Patents

Literature

66 results about "Solution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The rate of solution is the rate at which a substance dissolves. the factors on which the rate of solution depends are : particles area of the solute: greater the area , greater is the rate of solution.

Modular high-precision navigation system

InactiveUS20070032950A1High frequencyQuality improvementPosition fixationNavigation instrumentsAviationData stream

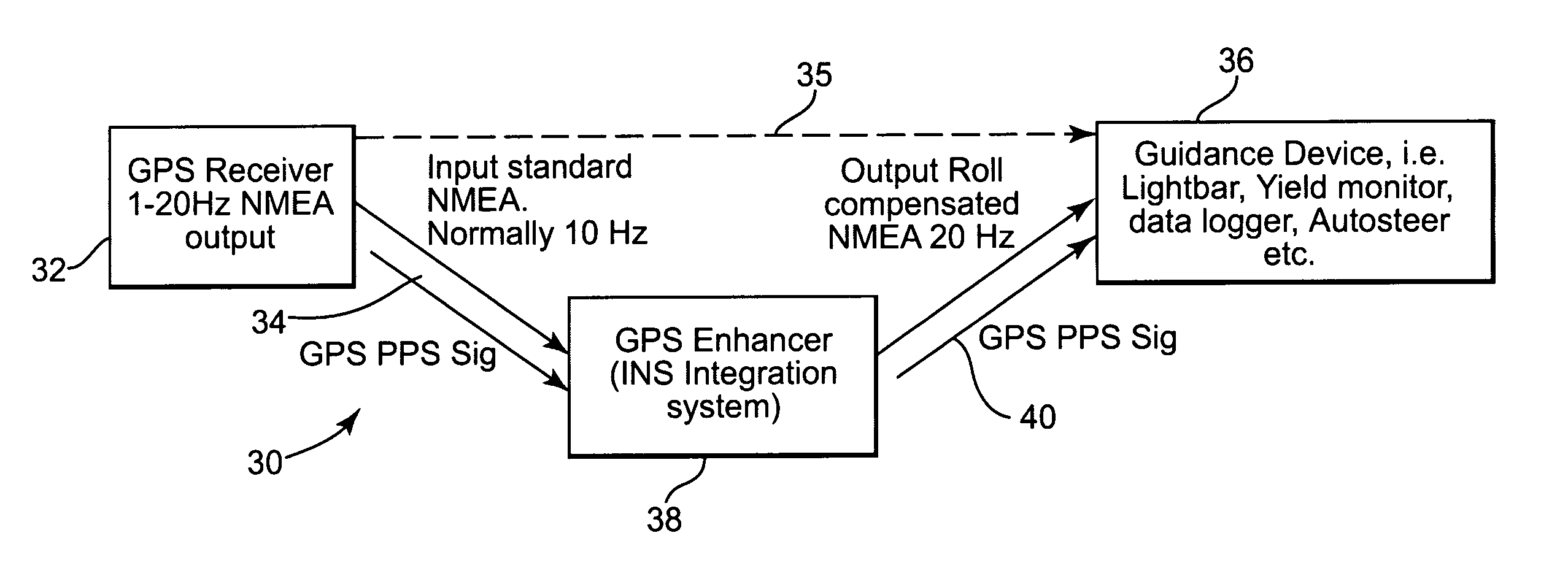

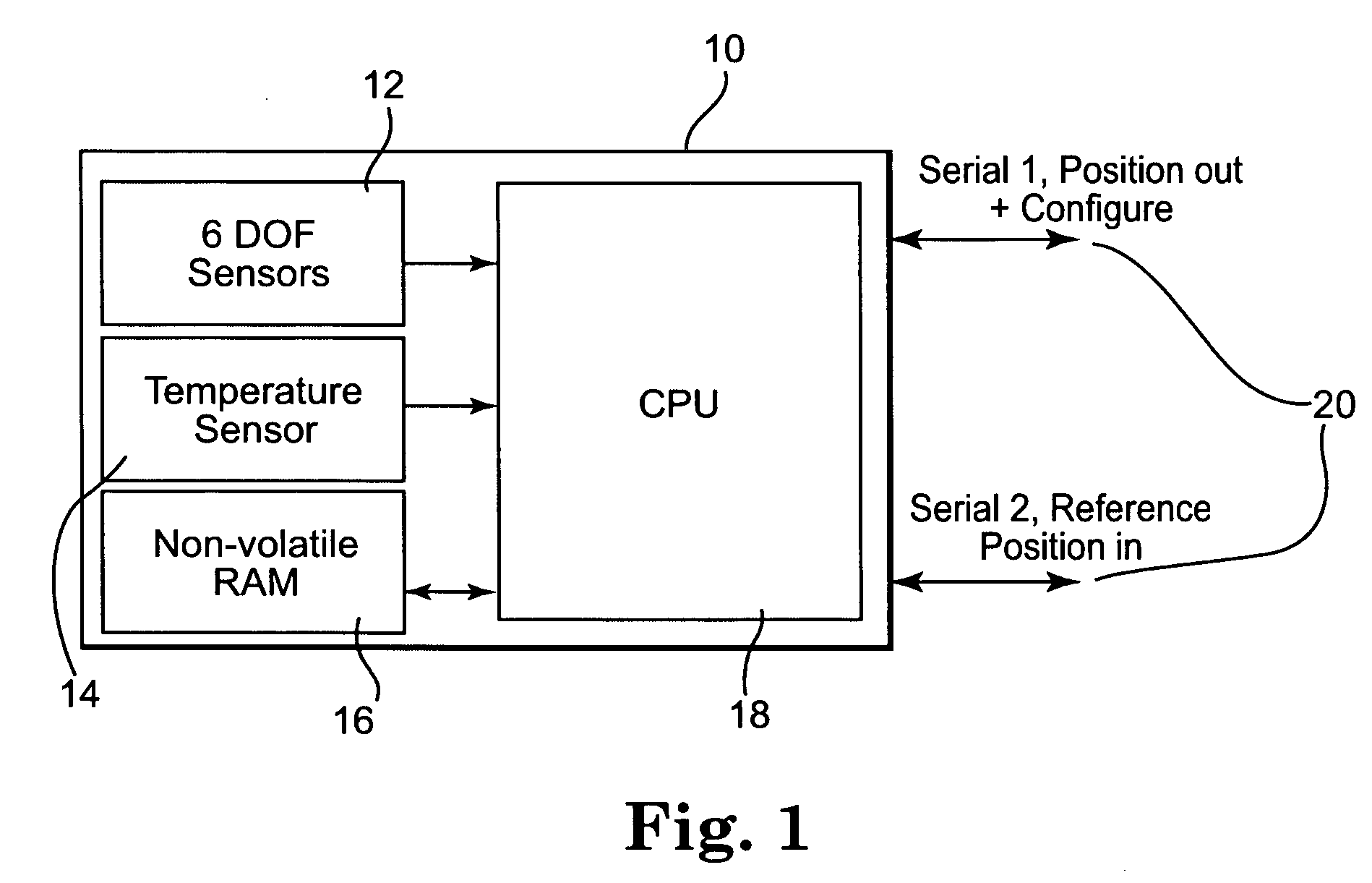

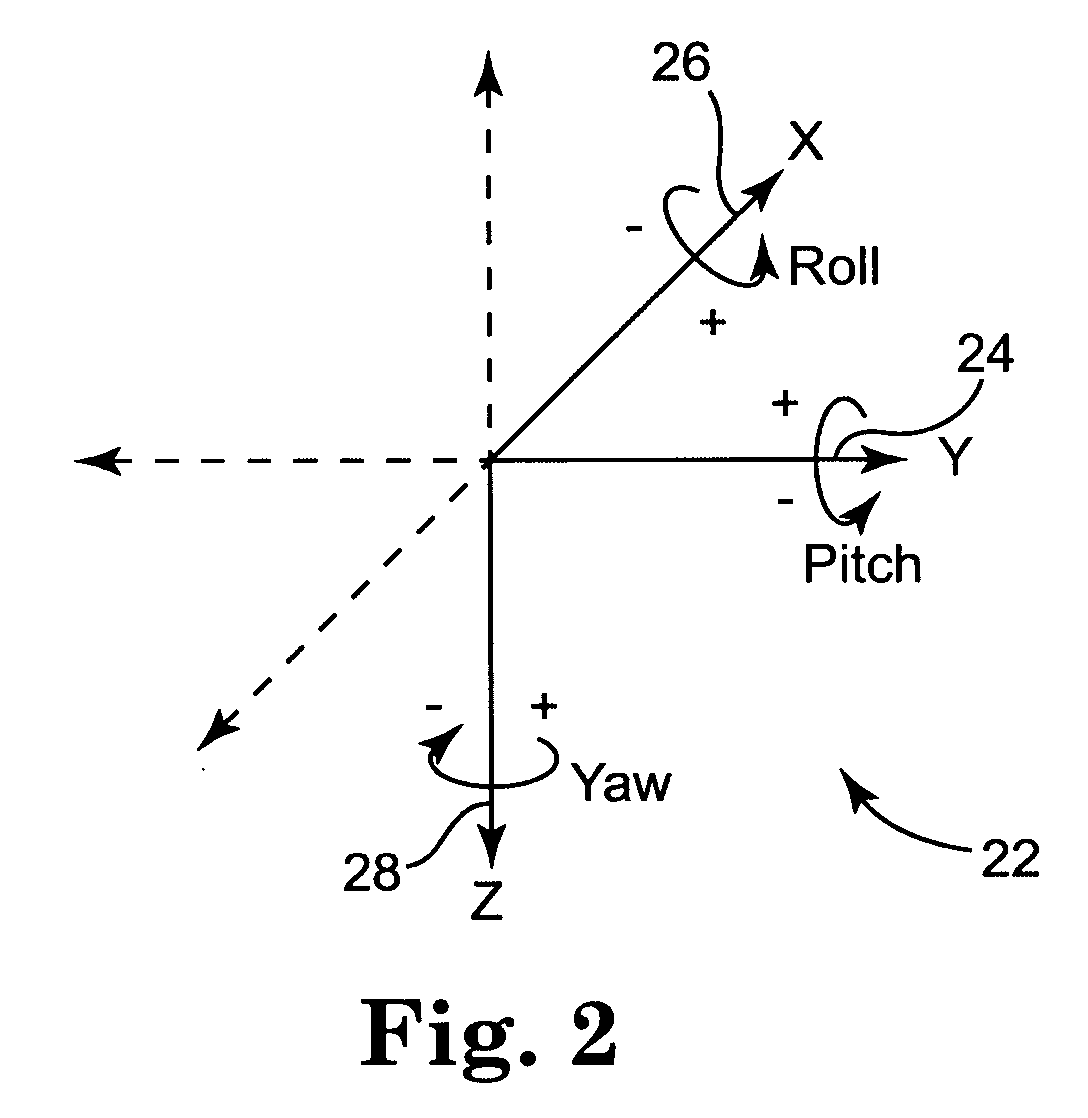

A modular device, system and associated method, used to enhance the quality and output speed of any generic GPS engine is provided. The modular device comprises an inertial subsystem based on a solid state gyroscope having a plurality of accelerometers and a plurality of angular rate sensors designed to measure linear acceleration and rotation rates around a plurality of axes. The modular inertial device may be placed in the data stream between a standard GPS receiver and a guidance device to enhance the accuracy and increase the frequency of positional solutions. Thus, the modular inertial device accepts standard GPS NMEA input messages from the source GPS receiver, corrects and enhances the GPS data using computed internal roll and pitch information, and produces an improved, more accurate, NMEA format GPS output at preferably 2 times the positional solution rate using GPS alone. The positional solution frequency using the present invention may increase to as much as 5 times that obtained using GPS alone. Moreover, the modular inertial device may assist when the GPS signal is lost for various reasons. If used without GPS, the modular inertial device may be used to define, and adjust, a vehicle's orientation on a relative basis. The modular inertial device and architecturally partitioned system incorporated into an existing GPS system may be applied to navigation generally, including high-precision land-based vehicle positioning, aerial photography, crop dusting, and sonar depth mapping to name a few applications.

Owner:RAVEN INDUSTRIES INC

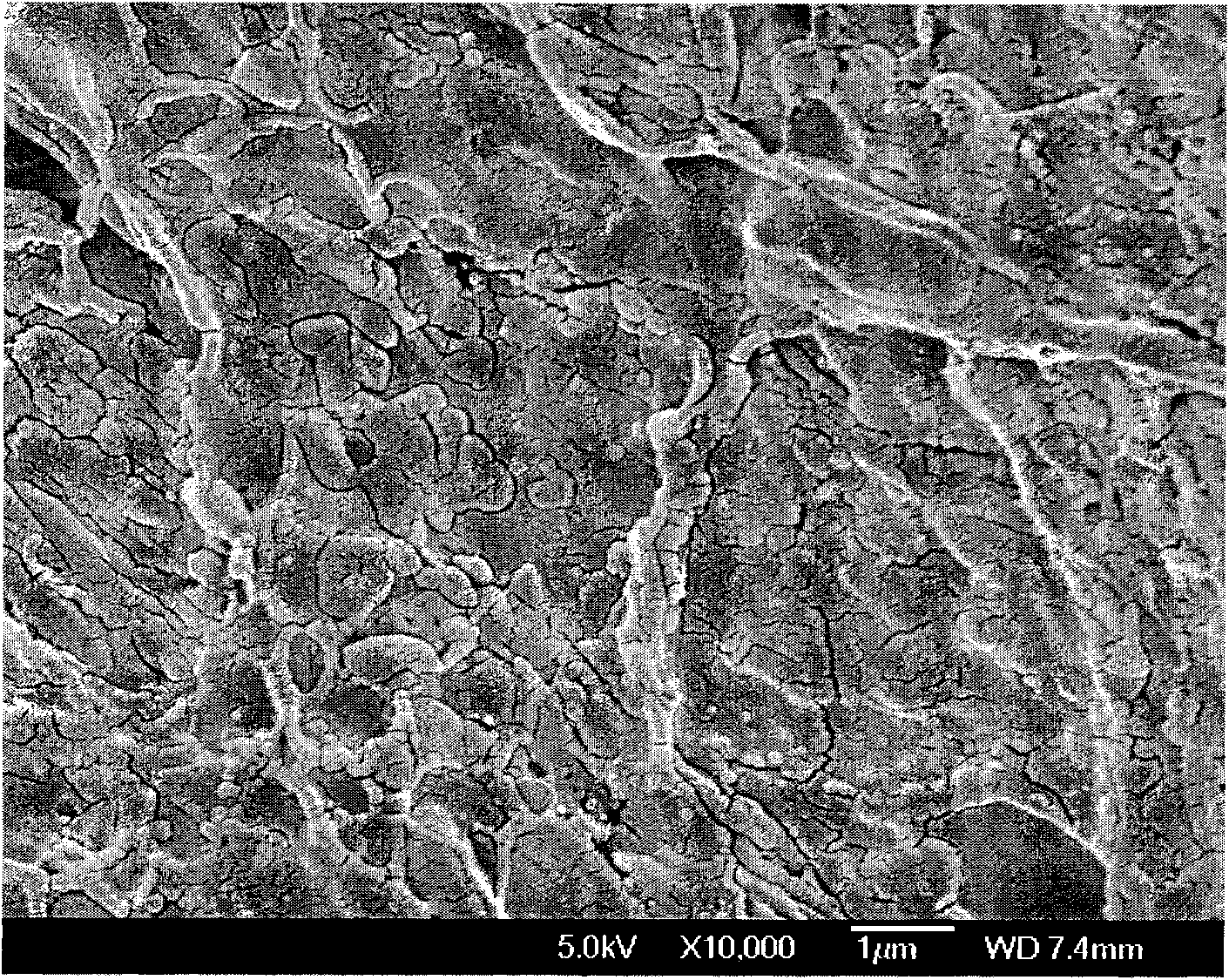

Dispersion polymeric acrylamide emulsion and its application in oil field produced liquid treatment

ActiveCN101161691AEasy to useFast dissolutionWashing/displacing pulp-treating liquorsReinforcing agents additionWater qualityDouble bond

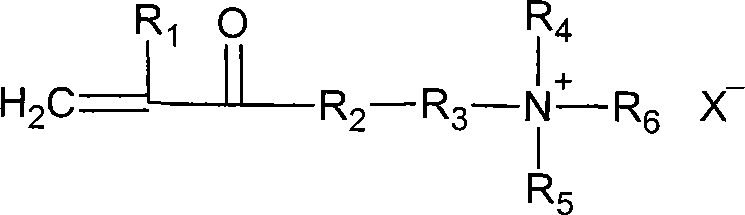

The present invention relates to a waterborne polyacrylamide emulsion, the preparation thereof and the application thereof. The waterborne polyacrylamide emulsion is prepared by the free radical polymerization of the nonionic monomer with the double bond or combined polymerization of the nonionic monomer with the double bond with the cation, using multi inorganic salt solution as the mediums and using polyelectrolyte as the stabilizer. The appearance of the product is cream white, the particle diameter is about 10-100 Mum, the emulsion has high solution rate, and the production process without any organic solvent is innocuous and environmental protection. Compared with the dry powder and the microemulsion of the traditional polyacrylamide, the emulsion of the invention is safe and convenient in use, is capable of being used in the treatment of the oilfield produced liquid combined with the demulsifier to promote the oil-water separation to increase the dehydration of crude oil, wherein the water quality of the dehydrate water. The product can be used as an oil-water separating agent of the oily wastewater in industry and as a water purificant, also be used for sewerage treatment of the oil field and the city as an organic flocculent, and be used in paper making field as a filter aid, a retention aid, a paper strengthening agent, etc.

