Synergistic purification composite absorbent for ceramic smoke multiple pollutants as well as preparation method and application

An absorbent and pollutant technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inability to meet the requirements of multi-pollution purification of flue gas, many processing units, and large floor space, and achieves a large footprint. The effect of small land area, high removal efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The total flue gas of two roller kilns in a ceramics factory is 40,000 m 3 / h, the measured dust concentration in the flue gas before purification is 700-1000mg / m 3 , SO 2 The concentration is 1900~2500mg / m 3 , NO X The concentration is 600~850mg / m 3 , the concentration of fluoride (calculated as HF) is 60~85mg / m 3 , the concentration of chloride (calculated as HCl) is 80~130mg / m 3 , the lead concentration is 3~4.8mg / m 3 , the concentration of cadmium is 0.7~1.2mg / m 3 , the nickel concentration is 1.4~3.6mg / m 3 .

[0052] The absorption tower adopts the high-efficiency absorption tower prepared by the existing patented technology: the height of the tower is 15m, the diameter of the tower is 3m, and the gas residence time is more than 4s.

[0053] The composite absorbent is composed of urea, limestone, and potassium permanganate additives, and the specific mass composition is: 8% of urea, 5% of limestone, 0.2% of potassium permanganate oxidant, and the rest is w...

Embodiment 2

[0056] The flue gas volume of a spray drying tower in a ceramic factory is 45,000 m 3 / h, the measured dust concentration in the flue gas before purification is 2500-3050mg / m3, SO 2 The concentration is 1500~2200mg / m 3 , NO X The concentration is 550~700mg / m 3 .

[0057]The absorption tower adopts the high-efficiency absorption tower prepared by the existing patented technology: the height of the tower is 15m, the diameter of the tower is 3m, and the gas residence time is more than 4s.

[0058] The composite absorbent is composed of urea, sodium hydroxide, and sodium chlorite additives, and the specific mass composition is: urea 5%, sodium hydroxide 2%, sodium chlorite 0.1‰, and the rest is water. During use, control the reaction temperature of the composite absorbent at 50°C and the pH at 5-7.

