Patents

Literature

72results about How to "Uniform and dense surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

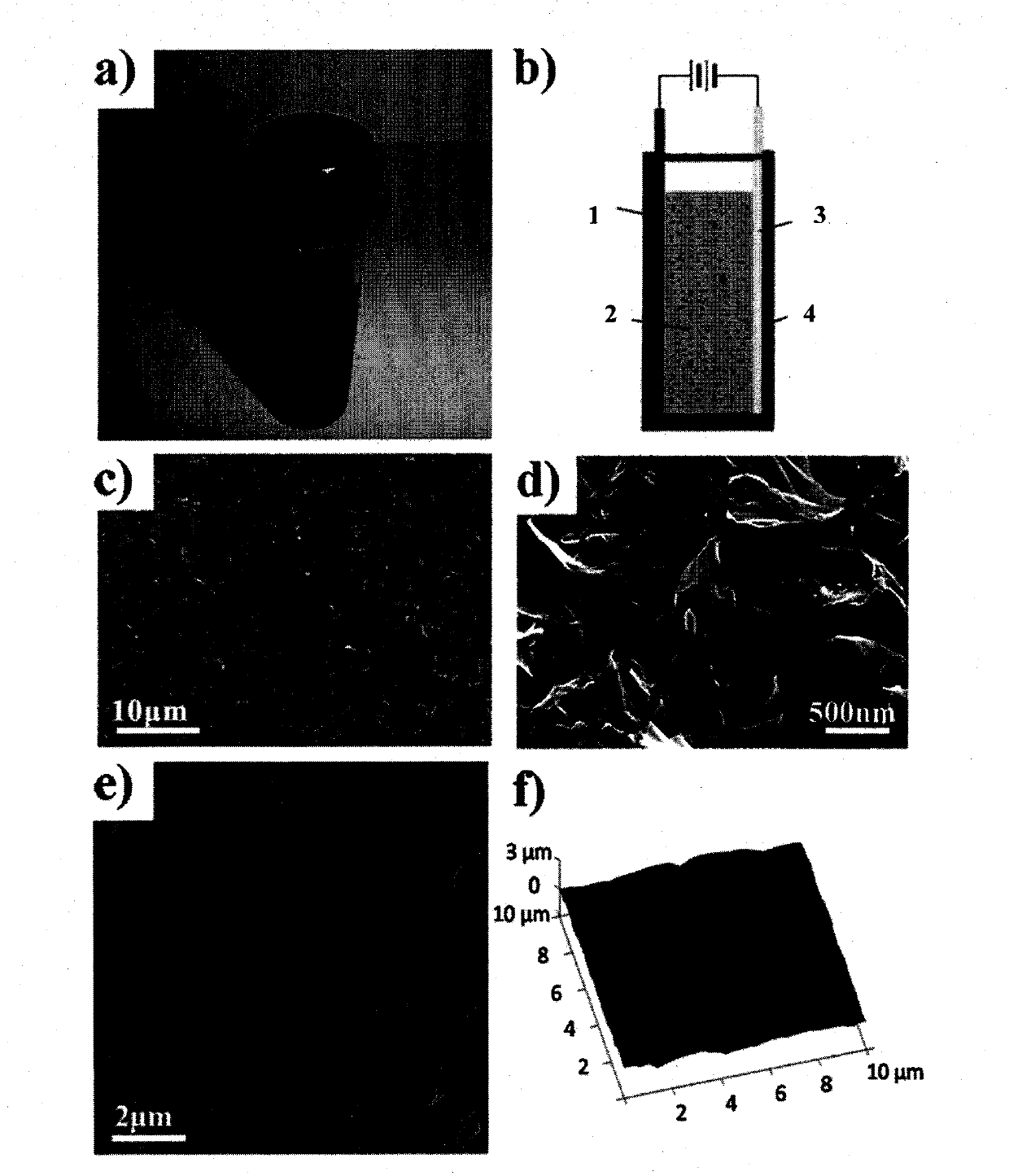

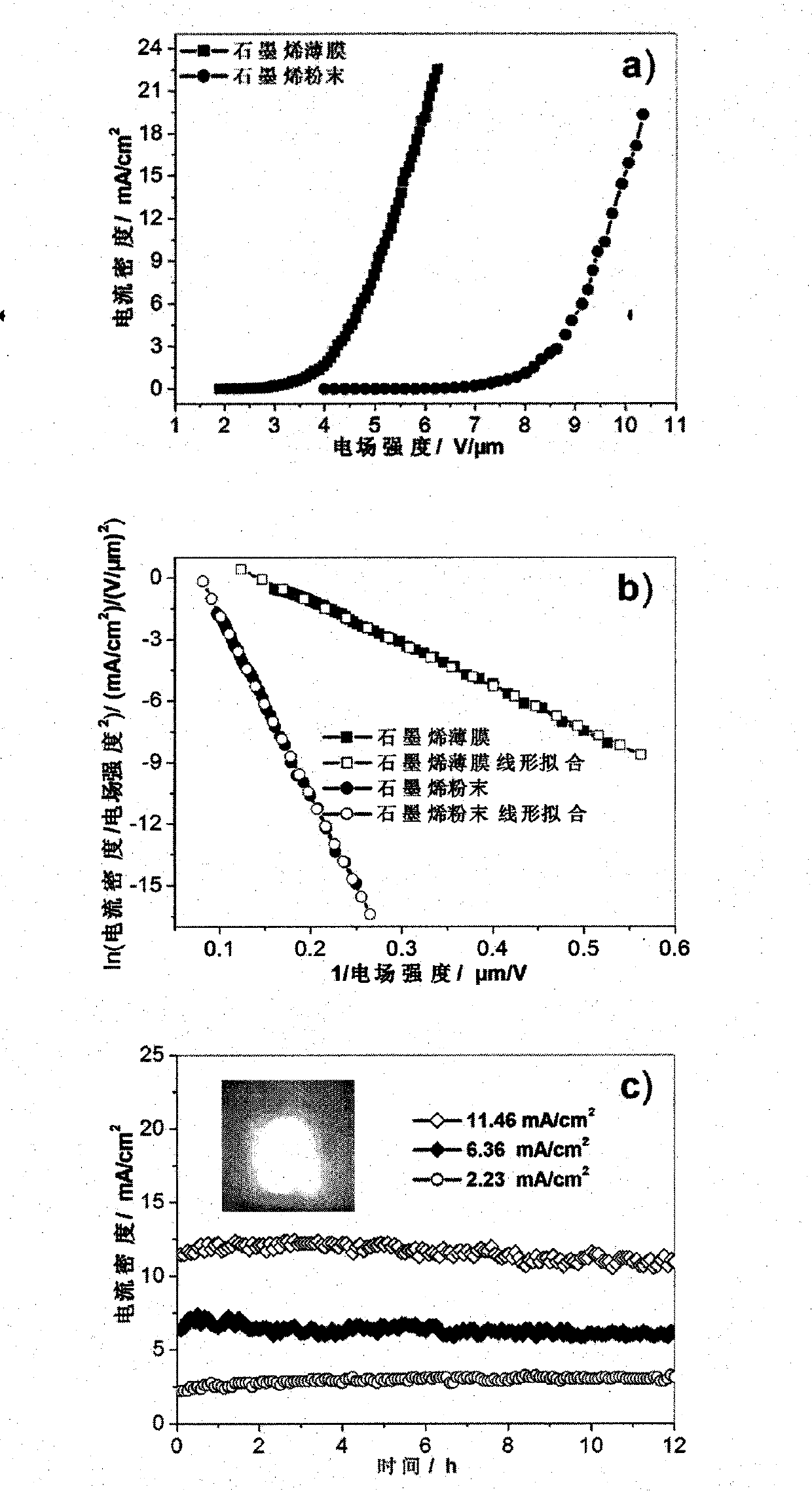

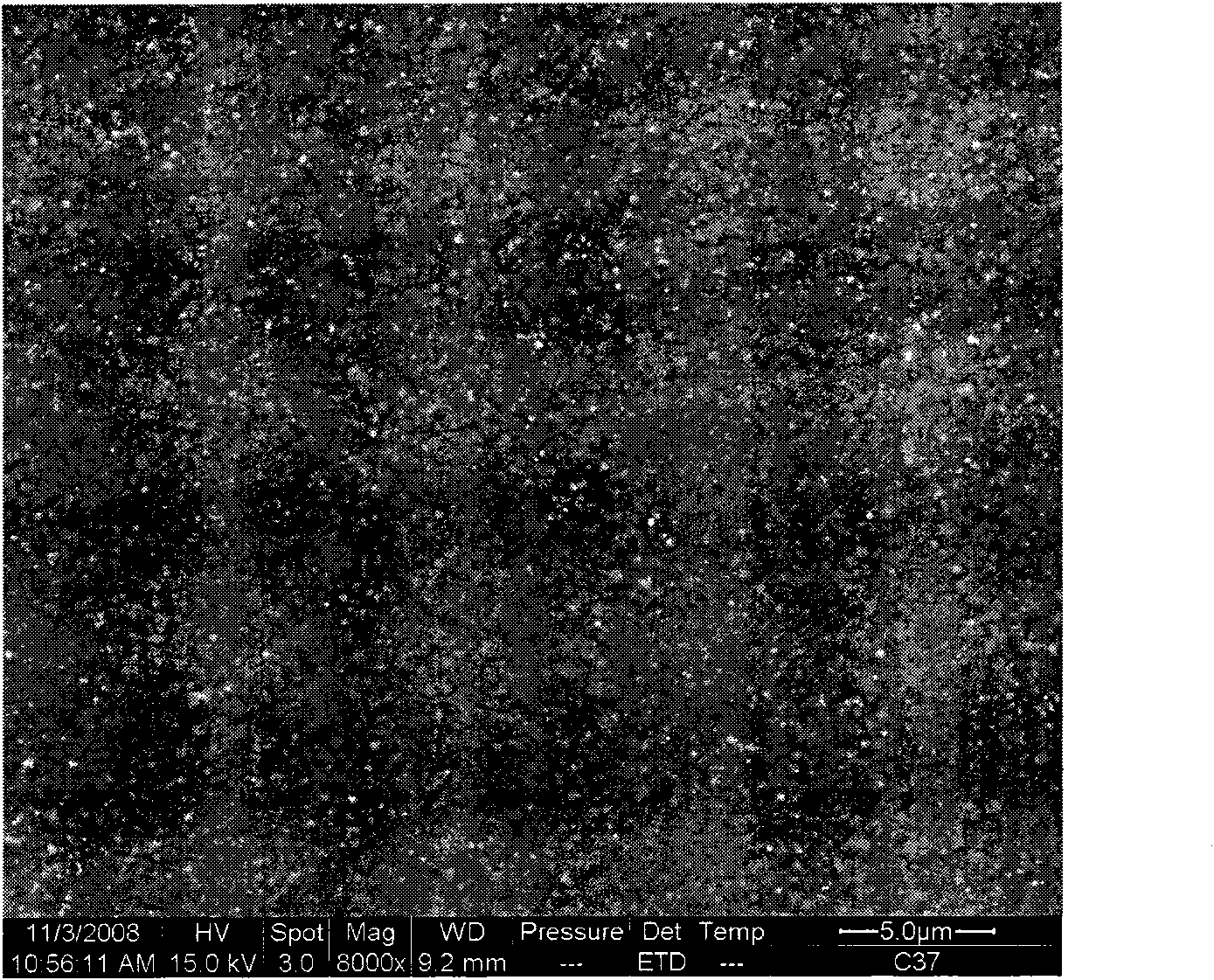

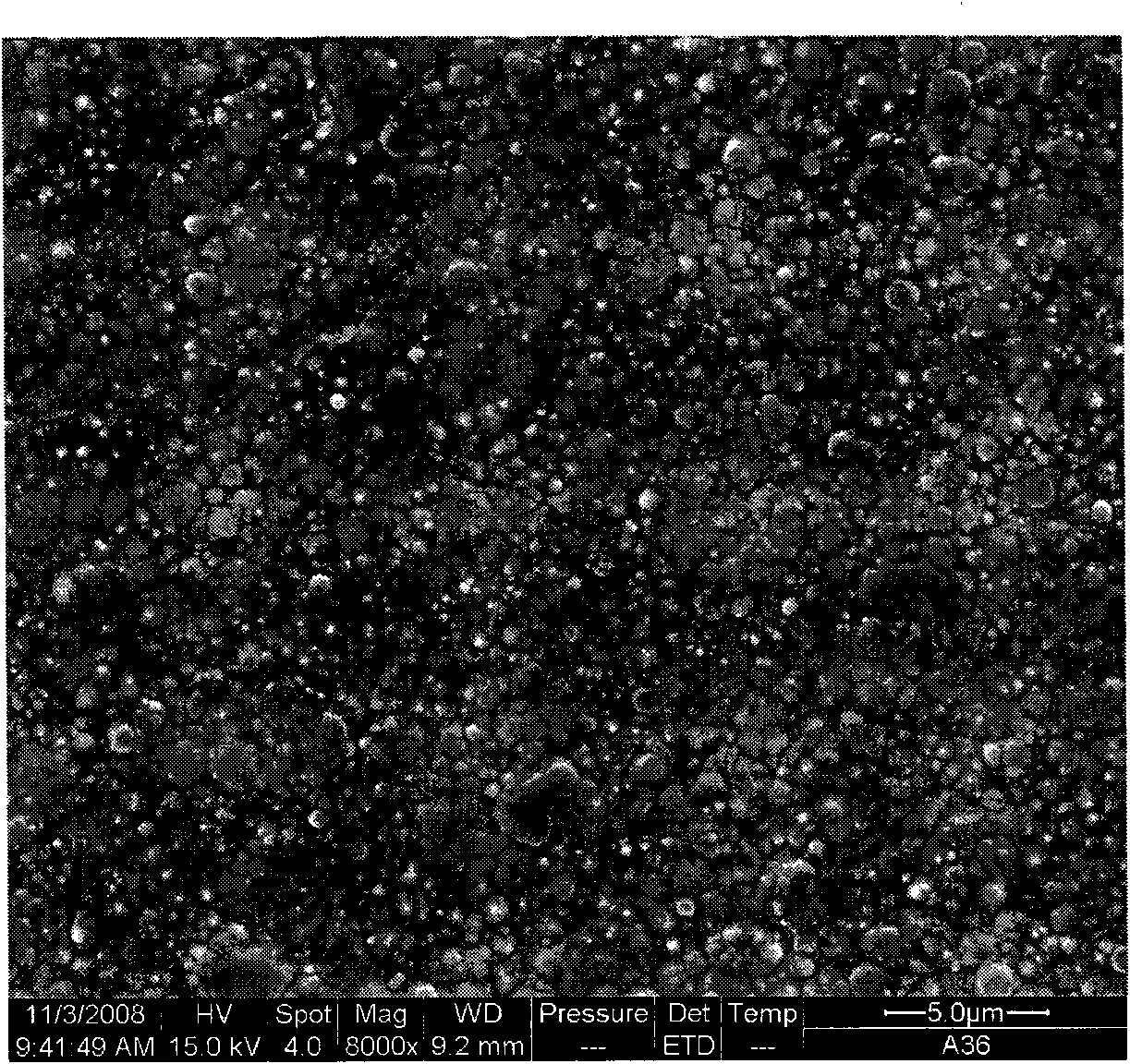

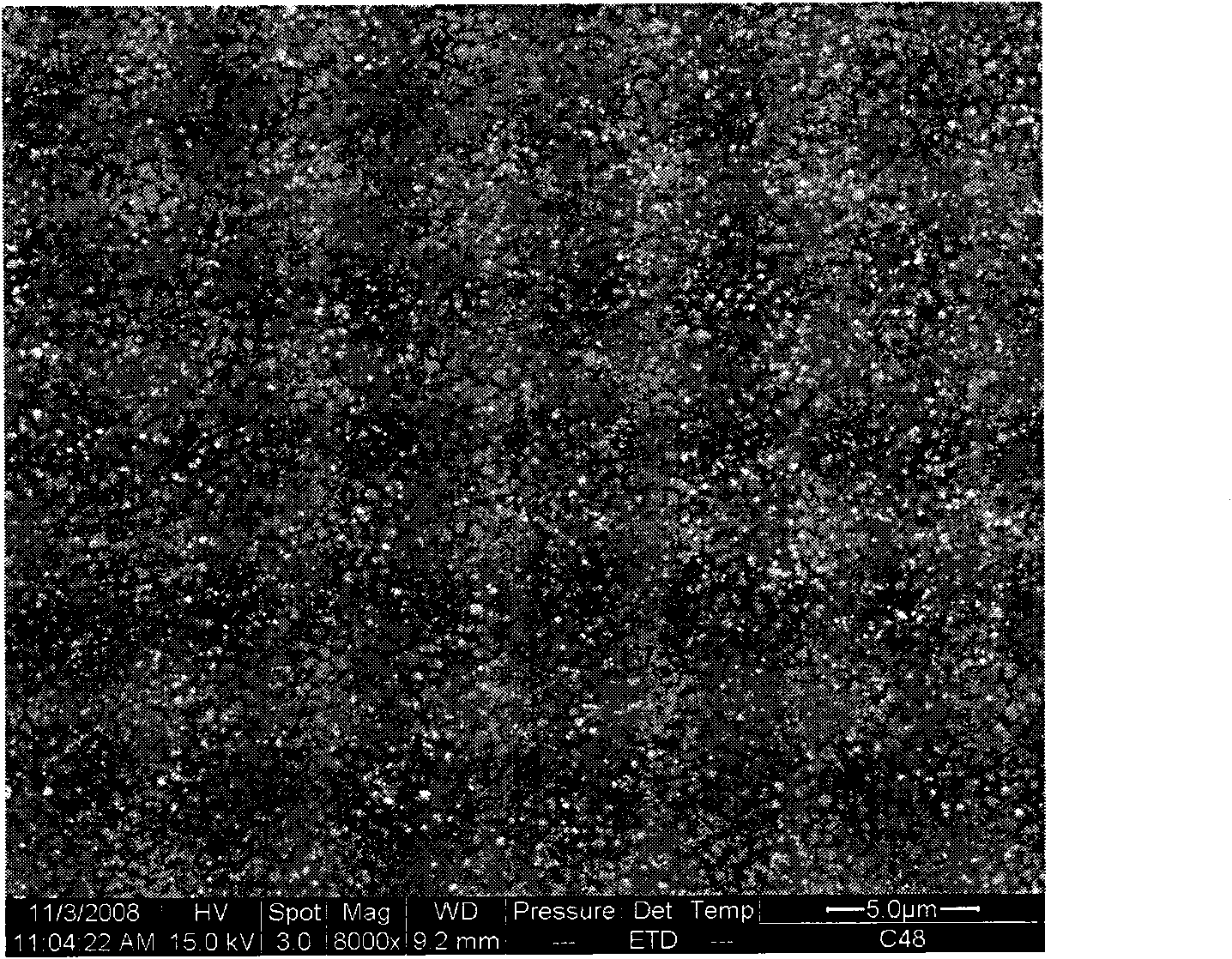

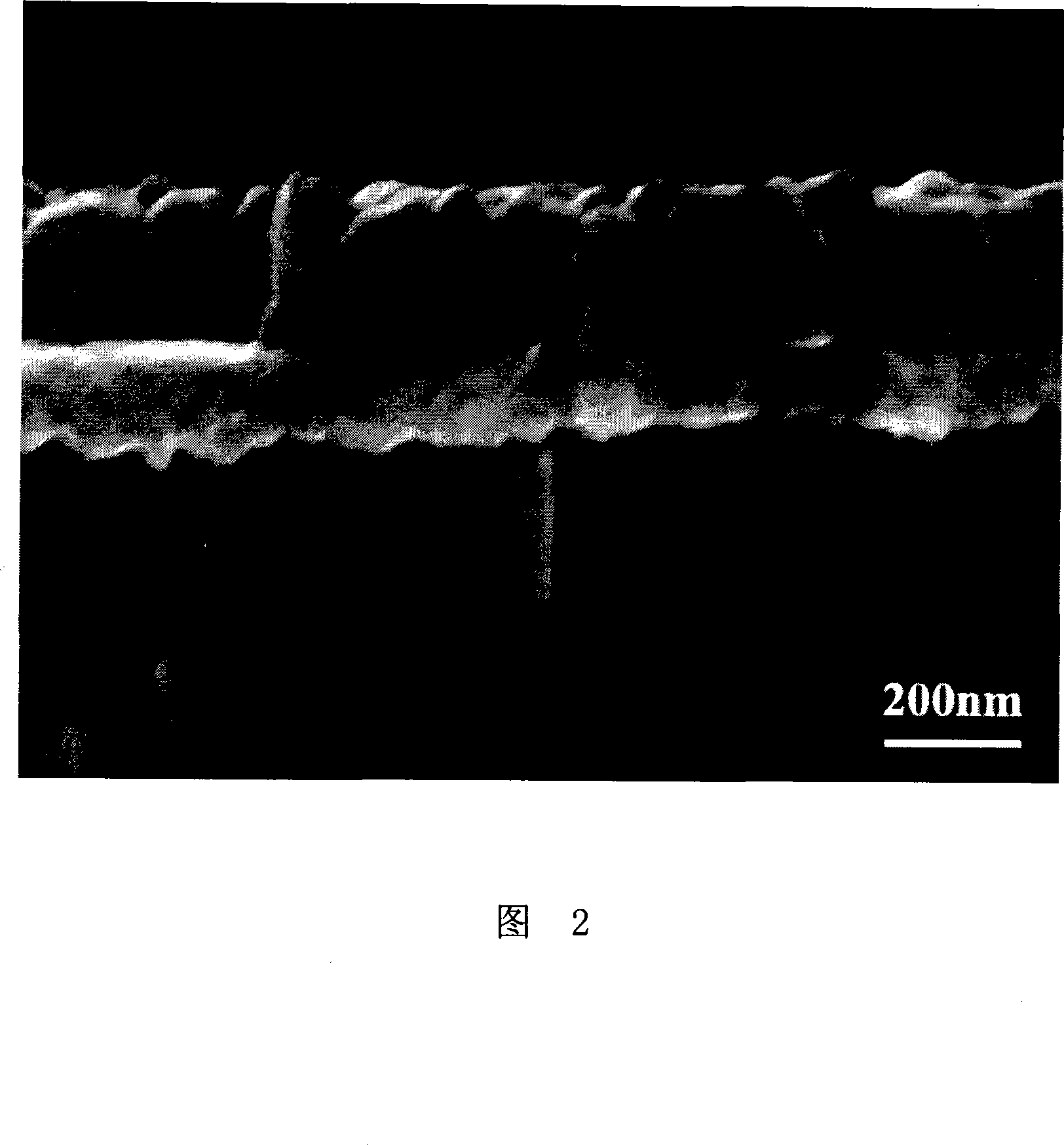

Preparation method of graphene thin film field emission material

InactiveCN102021633AUniform and dense surfaceEasy to operateElectrophoretic coatingsCvd grapheneElectrophoretic deposition

The invention relates to the field of field emission electronic materials, in particular to a preparation method of a graphene thin film field emission material. The method comprises the following steps of: (1) uniformly dispersing graphene and metal cation inorganic salt capable of providing charges into an low polar organic solvent or directly dispersing the graphene into an aqueous solution of an ionic surfactant by adopting an ultrasonic method to prepare a stable graphene solution with charges; and (2) orderly depositing the graphene with the charges on a conductive substrate under the action of an external electric field by utilizing an electrophoretic deposition method to prepare a graphene film. The field emission material of the invention is an even and compact graphene film rich in graphene sheets perpendicularly to the plane. The method has the advantages of simple operation, low cost and good controllability and is suitable for preparing large-area graphene films, and the excellent field emission characteristics of the graphene film lay the foundation for applying the graphene film as a cold cathode material to high-performance field emission displays, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Blackening liquid for chromium-free titanium-zinc panel surface and using method of blackening liquid

InactiveCN103849868ASimple compositionStrong corrosion resistanceMetallic material coating processesAluminium chlorideChromium free

The invention discloses blackening liquid for a chromium-free titanium-zinc panel surface and a using method of the blackening liquid. Raw materials of the blackening liquid comprise a main salt, auxiliary components, a complexing agent, a pH conditioning agent and water, wherein the main salt is one or several of molybdate with the massic volume concentration of 5-40g / L or sodium tungstate with the massic volume concentration of 0.5-10g / L or copper sulfate with the massic volume concentration of 0.5-20g / L or silver nitrate with the massic volume concentration of 5-40g / L; the auxiliary components comprise nickel sulfate with the concentration of 1.0-4g / L, sodium sulfite with the concentration of 0.5-4g / L, sodium thiosulfate with the concentration of 1.0-5g / L, aluminium chloride with the concentration of 2.0-5g / L, zinc chloride with the concentration of 2.0-5g / L and fluoric acid with the concentration of 0-40g / L. A black protective layer of a titanium-zinc panel is obtained by a series of treatment of the titanium-zinc panel workpiece. The black protective layer of the titanium-zinc panel is compact, uniform, pitch-black and glossy and has the characteristics of being low in cost, chromium-free, environmental-friendly and the like, the performances of the titanium-zinc panel can reach the level of foreign products, and therefore, the titanium-zinc panel has relatively strong application prospect and market competitiveness.

