Patents

Literature

322 results about "Ceramic industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight ceramic tile and production method

The invention discloses a light-weight ceramic brick, which is a light-weight ceramic brick fired at high temperature and has a honeycomb-like internal structure of closed pores. The invention also discloses a preparation method of the above-mentioned lightweight ceramic tiles, which is formed by dry pressing after wet ball milling, sieving, iron removal, spraying drying tower and powder spraying on the vitrified brick polishing waste produced in large quantities in the ceramic industry at present. Method forming, or kneading using wet extrusion molding, and then firing products in continuous or batch kilns. Manufacture a kind of lighter quality ceramic tiles, aiming at the insufficient use of waste materials in the past, more effectively utilize industrial waste residues in large quantities, and because of its light structure, it can be used in the decoration of high-rise building walls, It has good properties such as light weight, high strength, heat preservation, and sound absorption, and it can significantly reduce the weight of the wall structure. At the same time, it also has the characteristics of easy transportation, easy construction, and fast speed. It has great advantages in saving energy and reducing the weight of buildings. The outstanding advantage is that it is an environment-friendly building ceramic decoration material.

Owner:FOSHAN OCEANO CERAMICS

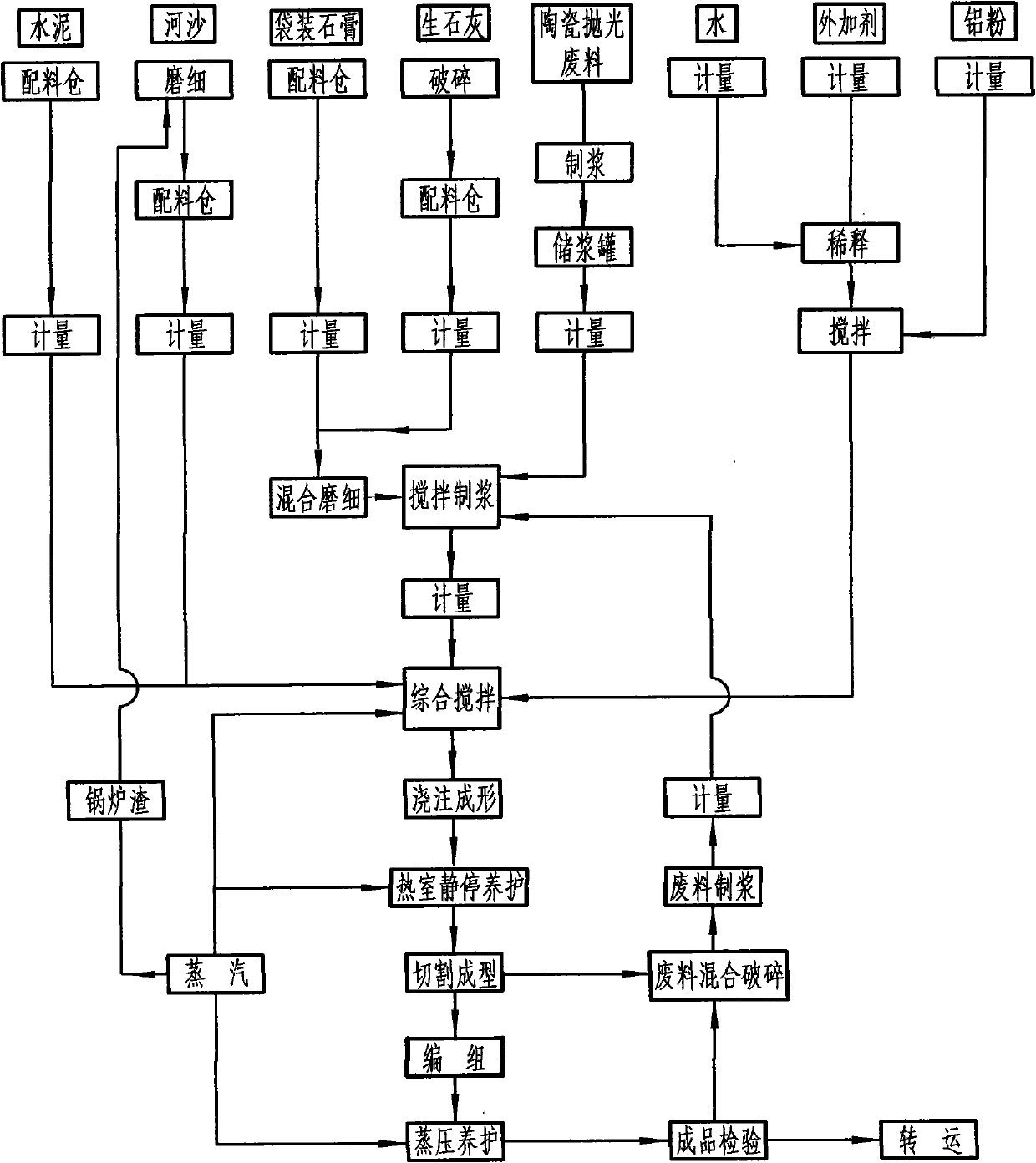

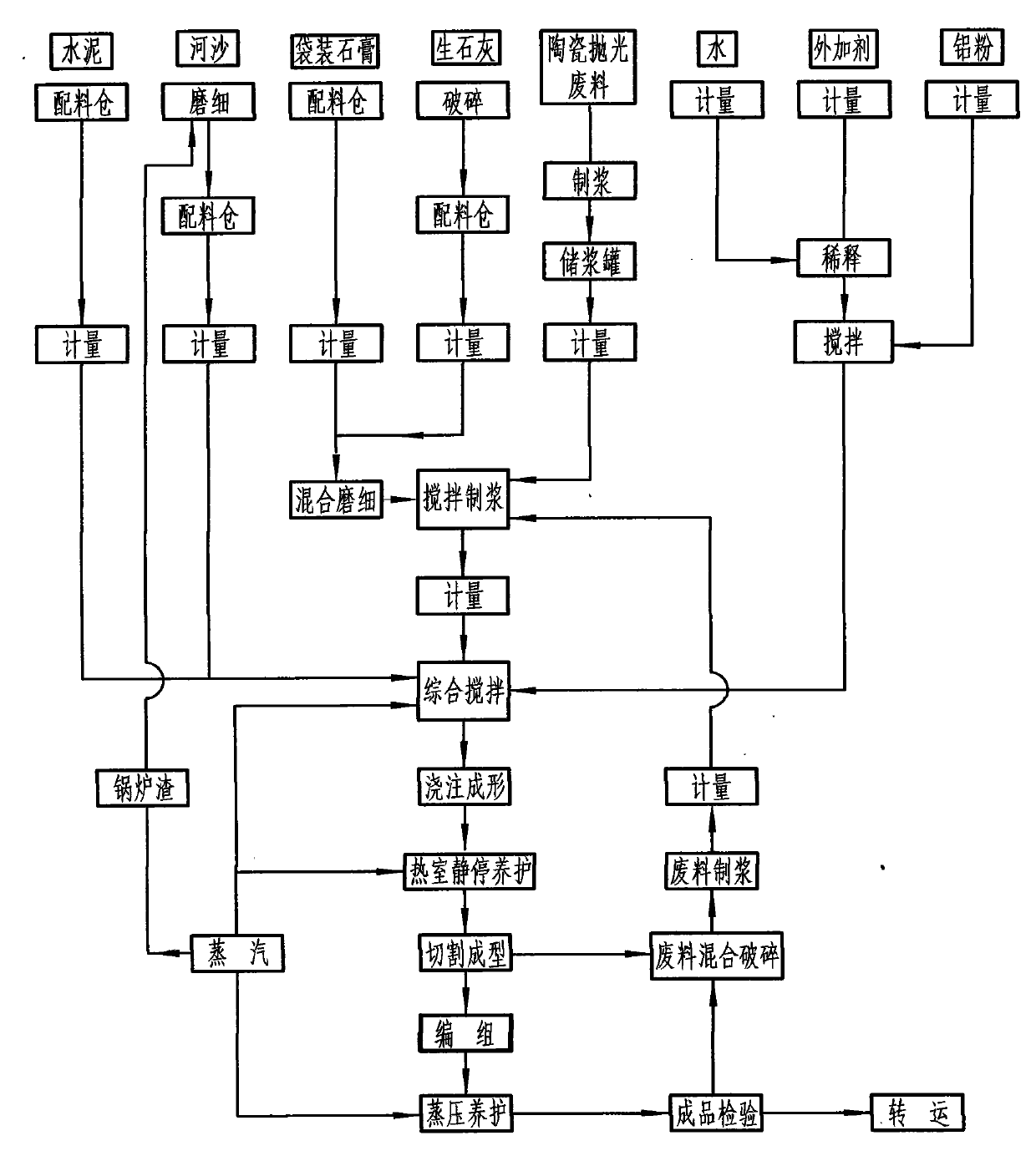

Autoclaved aerated concrete building block and preparation method thereof

The invention discloses an autoclaved aerated concrete building block, which is prepared by adding water into 50 to 55 weight parts of ceramic polishing waste, 10 to 15 weight parts of fine sand, 20 to 24 weight parts of calcined lime, 10 to 20 weight parts of cement, 0.05 to 0.09 weight part of aluminum powder and 3 to 5 weight parts of gypsum. The invention also discloses a preparation method for the autoclaved aerated concrete building block, which comprises the production processes of raw material fetching, slurry preparation, proportioning and pouring, standing and curing in a hot chamber, blank cutting, grouping, autoclaved maintenance, finished product inspection, recycle of waste liquid, waste slag and waste products and the like. The obtained autoclaved aerated concrete building block has the characteristics of high forming speed, light weight, high strength, heat insulation, sound insulation, good fireproof performance, low elasticity, seismic resistance, convenient construction and the like. The preparation method realizes utilization of the ceramic polishing waste, reduces the discharge of wastes of the ceramic industry, and is favorable for protection of ecological environment.

Owner:周石镭 +3

Method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste

InactiveCN101671160ARealize green productionEmission reductionSolid waste disposalCeramic materials productionFeldsparMaterials science

The invention discloses a method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste, comprising the following steps: all raw materials are mixed by weight percentage: 1-99percent of ceramic waste, 0-40 percent of ceramic clay, 0-30 percent of quartz, 0-35 percent of feldspar and 1-50 percent of aluminum oxide or aluminous rich matter; water is added by 50-150 percentof total weight of the raw materials, and 0.5-5 percent of grinding aids and 0.5-5 percent of binders are added to carry out ball-milling, the no-foaming and no-deformation ceramics can be prepared bydrying, formation and sintering. The technology provide by the invention not only solves the problem of the treatment of a great amount of ceramics in ceramic industry, but also solves excessive consumption problem of raw material resource in the ceramic industry, thereby greatly reducing the waste discharge in the ceramic industry and reducing environmental pollution caused by accumulation and land filling of the ceramic waste. The technology has the advantages of high waste utilization rate, simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

