Patents

Literature

197results about How to "Won't melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

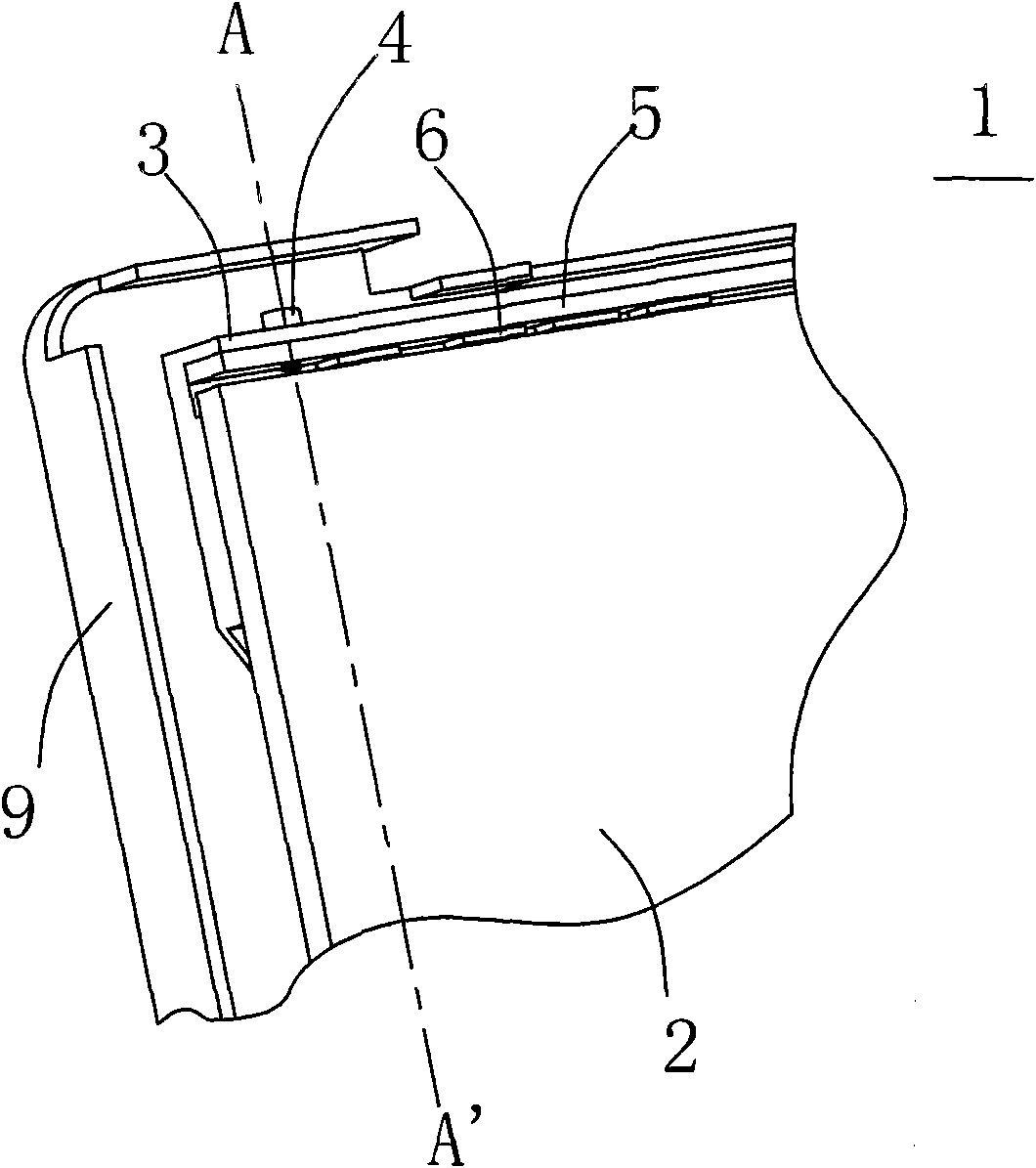

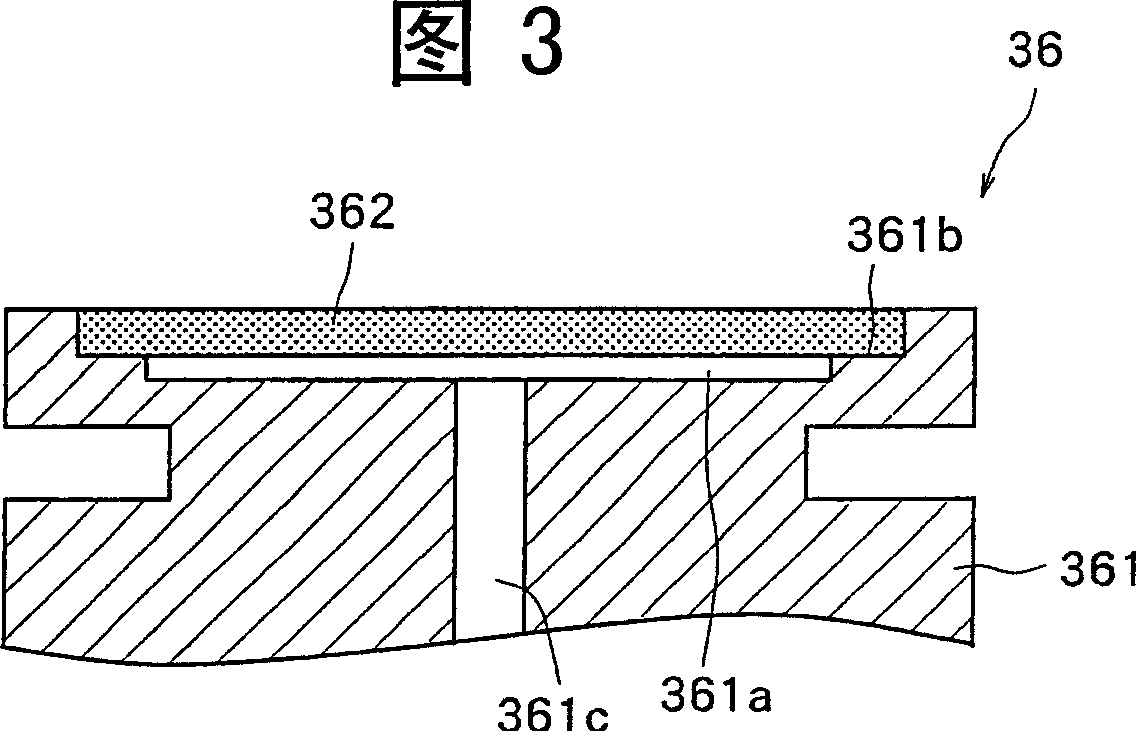

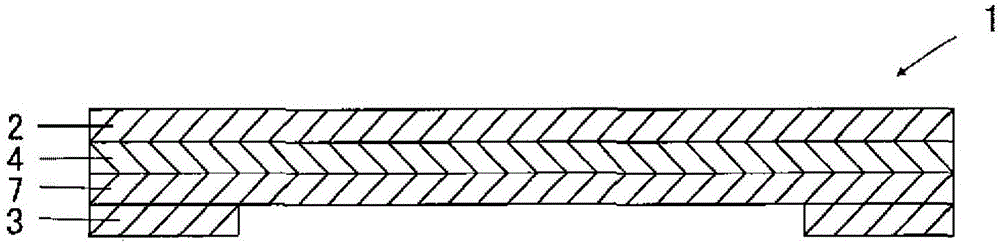

Backlight module and display device

InactiveCN101865404AWon't meltDecreased optical brightnessMechanical apparatusLighting heating/cooling arrangementsDisplay deviceEngineering

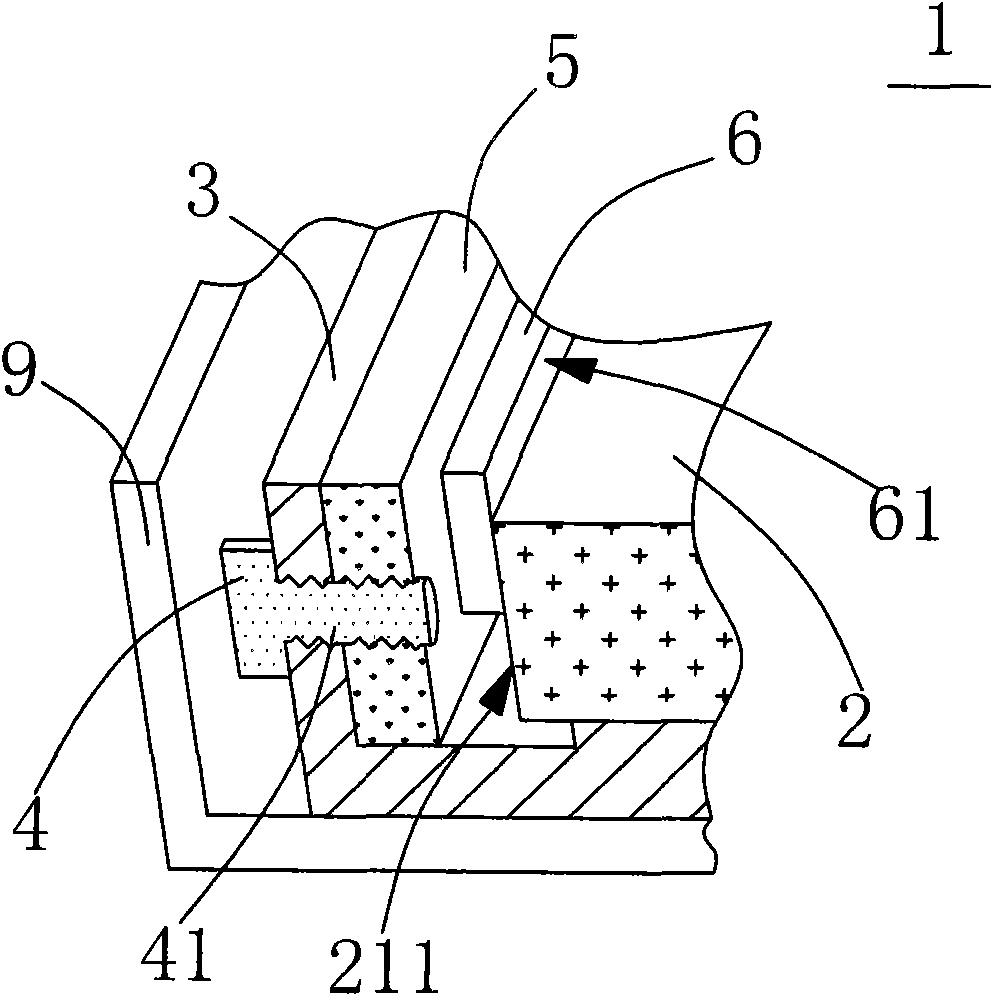

The invention discloses a backlight module and a display device. The backlight module comprises a light source module, a framework, a fixing part and an elastic element. The light source module comprises a circuit board provided with a first fixing hole and an LED; the side wall of the framework is provided with a second fixing hole; the fixing part comprises a first part, a second part and a third part, and the first part is in a thread structure; and the elastic element is arranged between the side wall and the circuit board. The first part penetrates through the second fixing hole to be locked and fixed with the first fixing hole, and the second part is movably positioned in the second fixing hole. When light source module is pressed to compress the elastic element, the light source module moves towards a first direction facing the side wall, and the second part moves towards the first direction along the second fixing hole; and when the elastic element recovers, the light source module moves towards a second direction far away from the side wall, and the second part moves towards the second direction along the second fixing hole. The elastic element of the light source module ensures that the light source module can move relative to the framework and can prevent the LED from being damaged by pressing.

Owner:DARWIN PRECISIONS SUZHOU CORP

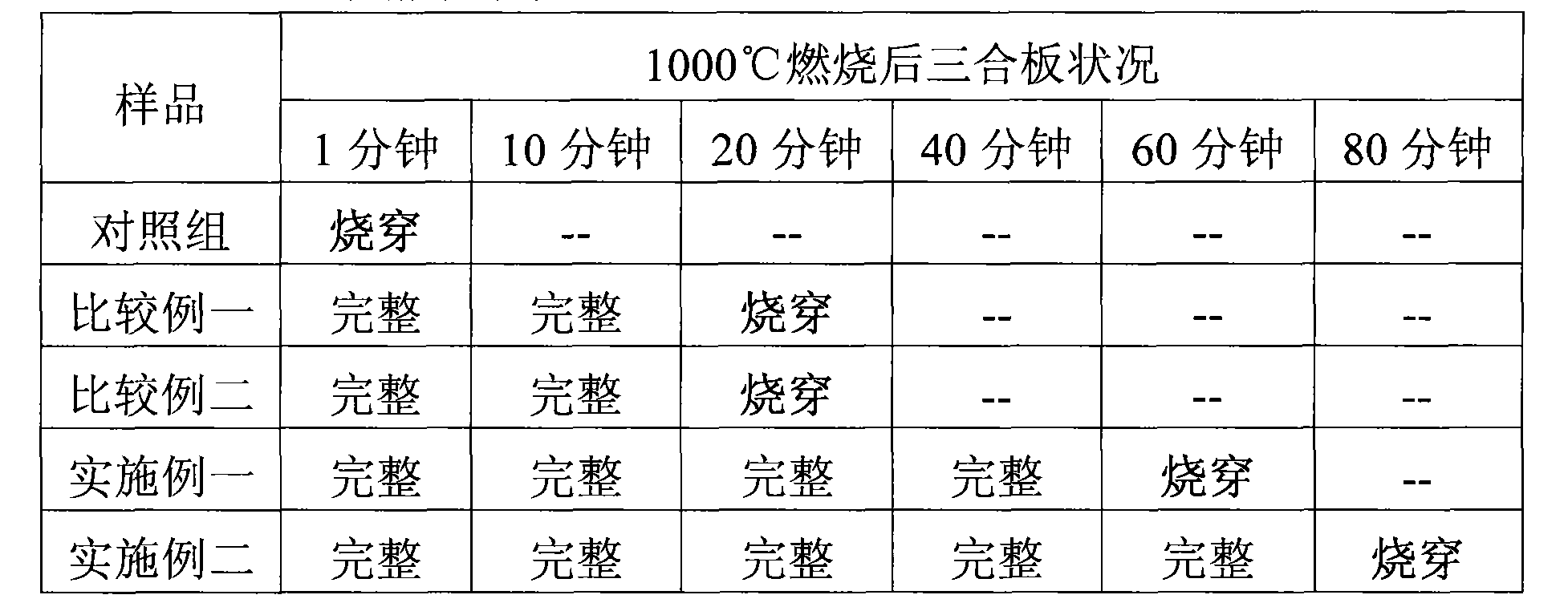

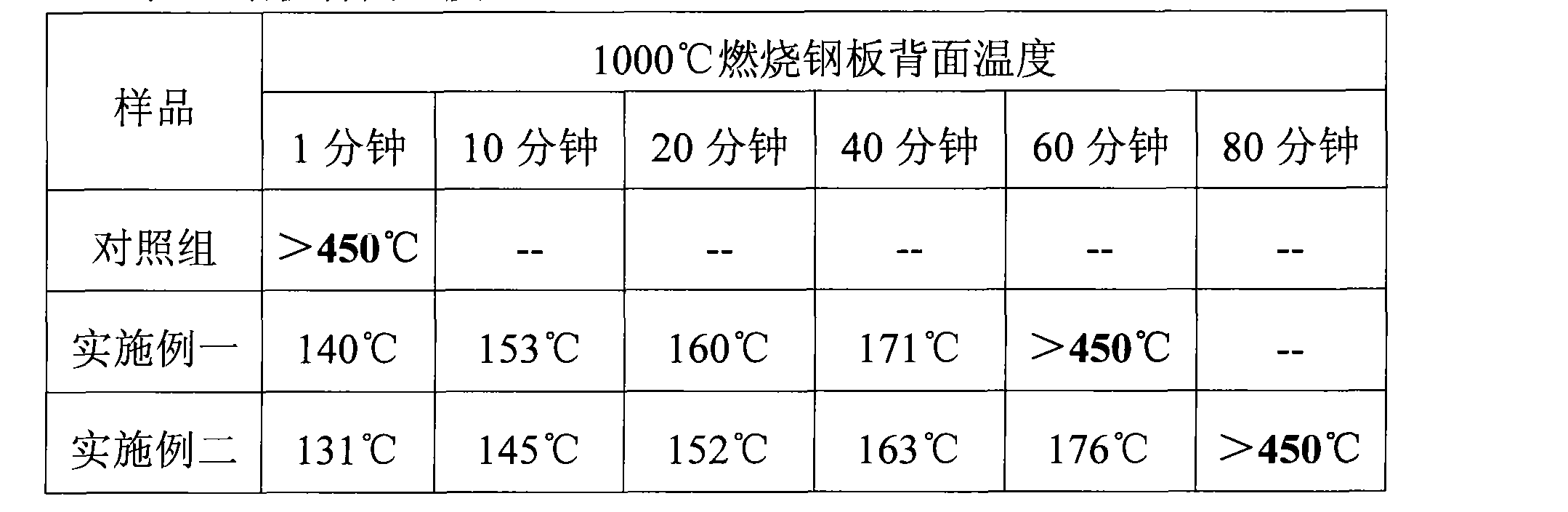

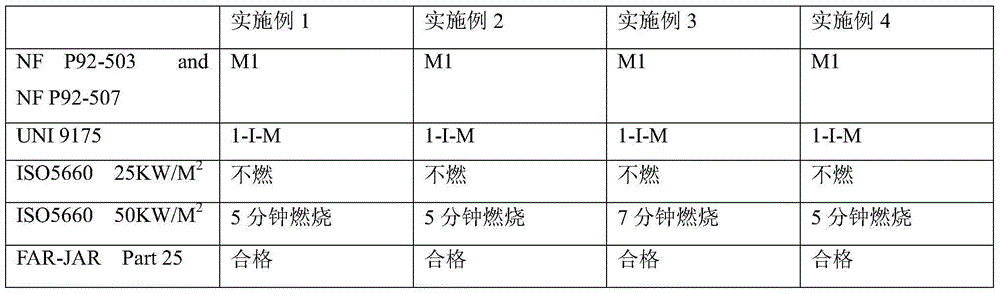

Transparent halogen-free fire-resisting paint constituent

InactiveCN101434760AImprove toughnessNot easy to crackFireproof paintsPolyurea/polyurethane coatingsSolventChemistry

The invention provides a transparent halogen-free fire-retardant paint composition, which consists of 100phr (Parts per Hundred of Resin) of adhesive, 50-400phr of solvent, 50-300phr of foaming agent, 10-200phr of carburetant, 1-100phr of carbonizing promoter and 0-100phr of auxiliary additive; wherein, the carbonizing promoter is a phosphorus-containing compound with reaction functional groups. A coat formed by the transparent halogen-free fire-retardant paint composition nearly generates no smoke when being heated but instantly generates an expanding layer of high toughness. The expanding layer is not likely to crack, does not melt, drop and droop and moreover, is capable of effectively obstructing oxygen and heat to fulfill fire-retardant effect. The paint composition has excellent compatibility and dispersibility among the ingredients, therefore has eminent transparency and can be used for the fire prevention of various buildings, furniture or in decoration without damaging the original appearance view thereof.

