Patents

Literature

266results about How to "Excellent fatigue properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

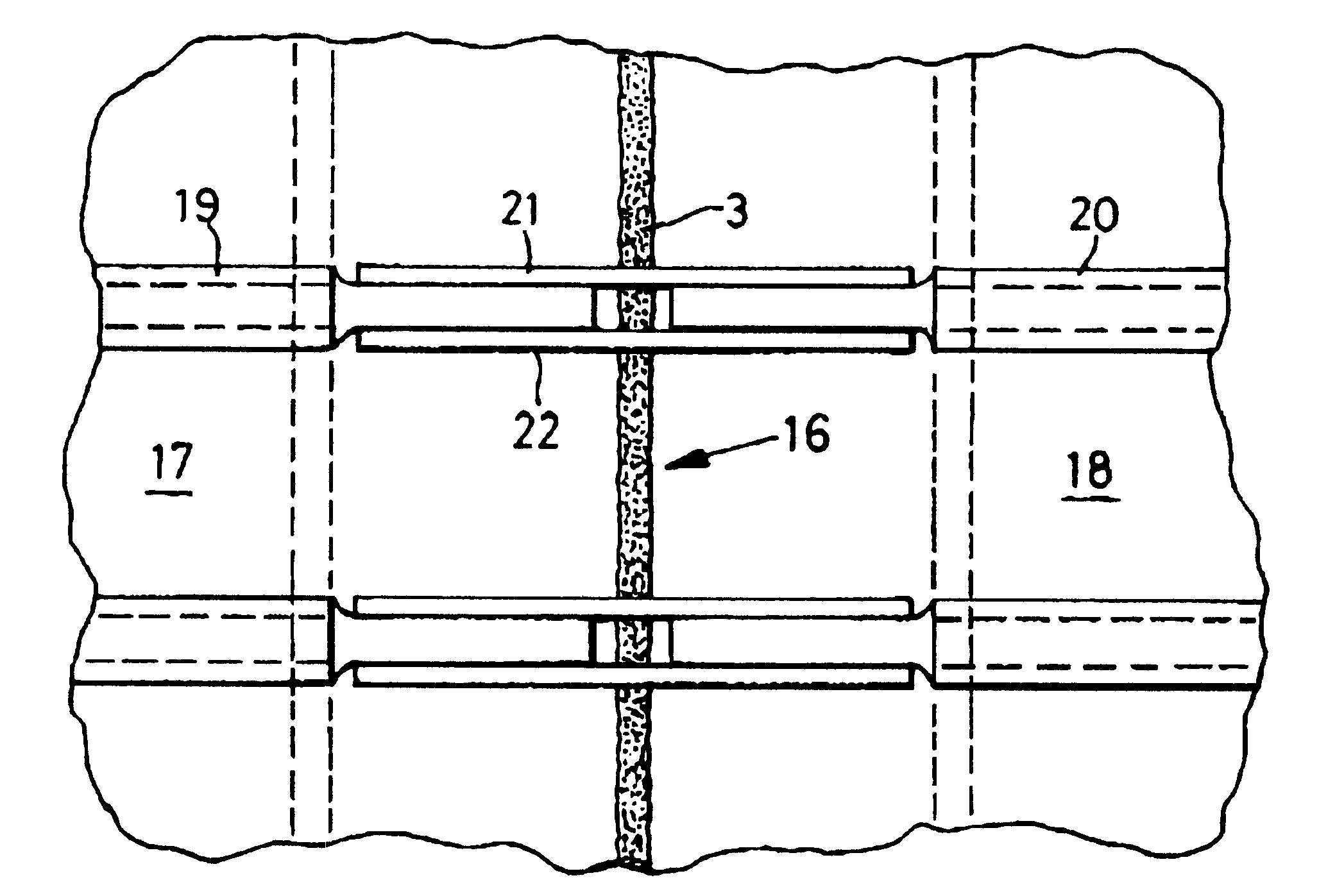

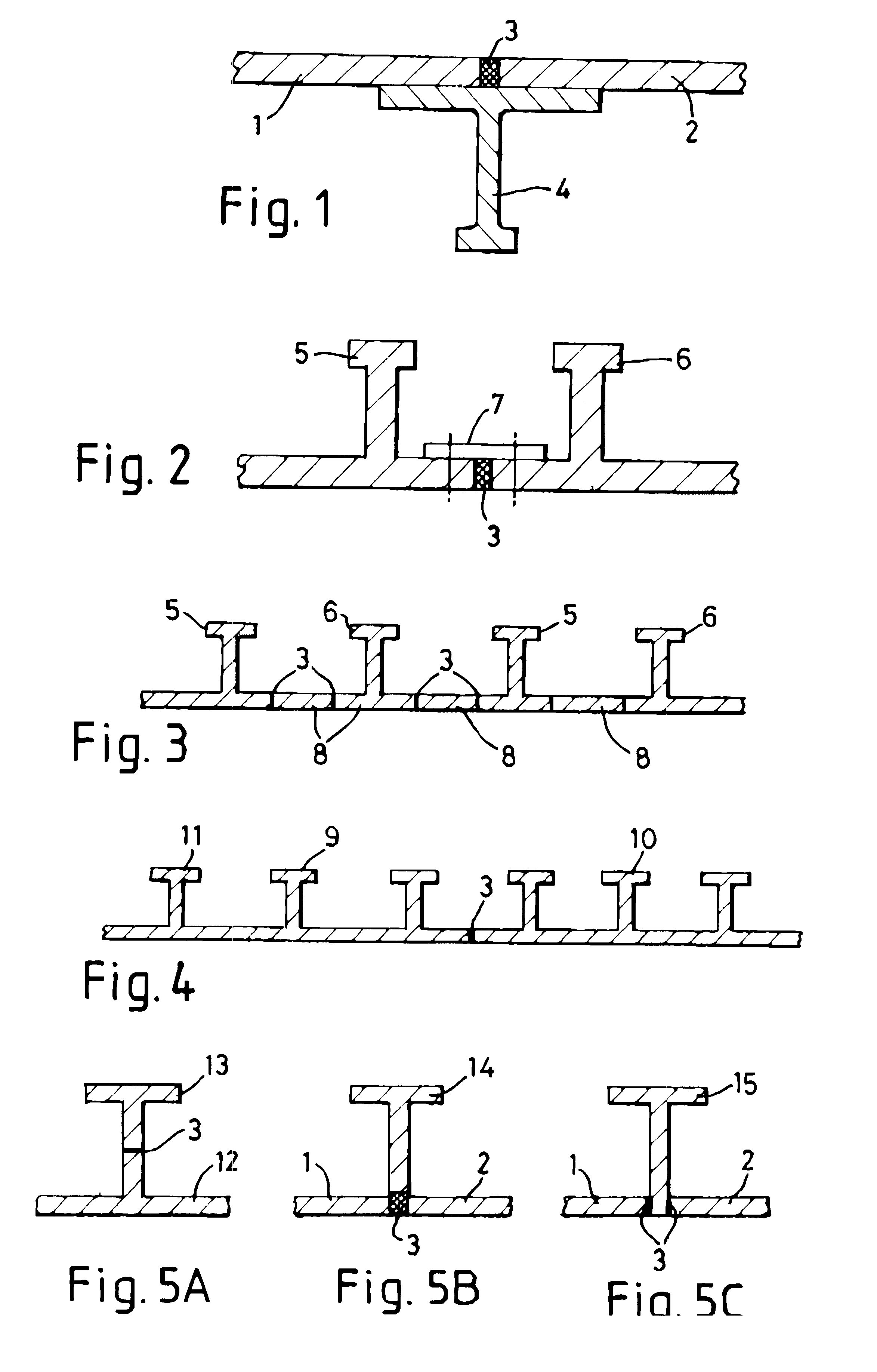

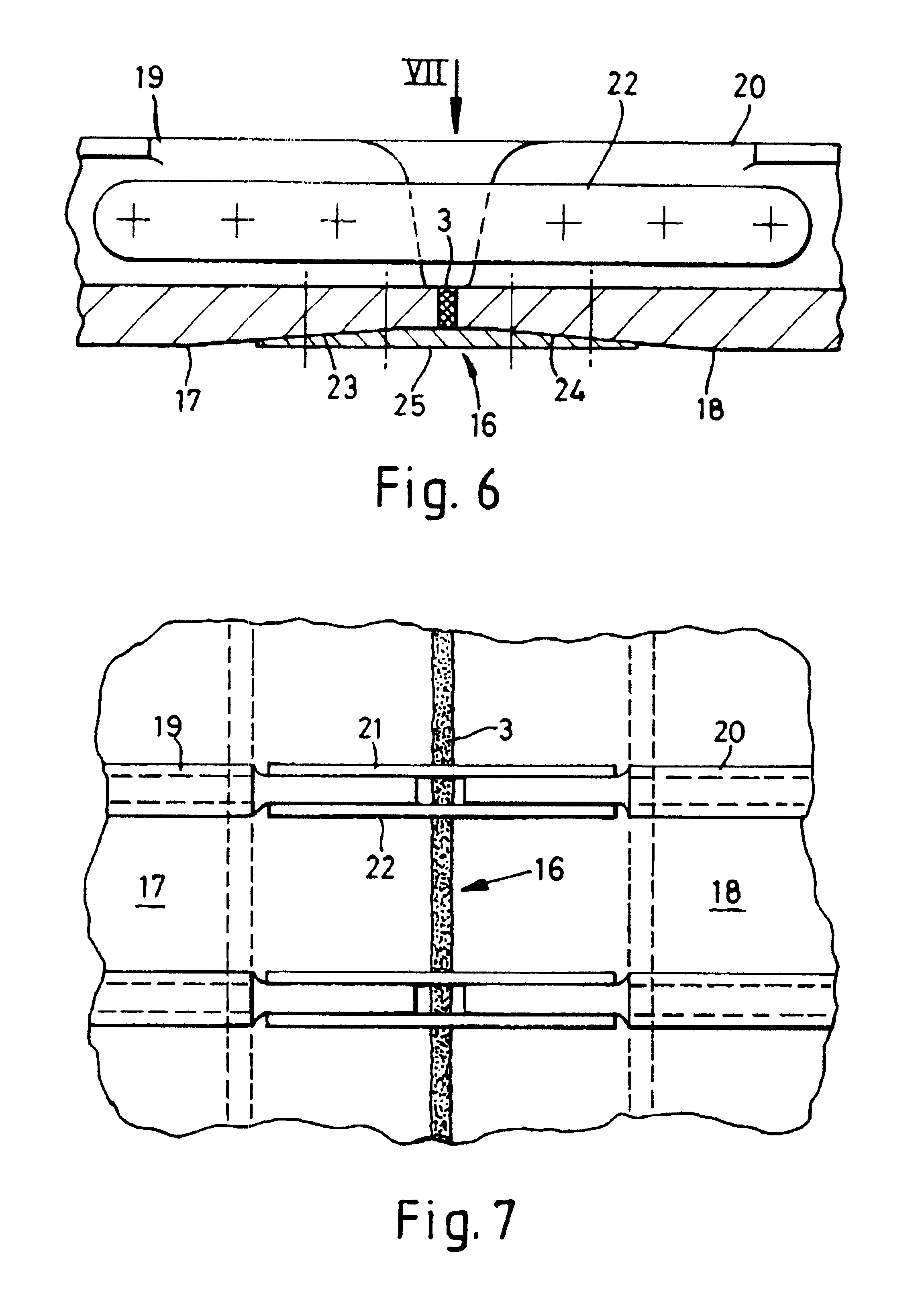

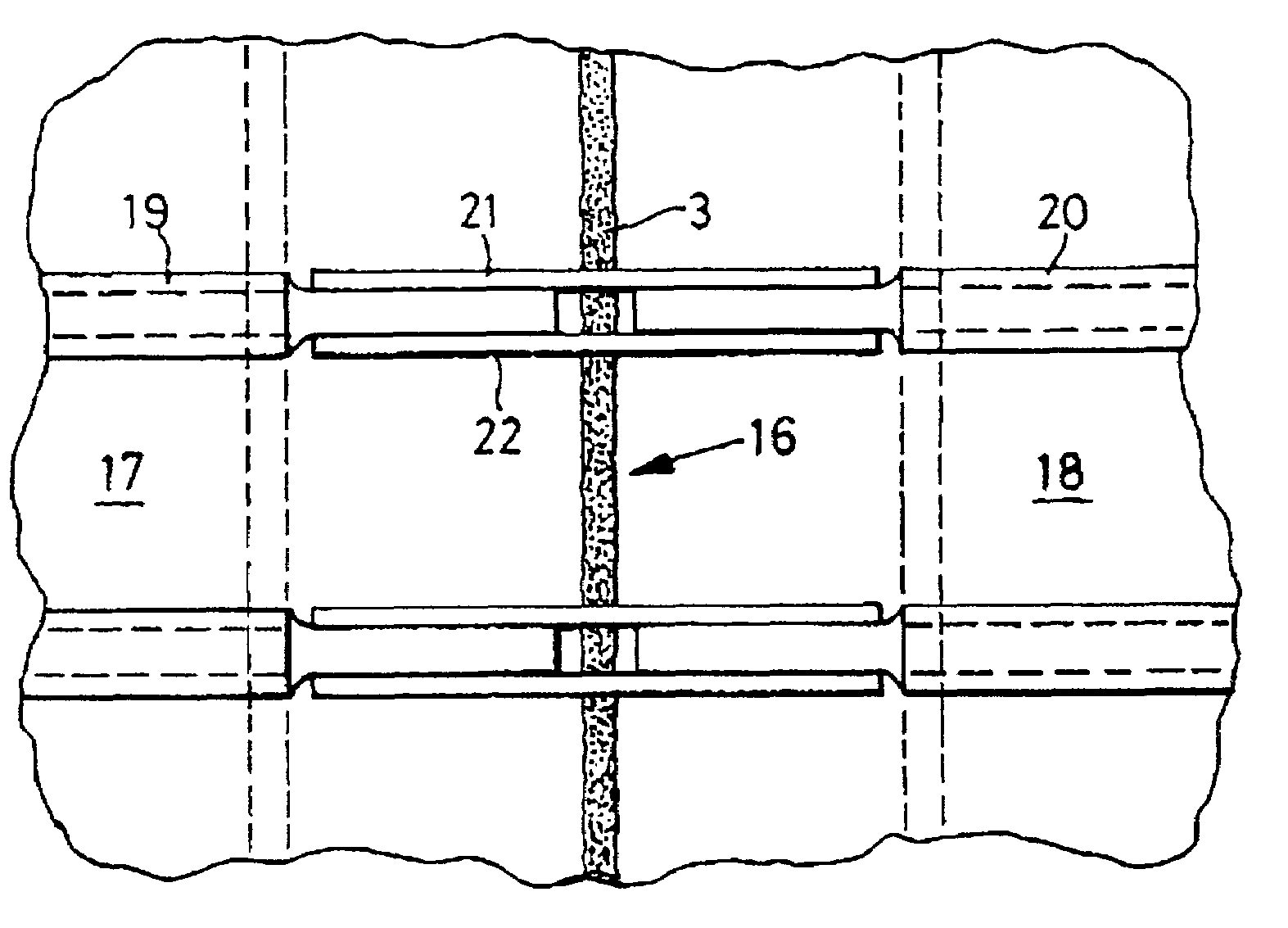

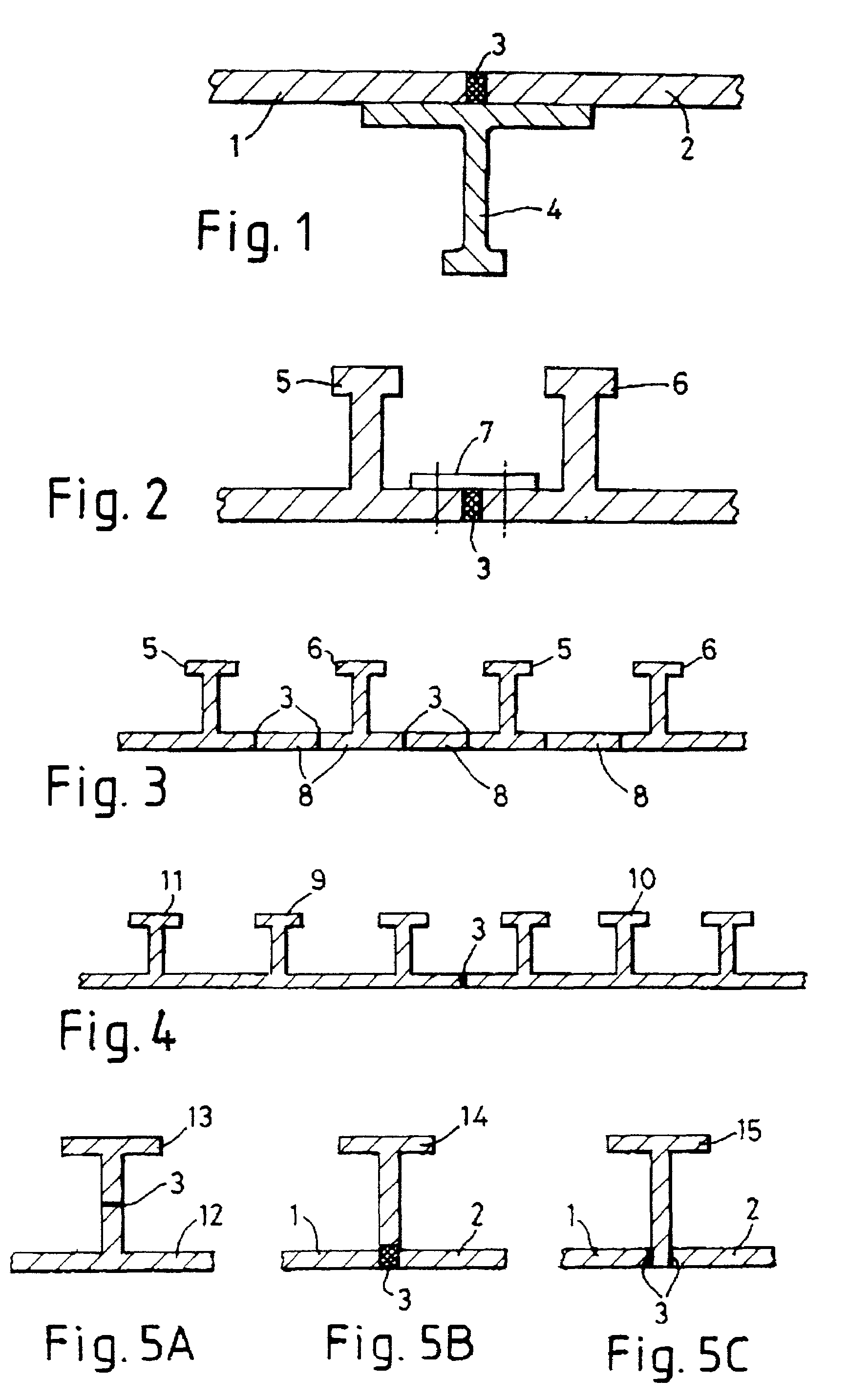

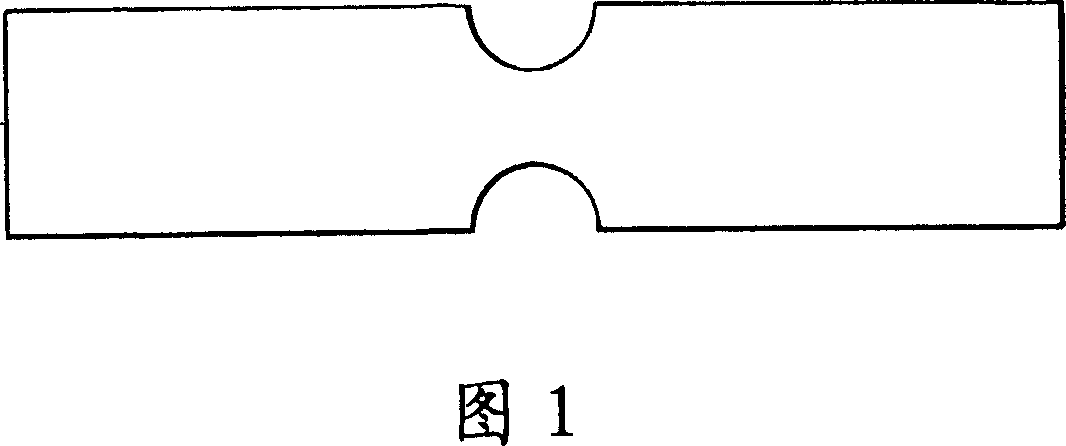

Friction welding metal components

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

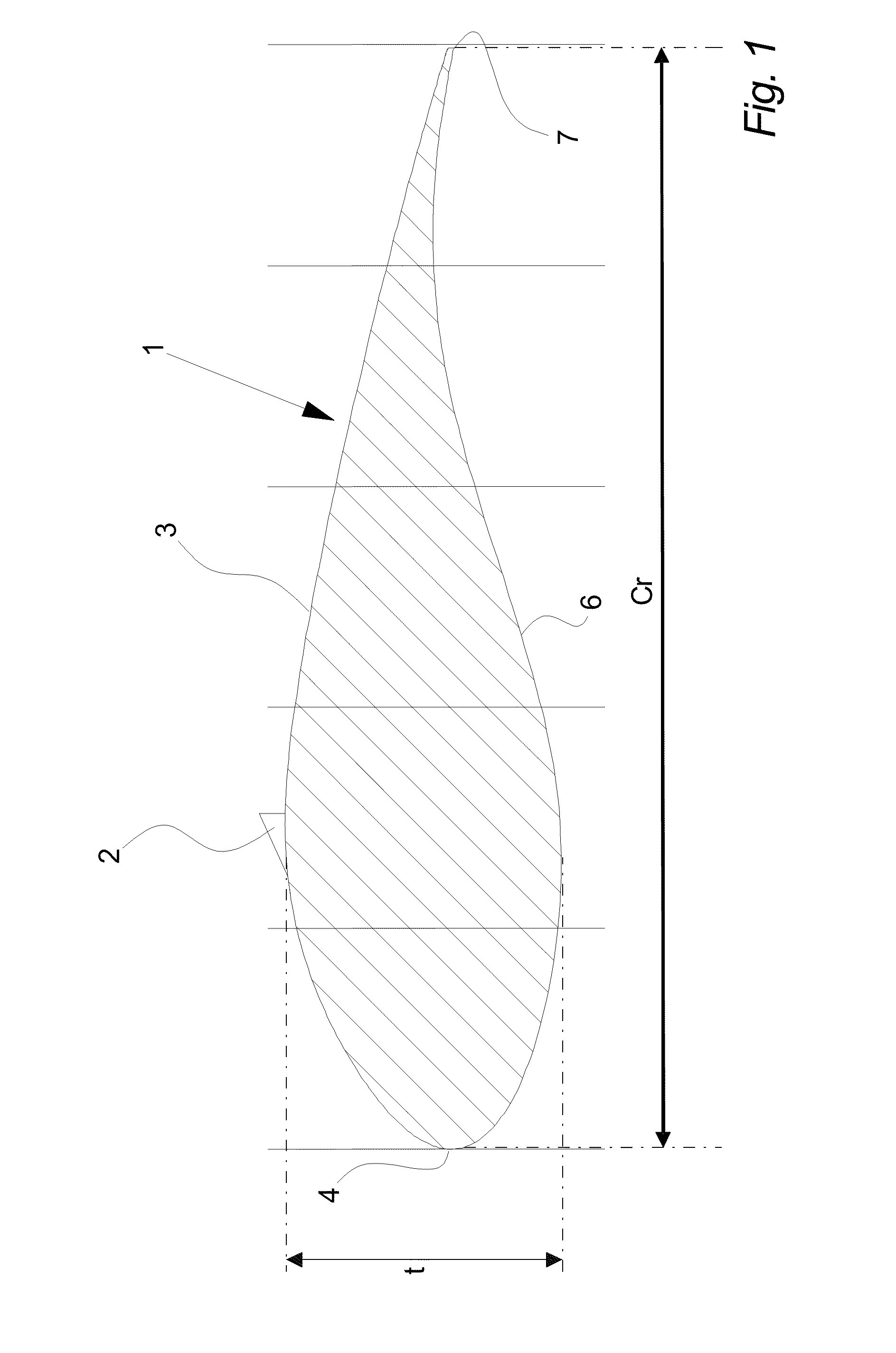

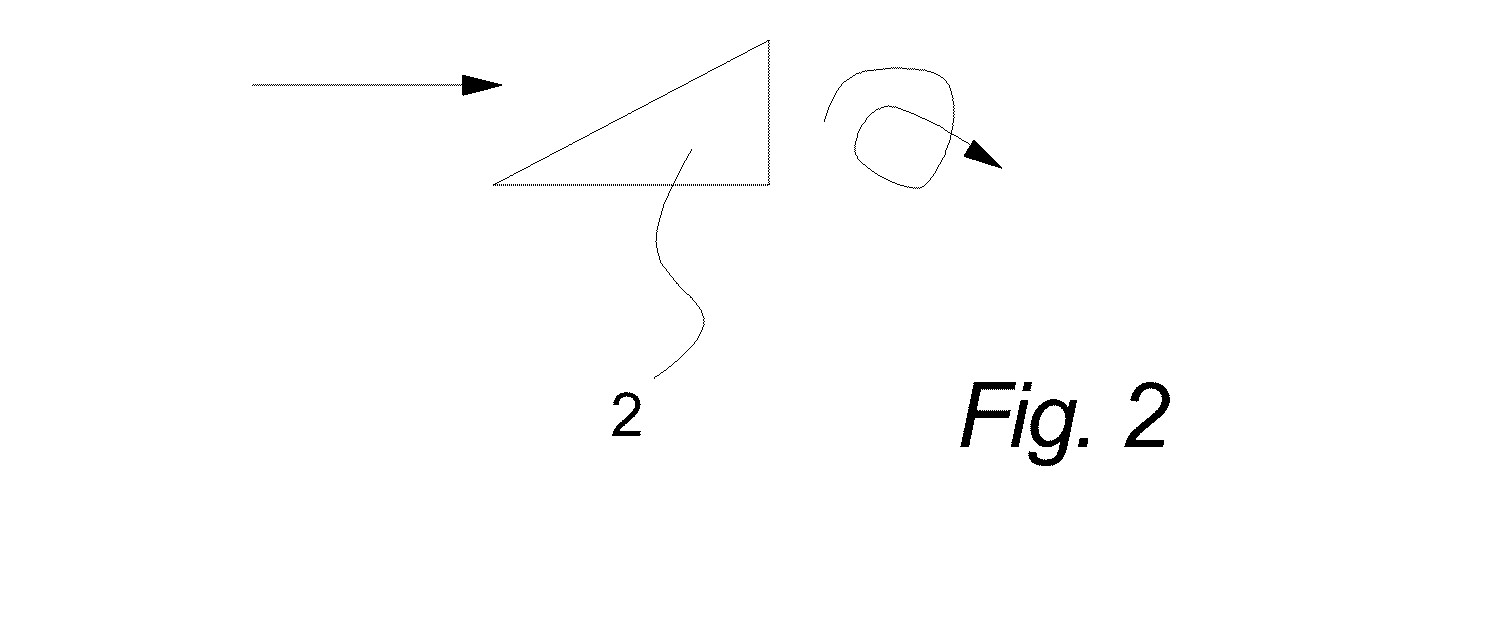

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

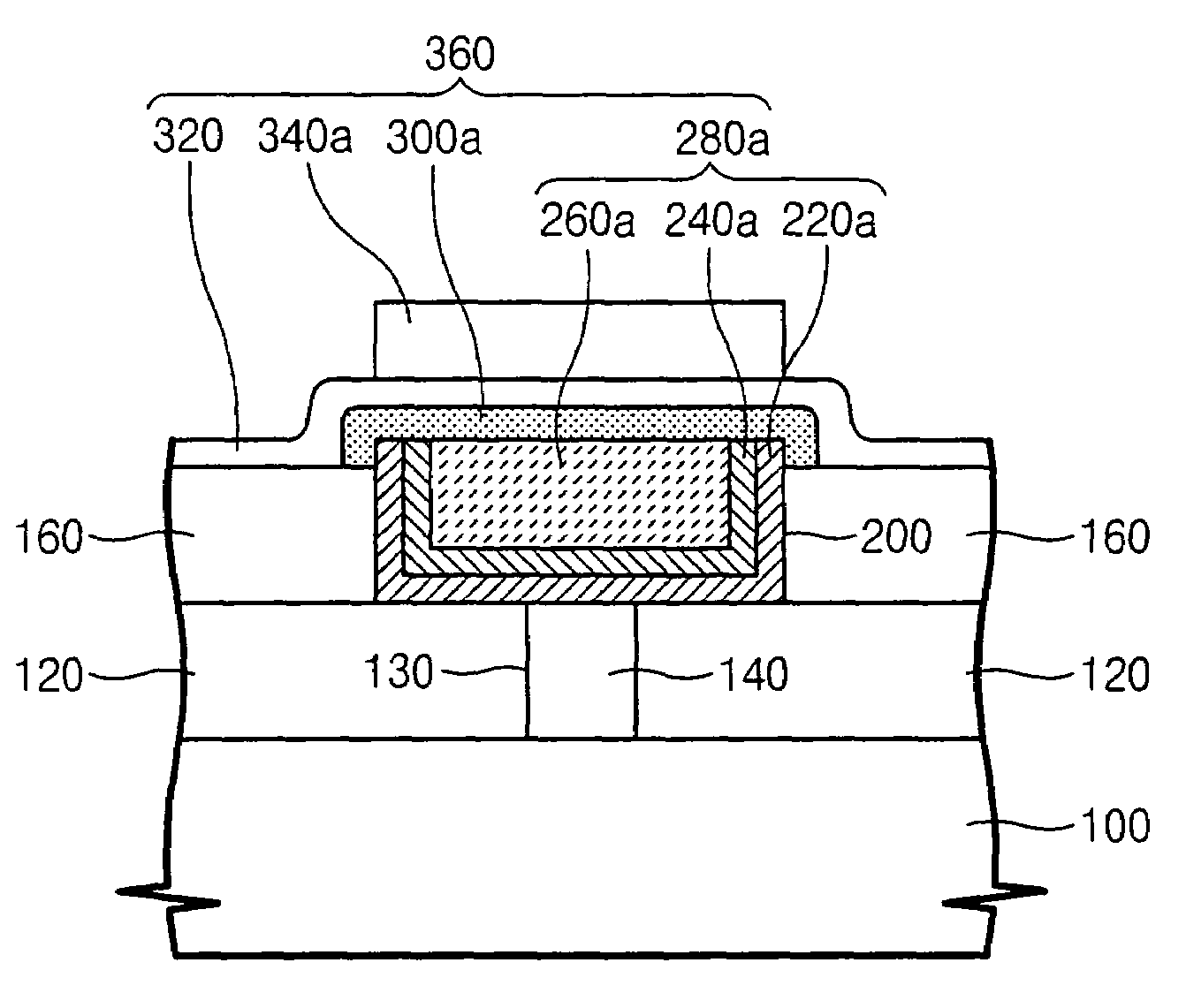

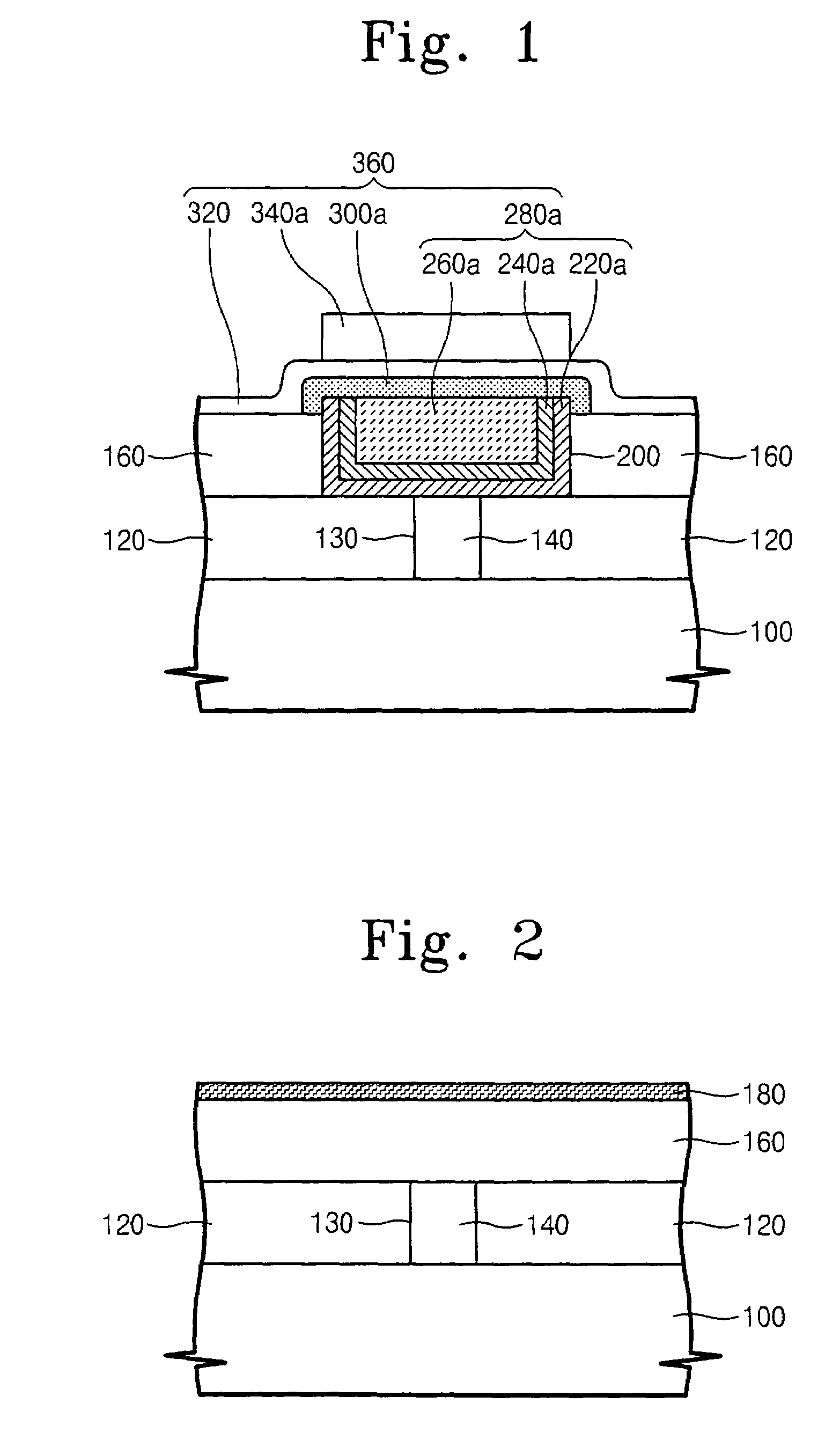

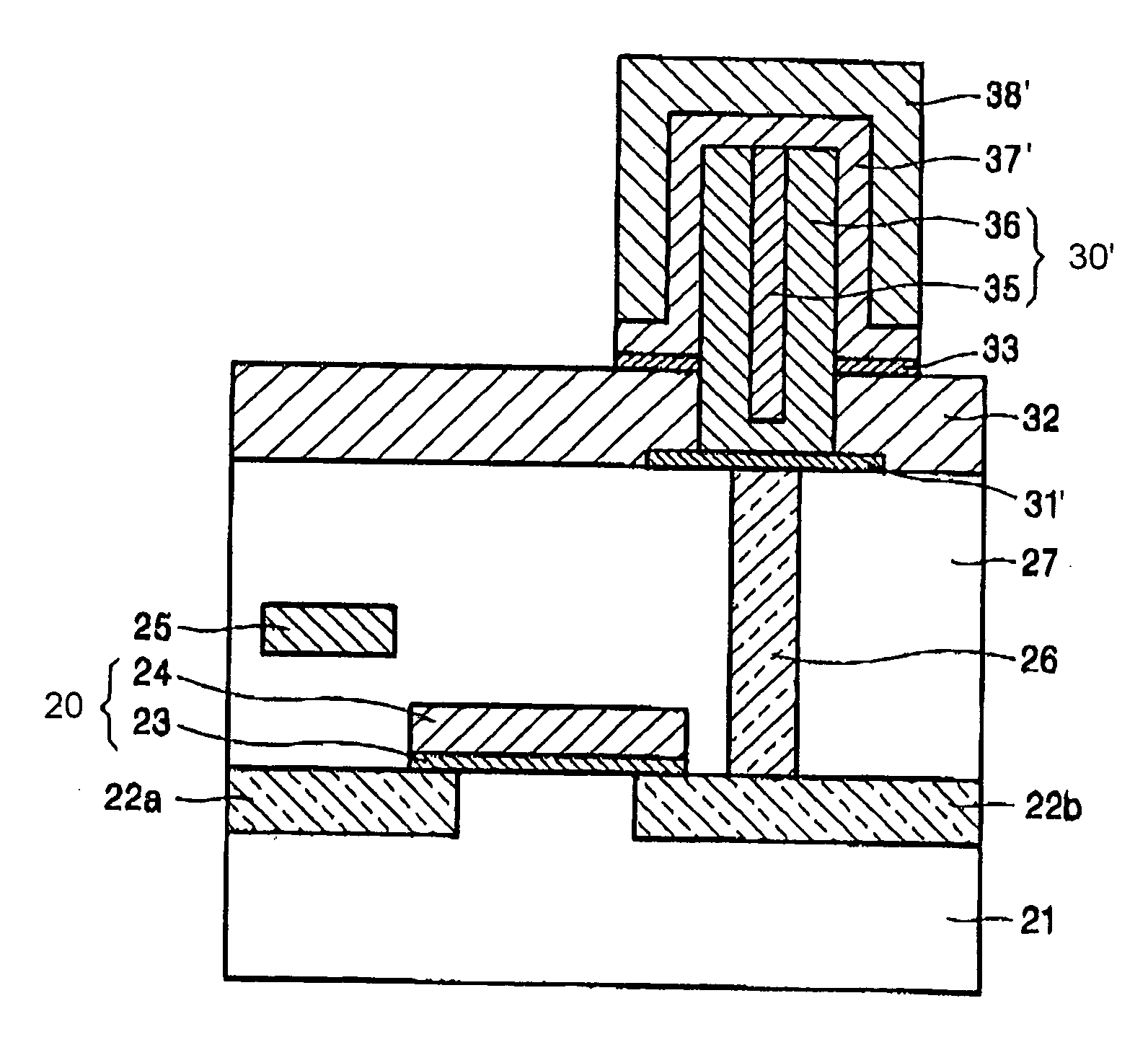

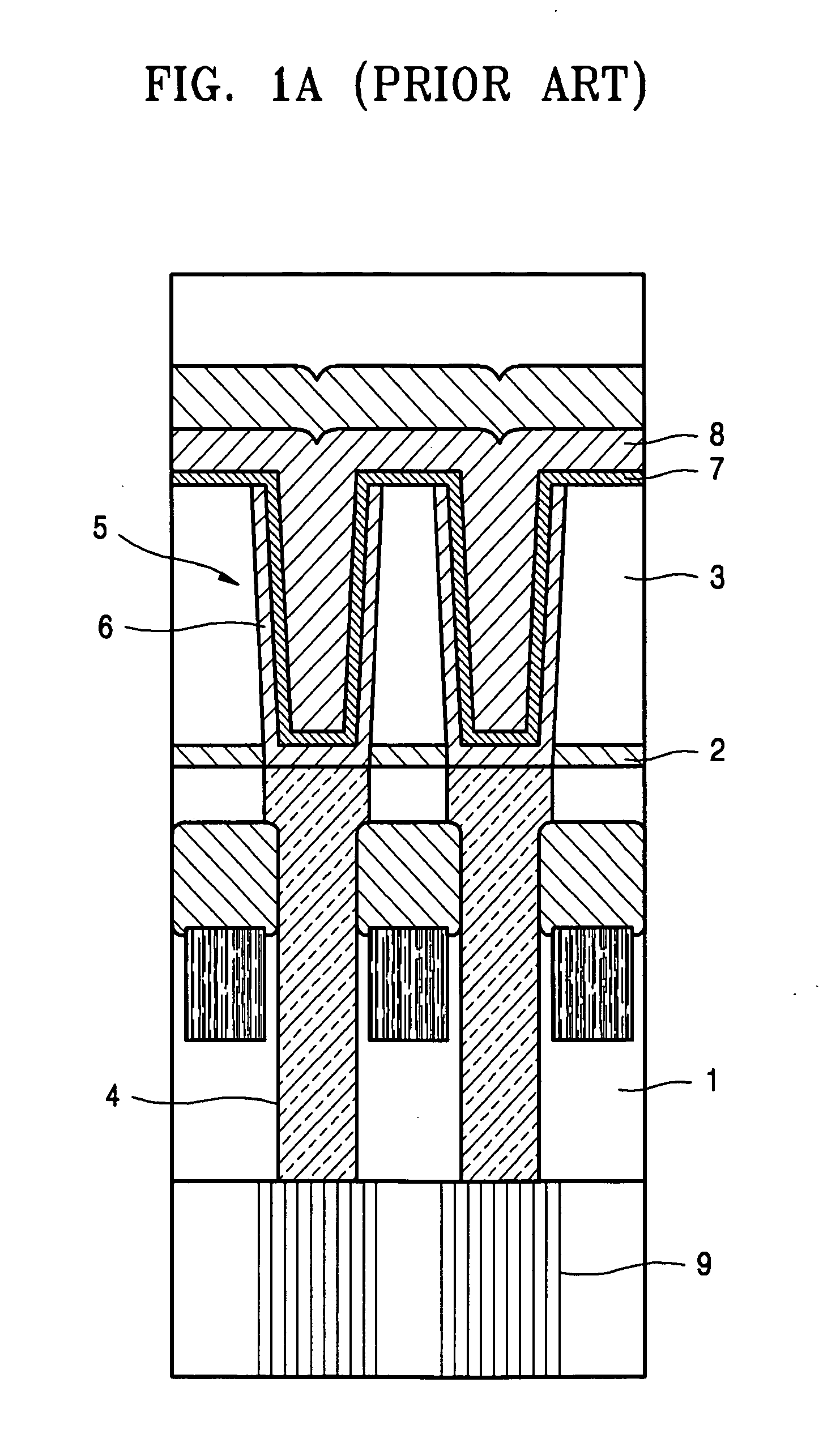

Ferroelectric capacitors including a seed conductive film

InactiveUS7064365B2Excellent fatigue propertiesSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric capacitorAdemetionine

Ferroelectric capacitors include a support insulating film on an integrated circuit substrate and having a trench therein. A lower electrode is on sidewalls and a bottom surface of the trench. A seed conductive film covers the lower electrode. A ferroelectric film is provided on the support insulating film and the seed conductive film and an upper electrode is provided on the ferroelectric film. The lower electrode may fill the trench and the ferroelectric film may extend over all of the seed conductive film and the support insulating film adjacent the seed conductive film.