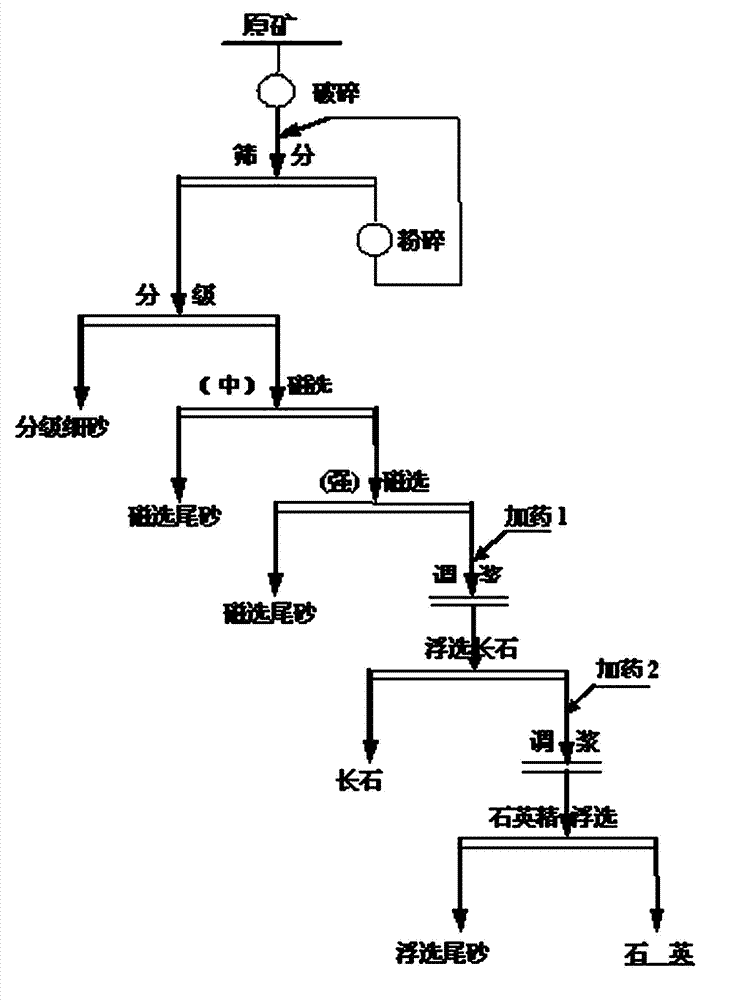

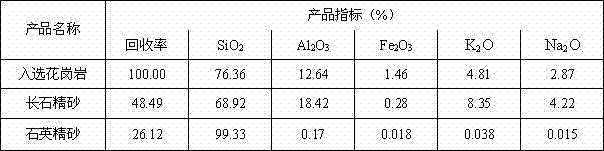

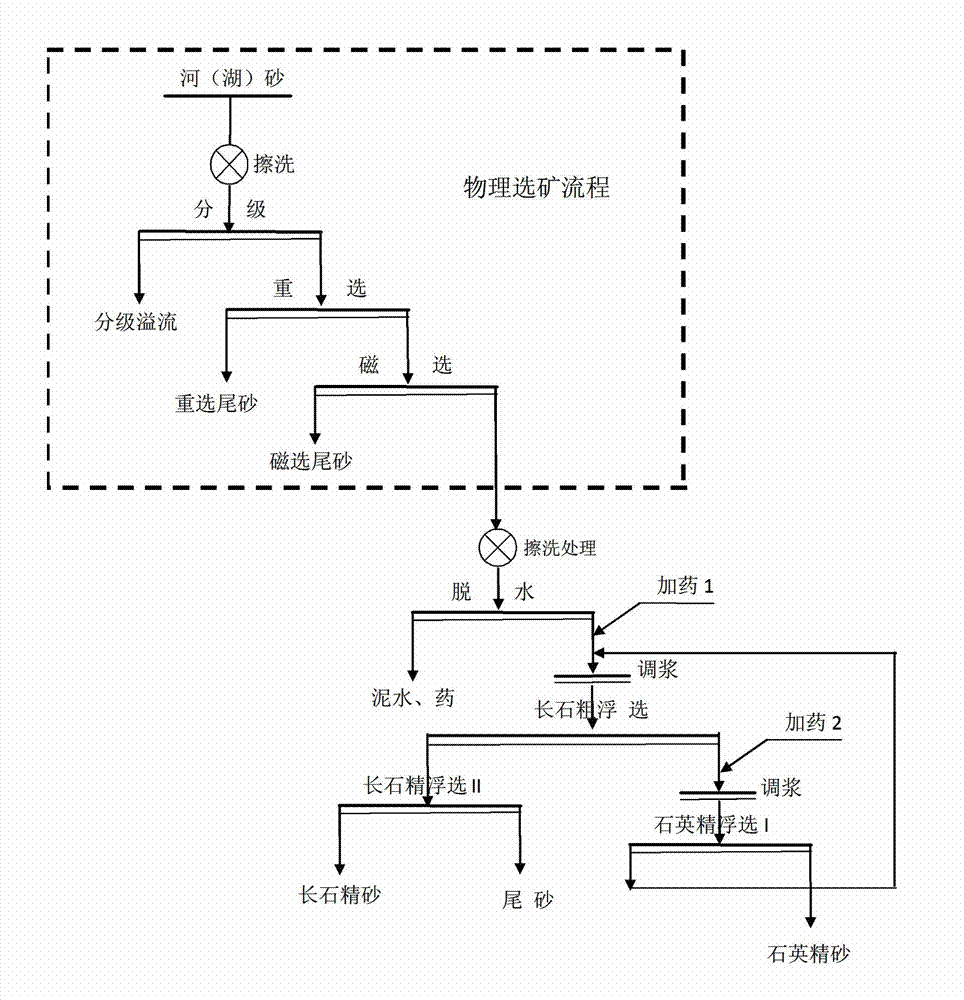

Beneficiation method for extracting feldspar and quartz from granite

InactiveCN102728478AEfficient separationAlleviate the crisis of depletionFlotationGranularityPre treatment

The invention discloses a beneficiation method for extracting feldspar and quartz from granite, comprising the following steps of: 1. carrying out physical beneficiation process treatment of crushing, sieving, grading, carrying out medium magnetic separation and carrying out strong magnetic separation on granite ores to remove almost parts of ferromagnetic minerals and obtain a primary product with qualified granularity combination; 2. carrying out pre-treatment of wiping and removing (medicine) water on the product; and then, carrying out size mixing and flotation selecting to realize the separation of the feldspar and the quartz; and 3. precisely selecting the quartz: utilizing a precise (floatation) selection process to reduce the content of Fe2O3 in the quartz. According to the beneficiation method for extracting the feldspar and the quartz from the granite, the feldspar and the quartz with high quality can be effectively separated from the granite, and a replaceable resource is provided for the feldspar and quartz raw materials needed by glass and ceramic industries; and therefore, the environment is protected, the cost is reduced and the dangers that resources are increasingly exhausted are reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

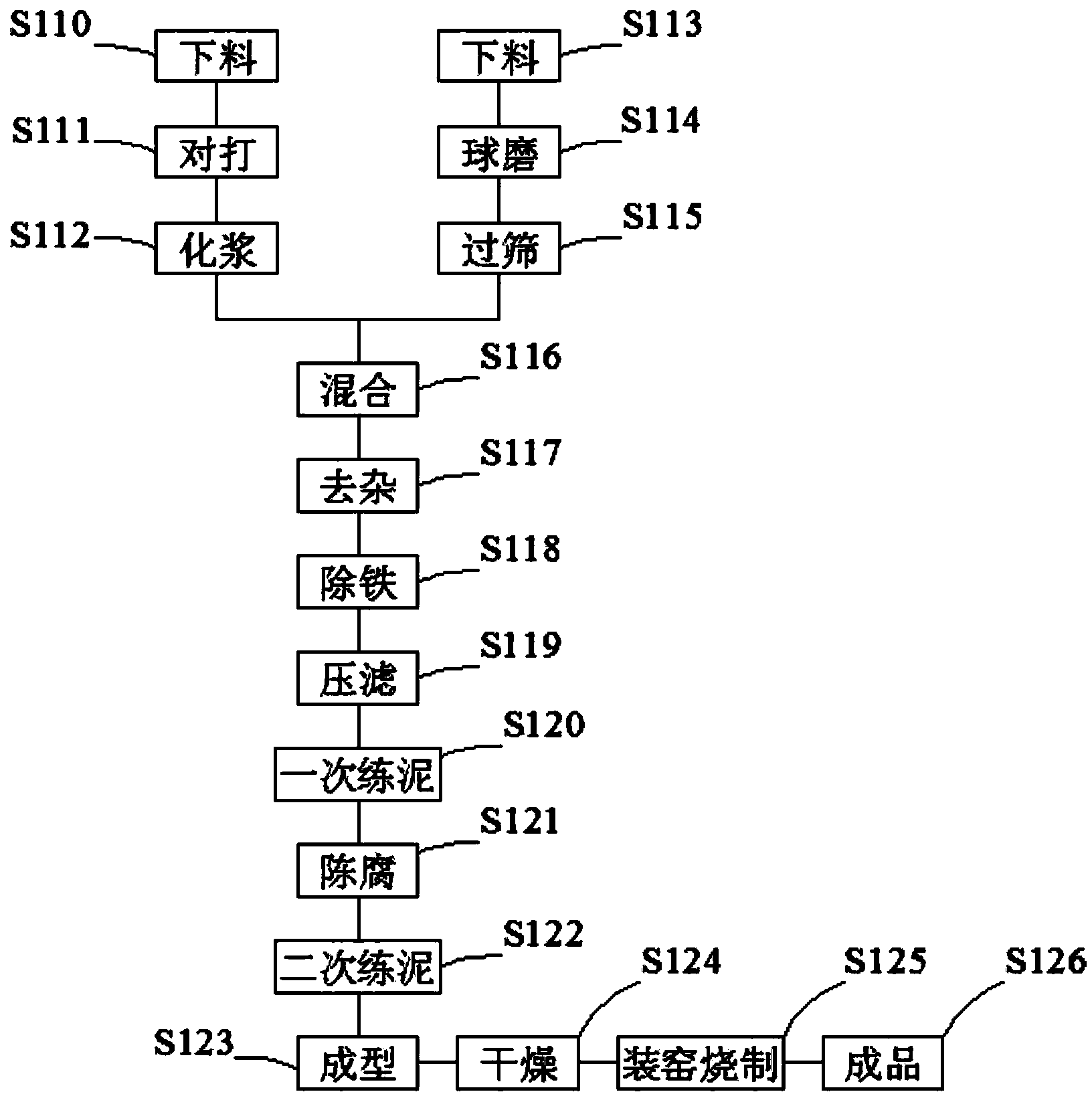

Self-forming glaze white jade porcelain pug and manufacturing method of porcelain pug product

The invention relates to self-forming glaze white jade porcelain pug and a manufacturing method of a porcelain pug product. The self-forming glaze white jade porcelain pug comprises the followings in percentage by weight: 13 to 21 percent of kaoline, 14 to 20 percent of feldspar, 2 to 7 percent of bentonite, 38 to 47 percent of quartz, 11 to 16 percent of wollostonite and 7 to 11 percent of calcite power. The manufacturing method provided by the invention comprises the steps of sparring, slurrying and the like. The method has the benefits as follows: traditional two-step firing is changed to be one-step firing, energy consumption is lowered, carbon discharge capacity is reduced, processes of glaze making and glazing are removed, the discharge capacity of three wastes is reduced, human resources are saved, the dissolving-out amount of heavy metals such as lead and cadmium and the like carried into glaze is reduced, the porcelain pug is glittering and translucent, like jade, and the section of the porcelain pug has no arrises and is shell-shaped. The porcelain pug product prepared by the invention is green, environmental-friendly and safe, can be used as dishware porcelain, daily porcelain, art porcelain, decorative porcelain, porcelain for lighting tools and the like in the ceramic industry.

Owner:何晓洪 +1

Preparation method for super white ceramic vitrified tile produced by using magnesium aluminum silicate as raw material

The invention provides a preparation method for a super white ceramic vitrified tile produced by using magnesium aluminum silicate as a raw material. The super white ceramic vitrified tile comprises components of potassium feldspar, albite, calcined talc, black clay, a water reducing agent, a lithium feldspar, diopside, an intensifier, washed mud and quartz. The ultralow temperature fast firing vitrified tile belongs to a special ultralow temperature, high-strength, high-hardness, high abrasion-resistance, strong antifouling, low-radiation, environment-friendly, healthy and novel vitrified tile material and product. The technology can reduce firing temperature and shorten a firing period greatly and is favorable for energy conservation and emission reduction of ceramic industry, green manufacturing and low carbon production.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

