Patents

Literature

533results about How to "Improve etching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

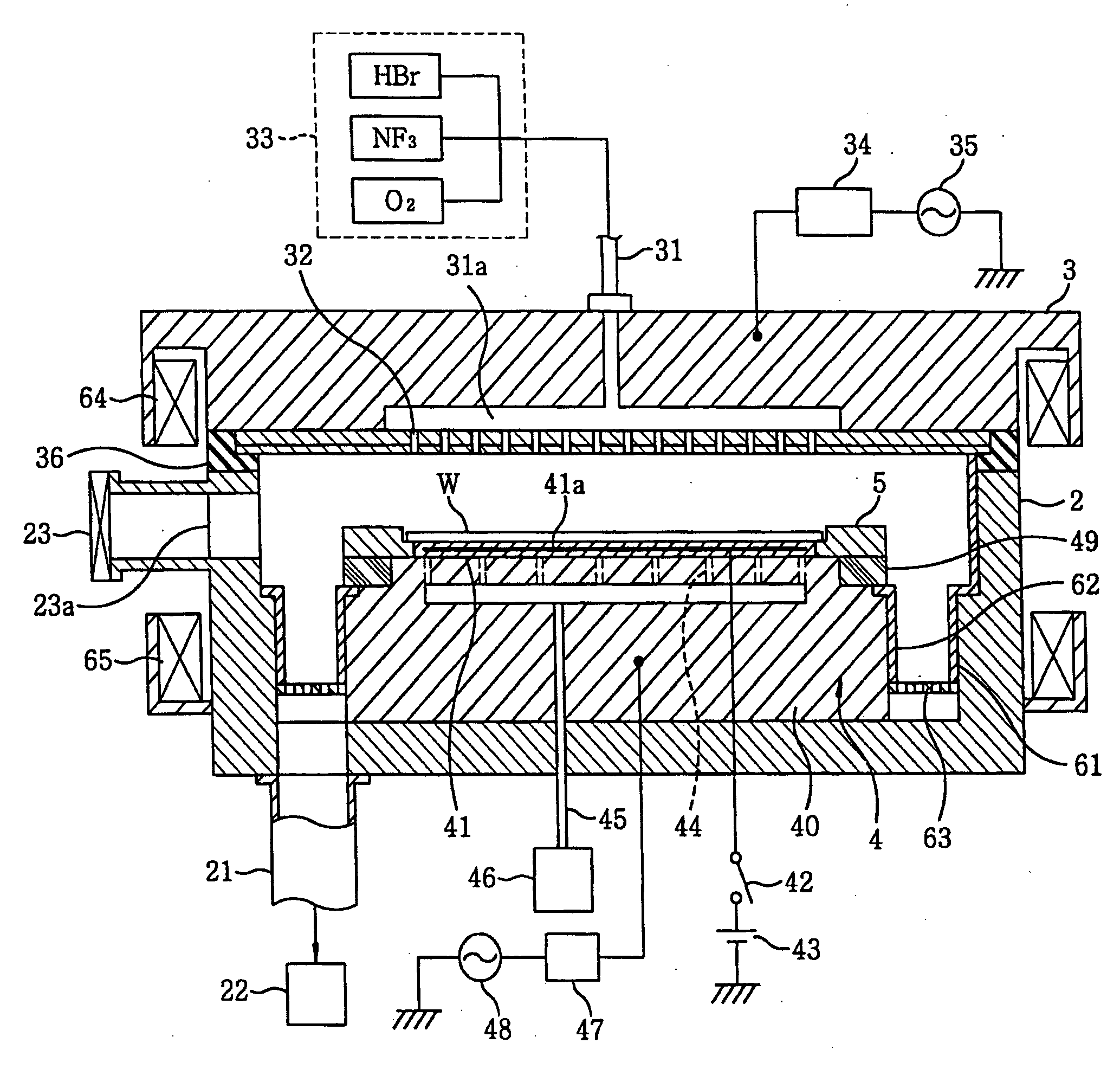

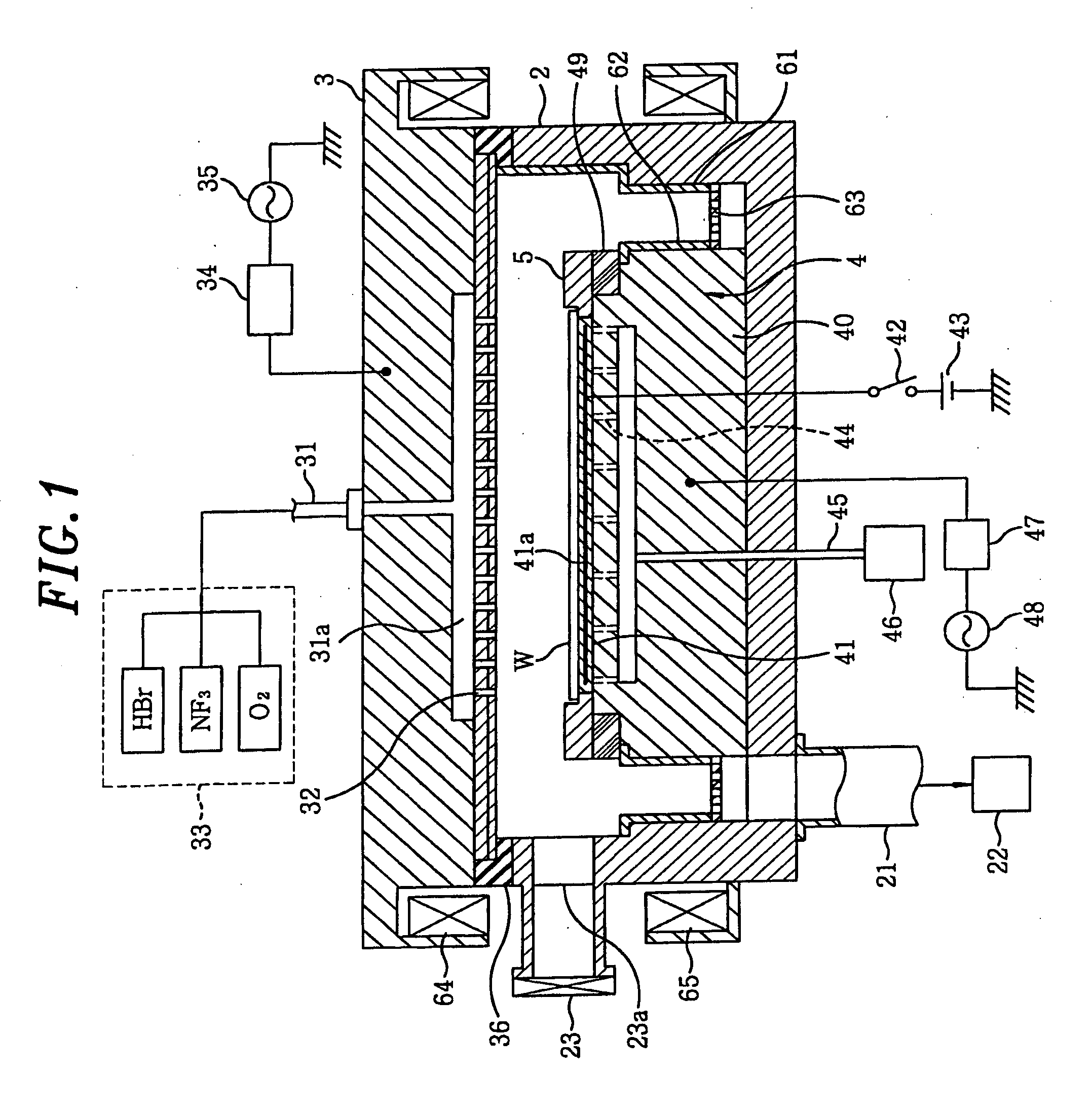

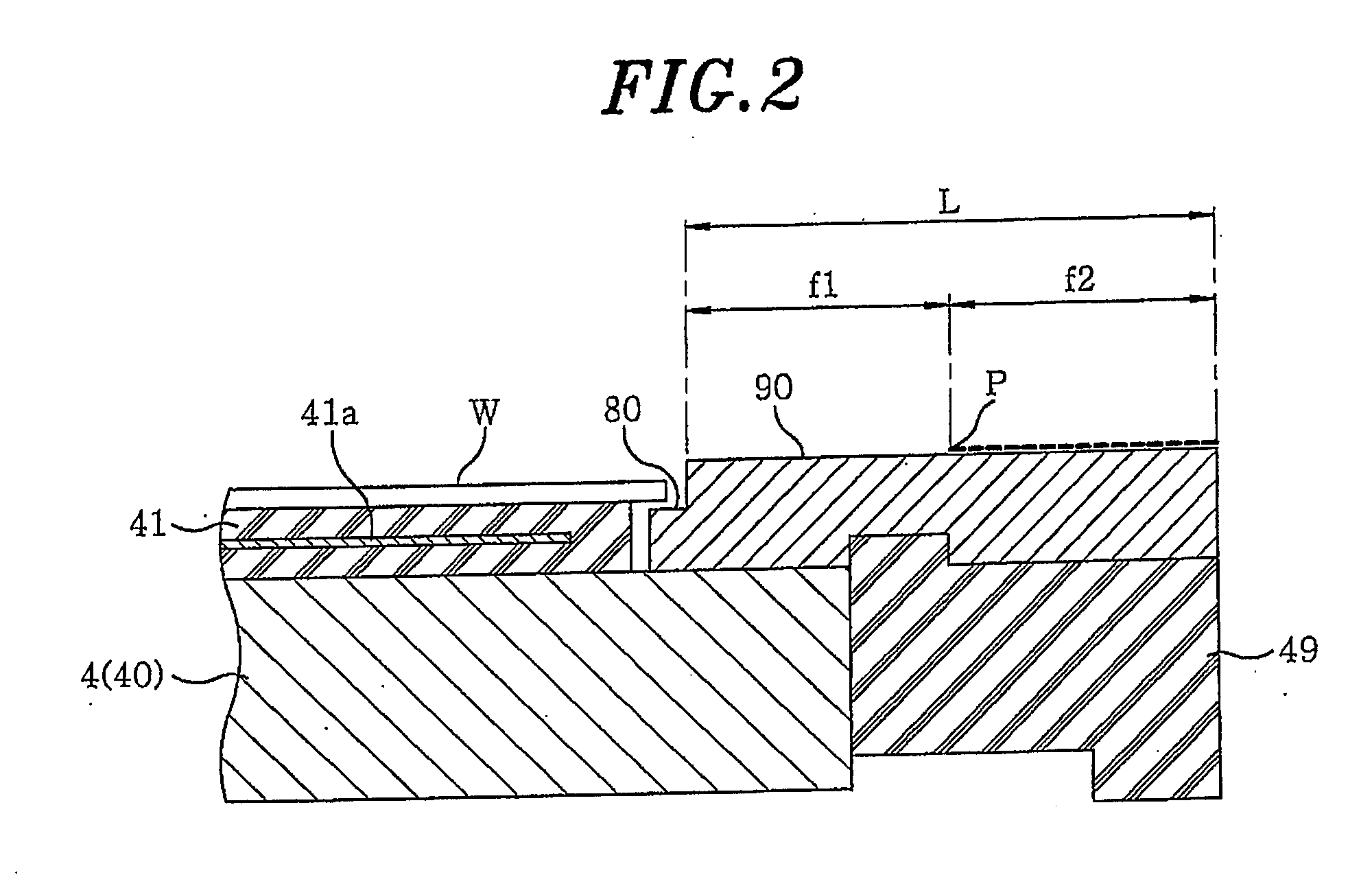

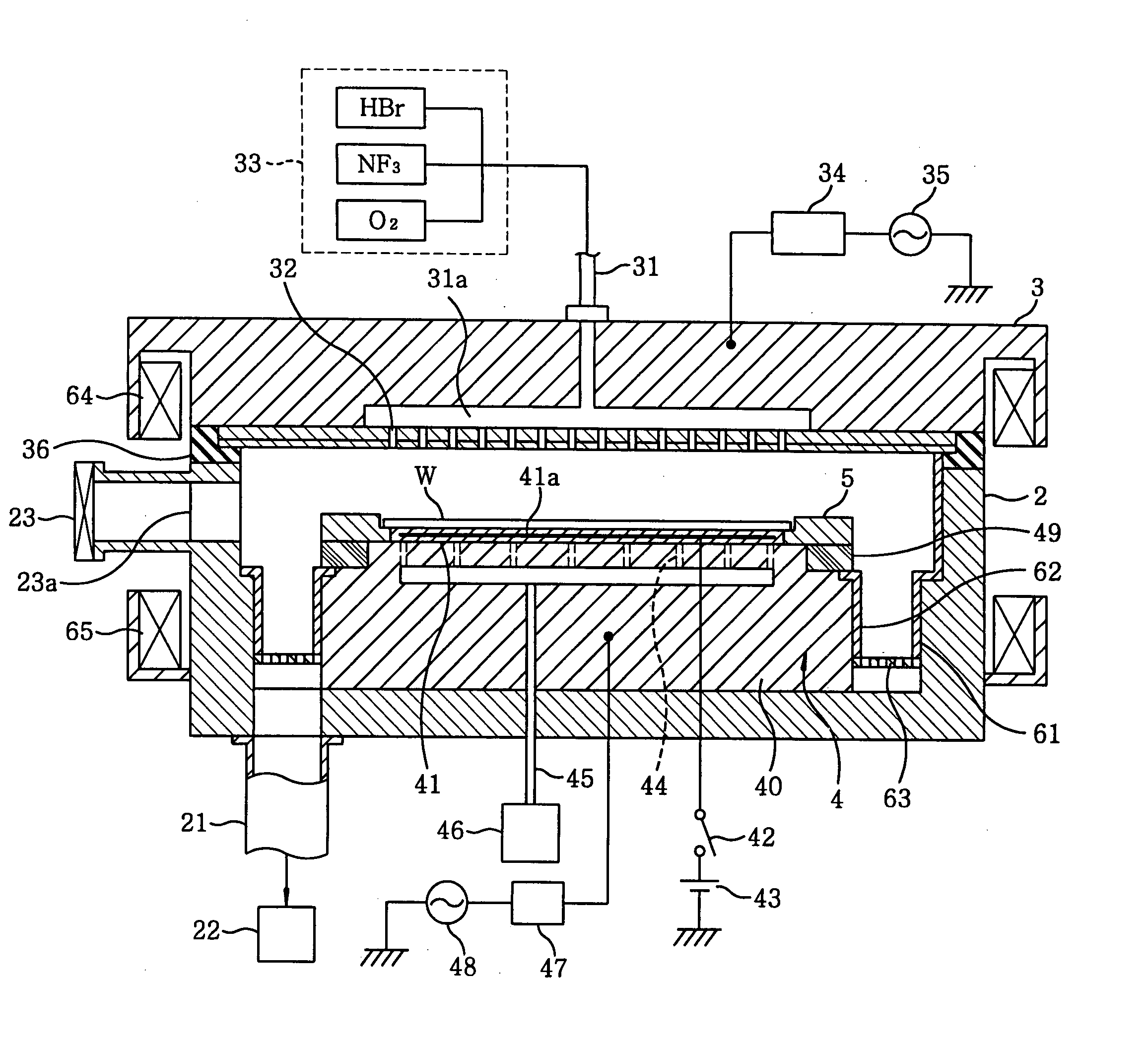

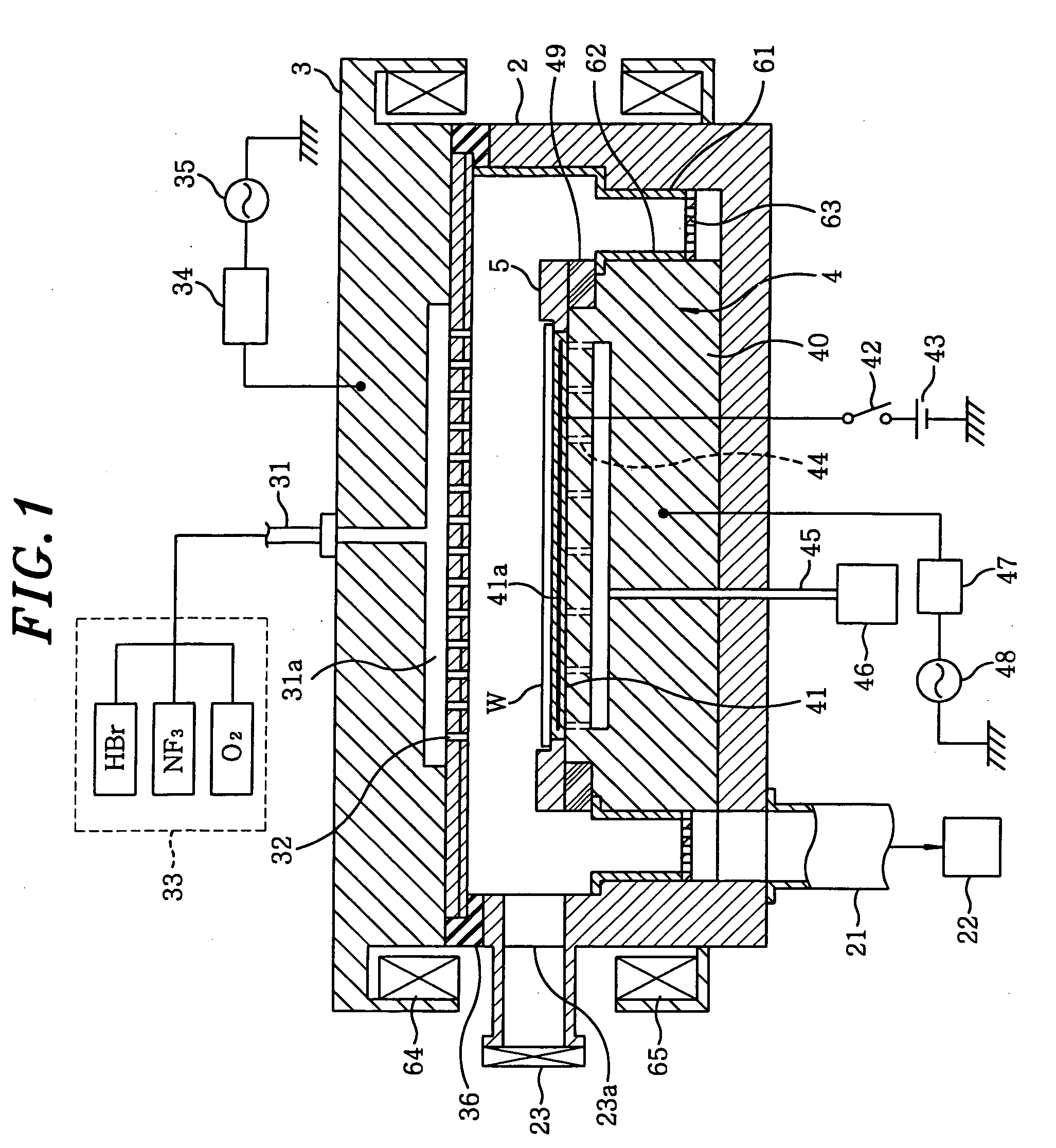

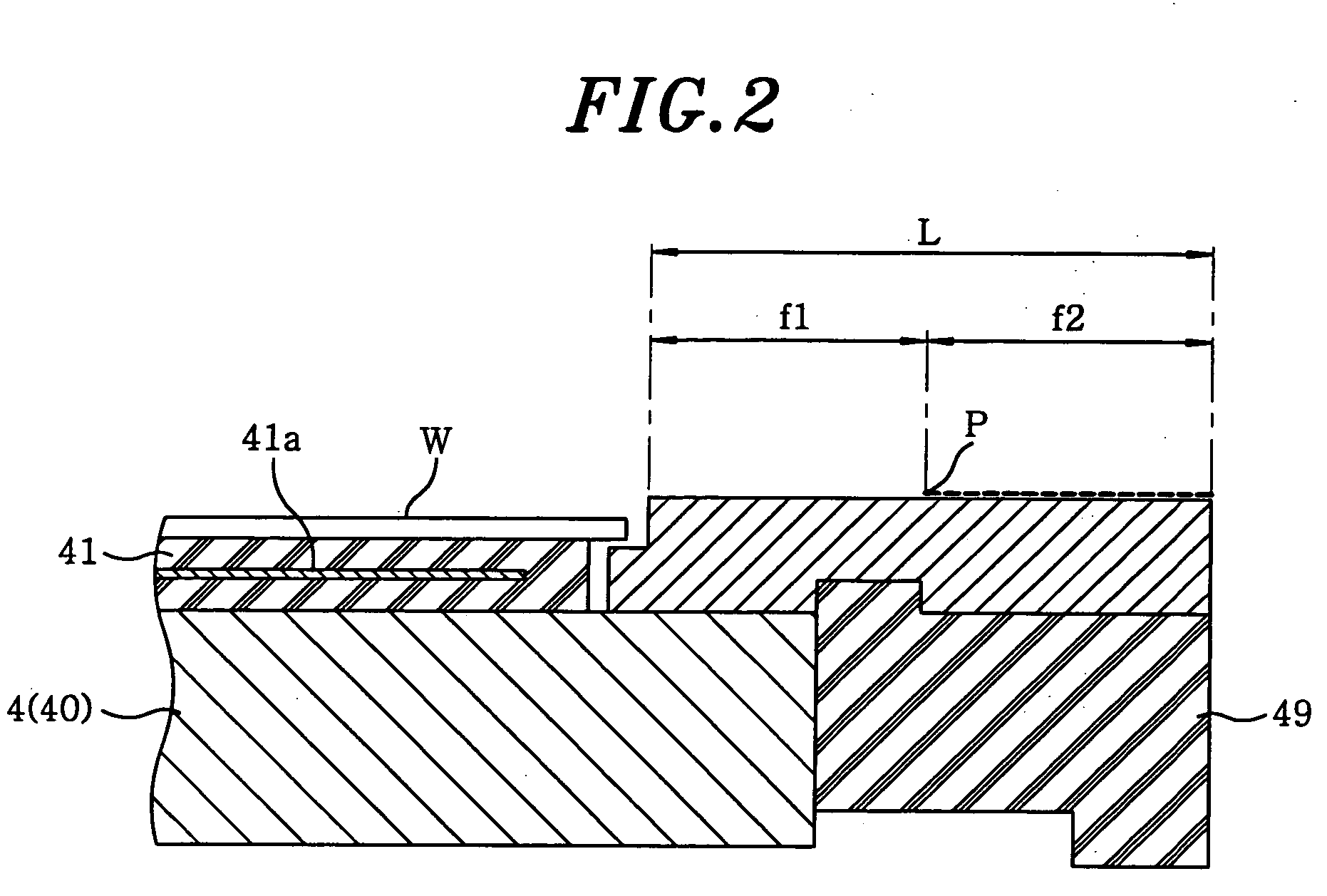

Focus ring, plasma etching apparatus and plasma etching method

ActiveUS20090255902A1Improve etching effectAccurate storageElectric discharge tubesDecorative surface effectsSusceptorSurface roughness

In a plasma etching apparatus for performing a plasma etching on a surface of a substrate mounted on a susceptor in a processing vessel, a focus ring is installed to surround the substrate and has a first region at an inner side on a surface thereof, in which an average surface roughness is small such that a reaction product produced during an etching processing is not captured to be deposited, and a second region at an outer side from the first region, in which an average surface roughness is large such that a reaction product produced during the etching process is captured to be deposited. A boundary between the first and the second region is a part where an etching amount is relatively significantly changed compared to other parts while the focus ring is equipped in the plasma etching apparatus and the plasma etching is performed on the substrate.

