Patents

Literature

219results about How to "Tune performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

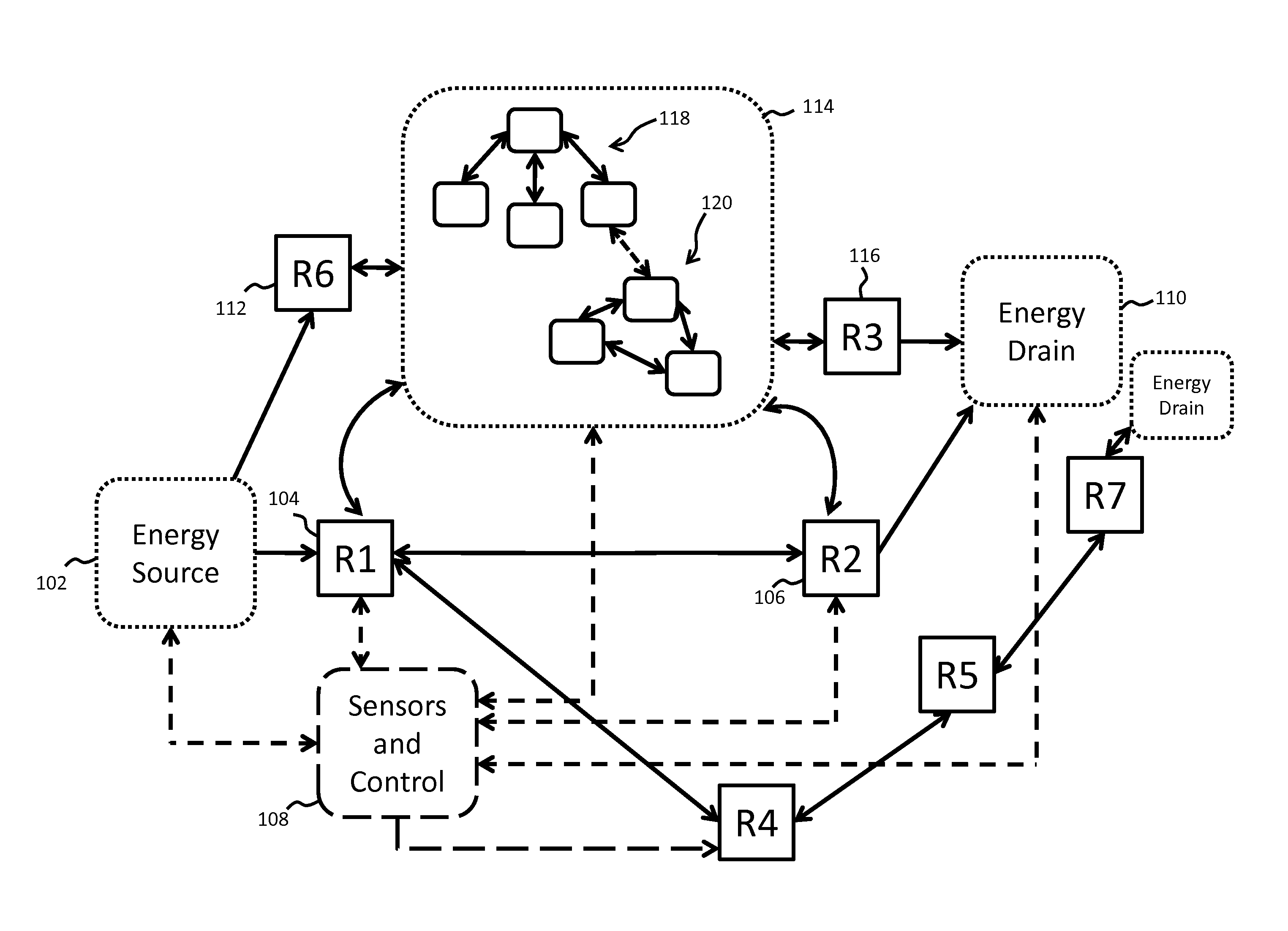

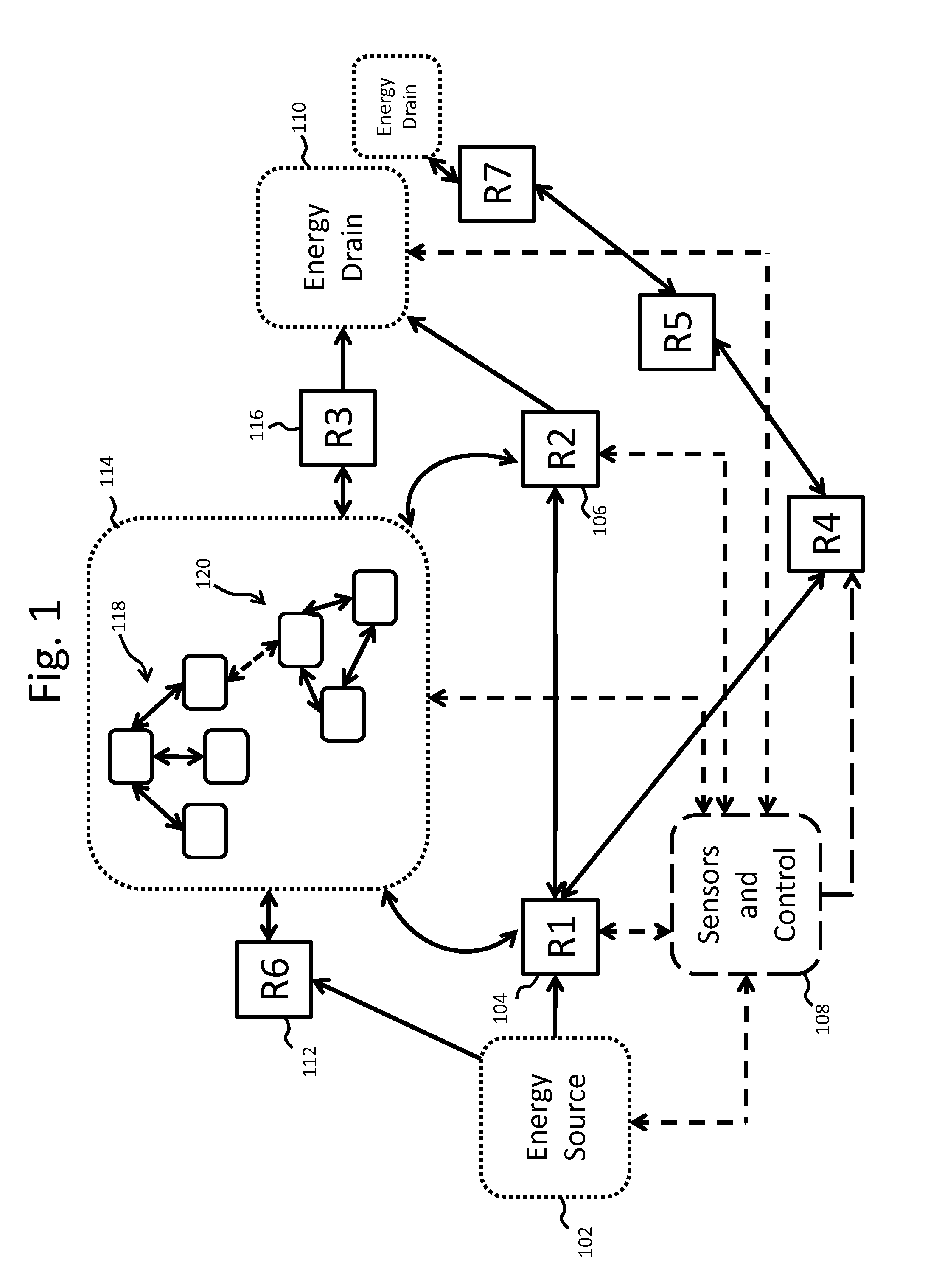

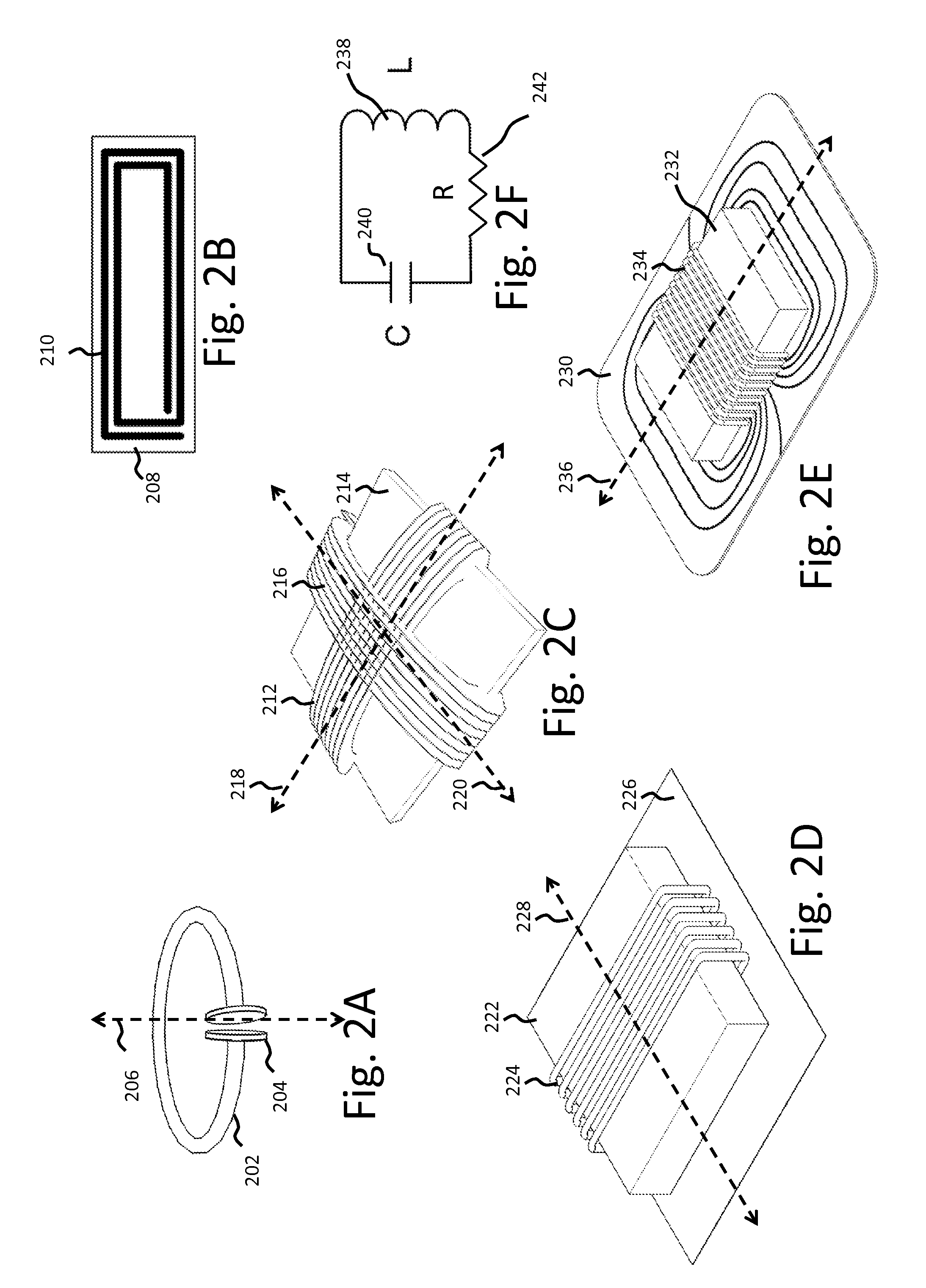

Wireless energy transfer modeling tool

ActiveUS20130159956A1Tune performanceCircuit arrangementsDesign optimisation/simulationEnergy transferElectromagnetic interference

A method includes defining and storing one or more attributes of a source resonator and a device resonator forming a system, defining and storing the interaction between the source resonator and the device resonator, modeling the electromagnetic performance of the system to derive one or more modeled values and utilizing the derived one or more modeled values to design an impedance matching network.

Owner:WITRICITY CORP

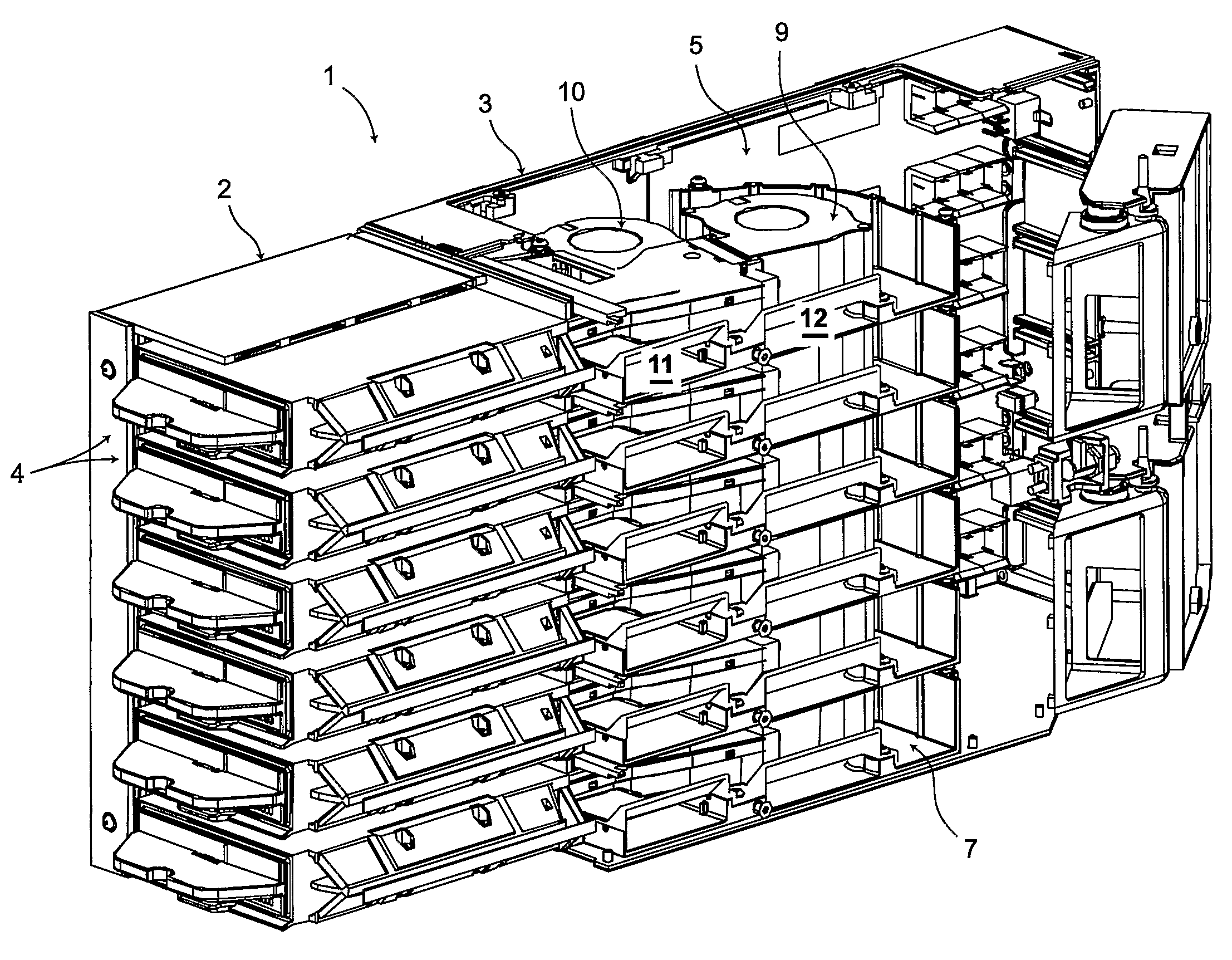

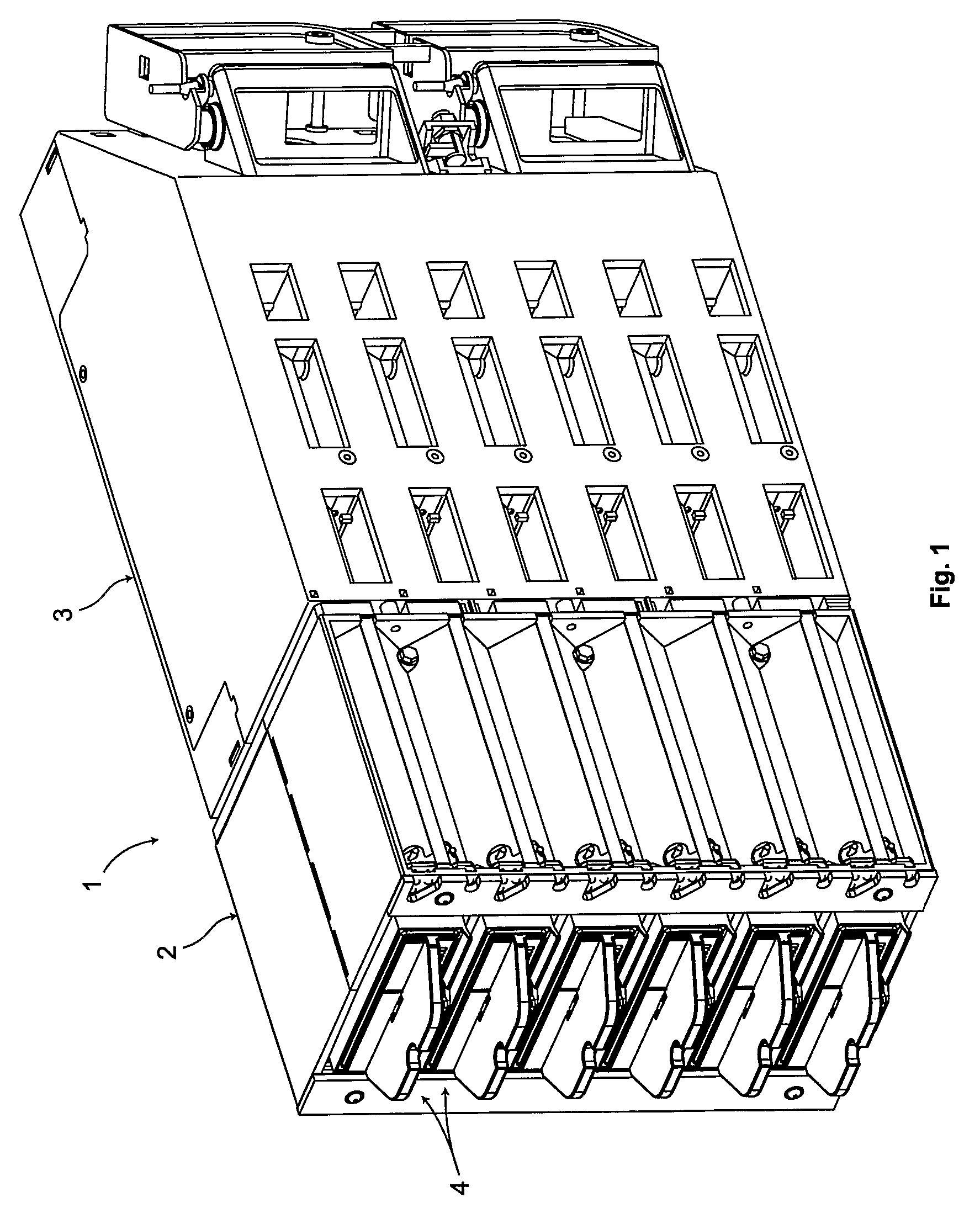

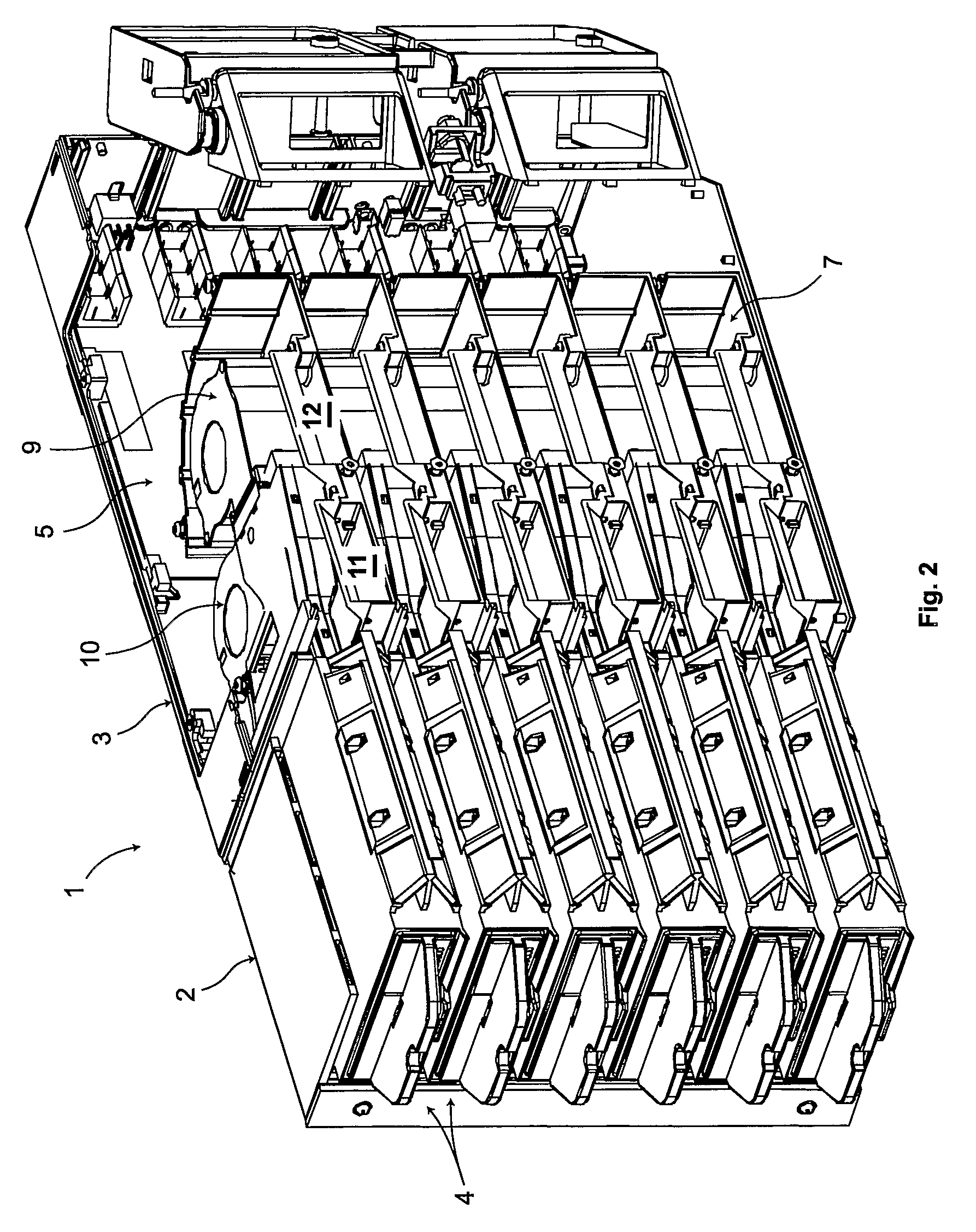

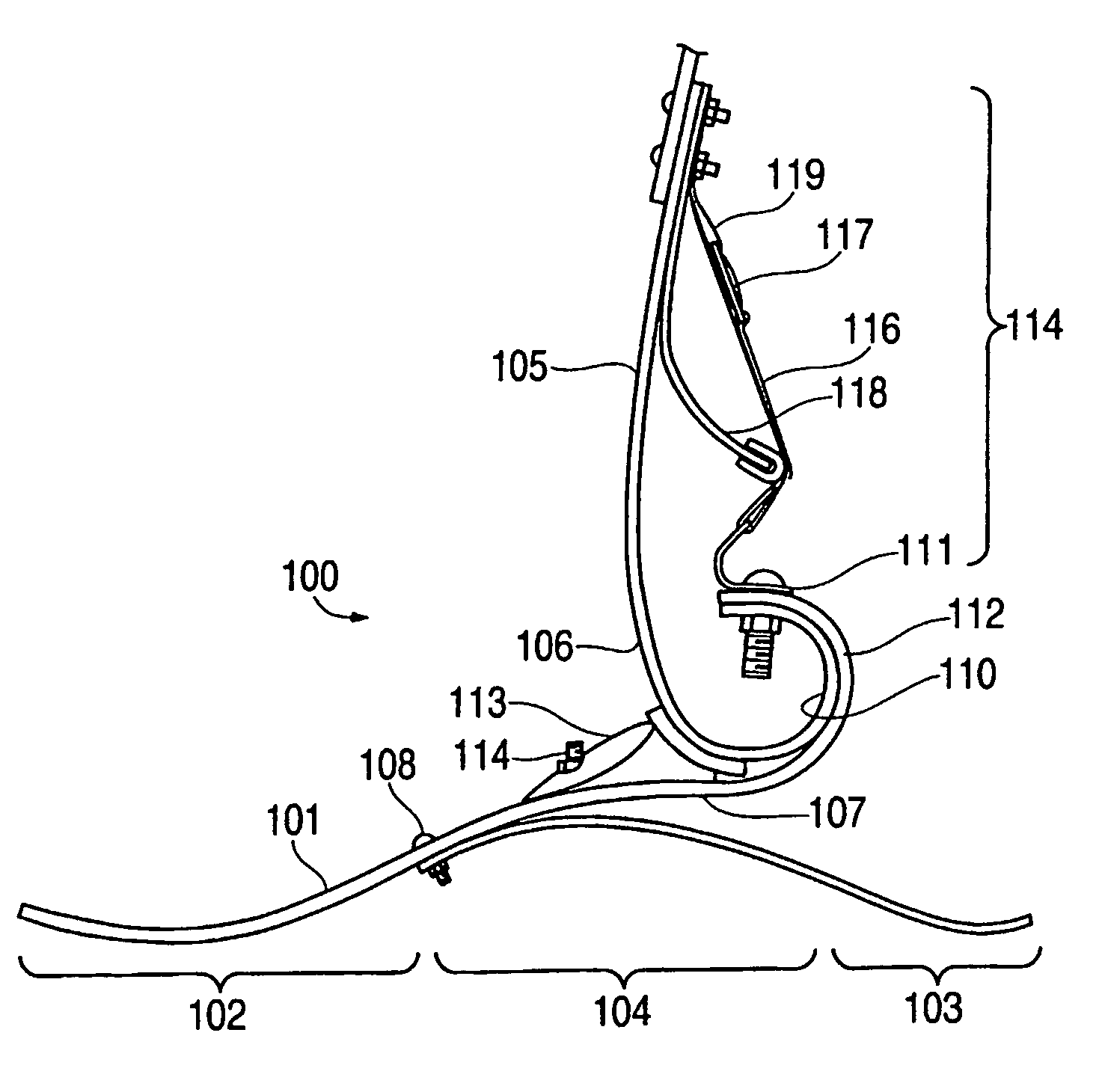

Housings and devices for disk drives

ActiveUS7729107B2Reduce vibrationTune performanceThermometer detailsElectronic circuit testingTest cardTest fixture

A disk drive test apparatus has a plurality of bays each for receiving a respective disk drive to be tested. A plurality of card slots are provided each for receiving a test card via which a disk drive can be tested. Each of the test cards is either an environment test card or an interface test card. The card slots and the test cards are arranged such that each card slot (6) can selectively receive an environment test card or an interface test card. Other arrangements for disk drive test apparatus or disk drive mounting apparatus are disclosed.

