Patents

Literature

144results about "Chemical fixing of textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

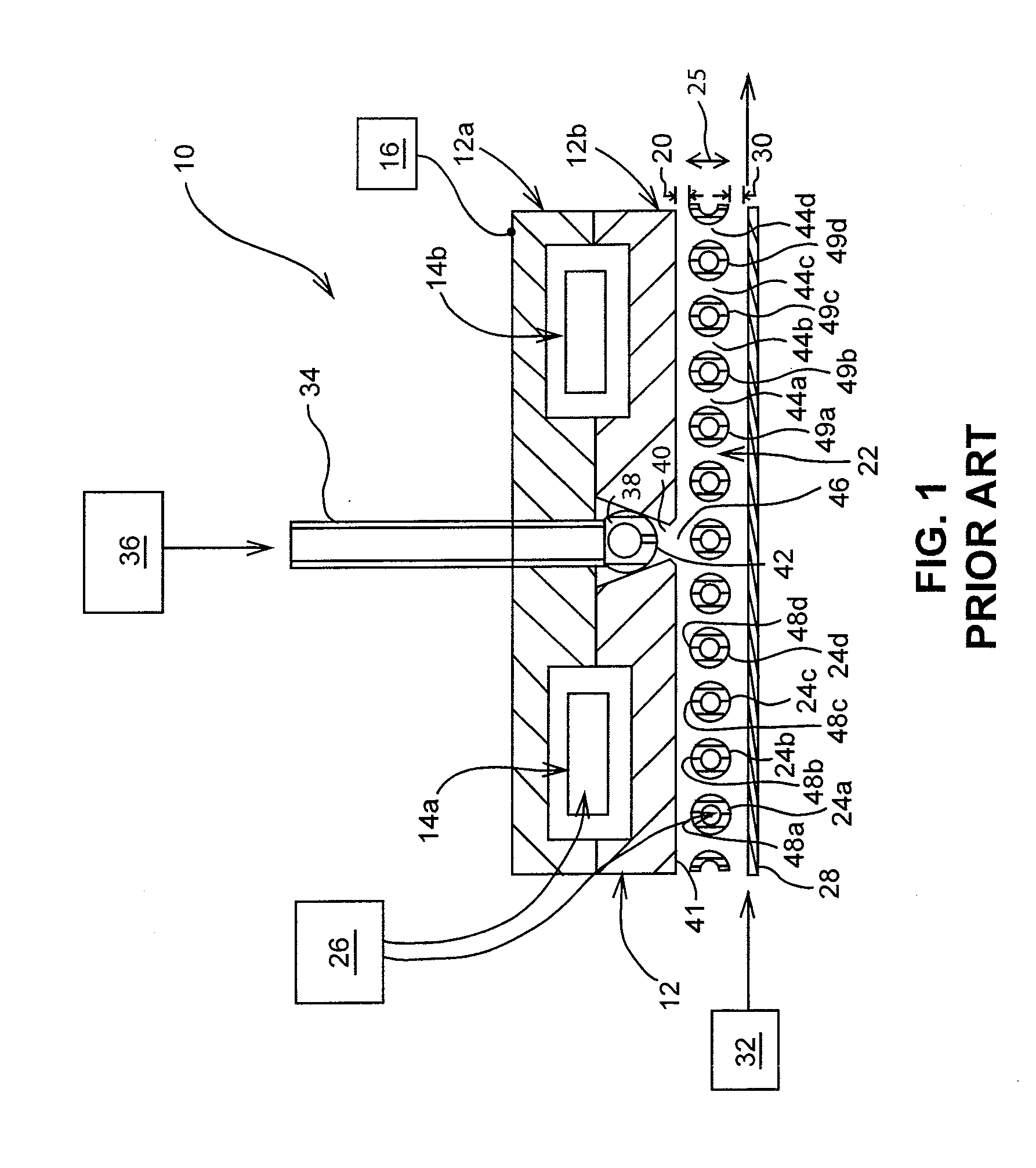

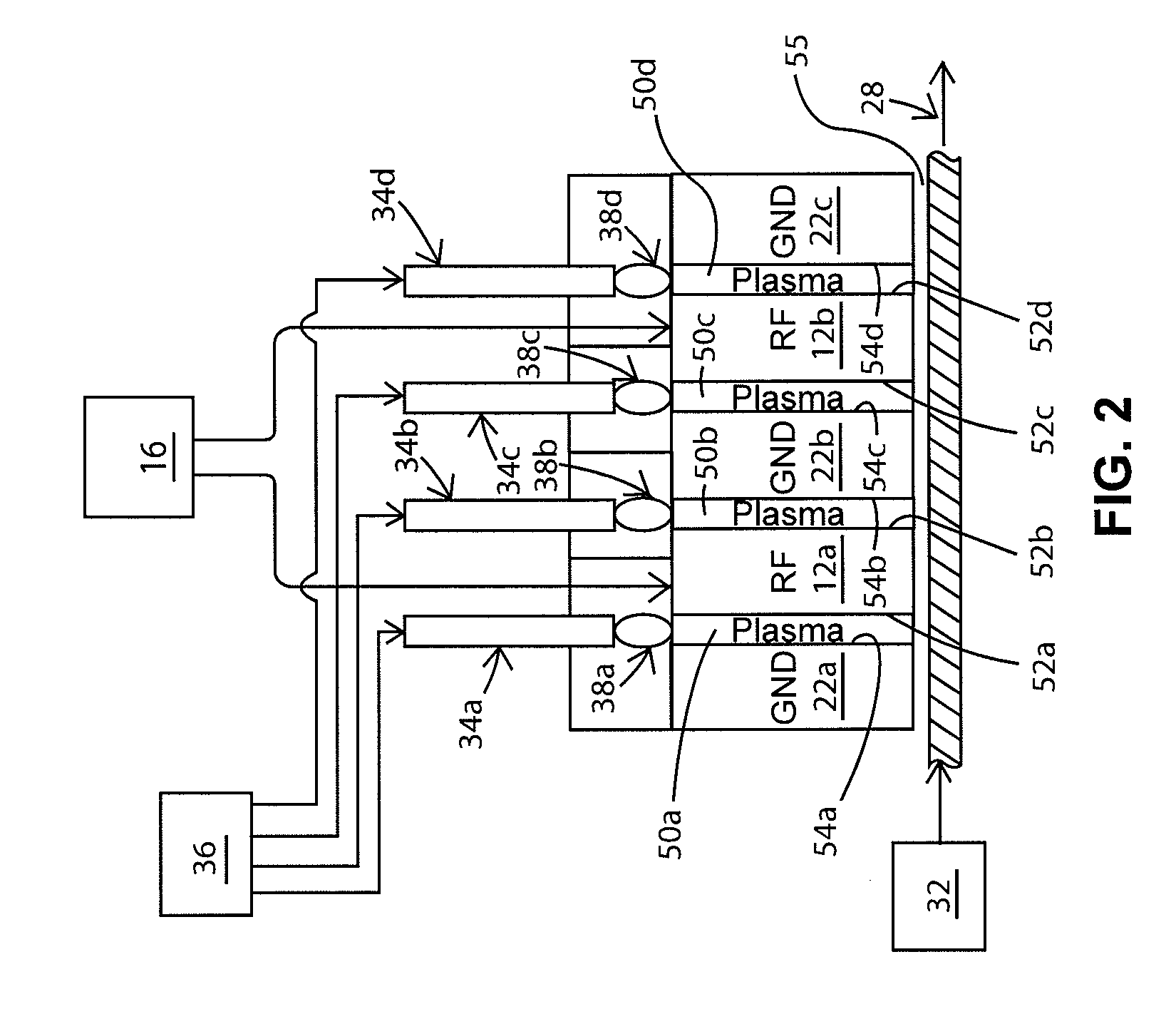

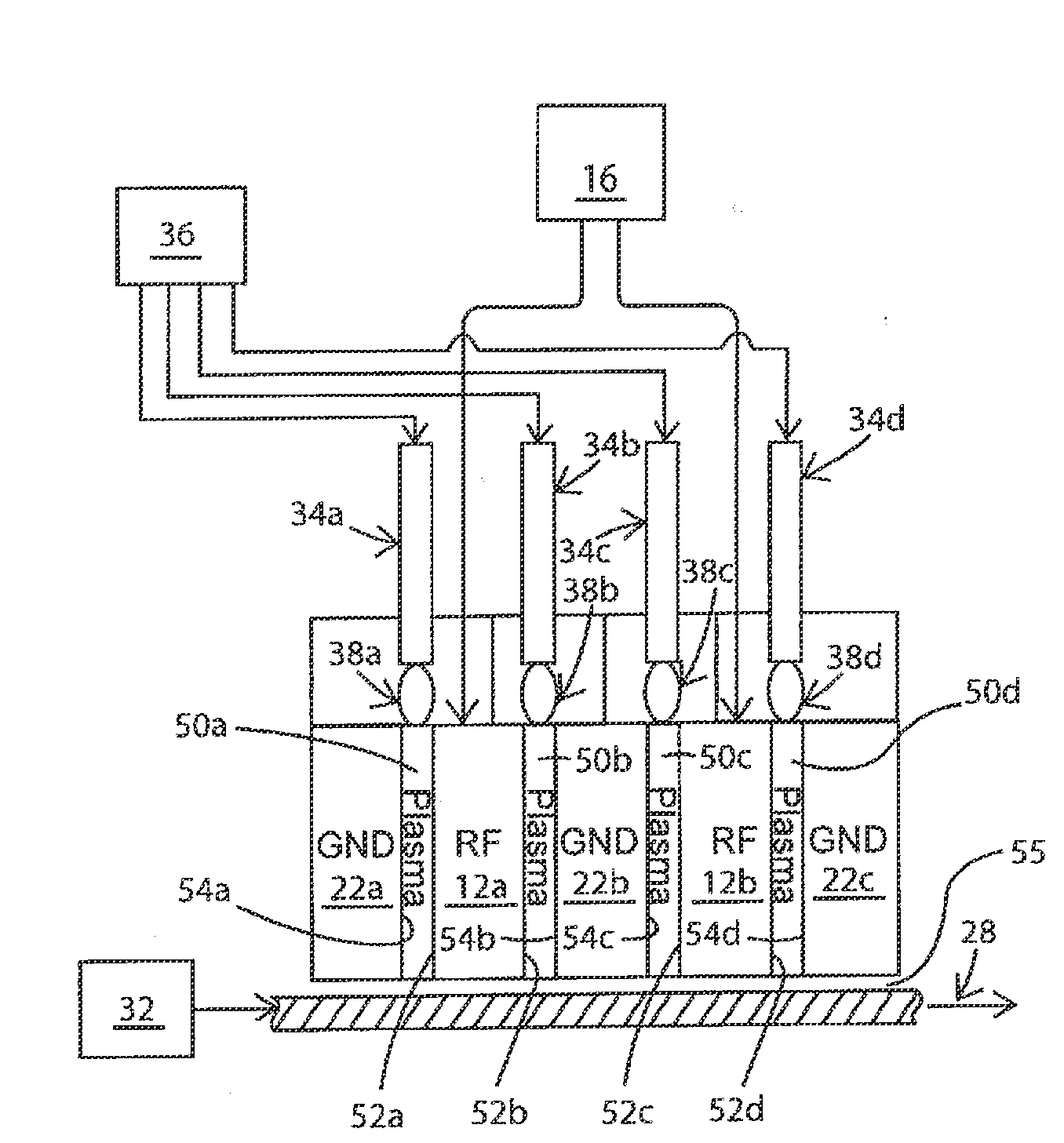

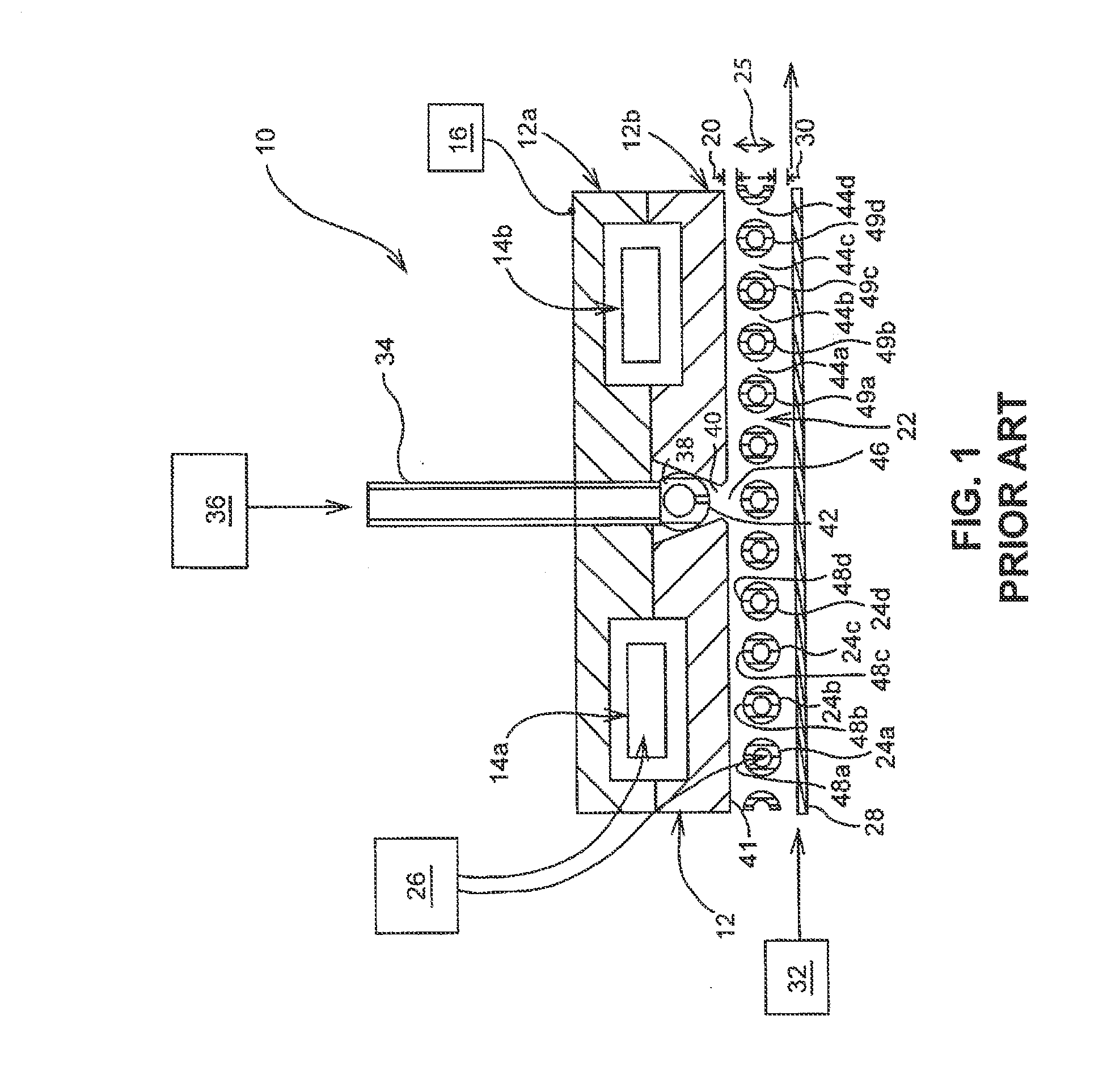

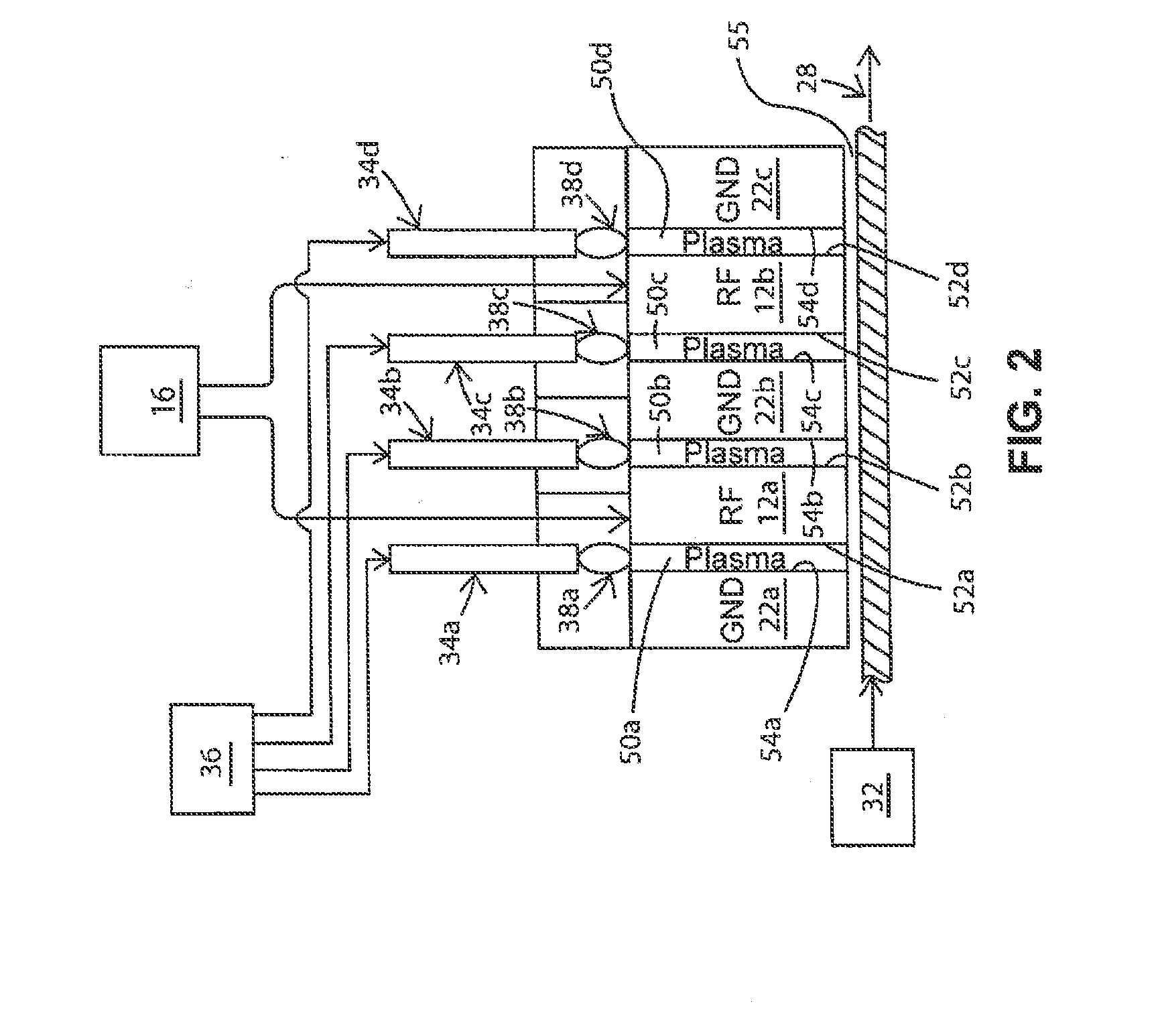

Atmospheric-pressure plasma processing apparatus and method

ActiveUS20140076861A1Faster plasma processing speedMinimum distanceChemical fixing of textilesArc welding apparatusEngineeringAtmospheric pressure

A plasma processing apparatus including powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, is described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

