Patents

Literature

1014results about How to "Reduce uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

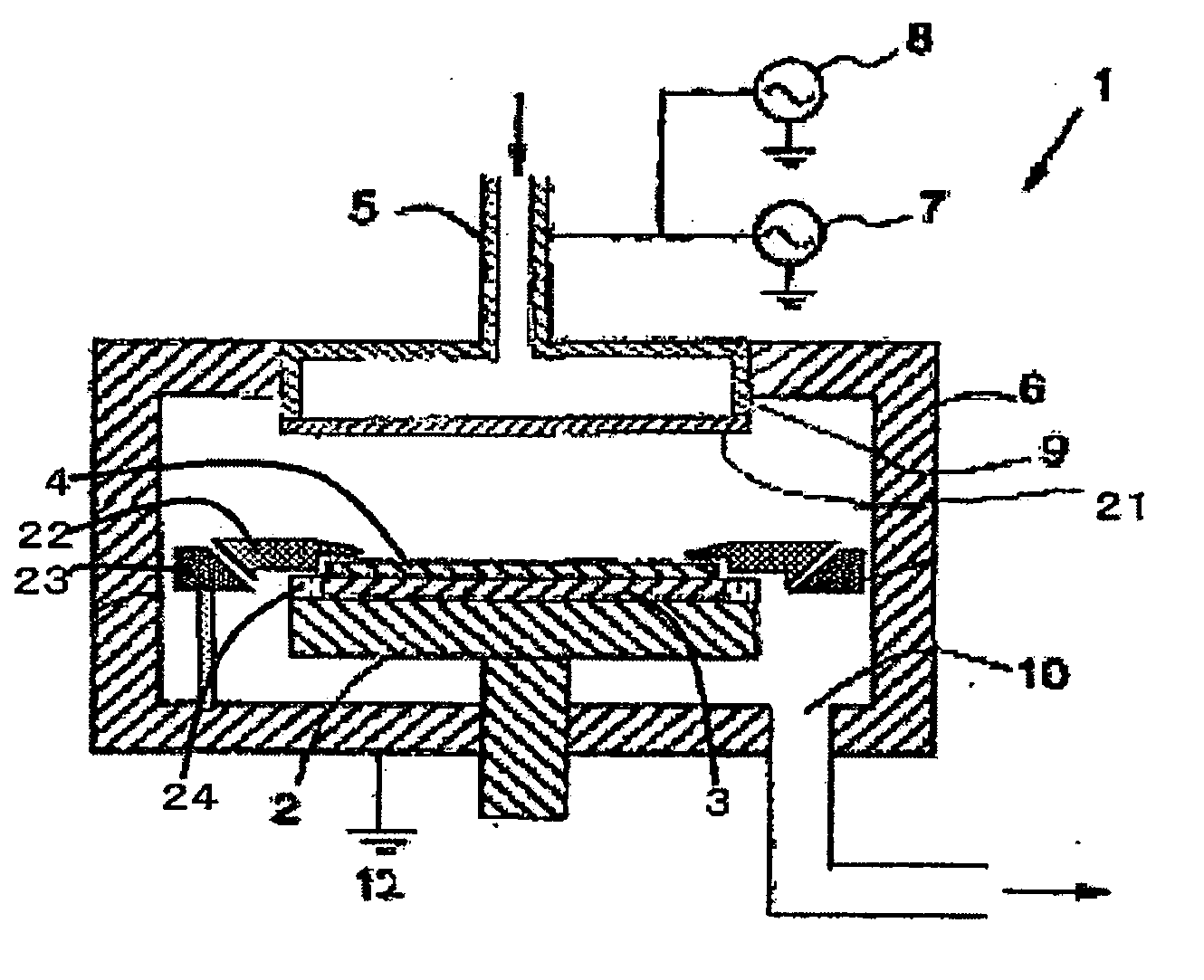

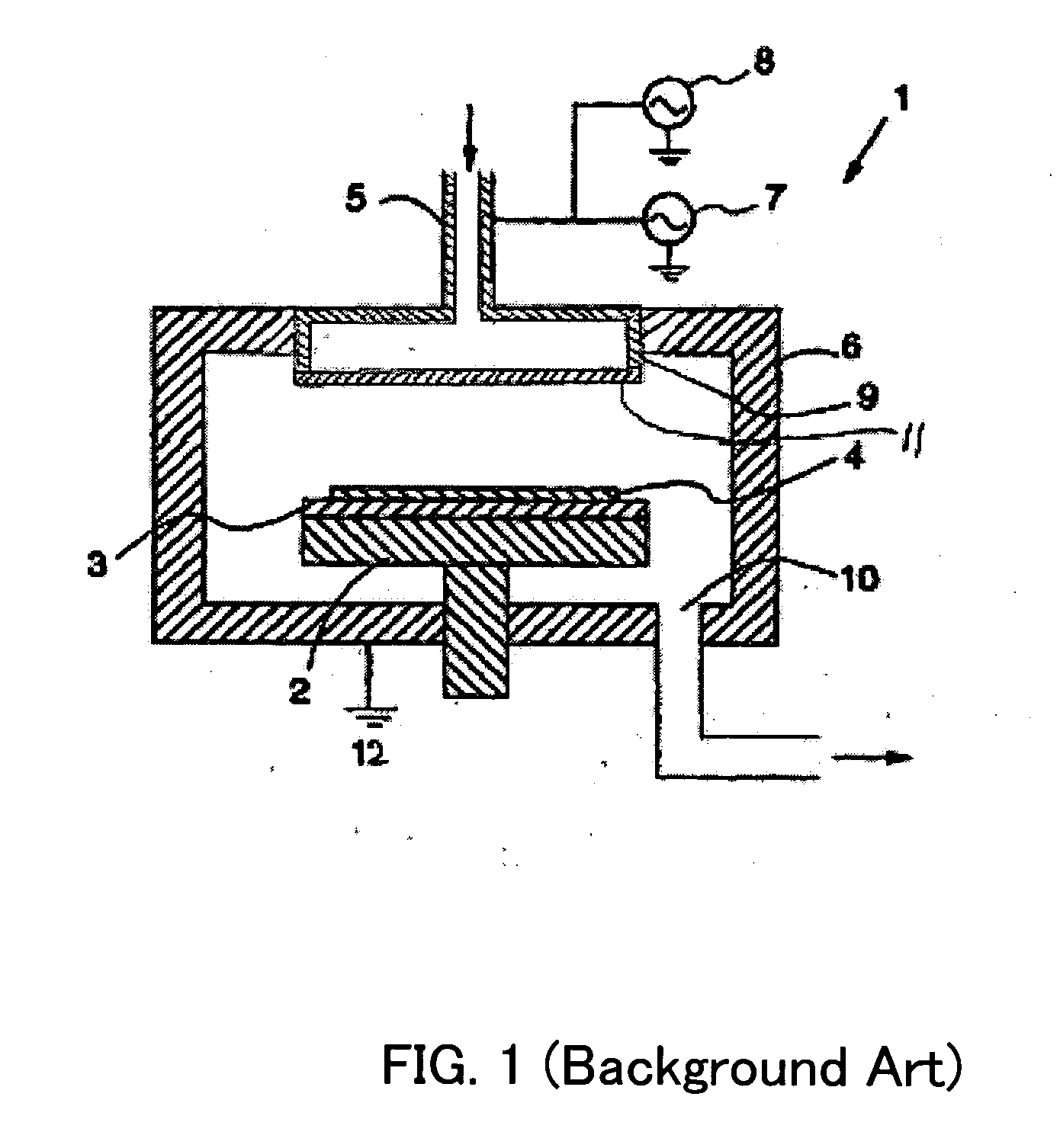

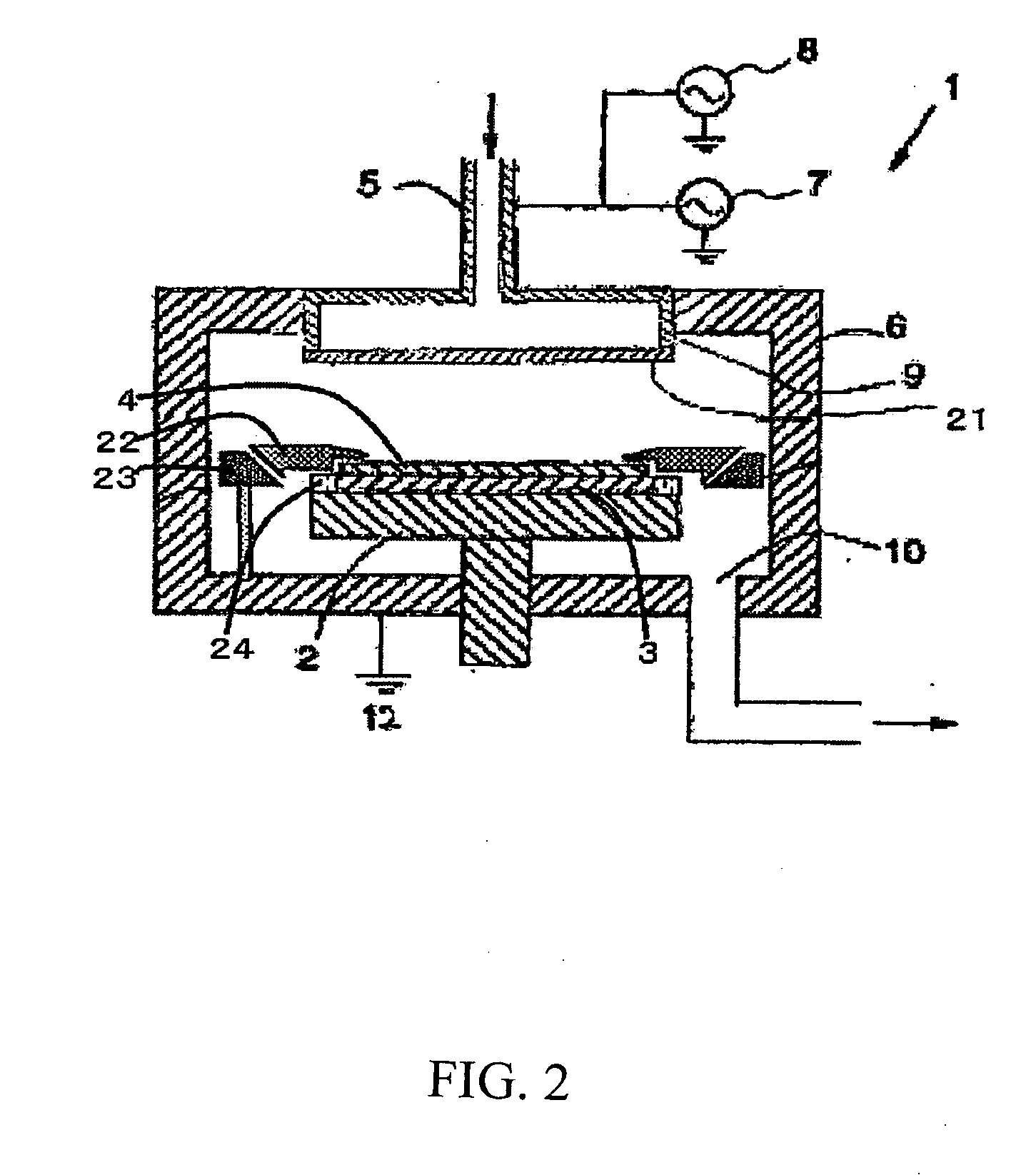

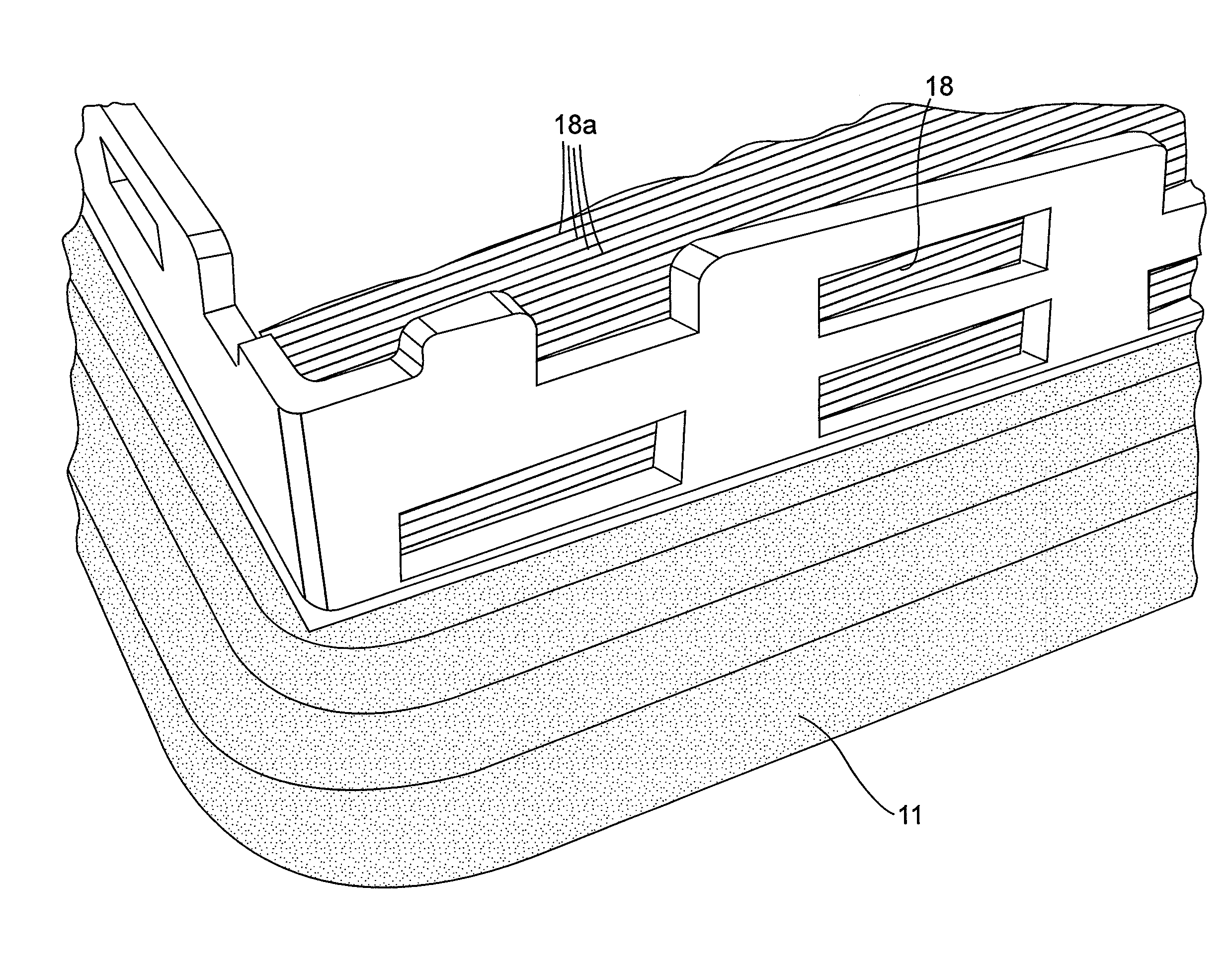

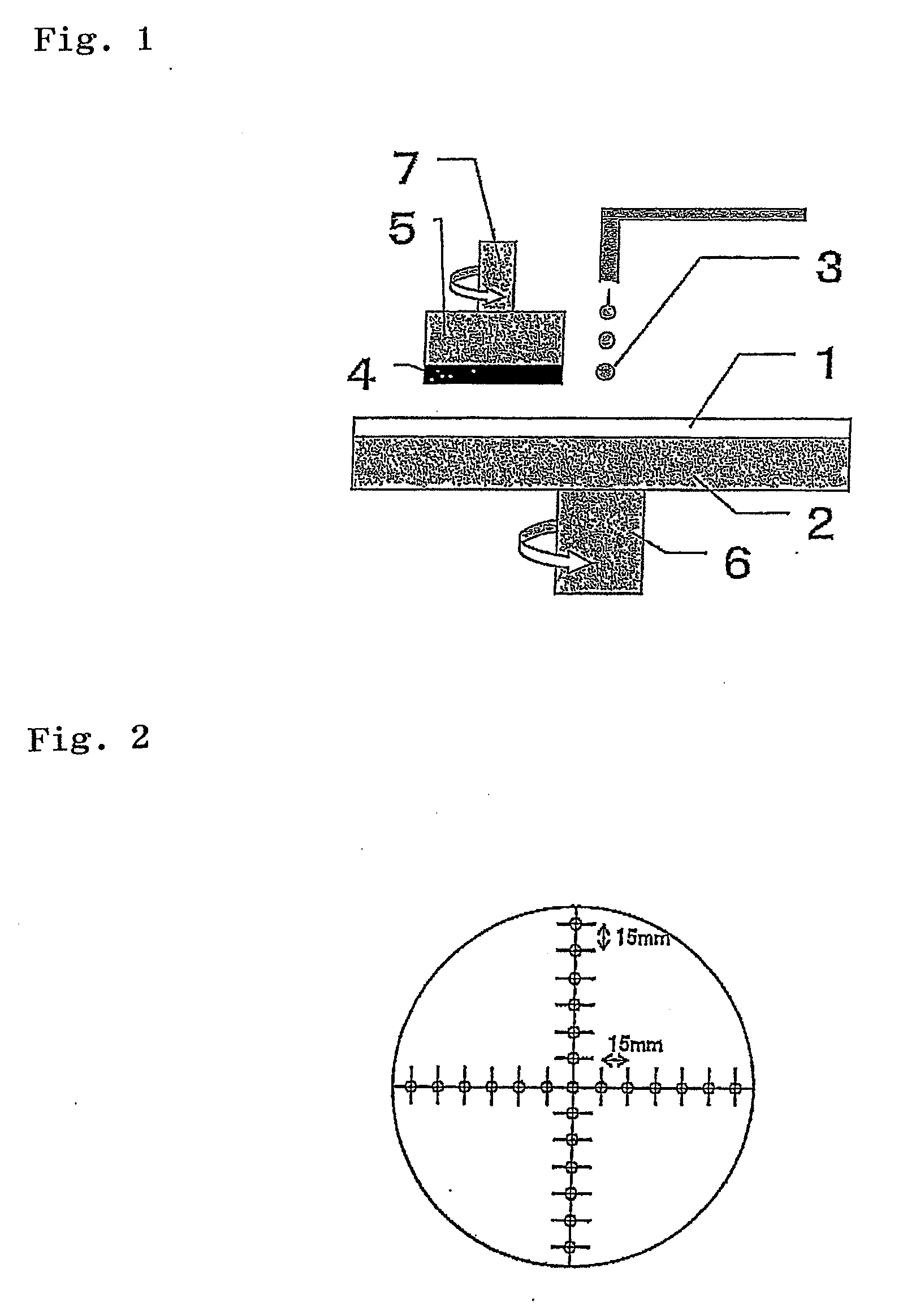

Plasma CVD film formation apparatus provided with mask

InactiveUS20070065597A1Uniform film thicknessUniform characteristicsElectric discharge tubesChemical vapor deposition coatingEngineeringVacuum chamber

A plasma CVD apparatus for forming a thin film on a wafer having diameter Dw and thickness Tw, includes: a vacuum chamber; a shower plate; a top plate; a top mask portion for covering a top surface peripheral portion of the wafer; and a side mask portion for covering a side surface portion of the wafer. The side mask portion has an inner diameter of Dw+α, and the top mask portion is disposed at a clearance of Tw+β between a bottom surface of the top mask portion and a wafer-supporting surface of the top plate, wherein α is more than zero, and β is more than zero.

Owner:ASM JAPAN +1

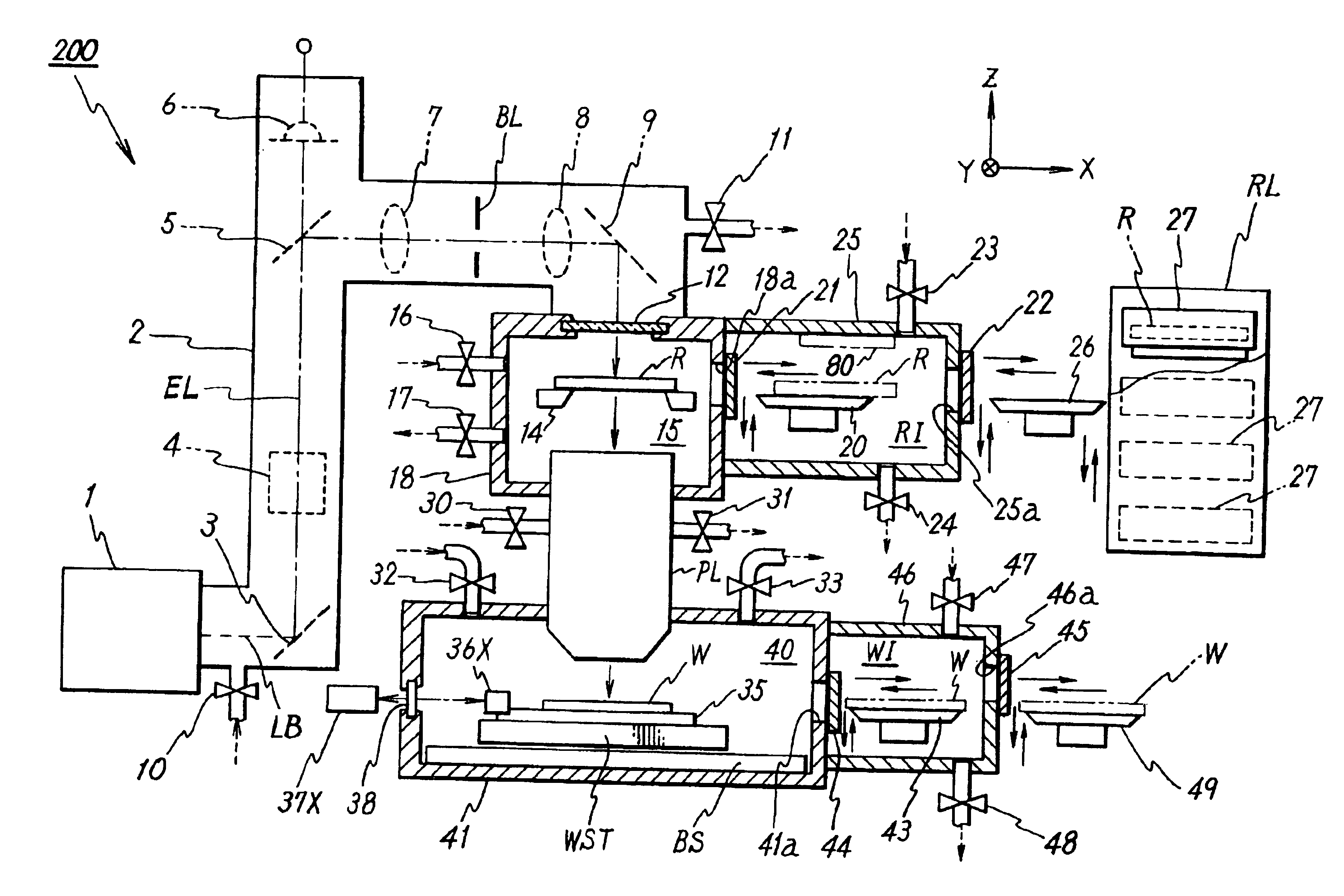

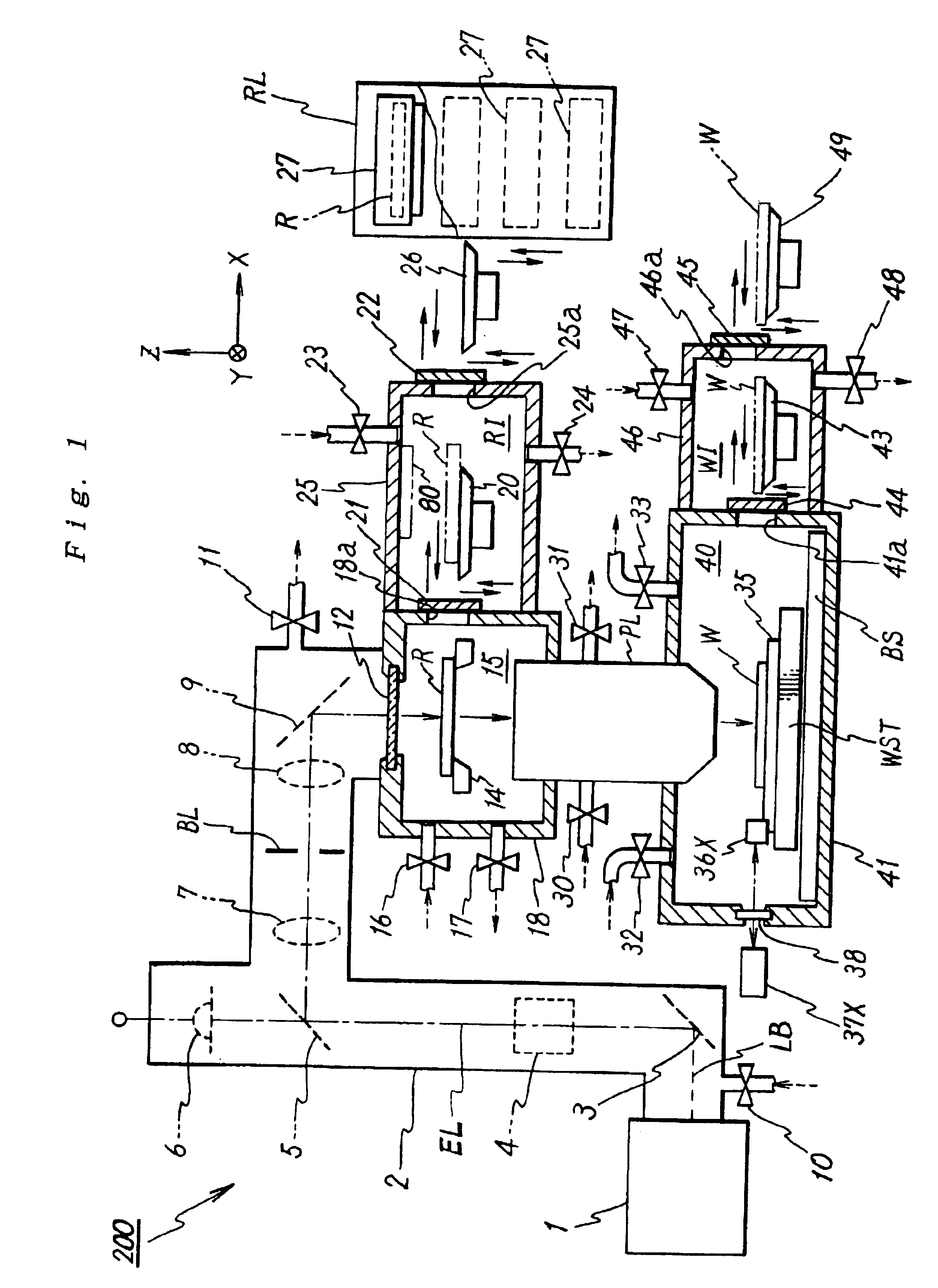

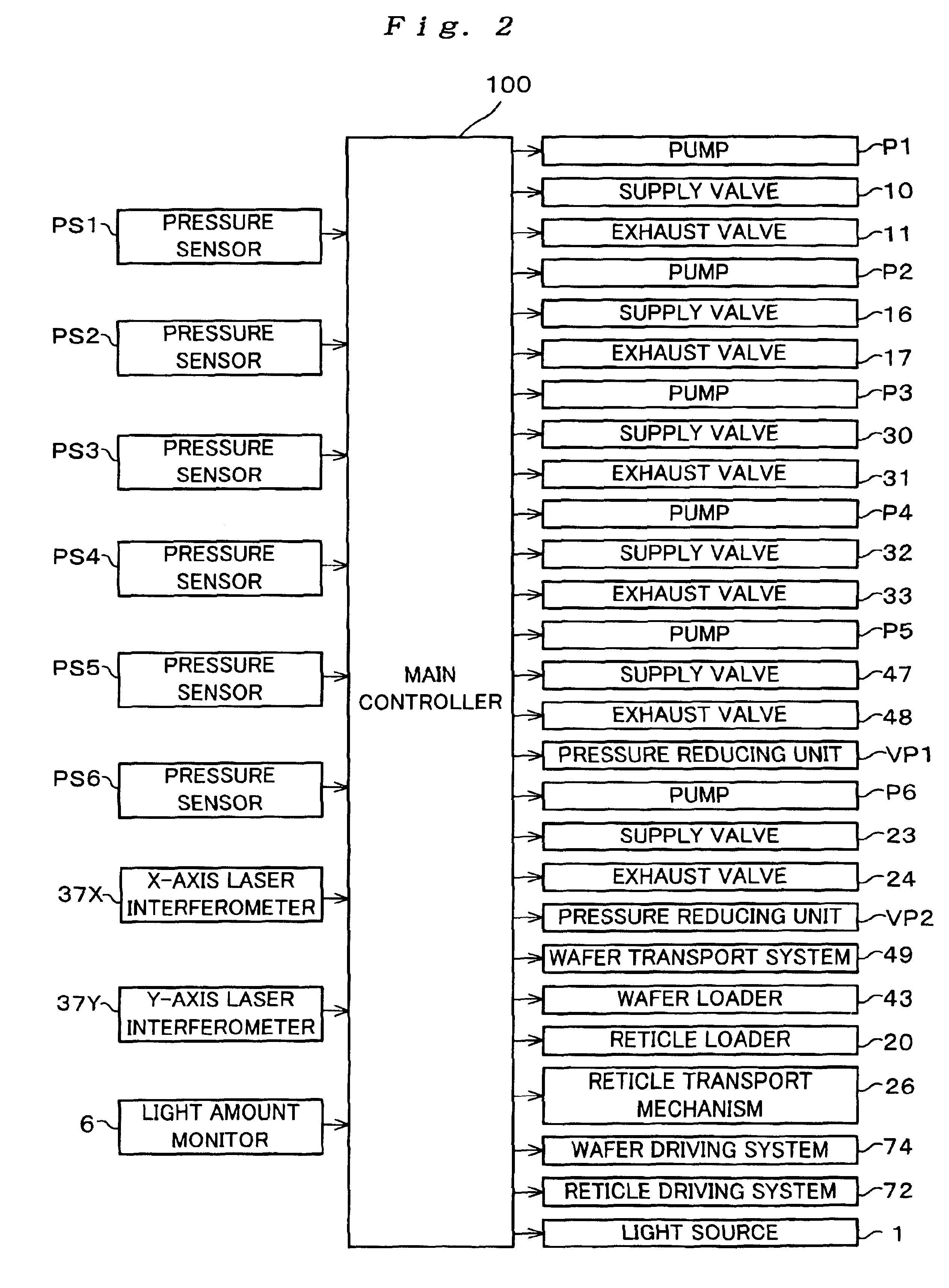

Exposure apparatus and exposure method, and device manufacturing method

InactiveUS6842221B1Stable exposure intensityForming accuratelyPhotomechanical exposure apparatusMicrolithography exposure apparatusMask ROMEngineering

After a mask is carried into a reserve room for temporarily storing before carrying into a mask room filled with specific gas that has an impurity concentration lower than a first concentration (e.g. 1 ppb) and that has a characteristic of absorbing little exposure light, gas-replacement mechanisms replace gas in the reserve room with specific gas having an oxygen concentration not lower than the first concentration. Therefore, when subsequently carrying the mask into the mask room, impurities from the outside (including absorbent gas) can be substantially prevented from getting into the optical path inside the mask room. When replacing a wafer, gas in a reserve room is also replaced in the same way as the above.