Owner:CHINA GENERAL PLASTICS

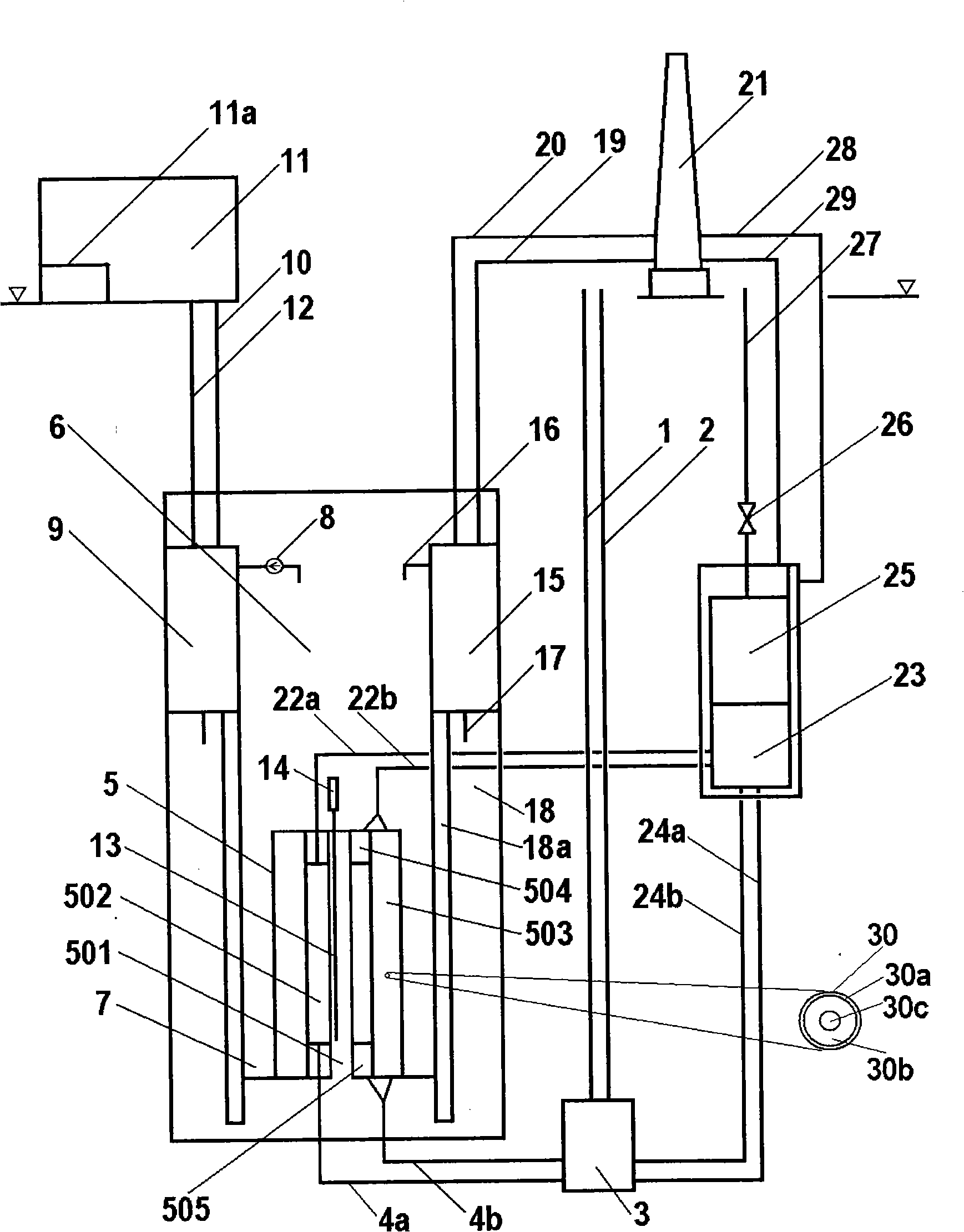

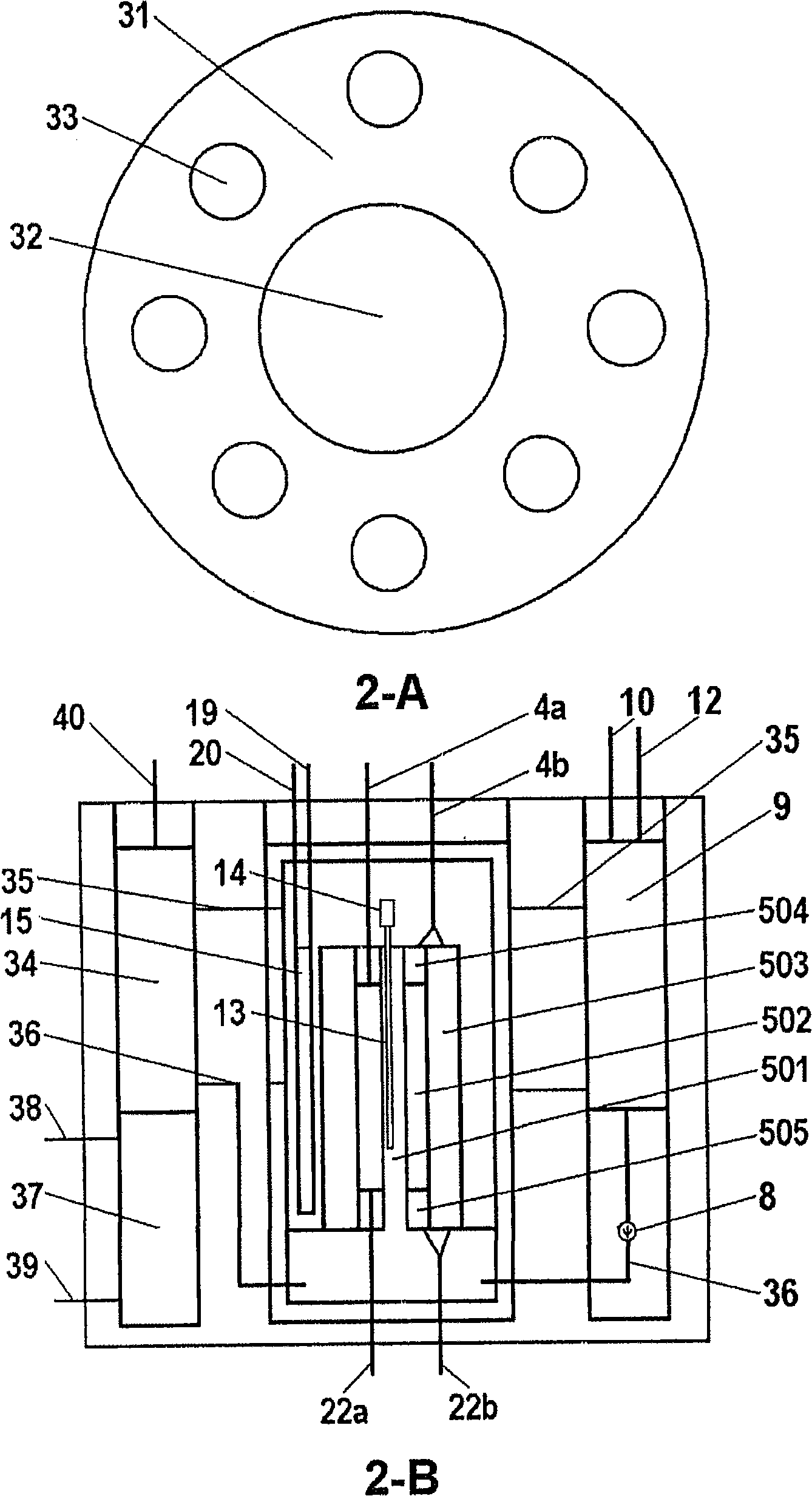

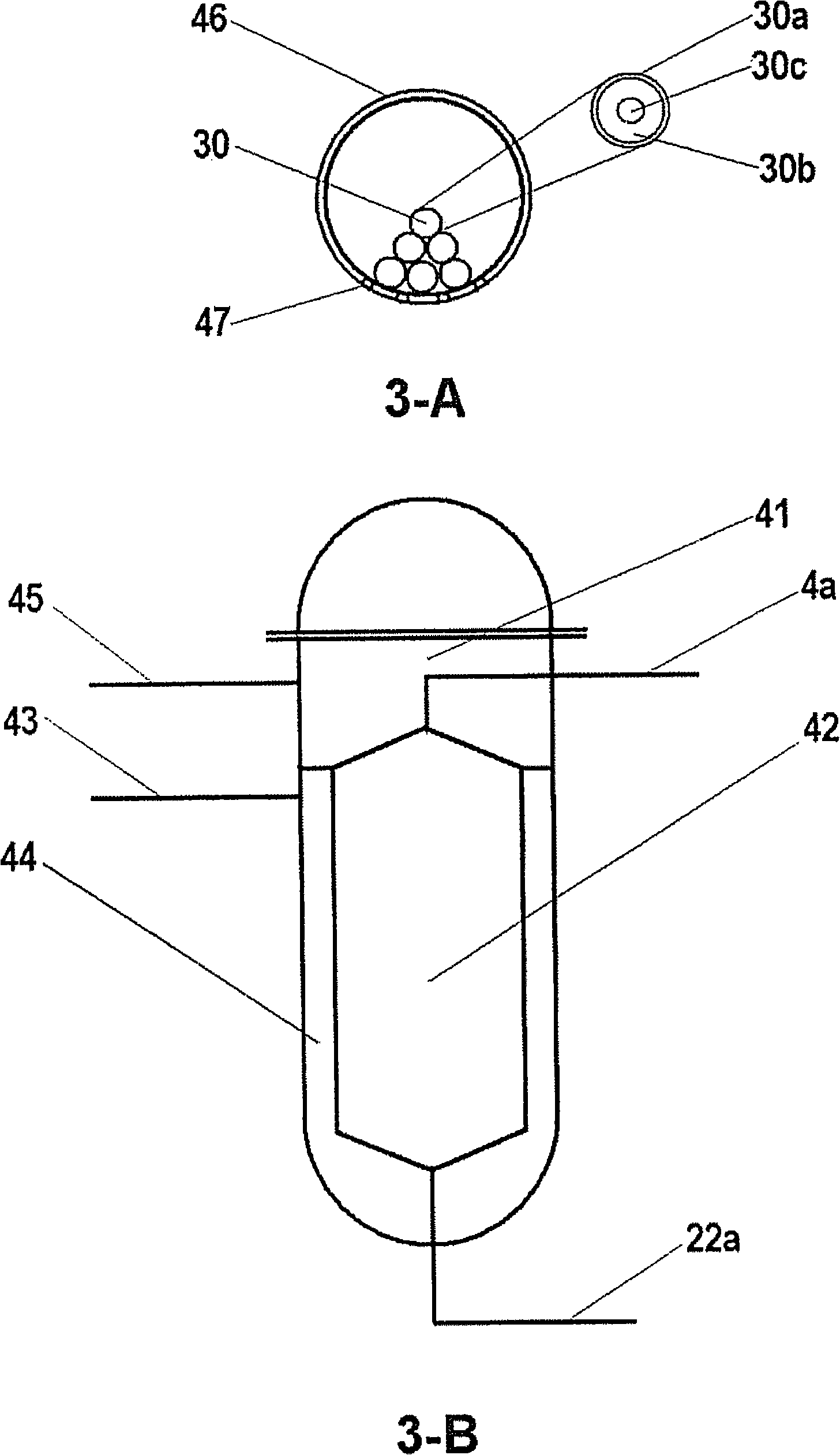

Method and device for fast breeding and converting nuclear fuel

InactiveCN101315815ALow costMeet needsFuel elementsNuclear energy generationInherent safetyNuclear power

The invention discloses a method and a device for fast multiplicating and transforming nuclear fuel with high inherent security and low cost, and the method and the device adopt 'moving solid nuclear fuel' which can flow and is similar to fluid, can be applied in a fast neutron reactor, and produce more nuclear fuel with less fissile fuel initial installation quantity and lower cost in a shorter time, thus satisfying the nuclear fuel demand at the current world nuclear power big development stage. The method and the device for fast multiplicating and transforming nuclear fuel are real nuclear reactors with inherent security, and can thoroughly eliminate the serious accident of massive radioactive release caused by element melting of the nuclear fuel which still possibly occurs in the current nuclear power station.