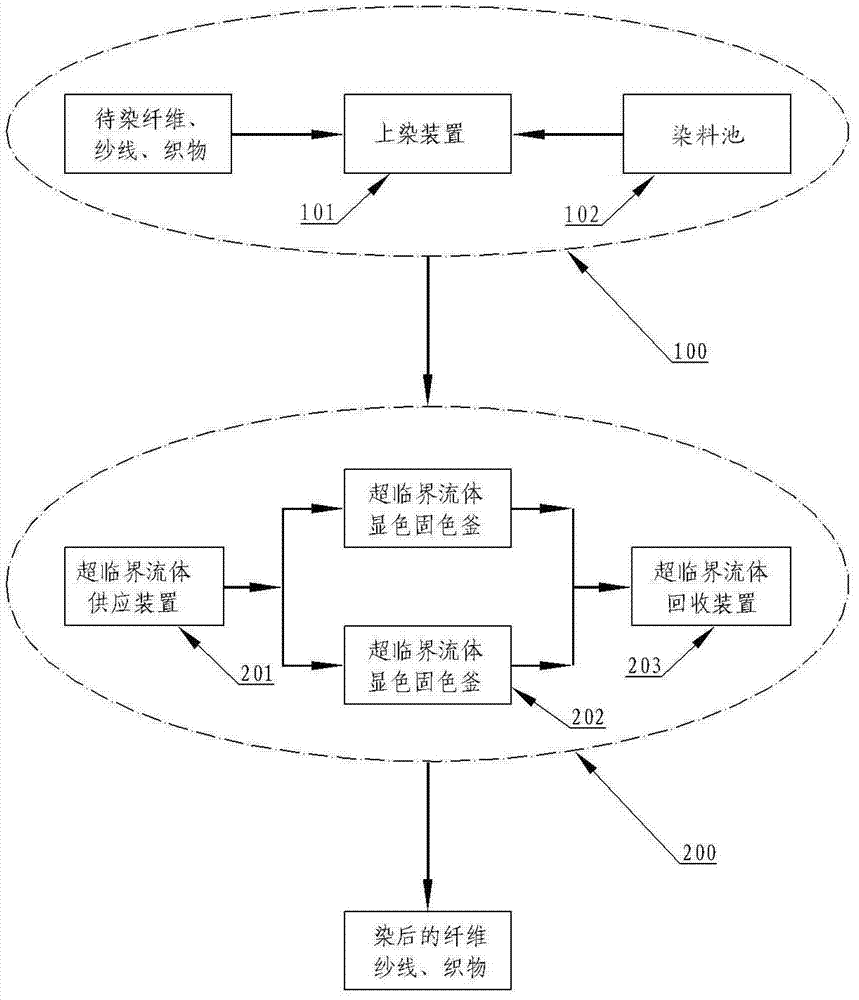

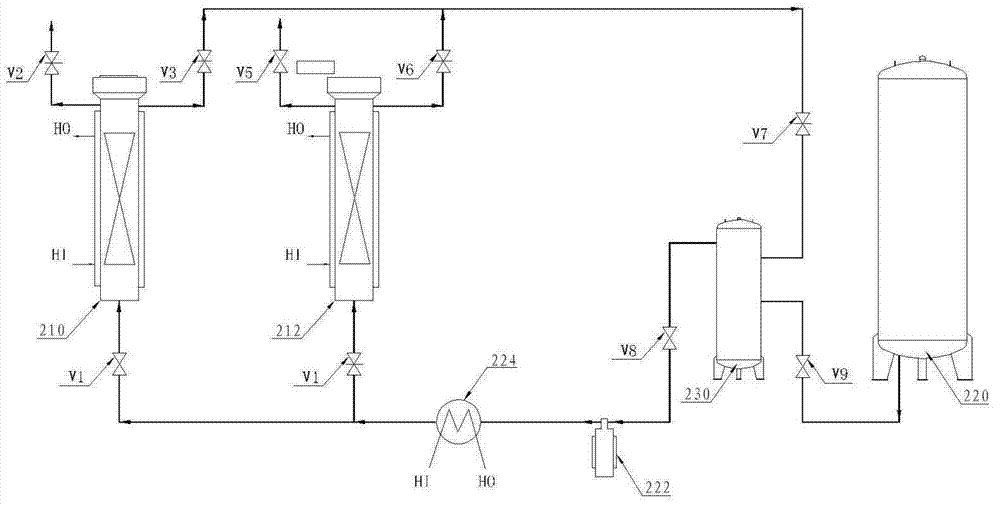

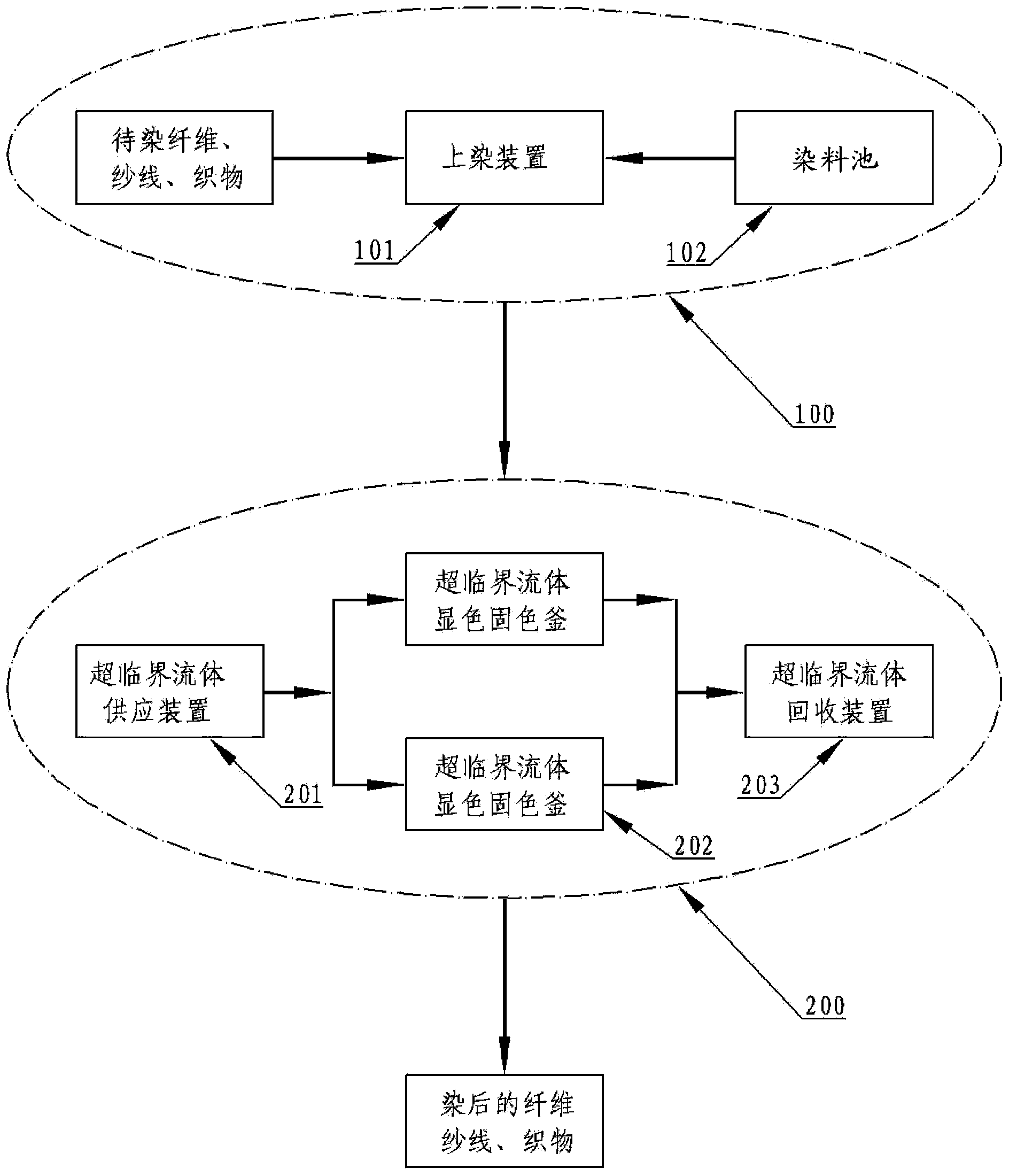

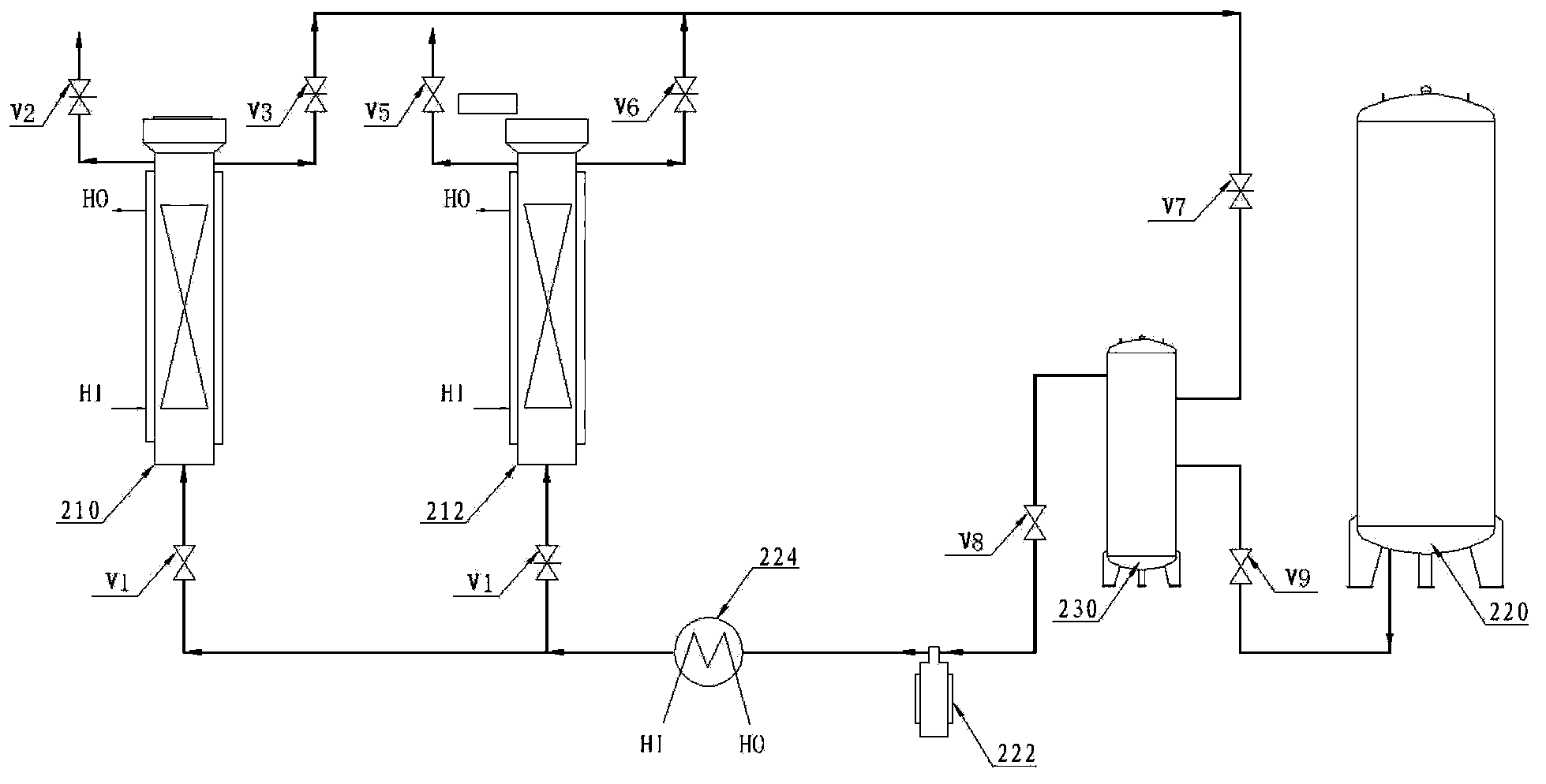

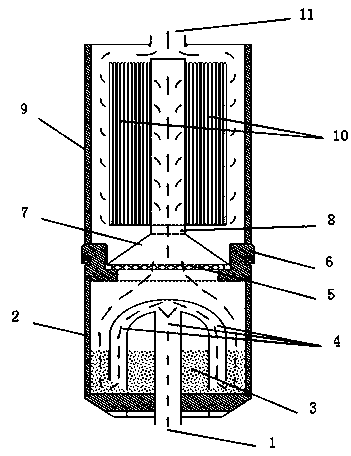

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194AMigration does not occurSolve uncontrollable difficultiesTextile treatment containersChemical fixing of textilesSystem pressureStationary state

