Patents

Literature

86 results about "Evacuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

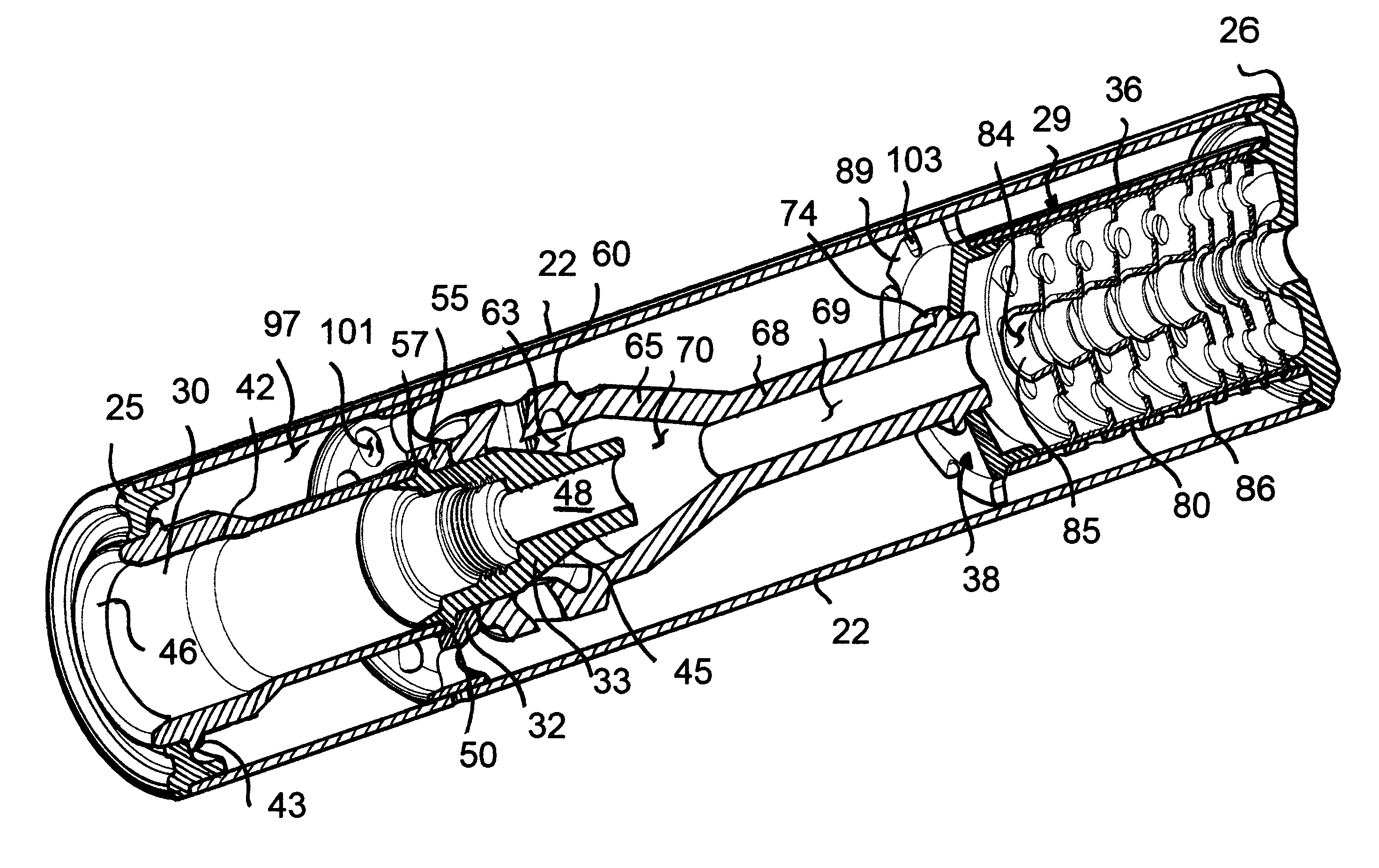

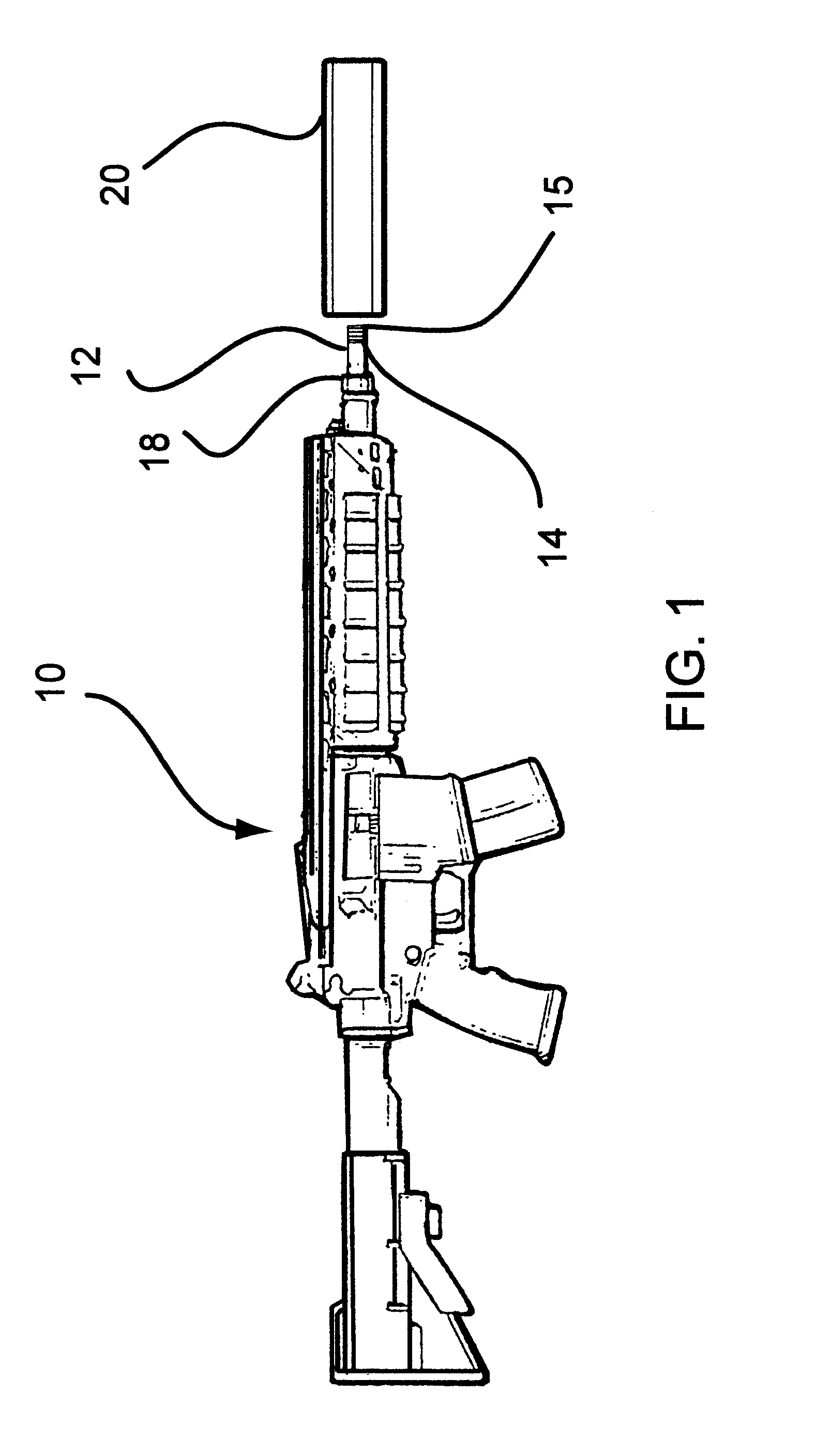

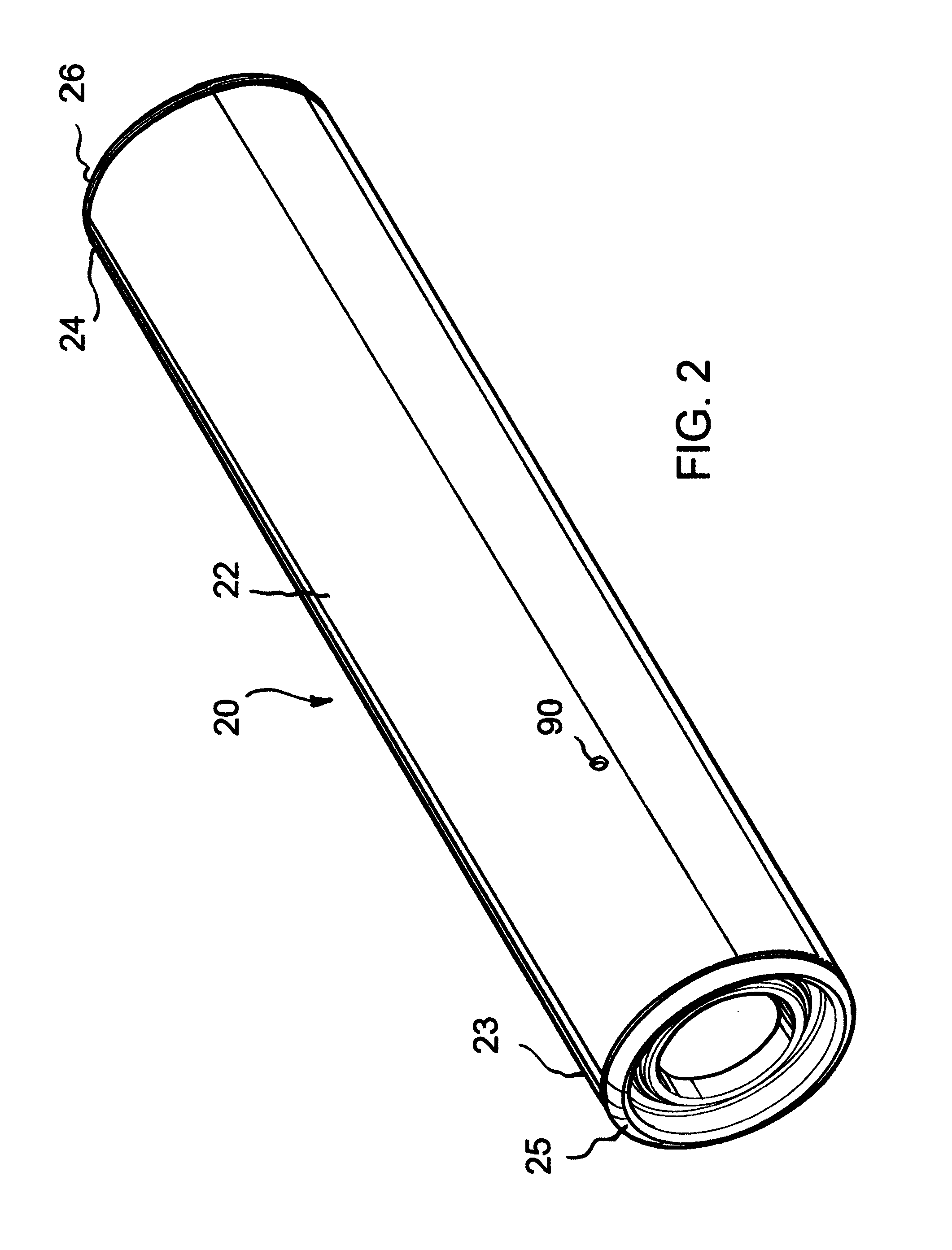

Firearm suppressor

A suppressor for use with a firearm having a barrel with a muzzle and a bore, the suppressor includes an outer casing having a rearward end and a forward end, an evacuator assembly for receiving the muzzle of the firearm carried by the outer casing, and an expansion chamber defined between the outer casing and the evacuator assembly in gaseous communication with an interior volume of the evacuator assembly.

Owner:STANOWSKI DAVID

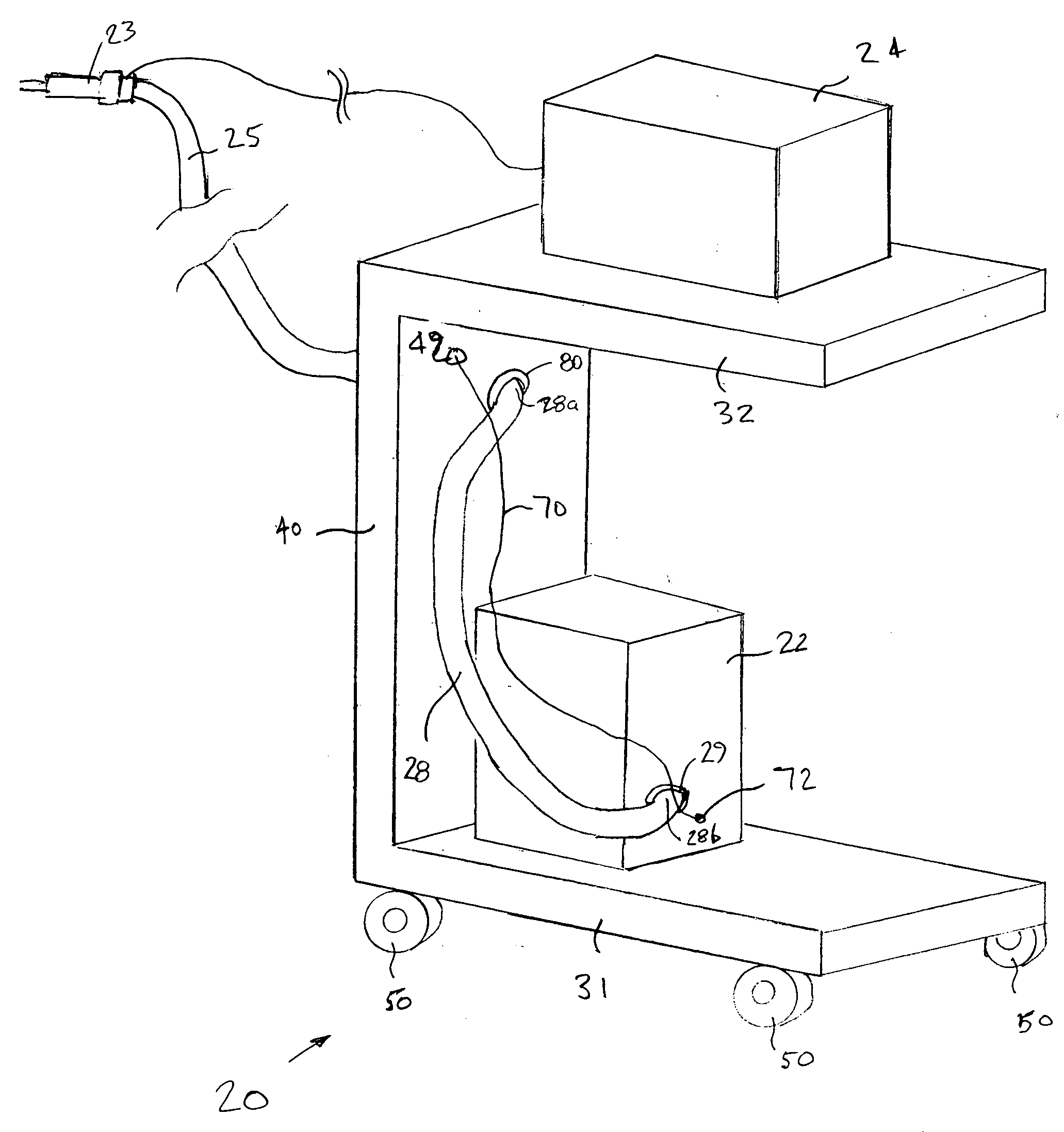

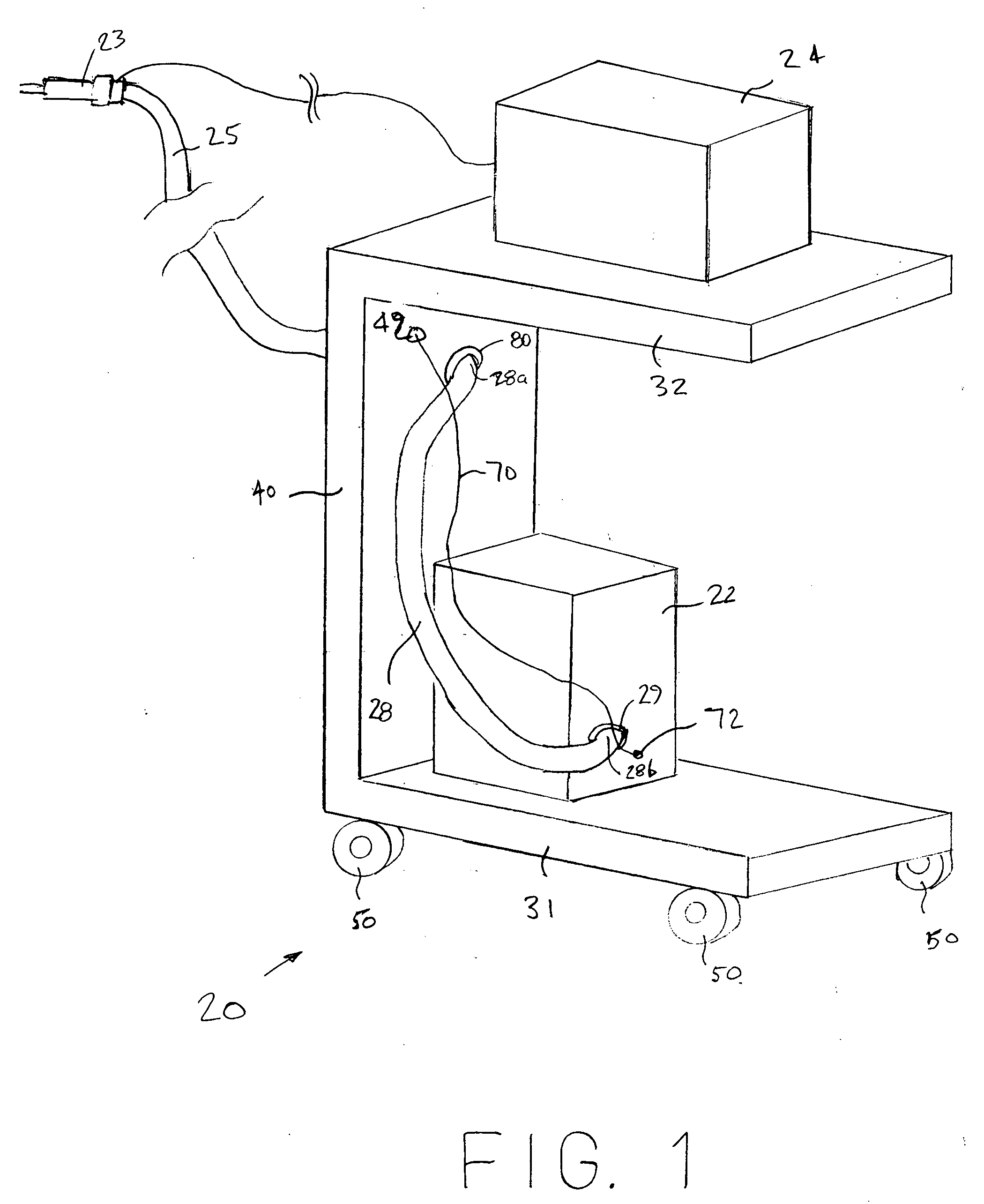

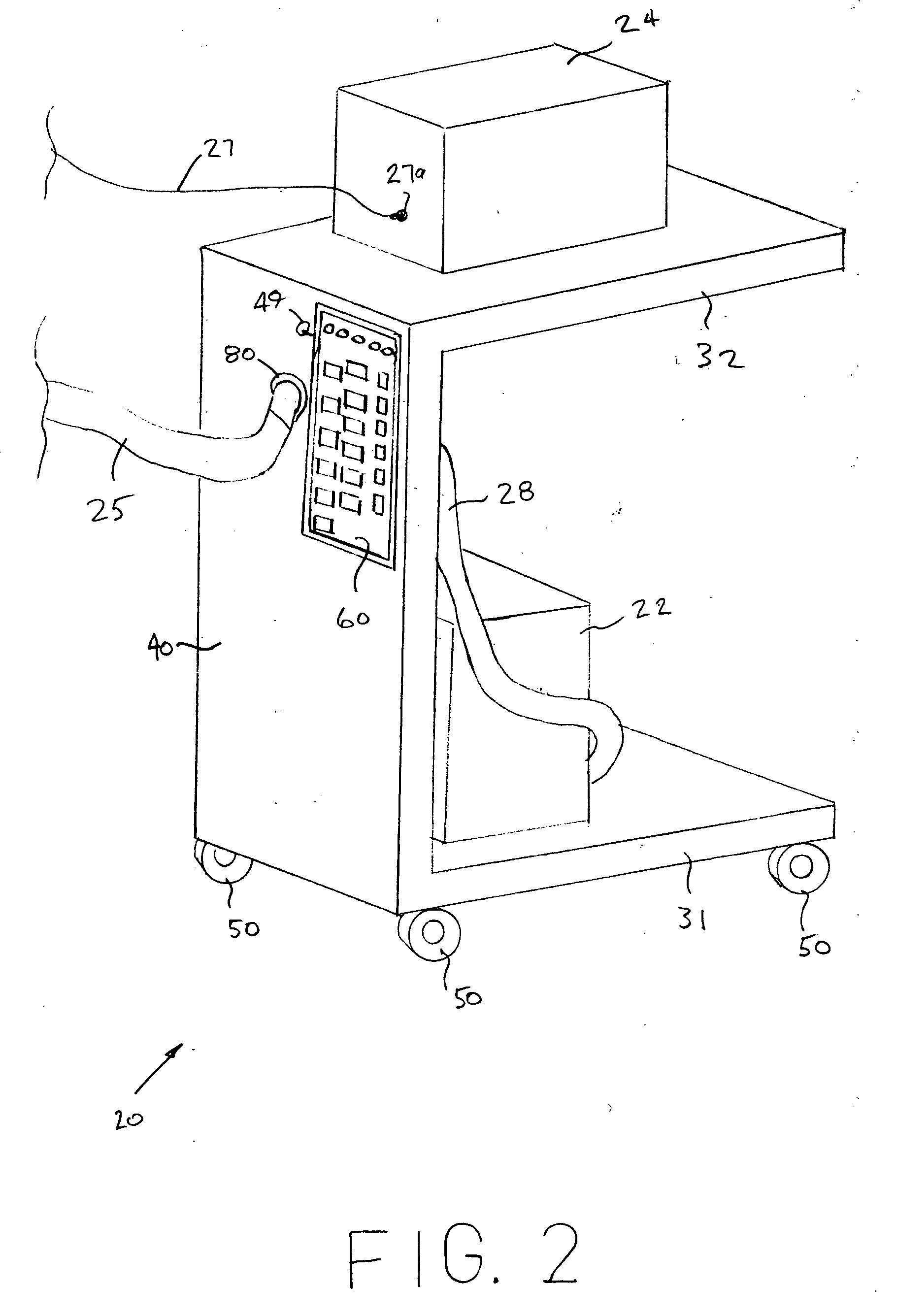

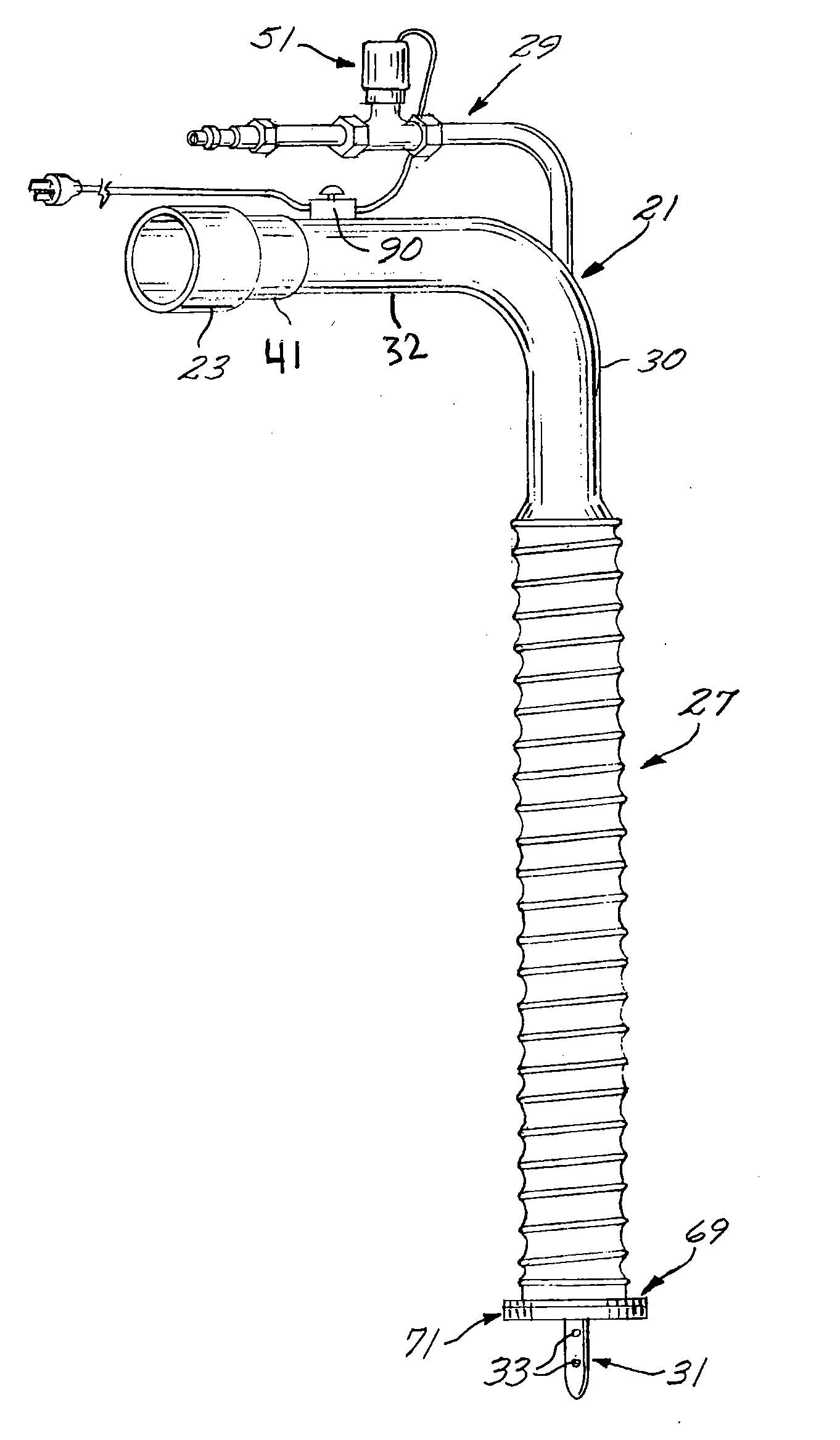

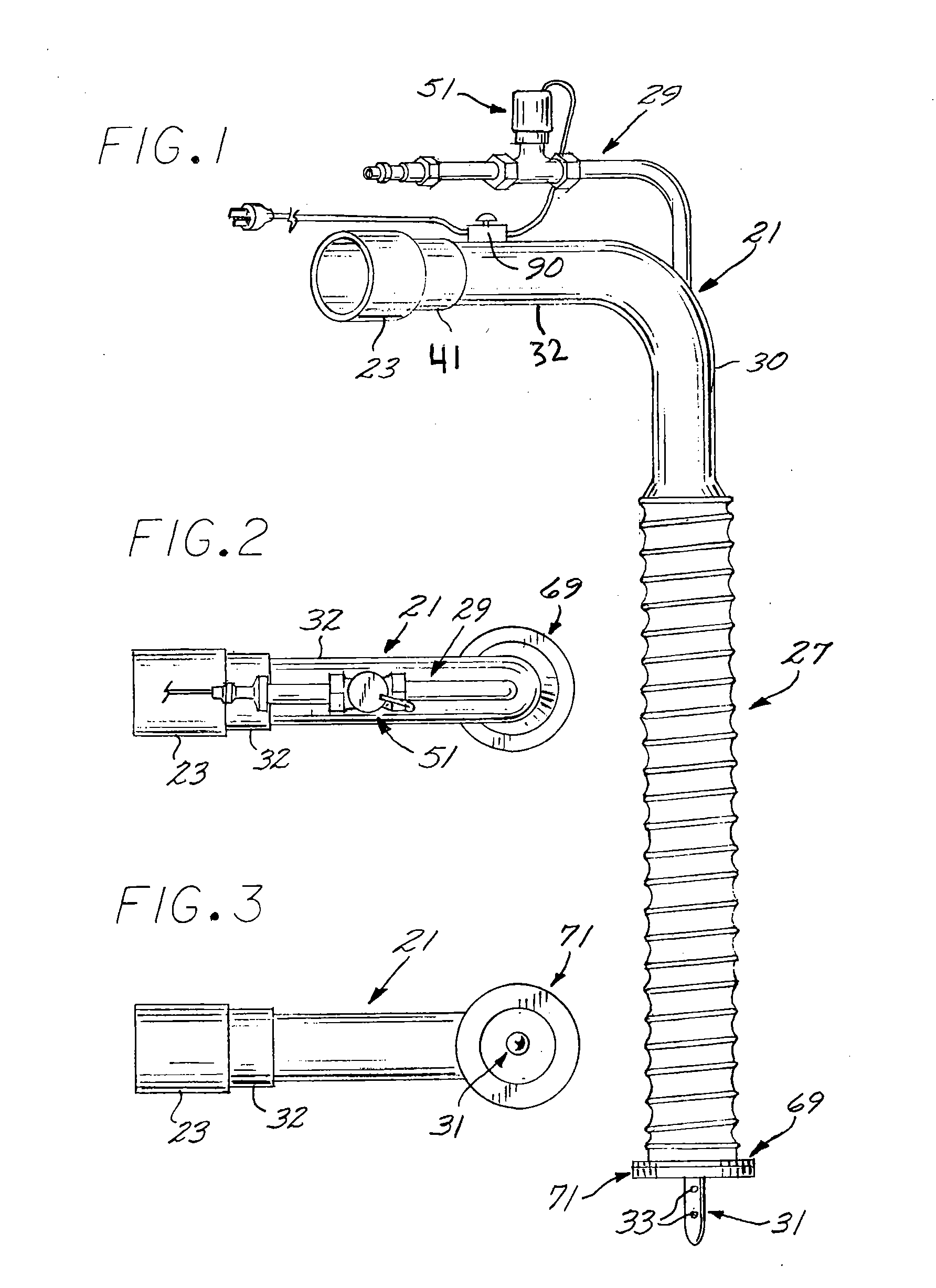

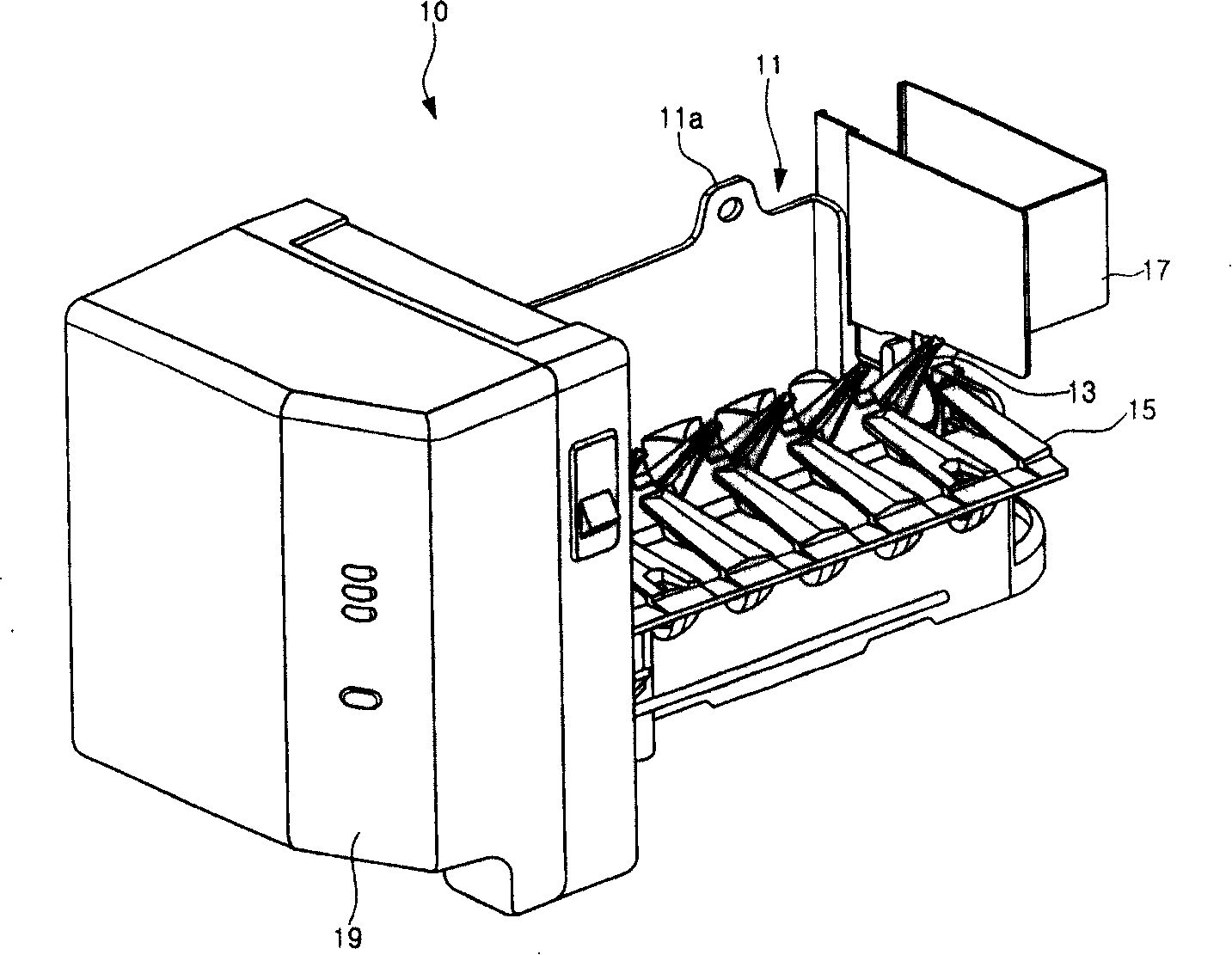

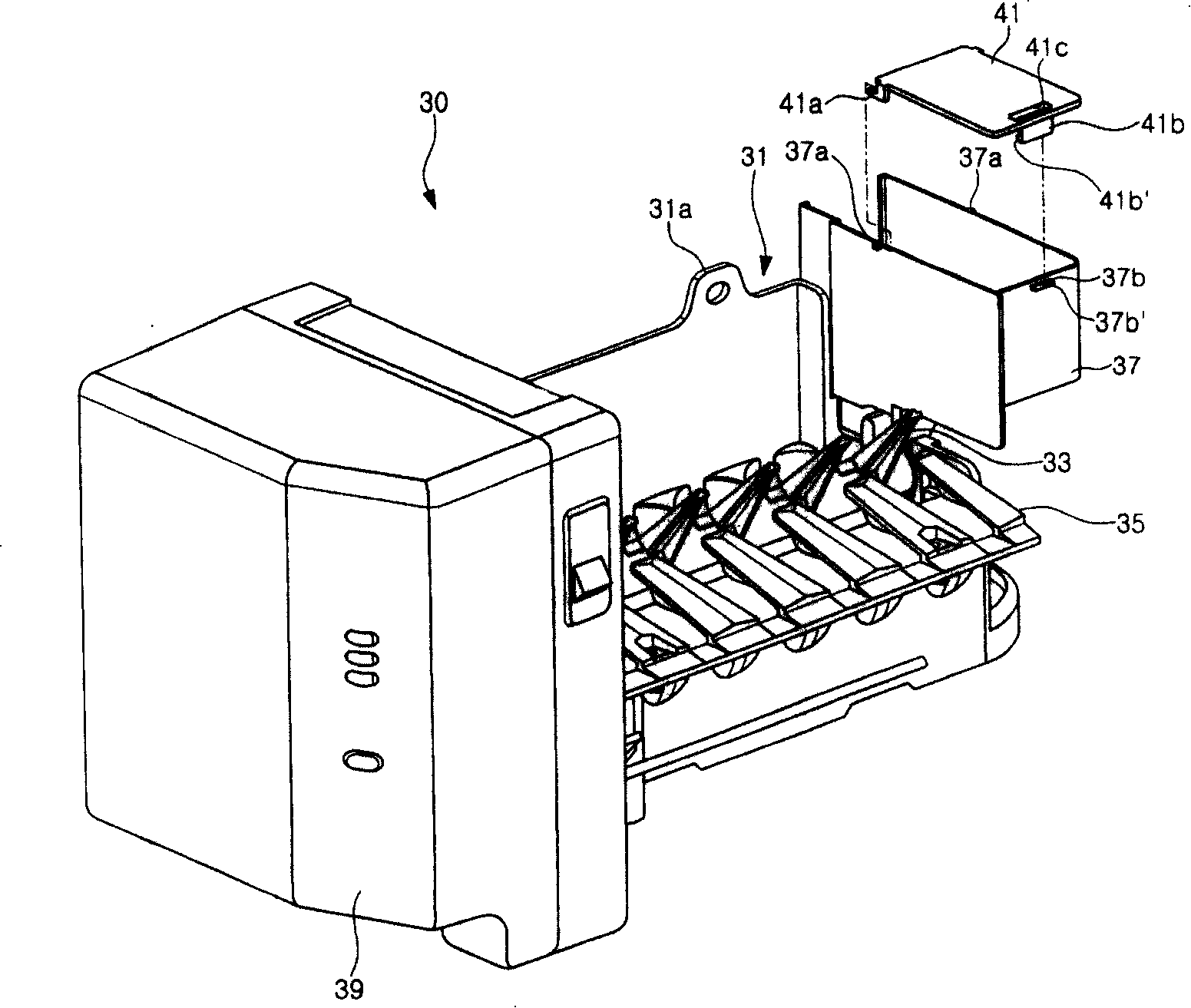

Integrated electrosurgical cart and surgical smoke evacuator unit

InactiveUS20070066970A1Surgical instruments for heatingSurgical instruments for aspiration of substancesElectricityElectrical control

An electrosurgical cart for use during surgery to support a surgical smoke evacuator unit comprises a first shelf for receiving and retaining a surgical smoke evacuator unit thereon. There is a substantially upright frame for structurally supporting the first shelf. There is also a plurality of wheels for rolling contact with a floor. An electrical control panel is mounted the electrosurgical cart, for controlling the surgical smoke evacuator unit. An electrical cable permits the transmission of electrical signals from the electrical control panel to the surgical smoke evacuator unit. A throughpassage on the front of the electrosurgical cart permits the flow of air from the inlet on the cart via a corrugated flexible hose to the filter on the smoke evacuation unit located on the bottom shelf.