Owner:SAMSUNG ELECTRONICS CO LTD

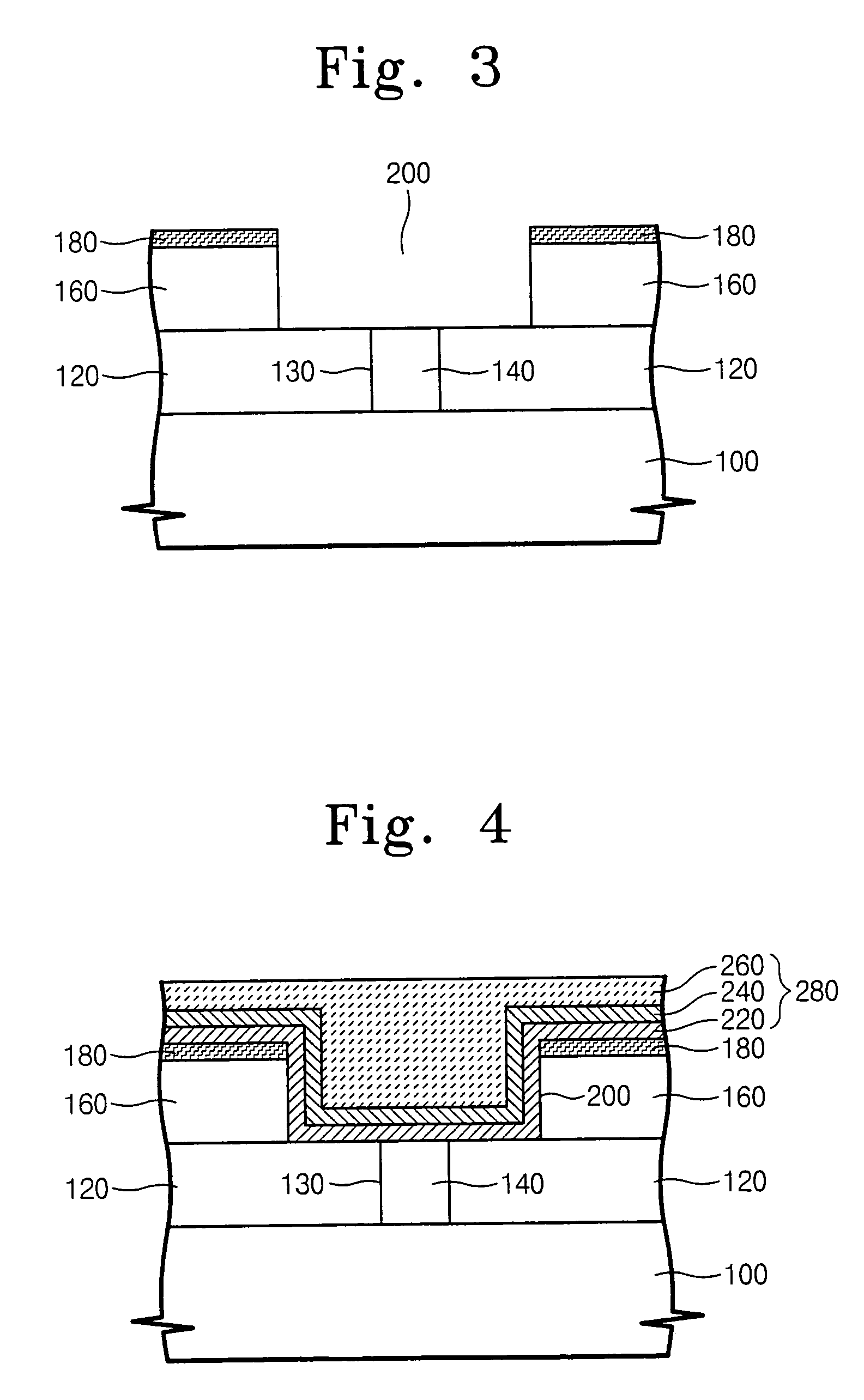

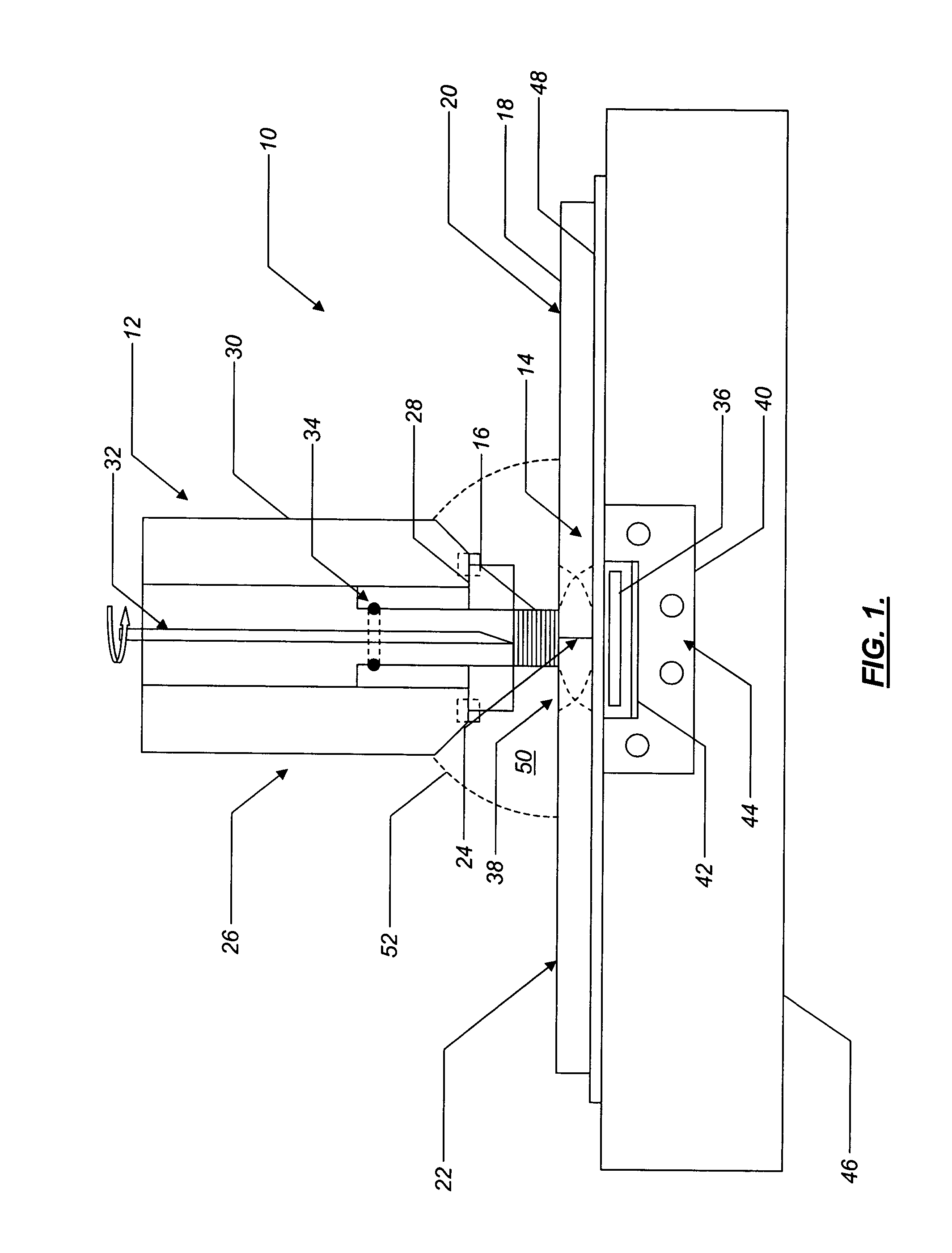

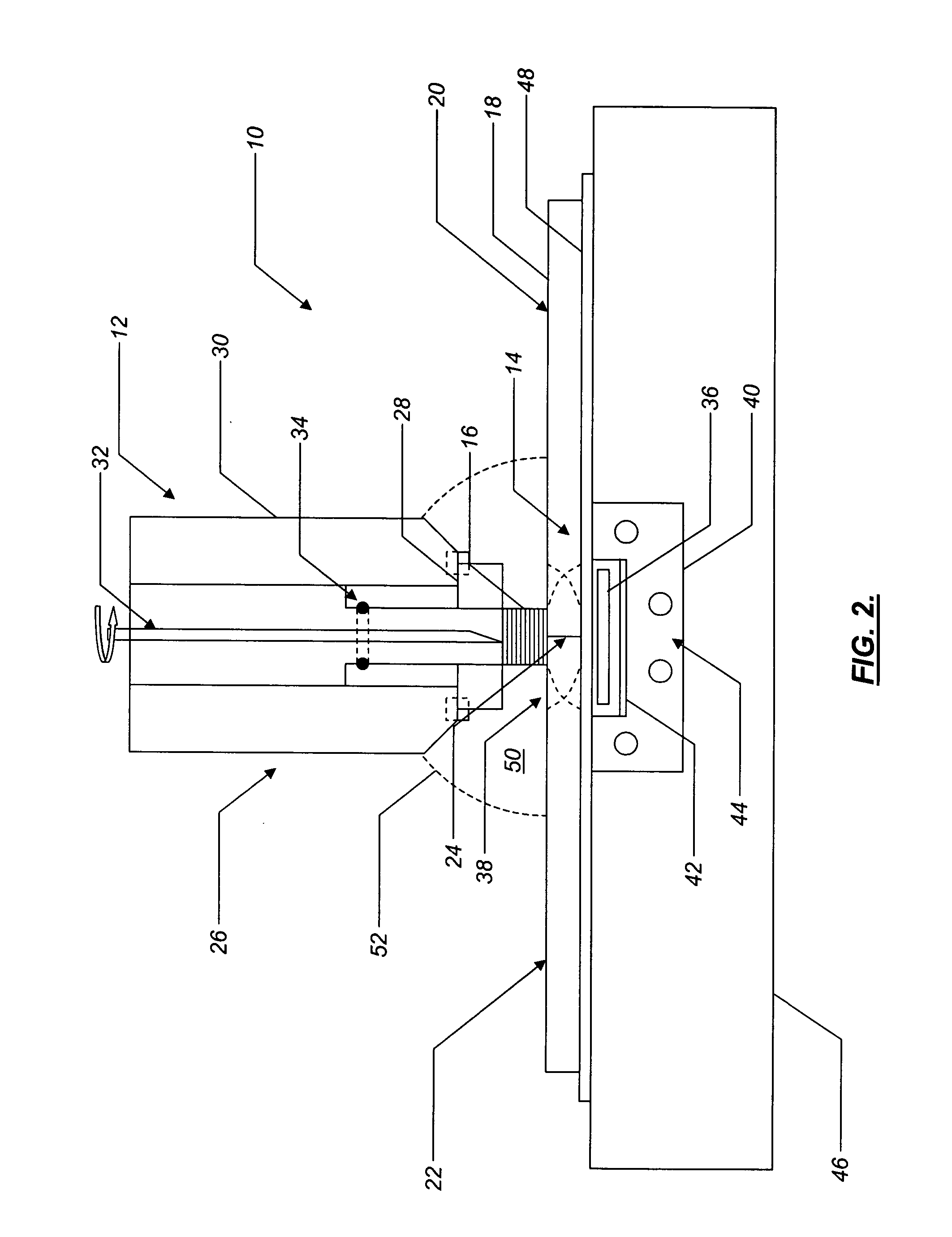

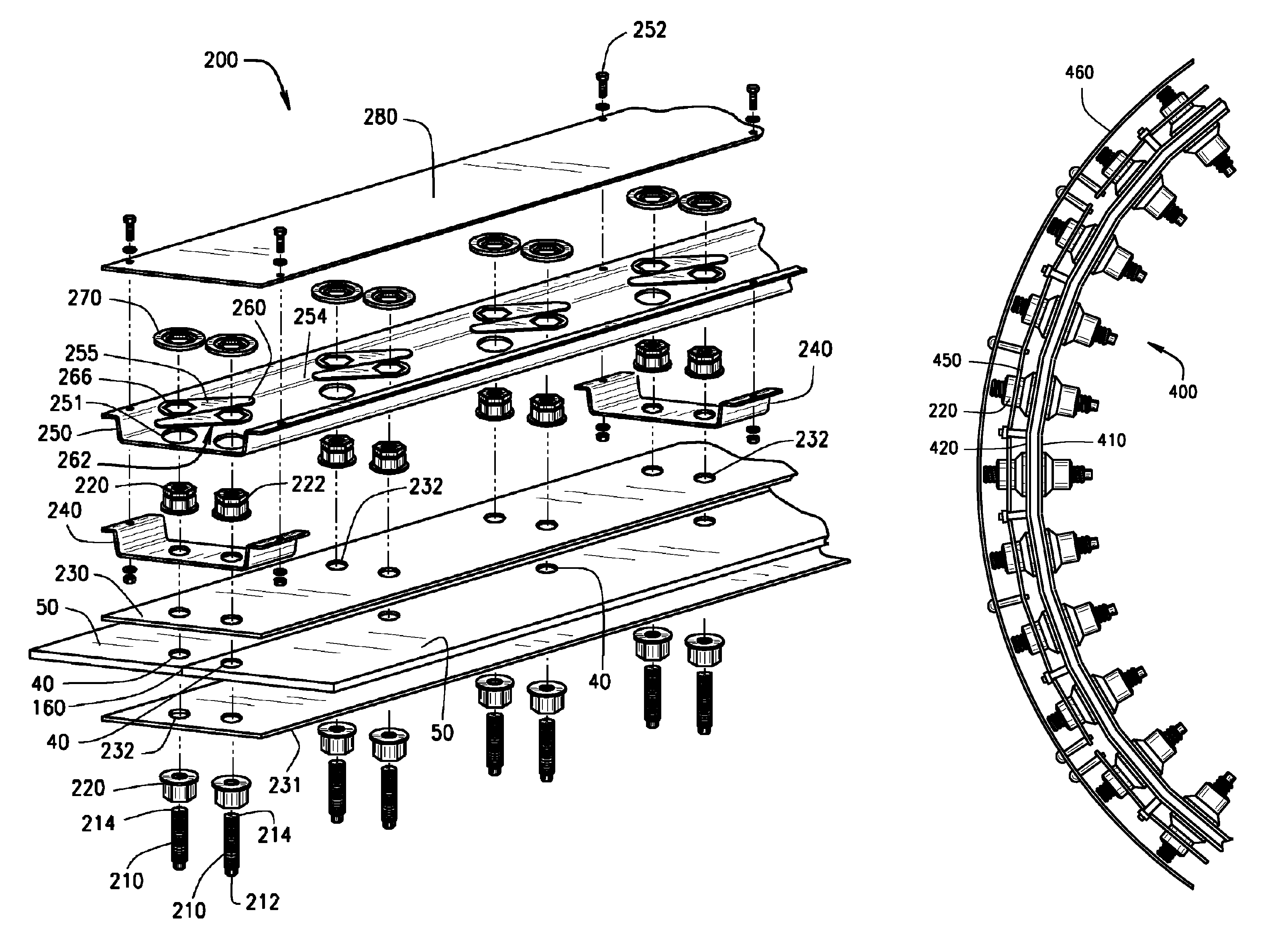

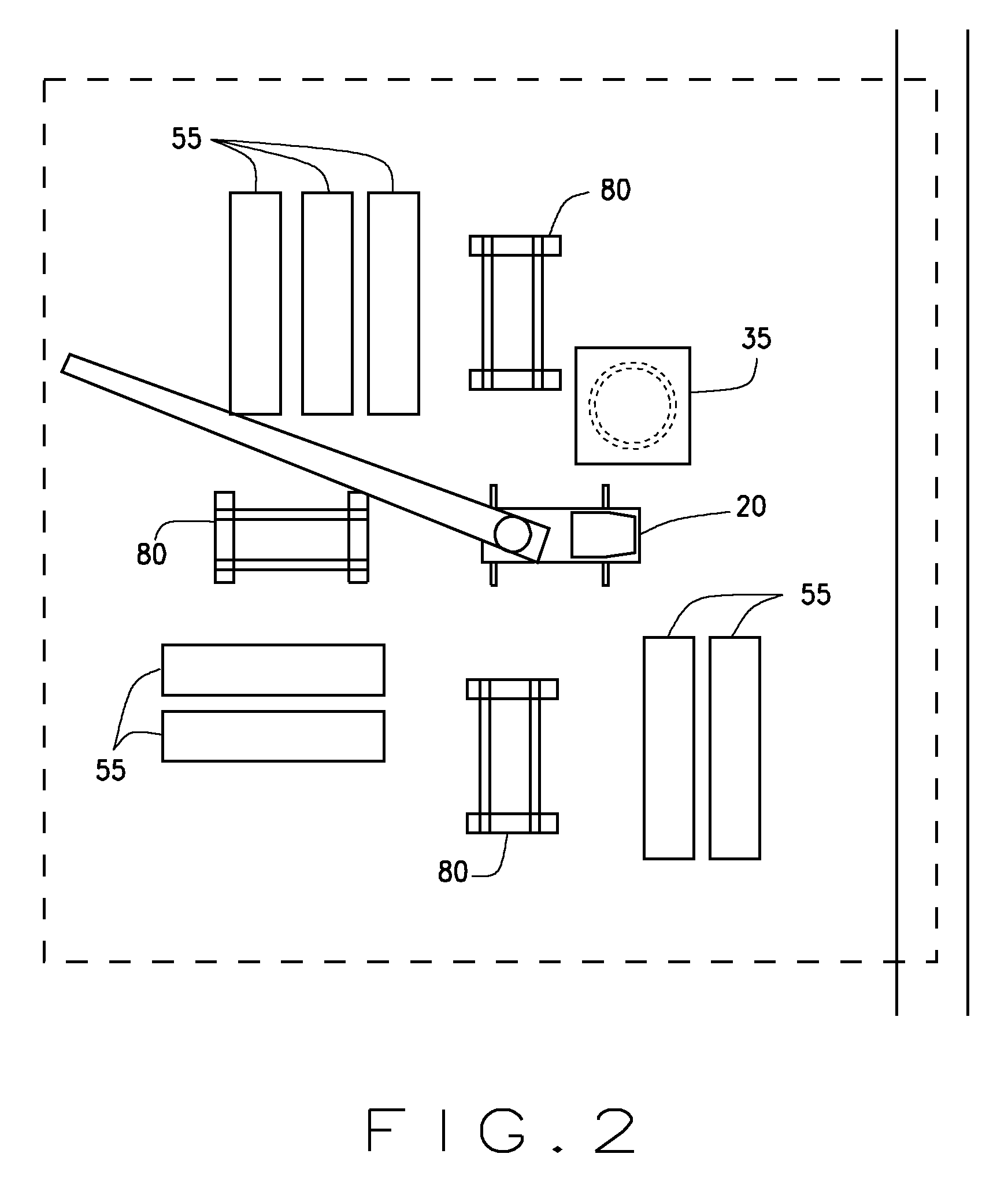

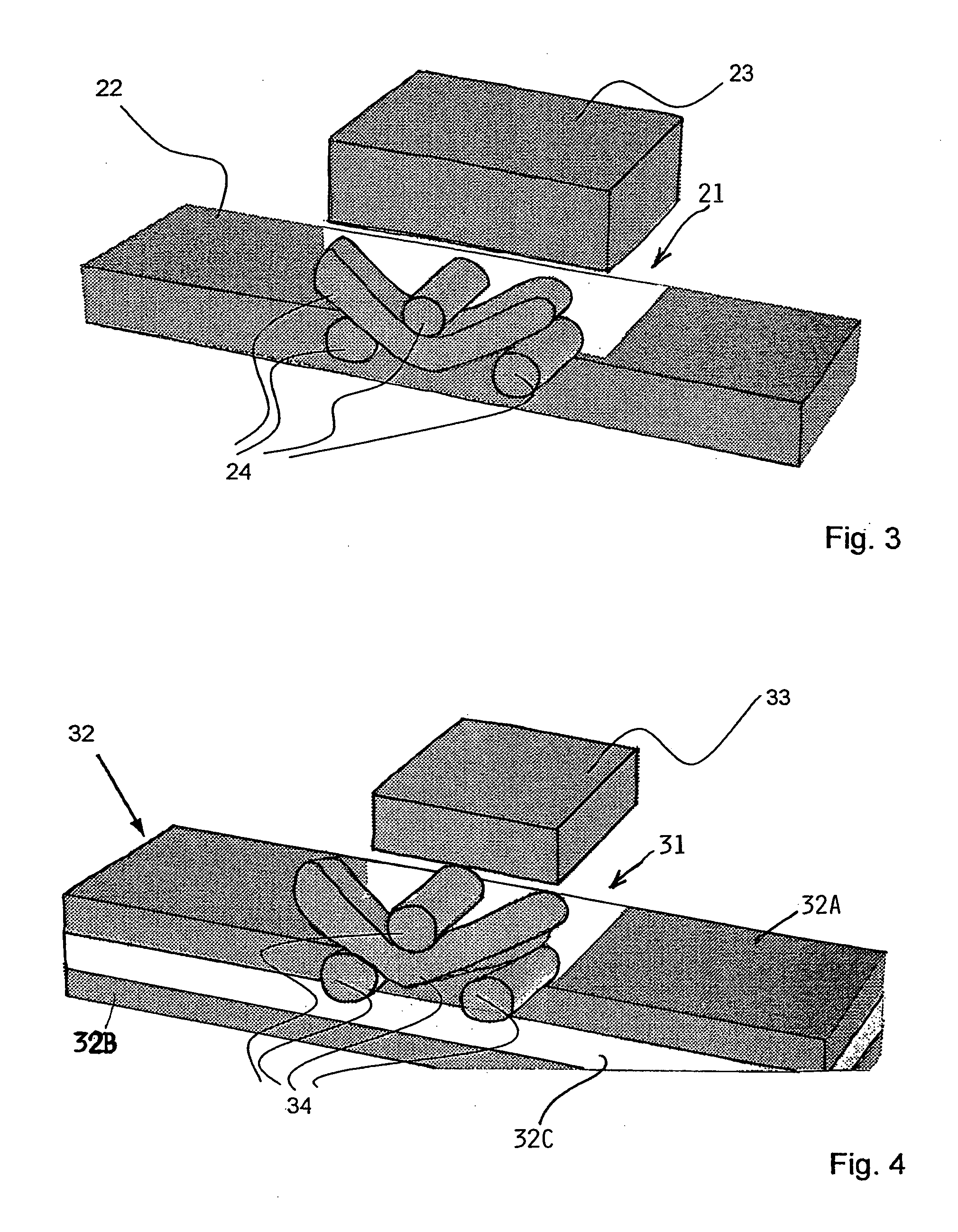

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

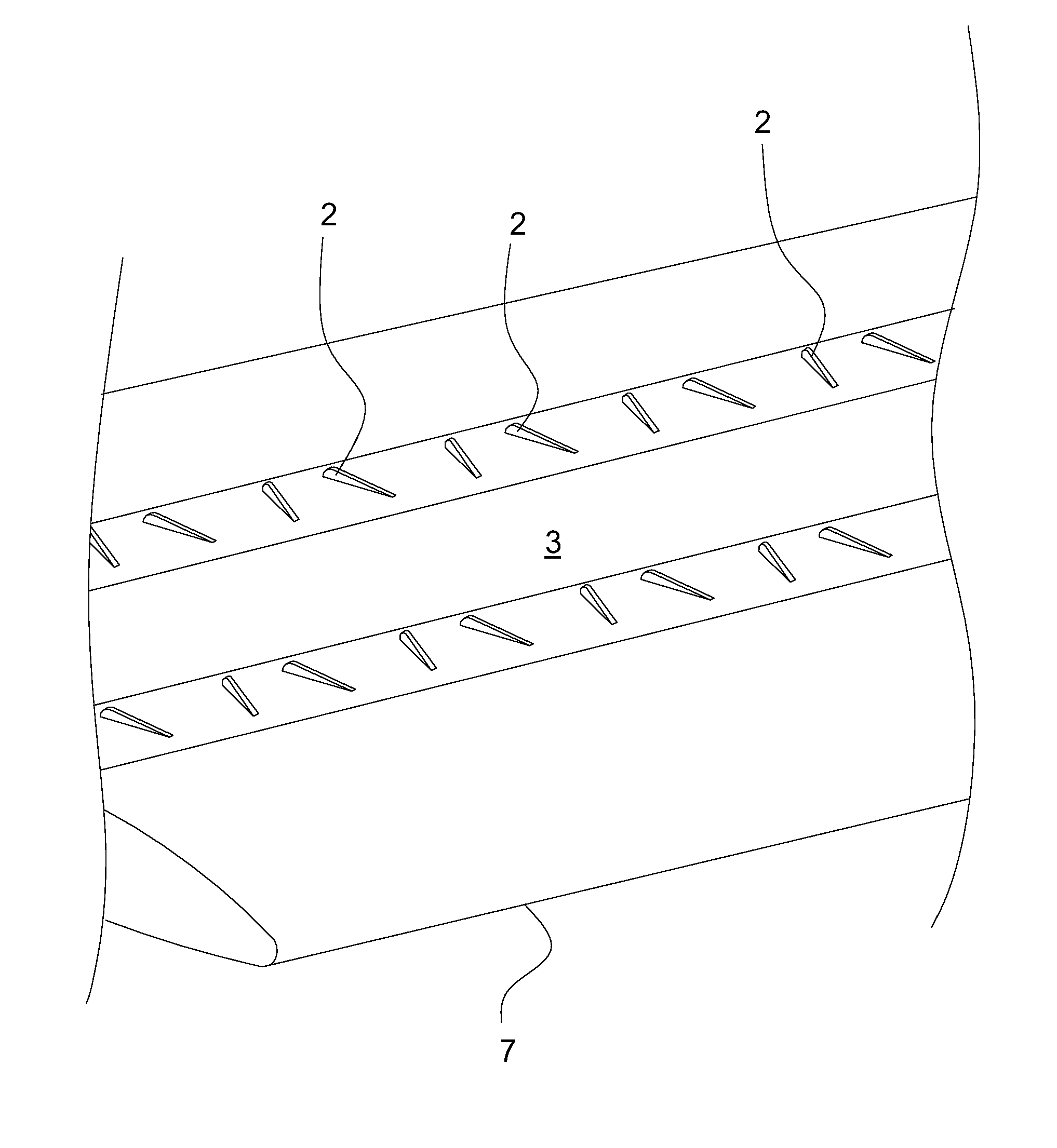

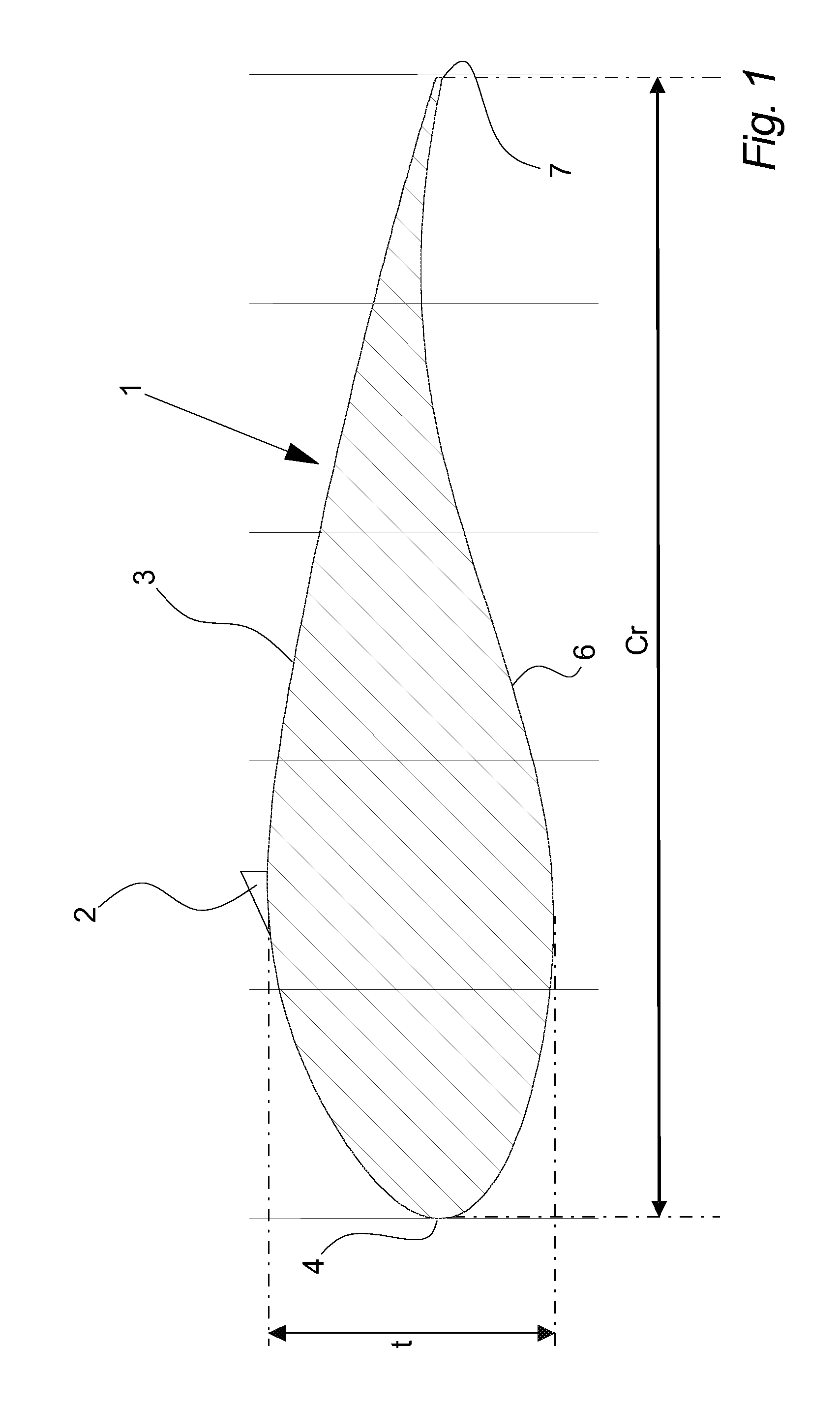

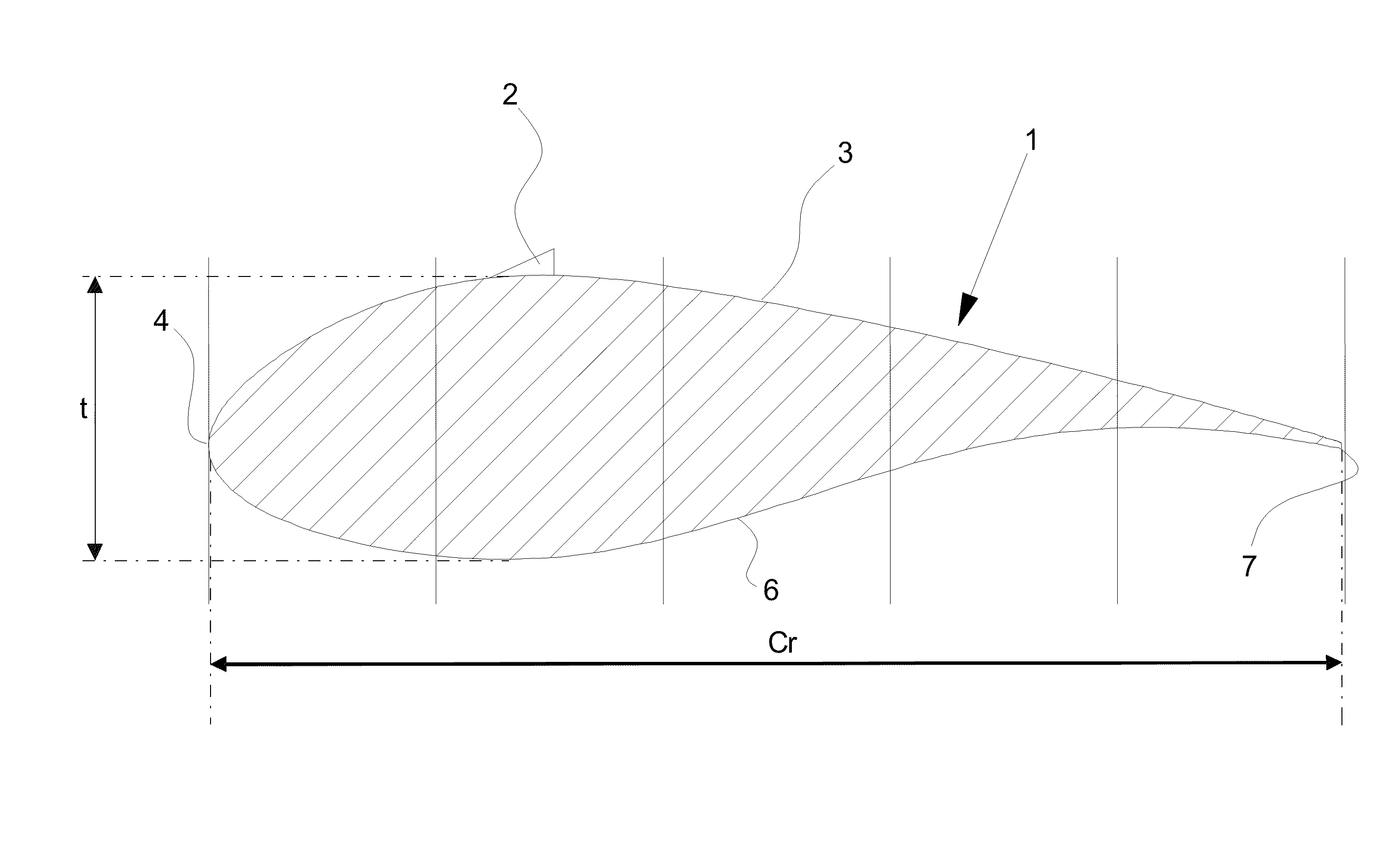

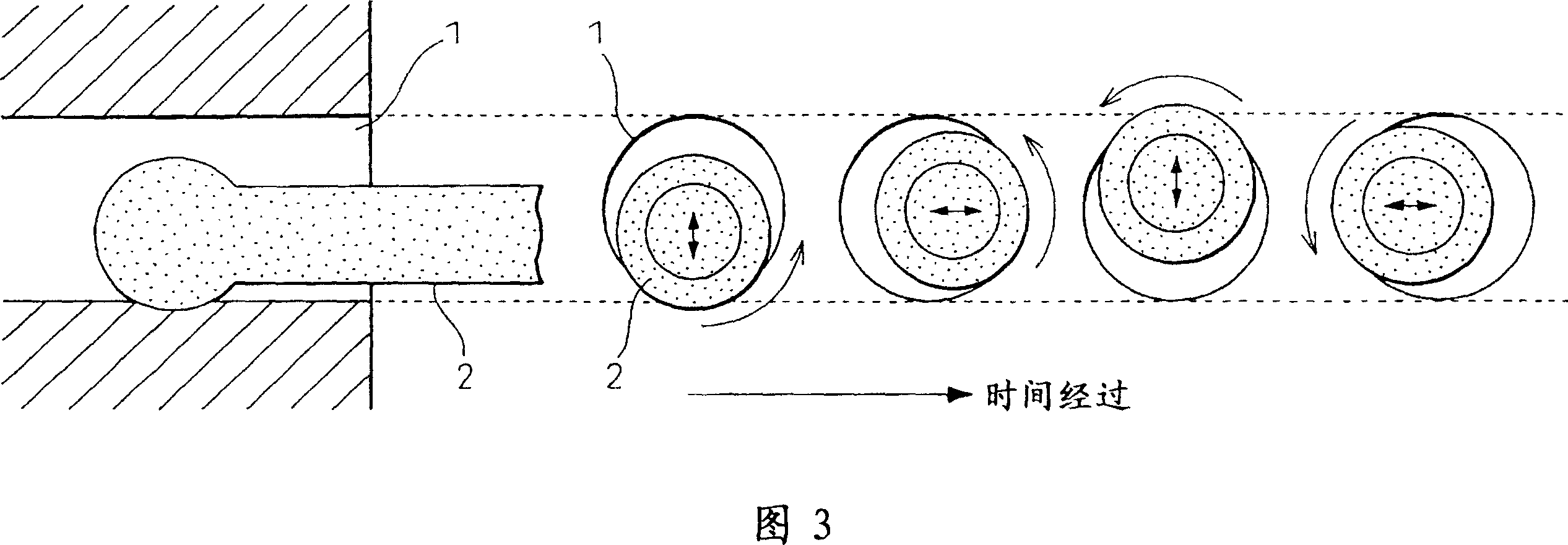

Wind turbine blades with vortex generators

ActiveUS7914259B2Large chordImprove carrying capacityPropellersFinal product manufactureTurbine bladeWind force

An advantageous new design of a wind turbine blade and rotor is obtained by providing one, two or more parallel rows of sub-boundary layer vortex generators, whereby a blade is obtained, which is resistant to stall and provides for a high maximum lift coefficient CL,max of the blades and a slender blade design, a low socalled radius specific solidity of the rotor. The very high lift coefficient CL can reduce the necessary blade area and loads or / and increase the length of the blade and maintain the original loads with higher production. The row or rows of sub-boundary layer vortex generators are in a preferred embodiment of the invention provided in combination with Gurney Flaps generating a very high lift coefficient CL with a relative gentle stall at very high angle of attack.

Owner:VESTAS WIND SYST AS

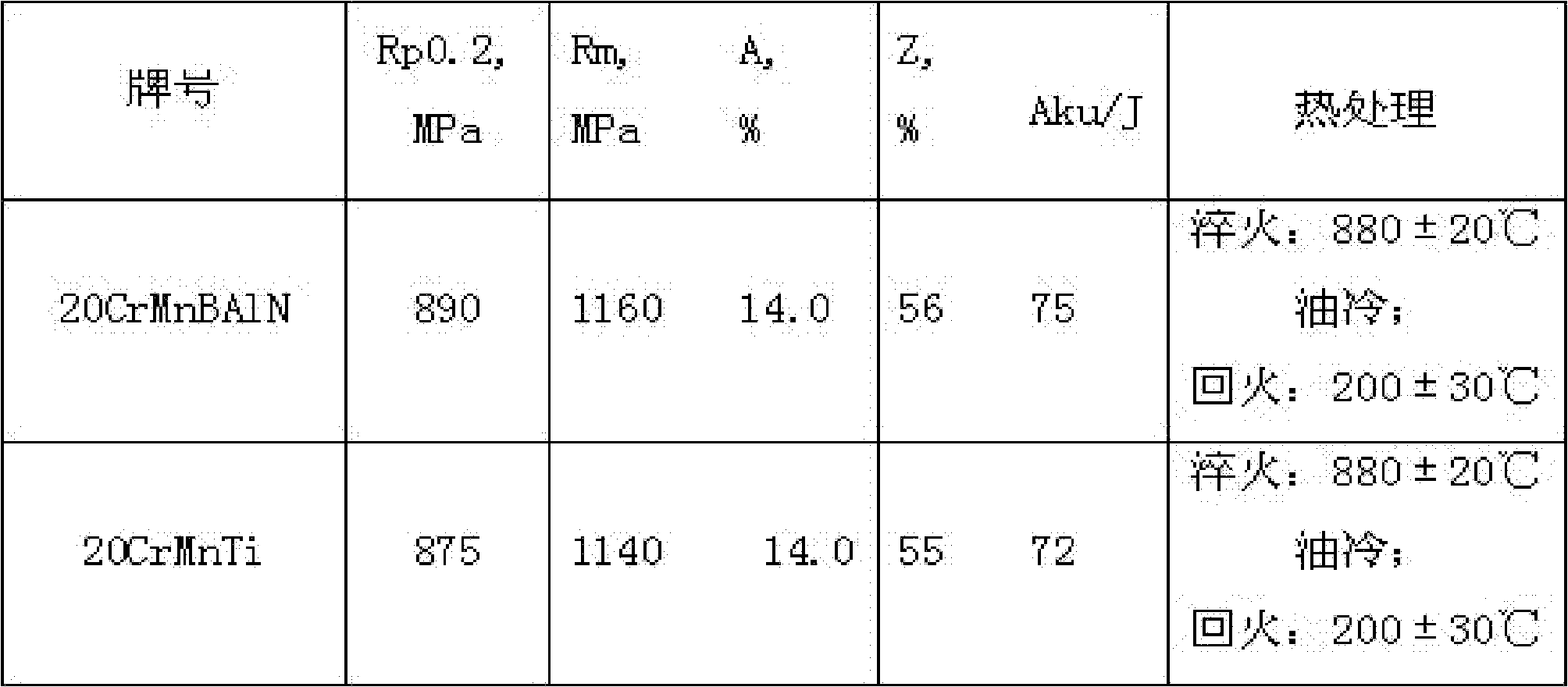

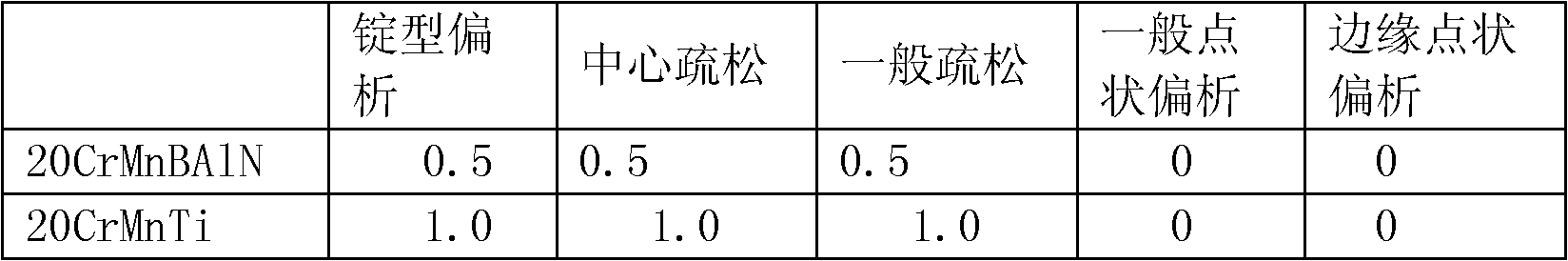

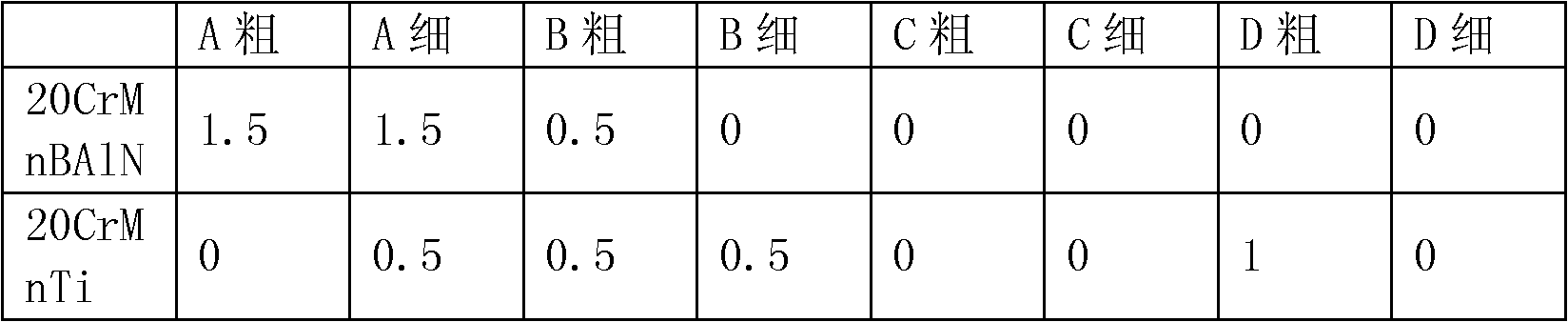

Grain-refined gear steel and production process thereof

The invention discloses grain-refined gear steel and a production process of the grain-refined gear steel. The gear steel comprises the following compositions in percentage by weight: 0.14-0.22% of C, 0.20-0.35% of Si, 0.80-1.15% of Mn, 0.80-1.25% of Cr, 0.030-0.060% of Al, less than or equal to 0.035% of P, 0.015-0.030% of S, 0.0005-0.030% of B, less than or equal to 0.080% and more than or equal to 0.0140% of N, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Mo, less than or equal to 0.20% of Cu, and the balance of Fe and inevitable impurities. The production process comprises the procedures of smelting, continuous casting and rolling. According to the invention, the refined grains of intracrystalline ferrite are fully used, so that the impact strength is improved, and the fatigue characteristic is improved.

