Patents

Literature

45results about How to "Play a cutting role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

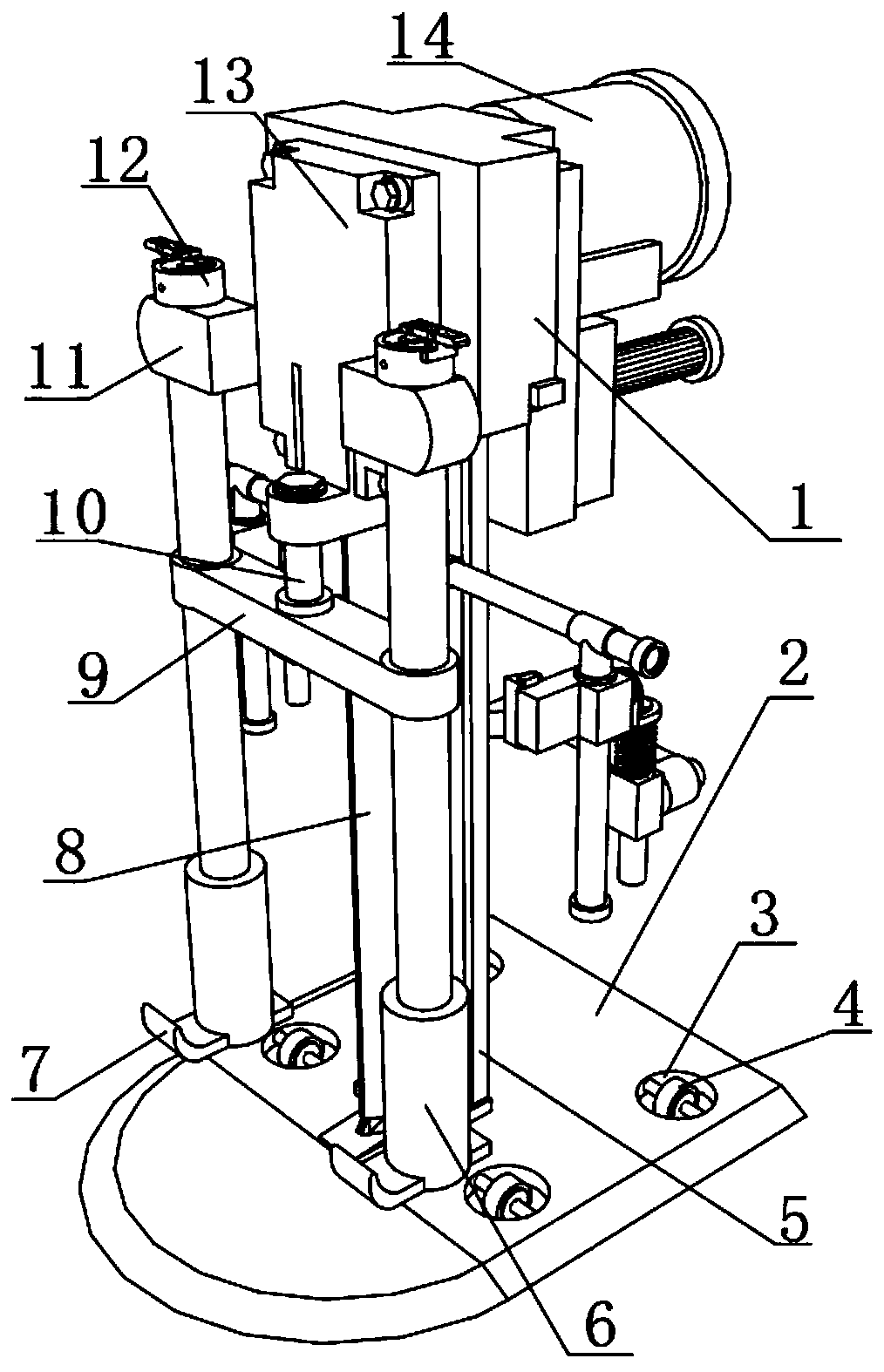

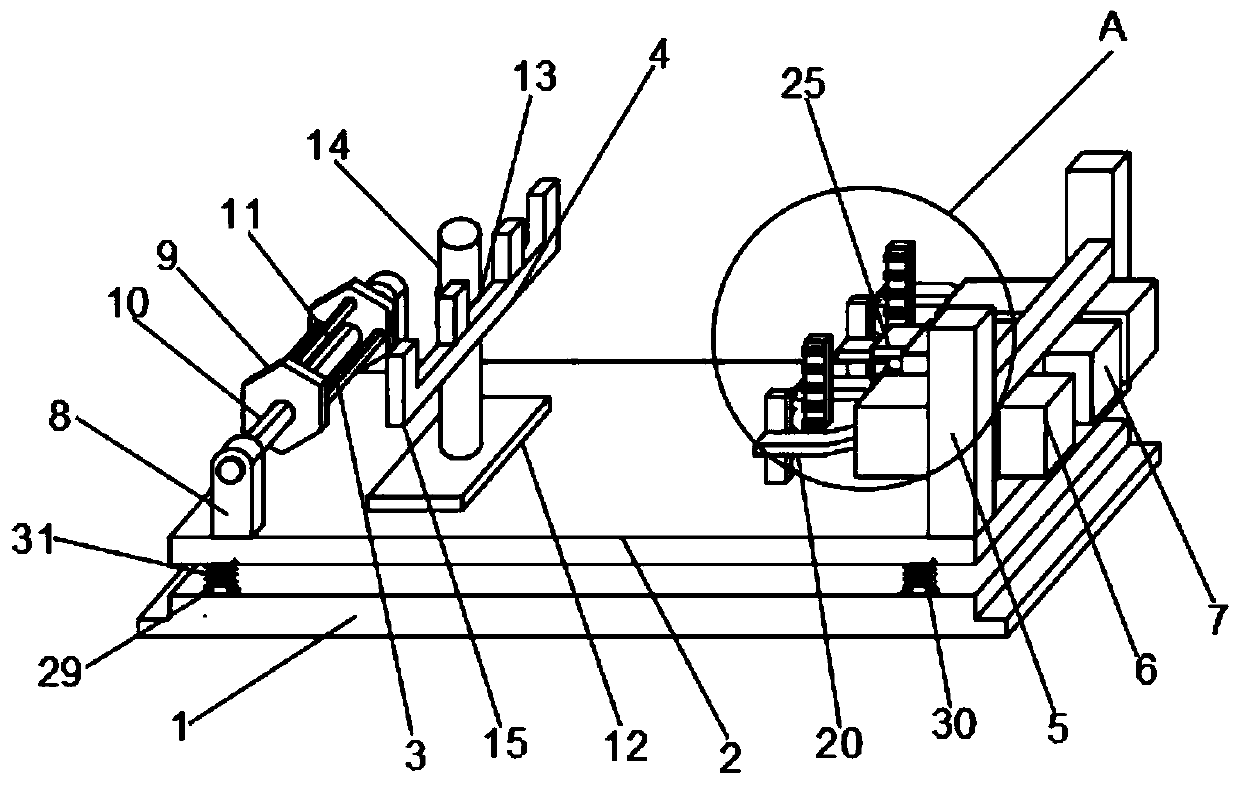

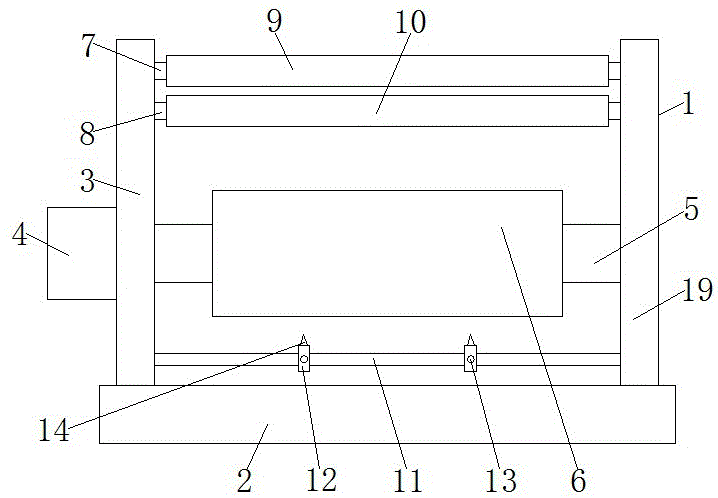

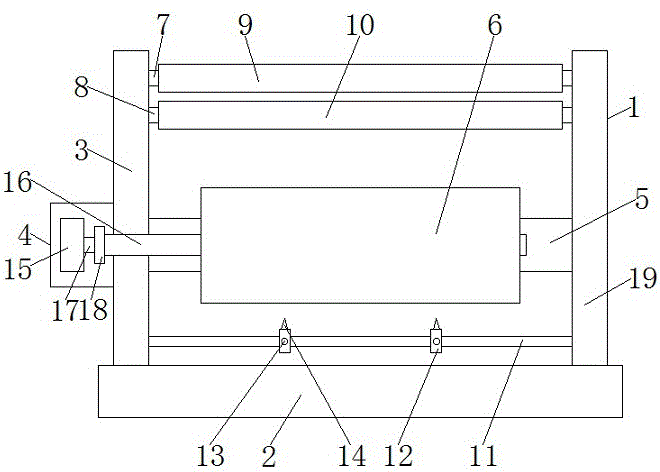

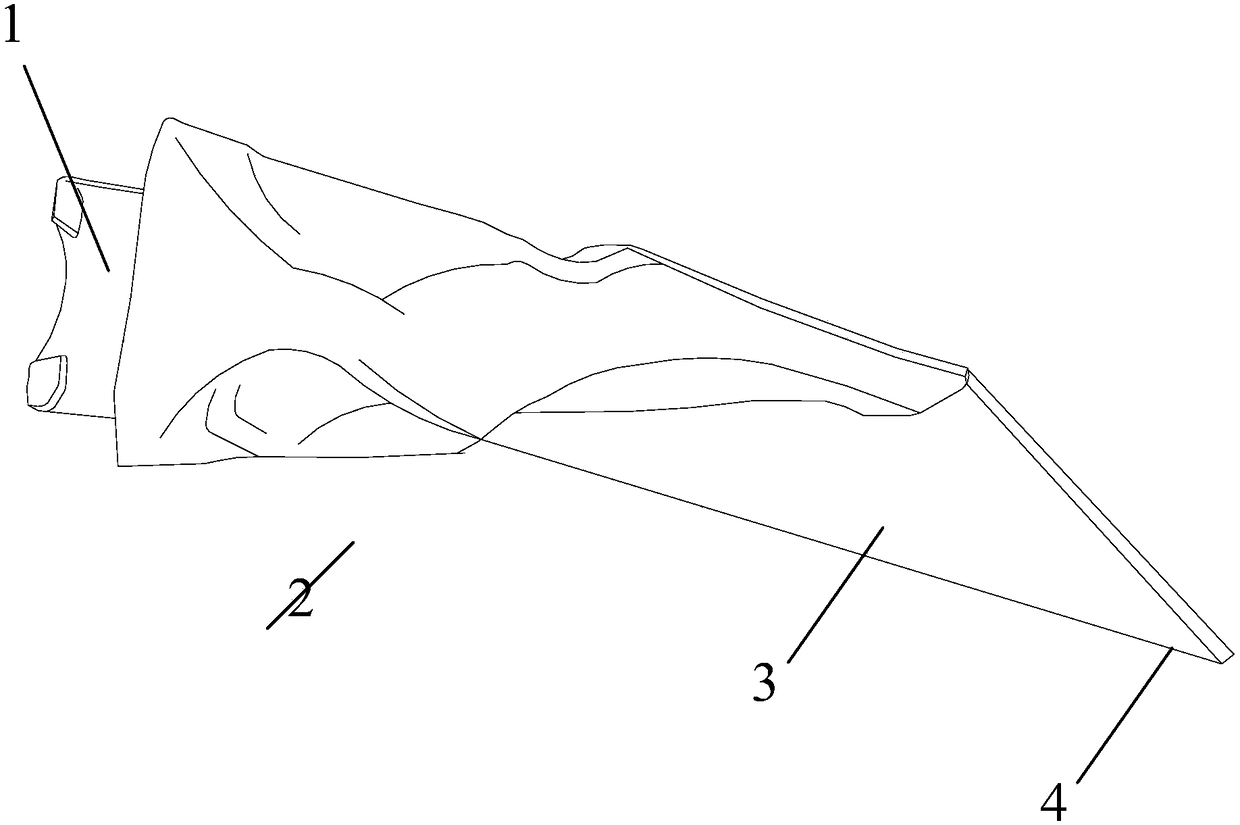

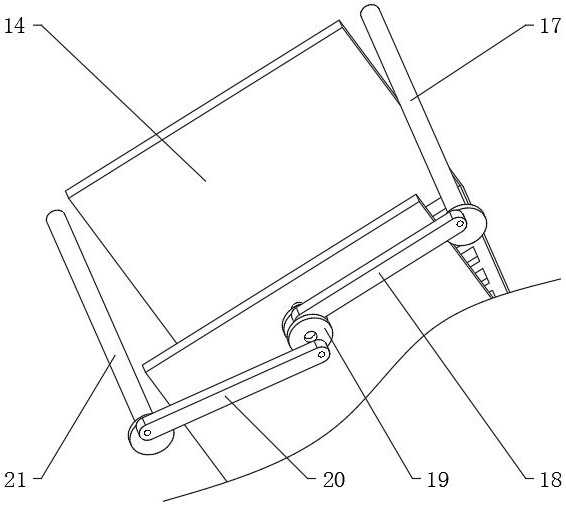

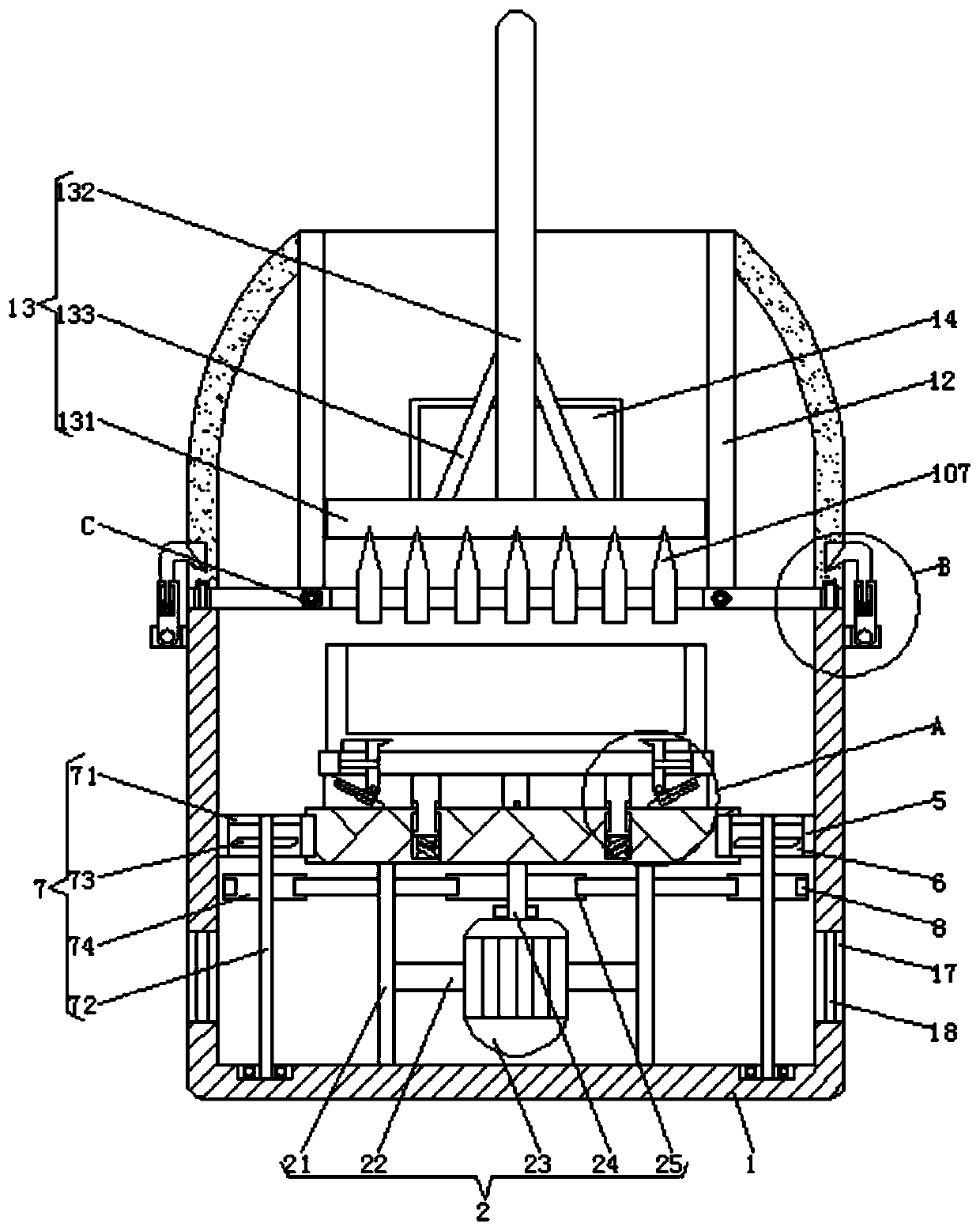

Cloth cutting device for clothing manufacture

ActiveCN110685144APlay a cutting roleLow costGrinding carriagesGrinding drivesStructural engineeringKnife holder

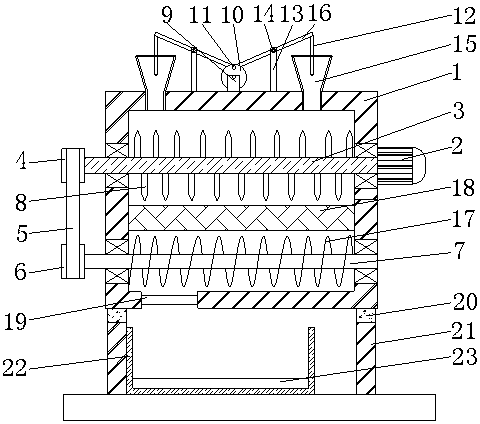

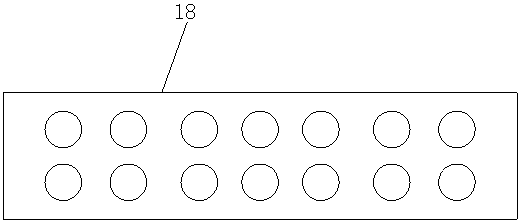

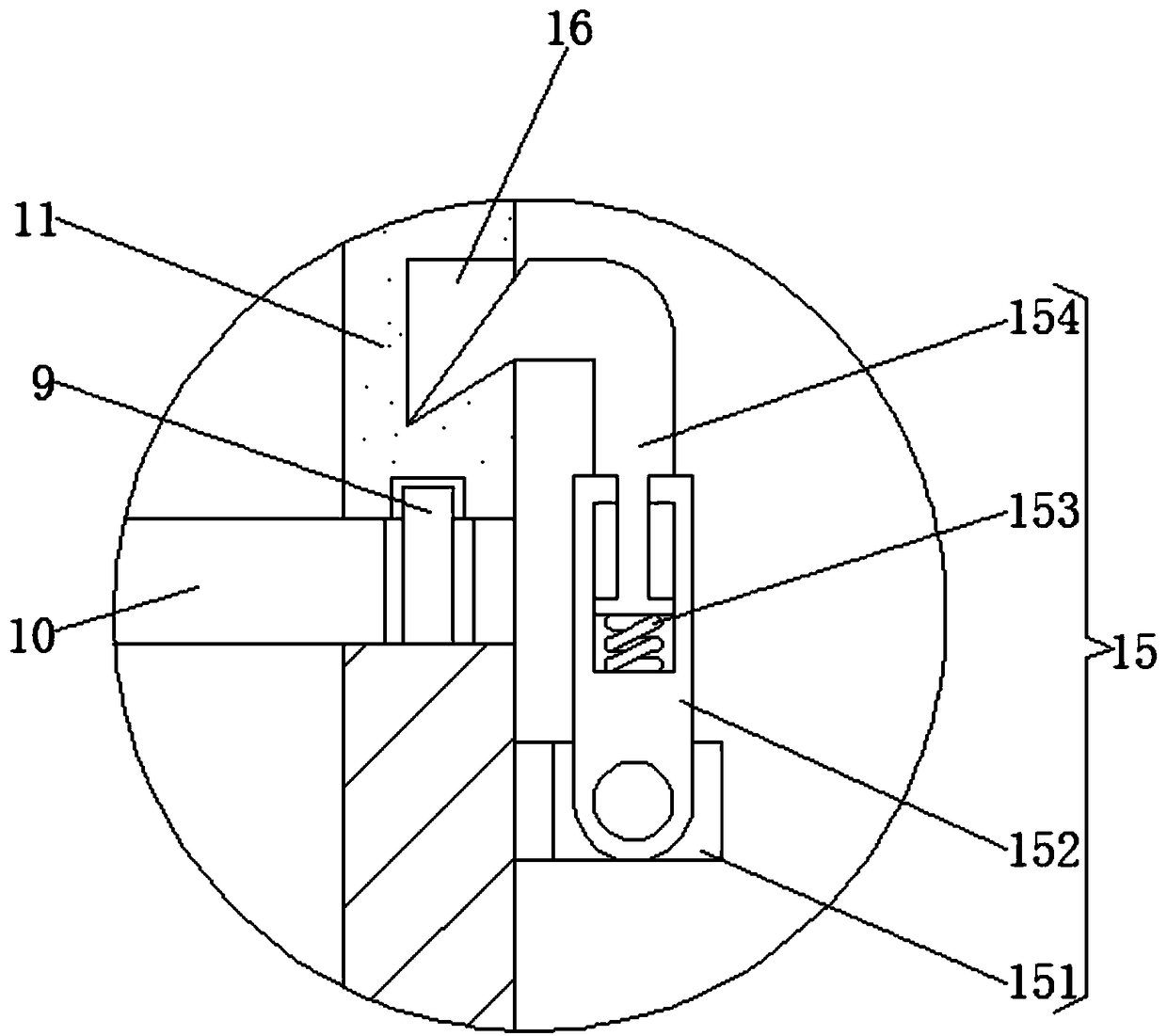

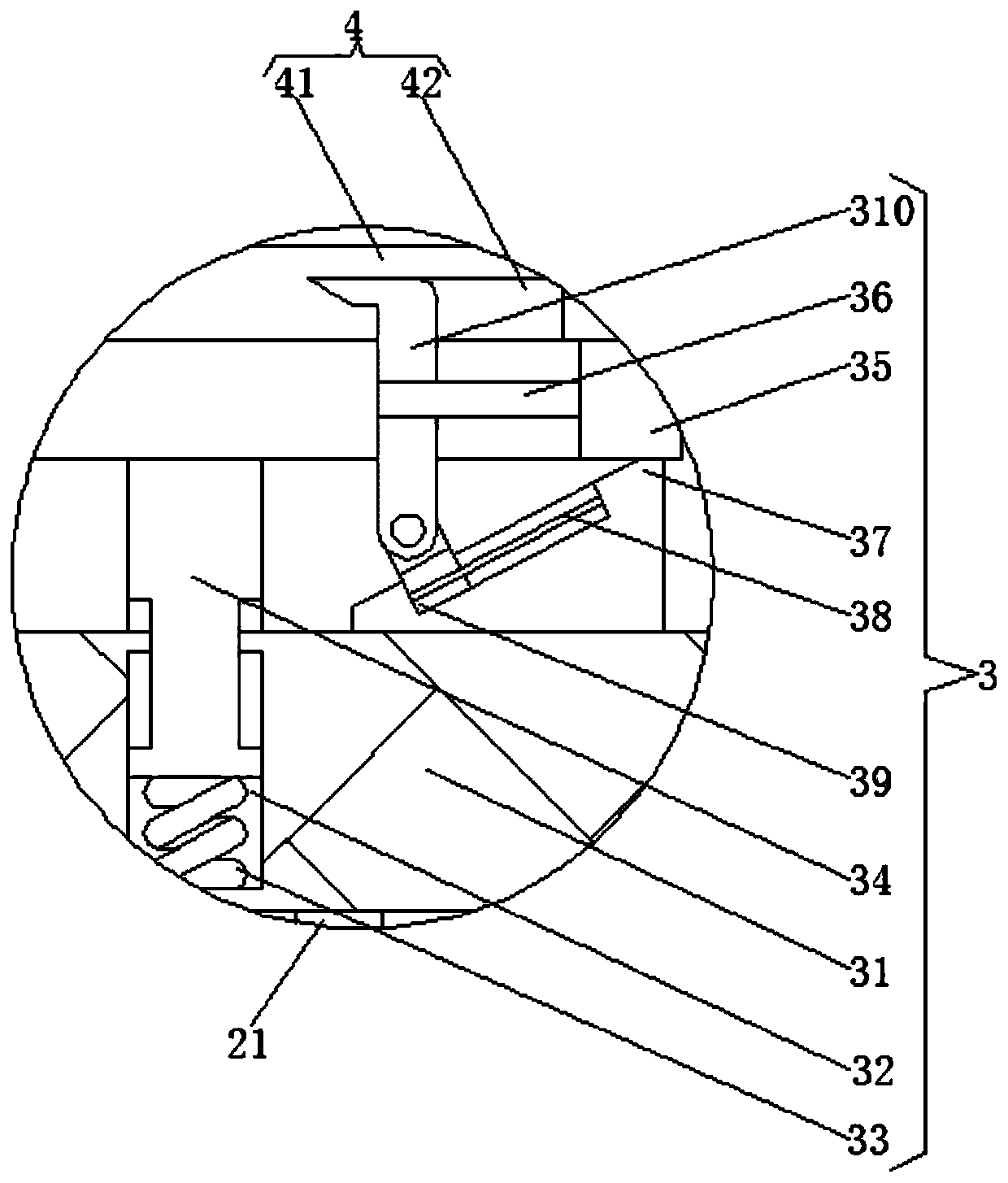

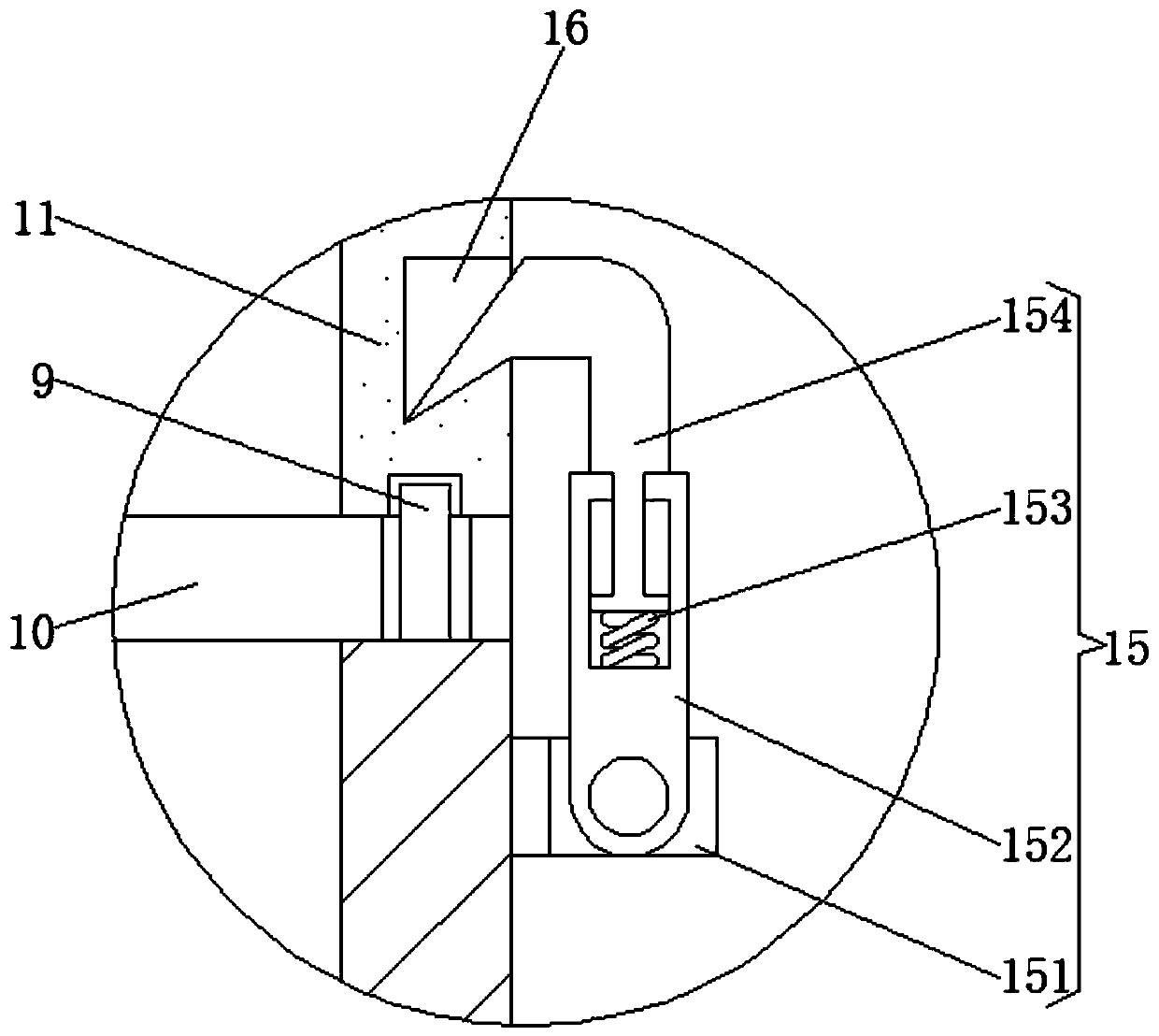

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cloth cutting, aiming to solve the problem that conventional bench type cutting devices are not adaptable to mass cutting of cloth. The cloth cutting device comprises a rack and a lower cutting plate; a blade carrier is arranged on the outer wall of the bottom of the rack, and the outer wall of the bottom of the blade carrier is welded to the outer wall of the top of the lower cutting plate; four mount holes are formed on the outer wall of the top of the lower cutting plate, and four rollers are respectively arranged inside the four mount holes; slide slots are respectively formed on the inner walls of two sides of the rack, two first sliders are slidably connected to the inner walls of two sides of the two slide slots respectively, the two first sliders are the same, mounting shafts are welded to outer walls of opposite sides of the two first sliders respectively, and holderssleeve the outer peripheral walls of the mounting shafts respectively; a cutting blade is fastened to the outer wall of the bottom of the holder, a U-shaped connecting frame is welded to the outer walls of backs of the two first sliders, and a second connecting plate is rotationally connected to the outer wall of the back of the U-shaped connecting frame. In application of the cloth cutting device, squeezing and fixing to single-layer or multi-layer cloth are facilitated, and accordingly, the cutting quality of the cutting blade is improved.