Owner:XYRATEX TECH LTD

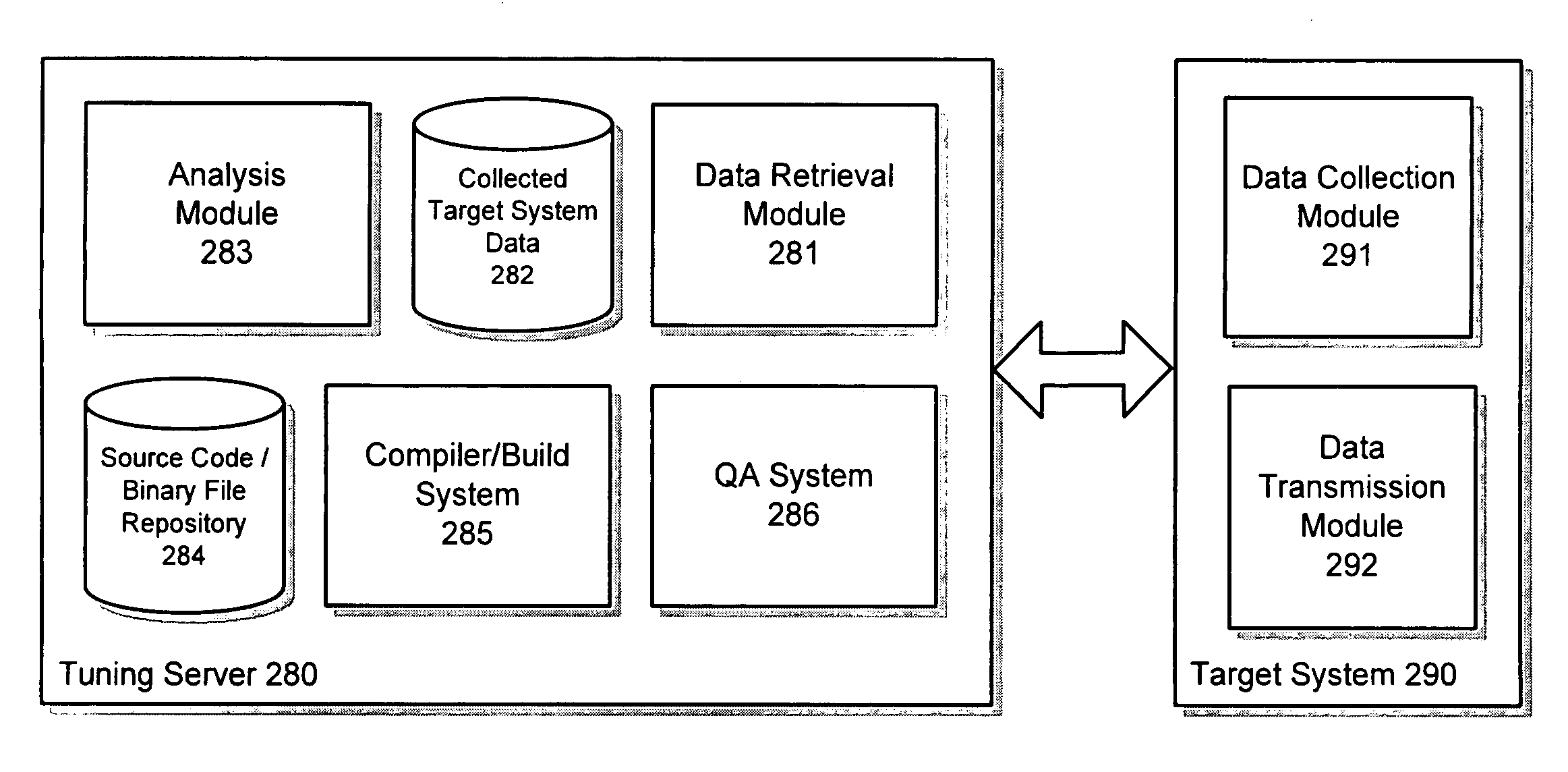

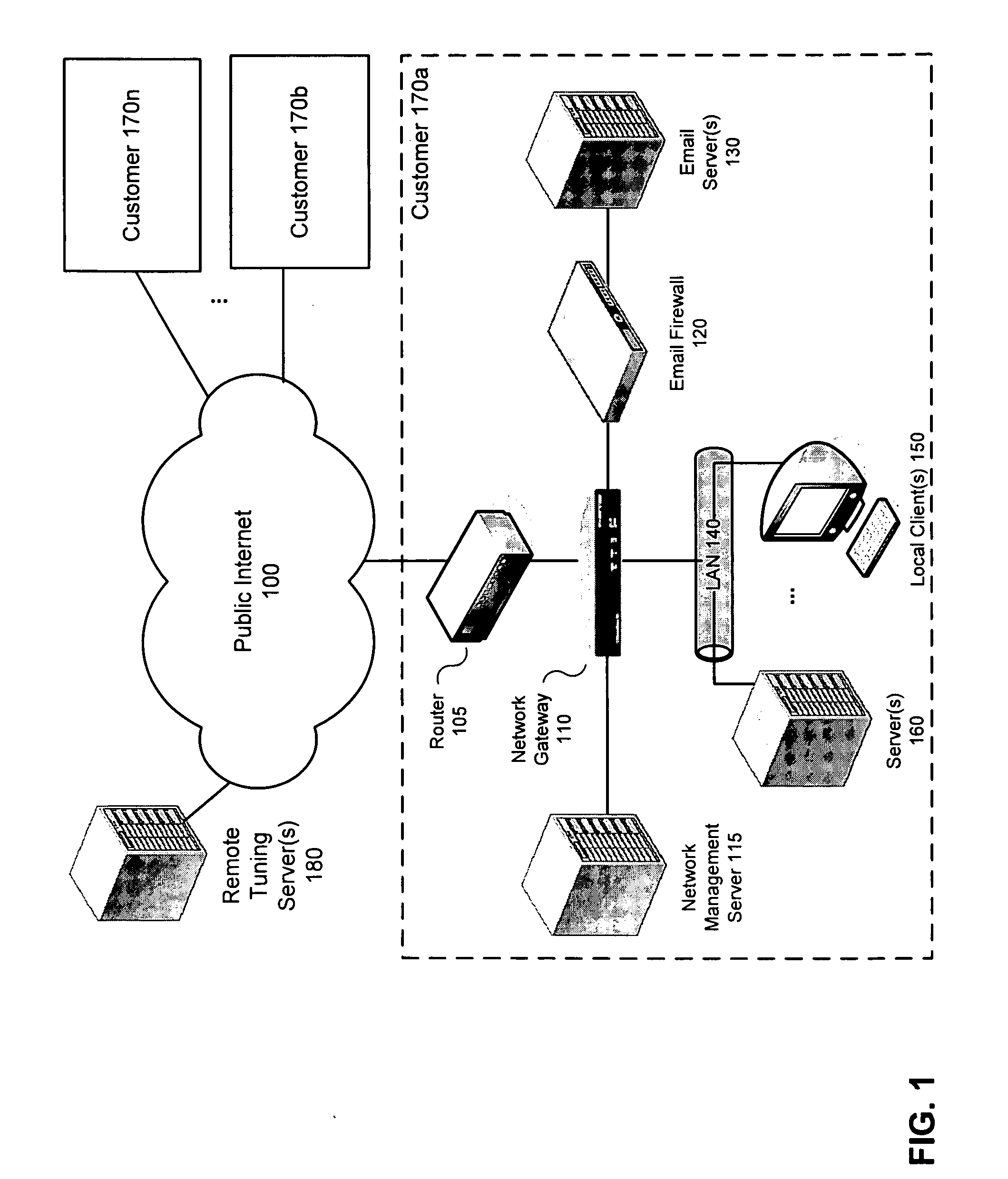

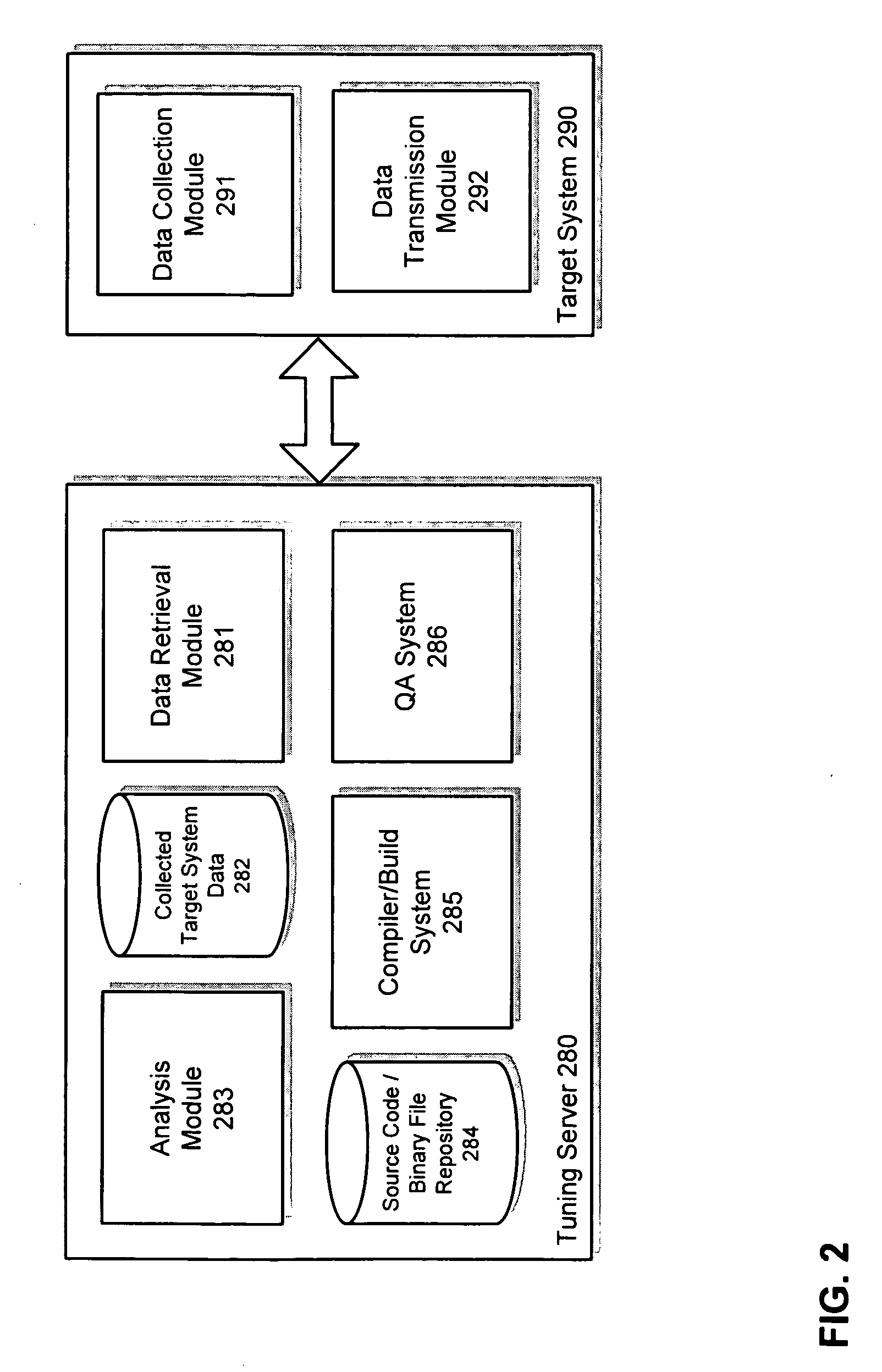

Monitoring and dynamic tuning of target system performance

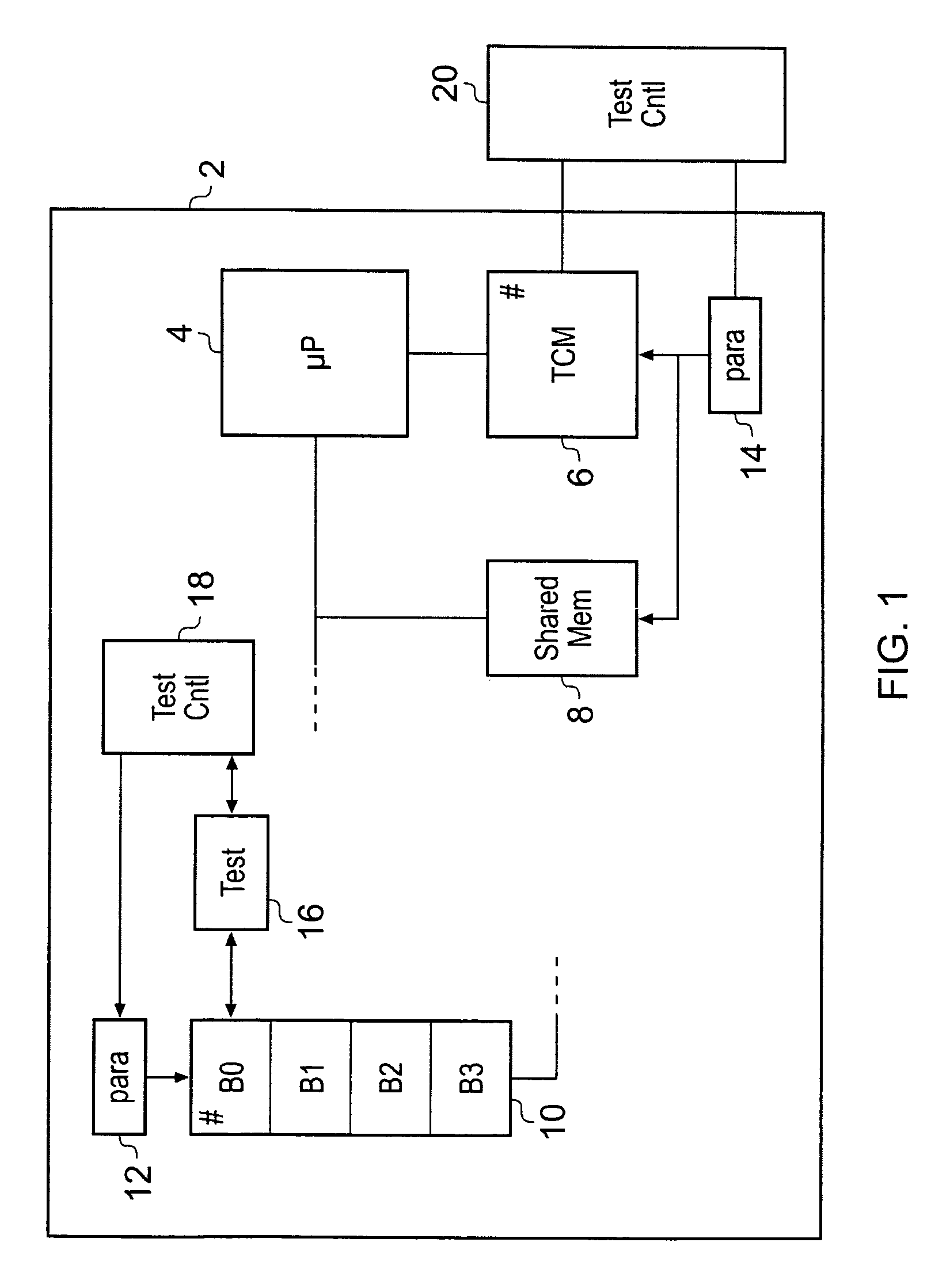

InactiveUS20090293051A1Improve performanceTune performanceError detection/correctionDigital computer detailsGoal systemEmbedded system

Methods and systems for remotely monitoring and tuning the performance of one or more target systems are provided. According to one embodiment, a separate tuning server receives data, such as profiling data, that has been collected regarding a target system. Then, if based on the data it is determined that performance attributes of the target system can be improved, the performance of the target system is dynamically tuned. Depending upon the circumstances, the target system may be caused to replace an application component of a program being executed by the target system with a new application component, which may be contained within an image chosen from a set of pre-built images or built and compiled by the tuning server specifically for the target system. In some cases, the dynamic tuning of the performance of the target system may involve making a change to a configuration file on the target system.

