Patents

Literature

906results about How to "Regular structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing seaweed cellulose aerogel oil absorption material

ActiveCN103980530AEnsure thoroughnessFast oil absorptionOther chemical processesCelluloseUltimate tensile strength

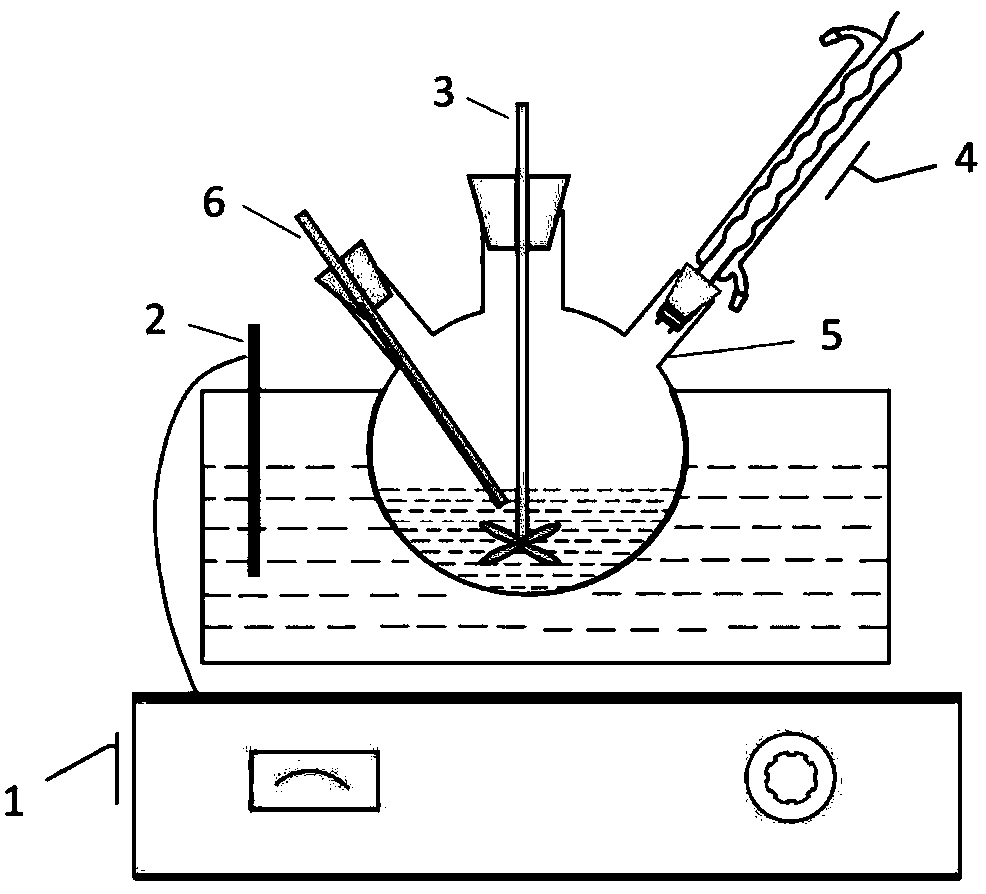

The invention discloses a method for preparing a seaweed cellulose aerogel oil absorption material and relates to a method for preparing an oil absorption material. The method comprises the following steps: I, purifying seaweed cellulose; II, preparing seaweed nano cellulose microfibril in a mechanical colloid milling mode; III, preparing seaweed cellulose aerogel; and IV, performing hydrophobic modification on the seaweed cellulose aerogel. The seaweed cellulose aerogel oil absorption material prepared by using the method is natural and pollution-free and has the advantages of high oil absorption efficiency, , good strength, simple secondary treatment and the like, and is an important development direction of novel aerogel oil absorption materials.

Owner:HARBIN INST OF TECH

Preparation method of metal-organic framework material/polymer composite proton exchange membrane

ActiveCN105789668AStrong penetrating powerImprove performanceRegenerative fuel cellsVanadium redox batteryMetal-organic framework

The invention relates to a preparation method of a metal-organic framework material / polymer composite proton exchange membrane. The method is characterized by comprising the following steps: dissolving a polymer matrix and a certain amount of metal-organic framework material with an organic solvent and carrying out ultrasonic dispersion to form a uniform membrane liquid; coating the flat and smooth surface of a glass plate with the obtained membrane liquid, and then removing the organic solvent to obtain a composite membrane; and carrying out vacuum drying on the composite membrane for 24 hours to prepare the composite proton exchange membrane for an all-vanadium redox flow battery. The composite proton exchange membrane is smooth in surface; the internal structure of the membrane is regular; the membrane is uniform in thickness and free of a defect; and the thickness is 10-300 microns. The composite proton exchange membrane provided by the invention has excellent vanadium ion permeation blocking ability, keeps excellent proton transfer performance, overcomes the defect of relatively high vanadium ion permeability of an existing all-vanadium redox flow battery membrane, and has the advantages of being simple in preparation process, high in proton transmittance, excellent in vanadium blocking property, excellent in oxidative resistance, easy to industrially amplify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of graphene-coated silicon dioxide nanoparticles

The invention discloses a preparation method of graphene-coated silicon dioxide nanoparticles. Graphite powder is taken as a raw material, graphene oxide with oxygen-containing functional groups is prepared with an improved Hummers method, the silicon dioxide nanoparticles are prepared with a hydrothermal method, a proper quantity of silane coupling agents are added to a solution containing silicon dioxide and uniformly stirred, the silane coupling agents are attached to the surfaces of silicon dioxide particles, and surface-modified silicon dioxide particles are obtained; graphene oxide is added to the modified silicon dioxide solution, and surfaces of the silicon dioxide particles are completely coated with graphene oxide under the interaction of functional groups. Finally, a reducing agent is added to the solution, graphene is formed by further removing the oxygen-containing functional groups of graphene oxide, and a composite with graphene completely coating silicon dioxide is prepared. The method has the advantages that a process is simple, the reaction time is short, regulation is easy and the like. The prepared composite has the characteristics of regular structure, high porosity, low density, good hydrophobicity and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Manufacturing method of carbon nano tube paper

A carbon nanotube paper is prepared from carbon nanotubes through adding them to acid, heating or thermal reflux, and / or ultrasonic stirring, removing impurity, diluting in water, filtering, washing the filtered cake, dispersing the carbon nanotubes in water by ultrasonic stirring, spreading on carrier, and drying. It has regular structure, high uniformity, purity and electric conductivity, and enough mechanical strength.

Owner:TSINGHUA UNIV

Preparation method of network interpenetrating functional aquagel

The invention discloses a method for preparing network interpenetrating functional aquagel through the click chemistry and the atom transfer radical polymerization (ATRP) synchronous reaction. The polymer network is generated through the click reaction of monomers A containing three or more than three end alkynyl radicals and monomers B at least containing two end laminated nitrogen radicals, and network interpenetrating polymers are obtained through the atom transfer radical polymerization (ATRP) by double-bond-containing monomers C with functional groups. The click chemistry and the atom transfer radical polymerization are synchronously carried out in the same catalytic system, and the network interpenetrating functional aquagel with the regular structure is obtained. The method of the invention has the advantages of the click chemistry and the ATRP, and also has the advantages of simple operation and fast reaction. The functional aquagel prepared by the method of the invention based on polyethyleneglycol has the characteristics of good biocompatibility, high tensile strength, high water absorption capacity, high swelling ratio, regular structure and the like.