Owner:TOKYO ELECTRON LTD

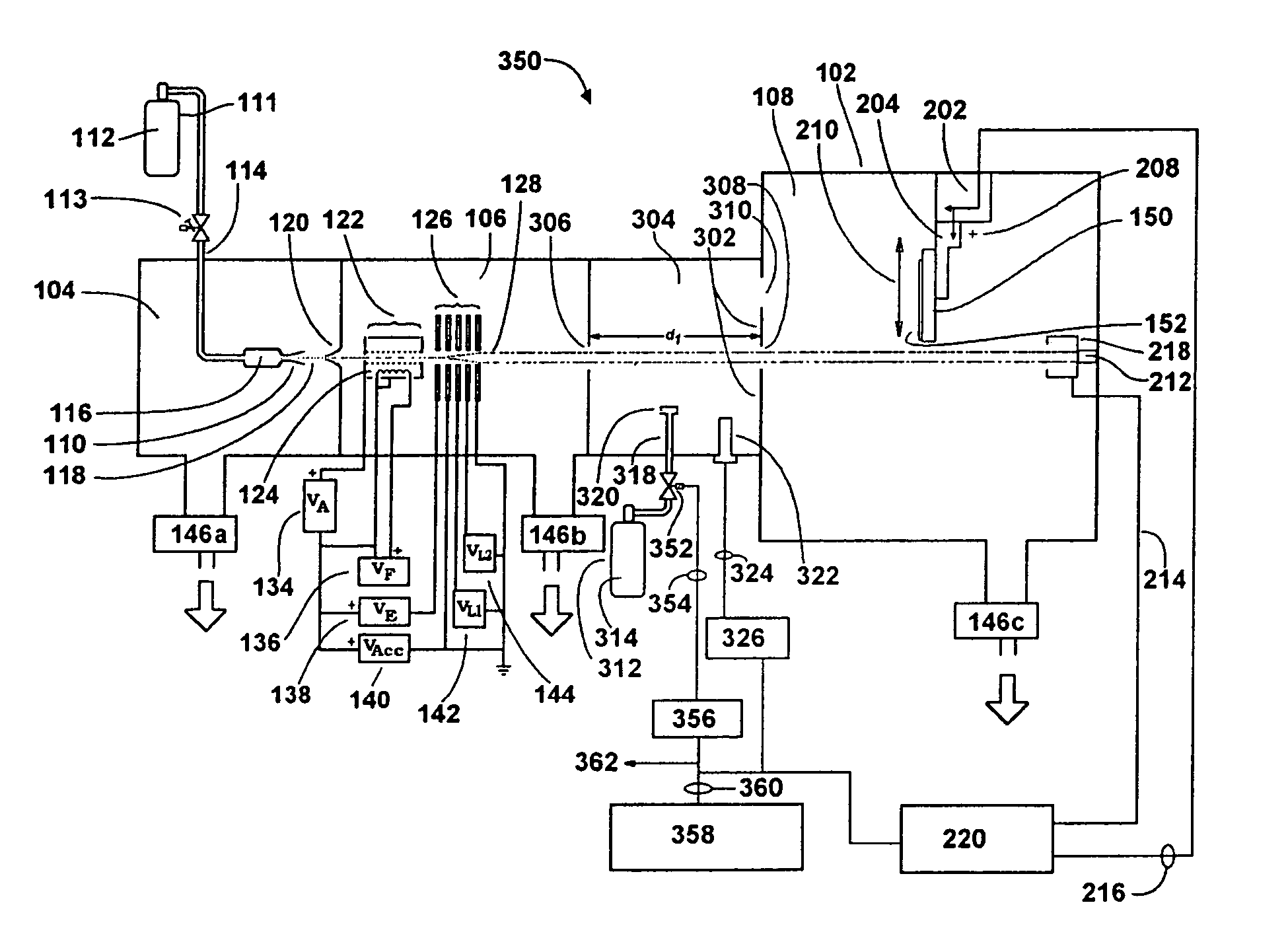

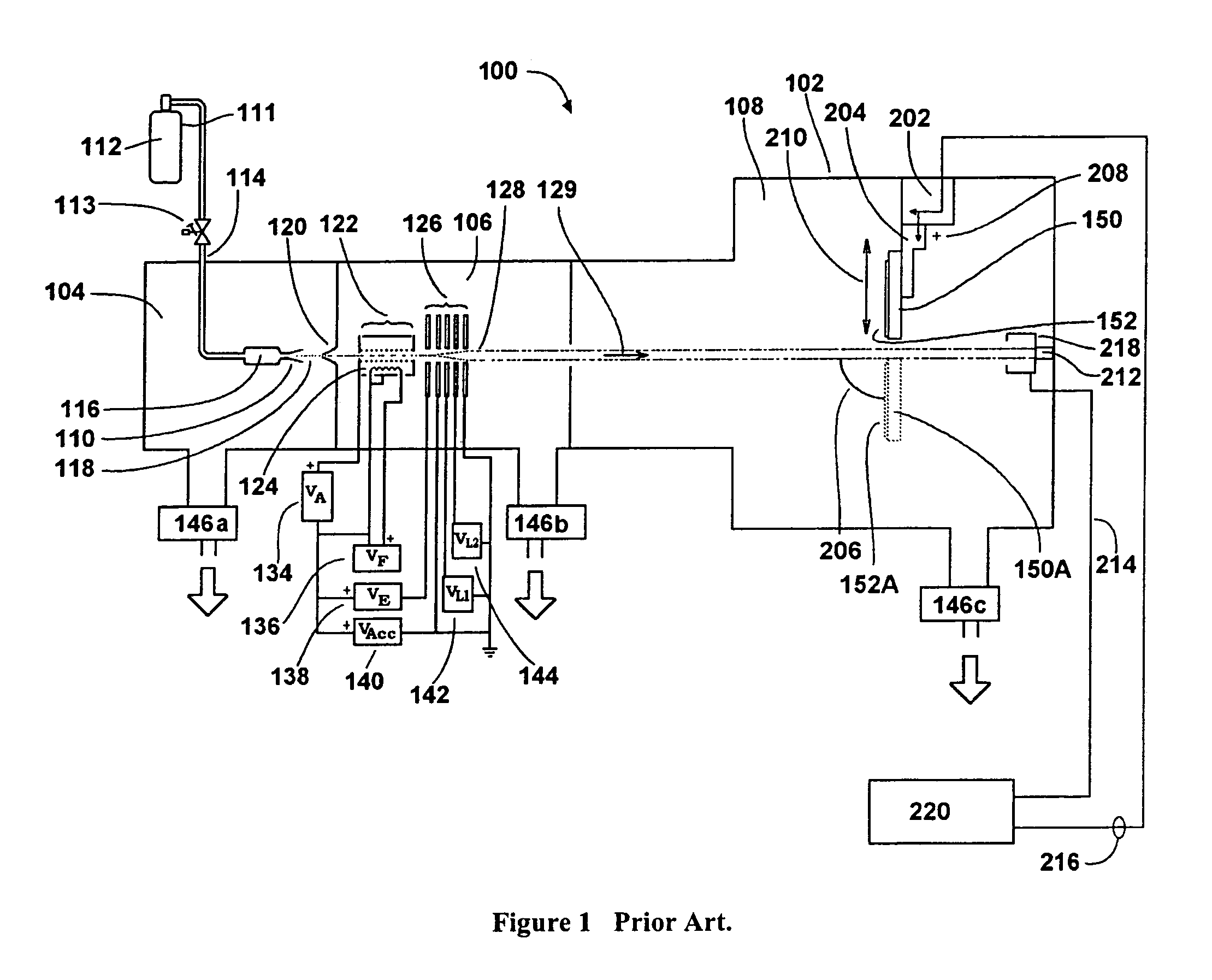

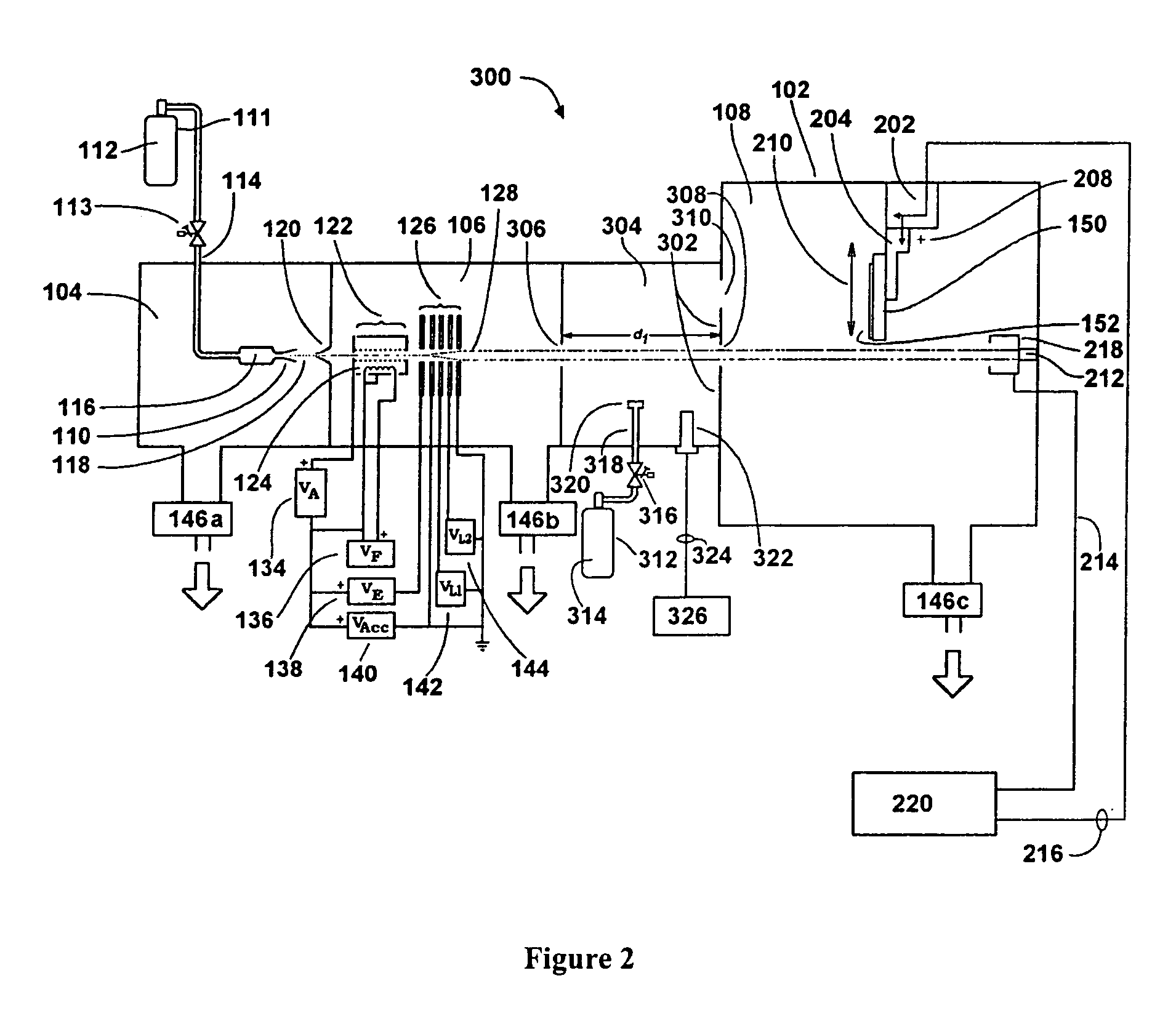

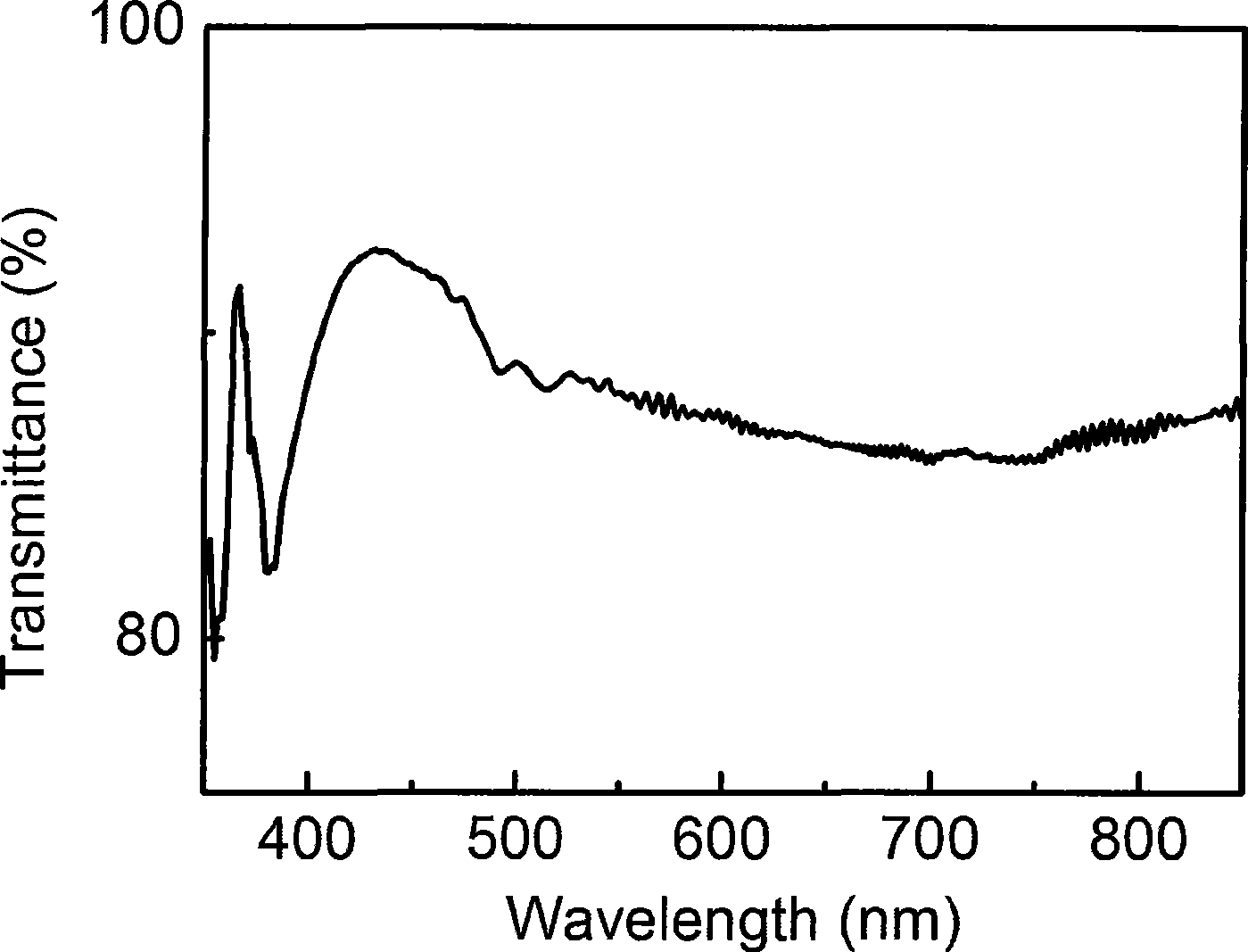

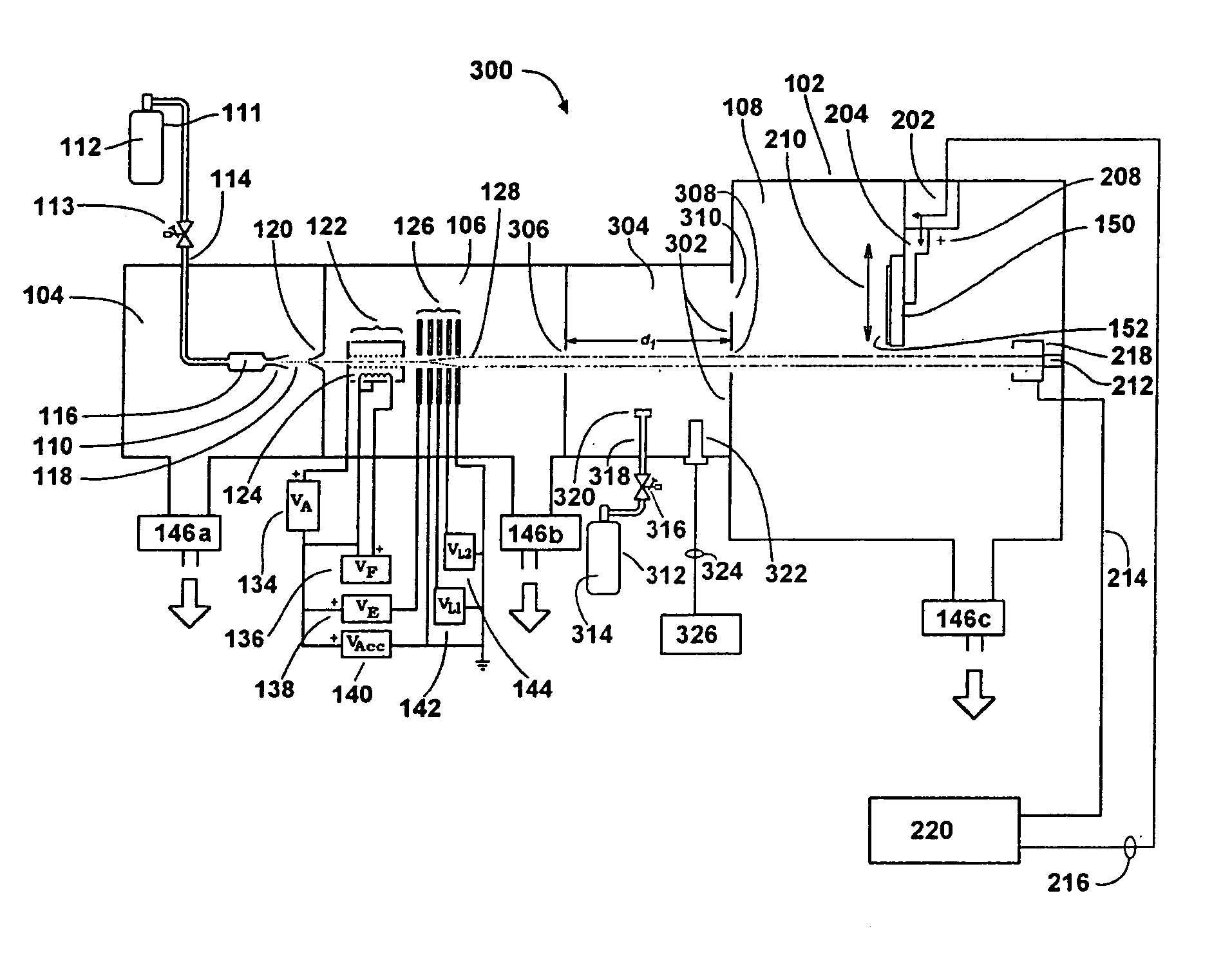

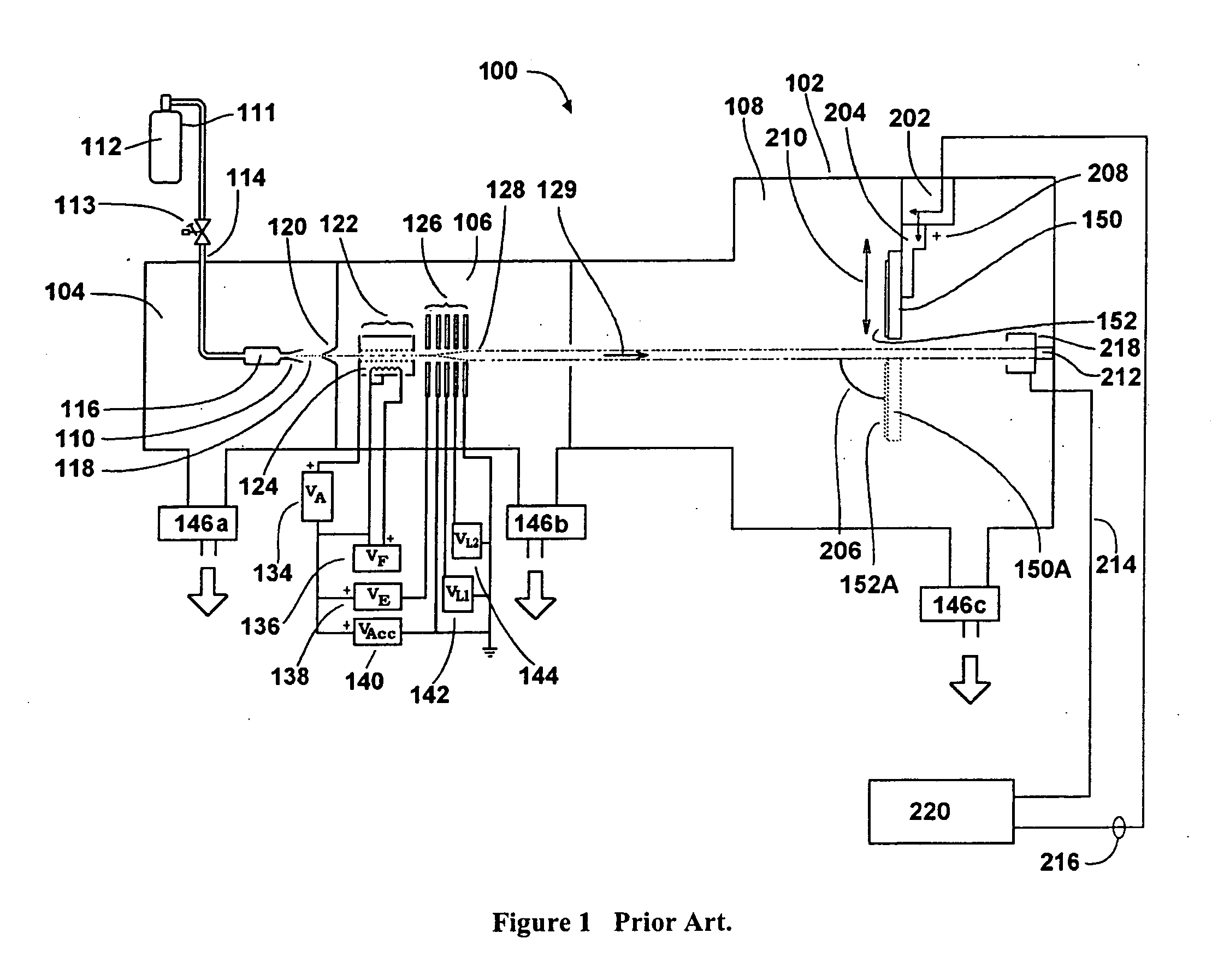

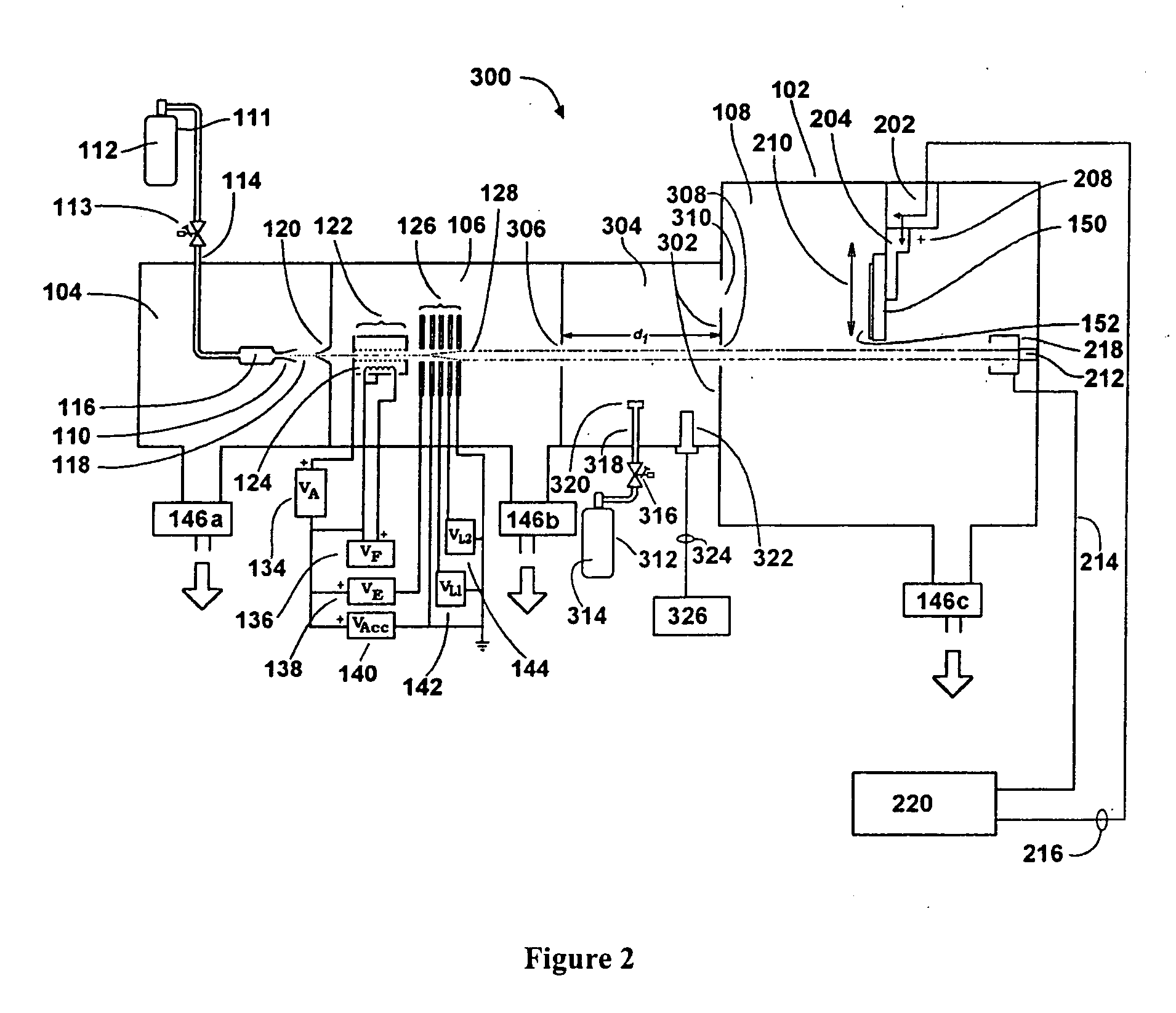

Method and apparatus for improved processing with a gas-cluster ion beam

ActiveUS7060989B2Smoothing capabilityImprove etching effectMaterial analysis by optical meansIon beam tubesGas cluster ion beamLight beam

Apparatus and methods for improving processing of workpieces with gas-cluster ion beams and modifying the gas-cluster ion energy distribution in the GCIB. In a reduced-pressure environment, generating an energetic gas-cluster ion beam and subjecting the beam to increased pressure region.