Owner:ZENITH STEEL GROUP CORP +1

Wind Turbine Blades With Vortex Generators

ActiveUS20100008787A1Large chordExtreme loadEngine fuctionsFinal product manufactureTurbine bladeSolidity

An advantageous new design of a wind turbine blade and rotor is obtained by providing one, two or more parallel rows of sub-boundary layer vortex generators, whereby a blade is obtained, which is resistant to stall and provides for a high maximum lift coefficient CL,max of the blades and a slender blade design, a low socalled radius specific solidity of the rotor. The very high lift coefficient CL can reduce the necessary blade area and loads or / and increase the length of the blade and maintain the original loads with higher production. The row or rows of sub-boundary layer vortex generators are in a preferred embodiment of the invention provided in combination with Gurney Flaps generating a very high lift coefficient CL with a relative gentle stall at very high angle of attack.

Owner:VESTAS WIND SYST AS

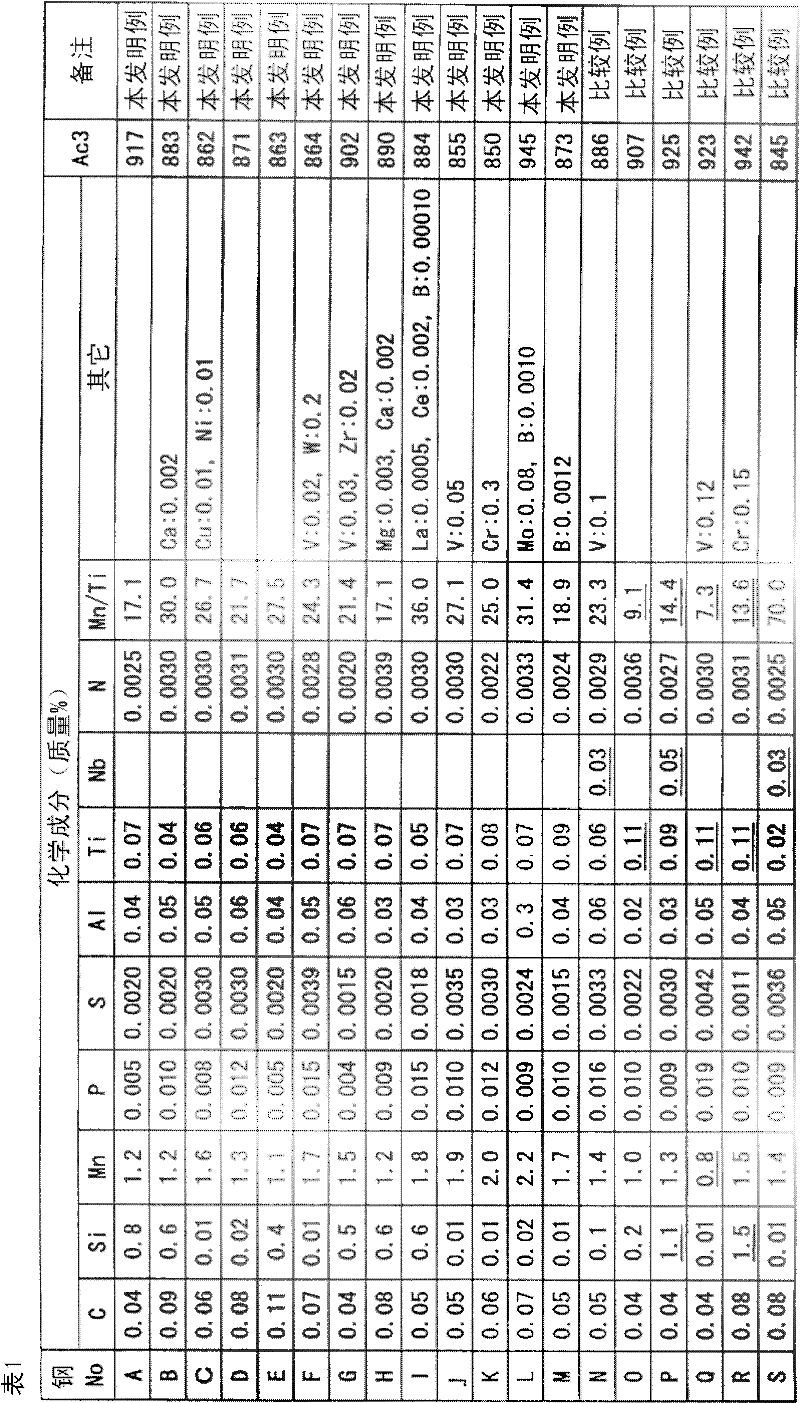

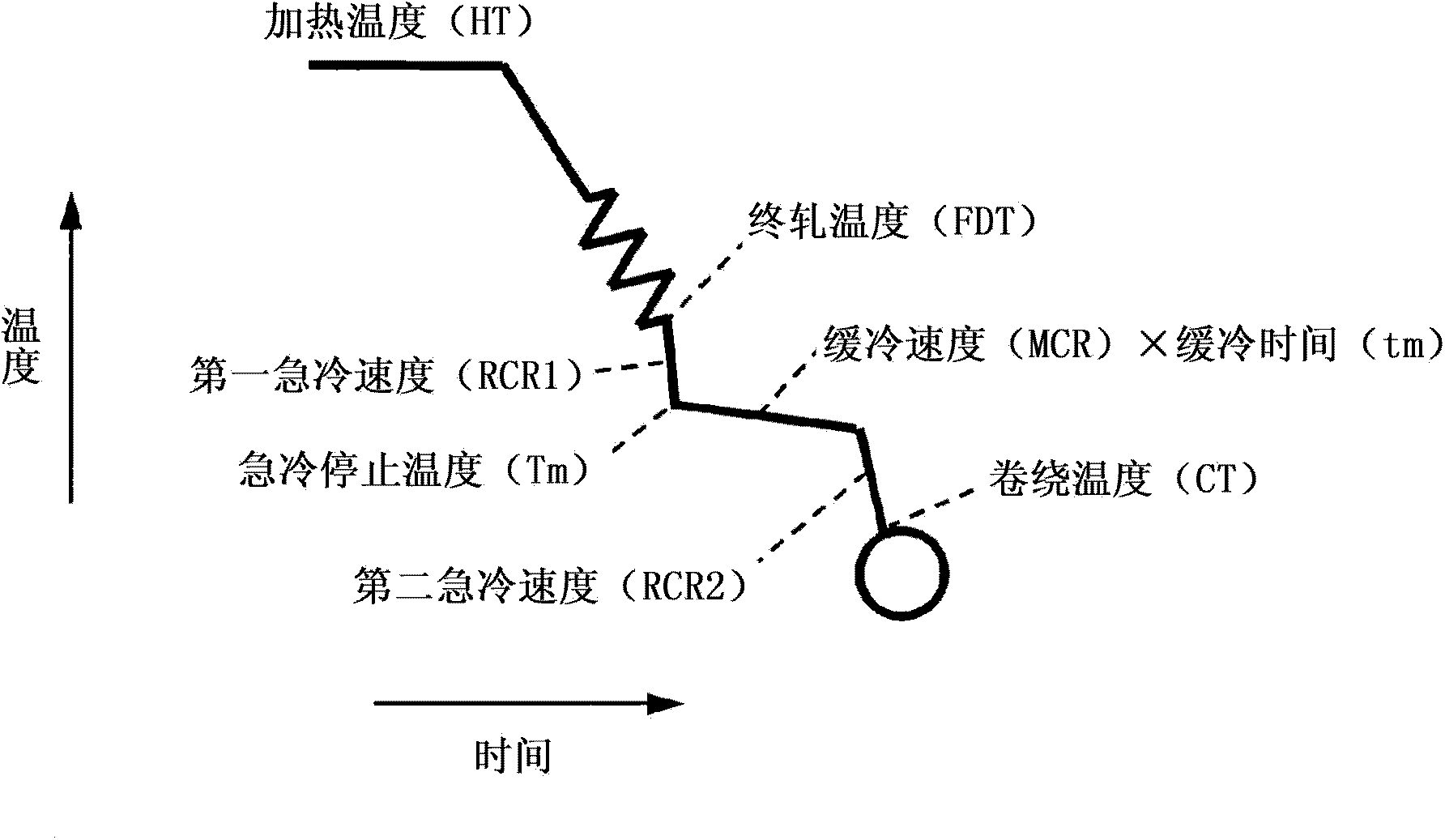

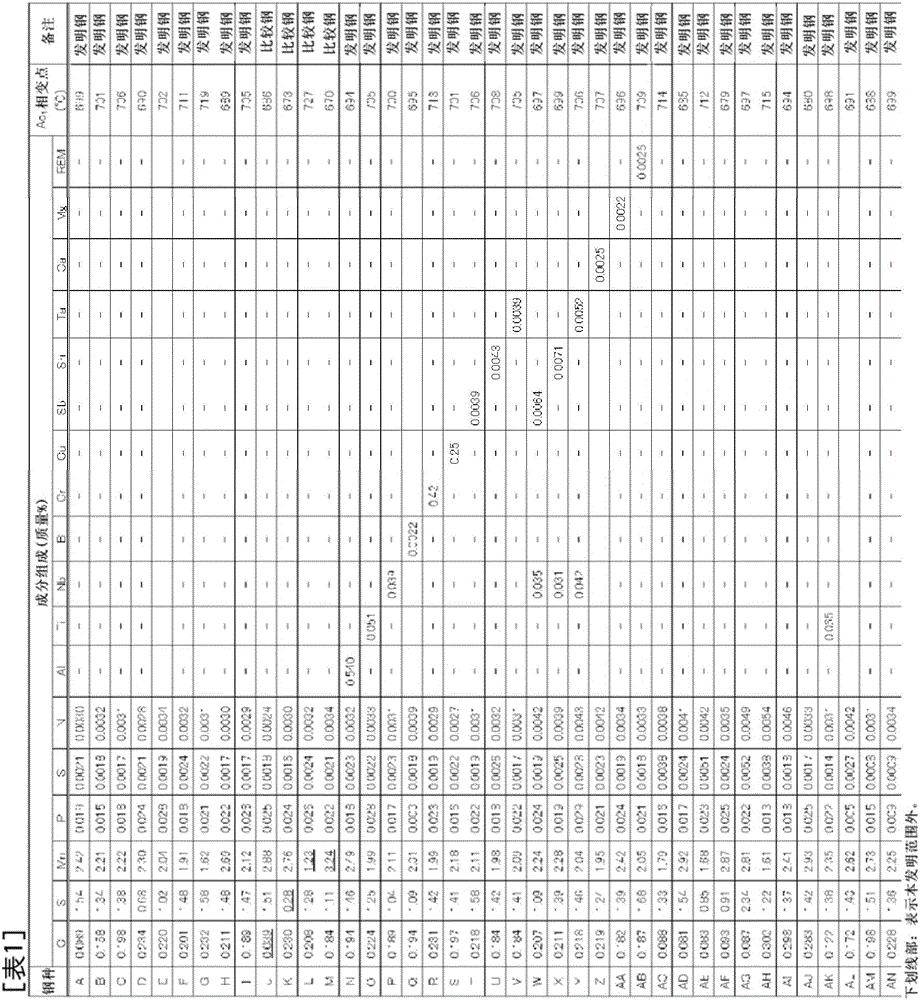

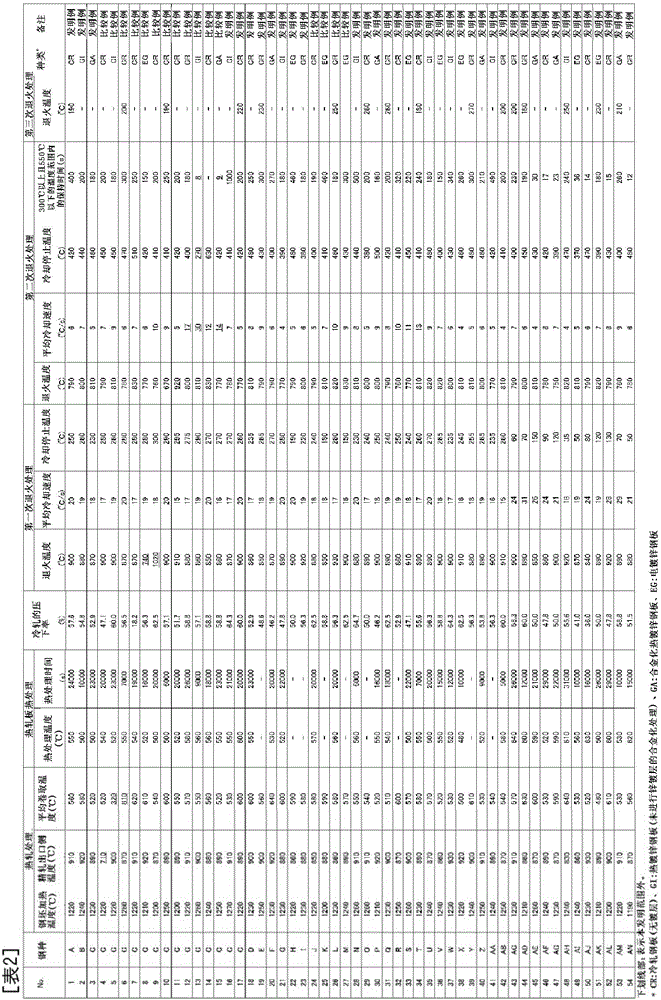

Hot rolled steel sheet having excellent punching workability and fatigue properties, hot dip galvanized steel sheet, and method for producing the same

ActiveCN102333899ALess end face damageExcellent fatigue propertiesFurnace typesMetal rolling arrangementsCarbideBrittle fracture

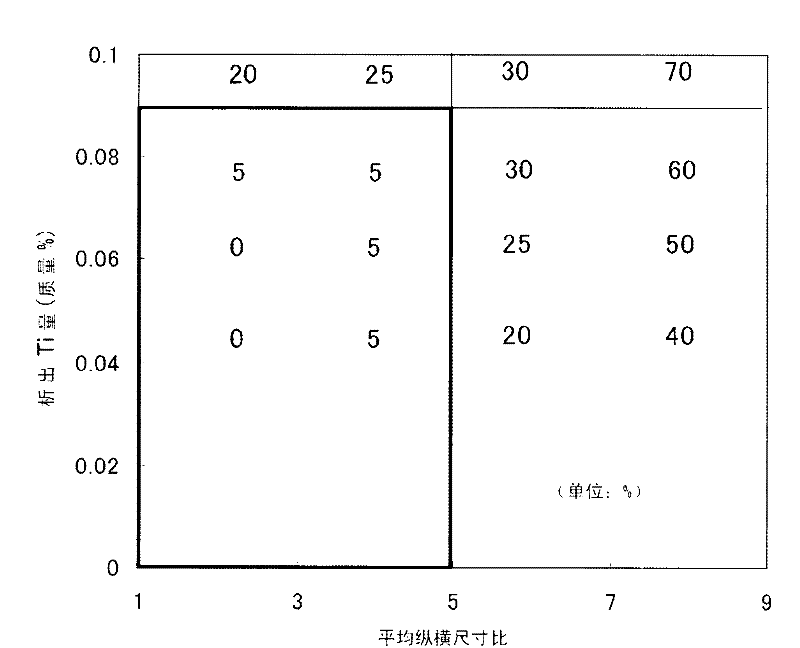

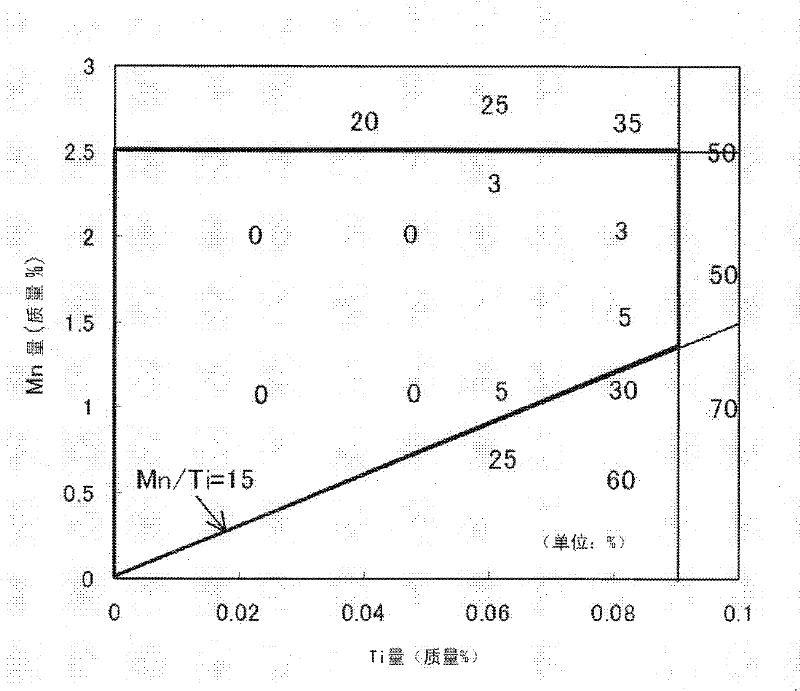

Provided is a hot rolled steel sheet comprising, by mass%, 0.025 to 0.15% of C, 0.01 to 1.0% or less of Si, 1.0 to 2.5% of Mn, 0.02% or less of P, 0.005% or less of S, 0.5% or less of Al, 0.04 to 0.10% of Ti, and 0.007% or less of N, as well as Fe and inevitable impurities as the balance, wherein the Mn / Ti ratio is 15 or greater; Nb is not added; the ferrite volume percentage is 30% or greater and the balance comprises one of or both pearlite and bainite; the average aspect ratio of the crystal grain corresponding ellipsoid is 5 or less; the average distribution density on the ferrite grain boundary surface of Ti carbide having a grain size of 20 nm or greater is 10 grains / [mu]m or less; the brittle fracture rate of surface fractured by punching is less than 20%; and the maximum tensile strength is 590 MPa or greater.