Owner:SOUTHEAST UNIV

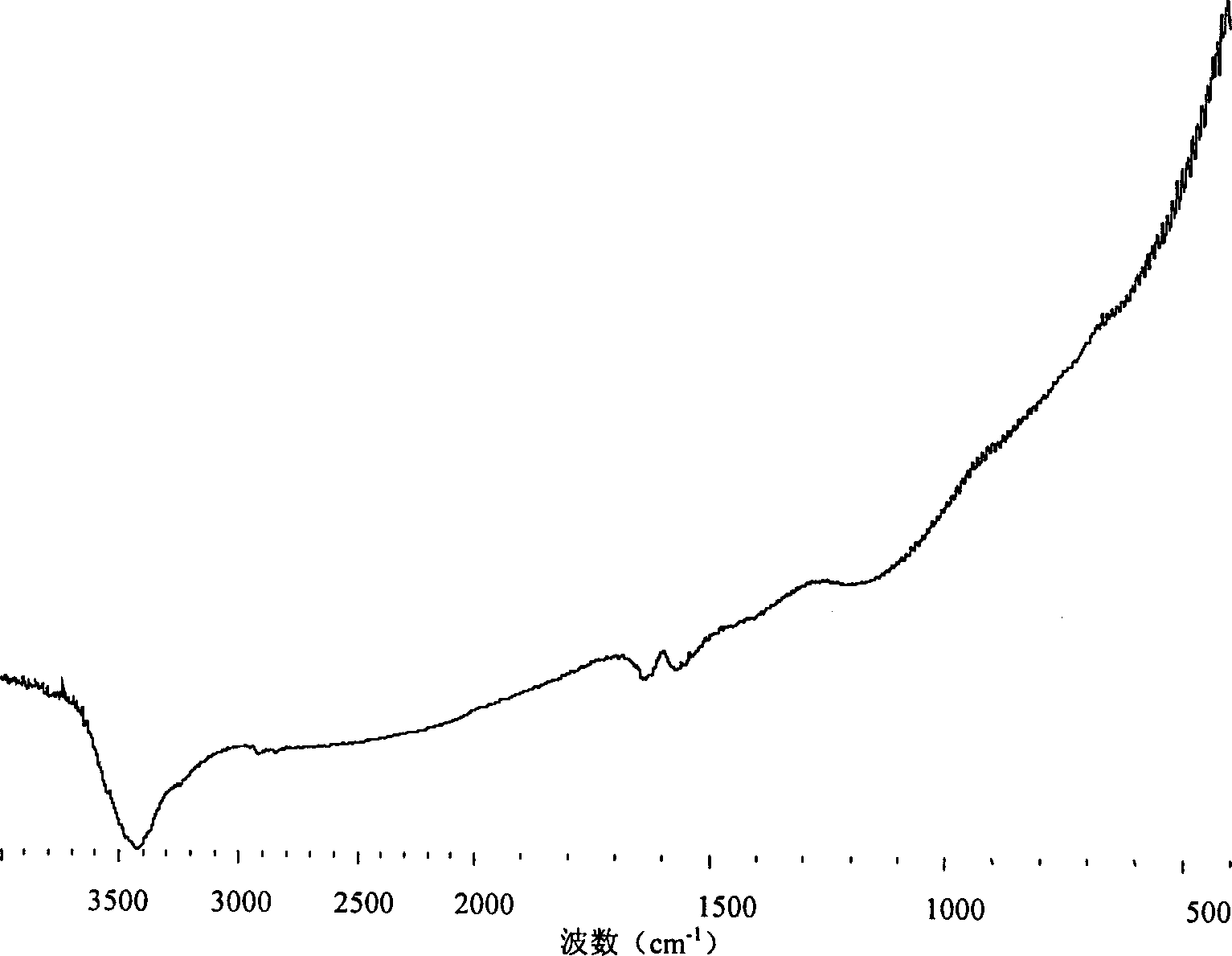

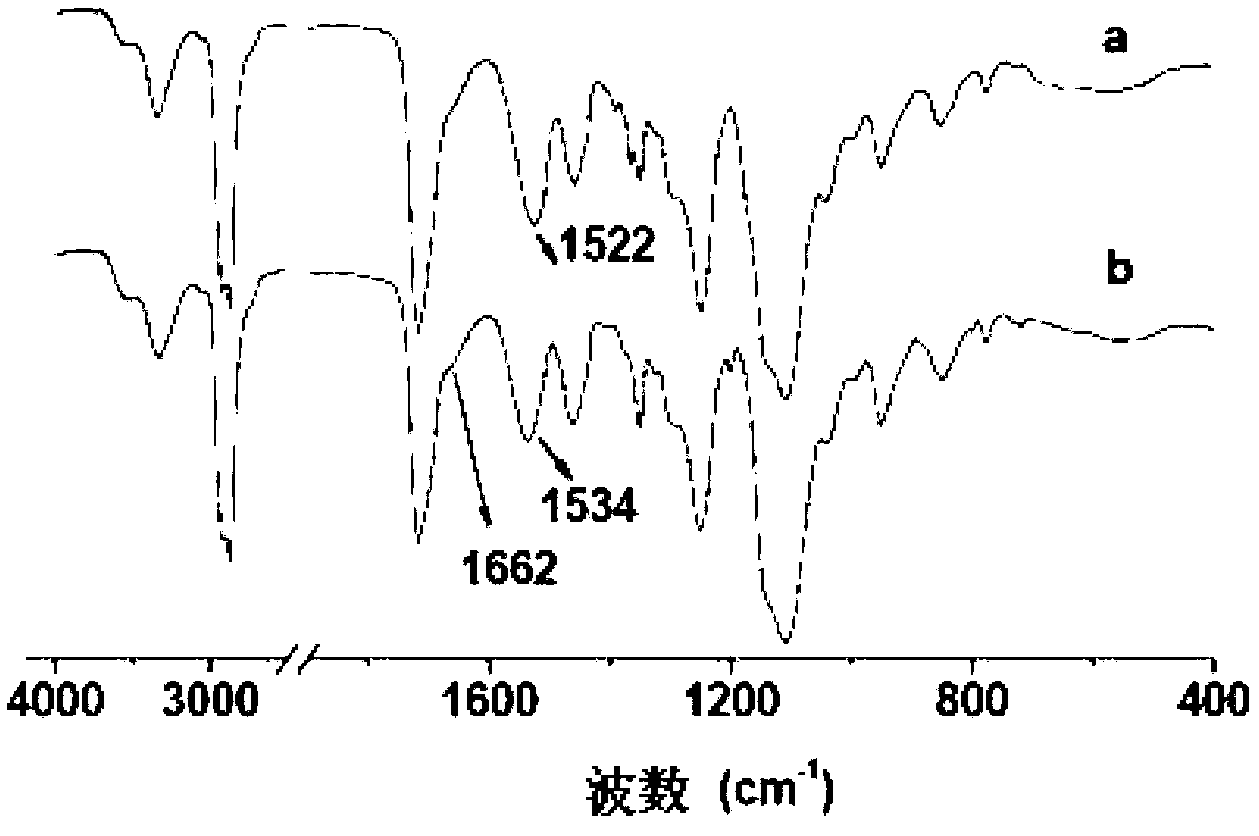

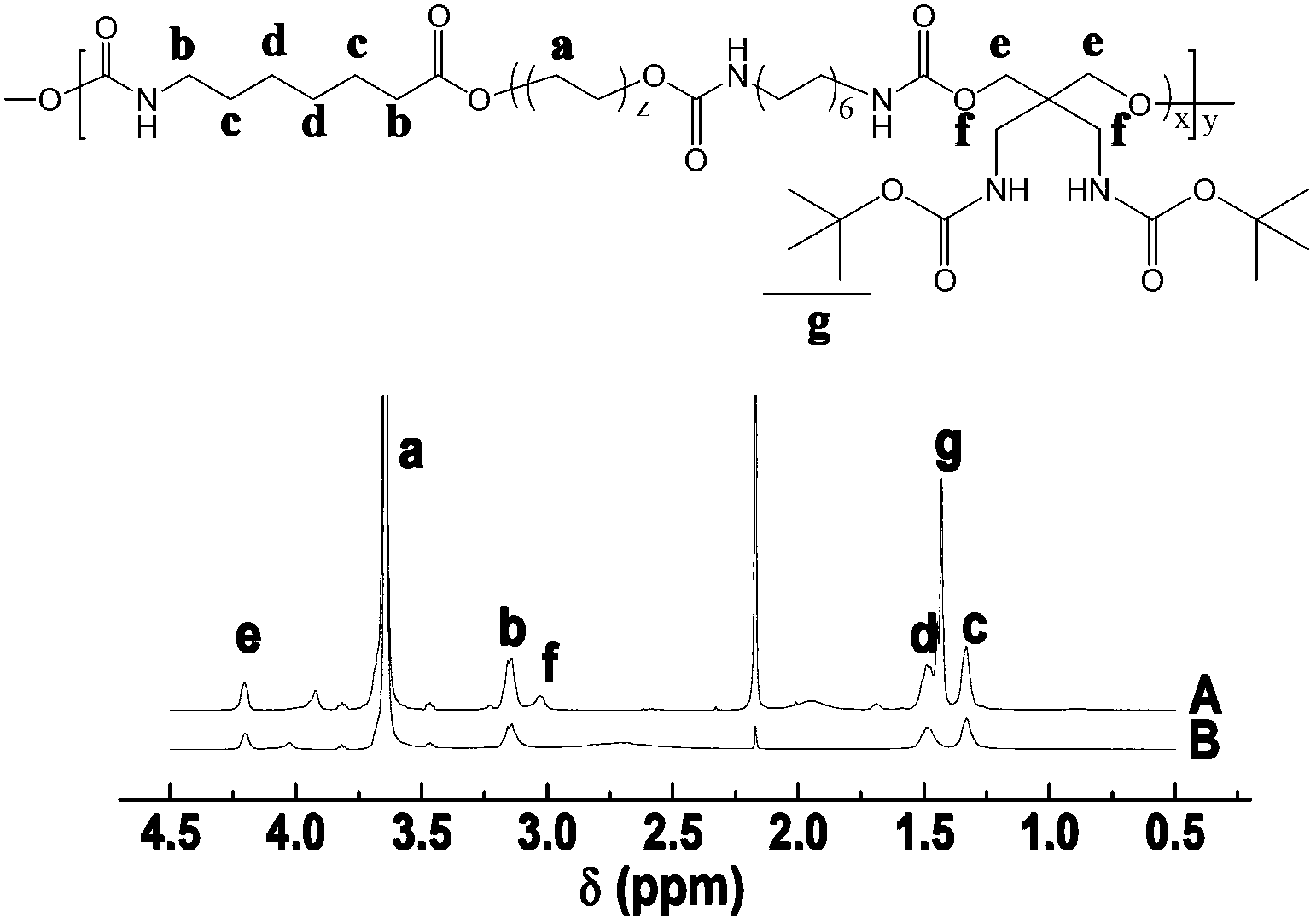

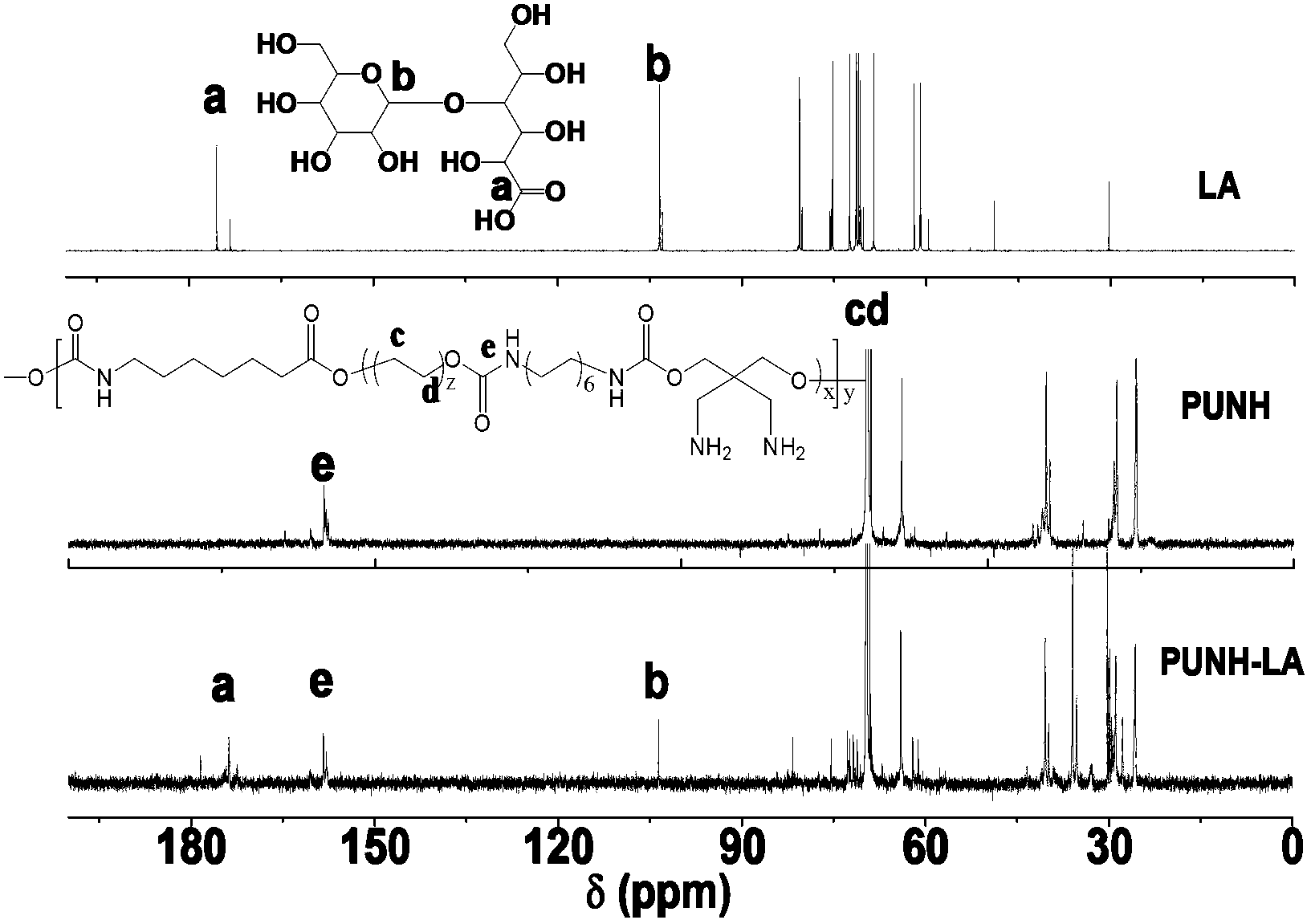

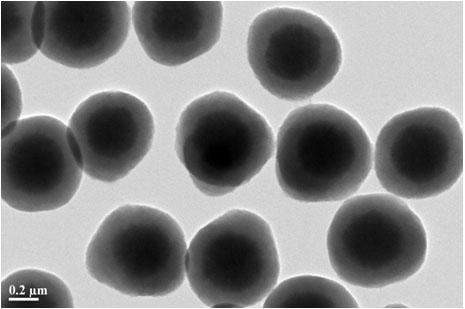

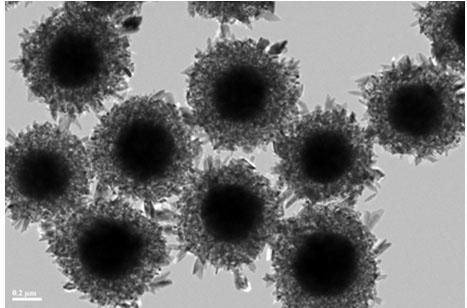

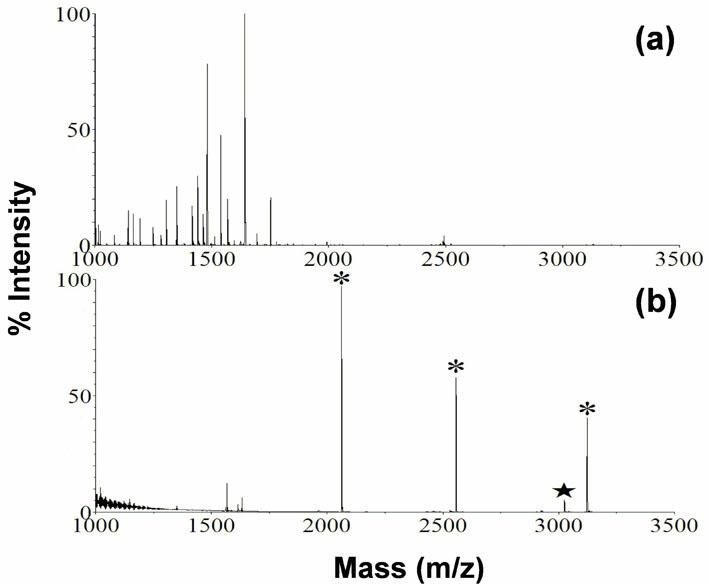

Biodegradable polyurethane with amino on side chain and preparation method and application thereof

InactiveCN103172819ARegular structureGood biocompatibility and biodegradabilityOrganic active ingredientsPharmaceutical non-active ingredientsIsocyanateFluorescence

The invention provides biodegradable polyurethane with an amino on the side chain and a preparation method and application thereof, belonging to the field of biomedical materials. Polyurethane is formed by a soft segment and a hard segment, wherein the soft segment is biodegradable polyester diol or biodegradable polyether diol; the hard segment is formed by aliphatic diisocyanate and a chain extender; and the hard segment is provided with the free or protected amino. The biodegradable polyurethane serves as a drug carrier, can wrap drug molecules to form drug carrying microspheres in the nanometer or micrometer scale and can be used for bonding drug molecules, fluorescent molecules and targeted molecules to prepare polyurethane bonded drugs, polyurethane fluorescent probes or polyurethane targeting carriers.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

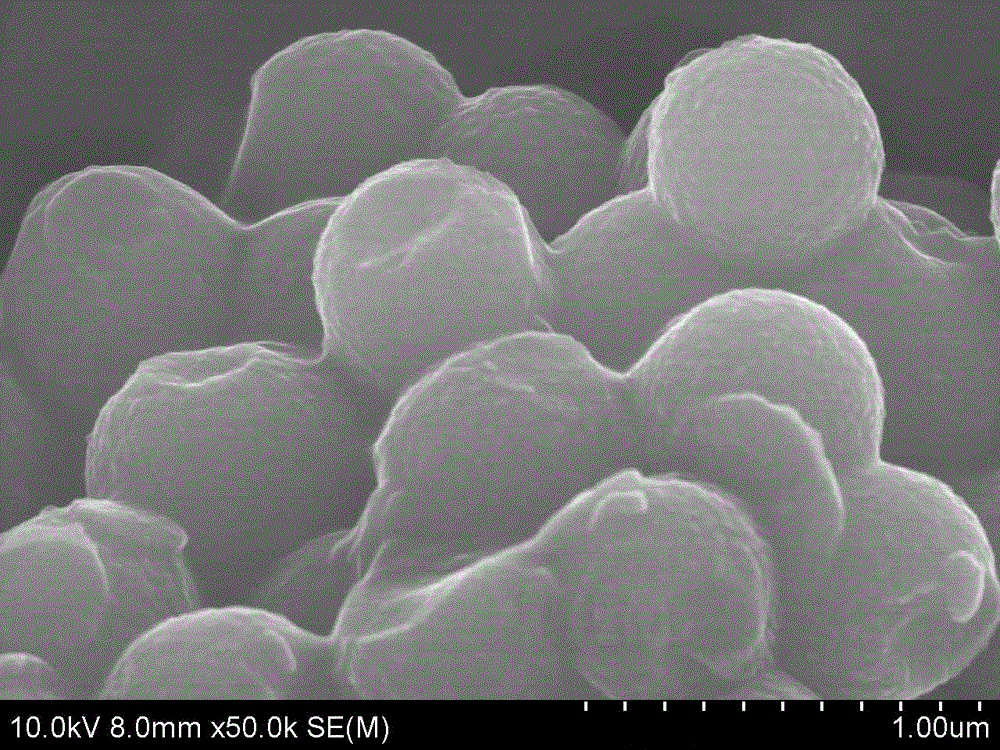

Magnetic mesoporous titanium dioxide core-shell type compound microsphere as well as preparation method and application thereof

InactiveCN102614818AGood effectRegular structureInorganic material magnetismMicroballoon preparationMicrosphereCrystallinity

The invention belongs to the technical field of functional material and particularly relates to a magnetic mesoporous titanium dioxide core-shell type compound microsphere as well as a preparation method and applications thereof. The core-shell type compound microsphere takes a ferroferric oxide nano particle cluster as the core and takes mesoporous titanium dioxide with high crystallinity as the shell. The preparation method comprises the following steps: firstly, preparing the ferroferric oxide nano particle cluster with stable citric acid, secondly, wrapping the surface of the cluster with an amorphous titanium dioxide shell through a sol-gel method, and finally, obtaining the magnetic mesoporous titanium dioxide core-shell type compound microsphere through hydro-thermal treatment. By being provided with the mesoporous titanium dioxide shell with high crystallinity, the compound microsphere has the characteristics of high selectivity, high enrichment capacity, high sensitivity and high recovery rate to phosphoeptide; and since a magnetic core exists, the microsphere enriched in phosphoeptide can be separated by magnetism quickly and very conveniently. The method provided by the invention has the advantages that the operation is simple, the process is controllable, and the prepared compound microsphere can be used for analyzing and identifying phosphoeptide with ultra low concentration in a biological sample.

Owner:FUDAN UNIV

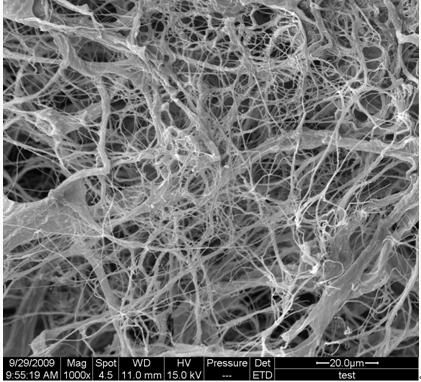

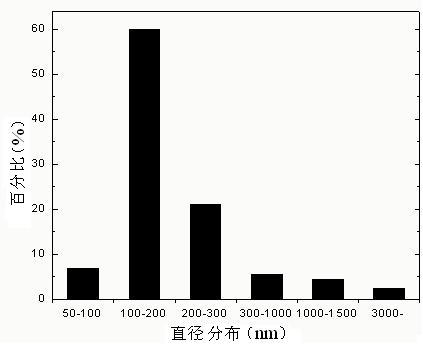

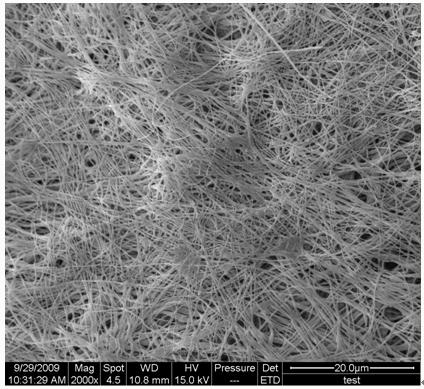

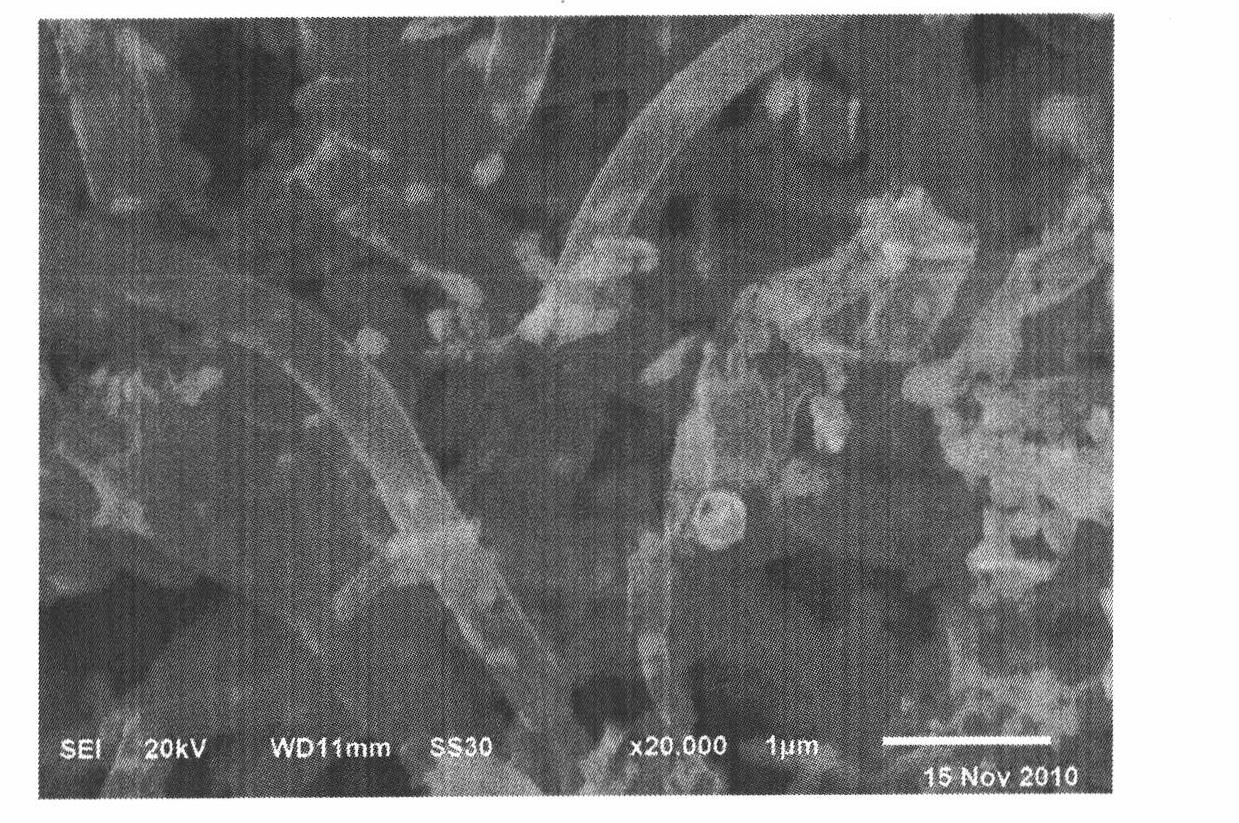

Method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment

InactiveCN101851801AUniform fibrillationRegular shapeArtificial filaments from cellulose solutionsBenzeneAlcohol

The invention provides a method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment, which relates to a preparation method of nanometer cellulose fiber. The invention solves the problems of short length, nonuniform fiber diameter distribution and easy interweaving between fiber into cluster nanometer fiber of the nanometer cellulose fiber prepared by the existing method only using mechanical high-pressure homogenization treatment. The method of the invention comprises the following steps that: 1. biomass fiber is extracted by an alcohol benzene solution; 2. the treatment by acidified sodium chlorite is carried out; 3. alkali liquor gradient treatment is carried out; 4. an ultrasonic cell crushing machine is used for treatment; and 5. high-pressure homogenization treatment is carried out, and nanometer cellulose fiber is obtained after being dried. The fiber diameter distribution is uniform, the length is longer than or equal to 150 mum, the slenderness ratio is larger than or equal to 600, and the fiber is mutually interwoven into a reticular winding structure. The method of the invention is applicable to the preparation of nanometer cellulose fiber from wood pulp, papermaking pulp materials, wood materials, bamboo materials and crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