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

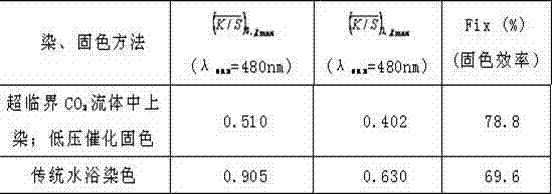

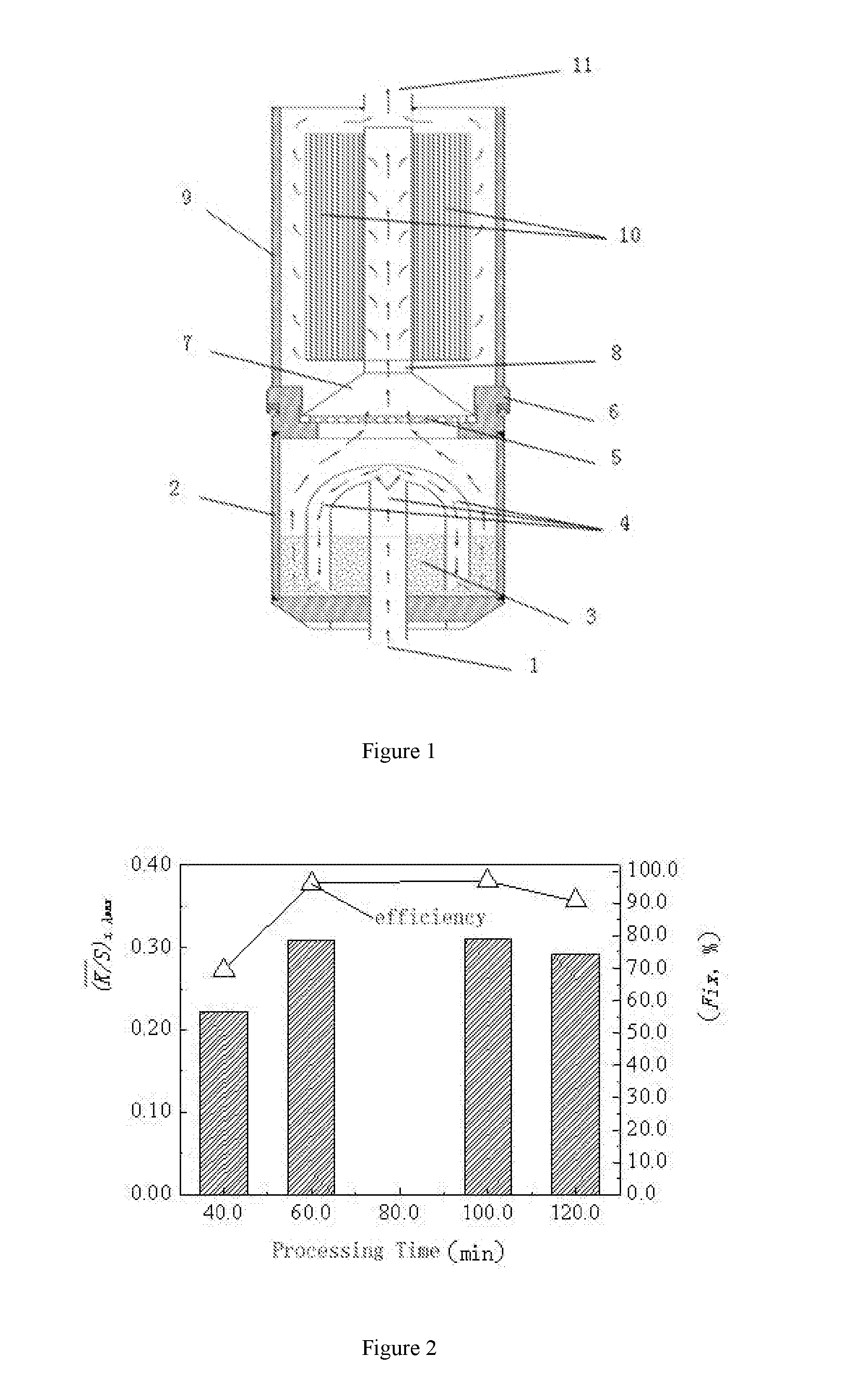

Method for fixing reactive disperse dyes in low-pressure carbon dioxide medium

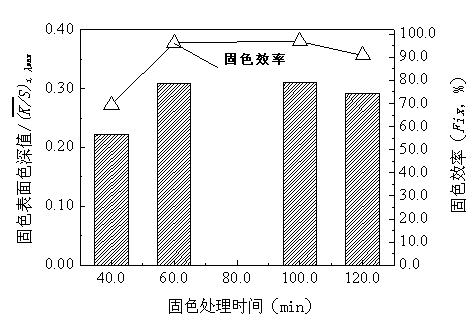

ActiveCN102392367AImprove color fixing efficiencyIncrease profitChemical fixing of textilesDyeing processDisperse dyePtru catalyst

The invention discloses a method for fixing reactive disperse dyes in a low-pressure carbon dioxide medium. The method is characterized in that: natural fiber textiles subjected to reactive disperse dye absorption and dyeing in a supercritical carbon dioxide fluid dyeing unit are put in a fixing unit; and in the presence of the carbon dioxide gas medium with pressure being 1.0-6.0MPa and a catalyst for fixation, the reactivity of the reactive groups of the dyes and reactive functional groups on the fibers is improved through unstable onium ion intermediate products formed by the catalyst for fixation and reactive groups of the dyes on the fibers, thus realizing catalytic fixation of the dyes on the fibers. The method has the characteristics that: the processing method of catalytic fixation in the low-pressure carbon dioxide gas medium is adopted for the dyes subjected to dyeing in the supercritical carbon dioxide fluid, thus improving the fixation efficiency of the dyes on the fibers and reducing the requirements for equipment and the investment in the equipment. The method has the advantages of simple process, high fixation efficiency and dye utilization rate, environment friendliness, high efficiency and the like.

