Ferroelectric film capacity used for ferroelectric memorizer and its manufacturing method

A technology of ferroelectric memory and ferroelectric thin film, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of poor crystallization properties of ferroelectric thin films, affecting material properties, poor leakage current characteristics, etc., and achieve residual Large polarization, good compatibility, and good fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

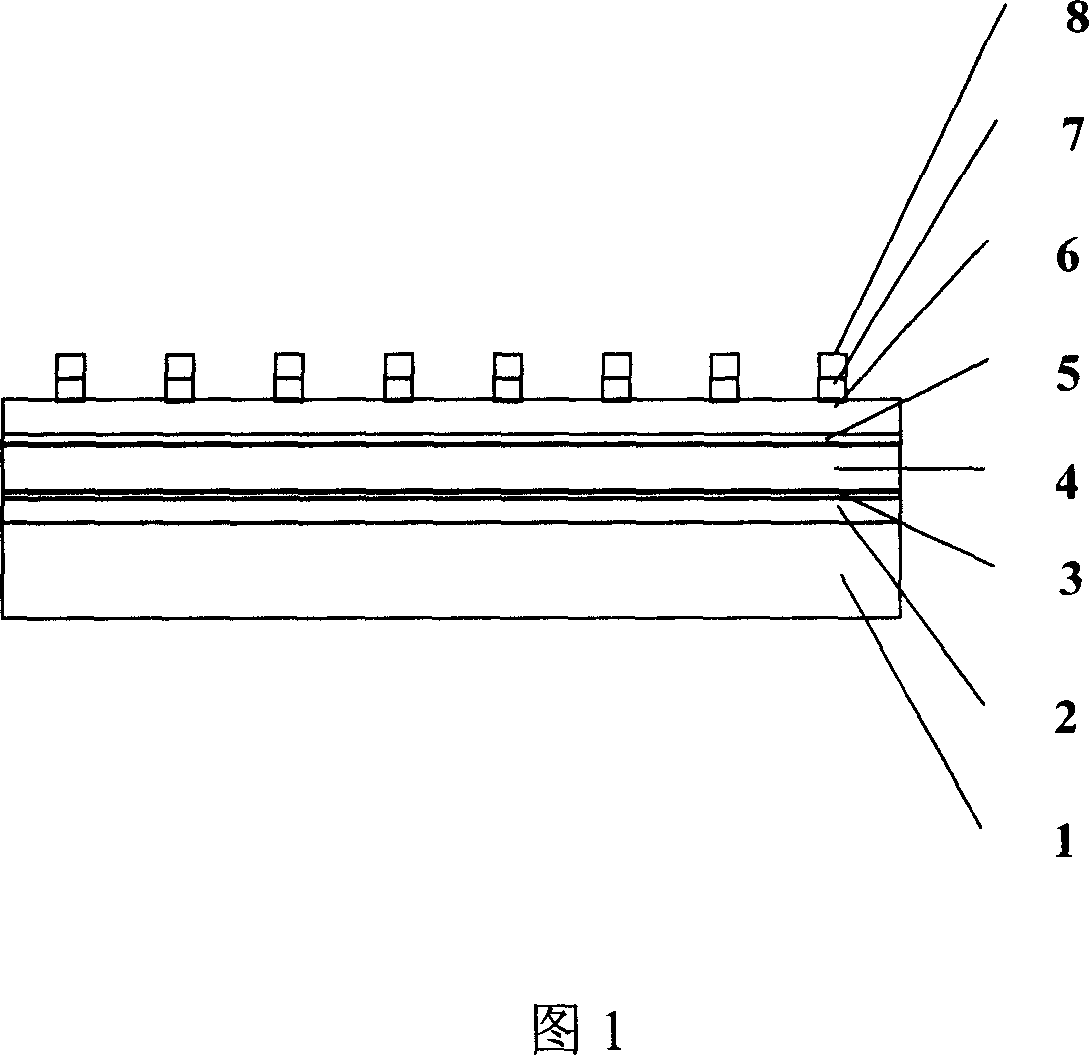

[0031] Embodiment 1 A method for preparing a ferroelectric film capacitor for a ferroelectric memory, comprising

[0032] ① Surface treatment and cleaning of the silicon substrate 1 according to the standard CMOS process;

[0033] ②A thermal oxidation method is used to form a silicon dioxide barrier layer 2 with a thickness of 150 nm on the surface of the silicon substrate 1;

[0034] ③ Prepare a 20nm-thick titanium dioxide bonding layer 3 on the silicon dioxide barrier layer 2 by magnetron sputtering. The shooting atmosphere is O 2 :Ar=1:9;

[0035] ④ Prepare a 150nm-thick lower electrode metal layer Pt4 on the titanium dioxide bonding layer 3 by magnetron sputtering. Ar gas;

