Patents

Literature

393 results about "Bell jar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bell jar is a glass jar, similar in shape to a bell, and can be manufactured from a variety of materials (ranging from glass to different types of metals). Bell jars are often used in laboratories to form and contain a vacuum; they may also serve as display cases or transparent dust covers. It is a common science apparatus used in experiments.

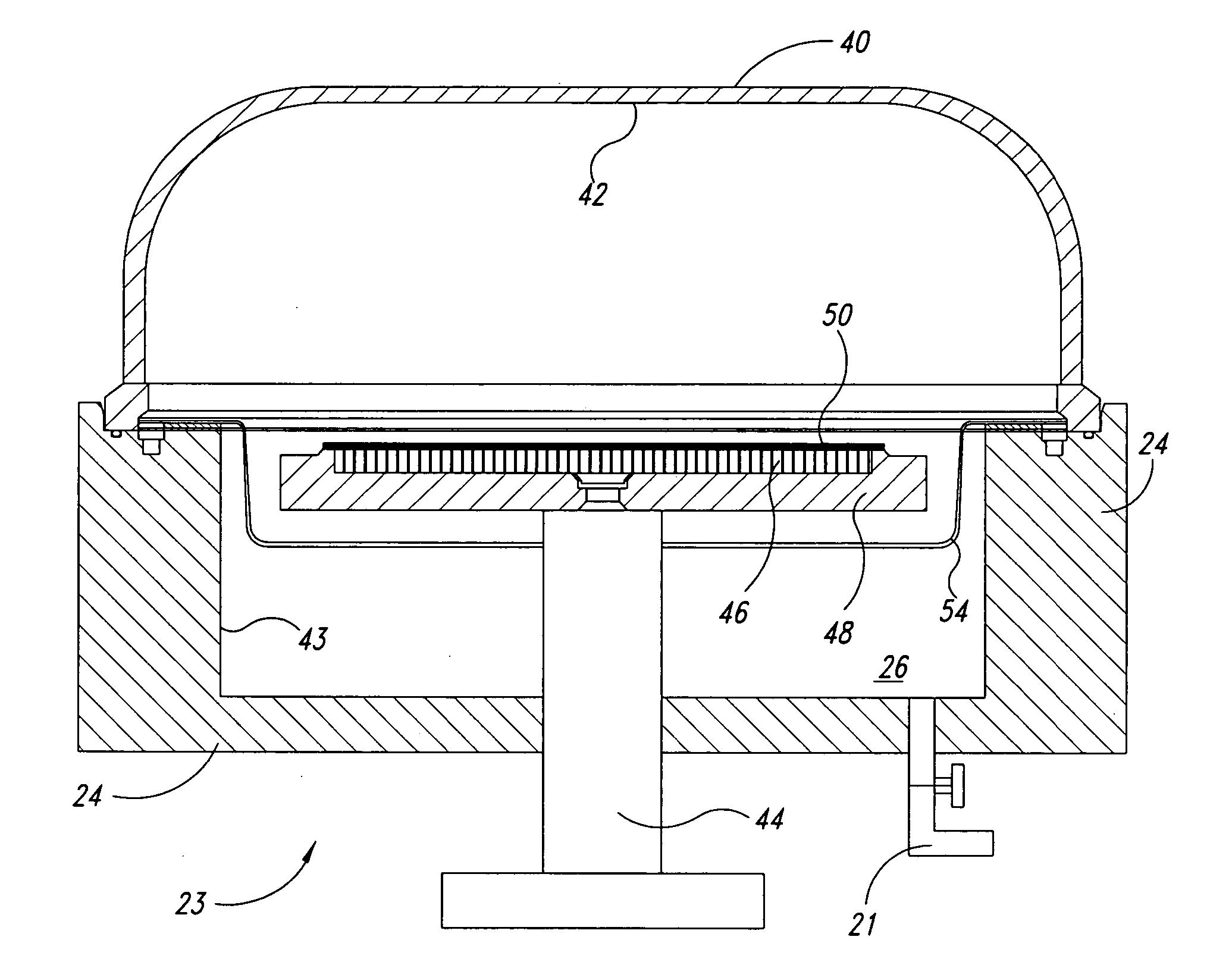

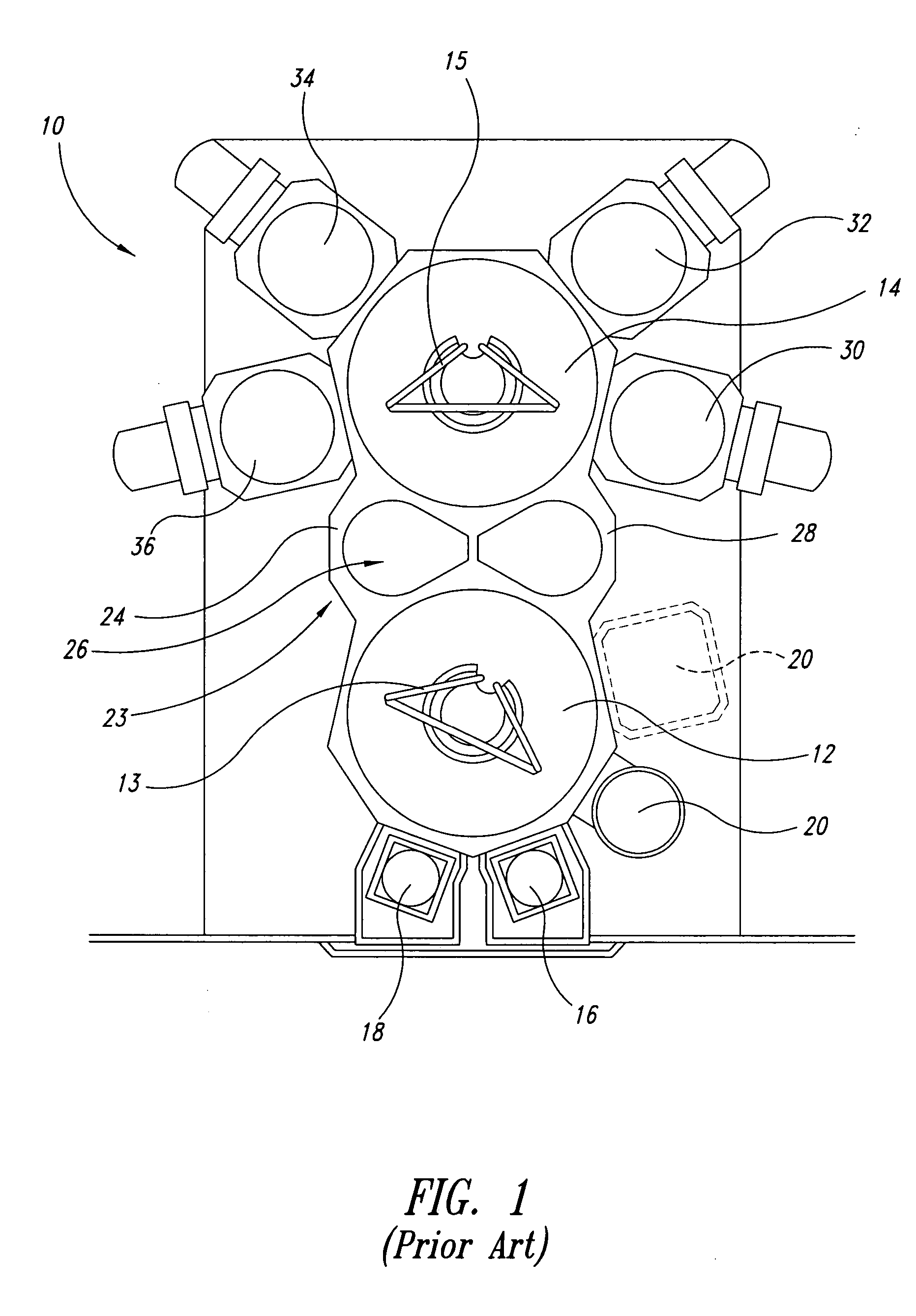

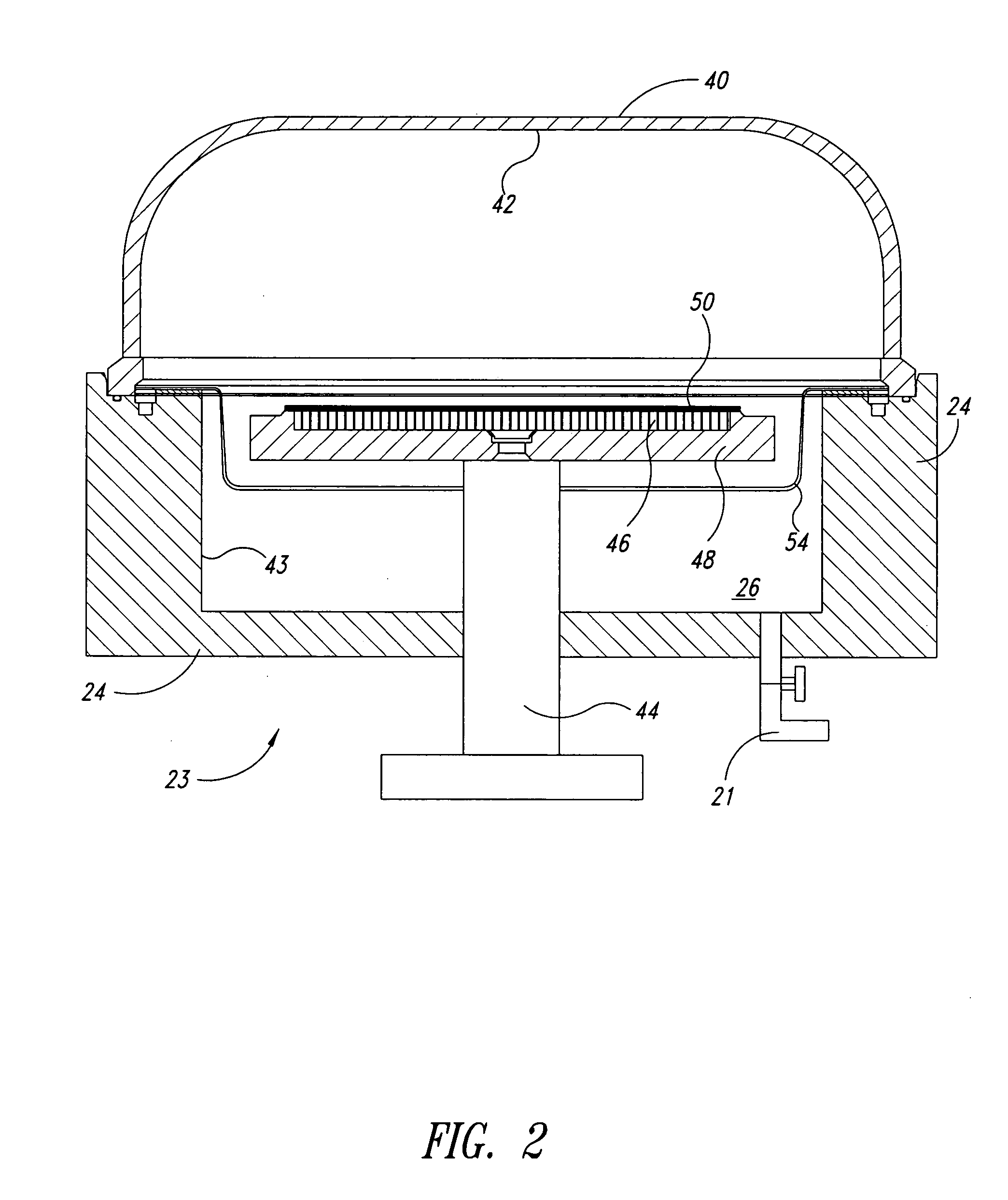

Substrate processing apparatus

ActiveUS20060048710A1Avoid pollutionUniform temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

