Stainless steel sheet for parts and process for manufacturing the same

A manufacturing method, stainless steel technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., to achieve high reliability and excellent fatigue characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

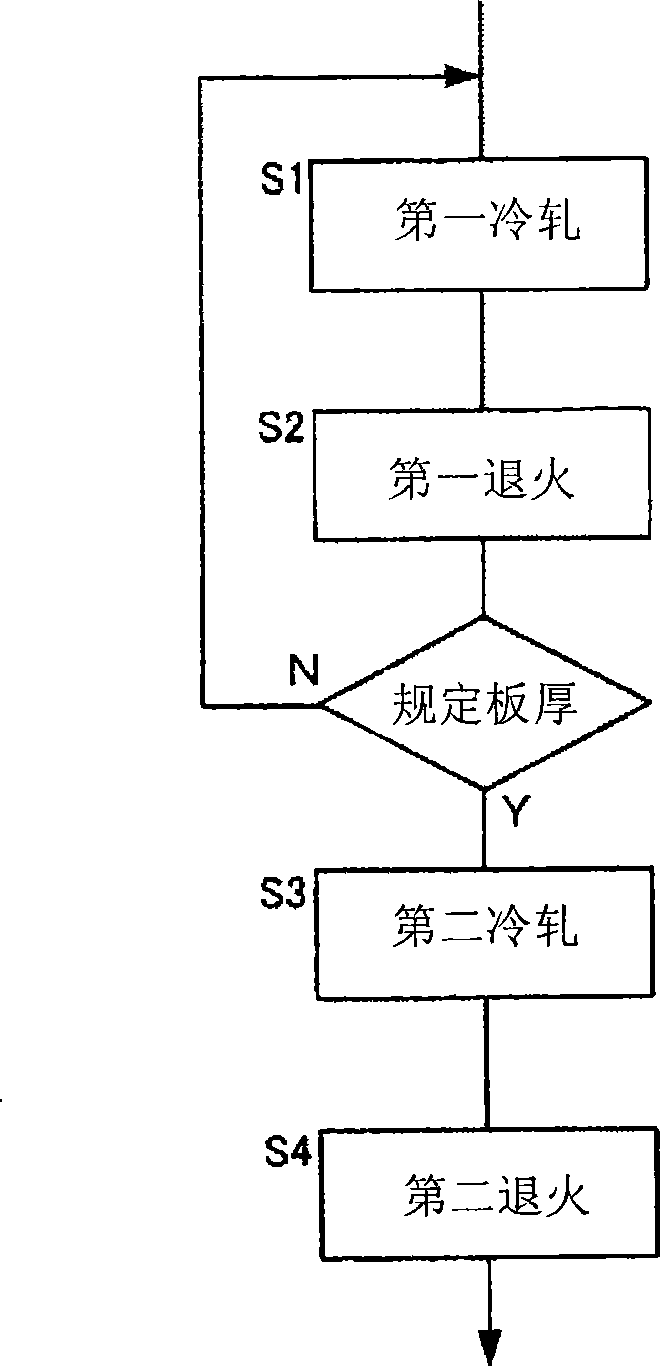

Method used

Image

Examples

Embodiment

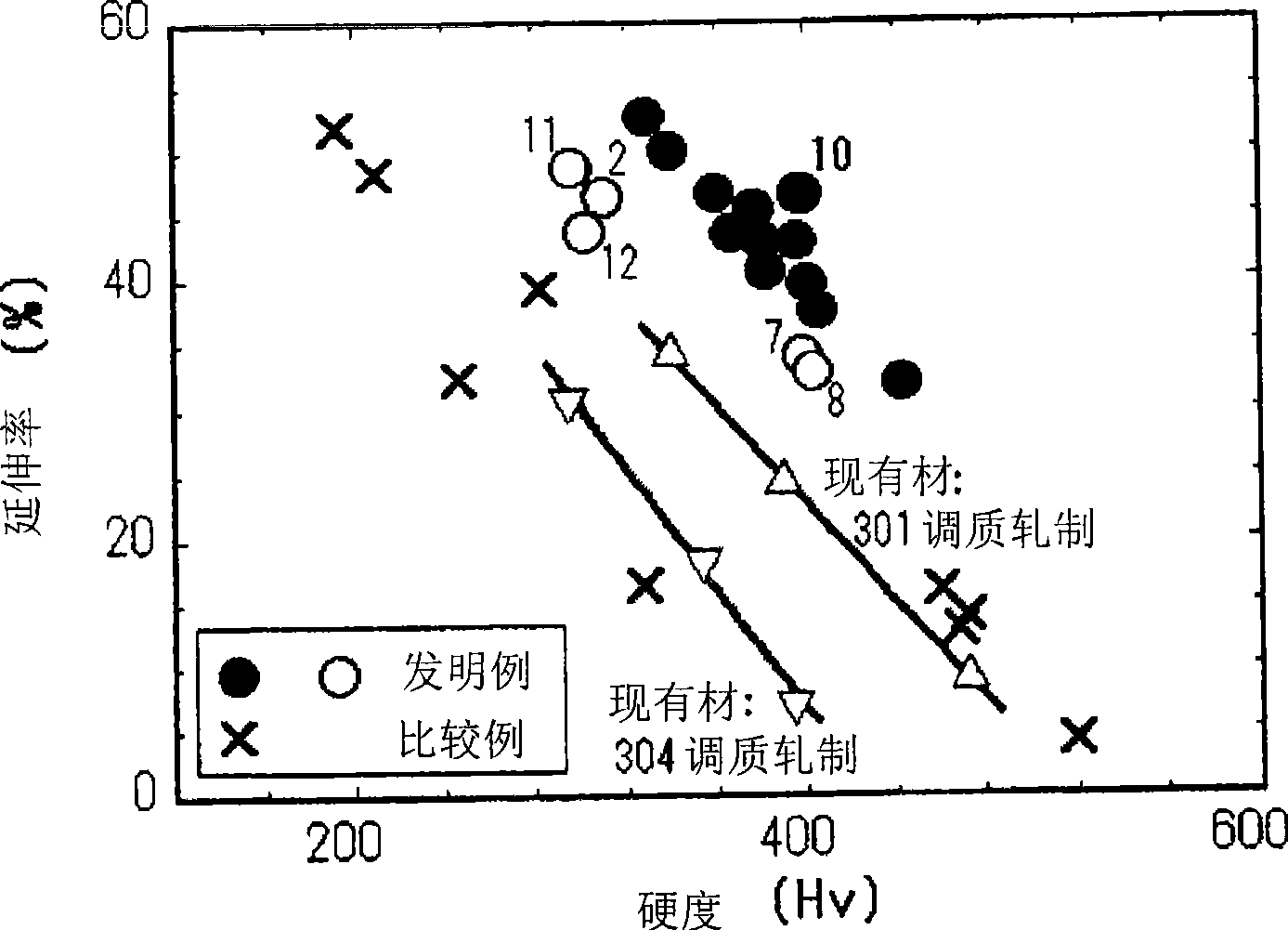

[0111] Next, it will be described in more detail through examples. However, the present invention is not limited by this embodiment. In the examples, a stainless steel steel plate corresponding to the present invention and a stainless steel steel plate not conforming to the present invention were produced and various evaluations were performed.

[0112] (i) Manufacturing of test materials

[0113] Table 1 shows the composition of the test materials. For each component that is outside the scope of the present invention, "*" is added to the number of its content.

[0114] [Table 1]

[0115]

[0116] Md=500-458(C+N)-9(Si+Mn)-14Cr-20Ni

[0117] or

[0118] Md=500-458(C+N)-9(Si+Mn)-14Cr-20Ni-65Nb-27Ti-61V

[0119] For each raw material having the composition shown in a to 1 in Table 1, a stainless steel steel plate was manufactured following each manufacturing condition. Table 2 shows the main conditions in the manufacturing process.

[0120] [Table 2]

[0121]

[0122] The manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com