Patents

Literature

40results about How to "High weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

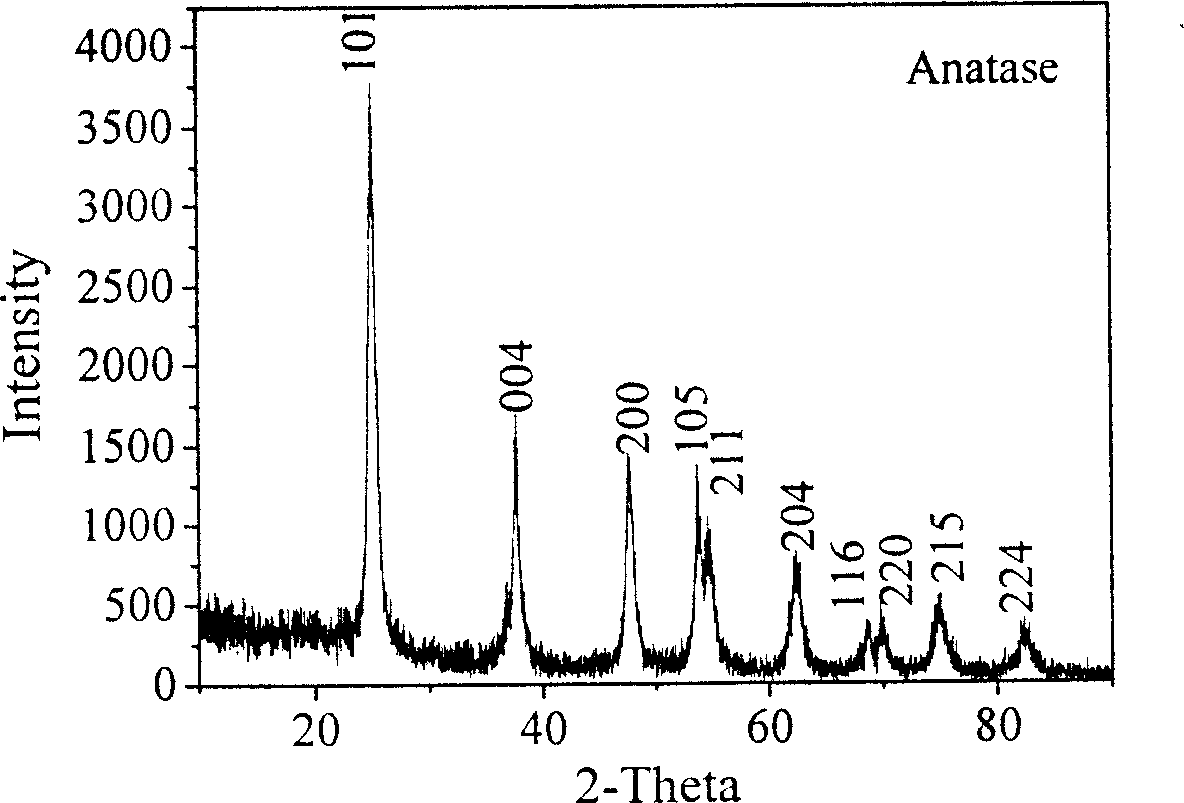

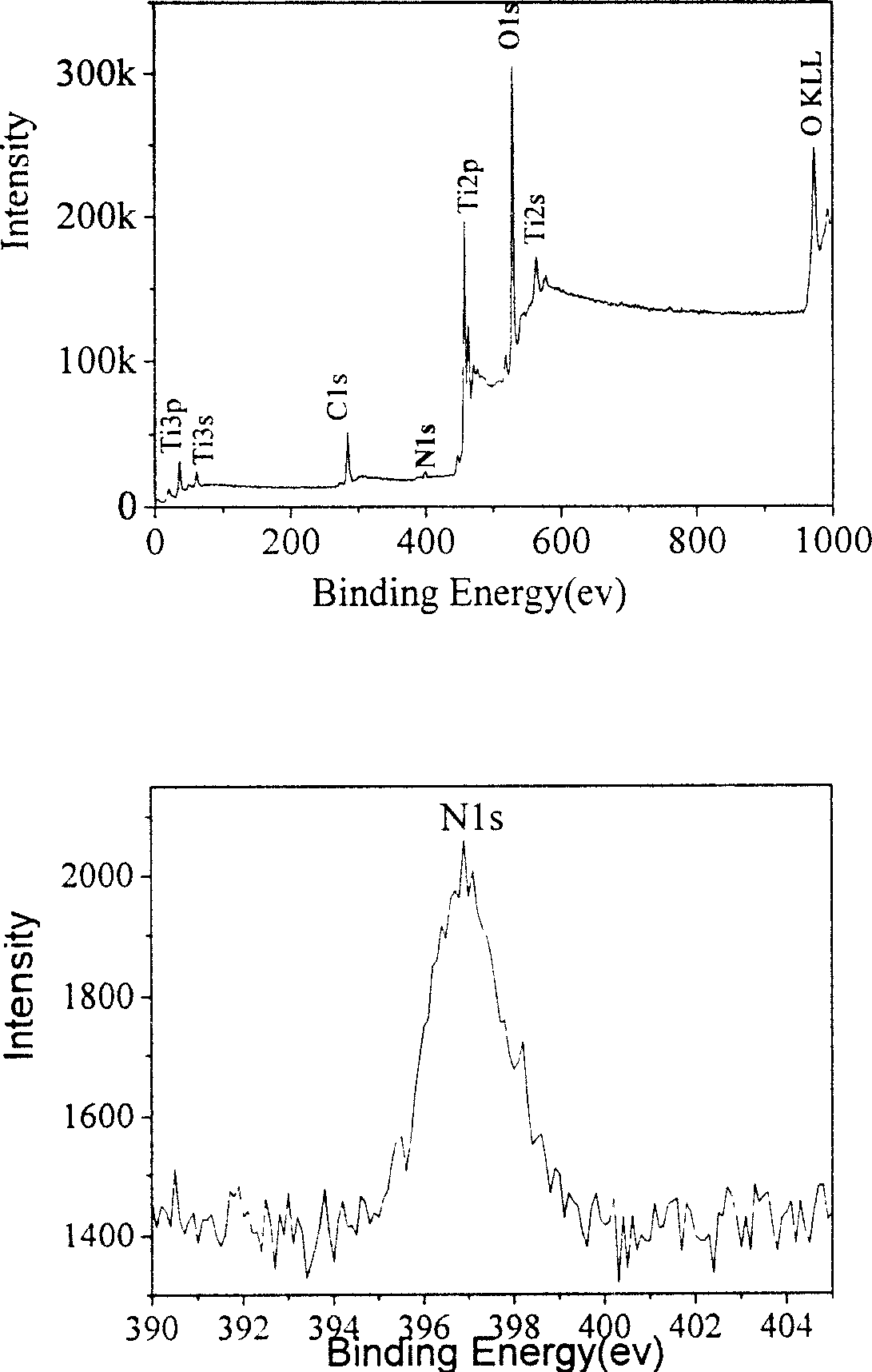

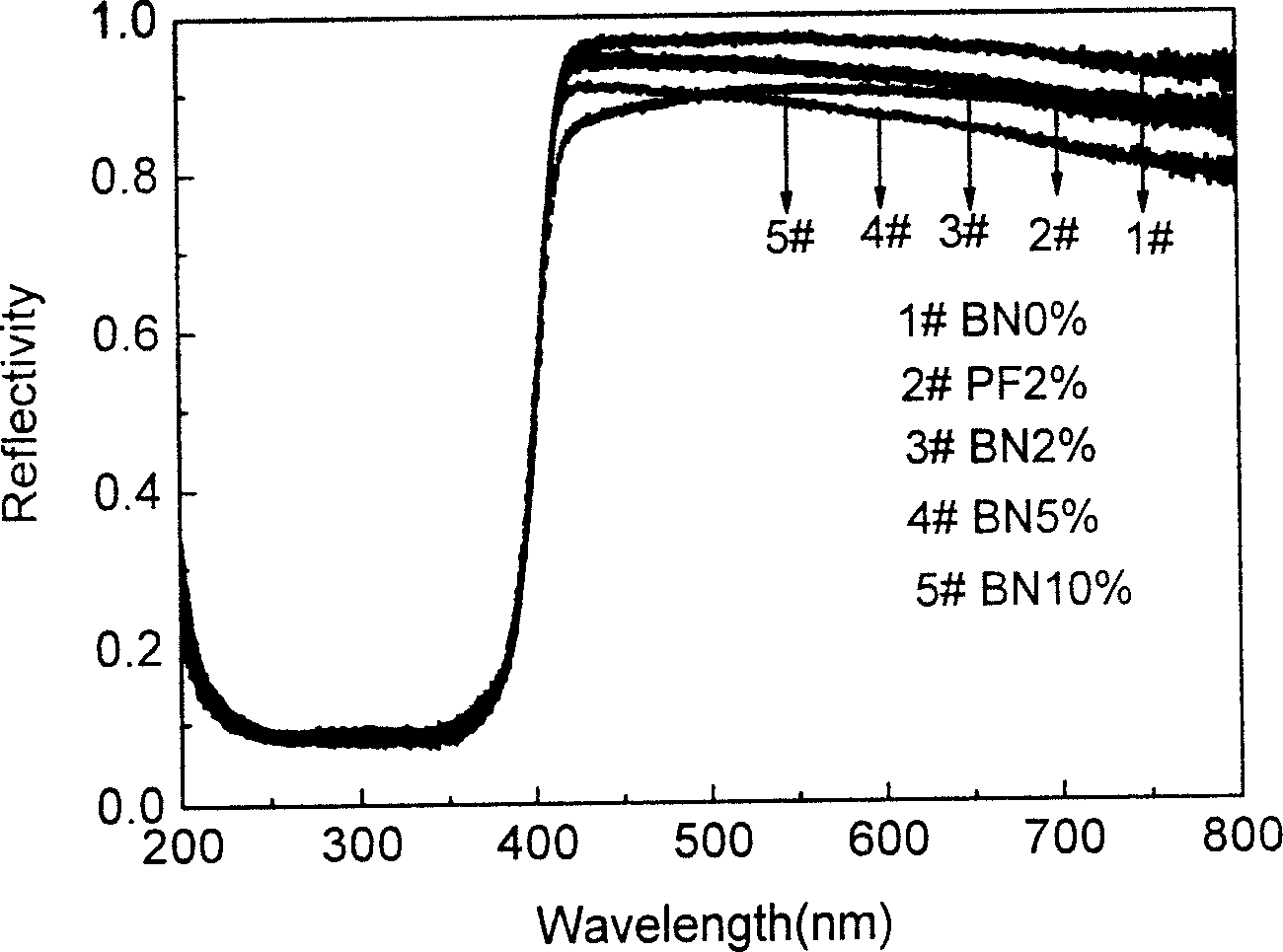

Light catalyzed coating modified by nitrogen dopen Nano titanium dioxide and preparation method

InactiveCN1696228AImprove efficiencyGood bactericidal and antibacterial effectCoatingsUltravioletTitanium oxide

A nitrogen doped nano-TiO2 modified photocatalytic paint with low content of volatile VOC, and high ultraviolet shielding-absorbing and antibacterial effect is prepared from silicic acrylate emulsion, nitrogen doped nano-TiO2, ordinary nano-TiO2, titanium oxide powder, kaolin, heavy and light calcium carbonate, wallastonite powder, assistant, water, ammonia water, defoaming agent and antimildew agent through proportional mixing, stirring and filtering.

Owner:UNIV OF SCI & TECH BEIJING

Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

The invention relates to the technical field of PVC (Polyvinyl Chloride) composite materials and particularly relates to a waste PVC and fly ash composite material and a preparation method thereof. The waste PVC and fly ash composite material comprises the following raw materials according to parts by weight: 80-120 parts of waste PVC, 35-55 parts of fly ash, 3-10 parts of plasticizer, 1-2 parts of flame retardant, 0.5-2 parts of stabilizer, 0.5-2 parts of impact modifier, 0.3-1 part of lubricant and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps of: weighing all the raw materials according to the parts by weight, mixing, stirring, extruding through a twin-screw extruder for granulation, chopping and air-cooling to obtain the waste PVC and fly ash composite material. The waste PVC and fly ash composite material prepared by the preparation method has excellent heat resistance, high strength, good flame retardant effect, high compression performance and toughness, and excellent processing performance and comprehensive performance; and the additive amount of renewable resources in the waste PVC and fly ash composite material reaches 90%-95%, thus lowering the production cost, reducing the environmental pollution, and bringing good economic benefit and social benefit.