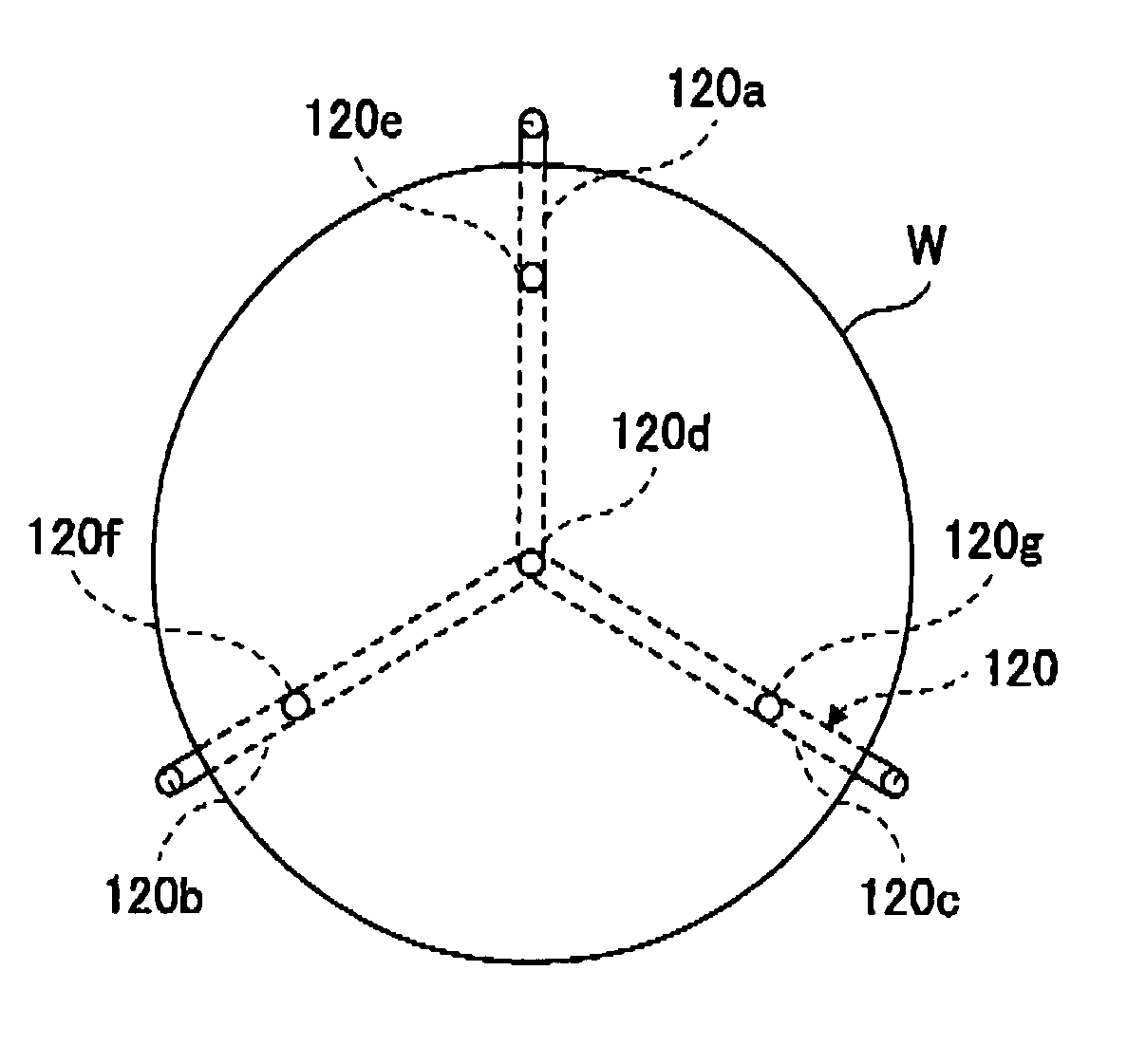

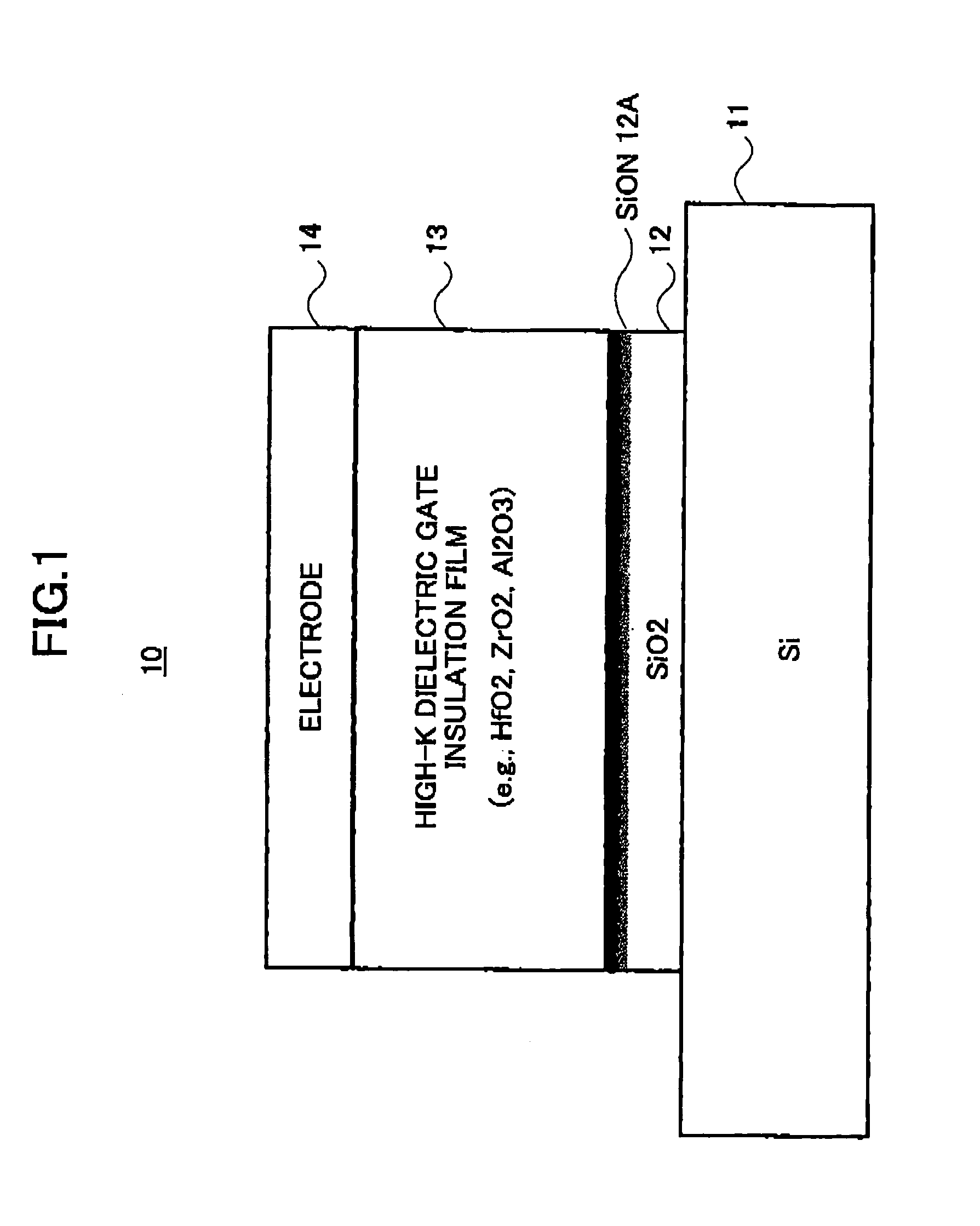

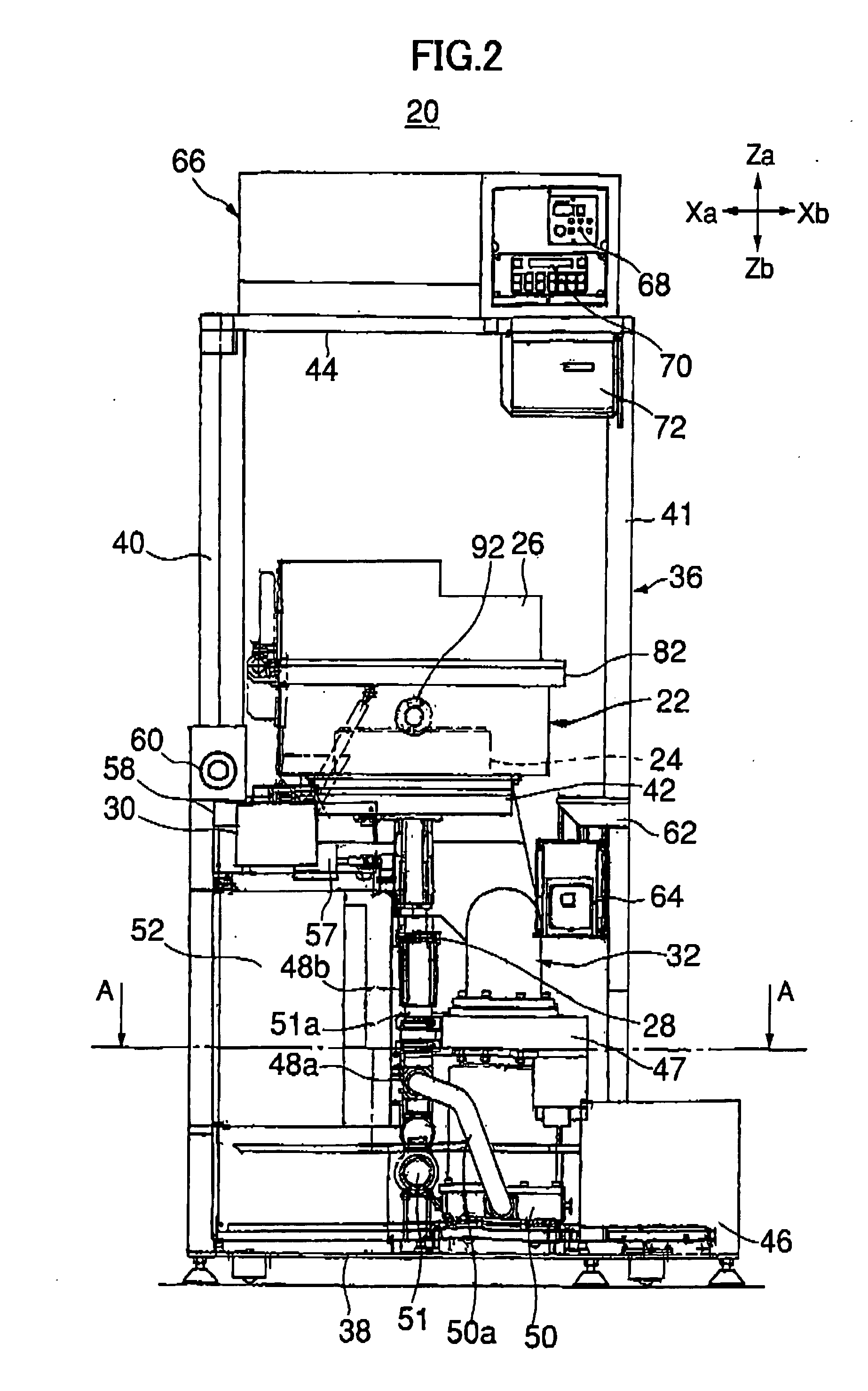

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

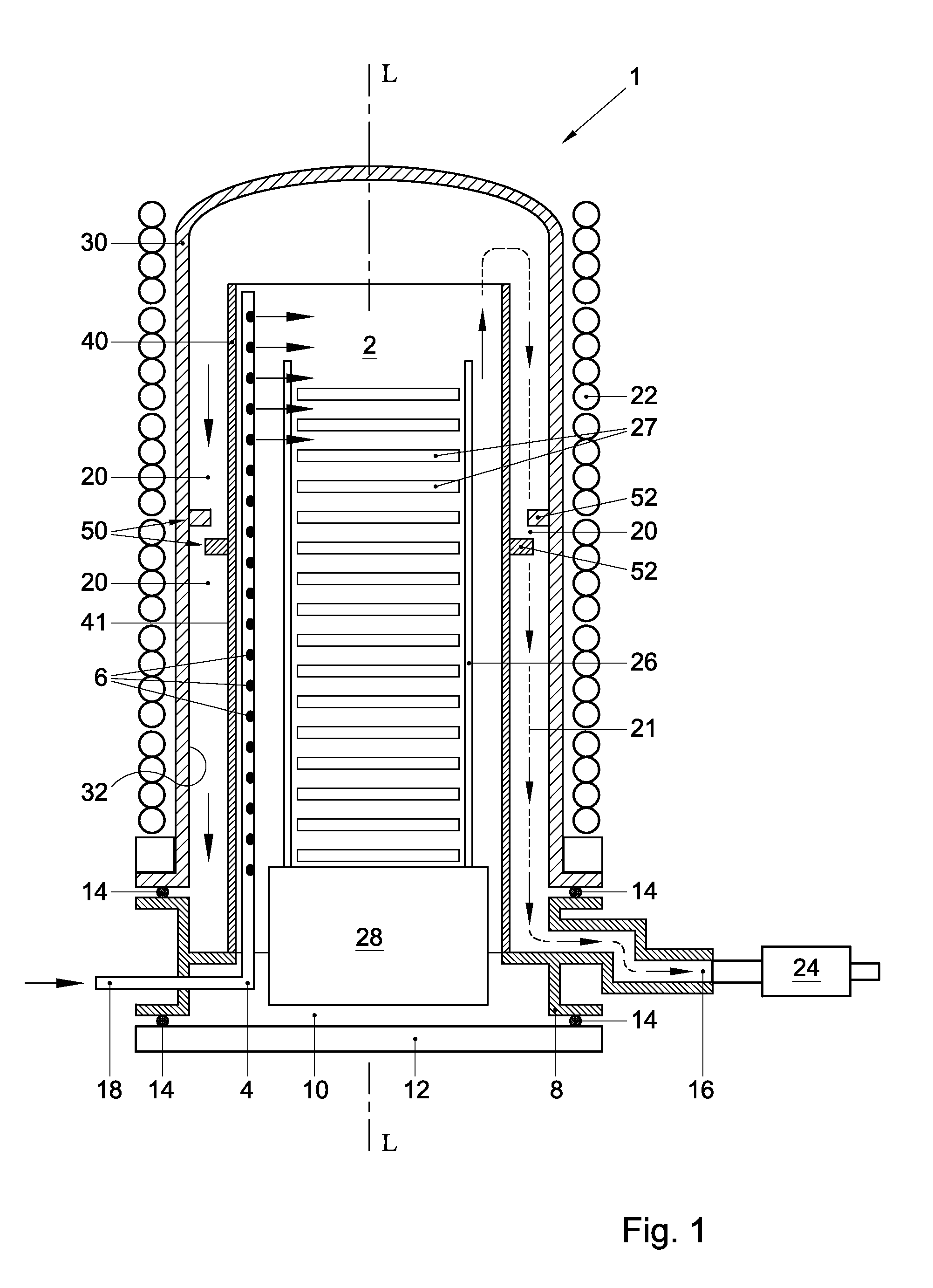

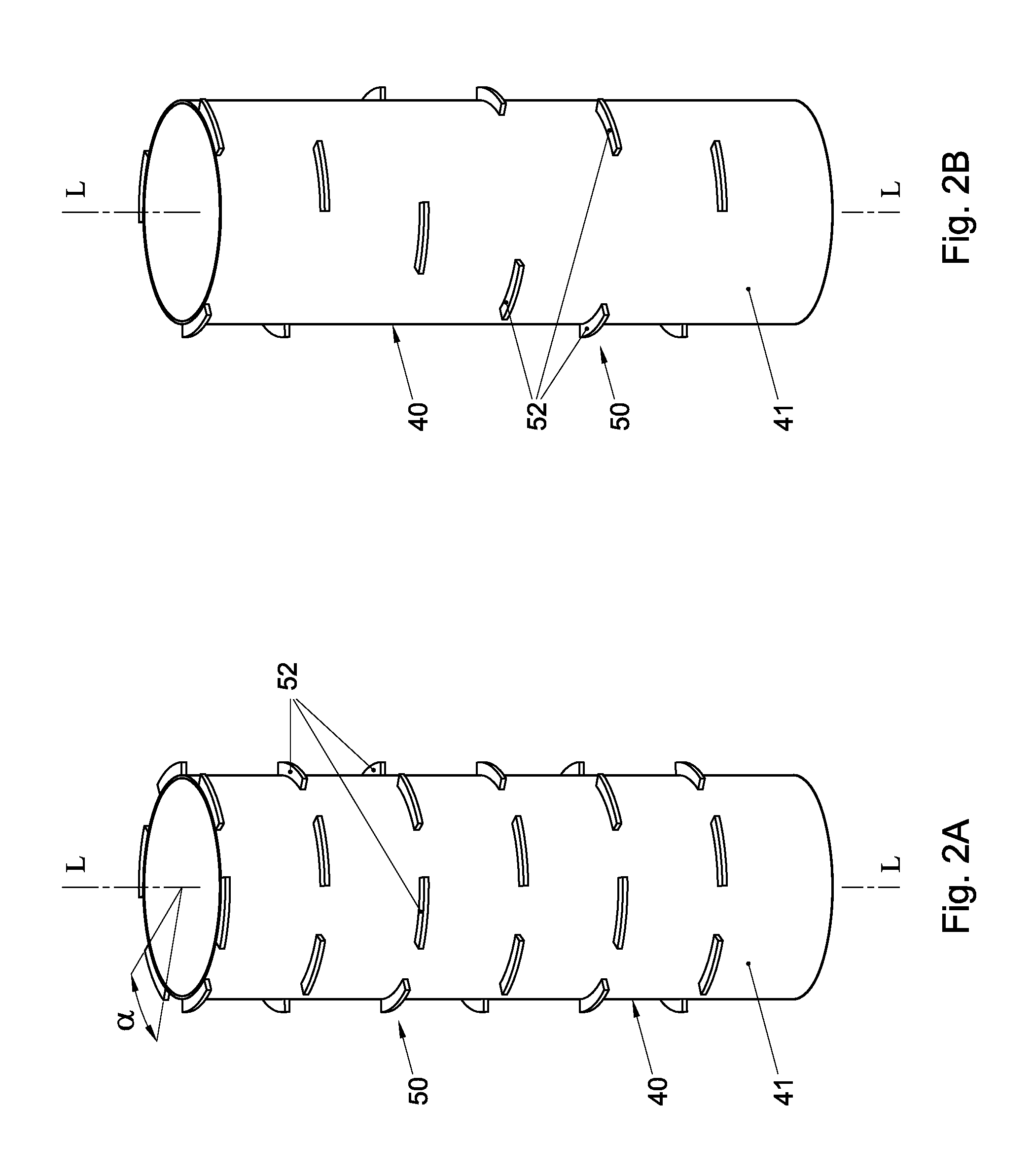

Thermal processing furnace and liner for the same

ActiveUS20120186573A1Easy to transportReduce decreaseDomestic stoves or rangesRotary drum furnacesEngineeringBell jar

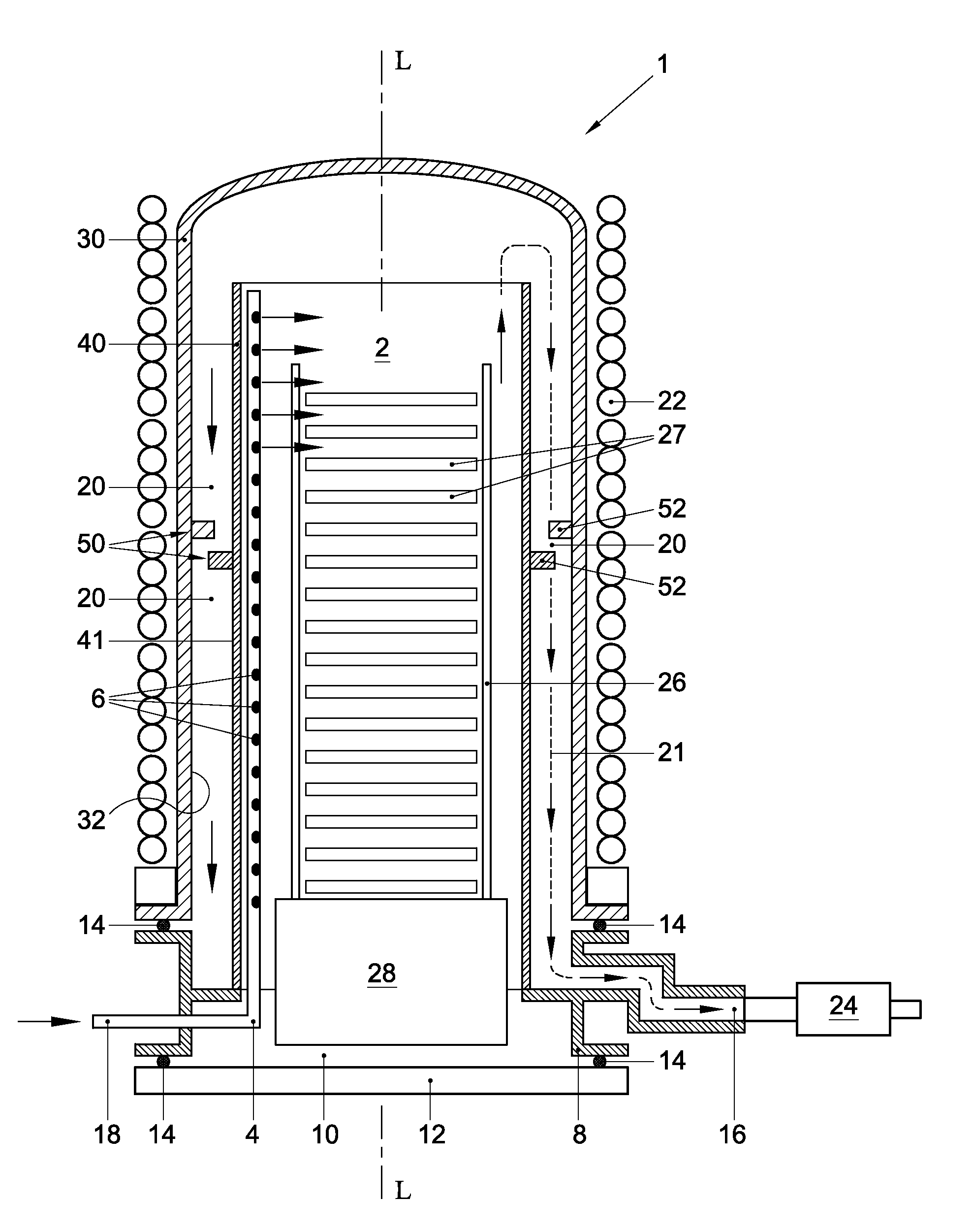

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

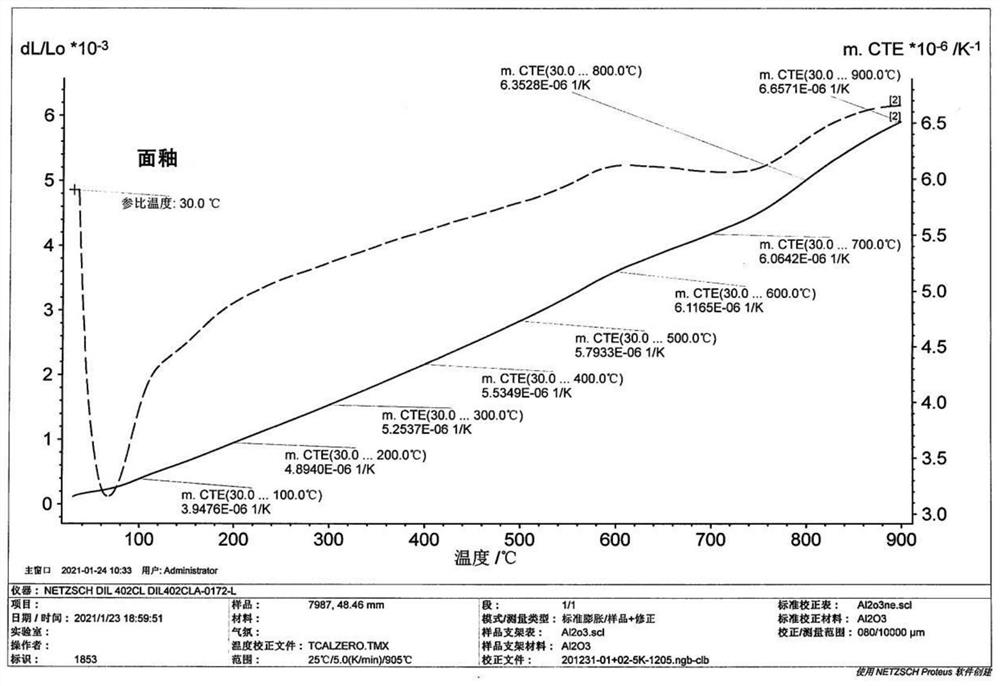

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

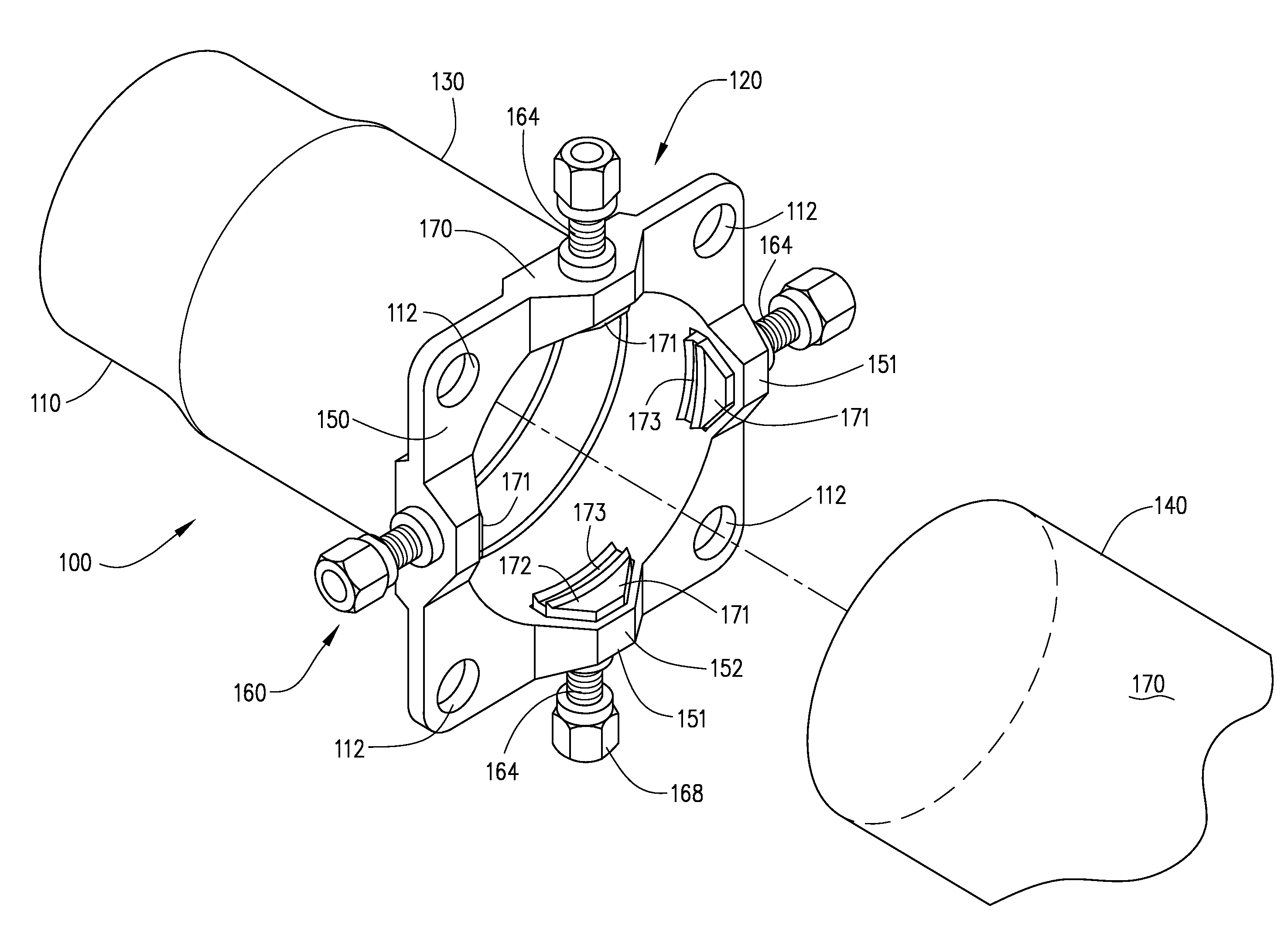

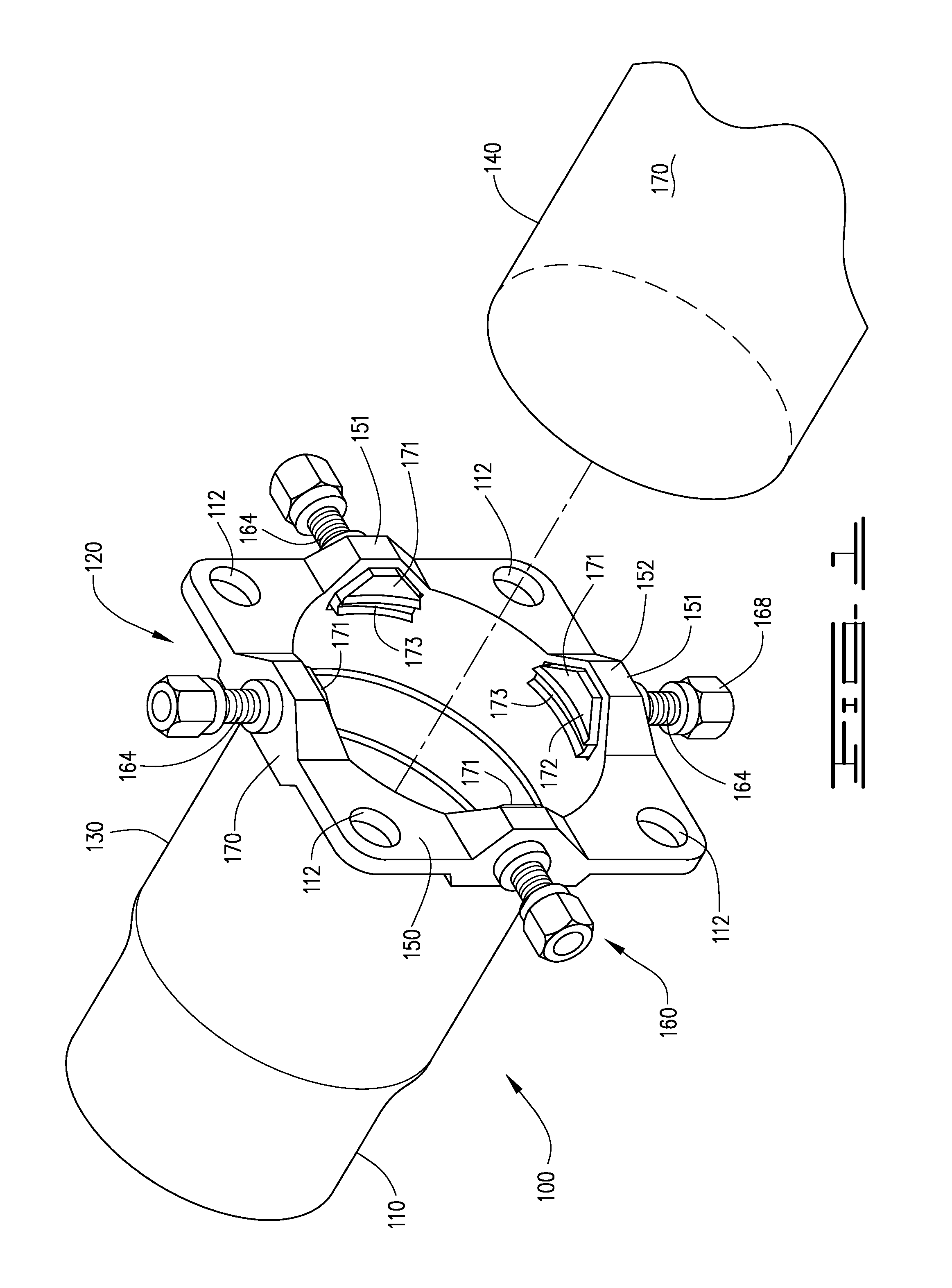

Mechanically restrained push-on pipe connection

An apparatus, system, and method for the secure attachment and restraint of a pipe end within a fitting is disclosed. The invention includes a mechanical restraint apparatus that is integral and monolithic with the flange of a bell of a spigot-and-bell joint architecture, along with one or more internally disposed grooves within the bell that receive a circumferential gasket, in order to maintain a seal about the pipe end when it is inserted into the bell. The inventive apparatus combines features of mechanical connections and push-on connections.

Owner:SMITH JONES ENTERPRISES

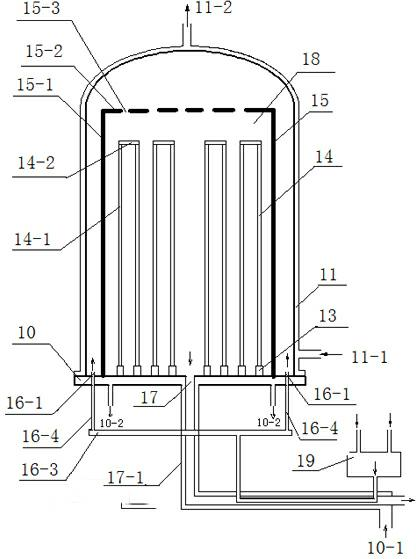

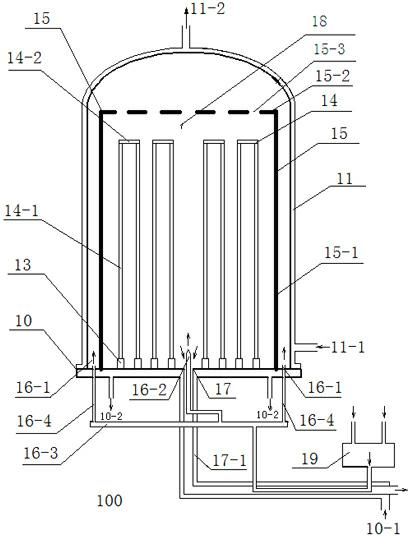

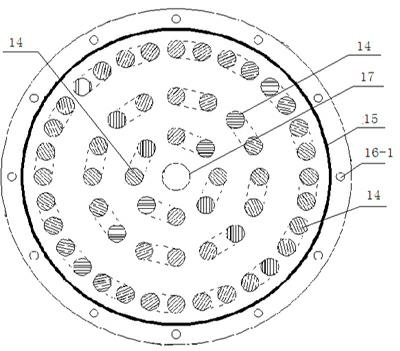

Energy-saving polysilicon reduction furnace and manufacturing method for polysilicon

InactiveCN102205967AReduce lossesImprove conversion rateChemical industrySilicon compoundsHeat lossesEngineering

The invention relates to an energy-saving polysilicon reduction furnace and a manufacturing method for polysilicon. The polysilicon reduction furnace comprises a bell jar type furnace wall, a base plate arranged on the lower side of the furnace wall, electrodes arranged on the base plate, silicon core rods arranged on the electrodes, and a raw material gas inlet and a tail gas outlet which are formed in the base plate. The polysilicon reduction furnace is characterized in that: the base plate is provided with a bell jar type heat screen which is concentric with the furnace wall and covers the silicon core rods; the heat screen consists of a cylinder part and a top part which is connected with the cylinder part and provided with a through hole; the raw material gas inlet is at least partially formed in the base plate between the cylinder part of the heat screen and the furnace wall; and the tail gas outlet is formed in the center of the base plate. In the polysilicon reduction furnace, the polysilicon is covered by the heat screen, so that the heat loss is reduced to a great extent, raw material gas is preheated, and the conversion rate of trichlorosilane can be improved.

Owner:NINGXIA SUNSHINE SILICON IND CO LTD

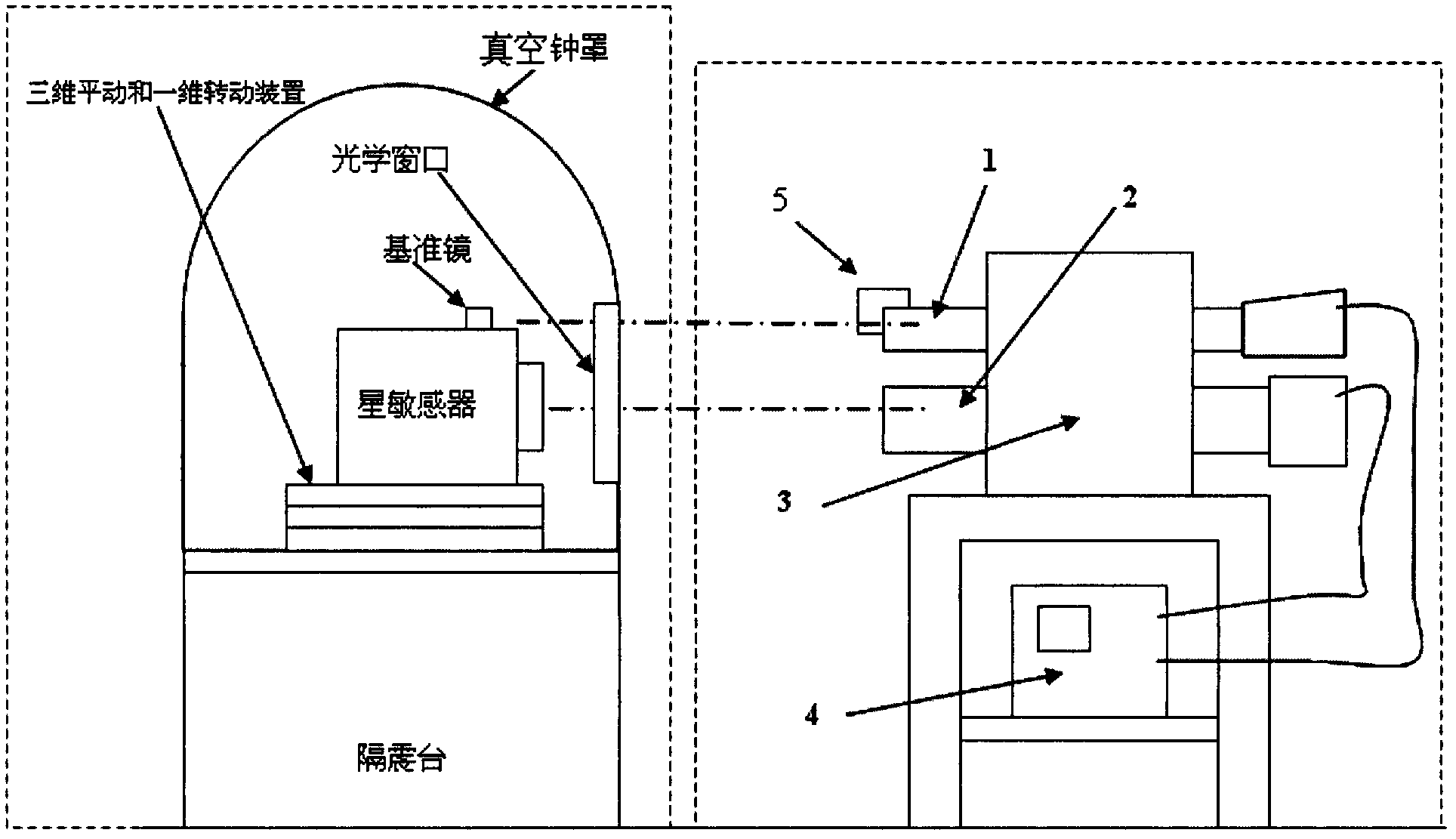

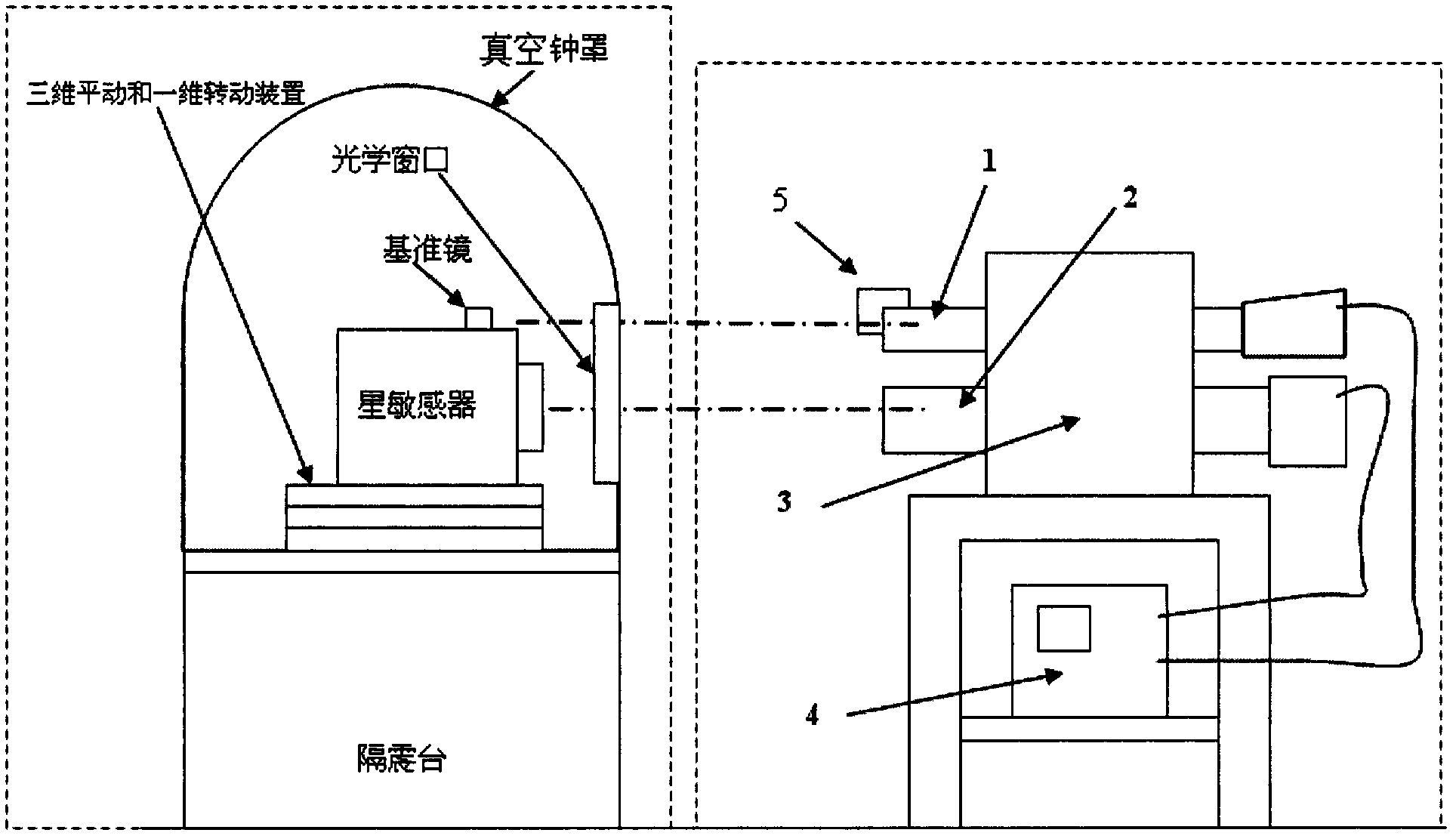

Low-frequency error measuring method for star sensor

ActiveCN102564458ARealize measurementHigh measurement accuracyMeasurement devicesFixed starsVibration isolation

The invention discloses a low-frequency error measuring method for a star sensor, and builds a low-frequency error measuring system comprising an auto-collimating collimator, a static multi-optical path star simulator, an adjusting bracket, a measuring system and a laser sight, wherein the star sensor is mounted on a vibration isolation table; a vacuum bell jar is used for providing a vacuum environment for the star sensor; a glass window is arranged on the vacuum bell jar; the transmittivity of the glass window is not less than 95 percent; and the star point imaging positions of the star sensor and the auto-collimating imaging positions of an optical datum mirror are monitored and measured at different temperatures under vacuum conditions, so as to fulfill the measuring of the low-frequency error of the star sensor. The invention further provides a measuring system to analog fixed stars of different spectra independently or simultaneously while measuring the auto-collimating angle of the optical datum mirror, and monitor and measure the star point imaging positions of the star sensor and the auto-collimating imaging positions of the optical datum mirror, so as to improve the measuring accuracy.

