Preparation method of nanometer fibril enteromorpha cellulose

A nanofibrillation, cellulose technology, applied in fiber raw material processing, textile and papermaking, etc., to achieve high conversion rate, low density, improve tensile strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

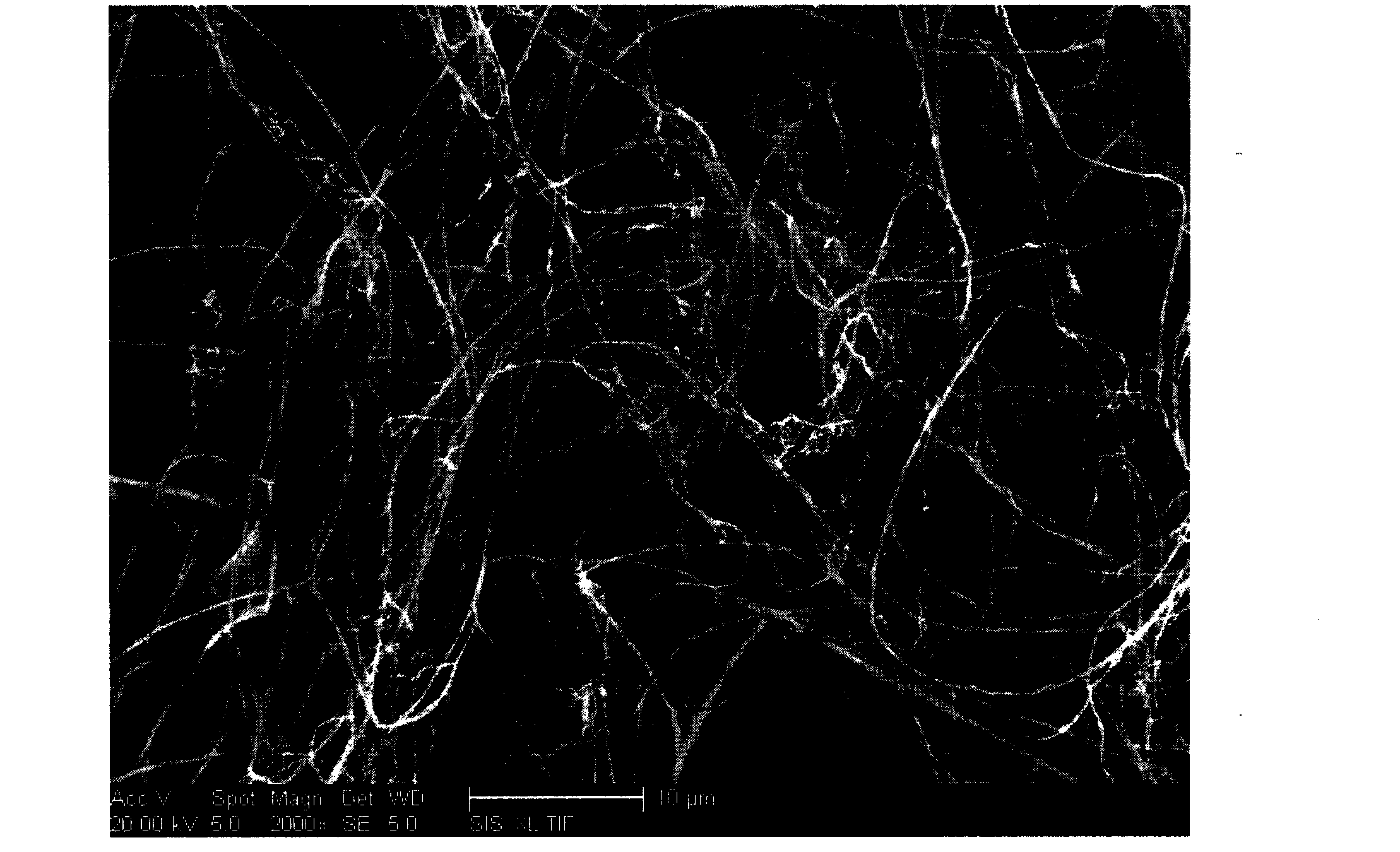

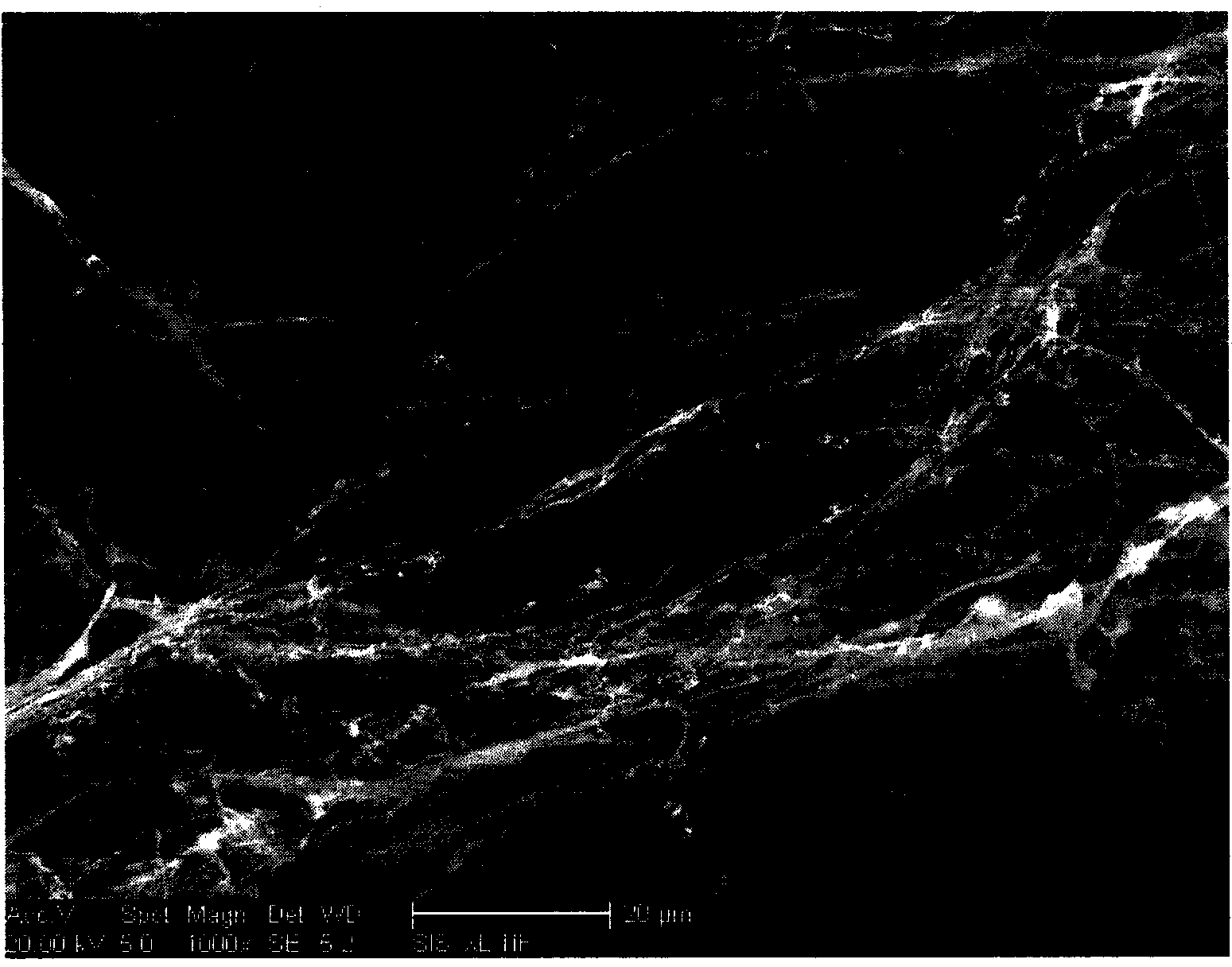

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of enteromorpha nanofibril cellulose, specifically finish according to the following steps:

[0030] 1. After collecting Enteromorpha, sort and remove miscellaneous algae and other small shellfish, wash, freeze-dry, crush and sieve to obtain 60 mesh Enteromorpha algae dregs powder;

[0031] 2. Mix 5 g of Enteromorpha algal residue powder with 300 mL of distilled water, perform cell crushing pretreatment with an ultrasonic power of 500 W for 20 minutes, and extract polysaccharides in a constant temperature water bath at 65°C for 4 hours;

[0032] 3. Centrifuge the obtained polysaccharide-extracted mixed solution at 3500 rpm for 5 minutes, pour off two-thirds of the liquid, then add distilled water and repeat the above centrifugal cleaning for 5 times to obtain the precipitated waste residue after extracting the crude polysaccharide;

[0033] 4. Add KOH aqueous solution to the precipitated waste residue obtained after extracting ...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of enteromorpha nanofibril cellulose, specifically finish according to the following steps:

[0042] 1. After collecting Enteromorpha, pick and remove miscellaneous algae and other small shellfish, wash, freeze-dry, crush and sieve to obtain 100 mesh Enteromorpha algae dregs powder;

[0043] 2. Mix 3 g of Enteromorpha algal residue powder with 300 mL of distilled water, perform cell crushing pretreatment with an ultrasonic power of 1000 W for 20 minutes, and extract polysaccharides in a constant temperature water bath at 90°C for 2 hours;

[0044] 3. Centrifuge the obtained mixed solution of polysaccharide extracted at 5500rpm for 5 minutes, pour off 2 / 3 of the liquid, add distilled water and repeat the above centrifugal cleaning 5 times, and obtain the precipitated waste residue of extracted crude polysaccharide;

[0045] 4. Add NaOH aqueous solution to the precipitated waste residue after extracting the crude polysaccharide f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com