Owner:NIKON CORP

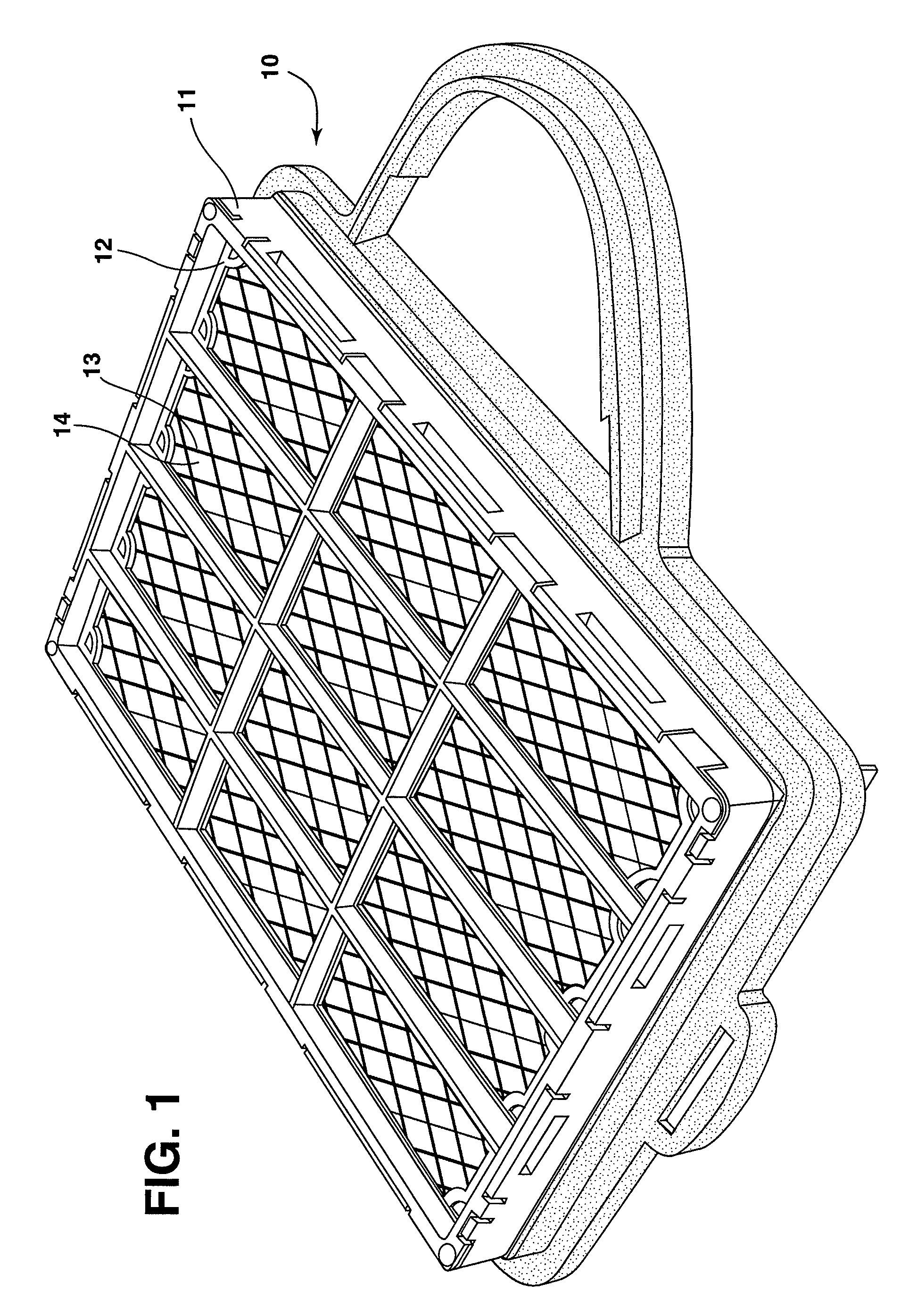

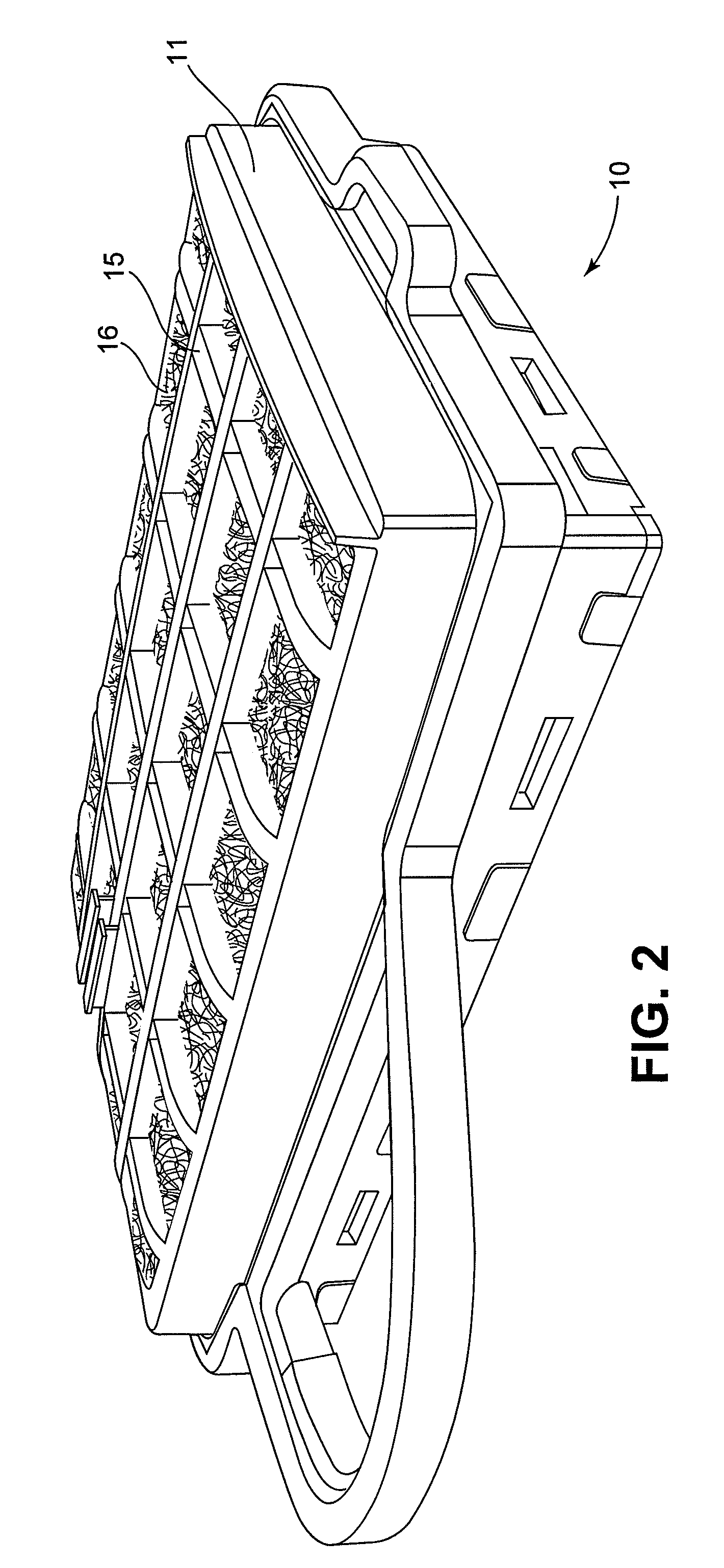

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

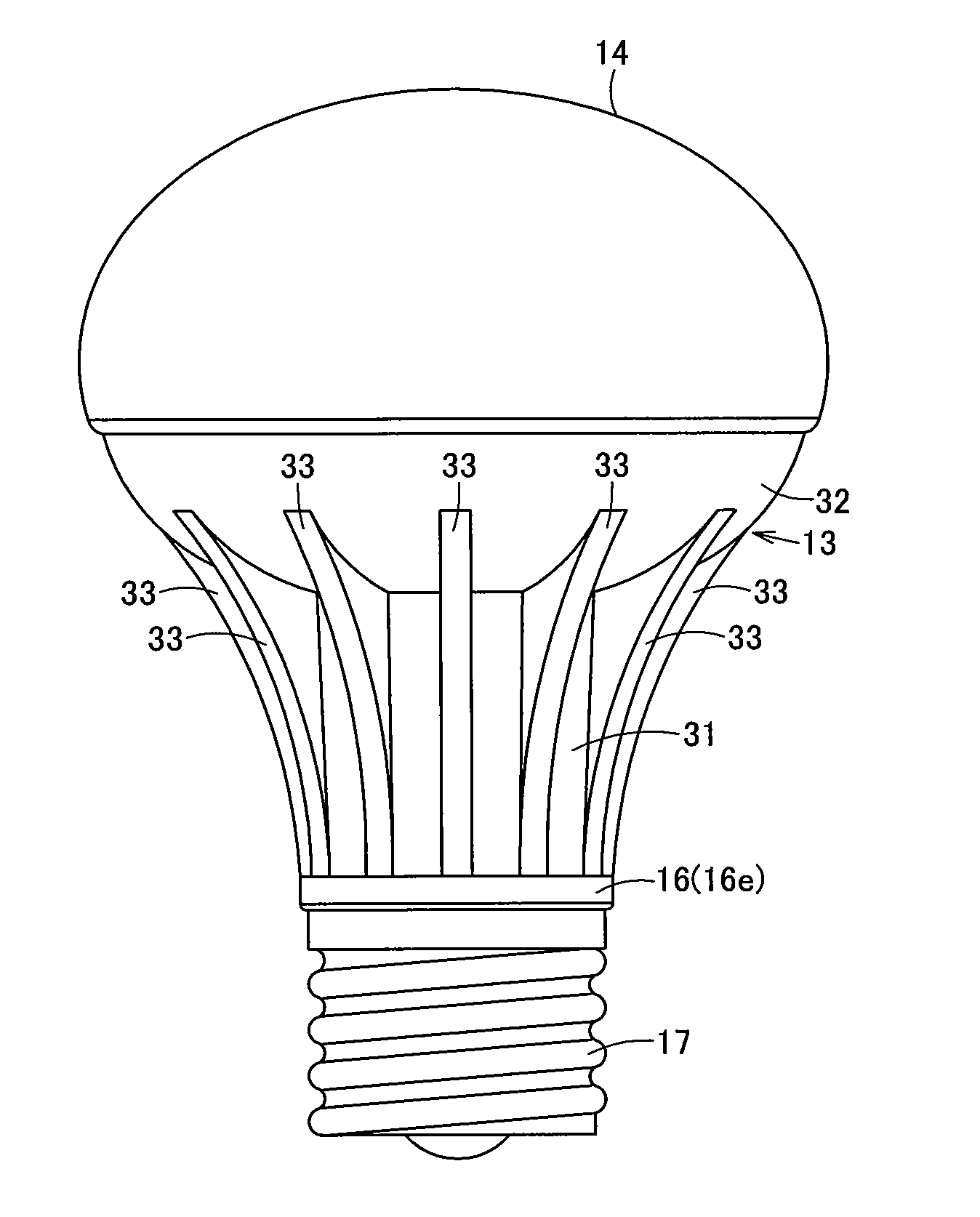

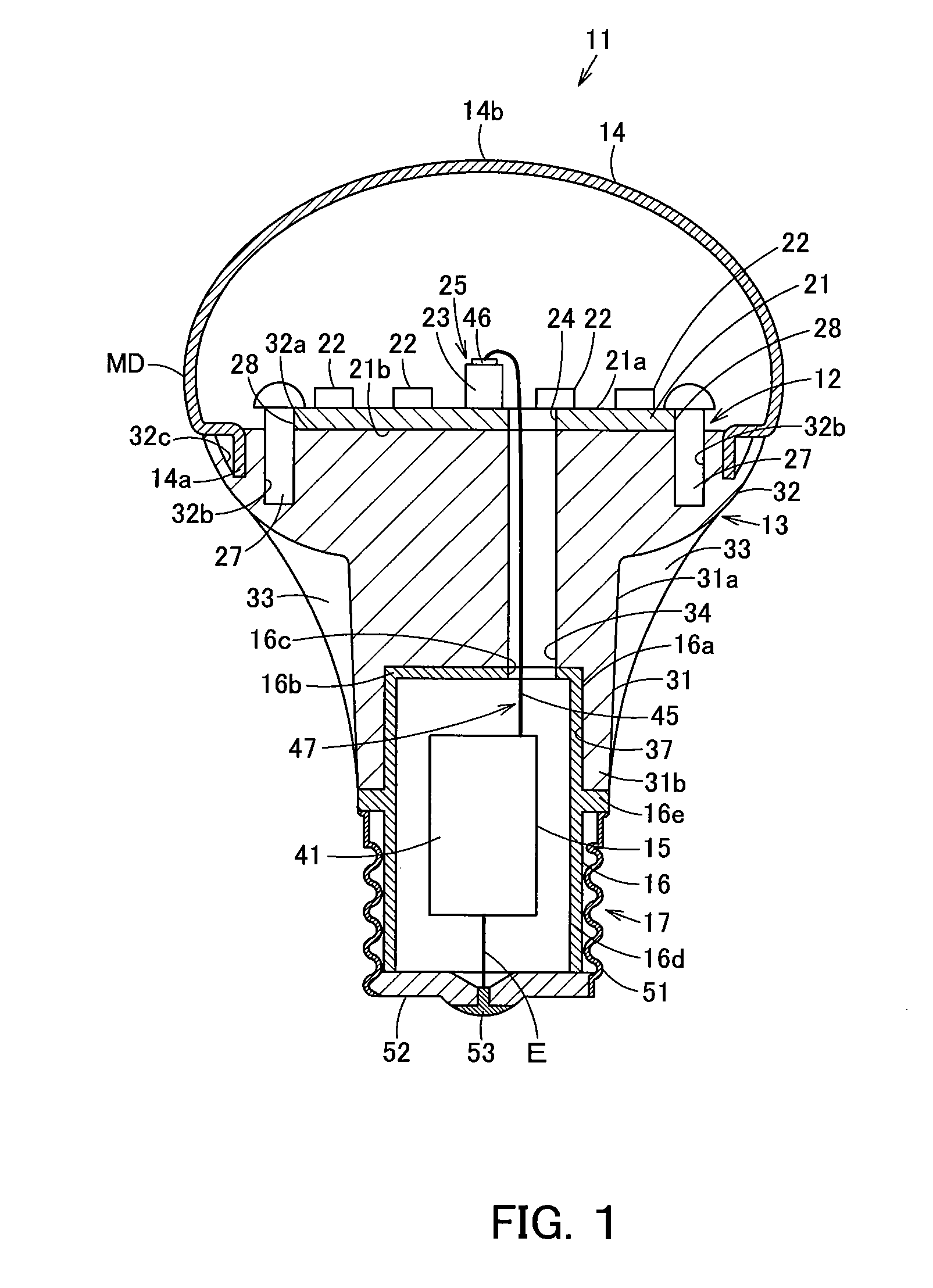

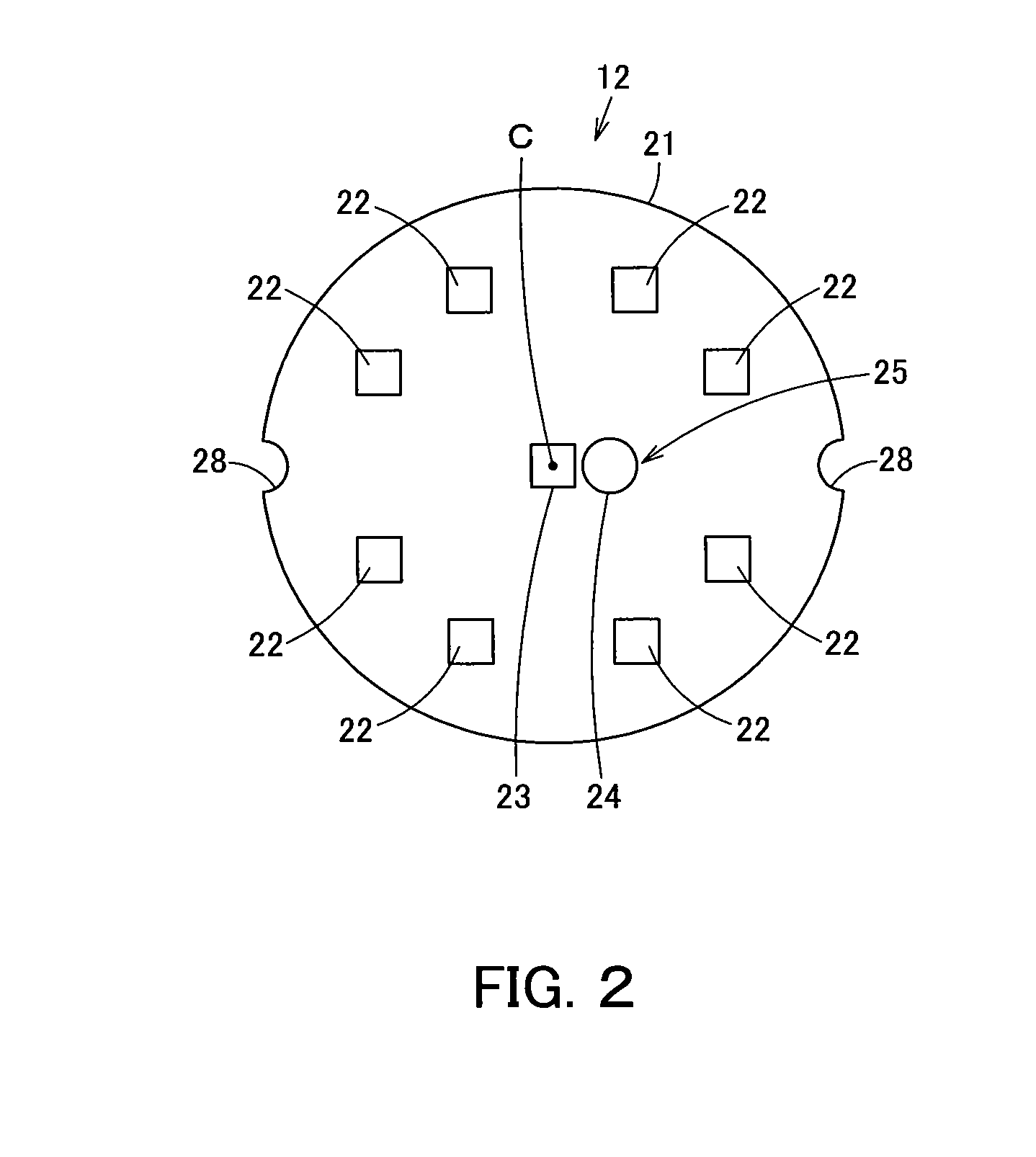

Lamp and lighting equipment

InactiveUS20100026157A1Decrease in light distribution uniformityImprove reliabilityPoint-like light sourceElectric discharge tubesEngineeringElectrical and Electronics engineering

A plurality of LEDs are provided to an outer edge side of a center position of one main surface of an LED substrate main body in a deviated manner respectively. The wiring part including the connector receiving part and the wiring hole are provided at a position that overlaps the center position of the one main surface side of the LED substrate main body. Since the power feeding part is inserted into the wiring hole, the connection part and the connector receiving part can be easily connected and therefore it becomes possible to ensure ease in assembly. Since the connector receiving part is kept away from each of the LEDs with substantially equal distance so that emitted light is hardly blocked, decrease in uniformity of light distribution can be suppressed.

Owner:TOSHIBA LIGHTING & TECH CORP

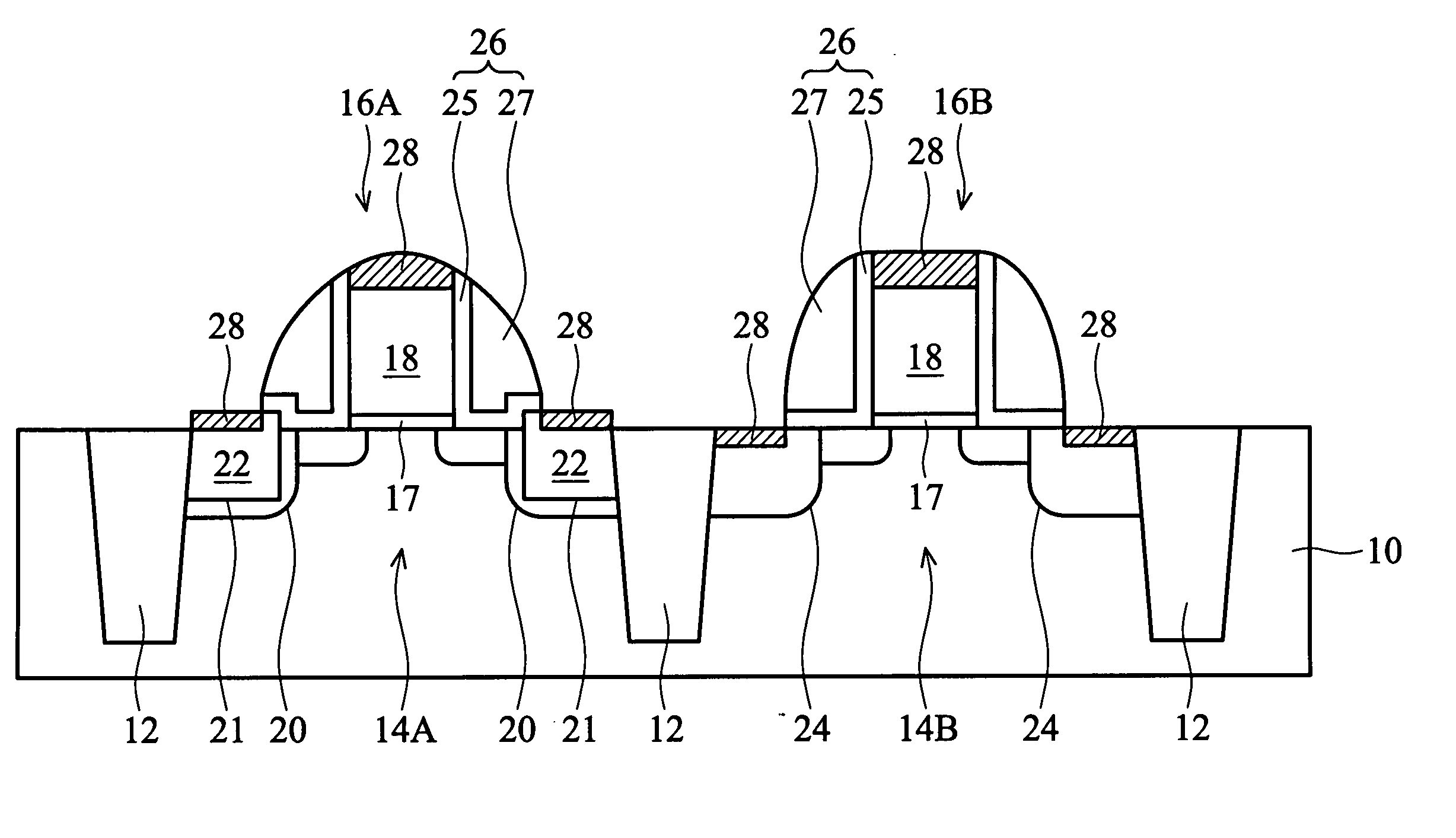

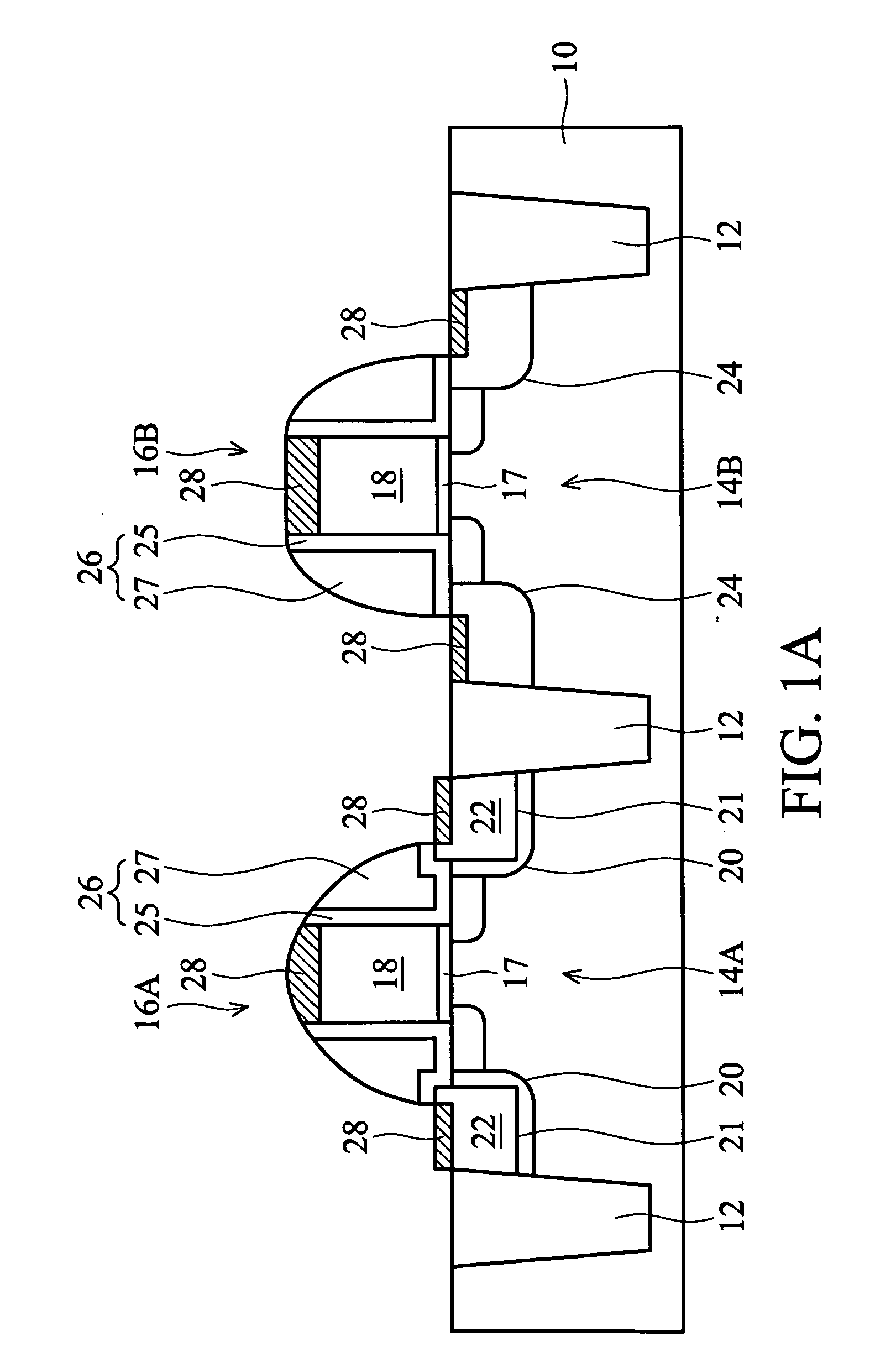

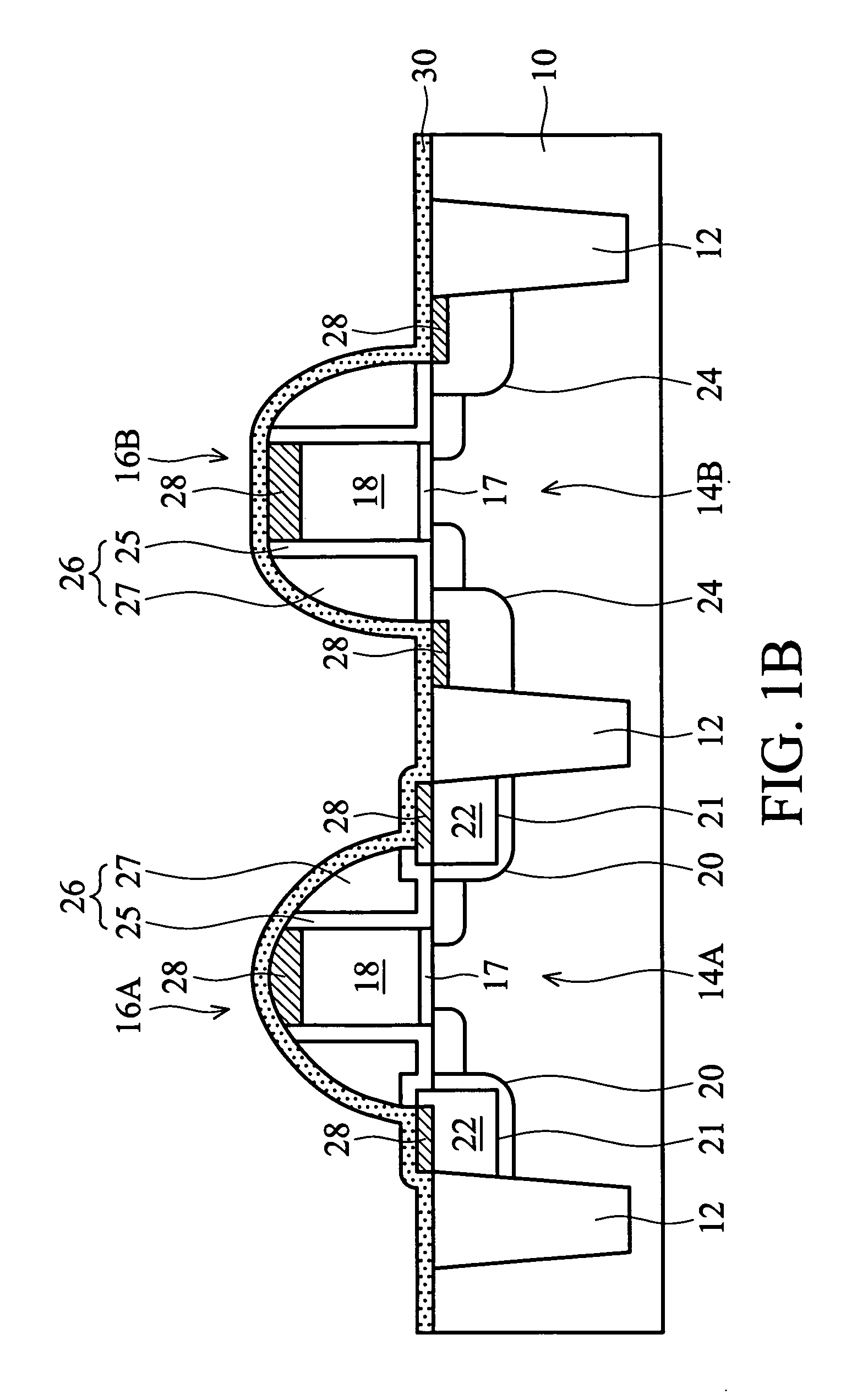

Strain enhanced CMOS architecture with amorphous carbon film and fabrication method of forming the same

InactiveUS20070200179A1High carrier mobilityImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesCMOSComposite material

A strain enhanced CMOS device using amorphous carbon films and fabrication methods of forming the same. The amorphous carbon (a-C) film, such as fluorinated amorphous carbon (a-C:F), is formed of a tensile film or a compressive film to act a stress capping film on the pMOS device region or the nMOS device region. The amorphous carbon film also acts a contact etching stop layer during a contact hole etching process.

