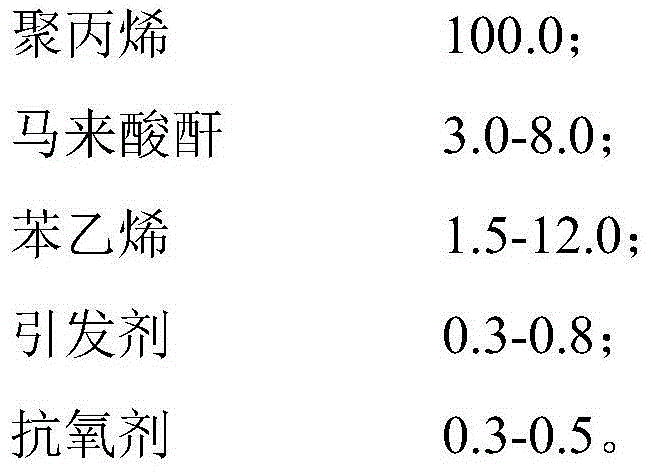

Polymer grafted graphene oxide and preparation method thereof

InactiveCN102731733ADoes not involve modification efficiency issuesEasy to preparePolymer scienceIrradiation

The invention relates to polymer grafted graphene oxide and a preparation method thereof. The method comprises the step that the polymer grafted modified graphene oxide is obtained through an irradiation graft polymerization reaction of C=C contained monomers and graphene oxide under anoxic conditions. The method of the invention, which does not need the modification of graphene oxide or polymers before grafting, has the advantages of simple operation process and wide application range, and is especially suitable for large-scale batch production; and the polymer grafted graphene oxide prepared in the invention has an obviously improved grafting rate, so the polymer grafted graphene oxide can be widely used.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Functional filter medium

InactiveUS20080230471A1Increase flexibilityHigh grafting rateIon-exchange process apparatusCation exchanger materialsIon exchangePolyamide

This invention relates to functional nonwoven filter media provided by radiation-induced graft copolymerization and its production method. Meltblown type of nonwoven (Meltblown) comprised of fine fibers, less than 8 micron in diameter, of polyolefin or polyamide is chosen as the suitable grafting trunk polymer. The production methods are composed of following steps, 1) irradiation less than 30 kGy dose to the Meltblown with electron beam or gamma ray; 2) graft copolymerization of emulsified vinyl monomer onto the Meltblown; and 3) chemical conversion of ion exchange group onto the grafted vinyl monomer. These steps are independently conducted in their suitable operation conditions.

Owner:KURASHIKI TEXTILE MFG

Intumescent flame retardant functional silicate and preparation method thereof

ActiveCN102757581AHigh grafting rateHigh flame retardant efficiencyPigment treatment with organosilicon compoundsNitrogenFire retardant

The invention discloses an intumescent flame retardant functional silicate and a preparation method thereof. According to the invention, the preparation method comprises the following two methods: one method comprises the steps of first preparing silane coupling agent organic functional silicate, and then preparing the intumescent flame retardant functional silicate on the basis of the former step; and the second method comprises the steps of first preparing a modified silane coupling agent containing phosphorus and nitrogen flame retardant elements, and then modifying inorganic silicate by using the modified silane coupling agent on the basis of the former step. According to the invention, the intumescent flame retardant functional silicate comprises an organic part B and an inorganic part A, wherein the organic part B is grafted to the inorganic part A in such a way that a silanol group formed by after a silane coupling agent containing amino has dehydration reaction with hydroxyls on the surface and between layers of the inorganic part A; and the organic part B is formed in such a way that a phosphoryl chloride compound has elimination reaction with an amino silane coupling agent. The intumescent flame retardant functional silicate disclosed by the invention is integrated with reinforcing, flame retardant and smoke suppressing functions.

Owner:SOUTH CHINA UNIV OF TECH +1

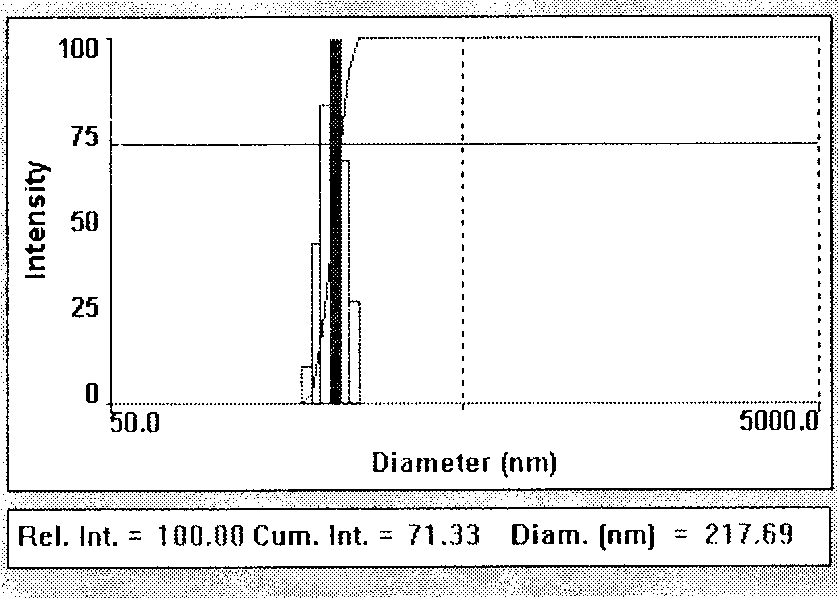

Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

InactiveCN101372527AUniform particle sizeImprove coating efficiency and grafting rateNano zinc oxideNanometre

The invention relates to the manufacturing field of nano composite emulsion materials, in particular to graft nano zinc oxide / polyacrylate composite emulsion and a manufacturing method thereof. Firstly an initiator azobisisovaleric acid is anchored on the surface of nano zinc oxide particles, two portions of hexadecane are added to 100 portions of mixed monomers, and 5 portions of nano ZnO particles anchoring the azo initiator are added and ultrasonically oscillated for 20 minutes to form an oil phase pre-dispersion solution. The pre-dispersion solution is added to an emulsifier aqueous solution and dispersed by a high-shear dispersion homogenizer at high speed for 30 minutes to form a mini-emulsion. The mini-emulsion is transferred to a reactor, heated to the temperature of 75 DEG C, with polyreaction initiated for 3 hours, and then heated to the temperature of 85 DEG C, polymerized for 2 hours, cooled to room temperature and discharged. The invention solves the problems of high cost and poor stability of the nano composite emulsion prepared by coupling agents, and low encapsulation efficiency and graft ratio of nano polymer composite particles. The composite emulsion has the advantages of simple preparation process, low cost, even particle size, good performance, high encapsulation efficiency and graft ratio of the nano-particles, forms nano monodisperse state in the polymer, and is suitable for the fields of coating materials, leather finishing materials, adhesives and functional plastics.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for grafting propylene polymer with polar monomer

The invention provides a method for grafting a propylene polymer with a polar monomer. The method comprises a, mixing a propylene polymer, an initiator and an organic solvent to obtain a mixture, b, removing the organic solvent in the mixture obtained by the step a and adding a polar monomer into the mixture for swelling, c, adding water into the swollen material obtained by the step b and heating the solution for a reaction, and d, washing and drying the reaction product obtained by the step c to obtain a propylene polymer grafted with the polar monomer. The method can utilizes an aqueous phase suspension grafting method for the propylene polymer, can observably improve polar monomer grafting efficiency and ratio and is conducive to wide application of the grafting-modified polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

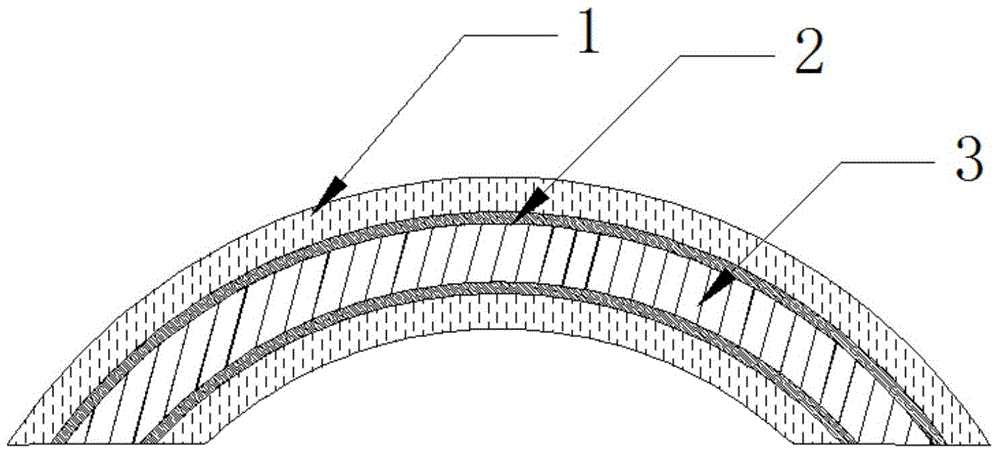

Cranioplasty prosthesis with biological activity and preparation method of cranioplasty prosthesis

InactiveCN104667345AFast productionSmall sizeAdditive manufacturing apparatusCoatingsBiocompatibility TestingDrug biological activity

The invention relates to cranioplasty prosthesis with biological activity and a preparation method of the cranioplasty prosthesis. The cranioplasty prosthesis with biological activity sequentially comprises an unmodified cranioplasty prosthesis layer, a modified cranioplasty prosthesis layer and a nanofiber membrane layer from inside to outside. The invention further provides a preparation method of the cranioplasty prosthesis. By virtue of a three-layer structure and polyaryletherketone materials which are equivalent to a bone of a human body in hardness, strength and weight, are good in biocompatibility, and a 3D printing technology, a cranioplasty prosthesis implant has reliably safety and effectivity and high matching degree. The cranioplasty prosthesis provided by the invention is capable of loading a plurality of bionic scaffolds and bioactive substances, and promoting exchange of nutrient substances inside and outside the prosthesis, and is beneficial to growth of tissues.