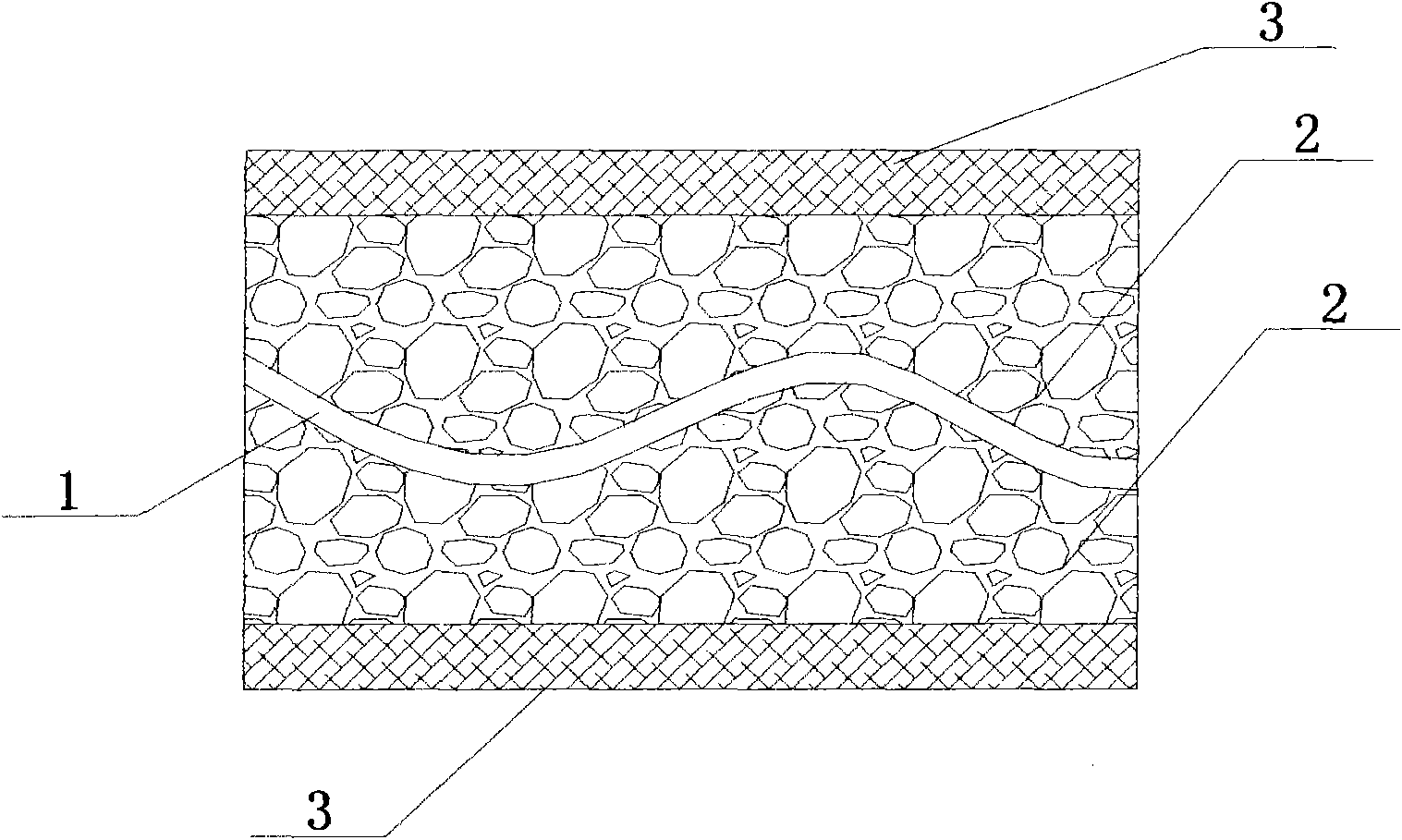

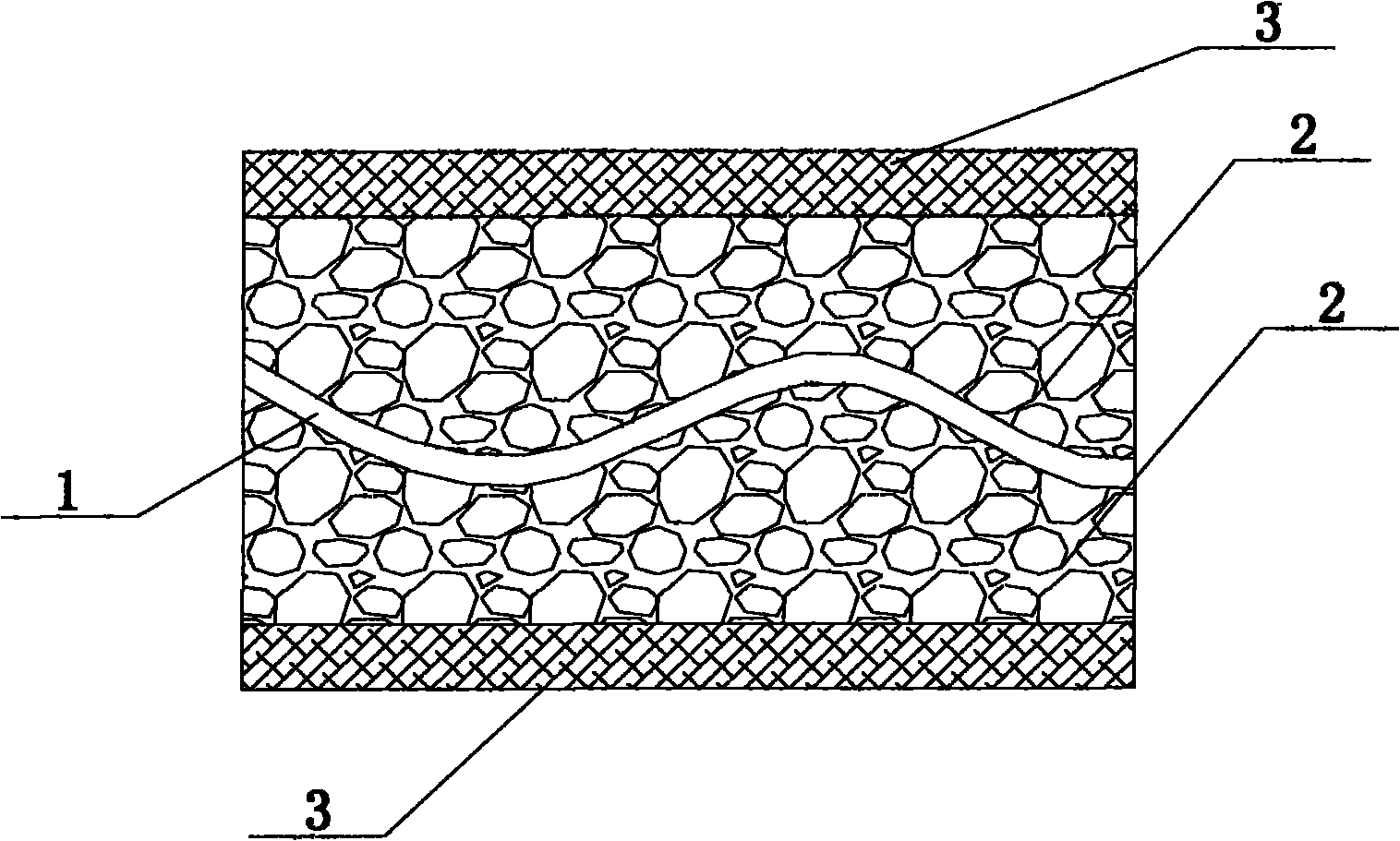

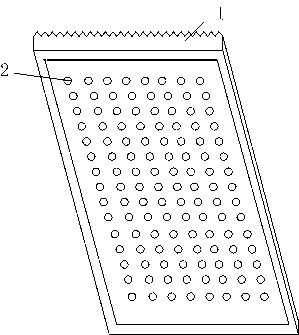

Composite needled filter felt

InactiveCN101979125AGuaranteed normal windingRealize secondary protectionSynthetic resin layered productsGlass/slag layered productsPolyesterBreaking strength

The invention discloses a composite needled filter felt, and relates to a filtering material for a ceramic industry. The filter felt consists of a glass fiber base cloth layer (1), a polyester fiber and polypropylene fiber composite layer (2) and a polytetrafluoroethylene-impregnated (PTFE) coating layer (3), wherein the polyester fiber and polypropylene fiber composite layer (2) is arranged on the outer layer of the glass fiber base cloth layer (1) and covered by the PTFE-impregnated coating layer (3); and the process flow of the filter felt comprises the following steps of: preparing polyester fiber and polypropylene fiber, opening, carding and netting; preparing glass fiber base cloth; opening, carding and netting; pre-needling; primarily needling; singeing; calendering; and impregnating to obtain the finished product. The filter felt has the advantages of high temperature resistance, high ventilation, high break strength in warp and weft directions, low elongation and long service life.

Owner:靳双林

Beneficiation method for producing quartz and feldspar by using river and lake sands

The invention discloses a beneficiation method for producing quartz and feldspar by using river and lake sands. The method is characterized by comprising the following steps of: (1) performing beneficiation to river (lake) sands by 'ore washing, desliming, grading, reselecting, magnetic selecting' and other conventional physical methods to control the product granularity and reduce the content of Fe2O3; (2) coarse separation, wherein primary separation of quartz and feldspar minerals can be realized by utilizing a flotation process; and (3) selected iron removal, wherein the content of Fe2O3 of quartz and feldspar minerals can be reduced by utilizing selection (flotation) process. After treatment by the process, quartz and feldspar for glass, ceramic and other industries can be widely obtained from river (lake) sands. The beneficiation method has the advantages that high-quality quartz and feldspar can be effectively separated from river and lake sands, so that a substitution resource is provided to the quartz and feldspar raw materials for the glass and ceramic industries, the environment is protected, the cost is reduced, and the risk that resources are increasingly exhausted can be reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Preparation technology of low-cost high-strength ceramic floor tile

InactiveCN103819176AAlleviating the crisis of scarcityReduce dependenceManufacturing technologyRed mud

The invention relates to a preparation technology of a low-cost high-strength ceramic floor tile, which comprises the following steps: 1)taking 30-40% of steel slag, 40-55% of bayer process red mud and 20-30% of talcum according to weight percentage for standby; 2)crudely crushing the steel slag into the particles with size below 10mm; 3)respectively performing ball milling on the steel slag particles and the bayer process red mud by a ball mill for 8 hours, and sieving through a sieve with 250 meshes; 4)placing the sieved raw material in a three-dimensional stereo feed mixer for mixing for 10 hours; and 5)adding water in a mixture, and preparing a green compact by an oil hydraulic press under 25MPa pressure, placing the dried green compact in a muffle furnace, and roasting to obtain the ceramic floor tile. The ceramic floor tile provided by the invention takes red mud and steel slag as main raw materials, and the red mud and steel slag substitute the rear kaolin with high cost and high quality, so that dependence of ceramic industry in our country to kaolin is reduced, and crisis of high-quality kaolin scarcity due to rapid development of industrial can be alleviated.

Owner:HENAN UNIV OF SCI & TECH

Heat-transfer-printing color tape capable of being printed with high-temperature-resistant marks and manufacturing method thereof

The invention discloses a heat-transfer-printing color tape capable of being printed with high-temperature-resistant marks, comprising a PET (polyethylene terephthalate) tape base and a heat-transfer-printing oil-ink layer adhered on the PET tape base. The heat-transfer-printing color tape is characterized in that the heat-transfer-printing oil-ink layer comprises the following materials in partsby weight: 5-35 parts of ionic liquid, 20-45 parts of composite inorganic binding agent, 5-40 parts of inorganic filler, 1-8 parts of organic silicon resin, 5-40 parts of high-temperature-resistant pigment, 0-5 parts of processing aid and 0-20 parts of solvent; and the ionic liquid is solid in normal temperature, is liquid when being heated in heat transfer printing, and is solid due to being decomposed at the temperature of higher than 300 DEG C. The heat-transfer-printing oil-ink layer is coated on a base film by adopting a blade coating or roll coating process. Compared with the prior art,the marks printed on the color tape disclosed by the invention such as characters, images and barcodes can resist high temperature without casting, deformation and blurring. The heat-transfer-printing color tape can be used for the industrial fields with high-temperature treatment procedures such as the ceramic industry, the iron-making and steel-making industry, the metal casting and forging industry, the glass industry and the like.

Owner:HEBEI UNIV OF ENG

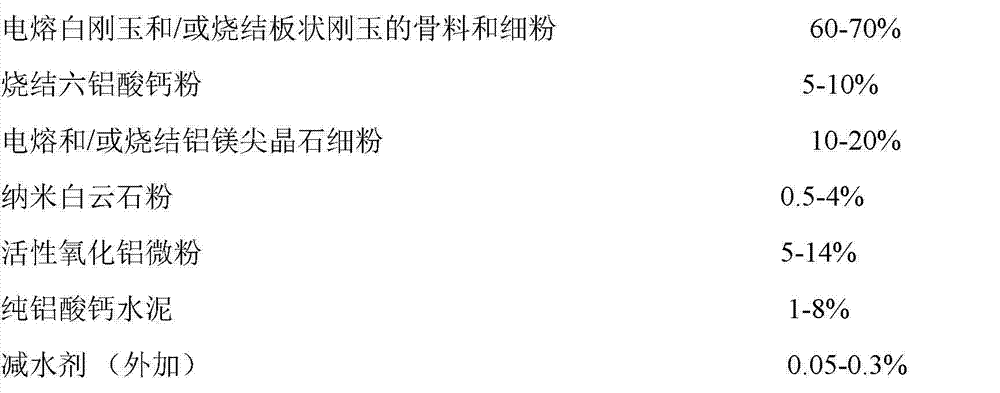

Nano dolomite-containing corundum spinel castable

The invention relates to a nano dolomite-containing corundum spinel castable and a preparation method thereof. On the basis of a corundum spinel castable which is commonly used at present, nano dolomite powder is added, spinel and calcium hexa-aluminate serving as seed crystals are introduced, and a high-efficiency dispersing agent and an appropriate mixing process are adopted, so that the nano dolomite-containing corundum spinel castable is prepared. The adverse effect of hydration of magnesia on the construction performance of the castable when spinel is generated in situ by adding the magnesia is avoided, and the slag resistance and thermal shock resistance of the corundum spinel castable which is used at present are improved; and the prepared nano dolomite-containing corundum spinel castable can be widely applied to the field of high-temperature industry such as steel industry, nonferrous metal industry, ceramic industry and petrochemical industry, and also can be applied to a fireproof material product formed by casting, forming and sintering a permeable brick and the like.

Owner:山国强

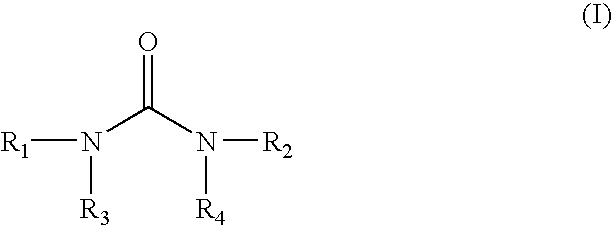

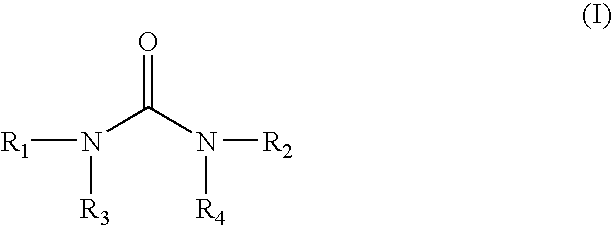

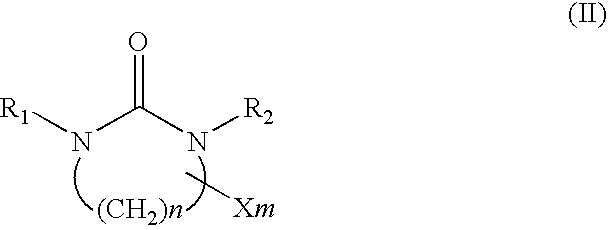

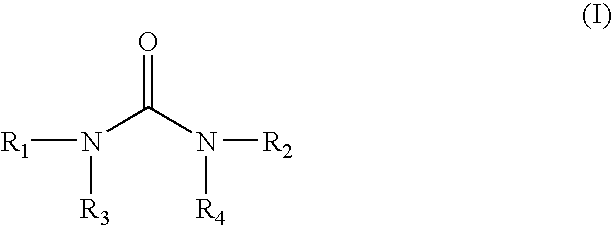

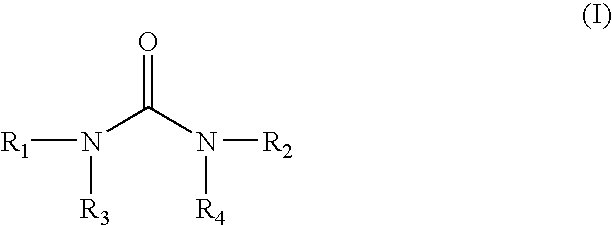

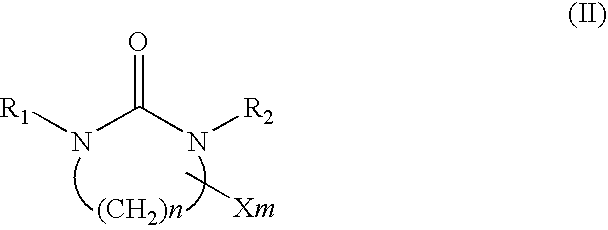

Ink composition

An ink composition is provided including an amide compound represented by formula 1, a coloring agent and a solvent. The amide compound and the polyhydric alcohol in the ink composition decrease the mobility of coloring agents and increase the adhesion to media, thereby minimizing the bleeding between colors of printed images, and improving the water fastness and dry and wet rub fastness to provide good color fastness on papers. The ink composition also improves the quality of the printed image, and also has good long-term storage stability. Thus, the ink composition can be widely used as ink-jet inks for ink-jet printers, printing inks, paints, textile printing, paper manufacturing, cosmetics manufacturing, ceramic industry, etc.

