Patents

Literature

223results about How to "Improve hair color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making fermented minced or cubed meat by utilizing fermenting agent

InactiveCN103704765AGood colorAdd flavorMeat/fish preservation using chemicalsFood ingredient for microbe protectionBiotechnologyFlavor

The invention provides a method for making fermented minced or cubed meat by utilizing a fermenting agent. The method comprises the steps of minced or cubed meat raw material pretreatment, preserving, fermenting, storing and the like, the above raw material selects cold meat or fresh meat, and a strain comprises one or more of lactic acid bacteria, Debaryomyces hansenii, Micrococcus Kristinae, Micrococcus varians and Staphylococcus xylosus. A fermented product obtained in the invention has the characteristics of fine texture, elasticity, rich and pure fragrance, possessing of the sour fragrance specially possessed by fermented meat products, good mouthfeel and unique flavor, and also has the advantages of high nutrition value, high safety, eating convenience, easy preservation, probiotic effect and the like.

Owner:胡永金

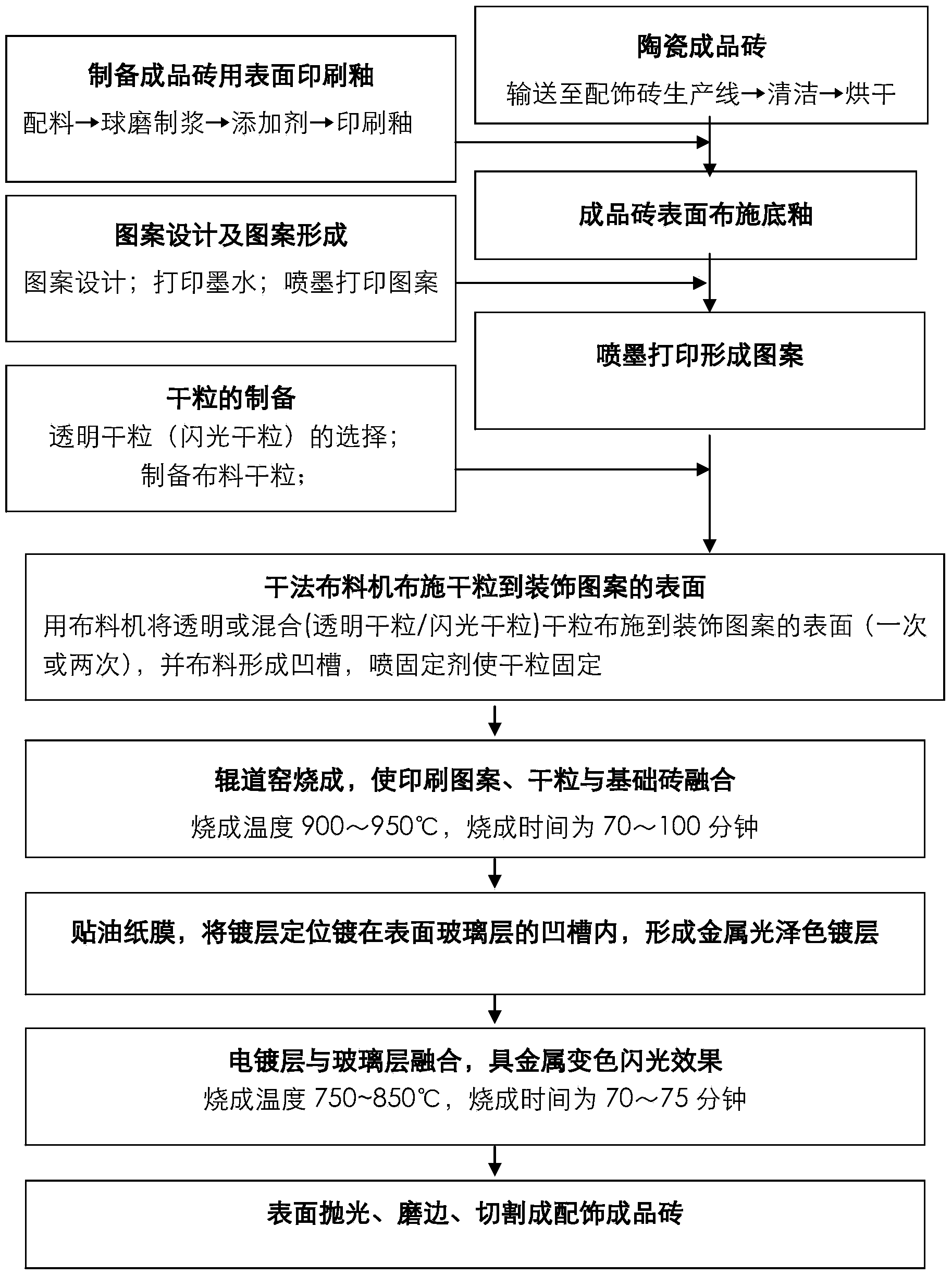

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

Production method of fermented beef jerky

The invention discloses a production method of fermented beef jerky. The production method is characterized by comprising the steps of: cutting fresh beef into 3-4cm strips, soaking the strips by a mixing solution of CaCl2, composite phosphate and ginger juice for a whole night, adding glucose and a fermenting agent in the mixture, fermenting for 8 hours and roasting for 12 hours, boiling in boiling water and roasting for 1 hour, and implementing vacuum packaging and high-pressure sterilization to obtain the fermented beef jerky. The production method makes use of the acid production capacity of acid kumiss from natural fermentation and lactobacillus which is excellent in growth property, and is easy to control a fermentation process and short in fermentation cycle; the production method changes conventional processes of boiling twice, frying and the like, so that the deterioration of a later product due to over oxidation in the frying process is avoided and the shelf life is prolonged; and by adding a tendering pickling process and the fermentation process, the fermented beef jerky is unique in flavor, and has soft lactic acid taste and good color, reflects the fermentation property of lactobacillus, is soft and tender in texture, and is applicable to people of all ages.

Owner:贺银凤 +1

External Chinese medicinal composition with functions of blackening hair and dressing hair and preparation method thereof

InactiveCN101829034AAchieve standardizationAchieve scaleCosmetic preparationsHair cosmeticsSide effectIrritation

The invention discloses a new external Chinese medicinal composition with functions of blackening hair and dressing hair and a preparation method thereof. The Chinese medicinal composition mainly comprises the following raw material medicaments: tuber fleeceflower root, ginseng, Chinese angelica, oriental arborvitae carbon, Szechuan lovage rhizome, incised notopterygium rhizome, fineleaf schizonepeta herb, cassia twig, Manchurian wildginger, mint, kudzuvine root, chrysanthemum, baical skullcap root, lightyellow sophora root, weeping forsythia, red paeony root, white paeony root, divaricate saposhnikovia root, storax, dahurian angelica root, mugwort leaf, Chinese honeylocust fruit, prepared rehmannia rhizome, clove, pseudoginseng root, root of red-rooted salvia, black sesame and yerbadetajo herb. The Chinese medicinal composition of the invention can be prepared into any external preparation by a conventional Chinese medicinal preparation method. The Chinese medicinal composition can remarkably improve qi and blood circulation, expel wind and cold pathogens, dredge qi and blood, activate blood circulation to dissipate blood stasis, expel head wind, blacken hair, dress hair and improve the symptoms such as white hair, gray hair, brown hair, easily broken hair, hair loss and the like, and has extract clinical effect, remarkable curative effect and quick response. The Chinese medicinal composition is combined by adopting the medicaments prescribed by the national formulary and an external therapy method is adopted, so the Chinese medicinal composition has no stimulation on the skin or dependency and has the advantages of low expense, no toxic or side effect and the like.

Owner:TAIYI HEPU BEIJING RES INST OF TCM

A stone-imitating porcelain tile with three-dimensional decoration effects and a producing method thereof

The invention discloses a stone-imitating porcelain tile with three-dimensional decoration effects and a producing method thereof. The method includes A) preparing a porcelain tile blank powder material according to conventional methods, B) preparing a porcelain tile backing material and a surface material, C) preparing a porcelain tile blank, D) drying the blank, E) spraying with the backing material, F) performing digital ink-jet printing, G) coating with the surface material by printing, H) drying the blank coated with the surface material, I) firing and J) performing edge polishing. Beneficial effects of the porcelain tile and the method are that the problems in the prior art due to a high using amount of surface layer pulp and dyeing assistant agents, namely high costs and absence of three-dimensional pattern expression in pattern textures, are overcome; technical problems that porcelain color-penetrated tiles at present are inaesthetic due to bottom exposure caused by slotting, chamfering, and other types of processing are overcome, and the producing method is provided for the porcelain tile that is environmental friendly, economical and richer in decoration effects.