Owner:MEDPRINSHENZHEN REGENERATIVEA MEDICAL TECH CO LTD

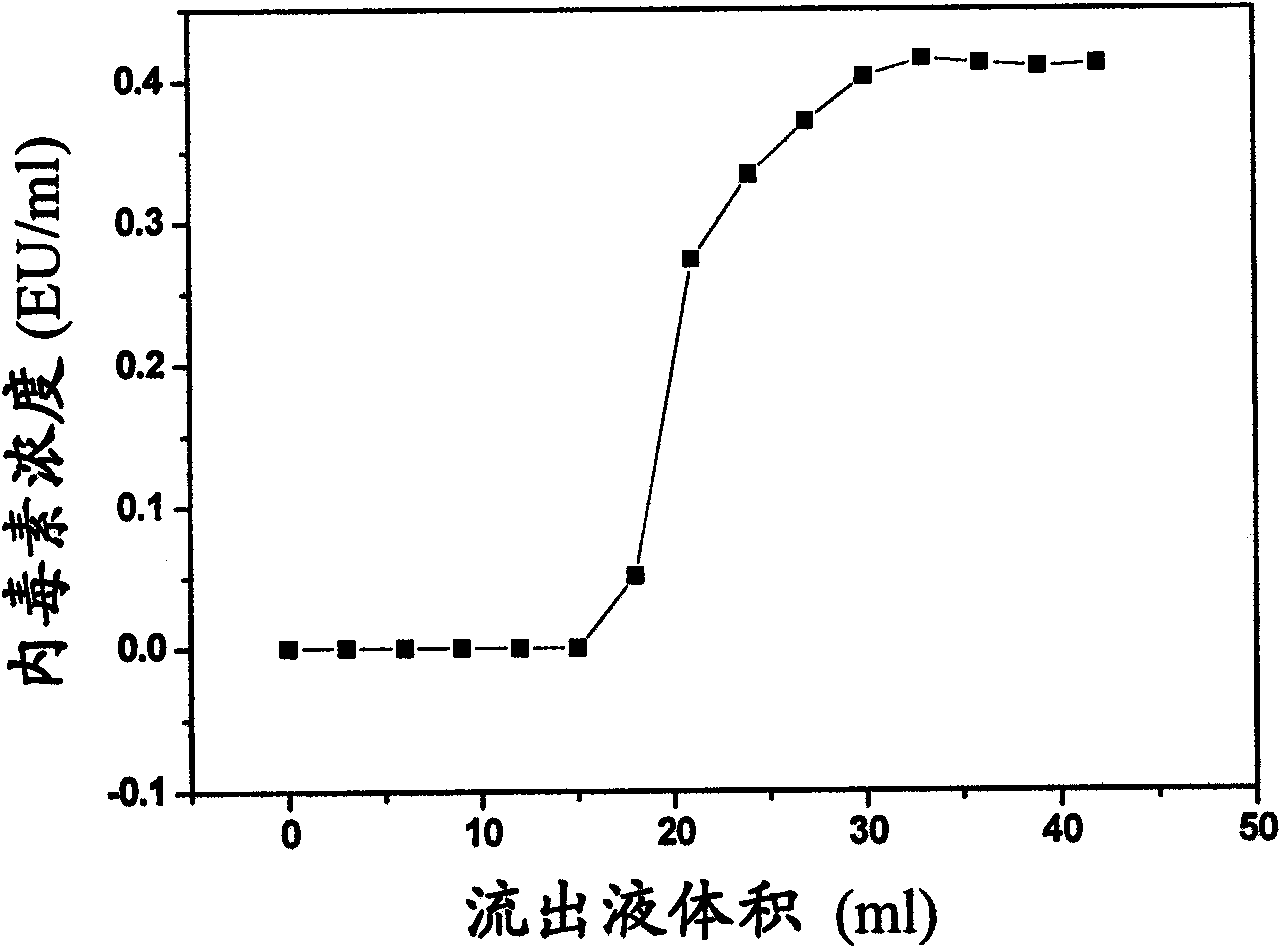

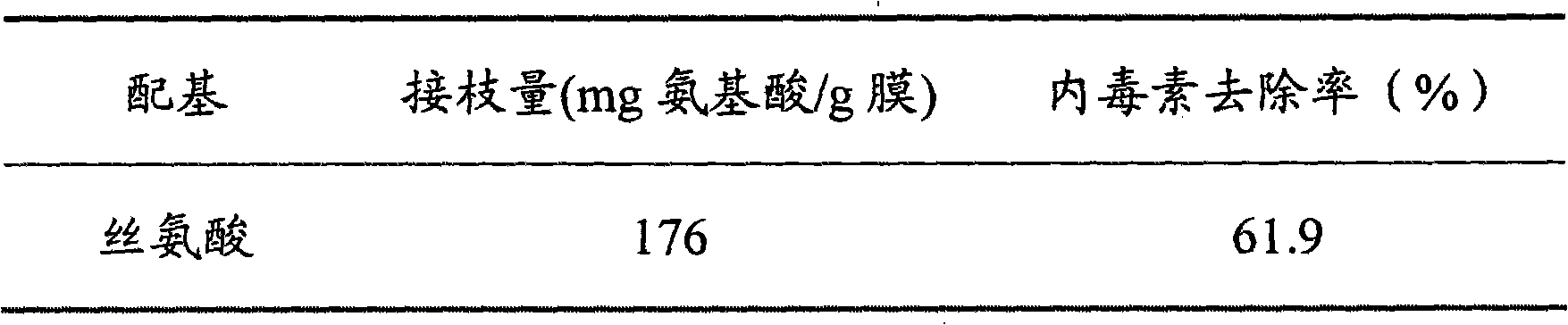

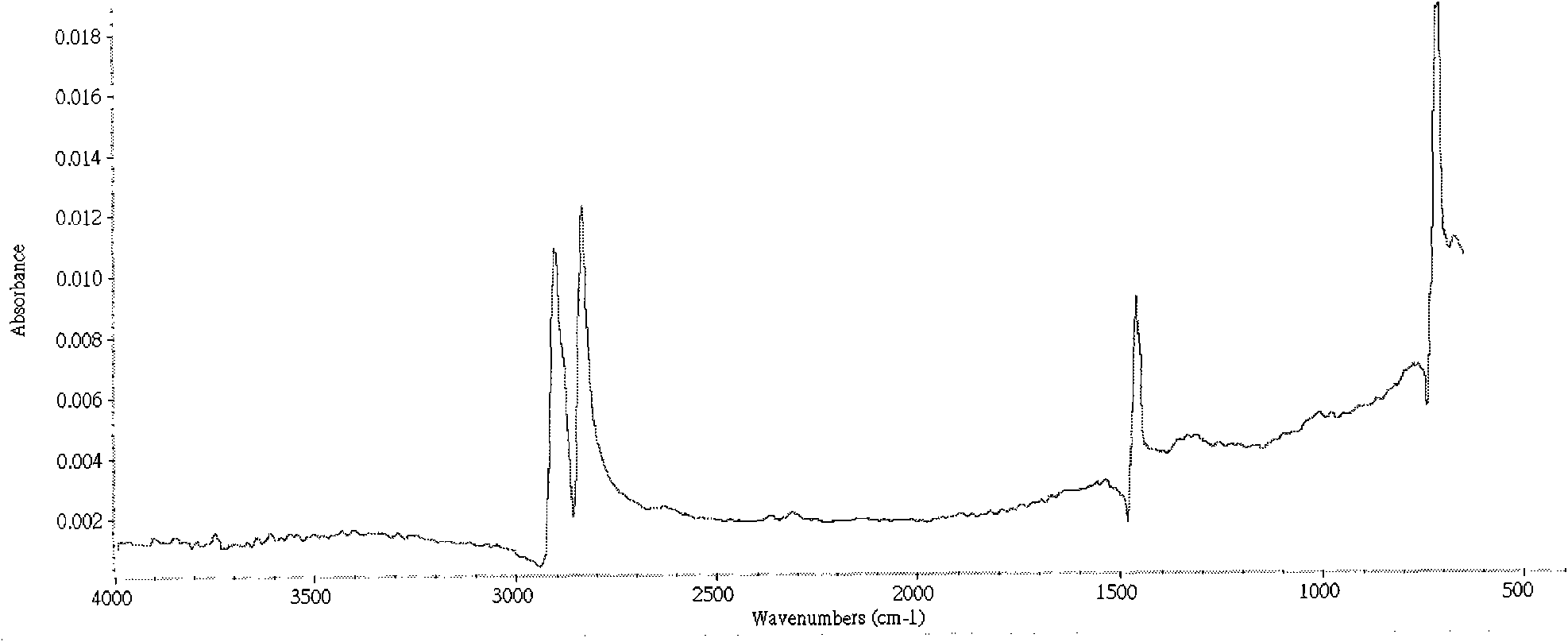

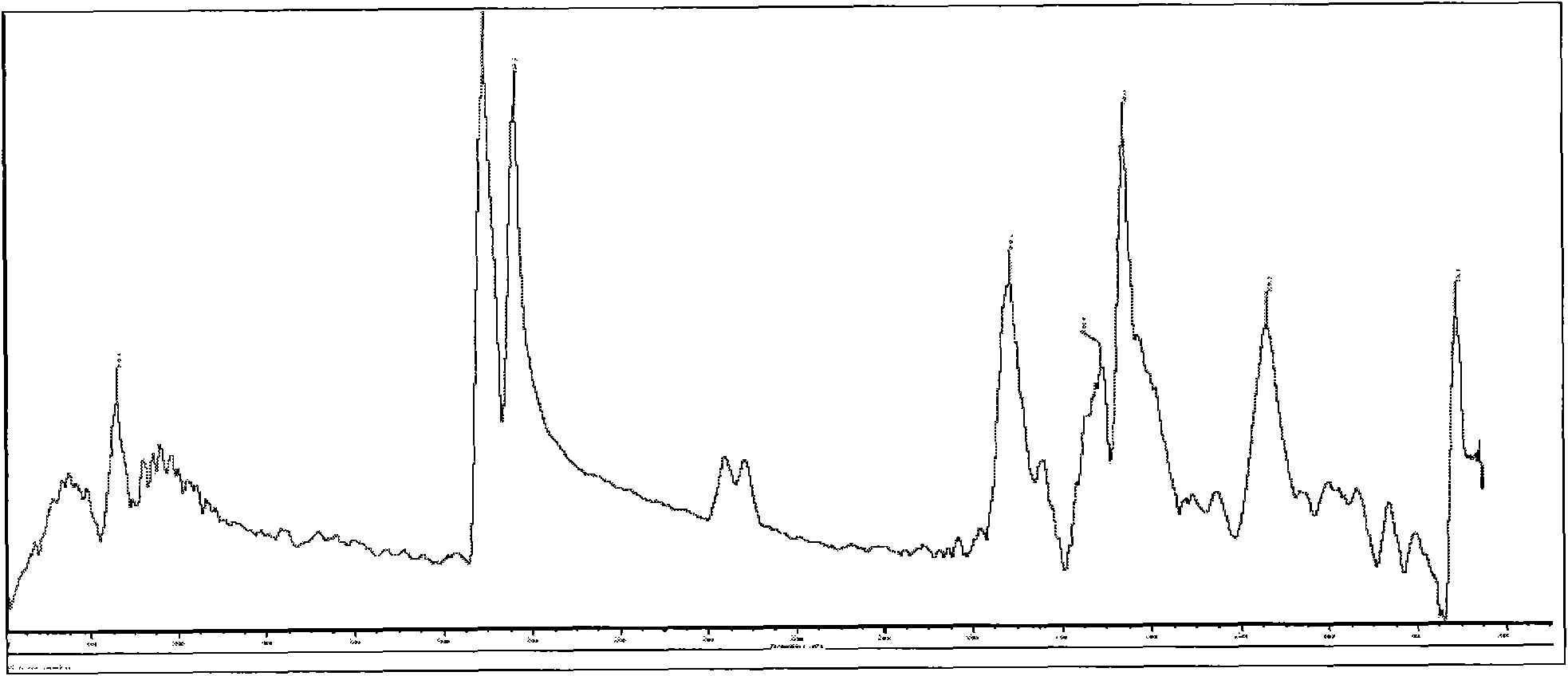

Method for preparing polyvinylidene fluoride affinity membrane using amino acid as ligand

InactiveCN101596422AImprove adsorption efficiencyStable physical and chemical propertiesSemi-permeable membranesHaemofiltrationPolyvinylidene difluorideBlood plasma

The invention discloses a method for preparing a polyvinylidene fluoride affinity membrane using amino acid as a ligand. The affinity membrane is prepared by hydrophilically modifying a polyvinylidene fluoride hollow fiber membrane and grafting the amino acid ligand. The grafting amount of the amino acid is 150 to 250mg / g for each membrane. The invention also discloses application of the affinity membrane in removing endotoxin in blood plasma, which removes the endotoxin in the blood plasma by a dynamic absorption means. The polyvinylidene fluoride affinity membrane prepared by the method has stable performance, good bio-compatibility and high endotoxin removing efficiency, and can be used for whole blood perfusion as well as blood plasma perfusion.

Owner:ZHEJIANG UNIV

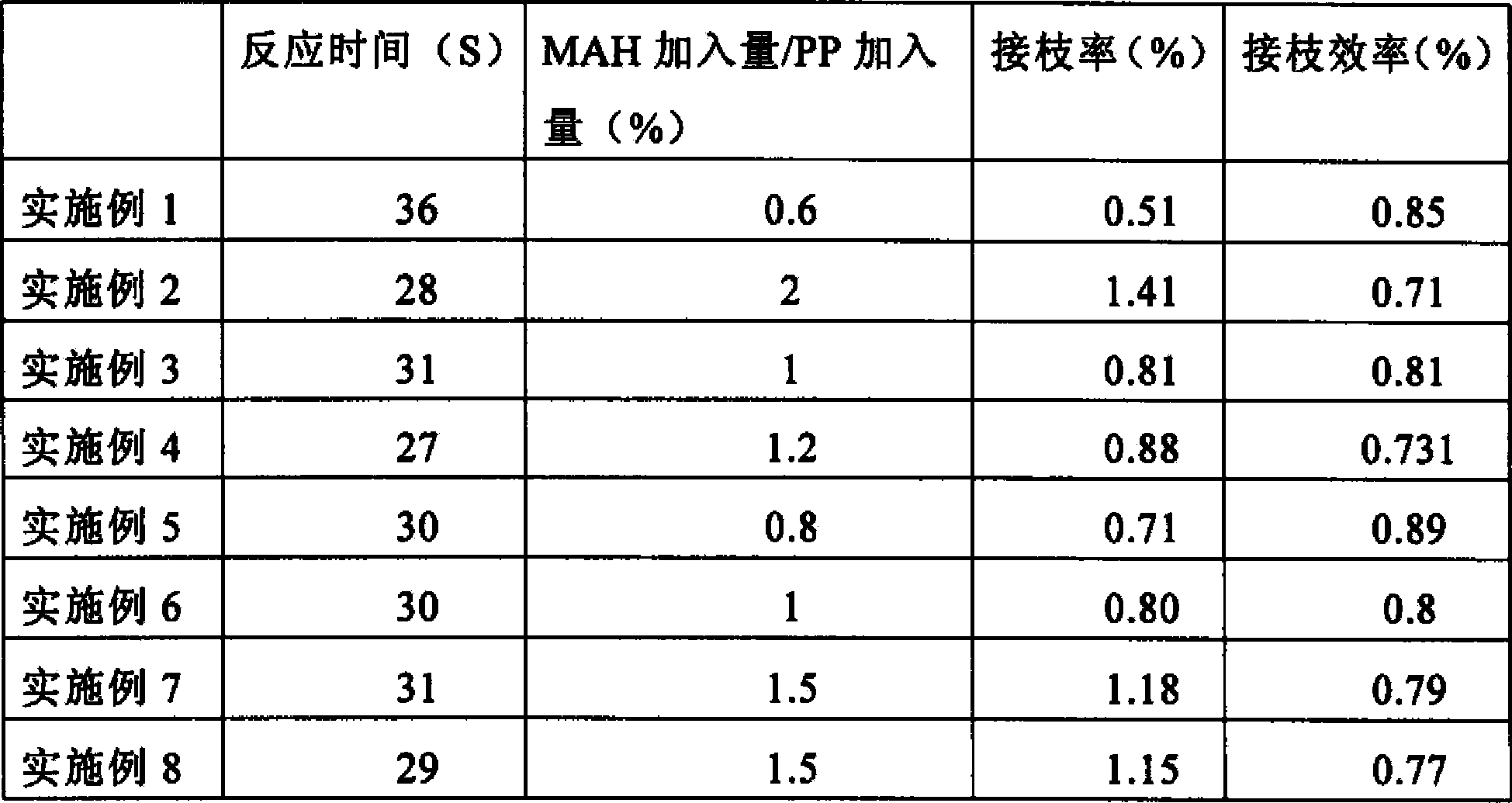

Preparation method for maleic anhydride-grafted polypropylene

The invention relates to a preparation method for maleic anhydride-grafted polypropylene. The preparation method comprises the following steps: (1) uniformly mixing 0.4 to 2 parts of an initiator and 0.6 to 2 parts of styrene by weight; (2) adding 110 parts of polypropylene and 0.6 to 2 parts of maleic anhydride by weight into a high-speed mixing machine and mixing for 1 to 3 minutes, and meanwhile dropwise adding the product obtained by the step (1); (3) adding the product obtained by the step (2) into a double-screw extruder, blending, extruding, melting and grafting to prepare the maleic anhydride-grafted polypropylene. Compared with the prior art, the preparation method has short reaction time, simple preparation and low production cost, and is suitable for industrialization; an anti-oxidant is not required to be added; the effective reaction time can be prolonged by controlling the factors, such as the rotating speed of a main machine, the feeding rotating speed, the temperature and the like; meanwhile, the maleic anhydride-grafted polypropylene with high grafting rate can be obtained by adding the styrene, so that the grafting efficiency of maleic anhydride is improved; the preparation method does not have special requirements on the double-screw extruder, a liquid feeding device is not required, and the length-diameter selection range is large.

Owner:HEFEI GENIUS NEW MATERIALS

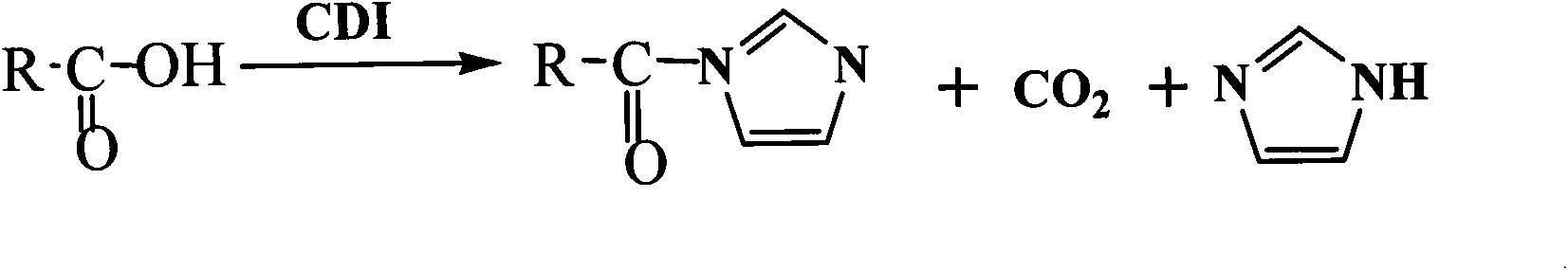

Method for modifying nano metal oxide by coupling graft

InactiveCN101880482AHigh grafting rateImprove grafting efficiencyPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCarbonyldiimidazoleEnergy conservation

The invention discloses a method for modifying a nano metal oxide by coupling graft, and belongs to the technical field of nano granule surface modification. The nano metal oxide is used as a raw material, N,N'-carbonyl diimidazole (CDI) is used as an activating agent, and a finished product is obtained by simple processes of drying treatment, coupling reaction, separation and purification, coupling graft, re-separation and re-purification. The method has the advantages of simplicity, mild reaction conditions, high grafting efficiency which reaches 87 percent, energy conservation, emission reduction, low cost and suitability for large-scale industrial production. The nano metal oxide prepared by using the method can be widely applied in the fields of rubber, coating, ink, dye, glass, piezoelectric ceramics, photoelectrons, medicament and the like.