Owner:BEIJING INST OF CONTROL ENG

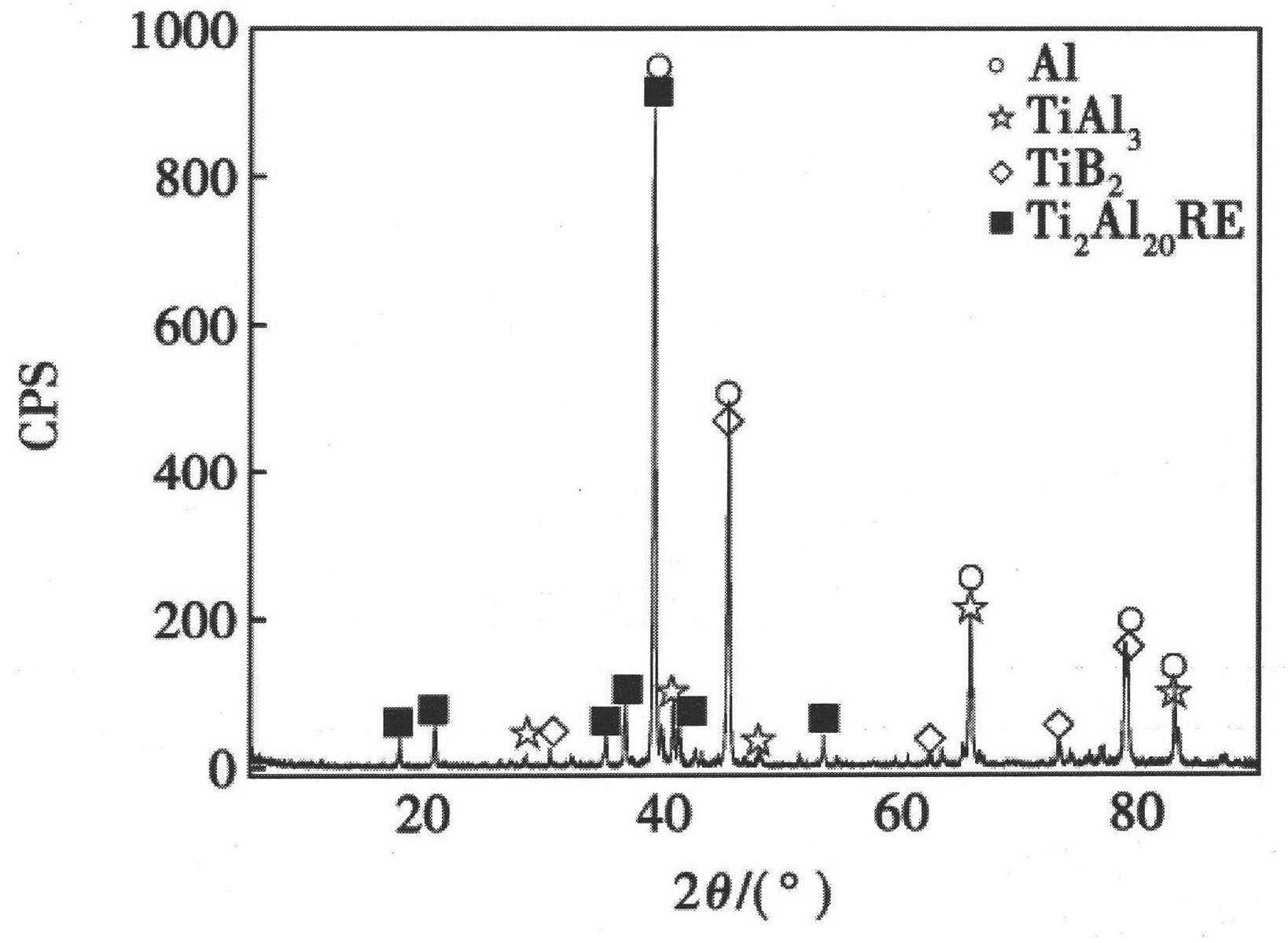

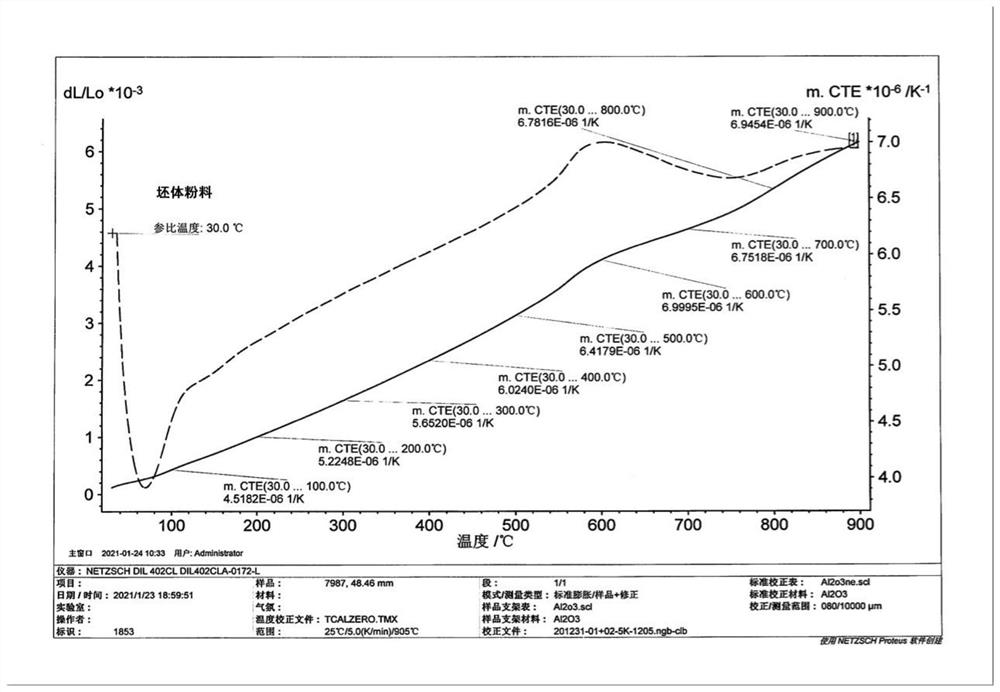

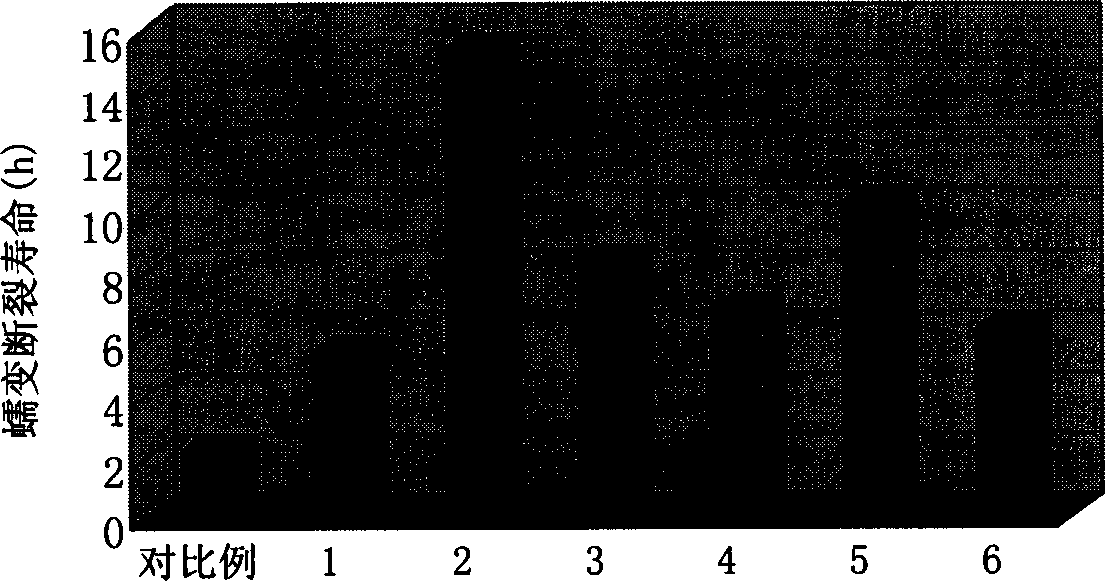

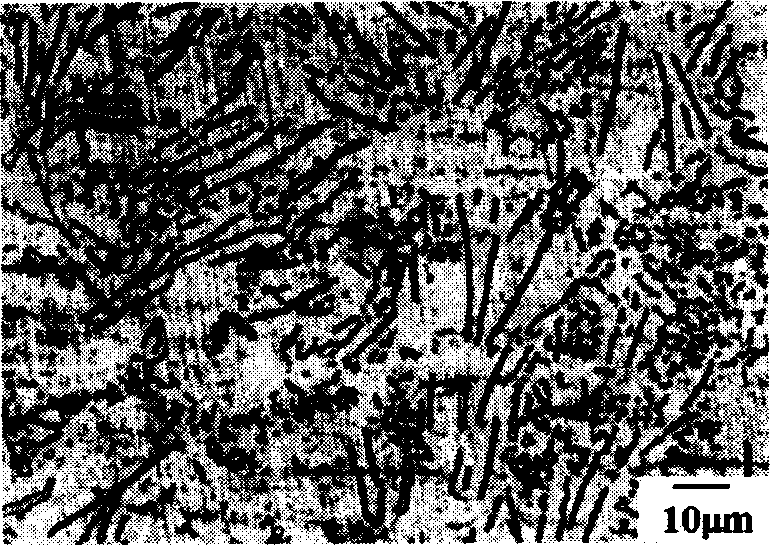

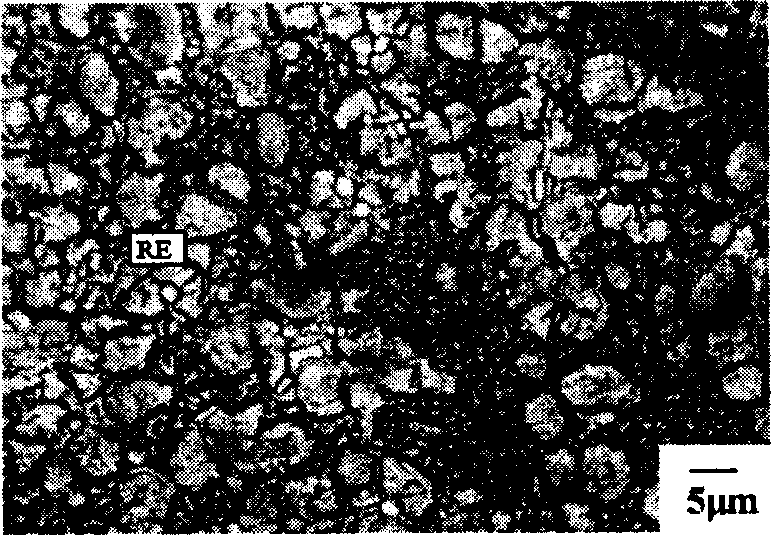

Al-Ti-B-rare earth(RE) grain refiner and preparation method thereof

The invention relates to an Al-Ti-B-RE grain refiner and a preparation method thereof. The Al-Ti-B-RE grain refiner is used for Al-Mg-Si alloy, and is characterized by containing the following components in percentage by weight: 6.9 to 7.9 percent of Ti, 1.31 to 1.75 percent of B and 1.5 to 2.0 percent of mixed RE. The mixed RE is cerium-enriched rare earth. The preparation method of the cerium-enriched rare earth comprises: mixing the raw materials according to a weight part ratio, wherein the mixing time is controlled to be 3 to 4 hours; heating an aluminum ingot in a medium frequency induction furnace to an overhigh temperature of 700 to 750 DEG C; filling a mixed pressed block of potassium fluotitanate and potassium fluoborate and cerium-enriched rare earth into a graphite bell jar; clamping the reversed bell jar by using forceps, and pressing the bell jar into the lower middle part of aluminum melt; raising the furnace temperature to 800 to 850 DEG C, and magnetically stirring for 25 to 30 minutes with the induction furnace; after reaction, taking the graphite bell jar out; standing and keeping the temperature for 20 minutes; forcefully stirring the melt once with an artificial graphite rod every 3 minutes, and stirring for more than five times; treating molten alloy; standing and keeping temperature for 15 to 20 minutes; and performing secondary slagging off.

Owner:HUANGGANG HUAER ALUMINUM ALLOY

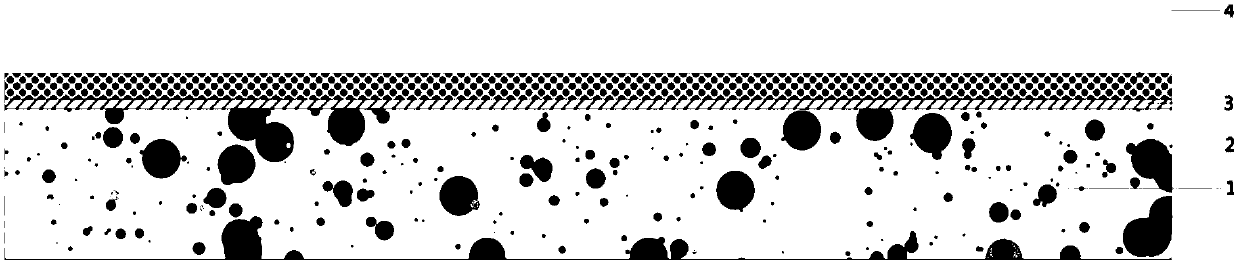

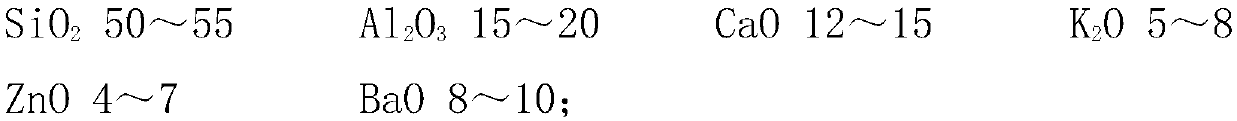

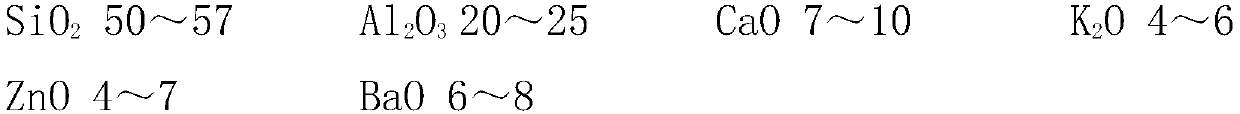

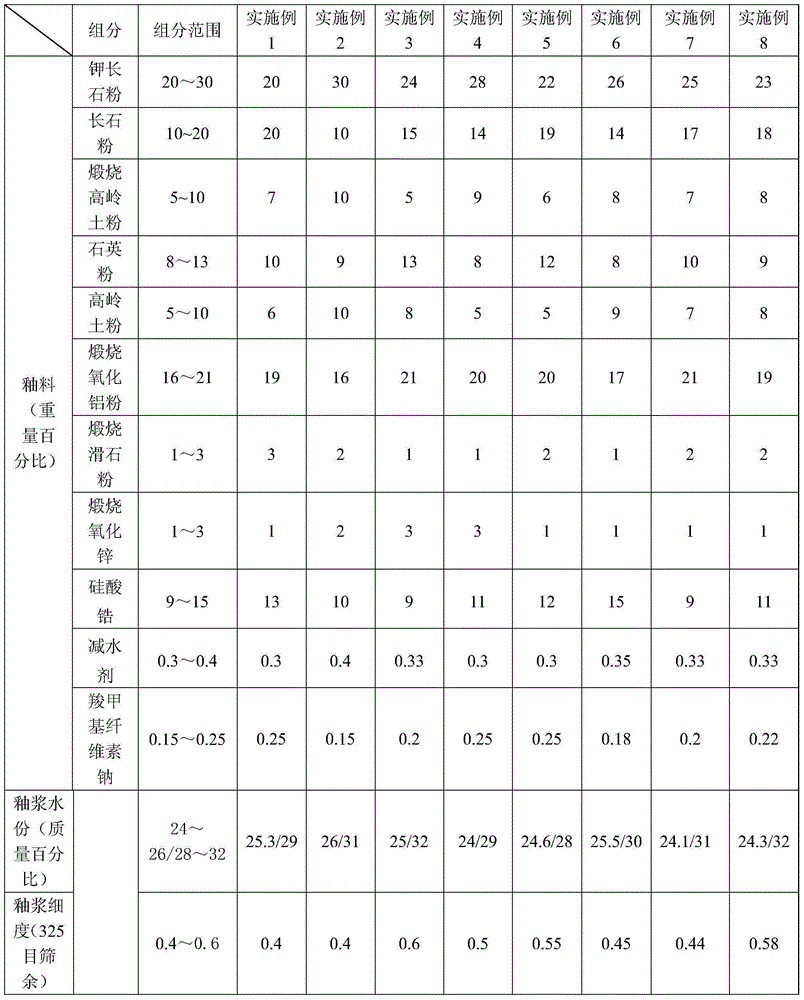

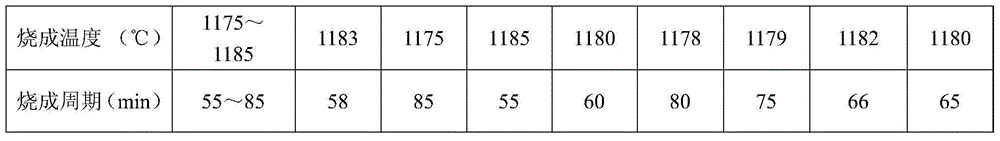

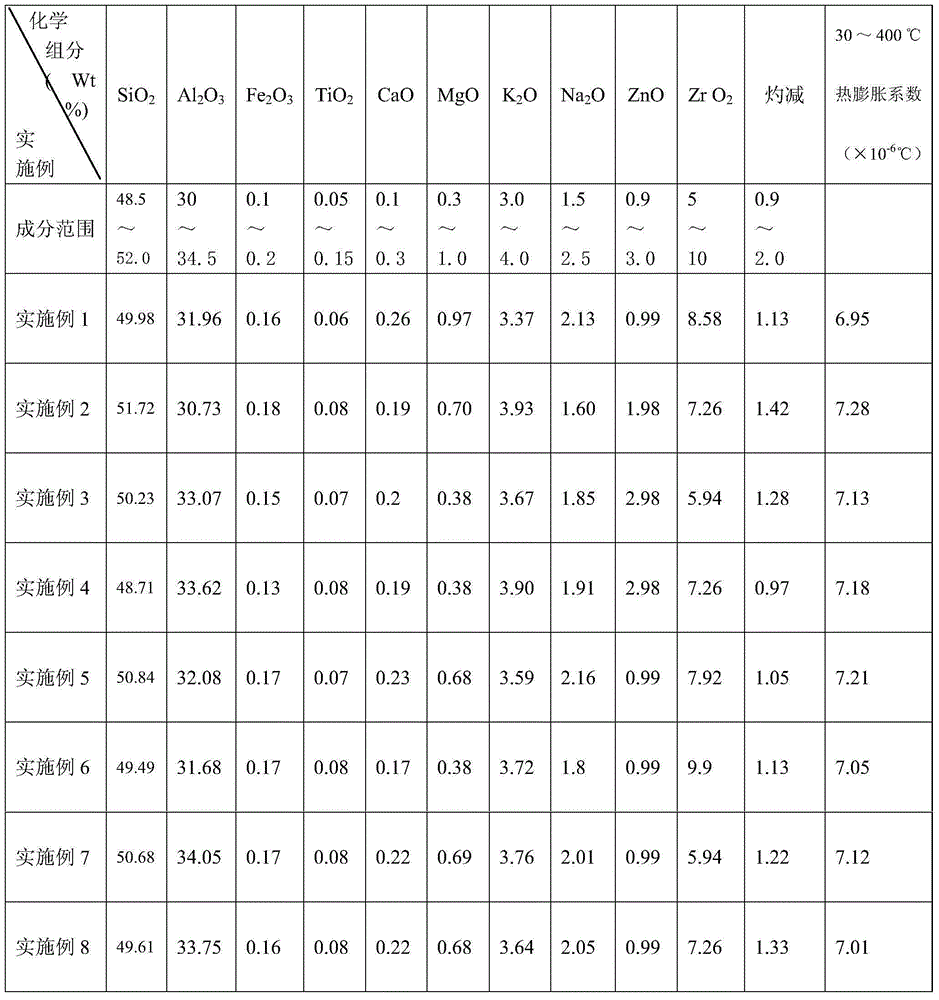

Ground coat used for producing fully-glazed ceramic tile and beneficial to color development of ceramic ink

The invention discloses a ground coat used for producing a fully-glazed ceramic tile and beneficial to color development of ceramic ink. The ground coat is mainly prepared from, by weight, 20%-30% of potassium feldspar powder, 10%-20% of feldspar powder, 5%-10% of calcined kaolin powder, 8%-13% of quartz powder, 5%-10% of kaolin powder, 16%-21% of calcined alumina powder, 1%-3% of calcined talcum powder, 1%-3% of calcined zinc oxide, 9%-15% of zirconium silicate, 0.3%-0.4% of water reducing agent and 0.15%-0.25% of methyl. The content of single raw material chemical component CaO is smaller than 3%. The raw material chemical components of the ground coat comprise 48.5%-52.0% of SiO2, 30%-34.5% of Al2O3, 0.1%-0.2% of Fe2O3, 0.05%-0.15% of TiO2, 0.1%-0.3% of the CaO, 0.3%-1.0% of MgO, 3.0%-4.0% of K2O, 1.5%-2.5% of Na2O, 0.9%-3.0% of ZnO, 5%-10% of ZrO2 and 0.9%-2.0% of igloss. The technological process of the ground coat includes the steps of blending, ball milling, sieving, deironing and glaze slip staling. The using method of the ground coat includes the step of glazing through a bell jar glaze pouring technology or a linear glaze pouring technology. By the adoption of the ground coat, the colors of the product are enriched, color development of the ceramic ink is facilitated, color development of each color is deeper, the hue is pure, and the rate of qualified products is high.