Owner:HANGZHOU NABEL CERAMIC +2

Matte brick and preparation method

The invention discloses a preparation method of a matte brick. The preparation method comprises the steps: preparing ground glaze, decorative patterns and surface glaze on the surface of a green bodysequentially, then performing drying and firing, performing polishing by using a matte grinding block and a fiber grinding block sequentially, and performing wax so as to obtain the matte brick finished product. The matte brick with a glossiness of 28-36 degrees is prepared through adoption of a reasonable surface glaze formula and a polishing technology, and the decorative patterns have good color and clear patterns, so that the brick is more similar to natural marble; and light reflection and light pollution are reduced through the brick, and broad application prospects are achieved.

Owner:肇庆乐华陶瓷洁具有限公司

Preparation method of Muslim low-temperature mutton ham

ActiveCN105581273AReduce dosageImprove durabilitySugar food ingredientsFood ingredient as flavour affecting agentFlavorRoom temperature

The invention discloses a preparation method of Muslim low-temperature mutton ham and belongs to the field of meat product processing. The preparation method of the Muslim low-temperature mutton ham comprises the steps that mutton is subjected to pretreatment, microwave-assisted vacuum rolling and kneading with specially-made curing liquid and ultrasonic wave composite variable pressure curing, then the mutton is filled and formed, and finally, after being sterilized in a composite mode at low temperature, the mutton is cooled to room temperature and stored at the temperature of 0 DEG C-4 DEG C. Hind quarters of sheep are used as raw materials of the prepared Muslim low-temperature mutton ham, and processed at low temperature, so that the loss of nutrient substances of mutton is reduced; moreover, original flavor of the mutton can be retained well, by means of ultrahigh pressure curing, tenderness of the mutton is improved, the color of the mutton is kept better, curing efficiency is improved, the processing period is shortened, novel products with high quality, high safety and long shelf life are produced, and a new thought is provided for deep processing in the mutton industry.

Owner:NINGXIA UNIVERSITY

Cantonese style sausage prepared via mixed bacterial fermentation and preparation method thereof

The invention discloses a cantonese style sausage prepared via mixed bacterial fermentation. According to a preparation method of the cantonese style sausage, raw material meat, water, table salt, sugar, monosodium glutamate, and sodium nitrite are mixed and are subjected to pickling; inoculation of microorganisms is carried out so as to prepare sausage; and the cantonese style sausage is prepared via fermentation. Based on the weight of the raw material meat, 1 to 3.5% of table salt, 1 to 12.0% of sugar, 0.01 to 0.2% of monosodium glutamate, 0.1 to 2% of liquor, 0.005 to 0.015% of sodium nitrite, and 1 to 3% of water are used. The invention also discloses the preparation method of the cantonese style sausage. The cantonese style sausage possesses unique fragrance, is safe and good for health; the preparation method is simple; fermentation is fast; and cost is low.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Nitrite-substituted meat processing method

InactiveCN106071907AGood effectGood muscle toneFood ingredient as antioxidantFood ingredient as taste affecting agentBetaninEthyl maltol

The invention discloses a nitrite-substituted meat processing method, and belongs to the technical field of food processing. The nitrite-substituted meat processing method comprises the following steps: selecting raw materials, carrying out pickling treatment and processing a meat product, so that the final products of the meat product are prepared; and the nitrite is substituted by a nitrite substitute during the step of carrying out pickling treatment. The nitrite substitute comprises the following components in parts by weight: 4-5 parts of monascorubin, 0.7-1.3 parts of betanin, 4-6 parts of potassium sorbate, 2-3 parts of D-sodium isoascorbate, 1.5-2.5 parts of nisin, 9-11 parts of sodium lactate, 1-2 parts of natamycin, 5-6 parts of natural vitamin E, 1-2 parts of a rosemary extract, 0.5-1.5 parts of sage essential oil, 1-2 parts of tea polyphenols, 15-16 parts of L-sodium glutamate, 0.5-1.5 parts of flavoring 5'-disodium ribonucleotide, 40-43 parts of a yeast extract, 4-5 parts of sodium tripolyphosphate and 0.5-1.5 parts of ethyl maltol. The nitrite-substituted meat processing method disclosed by the invention is simple, easy to operate and free of nitrite addition; and the prepared meat products are very good in qualities, color, luster and taste.

Owner:邯郸市锦园食品有限公司

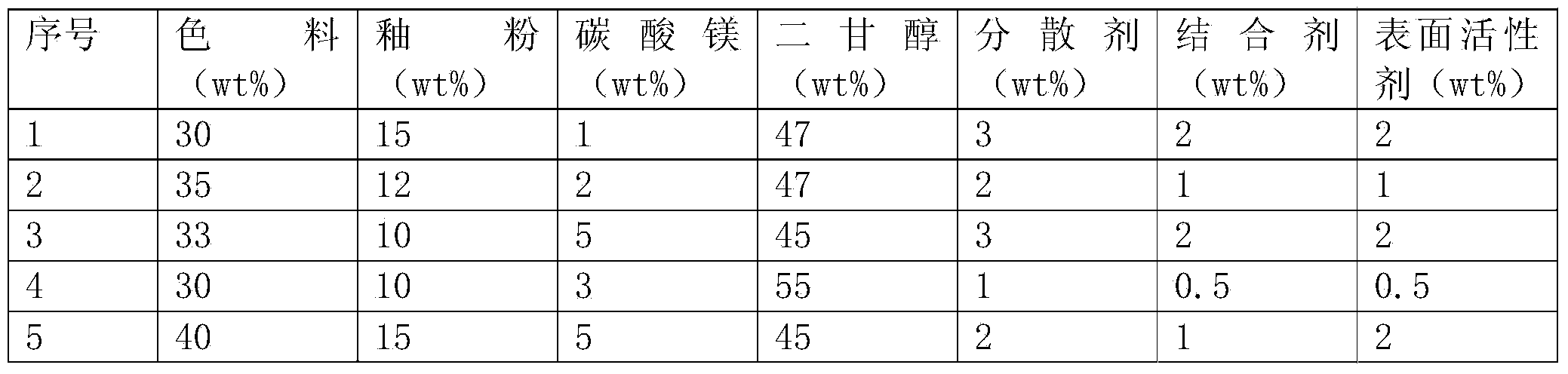

Colored glaze mixed type ink for ceramic ink-jet printing and preparation method thereof

The invention provides colored glaze mixed type ink for ceramic ink-jet printing and a preparation method thereof, belonging to the technology of ceramic tile decoration. The ink comprises the following components by mass percent: 30%-40% of pigment, 10%-15% of glaze powder, 1%-5% of magnesium carbonate, 45%-55% of diethylene glycol, 1%-3% of dispersing agent, 0.5%-2% of binding agent, and 0.5%-2% of surfactant. When the colored glaze mixed type ink for ceramic ink-jet printing is used for producing ceramic tiles for wall and floor, after ink-jet printing, the ceramic tiles can be directly sintered at high temperature without being applied with transparent protective glaze; the glaze in the ink is melted in sintering, so that the color development component of the ink is uniformly dispersed in the melted glaze, the formed ink-jet printing layer has good abrasion resistance, the production technology of the ink-jet printed ceramic tiles is greatly simplified, the production cost is lowered, and the production efficiency is improved.