Owner:FORTINET

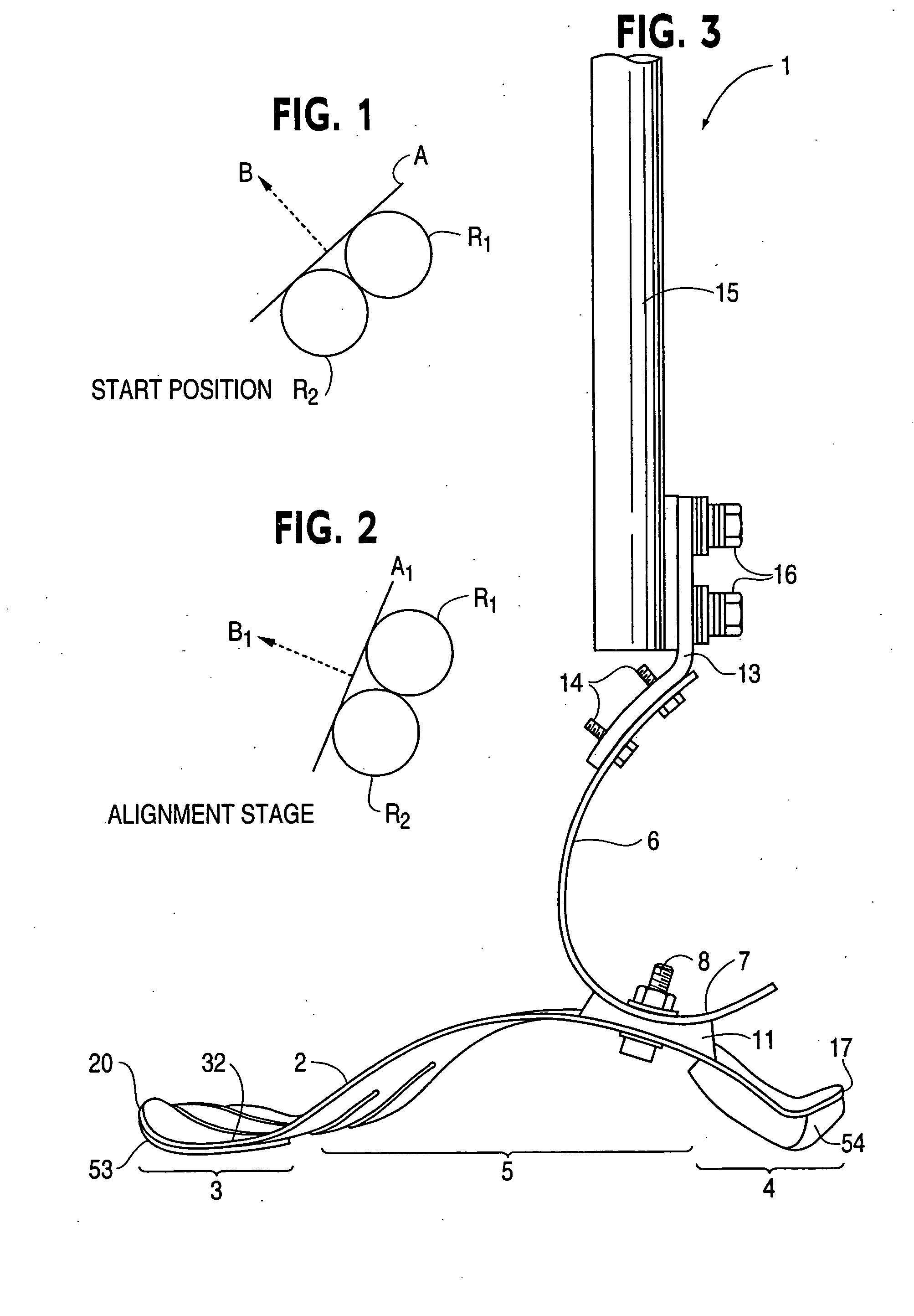

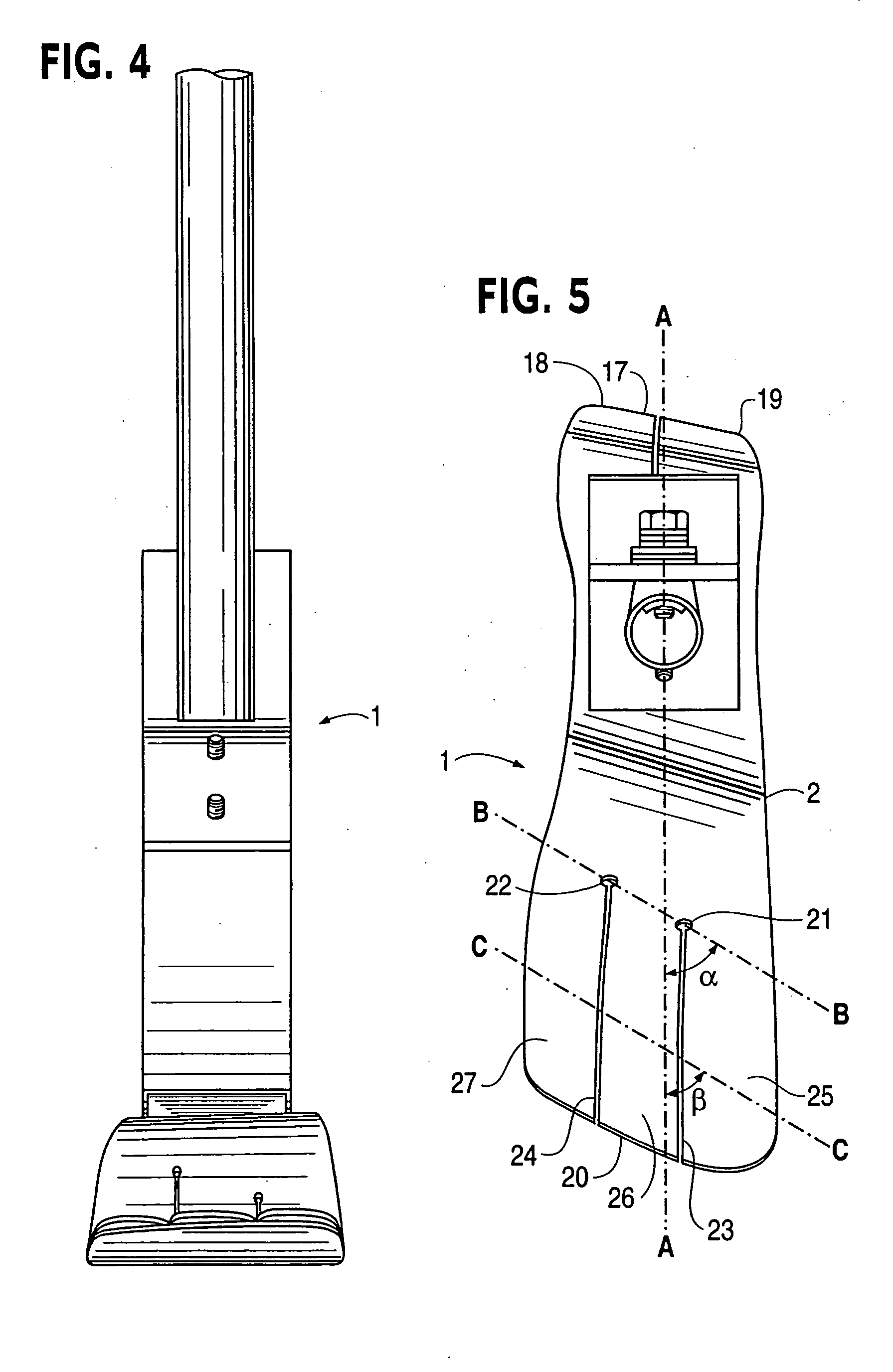

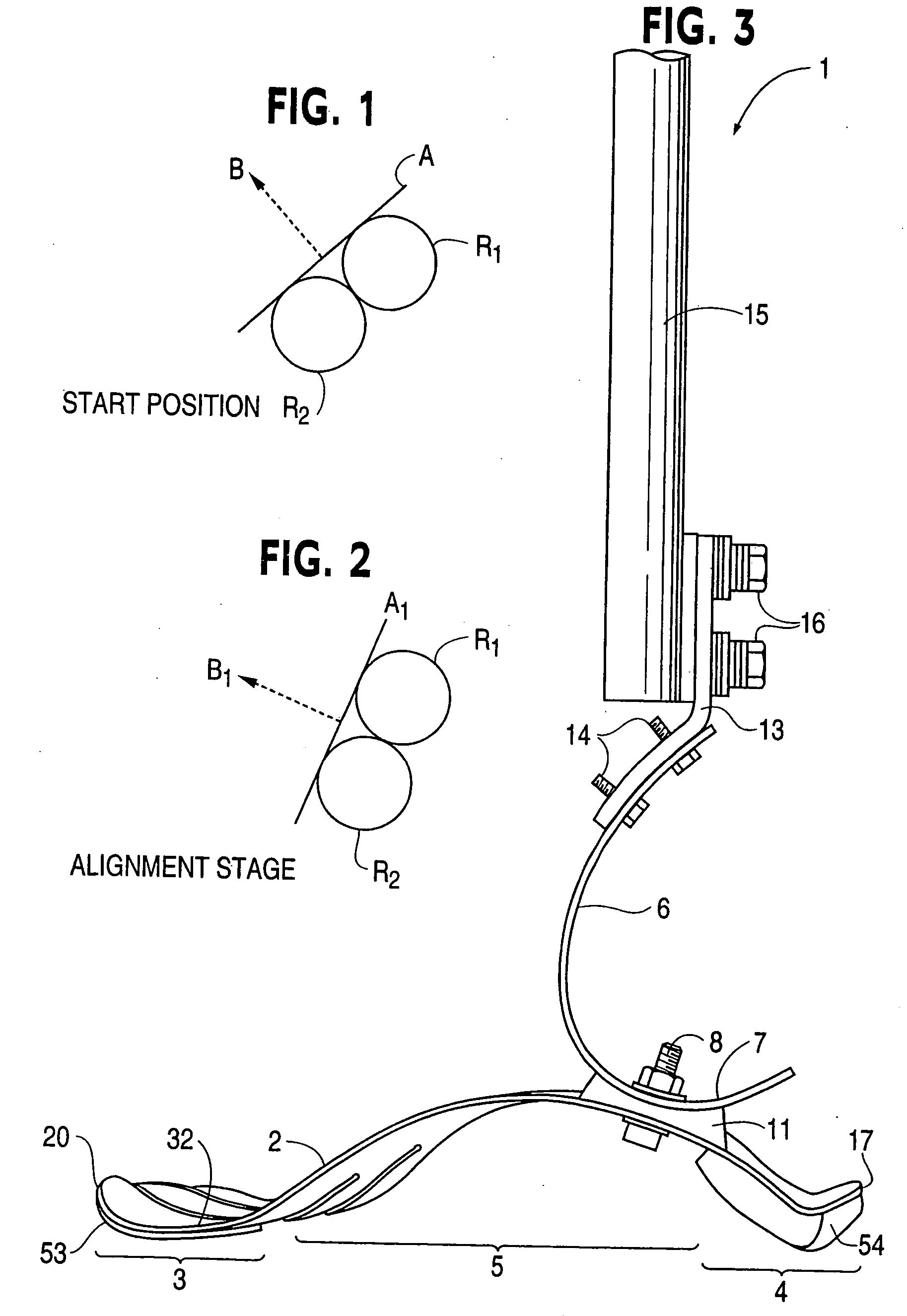

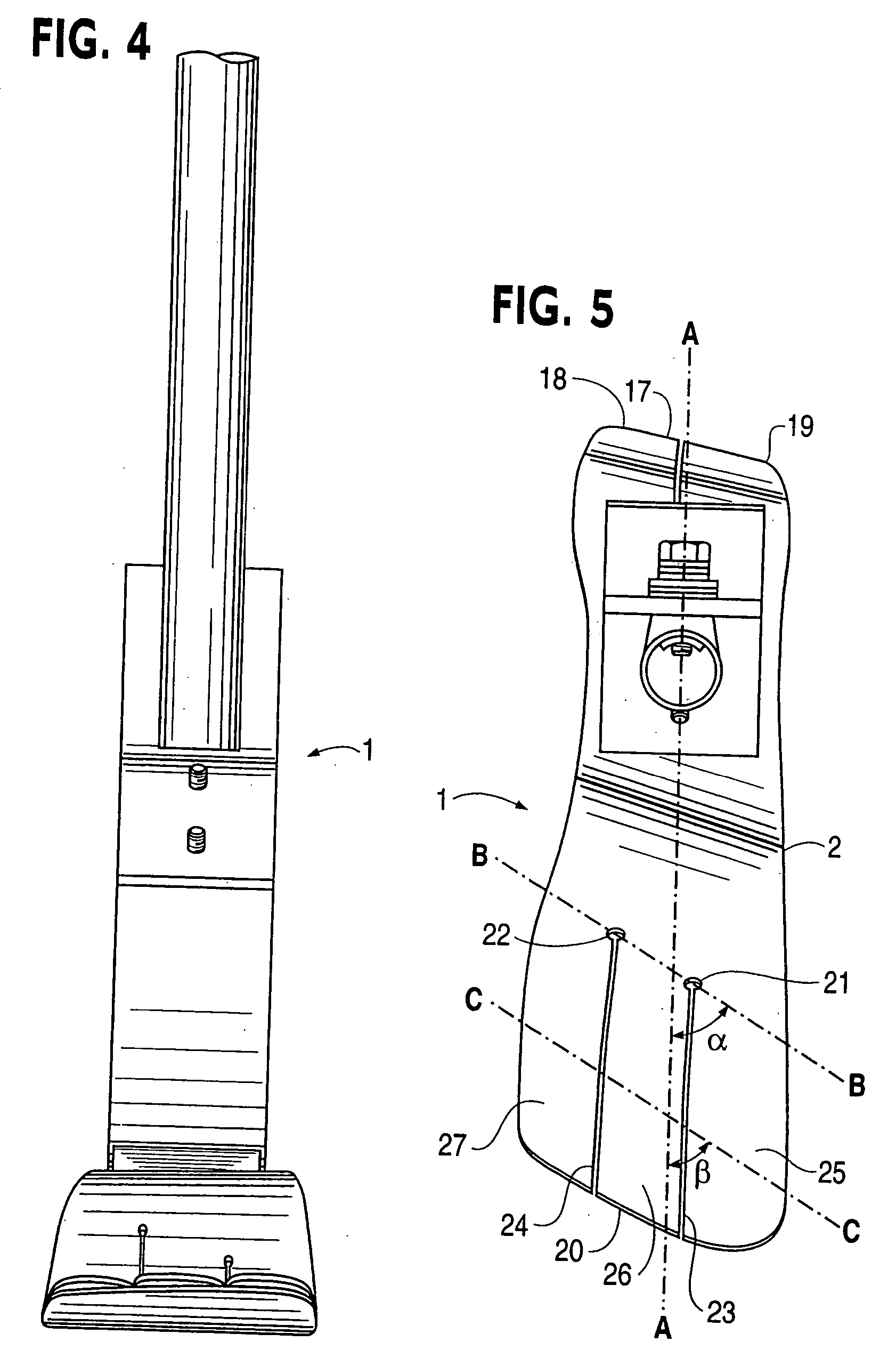

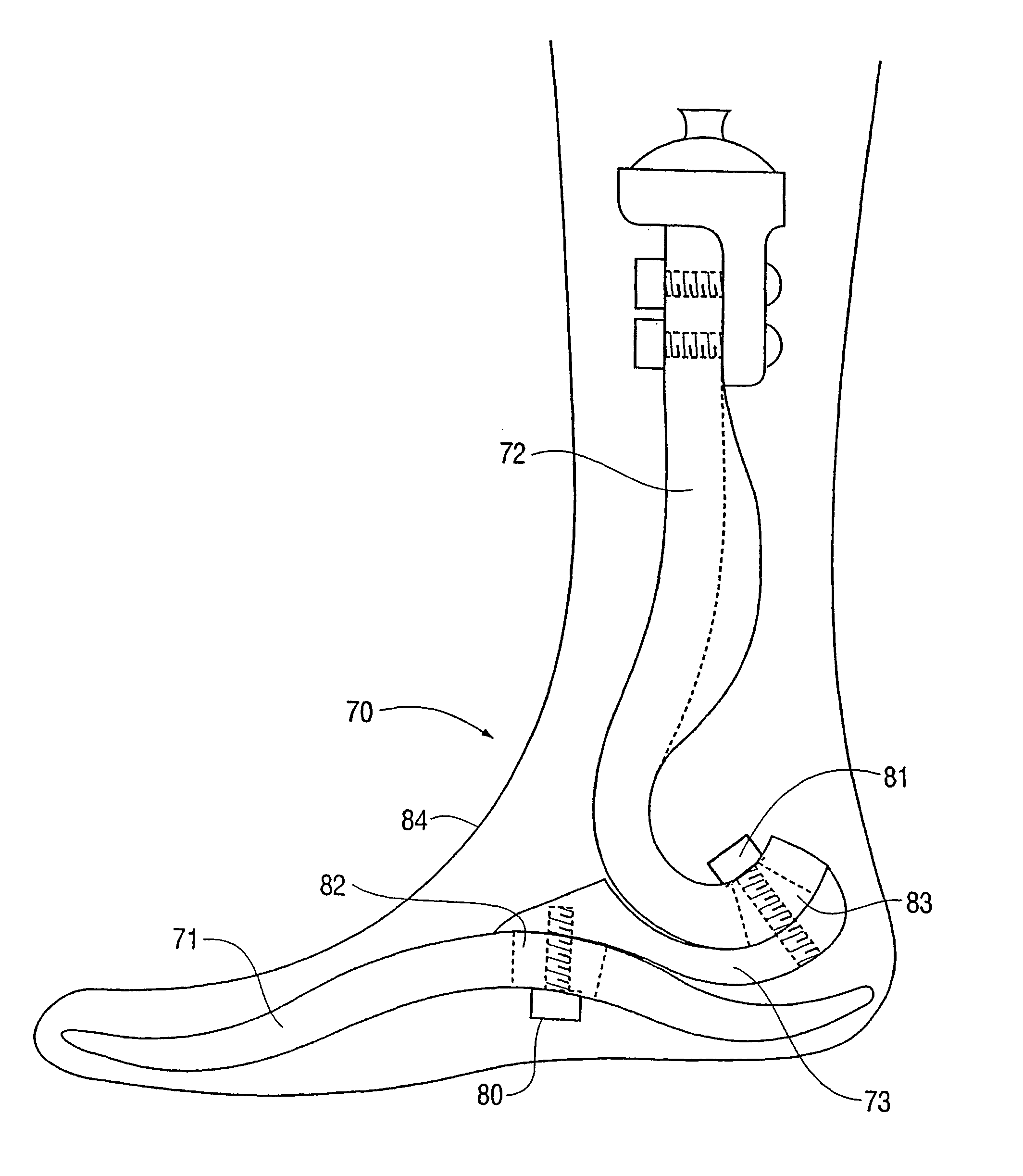

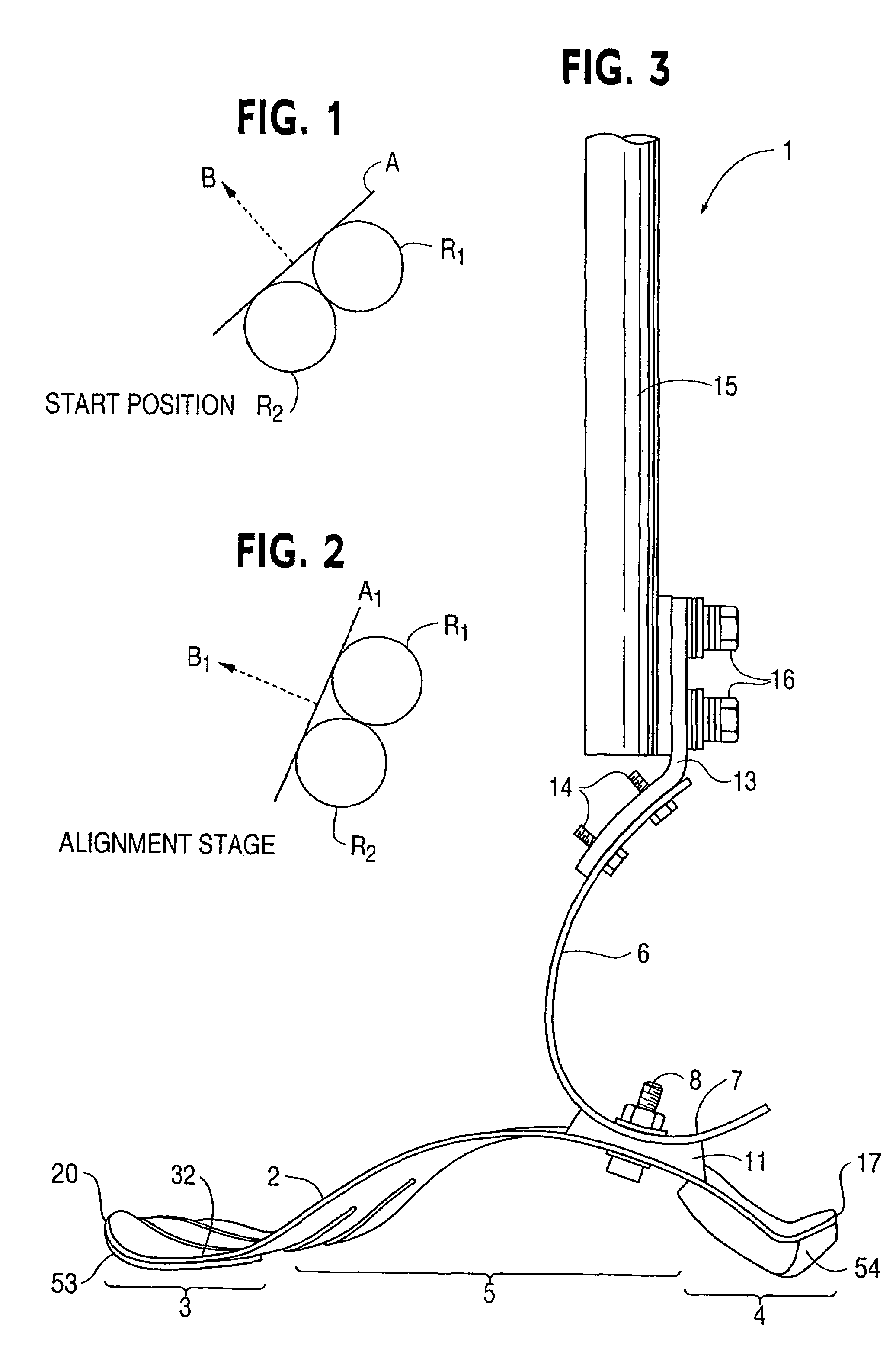

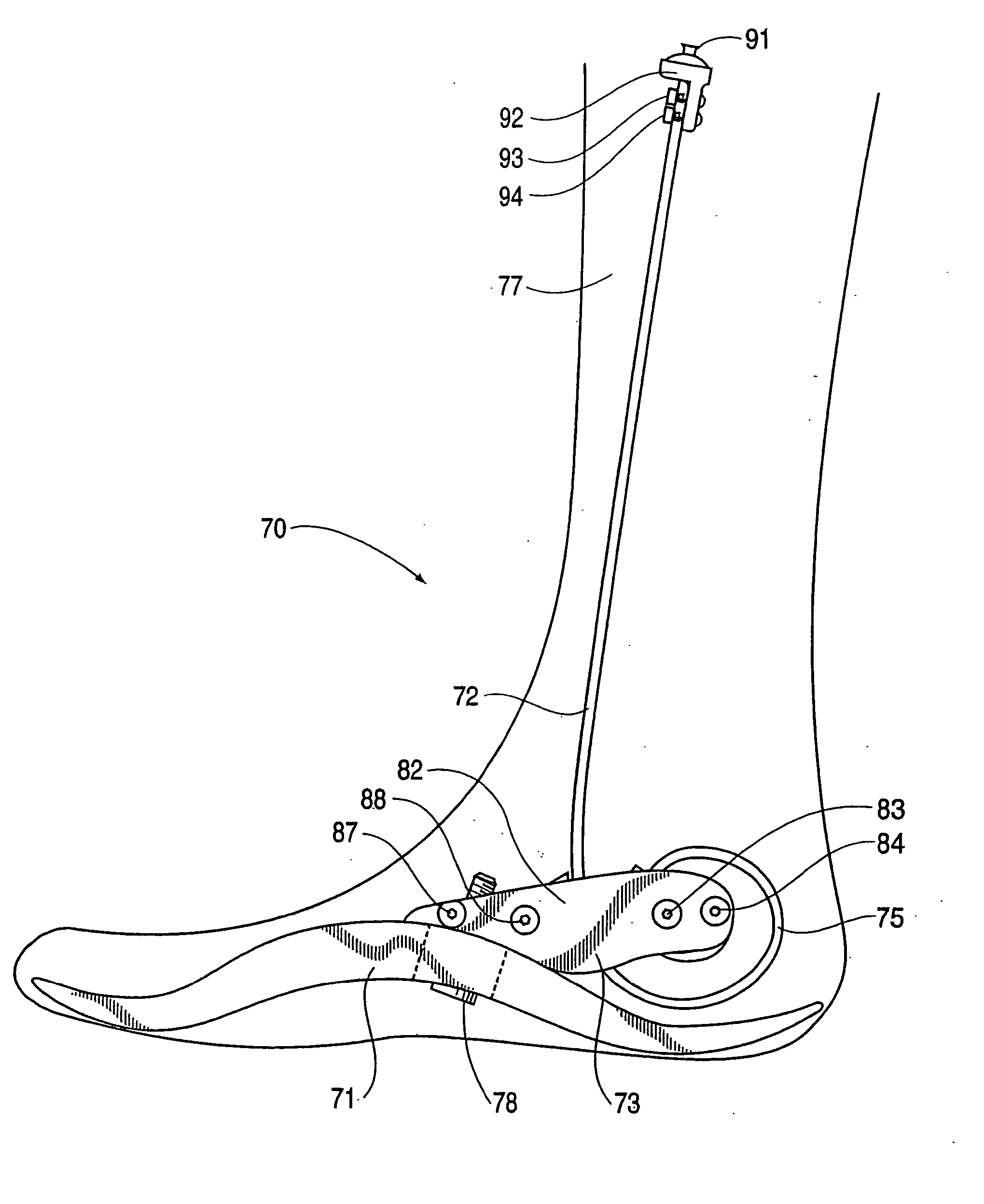

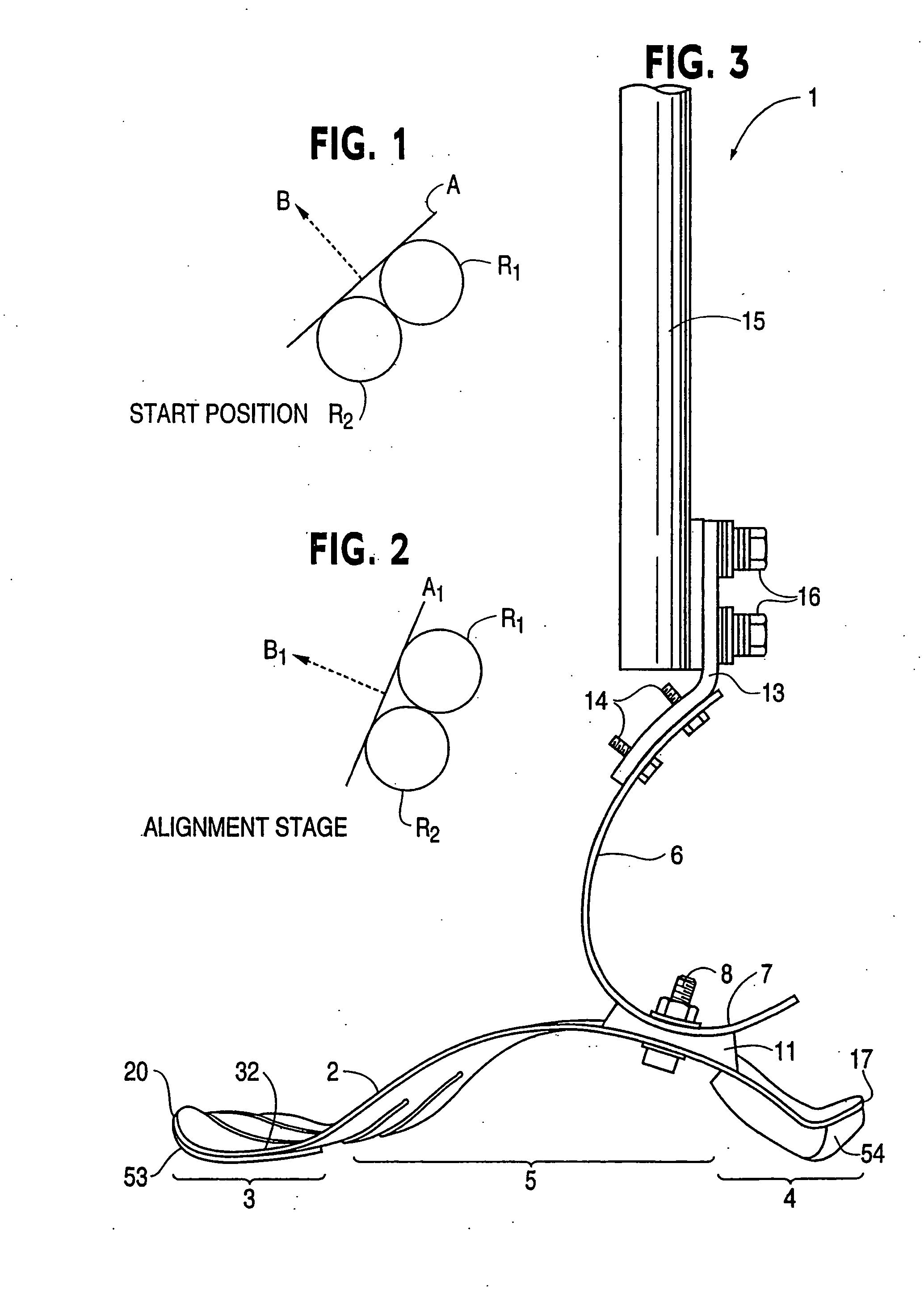

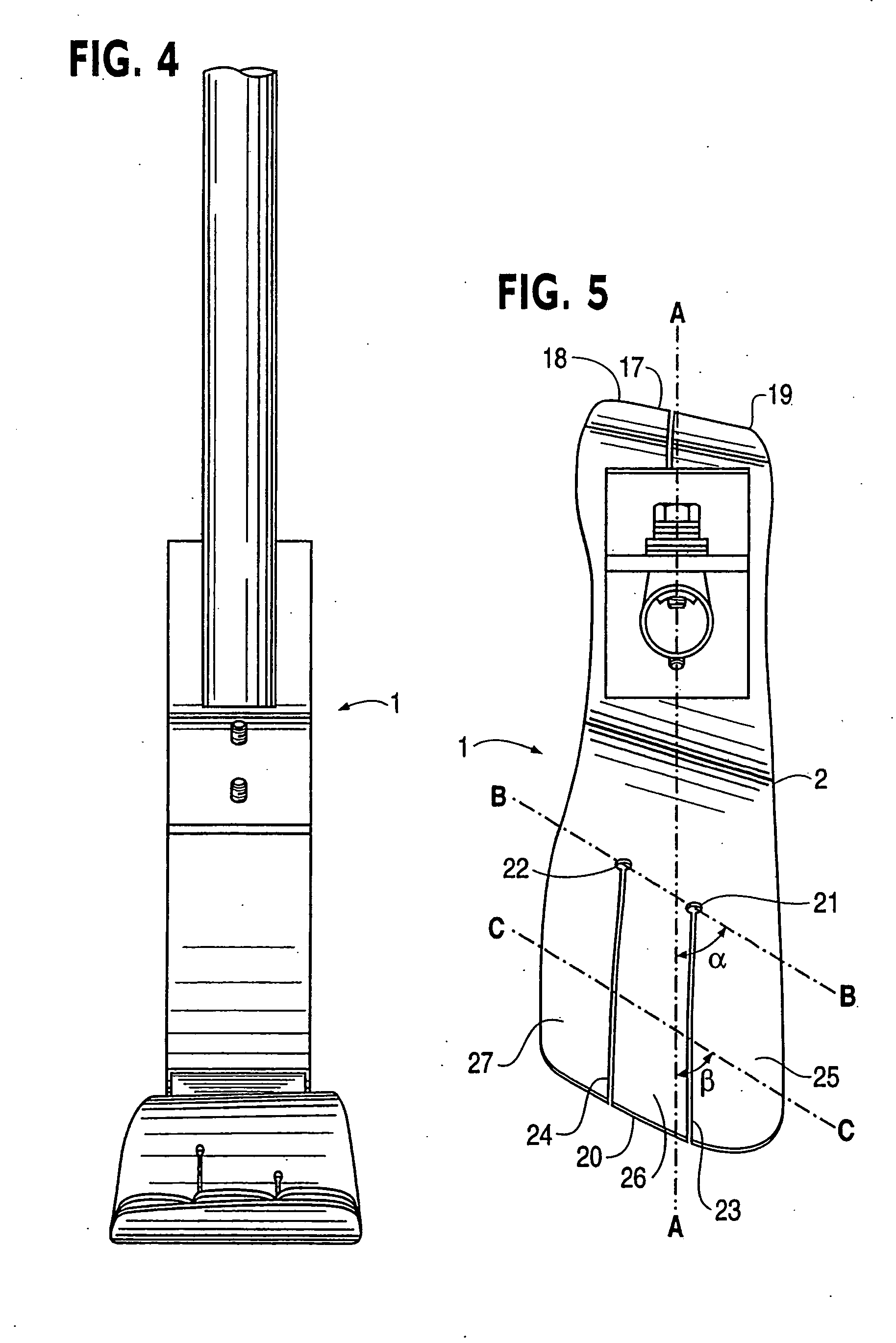

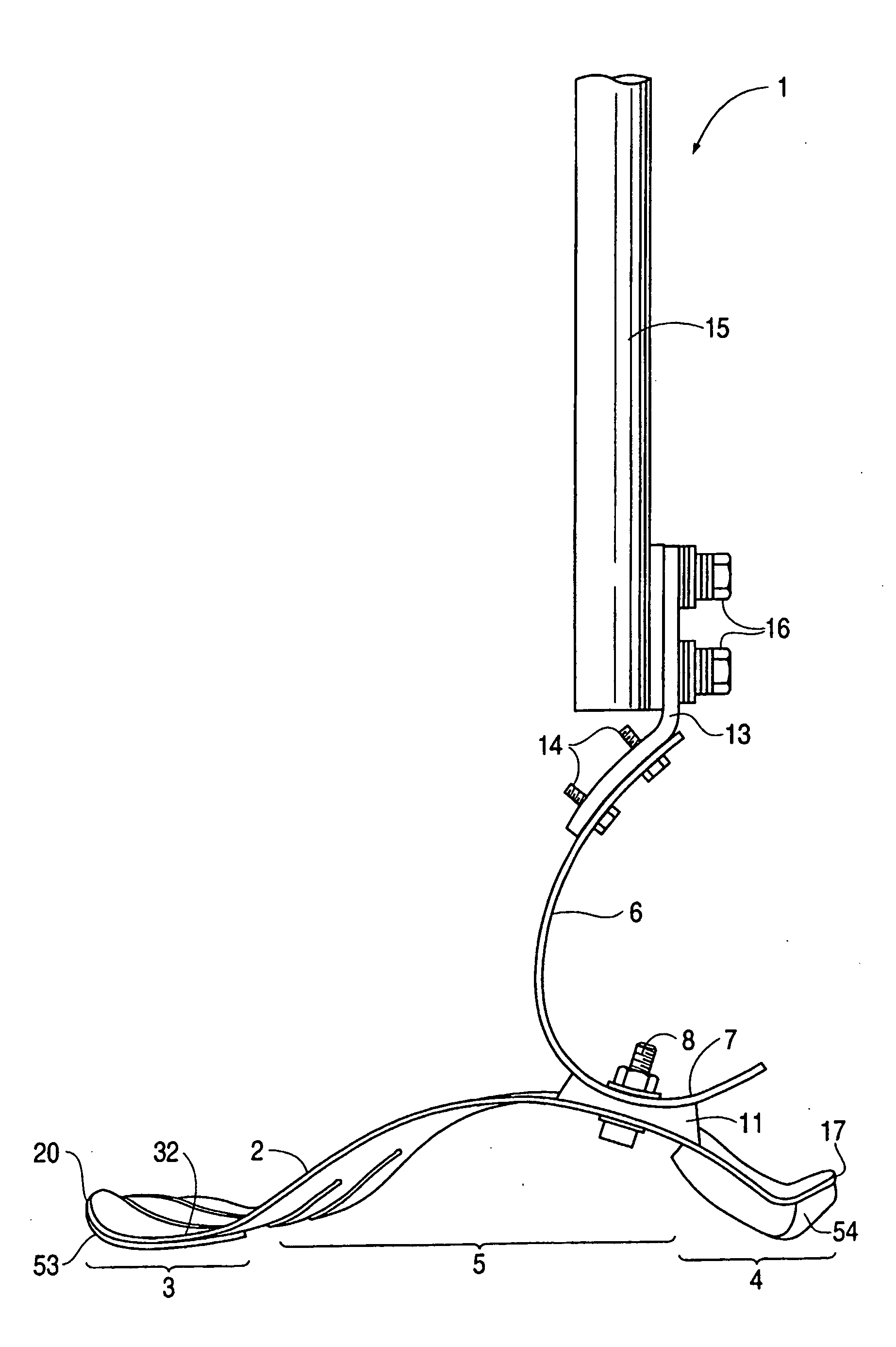

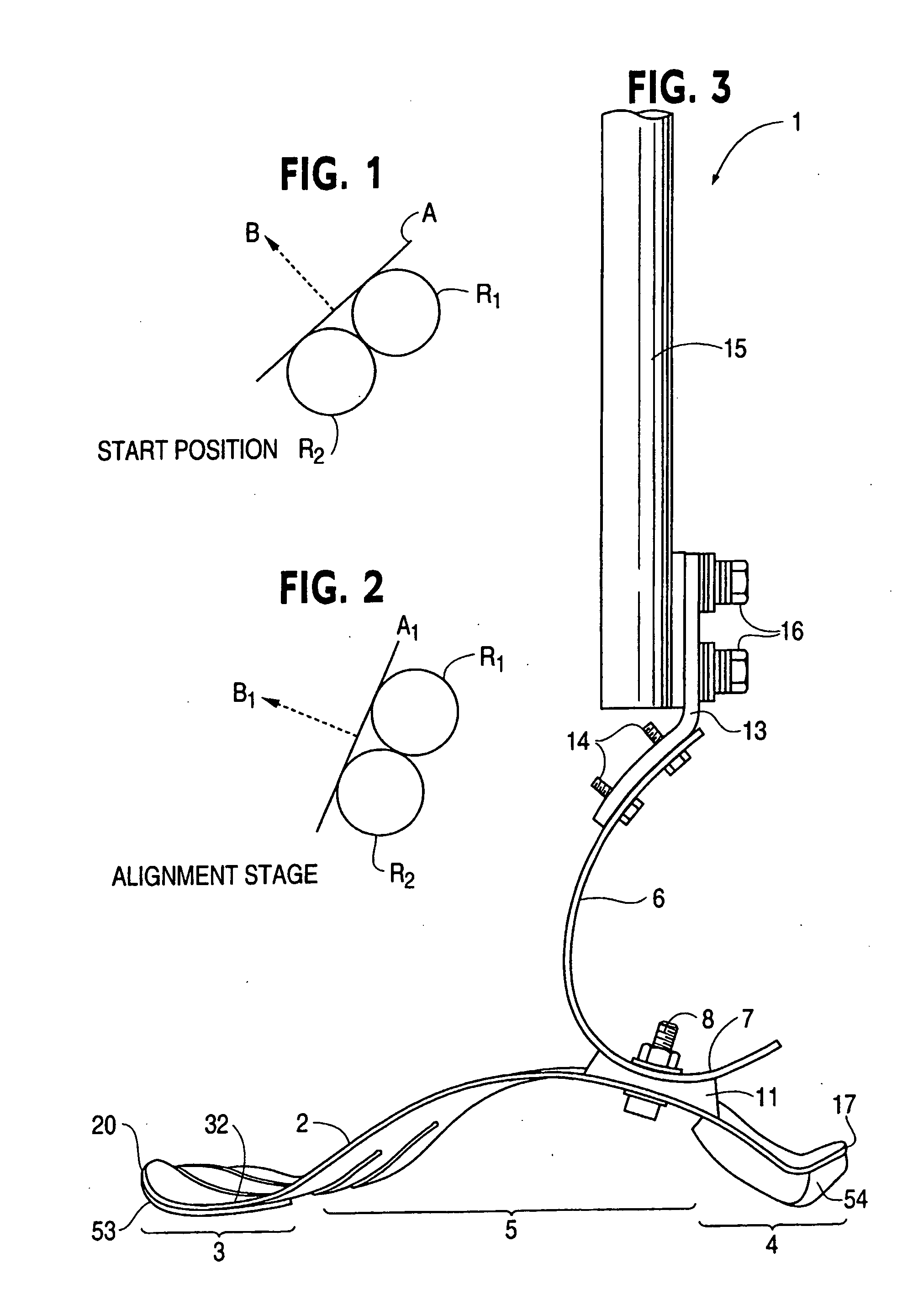

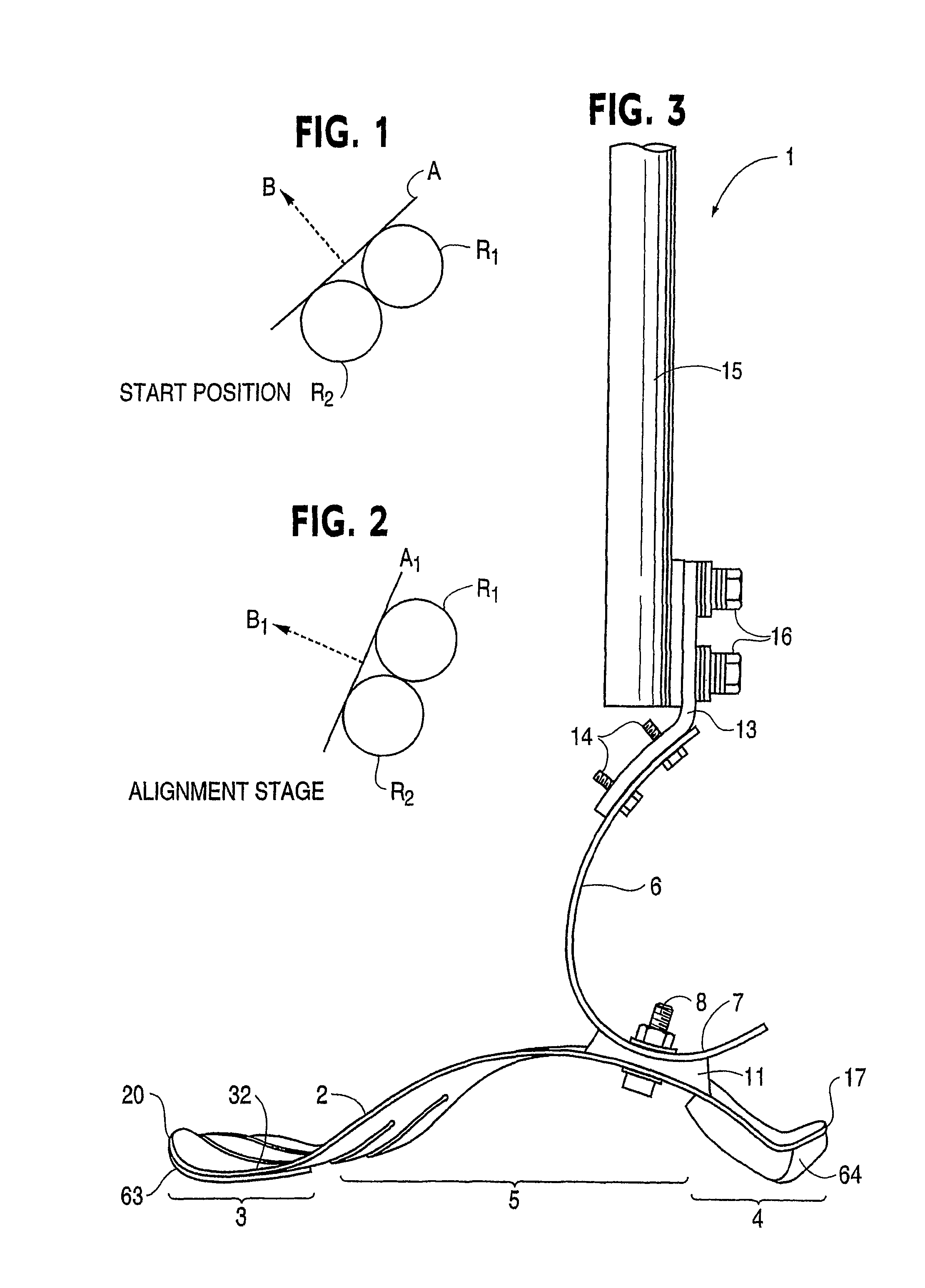

Prosthetic foot with tunable performance and improved vertical load/shock absorption

InactiveUS7578852B2Improve performanceImproved applied mechanicCapsule deliveryArtificial legsTibiaKeel

Owner:BIOQUEST PROSTHETICS

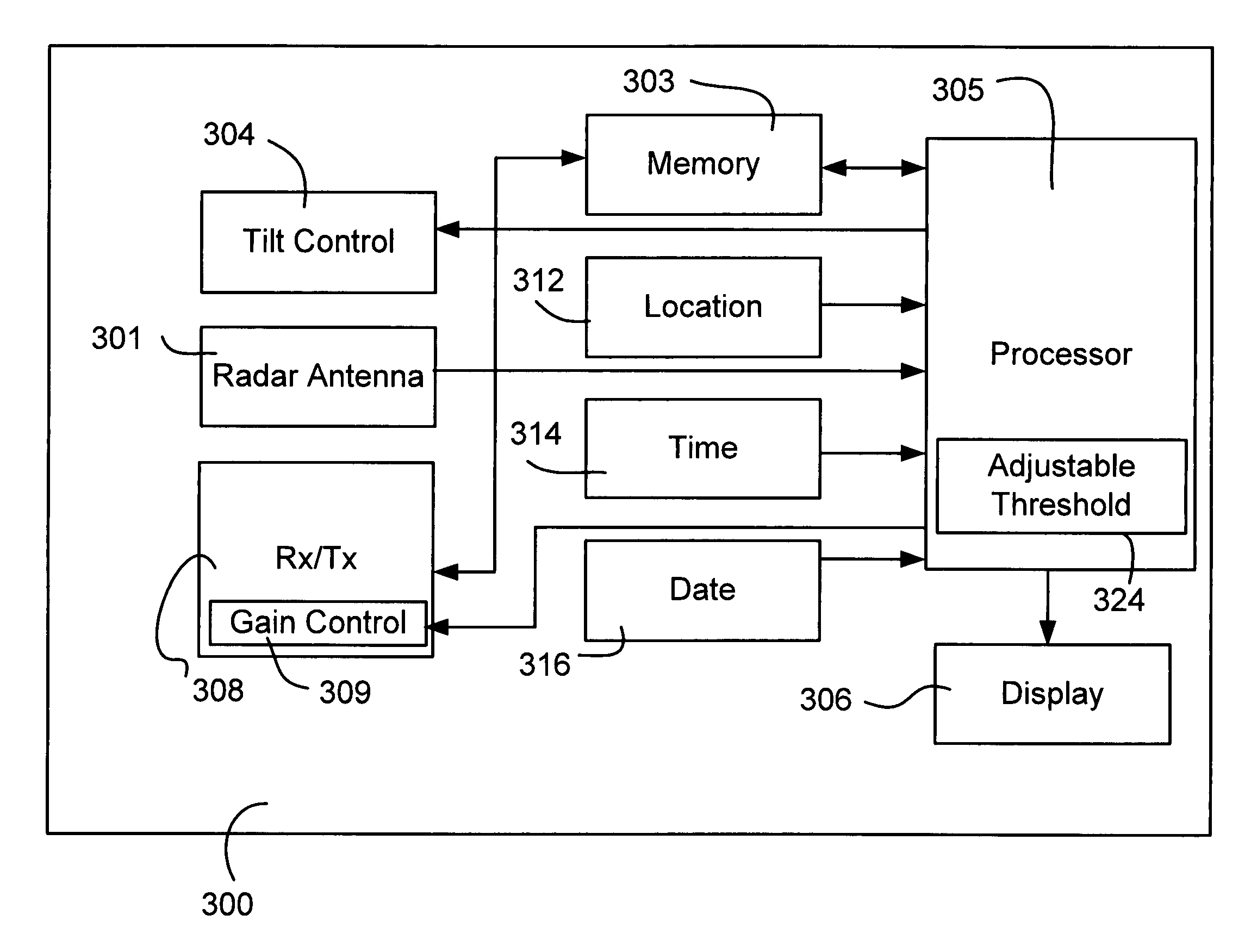

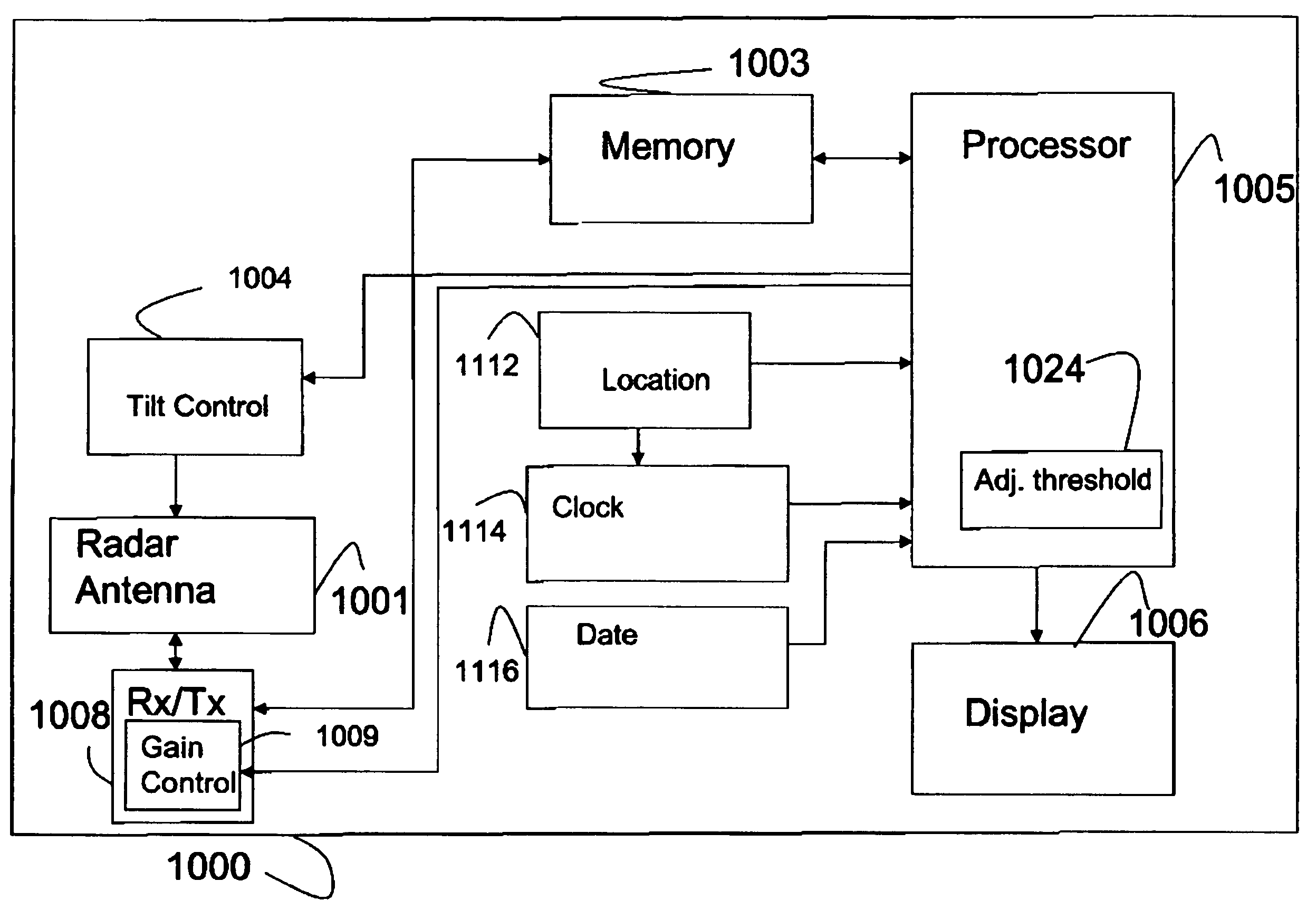

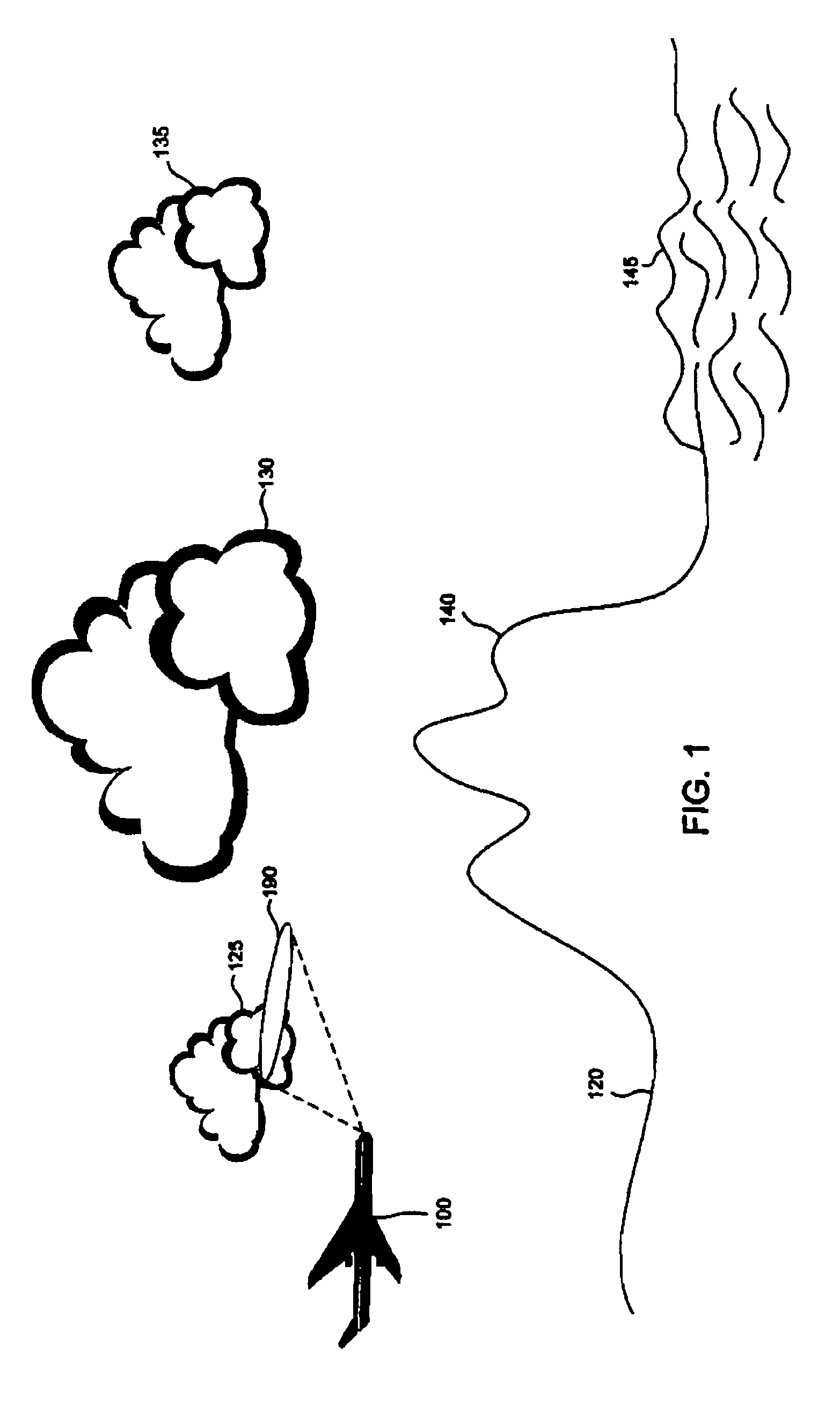

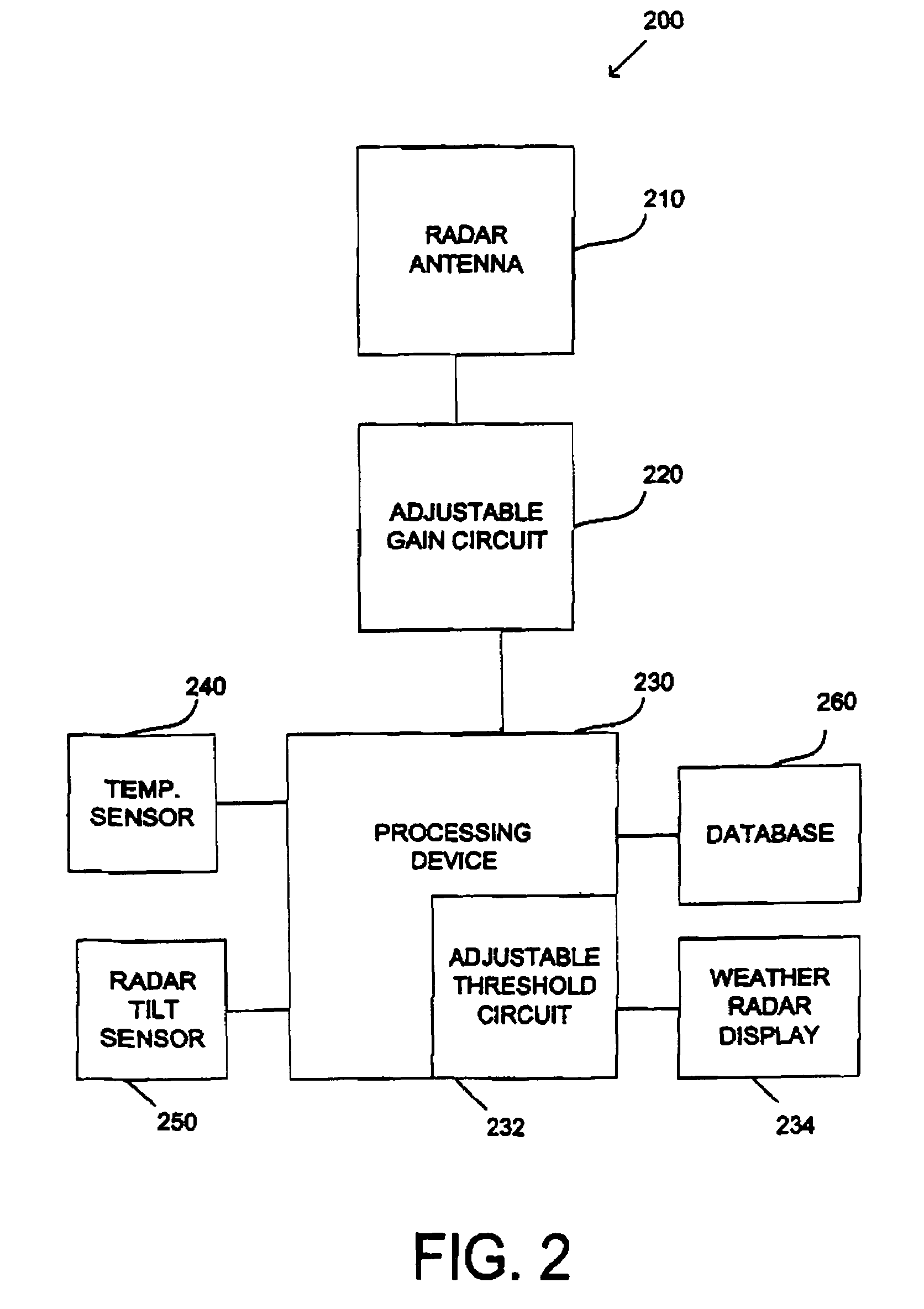

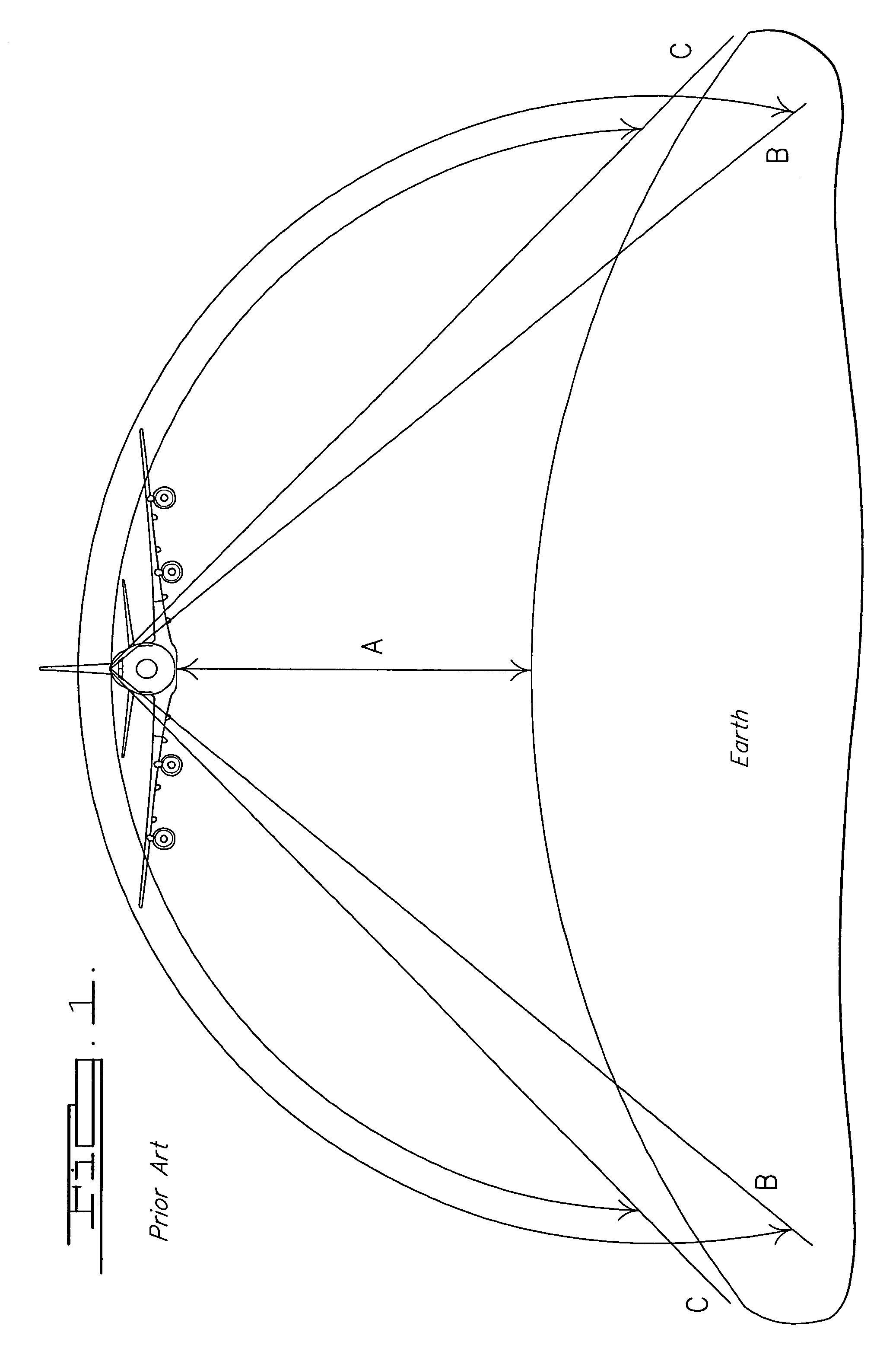

Predictive and adaptive weather radar detection system and method

ActiveUS7808422B1Tune performancePosition fixationNavigation instrumentsWeather radarPosition dependent

A method of detecting weather on an aircraft uses a weather radar system. The method includes determining a location of a reflective radar target, accessing a database having stored information relating to ground clutter of a reflective radar target, retrieving weather radar information associated with the location, and automatically adjusting the weather radar return threshold in response to the information. The method can adjust a threshold for a weather radar display, adjust a weather radar signal gain, adjust a tilt angle of the weather radar, or adjust a ground clutter suppression threshold. The method can be implemented by hardware and / or software.