Owner:CHONGQING UNIV

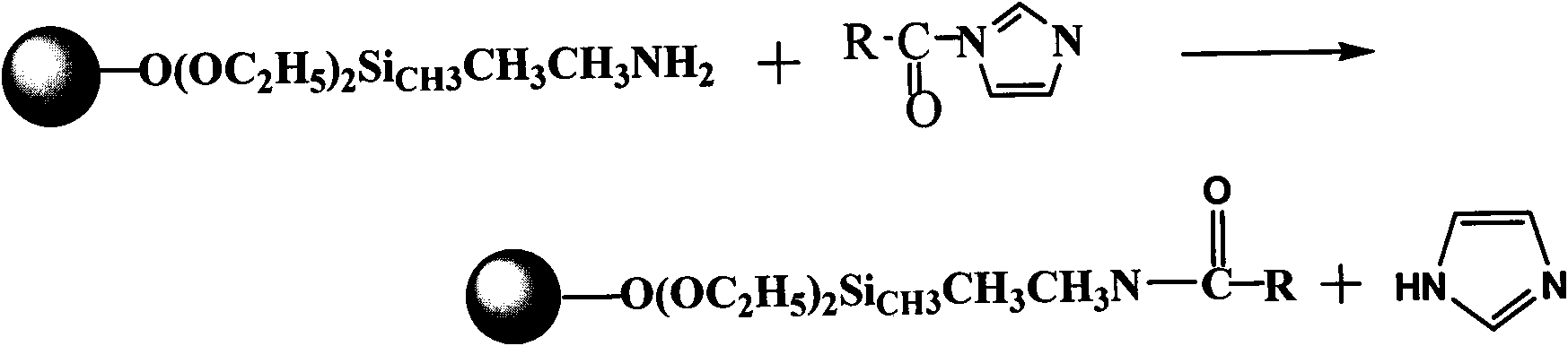

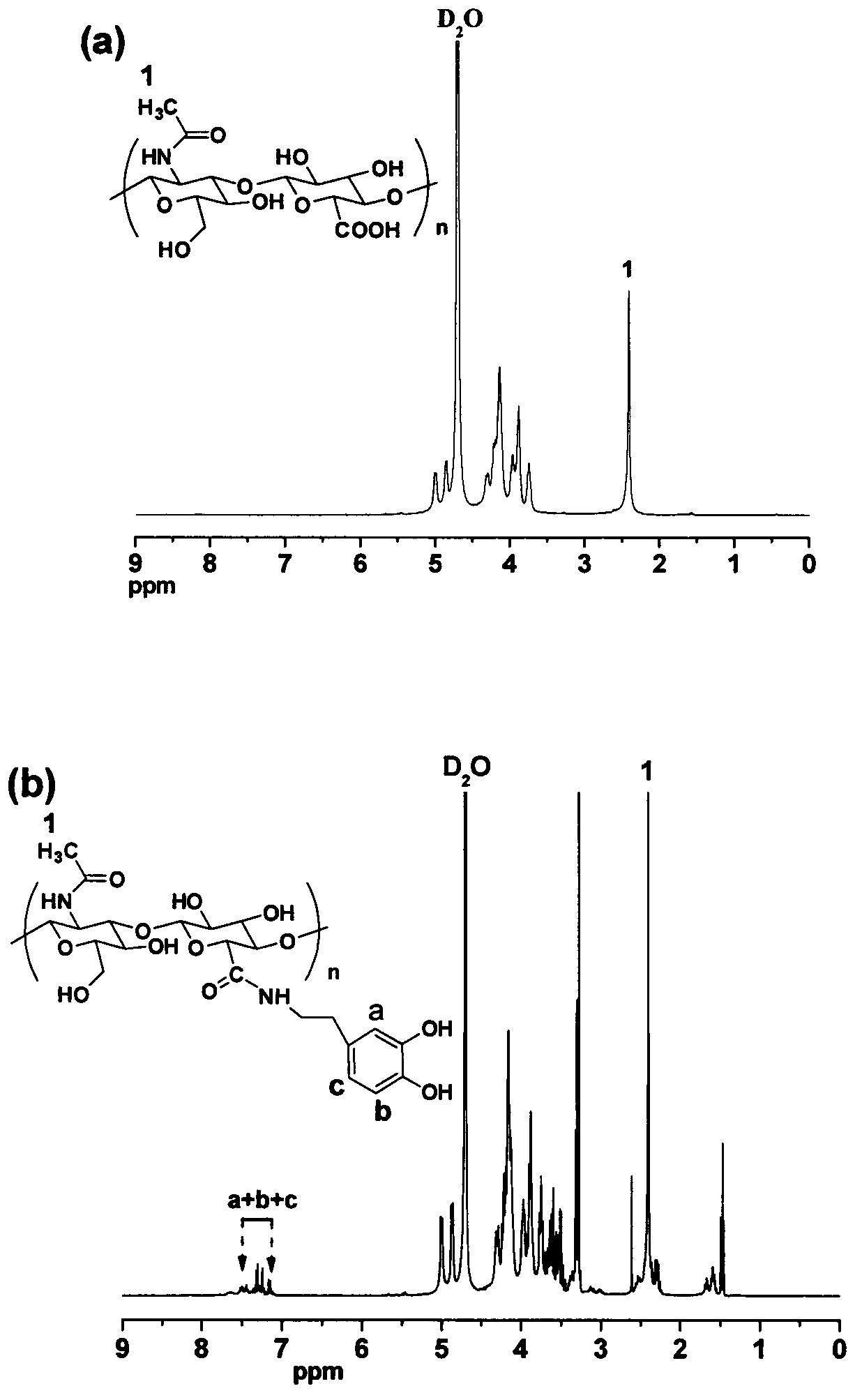

Method for preparing dopamine-modified hyaluronic acid micelle

ActiveCN102702539AUnique moisturizing typeGood biocompatibilityBiocompatibility TestingBiological materials

The invention provides a method for preparing dopamine-modified hyaluronic acid micelle and belongs to the technical fields of polymer material and natural polymer. The method comprises the steps of introducing dopamine element on a hyaluronic acid main chain by amidation so as to provide certain amphipathy to the hyaluronic acid, so that micelle with the grain size of 100-700nm is formed in water solution by self-assembling. The hyaluronic acid micelle is excellent in biocompatibility, hydrophilicity and viscoelasticity, and can be applied to the fields such as biological materials and hydrophilic colloid. The adhesiveness of the dopamine provides excellent interface property, and the micelle can be applied to the fields such as emulsion, food, cosmetic and the like as emulsifier.