Owner:HAISO TECH

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

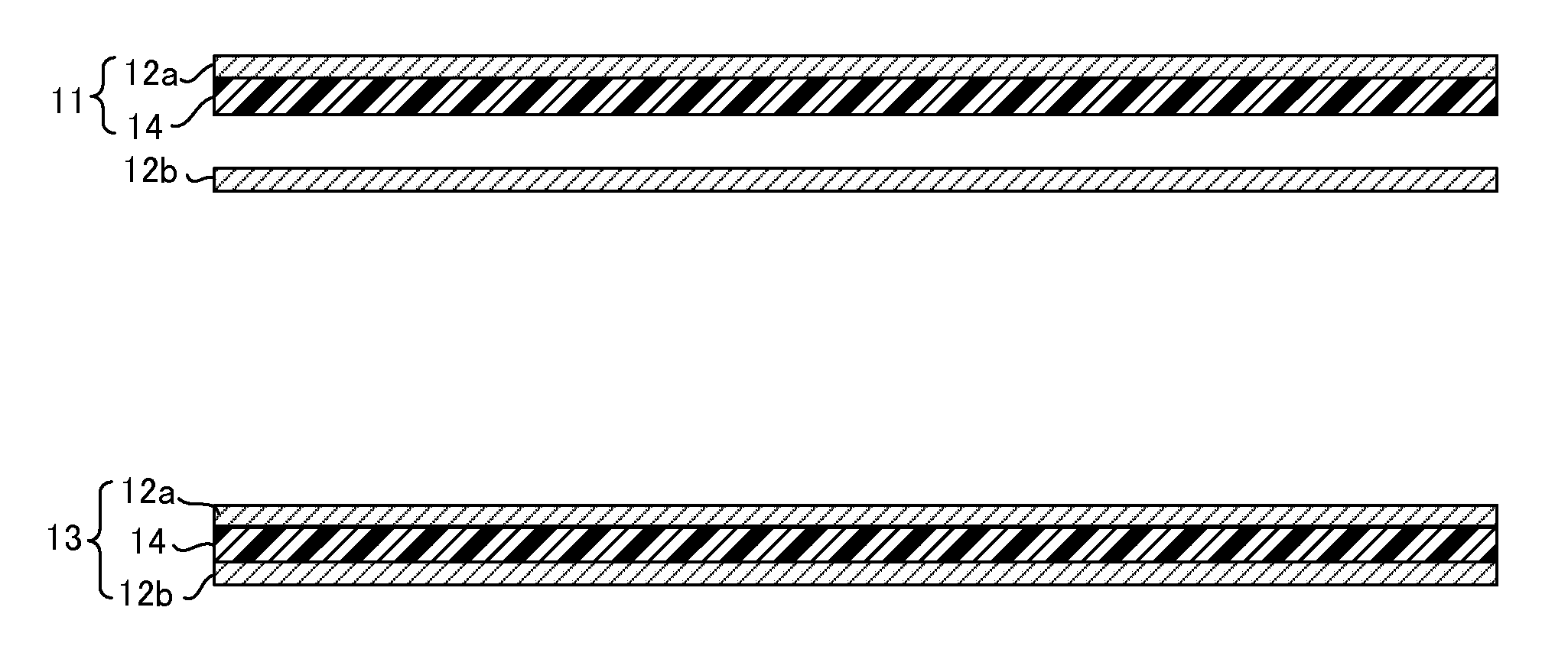

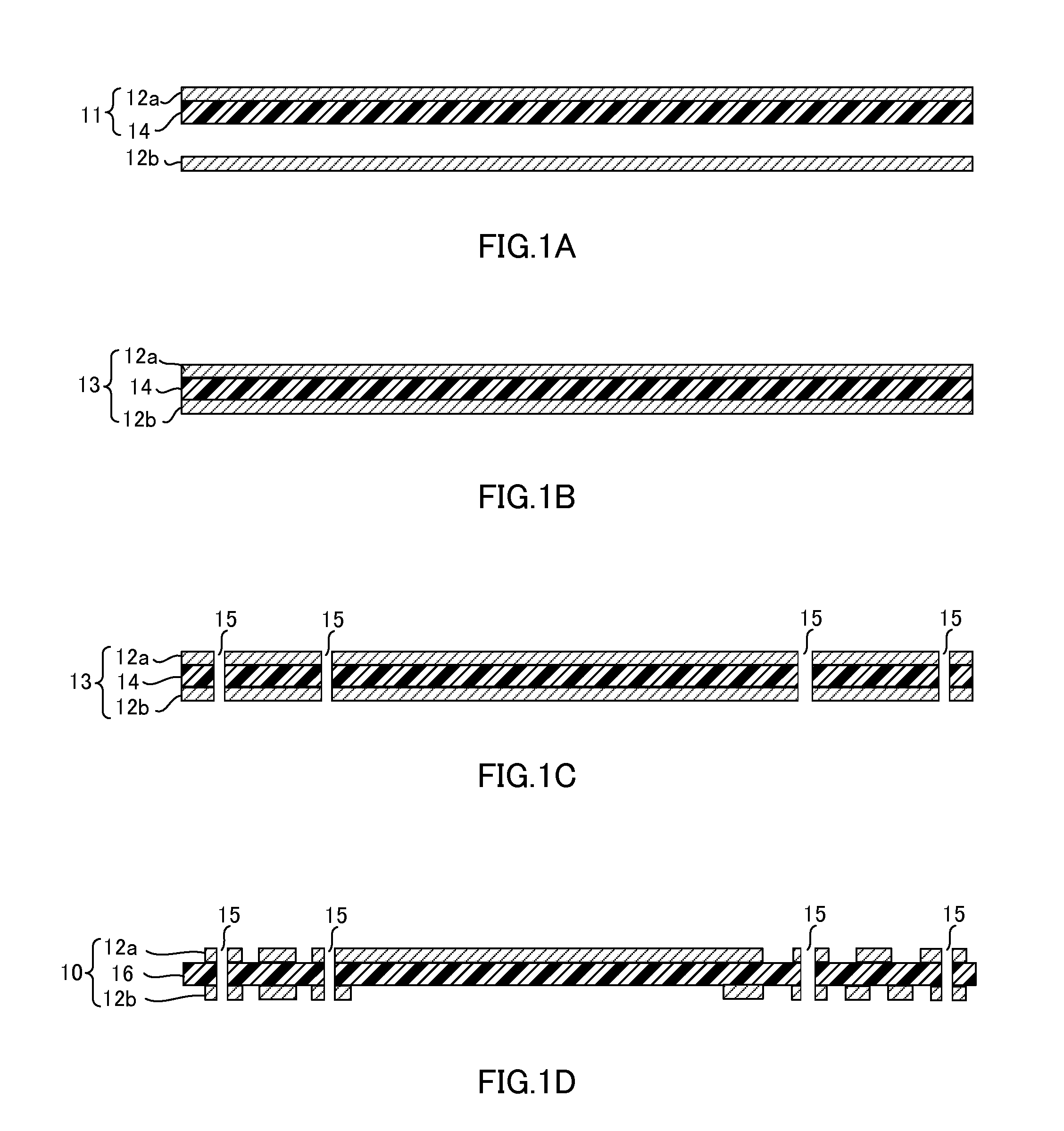

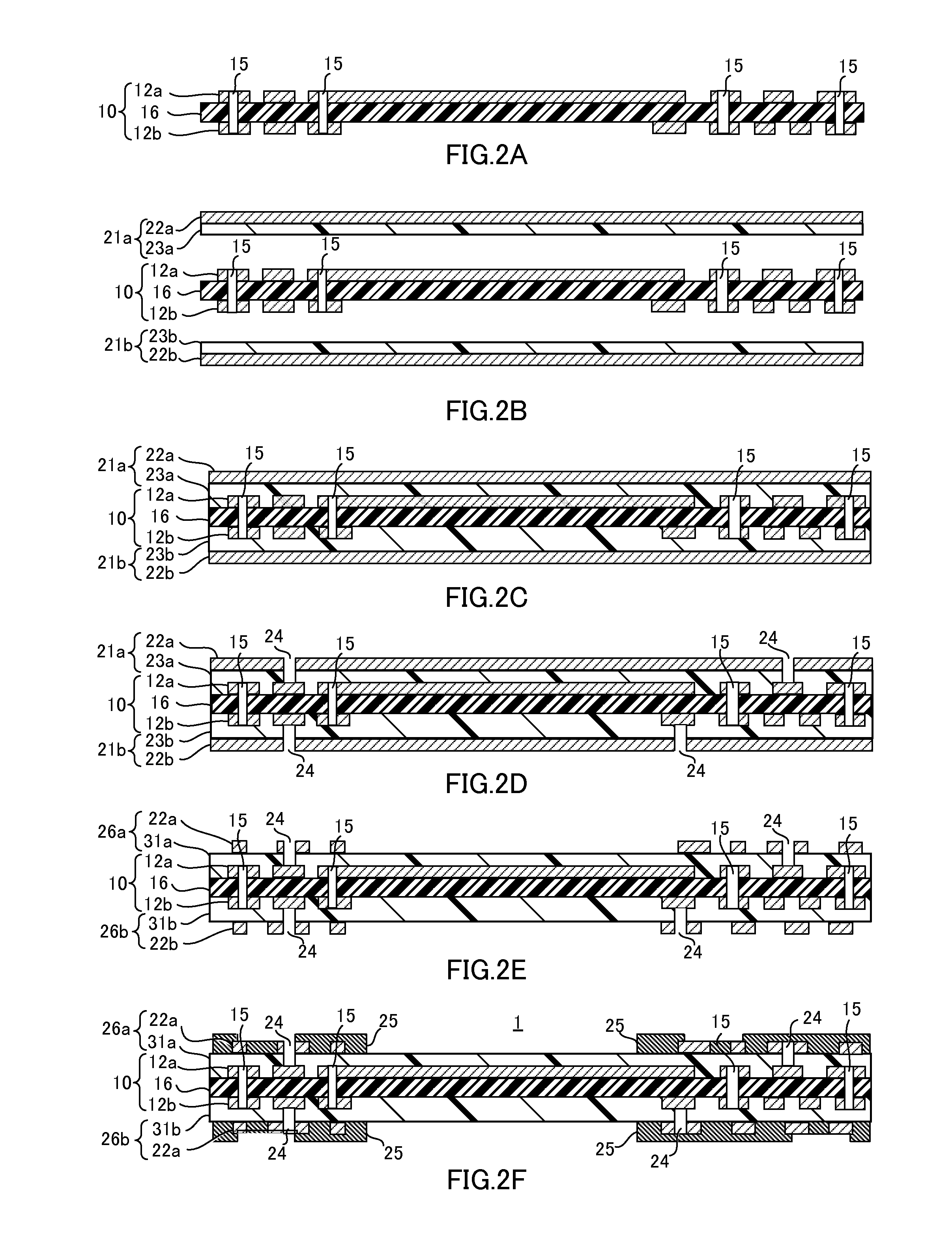

Resin composition, layered product, multilayer printed wiring board, multilayer flexible wiring board and manufacturing method of the same

ActiveUS20150027754A1Thinner plateGood in bending mountabilityNon-fibrous pulp additionSynthetic resin layered productsHeat resistanceAqueous sodium hydroxide

A resin composition containing (A) a polyimide having acidic functional groups and (B) a compound having functional groups that react with the acidic functional groups, where (a) a solution rate in 3 mass % aqueous sodium hydroxide at 45° C. is 0.95 or more after a heat history of 90° C. for 10 minutes with the solution rate before the heat history assumed to be 1, (b) the solution rate in 3 mass % aqueous sodium hydroxide at 45° C. ranges from 0.001 μm / sec to 0.02 μm / sec after the heat history of 180° C. for 60 minutes, (c) a bleed-out amount is 50 mg / m2 or less in storing at 40° C. for 2 weeks after the heat history of 180° C. for 60 minutes, and (d) a thermogravimetric decrease at 260° C. is 2.0% or less in measuring on a temperature rising condition of 10° C. / min from 40° C. by thermogravimetric analysis (TG). When a multilayer flexible wiring board is manufactured using the resin composition, it is possible to obtain the resin layer excellent in alkali processability, embeddability in press, heat resistance, bendability, insulation reliability, and adhesion to the conductive layer.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

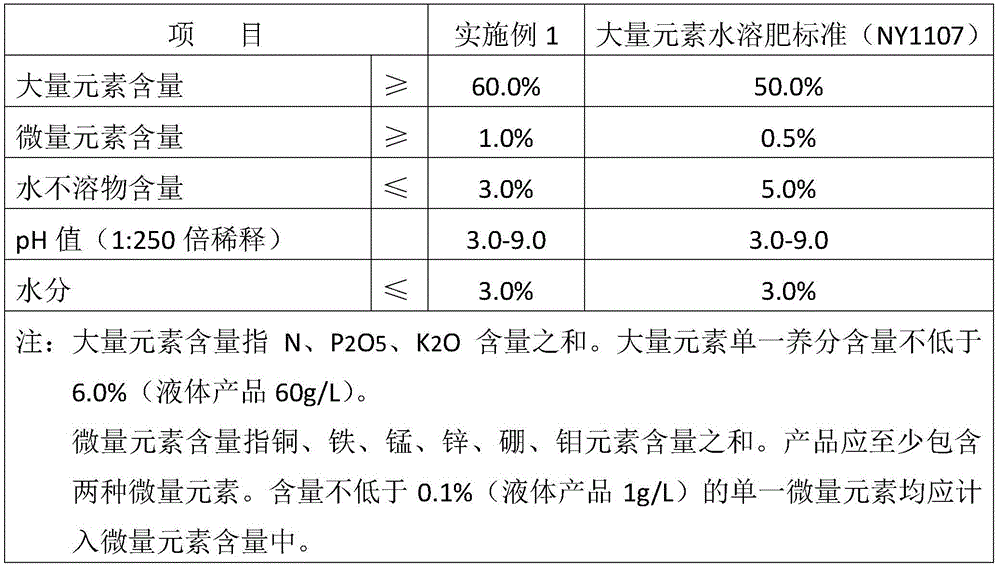

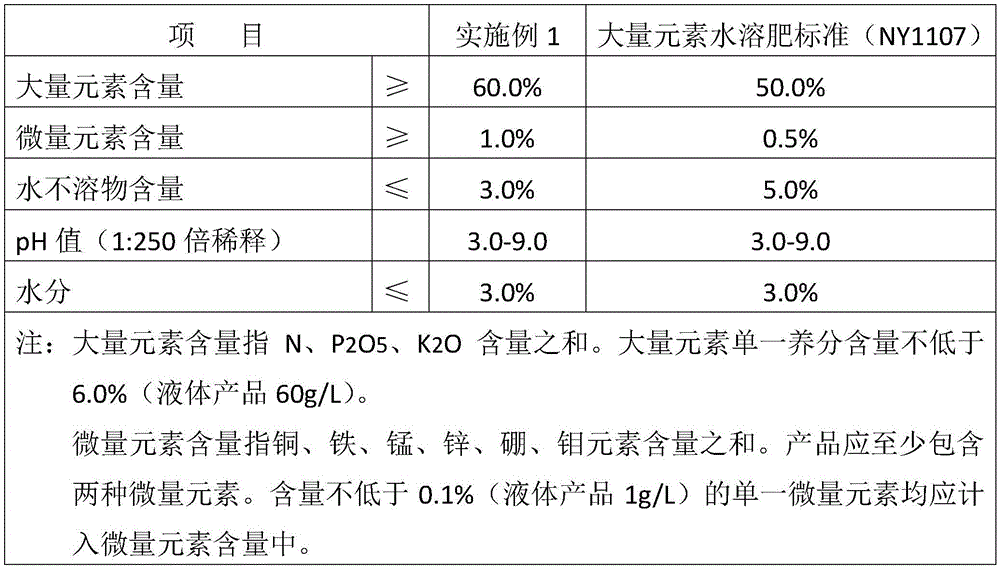

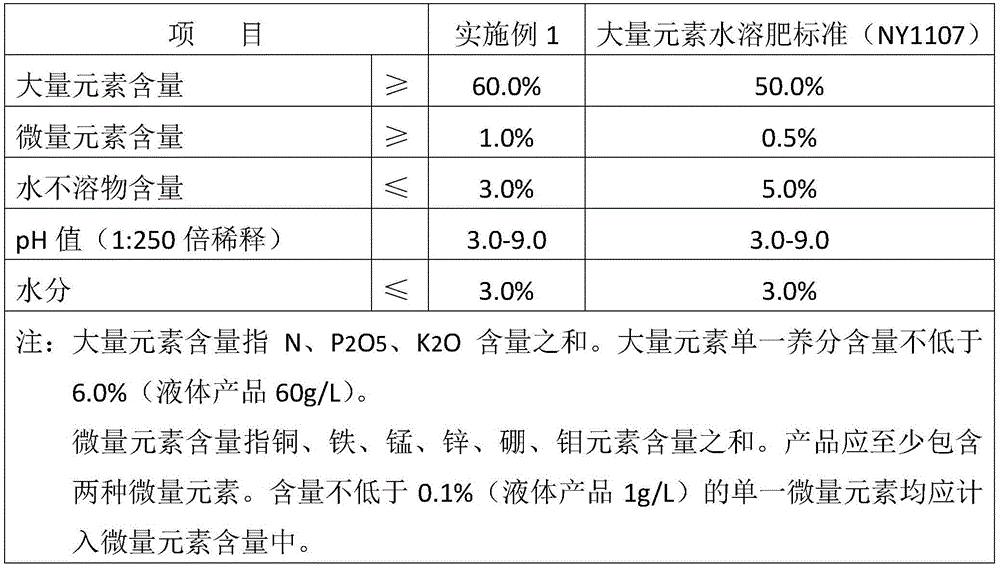

Ammonium potassium phosphate composite water-soluble fertilizer

The invention discloses an ammonium potassium phosphate composite water-soluble fertilizer which is prepared from the following components in parts by weight: 5-30 parts of nitrogen source, 10-20 parts of phosphorus source, 10-50 parts of potassium source and 4-20 parts of microelement mixture. The microelement mixture comprises nutrients of a sulfur source, a boron source, a zinc source and an iron source. The prepared fertilizer has the advantages of favorable solubility, high solution rate and no impurity, and is suitable for various trickle irrigation plants. According to the invention, the fertilizer can be properly and directly applied to the root system centralized layer in proper time, and is applied slightly and frequently, so that the fertilizer application is regular and positioned; and thus, the fertilizer can be conveniently absorbed by crops, thereby reducing the crop loss, fully displaying the fertilizer efficiency, improving the soil and obviously increasing the yield.