Owner:LIXIAN XINPENG CERAMIC +1

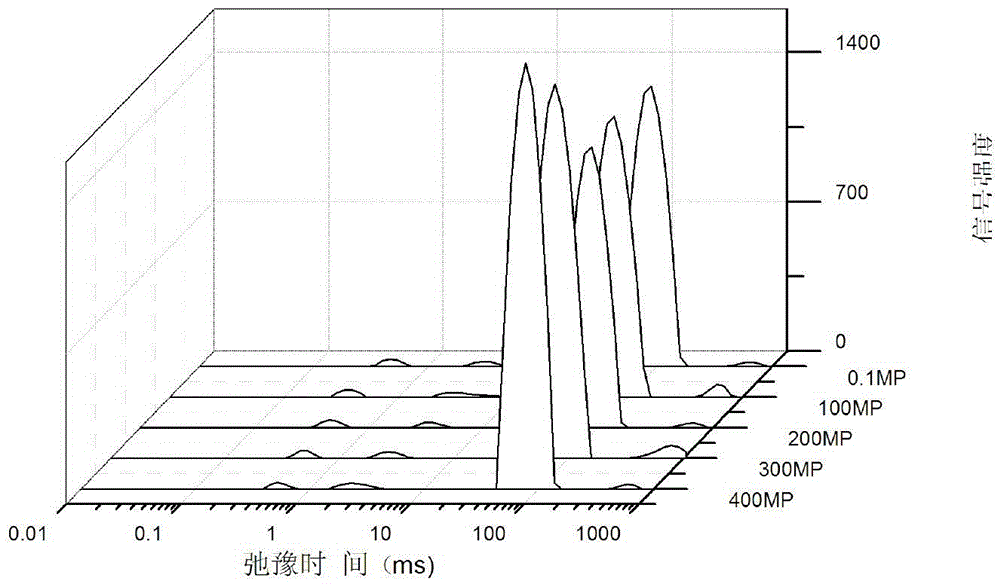

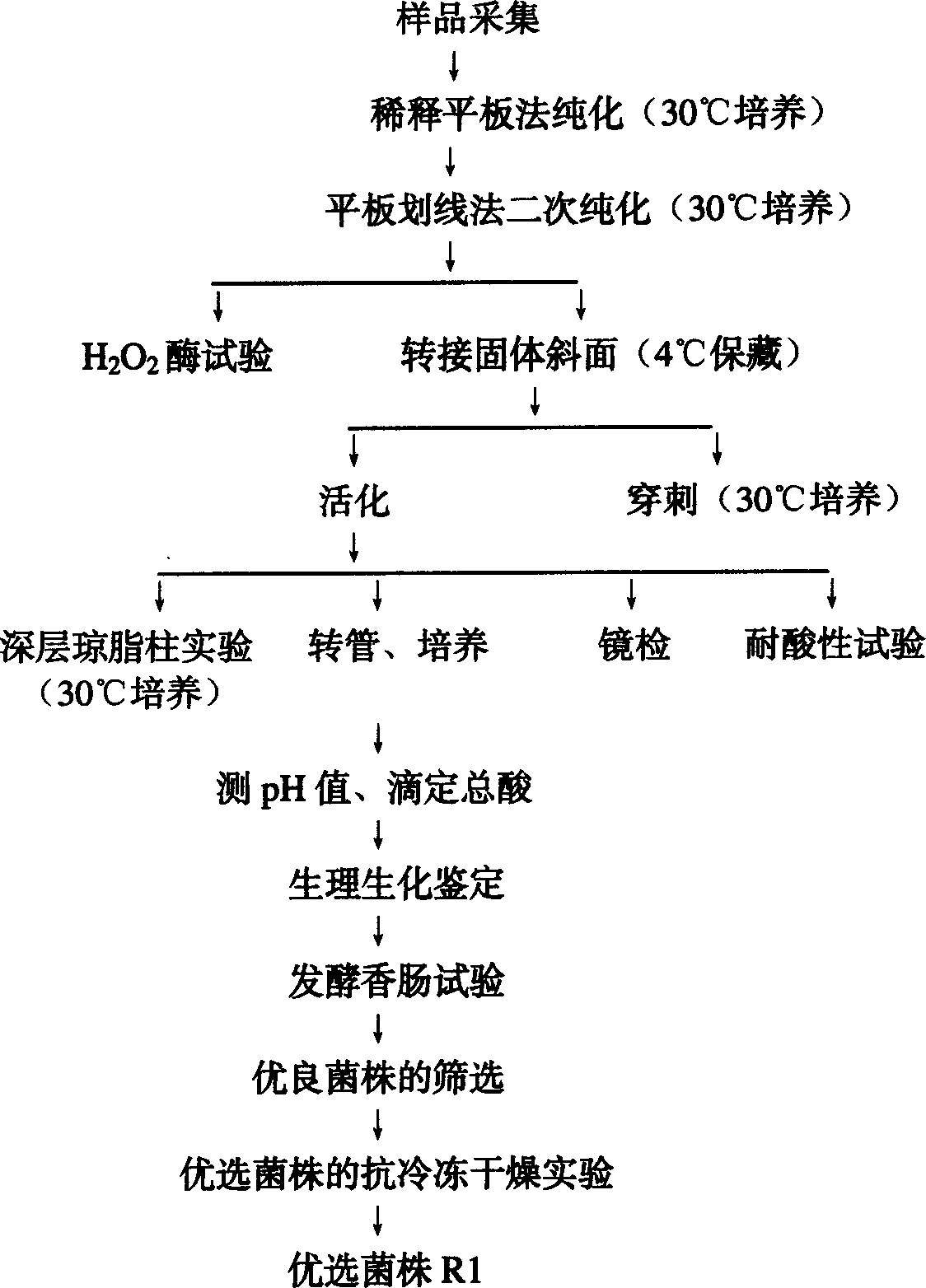

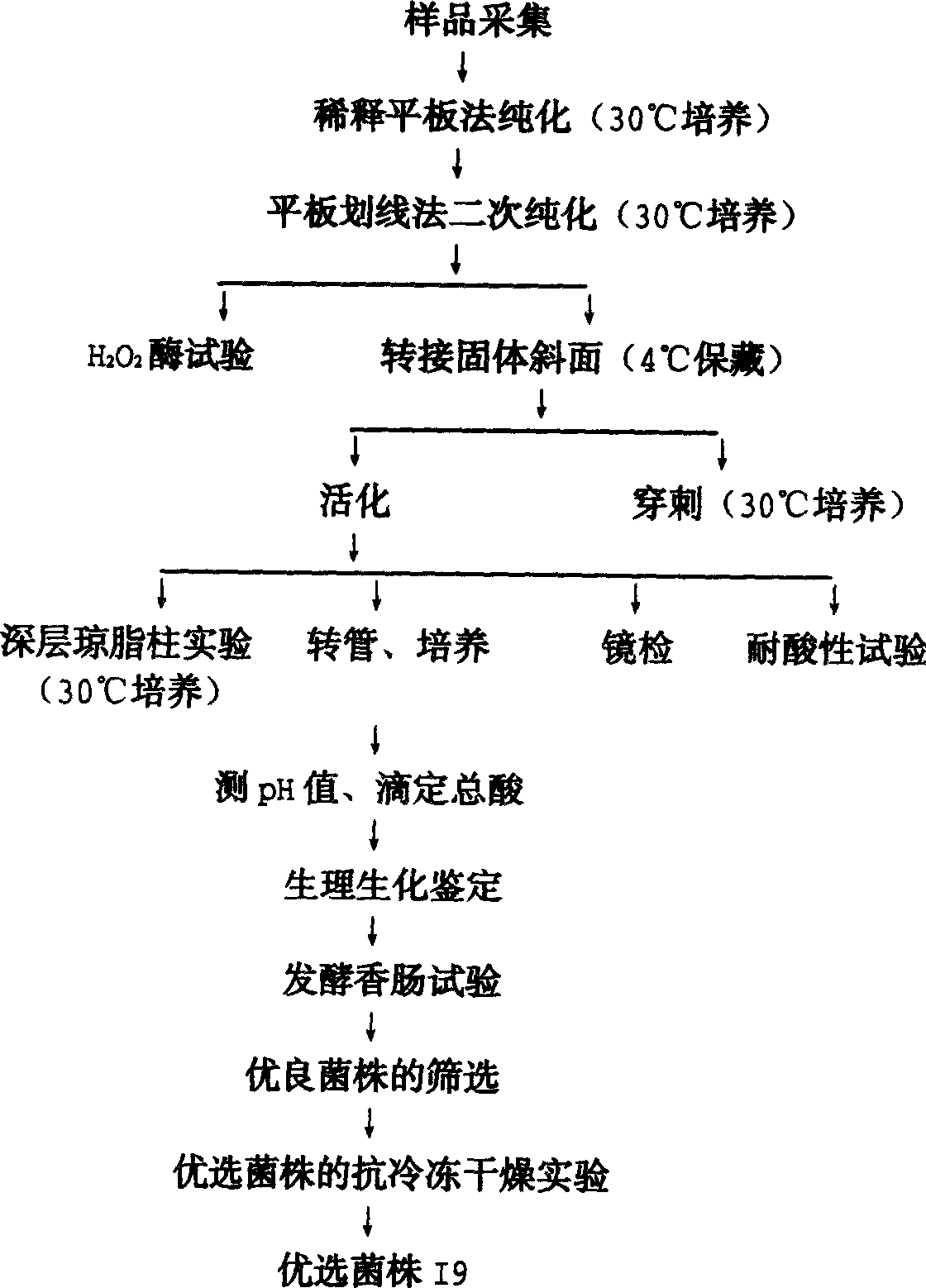

Lactobacillus pentosus strain, ferment produced thereby and the use of ferment in meat ware

The invention discloses a lactobacillus pentosus strain and ferment produced thereby, wherein the docket number of the R1(Lactobacillus pentosus R1) strain in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0917. The pentose lactobacillus R1 strain of the invention can endure 4.0% salt solution and nitrite solution whose concentration is 80-100mg / L. The leaven prepared from the bacterial can be applied into the fermentation production of meat food.