Owner:ZHEJIANG UNIV OF TECH +1

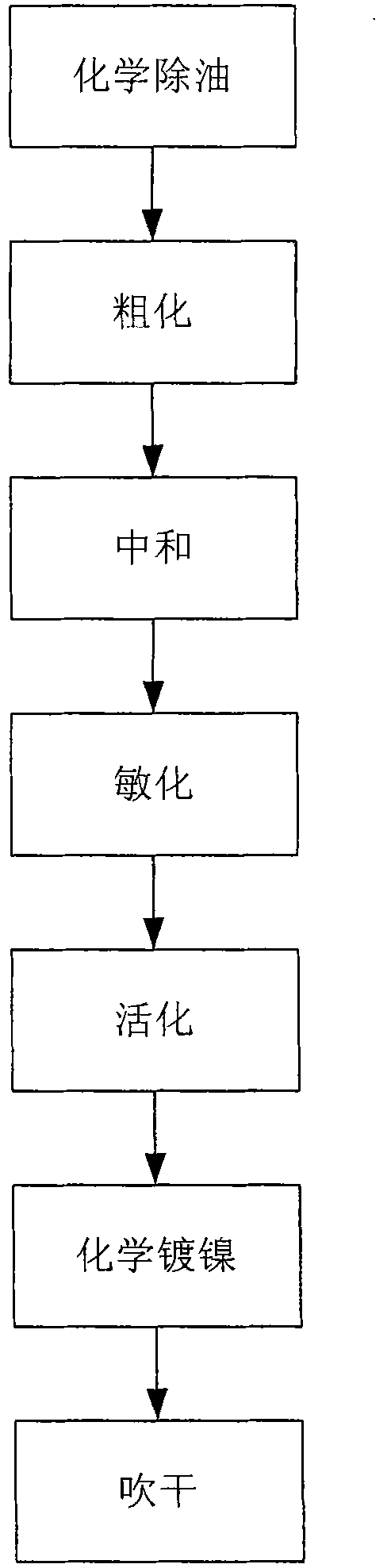

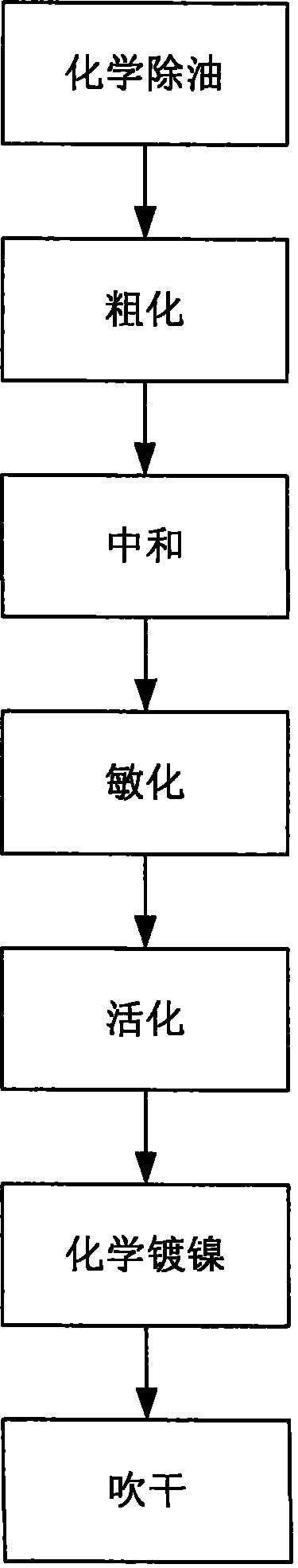

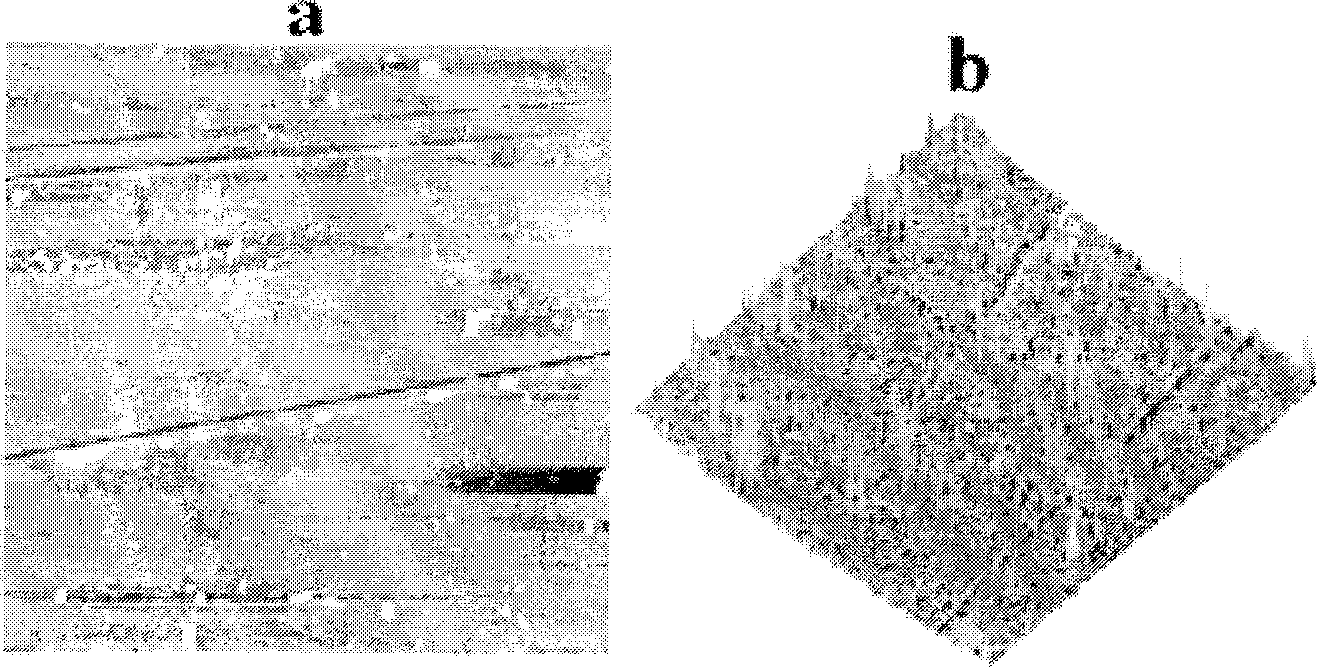

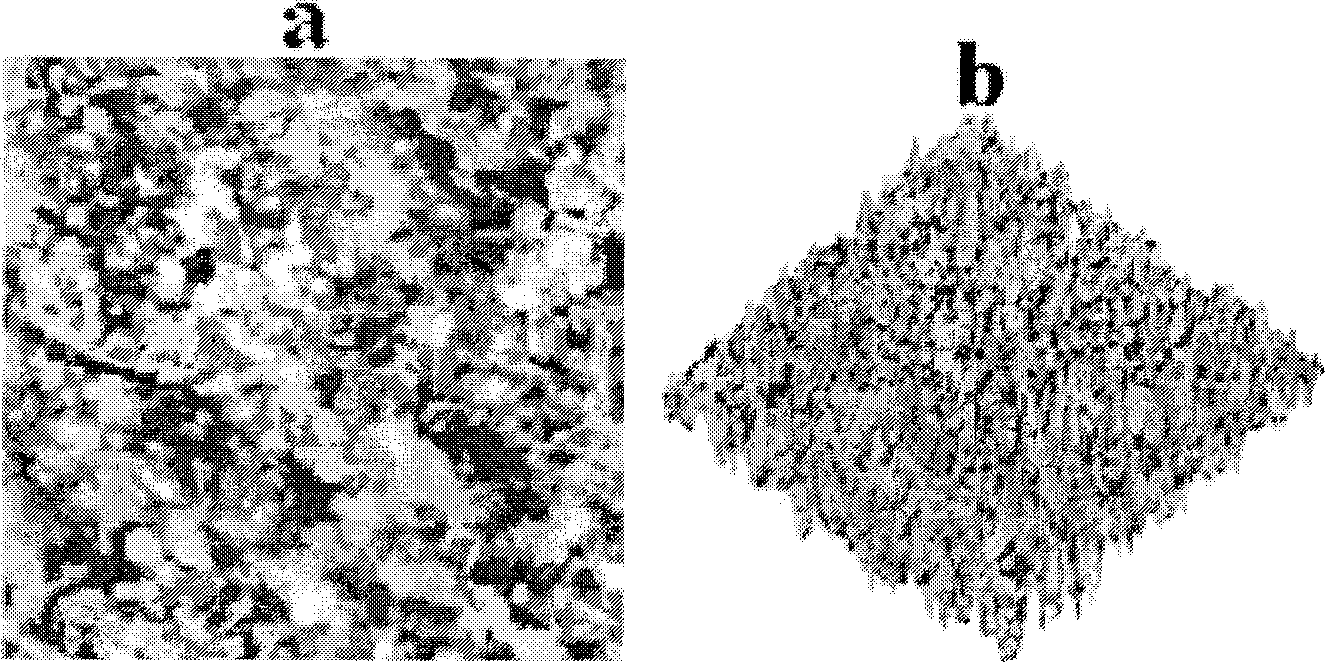

Method for preparing surface-metalized coating of epoxy resin matrix composite material

InactiveCN101967629AIncrease roughnessImprove hydrophilicityLiquid/solution decomposition chemical coatingEpoxyPretreatment method

The invention discloses a method for preparing a surface-metalized coating of an epoxy resin matrix composite material. According to the use requirement of a product, the surface of the product requires metal-plating treatment; and aiming at the problem that the epoxy resin matrix composite material has poor conductivity and cannot be directly plated on the surface. Through a test, a chemical nickel-plating method is adopted to metalize the surface of the epoxy resin matrix composite material; the surface metalized epoxy resin matrix composite material is used as an excellent conductive matrix for the plating; and the subsequent plating treatment is performed. Before the chemical nickel-plating, the material has poor surface activity, and the common pretreatment method only can remove the oil stain from the surface, so an obtained chemically nickel-plated layer has poor binding force. In the method, a pretreatment process of removing oil, roughening, neutralizing, sensitizing and activating is adopted so as to effectively form a catalytic and active center, and facilitate the binding of the chemically nickel-plated layer.

Owner:BEIJING SATELLITE MFG FACTORY

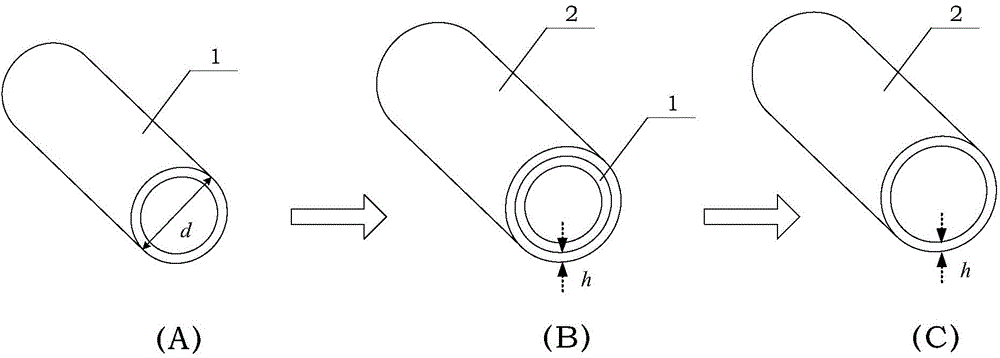

Method for preparing load type titanium dioxide photocatalytic film

InactiveCN101444725AUniform and dense surfaceNo sheddingPhysical/chemical process catalystsFilm-coated tabletFilm coating

The invention discloses a method for preparing a load type titanium dioxide photocatalytic film. The method comprises titanium dioxide sol preparation, titanium dioxide film coating by ultrasonic, dipping and pulling, and drying and calcining. As the method organically combines technology of sol-gel, ultrasonic coated film and dipping and pulling, the load type titanium dioxide photocatalytic film prepared by the method has an even and compact surface, basically does not have shedding phenomenon after three times of acid dipping and ultrasonic oscillating cleaning during a process of 200 hours use, and the photocatalytic efficiency of the film after cleaning is basically not changed. The load type titanium dioxide photocatalytic film has the advantages of stable photocatalytic property, basically invariable degradation velocity, firm attachment, difficult fall-off, high photocatalytic activity and stability and long service life.

