Aluminum alloy for casting engine cylinder cover and preparation method of aluminum alloy

An engine cylinder head and aluminum alloy technology, which is applied in the field of aluminum alloy materials, can solve problems such as the inability to meet the design performance requirements of the cylinder head, and achieve the effect of high strength and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

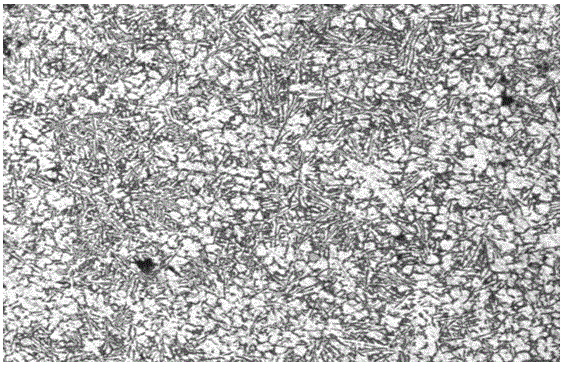

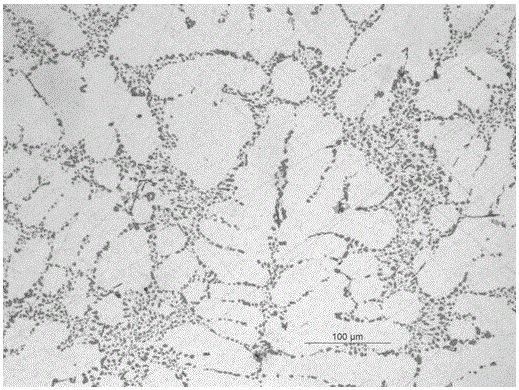

Image

Examples

Embodiment 1

[0026] The first step is to prepare 624Kg of pure aluminum ingot, 49Kg of pure silicon, 2.5Kg of pure magnesium, 23.8Kg of aluminum-titanium master alloy, 0.7Kg of aluminum-strontium master alloy, and the total weight of raw materials is 700Kg.

[0027] In the second step, add pure aluminum ingots and pure silicon prepared in the first step into the crucible furnace and heat to 760°C ± 10°C to melt;

[0028] In the third step, after all the added pure aluminum ingots and pure silicon are melted, press the pure magnesium and aluminum-titanium intermediate alloy prepared in the first step into the bottom of the aluminum and silicon solution with a bell jar, and control the temperature at 860 Alloying is carried out at about ℃.

[0029] In the fourth step, after the alloying is completed, the temperature is controlled between 740°C±10°C, and the aluminum-strontium master alloy AlSr prepared in the first step is added as a modifier;

[0030] The fifth step is to introduce high-pu...

Embodiment 2

[0035] The first step is to prepare 612Kg of pure aluminum ingot, 52Kg of pure silicon, 3Kg of pure magnesium, 32Kg of aluminum-titanium master alloy, 1Kg of aluminum-strontium master alloy, and the total weight of raw materials is 700Kg.

[0036] In the second step, add pure aluminum ingots and pure silicon prepared in the first step into the crucible furnace and heat to 760°C ± 10°C to melt;

[0037] In the third step, after all the added pure aluminum ingots and pure silicon are melted, press the pure magnesium and aluminum-titanium intermediate alloy prepared in the first step into the bottom of the aluminum and silicon solution with a bell jar, and control the temperature at 810 Alloying is carried out at about ℃.

[0038] In the fourth step, after the alloying is completed, the temperature is controlled between 740°C±10°C, and the aluminum-strontium master alloy AlSr prepared in the first step is added as a modifier;

[0039] The fifth step is to introduce high-purity n...

Embodiment 3

[0044] The first step is to prepare 639.5Kg of pure aluminum ingot, 46Kg of pure silicon, 2Kg of pure magnesium, 12Kg of aluminum-titanium master alloy, 0.5Kg of aluminum-strontium master alloy, and the total weight of raw materials is 700Kg.

[0045] In the second step, add pure aluminum ingots and pure silicon prepared in the first step into the crucible furnace and heat to 760±10°C to melt;

[0046] In the third step, after all the added pure aluminum ingots and pure silicon are melted, press the pure magnesium and aluminum-titanium intermediate alloy prepared in the first step into the bottom of the aluminum and silicon solutions with a bell jar, and control the temperature at 840 Alloying is carried out at about ℃.

[0047] In the fourth step, after the alloying is completed, the temperature is controlled between 740°C±10°C, and the aluminum-strontium master alloy AlSr prepared in the first step is added as a modifier;

[0048] The fifth step is to introduce high-purity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com