Owner:SUZHOU UNIV

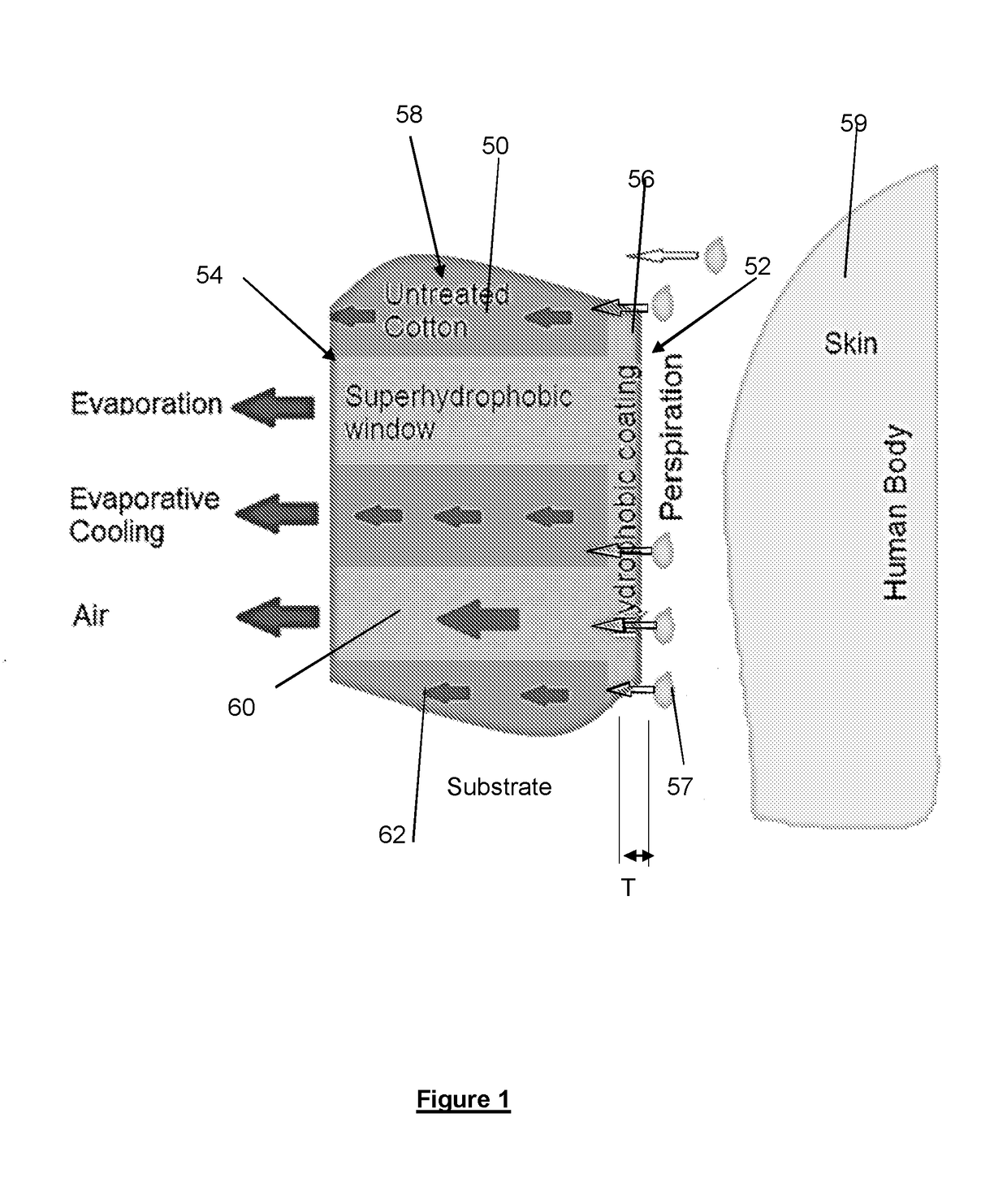

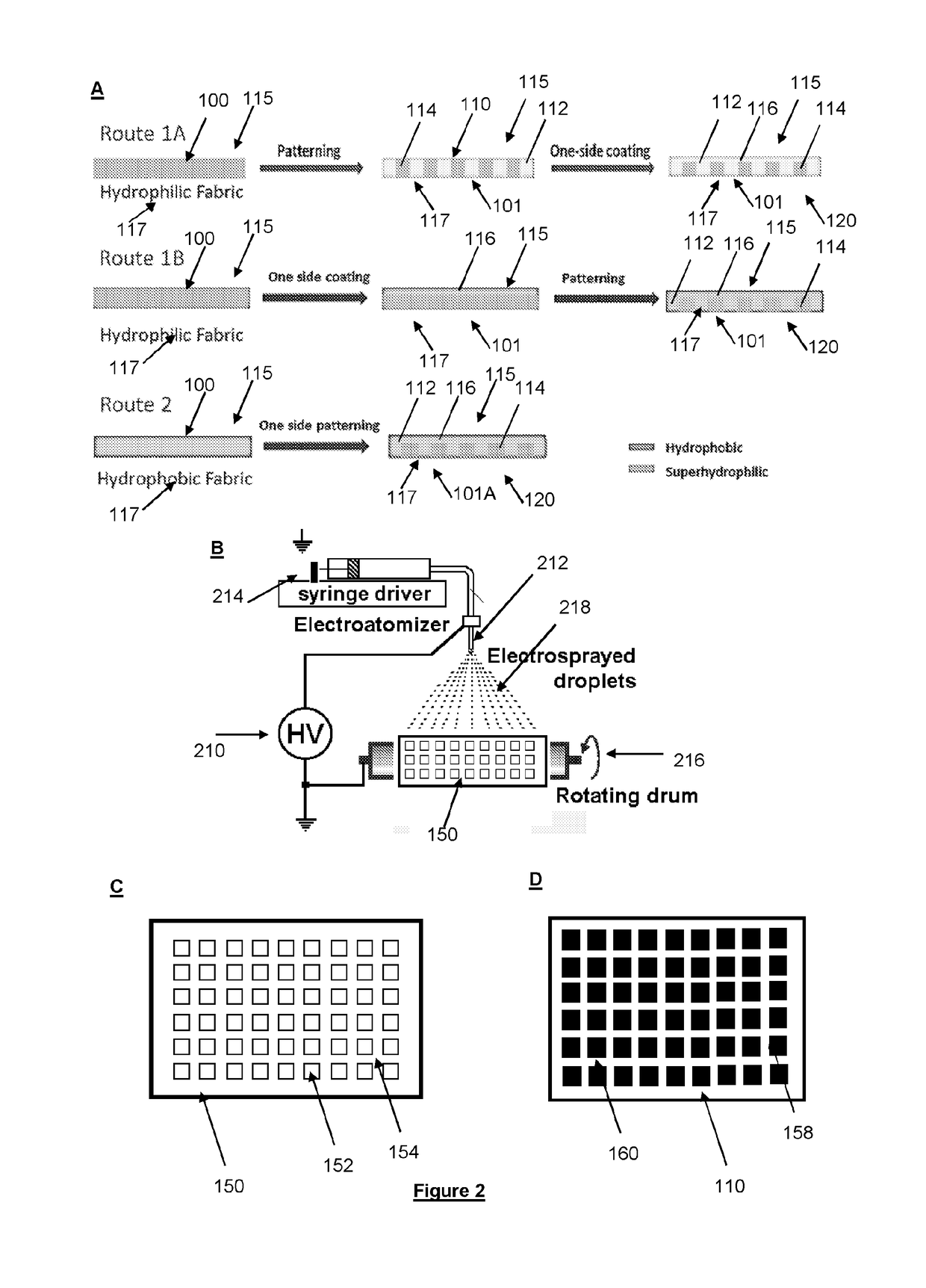

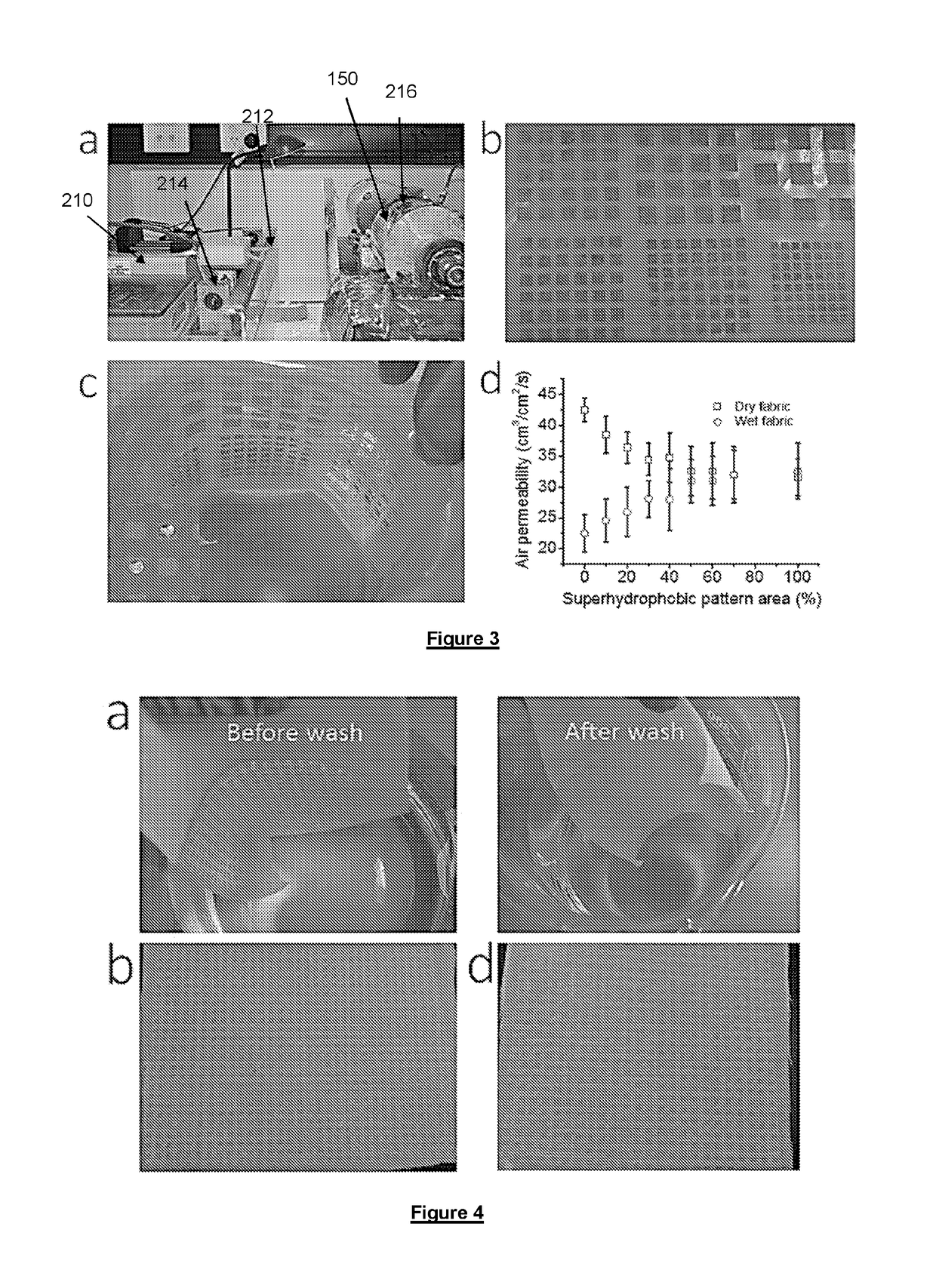

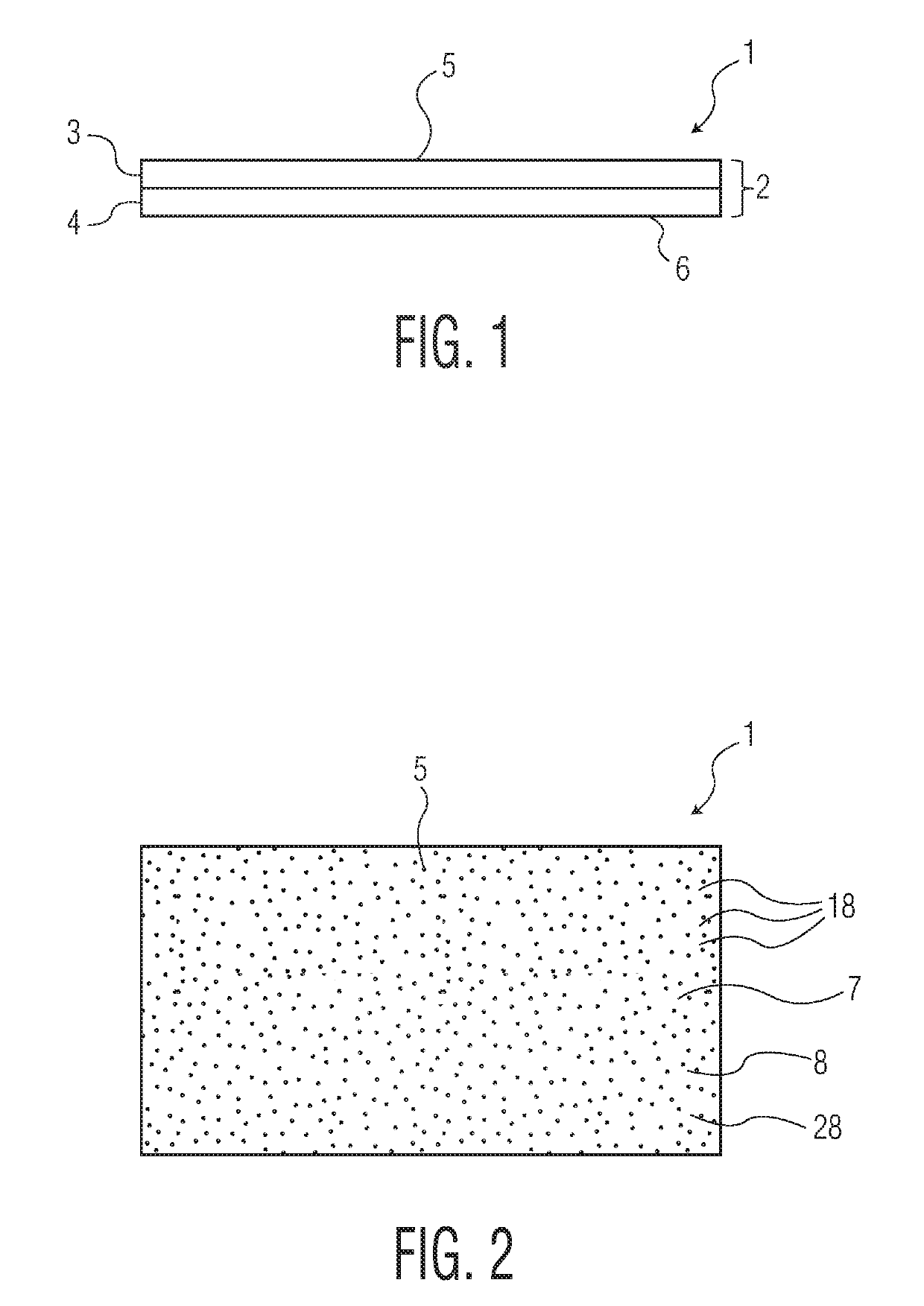

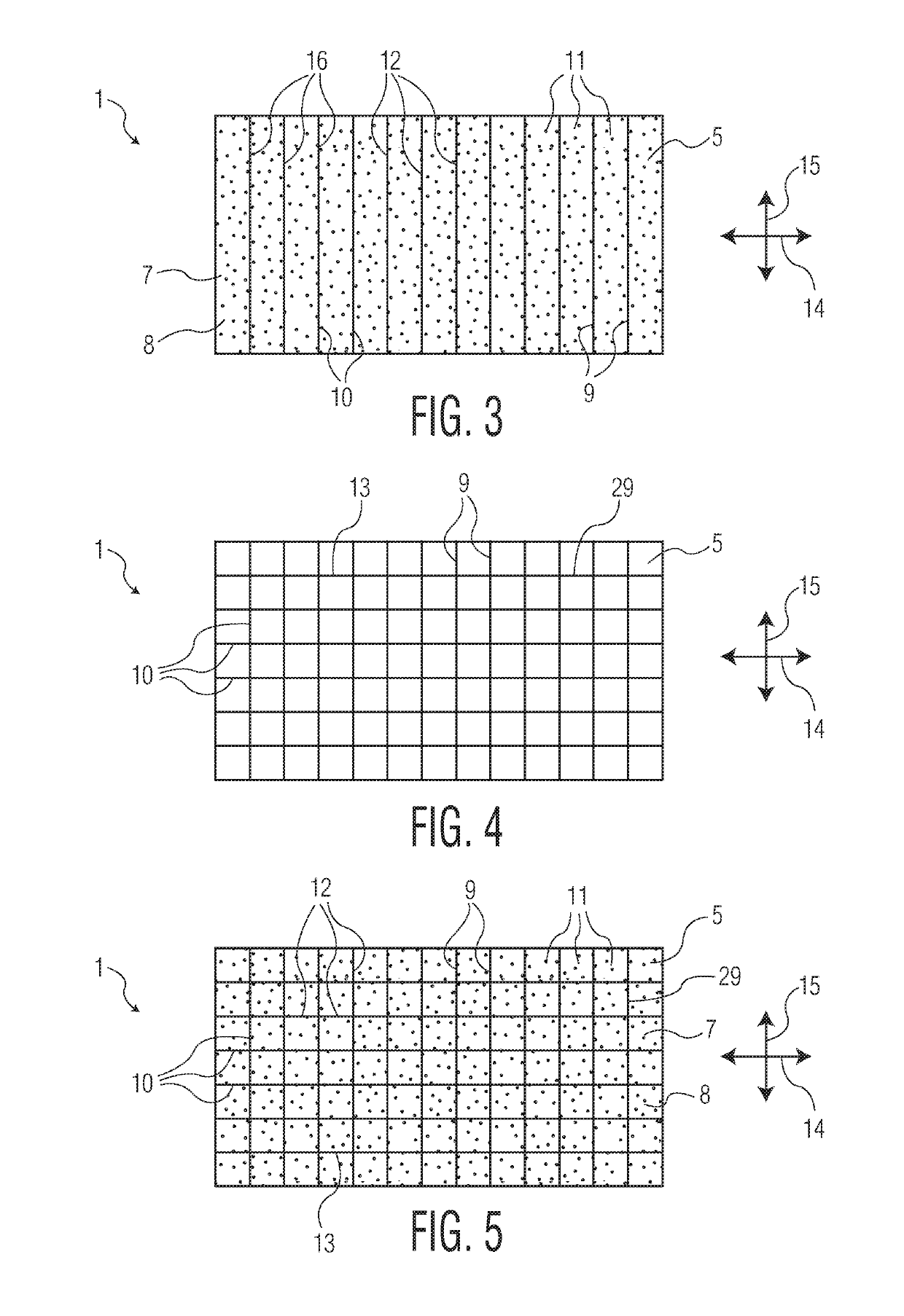

Unidirectional wicking substrate

ActiveUS20180371665A1Effective directional water-transport abilityImprove abilitiesGarment special featuresPlaten pressesOptoelectronicsWater transport

The present invention provides a substrate having a unidirectional water transport property, the substrate comprised of a fluid permeable structure and including: an inner side surface; and an outer side surface having a higher absorbent capacity than the inner side surface, wherein the inner side surface has a hydrophobic surface layer extending continuously over at least one section thereof, the hydrophobic surface layer having a predetermined thickness which, in use, produces a substantial hydrophobic property to contacting water, whilst allowing for water contacting the inner side surface of the substrate to wick through the hydrophobic surface layer into the substrate; and wherein the substrate is respectively comprised of hydrophobic channels and hydrophilic channels which respectively extend between the inner side surface and the outer side surface.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Woven materials with incorporated solids and processes for the production thereof

Owner:PURIFICATION PRODS +1

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194BRealize cycle workMeet the needs of large-scale productionTextile treatment containersChemical fixing of textilesProcess engineeringChemistry

