Gas-shielded arc welding method

A gas shielded and arc welding technology, applied in arc welding equipment, welding media, welding equipment, etc., can solve the problems of weld shape deterioration, weld width expansion, poor appearance, etc., improve joint fatigue characteristics, prevent cracks and Good porosity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail.

[0037] The invention relates to a gas-shielded arc welding method for pulse welding by adopting a solid welding wire.

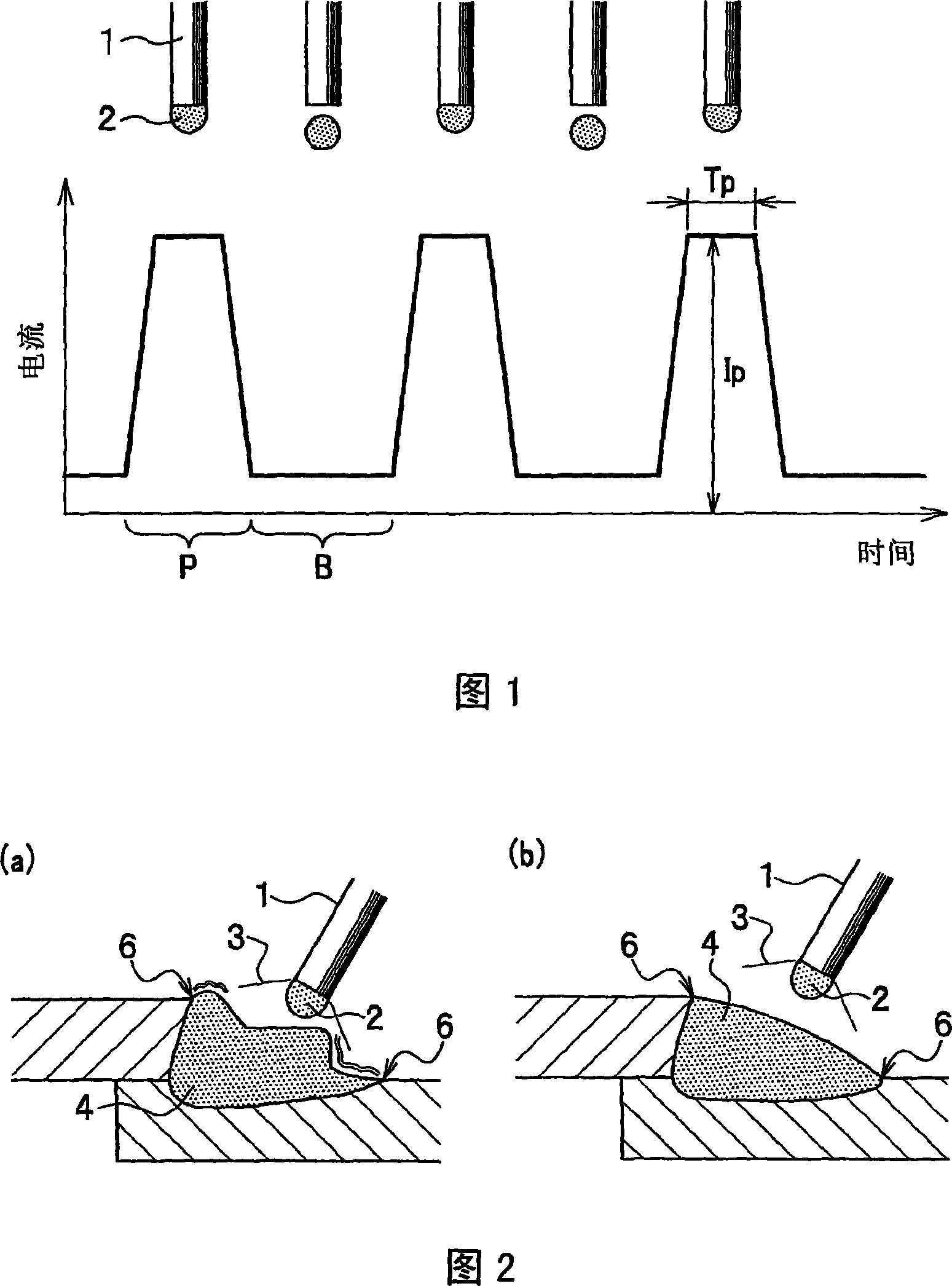

[0038] In addition, the so-called pulse welding here refers to welding performed by pulse-shaped current and voltage waveforms.