Owner:林玉洪

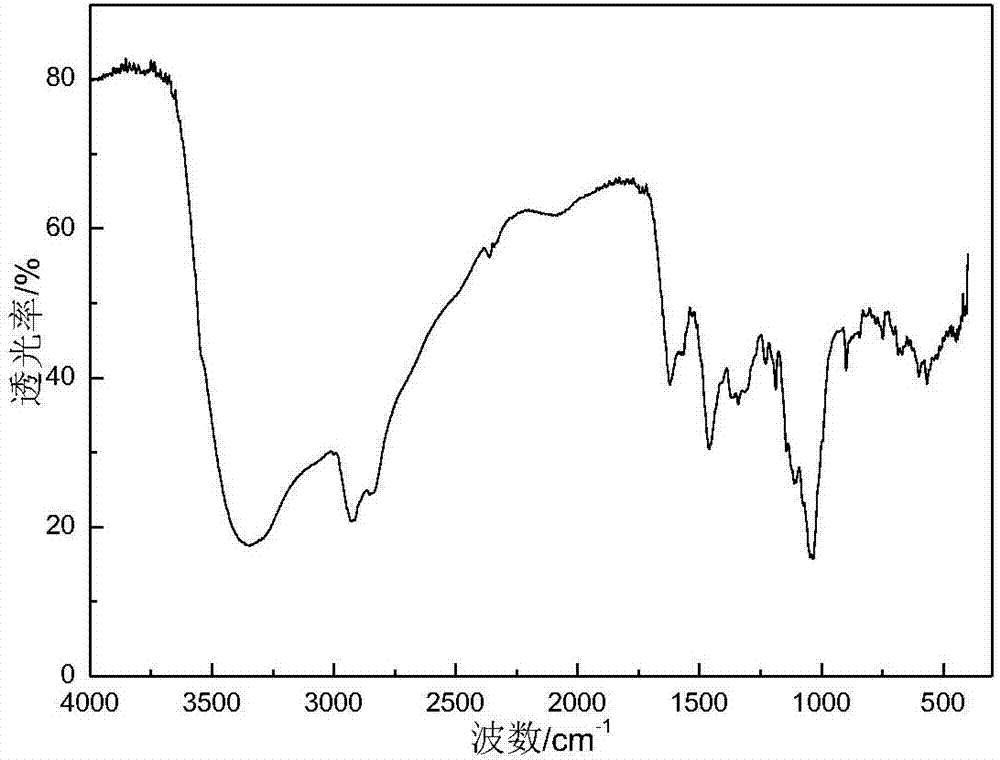

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

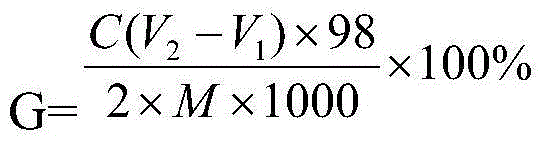

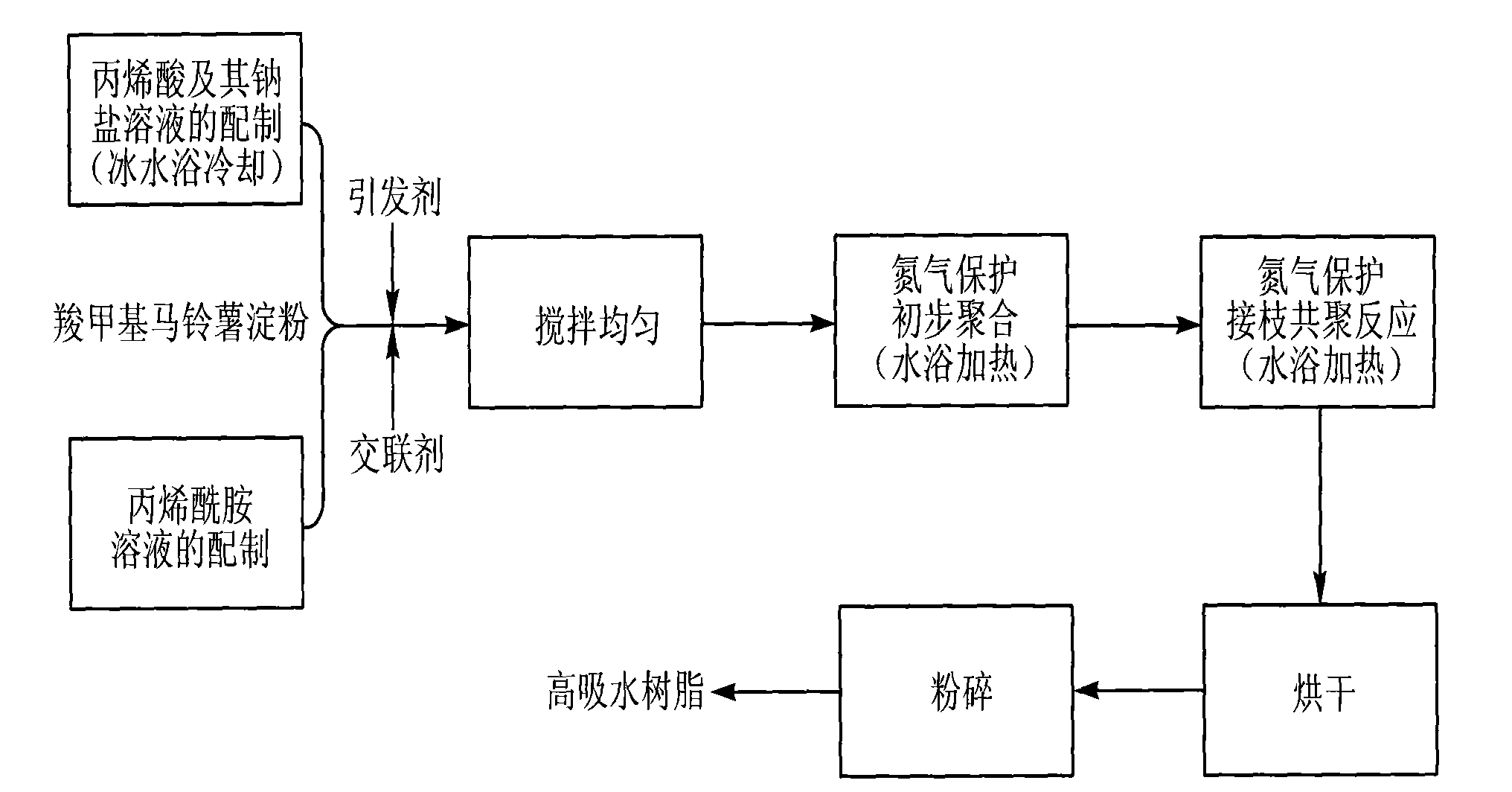

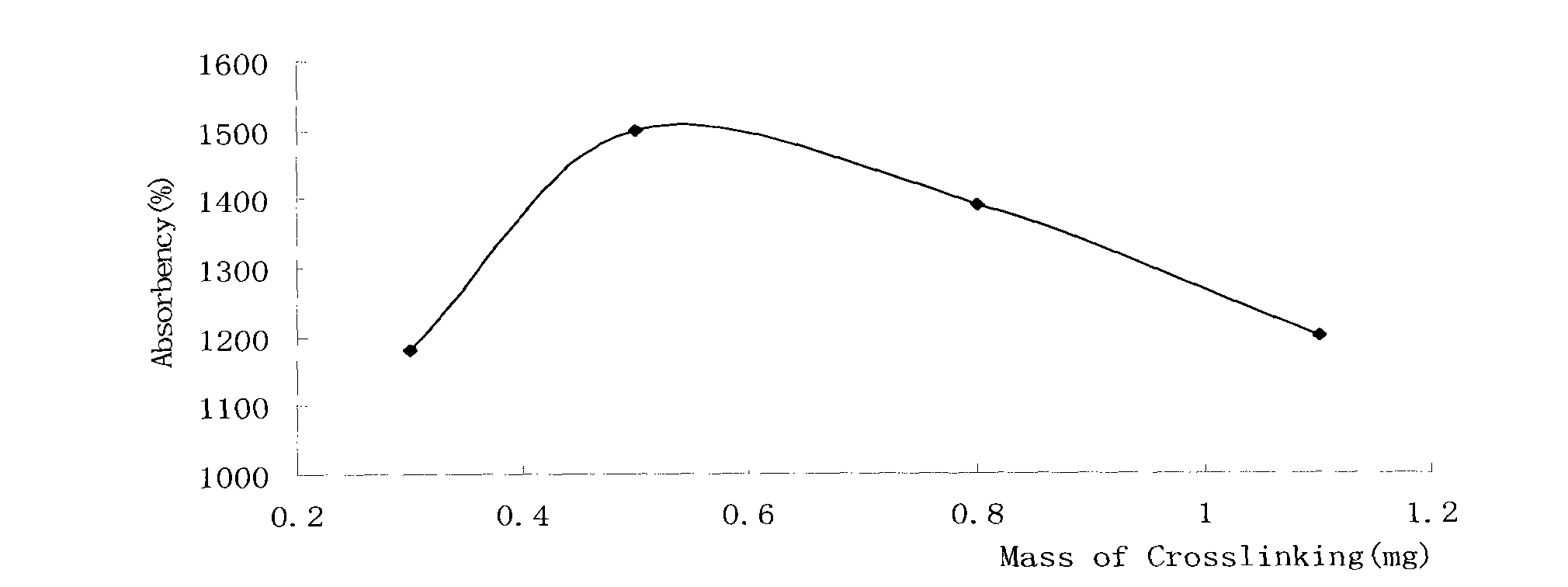

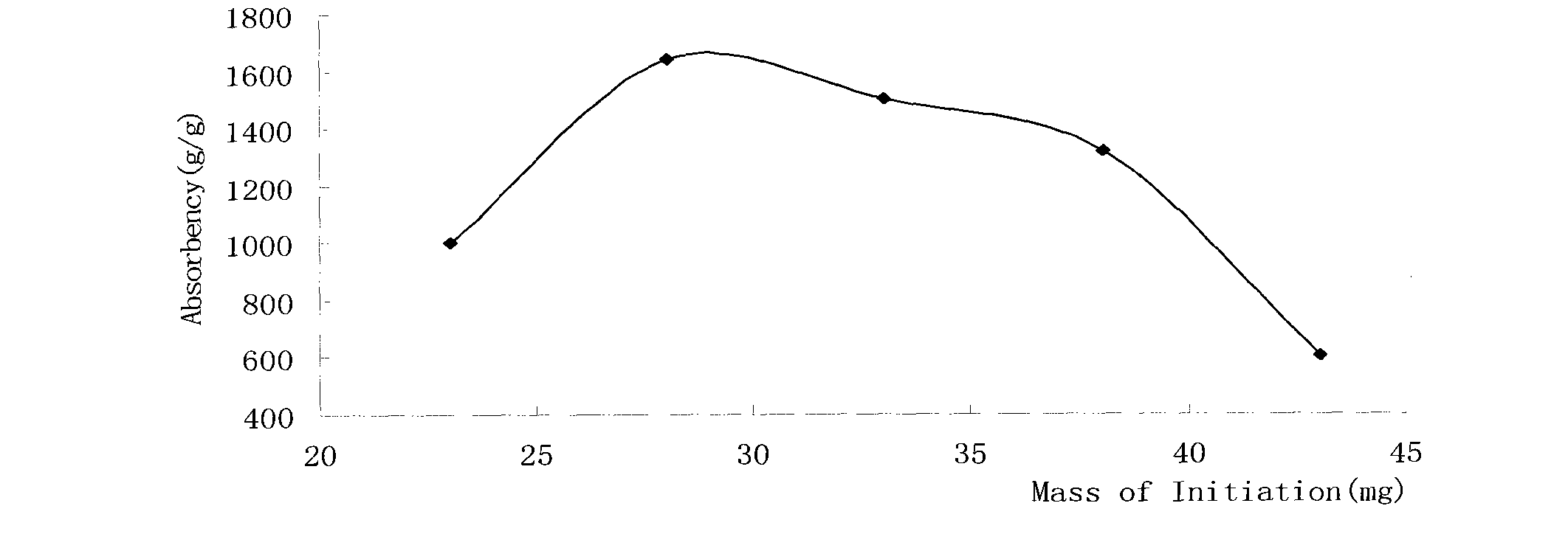

Method for preparing super absorbent resin by graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof

The invention discloses a method for preparing super absorbent resin by the graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof, which comprises the following main processes: carrying out neutralization reaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing acrylamide with de-ionized water to obtain an acrylamide solution; mixing the carboxymethyl potato starch with the prepared acrylic acid and the sodium salt solution and the acrylamide solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature so as to ensure that the carboxymethyl potato starch, the acrylic acid and the sodium salt thereof and the acrylamide generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin with high potassium content by using carboxymethyl potato starch as the raw material. Compared with the similar products, the water absorption of the super absorbent resin is greatly enhanced; the super absorbent resin contains nitrogen nutrition element, does not need pasting in comparison with theprocess of directly using starch and greatly improves the preparation process. The super absorbent resin has great effect on the water conservation, the desert control, the plant growth promotion andthe like of soil in dry regions.

Owner:内蒙古永业生物技术有限责任公司

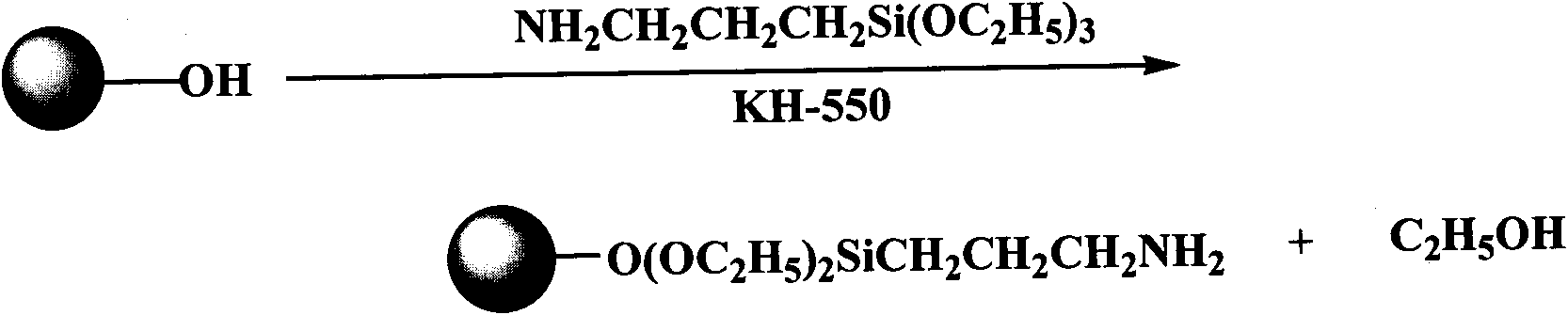

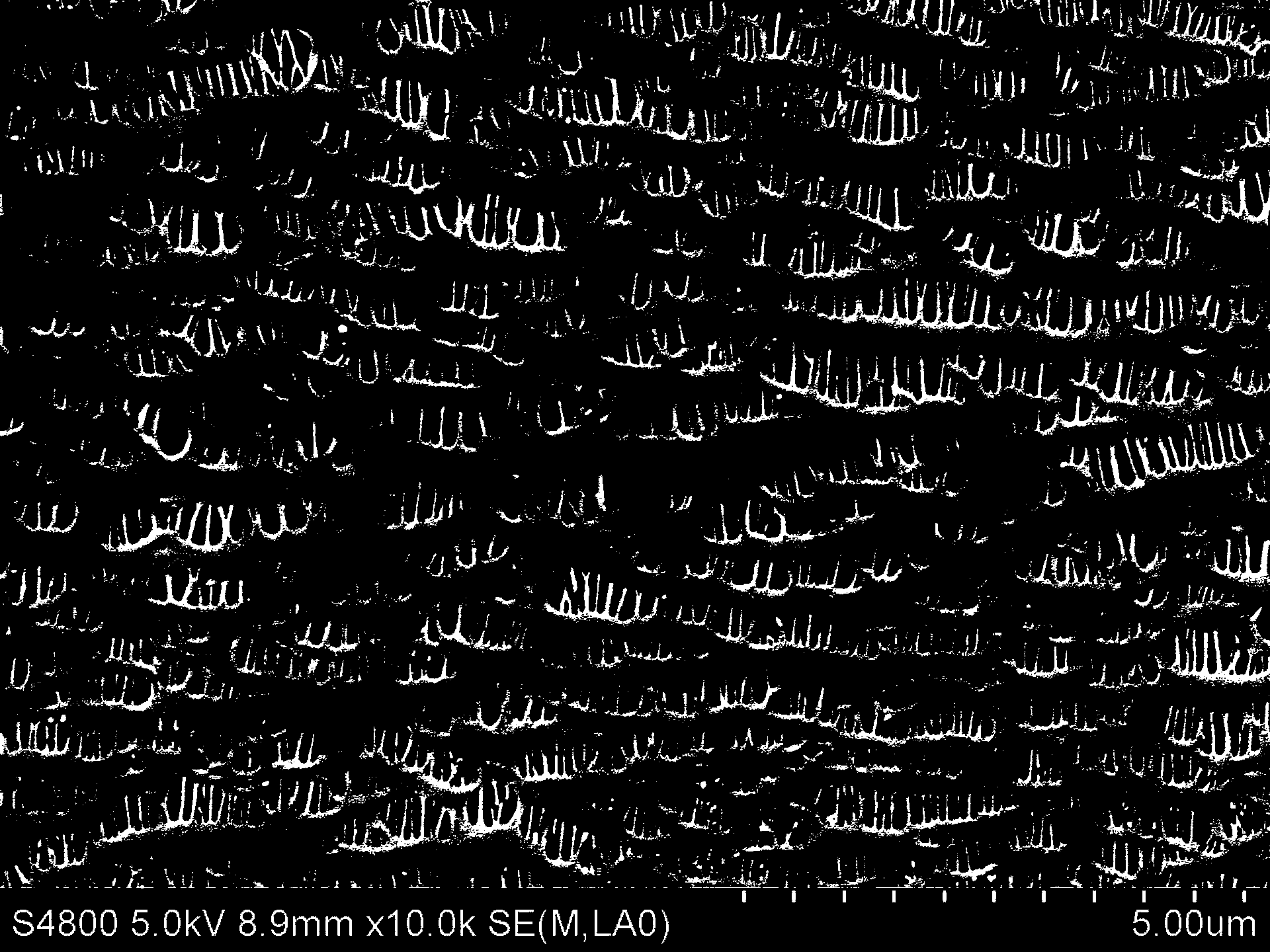

Method for grafting environment response macromolecule on nano silicon dioxde surface

The present invention relates to a preparation method for organic-inorganic hybrid materials through grafting polymerization-environment responsive macromolecules on the nanometer silicon dioxide surface, belonging to the organic-inorganic hybrid materials synthesis and preparation field. The present invention takes advantage of the action of silicon dioxide with hydroxyl on the surface with the silane coupling agent 3-amino-propyl silane to enable the end to be of an amino group; then the product reacts with the nanometer particle generated from the bromination propionyl bromine reaction; The end of the nanometer particle is the ATRP initiator; finally, the polymerization of the environmentally-responsive macromolecules on the nanometer silicon dioxide surface is initiated in the present of CuBr and PMDETA so as to obtain the target product. The graft rate of the silicon dioxide virgule environmentally-responsive macromolecule core-shell structure nanometer hybrid particles is 60 percent to 70 percent. No reunion of the nanometer hybrid particles appears. The nanometer hybrid particles are uniformly dispersed with environmental responsiveness.

Owner:TSINGHUA UNIV

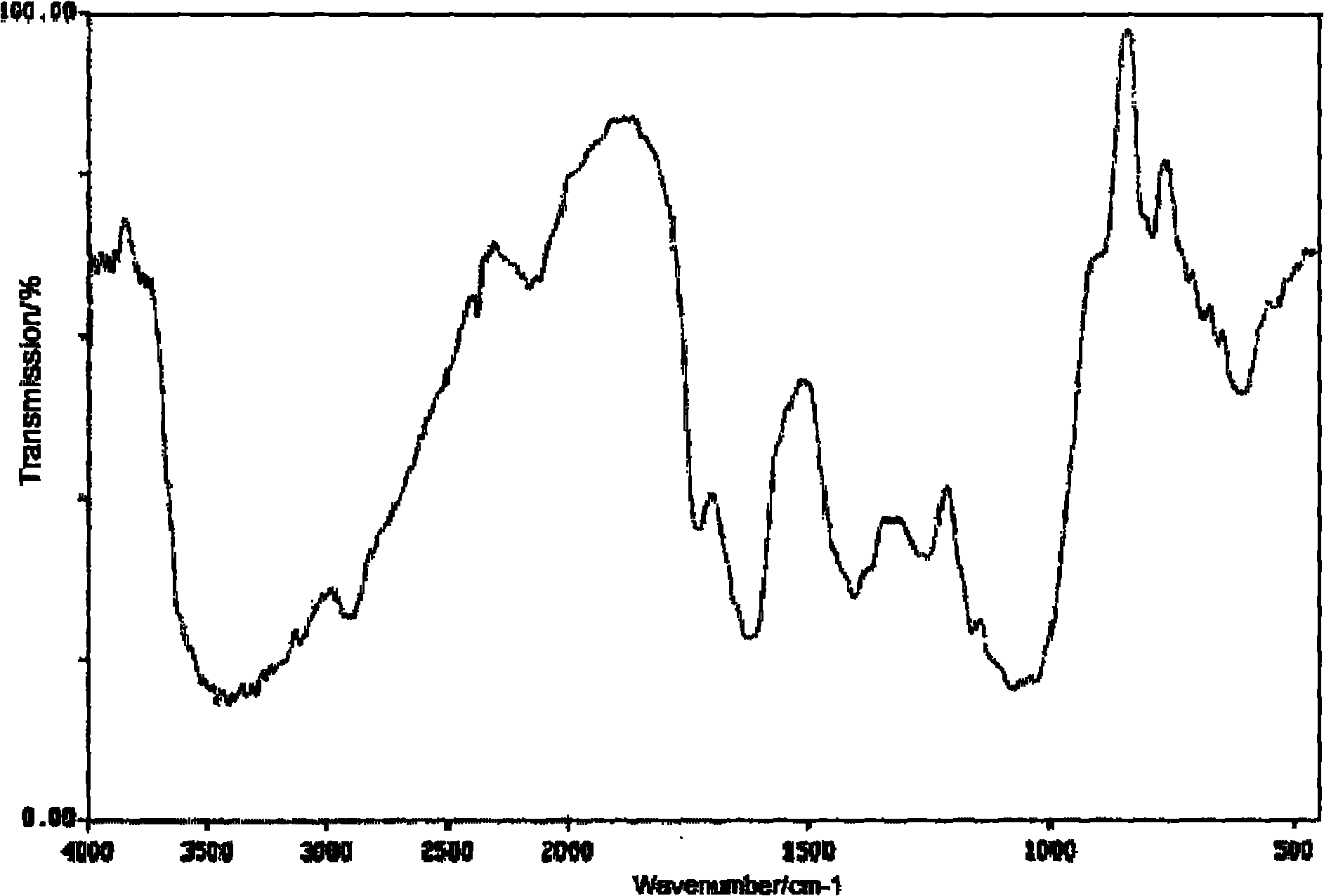

High temperature resistant modified starch filtration reducing agent and preparation method thereof

InactiveCN103396515AImprove temperature resistanceImprove salt toleranceDrilling compositionFermentationFiltrationOil phase

The invention discloses a high temperature resistant modified starch filtration reducing agent and a preparation method thereof. The modified starch filtration reducing agent and the preparation method comprise that: with starch, a phenolic compound, alkenyl amide and alkenyl sulfonic acid as raw materials, an oil phase solution as a continuous phase and a nonionic surfactant as an emulsifying agent, and under catalytic actions of a reduction substrate and a hydrogen acceptor substrate, a starch graft copolymer is generated through a reaction. The filtration reducing agent provided by the invention is resistant to temperature of up to 175 DEG C, and simultaneously also has good salt and calcium resistance capabilities; and the preparation method is simple and easy to implement, and has mild and controllable reaction conditions, high grafting efficiency, fast reaction speed and low cost.