Owner:NIPPON STEEL CORP

High-strength hot-rolled steel plate

InactiveCN103732779AExcellent fatigue propertiesGuaranteed forming effectFurnace typesMetal rolling arrangementsSheet steelCarbide

Owner:KOBE STEEL LTD

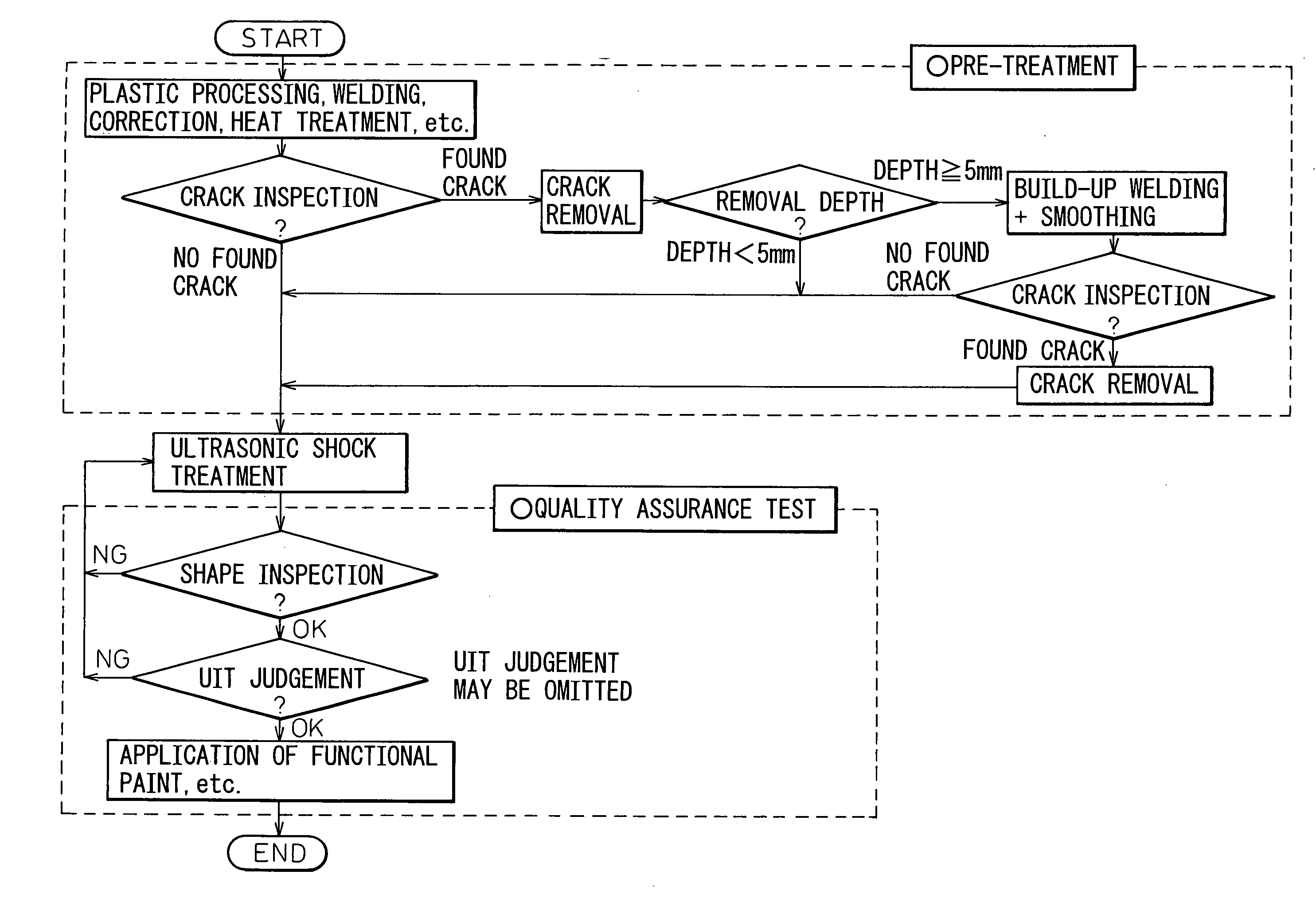

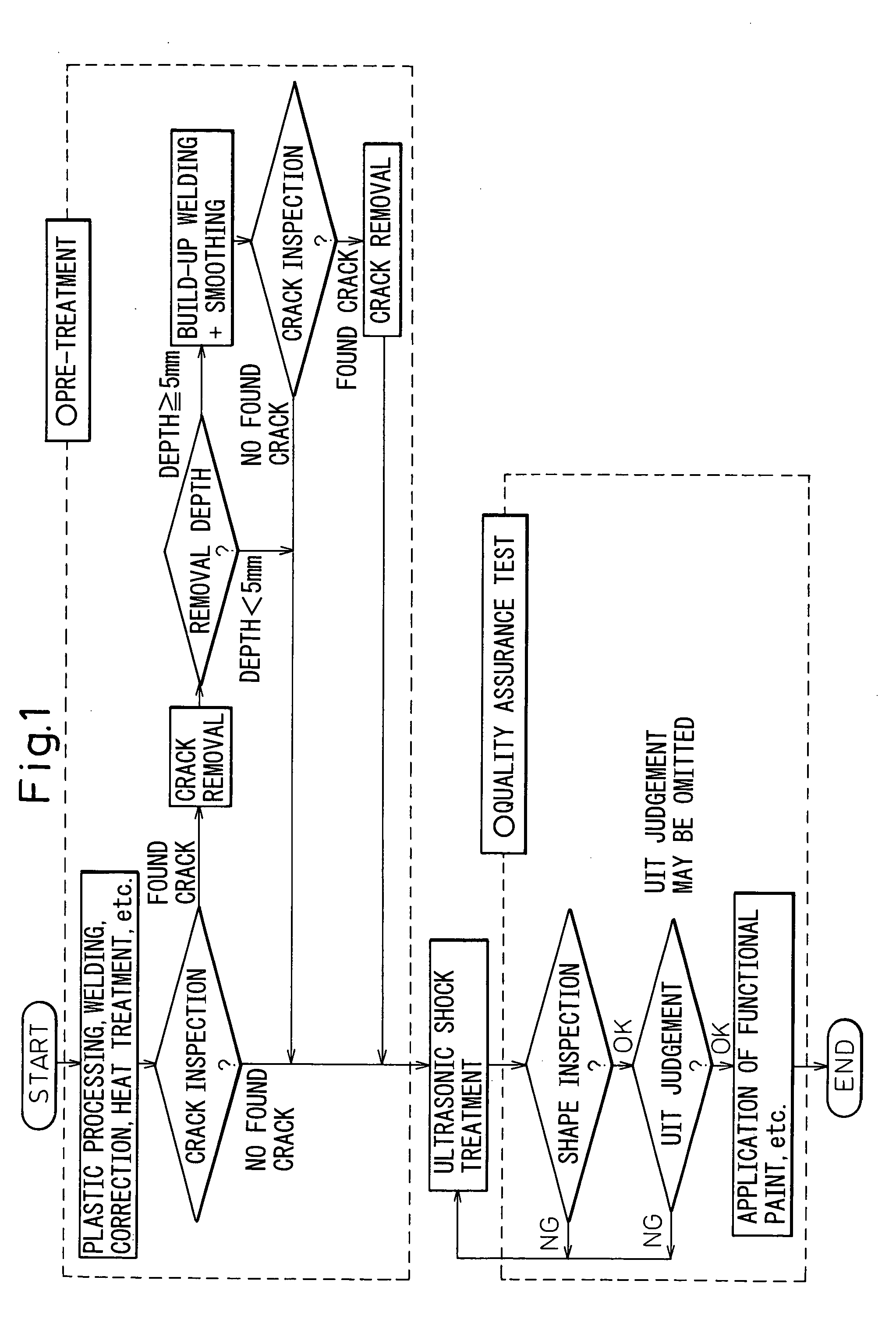

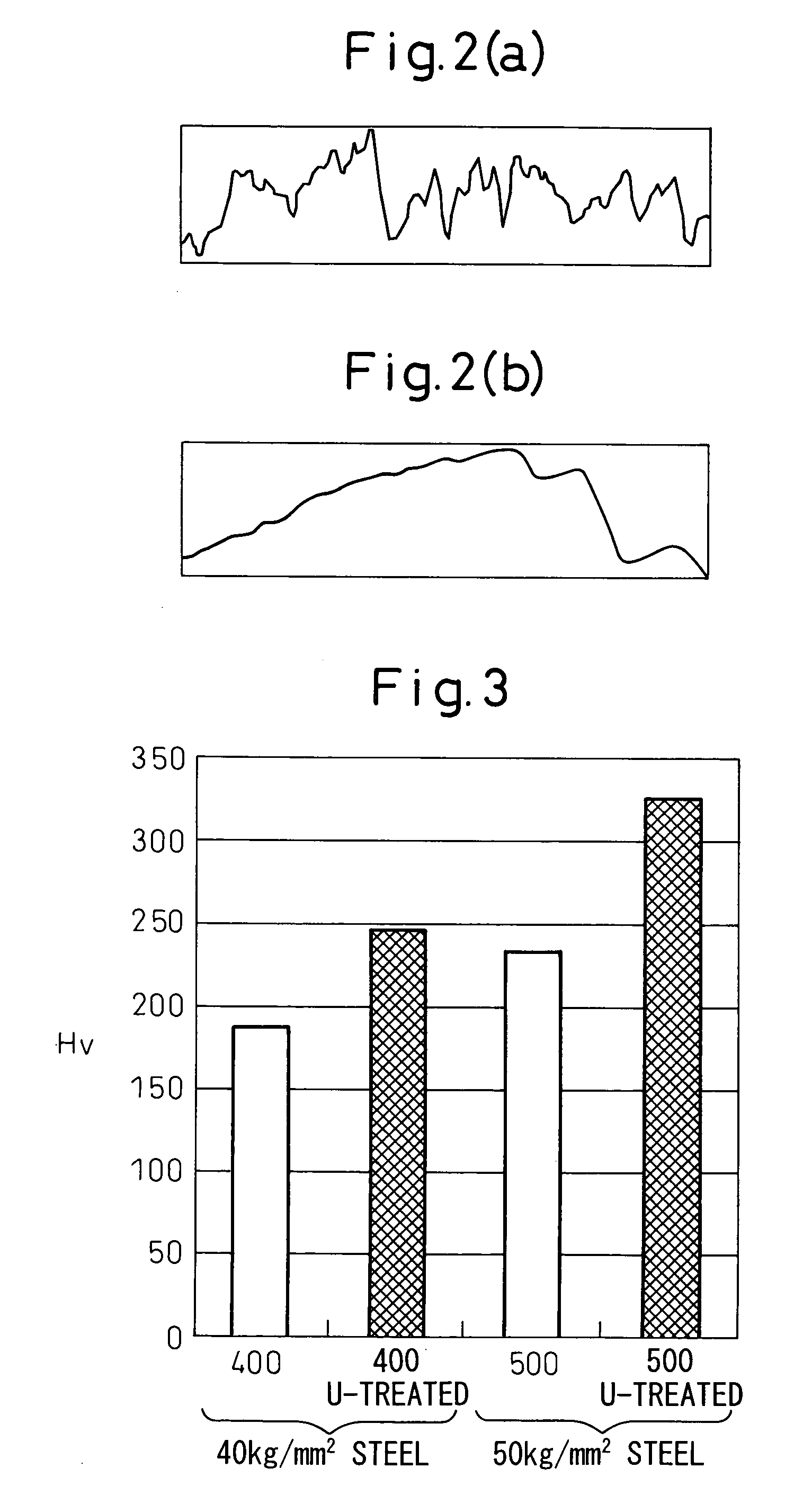

Treatment method for improving fatigue life and long-life metal material treated by using same treatment

InactiveUS20050230010A1Improve fatigue lifeExcellent fatigue propertiesBlast furnace detailsHeat treatment process controlQuality assurancePre treatment

A novel treatment method, for improving fatigue life, is provided that aims to resolve problems associated with conventional treatment methods for improving fatigue life of metal by reduction of stress concentration and conventional treatment methods for improving fatigue life of metal by introduction of compressive stress, that is, problems of poor efficiency in work execution, required level of skill of workers, and the impossibility of quality control due to lack of means for measuring the effect after treatment, characterized in that, for locations in metal for which fatigue is a problem, after pre-treatment is performed, ultrasonic impact treatment is performed, and thereafter, a quality assurance test is performed so as to improve the fatigue life of the metal.

Owner:NIPPON STEEL CORP

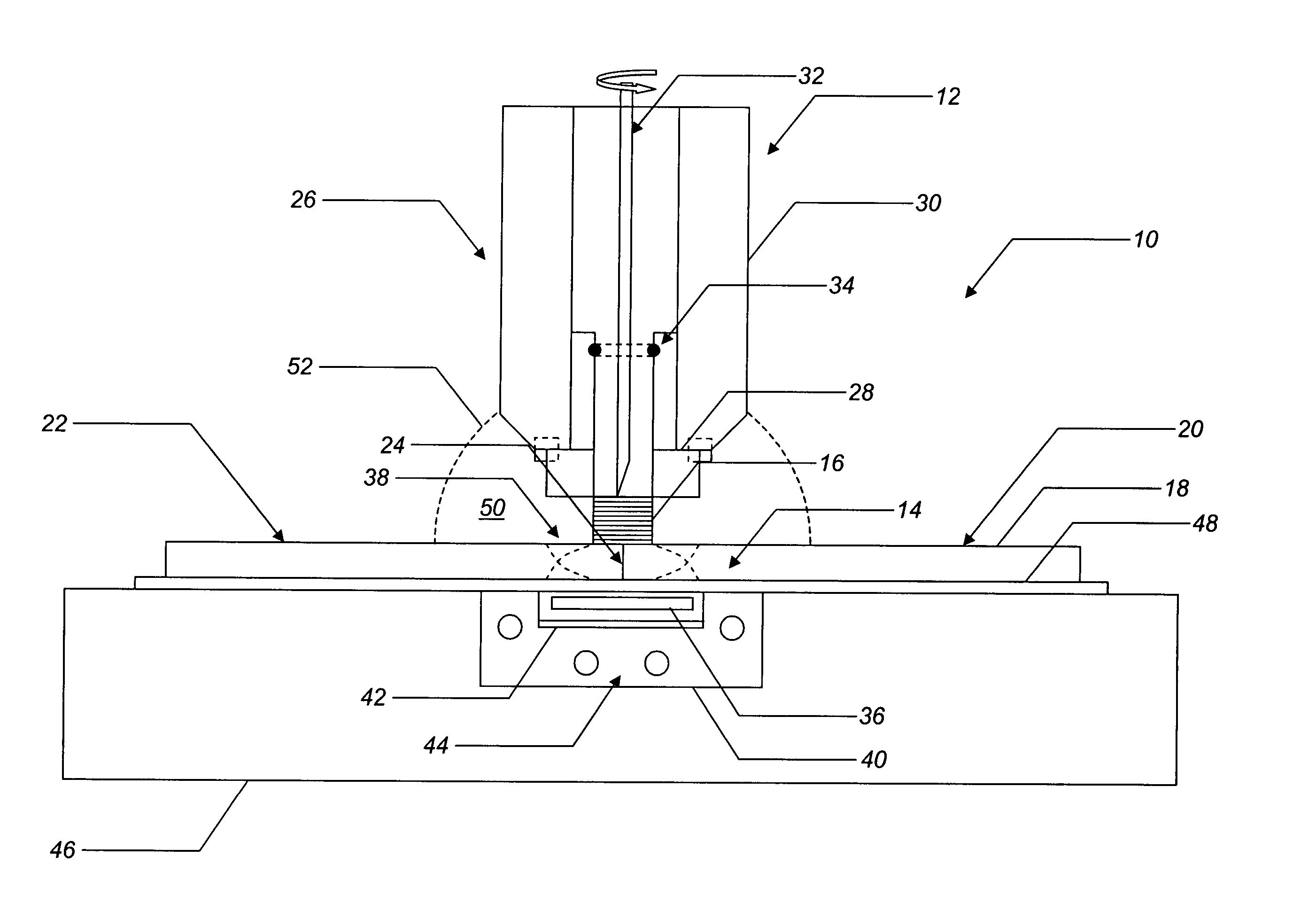

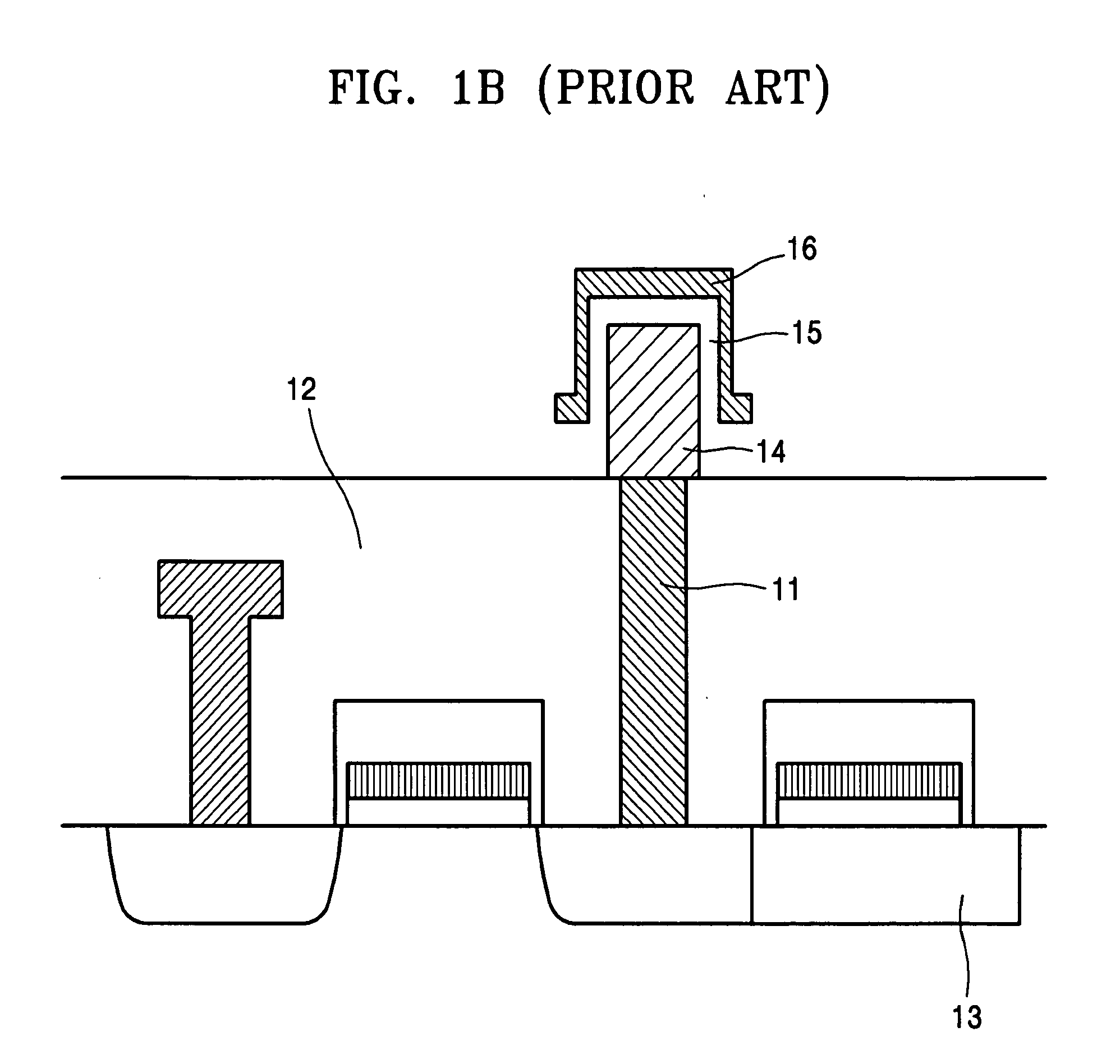

Capacitor of a memory device and fabrication method thereof

InactiveUS20060001070A1Excellent fatigue propertiesLow production costTransistorSolid-state devicesOptoelectronicsMetal electrodes

A capacitor of a memory device, and a method of fabricating the same, includes a lower electrode electrically coupled to a doping region of a transistor structure, the lower electrode having a metal electrode and a metal oxide electrode, a ferroelectric layer covering and extending laterally along the lower electrode, and an upper electrode formed on the ferroelectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

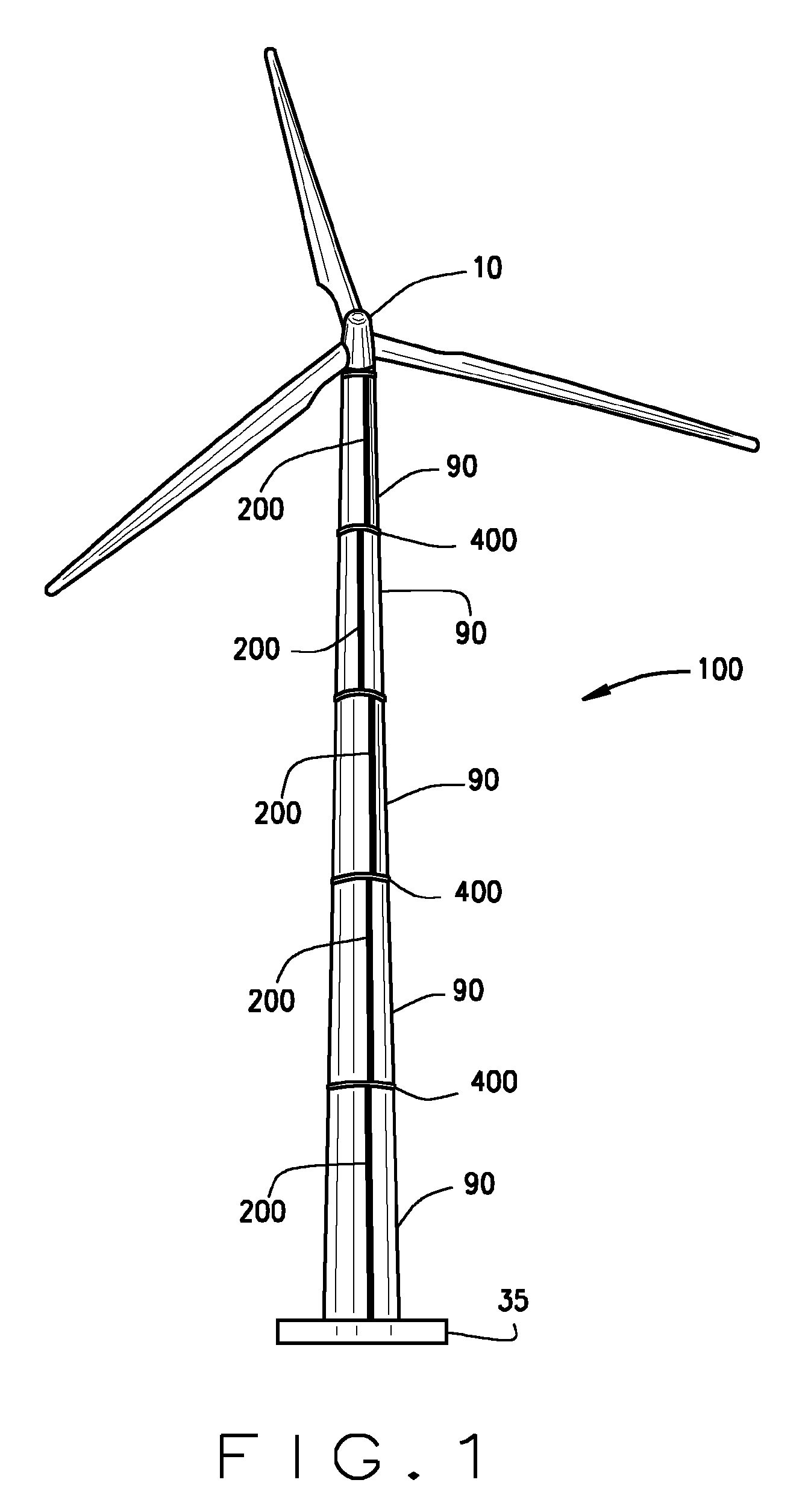

Tower structure and method of assembling

ActiveUS8136329B2Reduce the amount requiredCost-effectiveWind motor assemblyBuilding repairsVertical edgeArcuate shape

A modular tower structure is described herein. The modular tower uses a cost-effective, efficient design that reduces the amount of steel necessary for tower structures for wind turbines. The modular tower is constructed from sections. The sections are constructed from panels. The panels comprise a curved or arcuate shape. The panels include vertical edges and horizontal edges. A vertical connection connects or secures the panels at the vertical edges of the panels and forms the sections. The sections have a generally circular shape. The vertical connection includes an interior vertical friction plate positioned over a seam or gap between adjacent panels and an exterior vertical friction plate positioned over the seam or gap between adjacent panels. A horizontal connection connects or secures the sections at the horizontal edges of the panels. The horizontal connection comprises an interior friction plate that covers a seam or gap between the adjacent sections and an exterior friction plate that covers the seam or gap between the adjacent sections.

