Method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment

A technology of nanocellulose and high-pressure homogenization, which is applied in the field of preparation of nanocellulose fibers, can solve the problems of easy interweaving and clustering between fibers, uneven fiber diameter distribution, and low length of nanocellulose fibers, so as to improve tensile strength. The effect of strength, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

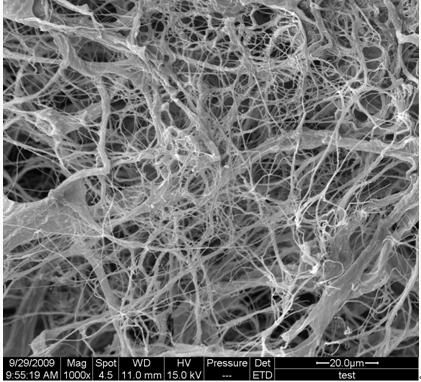

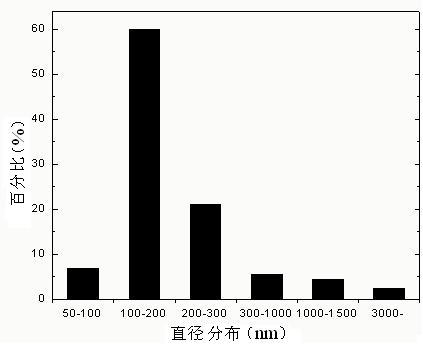

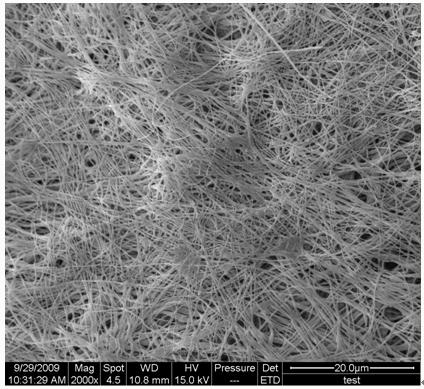

[0011] Specific implementation method 1: A method for preparing nanocellulose fibers by ultrasonic combined with high-pressure homogeneous treatment in this embodiment is carried out according to the following steps: 1. The mass ratio of biomass fiber and benzyl alcohol solution is 1:50-100. Biomass fiber and benzyl alcohol solution, and place the biomass fiber in the benzyl alcohol solution, and extract at a temperature of 85°C to 95°C for 5h to 7h; 2. The preparation concentration is 1% to 2% (mass) sodium chlorite solution, and adjust its pH value to 4-5 with glacial acetic acid, then add the biomass fiber treated in step 1 into the sodium chlorite solution for 4h-6h, and continue every 0.9-1.1h during this period Add sodium chlorite and glacial acetic acid to the sodium chlorite solution to keep the concentration of sodium chlorite in the sodium chlorite solution at 1% to 2% (mass), and the pH of the sodium chlorite solution to be 4~5; 3. Add the biomass fiber treated in s...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the biomass fiber described in step 1 is 50-70 mesh wood fiber, 50-70 mesh bamboo fiber, 50-70 mesh hemp fiber , 50-70 mesh pulp fiber, 50-70 mesh crop straw fiber or microcrystalline cellulose fiber. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the biomass fiber described in step one is 60 mesh wood fiber, 60 mesh bamboo fiber, 60 mesh hemp fiber, 60 mesh pulp fiber, 60 mesh fiber The target crop straw fiber or microcrystalline cellulose fiber. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com