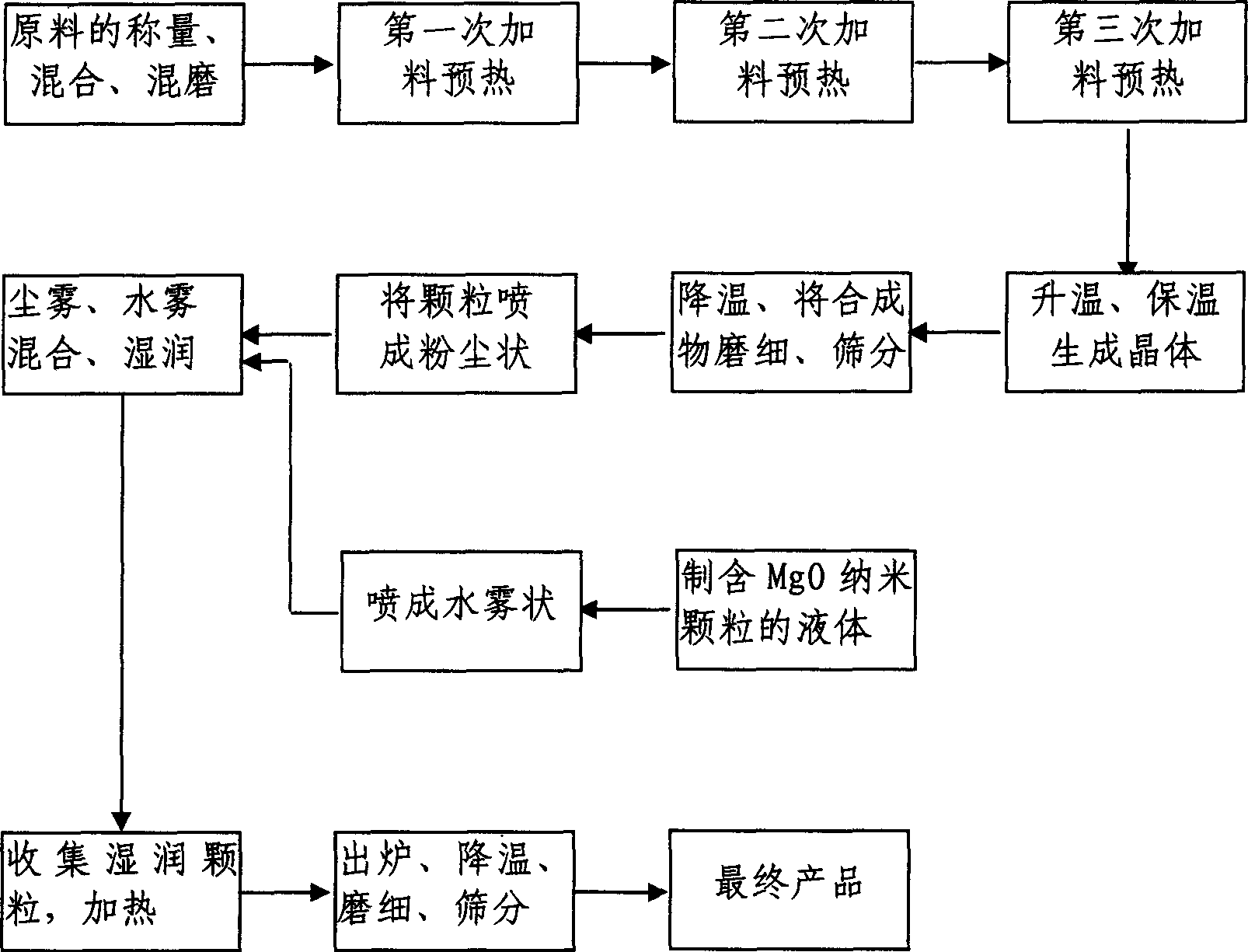

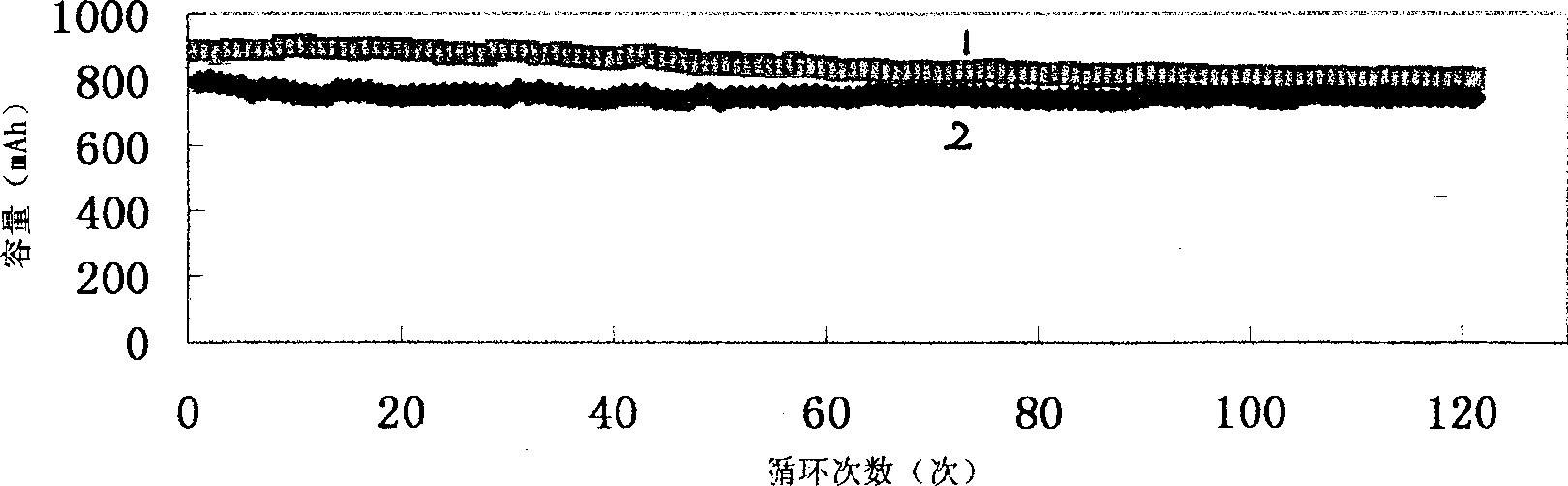

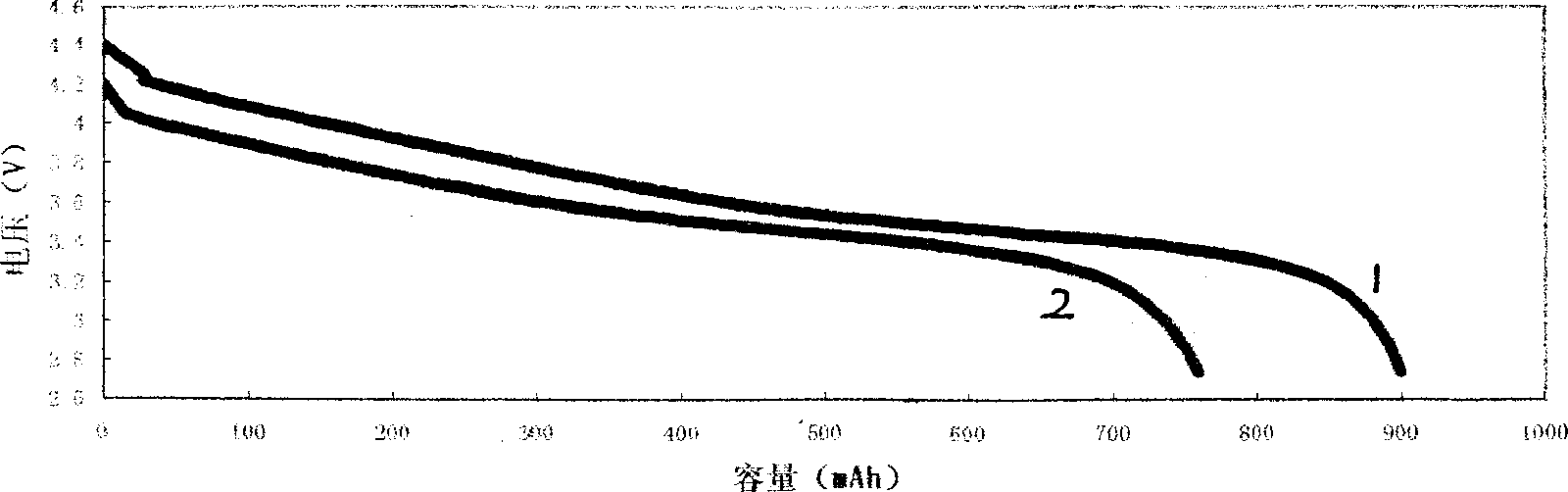

Doping and surface coating lithium nickel cobalt dioxide and its preparing method

This invention relates to lithium ion battery positive electrode mixture and surface nickel-to-cobalt acid lithium and its process method, which is characterized by the following: materials particle inner crystal core is LiNixCoyMgzO2 or LiNixCoyMnzO2; mixing Mg, Mn, or rare earth; outside surface layer is of nanometer MgO. The process method adopts three times adding and heating under 800 degrees temperature. The advantages of this invention embodies in crystal, structure, particle shape, large intensity and good flow and large capacity.

Owner:黎彦希

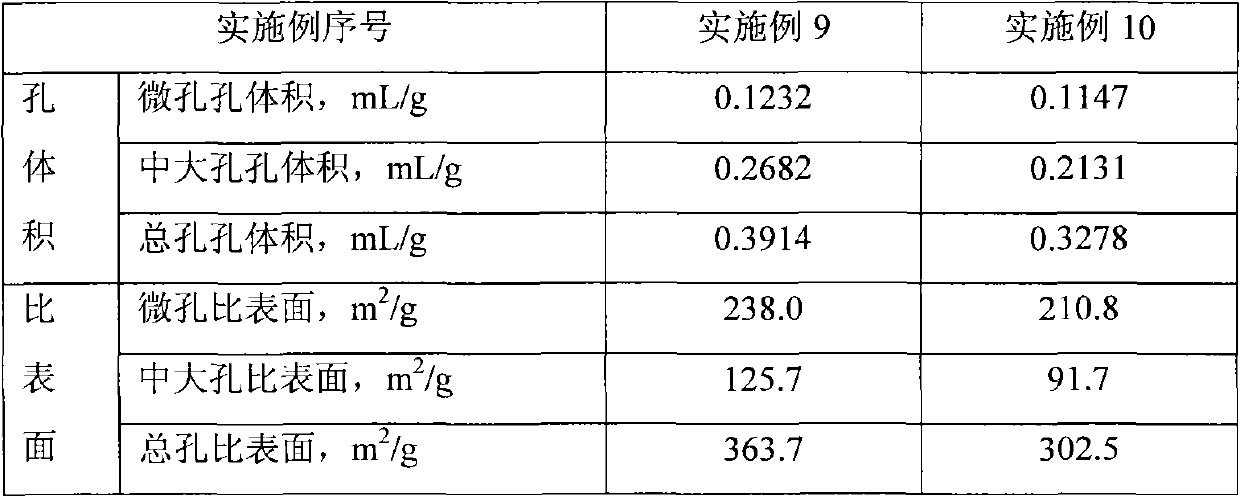

Method for improving pore structure of kaolin microsphere in-situ crystallization product

ActiveCN102019196AHigh molecular weightRegular structureMolecular sieve catalystsCatalyst activation/preparationPolyvinyl alcoholMicrosphere

The invention relates to a method for improving the pore structure of a kaolin microsphere in-situ crystallization product. The method comprises the following steps of: preparing kaolin spray microspheres with the particle sizes of between 20 and 110 mu m by using mixed kaolin grout by spray drying, wherein the mixed grout comprises kaolin, deionized water, a dispersant and an organic pore cannelforming template agent; the dispersant is sodium silicate or sodium pyrophosphate; and the organic pore cannel forming template agent is polyvinyl pyrrolidone or polyvinyl alcohol; baking the spray microspheres at the temperature of between 900 and 1,100 DEG C for 1 to 3 hours so as to obtain kaolin baked microspheres; mixing the kaolin baked microspheres with the mullite content of between 2 and12 percent, sodium silicate, a directing agent, solution of sodium hydroxide and deionized water; crystalizing the mixture at the temperature of between 90 and 95 DEG C for 16 to 36 hours; and filtering and drying so as to obtain a crystallization product which has a medium / large-pore structure and comprises a NaY molecular sieve. The crystallization product has a well-developed large-pore structure and the abrasion index of not more than 1.5 percent and comprises 20 to 50 percent of NaY molecular sieve.

Owner:PETROCHINA CO LTD +1

Method for preparing polyurethane-polyurea coated fertilizer

InactiveCN101747123ARegular structureHigh strengthFertiliser formsFertilizer mixturesPolyolAtmospheric pressure

The invention relates to a method for preparing polyurethane-polyurea coated fertilizer, comprising the following steps: dehydrating polyether polyol to obtain dehydrated polyether polyol, adding polyisocyanate to the dehydrated polyether according to the molar ratio of NCO to OH of 2-5, heating the temperature of the mixture of the dehydrated polyether and the polyisocyanate to 70-90 DEG C, making the mixture of the dehydrated polyether and the polyisocyanate react until the mass of NCO being 5-9 percent of the mass of the product of reaction, defoaming the product of reaction in vacuum to obtain -NCO-ended polyurethane prepolymer, filling fertilizer in a spray dryer, heating the fertilizer to 60 DEG C, mixing the polyurethane prepolymer with amine chain extender according to the mass ratio of 7-8:1 to obtain spraying liquid by controlling the fan frequency at 45 Hz, the nozzle atomization air pressure at 0.7-1.2 MPa, the inlet air temperature at 20-80 DEG C and the spray rate at 0.4-0.6 Kg / h, spraying the spraying liquid whose mass is 7-10 percent of the mass of the fertilizer on to the fertilizer, and curing the coating film to obtain the polyurethane-polyurea coated fertilizer.