Owner:SOUTHWEST PETROLEUM UNIV

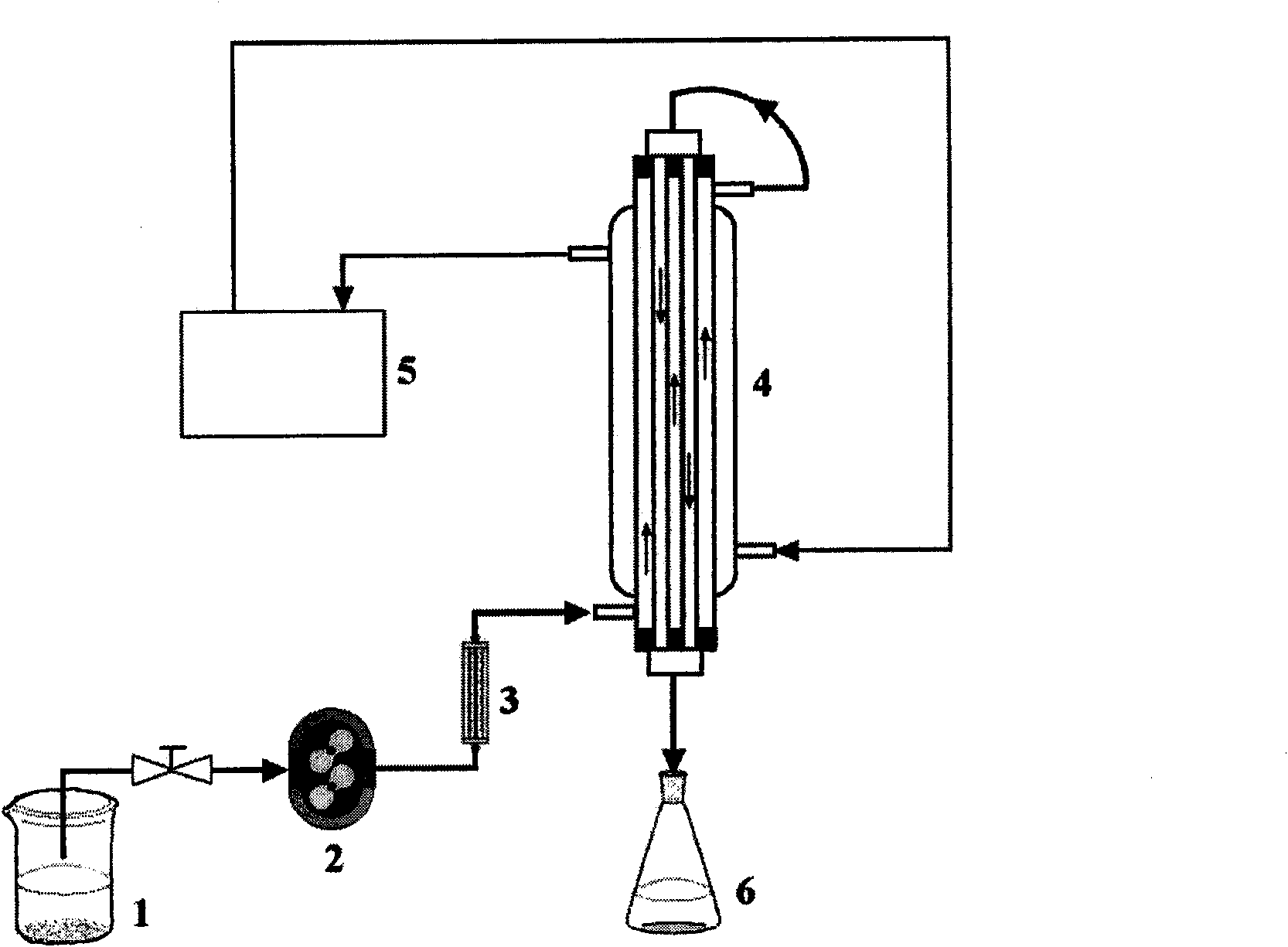

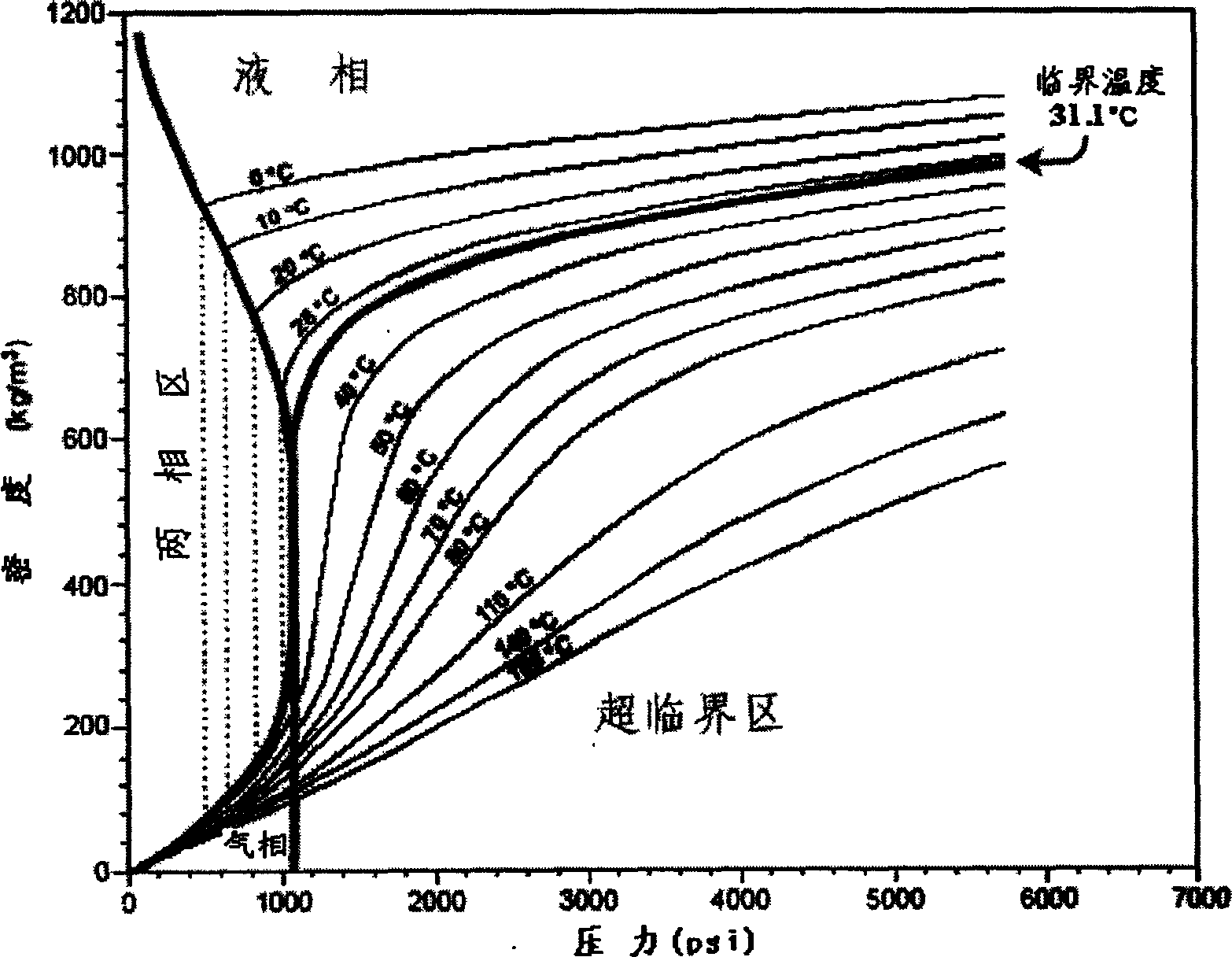

Process for modifying reaction at surface of separating film of polymer

InactiveCN1623639AEasy to operateGood repeatabilitySemi-permeable membranesHigh energyGraft reaction

A process for modifying the surface of polymer separating membrane by graft reaction includes such steps as immersing the membrane to be modified in supercritical CO2, triggering by free radical trigger or peroxide radical generated by high-energy radiation, diffusing various functional free-radical monomers onto the external and internal surfaces of said membrane by supercritical CO2 fluid, and graft reaction at proper temp and under proper pressure.