Owner:河南双汇投资发展股份有限公司

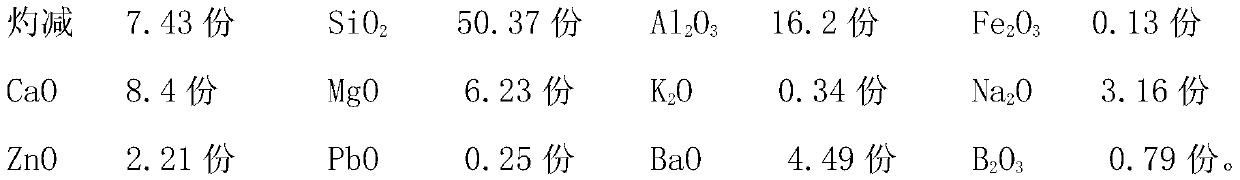

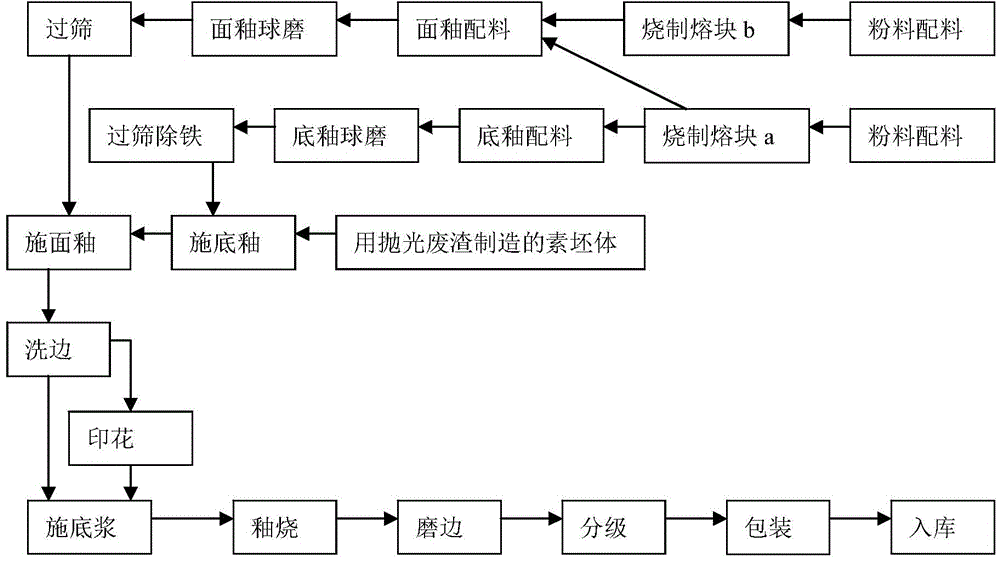

Black inkjet full-polished ceramic tile and preparation method thereof

InactiveCN109761583APlay the role of turning waste into treasureLower firing temperatureCeramic materials productionClaywaresBrickSlurry

The invention relates to a black inkjet full-polished ceramic tile and a preparation method thereof. The ceramic tile is of a composite layer structure consisting of a green body layer, a ground glazelayer, a pattern layer and a full-polished layer. The preparation method comprises the following steps: (1) ball milling of raw materials: placing ingredients into a ball mill, adding water to perform ball milling on the ingredients to obtain slurry, screening the slurry, and storing the screened slurry into a slurry pool for later use; (2) preparation of a powder compact by spray drying: conveying the slurry to a spray tower, drying the slurry into powder, controlling the moisture of the slurry at 5.8 to 7 percent, and performing dry pressing with a brick press; (3) green body drying: conveying the pressed green body into a drying kiln for drying at a temperature of 180 to 270 DEG C for 40 to 60 minutes; (4) spraying of ground glaze: conveying the ingredients into the ball mill, and adding 42 percent of water to perform ball milling to obtain glaze slurry; and (7) burning: implementing burning at a temperature of 1,080 to 1,150 DEG C for 45 to 60 minutes.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +3

Two-component polyester sheath core compound fibre and production method

InactiveCN1912199AImprove dyeabilityImproved color developmentFilament/thread formingConjugated synthetic polymer artificial filamentsChemistryPolyester

The invention discloses bi-component polyester sheath core complex fiber and its producing method. The core is ultra complete extinction polyester with 5-10% titanium dioxide. The sheath is polyester with dye-ability cationic dyes. The method includes the following steps: putting the sheath and core respectively; distributing into assembly; mixing and extruding by nozzle plate; spinning. The invention uses cationic dyeable polyester to increase fabric dye-ability and color emissivity, titanium dioxide to improve fiber permeability resistance. The produced fiber which can be used to make swimming cloth has the advantages of good fabric performance, color emissivity, permeability resistance etc. The technology is simple and easy to operate.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Raw material matte glaze, and preparation method and application thereof

The invention discloses raw material matte glaze, and a preparation method and application thereof, wherein the raw material matte glaze is prepared from the following ingredients in parts by weight: 1 to 5 parts of zinc oxide, 15 to 35 parts of barium carbonate, 15 to 30 parts of potassium feldspar, 10 to 15 parts of soda feldspar, 0 to 10 parts of dolomite, 3 to 10 parts of kaolin, 4 to 15 parts of quartz and 4 to 15 parts of calcium phosphate. The raw material matte glaze provided by the invention is formed by combining all raw materials; the materials do not need to be made into fused blocks; energy sources are saved; the cost is low; the raw material matte glaze is suitable for being used for one-step fast firing products; in addition, the phosphate ingredient is introduced for matte glaze proportioning; the introduction of infusible compounds is not needed. When the raw material matte glaze is applied to ceramic product production, the glaze surface texture of a final product of the matte glaze is fine; the glossiness is low; the anti-corrosion performance and the wear-resistant performance are good; the coloring of ink-jet printing ink can be facilitated; the problems of rough hand feeling, unstable anti-corrosion performance, poor coloring effect of the ink-jet printing ink and the like of matte glaze series products in the market at present can be solved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

Pure black glazed tile produced by using waste glaze slip and preparation method of pure black glazed tile

The invention provides a pure black glazed tile produced by using waste glaze slip and a preparation method of the pure black glazed tile in order to overcome the defects. On the basis of greatly unchanging the existing production process of glazed tiles, by optimizing the composition of ground coat and cover coat frits, the formula composition of the ground coat, the formula composition of the cover coat, regulating and optimizing ground coat and cover coat technological processes, especially the preferable section of green body types, the fired pure black glazed tile is pure in color, and the chromaticity (L *, a *, b *) value of an unprinted product is measured by a WSD-3C type whiteness colorimeter, wherein the L * (lightness) value is 6.25 to 6.43 and is close to the L * (lightness) value of 5.0 of standard carbon black, the a * (redness) value is -0.03 to 1.60, and the b * (yellowness) value is 0.15 to 0.18. The glazed tile is carbon black like pure black, the glaze has good quality, is moisturized and bright, and has no pinholes, glaze bubbles and other defects, and the glazed tile has strong decorative effect and aesthetic feeling; meanwhile, the technology has strong universality and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Pediococcus pentosaceus strain, ferment produced thereby and the use of ferment in meat ware

The invention discloses a pediococcus pentosaceus strain, ferment produced thereby and the use of ferment in meat product, wherein the docket number of the R9(Pediiococcus Pentosaceus I9) strain in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0918. The leaven prepared from the bacterial can be applied into the fermentation production of meat food.

Owner:河南双汇投资发展股份有限公司

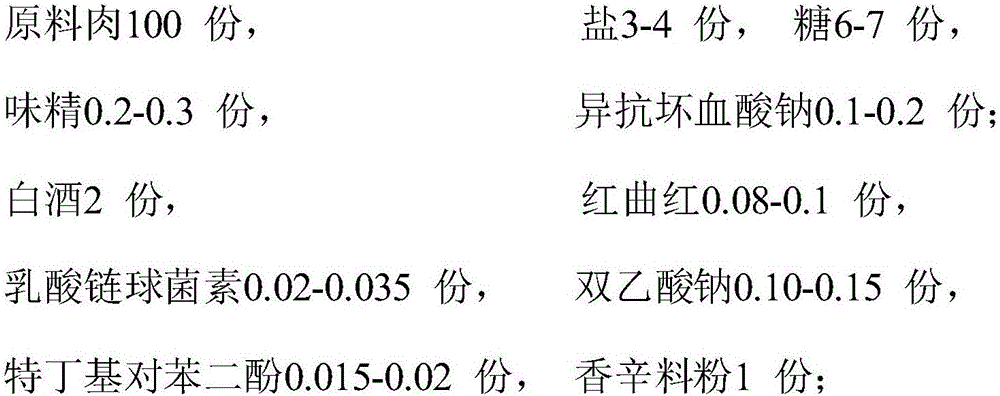

Nitrite-free Chinese-style sausage and production method

The invention relates to a nitrite-free Chinese-style sausage and a production process. The production process comprises the steps of selecting and preprocessing raw meat, mixing materials and salting, filling and bundling sausages, putting the sausages on a bar, putting the sausages in an oven, baking the sausages, cooling, packaging and warehousing, thereby obtaining the nitrite-free Chinese-style sausage. By using monascus color, tert-butylhydroquinone, sodium erythorbate, nisin and sodium diacetate to substitute for nitrite and nitrate and by adjusting the original material mixing and salting and baking process, effects of colorizing, anti-oxidation and anticorrosion are taken in the nitrite-free Chinese-style sausage, and the nutrient, delicious and healthy nitrite-free Chinese-style sausage is produced. According to physical and chemical inspection, the results show that the sausage does not contain residual nitride, the color and the flavor of the nitride-free sausage are superior to the color and the flavor of a nitride-containing sausage and the color of the nitride-free sausage is not changed after the nitride-free sausage is stored for one month in a incubator at 37 DEG C.