Owner:新疆阳光天雨生物科技有限公司

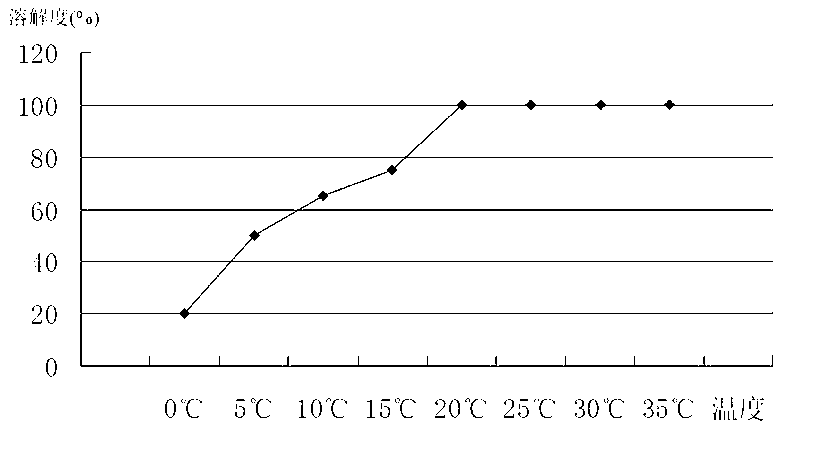

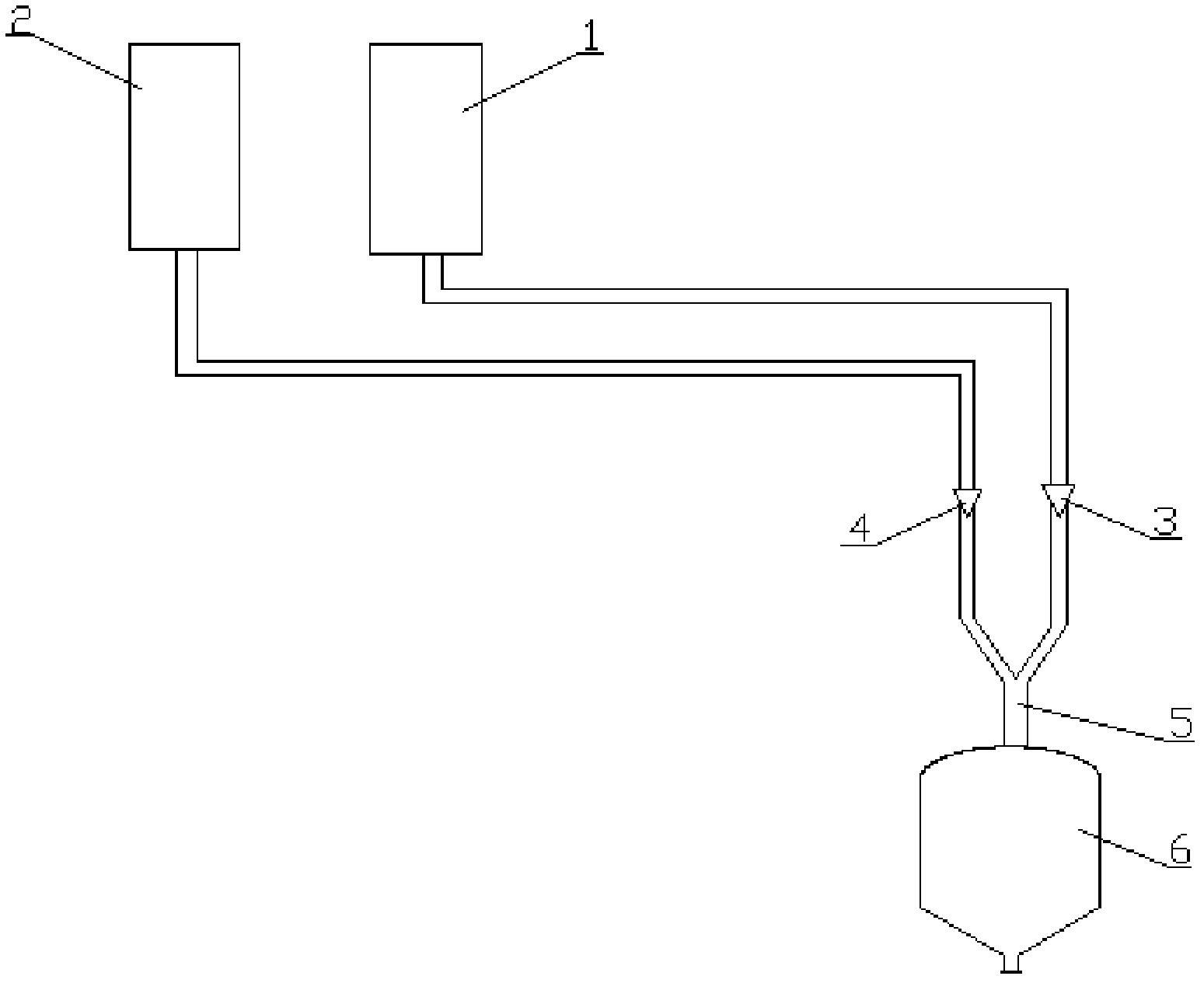

Florfenicol soluble power and preparation method thereof

InactiveCN102697730AImprove solubilityIncrease contentAntibacterial agentsOrganic active ingredientsSolubilityPolyethylene glycol

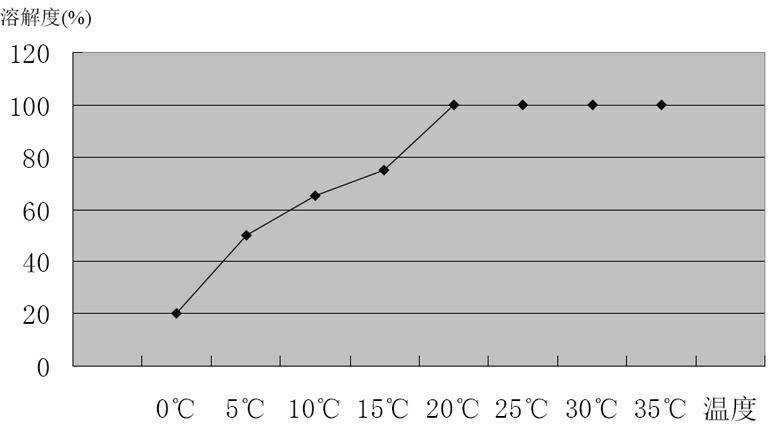

The invention discloses florfenicol soluble power. The florfenicol soluble power consists of by weight, florfenicol 65-75%, polyethylene glycol 6000 10-15%, polyvinyl pyrrolidone (PVP) 5-10% and carbomer 5-10%. By means of reasonable compounding of the florfenicol, the polyethylene glycol 6000, the PVP and the carbomer, the water solubility of the florfenicol is improved greatly, and the long-acting slow release effect is played. Due to the fact that the polyethylene glycol 6000, the PVP and the carbomer belong to high molecular polymers, the solution rate in a body is slow, the bioavailability of the florfenicol in the human body is improved fully, and the treatment effect of the florfenicol in an animal body is improved greatly (shown in figure). The florfenicol which is difficultly soluble in water is manufactured into the florfenicol soluble power capable of being soluble in water in clinical application, and the florfenicol soluble power is convenient and effective in the clinical application.

Owner:ZHENGZHOU HOUYI PHARMA

Self-dressing ultra-hard micro grinding tool pellet containing soluble resin material and preparation method thereof

ActiveCN106944939AEasy to trimNo change in preparation methodAbrasion apparatusGrinding devicesComing outSurface layer

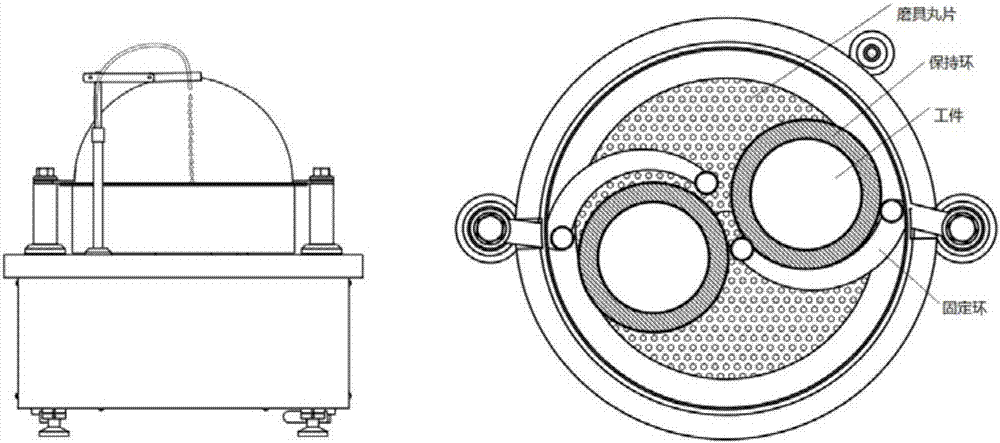

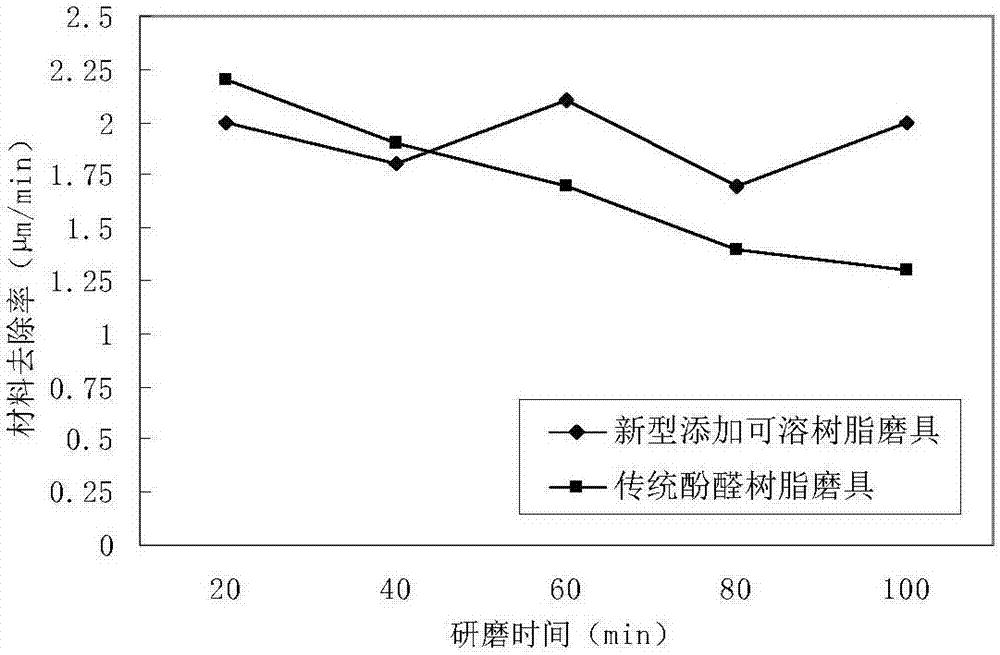

The invention discloses a self-dressing ultra-hard micro grinding tool pellet containing a soluble resin material and a preparation method thereof. The self-dressing ultra-hard micro grinding tool is composed of, by weight, 30-70% of an abradant, 0.5-5% of a wetting agent, 5-25% of a soluble resin, 15-30% of a dissoluble resin, 0-3% of a curing agent, and 20-50% of a filling agent. The dissoluble resin plays the role of a main binder, the soluble resin plays the role of an auxiliary binder, and the solution rate of the soluble resin is related to the PH value of a grinding fluid. The PH value of the grinding fluid can be adjusted according to the passivation degree of the grinding tool, therefore the rate of the grinding fluid saluting the soluble resin on the surface layer of the grinding tool can be adjusted, and the dressing rate can be controlled accordingly. In the process of dressing, the grinding fluid solutes the soluble resin material on the surface layer of the grinding tool to form voids among a binding agent, thereby reducing the strength of the binder and holding force on abrasive particles around, and thus the abrasive particles passivate the surface layer of the grinding tool fall off, new abrasive particles come out, and accordingly the purpose of automatically controlling dressing of the grinding tool online can be achieved.