Owner:NORTHSTAR ENDEAVORS

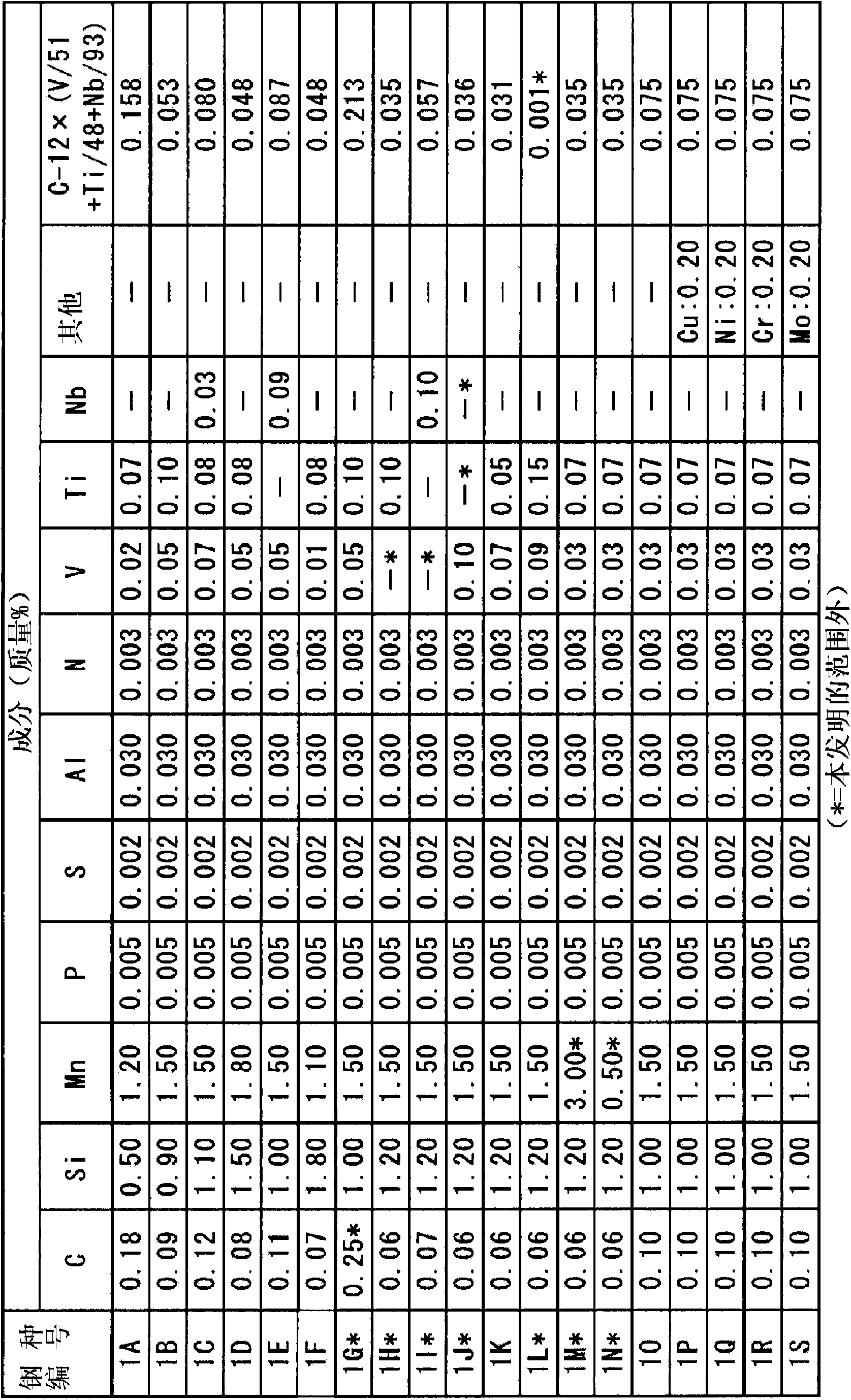

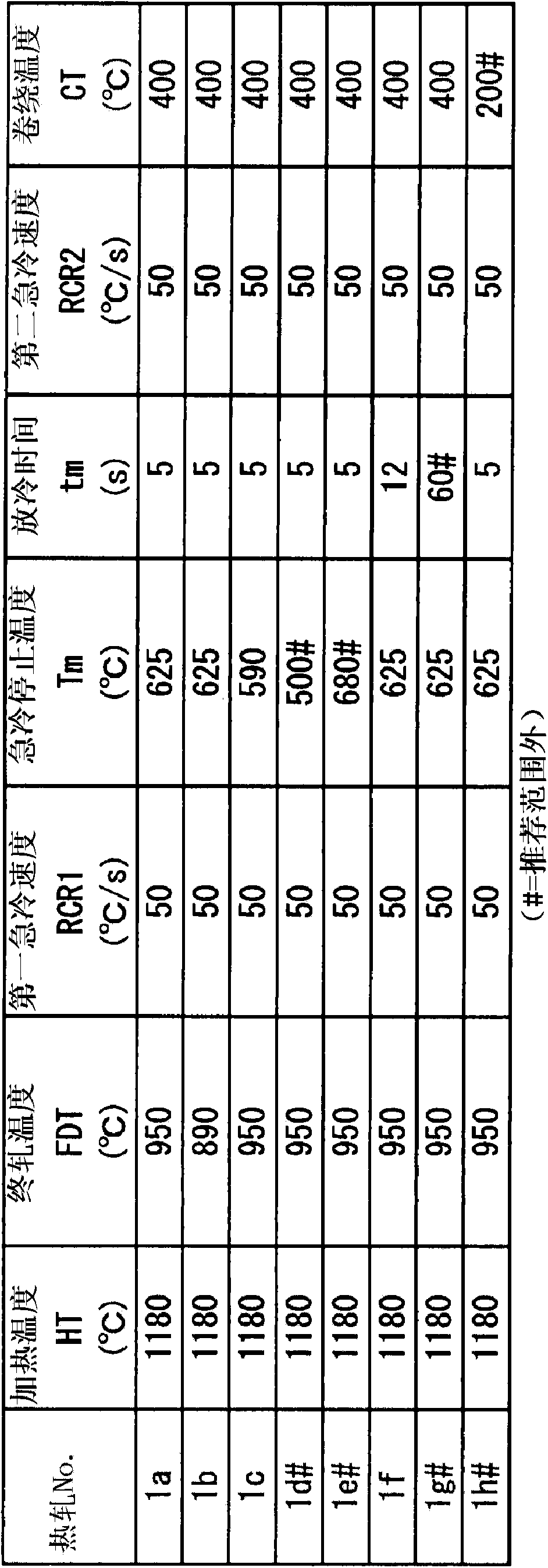

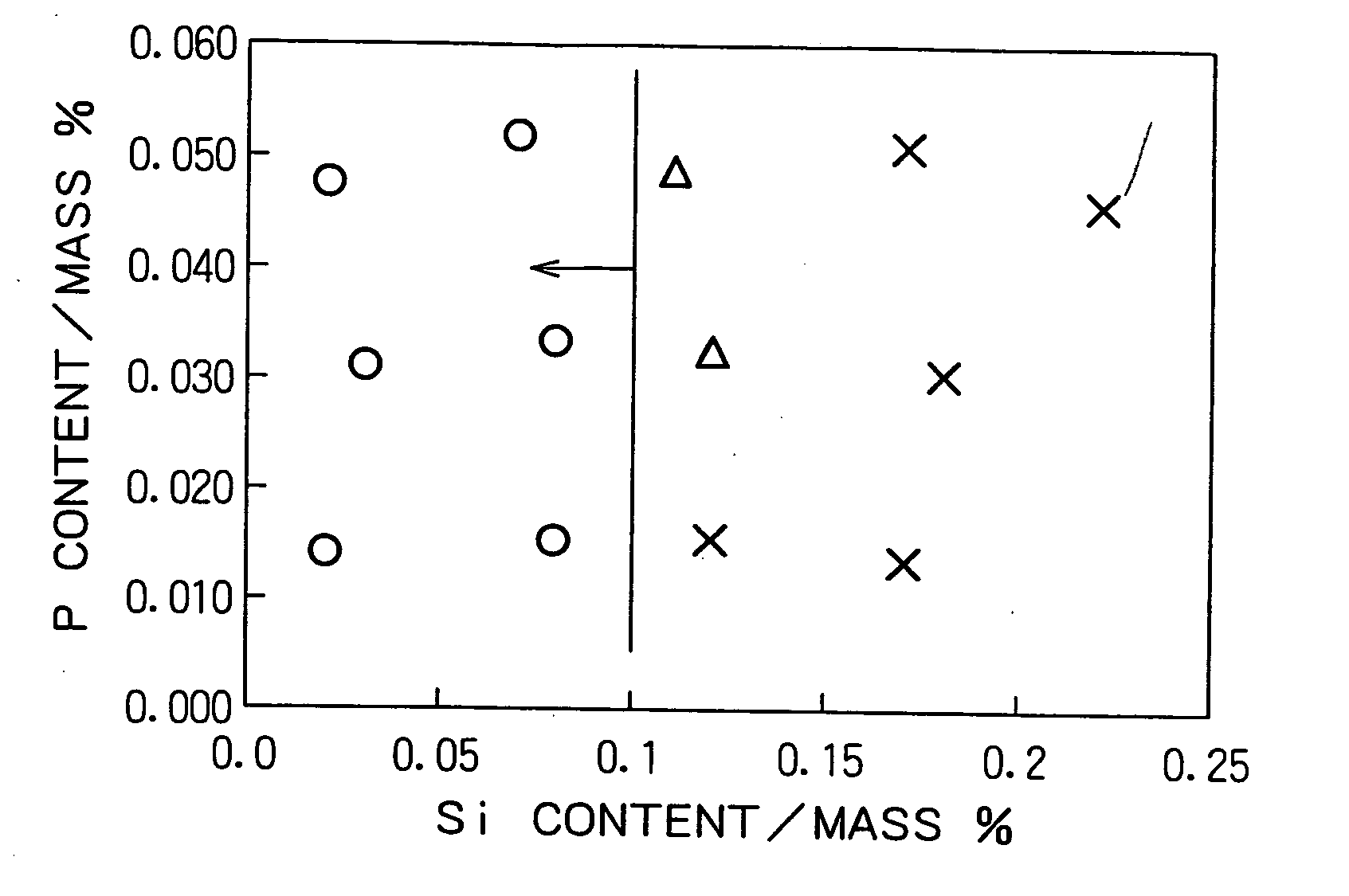

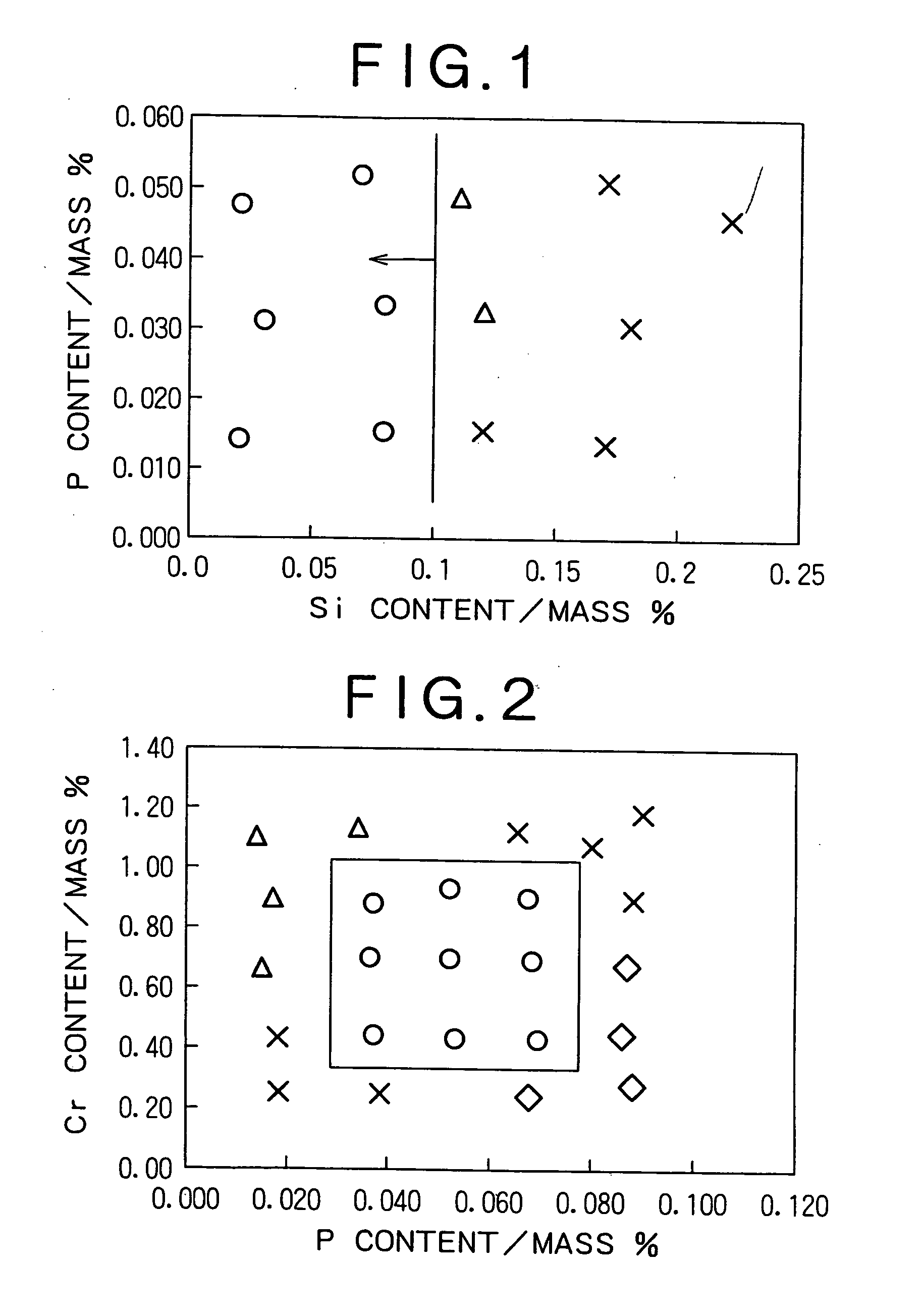

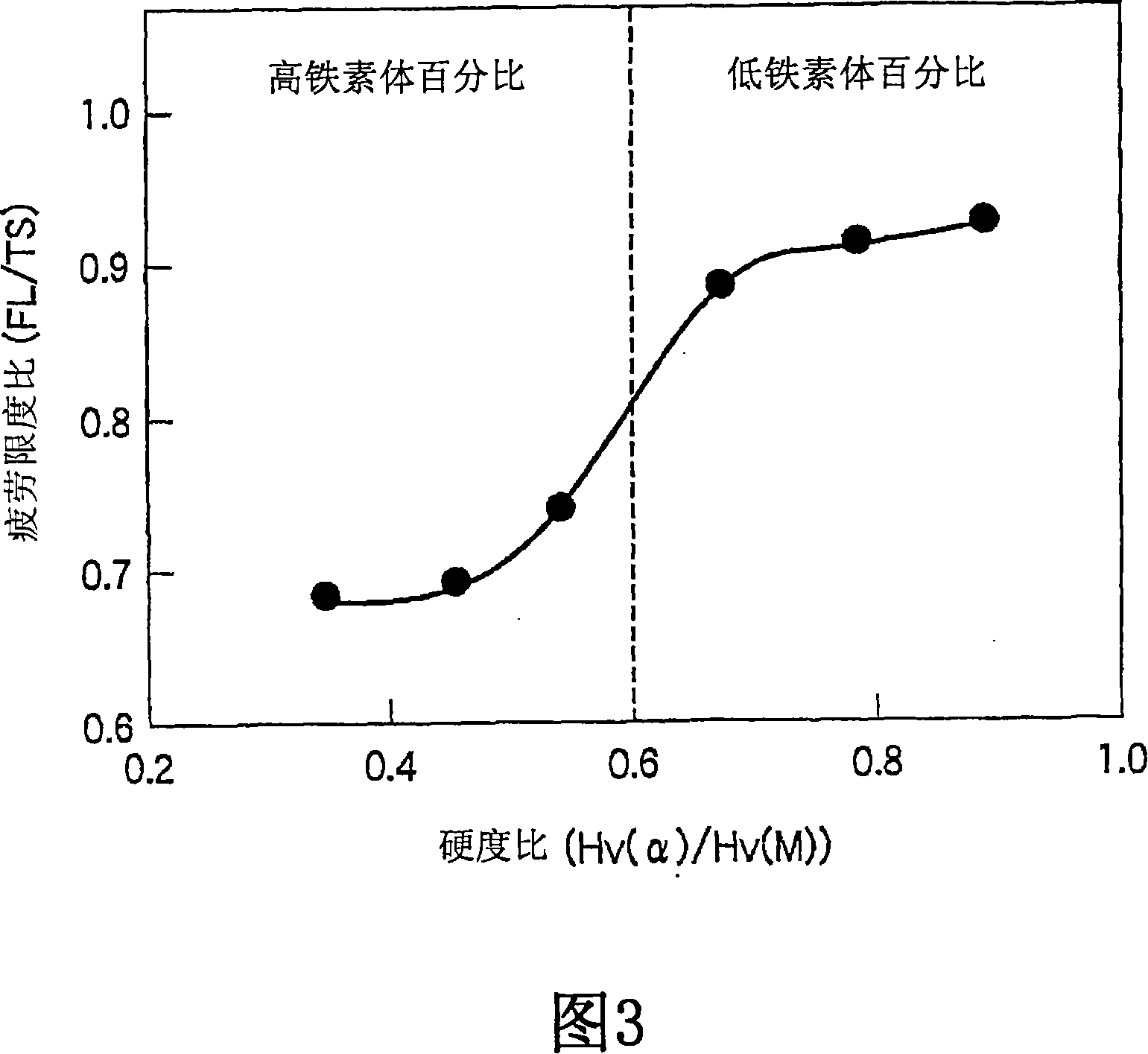

High strength hot rolled steel sheet superior in workability, fatigue property, and surface quality

ActiveUS20050155673A1Excellent fatigue propertiesImprove workabilityFurnace typesHeat treatment furnacesSheet steelHigh intensity

Disclosed is a high-strength hot-rolled steel sheet containing C in a range of 0.03 to 0.15 mass %, Mn in a range of 0.5 to 2 mass %, and Al in a range of 0.01 to 0.1 mass %, respectively, while controlling S to not more than 0.02 mass % (0% included), wherein the metallic structure thereof has a polygonal ferrite as the main phase, and contains martensite as a second phase, further containing P in a range of 0.030 to 0.08 mass %, and Cr in a range of 0.3 to 1.00 mass %, respectively, while controlling Si to not more than 0.1 mass % (0% included). Thus, a high-strength hot-rolled steel sheet superior in workability, and fatigue property, and excellent in surface quality is provided at a relatively low cost.

Owner:KOBE STEEL LTD

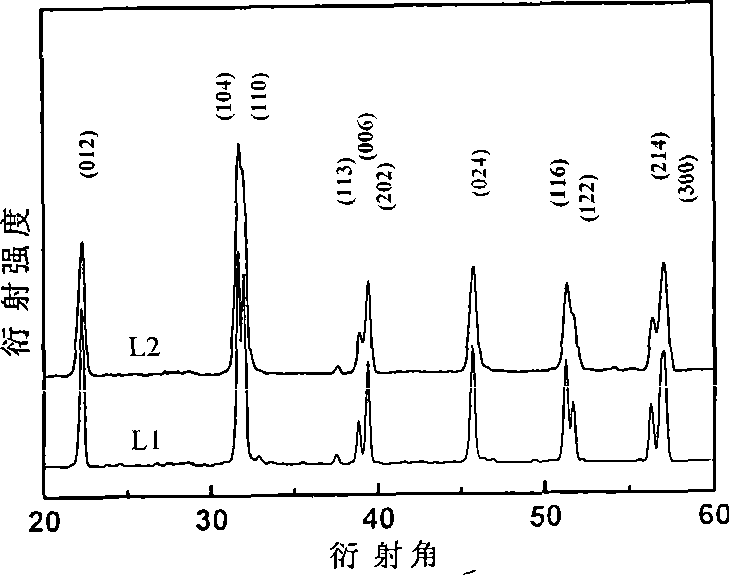

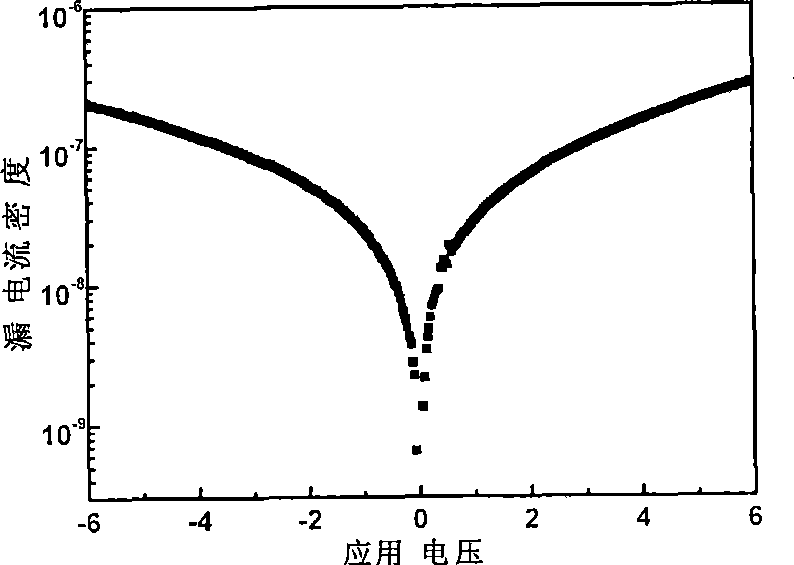

BiFeO3 target and film production method

InactiveCN101429642ALow costFine and uniform powderVacuum evaporation coatingSputtering coatingDrain currentOxide

The invention provides a preparation method for a BiFeO3 target material. The preparation method for the BiFeO3 target material comprises the following steps: carrying out grinding, ball milling, preburning, re-ball milling, granulation and screening for the mixture of bismuth oxide Bi2O3 and ferric oxide Fe2O3 to obtain the target material; and then carrying out batch dropping, baking, heating with pressure, heat insulation and cooling for the target material. The invention also provides a method for preparing a film through the BiFeO3 target material. The method comprises the following steps: selecting a Pt / TiO2 / SiO2 / p-Si substrate; preparing the BiFeO3 film through a radio frequency magnetron sputtering method; and finally carrying out the annealing treatment of the prepared BiFeO3 film. The target material has the advantages of no impurity phase, levelness and compactness. The film prepared through the target material has a compact and even surface, better crystallinity, no impurity phase, low drain current, saturated electric hysteresis loop, good fatigue characteristic, and good repeatability.

Owner:HUAZHONG UNIV OF SCI & TECH

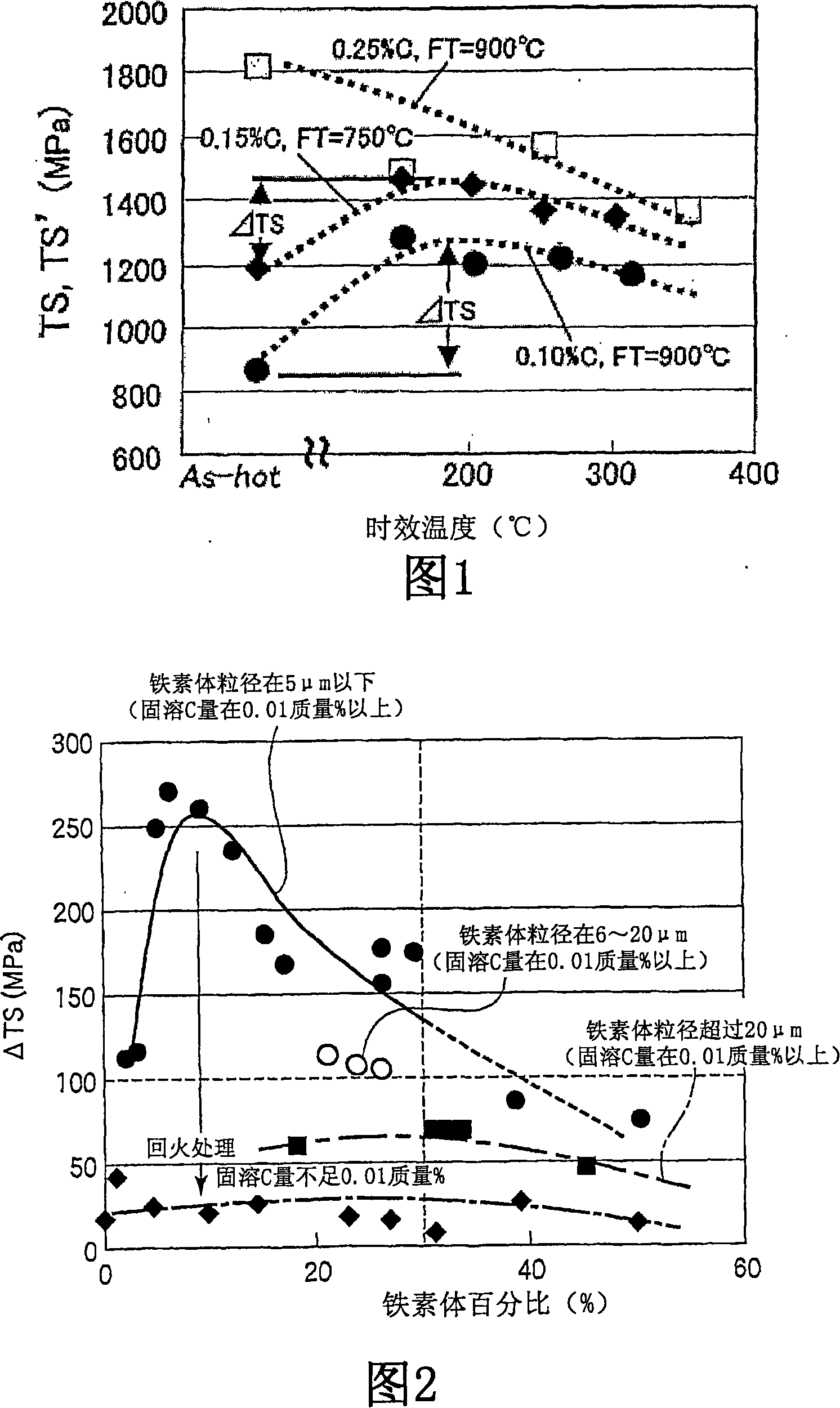

Hot-rolled steel sheet, method for production thereof and molded article formed from hot-rolled steel sheet

InactiveCN101151391AExcellent strain age hardening propertiesGood stamping performanceFurnace typesHeat treatment furnacesSheet steelSolid solution

A hot-rolled steel sheet which comprises 0.01 to 0.2% by mass of C, 2.0% by mass or less of Si and 3.0% by mass or less of Mn and has a martensite phase as the main phase and a ferrite phase as a second phase, the ferrite phase containing ferrite having a grain size of 20 [mu]m or less in such an amount that the area ratio of ferrite becomes 1 to 30% (inclusive) and also containing 0.01% by mass or more of solid solution carbon. The steel sheet has excellent press workability, and exhibits excellent strain ageing property, that is, can be markedly increased in its tensile strength by a heat treatment, after press forming, at a temperature around that for a conventional baking finish, and thus can be suitably used as a steel sheet for an automobile. Further, fatigue characteristics after the strain ageing treatment are improved by hardening the ferrite phase.

Owner:JFE STEEL CORP

High-strength steel sheet and production method for same, and production method for high-strength galvanized steel sheet

ActiveCN106574340AImprove ductilityExcellent fatigue propertiesHot-dipping/immersion processesFurnace typesMartensiteAustenite

The present invention provides a high-strength steel sheet having a tensile strength (TS) of at least 780 MPa, excellent ductility and fatigue characteristics, achieving a balance of high strength and ductility, and having excellent surface quality and sheet-conveying properties, achieved by: having a specific component composition; the steel structure having, in terms of area ratio, 20-50% ferrite, 5-25% bainitic ferrite, and 5-20% martensite, and having, in terms of volume fraction, at least 10% retained austenite; the average crystalline particle diameter of the retained austenite being not more than 2[mu]m; the average Mn volume (mass%) in the retained austenite being at least 1.2 times the Mn volume (mass%) in the steel; and the mean free path of the retained austenite being not more than 1.2[mu]m.

Owner:JFE STEEL CORP

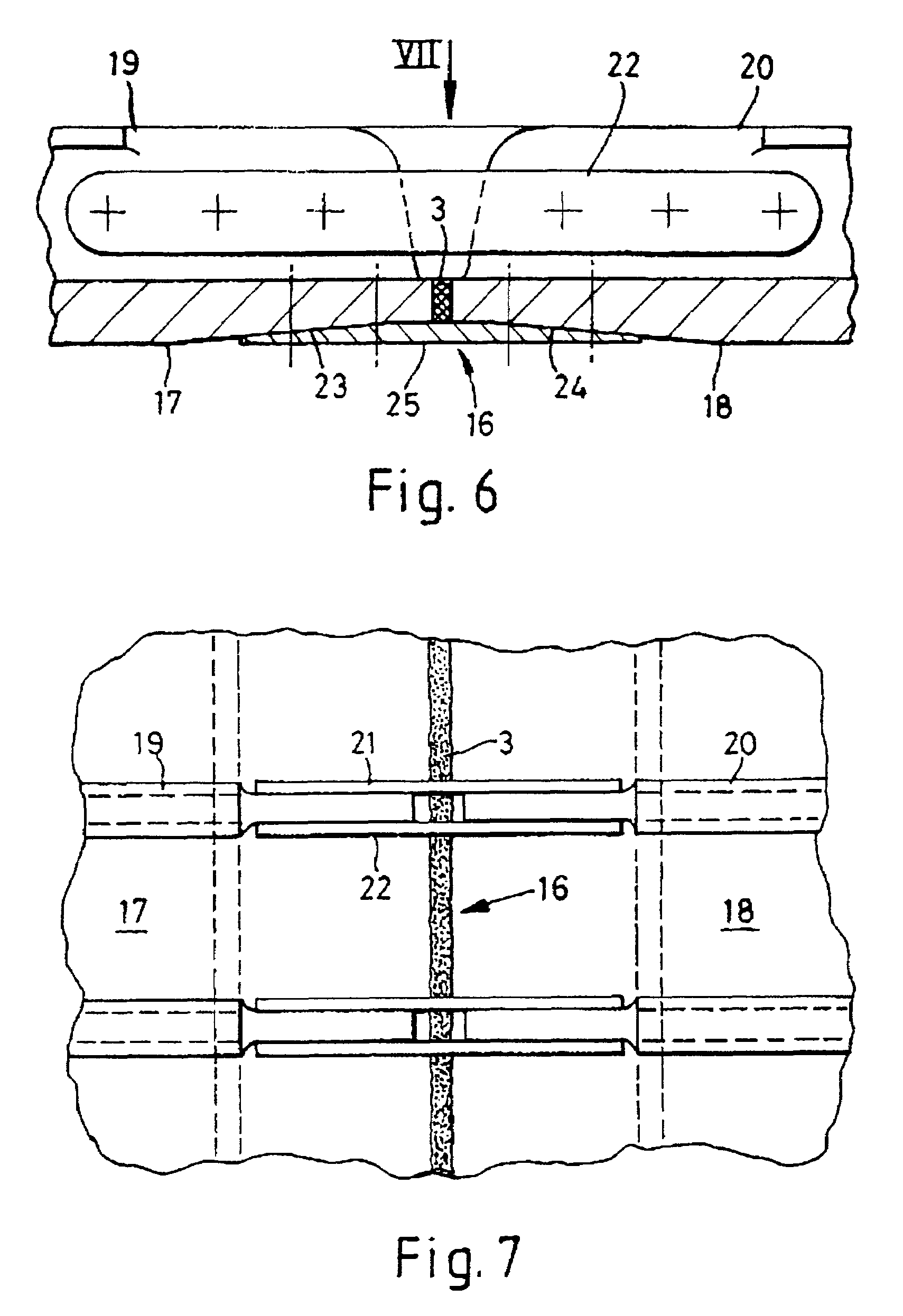

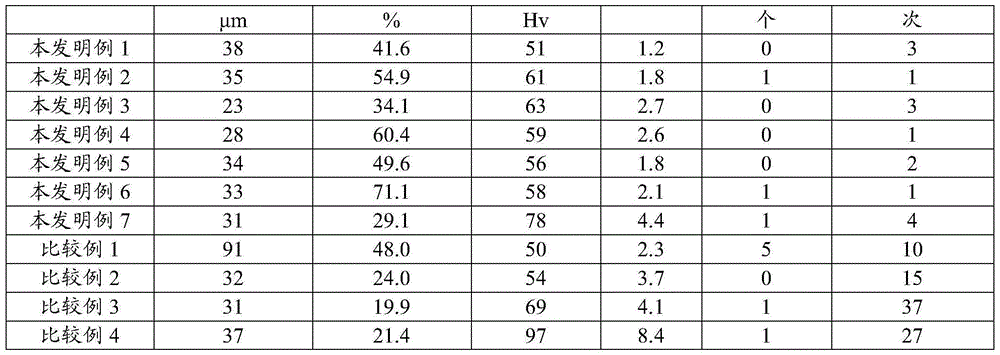

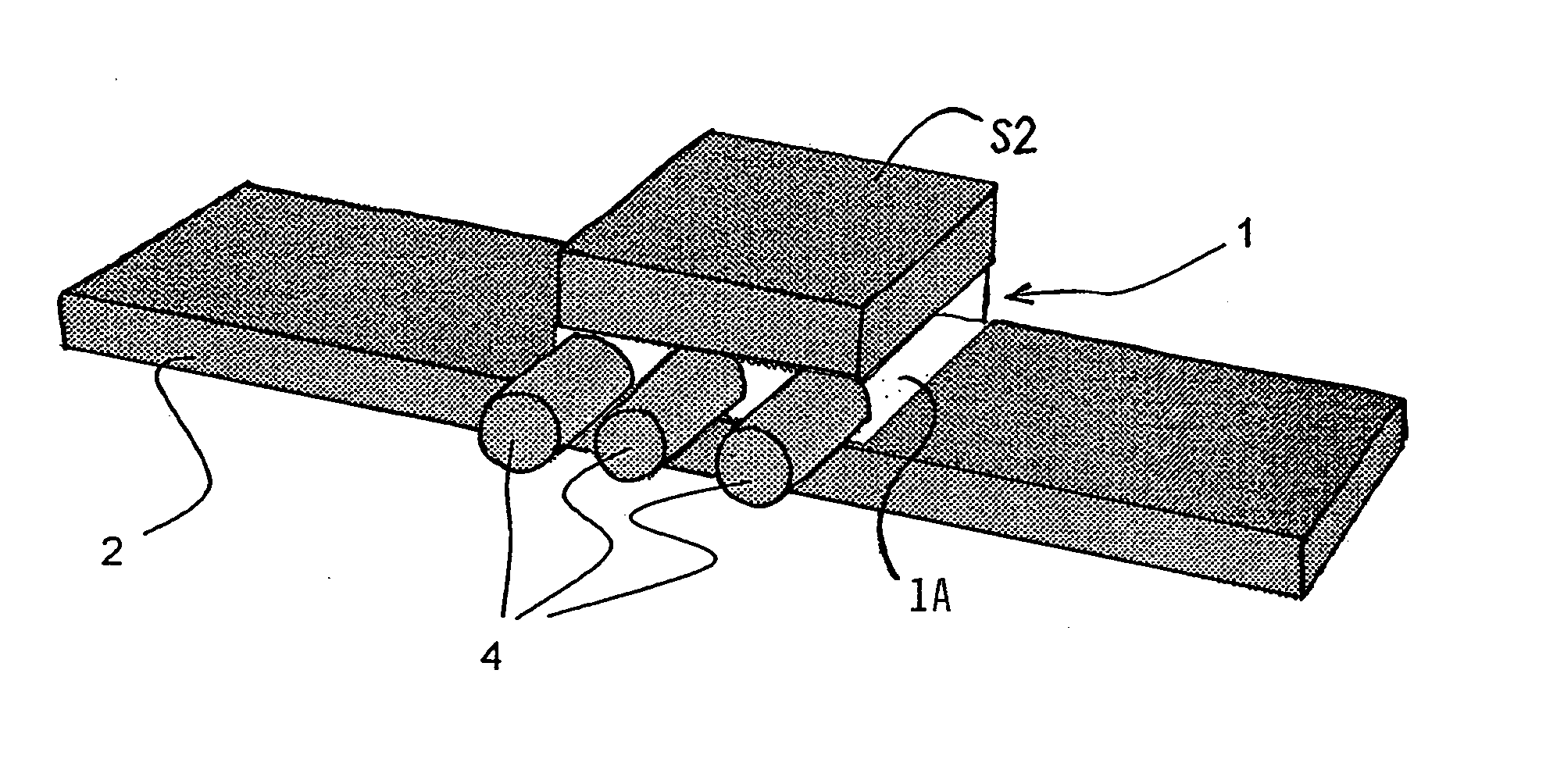

Friction welding metal components

InactiveUS7234668B2Additions can be avoidedPrevent skinWingsFuselage bulkheadsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component are provided. The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

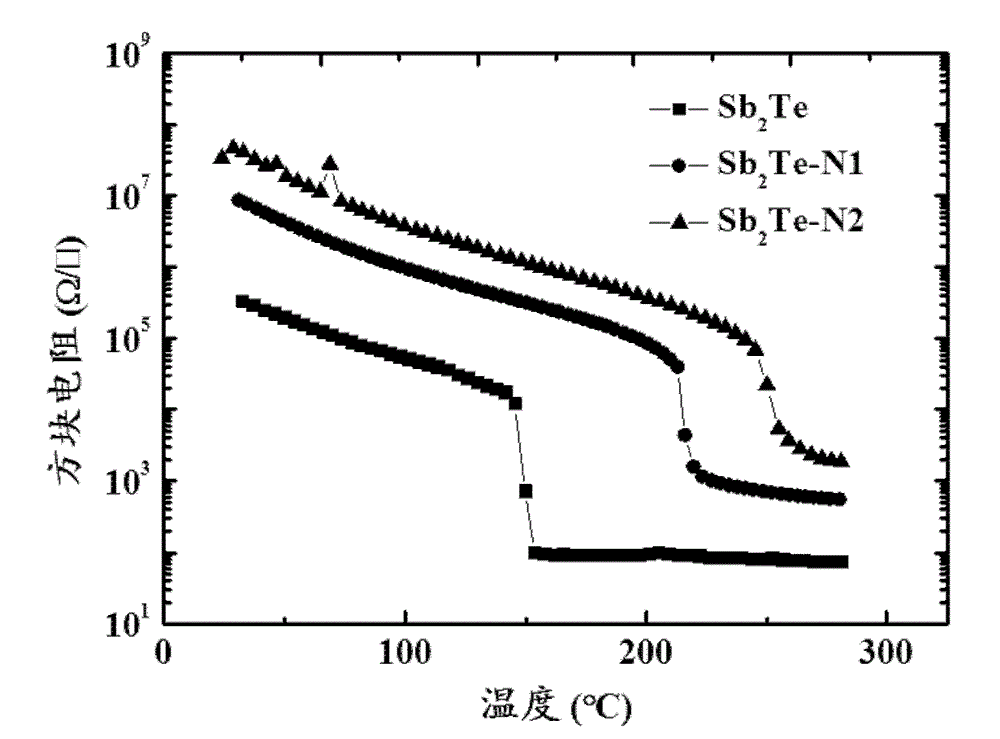

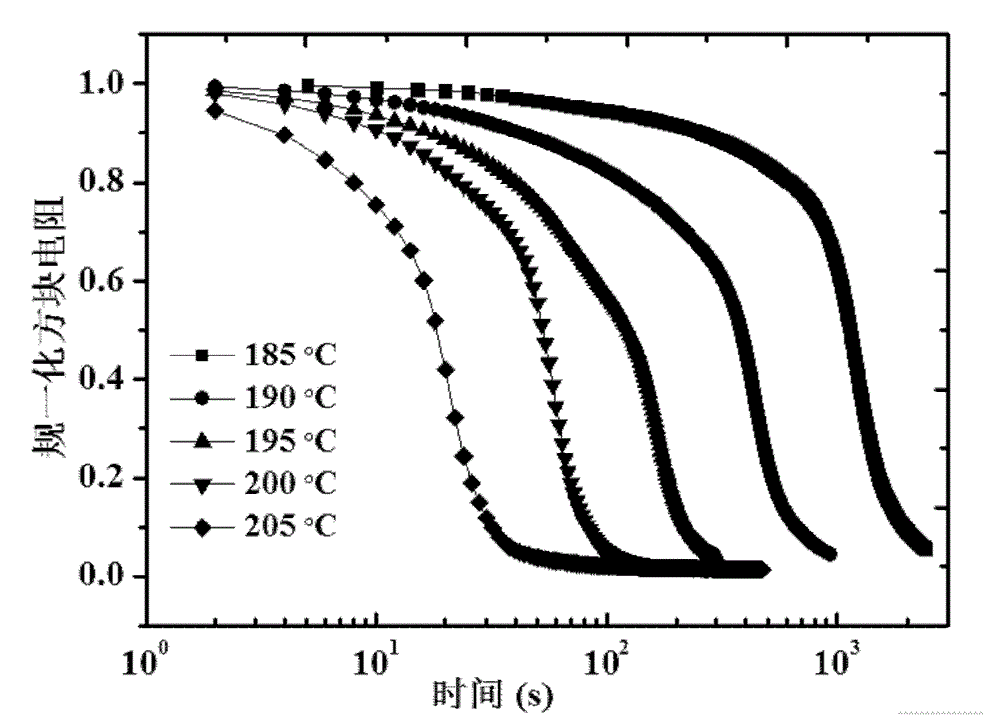

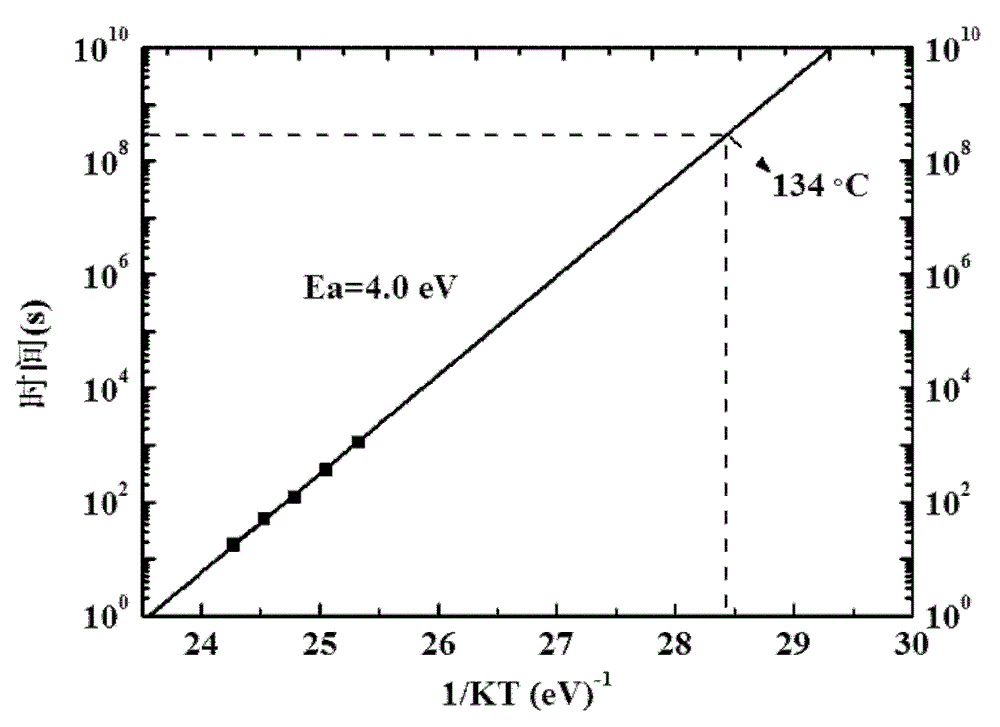

Phase change storage material and preparation method thereof

InactiveCN102751435ARaise the crystallization temperatureImprove stabilityElectrical apparatusVacuum evaporation coatingHeat stabilityCrystallization temperature