Owner:S PRINTING SOLUTION CO LTD

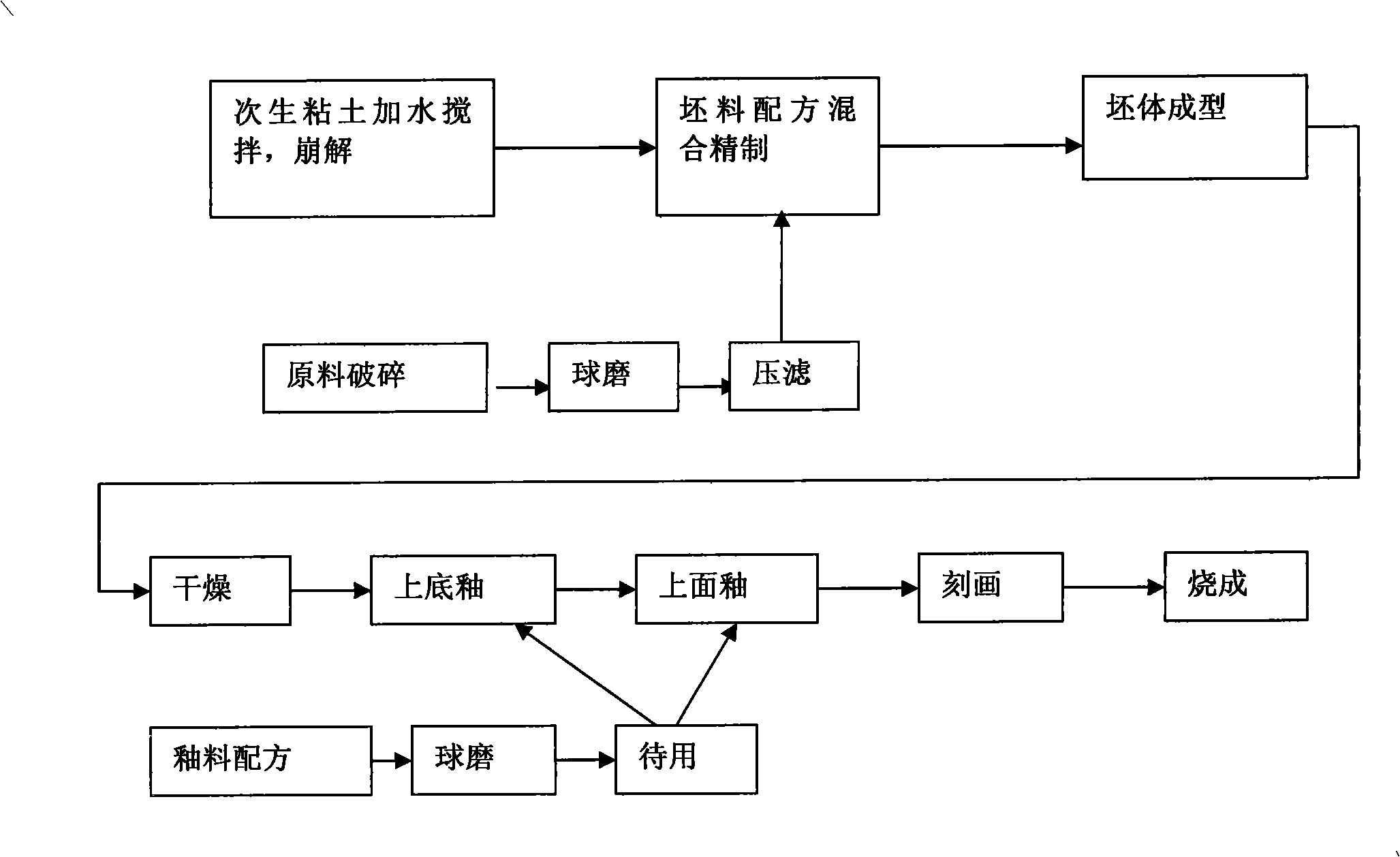

Manufacturing process of furnace transmutation enamel

ActiveCN101348329AOptimize resource allocationSignificant decorative color effectMineral SourcesCerium

The invention discloses a process for manufacturing a kiln transformation glaze porcelain. The manufacture process comprises the steps of blank making, forming, enameling and burning, wherein a carving step is arranged between the enameling step and the burning step; in the invention, inferior porcelain clay and secondary clay, which are abundant, low in price and high in ferrotitanium content, are used as main materials for production of kiln transformation glaze porcelains, by adding rare earth metal elements such as iron-titanium oxide, cerium and cesium, etc., the physical-chemical properties of blank glaze, and produced blank colors and kiln transformation colors of porcelain are mixed, and the color development is simple and natural, the coloring is mild, deep colors and light colors go well with each other, and lines and contours are clear; the invention optimizes the allocation of porcelain resources, fully utilizes unrenewable mineral resources, lowers production cost, improves economic benefits of the ceramic industry and opens up a new path for the supply of porcelain materials.

Owner:FUJIAN JIAMEI GRP

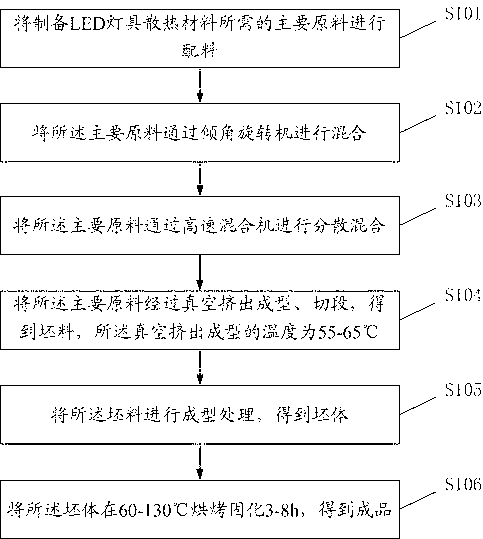

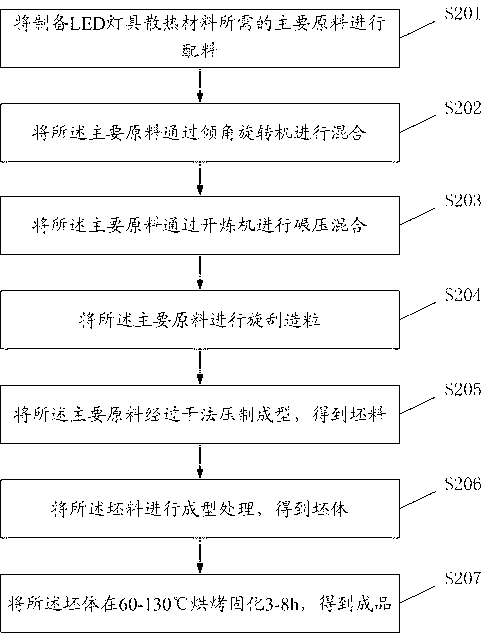

Light-emitting diode (LED) lamp heat dispersing material and preparation method thereof as well as radiator and LED lamp

InactiveCN103265792ALow costAchieve reductionLighting heating/cooling arrangementsEpoxyCeramic sintering

The invention discloses a light-emitting diode (LED) lamp heat dispersing material which comprises the following materials in percentage by volume: 15%-27% of epoxy resin and 73%-85% of ceramic powder filler, wherein the epoxy resin has the epoxide number of 0.38-0.54 mol / 100g; and the ceramic powder filler is one or more in mullite-corundum, mullite and silica glass phase, which are obtained by carrying out pretreatment on ceramic sintering wastes. Correspondingly, the invention also discloses a preparation method of the LED lamp heat dispersing material, a radiator made from the LED lamp heat dispersing material, and an LED lamp. The environment-friendly heat dispersing material made from the ceramic wastes is good in heat dissipation effect, low in cost of raw materials, light in weight, high in safety guarantee and beneficial to reduction, resource utilization and harmless disposal of the ceramic wastes, thus promoting the sustainable development of ceramic industry.

Owner:林浩青 +1

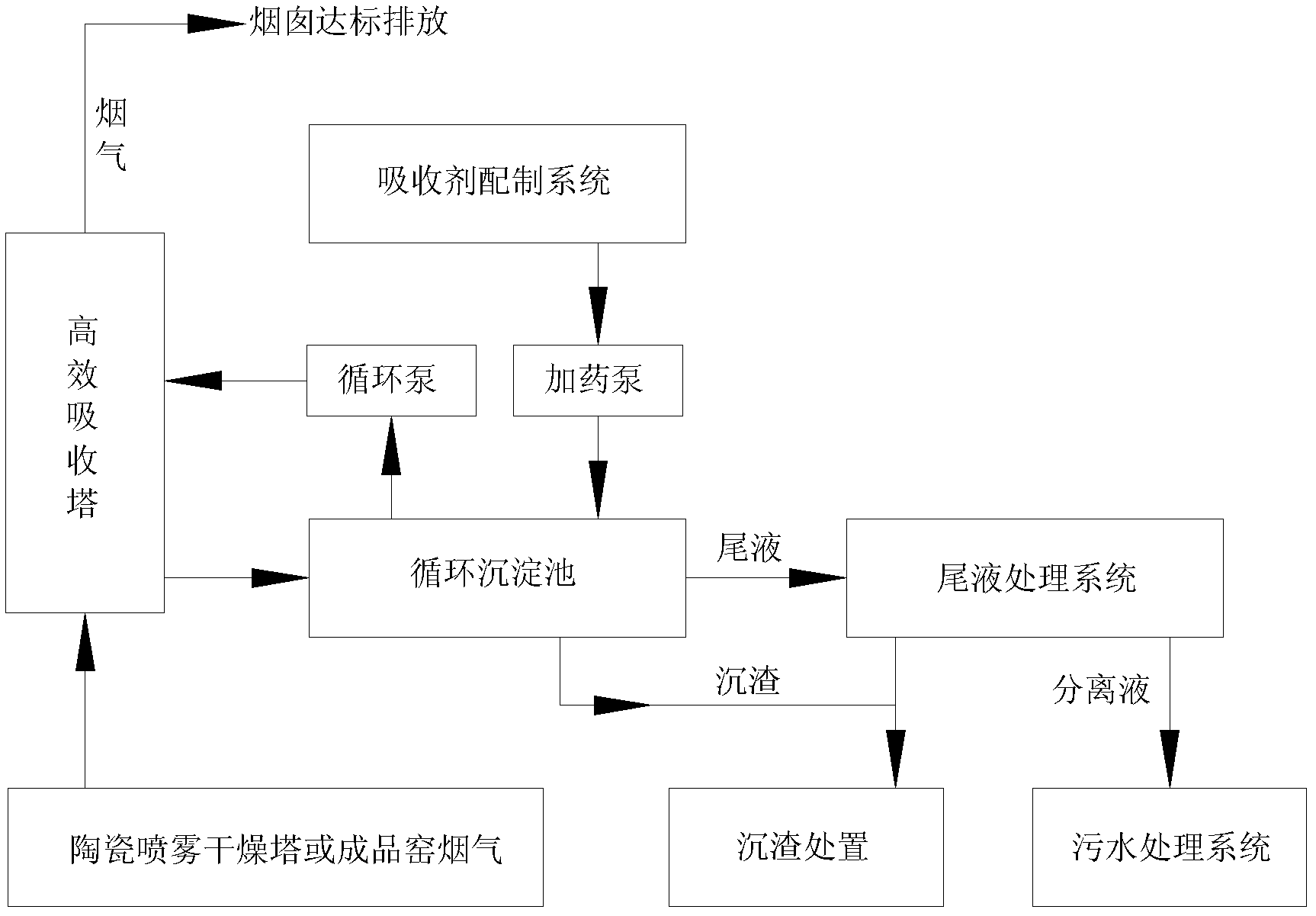

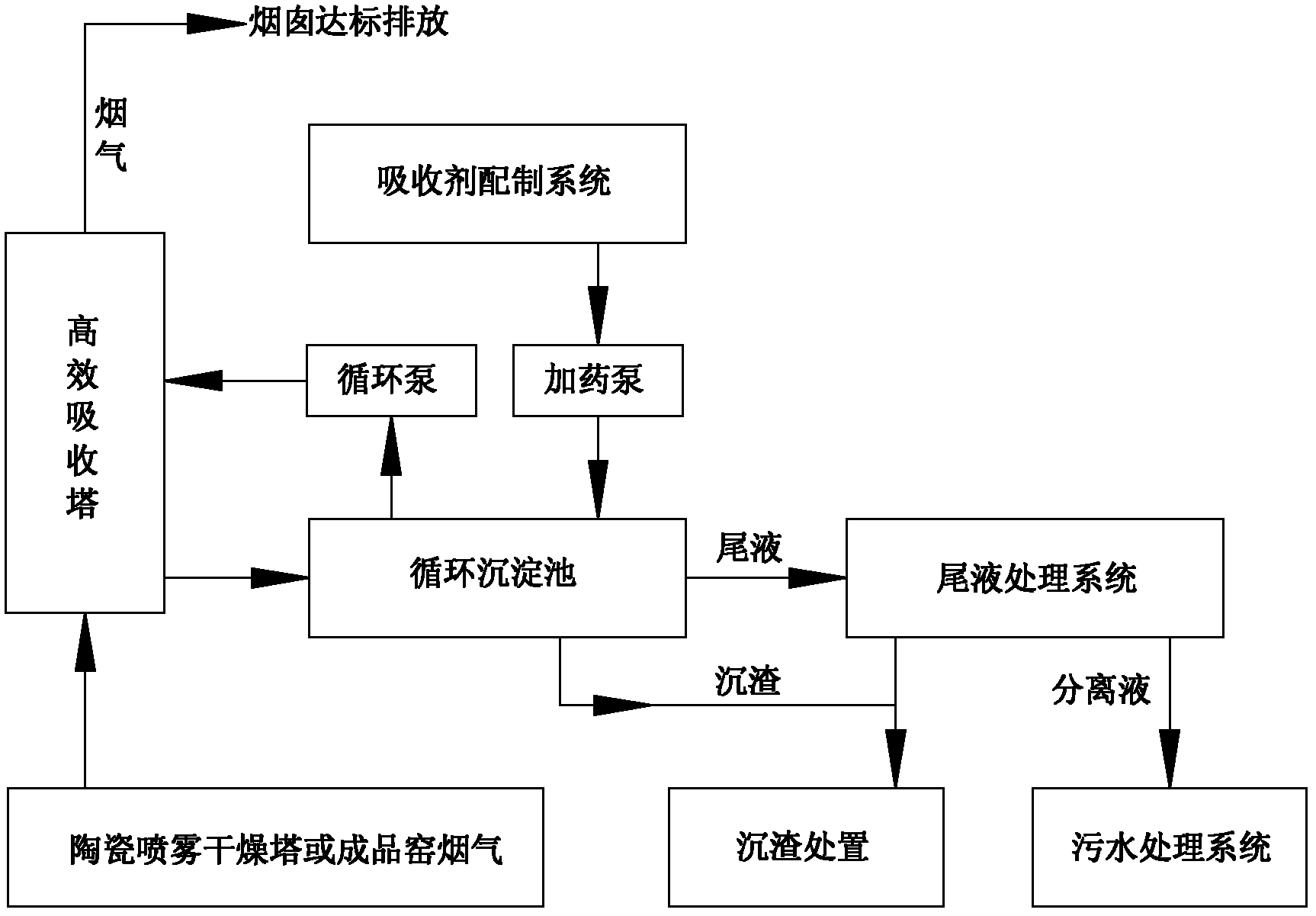

Synergistic purification composite absorbent for ceramic smoke multiple pollutants as well as preparation method and application

