Aluminum alloy extrudate for cutting

A technology of aluminum alloy and extruded materials, which is applied in the field of aluminum alloy extruded materials for cutting, can solve the problems of increased wall thickness, increased part weight, and undesired needs, and achieves the goals of increasing yield, improving fatigue characteristics, and high-temperature strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

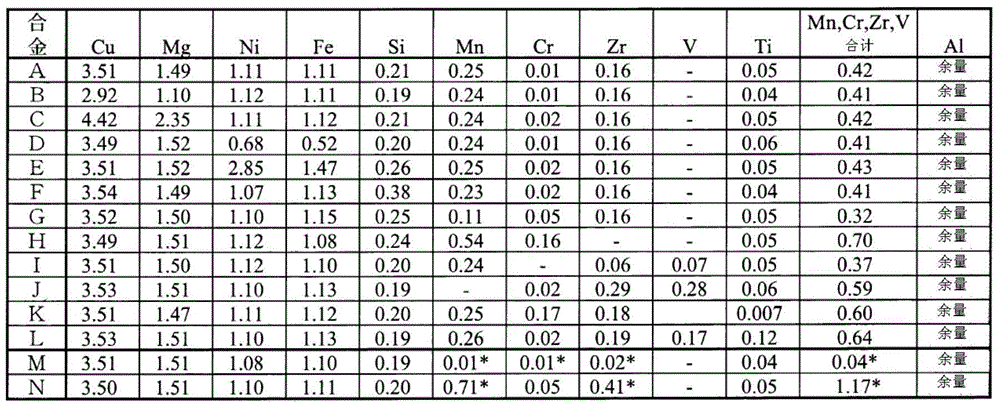

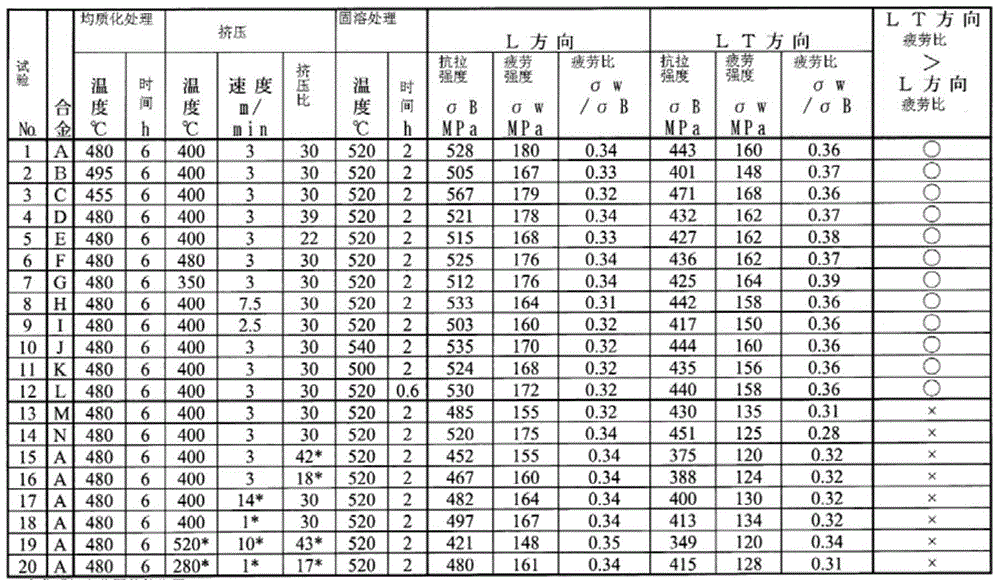

[0029] Hereinafter, the aluminum alloy extruded material for cutting according to the present invention and its manufacturing method will be described more specifically.

[0030] [alloy composition]

[0031] Cu: 2.9 to 5.5% by mass

[0032] Cu is an indispensable element required for improving the room temperature and high temperature strength of an Al—Cu—Mg-based aluminum alloy extruded material. When the content of Cu is less than 2.9% by mass, the effect of improving the strength is small, and when the content exceeds 5.5% by mass, extrusion processability will deteriorate. Therefore, the Cu content is 2.9 to 5.5% by mass. Preferably it is 3.0-4.5 mass %, More preferably, it is 3.4-4.5 mass %.

[0033] Mg: 1.0 to 2.5% by mass

[0034] Like Cu, Mg is an indispensable element required to improve the room temperature and high temperature strength of the Al—Cu—Mg based aluminum alloy extruded material. When the content of Mg is less than 1.0% by mass, the effect of improvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com