High-temperature-resistant lithium battery diaphragm and production method thereof

A technology for lithium battery separators and production methods, which is applied to battery components, circuits, electrical components, etc., to achieve the effects of good heat resistance, flame retardancy and self-extinguishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

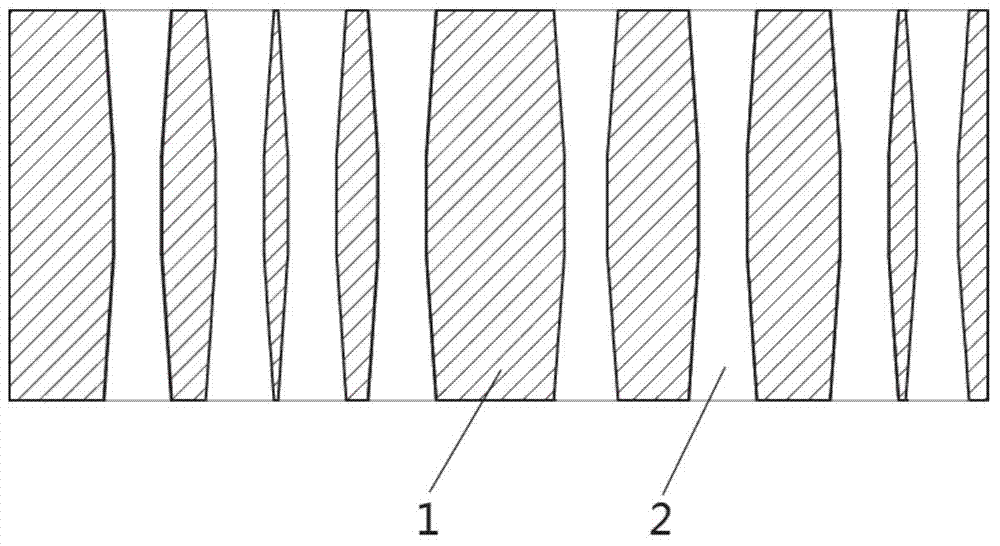

[0036] A high temperature resistant lithium battery separator, its cross-sectional schematic diagram, as figure 1 As shown, the substrate of the diaphragm is a polyimide film 1 with a thickness of 5 μm, and micropores 2 are uniformly distributed on the substrate, and the micropores 2 are perpendicular to the surface of the polyimide film 1, and the pore density is 1×10 7 cm -2 , with a pore size of 0.2 μm.

[0037] Through the verification of the heat resistance of the lithium battery separator, it is known that the lithium battery separator can be used for a long time at 230°C, has flame retardancy and self-extinguishing ability, will not melt at high temperatures, and can only be used at a high temperature of 800°C It is coked and insoluble in any known organic solvents.

[0038] The high-temperature-resistant lithium battery separator is used to prepare lithium battery samples, which can withstand 2C charge and discharge, and when the sample battery is charged and dischar...

Embodiment 2

[0040] The difference from Example 1 is that the polyimide diaphragm substrate is a polyimide film with a thickness of 15 μm, micropores are evenly distributed on the substrate, and the micropores are perpendicular to the surface of the polyimide film. 1×10 8 cm -2 , with a pore size of 1 μm.

Embodiment 3

[0042] The difference from Example 1 is that the polyimide diaphragm substrate is a polyimide film with a thickness of 35 μm, micropores are evenly distributed on the substrate, and the micropores are perpendicular to the surface of the polyimide film. 1×10 9 cm -2 , with a pore size of 3.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com