Owner:INESON LEONARD

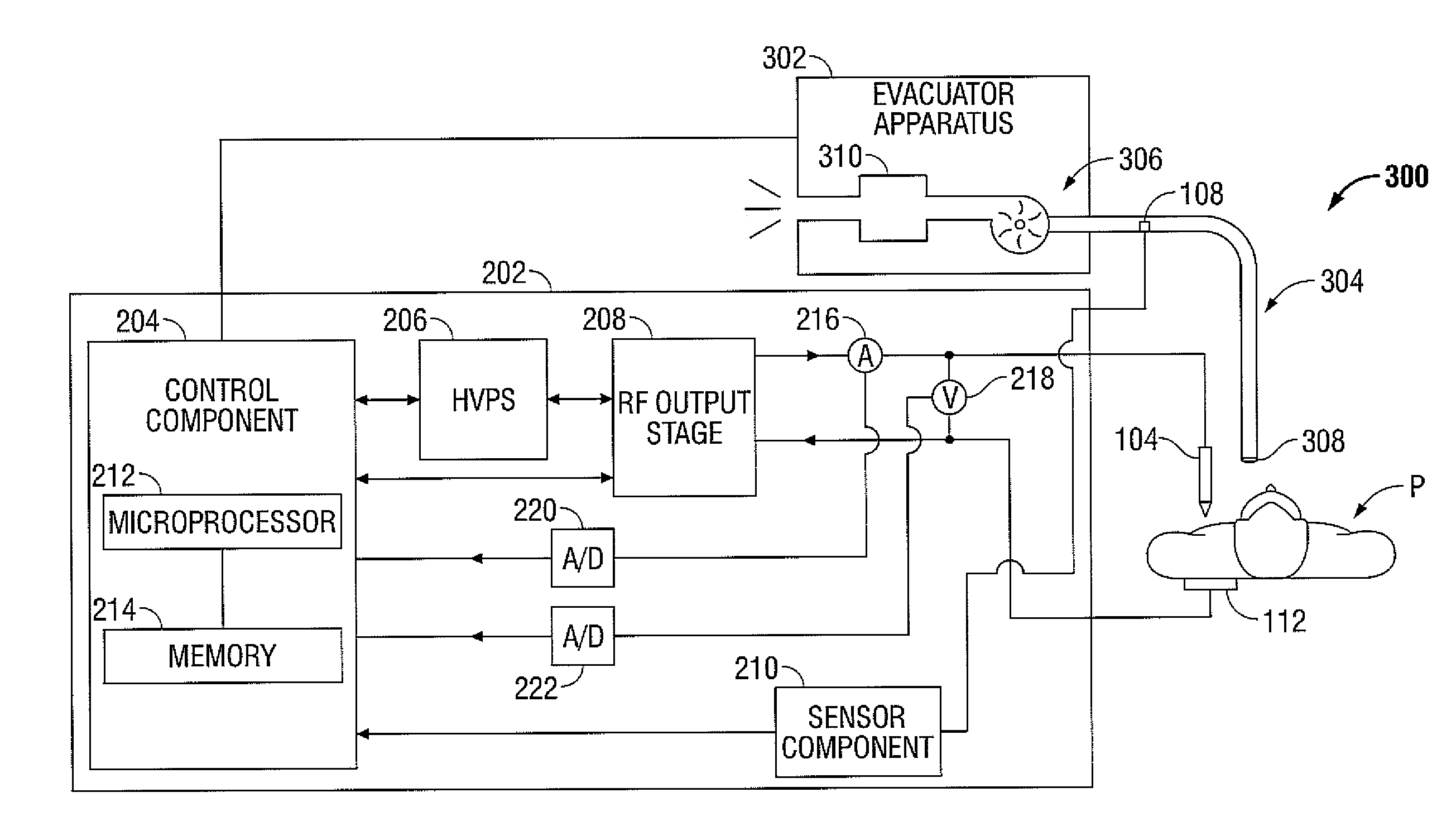

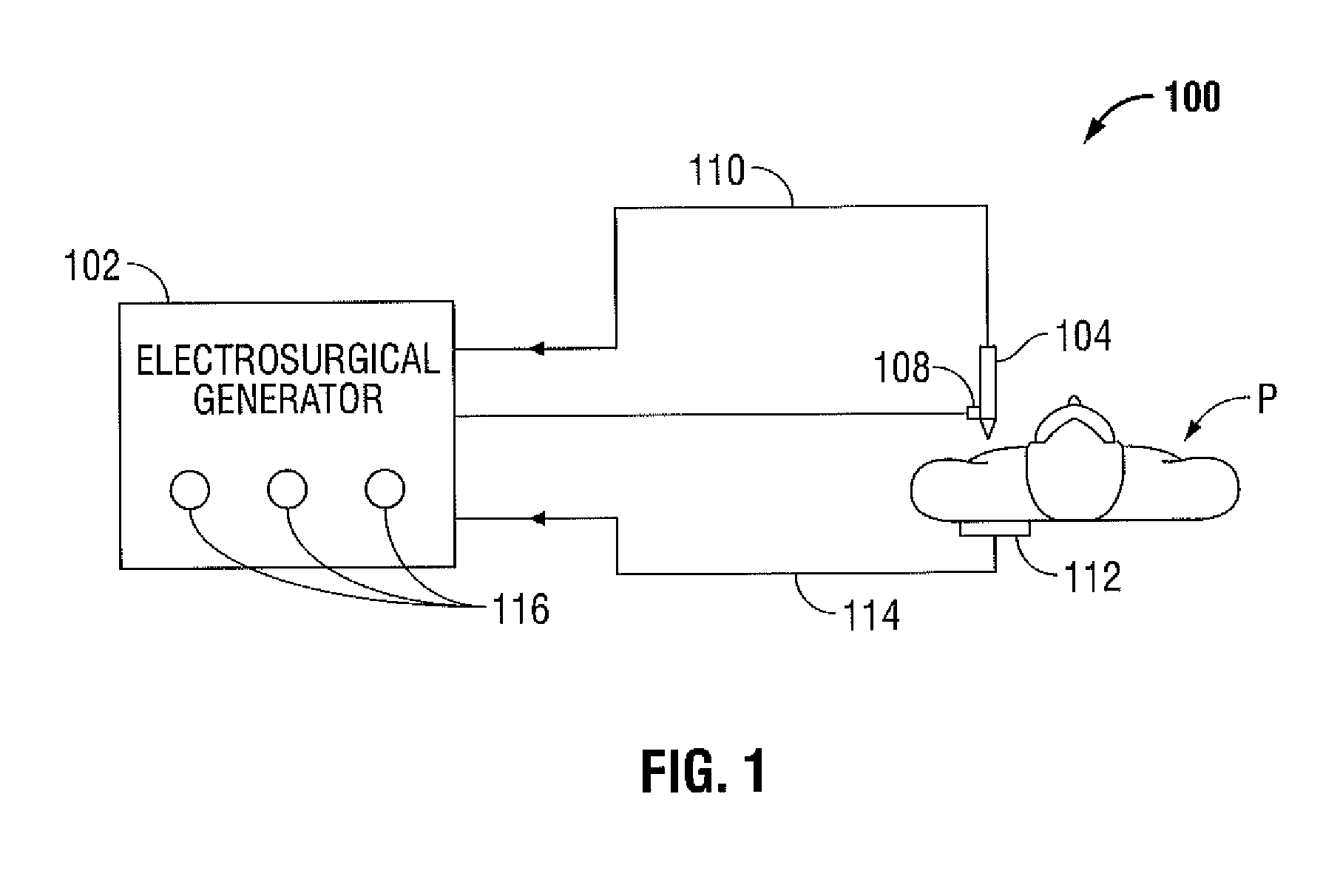

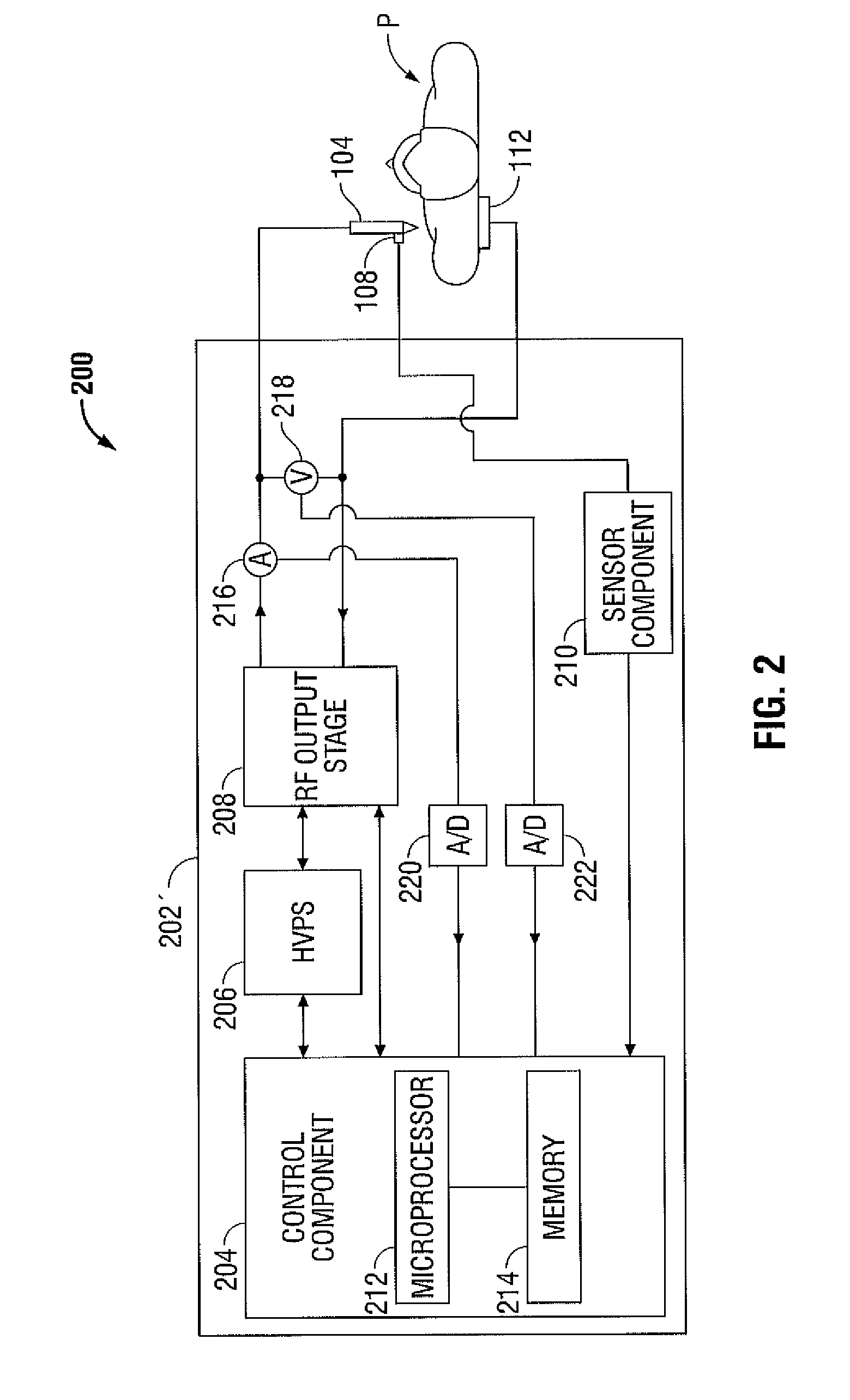

Electrosurgical System Having a Sensor for Monitoring Smoke or Aerosols

An electrosurgical system includes an evacuator apparatus and a sensor. The evacuator apparatus evacuates aerosol and smoke generated during application of electrosurgical energy. The sensor is operatively coupled to the evacuator apparatus and senses the aerosol and smoke generated during application of the electrosurgical energy. The sensor generates data in response to the sensed aerosol and smoke. The sensor operatively communicates the data to the evacuator apparatus and the evacuator apparatus evacuates the aerosol and smoke as a function of the data.

Owner:TYCO HEALTHCARE GRP LP

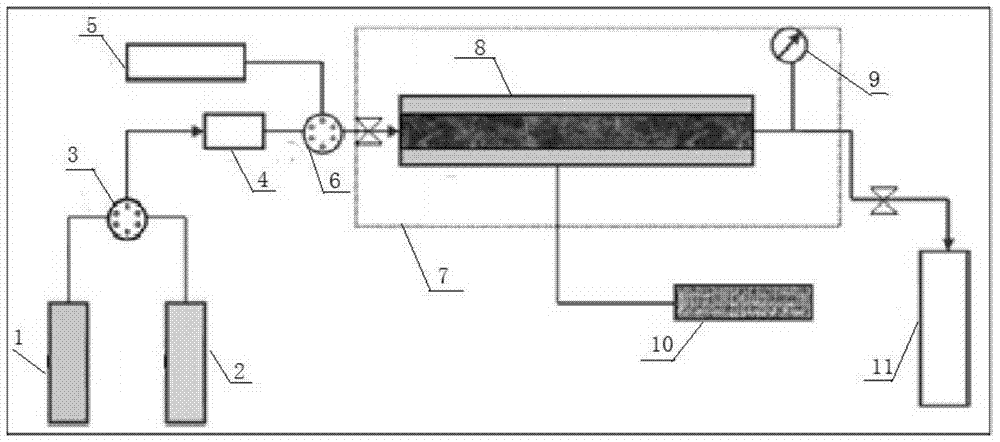

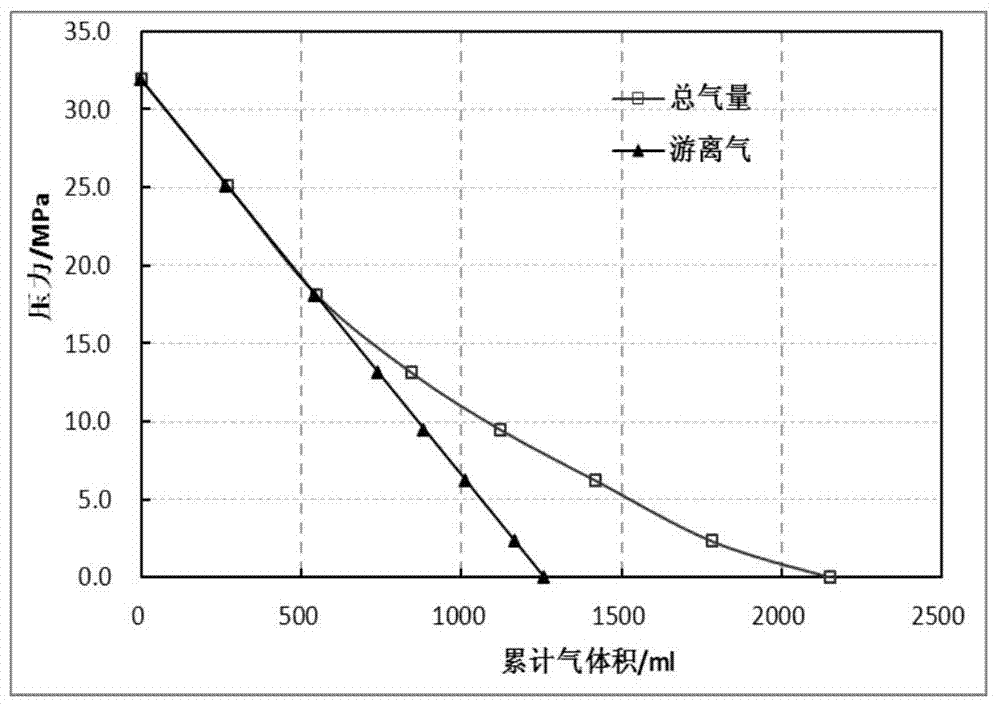

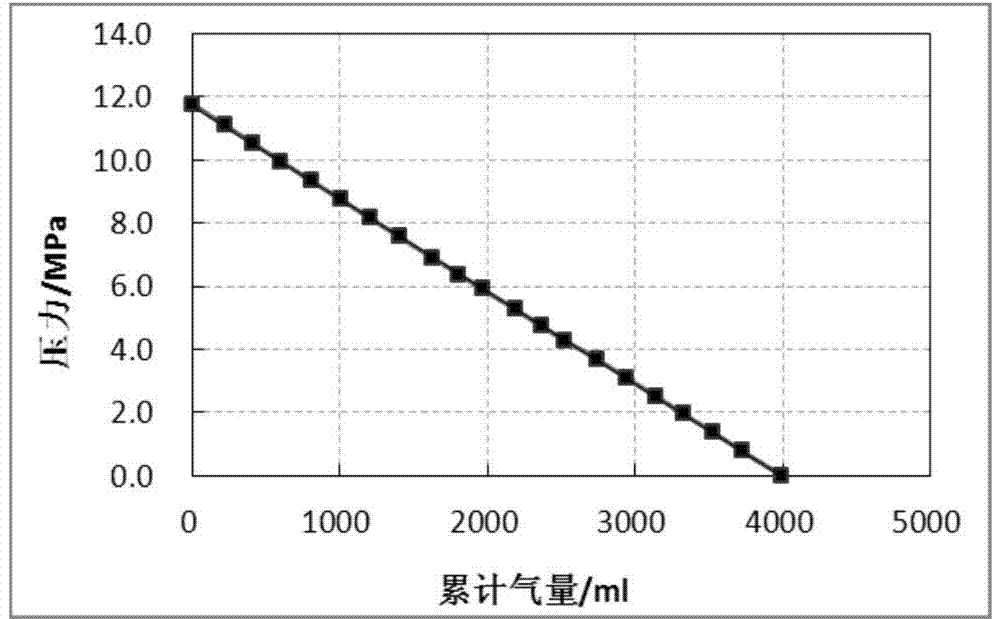

Method and device for testing gas content of shale gas reservoir

ActiveCN104713802AAutomatic monitoring and collectionHigh degree of automationMaterial analysisDesorptionAmbient pressure

The invention discloses a method and device for testing the gas content of a shale gas reservoir. The device for testing the gas content of the shale gas reservoir comprises a high-pressure nitrogen inlet device, a high-pressure natural gas inlet device, a first six-way valve, a booster pump, a second six-way valve, an evacuator, a thermostat, a rock core desorption flow model, a pressure sensor, a ring crush control pump and a gas metering device, wherein the high-pressure nitrogen inlet device and the high-pressure natural gas inlet device are connected with the second six-way valve by virtue of pipelines after passing through the first six-way valve and the booster pump; the evacuator is connected with the second six-way valve; the second six-way valve is connected with the gas metering device by virtue of a pipeline after pasting through the rock core desorption flow model arranged in the thermostat; and the rock core desorption flow model is respectively connected with the pressure sensor and the ring crush control pump which is used for performing follow-up control on the ambient pressure of the rock core desorption flow model. By adopting the device disclosed by the invention, the shale gas desorption in the development process of a gas reservoir is researched by virtue of a physical simulation method, and the gas production rate during shale gas exploitation is measured.

Owner:CHINA PETROLEUM & CHEM CORP +1

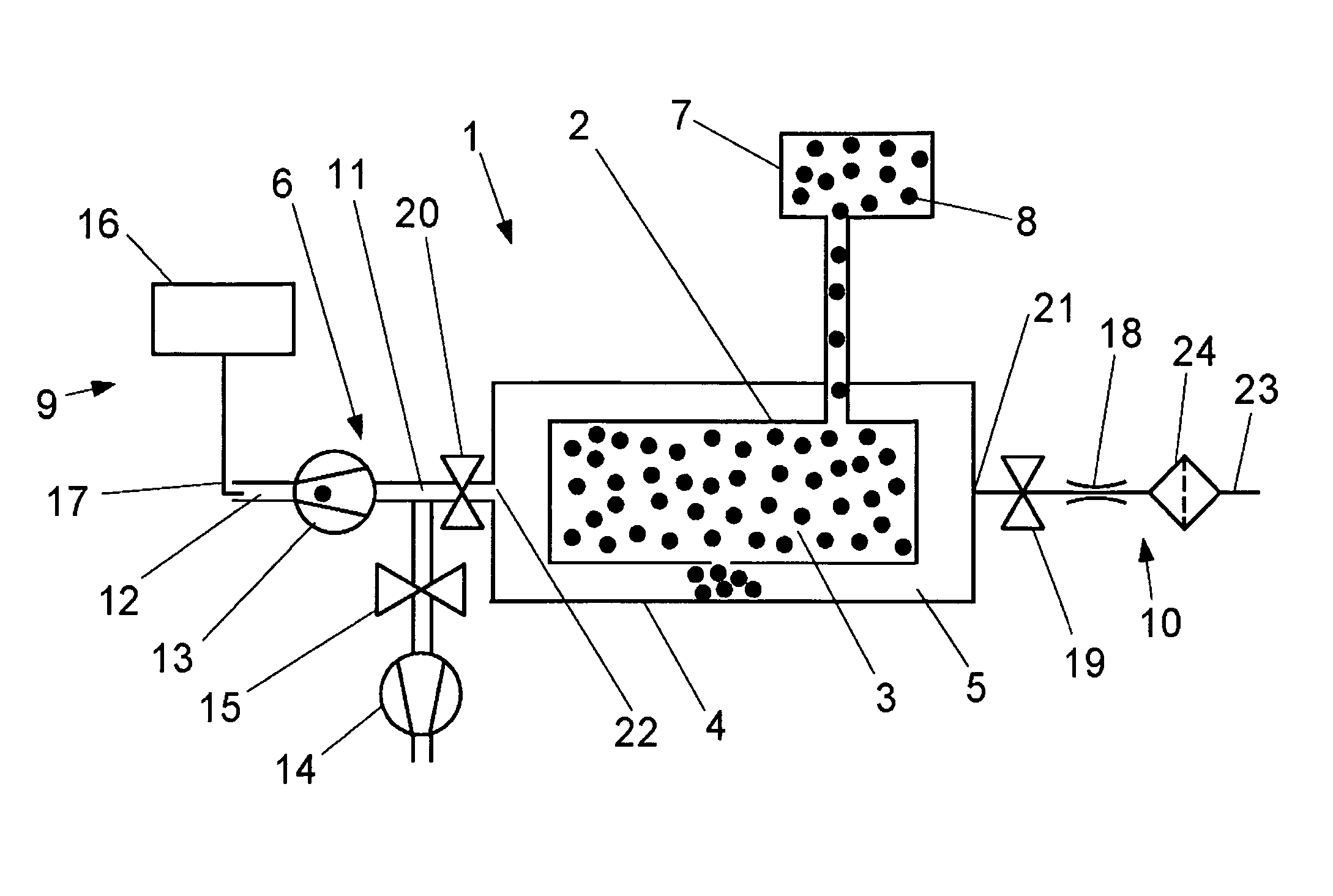

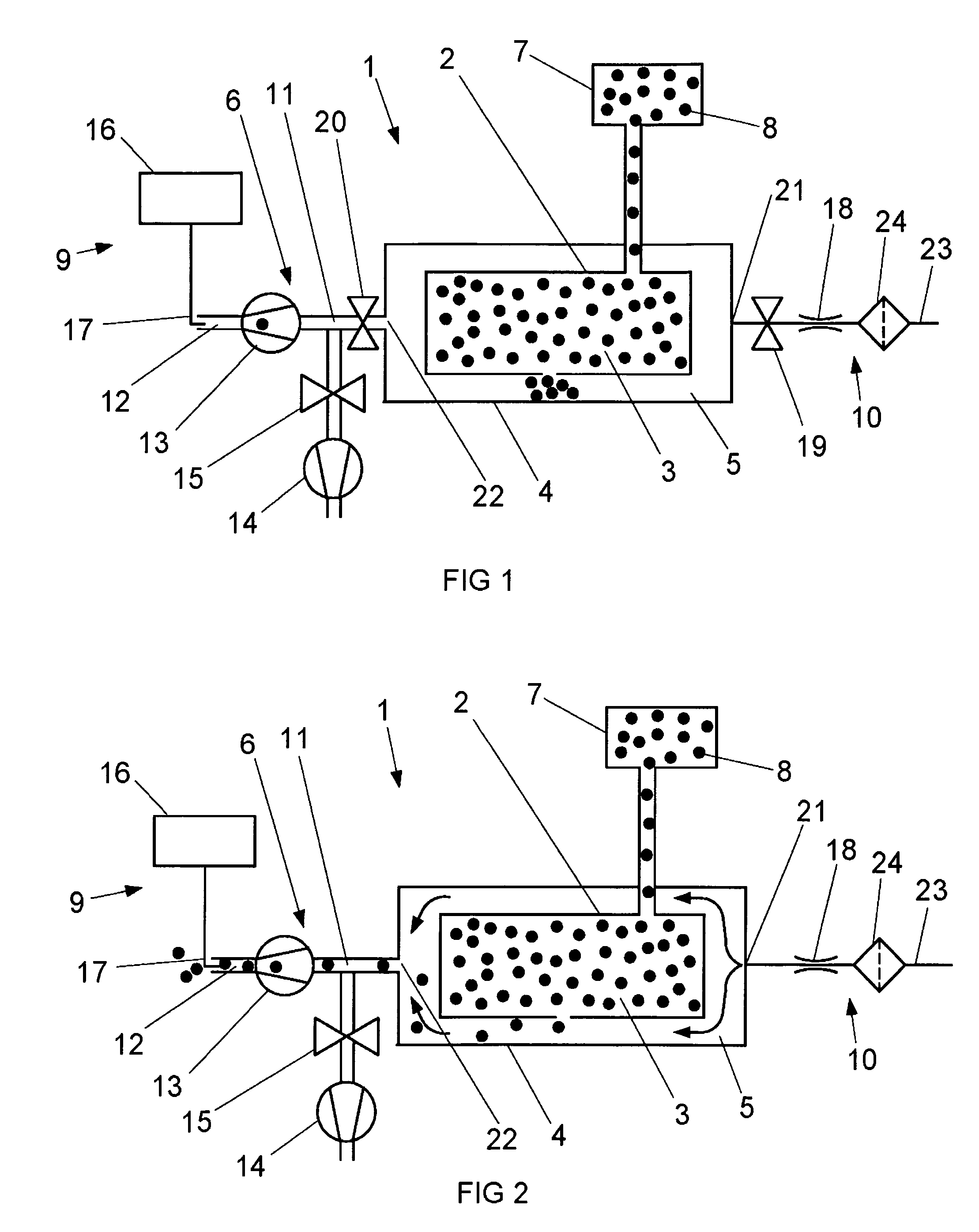

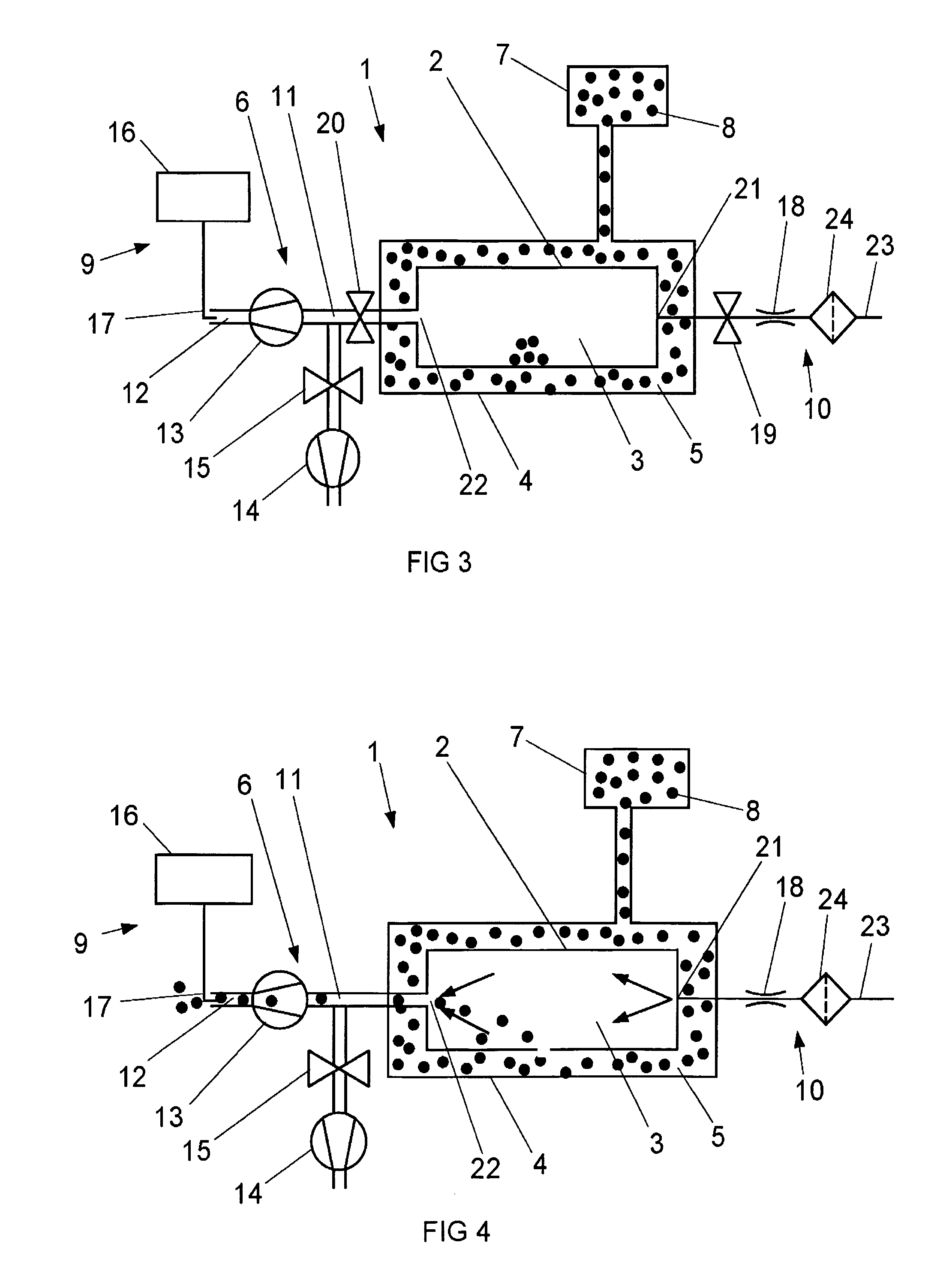

System and method for determining the leakproofness of an object

A system and a method for determining the leakproofness of an object having a first cavity. The system includes a closed chamber having a second cavity arranged to envelope the object, an evacuator for lowering the pressure inside one of the cavities, a supply for supplying a tracer gas into the one of the cavities rendered the higher pressure, a detector sensitive to the tracer gas and an introducer for introducing a transport gas into the one of the cavities rendered the lower pressure. Furthermore, the evacuator is arranged to compress arriving gas to the ambient pressure of the chamber and to communicate with the detecting means, which is suited for operation at the ambient pressure of the chamber. The tracer gas is hydrogen.

Owner:INFICON AB

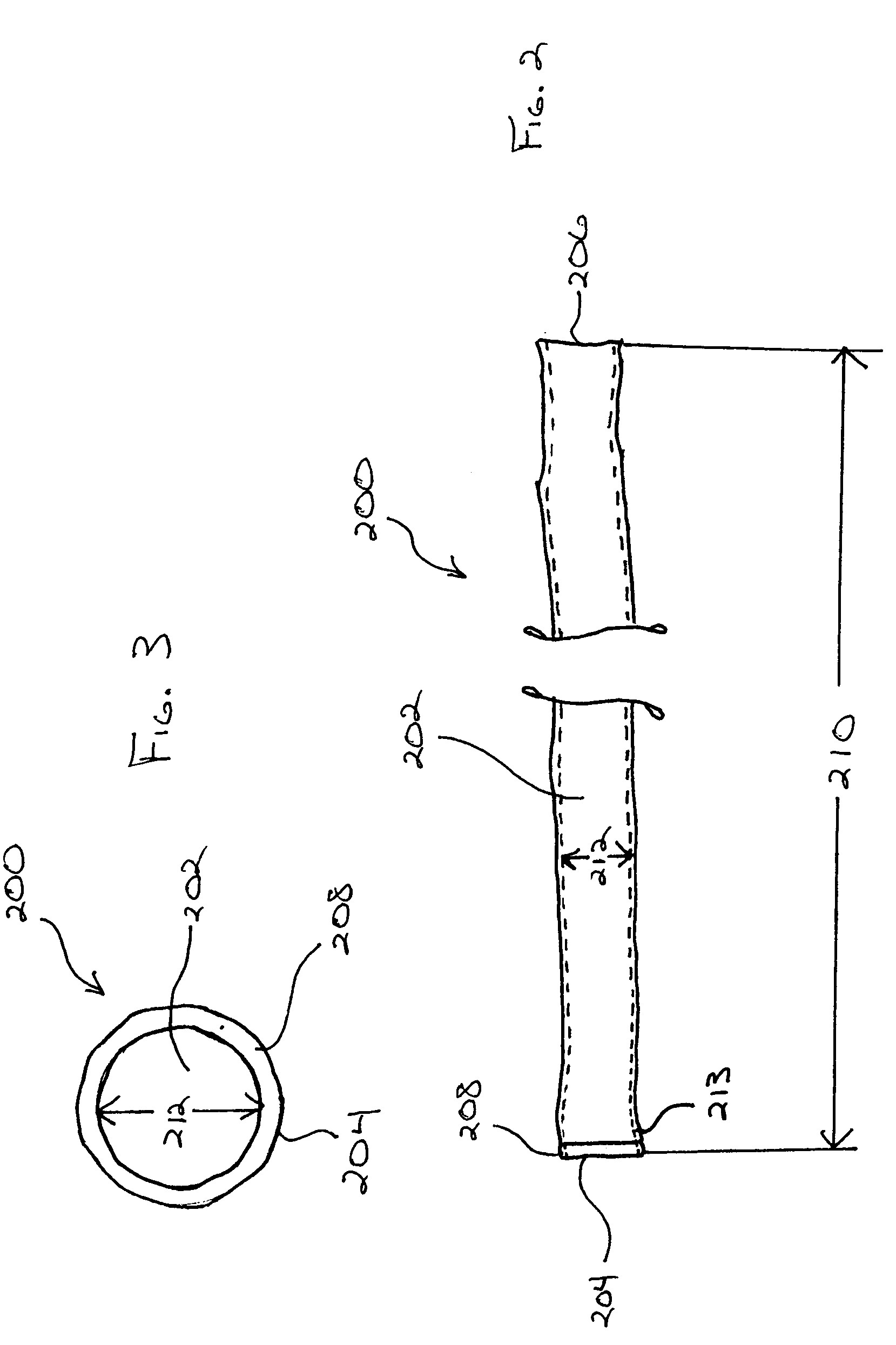

Backflow prevention sleeve for suctioning devices

A sleeve for preventing backflow and cross-contamination between patients of fluid and particulate matter as well as other contaminants present within a dental / medical suctioning device. The sleeve includes a sleeve inlet end that sealingly attaches to and surrounds at least a portion of the suctioning device the vacuum hose to the evacuator tip. The sleeve also has a sleeve exhaust end that is inserted into the control valve and can reside within the interior lumen of the vacuum hose during normal suction operation. During operation, the sleeve provides a seal between the patient contact part and the control valve of the suctioning device. The proximate end collapses, seals, and / or provides a barrier when the suctioning device does not draw a vacuum away from the patient and towards the vacuum source.