The invention provides a phase change storage material and a preparation method thereof, wherein the phase change storage materials are phase change storage material mixed with stibium-rich Sb-Te, and the chemical general formula of the phase change storage material mixed with stibium-rich Sb-Te is SbxTe, x>=0.5. Compared with the prior art, the phase change storage material mixed with stibium-rich Sb-Te has the advantages of being high in crystallization temperature, good in heat stability, strong in data retention, low in power consumption and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

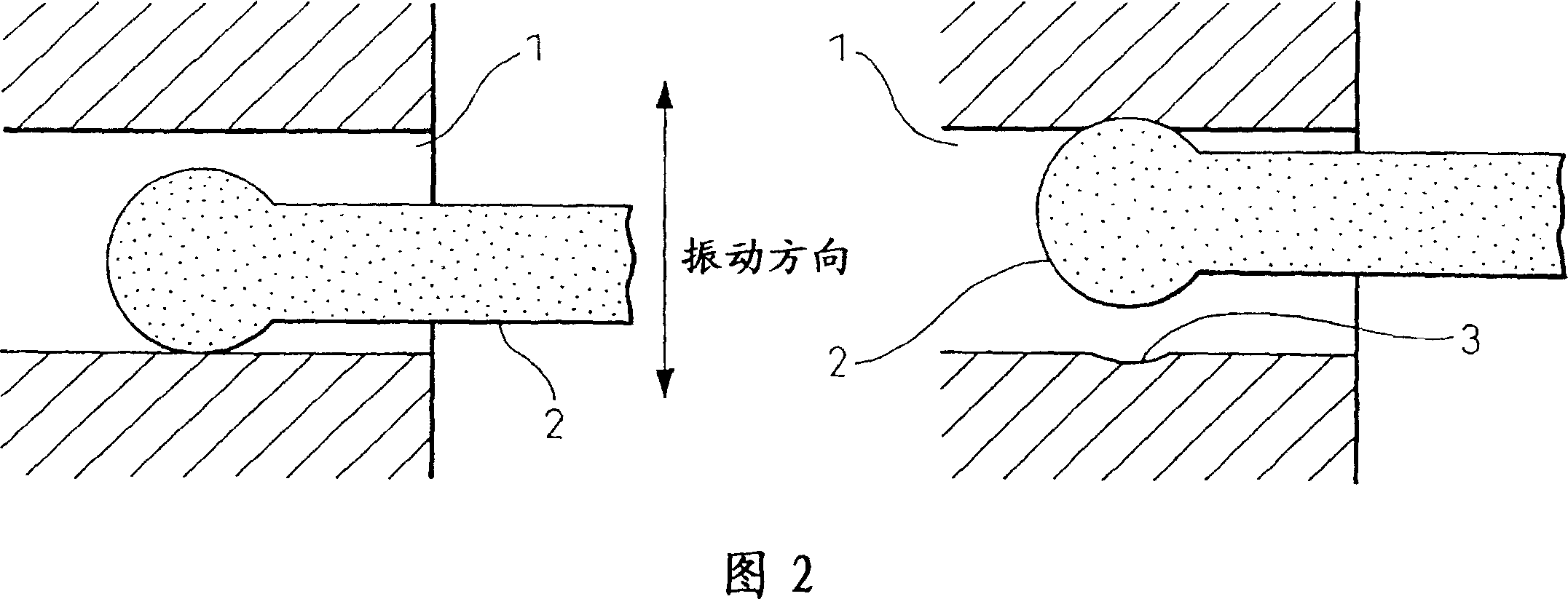

Impact treatment method for improving fatigue characteristics of welded joint, impact treatment device for improving fatigue characteristics for same, and welded structure superior in fatigue resistance characteristics

InactiveUS20110123820A1Good effectExcellent fatigue propertiesFurnace typesThin material handlingUltrasonic impact treatmentWeld line

An impact treatment method for improving fatigue characteristics of a welded joint comprising pressing an impact pin against the surface of a base metal material near a toe of a weld bead and making it move relatively to the weld line direction to apply hammer peening treatment or ultrasonic impact treatment, characterized by using as the impact pin an impact pin having a tip curvature radius of ½ or less of a thickness of the metal material and between 2 to 10 mm and, on a surface of a base metal material up to a range where a distance from the toe of the weld bead to the center of the impact treatment position is within 2.5 times the tip curvature radius of the impact pin and where the impact pin does not contact the weld metal during impact treatment, applying hammer peening or ultrasonic impact treatment so as to cause by the impact pin residual plastic deformation where an impact dent has a groove depth of 0.1 to 2 mm, the tip curvature radius of the impact pin or less, and 1 / 10th or less of the thickness of the metal material and where the impact dent has a width of 1.5 to 15 mm and five times or more the groove depth.

Owner:NIPPON STEEL CORP

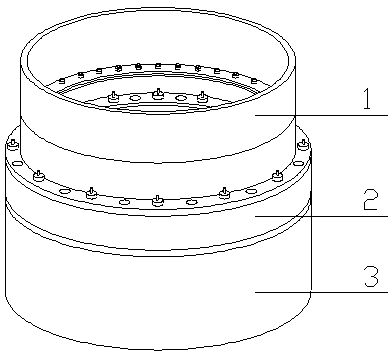

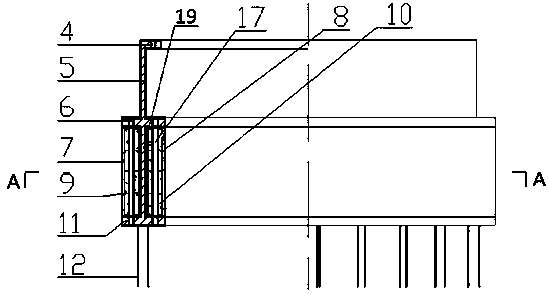

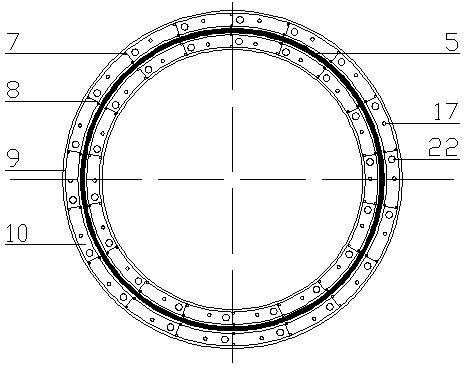

Connection device of prestress concrete and steel combination wind power generation tower

ActiveCN103994034AUniform stress distributionAvoid uneven distributionWind energy generationWind motor componentsTension stressWind force

The invention relates to a connection device of a prestress concrete and steel combination wind power generation tower. The lower surface of a lower connection flange is provided with anchor bars connected with a concrete tower section. The connection device is further provided with prestress application components, a tension anchor flange and the lower connection flange are respectively and uniformly provided with flange holes for the prestress application components to pass, and the flange holes of the tension anchor flange are the same as those of the lower connection flange in quantity and correspond to the flange holes of the lower connection flange in a one-to-one mode in the vertical direction. The prestress application components sequentially penetrate through the flange holes of the anchor flange and the flange holes of the lower connection flange and penetrate through the concrete tower section on the lower portion. The top ends of the prestress application components are anchored on the top face of a lower section connection steel cylinder through anchorage devices after the prestress application components are tensioned. Concrete is poured between the tension anchor flange and the lower connection flange to form a prestress concrete structure. Due to the connection mode, the concrete on the flange connection section is uniformly stressed, stress concentration is reduced, the tensile stress level of the concrete is improved, and the situation that the concrete cracks is avoided.

Owner:HUNAN UNIV

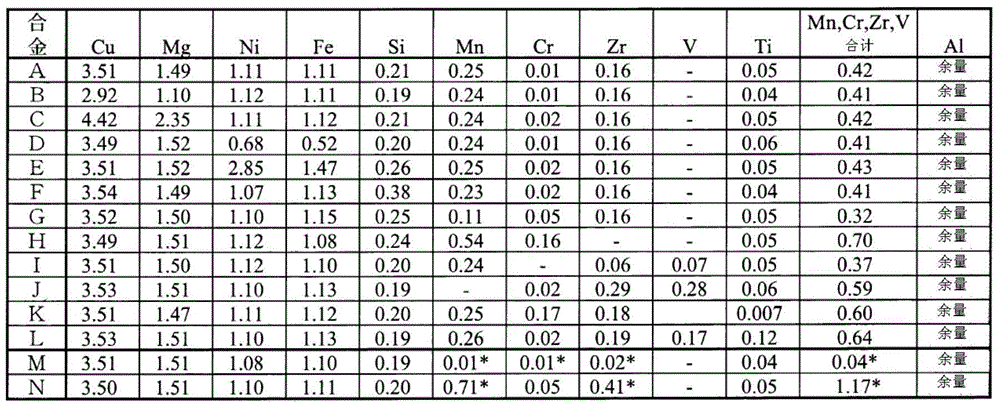

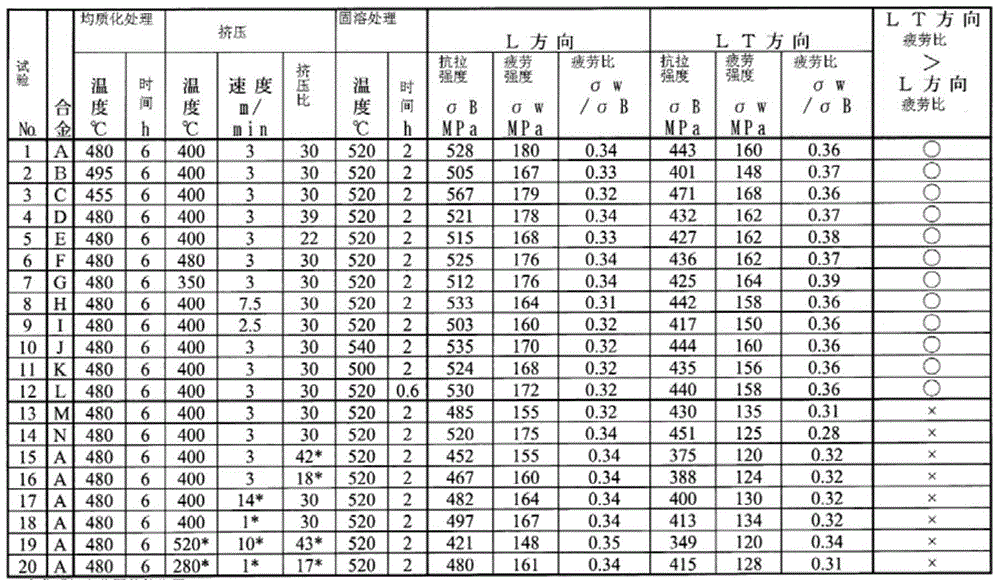

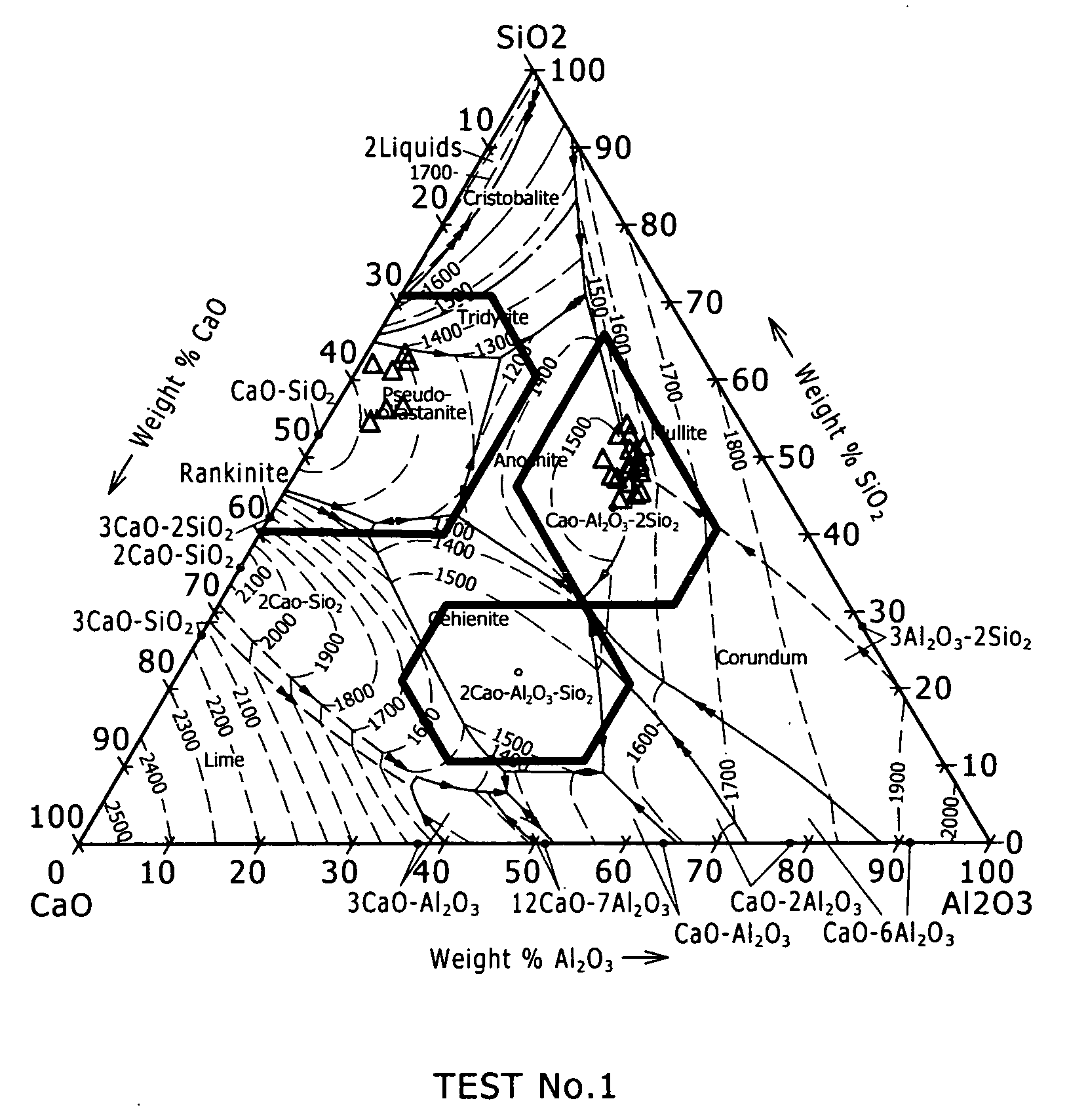

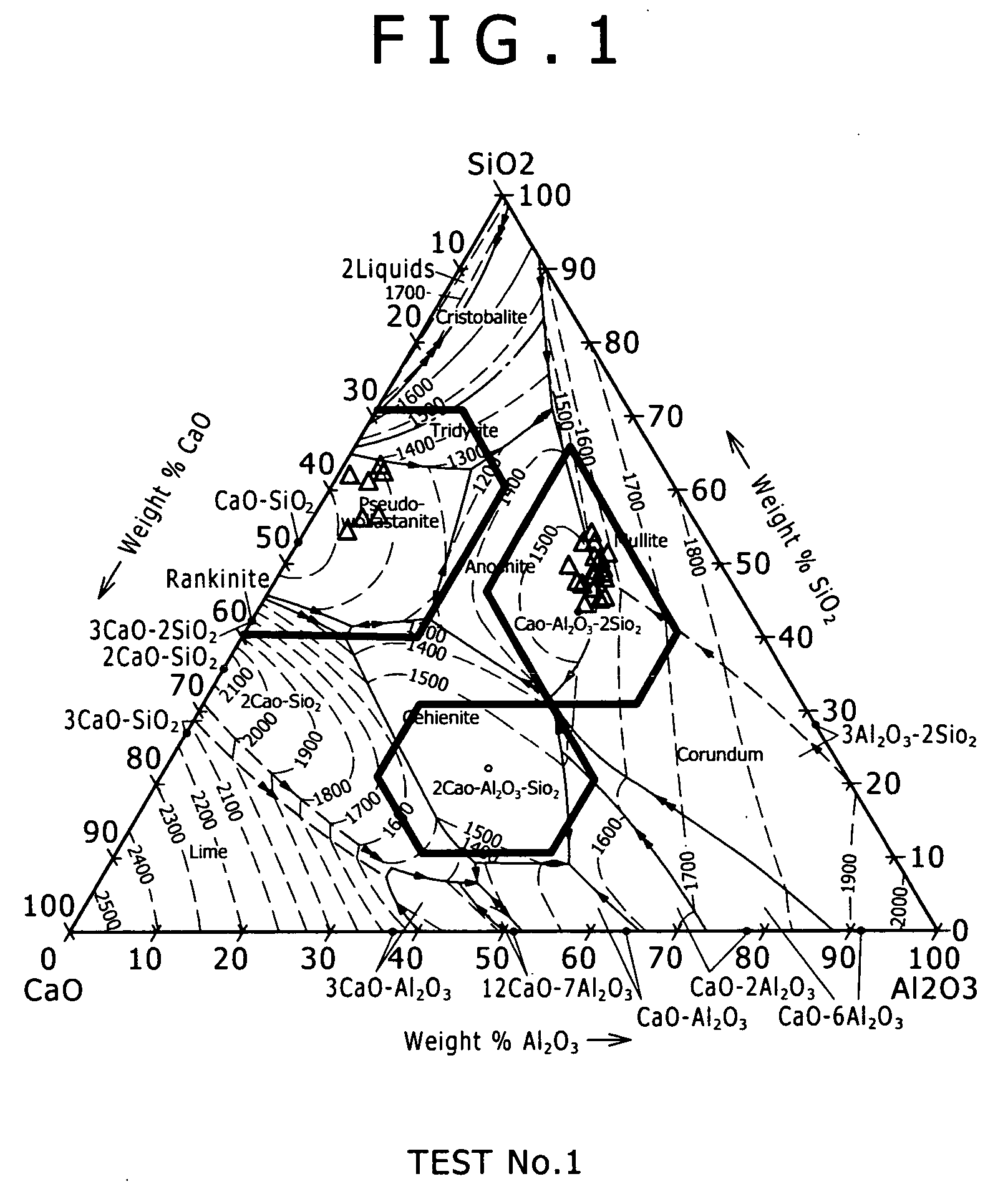

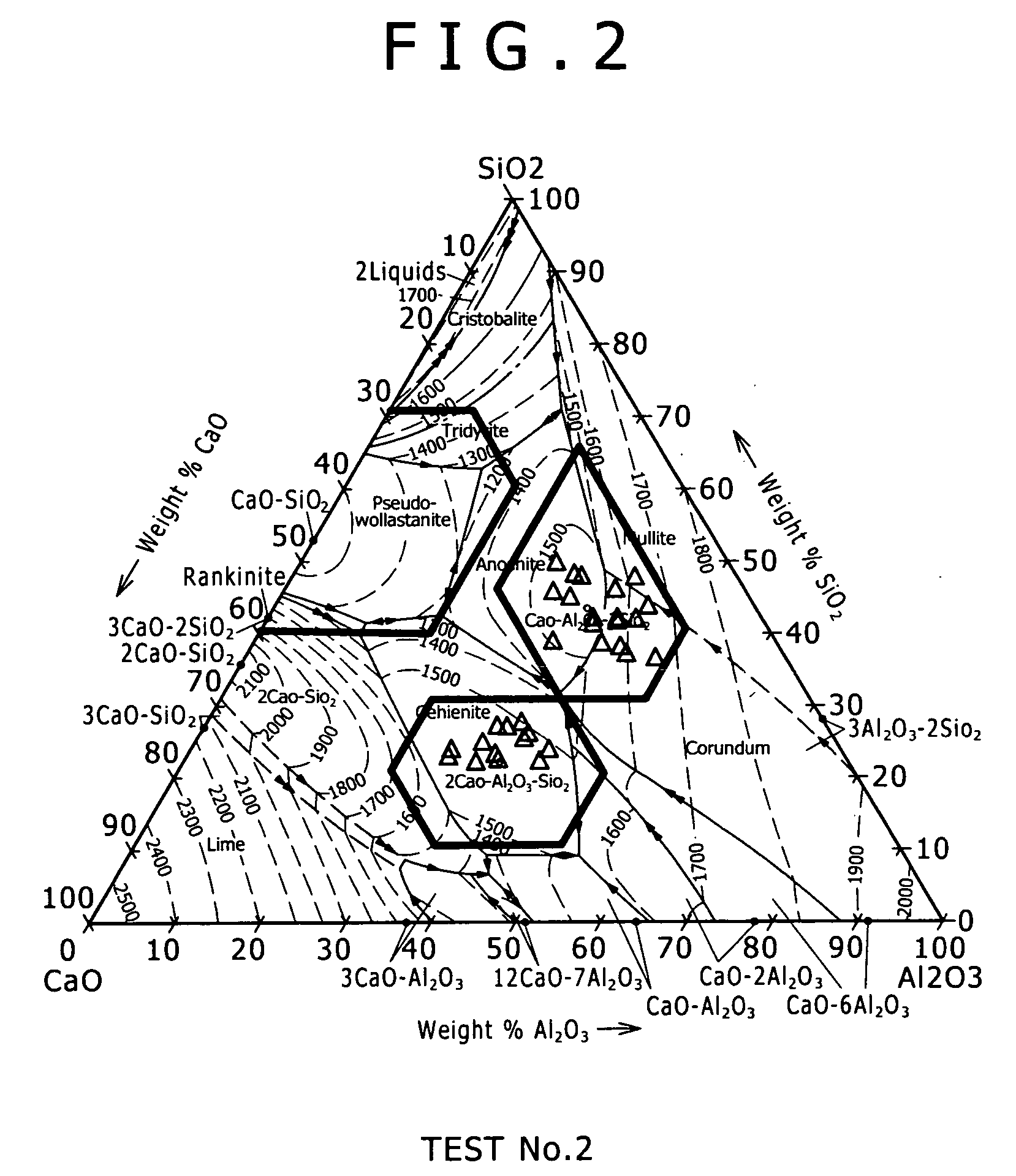

Aluminum alloy extrudate for cutting

InactiveCN104342590AHigh tensile strengthImprove fatigue strengthUltimate tensile strengthAluminium alloy

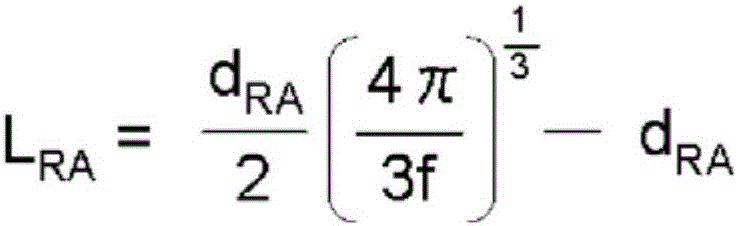

The invention provides an aluminum alloy extrudate for cutting, having high fatigue strength relative to a direction (LT direction) vertical to an extrusion direction of an extrudate. The aluminum alloy extrudate includes: 2.9-5.5 mass% Cu, 1.0-2.5 mass% Mg, 0.5-3.0 mass% Ni, 0.5-1.5 mass% Fe, lower than 0.4 mass% Si, and 0.005-0.15 mass% Ti, also includes lower than total 0.7 mass% one or more than two of 0.05-0.6 mass% Mn, 0.05-0.3 mass% Cr, 0.05-0.3 mass% Zr and 0.05-0.3 mass% V, and the remainder is formed by Al and unavoidable impurities. When [sigma]WLT represents fatigue strength in the LT direction, [sigma]WL represents fatigue strength in the L direction (extrusion direction), TSLT represents tensile strength in the LT direction, and TSL represents tensile strength in the L direction, the formula (I) is satisfied. [sigma]WLT / TSLT>[sigma]WL / TSL (I).

Owner:KOBE STEEL LTD

Ultra clean spring steel

Disclosed herein is an ultra clean spring steel which contains inclusions easily elongated and broken into fine particles by hot rolling and which is easily adaptive to cold rolling and yields springs excelling in fatigue characteristics. The spring steel is characterized in that the wire contains oxide inclusions with a sulfur concentration no more than 10 mass % such that no less than 70% (in terms of numbers) of such inclusions, which exist in the outer layer outside one quarter of the diameter of the wire and have a width no smaller than 3 μm, satisfies the formula (1) below, CaO+Al2O3+SiO2+MnO+MgO>80 (mass %) (1)

Owner:KOBE STEEL LTD

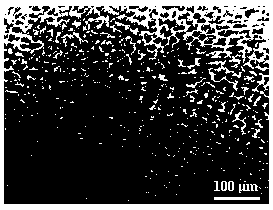

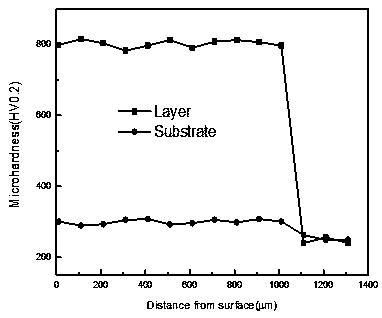

Iron-based memory alloy laser cladding composite coating powder

InactiveCN108359978AHigh hardnessImprove wear resistanceMetallic material coating processesNiobiumRare earth

The invention discloses an iron-based memory alloy laser cladding composite coating powder. The powder is prepared by the following raw materials of, by weight, 44-54 parts of pure iron powder, 23-30parts of manganese powder, 7-13 parts of silicon powder, 3-15 parts of chromium powder, 1-13 parts of nickel powder, 0.5-1.5 parts of niobium powder, 4-16 parts of tungsten carbide powder and 0.1-5 parts of yttrium oxide powder. According to the powder and a using method thereof, in the process of preparing the cladding coating powder by using the method, hard particles generates solid solution strengthening, the undecomposed hard particles can generate second phase strengthening, and meanwhile, the hardness and the wear resistance of the coating can be improved; and the grain boundary is purified through rare earth, the structure content of microporous structure is reduced, the coating cracking tendency is reduced, the surface potential of the coating is promoted to be consistent, and therefore the corrosion resistance of the coating can be improved.

Owner:GUIZHOU UNIV

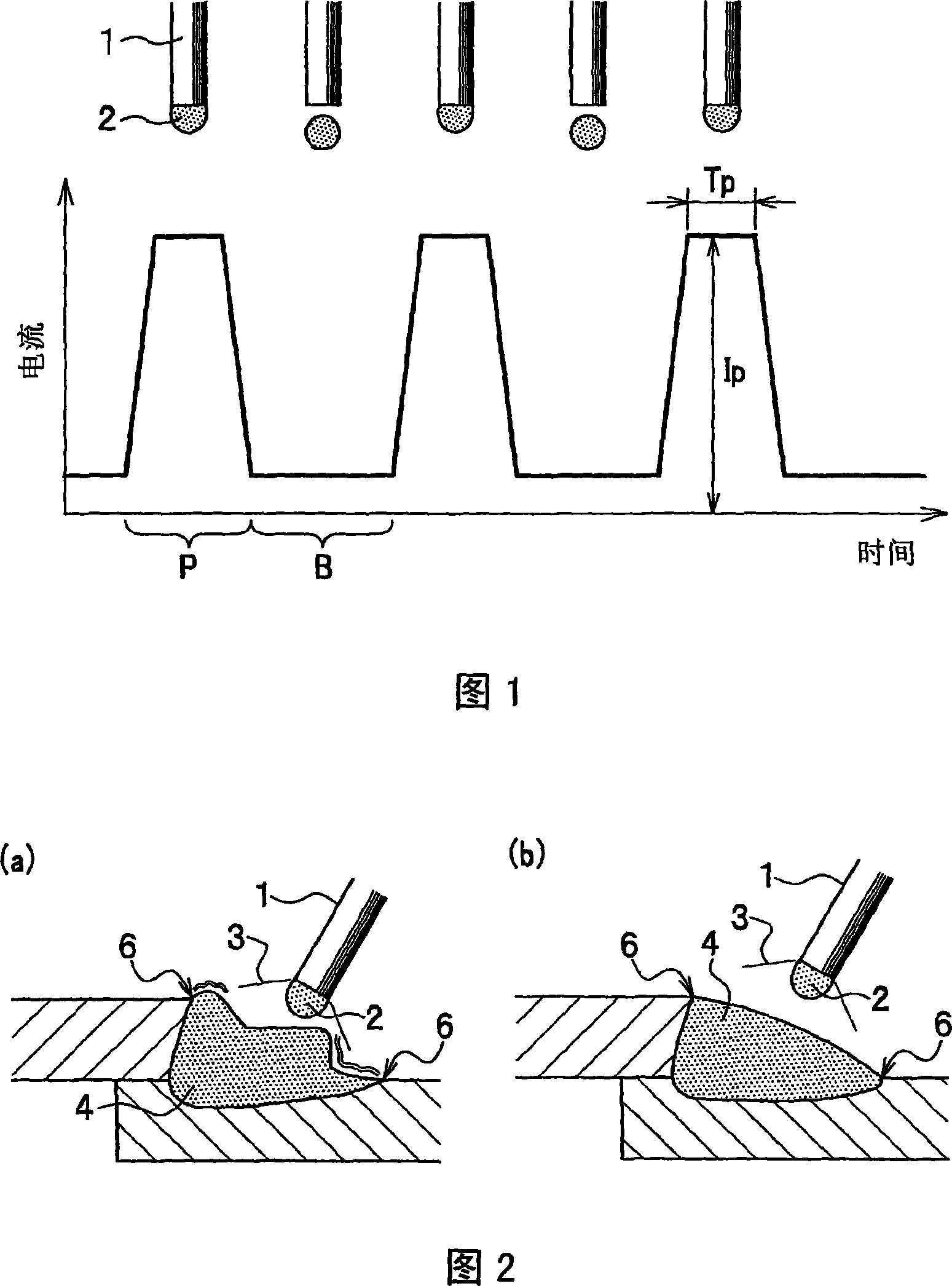

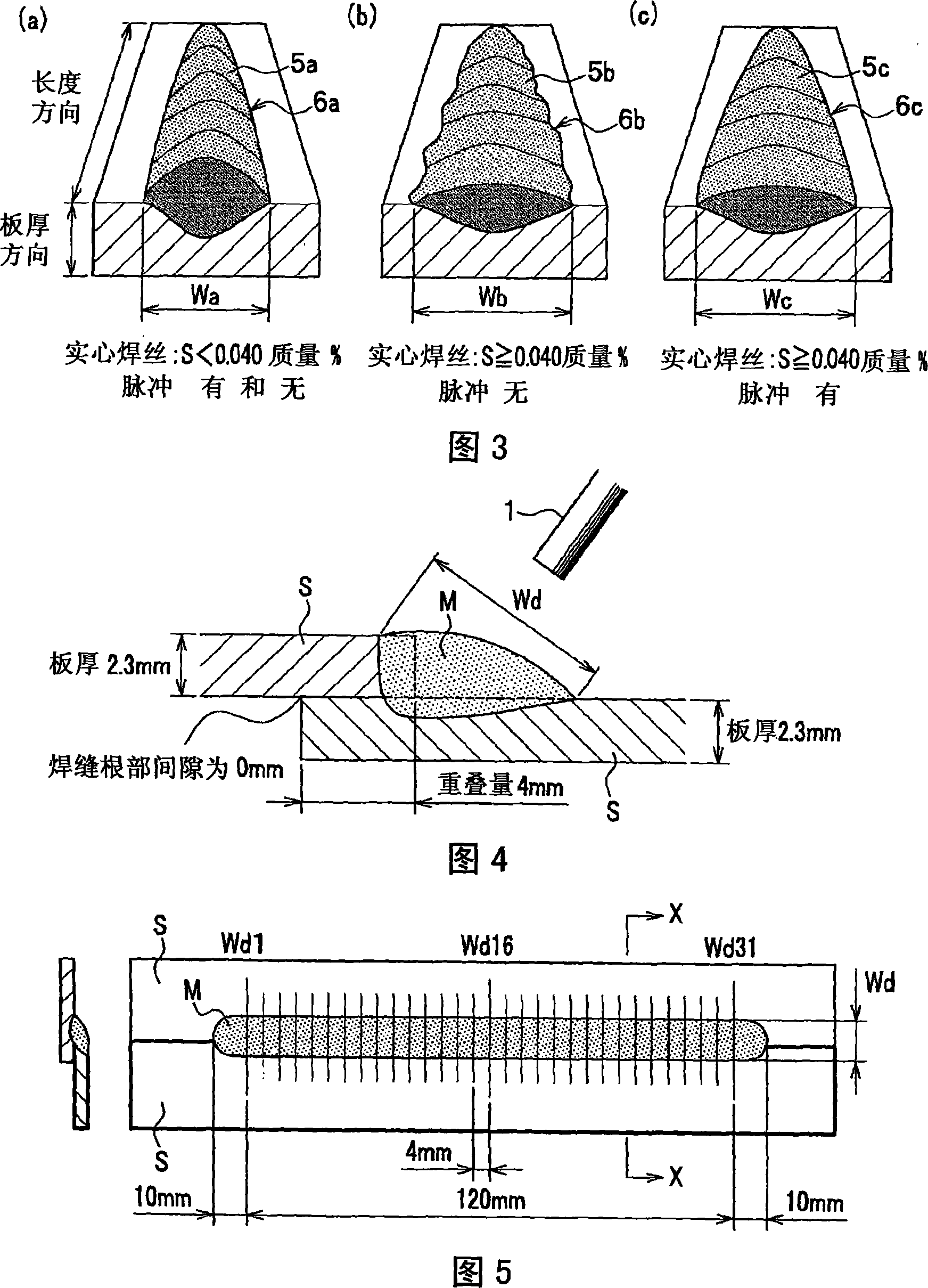

Gas-shielded arc welding method

InactiveCN101200017AImprove orderSuppress splashArc welding apparatusWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A gas-shielded arc welding method uses a shielding gas and a solid wire for pulsation welding. The solid wire contains S, Si, Mn, C and P in predetermined S, Si, Mn, C and P contents, and other elements including Fe and unavoidable elements. A pulsating current used for pulsation welding has a peak current Ip of 350 A or above and a pulse peak duration Tp between 0.5 and 2.0 ms. The shielding gas is a mixed gas containing 75 to 98% by volume Ar and others including at least either of CO2 and O2. The gas-shielded arc welding method can suppress the generation of spatters regardless of welding speed even if the welding speed is high, and can form a wide, flat bead having uniform toes. A weld metal produced by the gas-shielded arc welding method is resistant to cracking and excellent in preventing the formation of blowholes.