Owner:SHANGHAI NORMAL UNIVERSITY

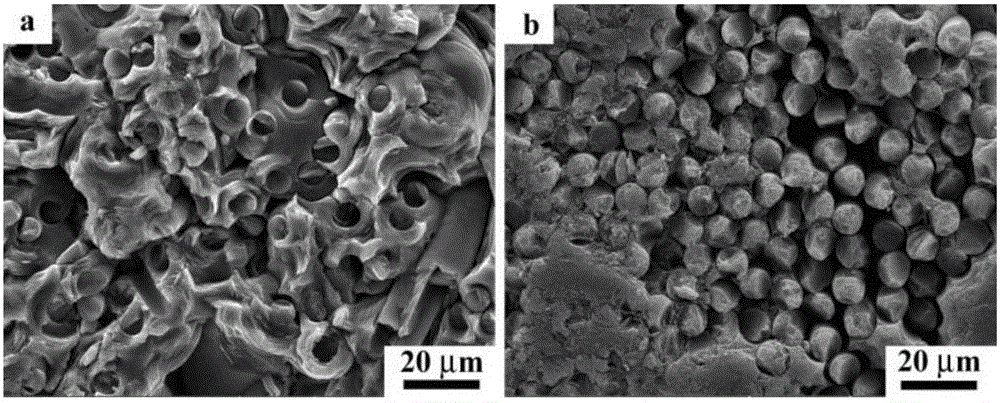

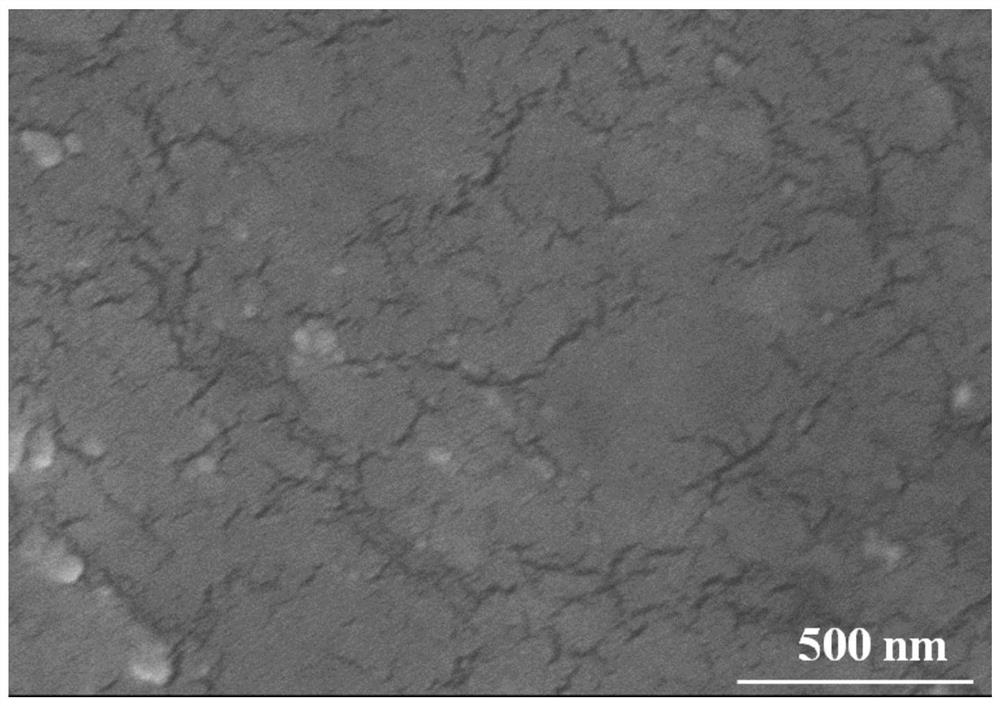

Preparation method of self-assembled folded rGO composite membrane

ActiveCN108295666ASolve the flux is smallResolve separabilityMembranesDistillationSeparation factorWater treatment

The invention discloses a preparation method of a self-assembled folded rGO composite membrane used for dehydration of organic matter and belongs to the field of membrane separation. The method comprises steps as follows: GO (graphene oxide) is sucked to a pretreated porous base membrane with rich amino, then, the base membrane is put in a preheated organic solvent to be modified and put in a glutaraldehyde water solution to be crosslinked, then, a polyelectrolyte is sucked to the surface of the modified GO composite membrane, and finally, the modified GO composite membrane is put in a water solution of a crosslinking agent to be crosslinked. The preparation process is simple, the film forming time is short, the composite membrane is applied to the field of pervaporation, the problems thatthe GO composite membrane has small flux and low separation factor in the pervaporation process are solved, and the composite membrane has uniform and compact surface and can be widely applied to thefield of water treatment.

Owner:BEIJING UNIV OF CHEM TECH

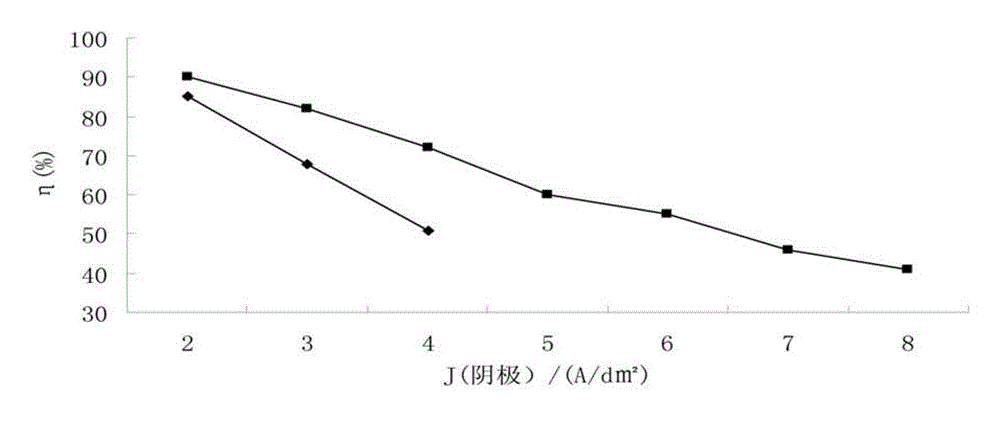

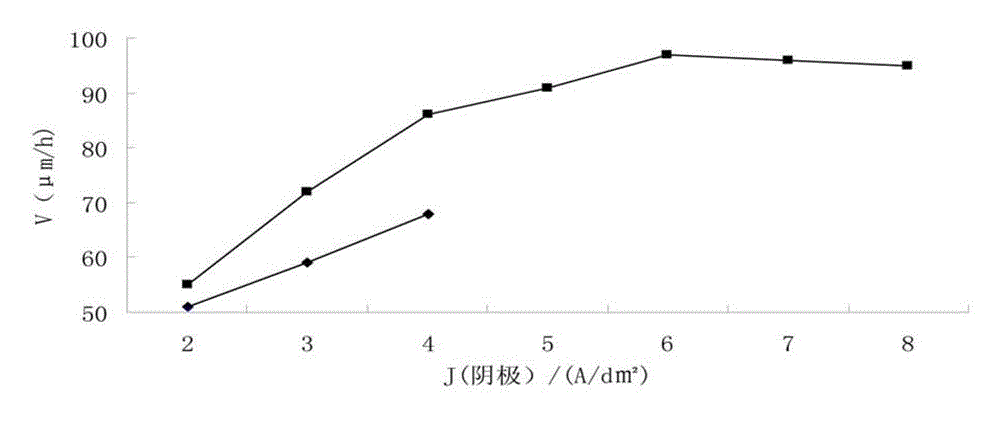

Method for ultrasonic electroplating of aluminum alloy

The present invention discloses a method for ultrasonic electroplating of an aluminum alloy. The method sequentially comprises the following steps: a pre-plating treatment, one time zinc deposition, ultrasonic electroplating of nickel, ultrasonic electroplating of acid copper, ultrasonic electroplating of tin, and a post-plating treatment. With the method, after a tin layer is electroplated on an aluminum alloy, the obtained tin layer has advantages of compact and uniform surface, fine crystal, silver white color, bright mirror surface, oxidation resistance, corrosion resistance and strong weldability.

Owner:中山市珑智金属表面处理有限公司

One-step method for making colour oxide film on surface of aluminium and aluminum alloy

InactiveCN1873059AUniform and dense surfaceImprove wear resistanceSurface reaction electrolytic coatingAlloySodium silicofluoride

This invention discloses a technique for forming a color oxide film on the surface of aluminum and aluminum alloy products. The technique comprises: oxidizing aluminum or aluminum alloy in an aqueous solution of sodium silicate 2-10 g / L, sodium hydroxide 0.5-3 g / L, sodium molybdate 0.2-4 g / L, sodium silicofluoride 0.1-9 g / L, sodium tungstate 0.2-10 g / L, and potassium permanganate 0.5-4 g / L at 10-50 deg.C and current density of 0.08-2 A / cm2 for 0.5-3 h to obtain a yellow / brown / black oxide film. The oxide film is uniform and compact, and has a thickness of 20-200 mum. Besides, the oxide film also has good wear and corrosion resistance. The technique has such advantages as simple process, and no pollution.

Owner:YANSHAN UNIV

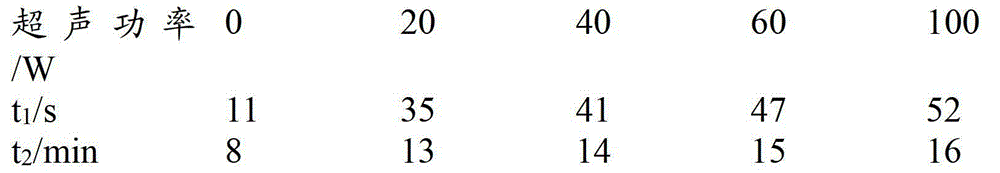

Method and apparatus of processing magnesium alloy surface utilizing vacuum composite plating film

ActiveCN1924078AImprove the finishImprove appearance qualityVacuum evaporation coatingSputtering coatingSurface finishElectrochemistry

The invention discloses a composite disposing method of magnesium alloy surface, which is characterized by the following: washing base material through plasmid or glow discharge; adopting electric arc ion coating method and magnetic spraying control method to coat chromium film on the magnesium base in the vacuum.

Owner:兰州大成科技股份有限公司

Compound plating solution for obtaining nano compound plating layer with resistance to abrasion and high temperature oxidation, and plating method thereof

Owner:HENAN UNIV OF SCI & TECH

Hollow-pipe micro-lattice ceramic material constructed by adopting template method and preparation method thereof

InactiveCN104694904AImprove performanceDesignableVacuum evaporation coatingSputtering coatingAviationPolymer science

The invention discloses a hollow-pipe micro-lattice ceramic material constructed by adopting a template method and a preparation method thereof. The method comprises the steps: preparing a three-dimensional micro-lattice polymer template of a designed structure by adopting a rapid forming technology; depositing ceramics on the surface of the micro-lattice polymer template so as to prepare a preformed body; removing a template, thereby obtaining the hollow-pipe micro-lattice ceramic material. According to the hollow-pipe micro-lattice ceramic material constructed by adopting the template method and the preparation method thereof, the template method and a thin-film deposition method are organically combined, and the prepared lightweight and porous hollow-pipe micro-lattice ceramic material has the characteristic of low density and the properties of high strength, high modulus, high hardness, high-temperature resistance, corrosion resistance, radiation resistance, small thermal expansion coefficient and the like and is a multifunctional, lightweight and porous micro-lattice material. The hollow-pipe micro-lattice ceramic material is applied to the fields of aviation, aerospace, electronic information and the like.

Owner:BEIHANG UNIV

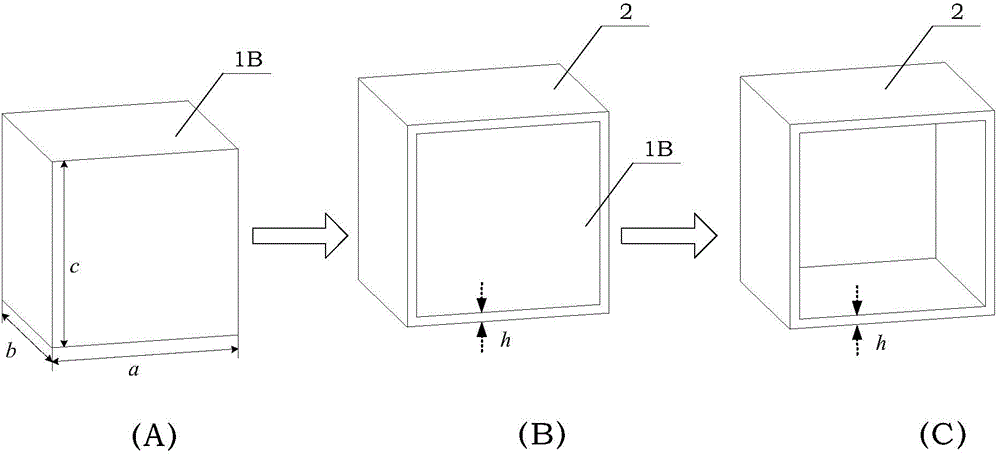

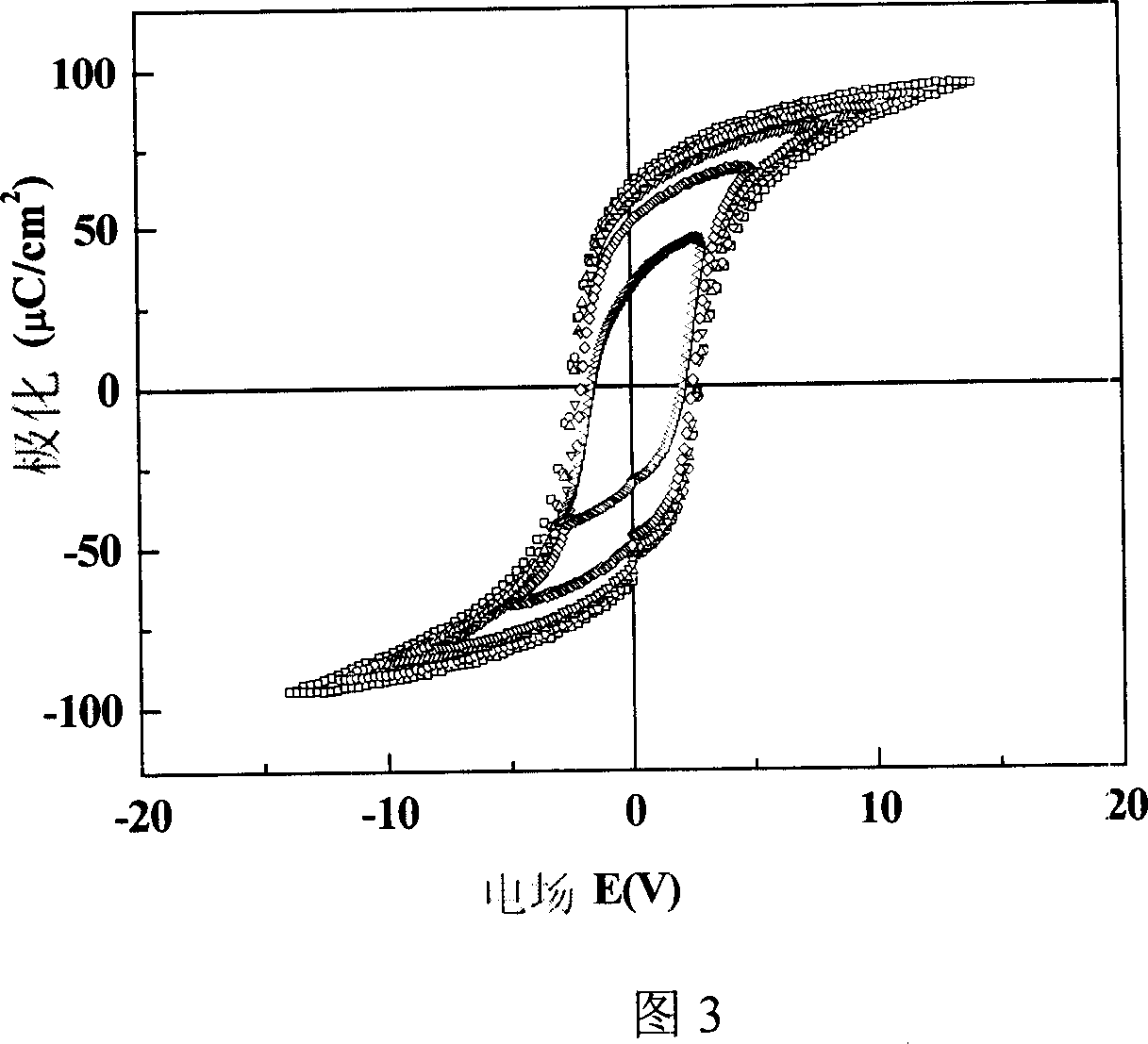

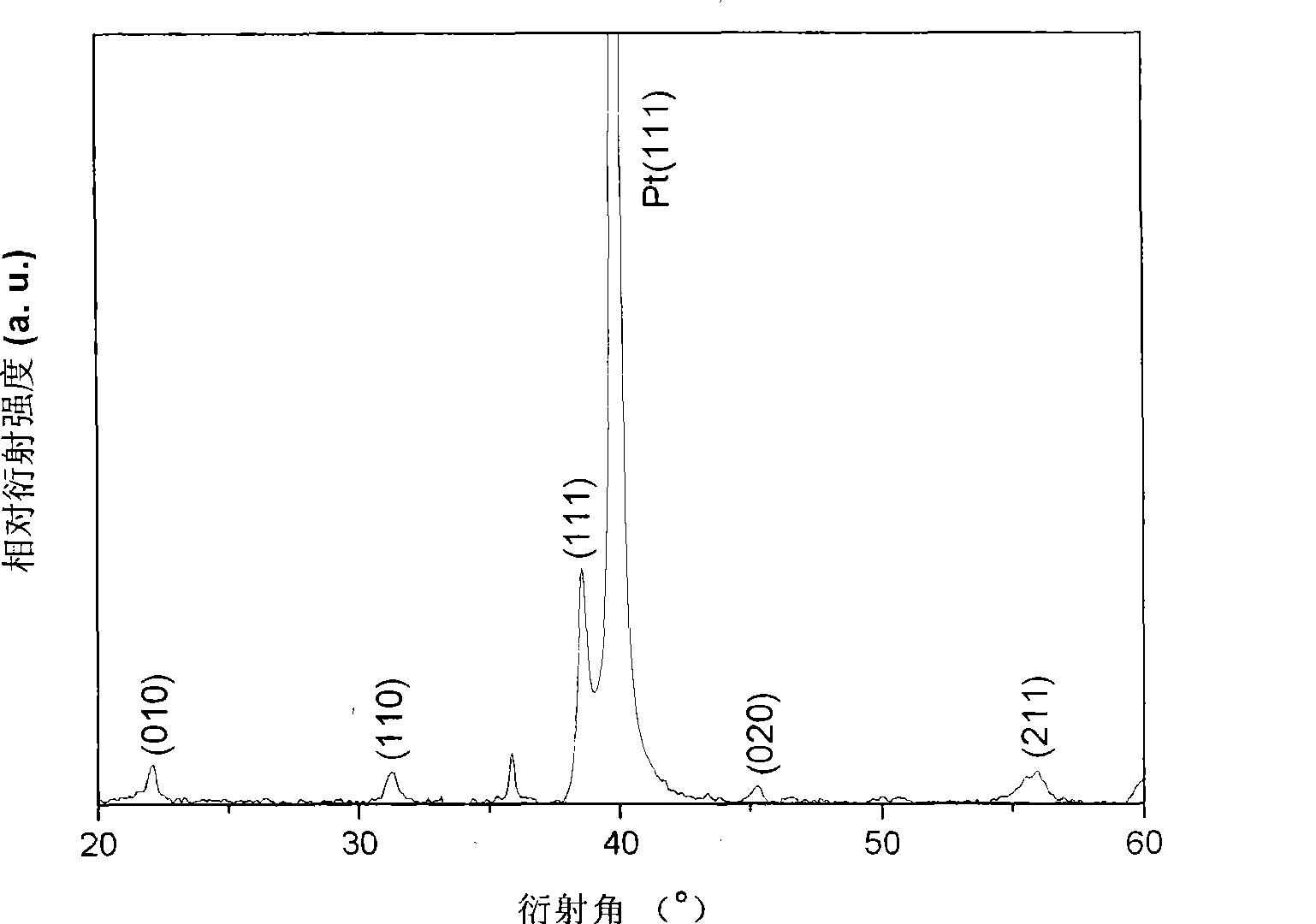

Ferroelectric film capacity used for ferroelectric memorizer and its manufacturing method

InactiveCN1967848AHigh crystallinityUniform and dense surfaceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceSputtering

The invention relates to a ferro-electricity film capacitor of ferro-electricity and relative preparation, wherein said film capacitor is formed by silicon substrate, silica dioxide baffle layer, titania adhesive layer, low electrode metal layer, low buffer layer, ferro-electricity film layer, up buffer layer, and up electrode metal layer; the adhesive layer is 10-30nm thick; the low electrode metal layer is 100nm-300nm; the low buffer layer is 5-20nm thick; the ferro-electricity is 200-500nm thick; the up buffer layer is 100-200nm thick; the up electrode metal layer is 80-150nm thick. The inventive capacitor has low fatigue speed, low drain current. The invention uses magnetic control splash method to layer-to-layer splash production, while the product has better property, with single direction.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of silicon chip used for planar solid discharge tube chip manufacturing process

InactiveCN102324386ASimple manufacturing processSimple processSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention provides a preparation method of a silicon chip used for a planar solid discharge tube chip manufacturing process. The method comprises the following steps: carrying out acid corrosion on a silicon chip to remove silicon and obtaining a silicon chip with a certain thickness; carrying out alkali etch on the silicon chip whose thickness becomes thinner until a surface of the silicon chip becomes compact and uniform; carrying out second acid corrosion on the silicon chip with a compact and uniform surface to obtain a silicon chip which meets a thickness requirement and has a compact and uniform surface. According to the invention, a principle that the acid corrosion can rapidly remove silicon and the alkali etch can obtain a compact and uniform surface is utilized, a corrosion mode is employed to process the silicon chip to obtain the silicon chip which meets the thickness requirement and has the compact and uniform surface; a corrosion process flow has the advantages of a simple process, a simple operation, small energy consumption, good silicon chip consistency, a large surface metal Ohm connecting area and a low chip broken rate.