Owner:湖南浚林服饰有限公司

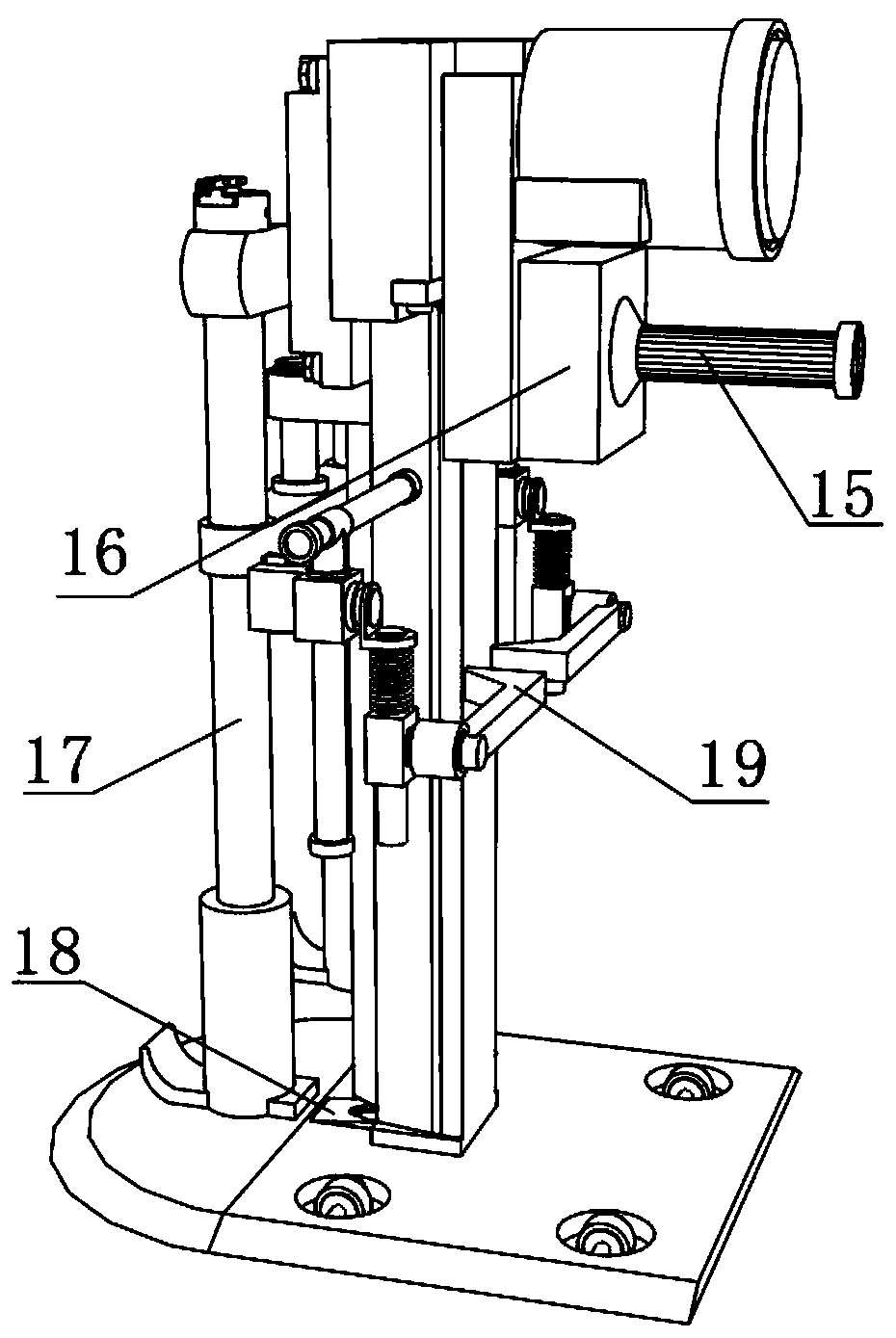

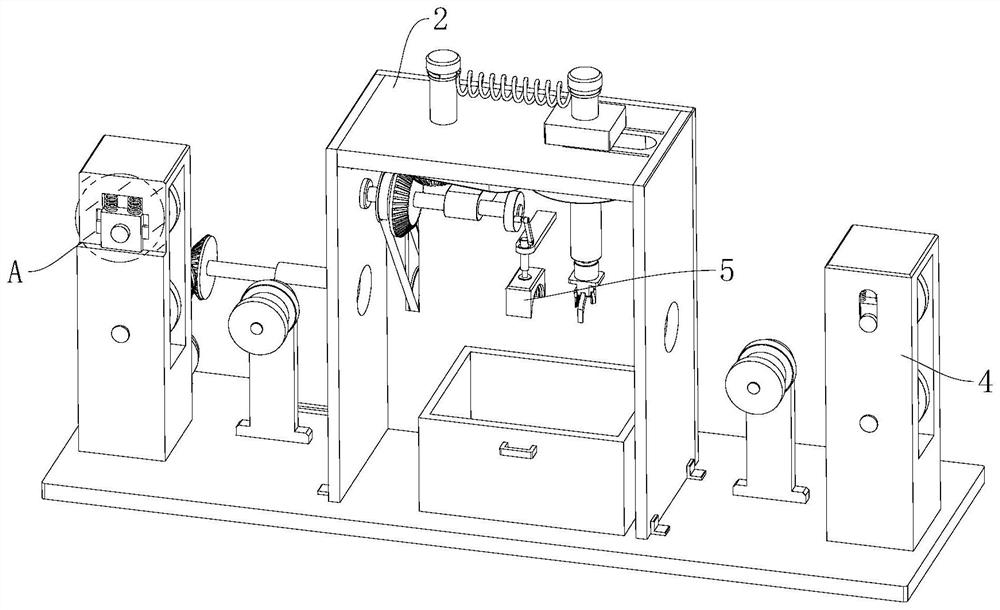

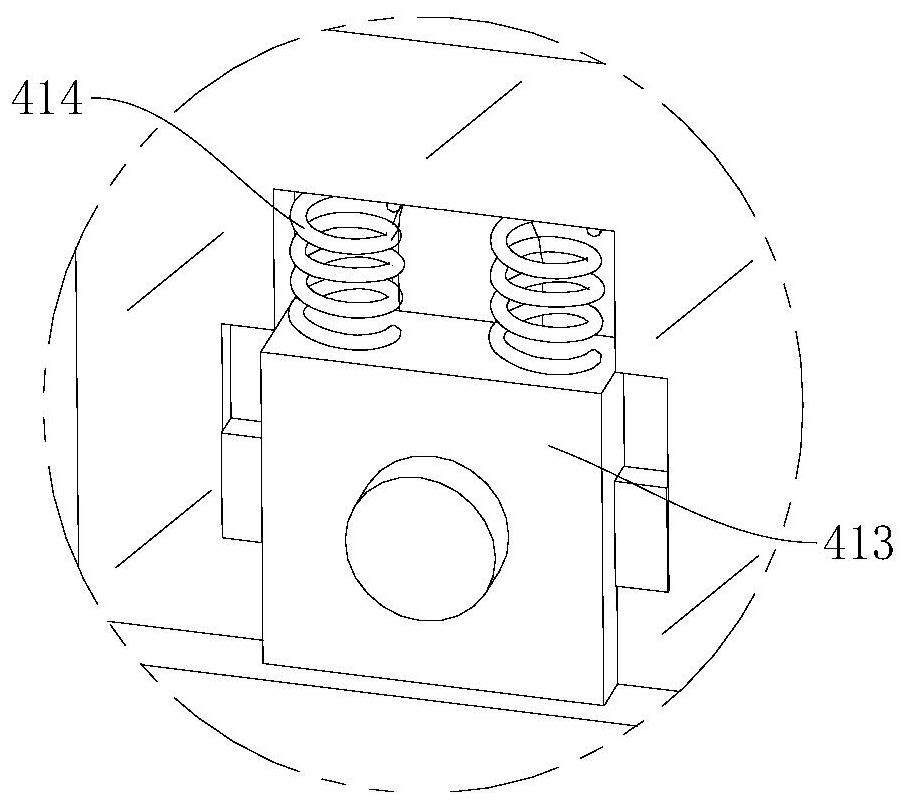

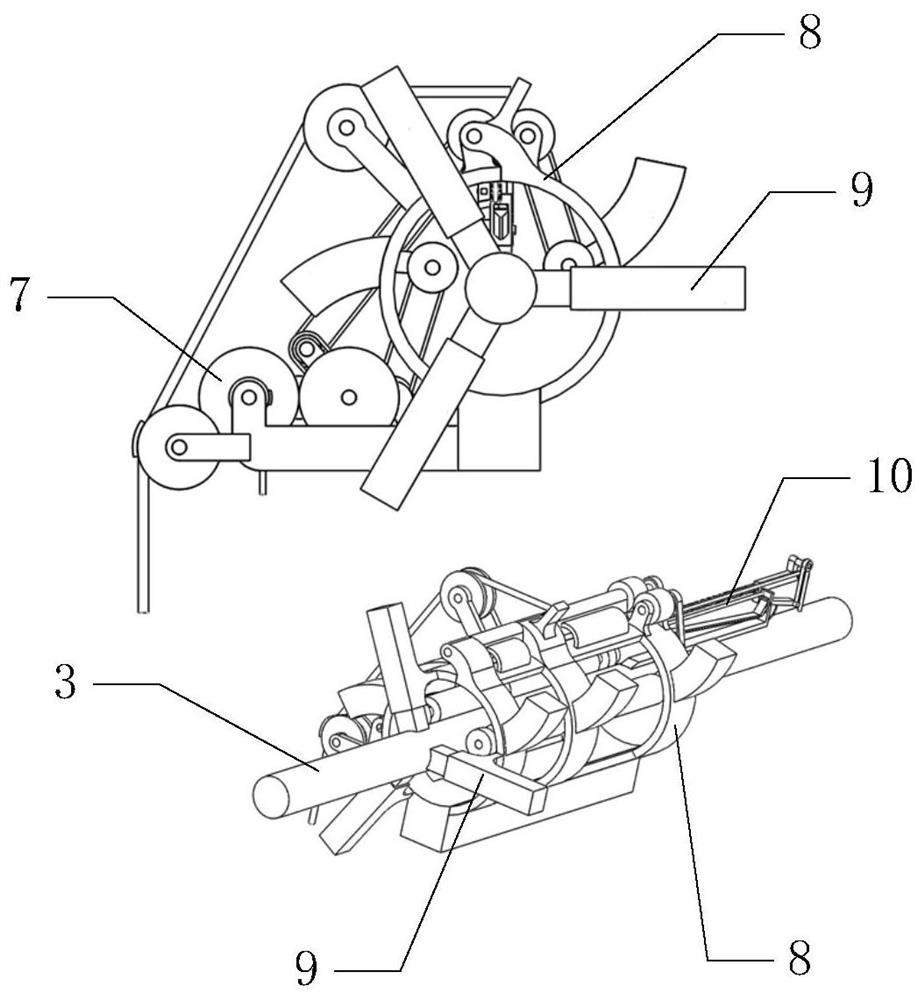

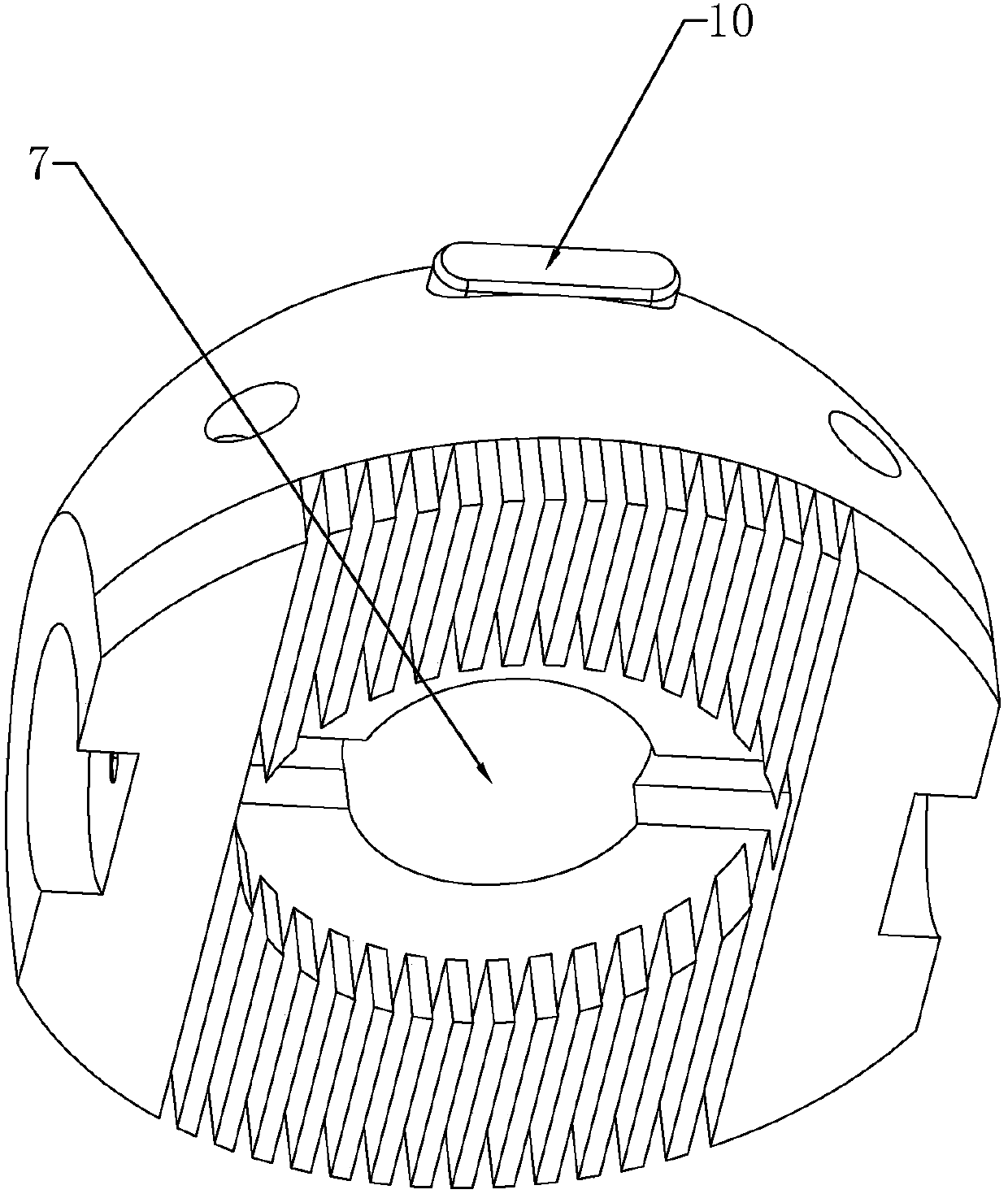

Construction site steel pipe surface cleaning equipment

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

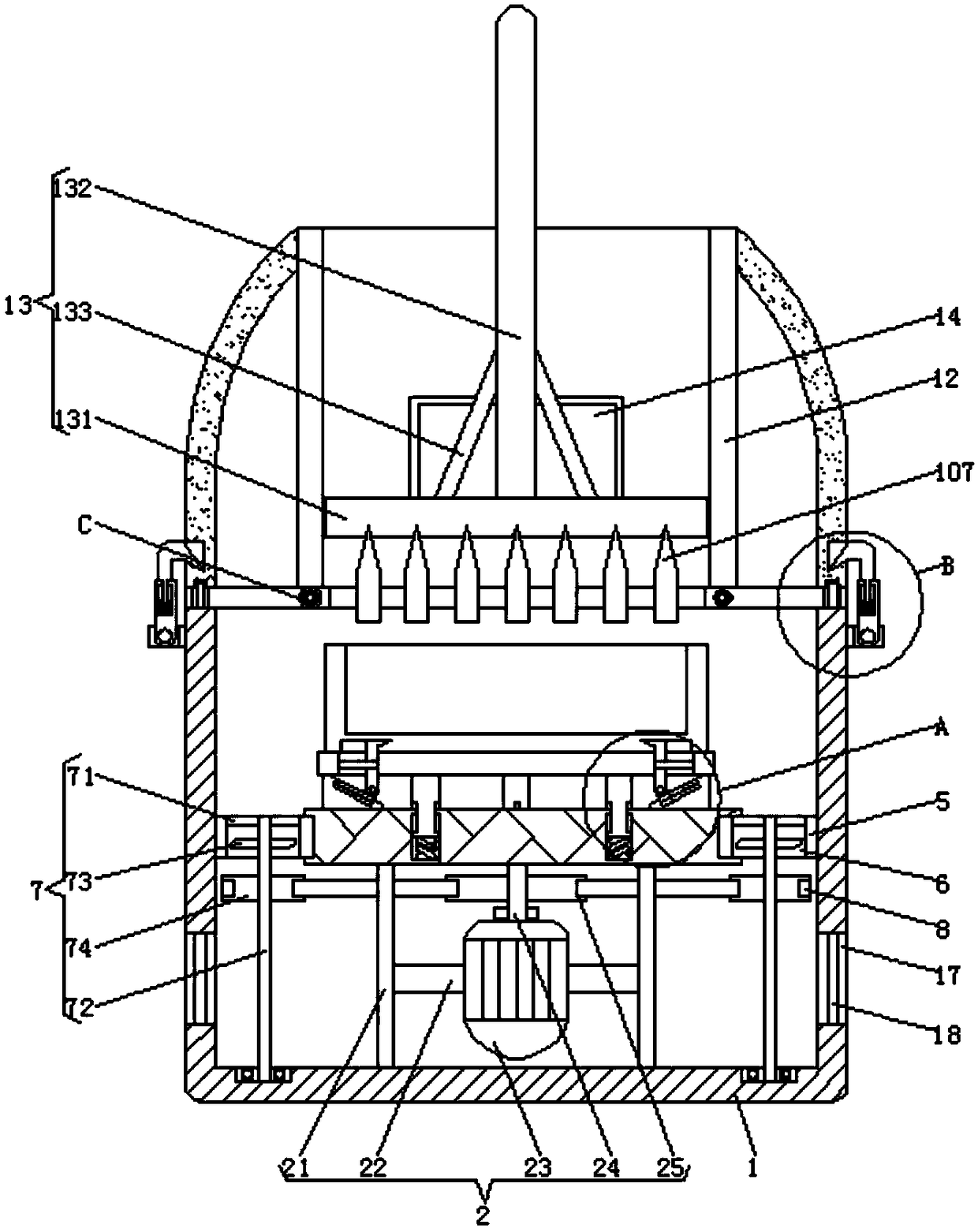

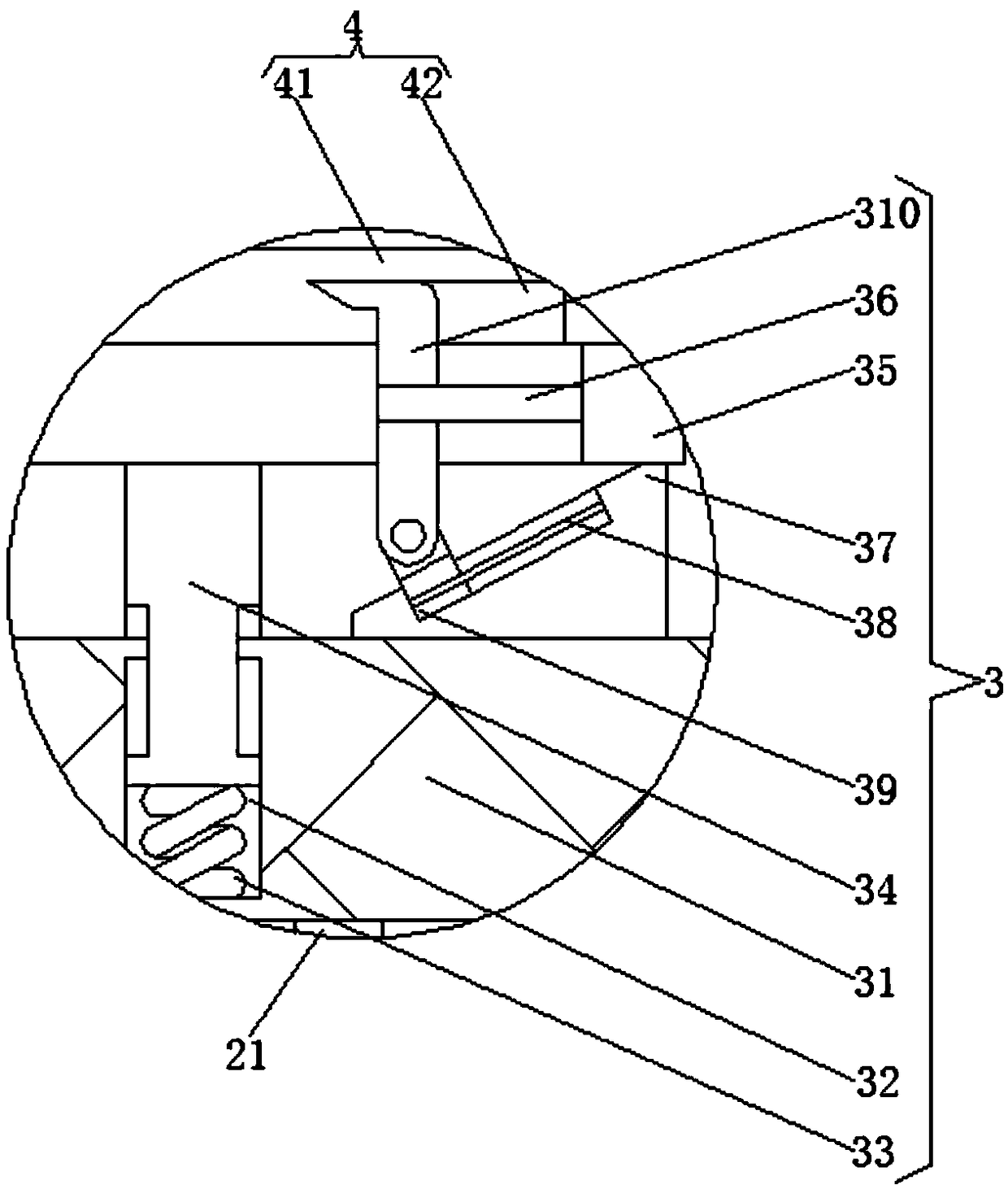

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

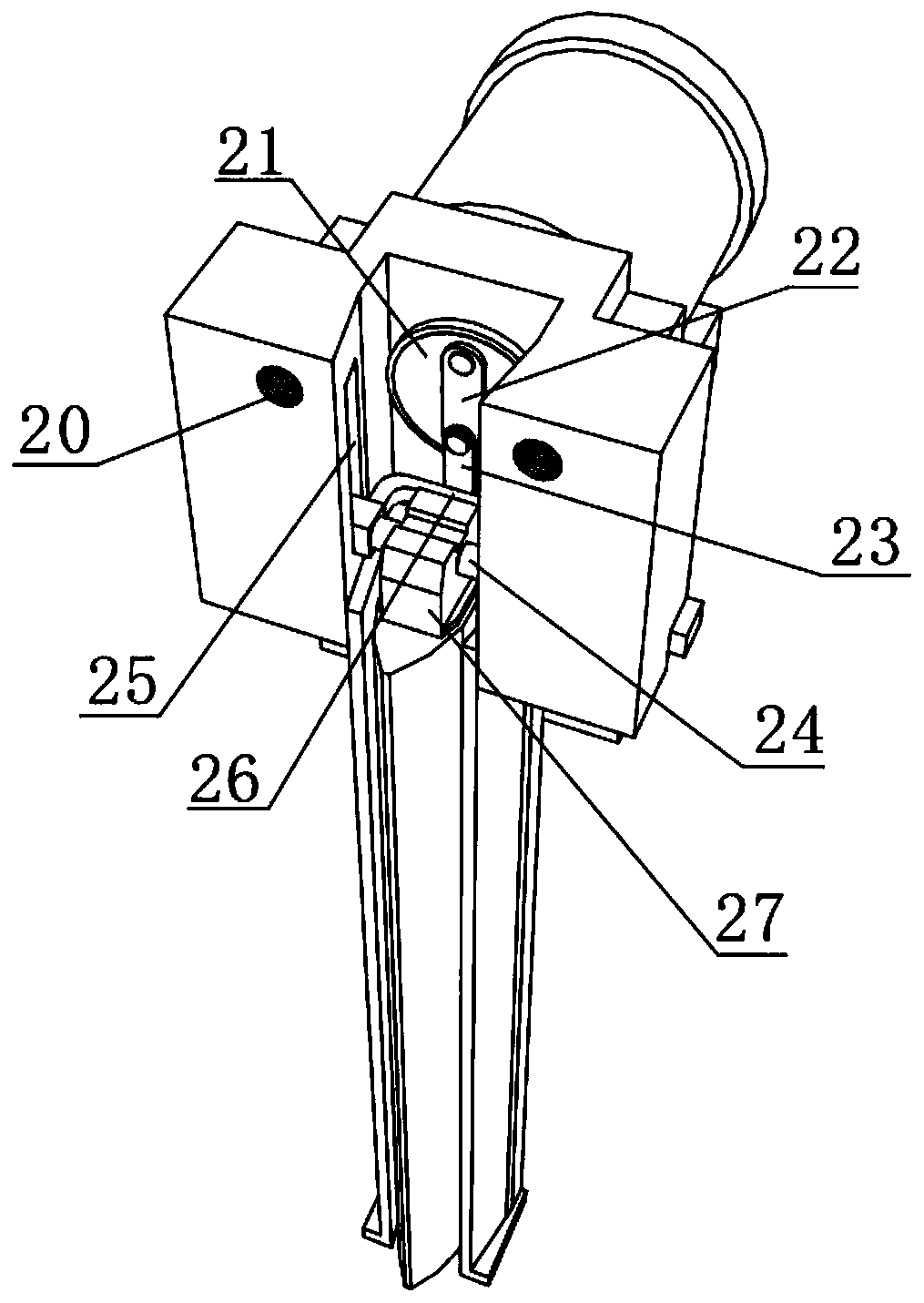

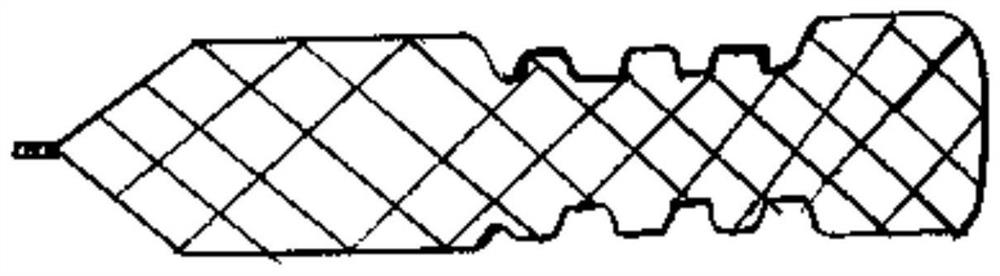

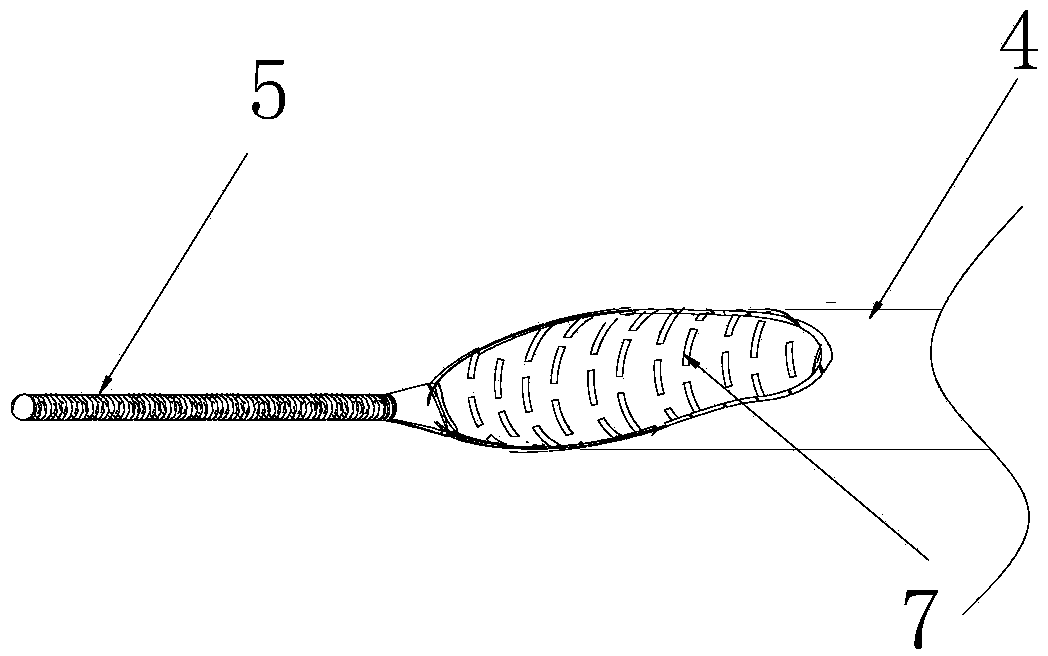

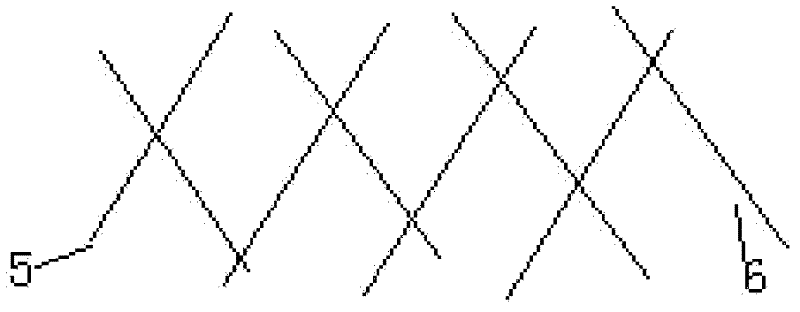

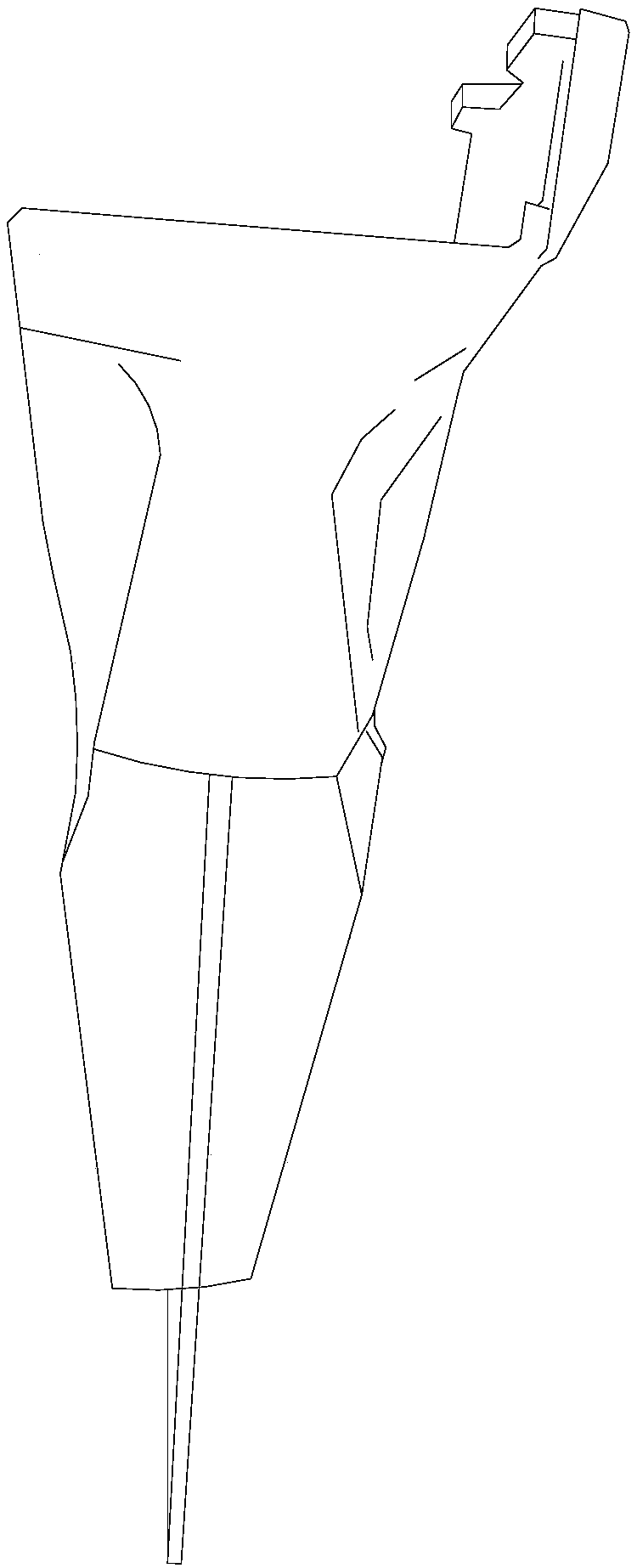

Minimally-invasive thrombus removing device for treating vascular thrombosis

The invention discloses a minimally-invasive thrombus removing device for treating vascular thrombosis. The minimally-invasive thrombus removing device comprises a thrombus remover, a conveying systemouter tube, a conveying system inner tube and a handle. The thrombus remover comprises a netting-tube-shaped proximal end, a distal end and a screw-shaped middle piece, and the distal end is coveredwith a macromolecular membrane. A distal end of the conveying system inner tube is connected with a proximal end of the thrombus remover, and the thrombus remover is gripped in a sandwiched chamber ofthe conveying system outer tube and the conveying system inner tube in a pressed manner. After the thrombus remover is released, the thrombus remover can be turned through twisting the handle, and the screw-shaped middle piece of the thrombus remover can play a role in cutting thrombi with relatively hard texture. During withdrawing of the thrombus-carrying thrombus remover, even if relatively small thrombi fall off, the relatively small thrombi will be captured by the distal end of the thrombus remover covered with the macromolecular membrane and cannot flow to and block up distal-end bloodvessels. A thrombus removing system disclosed by the invention is very suitable for removing arterial and venous thrombi, including obsolete thrombi with relatively hard texture and relatively large thrombi, blood flow reconstruction can be achieved quickly, and particularly, the death rate of pulmonary artery thrombosis can be lowered greatly.

Owner:尤东侠

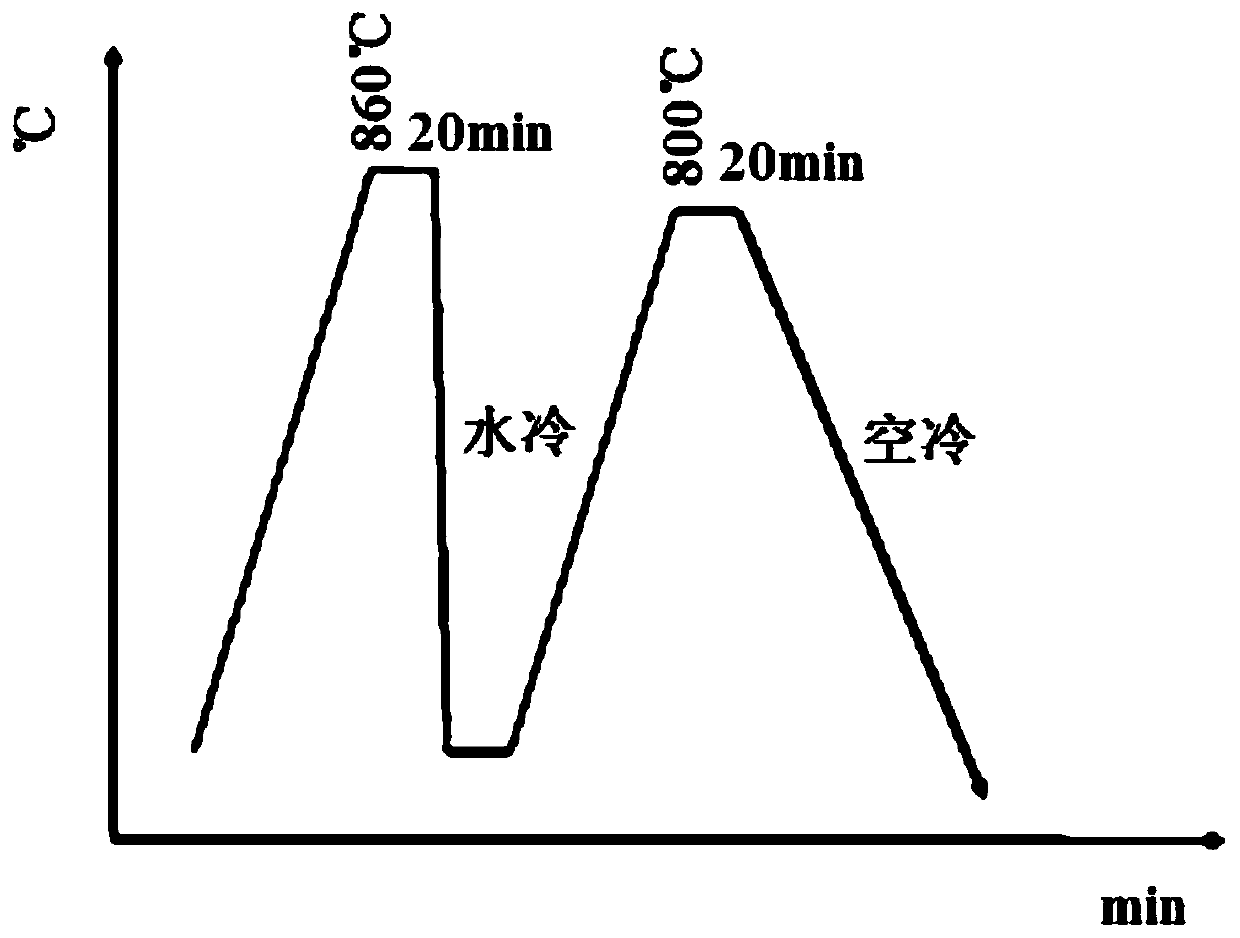

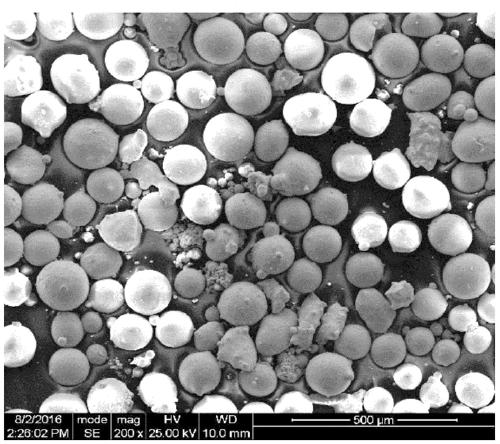

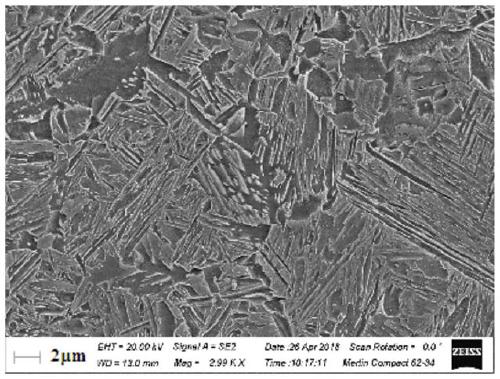

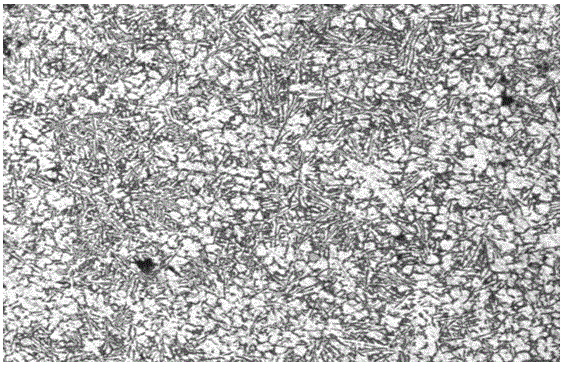

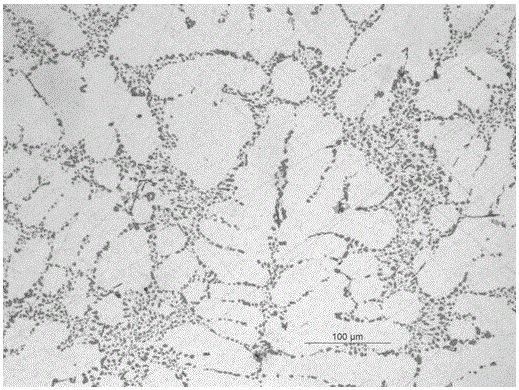

Post heat treatment method for laser additive manufacturing 12CrNi2 alloy steel

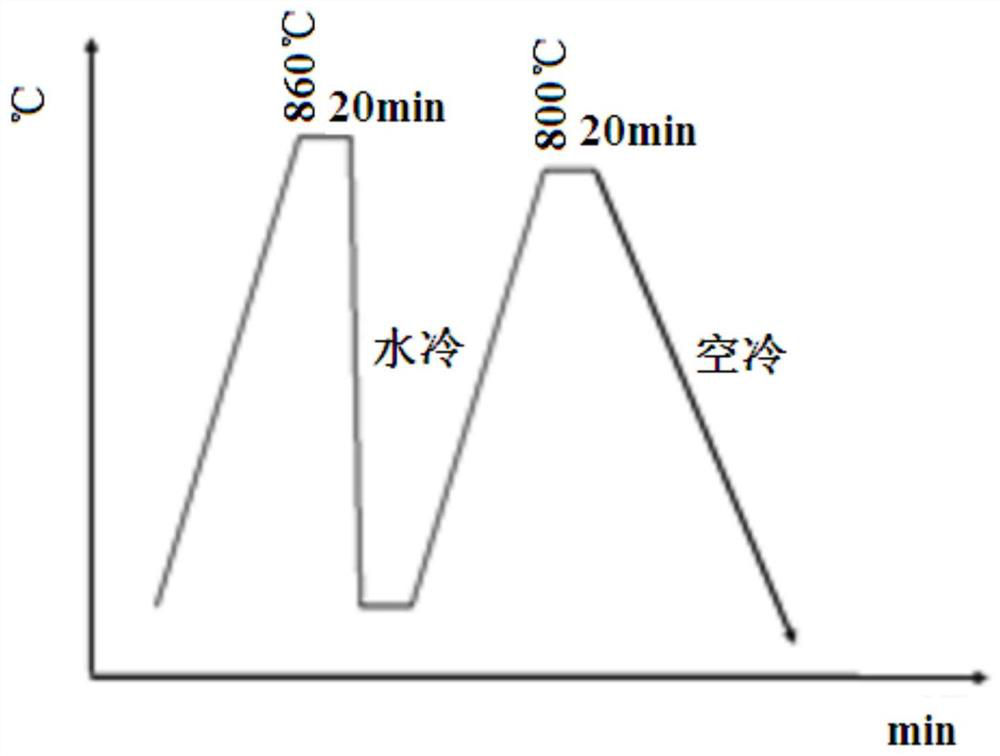

InactiveCN109880986ASolve the disadvantages of sub-temperature quenching that is difficult to homogenize the structureSolve the disadvantages of difficult to homogenize tissueIncreasing energy efficiencyRoom temperatureWater cooling

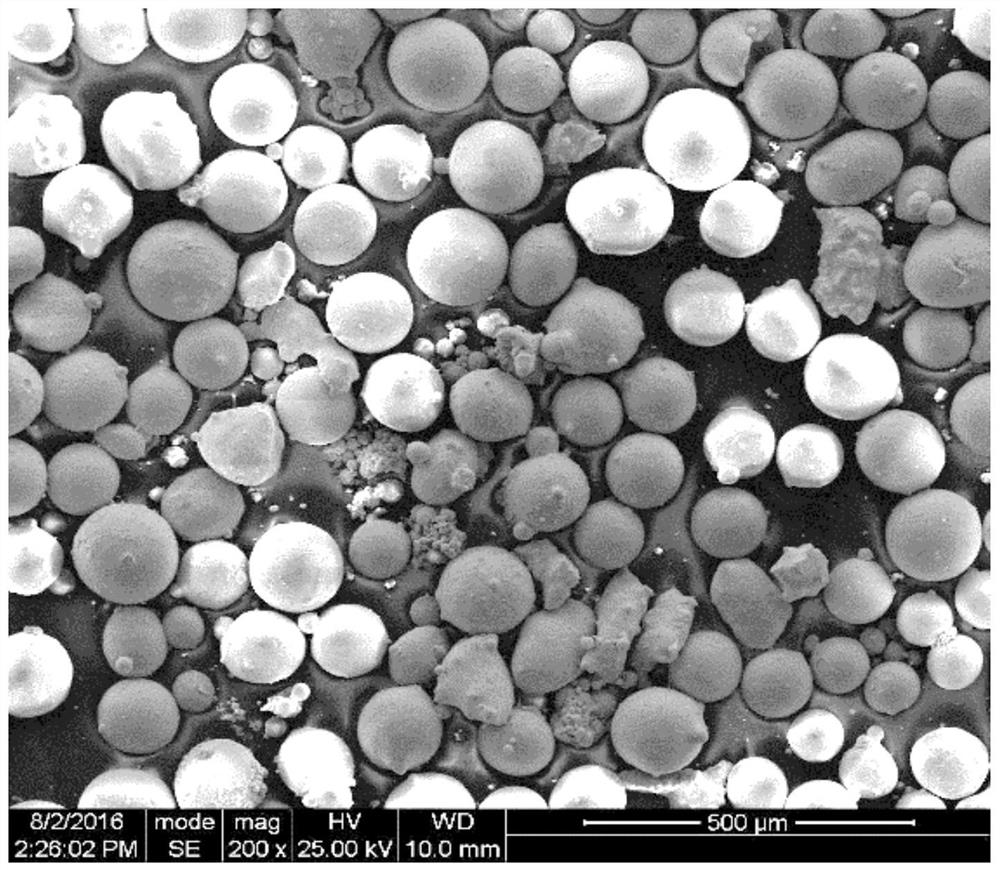