Owner:吕应中

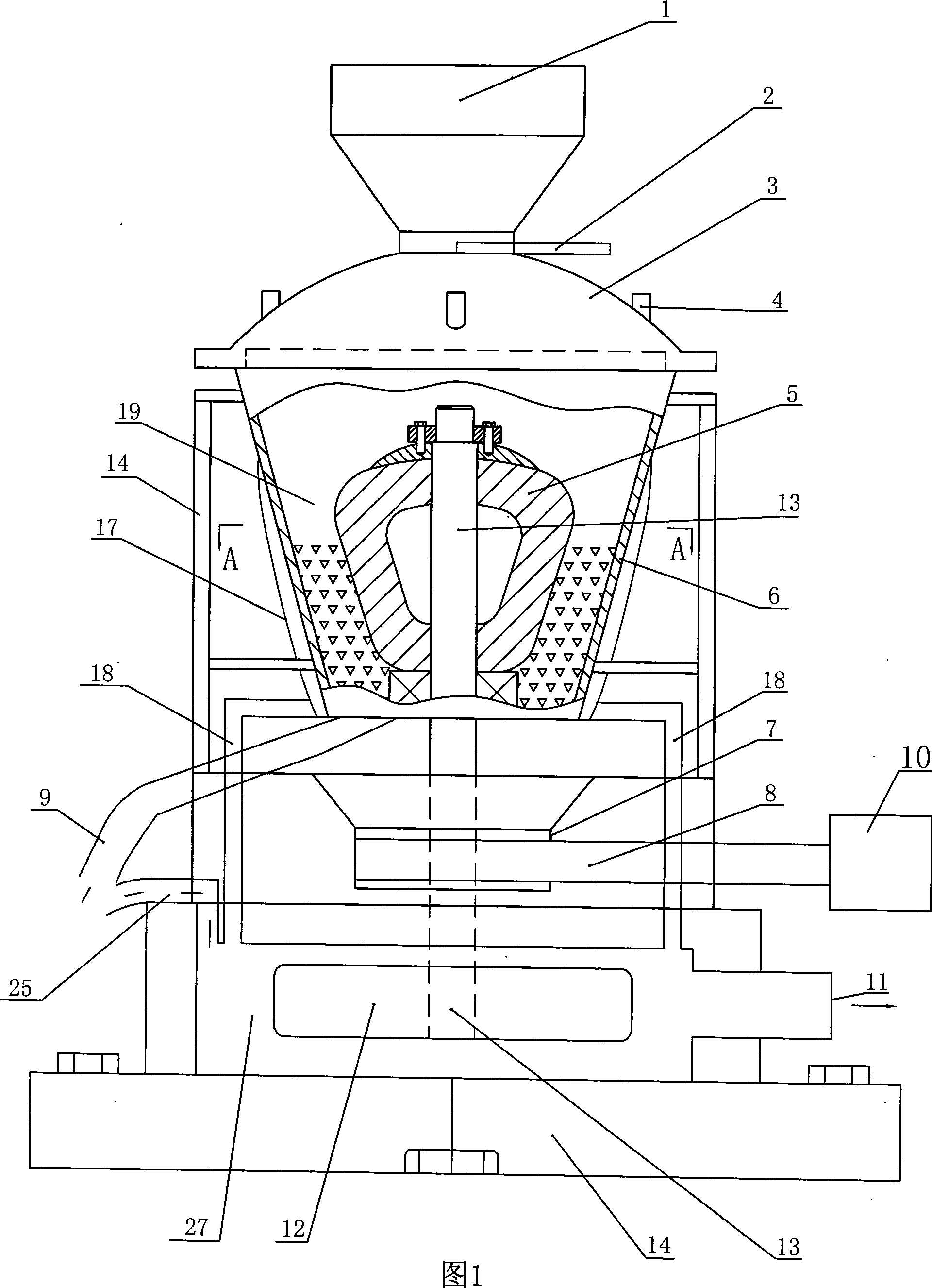

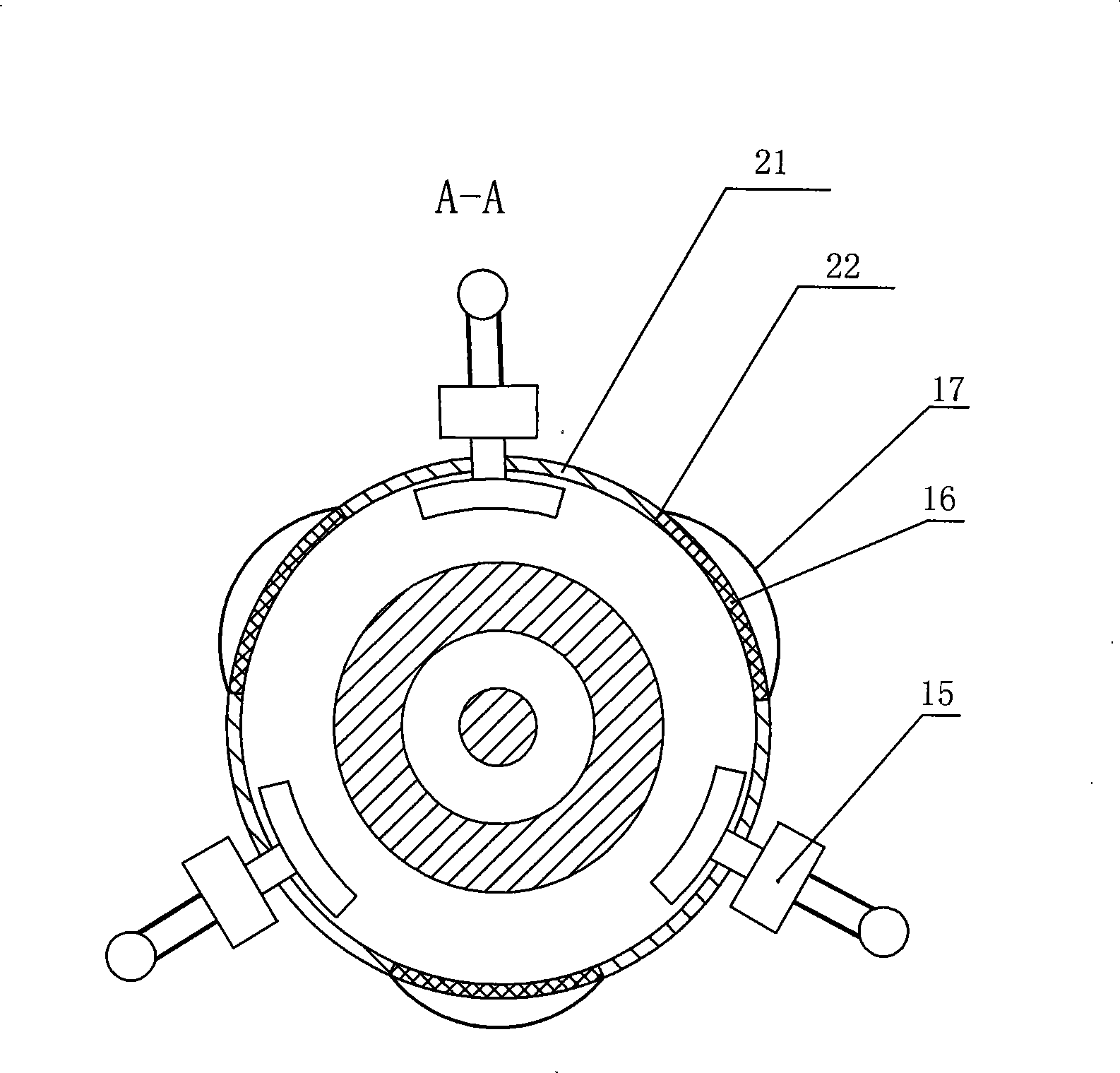

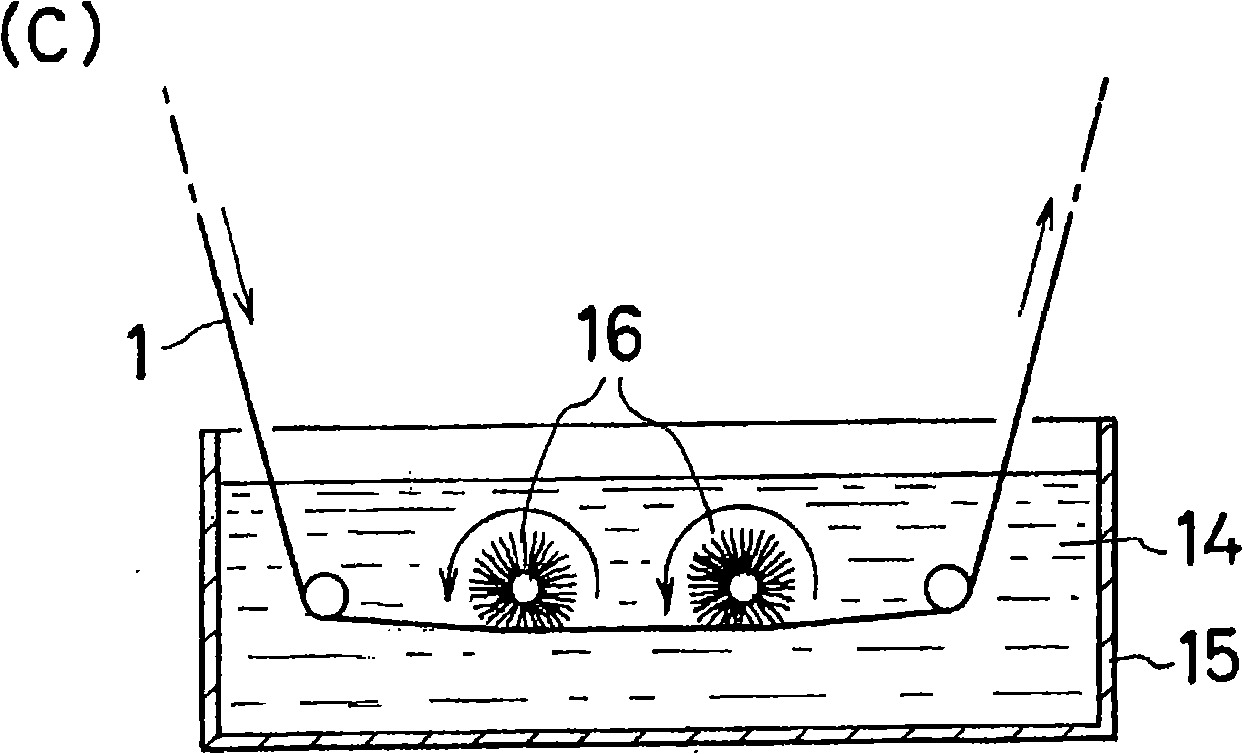

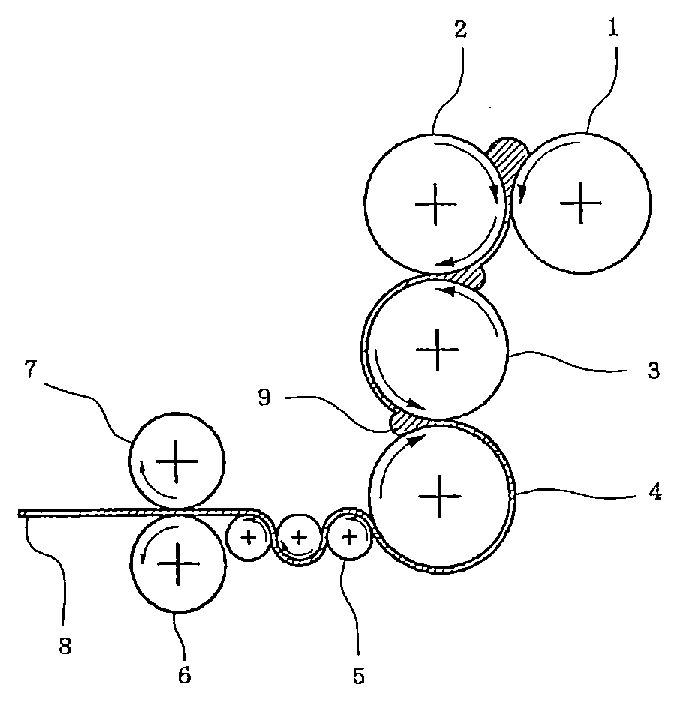

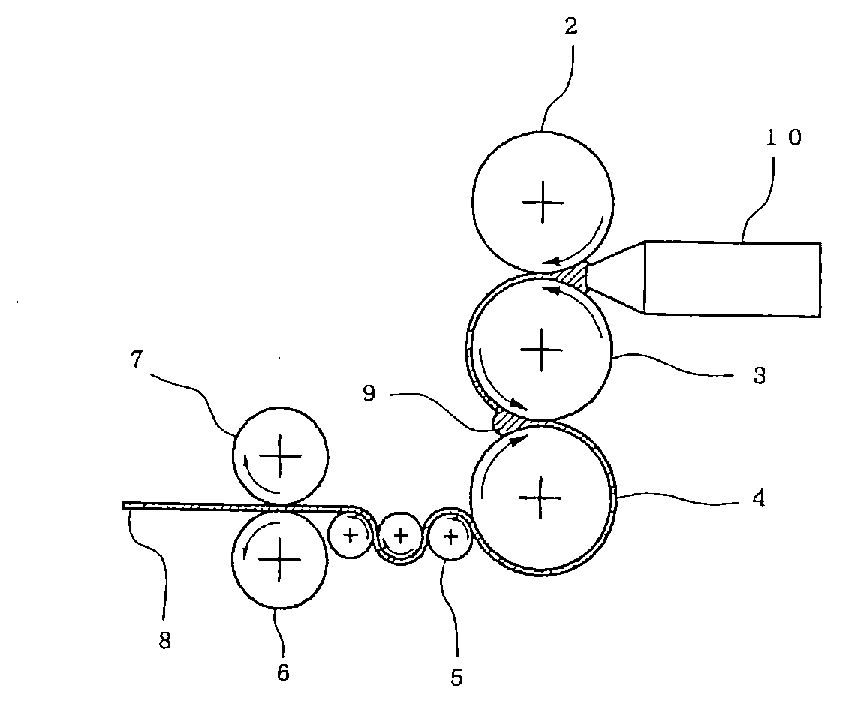

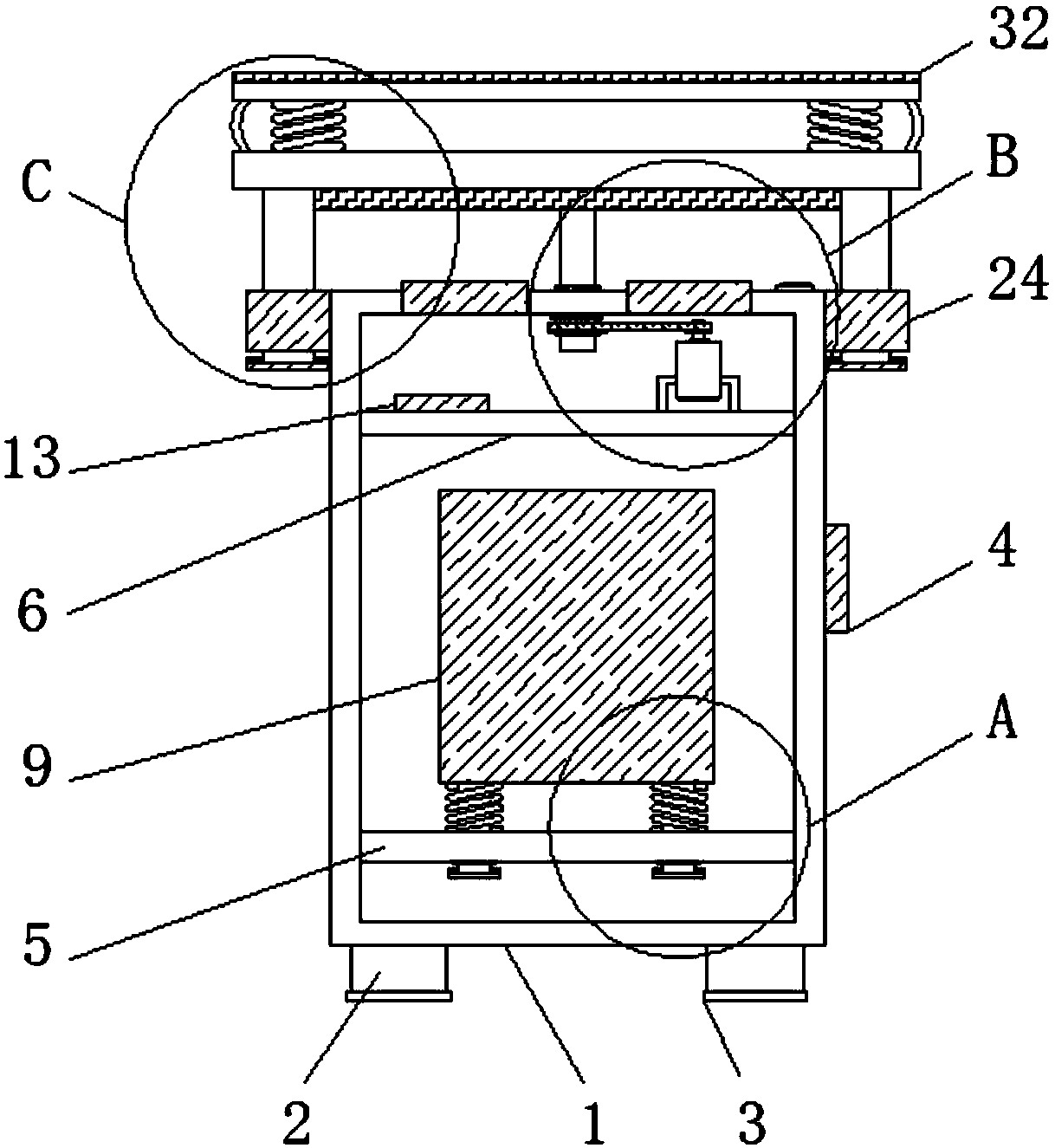

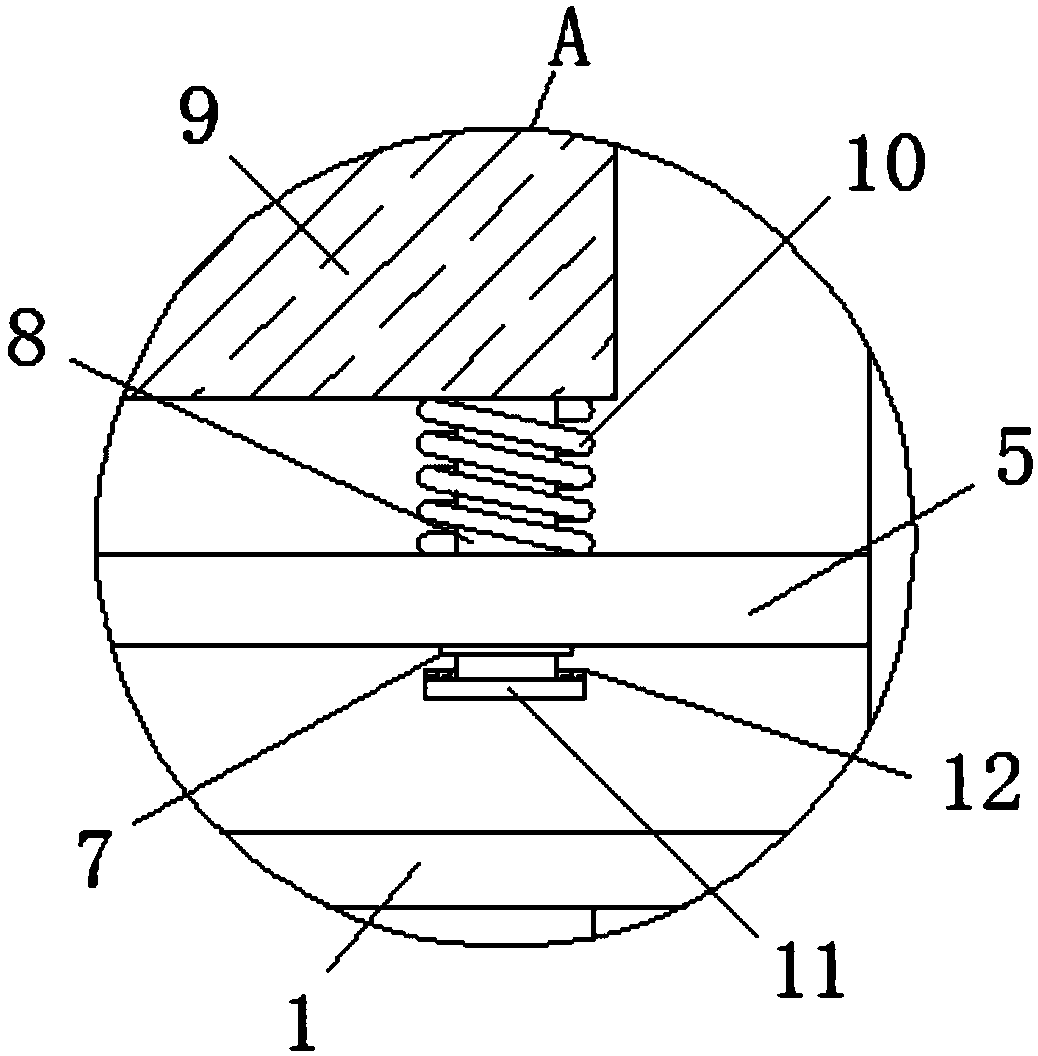

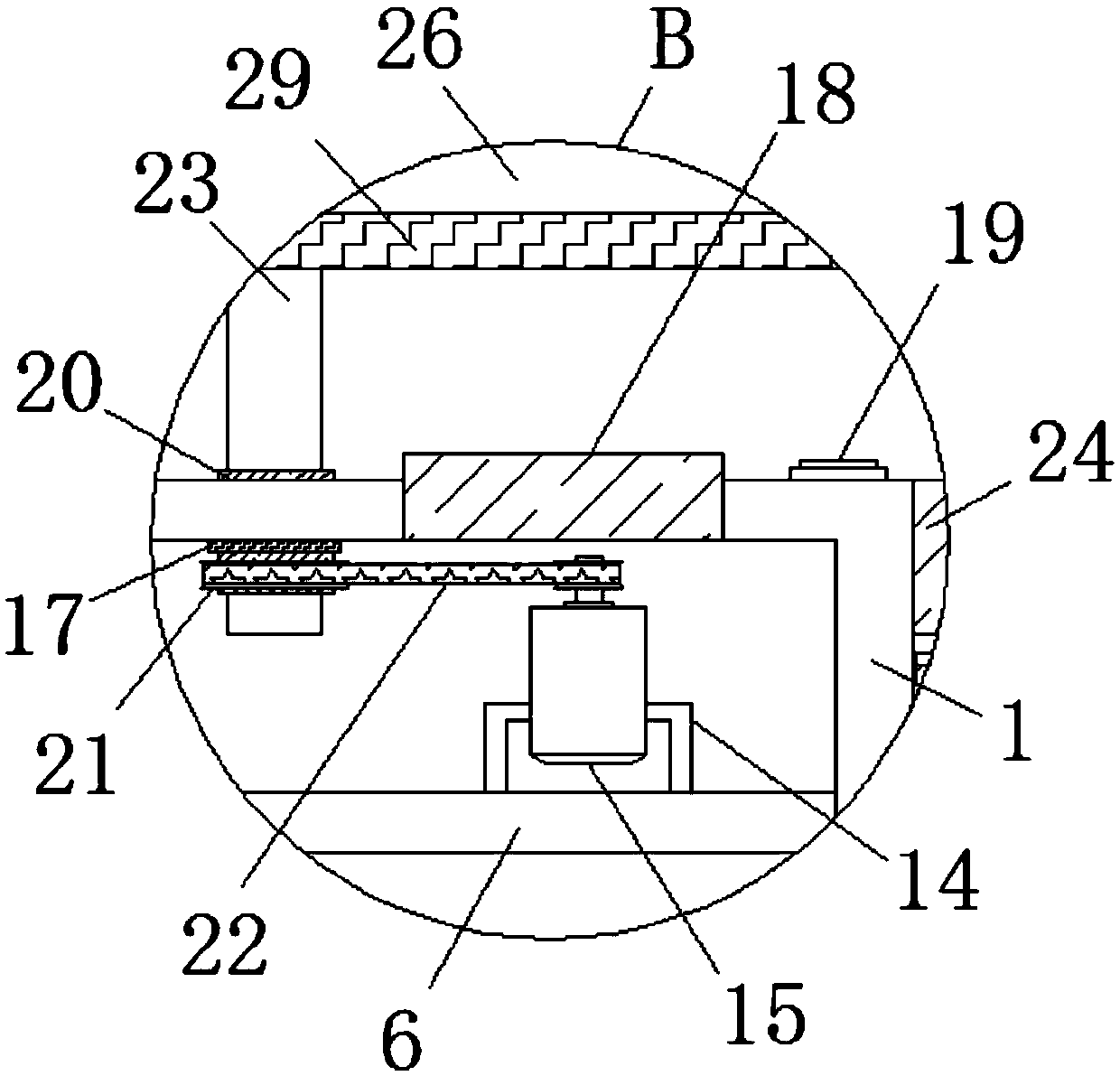

Method for peeling fresh kernel corn and machine for peeling quick freezing fresh kernel corn

ActiveCN101433363AGood peeling effectNo loss of nutritionSeed preservation by freezing/coolingVegetable peelingQuick FreezeHardness

The invention relates to a shelling method for fresh corn kernels and a quickly frozen fresh corn kernel sheller. The invention relates to the shelling method and the sheller. The invention solves the problem that the prior common grain sheller can not shell the fresh corn kernels. The shelling method comprises the following main steps: the fresh corn kernels are selected, stored and shelled in an environment of -40 to -30 DEG C and shelled after enzyme deactivation treatment and threshing; and the temperature in a grind cavity of the quickly frozen fresh corn kernel sheller is kept below -5 DEG C and chaff is removed. A grinding wheel (5) is arranged inside a grinding vessel (6); and at least one cooling air inlet (4) is arranged on a sealing cover (3). The fresh corn shelled through the method has good shelling effects and does not lose the nutrition of the fresh corn; the quickly frozen fresh corn kernel sheller is provided with the cooling air inlet, thereby having good heat dissipation effect, ensuring that the quickly frozen fresh corn kernels are not unfrozen by frictional heat during the process of shelling through mechanical friction, and consequently ensuring the hardness of the quickly frozen fresh corn kernels.

Owner:辽宁富安农业发展有限公司

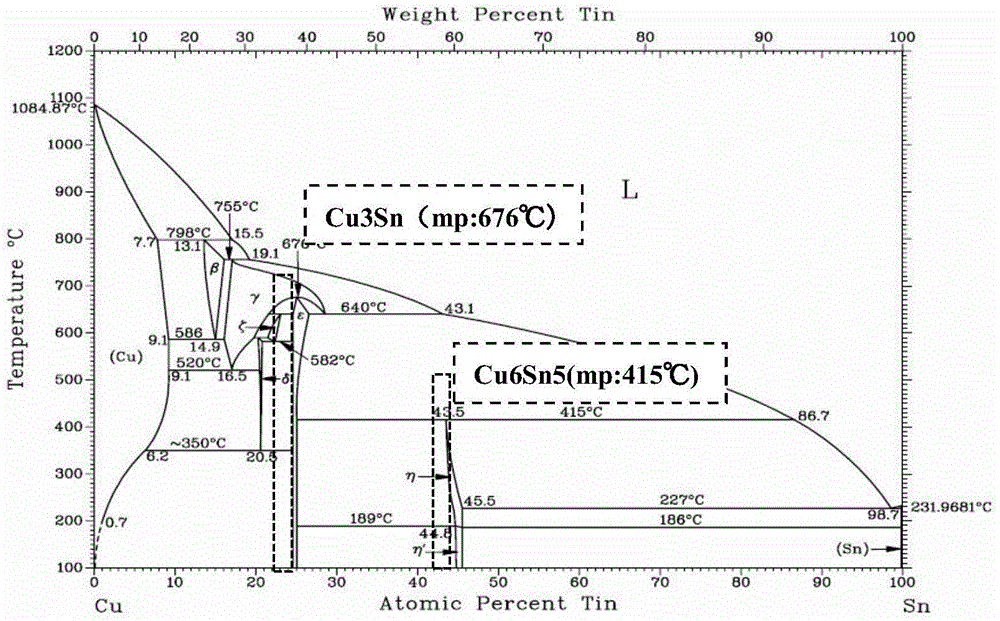

Lid for functional part and process for producing the same

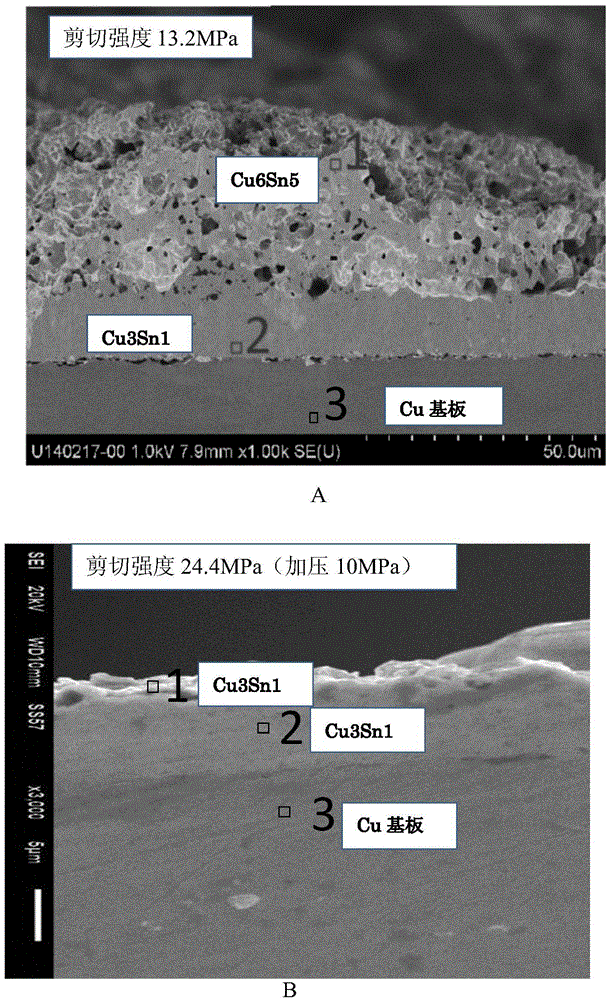

ActiveCN101529583ANo offsetEasy to manufactureHot-dipping/immersion processesSemiconductor/solid-state device detailsSolderabilityCopper

The invention provides a solder layer as a substitute for a high-temperature solder which bonds a functional-part package to a lid and has a solidus temperature of 250 DEG C or higher. It is obtained by: applying a solder paste obtained by mixing a copper-based metal powder having a solidus temperature of 400 DEG C or higher with a tin-based solder powder to a lid made of a material difficult to solder and plated beforehand with a material having excellent solderability; and heating the solder past applied. The solder layer formed on the deposit comprises the copper-based metal powder, an intermetallic compound of Cu6Sn5, and the lead-free solder. This solder layer functions as a high-temperature solder because the intermetallic compound is bonded to the material difficult to solder and particles of the intermetallic compound are connected to one another. Although high-temperature solders have poor soldering properties, this problem can be avoided with the solder layer.

Owner:SENJU METAL IND CO LTD

Electric deicing pickaxe and deicing method

ActiveCN105680398AControl cycleReduced strengthOverhead installationApparatus for overhead lines/cablesElectricityProtection mechanism

The invention discloses an electric deicing pickaxe and a deicing method. The electric deicing pickaxe comprises an insulating rod and a shell, wherein the shell is arranged on the insulating rod; a coil is arranged in the shell; an iron core is arranged in the coil; a sliding armature is arranged in the iron core; a return spring sleeves the sliding armature; a deicing shovel which extends out of the shell is arranged at the upper end of the sliding armature; and a deicing guide line protection mechanism is arranged on the shell. By the electric deicing pickaxe, a power failure is not needed in the deicing process; and a high voltage does not harm an operator.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Insulator for bare-packing and sintering ceramics to be stacked in multi-layered manner and application method thereof

The invention relates to an insulator for bare-packing and sintering ceramics to be stacked in a multi-layered manner and an application method thereof. The insulator comprises the following raw materials in parts by weight: 35-60 parts of quartz particles with 32-100 meshes, 40-65 parts of calcined Al2O3 or quartz particles with 100-140 meshes and 0.5-2 parts of peach gum or carboxyl methyl cellulose (CMC). The application method comprises the following steps during the preparation: firstly, dissolving the peach gum or the carboxyl methyl cellulose by using water with a weight ratio of 6-20 times, then adding the proportioned other raw materials, and finally, adding an appropriate amount of water to mix into thin paste. When in use, the insulator is sprayed, coated or brushed on the surfaces of stacked parts of ceramic tire products; and after the insulator is naturally aired, the same shape or different shapes of a plurality of layers of or a plurality of ceramic tire products are vertically stacked on sintered kiln furniture on a same plane to be sintered, and the sintering temperature is 1200-1280 DEG C. After the ceramics are sintered, viscose compositions in the ceramics aredecomposed and evaporated, and the quartz particles and the calcined Al2O3 particles are only remained among the ceramic tire products and can not be melted or bonded with ceramic tires, so that the purpose of dividing and separating the vertically-stacked and sintered ceramic tire products is achieved.

Owner:潮州市美地陶瓷有限公司

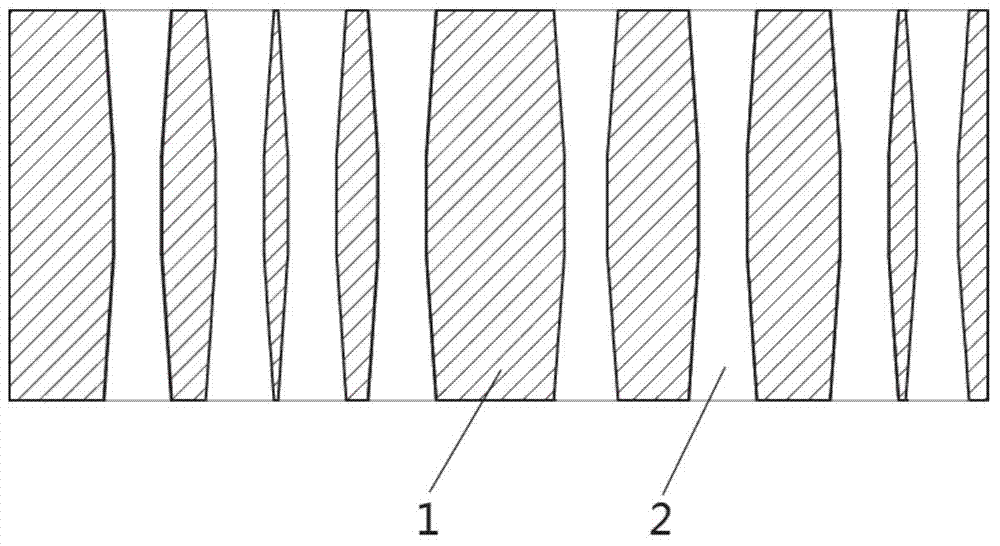

High-temperature-resistant lithium battery diaphragm and production method thereof

InactiveCN103928648AImprove heat resistanceSolving Etching ProblemsCell seperators/membranes/diaphragms/spacersHeat resistanceEngineering

The invention belongs to the technical field of battery diaphragms, and discloses a high-temperature-resistant lithium battery diaphragm and a production method thereof. A base material of the high-temperature-resistant diaphragm is a polyimide thin film, and micropores are uniformly formed in the base material. The production method comprises the steps of irradiating the polyimide thin film by heavy ions, and etching the irradiated polyimide thin film through a sodium hypochlorite solution. The high-temperature-resistant lithium battery diaphragm and the production method thereof have the advantages that the heat resistance is high, the tensile strength is high, environment pollution is avoided, the micropores are uniformly distributed, and high-current quick charging and discharging requirements for a lithium battery are met.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Sn-Cu high-temperature lead-free soldering paste, preparation method thereof and application method thereof

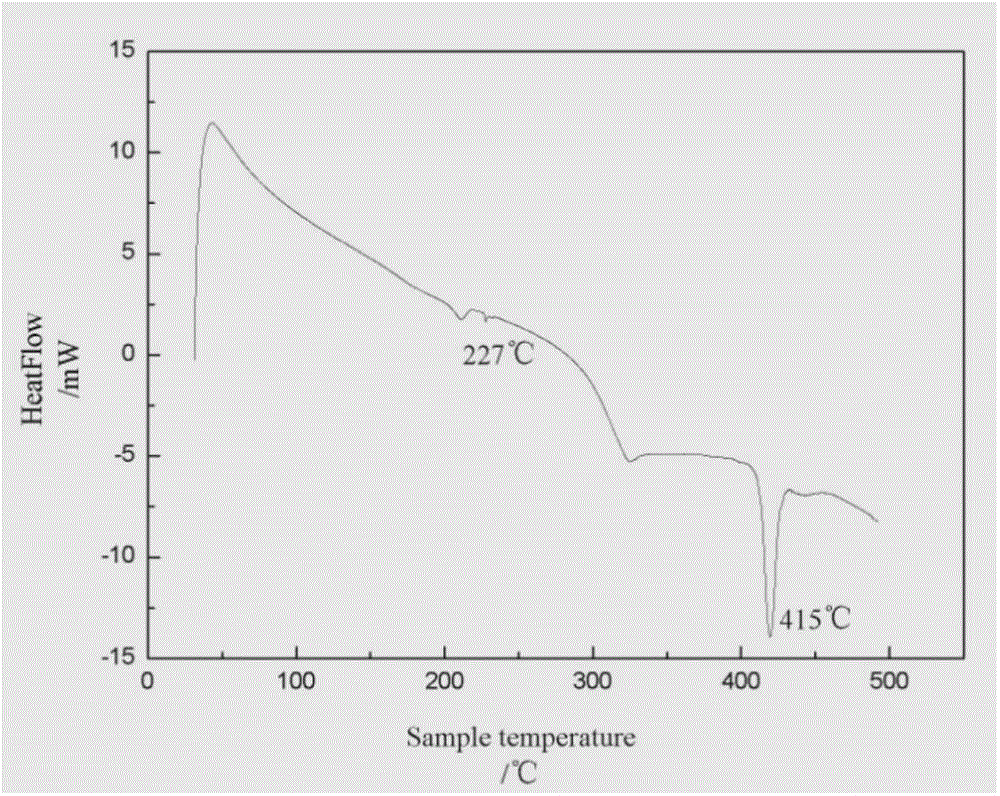

InactiveCN104588906AImprove mechanical propertiesWon't meltWelding/cutting media/materialsSoldering mediaEnvironmental resistanceWorking temperature

In order to solve the problems that soldering paste which is environmentally friendly, low in cost and reliable in welding joint under a high-temperature working environment does not exist at present, the invention provides a Sn-Cu lead-free soldering paste, a preparation method of the soldering paste and an application method of the soldering paste and belongs to the field of electronic packaging materials. The soldering paste is composed of tin powder, copper powder and rosin flux. The preparation method includes the steps that the rosin flux is added into the tin powder and the copper powder; next, the tin powder and the copper powder are mechanically mixed through a blender mixer for 10-15 min at the speed of 1,000-1,800 turns / min, and then the soldering paste is obtained. When the working temperature in the air is lower than 350 DEG C, the welding seam shear strength of the high-temperature lead-free soldering paste is greater than or equal to 10 MPa. If pressure of 5-10 MPa is exerted from the outside in the heat treatment process of a welding piece, the welding seam shear strength of the high-temperature lead-free soldering paste is greater than or equal to 20 MPa. The use temperature of samples welded through the soldering paste can reach as high as 400 DEG C, and the soldering paste is high in welding seam shear strength, simple in welding process, stable in performance and low in cost.