Owner:湖南唐人神肉制品有限公司

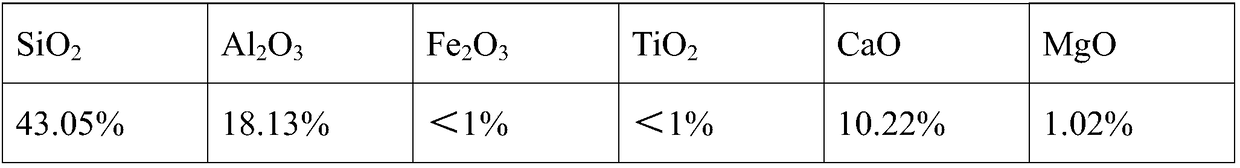

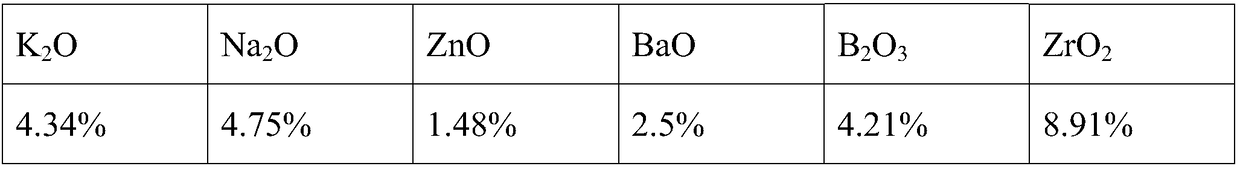

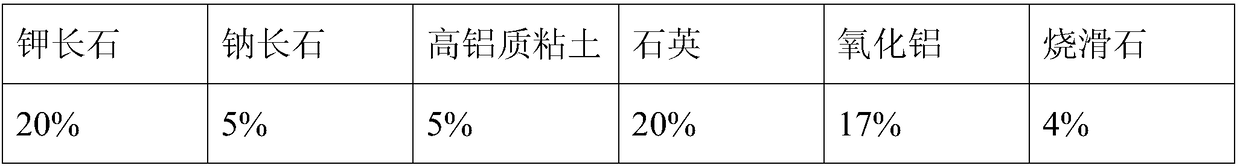

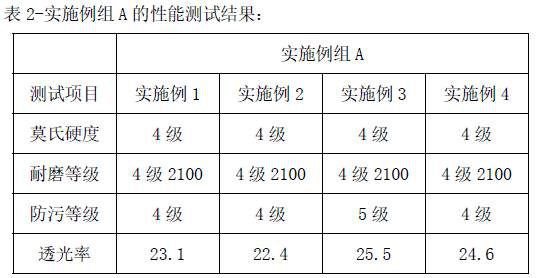

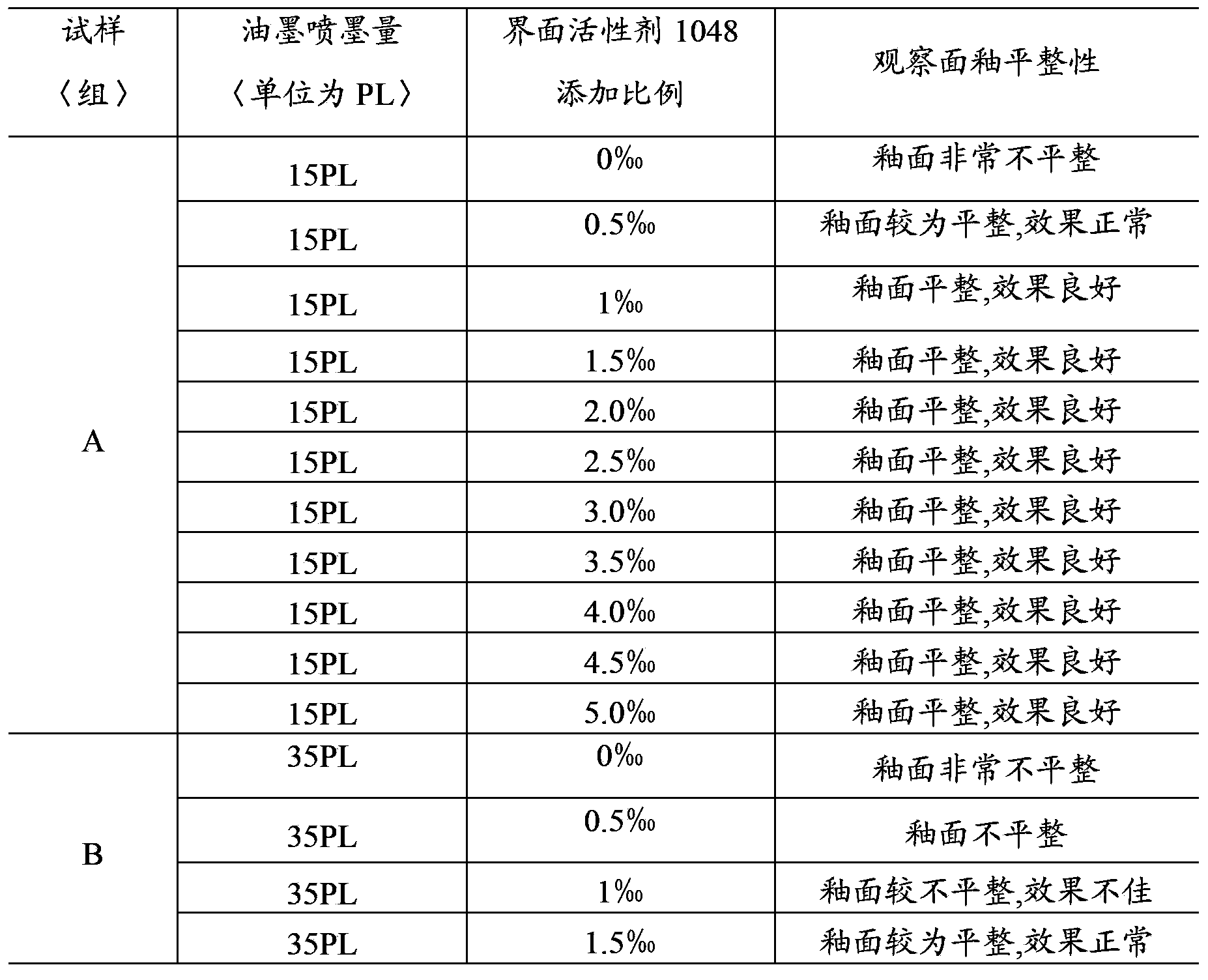

Low-light exquisite glaze, glaze slurry preparation method, glazed tile, and preparation method

InactiveCN108395101AFine and silky surfaceGood antifouling performanceCeramic glazeChemical composition

The invention discloses low-light exquisite glaze. The exquisite glaze is prepared from the following chemical components in percentage by weight: 33 to 55 percent of SiO2, 15 to 25 percent of Al2O3,less than 1 percent of Fe2O3, less than 1 percent of TiO2, 10 to 18 percent of CaO, 1 to 5 percent of MgO, 3 to 6 percent of K2O, 2 to 5 percent of Na2O, 1 to 2 percent of ZnO, 1 to 2.5 percent of BaO, 3 to 5 percent of B2O3 and 3 to 9 percent of ZrO2. The invention also discloses a glaze slurry preparation method of the low-light exquisite glaze, a glazed tile and a glazed tile preparation method. The glossiness of a glazed surface obtained through the low-light exquisite glaze is 4 to 18 degrees; the texture of the surface is exquisite; the antifouling property is good; the technical difficult points that the glazed surface in industry cannot meet the requirements of low light and exquisiteness are solved.

