Method for synthesizing octadecyl bi-polyoxyethylene benzyl ammonium chloride

A technology of octadecyldipolyoxyethylene benzyl ammonium chloride and its synthesis method, which is applied to the preparation of aminohydroxyl compounds, chemical instruments and methods, and the preparation of organic compounds to improve penetration and rubbing fastness , the effect of reducing the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 269g (1mol) octadecyl primary amine into the reactor, heat to 90°C, feed 79.2g (1.8mol) ethylene oxide, react until the pressure decrease rate is not greater than 0.005MPa per 10 minutes, add 0.035g Potassium hydroxide, continue to pass through 360.8g (8.2mol) ethylene oxide, control reaction temperature 100~105 ℃, pressure 0.3~0.4MPa. After the reaction, cool down, add methanol, stir and heat up to 65°C, start to add 126.5g (1mol) benzyl chloride dropwise, and control the temperature at 60-70°C during the dropwise addition. After the addition was complete, stirring was continued for 0.5h. Then gradually raise the temperature to 80-85° C., and keep warm for 4 hours to obtain octadecyldipolyoxyethylene (10) benzyl ammonium chloride with an HLB value of about 13.

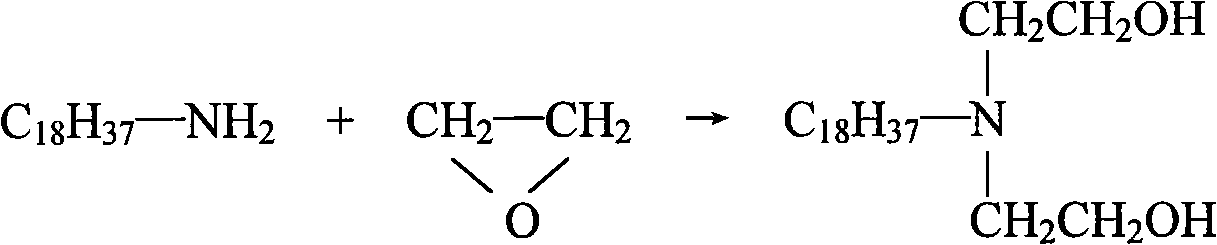

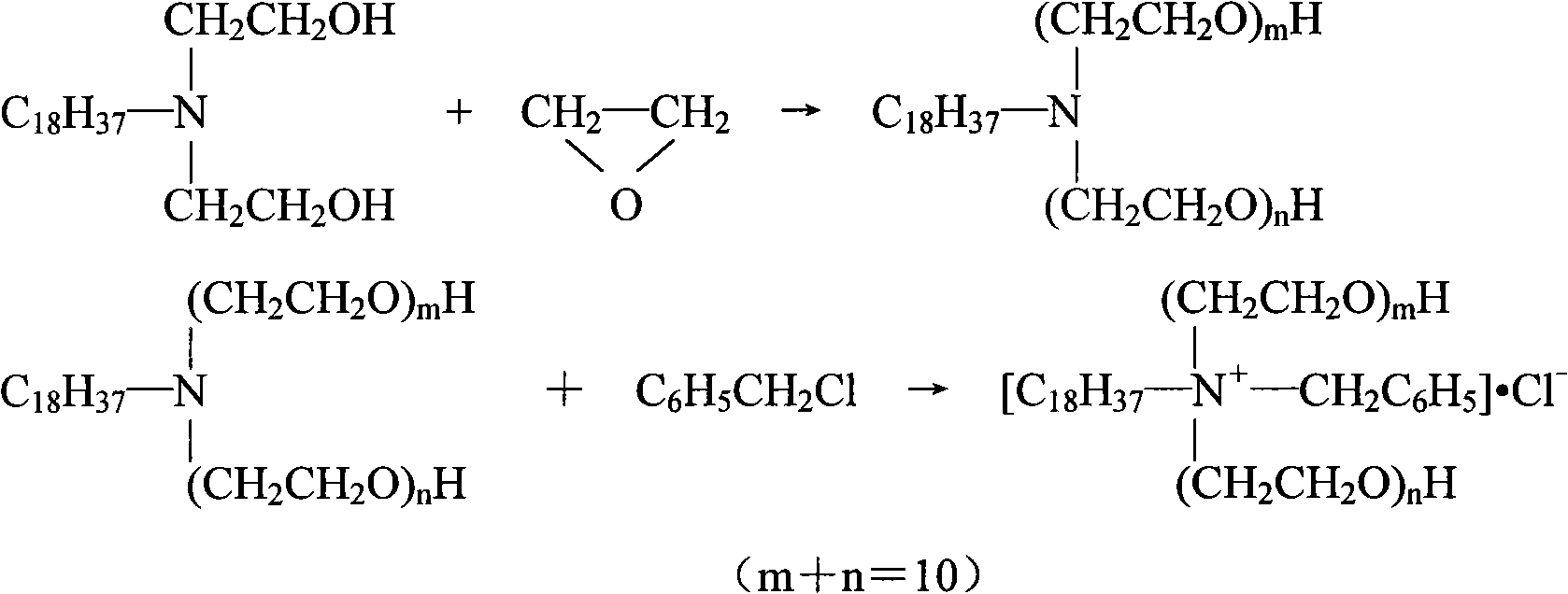

[0023] The chemical equation of the above reaction is:

[0024]

[0025]

Embodiment 2

[0027] Add 269g (1mol) of octadecyl primary amine to the reactor, heat to 100°C, feed 88g (2mol) of ethylene oxide, react until the pressure drop rate is not greater than 0.005MPa per 10 minutes, add 7.9g of hydroxide Sodium, continue to pass through 1232g (28mol) ethylene oxide, control reaction temperature 145~150 ℃, pressure 0.1~0.2MPa. After the reaction, cool down, add isopropanol and distilled water, stir and heat up to 75°C, start to add 75.9g (0.6mol) benzyl chloride dropwise, and control the temperature at 70-80°C during the dropwise addition. After the dropwise addition, stirring was continued for 0.5h. Then gradually raise the temperature to 90-95°C, and keep it warm for 7 hours to obtain octadecyldipolyoxyethylene (30) benzyl ammonium chloride with an HLB value of about 17.

Embodiment 3

[0029] Add 269g (1mol) octadecyl primary amine to the reaction kettle, heat to 95°C, feed 96.8g (2.2mol) ethylene oxide, react until the pressure decrease rate is not greater than 0.005MPa per 10 minutes, add 29.1g For sodium methoxide, continue to feed 2543.2g (57.8mol) of ethylene oxide, and control the temperature at 120-125°C and the pressure at 0.2-0.3MPa. After the reaction, cool down, add distilled water, stir and heat up to 90°C, start to add 139.1g (1.1mol) benzyl chloride dropwise, and control the temperature at 90-95°C during the dropwise addition. After the addition was complete, stirring was continued for 0.5h. Then gradually raise the temperature to 95-100° C., and keep warm for 12 hours to obtain octadecyldipolyoxyethylene (60) benzyl ammonium chloride with an HLB value of about 18.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com