Owner:衢州极目光电科技有限公司

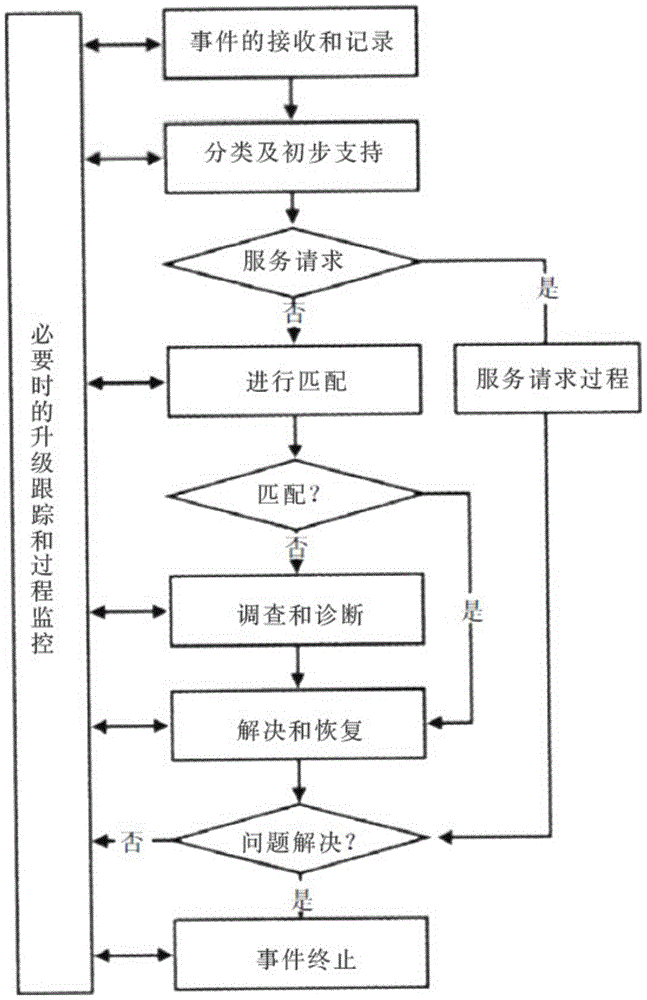

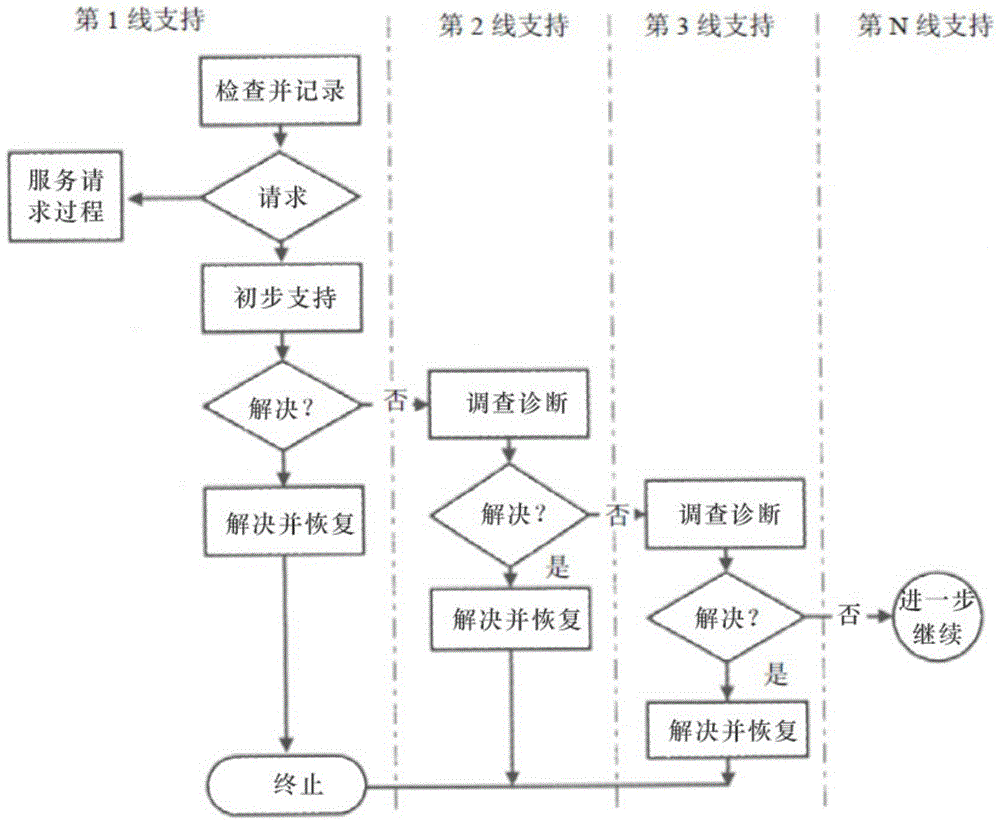

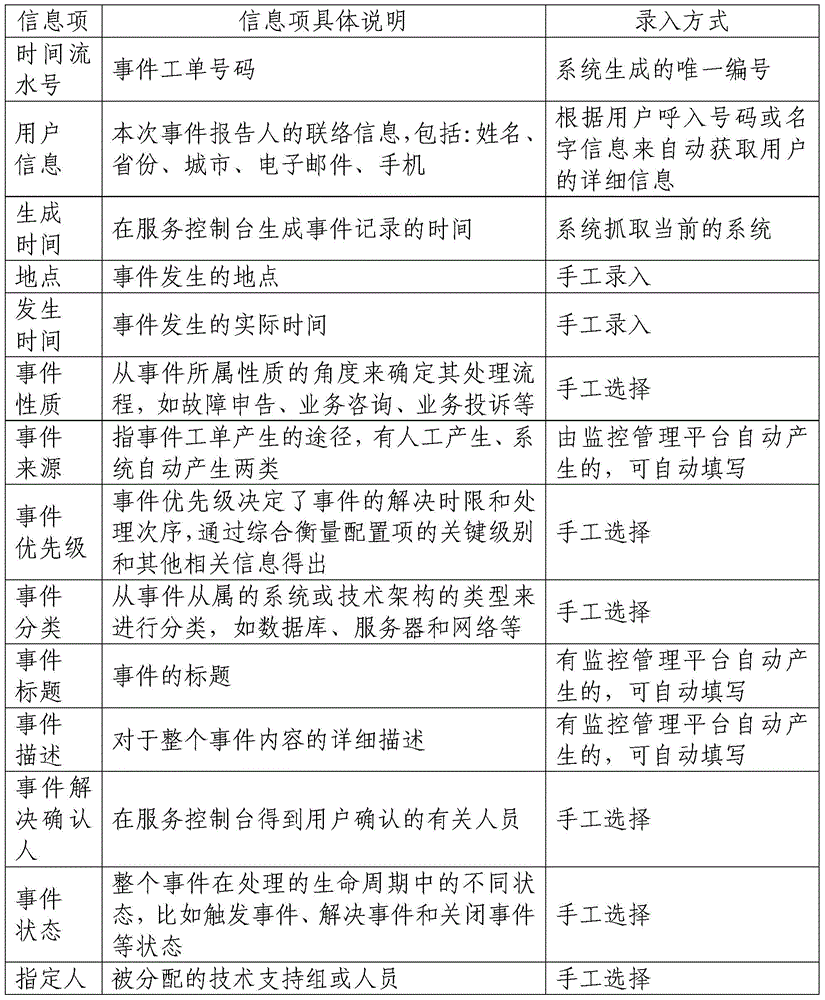

Small and medium-sized enterprise event management process

Disclosed is a small and medium-sized enterprise event management process. The process comprises the following steps: recording and accepting events; performing classification and online support; performing coupling; performing investigation and diagnosis; performing solution and recovery; and ending the events. Through such a management process, occurring events can be rapidly solved and service is recovered within an allowable cost scope, the stability of an enterprise service system is maintained, a highest possible event solution rate can be obtained, and satisfaction of a user is improved.

Owner:YILAN YUNLIAN TECH CO LTD

Health-care product capable of supplementing multiple trace elements and preparation method thereof

ActiveCN103535580AGreat tasteImprove solubilityFood thermal treatmentFood homogenisationSolubilityGluconates

The invention provides a health-care product capable of supplementing multiple trace elements. The health-care product is prepared from the following raw materials in parts by weight: 30-40 parts of calcium lactate, 20-30 parts of zinc lactate, 20-30 parts of magnesium lactate, 10-20 parts of ferrous lactate, 1-10 parts of manganese gluconate, 1-5 parts of copper gluconate and 0.1-1 part of selenic acid lipopolysaccharide. The health-care product has the advantages that the multiple trace elements are scientifically mixed together, the raw materials are subjected to microwave baking, sterilized and ground into finely pulverized powder, the lactate series trace elements and the gluconic acid series trace elements which have high solubility, fast solution rate, high bioavailability and good mouth feel are adopted and have the effects of assisting human bodies in absorbing the trace elements, reducing the morbility of osteoporosis, preventing cardiovascular diseases, resisting tumors and enhancing the metabolism and immunity of the organism, and especially the selenium can form antioxidant enzymes in vivo and has the effects of protecting cell membranes from undergoing oxidative damage, maintaining the permeability of the cell membranes, reducing the toxic effect of poisonous substances and preventing cancers.

Owner:哈福科技(武汉)集团有限公司

Calcium hypochlorite composition

Describes a composition comprising a mixture of (1) a major amount of calcium hypochlorite, e.g., hydrated calcium hypochlorite, and (2) a minor amount of calcium hypochlorite-compatible hydrophobic additive (other than discrete particulate Group IIA or IIIA metal stearates) in amounts sufficient to provide the composition with reduced hydrophilic properties. The composition has a solution rate in water at standard conditions that is less than the calcium hypochlorite used to prepare the composition, but sufficient for the intended application. Describes also calcium hypochlorite compositions in which the hydrophobic additive is an organo-silicon material, or a metal oxide, e.g., amorphous precipitated silica, treated with a hydrophobizing agent, such as an organo-silicon material, e.g., an organo-silane and / or organo-siloxane material.

Owner:EAGLE US 2 LLC

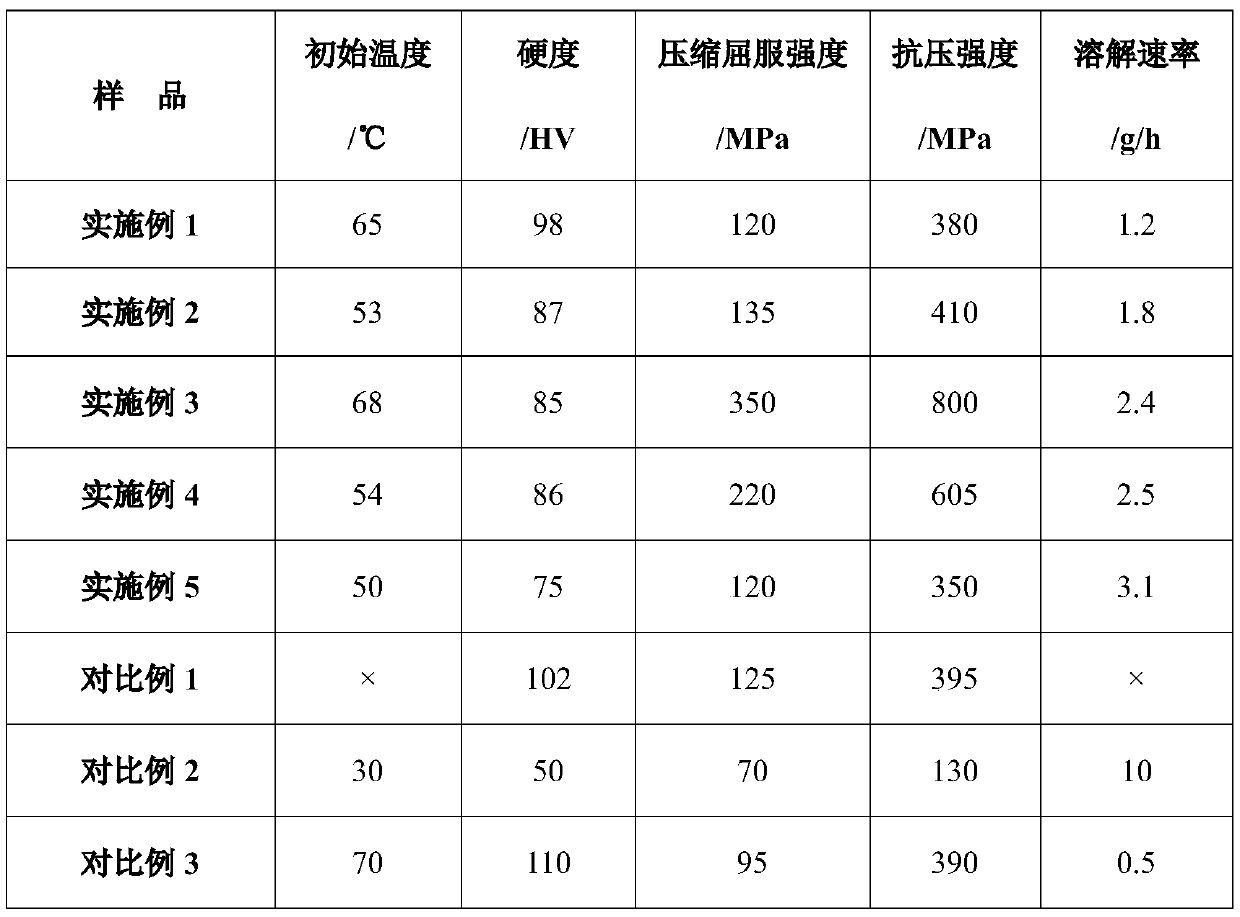

Soluble magnesium alloy composite fracturing ball and preparation method thereof

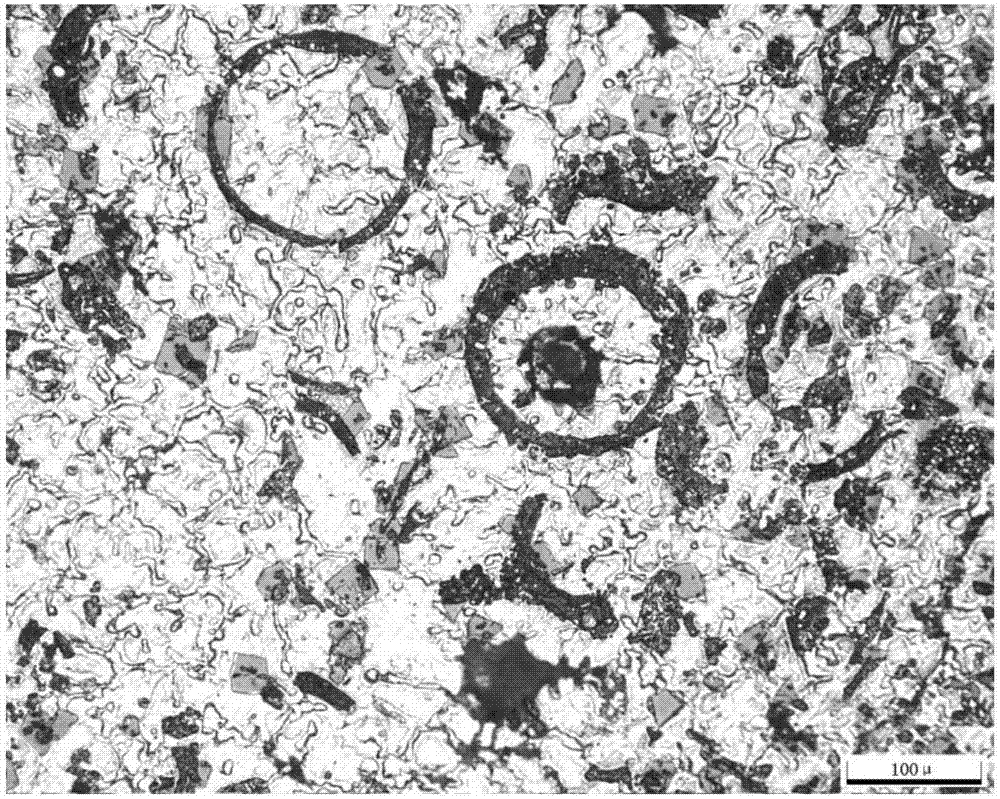

InactiveCN107099712AHigh compressive strengthLow densityAnodisationDrilling compositionPlasma electrolytic oxidationGraphite

The invention discloses a soluble magnesium alloy composite fracturing ball and a preparation method thereof, which belongs to the field of manufacturing of unconventional oil and gas equipment. The fracturing ball is prepared from the following components according to mass percent: 3% to 7% of Al, 0.5% to 3% of Zn, 0.5% to 3% of Fe, 0.5% to 3% of Cu, 0.5% to 3% of Ni, 4% to 8% of floating beads and the balance of Mg. The preparation method comprises the steps of melting magnesium alloy in a crucible resistance furnace, controlling the temperature to 550 to 580 DEG C, adding a certain proportion of preheated floating beads in a mechanical mixing condition, heating to 700 to 730 DEG C, uniformly mixing, insulating and standing for certain time, then pouring to a graphite mold with a spherical inner cavity, cooling and freezing, so that a workblank of the floating bead / magnesium alloy soluble composite fracturing ball is obtained; machining the workblank of the fracturing ball by adopting a center lathe and a hard alloy cutter, so that the soluble fracturing ball of the require size is obtained; and preparing a protective ceramic membrane on the surface of the soluble fracturing ball by adopting micro plasma oxidation. The fracturing ball has the advantages of light weight, pressure resistance, high solution rate, simple preparation process and low cost and is suitable for industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pasting film for treating oral ulcer and preparation method of pasting film

InactiveCN104013632AModerate dissolution rateLarge drug storageOrganic active ingredientsDigestive systemFiberVitamin C

The invention relates to the technical field of medical apparatuses and instruments, and particularly relates to a pasting film for treating oral ulcer and a preparation method of the pasting film. By virtue of coaxial electrostatic spinning method, dexamethasone, vitamin C and vitamin B2 are encapsulated into polyoxyethylene nano fiber in proportion. According to the pasting film for treating oral ulcer and a preparation method of the pasting film, the pasting film consists of core-shell structure nano fibers, is guaranteed to have large enough medicine storage amount and release area; moreover, the used polyoxyethylene is relatively moderate in solution rate in an oral cavity, and can continuously keep the ulcer part to have effective medicine concentration.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

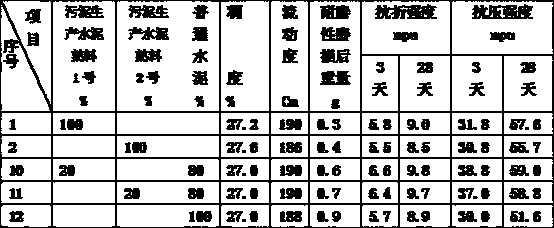

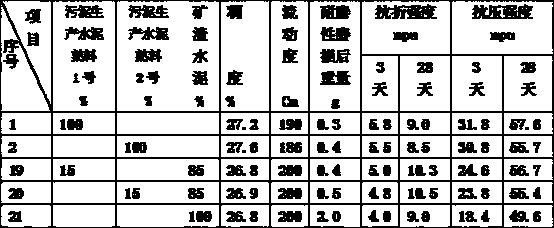

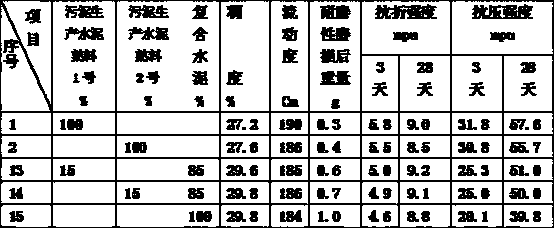

Method for preparing cement clinker by utilizing sludge

The invention relates to a method for preparing cement clinker by utilizing sludge. The method mainly comprises the steps of preparing materials, mixing materials, prilling, drying roasting, and the like, the key is to choose silicon ash and zeolite paste as auxiliary raw materials to be mixed with discharged sludge of a sewage treatment plant, then technical components act with one another, SiO2, Al2O3 are combined with SO3, a part of silicate ionic group is replaced by sulfate ionic group, and therefore, the solution rate can be slowed down and the problem of large water consumption of the previous sludge-type cement is solved. When the cement clinker prepared by the sludge with the method is compared with the existing produced high-temperature cement clinker, 80% of energy can be saved, and CO2 discharge can be reduced by 85%. The method conforms to national recycling cyclic development of waste residue of sludge, and the like and is beneficial to new technology and new material changing waste material to things of environmental policy.