Owner:FOSHAN DONGPENG CERAMIC +2

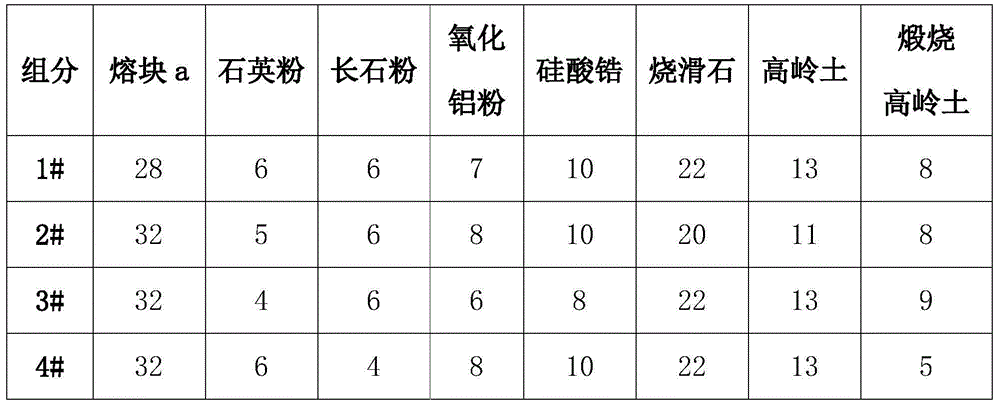

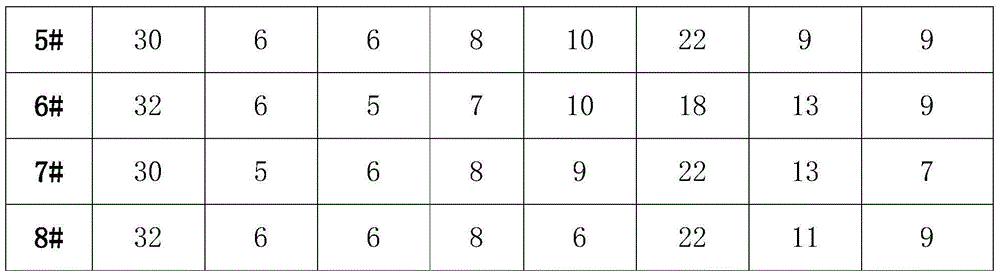

Wear-resistant glaze for glazed bricks, and preparation method thereof

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

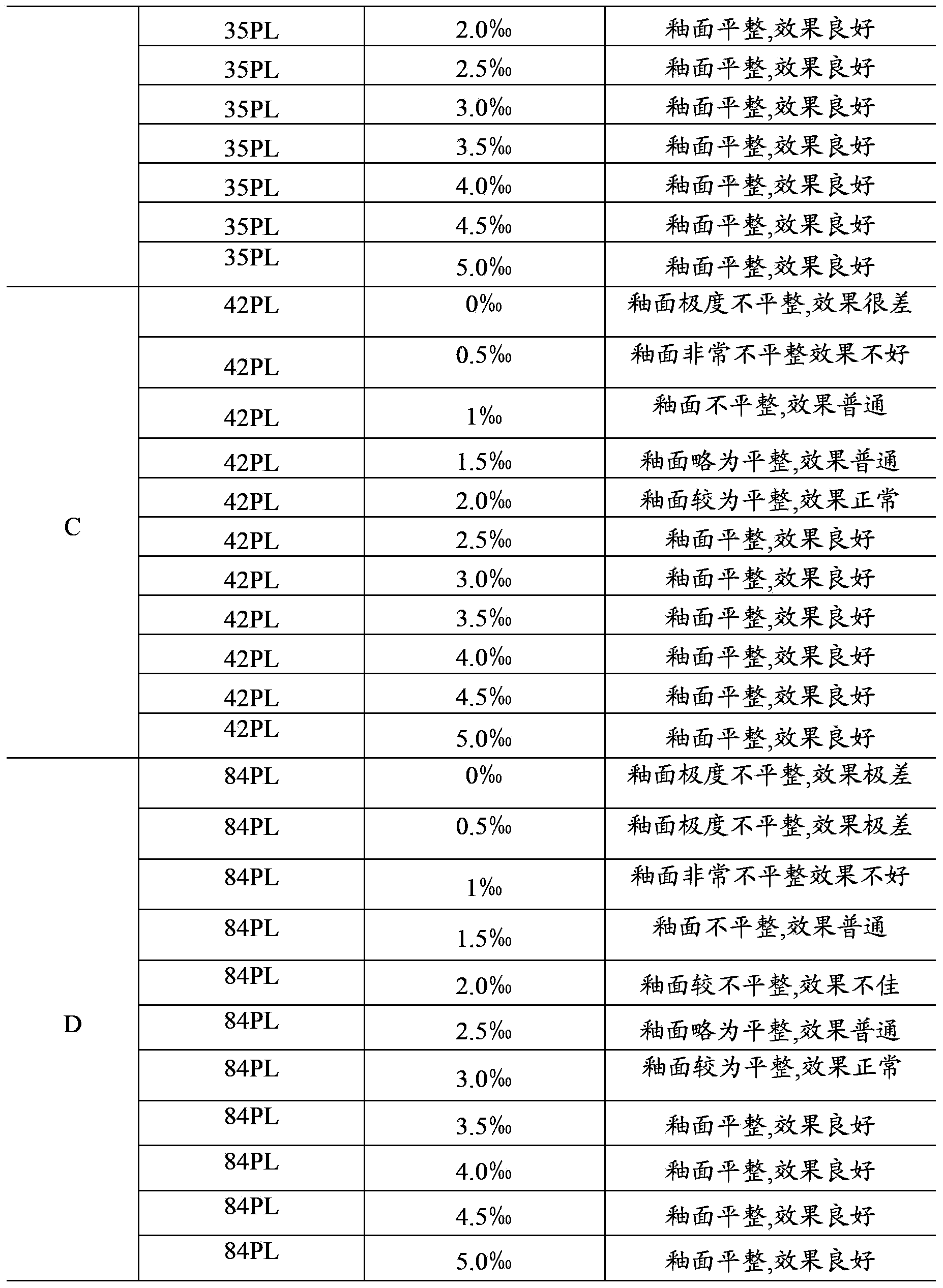

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 32% to 42% of albite, 8% to 12% of nepheline orthoclase, 3% to 5% of wollastonite, 3% to 5% of kaolin, 1.5% to 2.5% of ball clay, 3% to 5% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 7% to 9% of calcium carbonate, 4% to 7% of zinc oxide, 1% to 2% of talc, 3% to 5% of dolomite, 1% to 2% of barium carbonate, 4% to 8% of clinker, and 6% to 15% of zirconium silicate. The produced novel printing glaze material has the advantages that color development of the ink is better, a problem of color system variation does not exist, the definition of ink figures and the flatness of glaze surfaces can be guaranteed, and a defect of printing ink gloss variation is overcome through controlling a molten softening point.

Owner:CARLOBBIA GLAZE KUNSHAN

Satin glaze manufacturing formula

The invention discloses a satin glaze manufacturing formula. The satin glaze manufacturing formula comprises a ceramic green body and ground coat, and the ground coat is prepared from, by weight, 22-28% of potassium feldspar, 6-8 parts of kaolin, 30-33% of quartz, 11-15% of aluminum oxide, 5-7% of calcined talc and 1% of zinc oxide. Stain glaze obtained according to the formula is fine and smooth to touch, gentle, free of irritation and great in color development and anti-fouling effect and has efficacies of making people in tranquility and peace, relaxed physically and physiologically, relieved in fatigue, delighted and the like, and glossiness of the stain glaze is 8-12 degrees. In addition, by the brand-new manufacturing formula and process, defects of unsmooth glaze surfaces, orange-peel-like glaze surfaces, fine pores and the like in traditional production are overcome.

Owner:FOSHAN TAOYING NEW MATERIAL CO LTD

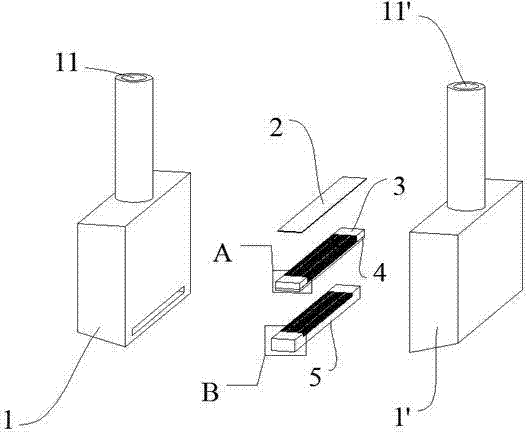

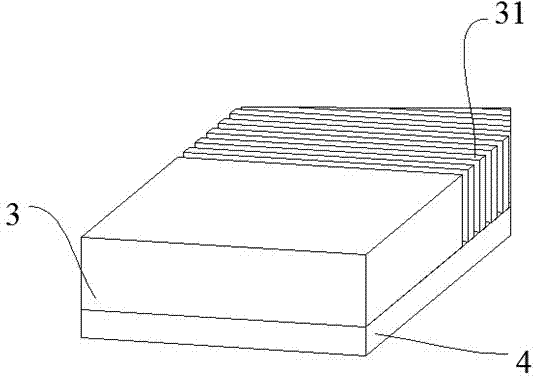

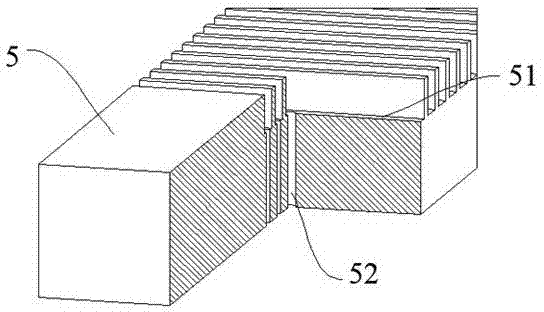

Ink-jet printing head and ink-jet printer

ActiveCN103496257ABraking structure is simpleLarge amount of deformationInking apparatusEngineeringActuator