Owner:MARCH MICHAEL S

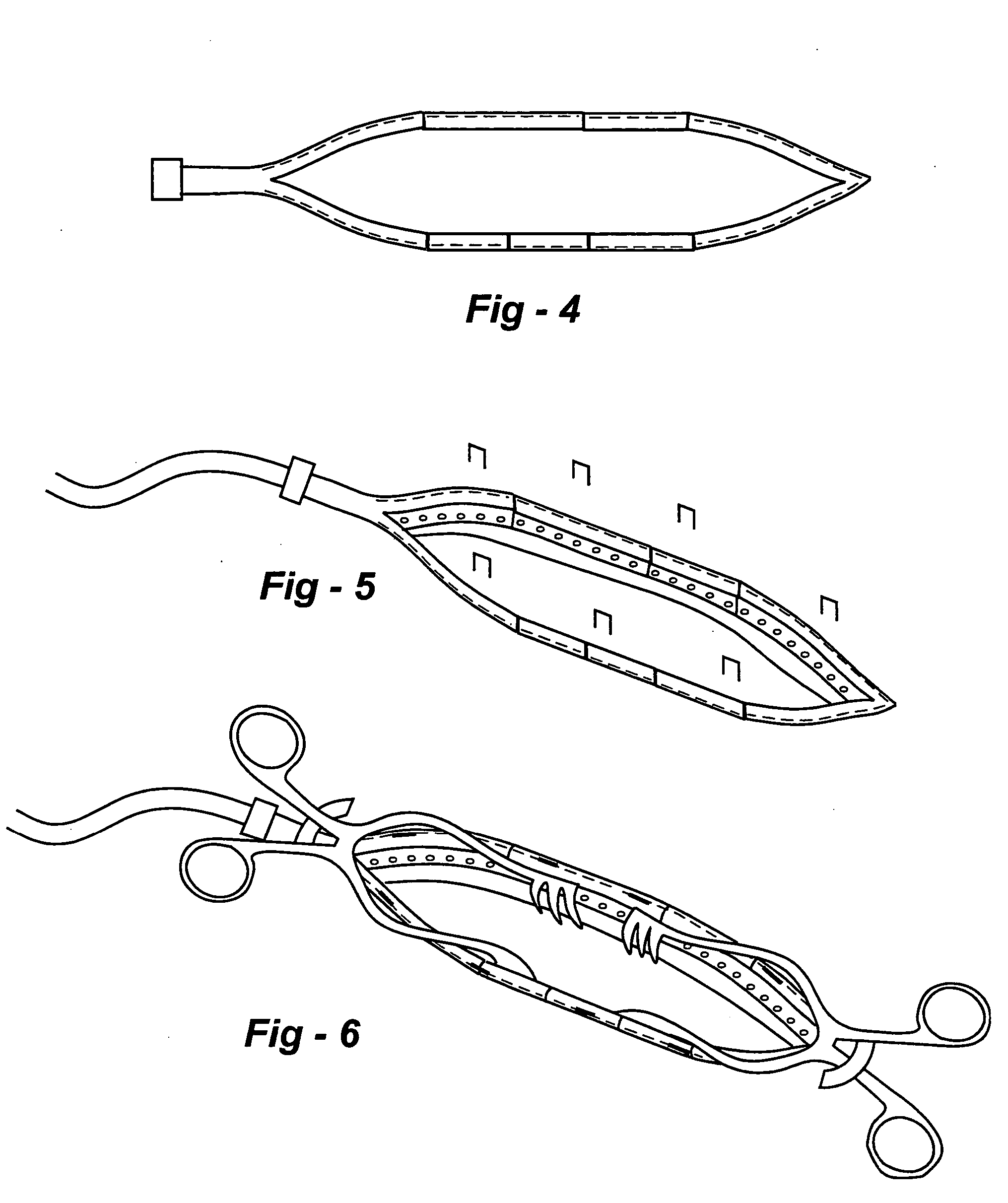

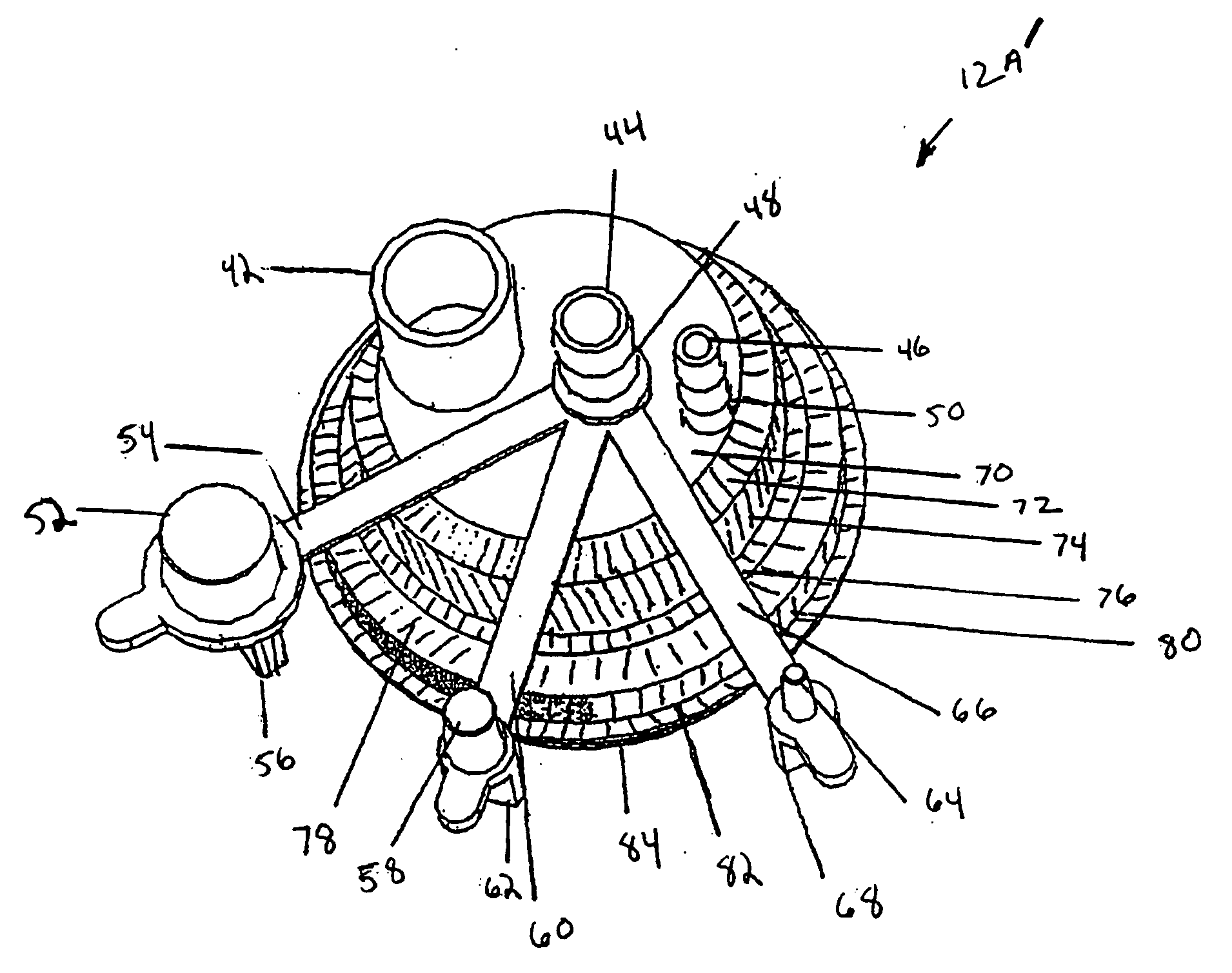

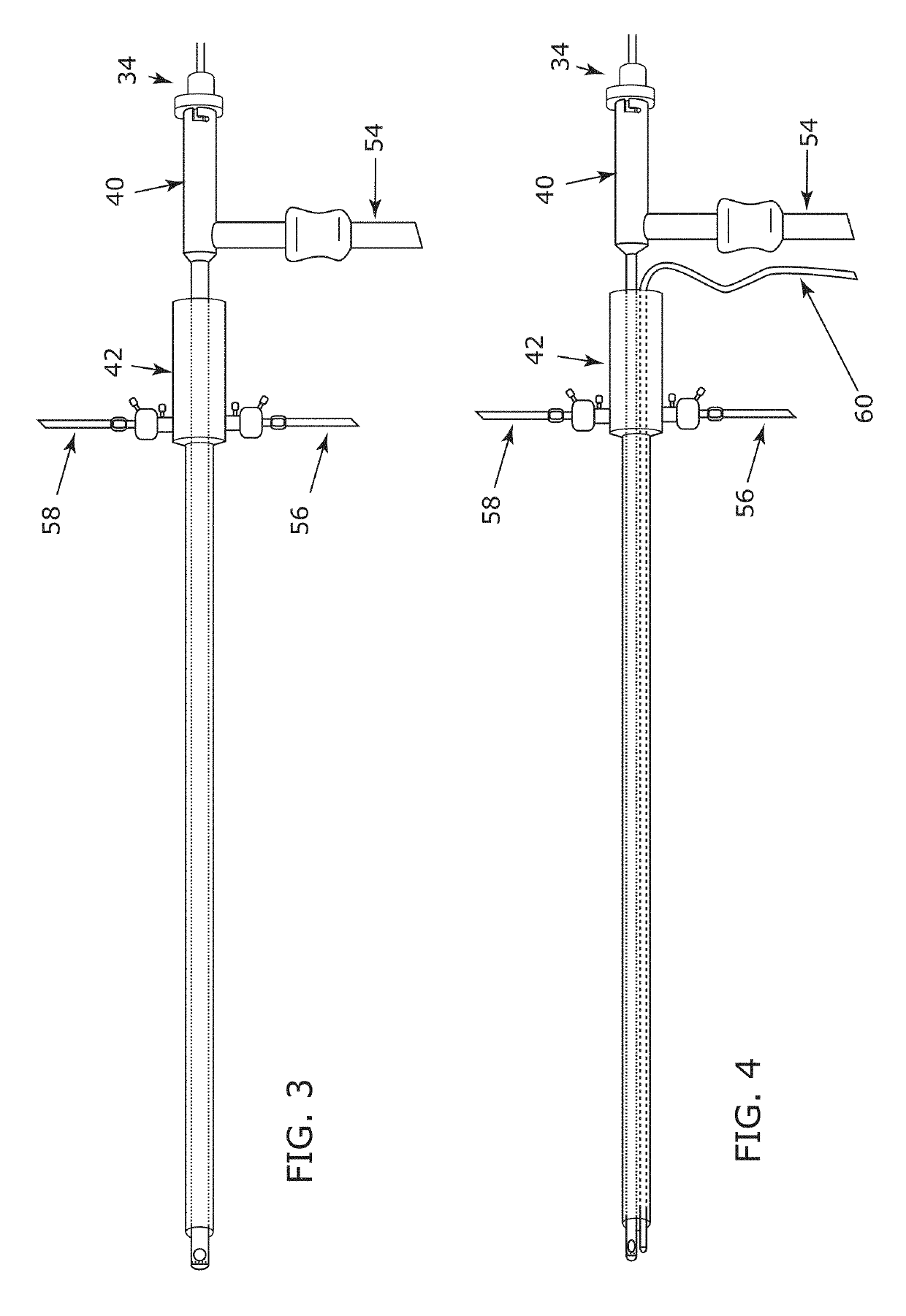

Surgical smoke field evacuators

InactiveUS20050054993A1Efficient use ofOut of operationIntravenous devicesSurgical instruments for aspiration of substancesProximateSurgical incision

Universally adaptable evacuators are adaptable to all surgical fields, easy to apply and, in most cases, may be expanded and / or removed as necessary. A hollow tube including a fitting adapted for connection to a vacuum source and at least one smoke inlet is held in position with the smoke inlet proximate to a surgical wound. According to a preferred embodiment, a stapling tab extending from a flexible perforated tube is used to hold the evacuator in place around the periphery of a surgical incision. According to an alternative embodiment, a smoke evacuator attaches temporarily or permanently to a retractor or other surgical instrument. Standard tubing and couplers may be used and the assembly may be prepackaged in sterile condition and disposed after use.

Owner:MEDICAL DESIGNS

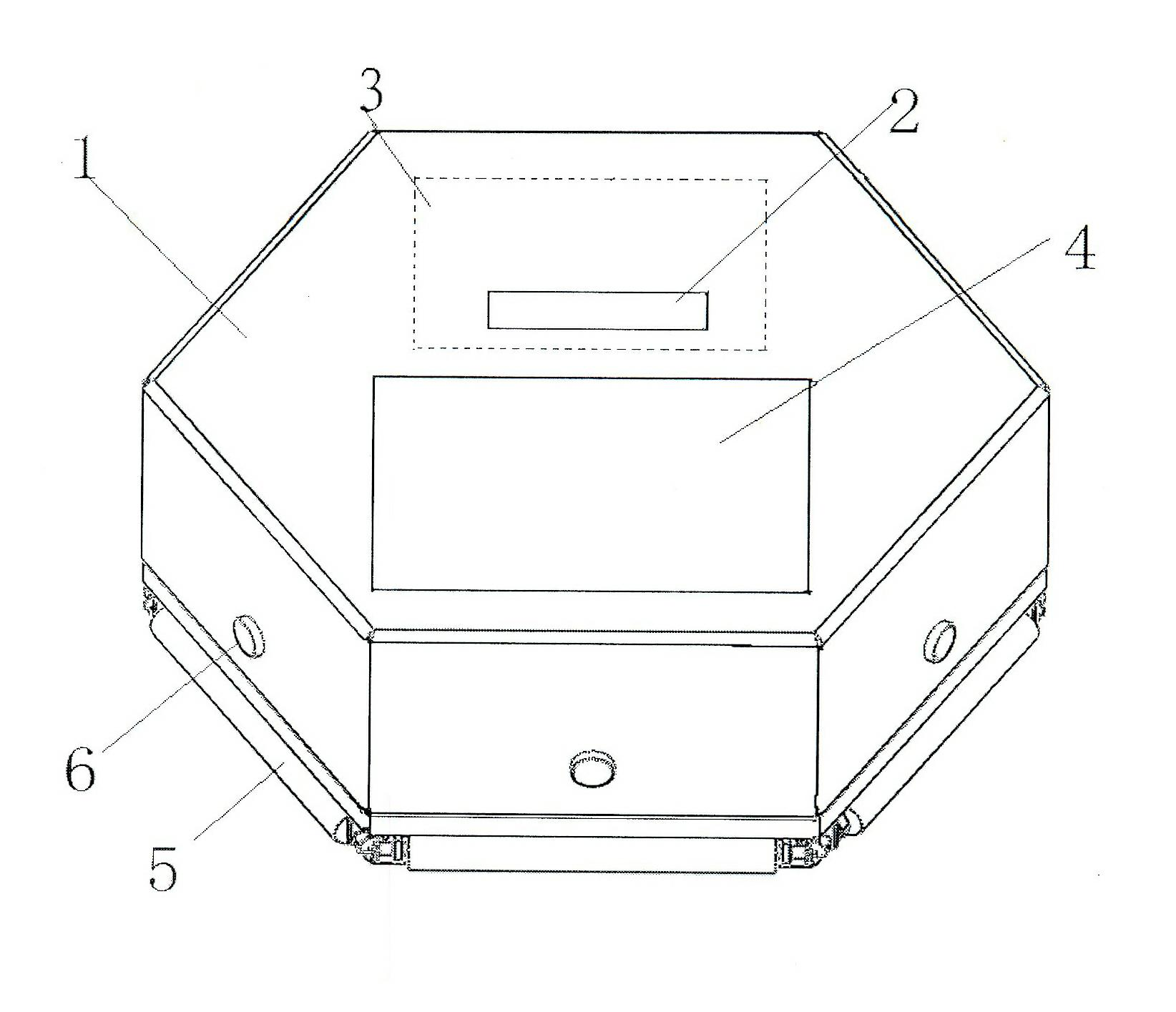

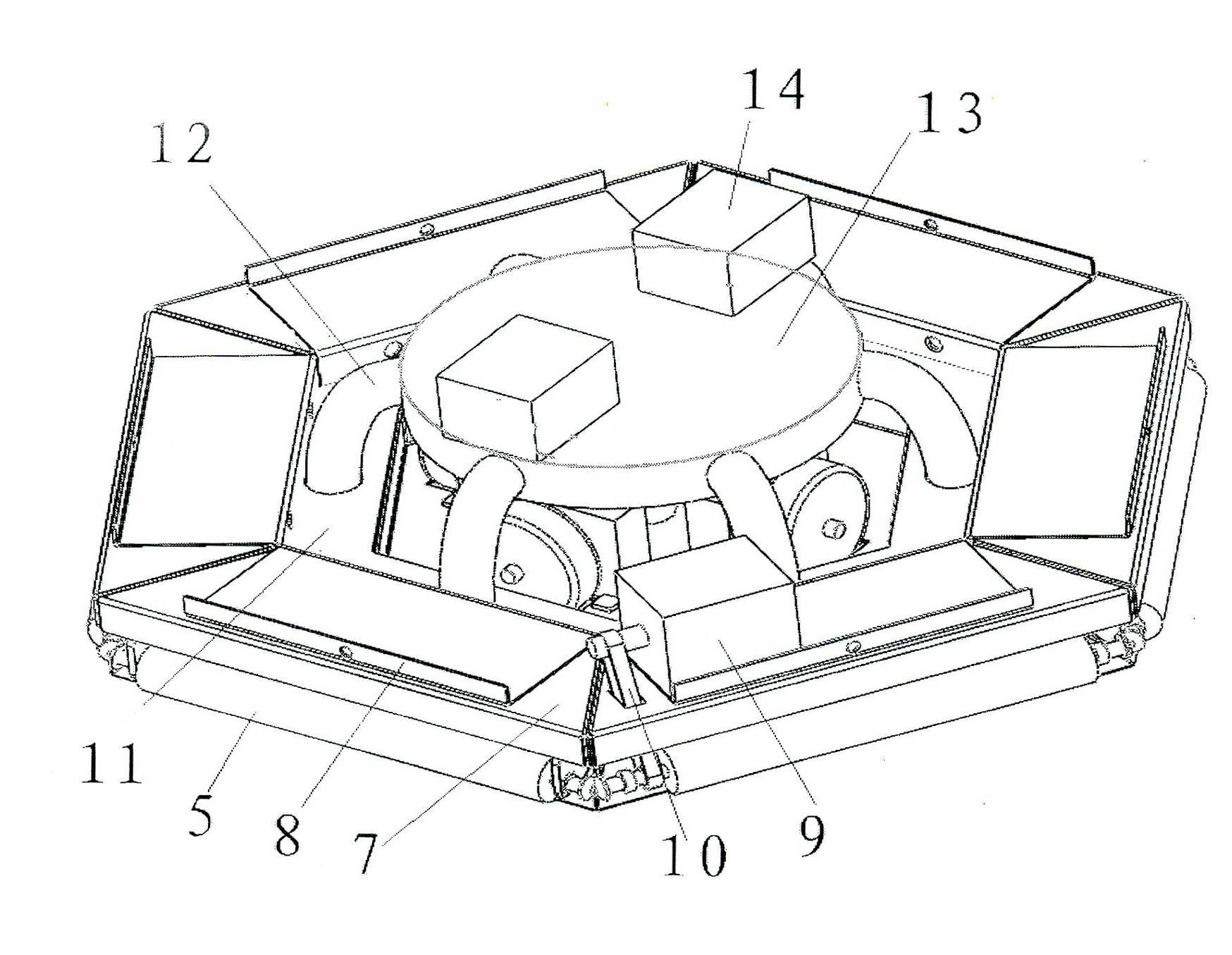

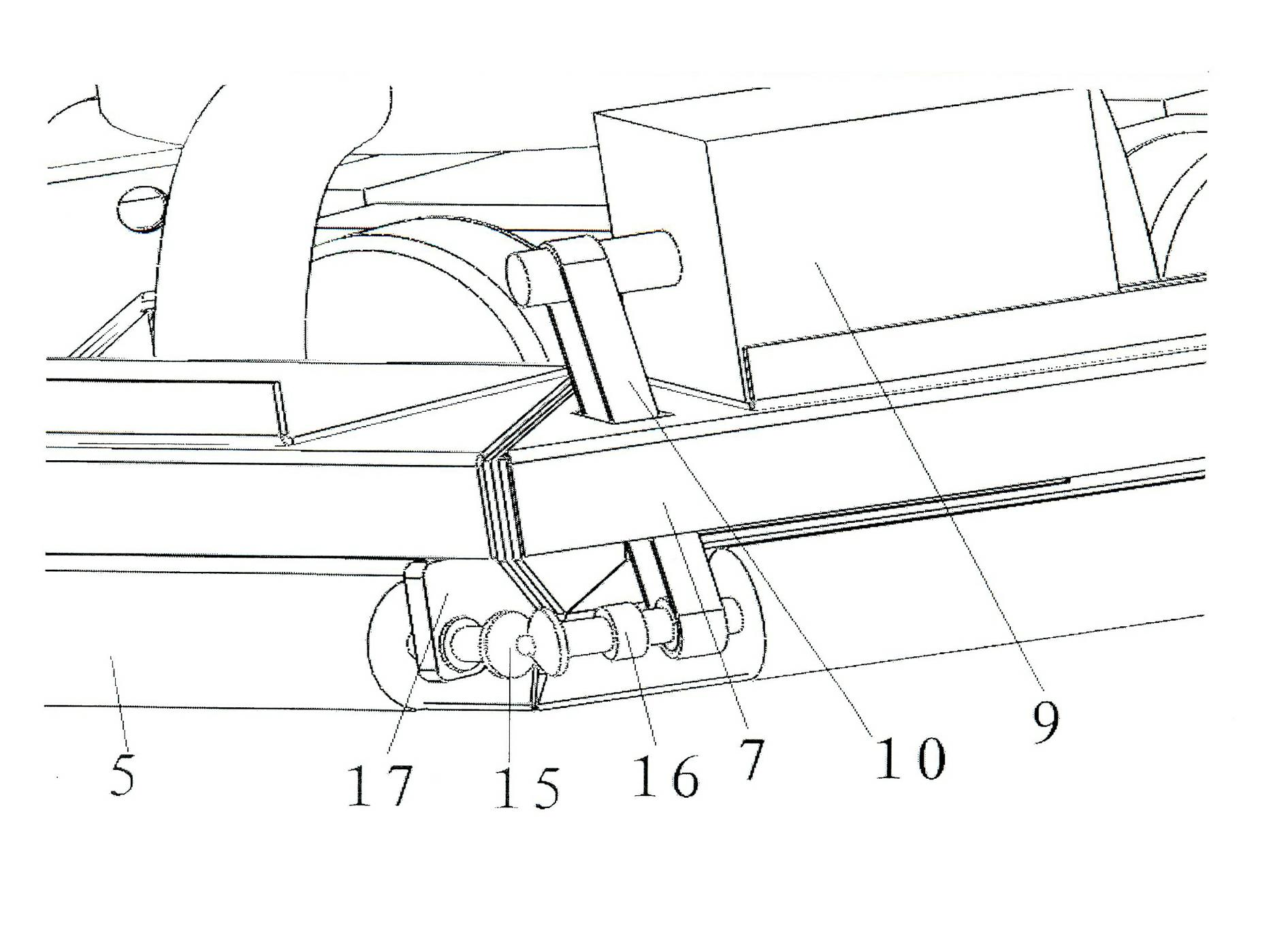

Indoor automatic detecting and cleaning robot

InactiveCN102525333AExtend your lifeIncrease the cleaning areaMachine detailsFloor sweeping machinesBristleDrive motor

The invention relates to an indoor automatic detecting and cleaning robot, which comprises a shell, a vortex evacuator, a garbage box and a four-wheel travelling mechanism. The robot is characterized in that: a shell is in a shape of regular hexagonal prism; a battery box, a touch display screen and a control circuit board are arranged on the top of the shell; a camera is arranged on each lateralsurface of the shell; the garbage box is a regular hexagonal annular box, the upper part of the garbage box is provided with a circular hole, the circular hole is connected with the vortex evacuator through a pipeline, and the four-wheel travelling mechanism is arranged on the middle part of an inner ring of the garbage box; and each lateral surface of the garbage box is provided with a garbage inlet, a dustpan is arranged on each lateral surface of the garbage box, the rear part of each dustpan is provided with a garbage outlet communicated with the garbage box, a rolling brush is arranged on the front part of each dustpan, the bristle of each rolling brush is crossed with a front edge plate of the dustpan, a helical gear is arranged on each rolling brush shaft, the adjacent helical gears are engaged, and one of the rolling brush shafts is in transmission connection with a driving motor shaft. The robot has the advantages of low energy consumption, comprehensive function and thoroughcleaning.

Owner:YANSHAN UNIV

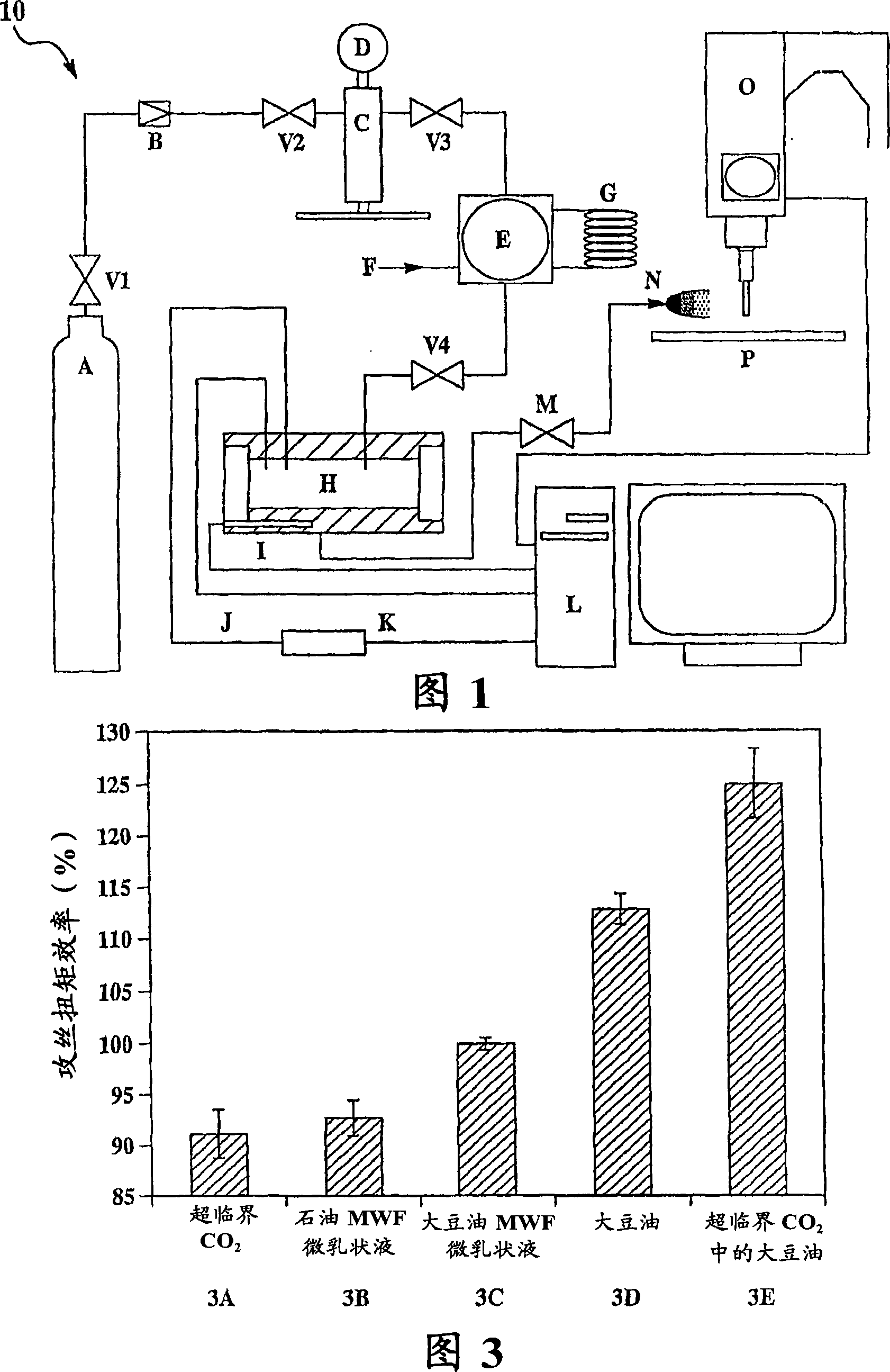

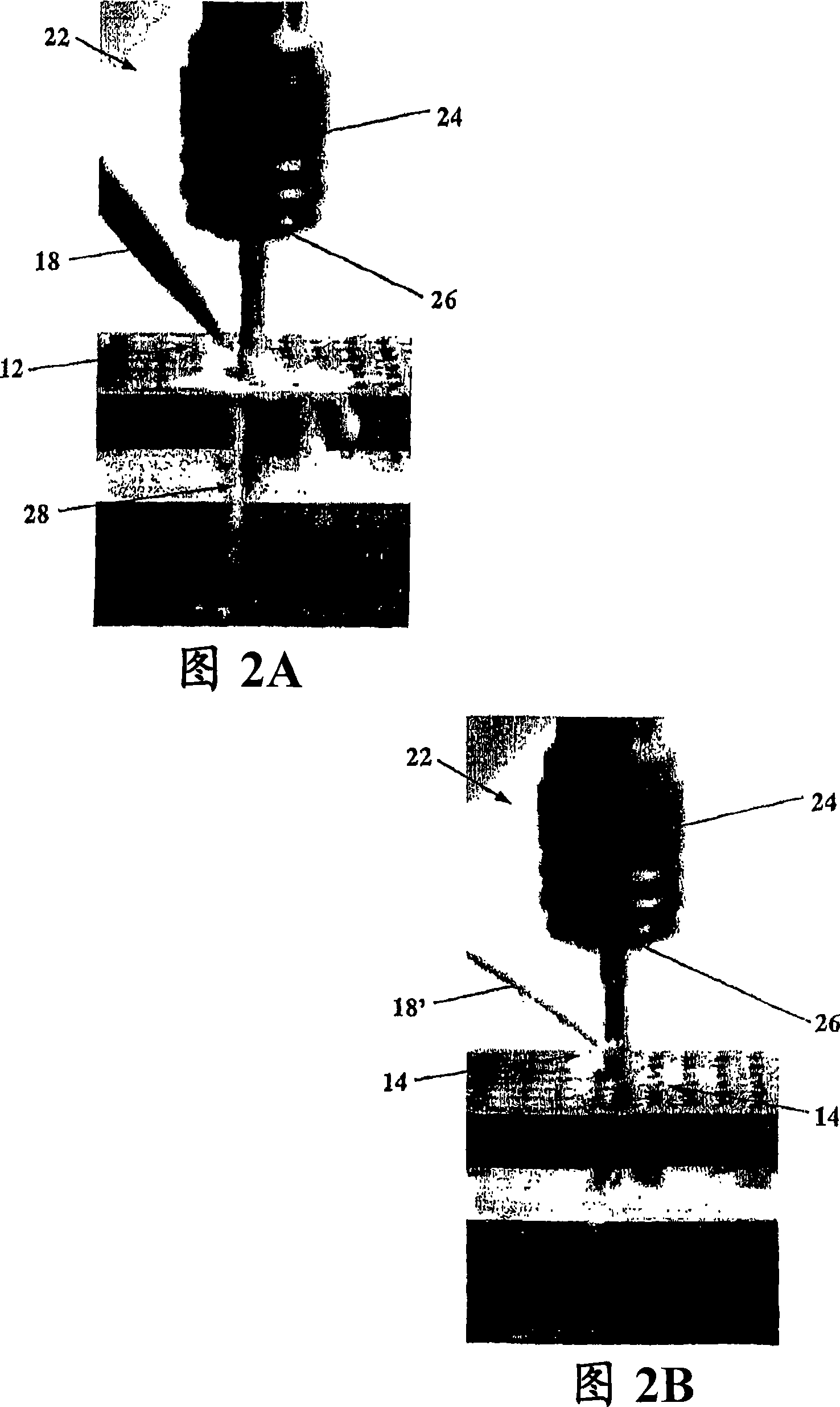

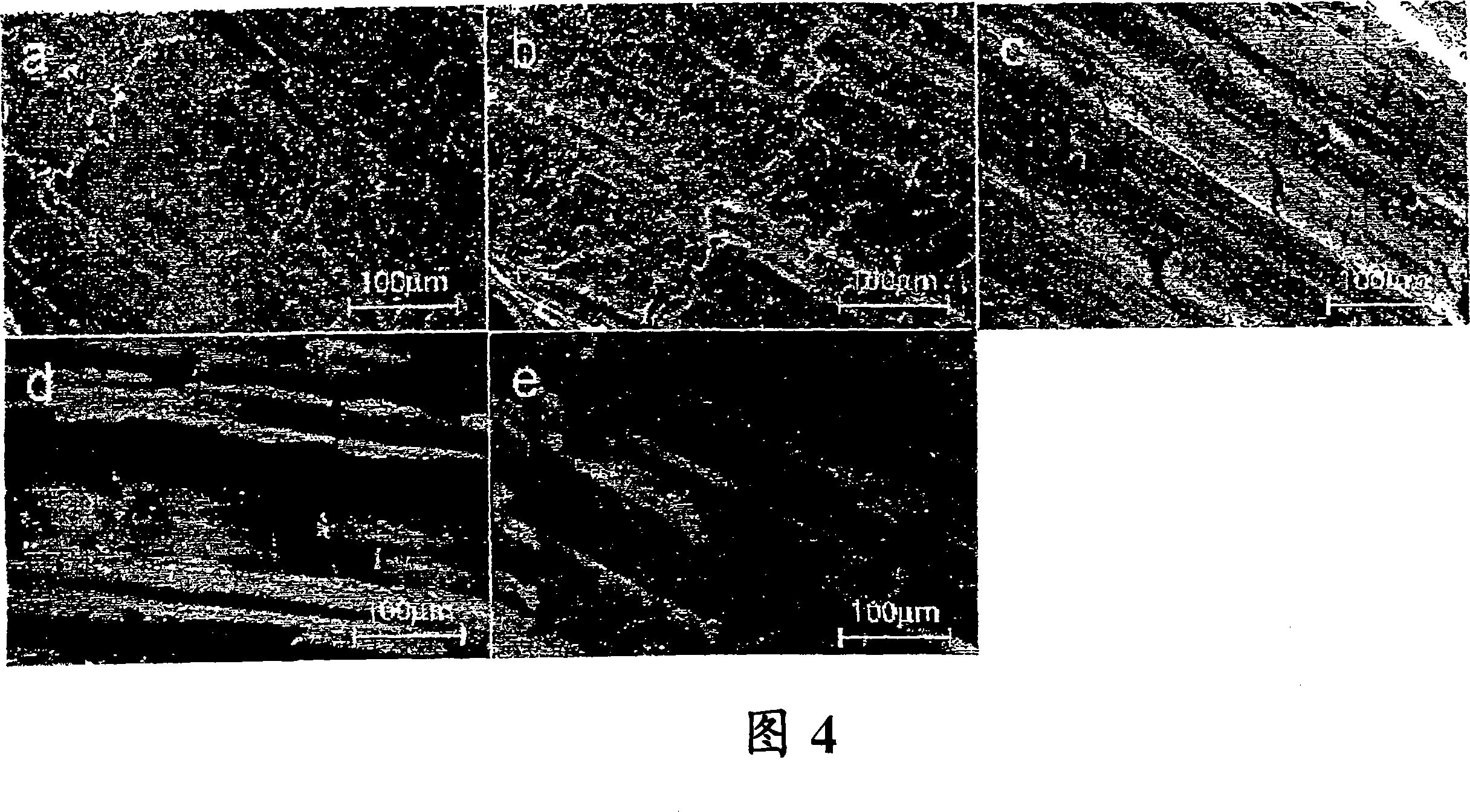

Metal working lubricant formulations based on supercritical carbon dioxide

A method for lubricating a metal workpiece during a metalworking process includes delivering supercritical carbon dioxide to the workpiece during the metalworking process. The supercritical carbon dioxide acts as a lubricant, coolant, chip evacuator, and / or carrier for another lubricant or corrosion inhibitor.