Owner:GUANGDONG XINRUNCHENG CERAMICS

Nucleation layer deposition on semiconductor process equipment parts

InactiveUS20070032072A1Strong adhesionImprove adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingProcess equipmentEngineering

A plasma chamber is provided having an upper insulating member as a lid of the plasma chamber. The lid of the plasma chamber, usually in the form of a bell jar, has an inside surface which will be exposed to the interior of the plasma chamber. A nucleation layer is affixed to the inside surface of the insulating member. The nucleation layer is selected to be a material which will enhance the growth on itself of the particular material being etched within the process chamber. For example, if the pre-clean chamber is being used to etch oxides, the nucleation layer is selected to be of a type which will create a large number of nucleation sites for the growth of an oxide layer on the interior wall of the bell jar. Each nucleation site becomes the starting point for the adherence of the etched oxide atoms onto the wall of the bell jar. Wafers pre-cleaned in such a chamber have a lower defect density. Further, longer times are permitted between cleaning and replacing components in the pre-clean chamber.

Owner:STMICROELECTRONICS SRL

Production process of superfine dry-particle ceramic large plate and product of same

The invention discloses a production process of a superfine dry particle ceramic large plate and a product of the same. The production process comprises the following steps: (1) brushing a green body and spraying water to wet the green body; (2) sequentially spraying overglaze on the surface of the green body and carrying out ink-jet printing on the surface of the green body; (3) spraying dry granular glaze slip on the surface of the green body obtained in the step (2) in a bell jar mode, and the dry granular glaze slip comprises, by weight, 110-130 parts of a suspending agent, 35-45 parts of superfine dry granules and 4.5-11 parts of raw transparent glaze; wherein the superfine dry particles comprise 19-21% of corundum powder; and (4) firing, brushing and throwing to obtain the superfine dry particle ceramic large plate. According to the invention, the dry granular glaze is sprayed on the surface of the green body, so that fine and smooth small particles with frosted texture are formed on the surface of the prepared large ceramic plate, thereby improving the wear resistance and skid resistance of the large ceramic plate, and solving the problems of poor wear resistance and poor skid resistance of the existing large ceramic plate.

Owner:FOSHAN DONGPENG CERAMIC +3

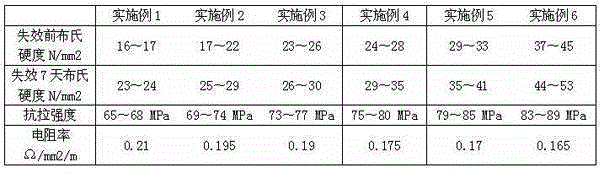

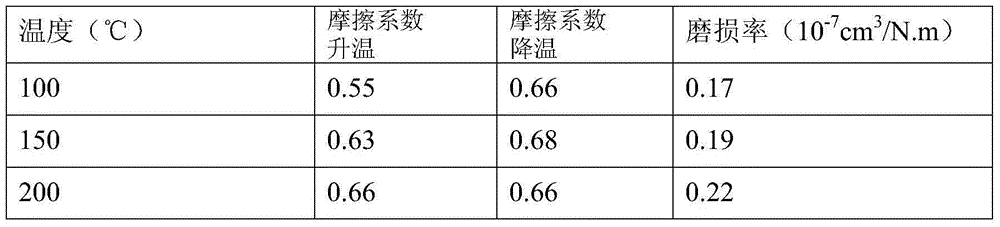

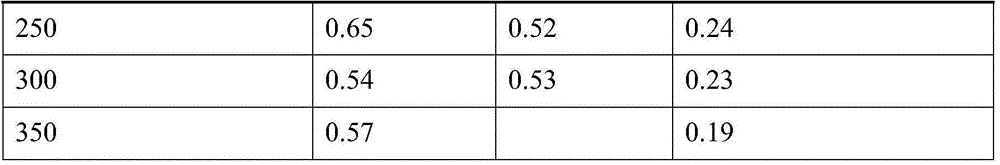

Method for manufacturing nano enhanced wet copper-based friction plate

ActiveCN102094916AIncrease frictionMeet technical requirementsFriction liningCopper platingDecomposition

The invention relates to a method for manufacturing a nano enhanced wet copper-based friction plate. The method mainly comprises the following steps of: 1, mixing materials; 2, performing ball-milling on mixed materials; 3, profiling; 4, plating copper on a core plate; 5, performing pressure sintering; and 6, processing an oil groove. The nano enhanced wet copper-based friction plate comprises the following components in percentage by weight: 60 to 75 percent of Cu, 2 to 6 percent of Sn, 3 to 8 percent of Zn, 12 to 25 percent of C, 2 to 5 percent of SiO2, and 0.5 to 1.5 percent of nano SiO2; the materials are mixed; the step of performing ball-milling on the mixed materials comprises the following substep of placing the mixed powdery materials and steel balls in a ball mill, wherein the ratio of the steel balls to the material is 5 to 1 and the time of the ball-milling is 1.5 to 2.5 hours; the step of performing pressure sintering comprises the substeps of stacking profiled powder blank of a frictional layer and a copper-plated steel core plate in a bell jar type pressure sintering furnace and performing pressure sintering, wherein the sintering temperature is 750 to 850 DEG C; preserving heat for 2.5 to 3.5 hours, wherein the atmosphere is ammonia decomposition gas; and the step of plating copper on the core plate is to plate copper on the core plate by an electroplating method and manufacturing the copper-plated core plate and comprises the following substeps of hanging the core plate on a cathode, hanging a copper plate on an anode, adding copper ion-containing electroplate liquid into a plating bath, introducing direct current and adjusting electroplating time according to the thickness of a plating layer. The nano enhanced wet copper-based friction plate manufactured by the method has frictional wear performance and a heat resistance coefficient which are obviously superior to those of the wet copper-based friction plate manufactured by the conventional method.

Owner:HANGZHOU ADVANCE GEARBOX GRP

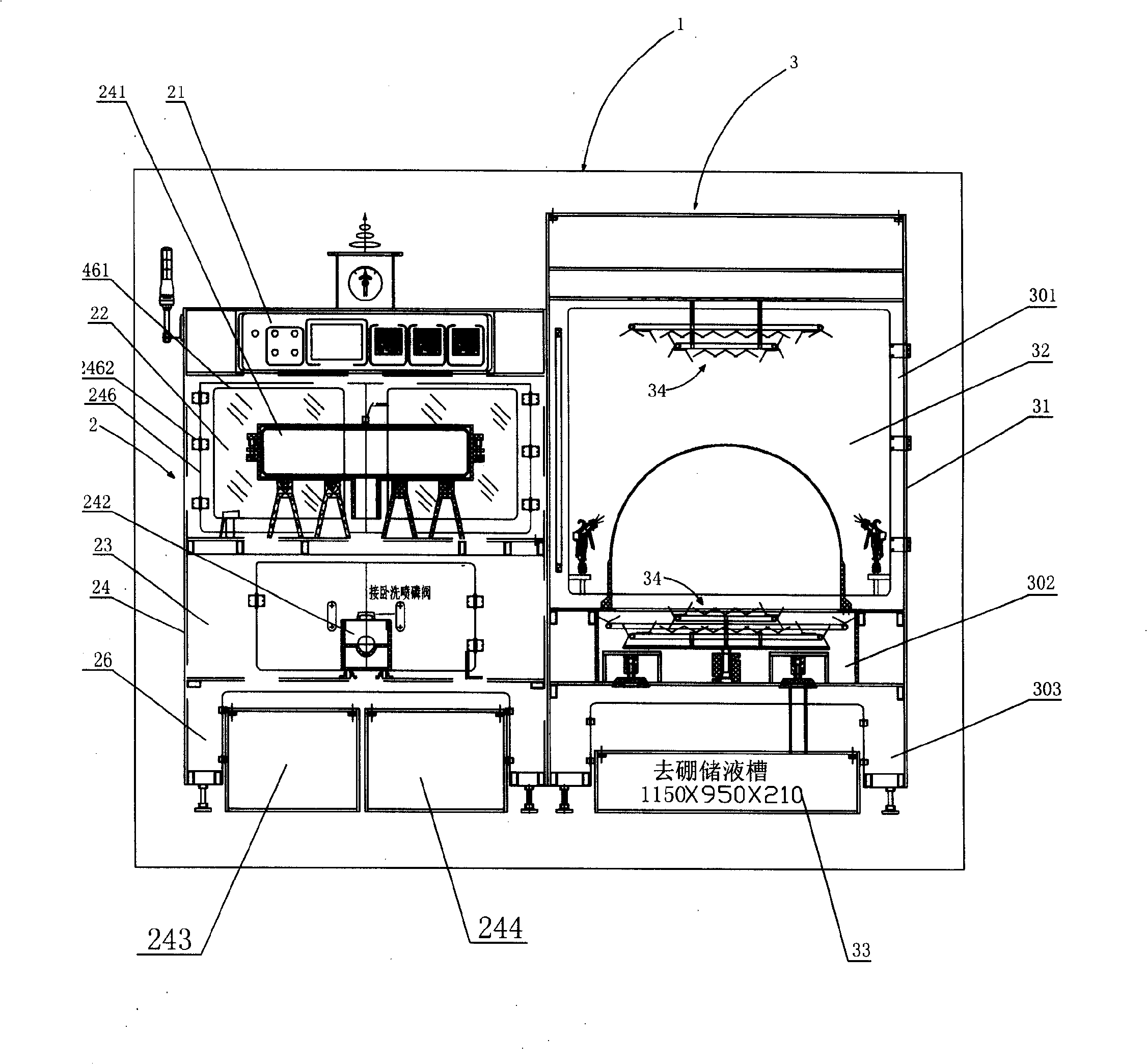

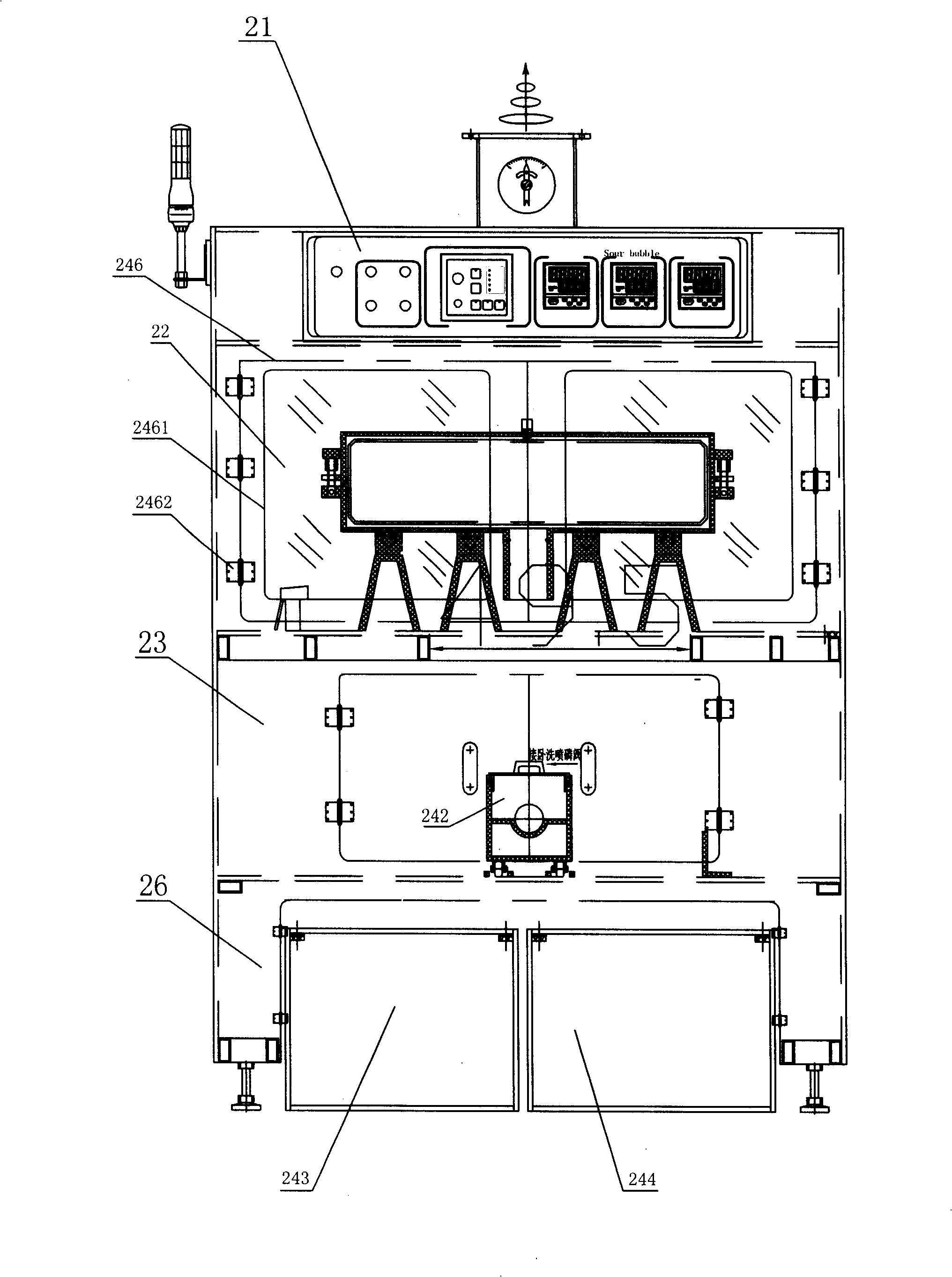

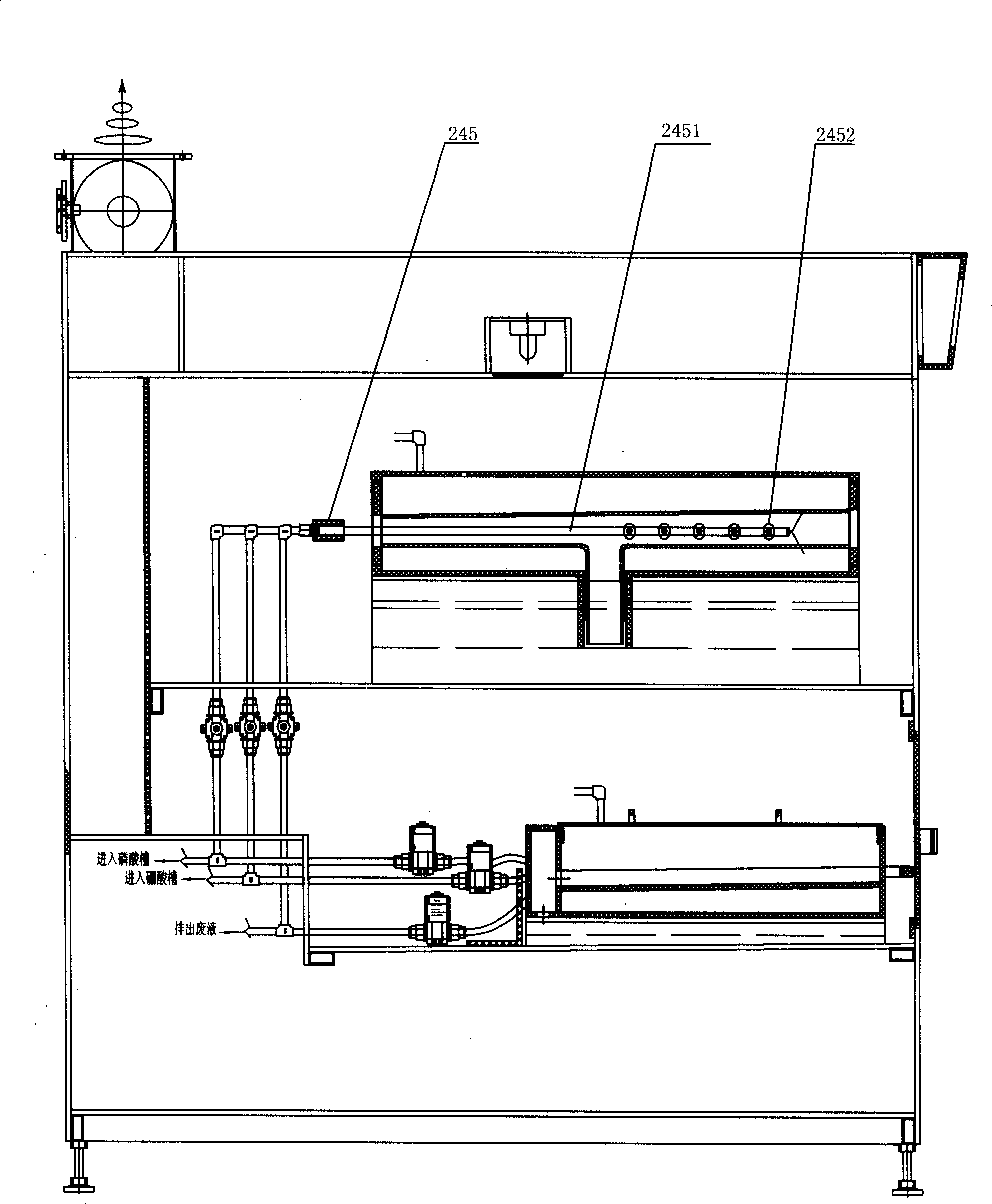

Combined bell glass washer and operation method thereof

InactiveCN101352714AAchieve even cleaning effectPrevent rotationHollow article cleaningCleaning using liquidsElectric machineLiquid storage tank

The invention discloses a combined bell jar cleaner for bell jar, which comprises a box body, a horizontal quartz bell jar cleaner and a vertical quartz bell jar cleaner; the horizontal quartz bell jar cleaner is arranged at the left side in the box body, and the vertical quartz bell jar cleaner is arranged at the right side of the box body; the horizontal quartz bell jar cleaner is divided into an electrical shelf area, a horizontal bell jar cleaning area, a matching parts cleaning area and a liquid storage tank placing area from the top bottom; and the vertical quartz bell jar cleaner is divided into a bell jar twin-fluid spray cleaning area, a liquid recovery area and a liquid storage tank placing area from the top bottom. The combined bell jar cleaner has the advantages of uniform cleaning, better erosion cleaning effect, greatly reducing the probability of machine failure, being safer and reducing cost, and as the motor is not used, the bell jar can not be driven to rotate; and the horizontal quartz bell jar cleaner has good sealing performance, and reduces injuries of an operator caused by liquid splashing, etc.

Owner:大正华嘉科技(香河)有限公司

High creep resistance rareearth contained tin base leadless soldering-flux and preparation method thereof

InactiveCN1385280AReduced creep resistanceRestricted movementWelding/cutting media/materialsSoldering mediaLithium chlorideSoldering

The present invention relates to a high creep resistance rare earth containing tin base leadless brazing filler metal and its preparation method. Said material contains (wt%) 2-5% of Ag, 0.2-1% of Cu, 0.025-1.0% of commercially-available Ce base mixed rare earth and the rest is Sn. Its preparation method includes the following steps: melting mixed salt of potassium chloride and lithium chloride with weight ratio of 1-1.6:0.8-1.2, pouring it on the Sn, after the Sn is melted, adding the weighed Ag and Cu into Sn solution to melt Ag and Cu, then using bell jar whose wall has hole to press the Ce base rare earth into the above-mentioned mixed salt and Sn-Ag-Cu alloy, turning bell jar, heat-insulating for 1-2 hr., stirring, standing still, setting and removing mixed salt from surface so as toobtain the invented brazing fill metal.