Owner:TAIWAN SEMICON MFG CO LTD

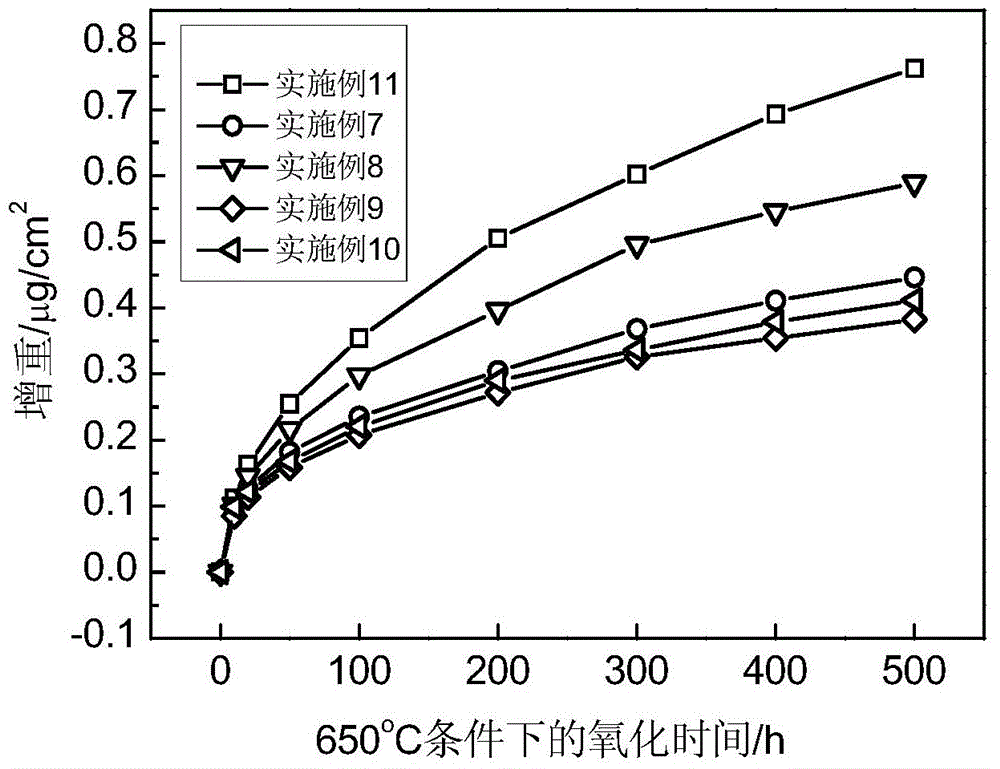

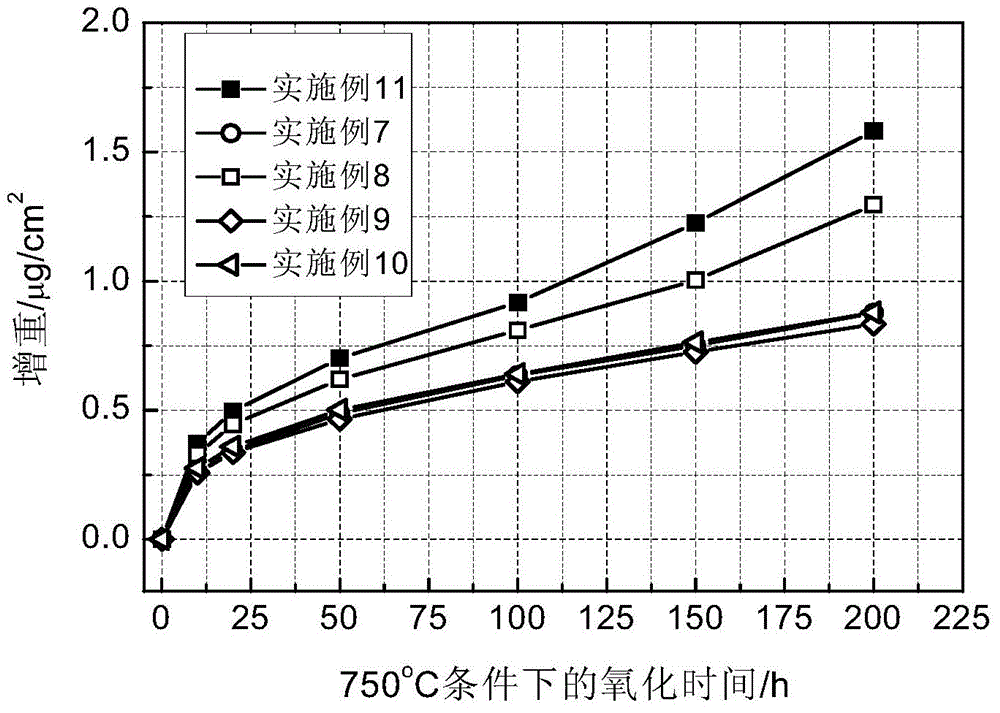

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

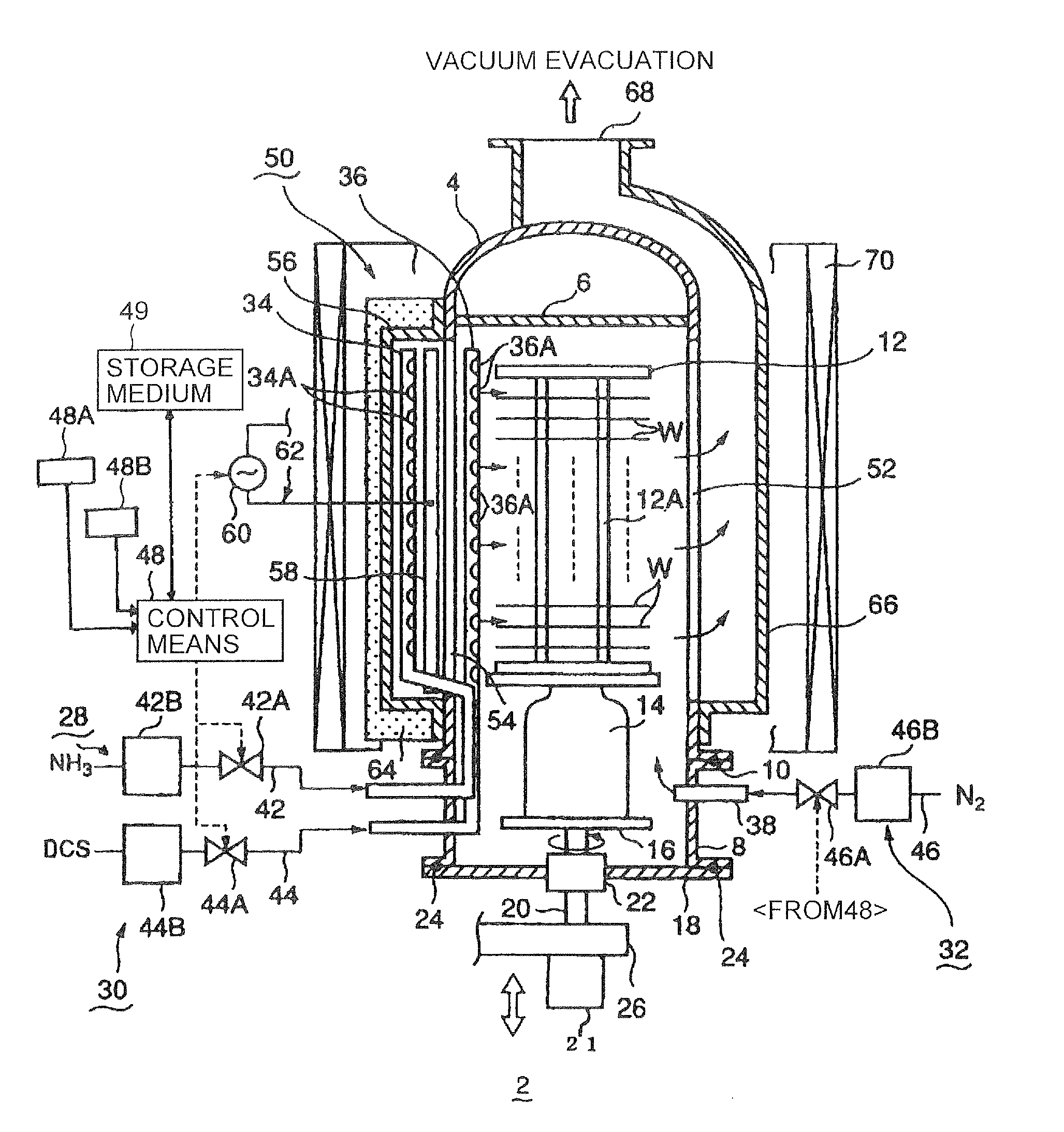

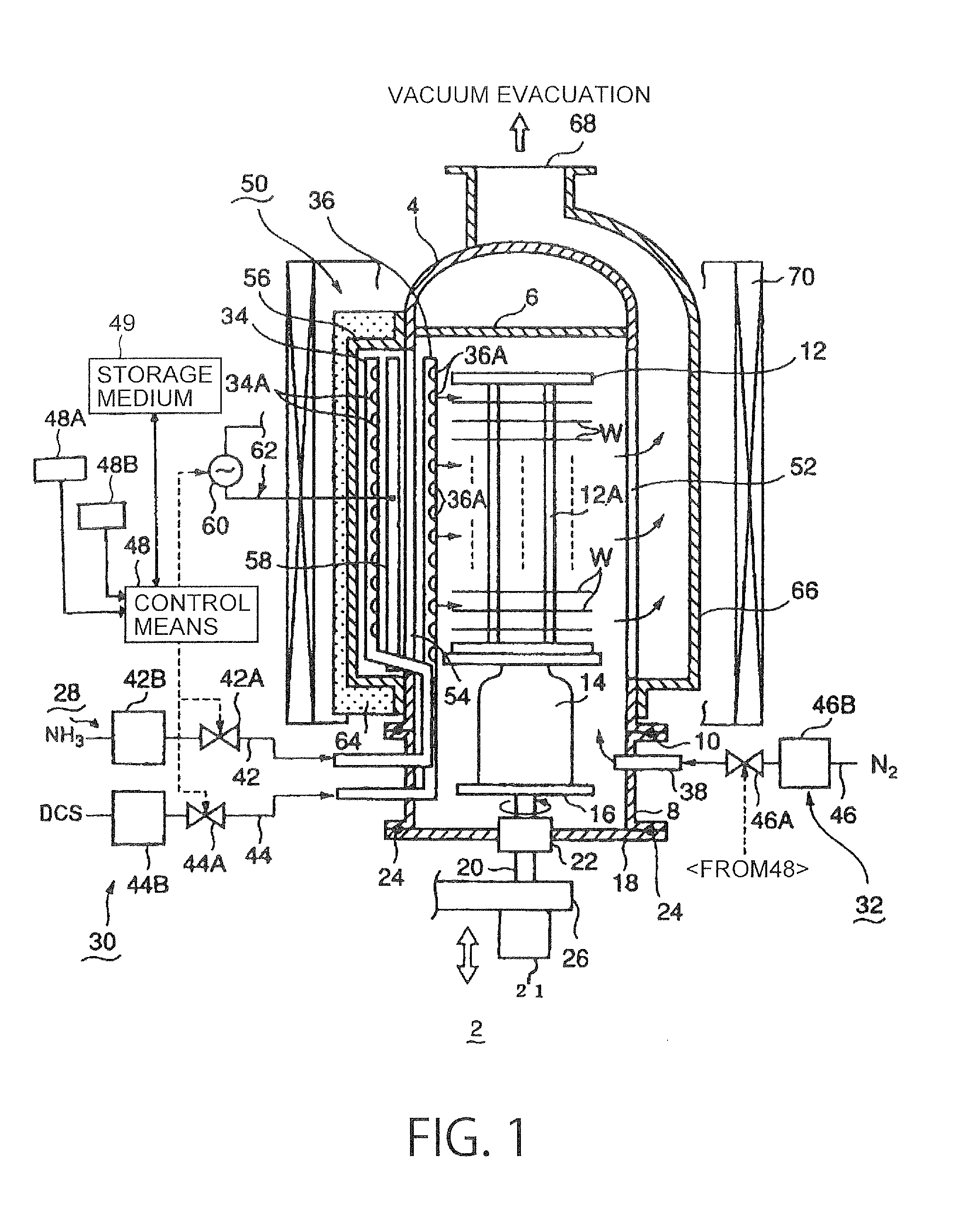

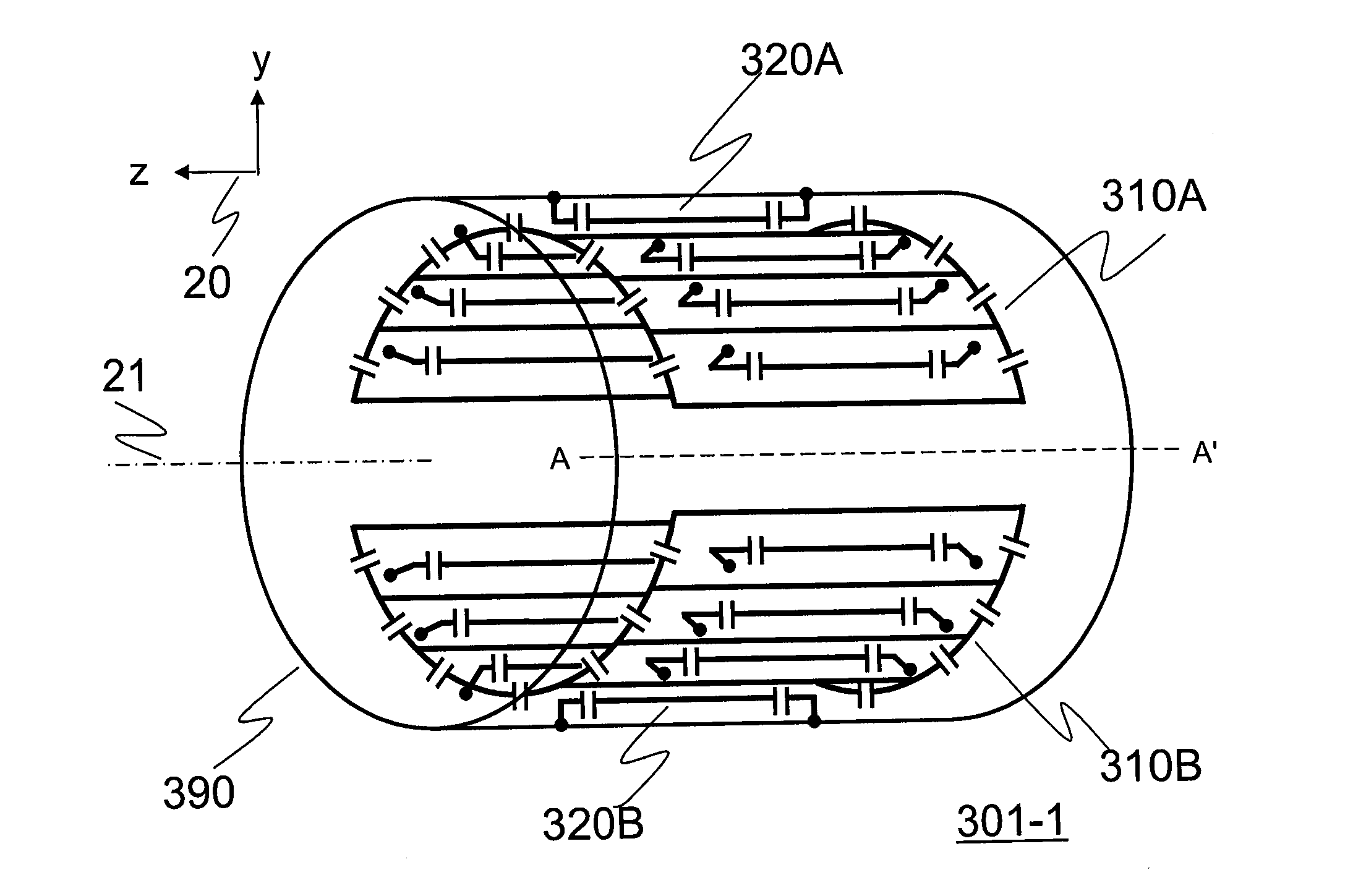

Film forming apparatus, film forming method, method for optimizing rotational speed, and storage medium

ActiveUS20120315394A1Good effectThickness uniformity is reducedLiquid surface applicatorsSemiconductor/solid-state device manufacturingGas supplyStopped periods

A film forming apparatus for forming a film on an object includes: a processing container; gas supply means, having gas jet ports, respectively; a holding means for holding the object; a drive mechanism for moving the holding means relative to the gas jet ports; and a control means which, when repeating P times a cycle, consisting of a supply period for supplying a gas and a supply stop period during which the supply of the gas is stopped, performs control so that as viewed from the center of the object, a gas supply starting position is sequentially shifted in the circumferential direction of the object for every cycle in such a manner that the entire circumference of the object to be processed is divided into K segments (K=P), K being an arbitrary division number, and the gas supply starting position is shifted by one segment for every cycle.

Owner:TOKYO ELECTRON LTD

Infrared reflective wall paint

ActiveUS7157112B2Reduce energy consumptionReduce absorptionLiquid surface applicatorsElectrostatic spraying apparatusInfraredLacquer

Owner:TEXTURED COATINGS OF AMERICA

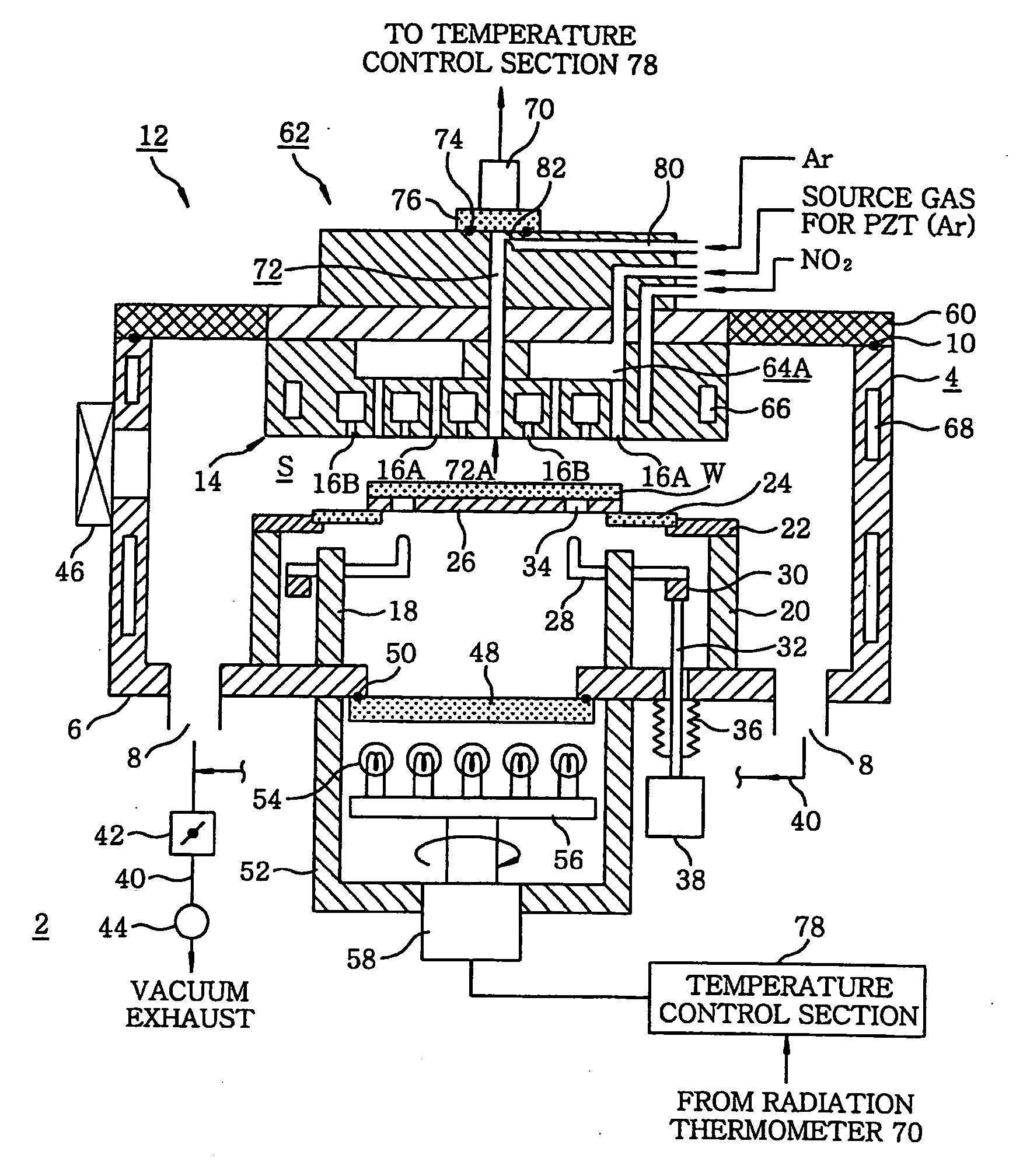

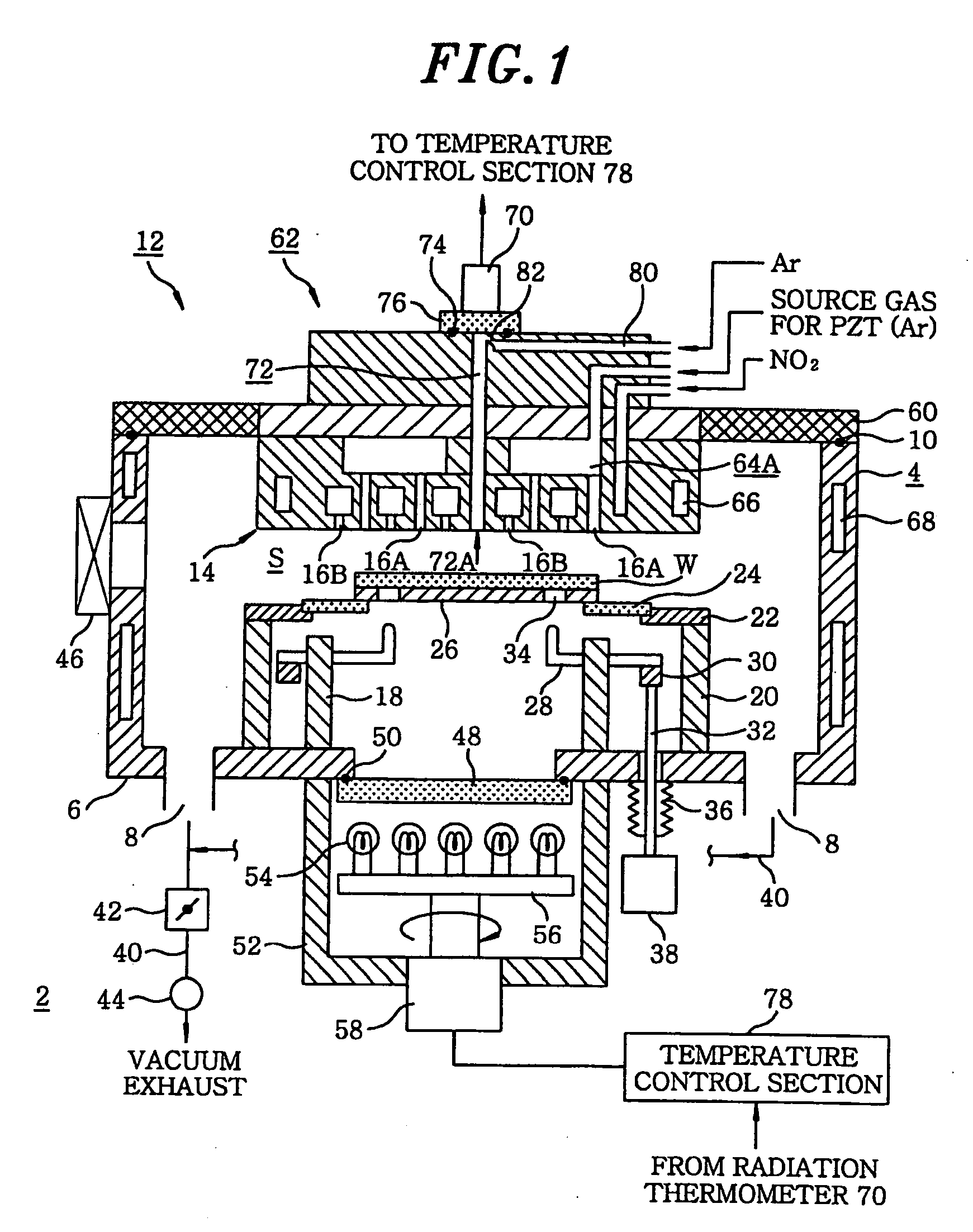

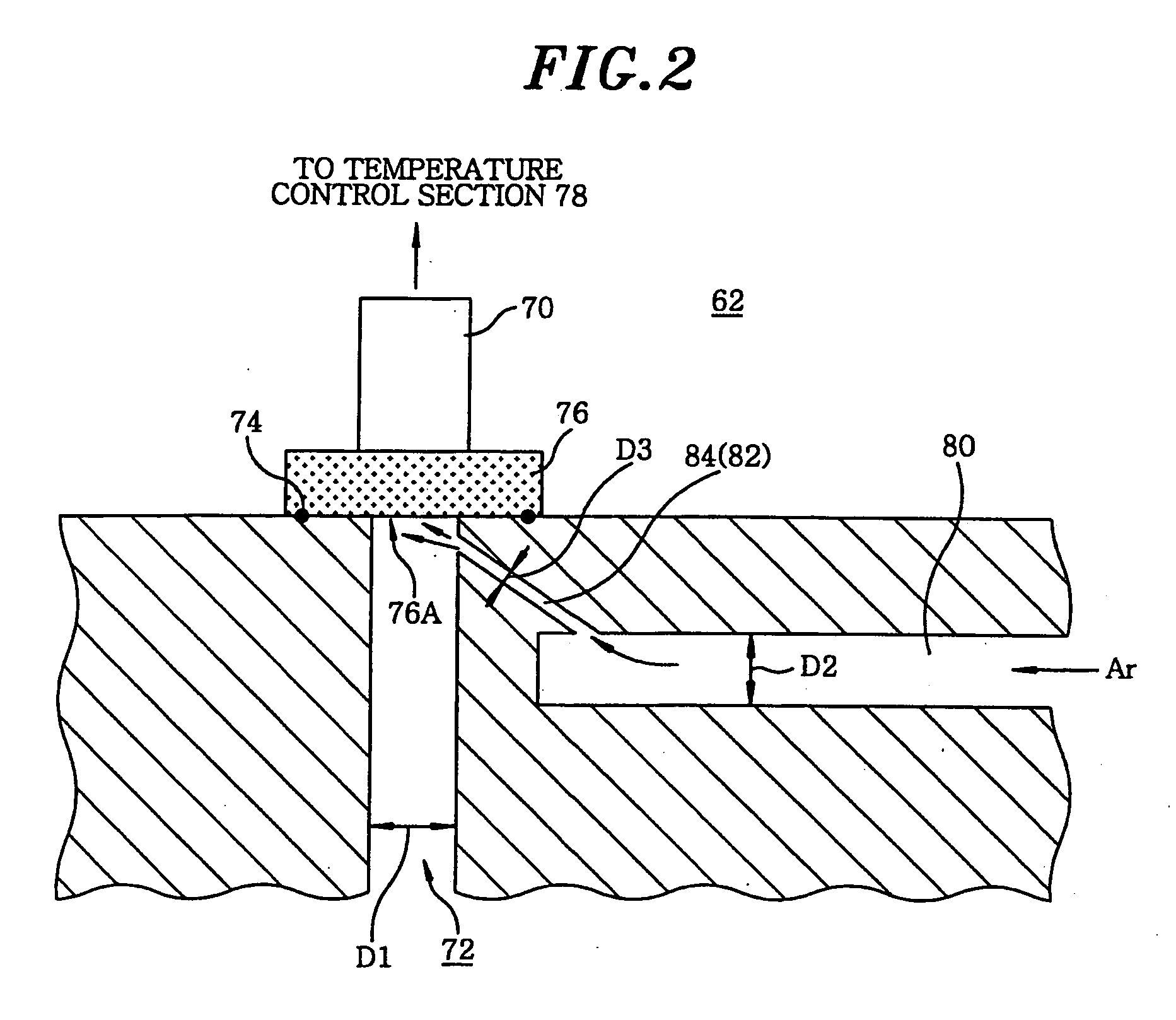

Shower head structure and treating device

InactiveUS20060021568A1Avoid depositionSuppression problemLiquid surface applicatorsSemiconductor/solid-state device manufacturingRadiation thermometerEngineering

A shower head structure characterized by comprising a shower head section, opposed to the upper surface of a mounting table in an evacuable treating vessel, for injecting a processing gas into the treating vessel; a temperature observation through-hole which opens in the lower surface of the shower head so as to be opposed to the upper surface of the mounting table, a transparent observation window which hermetically seals the upper end of the temperature observation through-hole, a radiation thermometer disposed on the upper surface of the transparent observation window, an adhesion preventive gas supply path communicating with the temperature observation through-hole to prevent a film from adhering to the transparent observation window, wherein the adhesion preventive gas supply path communicates with the temperature observation through-hole through an injection nozzle for injecting the adhesion preventive gas to the transparent observation window.