Owner:ROCKWELL COLLINS INC

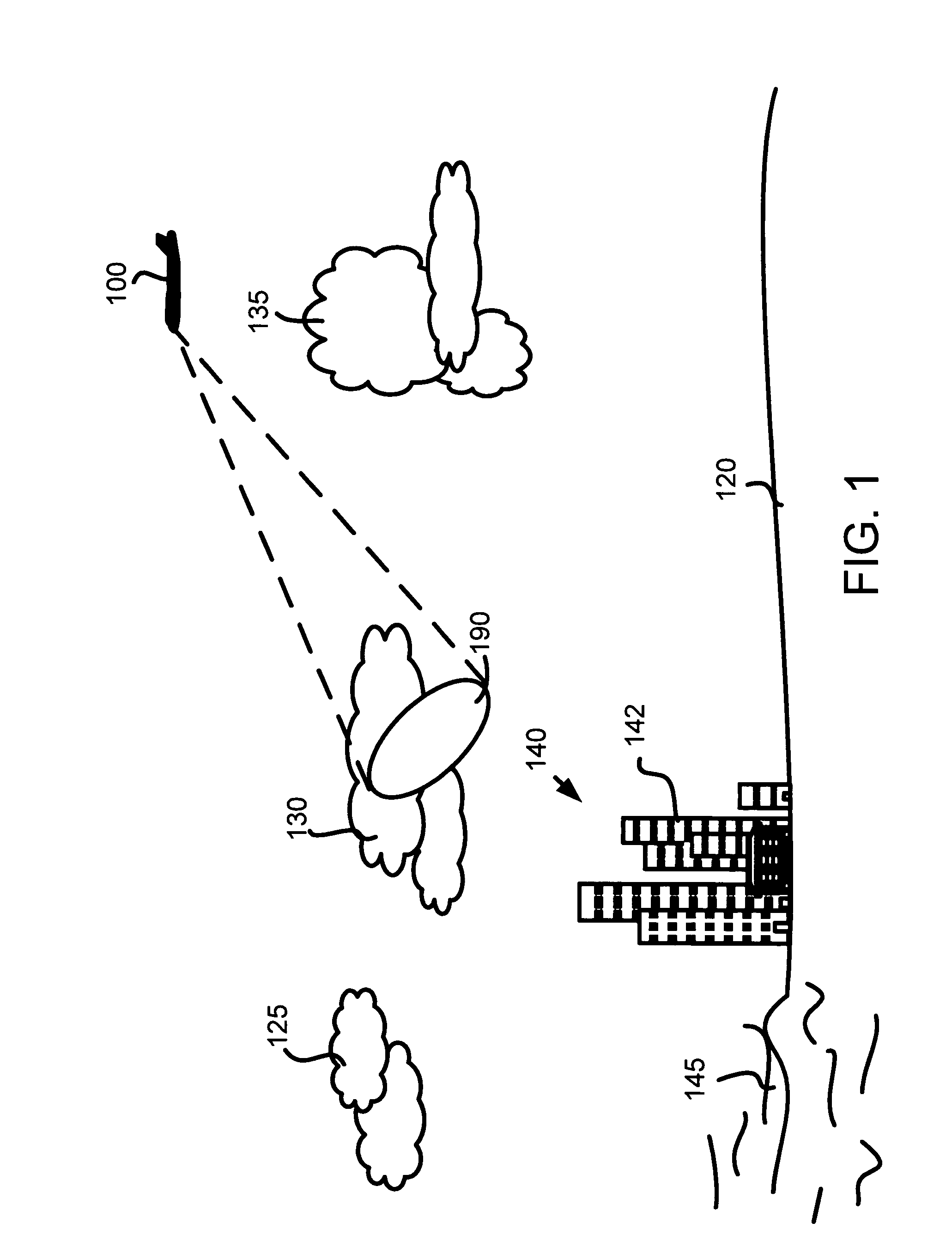

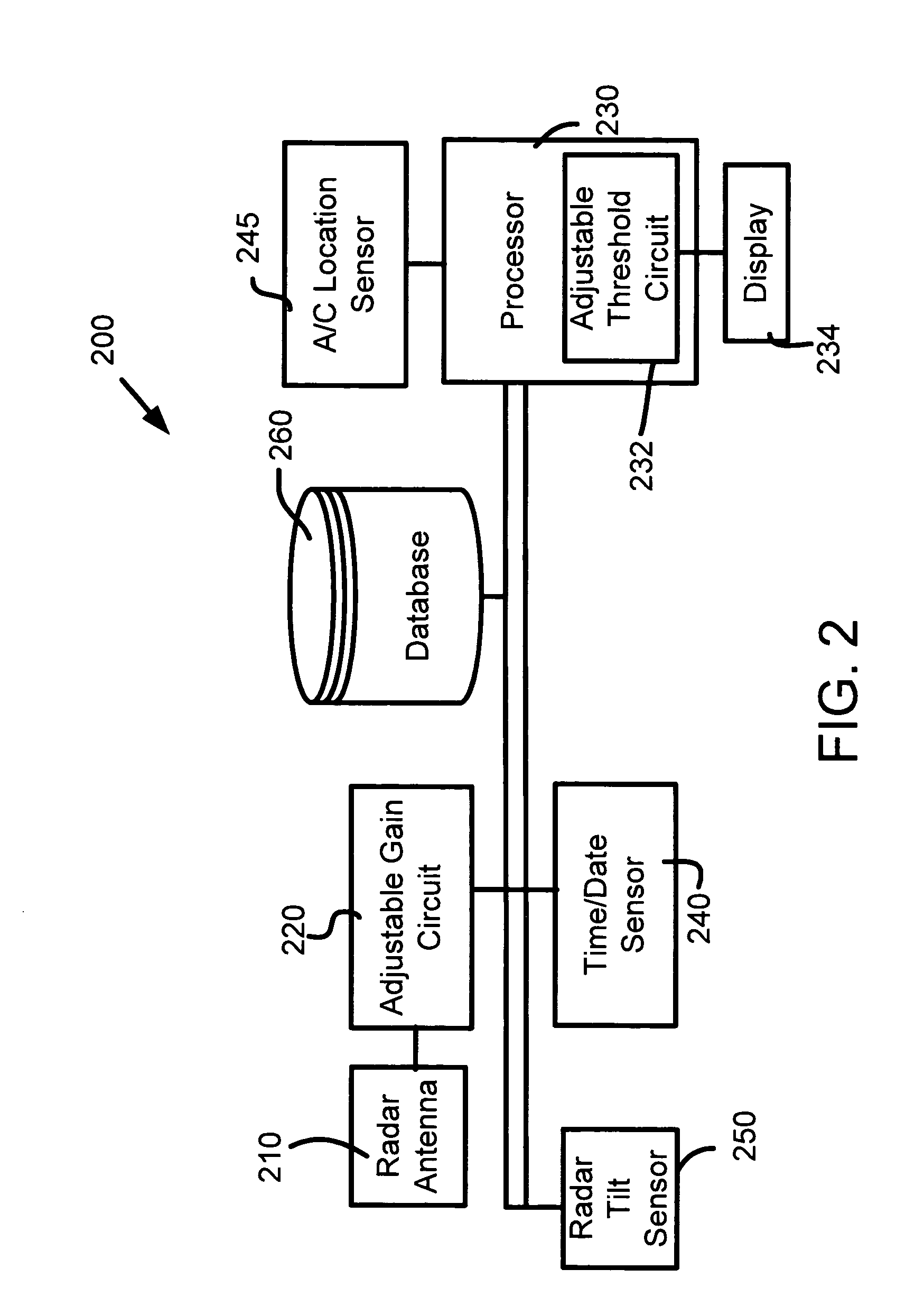

Adaptive weather radar detection system and method

InactiveUS7486219B1Tune performanceSatellite radio beaconingICT adaptationRadar systemsWeather radar

A method of detecting weather on an aircraft uses a weather radar system. The method adapts the weather radar system in accordance with a seasonal parameter, a time-of-day parameter, or a location parameter. The method includes determining the particular parameter and automatically adjusting the weather radar system to display the weather in response to the parameter. The system can be implemented in hardware or software and advantageously can more precisely predict and identify weather and / or weather hazards.

Owner:ROCKWELL COLLINS INC

Prosthetic foot with tunable performance

InactiveUS7507259B2Improve performanceImproved applied mechanicCapsule deliveryArtificial legsTibiaKeel

Owner:BIOQUEST PROSTHETICS

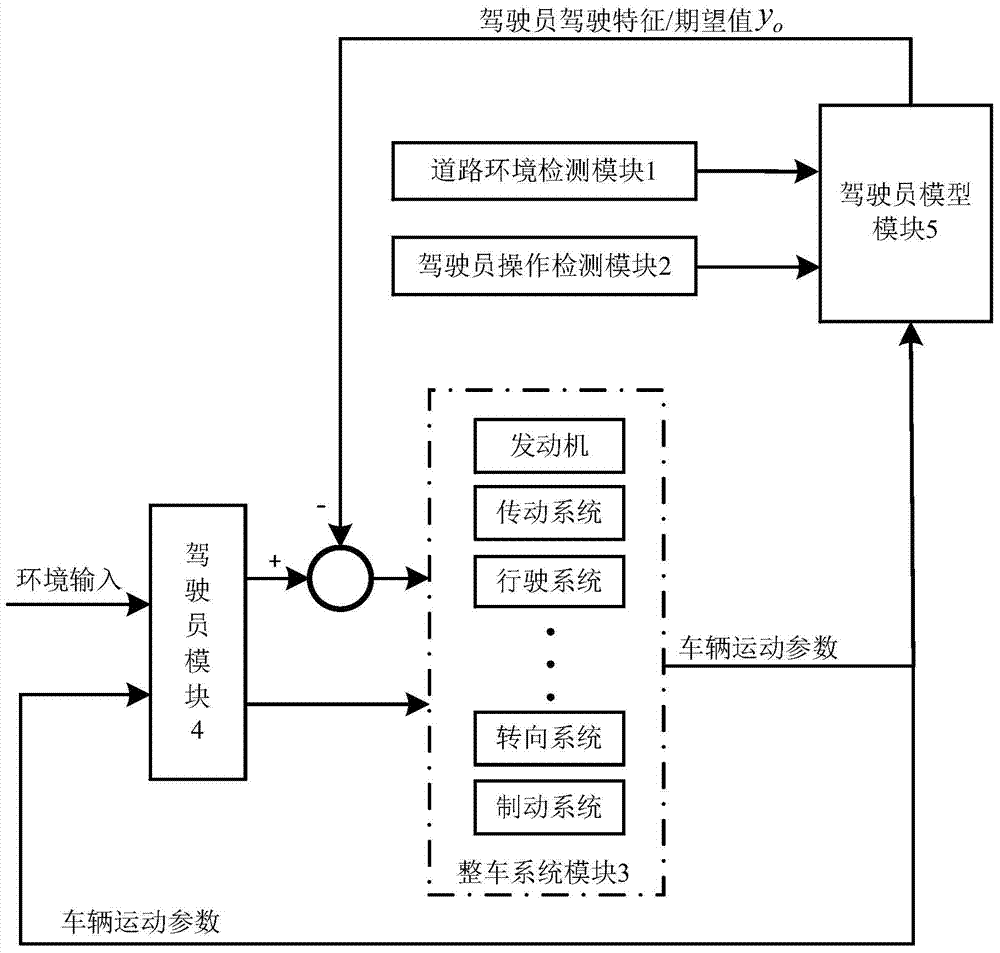

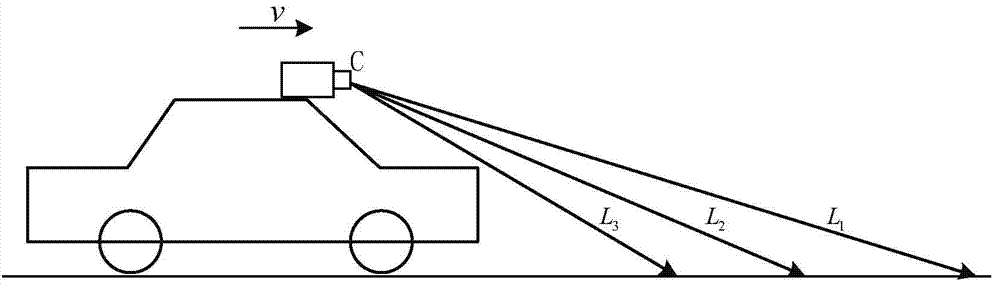

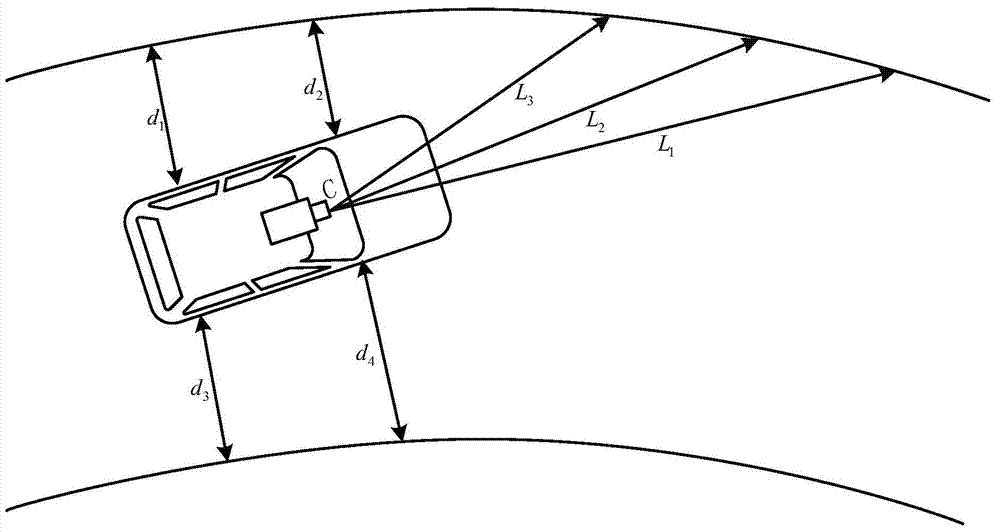

Intelligent driving system with driver model

ActiveCN104260725ATune performanceEnable seamless collaborationExternal condition input parametersMachine learningDriver/operatorEngineering

The invention discloses an intelligent driving system with a driver model. The intelligent driving system comprises a driver model module, wherein the driver model module adjusts the performance of a vehicle according to driving characteristics of a driver and road environment information. By means of the intelligent driving system, the visual and touch information of the driver can be considered in the vehicle driving process, accordingly the performance of the vehicle is adjusted, and the purpose of controlling the vehicle to adapt to the people is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

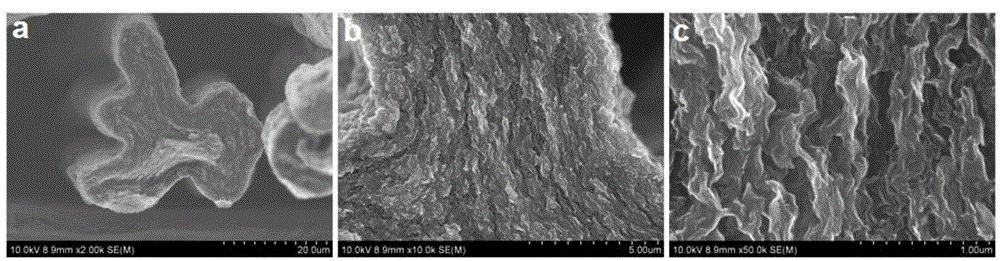

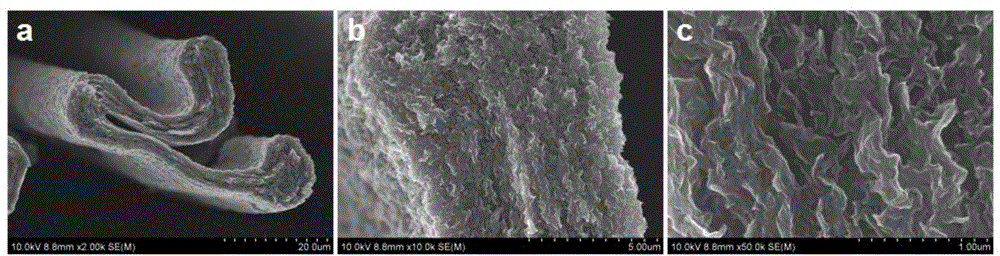

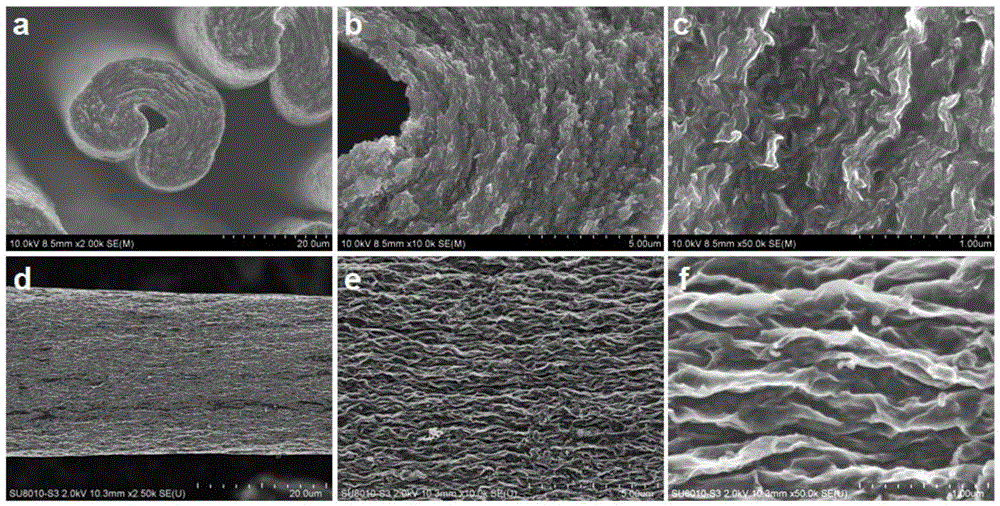

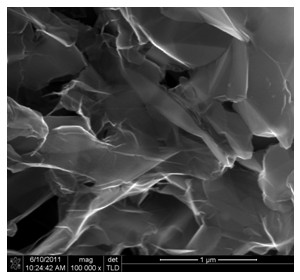

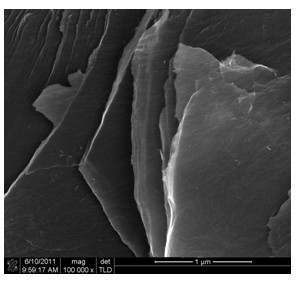

Water-soluble polymer/graphene composite fiber as well as preparation method and application thereof

ActiveCN104451925AHigh strengthImprove toughnessElectroconductive/antistatic filament manufactureElectrode carriers/collectorsFiberMicro structure

The invention relates to water-soluble polymer / graphene composite fiber as well as a preparation method and application thereof. The cross section of the fiber is special-shaped, the surface of the fiber is of an orientated micro-fiber-shaped structure, the strength of the fiber is greater than 100 MPa, the elongation at break is greater than 2%, and the conductivity of the fiber is greater than 0.1 S / cm. The preparation method comprises the following steps: preparing a composite spinning liquid, extruding into a coagulating bath for curing, drafting, leading out of the coagulating bath, drying, and coiling, thereby obtaining the water-soluble polymer / graphene composite fiber; and finally reducing by using a chemical or physical method, thereby obtaining the water-soluble polymer / graphene composite fiber. The cross section of the composite fiber provided by the invention is of a special-shaped structure, the surface of the fiber is of a rich groove micro structure, the strength and the toughness of the fiber are greatly improved when being compared with those of pure graphene fiber, and good conductivity is still maintained, so that the water-soluble polymer / graphene composite fiber has a wide application prospect in the fields such as anti-electrostatic and conductive fabrics, electromagnetic wave absorption and shielding fabrics, energy storage devices, sensors and water treatment.