Owner:晋盾防护(山西)科技有限公司 +1

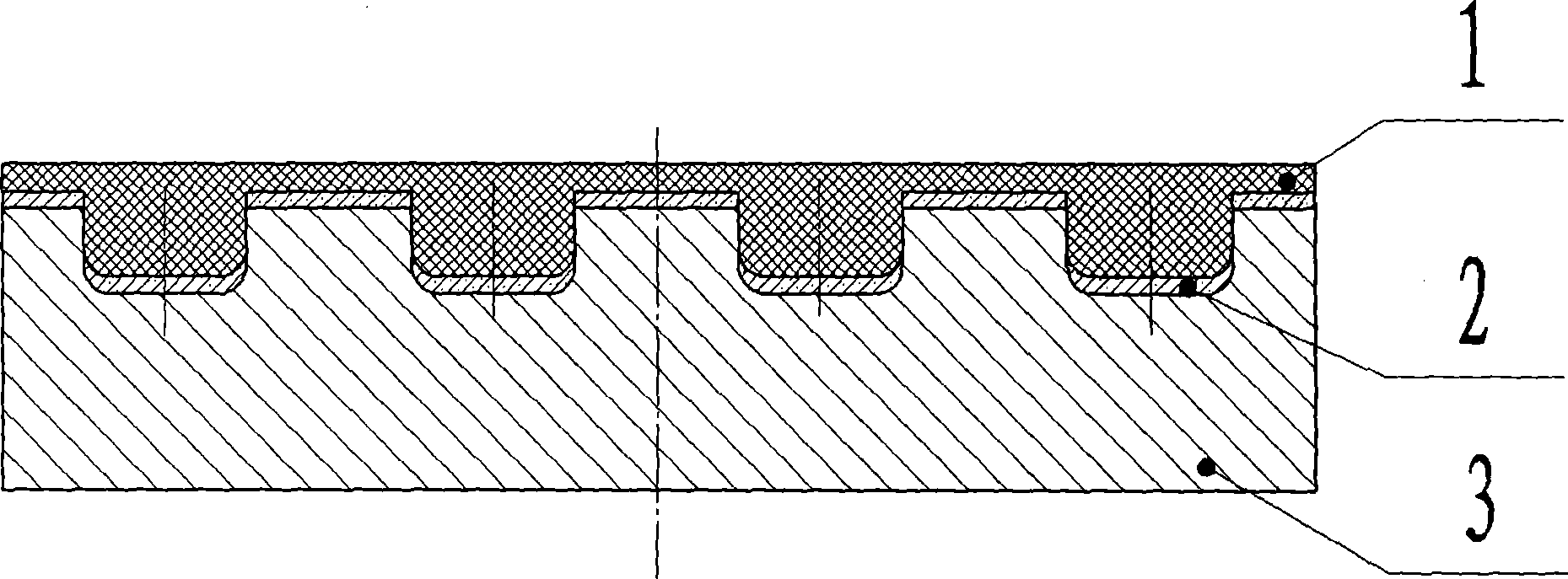

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

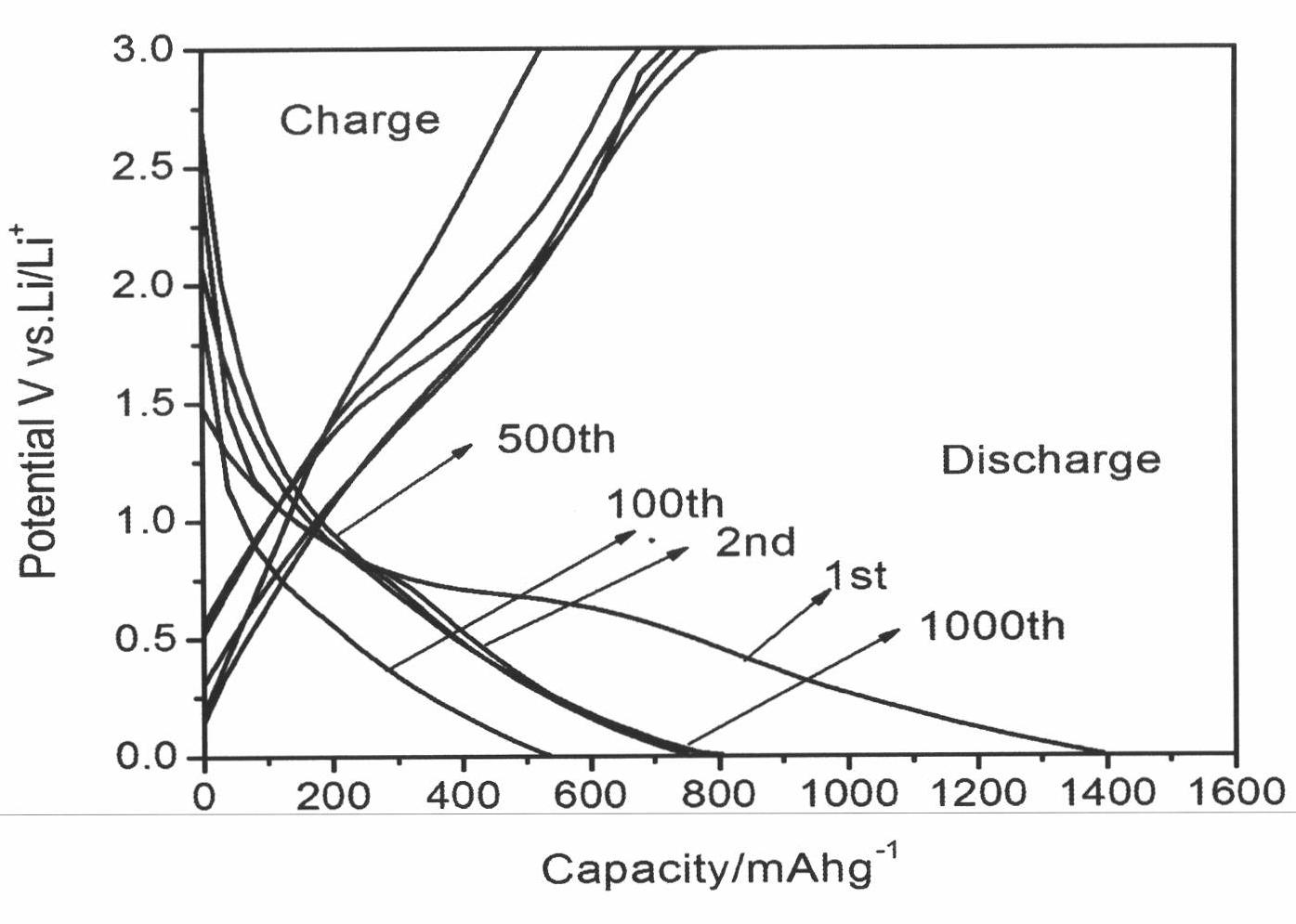

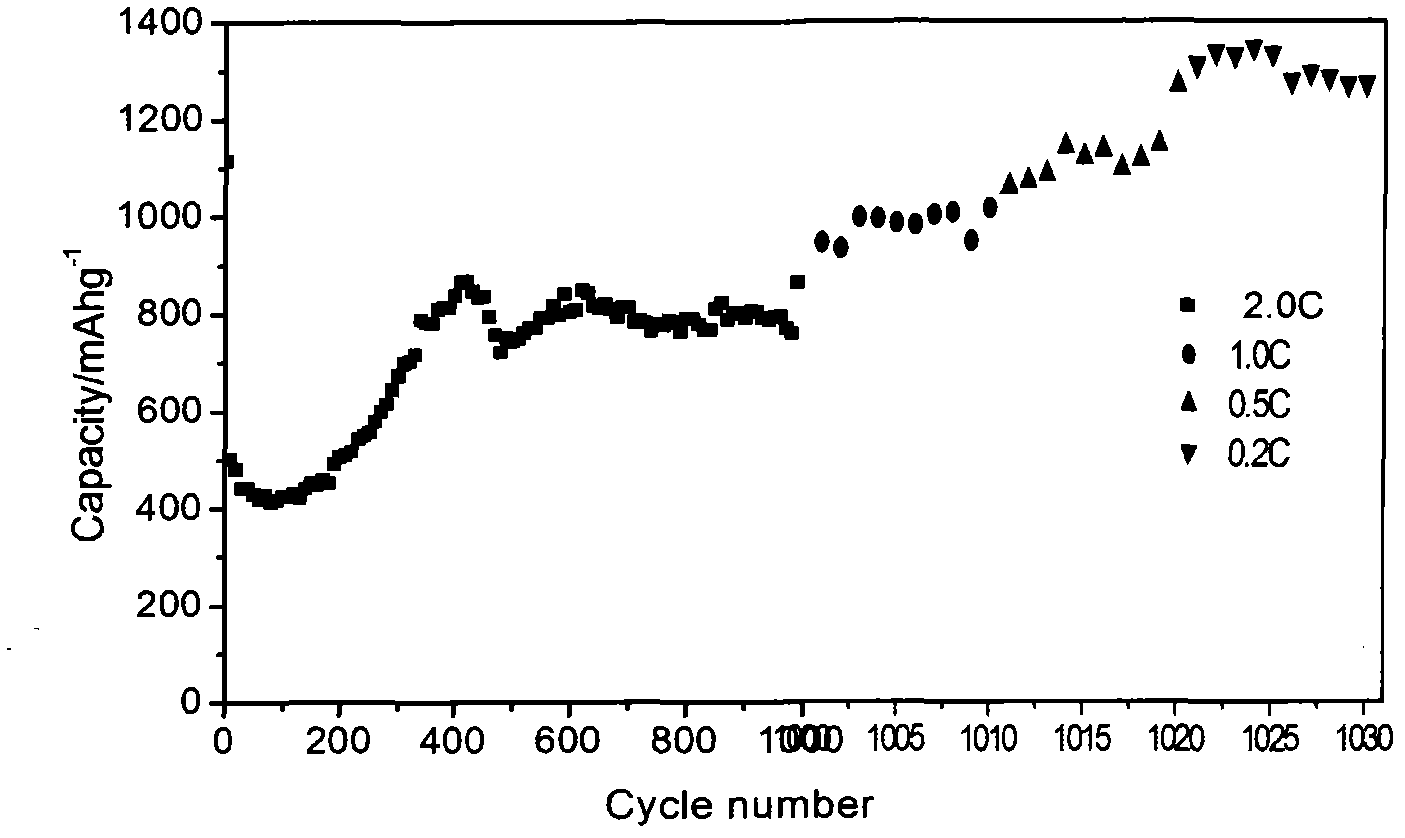

Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

InactiveCN102154739AControl diameterSolve reunionCell electrodesFilament/thread formingFiberCyclic process

The invention discloses a method for preparing lithium ion battery cathode material ZnFe2O4 / C nano fibers. The method has the advantages that: 1, the preparation process flow is short, the diameter of the nano fibers can be controlled more effectively, nano fiber precursors with regular structure are obtained, and the lithium ion battery cathode material ZnFe2O4 / C nano fibers with uniform structure are prepared by combining different change of two polymers in the calcining process; and 2, the prepared lithium ion battery cathode material ZnFe2O4 / C nano fibers are apparently nano fibers, the diameter of the nano fibers is about 200 to 400 nanometers, ZnFe2O4 nano granules are distributed in the continuous phase of carbon in the internal structure, and meanwhile, because of the carbon, the volume change in the electrode circulating process is greatly relieved, the problem of granule agglomeration in the circulating process is solved and the electrochemical circulating stability is improved.

Owner:XIANGTAN UNIV

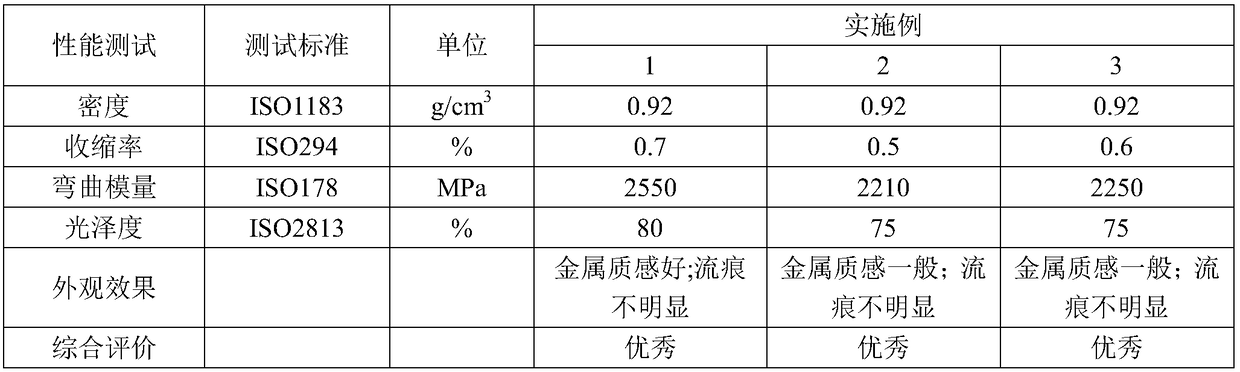

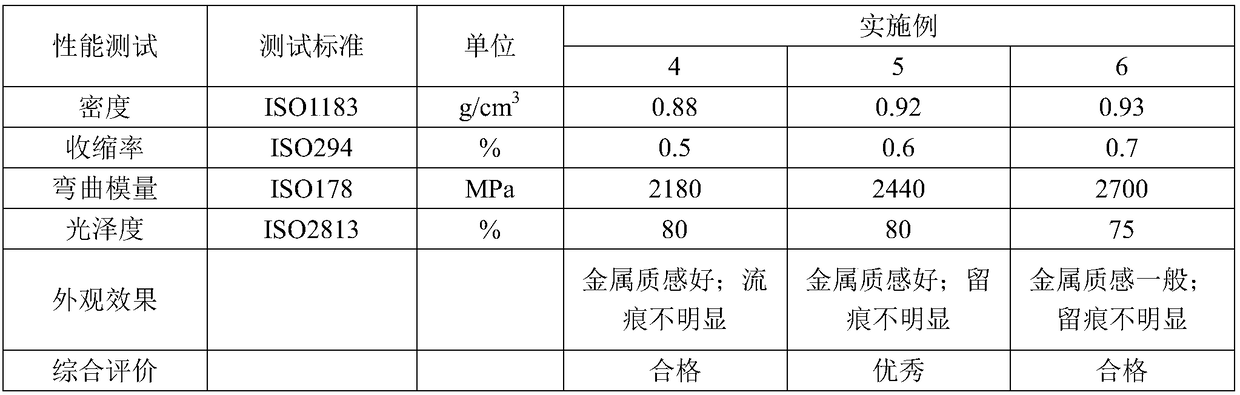

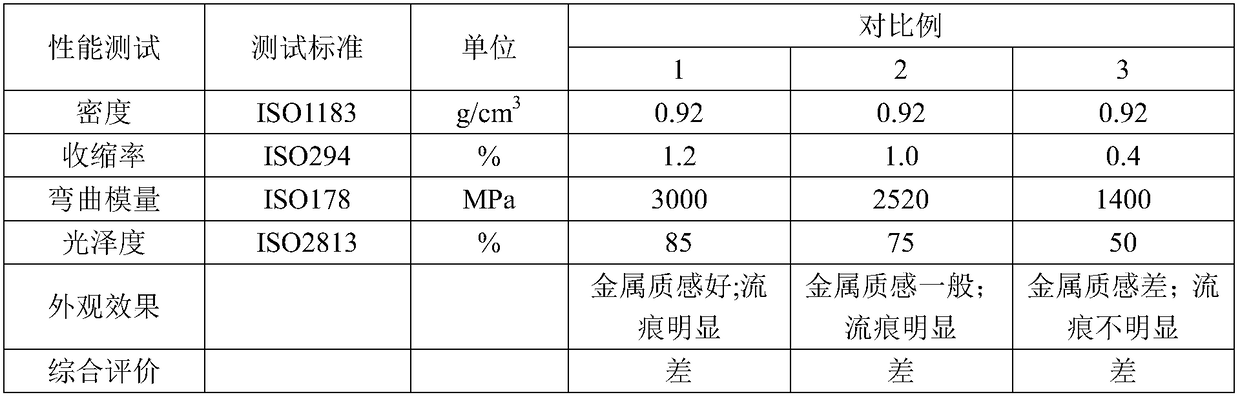

Low-density and low-shrinkage-rate silver metal texture polypropylene composite material and preparation method thereof

The invention discloses a low-density and low-shrinkage-rate silver metal texture polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises high-crystallized polypropylene, high-melt-value polypropylene, low low-shrinkage-rate polypropylene, hollow glass beads, ultra-white and ultra-fine talcum powder, toughening fillers, metal pigments, nano-zinc sulfide, hyperbranched resin, antioxidants and scratch-resistant agents. In the injection molding process of the free-spraying polypropylene composite material, obvious welding marks on the surface of the material are omitted, the appearance of the material approaches to spraying effects, components can be directly used, later spraying treatment is omitted, cost is saved, the material is green and environmentally friendly, the density of the material is much lower than that of common modified polypropylene, lightweight requirements of clients are met, the shrinkage rate of the material is lower than 0.5, the material can directly replace ABS (acrylonitrile butadiene styrene) in the field such as household electric appliance shells, secondary mold opening is omitted, and cost is saved.

Owner:WANHUA CHEM GRP CO LTD +1

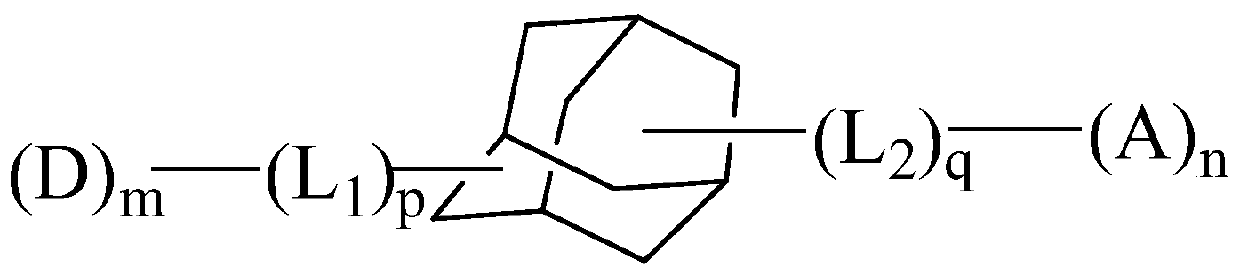

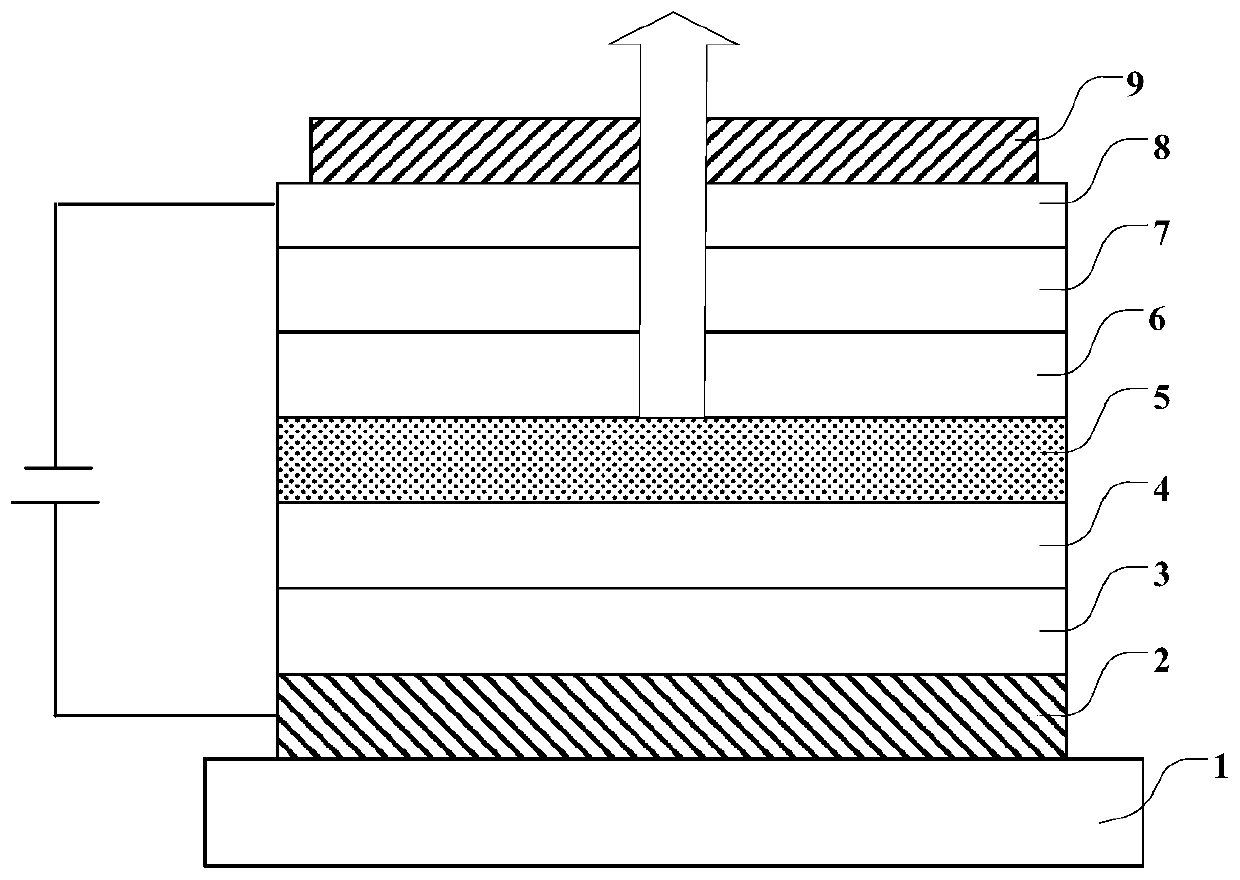

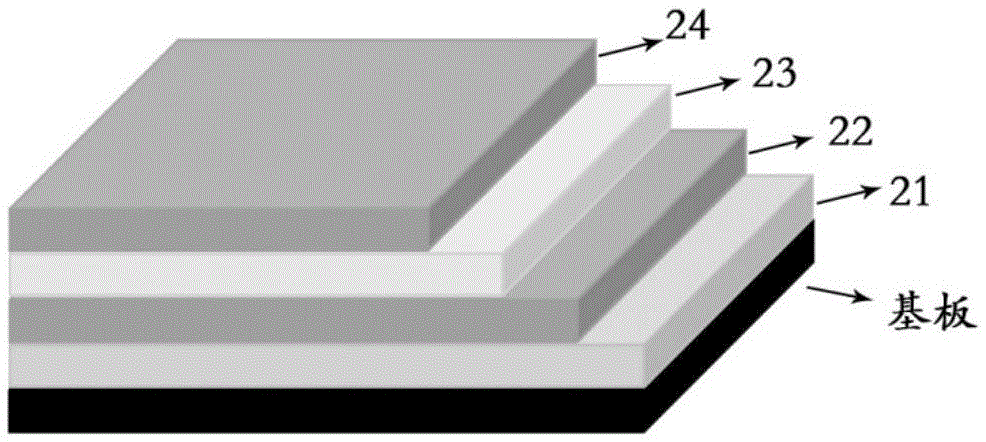

Compound, display panel and display device

PendingCN110156756AHigh luminous brightness and luminous efficiencyMacromolecule densityGroup 5/15 element organic compoundsSolid-state devicesAcridineElectron acceptor

The present invention relates to the technical field of OLED, and provides a light emitting main body material including an adamantane structure and having a structure represented by the formula (I).L1 and L2 are each independently selected from the group consisting mainly of a single bond, phenyl, naphthyl, and the like; electron donor D is mainly selected from that group consisting of carbazolegroup and derivatives thereof, diphenylamino groups and derivatives thereof, acridine group and derivatives thereof; electron acceptor A is mainly selected from nitrogen-containing heterocyclic substituents, cyano-containing substituent, and triarylboron substituents. D-(Pi)-sigma-(Pi)-A structure in the compound of the invention has bipolarity, and the intermediate sigma bond can effectively interrupt the charge transfer between electron donor D and electron acceptor A, so that the excited state is limited to the local excited state in the fragment of electron donor D or electron acceptor A,thus the compound has a small excited state dipole moment. When it is used as the main material of the light emitting layer of the OLED device, the efficiency roll-off of the blue light material canbe effectively reduced, and the luminous brightness and the luminous efficiency can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