Owner:YIXING HUANZHOU MICRO ELECTRONICS

ITO/Nb composite modified polymer electrolyte membrane fuel cell metal bipolar plate and preparation method therefor

InactiveCN106920977AUniform and dense surfaceReduce defectsFinal product manufactureCollectors/separatorsPolymer electrolytesFuel cells

The invention provides an ITO / Nb composite modified polymer electrolyte membrane fuel cell metal bipolar plate. A 2-6[mu]m ITO / Nb composite modification layer is on the surface of the metal bipolar plate, wherein the corrosion speed is lower than 10[mu]A / cm<2>, and contact resistance is lower than 10m<omega>.cm<2>. Under the premise of ensuring sufficient strength, a magnetron sputtering method is adopted by the preparation method disclosed by the invention, so that the corrosion resistance and surface electrical conductivity of the metal bipolar plate can be improved synchronously, and the performance of the polymer electrolyte membrane fuel cell is improved; and the preparation method has the advantages of mature process, continuous production, and excellent surface quality of the modification layer, so that large-scale batch production of the bipolar plate can be realized.

Owner:DALIAN JIAOTONG UNIVERSITY

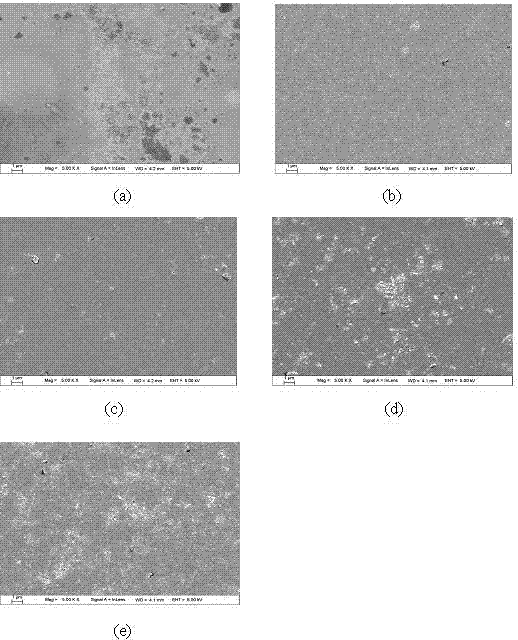

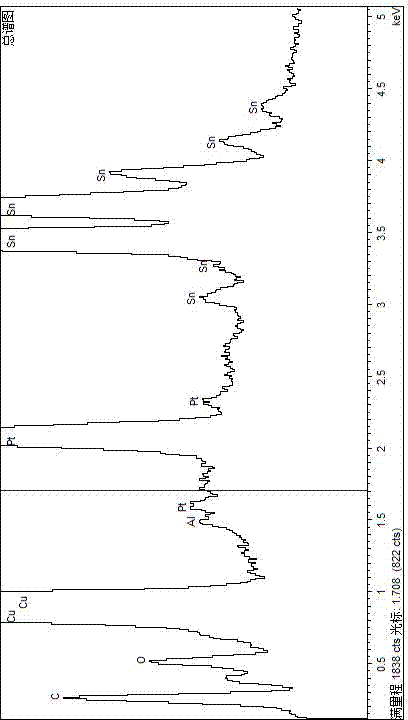

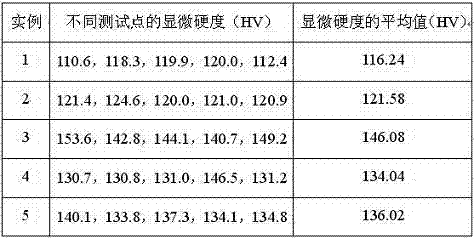

Preparation method for nano-composite high-tin copper alloy electroplating material

The invention relates to the field of composite electroplating technology, and particularly relates to a preparation method for a nano-composite high-tin copper alloy electroplating material. The preparation method comprises the steps of adding a certain amount of Al2O3 nano powder (with average particle size of less than 100nm) into pyrophosphate electroplating copper-tin alloy plating solution, stirring bath solution by a stirrer in the preparation process, fully suspending in the plating solution to avoid the clustering of the nano powder, reducing metal ions by utilizing the electro-deposition principle, embedding nano alumina into a plating layer, to reduce holes and cracks on the surface of the plating layer. The surface of the prepared coating is compact, and the microhardness distribution is relatively even.

Owner:安徽金瑞表面处理有限公司

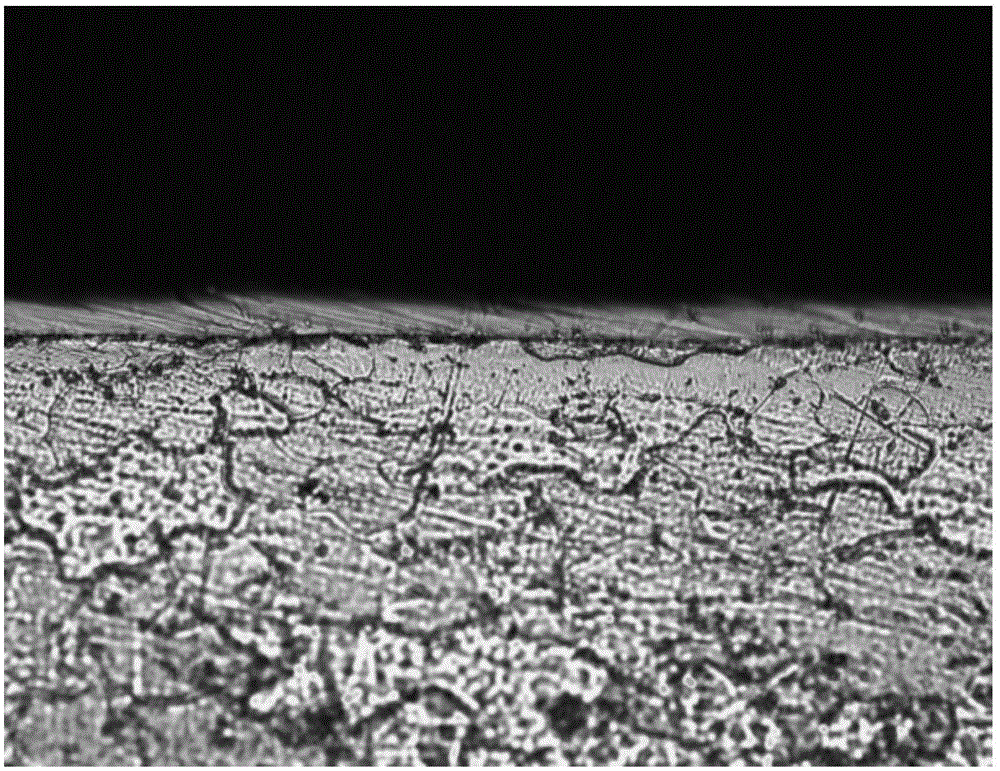

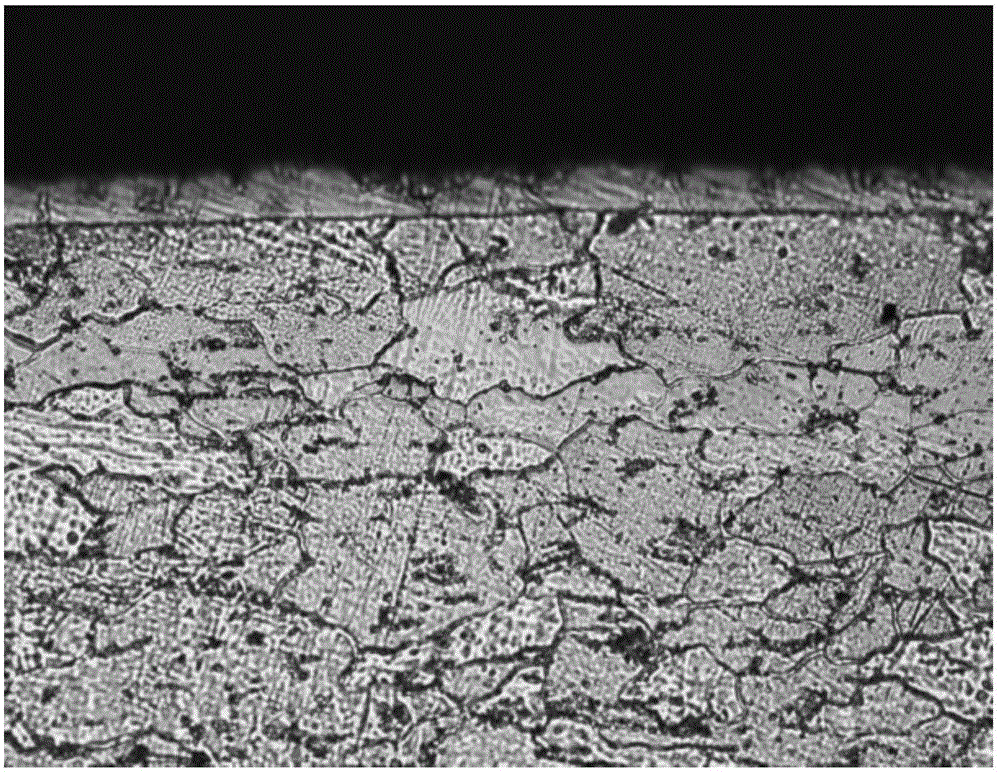

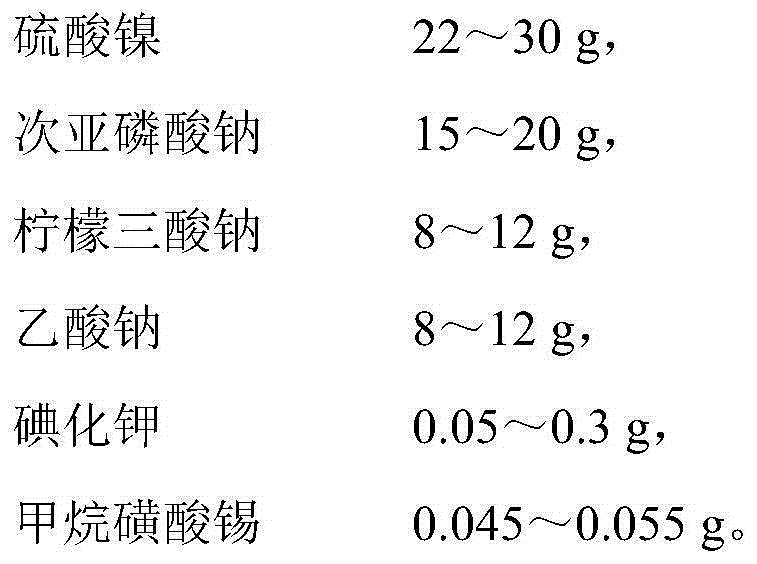

Ni-P electroless plating solution and preparation method for Ni-P nano cubic boron nitride composite coating

ActiveCN105132895AUniform and dense surfaceImprove bindingLiquid/solution decomposition chemical coatingBoron nitrideHardness

The invention provides a Ni-P electroless plating solution and a preparation method for a Ni-P nano cubic boron nitride composite coating. Potassium iodide serves as a single stabilizer for a conventional Ni-P electroless plating solution, so that the stability of the conventional Ni-P electroless plating solution is limited in some cases. According to the Ni-P electroless plating solution, the stability of the Ni-P electroless plating solution is improved through a potassium iodide / tin methanesulfonate compound stabilizer, and the harmful effect of tiny particles (such as nano particles) on the stability of the electroless plating solution in the electroless plating process is reduced. The Ni-P nano cubic boron nitride composite coating is prepared by using the Ni-P electroless plating solution. The composite coating prepared through the preparation method is compact, even, good in binding force, high in hardness and abrasion resistance, and has excellent corrosion resistance; the service life of workpieces is prolonged.