Owner:广东祺龙科技有限公司

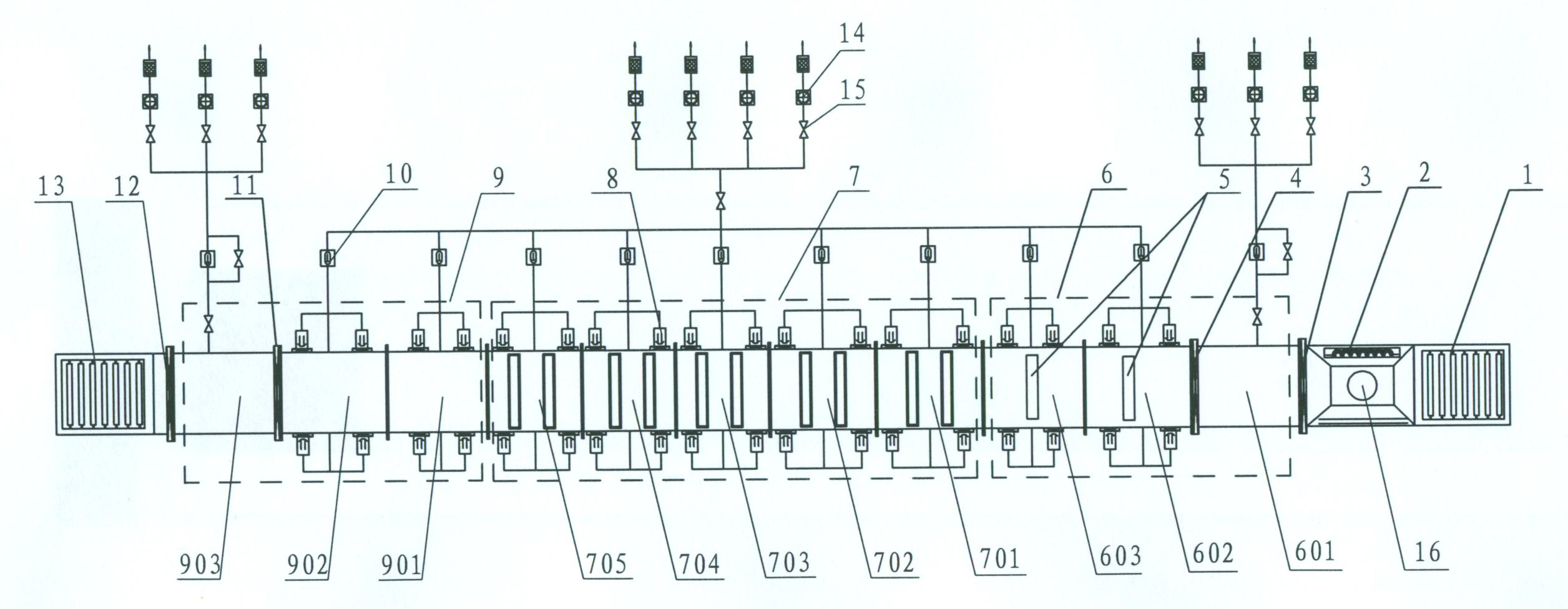

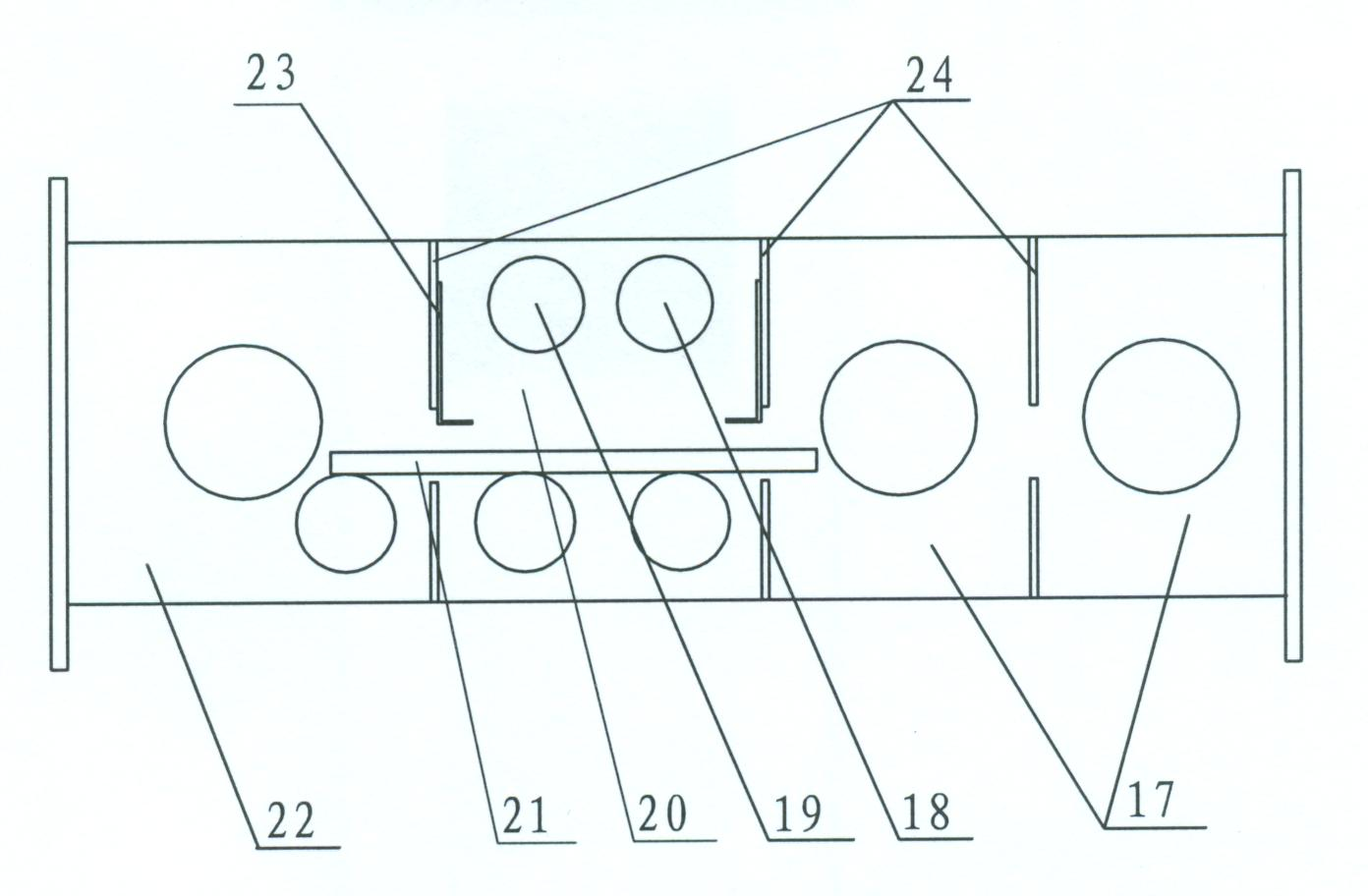

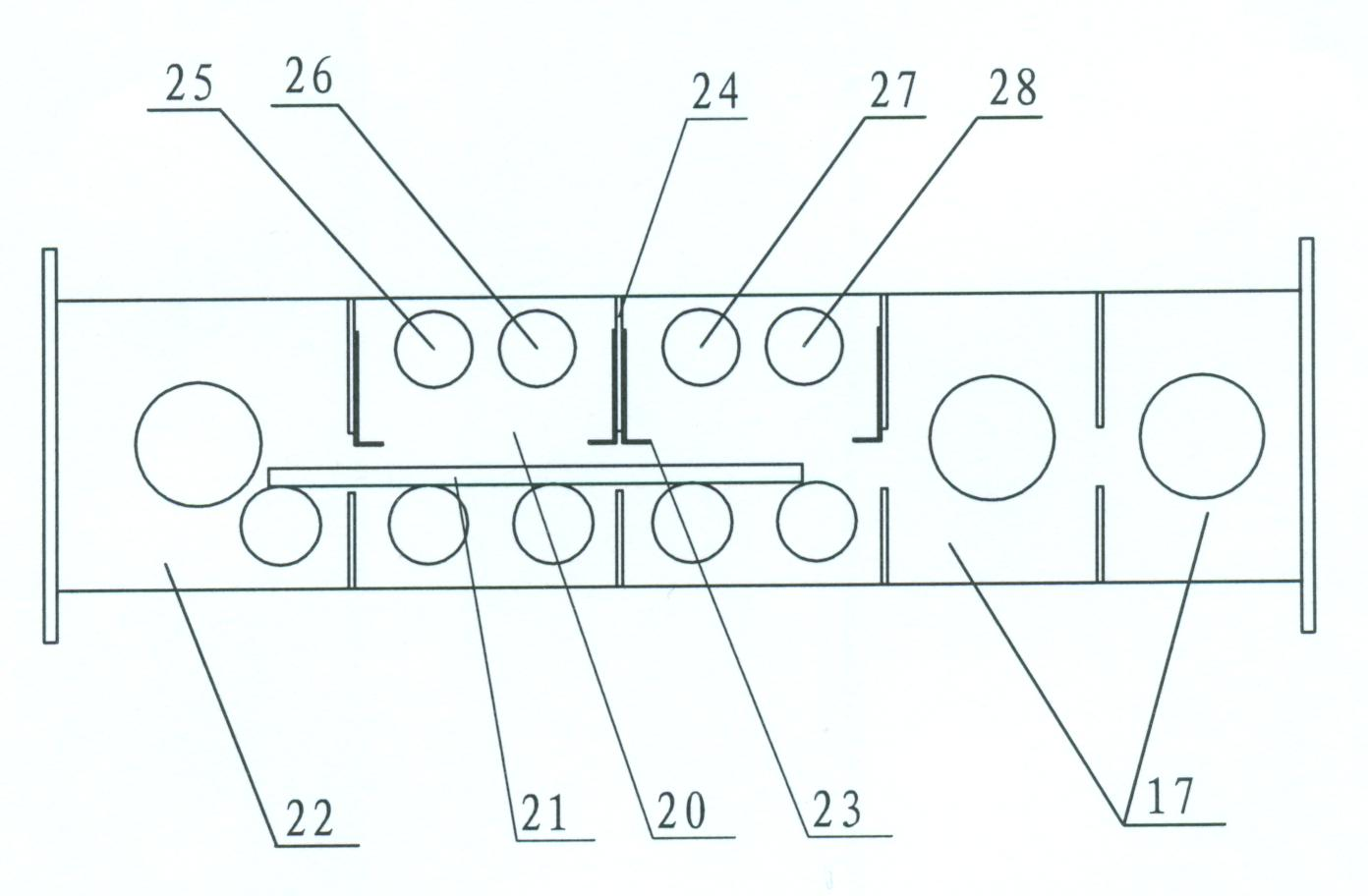

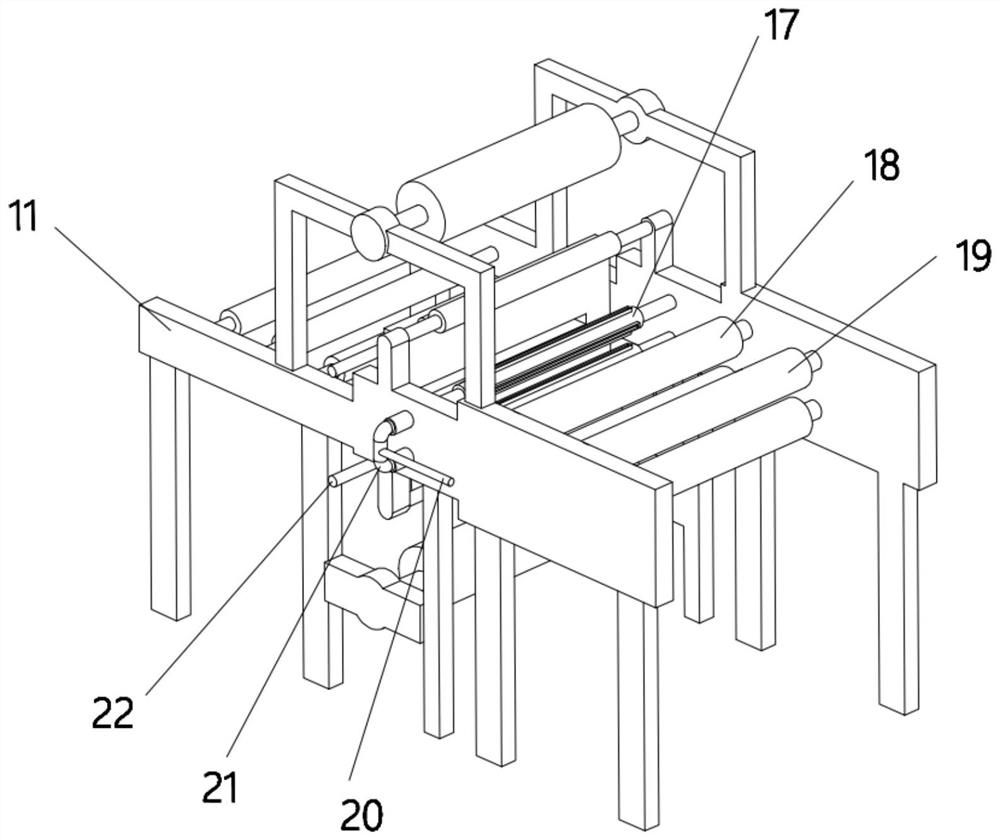

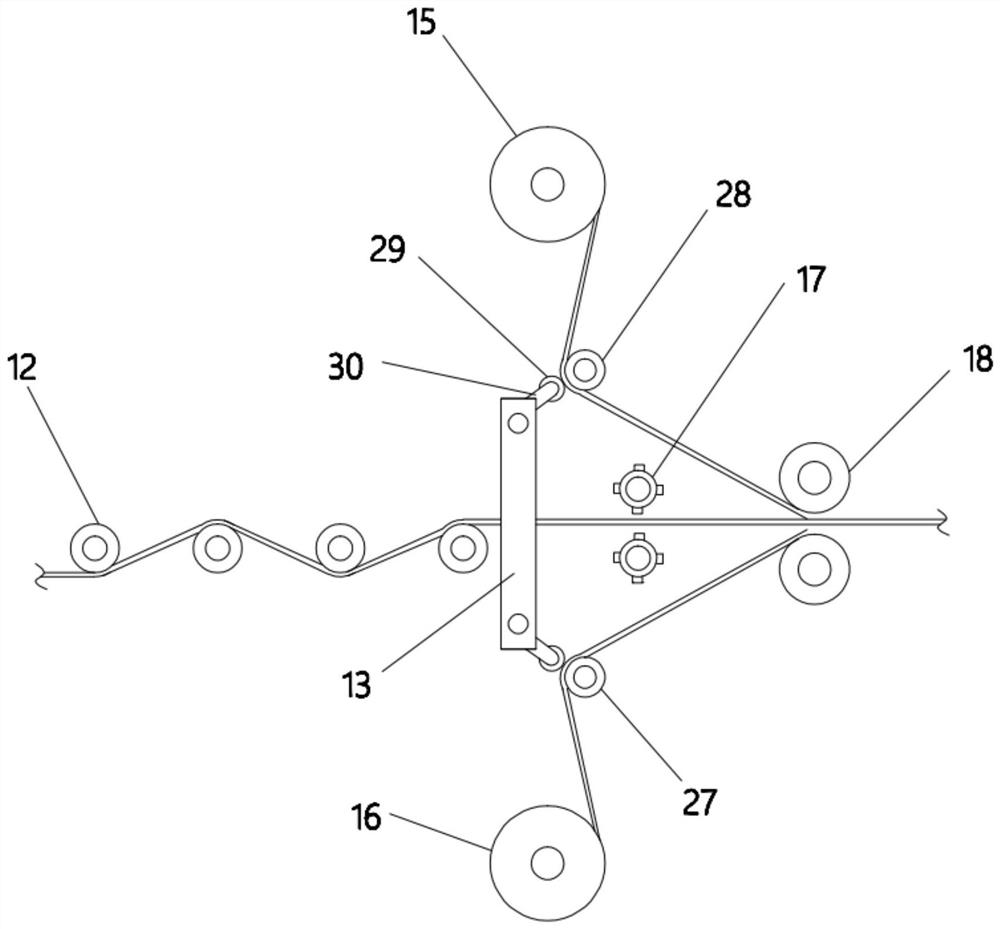

Vacuum magnetron sputtering coating production line system of continuous solar energy collector chip