Owner:DONGHUA UNIV

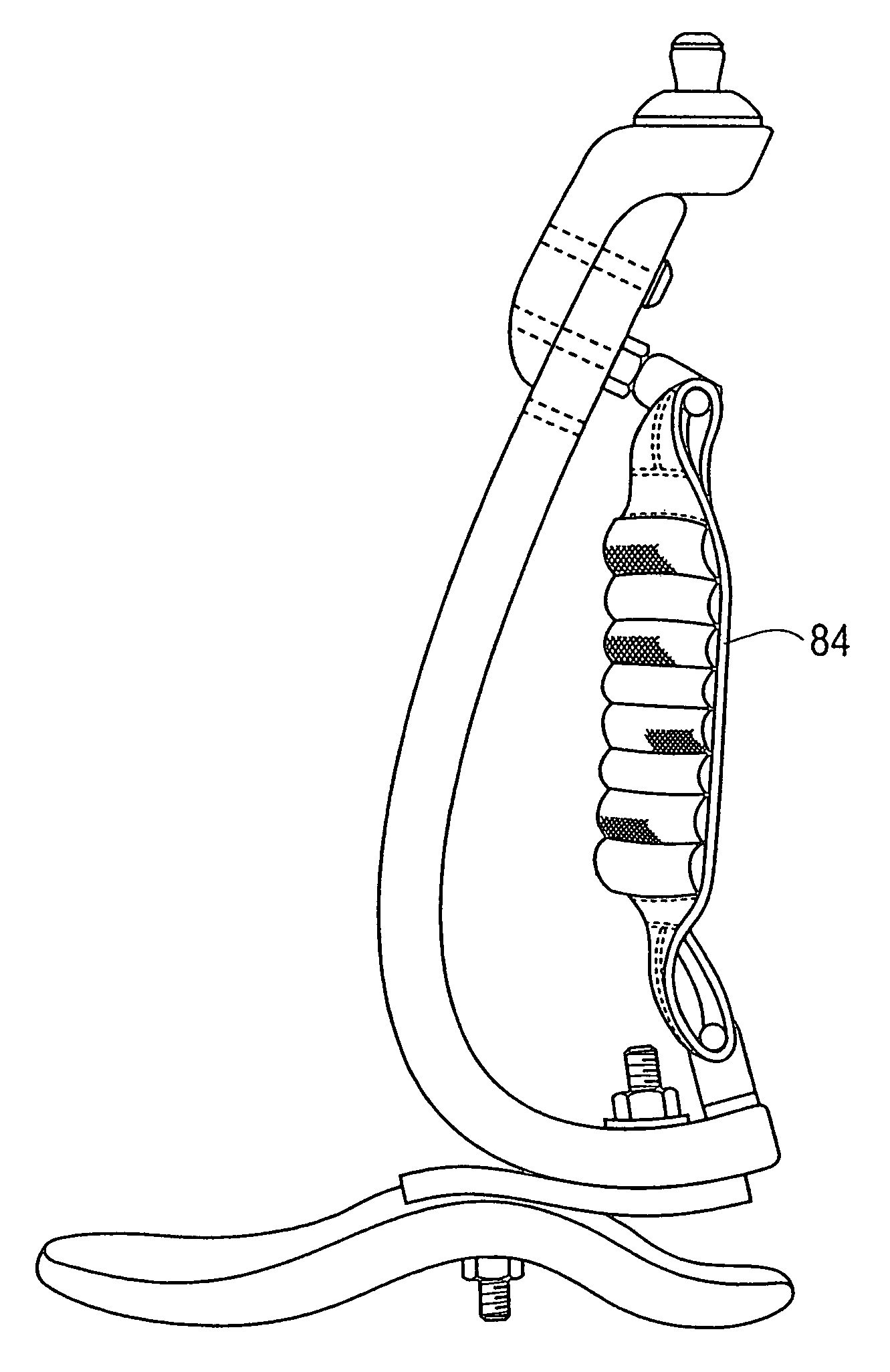

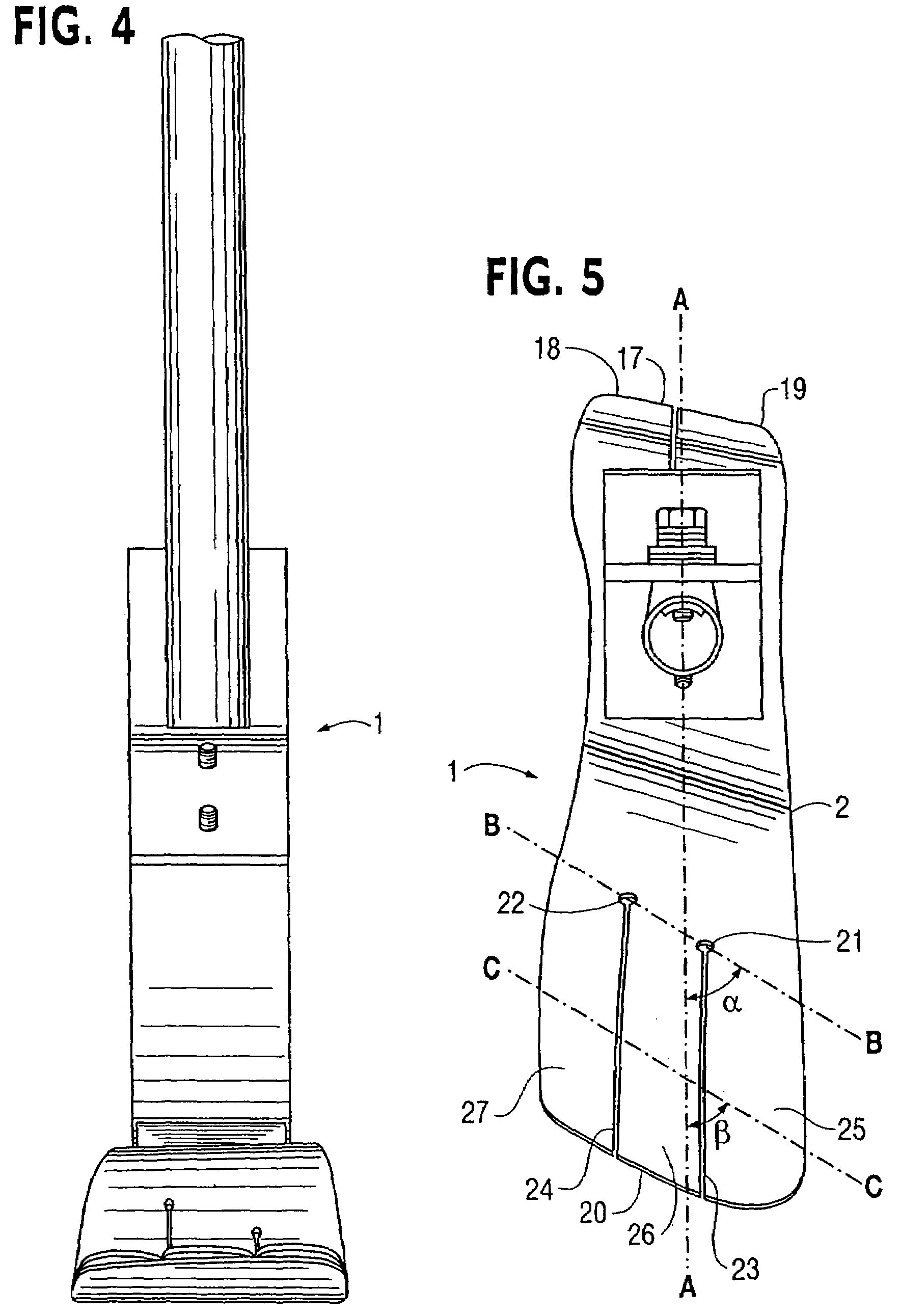

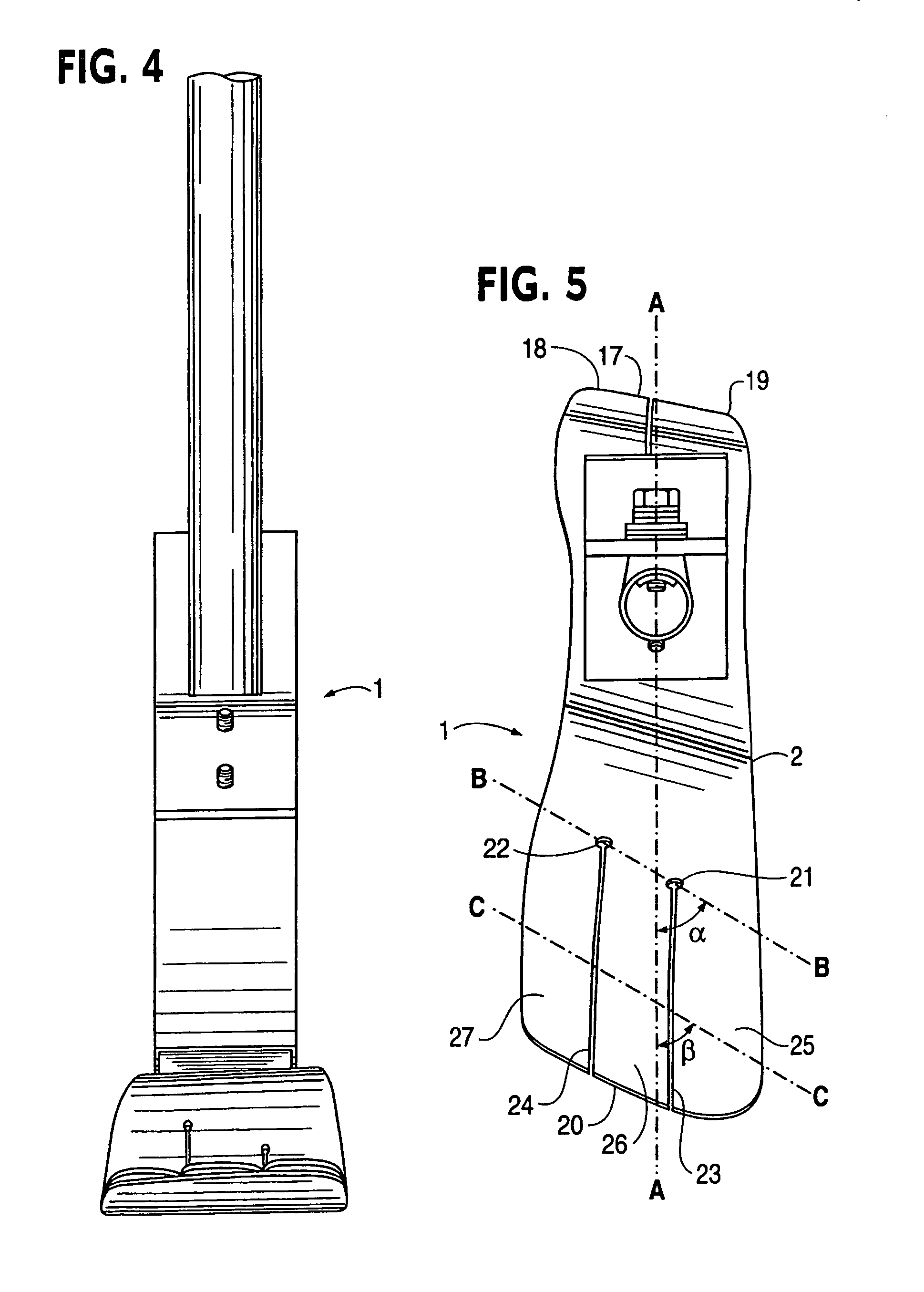

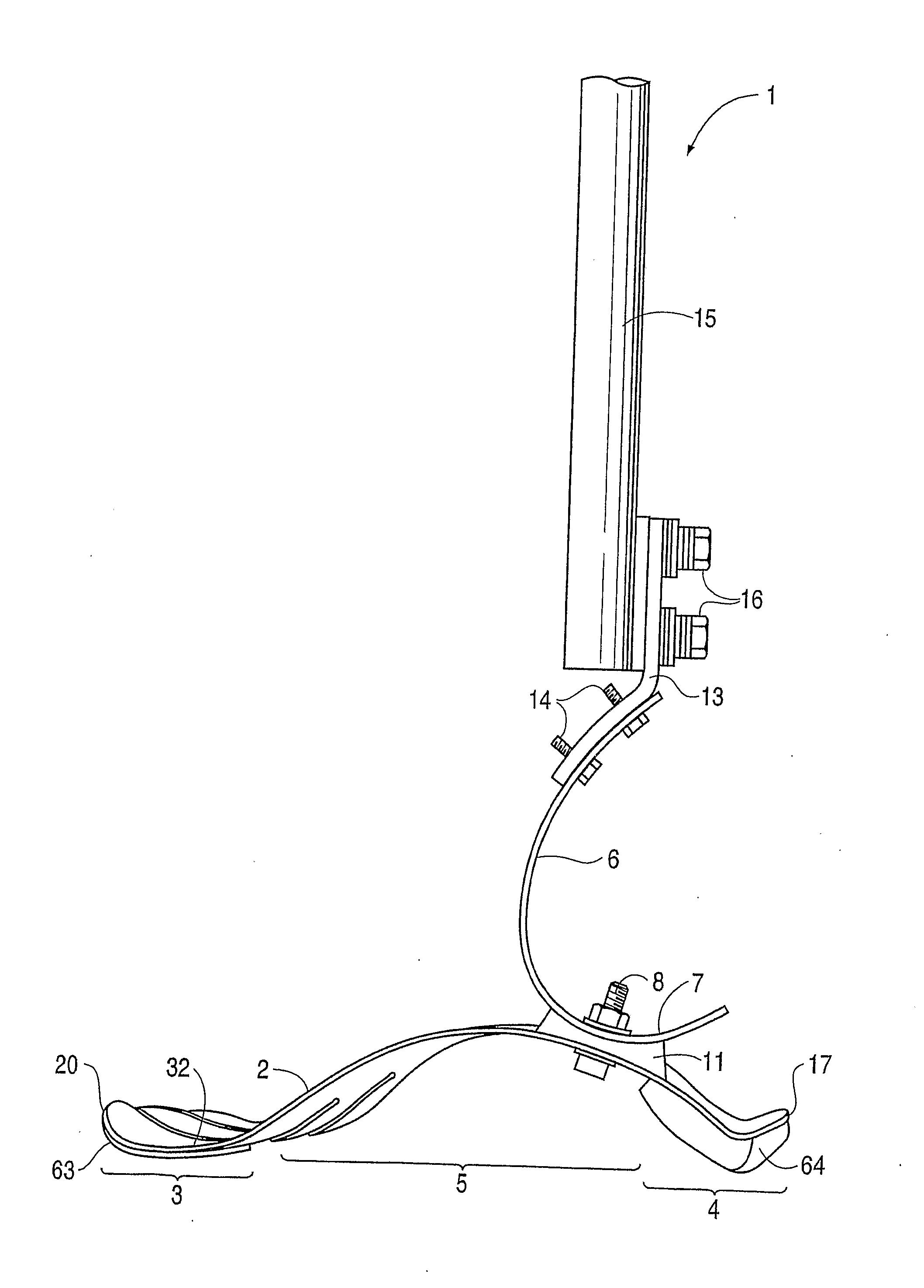

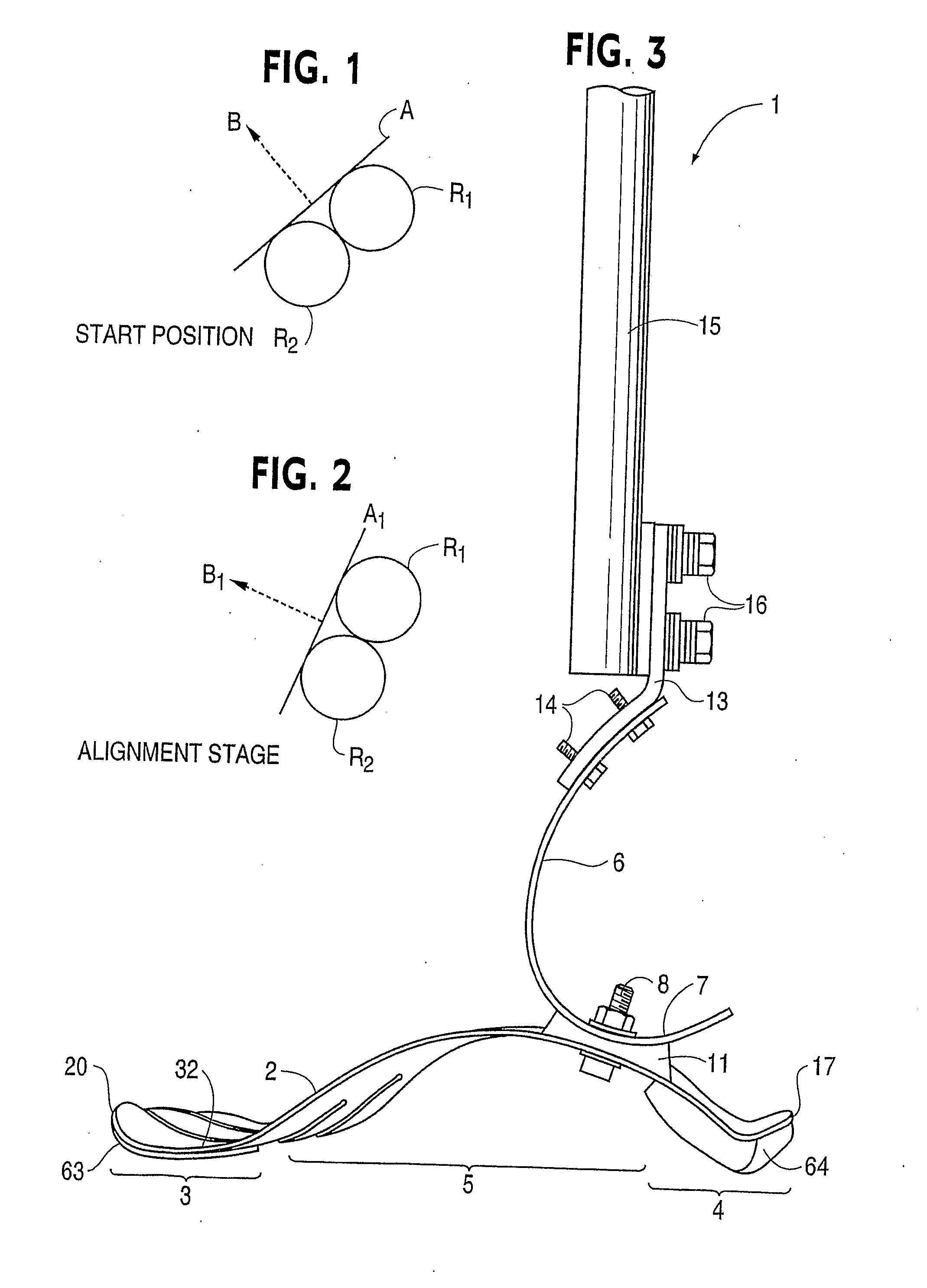

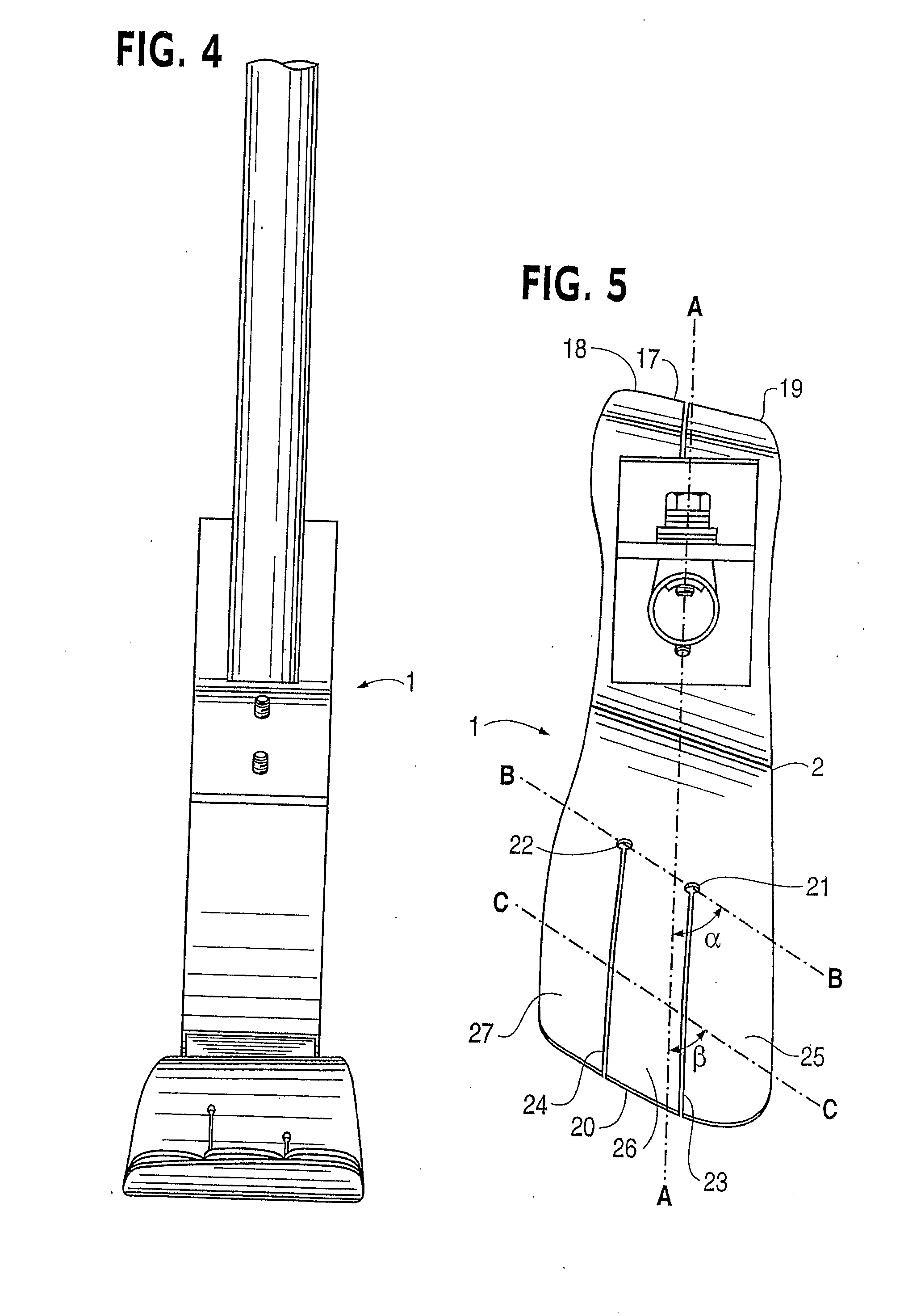

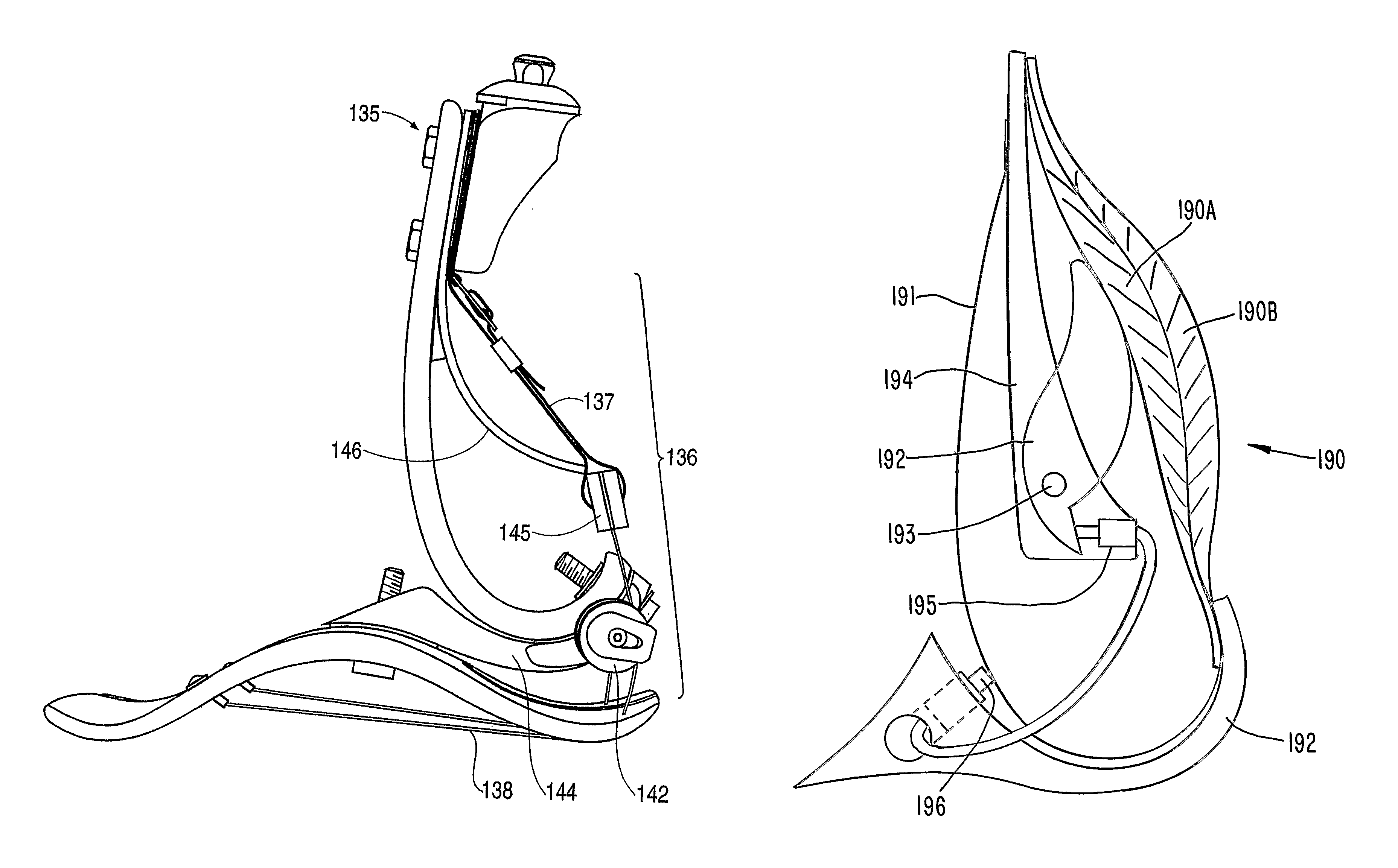

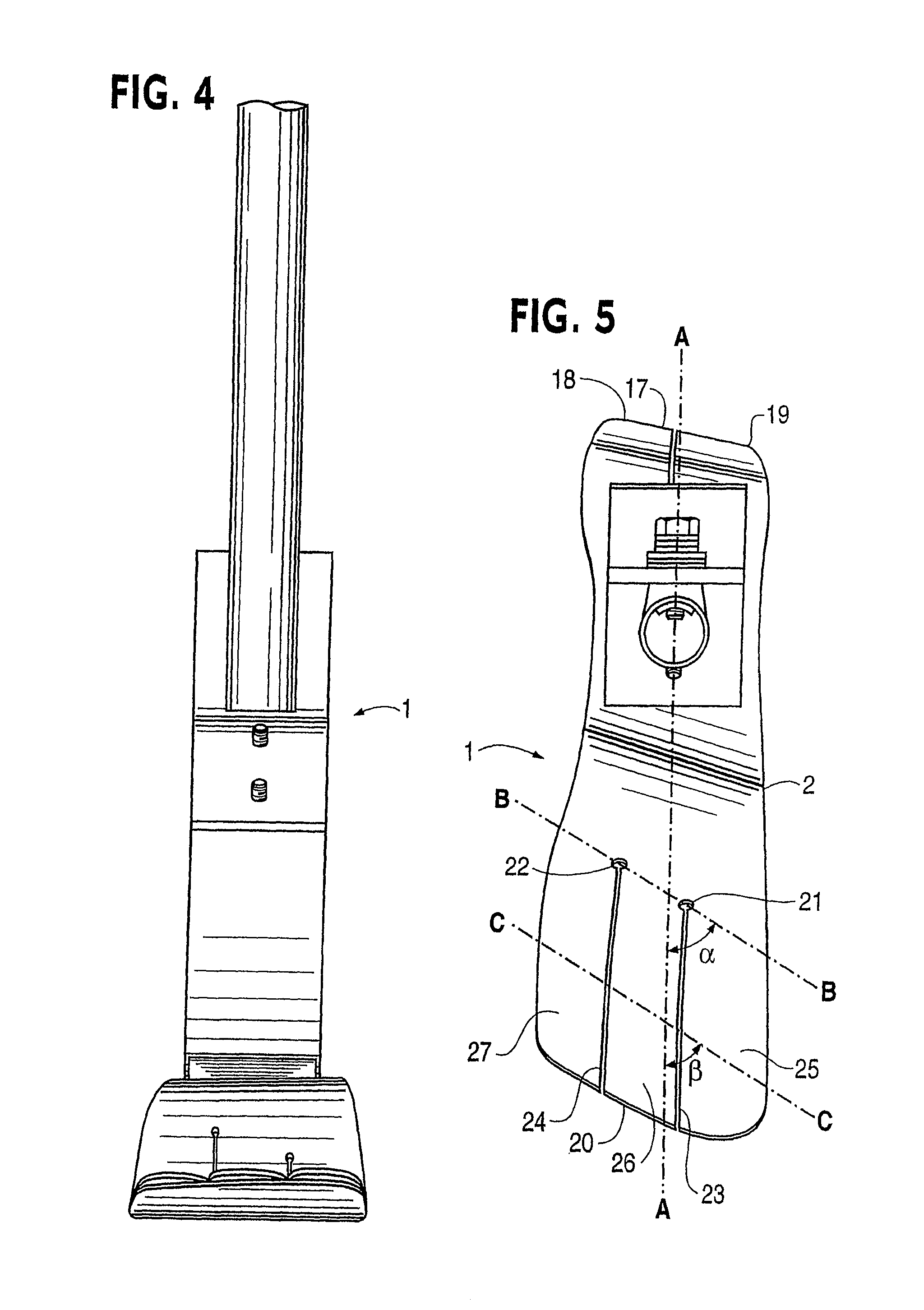

Prosthetic Foot with Tunable Performance

InactiveUS20080281436A1Improve performanceImproved applied mechanicArtificial legsStored energyCoil spring

A system for a lower extremity prosthesis comprising a foot, an ankle and a shank, has a posterior calf device (169) on the prosthesis to store energy during force loading of the prosthesis and return the stored energy during force unloading to increase the kinetic power generated for propulsive force by the prosthesis in gait. The device in several embodiments includes at least one elongated member (171) such as a flexible strap extending between an upper portion of the shank and a lower portion of the prosthesis, and at least one coiled spring (170) which has a free end connected to the elongated member. The coiled spring is expanded by the elongated member in response to anterior movement of the upper end of the shank for storing energy.

Owner:BIOQUEST PROSTHETICS

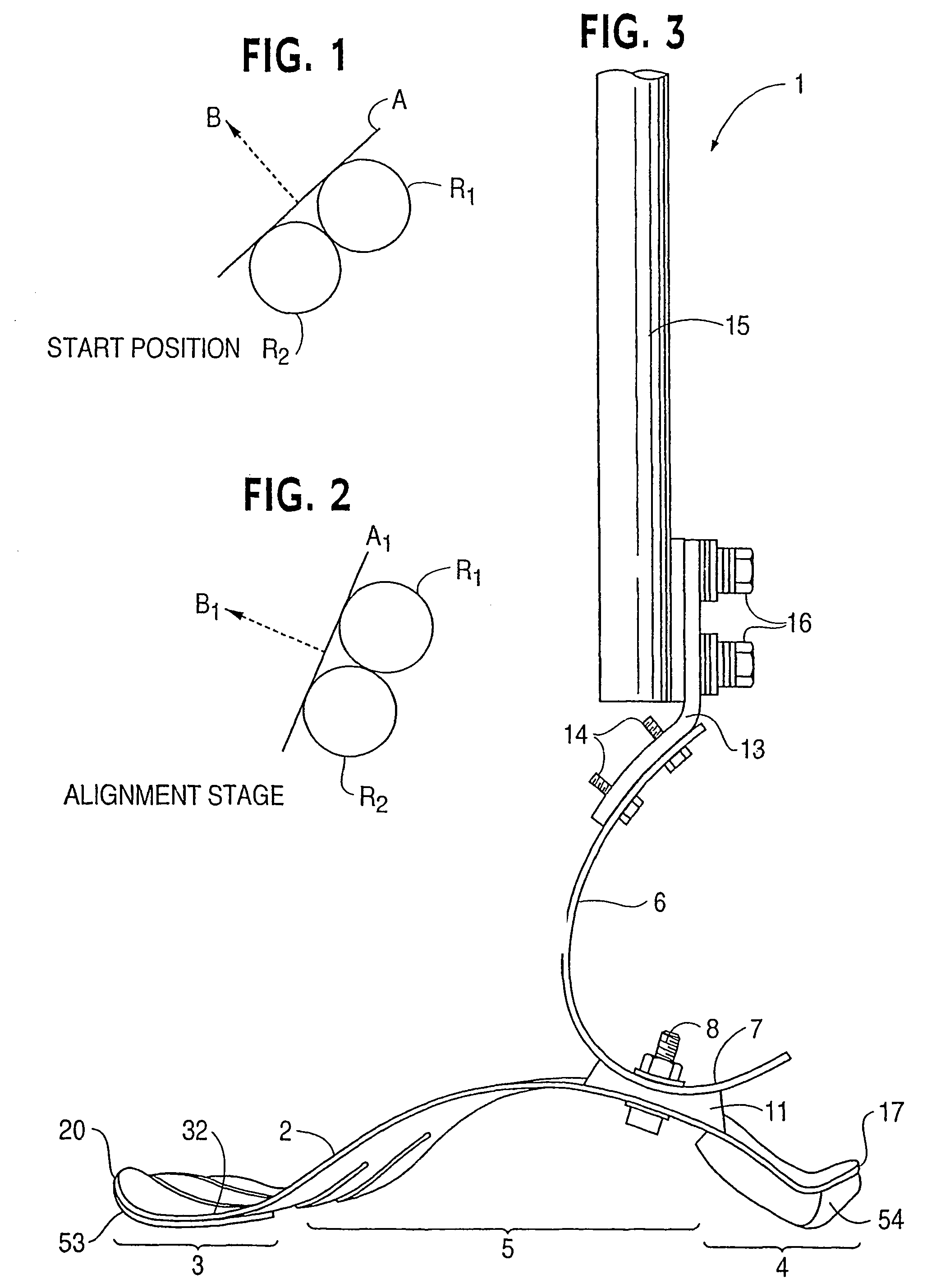

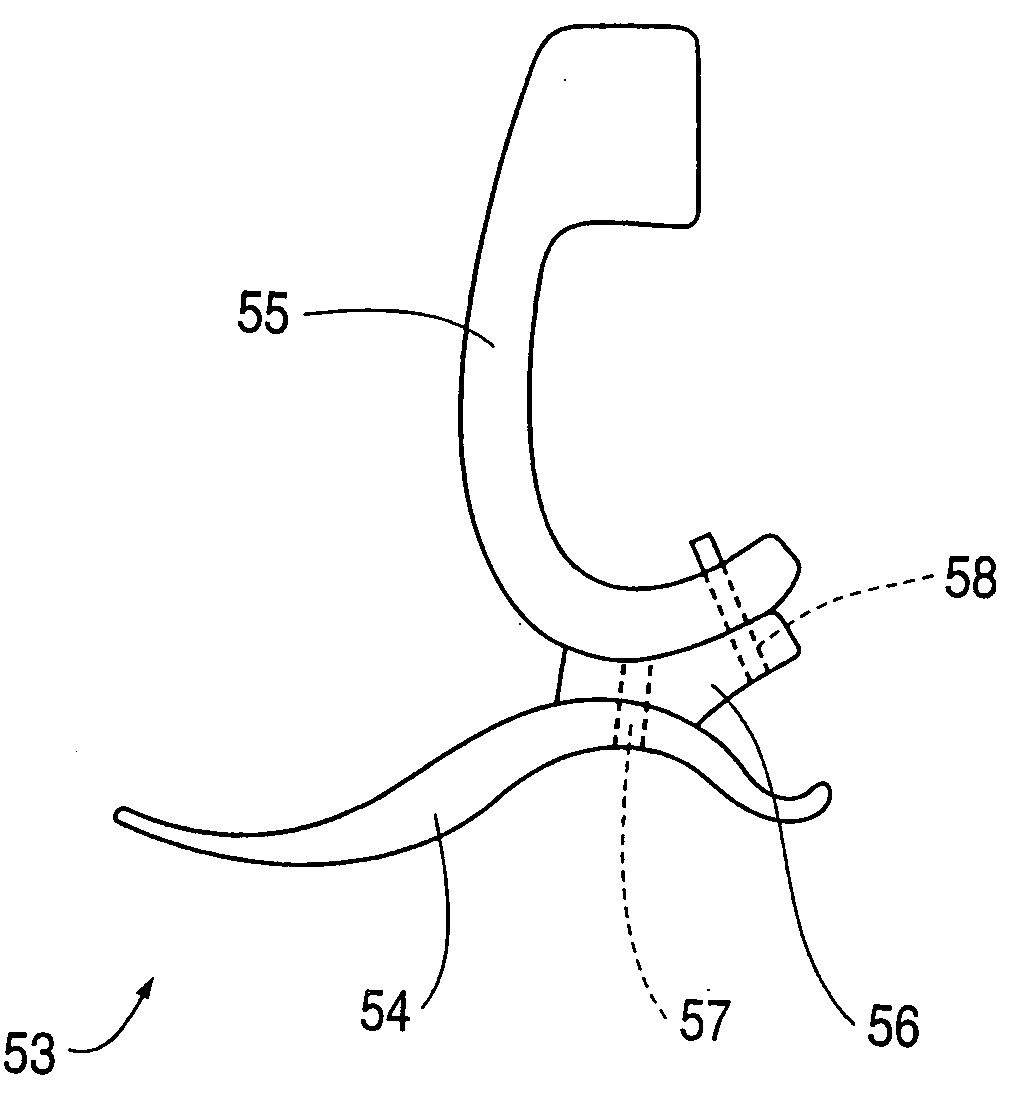

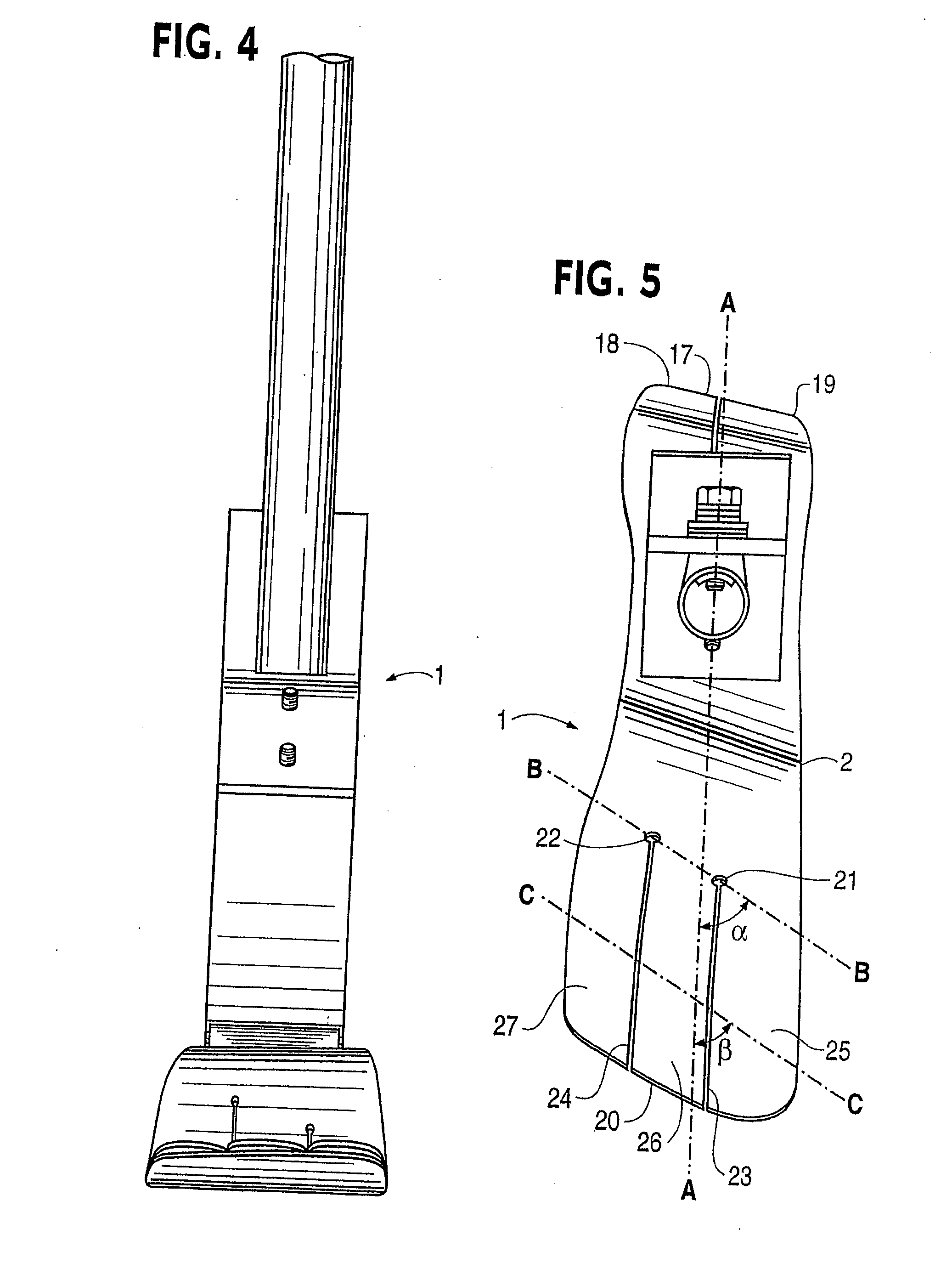

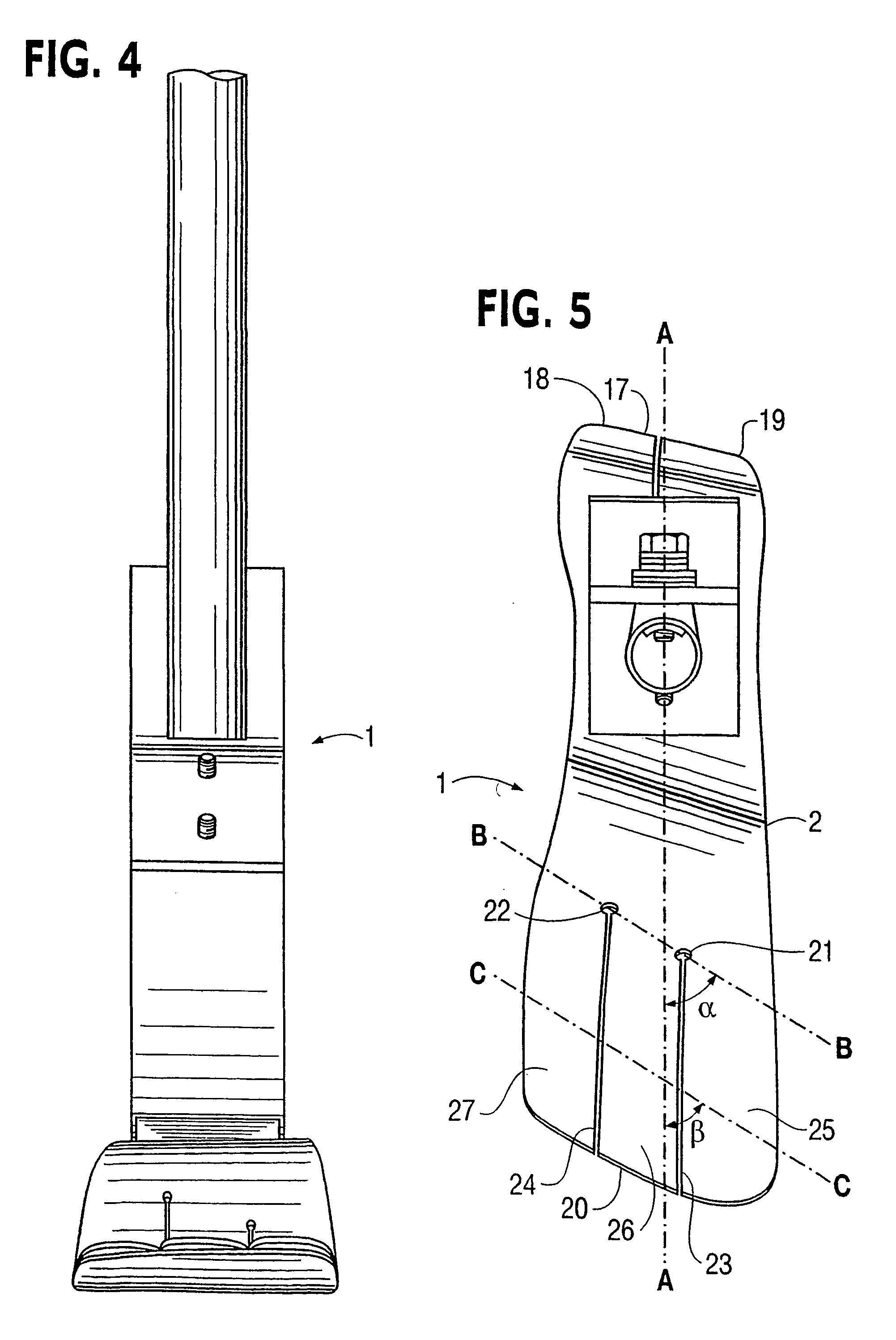

Prosthetic foot with tunable performance

InactiveUS20060030950A1High level of functionHigh level of performanceCapsule deliveryArtificial legsKeelCoupling

A prosthetic foot (190) incorporates a foot keel (192) and a resilient calf shank (193) with its lower end connected to the foot keel to form an ankle joint of the prosthetic foot. The calf shank extends upward from the foot keel by way of an anterior facing convexly curved portion (195) of the shank, and is secured to the foot keel by way of a coupling element (194). The lower end of the shank is reversely curved (196) and housed by a reversely curved portion of the coupling element. A posterior calf device (191) has a cable (204) which is untensioned in a normal gait cycle but tensioned by a force loading on the prosthesis greater than 120% of body weight of the user to limit, e.g. stop, further anterior motion of the upper end of the shank.