Owner:TEL EPION

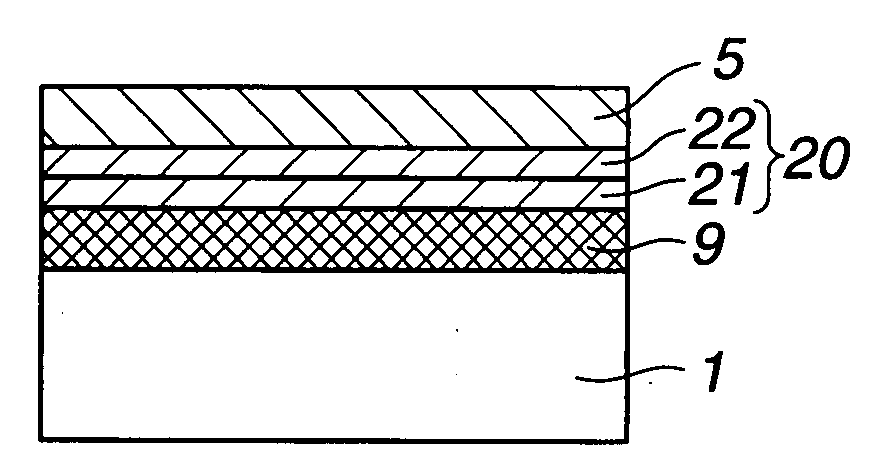

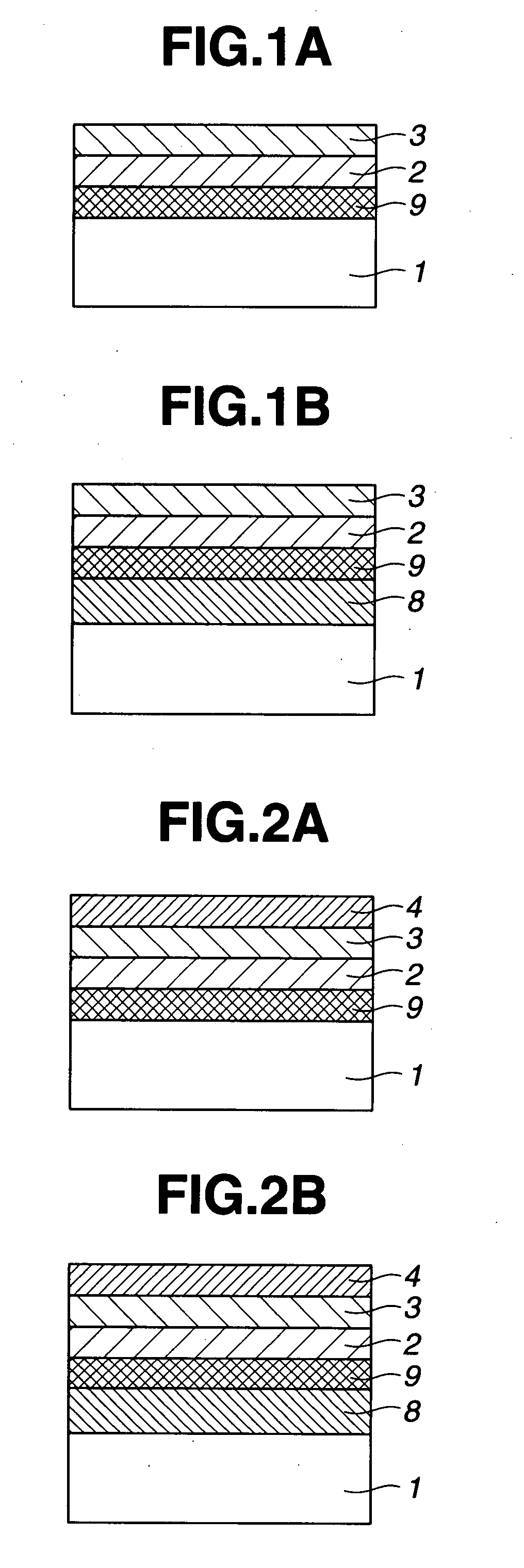

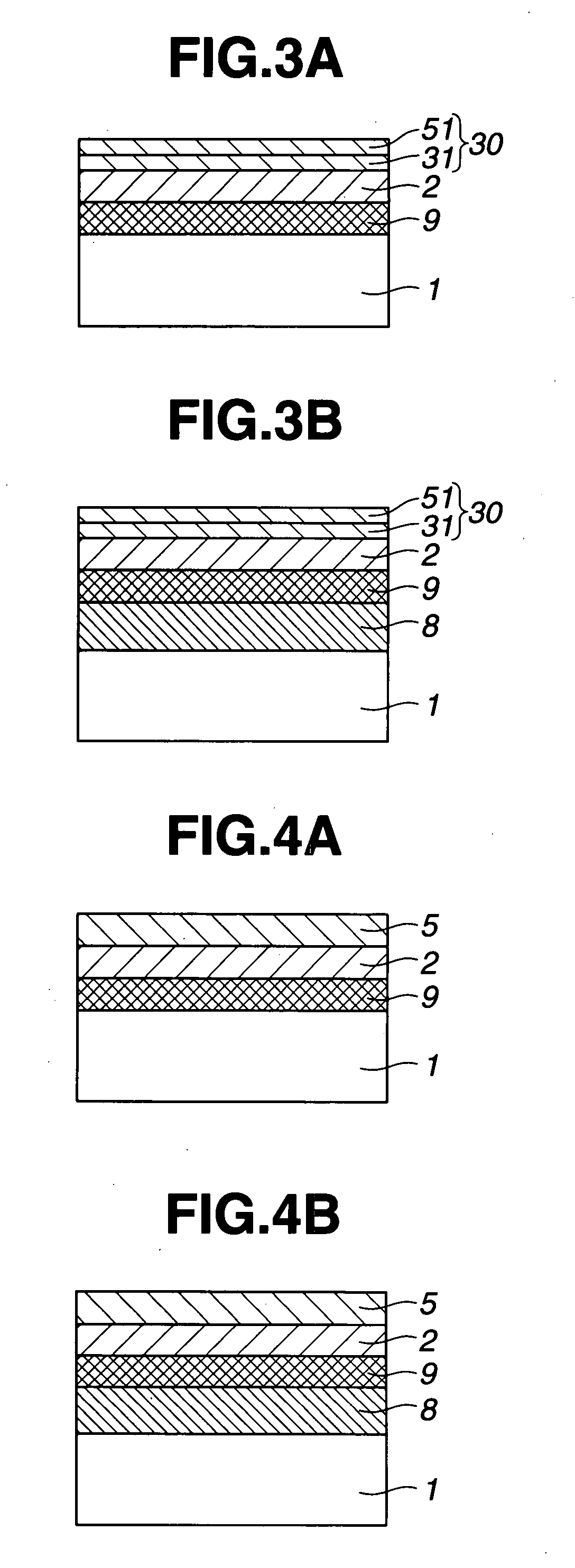

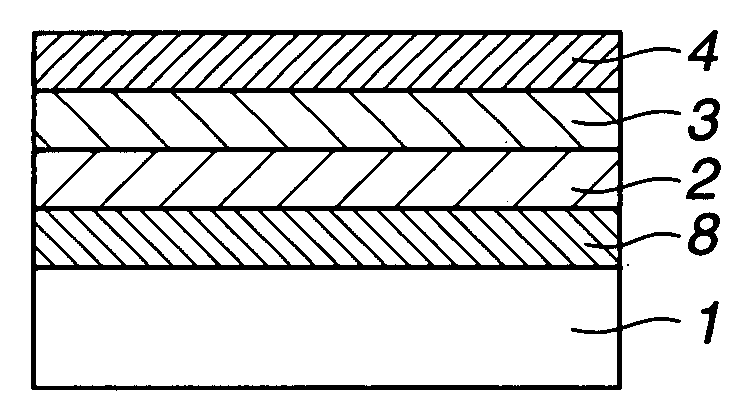

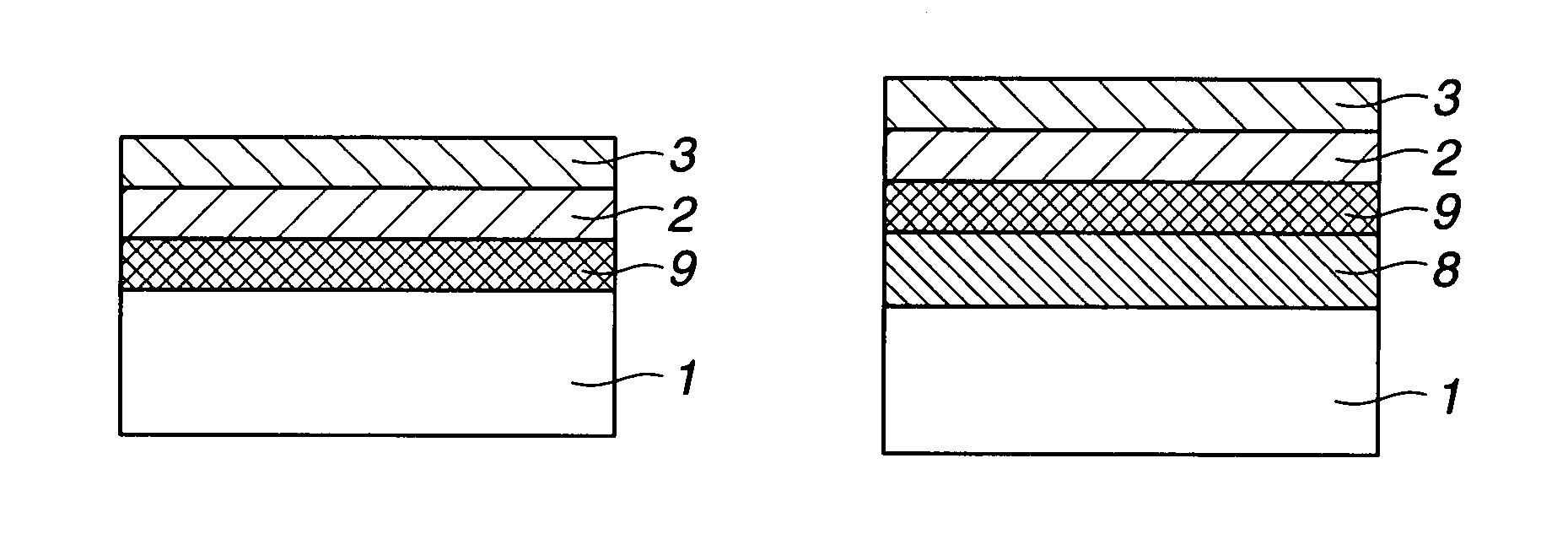

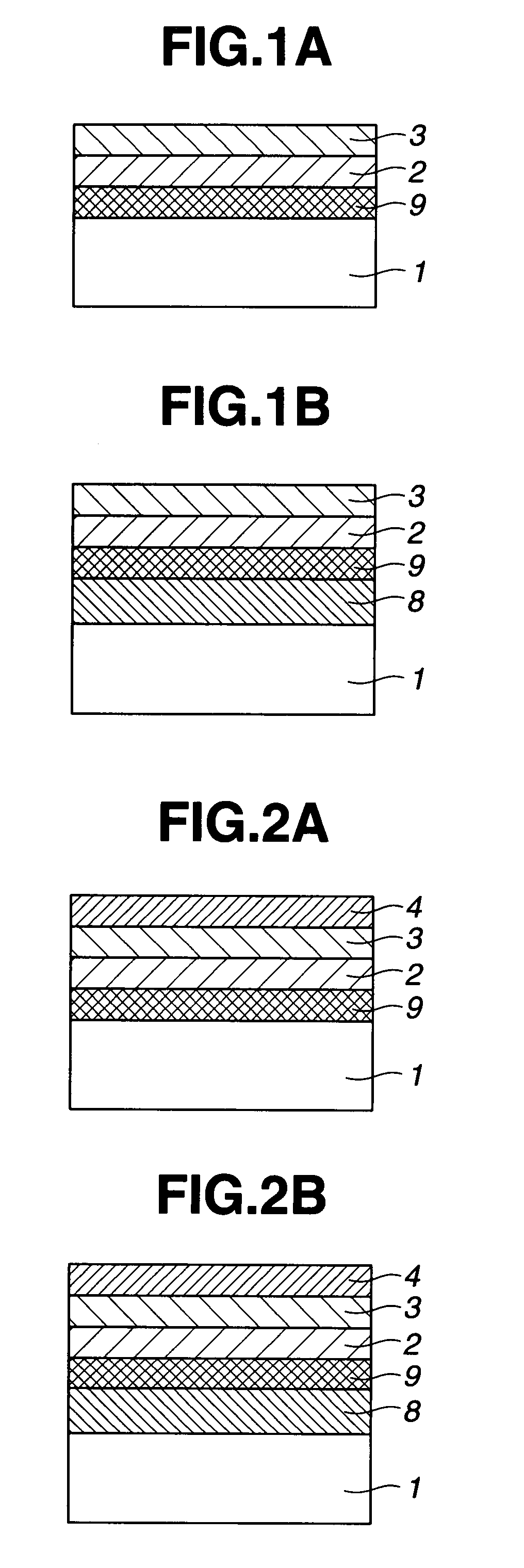

Photomask blank and photomask

ActiveUS20070212618A1High resolutionMinimized pattern densityPhotomechanical apparatusSemiconductor/solid-state device manufacturingSiliconDry etching

A photomask blank is provided comprising an etch stop film which is disposed on a transparent substrate and is resistant to fluorine dry etching and removable by chlorine dry etching, a light-shielding film disposed on the etch stop film and including at least one layer composed of a transition metal / silicon material, and an antireflective film disposed on the light-shielding film. When the light-shielding film is dry etched to form a pattern, pattern size variation arising from pattern density dependency is reduced, so that a photomask is produced at a high accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

Photomask blank and photomask making method

ActiveUS20070212619A1High resolutionImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingOptoelectronicsDry etching

A photomask blank comprises a transparent substrate, a light-shielding film deposited on the substrate and comprising a metal or metal compound susceptible to fluorine dry etching, and an etching mask film deposited on the light-shielding film and comprising another metal or metal compound resistant to fluorine dry etching. When the light-shielding film is dry etched to form a pattern, pattern size variation arising from pattern density dependency is reduced, so that a photomask is produced at a high accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

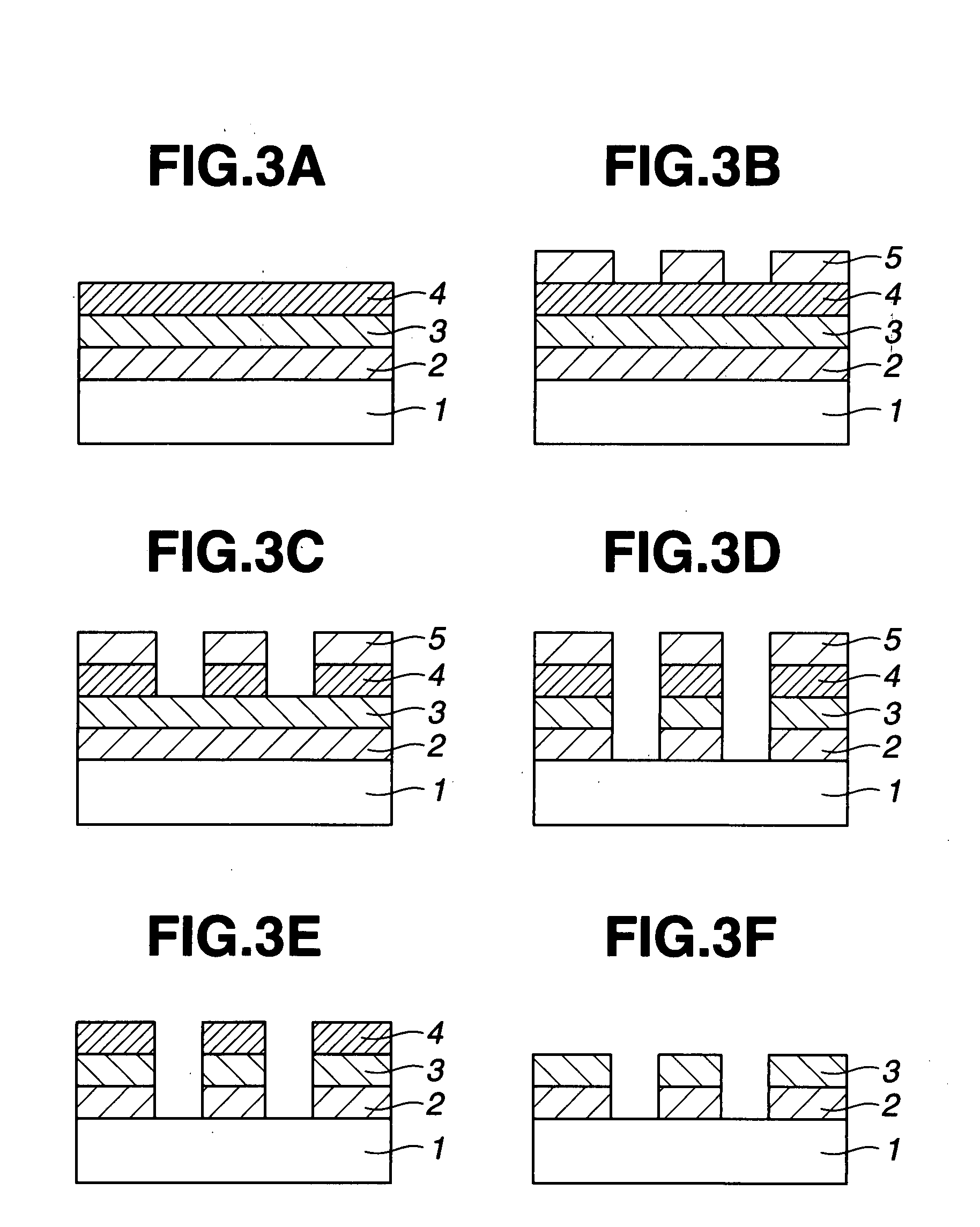

Silica film forming material, silica film and method of manufacturing the same, multilayer wiring structure and method of manufacturing the same, and semiconductor device and method of manufacturing the same

InactiveUS20070026689A1Reduced parasitic capacityImprove signal transmission speedSemiconductor/solid-state device manufacturingCoatingsSilicon dioxideSemiconductor

Owner:FUJITSU LTD

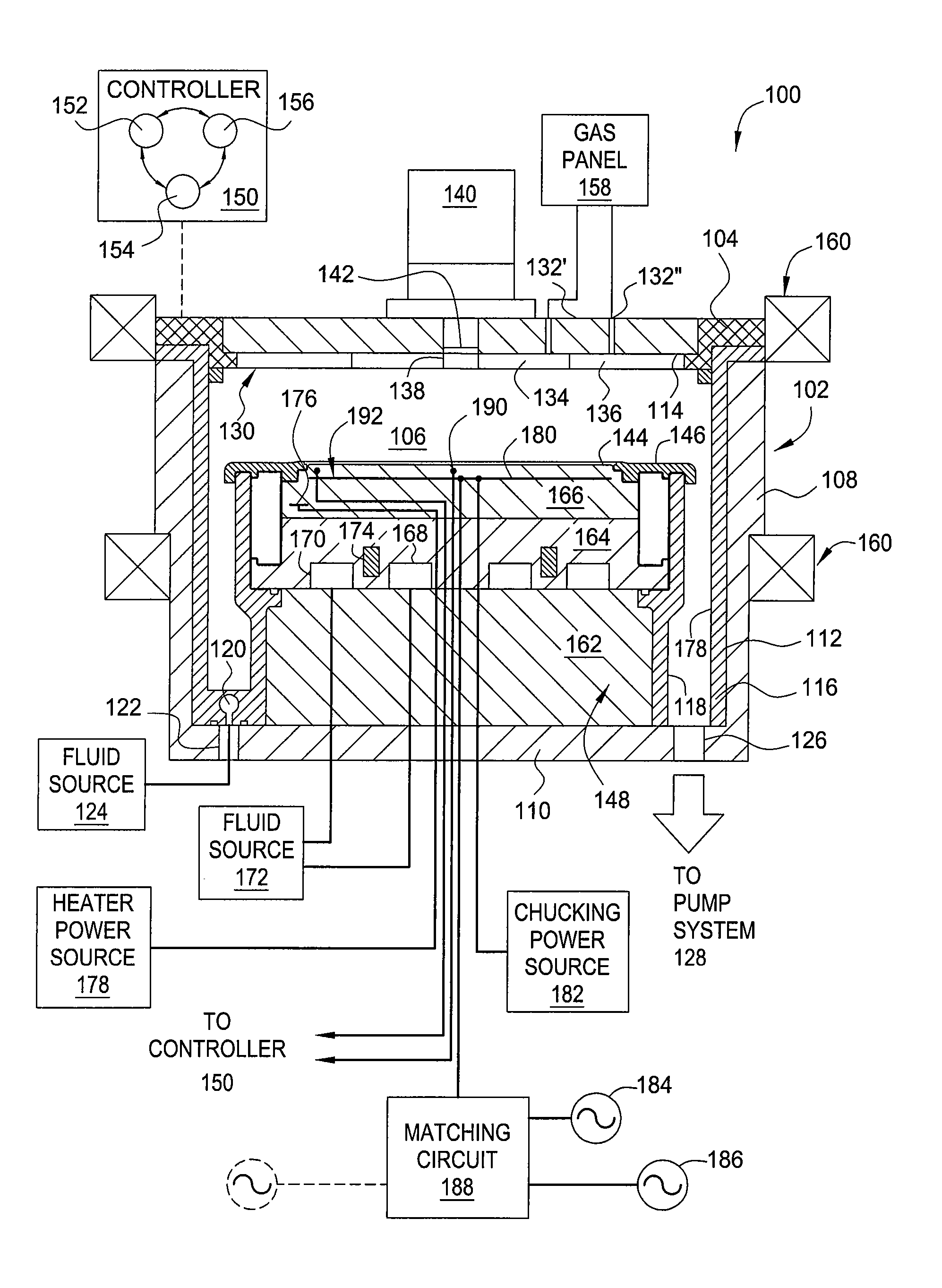

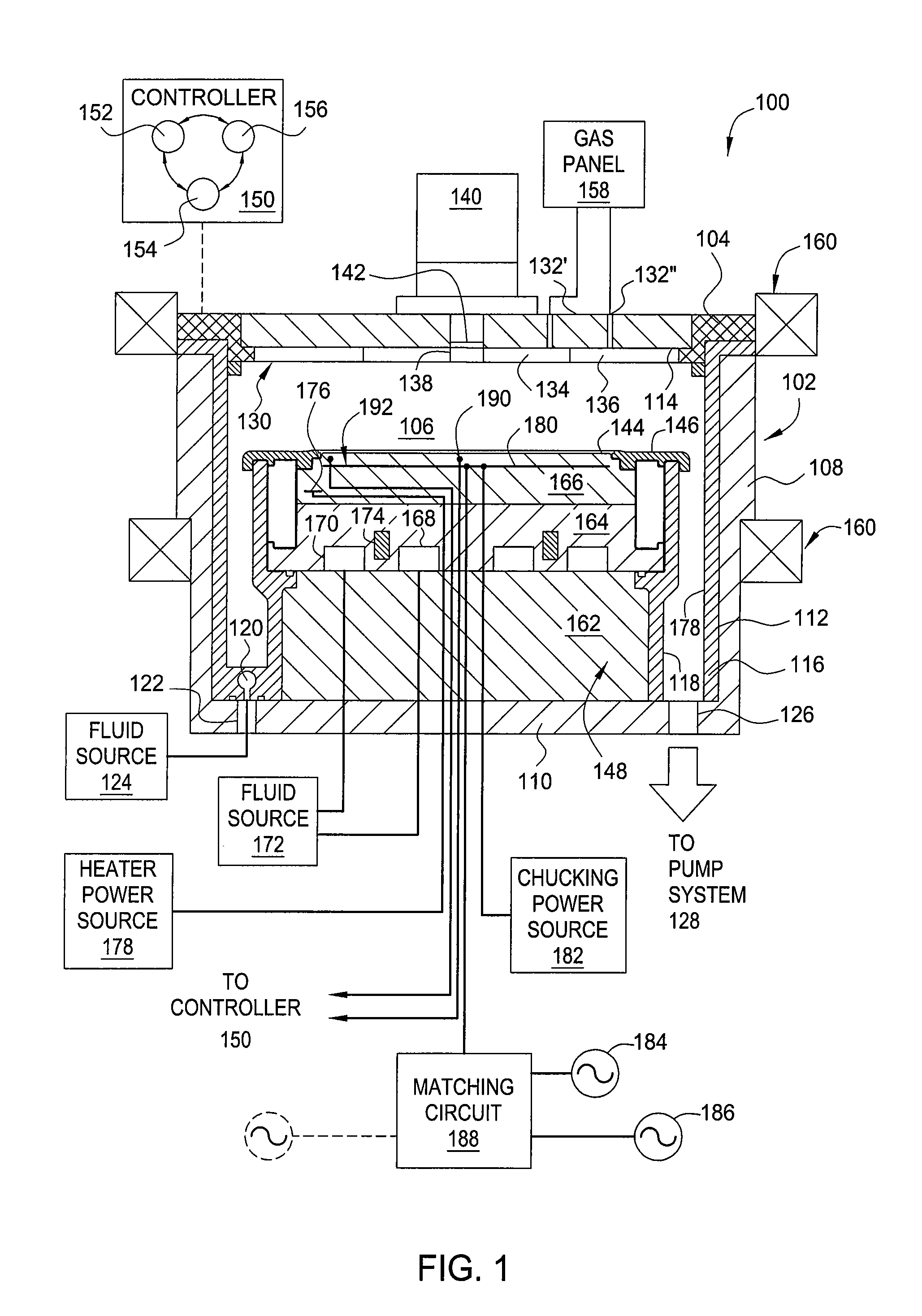

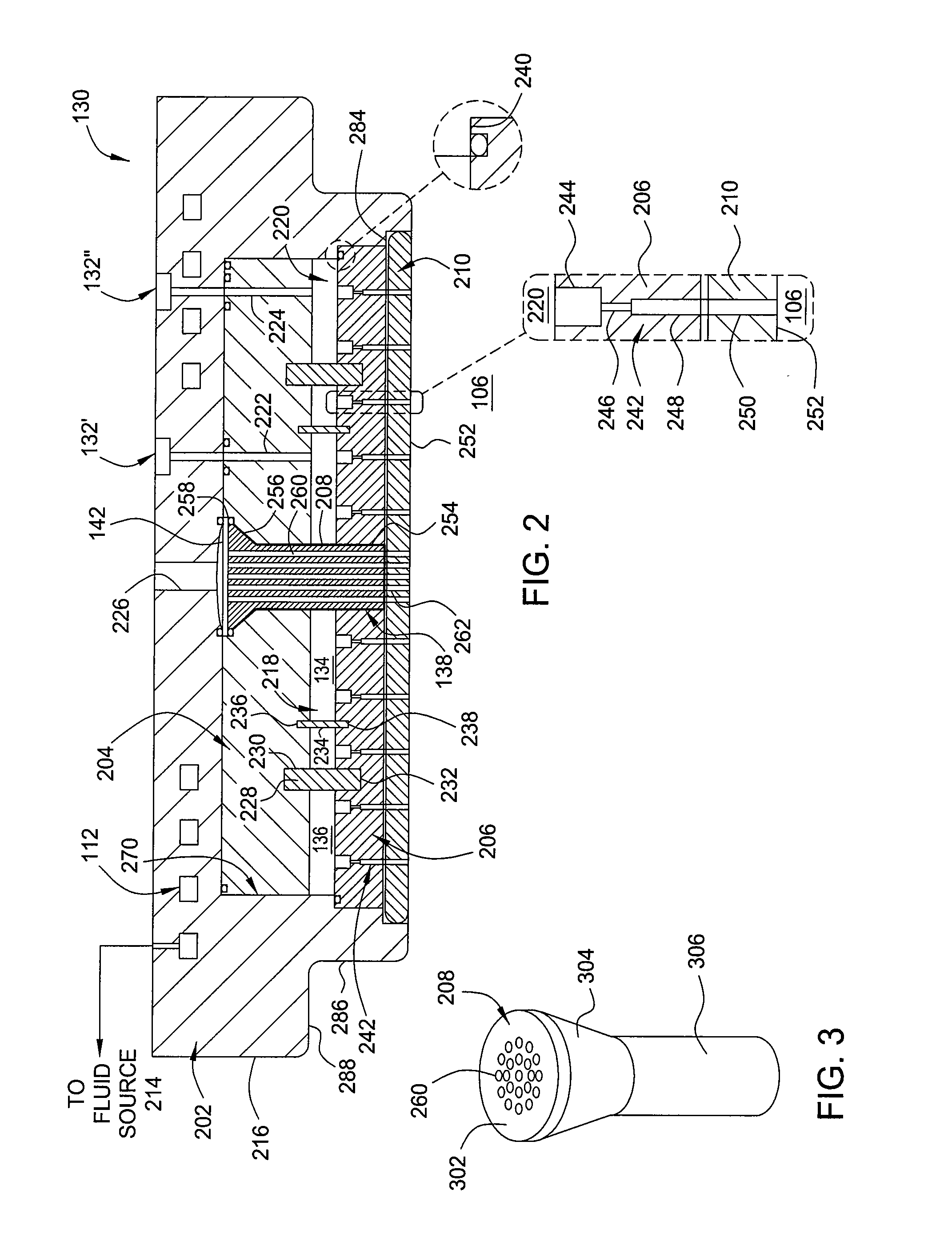

Apparatus for etching high aspect ratio features

InactiveUS20070256785A1Improve performanceHigh aspect ratioElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOptical metrology

Embodiments of the invention provide a method and apparatus, such as a processing chamber, suitable for etching high aspect ratio features. Other embodiments include a showerhead assembly for use in the processing chamber. In one embodiment, a processing chamber includes a chamber body having a showerhead assembly and substrate support disposed therein. The showerhead assembly includes at least two fluidly isolated plenums, a region transmissive to an optical metrology signal, and a plurality of gas passages formed through the showerhead assembly fluidly coupling the plenums to the interior volume of the chamber body.