The invention provides a post heat treatment method for a laser additive manufacturing 12CrNi2 alloy steel and relates to the technical field of post heat treatment of the additive manufacturing alloysteel. The purpose of the invention is to solve the problems that traditional laser additive manufacturing is uneven in tissue, difficult to remove residual stresses and low in alloy strength. The method comprises the steps of 1, heating and temperature raising, specifically, the laser additive manufacturing 12CrNi2 alloy steel is heated to 856-866 DEG C; 2, heat preservation, specifically, heatpreservation treatment is performed on the 12CrNi2 alloy steel after the heating and temperature raising under the condition of 856-866 DEG C; 3, cooling, specifically, the 12CrNi2 alloy steel after the heat preservation is water-cooled to the room temperature; and 4, the cooled 12CrNi2 alloy steel is heated to 734-836 DEG C and the heat preservation treatment is performed under this temperature condition, then water-cooling is performed to the room temperature, and the treated 12CrNi2 alloy steel is obtained. By means of the post heat treatment method for the laser additive manufacturing 12CrNi2 alloy steel, the post heat treatment method for the laser additive manufacturing 12CrNi2 alloy steel can be obtained.

Owner:HARBIN INST OF TECH

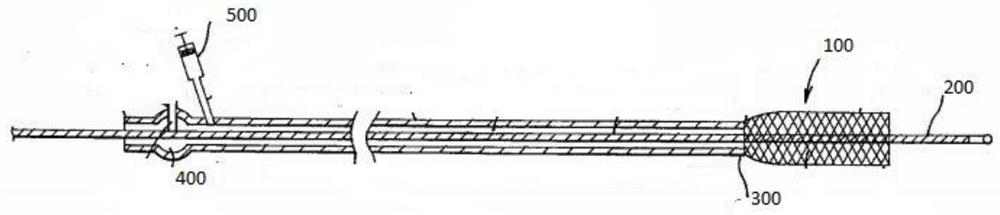

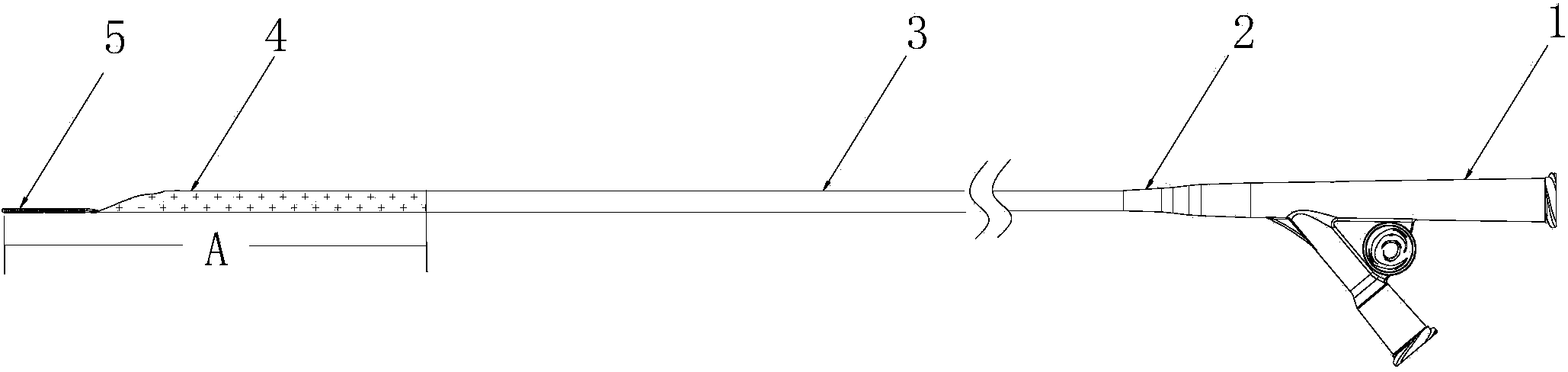

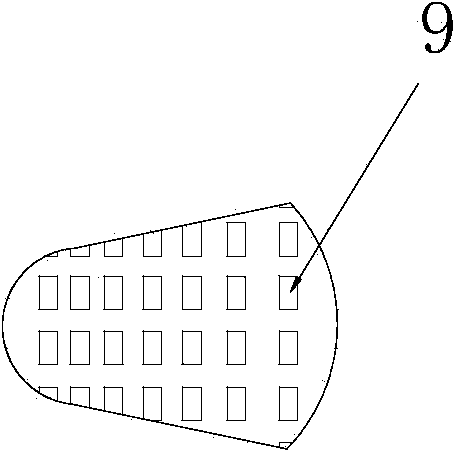

Auxiliary catheter for guiding delivery of endovascula stent

ActiveCN104068952AStrong penetrating powerEfficient piercing and crossingStentsInsertion stentThrombus

The invention discloses an auxiliary catheter for guiding the delivery of an endovascula stent to provide a safe channel free of propelling resistance for stent delivery in interventional therapy. The auxiliary catheter for guiding the delivery of the endovascula stent is provided with a tubular catheter body, wherein the hardness of the catheter body becomes smaller gradually from the near end to the far end, the far end of the catheter body is an oblique incision, the far end of the oblique incision is connected with the near end of a guide wire which is a stainless steel wire or a nitinol wire and is 2 mm - 12 mm long, and the diameter of the guide wire is 0.2 mm - 0.4 mm. Compared with the prior art, the auxiliary catheter has the advantages that the far end of the guide wire is filiform, has high penetrating power and can efficiently puncture and pass through a severe narrow tortuous, or calcified or CTO diseased region, the far end of a passing section connected with the guide wire is an oblique incision so that a hemadostenosis region can be passed through conveniently and cutting of a diseased region can be achieved, and cut-down thrombi or plaques are sucked to provide the safe channel free of propelling resistance for stent delivery.