ActiveCN102302896ASimple process equipmentSmall footprintDispersed particle separationMulti pollutantDissolution

The invention discloses a synergistic purification composite absorbent for ceramic smoke multiple pollutants as well as a preparation method thereof and application of the absorbent in smoke pollution control in a ceramic industry. The absorbent is characterized in that on the basis of the existing wet desulfuration facility, the multiple pollutants in the ceramic smoke are simultaneously and efficiently purified and removed through changing the compositions of the existing desulfuration absorbing liquid, namely, using a composite absorbent containing urea, alkali and additive to carry out absorption, dissolution, complexing, oxidation, reduction, precipitation and the like in the same equipment; when the composite absorbent is saturated due to absorption and then the saturated composite absorbent is discharged into a tail liquid treatment system for harmless safety treatment; and the composite absorbent comprises the following components by weight percent: 2%-15% of urea, 1%-10% of alkali, 0.01%-2% of additive and the balance of water. According to the invention, process is simple, the system is easy to control and manage, occupied area is small, investment and operation costs are low, pollutant removal efficiency is high, and the preparation method can be implemented just by simple improvement for a ceramic enterprise with the wet desulfuration facility and is extremely suitable for national conditions in China.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Preparation method of oxide solid electrolyte diaphragm

ActiveCN106384801AAvoid easily deformable problemsReduced Chances of ContaminationFinal product manufactureCell component detailsLithium hydroxideMechanical energy

The invention relates to a preparation method of an oxide solid electrolyte diaphragm, belonging to the fields of electro chemical engineering and ceramic industry. The method comprises the following steps: by using lithium carbonate or lithium hydroxide as a lithium source, putting previously prepared solid electrolyte powder in a crucible, and directly sintering at high temperature to obtain a compact block; and carrying out cutting and sanding on the block to obtain the solid electrolyte diaphragm sheet. The method avoids the complex mold preforming process in the conventional method; and the mechanical energy is converted into the surface free energy of the powder granules by ball milling, the excessive low-melting-point lithium salt is molten at high temperature to generate the liquid phase which is covered on the powder particle surfaces, and the powder automatic aggregates under the action of surface tension, so that the surface free energy is lowered, thereby forming the compact solid electrolyte block. The method has the advantages of simple technique, smooth and compact finished product and the like, can easily implement large-scale production, and is especially suitable for preparing oxide solid electrolyte diaphragms in the solid secondary battery.

Owner:NO 63971 TROOPS PLA

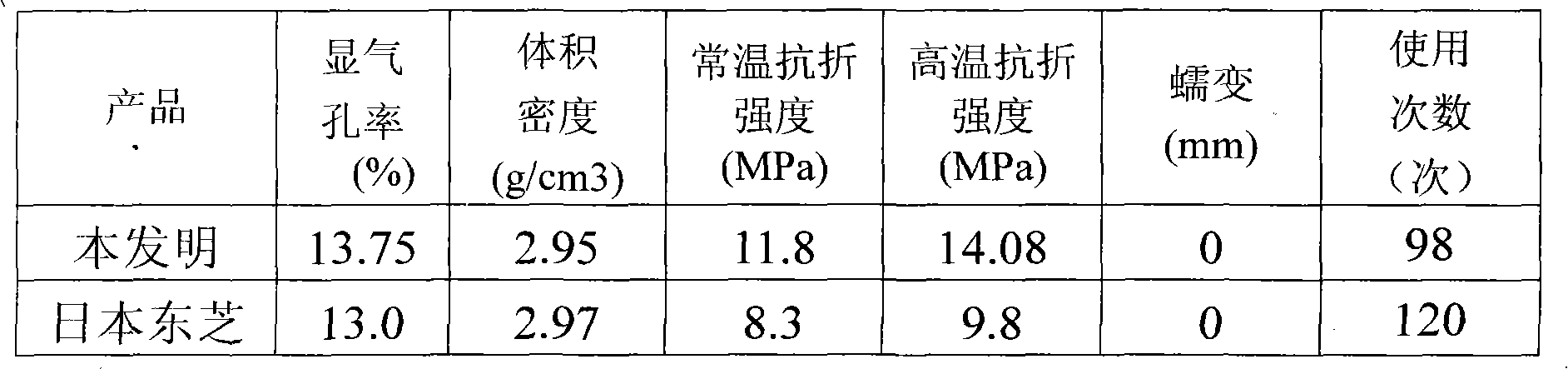

High-temperature corundum-porzite pushing plate and manufacture method thereof

The invention belongs to the technical field of fireproof materials and provides a high-temperature corundum-porzite pushing plate and a manufacture method thereof. The pushing plate is prepared by using fused porzite, corundum, andalusite, alumina powder and ultrafine fused silica powder as raw materials through mixing, tapping, forming, drying and finally sintering at a high temperature. The pushing plate manufactured by utilizing the invention has higher high-temperature strength, wear resistance, favorable creep resistance, favorable product use performance similar to imported products and low production cost. The popularization of the technical scheme can effectively decrease the production cost of domestic high-temperature ceramic industry.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Ink composition

An ink composition is provided including an amide compound represented by formula I, a coloring agent and a solvent. The amide compound and the polyhydric alcohol in the ink composition decrease the mobility of coloring agents and increase the adhesion to media, thereby minimizing the bleeding between colors of printed images, and improving the water fastness and dry and wet rub fastness to provide good color fastness on papers. The ink composition also improves the quality of the printed image, and also has good long-term storage stability. Thus, the ink composition can be widely used as ink-jet inks for ink-jet printers, printing inks, paints, textile printing, paper manufacturing, cosmetics manufacturing, ceramic industry, etc.

Owner:S PRINTING SOLUTION CO LTD

Method for separating quartz from low-grade potassium and sodium feldspar ore

ActiveCN105618271ALower surface oxidation potentialIncrease the surface contact angleFlotationPhysical chemistryPotassium

The invention provides a method for separating quartz from low-grade potassium and sodium feldspar ore. The method comprises the steps of providing low-grade potassium and sodium feldspar ore powder; mixing the low-grade potassium and sodium feldspar ore powder and water for obtaining low-grade potassium and sodium feldspar ore slurry; adjusting the pH value of the low-grade potassium and sodium feldspar ore slurry to 8-10 through conditioning agents, and then carrying out roughing, scavenging, concentrating and drying on the low-grade potassium and sodium feldspar ore slurry for obtaining fine potassium and sodium feldspar powder and floating the quartz; adding activating agents, inhibitors and amine collecting agents in the roughing process and the scavenging process each time. The method has the advantages that the production cost is low, the requirement for corrosion prevention of equipment is low, pollution to the environment is small, and the quality of the obtained fine potassium and sodium feldspar powder meets the use standard GB / T9195-1999 of the ceramic industry.

Owner:ZHENGZHOU SHANCHUAN HEAVY IND CO LTD

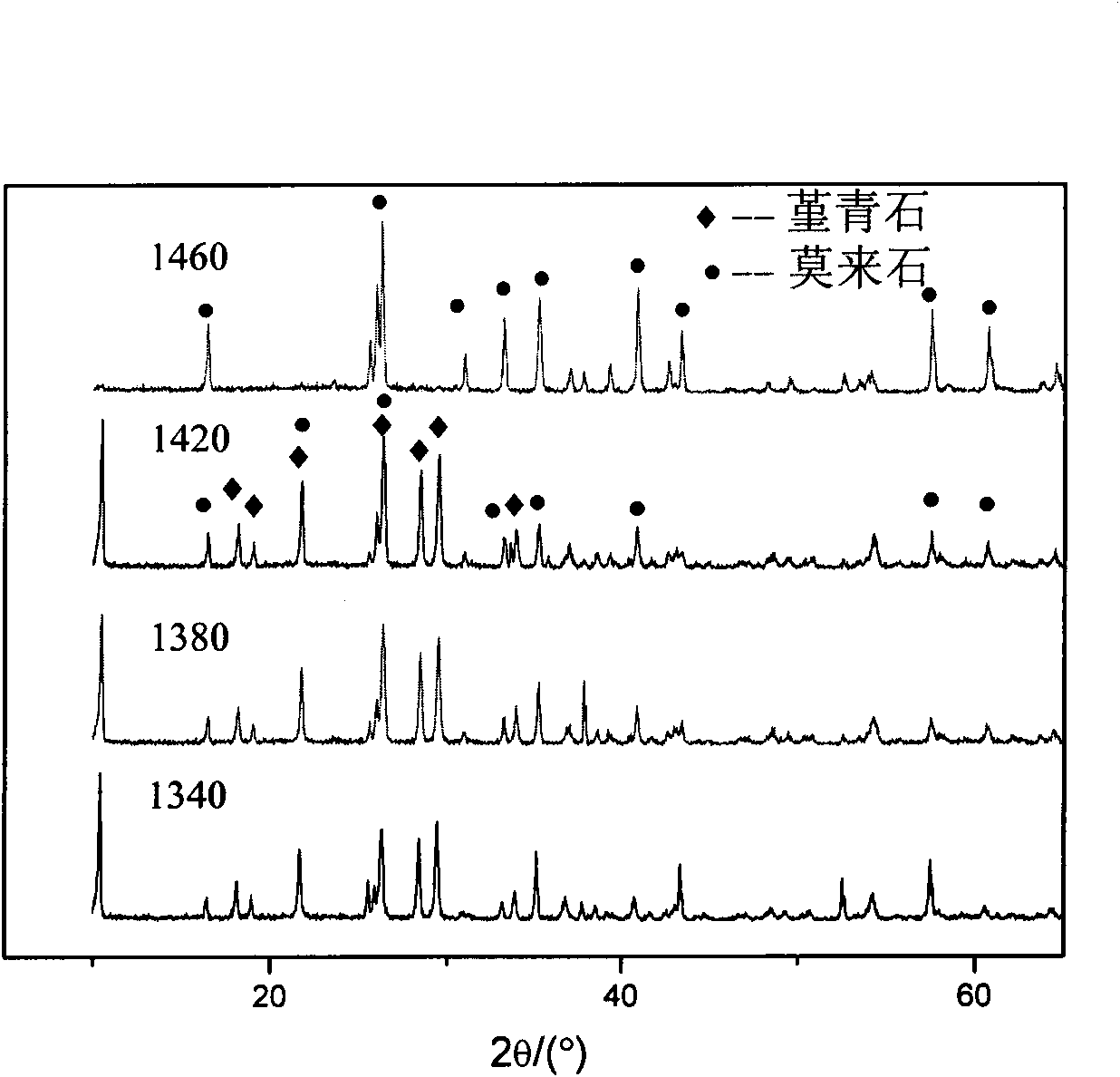

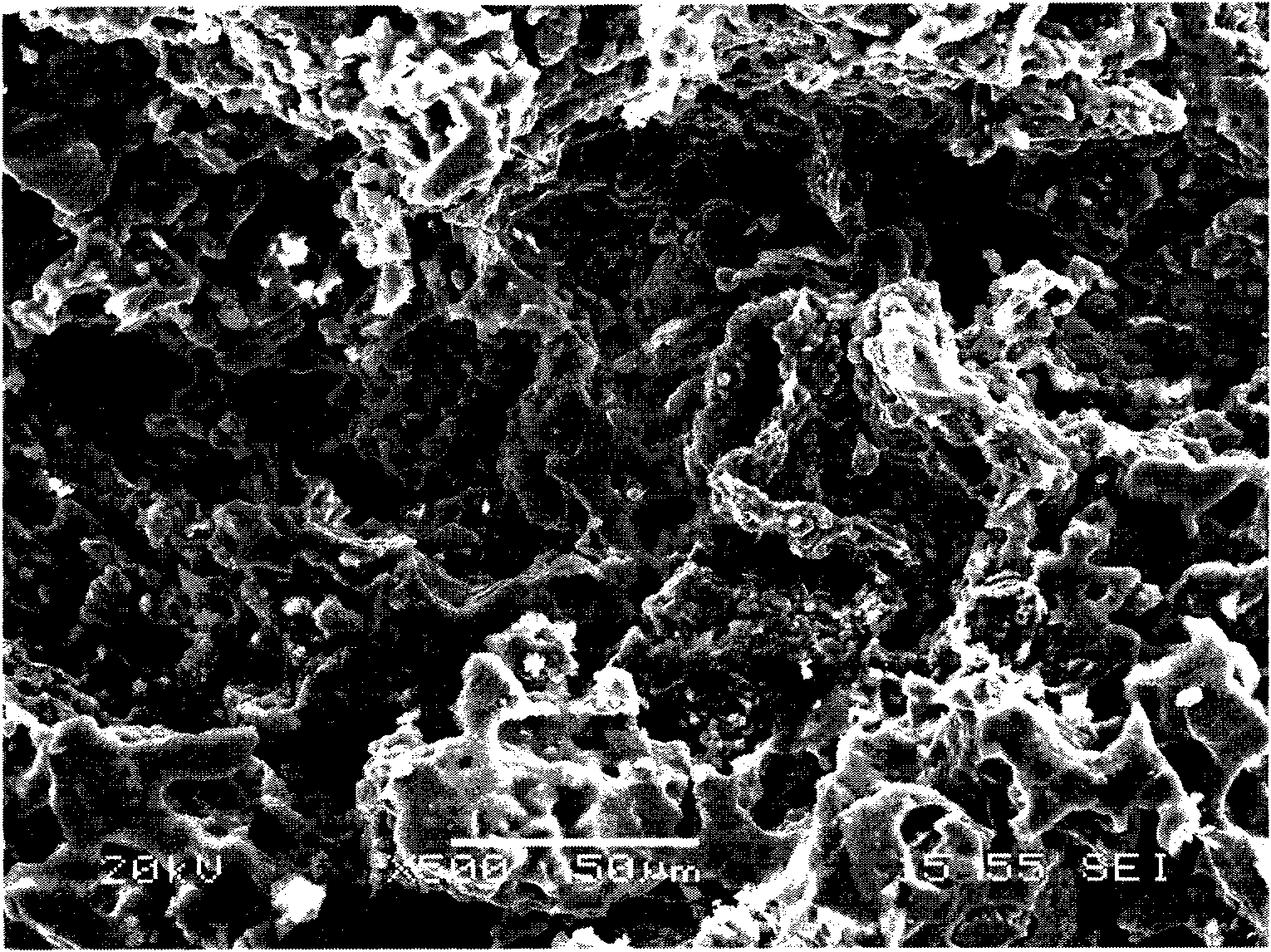

Method for synthesizing porous cordierite-mullite composite material by utilizing solid wastes

