Patents

Literature

34results about How to "Enabling Additive Manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

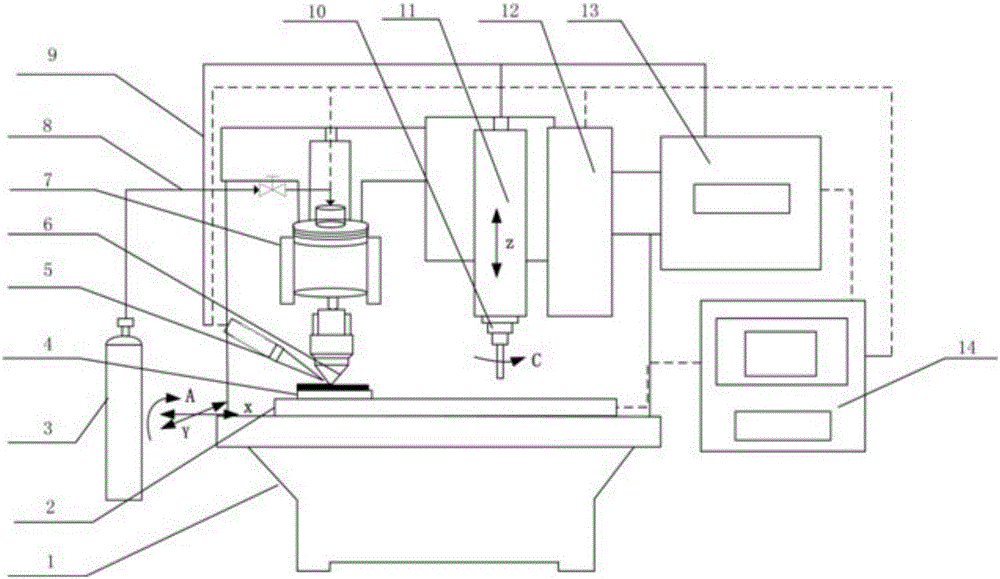

Composite forming device of molten coating added and decreased materials

InactiveCN105817625AAvoid dependenceConvenient location changeAdditive manufacturing apparatusIncreasing energy efficiencyMachiningAdditive layer manufacturing

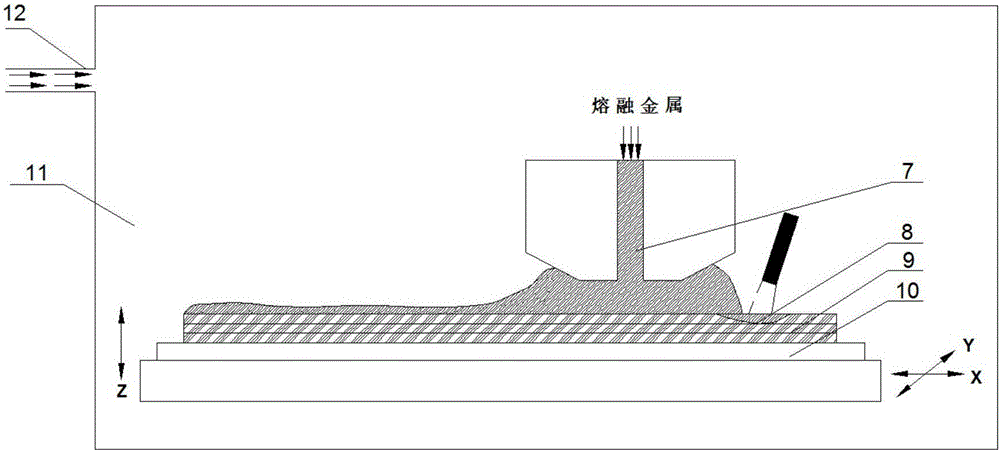

The invention discloses a composite forming device of molten coating added and decreased materials. The composite forming device comprises a coating added material forming part and a decreased material machining part arranged on the same one motion platform; the coating added material forming part includes an atmosphere protecting device; the atmosphere protecting device is connected with the top of a smelting device; a coating head and a laser are arranged at the bottom of the smelting device; a coating forming platform is arranged below the laser and the coating head; the decreased material part includes a main shaft; a cutter clamping device is arranged at the bottom of the main shaft; the main shaft drives the cutter clamping device to rotate; and the main shaft is connected with a cooling unit. The added material manufacturing and the decreased material manufacturing are combined; and after the coating added material forming is performed, the decreased material machining is used, the workpiece precision is improved, and the workpiece machining speed is accelerated.