Owner:APPLIED MATERIALS INC

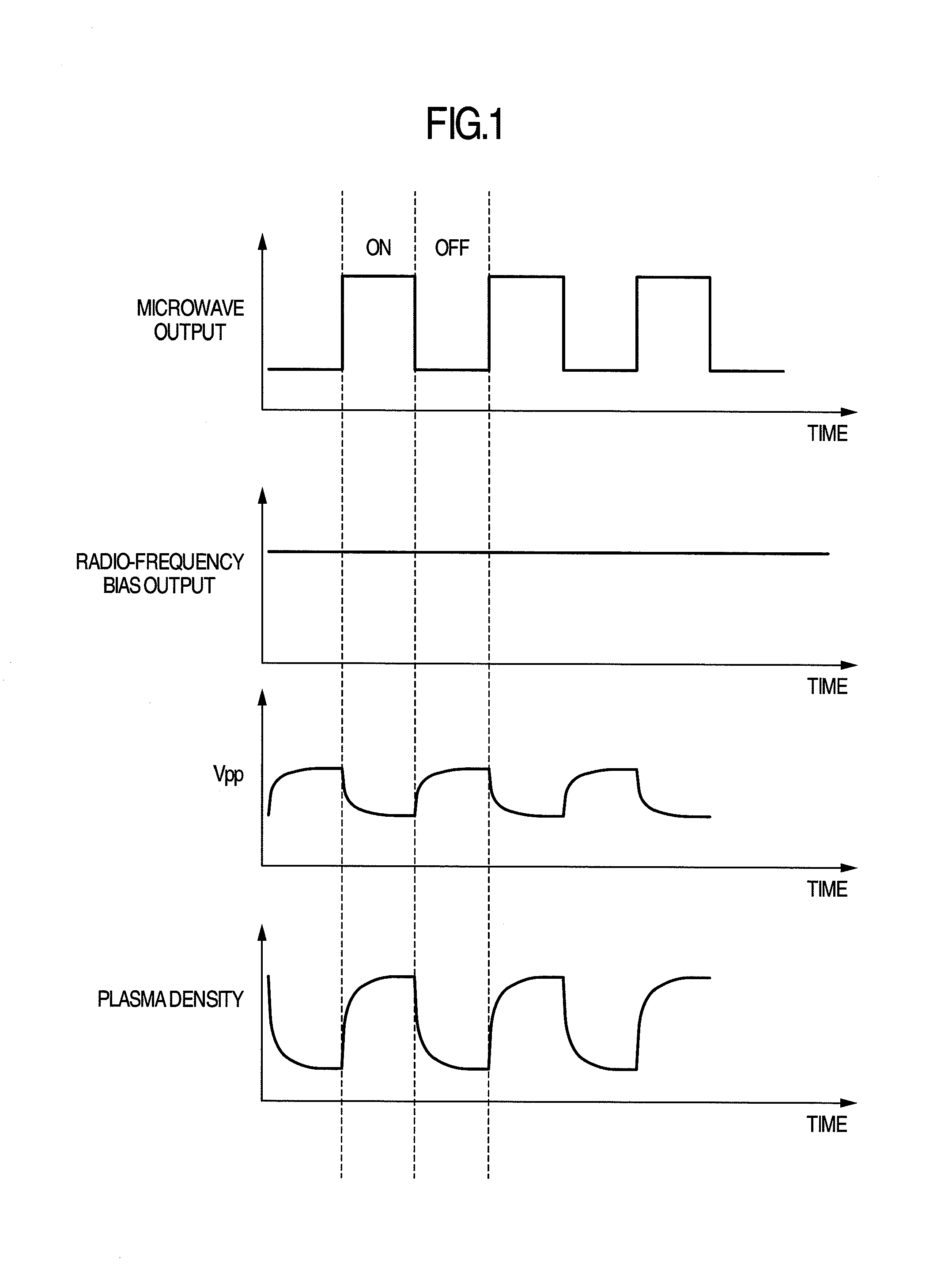

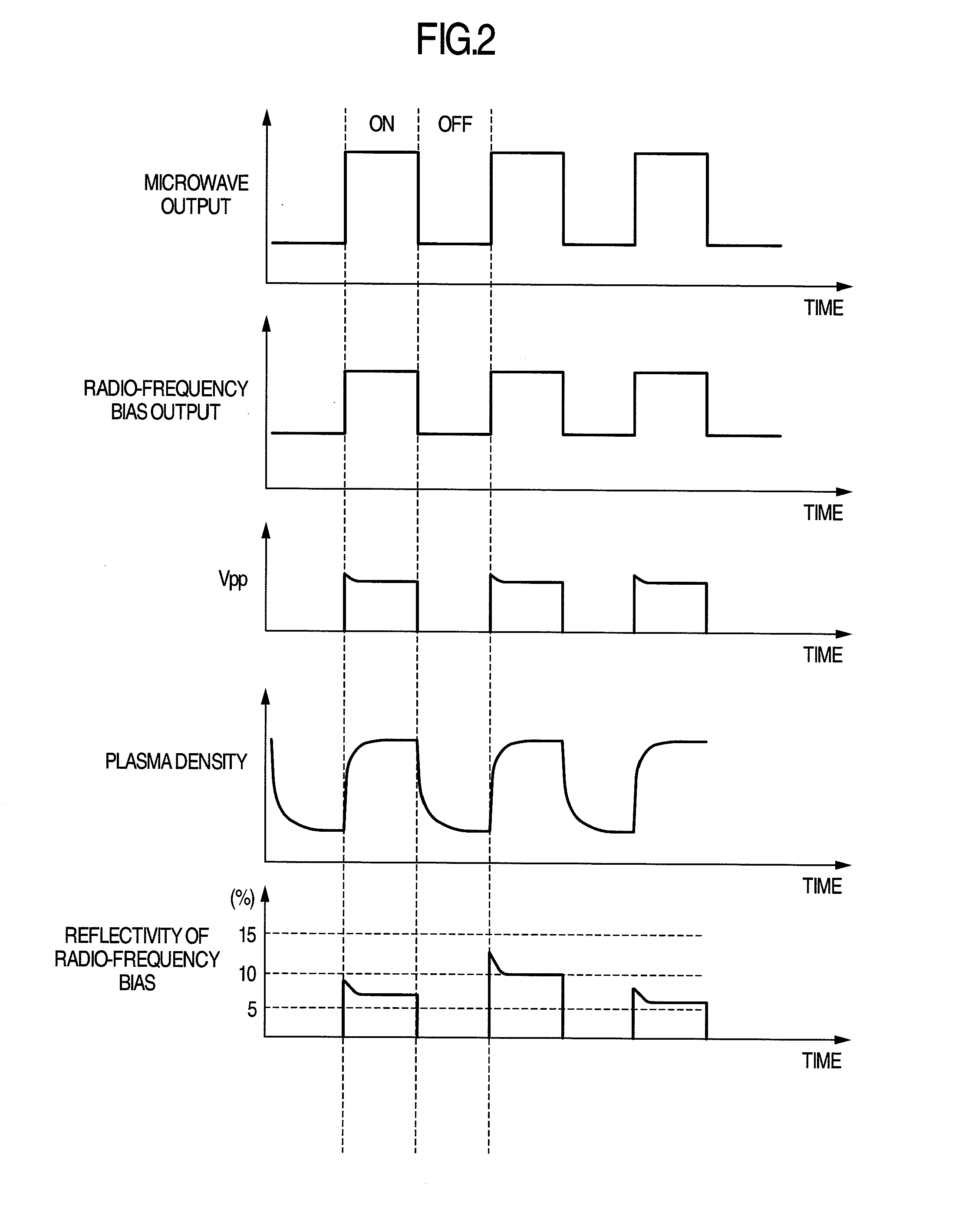

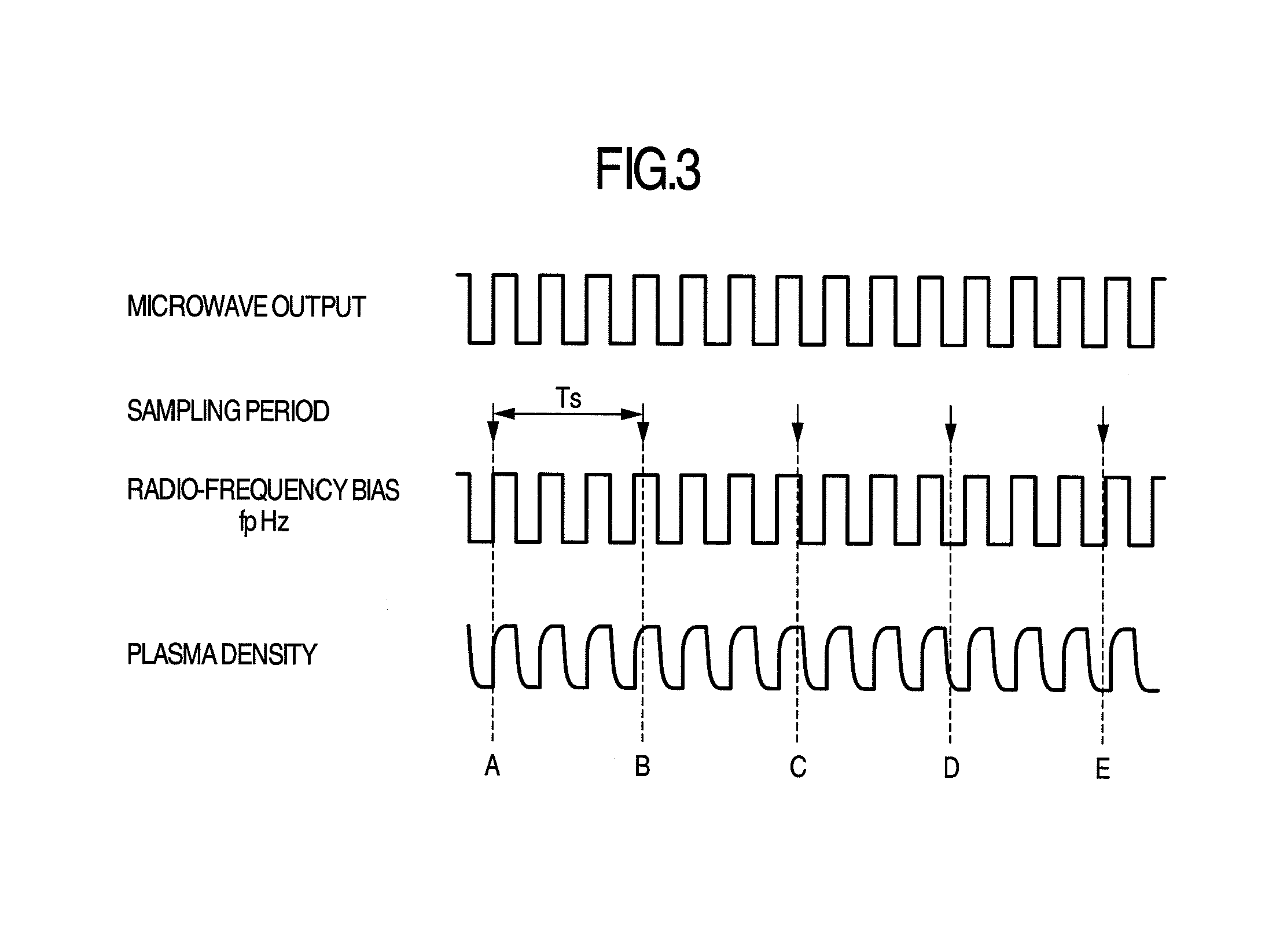

Plasma processing apparatus and plasma processing method

ActiveUS20140363977A1Stable supplyInfluence on the etching performance is generally smallElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringRadio frequency

In a plasma processing apparatus including a first radio-frequency power supply which supplies first radio-frequency power for generating plasma in a vacuum chamber, a second radio-frequency power supply which supplies second radio-frequency power to a sample stage on which a sample is mounted, and a matching box for the second radio-frequency power supply, the matching box samples information for performing matching during a sampling effective period which is from a point of time after elapse of a prescribed time from a beginning of on-state of the time-modulated second radio-frequency power until an end of the on-state and maintains a matching state attained during the sampling effective period from after the end of the on-state until a next sampling effective period.

Owner:HITACHI HIGH-TECH CORP

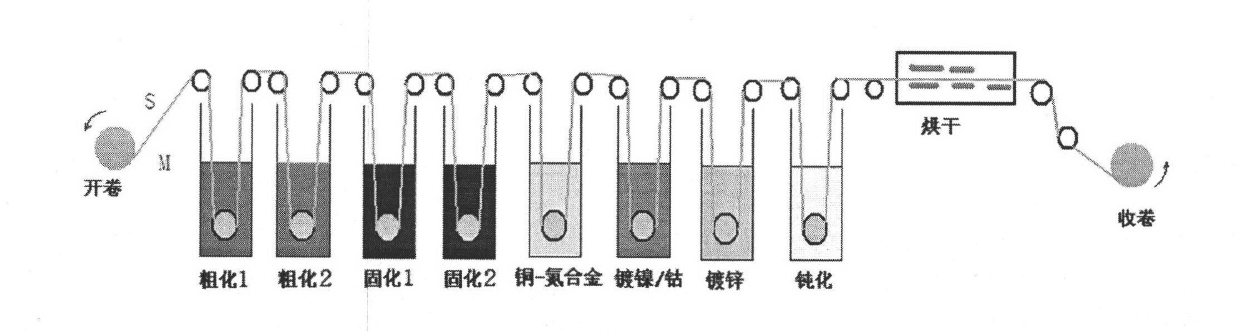

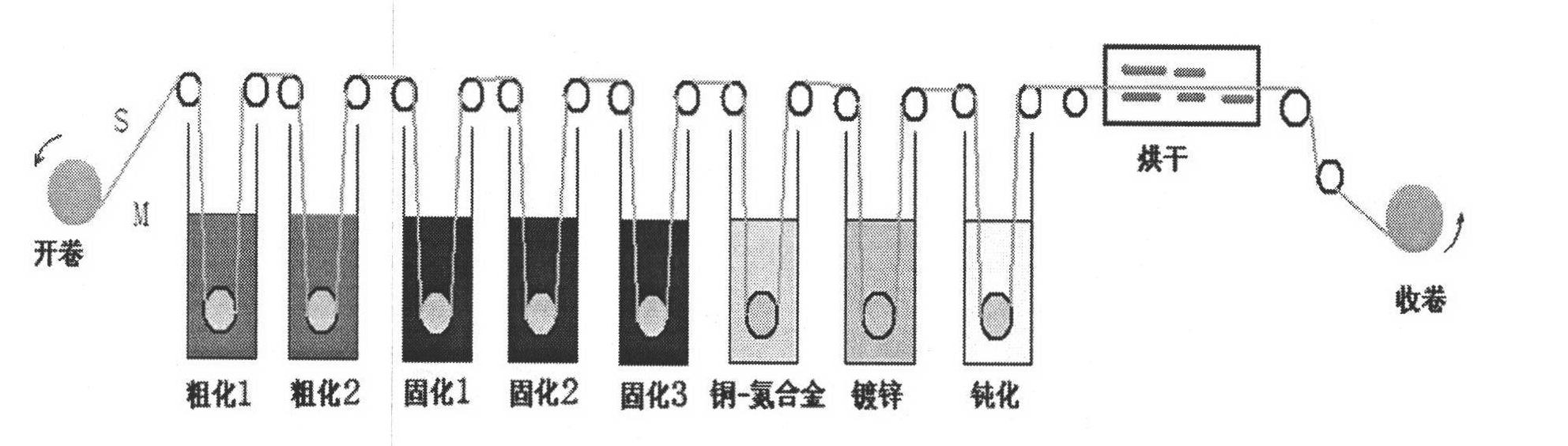

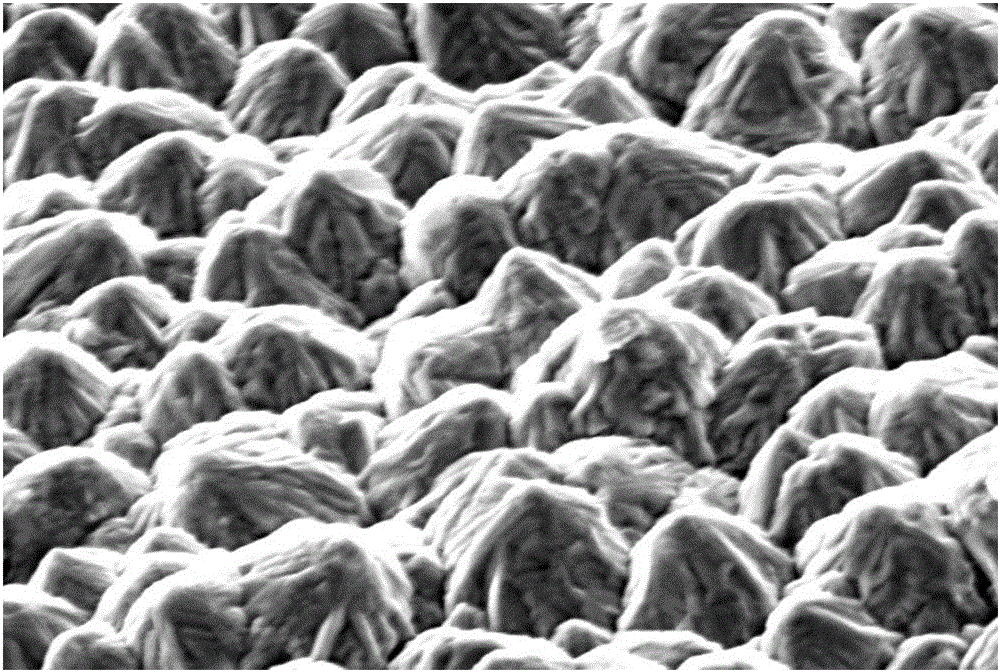

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

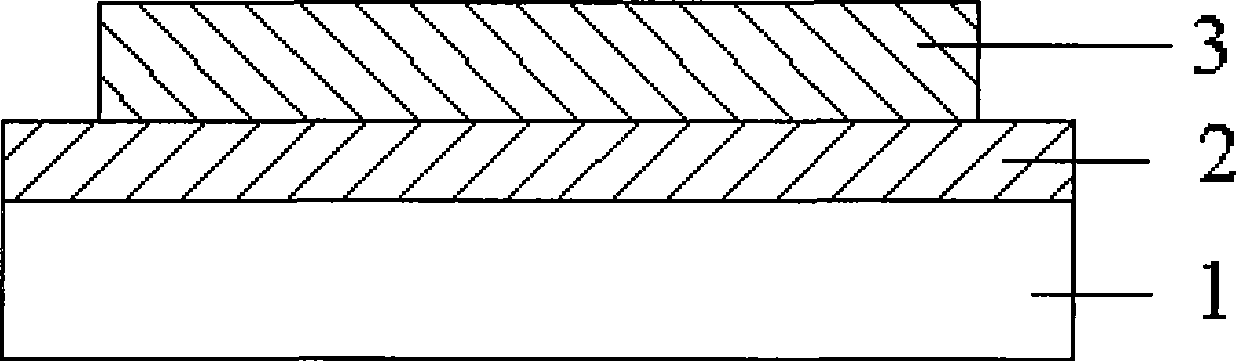

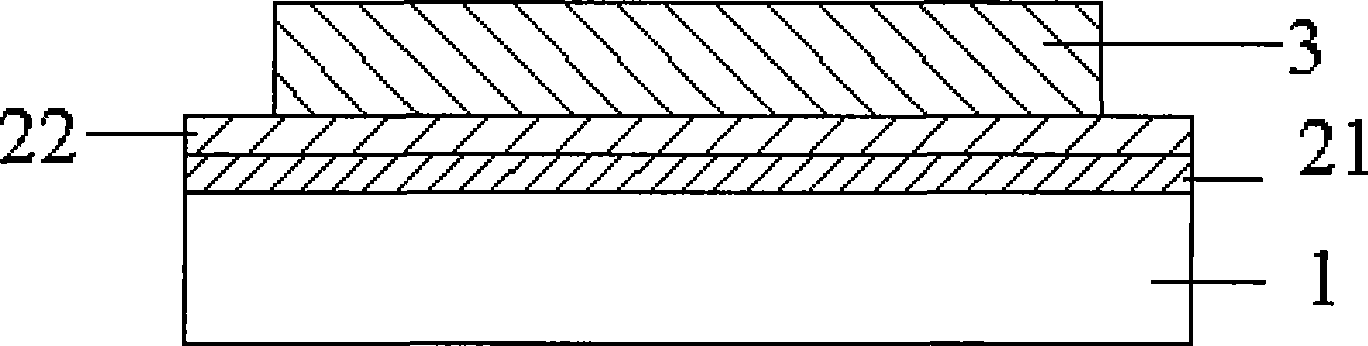

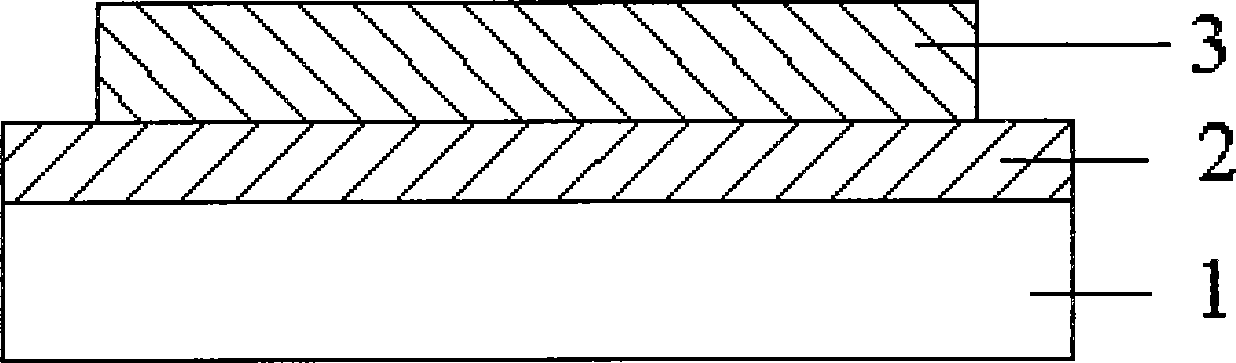

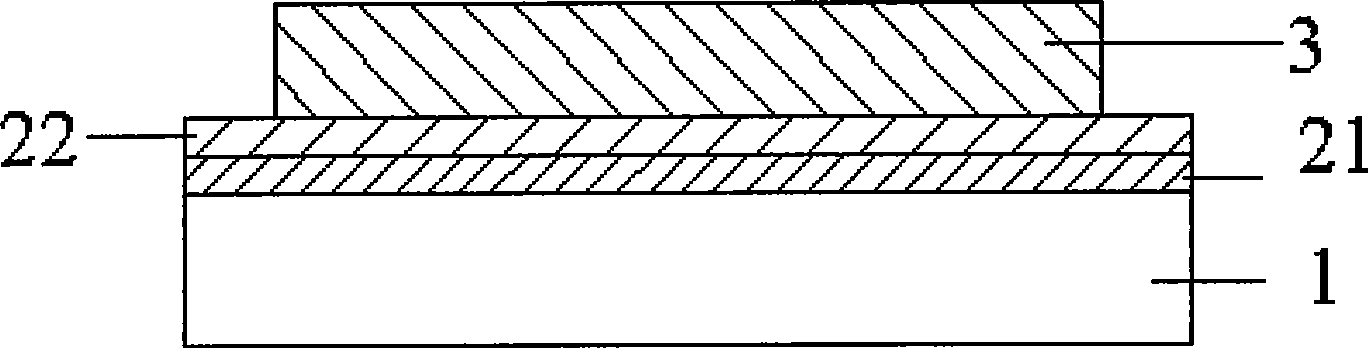

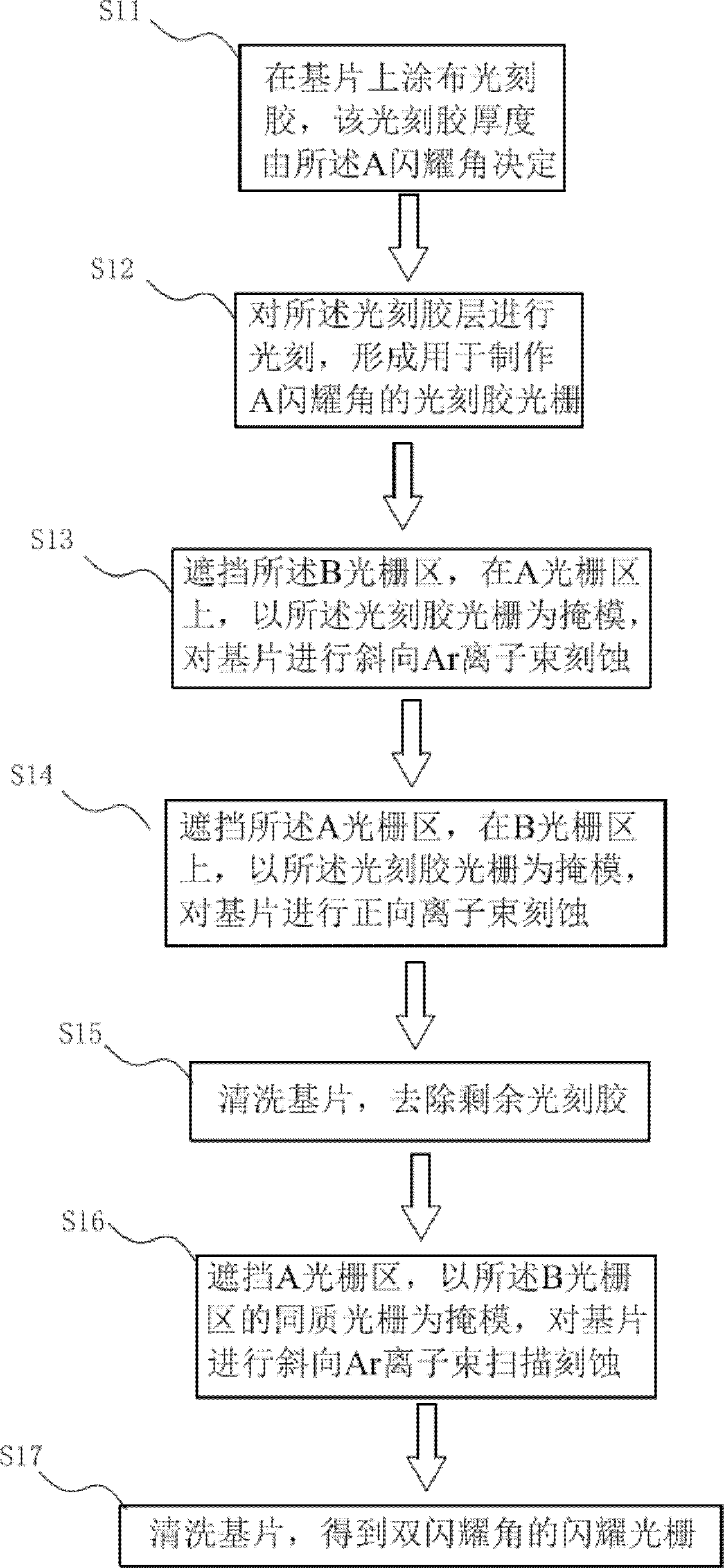

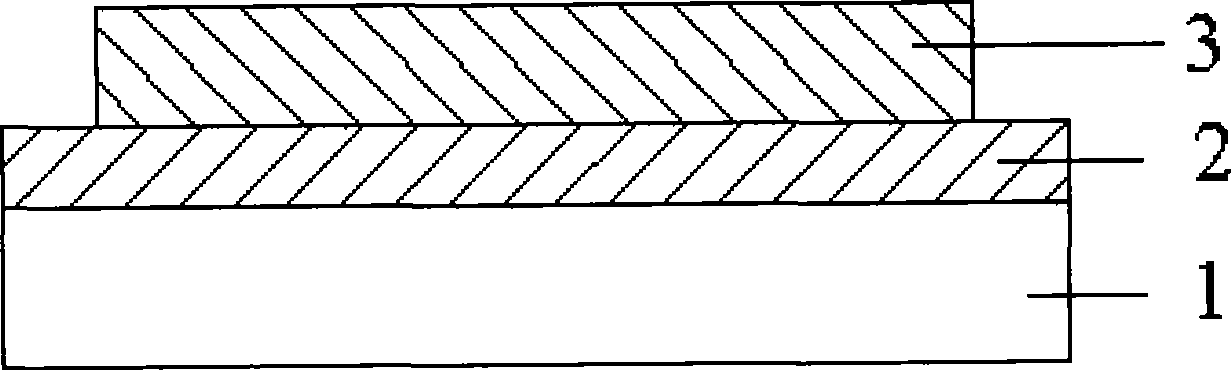

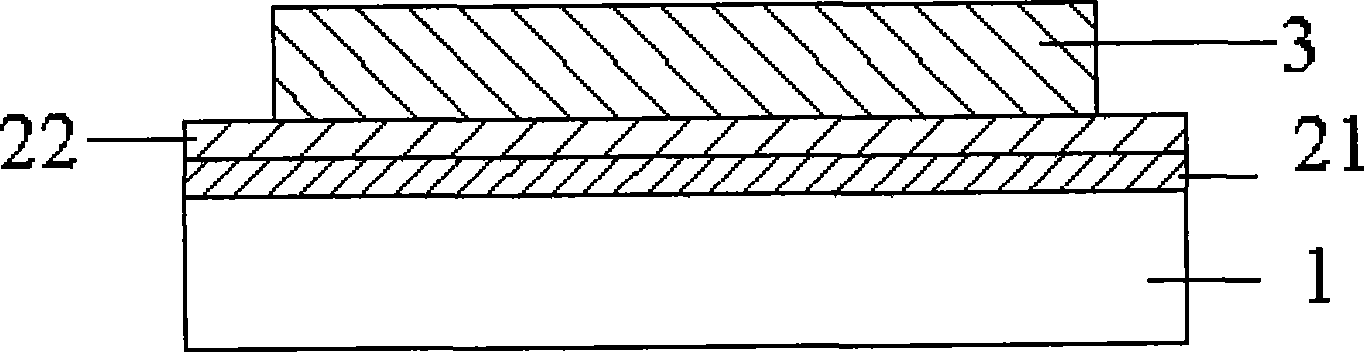

Substrate for flexible organic optoelectronic device and preparation method thereof

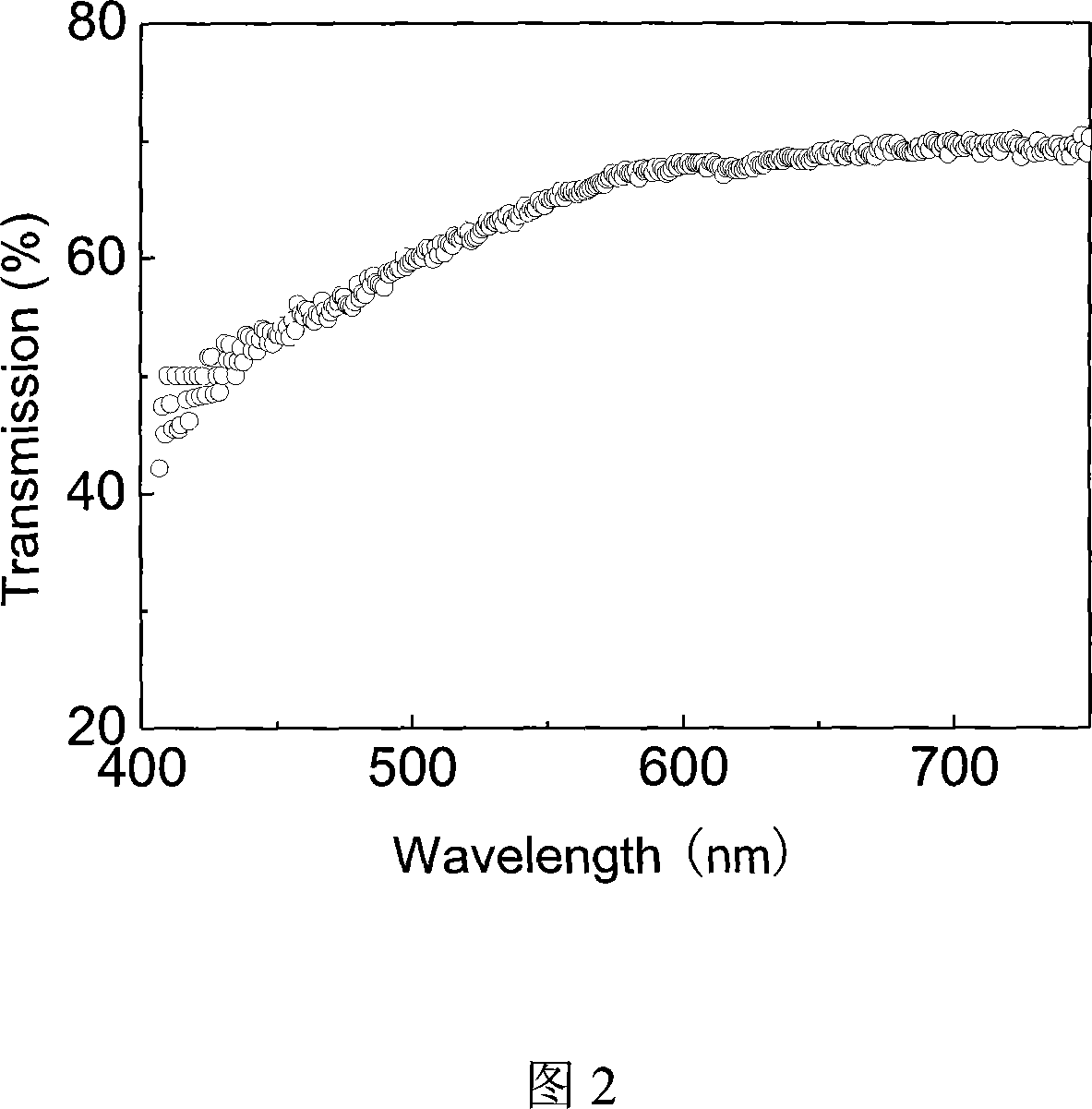

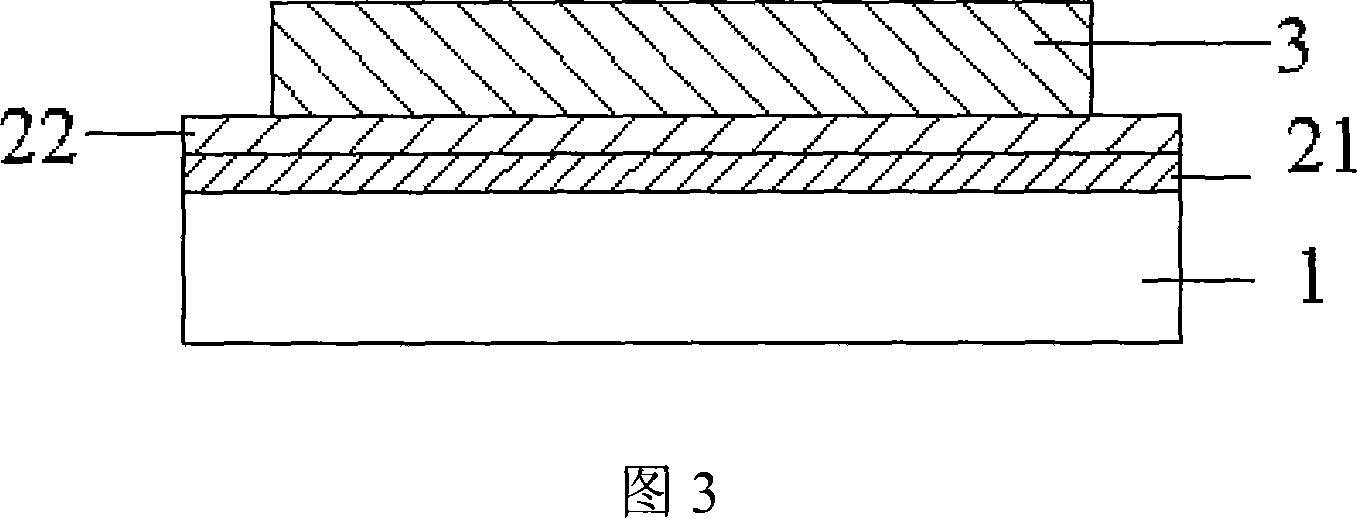

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method and apparatus for improved processing with a gas-cluster ion beam

ActiveUS20050205802A1Smoothing capabilityImprove etching effectMaterial analysis by optical meansIon beam tubesGas cluster ion beamIon energy

Apparatus and methods for improving processing of workpieces with gas-cluster ion beams and modifying the gas-cluster ion energy distribution in the GCIB. In a reduced-pressure environment, generating an energetic gas-cluster ion beam and subjecting the beam to increased pressure region.