InactiveCN101671198AAvoid pollutionRich reservesSolid waste disposalFurniture waste recoveryPorosityAir atmosphere

The method provides a method for synthesizing a porous cordierite-mullite composite material by utilizing solid wastes, belonging to the technical field of synthesis of inorganic nonmetallic materials. In the method, gangue, waste refractory materials (waste magnesium carbon bricks and sliding bricks) and sawdust (a pore-forming agent) are taken as raw materials, 35-55% of gangue, 3-10% of used magnesium carbon bricks, 10-50% of used sliding bricks and 5-40% of sawdust by mass are mixed, and the raw materials are insulated at the temperature of 1340-1460 DEG C for 2-6h in air atmosphere aftermolding to obtain synthetic sintered compact. The porous cordierite-mullite composite material synthesized by the invention has rupture strength of 24.33MPa, apparent porosity of 25.44%, thermal expansion coefficient of 3.8*10<-6>K<-1> and volume density of 1.94g / cm3, and has uniform micro appearance and good high temperature performance. The porous cordierite-mullite composite material not only solves the problem that stack of the solid wastes in quantity results in pollution to the environment and can be applied to kiln furniture in ceramic industry, but also conforms to the industrial policy, circular economy, advocated by the state.

Owner:UNIV OF SCI & TECH BEIJING

Production method for ultra low temperature rapid firing vitrification ceramic brick

The present invention provides a production method for an ultra low temperature rapid firing vitrification ceramic brick. In a blank entering ball mill step, low temperature ceramic mineral raw materials are mixed and poured into a ball mill to carry out wet grinding, wherein the low temperature ceramic mineral raw materials comprise a calcination material, lithium sand, black mud, a water reducing agent, a reinforcing agent and an auxiliary agent. The present invention relates to a production method for producing the ultra low temperature rapid firing vitrification brick by using the calcium magnesium silicate material and the tantalum-niobium tailings. The ultra low temperature rapid firing vitrification ceramic brick belongs to a special and novel vitrification brick material and a product, wherein the special and novel vitrification brick material has characteristics of ultra low temperature, high strength, high hardness, high wear resistance, strong pollution prevention, no radiation, environmental protection, and health. With the technology of the present invention, the firing temperature can be substantially reduced, the firing period can be substantially shortened, and the method provides good benefits for energy-saving emission reduction, green manufacturing and low carbon production of the ceramic industry.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Super large specification porous ceramic plate and method for manufacturing the same

InactiveCN101498398AWith thermal insulationSound-absorbingSheets/panelsFeeding arrangmentsMetallurgyPorous ceramics

The invention discloses an ultra-large dimension light porous ceramic plate and a manufacturing method thereof. The invention uses waste materials and polished waste residues produced in the architectural ceramic industry as main raw materials, and the waste materials and the polished waste residues account for 50 to 80 percent in the material formula. The ultra-dimension light high-strength porous ceramic plate which maximally can reach 1200*2400mm is obtained by the way that the raw materials are pressed into forming by an ultra-dimension double molding press of 1050*2060mm and then the formed materials are monofired at the temperature of 1150 to 1210 DEG C. The formed powders can be mono-color or mixed color materials, and are dry pressed into forming by one time or multiple-time material application; and the sandstone-like decorative effect can be obtained with the seep curlicue technology. The firing temperature is at the range of 1150 to 1210 DEG C, and the product volume weight is between 0.7 to 1.5g / cm. The porous ceramic plate not only can be used as a novel wall decoration material but also as a functional material, and further can be used as a novel wall material to be widely used.

Owner:MONALISA GRP CO LTD

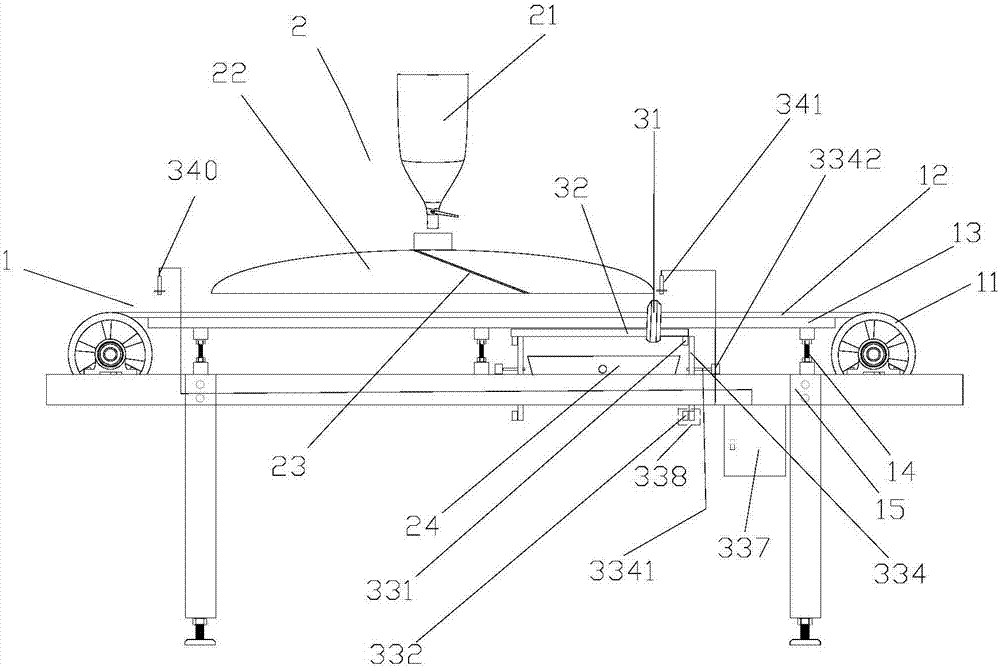

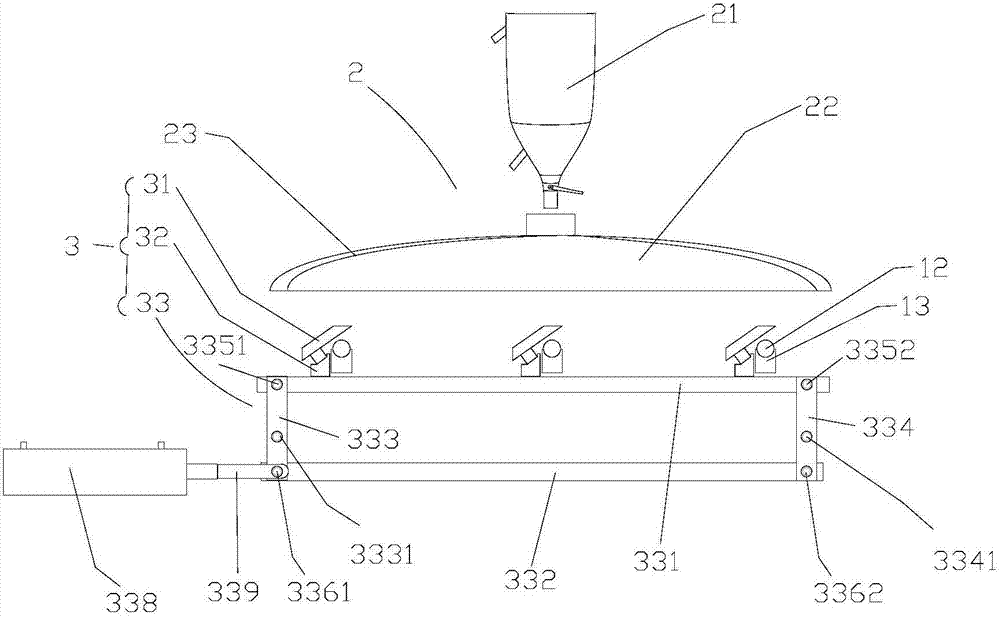

Device for preventing glaze slip from adhering to bottoms of ceramic tile blanks and control method of device

The invention relates to the field of ceramic tile production and manufacturing in the ceramic industry, in particular to a device for preventing glaze slip from adhering to the bottoms of ceramic tile blanks and a control method of the device. The device comprises a glaze line unit, a glaze pouring unit and a glaze stop unit, wherein the glaze stop unit comprises glaze stop troughs, glaze baffle fixing rods and a transmission mechanism, the glaze stop troughs are connected with the transmission mechanism through the glaze baffle fixing rods, and the glaze stop troughs are obliquely arranged above glaze line belts. When the ceramic tile blanks on the glaze line belts leave the positions below the glaze pouring unit, the oblique glaze stop troughs move upwards and stop moving when the tops of the glaze stop troughs are located over the glaze line belts, at the moment, the glaze slip flowing down from a bell cover returns to a glaze receiving plate without flowing onto the glaze line belts, and therefore, the effect that the glaze slip is prevented from adhering to the bottoms of the ceramic tile blanks moving on the glaze line belts is guaranteed; and as the glaze material flowing down is not contaminated, the glaze material can be recycled, and waste and environment pollution are avoided.