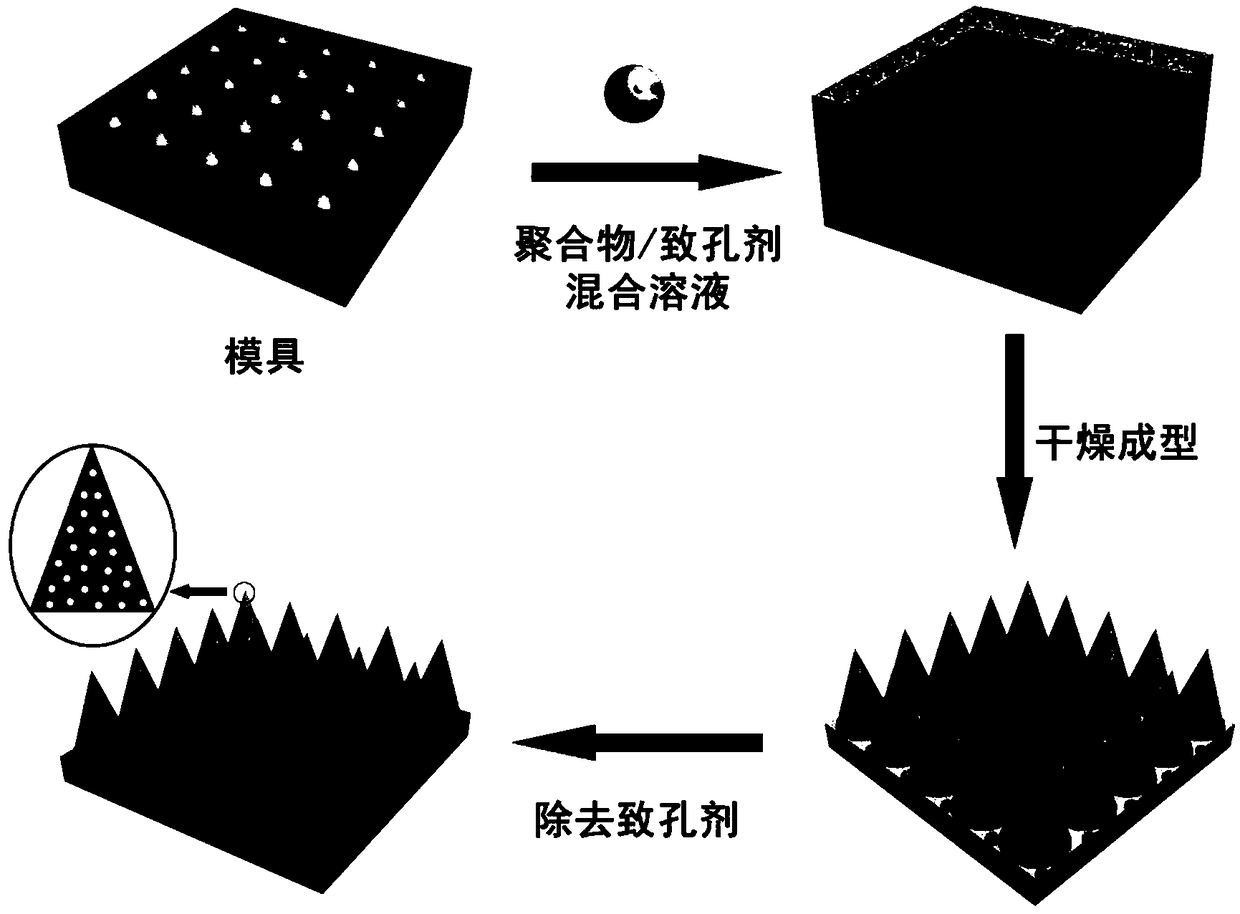

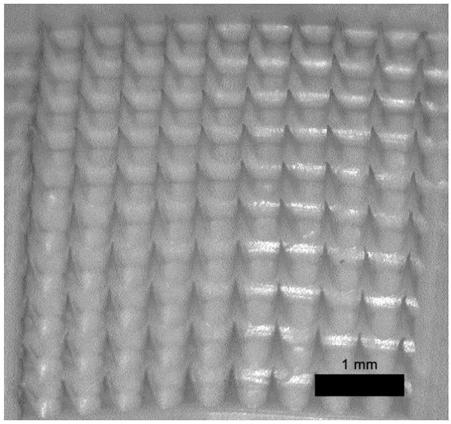

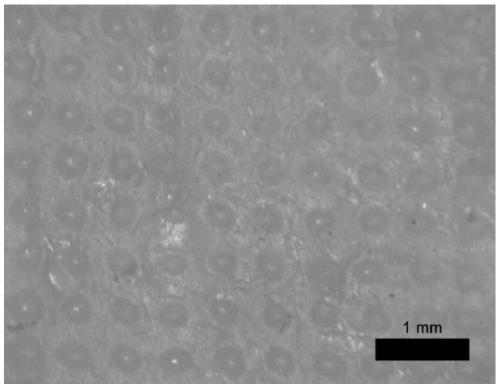

Method for preparing porous polymer micro needle by using template method and application thereof

InactiveCN109364366AOvercome the cumbersome preparation processOvercome the conditionsMicroneedlesPharmaceutical delivery mechanismTissue fluidHair growth

The invention discloses a method for preparing a porous polymer micro needle by using a template method and an application thereof. The method comprises the following steps of: (1) dissolving a polymer and a template agent in a solvent to prepare a polymer solution; (2) filling the polymer solution into a micro needle mould; (3) removing the solvent in the obtained micro needle mould to obtain a solid micro needle; (4) removing the template agent in the obtained solid micro needle to obtain the porous polymer micro needle. By improving the overall process flow design of the preparation method,the method can solve the technical problems of a complex preparation process, harsh conditions, a complicated process, high price, difficult control of the pore structure and size, difficult large-scale production and application and the like of the porous polymer micro needle, the obtained porous polymer micro needle can be used for tissue fluid extraction and transdermal administration, such asskin tissue fluid and blood extraction and transdermal administration of proteins, polypeptides and small molecular drugs in cosmetic, hair growth, immunity, treatment and other applications.

Owner:HUAZHONG UNIV OF SCI & TECH +1

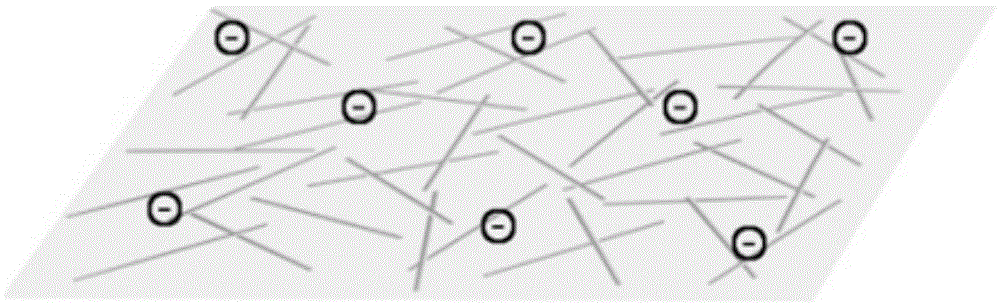

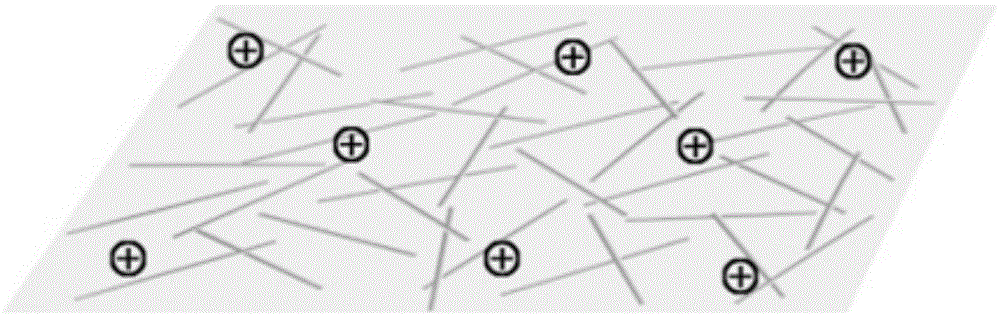

Metal nano wire transparent conductive film and preparation method thereof

InactiveCN105427917ARegular structureEvenly dispersedConductive materialMetal/alloy conductorsTransmittancePrecipitation

The invention discloses a metal nano wire transparent conductive film and a preparation method thereof. The method comprises the following steps: preparing two completely same metal nano wire suspending liquids, respectively adding electrolytes with opposite electric properties into the two suspending liquids to enable surfaces of metal nano wires in the two suspending liquids to respectively carry positive charge and negative charge, and afterwards, performing alternative precipitation to prepare the multi-layer metal nano wire film on the surface of a substrate through a spin coating method, a spray method, a scrape coating method or a dipping-coating method. According to the invention, the technical approach is simple, the operation is convenient, the cost is quite low, the effect of static interaction precipitation is taken into full consideration, and the uniformity of the metal nano wire film and the adhesiveness of the substrate are greatly improved. At the same time, the metal nano wire film is enabled to have quite good conductivity and light transmittance, can be applied to large-scale production, and can be applied to the photoelectric fields such as an organic light emitting diode (OLED), a solar battery, a sensor, a touch screen and the like as an electrode.

Owner:SHANGHAI JIAO TONG UNIV

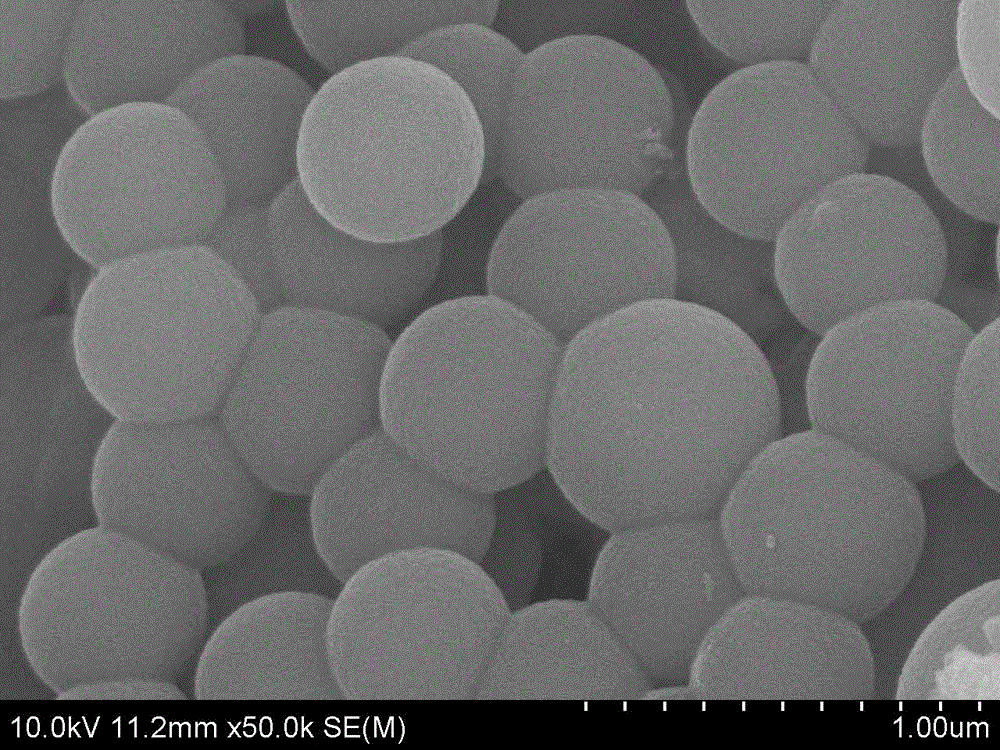

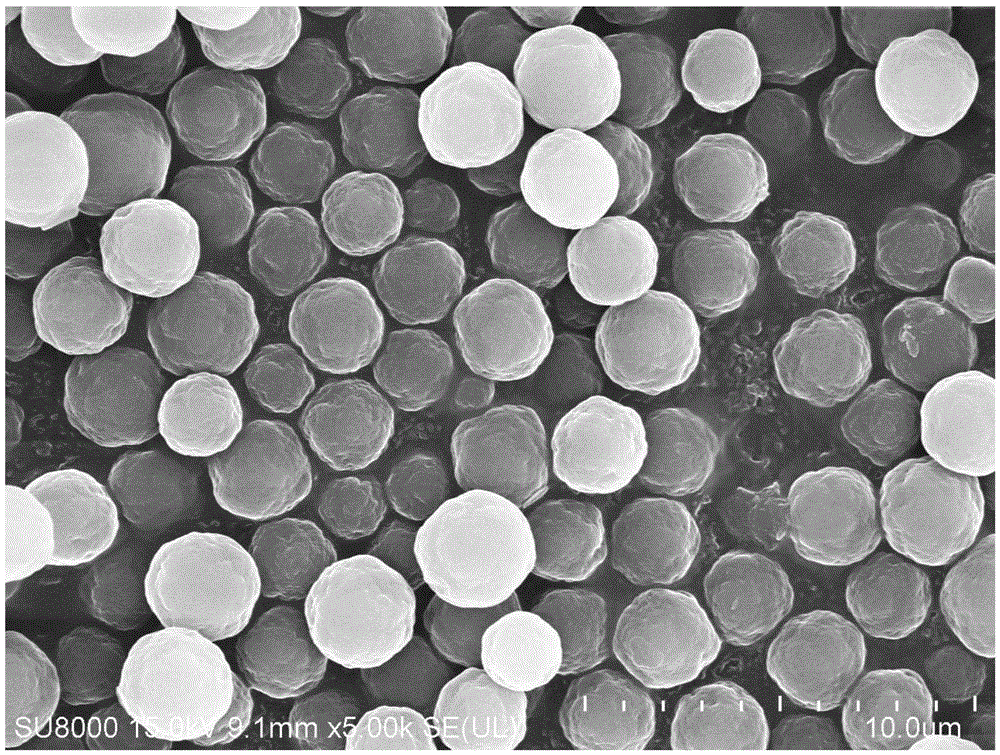

Method for preparing monodisperse carbon microspheres by using cane sugar as carbon source

The invention discloses a method for preparing monodisperse carbon microspheres by using cane sugar as a carbon source. According to the method, cane sugar is used as the silicon source, sodium polyacrylate is used as a dispersing agent, and after the hydrothermal reaction at the certain temperature, the monodisperse micron-sized carbon sphere is obtained. A one-step hydrothermal method is adopted in the method for preparing the monodisperse carbon microspheres, and sodium polyacrylate is used as a dispersing agent, and has an important effect on the particle diameter, the dispersity and the surface appearance of the carbon microspheres; the carbon microspheres are solid and have relatively rough surfaces, and can obtain lots of aperture passages through simple high temperature processing; the obtained carbon sphere particle diameter range is 1-6 microns, and the carbon sphere particle diameter can be adjusted controllably through experimental parameters such as cane sugar concentration, the reaction temperature and the reaction time; the obtained carbon sphere can be applied to the fields of liquid chromatograph stationary phases, super capacitors, protein separation, enrichment and removal of organic matter in water, and the like.

Owner:杭州飞山浩科技有限公司

Method for preparing color-adjustable gel photonic crystal film

InactiveCN104389024AColor adjustableRegular structurePolycrystalline material growthSingle crystal growth detailsPhotonic crystalMicrosphere

The invention provides a method for preparing a color-adjustable gel photonic crystal film. According to the method, by strictly controlling the concentration of PS (Polystyrene) microspheres and the volume ratio of PS microspheres to a precursor solution, the matching of the self-assembly rate of the PS microspheres and the polymerization rate of the precursor solution is adjusted and controlled at a low temperature, the PS microspheres are self-assembled into gel crystals having an ordered structure and meanwhile, hydrogel particles formed by polymerization of precursor solution are filled in gaps of the gel crystals so as to form a gel crystal-hydrogel compound structure, and after PS is removed, the color-adjustable gel photonic crystal film having a reverse opal structure is formed. The gel photonic crystal film having the inverse opal structure prepared by a co-deposition method has the characteristics of regular structure and three-dimensional ordered arrangement.

Owner:JIANGNAN UNIV

Process for producing high-stability central-hole material Cu-Zn-Al2O3, and application of the same in producing mellow wine dehydrogenating catalyst

InactiveCN101269331AGood thermal stabilityLarge specific surface areaCatalyst carriersCarbonyl compound preparation by oxidationChemistryOrganic synthesis

The invention discloses a synthetic method of a mesoporous material Cu-Zn-Al2O3 with high stability and the application in making an alcohol dehydrogenation catalyst, and belongs to the technical field of organic synthesis; the mesoporous material Cu-Zn-Al2O3 taking salt of copper, zinc, aluminum as raw materials, surfactants as templates, is synthesized at one step under a neutral or alkaline condition. The mesoporous material Cu-Zn-Al2O3 is used as a carrier in the preparation of the alcohol dehydrogenation catalyst, other Cu and Zn are loaded in the holes of the mesoporous material through sedimentation; while the masterbatch is made into a novel alcohol dehydrogenation catalyst after washing, drying, granulating, roasting and molding. Compared with the traditional catalyst made by coprecipitation method, the catalyst has the advantages of high catalytic activity, good product selectivity, etc.