InactiveCN101985737AHigh weather resistanceImprove heat collection effectVacuum evaporation coatingSputtering coatingThermodynamicsChip select

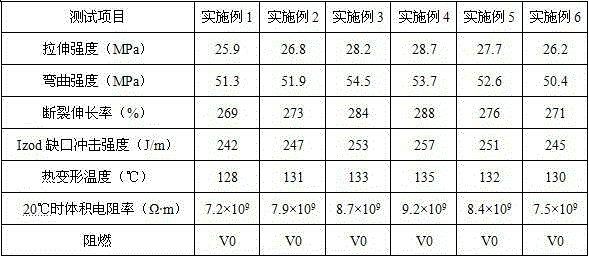

The invention provides a vacuum magnetron sputtering coating production line system of a continuous solar energy collector chip. The system comprises an upper chip board, a dustproof heating chamber, a chip inlet area, a coating area, a chip outlet area, a lower chip board, evacuators and a transmission mechanism penetrating through the whole production line system. The technical key points of the system are characterized in that each part is connected in sequence; and the evacuators are arranged at the two sides of the production line system. In the system provided by the invention, a modular structure is used and a whole plate solar energy collector chip is horizontally conveyed, thus realizing the continuous coating production from an atmosphere state to vacuum coating and then from the vacuum coating to the atmosphere state. The production line system has the advantages that an ideal spectral selection coating can be prepared on a large-area whole plate solar energy chip; and the coating is even, and is good in physicochemical performance and long in service life. By means of the production line system provided by the invention, mass industrial production of the selective absorption coatings of the solar energy collector chips can be realized, thus the production efficiency is improved, the cost is reduced, and pollution is not generated during the production process.

Owner:魏海波 +1

PVC (polyvinyl chloride) foam material for sole and preparation method of PVC foam material

InactiveCN105440505AImprove temperature resistanceGood weather resistanceSolesWeather resistanceFoaming agent

The invention relates to the technical field of PVC materials, in particular to a PVC (polyvinyl chloride) foam material for a sole and a preparation method of the PVC foam material. The PVC foam material for the sole comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 20-30 parts of a filling agent, 6-10 parts of a wear-resistant modifier, 4-8 parts of a thermal stabilizer, 2-4 parts of a foaming agent, 0.8-1.2 parts of a lubricant and 1-2 parts of a processing aid. The raw materials are adopted for preparation of the PVC foam material for the sole, the weight proportion of the raw materials is controlled strictly, the performance of the prepared PVC foam material for the sole exceeds the national standards, and the PVC foam material is environment-friendly and has good temperature resistance and weather resistance, high strength, excellent anti-impact performance, good flame-retardant effect, good processing performance and excellent comprehensive performance.

Owner:广东祺龙科技有限公司

Environmental-friendly polyvinyl chloride (PVC) extraction-resistant anti-seepage film and preparation method thereof

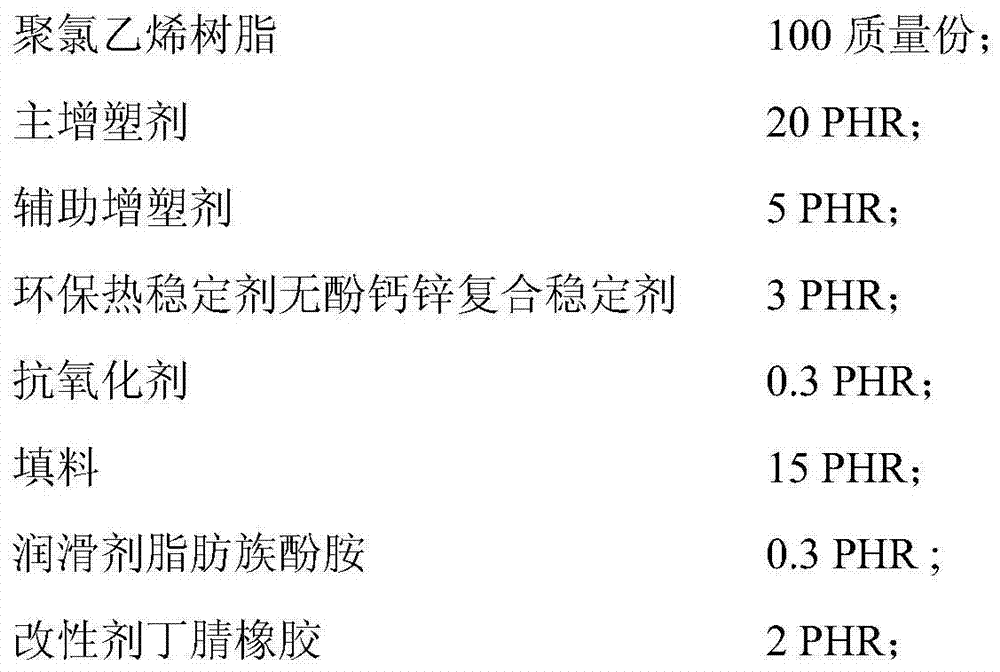

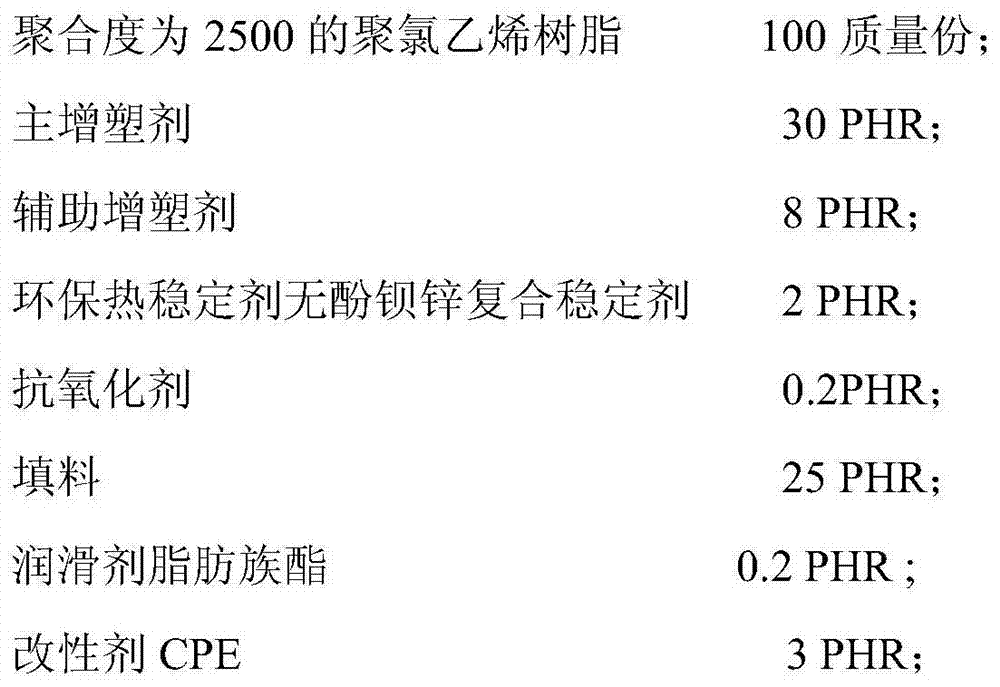

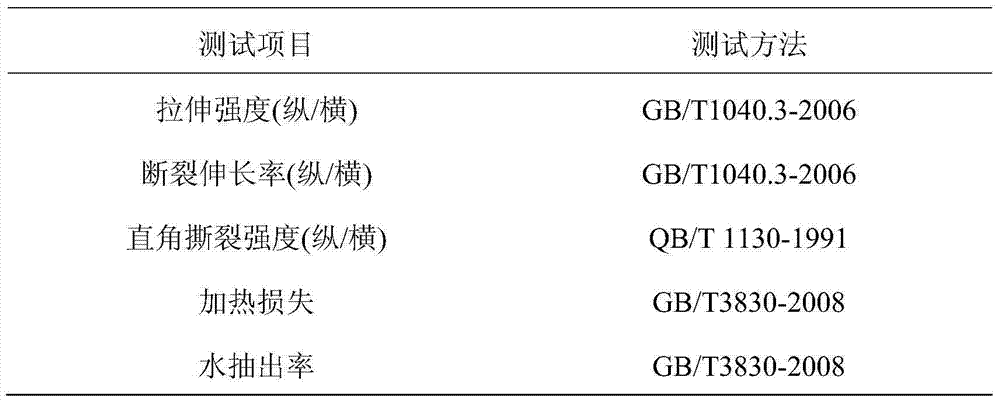

The invention relates to an environmental-friendly polyvinyl chloride (PVC) extraction-resistant anti-seepage film and a preparation method thereof, belonging to the technical field of salt film preparation. The environmental-friendly PVC extraction-resistant anti-seepage film contains the following ingredients in proportioning ratio: 100 parts by mass of PVC resin, 10-50PHR of primary plasticizer, 2-10PHR of secondary plasticizer, 2-5PHR of environmental-friendly heat stabilizer, 0.1-0.5PHR of antioxidant, 6-30PHR of filler and 0.1-0.3PHR of lubricant. The preparation method of the environmental-friendly PVC extraction-resistant anti-seepage film comprises the steps of (1) preparing a kneaded material: metering all the ingredients, mixing and cooling; (2) plasticizing: plasticizing by using a planetary extruder; (3) calendering: filtering the material in a filter, and feeding the material to a calender; (4) spreading: after the material passes through the calender, spreading to widen, and then, cooling for forming, thereby preparing the environmental-friendly PVC extraction-resistant anti-seepage film. According to the environmental-friendly PVC extraction-resistant anti-seepage film and the preparation method thereof, the preparation process is simple, and the controllability is good; the product has the advantages of good water and brine extraction resisting performance, high mechanical properties, little loss, high retention rate, and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Wear-resistant shock-absorbing foaming rubber material

The invention discloses a wear-resistant shock-absorbing foaming rubber material comprising the following raw materials in parts by weight: 58-62 parts of natural rubber, 36-42 parts of polyurethane rubber, 46-50 parts of butyl rubber, 13-17 parts of a foaming agent OBSH, 5-8 parts of a foaming agent ADC, 15-19 parts of sodium bicarbonate, 4-7 parts of zinc oxide, 3.3-3.8 parts of sulfur, 1.8-2.1 parts of a promoter DM, 2.1-2.4 parts of a promoter DOTG, 32-35 parts of sepiolite powder, 33-37 parts of modified kaolin, 22-28 parts of mica powder, 3-6 parts of styrene bromide, 2-4 parts of antimony trioxide, 5-8 parts of zinc borate pentahydrate, 9-13 parts of trioctyl trimellitate TOTM, 8-11 parts of chlorinated paraffin, 1.2-1.8 parts of an anti-aging agent MBZ and 2.1-2.4 parts of an anti-aging agent BLE. The wear-resistant shock-absorbing foaming rubber material disclosed by the invention has excellent wear resistance and high elasticity, and can be used for effectively absorbing shock.