Owner:NORTHEASTERN UNIV +1

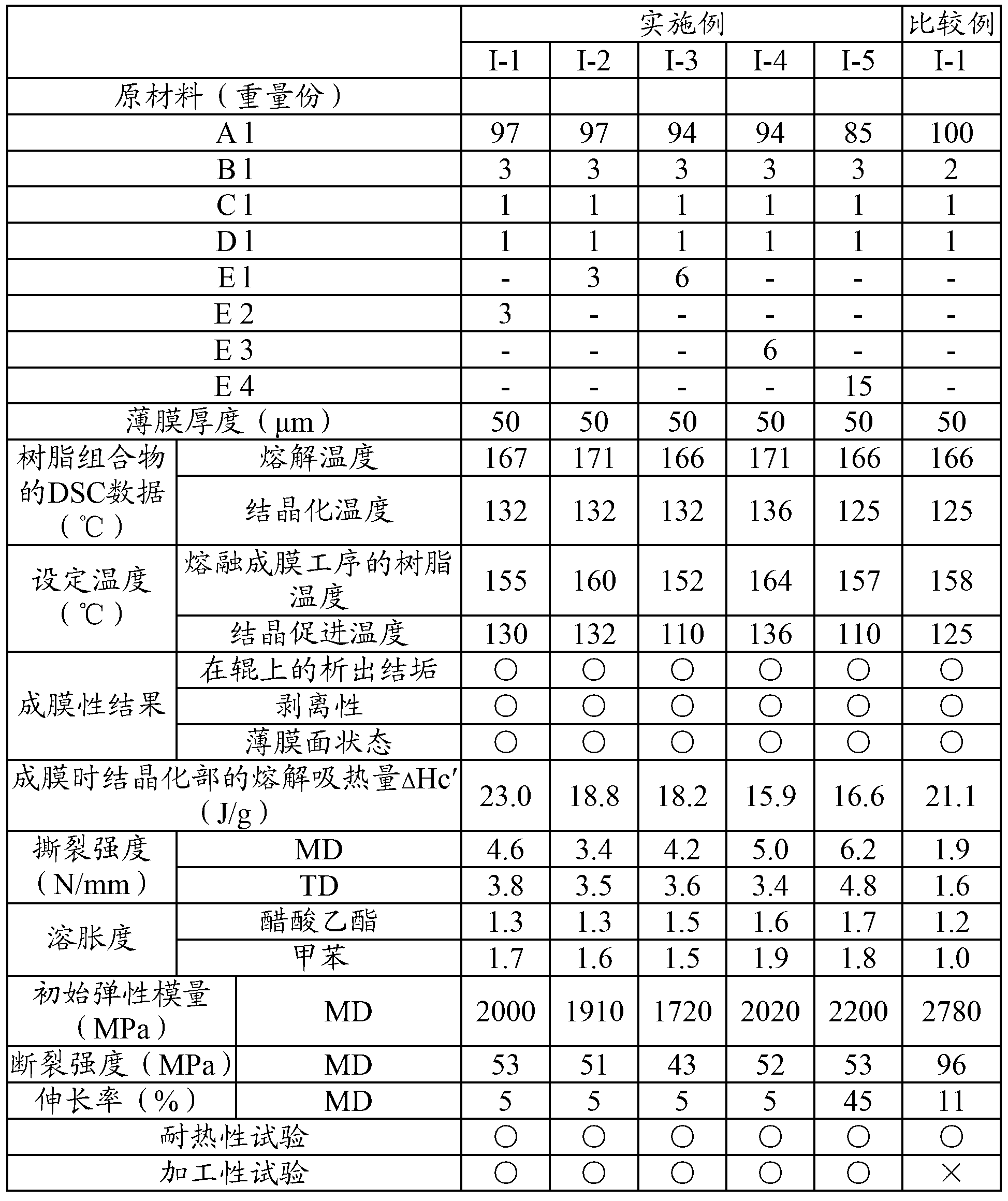

Polylactic acid film or sheet

A polylactic acid film or sheet is a resin film or a sheet containing polylactic acid (A), wherein the melting endothermic value (delta HC') in a crystallization section at the time of film-forming, which is called for by formula (1) delta HC'= delta Hm- delta Hc (1) (In the formula, delta HC is the exothermic value (J / g) accompanied with crystallization in the heating process of the film or sheet after film-forming, and is measured using a DSC; delta Hm is the endothermic value (J / g) accompanied with the melting thereafter.), is 10J / g or more, and a tearing strength in a flow direction (MD direction) and a width direction (TD direction) both are 2.5N / mm or more. This polylactic acid film or sheet does not melt or deform even at temperatures exceeding 100 DEG C, and furthermore, during production and machining of the film or sheet, no breakage or tearing, when the film or the sheet is rolled into a roll or the like, happans.