Owner:BIOQUEST PROSTHETICS

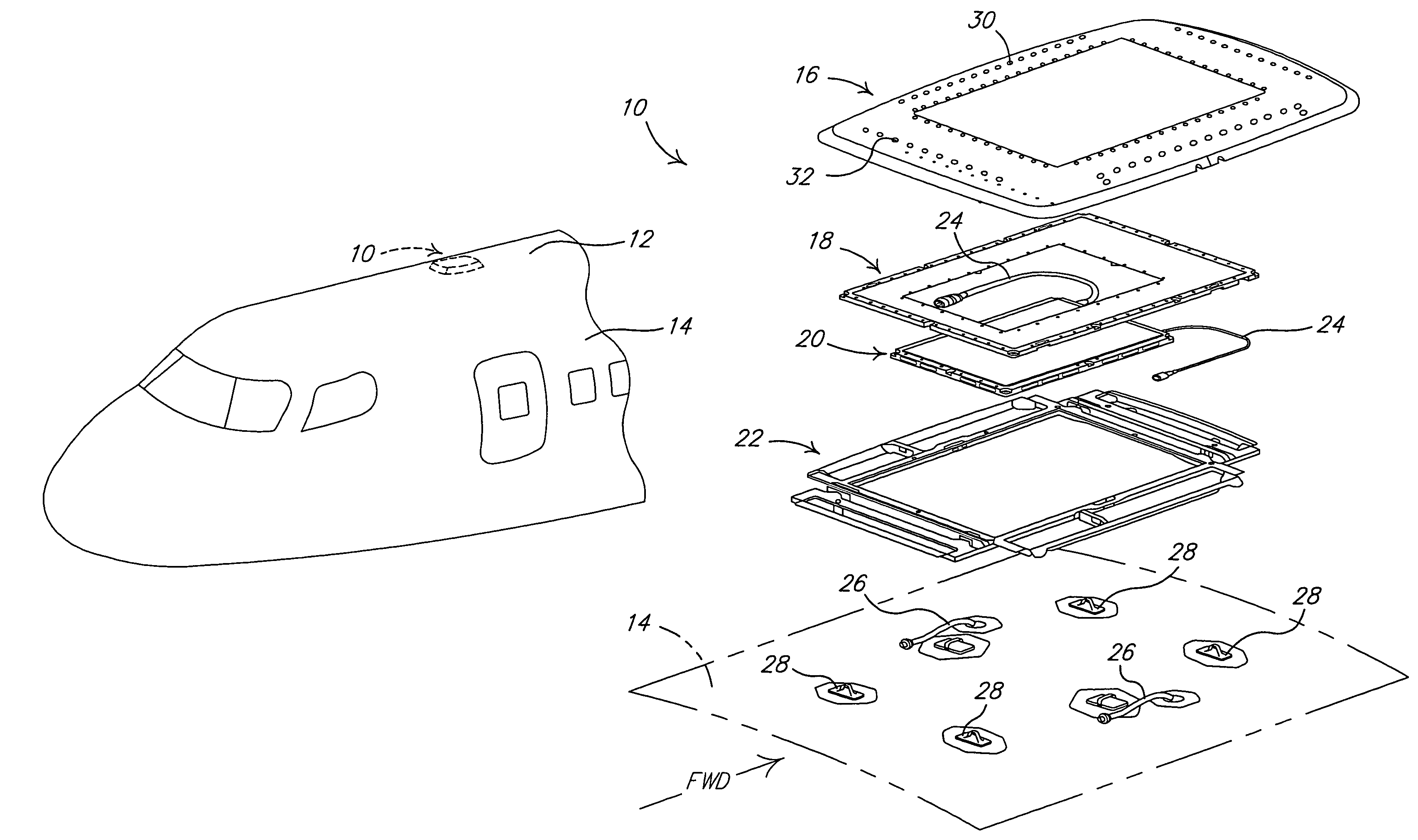

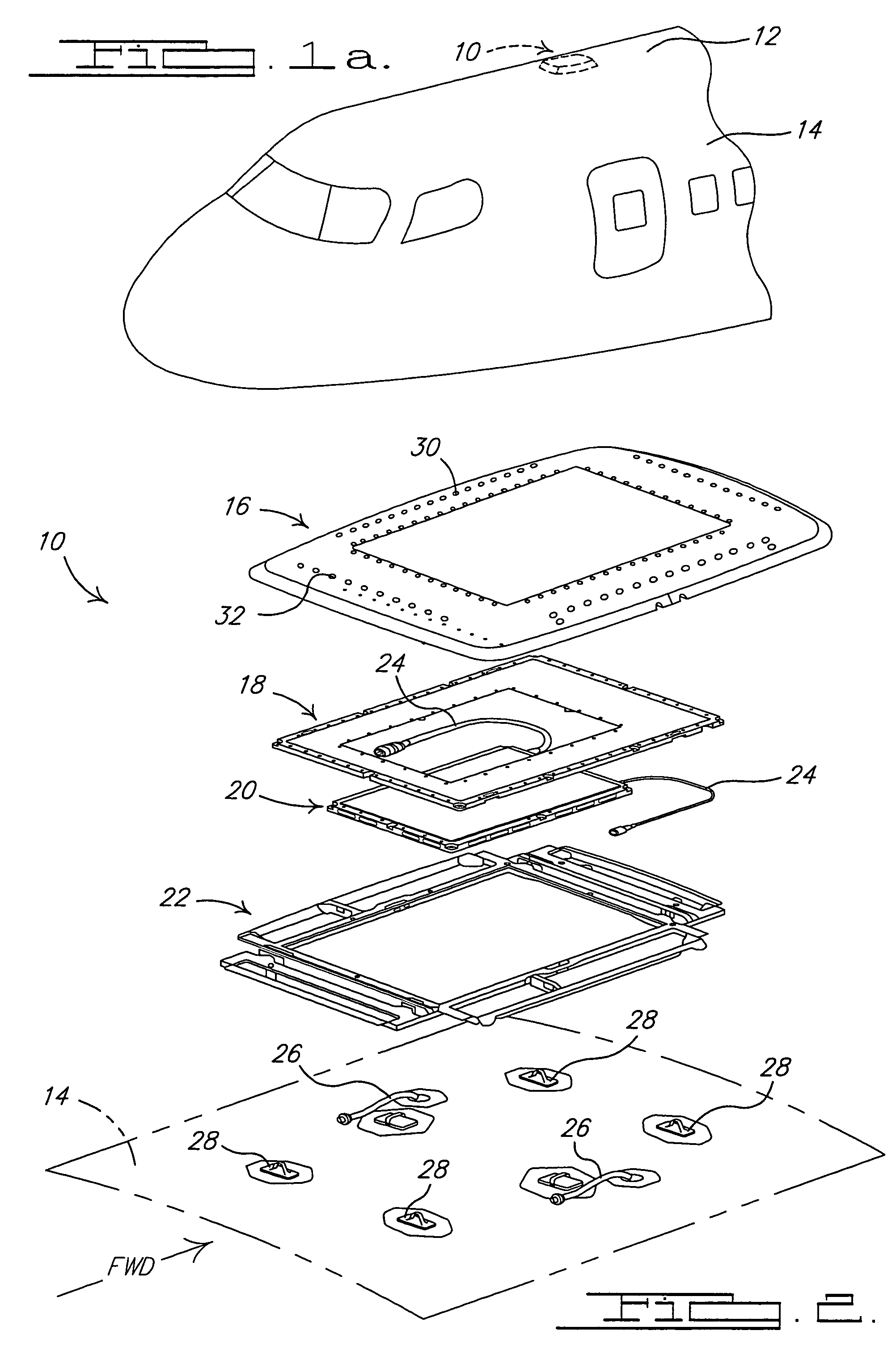

Phased array antenna choke plate method and apparatus

ActiveUS7295165B2Sufficient attenuationMore aerodynamicAntenna adaptation in movable bodiesHorizonEngineering

A phased array antenna system on an aircraft that incorporates a choke plate that significantly attenuates sidelobes of the antenna beam pattern at elevation angles that would cause RF interference with ground-based terrestrial wireless networks. The choke plate includes a plurality of choke grooves that substantially circumscribe the antenna aperture. The choke plate has an upper surface that is positioned generally coplanar with the upper surface of the antenna aperture. The grooves of the choke plate may be filled with a dielectric material. The choke plate provides a smooth aerodynamic component that significantly attenuates beam scattering, and thus the radiation pattern sidelobes of the antenna at or below the horizon, when the aircraft is in flight.

Owner:THE BOEING CO

Prosthetic Foot with Tunable Performance

InactiveUS20070213840A1Improve performanceImproved applied mechanicLigamentsMusclesStored energyHindlimb

A resilient lower extremity prosthesis comprising a foot, an ankle and a shank above the ankle is provided with an artificial muscle (190) on the shank (191) of the prosthesis for storing energy during force loading of the prosthesis in the active propulsion phase of a person's gait and in the later stages of stance-phase of gait releasing the stored energy to aid propulsion of the person's trailing limb and body.

Owner:BIOQUEST PROSTHETICS

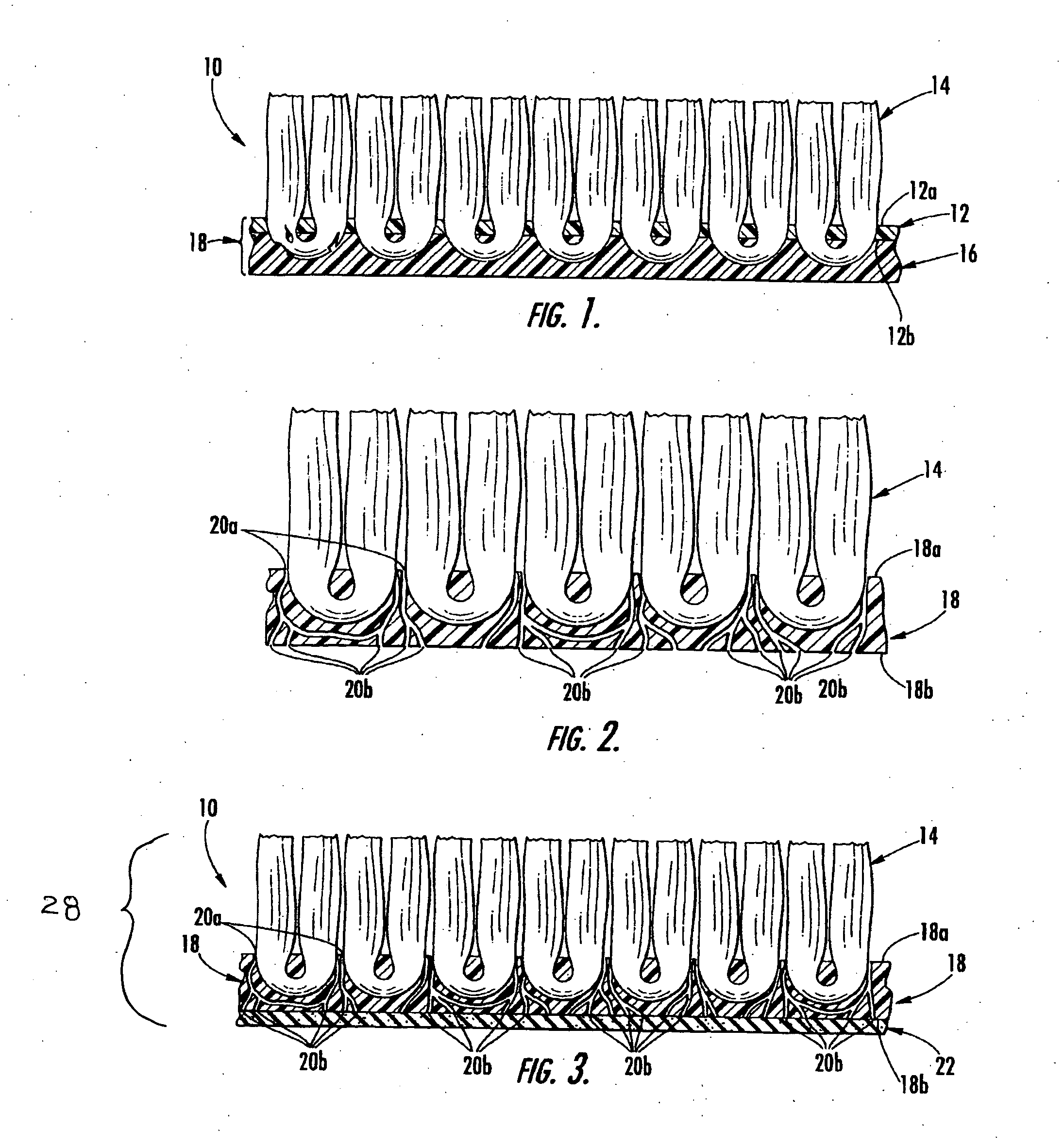

Sound absorbing/sound blocking automotive trim products

InactiveUS20050064779A1High mechanical strengthMaintain porosityVehicle arrangementsBristleUltrasound attenuationEngineering

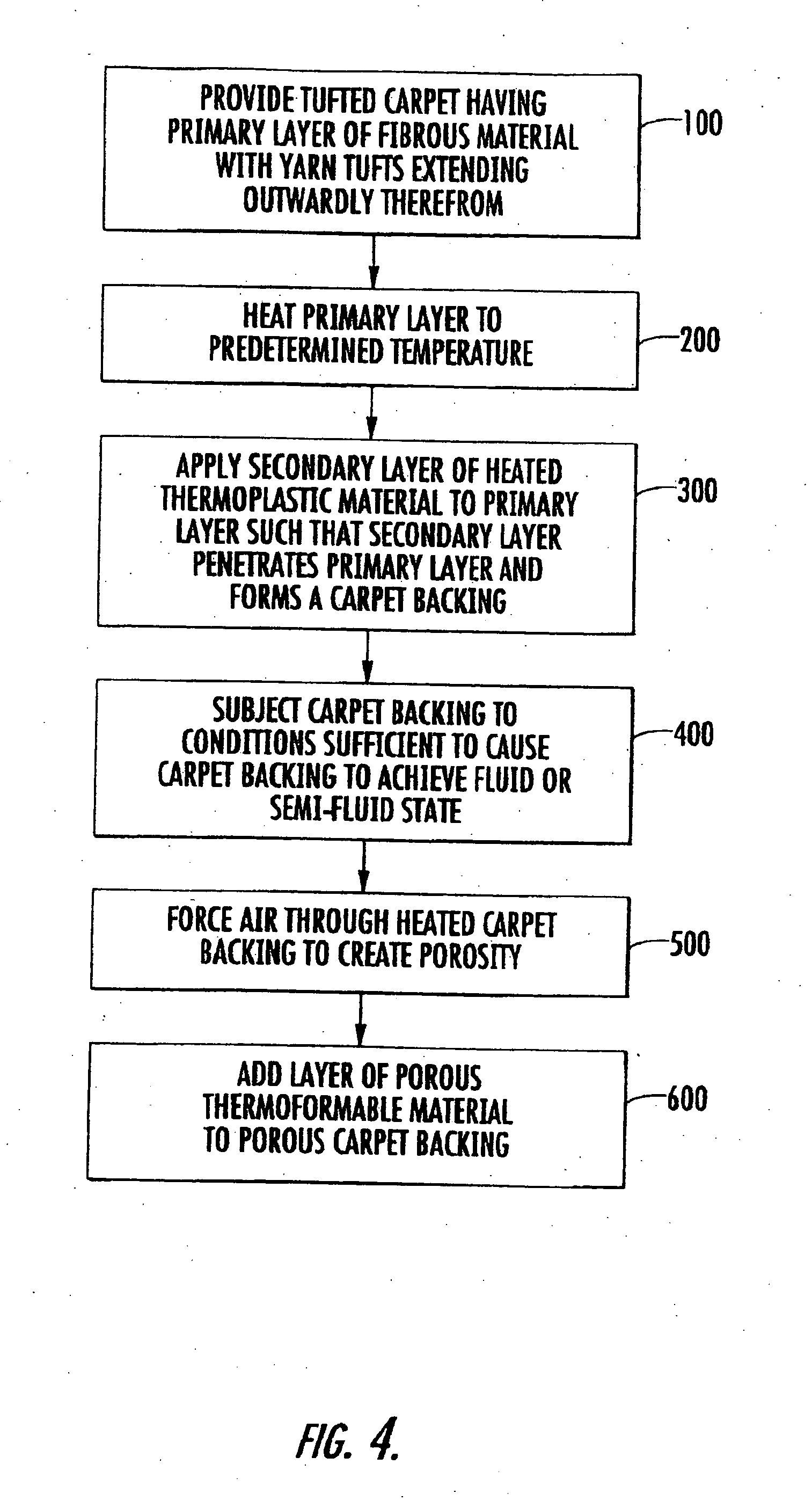

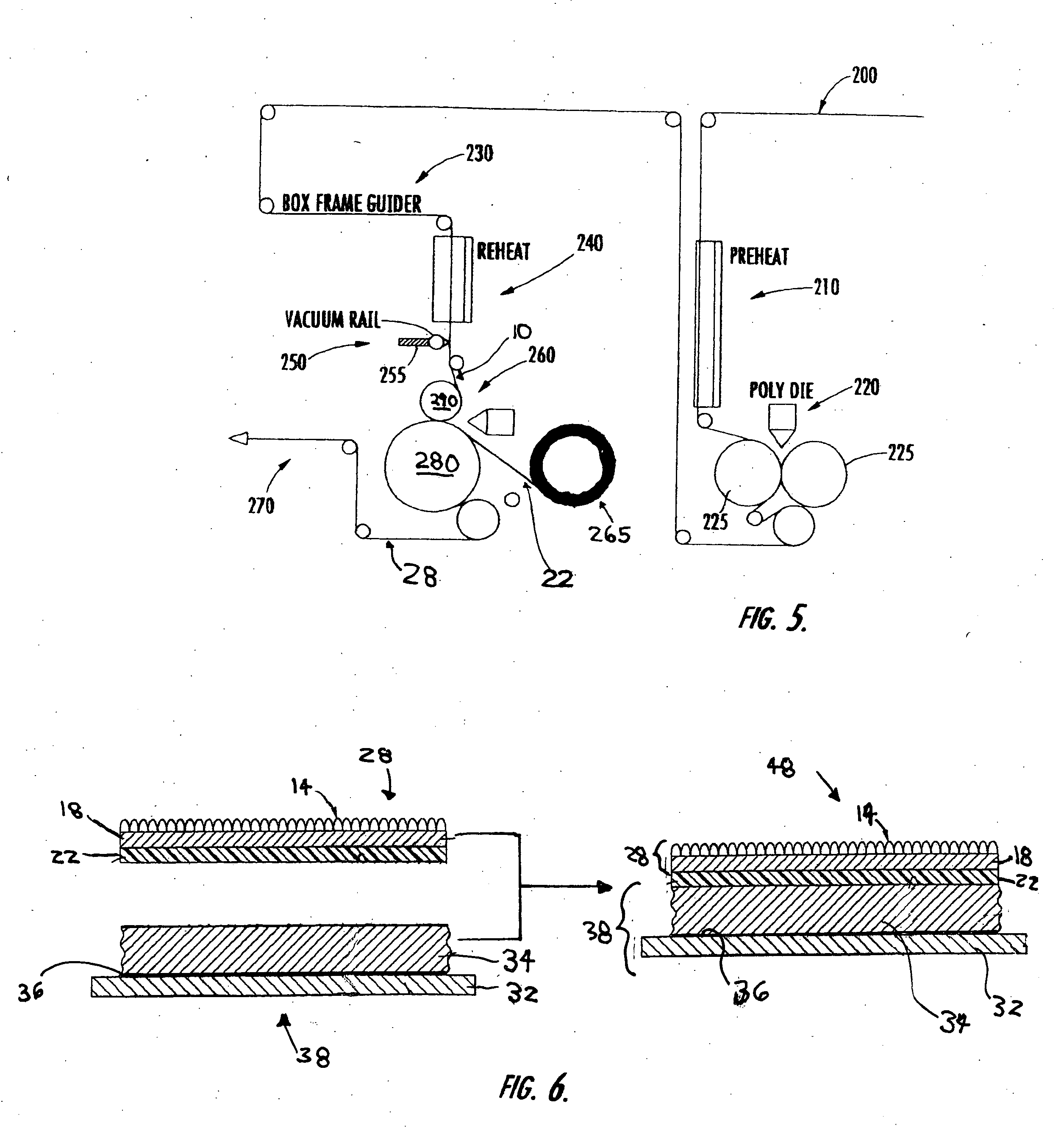

Sound absorbing / sound blocking products, including trim products formed from a porous fibrous layer backed by a sound absorbing layer and a sound blocking layer for use within vehicles, and methods of making same, are provided. A porous fibrous layer structure including a fibrous layer backing is heated to achieve a fluid or semi-fluid state and then subjected to vacuum to draw air through the fibrous layer backing to create a porous structure. A layer of sound absorbing and a layer of sound blocking material may be applied to the porous fibrous layer backing to provide improved acoustic properties. An underlayment may further be included to provide selected areas of increased thickness and provide tailoring of sound attenuation.

Owner:AURIA SOLUTIONS UK I LTD

Composition for stripping photoresist and organic materials from substrate surfaces

InactiveUS6368421B1Reduce capacityEfficient removalNon-ionic surface-active compoundsNon-surface-active detergent compositionsSolventPhotoresist

The invention relates to the field of microelectronics, such as integrated circuits, and more particularly to compositions and methods of removing photoresists or other organic materials from the surfaces of substrates used in the fabrication of integrated circuits. In particular the present invention relates to amine-free stripping compositions comprising solvent and surfactant that can effectively remove organic materials without corroding the underlying substrate, and the invention also relates to methods for removing these organic materials with the novel stripping composition.

Owner:MERCK PATENT GMBH

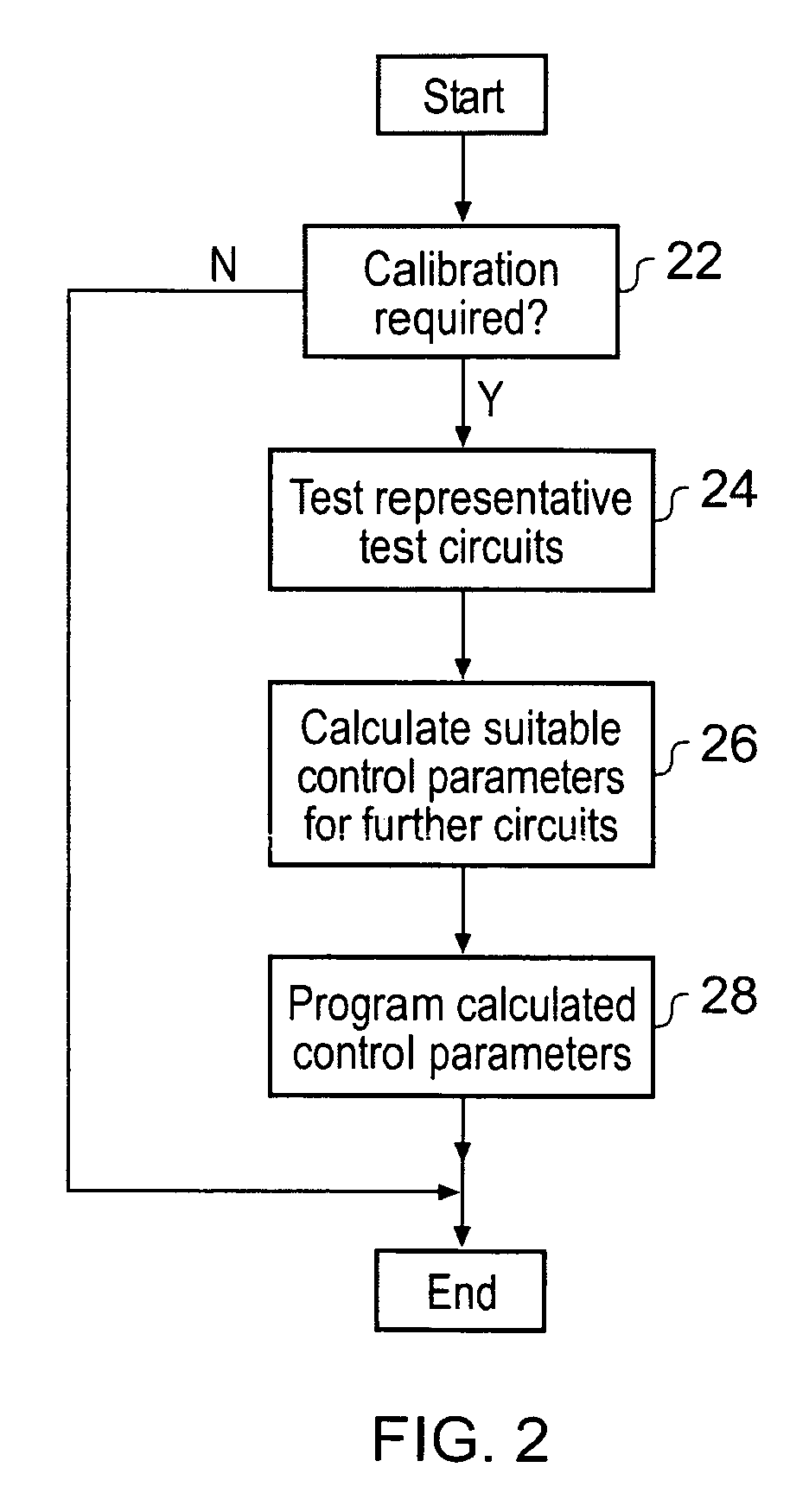

Performance control of an integrated circuit

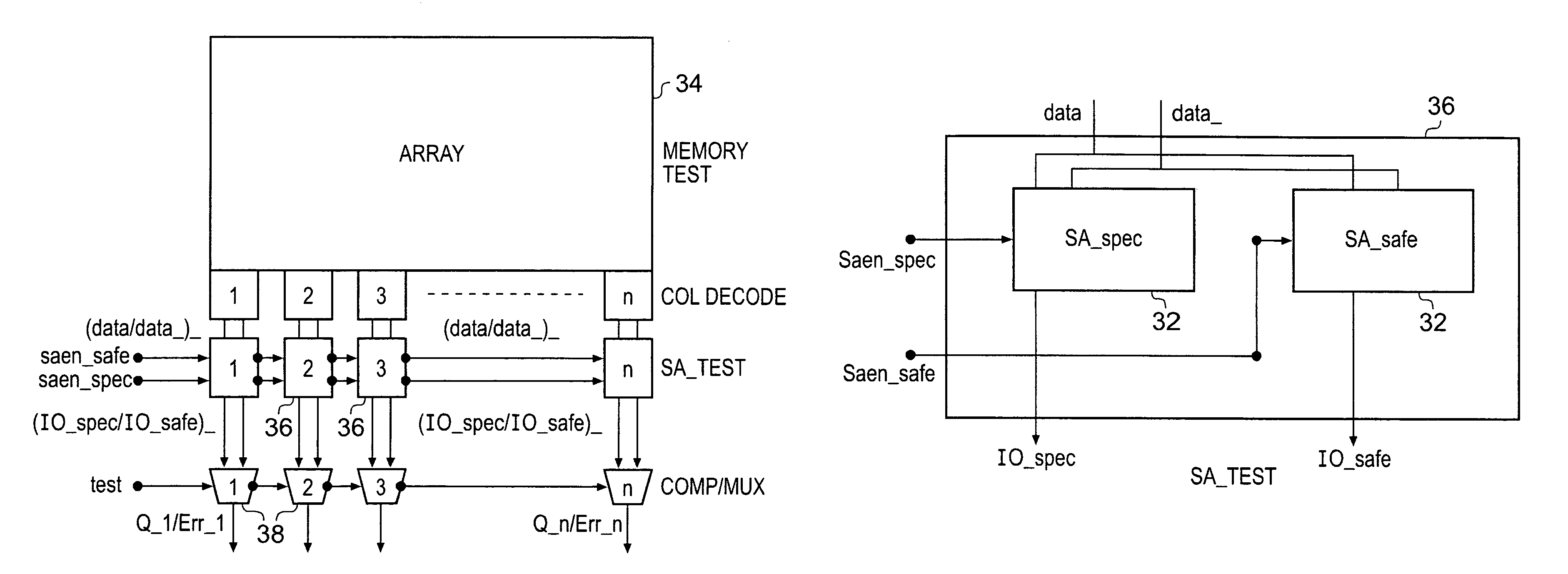

ActiveUS7603605B2Reduce overheadHigh degreeError detection/correctionElectrical testingMemory bankControl engineering

An integrated circuit is provided with a test circuit element and one or more further circuit elements. The performance of the test circuit element at various settings of a performance controlling parameter is determined. That performance controlling parameter is then applied across the one or more further circuit elements. The integrated circuit may include memory banks and the performance controlling parameter can be sense amplifier timing, delay line length or another parameter such as operating voltage, operating frequency and circuit timing in general.

Owner:ARM LTD

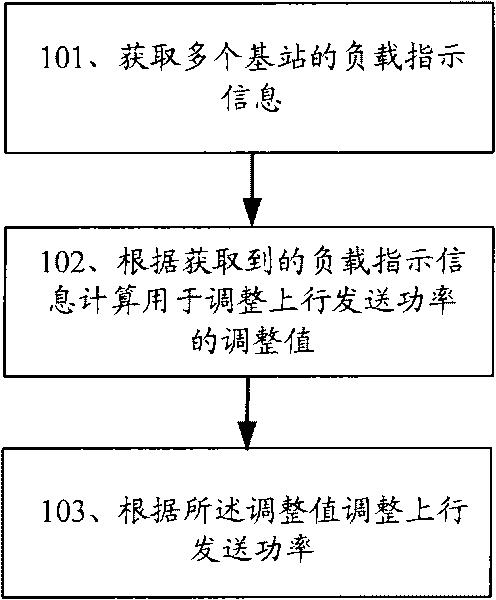

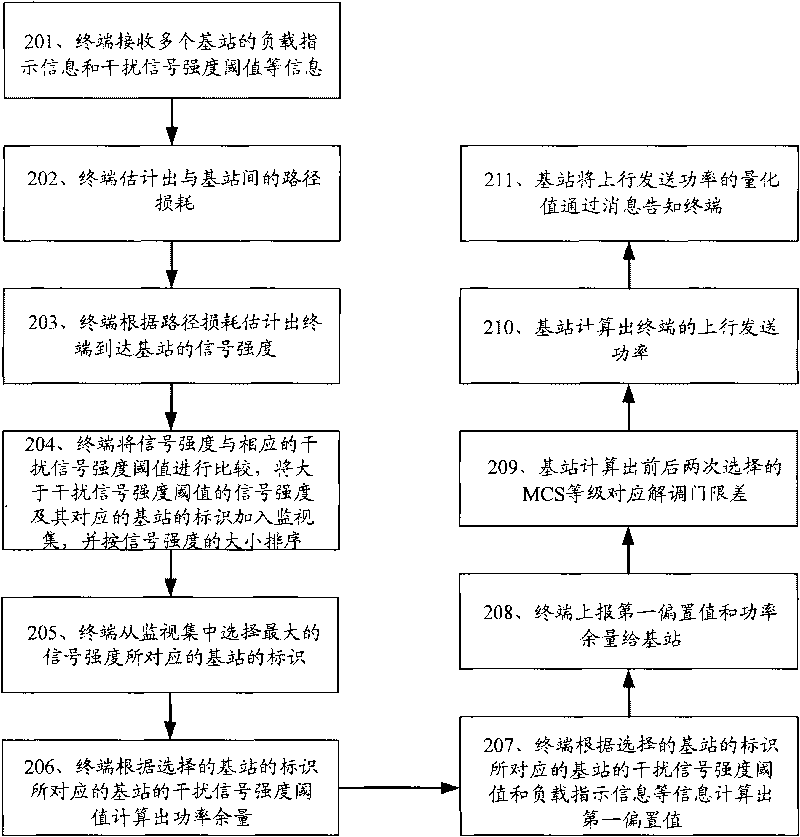

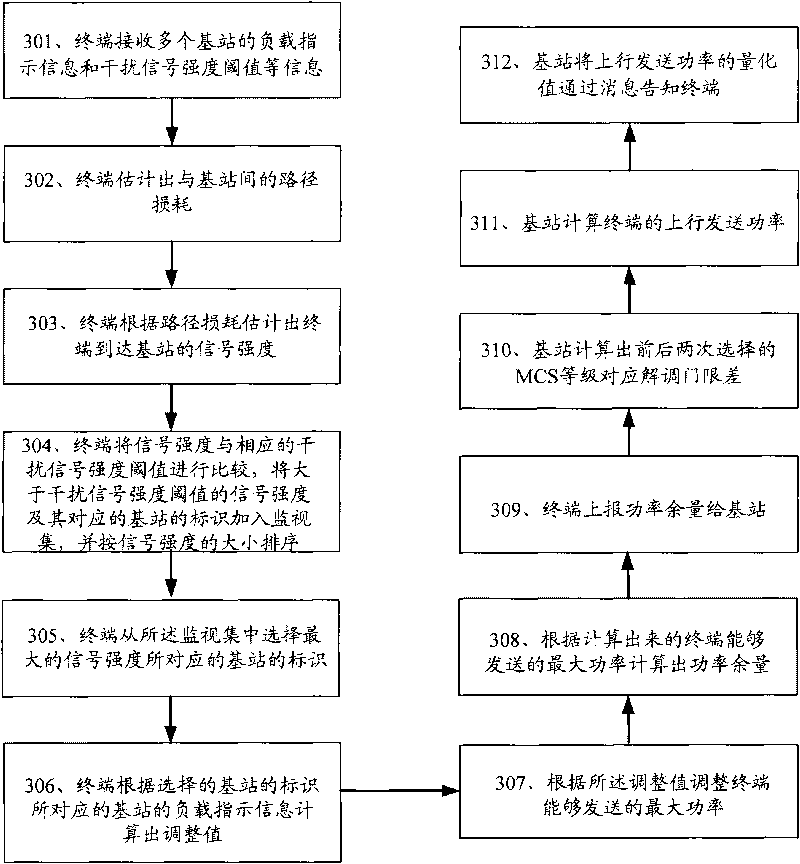

Communication equipment, communication system and method for controlling uplink transmission power

InactiveCN101729102ATune performanceAdjust uplink transmit powerTransmission control/equalisingRadio transmission for post communicationCommunications systemUplink transmission

The invention discloses communication equipment, a communication system and a method for controlling uplink transmission power. In the embodiment of the invention, the method comprises the following steps of: obtaining load indication information of a plurality of base stations; calculating an adjusting value for adjusting the uplink transmission power according to the load indication information; and adjusting the uplink transmission power according to the adjusting value; or the method comprises the following steps of: obtaining a second interfering signal intensity threshold value of the plurality of base stations; and calculating the uplink transmission power according to second interfering signal intensity threshold value, wherein the second interfering signal intensity threshold value is obtained through each base station by adjusting the interfering signal intensity threshold value thereof according to the loading degree. Since the scheme provided by the invention takes the load indication information of the base stations into consideration while controlling the uplink transmission power, the problem that the uplink transmission power is not further adjusted when the loads of the base stations are too high is avoided. Therefore, the method can adjust the uplink transmission power of a terminal more correctly and improve the performance of the terminal in a covering surface of the base stations.