Owner:NINGGUO NINGSHENG RUBBER PROD

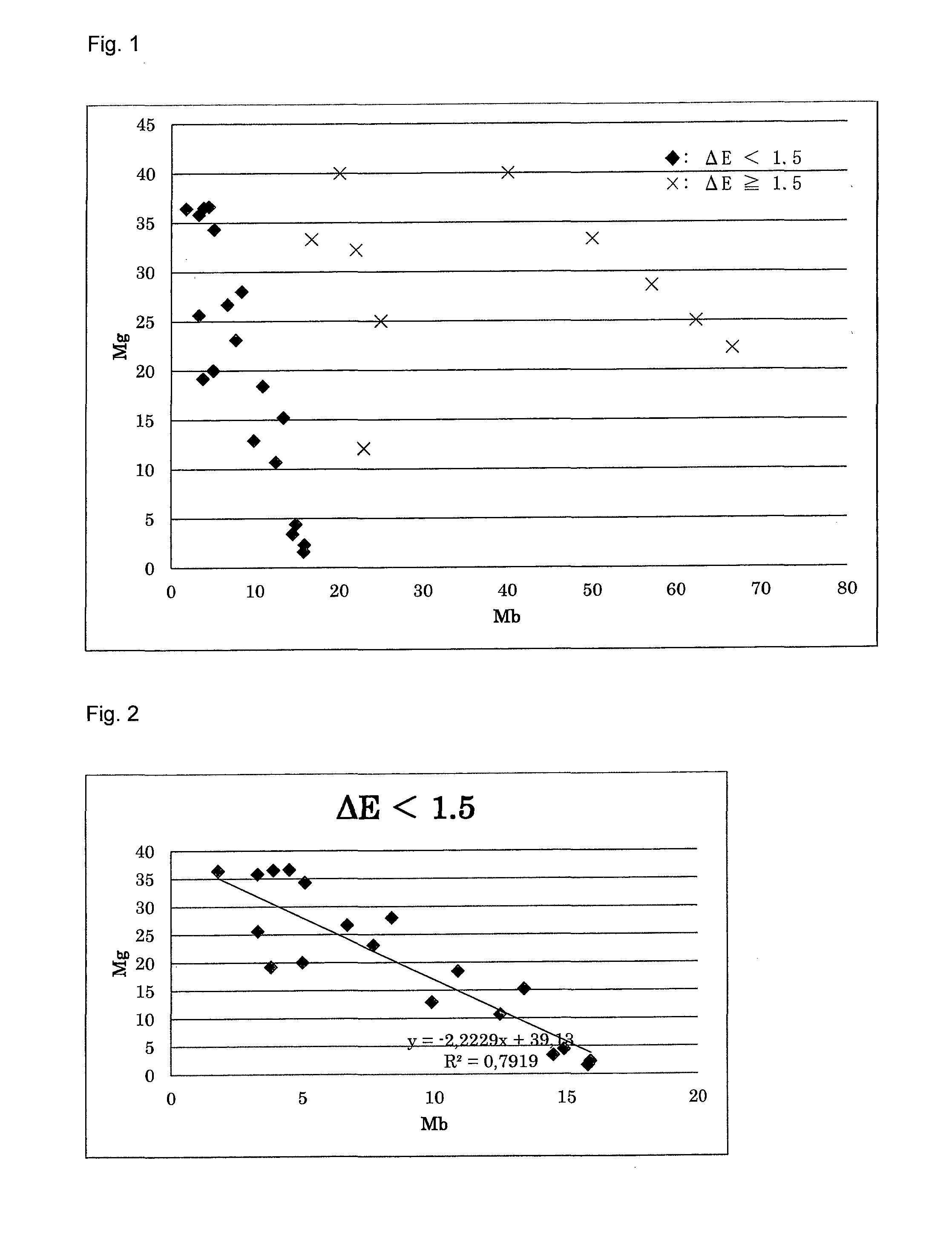

Black Pigment Composition For Heat-Shielding Coating, Heat-Shielding Coating Using Same And Use Of Same For Shading And Coating

InactiveUS20150307688A1High weather resistanceAdvantageous in costOrganic dyesPolyurea/polyurethane coatingsChemistryTransmittance

Provided are a black pigment composition for heat-shielding coatings which exhibits high infrared radiation transmittance, facilitates adjustment of hue when it is mixed with a chromatic coating and a white coating since it approximates the hue of carbon black pigment in the case of not only a dark color but a light color as well, and is also advantageous in terms of weather resistance and cost; a heat-shielding coating based on the same; and a shading method. The black pigment composition for heat-shielding coatings includes a phthalocyanine blue pigment as a first pigment, a phthalocyanine green pigment as a second pigment, and at least one other chromatic pigment, wherein, regarding the amounts in parts by weight of the phthalocyanine blue pigment as Mb, the phthalocyanine green pigment as Mg, and the total of the at least one other chromatic pigment as Mn, Mb+Mg+Mn=100 and 20<Mg+2.2 Mb<60 are established, based on 100 parts by weight of the pigment composition.

Owner:CLARIANT INT LTD

Method for manufacturing light outdoor recombination bamboo landscape material

InactiveCN102233603AImprove stabilityNo deformationWood working apparatusPolyurethane adhesiveWeather resistance

The invention belongs to landscape materials, and discloses a method for manufacturing a light outdoor recombination bamboo landscape material. The conventional outdoor recombination bamboo material has unstable product quality, low weather resistance and short service life and is easy to deform and mildew. The method comprises the following steps of: cutting off bamboo; removing green and yellow; rolling to obtain bamboo filaments; drying until moisture content is less than 8 percent; putting the bamboo filaments into an impregnation tank; vacuumizing and keeping the vacuum state for 12 to 15 minutes; sucking a modified chitosan metal complex preservative into the impregnation tank; increasing the pressure to be between 0.8 and 1.0MPa, and keeping the pressure for 40 to 50 minutes; reducing the pressure to be between 0.1 and 0.08MPa, and keeping the pressure for 20 minutes; taking the bamboo filaments out; drying at a low temperature until the moisture content is 8 to 10 percent; soaking in a modified adhesive; drying until the moisture content is 15 to 18 percent; spraying a polyurethane adhesive; combining blanks by using a mould; and hot-pressing and foaming to obtain the material. The method has the advantages that: a product does not deform due to high stability, and has long service life due to high rot resistance; and the weather resistance of the product is improved, so that the product is suitable to be used as the outdoor landscape material.

Owner:潘金瓶

Anticorrosive PVC modified material and preparation method thereof

InactiveCN105566805AImprove corrosion resistanceImprove temperature resistanceWeather resistancePlasticizer

The invention relates to the technical field of PVC materials, and concretely relates to an anticorrosive PVC modified material and a preparation method thereof. The anticorrosive PVC modified material comprises, by weight, 80-120 parts of PVC resin, 50-70 parts of a plasticizer, 20-30 parts of a filler, 4-8 parts of an impact modifier, 3-5 parts of a heat stabilizer, 1-2 parts of a synergistic agent, 0.6-1.0 part of a lubricant and 0.3-0.7 parts of an antioxidant. All performances of the anticorrosive PVC modified material prepared through strictly controlling the weight ratio of all above raw materials exceed national stands, and the anticorrosive PVC modified material has the advantages of good anticorrosion effect, environmental protection, excellent temperature and weather resistance, high strength, excellent impact resistance, good flame retardation effect, excellent processing properties and excellent comprehensive performances.

Owner:广东祺龙科技有限公司

Powder coating for automotive topcoat

ActiveCN103289543AHigh strengthHigh weather resistancePolyurea/polyurethane coatingsPowdery paintsEpoxyAcrylic resin

The invention relates to a powder coating for automotive topcoat. The powder coating comprises the following components by weight percent: 3-5% of hydroxy acrylic resin, 0.8-2% of epoxy resin, 12.5-14.5% of polyether ester, 45-50% of polyester resin, 0.3-0.6% of dibutyltin dilaurate, 0.4-0.6% of benzoin, 2-2.2% of a levelling agent, 22.5-25.5% of titanium dioxide and 8-12% of epsilon-caprolactam blocked isophorone diisocyanate. The softness is well maintained while the strength of the powder coating is improved and the weatherability of the powder coating is improved to some extent.