Owner:YANTAI UNIV +1

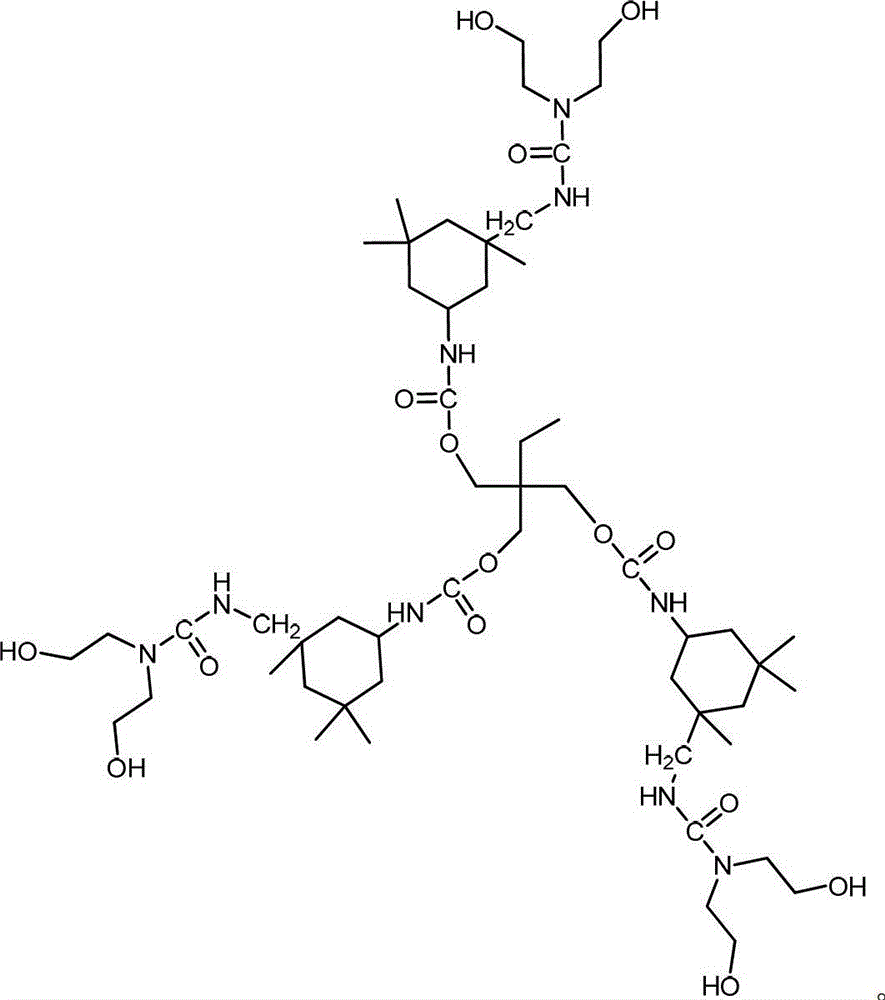

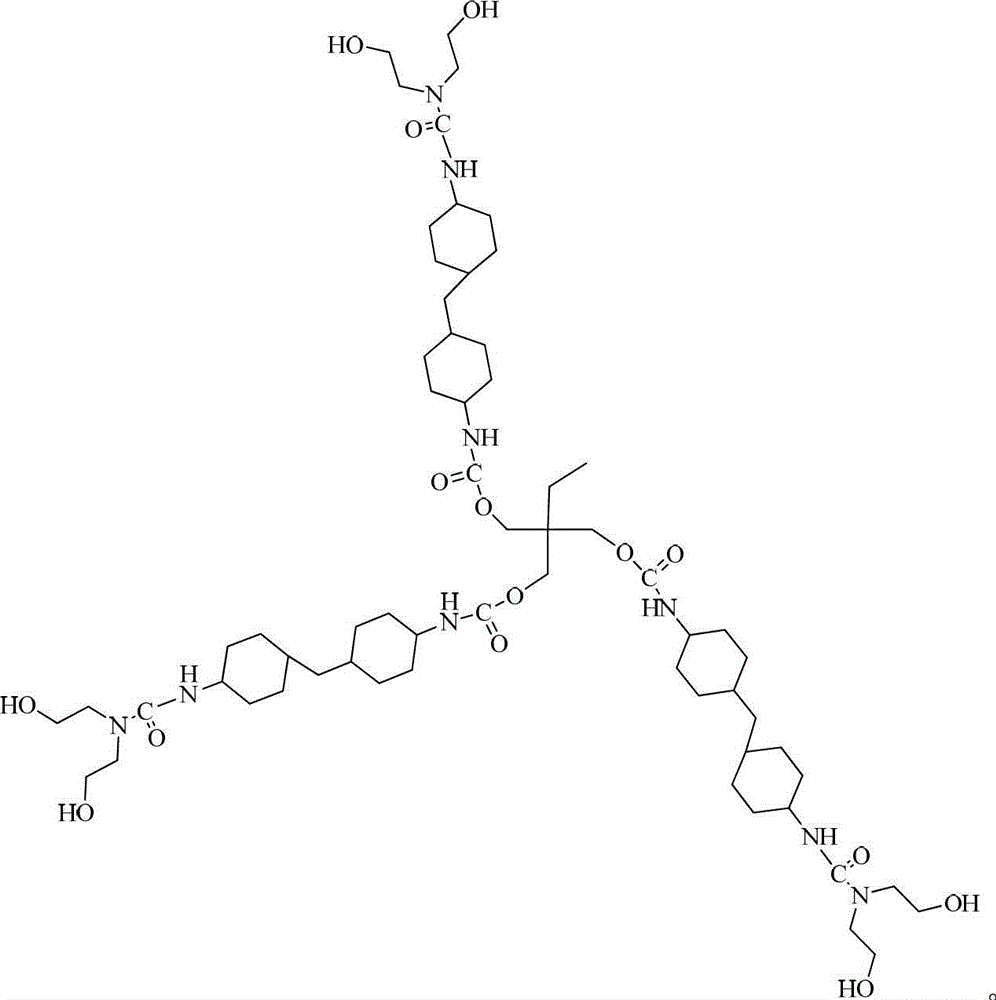

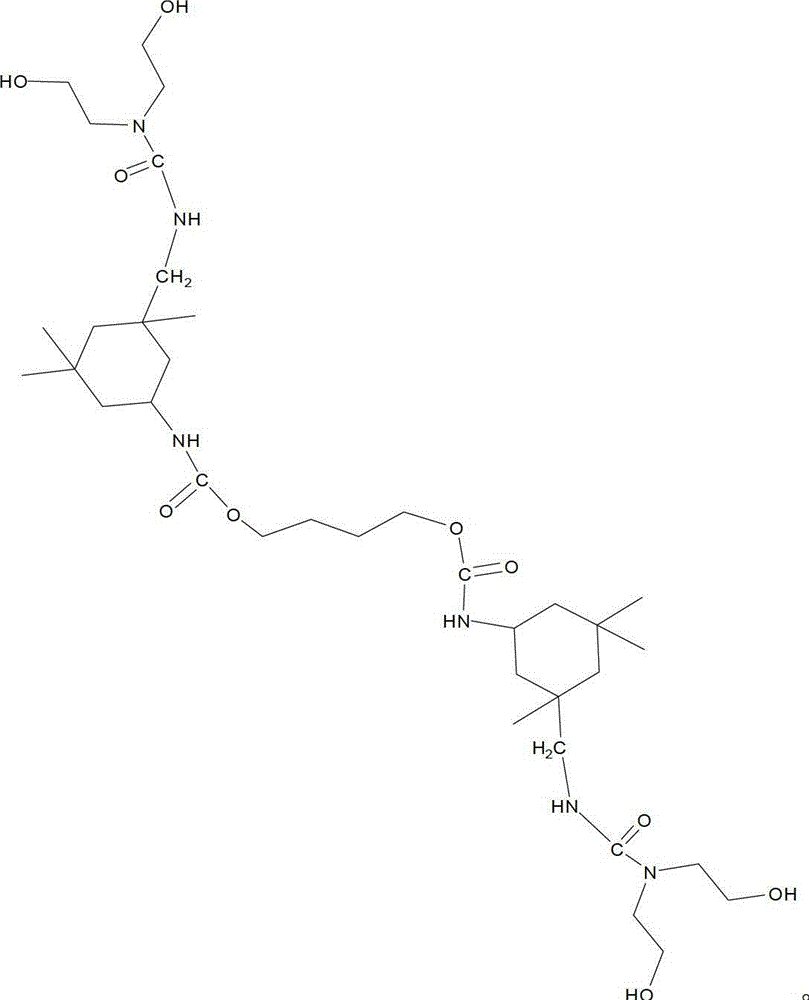

Preparation method of hydroxyl-terminated hyperbranched polyurethane

The invention relates to a preparation method of hydroxyl-terminated hyperbranched polyurethane. The operation steps include that 1 hydroxyl-terminated micromolecule polyhydric alcohol is dissolved in a non-proton organic solvent to obtain a hydroxyl-terminated micromolecule polyhydric alcohol solution; 2 the temperature of diisocyanate is raised to 70-90 DEG C, the hydroxyl-terminated micromolecule polyhydric alcohol solution is added, catalyst is added, and a reaction is conducted to obtain first generation hyperbranched prepolymer a1; and 3 the temperature of the first generation hyperbranched prepolymer a1 and di-alkanolamine is reduced to 0-15 DEG C, the temperature is kept, a reaction is conducted after blending, and products are separated and purified through precipitator and vacuum-dried to obtain first generation hydroxyl-terminated hyperbranched polyurethane A1. A synthesizing process is good in controllability, and the synthesized hyperbranched polyurethane is high in purity and neat in structure, contains large amount of terminated hydroxyl and is suitable for being used as a biological medicine carrier, a cross-linking agent, a viscosity modifier, a thermosetting material curing agent, a phase solubilizer, a rheological agent, thixotrope, a nucleating agent and the like.

Owner:ANHUI UNIVERSITY +1

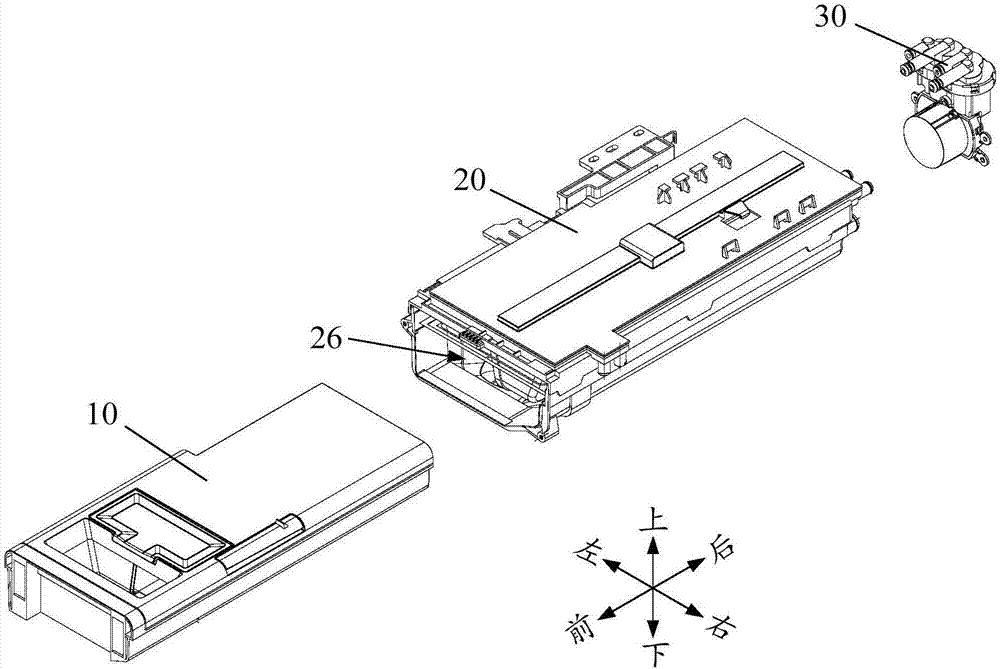

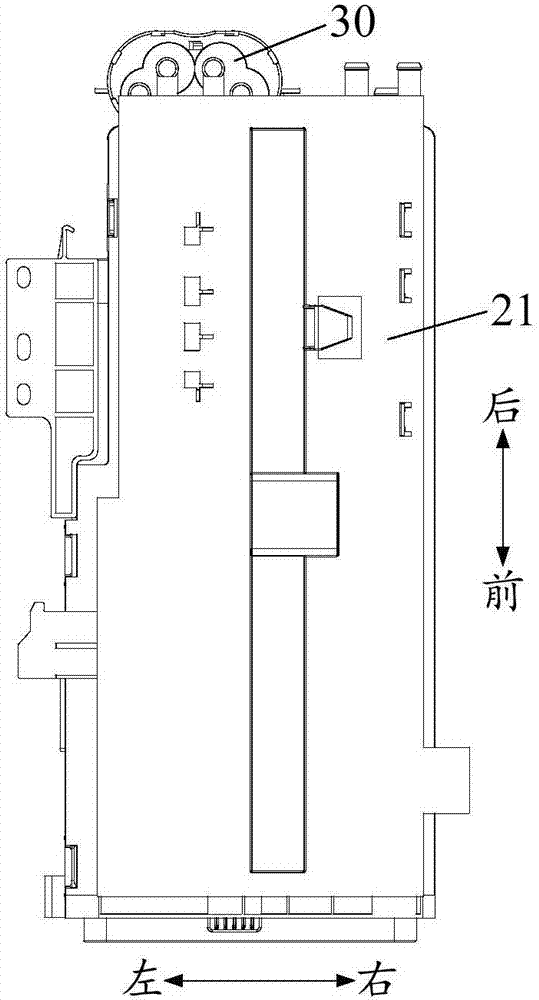

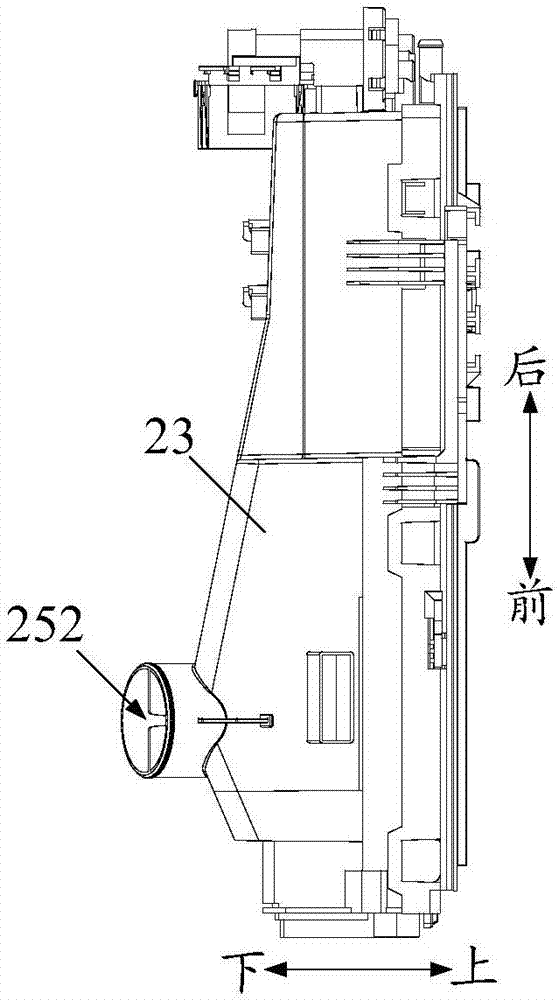

Detergent dispensing device and washing machine

ActiveCN107385800AAvoid enteringThere will be no pollution of the user's household water sourceOther washing machinesTextiles and paperWater sourceWater flow

The invention provides a detergent dispensing device and a washing machine. The detergent dispensing device comprises a detergent box component, a dispenser box component and a pumping component. The detergent box component is internally provided with a water flow channel and a mixing chamber. The water flow channel is provided with a water inlet and an automatic dispensing and flushing hole, and the mixing chamber is provided with a flushing inlet communicated with the automatic dispensing and flushing hole and a common outlet communicated with an inner barrel of the washing machine. The dispenser box component is mounted on the detergent box component and internally forms a storage chamber, and the storage chamber is provided with a liquid pumping outlet. A delivery inlet of the pumping component is communicated with the liquid pumping outlet, and a delivery outlet of the pumping component is communicated with the mixing chamber and used for feeding dispensed detergent in the storage chamber into the mixing chamber. The detergent dispensing device delivers water flow and dispensed detergent into the mixing chamber separately and independently so as to avoid the detergent entering a water inlet pipe, so that the condition that the detergent causes pollution to the domestic water source of households is avoided during backflow.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

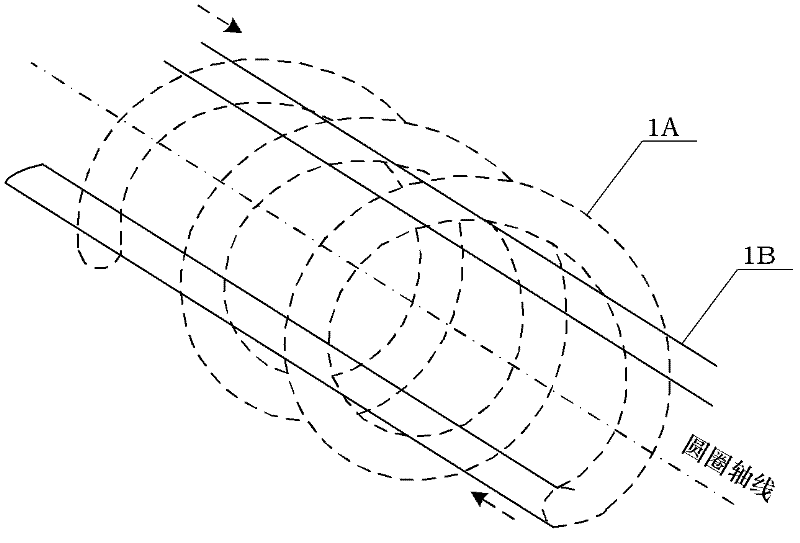

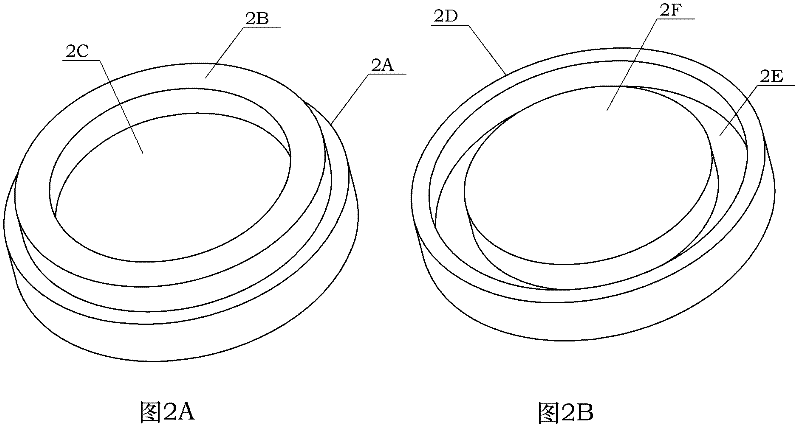

Method for manufacturing damping structural piece of aviation engine supporting system

InactiveCN102644686AWith shape memoryBoth featuresHigh internal friction springsAviationMetal rubber

The invention discloses a method for manufacturing a damping structural piece of an aviation engine supporting system; a shape memorizing alloy wire is manufactured into metal rubber through the combined processes of manufacturing an elastic wire at low temperature, heat setting, winding and full-constraint heat setting; and the damping structural piece which is manufactured through the method has a shape memorizing effect and a variable rigidity characteristic. According to the method for manufacturing the damping structural piece of the aviation engine supporting system, a damping material in the metal rubber structure is integrated with a shape memorizing alloy, and a novel metal structural functional material with the advantages of the metal rubber and the shape memorizing alloy is developed. The material has good damping performance, high deformation capability and high bearing capability, and has the advantages of active and controllable elastic modulus, strong environment adaptability and stable and reliable structure. Because the advantages of the metal rubber and the shape memorizing alloy are integrated, the method can be applied in aviation engine rotor supporting and a non-peak rotor can be realized.