Owner:XI AN JIAOTONG UNIV

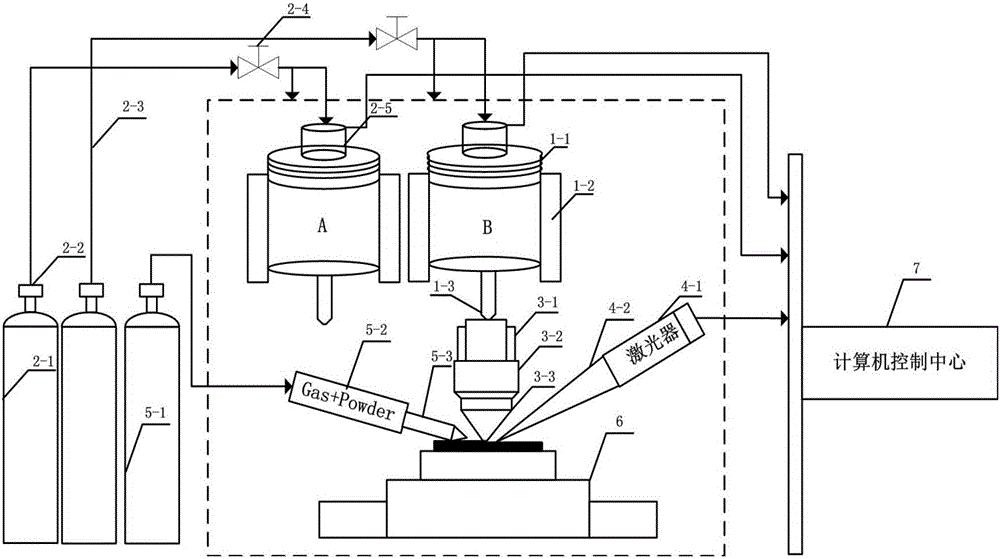

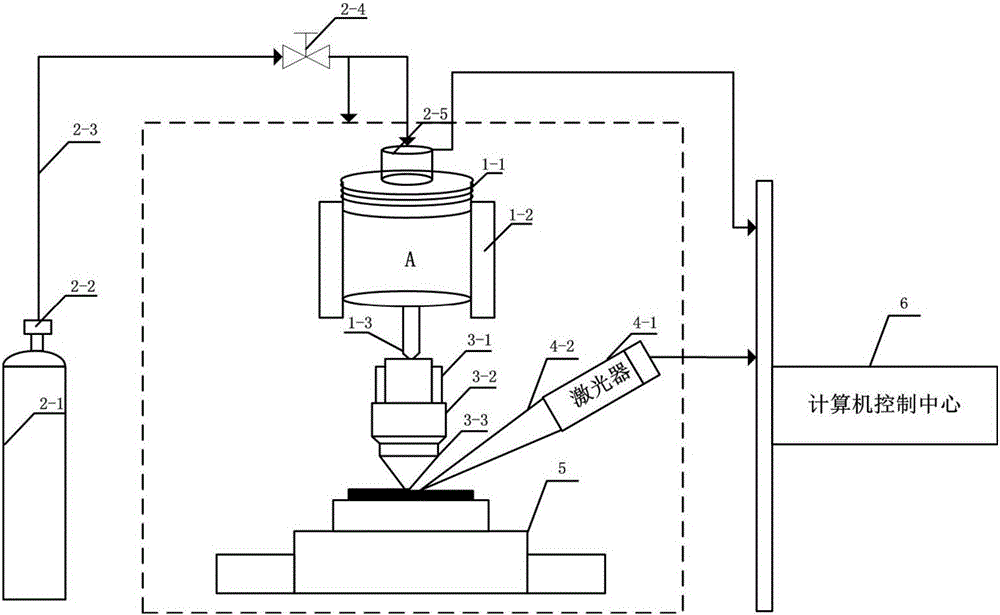

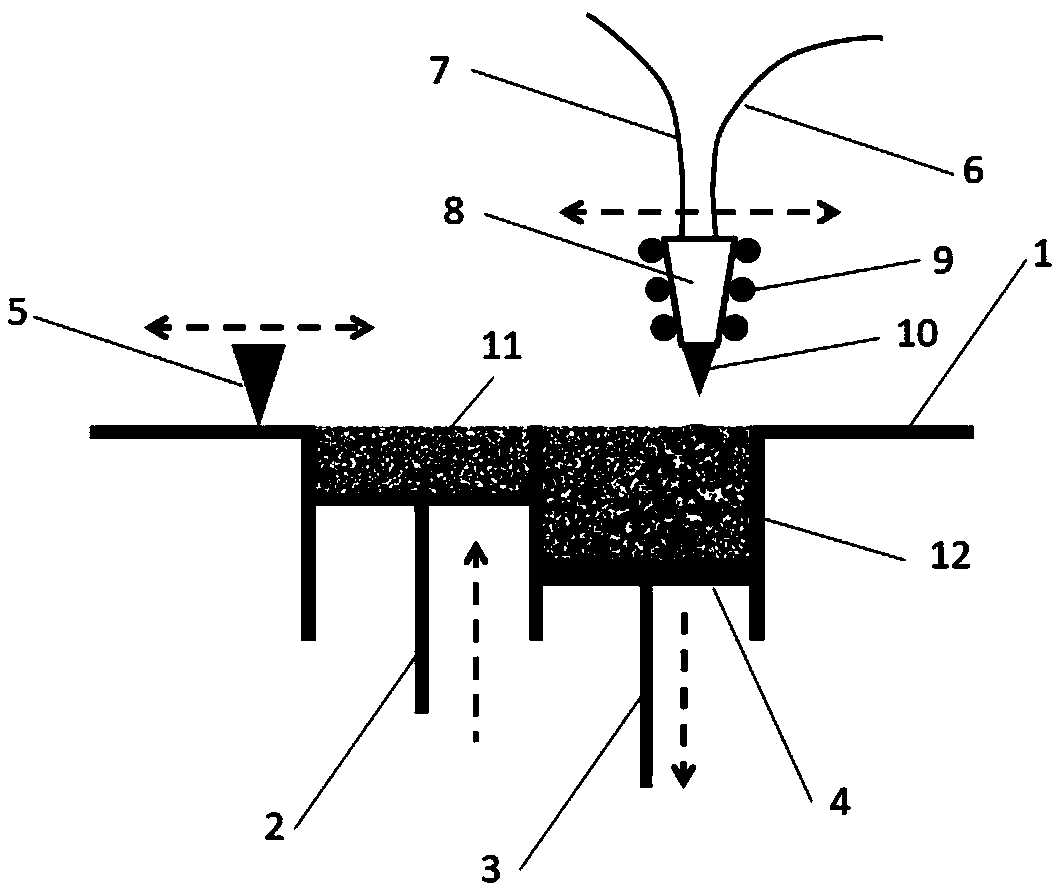

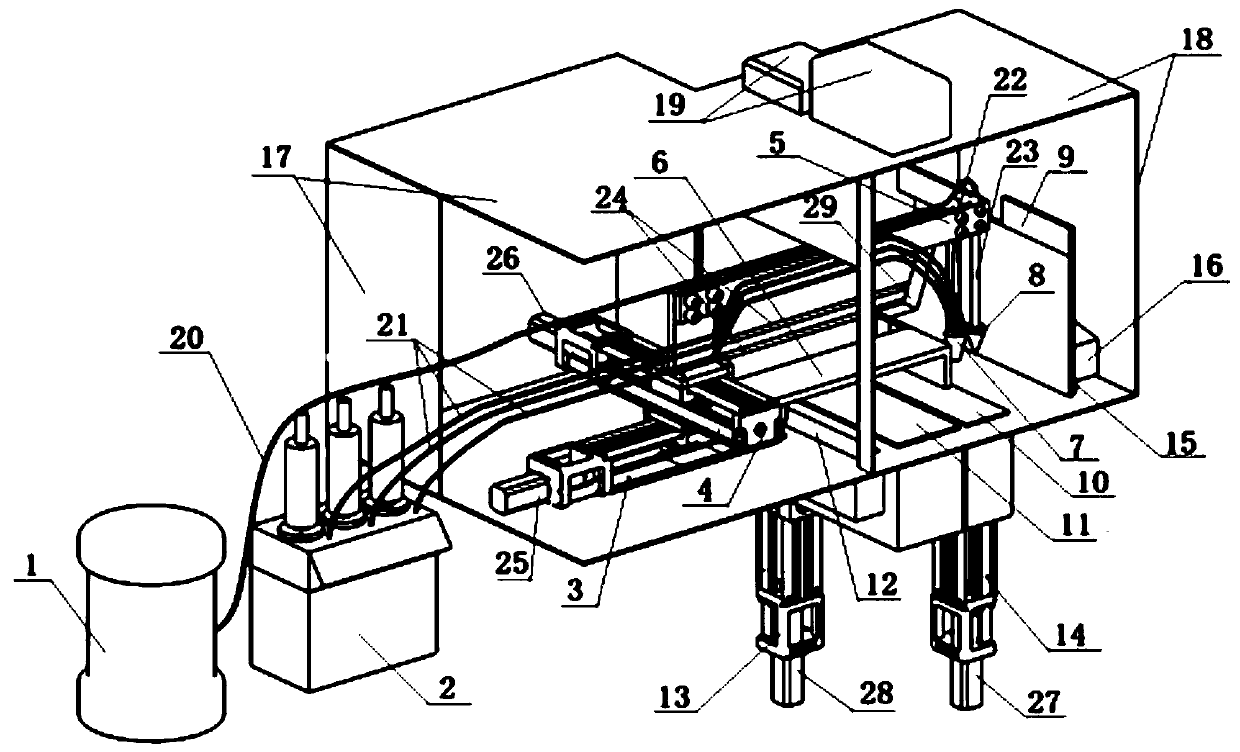

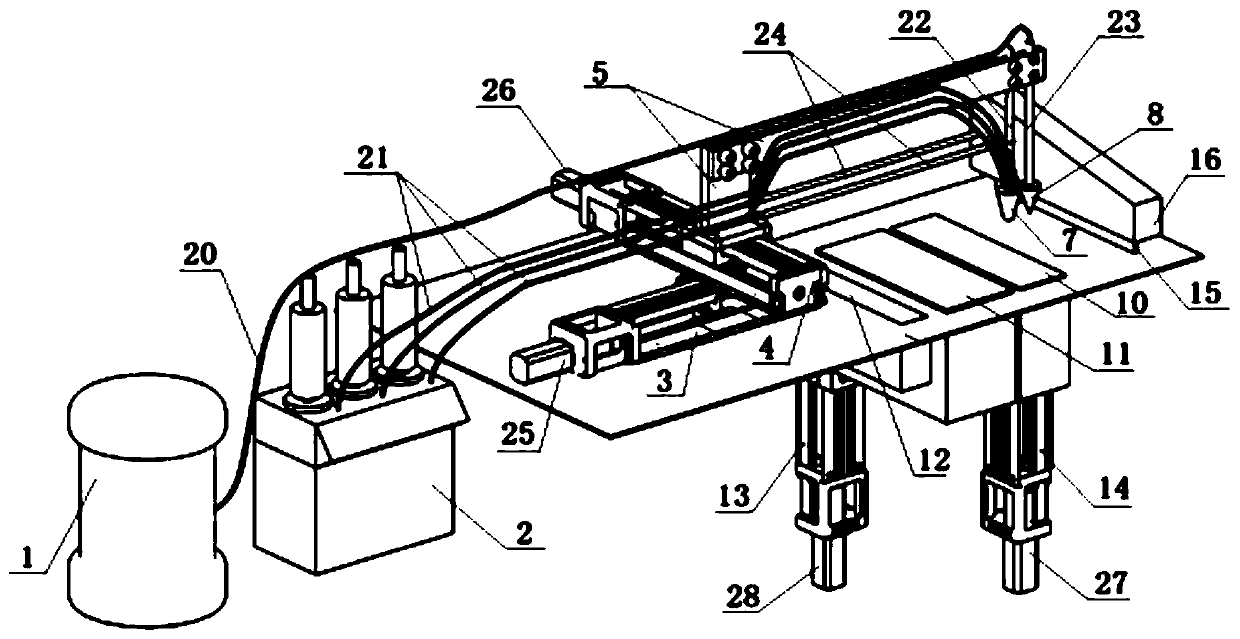

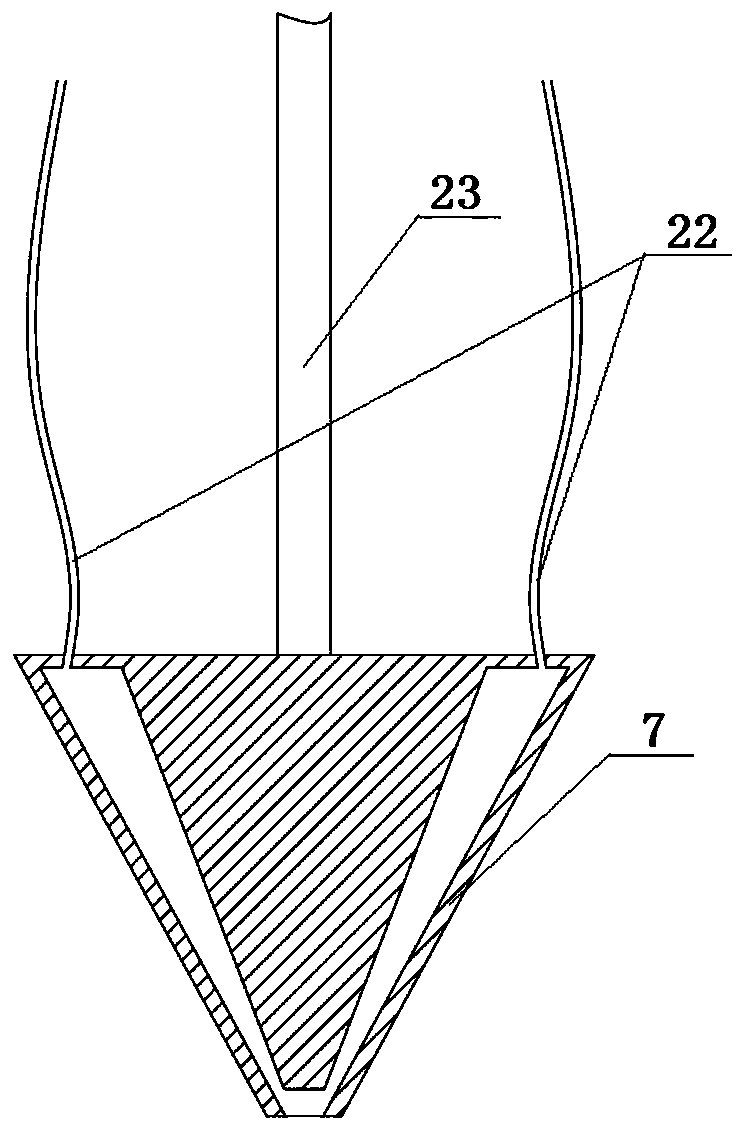

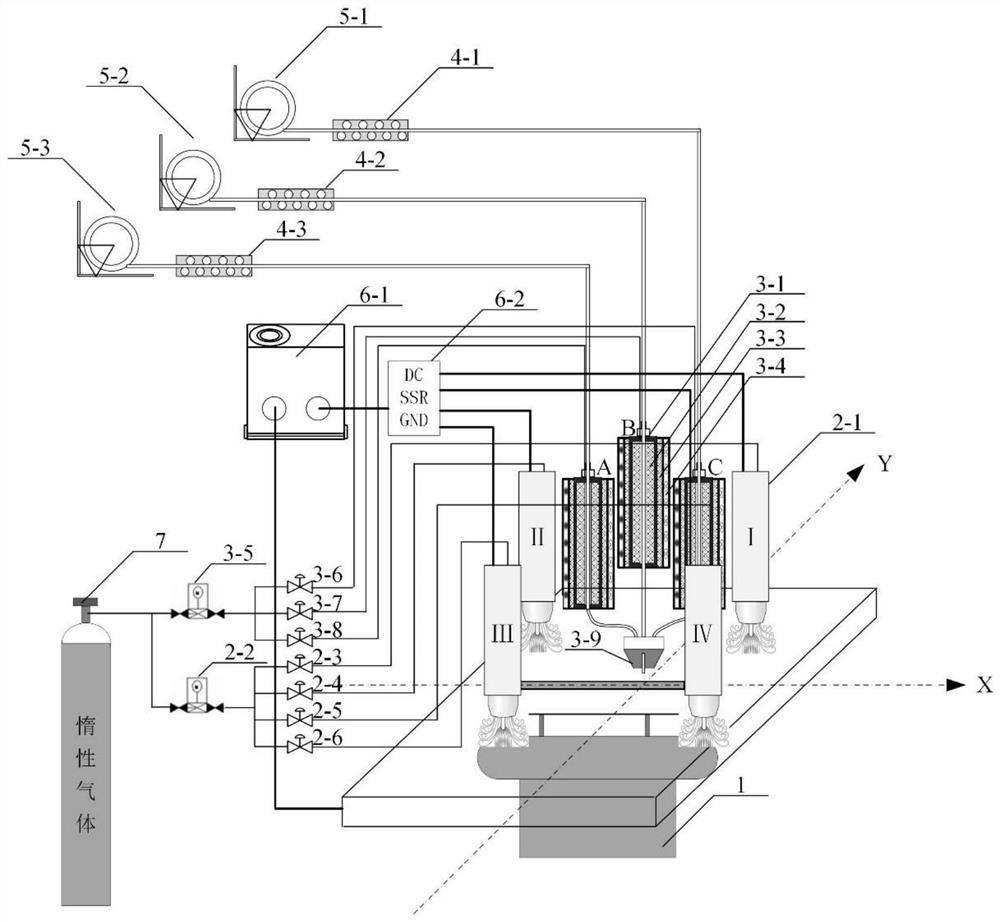

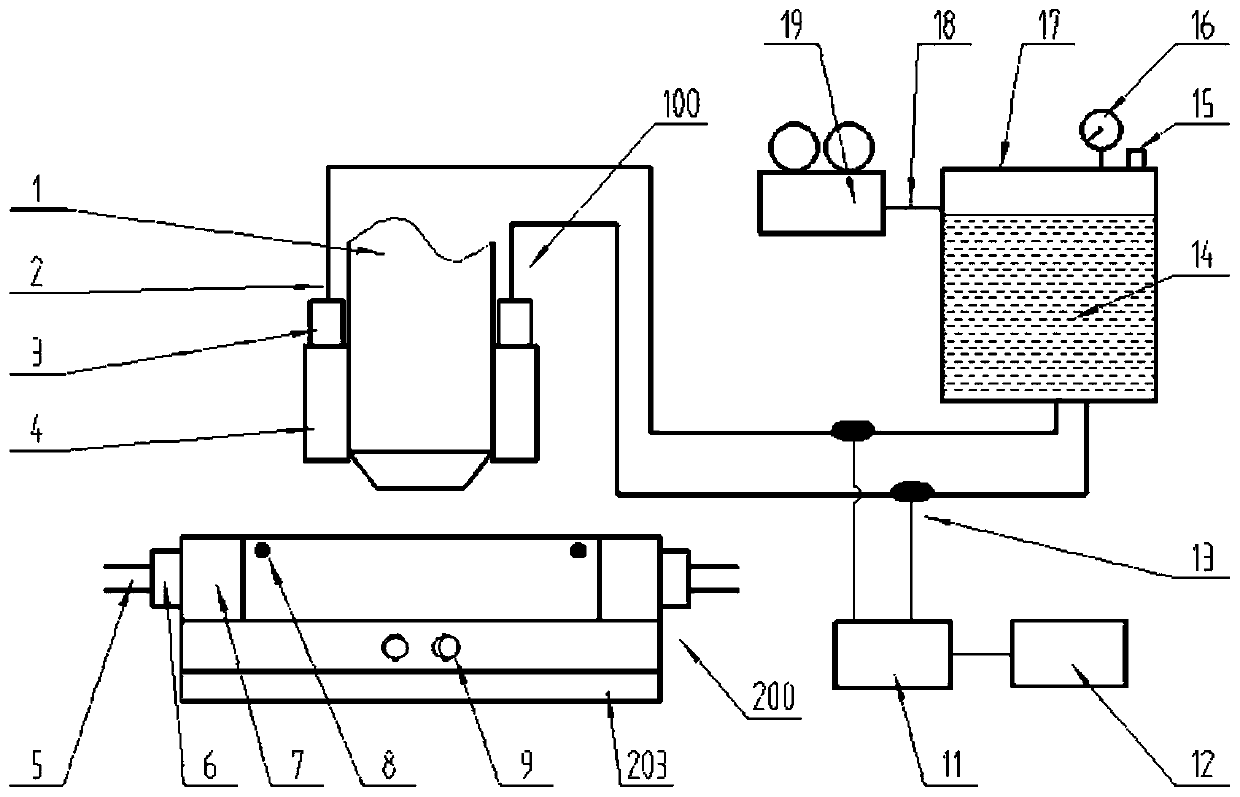

Molten coating forming device and method of metal material gradient components

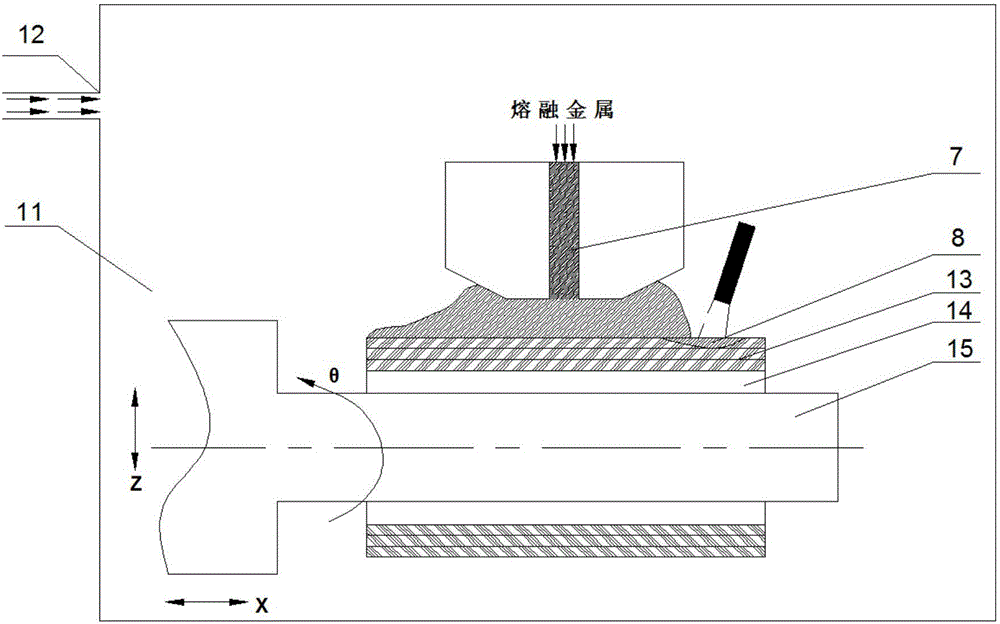

InactiveCN105817626AEnabling Additive ManufacturingLow costAdditive manufacturing apparatusAtmospheric pressureAdditive layer manufacturing

The invention discloses a molten coating forming device and a method of metal material gradient components. The device comprises at least two metal smelting units, and further comprises an air pressure driving device, a molten coating head, a laser surface auxiliary remelting device, a powder feeder, a three-dimensional forming platform and an atmosphere protecting device; the air pressure driving device is connected with the metal smelting units through pipelines; the molten coating head is connected to the lower ends of the metal smelting units; the three-dimensional forming platform is arranged below the molten coating head; the laser surface auxiliary remelting device is arranged on one side of the three-dimensional forming platform; the powder feeder is arranged on the other side of the three-dimensional forming platform; and the metal smelting units, the molten coating head, the laser surface auxiliary remelting device, the powder feeder and the three-dimensional forming platform are all arranged in the atmosphere protecting device. The device can realize the added material manufacturing of part and gradient components with metal materials with high efficiency, high quality and low cost.

Owner:XI AN JIAOTONG UNIV

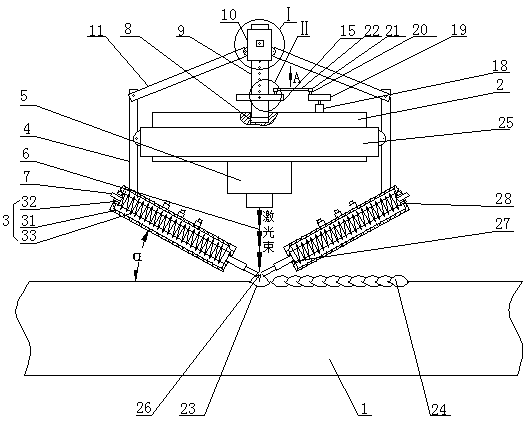

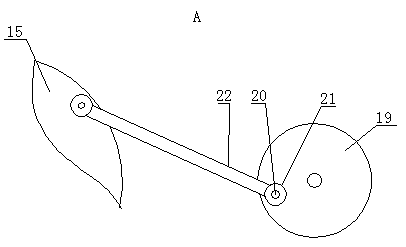

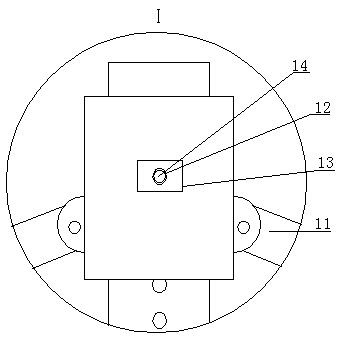

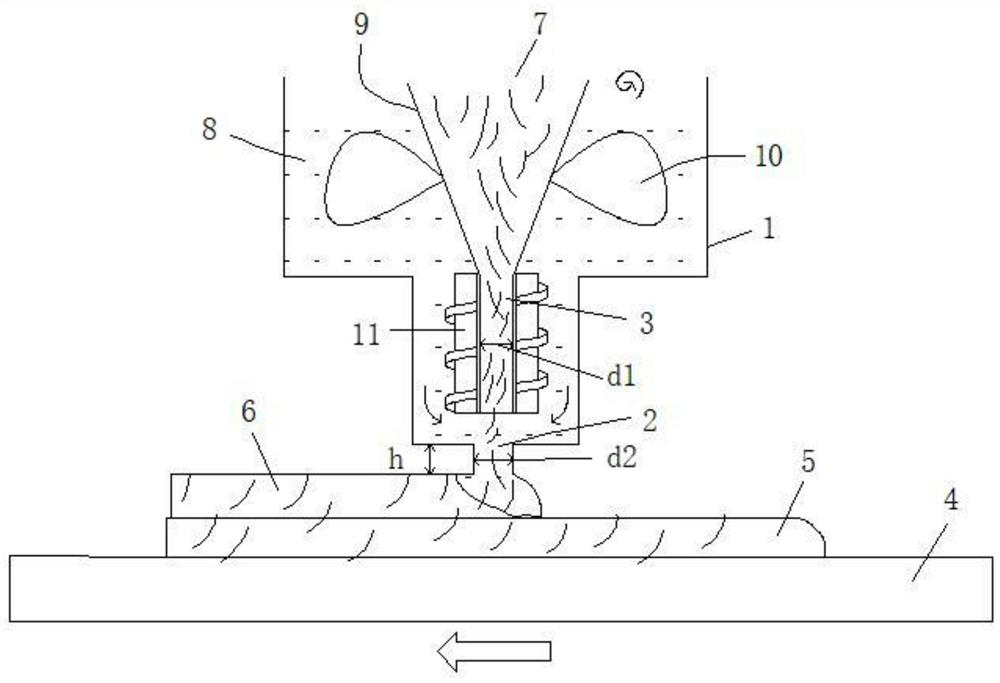

Filler wire static shaft shoulder friction stir welding and additive manufacturing device and method

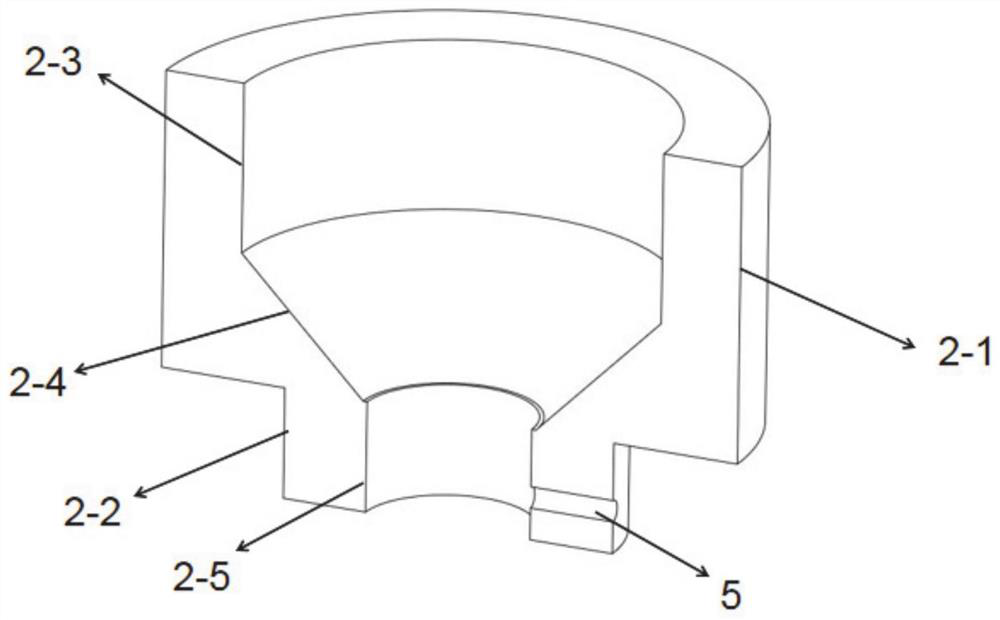

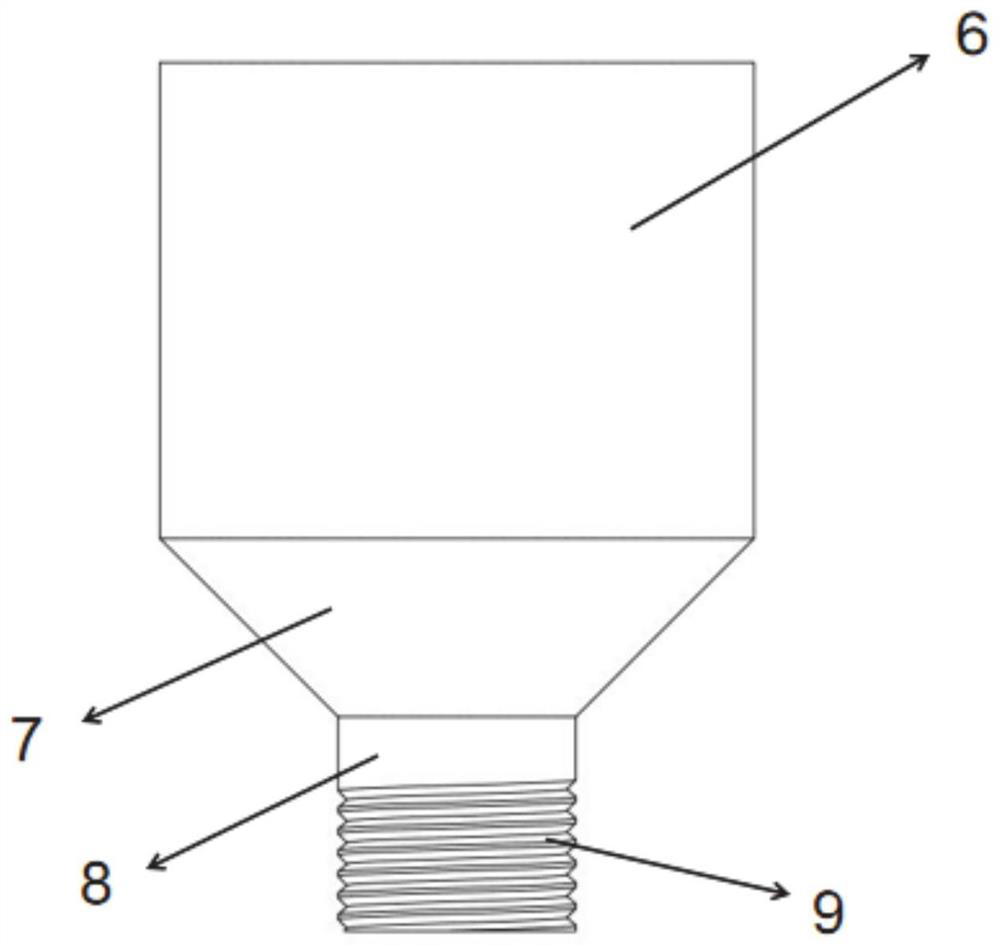

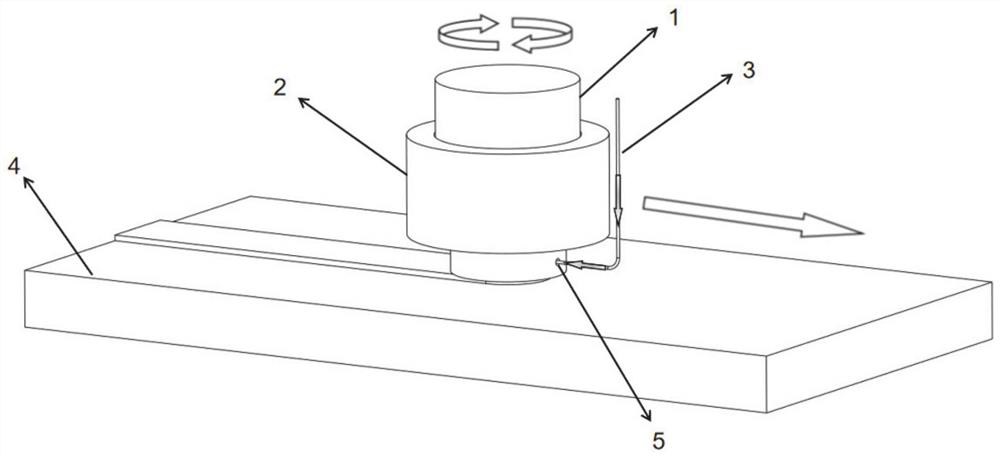

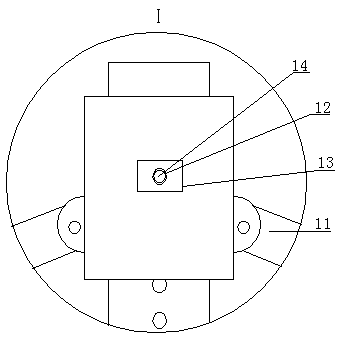

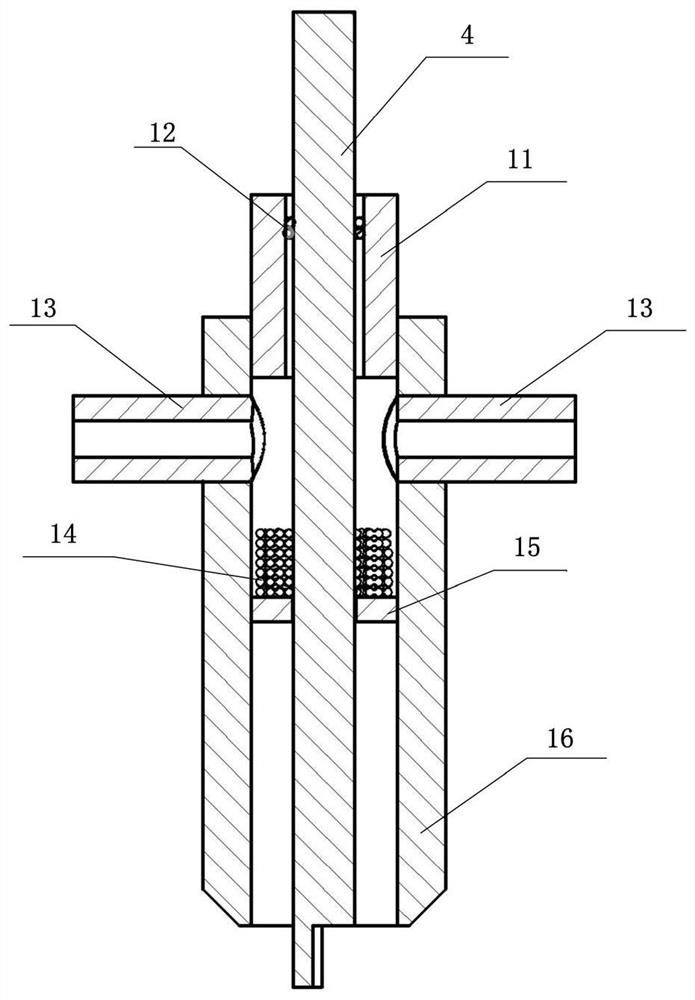

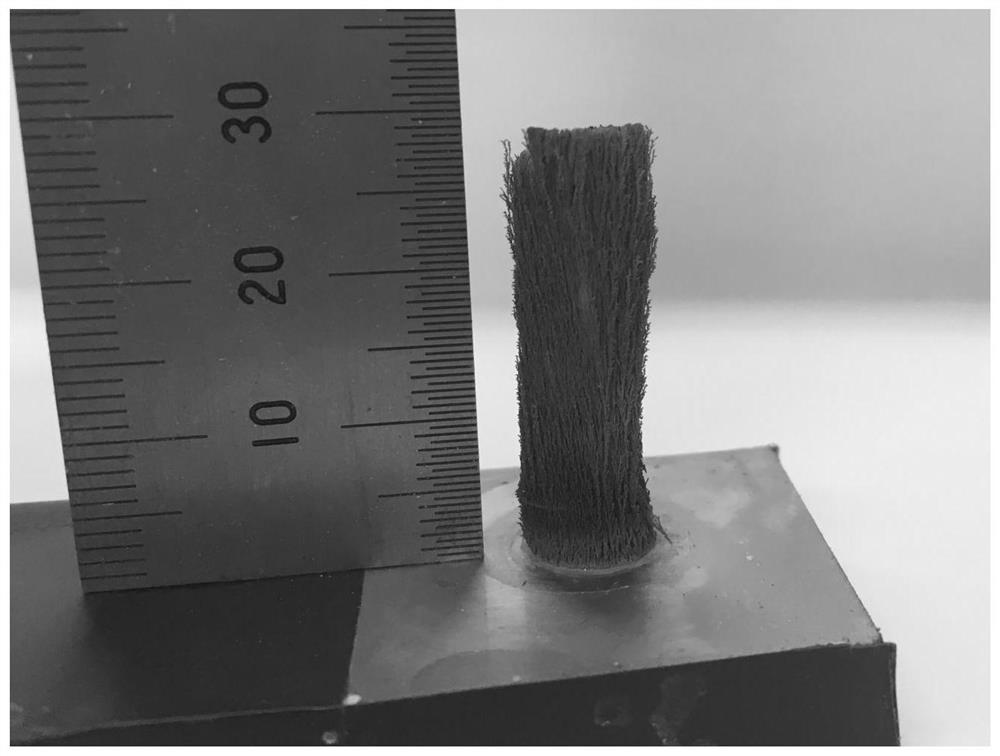

PendingCN112958902AImprove mechanical propertiesEnabling Additive ManufacturingAdditive manufacturing apparatusNon-electric welding apparatusScrew threadMechanical property

The invention relates to a filler wire static shaft shoulder friction stir welding and additive manufacturing device and method. The filler wire static shaft shoulder friction stir welding and additive manufacturing device comprises a stirring head, the periphery of the stirring head is sleeved with a static shaft shoulder, the stirring head and the static shaft shoulder are configured to synchronously move along a machining track, and the stirring head can rotate around the axis of the stirring head. A threaded groove is formed in the peripheral face of the machining end of the stirring head, the static shaft shoulder is provided with a wire feeding hole, and the wire feeding hole is used for feeding wires to the space between the part, provided with the threaded groove, of the stirring head and the hole face of a through hole formed in the static shaft shoulder. When the device is used for additive manufacturing, the interface bonding defects are avoided, and the bonding strength is guaranteed. And the mechanical property of additive manufacturing parts is greatly improved.