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

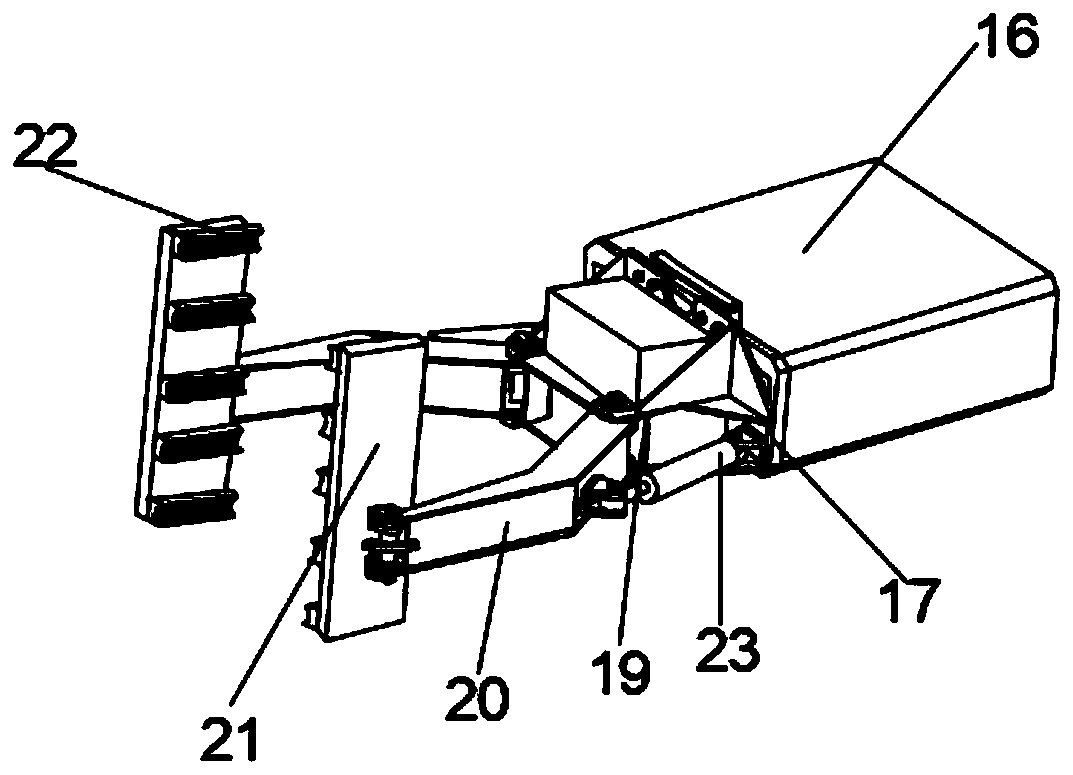

Separator for cable processing

ActiveCN110808127APlay a supporting roleAvoid entanglementCable/conductor manufactureDistribution frameEngineering

The invention discloses a separator for cable processing, which belongs to the technical field of steel cable processing. The separator for cable processing comprises a supporting base, a workbench installed above the supporting base and a winding frame located above the workbench. The winding frame is arranged at one end of the workbench. A first supporting frame is arranged on one side of the workbench. A fixed installation frame is integrally formed at the end, away from the winding frame, of the workbench; clamping machine boxes and a cutting machine box are fixedly installed in an inner screw of the fixed installation frame; the cutting machine box is arranged between the clamping machine boxes; a drawing clamping mechanism is installed in the clamping machine box; and a cable cuttingmechanism is installed in the cutting machine box. One end of a cable penetrates through the cable distribution frame, on one hand, the cable is supported, and on the other hand, the cable is distributed, so that the cable is prevented from being wound.

Owner:KUNSHAN XINGHONGMENG ELECTRONICS CO LTD

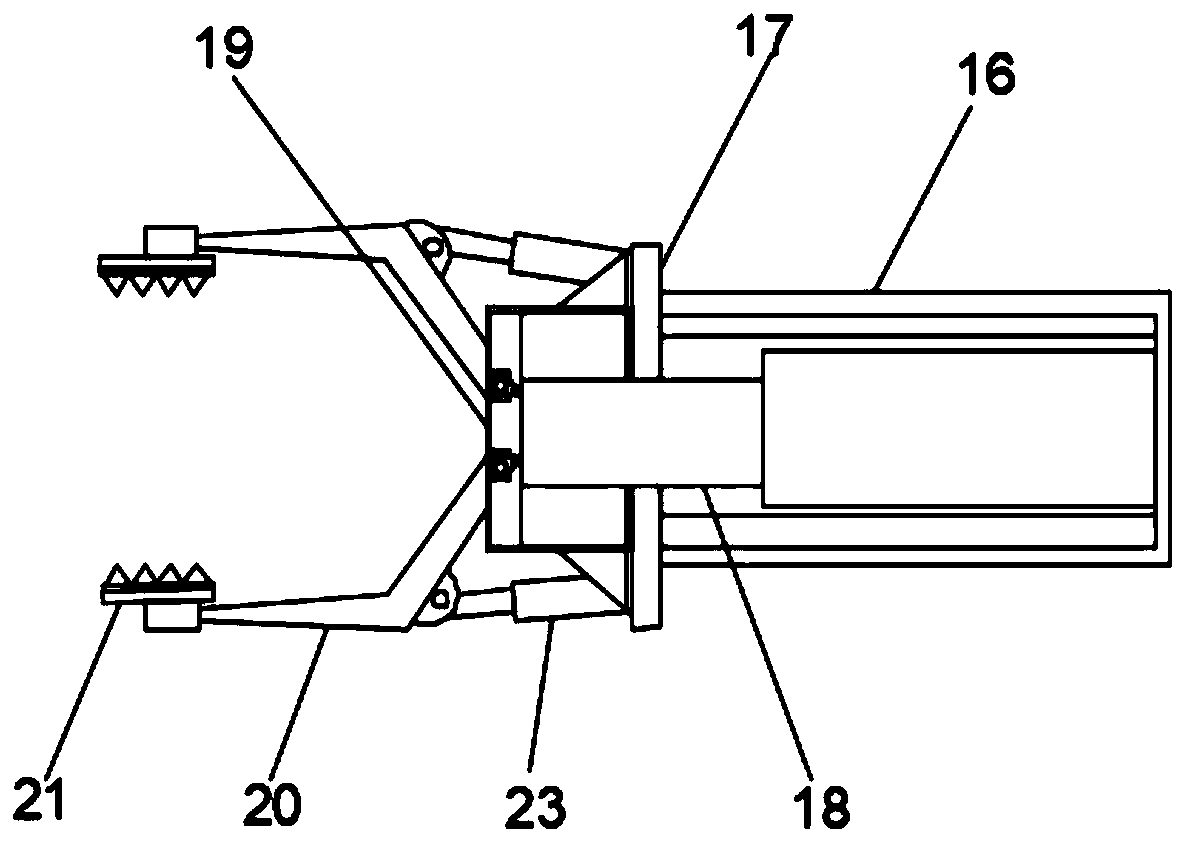

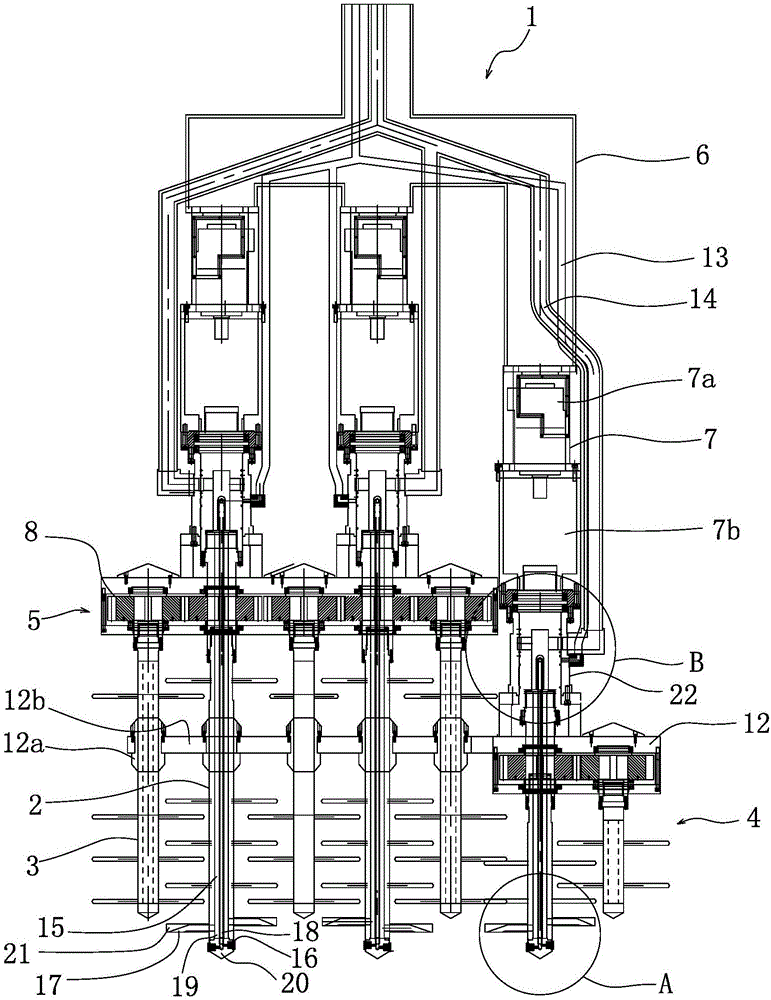

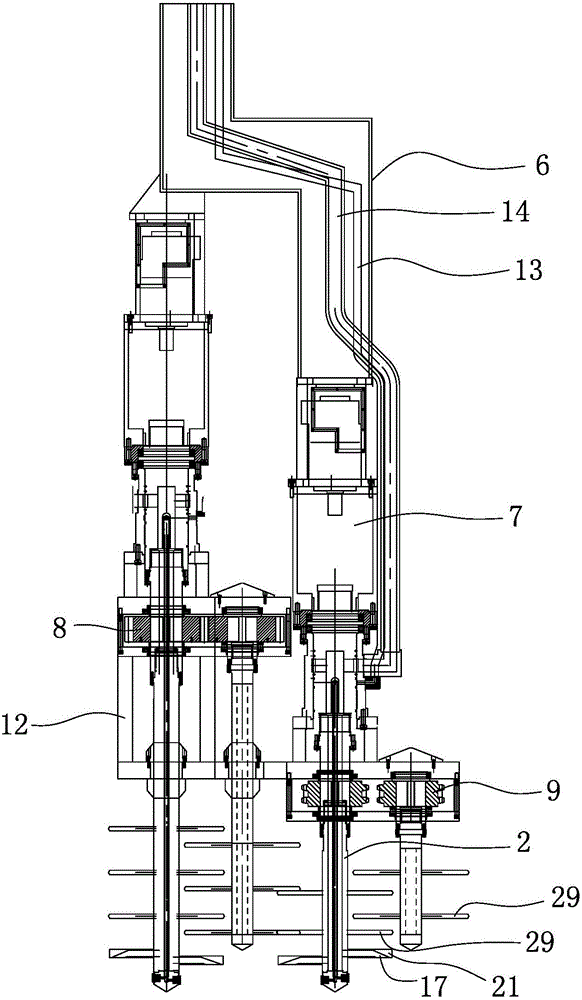

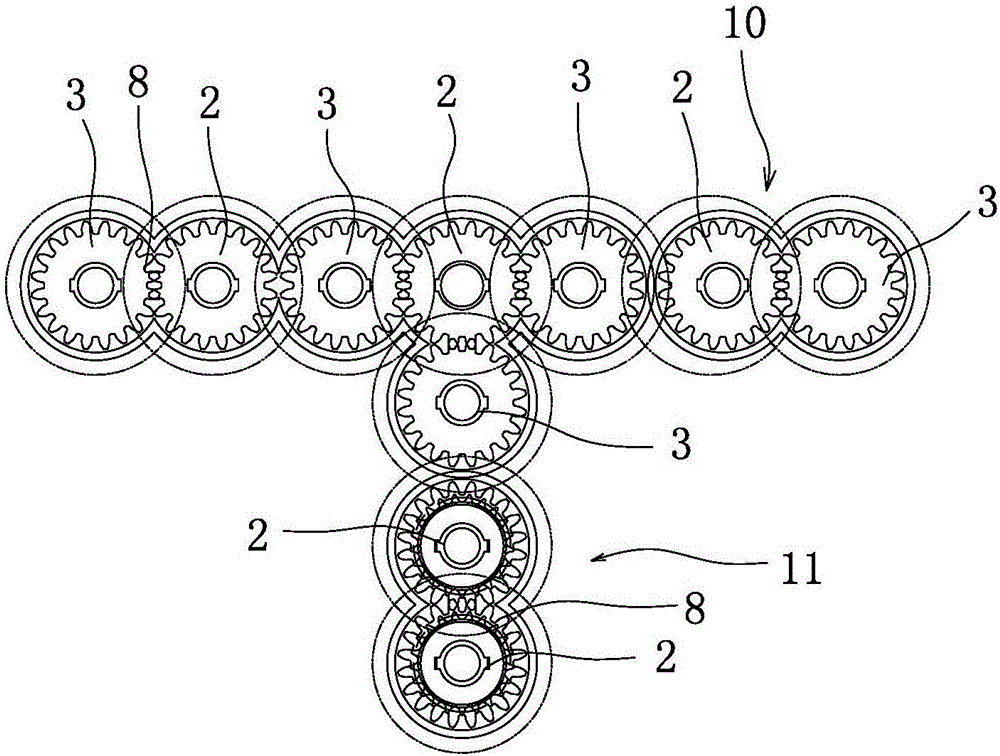

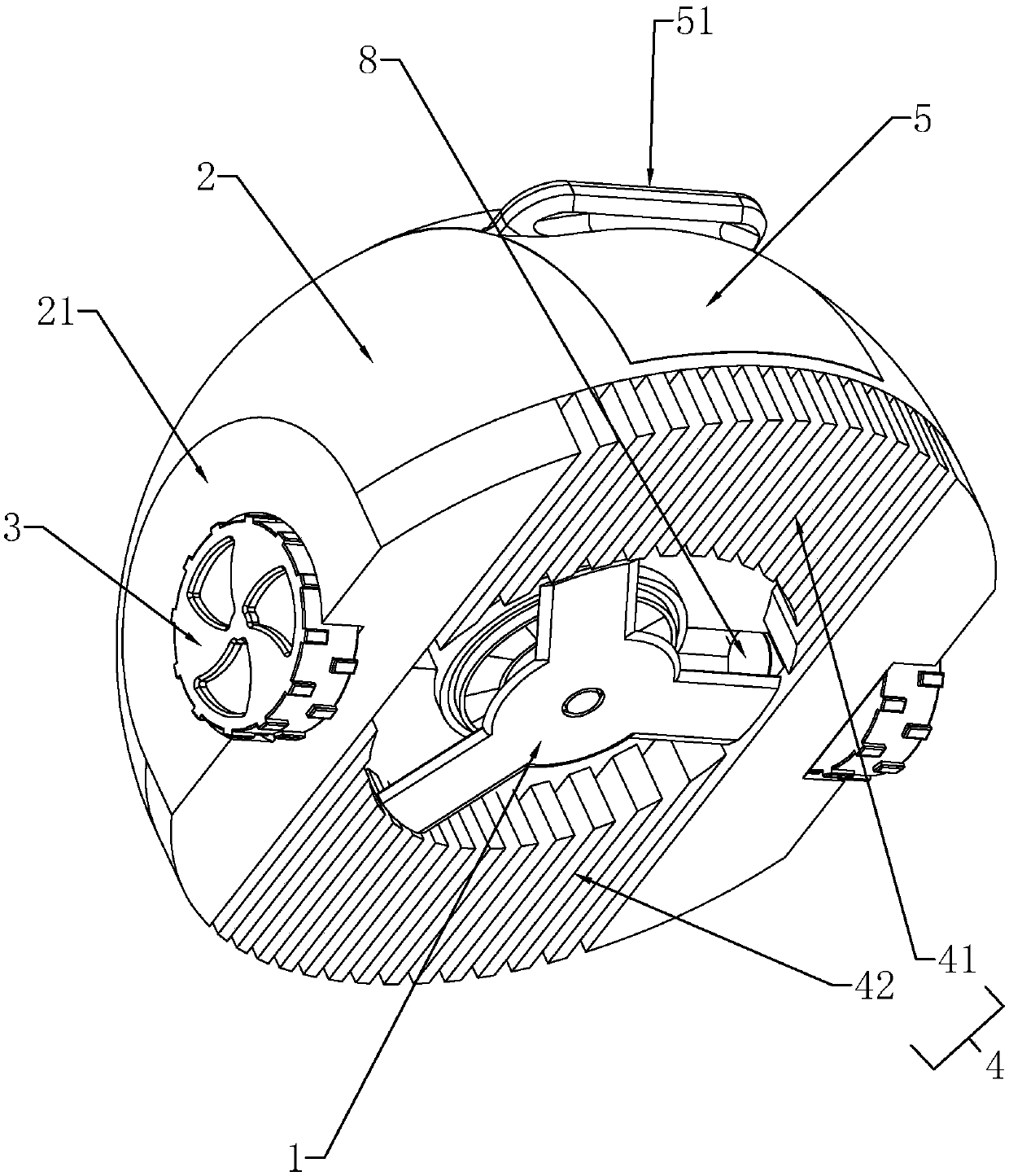

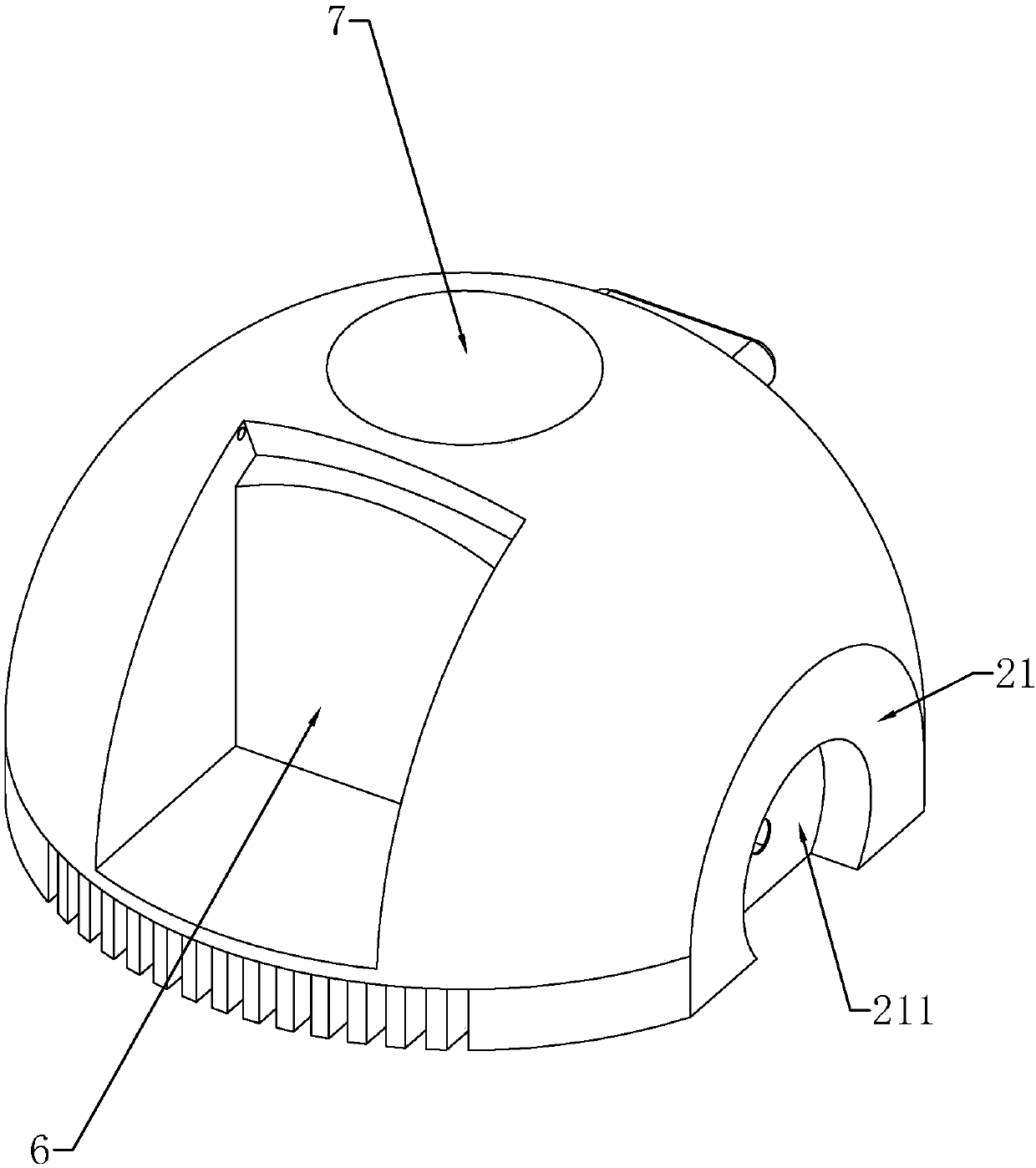

Diving power head for producing pile with nonlinear section

InactiveCN106481271AHigh strengthFast preparationDrilling rodsRotary drillingSoil mixingUltimate tensile strength

The invention relates to a diving power head for producing a pile with a nonlinear section. The diving power head comprises a driver system capable of providing circumferential rotating power, and is characterized in that the driver system is connected with a drill rod mechanism consisting of driving drill rods and driven drill rods; the center lines of the driving drill rods and the driven drill rods which form the drill rod mechanism are not in the same plane; the driving drill rods and the driven drill rods in the drill rod mechanism are mutually connected through a transmission system, so that a plurality of driving drill rods and a plurality of driven drill rods can rotate at the same time. In the working process of the diving power head, a nonlinear cement-soil mixing pile is directly formed; the production process is fast and high in efficiency; the nonlinear cement-soil mixing pile is high in strength.

Owner:周兆弟

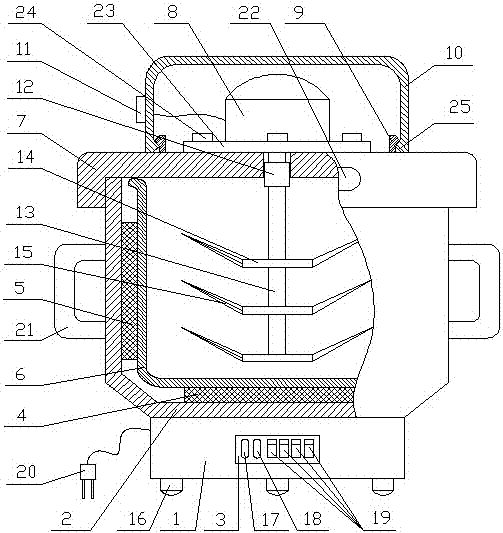

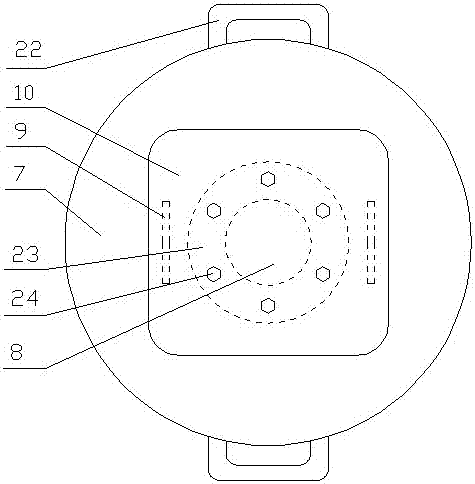

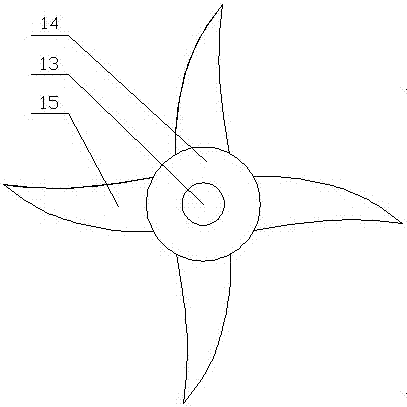

Drug boiling device

PendingCN106963647AEasy cookingPrevent danger caused by excessive air pressurePharmaceutical product form changeDomestic articlesMedicineElectric machinery

The invention discloses a drug boiling device which comprises a device base, the top of which is connected to an outer shell of the device, wherein the device base is provided with a switch base and a bottom heater is arranged below the inner portion of the outer shell; a lateral heater is mounted on the side walls inside the outer shell, moreover, the outer shell is also provided with an inner container inside and connected in a screw joint mode to a device header at the top; the top portion of the device header is connected in a detachable mode to a stirring motor and a group of lock catches, and the lock catches are matched with a shell cover; a stirring switch connected through electricity to the stirring motor, is mounted outside the shell cover, additionally, the stirring motor is matched with a stirring shaft by a coupler; the stirring shaft is welded with a group of stirring loops which are welded with a group of stirring blades. The drug boiling device has the advantages that an adjustable heating function is realized, and meanwhile, a wide heating coverage facilitates all-directional quick heating of drugs and the using flexibility is great to meet the requirement of boiling.