Owner:江苏启坤循环经济产业技术开发有限公司

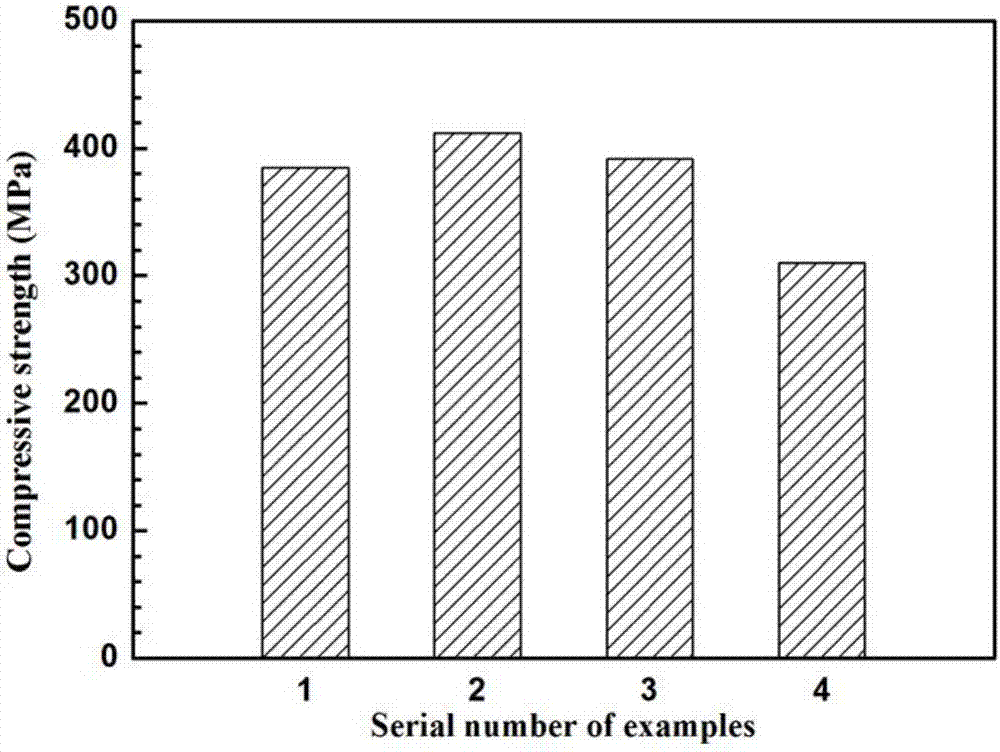

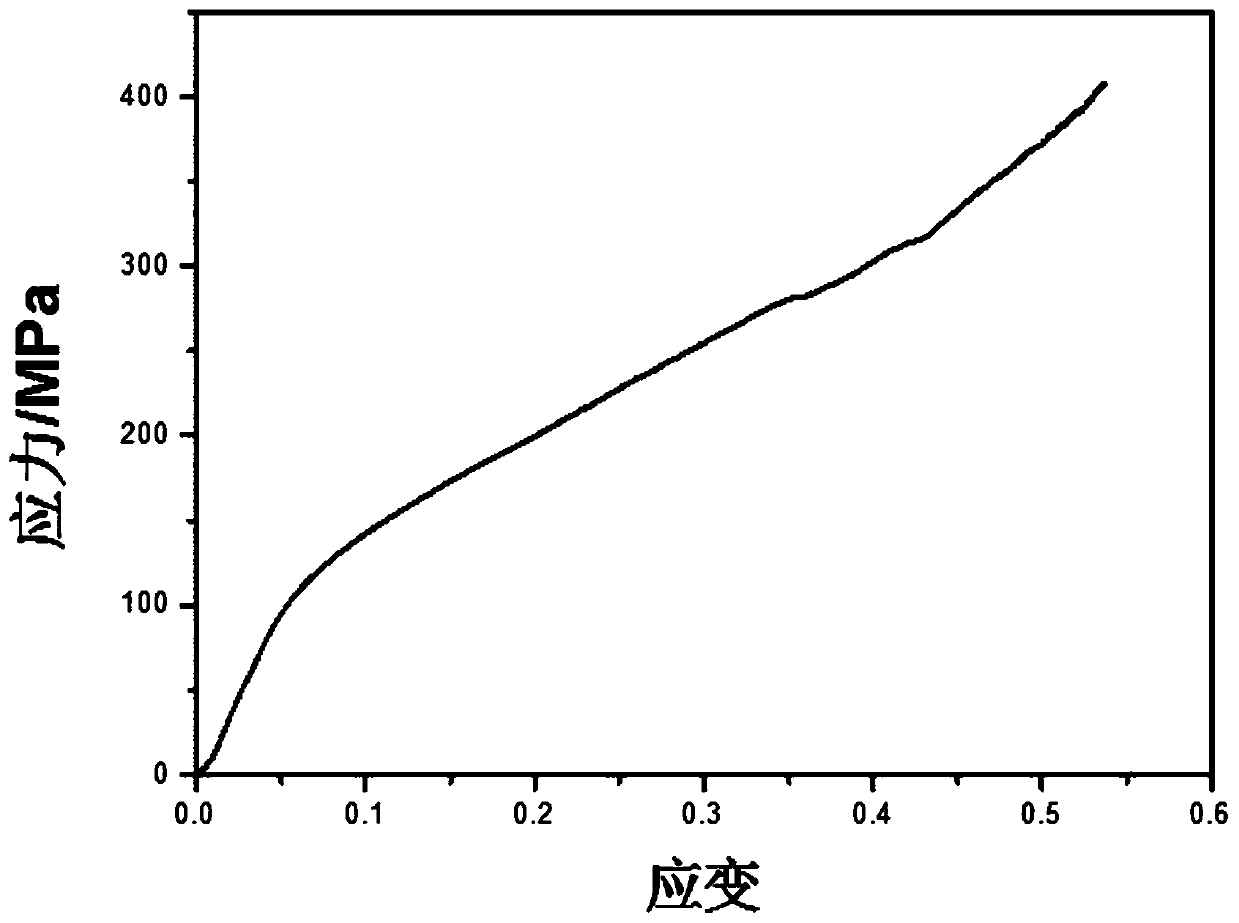

High-strength soluble aluminum alloy and preparation method and application thereof

InactiveCN110512123AAdjust the dissolution rateMeet different requirements of dissolution ratePetroleumMaterials science

The invention relates to a high-strength soluble aluminum alloy and a preparation method and application thereof, and belongs to the technical field of powder metallurgy. According to the high-strength soluble aluminum alloy, low-melting-point metal and strengthening elements are added in aluminum-based powder, and a soluble aluminum alloy material is prepared through a powder metallurgy method. Low-melting-point metal elements Ga, In, Sn, Zn, Bi and Pb are added into an aluminum matrix, low-melting-point Al-Ga-In-Sn alloy eutectoid can be formed, and the situation that the aluminum surface isdamaged to form an oxide film is avoided. The ratio and contents of the low-melting-point metal and strengthening metal in the alloy are adjusted, and therefore the solution rate of the soluble aluminum alloy material in a Cl- salt solution can be adjusted. Meanwhile, strengthening elements Cu, Mg, Ti, Si, Fe, Re, Mo and Mn are added, and the functions of solution strengthening and dissolution rate adjusting are achieved. In the prepared high-strength soluble aluminum alloy, compressive strength ranges from 130 MPa to 800 MPa, yield strength ranges from 70 Mpa to 350 Mpa, solubleness is controllable, and the high-strength soluble aluminum alloy can be applied to a petroleum downhole fracture tool. Raw materials can be obtained easily, the preparation method is stable and reliable, and thehigh-strength soluble aluminum alloy is suitable for large-scale production.

Owner:青岛大地新能源技术研究院

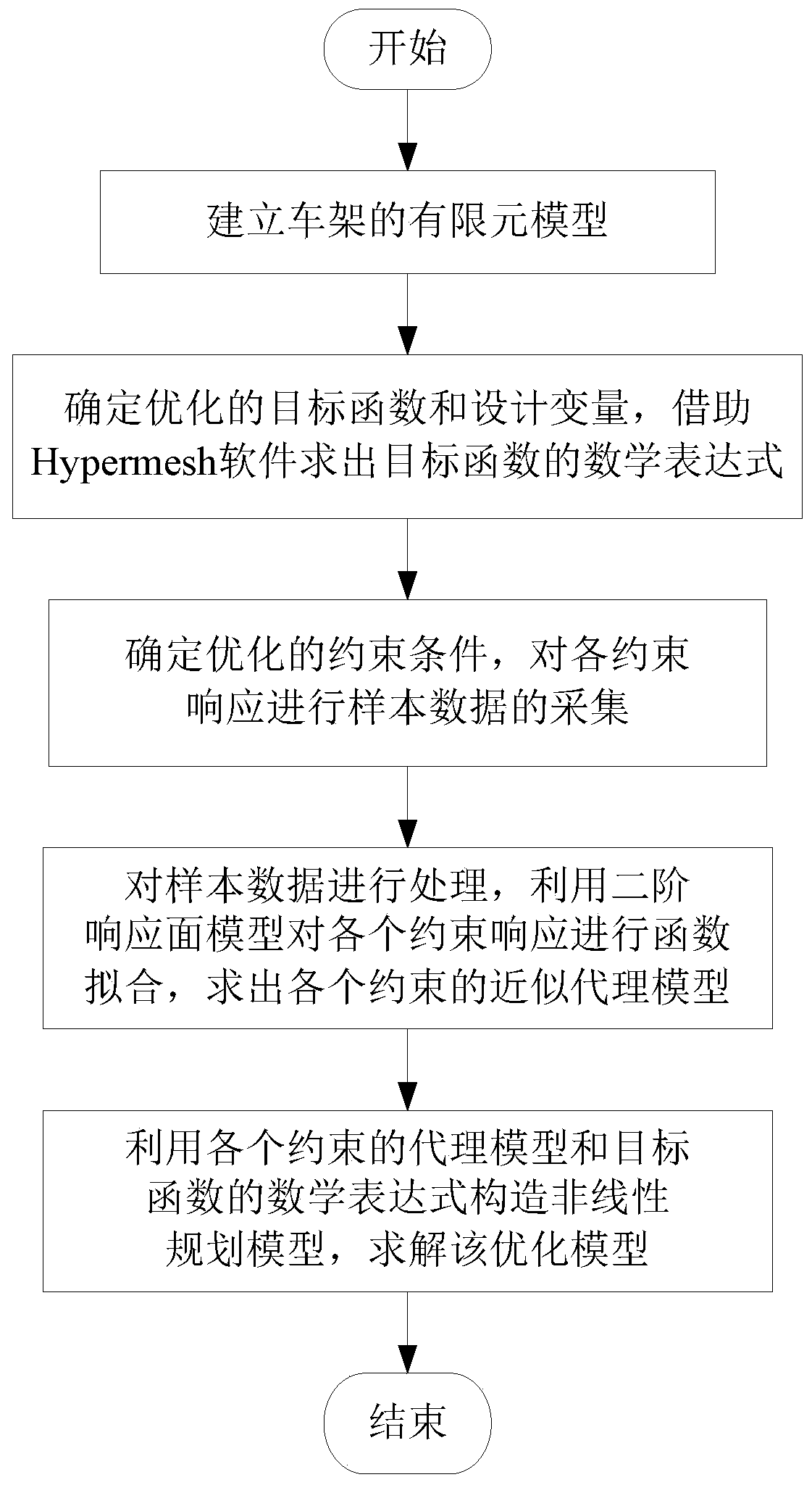

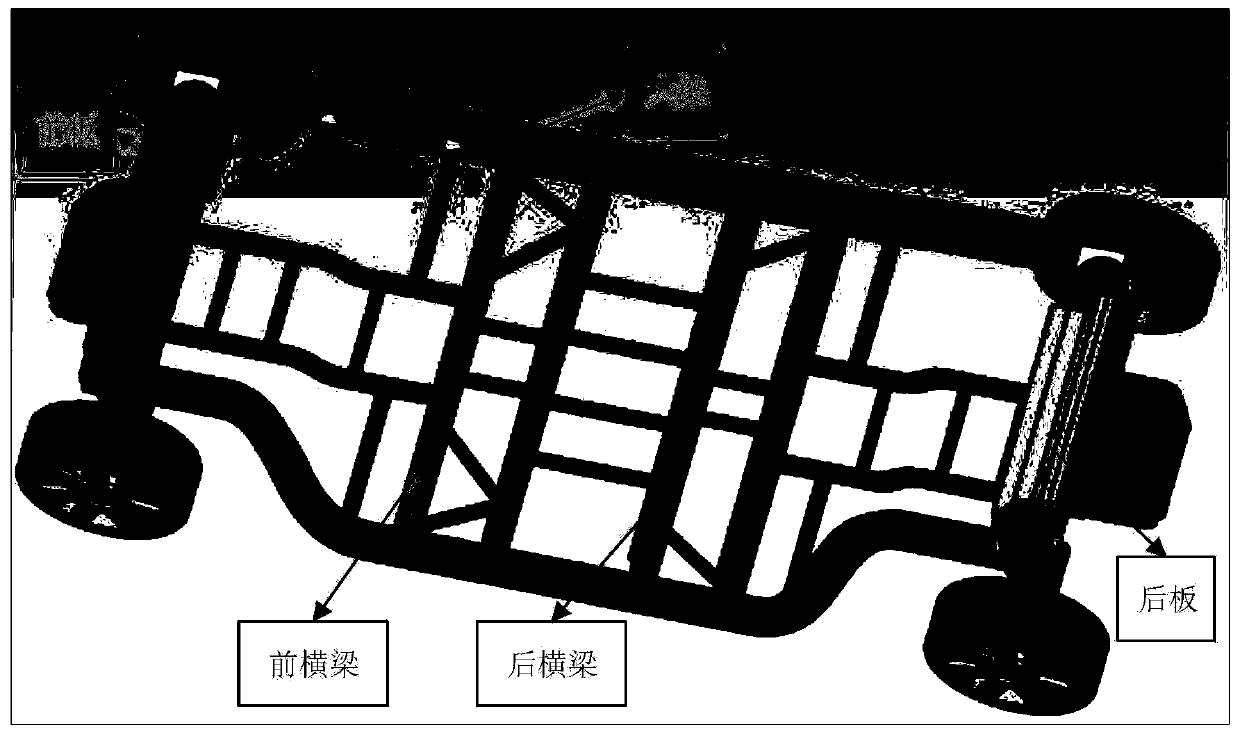

Pure electric vehicle frame lightweight method based on nonlinear programming

InactiveCN110110467AThe principle is simpleImprove solution rateGeometric CADDesign optimisation/simulationElement modelVehicle frame

The invention discloses a pure electric vehicle frame lightweight method based on nonlinear programming. The method comprises the following steps of S1, establishing a finite element model of a frame;S2, determining an optimized objective function and an optimized design variable, and solving a mathematical expression of the objective function by means of the Hypermesh software; S3, determining an optimized constraint condition, and collecting the sample data of each constraint response; S4, processing the sample data, performing function fitting on each constraint response by using a second-order response surface model, and solving an approximate agent model of each constraint; and S5, constructing a nonlinear programming model by using the agent model of each constraint and the mathematical expression of the objective function, and solving the optimization model. According to the method, by adopting the nonlinear programming model, and using the Lingo software for solving and optimizing, the optimal solution can be obtained within the extremely short time, and the optimization efficiency is greatly improved. The optimization method has the characteristics of simple principle, high solution rate, high optimization precision and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

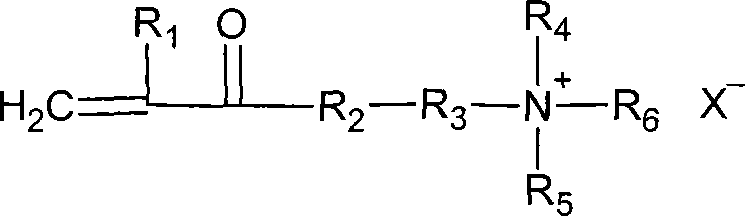

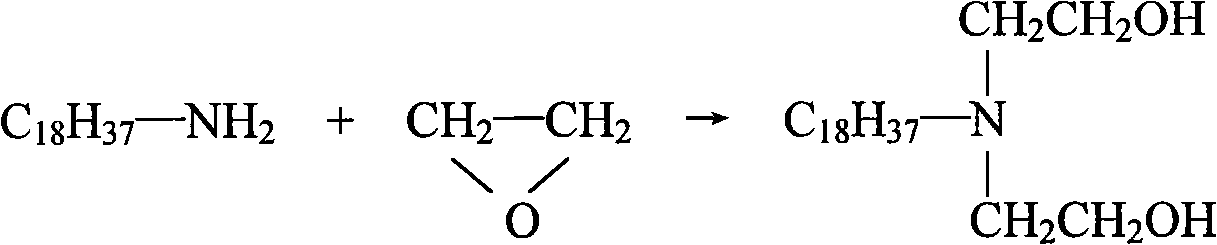

Method for synthesizing octadecyl bi-polyoxyethylene benzyl ammonium chloride

InactiveCN102108054AImprove shadingImprove permeabilityOrganic compound preparationDyeing processFiberSolubility

The invention discloses a method for synthesizing octadecyl bi-polyoxyethylene benzyl ammonium chloride. Octadecylamine, ethylene oxide and benzyl chloride are taken as raw materials; and the method is characterized by comprising the following steps of: A) polymerizing the octadecylamine and the ethylene oxide to obtain polyoxyethylene octadecylamine; and B) performing quaterisation reaction on the polyoxyethylene octadecylamine and the benzyl chloride in a molar ratio of 1:(0.5-1.1) at the temperature of between 70 and 100DEG C for 4 to 12 hours in a polar medium under the condition of refluxing to obtain the octadecyl bi-polyoxyethylene benzyl ammonium chloride. The product prepared by the method is suitable for dyeing of various acid dyes, the using amount of acid can be reduced, and the damage to fibers is reduced; and when the using amount is large, the product can be used as a stripping agent. The product has high solubility in water, high solution rate, good solubilization effect and obvious solubilization effect on most acid dyes.