Owner:JIANGXI HEMEI CERAMICS

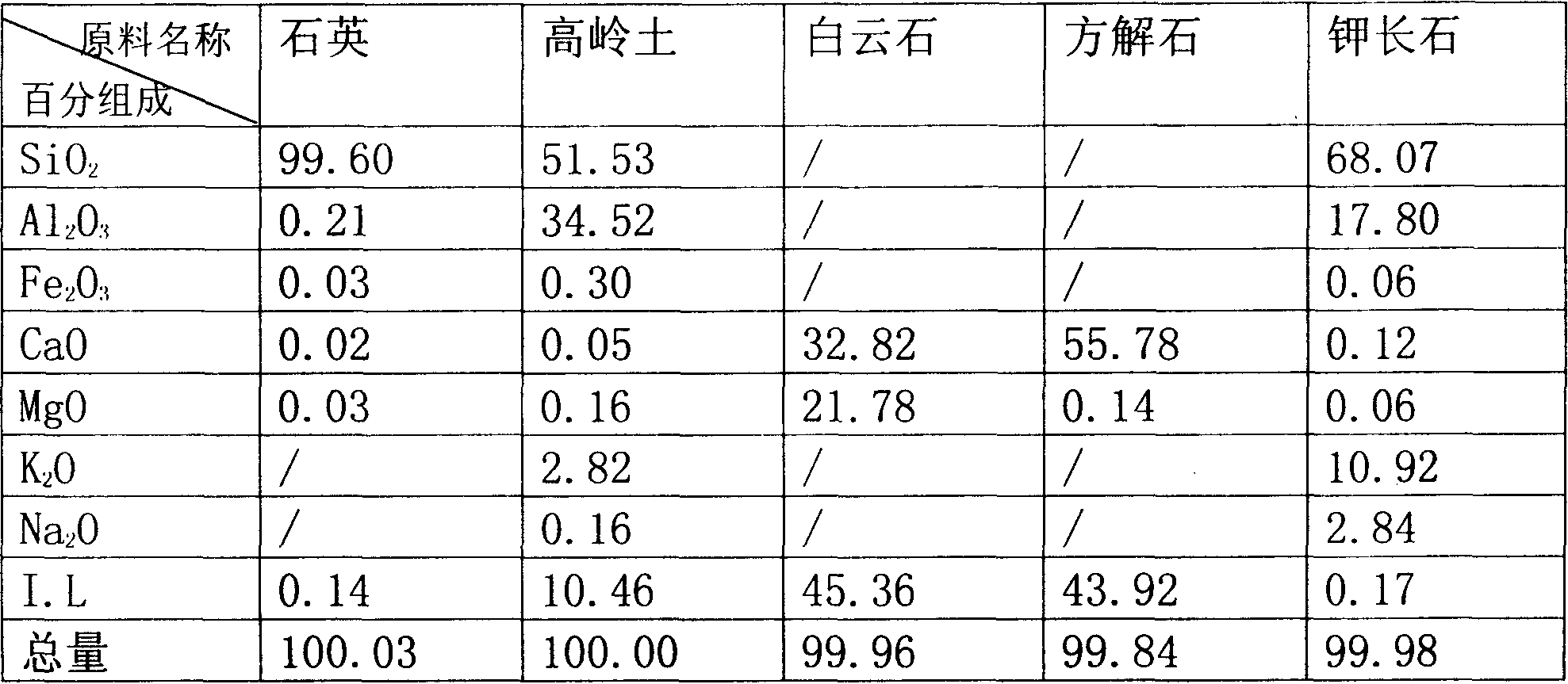

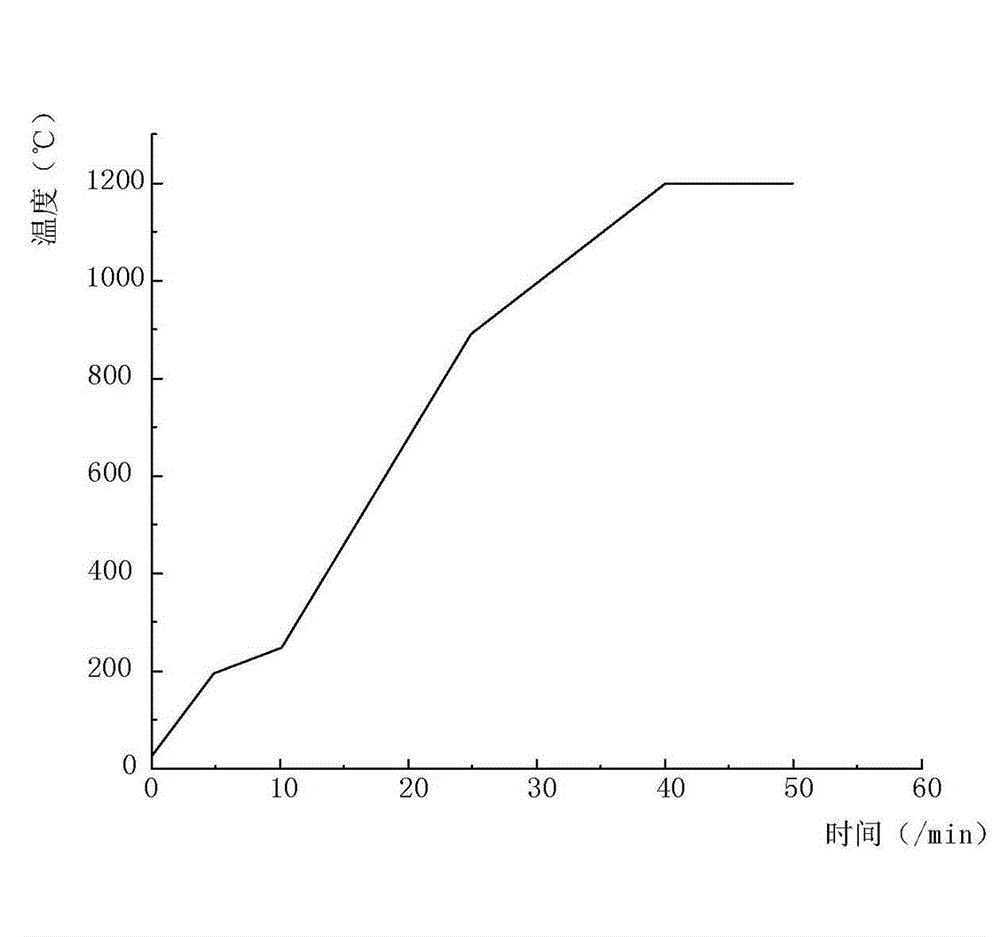

Quick fired fine ceramics made in open flame roller hearth kiln and technical method

The present invention is a new ceramic material and new producing technology. The quick fired fie ceramic is produced with the material including kaolin 20-55 wt%, feldspar 10-20 wt%, and quartz 35-60 wt%, and through quick high temperature biscuit firing in an open flame roller hearth kiln and low temperature glaze firing. The low temperature glaze firing in reducing atmosphere can obtain bright and soft glaze with high transmittance, and product with high impact strength, high heat impact strength and high acid and alkali resistance; and the low temperature glaze firing in oxidizing atmosphere can obtain bright glaze without pinhole. The present invention has simple technological process, low cost, great output and low power consumption, and may be applied widely in ceramic industry.

Owner:张民

Preparation method of antifouling heat insulation light ceramics

The invention discloses a preparation method of antifouling heat insulation light ceramics, in particular to a method for preparing environment-friendly light ceramics with low water absorption rate, good antifouling effect and good heat insulation performance by utilizing ceramic waste, coal cinder, sewage sludge, dredging mud and other solid waste; the technology provided by the invention can well solve the pollution problems of industrial production and solid waste in life and can effectively lighten the problem of excessive consumption of the raw material in the ceramic industry; on one hand, the invention opens up a new way for high-efficiency resource recycling of the solid waste, on the other hand, the invention makes a contribution to the novel wall body material and building energy saving; in the technology of the invention, the solid waste utilization rate is high, the process is simple, the operation is convenient and the operation cost is low, and under the condition of not using any additive coating or colored glaze materials, the produced product has the characteristics of low water adsorption rate, good antifouling effect and good heat insulation performance, and the pore size and porosity are easy to control.

Owner:SOUTH CHINA UNIV OF TECH

Fluorescent glaze and preparation method thereof

ActiveCN103332967AMeet general requirementsHigh fluorescence brightnessRare-earth elementFluorescence

The invention provides a fluorescent glaze and a preparation method thereof. The fluorescent glaze is mainly prepared from the following raw materials by weight percentage: 50%-70% of glass frit, 20%-40% of feldspar and 2%-15% of calcined kaolin. The preparation method comprises the following steps of: firstly, mixing feldspar, calcium carbonate, barium carbonate, zinc oxide, aluminium oxide, borax, boric acid, quartz, strontium carbonate, vanadium pentoxide and bismuth oxide together in a certain weight ratio and then smelting the mixture at a temperature in the range from 1250 to 1350 DEG C; secondly, forming the glass frit after water quenching; and then enabling the glass frit to be subjected to coarse crushing, fine crushing and dosing grinding orderly, and mixing the ground powder with the feldspar and the calcined kaolin proportionally through a ball mill and grinding evenly, thereby obtaining the fluorescent glaze. The fluorescent glaze provided by the invention is free of rare-earth element, and can be excited under either natural light or a fluorescent lamp; the fluorescent glaze is high in fluorescent brightness and has persistence as long as 1300 min; the process of the preparation method of the fluorescent glaze is simple and capable of well meeting common requirements of the building ceramic industry.