Owner:TOKYO ELECTRON LTD

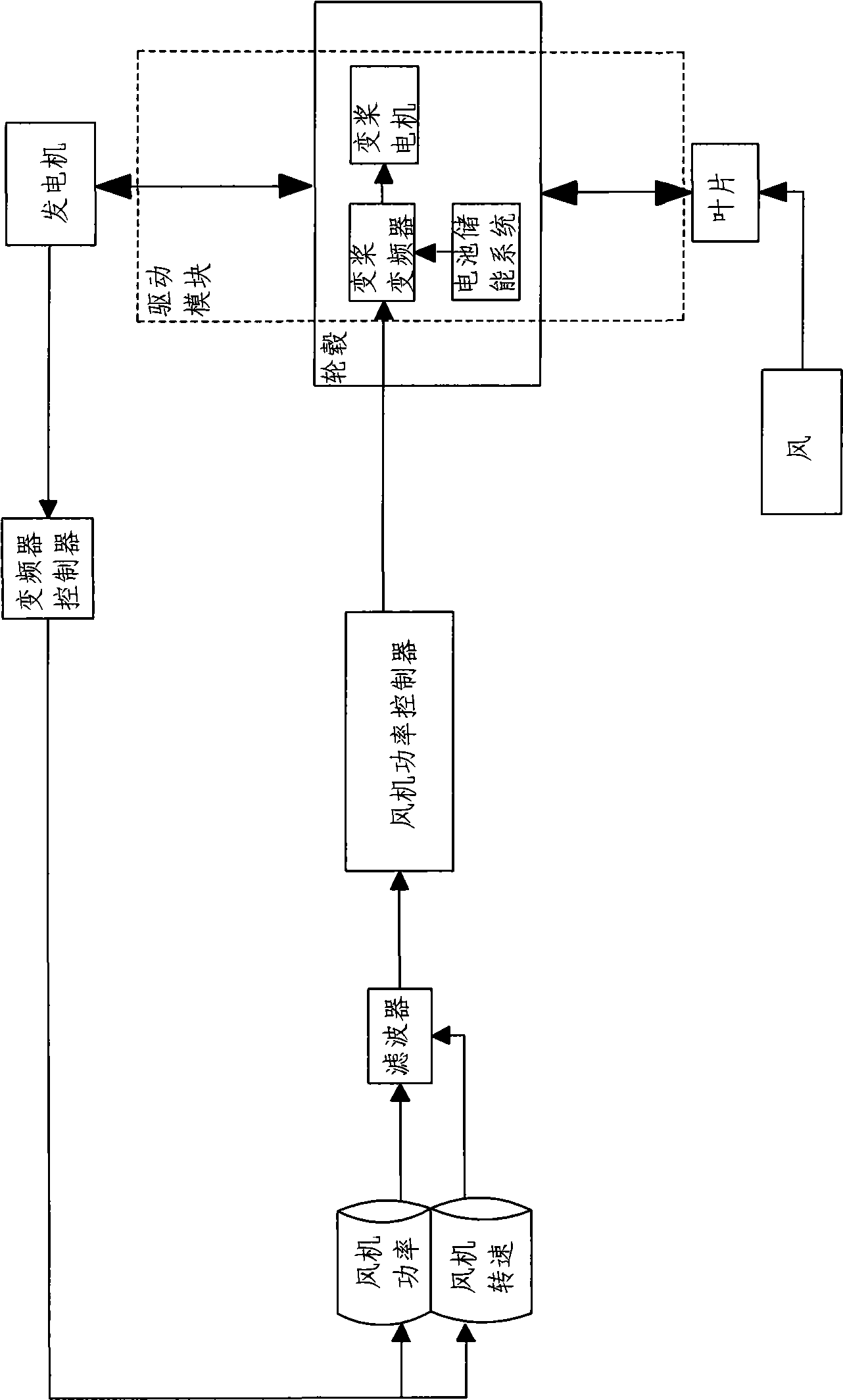

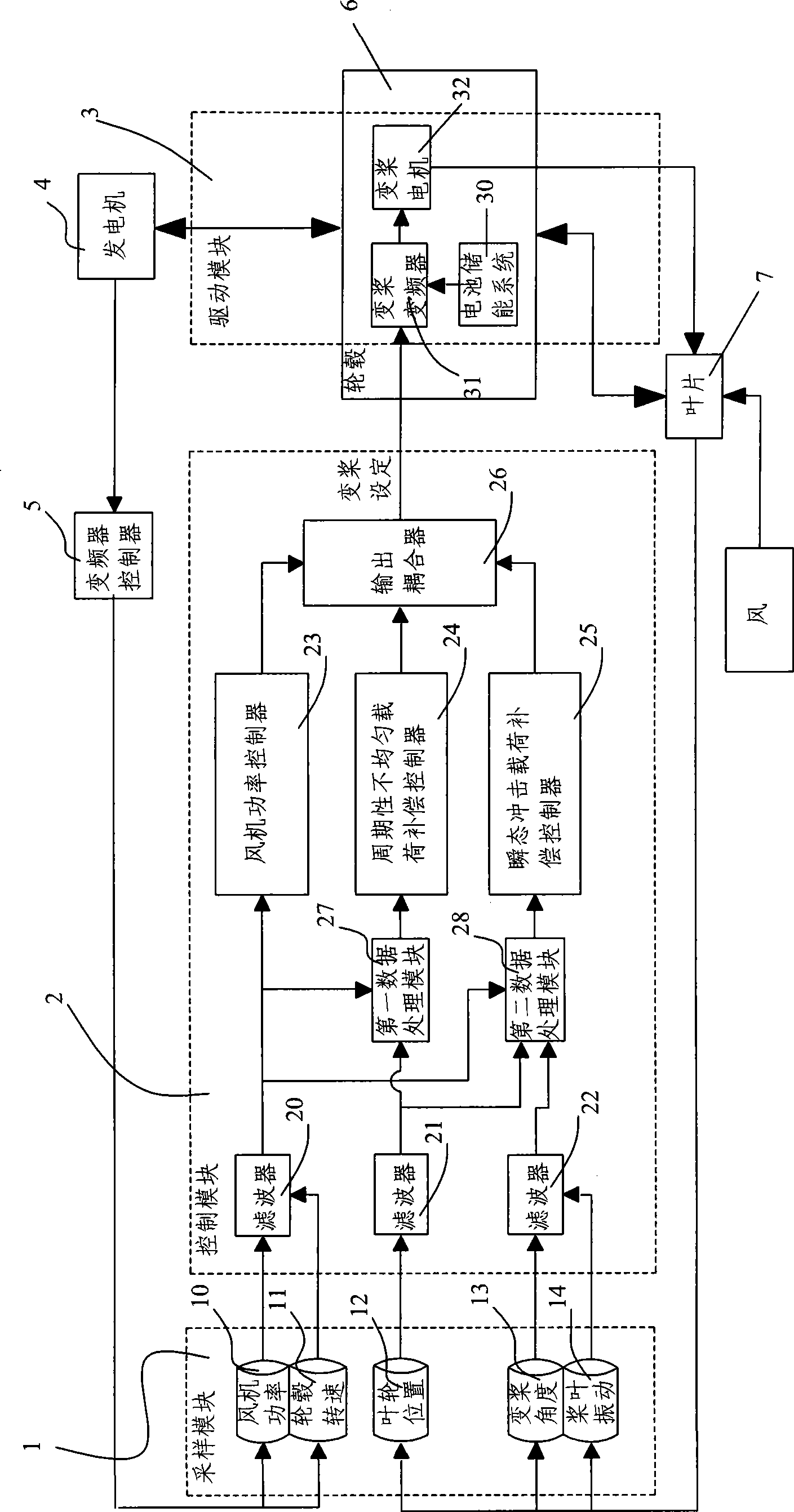

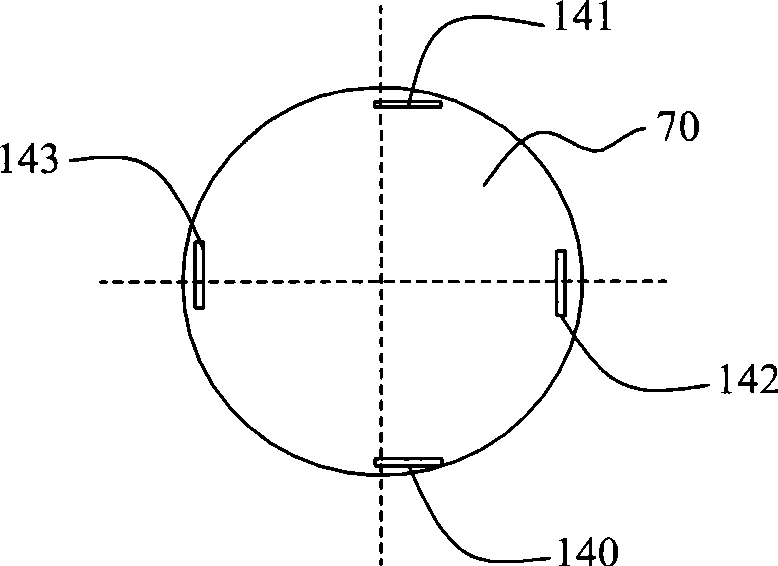

Independent variable oar control system and control method for wind generator set

ActiveCN101476541AIncreased fatigue loadLow mechanical requirementsWind motor controlMachines/enginesWind drivenReduction drive

The invention relates to an independent feathering control system and a control method for a wind driven generating set, wherein the control system comprises a sampling module, a control module and a driving module. A feathering motor in the driving module is connected with the blades of the wind driven generating set through a speed reducer. The sampling module is used to acquire the signals such as the wind driven generating set power, the boss rotating speed, the impeller position, the feathering angle, the paddle vibration, and the like, and to respectively send the acquired signals to the control module. The control module comprises a wind machine power controller for processing the wind driven generating set power signal and the boss rotating speed signal, a periodic unbalanced load compensation controller for processing the impeller position signal, the wind machine power signal and the boss rotating speed signal, a transient state impact load compensation controller for processing the feathering angle signal, the paddle vibration signal, the impeller position signal, the wind machine power signal and the boss rotating speed signal, and an output coupler for processing the signals outputted from the three controllers and comprehensively outputting the signals to the driving module.

Owner:SINOVEL WIND GRP

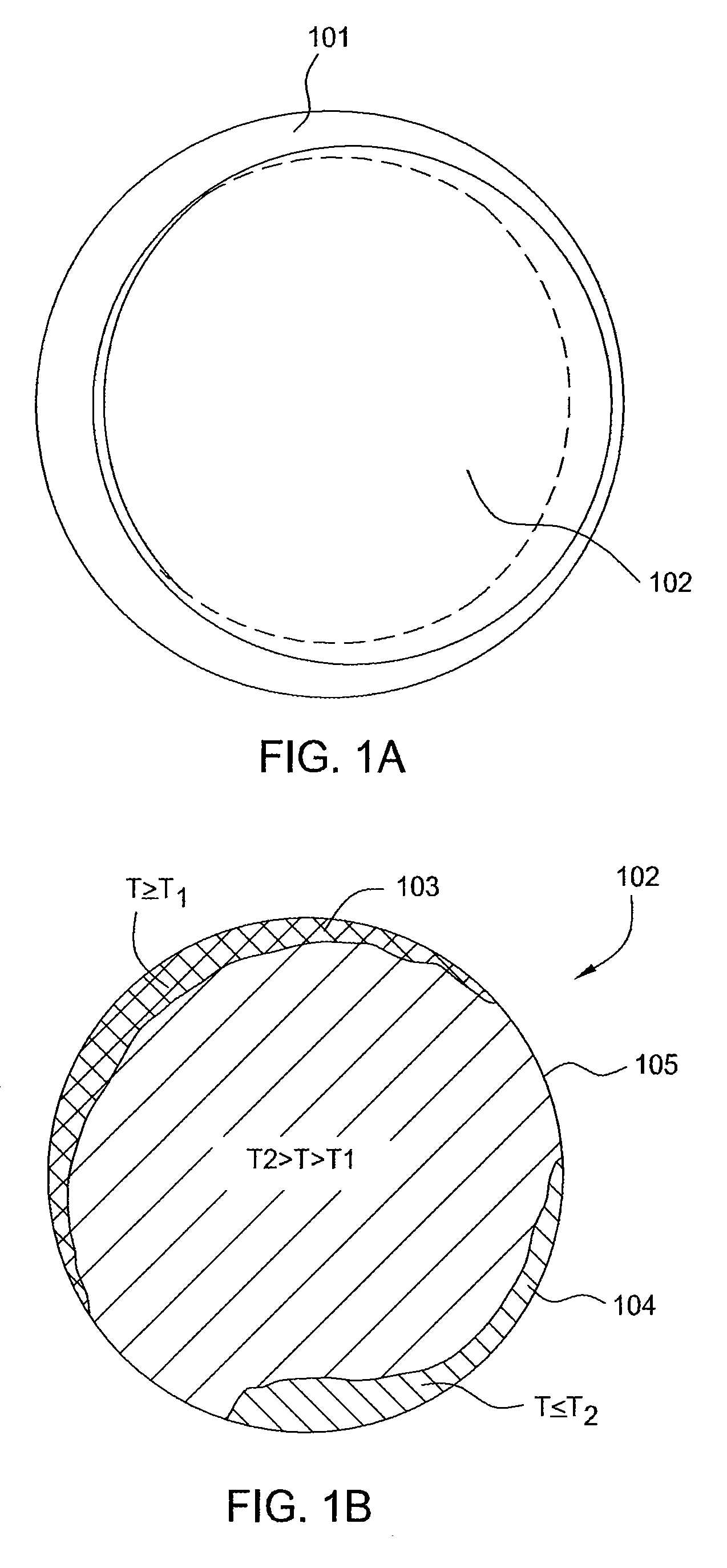

System for non radial temperature control for rotating substrates

ActiveUS20090274454A1Reduce unevennessReduce uniformityDomestic stoves or rangesDrying solid materials with heatTemperature controlPulse energy

Embodiments of the present invention provide apparatus and method for reducing non uniformity during thermal processing. One embodiment provides an apparatus for processing a substrate comprising a chamber body defining a processing volume, a substrate support disposed in the processing volume, wherein the substrate support is configured to rotate the substrate, a sensor assembly configured to measure temperature of the substrate at a plurality of locations, and one or more pulse heating elements configured to provide pulsed energy towards the processing volume.

Owner:APPLIED MATERIALS INC

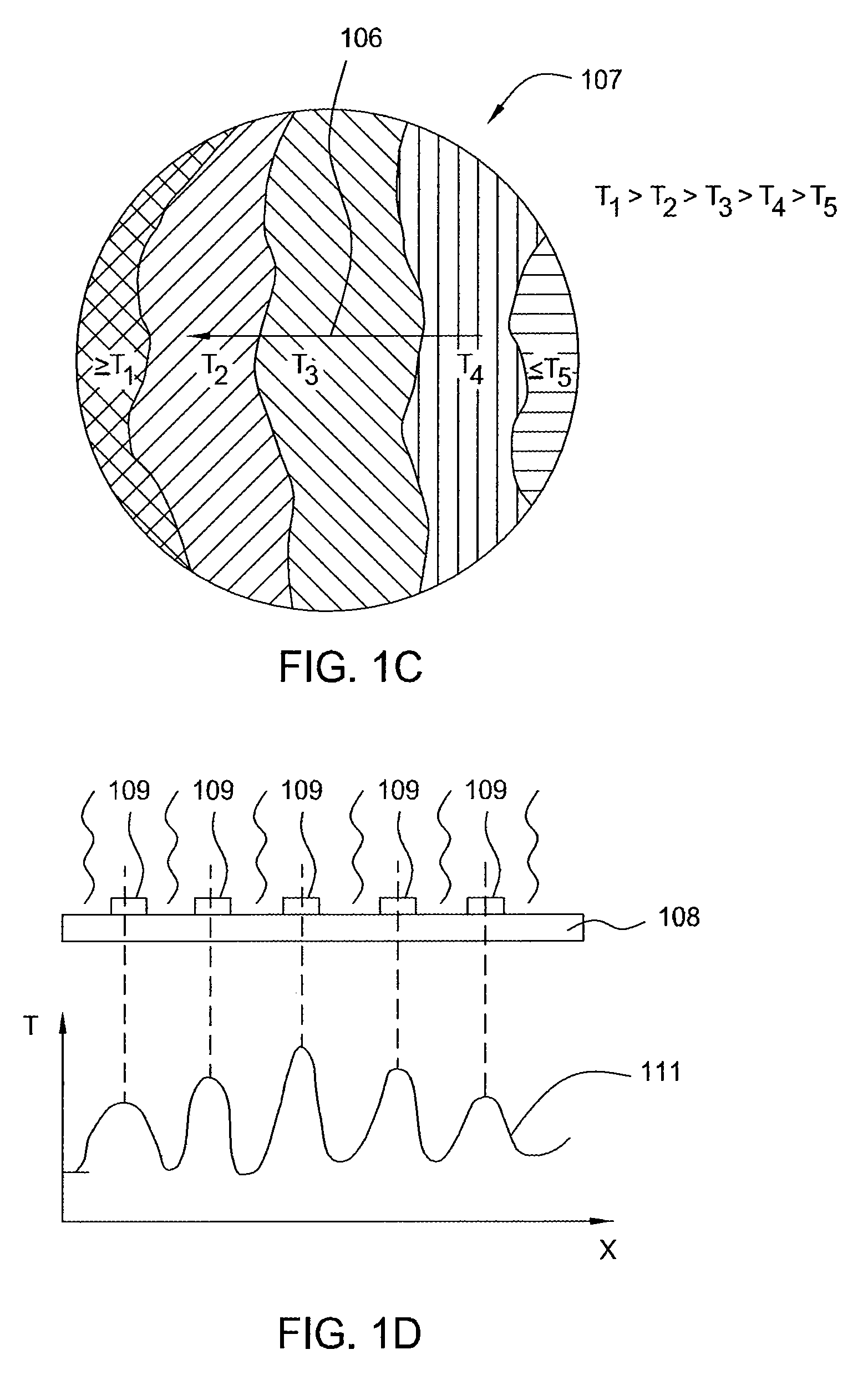

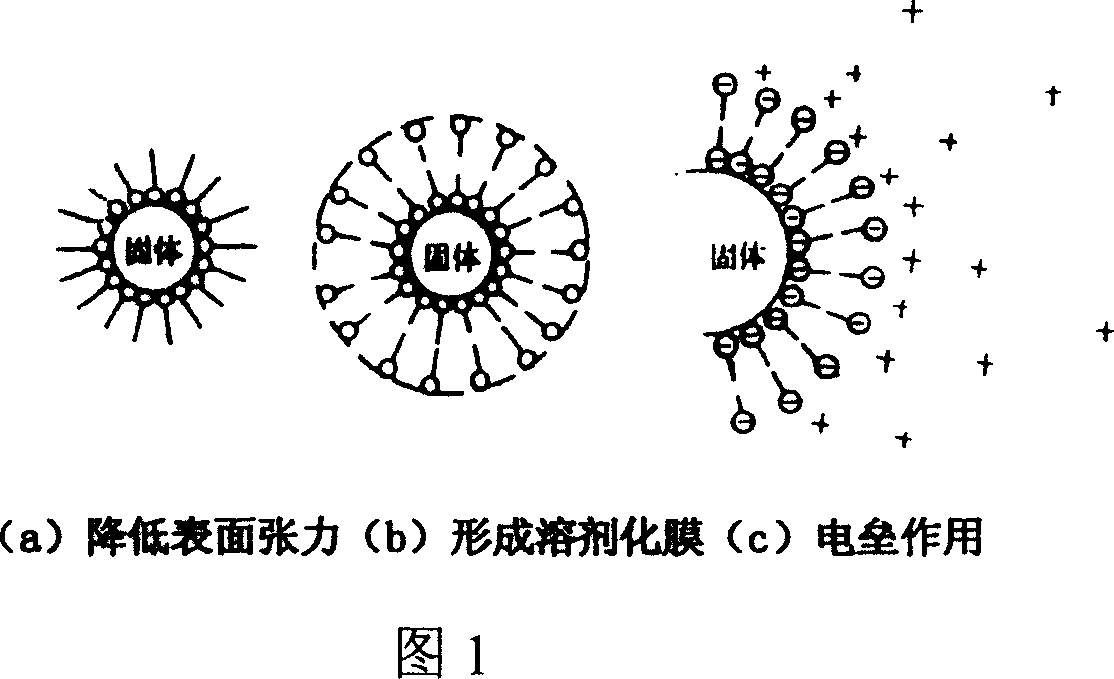

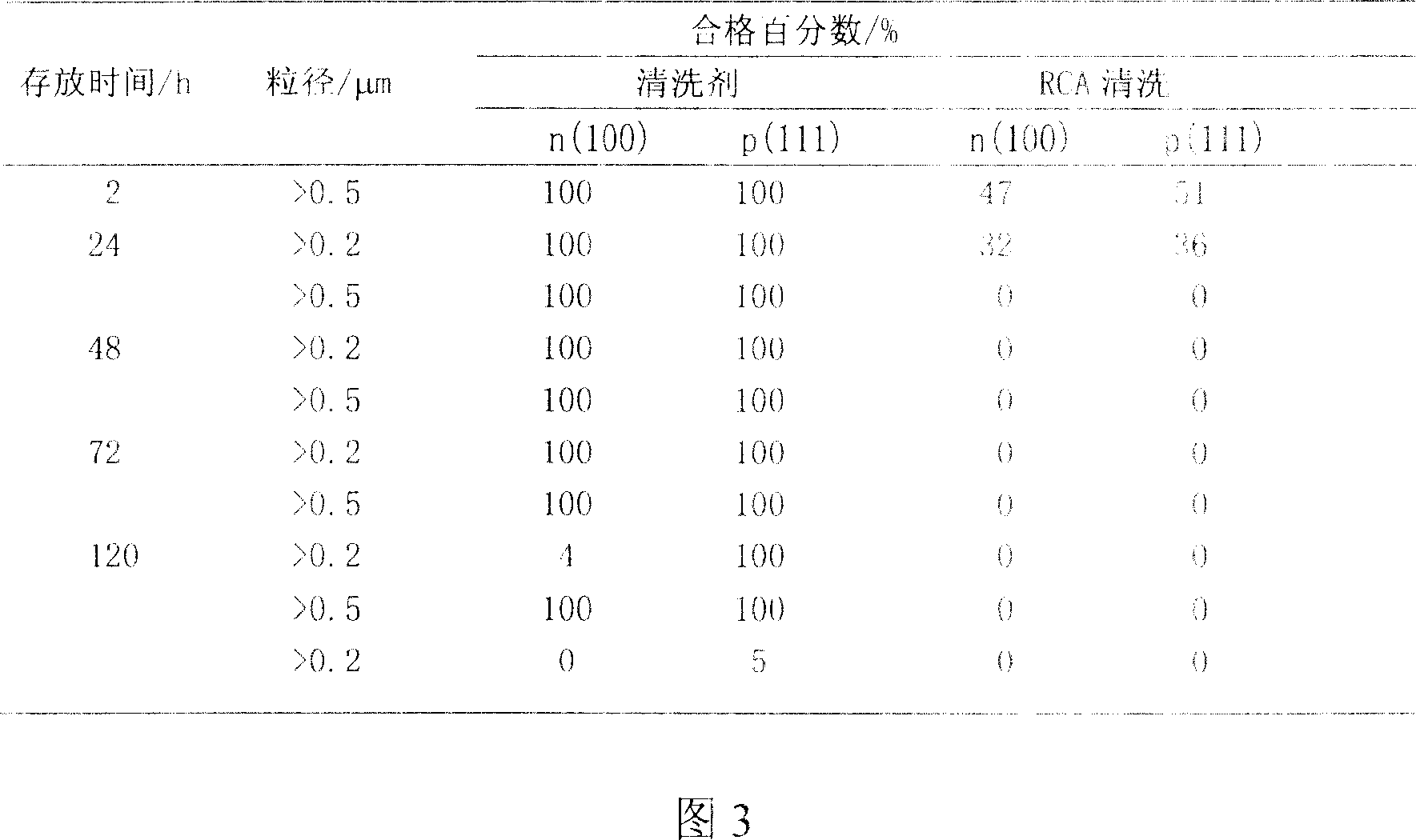

Cleaning agent for integrated circuit substrate silicon chip and its cleaning method

InactiveCN1944613AReduce surface tensionIncrease surface tensionNon-ionic surface-active compoundsOrganic detergent compounding agentsOrganic baseCleansing Agents

The cleaning agent for integrated circuit substrate silicon chip features that it consists of organic base functioning as pH regulator, complexing agent, corrosion inhibitor, dispersant and oxidizing assistant simultaneously in 40-45 %, surfactant functioning to lower surface tension of the solution, enhance mass transfer and eliminate metal ion simultaneously in 7-15 %, and water in 40-53 %. The cleaning method with the cleaning agent includes adding deionized water in 8-15 times, twice ultrasonic cleaning at 50-60deg.c for 5-10 min each, twice ultrasonic rinsing in deionized water at 50-60deg.c for 5-10 min each, sprinkling and stoving. The present invention has the advantages of excellent cleaning effect, simple preparation process, convenient operation and environment friendship.

Owner:天津晶岭电子材料科技有限公司

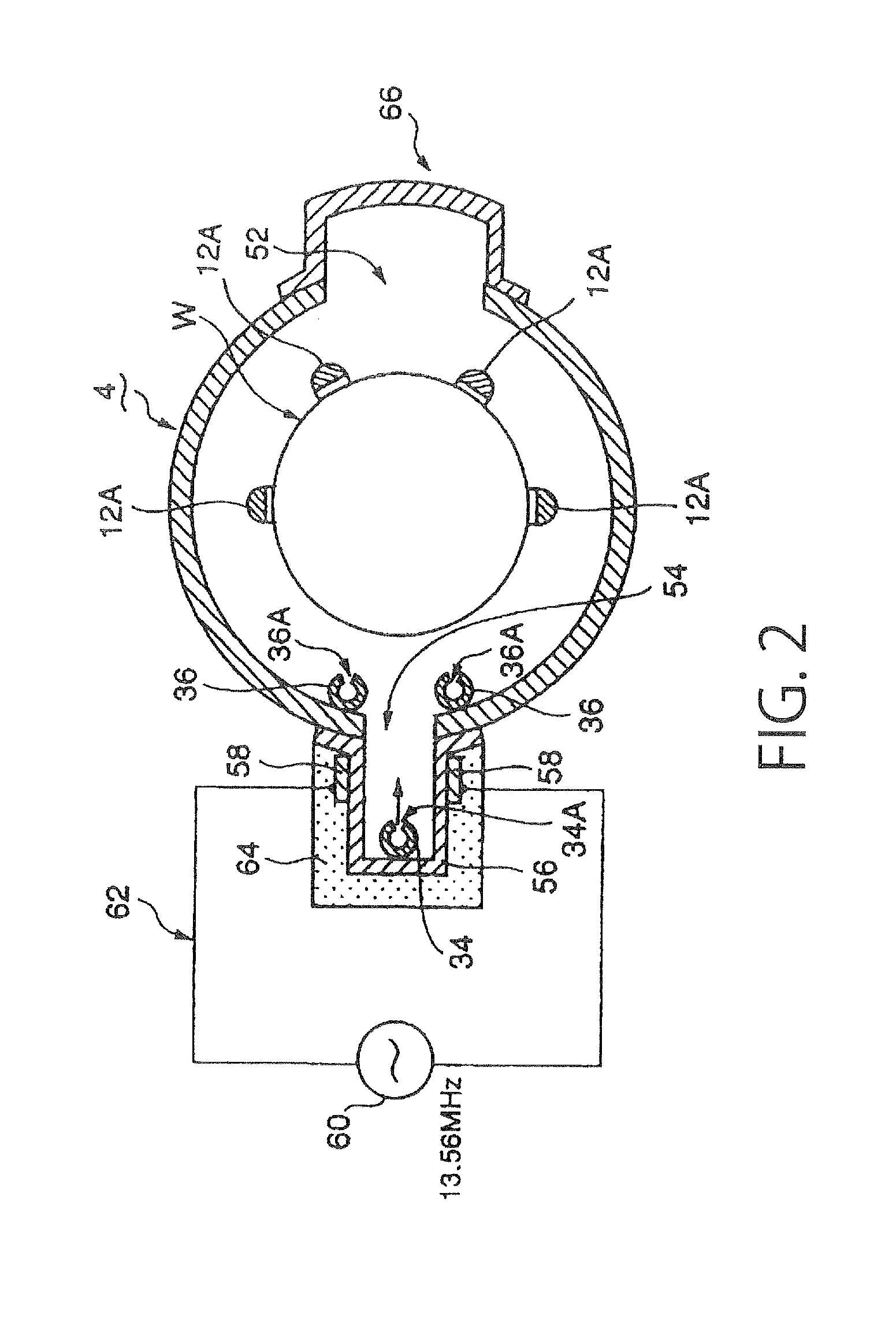

Process for uniformly coating hollow bodies

InactiveUS20020155218A1Low costShorten the timeLiquid surface applicatorsLinings/internal coatingsMaterials scienceCoating

The present invention relates to a process for uniformly coating hollow bodies, in which one open end of the hollow body is closed off in a gas-tight manner by a cover, the hollow body is introduced into a plasma-induced CVD reactor, vacuum is applied to the hollow body, a coating temperature is established and the plasma-induced coating takes place. The present invention also relates to the use of the process for uniformly coating hollow bodies according to the invention for coating tubes, vessels, syringe bodies, reflectors, domes and funnels.

Owner:SCHOTT AG

Cu-Mn Alloy Sputtering Target and Semiconductor Wiring

InactiveUS20100013096A1Functional deteriorationStrong oxidizing powerCellsSemiconductor/solid-state device detailsSelf-diffusionDeposition process

Proposed is a Cu—Mn alloy sputtering target, wherein the Mn content is 0.05 to 20 wt %, the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce is 500 wtppm or less, and the remainder is Cu and unavoidable impurities. Specifically, provided are a copper alloy wiring for semiconductor application, a sputtering target for forming this wiring, and a manufacturing method of a copper alloy wiring for semiconductor application. The copper alloy wiring itself for semiconductor application is equipped with a self-diffusion suppression function for effectively preventing the contamination around the wiring caused by the diffusion of active Cu, improving electromigration (EM) resistance, corrosion resistance and the like, enabling and facilitating the arbitrary formation of a barrier layer, and simplifying the deposition process of the copper alloy wiring for semiconductor application.