Owner:TEL EPION

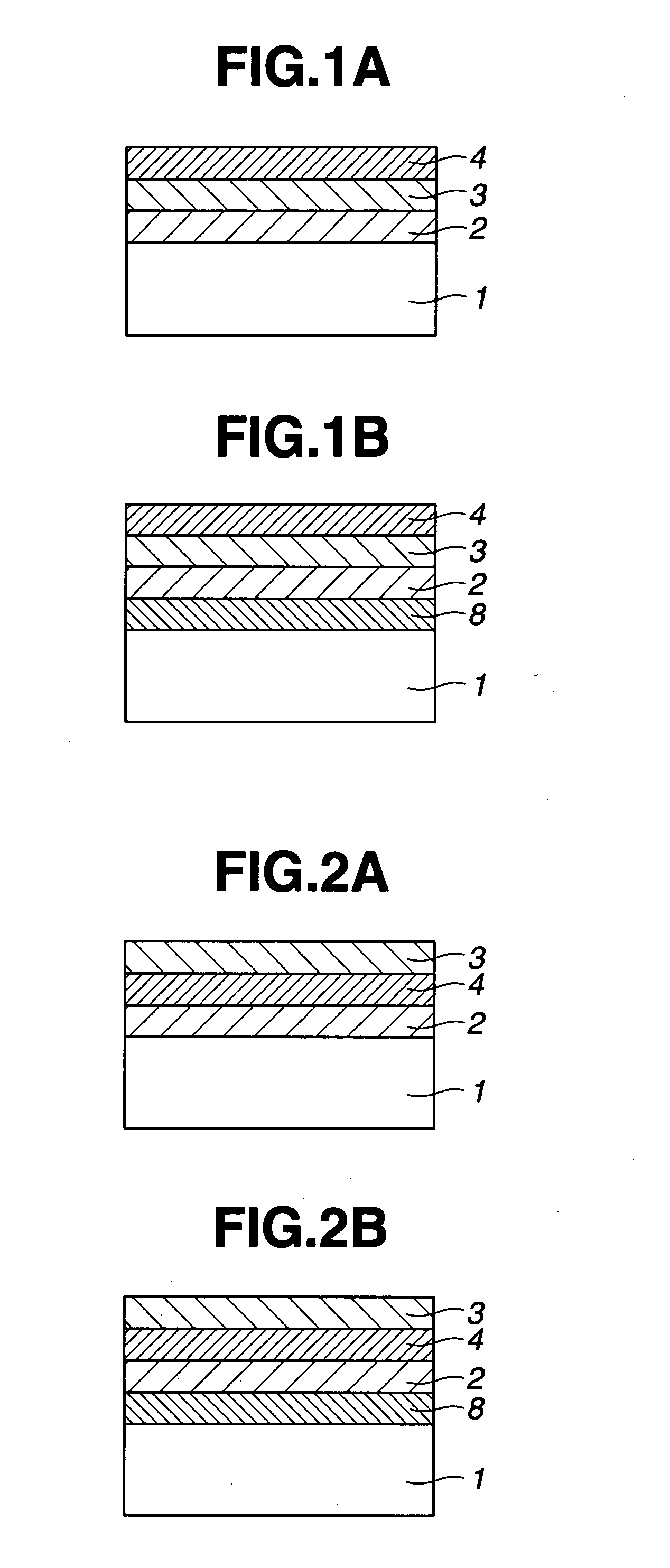

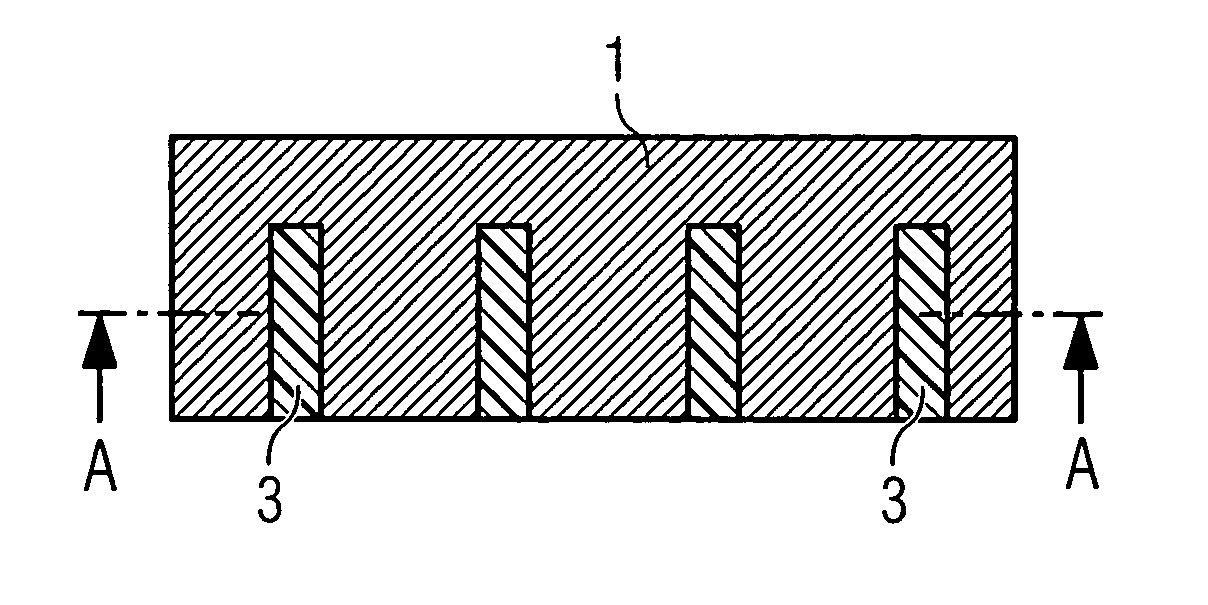

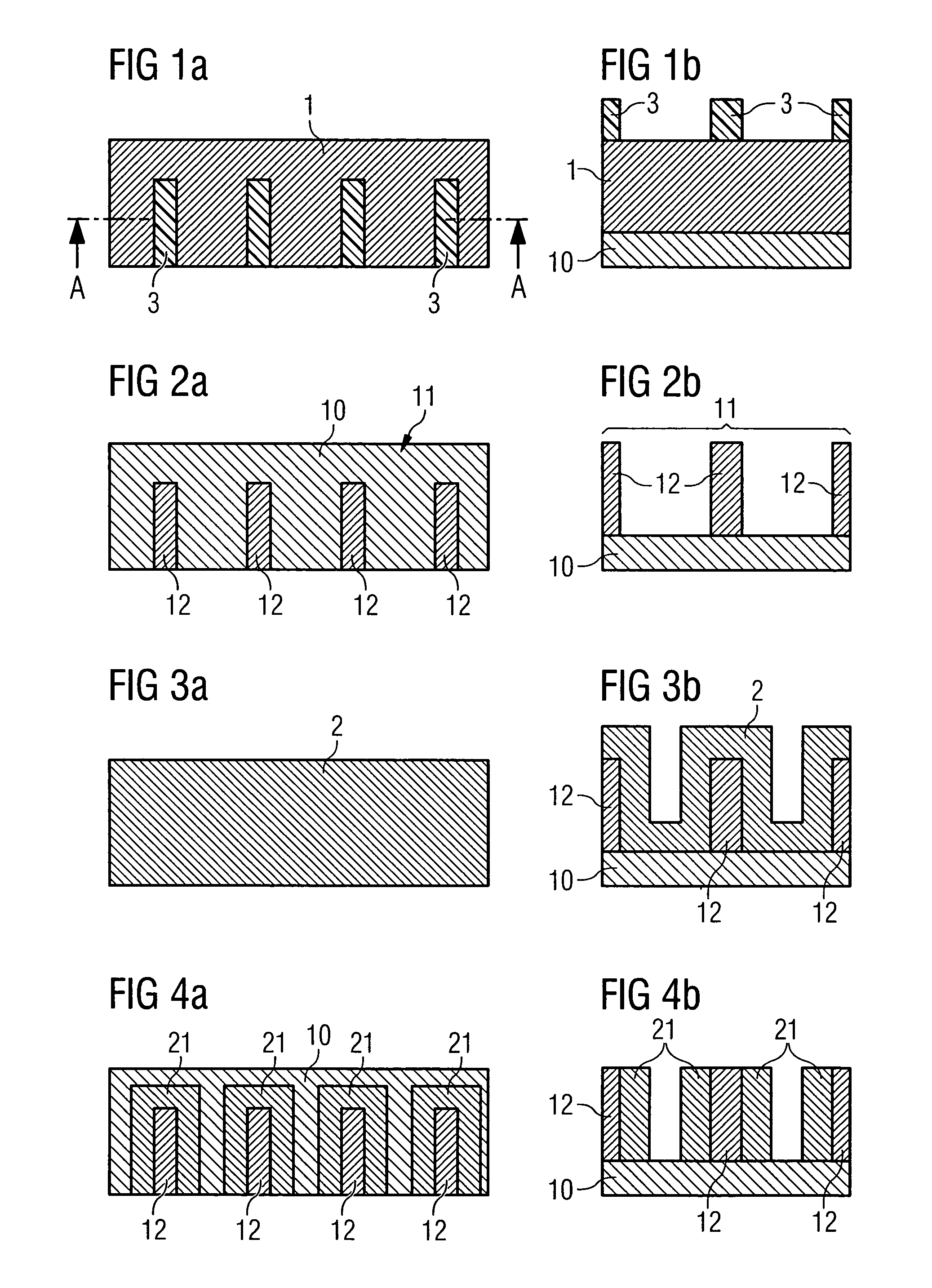

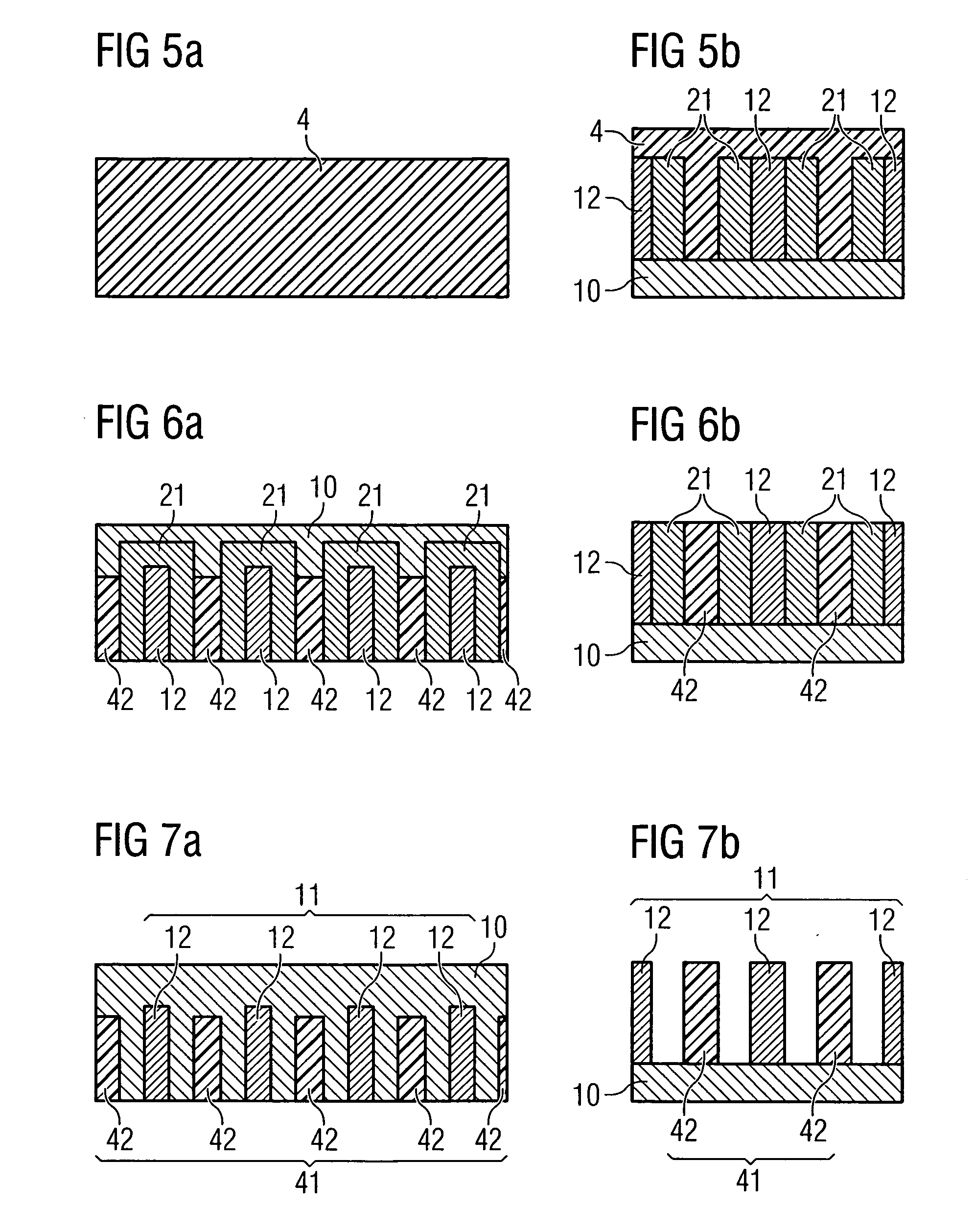

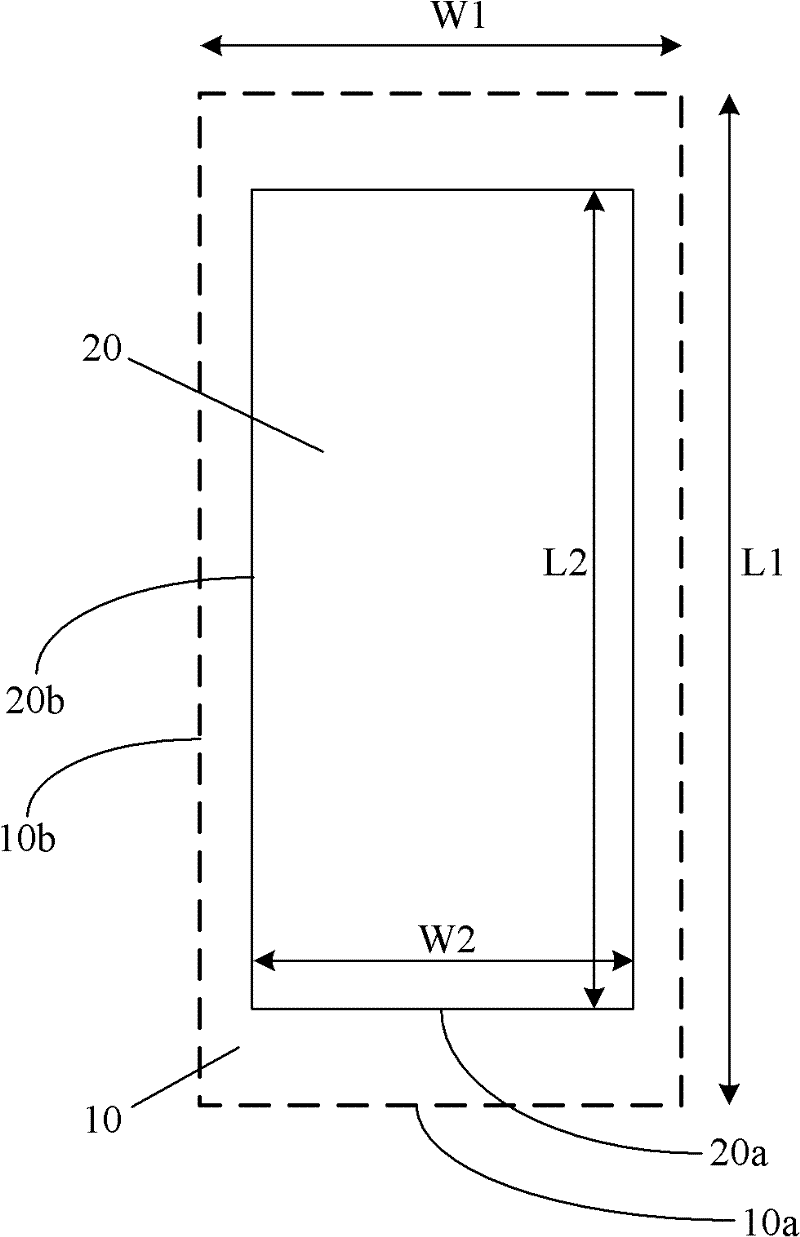

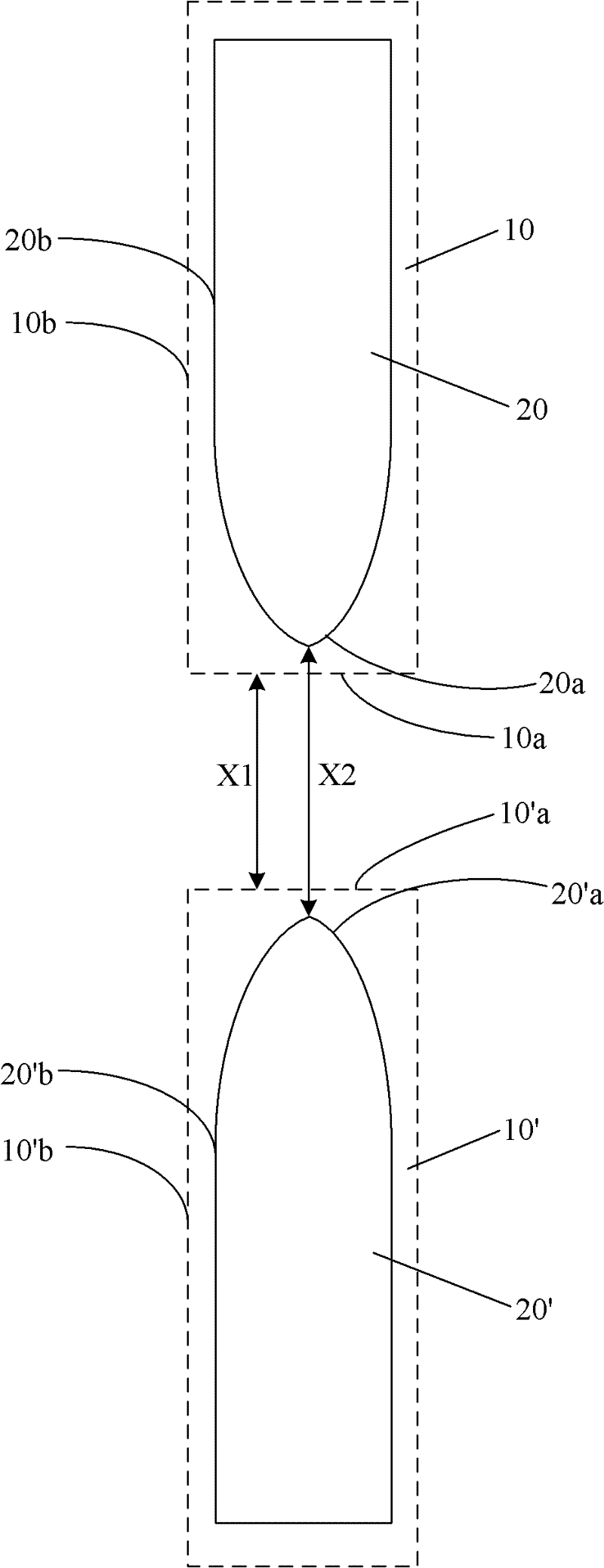

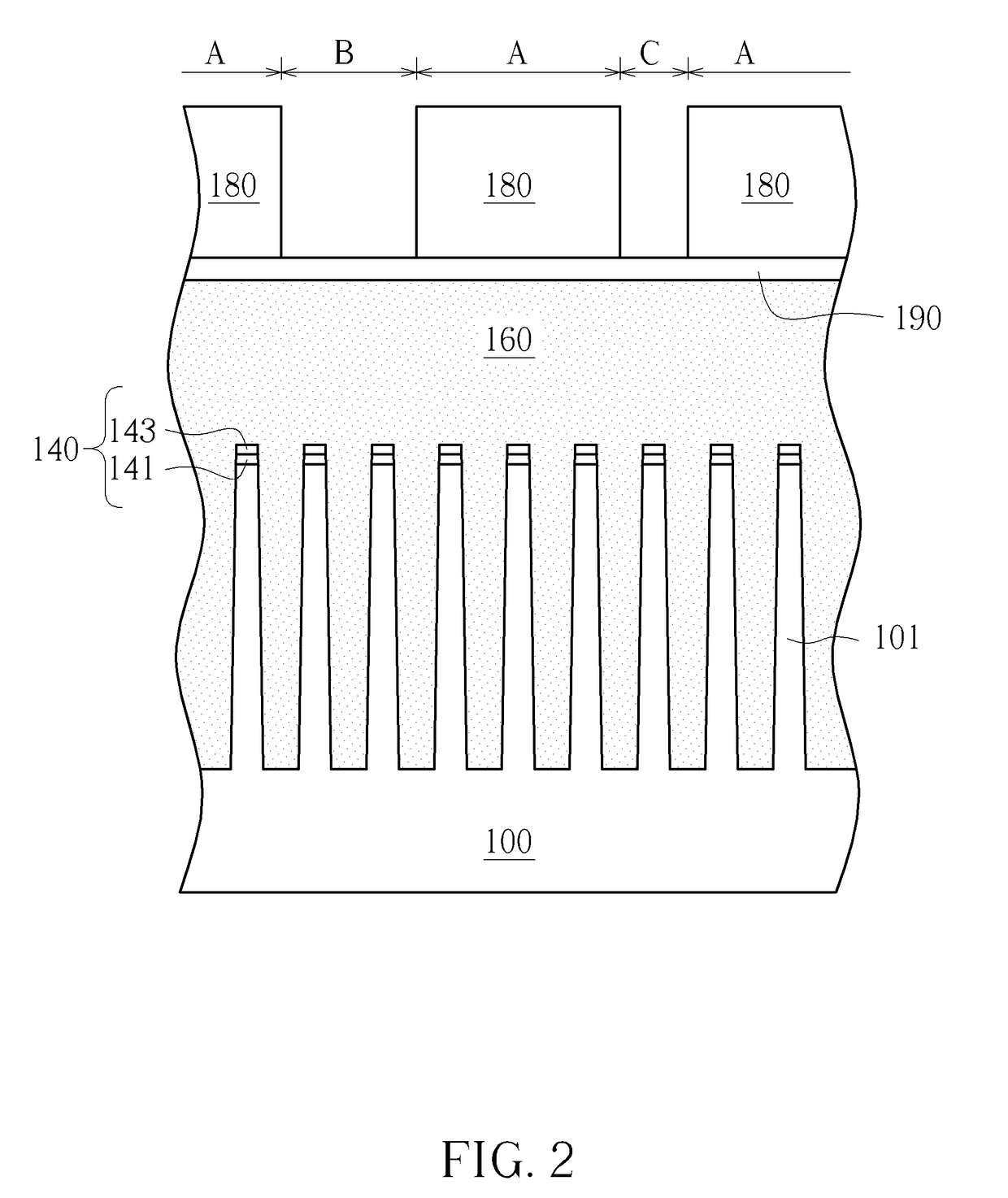

Method of producing a structure on the surface of a substrate

ActiveUS20060024621A1Improve etching effectSmall inclinationSemiconductor/solid-state device detailsSolid-state devicesFilling materialsEngineering

The present invention relates to a method for producing a structure serving as an etching mask on the surface of a substrate. In this case, a first method involves forming a first partial structure on the surface of the substrate, which has structure elements that are arranged regularly and are spaced apart essentially identically. A second method involves forming spacers on the surface of the substrate, which adjoin sidewalls of the structure elements of the first partial structure, cutouts being provided between the spacers. A third method step involves introducing filling material into the cutouts between the spacers, a surface of the spacers being uncovered. A fourth method step involves removing the spacers in order to form a second partial structure having the filling material and having structure elements that are arranged regularly and are spaced apart essentially identically. The structure to be produced is composed of the first partial structure and the second partial structure.