Owner:SHANDONG UNIV

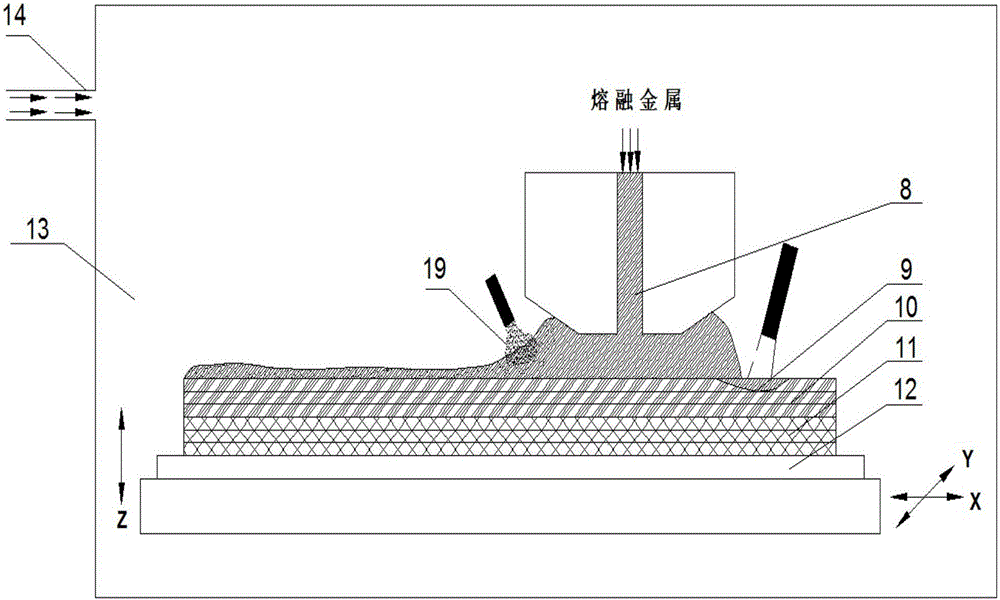

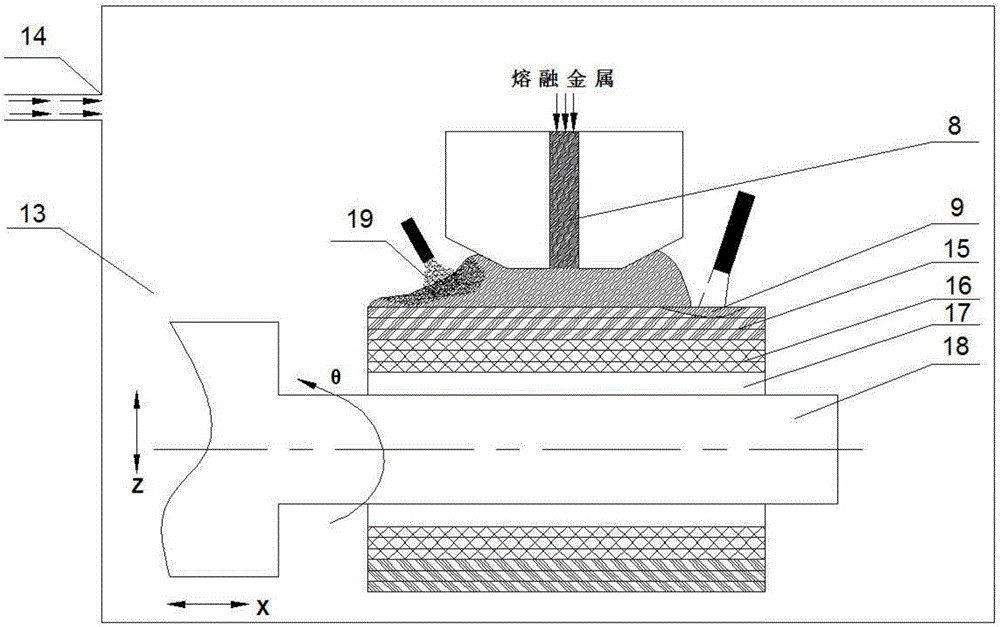

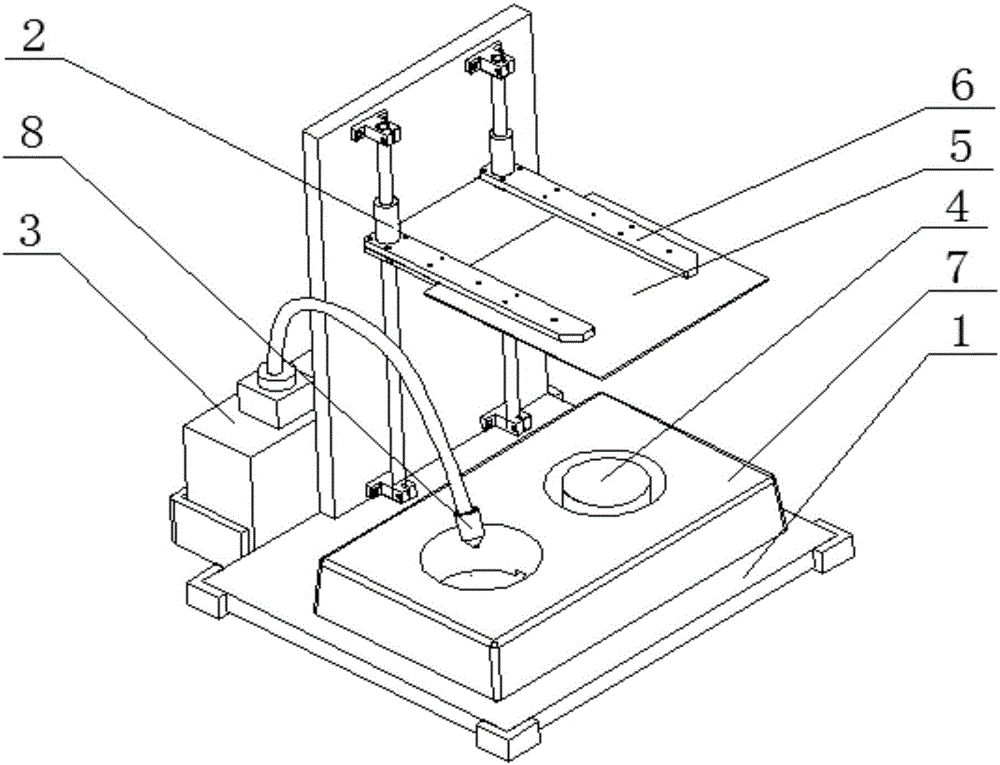

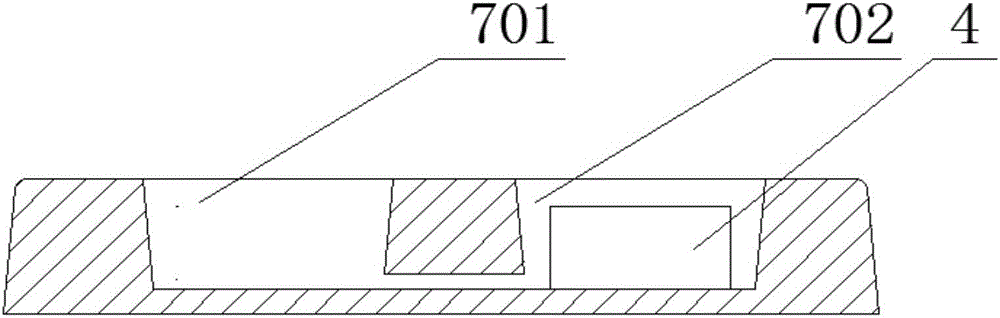

Metal material melt coating forming device and method

InactiveCN106011839AEnabling Additive ManufacturingLow costAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsAtmospheric pressure

The invention discloses a metal material melt coating forming device and a metal material melt coating forming method. The device comprises a metal smelting unit, and further comprises a pneumatic driving device, a melt coating head, a laser surface auxiliary remelting device, a three-dimensional forming platform and an atmosphere protection device, wherein the pneumatic driving device is connected with the metal smelting unit through a pipeline; the melt coating head is connected to the lower end of the metal smelting unit; the three-dimensional forming platform is arranged below the melt coating head; the laser surface auxiliary remelting device is arranged on one side of the three-dimensional forming platform; and the metal smelting unit, the melt coating head, the laser surface auxiliary remelting device and the three-dimensional forming platform are arranged on the atmosphere protection device. The melt coating forming device can be used for additive manufacturing of an efficient, high-quality and low-cost metal material part.

Owner:XI AN JIAOTONG UNIV

Jet angle controllable ultrasonic droplet jetting additive manufacturing device and method

ActiveCN106273491ASolve pollutionEasy to controlAdditive manufacturing apparatusFocus ultrasoundUltrasonic sensor

The invention relates to jet angle controllable ultrasonic droplet jetting additive manufacturing device and method, belonging to the field of additive manufacturing. The device is characterized in that a base is installed at the bottom; a jet tank is installed on the base; a focused ultrasonic transducer is installed in the jet tank; a base plate is fixed below wafer bearing platforms and above the jet tank; the wafer bearing platforms are installed on a Z-direction workbench; the Z-direction workbench is installed on the base; the jet tank is communicated with a liquid storage tank; a high-precision injection pump is connected with a feeding head; through focused ultrasound, liquid overcomes the surface tension and jets droplets from the liquid level; the power of four focused ultrasonic vibrators of the focused ultrasonic transducer is controlled by a computer and the focused ultrasonic vibrators interact and then change the jet angles of the droplets to jet the droplets to different positions on the base plate; a Z-axis motion platform cooperates with different jet angles to complete printing of different position points on the base plate. The device and the method have the effects of improving the printing precision and ensuring the physical and chemical properties and other properties of formed parts without needing print heads, thus avoiding pollution and cleaning difficulty of liquid materials.

Owner:JILIN UNIV

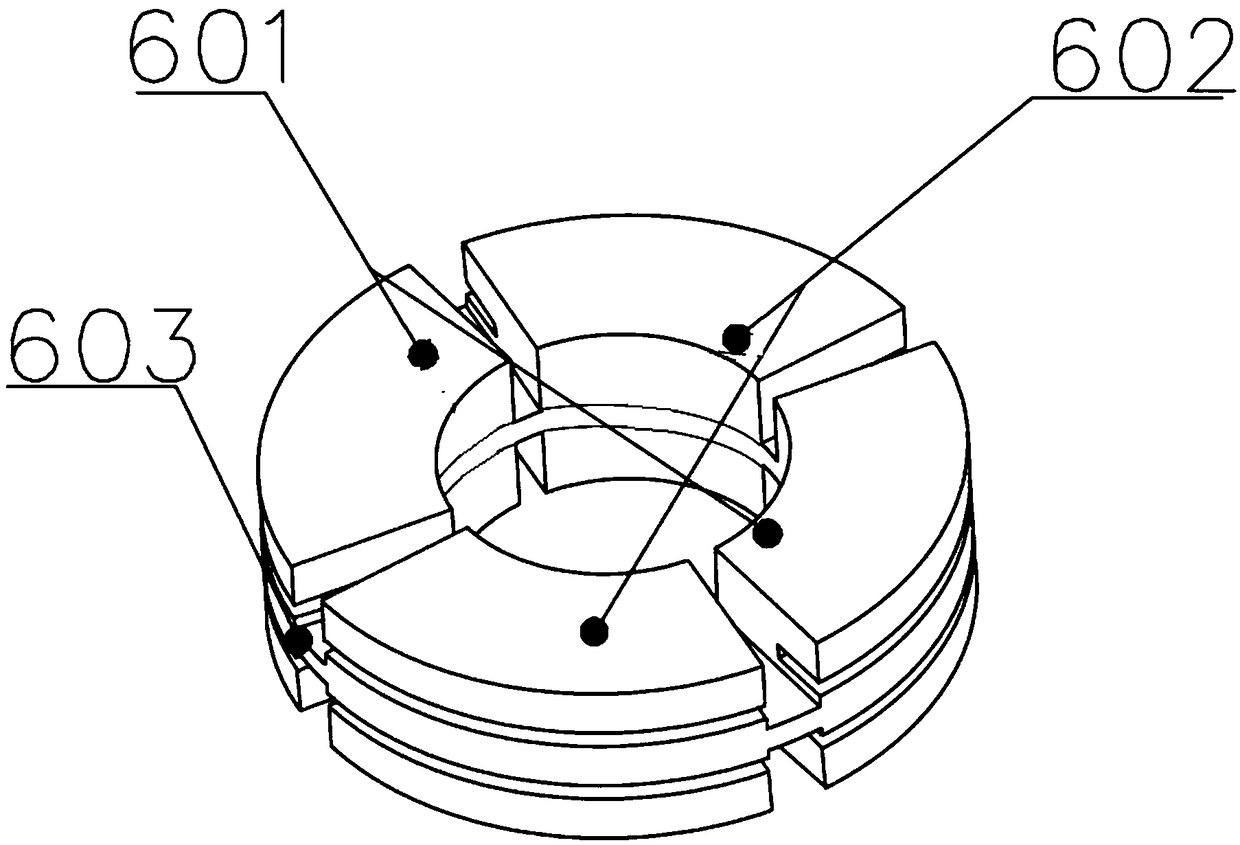

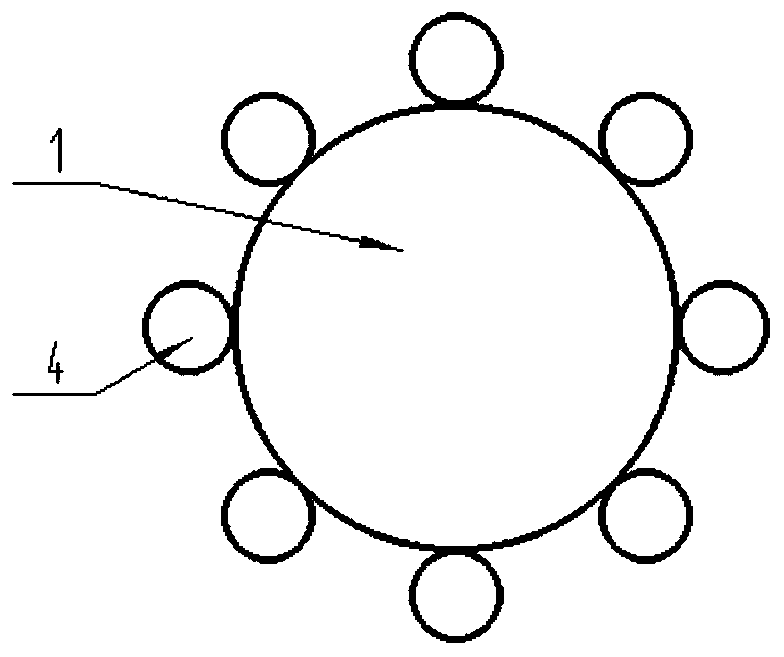

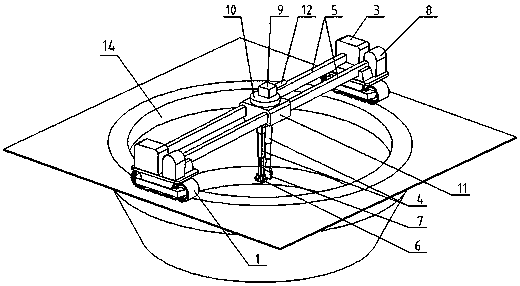

Induction heating fuse wire and laser compound based additive manufacturing device and method

ActiveCN108672936AEasy to integratePrecise control of ejection speedAdditive manufacturing apparatusLaser beam welding apparatusMulti materialMelting tank

An induction heating fuse wire and laser compound based additive manufacturing device comprises a bottom plate, wherein a transverse circular plate is arranged at the upper part of the bottom plate; acircular ring sleeves the outer circumference of the circular plate and is movably connected to the outer circumference of the circular plate through a bearing; a plurality of uniformly-distributed induction heating devices are arranged at the bottom part of the circular plate; the lower ends of the induction heating devices are pointed to a part where a central axis of the circular plate is connected to the top surface of the bottom plate; vertical rods are fixedly mounted at the upper ends of the induction heating devices, and the side parts of the vertical rods are connected to the side part of the circular ring by hinging. According to the device, an induction heating fuse wire and laser compound based additive manufacturing method is used for performing additive manufacturing; a fusewire is molten by induction heating; a laser beam is capable of promoting the stirring in a metal melting pond; the material feeding capacity per unit of time is high in the manufacturing process, and the formed metal melting pond is large, so that the additive manufacturing efficiency is high; and meanwhile, the fuse wires manufactured through a plurality of materials can be synchronously fed, so that the additive manufacturing of an alloy material is achieved; and a novel device and a novel method are provided to realize additive manufacturing.

Owner:HUNAN UNIV OF SCI & TECH

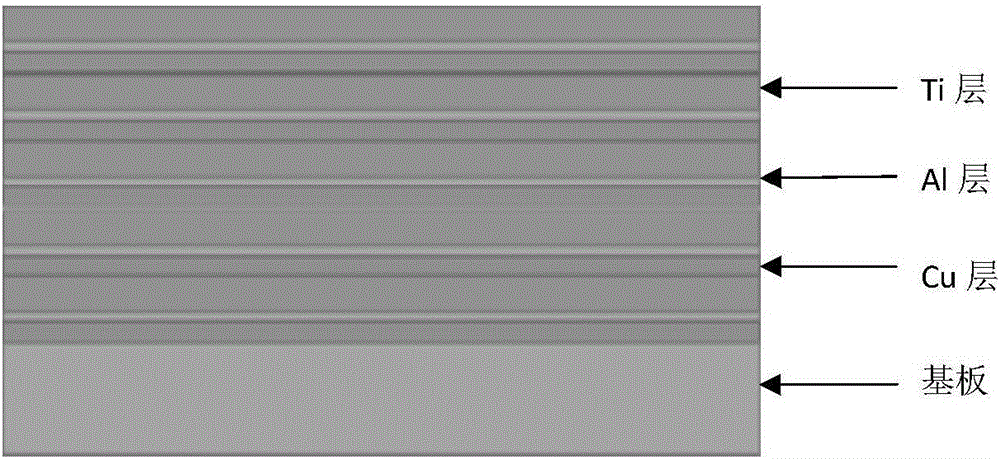

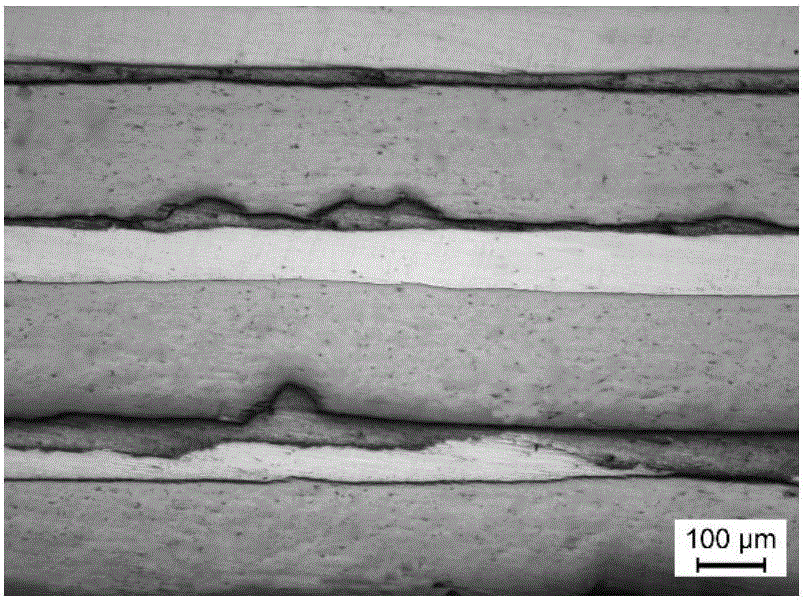

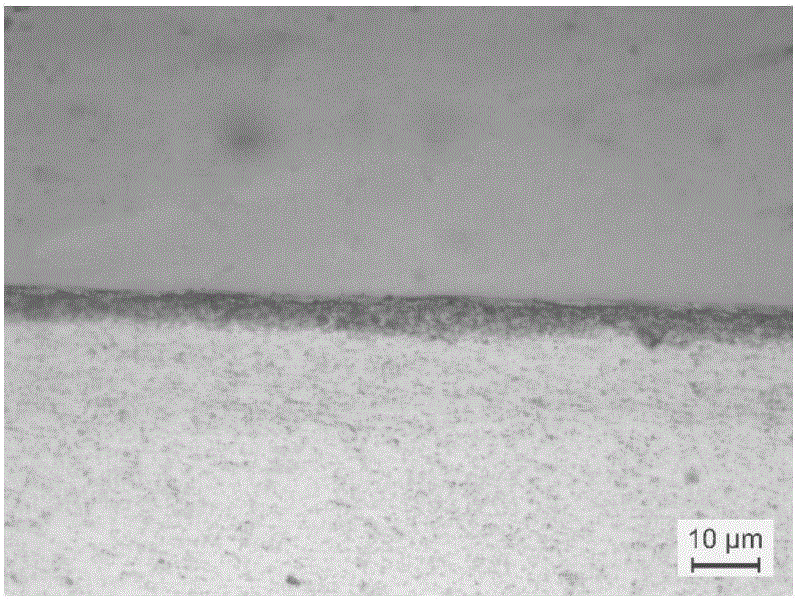

Rapid preparation method of titanium copper lamellar electrode composite material

ActiveCN106476395ALow costEasy to purchase materialsLamination ancillary operationsLaminationMetal foilCopper foil

The present invention provides a rapid preparation method of a titanium copper lamellar electrode composite material, which comprises the steps that: (1) copper foils, aluminum foils and titanium foils are superposed to form unit bodies, and one unit body is put on an ultrasonic quick-consolidating moulding work table; (2) an ultrasonic quick-consolidating moulding work table substrate is pre-heated to a temperature between 50 DEG C and 200 DEG C, and consolidating preparation is started and a metal foil material is formed; (3) the next unit body is put on the metal foil material, and the consolidating preparation is carried out by using the same parameters with the step (2) and the metal foil material is formed; and (4) the step (3) is repeated and after a predetermined thickness is reached, corner waste materials are milled and removed and the titanium copper lamellar electrode composite material is obtained. The titanium copper lamellar electrode composite material is prepared in the low temperature and is energy saving and environment-friendly. The cost of the raw materials is low. The titanium copper lamellar electrode composite material is prepared through solid-state physical metallurgical bonding. Diffusion layers are thin and by-products are few. The equipment cost is low because no vacuum devices or gas protection devices are used. The production period is short and the production efficiency is substantially improved. The precision and the yield are high.