Owner:FOSHAN ENZHENG BIOMEDICAL TECH CO LTD

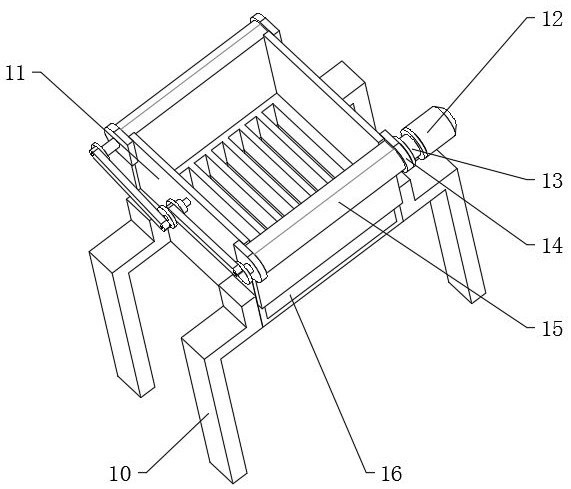

Convenient and practical rubber open mill

The invention discloses a convenient and practical rubber open mill comprising a rubber open mill body. A base is arranged at the bottom of the rubber open mill body. A first rack and a second rack are fixedly connected to the top of the base. The first rack is located on the left side of the second rack. A driving device is fixedly connected to the left side of the first rack. Fixing rods are fixedly connected to the right side of the first rack and the left side of the second rack correspondingly. An open mill roller is movably connected between the fixing rods. The open mill enables rubber to be extruded and sheared, by means of multiple times of kneading and the accompanied chemical effect in the kneading process, macromolecular chains of the interior of the rubber are broken, and various components of the interior of the rubber are mixed uniformly, so that the rubber mixing purpose is achieved; and manpower is saved greatly, so that production efficiency is improved, the production efficiency of the rubber open mill is improved, and the advantage of high production efficiency is achieved, and accordingly the problem that the manpower consumption of an existing rubber open mill is large so as to affect the production efficiency is solved effectively.

Owner:WUXI HITXINCHENG POLYMER TECH

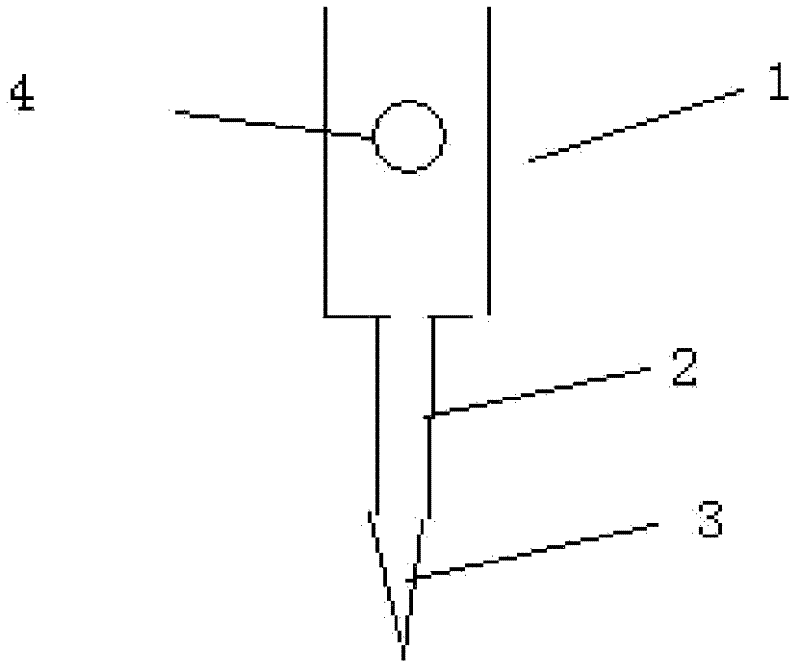

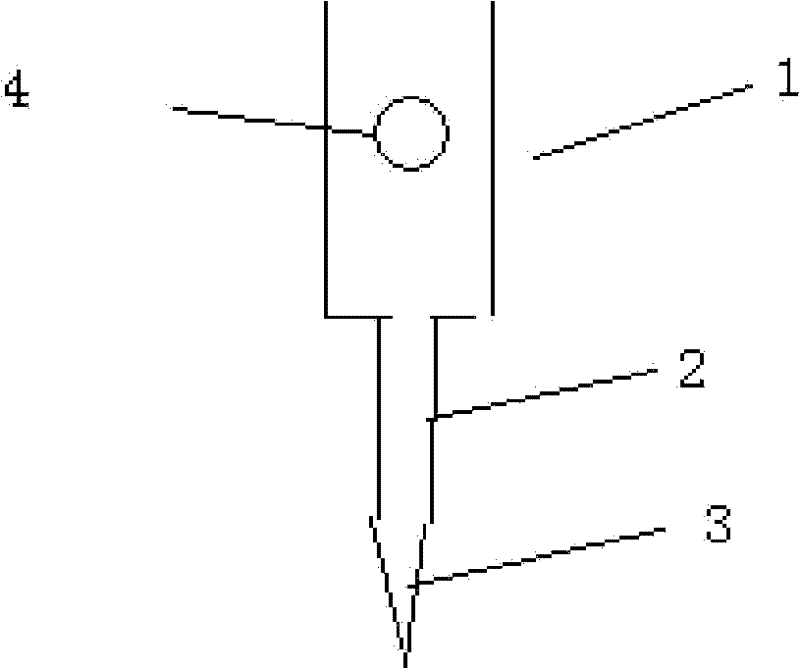

Stirring knife for sewage treatment, using method and equipment

InactiveCN102502898APlay a stirring rolePlay a cutting roleWater/sewage treatmentMixer accessoriesEngineeringStructural engineering

The invention discloses a stirring knife for sewage treatment, characterized by comprising a knife handle and a knife edge, wherein the knife handle is composed of two sections, the first section is flat, and the second section is cylindrical; the flat part is connected with the cylindrical part; the cylindrical knife handle part is connected with the knife edge part; and the flat part comprises a bolt hole for fixed connection. The stirring knife for sewage treatment can adequately stir, cut some solid precipitates and accelerate processing progress.

Owner:无锡欧亚精密冲压件有限公司

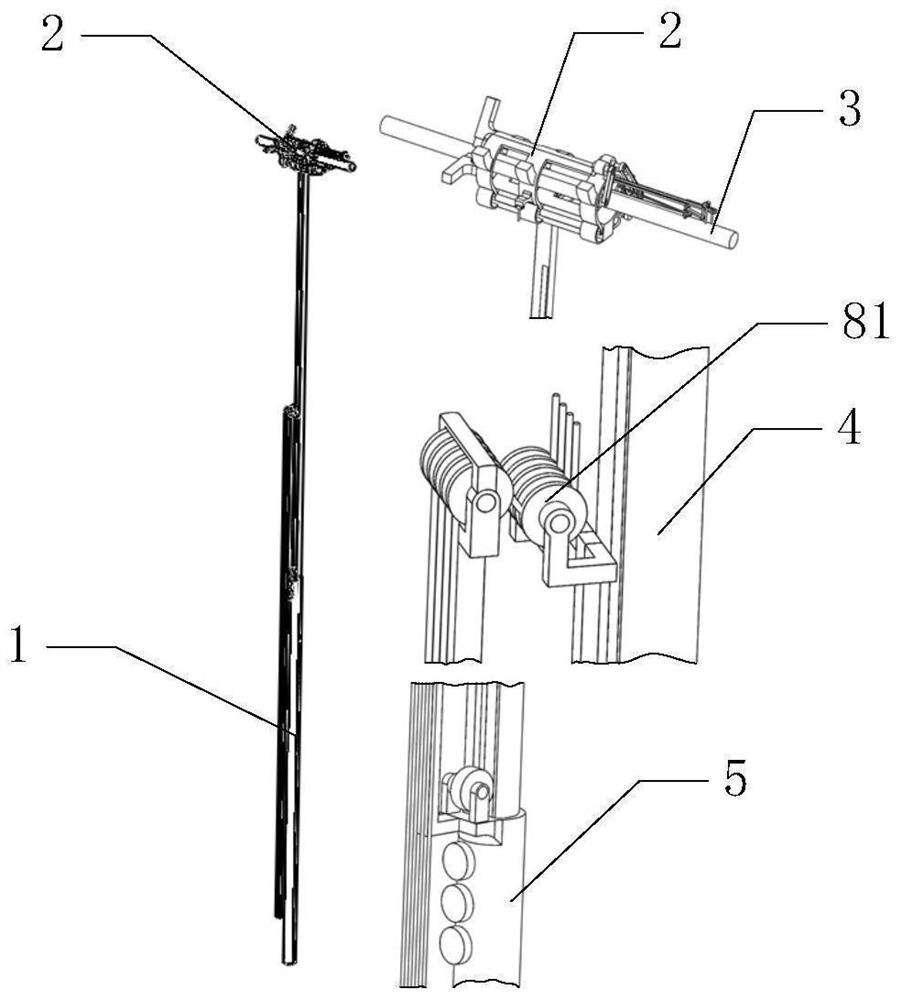

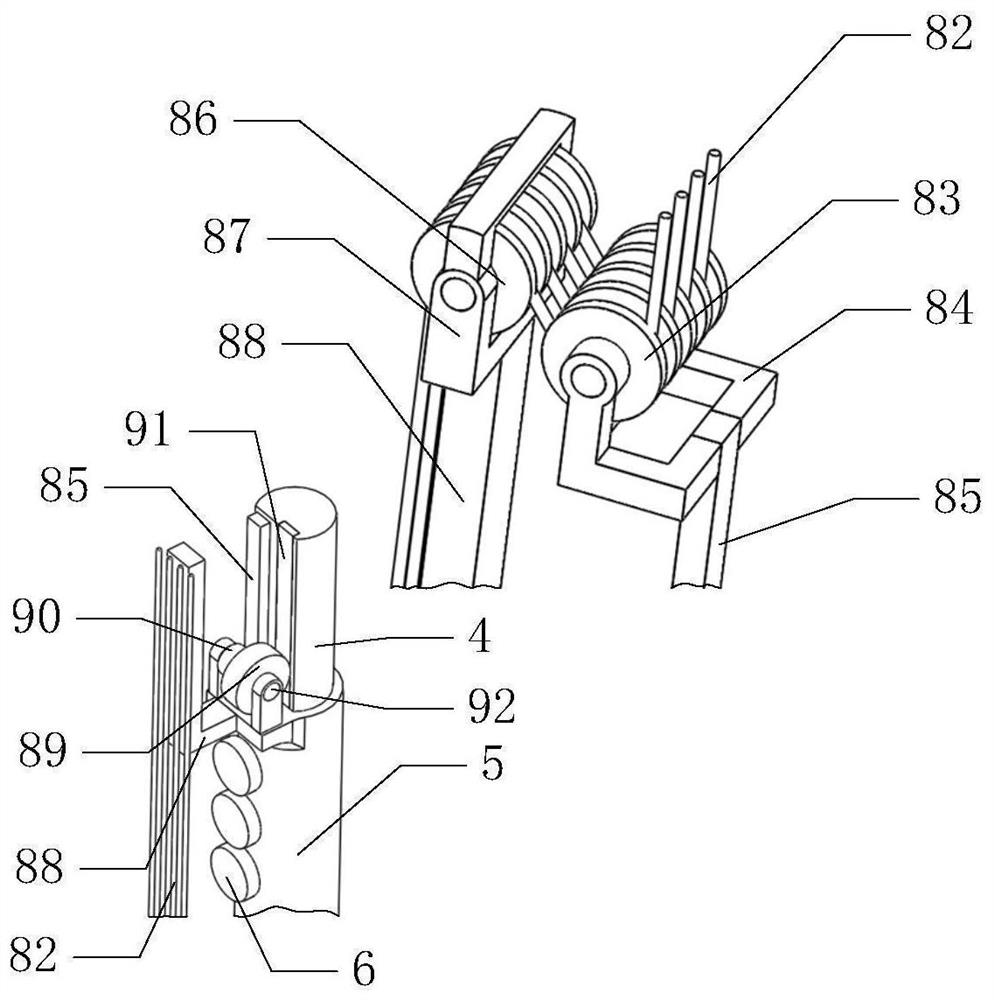

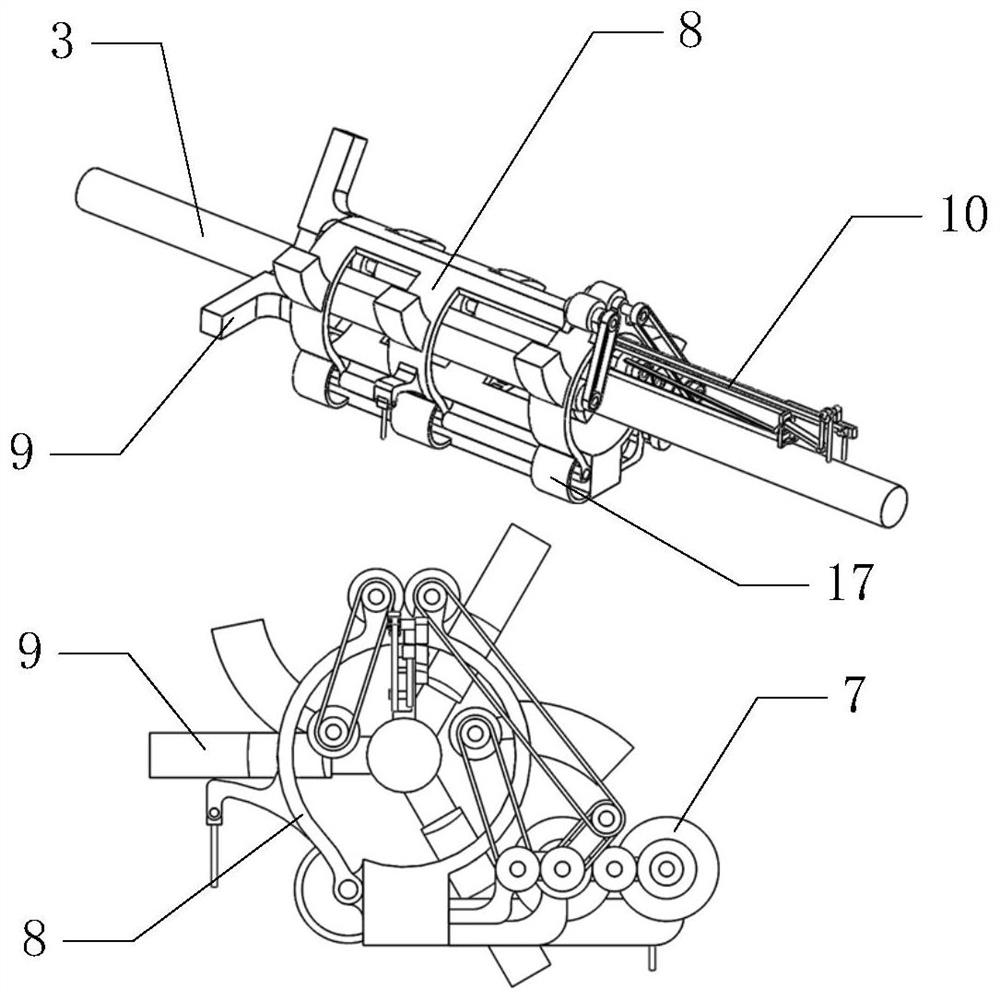

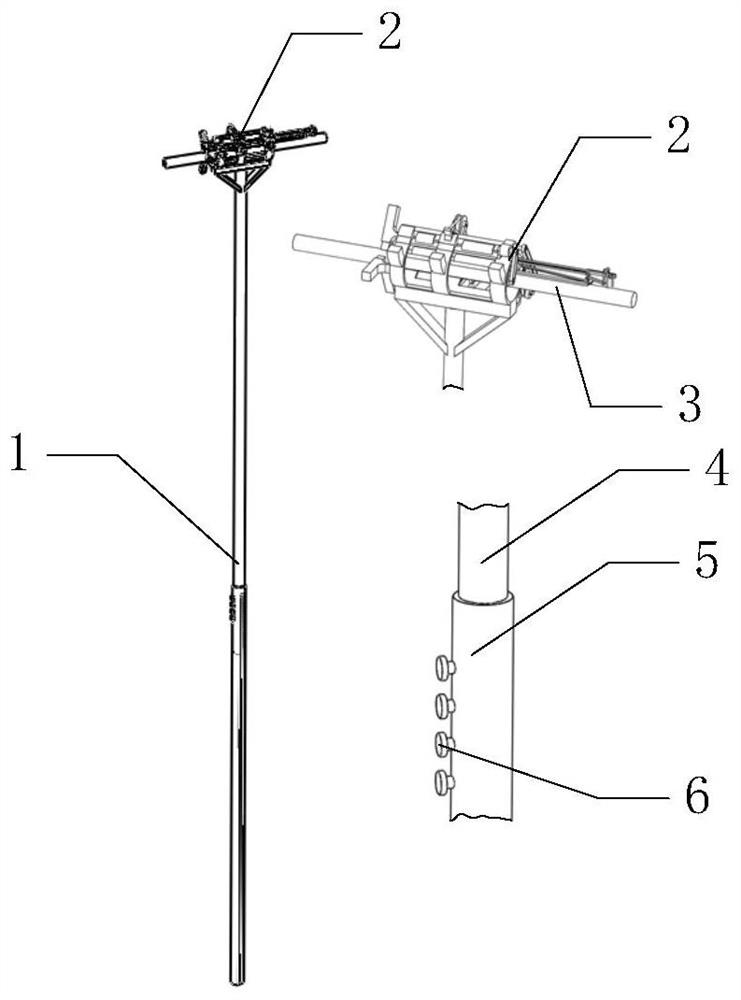

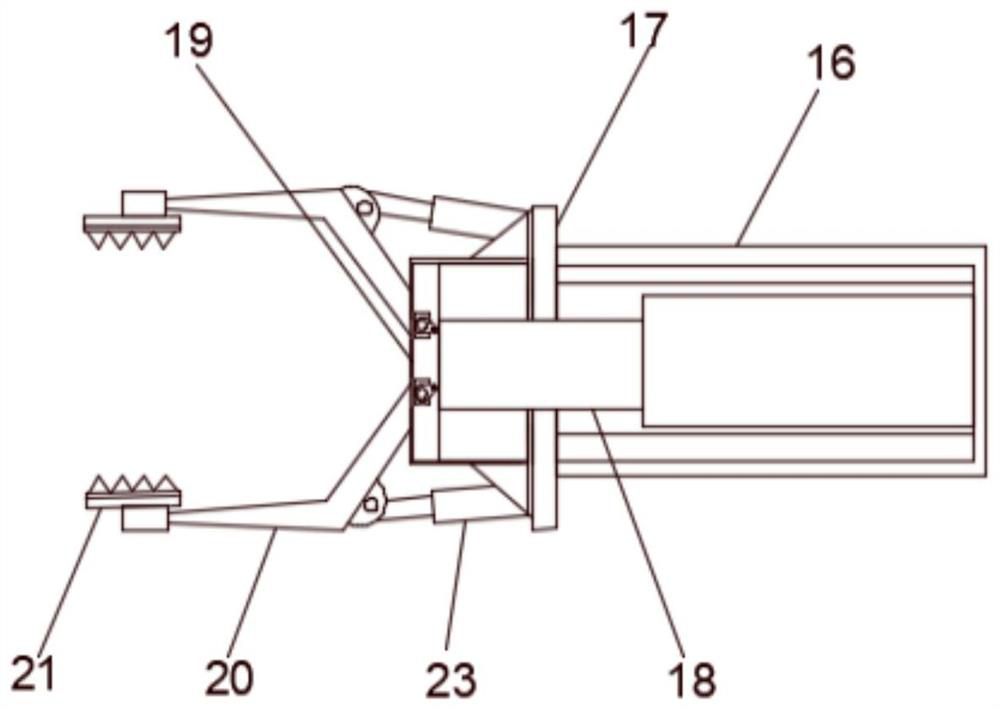

Foreign matter picking equipment used in power transmission line

PendingCN113851999APlay a role in scraping and accumulatingImprove loosenessApparatus for overhead lines/cablesForeign matterEngineering

The invention belongs to the technical field of wire foreign matter picking, and particularly relates to foreign matter picking equipment used in a power transmission line. The foreign matter picking equipment comprises a telescopic rod and a removing mechanism, the telescopic rod is composed of a telescopic inner rod and a telescopic outer sleeve, and a fixing screw is installed between the telescopic inner rod and the telescopic outer sleeve; the removing mechanism is mounted at the upper end of the telescopic inner rod; and height adjustment can be carried out through the telescopic rod, and the device is suitable for electric wires of different heights. According to the invention, three pressing mechanisms can be used for scraping and stacking plastic bags and foreign matters wound on an electric wire, so that the plastic bags and the foreign matters which are wound in a dispersed manner are stacked together, and the plastic bags and the foreign matters can be loosened and cut conveniently. A cutting mechanism is used for cutting the plastic bags and the foreign matters wound on the electric wire, so that the plastic bags and the foreign matters can be conveniently taken down from the electric wire.

Owner:王丹青

Device for removing foreign matters hung on wire

InactiveCN113708293APlay a role in scraping and accumulatingImprove loosenessApparatus for overhead lines/cablesHeavy equipmentPlastic bag

The invention belongs to the technical field of wire foreign matter removal, and particularly relates to a device for removing foreign matter hung on a wire. The device comprises a telescopic rod and a removal mechanism, when the device is used, a swing arc plate and a fixed arc plate are controlled to be opened, and the wire is clamped into the swing arc plate and the fixed arc plate; and then the first clearing wheel and the second clearing wheel are controlled to rotate, so that the plastic bags and the foreign matters wound on the electric wire are cleared, and the use is relatively convenient. Power for loosening of plastic bags and foreign matters wound on the electric wire is achieved by pulling a pull rope from the lower side to enable a winding wheel to rotate, then a first clearing wheel and a second clearing wheel are driven to rotate through transmission of a gear and a synchronizing wheel, the plastic bags and the foreign matters wound on the electric wire are cleared, and the power is applied from the lower side; the device is not equipped with heavy equipment such as a motor, so that the use is convenient.

Owner:王丹青

Weeding machine

The invention discloses a weeding machine. The problem that the existing weeding machine is inconvenient to use is solved. The weeding machine comprises a shell, a power supply, a weeding mechanism and a drive mechanism, wherein the power supply is respectively and electrically connected with the weeding mechanism and the drive mechanism, and the weeding mechanism comprises a weeding motor and a blade; the weeding motor is arranged in the shell, and the blade is connected onto an output shaft of the weeding motor and is positioned below the shell; the drive mechanism comprises roller wheels, driving motors and an electric drive system, the two roller wheels are arranged on the two sides of the shell, the two driving motors are respectively connected with the two roller wheels; the electricdrive system is positioned in the shell, and comprises a gyroscope, an acceleration sensor and a controller, and the gyroscope, the acceleration sensor and the driving motors are all connected with the controller. The weeding machine provided by the invention combines the drive mechanism and the weeding mechanism to achieve the weeding function of the weeding machine while moving, and does not need to be manually pushed, thereby facilitating the weeding work of the staff.