Owner:CHANGXIN MEMORY TECH INC

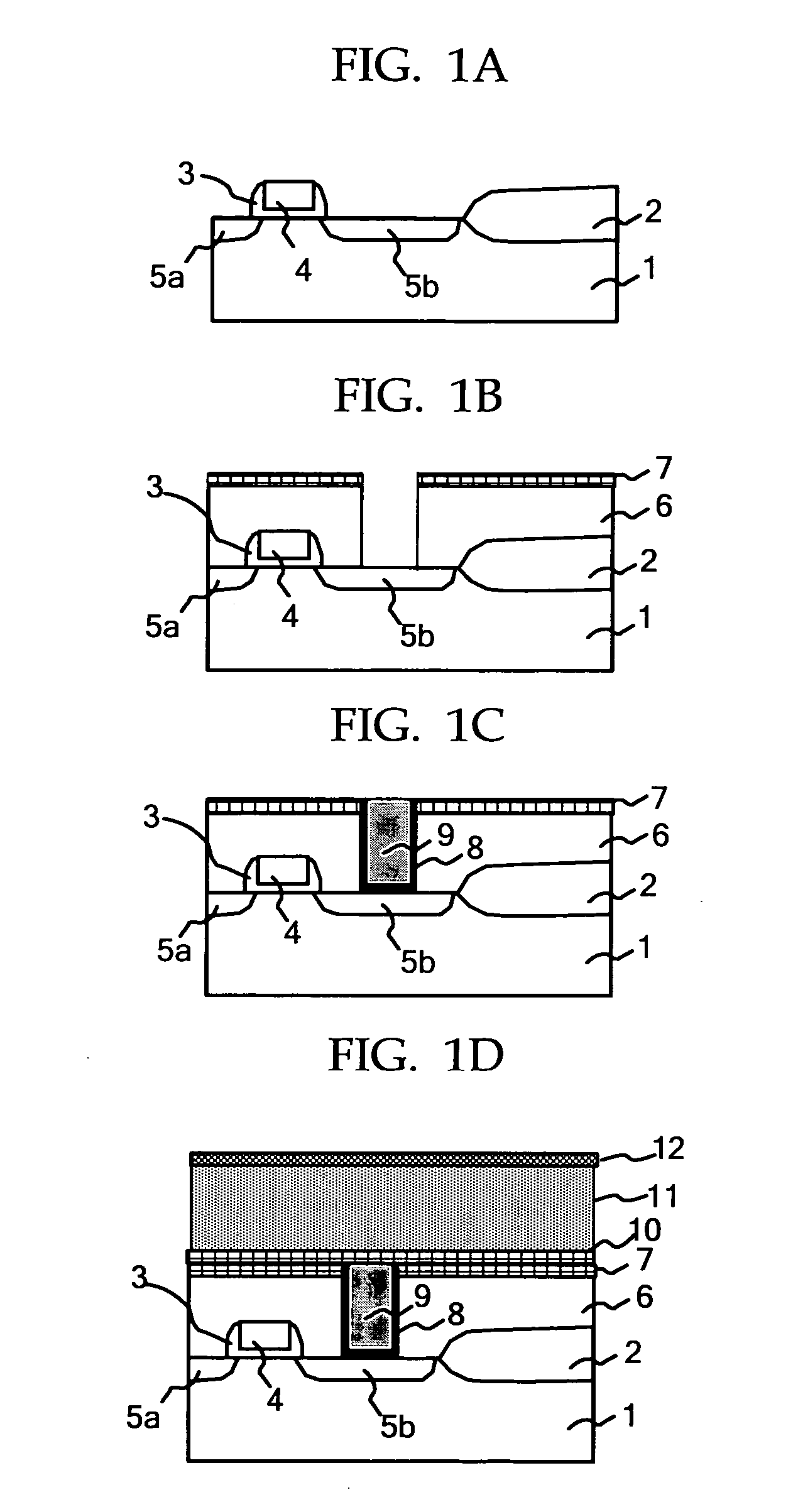

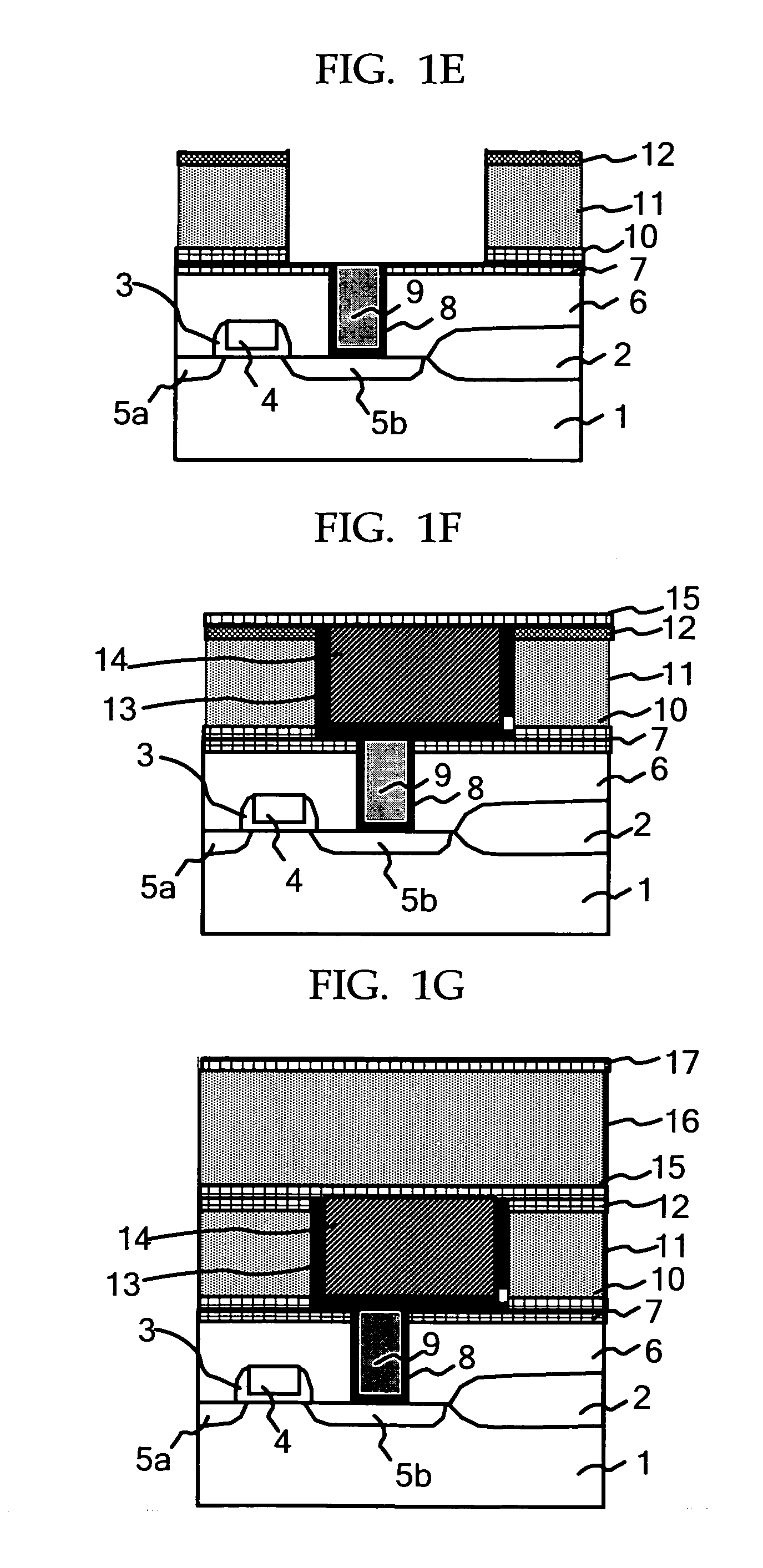

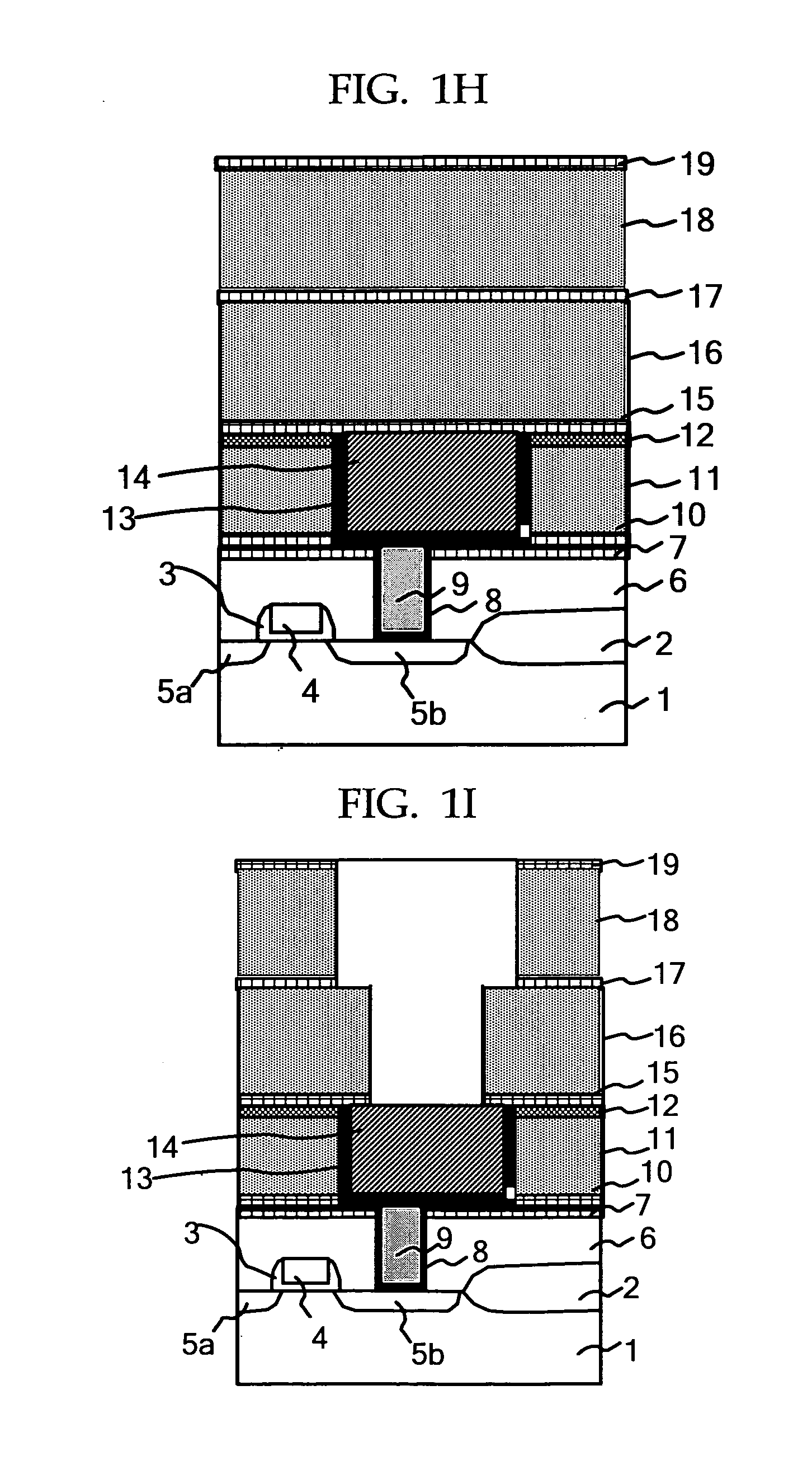

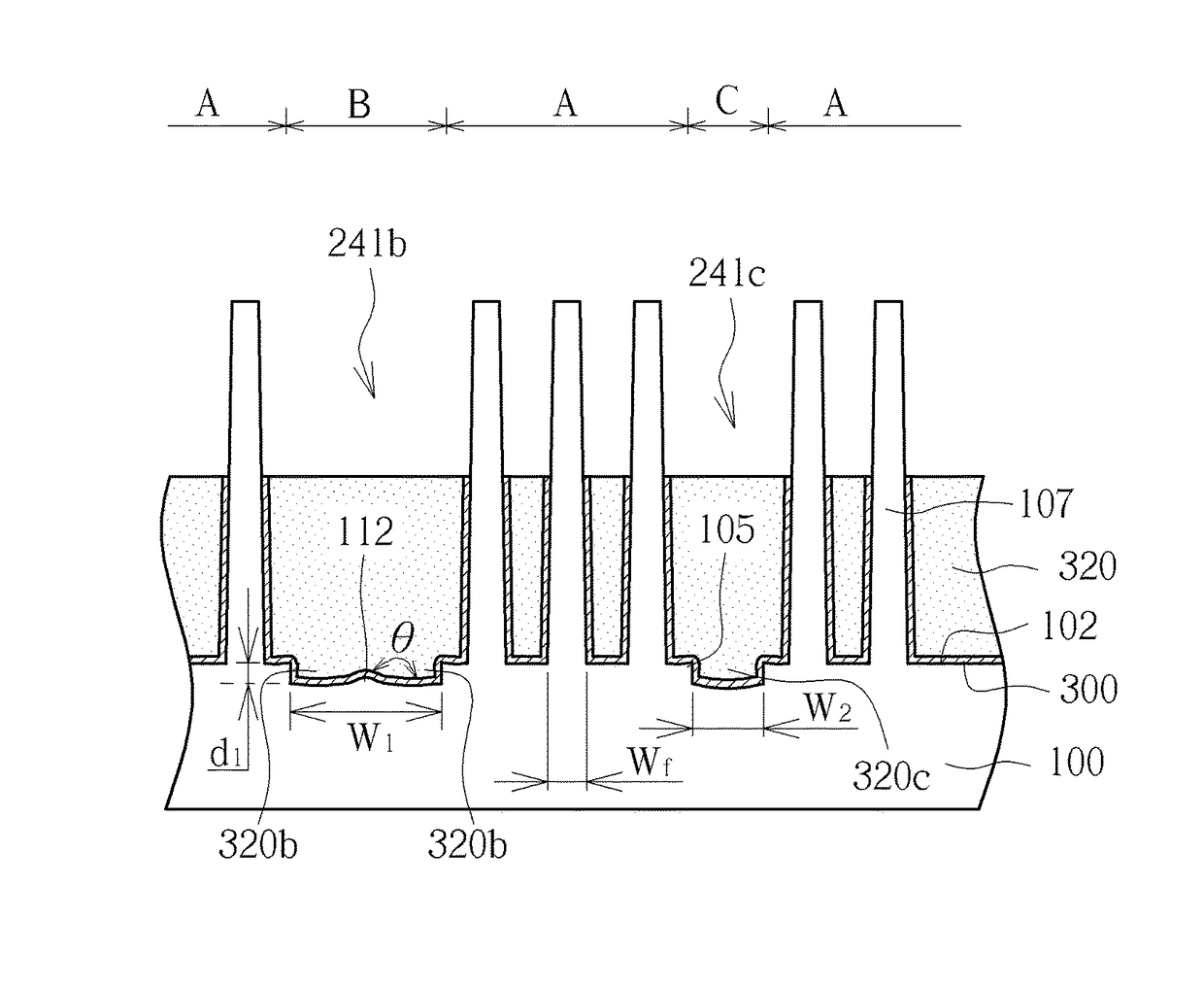

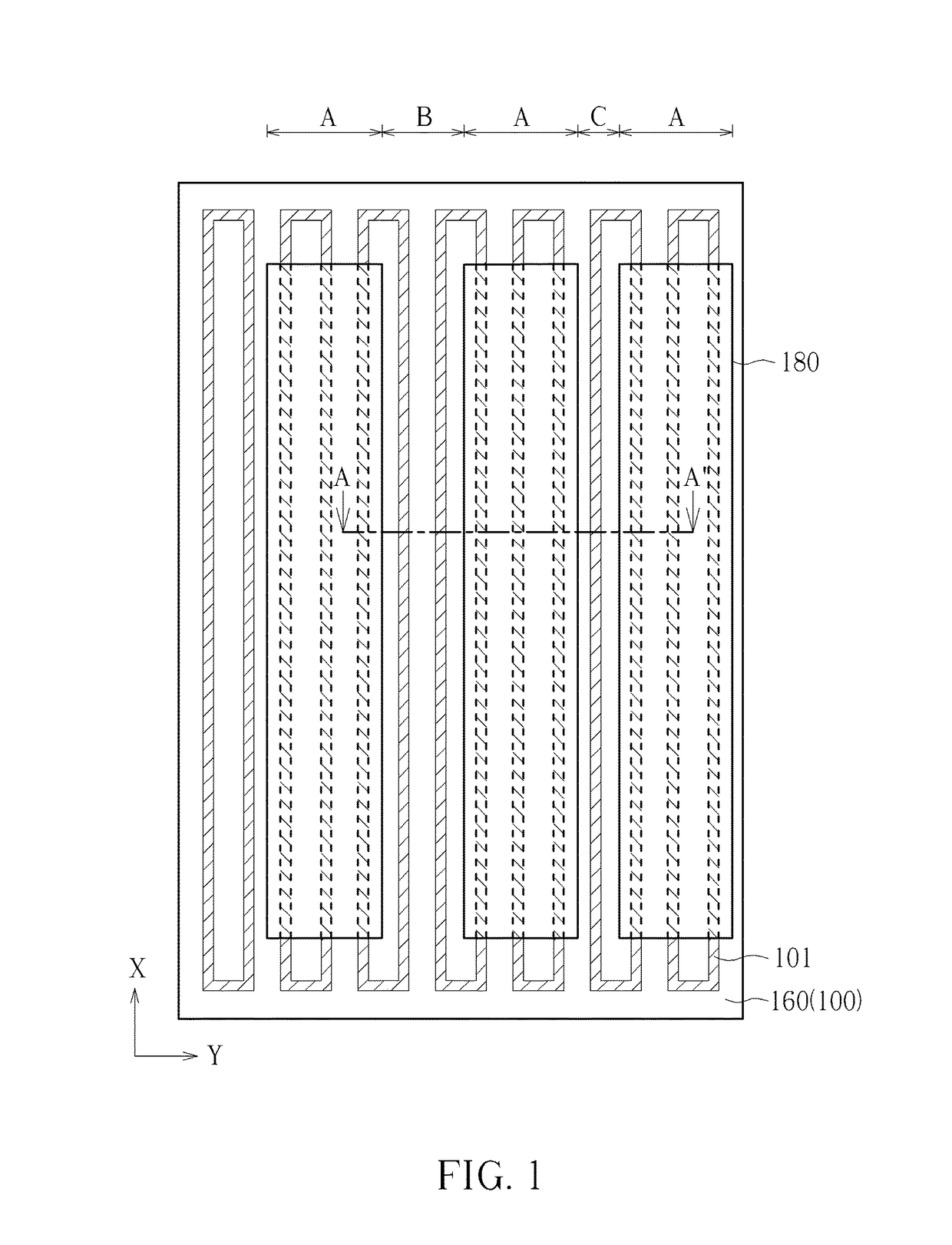

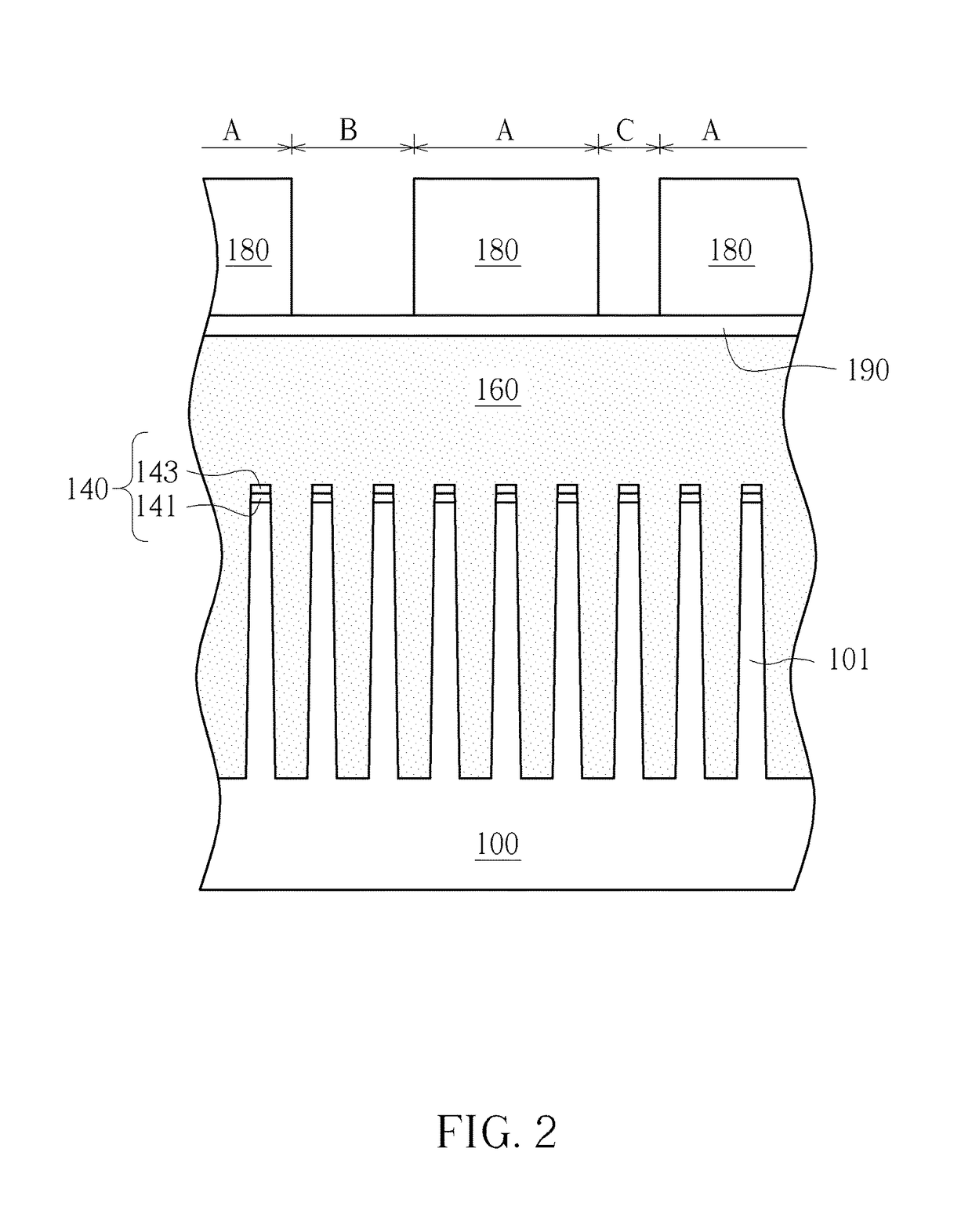

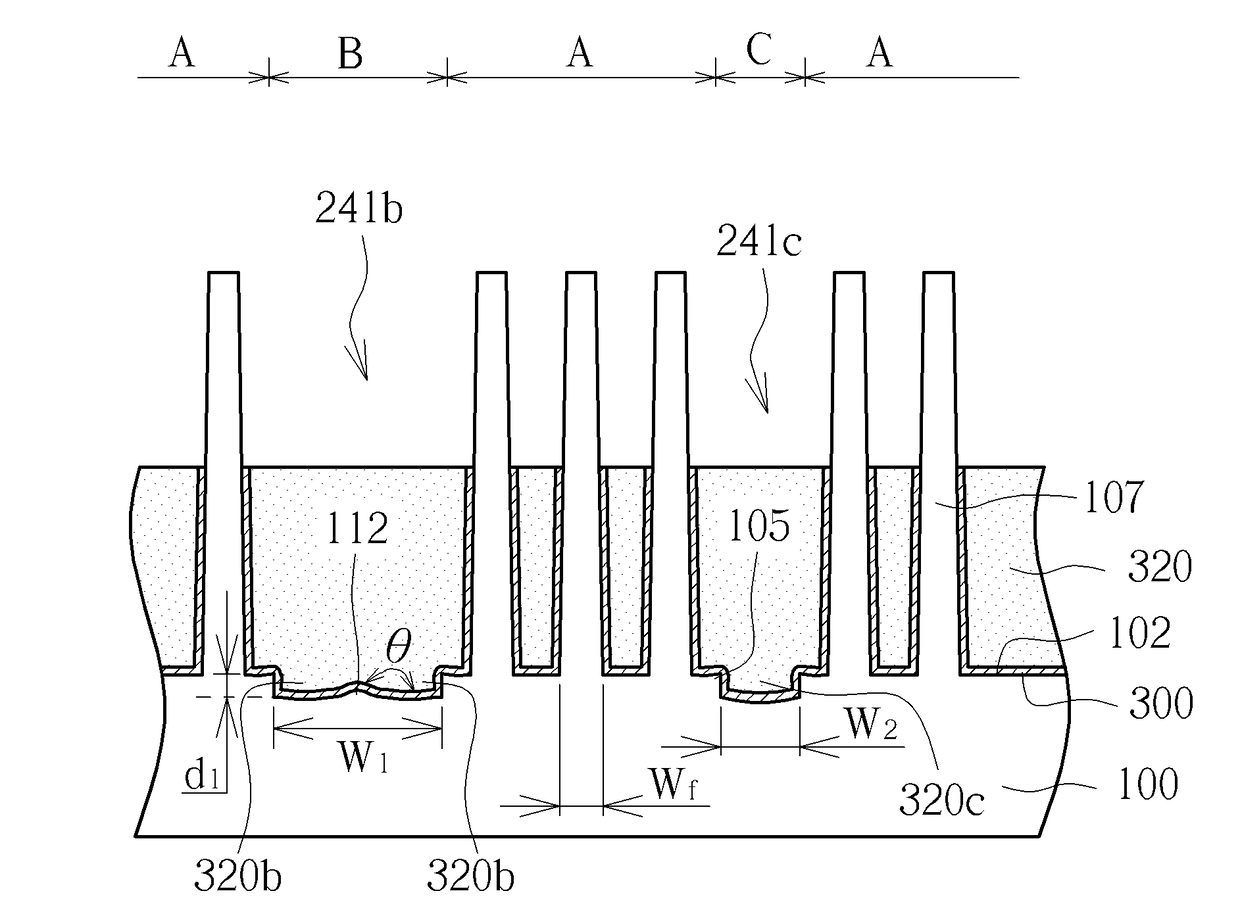

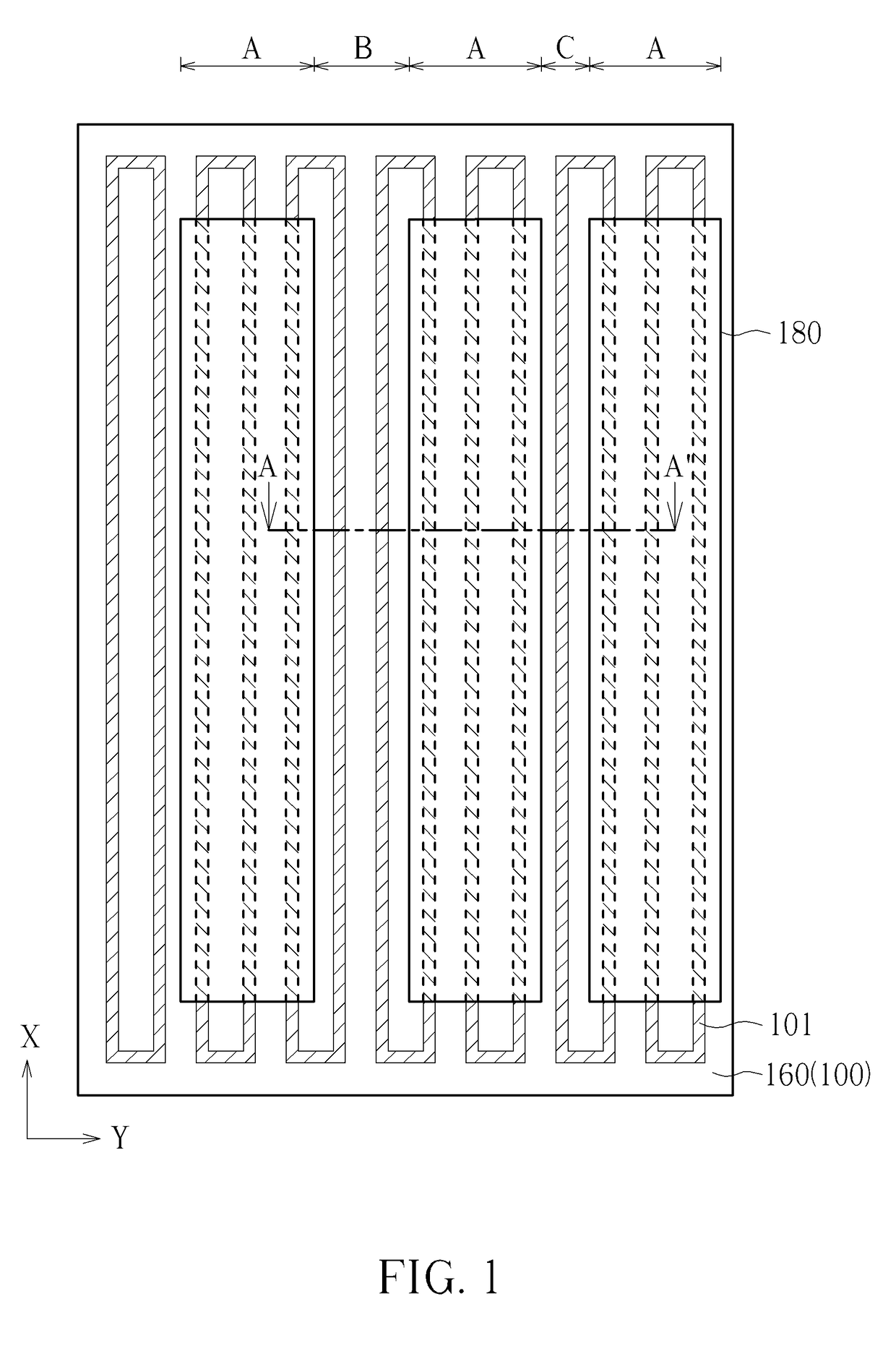

Semiconductor device and method of fabricating the same

ActiveUS9607985B1Improve etching effectImprove isolationTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device and a method of fabricating the same, the semiconductor device includes a substrate, a plurality of fin shaped structures, a first trench and at least one bump. The substrate has a base. The fin shaped structures protrude from the base of the substrate. The first trench recesses from the base of the substrate and has a depth being smaller than a width of each of the fin shaped structures. The at least one bump is disposed on a surface of the first trench.