Owner:ZHEJIANG HUANGMA TECH

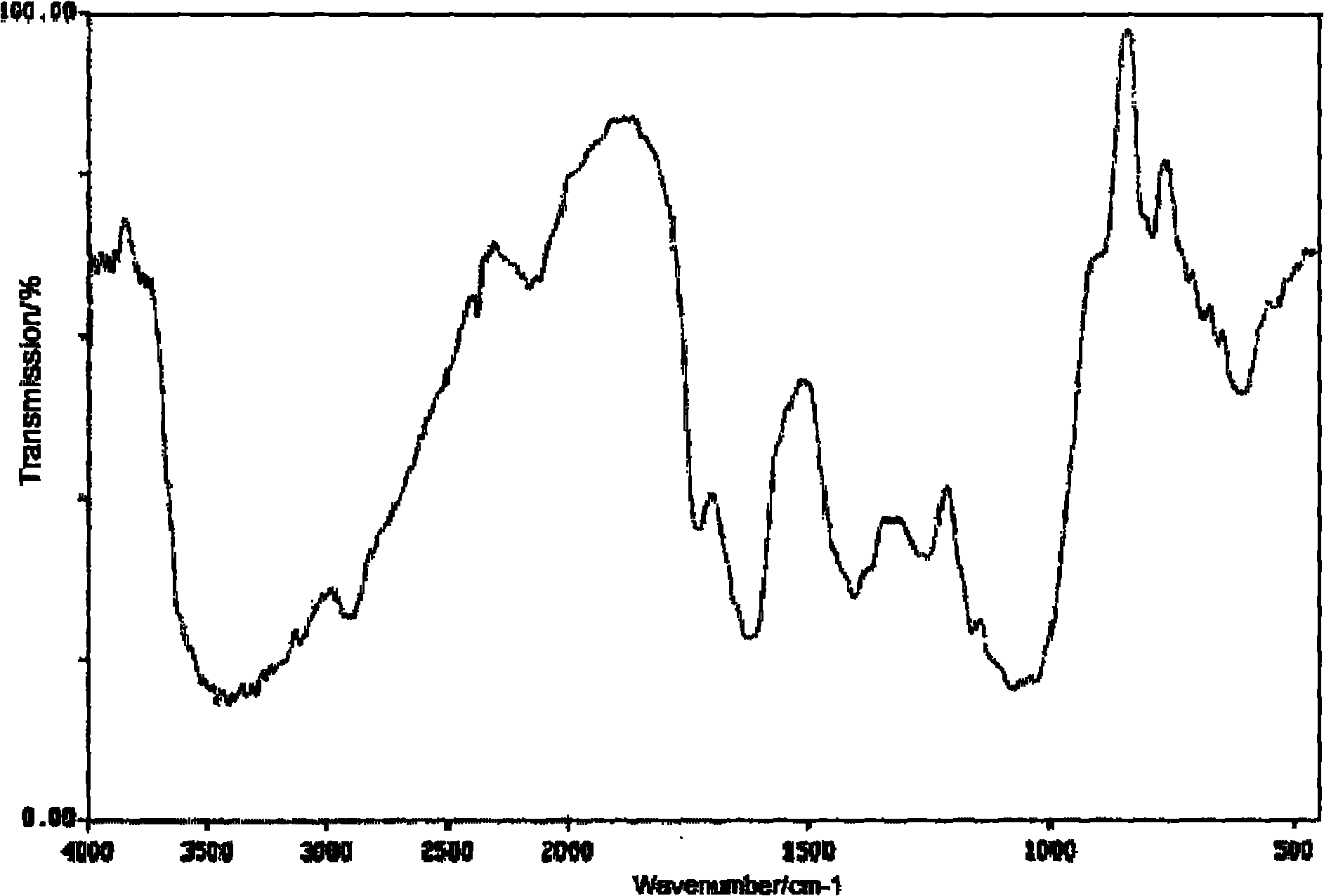

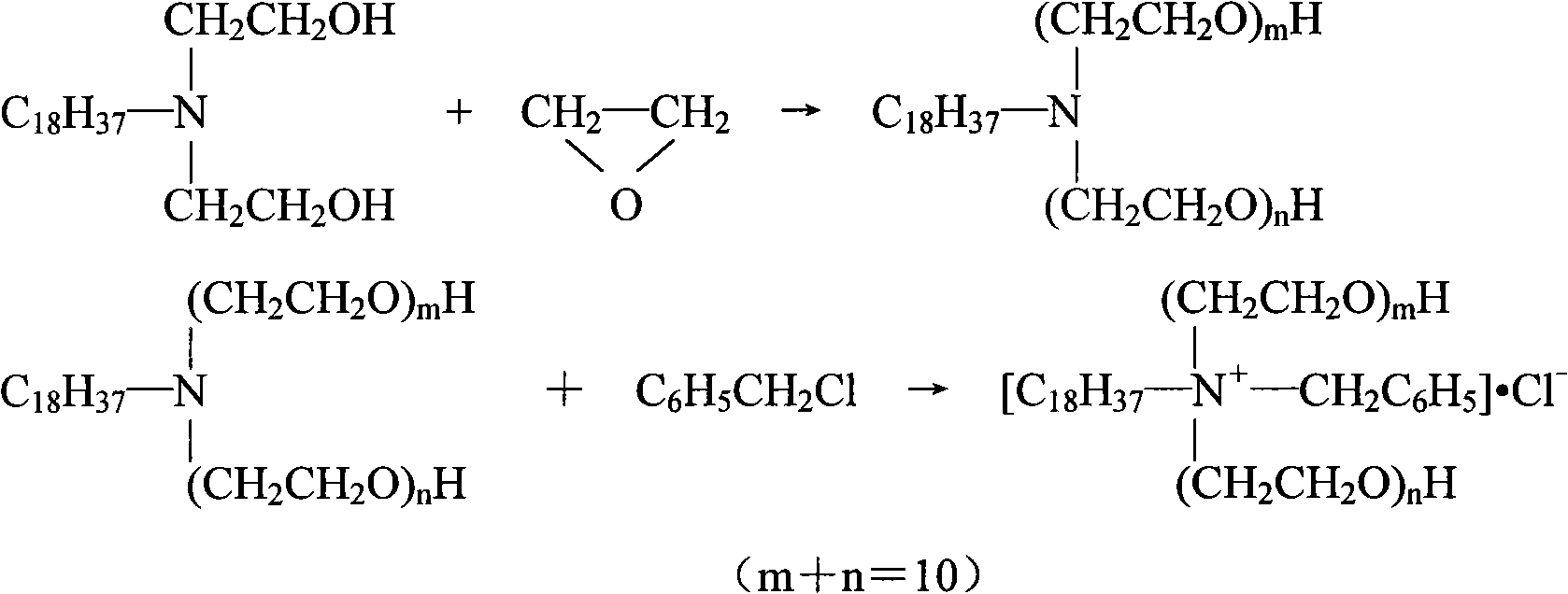

Temperature-resistant and salt-resistant fluid loss additive emulsion and preparation method thereof

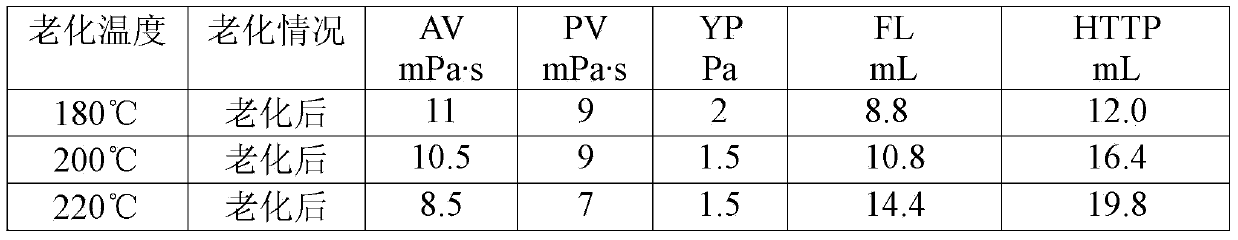

ActiveCN103694407AGood repeatabilityFast dissolutionDrilling compositionEmulsionTemperature resistance

The invention discloses a temperature-resistant and salt-resistant fluid loss additive emulsion which is prepared by four simple substances, namely acrylamide, N-vinyl pyrrolidone, dimethyl diallyl ammonium chloride and 2-methyl-2-acrylamide propanesulfonic acid, water, white oil, an emulsifier and an initiator. The invention further discloses a preparation method of the temperature-resistant and salt-resistant fluid loss additive emulsion. The temperature-resistant and salt-resistant fluid loss additive emulsion can resist temperature up to 220 DEG C and can resist salt to saturation; the emulsion contains an amide group, a sulfonic group, an amine group, cation ammonium and a six-membered ring, so that a polymer has very high temperature resistance; strong adsorption groups of the polymer can ensure that the polymer has a good adsorption effect to clay under the high temperature condition, and can ensure that the fluid loss additive emulsion has a better fluid loss effect at a high temperature; and in addition, the emulsion is good in repeatability and high in solution rate, and can be directly applied to a site.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

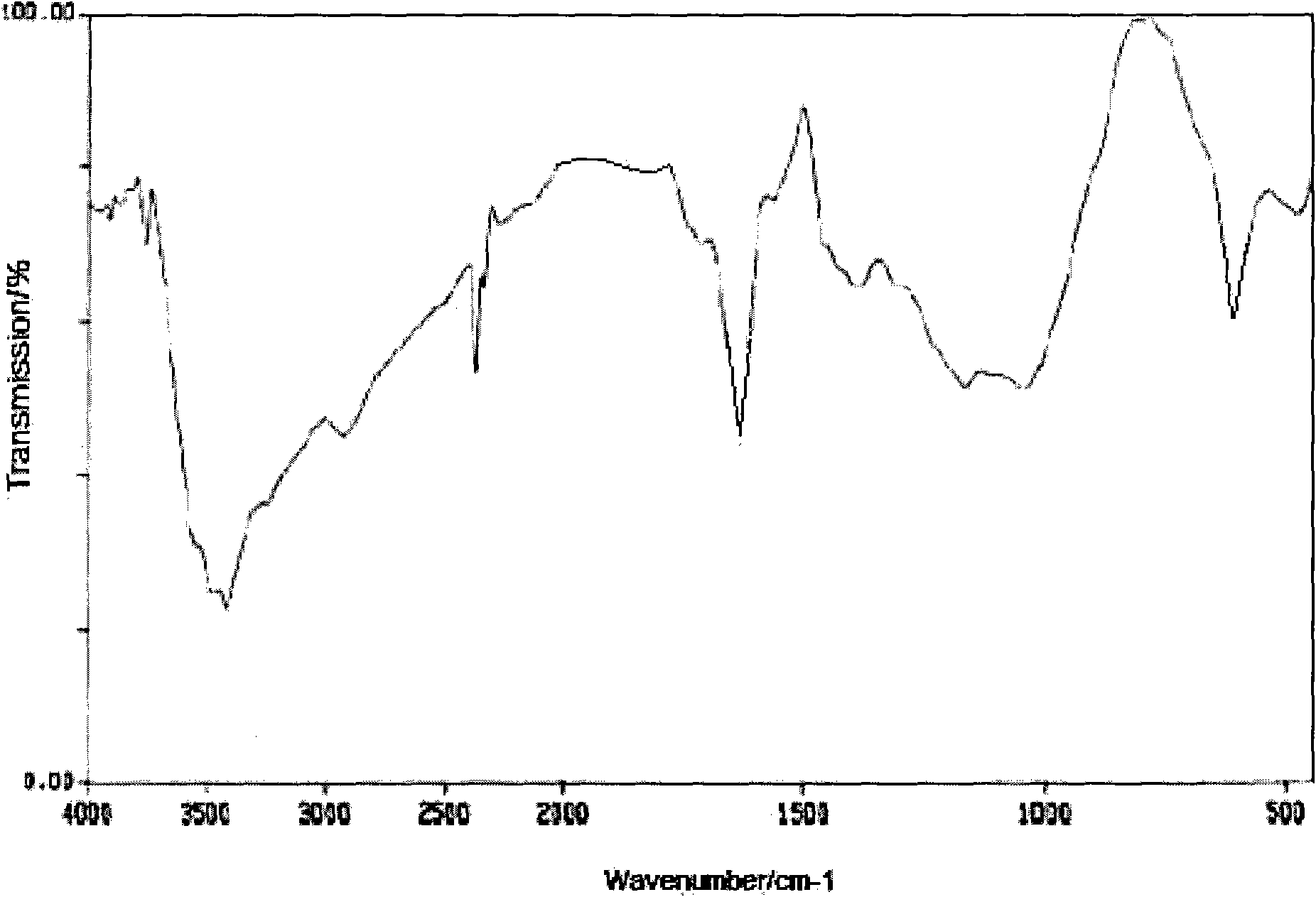

Preparation method of ionic liquid for efficiently extracting cellulose and application thereof

InactiveCN102796048AImprove solubilityFast dissolutionCarboxylic acid salt preparationPaper material treatmentCelluloseSolubility

The invention relates to a preparation method of an ionic liquid for efficiently extracting cellulose, which comprises the following steps: reacting raw materials N-methylimidazole and 3-bromopropylene in a nitrogen protective atmosphere to synthesize 1-allyl-3-methylimidazolyl bromine salt; mixing the 1-allyl-3-methylimidazolyl bromine salt and a lead acetate water solution to react, thereby obtaining a 1-allyl-3-methylimidazolyl acetate water solution and a lead bromide precipitate; and after freeze-drying to remove the lead bromide, extracting the 1-allyl-3-methylimidazolyl acetate water solution with ethyl acetate, and carrying out vacuum distillation and acetone extraction to obtain the ionic liquid which can be used for extracting cellulose and can be recycled for repeated use. The preparation method is simple, does not use any organic solvent, and has the advantages of high conversion rate, no toxicity and no pollution; and the ionic liquid has the advantages of high solubility, high solution rate, low temperature requirement and lower viscosity under the condition of dissolving the same mass of cellulose, and is beneficial to cellulose regeneration and after treatment.

Owner:NANKAI UNIV

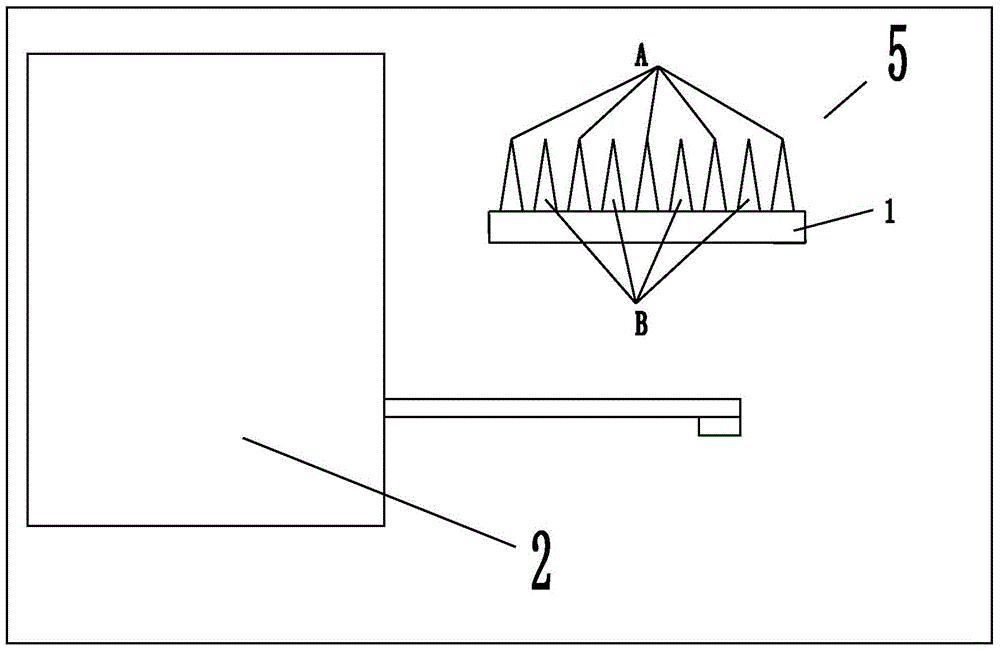

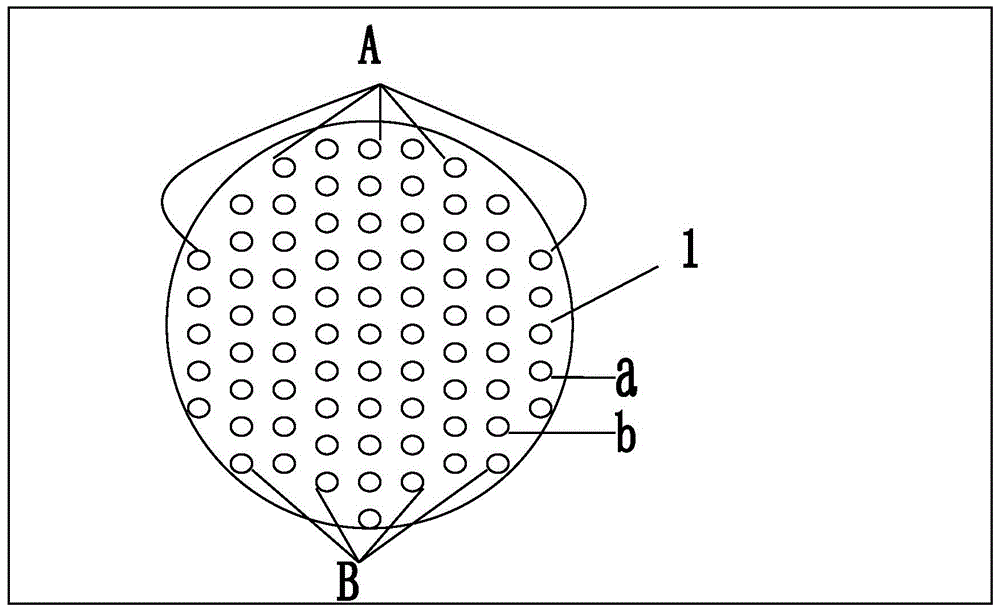

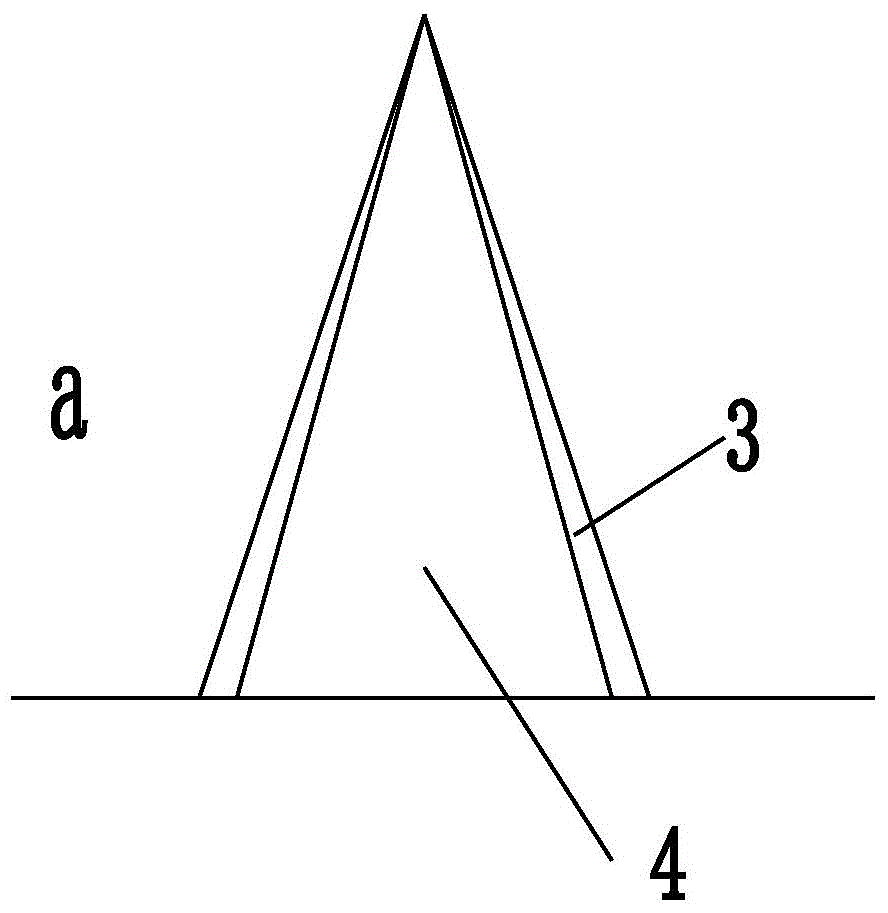

Photorejuvenation system combined with microneedle sticker

InactiveCN104815398AEasy to useEasy to operateCosmetic preparationsToilet preparationsPhotorejuvenationBiomedical engineering

The invention relates to a photorejuvenation system combined with a microneedle sticker. The system comprises the microneedle sticker and a photorejuvenation instrument. The photorejuvenation instrument is a medical cosmetology intense pulsed light generation device, of which the emission frequency is adjustable. The microneedle sticker comprises a substrate, a soluble first microneedle array and a soluble second microneedle array which are arranged on the upper surface of the substrate, and a back coating layer, wherein the first microneedle array and the second microneedle array have different solution rates, the first microneedle array comprises a plurality of first microneedles, and the second microneedle array comprises a plurality of second microneedles.