Owner:RGT UNIV OF MICHIGAN

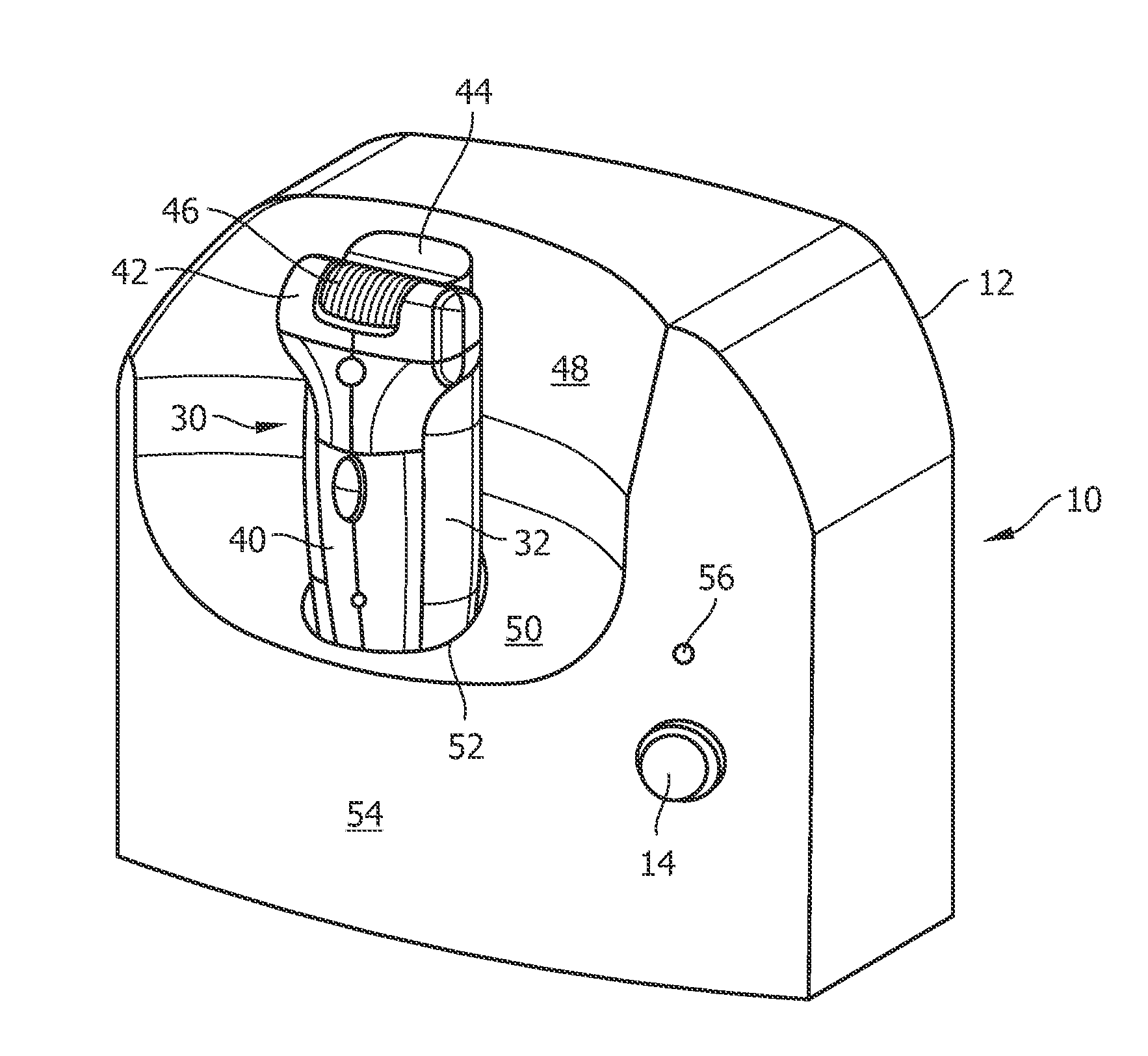

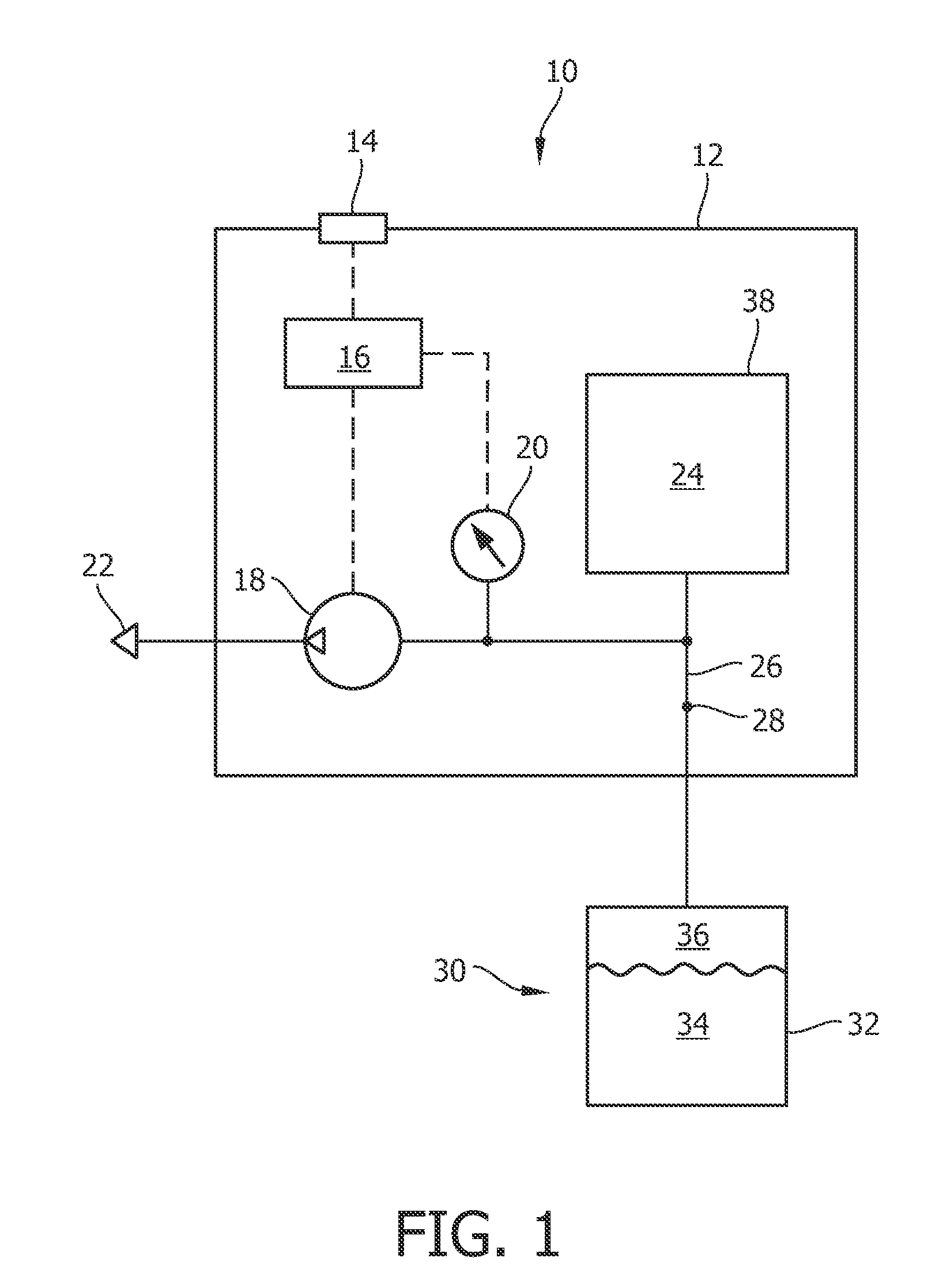

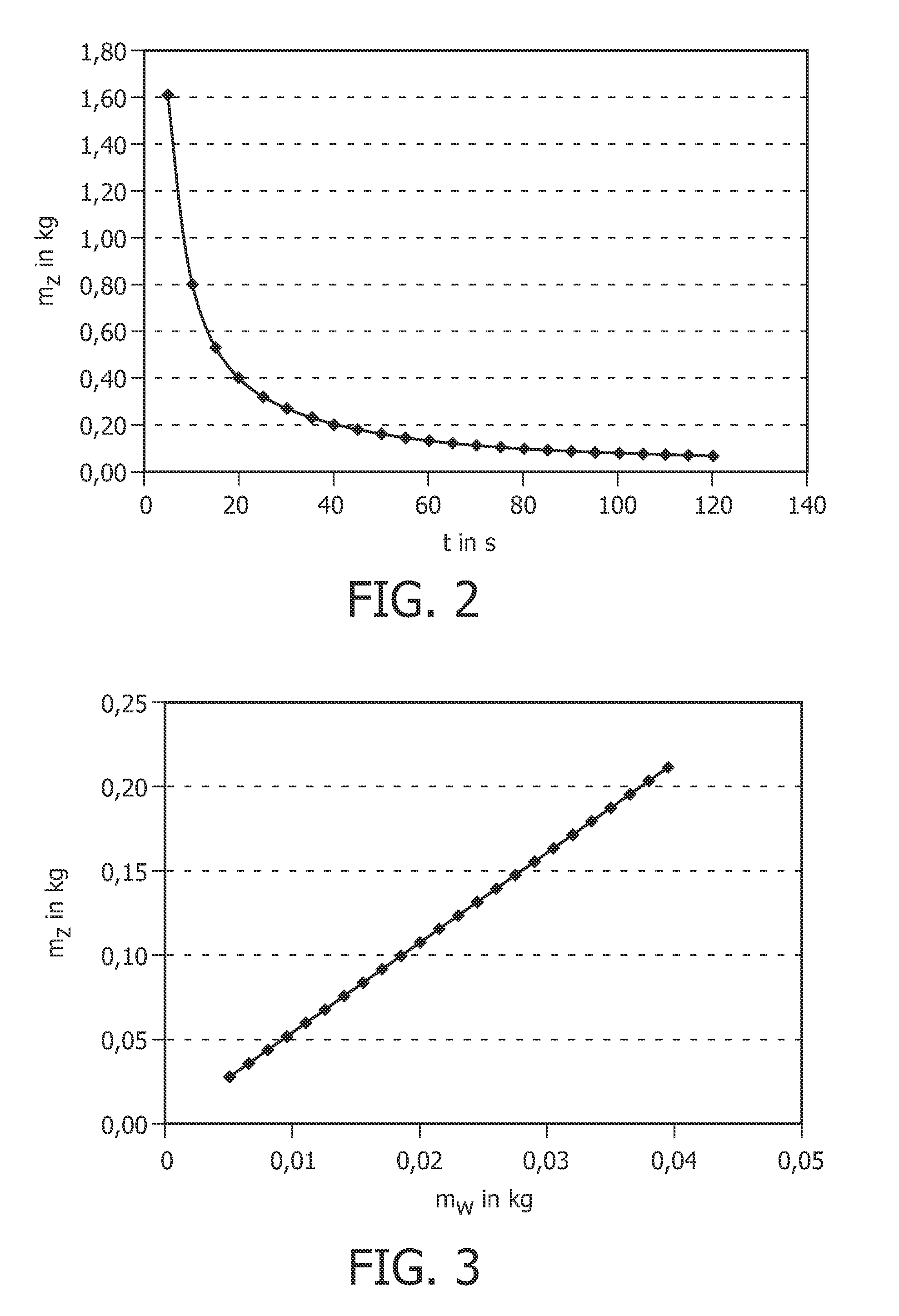

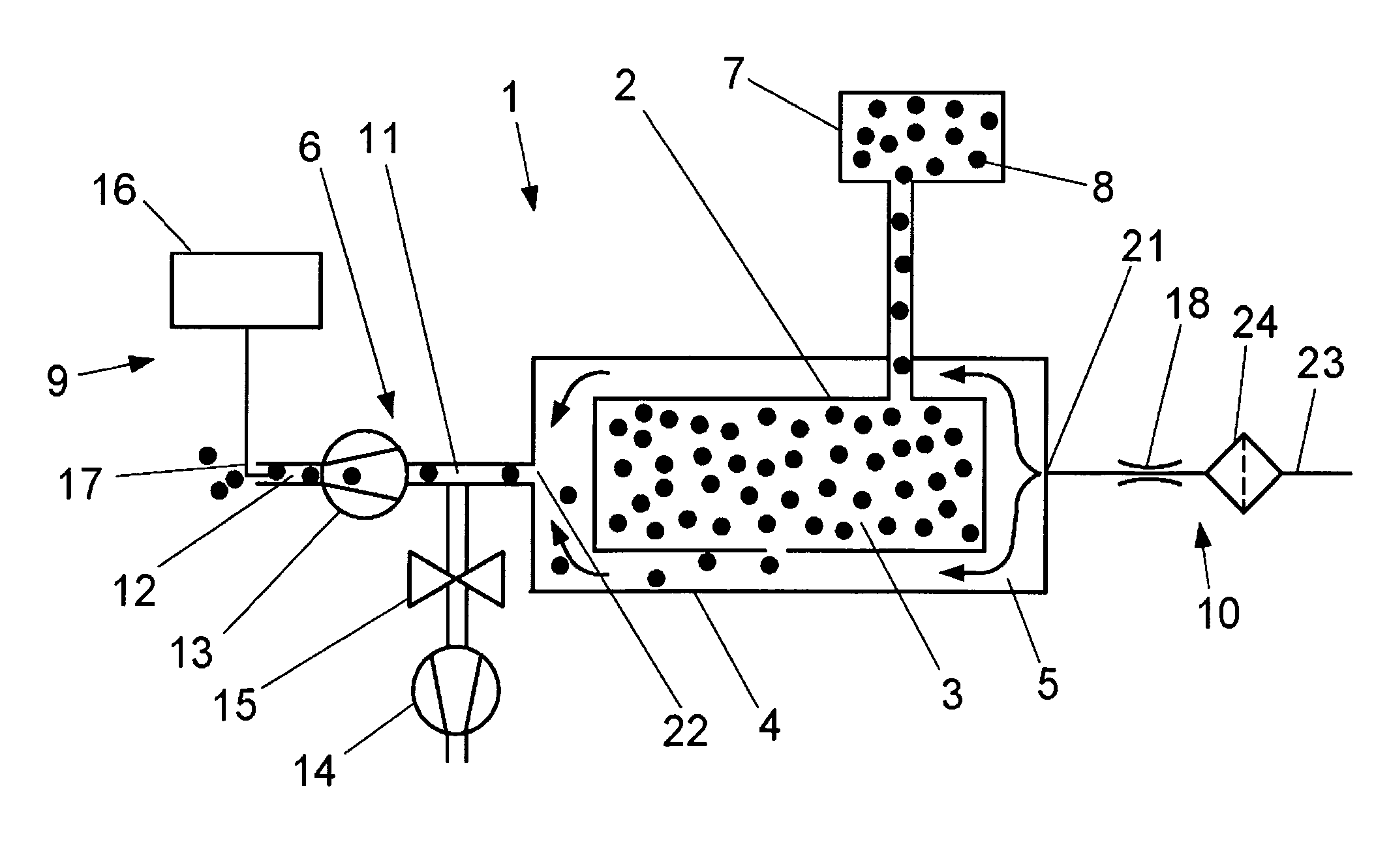

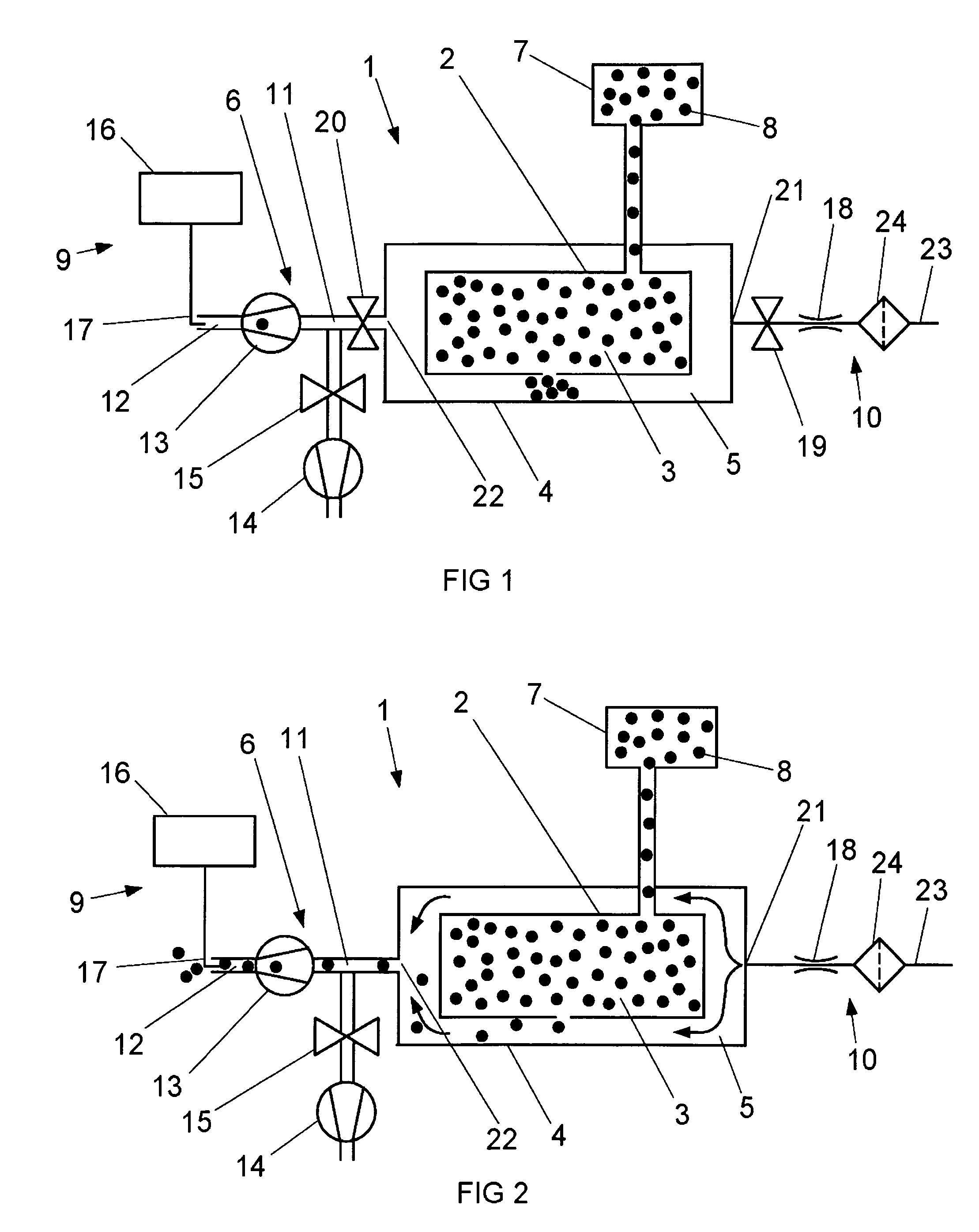

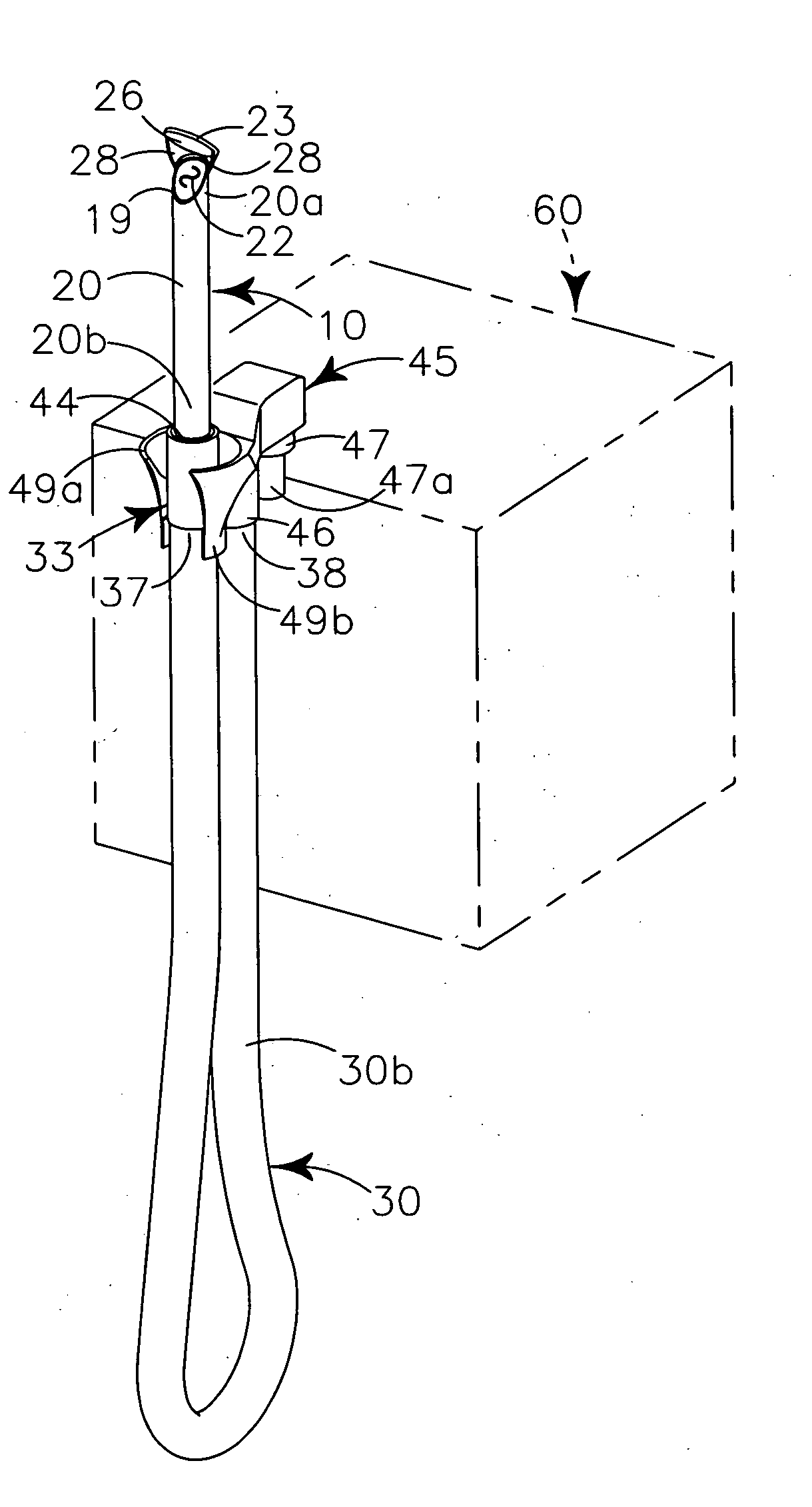

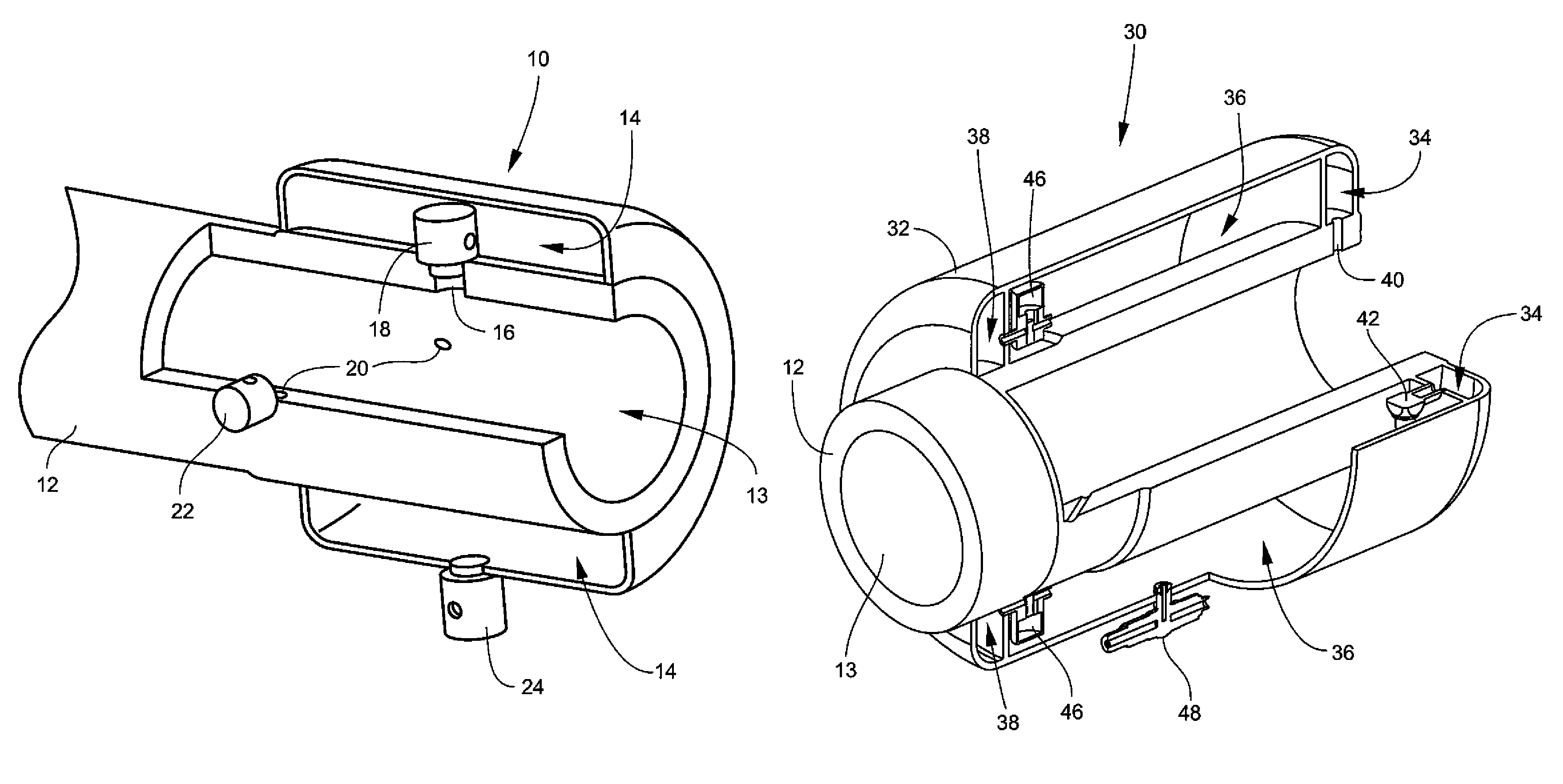

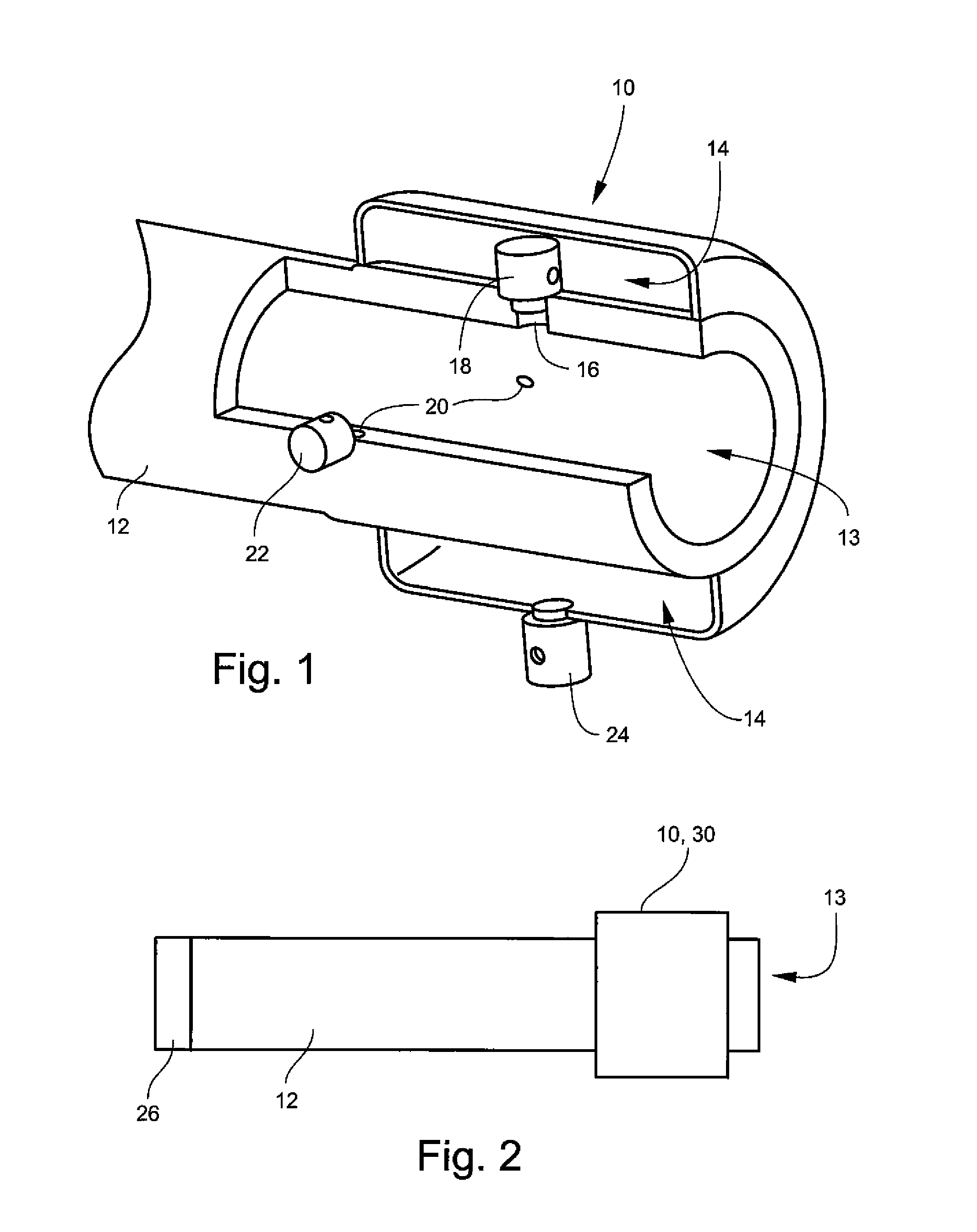

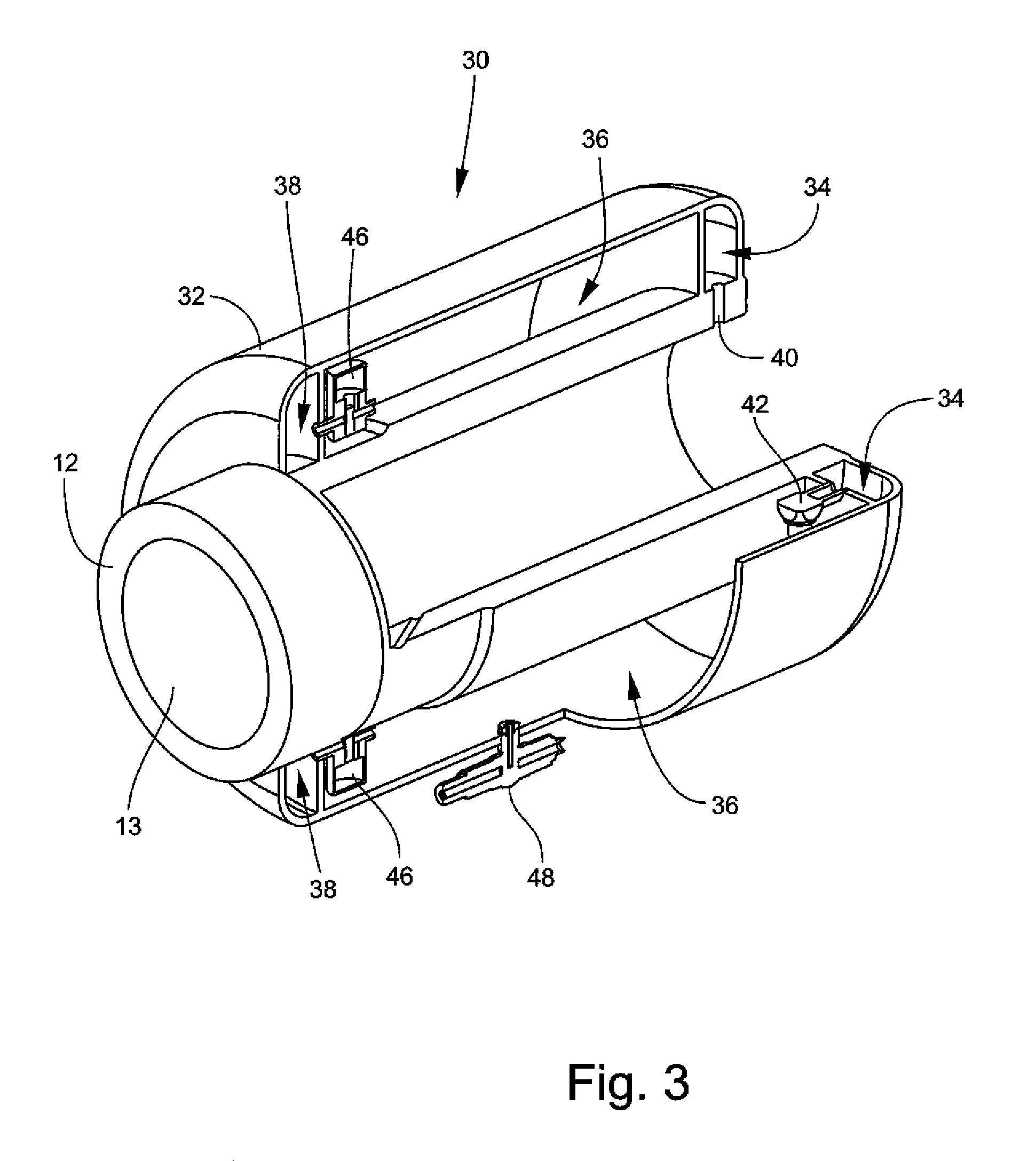

Docking station for a skin treatment device having a cooling member

InactiveUS20110015652A1Easy to takeAdvantageously employedHair-singeingSurgeryDocking stationSkin treatments

The invention relates to a docking station (10) for a skin treatment device (30) having a cooling member (32). According to the invention, the docking station comprises: an evacuator (18) for lowering a pressure inside the cooling member, and means (28) for connecting an interior of the cooling member to a sorbent (24). The sorbent preferably comprises a zeolite. The invention further relates to a skin treatment device (30), particularly an epilator, comprising a cooling member (32) for containing a cooling agent (34, 36). According to the invention, the skin treatment device comprises means (28) for connecting the cooling member to a docking station (10) as mentioned above. The cooling agent is preferably water or an aqueous solution.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

System and method for determining the leakproofness of an object

A system and a method for determining the leakproofness of an object having a first cavity. The system includes a closed chamber having a second cavity arranged to envelope the object, an evacuator for lowering the pressure inside one of the cavities, a supply for supplying a tracer gas into the one of the cavities rendered the higher pressure, a detector sensitive to the tracer gas and an introducer for introducing a transport gas into the one of the cavities rendered the lower pressure. Furthermore, the evacuator is arranged to compress arriving gas to the ambient pressure of the chamber and to communicate with the detector, which is suited for operation at the ambient pressure of the chamber. The tracer gas includes hydrogen.

Owner:INFICON AB

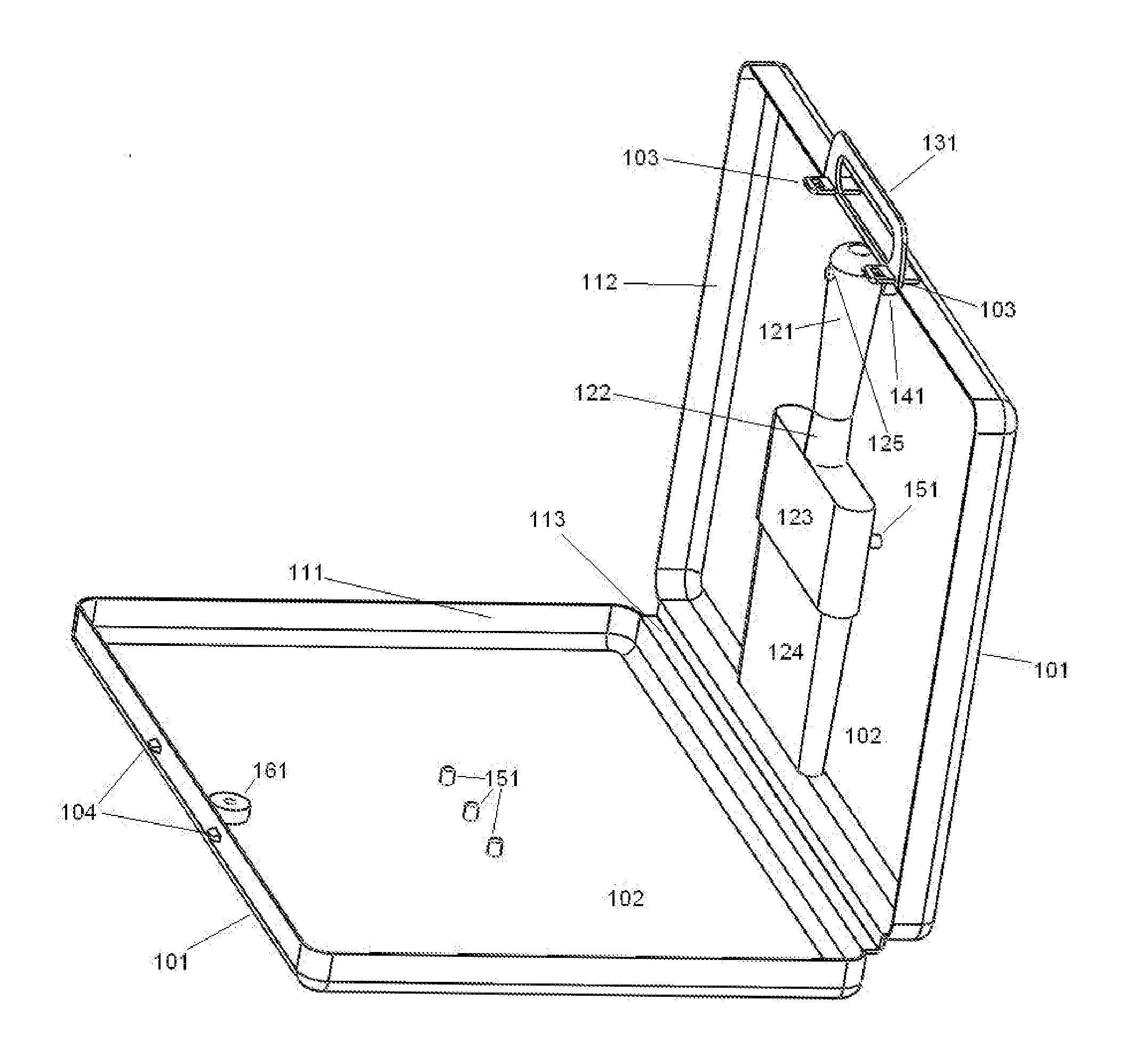

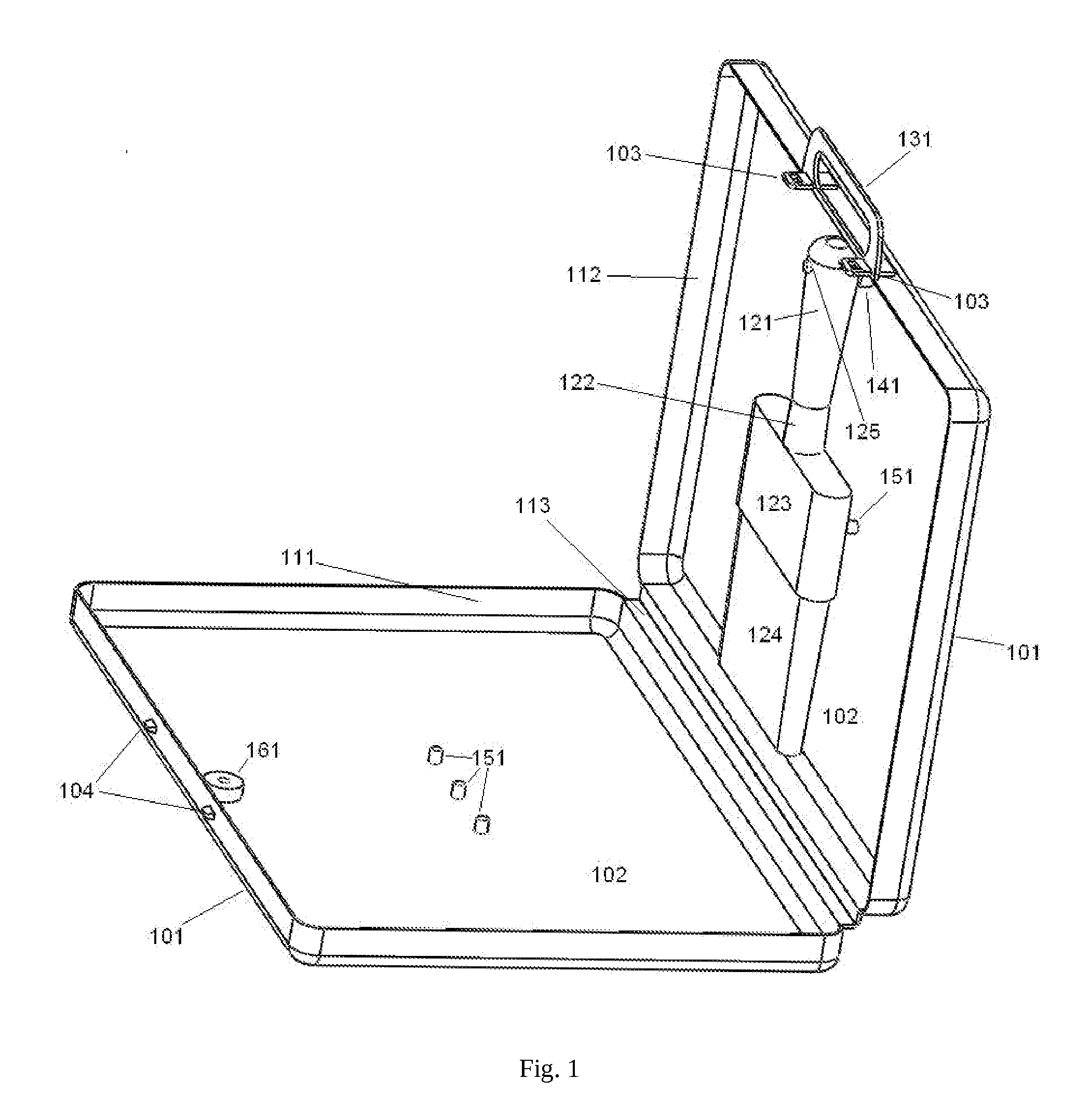

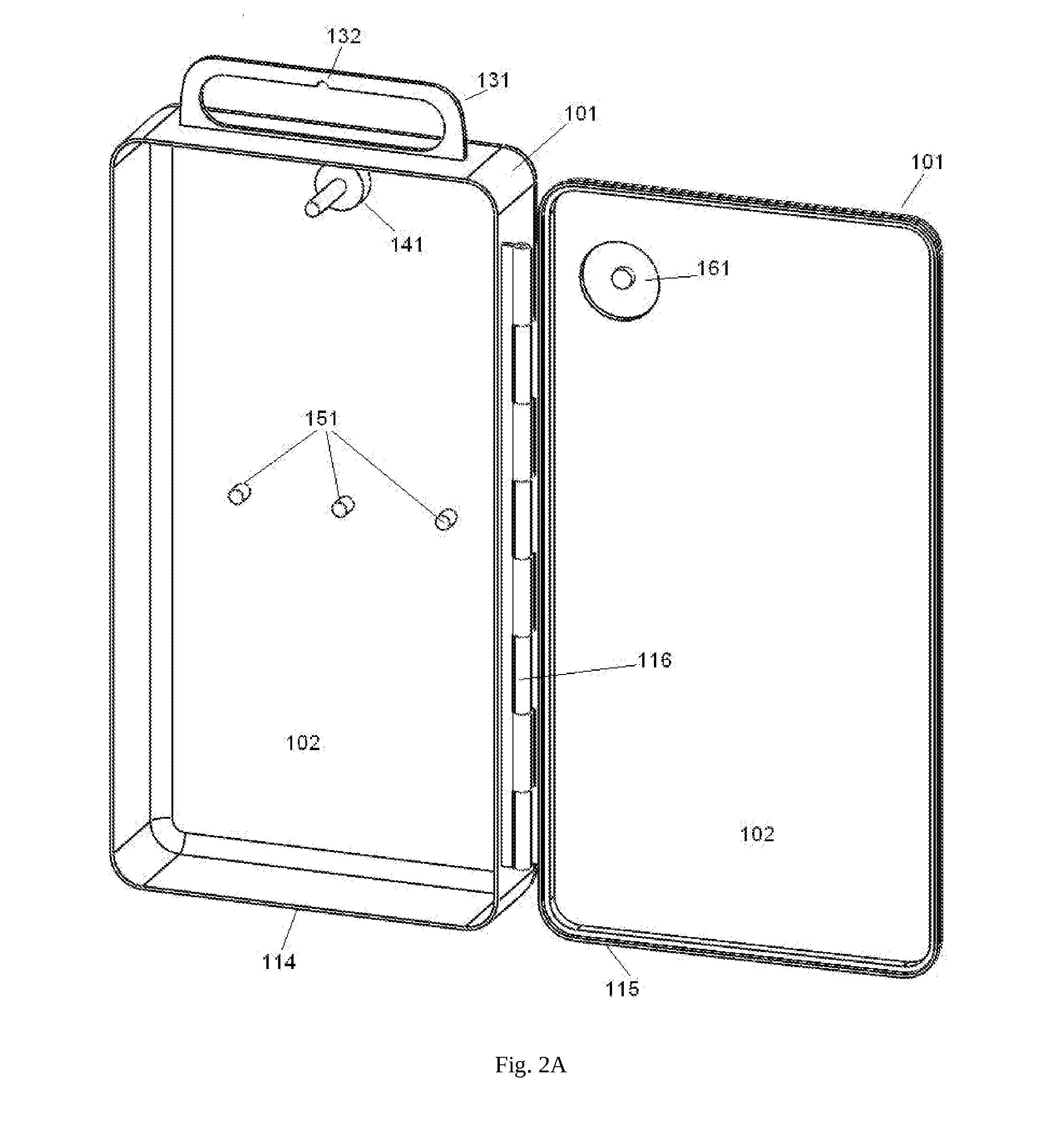

Case for Holding Paintbrushes

A case that stores one or more paintbrushes in manner to prevent paint in them from drying out, so that there is no need to clean those brushes between uses; moreover the case containing a pump evacuator to remove air from the case when it is closed, thus further retarding the drying of the brushes inside; and finally the case holding paint drying retardant that evanesces into the atmosphere inside the case, further slowing down the drying of the brushes inside.