Owner:HUAWEI TECH CO LTD

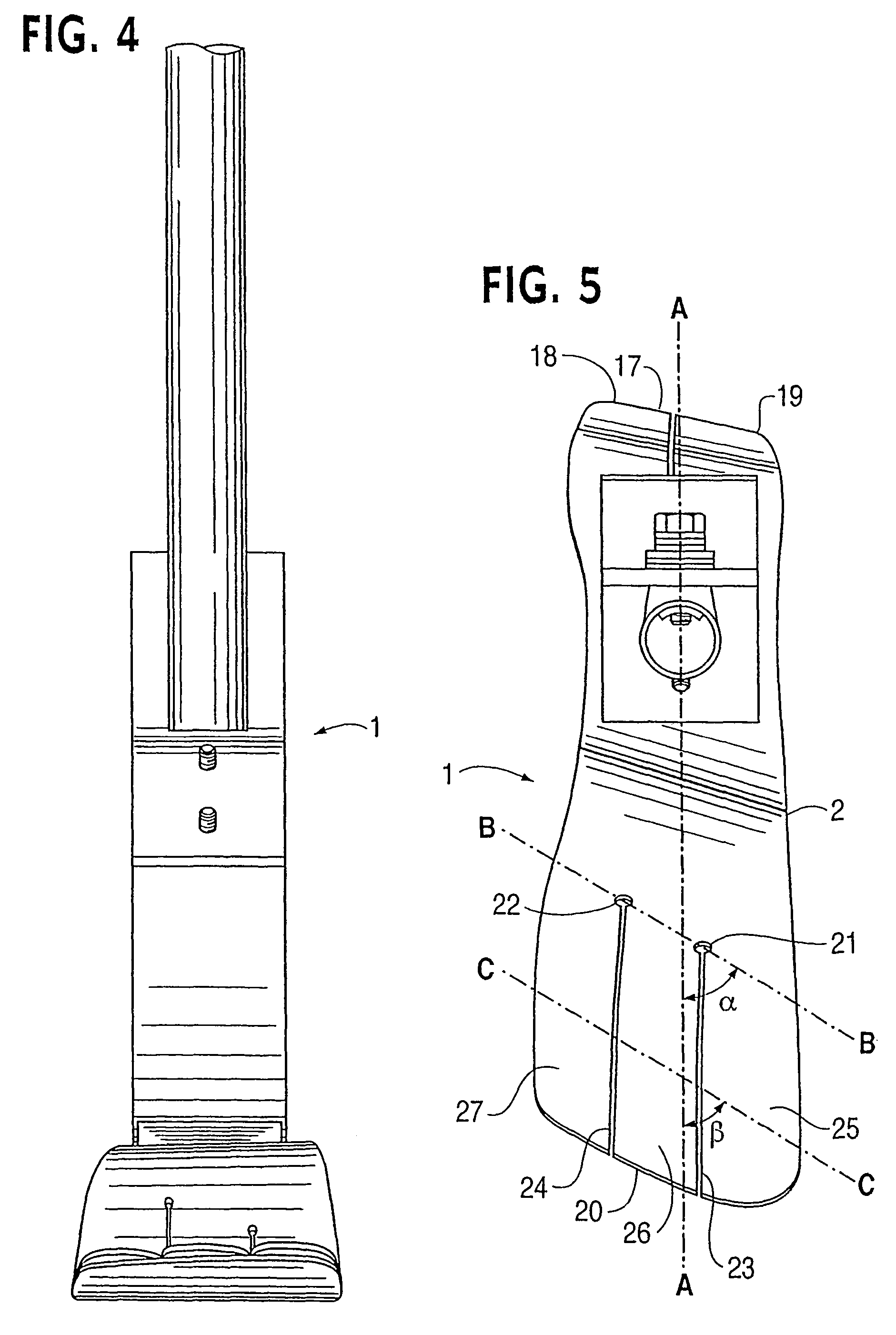

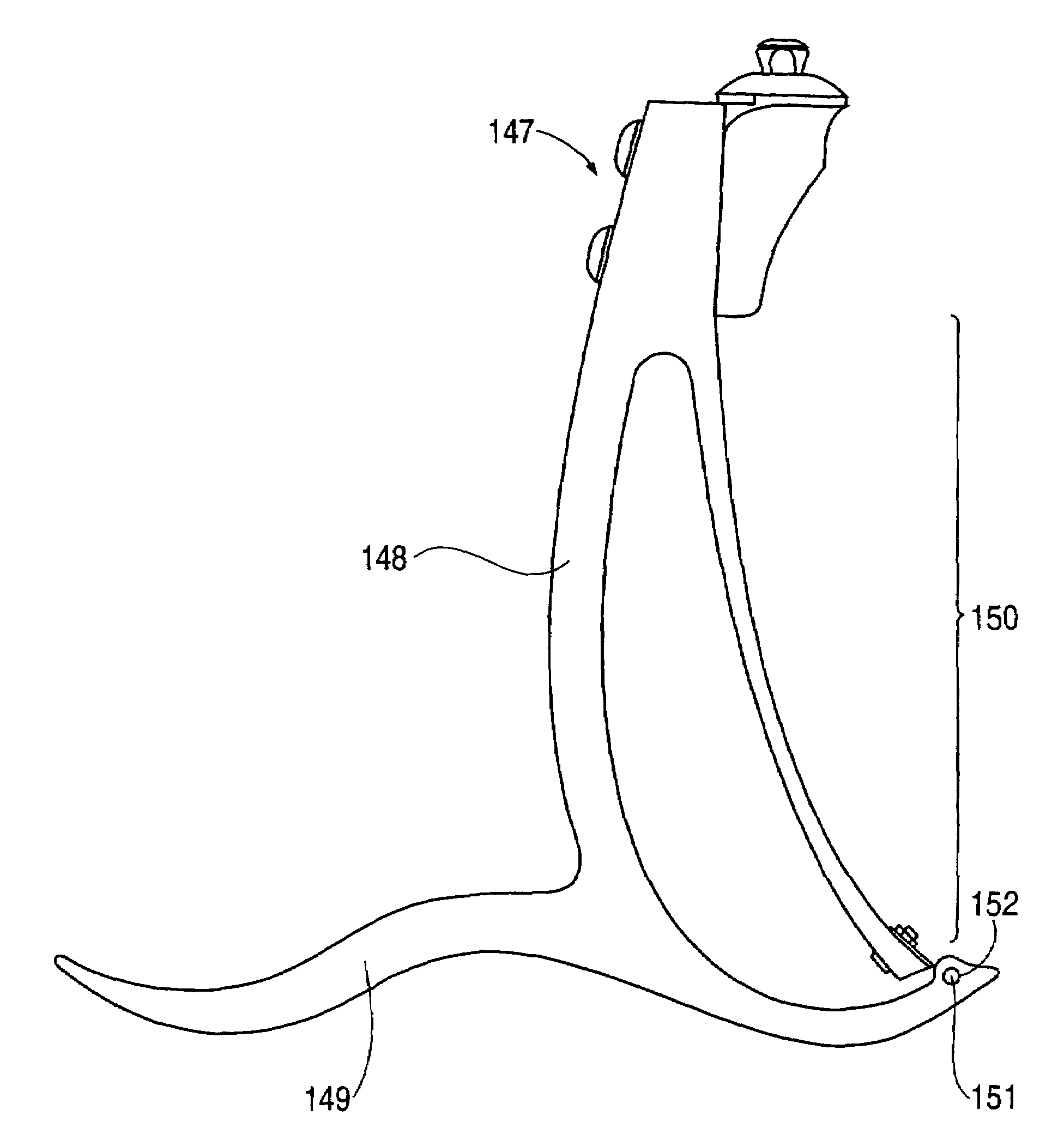

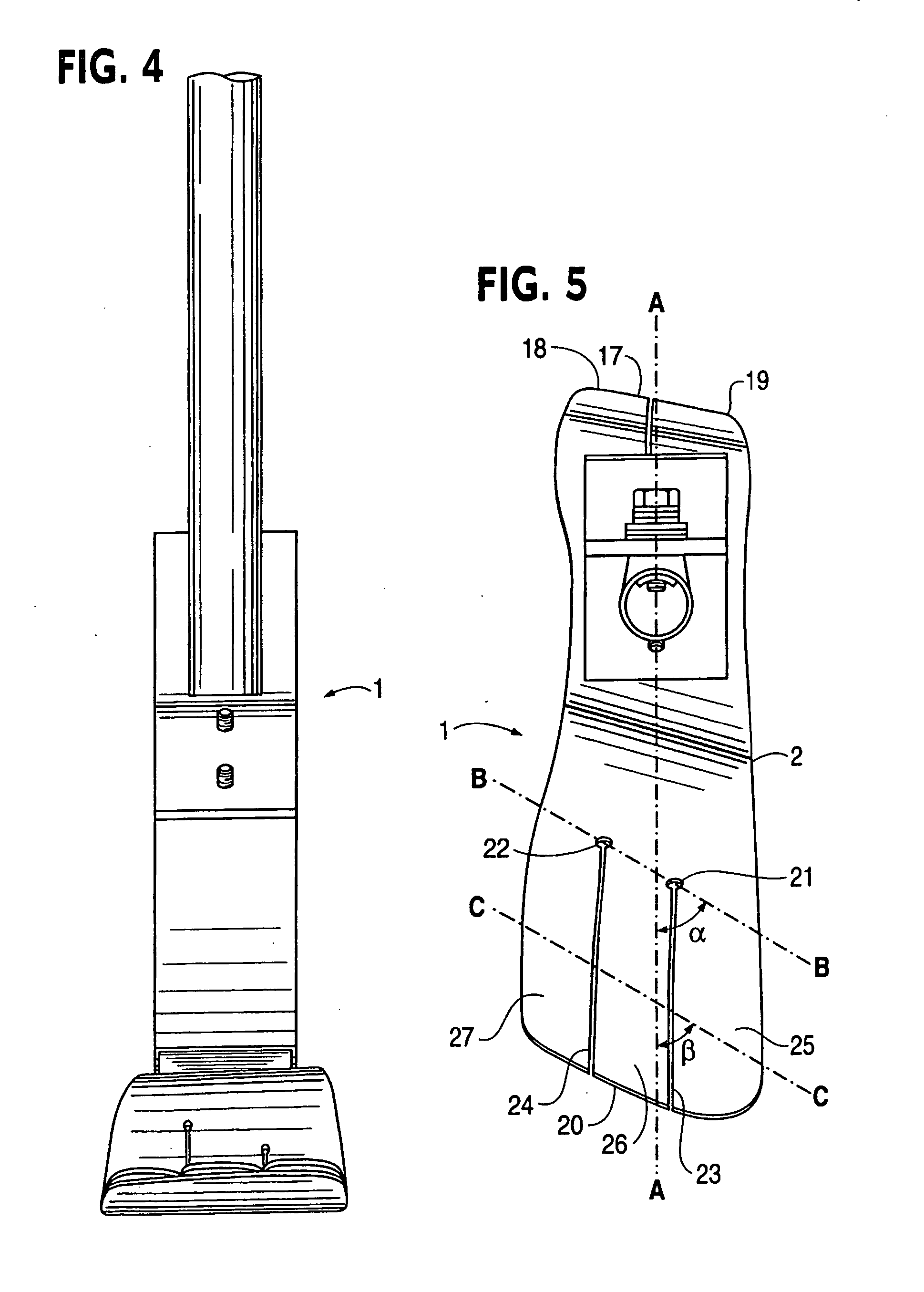

Prosthetic foot with tunable performance

InactiveUS7410503B2Improve performanceImproved applied mechanicArtificial legsTibiaPhysical medicine and rehabilitation

A prosthetic foot (147) has a longitudinally extending foot keel (149) and a resilient, monolithically formed calf shank (148) extending upwardly from the foot keel to form an ankle joint area of the prosthetic foot and a lower, prosthetic part of a leg above the ankle joint area for connection with a lower extremity prosthetic socket on a person's leg stump. At least the lower portion of the calf shank extending upwardly from the foot keel is anterior facing convexly curved. The shank and at least a portion of the foot keel are monolithically formed.

Owner:BIOQUEST PROSTHETICS

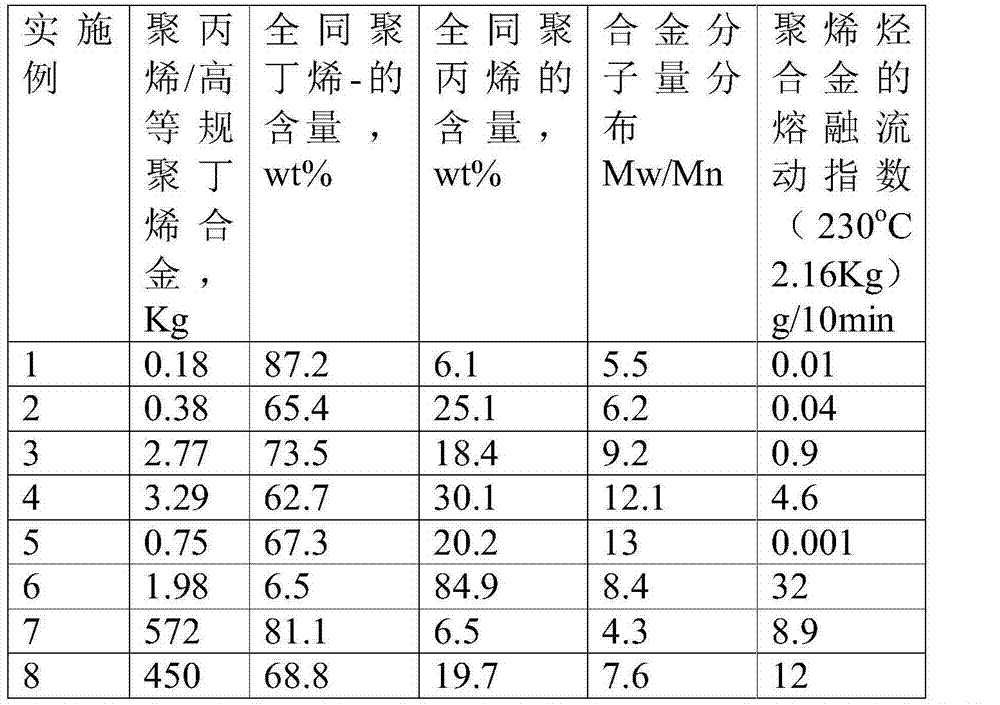

High isotactic polypropylene alloy material and preparation method thereof

The invention discloses a high isotactic polypropylene alloy material and a preparation method thereof. The material contains 5-98.9 parts by weight of polybutylene, 1-80 parts by weight of polypropylene and 0.1-15 parts by weight of propylene-butene copolymer; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotatic polypropylene is 115-129 DEG C; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotactic polypropylene is 155-169 DEG C; the propylene-butene copolymer contains a random copolymer and a segmented copolymer of propylene-butene. The preparation method uses a titanium / vanadium supported catalyst and adopts a multistage sequential polymerization manner and specifically comprises the steps of carrying out propylene polymerization or butane-1 polymerization, then initiating butane-1 polymerization or propylene polymerization, and respectively carrying out propylene polymerization or butane-1 polymerization, and so on to synthesize the high isotactic polypropylene alloy material. The material is a powdery or spherical product, and has the advantages of excellent impact resistance, thermal creep resistance and low shrinking percentage of polybutylene, high modulus, high surface hardness and fast setting of polypropylene, and the like.

Owner:QINGDAO UNIV OF SCI & TECH +1

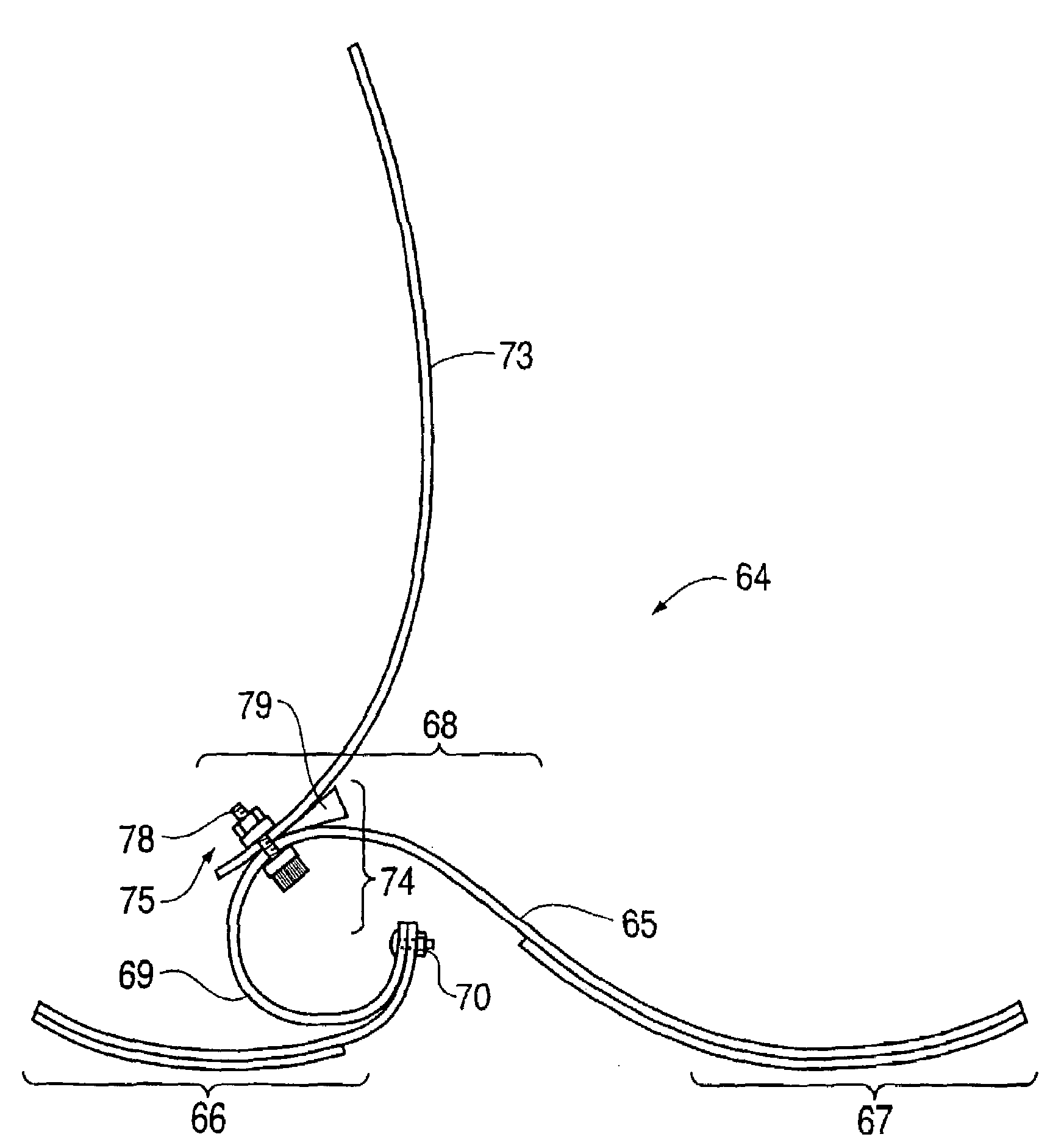

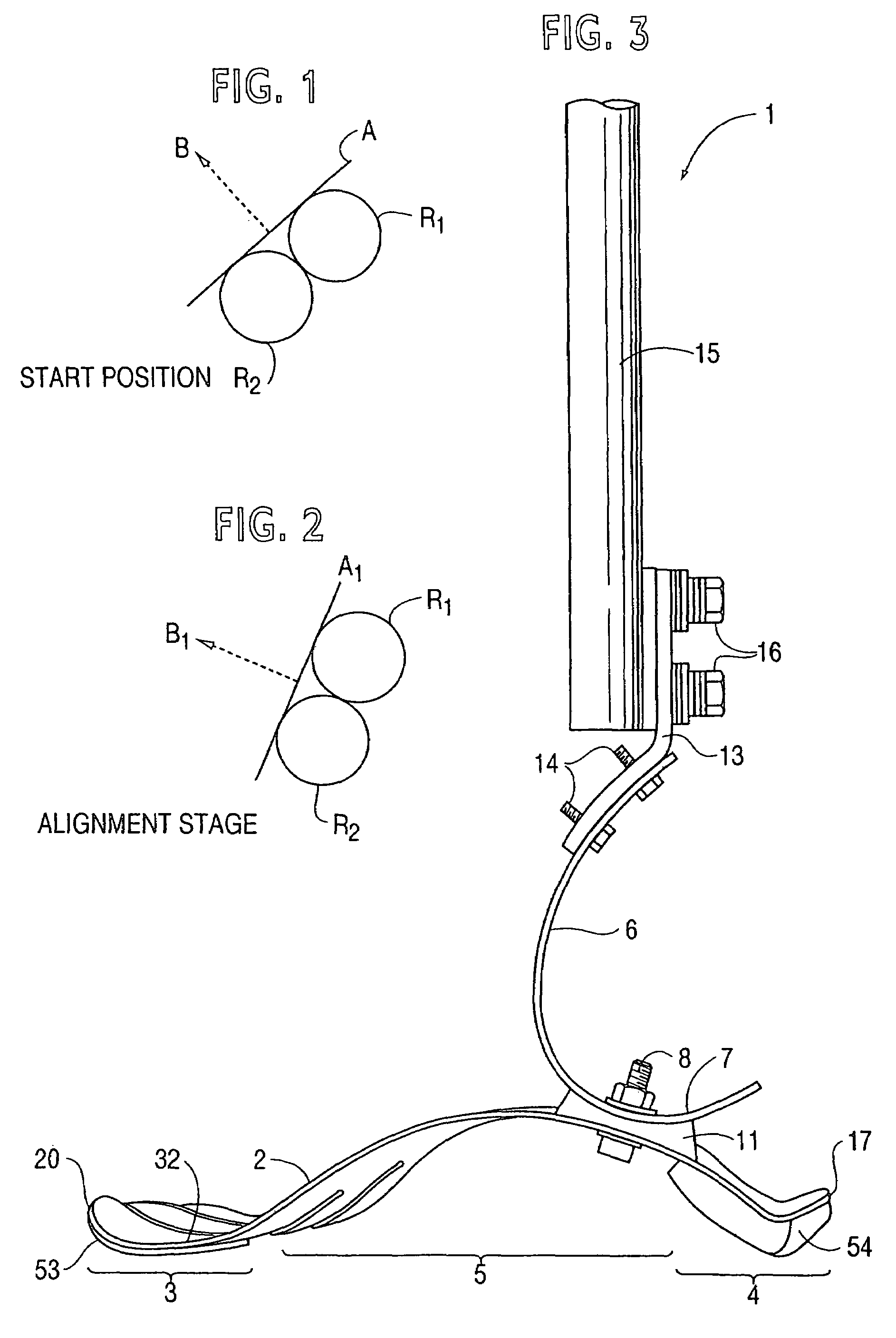

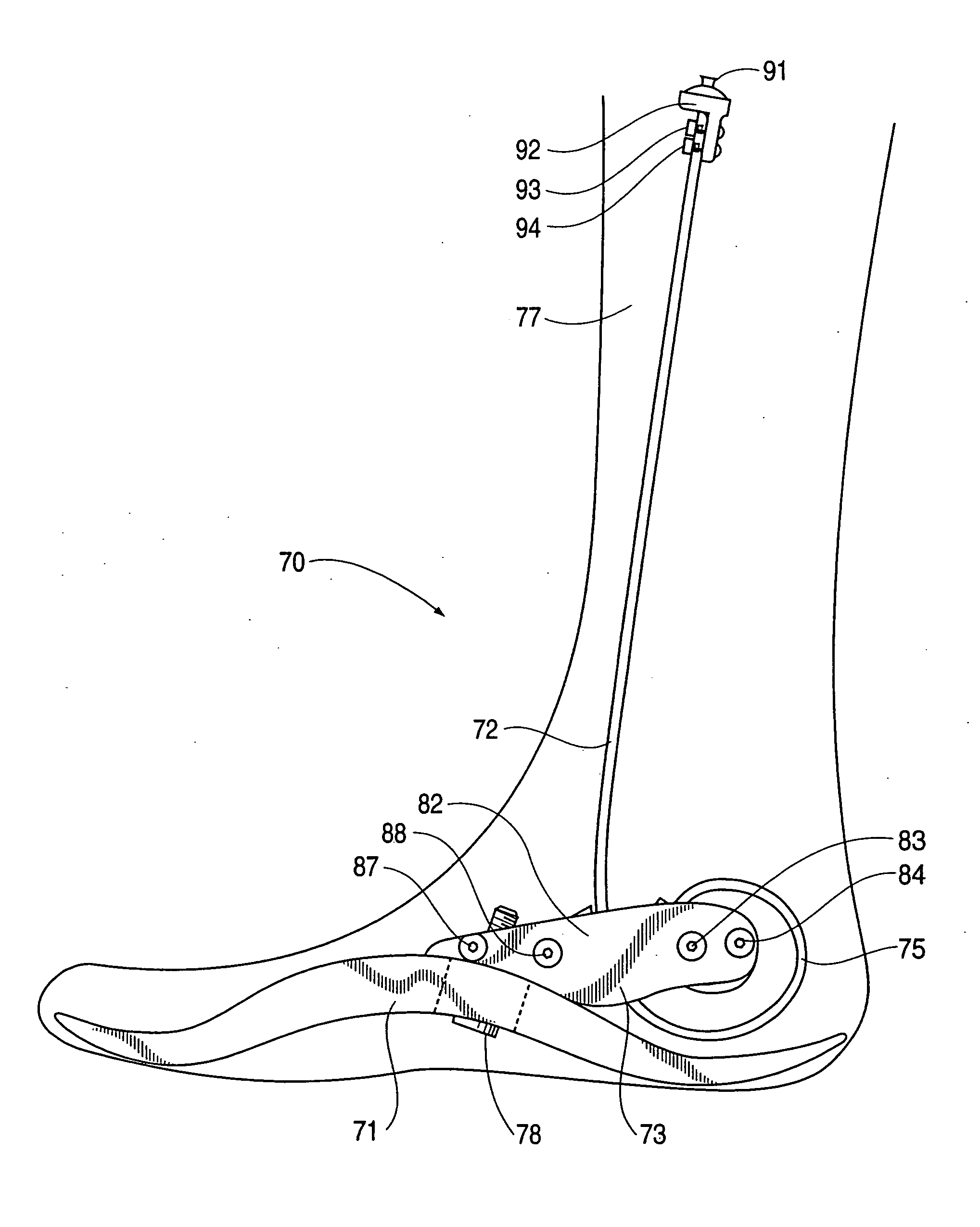

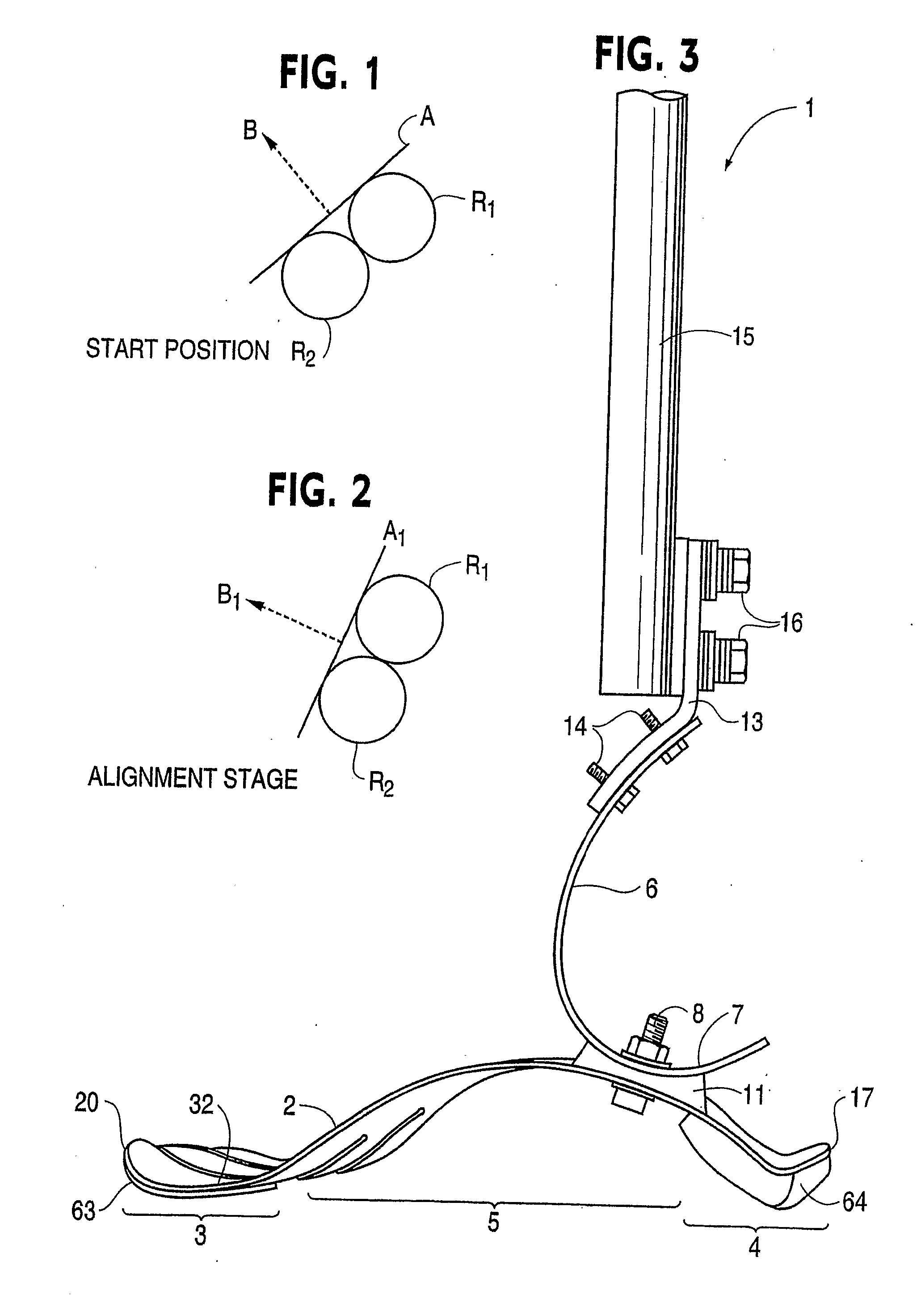

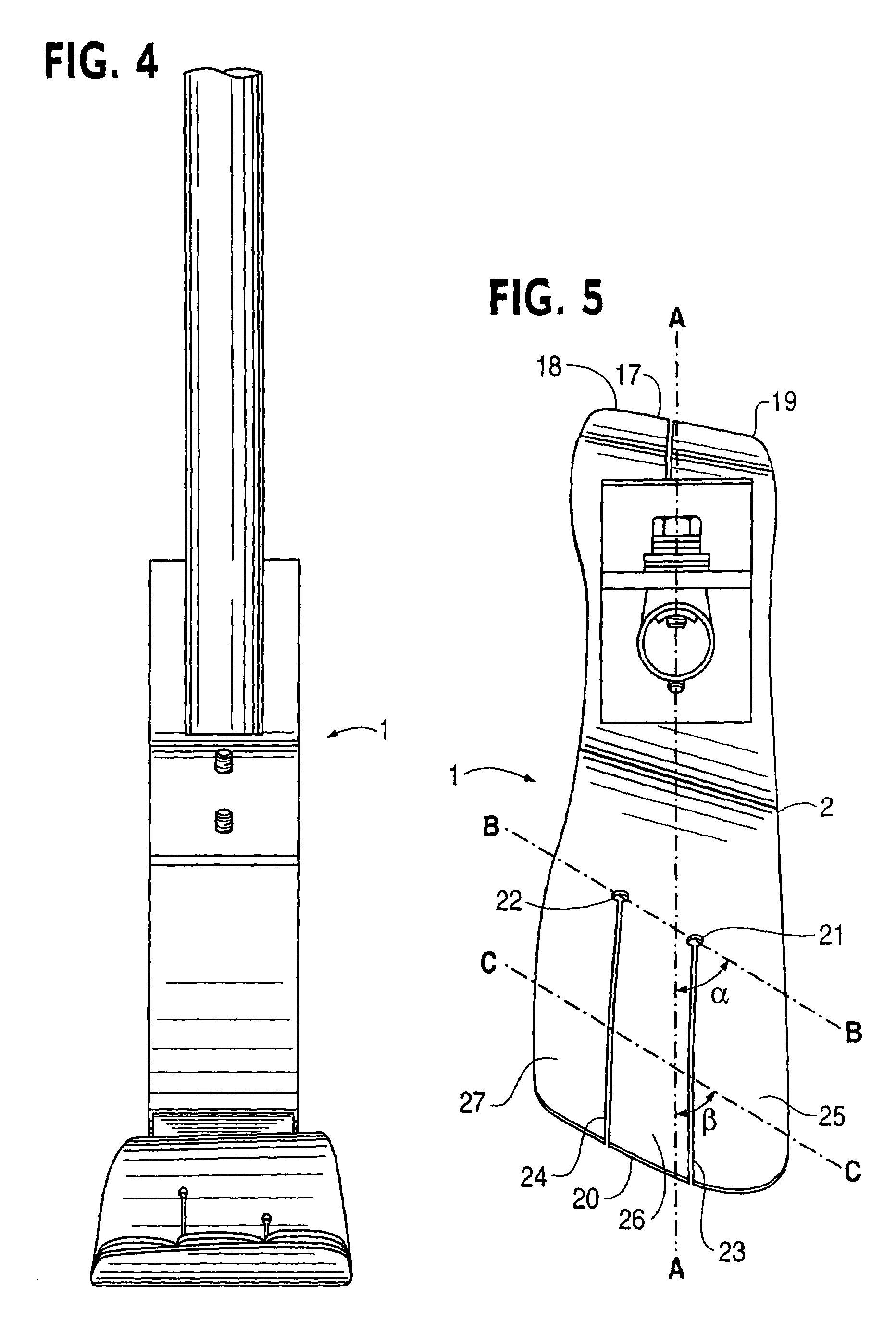

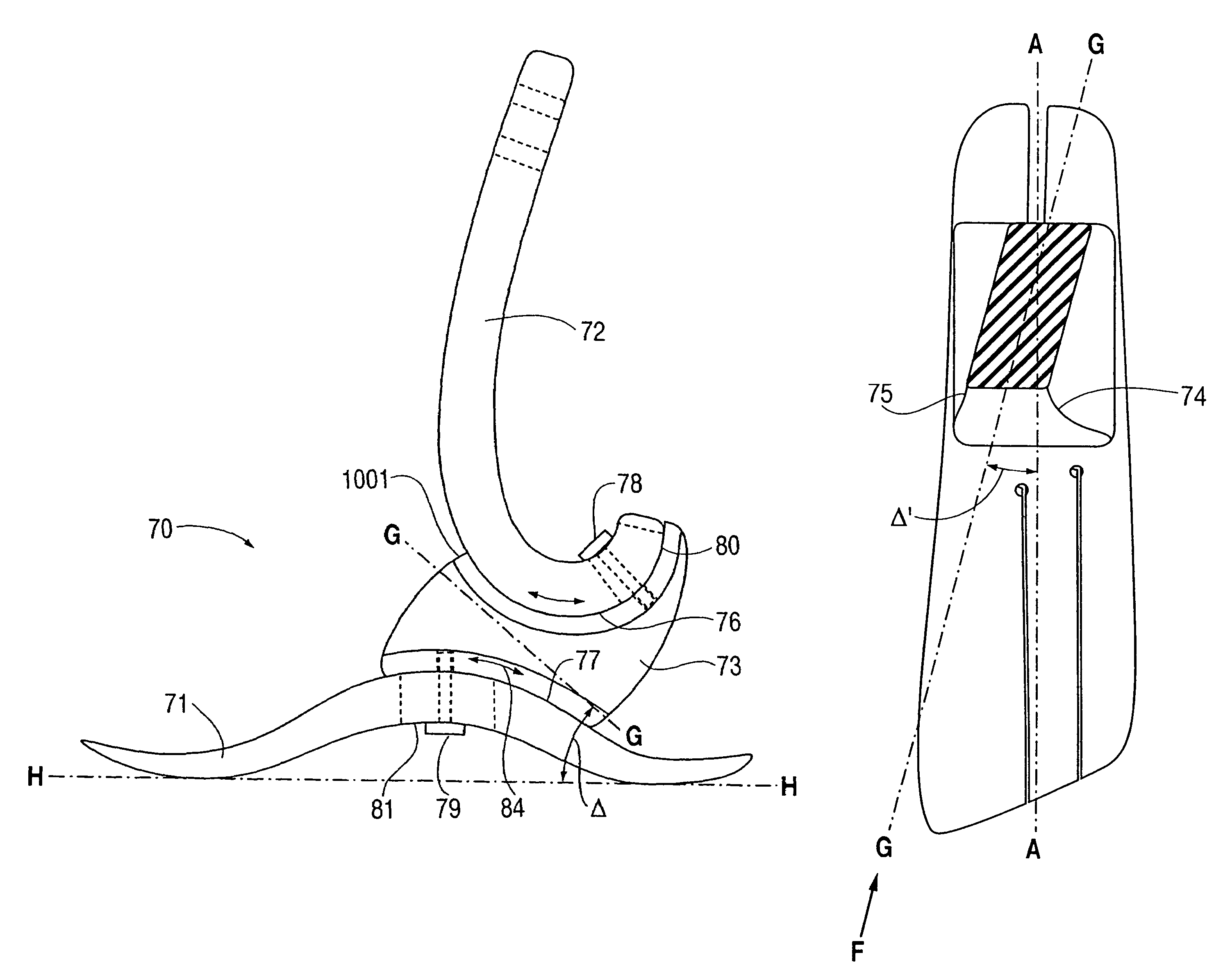

Prosthetic foot with tunable performance

InactiveUS7211115B2High level of performanceImproved applied mechanicCapsule deliveryArtificial legsTibiaPhysical medicine and rehabilitation

A prosthetic foot (70) incorporates a foot keel (71) and a calf shank (72) connected to the foot keel to form an ankle joint area of the prosthetic foot. The foot keel has forefoot and hindfoot portions and an upwardly arched midfoot portion extending between the forefoot and midfoot portions. The calf shank includes a downward convexly curved lower end which is secured to the foot keel by way of a coupling element (73). The lower end of the calf shank extends upwardly, and initially anteriorly therefrom into a reversely curved portion (75) of the calf shank leading to an upstanding upper end thereof.

Owner:BIOQUEST PROSTHETICS

Method for numerously preparing asphalt-based graphene material with low cost

The invention discloses a method for numerously preparing a graphene material, which takes asphalt as a raw material and comprises the processes of preparing, pyrolyzing and carrying out carbonization. Compared with the conventional preparation of the graphene material, the method disclosed by the invention has low preparation cost, little equipment investment, simplicity for operating, no pollution, and easiness for realizing industrialization; and in addition, the purity of a product is high, the structure defect of the product is little, and the performance of the product is excellent.