Owner:HARBIN ENG UNIV

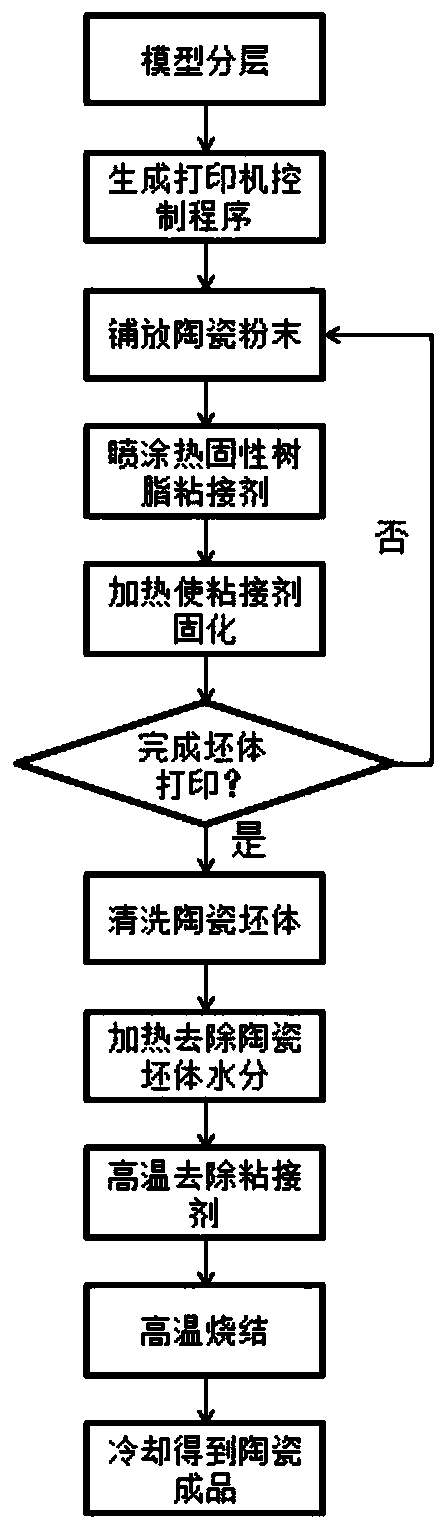

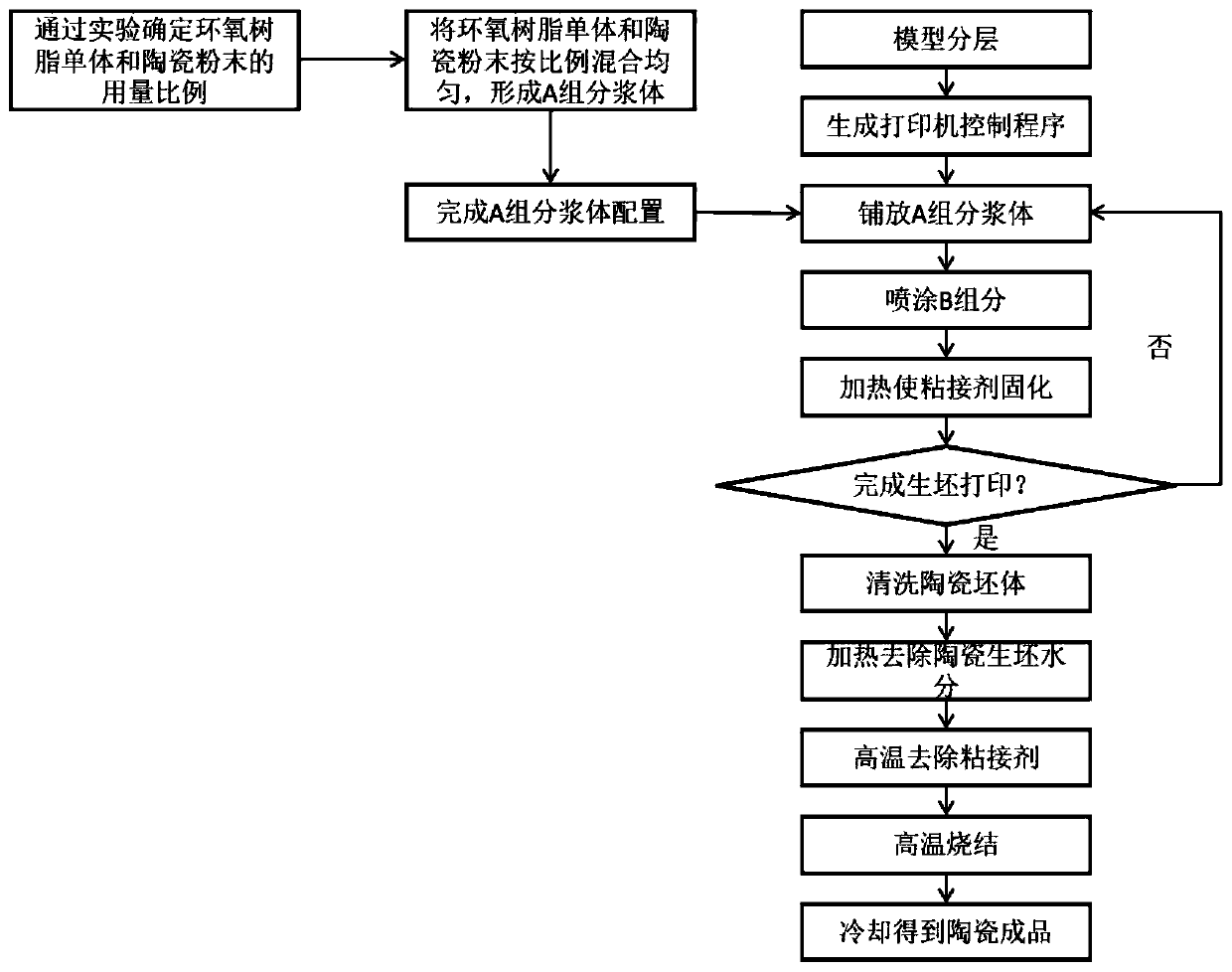

Ceramic material additive manufacturing method

PendingCN108947494ASmall molecular weightEffective bondingAdditive manufacturing apparatusEpoxyMetallurgy

The invention relates to a ceramic material additive manufacturing method. The method includes performing layering on a ceramic part model to be printed, and determining areas where each layer needs to be bonded; laying a layer of ceramic powder on a work tray; spraying a thermosetting resin adhesive in the area where the layer needs to be bonded by using a nozzle, the thermosetting resin adhesiveincluding an epoxy resin monomer and a hardener; heating the thermosetting resin adhesive on the layer of the ceramic powder by using a heating device to be in thermal curing cross-linking polymerization so that the layer of the ceramic powder can be bonded; performing layer by layer printing until a complete ceramic body can be formed; cleaning the ceramic body; and putting the cleaned ceramic body into a sintering furnace to perform calcining so that a compact ceramic part finished product can be formed. Equipment which can realize the manufacturing method is also provided.

Owner:TIANJIN UNIV

Additive manufacturing device and method for micro-system three-dimensional structure

PendingCN109049674AEnabling Additive ManufacturingAchieve extrusionAdditive manufacturing apparatus3D object support structuresElectrode arrayHigh frequency

The invention relates to an additive manufacturing device and method for a micro-system three-dimensional structure, and belongs to the field of additive manufacturing. A high-viscosity microdroplet extrusion nozzle is fixed to a guide upright column through a supporting frame, an X-axis moving device is fixed to a base, a Y-axis moving device is fixed to the X-axis moving device, a deflection electric field electrode is installed on the guide upright column through a Z-axis moving device, a dielectric layer adheres to an electrode array, the electrode array is fixed to the Y-axis moving device, and a polarization module is fixed to the base and above the dielectric layer. According to the device and method, a layered manufacturing technology is utilized, the technical characteristic thatliquid material droplets solidify and are formed under a pulsed electric field, and the precise control over additive manufacturing is realized by using a pulsed electric field separation technology.Accurate jetting of the micron-scale droplets is achieved by adjusting voltage parameters so as to achieve high-viscosity liquid high-frequency jetting.

Owner:JILIN UNIV

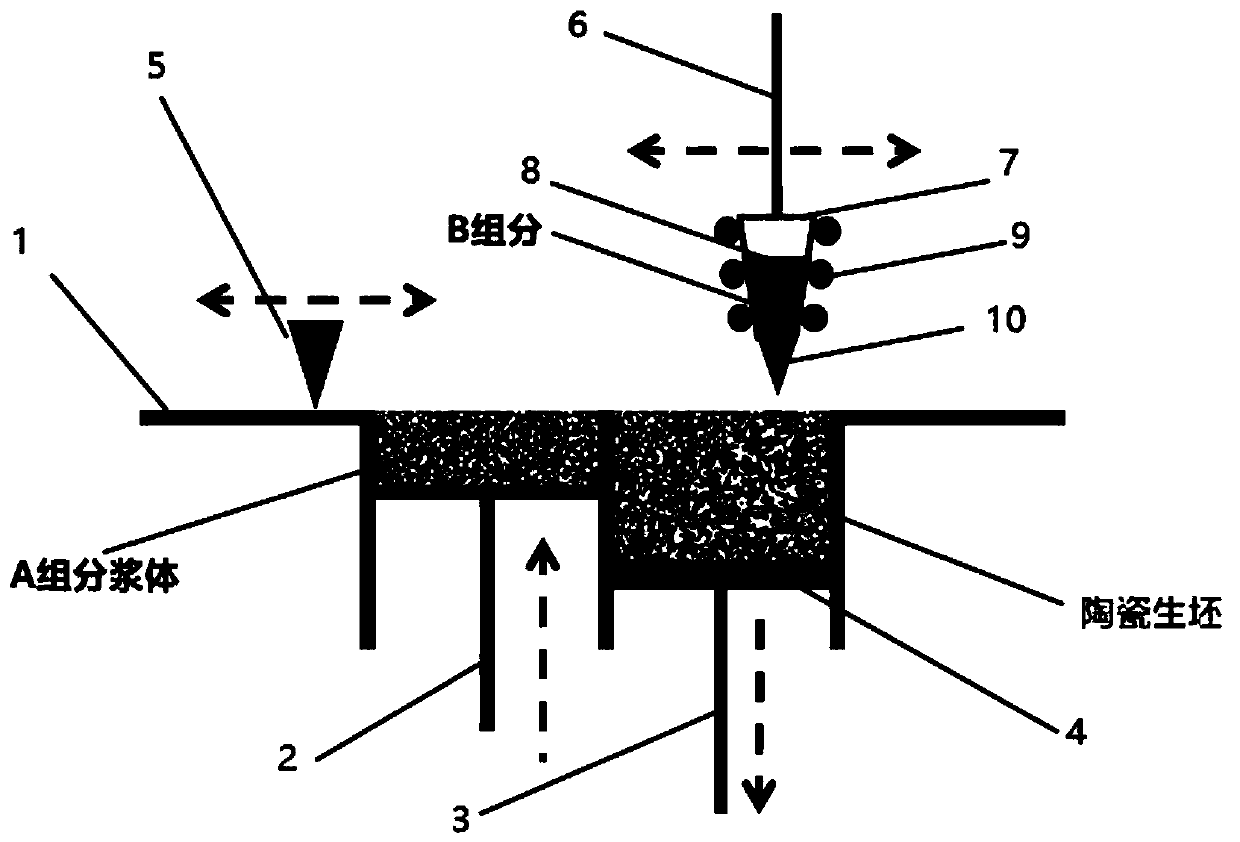

Thermosetting bonding based ceramic additive production method and equipment

PendingCN110240485ASmall molecular weightReduce stickingAdditive manufacturing apparatusCeramic shaping apparatusEpoxyMetallurgy

The invention relates to a thermosetting bonding based ceramic additive production method. The method comprises the steps: layering a mold for ceramic parts required to be printed, determining an area required to be bonded of each layer, and creating a printer control program; uniformly mixing an epoxy resin monomer with ceramic powder to form slurry with relatively good fluidity as component A slurry, wherein for a consumption ratio of the epoxy resin monomer and the ceramic powder, the proportion of the ceramic powder in the component A slurry should be as high as possible on the premise of meeting the requirements on fluidity so as to achieve that a final ceramic finished product is high in compactness and low in shrinking percentage; laying a layer of component A slurry on a working tray; spraying a hardener of epoxy resin as a component B to the area required to be bonded of the corresponding layer with a sprayer according to the program; heating the ceramic powder of the corresponding layer with a heating device; carrying out printing layer by layer until a complete ceramic green body is formed; carrying out washing clean; and carrying out high-temperature calcination. The invention simultaneously provides equipment achieving the method, i.e., a ceramic powder bonding printer.

Owner:TIANJIN UNIV

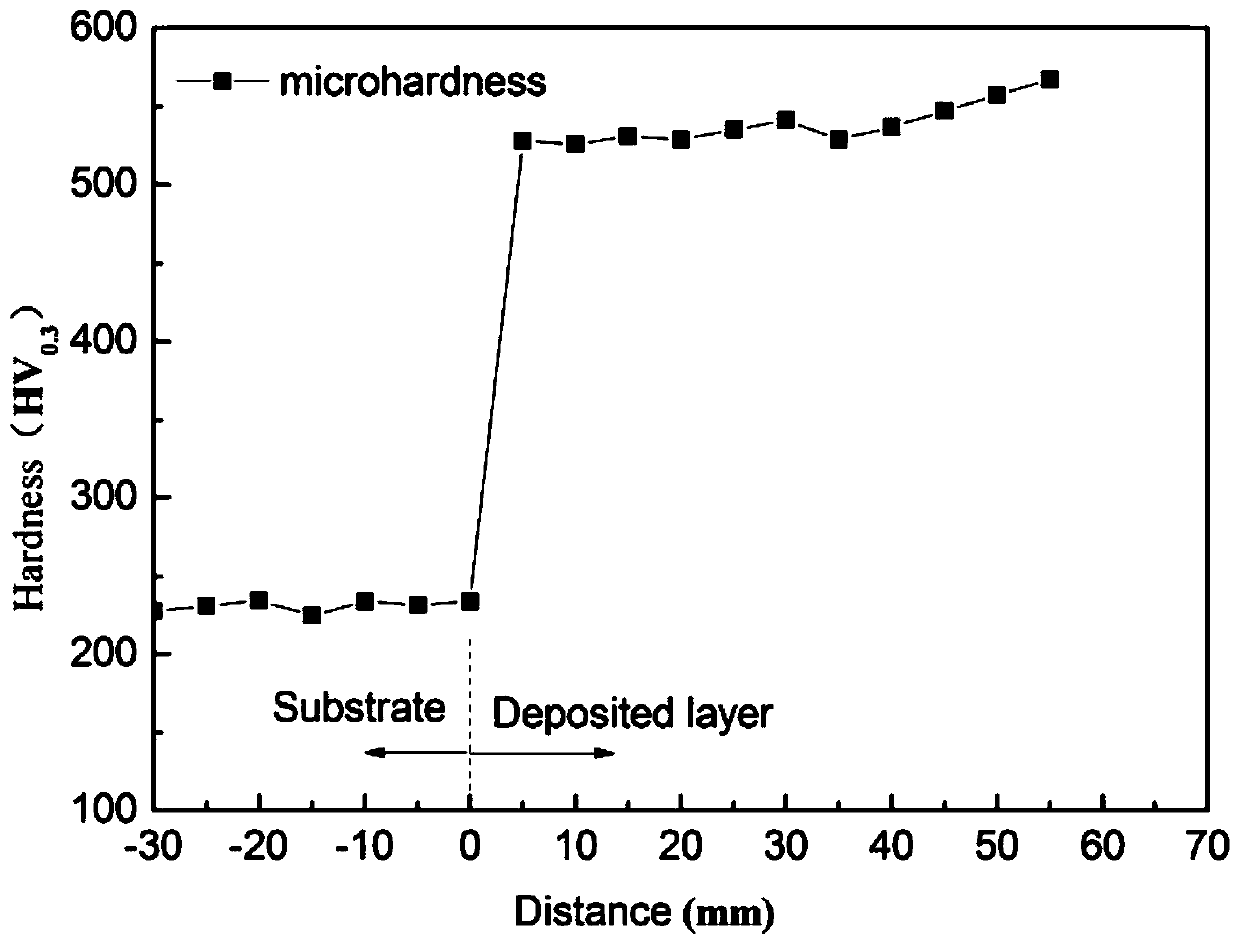

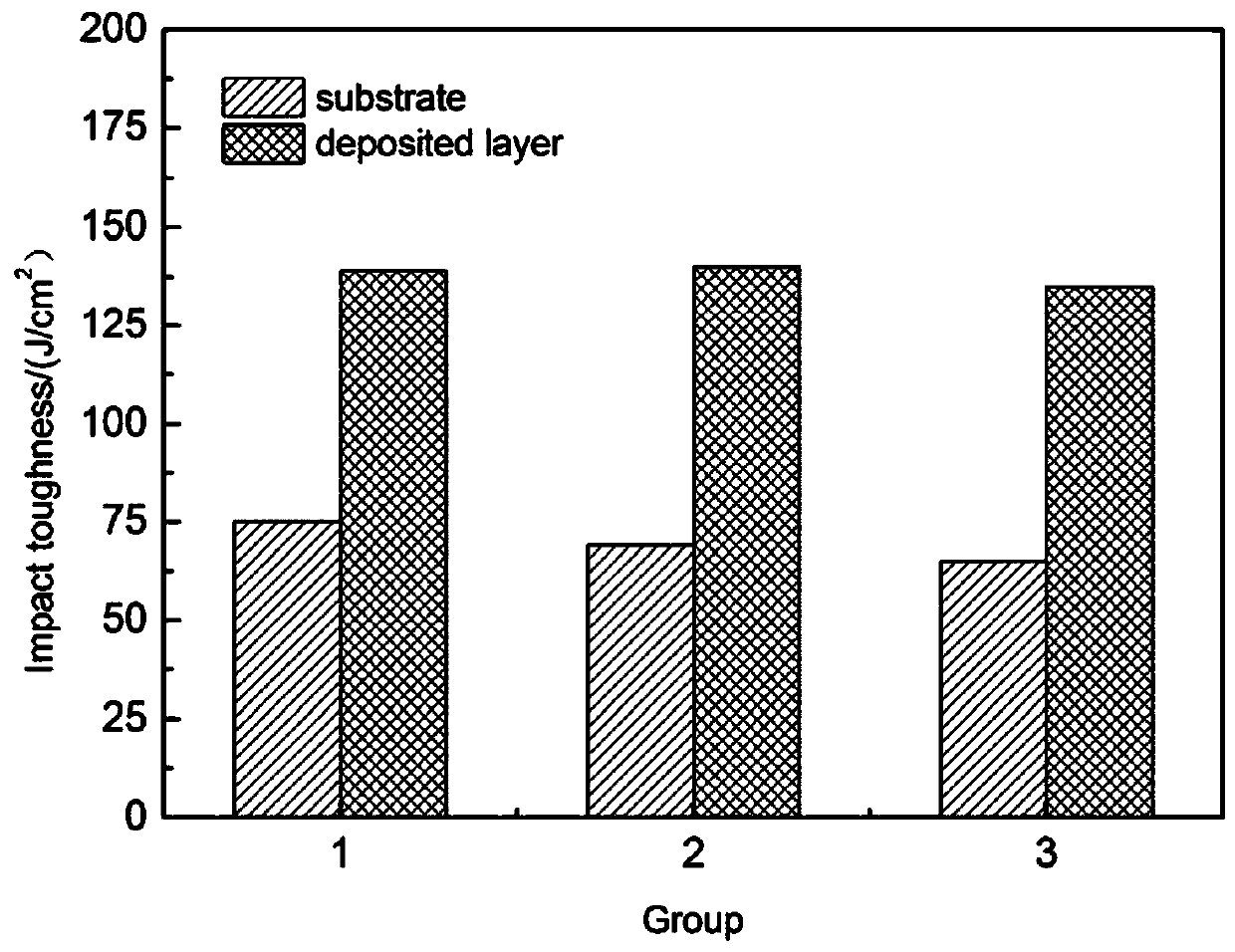

Method for improving wear resistance and impact resistance of laser additive manufacturing alloy steel component

ActiveCN110788323AGuaranteed coefficient of thermal expansionInhibitionAdditive manufacturing apparatusTransportation and packagingDeposition processLaser additive manufacturing

The invention belongs to the field of metal laser additive manufacturing, and particularly relates to a method for improving wear resistance and impact resistance of a laser additive manufacturing alloy steel component. The method is suitable for obviously improving the wear resistance and impact resistance of various alloy steel component laser additive materials. First, one, two or more powdersof Mo, TiC, B, Si, V, Cr, Ni and the like which have the same particle size as an alloy steel powder are adopted, are uniformly mixed for a certain proportion in the alloy steel powder through a ballmill, a laser deposition substrate is preheated, then laser deposition is performed in a vacuum glove box by using a synchronous powder feeding method, a laser deposition active area is covered with argon with a certain flow rate in the deposition process, and the substrate is heated and maintained by using induction, so that the compact deposited layer and timely controllable wear resistance andimpact resistance laser additive manufacturing can be realized. According to the method, an efficient and reliable novel technological method for improving the wear resistance and impact resistance ofthe laser additive manufacturing of the alloy steel component is provided, and the method has important significance for manufacturing the alloy steel component and the laser surface modification ofthe alloy steel component.