Owner:YIYUAN ELECTRONICS TECH

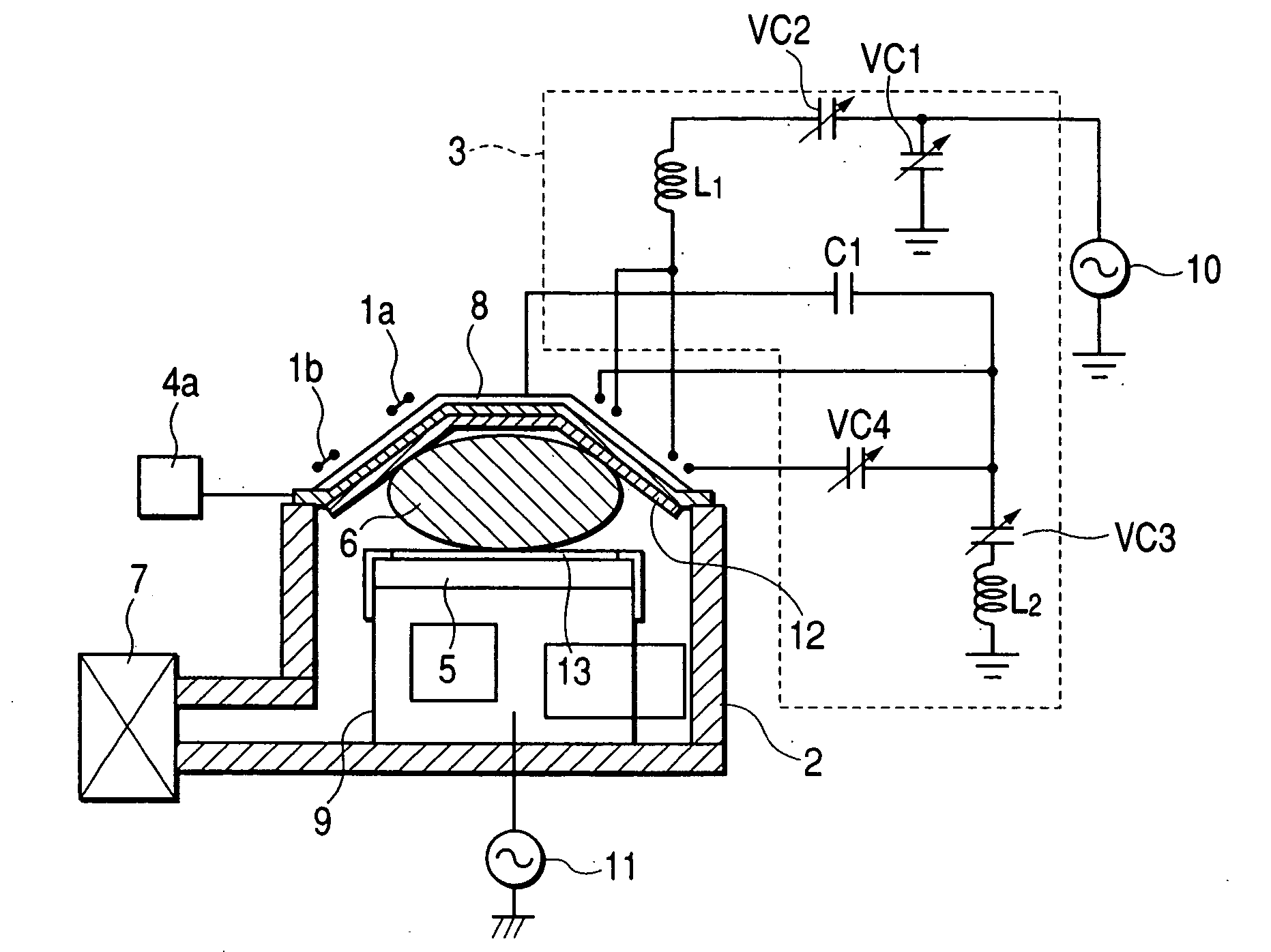

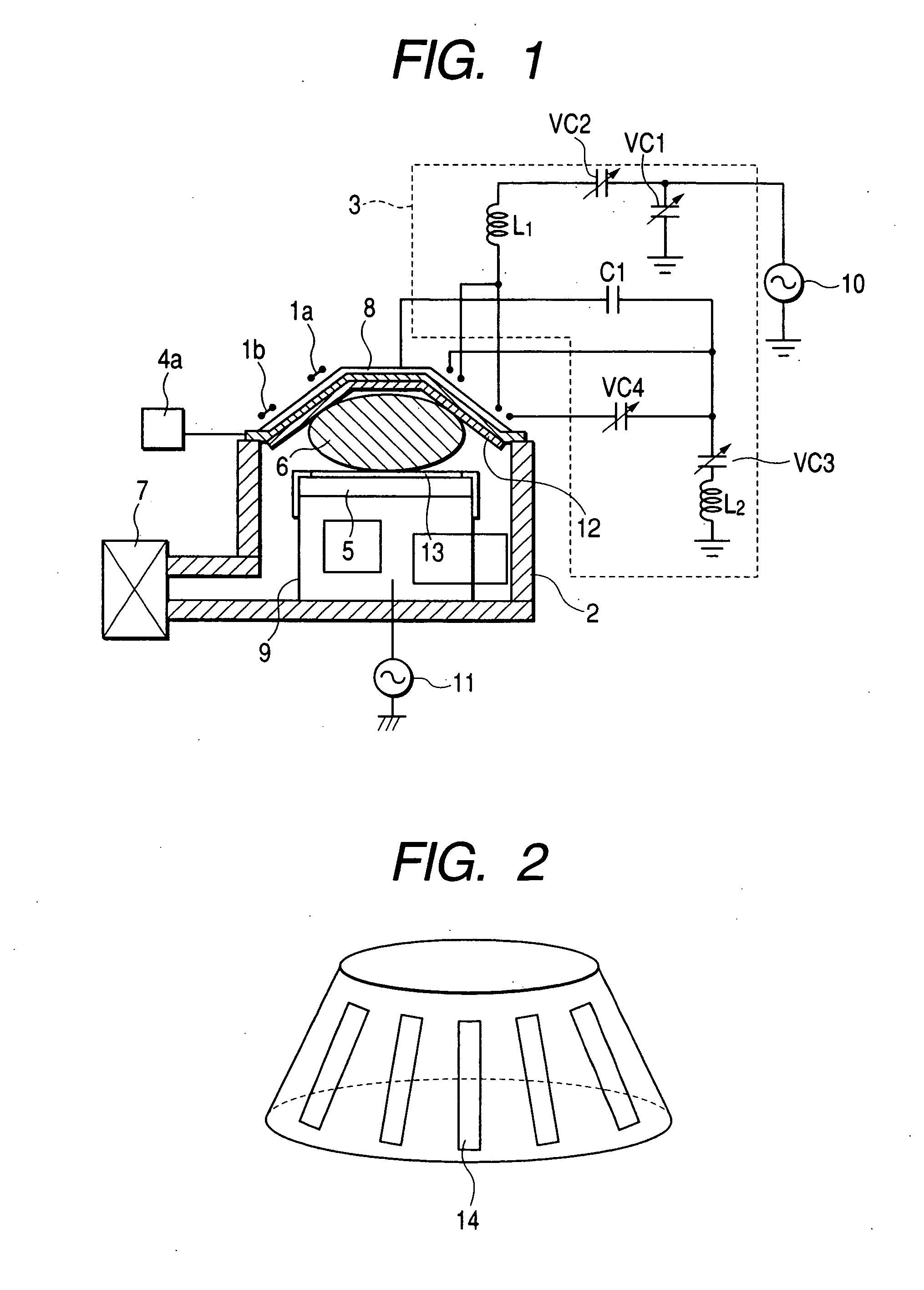

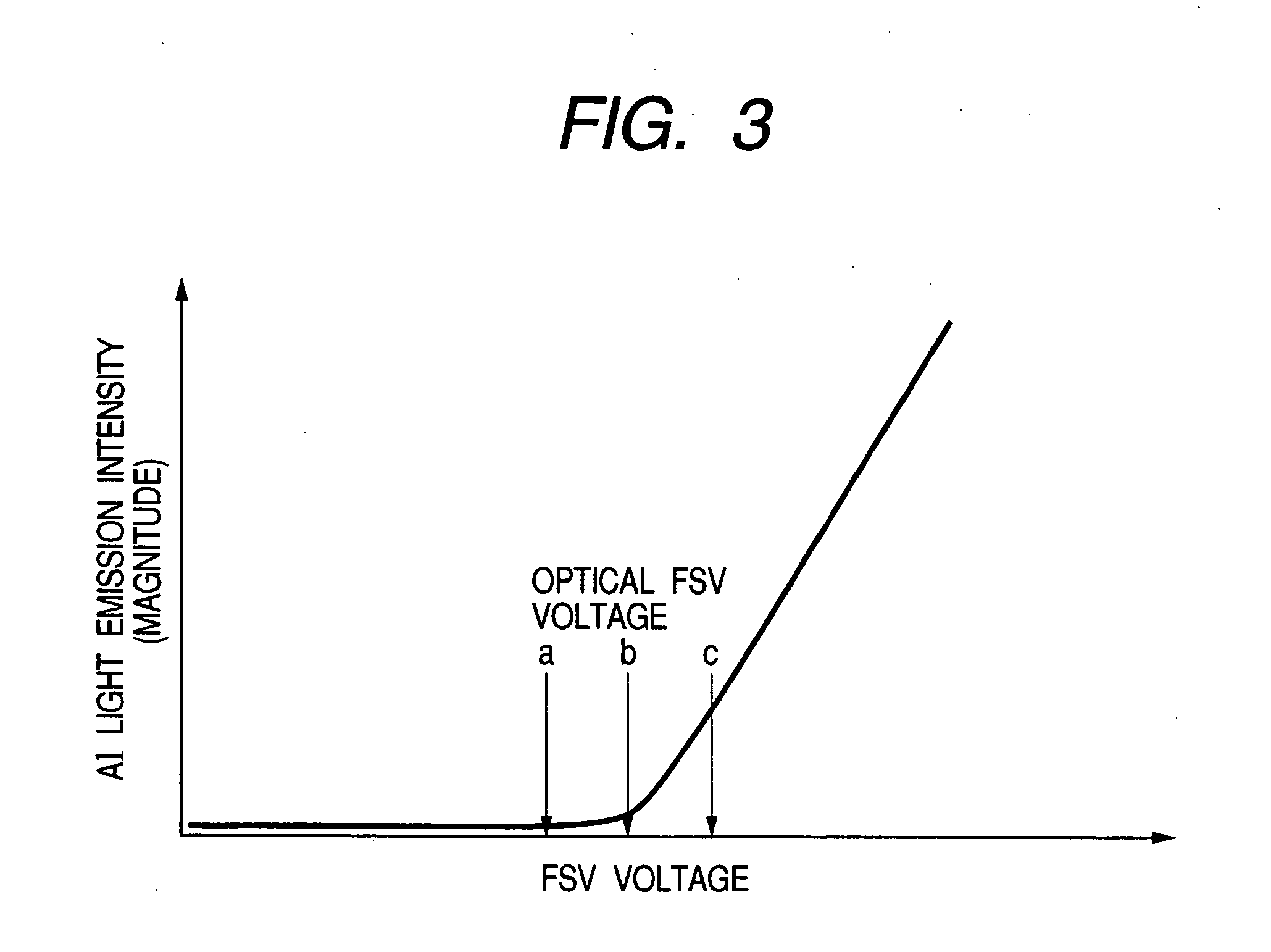

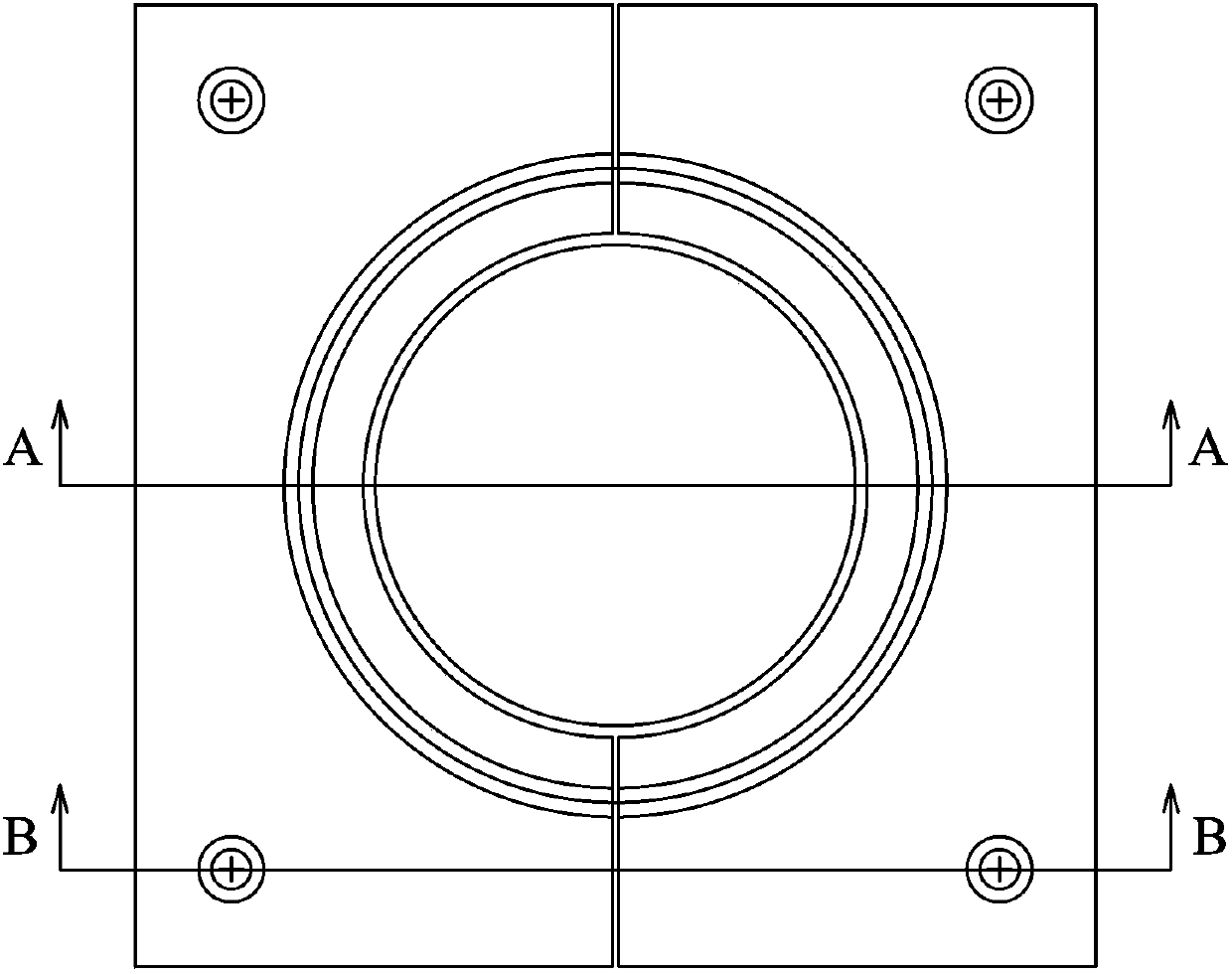

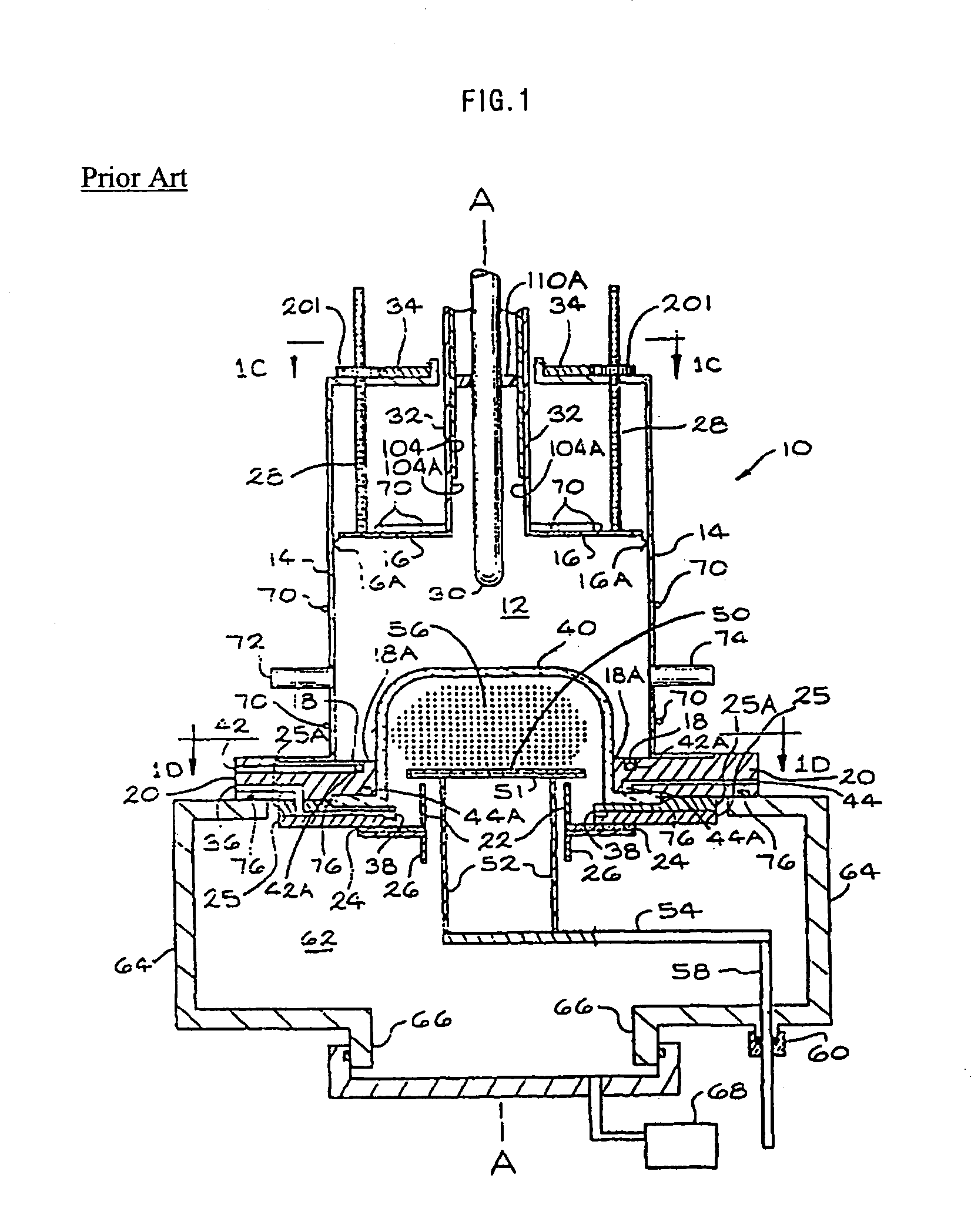

Plasma processing apparatus and method

ActiveUS20050087305A1Improve mass production stabilityElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorEngineering

A plasma processing apparatus includes a gas ring forming a portion of a vacuum processing chamber and having a blowing port for a processing gas, a bell jar to define a vacuum processing chamber, an antenna for supplying an RF electric field into the vacuum processing chamber to form plasmas, a sample table, a Faraday shield, and a deposition preventive plate attached detachably at least to the inner surface of the gas ring excluding the blowing port. An area of the inner surface of the gas ring including the deposition preventive plate that can be viewed from the sample surface is set to about ½ or more of the area of the sample. A susceptor made of a dielectric material covers the outer surface and the outer lateral side of the sample table. A metal film is disposed with respect to the susceptor, and an RF voltage is applied to the metal film.

Owner:HITACHI HIGH-TECH CORP

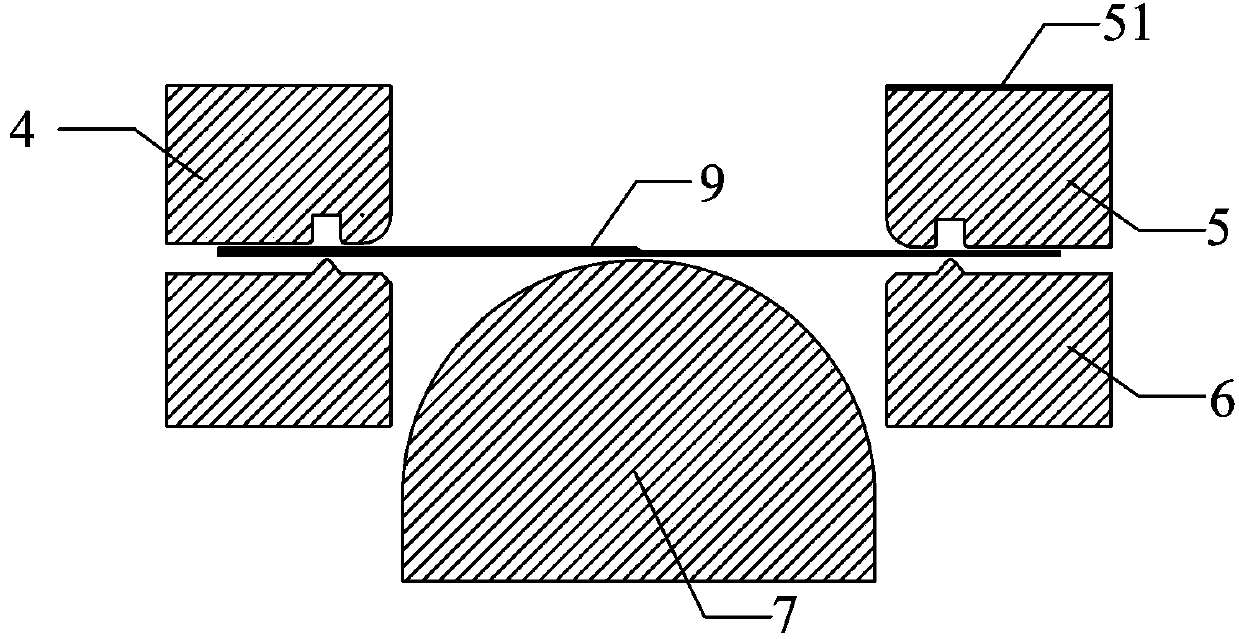

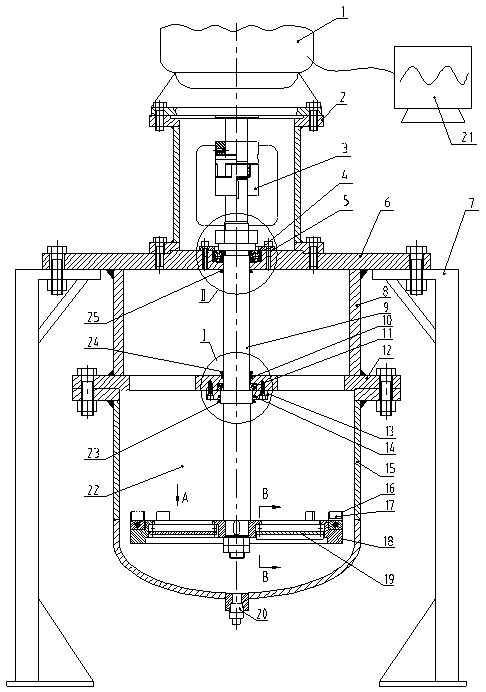

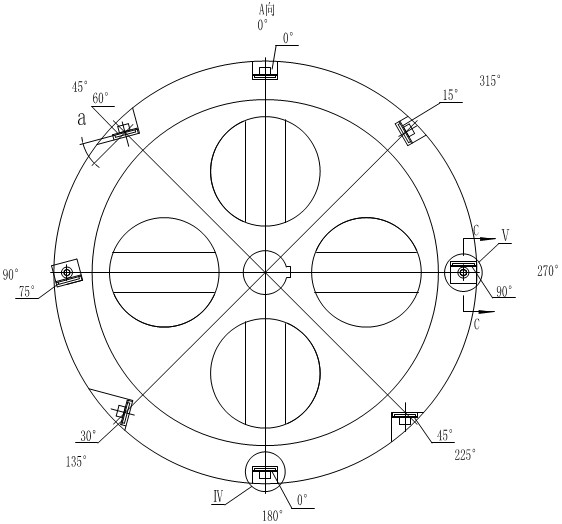

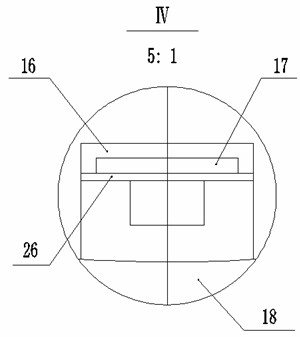

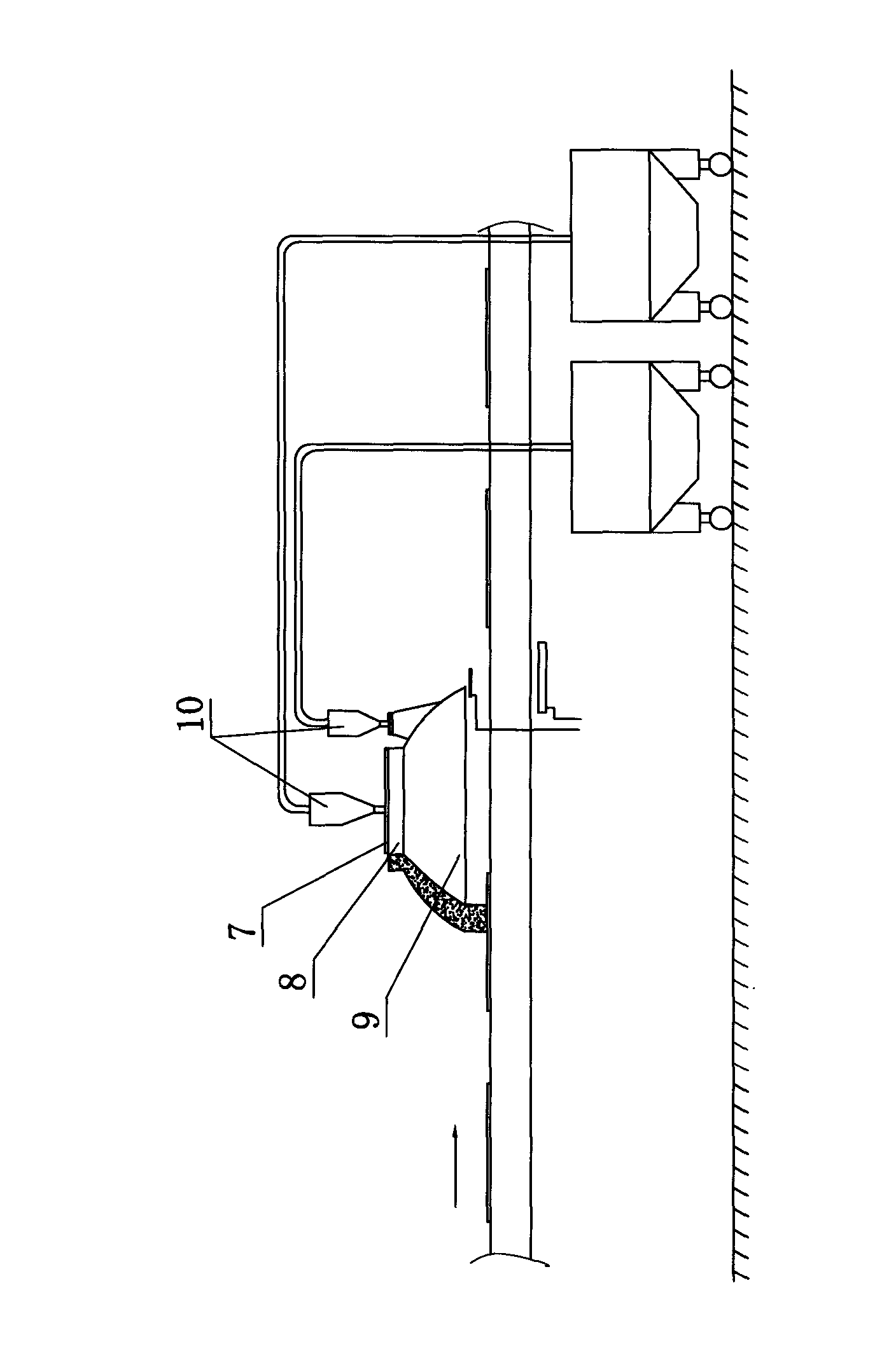

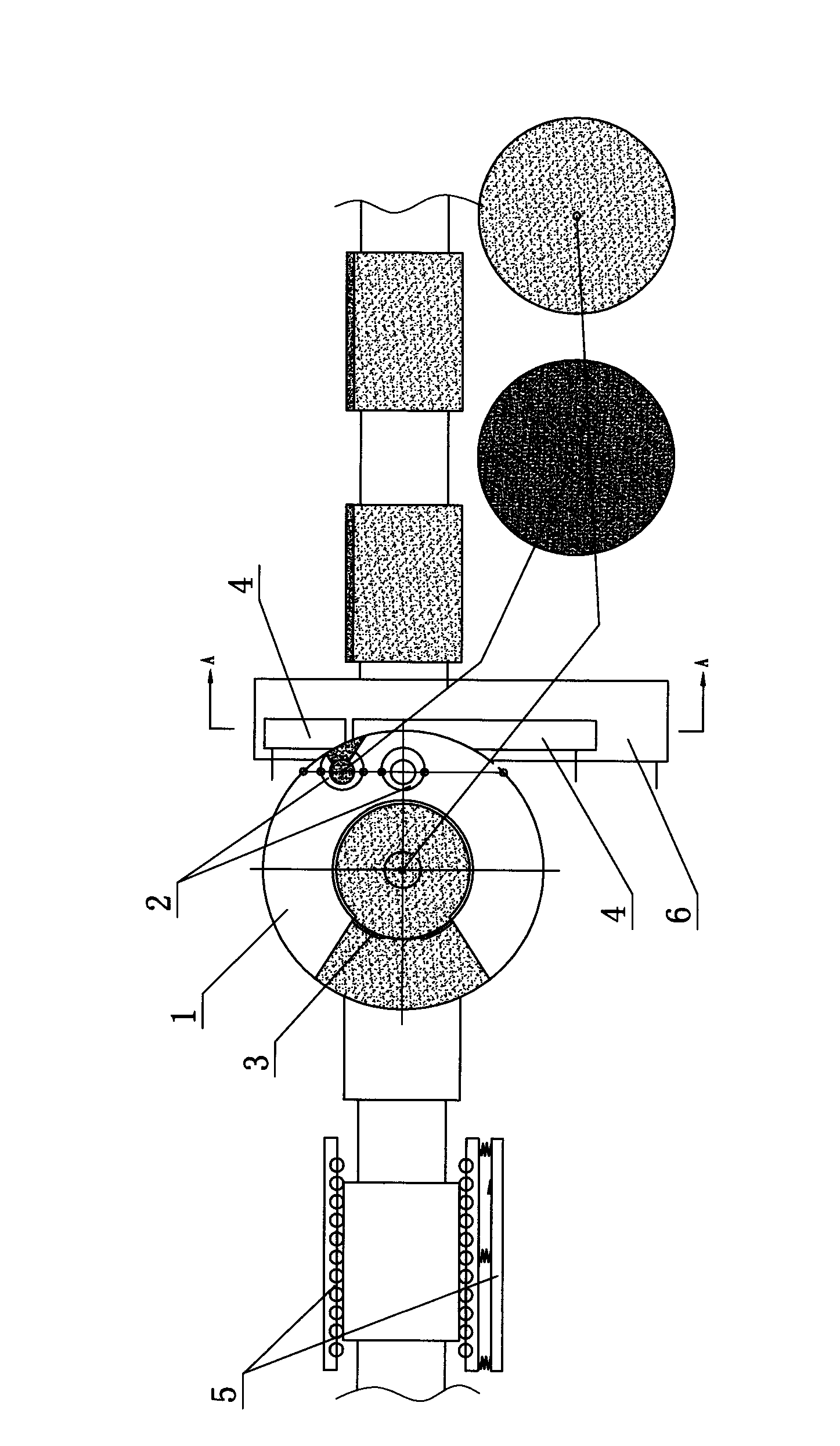

Experimental facility for measurement of hot forming limit of laser tailor-welded blank

InactiveCN103424315AEffective flow controlAccurately obtainedMaterial strength using tensile/compressive forcesTemperature controlTest sample

The invention discloses an experimental facility for the measurement of the hot forming limit of a laser tailor-welded blank. The experimental facility is characterized by comprising an upper mould base and a lower mould base; an accommodating space for accommodating a main body of the experimental facility is defined by the upper mould base and the lower mould base; the main body of the experimental facility comprises a heating and temperature-controlling bell jar placed on a supporting platform of the lower mould base, a spherical punch placed in the heating and temperature-controlling bell jar, a convex mould blank holder and a concave mould blank holder; the experimental facility further comprises a gas protection system communicated with the heating and temperature-controlling bell jar. The experimental facility has the advantages of effectively controlling the flow of the tailor-welded blank, providing a constant-temperature interior experimental environment, and performing on-line high temperature strain measurement and the like; through the test of the experimental facility, the test sample, which is used for establishing a hot forming limit map, of the laser tailor-welded blank can be obtained accurately under different high temperature conditions, so that the hot forming limit map of the laser tailor-welded blank is established.

Owner:DALIAN UNIV OF TECH

Magnesium-lithium alloy and manufacture method thereof

The invention discloses an Mg-Li alloy and preparing method, which comprises the following steps: adopting 1-5wt% Al, 0.6-1.4wt% Zn, 1-10wt% Li, not more than 0.010wt% Fe and less than 0.001wt% Ni as raw material, adding LiCl / LiF covering agent in the manganese steel copple furnace; heating to 400-650 deg.c; adding pure magnesium; adding other alloys except Li at 690-730 deg.c; pressing pure Li cladded by aluminium foil in the fuse through bell jar under 660-720 deg.c; stirring; stewing for 10-20min; casting under 680-730 deg.c; obtaining the cast ingot.

