Novel printing glaze material and production method thereof

A printing glaze, a new type of technology, applied in the new printing glaze and its production field, can solve the problem of inconsistent gloss of graphic effects, and achieve the effect of overcoming ink gloss variation, ensuring clarity and good color development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

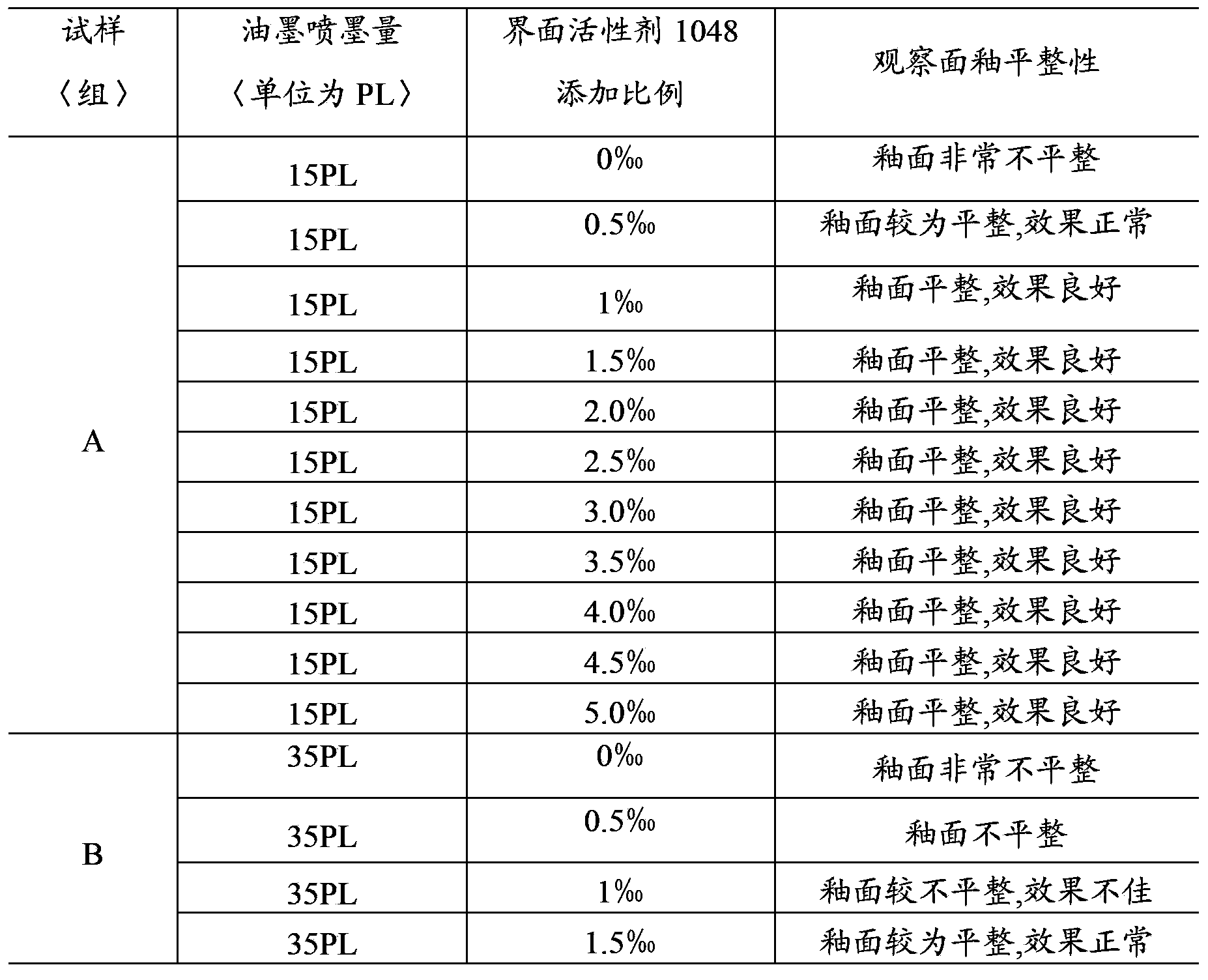

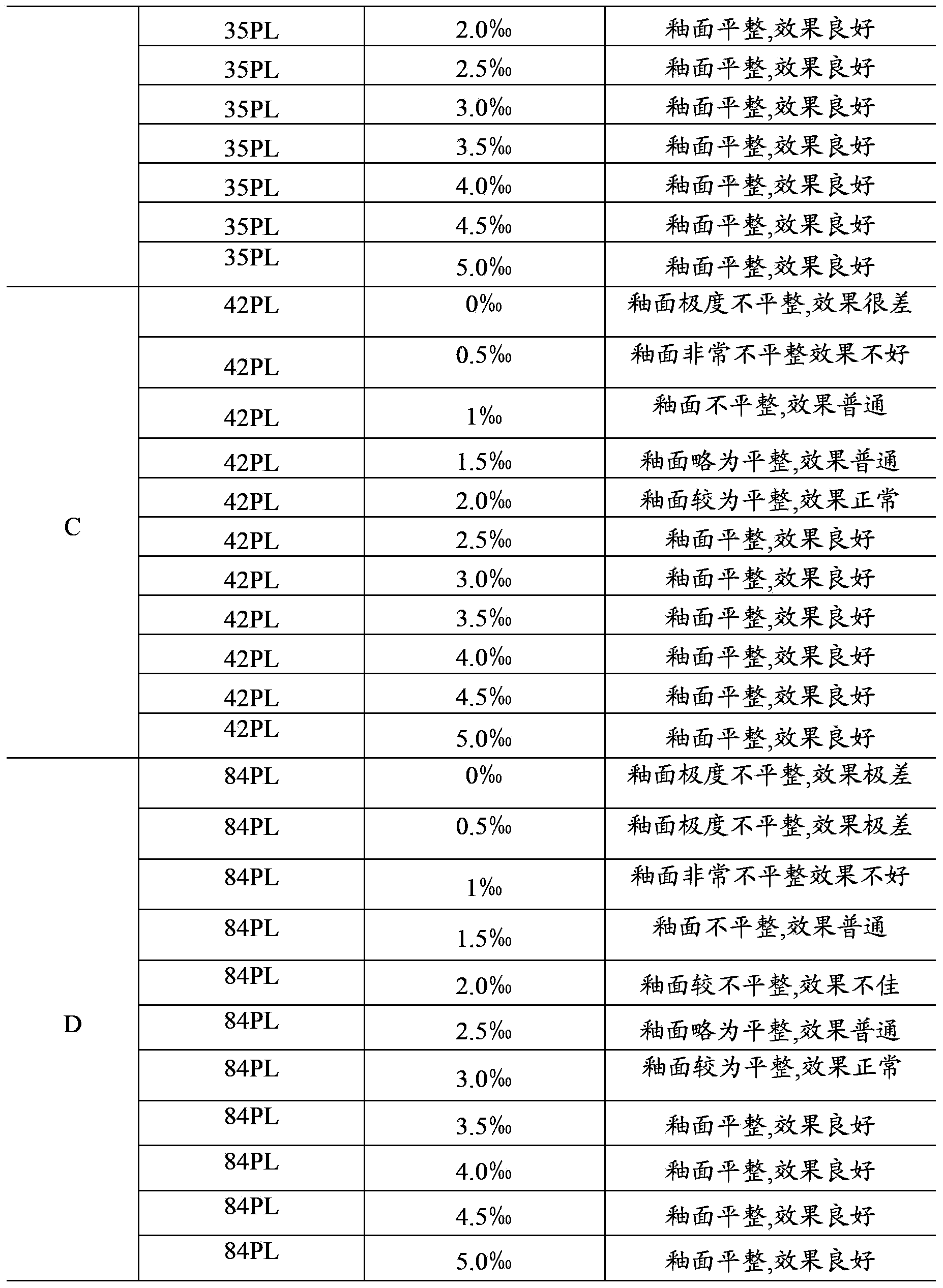

[0045] In order to better explain the gist of the present invention, several preferred implementation modes are provided below.

[0046] First provide several groups of existing printing glaze components and their ratios

[0047] component name

Matching ratio 1

Matching 2

Matching ratio 3

40

44

40

[0048] nepheline orthoclase

10

0

10

4

12

4

Kaolin

0

4

8

spherical clay

6

2

2

4

4

4

Aluminum oxide

4

4

14

6

6

0

Zinc oxide

6

2

2

8

10

8

barium carbonate

1.5

1

1

1.5

1

1

4

4

4

5

5

2

[0049] The various components in the ratios in the above tables are calculated by weight percentage of the overall mass.

[0050] Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com