Owner:JIAXING NANYANG POLYTECHNIC INST

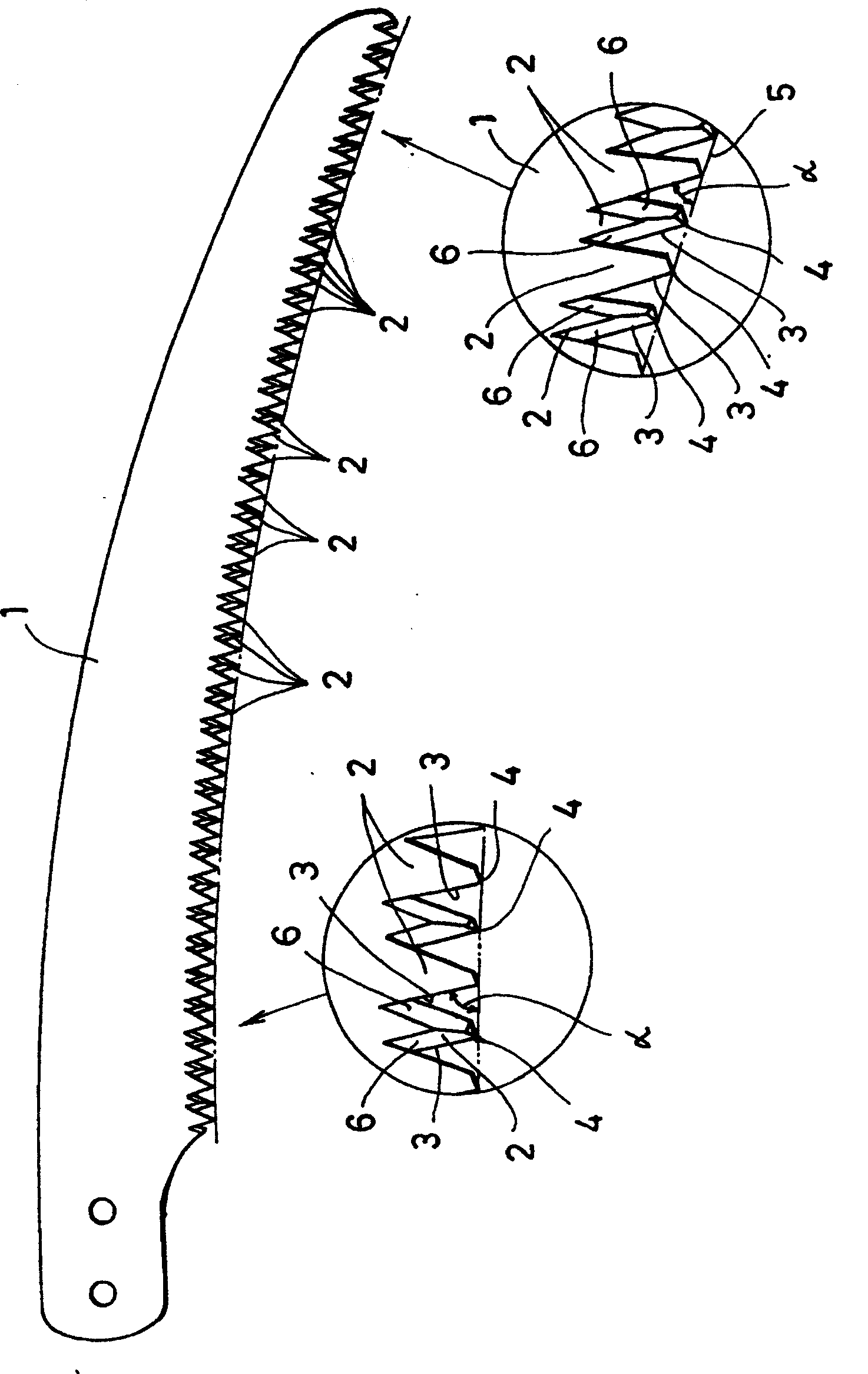

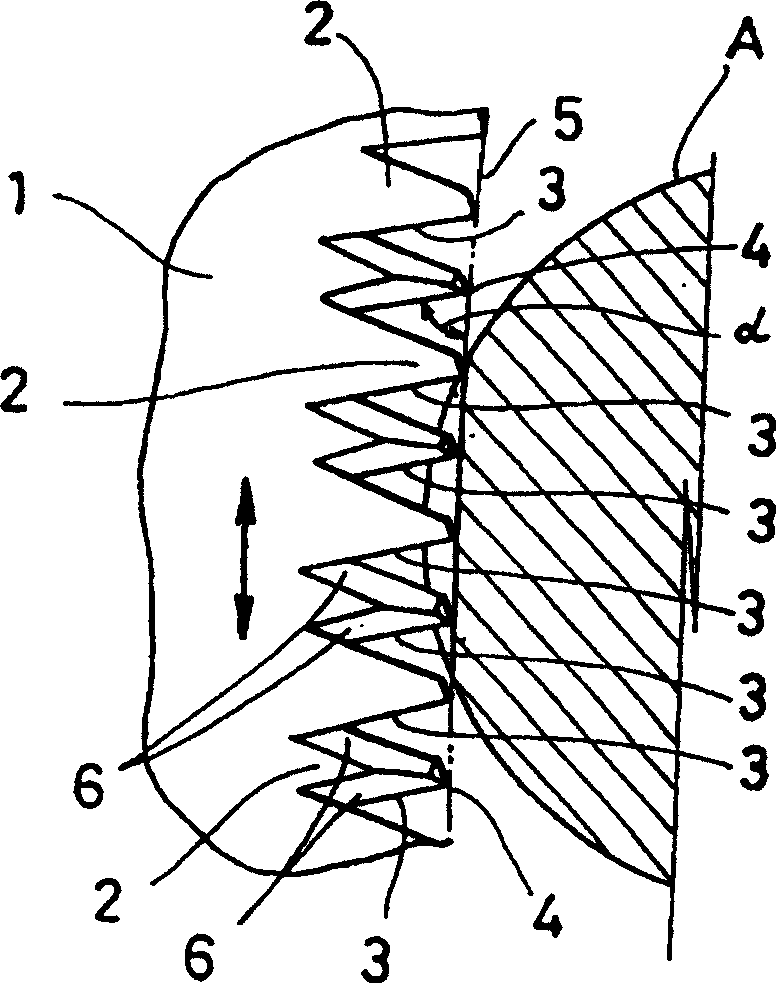

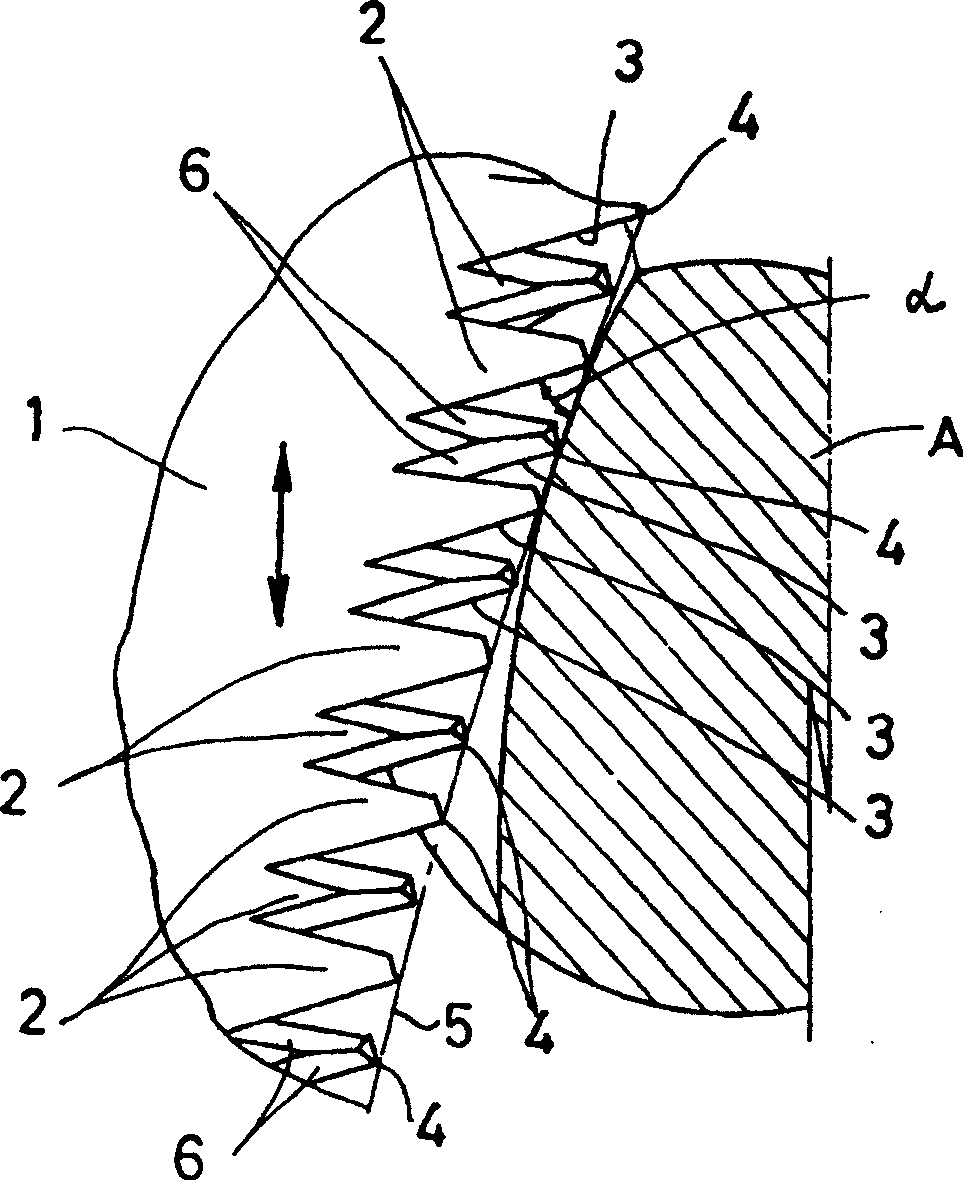

Curved saw

ActiveCN100469234CEasy to keep offEliminates the disadvantage of not being able to perform smooth cutting operationsPad sawsCheck valvesConstant forceEngineering

This invention relates to a curved saw, the saw body 1 is curved from the base toward the tip. The concavely arch-shaped side rim of the curved saw body 1 is provided with many saw teeth 2. The cross angle ([alpha]) of a cutting edge 3 as the base side rim of the saw tooth 2 situated at the base of the saw body 1 with a tooth point line 5 joining the tooth points 4 of the saw teeth 2 each other is made larger, while the cross angle ([alpha]) of the cutting edge 3 as the base side rim of the saw tooth 2 situated at the tip of the saw body 1 with a tooth point line 5 joining the tooth points 4 of the saw teeth 2 each other is made smaller. Thereby, the total saw teeth from the base to the tip of the saw body can be utilized, realizing the objective saw, mainly a pruning saw, enabling cutting works to be smoothly performed with a constant force.

Owner:KANZAWA SEIKO

Environment-friendly household garbage feeding machine

InactiveCN108380337ARealize vibration cuttingSolve the problem of easy to block the feed inletGrain treatmentsDrive wheelEngineering

The invention discloses an environment-friendly household garbage feeding machine. The environment-friendly household garbage feeding machine comprises a feeding box. One side of the feeding box is provided with a first motor. The output end of the first motor is fixedly connected with a rotating shaft. One end of the rotating shaft is fixedly connected with a drive wheel, and the surface of the drive wheel is wound by a belt. The drive wheel is rotationally connected with a driven wheel through the belt. A rotating rod is fixedly connected to the axis position of the driven wheel. The outer surface of the rotating shaft is fixedly connected with cutters. A second motor is fixedly connected to the center position of the top of the feeding box. The environment-friendly household garbage feeding machine is provided with the second motor, an eccentric wheel, a hinge, movable rods, smashing rods, fulcrum bars, hinge pins, the first motor, the rotating shaft, the cutters, the drive wheel, the belt, the driven wheel, the rotating rod and a spiral cutter, and the problem that during discharging, due to the fact that the diameter of a feed port is definite, the feed port is prone to beingblocked by the garbage, the feeding machine only can convey the garbage and cannot lower the later processing difficulty is solved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Negative pressure type domestic onion slicing device

InactiveCN109049024APlay a guiding roleFirmly connectedDispersed particle separationMetal working apparatusLocking mechanismEngineering

The invention discloses a negative pressure type domestic onion slicing device and relates to the technical field of onion processing. The negative pressure type domestic onion slicing device comprises a first shell. A driving mechanism is fixedly connected to the bottom of the inner wall of the first shell. A self-locking mechanism is fixedly connected to the upper surface of the driving mechanism. A material receiving mechanism is arranged on the upper surface of the self-locking mechanism. The inner wall of the material receiving mechanism is matched with the surface of the self-locking mechanism. The inner wall of the self-locking mechanism is connected with a support ferrule in a sleeving mode. According to the negative pressure type domestic onion slicing device, stimulating substances in gas discharged through an air outlet are sucked out through a filter plate, thus the gas discharged through the air outlet does not contain stimulating substances, and the problems that onion contains stimulating and volatile substances, when the onion is sliced, stimulating substances are generated, diffuse in air and stimulate eyes of people, eyes feel uncomfortable, and people cannot slice the onion conveniently are effectively solved.

Owner:瑞安市金意鞋业有限公司

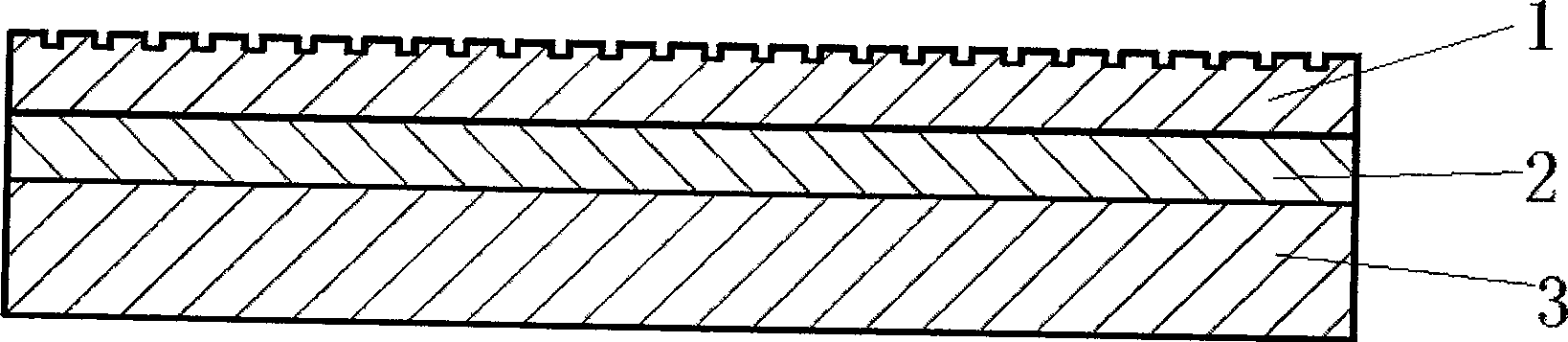

Solidified abrasive lapping polishing pad having self-modifying function and preparation method

InactiveCN100506487CReduce surface roughnessImprove flatnessAbrasion apparatusGrinding devicesPolymer scienceDimethyl siloxane

The invention relates to a grinding and polishing pad of consolidation abrasive with self-adjusting function and the preparation method, belonging to ultra-precision grinding and polishing machining technical field, which is characterized in that components of the abrasive layer (3)comprises 1-20% by wt of abrasive with granularity of 1-40 nanometer, 20-80% by wt of acrylic pre-polymer, 1-3% by wt of free radical photo initiator, 0-2% by wt of poly (dimethylsiloxane) / acrylic polymer, 0-20% by wt of adjustment additive with system cross-linking density performance, and 5-40% by wt of acrylic active diluent. The preparation process comprises (1)mixing stock fully and uniformly, (2)preparing rigid polymer matrix, (3)daubing uniformly by screen-printing, and (4)solidifying by ultraviolet cured machine. The invention is provided with stable grinding and polishing performance and self-adjustment performance. It is suitable for precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Aluminum alloy for casting engine cylinder cover and preparation method of aluminum alloy

The invention relates to an aluminum alloy for casting an engine cylinder cover. The aluminum alloy is prepared from the following components in percentage by mass: 6.5 to 7.5 percent of Si, 0.25 to 0.45 percent of Mg, less than or equal to 0.17 percent of Fe, 0.08 to 0.25 percent of Ti, 0.005 to 0.015 percent of Sr and the balance of Al. The invention further relates to a preparation method of the aluminum alloy. The preparation method comprises the following steps: preparing the materials according to the above component requirements; heating pure aluminum ingots and pure silicon in a crucible furnace to 760 + / - 10 DEG C to melt the pure aluminum ingots and the pure silicon; pressing a pure magnesium, aluminum and titanium intermediate alloy into the bottom of an aluminum and silicon solution with a bell jar, and controlling the temperature at 810 to 860 DEG C for alloying; after the alloying is completed, controlling the temperature between 740 + / - 10 DEG C, and adding an aluminum-strontium intermediate alloy AlSr; feeding high-purity nitrogen for gas removal; adding a covering agent; performing stewing and drossing; and pouring an alloy solution into a preheating die to obtain the aluminum alloy for casting the engine cylinder cover. After the aluminum alloy is subjected to T6 thermal treatment, the tensile strength of the aluminum alloy is 305 to 325 MPa, the yield strength is 240 to 260 MPa, the hardness is 90 to 110 HBS, and the ductility is up to 6 percent; and the strength and the toughness can meet the performance requirements of an engine cylinder cover product.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

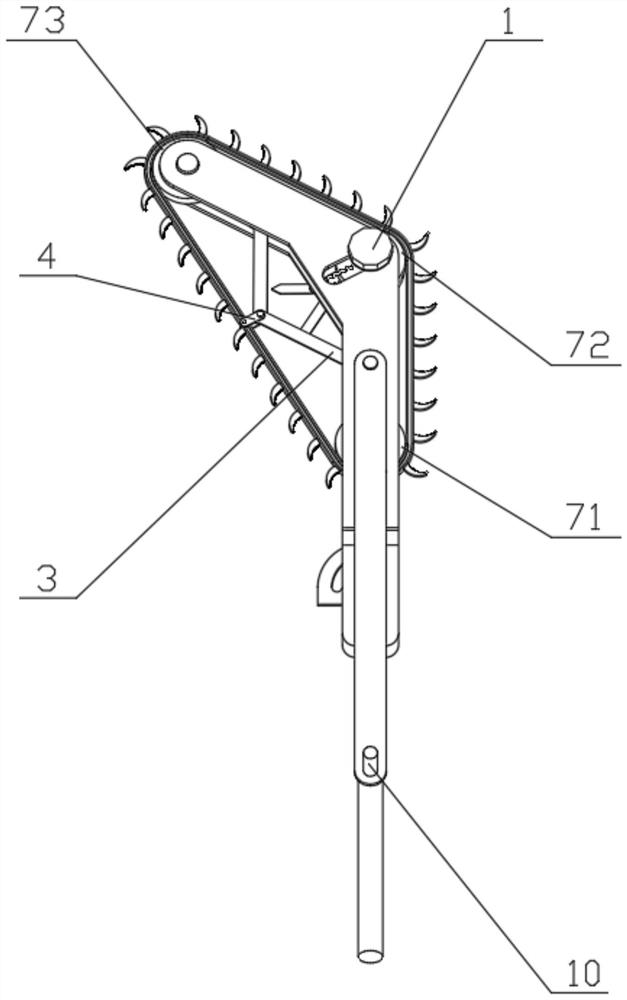

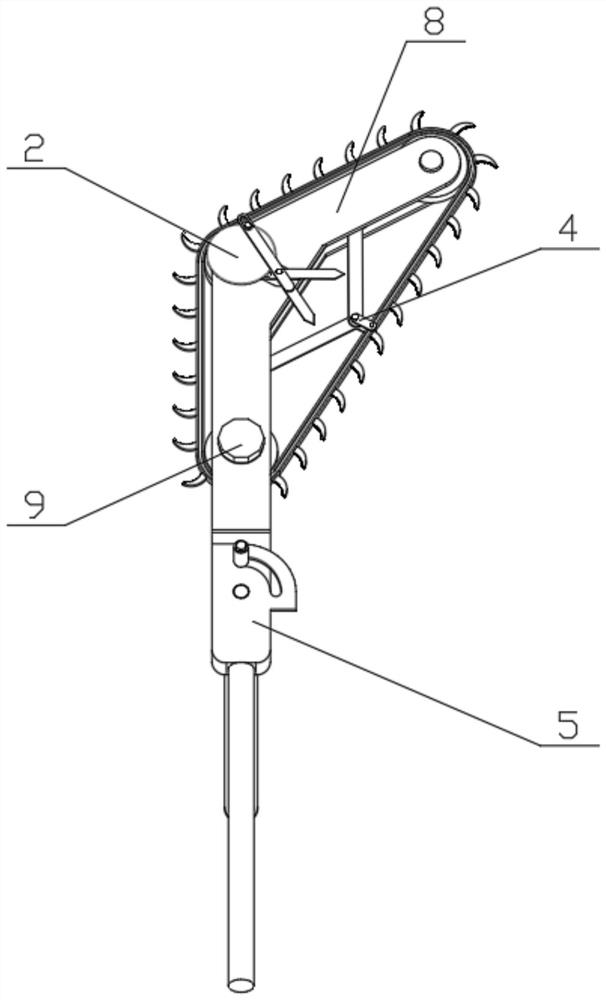

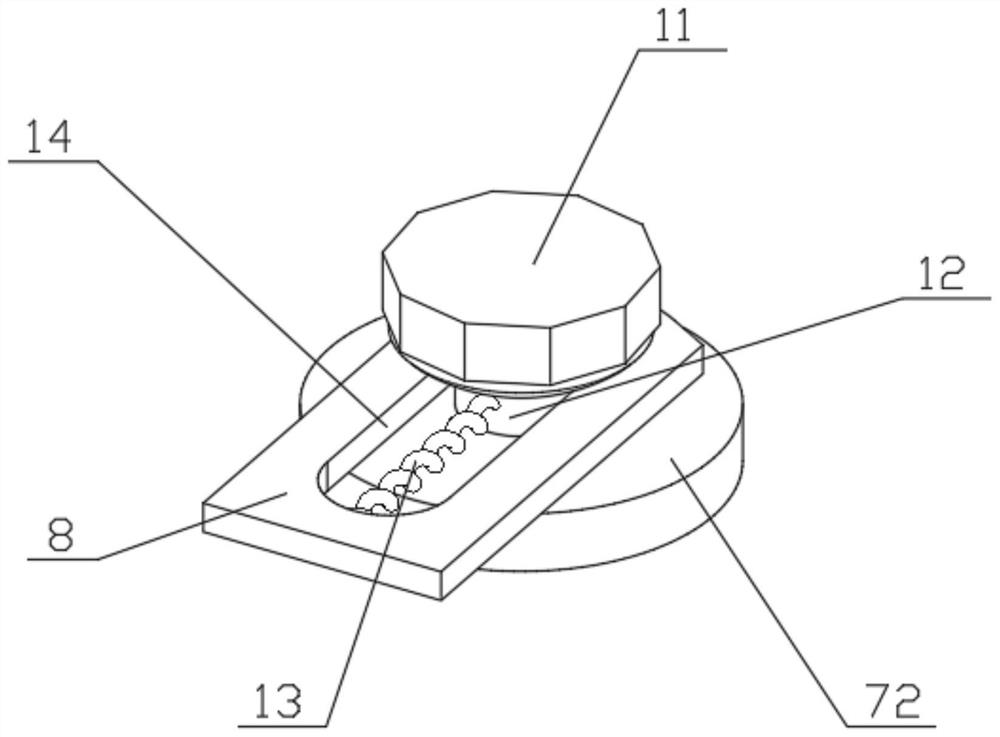

Walnut tree pruning device and method

ActiveCN113475258AImprove stabilityImprove functionalityCuttersCutting implementsAlgorithmStructural engineering

The invention discloses a walnut tree pruning device and method. The walnut tree pruning device comprises a shell and a tightening wheel mechanism, wherein the upper end and the lower end of the shell are of hollow structures, the tightening wheel mechanism is installed on the shell in a sliding mode, the lower end of the shell is connected with a steering structure used for adjusting the use angle of the shell, and rolling wheel assemblies are installed at the end corners of the shell. The tightening wheel mechanism can be arranged to push a connecting rod mechanism after making contact with a supporting rod or a rotating hook claw mechanism pulls the supporting rod, so that a shear mechanism can achieve feed shearing conveniently, different pruning devices and pruning methods can be used according to different branches, the stability of the walnut tree in the pruning process is improved, the functionality of the pruning tool is improved, the walnut tree pruning device is suitable for shearing operation of branches with different hardness, the angle of the device shell can be adjusted according to the height of the branches and the branch and trunk angles, the cutting position of the shear mechanism can be matched with the specific positions of the branches and trunks, accordingly, shearing operation can be rapidly carried out, the shearing efficiency can be improved, and meanwhile, various shearing requirements can be met.

Owner:濮阳市林业科学院

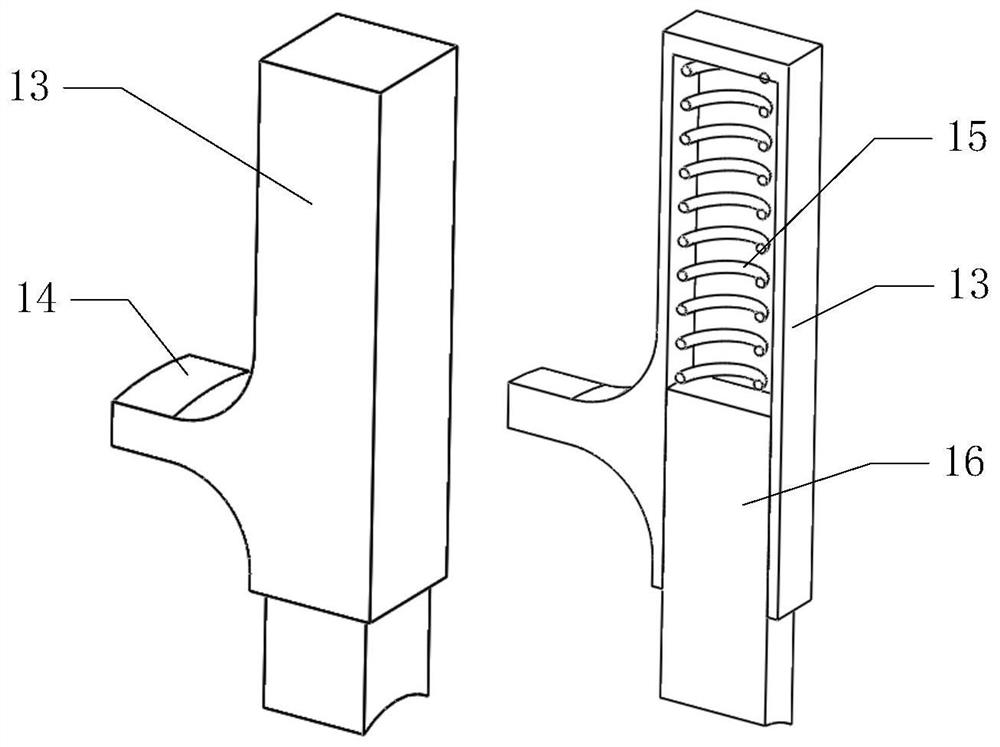

Triangular cutting edge tooth for dredging rake head

PendingCN108316376AEasy to digExcavation applicableMechanical machines/dredgersEngineeringHigh pressure water

The invention relates to a triangular cutting edge tooth for a dredging rake head, and belongs to the technical field of dredging engineering. The triangular cutting edge tooth for the dredging rake head is characterized in by being composed of a tooth root, a tooth stem and a tooth edge, wherein the tooth root is used for being installed on a rake head tooth seat of a rake suction boat, and the tooth edge is a triangular cutting edge tooth. The triangular cutting edge tooth has better cutting effect on compact soil compared with other rake teeth of the same series, so that the dredged soil can be fully separated into strips before being excavated and conveyed by the dredging rake head, and the excavation efficiency of the soil is fully improved; and the relatively thin tooth edge and a relatively small tooth head are used for reducing the possibility that clay blocks the rake tooth, so that the negative influence caused by the fact that high-pressure water blowing is not opened so asto ensure the concentration when silty clay dredging is carried out is avoided.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

A pulverizing device for solid waste treatment

The invention discloses a pulverizing device for solid waste treatment, which relates to the field of solid waste treatment. In order to solve the problem that the pulverizing area of the existing device cannot be opened; the device specifically includes a bottom plate, and a cleaning component and a receiving component are fixedly connected to the outer wall of the top of the bottom plate. The inner wall of the receiving component is slidably connected with a jacking component, the outer wall of one side of the jacking component is fixedly connected with a secondary grinding component, the receiving component includes a bracket and a frame, and the bottom outer wall of the bracket is fixedly connected to the top outer wall of the bottom plate. The present invention is provided with a receiving component, wherein when the initially crushed material is to be discharged or the receiving component needs to be cleaned, the gate motor starts to drive the rotation of the rotating rod, and at the same time, the circular platform of the rotating rod drives the connecting rod to move, thereby driving the first rotation of the connecting rod. The connecting plate rotates, and the two inclined connecting rods drive the second rotating rod to rotate, so that the first rotating rod and the second rotating rod can rotate relative to each other.