Owner:BEIHANG UNIV

Gold nanorod array and preparation method and application thereof

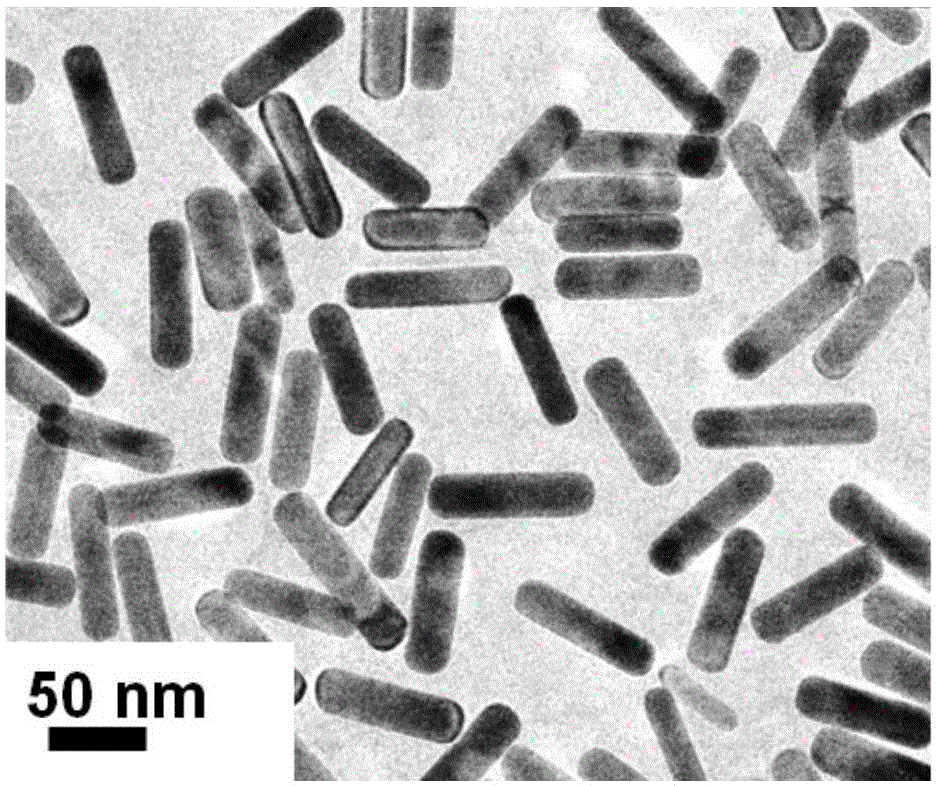

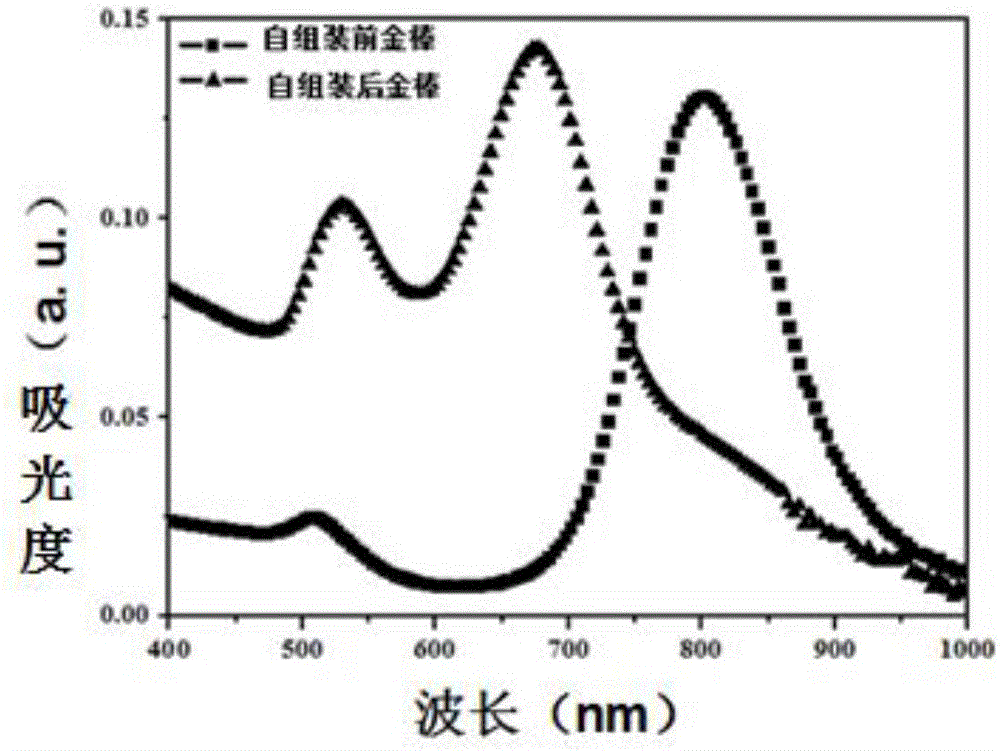

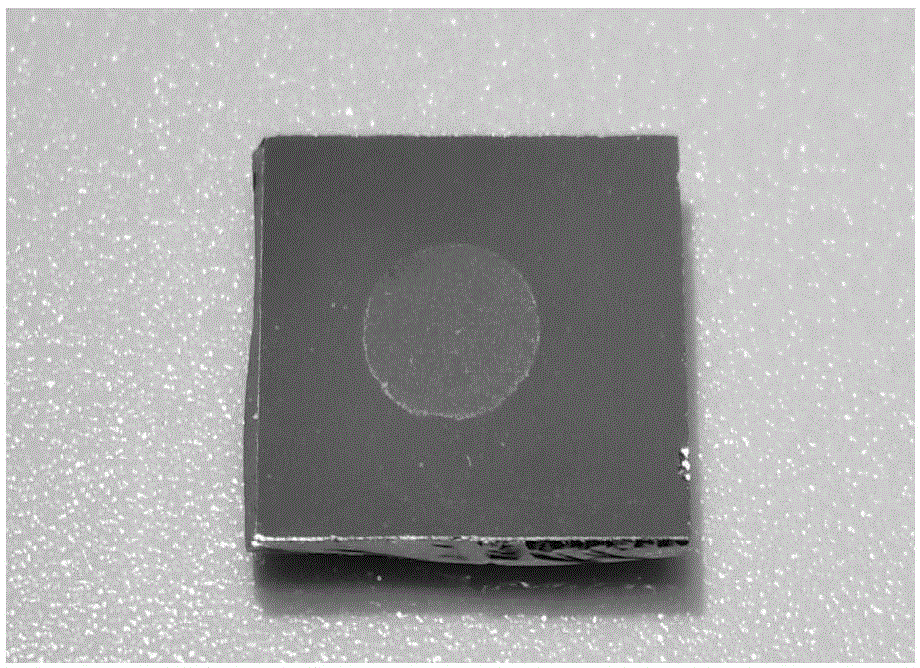

ActiveCN104999071AEfficient self-assemblyRegular structureRaman scatteringNanotechnologyGold nanorodPlanar substrate

The invention discloses a preparation method of a gold nanorod array. The method includes the steps that a gold nanorod aqueous solution modified by cetyl trimethyl ammonium bromide (CATB) is prepared; the final concentration of gold nanorods and the final concentration of the CATB are adjusted to be 0.2-0.6 nmol / L and 0.5-2 mmol / l respectively; sulfhydryl compounds are added and stirred, and a mixed solution can be obtained; the final concentration of the sulfhydryl compounds is 0.01-0.2 mmol / L; after being concentrated, the mixed solution is dripped to a hydrophilic planar substrate; and the gold nanorod array is obtained after natural drying. The preparation method of the gold nanorod array is easy to operate and mild in condition. The prepared gold nanorod array is regular in structure and at the macroscopic millimeter level; and evenly-distributed SERS hot spots are arranged on the surface of the gold nanorod array, and therefore the gold nanorod array can serve as an SERS enhanced substrate easily. The invention further provides the gold nanorod array and application thereof.

Owner:武汉中科先进材料科技有限公司

Preparation method of ordered graphene porous membrane

ActiveCN104229782AWide variety of sourcesConvenient sourceHybrid/EDL manufactureSupercritical dryingPtru catalyst

The invention discloses a preparation method of an ordered graphene porous membrane. The preparation method comprises the following steps: mixing 1 part by weight of graphene or graphene oxide with 10-1000 parts by weight of water to obtain a mixture; then, squeezing the mixture in a preparation device with a straight outlet, freezing the mixture in liquid nitrogen, performing freeze-drying or supercritical drying on the frozen mixture to obtain the ordered graphene porous membrane. The obtained graphene porous membrane has low density, high porosity, a controllable pore size, excellent mechanical performances and good toughness, and can be used for a plurality of different fields such as energy devices, water treatment, loading of various catalysts and electrochemical sensors.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Image processing method, device, storage medium, and mobile terminal

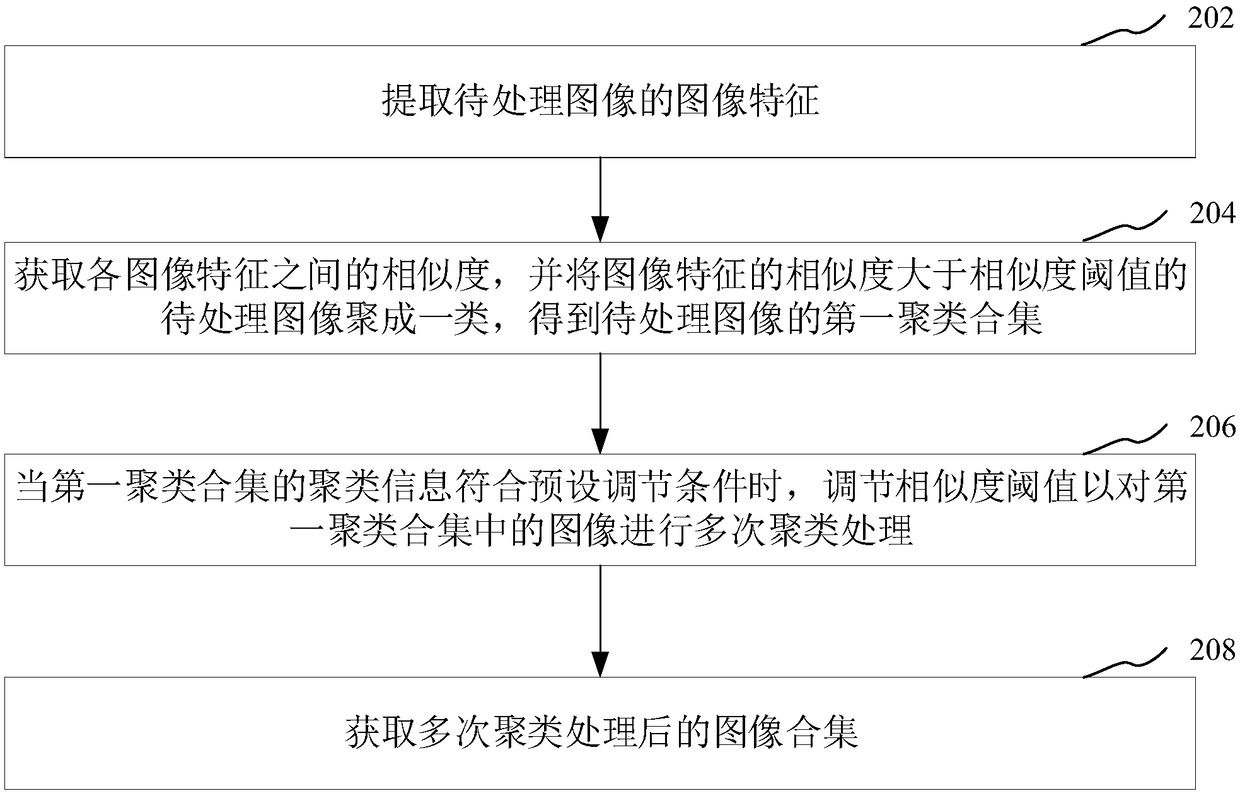

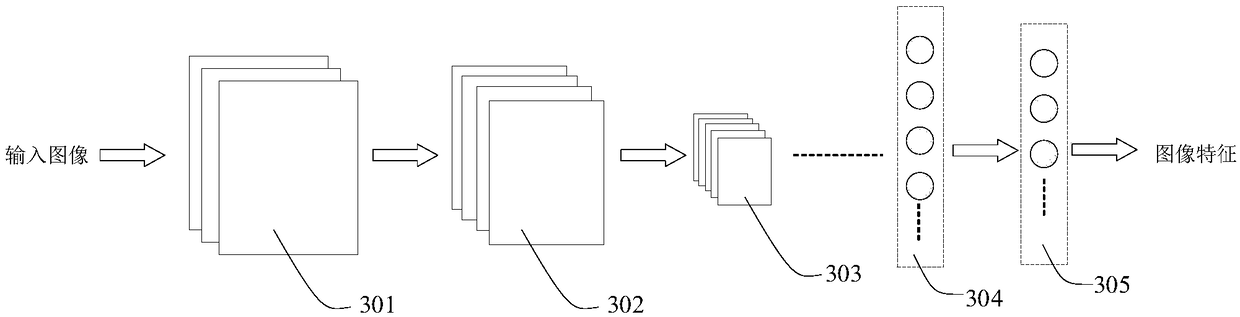

InactiveCN109063737AClassification hierarchy is clearRegular structureCharacter and pattern recognitionPattern recognitionImaging processing

The present application relates to an image processing method, an apparatus, a storage medium and a mobile terminal. The processing method comprises the following steps of: extracting image features of an image to be processed; Acquiring similarities between the image features, clustering images to be processed whose similarities are greater than a similarity threshold value into a class, and obtaining a clustering composite set of the images to be processed; Adjusting the similarity threshold to perform a plurality of clustering processes on the images in the first clustering set when the clustering information in the first clustering set satisfies a preset adjustment condition; Gets the combined set of images after multiple clustering processing. The image processing method makes the image classification hierarchy clear and the structure regular by clustering for many times, facilitates the user to select images, and improves the user experience degree.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for preparing high-strength gypsum by adopting atmospheric pressure solution method

ActiveCN103964483AWide variety of sourcesSimple equipmentCalcium/strontium/barium sulfatesPhysicsOrganic acid

The invention provides a method for preparing high-strength gypsum by adopting an atmospheric pressure solution. The method comprises the following steps: preparing a composite chloride salt solution with a mass concentration of 5-30 %; stirring and heating the composite chloride salt solution to 65-96 DEC G and keeping the constant temperature stably for 30 min; then, adding flue gas desulfurization gypsum with the mass concentration of 5-20 % and organic acids crystal modifier with the mass concentration of 0.1-1.8 % to the composite chlorate solution; controlling the reaction temperature and keeping the reaction temperature at the pre-arranged temperature; in a reaction condition of 5 to 8 pH value and 0.5-6 h stirring time, quickly filtering the mixed slurry with hot water of 95-98 DEC G; obtaining the high-strength gypsum after drying and powder grinding. According to the invention, building materials recycling of the desulfurized gypsum and the high-strength gypsum is realized; the wastes are changed into valuable, so that the method provided by the invention has remarkable social, environmental and economic benefits; pressure vessels are not required during the technological process; the energy consumption is low; the equipment is simple; the operation is convenient; the reaction conditions are easy to control; the obtained product is uniform in crystal structure and stable in quality; the standard consistency of water is 43%; the rupture strength reaches 5.34 M pa within two hours; the absolutely dry strength of the high-strength gypsum reaches 30.21 M pa.

Owner:WUHAN UNIV

Lignin graft copolymerization compound adsorption resin and preparation method thereof

InactiveCN103301821ARegular structureHigh molecular weightOther chemical processesSulfonatePolymer science

The invention belongs to the technical field of adsorption resin and particularly relates to lignin graft copolymerization compound adsorption resin and a preparation method thereof. The compound adsorption resin is formed by acrylic amide, maleic anhydride, sodium lignin sulfonate, chitosan, potassium peroxodisulfate and N,N'-methylene bisacrylamide. According to the method, a graft copolymerization short chain is introduced on a lignin molecular chain so that the structure of lignin is more regular and the molecular weight of the lignin is more greatly improved. The compound adsorption resin has a certain water adsorption performance and mainly aims at a multi-element mixed metal ion solution system to improve the adsorption amount of metal ions and the competitive adsorption selection of the metal ions.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

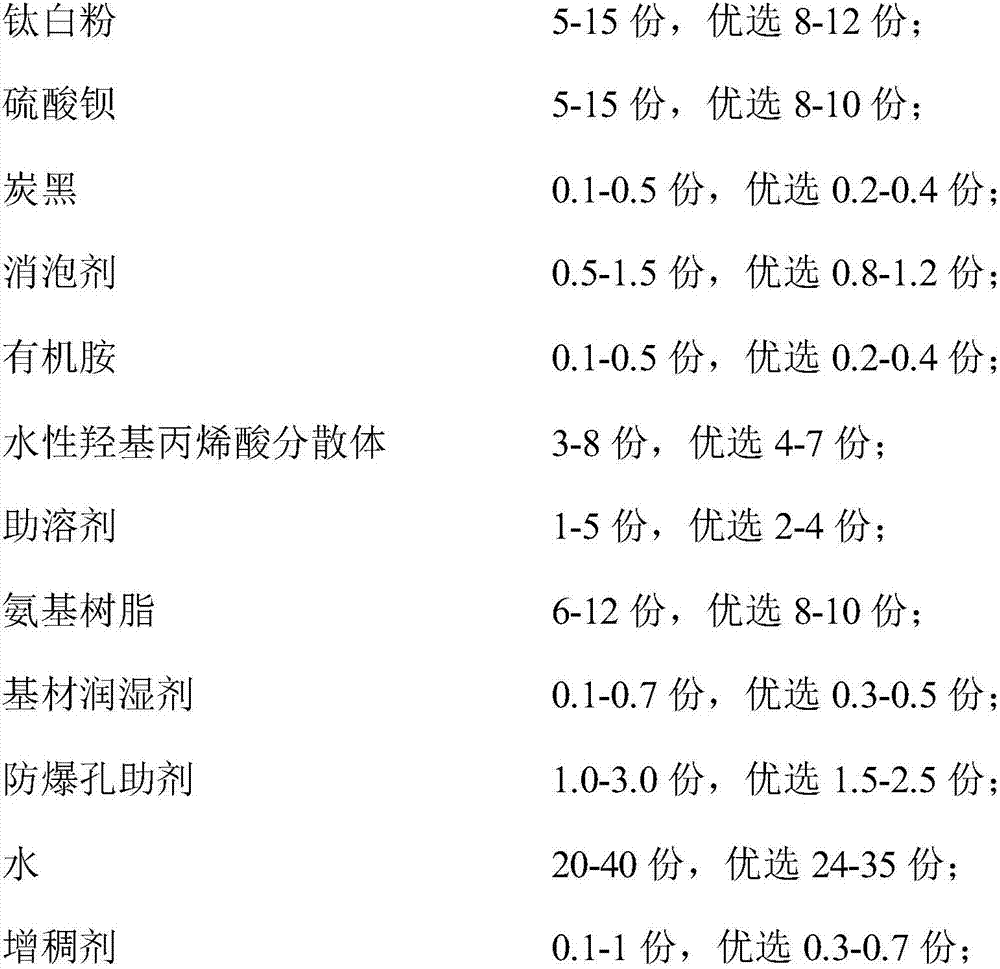

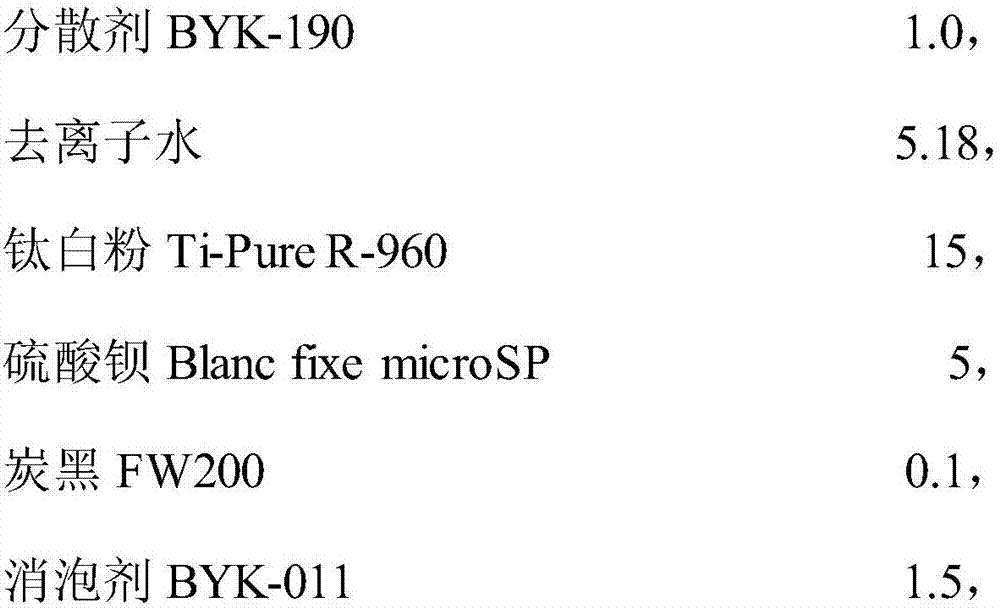

A waterborne automobile coating composition and a preparing method and applications thereof