Owner:FUNIK ULTRAHARD MATERIAL

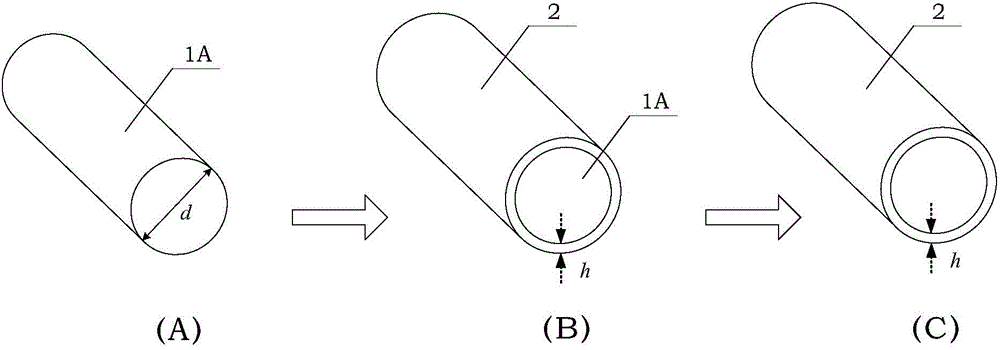

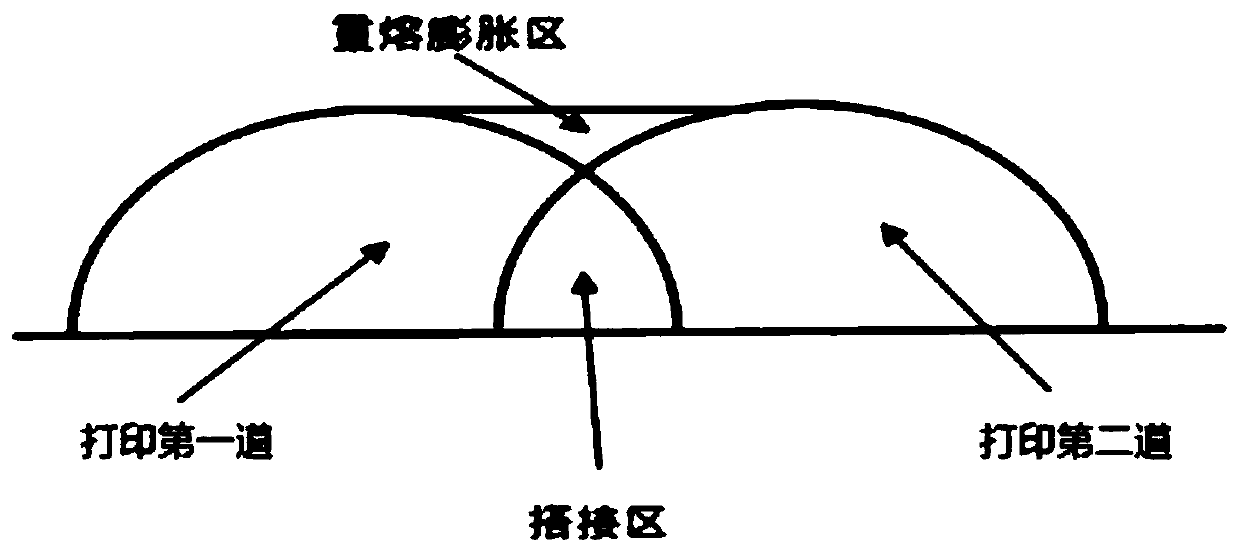

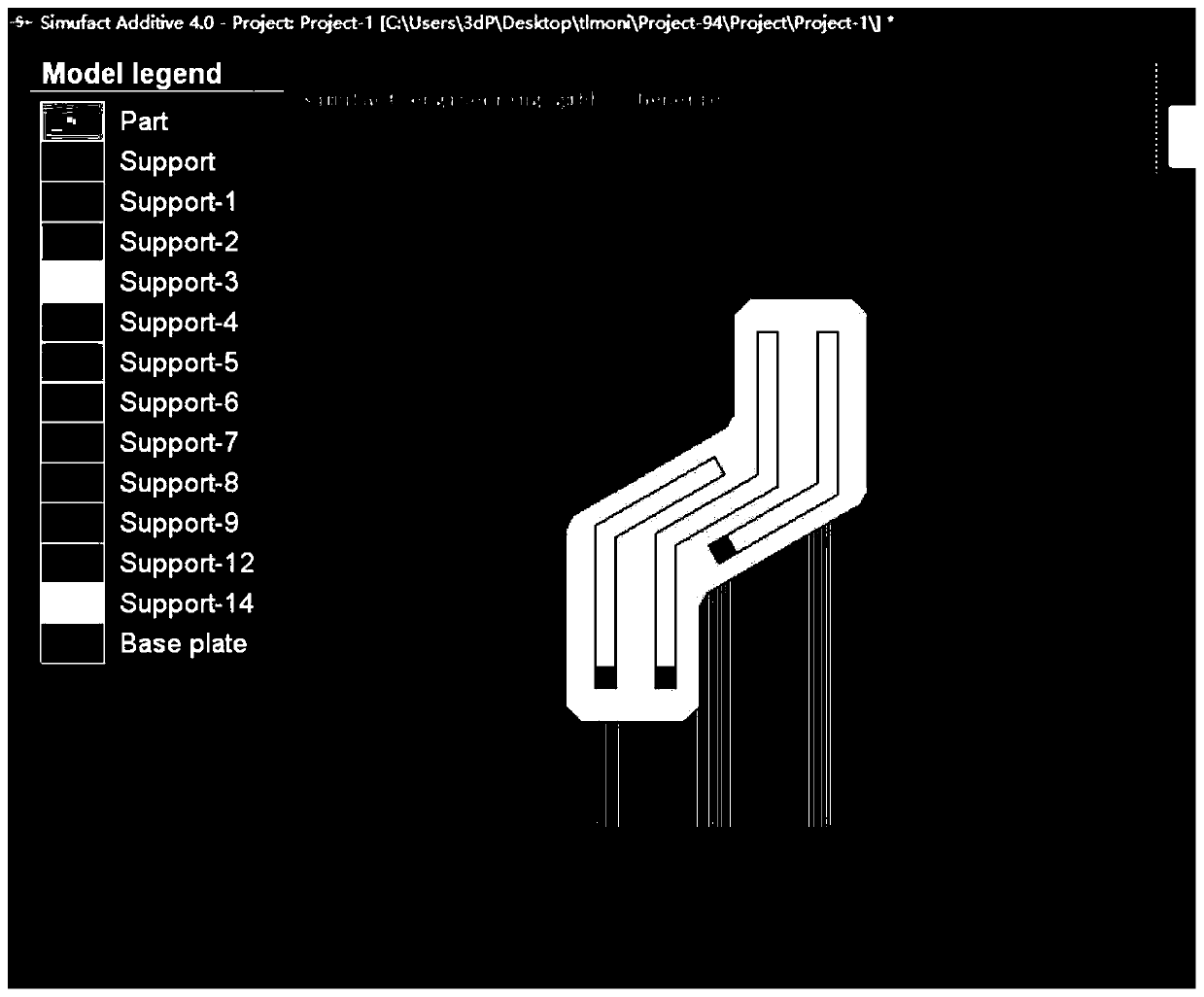

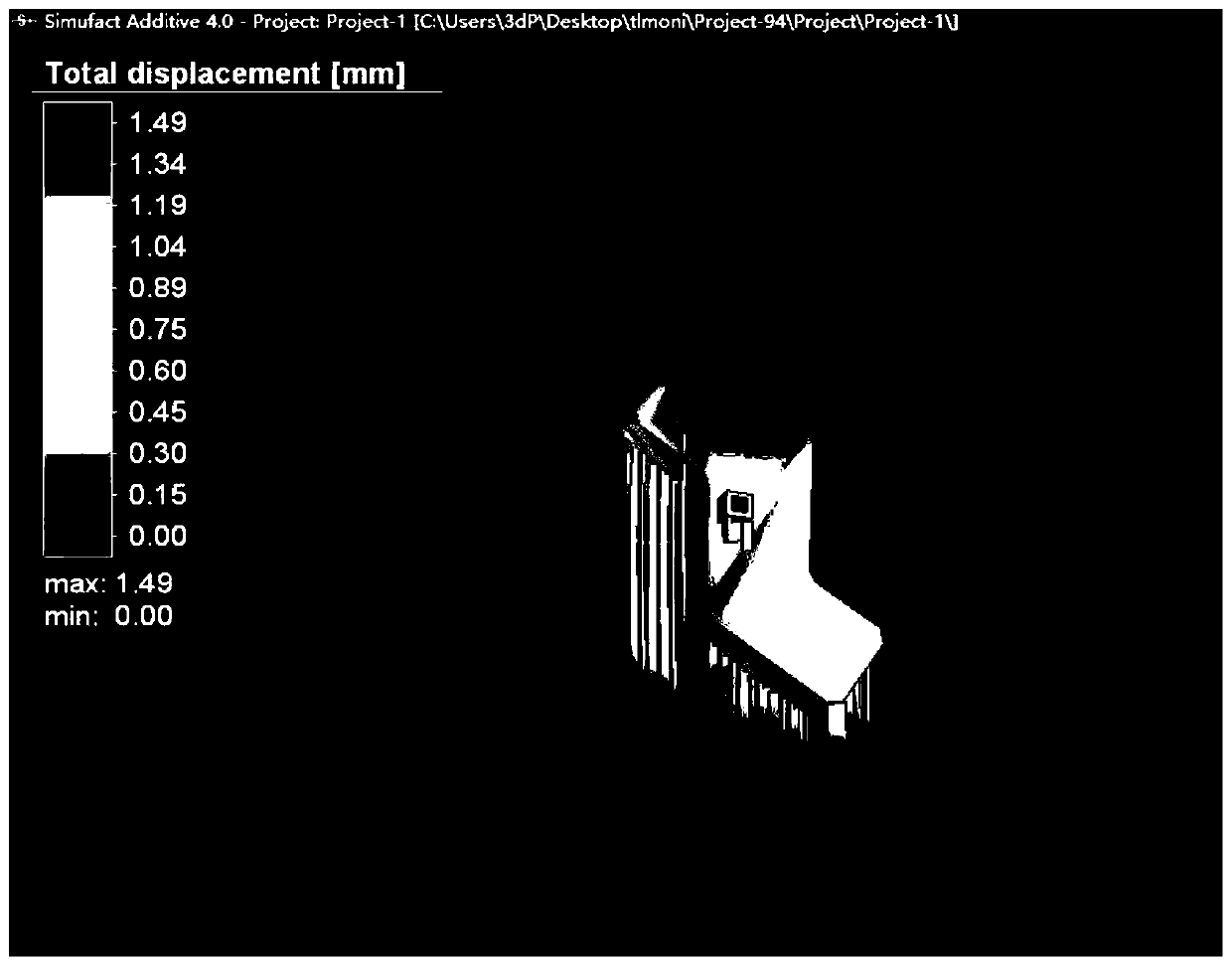

Material additive manufacturing method of square hole pipeline aluminum alloy part

PendingCN110170654AUniform and dense surfaceAvoid surface defectsAdditive manufacturing apparatusIncreasing energy efficiencyAluminium alloyTime integral

The invention discloses a material additive manufacturing method of a square hole pipeline aluminum alloy part. The material additive manufacturing method of the square hole pipeline aluminum alloy part includes: first, performing modeling and hierarchy slicing for the square hole pipeline aluminum alloy part, then feeding raw material into a 3D (three dimensional) printing device for melting, printing and shaping, and finally obtaining the square hole pipeline aluminum alloy part. The material additive manufacturing method of the square hole pipeline aluminum alloy part converts horizontal plane printing to oblique plane printing, achieves material additive manufacturing of the square hole pipeline aluminum alloy part on the premise of meeting accuracy of the inner wall of a square hole pipeline, obtains a uniform and compact surface for the square hole pipeline aluminum alloy part manufactured through simple scanning and chessboard scanning modes, avoids surface defects in machining,simplifies the manufacturing process, shortens a manufacturing period, achieves one-time integral shaping for the square hole pipeline aluminum alloy part, and greatly improves production efficiency.

Owner:SHAANXI SCI TECH UNIV

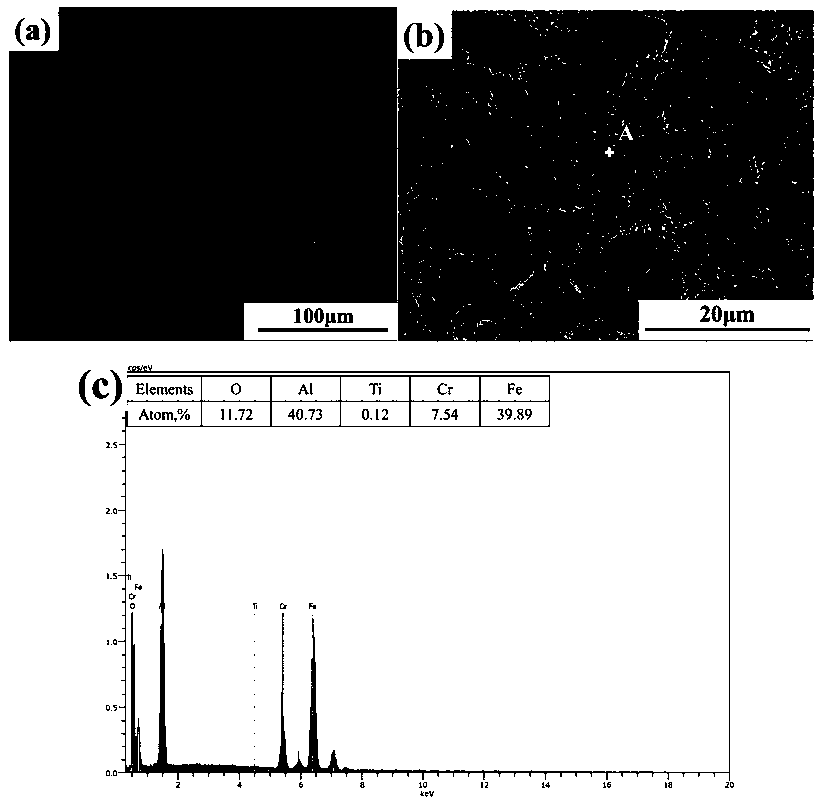

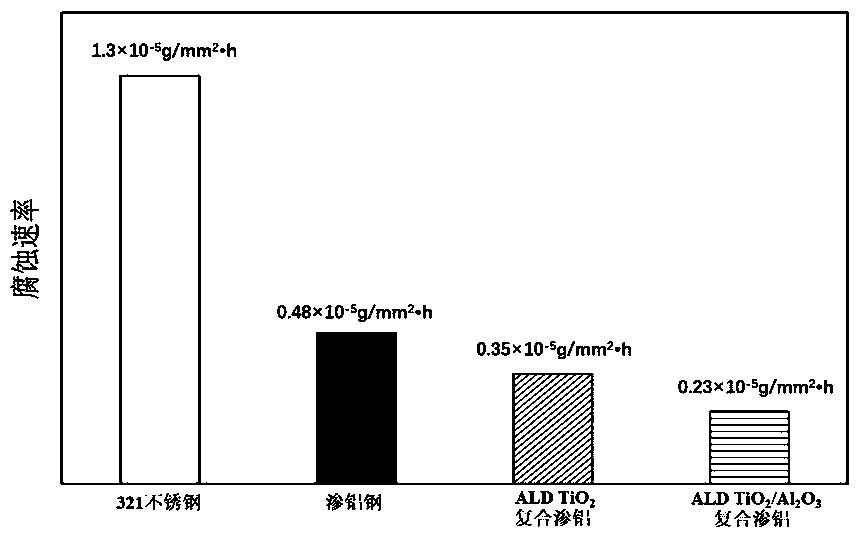

Anti-fusion aluminum silicon alloy corrosion composite coating layer and preparation method and application thereof

ActiveCN109943803AAccelerated corrosionImprove bindingSolid state diffusion coatingChemical vapor deposition coatingSilicon alloySand blasting

The invention discloses an anti-fusion aluminum silicon alloy corrosion composite coating layer and a preparation method and application thereof. The composite coating layer comprises an aluminum permeating layer and a TiO2 film layer from the surface of a basal body to the external in sequence. The preparation method of the coating layer comprises the following steps: (S1) the surface of an ironbase alloy is treated; and then, a solid powder permeating agent is adopted to permeate aluminum; (S2) sand is blasted to the iron base alloy after aluminum permeation; (S3) the iron base alloy is washed and dried after sand blasting; and (S4) a TiO2 film layer is deposited on the surface of the dried iron base alloy after aluminum permeation by adopting an atomic layer vapor deposition method. The composite coating layer is uniform in structure, low in internal stress, tight in combination and small in porosity, can separate the combination between fused metal and the basal body, is excellentin corrosion resistance of an anti-fusion aluminum silicon alloy, and can be applied to solar heat power generation heat exchange tubes.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

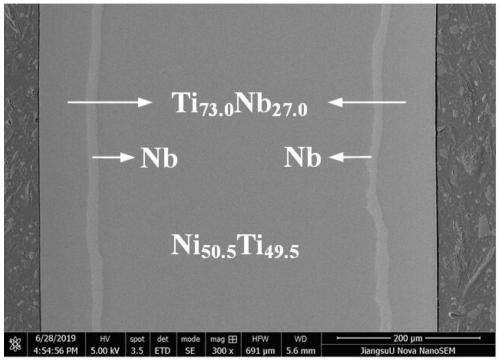

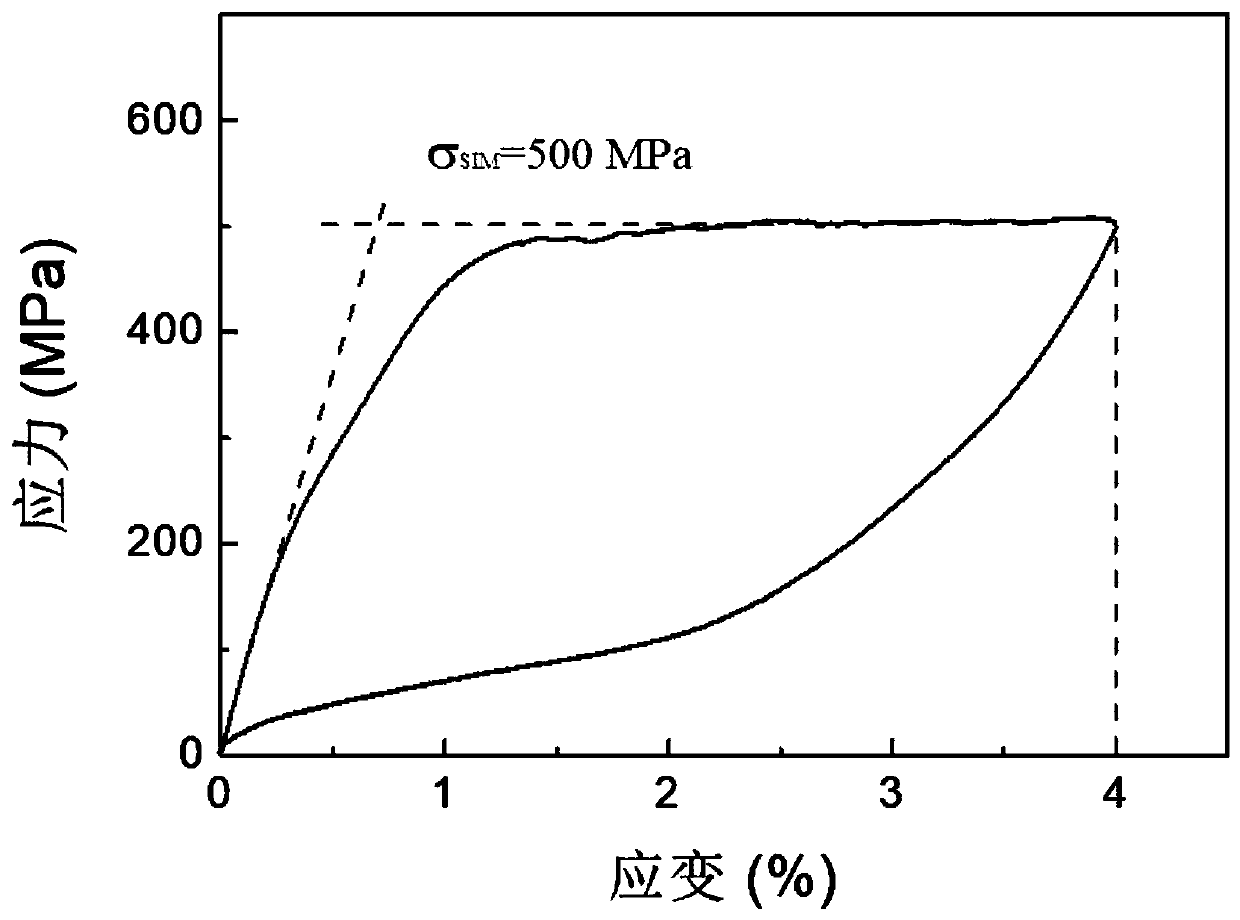

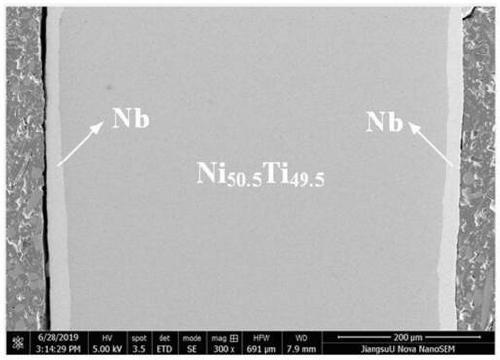

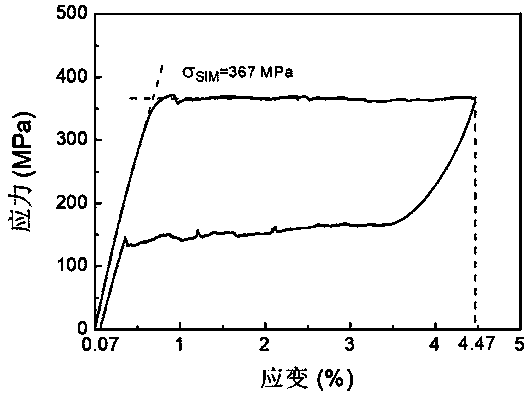

Nb layer-containing TiNb/NiTi memory material and preparation method

ActiveCN111187945AGood biocompatibilityImprove mechanical propertiesTemperature control deviceWork heating devicesMartensite transformationShape-memory alloy

The invention relates to the technical field of biomedical shape memory composite materials, in particular to a Nb transition layer-containing TiNb-coated NiTi shape memory composite material and a preparation method thereof. The composite material prepared by the method has good biocompatibility, relatively high stress-induced martensitic transformation critical stress and large recoverable dependent variable. The Nb transition layer-containing TiNb-coated NiTi shape memory composite material is expected to solve the problems that existing single biomedical shape memory alloys, such as NiTi-based alloys and Ni-free beta-titanium alloys, cannot simultaneously have good biocompatibility, relatively high stress-induced martensite transformation critical stress and large recoverable dependentvariable, and is expected to be applied in the field of biomedicines.