Owner:苏州有色金属研究院有限公司

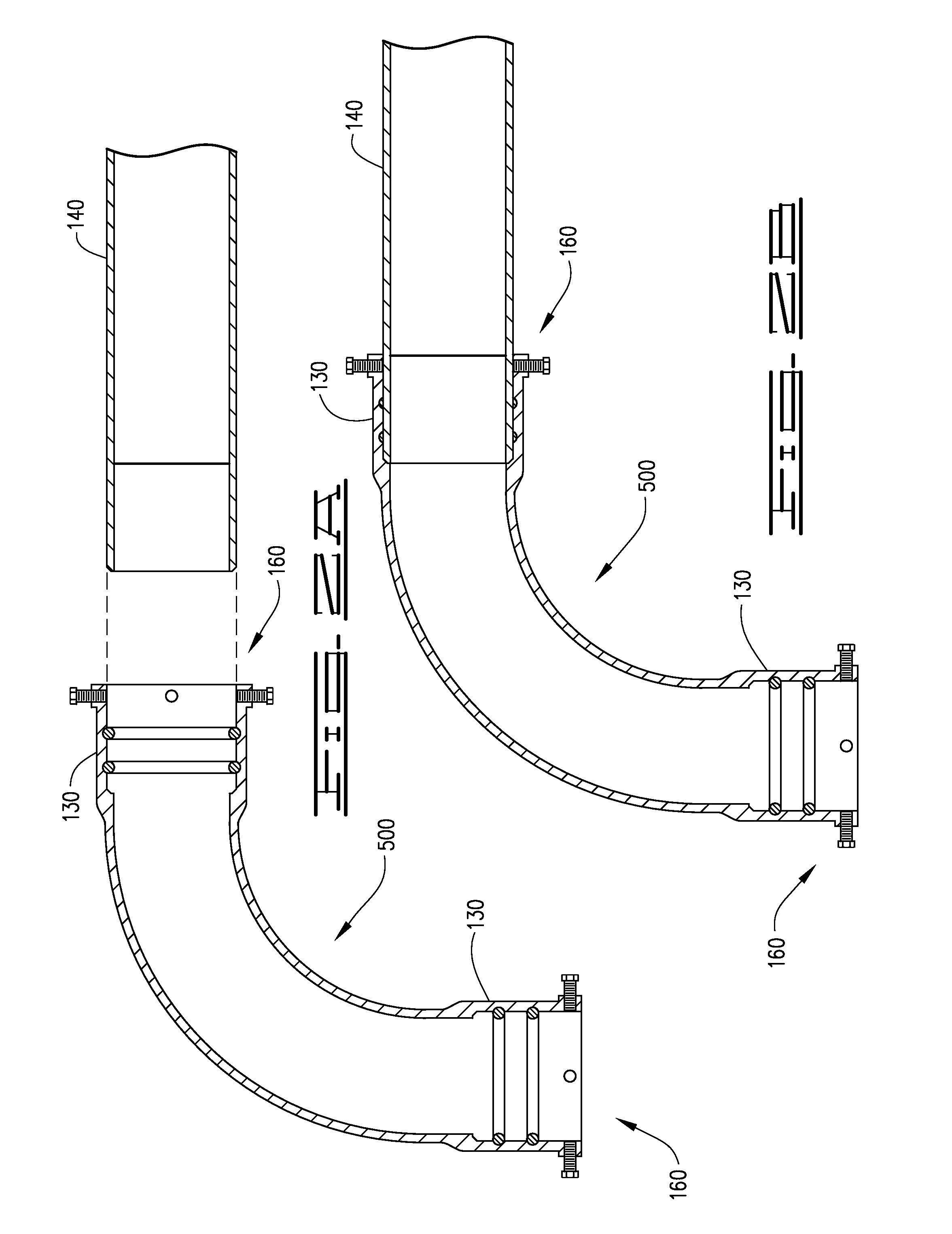

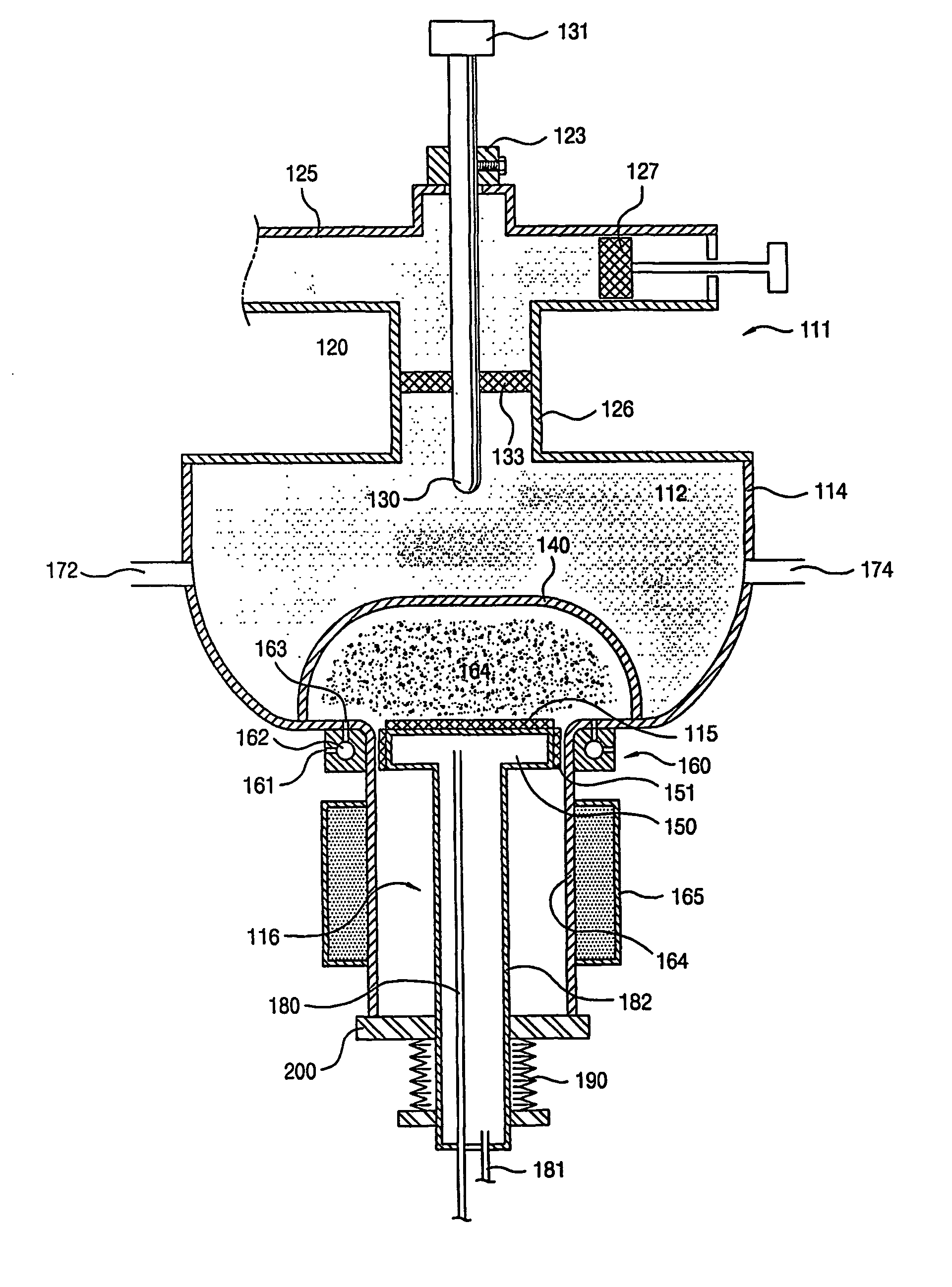

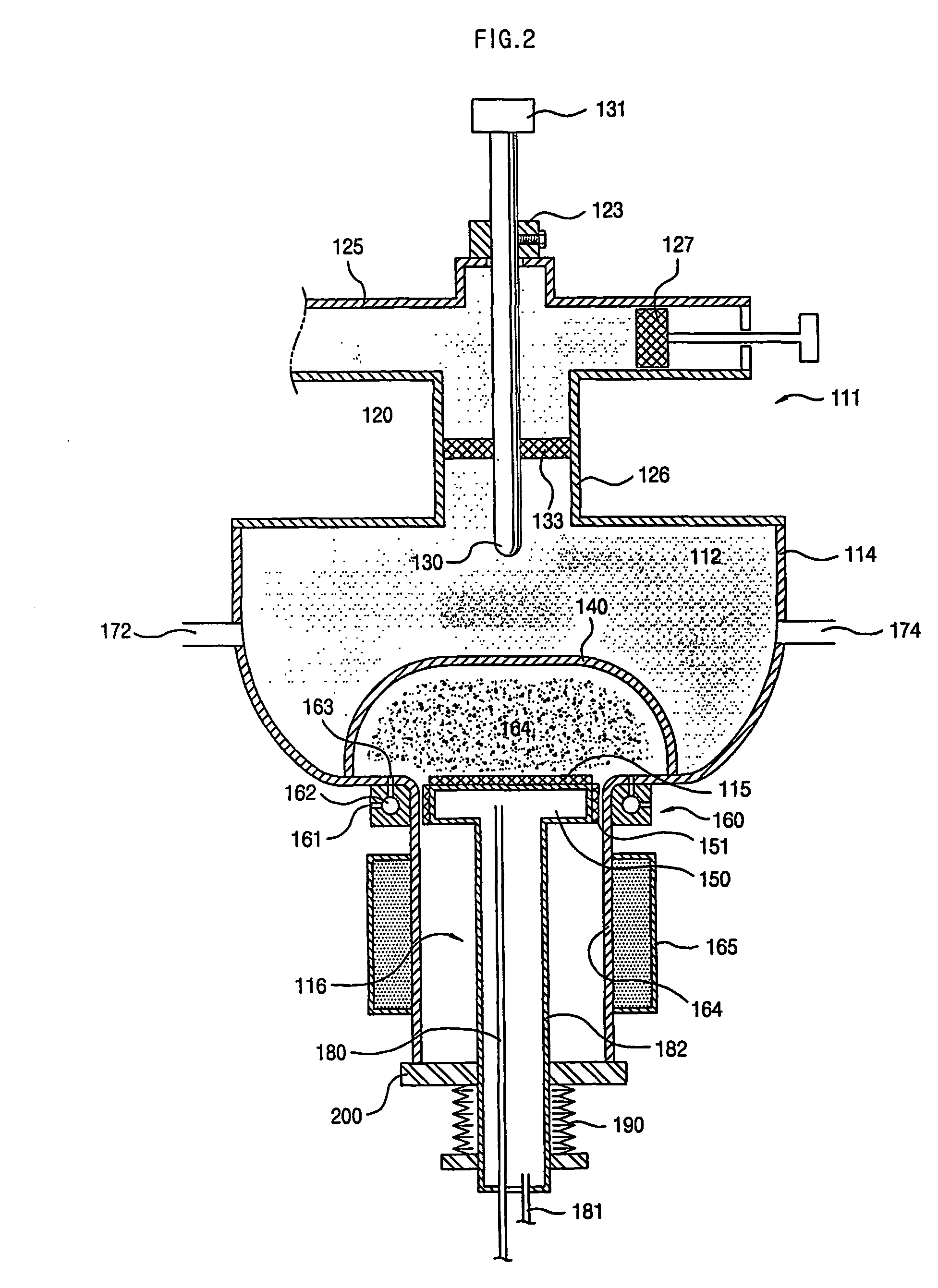

Diamond film depositing apparatus using microwaves and plasma

InactiveUS7171919B2Improve concentrationElectric discharge tubesElectric arc lampsMicrowave cavityEngineering

Disclosed herewith is a diamond film depositing apparatus using microwaves and plasma. The apparatus comprises a rectangular wave guide (125), a mode transition coupler (120), an antenna rod (130), a quartz bell jar (140), a workpiece holder (116), a microwave cavity resonator (112), a source gas inflow ring (160), a mechanical support cylinder (164), a cooling jacket (165), gas inflow and outflow conduits (172 and 174) and a vacuum seal (190). The microwave cavity resonator (112) has a cylindrical shape the diameter of which is decreased in a downward direction. The microwave cavity resonator (112) may have a hemispherical shape, the flat surface of which is oriented upward.

Owner:SOHN HEE SIK

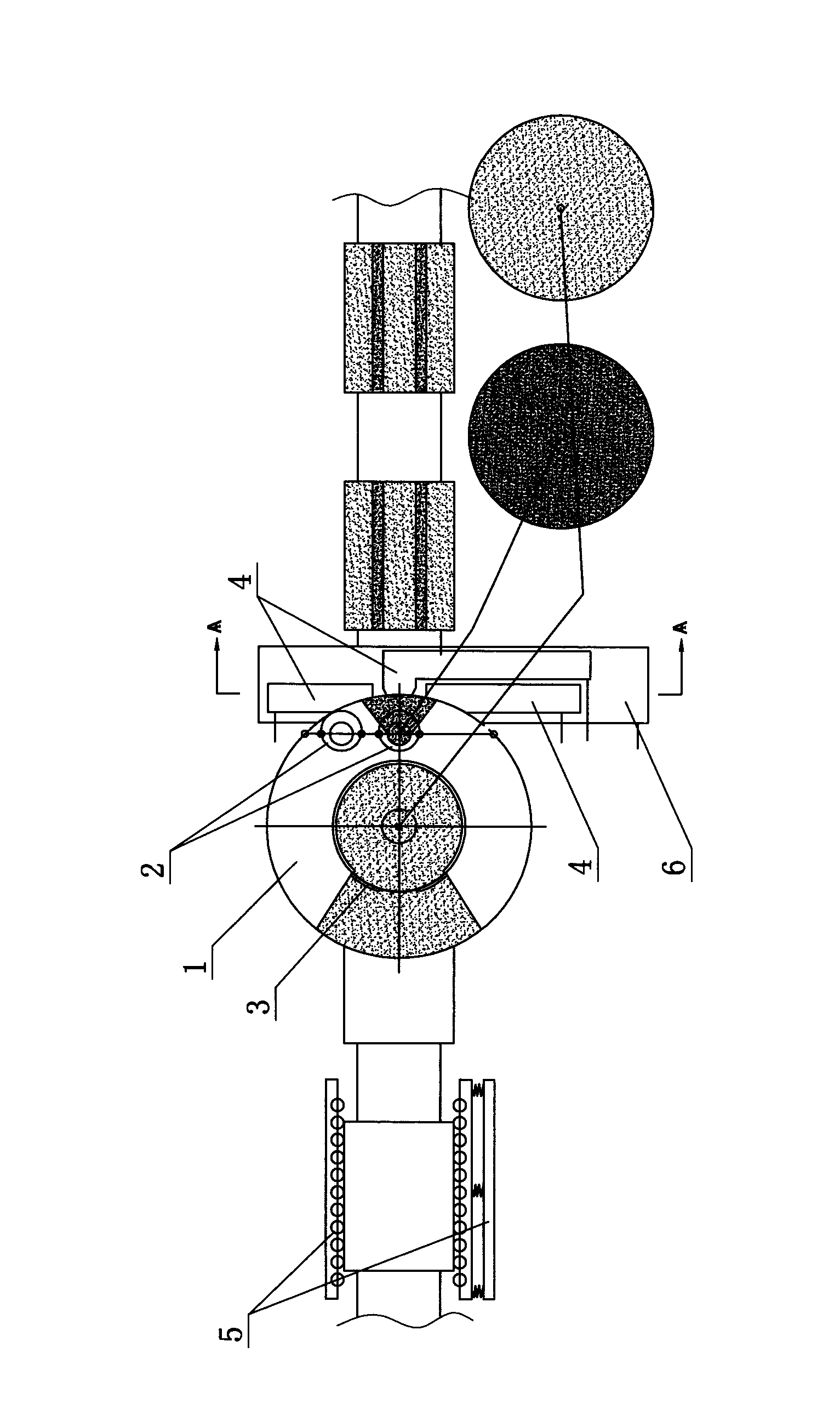

Rotary type liquid-solid two-phase flow erosive wear test device

InactiveCN102564934ASimple designSimple structureWeighing by removing componentWeather/light/corrosion resistancePipe fittingCoupling

The invention discloses a rotary type liquid-solid two-phase flow erosive wear test device. A variable frequency motor is arranged at the upper end of a bell-shaped cover; a stirring shaft passes through an upper installation plate and a lower installation plate from bottom to top and is connected with a shaft head of the variable frequency motor through a coupler; the tail end of the stirring shaft passes through a rotary table; eight test pieces are uniformly arranged in eight opened grooves which are arranged at the edge of the rotary table at intervals; the upper installation plate and the lower installation plate are welded by a coupling sleeve; a slurry tank filled with a fluid medium is connected and fixed with the lower installation plate; and stirring blades are uniformly distributed and fixed inside the rotary table in a manner of forming a 15-degree angle with the horizontal plane. The test device can realize testing to the erosive wear characteristic of different materialsby utilizing the characteristic that the variable frequency motor generates different rotation speeds so as to obtain the functional relations between the erosive wear rate and the variables such as material characteristics, rotation speeds and impact angles, therefore the test device can provide important data support for erosive wear prediction of engineering actual pipelines and is applicable to research on safety guarantee technologies such as erosive wear predication and optimal design of pipe fittings such as multiple-phase flow pipelines and valves in the fields of petrochemical industry and coal chemical industry.

Owner:HANGZHOU FURUDE TECH

Graphene-containing lead alloy for lead storage battery grids, and preparation method thereof

ActiveCN104993154AReduce corrosionHigh mechanical strengthElectrode carriers/collectorsCharge and dischargeCorrosion

The invention discloses a graphene-containing lead alloy for lead storage battery grids. The graphene-containing lead alloy includes 0.015-0.15% of graphene, 1.0-1.5% of tin, 0.02-0.04% of aluminum, 0.05-0.1% of calcium and 98.21-98.915% of lead. A preparation method of the graphene-containing lead alloy comprises the following steps: putting 2 / 3 of lead in a lead melting pot, and heating to 680DEG C in order to melt lead; adding graphene to molten lead; adding pure tin strips and pure aluminum strips 20min later, and stirring and mixing for above 0.5h; adding lead sheath packaged calcium, pressing calcium into the bottom of the molten lead by using a bell jar with the bottom provided with leakage holes, slowly stirring and mixing for above 0.5h when the molten lead does not bubble, adding the residual lead into the lead melting pot, continuously stirring after the lead is completely molten, and carrying out ingot casting 1h later. The preparation method has the advantages of simplicity, reliability, simple structure of a used device, and low cost; and the grids made by using the lead alloy prepared through the method have strong creep and corrosion resistance, and can meet deep cycle and heavy current charge and discharge requirements.

Owner:SINO INNOV SEMICON (PKU) CO LTD

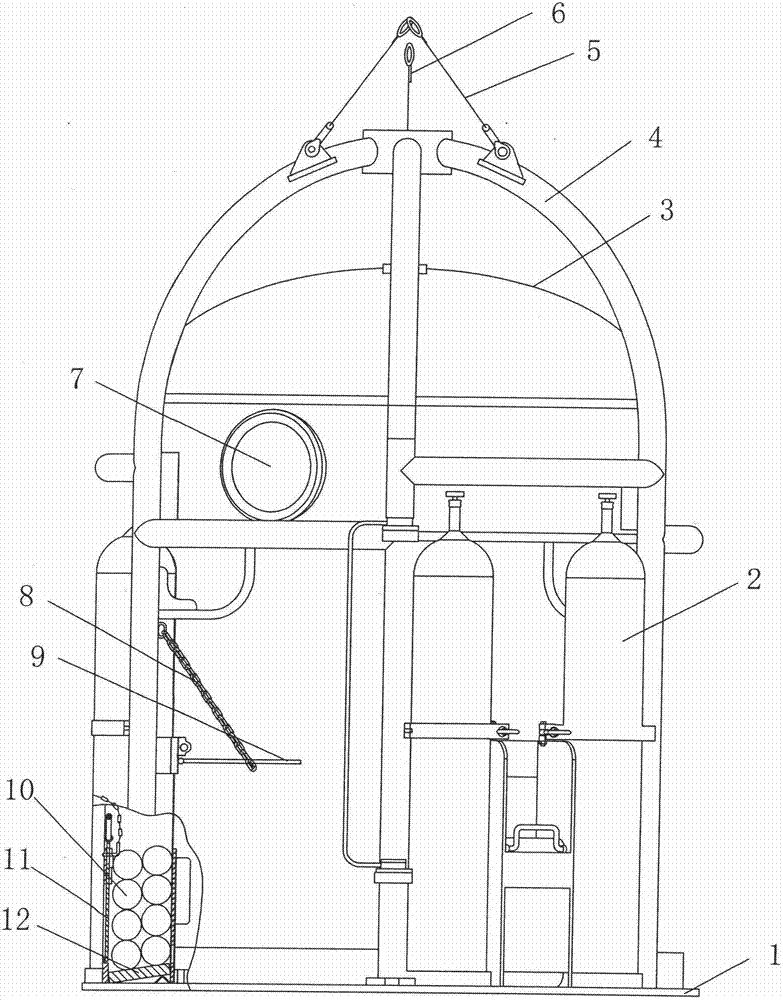

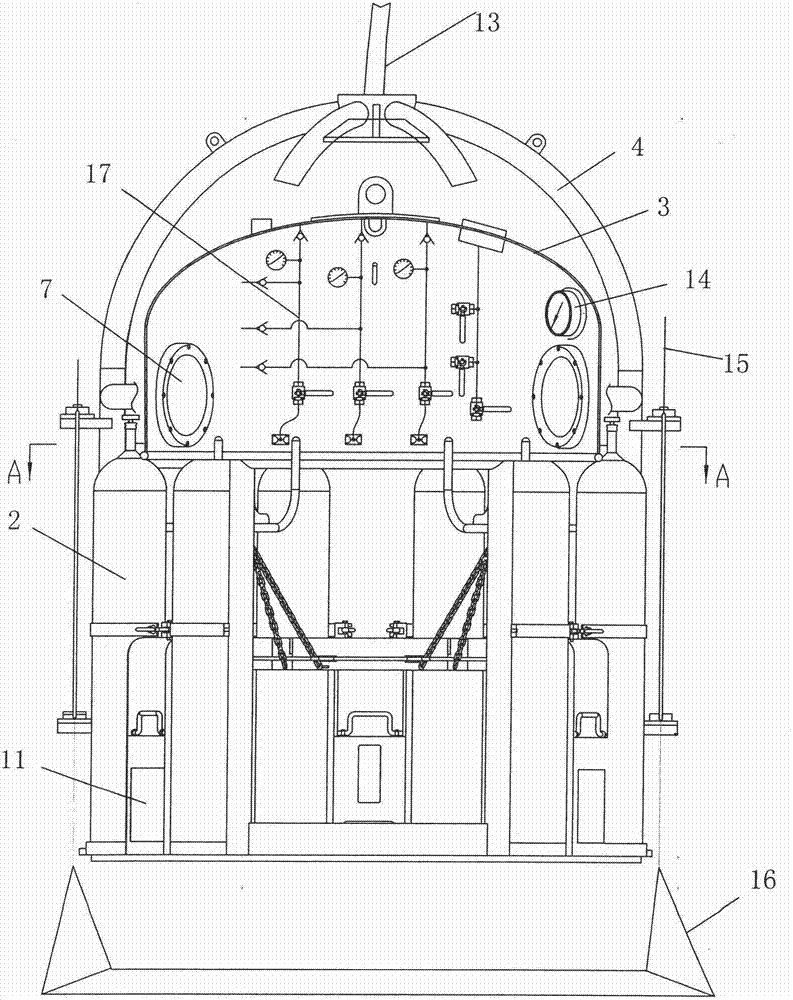

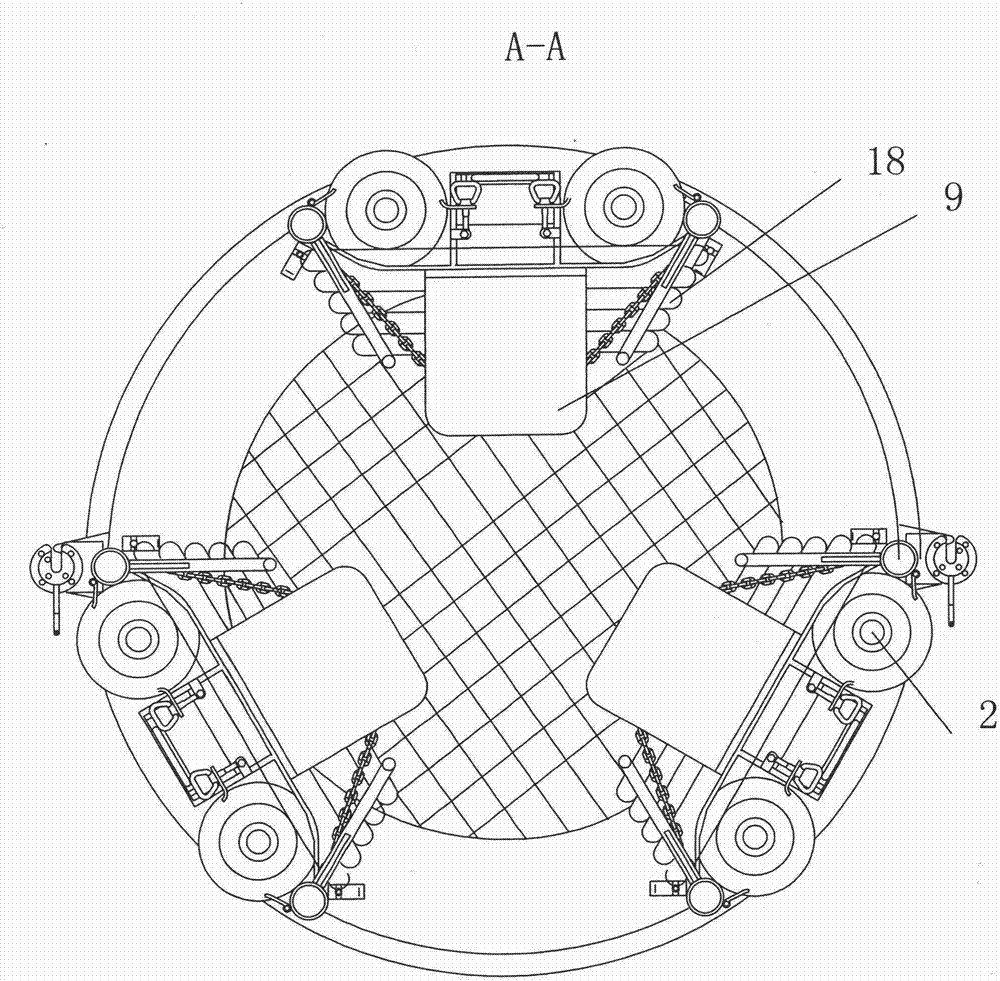

Deepwater open diving bell and self-rescuing method thereof

The invention discloses a deepwater open diving bell and a self-rescuing method thereof. The deepwater open diving bell comprises a platform and is characterized in that a bell jar is hung above the platform, a space between the top of the bell jar and the platform is adaptive to the height of a human body, a main belly belt is connected to the top of the bell jar, a basic surviving device is arranged in the bell jar, viewing windows capable of viewing situations outside the bell are formed in the side wall of the bell jar, and a guiding weight is arranged at the lower part of the platform. Due to the adoption of the technical scheme of the deepwater open diving bell and the self-rescuing method thereof, the 120 meters of diving depth of the diving bell is realized, the simultaneous diving of three users is satisfied, and the working efficiency of diving operation is improved.