Owner:美艺陶(福建)高新建材有限公司

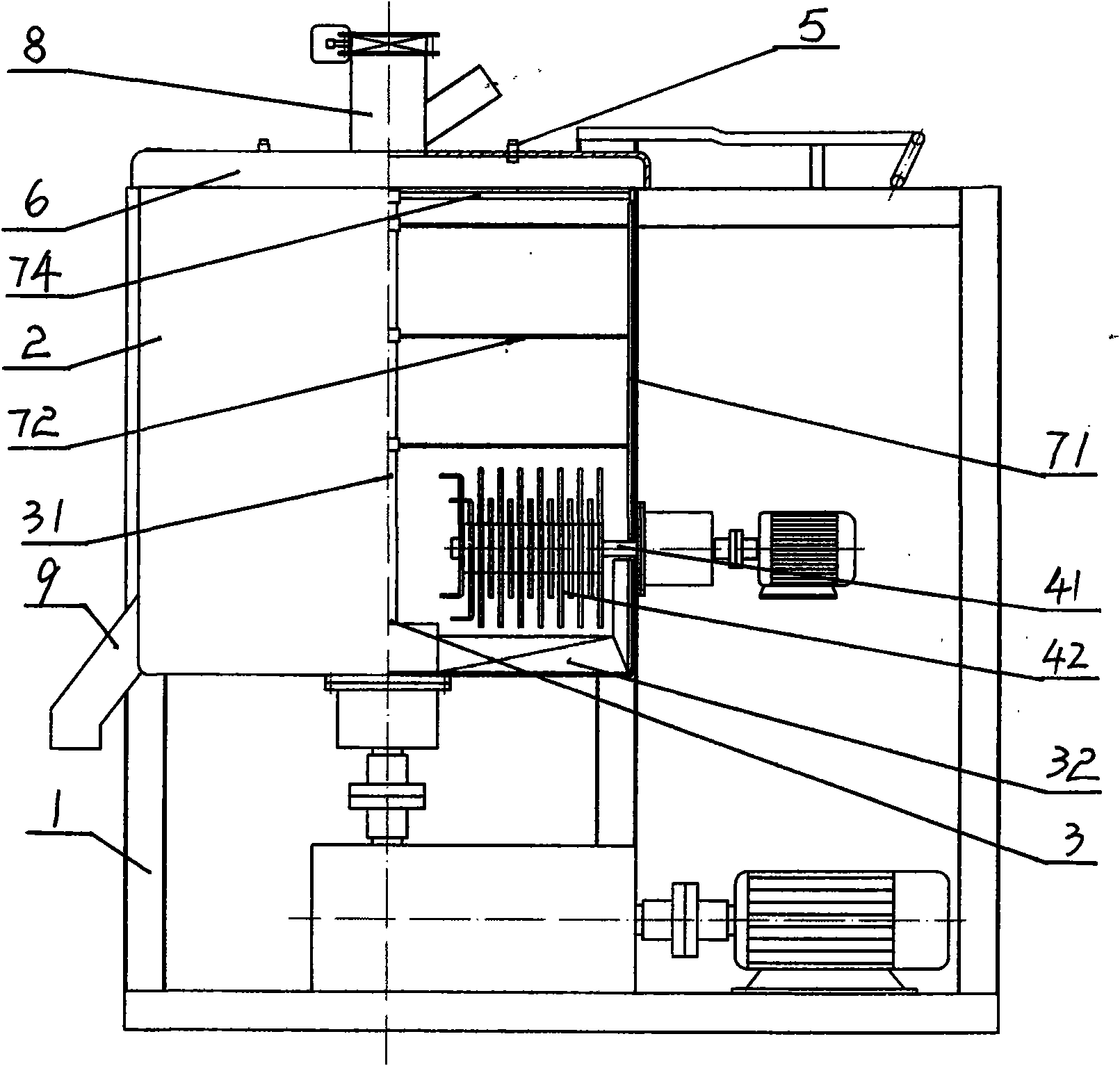

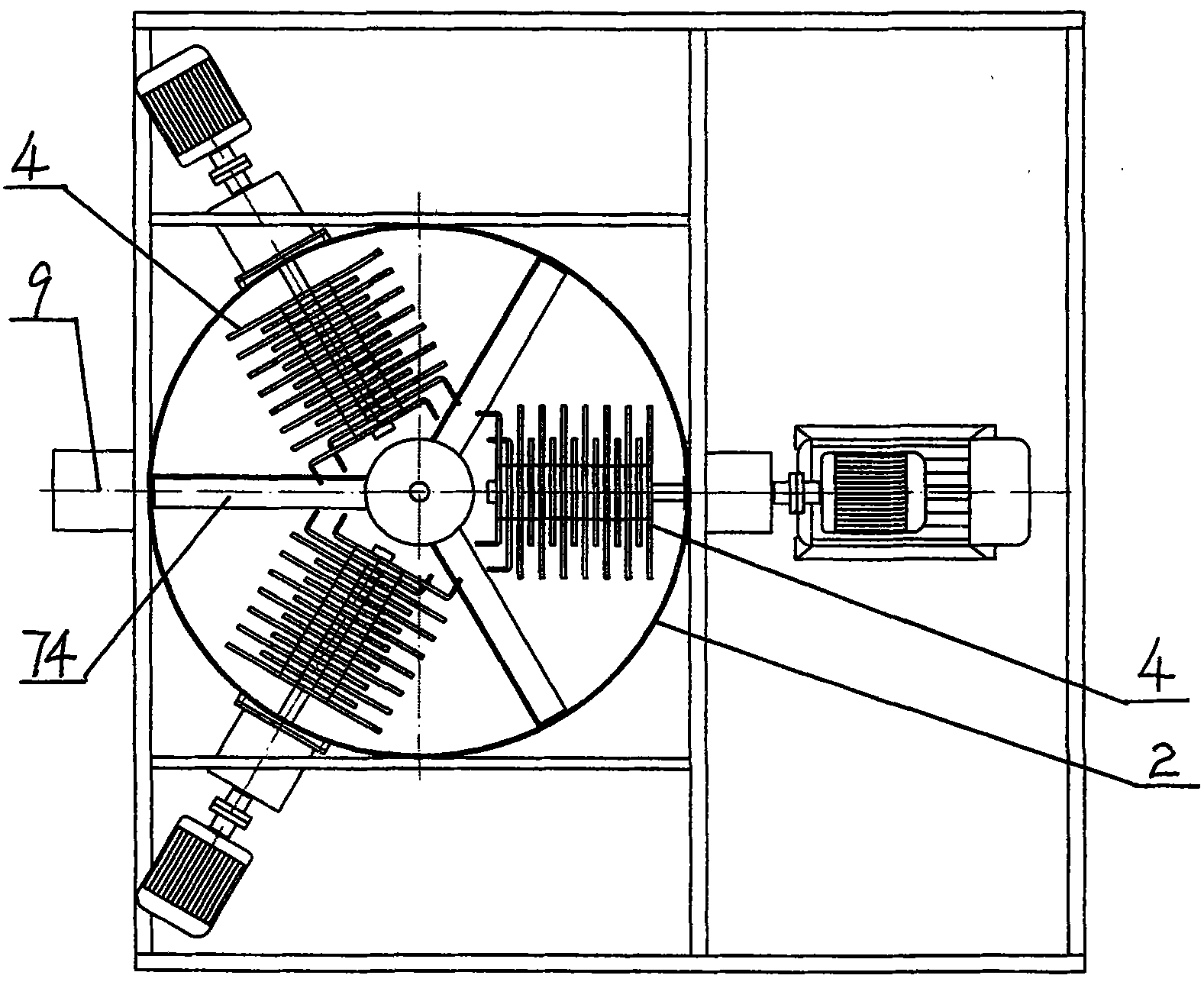

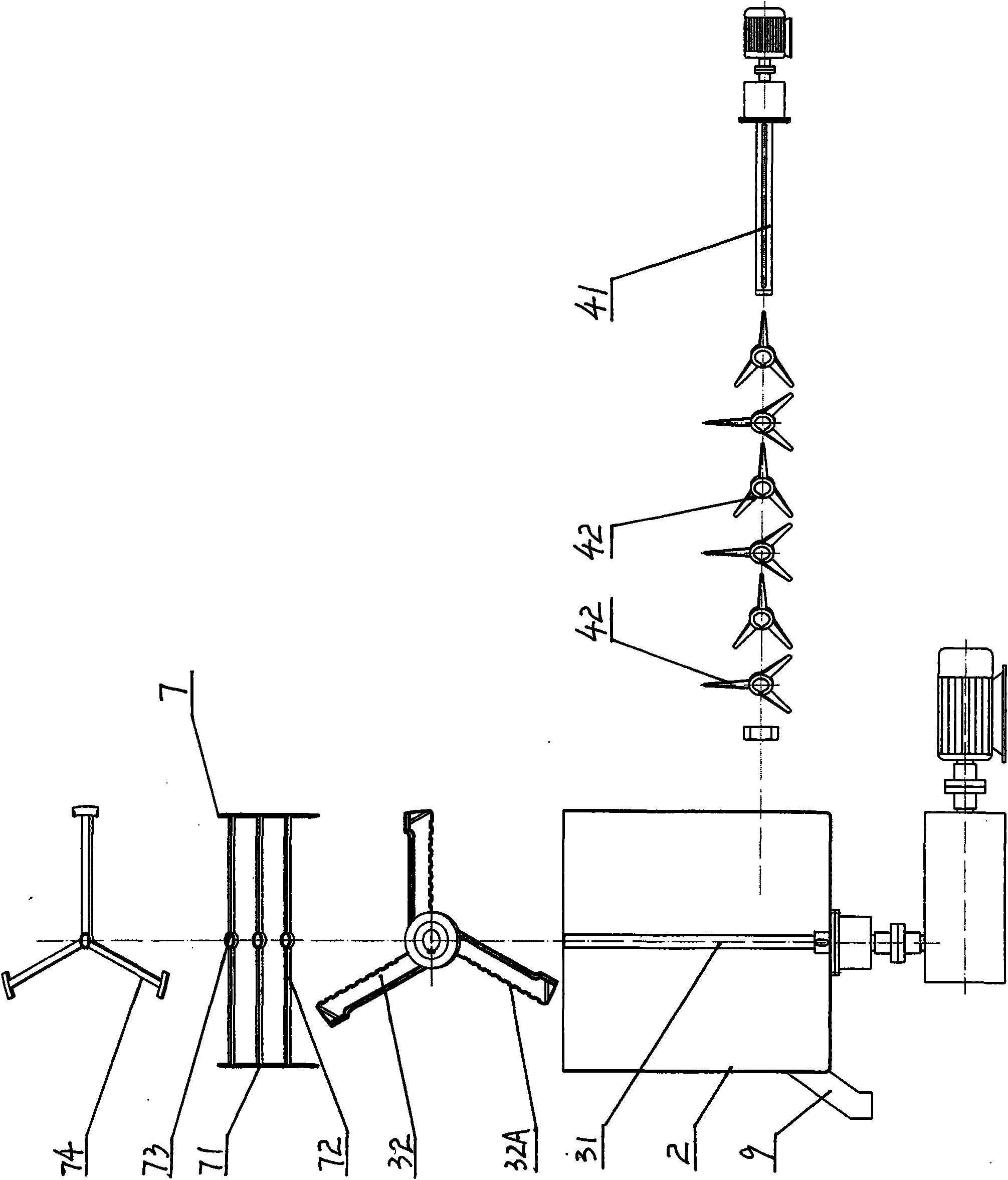

Equipment for preparing ceramic powder by humidifying dry powder

The invention relates to equipment for preparing ceramic powder by humidifying dry powder. The equipment consists of a machine frame, a pelleting tank, a stirring mechanism, an atomization water-supplying sprayer, a sealed cover, a feed inlet, a discharge outlet and a power mechanism, wherein the stirring mechanism is axially arranged at the bottom in the pelleting tank; a main stirring shaft drives a stirring paddle to rotate; a scraping mechanism is additionally arranged in the pelleting tank and above the stirring paddle; a scraper blade of the scraping mechanism rotates by abutting against the inner wall of the pelleting tank; a cutting mechanism is arranged in the pelleting tank and between the stirring paddle and the scraping mechanism; and a cutting knife of the cutting mechanism is driven by a main cutting shaft to rotate. Due to the structure, the equipment has the advantages of clear processing functions of stirring, scraping, cutting, pelleting and the like, high controllability, high proportion of sphere-like grains in the produced powder, high flowability, capacity of efficiently producing the powder meeting the forming requirement of an automatic brick press, compact structure, high production efficiency and low energy consumption. The equipment can be widely applied to raw material processing in ceramic industries.

Owner:FOSHAN RONGZHOU NO 2 BUILDING CERAMICS FACTORY

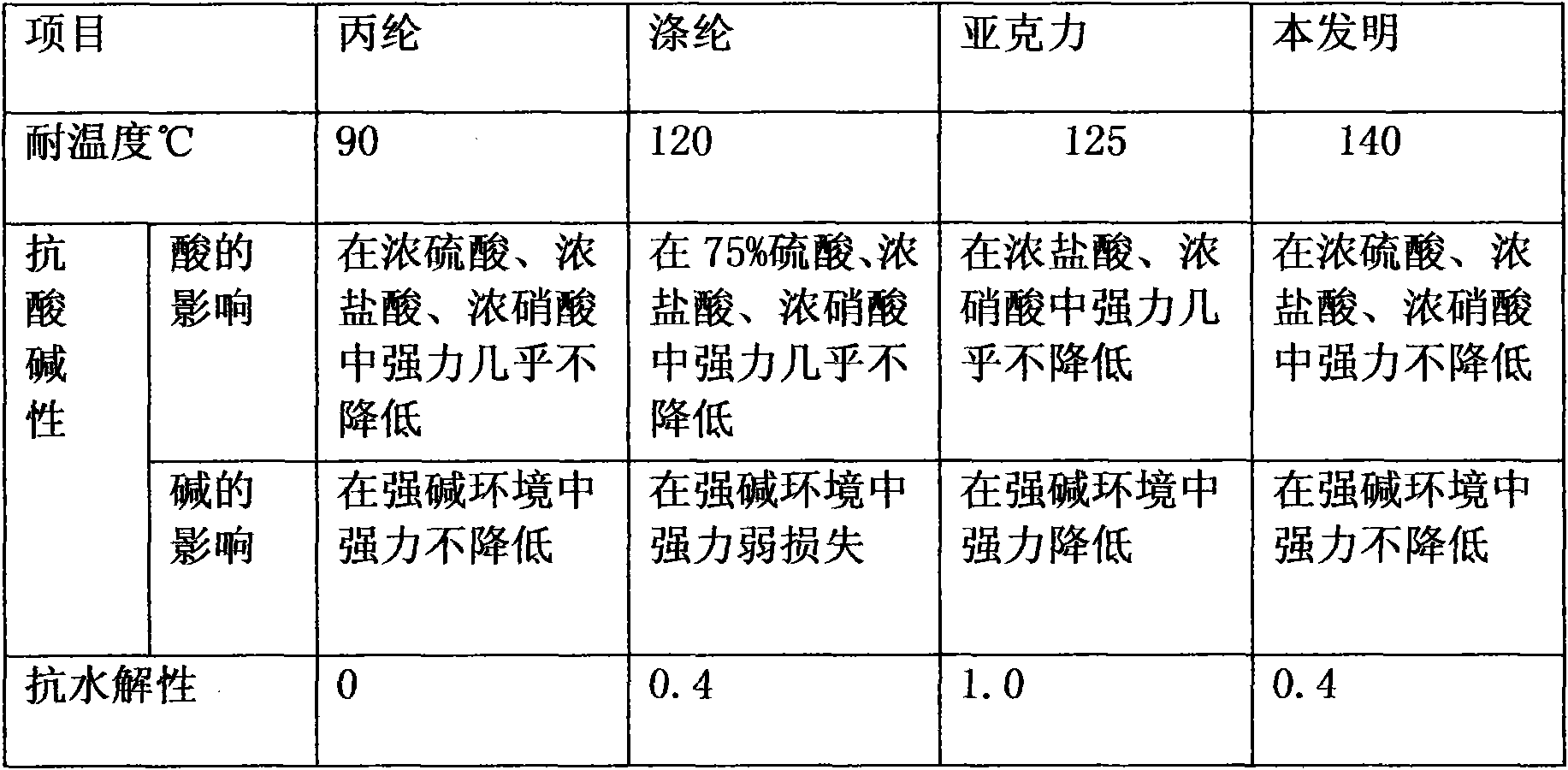

Filter material suitable for flue gas dust removal, manufacture method and treating liquid thereof

InactiveCN101564620AAnti-acid corrosionImprove acid resistanceFiltration separationFlue gasFiltration

The invention relates to a filter material suitable for flue gas dust removal, in particular to treating liquid used for flue gas dust removal and filter material finishing in ceramic industry and a filter material finished with the treating liquid. The treating liquid used for flue gas dust removal and filter material finishing consists of the following components of 10-20 percent of polytetrafluoroethylene latex; 5-10 percent of polyacrylate, 10-25 percent of waterproof agent; 1.0-2.0 percent of silane coupling agent, 0.5-2.0 percent of color paste and the balance of de-ionized water. The invention also discloses a filter material treated by the treating liquid. The surface of the filter material treated by the treating liquid has an organic protective film which has the property of resisting corrosion of concentrated sulfuric acid, has excellent acid resistance, good alkali resistance, water repellency and oil repellency and smooth surface, and is easy for ash removal. In the application of the filer material to the dust removal in the ceramic industry, the service life of the filer material is greatly prolonged up to over 10 months which is 3 times of that of a terylene filter material; and the price of the filter material only rises by about 10 percent on the basis of terylene needle-punched felt filter material; therefore, the filer material is a fairly ideal material for the dust removal and flue gas filtration in the ceramic industry.

Owner:ANJI SHENGFENG FIBERGLASS

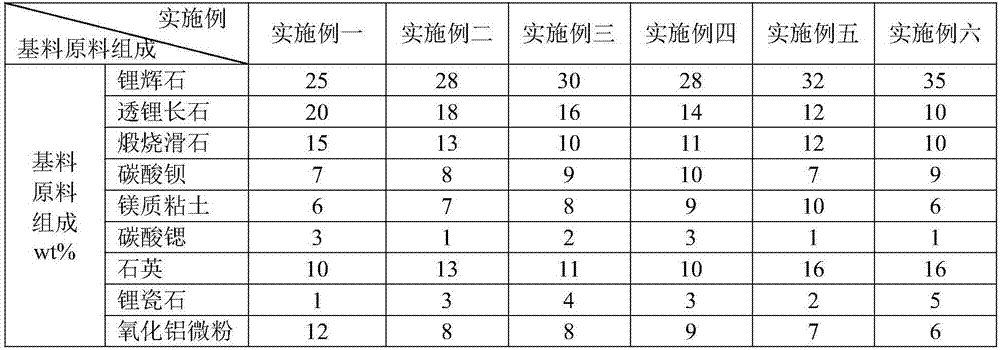

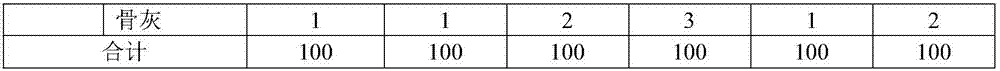

Low cost low expansion ceramic zirconium-free white glaze and preparation method thereof

The invention discloses a low cost low expansion ceramic zirconium-free white glaze, which comprises a basic material and additives. The basic material is composed of the following raw materials in percentage by weight: 20 to 35 wt% of spodumene, 10 to 25 wt% of petalite, 10 to 15 wt% of calcined talcum, 7 to 10 wt% of barium carbonate, 6 to 10 wt% of magnesite clay, 1 to 3 wt% of strontium carbonate, 10 to 20 wt% of quartz, 1 to 5 wt% of lithium containing porcelain stone, 6 to 12 wt% of alumina micro powder, and 0 to 3 wt% of bone ash. The additives are hydroxypropyl methyl cellulose and sodium tripolyphosphate; wherein hydroxypropyl methyl cellulose accounts for 0.05 to 0.1 wt% of the basic material and sodium tripolyphosphate accounts for 0.20 to 0.30 wt% of the basic material. Furthermore, the invention also discloses a preparation method of the low cost low expansion ceramic zirconium-free white glaze. The low cost low expansion ceramic zirconium-free white glaze has the advantages of low production cost, safe application, no radiation, high whiteness, good melting performance, and adjustable expansion coefficient; can well meet the use requirements of various low expansion ceramic blanks, and is beneficial for the development of low expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method of ball clay for high-grade sanitary appliance

InactiveCN101844913AWhiteness stabilityHigh strengthCeramic materials productionClaywaresSocial benefitsLower grade

The invention relates to a preparation method of ball clay for high-grade sanitary appliance, which is characterized in that blackmud, plaster and kaolin are used as raw materials for preparing ball clay used by the high-grade sanitary appliance; the size comprises according to the percentage by volume: 10-60% of blackmud, 10-20% of plaster and 20-80% of kaolin; the preparation method overcomes the defect which is brought about by changeable raw material components caused by organic impurity and sand contents of low-grade ball clay; the formed ball clay has stable whiteness, intensity and stickiness and good slip-casting mobility, can be widely applied to high-grade ceramic industries and is the vanguard and demonstration in the process of national ceramic raw material standardizing, and has obvious economic benefic and social benefit.

Owner:广州市花都区梯面金鹏高岭土原料厂 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com