Owner:UNITED MICROELECTRONICS CORP

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465408AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; the bonding layer is made of UV-curable adhesive; and the adhesive is the mixture of free radical type UV-curable adhesive and cationic type UV-curable adhesive. The cationic-type and free radical-type UV-curable adhesives are united in one to make full use of light energy and achieve mutual modification; the curing product concentrates the advantages of epoxy resin and acrylic resin and overcomes certain shortcomings, thereby creating a brand-new system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Photomask blank and photomask

ActiveUS7767366B2High resolutionMinimized pattern densityPhotomechanical apparatusSemiconductor/solid-state device manufacturingDry etchingSilicon

A photomask blank is provided comprising an etch stop film which is disposed on a transparent substrate and is resistant to fluorine dry etching and removable by chlorine dry etching, a light-shielding film disposed on the etch stop film and including at least one layer composed of a transition metal / silicon material, and an antireflective film disposed on the light-shielding film. When the light-shielding film is dry etched to form a pattern, pattern size variation arising from pattern density dependency is reduced, so that a photomask is produced at a high accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

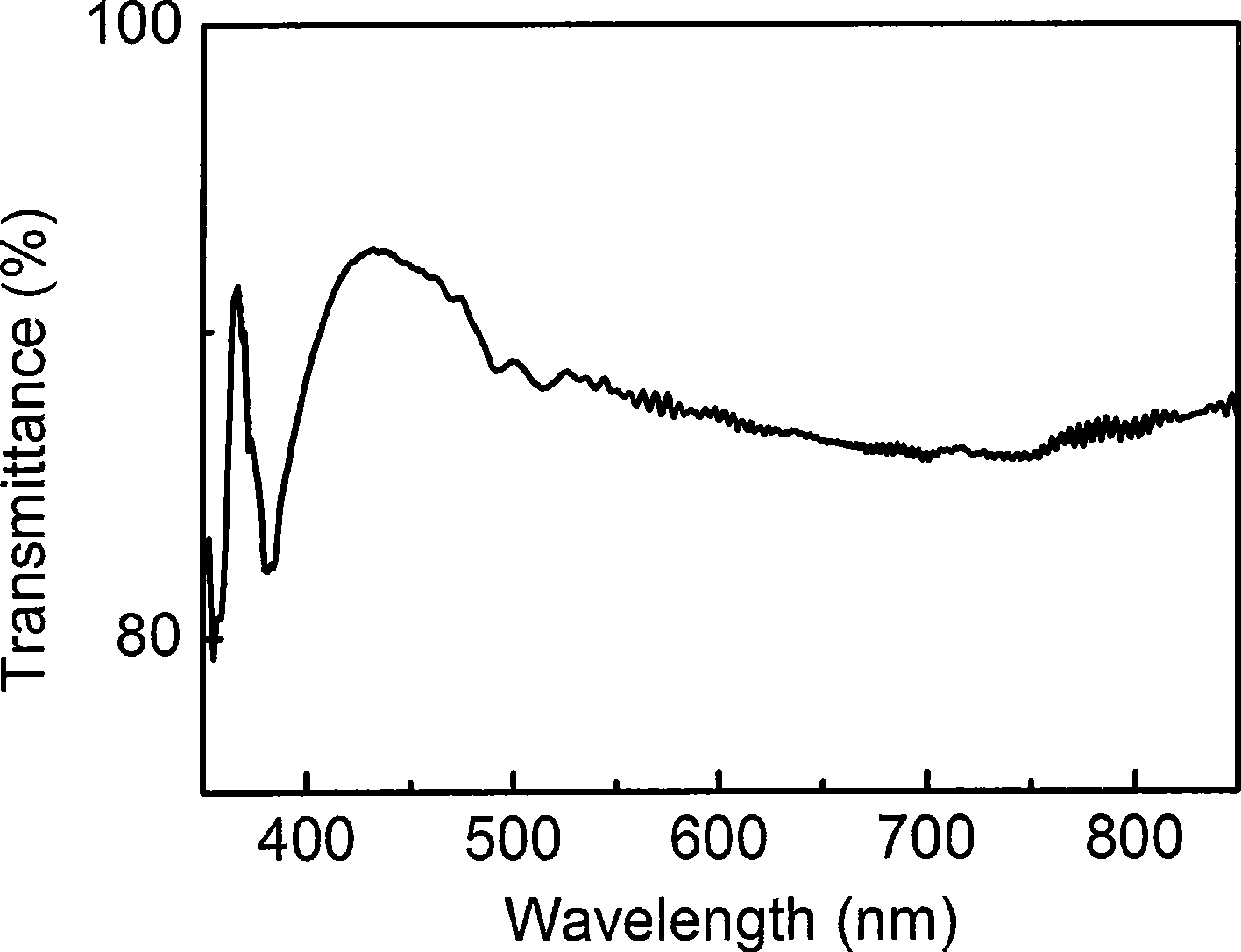

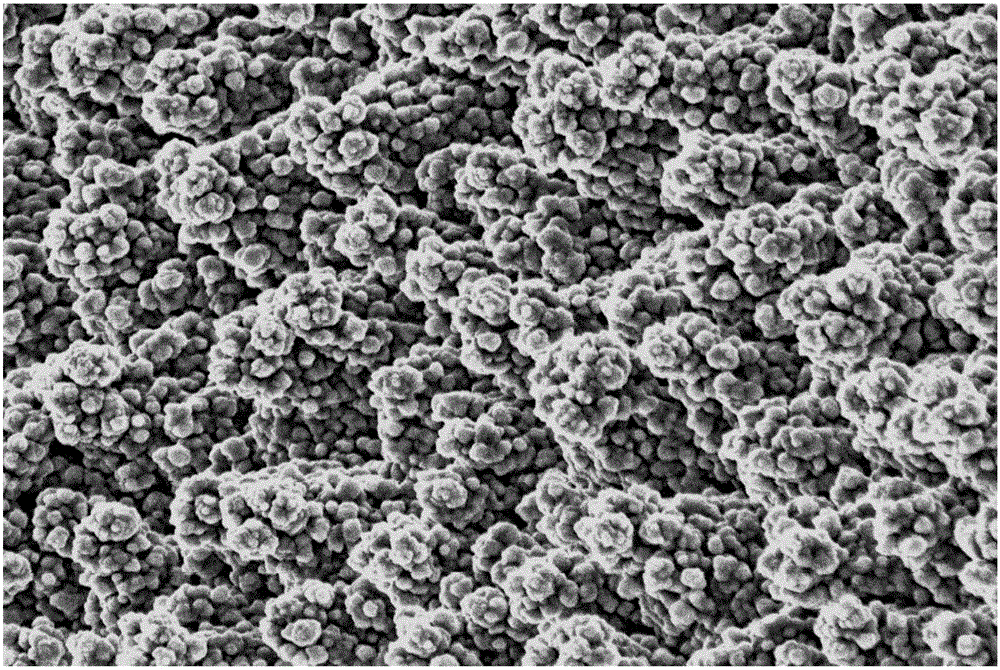

Sputtering Target, Transparent Conductive Film, and Their Manufacturing Method

InactiveUS20080308774A1Suppress generationBehavioral stabilityCellsConductive materialSputteringIndium

A sputtering target including indium oxide and tin oxide, the content by percentage of the tin atoms therein being from 3 to 20 atomic % of the total of the indium atoms and the tin atoms, and the maximum grain size of indium oxide crystal in the sputtering target being 5 μm or less. When a transparent conductive film is formed by sputtering, this sputtering target makes it possible to suppress the generation of nodules on the surface of the target and to conduct the sputtering stably.

Owner:IDEMITSU KOSAN CO LTD

Flat glass substrate attenuation etching liquid

The invention relates to a reduction etching liquid for base plates of sheet glass, components percentage by weight of which comprise: hydrofluoric acid holding 5-25%, strong acid holding 5-30% and pure water holding 45-90%. The reduction etching liquid for base plates of sheet glass of the invention is less in volatilization and toxicity. The using rate of the etching liquid is high and etching speed is rapid and stable. Costs of waste liquor treatment and subsequent treatment are low. The etching effect is excellent. Therefore, the invention has wide prospects for application.

Owner:BOE TECH GRP CO LTD +2

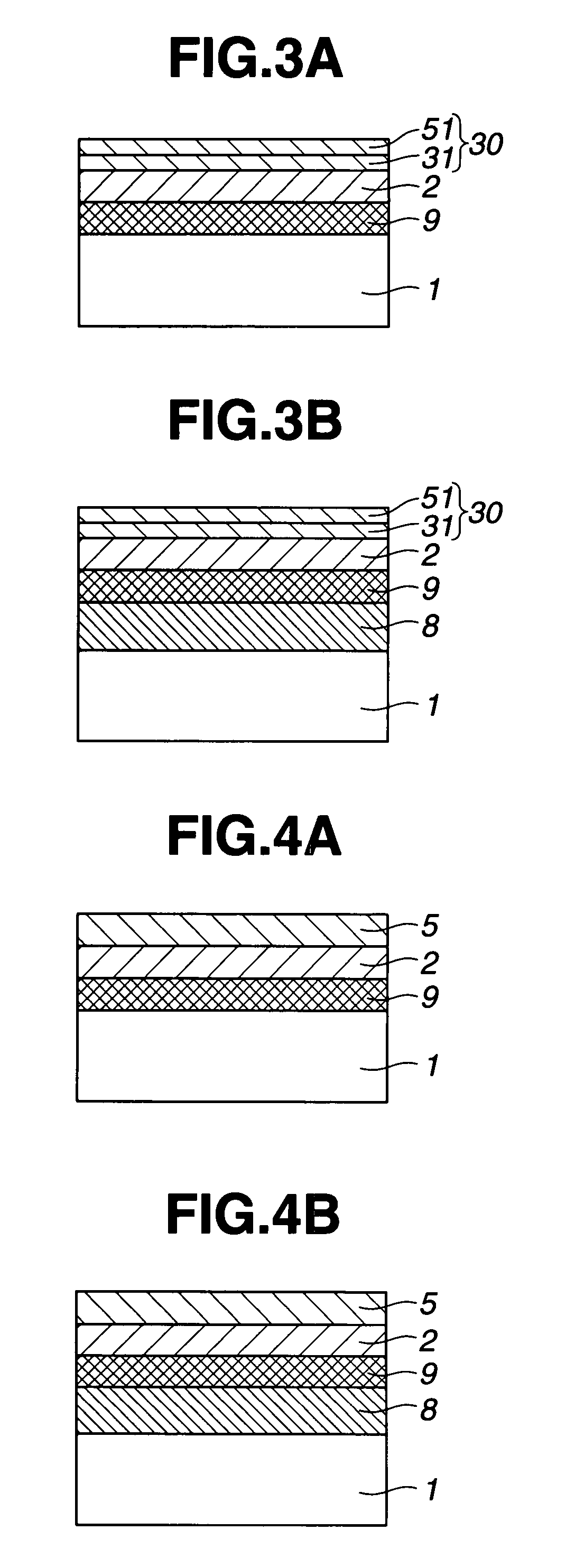

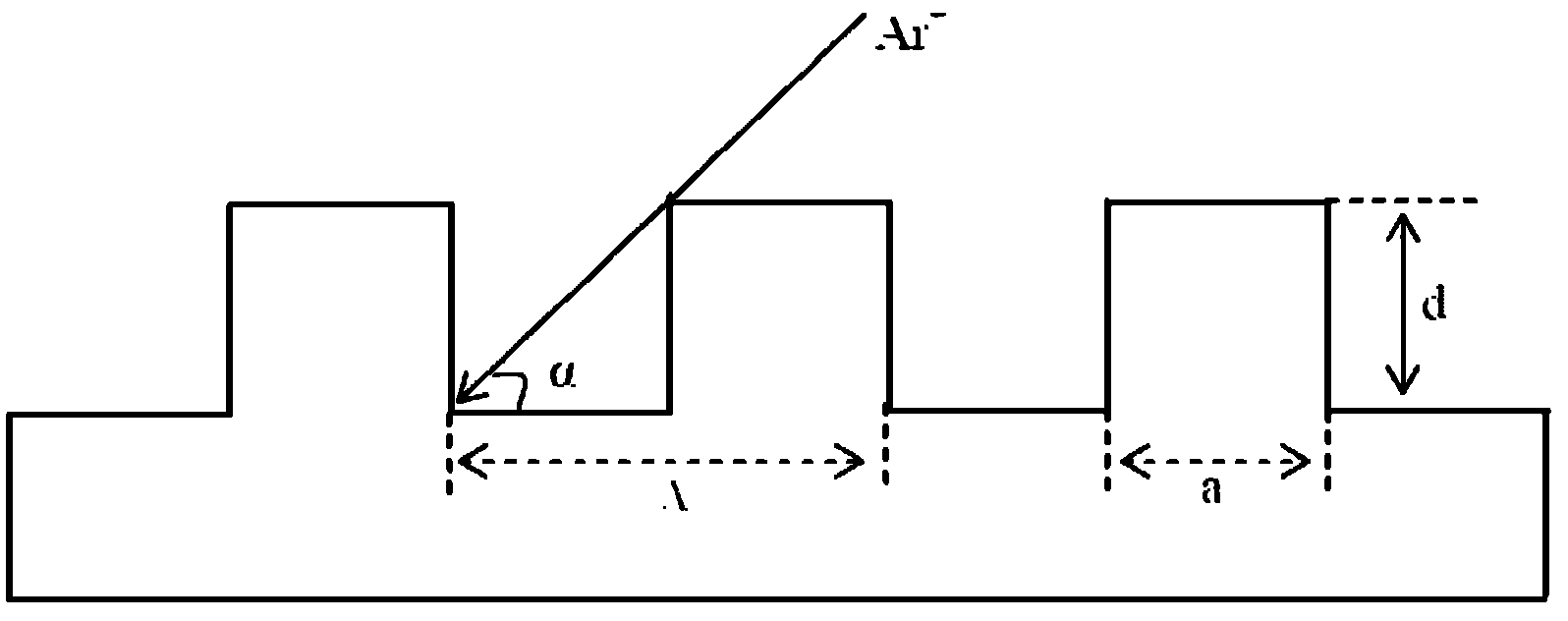

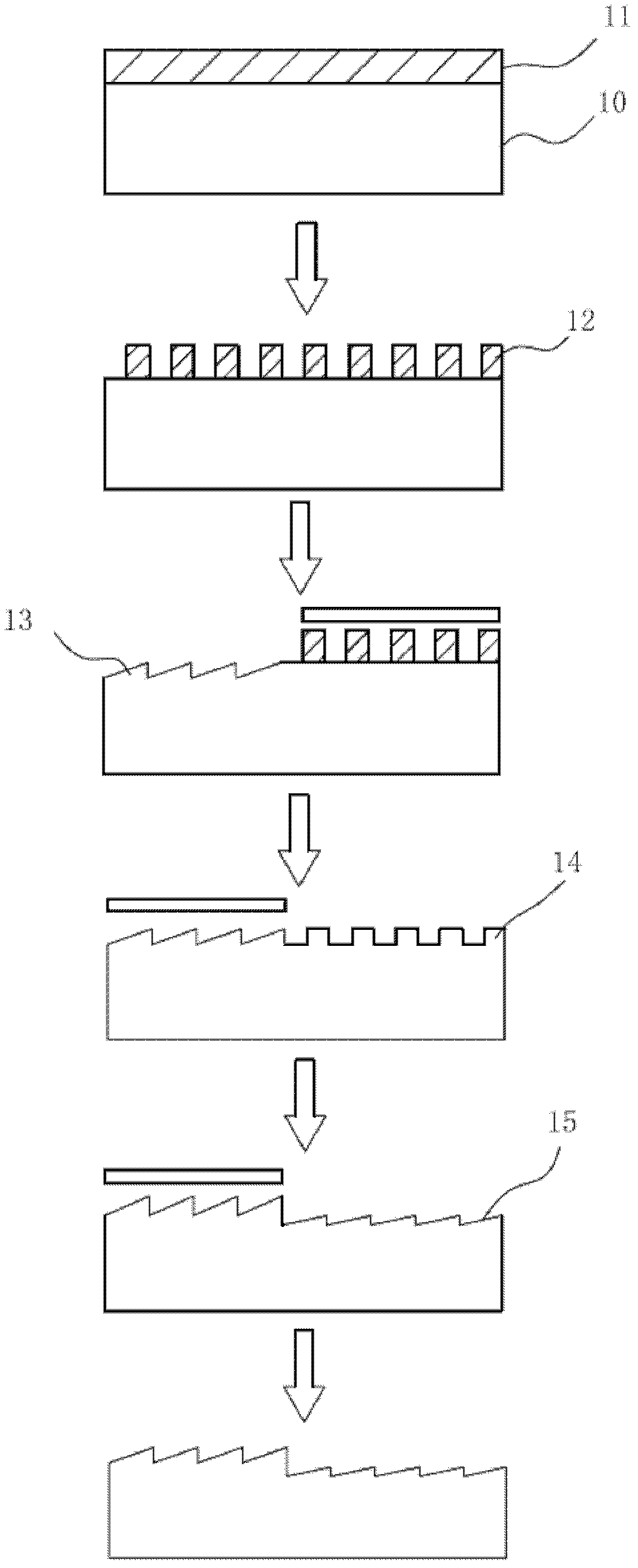

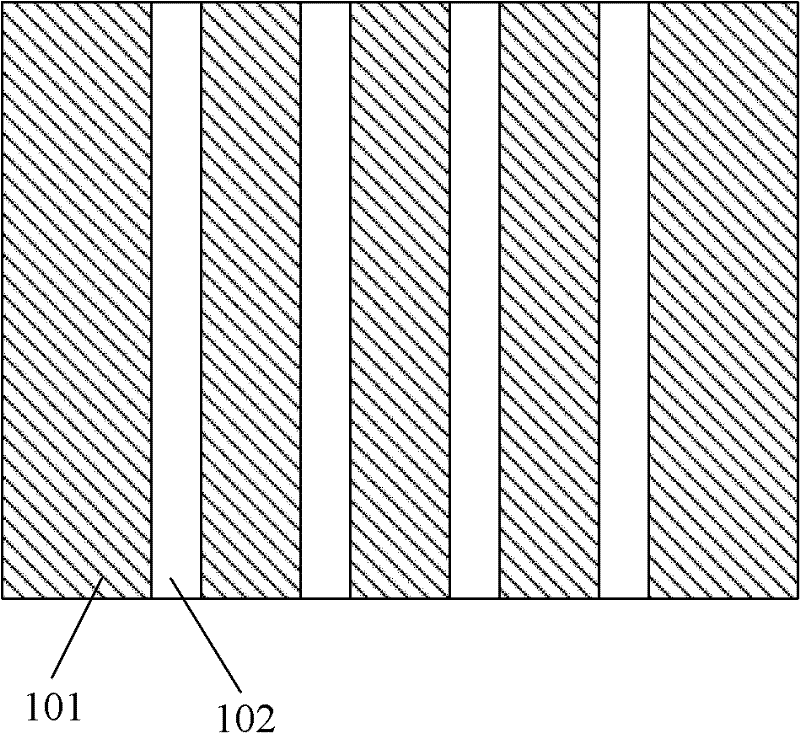

Manufacturing method for holographic dual-blazed grating

ActiveCN102323634AAvoid secondary photoresist lithography processEasy to controlPhotomechanical apparatusDiffraction gratingsBlazed gratingGrating

The invention discloses a manufacturing method for a holographic dual-blazed grating. The two blaze angles of the holographic dual-blazed grating are respectively a blaze angle A and a blaze angle B. Different control of the two blaze angles is realized by performing oblique ion beam etching by using a photoresist grating and a homogenous grating as masks on two grating areas A and B, so that a secondary photoresist photoetching process is avoided. When the homogenous grating is manufactured, the positive ion beam etching time can be controlled so that the groove depth of the homogenous grating is controlled precisely. In addition, the homogenous grating mask and the substrate are made of the same material, and the etching rate of the homogenous grating mask and the etching rate of the substrate are kept consistent all the time, so that precise control of the blaze angles can be realized.

Owner:SUZHOU UNIV

Method for forming gate electrode

ActiveCN102651312AImprove the problem of line end shorteningImprove yieldSemiconductor devicesGate dielectricForming processes

The invention relates to a method for forming a gate electrode. The method comprises the following steps of: sequentially forming a gate dielectric layer, a gate electrode layer and a barrier layer on a substrate; forming a first mask layer for covering the barrier layer and impressing to form the first mask layer with a first pattern comprising at least one opening which defines a distance between tail ends of a line which is to form the gate electrode; depositing an antireflective layer filling the opening in and covering the first mask layer; forming a second mask layer for covering the antireflective layer, and patterning to form the second mask layer with a second pattern which defines a line width which is to form the gate electrode; taking the second mask layer with the second pattern as a mask to etch the antireflective layer and the first mask layer to for a first mask layer with a third patter; and taking the first mask layer with the third pattern as a mask to etch the barrier layer and the gate electrode layer to form the gate electrode. Through the method provided by the invention, the line-end shortening problem in the gate electrode etching forming process can be improved, and the yield can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Rolled Copper or Copper Alloy Foil with Roughened Surface and Method of Roughening Rolled Copper or Copper Alloy Foil

ActiveUS20090162685A1Improve featuresInhibition formationPrinted circuit aspectsPrinted circuit manufactureTin platingCopper sulfate

Provided is a rolled copper or copper alloy foil having a roughened surface formed of fine copper particles, obtained by subjecting a rolled copper or copper alloy foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of a temperature of 20 to 50° C. and a current density of 10 to 100 A / dm2. The provided rolled copper or copper alloy foil subject to roughening is reduced in craters which are obvious defects unique to rolled copper or copper alloy foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and also suits for use in producing a flexible printed wiring board capable of bearing a fine wiring pattern. Additionally provided is a method of roughening the rolled copper or copper alloy foil.

Owner:JX NIPPON MINING& METALS CORP

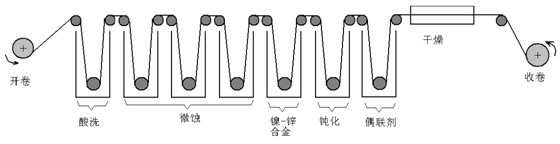

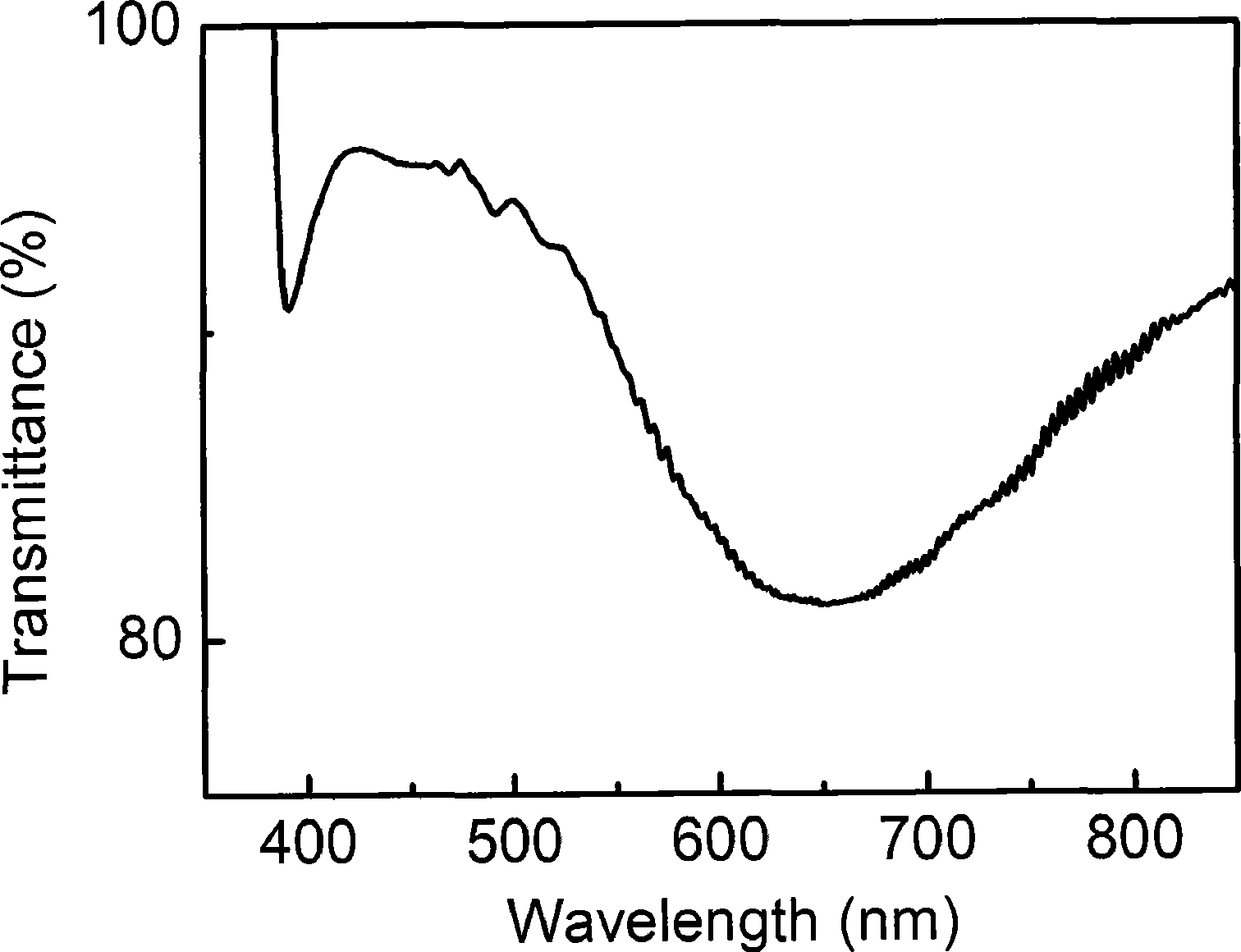

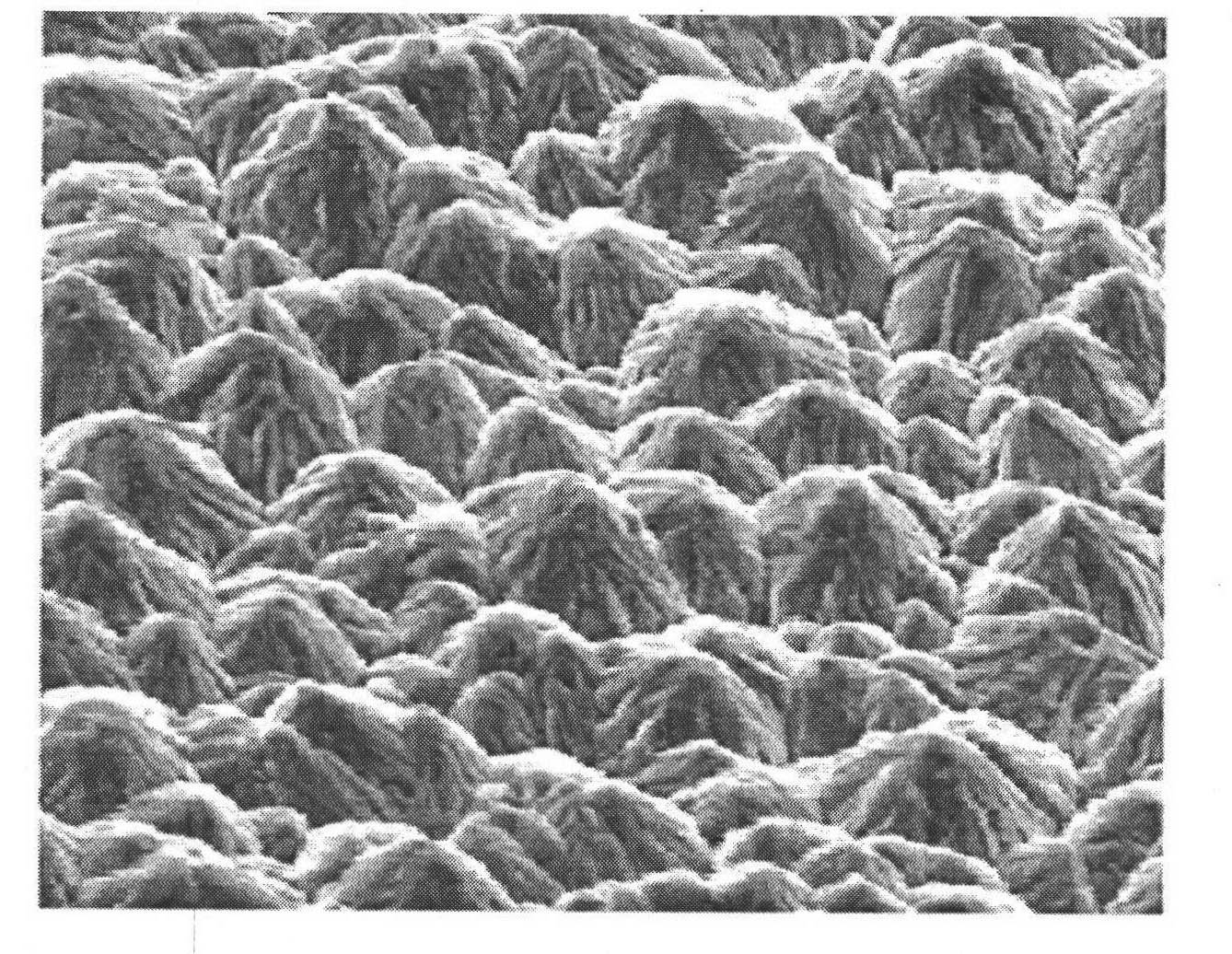

Surface treatment process for reducing roughness of electrolytic copper foil

ActiveCN102586831AReduce roughnessAccelerated corrosionPrinted circuit detailsMetallic material coating processesElectrolysisEtching

The invention relates to a surface treatment process for reducing roughness of an electrolytic copper foil, belonging to the technical field of electrolytic copper foil production processes. The surface treatment process comprises the following steps of: carrying out treatment steps of acid washing, micro etching, nickel-zinc alloy plating, passivating, coupling, drying and the like on the electrolytic copper foil with surface roughness (Rz) of 3-5 microns to form a VLP (Very Low Profile) copper foil, wherein the surface roughness (Rz) is reduced to 0.5-1.5 micron. The surface treatment process disclosed by the invention has the advantages that: the treated copper foil surface is reddish-brown and has excellent corrosion resistance, etching property and excellent normal-temperature and high-temperature oxidation resistance so as to be suitable for flexible copper-clad plates.