Owner:KOBE STEEL LTD

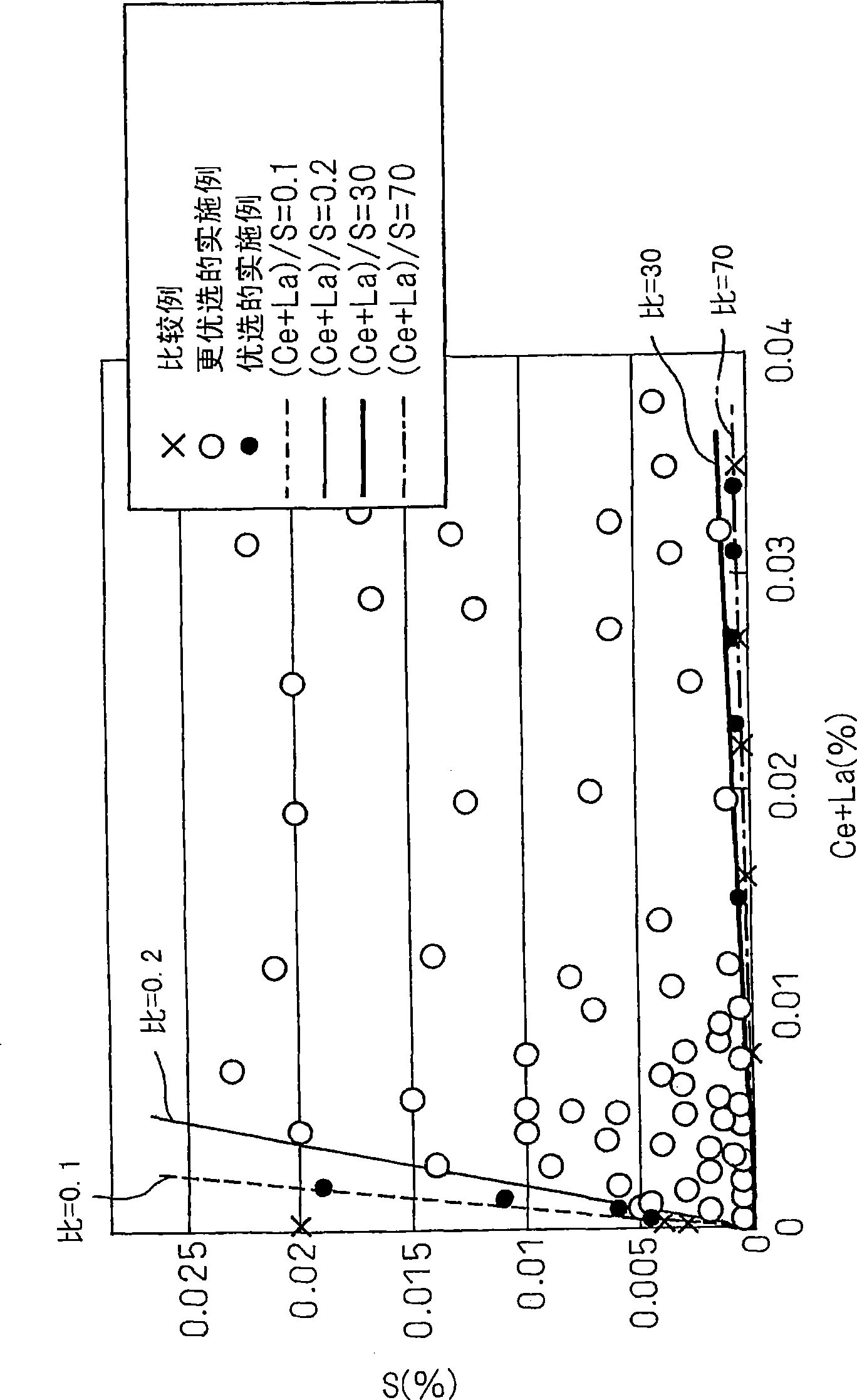

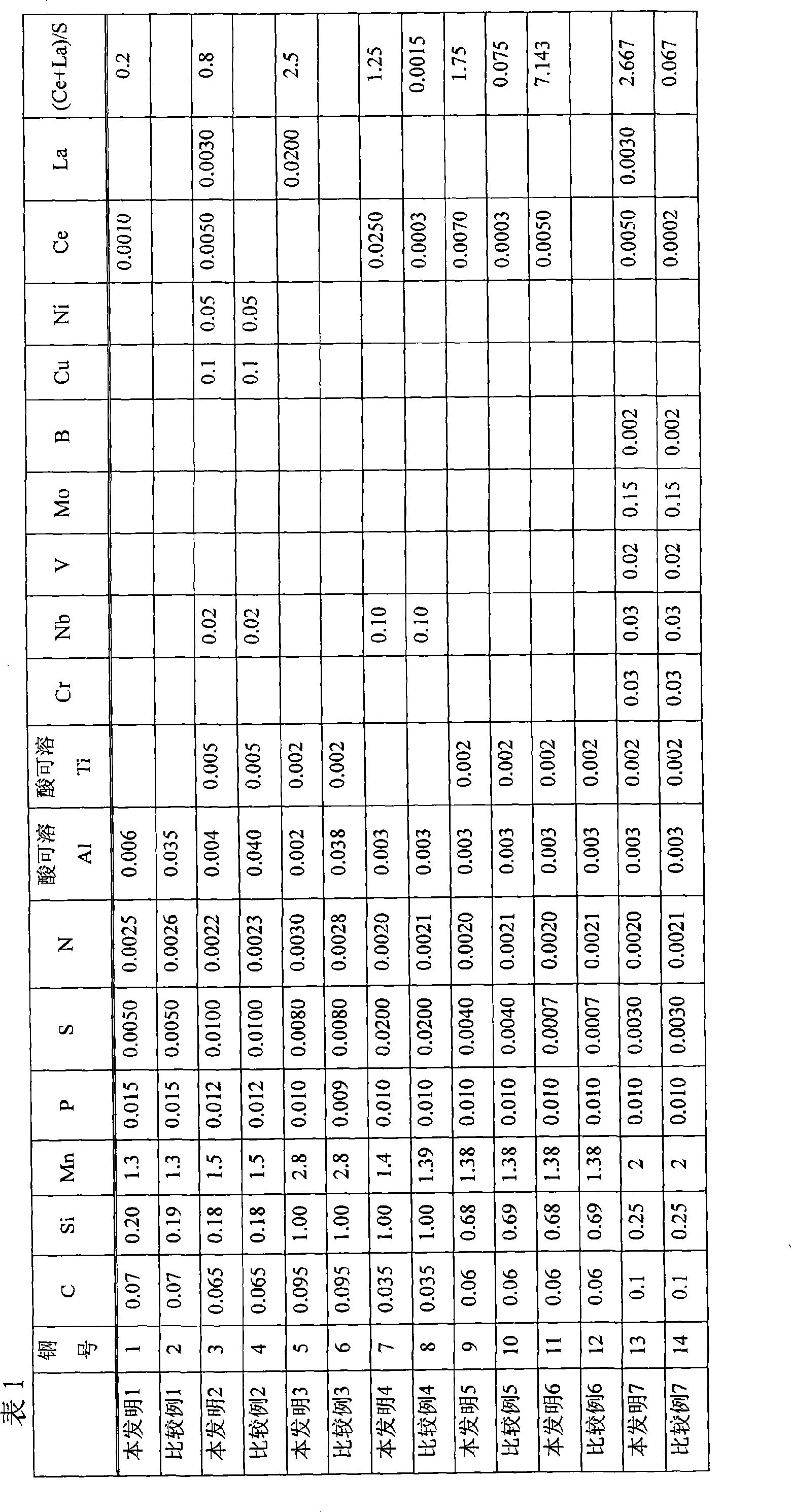

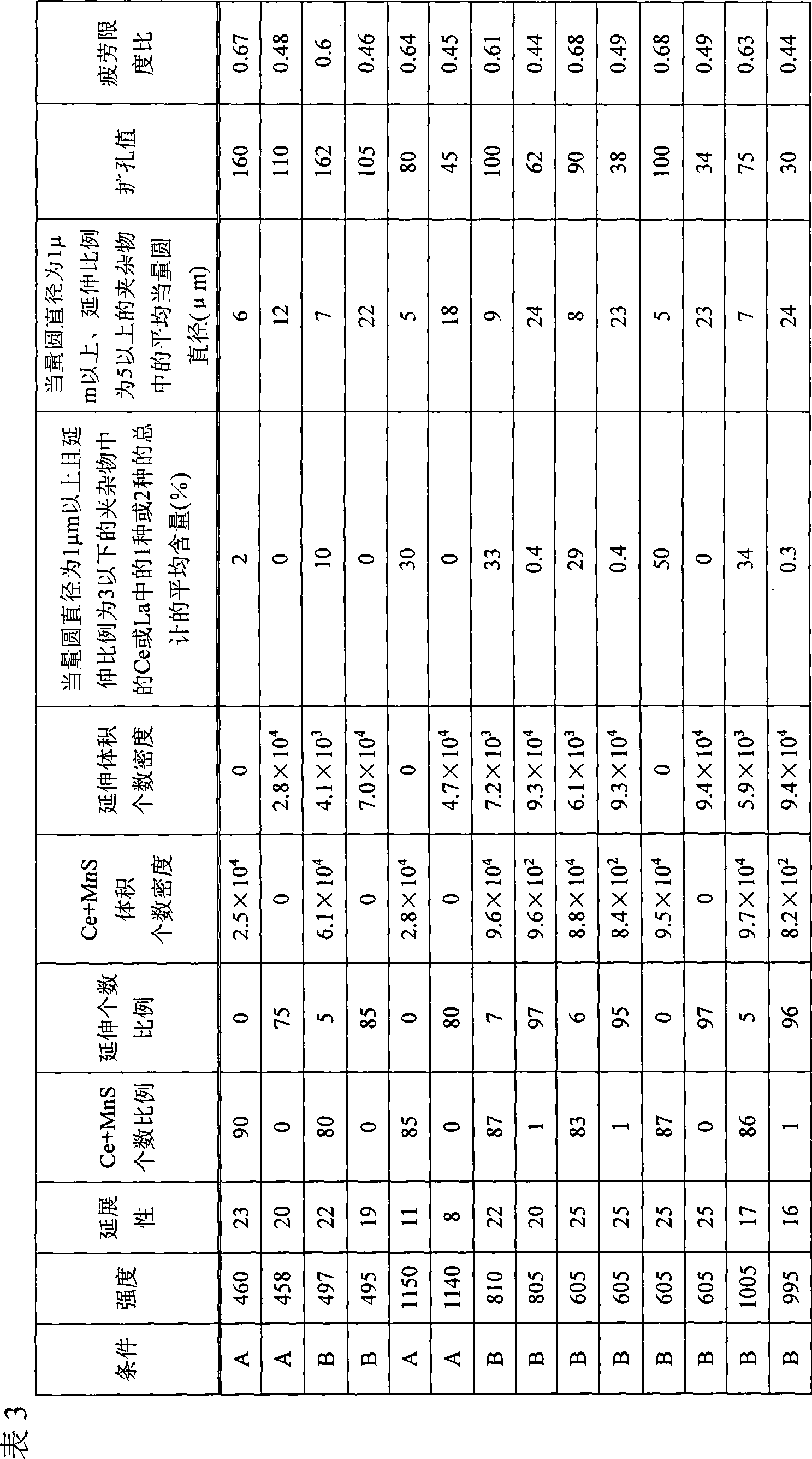

High-strength steel sheet excellent in stretch flangeability and fatigue property

ActiveCN101490295AExcellent fatigue propertiesFurnace typesHeat treatment furnacesHigh intensityMinor axis

The invention provides a high-strength hot-rolled steel sheet excellent in stretch flangeability and fatigue properties. The steel sheet contains 0.03-0.20% C, 0.08-1.5% Si, 1.0-3.0% Mn, up to 0.05% P, at least 0.0005% S, 0.0005-0.01% N, up to 0.01% acid-soluble Al, less than 0.008% acid-soluble Ti, and 0.0005-0.04% at least either of Ce and La, the remainder being iron and unavoidable impurities. The steel sheet contains stretched inclusions which have a diameter, in terms of equivalent-circle diameter, of 1 mum or larger and in which the ratio of the major-axis length to the minor-axis length is 5 or higher, in a proportion of 20% or higher by number.

Owner:NIPPON STEEL CORP

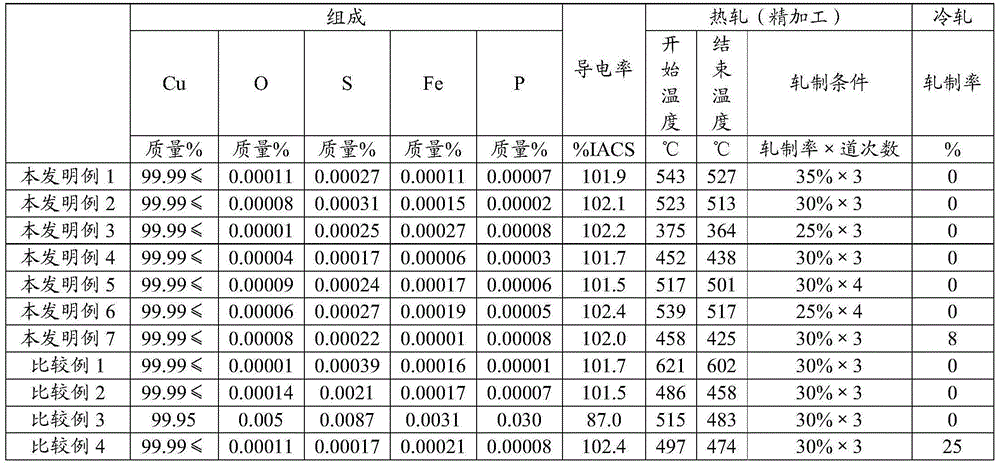

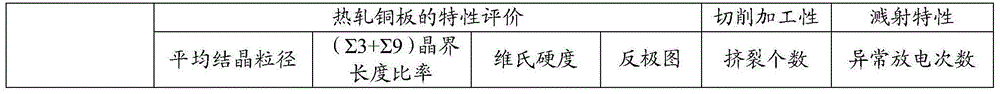

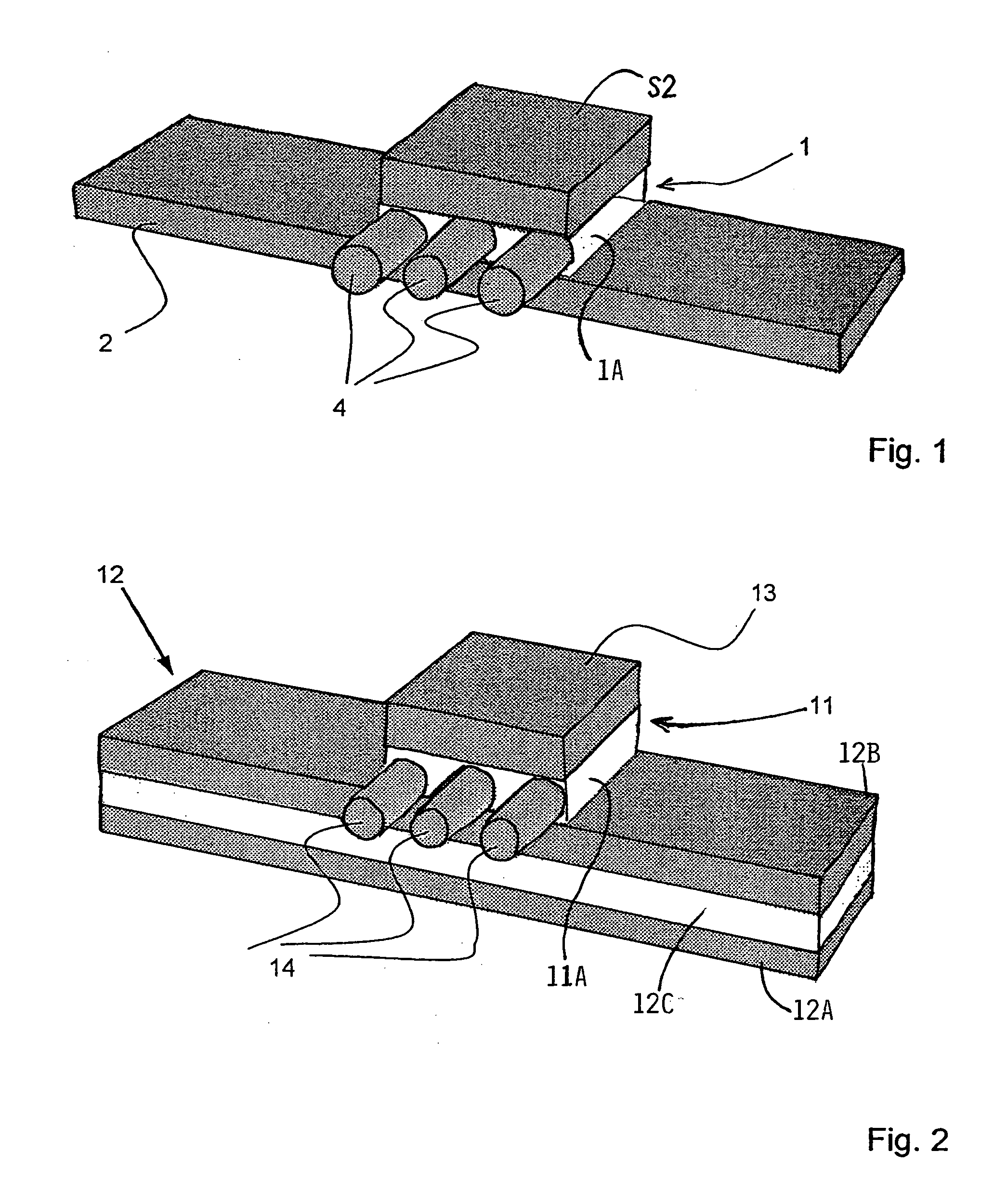

Hot-rolled copper plate

ActiveCN105189792AEasy to processExcellent fatigue propertiesSingle bars/rods/wires/strips conductorsConductive materialCopperGrain boundary

This hot-rolled copper plate is made from pure copper having a purity of 99.99 mass% or greater, the average crystal grain diameter being 40 microns or less, and the (Sigma 3+Sigma 9) grain boundary length ratio (L(sigma 3 + sigma 9) / L), which is the ratio between the total crystal grain boundary length (L) measured by the EBSD method and the sum (L(sigma 3 + sigma 9)) of the Sigma 3 grain boundary length (L sigma 3) and the Sigma 9 grain boundary length (L sigma 9) is 28% or greater.

Owner:MITSUBISHI MATERIALS CORP

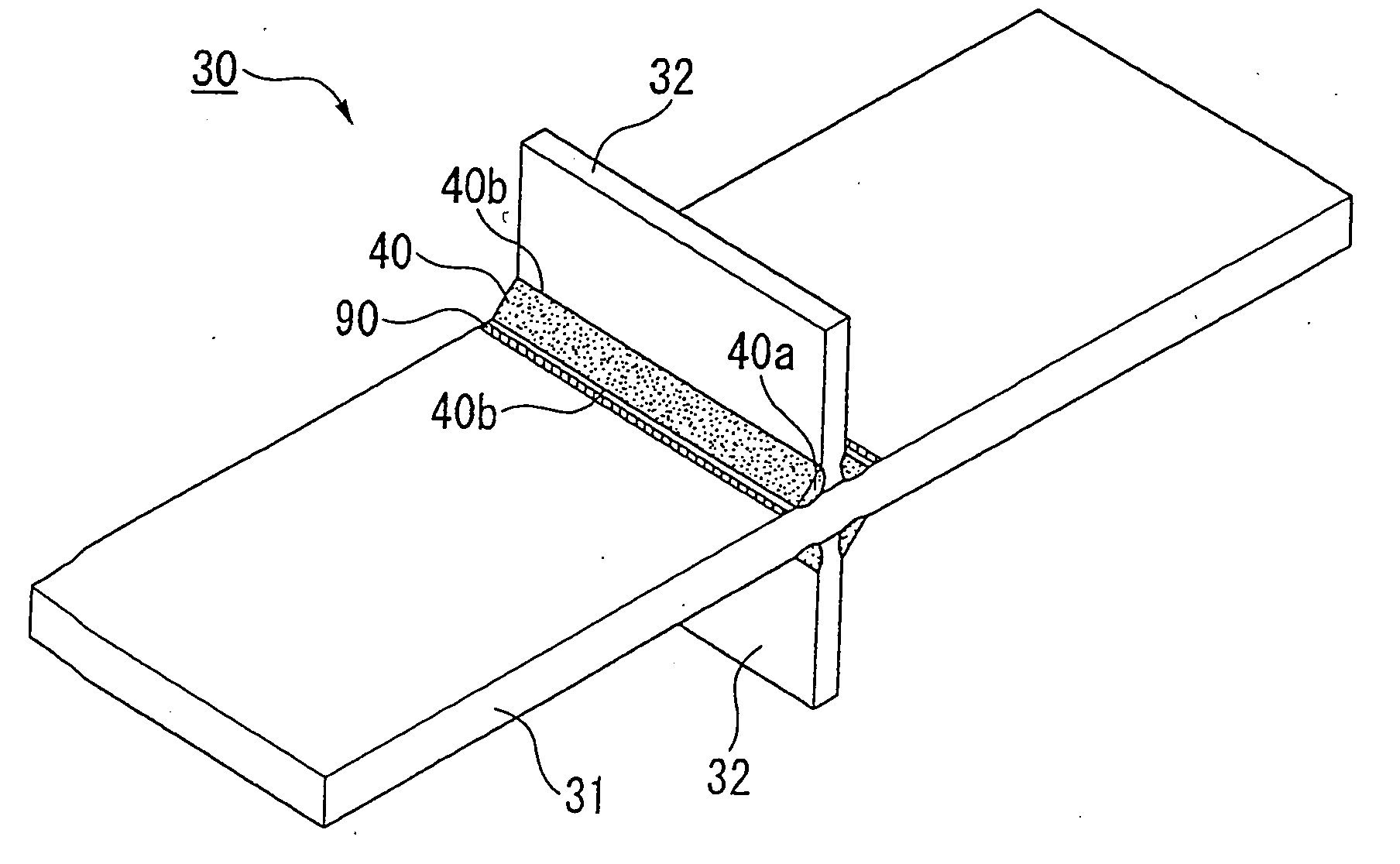

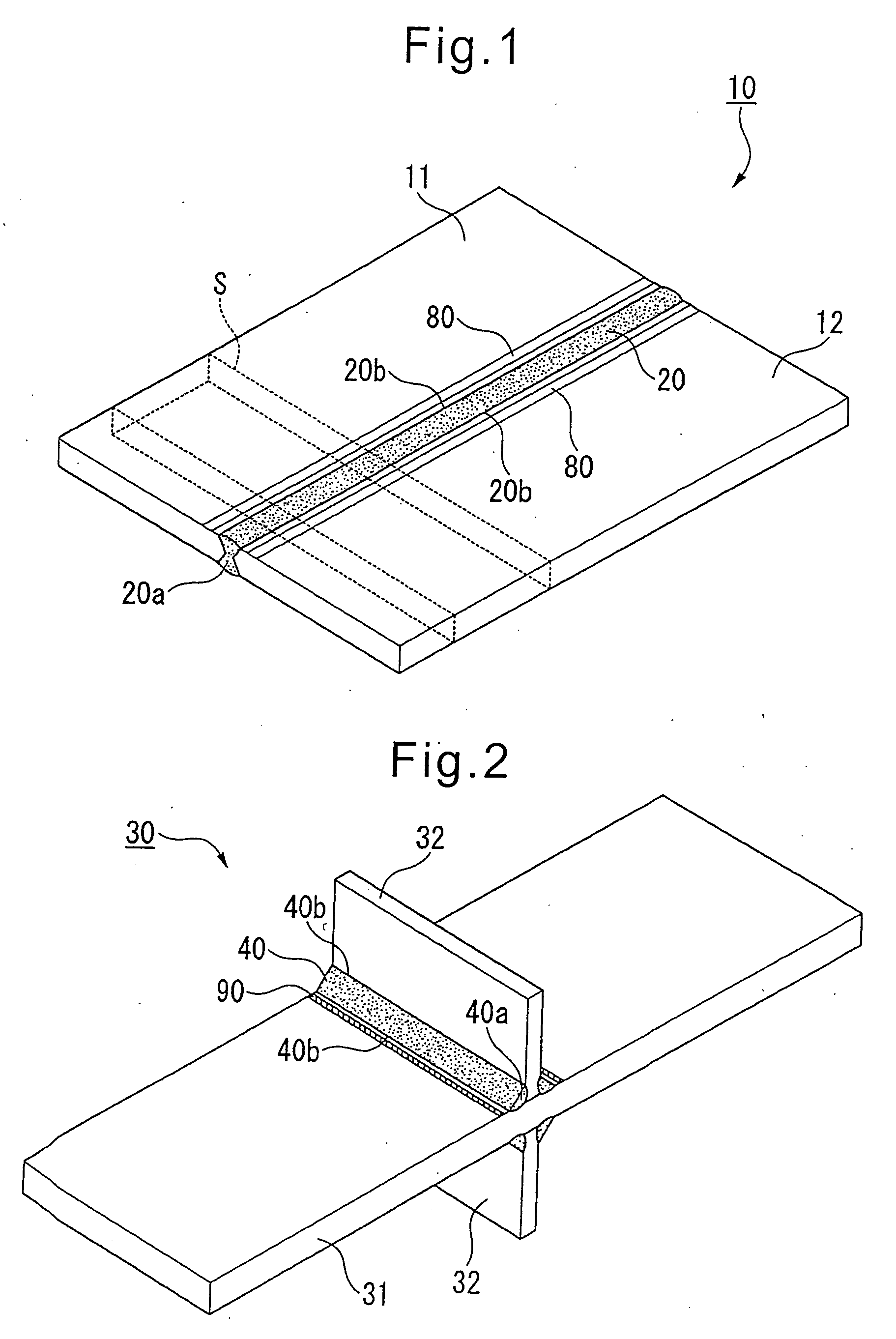

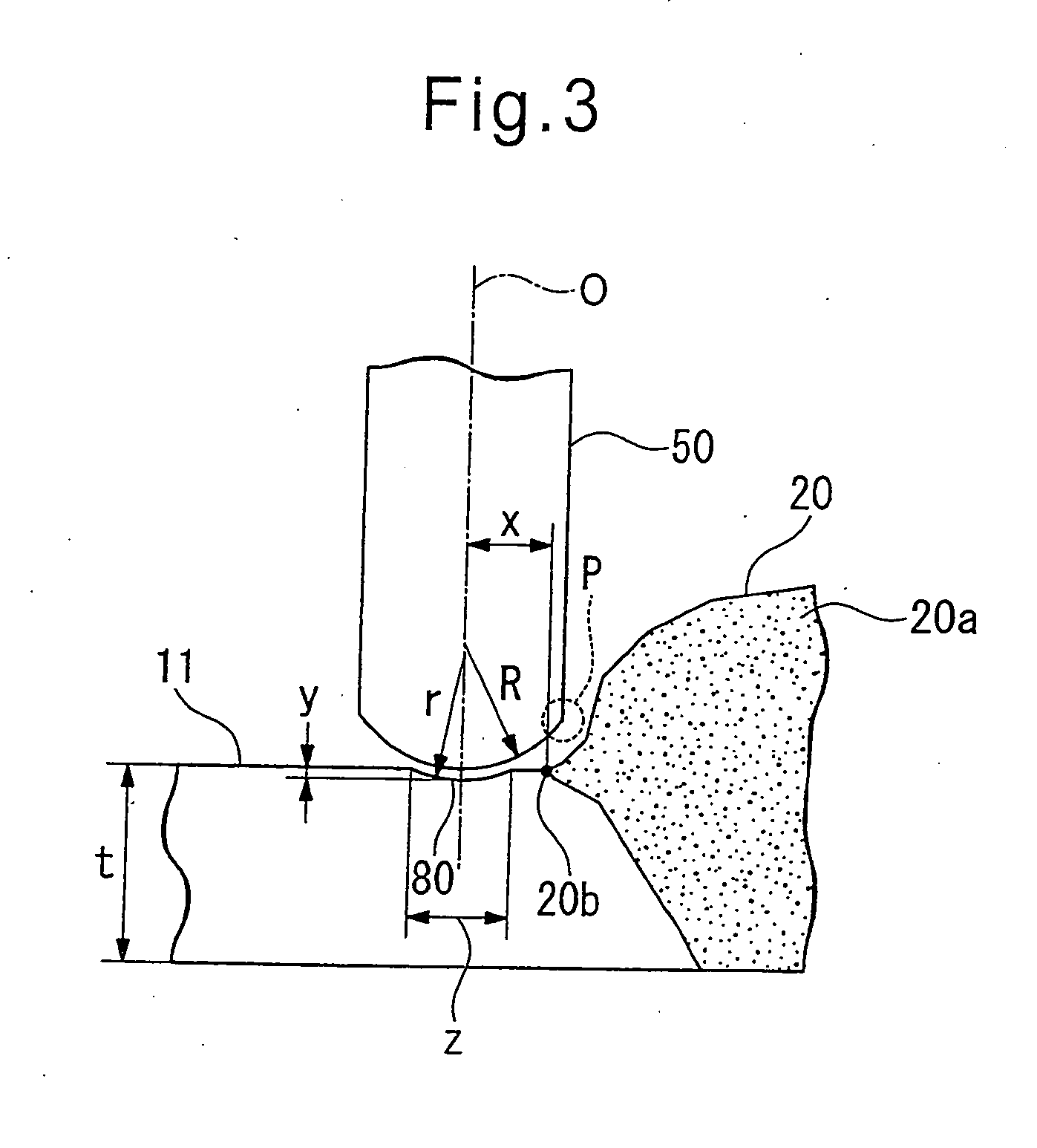

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS20050112347A1Decrease their propagationExtended service lifeNon-woven fabricsThin material handlingEngineeringParallel fiber

An additional fiber reinforced layer reduces crack propagation in a lightweight structure of an outer skin adhesively bonded to a reinforcing frame. For this purpose the additional fiber reinforced layer is interposed between the outer skin and the frame and adhesively bonded to the outer skin and to the frame. The additional layer has reinforcing fibers extending in parallel to each other or the reinforcing fibers are woven into a fabric embedded in a synthetic adhesive bonding material. The embedding of the parallel fibers or of the fiber fabric in the bonding material is performed either prior to the bonding or during the bonding of the additional layer to the outer skin and to the reinforcing frame.

Owner:AIRBUS OPERATIONS GMBH

High strength machine parts and shaft excellent in fatigue characteristics, and method for improving fatigue characteristics thereof

High strength machine parts excellent in fatigue strength which contain 0.1 to 1.2 mass % of C, and have a notch having a radius of curvature of 25 mm or less, wherein the surface thereof has an HV hardness of 250 or more and a surface layer of the notch has a compression residual stress of -100 to -1500 MPa; and a method for improving the fatigue strength thereof. A shaft excellent in fatigue resistance characteristics which comprises a steel product having a chemical composition, in mass %, that C: 0.1 to 1.2 %, Si: 0.05 to 2.5 %, Mn: 0.2 to 3 %, Al: 0.005 to 0.1 %, N: 0.001 to 0.02 % and the blance: Fe and inevitable impurities, and exhibiting a tensile strength of 800 MPa or more, characterized in that the shaft has an oil hole, and the surface layer of the oil hole has a compression residual stress of 50 to 90 % of the tensile strength of the above steel product; and a method for improving the fatigue strength thereof.