Owner:成都凤磐生物科技有限公司

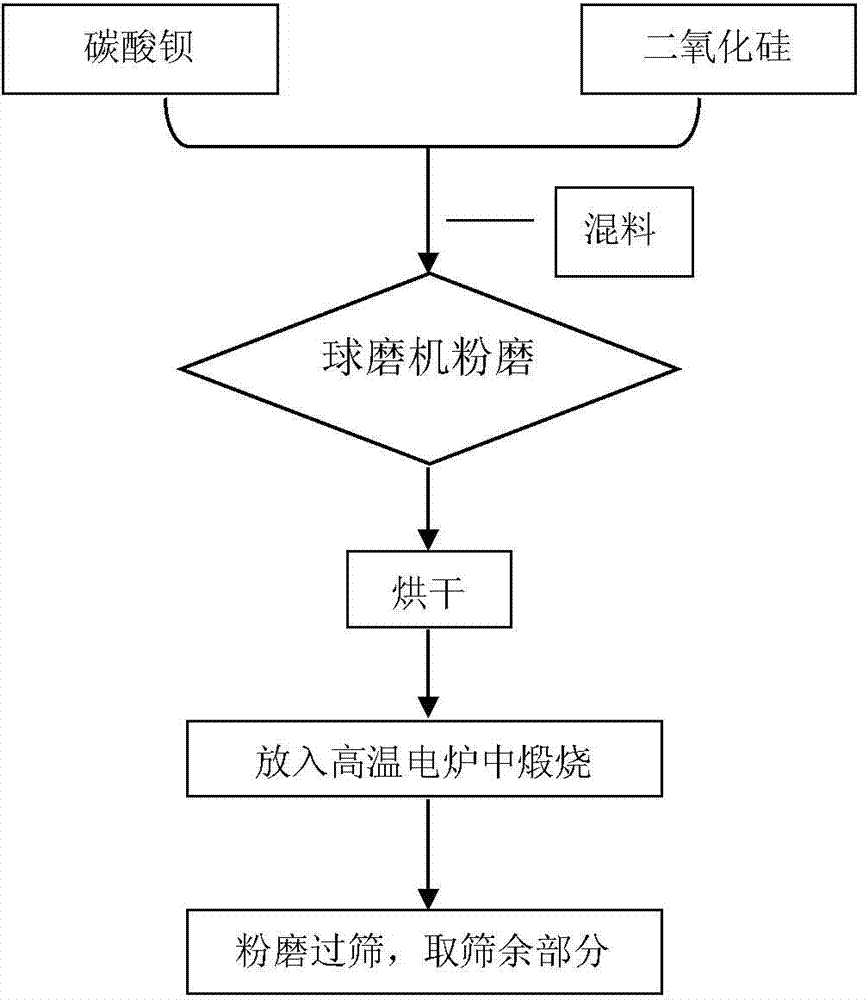

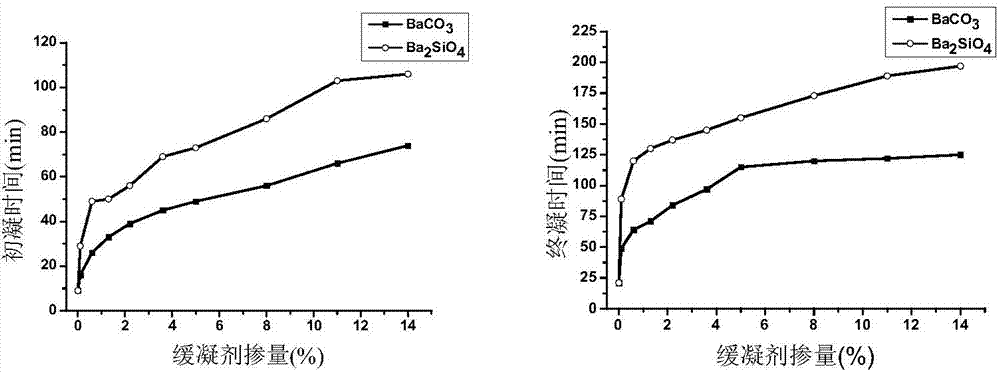

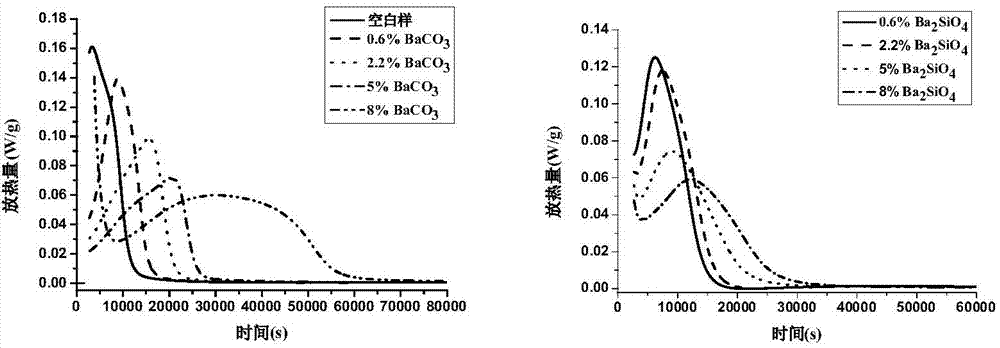

High-strength gypsum retarder and preparation method thereof

The invention relates to a high-strength gypsum retarder and a preparation method thereof. The gypsum retarder is obtained by mixing barium carbonate and / or dibarium silicate, wherein dibarium silicate is obtained by mixing and calcining barium carbonate and silicon dioxide. According to the mechanism that the Ba<2+> and calcium sulfate in the gypsum are reacted to generate water insoluble barium sulfate, and barium sulfate is wrapped on the surface of the gypsum granule and the solution rate of the gypsum is reduced, so that the retarder has the functions of inhibiting the gypsum hydration and prolonging the gypsum setting time. The retarding effect of dibarium silicate is better than that of barium carbonate under the same adulterate amount and the strength descent of the gypsum caused by a common retarder is simultaneously reduced.

Owner:SOUTHEAST UNIV

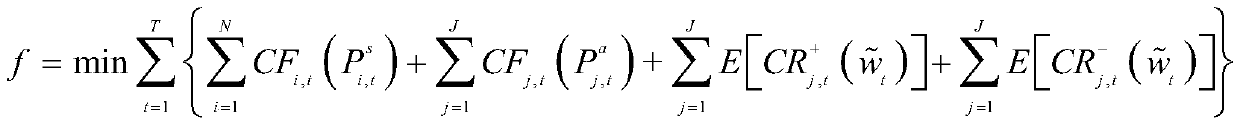

Wind/light contribution cauchy distribution-based dynamic and real-time dispatching method of thermal power generation set

ActiveCN109755959AImprove solution efficiencyEliminate conservatismSingle network parallel feeding arrangementsWind energy generationElectricityRisk level

The invention relates to a wind / light contribution cauchy distribution-based dynamic and real-time dispatching method of a thermal power generation set, and belongs to the technical field of power system running. The wind / light contribution cauchy distribution-based dynamic and real-time dispatching method comprises the steps of firstly, analyzing historical data of wind power contribution, performing combined cauchy distribution fitting by statistic or fitting software, and building a random dynamic and real-time dispatching model of chance constraint with regard to the detected parameter ofa power system; secondly, converting an original problem to a linear constraint convex optimization problem easy to solve by mathematic property of cauchy distribution; and finally, solving the dispatching model to obtain a dispatching strategy. The excellent and favorable mathematic characteristic of the cauchy distribution in a short-term forecast aspect of wind power / photovoltaic power stationcontribution are fully utilized, and the solution rate of the model is effectively improved; and meanwhile, the conservation property of traditional robust economic dispatching is eliminated by a chance constraint model with adjustable risk level, and more reasonable dispatching basis is provided for a decision maker. The method can be used for active power real-time economic dispatching of a large-scale wind and power grid-connected power system.

Owner:TSINGHUA UNIV

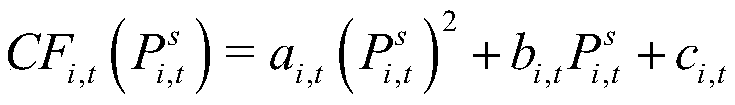

Washing machine

PendingCN106757957AImprove decontamination abilitySuitable temperatureOther washing machinesWashing machine with receptaclesEngineeringWater circulation

The invention discloses a washing machine which comprises an inner barrel, an outer barrel, a heating water circulation device and a spraying device. The heating water circulation device is provided with a water inlet and a water outlet, the water inlet is communicated with water storage space between the inner barrel and the outer barrel, and the spraying device is connected with the water outlet and used for spraying to the inner barrel. According to the washing machine, water in the washing machine can keep proper temperature by the aid of the heating water circulation device, so that solution rate of washing powder or laundry detergent is increased, decontamination effect of the washing machine is improved, the heating water circulation device is small in size and has the function of heating and facilitating water circulation, and the size of the washing machine can be reduced.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Preparation method of ultrafine artesunate sterile powder

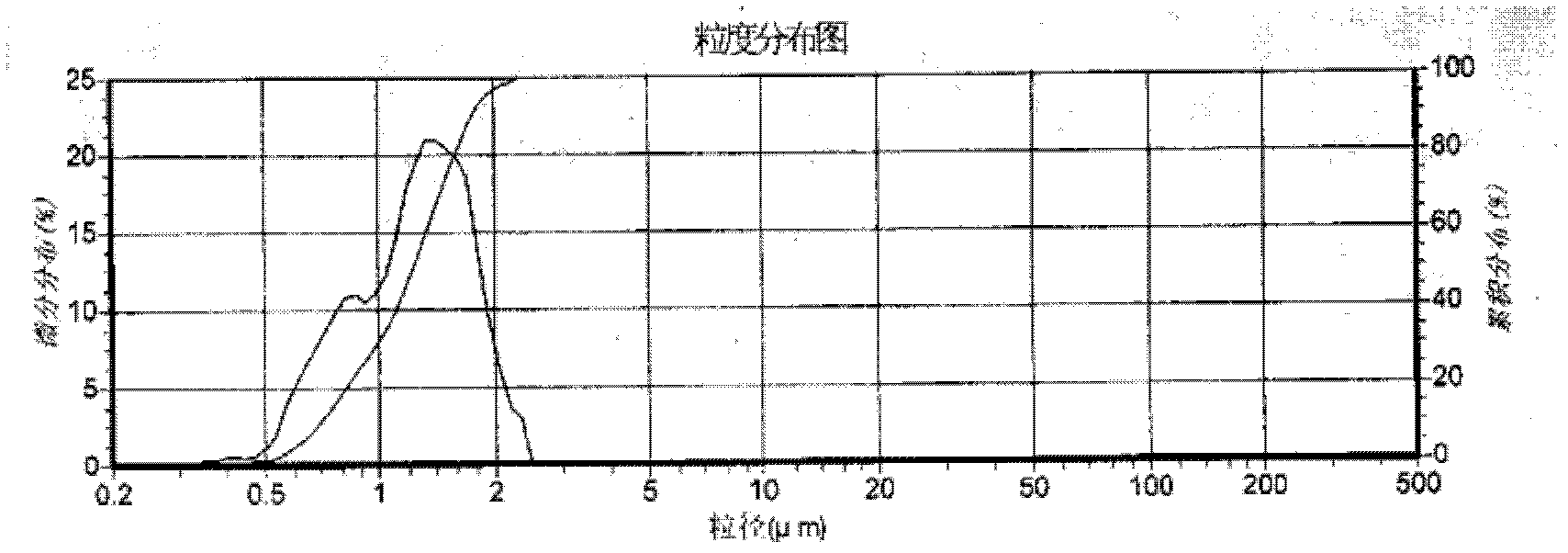

InactiveCN103169663ANarrow particle size distributionFast dissolutionPowder deliveryOrganic active ingredientsSolubilityMicroreactor

The invention discloses a preparation method of an ultrafine artesunate sterile powder, which comprises the following steps: 1) preparing a 1-20% (w / v) active pharmaceutical ingredient solution; 2) simultaneously adding the active pharmaceutical ingredient solution and a counter solvent into a microreactor by a constant-flux pump respectively through a solution inlet and a counter solvent inlet, and recrystallizing at 10-15 DEG C, wherein the volume ratio of the active pharmaceutical ingredient solution to the counter solvent is 1:(10-30), the flow rates of the active pharmaceutical ingredient solution and counter solvent entering the microreactor are respectively 1-80 ml / minute, and the flow rate ratio is 1:(5-25); and 3) filtering the recrystallized slurry, washing and drying to obtain the artesunate sterile powder with the particle size of 0.3-30 mu m prepared by a distribution method. The artesunate sterile powder has the advantages of narrow particle size distribution, high water solubility and high solution rate.

Owner:GUILIN PHARMA

Water-soluble environment-friendly rubber plastic

InactiveCN104558748AAvoid pollutionFacilitate water solubility rateEnvironmental resistancePolymer science

The invention discloses water-soluble environment-friendly rubber plastic which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of polyethylene, 0.6-0.8 part of a photosensitizer, 8-10 parts of polystyrene, 20 parts of polyvinyl chloride, 4-6 parts of terephthalic acid gylcol ester, 7-9 parts of dioctyl phthalate, 0.1-0.3 part of zinc stearate, 0.2-0.3 part of calcium carbonate, 0.3-0.4 part of paraffin and 0.2-0.4 part of an additive. Added with a rubber compound, the water-soluble environment-friendly rubber plastic disclosed by the invention has the mechanical properties required by packaging and can realize the aims of clean production and simplification of equipment. By introduction of sulfonic acid groups, the water-soluble environment-friendly rubber plastic has the advantage of being improved in hydrophilia and reduced in surface activation energy and conductive to increasing the water solution rate of a water-soluble plastic film. By vaporization of hydrogen peroxide, a sterilizing effect is achieved; the product quality is improved; an environmental protection function is realized.

Owner:QINGDAO HUAHONGXING PLASTIC

Hydrolysis technology for protease of heparin sodium

InactiveCN102633904APromote decompositionAvoid decompositionAntibacterial agentsMetabolism disorderSolubilityUltrasound - action

The invention discloses a hydrolysis technology for protease of heparin sodium, which is mainly used for extracting heparin sodium by hydrolyzing protein by protease. The hydrolysis technology is characterized by comprising the following steps of: controlling the content of the mucous membrane of small intestine to be 2.5-4% of the weight of the mucous membrane of small intestine when the mucous membrane of small intestine is processed, adding alkaline agent, and adjusting the pH value of the alkaline agent to be 9; and when the heparin sodium is extracted by hydrolyzing the protein by the protease, supplementarily using ultrasonic wave. The hydrolysis technology mainly adopts the intervention of the ultrasonic wave, when the ultrasonic wave is acted on to liquid medium, not only can the cavitation effect and the heat effect be generated and the momentum be given to the liquid molecule, but also the influence of the mass and heat transferring speed to the solubility and the solution rate of the solute can be increased, the yield of the heparin sodium can be improved, and the defect that the production efficiency is reduced caused by lower salinity can be overcome. The production mode of being high in yield, high in efficiency, green, environment-friendly, and less in wastewater discharge can be realized.