Owner:JIANGSU UNIV

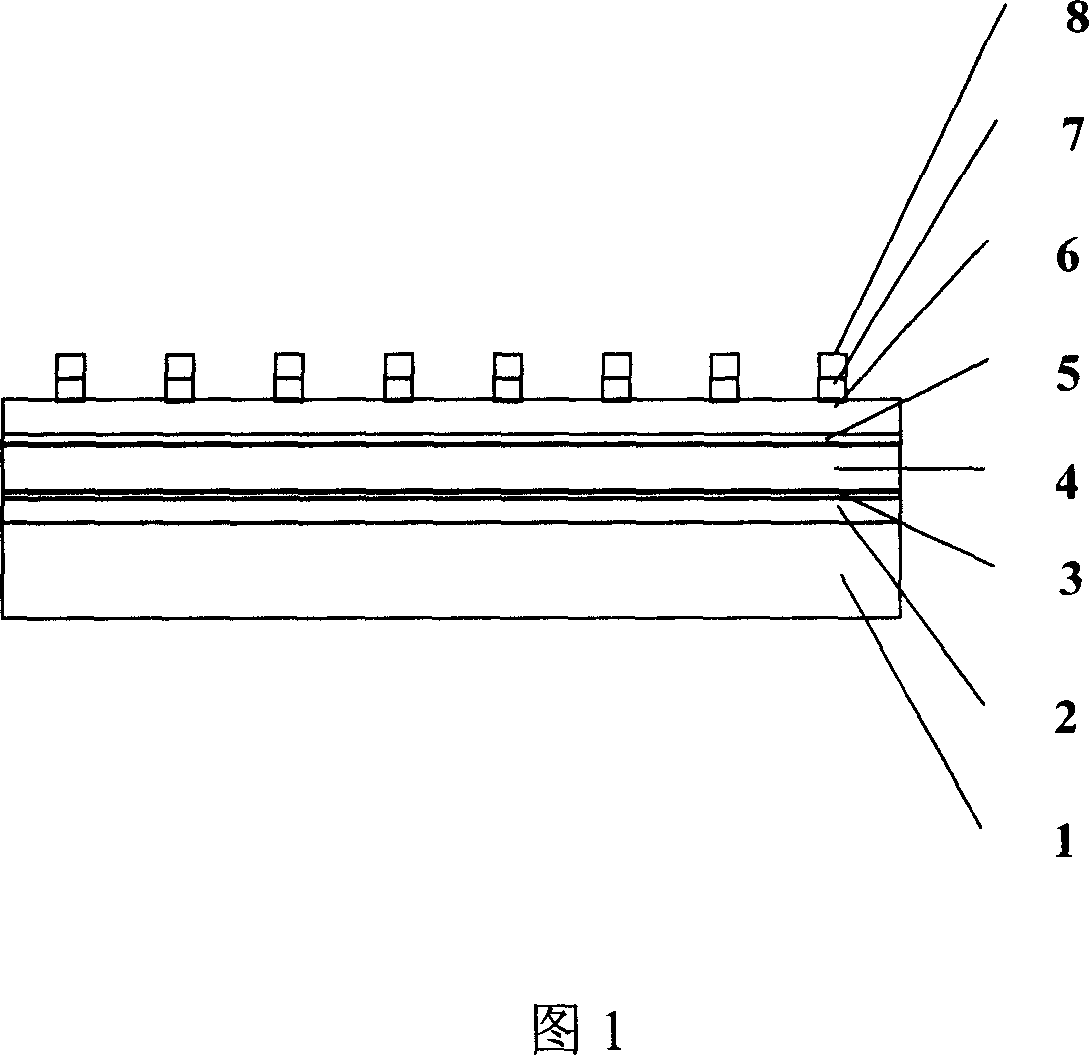

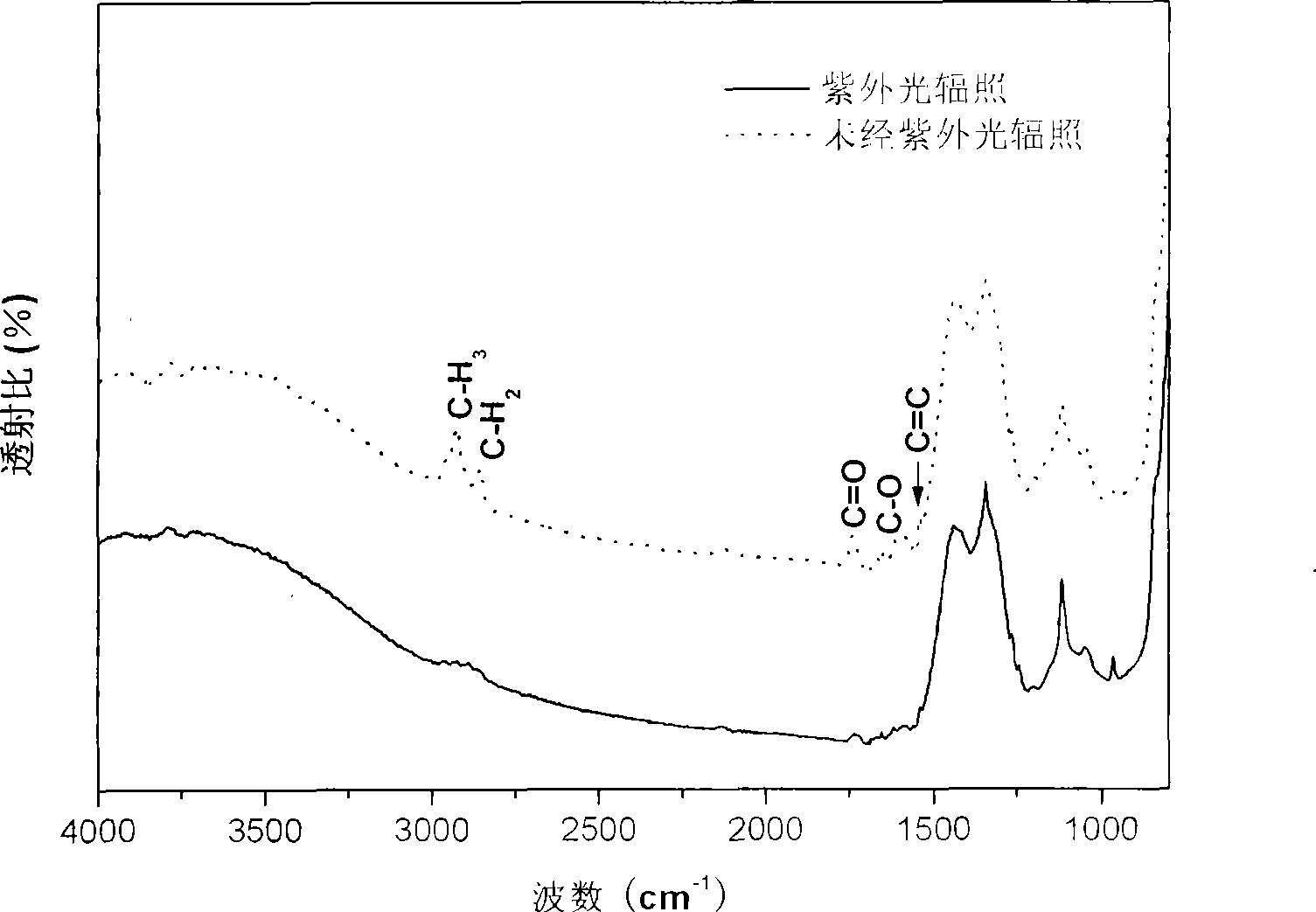

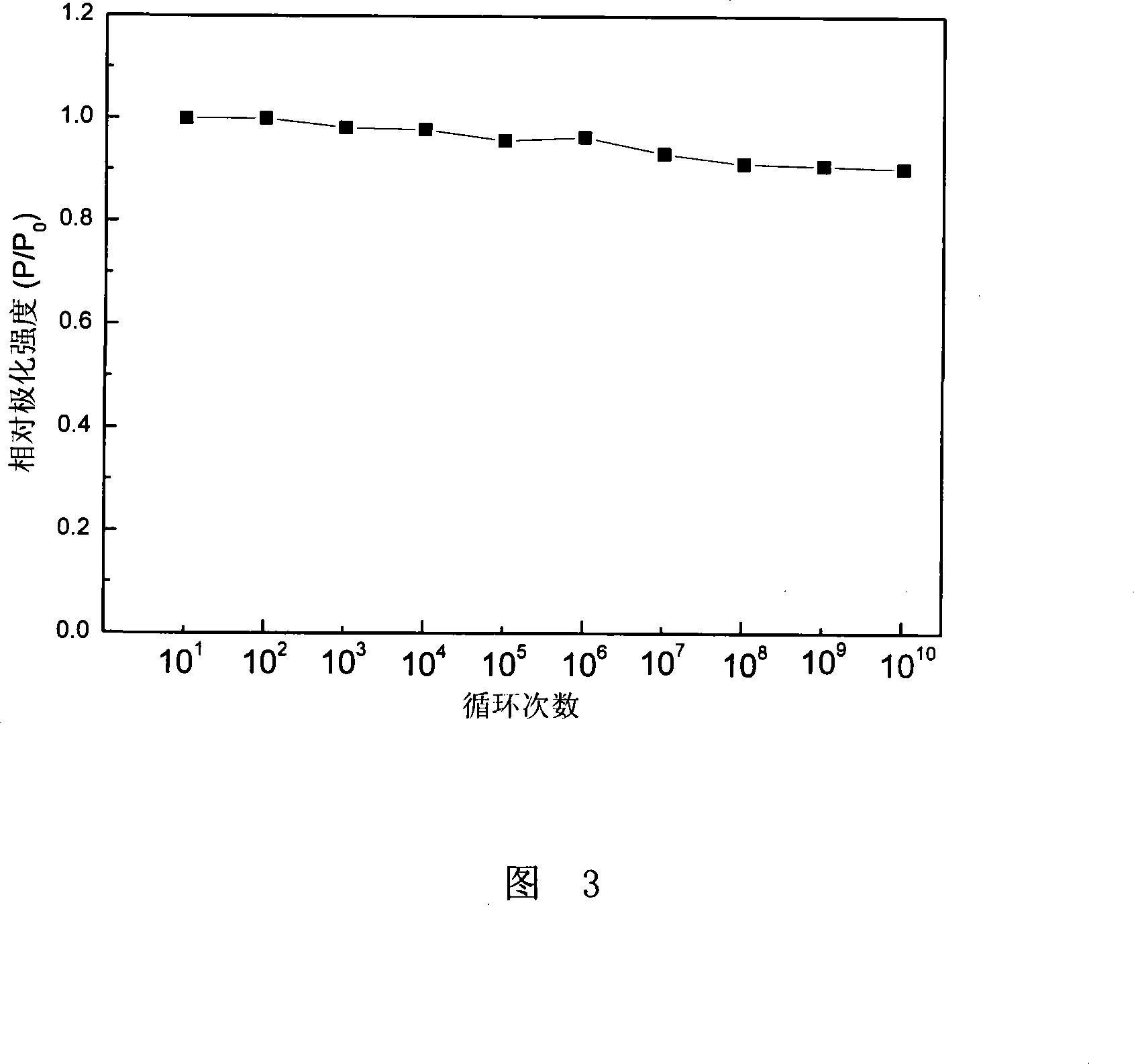

Ultraviolet light assistant preparation method for ferro-electricity film of ferro-electric memory

InactiveCN101436532AGuaranteed ferroelectricityFerroelectricity maintained or enhancedSemiconductor/solid-state device manufacturingUltraviolet lightsCrystallization temperature

The invention discloses an ultraviolet light assistant preparation method for a ferroelectric film for a ferroelectric memory, and belongs to the field of microelectronic information functional materials and devices. The concentration of PZT precursor solution for the ferroelectric memory is 0.1-0.3 mo1 / 1. The method comprises: after glue evening of each rotation, a film is baked and radiated by even ultraviolet light, the intensity of illumination is between 10 and 15 mW / cm<2>; then the film is subjected to pyrolysis treatment; and finally the PZT film is subjected to annealed treatment at a temperature of between 550 and 600 DEG C. The PZT ferroelectric film for the ferroelectric memory is a polycrystalline film, has the characteristics of good ferroelectric performance, fatigue endurance and current leakage resistance, has the advantage of low crystallization temperature, and can be compatible with the prior Si semiconductor process.

Owner:HUAZHONG UNIV OF SCI & TECH

Composite middle layer for titanium-based oxide electrode, titanium-based oxide electrode and preparation method of electrode