Owner:NIPPON STEEL CORP

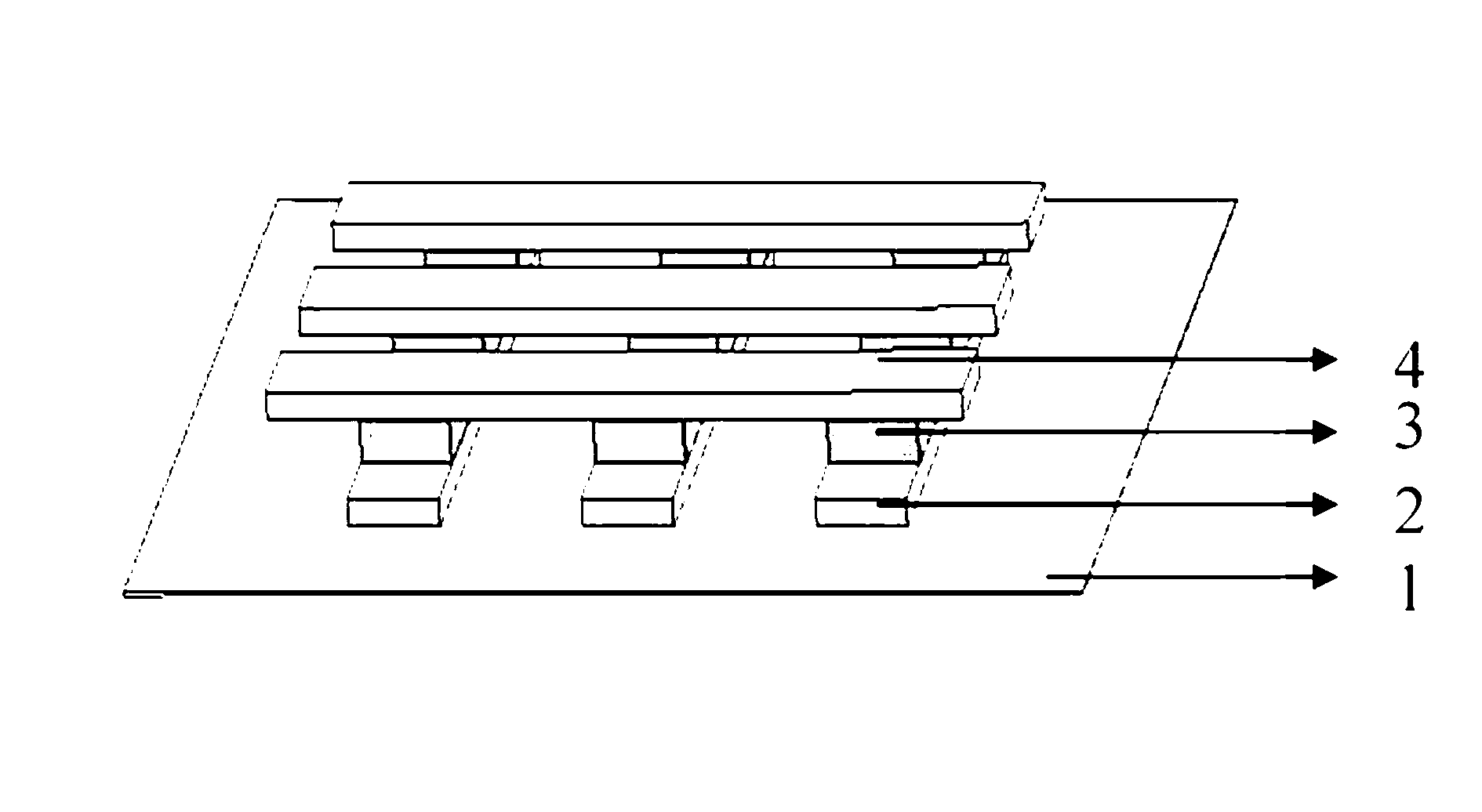

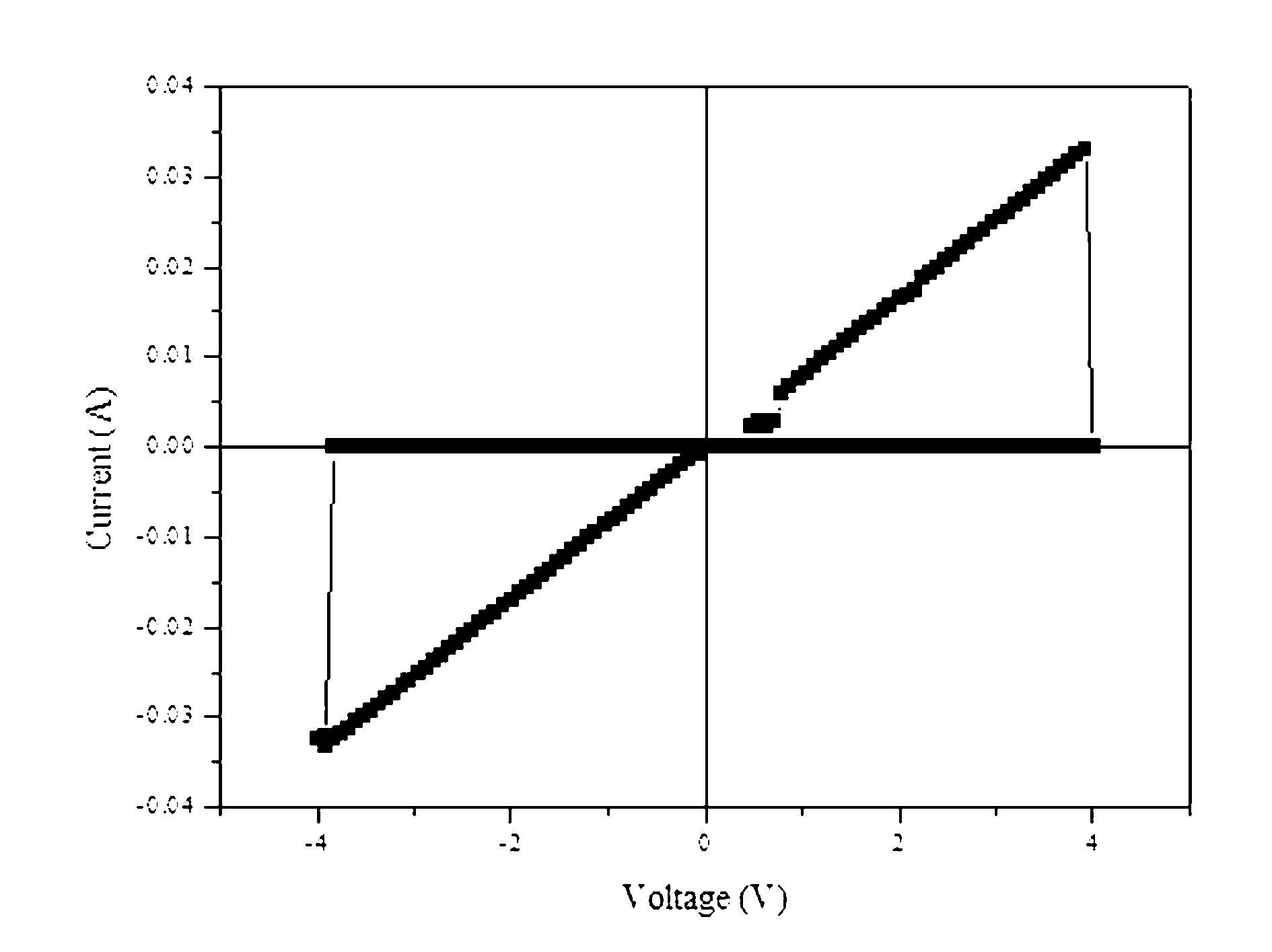

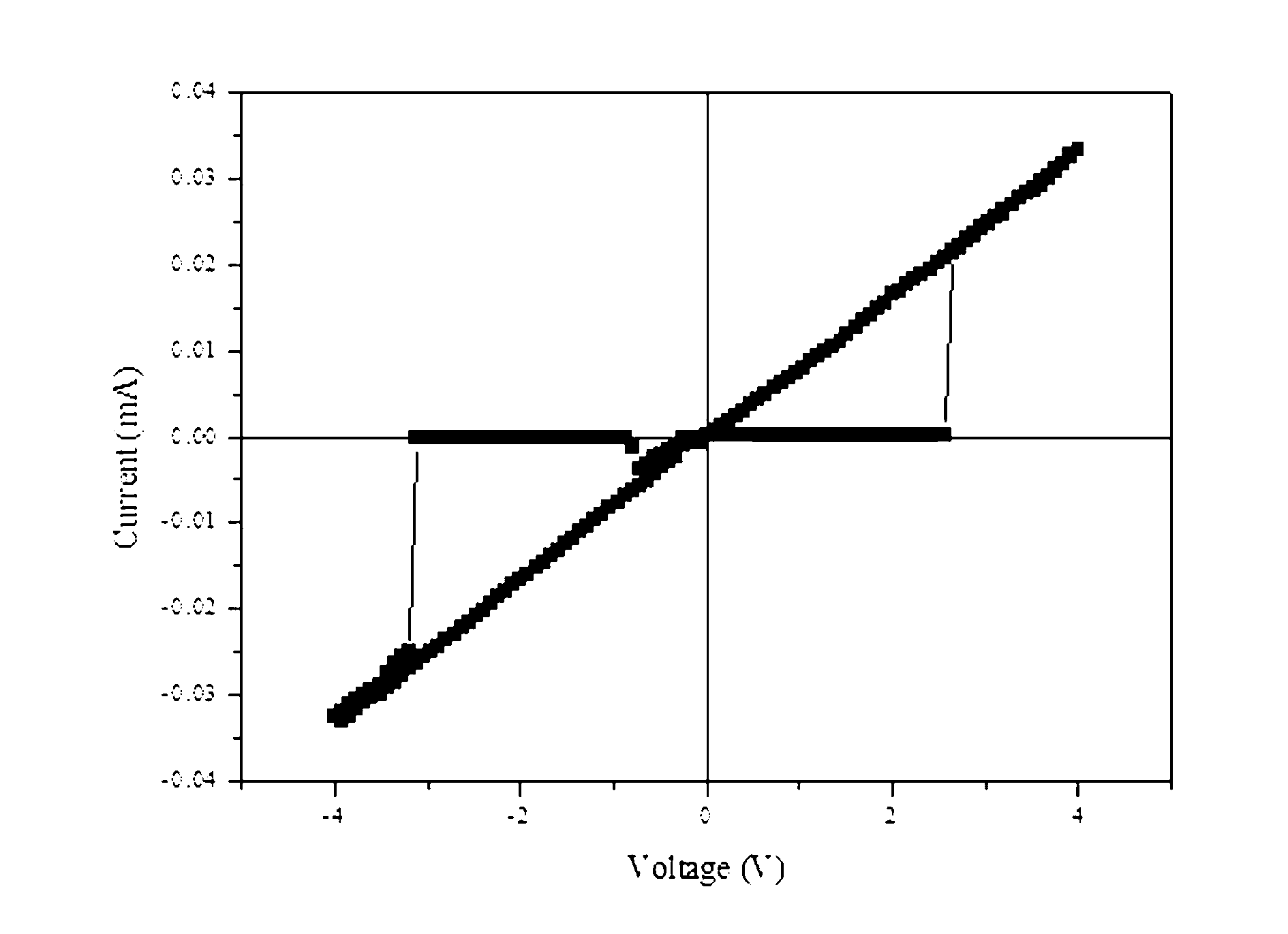

Organic resistive random access memory and preparation method thereof

InactiveCN103219466AImprove thermoplasticityImprove thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingImidePolyetherimide

The invention provides an organic resistive random access memory and a preparation method thereof. The memory comprises a substrate, bottom electrodes, resistive change layers and top electrodes which are overlapped and connected from bottom to top. The memory is characterized in that the storage structure is an array structure; and an organic resistive change transition material of the resistive change layer is a blend of polymethyl methacrylate (PMMA) and polyetherimide (PEI). In preparation, firstly, the strip bottom electrodes are prepared on the substrate, then the organic resistive change layer films are coated on the strip bottom electrodes, and after low-temperature setting, the crossed strip electrodes are prepared on the surfaces of the resistive change layer films to form the array storage structure. According to the invention, the organic resistive random access memory has the advantages of high switch ratio, stable memory property, extremely small switch current, and relatively low preparation temperature.

Owner:GUILIN UNIV OF ELECTRONIC TECH

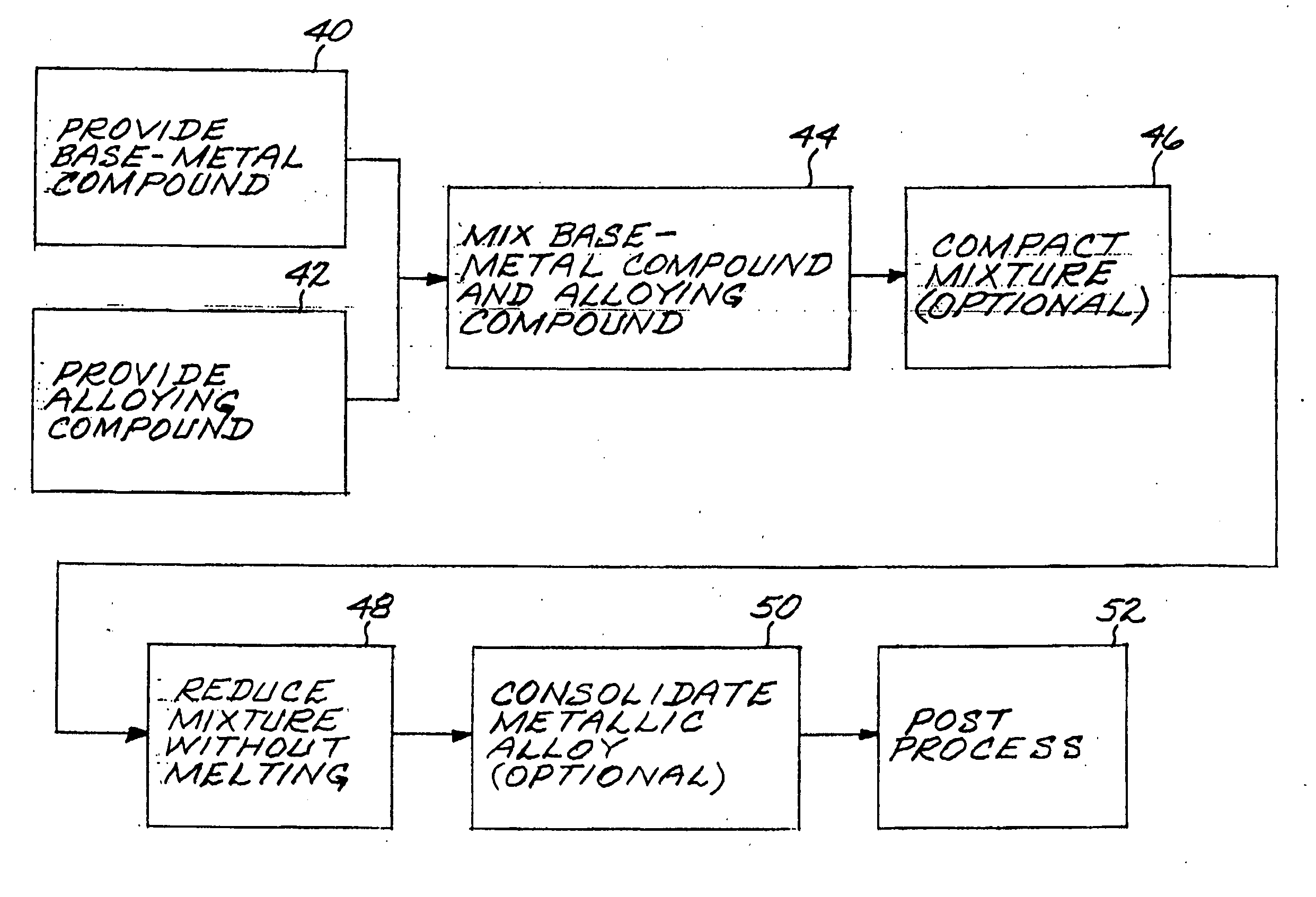

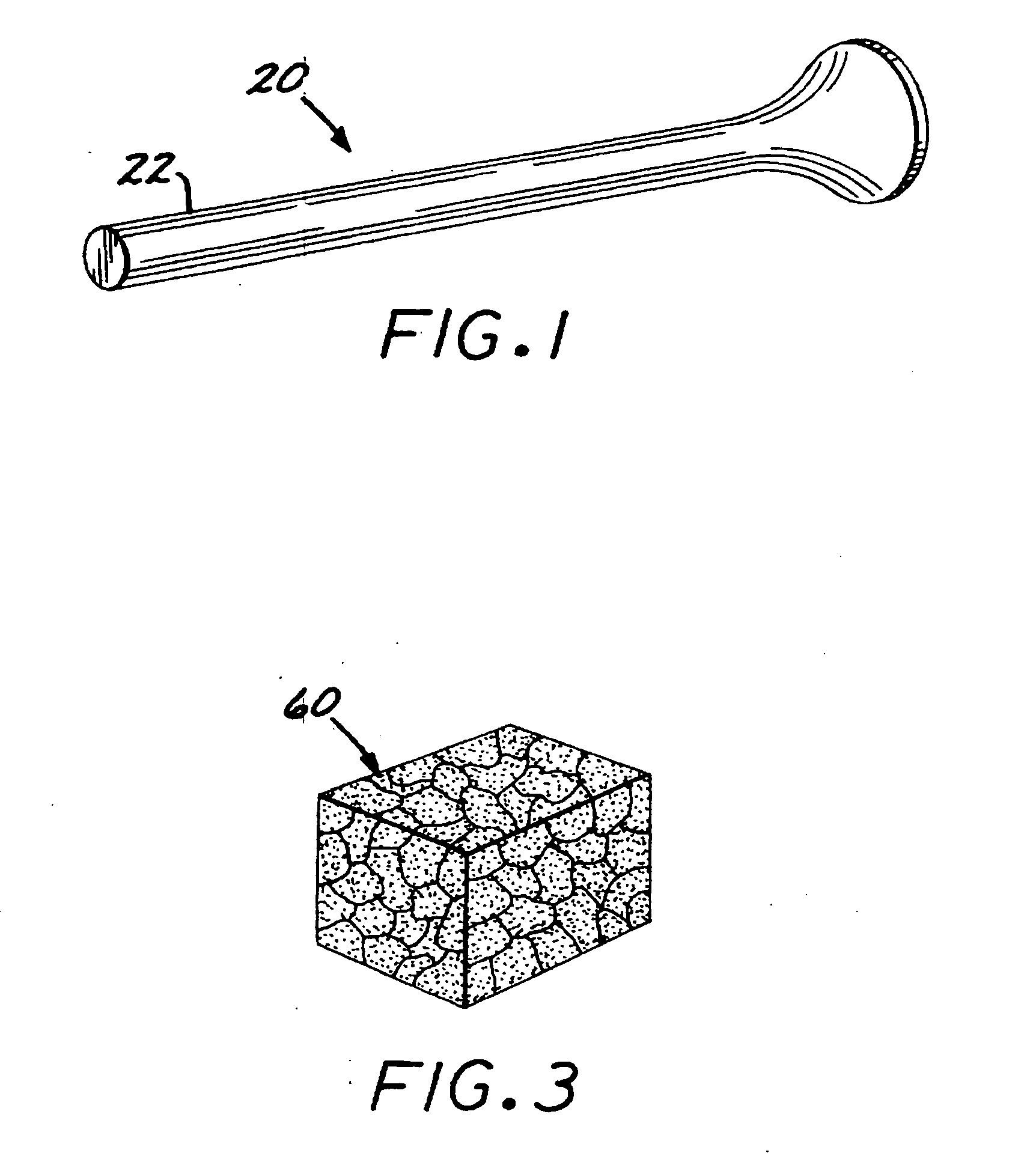

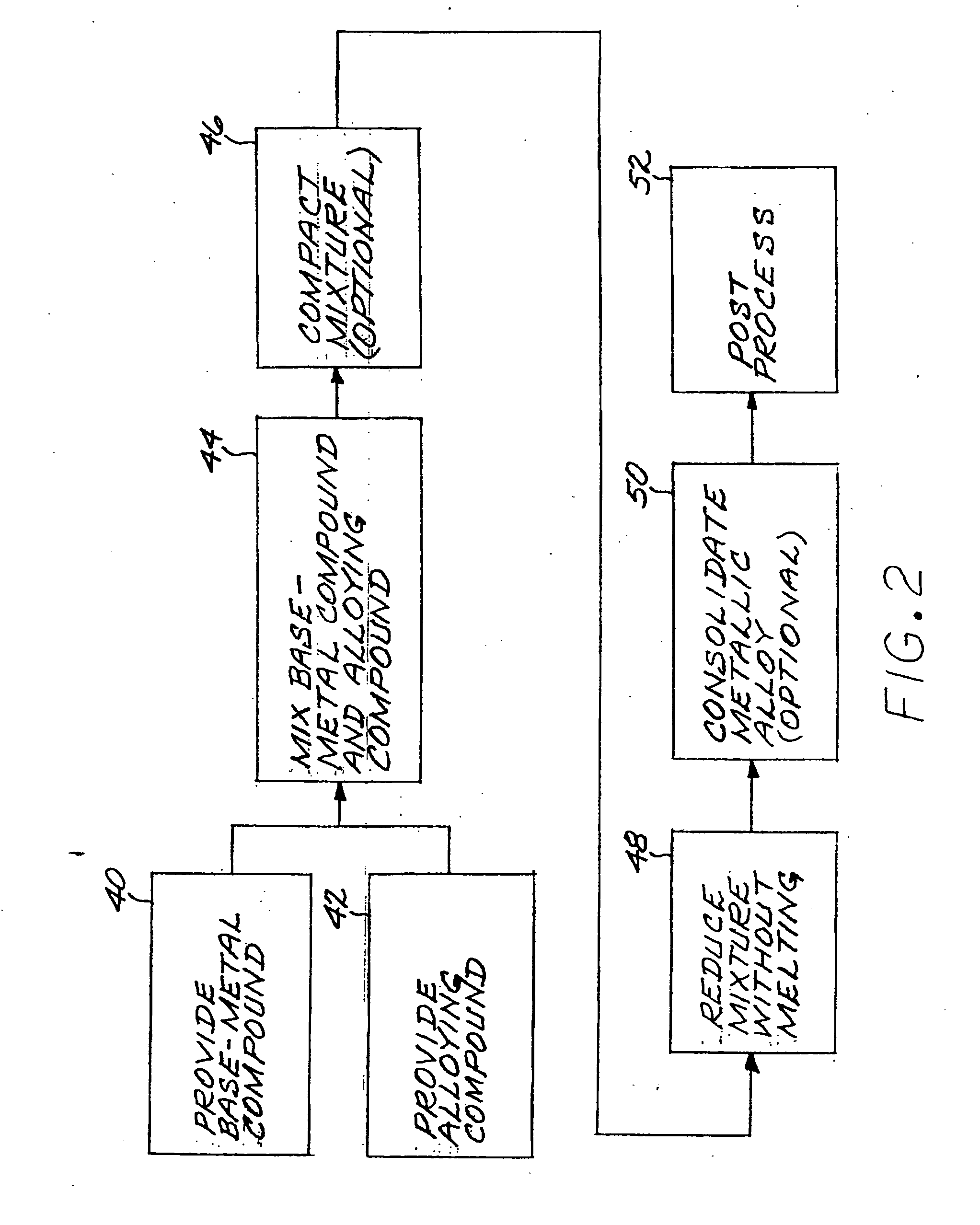

Meltless preparation of martensitic steel articles having thermophysically melt incompatible alloying elements

An article of iron base metal base metal alloyed with an alloying element is prepared by mixing a chemically reducible nonmetallic base-metal precursor compound of the iron base metal and a chemically reducible nonmetallic alloying-element precursor compound of an alloying element to form a compound mixture. The alloying element is preferably thermophysically melt incompatible with the iron base metal. The method further includes chemically reducing the compound mixture to a metallic alloy, without melting the metallic alloy, and thereafter consolidating the metallic alloy to produce a martensitic-composition consolidated metallic article, without melting the metallic alloy and without melting the consolidated metallic article.

Owner:GENERAL ELECTRIC CO

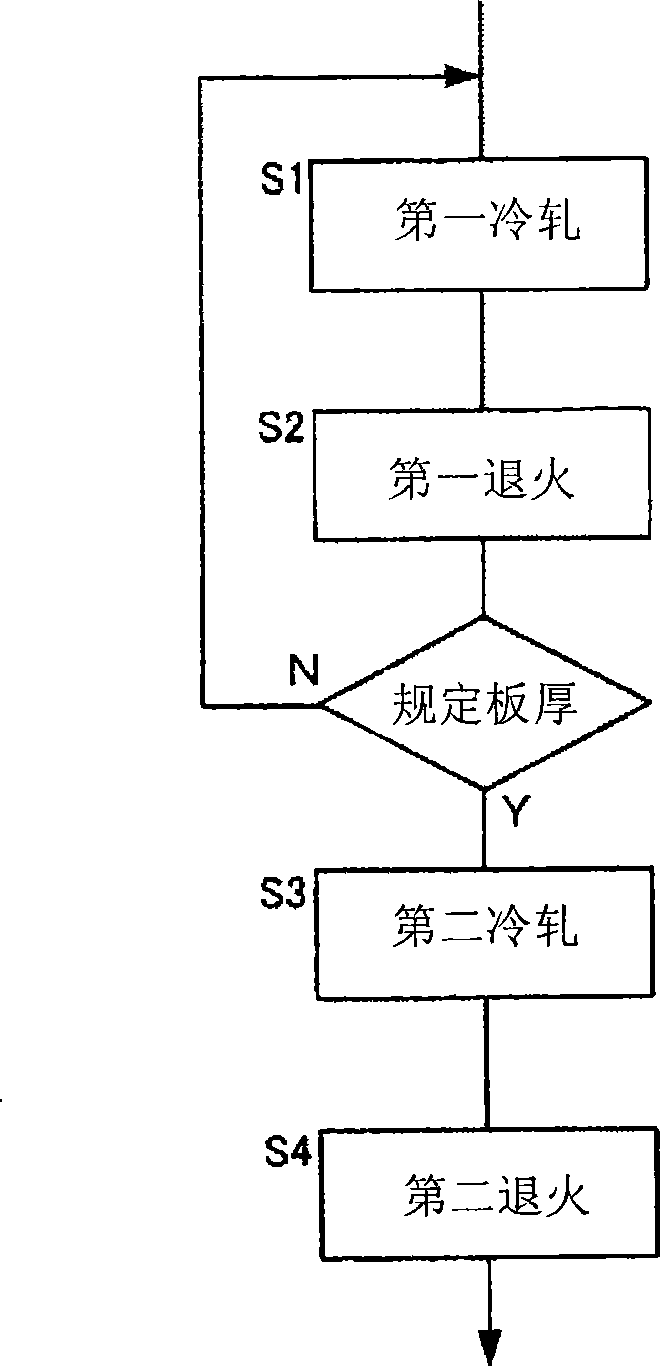

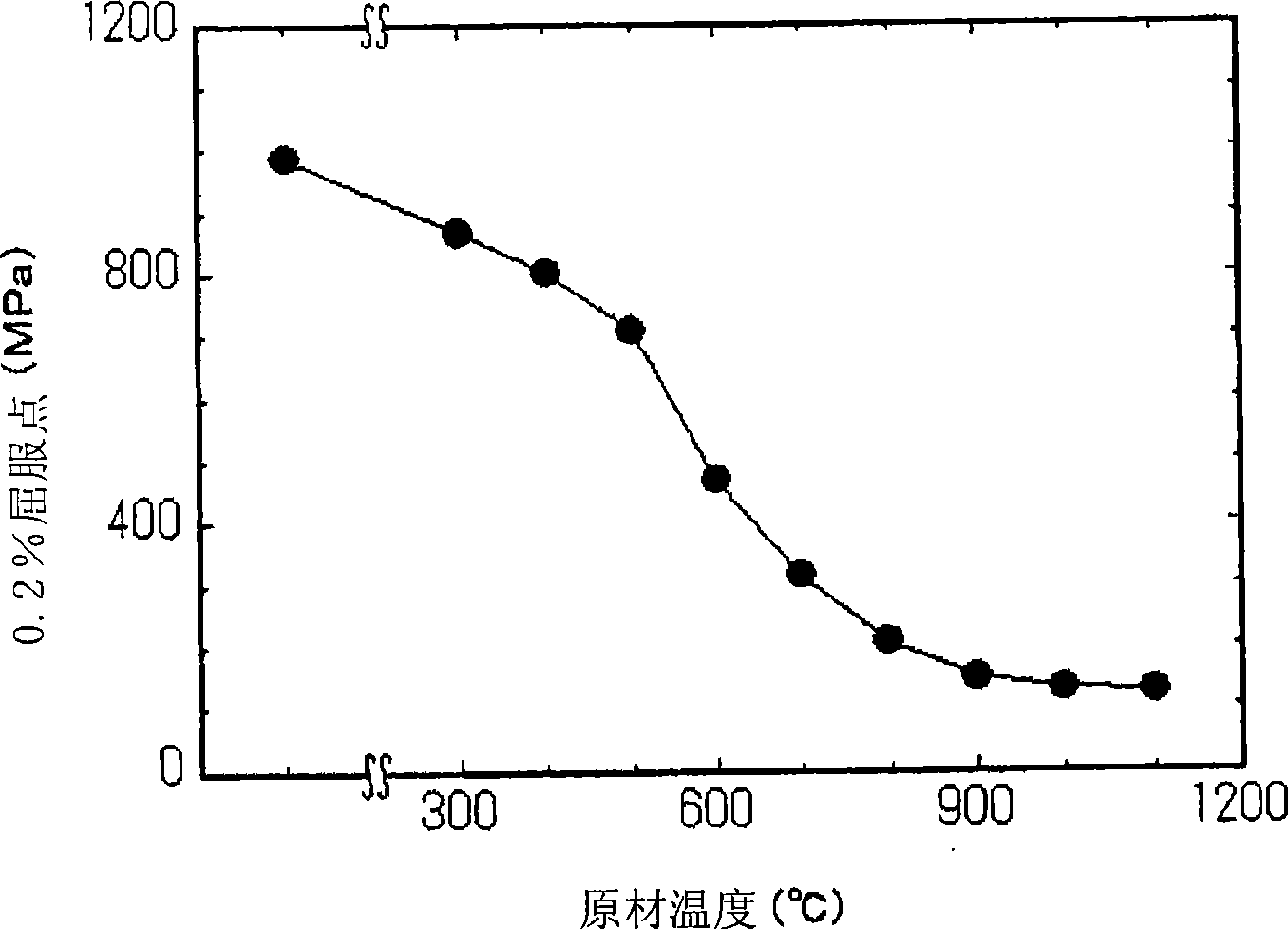

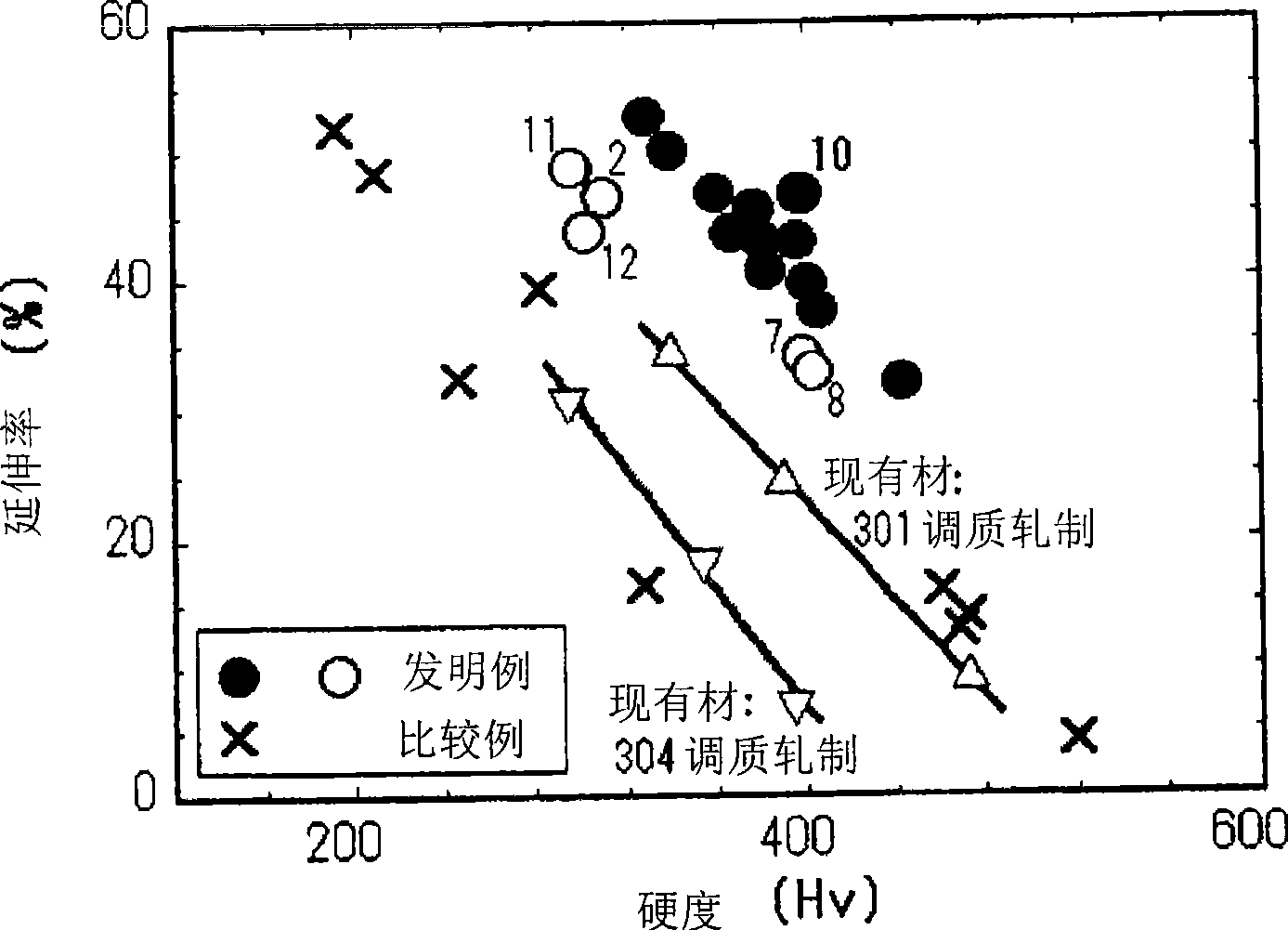

Stainless steel sheet for parts and process for manufacturing the same

ActiveCN101490298AImprove reliabilityStable formabilityFurnace typesHeat treatment furnacesSheet steelMaximum diameter

The invention provides a stainless steel sheet which has excellent strength and ductility and is improved in workability (formability and etchability) and fatigue characteristics and a process for manufacturing the stainless steel sheet. Further, the invention ensures industrial and stable supply of the stainless steel sheet at a low cost. A stainless steel sheet which contains by mass C: 0.01 to 0.08%, Si: 0.1 to 2.0%, Mn: 3.0% or below, Cr: 10.0 to 20.0%, Ni: 3.0 to 12.0% and N: 0.02 to 0.24% when the whole amount of the stainless steel is taken as 100% by mass and has an Md value of 0 to 80 as defined by the formula: Md=500-458(C+N)-9(Si+Mn)-14Cr-20Ni and in which compounds formed from the above components and having maximum diameters of 20mum or above reside in an amount of at most 30 pieces per 5g by mass of the stainless steel and the metal structure of the whole of the stainless steel is a mixed structure composed of recrystallized grains and unrecrystallized parts.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com