Preparation device and method of dendritic nickel-based catalytic electrode based on 3D printing

A catalytic electrode and 3D printing technology, applied in the direction of electrodes, electroforming, electrolytic components, etc., can solve time-consuming and other problems, achieve the effects of simple preparation process, promotion of catalytic reaction area, and improvement of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments.

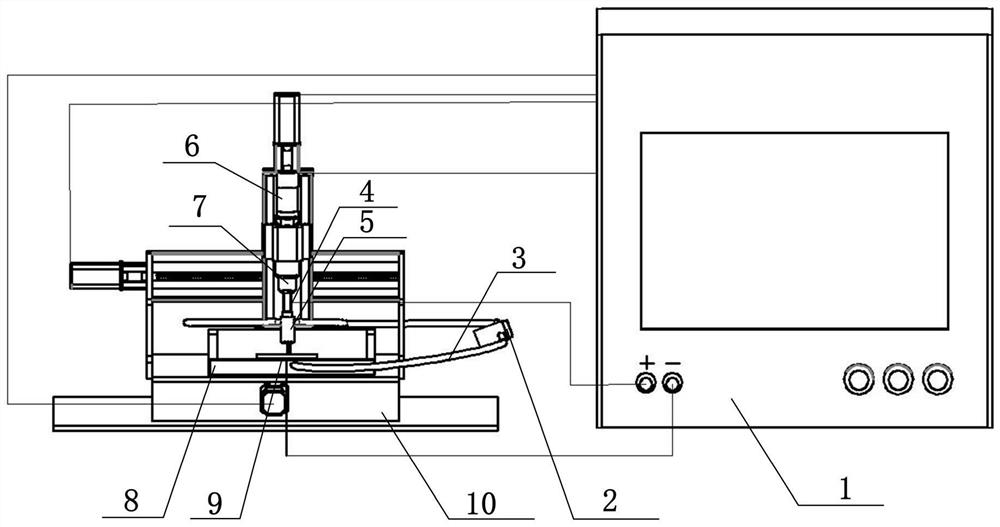

[0032] Such as figure 1 and figure 2 As shown, a large-scale novel dendritic nickel-based catalytic electrode preparation device based on 3D printing, including industrial computer 1, chemical pump 2, anode tool electrode 4, plating solution nozzle 5, connector 7, plating tank 8, three-dimensional moving The platform 10; the industrial computer 1 is used as a three-dimensional motion control system for receiving the modeling graphic data of the user's nickel-based catalytic electrode, and automatically converting it into motion control data of the three-dimensional mobile platform, which is used to control the three-dimensional mobile platform in X, Y, Z Axial movement;

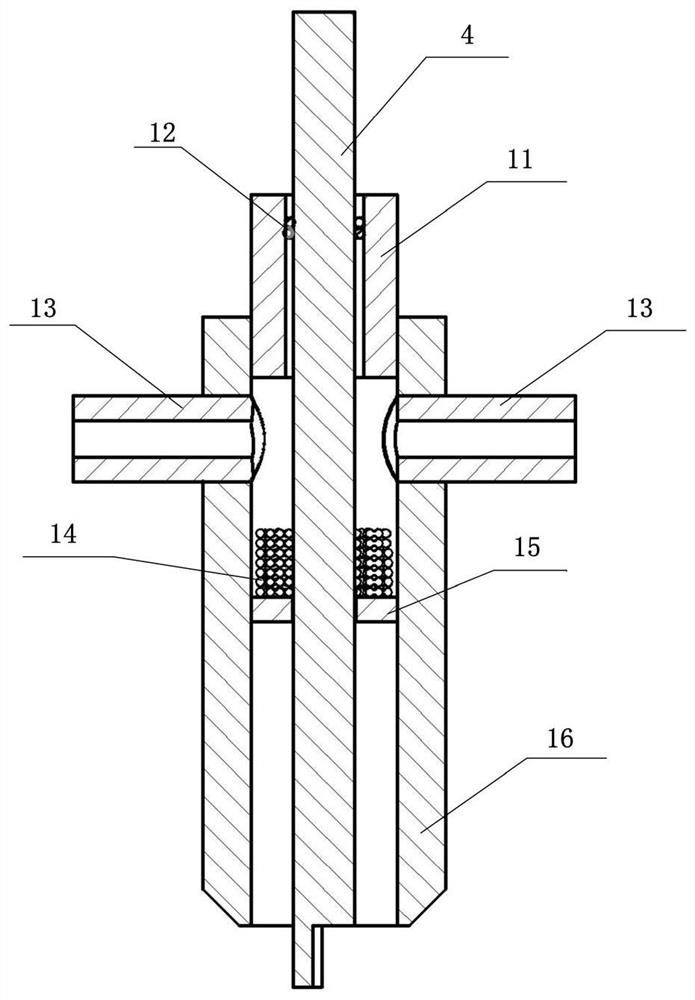

[0033]The plating solution nozzle 5 includes a guide tube 11, a porous baffle 15, and a nozzle housing 16; wherein the nozzle housing 16 is cylindrical; the upper end of the nozzle housing 16 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com