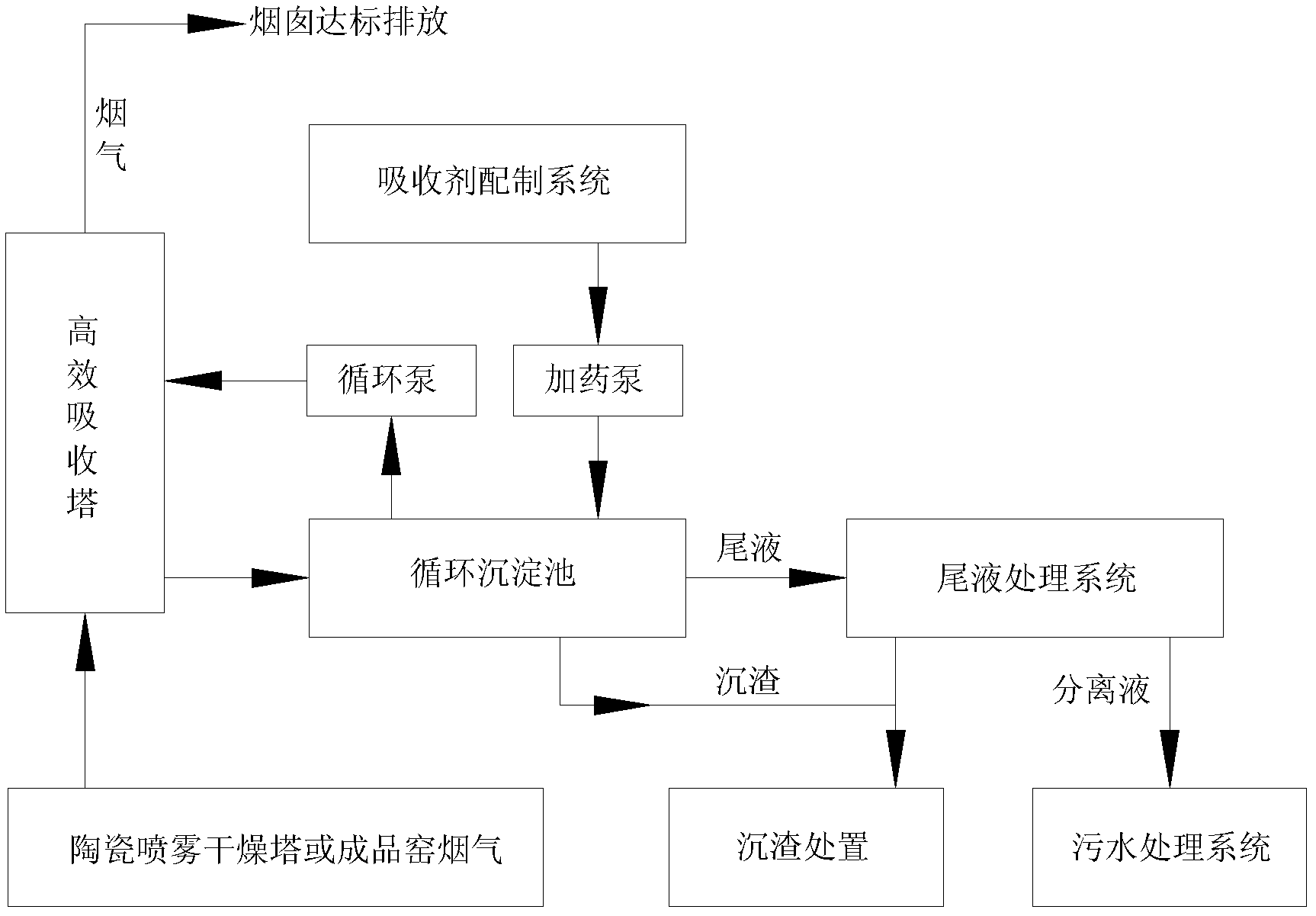

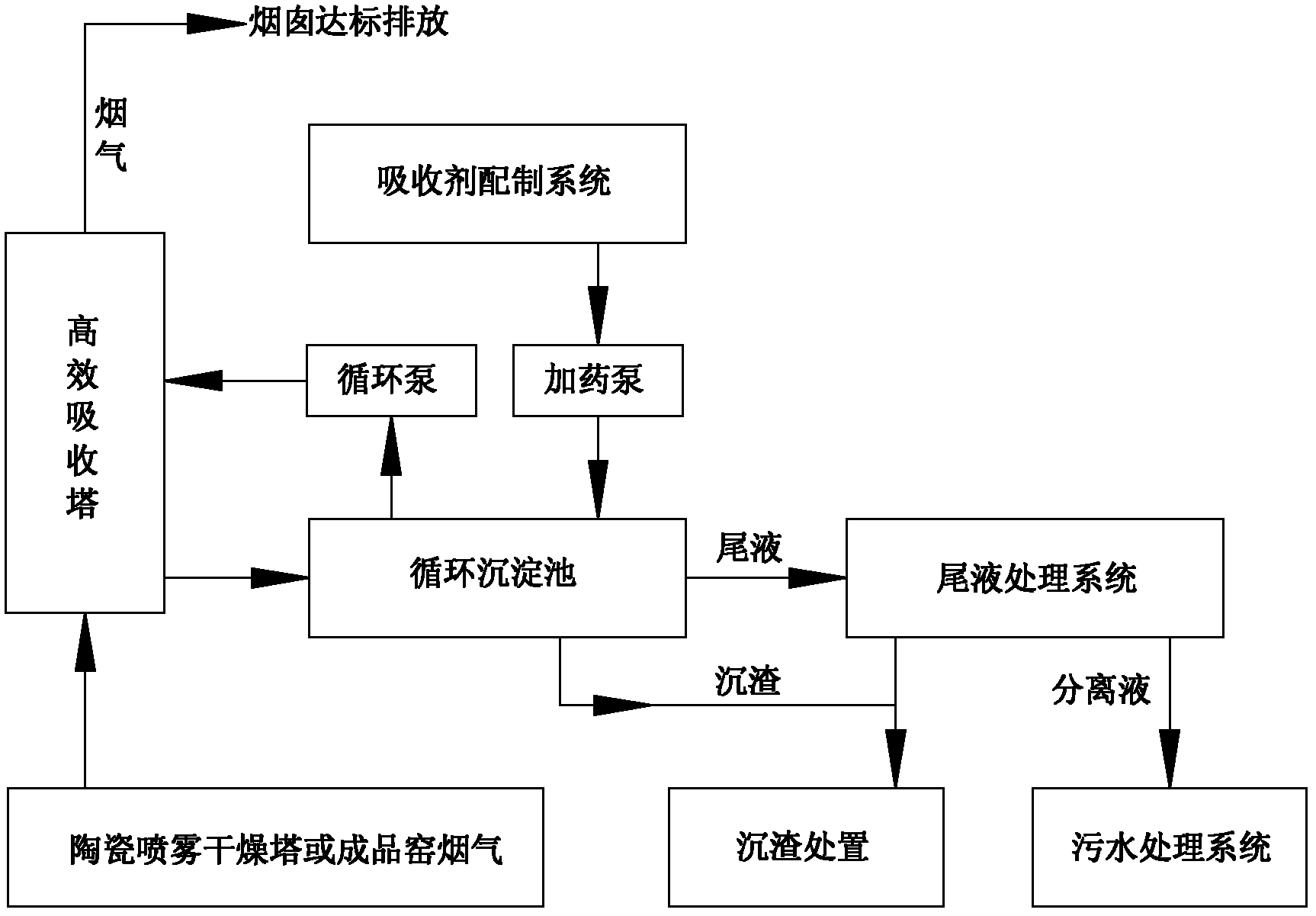

[0059] process such as figure 1 As shown, in the specific production process, the flue gas enters the high-efficiency absorption tower from the high-speed swirl at the bottom of...

Embodiment 3

[0061] The flue gas volume of a spray drying tower in a ceramic factory is 45,000 m 3 / h, the measured dust concentration in the flue gas before purification is 2500-3050mg / m3, SO 2 The concentration is 1500~2200mg / m 3 , NO X The concentration is 550~700mg / m 3 .

[0062] The absorption tower adopts the high-efficiency absorption tower prepared by the existing patented technology: the height of the tower is 15m, the diameter of the tower is 3m, and the gas residence time is more than 4s.

[0063] The composite absorbent is composed of urea, sodium hydroxide and sodium hypochlorite additives, and the specific mass composition is: 2% of urea, 10% of sodium hydroxide, 1% of sodium hypochlorite, and the rest is water. During use, control the reaction temperature of the composite absorbent at 40°C and the pH at 5-6.

[0064] process such as figure 1 As shown, in the specific production process, the flue gas enters the high-efficiency absorption tower from the high-speed swirl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com