Owner:JX NIPPON MINING& METALS CORP

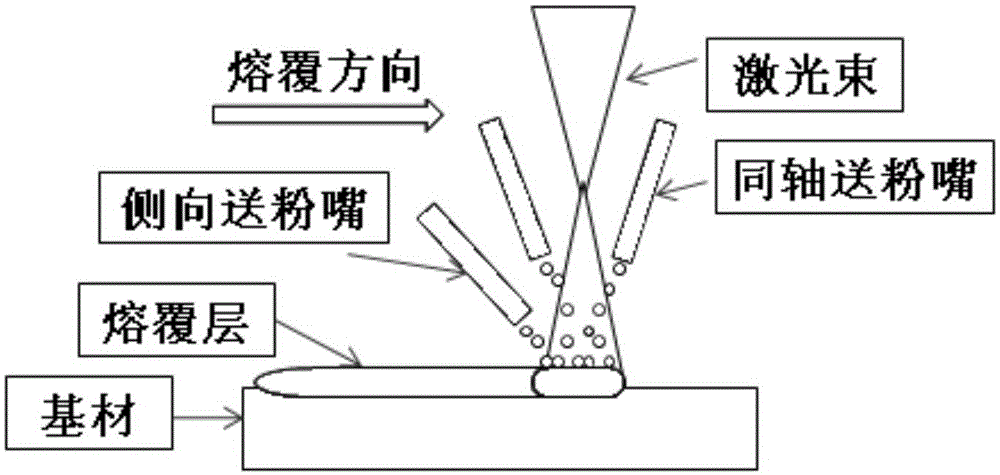

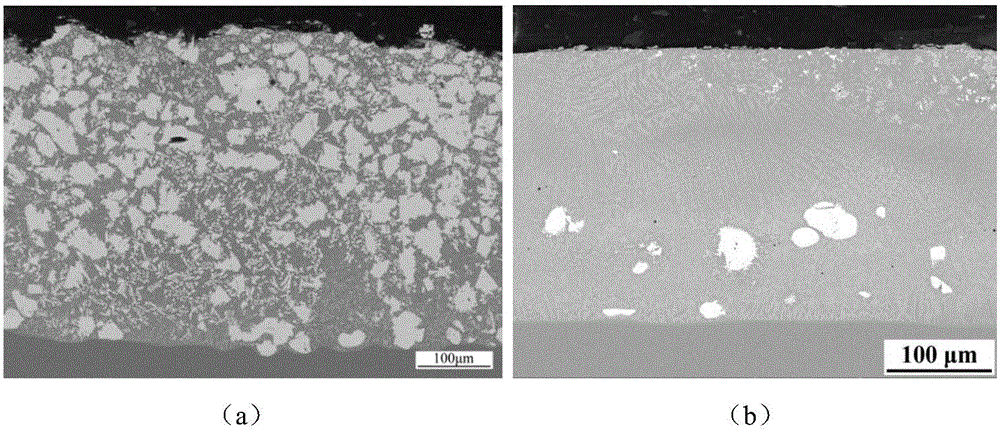

Method for preparing ceramic particle enhanced metal matrix composite coating in laser cladding mode through asynchronous powder feeding method

ActiveCN105002492AImprove performanceSimple processMetallic material coating processesDecompositionLaser scanning

The invention provides a method for preparing a ceramic particle enhanced metal matrix composite coating in a laser cladding mode through an asynchronous powder feeding method. A lateral powder feeding nozzle is fixed to one coaxial powder feeding nozzle and assembled into an asynchronous powder feeding nozzle; the lateral powder feeding nozzle is used for feeding ceramic particle enhancing phases into the portion between the middle portion and the tail portion of the side, opposite to the laser scanning direction, of a molten pool; the coaxial powder feeding nozzles are used for feeding alloy powder or metal ceramic composite powder to the center of the molten pool; a laser device is used for conducting laser cladding, and then the ceramic particle enhanced metal matrix composite coating is obtained. According to the method, the coaxial powder feeding method and the lateral powder feeding method are combined, the ceramic particle enhancing phases are fed into the low-temperature region at the rear portion of the molten pool, so that the phenomena of nonuniformity of melting decomposition, clustering and distribution of the ceramic particle enhancing phases are reduced, and the ceramic particle enhancing phases are evenly distributed in the whole coating by keeping the original appearance to the maximum extent; accordingly, the ceramic particle enhancing phases are effectively retained and evenly distributed, and the performance of the composite coating can be substantially improved.

Owner:西安合方长激光智能科技有限公司

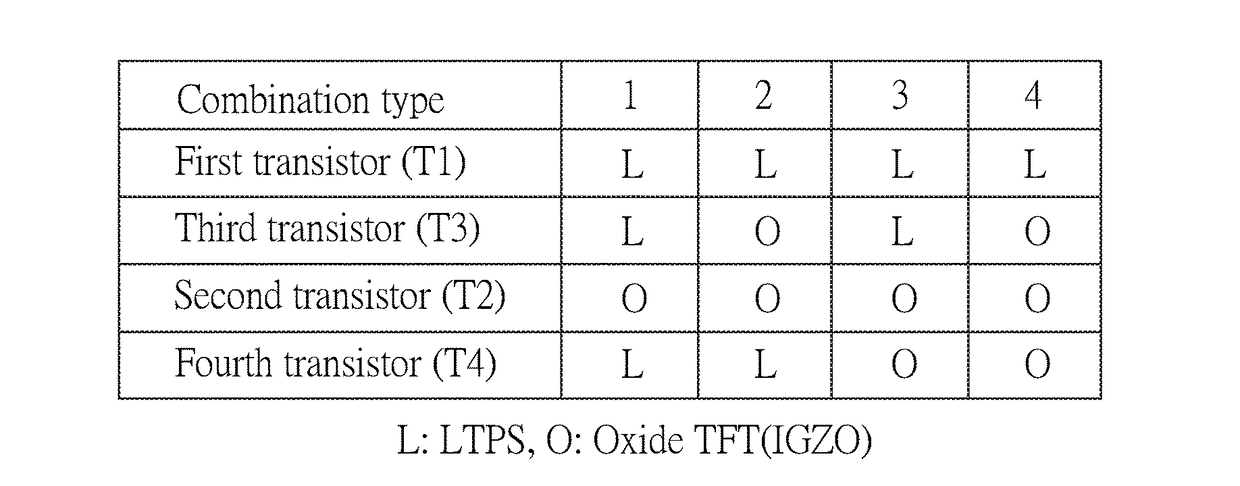

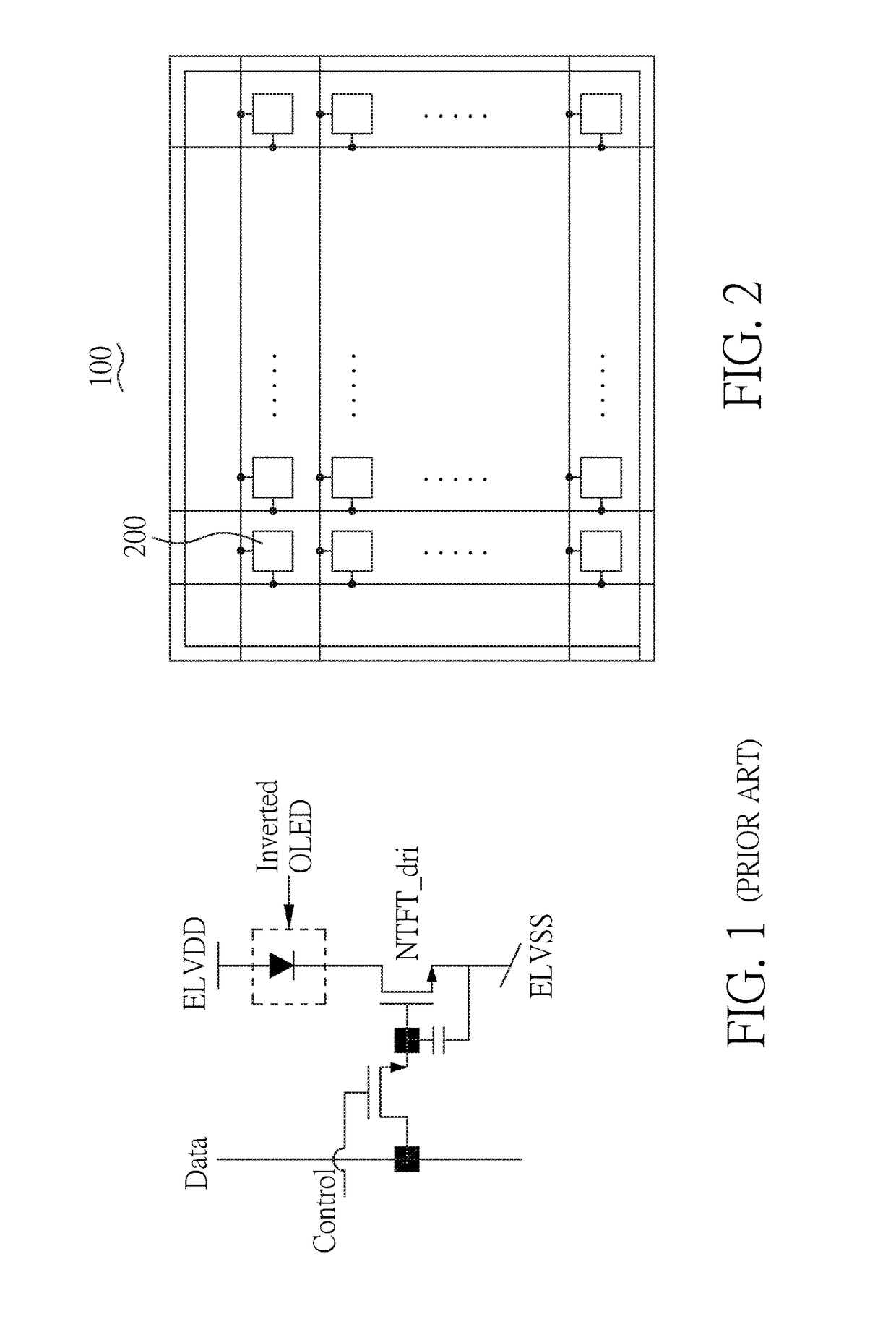

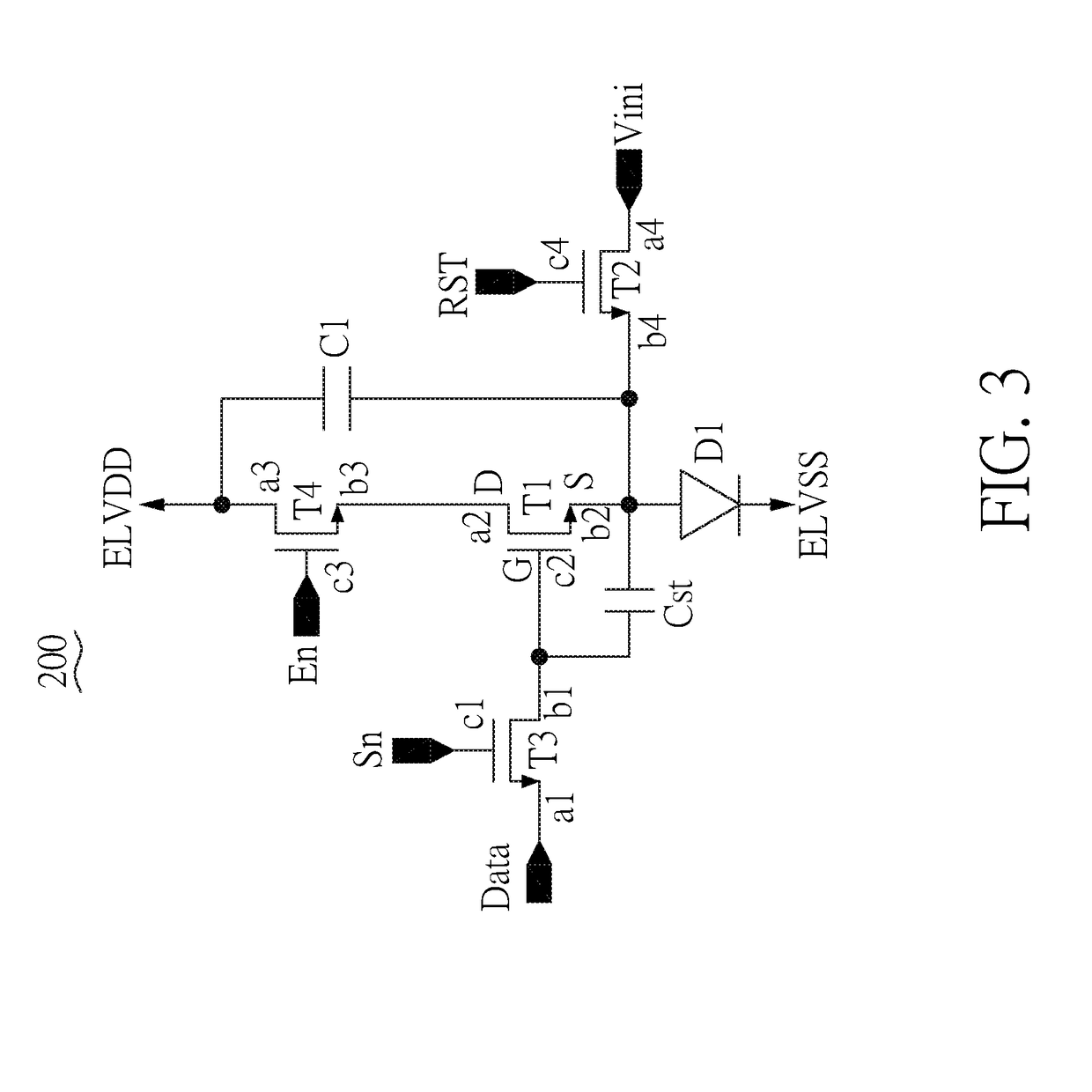

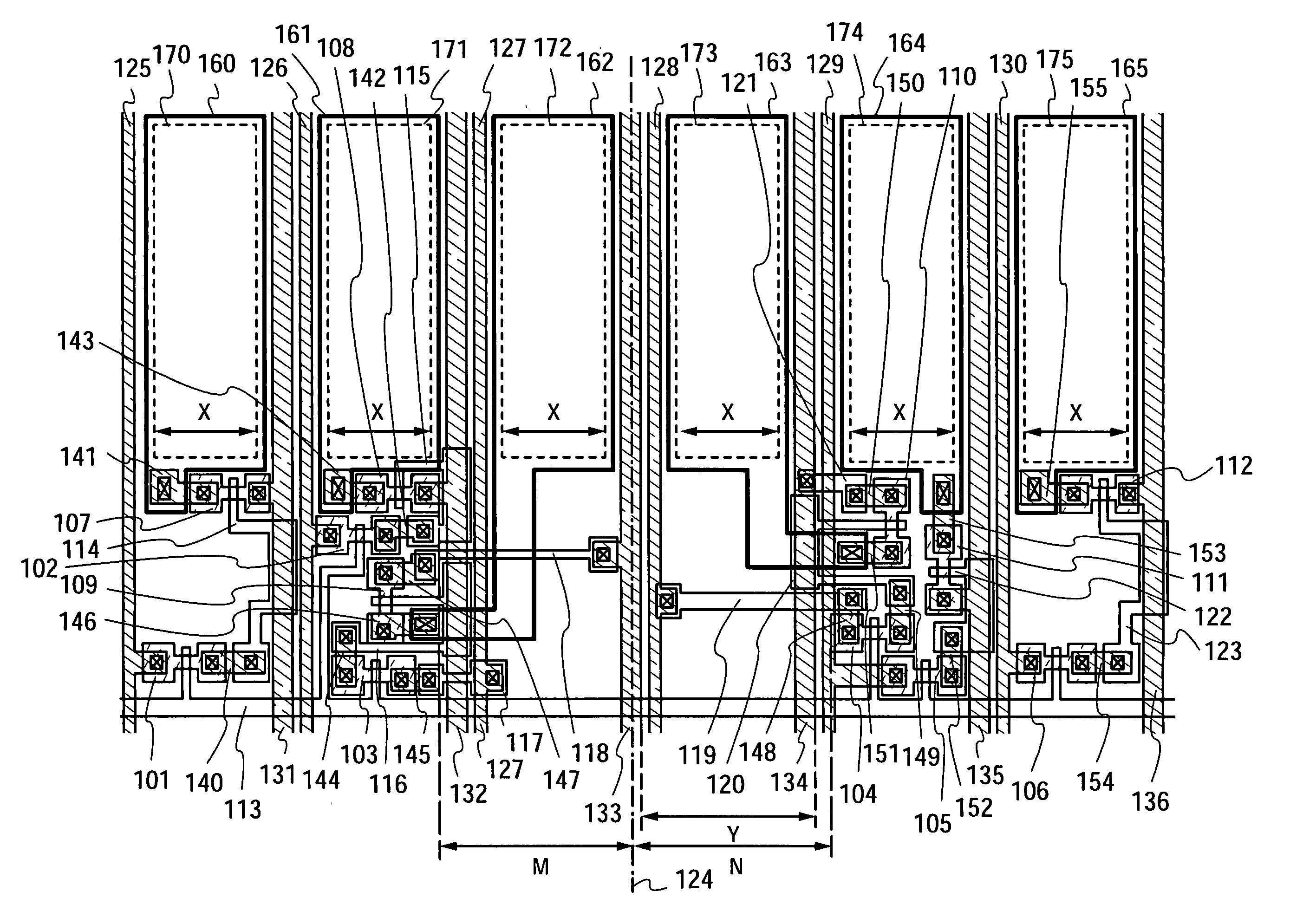

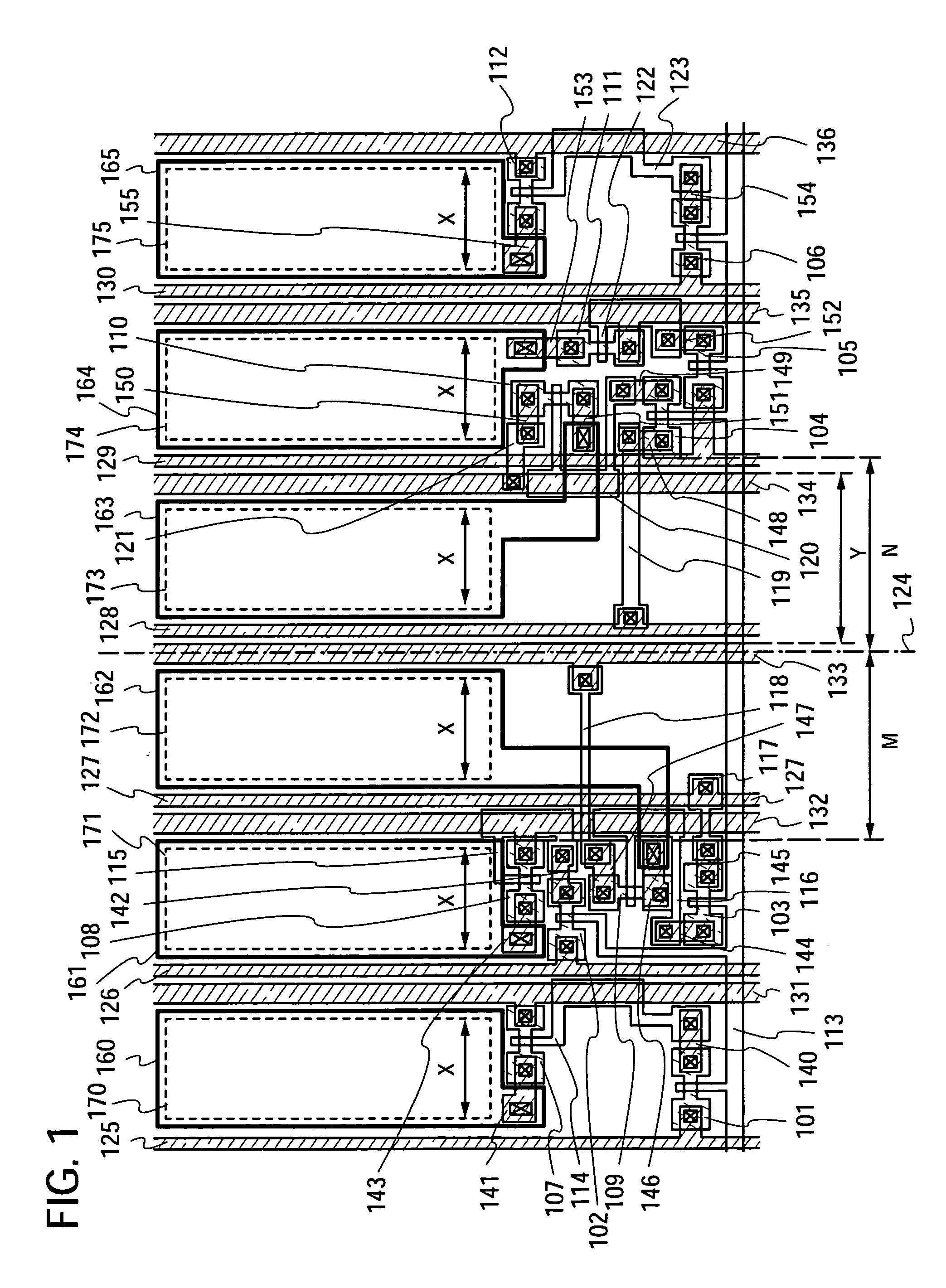

Pixel circuit of active-matrix light-emitting diode and display panel having the same

InactiveUS20170186782A1Large driving capabilityPoor brightness uniformityStatic indicating devicesSolid-state devicesEngineeringElectrical conductor

A display includes a pixel circuit. The pixel circuit includes a light emitting diode, a first transistor, a second transistor and a third transistor. The first transistor includes a first semiconductor layer. The first transistor has a first control terminal, a second terminal, and a third terminal electrically connected to the light emitting diode. The second transistor includes a second semiconductor layer, and is electrically connected to the third terminal. The third transistor is electrically connected to the first control terminal. A material of the first semiconductor layer is different from a material of the second semiconductor layer.

Owner:INNOLUX CORP

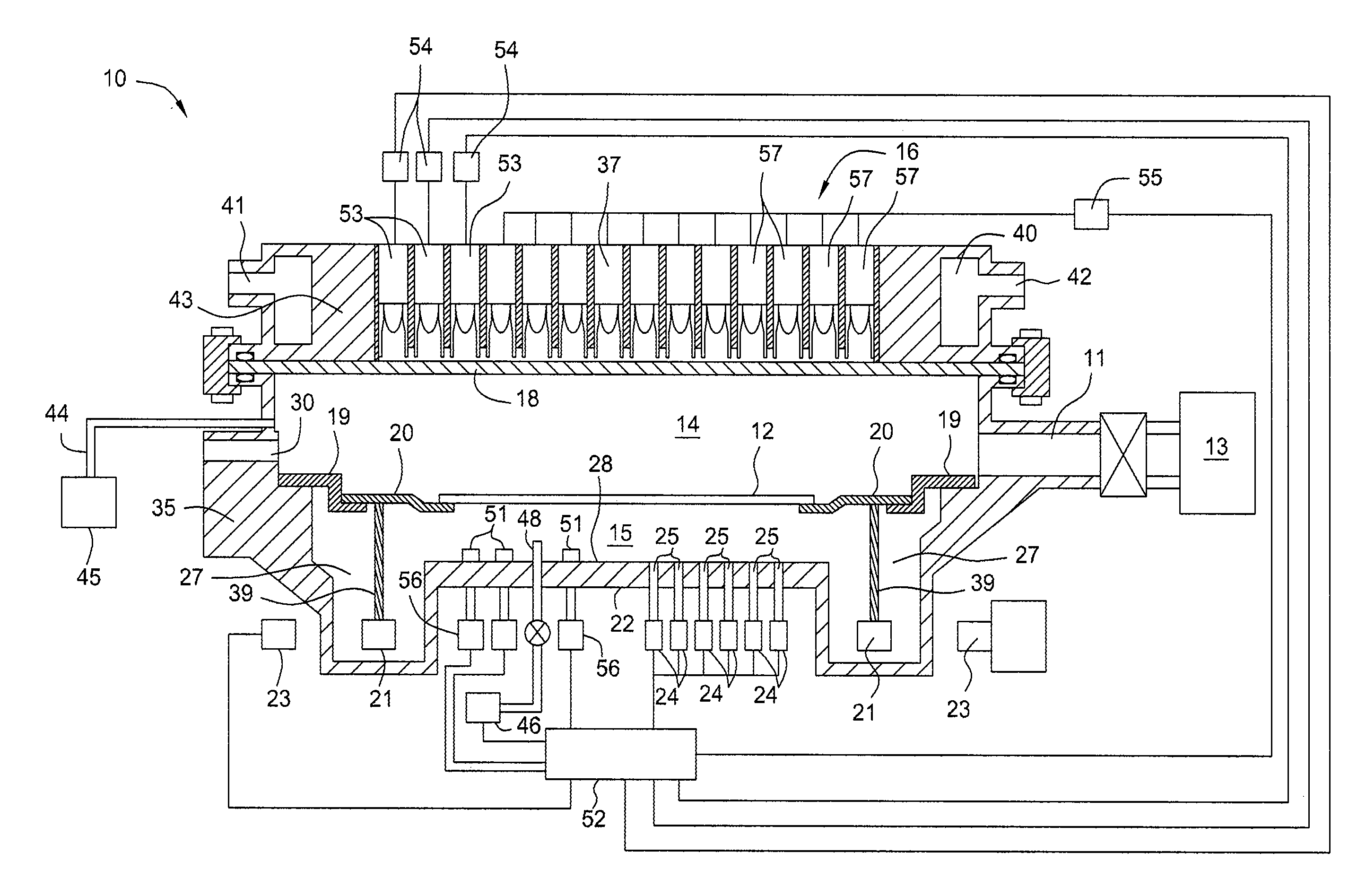

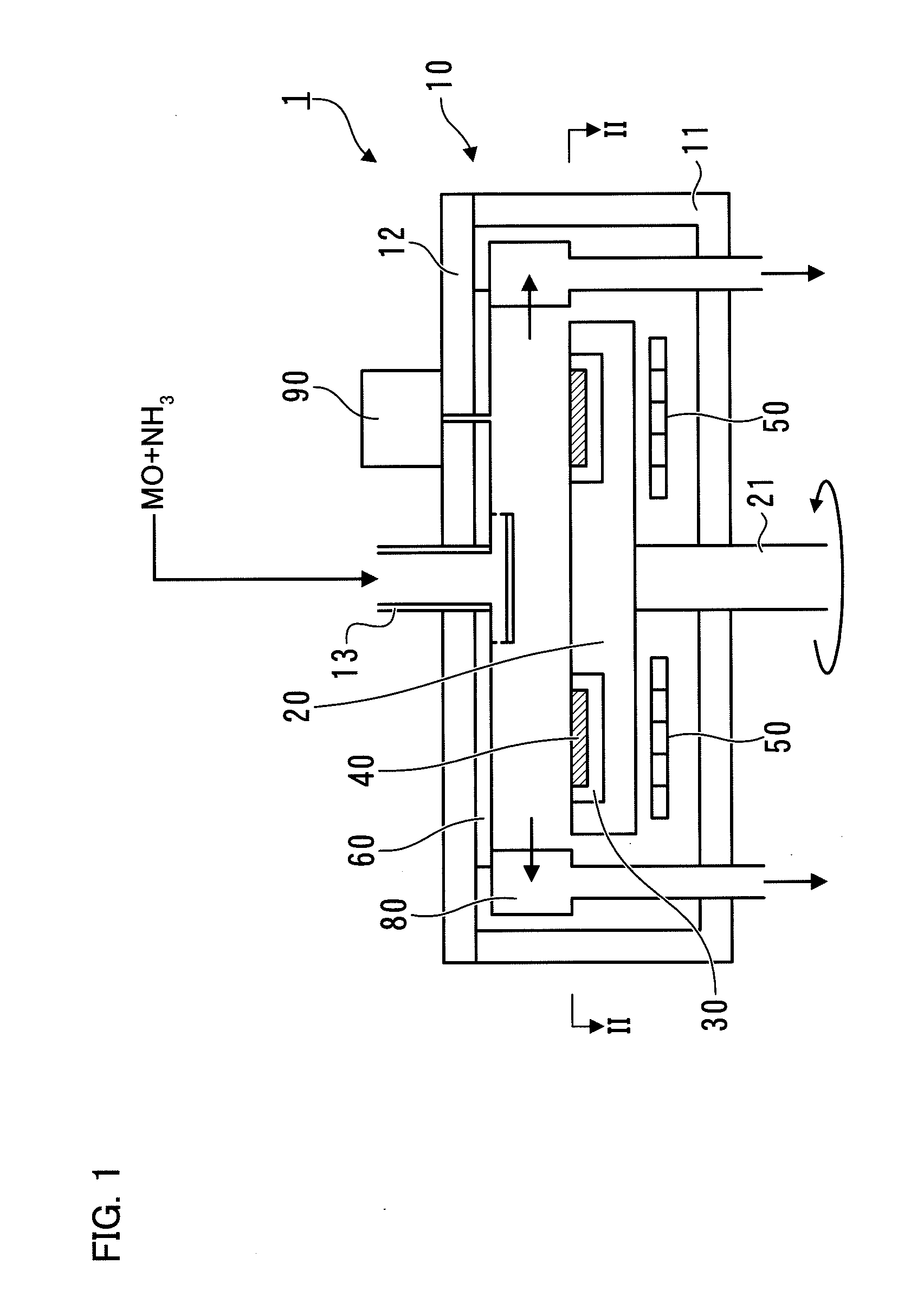

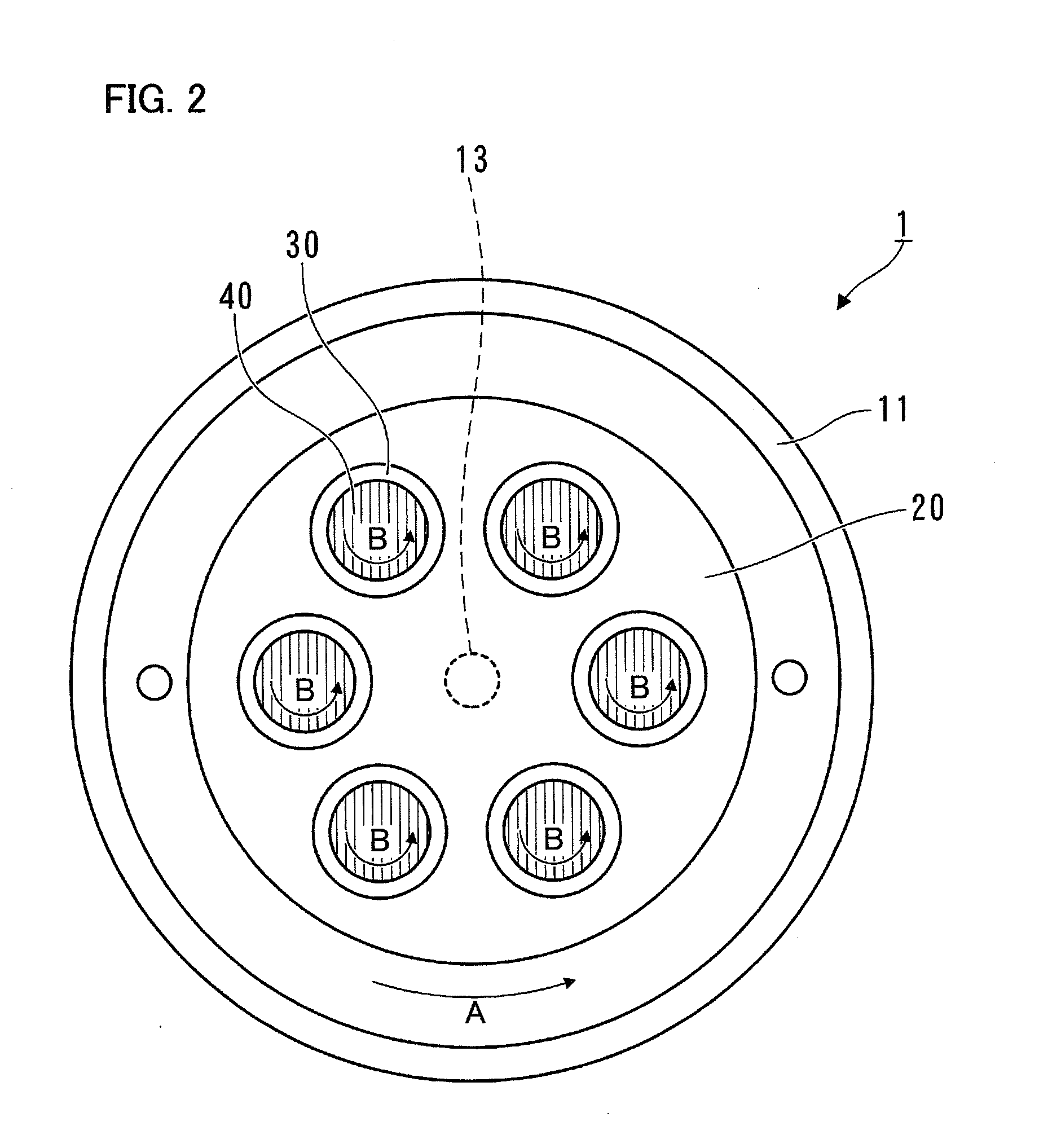

Apparatus and method for manufacturing compound semiconductor, and compound semiconductor manufactured thereby

ActiveUS20120146191A1Reduce uniformityChange the temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineering

Provided is an apparatus for manufacturing a compound semiconductor by use of metal organic chemical vapor deposition including: a reaction container; a holder on which a formed body is to be placed so that a formed surface of the formed body on which layers of a compound semiconductor are to be formed faces upward, the holder being arranged in the reaction container; and a material supply port supplying a material gas of the compound semiconductor into the reaction container from outside, wherein the holder includes a support member supporting the formed body so that an undersurface of the formed body and a top surface of the holder on which the formed body is to be placed keep a predetermined distance.