Owner:HURLEY JAMES STEVEN +2

Fluid evacuator system

A device is delineated for removing body fluid from a wound site. The device may include a drain sealed within the wound site, a conduit connected to the drain and a fluid container connected to the other end of the conduit. The fluid container may include at least one inlet passage of larger diameter to reduce likelihood of clogging during body-fluid inflow. An additional inlet passage may be included. The fluid container may also include at least one outlet passage of larger diameter to improve draining efficiency.

Owner:SCOTTSDALE MEDICAL DEVICES

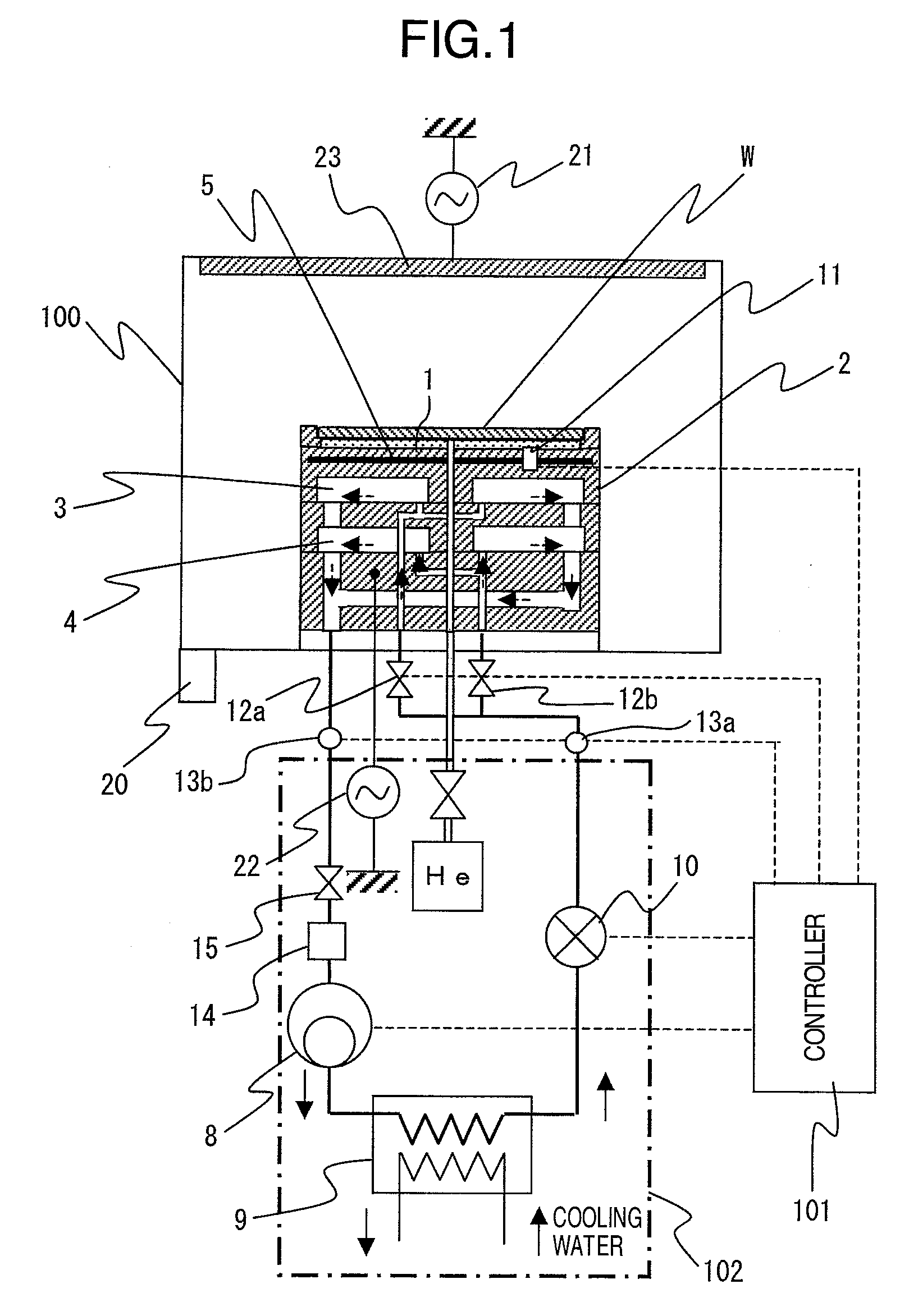

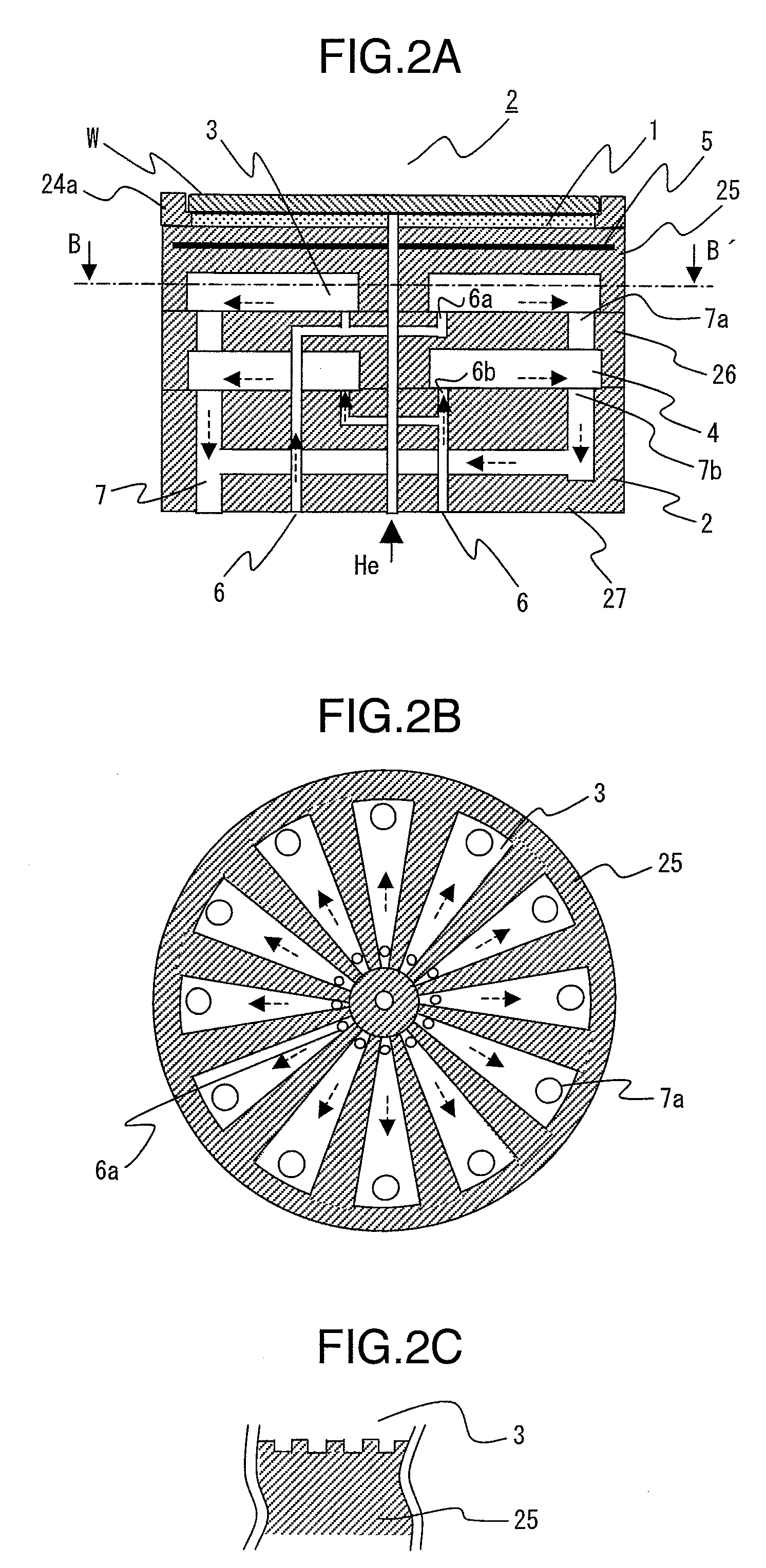

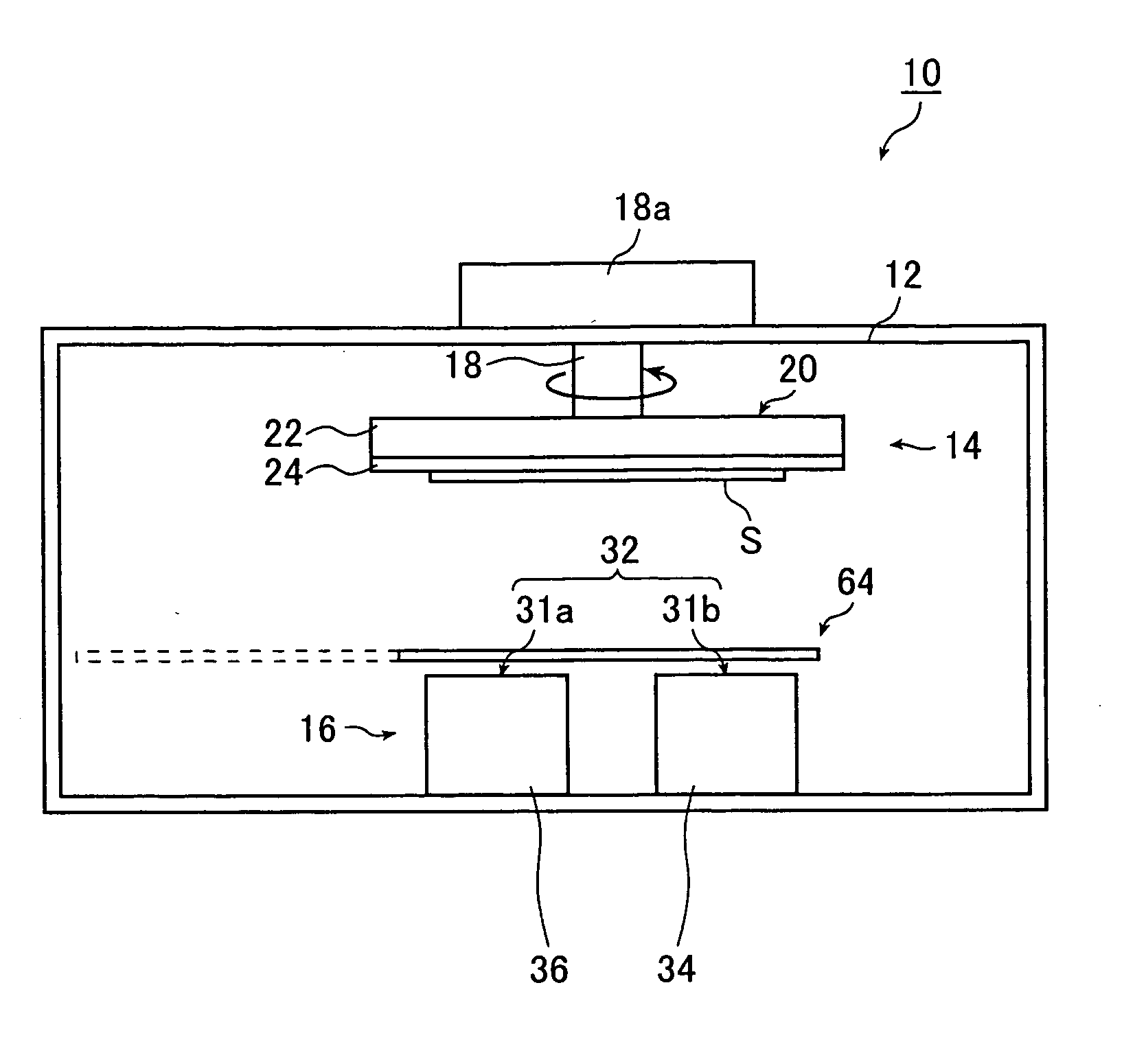

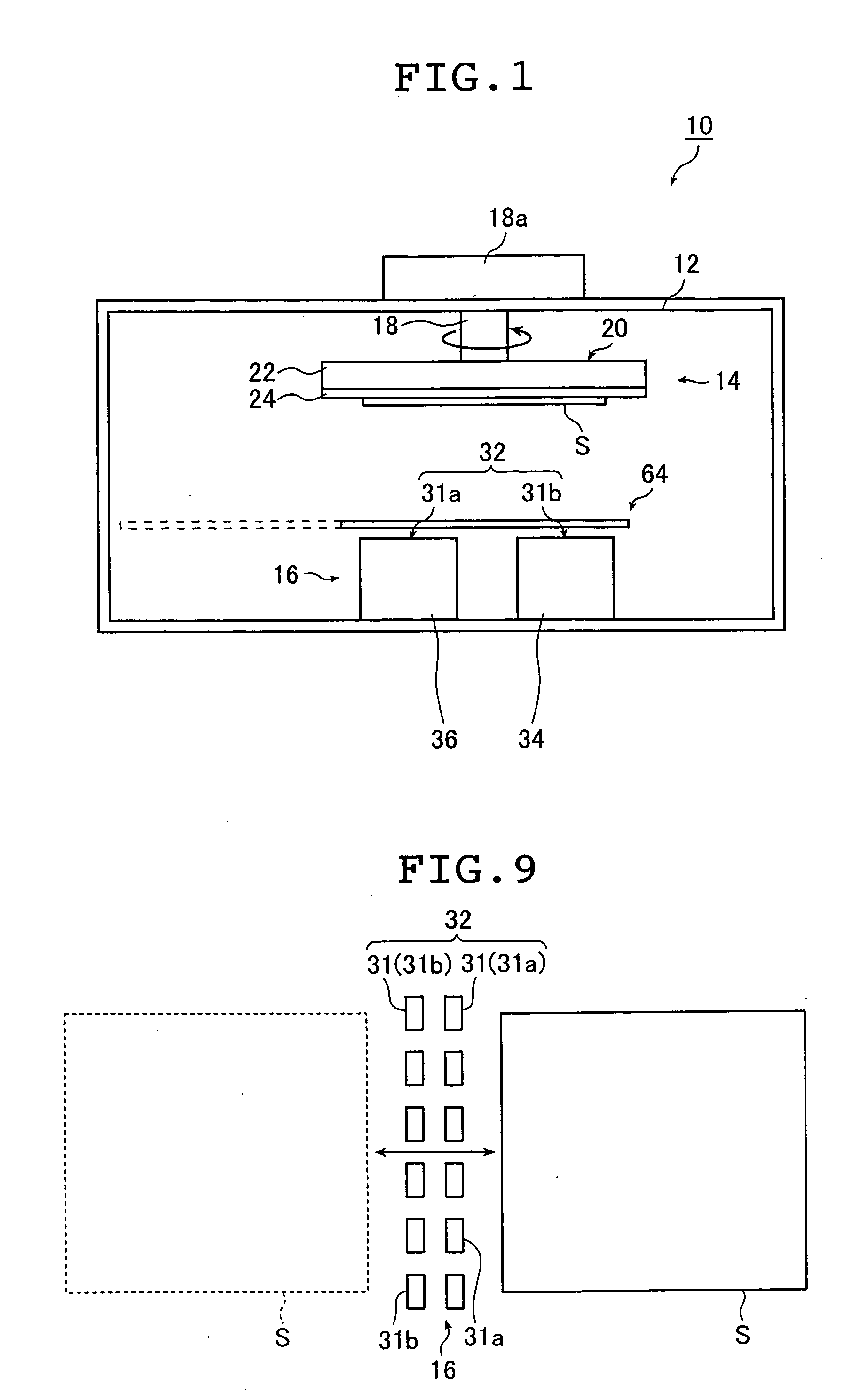

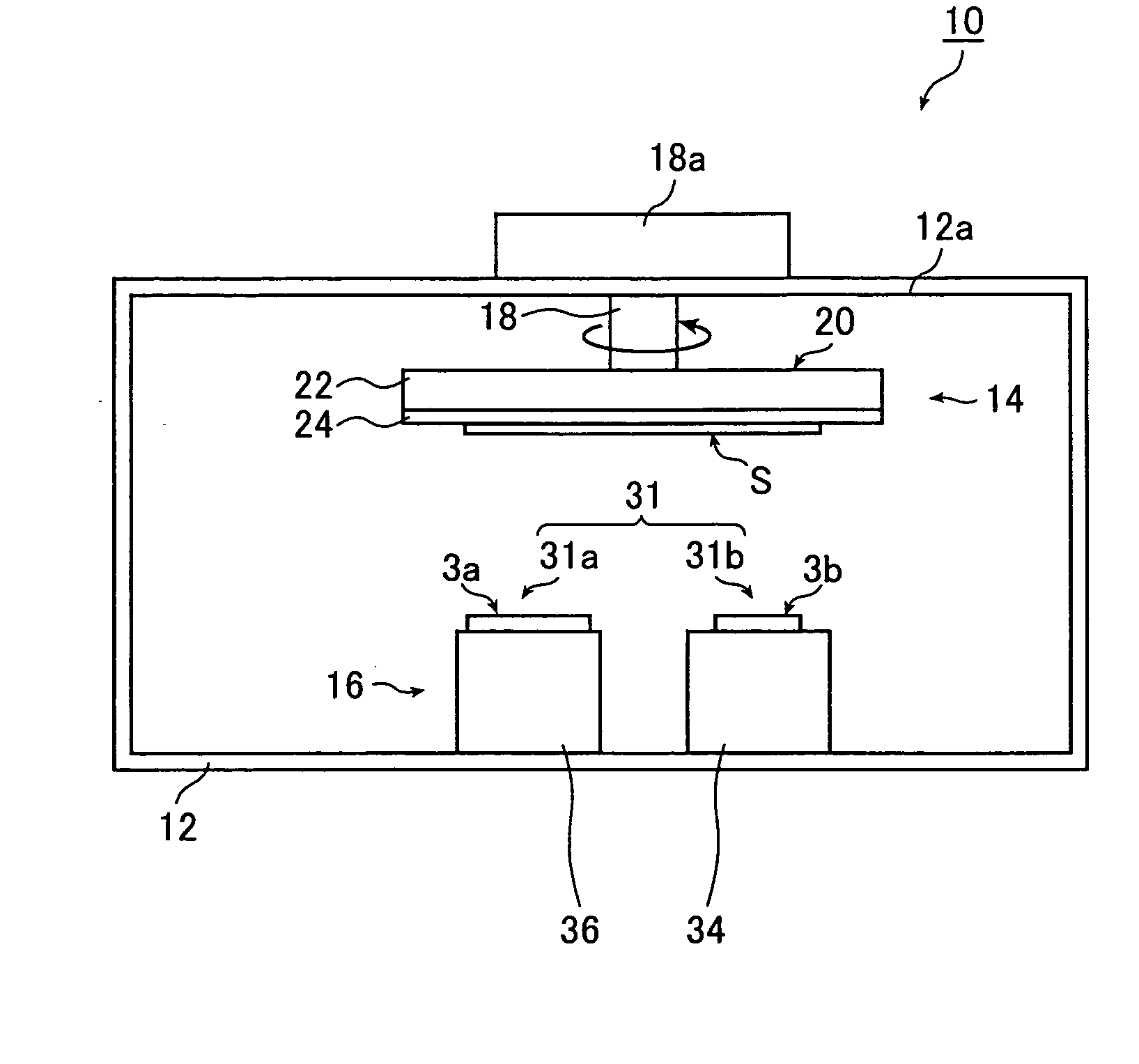

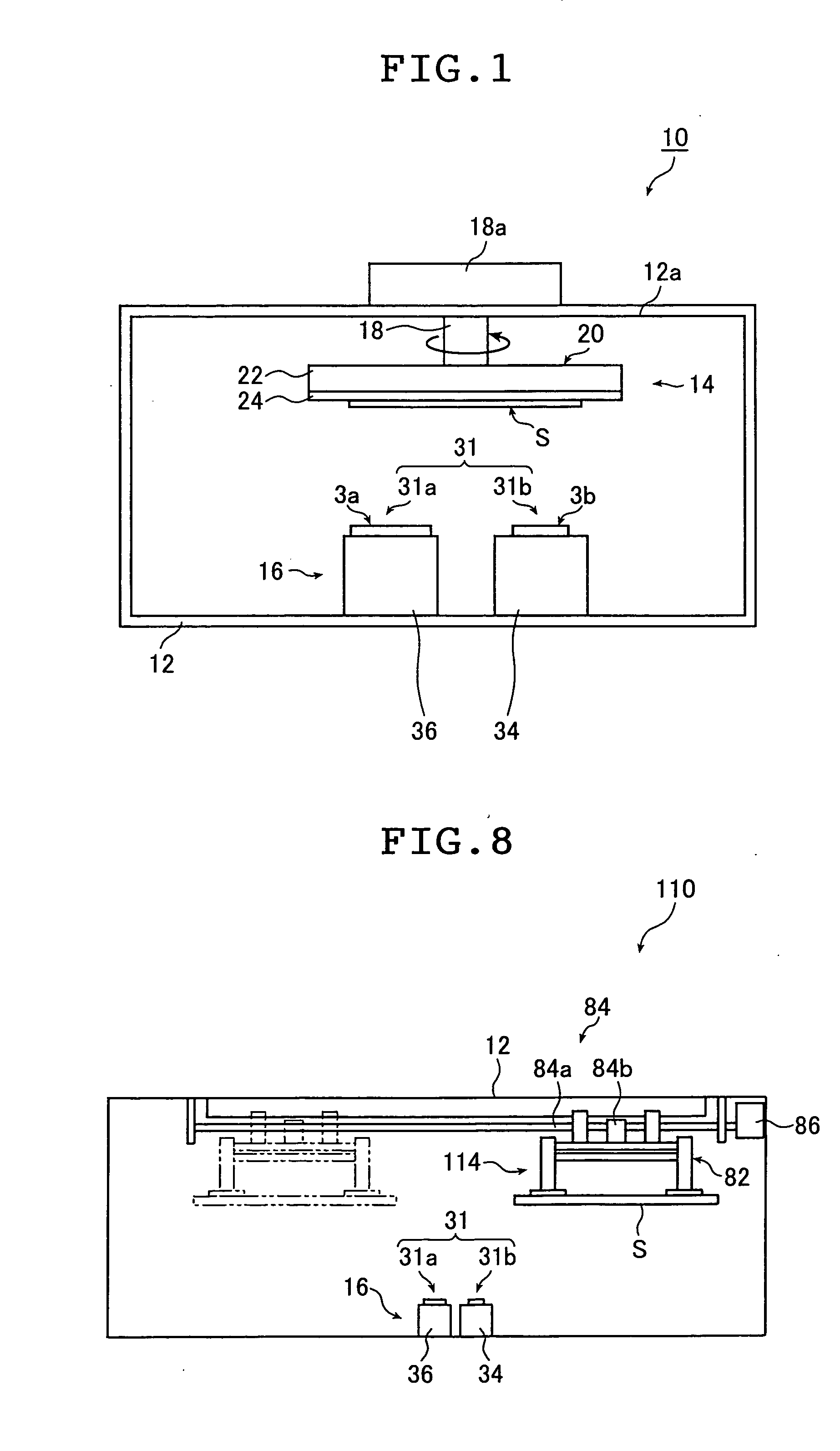

Plasma processing apparatus

InactiveUS20080203925A1Improve processing efficiencyReduce uniformityElectric discharge tubesElectric arc lampsEngineeringRefrigerant

A plasma processing apparatus includes a processing chamber encased in a vacuum vessel equipped with an evacuator; a sample stage located in the processing chamber and having an upper surface on which a sample as an object to be processed rests; a gas feeding unit for feeding processing gas into the processing chamber; a plurality of refrigerant ducts which are laid out in the internal of the sample stage and through which liquid refrigerant flows and can be evaporated; a cooling circuit including a compressor, a condenser, an expansion valve and a set of pipelines to connect the compressor, the condenser and the expansion valve in this order; and a selecting unit for selectively feeding the refrigerant through the plural refrigerant ducts in the different steps of the processing. The sample is processed by using plasma while the temperature of the sample stage is being controlled by the cooling circuit.

Owner:HITACHI HIGH-TECH CORP

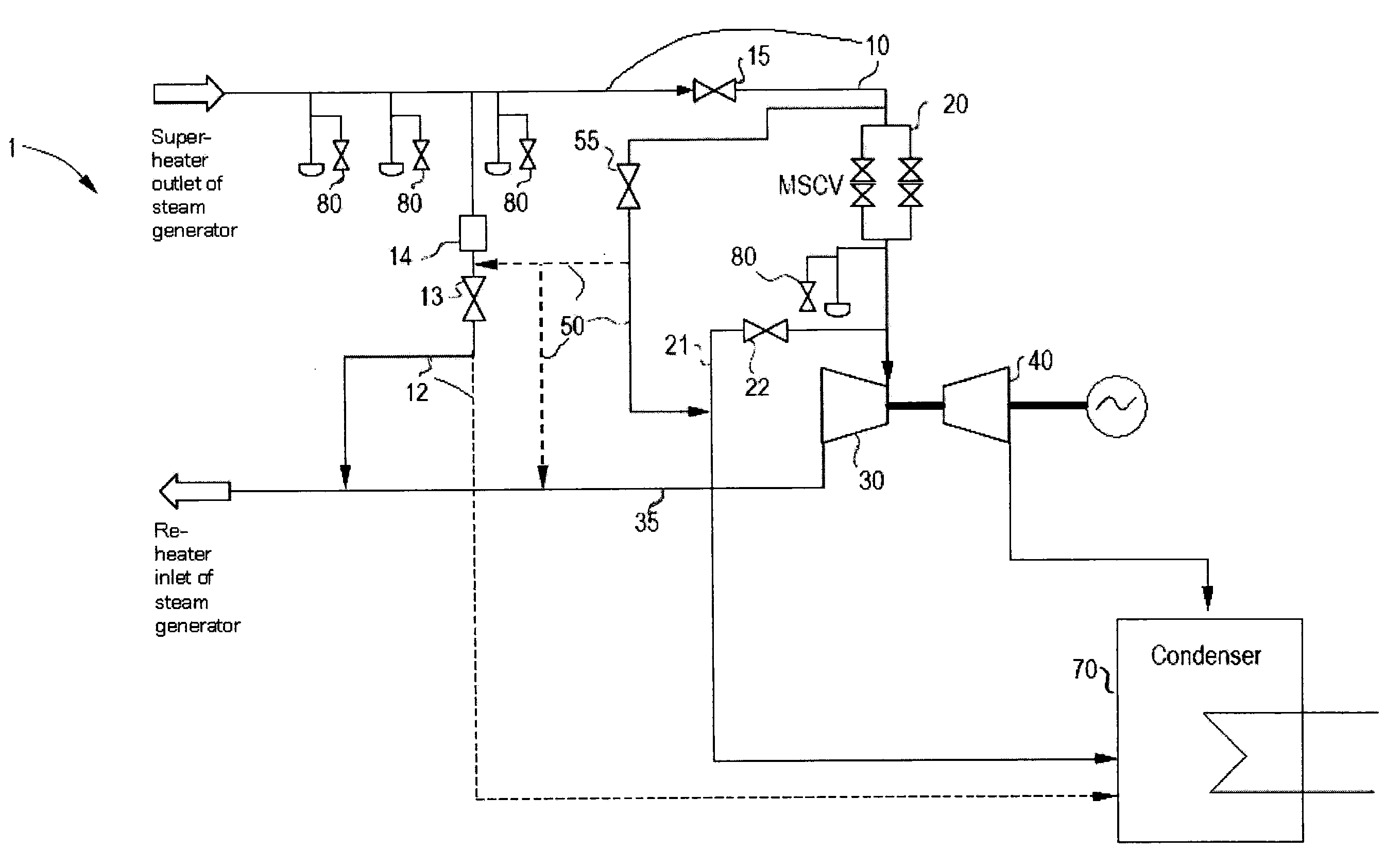

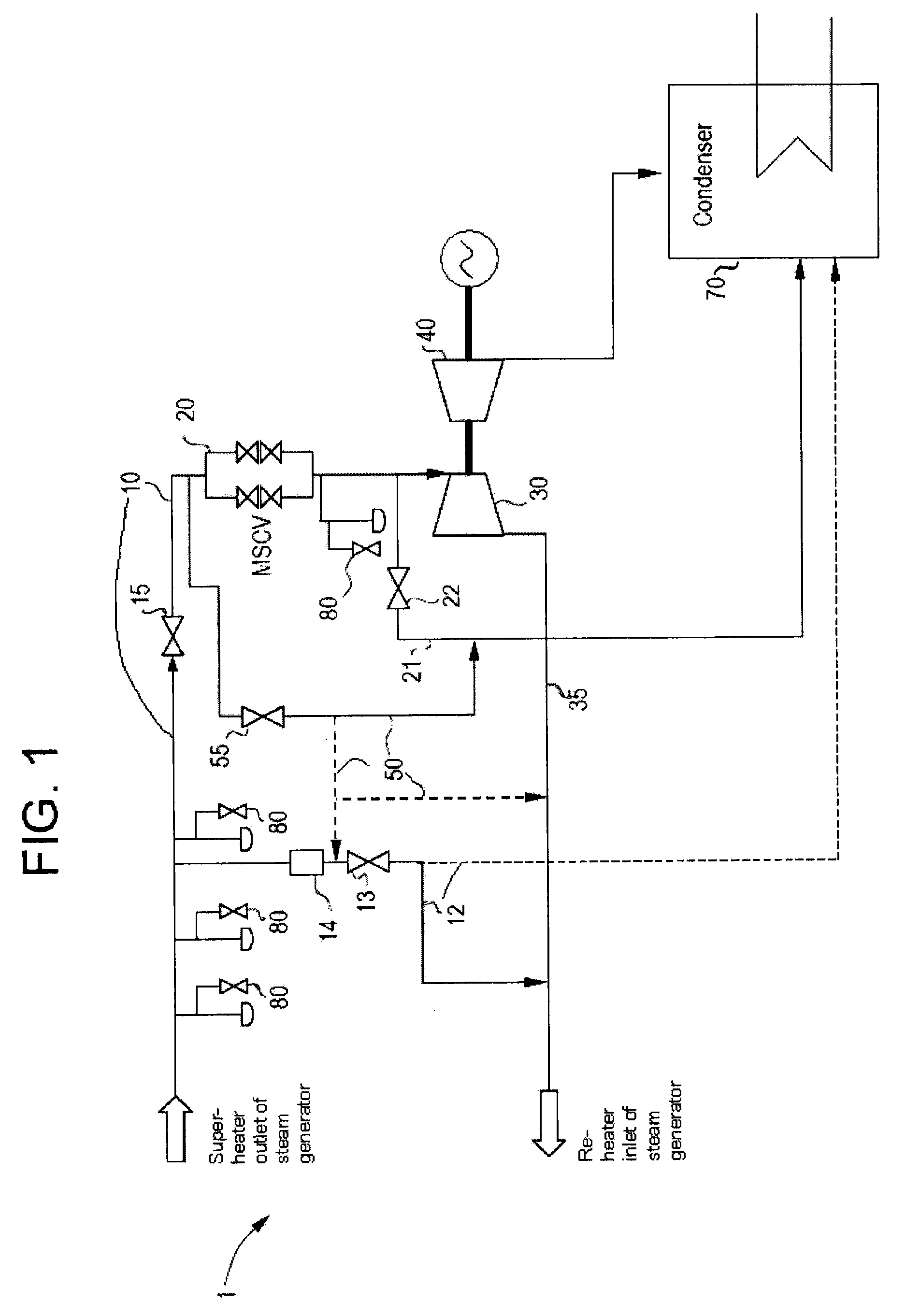

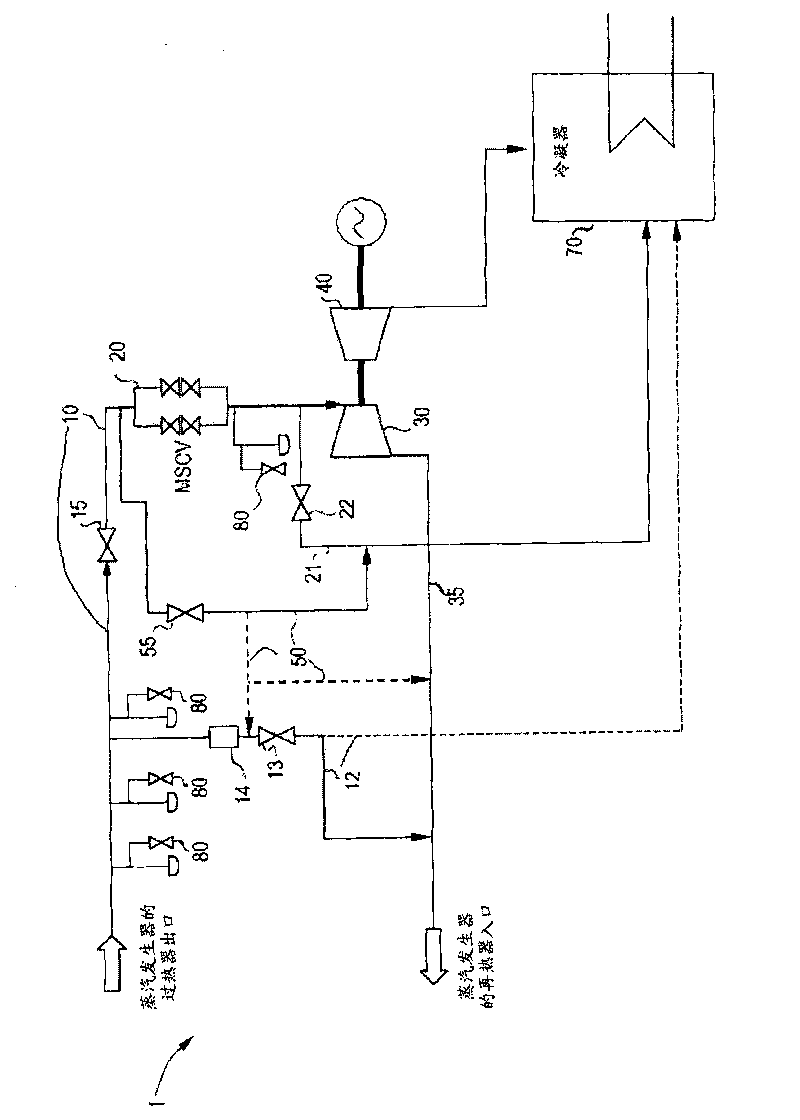

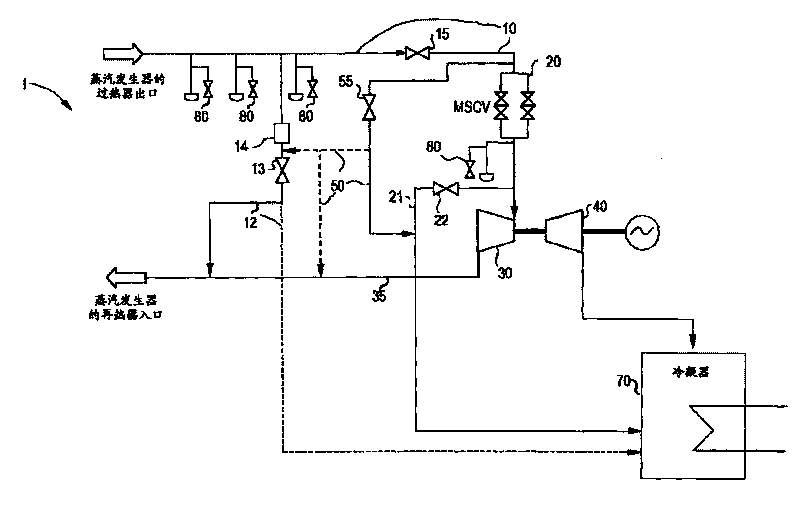

Provision for rapid warming of steam piping of a power plant

A steam power plant, in which steam from a steam generator is received by a steam turbine, is provided and includes a conduit, a main steam control valve (MSCV) disposed along the conduit to admit the steam to the steam turbine when a characteristic thereof satisfies a threshold, a bypass line, coupled to the conduit between a super-heater and a valve, including a bypass line valve which is opened until the threshold is satisfied such that the bypass line removes a portion of the steam, an evacuator line, coupled to the conduit between the MSCV and the steam turbine, including an evacuator valve which is opened to regulate a thermal environment within the steam turbine during a start up thereof, and a warming line originating between the valve and the MSCV on the conduit and terminating downstream of the evacuator valve disposed along the evacuator line.

Owner:GENERAL ELECTRIC CO

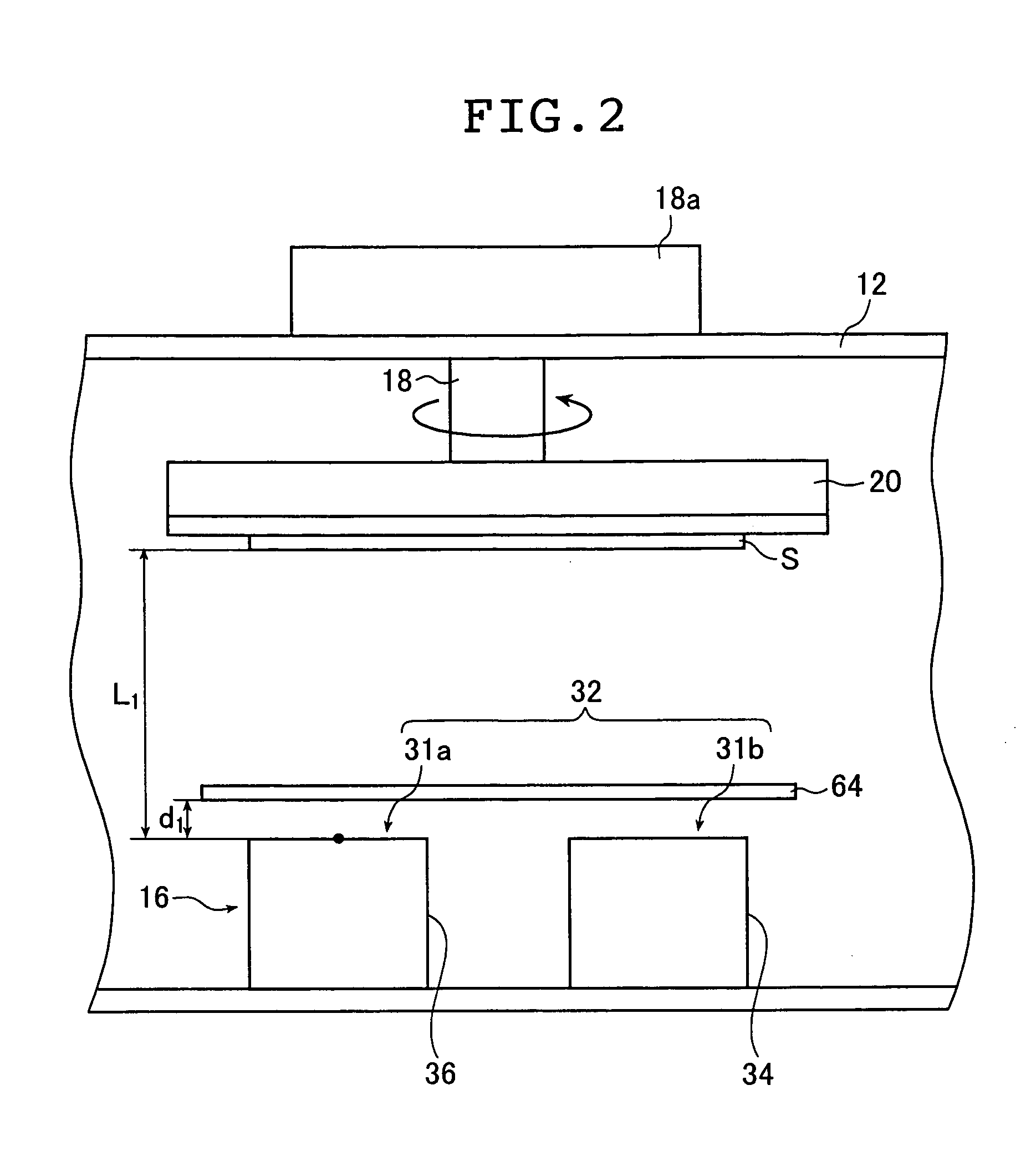

Vacuum deposition device and pretreatment method for vacuum deposition

InactiveUS20050120959A1StructuredAvoid stickingProductsX-ray/infra-red processesMulti materialPretreatment method

The vacuum deposition device includes a vacuum deposition chamber, a vacuum evacuator for evacuating an inside of the chamber, an evaporating unit for evaporating one or more film forming materials in the chamber, a holding unit provided above the evaporating unit for holding a substrate for the vacuum deposition, and a preventing unit for preventing evaporated particles of the one or more materials from adhering to the substrate when the vacuum deposition is carried out at a pressure of 0.05 to 10 Pa. The pretreatment method for the vacuum deposition prepares the prevention unit in the chamber and melts the one or more materials by heating in the chamber at the pressure of 0.05 to 10 Pa while preventing the evaporated particles from adhering to the substrate by using the preventing unit.