Owner:浙江翰德圣智能再制造技术有限公司

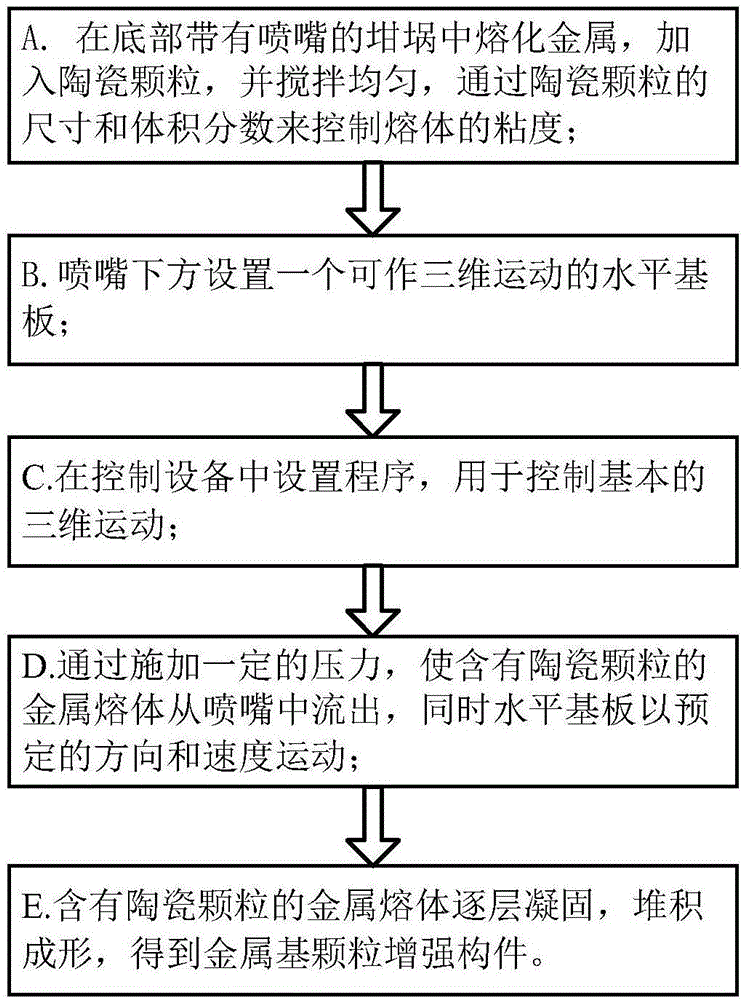

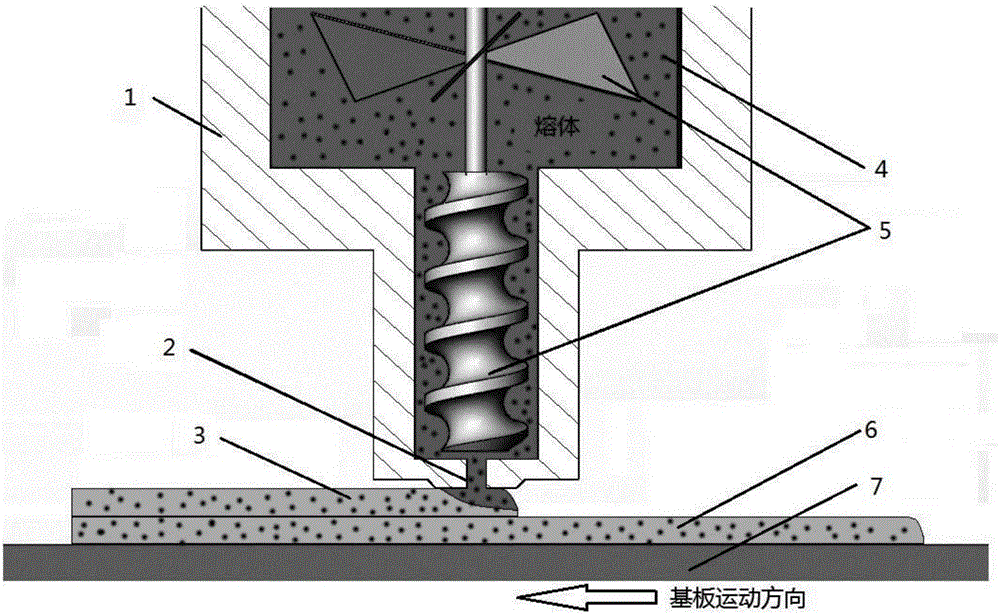

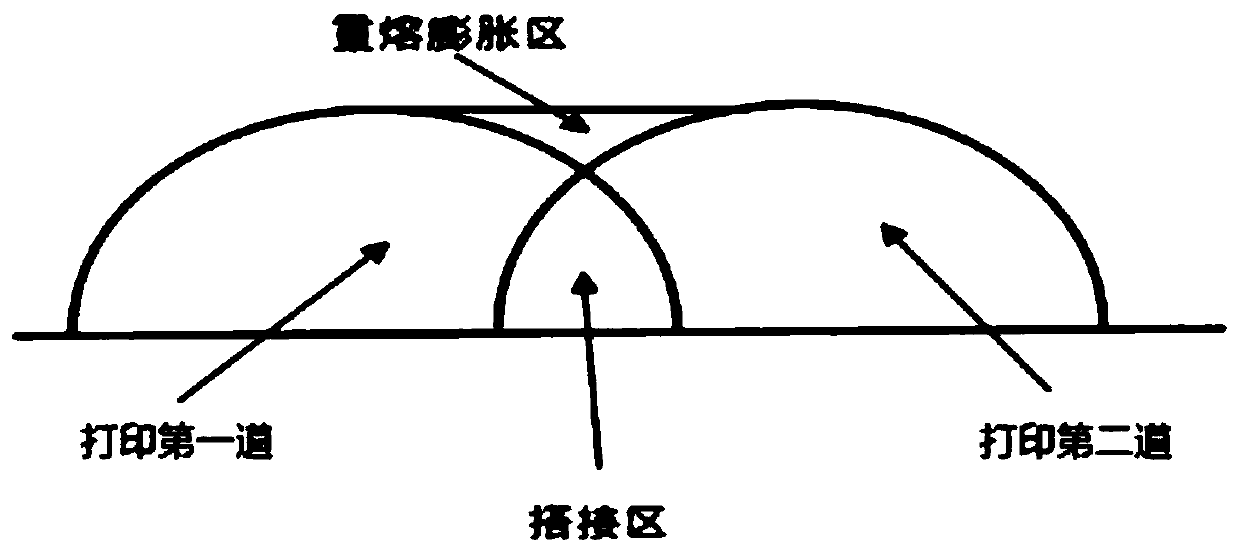

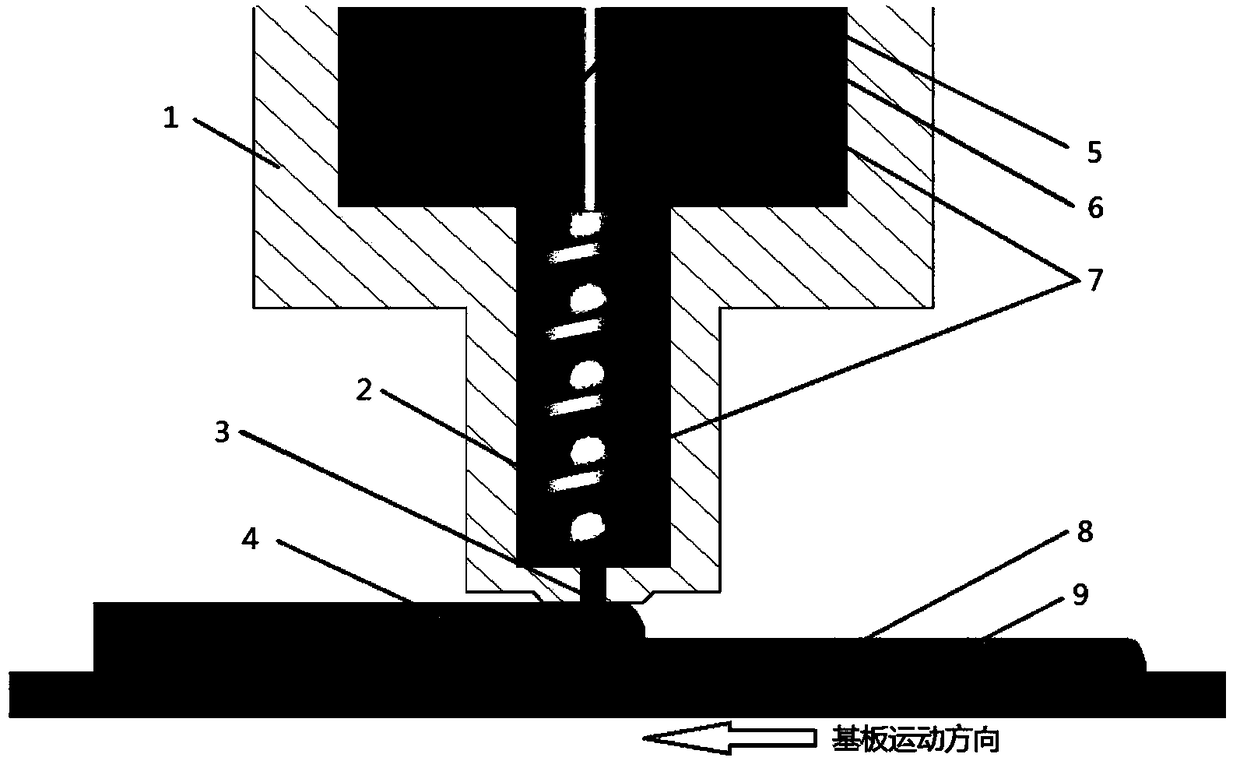

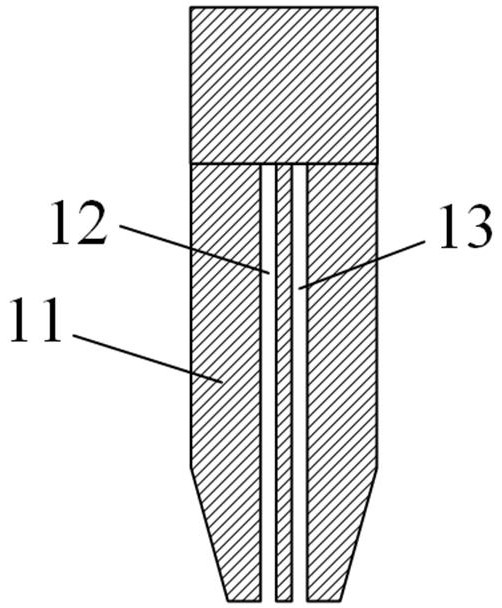

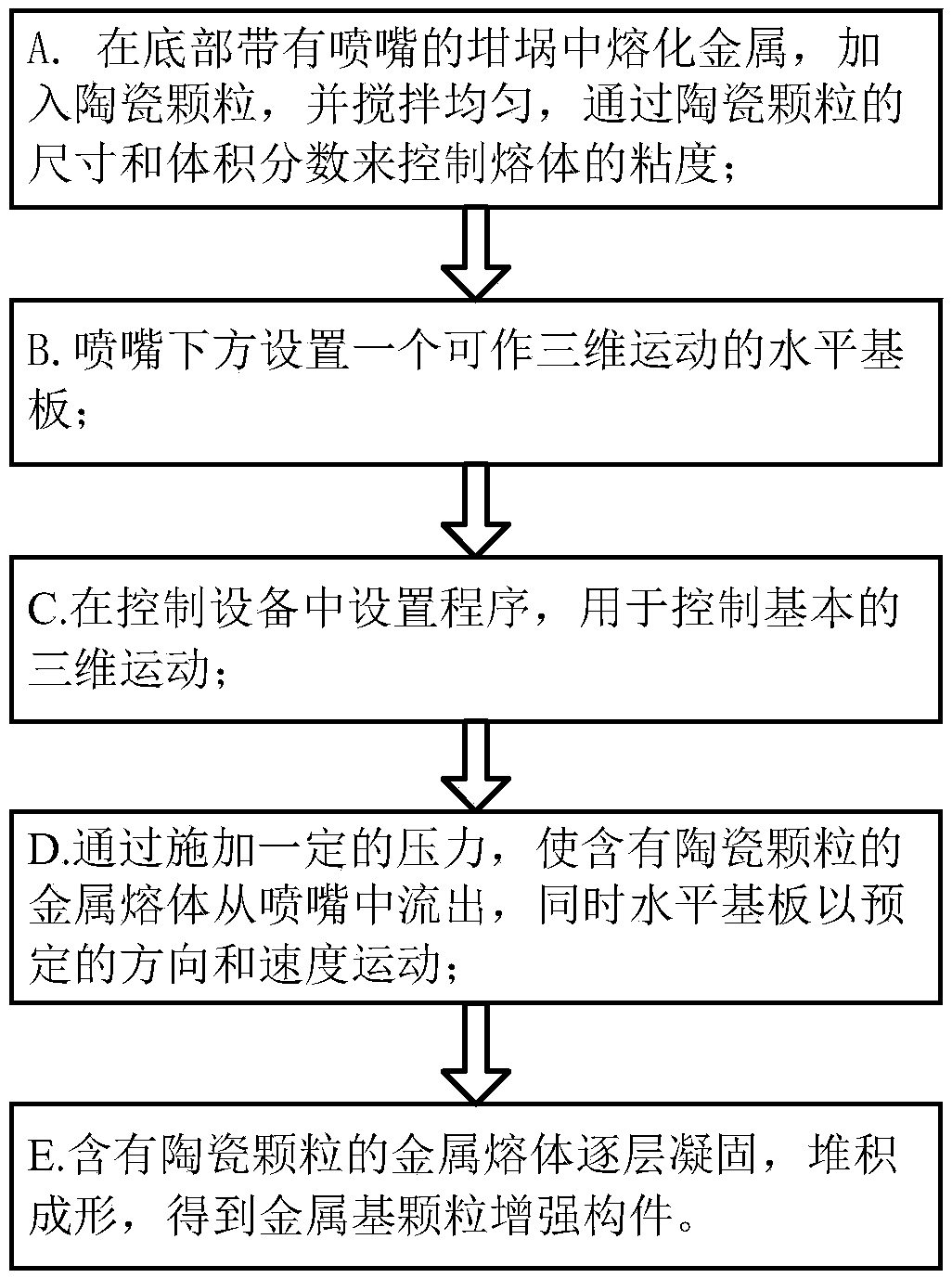

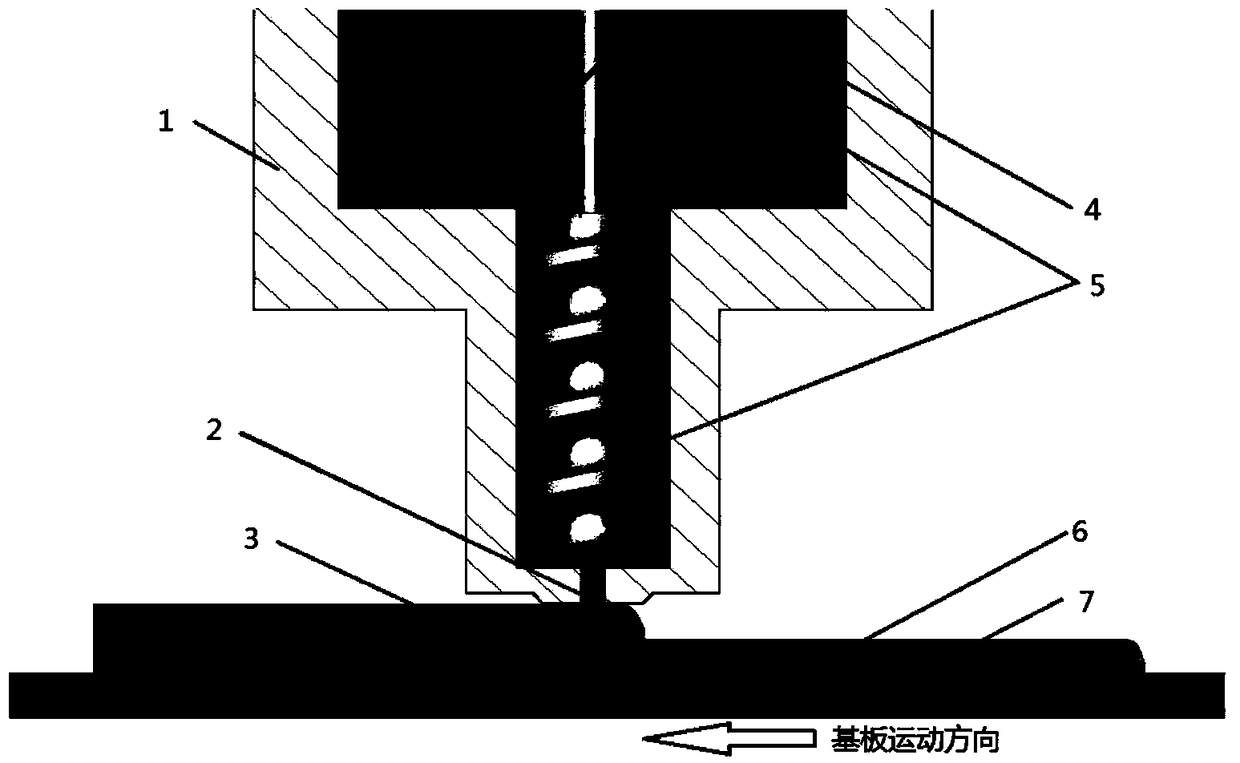

Additive manufacturing method for metal-based particle reinforced member

ActiveCN106583727ASolve associativitySolve problems that are not conducive to formingAdditive manufacturing apparatusChemical reactionCrucible

The invention discloses an additive manufacturing method for a metal-based particle reinforced member. The method includes the steps that metal is melted in a crucible with a nozzle at the bottom, and then ceramic particles are added; a horizontal base plate which can make three-dimensional movement is arranged, and a control program of the horizontal base plate is set; and certain pressure is applied to enable metal melt containing the ceramic particles to flow out from the nozzle, the melt is solidified layer by layer, and the layers of melt are stacked to form a product. According to the method, the ceramic particles which do not chemically react with the metal melt are added, the viscosity of the melt is controlled through the size and volume fraction of the ceramic particles, the purpose of controlling flowing and forming is achieved, and the problems that in the prior art, interlayer bonding is poor, and forming is affected are solved; and the additive manufacturing method is a novel method for preparing the metal-based particle reinforced member.

Owner:广东空天科技研究院

Material additive manufacturing method of square hole pipeline aluminum alloy part

PendingCN110170654AUniform and dense surfaceAvoid surface defectsAdditive manufacturing apparatusIncreasing energy efficiencyAluminium alloyTime integral

The invention discloses a material additive manufacturing method of a square hole pipeline aluminum alloy part. The material additive manufacturing method of the square hole pipeline aluminum alloy part includes: first, performing modeling and hierarchy slicing for the square hole pipeline aluminum alloy part, then feeding raw material into a 3D (three dimensional) printing device for melting, printing and shaping, and finally obtaining the square hole pipeline aluminum alloy part. The material additive manufacturing method of the square hole pipeline aluminum alloy part converts horizontal plane printing to oblique plane printing, achieves material additive manufacturing of the square hole pipeline aluminum alloy part on the premise of meeting accuracy of the inner wall of a square hole pipeline, obtains a uniform and compact surface for the square hole pipeline aluminum alloy part manufactured through simple scanning and chessboard scanning modes, avoids surface defects in machining,simplifies the manufacturing process, shortens a manufacturing period, achieves one-time integral shaping for the square hole pipeline aluminum alloy part, and greatly improves production efficiency.