InactiveCN107099238AImprove stone impact resistanceIncreased chemical resistancePolyurea/polyurethane coatingsPolyesterCooking & baking

A waterborne automobile coating composition is provided. The composition is prepared from, by weight, 20-60 parts of a waterborne polyurethane dispersoid, 1.0-3.5 parts of a dispersing agent, 5-15 parts of titanium dioxide, 5-15 parts of precipitated barium sulfate, 0.1-0.5 part of carbon black, 0.5-1.5 parts of a defoamer, 3-8 parts of a waterborne hydroxy acrylic acid dispersoid, 0.1-0.5 part of an organic amine, 6-12 parts of amino resin, 0.1-1 part of a substrate wetting agent, 1-3 parts of an explosion-proof auxiliary agent, 1-5 parts of a cosolvent, 20-40 parts of deionized water and 0.1-1 part of a thickening agent. The waterborne polyurethane dispersoid is a compound of a polycarbonate-type waterborne polyurethane dispersoid having hydroxy groups and a polyester-type waterborne polyurethane dispersoid preferably. The coating composition has excellent resistance to rock crash, and can meet requirements on an automobile coating process including three times of coating and one time of baking, namely a 3C1B process, in the field of environment protection.

Owner:WANHUA CHEM GRP CO LTD

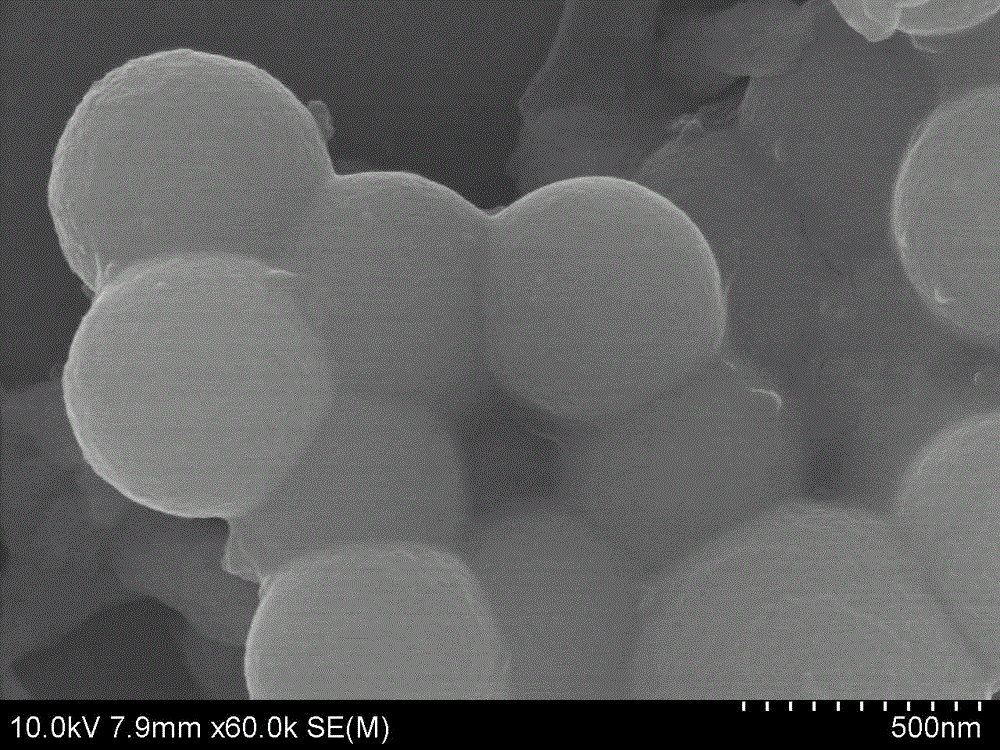

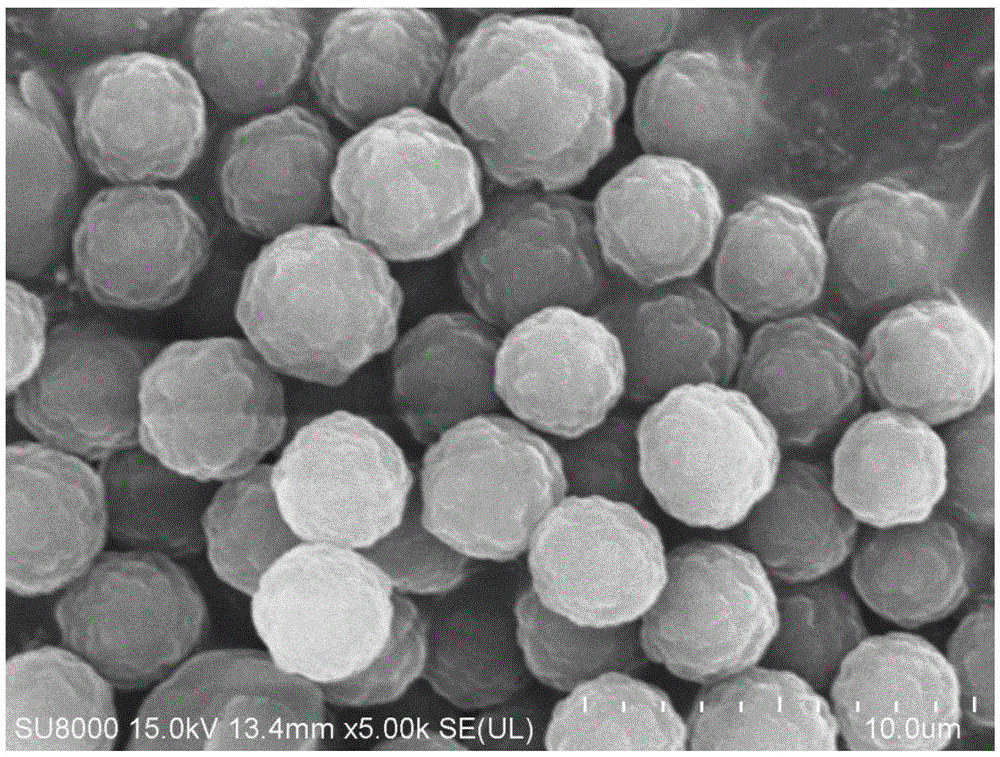

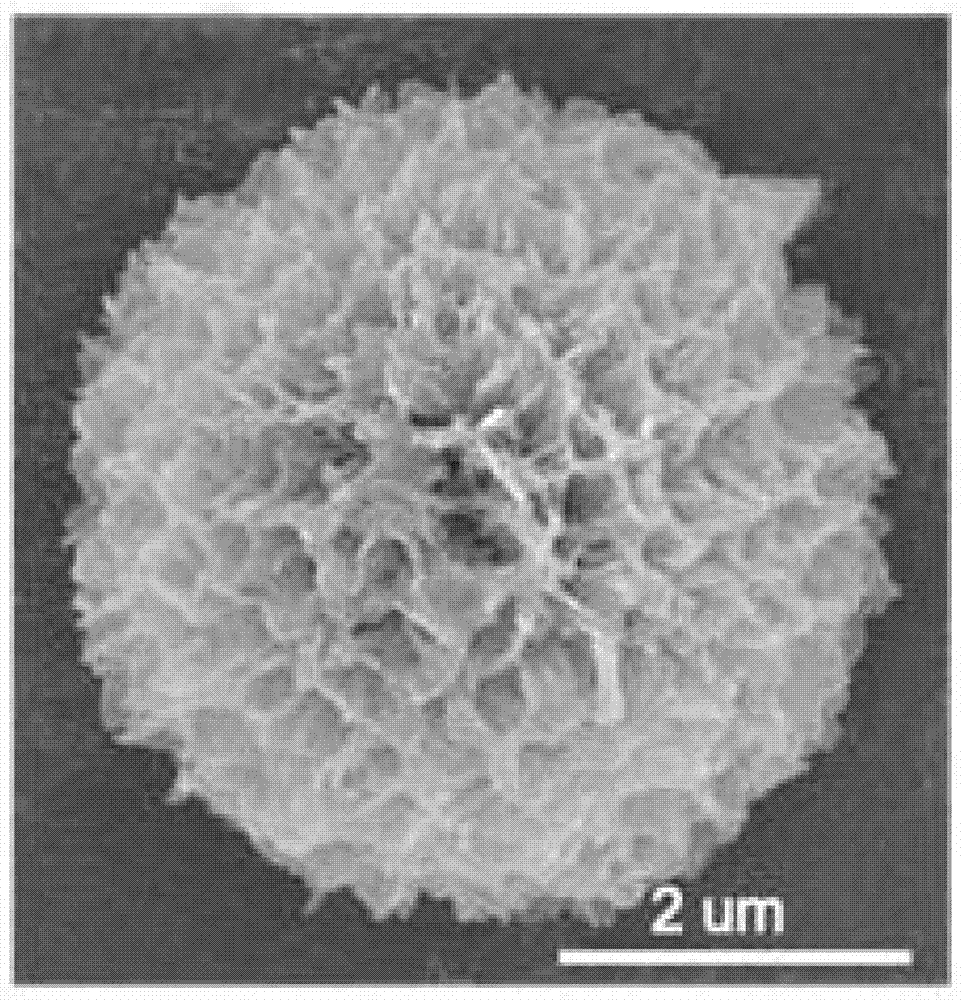

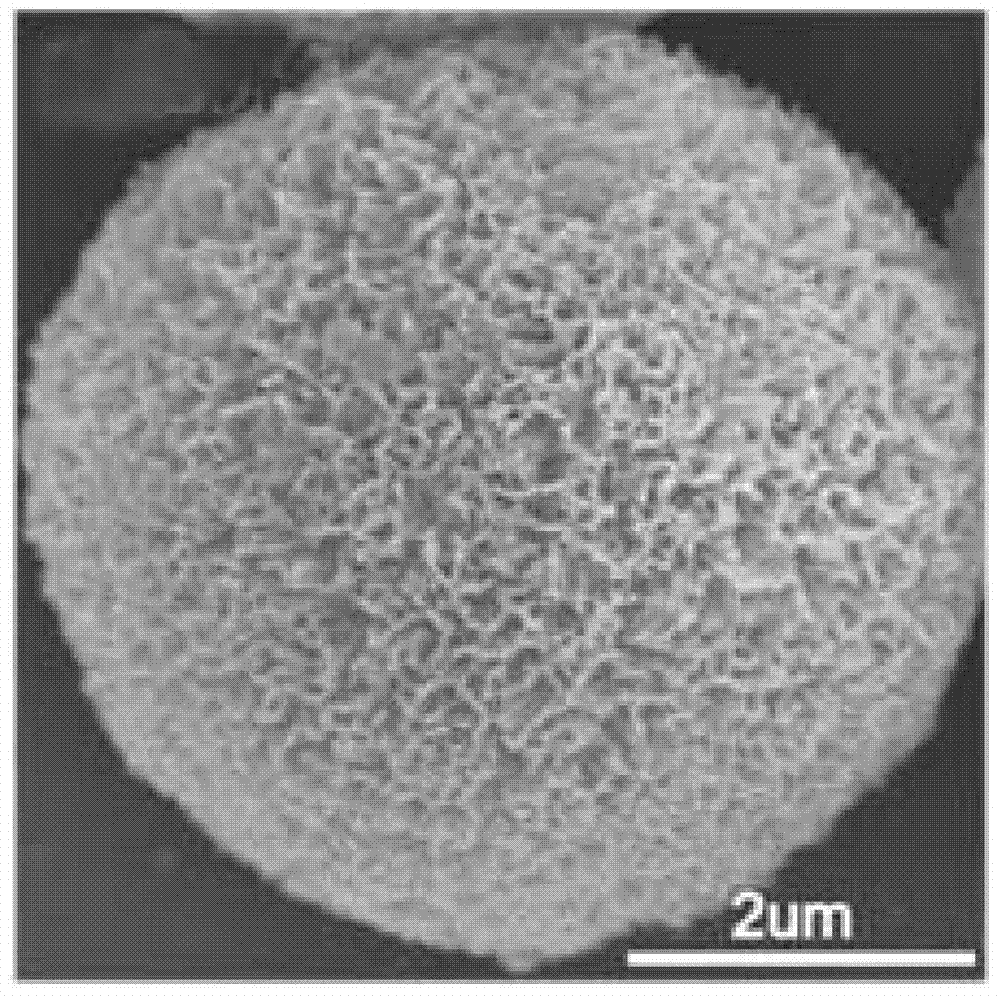

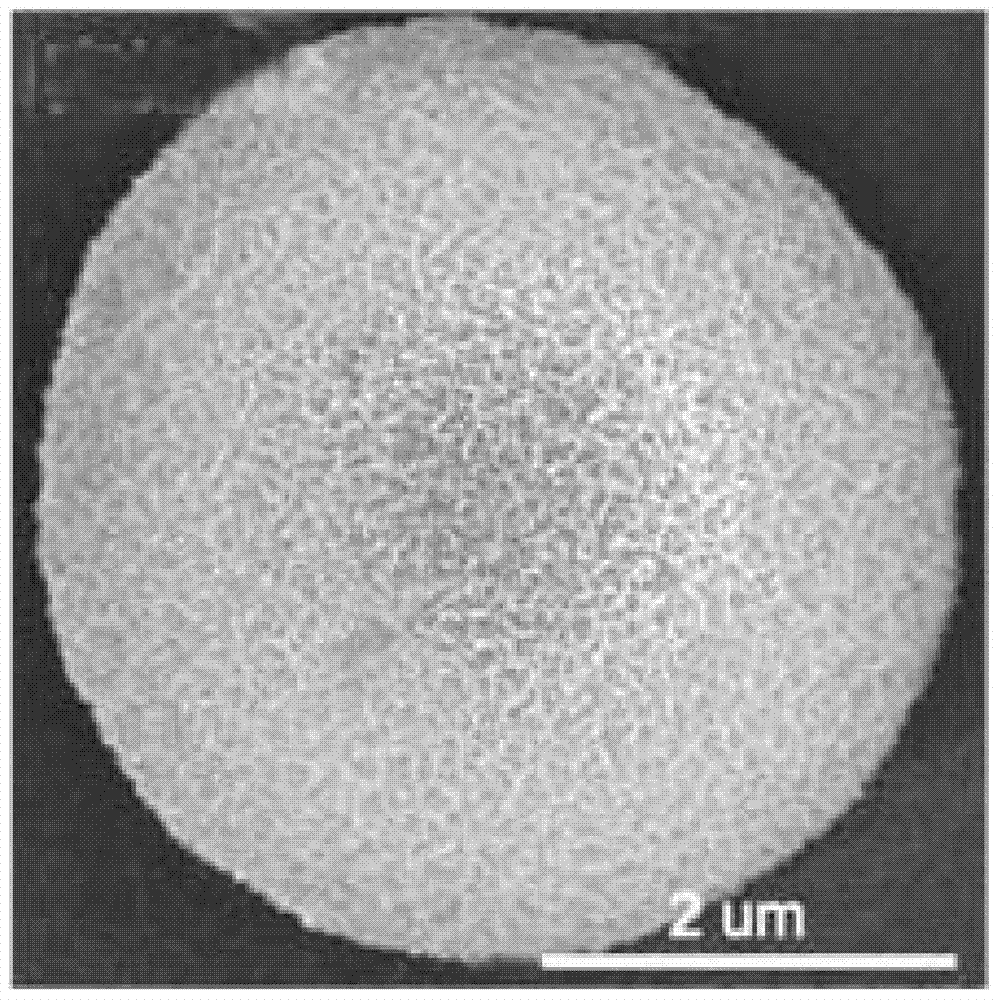

Graphite phase carbon nitride porous microsphere and preparation method thereof

ActiveCN106938198ALarge specific surface areaRegular structurePhysical/chemical process catalystsNitrogenCarbon nitride

The invention discloses a graphite phase carbon nitride porous microsphere. The graphite phase carbon nitride porous microsphere is a spherical nearly spherical particle, at least the surface of the microsphere has a porous structure, and pores are connected by graphite phase carbon nitride nanosheets. A preparation method of the graphite phase carbon nitride porous microsphere comprises the following steps: carrying out high temperature calcining on a nitrogen-containing compound used as a precursor to obtain graphite phase carbon nitride; dissolving the graphite phase carbon nitride in sulfuric acid; and re-crystallizing the graphite phase carbon nitride through changing the solvent condition of the above obtained graphite phase carbon nitride solution in order to obtain the graphite phase carbon nitride porous microsphere. The porous microsphere is obtained by interconnecting the nanosheets. The porous microsphere has a special porous structure, thereby inhibiting the agglomeration of the nanosheets. Raw materials used in the invention have wide sources, and the prepared graphite phase carbon nitride porous microsphere has the advantages of high specific surface area, regular structure, narrow pore size distribution and low cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com