Owner:ZHEJIANG UNIV

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

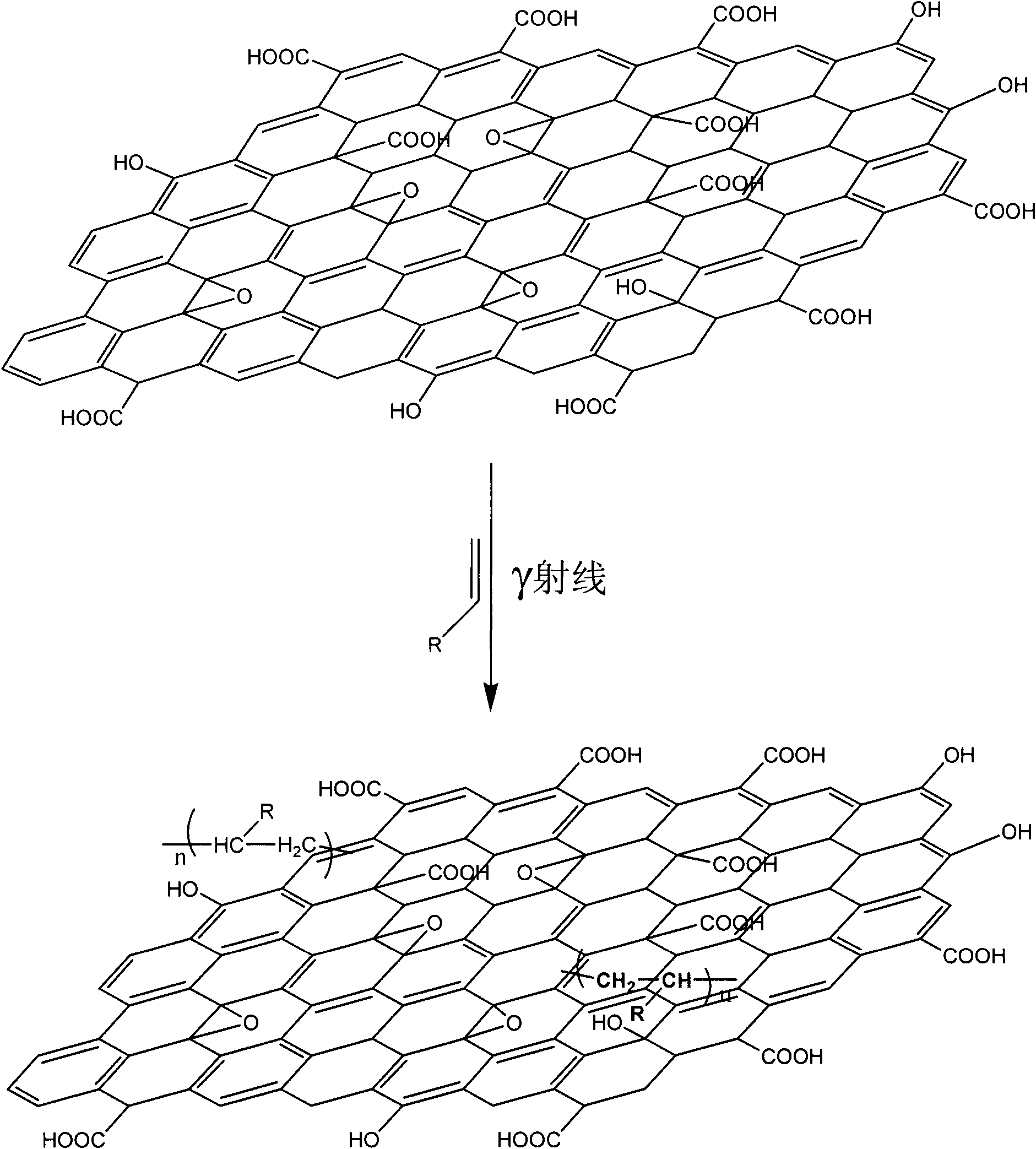

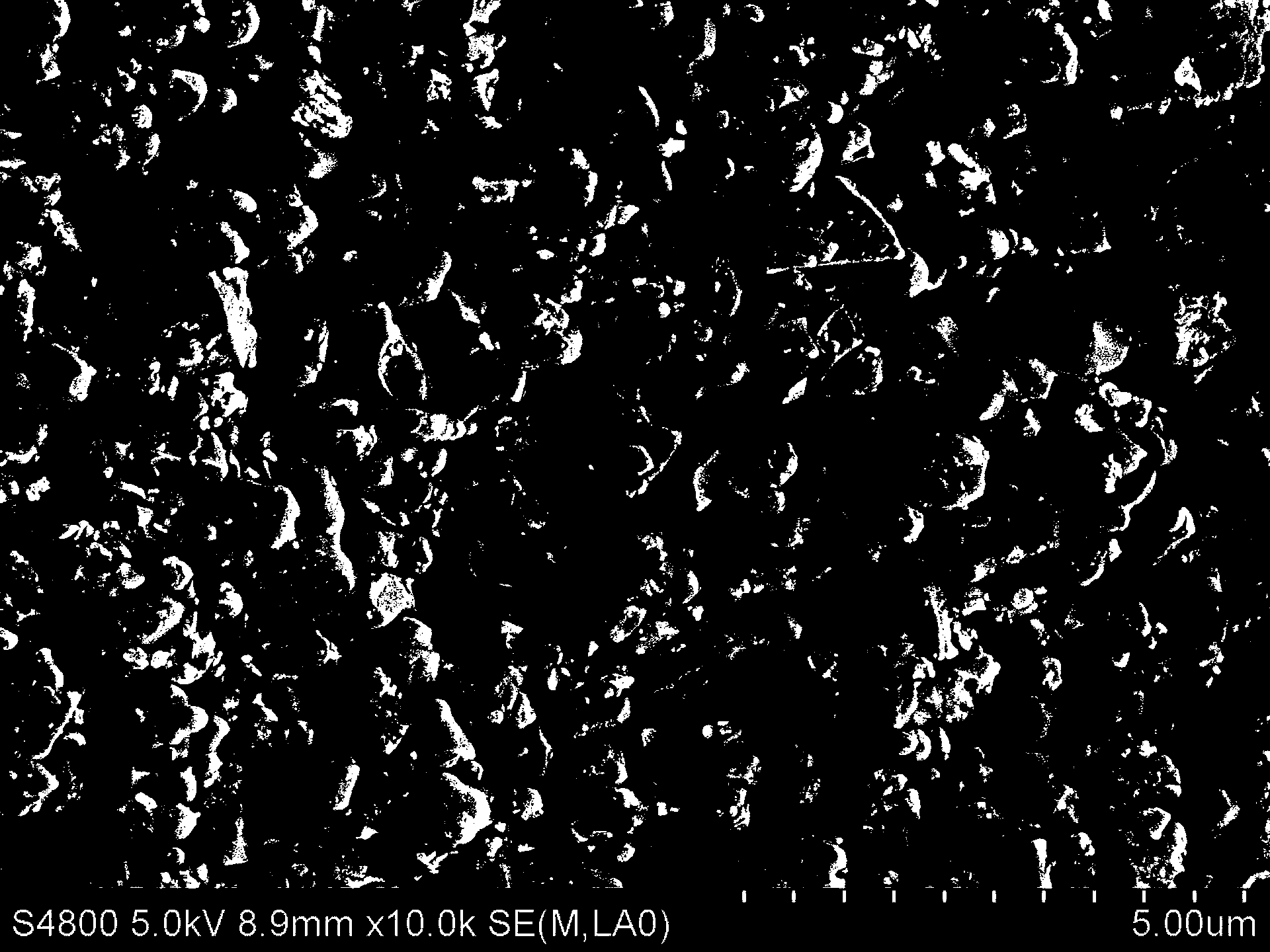

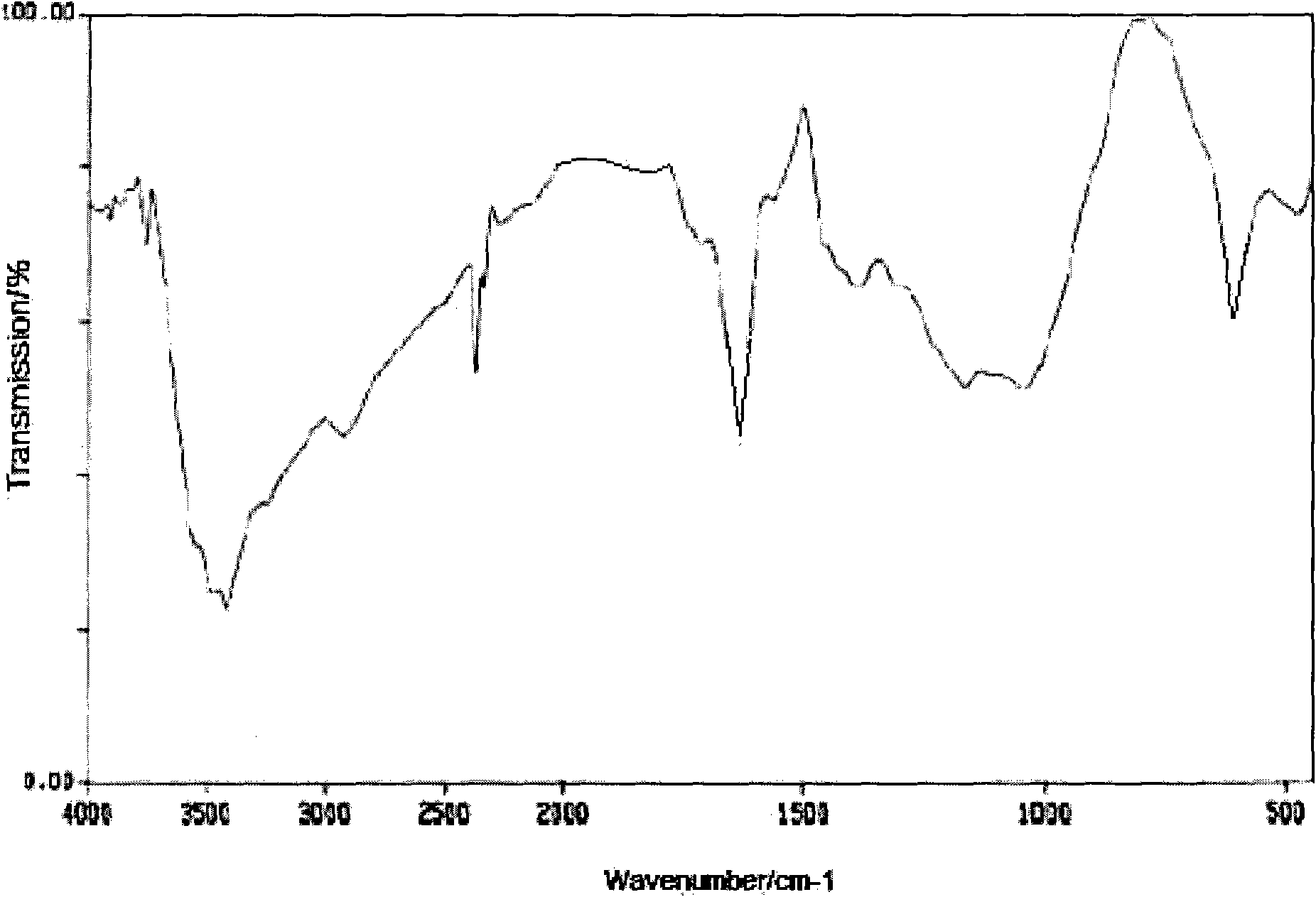

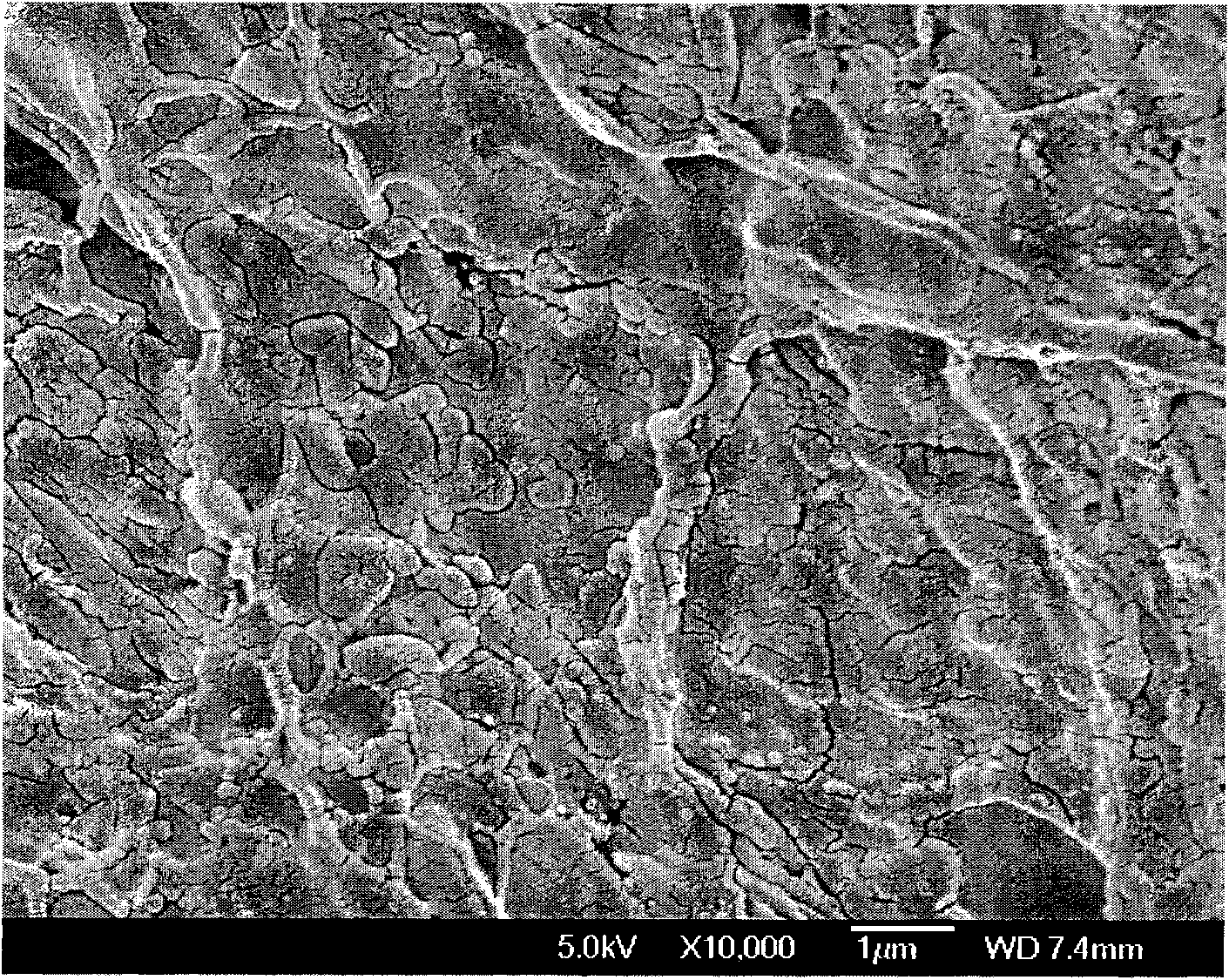

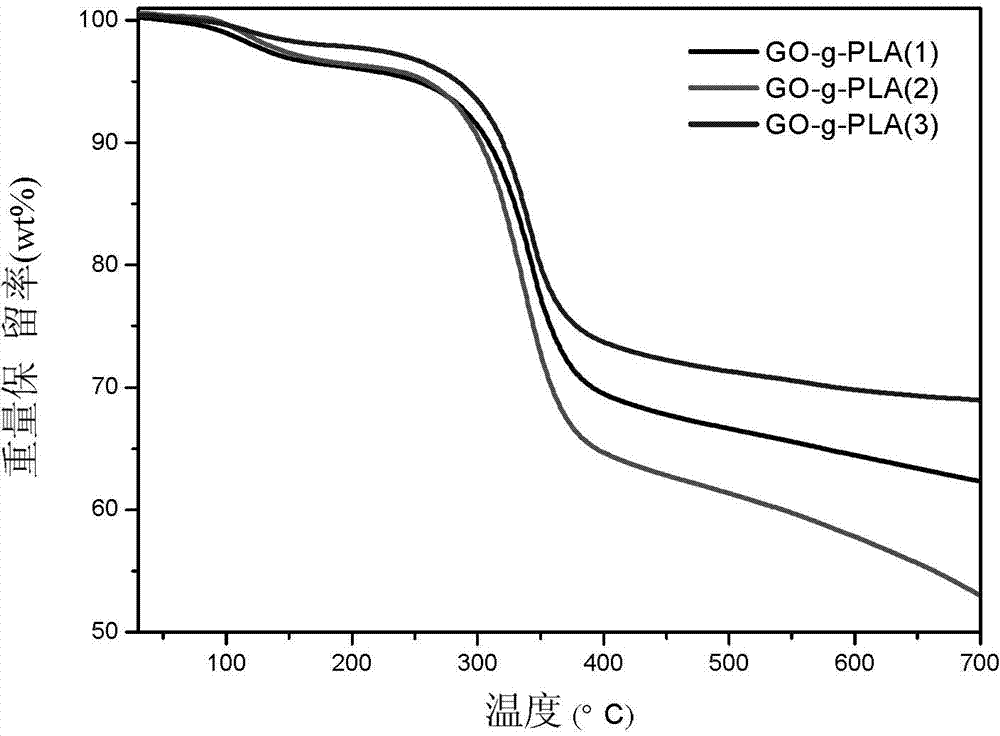

Preparation method of polylactic acid functionalized graphene

The invention discloses a preparation method of polylactic acid functionalized graphene, which comprises the steps of preparing graphite oxide by adopting an improved Hummers method; performing ultrasonic peeling and freeze drying to obtain graphene oxide; mixing the graphene oxide with anhydrous lactic acid at certain proportion; adding a catalyst, and performing in-situ polymerization in vacuum environment to obtain a graphene / polylactic acid complex; and washing off the polylactic acid not in covalent binding with graphene to obtain polylactic acid functionalized graphene. The preparation method of polylactic acid functionalized graphene provided by the invention takes graphene oxide as an initiator and grafts polylactic acid to the surface of graphene oxide through lactic acid condensation polymerization by adopting a one-step method. The method does not need to perform pretreatment on graphene; the treatment process of lactic acid condensation polymerization is relatively simple and easy to realize, and the cost is relatively low. Moreover, the surface of graphene oxide is rich in oxygen-containing functional groups such as carboxyl group, hydroxyl group and the like; and relatively high grafting rate can be obtained through simple treatment.