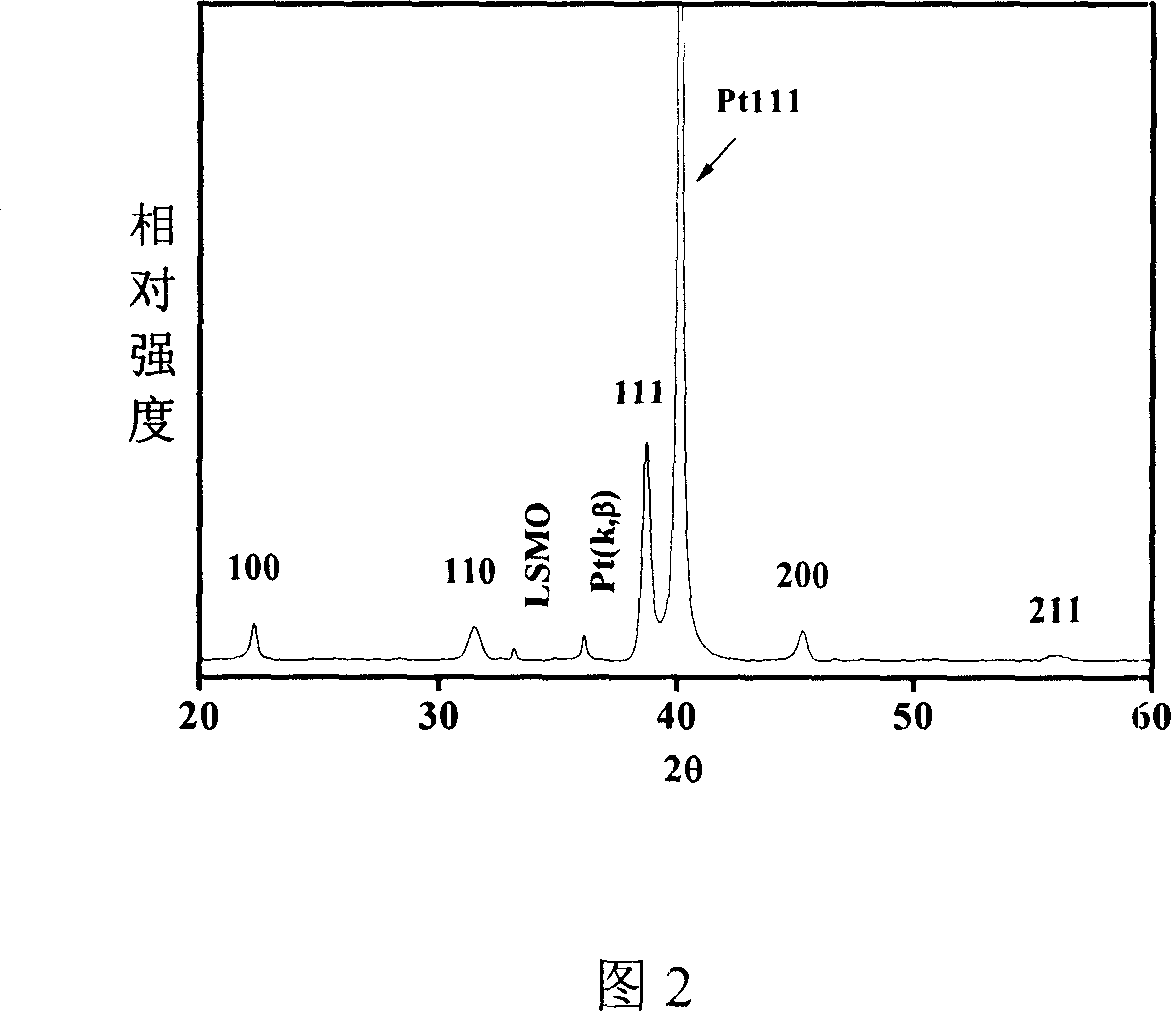

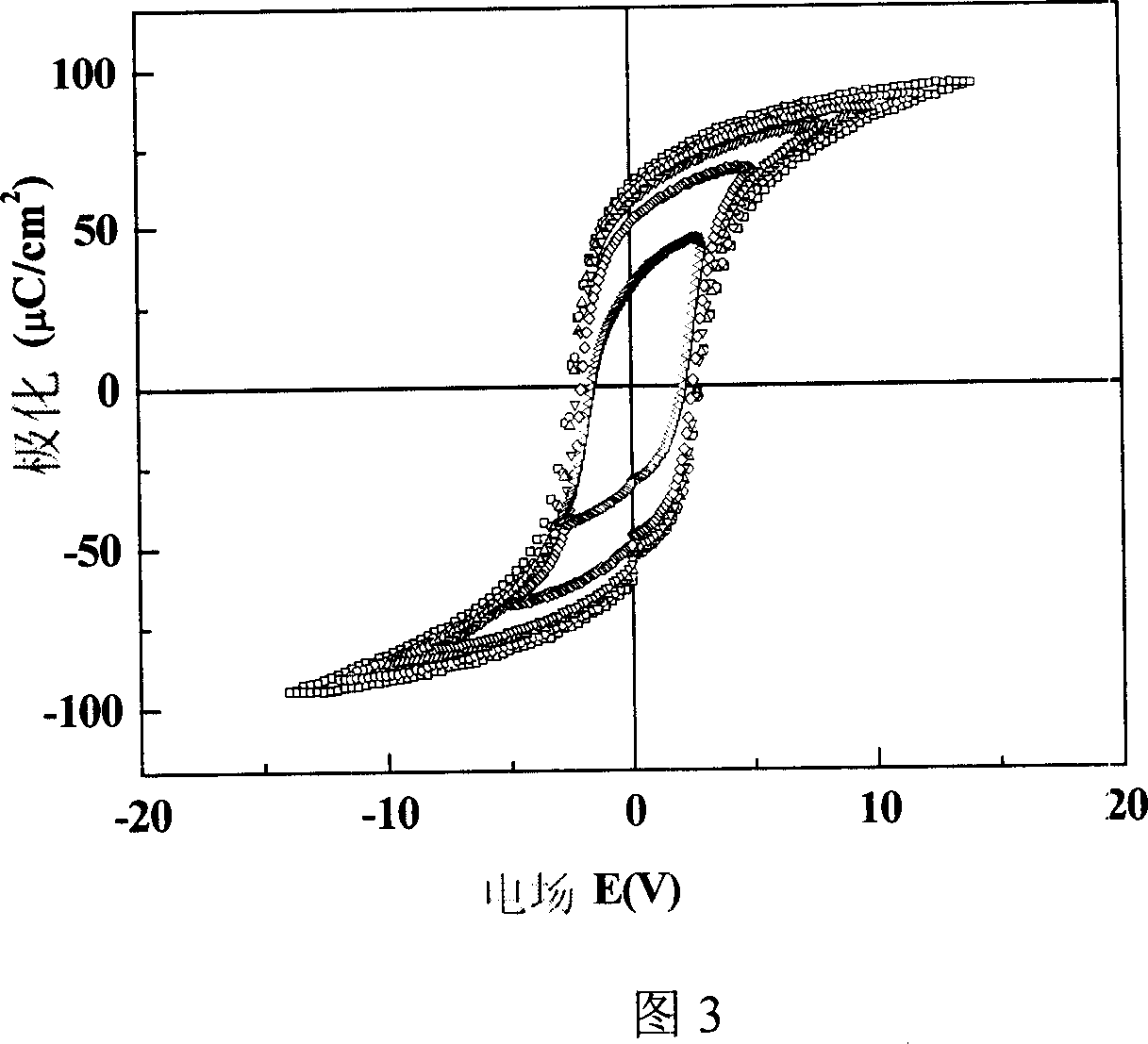

[0036] ⑤ The LSMO target is prepared by the standard solid-state reaction method, and the LSMO ultra-large magnetoresistance material can be the nominal chemical formula (La 2 / 3 Sr 1 / 3 )MnO 3 , select the following preparation process: according to the stoichiometric ratio of 1 / 3:1 / 3:1, weigh hi...

Embodiment 2

[0047] Embodiment 2 A method for preparing a ferroelectric film capacitor for a ferroelectric memory, comprising

[0048] ① Surface treatment and cleaning of the silicon substrate 1 according to the standard CMOS process;

[0049] ②A thermal oxidation method is used to form a silicon dioxide barrier layer 2 with a thickness of 120 nm on the surface of the silicon substrate 1;

[0050] ③A 30nm-thick titanium dioxide bonding layer 3 was prepared on the silicon dioxide barrier layer 2 by magnetron sputtering. The shooting atmosphere is O 2 :Ar=2:9;

[0051] ④ Prepare a 150nm-thick lower electrode metal layer Pt4 on the titanium dioxide bonding layer 3 by magnetron sputtering. The atmosphere is Ar gas;

[0052] ⑤ The LSMO target was prepared by the standard solid-state reaction method, and the specific preparation process was the same as in Example 1 ⑤;

[0053] ⑥ Prepare a 10nm thick lower buffer layer 5 on the lower electrode metal layer Pt4 by magnetron sputtering. The pro...

Embodiment 3

[0059] Embodiment 3 A method for preparing a ferroelectric film capacitor for a ferroelectric memory, comprising

[0060] ① Surface treatment and cleaning of the silicon substrate 1 according to the standard CMOS process;

[0061] ②Using a thermal oxidation method to form a 200nm thick silicon dioxide barrier layer 2 on the surface of the silicon substrate 1;

[0062] ③ Prepare a 20nm-thick titanium dioxide bonding layer 3 on the silicon dioxide barrier layer 2 by magnetron sputtering. The atmosphere is O 2 :Ar=1:9;

[0063] ④ Prepare a 100nm-thick lower electrode metal layer Pt4 on the titanium dioxide bonding layer 3 by magnetron sputtering. Ar gas;

[0064] ⑤ The LSMO target was prepared by the standard solid-state reaction method, and the specific preparation process was the same as in Example 1 ⑤;

[0065] ⑥A lower buffer layer 5 with a thickness of 20nm is prepared on the lower electrode metal layer Pt4 by magnetron sputtering. The process conditions of magnetron sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com