Owner:NITTO DENKO CORP

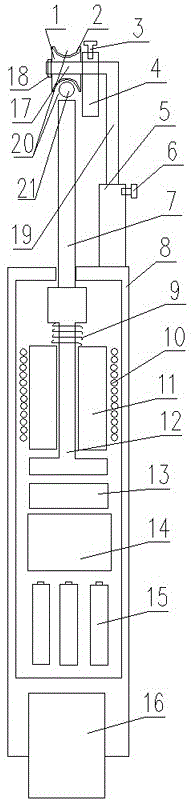

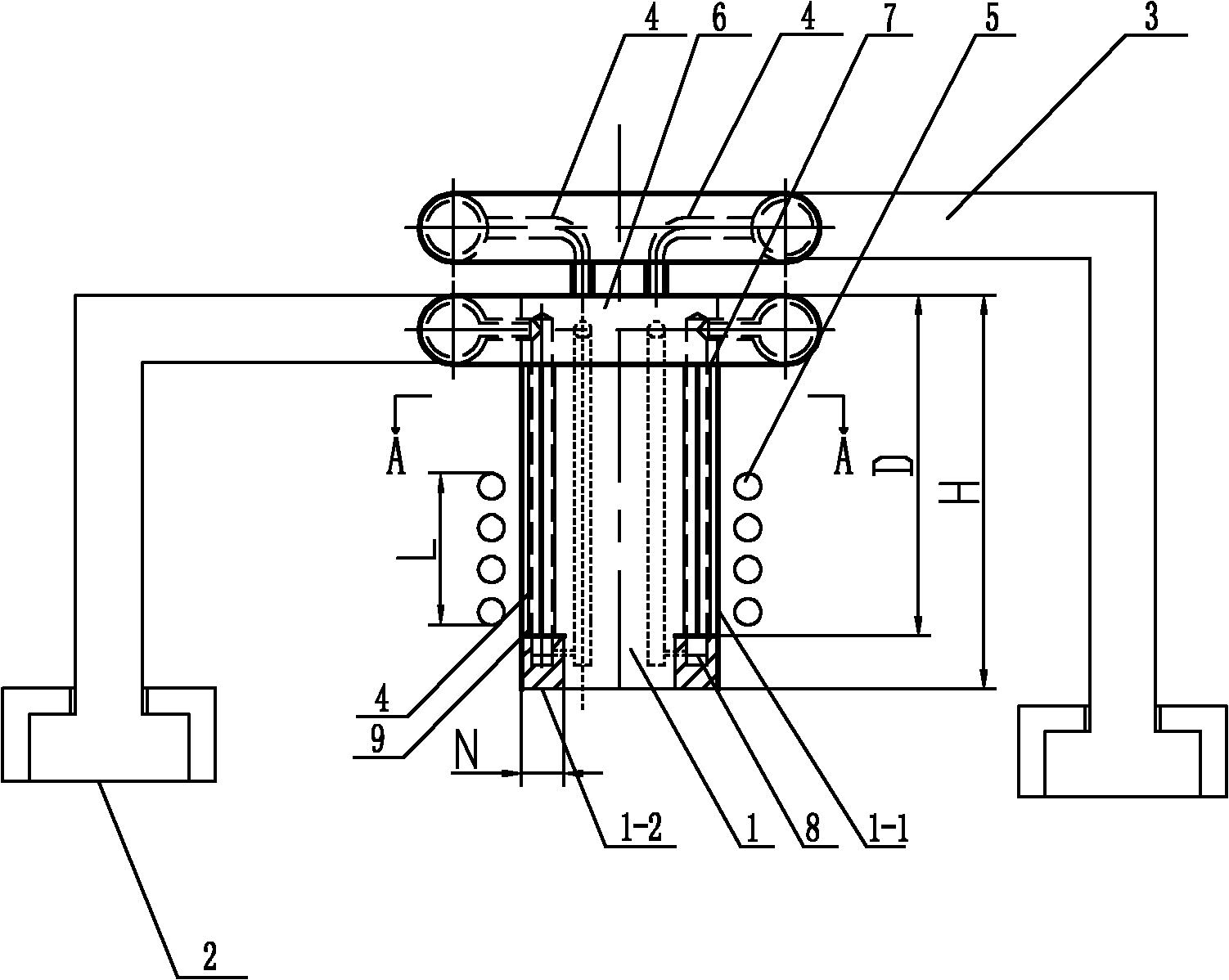

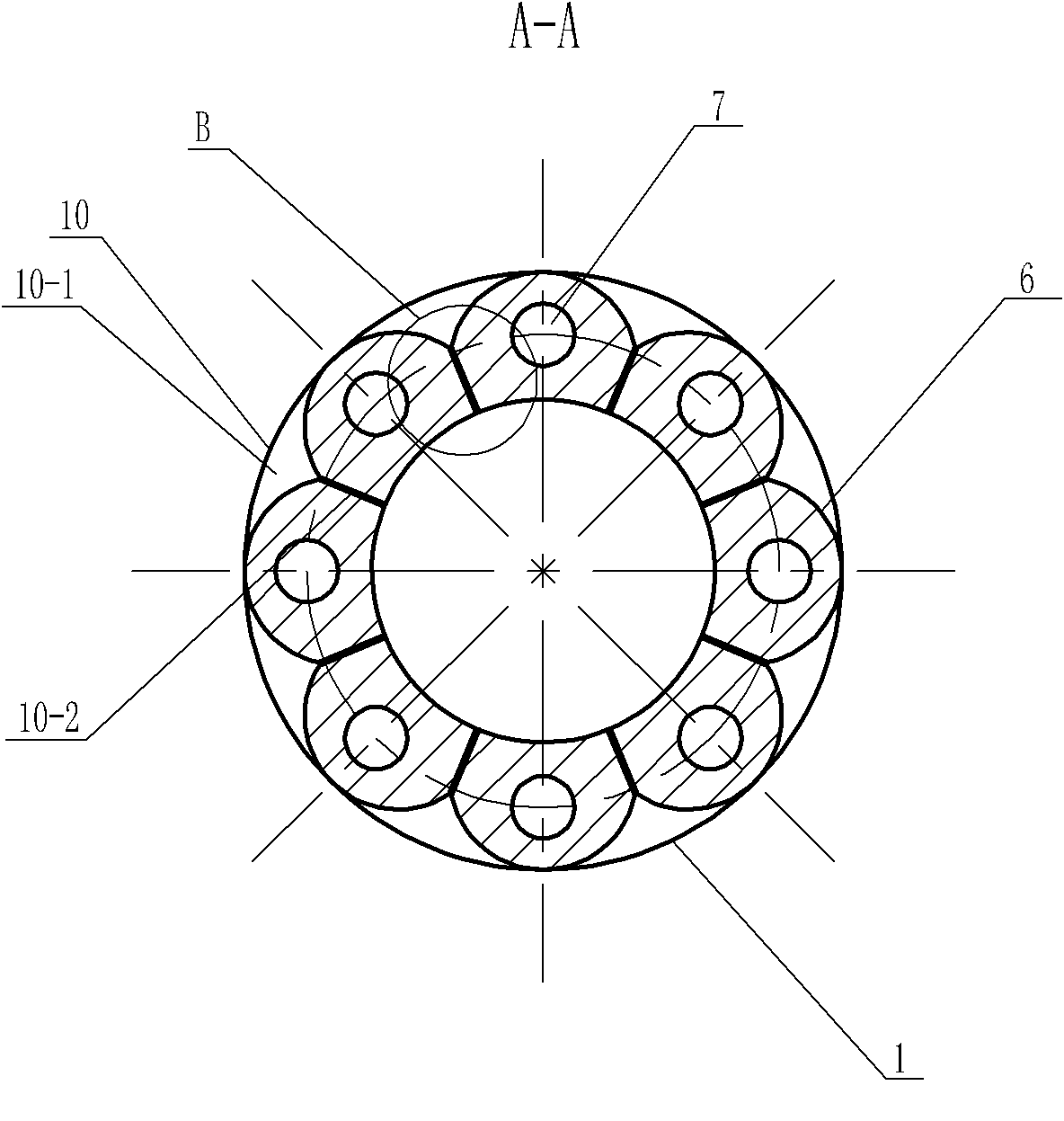

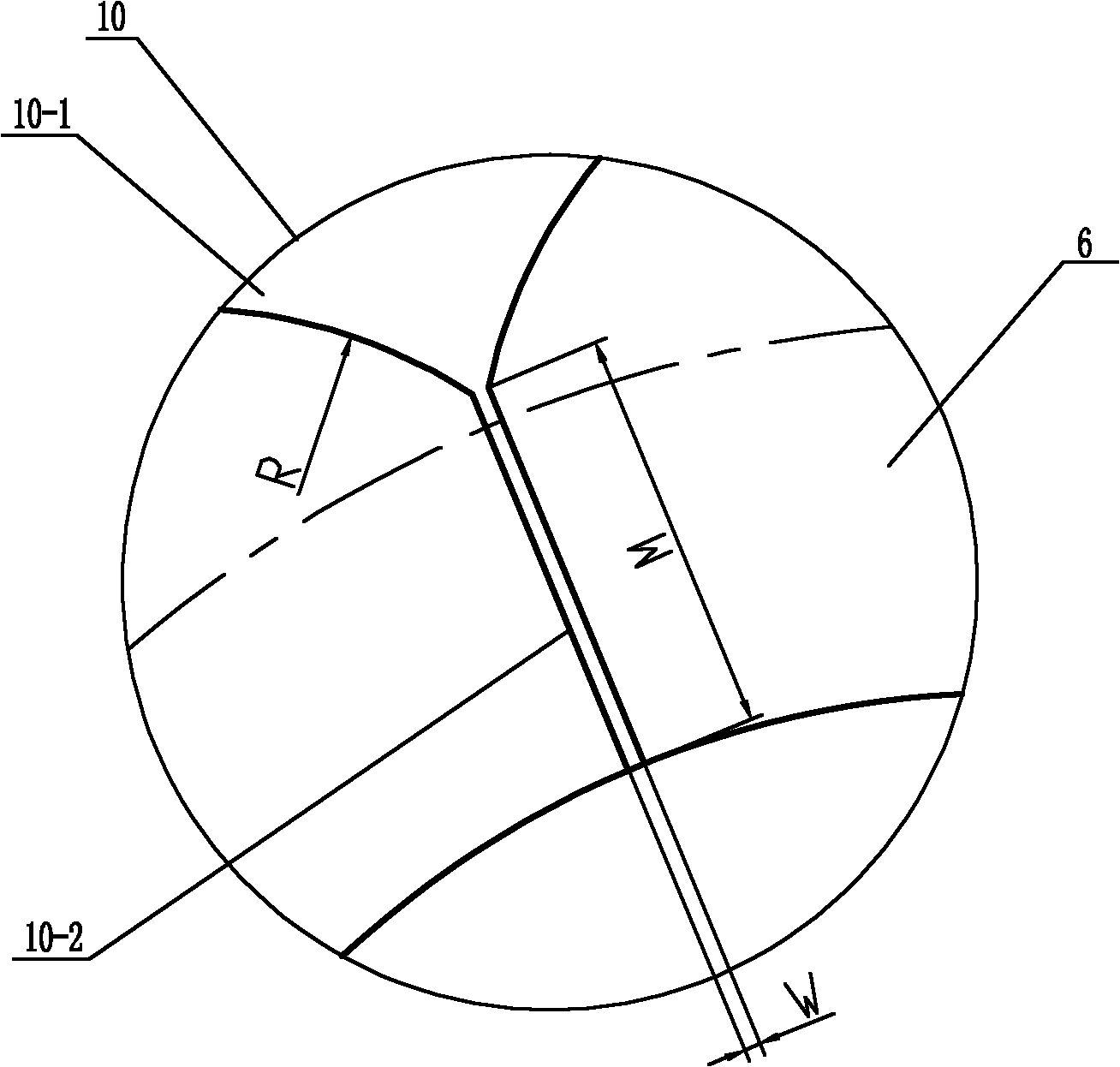

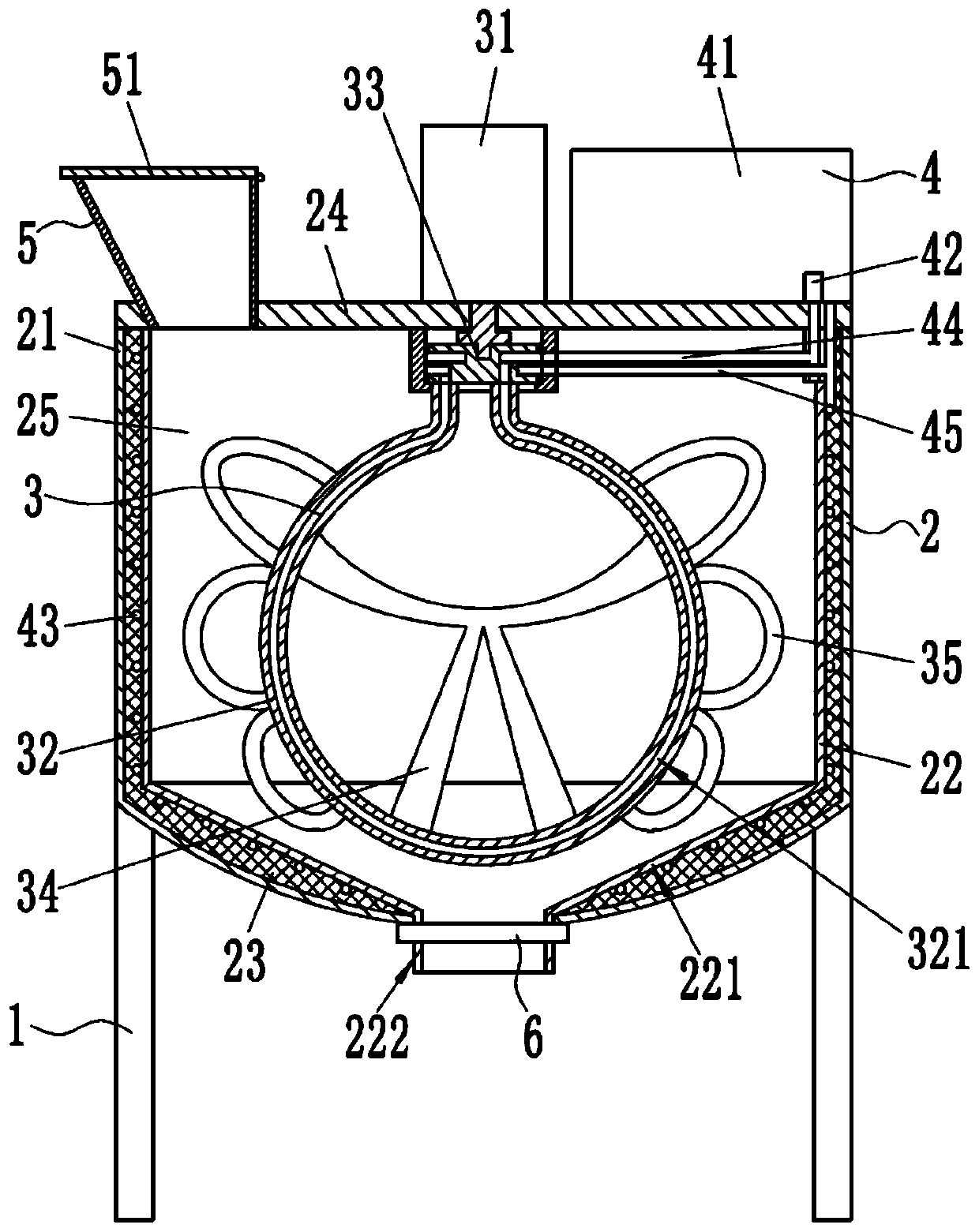

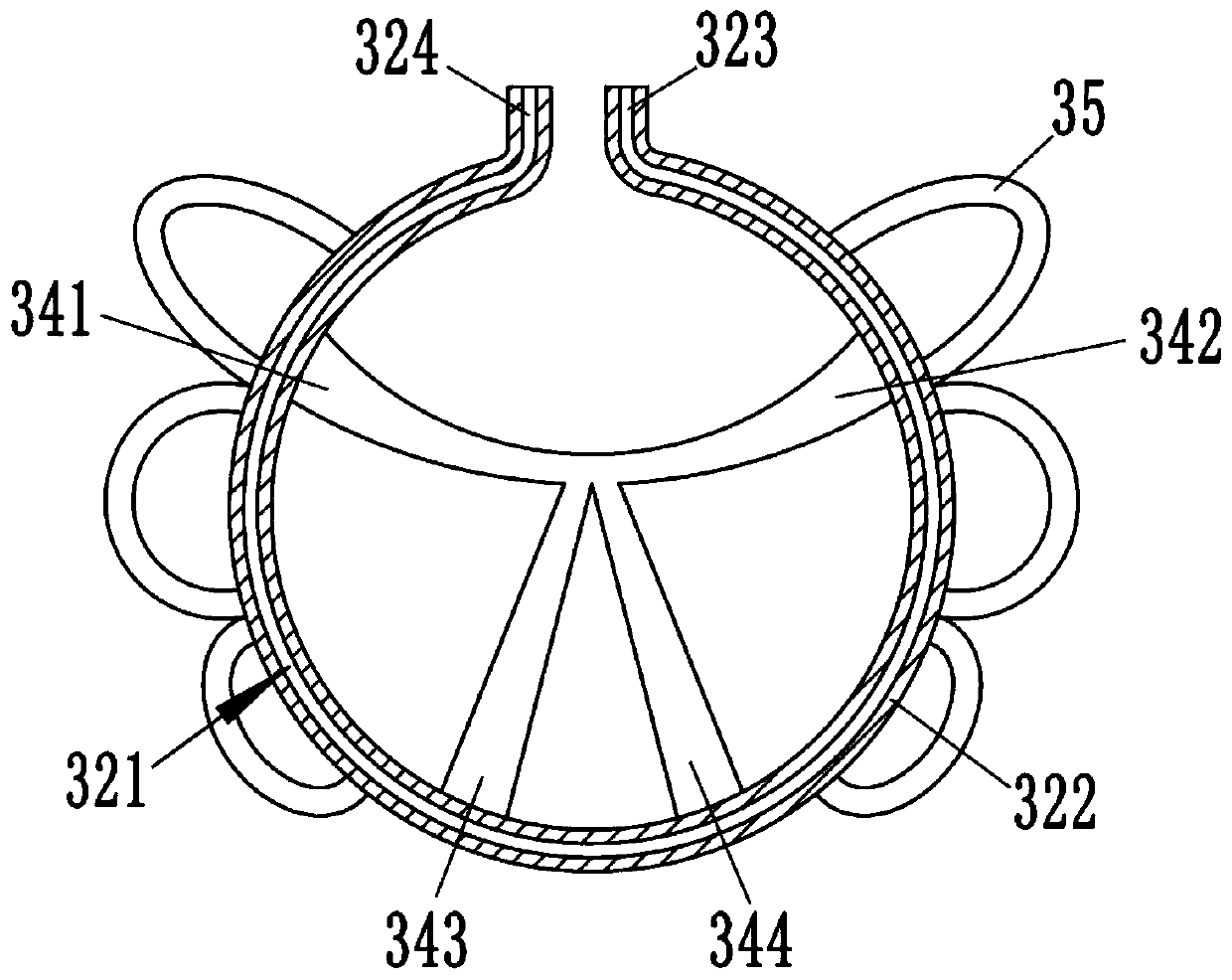

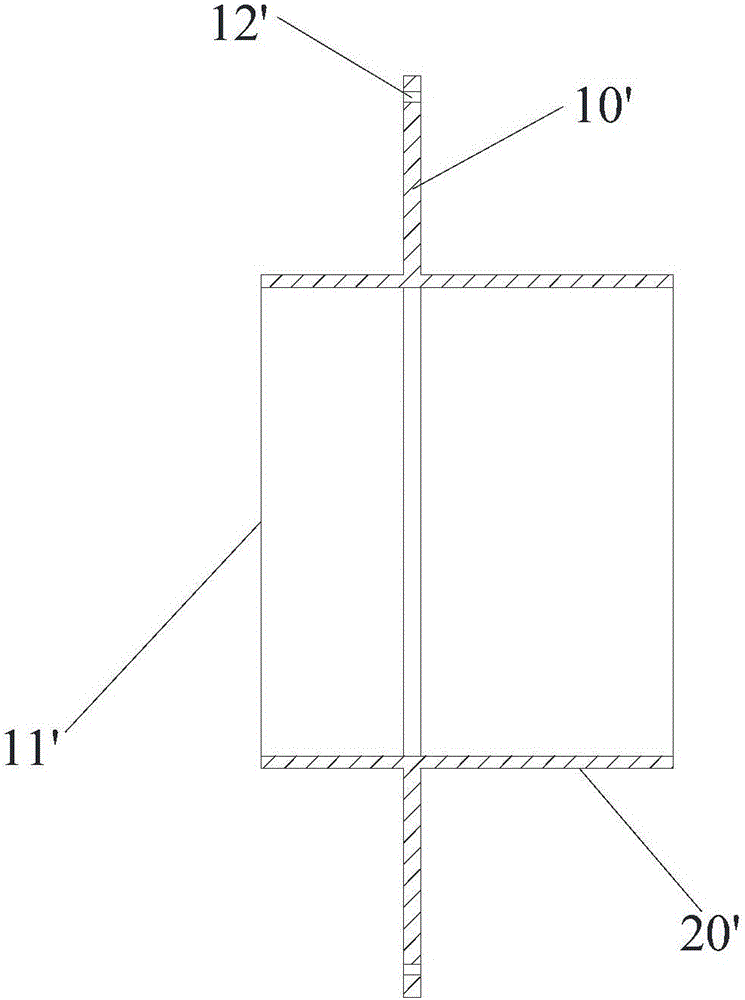

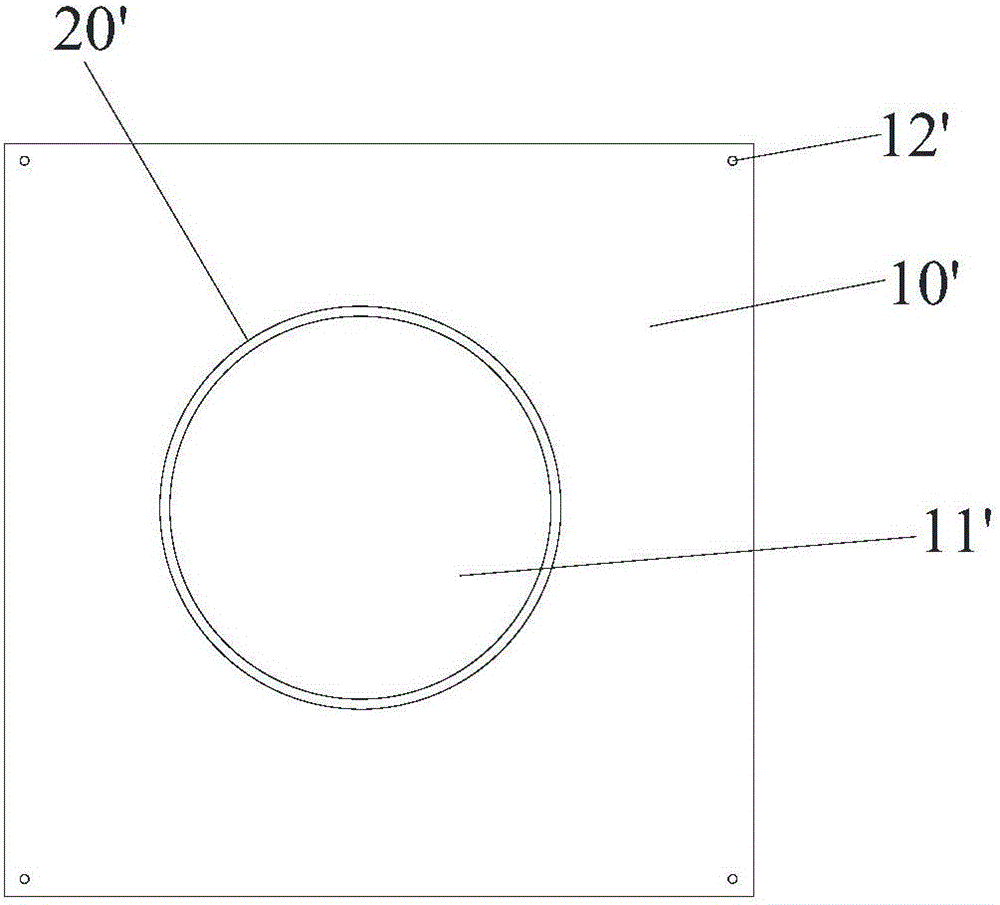

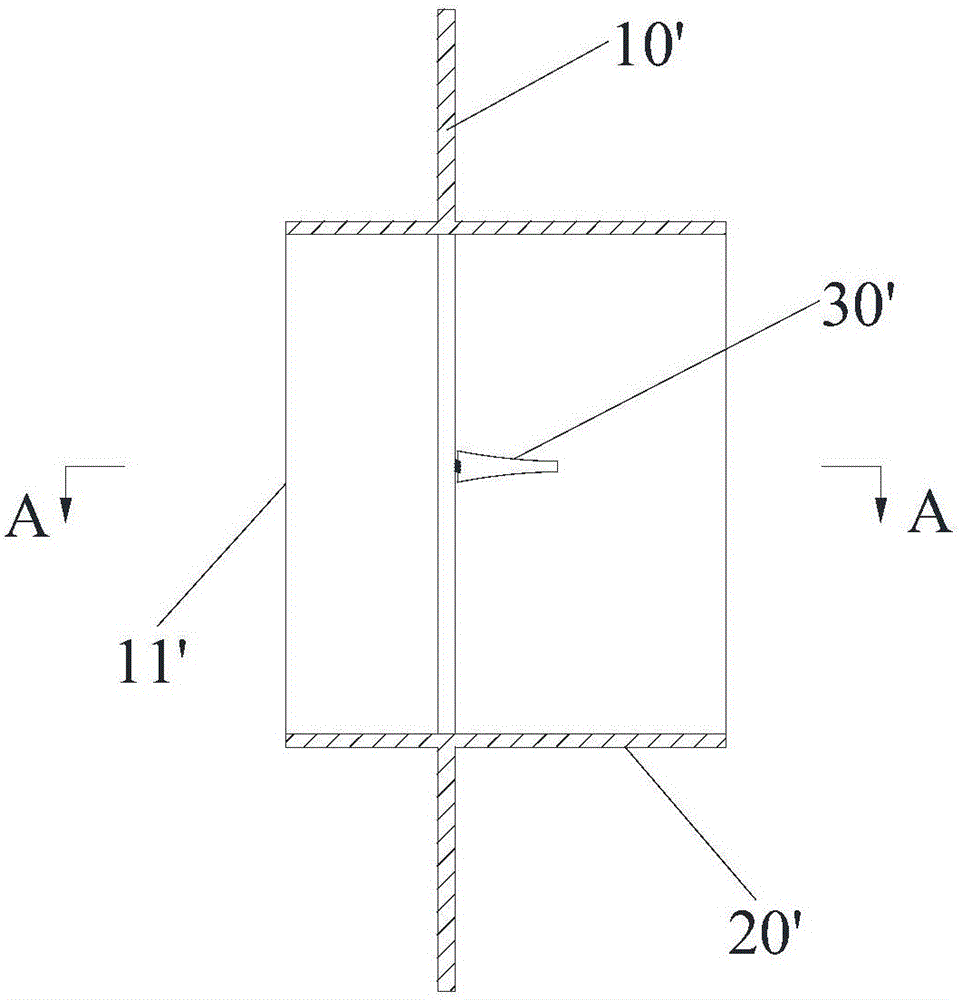

Cold crucible for directional solidification of magnetic AlNiCo alloy

InactiveCN102174707AImprove magnetic permeabilityIncrease profitEutectic material solidificationCrucibleDirectional solidification

The invention discloses a cold crucible for directional solidification of magnetic AlNiCo alloy, relating to a cold crucible. The invention aims to solve the problems that when the existing cold crucible is used for directional solidification of magnetic alloy, the utilization rate of energy is low, and the side heat dissipation cannot have well thermal compensation, thereby resulting in discontinuous columnar crystals. The outer wall of the upper half of the cold crucible is divided into eight cylinders with arc petal-shaped sections, an opening seam is arranged between every two adjacent cylinders with the arc petal-shaped sections, the arc radius of each arc petal-shaped cylinder is 9 mm, the opening seam length of the opening seam is 4 mm, the opening seam width is 0.5 mm, a through hole is arranged inside each cylinder with the arc petal-shaped section, every odd number of cooling connection water pipe in eight cooling connection water pipes is communicated with a water inlet pipe, every even number of cooling connection water pipe in the eight cooling connection water pipes is communicated with a water outlet pipe, the height of the main body of the crucible is 110mm-130mm, and the wall thickness of the main body of the crucible is 12mm-15mm. The cold crucible is suitable for directional solidification of magnetic alloy.

Owner:HARBIN INST OF TECH

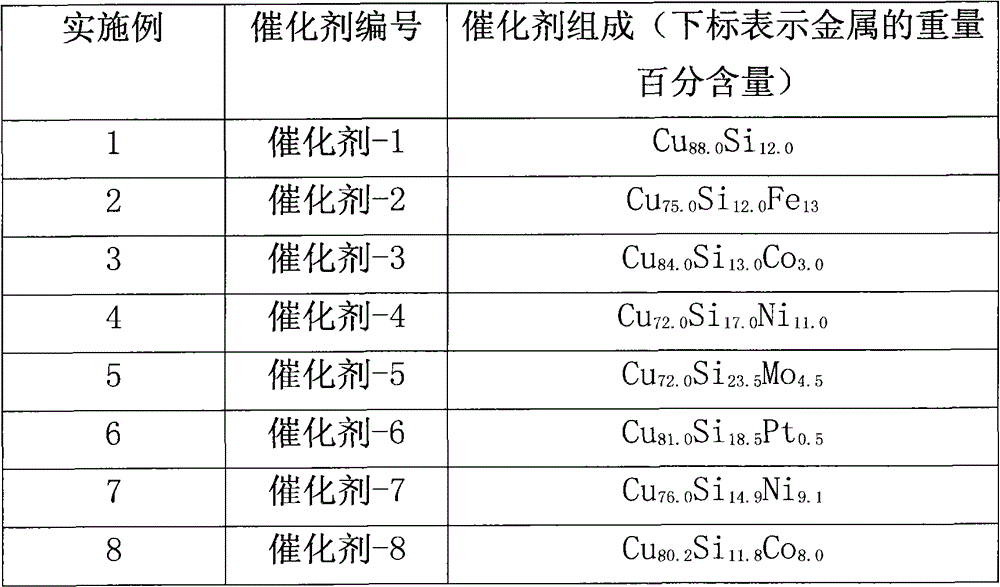

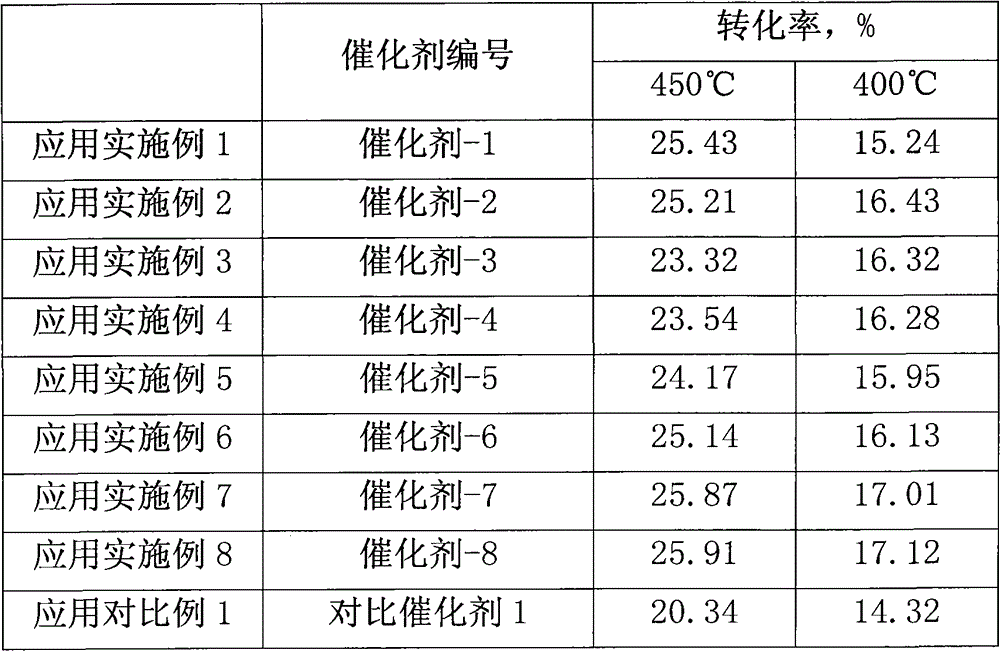

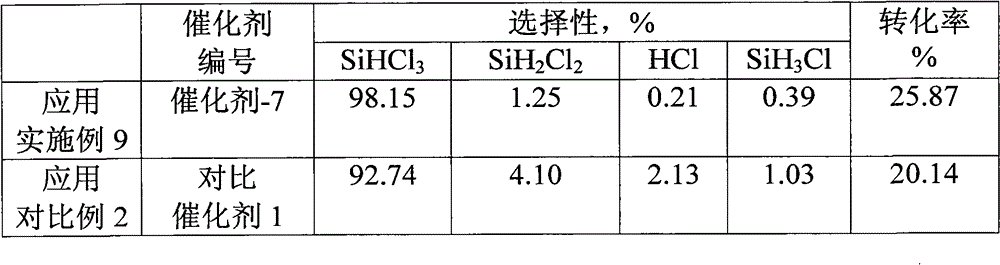

Copper catalyst and preparation method and application thereof

ActiveCN103055861AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHalogenated silanesHydrogenation reactionAlloy

The invention discloses a copper catalyst. The copper catalyst is characterized by containing 20-95wt% of copper and 0.5-70wt% of silicon. The catalyst is obtained by heating copper, silicon and / or transition metals until the components are molten, cooling and curing the melt and carrying out extraction treatment on the alloy obtained after curing with an alkali-acid solution to extract part of silicon. The catalyst has higher activity and selectivity than conventional copper catalysts and has good stability when used in the silicon tetrachloride hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant hot melting type colorful pavement crack encapsulating material and preparation process thereof

ActiveCN102391610AExtended service lifeImprove plasticityPaving detailsBuilding insulationsRoad surfaceFurfural

The invention discloses a high-temperature-resistant hot melting type colorful pavement crack encapsulating material and a preparation process thereof. The encapsulating material is obtained by mixing, stirring and shearing the following raw materials in parts by weight: 35-40 parts of furfural extract oil, 3-4 parts of styrene-butadiene-styrene block copolymer, 4-5 parts of ethylene-vinylacetatecopolymer, 23-25 parts of petroleum resin, 3 parts of dioctyl phthalate, 17-21 parts of calcium carbonate, 0.5-1 part of methyl silicone oil and 0.2-0.4 of pigment. Compared with the prior art, the encapsulating material prepared by the process in the invention has the advantages that cost is low, the service life is long, high temperature can be resisted and simultaneously the color and adheringproperty of the encapsulating material are maintained to be the same as those of colorful pavement, and the technical index of the encapsulating material reaches the requirement of highway bituminouspavement regeneration technical regulation (JTGF41-2008).

Owner:河南金欧特实业集团股份有限公司

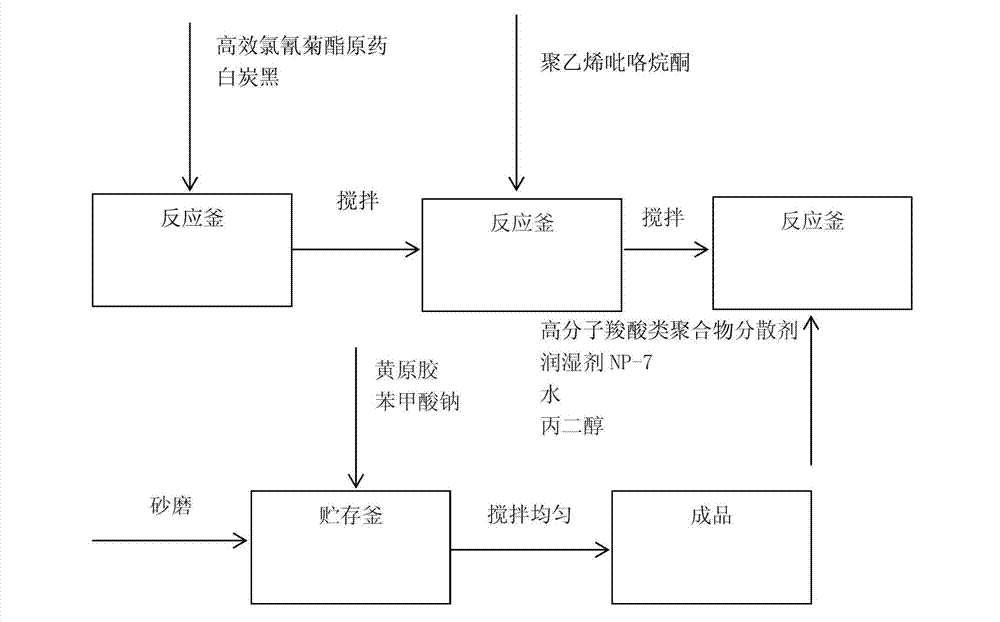

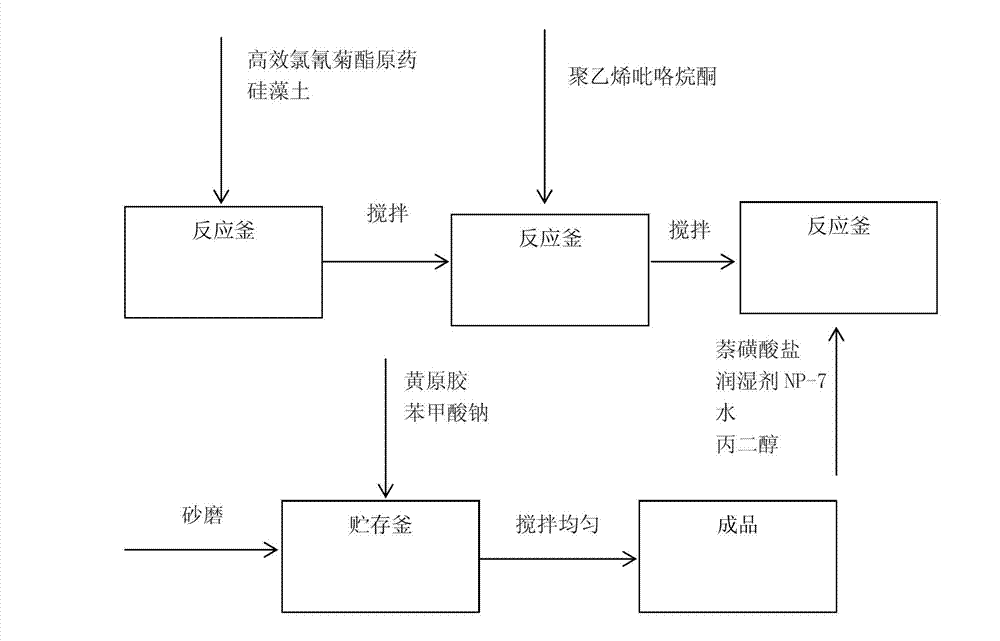

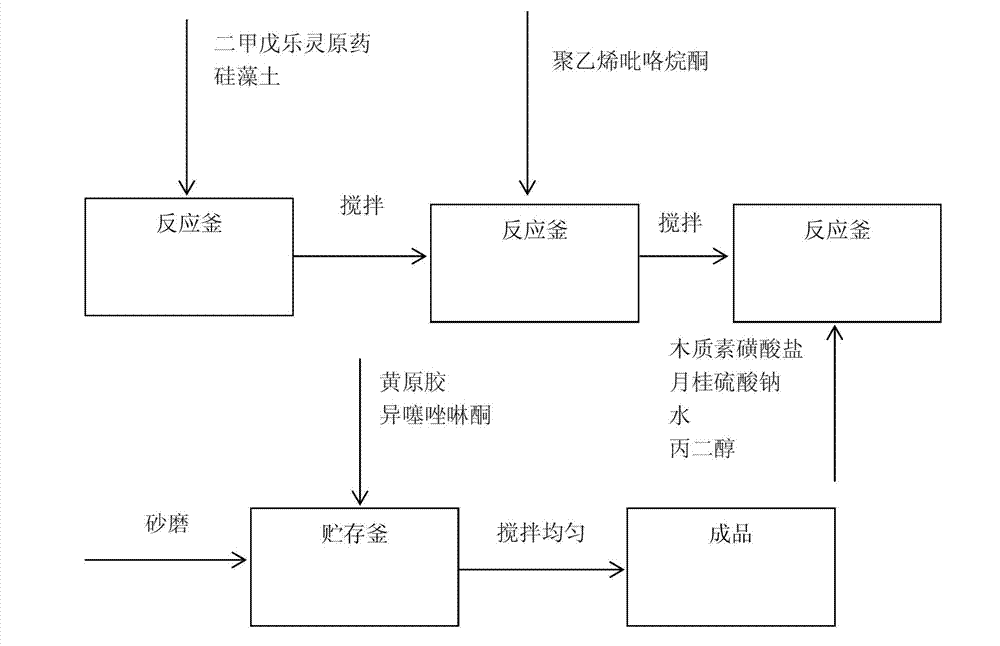

Low-melting-point compound suspending agent and preparation method thereof

The invention discloses a low-melting-point compound suspending agent and a preparation method thereof. The low-melting-point compound suspending agent is composed of the following substances by mass: 1%-50% of low-melting-point compound, 1%-10% of dispersing agent, 1%-6% of wetting agent, 5 %-30% of porous carrier, 1%-3% of polyvinylpyrrolidone, 0.1%-0.5% of thickener, 3%-5% of anti-freezing agent, 0.1%-0.5% of preservative and deionized water as the balance. The low-melting-point compound refers to the compound with the melting point as 50 DEG C- 70 DEG C. The suspending agent adopts a porous carrier to adsorb the low-melting-point compound, utilizes polyvinylpyrrolidone for wrapping, utilizes the proper dispersing agent and the proper wetting agent for assistance and improves physical stability. The agent is good in physical stability if stored under common condition and is still qualified, is not agglomerated and is good in mobility if stored under high temperature like 54 DEG C.

Owner:SINO AGRI LEADING BIOSCI

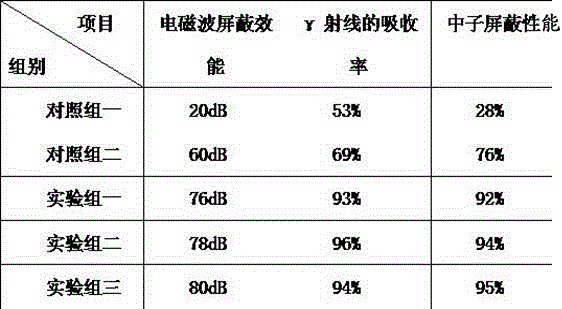

Tungsten alloy shield plate and preparation method thereof

The invention discloses a tungsten alloy shield plate. The tungsten alloy shield plate comprises, by weight, 140-200 parts of tungsten powder, 10-70 parts of nickel powder, 50-120 parts of copper powder, 20-80 parts of samarium powder, 2-8 parts of neodymium powder, 10-16 parts of silver powder, 2-8 parts of yttrium oxide, 10-16 parts of molybdenum wires, 10-16 parts of rhenium wires and 3-9 parts of stannic oxide. The tungsten alloy shield plate has the excellent radiation protection effect.