The invention discloses an ink-jet printing head which comprises at least one jetting unit, a cover film, a piezoelectric ceramic actuator, a cover plate, a fluid inflowing pipeline, a fluid outflowing pipeline and a driving circuit device. The cover film, the piezoelectric ceramic actuator and the cover plate are matched with the jetting unit, the piezoelectric ceramic actuator and the cover plate are connected to form a plurality of disconnected and independent piezoelectric ceramic units, the cover plate is connected with the jetting unit, a plurality of fluid grooves are formed in the position, arranged on one side of the jetting unit, of the connecting contact face, the piezoelectric ceramic units correspond to grooves in the fluid grooves in position, the fluid grooves and the cover plate form a fluid channel, each fluid channel is correspondingly provided with at least one nozzle to be communicated with the exterior, and therefore the ink-jet printing head forms the side face or end face jetting. Correspondingly, the invention further discloses an ink-jet printer. According to the ink-jet printing head and the ink-jet printer, on the premise that the deformation amount of the piezoelectric ceramic actuator can be increased, and the effective jetting motion of the large-particle-size ink is achieved, the adjacent nozzles can conduct simultaneous motion, therefore all the nozzles can work at the same time, and the working efficiency is improved.

Owner:广东金刚新材料有限公司 +2

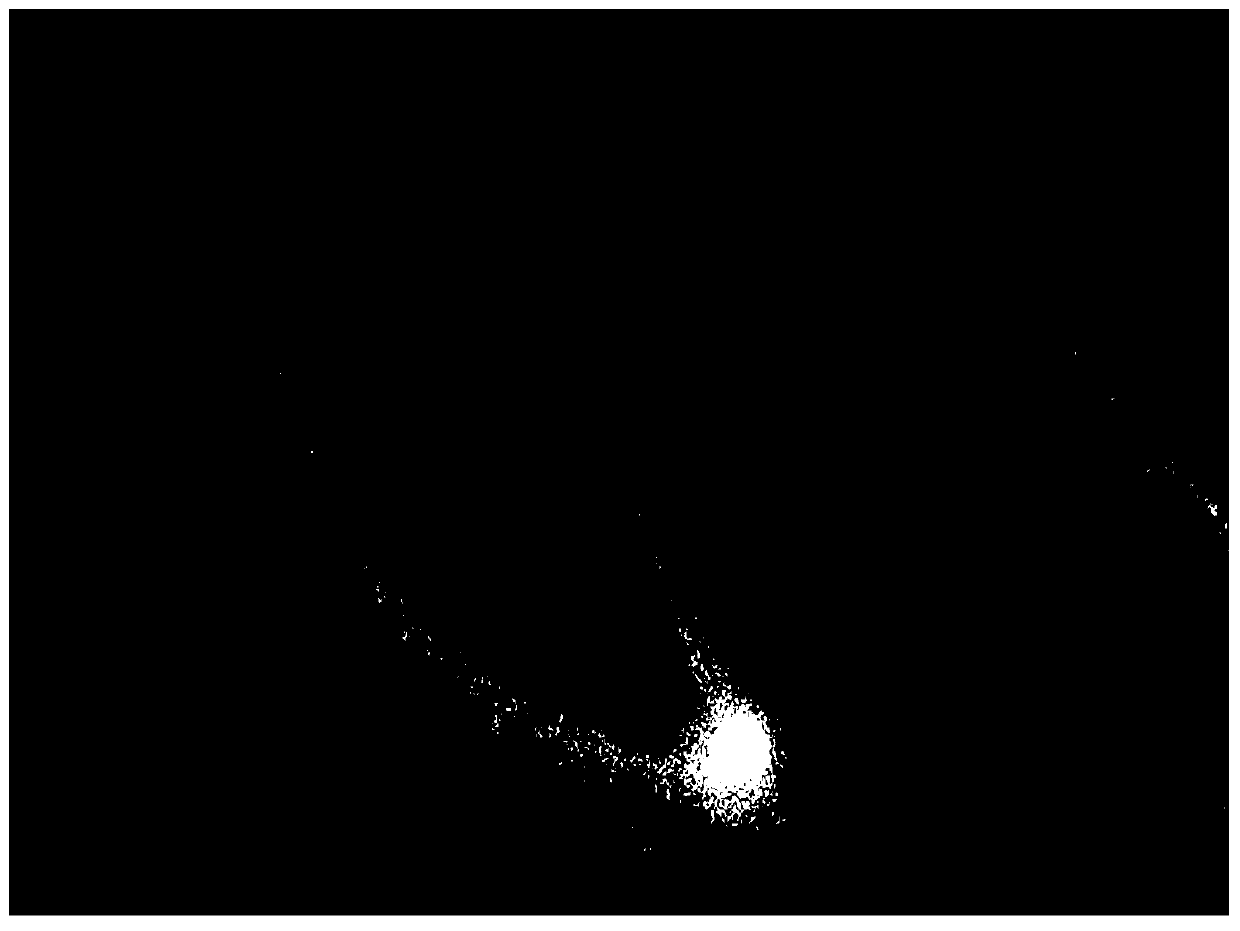

4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof

InactiveCN101440071AStrong nucleophilicityHigh sensitivityOrganic chemistryMaterial analysis by observing effect on chemical indicatorTriazene CompoundFluorescence

The invention relates to a bistriazene compound, in particular to 4, 4'-bis[5, 6-dichloro-2-benzothiazolylazo-amino]biphenyl-3, 3'-disulfonic acid and a preparation method and application thereof. The invention solves the problem existing in the prior art that a reagent for detecting heavy metal ions has nonideal sensitivity. The molecular structural formula of the 4, 4'-bis[5, 6-dichloro-2-benzothiazolylazo-amino]biphenyl-3, 3'-disulfonic acid is shown as follows. The 4, 4'-bis[5, 6-dichloro-2-benzothiazolylazo-amino]biphenyl-3, 3'-disulfonic acid is used for the detection of the heavy metal ions, has the advantages of good selectivity, high sensitivity, and steady performance, can be used for fluorescence detection of Ni (II) in alkaline medium in the presence of a triton surfactant, and can also be used as a visualization reagent for photometric analysis.

Owner:SHANXI DATONG UNIV

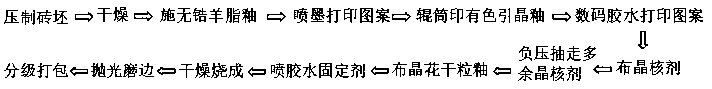

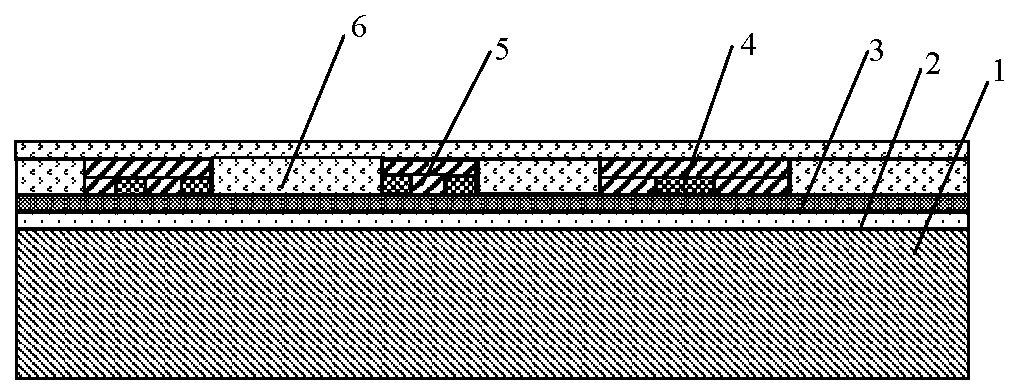

Fine dry grain ceramic tile, preparation method thereof and fine dry grain glaze

The invention discloses a fine dry grain glaze. The fine dry grain glaze comprises, by weight, 5-15 parts of fine dry grains, 35-50 parts of glue and 35-50 parts of a glaze slip, wherein the chemicalcomponents of the fine dry particles comprise 29-33% of SiO2, 45-52% of Al2O3, 1-2.35% of Fe2O3, 0.2-0.5% of TiO2, 0.6-1.5% of CaO, 0.8-1.7% of MgO, 2-4.5% of K2O, 1.5-2.0% of Na2O, 1.8-2.6% of ZnO, 0.5-1.0% of BaO and 4-6.5% of LOI; and the granularity of the fine dry particles is less than or equal to 250 meshes. Correspondingly, the invention further discloses a fine dry grain ceramic tile anda preparation method thereof. The particle size of the dry particles in the fine dry particle glaze is greatly reduced, so that the brick surface is not prone to hiding dirt. Meanwhile, the fine dry granular glaze is outstanding in decorative effect, and the brick surface has a dazzling metal aperture under light irradiation.