Owner:宁波派特勒新材料股份有限公司

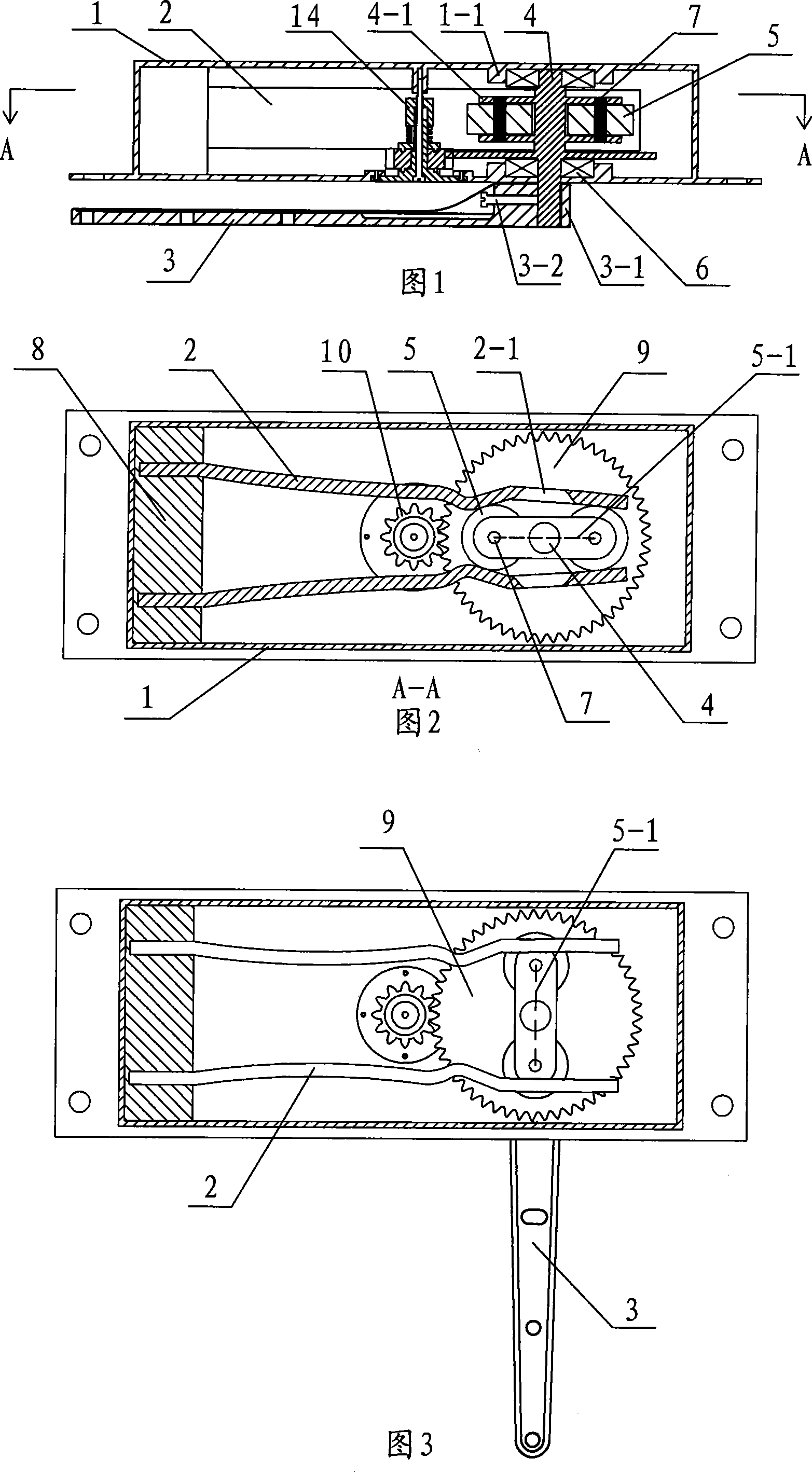

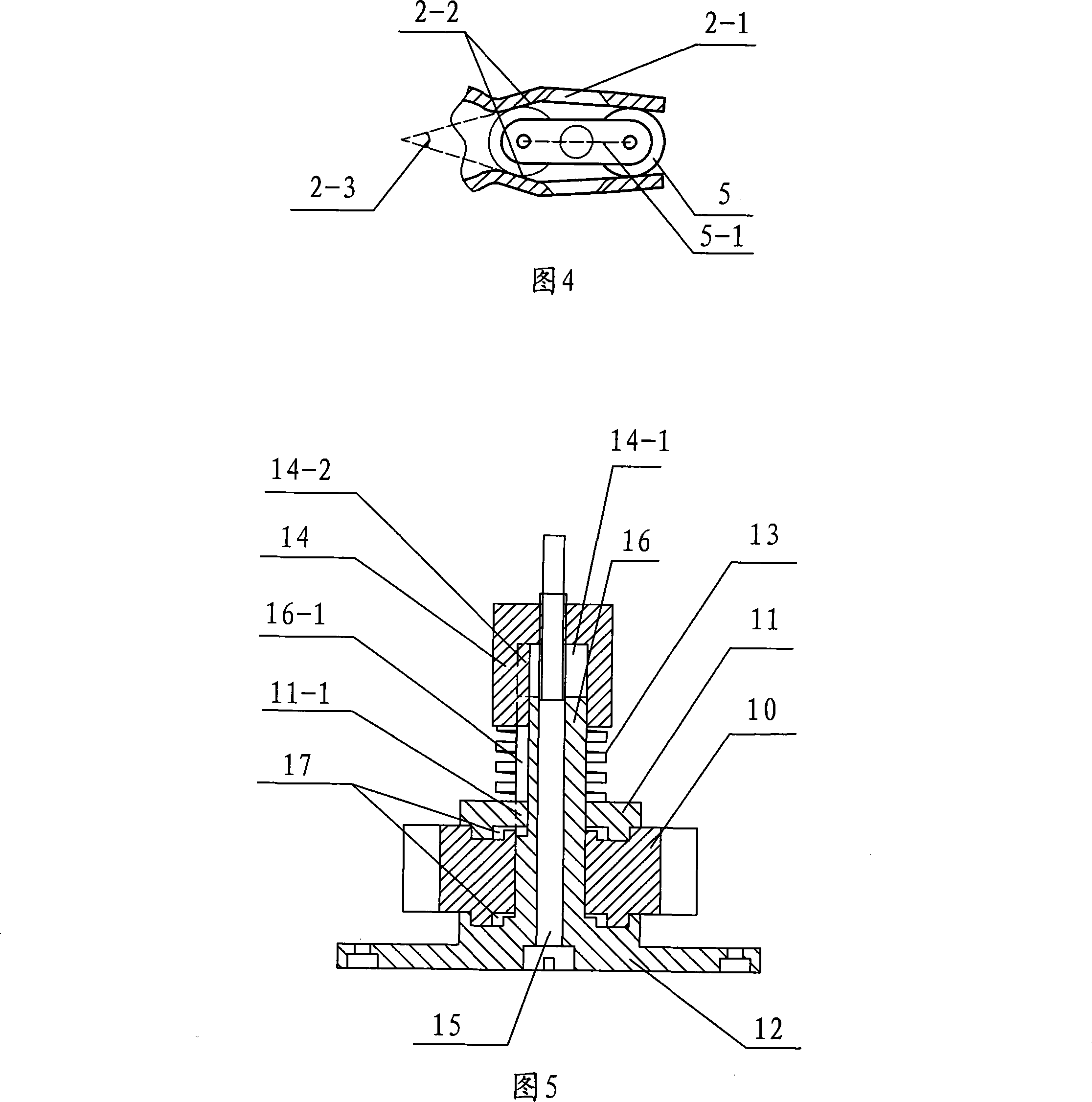

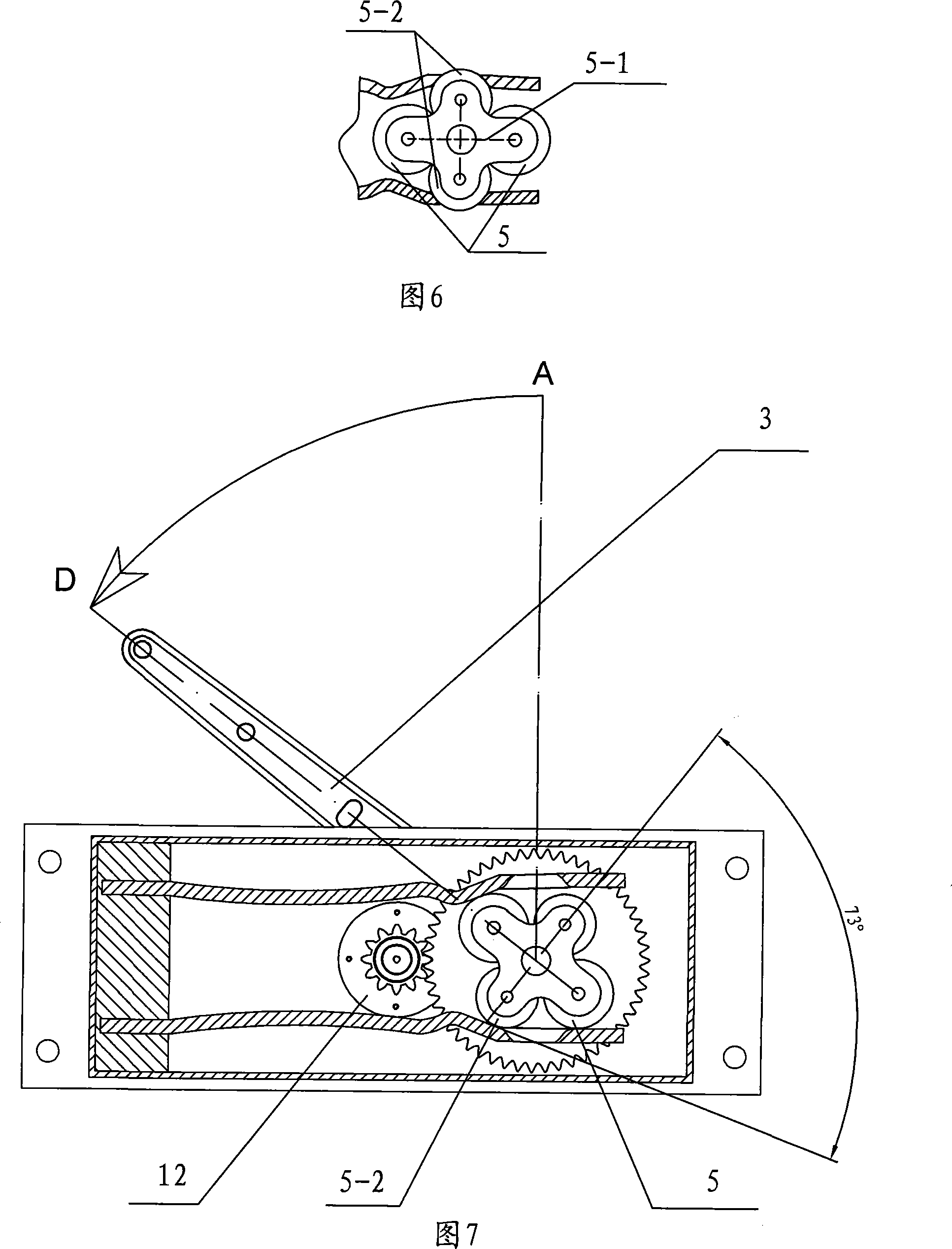

Free door controller

InactiveCN101200989AReduce volumeReduce weightBuilding braking devicesWing openersControl theoryRotation control

The invention relates to a free gate controller used in construction, consisting of door leaves, a door frame, an upper shaft rotation control device, a lower shaft locating device and a shaft terminal locating block. The upper shaft rotation control device is fixed on the upper frame of the door frame; the lower shaft locating device is fixed on the lower frame of the door frame or the floor; the central rotating arm of the upper shaft rotation control device is connected fixedly with the upper architrave or the upper part of the upper gate folder of the door leaves; the bearing seat of the lower shaft locating device is fixed on the lower architrave or the lower part of the lower gate folder of the door leaves; the shaft terminal locating block contacts the rotary shaft of the rotary connecting arm of the upper shaft rotation control device and is fixed in the upper architrave or the upper part of the upper gate folder of the door leaves. Compared with the prior art, the invention is characterized by: 1. Time saving and laboring assembly; 2. Small volume, light weight, little consumption of the material, simple structure, low cost, easy manufacture, easy production; and characterized in that: 3. the invention changed that the lower shaft control device bears the weight of the gate in the prior art; the rotary device of the upper shaft is connected by bearing, thereby the stress and the wear of different working components are little, the service life is long and the reliability is high.

Owner:初恒毅

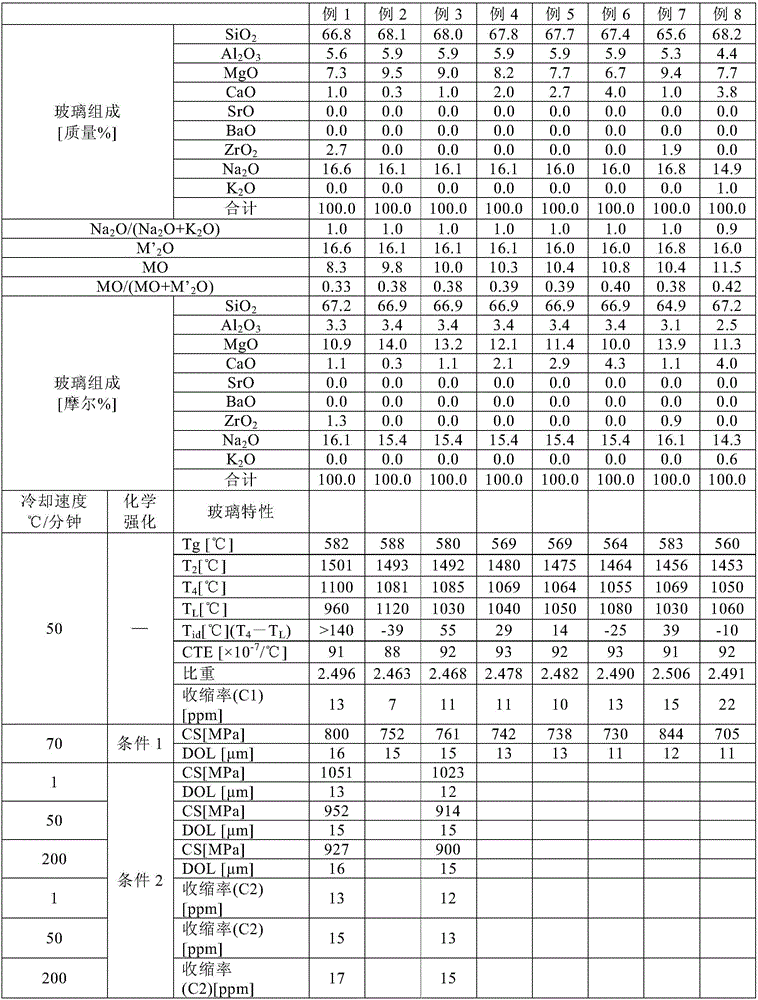

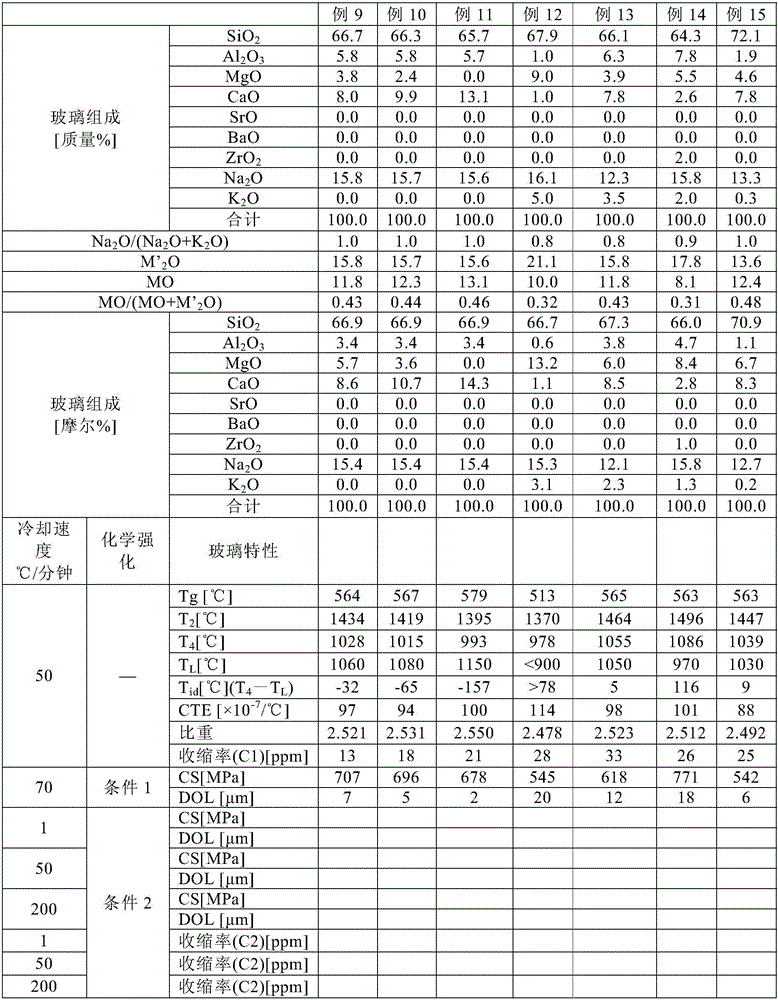

Glass for chemical strengthening, and chemically strengthened glass

ActiveCN106470951APosition deviation is not easy to occurLow shrinkageGlass productionGlass sheetHeat treated

Provided are: a glass for chemical strengthening, suitable for a display member and having high precision of film formation and patterning (not being prone to positional misalignment) on a glass sheet and low compaction in heat treatment at low temperature (150-300 DEG C) during manufacturing of a display member, even in the case of a glass sheet manufactured by a fusion method or the like in which the cooling rate during glass forming is high; and a chemically strengthened glass obtained using the glass for chemical strengthening. A glass for chemical strengthening, obtained by melting and cooling a glass raw material, the glass for chemical strengthening containing, in percent by mass in terms of oxide, 61-75% SiO2, 2.5-10% Al2O3, 6-12% MgO, 0.1-8% CaO, 14-19% Na2O, and 0-1.8% K2O.

Owner:ASAHI GLASS CO LTD

Heat-ray shielding film and method for manufacturing the same, and heat-ray shielding laminated transparent base material

ActiveUS20140106175A1Excellent optical characteristicHigh weather resistanceBuilding constructionsGlass/slag layered productsWeather resistancePlasticizer

To provide a heat-ray shielding film mainly composed of polyvinyl acetal resin and a method for manufacturing the same capable of exhibiting excellent optical characteristics and high weather resistance by using composite tungsten oxide fine particles having a high heat-ray shielding effect, and a heat-ray shielding laminated transparent base material using the heat-ray shielding film, the heat-ray shielding film containing fine particles having a heat-ray shielding function, polyvinyl acetal resin, and a plasticizer, wherein the fine particles having the heat-ray shielding function is expressed by a general formula MyWOz (wherein M is one kind or more elements selected from a group consisting of Cs, Rb, K, Tl, In, Ba, Li, Ca, Sr, Fe, Sn, Al, and Cu, satisfying 0.1<=y<=0.5, 2.2<=z<=3.0), which are composite tungsten oxide fine particles having a hexagonal crystal structure, the heat-ray shielding film further containing metal carboxylate.