Owner:GUANGDONG HUASITE ALLOY PROD CO LTD

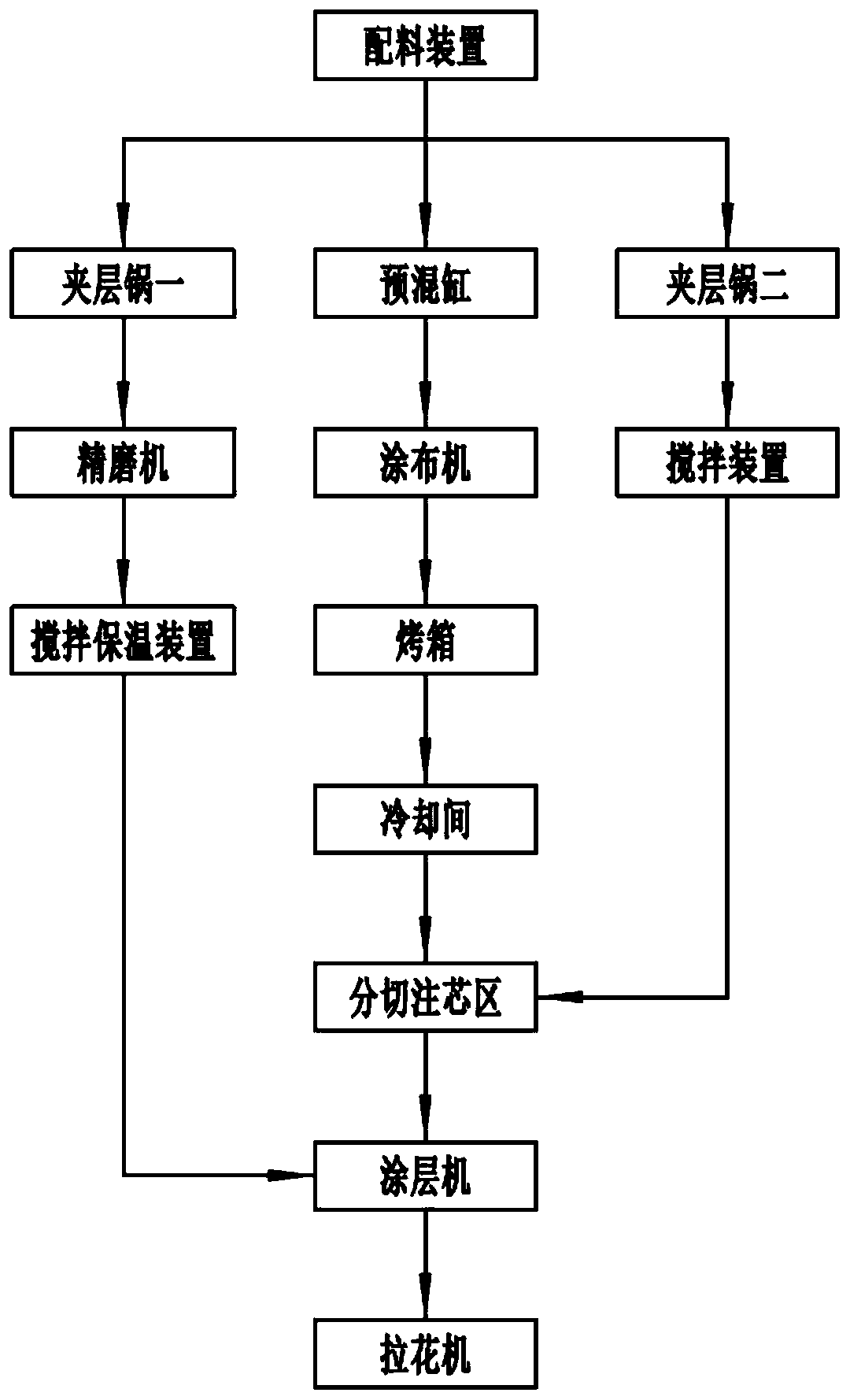

Coated sandwich cake and production process and production line thereof

InactiveCN111034769AGreat tasteNutrient maintenance and strengtheningDough treatmentRotary stirring mixersBiotechnologyEngineering

The invention discloses a coated sandwich cake and a preparation method thereof. The coated sandwich cake is a cold-processed cake processed by taking eggs, wheat flour, white sugar and the like as main raw materials, adding grease, milk powder, an emulsifier and other auxiliary materials, and carrying out procedures of flour beating, flour injecting, baking, demolding, cooling, slitting, core injecting, shaping, coating, drawing, cooling, packaging and the like. The coated cake produced by the invention has high environment adaptability. Through scientifically designed coating and filling slurry formulas, the good mouth melting property of the chocolate coating is ensured, and the coating and the filling are prevented from melting under the conventional logistics transportation and storage environment conditions.

Owner:FUJIAN CHANGTING PANPAN FOOD CO LTD

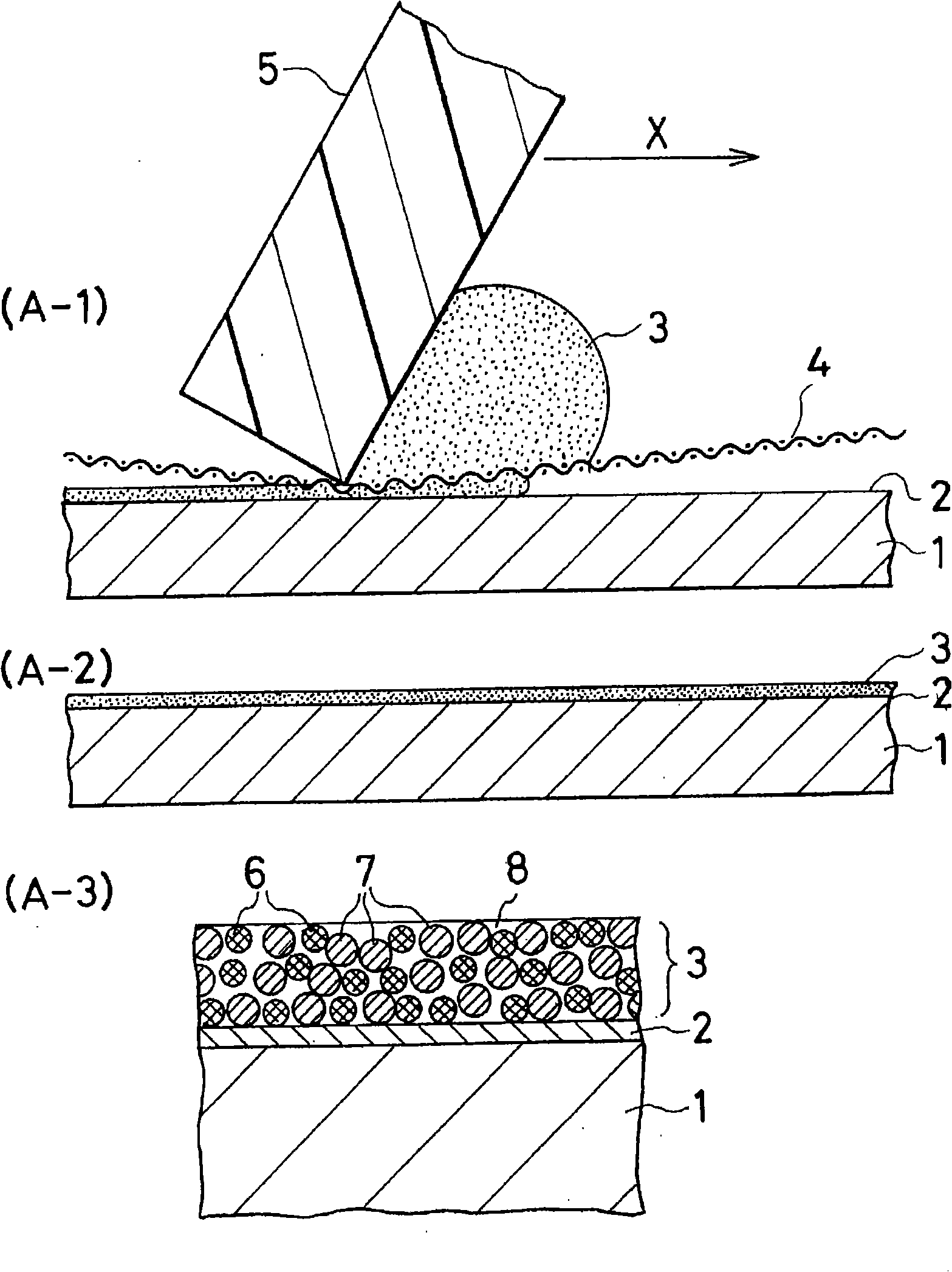

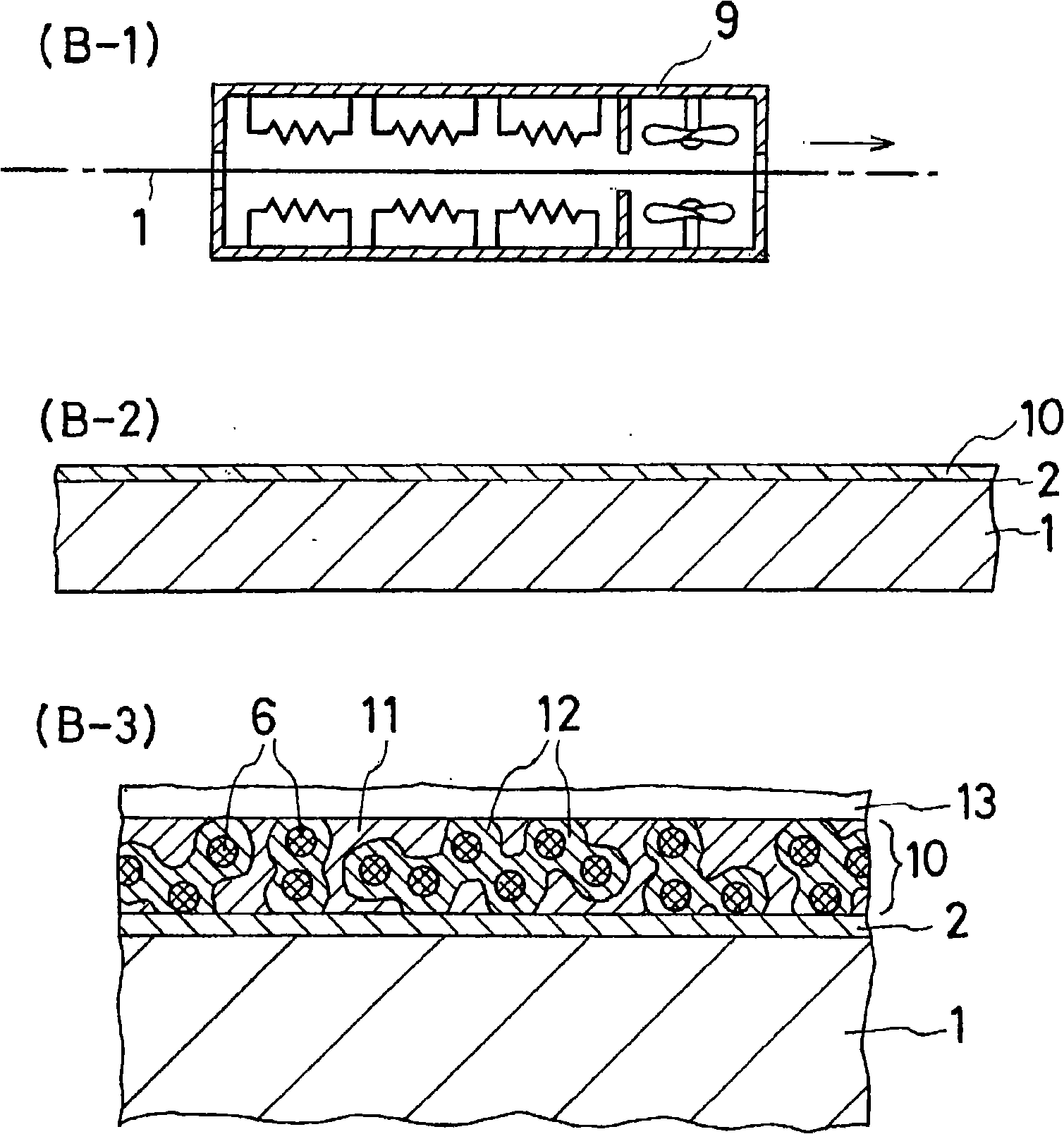

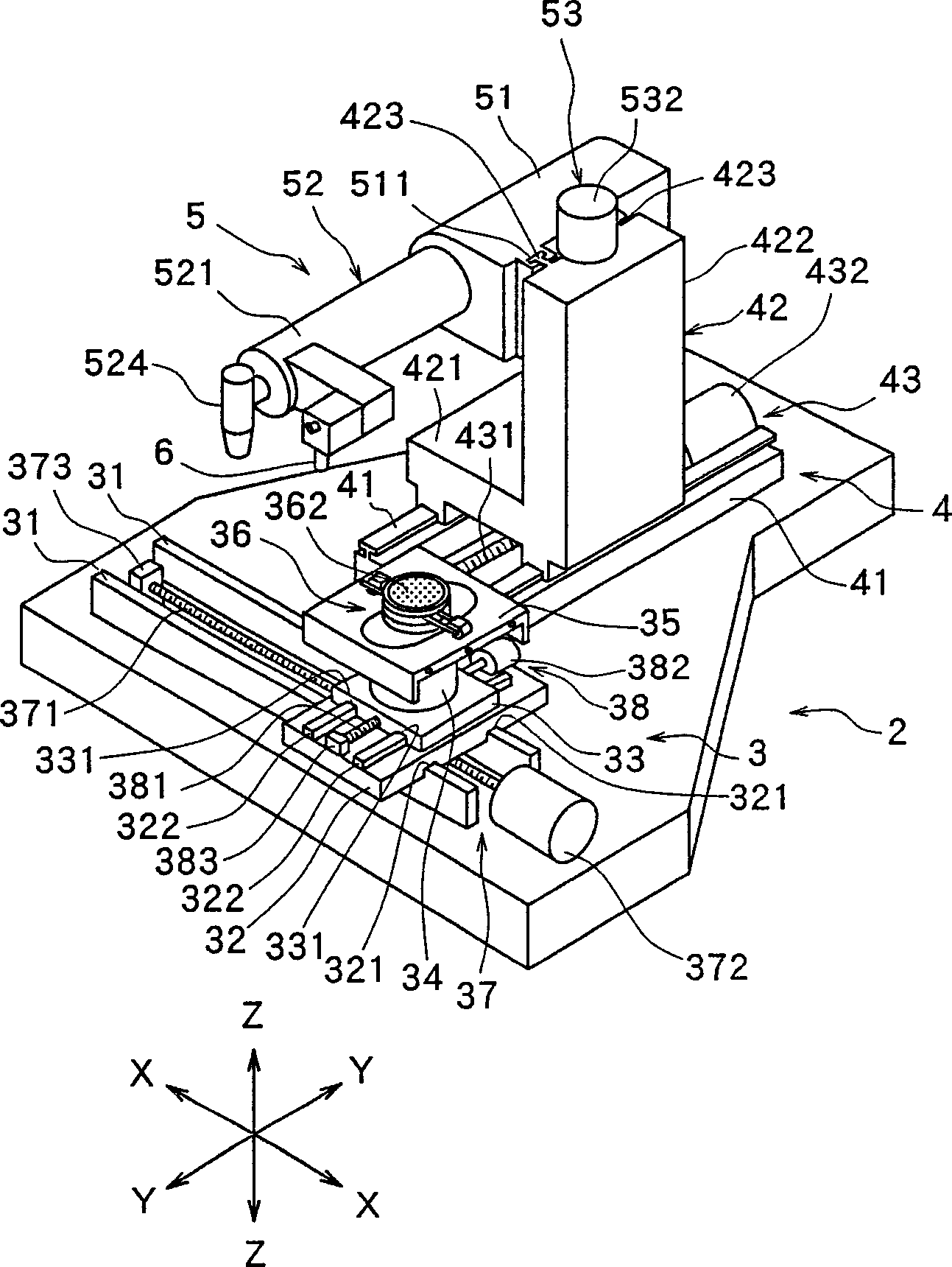

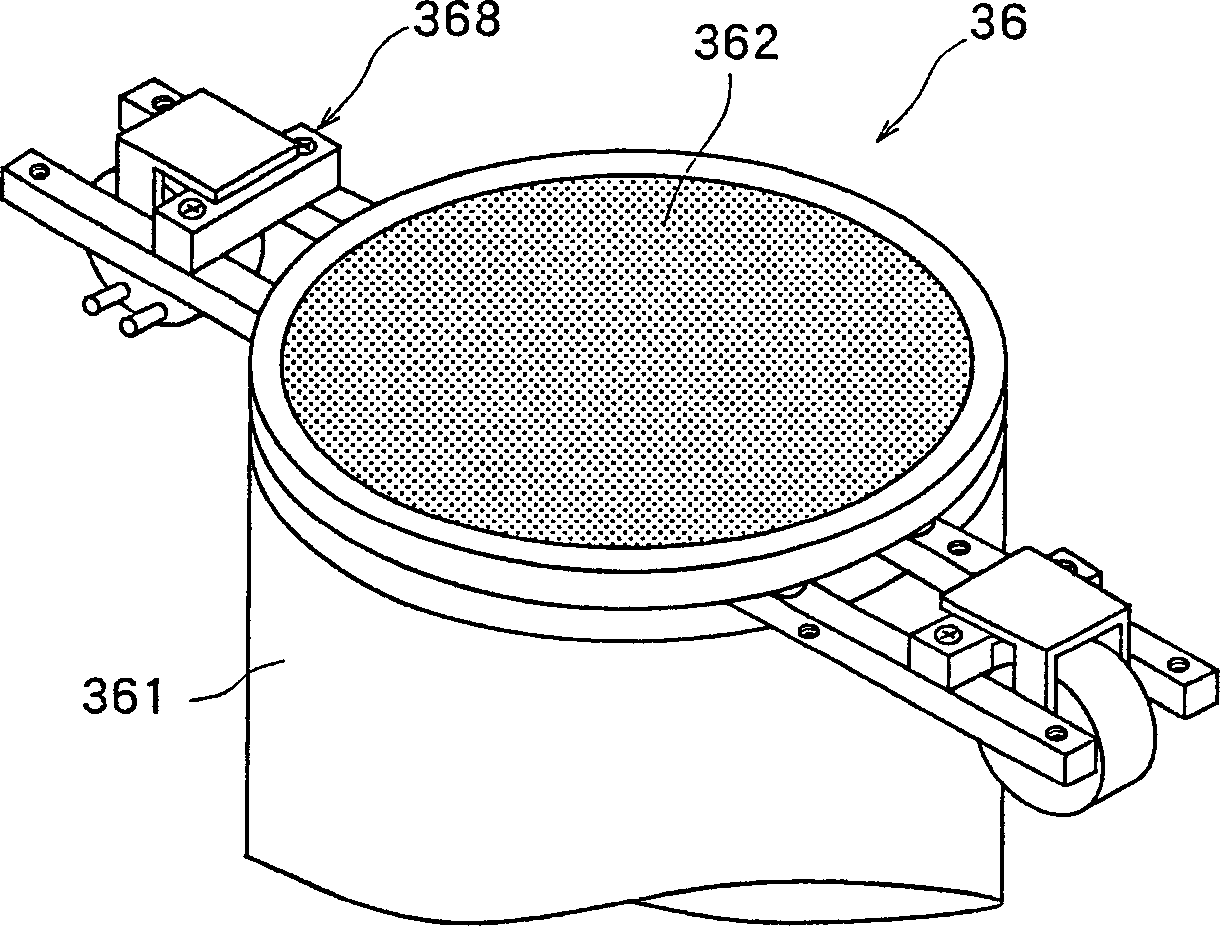

Laser beam processing machine

InactiveCN1810435ASuppress feverWon't meltWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingLaser processingLight beam

The present invention provides a laser beam processing machine comprising a chuck table for holding a workpiece, a laser beam application means for applying a laser beam to the workpiece held on the chuck table, and a processing-feed means for moving the chuck table and the laser beam application means relative to each other, wherein the chuck table comprises a body and a workpiece holding member disposed on the top surface of the body, and the workpiece holding member is made of a material which transmits a laser beam having a predetermined wavelength.