Owner:FUJIFILM CORP +1

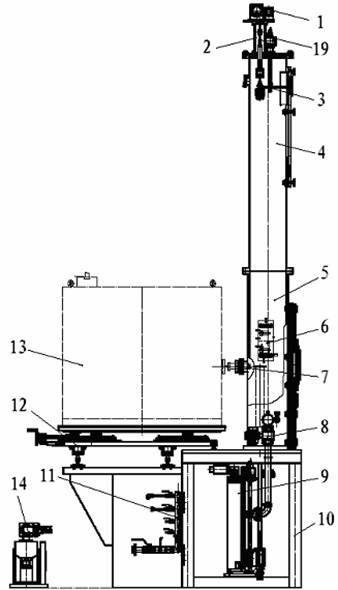

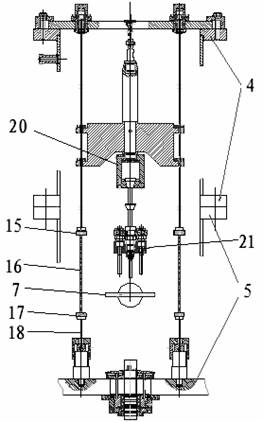

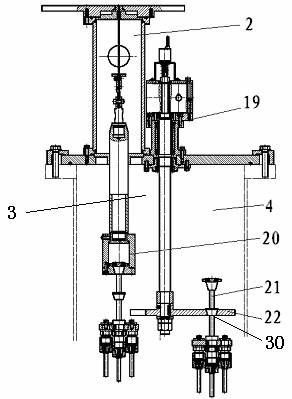

Silicon core furnace repeatedly pulling multiple silicon cores in one heat

InactiveCN101892519AIncrease productivityReduce energy consumptionPolycrystalline material growthSingle crystal growth detailsEngineeringPolycrystalline silicon

The invention discloses a silicon core furnace repeatedly pulling multiple silicon cores in one heat. A lower transmission device and a water cooling device are arranged in a rack, a lower furnace chamber and a slot way pulley are arranged on the rack, the slot way pulley is provided with a high frequency slot way, the lower furnace chamber is internally provided with an air charging device, a high frequency electrode and induction heating assembly and an evacuator, and the high frequency electrode and induction heating assembly is connected with the high frequency slot way; and the lower furnace chamber is communicated with the upper furnace chamber, guide steel wires are arranged in the lower furnace chamber and the upper furnace chamber and run through the lower furnace chamber and the upper furnace chamber from top to bottom, a guide frame is arranged on the guide steel wire and is provided with a seed card head seat and a seed card head, the upper end of the upper furnace chamber is provided with a seed unloading and turnplate dividing device, an upper transmission device is arranged above the upper furnace chamber, a transition assistant chamber is arranged between the upper furnace chamber and the upper transmission device, and the upper transmission device is connected with the seed card head seat by a flexible shaft. The silicon core furnace in the invention can realize broaching of 15-18 silicon cores in one heat, improves production efficiency of silicon cores, and lowers cost for producing polysilicon.

Owner:XAUT CRYSTAL GROWING TECH CO LTD

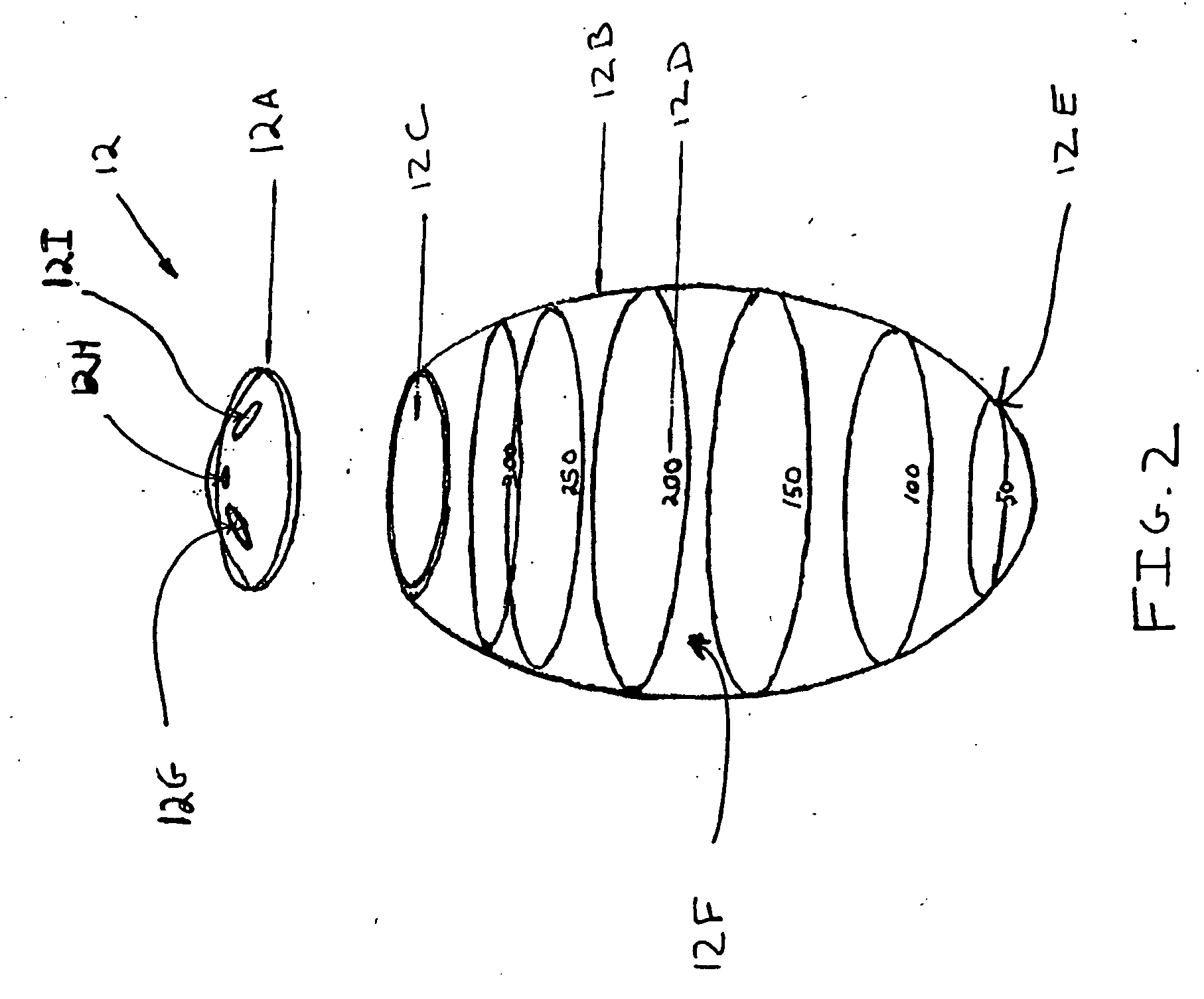

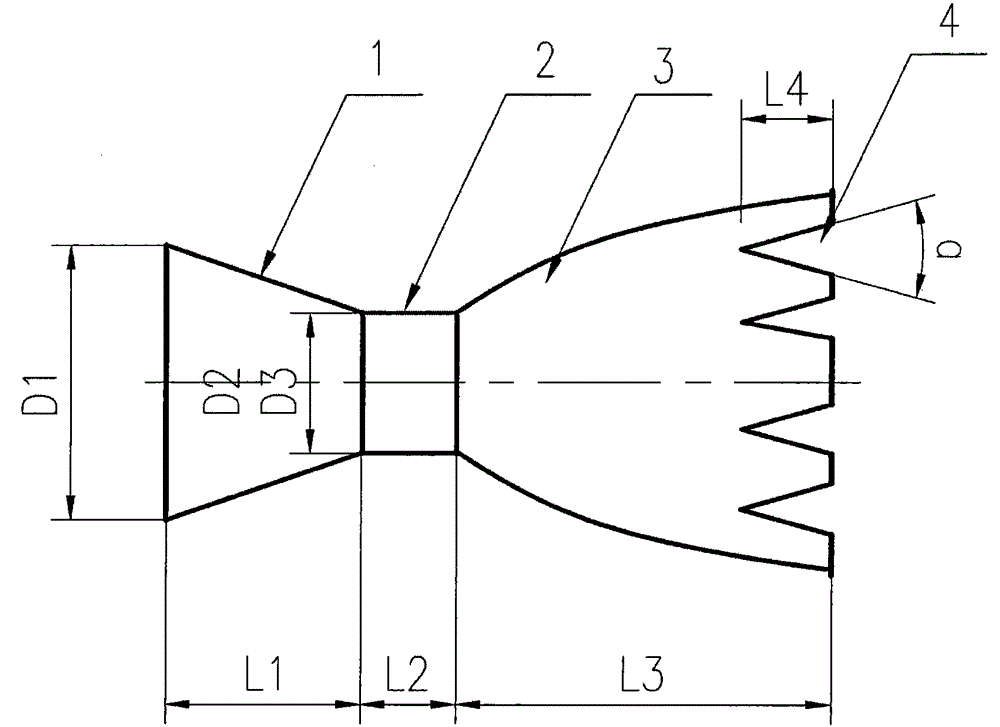

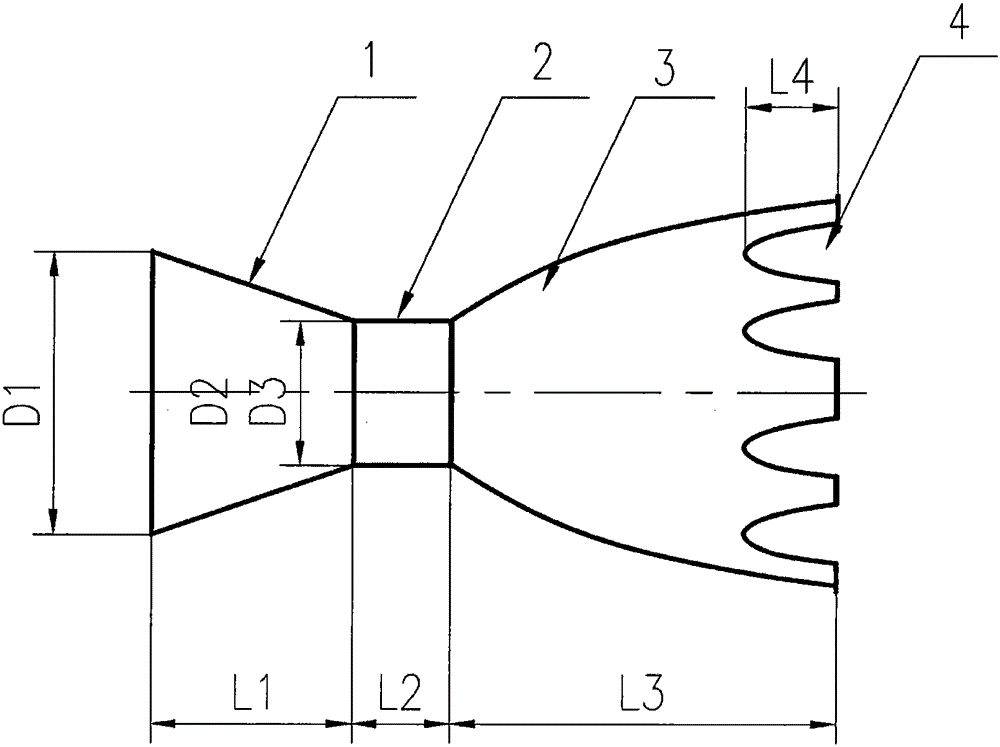

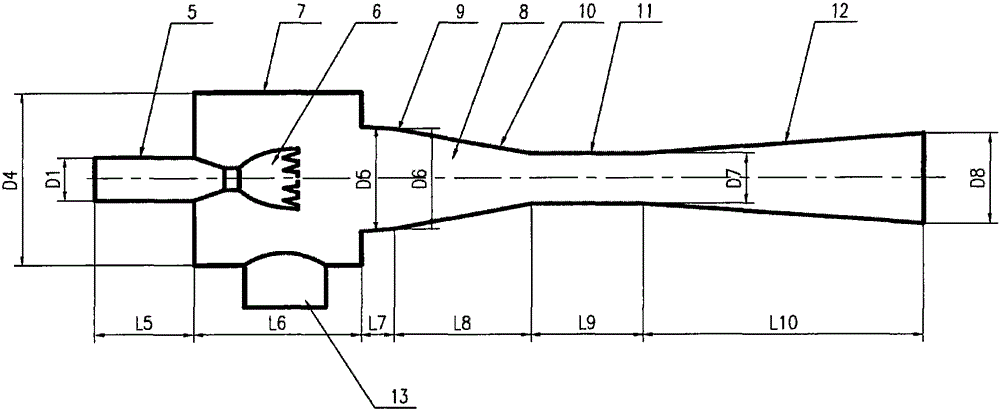

Sawtooth jet type evacuator

The invention discloses a supersonic sawtooth nozzle and a sawtooth jet type evacuator installing the same. The supersonic sawtooth nozzle comprises an inlet section, a nozzle throat, a nozzle outlet section and a triangular or concave fan-shaped modified profile at the tail edge of a nozzle outlet. The sawtooth jet type evacuator installing the supersonic sawtooth nozzle comprises: 1) a main fluid pipeline inlet section; 2) the supersonic sawtooth nozzle; 3) a suction chamber and a secondary fluid inlet which is connected with the suction chamber; and 4) a mixed diffusion chamber, wherein the mixed diffusion chamber is composed of: 1) a mixed section which is composed of two parts which are an inlet part and a contraction part; 2) a throat; and 3) a diffusion section. According to the supersonic sawtooth nozzle and the sawtooth jet type evacuator installing the same, the ejection coefficient and the working efficiency are high in mechanism and effect, and energy conservation and consumption reduction can be dramatically carried out.

Owner:苏州中尧节能环保设备有限公司

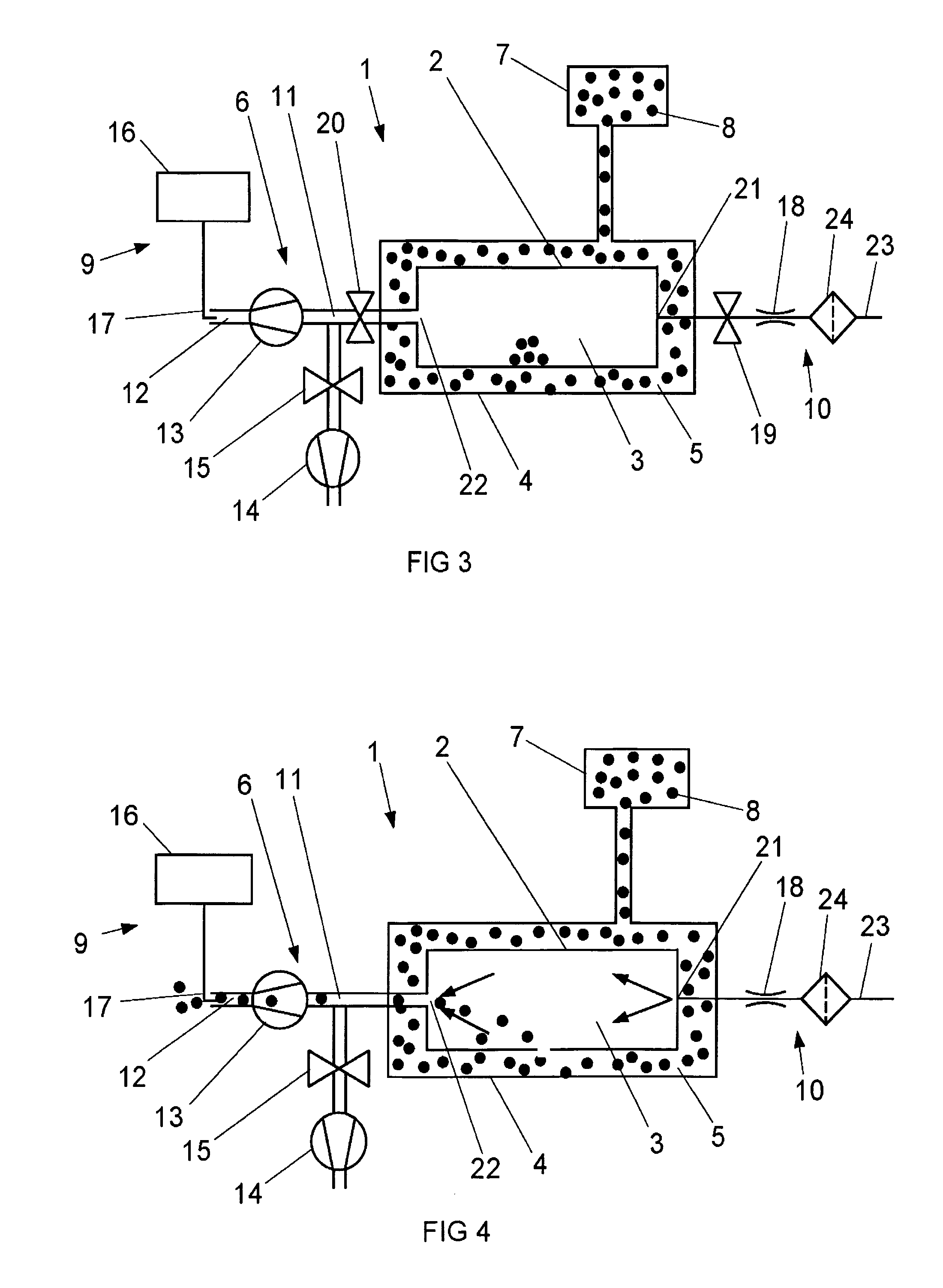

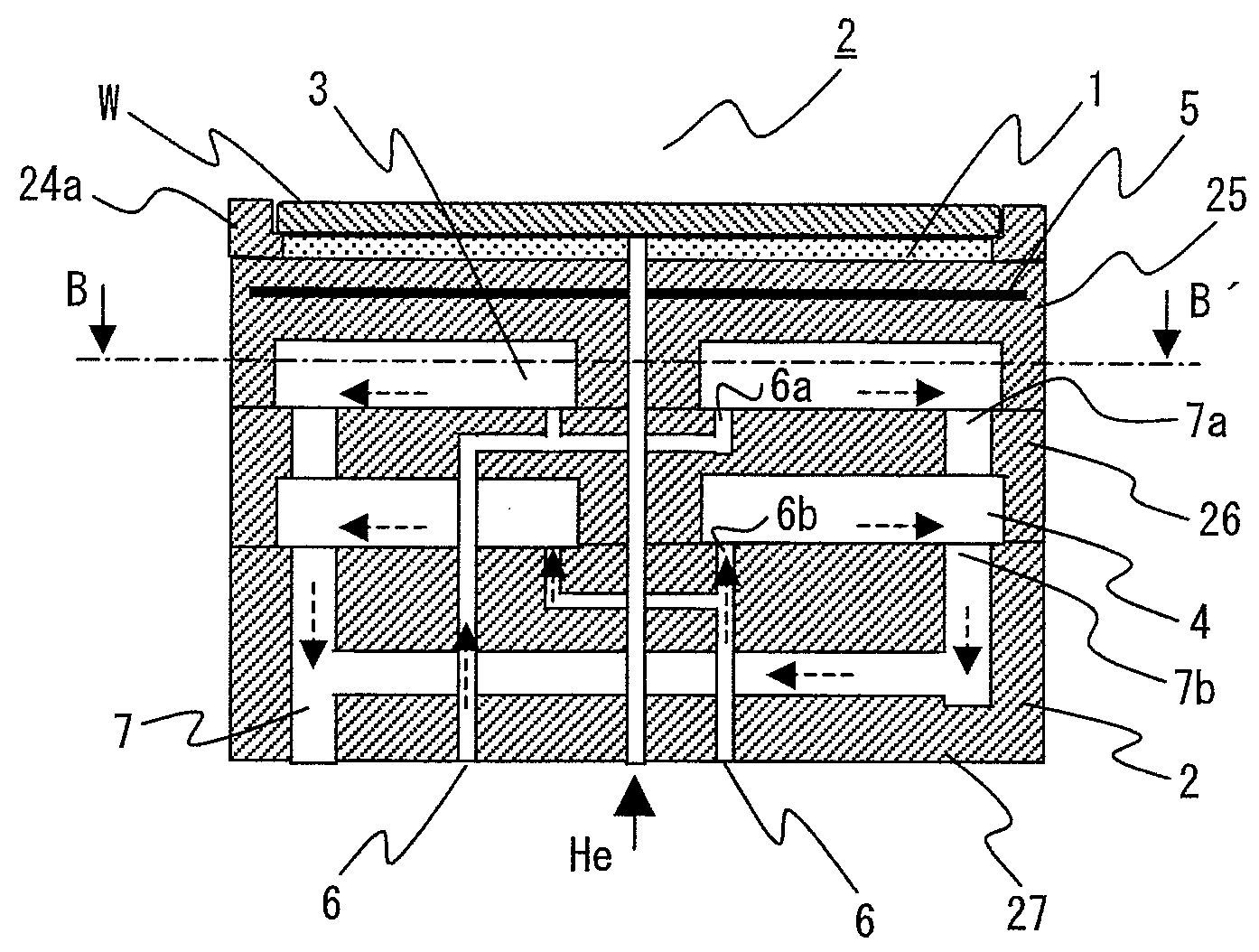

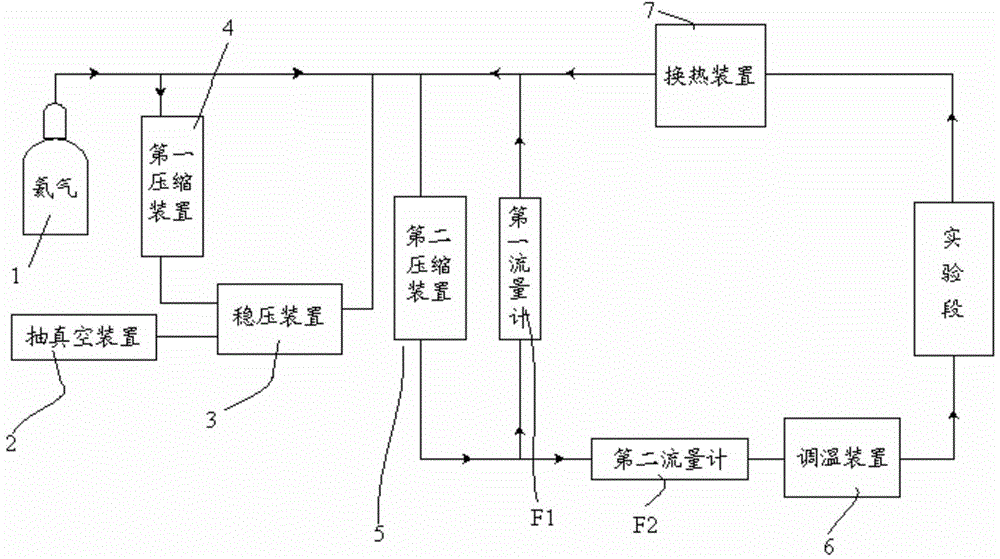

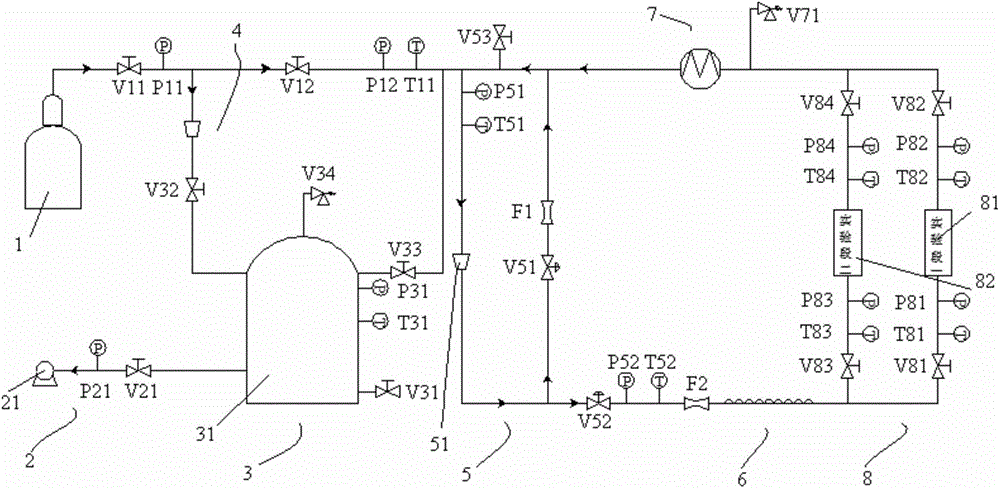

Helium circulating system

InactiveCN104676248AAchieve coolingRealize the heating effectPipeline systemsEngineeringTemperature and pressure

The invention discloses a helium circulating system comprising a helium cylinder, a heat exchanger, an evacuator, a pressure stabilizer, a first compressor, a second compressor, a temperature regulator, and an experimental segment. The output end of the helium cylinder is connected with the input end of the first compressor and the input end of the second compressor at the same time. The first compressor is connected with the pressure stabilizer. The pressure stabilizer is connected with the evacuator. The output end of the pressure stabilizer is connected to the input end of the second compressor. The output end of the second compressor is connected to the input end of the second compressor through a first flowmeter, forming a second compressor loop; the output end of the second compressor is connected to the input end of the temperature regulator through a second flowmeter, the output end of the temperature regulator is connected to the input end of the experimental segment, and the output end of the experimental segment is connected to the input end of the second compressor through the heat exchanger. The helium circulating system has the advantage that helium is fed into the experimental segment to provide the required low temperature or high temperature and pressure for the experimental segment.