Owner:RUGAO BAXIN CASING

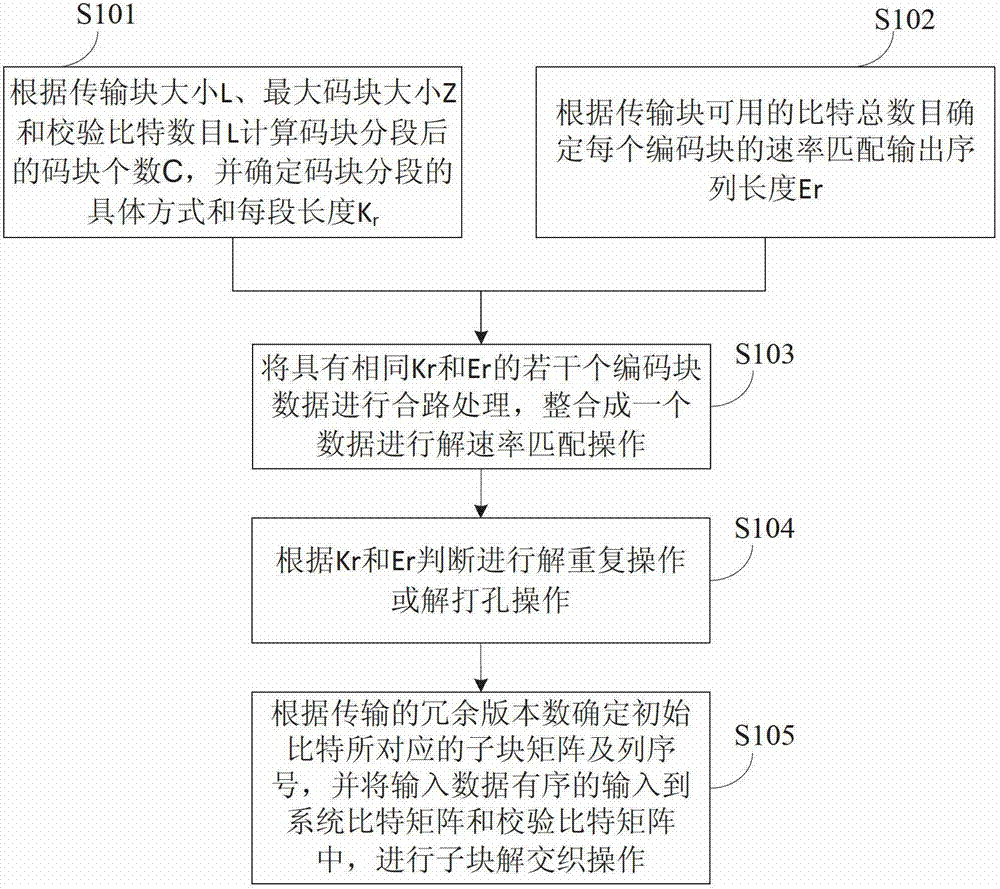

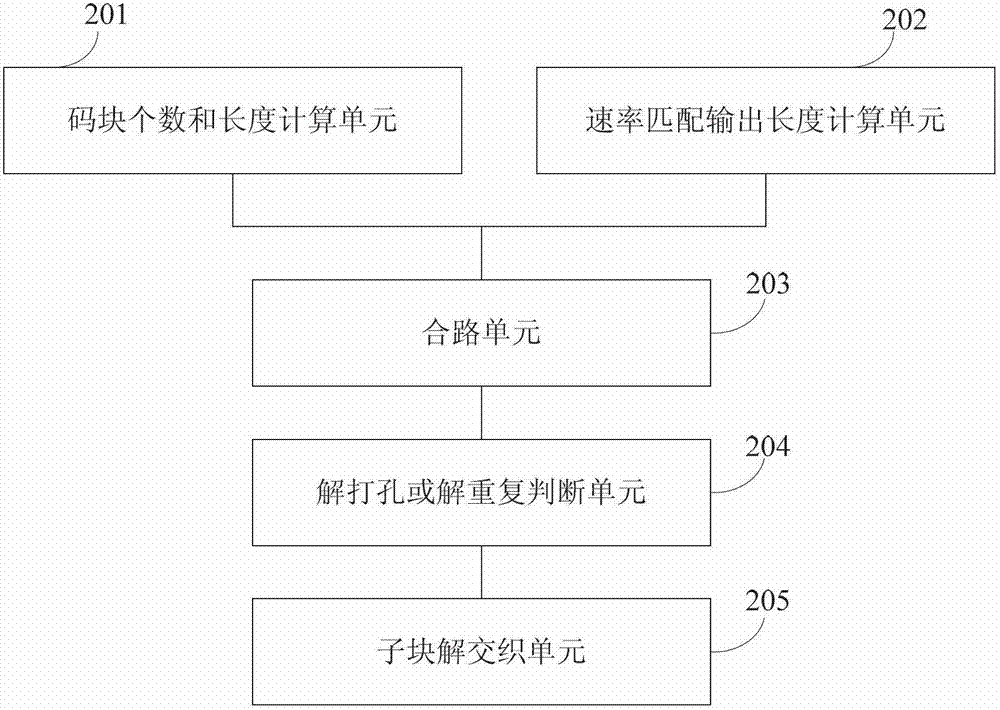

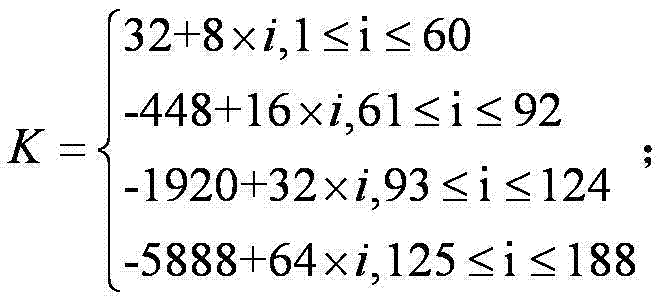

Parallel solution rate matching method and device

The invention discloses a parallel solution rate matching generation method and a device thereof. The method comprises the following steps of: calculating the quantity of code blocks formed after code block segmentation according to the size of a transmission block, the size of a largest code block and the quantity of check bits, and determining a specific way of code block segmentation and the length Kr of each segment; determining the length Er of a rate matching output sequence of each code block according to the quantity of available bits of the transmission block; integrating a plurality of code block data of the same Kr and Er into one datum for performing solution rate matching operation; judging to perform solution repeated operation or solution punching operation according to the Kr and Er; and determining a sub-block matrix which corresponds to an initial bit and a column sequence according to the quantity of transmitted redundancy versions, orderly inputting input data into a system bit matrix and a check bit matrix, and performing sub-block de-interleaving operation. Due to the adoption of the method and the device, the processing speed of solution rate matching can be increased, and the processing time delay is reduced.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

Granular water-soluble fertilizer and preparation method thereof

InactiveCN105541496AFast dissolutionPromote absorptionMagnesium fertilisersBioloigcal waste fertilisersRhizomeFermentation

The invention relates to a granular water-soluble fertilizer and a preparation method thereof, and belongs to the technical field of fertilizer production. The granular water-soluble fertilizer is prepared from 83%-86% of ammonium sulfate, 4.8%-5.2% of potassium sulfate, 2%-5% of magnesium sulfate, 2.4%-3% of potassium fulvic acid, 0.2%-1.2% of ethylenediamine tetraacetic acid and 2%-3.5% of molasses fermentation liquor. The fertilizer is a water-soluble granular fertilizer composed of multiple elements, the elements not only contain nitrogen, phosphorus and potassium which can meet the basic requirements of economic crops, but also contain multiple medium-trace elements needed by the crops, the fertilizer is suitable for the economic crops such as fruits and vegetables, leafy vegetables and rhizomes, and the fruit swelling, coloring, rooting and root strengthening effects are significant. In addition, the granular water-soluble fertilizer is high in solution rate, capable of being easily absorbed by plants, higher in absorptivity, capable of achieving integration of water and the fertilizer, convenient to transport and use, lower in cost, capable of being accepted by users more easily and wider in market application.

Owner:寿光志同道合农业发展集团有限公司

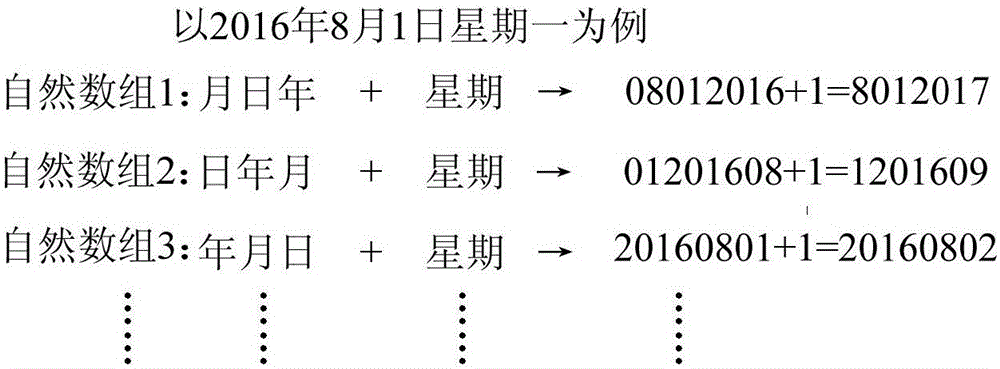

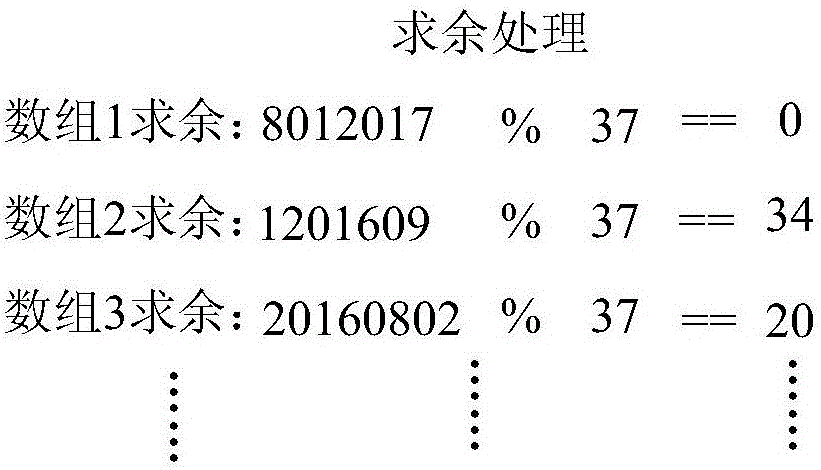

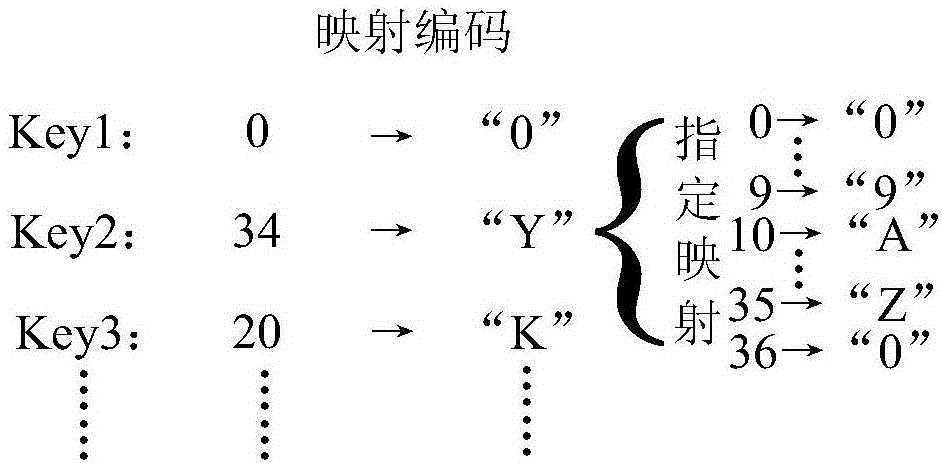

Dynamic password combination generation method based on natural time sequence

InactiveCN106656482AGuaranteed auto-refreshKeep pseudo-randomnessKey distribution for secure communicationTemporal informationArray data structure

A dynamic password combination generation method based on a natural time sequence comprises the following steps of step1, extracting current nature time information; step2, carrying out permutation and combination on three-array information corresponding to ''year'', ''month'' and ''day'' in the acquired nature time information, and then adding with digit information corresponding to ''weak'' so as to form n groups of natural number groups; step3, carrying out prime number complementation processing on the acquired natural number groups and acquiring a complementation result corresponding to each natural number group; step4, according to an edited coding Key value mapping mode, mapping the acquired complementation result of each natural number group, and acquiring a coding Key value corresponding to each natural number group; and step5, carrying out permutation and combination on the acquired coding Key value so as to acquire different password combinations, and selecting one group as a password. In the invention, the combined password can be guaranteed to be refreshed every day, based on few operation requirements and under a deliberate solution condition, a random solution rate which is not higher than 0.1% is realized and system safety is increased.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

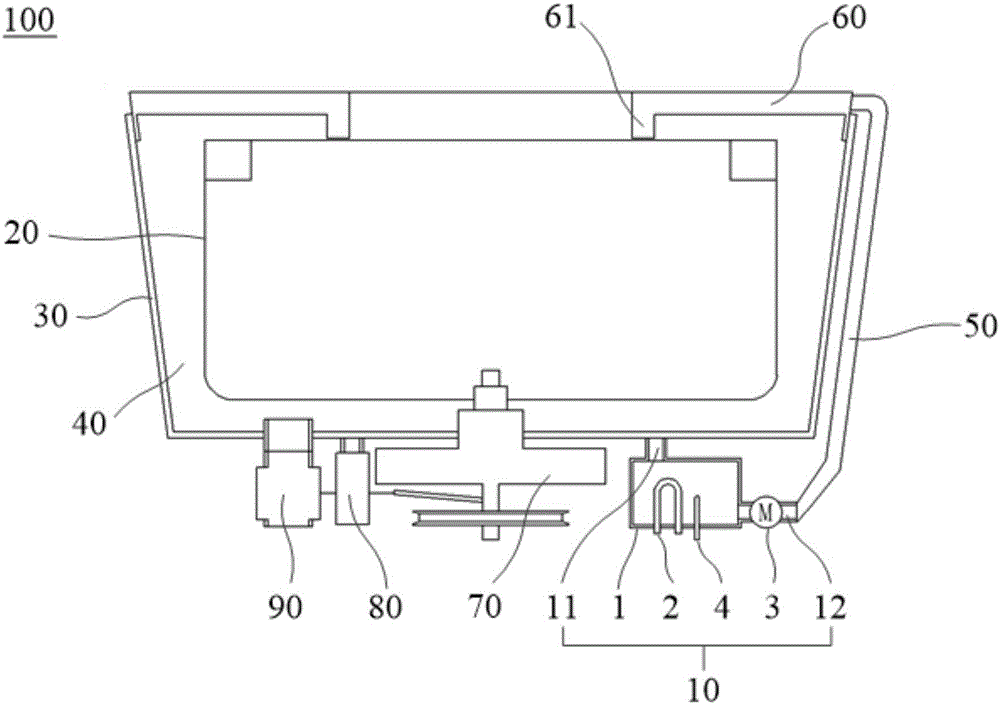

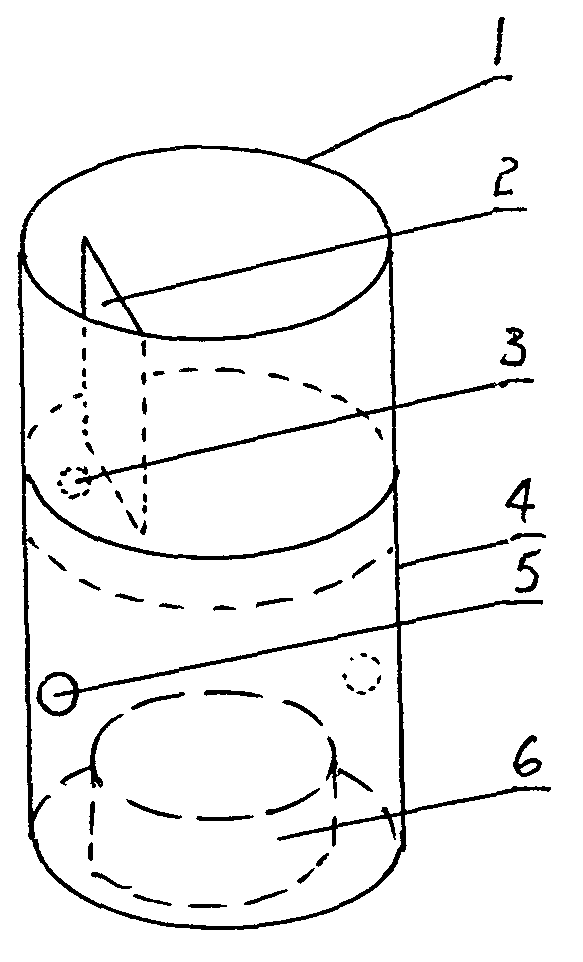

Toilet cleaner accommodating device

InactiveCN103696473ASlow down the dissolution rateLavatory sanitoryEngineeringMechanical engineering

A toilet cleaner accommodating device relates to a sanitary appliance, and consists of an accommodating box and a balance weight box, wherein the accommodating box can accommodate a toilet cleaner; the bottom of the accommodating box is provided with a baffle and a small round hole; the accommodating box is connected and inserted into the opening of the balance weight box; the box wall in the middle of the balance weight box is provided with two round holes; a balancing weight is arranged at the bottom of the balance weight box. The toilet cleaner accommodating device can slow down the solution rate of the toilet cleaner, and has the beneficial effect of slowing down the solution rate of the toilet cleaner.

Owner:徐正文

Preparation method of edible bird's nest polypeptide powder

InactiveCN107495388AFast dissolutionImprove solubilityNatural extract food ingredientsFood ingredient functionsUF - UltrafiltrationGanoderma

The invention discloses a preparation method of edible bird's nest polypeptide powder. The method comprises: selecting edible bird's nest, and performing air drying, pulverization wall breaking, sieving, enzymatic hydrolysis, ultrafiltration and drying to obtain edible bird's nest pure polypeptide powder; through cooperation of Chinese dates, Chinese wolfberry fruits, poria, glossy privet fruits, rose-boots, palmleaf raspberry fruits, Chinese angelica, Korean ginseng, American ginseng, tangshen, milkvetch roots, glossy ganoderma, pilose antler, musk, Chinese caterpillar fungus, saussurea involucrate, pearl powder and honey, and through cleaning, drying, grinding, microwave decoction, microfiltration, drying and grinding, making auxiliary material powder; and performing mixing according to a ratio to obtain the edible bird's nest polypeptide powder. The edible bird's nest polypeptide powder is fast in solution rate, good in solution effect, and easy to be absorbed by the human body. Through cooperation with multiple rare traditional Chinese medicines, the edible bird's nest polypeptide powder has the health-care function and the beautifying effect.

Owner:广西佛斯肽生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com