Owner:SHAANXI SCI TECH UNIV

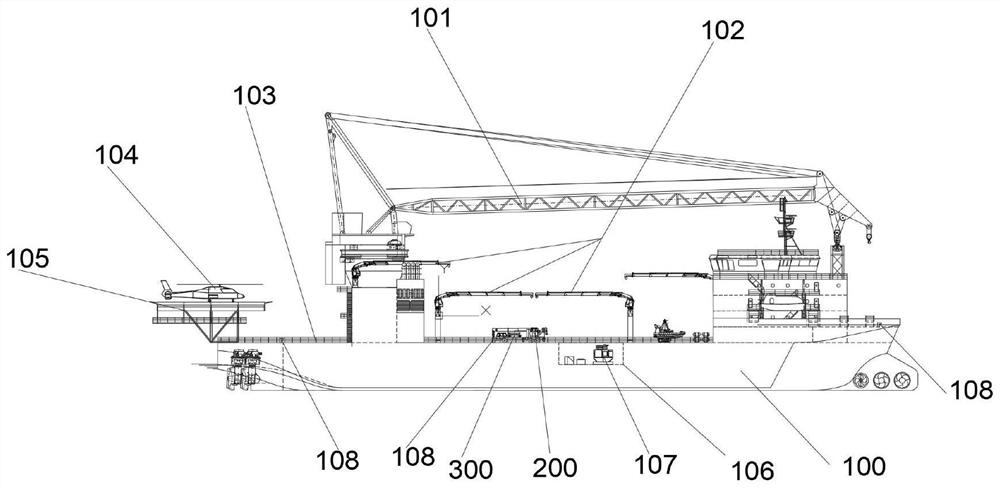

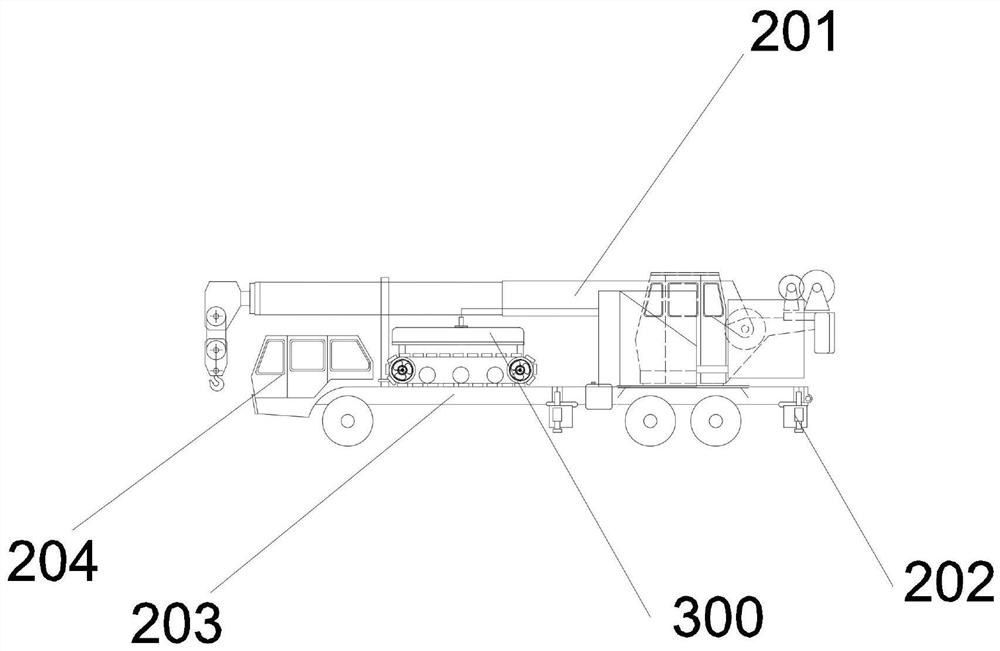

Marine equipment with self-repairing and underwater facility repairing functions and method

InactiveCN111846145AAuxiliary detectionAuxiliary restorationWaterborne vesselsEndless track vehiclesMarine equipmentMechanical engineering

The invention discloses marine equipment with self-repairing and underwater facility repairing functions and method. The marine equipment comprises a marine equipment main body, a self-repairing vehicle and a magnetic adsorption type self-propulsion repairing robot, wherein the self-repairing vehicle is parked on a deck of the marine equipment main body, and the magnetic adsorption type self-propulsion repairing robot is parked on the self-repairing vehicle; the self-repairing vehicle can carry the magnetic adsorption type self-propulsion repairing robot to a target site and then release the magnetic adsorption type self-propulsion repairing robot; the magnetic adsorption type self-propulsion repair robot can move to a to-be-repaired area through the navigation capacity of the robot and recognize and repair damage to the to-be-repaired area. Therefore, self damage detection and repair can be achieved, and meanwhile damage detection and repair of other marine equipment or underwater facilities can be assisted. And the problem of damage expansion caused by difficult homeward voyage maintenance, high maintenance cost, untimely maintenance and the like of ocean equipment is solved. Theservice life of ocean engineering equipment is prolonged, and the operation efficiency is improved.

Owner:SOUTHEAST UNIV

Integrated forming additive manufacturing device and method of multi-material component

PendingCN110548874AIntegrated forming realizationEnabling Additive ManufacturingAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialSuction force

The invention discloses an integrated forming additive manufacturing device and method of a multi-material component. The forming device comprises a powder feed system and a forming cylinder. The powder feed system comprises a powder flow powder feeder, powder feed pipelines and a multi-way powder mixing nozzle. The multiple powder feed pipelines are arranged, and the powder feed pipelines serve as pipelines used for allowing the powder flow powder feeder to convey powder to the multi-way powder mixing nozzle. The device further comprises a powder clearing system. The powder clearing system comprises a dust collector, a powder clearing pipeline and a powder clearing nozzle. The powder clearing pipeline serves as a connecting pipeline between the dust collector and the powder clearing nozzle, so that when the dust collector works, suction force for sucking powder on a powder feed cylinder and the forming cylinder is generated at the inlet end of the powder clearing nozzle. The forming device further comprises a drive mechanism used for changing positions of the multi-way powder mixing nozzle and the powder clearing nozzle in space. Under the action of the drive mechanism, the work coverage area of the multi-way powder mixing nozzle and the powder clearing nozzle can cover the whole work face of the forming cylinder. The method is based on the device. By means of the device and method provided by the scheme, integrated forming additive manufacturing of the multi-material component can be achieved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

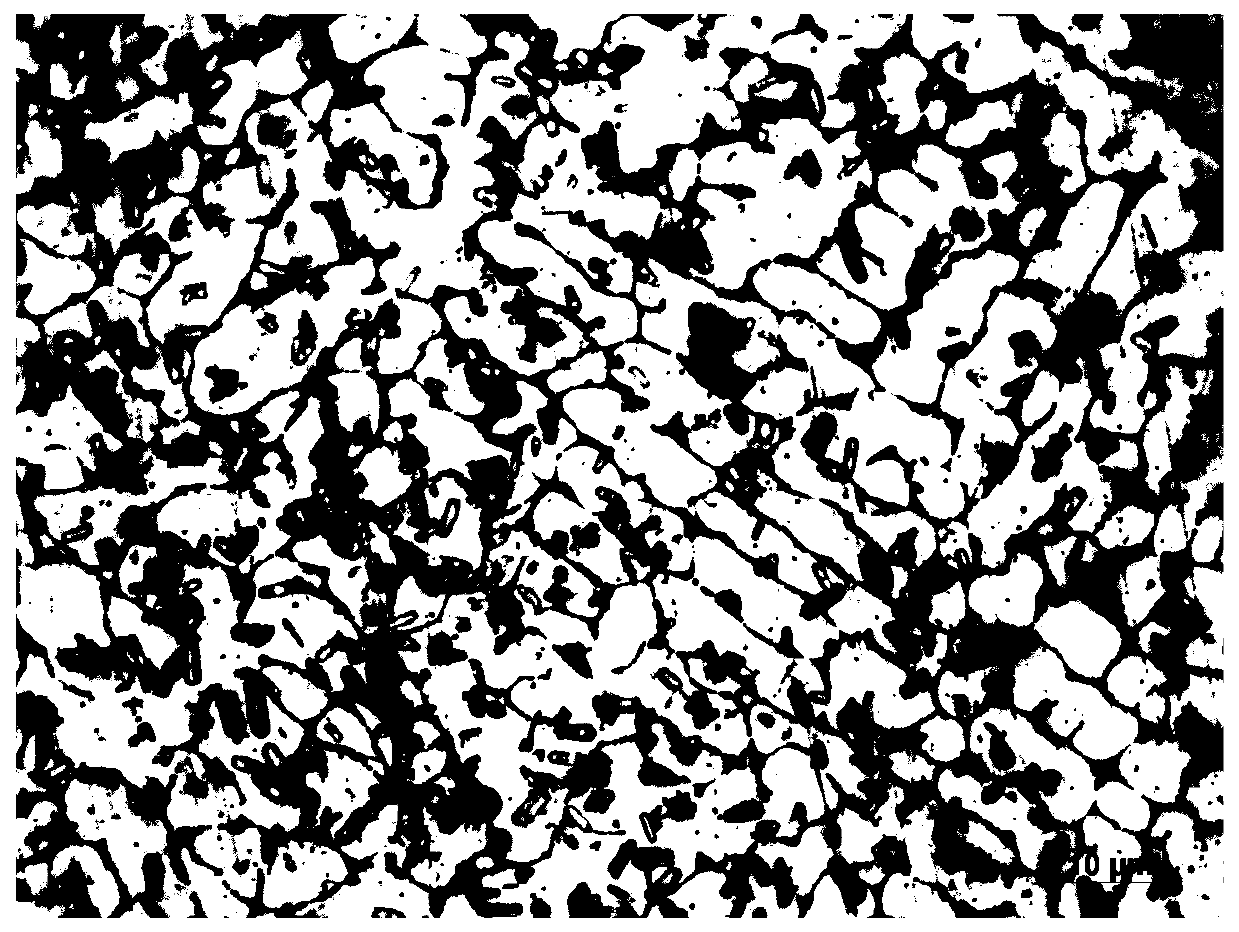

Additive manufacturing method of cast iron roll

ActiveCN110052610AEnabling Additive ManufacturingAchieve recyclingAdditive manufacturing apparatusArc welding apparatusWear resistantCrystal structure

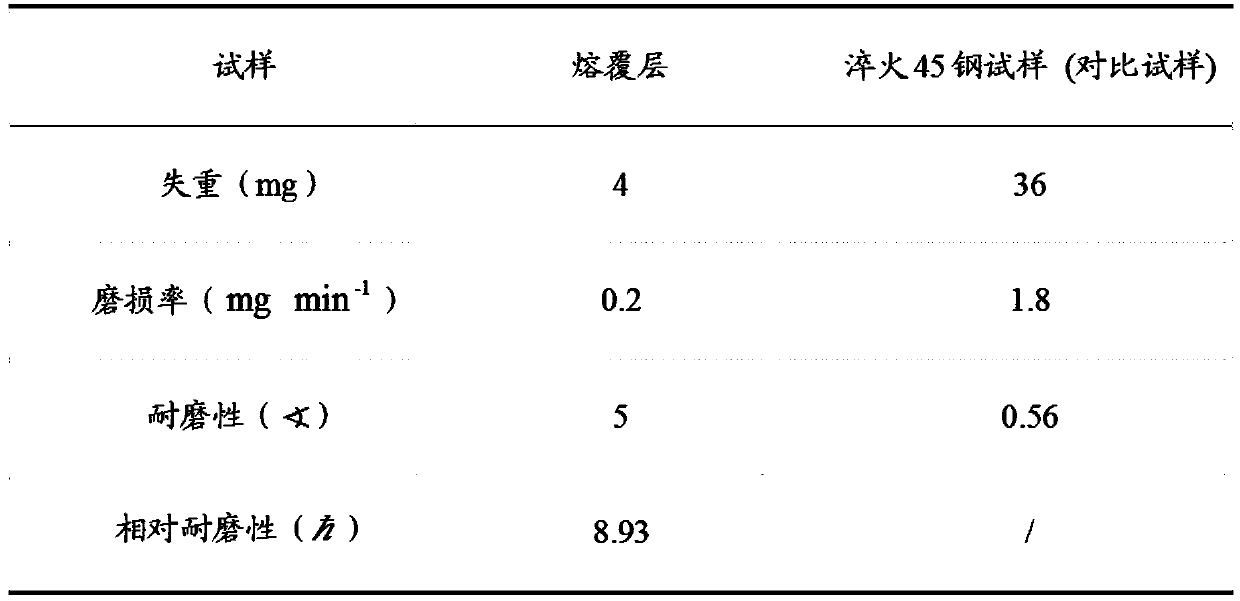

The invention belongs to the technical field of metal surface processing, and particularly relates to an additive manufacturing method of a cast iron roll. The CMT technology and laser cladding combined composite additive manufacturing process is adopted, the heat input in the welding process is small, the manufactured cast iron roll comprises a uniform surface cladding layer, the surface claddinglayer has a sequentially-arranged and compact crystal structure, and therefore the cast iron roll subjected to material addition can have better corrosion-resistant and high-temperature-resistant performance, and the service life of the cast iron roll is remarkably prolonged. According to the embodiment, it can be known that the wear-resistant performance of the cast iron roll manufactured through the method is eight times higher than the wear-resistant performance of a quenched 45 steel sample.

Owner:YANSHAN UNIV

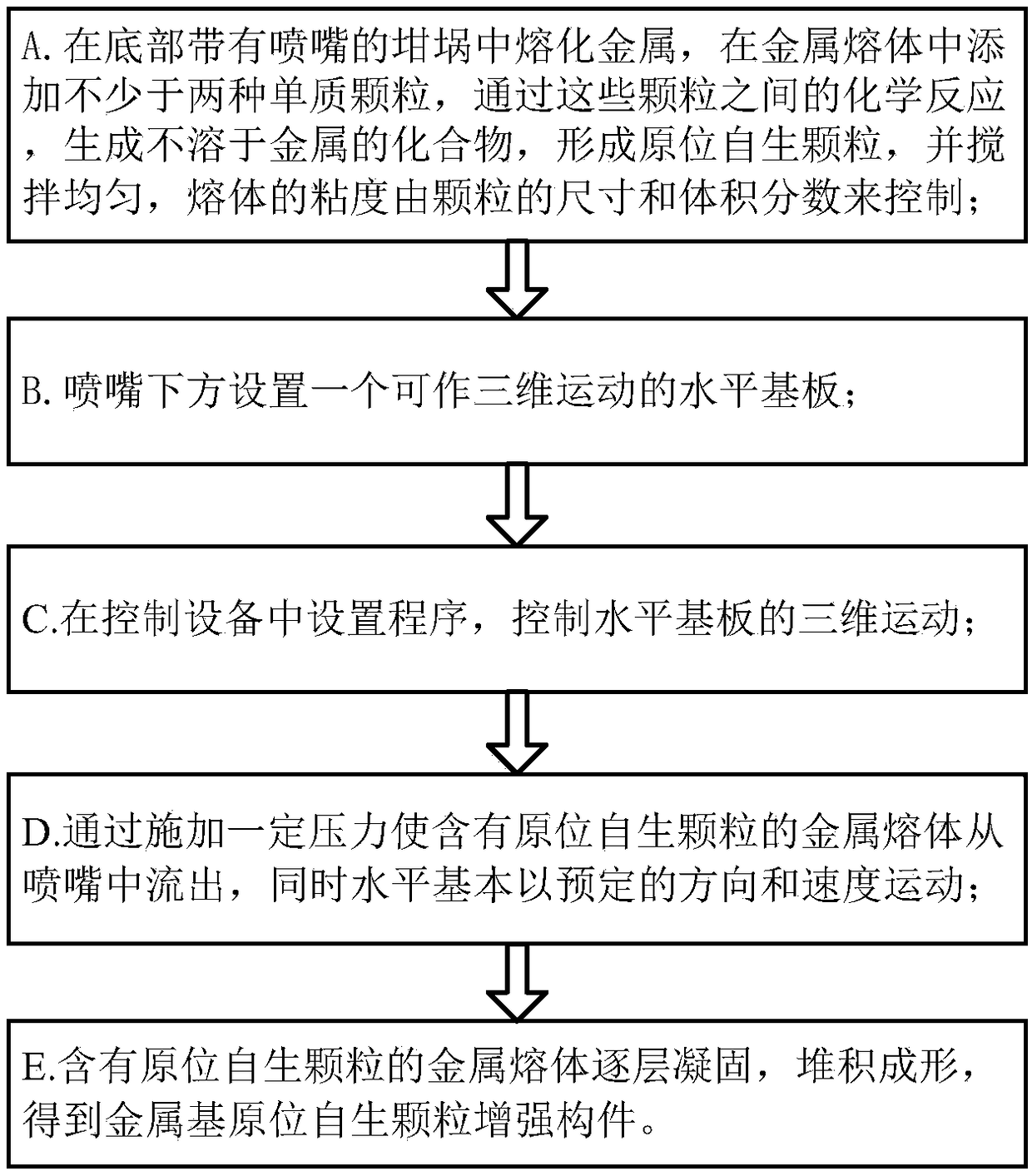

Additive manufacturing method for metal-based in-situ autogeny particle reinforced component

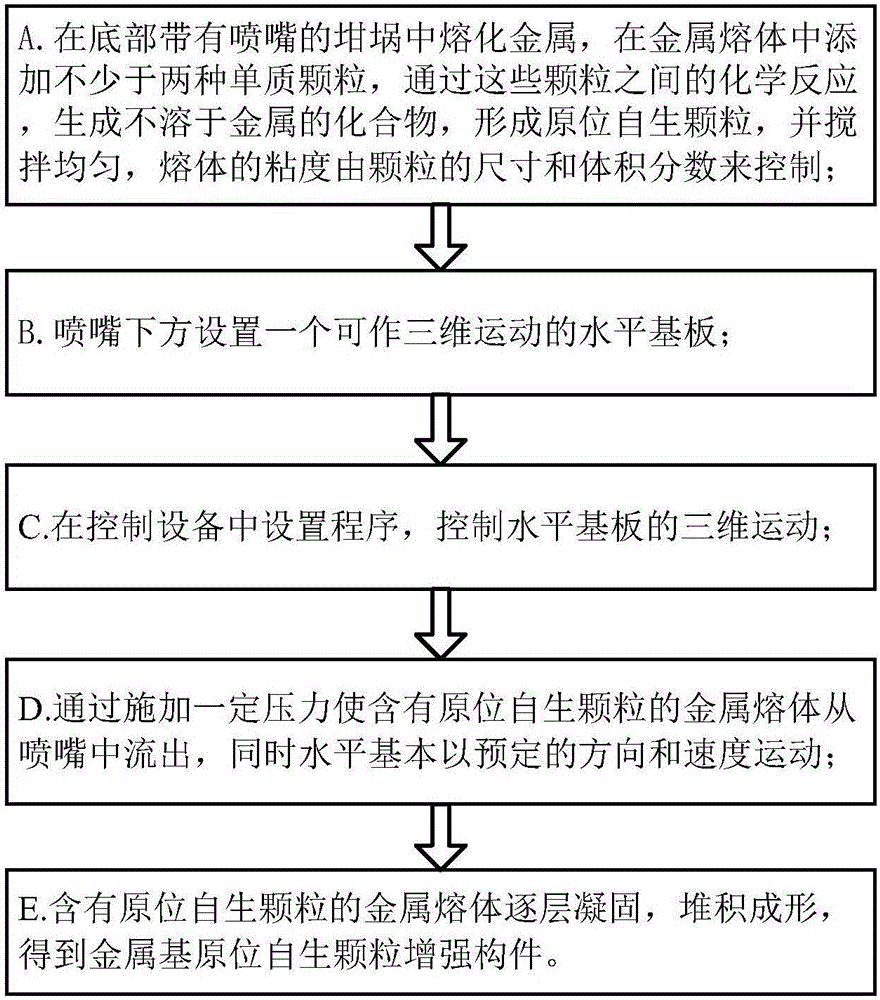

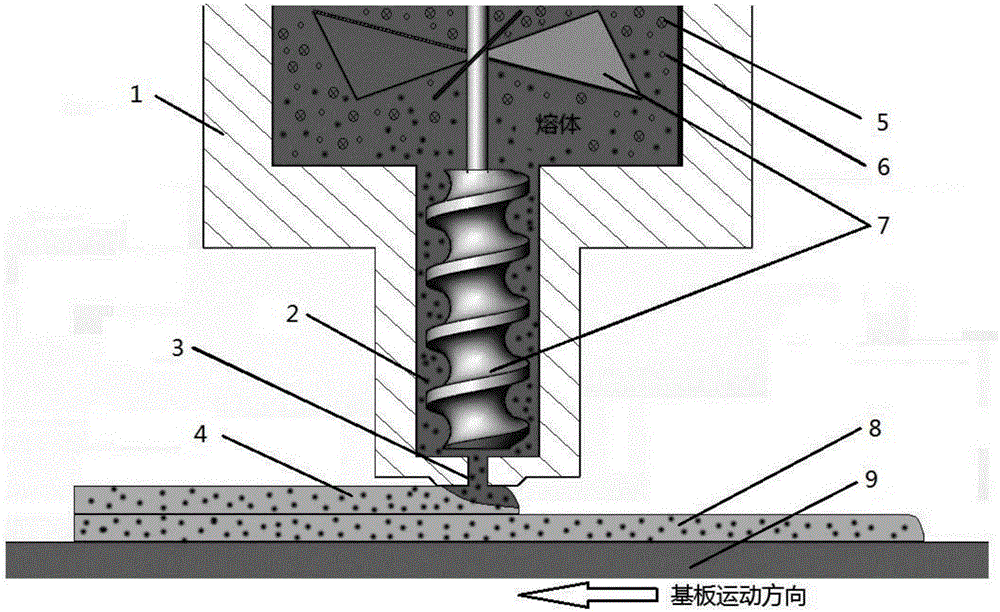

ActiveCN106735223AEnabling Additive ManufacturingAdditive manufacturing apparatusChemical reactionCrucible

The invention discloses an additive manufacturing method for a metal-based in-situ autogeny particle reinforced component. The method includes the steps that metal is molten in a crucible with a nozzle at the bottom, two or more kinds of simple-substance particles are added, in-situ autogeny particles not dissolved in metal are generated through chemical reactions between the particles, and the in-situ autogeny particles are formed; a horizontal base plate capable of moving in a three-dimensional mode is arranged, a control program of the horizontal base plate is set, metal melt containing the in-situ autogeny particles flows out of the nozzle by applying certain pressure, the melt is solidified layer by layer, and stacking forming is conducted. The in-situ autogeny particles are obtained by means of the chemical reactions between the simple-component particles added into the metal melt and between the metal melt and the single-component particles, then the viscosity of the metal melt is controlled according to the sizes and the volumes of the in-situ autogeny particles, the aim of controlling flowing and forming is achieved, the problems that interlayer bonding in the prior art is not good and forming is not easy are solved, and the novel method for preparing the metal-based in-situ autogeny particle reinforced component is disclosed.