Owner:上海打捞局芜湖潜水装备厂有限公司

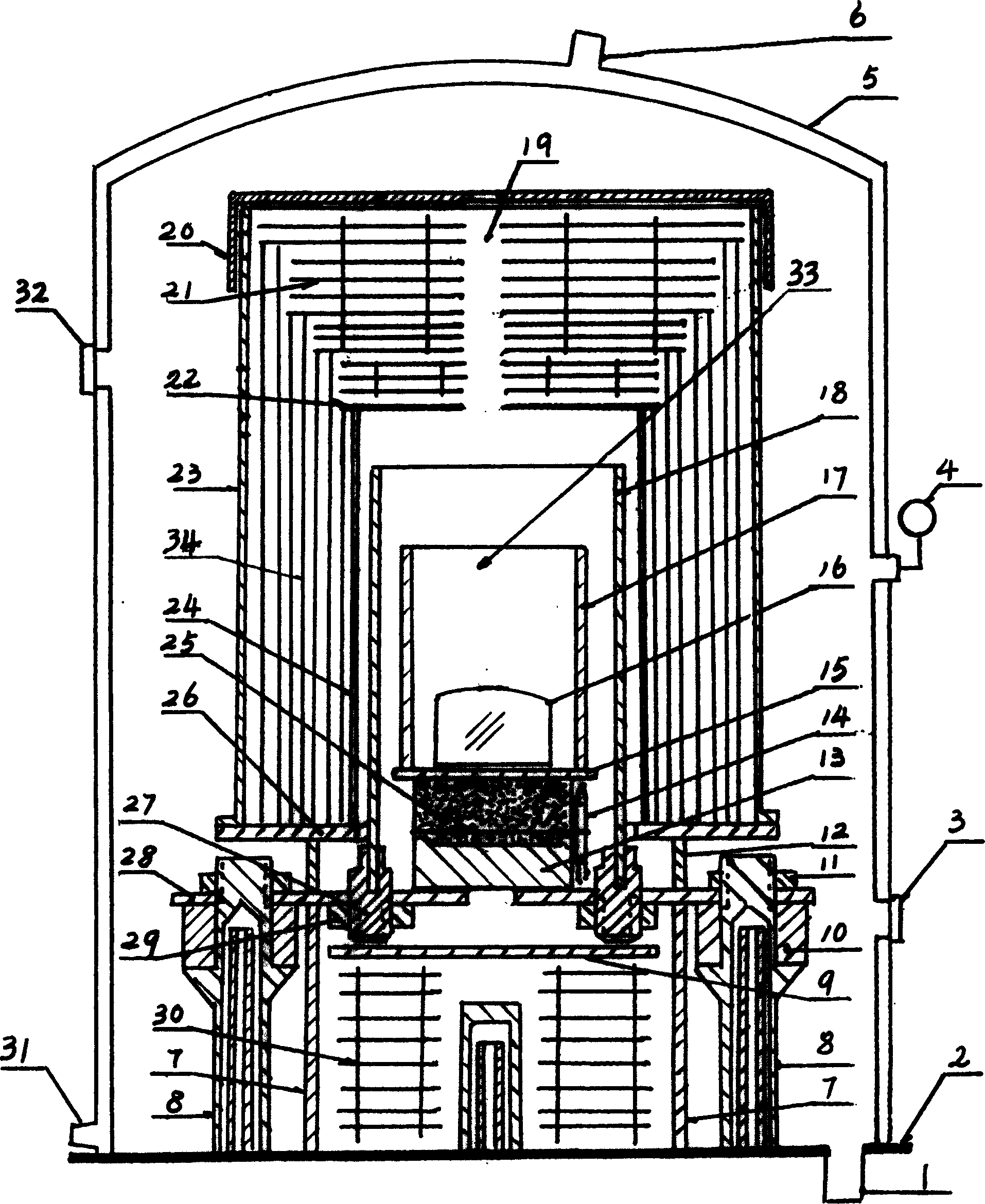

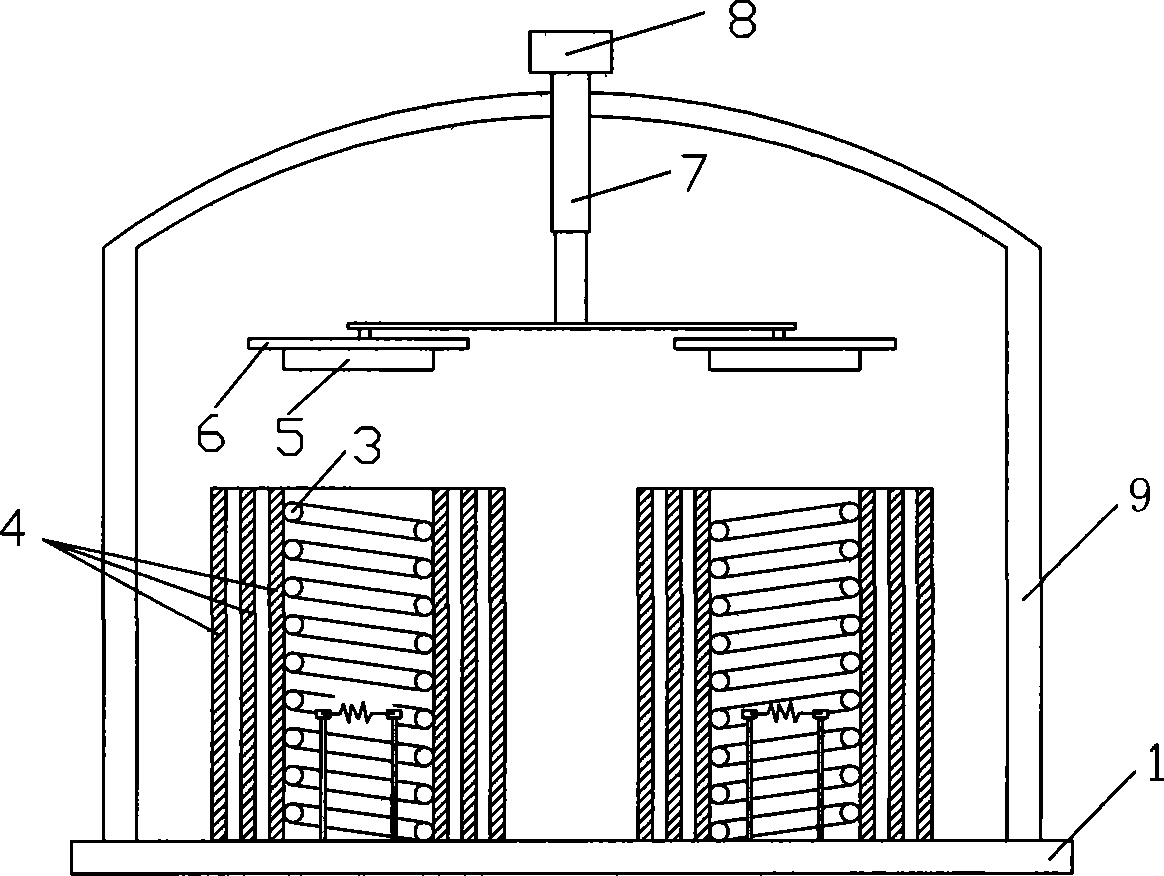

Apparatus for annealing of crystal with high temp. resistance

InactiveCN1560334AUniform temperatureStable temperature fieldAfter-treatment detailsInlet valveElectrode Contact

The invention is a high temperature-resistant crystal annealing device, including a bell-jar, arranged on an underframe with vacuum vent, hermetically contacting with the underframe through vacuum seal ring, and provided with water inlet and outlet as well as air pressure meter, there is a heat-preserving screening device containing side screening tube and top and bottom heat baffles, arranged in the bell-jar body, there are air-inlet valve and air-outlet valve arranged on the bell-jar body; a heating body arranged in the innermost layer and on tow sides of the side screening tube is made of Wu bar and fastened on a Mo electrode plate through electrode contact; the Mo electrode plate is supported by corundum insulating ring bracket, where the two ends of the Mo electrode plate are both fastened on a water-cooled electrode plate; a space encircled by the heating body above the Mo electrode plate is provided with a crystal annealing room; there is a heat-insulating plate arranged inside the corundum insulating ring bracket under the Mo electrode plate. The invention can increase the factor of merit (FOM) value of high-doped Ti:sapphire laser crystal by a large margin and improve optical quality of high-temperature oxide crystal.

Owner:周永宗

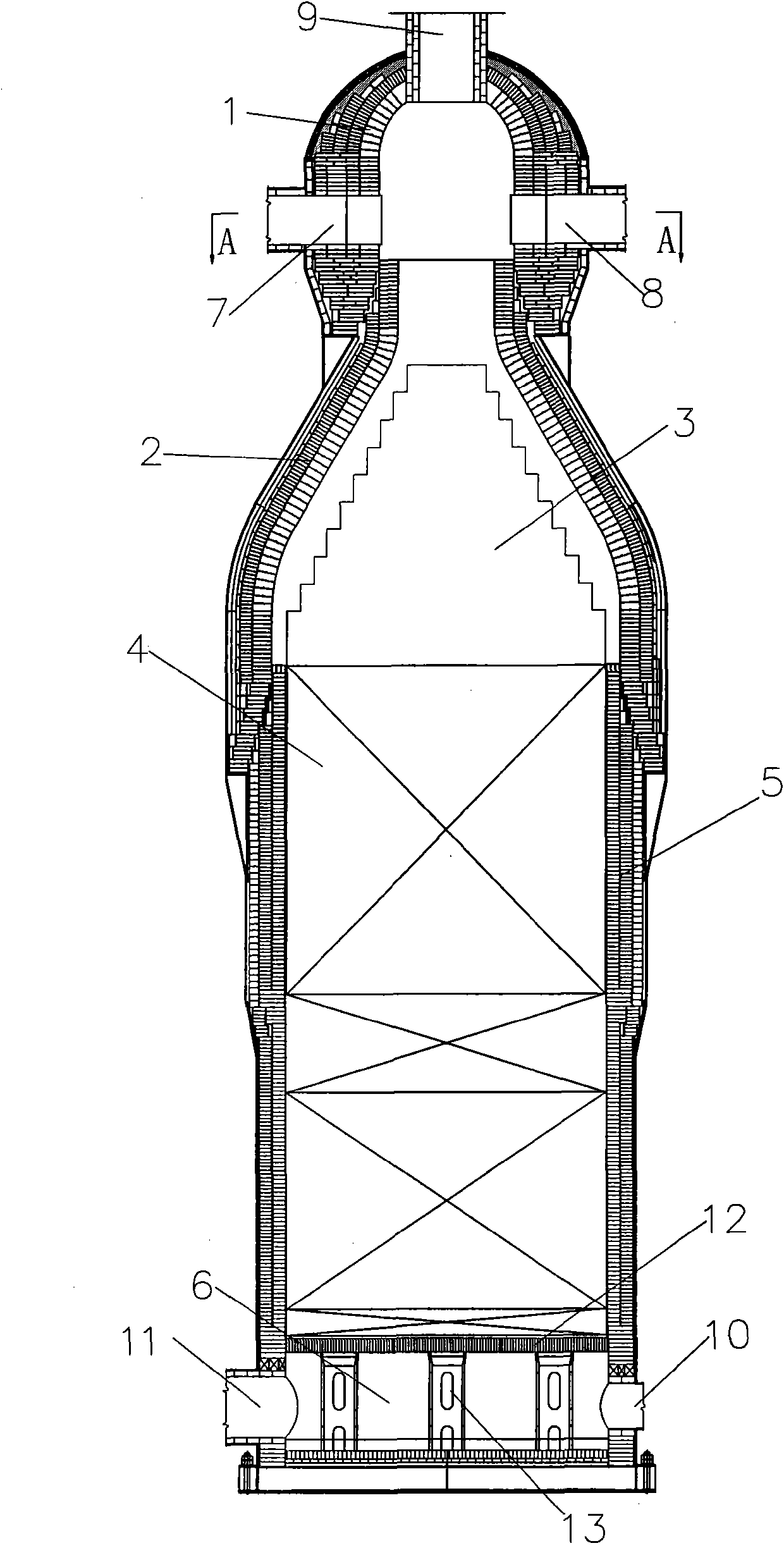

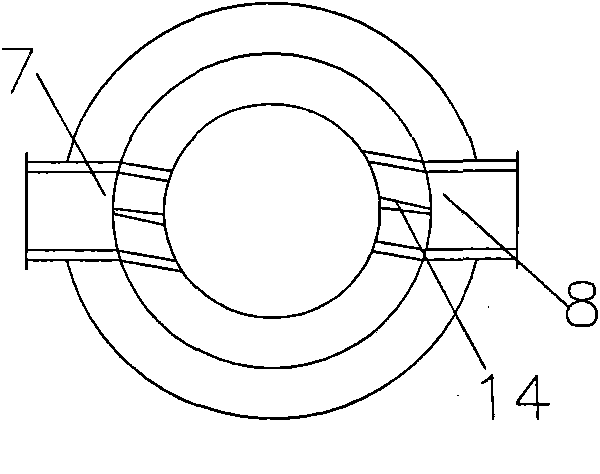

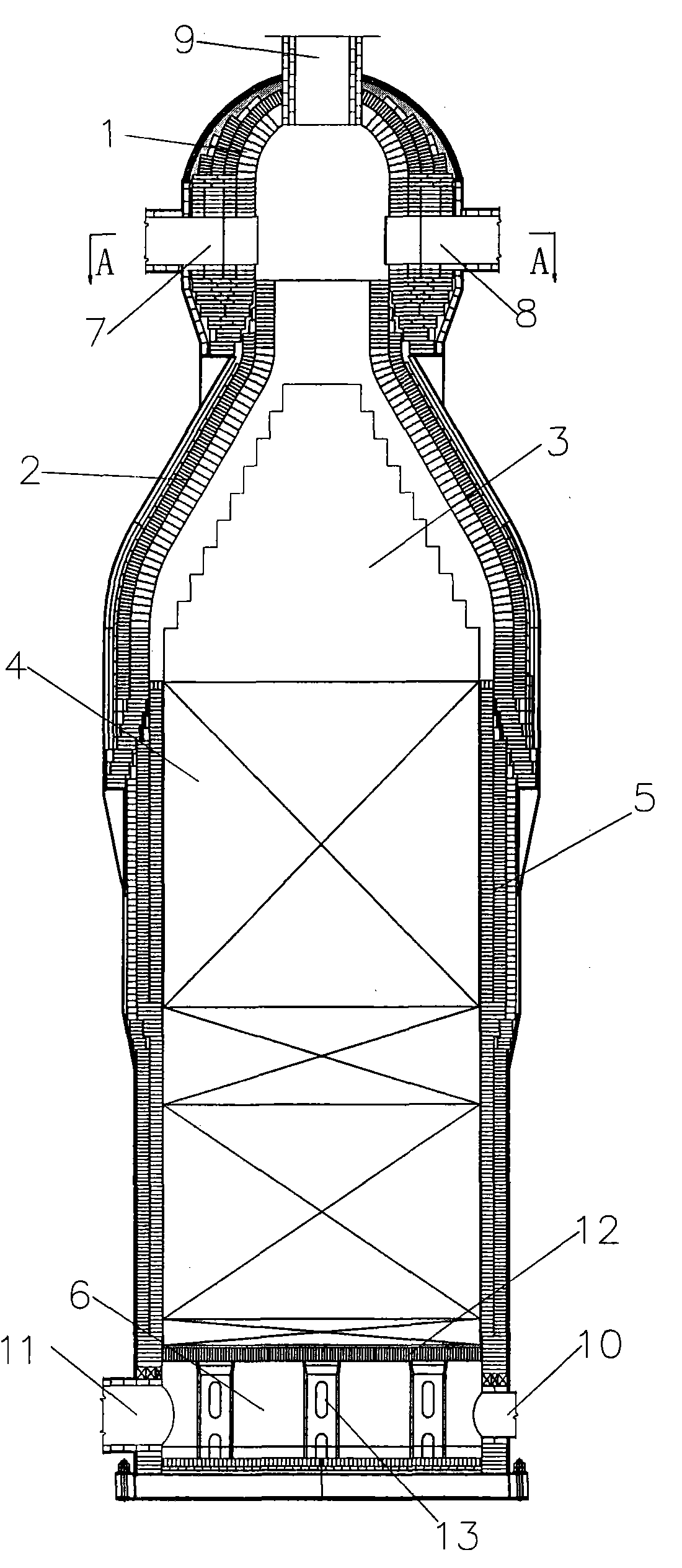

High-blast-temperature hot-blast stove burnt in convection swirling heat storage medium

InactiveCN101906496AFix stability issuesSolve the strength problemBrick-hot blast stovesCombustion chamberBrick

The invention relates to a high-blast-temperature hot-blast stove burnt in a convection swirling heat storage medium, effectively solving the problems of complicated structure, non-uniform gas mixing, insufficient burning, environmental pollution and energy waste. The stove adopts the structure that a pre-burning chamber of a bell jar on the top of a ball and a taper-section barrel-shaped burning chamber below the pre-burning chamber are connected by using a labyrinth without stress action; the taper-section burning chamber is sufficiently filled with porous heat storage bodies; a coal gas inlet pipe and an air inlet pipe are distributed on the vertical wall of the pre-burning chamber; a barrel-shaped heat storage chamber is arranged below the burning chamber, and checker brick heat storage bodies are stacked on grates in the heat storage chamber; a cold air chamber is arranged below the heat storage chamber, and a smoke exhaust pipe and a cold air inlet pipe are connected to the wall; the grates for holding the heat storage bodies are mutually spaced with expansion gaps, put on a beam and supported by grate supporting posts; the supporting posts are fixed on a rigid base of the hot-blast furnace; and a central vault line of the pre-burning chamber is provided with a hot-blast outlet pipe coaxial with the hot-blast furnace. The invention has the advantages of simple structure, high mixed burning intensity, good air flow heat exchange effect and raised hot-blast temperature.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Short-process high-performance oxygen-free copper strip production method

InactiveCN105729064AReduce dosageOptimize process flowMetal rolling arrangementsSurface cleaningShielding gas

The invention discloses a short-process high-performance oxygen-free copper strip production method which comprises the following steps: blank withdrawing during horizontal continuous casting; double-sided milling, reversible copper strip roughing and intermediate milling; primary trimming by thick strip slitting shears; primary annealing by a bell-jar bright annealing furnace; surface cleaning by a thick strip degrease cleaning line; finish rolling by a four-roll reversible finishing mill; secondary annealing of the finished product by the bell-jar bright annealing furnace; surface cleaning by a thin strip degrease cleaning line; and post-processing. The method provided by the invention has the advantages that through optimization of the technological process as well as the processing sequence of the rough rolling and finish rolling procedures, the processing flow is simplified, the production efficiency is improved and the process period is shortened; and through optimization of the annealing temperature, the heat preservation period and the shielding gas flow rate, the product performance is improved.