Owner:肇庆乐华陶瓷洁具有限公司 +1

Manufacturing method of ceramic sheet with infiltration layer

The invention provides a manufacturing method of a ceramic sheet with an infiltration layer. The manufacturing method comprises the following steps: A, sending an unfired brick, with thickness not more than 6.5mm, of a ceramic sheet to a kiln and performing first firing at 600-1050 DEG C; B, applying organic infiltrated glaze ink and organic infiltration aid ink to the green body subjected to first firing; C, carrying out second firing at 1150-1250 DEG C; and D, carrying out polishing and edging to obtain the ceramic sheet product. The ceramic sheet manufactured by adopting the method has the beneficial effects that an infiltration layer formed by infiltrated glaze ink has certain thickness and infiltrates into a precoat, so that the decorative patterns are resistant to wear, thus solving the problems in the prior art that printed decoration layers formed by conventional ink-jet printing do not have a stereoscopic sense of layering and are not resistant to wear.

Owner:FOSHAN DONGPENG CERAMIC +2

Zirconium-free mutton fat glaze and positioning crystal pattern ceramic tile prepared from the same

The invention discloses a zirconium-free mutton fat glaze and a positioning crystal pattern ceramic tile prepared from the same. The zirconium-free mutton fat glaze comprises the following chemical composition by the mass percentage: 59.0-64.0% of SiO2, 24.5-28.0% of Al2O3, 0-0.18% of Fe2O3, 0-0.1% of TiO2, 0-0.5% of CaO, 0-0.5% of MgO, 4.5-6.0% of K2O, 3.0-4.0% of Na2O and 3.0-4.5% of loss on ignition.

Owner:MONALISA GRP CO LTD

Method for producing electric-melting zirconia used for turquoise pigment and glaze

ActiveCN101703958ANarrow particle size distributionThe particle size distribution range is reasonableGrain treatmentsZirconium oxidesCalorescenceAtmospheric pressure

The invention relates to a method for producing electric-melting zirconia used for turquoise pigment and glaze, which is characterized in that: in a process of fine crushing, a feed particle size D50 is controlled between 20 and 25mu m, the working air pressure of a nozzle of a jet mill is 0.8MPa, a cyclonecluster is adjusted to 45Hz, a grader is adjusted to 18Hz, and the size distribution after the crushing meets the conditions that: D10 is not less than 3mu m, D50 is kept between 14 and 15mu m, and the difference between D90 and D10 is not more than 30mu m. The method has the advantages that: the narrow size distribution range of zirconia powder is realized, and reasonable grain size distribution is realized; and the electric-melting zirconia is favorable for color development of the turquoise pigment and glaze compared with the traditional electric-melting zirconia, comprehensively improves the blue degree of corresponding pigment and glaze, reduces a brightness value, makes the pigment develop more bright and vivid color in the glaze, and improves the beautifulness of corresponding ceramic products. The electric-melting zirconia after reasonable particle size control and adjustment can improve the high temperature resistance of the turquoise pigment and glaze more obviously than the electric-melting zirconia which is not controlled, and still can keep bright tone at the temperature higher than 1,200DEG C so as to promote the application to high temperature pigments.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

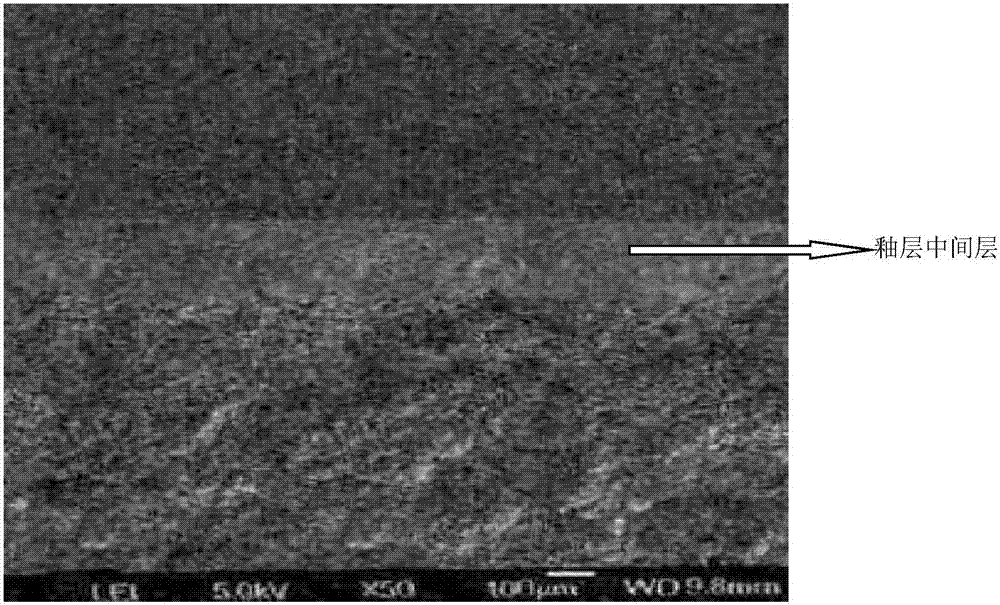

Ceramic inkjet penetrated overglaze containing lepidolite tailings

The invention discloses ceramic inkjet penetrated overglaze containing lepidolite tailings. The ceramic inkjet penetrated overglaze is prepared from potassium feldspar, albite, quartz, kaolin, calcined talc and lepidolite tailings. The ceramic inkjet penetrated overglaze has the advantages as follows: (1) the composition proportion of each mineral of glaze slip produced with the process is reasonable, mixing of melting substances of a green body and glaze is facilitated, the chemical composition and property of a middle layer are gradually transited from the composition of the green body to composition of the glaze, so that harmful stress caused by property difference is reduced, and defects of ceramic tile products are reduced; (2) the glaze has proper viscosity and good suspension property and thus conforms to the ceramic production process, and smooth and defect-free glaze can be obtained easily; (3) the glaze produced with the process is ground very fine and has the fineness being 325 meshes or below, all minerals are uniformly mixed, quartz is promoted to transform at the high temperature, melting tends to be complete, and the tendency of glaze crazing of an inkjet penetrated product can be reduced.

Owner:GUANGDONG DOWSTONE TECH

Staphylococcus xylosus I2 strain, composite ferment produced thereby and the use of ferment in meat ware

The invention relates to an xylose staphylococcus I2 strain, whose docket number in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0919, the leaven can be applied into the production process for meat product e.g. fermentation sausage.

Owner:河南双汇投资发展股份有限公司

UV jet ink and preparation method and application thereof

The invention belongs to the field of ceramic ink, and particularly relates to UV jet ink and a preparation method and application thereof. Raw materials of the UV jet ink include toner, resin, monomer diluent, dispersing agent, photoinitiator, antioxidant, surface auxiliary and rheology auxiliary. Meanwhile, the invention further provides the preparation method of the UV jet ink, and application of the UV jet ink or a product obtained through the preparation method in the field of ceramic ink. Through measurement, the prepared UV jet ink is high in thermal stability, can meet technological parameters of artistic ceramic, can be suitable for artistic ceramic, and widens the use range. The novel UV ceramic ink which is applied in an ink spraying mode can meet the requirement for building ceramic and can completely meet the requirement of the field of artistic ceramic.

Owner:佛山市南海万兴材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof 4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof](https://images-eureka.patsnap.com/patent_img/cb2296ce-2e42-42a5-82ee-a07b35b0d555/a200810080130e00111.PNG)

![4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof 4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof](https://images-eureka.patsnap.com/patent_img/cb2296ce-2e42-42a5-82ee-a07b35b0d555/a200810080130c00021.PNG)

![4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof 4,4'-bis[5,6- dichloro-2-benzothiazolylazoamino] biphenyl-3,3'-disulfonic acid, preparation and use thereof](https://images-eureka.patsnap.com/patent_img/cb2296ce-2e42-42a5-82ee-a07b35b0d555/a200810080130d00041.PNG)