Owner:DISCO CORP

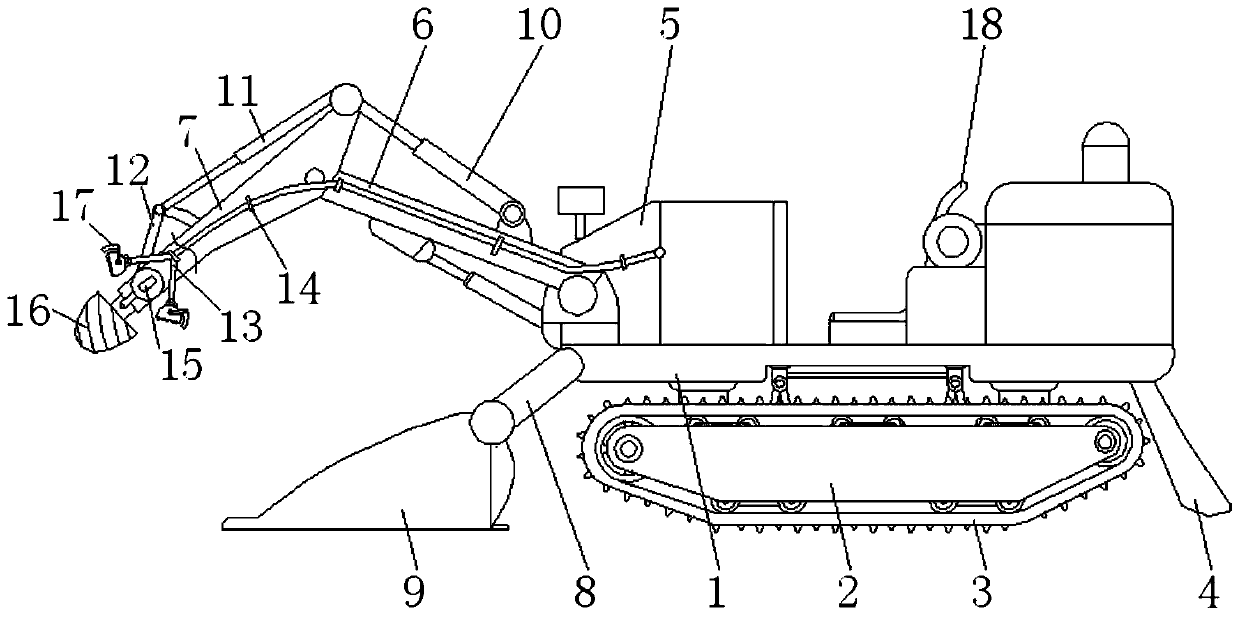

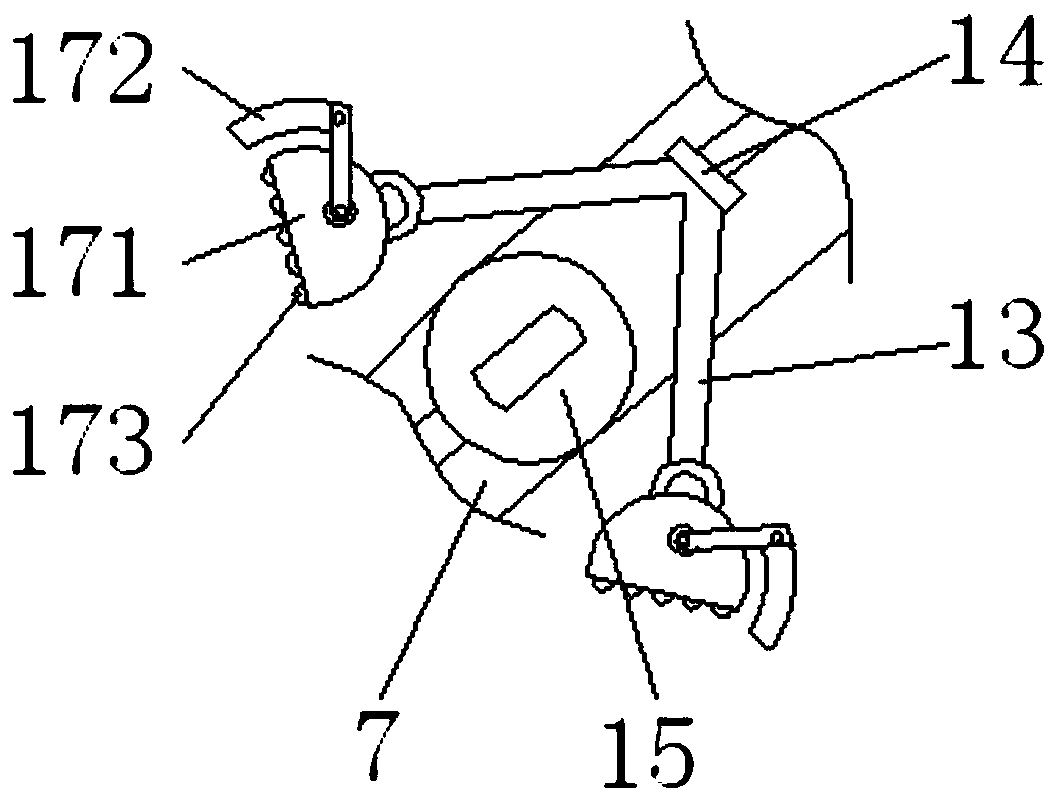

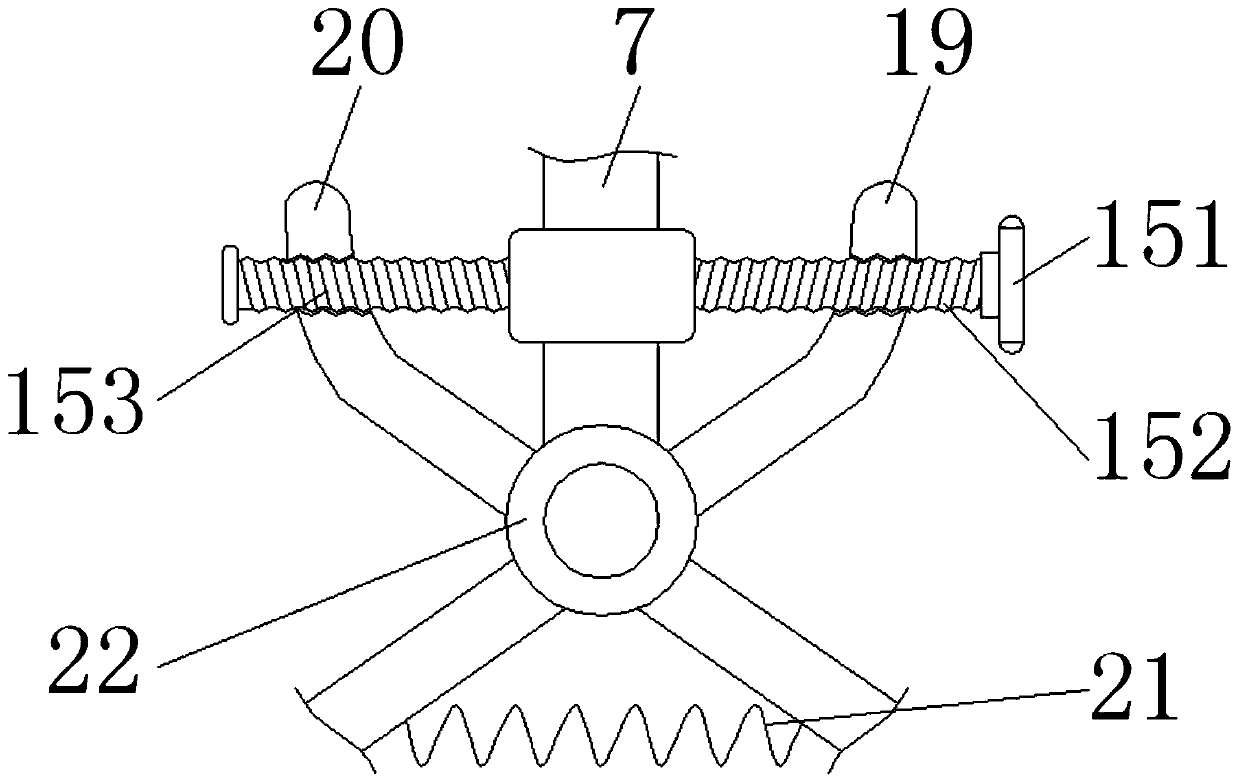

Cantilever type heading machine for tunnel excavation

The invention relates to the technical field of heading machines and discloses a cantilever type heading machine for tunnel excavation. The heading machine comprises a heading machine body, the left side of the upper surface of the heading machine body is fixedly connected with a box, the bottom of the heading machine body is fixedly connected with a driving supporting device, the outer surface ofthe driving supporting device is in transmission connection with a crawler belt, the left side of the box is movably connected with a supporting arm, the left end of the supporting arm is movably sleeved with a transmission arm, and the left end of the transmission arm is clamped with a heading head through a fastening device. According to the cantilever type heading machine for tunnel excavation, an included angle of 90 degrees is formed between two dust removal devices and a conveying tube, so that a proper amount of dustproof foam is conveniently sprayed on the position of a heading end for exploitation, the dustproof foam plays a role in solidifying dust, the spraying coverage rate is high, the flying degree of dust in a tunnel is reduced, the definition of the visual field of a useris improved, meanwhile, the dustproof foam cannot melt geology which is melted immediately when meeting water and is extremely easy to disintegrate, and the user can conveniently excavate.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Electric power cabinet having waterproof function

InactiveCN107658746AWith waterproof functionExtended service lifeSubstation/switching arrangement casingsAnti-seismic devicesTester deviceEngineering

The invention discloses a power cabinet with waterproof function, which comprises a cabinet body, a humidity tester is fixedly connected to one side of the outer wall of the cabinet body, and a fixing rod is fixedly connected to the inside of the cabinet body, and the tops of the fixing rods are respectively fixed from left to right The controller and the motor are connected, and the inner cavity on the top of the cabinet is fixedly connected with a bearing. The inner part of the bearing is fixedly sleeved with a nut, and the outer part of the bottom of the nut is fixedly sleeved with a wheel. The outer wall of the wheel is connected to the output shaft of the motor through a belt drive. The outer wall of the nut, the inner thread of the nut is sleeved with a threaded rod. The power cabinet with waterproof function, through the cooperation between the humidity tester, controller, motor, bearings, nuts, belts and threaded rods, can ensure that no matter how heavy the rainwater is, it will not float into the power cabinet and keep the inside of the cabinet. Dry to ensure that the circuit inside the cabinet will not be short-circuited by rain, thereby reducing the loss of the circuit inside the cabinet and improving the service life of the power cabinet.

Owner:郑艳峰

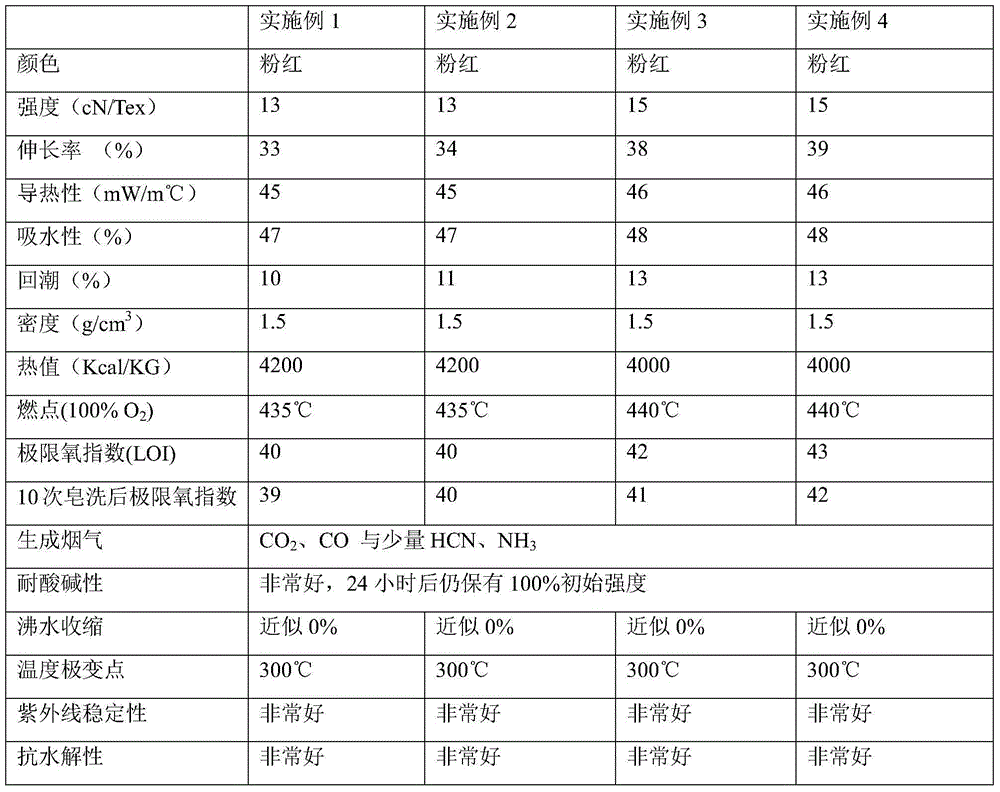

High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

ActiveCN105986474AHigh limiting oxygen indexWon't meltFibre typesDyeing processPolymer scienceMoisture regain

The invention relates to a polyacrylonitrile fiber, and concretely relates to a high temperature-resistant flame retardation polyacrylonitrile fiber and a production method thereof. The method concretely comprises the following steps: processing a polyacrylonitrile fiber in a hydrazine solution with the concentration of 7-20wt%, processing the hydrazine processed fiber in an alkaline solution with the concentration of 3-10wt%, washing the alkali processed fiber with water until the fiber is neutral, processing the neutral fiber in an aqueous metal ion salt solution with the concentration of 3-10wt%, oiling the metal salt processed fiber, dehydrating the oiled fiber, and drying the dehydrated fiber to obtain the high temperature-resistant flame retardation polyacrylonitrile fiber. The flame retardation performance LOI of the flame retardation fiber obtained in the invention can reach 40-45, the flame retardation grade is M1, and the amount of smoke generated in the combustion process is very small, the grade of toxic gases is FO, and the smoke amount of the flame retardation fiber in the invention is lower than that of other flame retardation fibers. The flame retardation fiber in the invention has the advantages of high moisture regain rate, high water absorption rate, good dyeability and low shrinkage in boiling water.

Owner:JILIN ACRYLIC FIBERS CO LTD

Polymer battery lug and surface processing method thereof

InactiveCN101667632AImprove sealingHigh melting pointCell component detailsSodium phosphatesPhysical chemistry

The invention discloses a polymer battery lug and a surface processing method thereof, which comprises Ni, Al and insulating tape; the invention is characterized in that: the surface of the lug is coated with ammonium bifluoride, chromic oxide, sodium phosphate and boric acid; and the weight thereof are as follows respectively: 3 to 3.5g of ammonium bifluoride, 20 to 26g of chromic oxide, 2 to 2.5g of sodium phosphate and 0.4 to 0.6g of boric acid. The invention fundamentally solves the weakest link of electrolyte non-resistance of a normal lug, thus guaranteeing the long-term tightness of encapsulated cell in subsequent storage and use processes. The invention improves the safety of the battery and electric equipment.

Owner:深圳世纪新能源电池有限公司

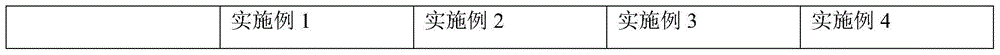

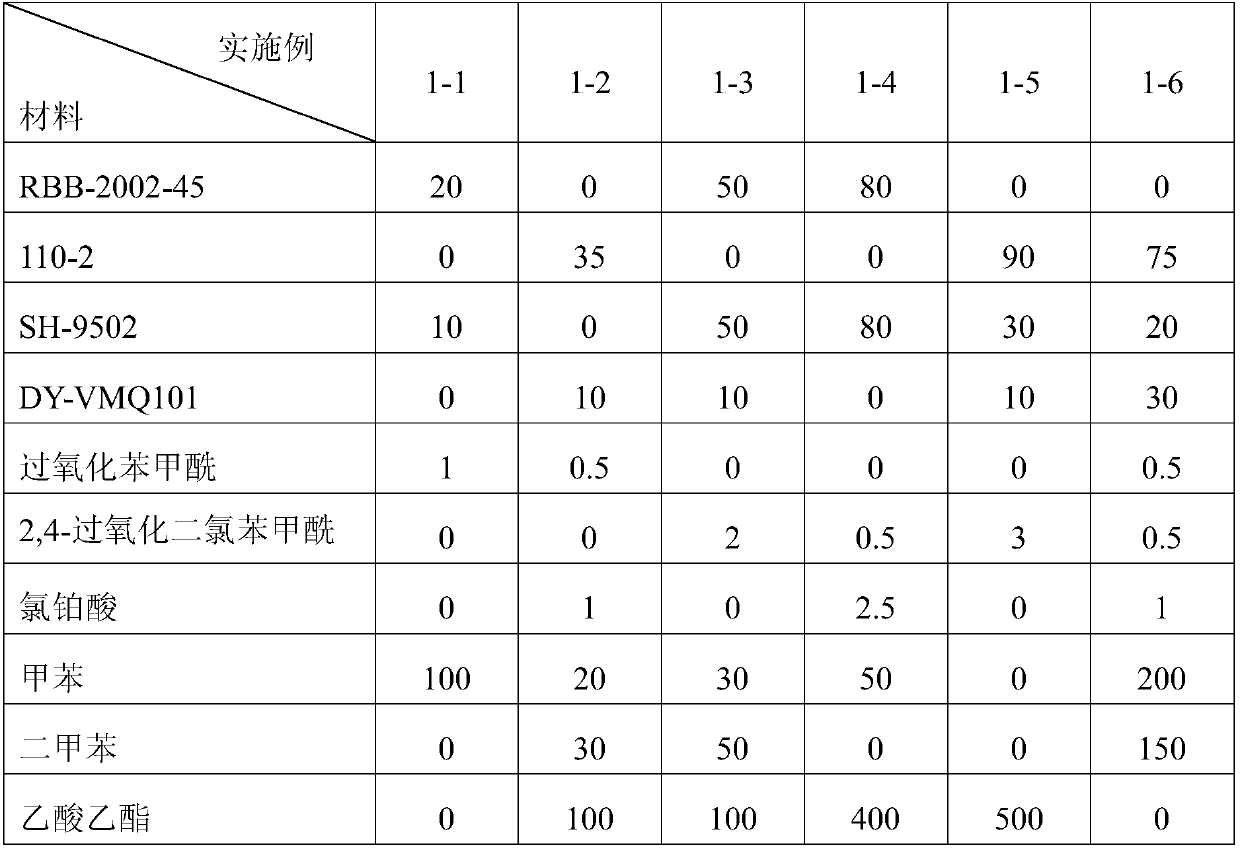

Preparation method of high-temperature-resistant grid acrylic pressure-sensitive adhesive tape

InactiveCN109609051AEnsuring Surface Venting PerformanceWon't meltEster polymer adhesivesCoatingsPolyesterResin coating

The invention discloses a preparation method of a high-temperature-resistant grid acrylic pressure-sensitive adhesive tape, which is characterized in that: 20-90 parts by mass of silicone rubber, 10-80 parts by mass of silicone resin, 1-3 parts by mass of catalyst and 100-500 parts by mass of solvent are uniformly mixed to prepare an organic silicone resin coating material; a PET precoating film silicone coated with a thin film surface treatment agent is coated by the organic silicon resin coating material, after pre-drying, a high-temperature-resistant grid PET release film is prepared, and then the high-temperature-resistant grid PET release film is coated with acrylic pressure sensitive adhesive, after pre-drying, the high-temperature-resistant grid PET release film is bonded with cloth-based materials such as thin films such as polyester, polypropylene, polycarbonate, polyimide thin film or cotton cloth, non-woven cloth, glass cloth and the like, and then rolled up to prepare the high-temperature-resistant grid acrylic pressure sensitive adhesive tape. The high-temperature-resistant grid acrylic pressure-sensitive adhesive tape prepared by the invention greatly improves the temperature resistance, does not melt when the use temperature reaches 200 DEG C, keeps the grid structure undeformed, and ensures the surface exhaust performance of the pressure-sensitive adhesive tape.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

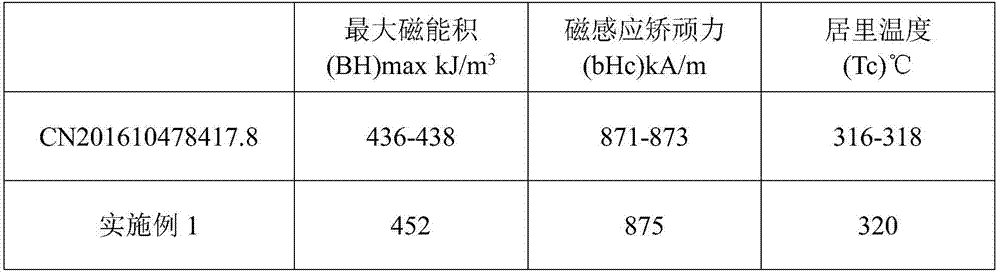

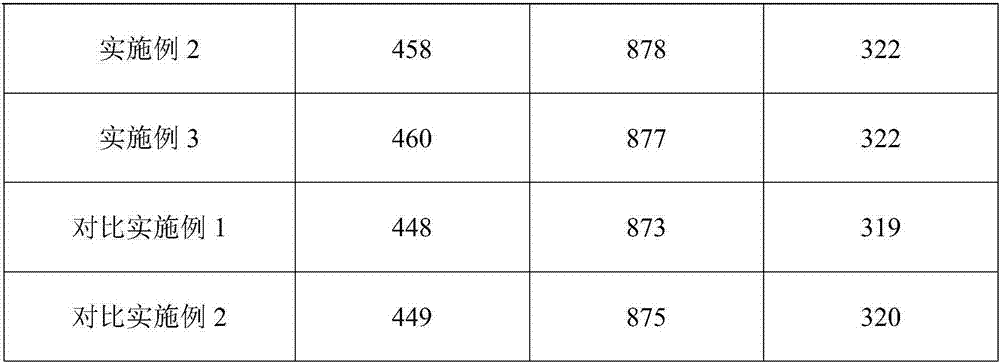

Sintered neodymium-iron-boron material and preparation method therefor

ActiveCN106920615AImprove magnetismHigh melting pointInductances/transformers/magnets manufactureMagnetic materialsFerrite powderMaterials science

The invention discloses a sintered neodymium-iron-boron material and a preparation method therefor. The sintered neodymium-iron-boron material is prepared from iron-based neodymium-iron-boron powder, composite ferrite powder, and nanometer SnO<2>-Ni composite powder in a sintering manner; the iron-based neodymium-iron-boron powder comprises the following components based on mass percentage: 21-25% of Nd, 0.3-0.9% of B, 0.1-0.4% of Sn,0.2-0.9% of Co, 0.3-0.8% of Y, 0.3-0.7% of Ni, 0.1-0.4% of Pb and the balance of Fe; and the iron-based neodymium-iron-boron powder also comprises 0.05-0.3% of AlN micro particles based on weight percentage. The sintered neodymium-iron-boron material disclosed by the invention has extremely high magnetic property; the preparation method for the high-magnetic-energy-product sintered neodymium-iron-boron material does not use many rare and noble materials; and instead, the preparation method is simple in preparation cost, simple in process, convenient to operate, and suitable for popularization.

Owner:XUZHOU NANFANG YONGCI MATERIAL

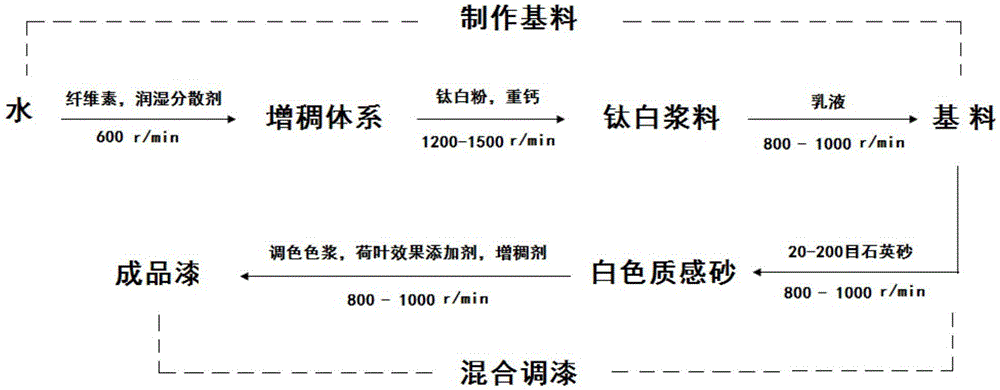

Sand with exterior wall texture and lotus leaf effect as well as production method thereof

The invention discloses sand with exterior wall texture and lotus leaf effect as well as a production method thereof. The sand with exterior wall texture is prepared by the following raw materials in percentage by mass: 10.0-20.0% of water, 0.2-0.3% of hydroxyethyl cellulose, 0.2-0.3% of an antifoaming agent, 0.1-0.2% of a pH conditioning agent, 0.1-0.3% of a wetting agent, 0.3-0.6% of a dispersant, 1.0-1.5% of glycol, 0.9-1.2% of a film forming auxiliary agent, 2.0-10.0% of titanium dioxide, 5.0-15.0% of coarse whiting, 15.0-20.0% of an acrylic acid emulsion, 5.0-10.0% of a wax emulsion, 0.2-1.0% of a bactericide, and 50.0-70.0% of quartz sand. The production process is divided into two stages including production of base materials and paint mixing. The sand has an automatically cleaning function, which is similar to lotus leaf effect, other performances of the sand meet the national standard JG / T24-2000 requirement, comprising: storage stability, artificial aging resistance, cracking resistance at initial stage, shock resistance, water resistance, alkali resistance, etc.

Owner:HUBAO NEW MATERIAL TECH SHANGHAI CO LTD

Residence fireproof exhaust valve

The invention relates to the technical field of residence kitchen and bathroom exhaust way systems and provides a residence fireproof exhaust valve which comprises a faceplate with a through hole and a diversion pipe arranged on the inner side of the faceplate and communicated with the through hole. The residence fireproof exhaust valve is characterized by further comprising at least two metal transmission combination mechanism in symmetric arrangement, each transmission combination mechanism comprises a base, a hooking member, a pulling member and a screw, a first hinging point is arranged on each hooking member and hinged to the corresponding base, each base is fixed on the outer wall of the diversion plate or the inner wall of the faceplate, each hooking member is provided with a second hinging point which is hinged to one end of the corresponding pulling member, a threaded hole is formed in the other end of each pulling member, each screw is extended in from the front of the faceplate to be matched with the threaded hole in the corresponding pulling member and rotates to drive the pulling member to move, and each hooking member presses the wall of an exhaust pipeline under action of the corresponding pulling member through the corresponding first hinging point and the corresponding second hinging point. By using the residence fireproof exhaust valve, the problem of defects of being instable, non-fireproof, prone to pipe breaking, time-consuming, material-consuming and power-consuming when several fireproof exhaust valves are fixed on an exhaust pipe in the prior art is solved.