Owner:广东空天科技研究院

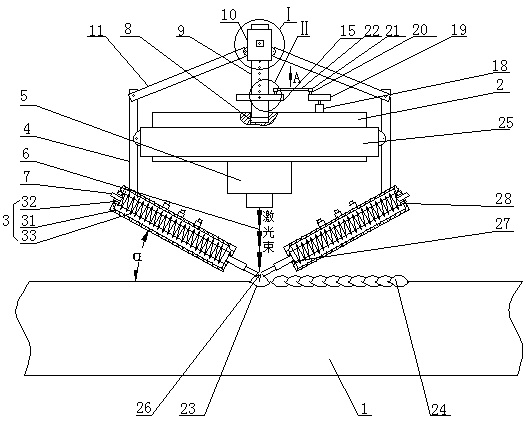

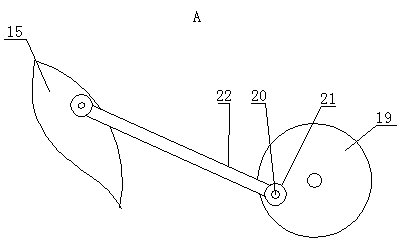

Aluminum-based gradient component multi-bypass premelting-TIG efficient forming device and method

ActiveCN112518081AEnabling Additive ManufacturingDesign function firstIncreasing energy efficiencyWelding accessoriesPhysicsAluminium

The invention requests protection of a multi-material metal gradient component efficient forming device and method. The device comprises at least three metal premelting units and further comprises a wire feeding transmission device, four TIG welding gun heads, a three-dimensional forming platform and an atmosphere protection device, wherein the three metal premelting units are arranged at the center position of a whole working space and are tightly arranged at an angle of 120 degrees correspondingly, each metal premelting unit is provided with a welding wire conveying hole, the four TIG welding gun heads are located in four quadrants divided by taking the premelting units as the center points and are located on angular bisectors of all the quadrants, the three-dimensional forming working platform is arranged below the premelting units, and the whole forming process is performed under the atmosphere protection of inert gases. By means of the multi-material metal gradient component efficient forming device and method, efficient, low-cost, integrated and accurate additive manufacturing of metal gradient material components can be realized.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Additive manufacturing device with temperature control function

InactiveCN111516265AReduce spreadReduce residual stressManufacturing platforms/substratesManufacturing heating elementsTemperature controlInsulation layer

The invention discloses an additive manufacturing device with a temperature control function. The additive manufacturing device comprises a processing head and a working platform, and is characterizedin that the processing head consists of a cladding head and a plurality of cooling spray guns; the cooling spray guns are mutually independent and used for improving the cooling effect of a machinedarea and improving the cooling rate of a molten pool; and the working platform comprises a cooling layer, a heating layer and a heat insulation layer from top to bottom, the cooling layer is providedwith a thermocouple, and the temperature of the working platform during heating and cooling can be fed back in real time. The cooling and heating functions of the working platform can influence the solidification process of the molten pool, on one hand, the working platform are matched with the cooling spray head, a high cooling rate can be provided for solidification of amorphous materials, on the other hand, residual stress generated in the common metal additive process can be reduced, and therefore the performance of machined parts is improved. The additive manufacturing device is particularly suitable for additive manufacturing of materials which need a high cooling rate or are greatly influenced by residual stress.

Owner:JIANGSU UNIV OF SCI & TECH

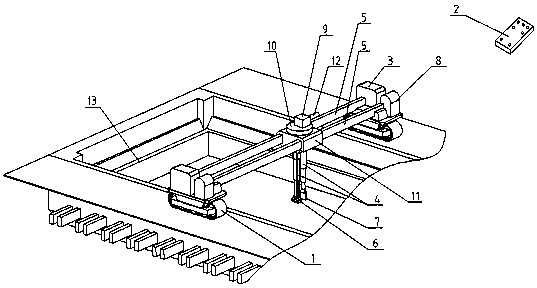

A method for building a metallurgical furnace and its 3D printing robot

ActiveCN105571324BEfficient use ofReduce dosageAdditive manufacturing apparatusLinings repairControl systemWorkload

The invention discloses a building method of a metallurgical furnace and a 3D printing robot adopted forbuildingthe metallurgical furnace. Furnace building materials are tamped and printed in a hearth layer by layer by a 3D printing robot according to design requirements and reverse modelling results of a 3D scanner, so that a novel building furnace or the restoration of the hearth is realized. A control system of the 3D printing robot drives the 3D scanner and an execution mechanism to move for performing three-dimensional scanning on the hearth, analyzing and processing scanning data and reversely modelling; then modelling results are compared with hearth design to determine an adding area of a furnace building material, and formulate a printing plan; and in addition, multi-dimension motion robot arms drive a material distributing mechanism and a furnace building tool for building the furnace. According to the 3D printing robot adopted for building the metallurgical furnace, disclosed by the invention, material increase manufacturing can be realized according to the shape of the hearth and design requirements; an existing useable cathode is effectively utilized, the workload of planning the furnace and rebuilding the furnace is reduced, wastes are avoided and the consumption of materials such as the cathode is reduced; and the furnace building efficiency is improved, furnace building workers are reduced, labor efficiency is improved, and physical and psychological health of the workers is protected.

Owner:GUIYANG AL-MG DESIGN & RES INST

Additive manufacturing device and manufacturing method for short fiber reinforced metal composite material

PendingCN113070487AEnabling Additive ManufacturingShort preparation cycleAdditive manufacturing apparatusMolten stateCrucible

The invention provides an additive manufacturing device and manufacturing method for a short fiber reinforced metal composite material, and belongs to the technical field of metal additive manufacturing. The manufacturing device comprises a crucible, a heating device, a base plate, a rotating rod and a pressurizing device. The manufacturing method comprises the steps that the hollow rotating rod capable of rotating is arranged in the crucible, after the rotating rod is started to rotate, a short fiber material is properly and orderly put into a funnel, a metal material in the crucible is heated into a molten state, the short fiber material is mixed with the melt under the action of gravity and is brought out of a discharge opening by the melt, the discharged mixture is placed on the base plate or a previous solidification layer, the melt is solidified layer by layer and is stacked and formed, and the metal-based fiber reinforced member is obtained. The device and the manufacturing method have the advantages that the change of the viscosity does not depend on the temperature by increasing the short fiber material, and the purposes of flow control and forming are achieved.

Owner:连云港倍特超微粉有限公司

An additive manufacturing device and method based on induction heating fuse and laser combination

ActiveCN108672936BEasy to integratePrecise control of ejection speedAdditive manufacturing apparatusLaser beam welding apparatusEngineeringLaser beams

An induction heating fuse wire and laser compound based additive manufacturing device comprises a bottom plate, wherein a transverse circular plate is arranged at the upper part of the bottom plate; acircular ring sleeves the outer circumference of the circular plate and is movably connected to the outer circumference of the circular plate through a bearing; a plurality of uniformly-distributed induction heating devices are arranged at the bottom part of the circular plate; the lower ends of the induction heating devices are pointed to a part where a central axis of the circular plate is connected to the top surface of the bottom plate; vertical rods are fixedly mounted at the upper ends of the induction heating devices, and the side parts of the vertical rods are connected to the side part of the circular ring by hinging. According to the device, an induction heating fuse wire and laser compound based additive manufacturing method is used for performing additive manufacturing; a fusewire is molten by induction heating; a laser beam is capable of promoting the stirring in a metal melting pond; the material feeding capacity per unit of time is high in the manufacturing process, and the formed metal melting pond is large, so that the additive manufacturing efficiency is high; and meanwhile, the fuse wires manufactured through a plurality of materials can be synchronously fed, so that the additive manufacturing of an alloy material is achieved; and a novel device and a novel method are provided to realize additive manufacturing.

Owner:HUNAN UNIV OF SCI & TECH

A method for additive manufacturing of metal-based in-situ autogenous particle-reinforced components

ActiveCN106735223BEnabling Additive ManufacturingAdditive manufacturing apparatusChemical reactionCrucible

The invention discloses an additive manufacturing method for a metal-based in-situ autogeny particle reinforced component. The method includes the steps that metal is molten in a crucible with a nozzle at the bottom, two or more kinds of simple-substance particles are added, in-situ autogeny particles not dissolved in metal are generated through chemical reactions between the particles, and the in-situ autogeny particles are formed; a horizontal base plate capable of moving in a three-dimensional mode is arranged, a control program of the horizontal base plate is set, metal melt containing the in-situ autogeny particles flows out of the nozzle by applying certain pressure, the melt is solidified layer by layer, and stacking forming is conducted. The in-situ autogeny particles are obtained by means of the chemical reactions between the simple-component particles added into the metal melt and between the metal melt and the single-component particles, then the viscosity of the metal melt is controlled according to the sizes and the volumes of the in-situ autogeny particles, the aim of controlling flowing and forming is achieved, the problems that interlayer bonding in the prior art is not good and forming is not easy are solved, and the novel method for preparing the metal-based in-situ autogeny particle reinforced component is disclosed.

Owner:广东空天科技研究院

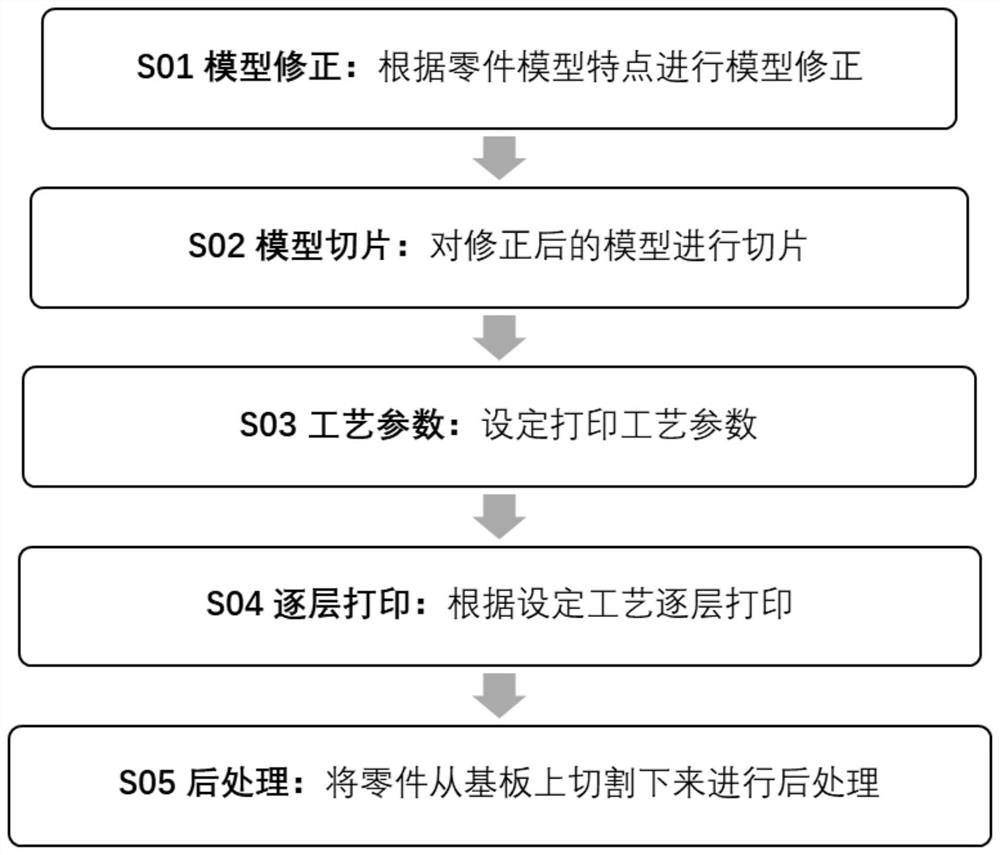

Multi-beam electron beam forming method

PendingCN111687414AImprove printing efficiencyHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringBeam electron

The invention relates to a multi-beam electron beam forming method. The method adopts a 3D printer with multi-beam electron beams, and comprises the following steps of firstly, correcting a model, namely correcting the model through general software according to the characteristics of a part model, calculating machining allowance, and modifying local characteristics, so that the model is suitablefor multi-beam electron beam forming; carrying out slicing, specifically, slicing and dividing the part model through the general software, generating a program capable of being executed by multi-beamelectron beam forming, and finally generating a slicing file; setting process parameters, specifically, setting a wire feeding speed, electron beam power and a substrate moving speed according to thesize of a formed part; printing layer by layer to finally obtain the required part appearance; and carrying out post-processing, specifically, cutting the substrate and the part. According to the method, double electron beams are adopted as energy sources, heating metal wires are coaxially conveyed, the printing efficiency is high, the precision is high, and additive manufacturing of metal structural parts is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

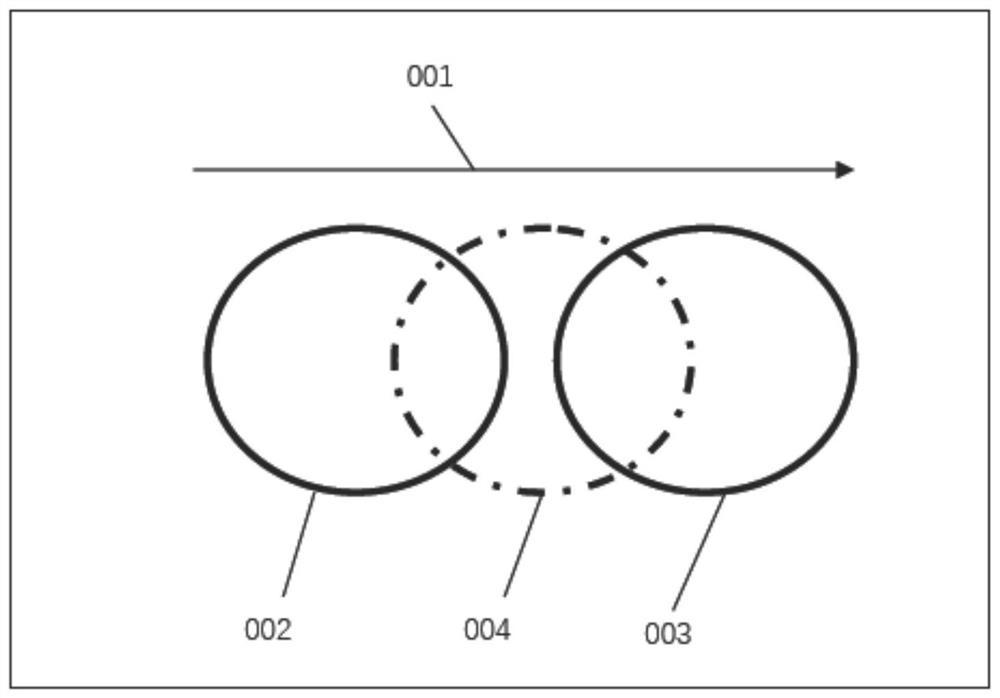

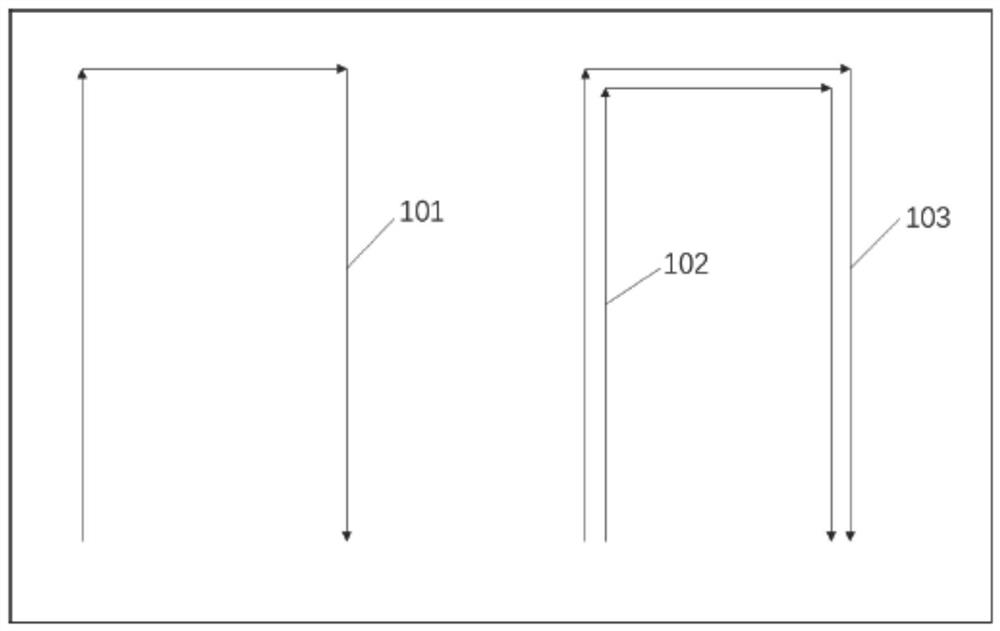

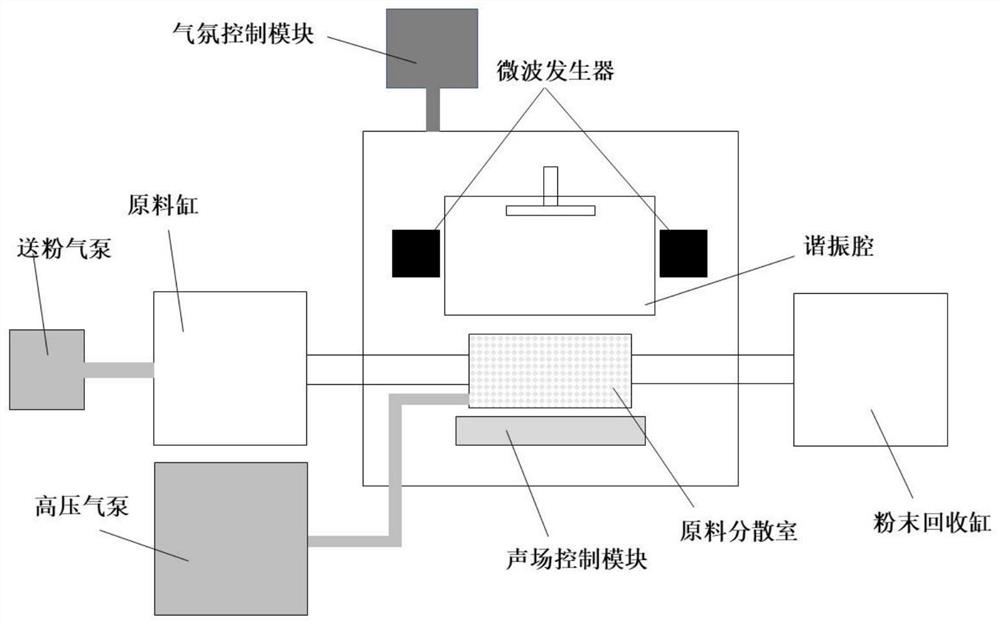

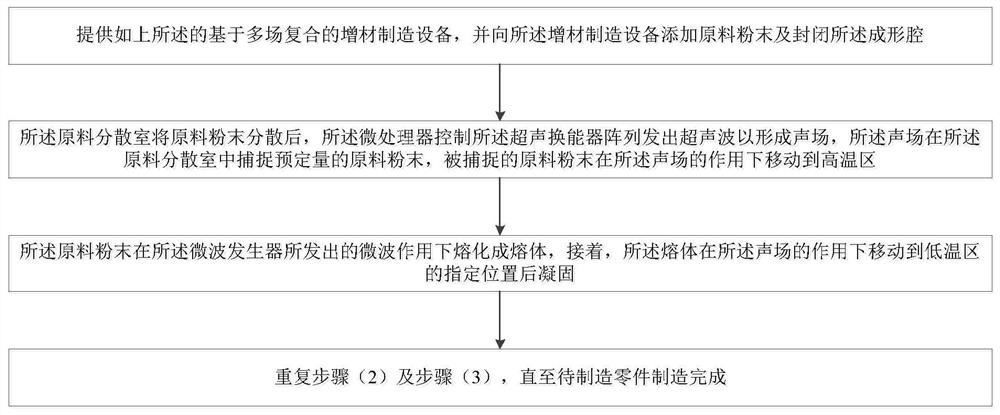

A kind of additive manufacturing equipment and method based on multi-field compounding

ActiveCN110919819BEnabling Additive ManufacturingAvoid crackingAdditive manufacturing apparatusAuxillary shaping apparatusMicrowaveMechanical engineering

The invention belongs to the related technical field of additive manufacturing, and discloses an additive manufacturing equipment and method based on multi-field compounding. The equipment includes a powder conveying adjustment module, a sound field control module, a microwave field / thermal field control module and a microprocessor. The powder conveying adjustment module, the sound field control module and the microwave field / heat field control module are respectively connected to the microprocessor; the powder conveying adjustment module includes a raw material dispersion chamber, and the raw material dispersion chamber is arranged in the forming cavity formed by the casing; the sound field control module is also It is arranged in the forming cavity, and it is located below the raw material dispersion chamber; the microwave field / thermal field control module includes multiple microwave generators set in the forming cavity, and the multiple microwave generators are respectively located on both sides of the forming area, and the microwave The generator and the sound field control module are respectively located on opposite sides of the raw material dispersion chamber; wherein, the forming area is divided into a high temperature area and a low temperature area, and the temperature of the high temperature area is higher than that of the low temperature area. The invention reduces the tendency of cracking, and the forming efficiency and precision can be adjusted.

