Fine roughing treatment technology for surface of electrolytic copper foil

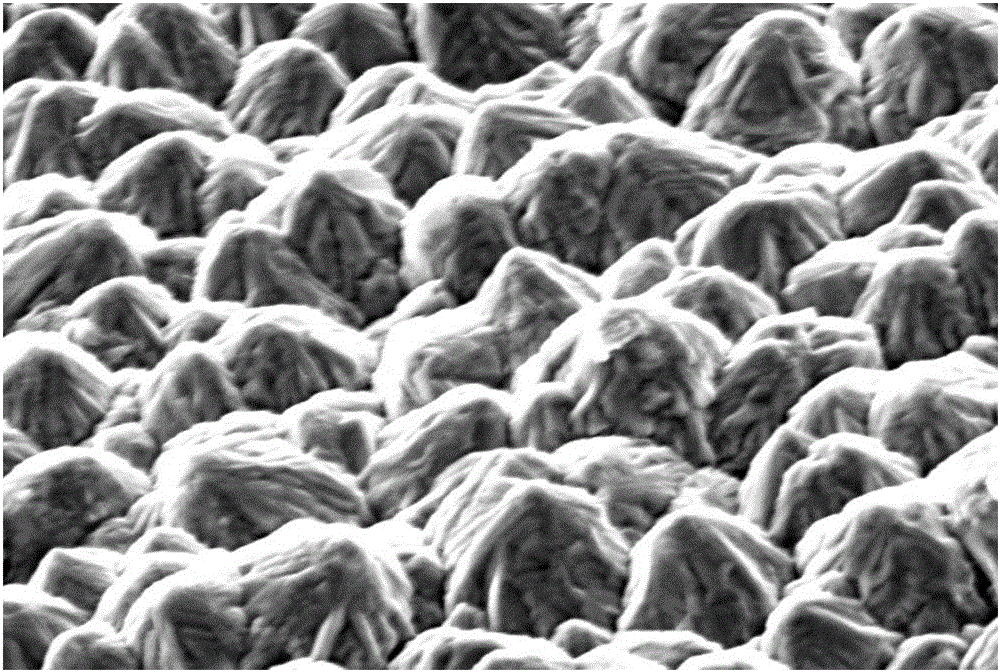

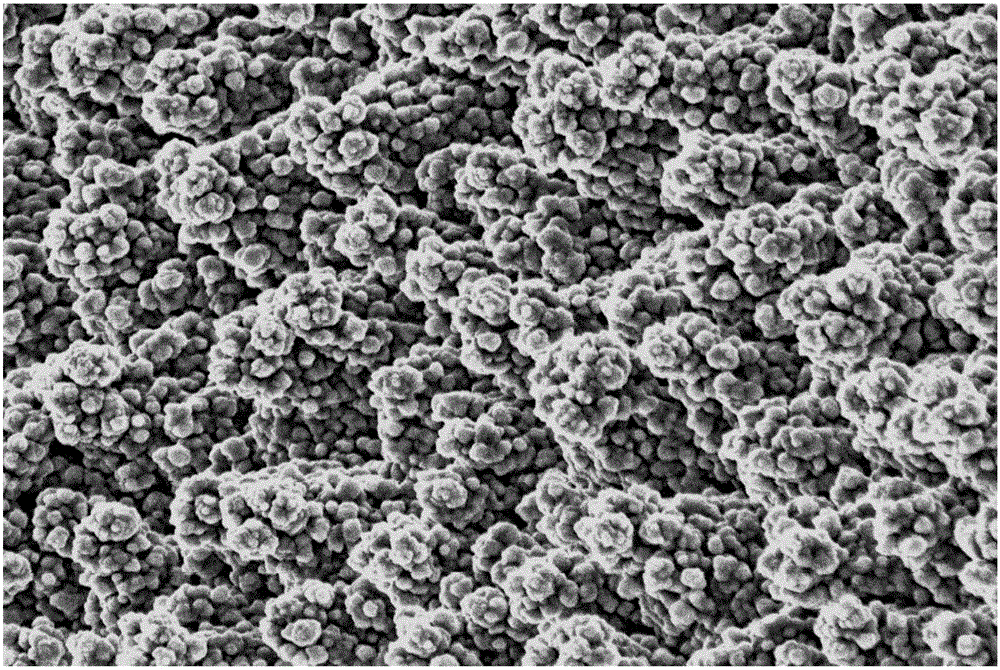

A technology of electrolytic copper foil and roughening treatment, which is applied in the surface roughening treatment process of electrolytic copper foil and the surface treatment process of copper foil. Circuit and other problems, to achieve the effect of low surface roughness, high anti-peel strength, excellent smooth surface micro-etching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