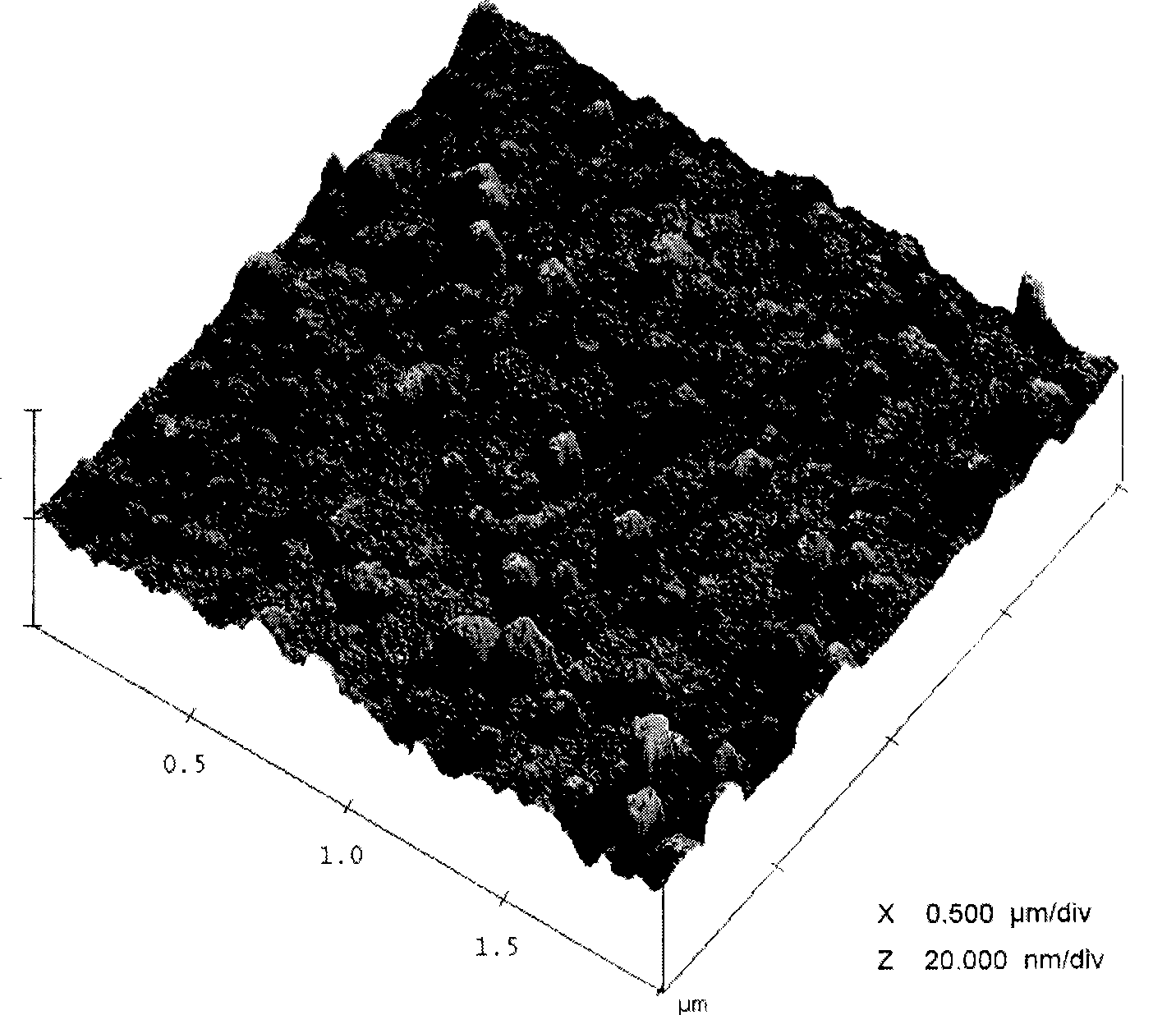

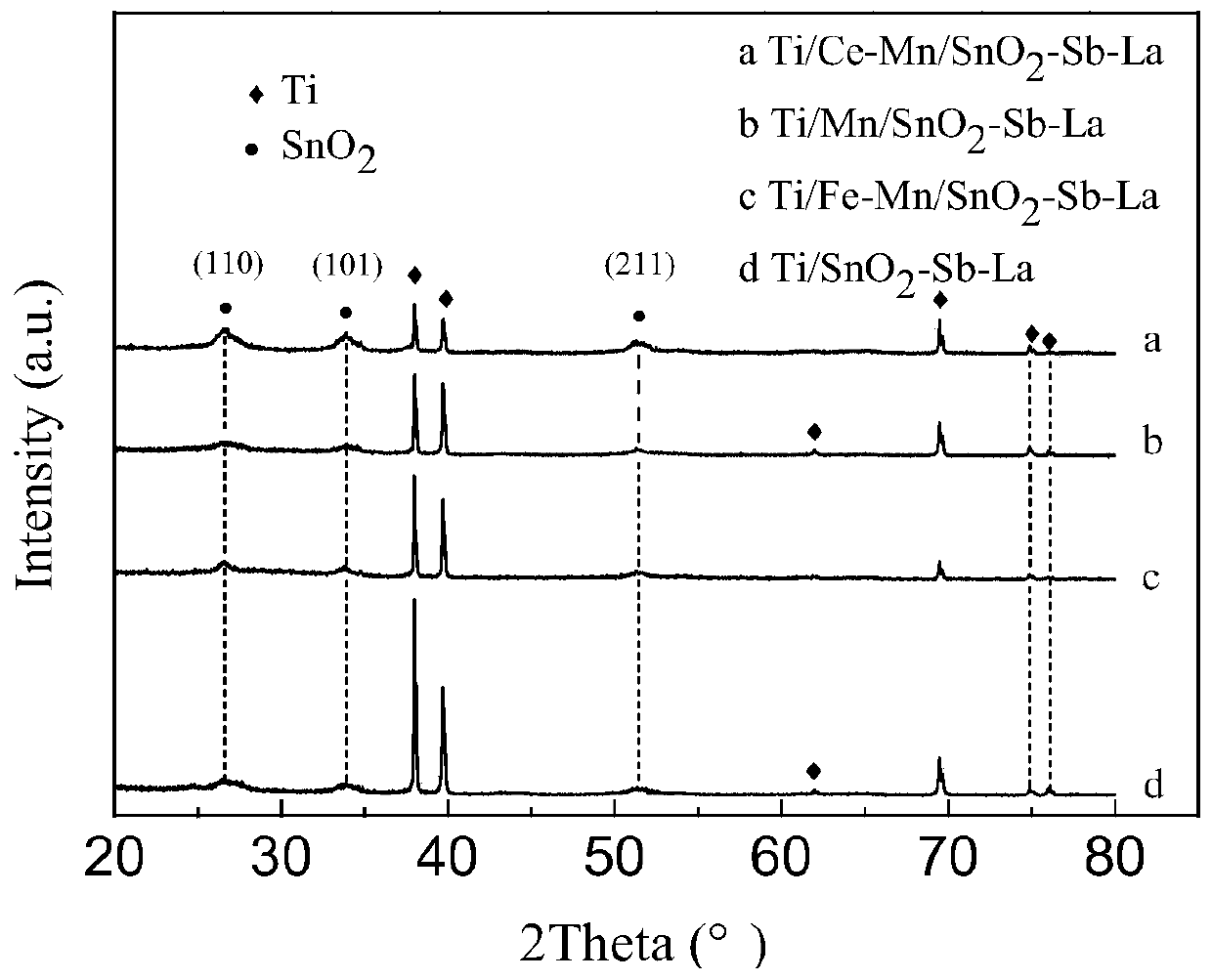

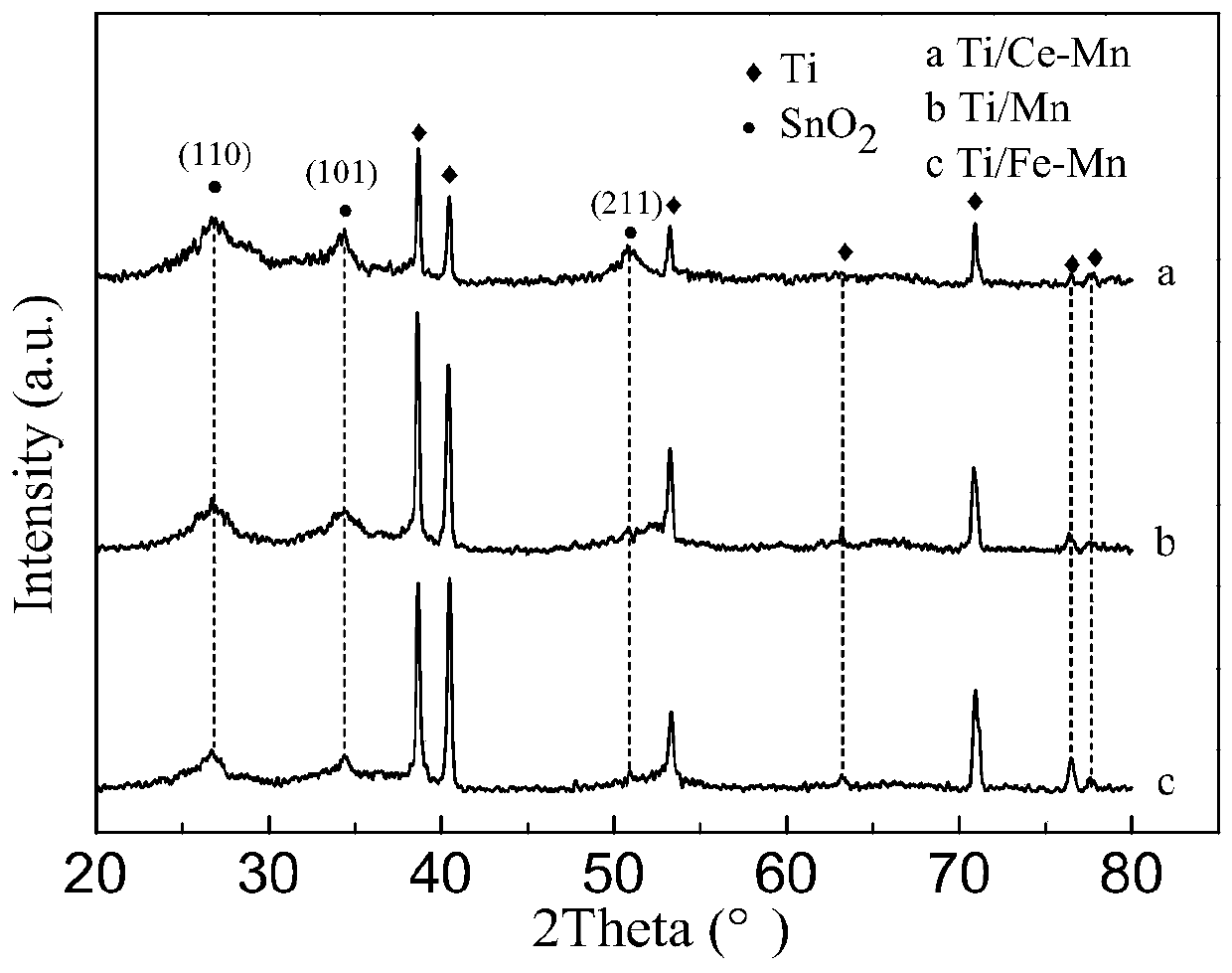

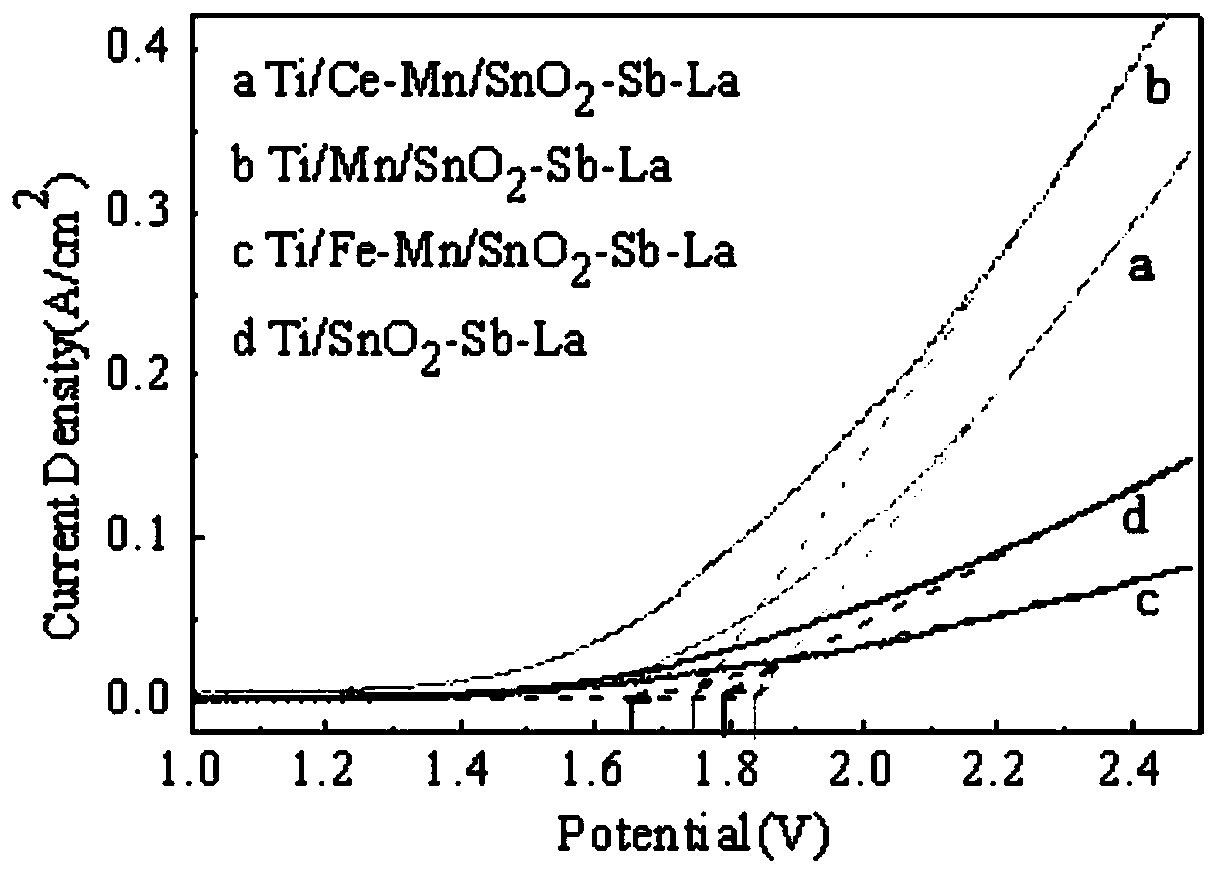

ActiveCN109775813AHigh catalytic activityUniform and dense surfaceWater contaminantsWater/sewage treatment using germicide/oligodynamic-processTitaniumSolid solution

The invention provides a composite middle layer for a titanium-based oxide electrode and relates to the technical field of metal oxide electrodes. The composition of the composite middle layer comprises MnO2, CeO2, SnO2 and Sb2O3; the MnO2 and the CeO2 are doped in the SnO2 and the Sb2O3 through a solid solution form; the molar ratio of the Mn element to the Ce element to the Sn element to the Sbelement in the composite middle layer is (0.01-0.05):(0.01-0.2):(0.5-1.5):(0.05-0.15). The invention provides the titanium-based oxide electrode and a preparation method thereof. The titanium substrates in the composite middle layer and the titanium-based oxide electrode are well combined, the electrochemical performance of the titanium-based oxide electrode, the electrocatalytic oxidation degradation capacity of the titanium-based oxide electrode to phenol and the stability the titanium-based oxide electrode can be obviously improved, and the service life of the titanium-based oxide electrodecan be obviously prolonged.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Zinc-based antibacterial non-woven fabric and preparation method thereof

InactiveCN111455664AHigh specific surface energyLarge surface structureBiochemical fibre treatmentFibre typesPolymer scienceNonwoven fabric

The invention relates to a zinc-based antibacterial non-woven fabric and a preparation method thereof. The zinc-based antibacterial non-woven fabric is prepared by preparing a zinc-based nano-antibacterial dispersion liquid, mixing the zinc-based nano-antibacterial dispersion liquid with a dispersant and a synergist, carrying out dipping treatment on a polypropylene fiber non-woven fabric, and drying the polypropylene fiber non-woven fabric. The zinc-based antibacterial non-woven fabric is green, environment-friendly, non-toxic, non-irritating, short in antibacterial action time and lasting inantibacterial effect, and has excellent properties of good stability, no decomposition when meeting light and heat and the like.

Owner:南京凯创协同纳米技术有限公司

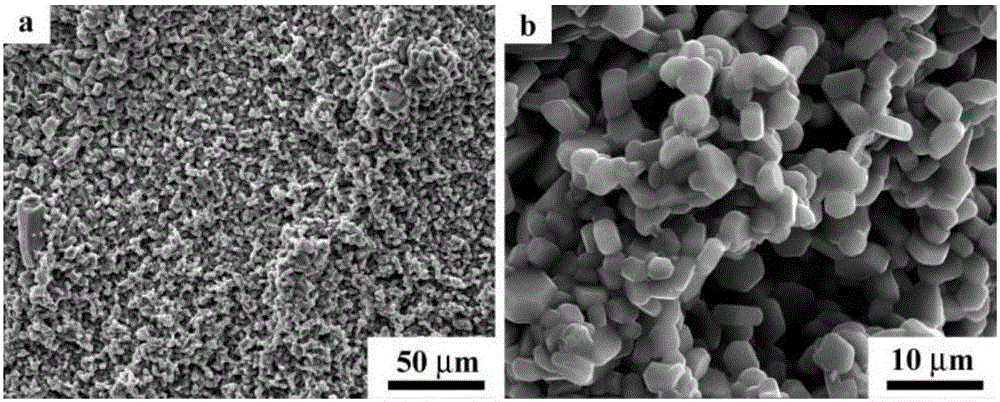

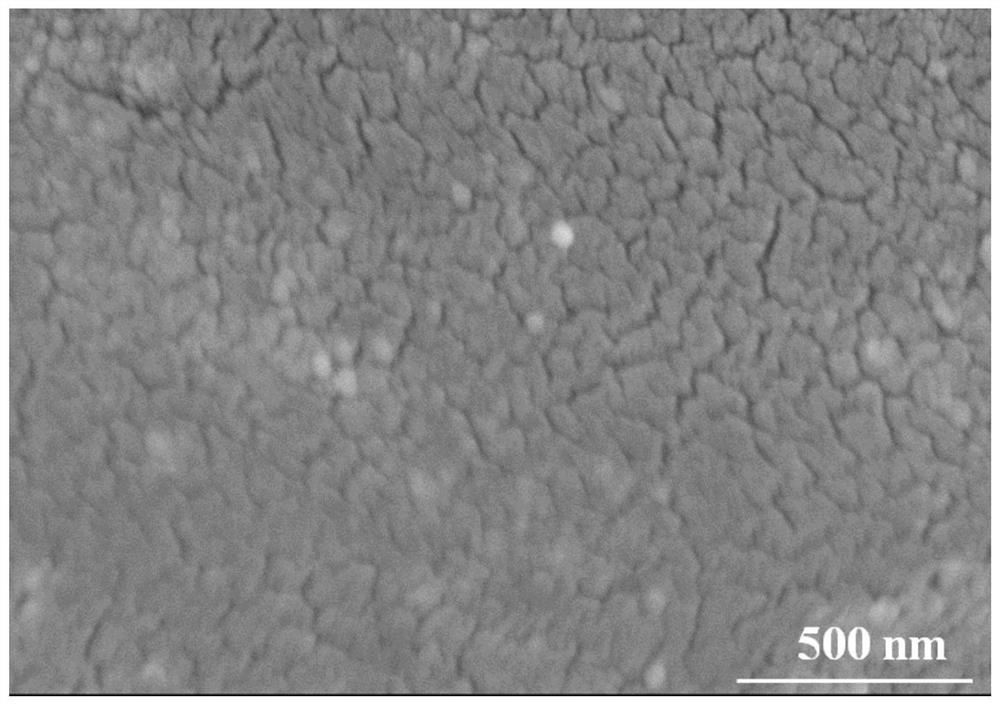

Method for preparing electrode material by graphene oxide and poly 3, 4-ethylenedioxythiophene

InactiveCN107919479AIncrease the areaImprove conductivityCell electrodesBiocompatibility TestingCarbon felt

The invention discloses a method for preparing an electrode material by graphene oxide and poly 3, 4-ethylenedioxythiophene. The method comprises the following steps of (1) immersing carbon felt in ahydrogen peroxide solution, performing constant-temperature reaction under 90 DEG C, washing the carbon felt with deionized water, and drying the carbon felt; (2) mixing a graphene oxide solution, 3,4-ethylenedioxythiophene solution and an electrolyte sodium sulfate solution, performing ultrasonic reaction to obtain an electrolyte suspension liquid, immersing the carbon felt in the electrolyte suspension liquid, performing immersion for 30 minutes under a room temperature, performing immersing for 2-3 hours under 40 DEG C, and performing electrodeposition; and (3) performing microwave reaction on the carbon felt for 5 minutes, and performing drying. The electrode material prepared by the method is compact and uniform in surface, the electrode is high in specific area and conductivity, lowin impedance and high in electron transfer efficiency, and has favorable biocompatibility, namely power generation performance.

Owner:SHAANXI SHENGMAI PETROLEUM

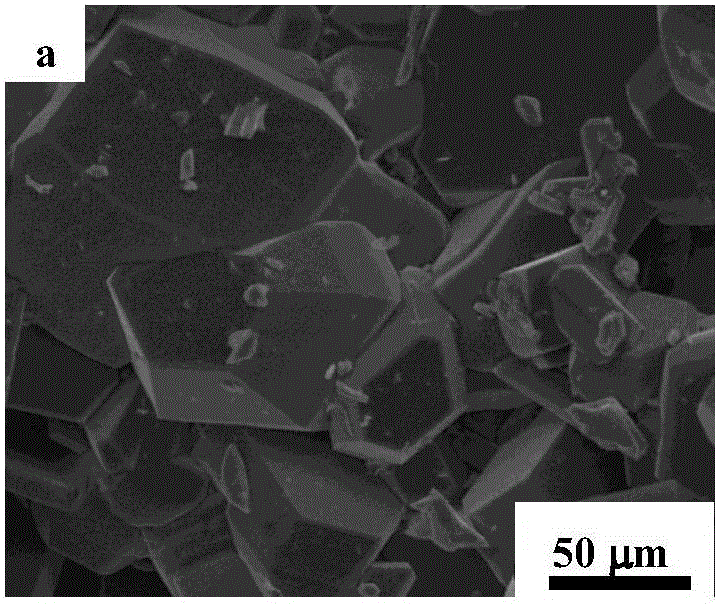

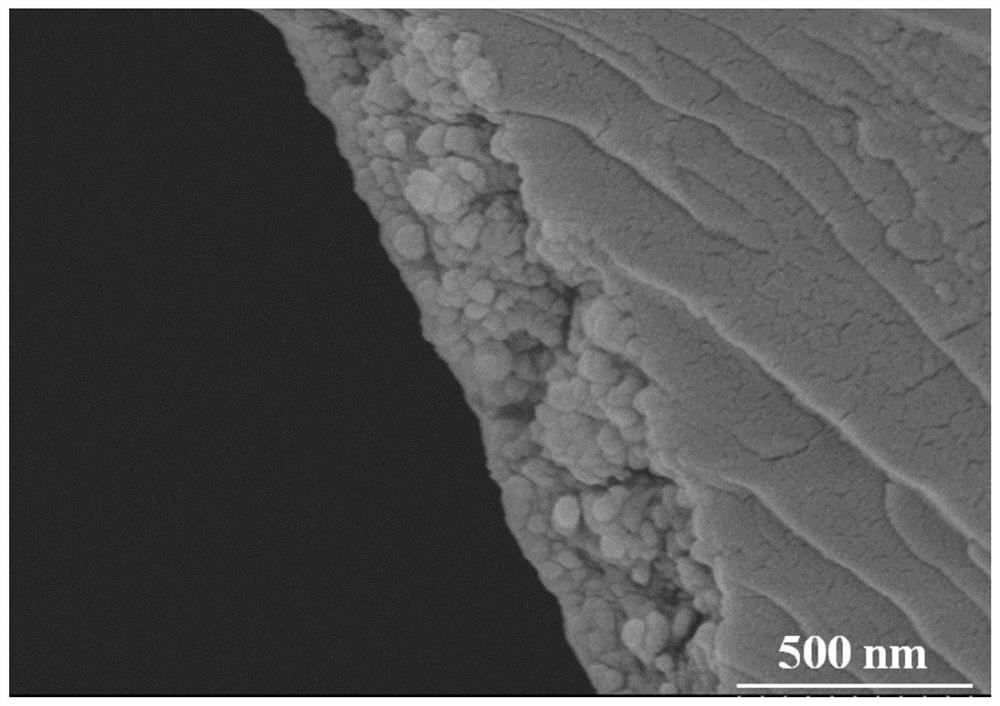

Method for preparing SiC (silicon carbide) coating with fine grains on surface of C/C (carbon/carbon) composite

The invention relates to a method for preparing a SiC (silicon carbide) coating with fine grains on the surface of a C / C (carbon / carbon) composite. The C / C composite which is polished, washed and dried is subjected to atomic oxygen oxidation treatment, the surface of the C / C composite subjected to atomic oxygen oxidation treatment is fluffy, the fluffy surface can provide a large quantity of nucleation points, nucleation of the SiC coating is facilitated, and a more uniform and compact coating can be formed on the surface of the C / C composite. The SiC coating is prepared on the surface of the C / C composite subjected to atomic oxygen oxidation treatment in a vacuum furnace under the protection of argon with an embedding method, the size of the grains of the prepared SiC coating ranges from 1 mu m to 5 mu m, and the size of grains of a SiC coating prepared with a traditional embedding method is about 20-100 mu m. After a sample which is not subjected to atomic oxygen oxidation treatment is oxidized, a large quantity of pores and cracks occur on the surface and the size of the pores is about 20-500 mu m; however, after a sample subjected to atomic oxygen oxidation treatment is oxidized, a few pores are formed in the surface, the size of the pores is about 20-110 mu m, and the glassy state formed on the surface is relatively continuous and can effectively protect the C / C composite.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