Owner:SUMITOMO METAL MINING CO LTD

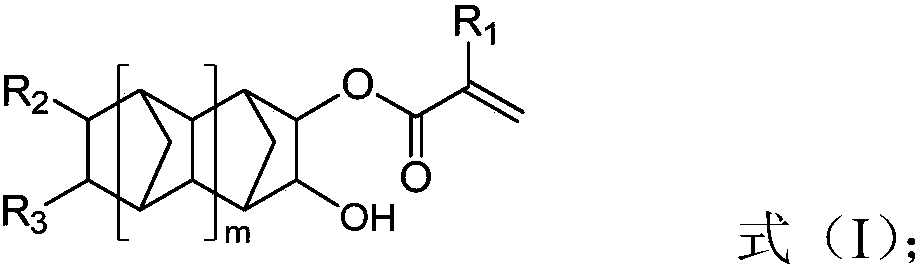

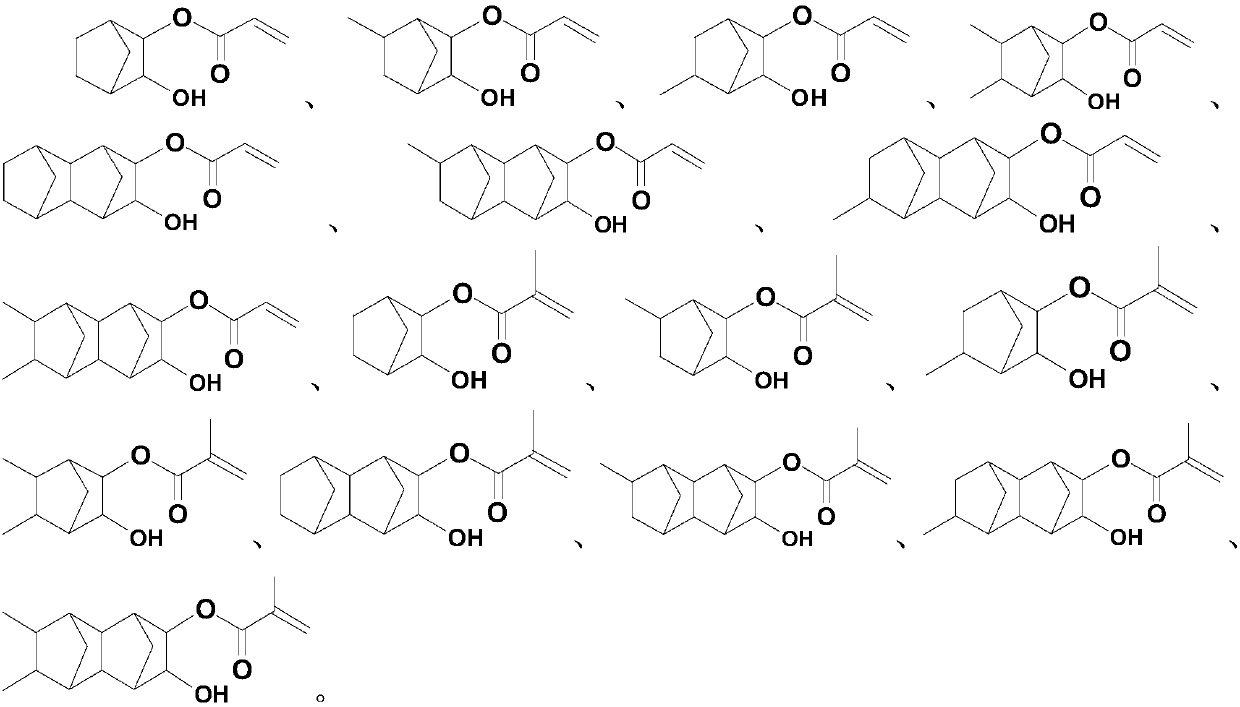

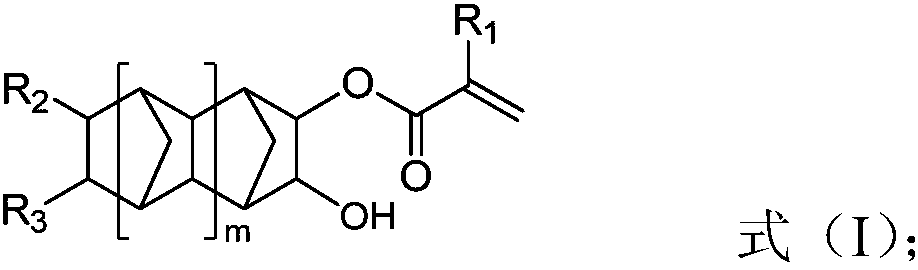

Acrylate compound for coatings, preparation method of acrylate compound, and coating comprising acrylate compound and application of coating

ActiveCN109956867AGood weather resistanceHigh weather resistanceAntifouling/underwater paintsOrganic compound preparationWater basedSolubility

The invention relates to an acrylate compound for coatings. The compound has a structure represented by a formula (I). The acrylate compound for coatings has lipophilic polycyclic aliphatic groups andhydrophilic hydroxyl groups at a same time and has high polymerization reaction activity. When the acrylate compound is used for a solvent-type acrylic coating, the coating layer shows relatively excellent weather resistance and wear resistance, high glossiness and fullness and the like. When the acrylate compound is used for a water-based acrylic coating, the hydrophilic hydroxyl groups and thelipophilic alicyclic groups of the compound show good solubility in an emulsion system, the polymerization activity is high, the monomer residue amount is low, and the coating after film forming showsexcellent weather resistance, water resistance, oil resistance, impact resistance, high glossiness and the like. The preparation method has the advantages that the technological process is simple, conditions are easy to control, side reactions are few, the raw material conversion rate of reactions is high, and purity of products is high.

Owner:WUXI ACRYL TECH

Cold ironing membrane for hose and production process of cold ironing membrane

InactiveCN107936278AImprove water resistanceReduce the ratioPolyurea/polyurethane coatingsMedia layerChemistry

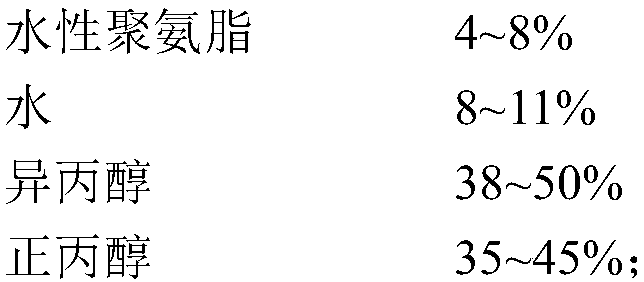

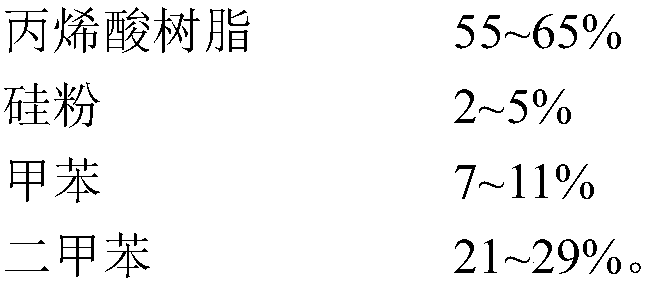

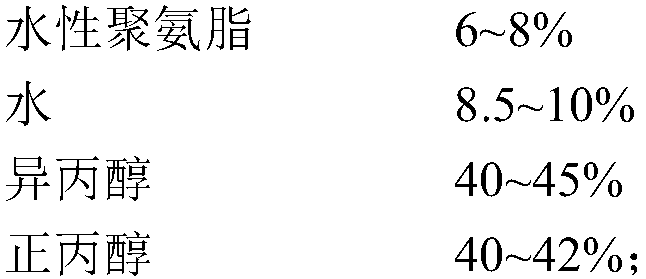

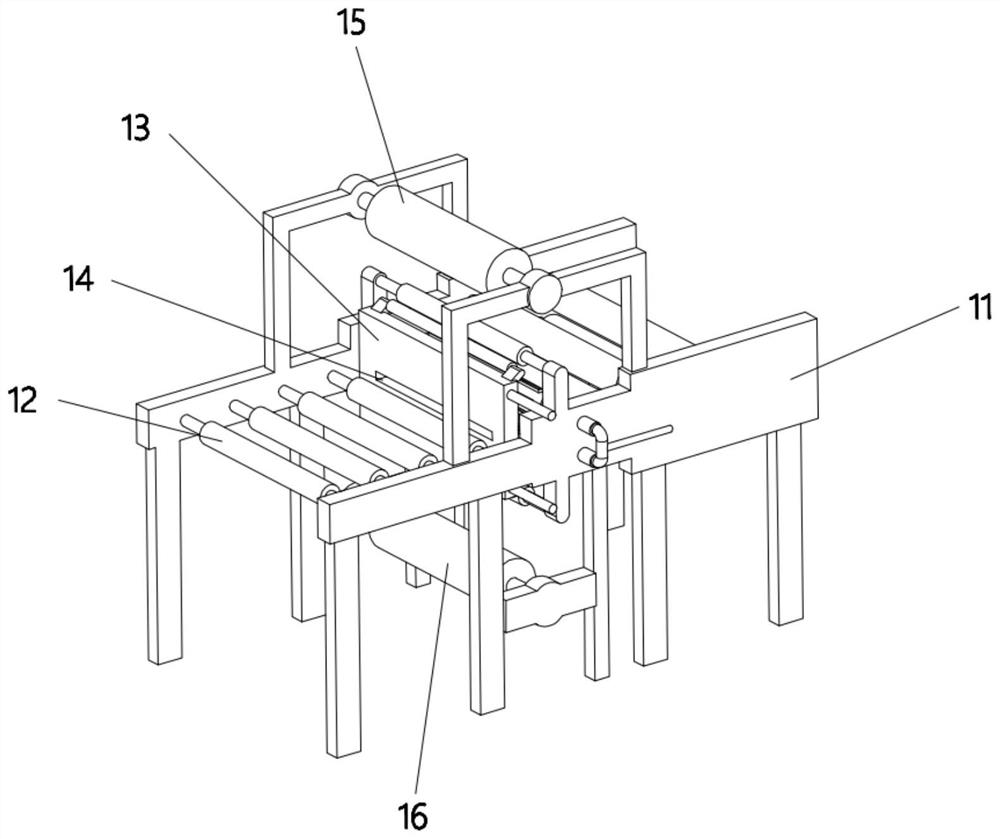

The invention relates to the technical field of cold ironing membranes and particularly relates to a cold ironing membrane for a hose and a production process of the cold ironing membrane. The cold ironing membrane consists of a separation layer, a color layer, an aluminum plated layer and a medium layer in an overlapped manner, in addition, the separation layer, the color layer and the medium layer are made of raw materials of specific weight percentages respectively, and the cold iron membrane can be relatively well adhered to a hose substrate and has the characteristic of environment protection; the production process of the cold ironing membrane comprises steps of preparing materials of the separation layer, the color layer and the medium layer, and performing coating and aluminum plating; the advantage of simple production process is achieved.

Owner:DONGGUAN K LASER TECH

Mildew-resistant PVC modified material and preparation method therefor

InactiveCN105419169AGood anti-mildew effectImprove temperature resistanceWeather resistancePlasticizer

The invention relates to the PVC material technology field, and concretely relates to a mildew-resistant PVC modified material and a preparation method therefor. The mildew-resistant PVC modified material comprises the following raw materials, by weight, 80-120 parts of PVC resin, 50-70 parts of plasticizer, 20-30 parts of filler, 3-7 parts of heat stabilizer, 1-3 parts of mildew inhibitor, 0.6-1.0 part of synergistic agent and 0.2-0.6 part of lubricant. The above raw materials are employed, the weight ratios of the raw materials are controlled strictly, various performances of the prepared mildew-resistant PVC modified material exceed national standards, and the provided modified material is advantaged by good mildew-resistant effects, environmental protection, excellent temperature resistance, excellent weather resistance, high intensity, excellent shock resistance, good flame retardation effects, excellent processing property and excellent comprehensive properties.

Owner:广东祺龙科技有限公司

Rat-proof PVC (polyvinyl chloride) modified material and preparation method thereof

The invention relates to the technical field of PVC (polyvinyl chloride) materials, in particular to a rat-proof PVC modified material and a preparation method thereof. The rat-proof PVC modified material comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 45-65 parts of a plasticizer, 25-45 parts of a filling agent, 3-7 parts of a heat stabilizer, 2-4 parts of an impact modifier, 0.8-1.6 parts of a rat proof agent, 0.6-1.0 part of a lubricating agent and 0.3-0.7 parts of other aids. According to the rat-proof PVC modified material, each property of the prepared rat-proof PVC modified material exceeds the national standard with the adoption of the raw materials and through strict control of the weight ratio of the raw materials, the rat proof effect is good, and the rat-proof PVC modified material is environment-friendly and has excellent temperature resistance and weather fastness, high strength, excellent impact resistance, good flame retardant effect, excellent processing performance and excellent overall performance.

Owner:广东祺龙科技有限公司

Plastic product surface spraying method

The invention discloses a plastic product surface spraying method. The method includes steps: subjecting plastic products to heating and annealing; performing deoiling treatment; soaking in sodium hydroxide solution, flushing and airing; adopting a plasma fan for destaticizing and dedusting treatment; spraying alcohol-containing epoxy resin curing liquid to dedusted surfaces, airing, and coating with an epoxy resin and curing agent mixture; adopting a spray gun for primary spray coating, and standing; adopting the spray gun for secondary spray coating, and standing; drying. The plastic productsurface spraying method has advantages that by intermolecular force of epoxy resin between the plastic products and coatings, the coatings can be firmly adhered to the plastic products to improve bonding strength between the coatings and the plastic products, and surface defects of formed products can be concealed; in addition, electrostatic performances of the plastic products can be improved, dust adsorption is reduced, and plastic corrosion resistance is improved.