Owner:张琦

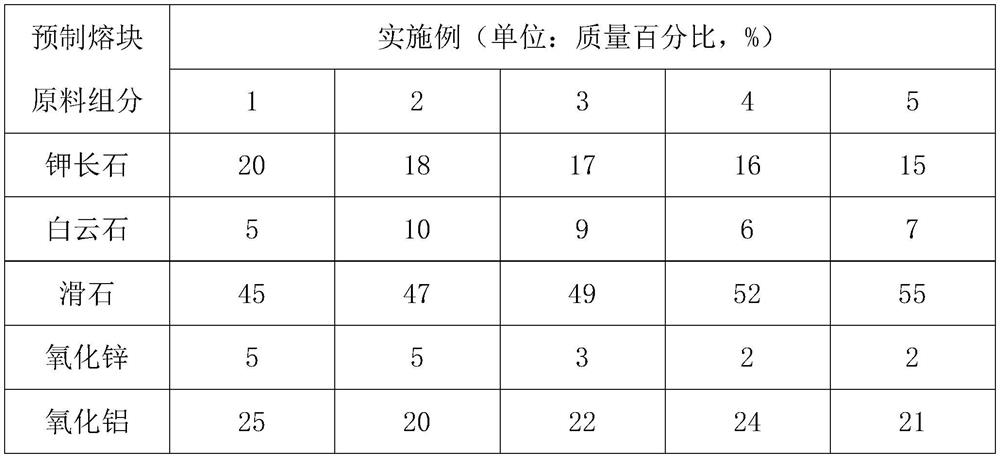

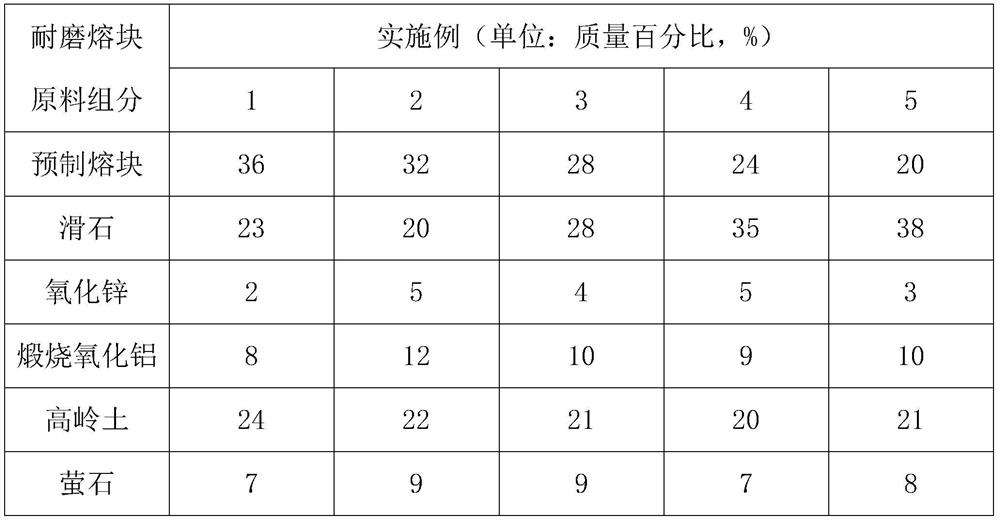

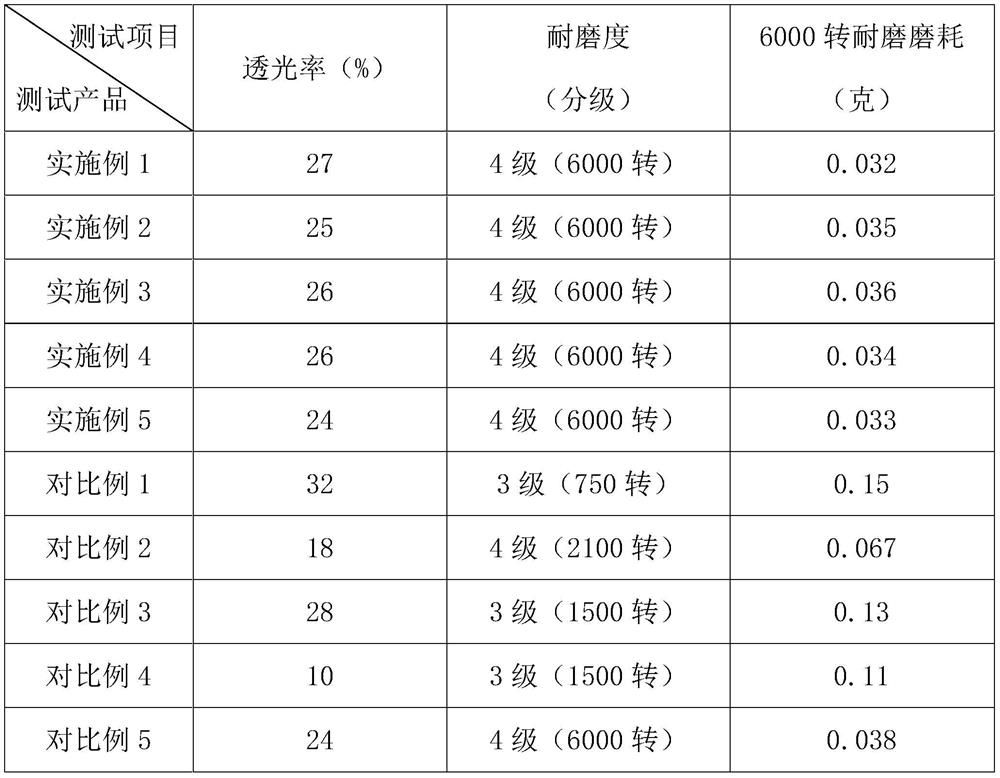

Wear-resistant frit, preparation method of frit and glaze using frit

The invention discloses a wear-resistant frit, a preparation method of the frit and a glaze using the frit, and the wear-resistant frit is prepared from the following raw materials in percentage by mass: 20-36% of prefabricated frit, 20-38% of talc, 2-5% of zinc oxide, 8-12% of calcined aluminum oxide, 20-24% of kaolin and 7-9% of fluorite. The prefabricated frit is prepared from the following rawmaterials in percentage by mass: 15 to 20 percent of potassium feldspar, 5 to 10 percent of dolomite, 45 to 55 percent of talc, 2 to 5 percent of zinc oxide and 20 to 25 percent of aluminum oxide. The wear-resistant frit is good in transparency and good in wear resistance, the preparation method of the wear-resistant frit is simple, all the raw material components are fully fused in the high-temperature firing process, and the prepared wear-resistant frit is high in transparency and good in wear resistance. The glaze using the wear-resistant frit has the advantages of favorable wear resistance of the glaze layer, favorable surface gloss of the glaze surface and favorable light transmission property.

Owner:佛山市东鹏陶瓷发展有限公司 +2

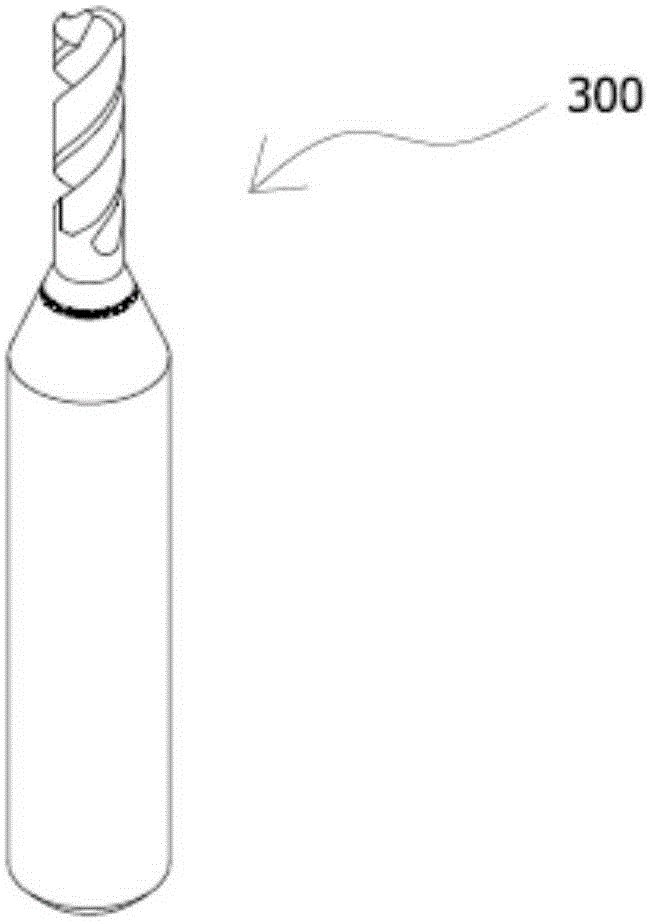

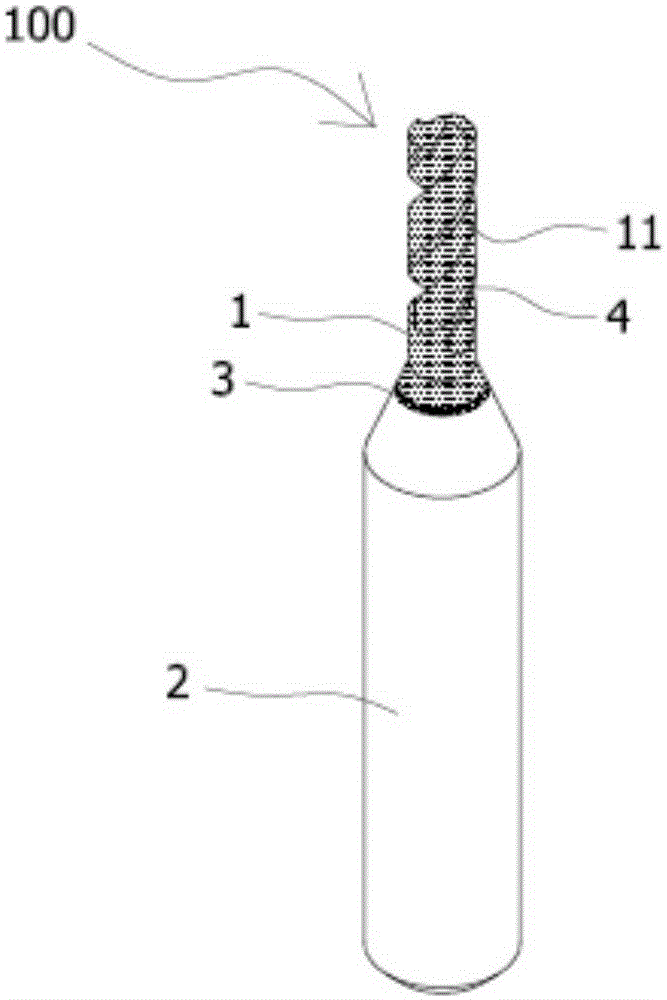

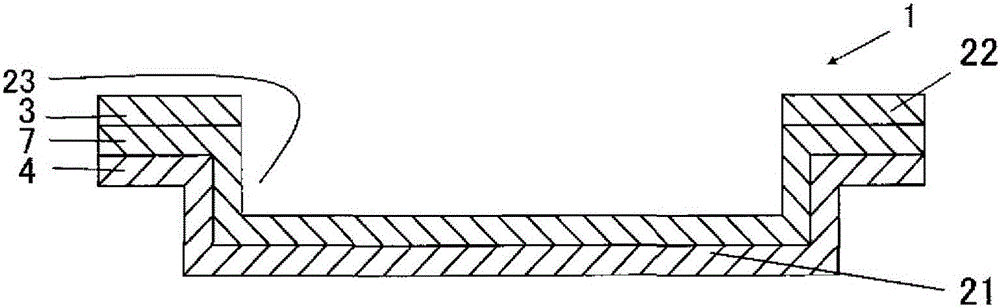

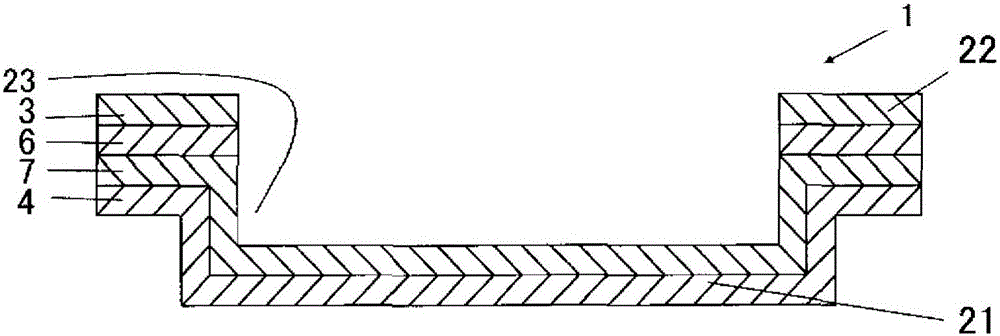

Diamond coating cutter and manufacturing method thereof

InactiveCN106583803AConcentricity is not affectedWon't meltMilling cuttersWorkpiecesButt jointMetallic materials

The invention aims at providing a diamond coating cutter and a manufacturing method thereof. The diamond coating cutter comprises a first section of cylindrical bar, a second section of cylindrical bar, a welding part and a diamond film. The first section of cylindrical bar is made of sintered tungsten carbide materials. The second section of cylindrical bar is made of metal materials. The welding part is located between the first section of bar and the second section of bar. The whole surface of the first section of bar is coated with the diamond film through a chemical vapor deposition manufacturing procedure. The manufacturing method of the diamond coating cutter comprises the steps that firstly, sintered tungsten carbide and the metal bar are combined into a bar material with high-temperature solder through a hard soldering manufacturing procedure in a butt joint mode; then after forming machining, the cutter with the first section of bar, the second section of bar and the welding part can be obtained preliminarily; and then the chemical vapor deposition manufacturing procedure is conducted on the cutter, so that the whole surface of the first section of bar is coated with the diamond film, and finally the diamond coating cutter is obtained.

Owner:天钻科技股份有限公司

Package for power storage device and power storage device

ActiveCN106328834ARealize thin wallAchieve lightweightFinal product manufactureSecondary cellsInsulation layerMetal foil

A package for a power storage device includes a metal foil layer, an insulation layer laminated on at least center portion of one surface of the metal foil layer, and a heat-sealable resin layer arranged one surface of the metal foil layer or a region corresponding to a periphery of the one surface of the metal foil layer. With this, thinning, weight saving, and shortening of the production time can be attained.

Owner:LISSENOK PACKAGING CO LTD

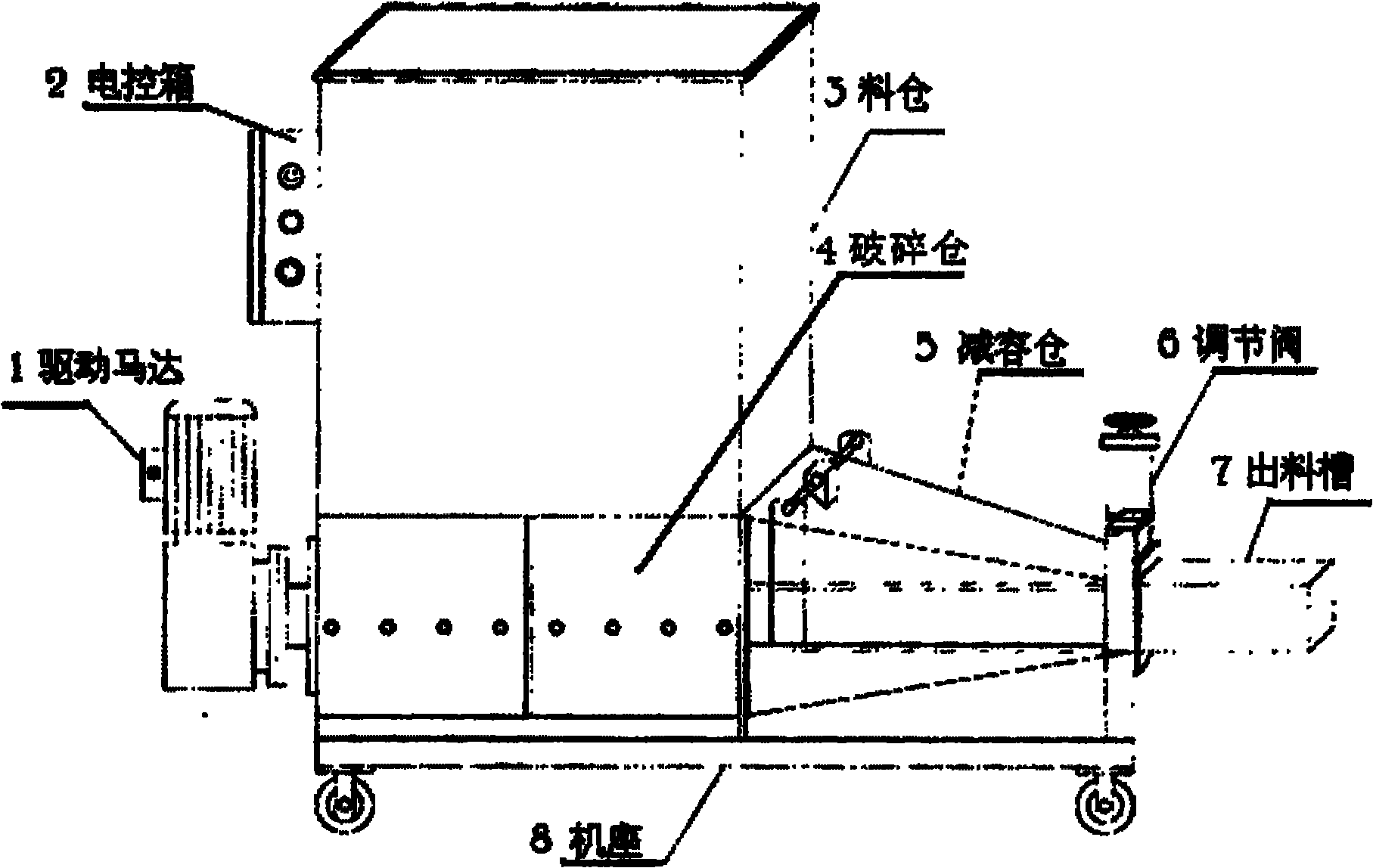

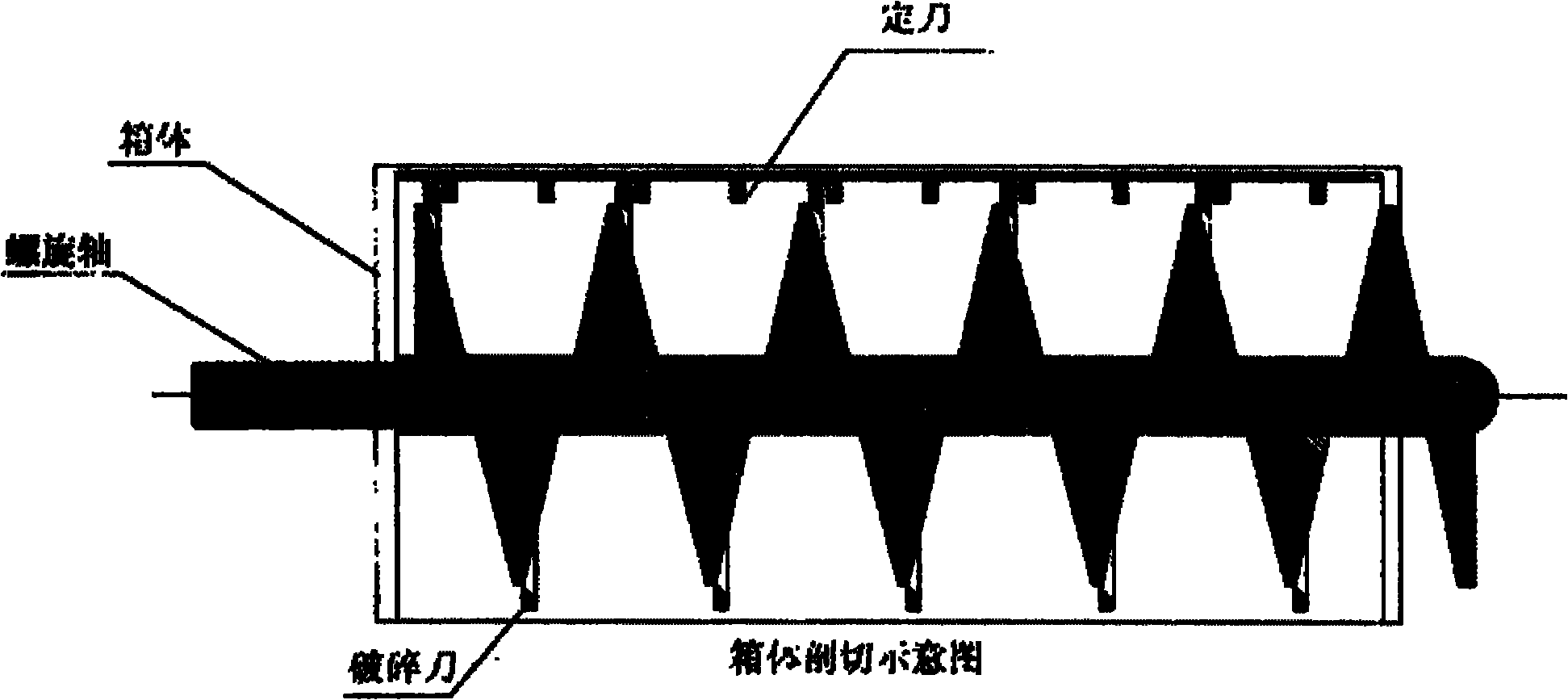

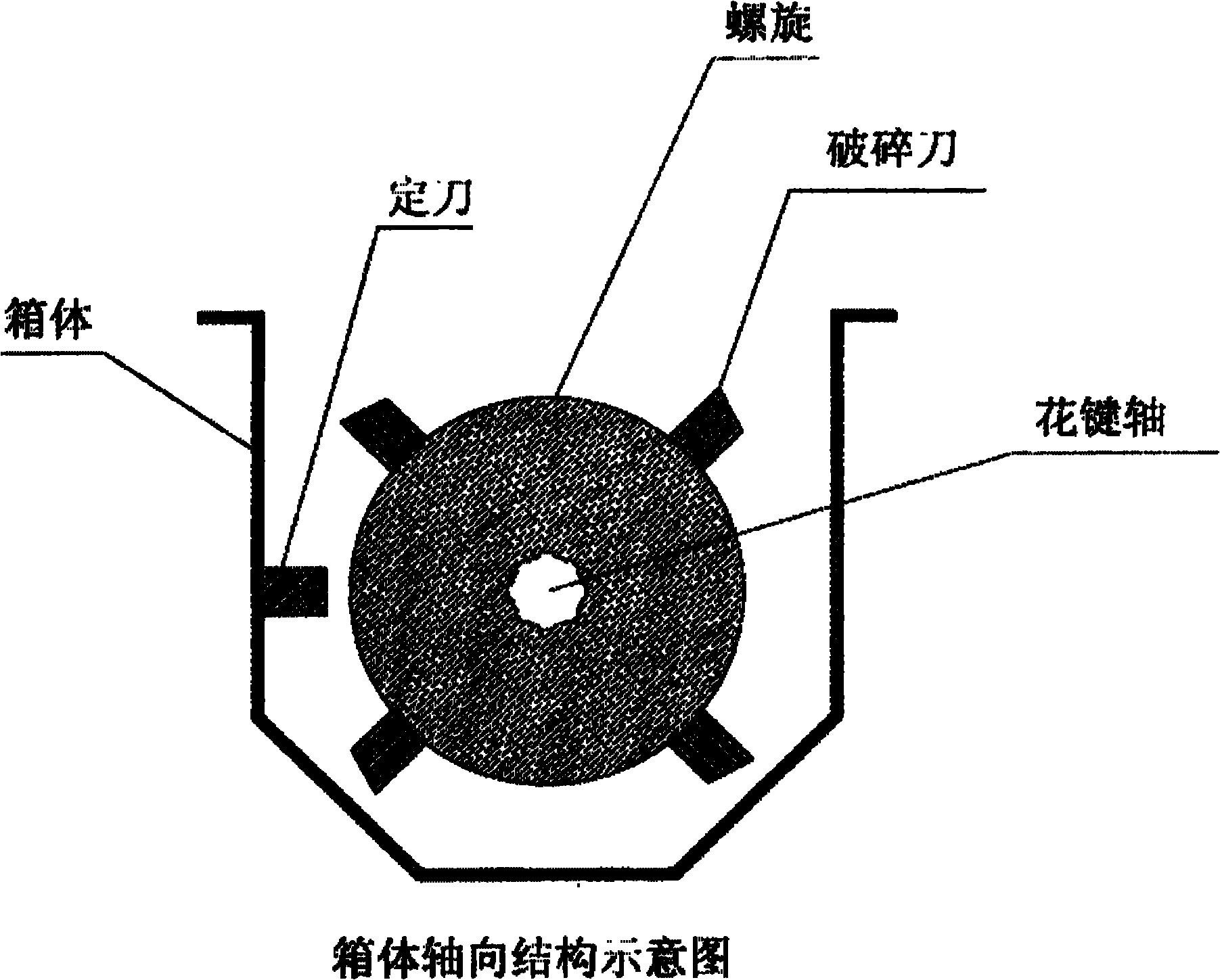

Novel foamed plastic volume reduction machine

The invention discloses a foamed plastic volume reduction machine. The machine can adopt a spiral inclined plane mechanism to reduce the volume of a foamed plastic under the action of shearing and extrusion; the spiral inclined plane mechanism is provided with crushing knife blades, has a function of crushing bulk materials, and cannot make the materials generate excessive heat to melt the materials due to shearing in the shearing and defoaming processes; and a discharge end is provided with a pressure adjusting device which can adjust the volume reduction ratio.

Owner:广州希盾技术有限公司 +2

High-temperature-resistant photocatalysis sustained-release type aldehyde-removing odor-removing paste and preparation method thereof

InactiveCN109794134AWon't meltImprove high temperature resistanceDispersed particle separationCarrageenanDecomposition

The invention relates to the technical field of aldehyde removal, and specifically discloses a high-temperature-resistant photocatalysis sustained-release type aldehyde-removing odor-removing paste, which is prepared from the following raw materials in percentage by weight: 90-97% of deionized water, 1-4% of L-shaped carrageenan, 0.1-0.6% of locust bean gum, 0.1-0.3% of calcium chloride, 0.5-1.5%of potassium chloride, 0.3-1.5% of a preservative, 0.5-1.5% of essence, 0.5-1.5% of ethanol, 1-6% of zinc ricinoleate and 0.03-0.6% of nano titanium dioxide. The invention further discloses a preparation method of the high-temperature-resistant photocatalytic sustained-release type aldehyde-removing odor-removing paste. The aldehyde-removing odor-removing paste has high temperature resistance, good toughness and no friability, and further has the effects of high-efficiency adsorption, continuous decomposition of formaldehyde and air purification.

Owner:中山爱居环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com