Owner:TIANJIN POLYTECHNIC UNIV

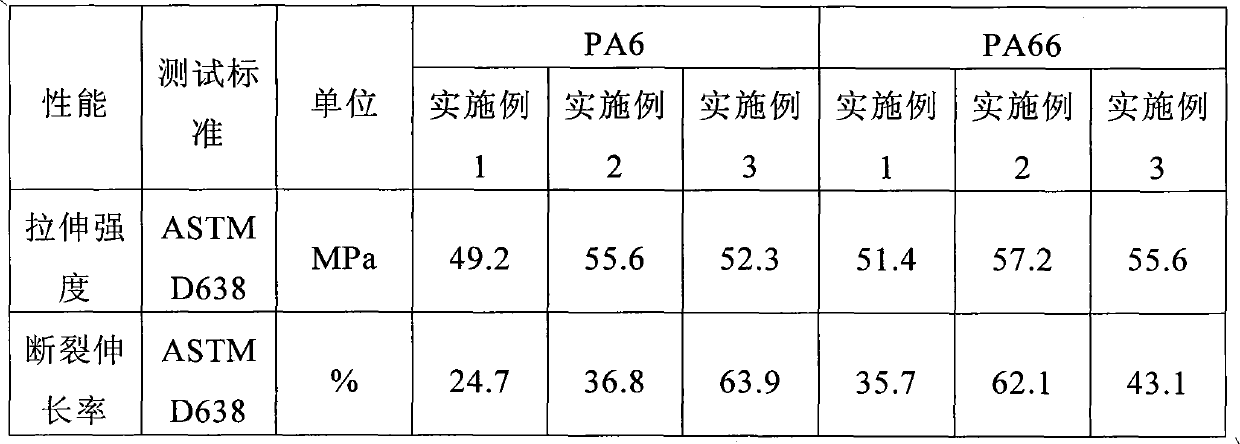

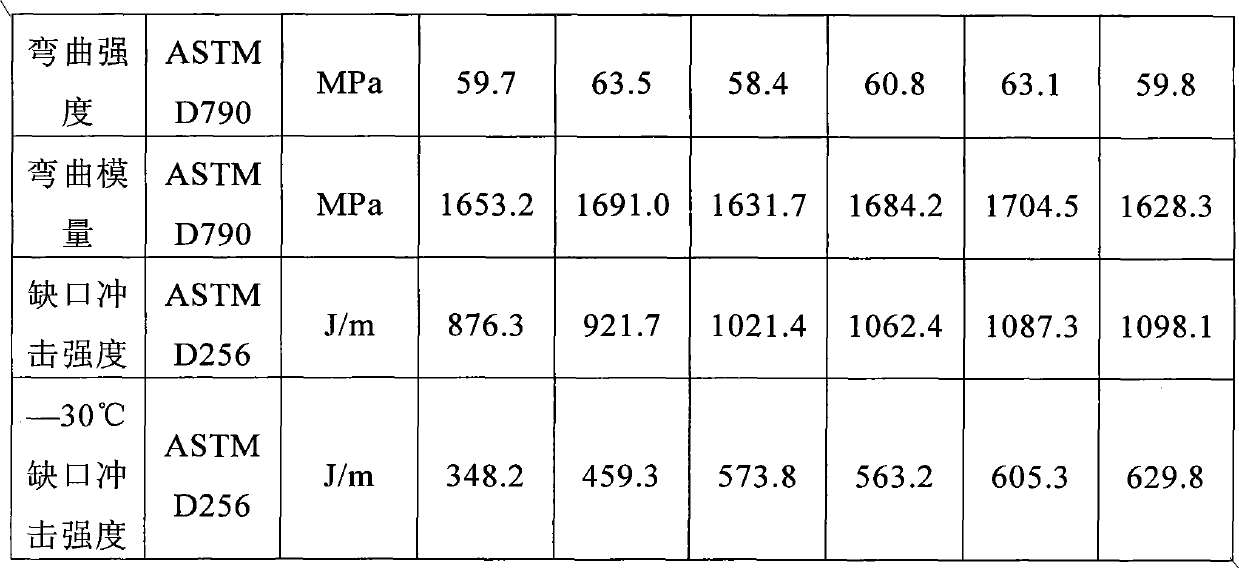

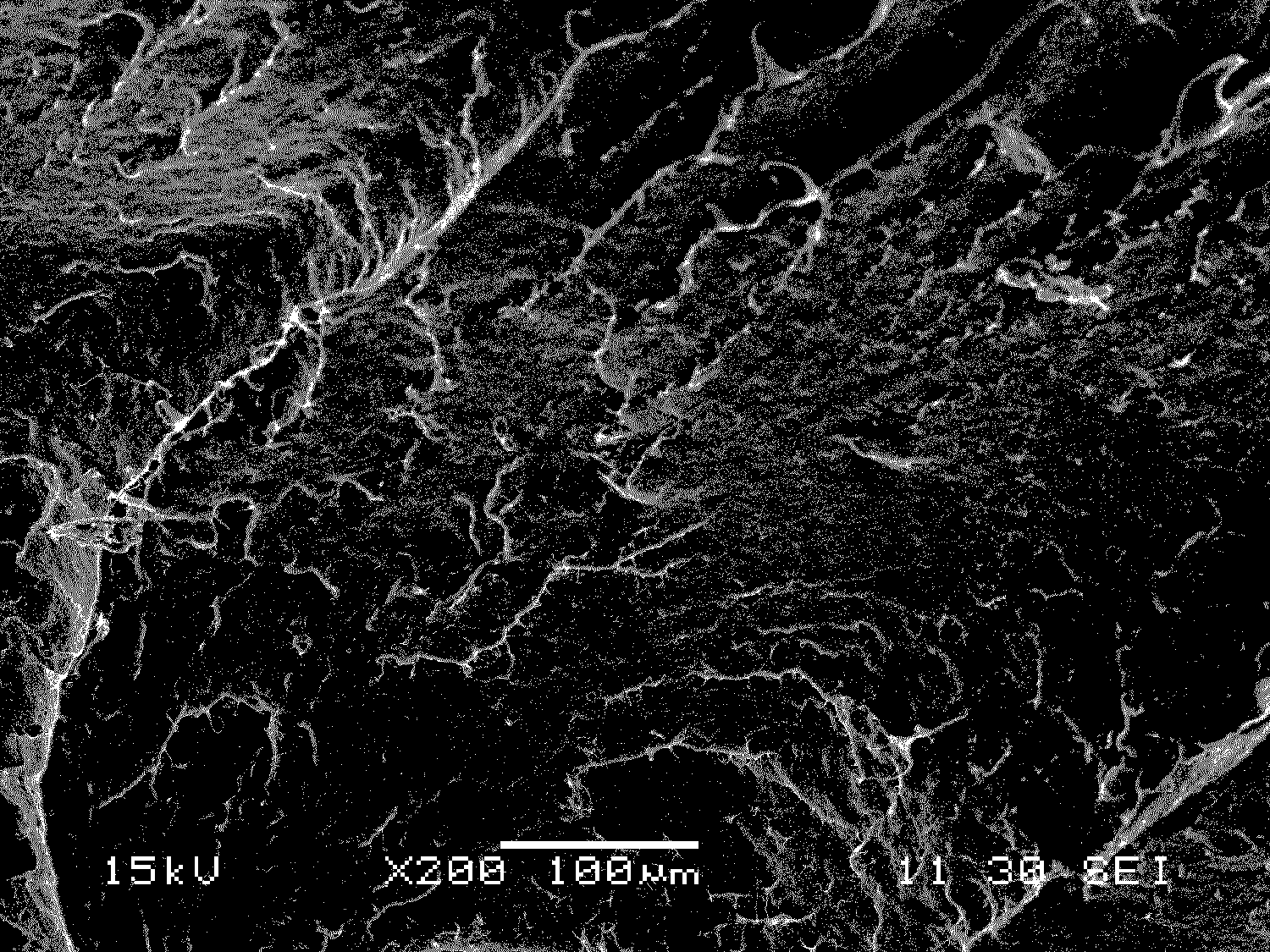

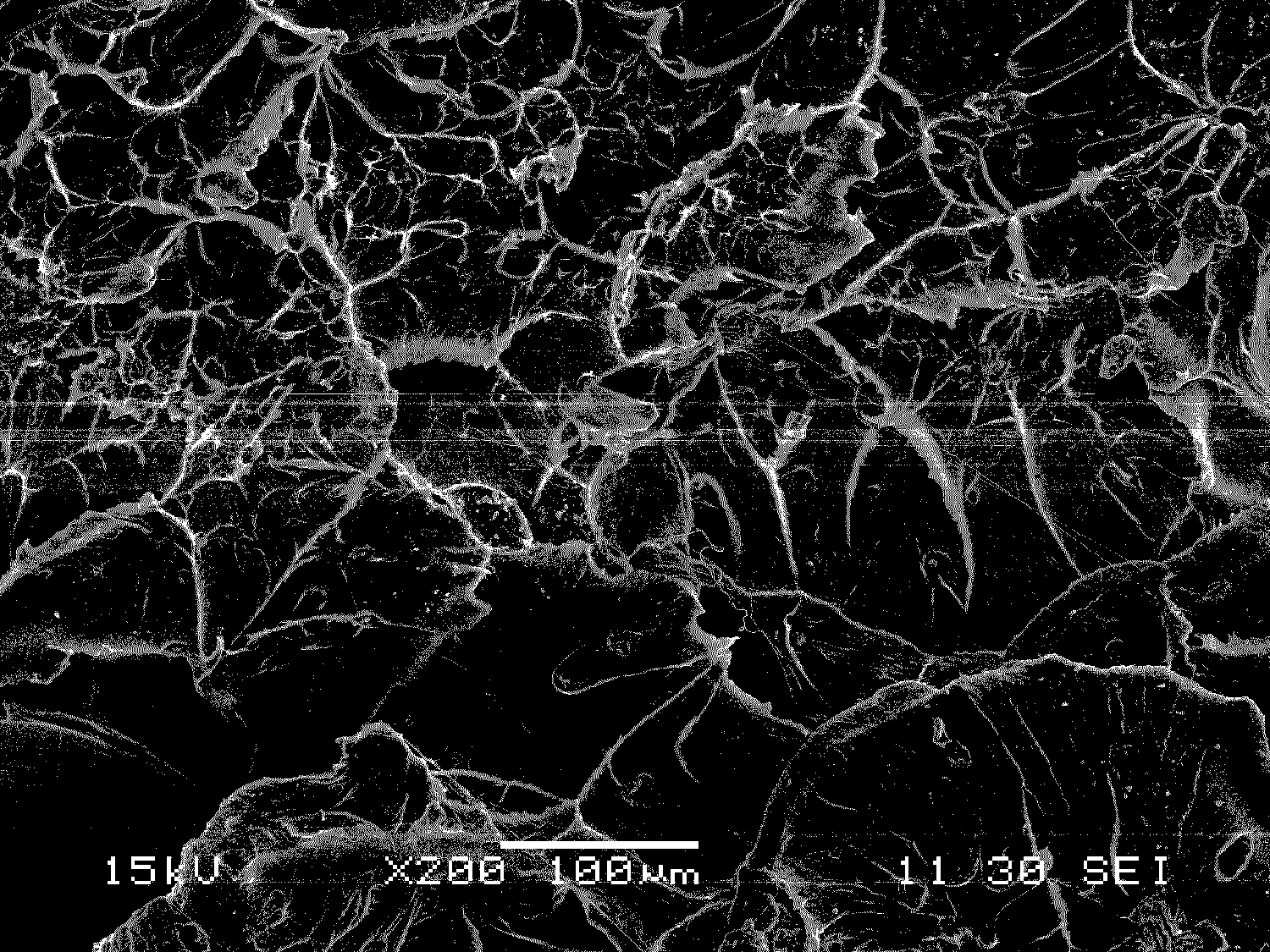

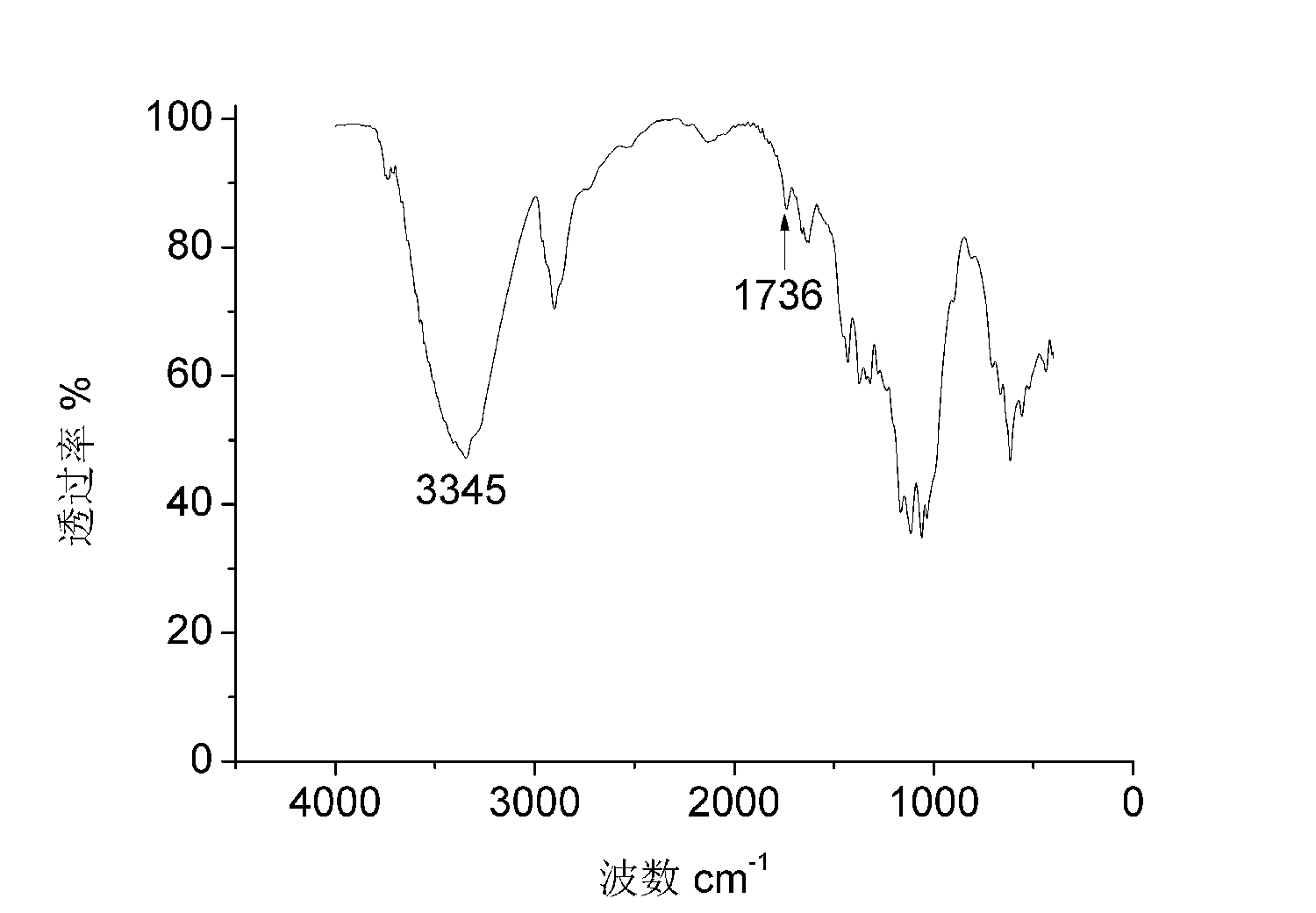

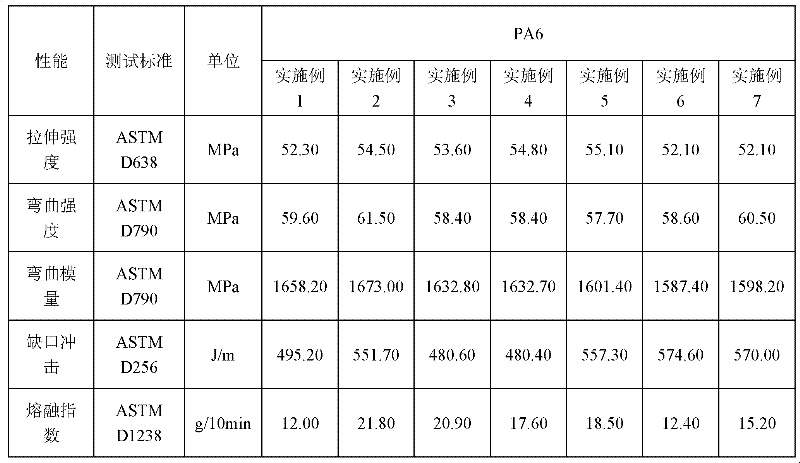

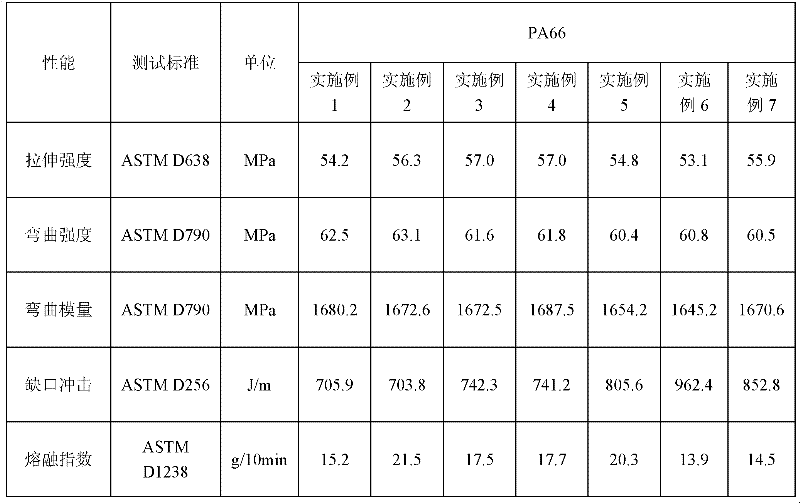

Low temperature impact resistant nylon flexibilizer and preparation method of low temperature impact resistant nylon flexibilizer

The invention relates to a low temperature impact resistant nylon flexibilizer and a preparation method of the low temperature impact resistant nylon flexibilizer. The low temperature impact resistant nylon flexibilizer comprises the following components in parts by weight: 50-95 parts of ethylene-alpha-octylene copolymer resin, 4-40 parts of polypropylene copolymer, 1-30 parts of linear low density polyethylene, 0.5-10 parts of graft monomer, 0.01-2 parts of initiator, 0.1-1 part of lubricator, 0.1-1 part of antioxidant and 0.1-2 parts of liquid additive. The preparation method of the low temperature impact resistant nylon flexibilizer comprises the steps of: mixing the above components except for the initiator, and adding into a double-screw extruder; laterally feeding and metering the initiator, and adding into the extruder; and extruding and pelletizing to obtain the low temperature impact resistant nylon flexibilizer as a product. The graft ratio of the flexibilizer is increased and the gel content of the flexibilizer is reduced by the lateral feeding technology; after the flexibilizer is applied to nylon (nylon 6, nylon 66), the flexibilizer is good in comprehensive performance and more excellent in low temperature impact performance; and the notch impact strength of the flexibilizer can reach 600J / m at a temperature of -30 DEG C, so that the flexibilizer can be applied to the fields of auto accessories and bumpers, railway equipment and the like under low temperature resistance.