Owner:HEFEI SHUSHI IND & TRADE CO LTD

Heat discoloration composite material and preparation method thereof

PendingCN113442518ALoss or weakening of discoloration effectGuaranteed uniformityLamination ancillary operationsSynthetic resin layered productsPolymer scienceColor changes

The invention discloses a heat discoloration composite material and a preparation method thereof, wherein the heat discoloration composite material comprises a base cloth layer; one side of the base cloth layer is connected with a heat discoloration PVC composite surface layer, the other side of the base cloth layer is connected with a heat discoloration PVC bottom layer, and the heat discoloration PVC composite surface layer is formed by compounding a transparent PVC film and a heat discoloration PVC film. The thermochromic composite material is designed according to existing requirements, different thermochromic pigments can be designed to be matched with conventional pigments, various color combinations are presented, the thermochromic film is made into a semitransparent effect, the use amount of the pigments is reduced, the cost is reduced, the color changing effect is not affected, and the surface effect of the thermochromic composite material is improved; the color changing effect of the material outside the temperature change critical point is obvious, the base cloth layer, the thermochromic PVC composite surface layer and the thermochromic PVC bottom layer can be evenly preheated before being attached, the attaching tightness is guaranteed, and the produced thermochromic composite material is stable in structure and smooth in surface after being attached.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

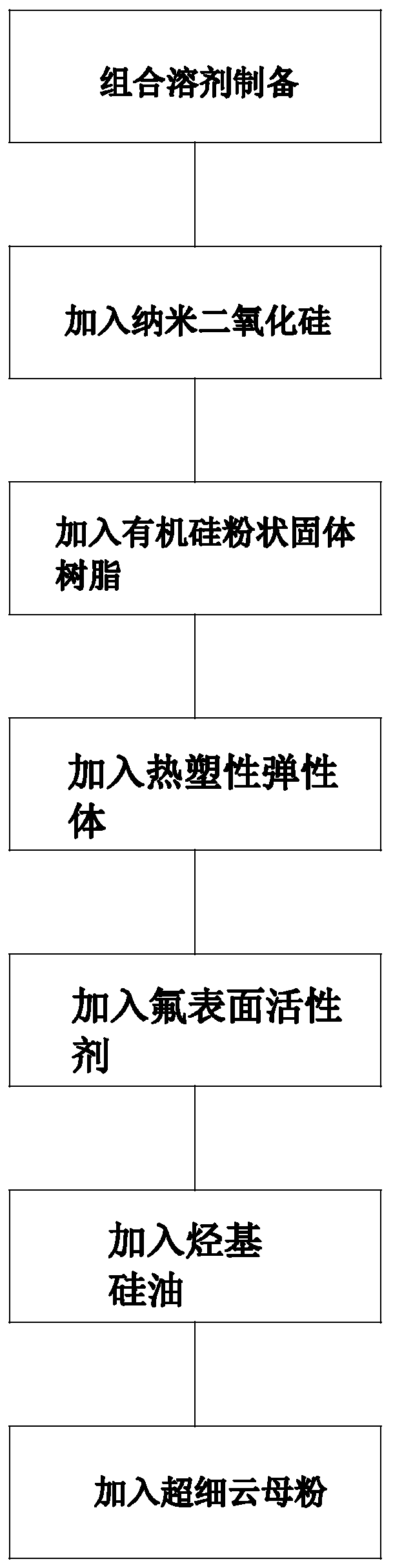

Insulating coating and processing technology thereof

InactiveCN111349392ASolution to short lifeStrong anti-destructiveFireproof paintsPolyurea/polyurethane coatingsElastomerActive agent

The invention provides an insulating coating and a processing technology thereof. The problem that an existing coating is short in service life is solved. According to the insulating coating and the processing technology thereof, the insulating coating is composed of the following materials in parts by mass: 90-110 parts of organic silicon powder solid resin, 75-150 parts of a combined solvent, 8-12 parts of a thermoplastic elastomer, 3-10 parts of a fluorine surfactant, 50-80 parts of ultrafine mica powder, 2-9 parts of nano silicon dioxide and 3-8 parts of alkyl silicone oil, wherein the combined solvent is used for dissolving the organic silicon powder solid resin. The process comprises the following steps: A, preparing the combined solvent; B, adding nano silicon dioxide; C, adding theorganic silicon powder solid resin; D, adding the thermoplastic elastomer; E, adding the fluorine surfactant; F, adding alkyl silicone oil; and G, adding superfine mica powder. The insulating coatingand the processing technology thereof are long in service life.

Owner:WENLING CITY ELECTRICITY INSULATED EQUIP CO LTD

Insulating material for power maintenance protective garment

ActiveCN105506829AImprove practicalityImprove insulation performanceFibre typesHeating/cooling textile fabricsYarnPolyester

The invention relates to an insulating material for a power maintenance protective garment. The insulating material is a polyester terphthalate fiber fabric which comprises warps and wefts, the weight of the polyester terphthalate fiber fabric is 15-30g / m<2>, any one of the warps and the wefts is 90 or more in denier and thicker than the other one, and yarn density of the thicker yarns in a unit length is smaller than that of other yarns in the unit length. At least one of the warps and the wefts is formed by twin yarns with filament diameter being 0.005-0.010mm. The insulating material for the power maintenance protective garment is an electrical insulating fabric with an excellent insulating performance and excellent anti-mildew, anti-dampness and chemical resistance performances and has the advantages of high weather resistance, high strength, abrasion resistance, heat conduction, antibacterial performance, freeness of toxicity and environment friendliness.

Owner:YONGKANG ELECTRIC POWER EQUIP FACTORY +1

Rapid roadbed construction process

ActiveCN114197266AImprove heat resistanceGood weather resistanceIn situ pavingsArchitectural engineeringAsphalt

The invention relates to the technical field of road construction, in particular to a rapid roadbed construction process which comprises the following steps: S1, roadbed flattening: removing sundries of a roadbed, flattening and jolt-ramming; s2, width limiting of a roadbed: the width of the roadbed is limited, and baffles are mounted on the two sides of the roadbed; s3, aggregate paving: paving the aggregate on a roadbed, leveling and jolt-ramming; s4, paving a roadbed: heating the modified asphalt to 160-180 DEG C, paving the modified asphalt on the aggregate of the roadbed, and leveling the modified asphalt so that the modified asphalt is mixed with the aggregate; s5, rolling and surface finishing are conducted, wherein rolling is conducted for four times; after rolling is finished, when the pavement temperature is lower than 45 DEG C, traffic is opened; the construction method has the advantage of high construction efficiency.

Owner:SHANDONG LUQIAO CONSTR

Vitrified microbead thermal insulation mortar and preparation method thereof

The invention discloses vitrified microbead thermal insulation mortar and a preparation method thereof. The thermal insulation mortar is prepared from the following raw materials: portland slag cement, lime paste, river sand, vitrified microbeads, sugar calcium, calcium carbonate, white latex, modified attapulgite clay powder, sodium lignin sulfonate, barium stearate, polyester fibers, hydroxypropyl methyl cellulose, polyvinyl alcohol, an organosilicon waterproofing agent and water. The preparation method comprises the following steps: firstly mixing the raw materials such as the vitrified microbeads and sugar calcium, and uniformly stirring, so that slurry A is obtained; then mixing the raw materials such as sodium lignin sulfonate, and uniformly stirring, so that slurry B is obtained; and finally conveying the portland slag cement, the lime paste and the river sand to a mortar stirring machine, and sequentially adding the slurry B and the slurry A, so that the vitrified microbead thermal insulation mortar finished product is obtained. The thermal insulation mortar disclosed by the invention has the advantages that tension and compression strengths and thermal insulation and sound insulation performances are further enhanced compared with the national standard and existing thermal insulation mortar, so that the problems of empty drums, cracks and drops are hardly caused when the mortar disclosed by the invention is applied to a wall body, and durability and practicability of the mortar are improved.