Owner:盐城市嘉农食品科技有限公司

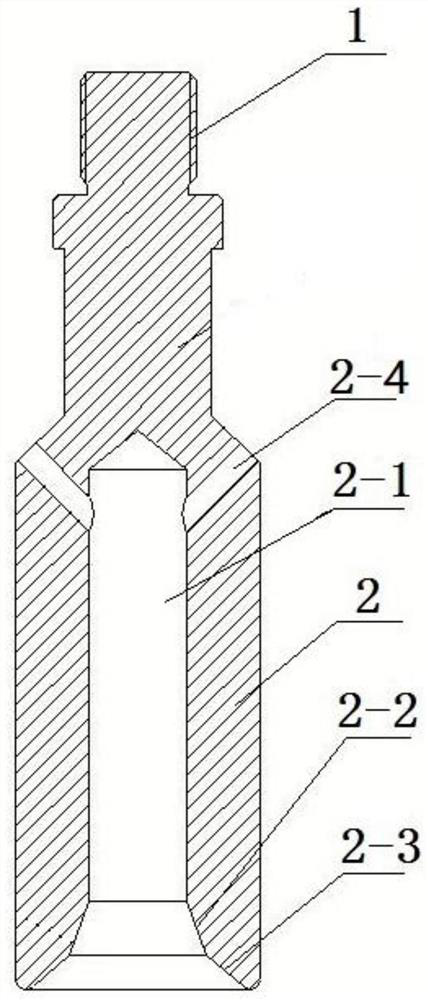

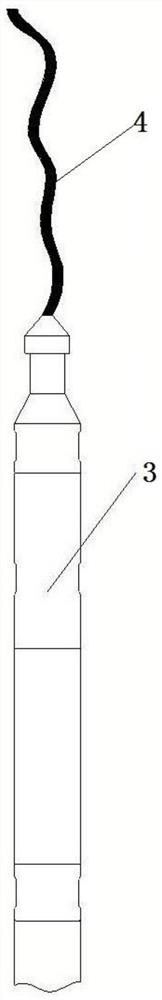

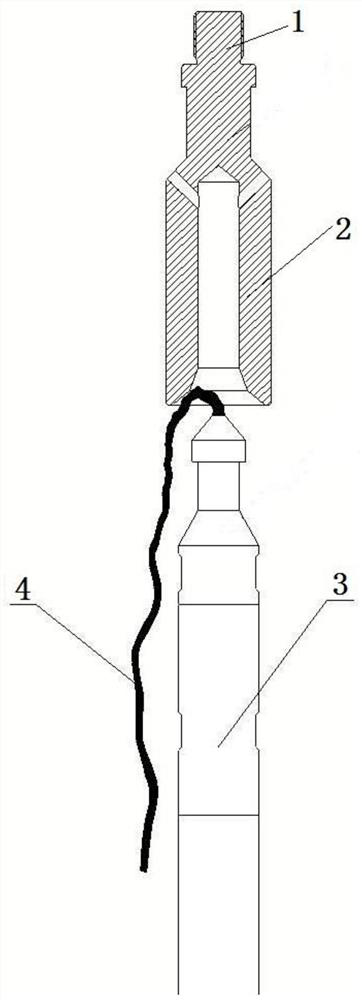

A kind of underground short cable cutter and using method thereof

ActiveCN110359873BImprove efficiencyIncrease success rateBorehole/well accessoriesMarine engineeringUnderwater

The invention discloses a downhole short cable cutter and a using method thereof, which belong to the technical field of petroleum well logging. Including the connecting part and the cutting part, when salvaging the jammed instrument, it is connected in series with the upper instrument through the connecting part, and the end of the jammed instrument is guided into the blind hole through the guide shoe surface, and the blind hole is set on the end of the jammed instrument. The short cable at the end of the stuck instrument enters the range of action of the cutting surface and the boot surface. When the force is applied by the upper salvage instrument string, the cutting edge can cut off the short cable at the end of the stuck instrument, so as not to damage the stuck instrument. Fundamentally solve the impact of the short cable remaining in the wellbore on the subsequent fishing operation under the premise of this method. The structure design of the device is reasonable, the efficiency and success rate of the salvage work are improved, and the cost is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

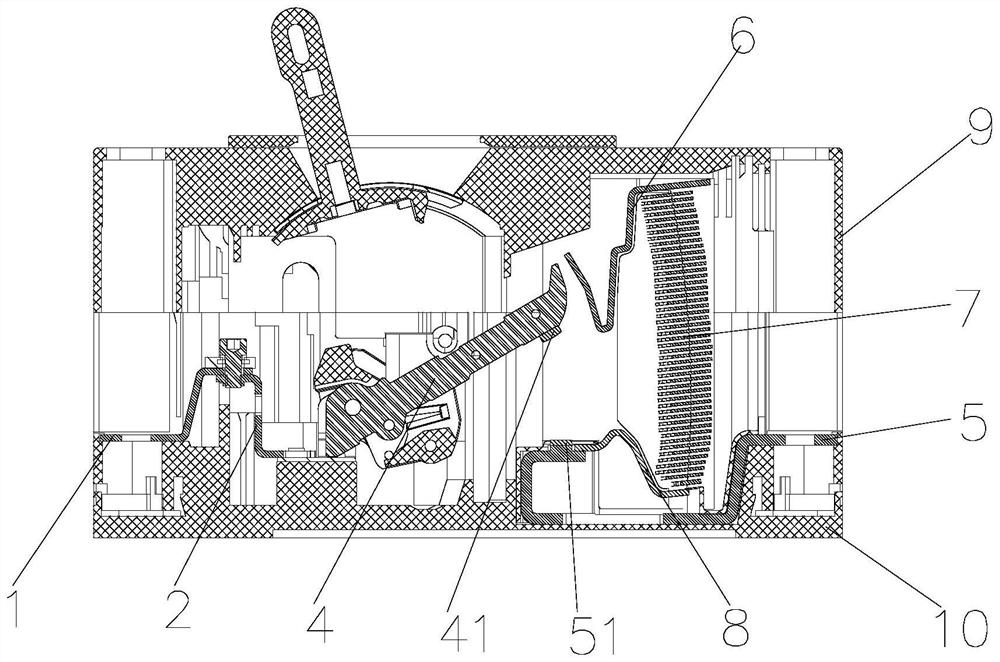

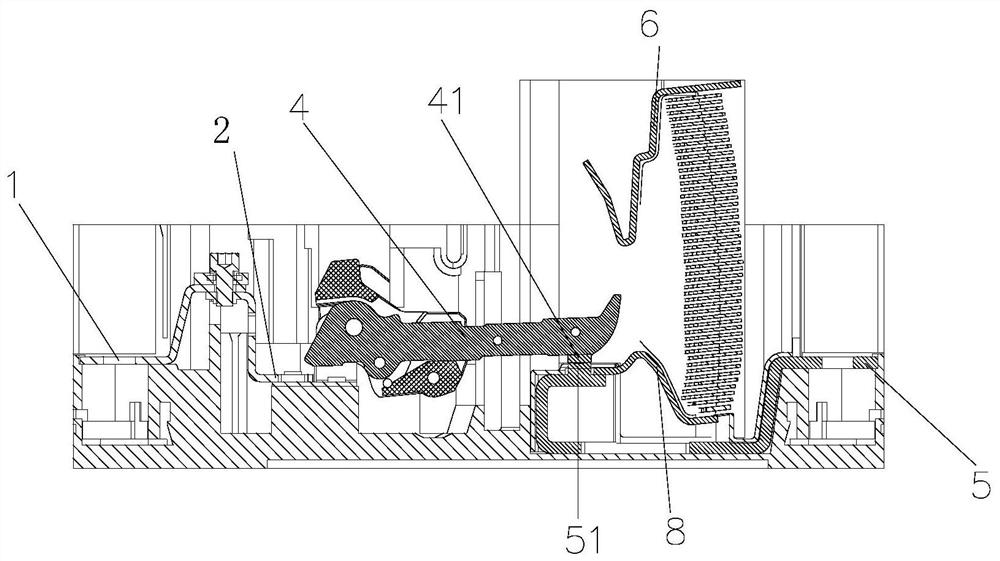

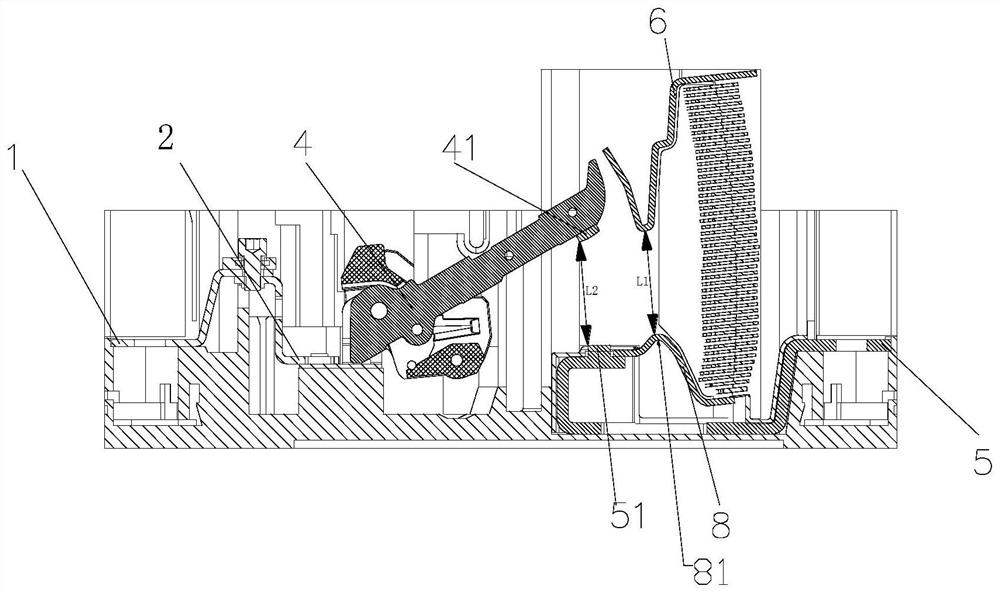

Circuit breaker with high arc extinguishing performance

PendingCN112908789AIncrease profitImprove arc extinguishing performanceProtective switch detailsCircuit-breaking switch contactsElectric arcArc extinction

The invention discloses a circuit breaker with high arc extinguishing performance, which comprises an arc extinguishing chamber, an upper arc striking sheet, a movable feeler lever and a connecting rod are arranged in the arc extinguishing chamber, the upper arc striking sheet and the movable feeler lever form equipotential through connection, one end of the connecting rod is connected to the upper arc striking sheet, and the other end of the connecting rod is connected to an outgoing line bar. The connection point is any point between the movable feeler lever and the outgoing line bar loop; an equipotential device is additionally arranged in the arc extinguishing system, the utilization rate of the number of the grid pieces of the arc extinguishing chamber can be improved on the premise that the opening distance of the contacts is not changed, it is guaranteed that more grid pieces can play a role in cutting the electric arc, the arc extinguishing performance of a product is improved, the minimum distance between the movable contact and the static contact is L1 after the movable contact is opened and the static contact is opened, the minimum distance between the upper arc striking sheet and the lower arc striking sheet is L2, and L2 is smaller than L1, so that the arc root can be transferred to the upper arc striking sheet and the lower arc striking sheet from the movable contact and the static contact , the burning loss of the movable contact and the static contact is reduced, and the service life of the circuit breaker is prolonged.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