Owner:SOUTHWEST PETROLEUM UNIV

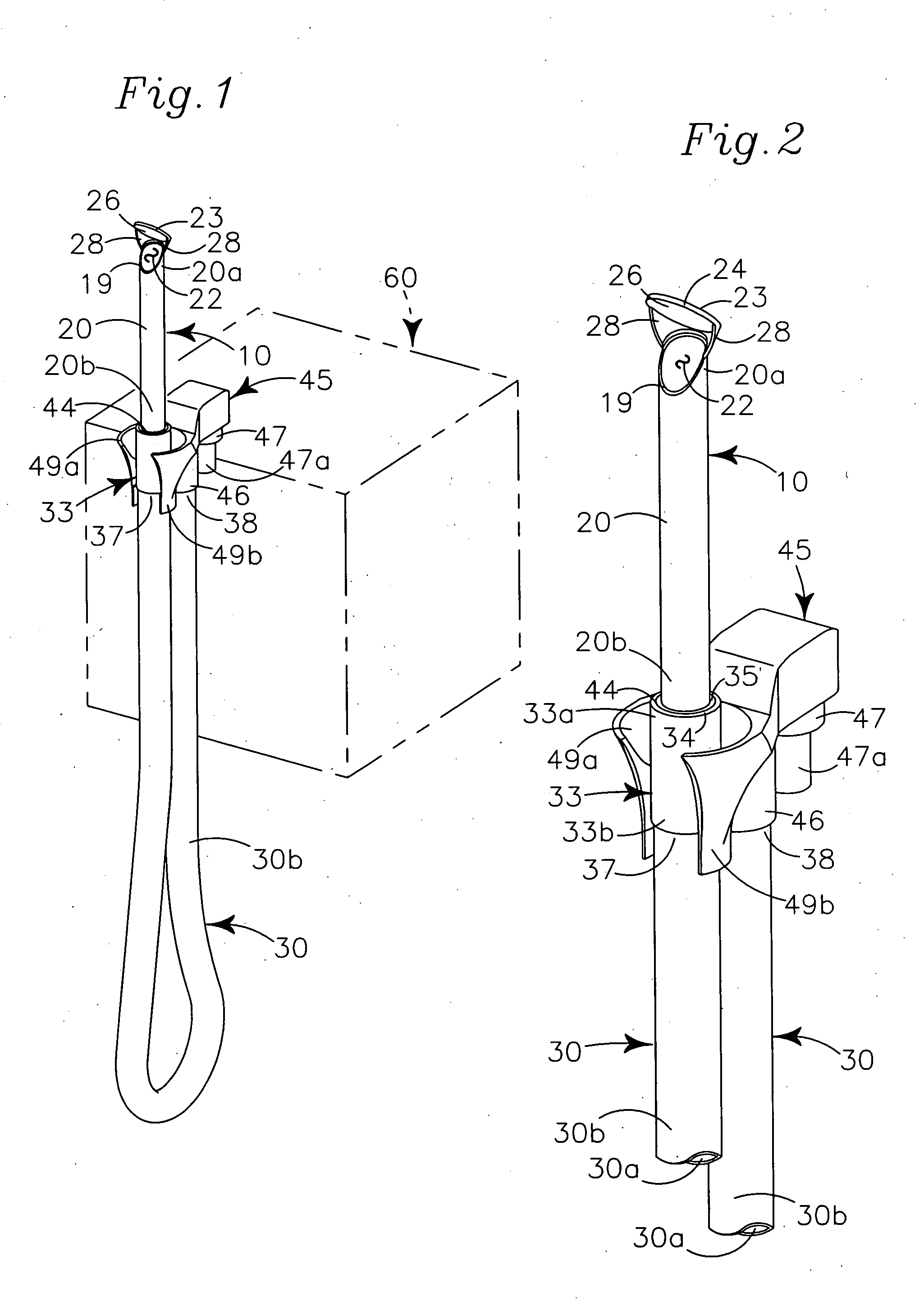

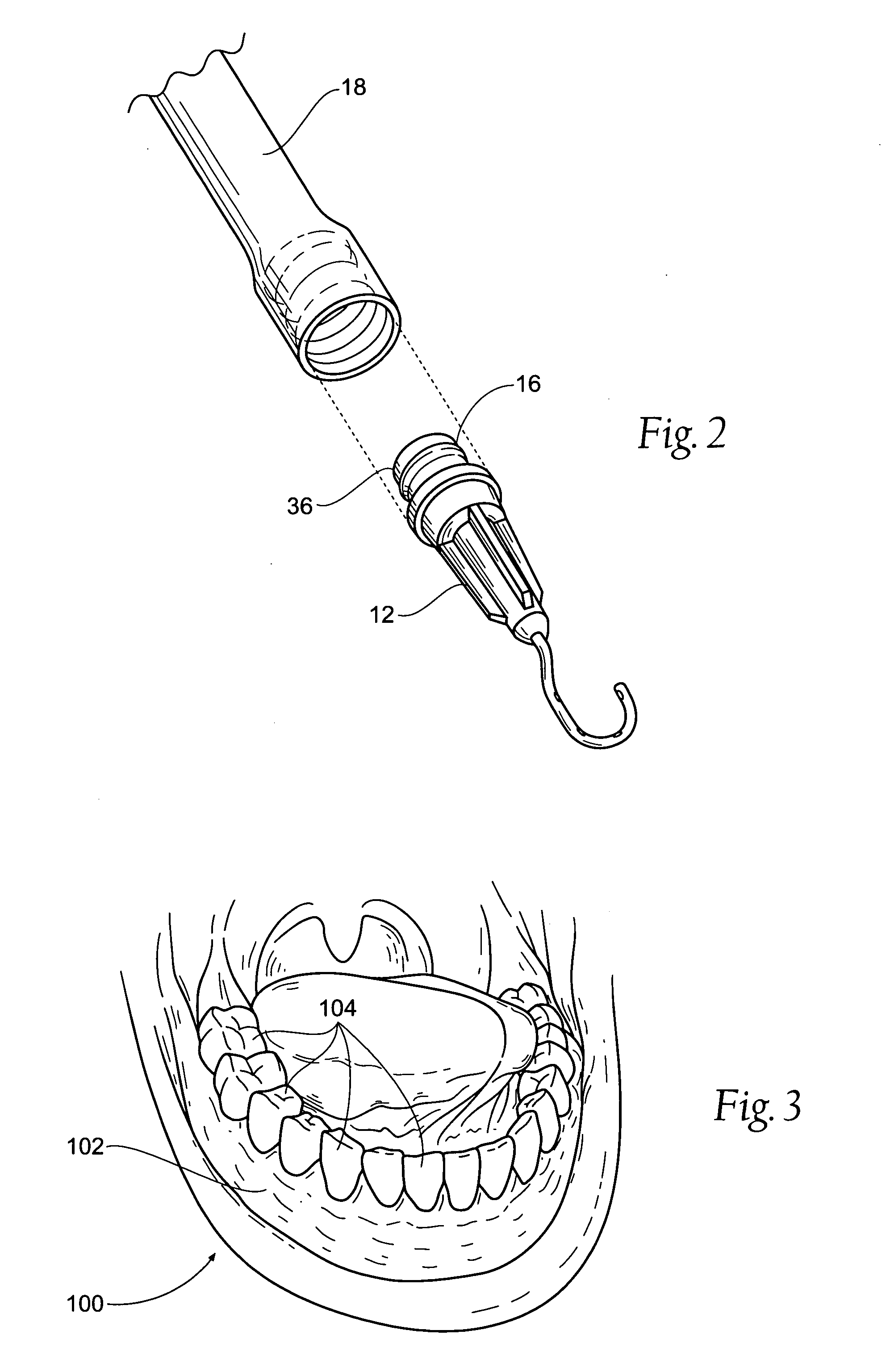

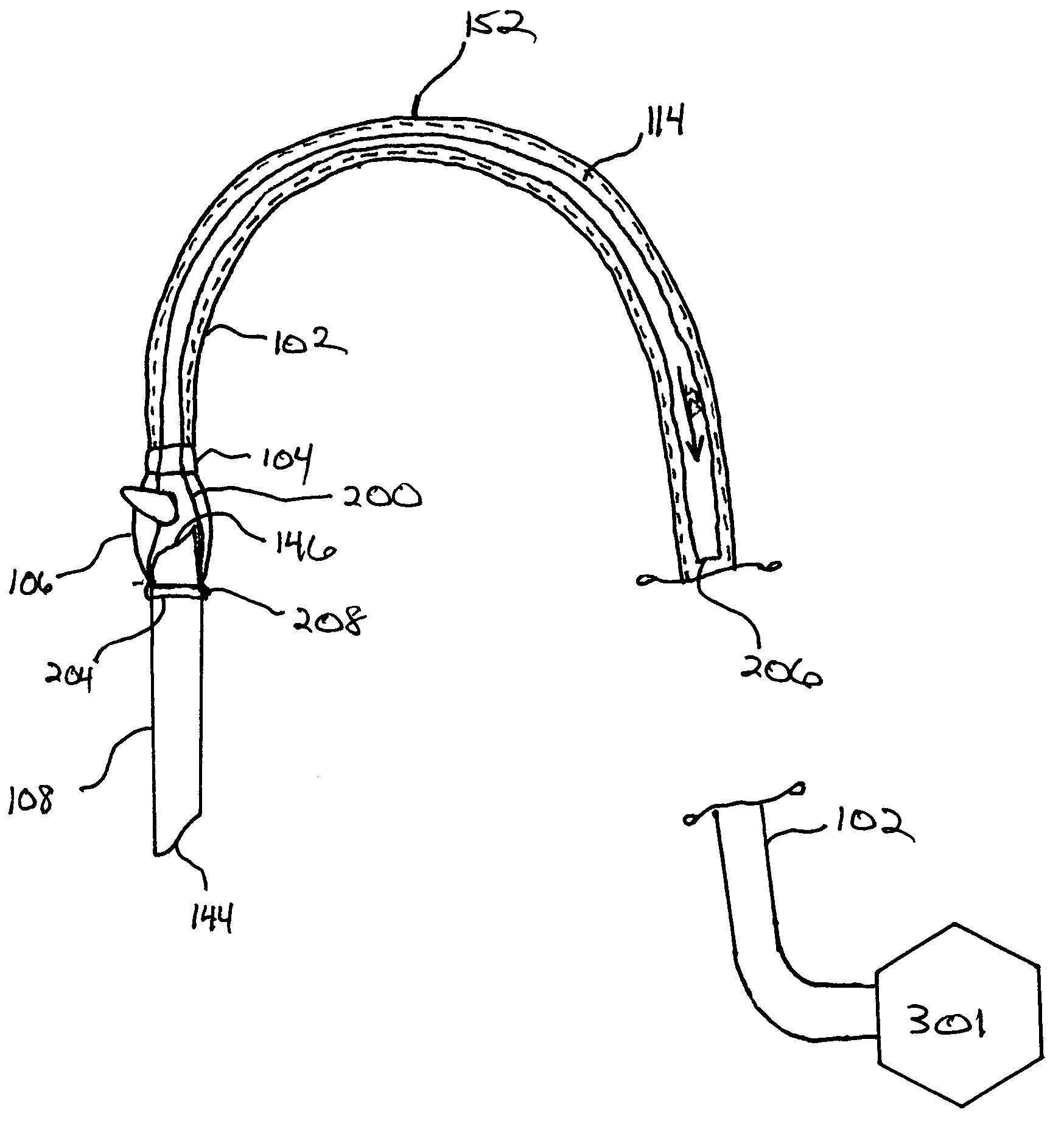

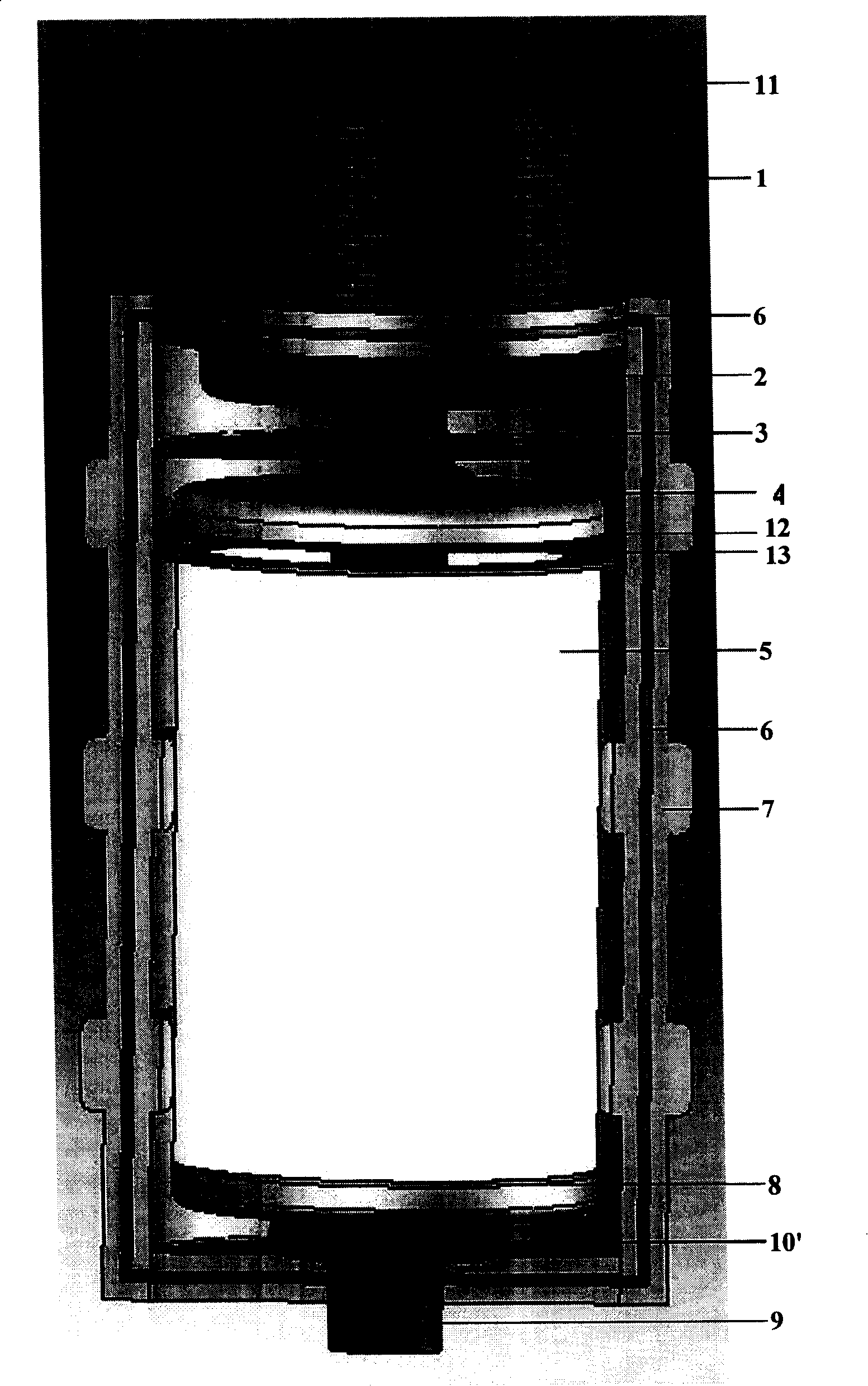

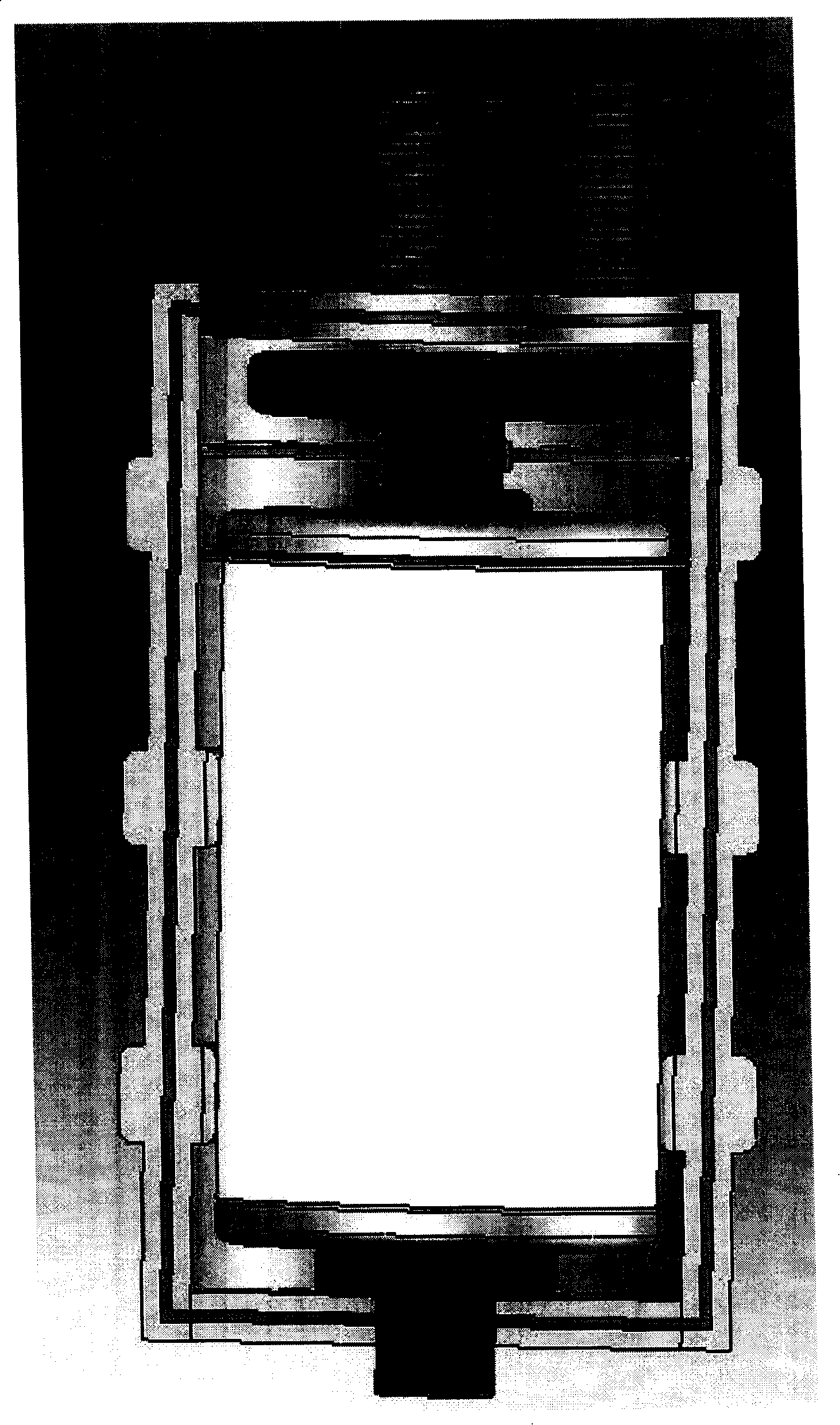

Ergonomic high volme evacuator system

InactiveUS20100021860A1Easy to operateMinimize hand and wrist fatigueSomatoscopeSaliva removersCoil springEngineering

An ergonomic high volume evacuator system provides a tapered tubular evacuator tool having a body defining a medial channel with an angulated mirrored guard having an optically reflective insert adjacent a beveled input orifice. A flexible evacuation hose having an integral coil spring and a vacuum connector pneumatically releasably interconnect the evacuator tool with a vacuum source. An axially rotatable evacuator tool connector provides a releasable pneumatic and fluidic sealed interconnection between the evacuator tool and the evacuation hose.

Owner:CHRISTMAN STEPHANIE +1

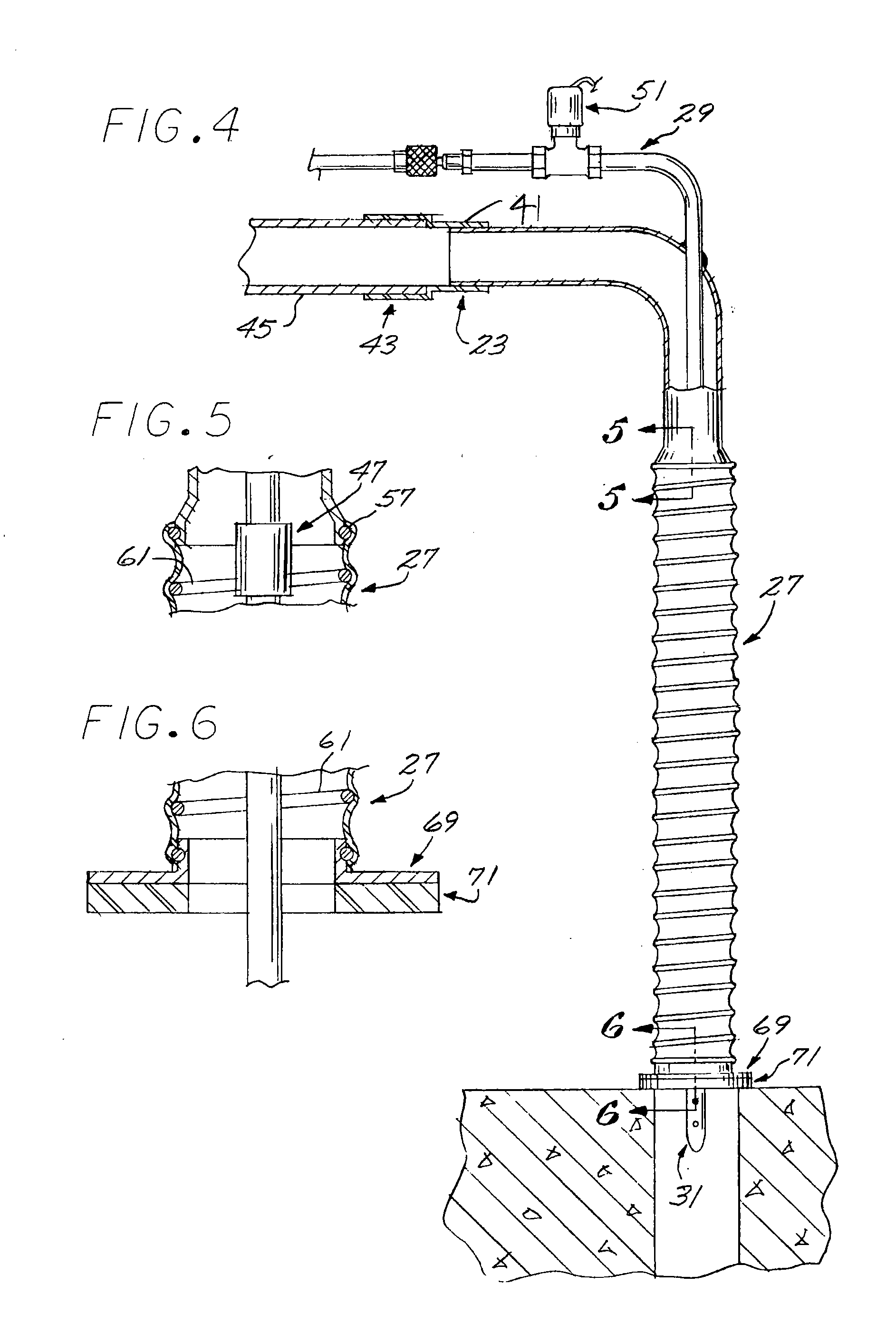

Debris evacuator for cleaning a masonry bore

Owner:CANEER HADLEY H

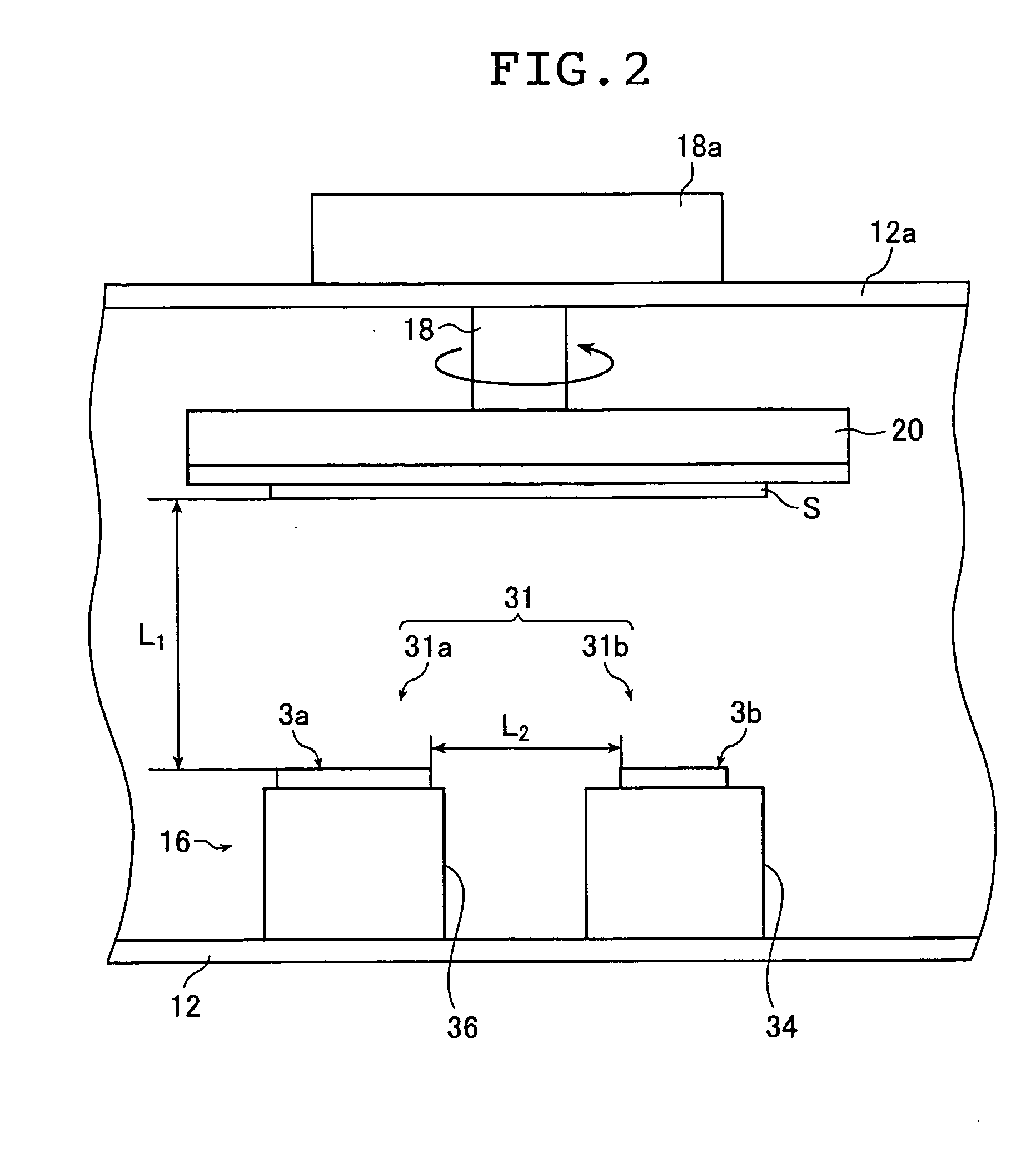

Vacuum deposition method and vacuum deposition device

InactiveUS20050066901A1Improve efficiencyWide range of fieldsX-ray/infra-red processesVacuum evaporation coatingFree spaceEvacuators

The vacuum deposition device includes a vacuum deposition chamber, a vacuum evacuator for evacuating an inside of the chamber, at least one first evaporator which evaporates a first film forming, at least one second evaporator which evaporates a second film forming material. One of the first and second evaporators which is closer to the substrate is spaced apart from the substrate in a vertical direction by 100 to 300 mm. The substrate, the first evaporator and the second evaporator are installed at positions, which satisfy a condition of an expression (1): 0.3≦L1 / L2≦50. L1 is a distance in a vertical direction from a horizontal plane of a first or second evaporation port of the first or second evaporator to a surface of the substrate, and L2 is the shortest distance between the first evaporation port and the second evaporation port.

Owner:FUJIFILM CORP +1

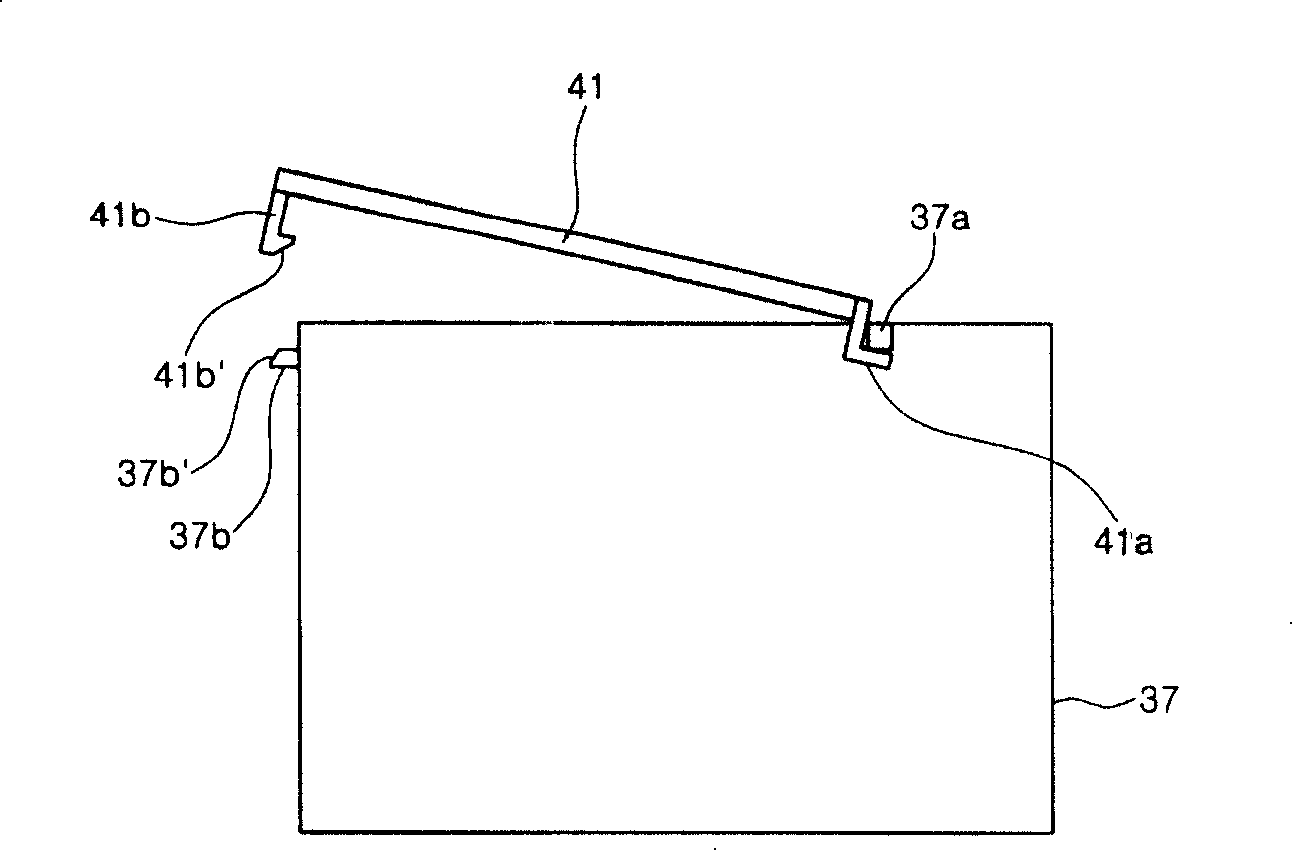

Ice-making machine for refrigerator

ActiveCN101231054APrevent splashHygienic useLighting and heating apparatusIce productionFrostWater source

The invention discloses an ice-making device used for a refrigerator, and belongs to other freezing equipment combined with the refrigerator. The invention comprises a main body of the ice-making device, which is positioned at one side of the refrigerator and is rotationally provided with an ice-making plate; an evacuator which can be rotationally arranged at one side of the ice-making device used for evacuating the ice blocks made by the main body of the ice-making device; a water supply tank which is arranged at one side of the main body of the ice-making device with at least one side being kept open and, the water supply tank can receive water from an external water supply source via water pipes and then feed the water into the ice-making plate; a tank cover which can seal the open side of the water supply tank is combined with the water supply tank. The invention has the advantages that the device can prevent the water inside the water supply tank to splash out to possibly result in the formation of ice or frost inside the refrigerator.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

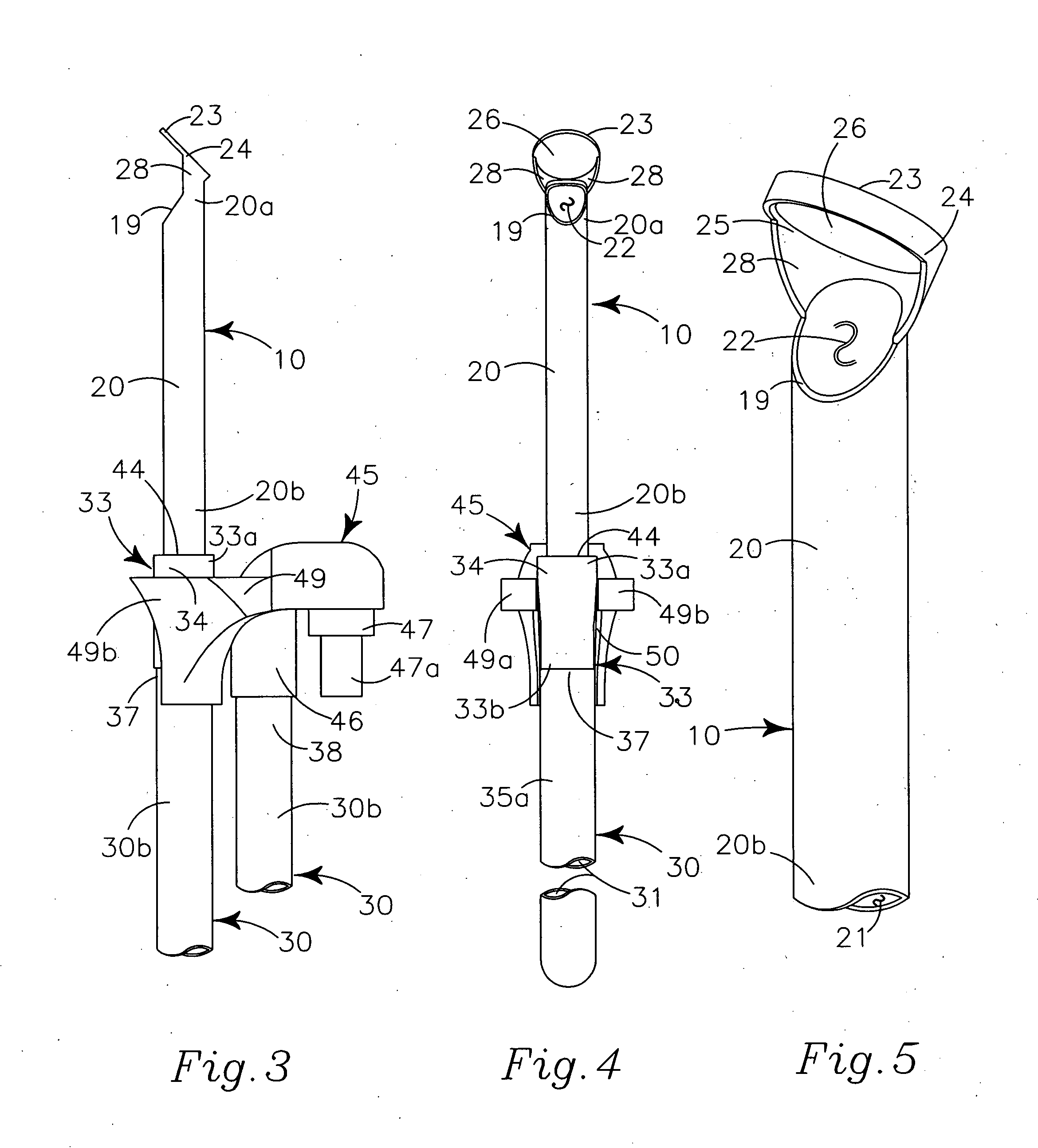

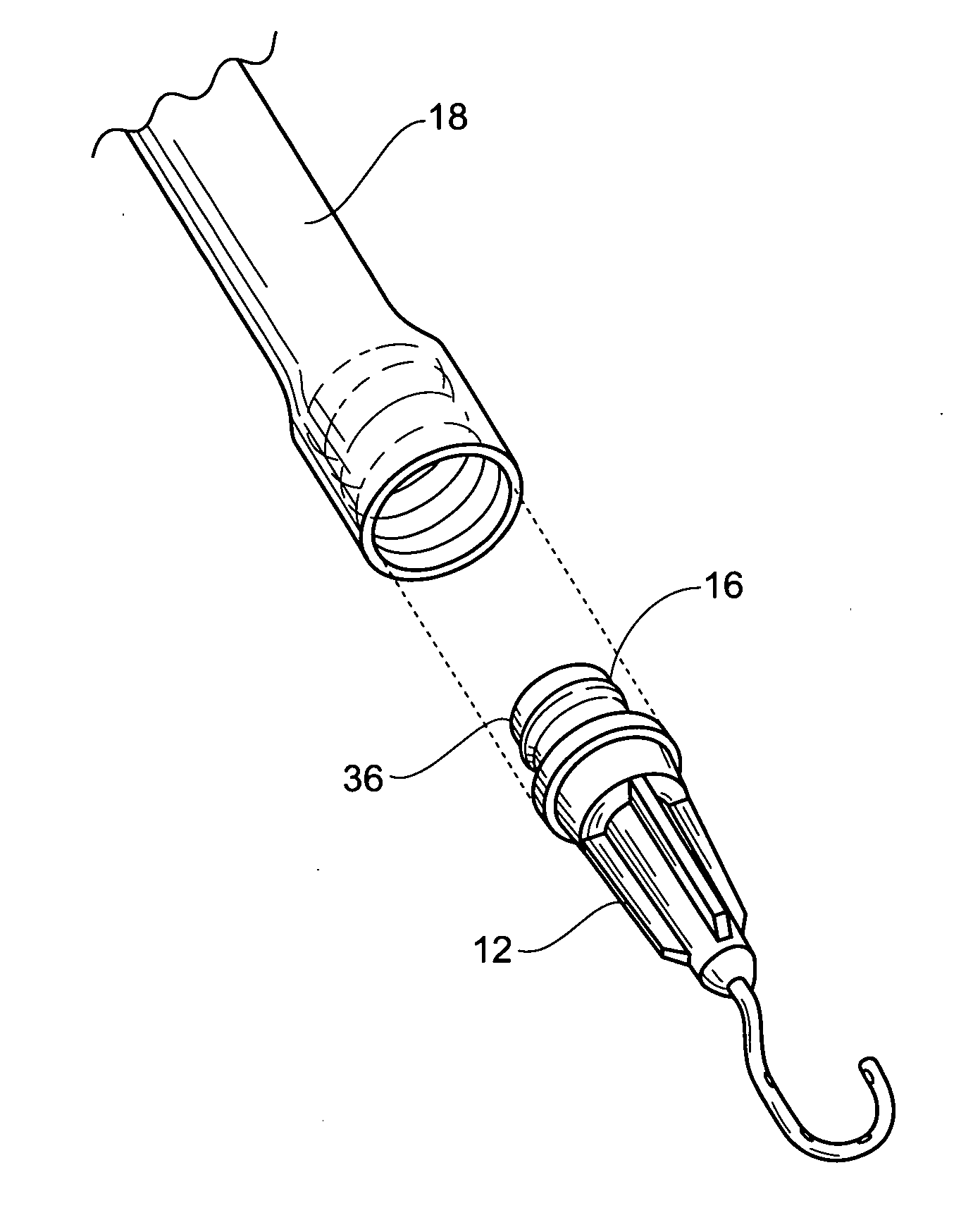

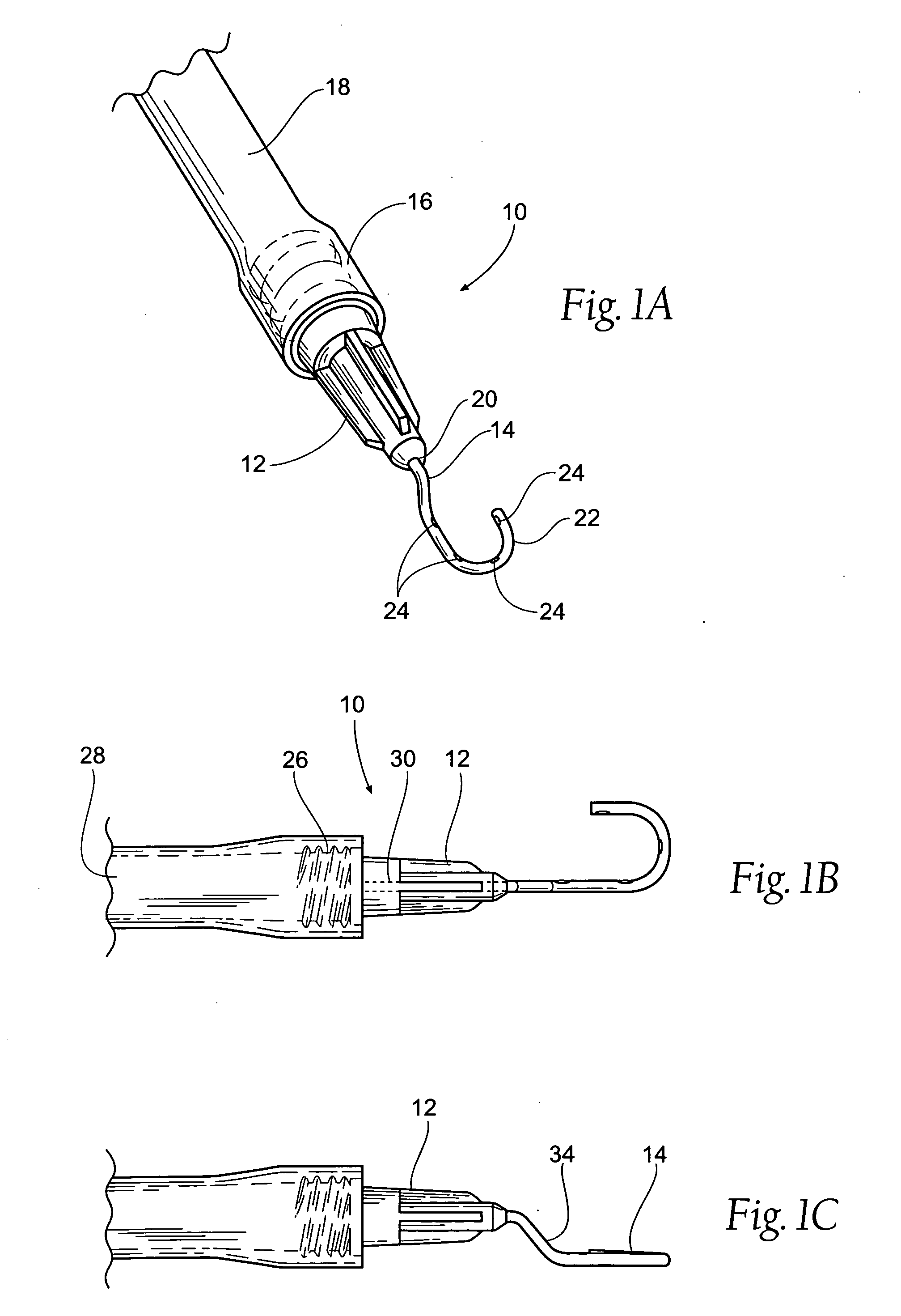

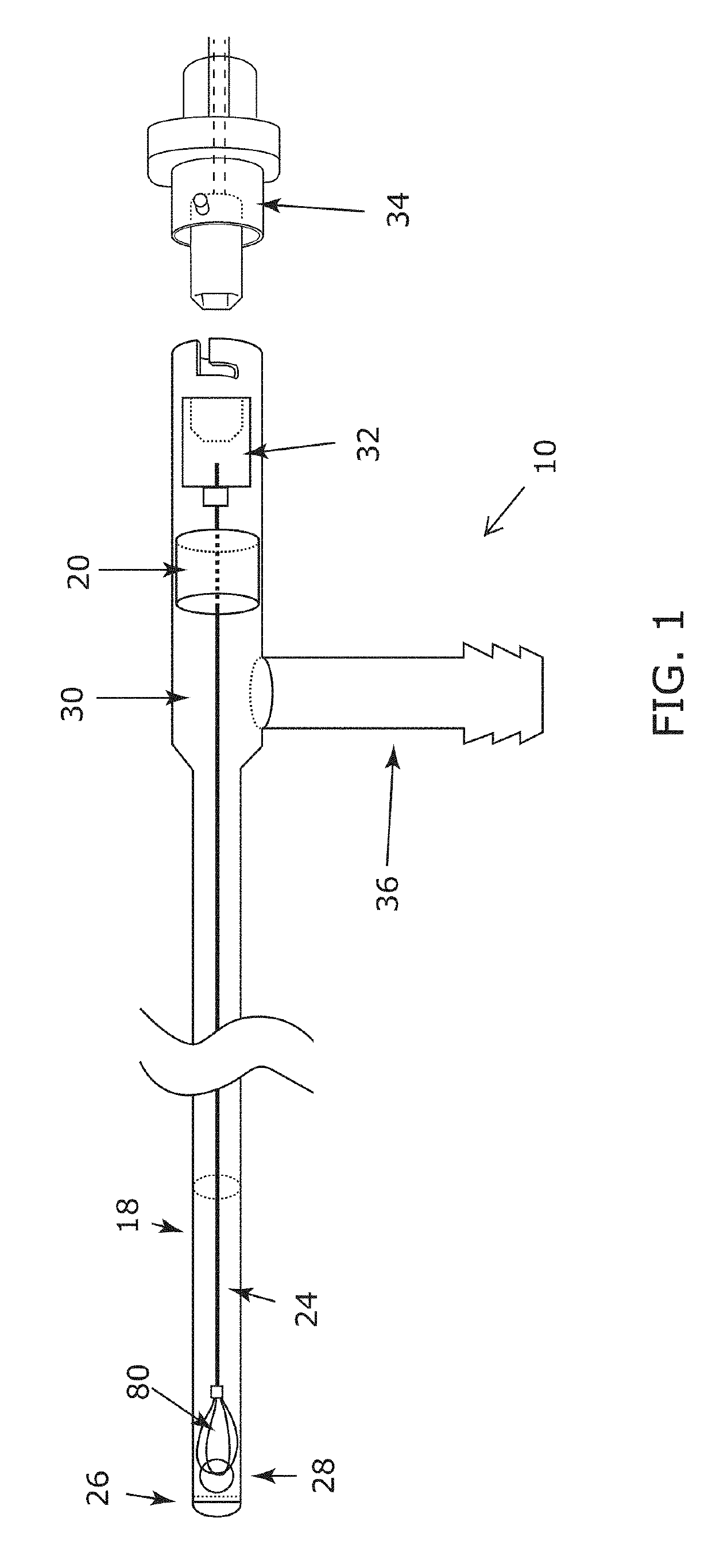

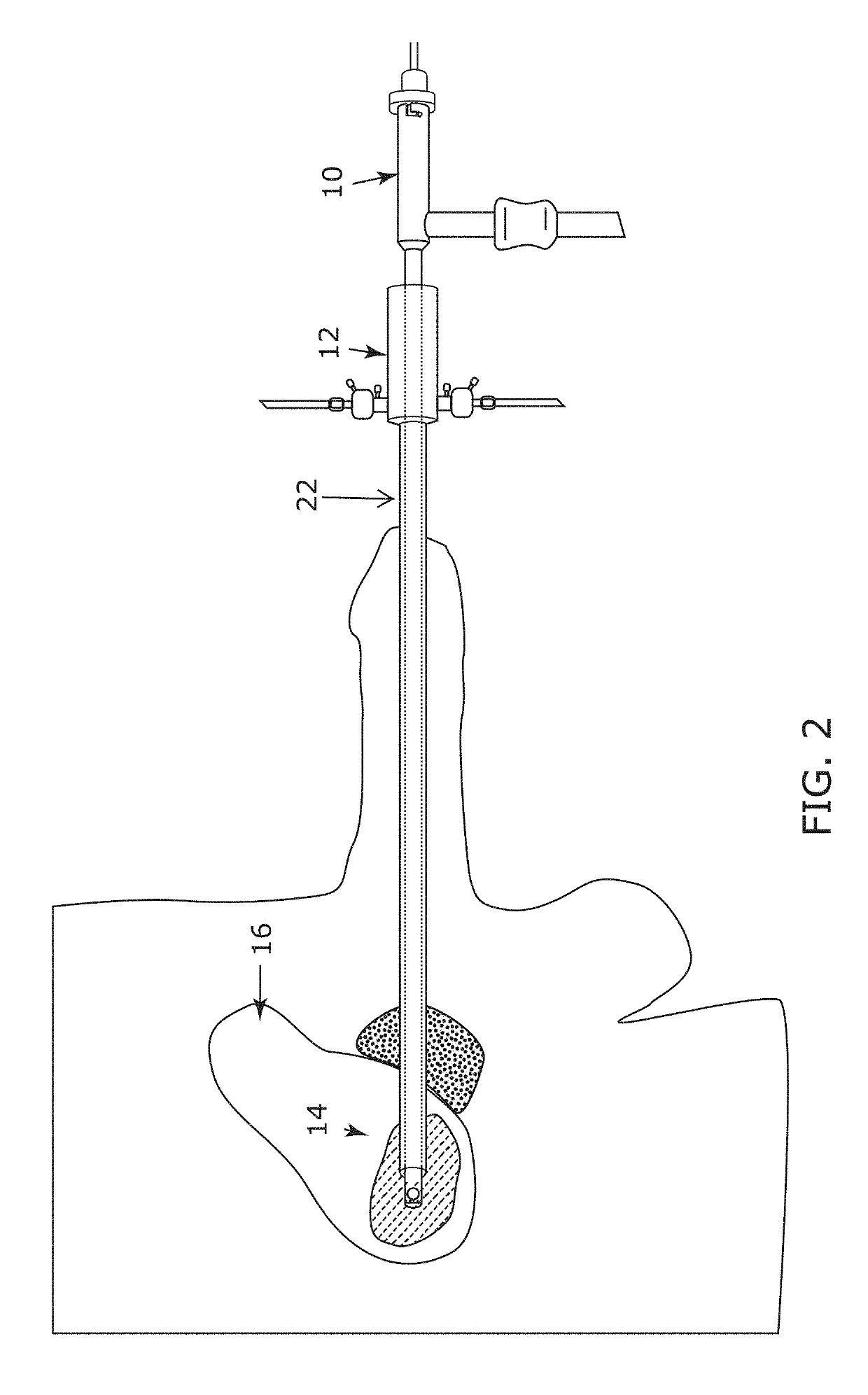

Micro evacuator and method of use

InactiveUS20110070556A1Shorten the timeQuality improvementTooth rinsingSaliva removersCombined useBiomedical engineering

An evacuation and / or irrigation device for use in connection with a vacuum source and used in a relatively localized surgical area. The evacuation device has a main body connected to a dental tool and a hook-like evacuation needle connected to the body. The needle has a plurality of spaced apart vacuum ports to provide irrigation circumferentially to sterilize and clean the surgical area.