Owner:合肥天沃能源科技有限公司

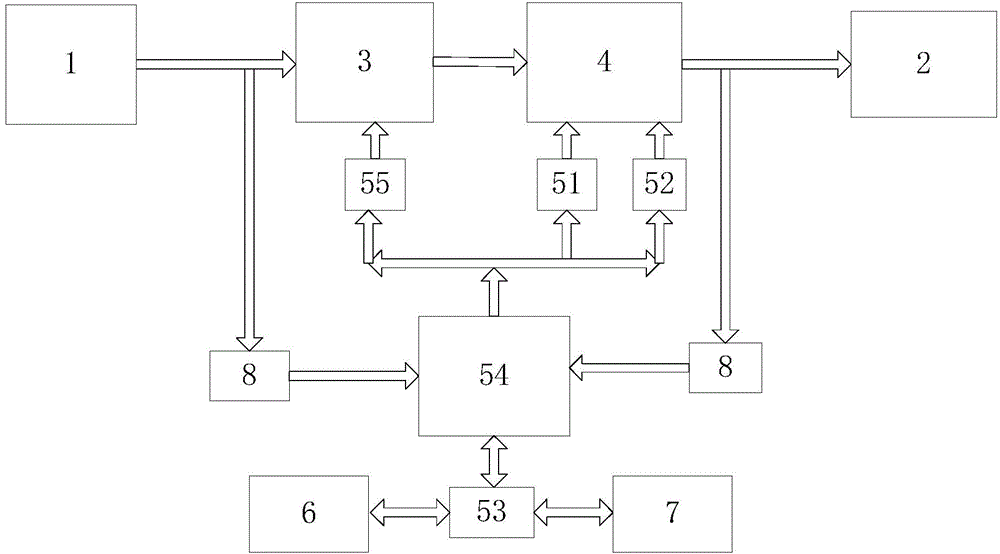

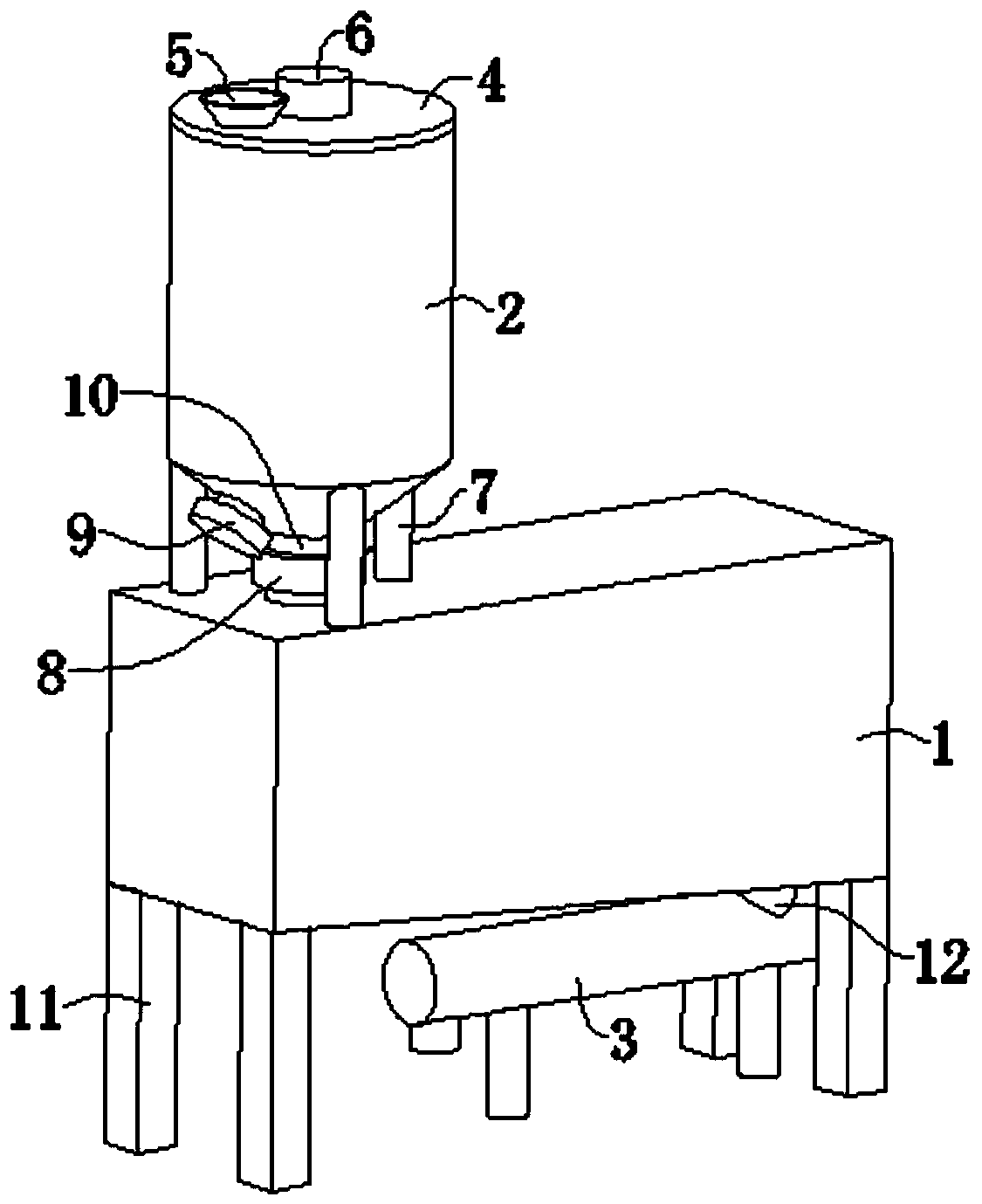

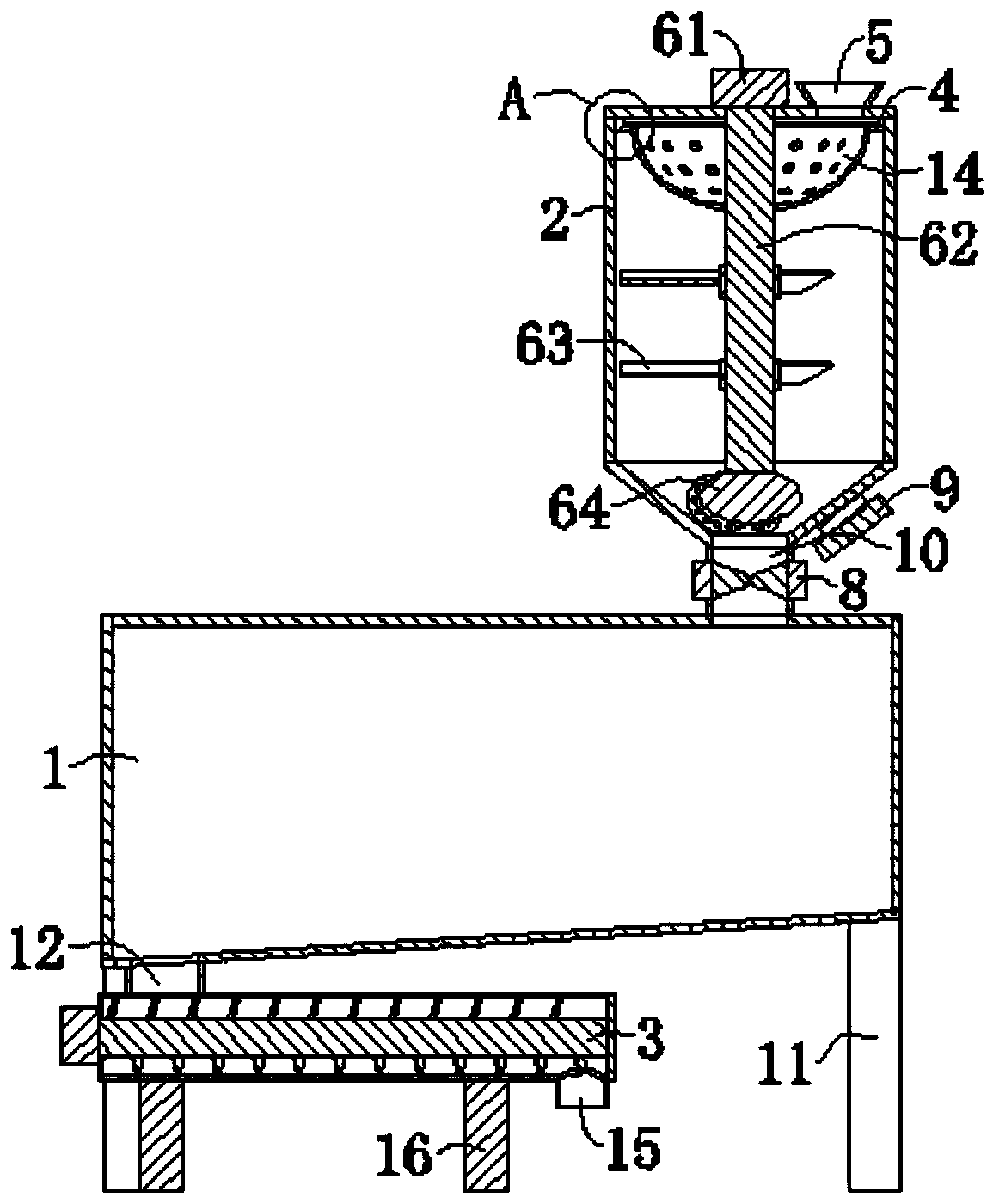

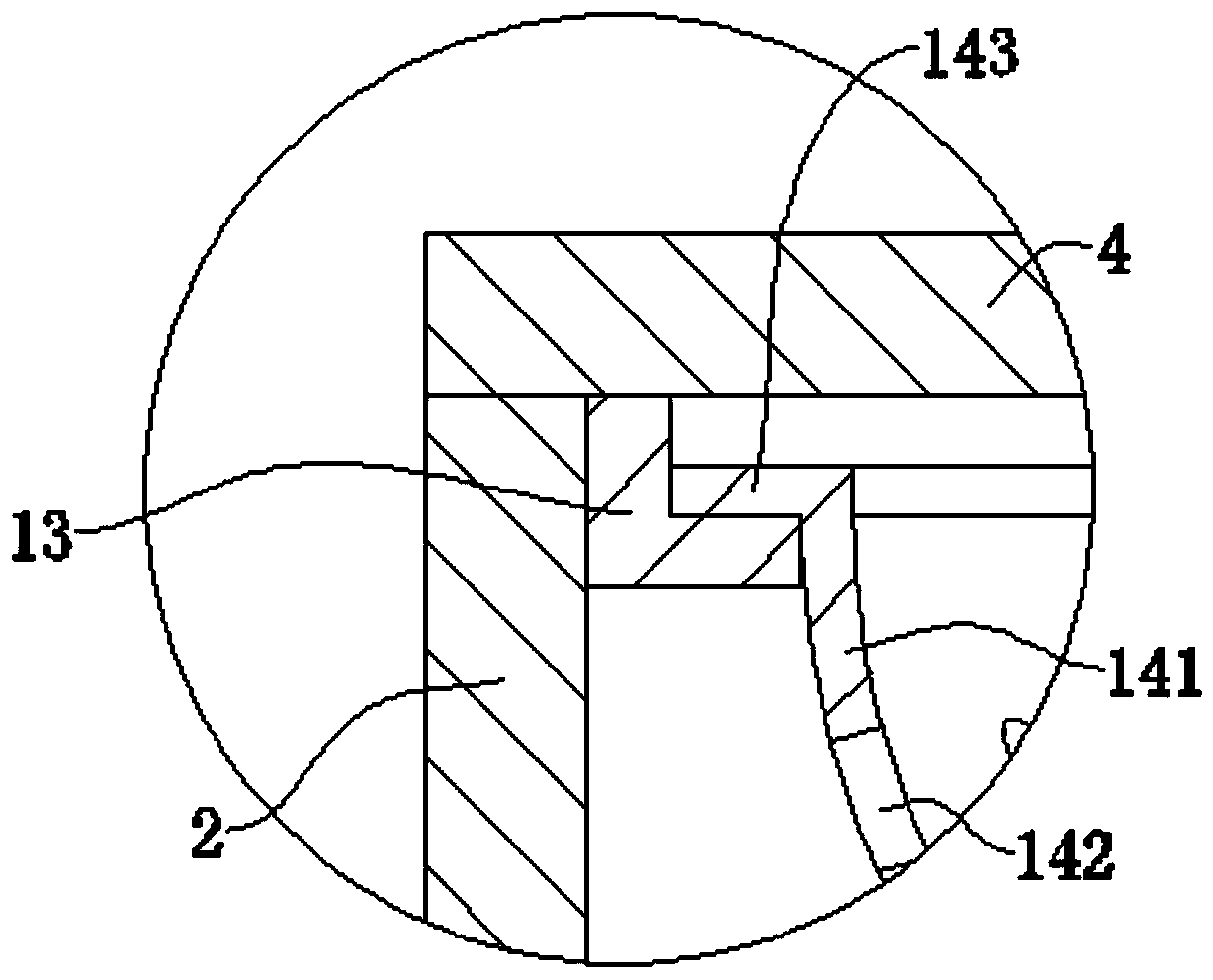

PV direct current simulation power supply with touch screen

InactiveCN105743438AEasy to operateImprove human-computer interactionPhotovoltaic monitoringPhotovoltaic energy generationPower gridComputer module

The present invention relates to a PV direct current simulation power supply with a touch screen. Two ends of the direct simulation power supply are respectively connected with a photovoltaic inverter, and the direct simulation power supply comprises a rectifying circuit and a master control assembly. The direct current simulation power supply also comprises a DC / DC convertor and a touch display assembly. The power grid, the rectifying circuit, the DC / DC convertor and the photovoltaic inverter are connected in order, the master control assembly is connected with the rectifying circuit and the DC / DC convertor, and the touch display assembly is connected with the master control assembly, and the touch display assembly is configured to control the rectifying circuit and the DC / DC convertor through the master control assembly to output alternate current, after rectification and direct current conversion, in the power grid to the photovoltaic inverter. Compared with the prior art, the PV direct current simulation power supply with a touch screen is provided with a resistor touch screen which is able to be arranged near the main circuit of the PV direct current simulation power supply, and is configured to design different display interface modules aiming at different modes, so that the PV direct current simulation power supply with a touch screen is convenient for operation and fast in man-machine interaction, etc.

Owner:上海航天智能装备有限公司

Novel PVC lubrication modifier

The invention discloses a novel PVC (polyvinyl chloride) lubrication modifier. According to a formula, the modifier comprises the following components by weight: 30-50 parts of allene, 15-20 parts of allyl acetate, 10-30 parts of carbon fibers, 5-7 parts of malonic acid, 3-5 parts of phosphoric acid, and 4-5 parts of calcium silicate. The modifier provided in the invention can effectively increase the flowing property and plasticizing property of a PVC product, and increases weather resistance and impact resistance.

Owner:青岛永卓真塑料制品有限公司

Impact-erosion resistant marine concrete dual-ash gelling powder and preparation method and device thereof

InactiveCN110922117AImproves carbonation resistanceImproves resistance to sulfate attackSlagSilica fume

The invention discloses an impact-erosion resistant marine concrete dual-ash gelling powder and a preparation method and device thereof, and belongs to the field of gelling materials. The dual-ash gelling powder comprises following raw materials in parts by weight: 30 to 40 parts of cement, 15 to 25 parts of furnace steel ash, 12 to 20 parts of slag, 15 to 18 parts of silica fume, 2 to 5 parts ofexpanded graphite, 2 to 5 parts of ceramic micro powder, and 5 to 12 parts of rubber powder. The preparation method comprises following steps: preparing raw materials; preparing a basic material; andpreparing the dual-ash gelling powder. The problem that in the prior art, the impact-erosion resistant performance of conventional marine concrete is bad is solved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

Processing method for preventing metal layer on surface of plastic product from falling off

The invention relates to a processing method for preventing a metal layer on the surface of a plastic product from falling off, belongs to the technical field of plastic products, and in particular relates to a processing method of preventing the metal layer on the surface of the plastic product from falling off. The method comprises the following steps: annealing the plastic product; oiling the annealed plastic product; removing electricity and dust of the deoiled plastic product; treating the surface of the plastic product treated in the step 3, wherein the surface smoothness is 1-5 mm; coating the surface of the plastic product treated in the step 4 with a mixture of bisphenol A epoxy resin and a curing agent to form a coating layer; thermally spraying a metal wire to the surface of thecoating layer of the plastic product treated in the step 5 to form a metal coating; and drying the plastic product treated in the step 6. After treatment, the surface performance, for example, wear resistance, heat resistance, weather resistance, corrosion resistance and the like, of the plastic product is improved greatly.

Owner:嘉兴松尚电器有限公司

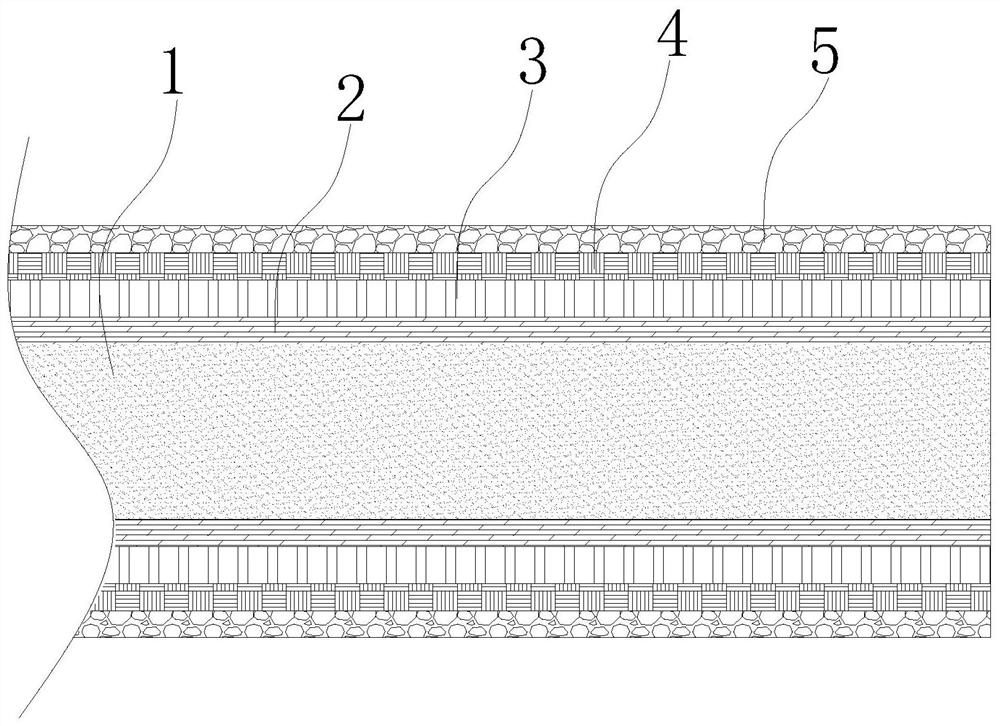

Weather-proof composite board

PendingCN112976739APrevent agingHigh weather resistanceSynthetic resin layered productsWater-setting substance layered productWeather resistanceComposite slab

A weather-proof composite board is disclosed. A wood-plastic base plate serves as a basic board, a weather-proof layer is arranged outside the wood-plastic base plate, the wood-plastic base plate is sealed through the weather-proof layer, the wood-plastic base plate is prevented from making contact with the outside, and therefore aging of the internal wood-plastic base plate is avoided, the weather-proof performance of the composite board is improved, and the weather-proof layer is not affected by the outside temperature. Meanwhile, a steel structure layer is arranged on the outer side of the weather-proof layer, and the rigidity of the composite board is improved through the steel structure layer; a sealing layer is arranged outside the steel structure layer, so that the sealing performance of the composite board is further guaranteed; a fireproof layer is arranged outside the sealing layer so that fireproof performance of the composite board is effectively improved, and the sealing layer is effectively protected from being damaged, the weather-proof structure of the composite board is not damaged, and the problems that an existing wood-plastic composite board is prone to corrosion and deformation after being used for a long time, and the weather-proof performance is poor are effectively solved.

Owner:湖北亚飞新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com