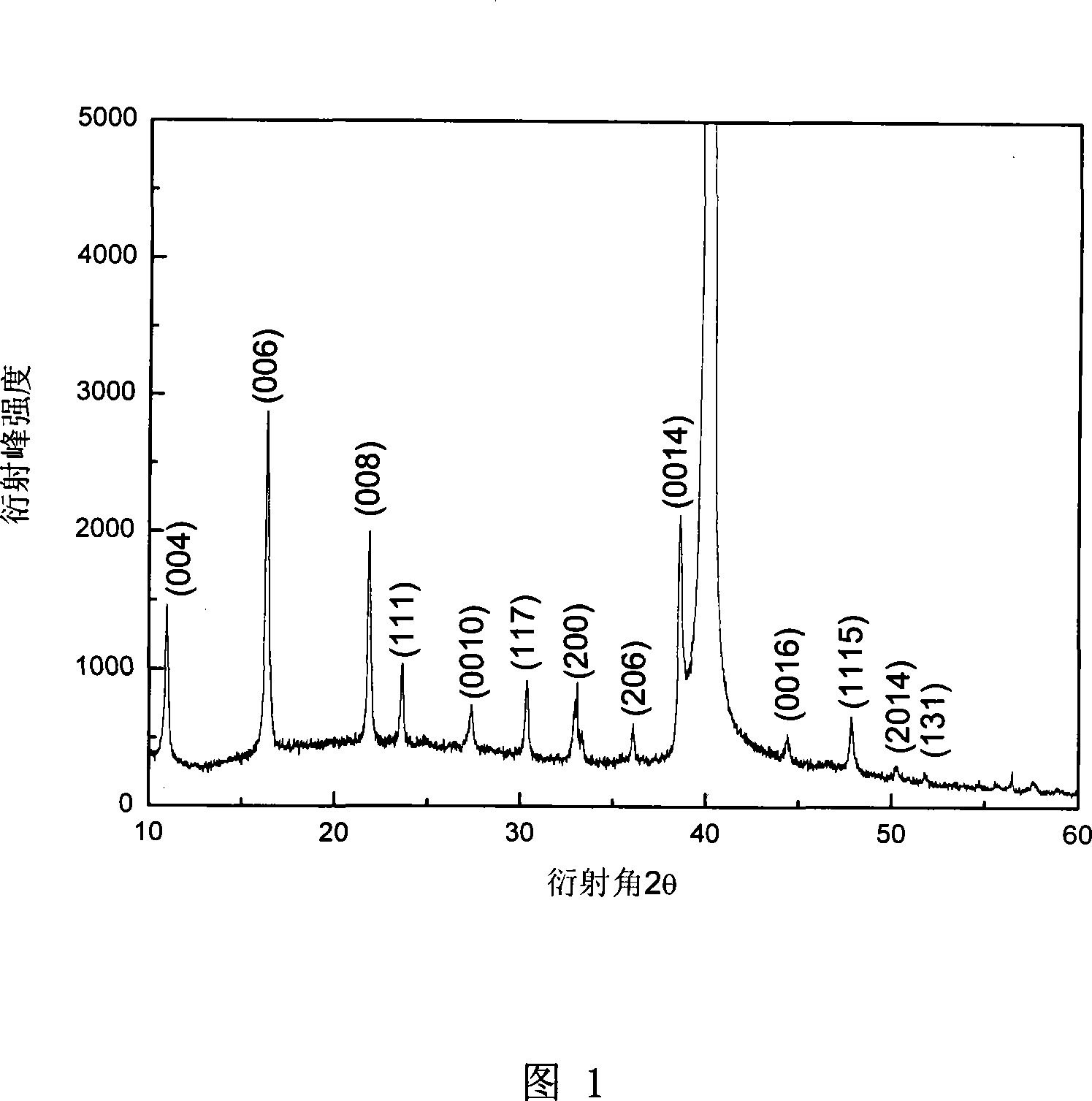

Method for preparing column-shape neodymium-doping bismuth titanate ferroelectric thin film used for ferroelectric memory

InactiveCN101168488AHigh crystallinityUniform and dense surfaceFerroelectric carrier recordingAir atmosphereFerroelectric thin films

The invention discloses a method for preparing a columnar neodymium-doped bismuth titanate ferroelectric thin film for ferroelectric memory, belonging to the scope of new microelectronic materials and devices. The ferroelectric memory columnar neodymium-doped bismuth titanate ferroelectric film of the present invention is prepared by a sol-gel method, the concentration of the precursor solution is 0.04-0.05 mol / liter, and after each spin coating, it is baked and pyrolyzed. The thin film is annealed. During annealing, the thin film sample is directly placed in a tube furnace that has been heated to 645-655°C from room temperature and atmospheric environment, and annealed for 5-10 minutes in an air atmosphere. The columnar neodymium-doped bismuth titanate ferroelectric thin film used in the ferroelectric memory of the present invention is a polycrystalline thin film with preferred orientation, the crystal grains are columnar and larger in size, and has the advantages of better fatigue characteristics and lower crystallization temperature, and can be compared with the existing CMOS Process compatible.

Owner:HUAZHONG UNIV OF SCI & TECH

Nb coated NiTi shape memory composite material and preparation method thereof

ActiveCN111167860AGood biocompatibilityImprove mechanical propertiesMedical devicesAuxillary arrangementsShape-memory alloyStress induced martensite

The invention relates to the technical field of biomedical shape memory composite materials, in particular to an Nb coated NiTi shape memory composite material and a preparation method thereof. According to the method, the prepared composite material has good biocompatibility, high stress-induced martensite phase transformation critical stress and large recoverable dependent variable, the problemthat an existing single biomedical shape memory alloy, such as a NiTi-based alloy and a no-Ni beta titanium alloy, cannot has the good biocompatibility, high stress-induced martensite phase transformation critical stress and large recoverable dependent variable at the same time can be solved, and the composite material can be applied to the field of biomedicine.

Owner:JIANGSU UNIV

Composition for surface treatment on aluminum flexible connection

The invention relates to the technical field of surface treatment, in particular to a composition for the surface treatment on aluminum flexible connection. Each 1L composition is prepared from 190-215g of nickel sulfate, 32-46g of chlorate, 30-48g of boric acid, 5-15g of a complexing agent and 1-2g of an addition agent. According to the composition for the surface treatment on the aluminum flexible connection, the nickel sulfate, the chlorate, the boric acid, the complexing agent, the addition agent and a wetting agent are adopted to jointly prepare the composition for the surface treatment on the aluminum flexible connection, a better synergistic effect is achieved among the nickel sulfate, the chlorate, the boric acid, the complexing agent, the addition agent and the wetting agent, theprepared composition has the better surface treatment effect on the aluminum flexible connection, the surface is dense and homogeneous, and brightness is higher; and phenomena such as graying and darkening cannot appear on the surface of the aluminum flexible connection after the composition is placed for a period of time. In addition, the binding strength of surface cladding and the aluminum flexible connection is higher, the aluminum flexible connection is repeatedly bent to breakage, and phenomena such as peeling and falling off cannot appear to the surface of the aluminum flexible connection.

Owner:常州极太汽车配件有限公司

Method for preparing VO2 thin film

PendingCN111088477AFine surfaceUniform and dense surfaceVacuum evaporation coatingSputtering coatingEvaporation (deposition)Single crystal

The invention discloses a method for preparing a VO2 thin film. The method comprises the following steps that the surface of an Al2O3 substrate is subjected to deionized water cleaning by an ultrasonic cleaning instrument, then an acetone solution and absolute ethyl alcohol are sequentially used for cleaning, and blow-drying is carried out; the cleaned Al2O3 monocrystalline substrate was transferred to a high vacuum growth chamber, and the vacuum was evacuated to better than 1*10<-6> Pa, and the substrate was rotated and was heated to 610 DEG C to 630 DEG C; after the metal vanadium powder isheated to an evaporation state, a gas activation source is opened and oxygen is introduced, the vanadium atomic beam and the active oxygen atomic beam are sprayed on the substrate for reaction, and the film growth time is 34-36 min; after the film deposition is completed, N2 is introduced, the temperature of the vacuum chamber is naturally cooled below 150 DEG C, and the thin film is taken out. According to the method, the VO2 thin film with a smooth surface and a light yellow semi-transparent shape is prepared, the film is good in crystallization, high in purity, uniform and compact in surface, and good in mid-infrared modulation characteristic.

Owner:南通安广美术图案设计有限公司

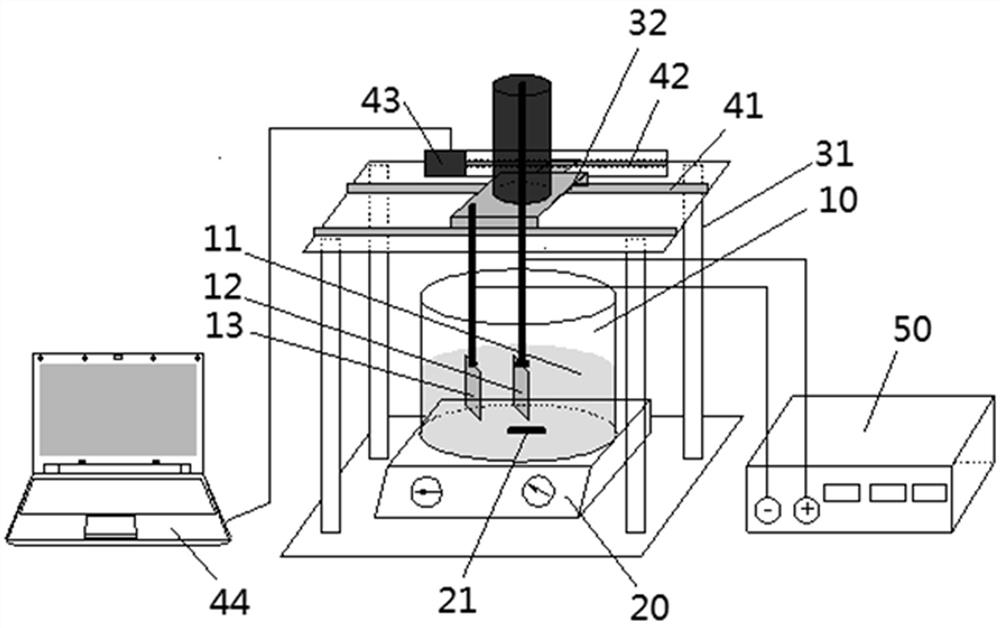

A kind of loading preparation method of nanometer metal oxide based on anodic oxidation method

ActiveCN110102301BLow costMild preparation conditionsWater/sewage treatment by irradiationWater treatment compoundsElectrolytic agentMetallic materials

The invention discloses a nano-metal oxide loading preparation method based on an anodic oxidation method, comprising: step 1, relatively fixing the cathode and the anode, immersing in the electrolyte, the anode adopts a metal element material of nano-metal oxide, and the cathode adopts Carrier metal material; step 2, stir the electrolyte at a constant speed, and the rotation speed is not lower than 500rpm; step 3, connect the power supply, and the output voltage is between 10-50v; anodic oxidation reaction occurs on the metal elemental material, and metal oxide nanotubes / nanotubes are formed on the surface Particles, under the action of stirring, the metal oxide nanotubes / nanoparticles on the surface of the anode gradually dissolve and fall off, and enter the electrolyte; under the action of the electric field force, the dissolved and fallen nano-fragments move to the cathode and attach to the surface of the cathode material, forming Metal oxide nanofilms. The preparation method of the thin film provided by the invention has mild conditions, simple equipment, convenient operation and low cost, the prepared thin film has good loading effect, and the metal oxide is not easy to fall off.

Owner:SHANGHAI MARITIME UNIVERSITY

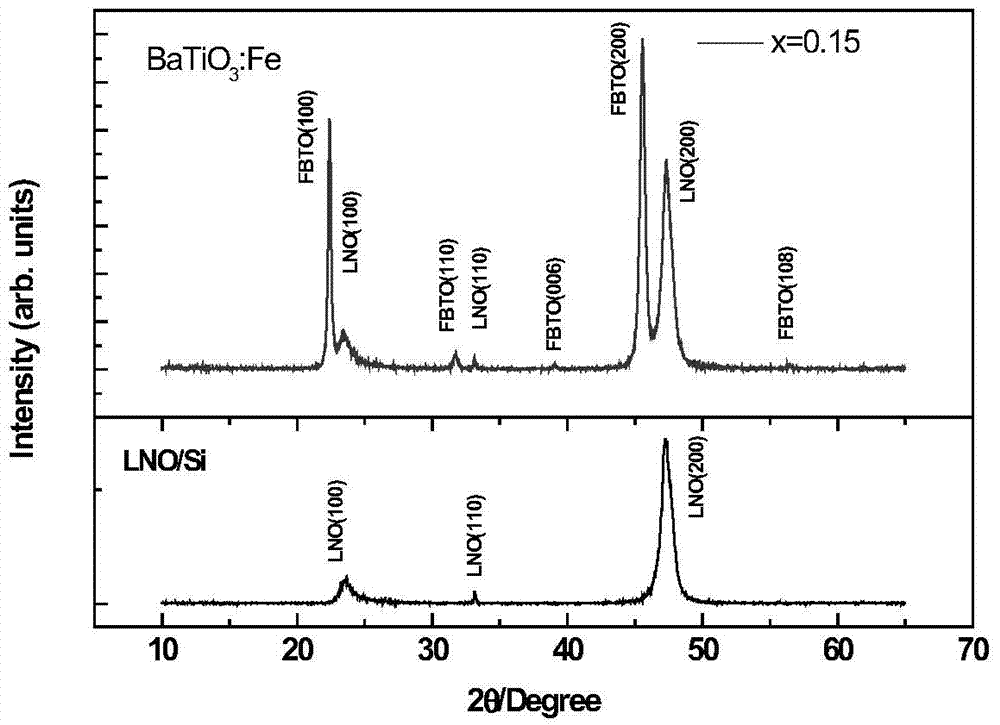

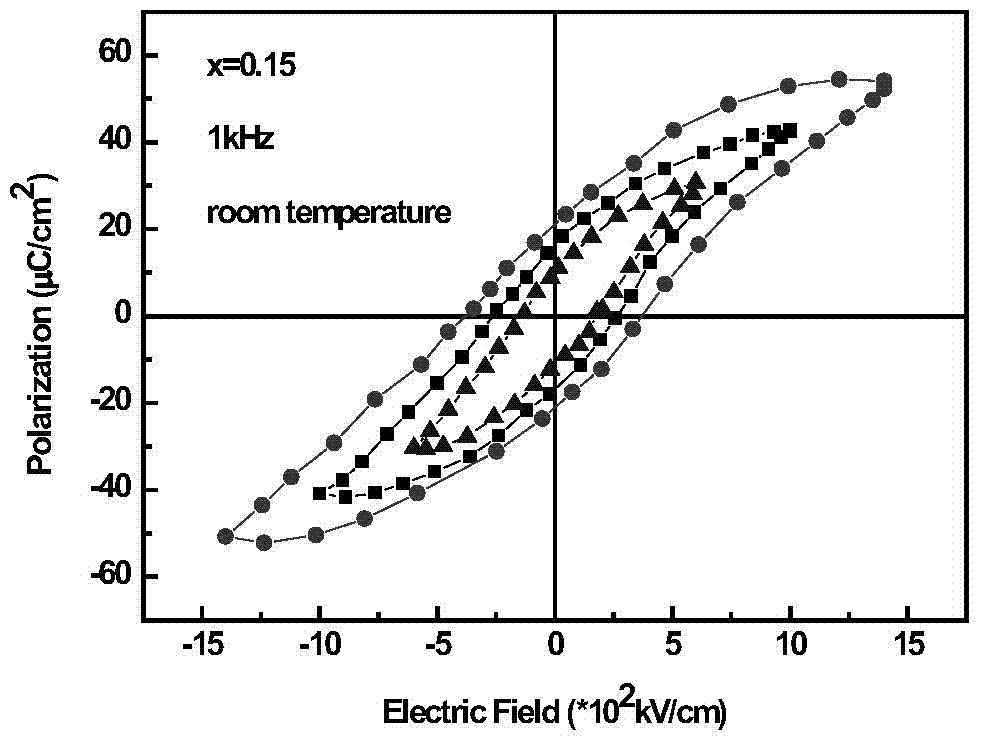

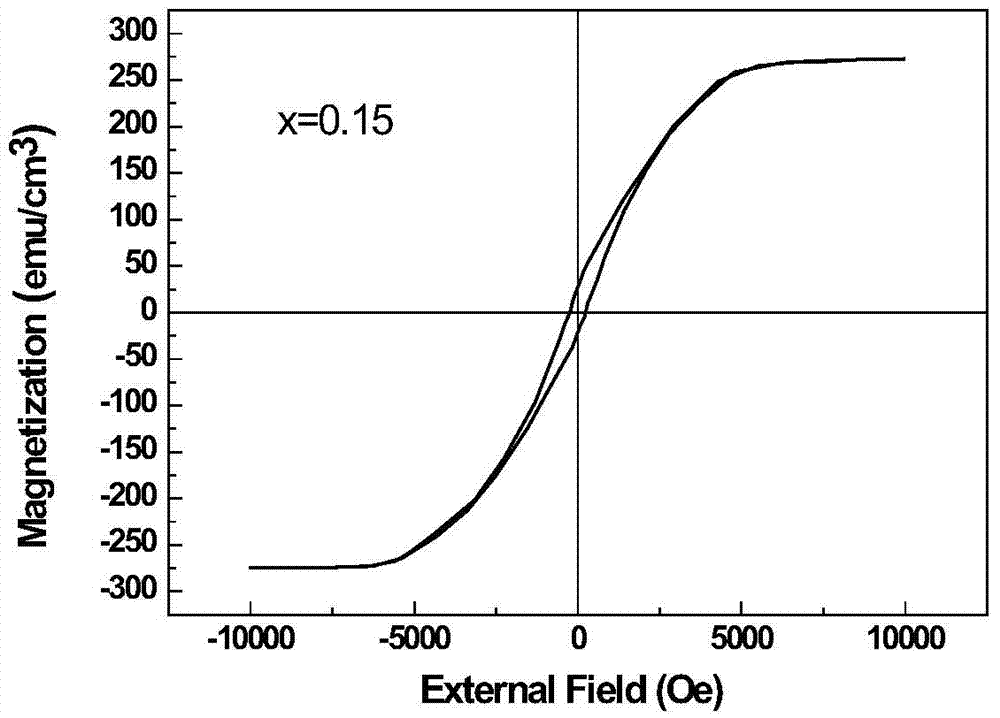

Highly doped batio3:fe multiferroic thin film material and preparation method thereof

InactiveCN105568265BImprove one-wayUniform and dense surfaceChemical vapor deposition applicationLiquid applicationSpinsRoom temperature

The invention relates to a high-Fe-content doped BaTiO3 multiferroic thin-film material and a preparation method thereof. The molecular formula of the high-Fe-content doped BaTiO3 multiferroic thin-film material is BaTi<1-x>FexO3, wherein x is the atomic ratio of doped components and ranges from 0.01 to 0.4. The preparation method sequentially includes the steps that (1) a precursor is prepared; (2) a substrate is cleaned and pretreated; (3) a highly doped BaTiO3:Fe multiferroic thin film is prepared, specifically, the substrate obtained in the step (2) is spin-coated with the highly doped BaTiO3:Fe sol precursor prepared in the step (1), and then stepped annealing is conducted on the precursor; and (4) the sol coating and annealing processes of the step (3) are repeated, and a thin film sample of a needed thickness is obtained. A precursor solution is clear and transparent and can be stored for a long time; the grown thin film is uniform and compact in surface, good in crystallization property and free of impurity phases, and the grown thin film is good in thickness controllability and high in unipolarity; and the thin-film material has good ferroelectricity and ferromagnetism at the room temperature.

Owner:HENAN UNIVERSITY

Preparation method of silicon dioxide/NaA molecular sieve composite membrane

PendingCN113634132AUniform and dense surfaceStable structureSemi-permeable membranesHydroxy compound separation/purificationSilicic acidActive agent

The invention discloses a preparation method of a silicon dioxide / NaA molecular sieve composite membrane. The preparation method comprises the following steps: dipping a tubular NaA molecular sieve membrane in a nonionic surfactant aqueous solution at room temperature, slowly conducting stirring, taking out the tubular NaA molecular sieve membrane after dipping for at least 1 hour, then conducting washing with ethanol and water respectively, removing unstable attached residues, and then conducting vacuum drying; and immersing the dried tubular NaA molecular sieve membrane into a mixed solution prepared from tetraethoxysilane, ethanol, deionized water and ammonia water, slowly conducting stirring for at least 6 hours, taking out the stirred materials, conducting washing with ethanol, and carrying out vacuum drying to obtain the silicon dioxide modified NaA molecular sieve membrane. According to the preparation method disclosed by the invention, hydrophilic silicon dioxide particles grow on the surface of the NaA molecular sieve membrane in situ, and the prepared composite membrane is applied to ethanol dehydration and has an excellent separation effect on an ethanol / water system.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com