Owner:SHANDONG JINBAO ELECTRONICS

Etching Solutions

ActiveUS20080277381A1Non-corrosive and stableImprove etching effectDecorative surface effectsSurface treatment compositionsAmmonium compoundsMetallurgy

Owner:INKTEC CO LTD

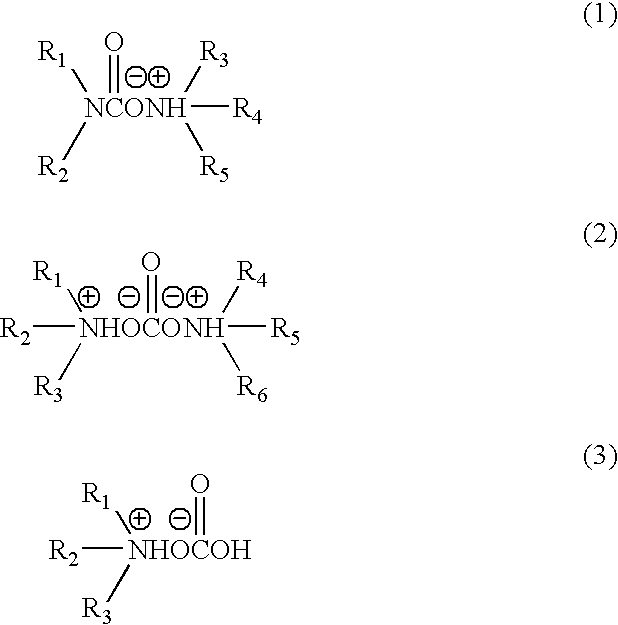

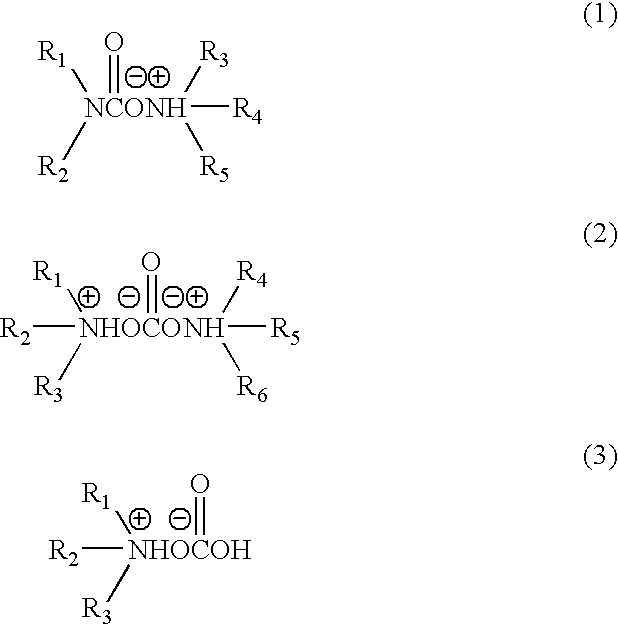

Anisotropic silicon etchant composition

InactiveUS20090218542A1Maintain good propertiesHigh of effectSemiconductor/solid-state device manufacturingSurface treatment compositionsColloidal silicaEthylenediamine

An etchant composition contains (a) an alkaline compound mixture of an organic alkaline compound and inorganic alkaline compound and (b) a silicon-containing compound. The organic alkaline compound is composed of one or more ingredients from quaternary ammonium hydroxide and ethylenediamine. The inorganic alkaline compound is composed of one or more ingredients from sodium hydroxide, potassium hydroxide, ammonia and hydrazine. The silicon-containing inorganic compound is composed of one or more ingredients from metal silicon, fumed silica, colloidal silica, silica gel, silica sol, diatomaceous earth, acid clay and activated clay, and the silicon-containing organic compound is composed of one or more ingredients from quaternary ammonium salts of alkyl silicate and quaternary ammonium salts of alkyl silicic acid.

Owner:SYST SOLUTION +1

Substrate for flexible organic optoelectric device and preparation thereof

InactiveCN101425560AImprove flatnessImprove surface propertiesFinal product manufactureSolid-state devicesAdhesiveUltraviolet lights

The invention discloses a base plate for a flexible optoelectronic device, which comprises a flexible underlay. The base plate is characterized in that a binding layer and a conducting film are arranged on the surface of the flexible underlay; the conducting film is deposited on the surface of the binding layer; the binding layer is made of an adhesive required to be solidified by ultraviolet light; the raw material of the adhesive comprises the following componentsof polythiol-polyene system, simple function group or polyfunctional group acrylic acid, a photoinitiator, a photosensitizer and an additive. The base plate solves the problem that the cohesion of the conducting film deposited and the underlay is bad due to low energy on the surface of the flexible underlay, improves the blocking performance of the underlay to water oxygen, and simultaneously plays a good smoothing role in the surface of the underlay; and the preparation method is simple and effective, the production cost and the process difficulty of the base plate can be greatly reduced, and the yield rate of the base plate during the etching process is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

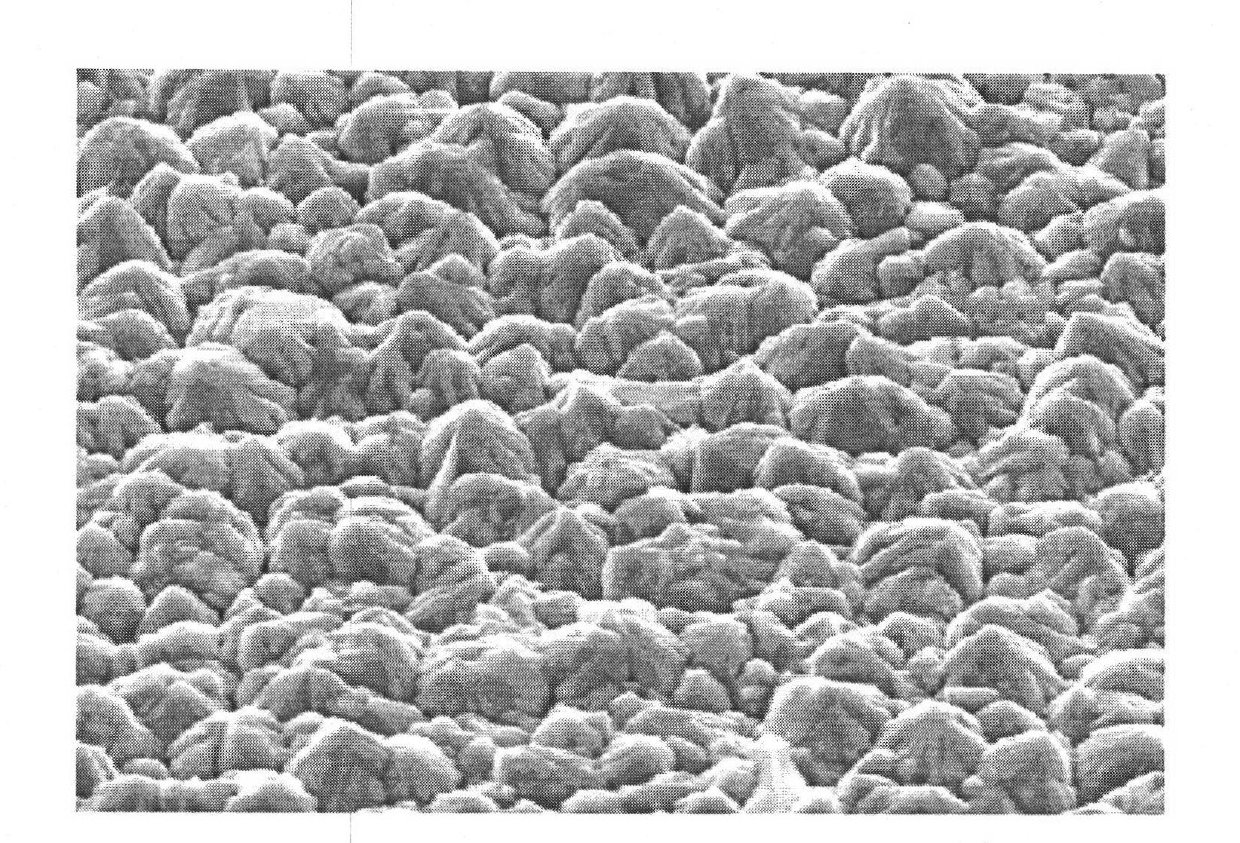

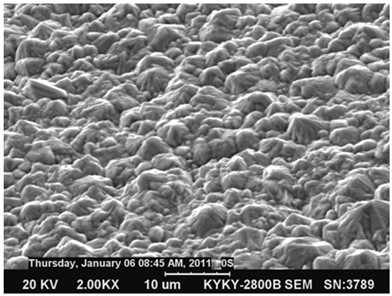

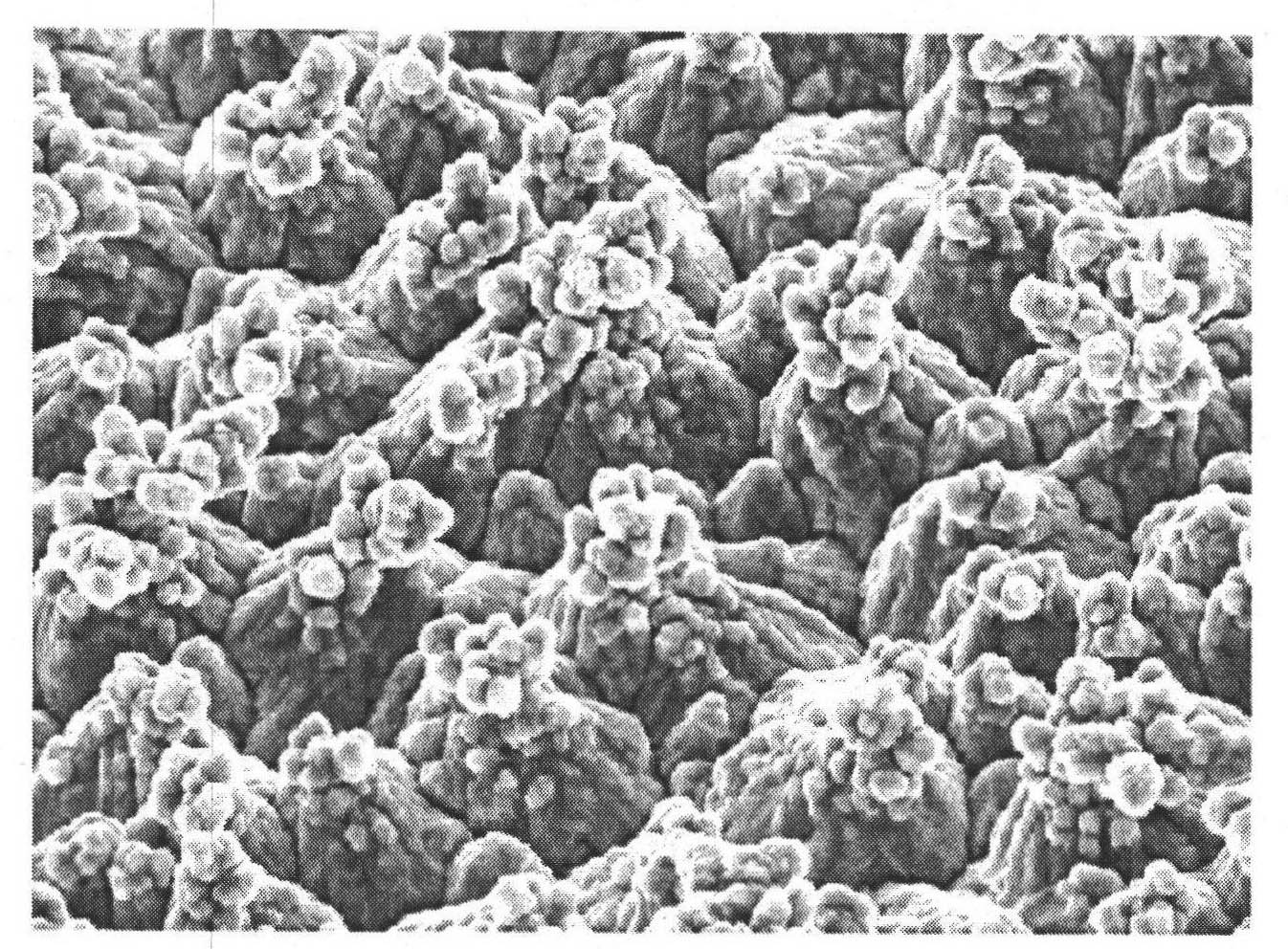

Surface treatment process of reddened copper foil for high-grade FR-4 copper-clad plate

ActiveCN101935836AImprove appearance characteristics and corrosion resistanceExcellent anti-plating diffusion performanceInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilSurface finishing

The invention relates to a surface treatment process of reddened copper foil for a high-grade FR-4 copper-clad plate, belonging to the field of a copper foil production process. The surface treatment process of the reddened copper foil for the high-grade FR-4 copper-clad plate is characterized by comprising the following steps: taking 12-70mu m high-temperature high-extensibility copper foil as a cathode, operating at a rate of 25.0+ / -0.1m / min, carrying out coarsening and solidifying fractal electro-deposition of tuberculiform metallic copper on the surface of the copper foil; electrodepositing a nano-level copper alloy layer, wherein the copper alloy can be observed that the crystal is in a punctiform shape by utilizing an electron scanning microscope, and the crystal belongs to whisker; and electrodepositing a nano-level zinc layer; and finally carrying out alkaline chromating, and coating a layer of silane coupling agent. In the process of electrodepositing a nano-level punctiform whisker copper-nitrogen alloy layer, the invention adopts nitrogen-containing heterocyclic ring organic addition agent to improve the appearance characteristic and the corrosion resistance after surface treatment. The reddened copper foil in the invention has the advantages of favorable normal temperature resistance, high-temperature oxydation performance, plating diffusion resistance, corrosion and etching resistance, favorable peeling resistance and high-temperature conversion resistance.

Owner:SHANDONG JINBAO ELECTRONICS

Surface blackening treatment method for rolled copper foil

InactiveCN106191980AImprove acid resistanceGood alkali resistanceChromatisationSuperimposed coating processFolding enduranceSurface roughness

The invention discloses a surface blackening treatment method for a rolled copper foil. The surface blackening treatment method orderly comprises the following steps: (1) electrochemical oil removal, (2) coarsening treatment, (3) solidification treatment, (4) nickel-cobalt plating treatment, (5) zinc plating treatment, (6) passivation, (7) silicone coupling agent coating treatment, and (8) drying treatment, and obtaining the product. Current is applied in step (1) to step (6). The surface blackening treatment method for a rolled copper foil provided by the present invention has the advantage that the black appearance of the copper foil obtained after various electric plating steps meets FPC requirements. Through determination, the copper foil has a surface color blackness value of less than 30, surface roughness Ra of less than or equal to 1.0 micron and Rz of less than or equal to 2.0 microns, peel strength of more than 1.4 N / mm, and folding endurance MIT of more than 800; the copper foil has favorable acid resistance, alkali resistance, soldering resistance, and etching performance. With the blackness value RAL7016, a good extinction effect is achieved.

Owner:中铜(上海)铜业有限公司

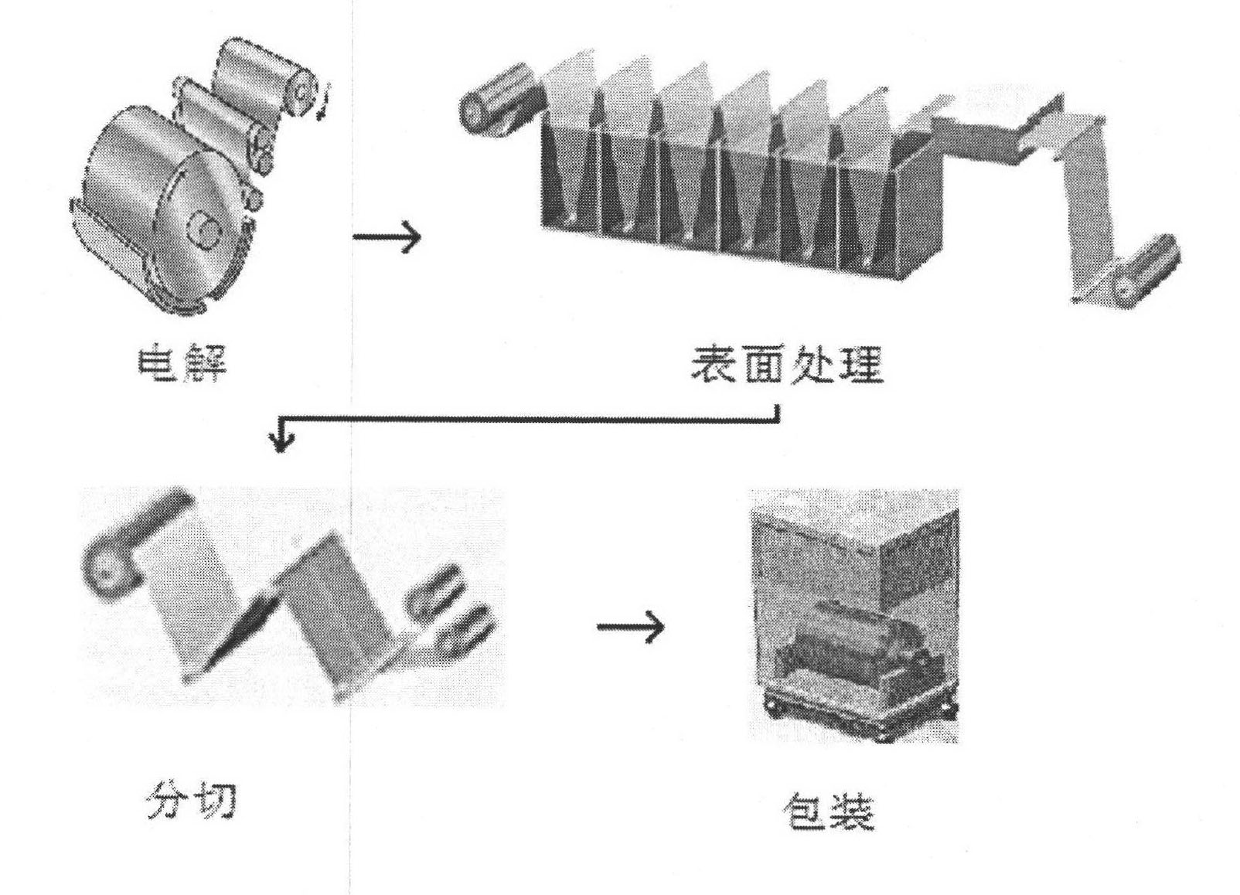

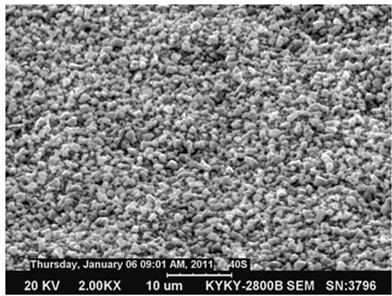

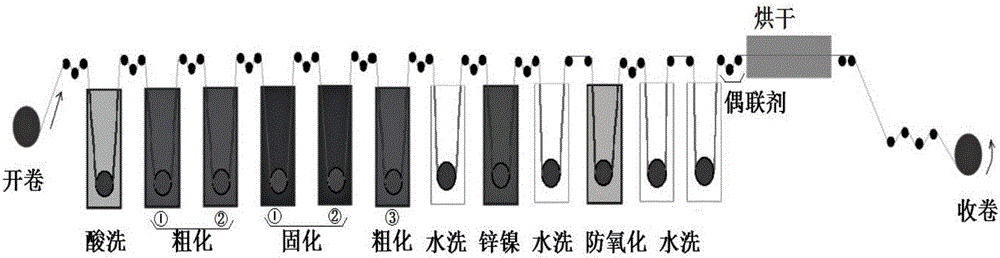

Fine roughing treatment technology for surface of electrolytic copper foil

The invention relates to a fine roughing treatment technology for the surface of electrolytic copper foil. The fine roughing treatment technology includes the following processes of primary roughing, secondary roughing, primary curing, secondary curing, third-level roughing, zinc and nickel alloy plating, oxidization preventing, silane coupling agent treating and drying. The copper foil produced through the technology has relatively low surface roughness, meanwhile has very high stripping resisting strength, especially shows excellent bonding strength on plates of Tg 170 or above and is very suitable for low-loss and ultra-low-loss high-speed circuit boards. Key technology indexes of the copper foil produced through the technology reach the level of the same kind of products of advanced copper foil manufacturers such as Mitsui Mining and Smelting (MHT), Furukawa Electric (MP) and JX Nippon Oil (JTC-LC), replaces imported copper foil of the same kind and is applied to high multi-layer high-end plates, HDI high-end plates, halogen-free high-end plates and other high-end plates in China or Euramerican countries.

Owner:SHANDONG JINBAO ELECTRONICS

Focus ring, plasma etching apparatus and plasma etching method

ActiveUS20060102288A1Improve etching effectAccurate storageElectric discharge tubesDecorative surface effectsPlasma etchingMaterials science

In a plasma etching apparatus for performing a plasma etching on a surface of a substrate mounted on a susceptor in a processing vessel, a focus ring is installed to surround the substrate and has a first region at an inner side on a surface thereof, in which an average surface roughness is small such that a reaction product produced during an etching processing is not captured to be deposited, and a second region at an outer side from the first region, in which an average surface roughness is large such that a reaction product produced during the etching process is captured to be deposited. A boundary between the first and the second region is a part where an etching amount is relatively significantly changed compared to other parts while the focus ring is equipped in the plasma etching apparatus and the plasma etching is performed on the substrate.

Owner:TOKYO ELECTRON LTD

Semiconductor device and method of fabricating the same

ActiveUS20170092643A1Improve etching effectImprove isolationTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device and a method of fabricating the same, the semiconductor device includes a substrate, a plurality of fin shaped structures, a first trench and at least one bump. The substrate has a base. The fin shaped structures protrude from the base of the substrate. The first trench recesses from the base of the substrate and has a depth being smaller than a width of each of the fin shaped structures. The at least one bump is disposed on a surface of the first trench.

Owner:UNITED MICROELECTRONICS CORP

Base board for flexible optoelectronic part and its making method

InactiveCN101034687AImprove flatnessImprove surface propertiesSemiconductor/solid-state device detailsSolid-state devicesOxygenSubstrate surface

The invention is a substrate for a flexible photoelectronic device, comprising flexible substrate, and characterized by also comprising organic buffer layer spin-coated on the substrate surface and conductive film, where the conductive film is deposited on the surface of the organic buffer layer, and the material of the organic buffer layer is organic photo-curing agent. And it solves the problem of bad adhesion between the deposited film and the substrate caused by low surface energy of the flexible substrate and improves the obstruction performance of the substrate to water-dissolved oxygen, and besides play a good role of smoothening the substrate surface; and the preparing method is simple, effective and able to largely reduce substrate production cost and process difficulty.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

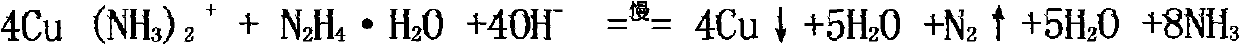

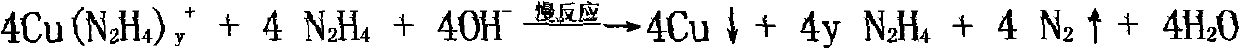

Method for recovering copper from alkaline etching waste liquid and recycling alkaline etching liquid

The invention discloses a method for recovering copper from alkaline etching waste liquid and recycling the alkaline etching liquid, comprising the step of adding a hydrazine hydrate reducing agent and a catalyst into the alkaline etching waste liquid to recover copper powder, wherein the alkaline etching waste liquid can be recycled after the copper powder is recovered. The invention has the optimum conditions of: placing the alkaline etching waste liquid into a reactor; adding hydrazine hydrate with mass percent concentration of 40 percent according to added quantity of 160-200mL / L; adding a solution of various salts of ruthenium, palladium, nickel and cobalt as the catalyst with added quantity of 0.01-0.2g / L (metered by the masses of the ruthenium, the palladium, the nickel and the cobalt), reacting for 30-35 minutes at temperature between 70DEG C and 100DEG C; and separating to obtain the copper powder. The invention has the beneficial effect that after the copper is recovered from the alkaline etching waste liquid, the alkaline etching waste liquid can be regenerated and recycled, therefore, various resources in the alkaline etching waste liquid can be used fully, and the etching cost of a printing plate and the discharge of pollutants can be reduced.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com