Owner:ZHONGTIAN ALLOY TECH

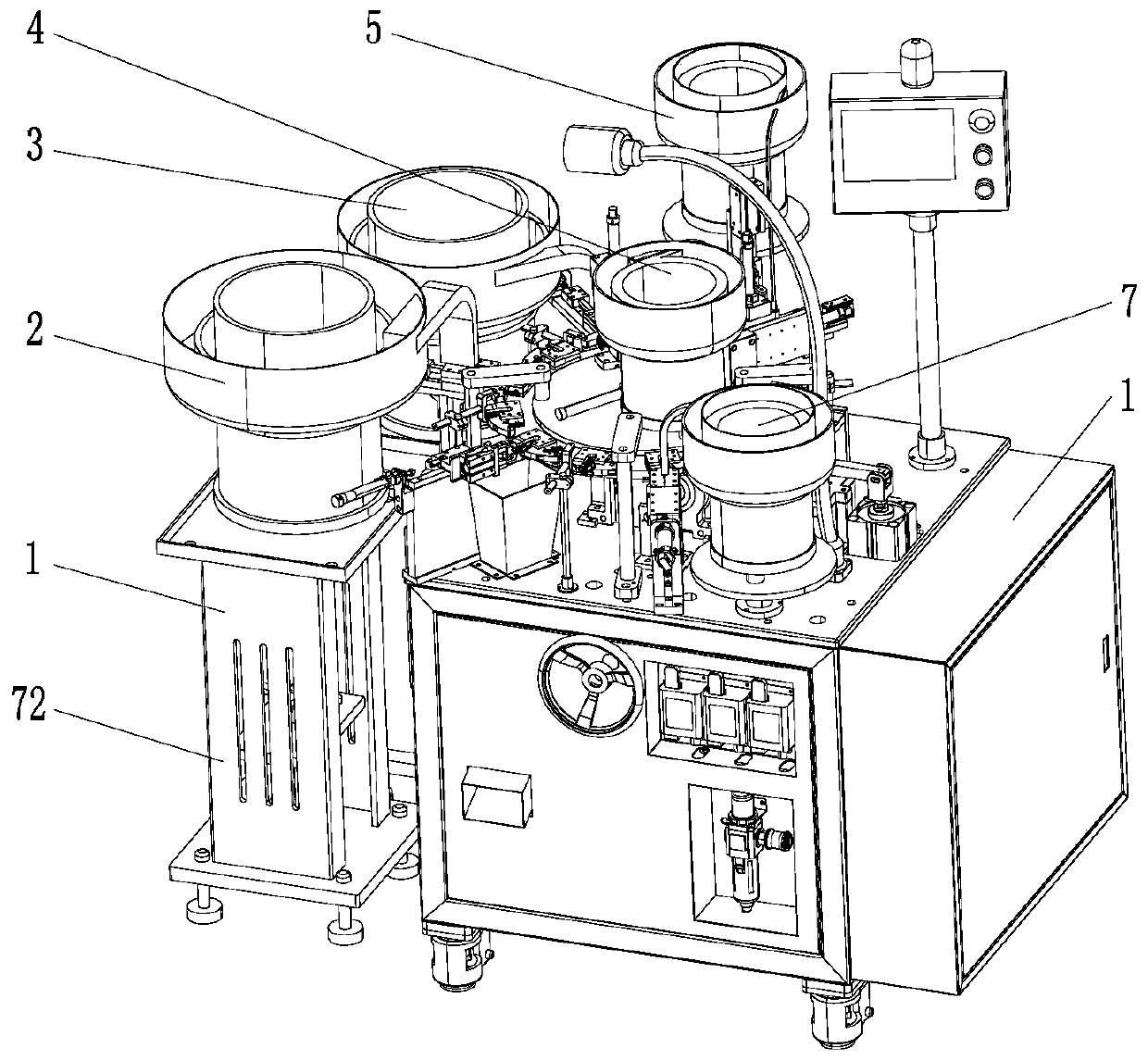

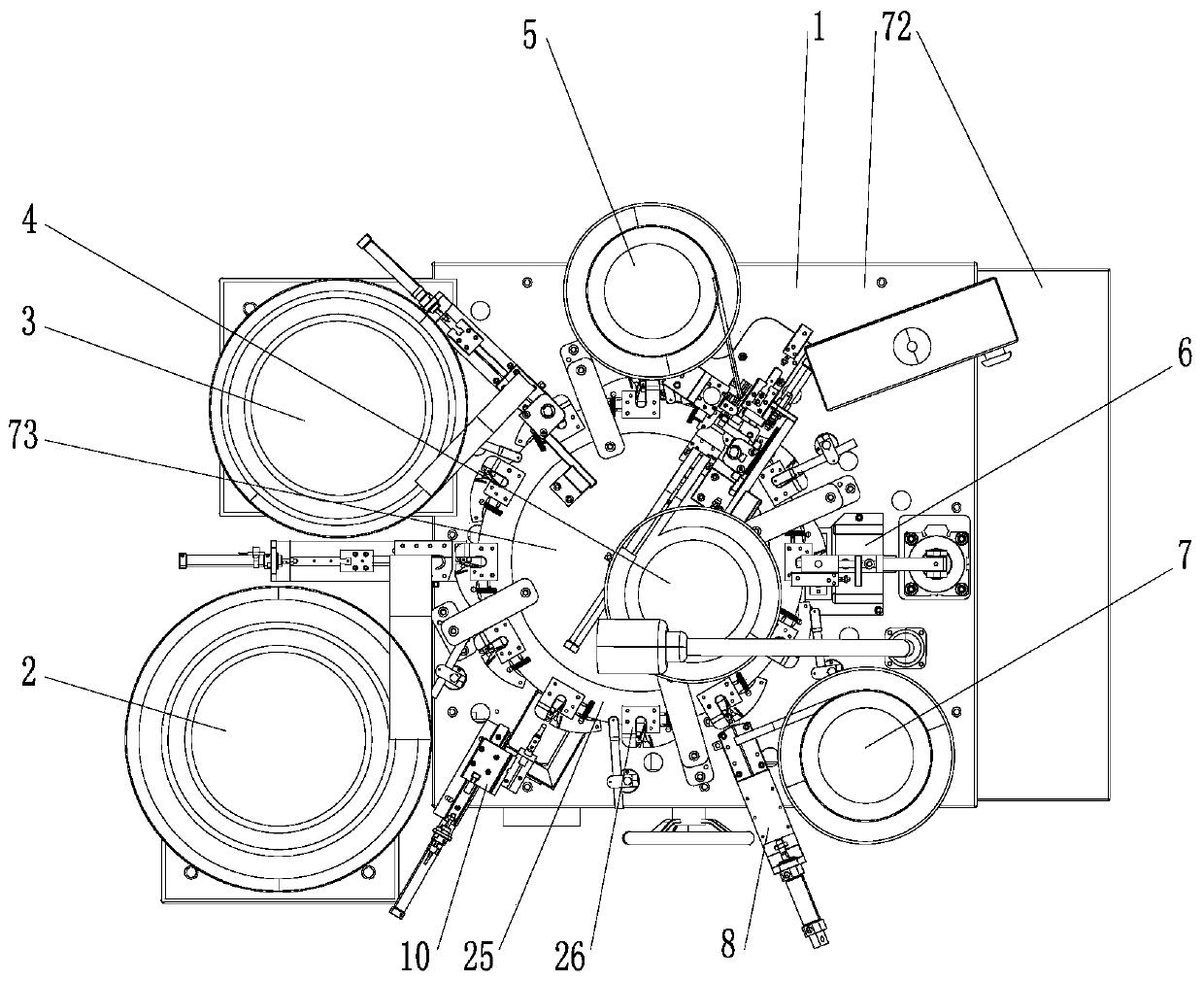

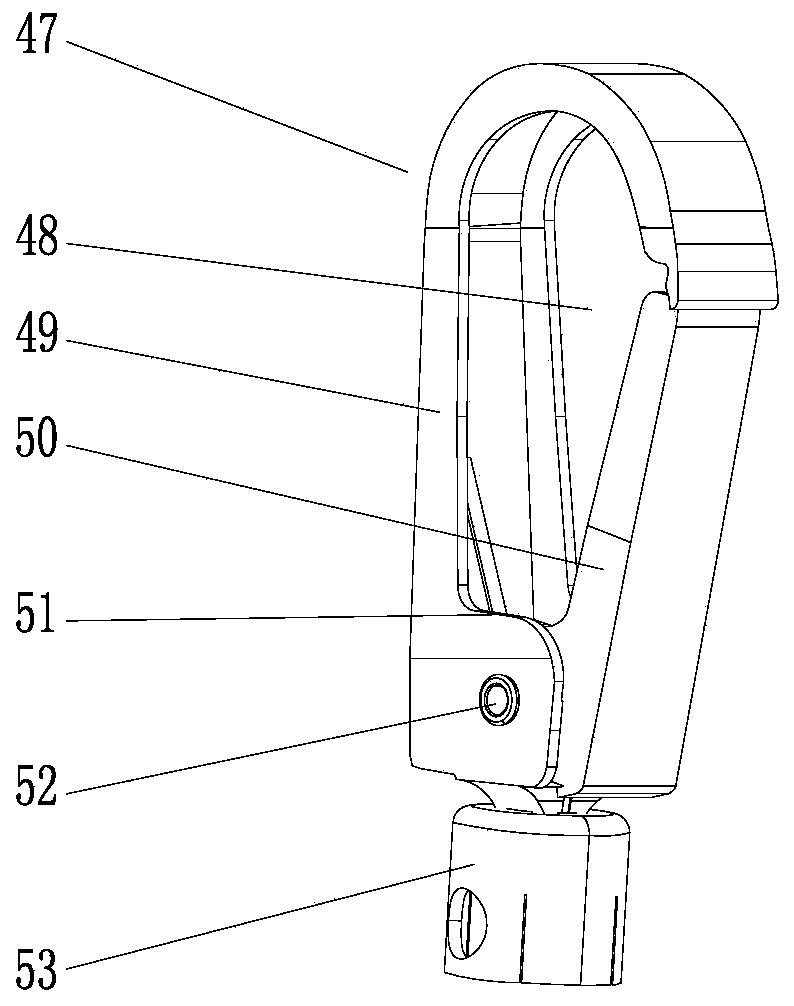

Automatic fastener assembling equipment

ActiveCN111558827AImprove assembly efficiencyStable product qualityAssembly machinesEngineeringBell jar

The invention discloses automatic fastener assembling equipment which is used for assembling a buckle body, a buckle head, a torsional spring and a dowel into a fastener, and then, a bell jar is riveted to the tail part of the fastener to finish the assembling technology. The automatic assembling process of the automatic fastener assembling equipment comprises the following steps: at the buckle body feeding stations, controlling the buckle bodies to enter corresponding clamping jigs one by one, and along with rotation of an indexing rotary disc, enabling the clamping jigs carrying the buckle bodies to sequentially pass through the buckle body feeding stations to fix the buckle heads entering the clamping jigs; in a torsional spring feeding and dowel feeding stations, enabling a torsional spring feeding mechanism to automatically insert a spring, enabling a dowel feeding mechanism to insert the dowel through guidance of a guiding needle and rivet the dowel at a dowel riveting station; in a bell jar assembling station, enabling a bell jar feeding mechanism to mount a bell jar, and enabling a bell jar riveting device to rivet the bell jar onto the fastener; and later, finishing collection of a finished fastener at a finished product reclaiming station. The automatic fastener assembling equipment completely realizes automatic operation; and new fastener design is matched with new automatic fastener assembling equipment, so that higher practical value is realized.

Owner:义乌市宏日智能科技有限公司

Copper-based friction plate for heavy-duty truck clutch and manufacturing method

InactiveCN105179537AMeet technical requirementsSimple preparation processFriction liningCopper platingMixed materials

The invention provides a copper-based friction plate for a heavy-duty truck clutch and a manufacturing method. The copper-based friction plate is mainly formed by sintering a pressed friction layer powder sheet and a copper-plated core board in a compounded manner. The friction layer powder sheet is composed of, by weight percent, 40% of Cu, 3% of Pb, 5% of C, 12% of zirconium silicate, 15% of Fe, 2% of calcium oxide and 2% of aluminum oxide. The manufacturing method includes the steps that firstly, materials of the friction layer powder sheet are prepared; secondly, the materials of the friction layer powder sheet are mixed; thirdly, the friction layer powder sheet is pressed, the mixed materials mixed through the second working procedure are placed in a mold and pressed by a press machine to form the friction layer powder sheet; fourthly, the core board is plated with copper, wherein the core board is electroplated with copper through an electroplating method; fifthly, compound-sintering is performed, the friction layer powder sheet pressed through the third working procedure and the copper-plated core board manufactured through the fourth working procedure are compounded together and then placed in a bell jar furnace so as to be pressurized and sintered; and sixthly, coining is performed, wherein the copper-based friction plate compound-sintered through the fifth working procedure is pressed through the press machine.

Owner:HANGZHOU ADVANCE GEARBOX GRP

High-strength bolt production process

ActiveCN104625617AReduce heating timesReduce consumptionFurnace typesHeat treatment furnacesSolution treatmentCarbonization

The invention discloses a high-strength bolt production process. The high-strength bolt production process includes the following steps that bar-shaped raw materials are selected and used, the raw materials are medium-carbon alloy steel, base materials are upset through hot upsetting dies, and therefore semi-finished bolt workpieces are acquired; solution treatment is conducted on the semi-finished bolt workpieces; bolt blanks are placed in a bell jar furnace for heat preservation and cooling; quenching is conducted; formed pieces are quenched in a salt bath furnace; tempering is conducted; the semi-finished bolt workpieces are coarsely machined in the aspects of the appearance and the size; the semi-finished bolt workpieces are finely machined in the aspects of the appearance and the size, rods of the semi-finished bolt workpieces are rolled to machine external threads, and therefore finished bolt workpieces are acquired; carbonization is conducted; the surfaces of the blanks are treated. By the adoption of the high-strength bolt production process, the strength of bolts can be improved, the technological process is simple, manufacturing cost is low, the technological process is good in continuity, and production efficiency is high.

Owner:海盐双赢管件制造有限公司

Bell jar type coating device capable of coating various glazes simultaneously

The invention discloses a bell jar type coating device capable of coating various glazes simultaneously. The bell shape coating device comprises a large bell jar and a small bell jar, wherein the lower bell jar of the small bell jar is provided with an arc-shaped connecting gap corresponding to the surface radian of the lower bell jar of the large bell jar, and is tightly connected with the outer surface of the lower bell jar of the large bell jar by virtue of the arc-shaped connecting gap. Glazed curtains simultaneously coated by the bell jar type coating device capable of coating various glazes simultaneously provided by the invention are uniform and stable, and glaze materials on coated adobe surfaces are uniform, so that the glazes are rich in color.

Owner:GUANGDONG WINTO CERAMICS +1

Anti-slip glaze and processing method thereof, and method for using anti-slip glaze in sintered brick

The invention discloses an anti-slip glaze, which comprises the following raw materials: potassium feldspar, albite, nepheline, zinc oxide, calcined talc, barium carbonate, calcined kaolin, kaolin, quartz, corundum, and frit. The processing method of the anti-slip glaze comprises: 1, material preparing; 2, material adding, wherein the raw materials are sequentially added to a material mixing machine; 3, material mixing; 4, inspection; and 5, packaging treatment. The method for using the anti-slip glaze in a sintered brick comprises: ratio testing, wherein the raw materials are prepared according to the glossiness, the generated color, the touch and the anti-fouling index; pre-treating, wherein a surface glaze is watered into a brick billet by a bell jar glaze watering device; inkjet, wherein the pre-treated brick surface is sprayed with ink patterns and colors according to the design; glazing, wherein the ink-jetted brick surface is printed with an anti-slip glaze; and firing, whereinthe glazed brick is fed into a kiln and is fired. The anti-slip glaze of the present invention has characteristics of good gloss, no reflection, comfortable hand feeling, high friction coefficient, good antifouling effect and good color generation.

Owner:FOSHAN TAOYING NEW MATERIAL CO LTD

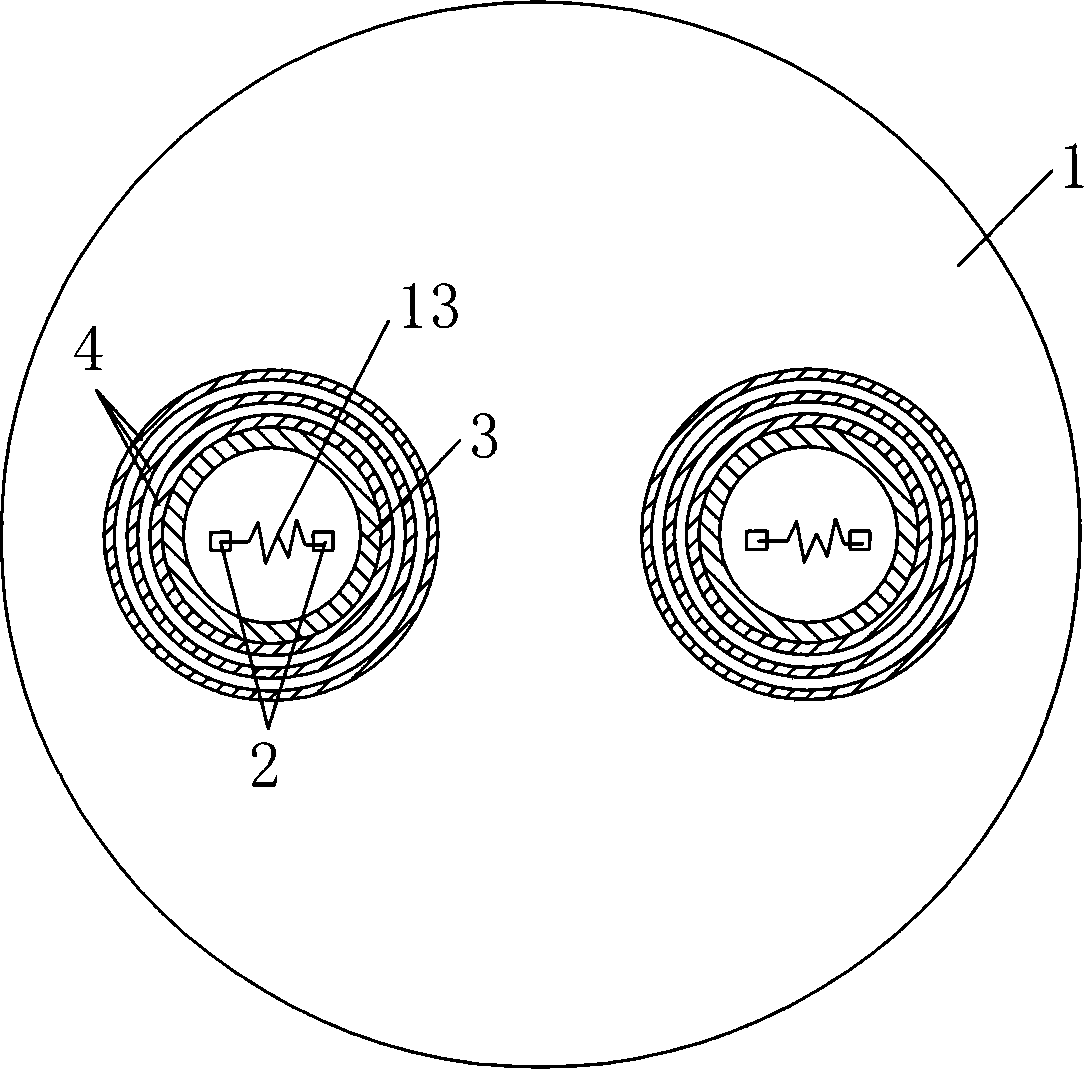

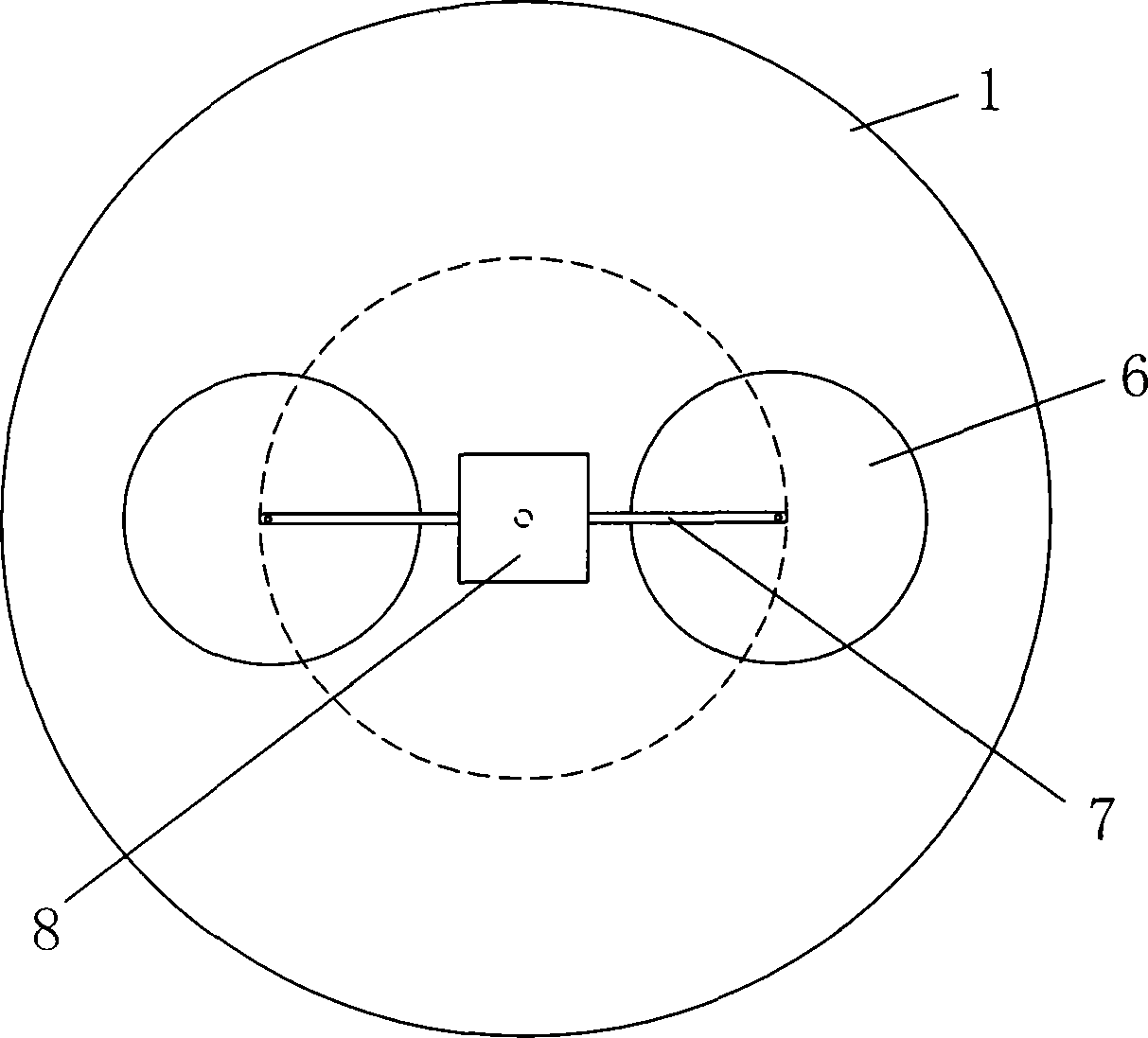

High temperature heating vacuum evaporation film coating device

InactiveCN101245441AGuaranteed purityIncrease profitVacuum evaporation coatingSputtering coatingEngineeringVacuum evaporation

The invention relates to a vacuum evaporation coater with high temperature heating, belonging to the field of electromechanical technique. The invention comprises a bell jar, substrate clips and evaporating chambers which are positioned in a foundation bed. A heating device is arranged in the evaporating chamber. At least two groups of the substrate clips, the evaporating chambers and the heating device are prepared; each substrate clip is installed on the foundation bed of the substrate clip; the invention also comprises a driving device which drives the foundation beds of the substrate clip to relatively lift and rotate. The vacuum evaporation coater of the invention has the advantages that more than two different materials can be simultaneously evaporated and various materials can be successively evaporated by the substrate clips, thus avoiding cross contamination and ensuring the purity of evaporants, meanwhile, the vacuum evaporation coater can improve the utilization of the evaporants, save time, simplify operating procedure and enhance adhesive properties of substrates and evaporation materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

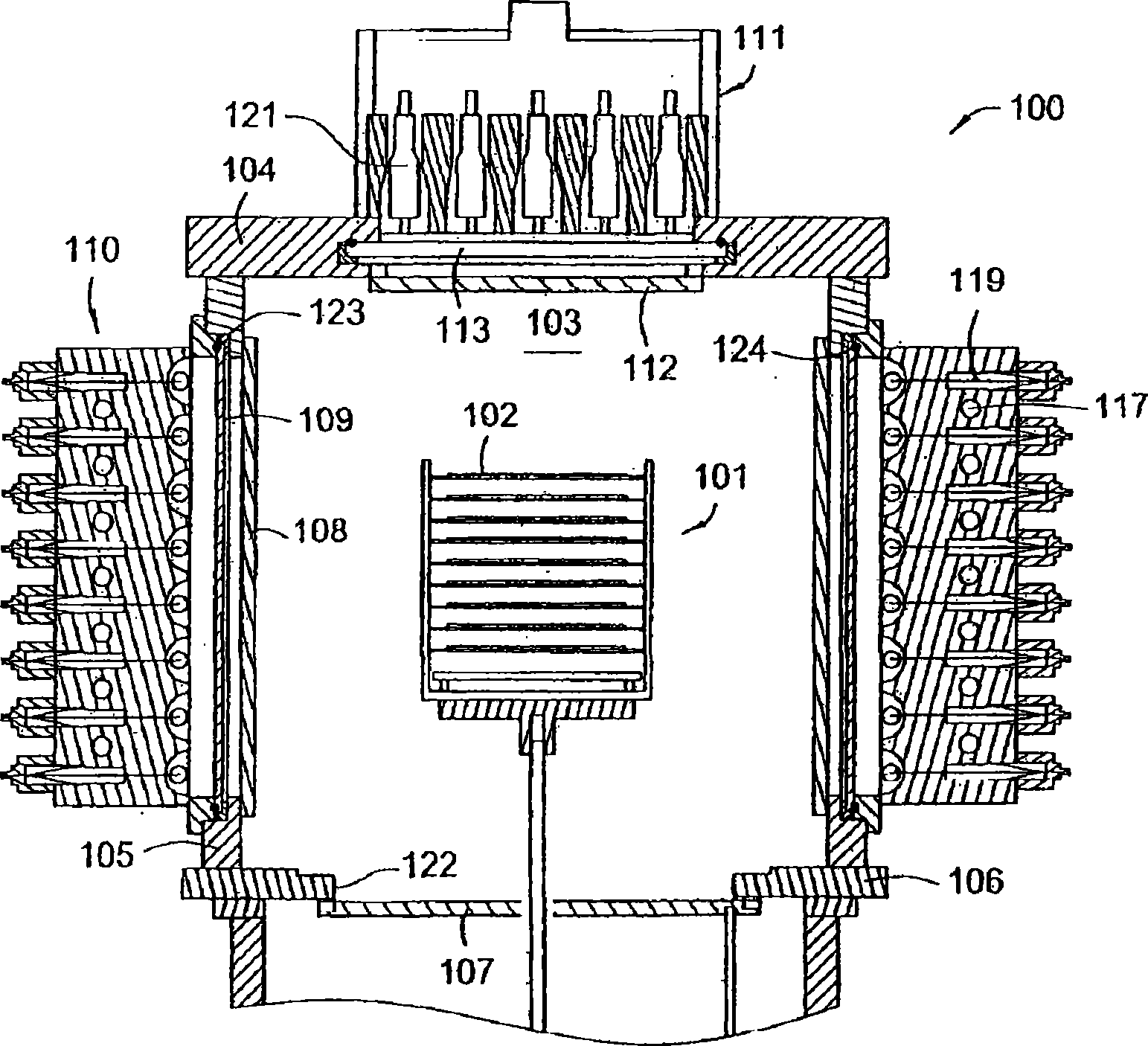

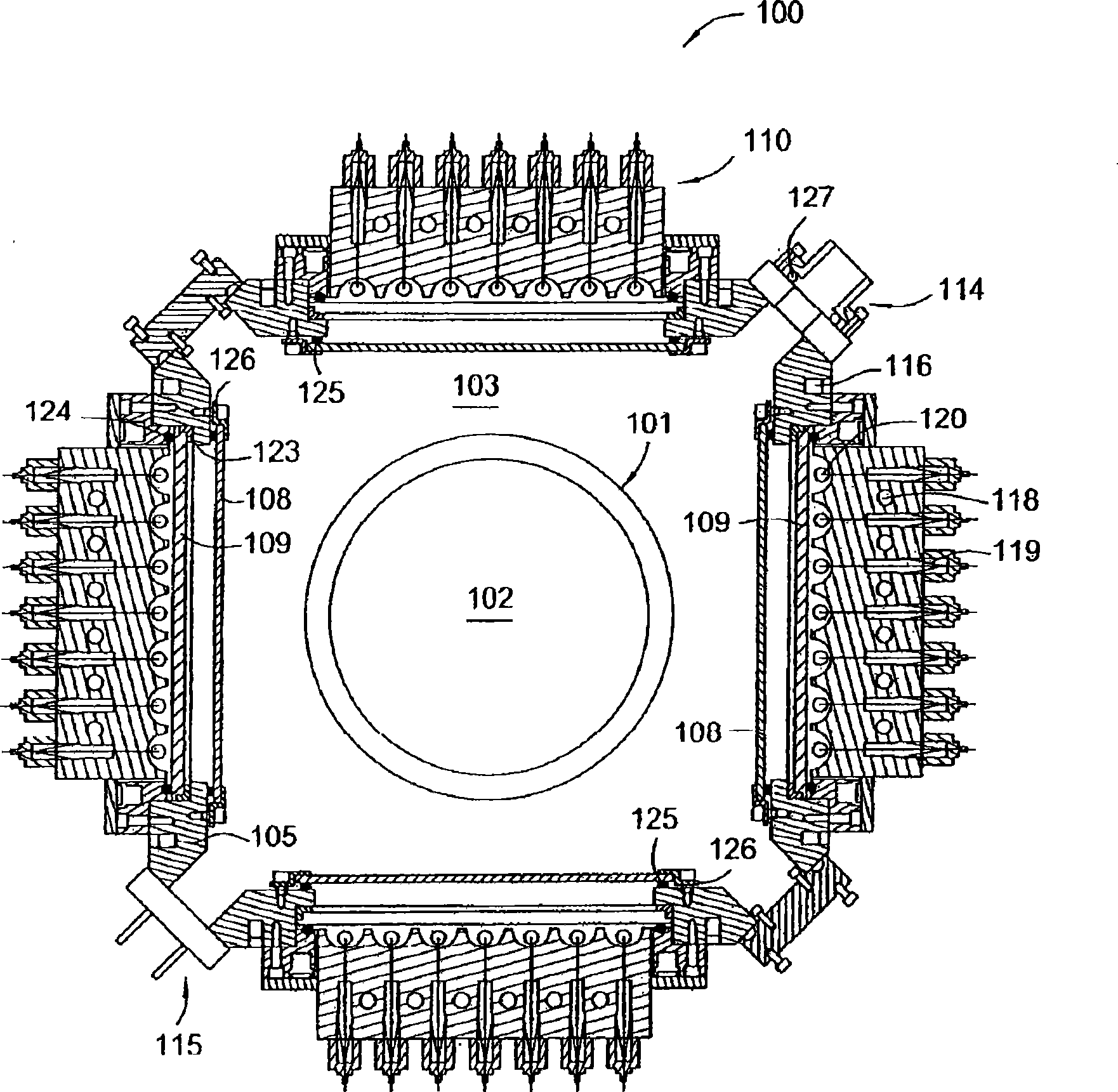

Batch processing chamber with diffuser plate and injector assembly

InactiveCN101437979ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingBatch processingEngineering

An apparatus for batch processing of a wafer is disclosed. In one embodiment the batch processing apparatus includes a bell jar furnace having a diffuser disposed between gas inlets and the substrate positioned within the furnace to direct flows within the chamber around the perimeter of the substrate.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com