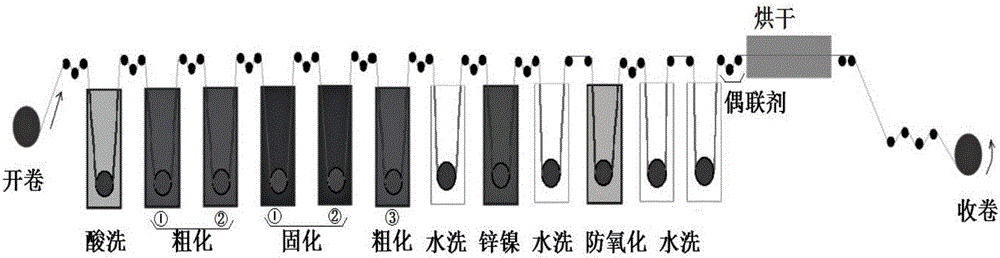

[0034] A micro-roughening treatment process for the surface of electrolytic copper foil, comprising the following process steps:

[0035] 1) The 35 μm HTE copper foil is used as the original foil, and the arc-shaped titanium anode coated with nano-iridium dioxide and the drum-shaped rotating titanium cathode with a diameter of 2700mm are used to form a copper foil on CuSO 4 ·5H 2 O 300g / L, H 2 SO 4 140g / L, Cl - 30mg / L, temperature 57℃, current density 69A / dm 2 Under the condition, with the continuous rotation of the cathode, the copper is peeled off to obtain the electrolytic copper foil;

[0036] 2) The copper foil obtained in step 1) is put into 10wt% dilute sulfuric acid for pickling for 3s;

[0037] 3) Primary roughening and secondary roughening: Put the copper foil after step 2) into the following process conditions for primary roughening: CuSO 4 ·5H 2 O 60g / L, H 2 SO 4 180g / L, Na 3 PO 4 12MO 3 0.5g / L, temperature 28℃, current density 18A / dm 2 ,2.6s, the co...

Embodiment 2

[0044] A micro-roughening treatment process for the surface of electrolytic copper foil, comprising the following process steps:

[0045] 1) The 70 μm HTE copper foil is used as the original foil, and the arc-shaped titanium anode coated with nano-iridium dioxide and the drum-shaped rotating titanium cathode with a diameter of 2700 mm are used to form a copper foil on CuSO 4 ·5H 2 O 300g / L, H 2 SO 4 140g / L, Cl - 30mg / L, temperature 57℃, current density 69A / dm 2 , as the cathode continues to rotate, the copper is peeled off to obtain an electrolytic copper foil; 2) The copper foil obtained in step 1) is soaked in 10 wt% dilute sulfuric acid for pickling, and the time is 5s;

[0046] 3) Primary roughening and secondary roughening: Put the copper foil after step 2) into the following process conditions for primary roughening: CuSO 4 ·5H 2 O 60g / L, H 2 SO 4 180g / L, Na 3 PO 4 12MO 3 1.0g / L, temperature 35℃, current density 25A / dm 2 , 2s, the copper foil after the pri...

Embodiment 3

[0053] A micro-roughening treatment process for the surface of electrolytic copper foil, comprising the following process steps:

[0054] 1) Using 100 μm HTE copper foil as the original foil, using a curved titanium anode coated with nano-iridium dioxide and a drum-shaped rotating titanium cathode with a diameter of 2700mm, the 4 ·5H 2O 300g / L, H 2 SO 4 140g / L, C l - 30mg / L, temperature 57℃, current density 69A / dm 2 , with the continuous rotation of the cathode, the copper is peeled off to obtain an electrolytic copper foil;

[0055] 2) Soak the copper foil obtained in step 1) into 10wt% dilute sulfuric acid for pickling for 3s;

[0056] 3) Primary roughening and secondary roughening: Put the copper foil after step 2) into the following process conditions for primary roughening: CuSO 4 ·5H 2 O 100g / L, H 2 SO 4 220g / L, Na 3 PO 4 12MO 3 1.5g / L, temperature 30℃, current density 15A / dm 2 ,3s, the copper foil after primary roughening enters secondary roughening, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com