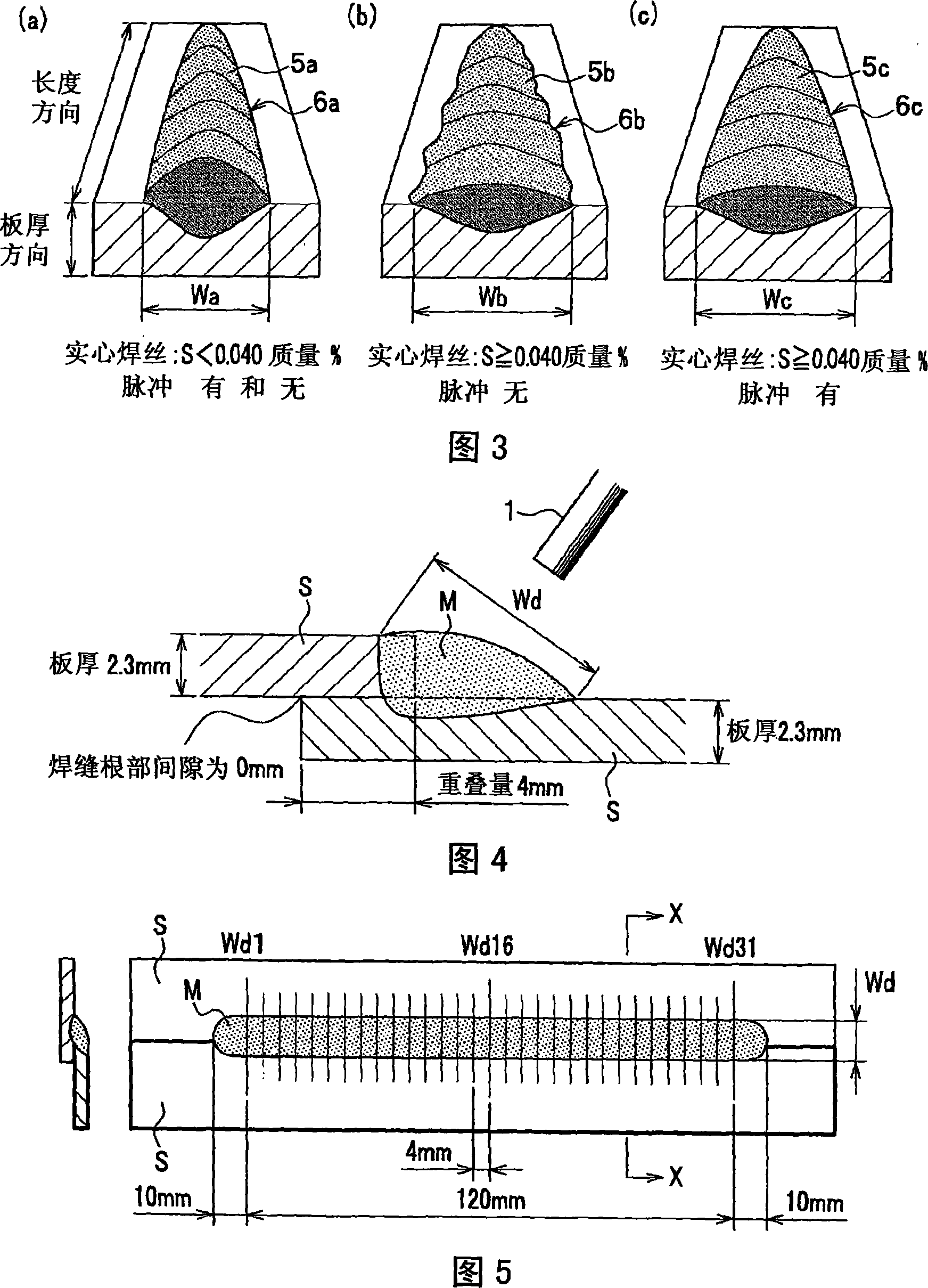

[0039] Moreover, the welding wire contains 0.040 to 0.200% by mass of S, and also contains a predetermined amount of Si, Mn, C, and P, the balance is composed of Fe and inevitable impurities, and the pulse peak current in the pulse of the pulse welding (Ip) is specified to be 350A or more, and the pulse peak period (Tp) is specified to be 0.5 to 2.0 msec. Furthermore, the protective gas used is specified as a prescribed type.

[0040] Hereinafter, each configuration will be described.

[0041] (Solid welding wire)

[0042] In general, the welding wire includes a linear solid welding wire and a flux-cored welding wire filled with flux at the center. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com