Owner:TOYODA GOSEI CO LTD

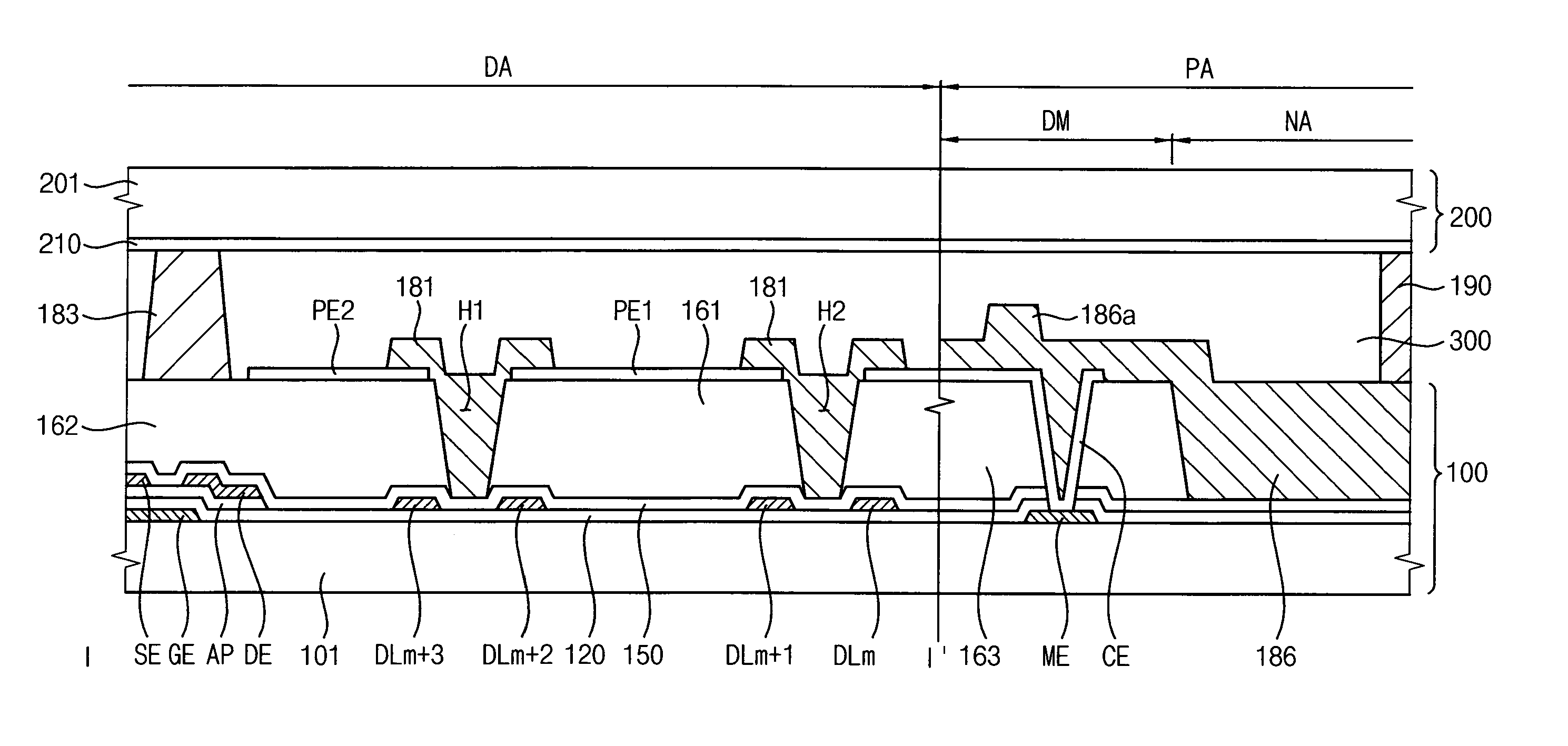

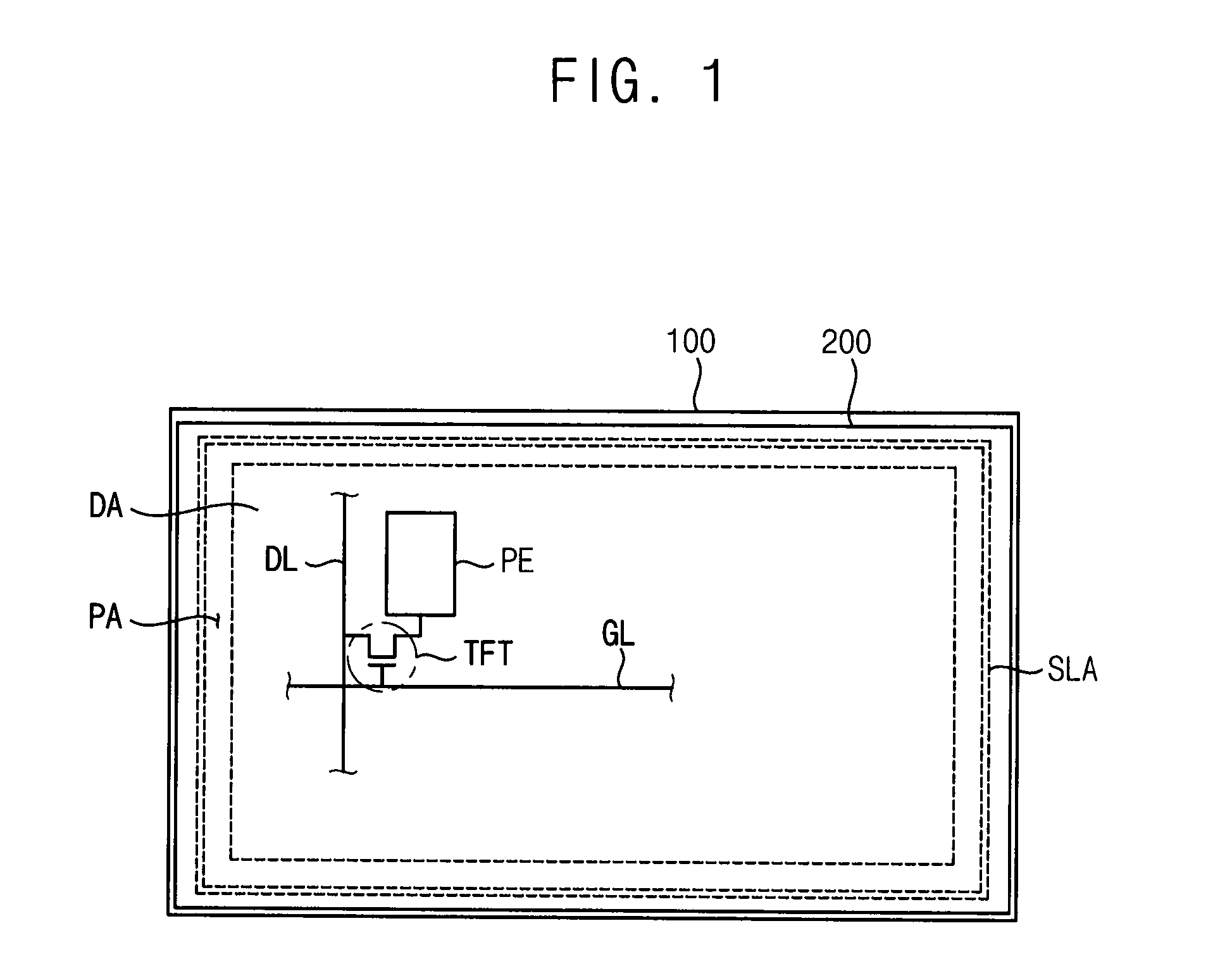

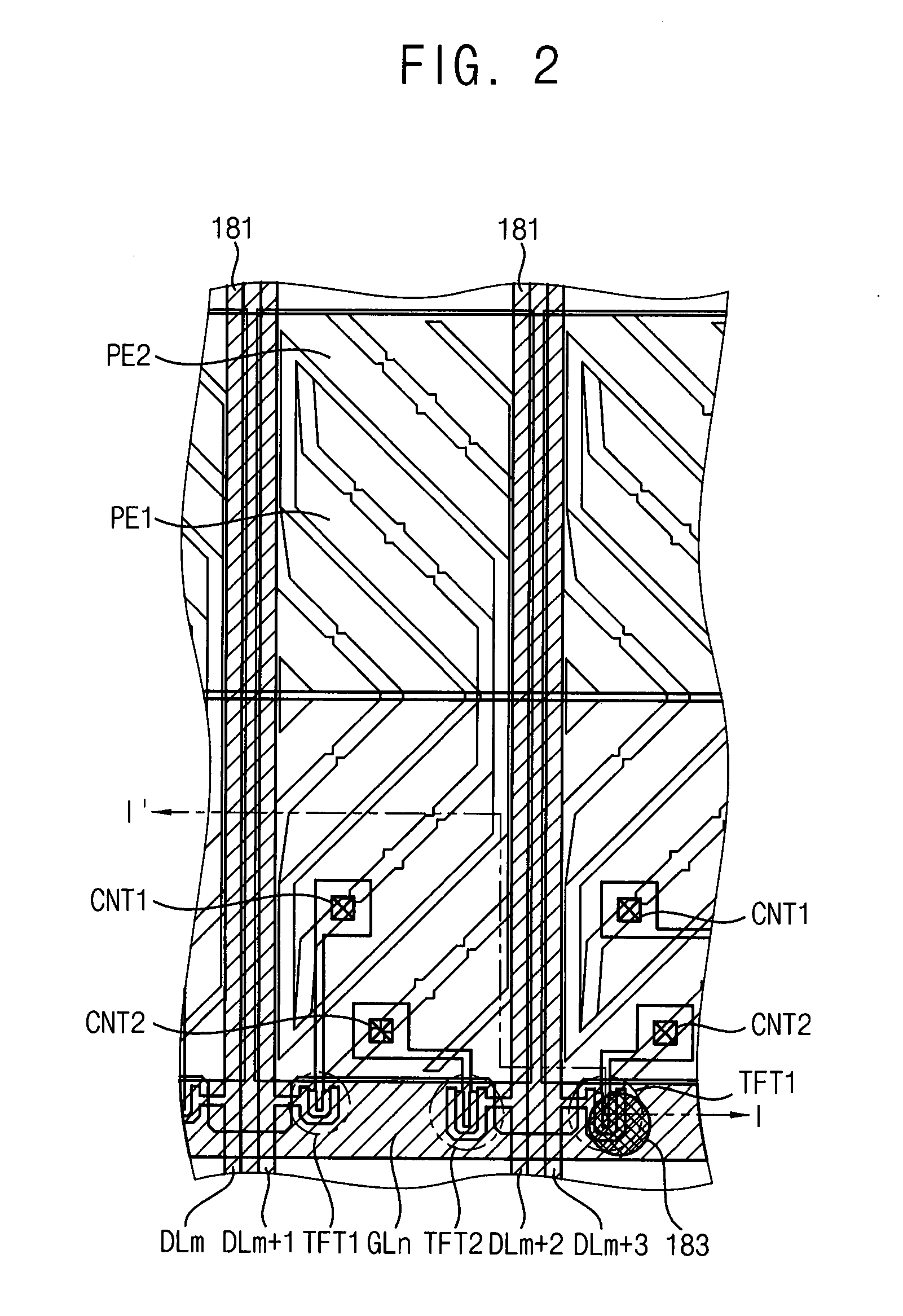

Array substrate, liquid crystal display panel having the same and method of manufacturing the same

ActiveUS20150198842A1Improve reliabilityImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayDisplay device

An array substrate includes a base substrate including a display area and a peripheral area adjacent to the display area, a gate line extending in a first direction, a data line extending in a second direction crossing the gate line, a switching element electrically connected to the gate and data lines, a color filter pattern and a dummy color pattern in the display and peripheral areas, respectively, a pixel electrode on the color filter pattern, and a light blocking pattern including a black matrix pattern partially overlapping the color filter pattern and a black boundary pattern overlapping the dummy color pattern. The black boundary pattern covers the peripheral area and includes a first portion which overlaps the dummy color pattern and a second portion which does not overlap the dummy color pattern. A cross-sectional thickness of the first portion is smaller than that of the second portion.

Owner:SAMSUNG DISPLAY CO LTD

Infrared reflective wall paint

ActiveUS20050215685A1Reduce energy consumptionReduce absorptionLiquid surface applicatorsElectrostatic spraying apparatusInfraredLacquer

Presented are methods for reducing energy consumption by coating external vertical walls of a building with a wall paint comprising reflective metal oxide pigments. Methods for painting external vertical walls as well as compositions comprising base paint combined with reflective metal oxide pigments are also presented.

Owner:TEXTURED COATINGS OF AMERICA

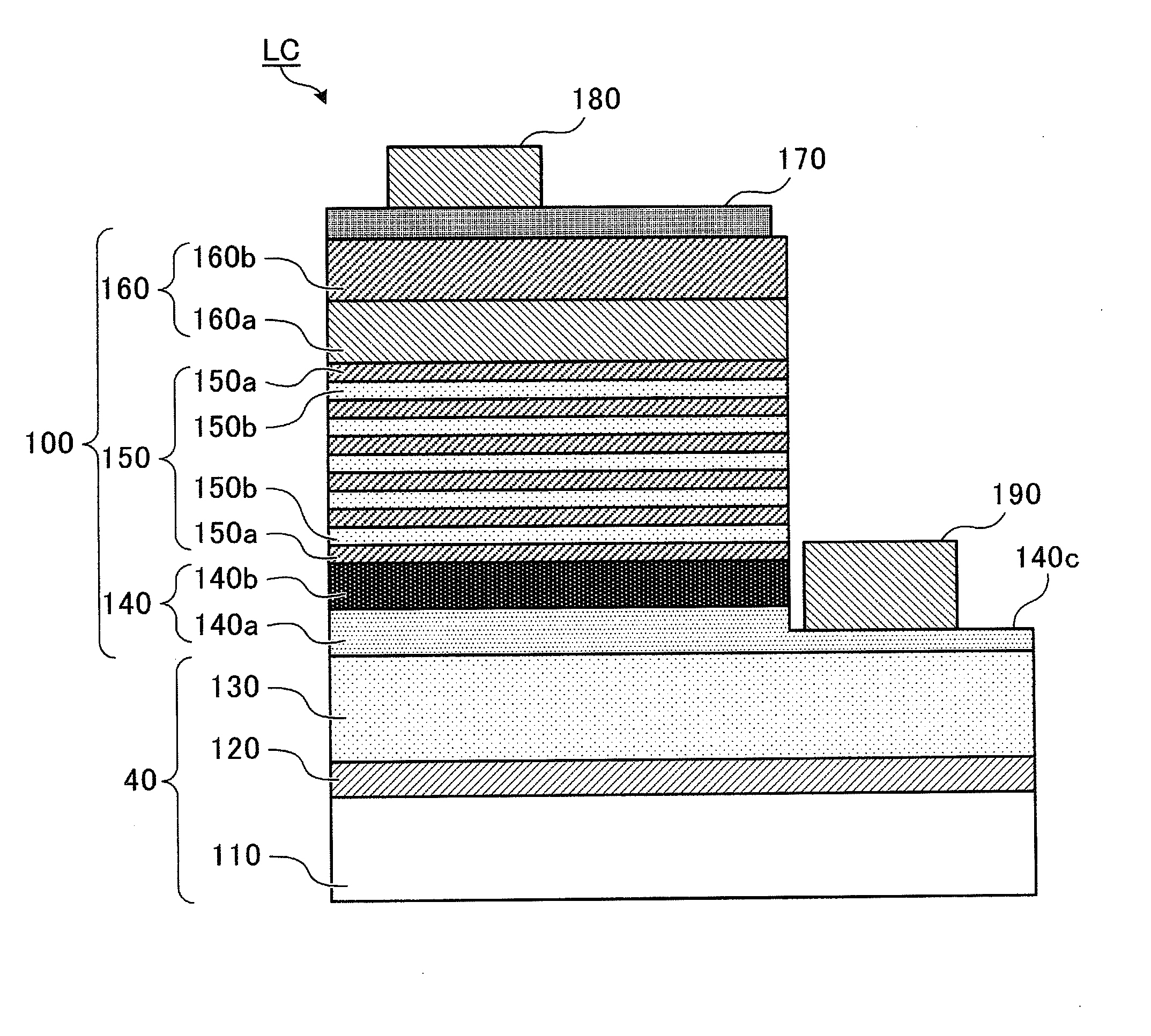

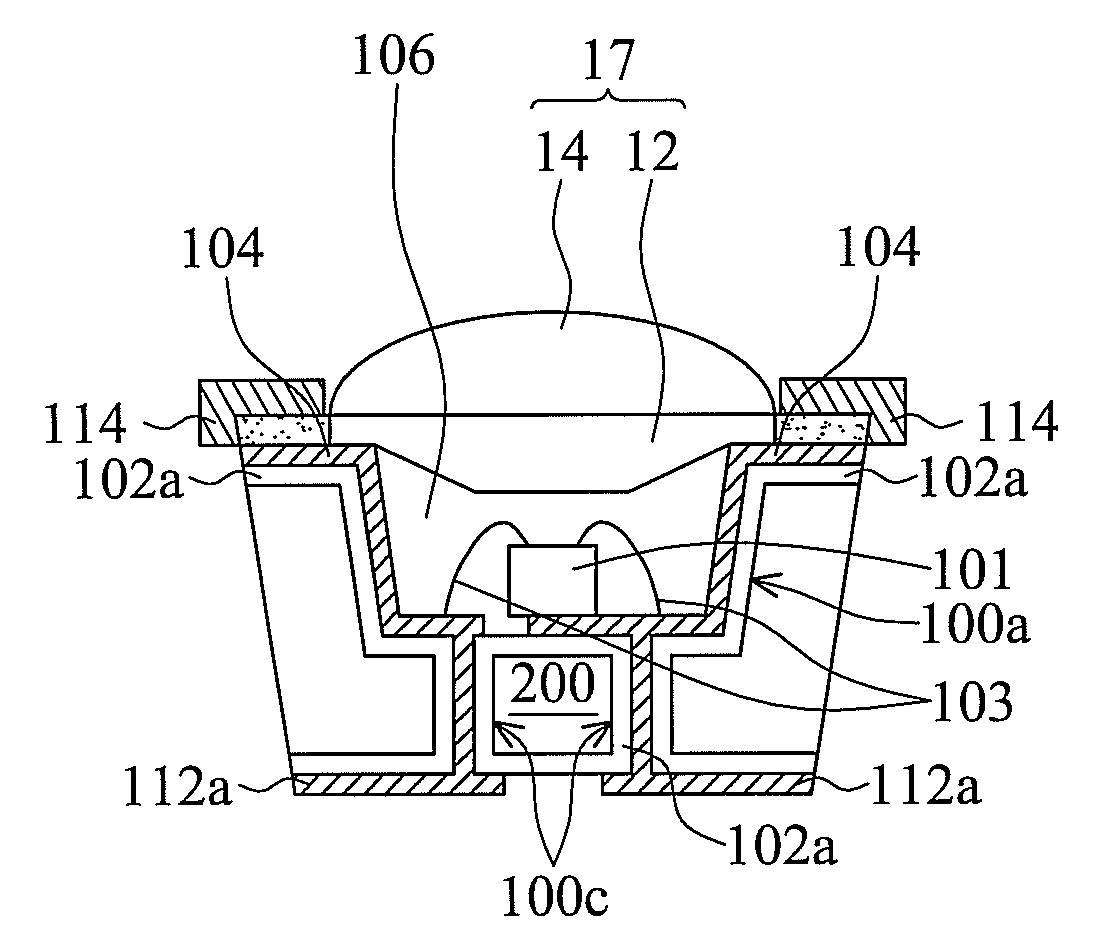

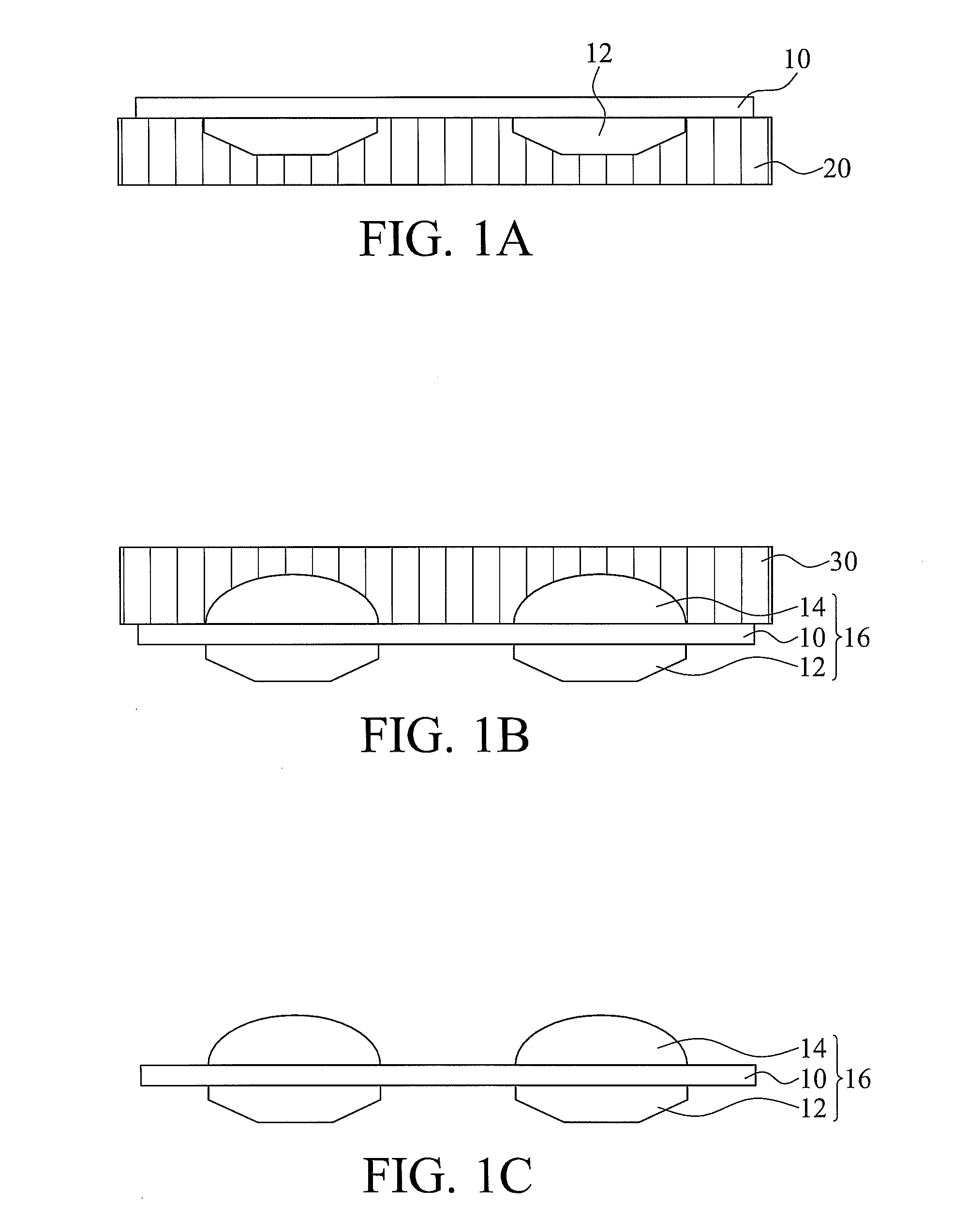

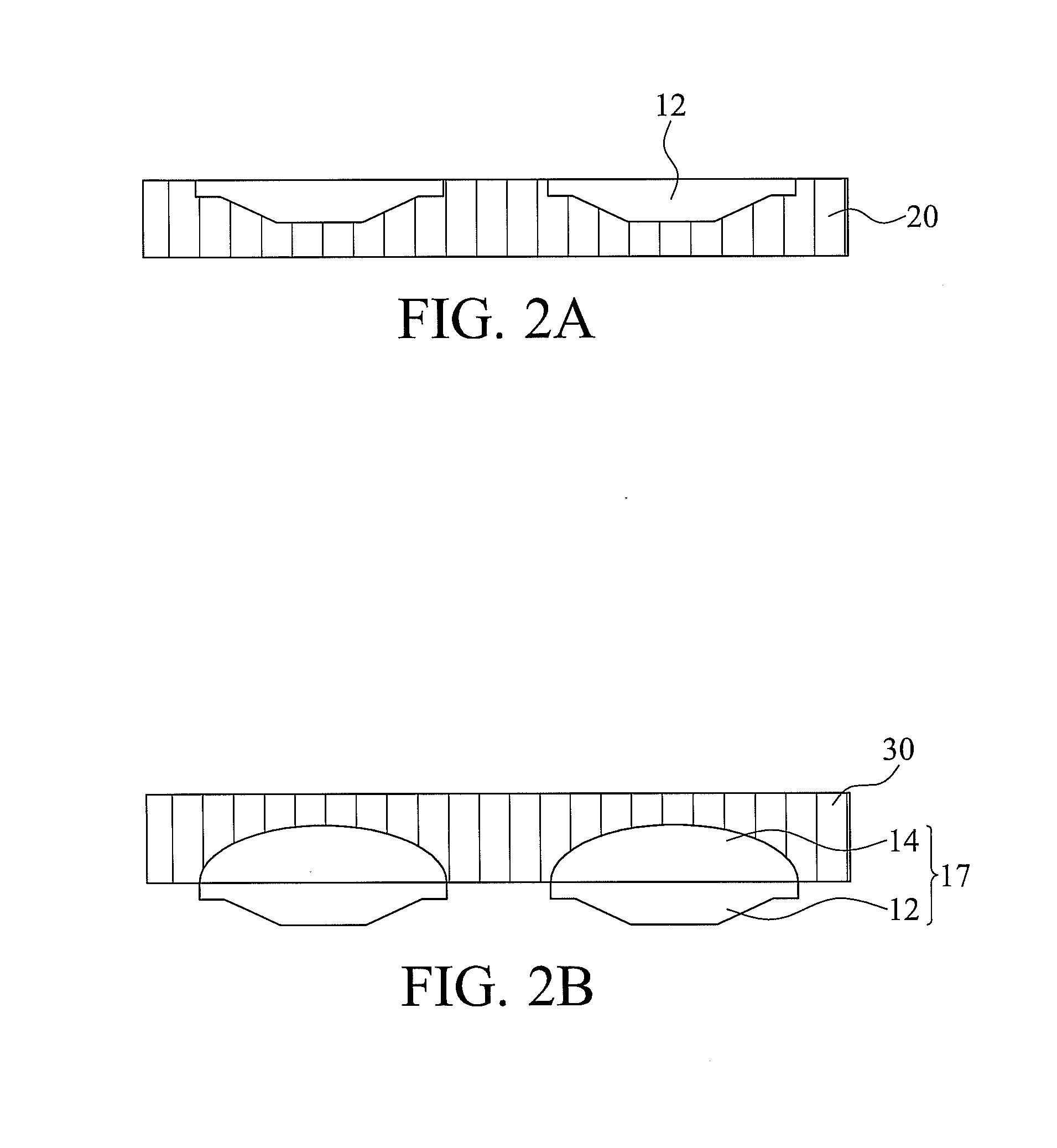

Light-emitting diode device and method for fabricating the same

InactiveUS20100012957A1Improve suppression propertiesReduce uniformitySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceLight-emitting diode

A semiconductor device is disclosed. The semiconductor device comprises a light-emitting diode chip disposed in a cavity of a semiconductor substrate. At least two isolated outer wiring layers are disposed on the bottom surface of the semiconductor substrate and are electrically connected to the light-emitting diode chip, serving as input terminals. A lens module is adhered to the top surface of the semiconductor substrate to cap the cavity, in which the lens module comprises a molded lens and a molded fluorescent layer thereunder and the molded fluorescent layer faces the light-emitting diode chip. A method for fabricating the semiconductor devices is also disclosed.