Owner:FUZHOU UNIV

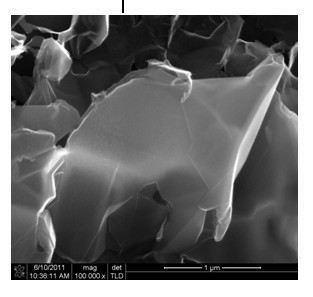

Prosthetic foot with tunable performance

InactiveUS7955399B2High levelImproved applied mechanicArtificial legsTibiaPhysical medicine and rehabilitation

A prosthetic foot (100) incorporates a foot keel (101) and a resilient calf shank (105) with its lower end connection to the foot keel to form an ankle joint of the prosthetic foot. The foot keel has forefoot and hindfoot portions and a midfoot portion extending between the forefoot and hindfoot portions. The calf shank extends upward from the foot keel by way of an anterior facing convexly curved portion (106) of the shank, and is secured to the foot keel by way of a coupling element (107) which is monolithically formed with the forefoot portion of the foot. The lower end of the shank is reversely curved (110) and housed by a reversely curved portion (112) of the coupling element.

Owner:BIOQUEST PROSTHETICS

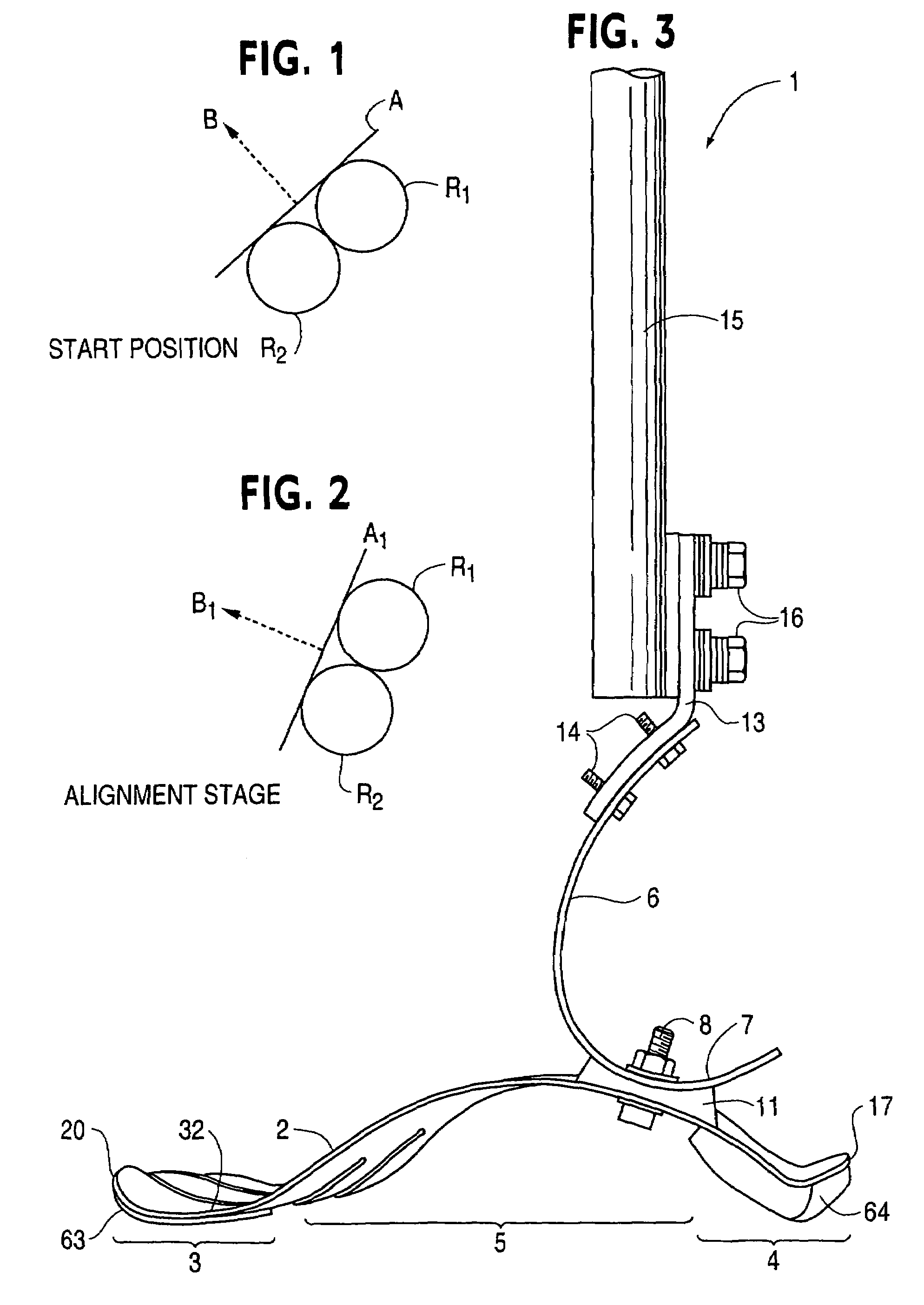

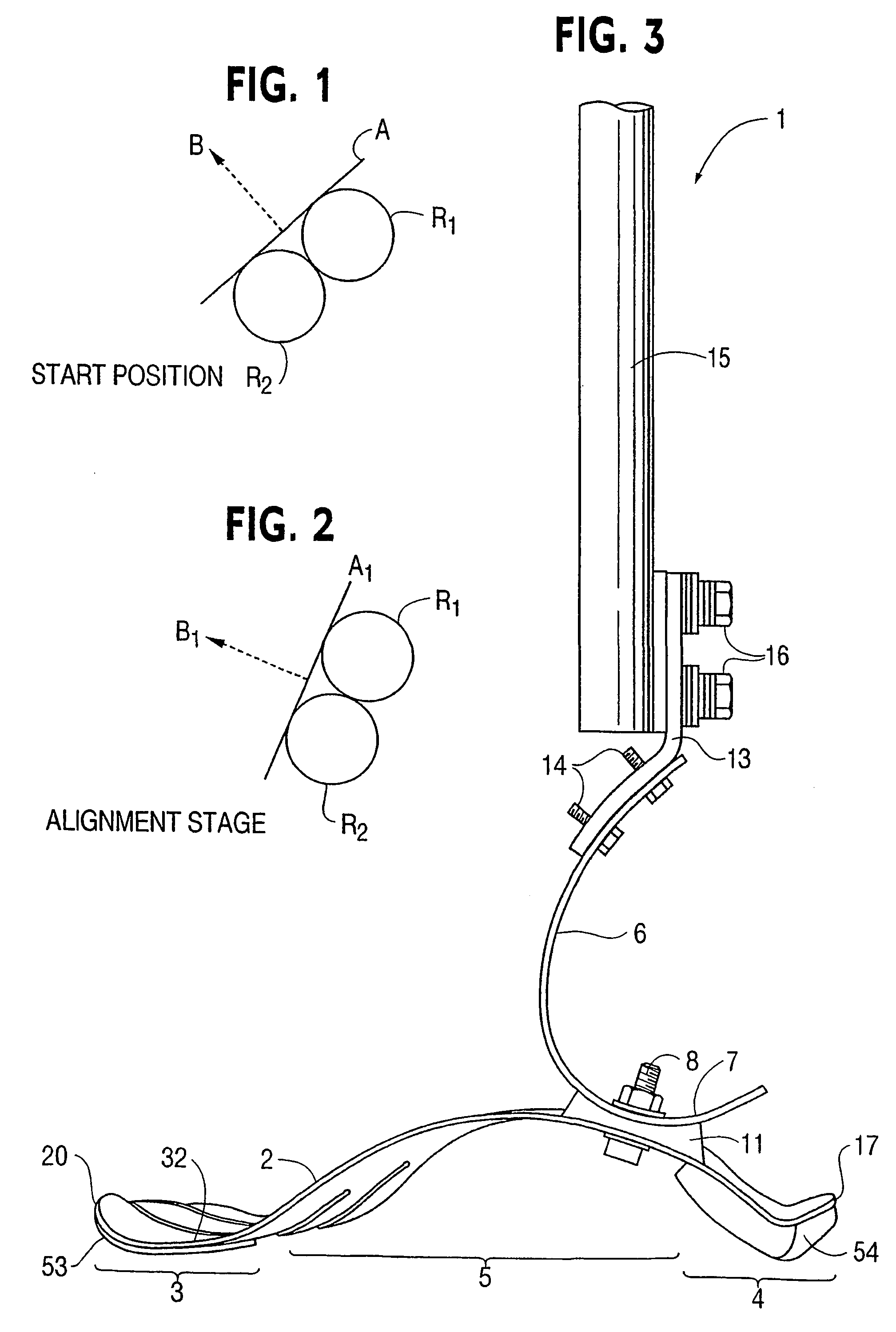

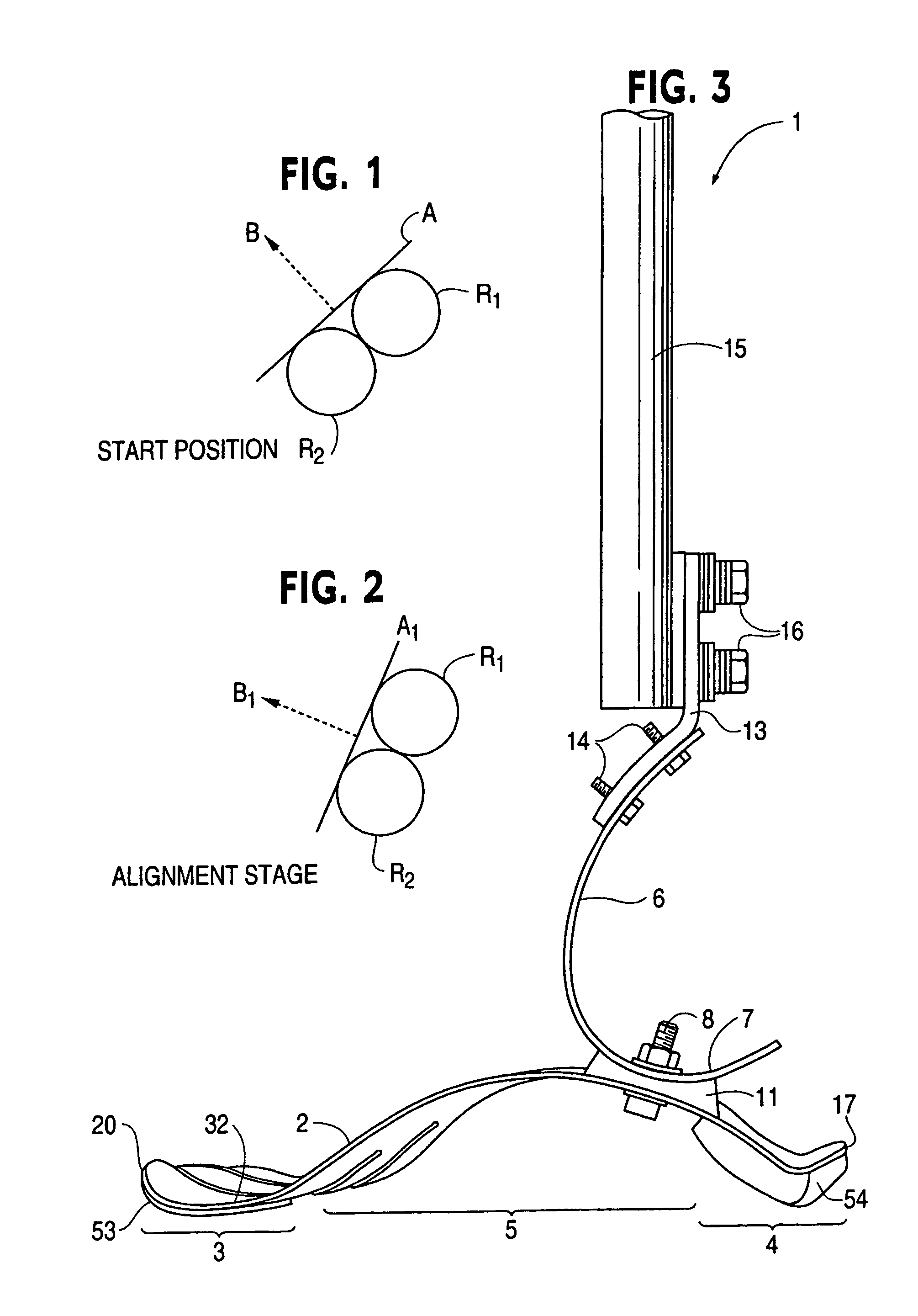

Method for the Continuous Implementation of Polymerisation Processes

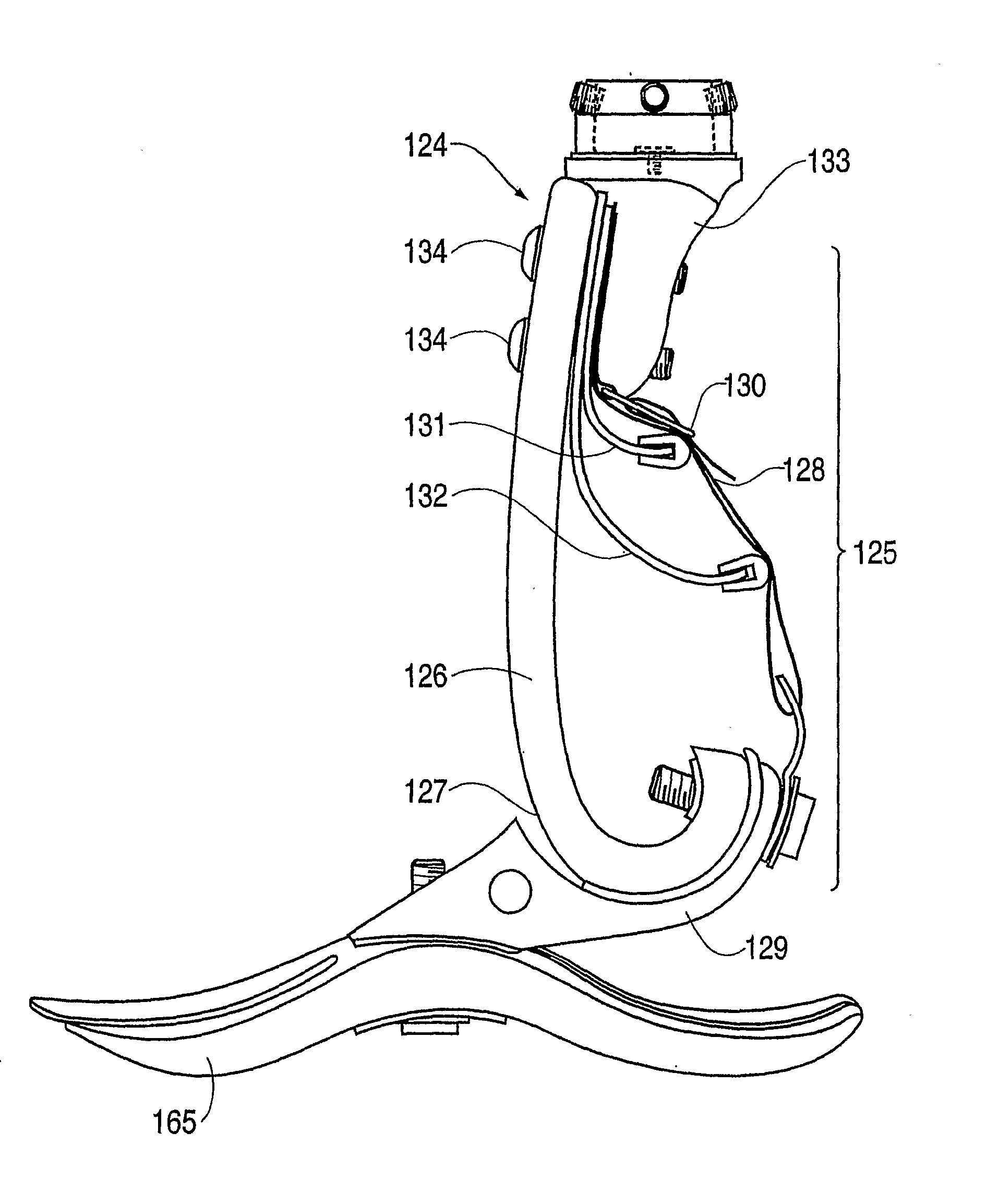

ActiveUS20080188950A1High level of performanceImprove apply mechanicFlow mixersTransportation and packagingProsthetic kneeTibia

A prosthetic foot (124) incorporates a foot keel (165) and a calf shank (126) connected to the foot keel to form an ankle joint area of the prosthetic foot. A device (125) connected between the upper end of the calf shank and the lower portion of the prosthesis can be used to assist posterior movement of the upper end of a calf shank and control anterior movement of the upper end of the calf shank during use of the prosthesis. The device (125) has springs which store energy during force loading with anterior motion of the upper end of the calf shank in gait and which, during force unloading, return the stored energy as kinetic power for adding to the propulsive force on the user's body generated by the prosthesis in gait.

Owner:LIST TECHNOLOGY AG +1

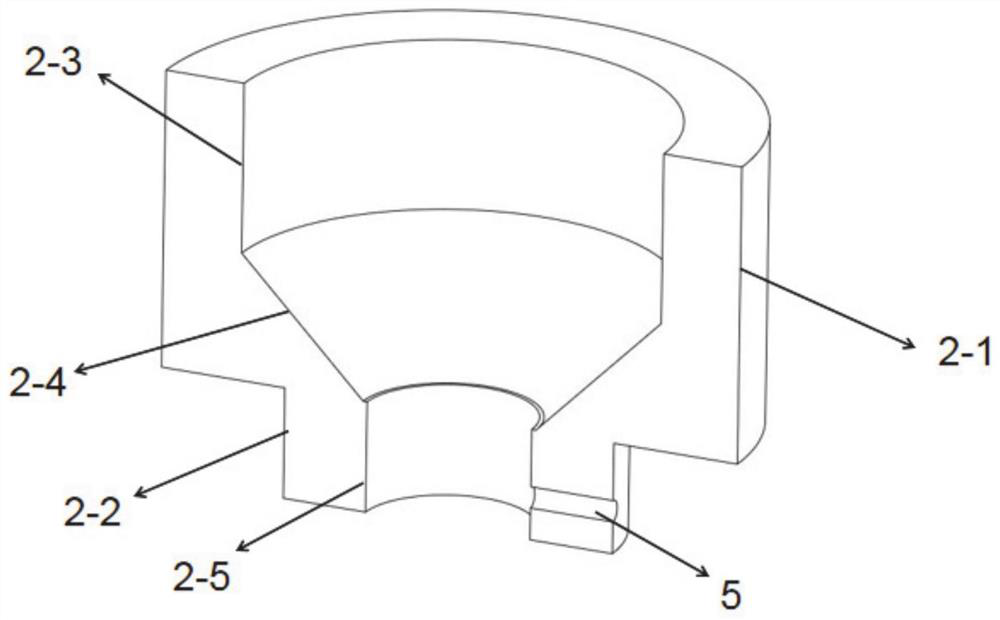

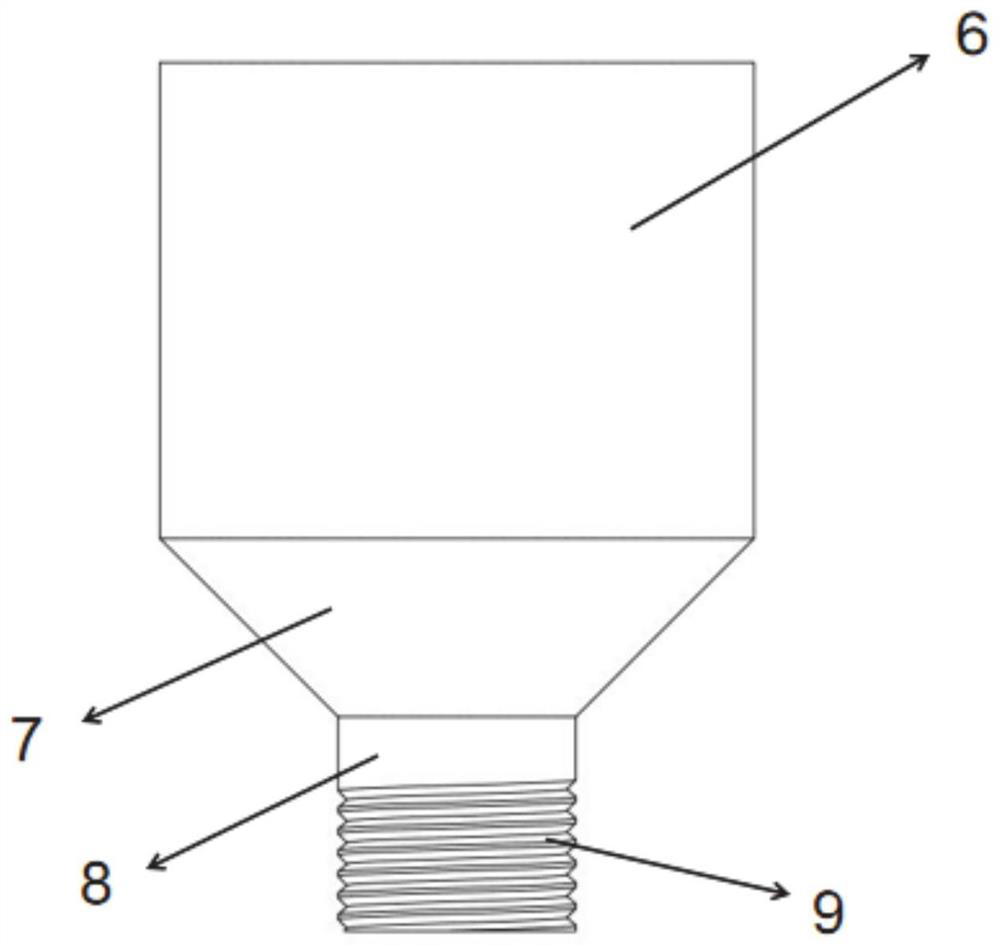

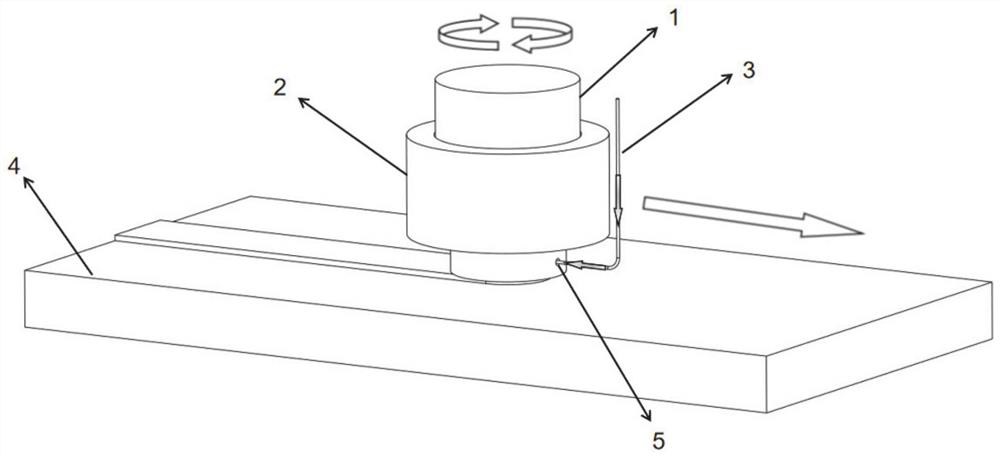

Filler wire static shaft shoulder friction stir welding and additive manufacturing device and method

PendingCN112958902AImprove mechanical propertiesEnabling Additive ManufacturingAdditive manufacturing apparatusNon-electric welding apparatusScrew threadMechanical property

The invention relates to a filler wire static shaft shoulder friction stir welding and additive manufacturing device and method. The filler wire static shaft shoulder friction stir welding and additive manufacturing device comprises a stirring head, the periphery of the stirring head is sleeved with a static shaft shoulder, the stirring head and the static shaft shoulder are configured to synchronously move along a machining track, and the stirring head can rotate around the axis of the stirring head. A threaded groove is formed in the peripheral face of the machining end of the stirring head, the static shaft shoulder is provided with a wire feeding hole, and the wire feeding hole is used for feeding wires to the space between the part, provided with the threaded groove, of the stirring head and the hole face of a through hole formed in the static shaft shoulder. When the device is used for additive manufacturing, the interface bonding defects are avoided, and the bonding strength is guaranteed. And the mechanical property of additive manufacturing parts is greatly improved.

Owner:SHANDONG UNIV

Prosthetic foot with tunable performance

A prosthetic foot (70) incorporates a foot keel (71) and a calf shank (72) connected to the foot keel to form an ankle joint area of the prosthetic fool. The foot keel has forefoot and hindfoot portions and an upwardly arched midfoot portion extending between the forefoot and midfoot portions. The calf shank includes a downward convexly curved lower end which is adjustably attached at a portion thereof to the foot keel by way of a releasable fastener arrangement which includes a coupling element (73) intermediate the calf shank and foot keel. The coupling element includes a resilient material forming a joint permitting subtalar joint-like motion of the prosthetic foot in gait.

Owner:BIOQUEST PROSTHETICS

Biological enzyme preparation and preparing method thereof

InactiveCN103651663AImprove qualityImprove featuresPre-baking dough treatmentFood preparationProteaseSieve

The invention relates to a biological enzyme preparation. The biological enzyme preparation comprises, by weight, 1.2-1.5 parts of dextranase, 2.5-8 parts of amylase, 1-5.3 parts of lipase, 1.8-4.5 parts of protease, 1.5-3.8 parts of oxidase, 0.8-1.6 parts of glutamine transaminase, 0.5-1.2 parts of phytase, 1.5-5.0 parts of emulgator, 1.0-5.0 parts of water retention agents and 0.5-3.5 parts of flour gluten fortifier. By means of the biological enzyme preparation, the dough performance can be adjusted obviously, the bread size is increased, the bread stiffness is obviously improved, and the bread softness is improved. A preparing method of the biological enzyme preparation includes the steps of weighing the above raw materials by weight to be stirred and evenly mixed, passing through an 80-mesh sieve, further stirring and even mixing until the raw materials are completely and evenly mixed, and obtaining the biological enzyme preparation.

Owner:ZHONGSHAN NAIDE BIOTECH

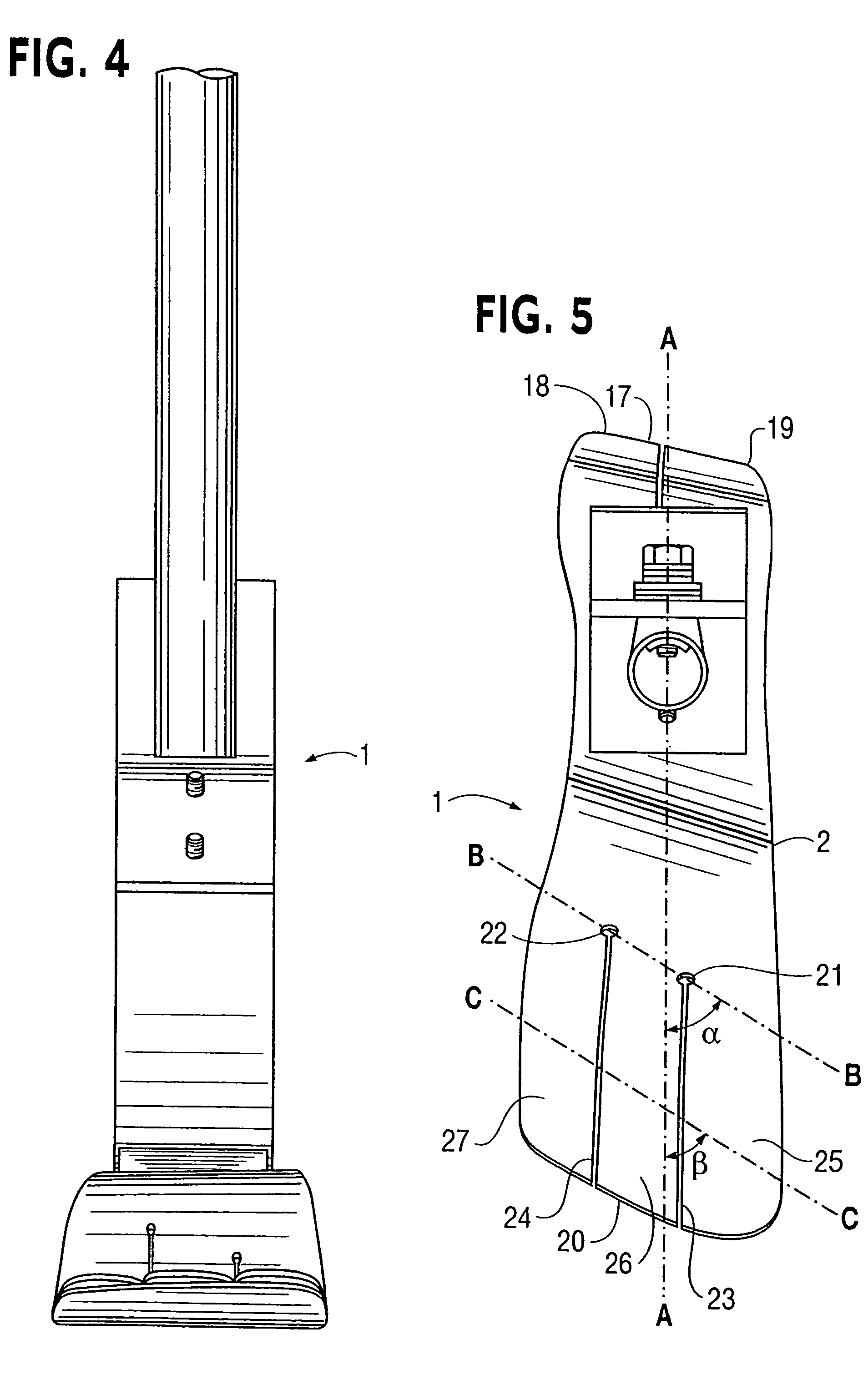

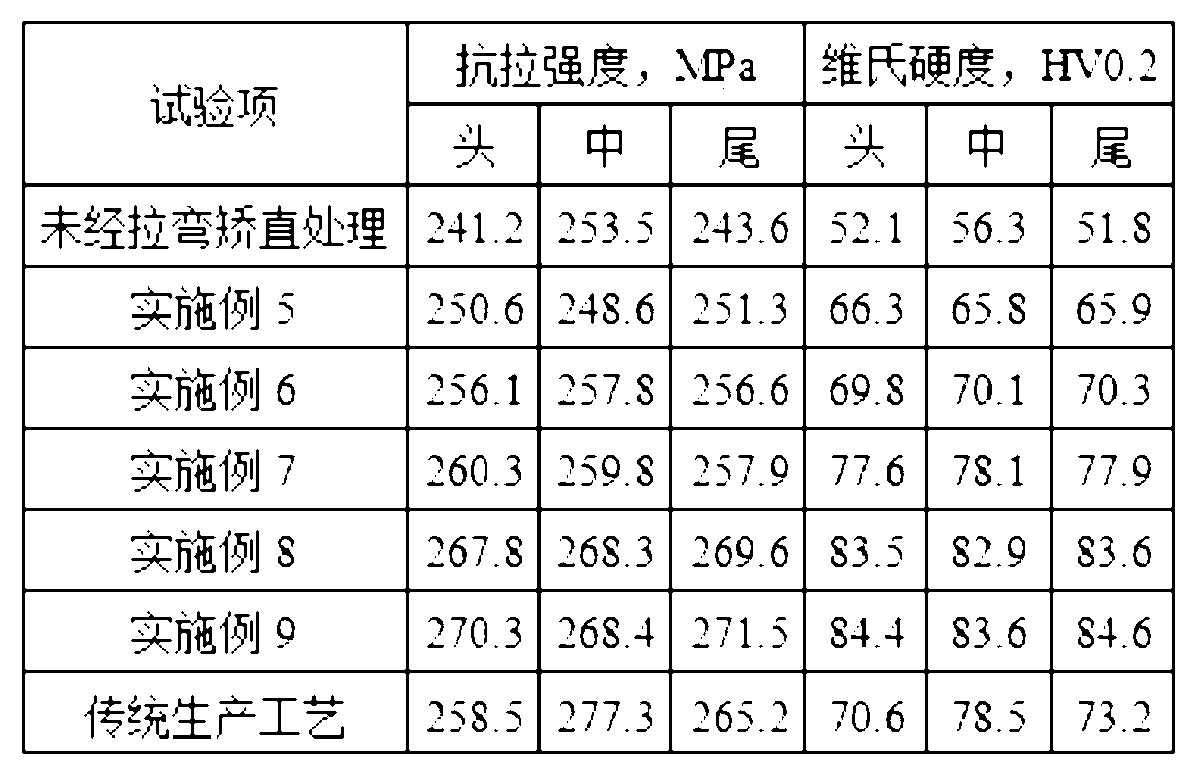

Production process of semi-hard soft copper belts

ActiveCN102699024ATune performanceUniform performanceMetal rolling arrangementsCopperMaterials science

The invention discloses a production process of semi-hard soft copper belts. The process comprises a coarse rolling work procedure, an annealing work procedure, a middle rolling work procedure, an annealing work procedure, a fine rolling work procedure, a normal annealing work procedure, a cleaning work procedure, a bending pulling straightening work procedure, a cutting work procedure and a packing work procedure. Compared with the prior art, the production process has the advantages that the normal annealing is adopted. Compared with the low-temperature annealing process, the production process has the advantages that soft copper belt products can be obtained, in addition, the bending pulling straightening work procedure is added, the bending pulling straightening is mainly used for improving the belt form quality of hard belt materials, the process is equivalent to once rolling at an ultralow processing rate, and the belt materials can generate certain plastic deformation after the bending pulling straightening, so the products are processed into the semi-hard soft state from the soft-state processing, the product performance regulation is reached through controlling the elongation rate and the tension, the obtained copper belt products have uniform performance, in addition, the belt form quality of products is greatly improved, the product grade is improved, and the use requirements of customers are met.

Owner:ANHUI ZHONGYUAN NEW MATERIALS CO LTD

Prosthetic foot with tunable performance

InactiveUS20070213841A1High level of performanceImproved applied mechanicLigamentsMusclesStored energyCoil spring

A lower extremity prosthesis including a foot, an ankle, a shank and a posterior calf device to store energy during force loading of the prosthesis and return the stored energy during force unloading to increase the kinetic power generated for propulsive force by the prosthesis in gait. The posterior calf device includes at least one coiled spring formed monolithically with the shank and having a free end, and at least one elongated member extending between the free end of the at least coiled spring and the lower portion of the prosthesis. The at least one coiled spring is resiliently uncoiled in response to anterior movement of the upper end of the shank in gait for storing energy.

Owner:BIOQUEST PROSTHETICS

Prosthetic Foot With Tunable Performance

InactiveUS20070219643A1High level of functionHigh level of performanceArtificial legsPhysical medicine and rehabilitationKeel

A prosthetic foot (100) incorporates a foot keel (101) and a resilient calf shank (105) with its lower end connected to the foot keel to form an ankle joint of the prosthetic foot. The foot keel has forefoot and hindfoot portions and a midfoot portion extending between the forefoot and hindfoot portions. The calf shank extends upward from the foot keel by way of an anterior facing convexly curved portion (106) of the shank, and is secured to the foot keel by way of a coupling element (107) which is monolithically formed with the forefoot portion of the foot. The lower end of the shank is reversely curved (110) and housed by a reversely curved portion (112) of the coupling element.

Owner:BIOQUEST PROSTHETICS

Prosthetic foot with tunable performance

InactiveUS8070829B2Improve performanceImproved applied mechanicLigamentsMusclesHindlimbArtificial muscle

Owner:BIOQUEST PROSTHETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com