Owner:INTERMED

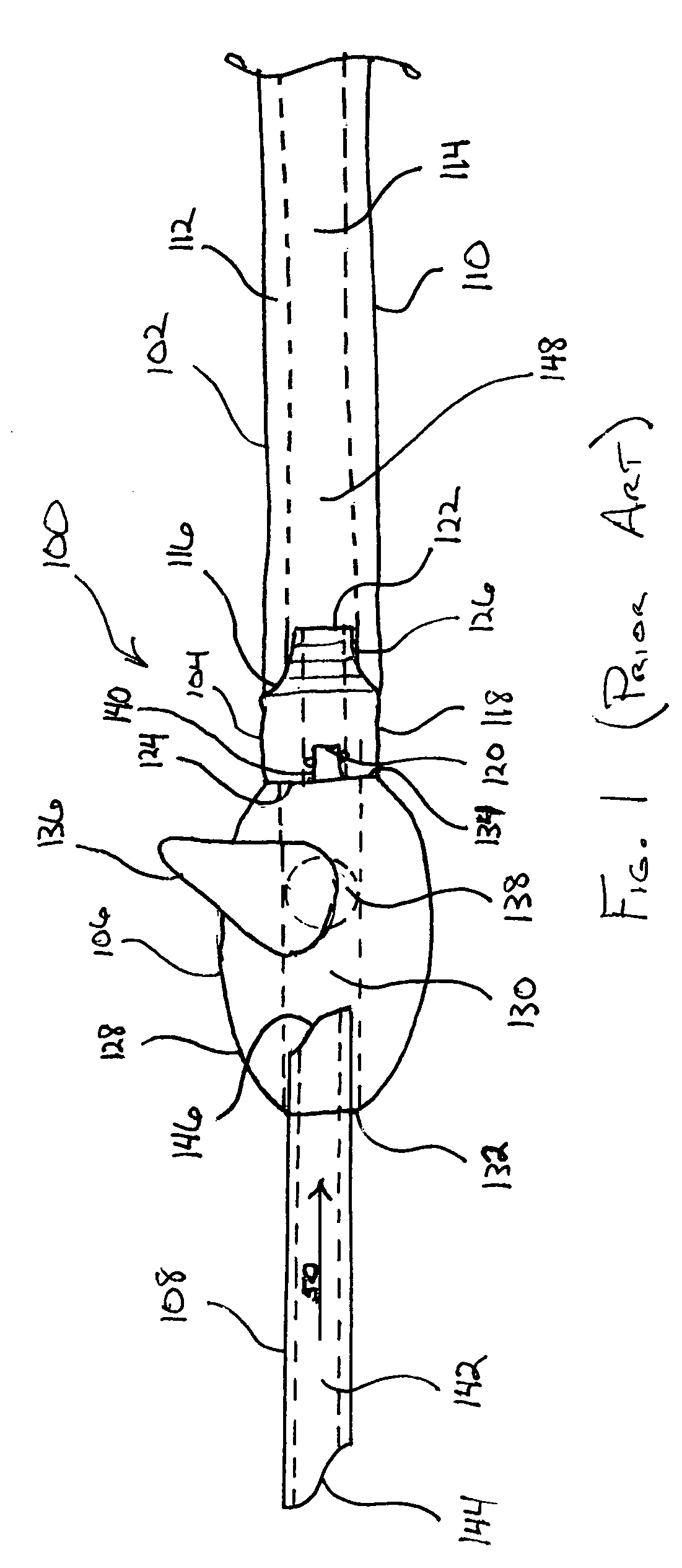

Backflow prevention sleeve for suctioning devices

A sleeve for preventing backflow and cross-contamination between patients of fluid and particulate matter as well as other contaminants present within a dental / medical suctioning device. The sleeve includes a sleeve inlet end that sealingly attaches to and surrounds at least a portion of the suctioning device the vacuum hose to the evacuator tip. The sleeve also has a sleeve exhaust end that is inserted into the control valve and can reside within the interior lumen of the vacuum hose during normal suction operation. During operation, the sleeve provides a seal between the patient contact part and the control valve of the suctioning device. The proximate end collapses, seals, and / or provides a barrier when the suctioning device does not draw a vacuum away from the patient and towards the vacuum source.

Owner:MARCH MICHAEL S

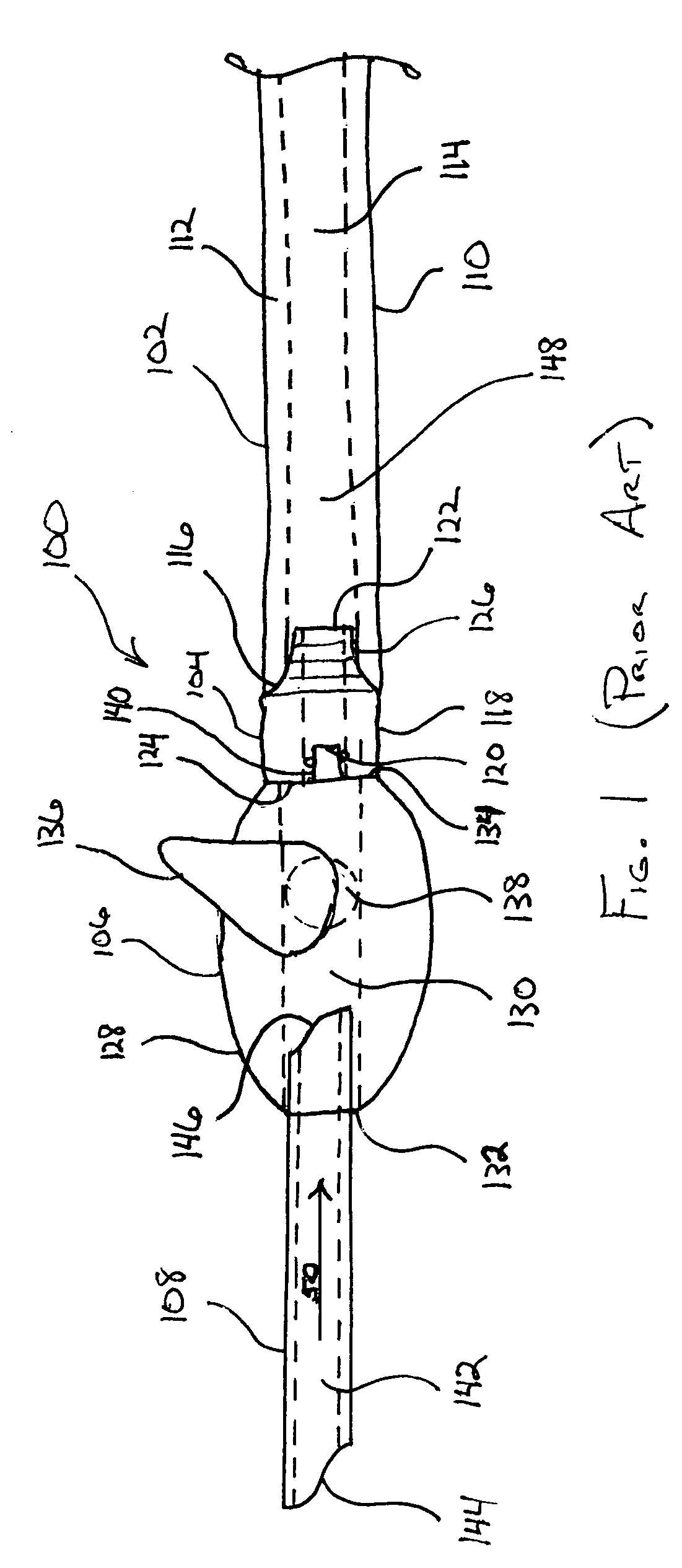

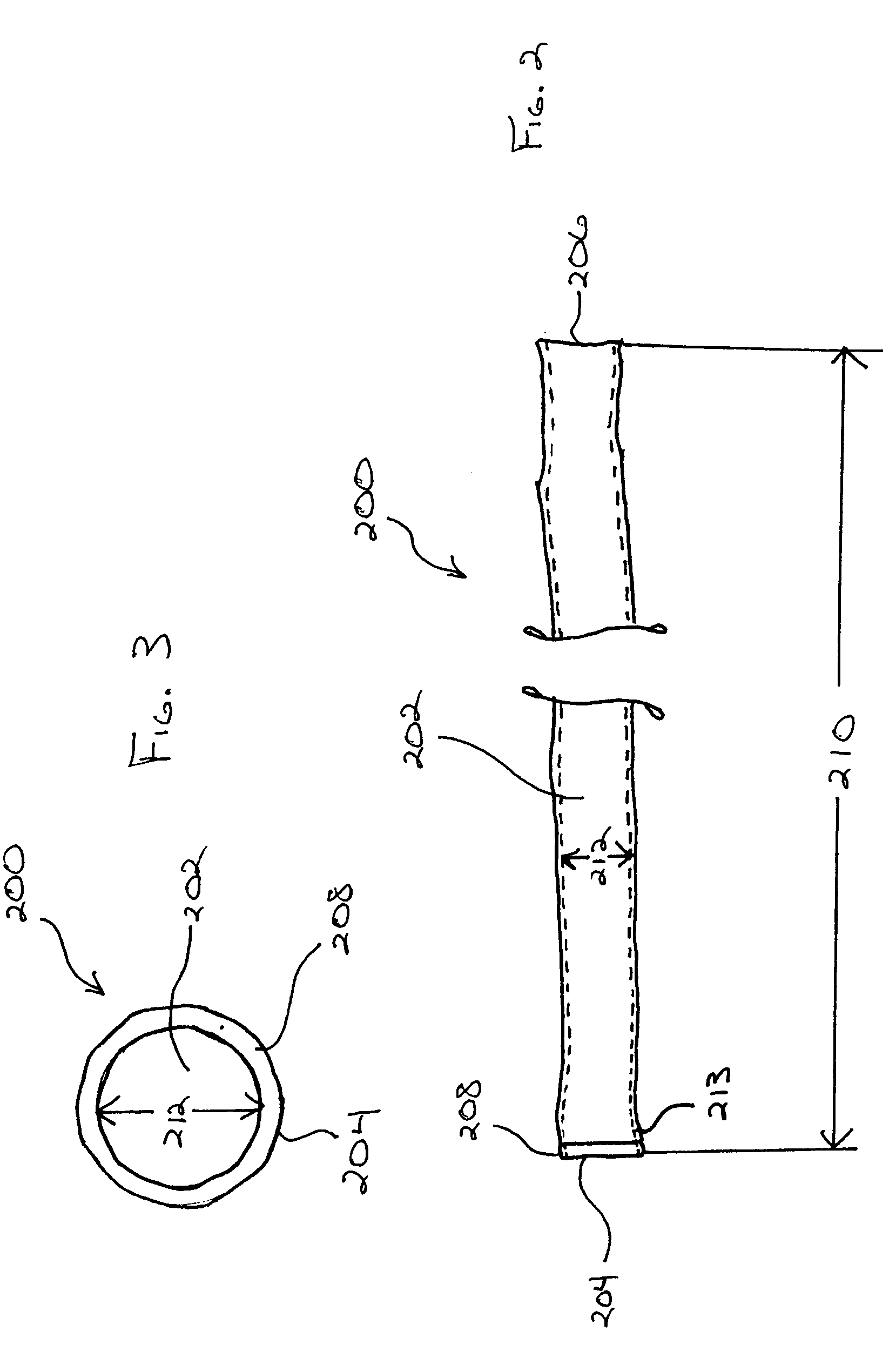

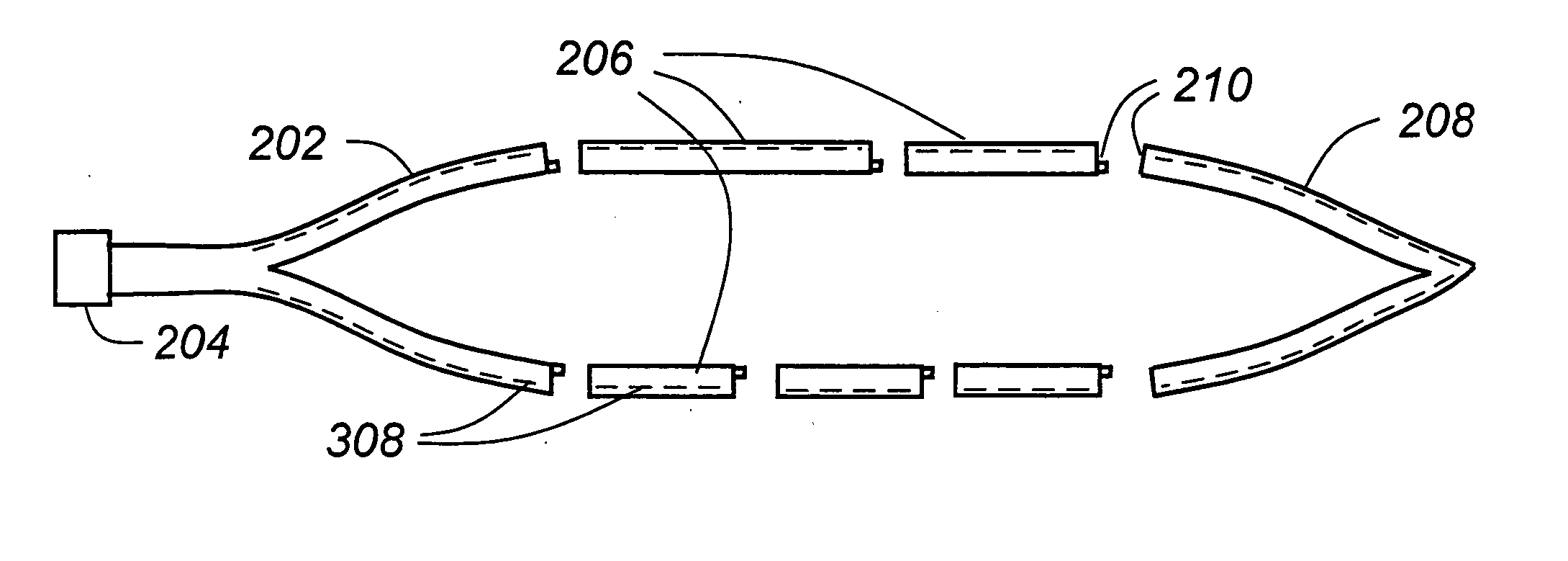

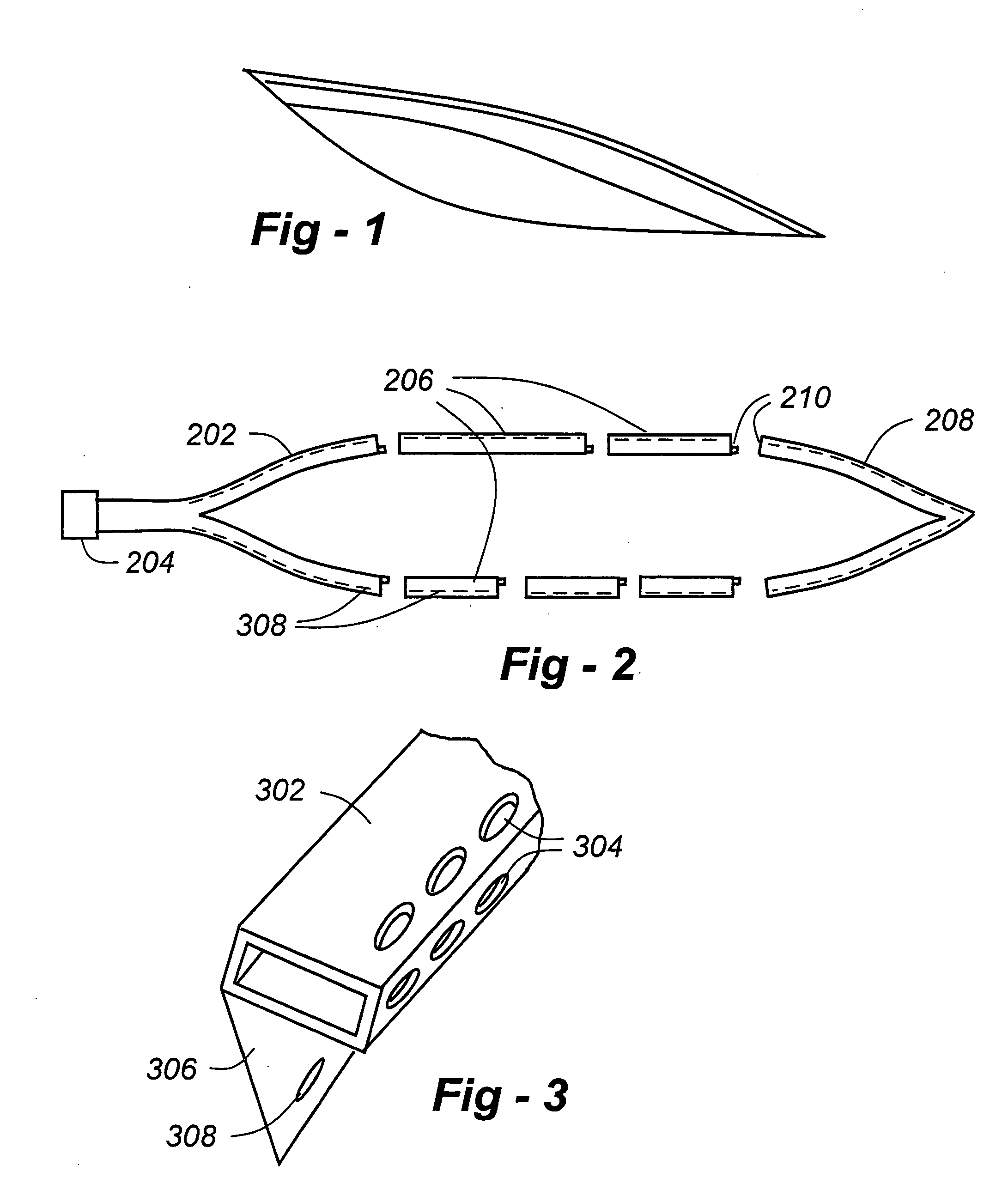

Time-delayed gun bore evacuator

A bore evacuator for a gun tube may include a time-delayed discharge valve. The time-delayed discharge valve may open substantially simultaneously with the opening of the breech of the gun tube. Gas discharged from the bore evacuator may evacuate the bore of the gun tube. The time delay of the time-delayed discharge valve may be activated by gas pressure in the bore evacuator. The bore evacuator may include a pressure-regulating valve for regulating the maximum pressure in the bore evacuator.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Device and method for for rapid warming of steam piping of a power plant

Owner:GENERAL ELECTRIC CO

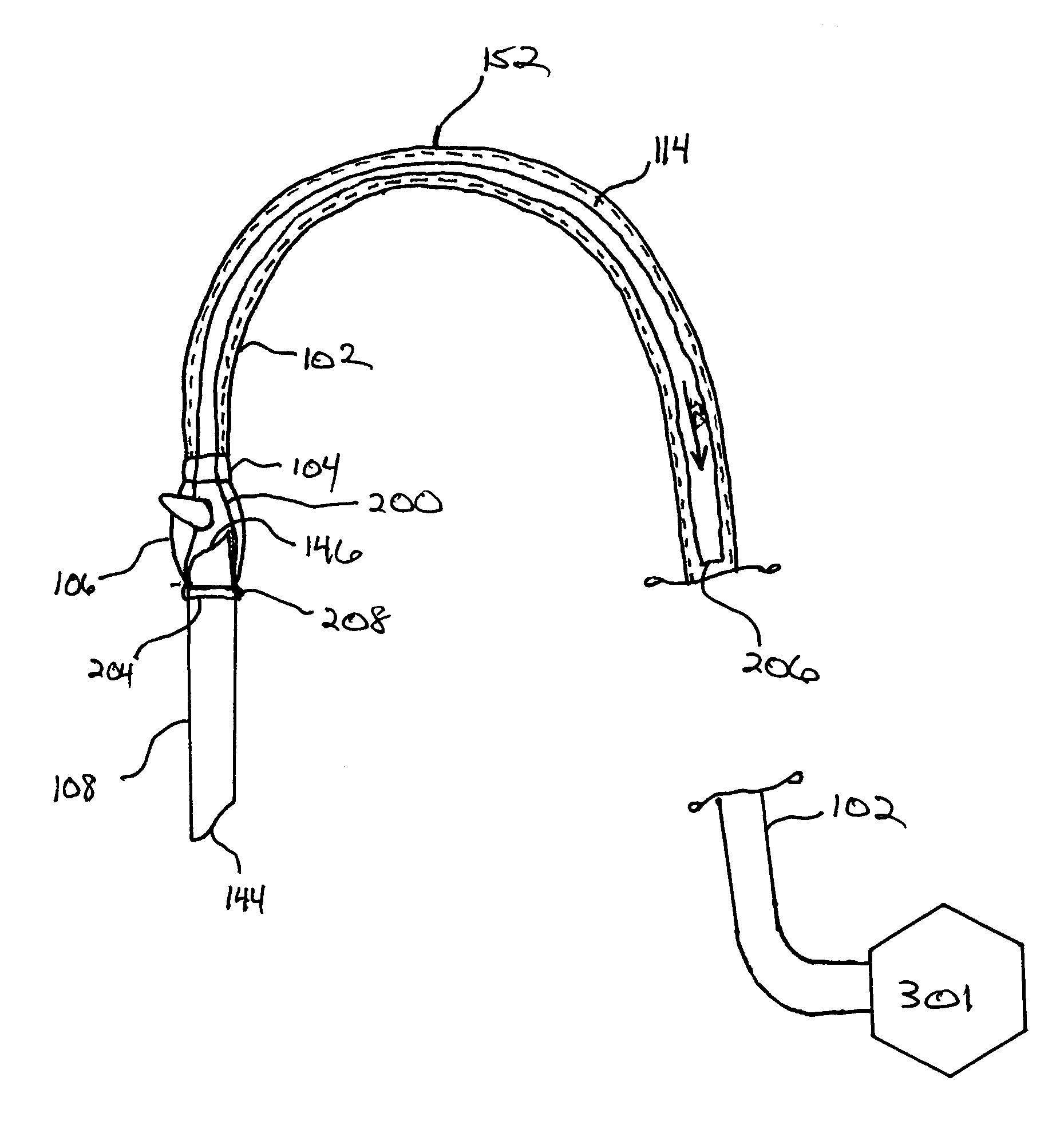

Cystothrombus and gastroentero-thrombus evacuators

Thrombus evacuator devices are provided. A cystothrombus provides an aspirator tube fluidly communicating to a suction intake, wherein a maceration blade is provided within the aspirator tube adjacent to the suction intake. A rotational element us operatively associated to the maceration blade for morcellating blood clots urged through the suction intake, wherein the aspirator tube is dimensioned to slidably nest in a cystoscope sheath adapted to be inserted into a human urethra. In another embodiment, a gastroentro-thrombus evacuator includes a double lumen tube having non-fluidly connected first and second lumens terminating into a coupling cavity of a coupling device removably attached to a distal end of the double lumen tube. The coupling device provides a suction intake and a flushing outlet fluidly communicating with the coupling cavity. A rotating maceration blade is operational adjacent to the suction intake, while a suction is urged through the first lumen.

Owner:SUTLIFF III VINCENT

Improved method for making vacuum switch device

InactiveCN101236857ALow costRemove restrictionsHigh-tension/heavy-dress switchesAir-break switchesMagnetic tension forceEngineering

The invention provides a method for improving the manufacturing of a vacuum switching device. The method adopts a smaller evacuator which can work for a long time at a high temperature; in a minitype evacuating container, parts are kept separated by the magnetic force or corrugated pipes; once the container is evacuated, the needed high vacuum is obtained, and the magnetic polarity is converted, thereby the vacuum switching device is closed; in the process of the inner-part rolling seam welding(without welding blocks) or the induction heating(with welding blocks), the vacuum switching device is hermetically sealed, and the vacuum in the vacuum switching device is sealed in the vacuum switching device.

Owner:开关工艺欧洲有限公司

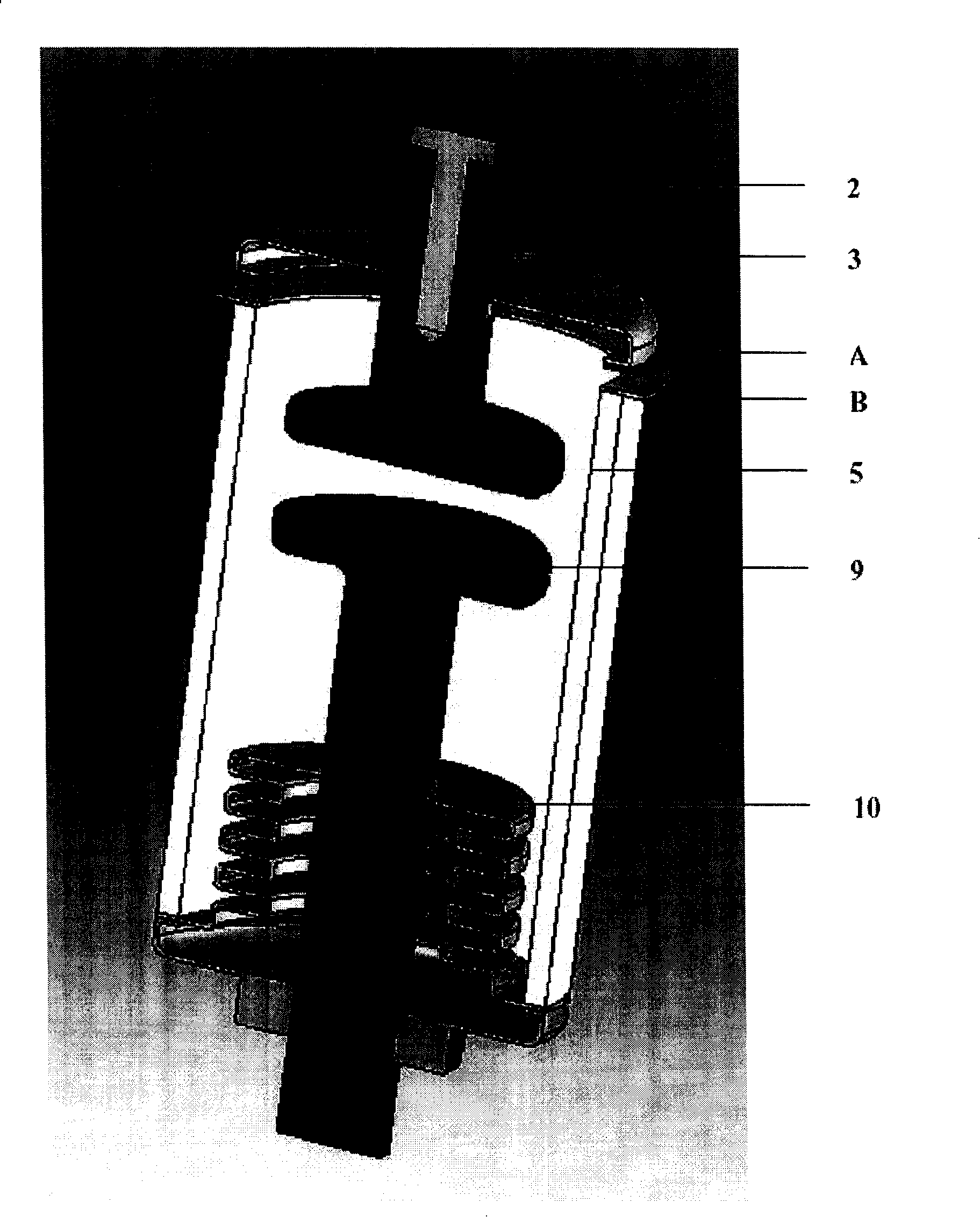

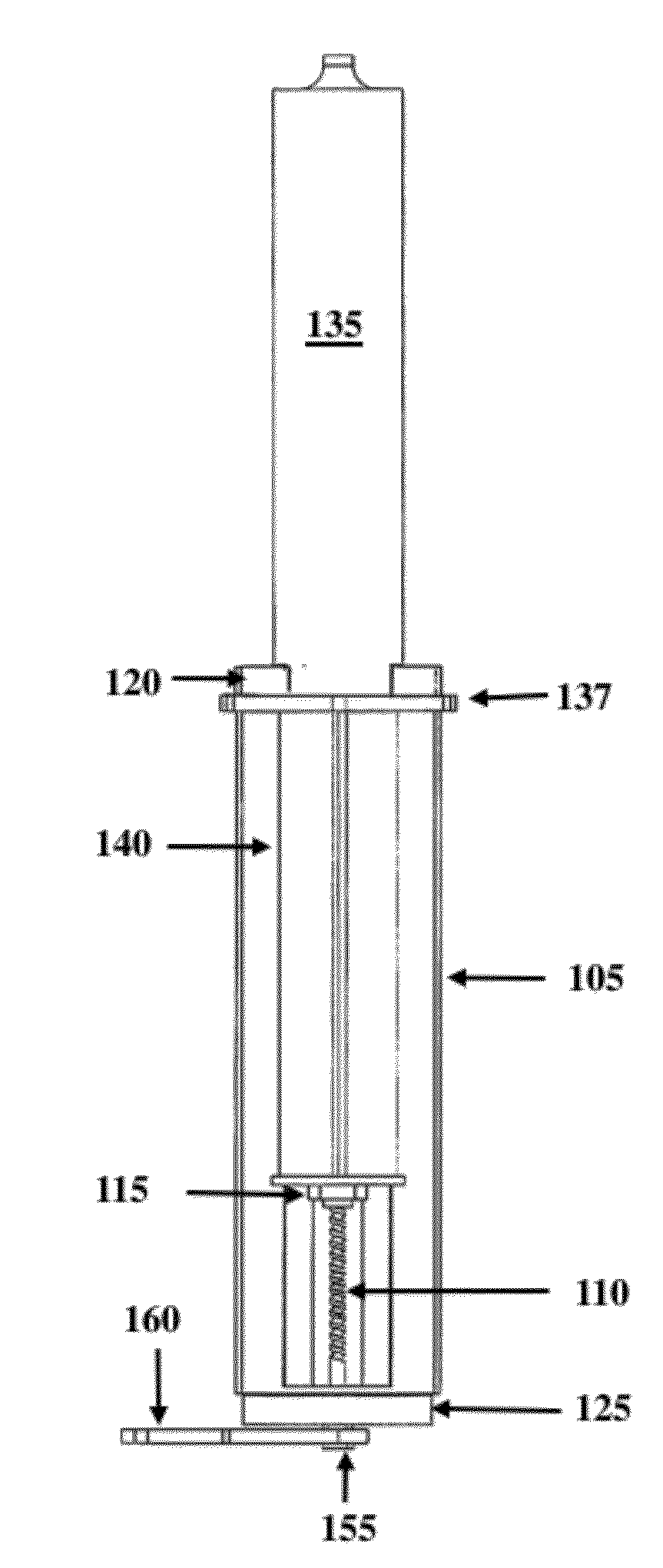

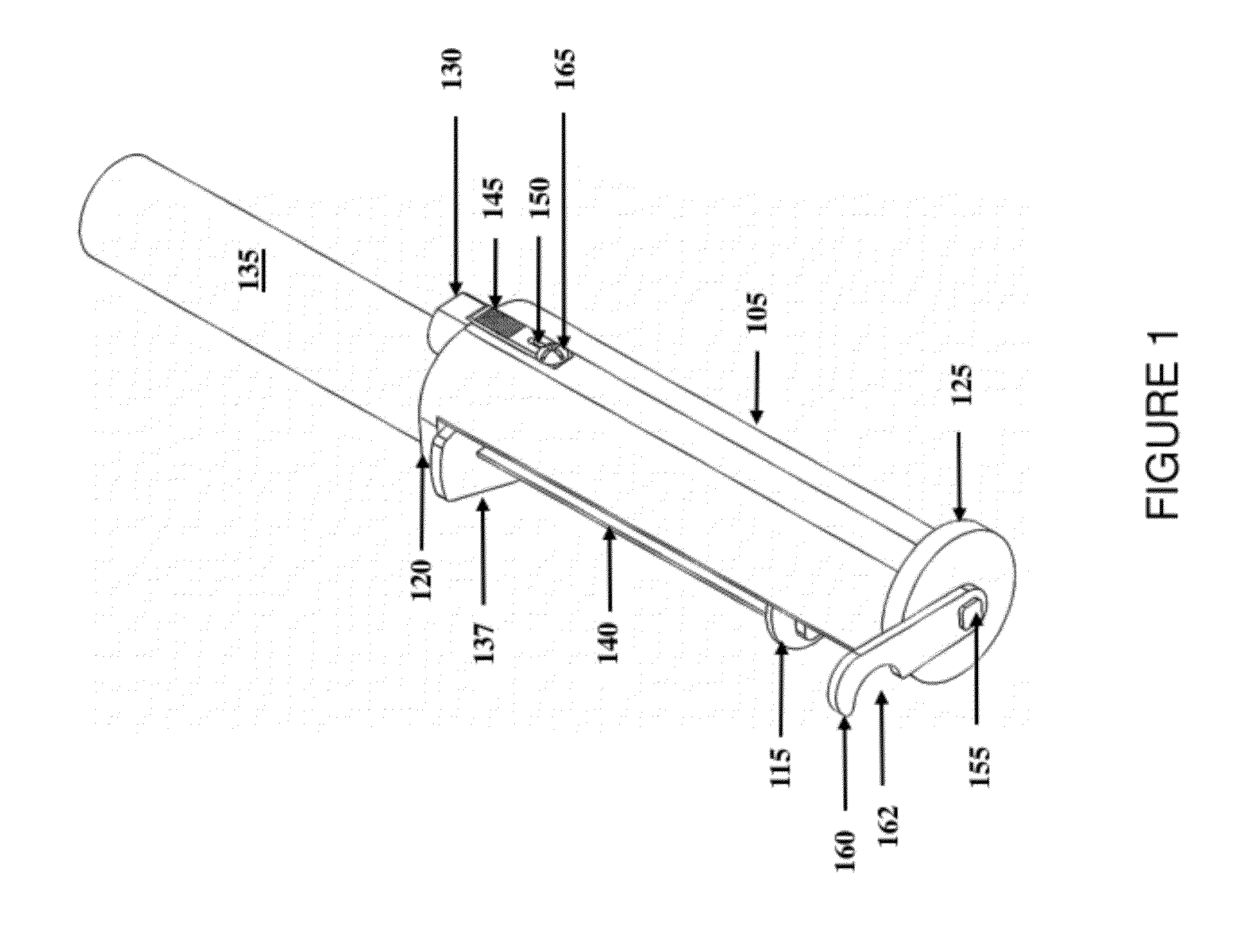

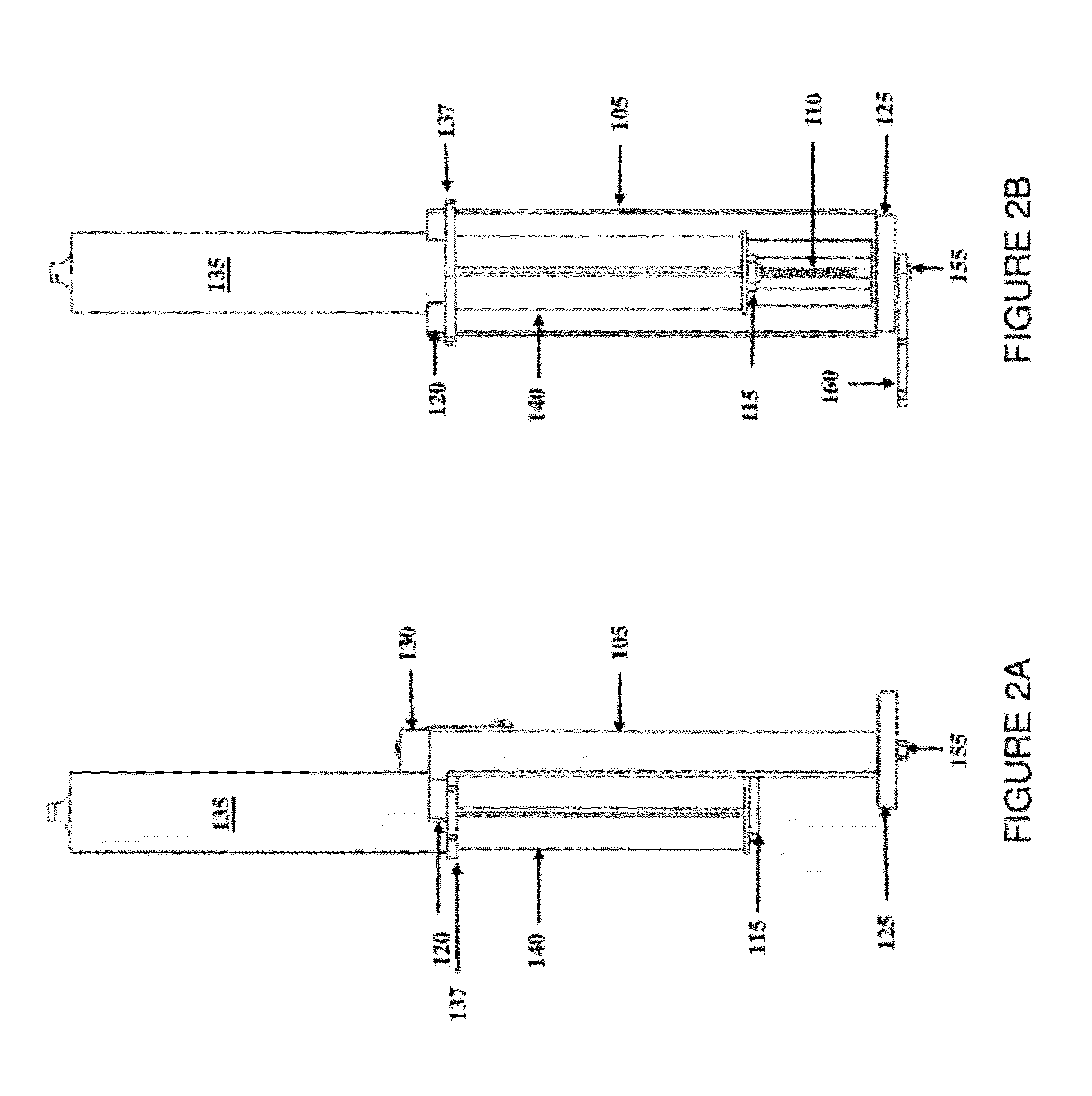

Syringe Evacuator

A syringe evacuator configured to discharge a syringe at a controllable rate. In one embodiment, the syringe evacuator includes a threaded shaft and a syringe depressor platform threaded onto the threaded shaft. The syringe evacuator also includes a spiral spring coupled to the threaded shaft configured to rotate the threaded shaft.

Owner:MEDINVENTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com