Owner:SHANGHAI SUNNY

Preparation method of surface-grafted modified nanocellulose crystal

InactiveCN103214623AExpand the scope of applicationAbundant sources of raw materialsMaleic anhydrideDouble bond

The invention belongs to the field of cellulose modification and utilization and in particular relates to a preparation method of a surface-grafted modified nanocellulose crystal. The preparation method of the surface-grafted modified nanocellulose crystal comprises the following steps of: dispersing nanocellulose crystal in an organic solvent; introducing an unsaturated double bond onto the surface of the nanocellulose crystal through a reaction of maleic anhydride and hydroxyl groups on the surface of the nanocellulose crystal; and introducing an initiator and an unsaturated monomer to prepare the surface-grafted modified nanocellulose crystal through a radical polymerization reaction. The surface-grafted modified nanocellulose crystal is uniformly dispersed in a polymer matrix and good in compatibility with the interface of the polymer matrix, and therefore, the prepared polymer nanometer composite material has higher tensile strength and elongation at break. The preparation method of the surface-grafted modified nanocellulose crystal has the advantages of rich raw material resource, simple process, completely biodegradable product, high mechanical performance and the like, and can be used for a plurality of fields including the packaging field, the biological field, the medical field, the engineering plastic field and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

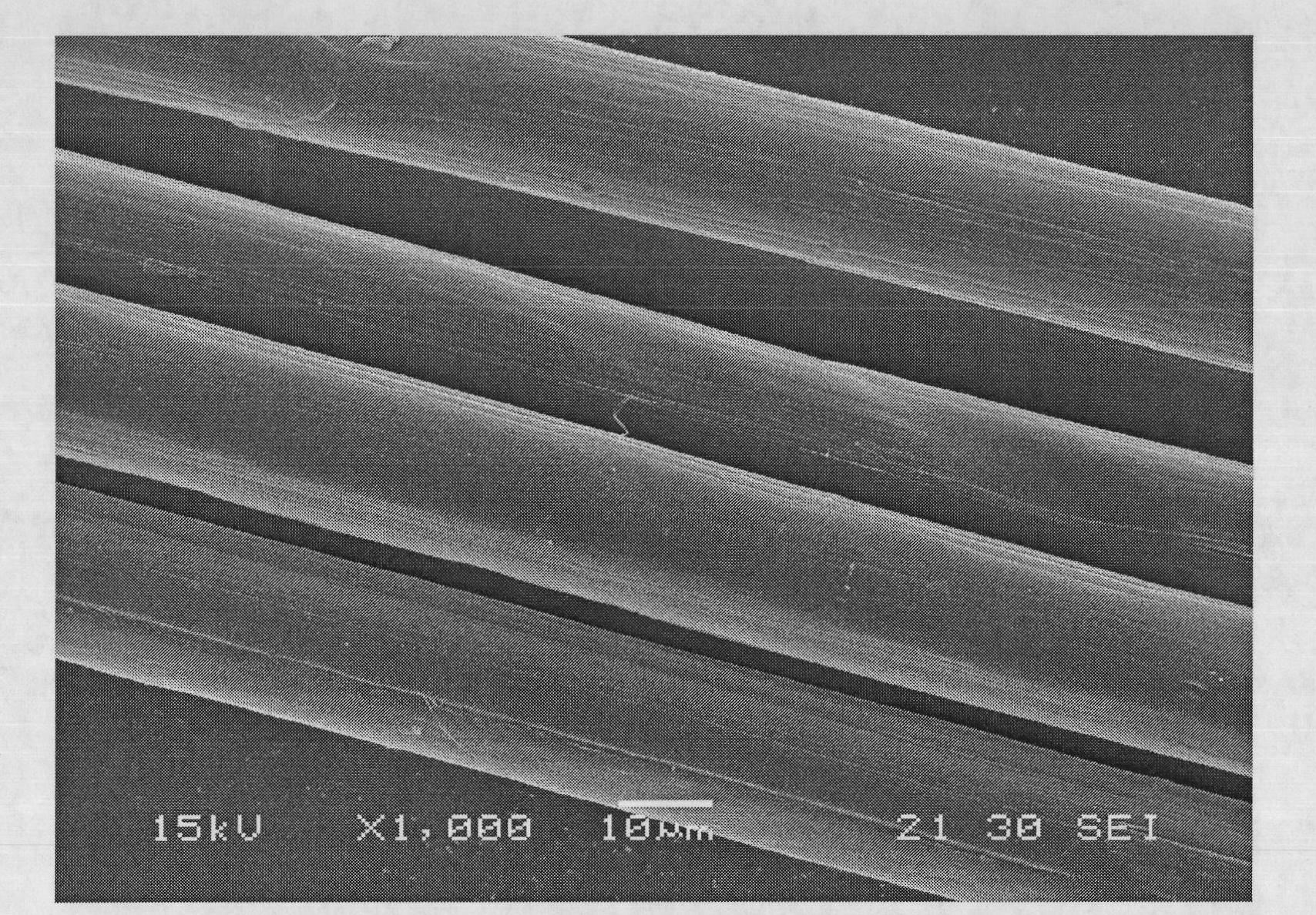

Ultraviolet radiation two-step grafting method on surface of polyethylene fiber with ultrahigh molecular weight

The invention relates to an ultraviolet radiation two-step grafting method on the surface of polyethylene fiber with ultrahigh molecular weight. The method comprises the following steps of: coating a photosencitizer on the surface of preprocessed polyethylene fiber with ultrahigh molecular weight; soaking the polyethylene fiber in a first grafting monomer solution; forming a surface dormant group by adopting ultraviolet radiation or direct illumination; then, soaking in a second grafting monomer solution; initiating a secondary monomer surface free radical grafting reaction by ultraviolet radiation or heating; and finally, post-processing. Compared with the prior art, the invention has the advantages that the polar group is introduced to the surface of the polyethylene fiber with ultrahigh molecular weight, the reaction is controllable, the grafting efficiency and the grafting rate are higher, the second monomer with higher reaction activity is grafted on a primary grafting basis, and the adhesive performance of a matrix and the polyethylene fiber with ultrahigh molecular weight is greatly improved.

Owner:SHANGHAI RES INST OF CHEM IND

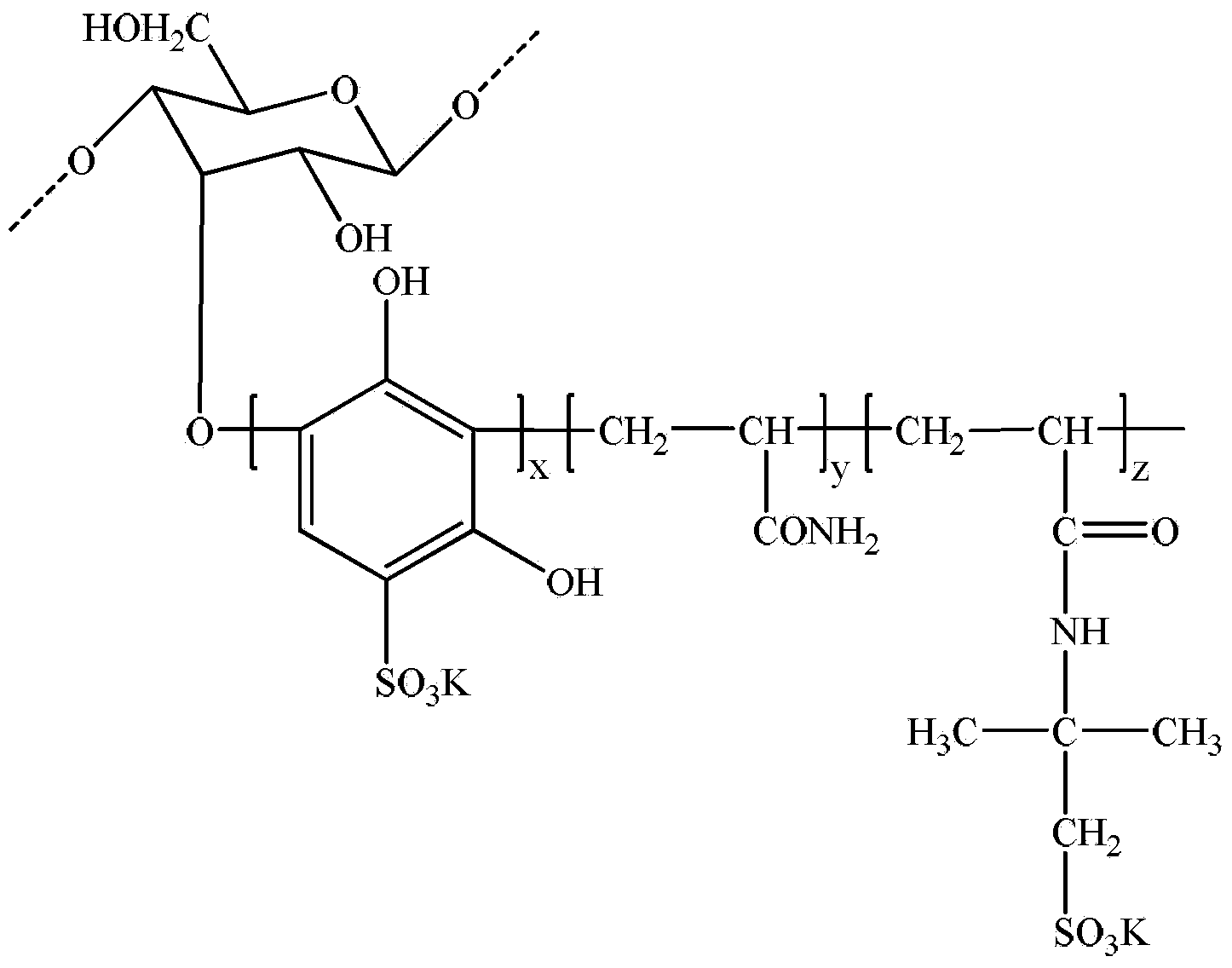

Aminoalkyl glucoside graft copolymer and preparation method thereof, and drilling fluid

InactiveCN107973827AEnhanced inhibitory effectImprove the lubrication effectSugar derivativesDrilling compositionFatty amineAlkyl polyglycoside

The invention provides a preparation method for an aminoalkyl glucoside graft copolymer. The preparation method comprises the following steps: (1) subjecting alkyl glucoside, epoxide, chloride and anacidic catalyst to a reaction so as to obtain a first intermediate; (2) reacting the first intermediate with alicyclic amine so as to obtain a second intermediate; and (3) under the action of an initiator, subjecting the second intermediate, acrylamide and 2-acrylamide-2-methylpropanesulfonic acid to a reaction so as to obtain the aminoalkyl glucoside graft copolymer. With the method provided by the invention, the aminoalkyl glucoside graft copolymer with a specific structure is prepared and has good inhibition performance, lubrication performance, filtrate loss reducing performance, and resistance to contamination by saturated salts and composite salts. Moreover, the aminoalkyl glucoside graft copolymer is free of biological toxicity. The invention also provides the aminoalkyl glucoside graft copolymer and a drilling fluid.

Owner:中石化石油工程技术服务有限公司 +1

Silicon carbide surface modifying method

InactiveCN1636938ALong-term repeated useHigh grafting ratePigment treatment with macromolecular organic compoundsCross-linkSodium bicarbonate

The surface modification process of silicon carbide includes: soaking silicon carbide powder in mixed solution of concentrated sulfuric acid and hydrogen peroxide solution; taking out, flushing with deionized water and stoving; reacting with coupling agent for 1-4 hr; setting silicon carbide inside acetone solution for supersonic cleaning and centrifuging for 2-5 times to obtain processed silicon carbide; adding cross-linking agent to acrylic acid aqua and regulating pH to 5-9 with sodium hydroxide, sodium carbonate or sodium bicarbonate; adding initiator to form the polymerizing precursor solution; mixing processed silicon carbide and the polymerizing precursor solution to obtain surface modified silicon carbide. The product has grafting rate of 0.6-16.2 % and water absorbing rate of 3.0-30 g / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Maleic anhydride grafted polypropylene material

The invention discloses a maleic anhydride grafted polypropylene material. Maleic anhydride, polypropylene and an assistant grafting monomer are grafted under the effects of an initiator and an antioxidant to obtain the maleic anhydride grafted polypropylene material. The used assistant grafting monomer can play a role of increasing the grafting ratio and inhibiting the polypropylene to be degraded, and therefore the grafting ratio is effectively increased. Meanwhile, a new initiator is introduced to reduce the pungent smell of the maleic anhydride grafted polypropylene material, and the degree of grafting reaction and the degree of copolymerization of the assistant monomer are enhanced, so that the prepared product has a high grafting ratio and low pungent smell.

Owner:HUANGSHAN BANNER TECH

Ultrahigh-mobility propenyl elastomer grafting copolymer and preparation method thereof

The invention relates to an ultrahigh-mobility propenyl elastomer grafting copolymer and a preparation method thereof. The copolymer comprises the following components in percentage by weight (wt%): 50-100wt% of propenyl elastomer resin, 0-50wt% of polyolefin resin, 0.5-5wt% of grafted monomer, 0.01-2wt% of initiator, 0.1-1wt% of crosslinking inhibitor, 0.1-1wt% of antioxygen and 0.1-2wt% of liquid accessory ingredient, wherein other components except the initiator are mixed in a high-speed mixer at a certain ratio and are added into a double-screw extruder by main feeding; the initiator is added into the extruder by side feeding; and a product is obtained by fusing, plastifying, kneading, mixing, extruding from a handpiece, bracing, cooling, pelletizing and drying. Compared with the prior art, the ultrahigh-mobility propenyl elastomer grafting copolymer disclosed by the invention has the advantages of higher product grafting ratio, lower gel content, excellent comprehensive performance and excellent impact performance by the side feeding technology, and is especially suitable for thin-wall products and large producing pieces in the fields, such as interior / exterior trim parts ofautomobiles, bumpers, railway equipment and the like.

Owner:SHANGHAI SUNNY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com