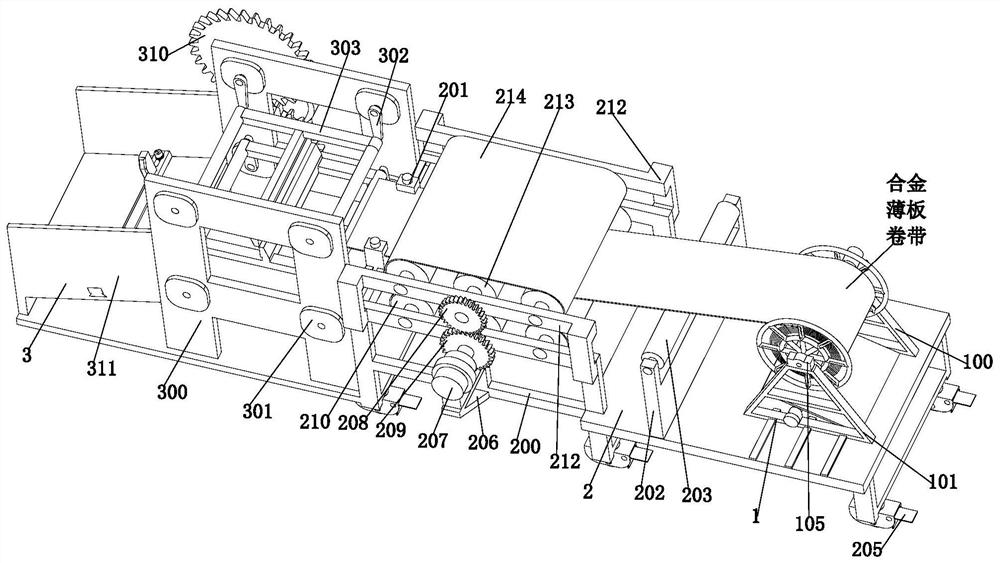

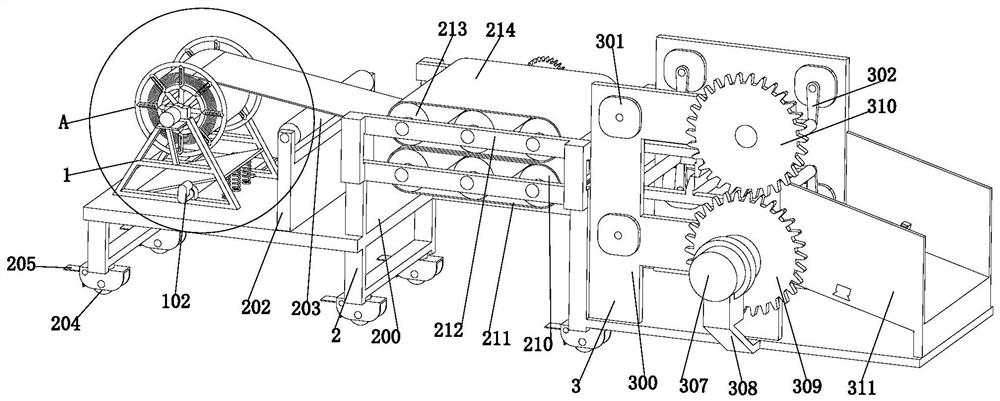

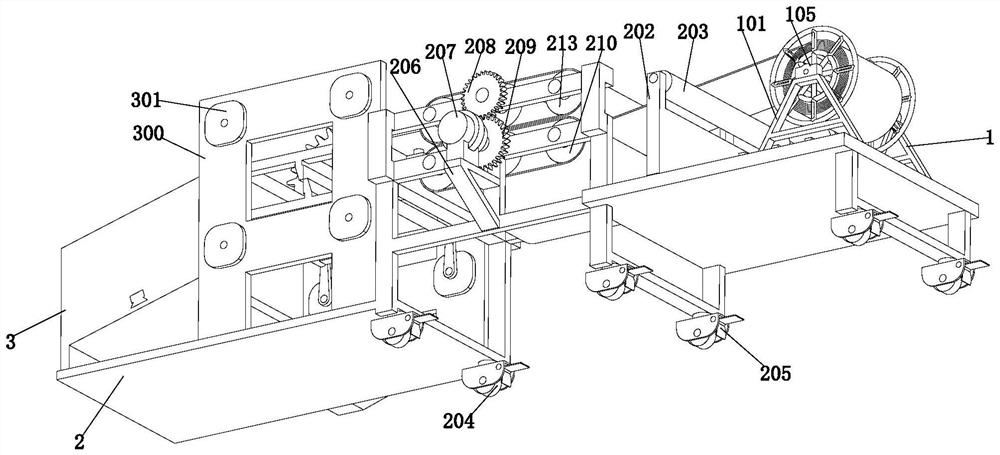

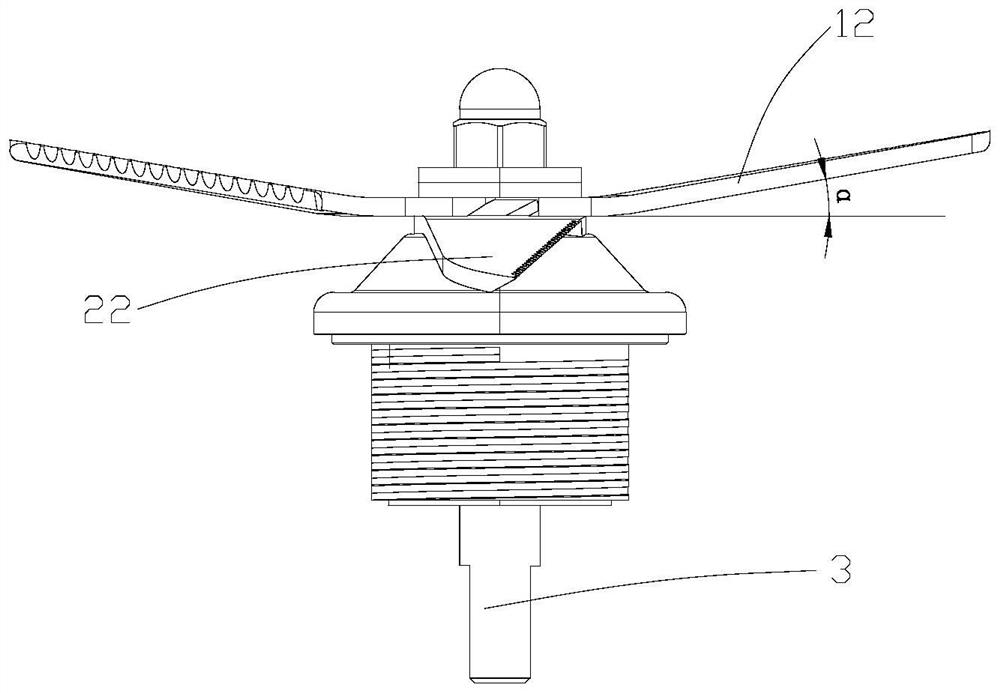

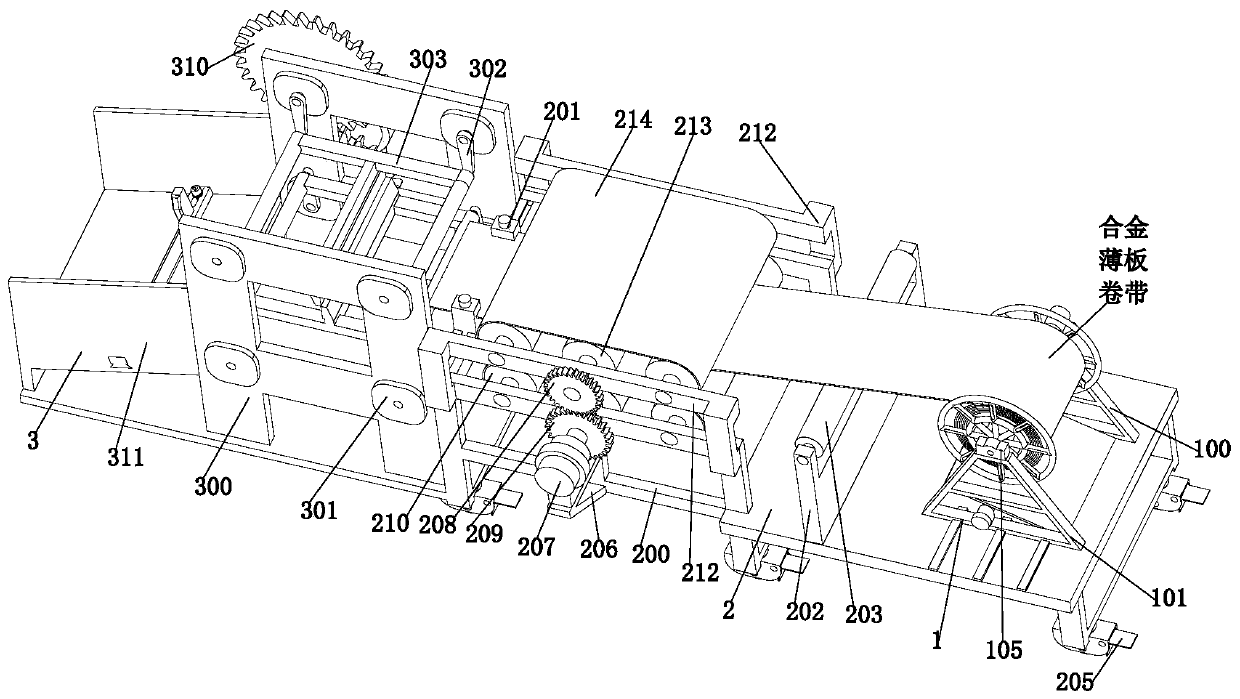

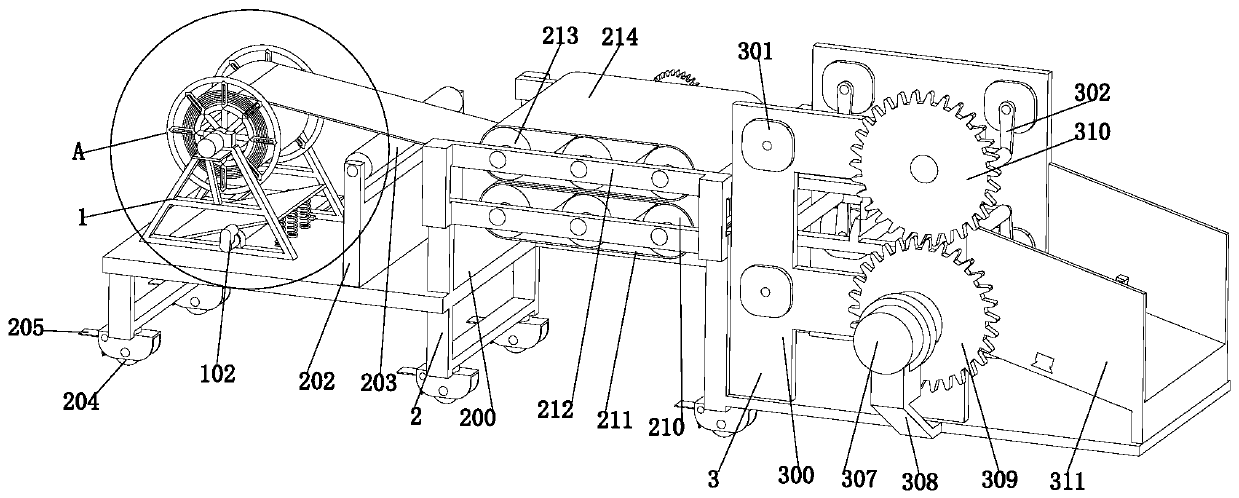

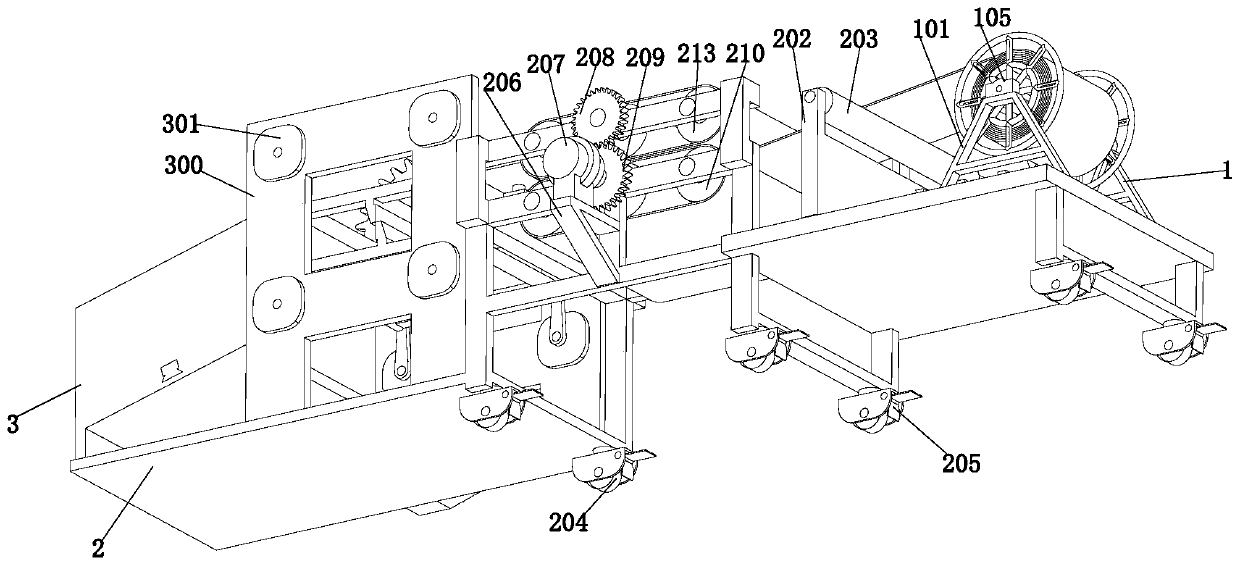

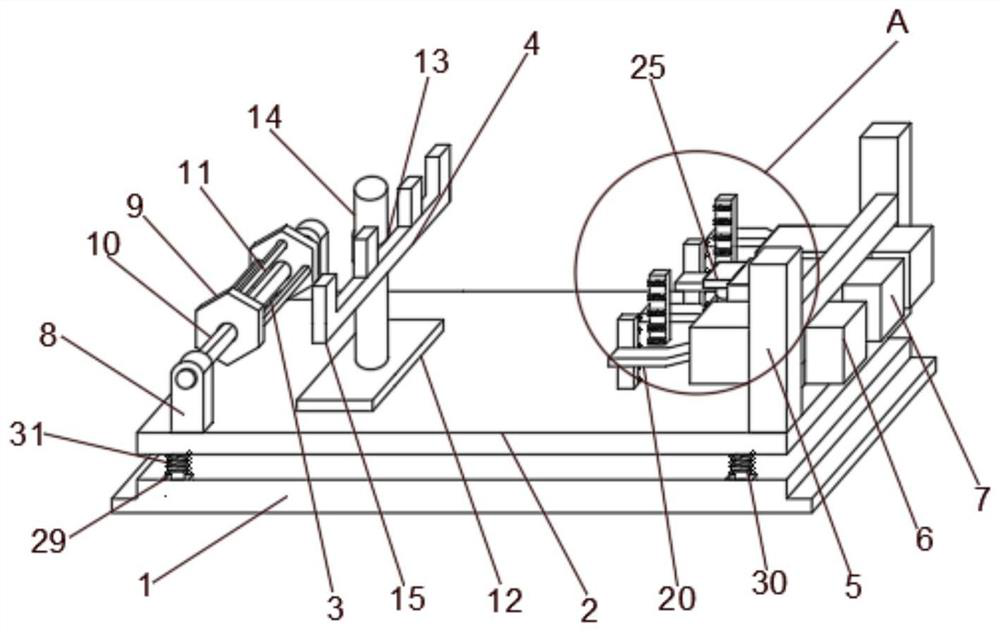

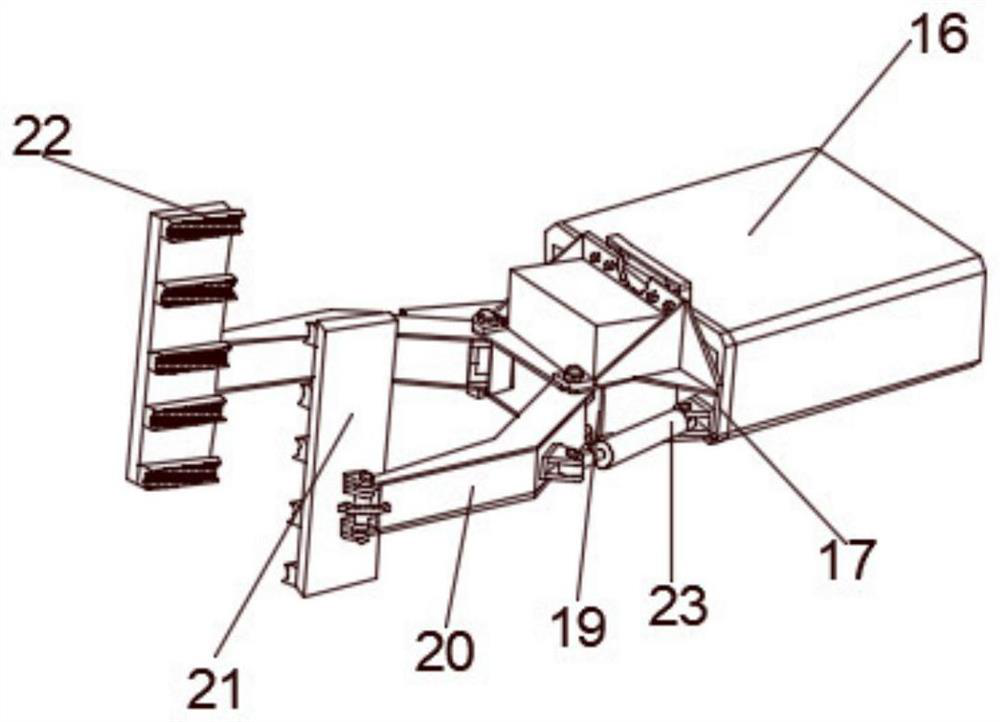

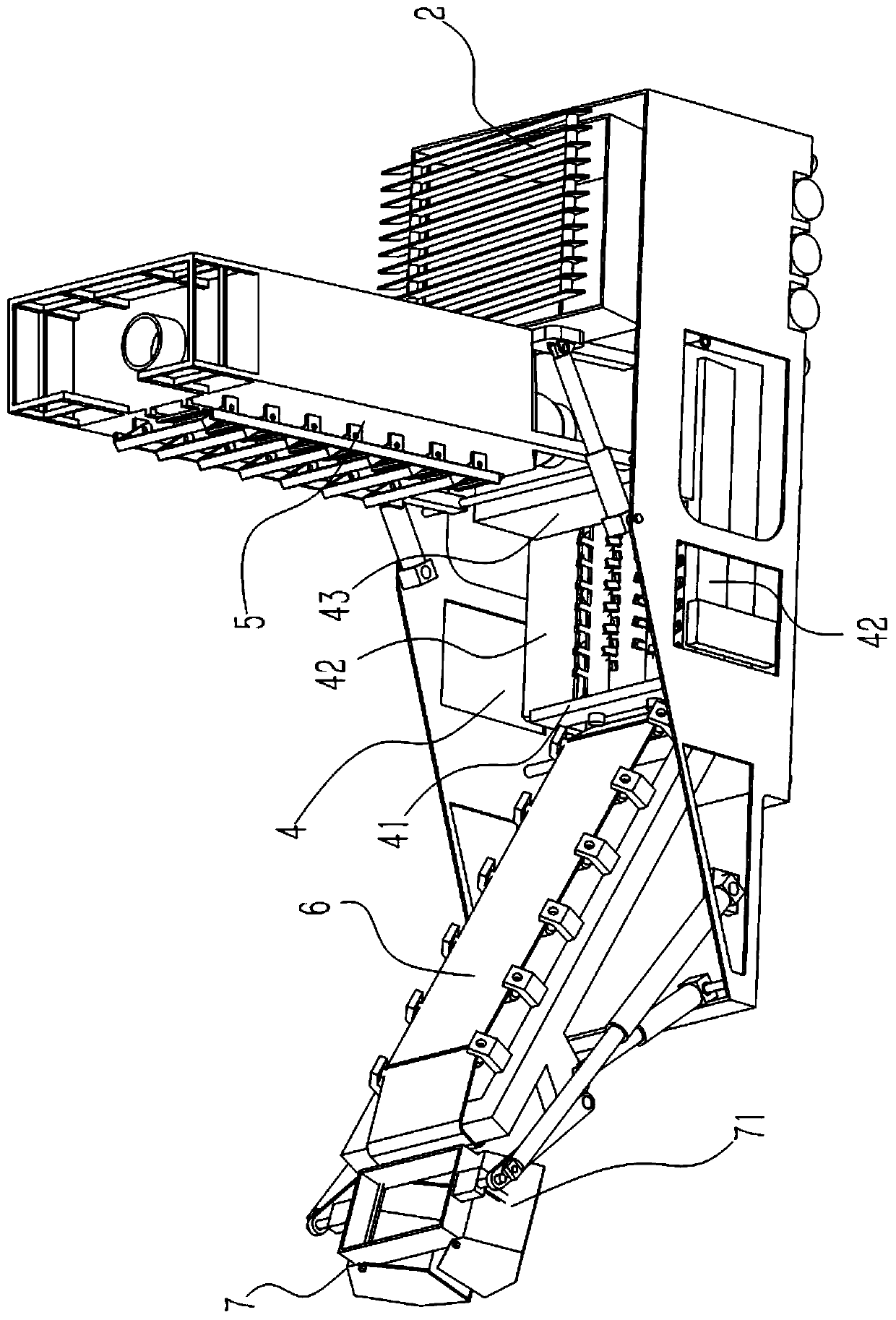

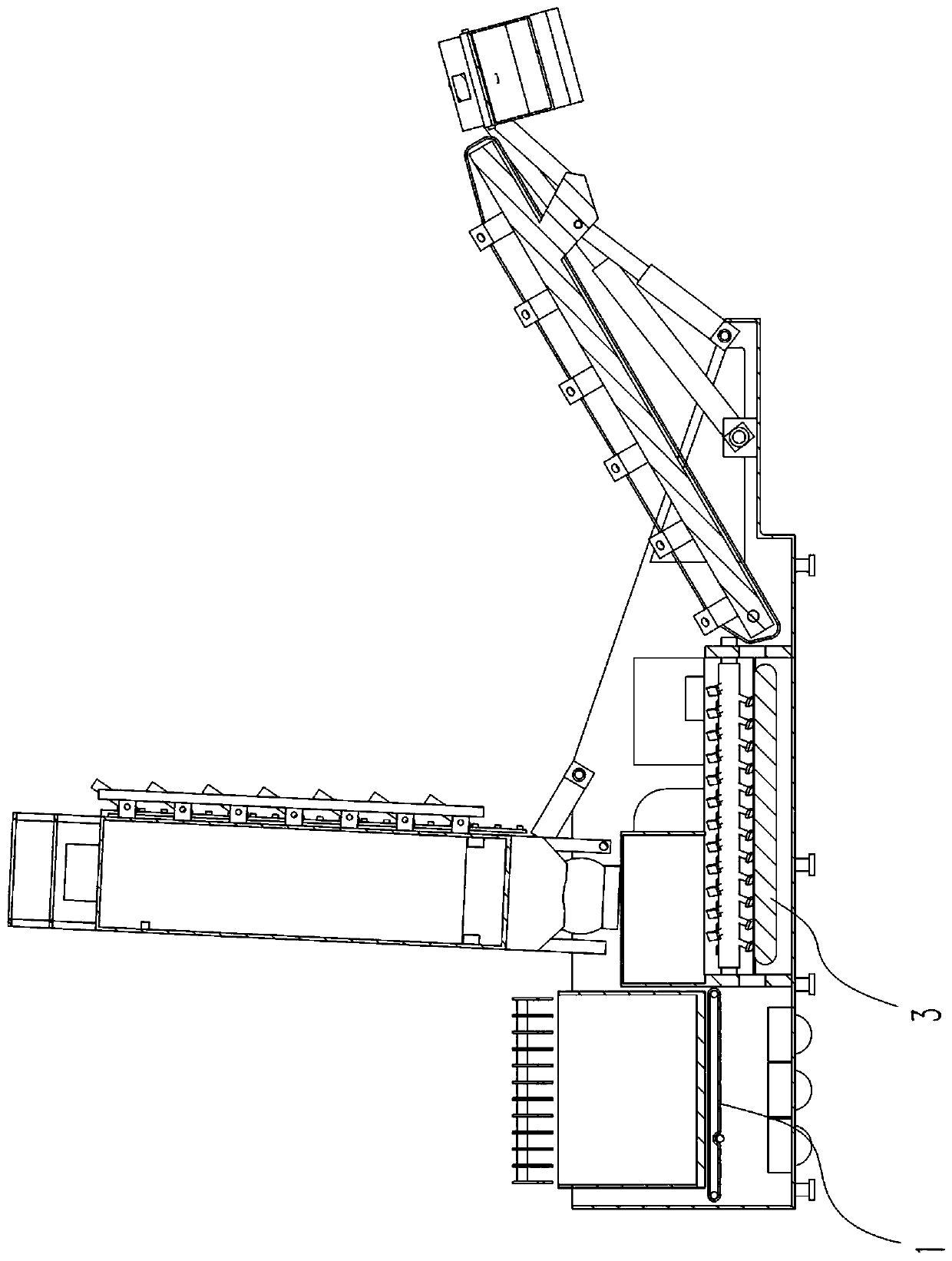

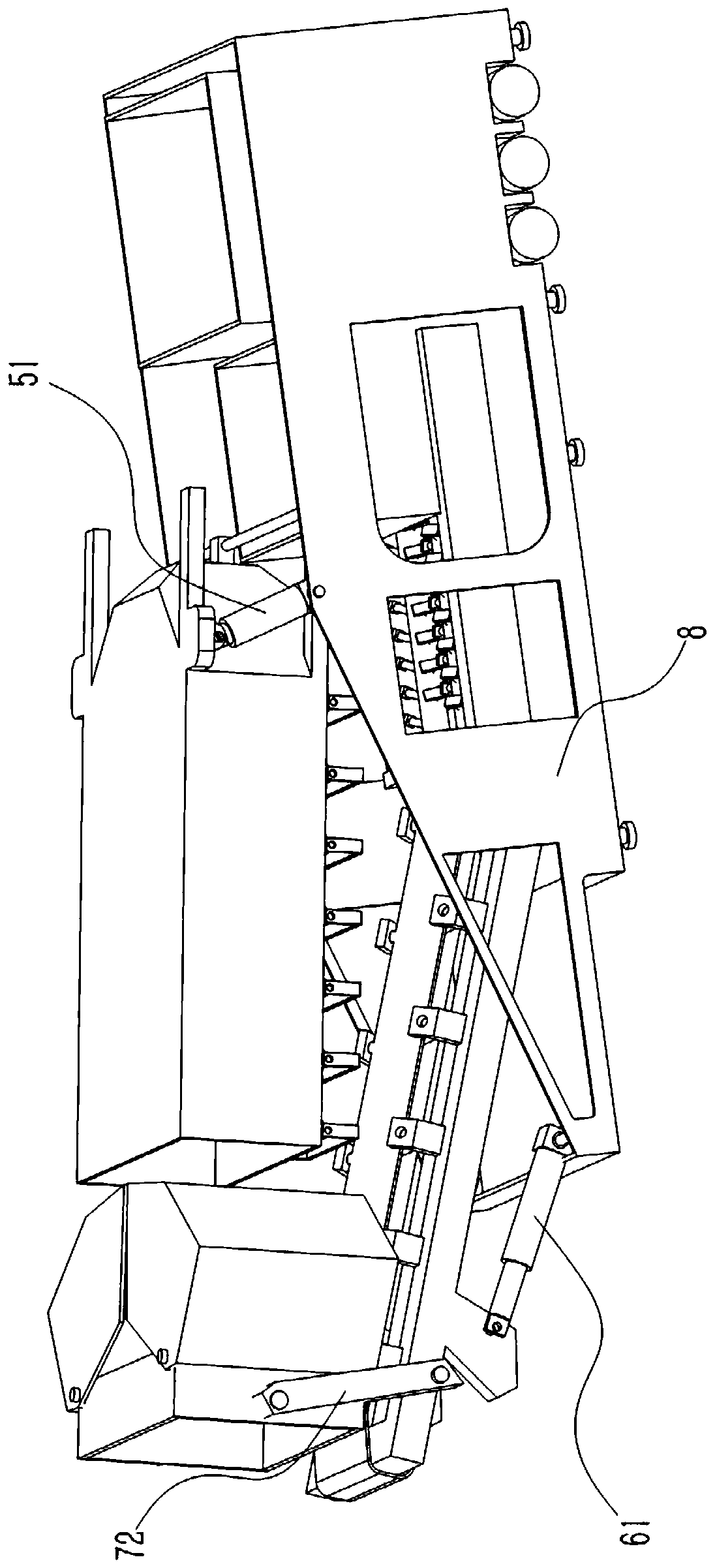

A shearing machine for the production and manufacture of alloy saw blades

ActiveCN111112719BPlay a supporting roleQuick cutShearing machinesShearing machine accessoriesThin slabAlloy

The invention provides producing, manufacturing and cutting machinery for alloy saw blades. The machinery comprises a winding mechanism, a conveying mechanism and a cutting mechanism; the winding mechanism is mounted on the conveying mechanism; the cutting mechanism is arranged on the conveying mechanism; and the conveying mechanism is arranged between the winding mechanism and the cutting mechanism. By the aid of the machinery, the problems that for current linear cutting of alloy sheets, the alloy sheets are mostly cut off manually by the aid of manual cutting machines, the manual cutting machines are inapplicable to efficient linear cutting of the alloy sheets and are very strenuous to operate, burrs are produced at cuts easily, and the manual cutting machines are inapplicable to large-scale low-cost production and manufacturing can be solved.

Owner:江苏风力士智能科技有限公司

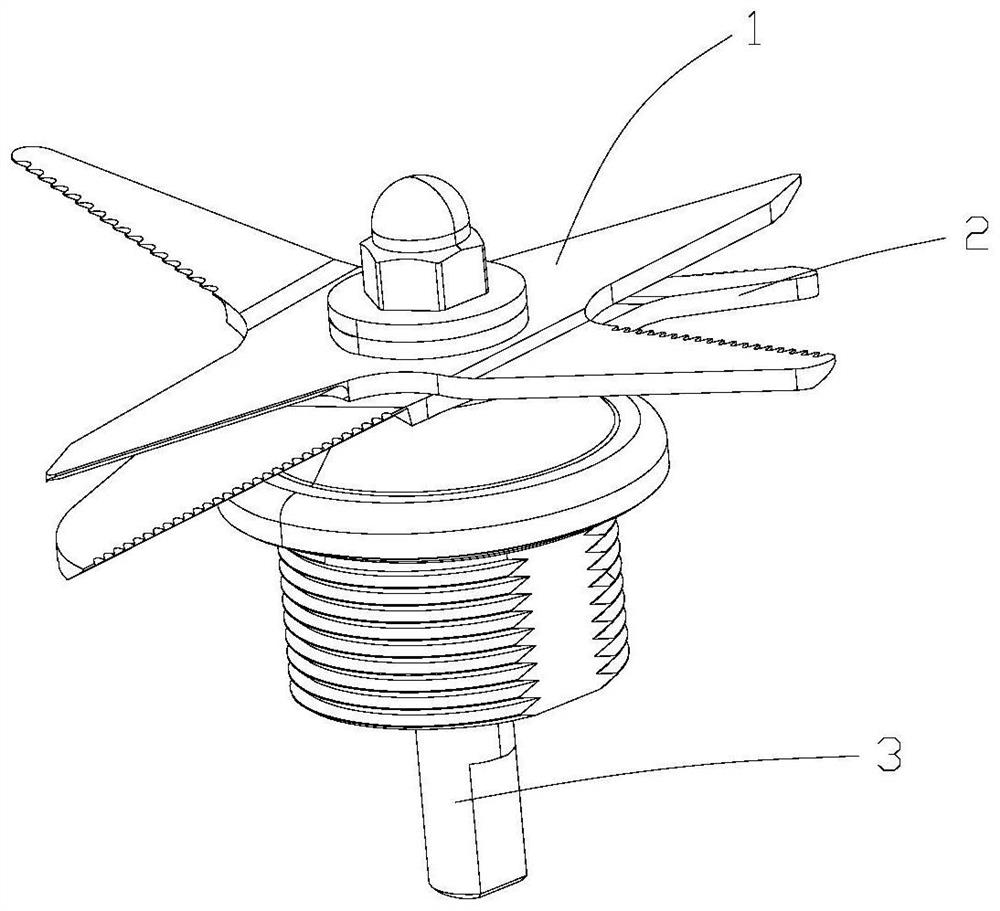

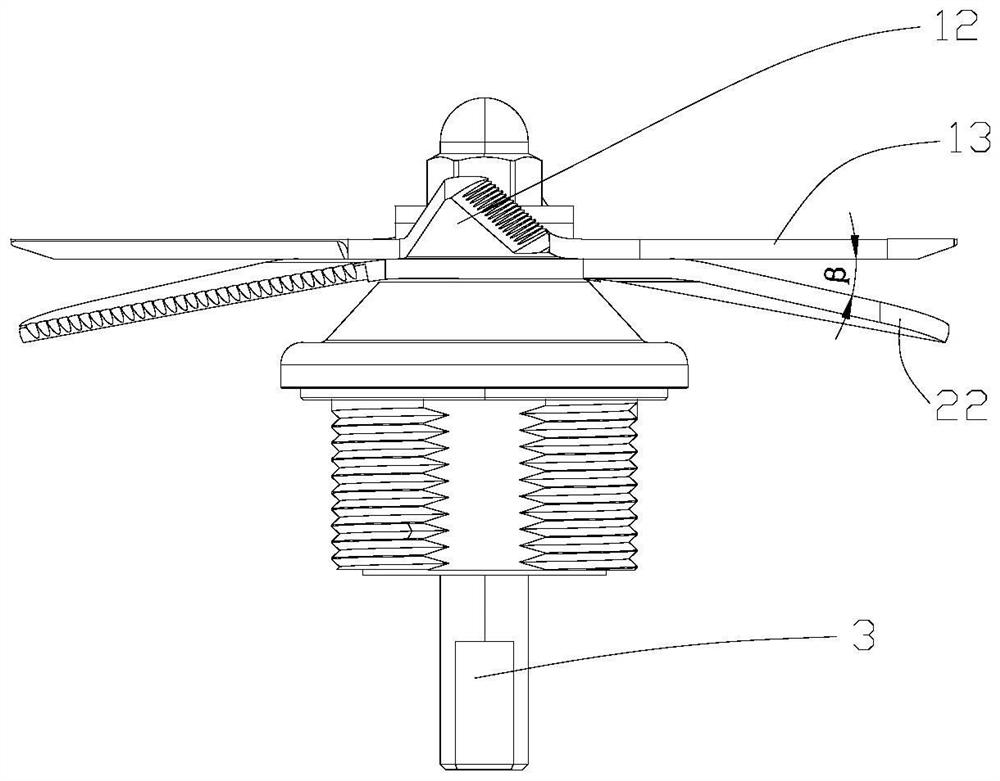

Stirring knife

PendingCN114766933APlay a cutting roleReasonable structureKitchen equipmentStructural engineeringFood material

The invention relates to a stirring knife which comprises a rotating shaft (3), a first blade (1) and a second blade (2), the first blade (1) and the second blade (2) are arranged on the rotating shaft (3), the first blade (1) comprises a first wing root (11), a first rotating shaft hole (10) for the rotating shaft (3) to penetrate through is formed in the middle of the first wing root (11), and a knife body below the stirring knife is bent downwards, is mainly used as a paddle and is used for small-amount cutting; the knife on the upper layer is bent upwards to cut food materials and throw the food materials upwards, the food materials are beaten to interference ribs on the cup wall of the stirring cup, and the flat knife mainly plays a role in cutting; the saw teeth are used for cutting food materials with higher hardness, such as ice and frozen fruits; the toothless blade is used for cutting food materials with high toughness and low hardness; food materials with different hardness can be cut by the knife; and cutting and stirring can be achieved.

Owner:ZHONGSHAN JUNGUO ELECTRICAL APPLIANCES CO LTD

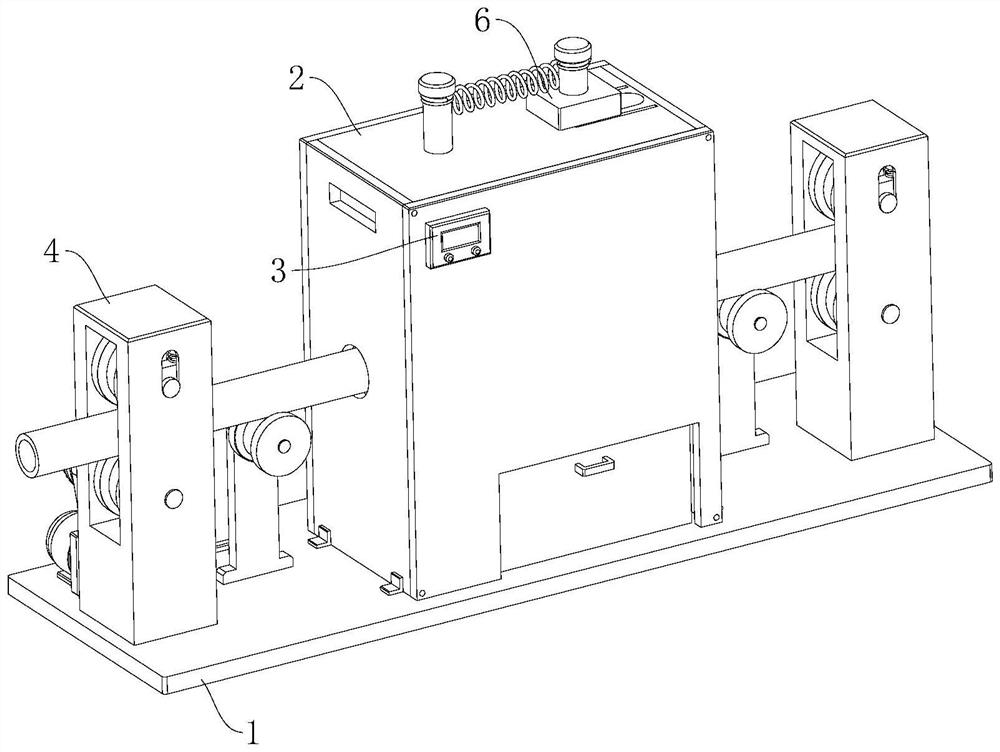

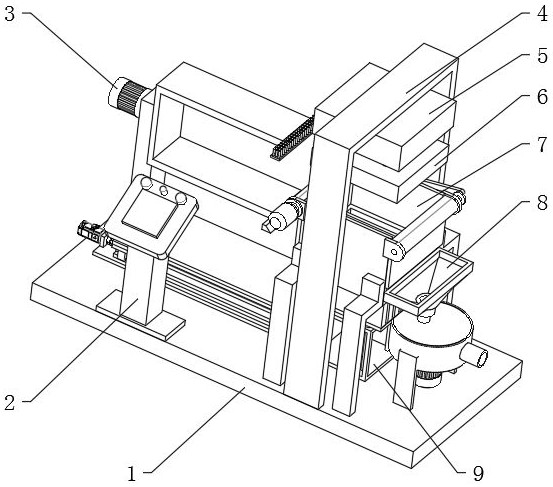

Producing, manufacturing and cutting machinery for alloy saw blades

ActiveCN111112719APlay a supporting roleQuick cutShearing machinesShearing machine accessoriesAlloyMechanical engineering

The invention provides producing, manufacturing and cutting machinery for alloy saw blades. The machinery comprises a winding mechanism, a conveying mechanism and a cutting mechanism; the winding mechanism is mounted on the conveying mechanism; the cutting mechanism is arranged on the conveying mechanism; and the conveying mechanism is arranged between the winding mechanism and the cutting mechanism. By the aid of the machinery, the problems that for current linear cutting of alloy sheets, the alloy sheets are mostly cut off manually by the aid of manual cutting machines, the manual cutting machines are inapplicable to efficient linear cutting of the alloy sheets and are very strenuous to operate, burrs are produced at cuts easily, and the manual cutting machines are inapplicable to large-scale low-cost production and manufacturing can be solved.

Owner:江苏风力士智能科技有限公司

A wire splitting machine for cable processing

ActiveCN110808127BPlay a supporting roleAvoid entanglementCable/conductor manufactureDistribution frameWorkbench

The invention discloses a separator for cable processing, which belongs to the technical field of steel cable processing. The separator for cable processing comprises a supporting base, a workbench installed above the supporting base and a winding frame located above the workbench. The winding frame is arranged at one end of the workbench. A first supporting frame is arranged on one side of the workbench. A fixed installation frame is integrally formed at the end, away from the winding frame, of the workbench; clamping machine boxes and a cutting machine box are fixedly installed in an inner screw of the fixed installation frame; the cutting machine box is arranged between the clamping machine boxes; a drawing clamping mechanism is installed in the clamping machine box; and a cable cuttingmechanism is installed in the cutting machine box. One end of a cable penetrates through the cable distribution frame, on one hand, the cable is supported, and on the other hand, the cable is distributed, so that the cable is prevented from being wound.

Owner:KUNSHAN XINGHONGMENG ELECTRONICS CO LTD

A negative pressure household onion slicing device

InactiveCN109049024BPlay a guiding roleFirmly connectedDispersed particle separationMetal working apparatusMedicineEngineering

Owner:瑞安市金意鞋业有限公司

A post-heat treatment method for laser additive manufacturing of 12crni2 alloy steel

InactiveCN109880986BSolve the disadvantages of sub-temperature quenching that is difficult to homogenize the structureSolve the disadvantages of difficult to homogenize tissueIncreasing energy efficiencyLaser additive manufacturingUltimate tensile strength

The invention discloses a post-heat treatment method for laser additive manufacturing of 12CrNi2 alloy steel, and relates to the technical field of post-heat treatment for additive manufacturing of alloy steel. The purpose of the invention is to solve the problems of non-uniform structure, difficult elimination of residual stress and low alloy strength in traditional laser additive manufacturing. Method: 1. Heating and heating: heating the 12CrNi2 alloy steel manufactured by laser additive to 856°C-866°C; 2. Heat preservation: heat-preserve the heated 12CrNi2 alloy steel at 856°C-866°C; 3. Cooling: Cool the 12CrNi2 alloy steel after heat preservation to room temperature; 4. Heat the cooled 12CrNi2 alloy steel to 734 ° C ~ 836 ° C and perform heat preservation treatment under this temperature condition, and then water cool to room temperature to obtain the treated 12CrNi2 alloy steel. The invention can obtain a post-heat treatment method for laser additive manufacturing of 12CrNi2 alloy steel.

Owner:HARBIN INST OF TECH

Soil remediation device capable of simultaneously stirring and conveying soil

ActiveCN110238176APlay a cutting roleExtended service lifeContaminated soil reclamationSoil remediationEngineering

The invention discloses a soil remediation device capable of simultaneously stirring and conveying soil. The soil remediation device comprises a material inlet part, and the material inlet part comprises a first conveyor belt and a material inlet hopper; an outlet in the lower part of the material inlet hopper is arranged above the first conveyor belt, a screener covers an inlet in the upper part of the material inlet hopper, the upper surface of the screener has a predetermined slope, and the lower side of the upper surface of the screener extends to the outer side of the soil remediation device to intercept impurities exceeding a designed remediation maximum size or agglomerated soil to the outside of the soil remediation device; and the front and rear parts of the first conveyor belt are respectively provided with one power roller. The device provided by the invention has the following beneficial effects: one side, close to the middle of a stirring cabin, of each rotating shaft rotates from the bottom to the top, so that the soil accumulated in the middle of the conveyor belt is evacuated to two sides, a stirring tooth plate with an inclined angle is also used, so that the soil is pushed forwards, and the soil is conveyed by a second conveyor belt while the soil is stirred.

Owner:上海建工环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com