Owner:SEMILEDS OPTOELECTRONICS CO LTD +1

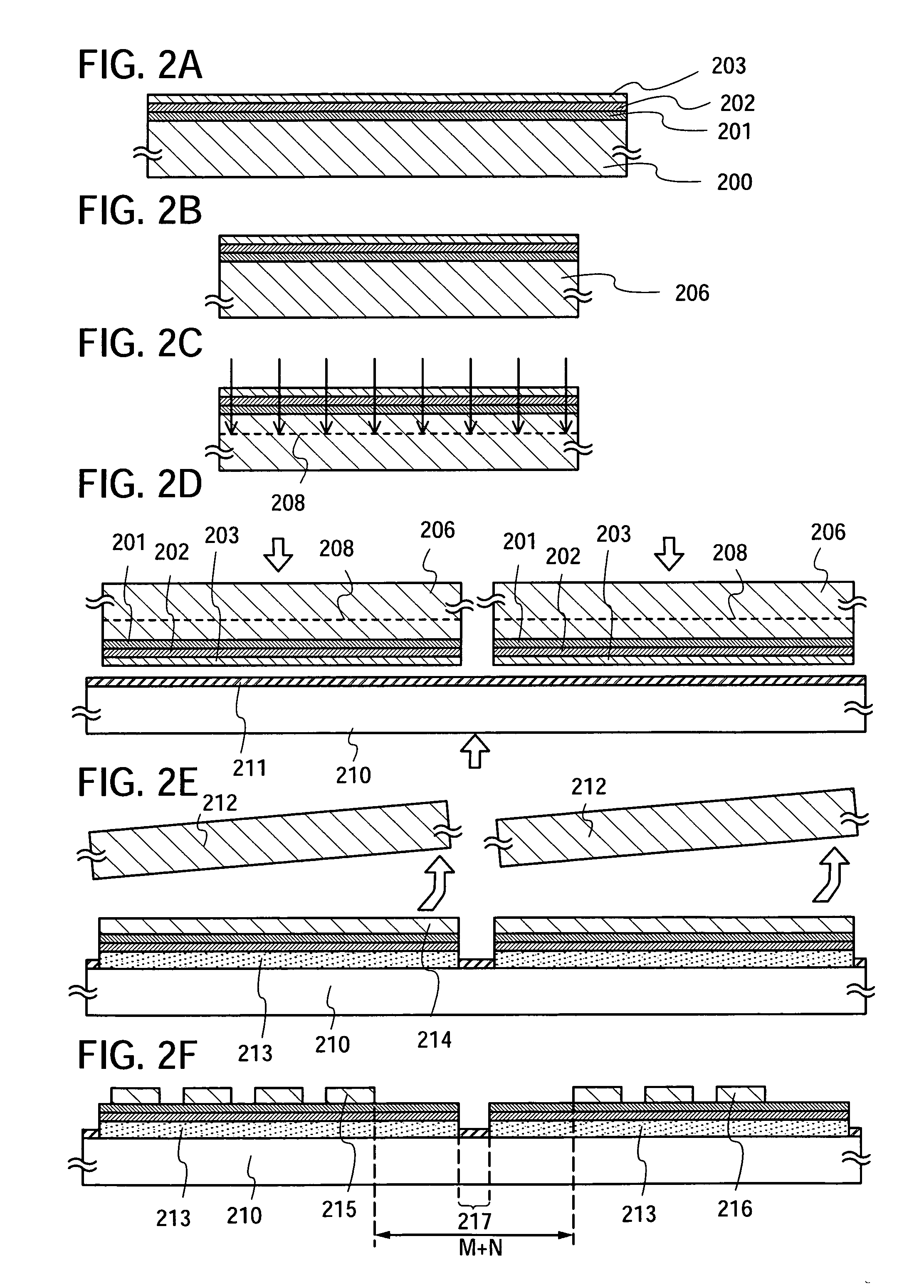

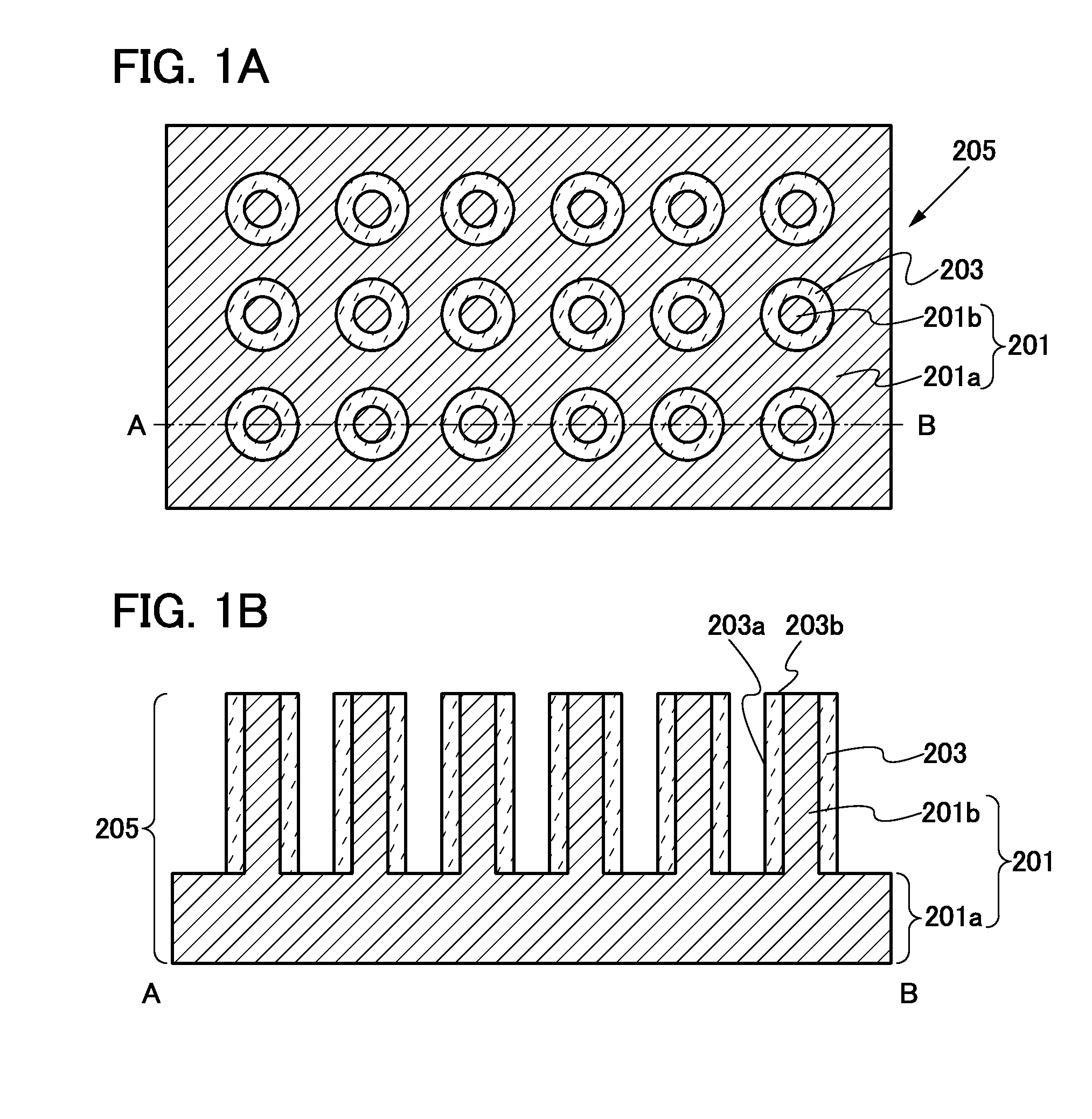

Semiconductor device and method for manufacturing the same

InactiveUS20080283848A1Suitable for mass productionIncrease the areaTransistorElectroluminescent light sourcesSingle crystalSemiconductor

A plurality of rectangle semiconductor substrates are attached to a single mother glass substrate. A pixel structure is determined so that even if a gap or a an overlapping portion is generated in a boundary between a plurality of semiconductor substrates, a single-crystal semiconductor layer does not overlap with the gap or the overlapping portion. Two TFTs are located in a first unit cell including the first light emitting element, four TFTs are located in a second unit cell including the second light emitting element, and no TFT is located in a third unit cell including the third light emitting element. A boundary line is between the third unit cell and a fourth unit cell.

Owner:SEMICON ENERGY LAB CO LTD

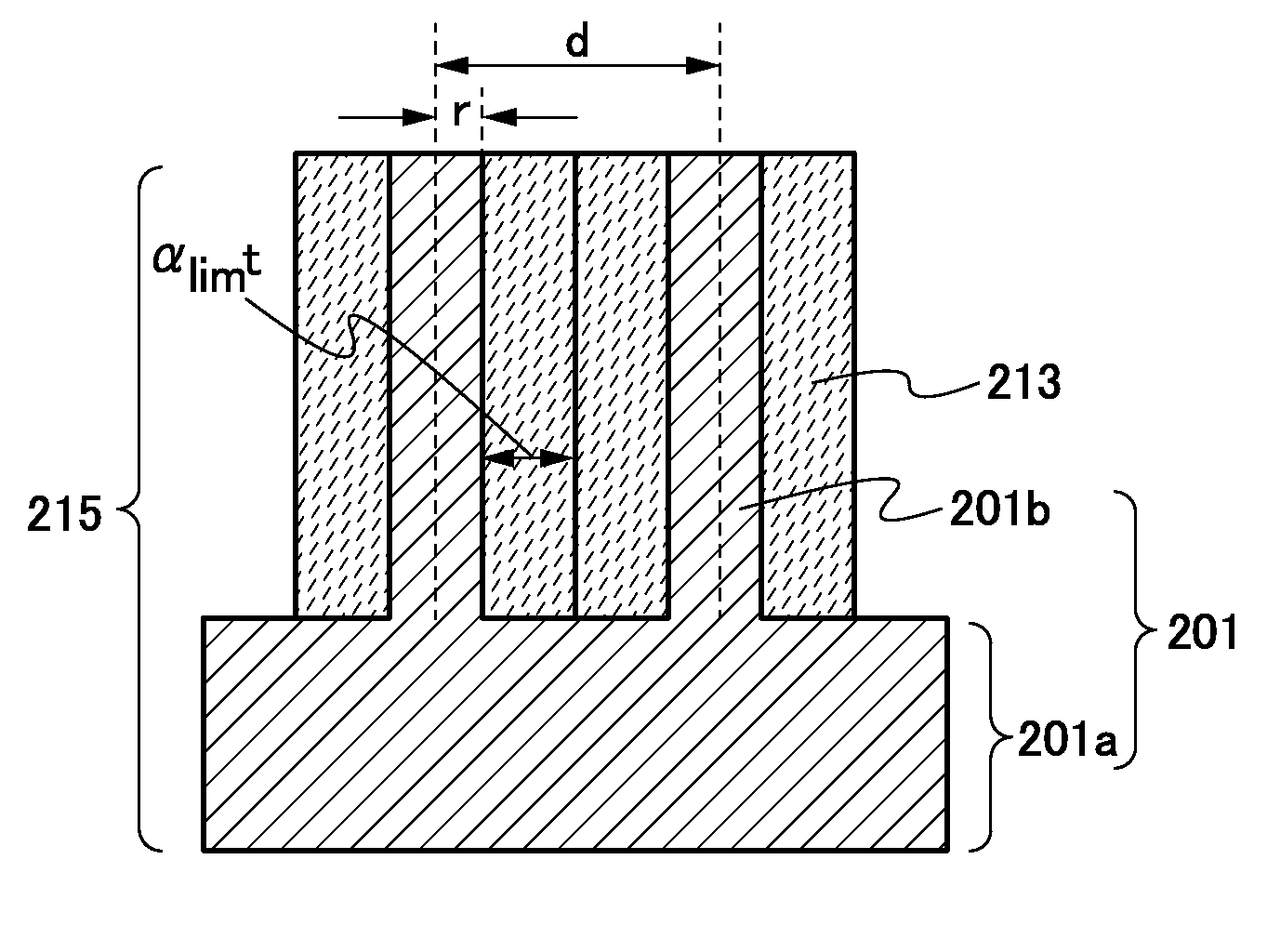

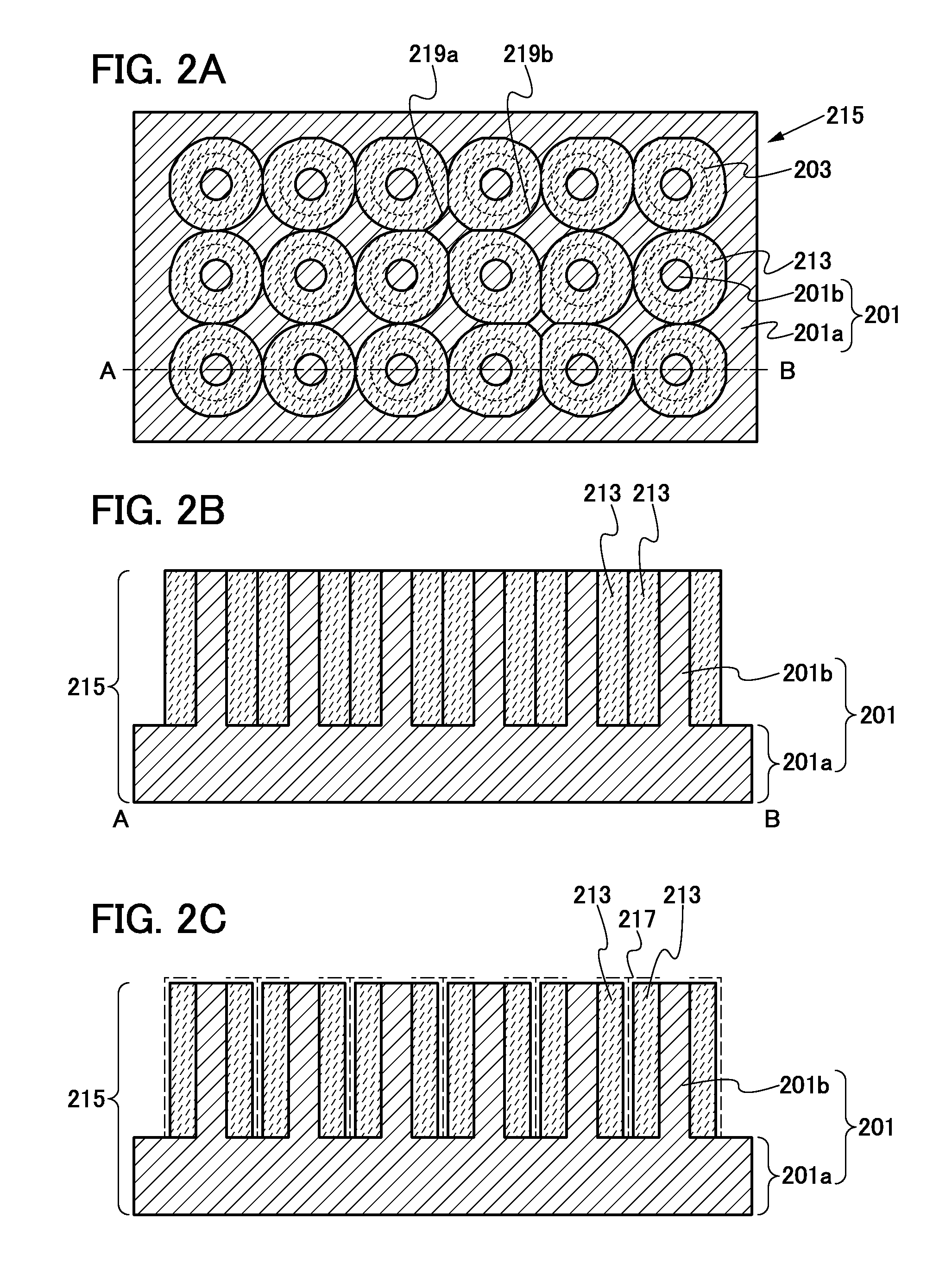

Power storage device

InactiveUS20130164611A1Prevent materialControl expansionElectrode carriers/collectorsActive material electrodesElectric forceEngineering

Disclosed is a power storage device including a negative electrode and a positive electrode. The negative electrode includes a negative electrode current collector including a common portion and a plurality of protrusions protruding from the common portion, and a negative electrode active material layer which covers a side surface of the protrusion. The positive electrode faces the negative electrode with an electrolyte provided therebetween. In the plurality of protrusions, a distance between adjacent protrusions is a distance with which adjacent negative electrode active material layers are in contact with each other before the capacity of the negative electrode active material layer reaches the theoretical capacity of the negative electrode active material layer by insertion of carrier ions from the positive electrode.

Owner:SEMICON ENERGY LAB CO LTD

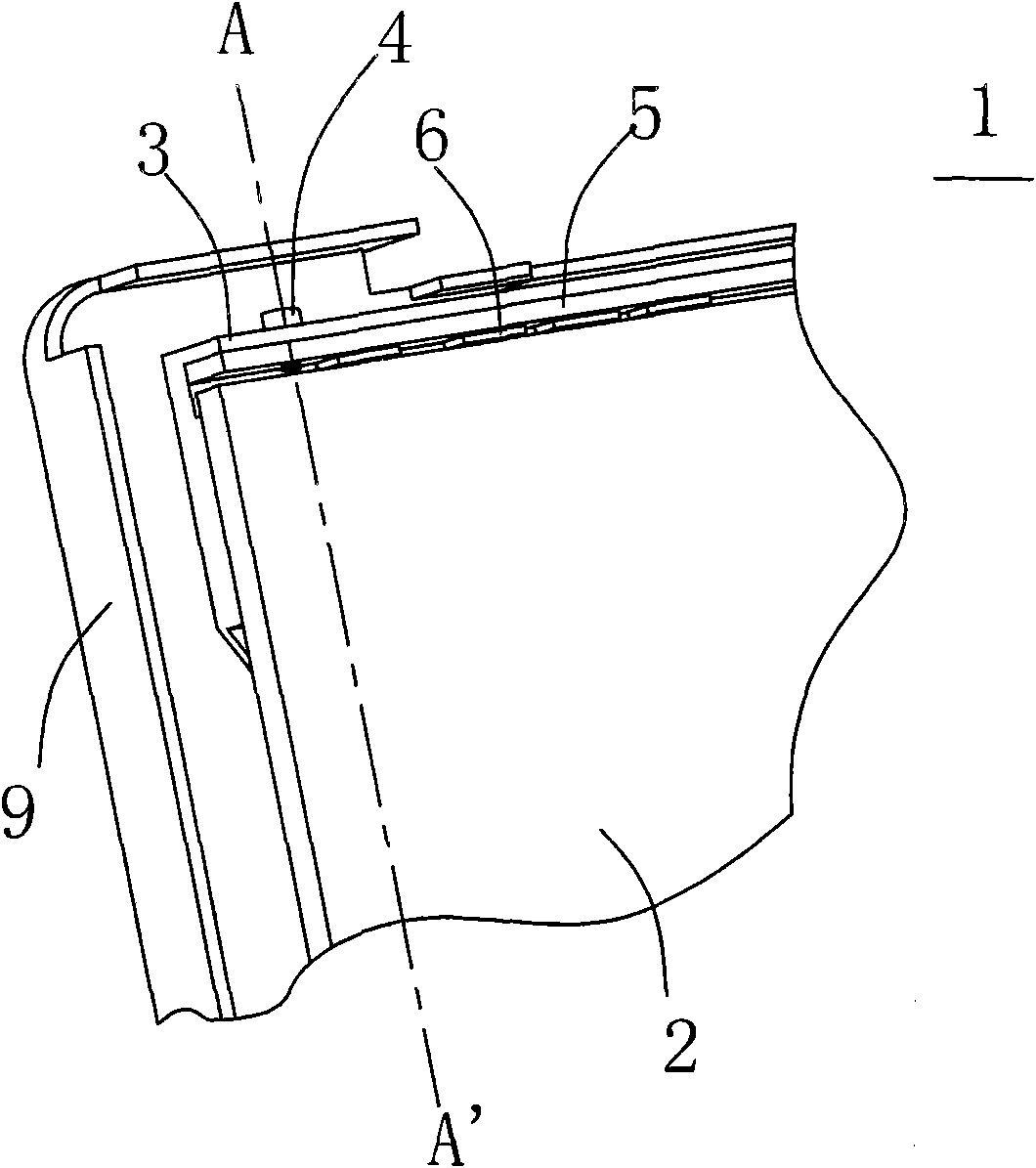

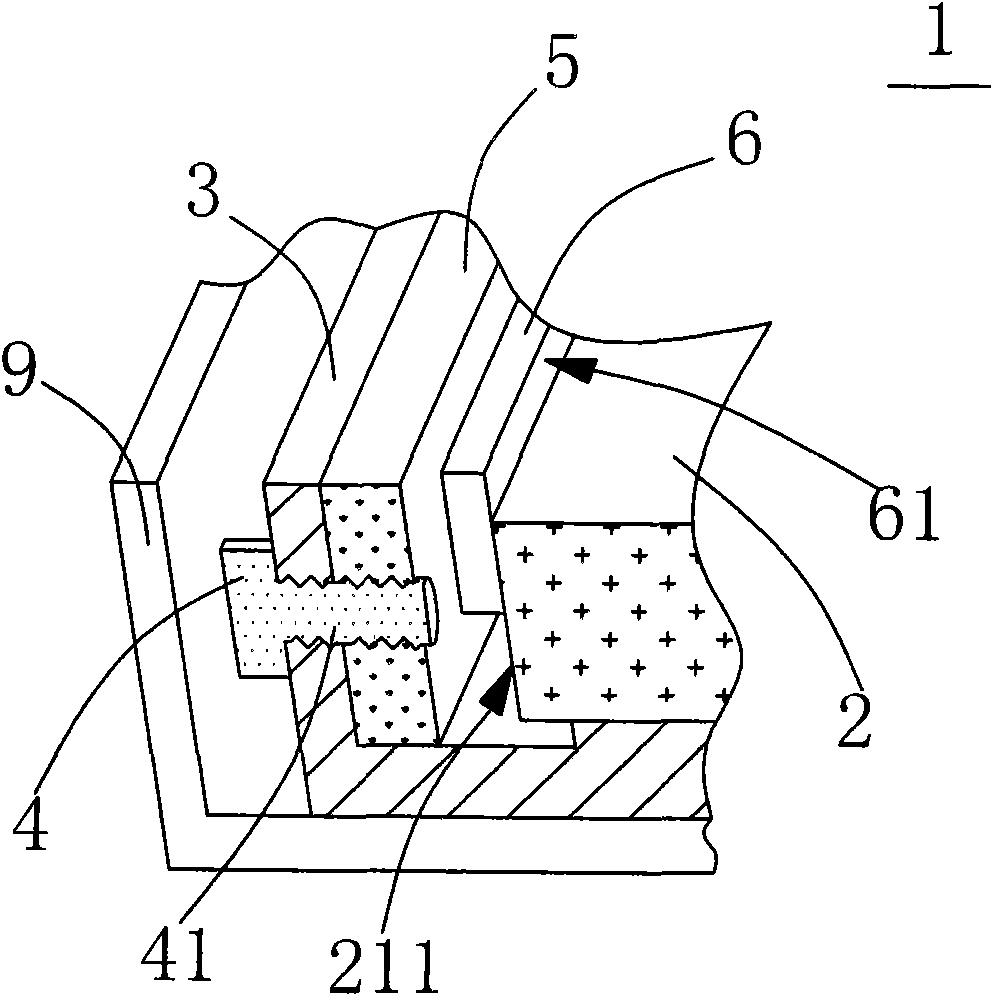

Backlight module and display device

InactiveCN101865404AWon't meltDecreased optical brightnessMechanical apparatusLighting heating/cooling arrangementsDisplay deviceEngineering

The invention discloses a backlight module and a display device. The backlight module comprises a light source module, a framework, a fixing part and an elastic element. The light source module comprises a circuit board provided with a first fixing hole and an LED; the side wall of the framework is provided with a second fixing hole; the fixing part comprises a first part, a second part and a third part, and the first part is in a thread structure; and the elastic element is arranged between the side wall and the circuit board. The first part penetrates through the second fixing hole to be locked and fixed with the first fixing hole, and the second part is movably positioned in the second fixing hole. When light source module is pressed to compress the elastic element, the light source module moves towards a first direction facing the side wall, and the second part moves towards the first direction along the second fixing hole; and when the elastic element recovers, the light source module moves towards a second direction far away from the side wall, and the second part moves towards the second direction along the second fixing hole. The elastic element of the light source module ensures that the light source module can move relative to the framework and can prevent the LED from being damaged by pressing.

Owner:DARWIN PRECISIONS SUZHOU CORP

Polishing pad

ActiveUS20100048102A1Improve the level ofHigh polishing rateAbrasion apparatusSemiconductor/solid-state device manufacturingEndcappingPolyol

A polishing pad capable of maintaining a high level of dimensional stability upon moisture absorption or water absorption and providing high polishing rate includes a polishing layer of a polyurethane foam having fine cells, wherein the polyurethane foam includes a cured product of a reaction of (1) an isocyanate-terminated prepolymer (A) that includes an isocyanate monomer, a high molecular weight polyol (a), and a low molecular weight polyol, (2) an isocyanate-terminated prepolymer (B) that includes a polymerized diisocyanate and a polyethylene glycol with a number average molecular weight of 200 to 1,000, and (3) a chain extender.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

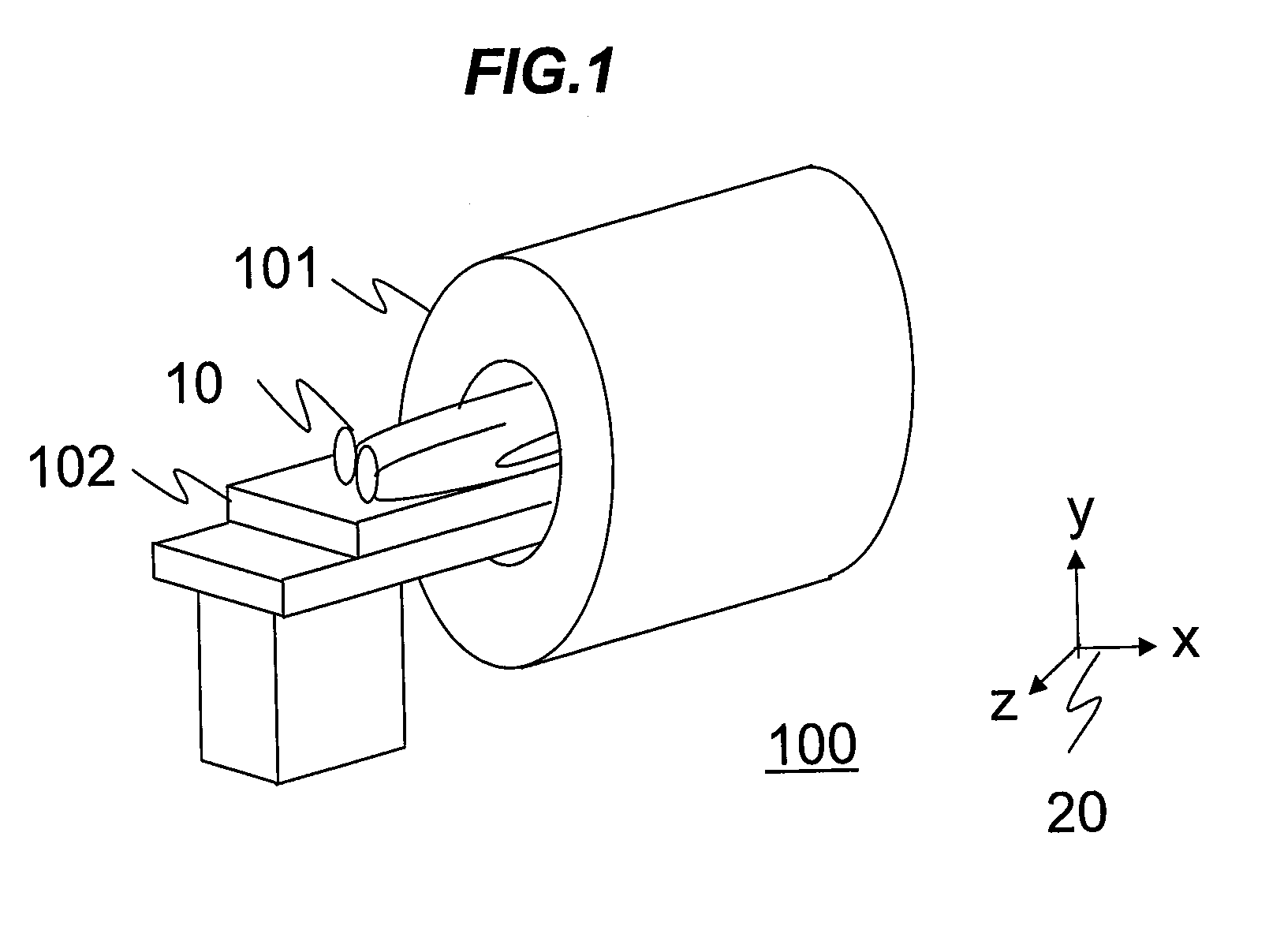

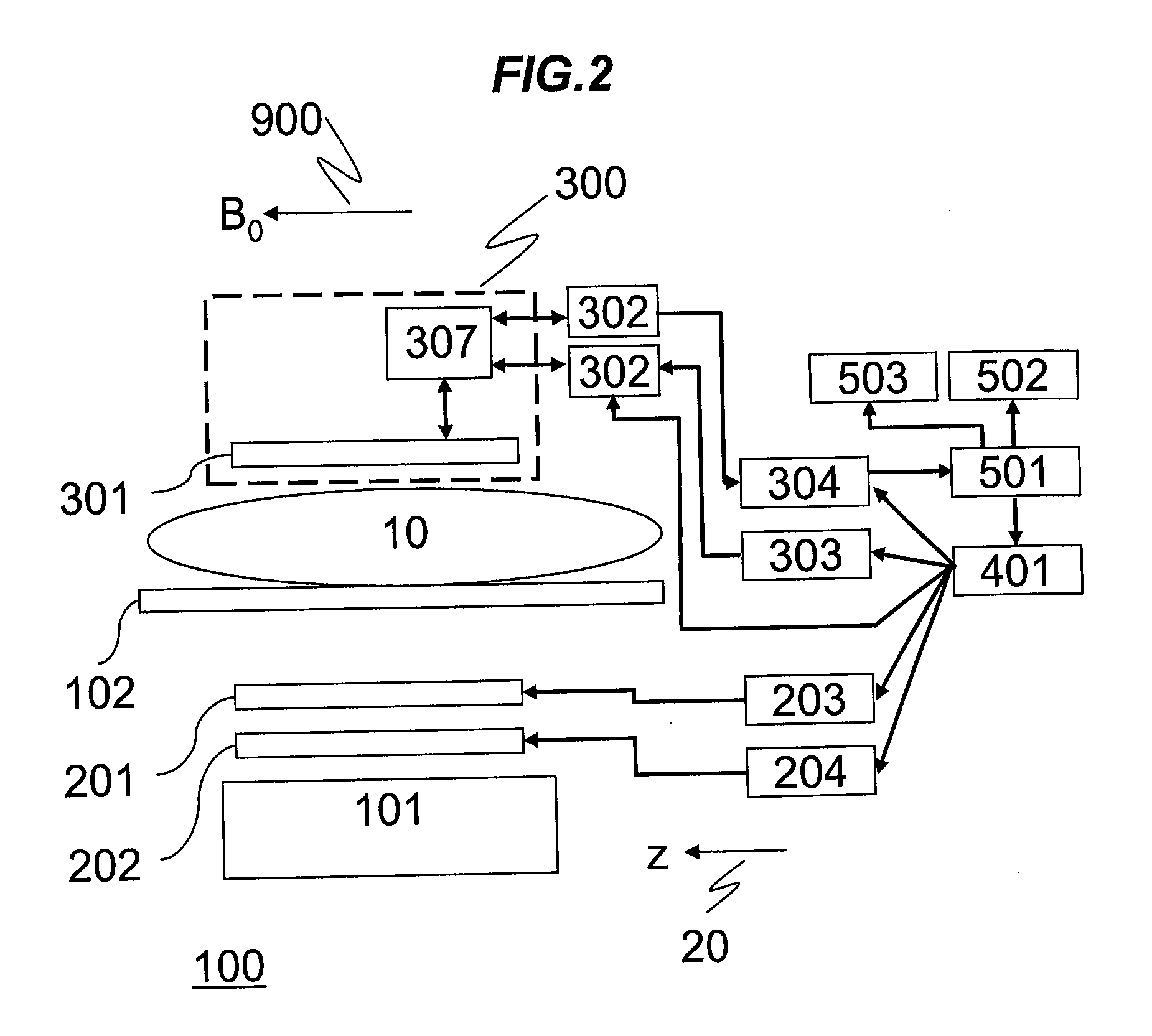

High-frequency coil unit and magnetic resonance imaging device

ActiveUS20120262173A1Increase manufacturing costBig spaceMeasurements using NMR imaging systemsElectric/magnetic detectionPhase differenceElliptical polarization

There is provided a technique for securing a large examination space in a tunnel type MRI device without inviting increase of manufacturing cost and without significantly reducing irradiation efficiency or uniformity of the irradiation intensity distribution in an imaging region. Between rungs of a partially cylindrical RF coil, which coil corresponds to a cylindrical RF coil of which part is removed, there are disposed half-loops generating magnetic fields, which are synthesized with magnetic fields generated by loops constituted by adjacent rungs of the partially cylindrical RF coil and rings connecting the rungs to generate a circularly polarized or elliptically polarized magnetic field. Further, high-frequency signals of the same reference frequency having a desired amplitude ratio and phase difference are supplied to the partially cylindrical RF coils and half-loops.