Owner:HUAZHONG UNIV OF SCI & TECH

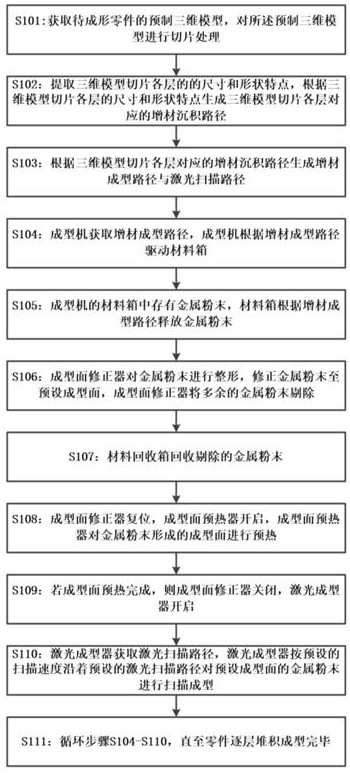

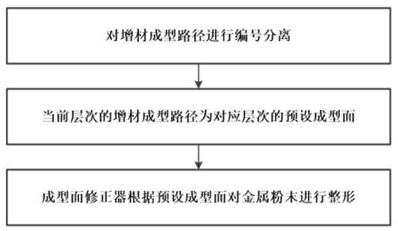

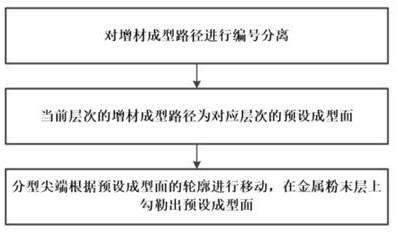

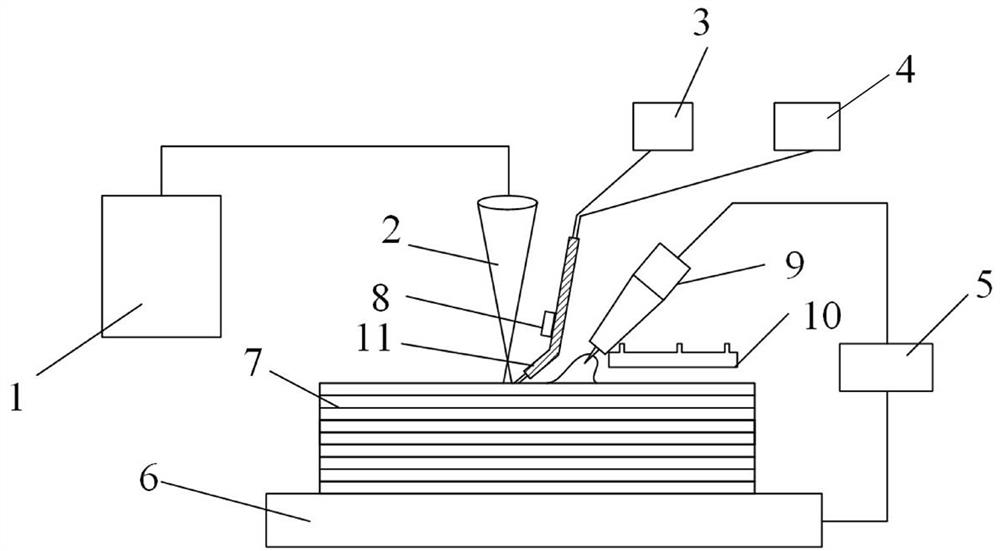

An additive manufacturing process for metal parts

ActiveCN111001804BEnabling Additive ManufacturingTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMolding machine

Owner:四川三阳激光增材制造技术有限公司

Heterogeneous intermetallic compound additive processing equipment and processing method thereof

ActiveCN114850632ASolving Melting InstabilitySolve for uniformityAdditive manufacturing apparatusArc welding apparatusWelding power supplyIntermetallic

The invention discloses dissimilar intermetallic compound additive processing equipment and a processing method thereof. The dissimilar intermetallic compound additive machining equipment comprises a heating plate, a first welding power source, a double-hole wire feeding contact tube, a first wire feeder, a second wire feeder and a second welding power source, the heating plate is used for containing a substrate, and the first welding power source is used for heating and melting an additive deposition layer on the substrate; the first wire feeder and the second wire feeder are both connected with the double-hole wire feeding contact tube and communicate with a first wire feeding hole and a second wire feeding hole of the double-hole wire feeding contact tube correspondingly, and the second welding power source can move and is used for heating and melting an additive deposition layer. The double-hole wire feeding contact tube, the first welding power source and the second welding power source are all arranged opposite to the heating plate. By means of the dissimilar intermetallic compound additive machining equipment, the structure property uniformity of a complex special-shaped component can be improved.

Owner:湖南湘投金天科技集团有限责任公司

A method for additive manufacturing of metal-based particle-reinforced components

ActiveCN106583727BEnabling Additive ManufacturingAdditive manufacturing apparatusChemical reactionCrucible

The invention discloses an additive manufacturing method for a metal-based particle reinforced member. The method includes the steps that metal is melted in a crucible with a nozzle at the bottom, and then ceramic particles are added; a horizontal base plate which can make three-dimensional movement is arranged, and a control program of the horizontal base plate is set; and certain pressure is applied to enable metal melt containing the ceramic particles to flow out from the nozzle, the melt is solidified layer by layer, and the layers of melt are stacked to form a product. According to the method, the ceramic particles which do not chemically react with the metal melt are added, the viscosity of the melt is controlled through the size and volume fraction of the ceramic particles, the purpose of controlling flowing and forming is achieved, and the problems that in the prior art, interlayer bonding is poor, and forming is affected are solved; and the additive manufacturing method is a novel method for preparing the metal-based particle reinforced member.

Owner:广东空天科技研究院

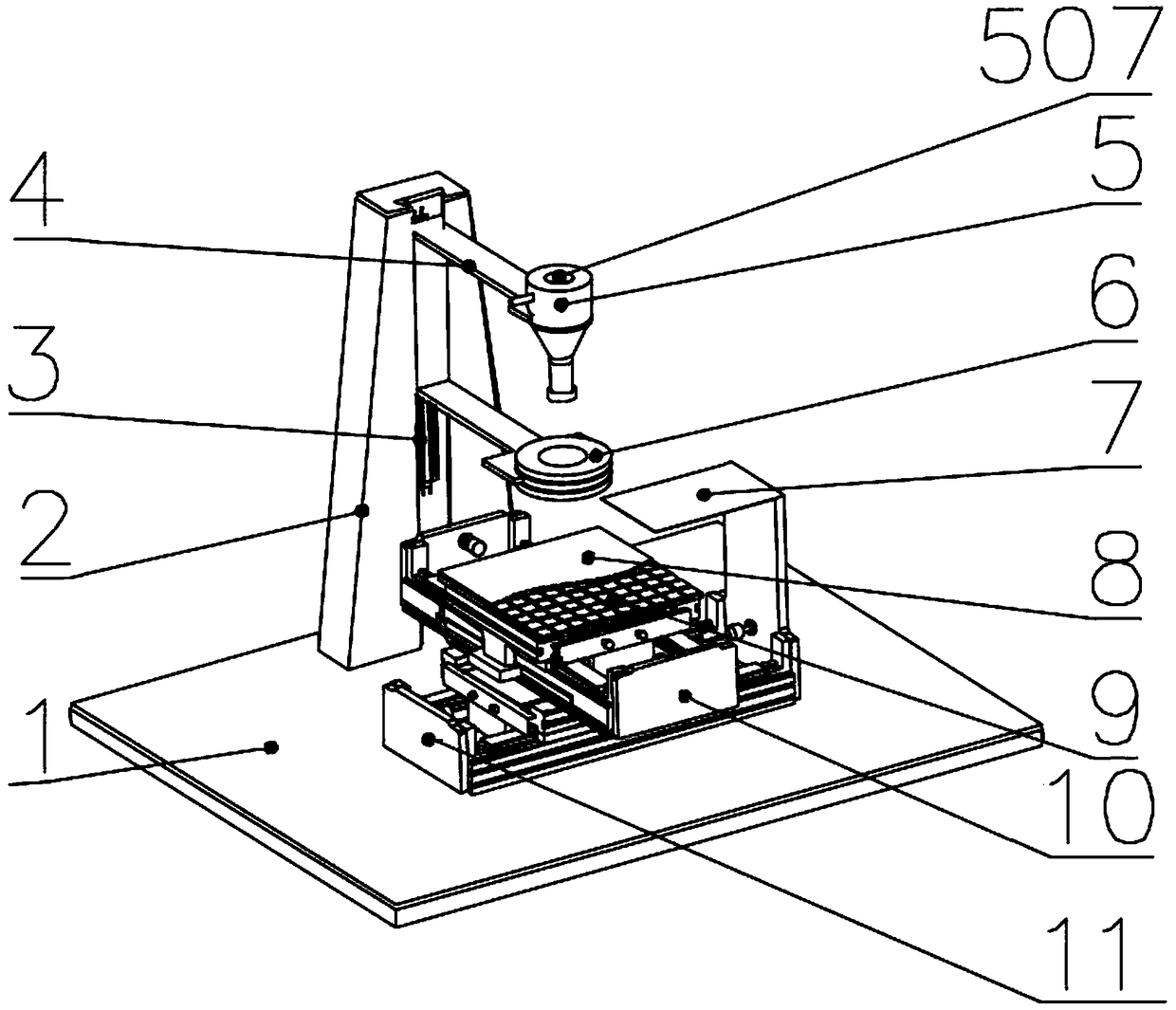

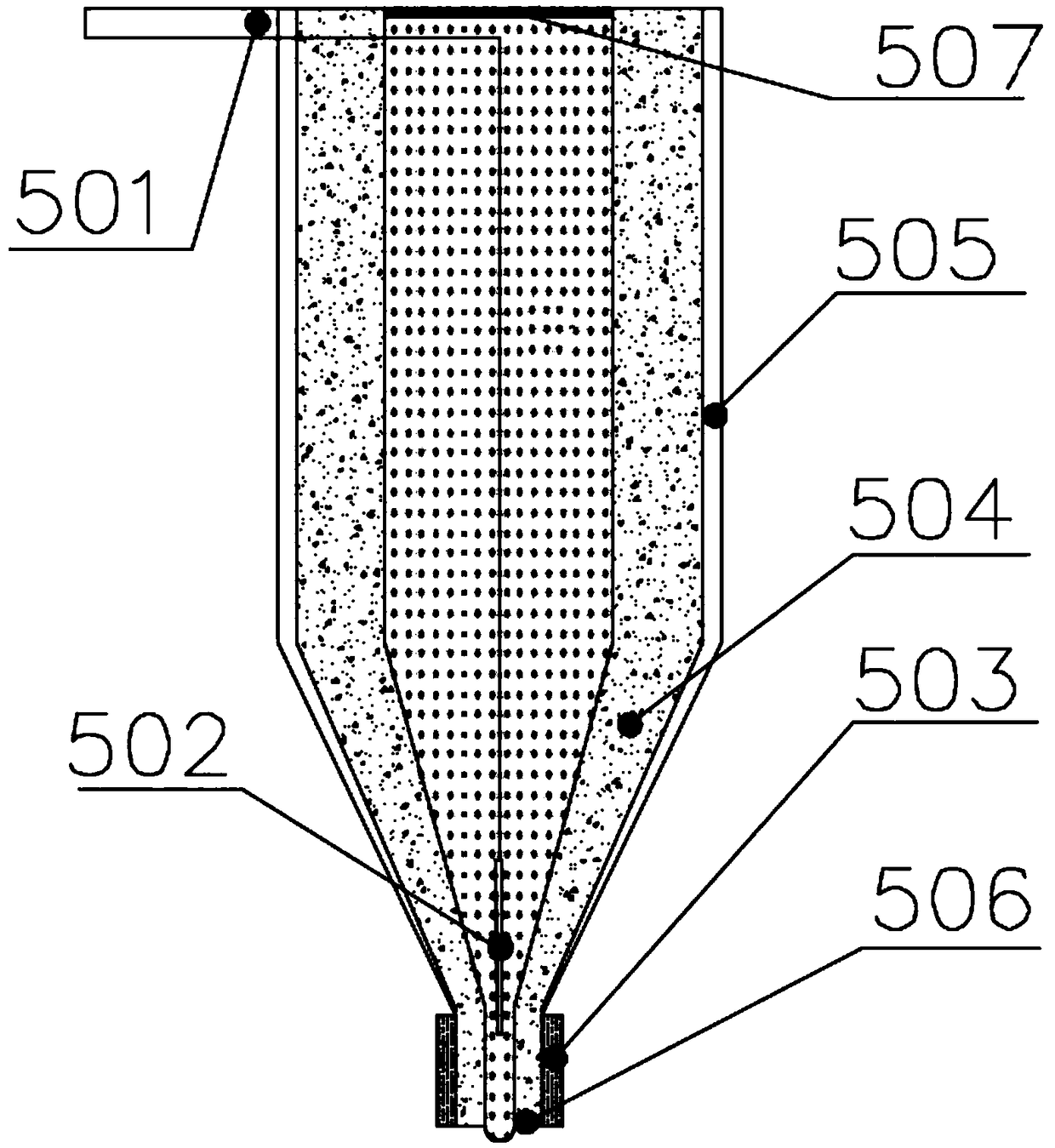

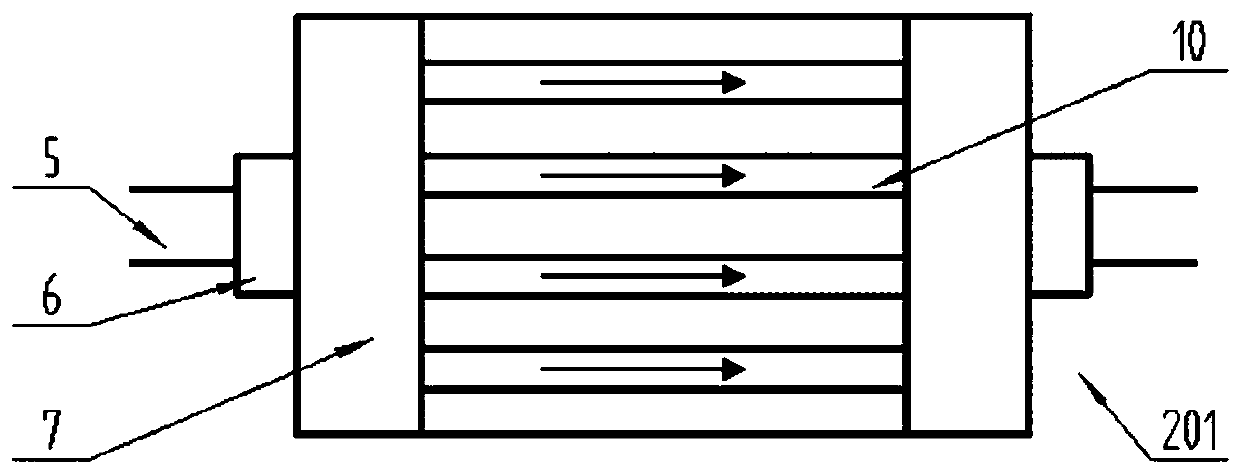

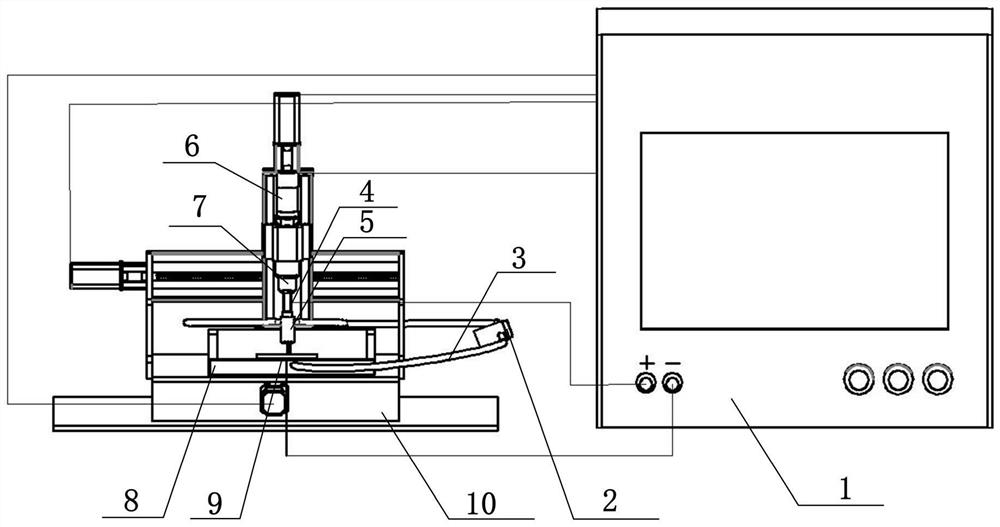

Preparation device and method of dendritic nickel-based catalytic electrode based on 3D printing

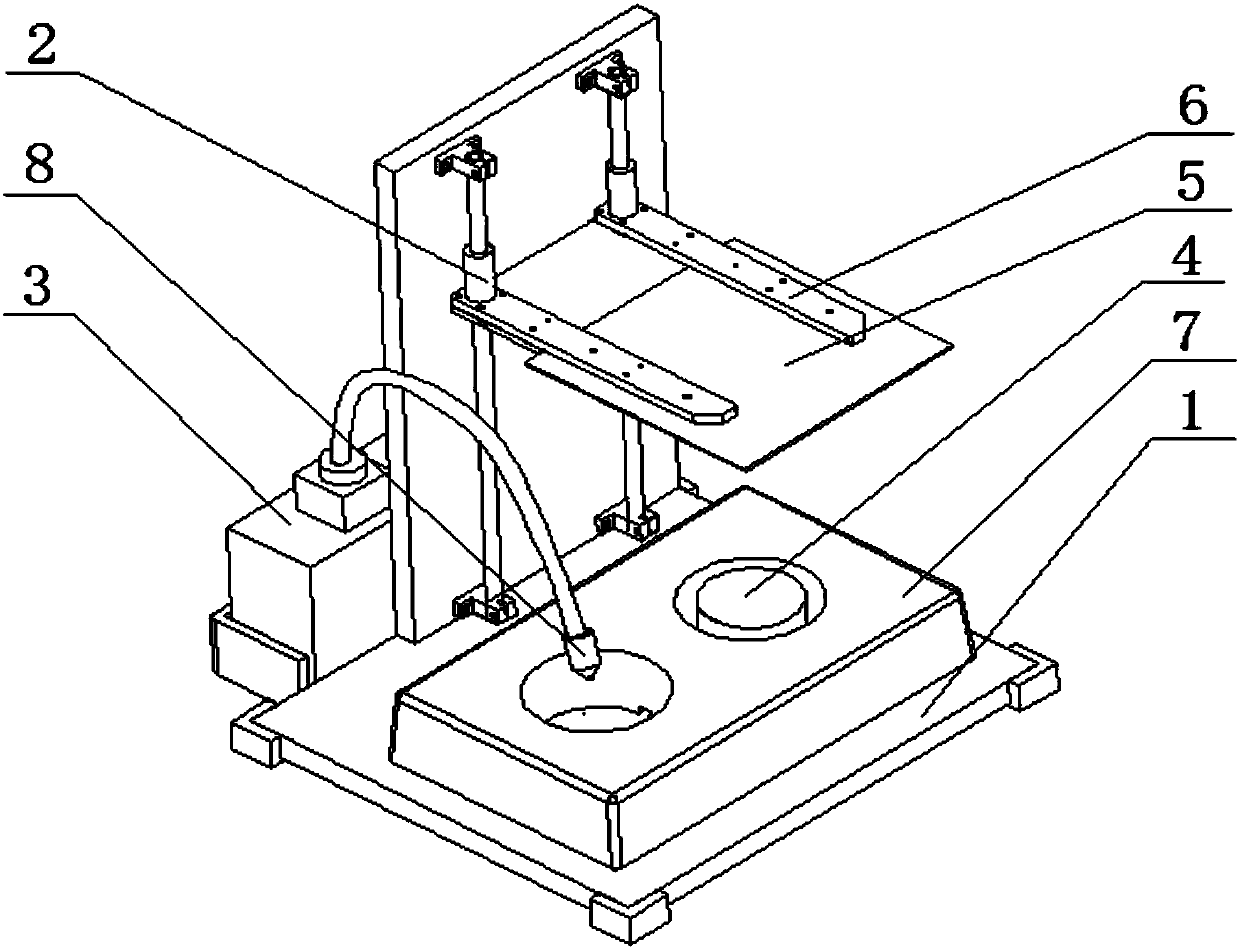

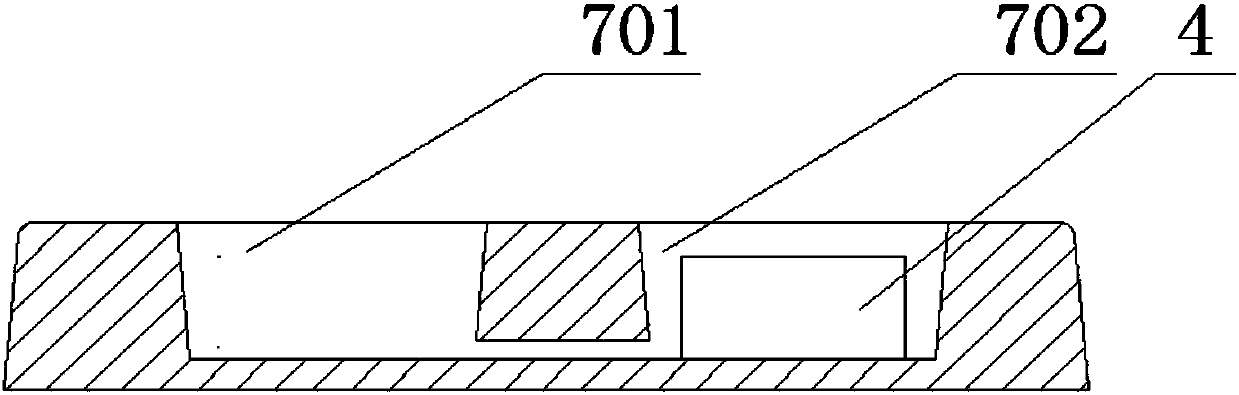

ActiveCN109825856BEasy to prepareEnabling Additive ManufacturingAdditive manufacturing apparatusElectroforming processesPhysicsThree dimensional motion

The invention discloses a dendritic crystal nickel base catalytic electrode preparation device and method based on 3D printing. The device comprises an industrial personal computer (1), a chemical pump (2), an anode tool electrode (4), a plating liquid nozzle (5), a connecting head (7), a plating tank (8) and a three-dimensional mobile platform (10); the industrial personal computer (1) is used asa three-dimensional motion control system for receiving modeling pattern data of nickel base catalytic electrodes of users and automatically converting to motion control data of the three-dimensionalmobile platform to control the three-dimensional mobile platform to move in X, Y and Z axle directions. Through downwards vertical flowing of plating liquid, dendritic crystal structures are formed on the surfaces of the electrodes to effectively promote the catalytic reaction area of the electrodes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Spray Angle Controllable Ultrasonic Droplet Jetting Additive Manufacturing Device and Method

ActiveCN106273491BSolve pollutionEasy to controlAdditive manufacturing apparatusUltrasonic sensorLiquid storage tank

The invention relates to jet angle controllable ultrasonic droplet jetting additive manufacturing device and method, belonging to the field of additive manufacturing. The device is characterized in that a base is installed at the bottom; a jet tank is installed on the base; a focused ultrasonic transducer is installed in the jet tank; a base plate is fixed below wafer bearing platforms and above the jet tank; the wafer bearing platforms are installed on a Z-direction workbench; the Z-direction workbench is installed on the base; the jet tank is communicated with a liquid storage tank; a high-precision injection pump is connected with a feeding head; through focused ultrasound, liquid overcomes the surface tension and jets droplets from the liquid level; the power of four focused ultrasonic vibrators of the focused ultrasonic transducer is controlled by a computer and the focused ultrasonic vibrators interact and then change the jet angles of the droplets to jet the droplets to different positions on the base plate; a Z-axis motion platform cooperates with different jet angles to complete printing of different position points on the base plate. The device and the method have the effects of improving the printing precision and ensuring the physical and chemical properties and other properties of formed parts without needing print heads, thus avoiding pollution and cleaning difficulty of liquid materials.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com