Owner:FUJIFILM HEALTHCARE CORP

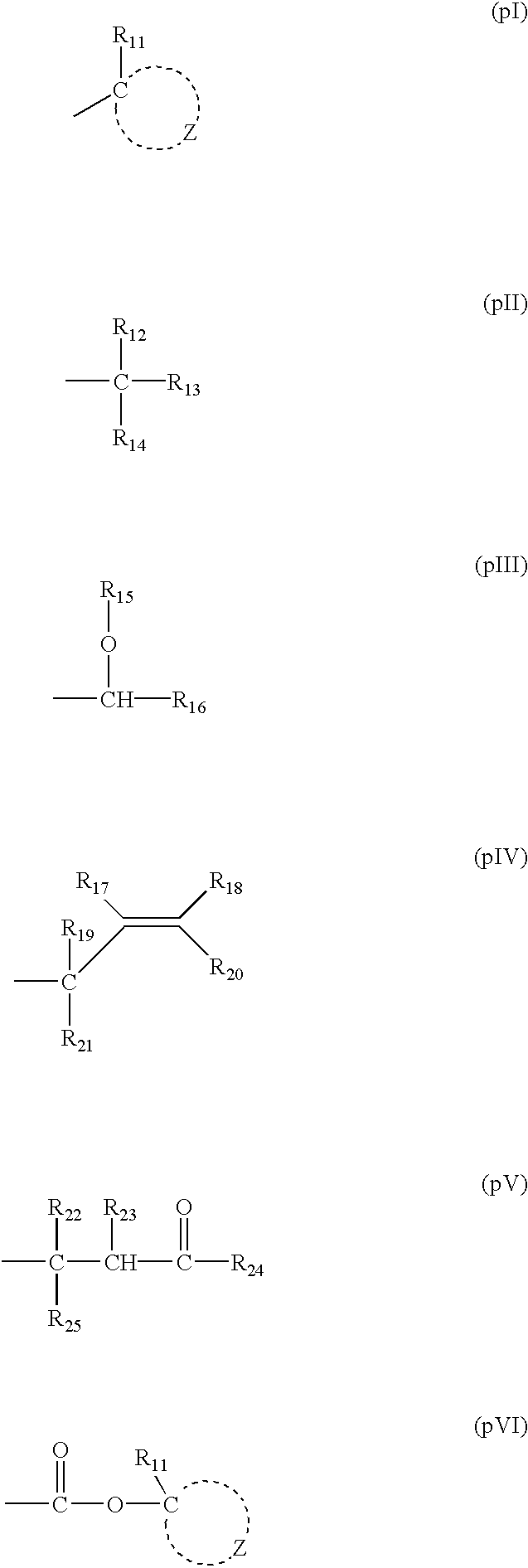

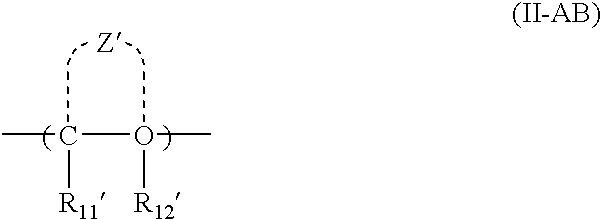

Positive photosensitive composition

InactiveUS6858370B2Increase exposureAvoid sensitivityPhotosensitive materialsRadiation applicationsActinic RaysAlicyclic Hydrocarbons

A positive photosensitive composition comprises: (A) an acid generator capable of generating an acid upon irradiation with one of an actinic ray and a radiation; and (B) a resin having a monocyclic or polycyclic alicyclic hydrocarbon structure and capable of decomposing by the action of an acid to increase the solubility in an alkali developer, wherein the acid generator (A) comprises at least two compounds of a sulfonium salt compound not having an aromatic ring, a triarylsulfonium salt compound, and a compound having a phenacylsulfonium salt structure.

Owner:FUJIFILM HLDG CORP +1

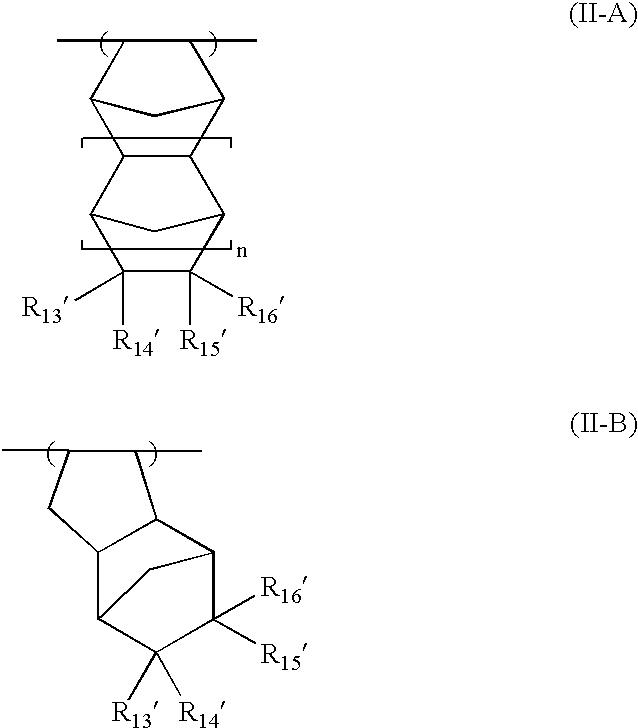

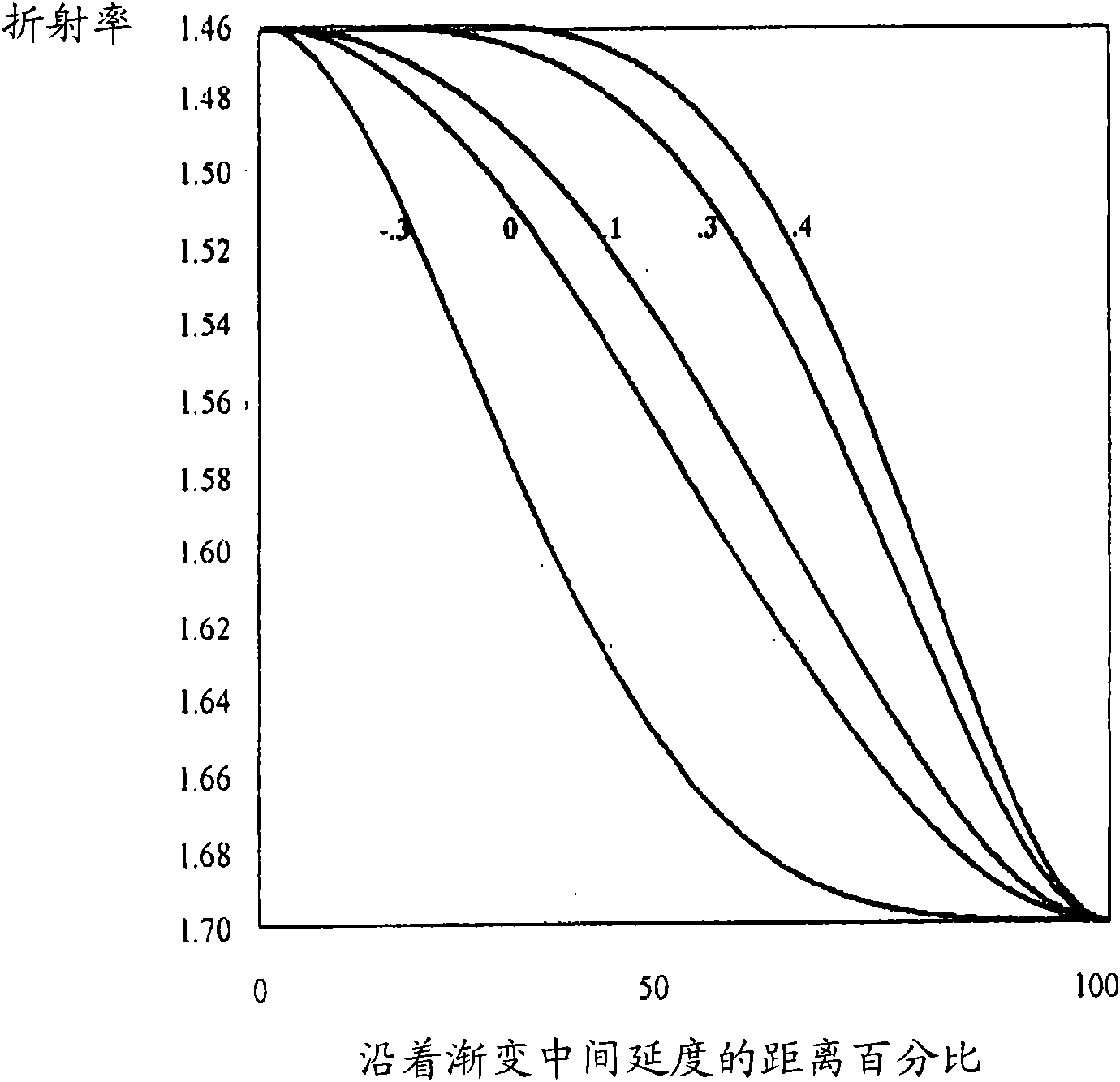

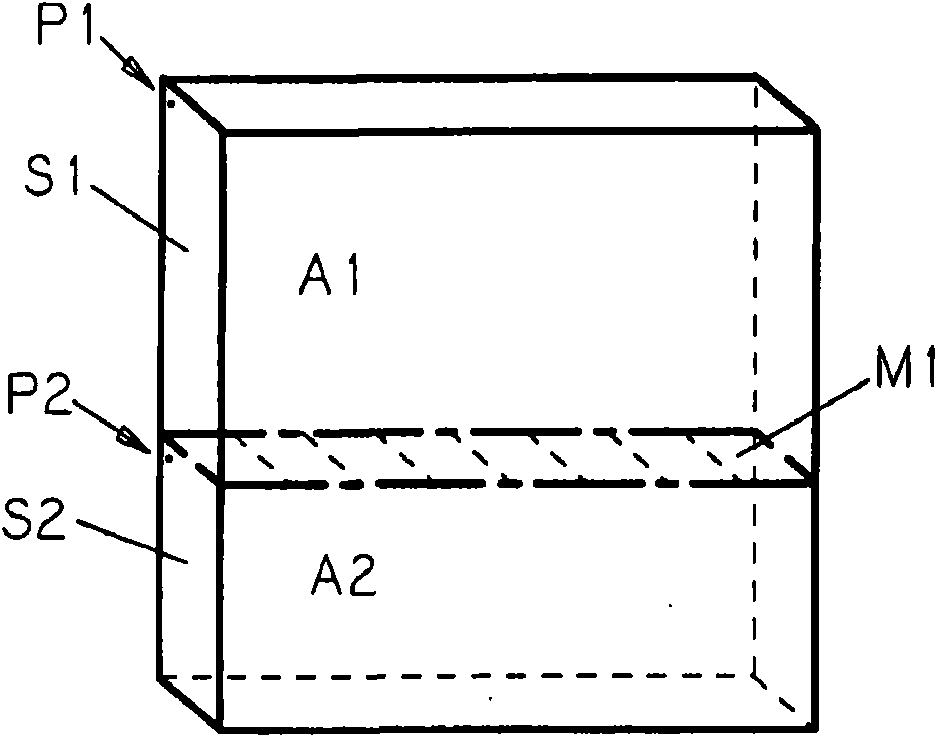

Multi-layered gradient index progressive lens

InactiveCN101681028AIncrease negative powerIncrease the refractive index differenceSpectales/gogglesOptical partsVisual field lossMultifocal lenses

The present invention relates to a gradient index progressive addition spectacle lens that provides improved optical performance and a wide visual field. The lens comprises a plurality of axially layered and bonded lens sections of continuous curvature at least one of which has a refractive index gradient oriented transverse to a meridian of the lens that functions as a progressive intermediate vision zone between viewing portions of different refractive index that provide the refractive powers for corresponding vision portions of the lens. The other layer(s) of the lens incorporates a generally constant or similarly changing refractive index.

Owner:唐纳德·A·沃尔克

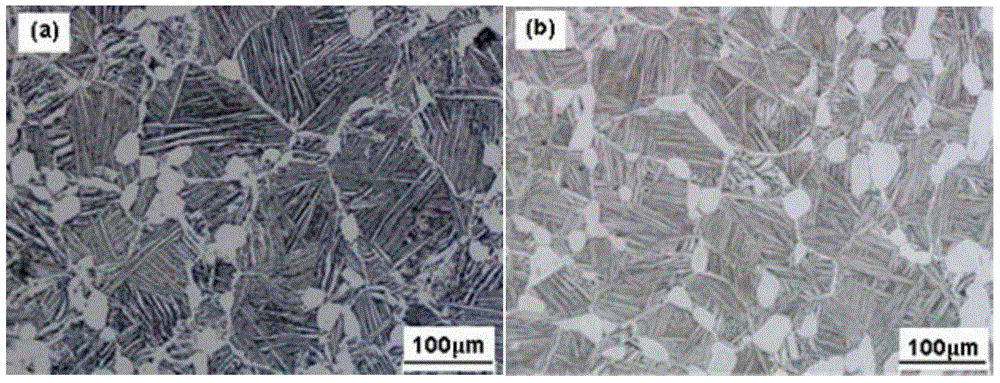

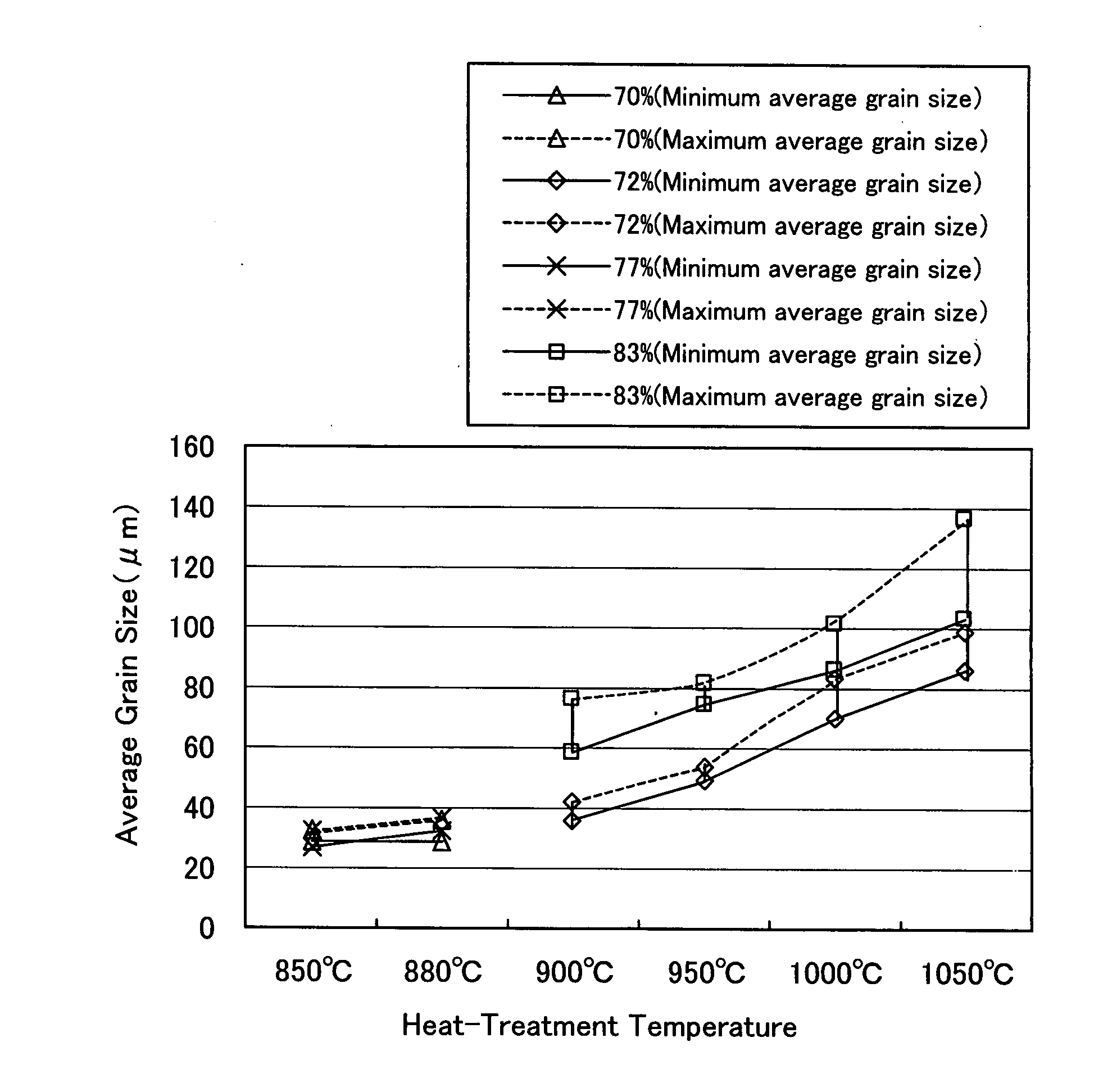

Ta sputtering target and method for producing the same

InactiveUS20070240795A1Reduce uniformityFine and uniform microstructureVacuum evaporation coatingSputtering coatingIngotMaterials science

A method for producing a Ta sputtering target including the following steps: (a) a step of forging a Ta ingot, comprising subjecting the Ta ingot to a forging pattern over at least 3 times, wherein each forging pattern is “a cold forging step comprising stamp-forging and upset-forging operations alternatively repeated over at least 3 times; (b) an in-process vacuum heat-treating step carried out between every successive two forging patterns to thus prepare a Ta billet; (c) a step of rolling the Ta billet to obtain a rolled plate; and (d) a step of vacuum heat-treating the rolled plate to obtain a Ta sputtering target. A sputtering target produced by the above method.

Owner:ULVAC INC

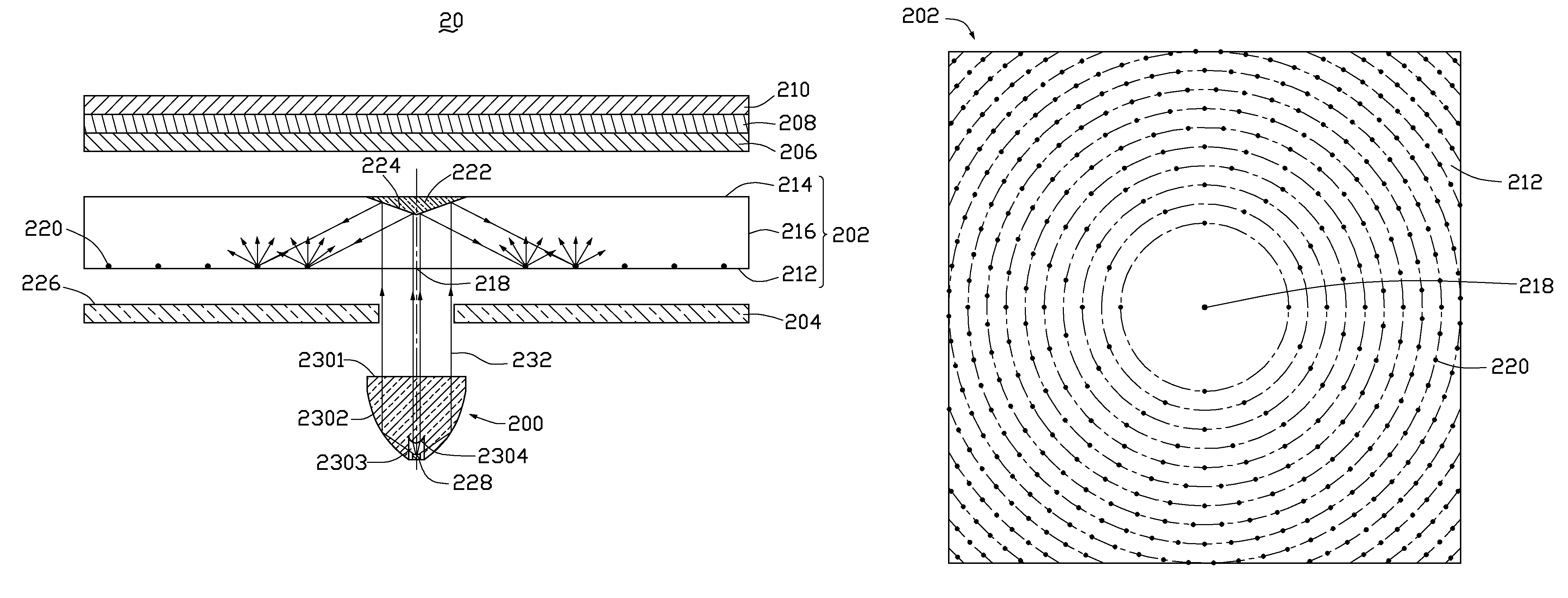

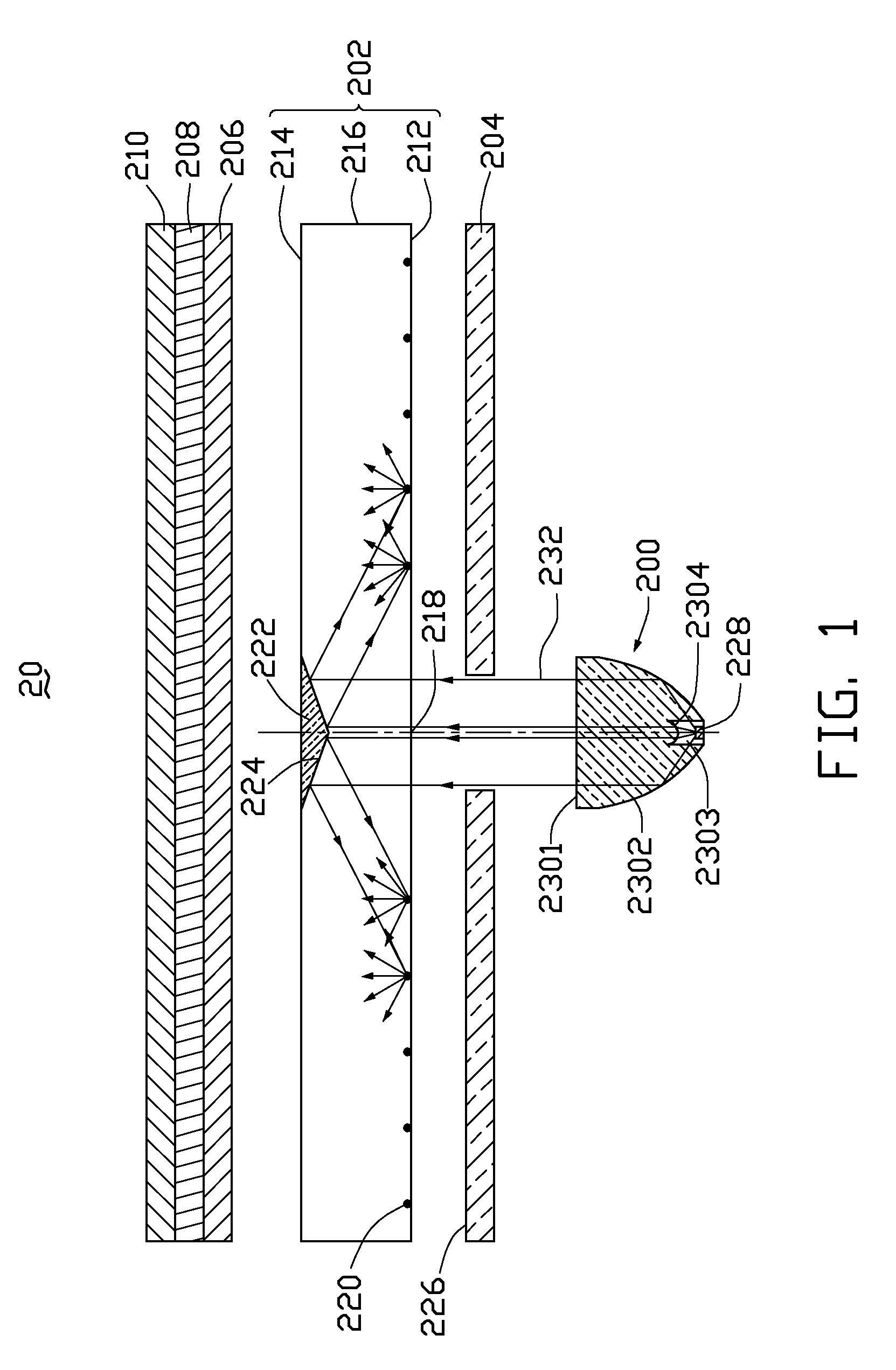

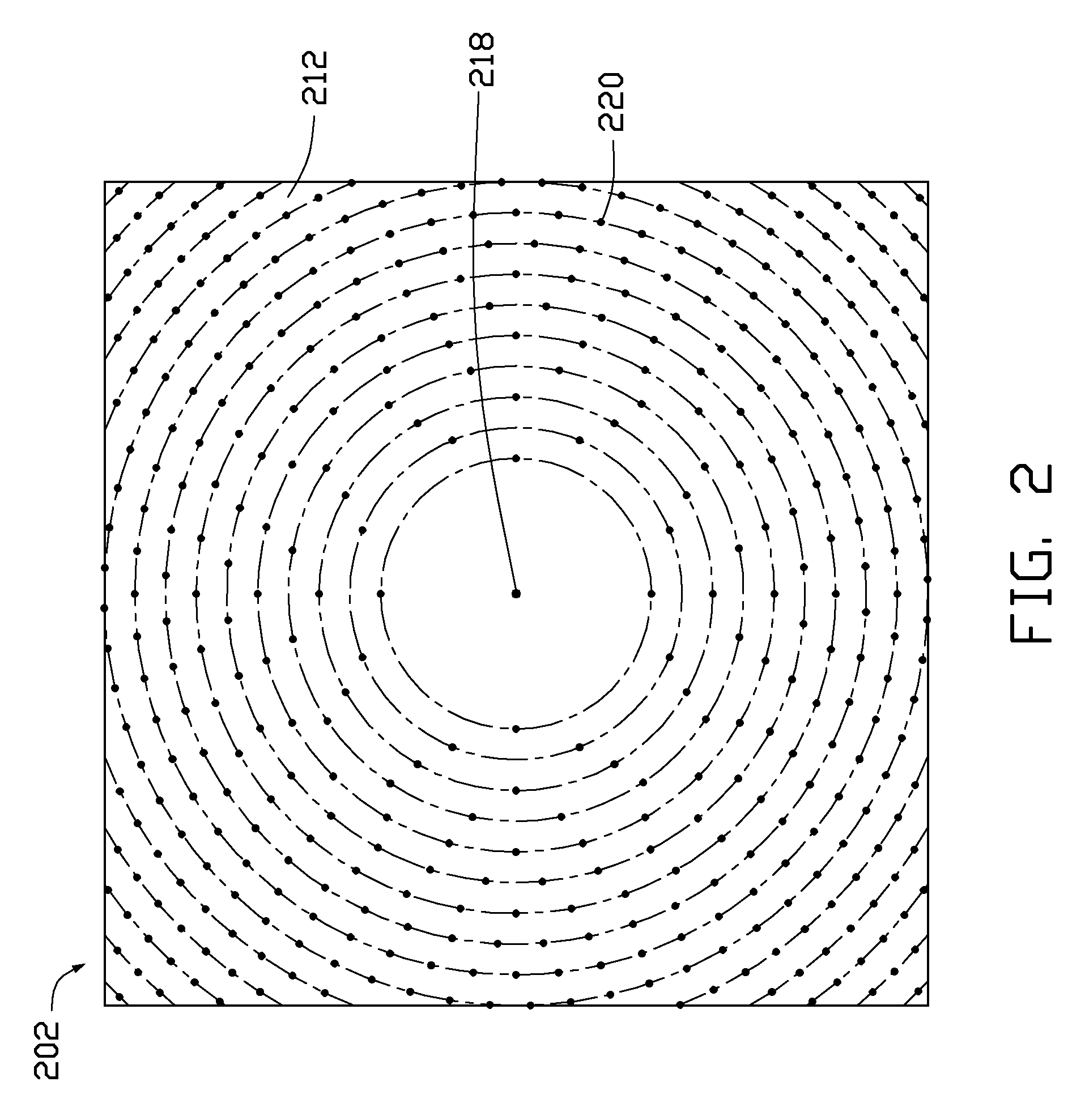

Light guide plates and backlight module

ActiveUS8070345B2Reduce uniformityOptical light guidesIlluminated signsLight guideClassical mechanics

A light guide plate includes a body having a bottom surface and a light output surface opposite to the bottom surface. A reflector is located on the light output surface opposite to the center of the bottom surface. The reflector is a cavity concaved from the light output surface to the inside of the body. A plurality of scattering dots are located on the bottom surface. The scattering dots are arranged in the form of a plurality of concentric circles around the center of the bottom surface. The number of the scattering dots is defined based on a radius of the circle they reside on, and the radius of the circle is greater than or substantially equal to 4 millimeter.

Owner:TSINGHUA UNIV +1

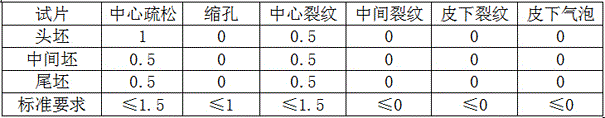

18CrNiMo7-6 round billet continuous casting method for vertical type continuous casting production gear steel

The invention belongs to the technical field of metallurgy, and mainly relates to an 18CrNiMo7-6 round billet continuous casting method for vertical type continuous casting production gear steel. The method includes the steps that primary melting molten steel with low carbon, phosphorous and harmful element contents is obtained through smelting in an electric-arc furnace; deoxygenation, desulfuration and complete alloying are carried out in a steel ladle refining furnace, and vacuum degassing is carried out in a VD furnace; continuous casting round billets are obtained on a vertical type continuous casting machine in a pouring manner; in the continuous casting process, long nozzle argon blowing and stopper rod argon blowing are adopted for protecting pouring, and two-stage electromagnetic stirring is achieved through a crystallizer and casting strands; the round billets are cooled in a second cooling zone at three periods; and symmetrical solidification and flame cutting are carried out in the vertical direction. According to the continuous casting round billets produced according to the method, the problems that in the prior art, 18CrNiMo7-6 gear steel is high in production cost, the banded structure is disqualified, and the oxygen content is high are solved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com