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

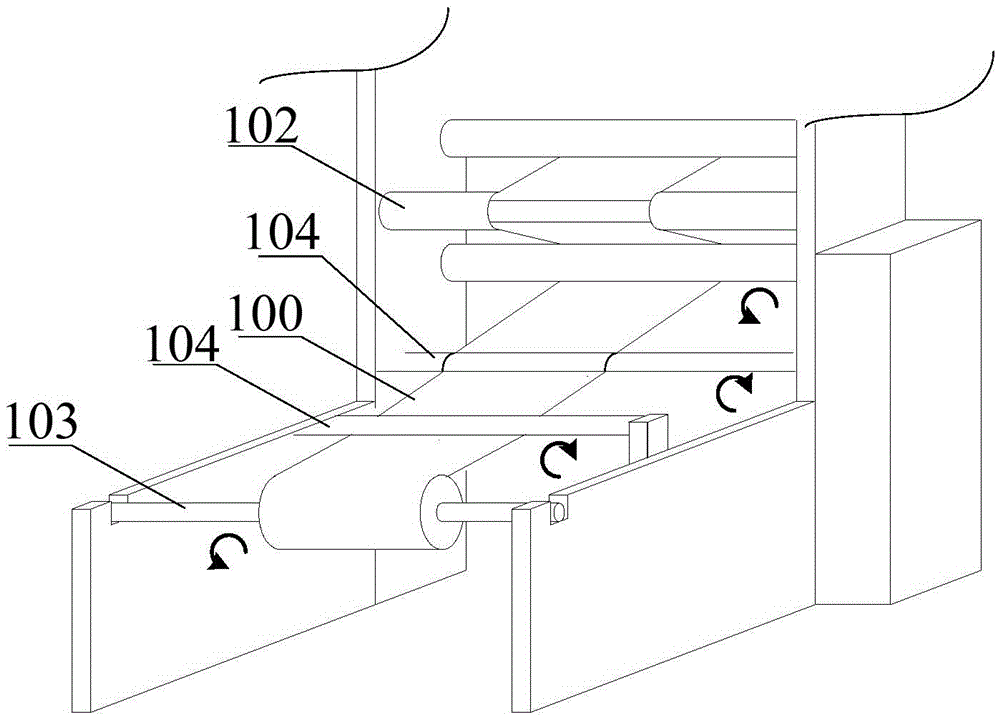

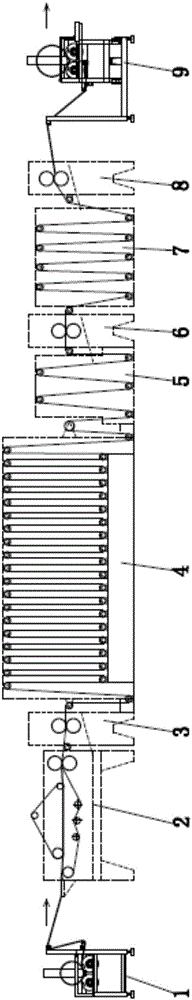

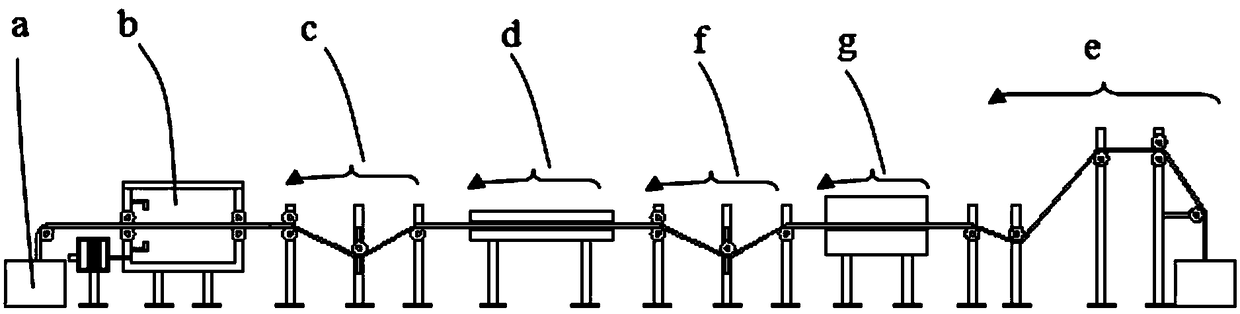

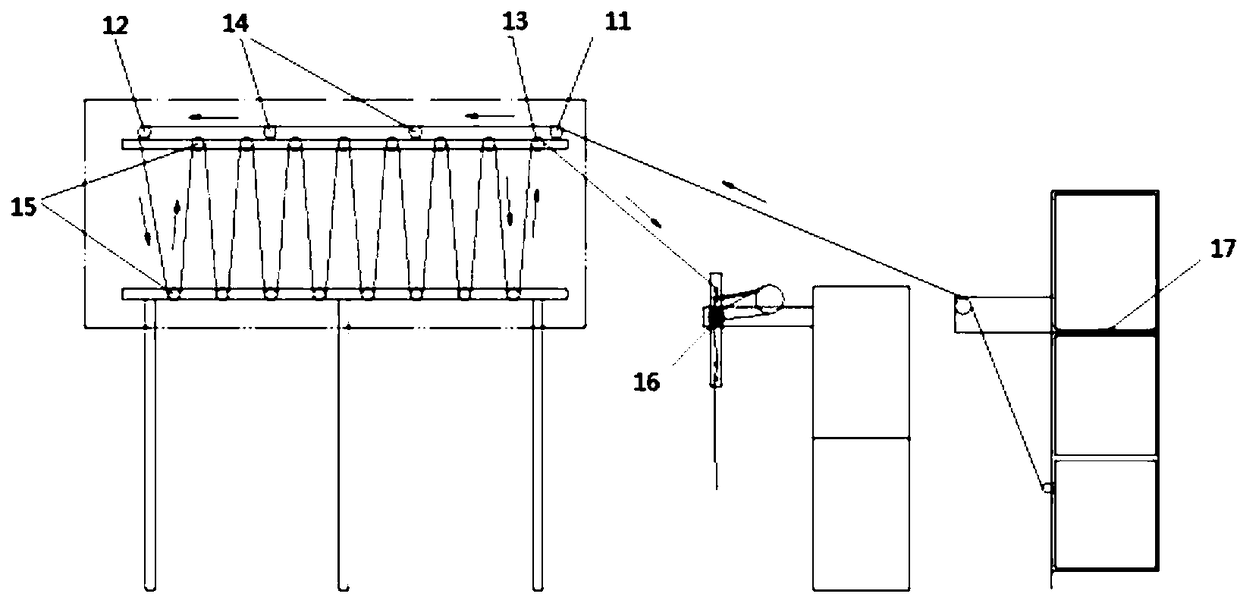

Winding structure

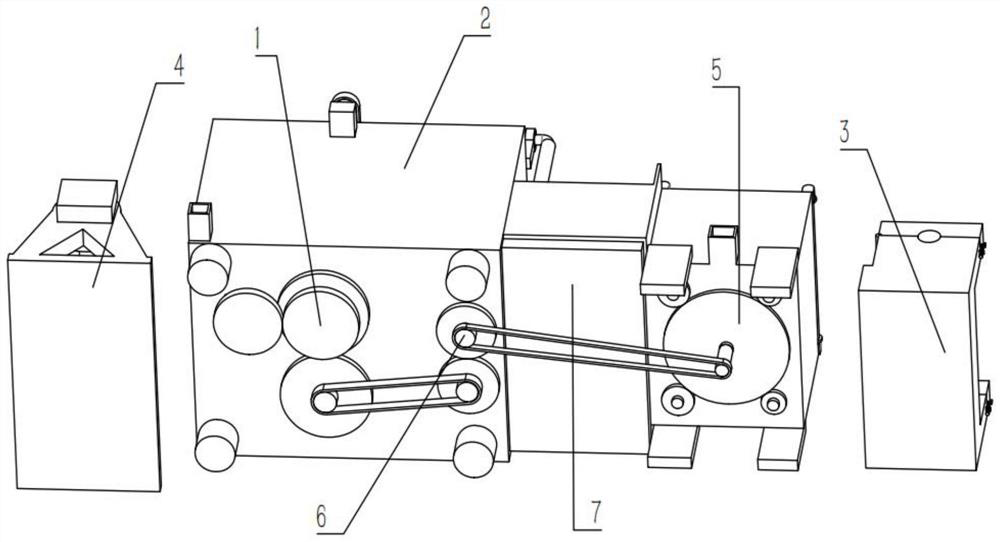

ActiveCN105460653AGuaranteed flatnessSimple structureChemical fixing of textilesTextile treatment carriersMeasuring instrumentTransmittance

The embodiment of the invention provides a winding structure. The problem that the cost performance and the working efficiency of an existing winding structure need to be improved is solved. The winding structure comprises a controller, a power device, a winding platform, a plurality of carrier rollers and a plurality of winding rollers. The multiple carrier rollers and the multiple winding rollers are installed on the winding platform. Tensioning shafts, dyeing devices and color fixing devices are further installed on the winding platform, wherein the dyeing devices and the color fixing devices are connected with the controller. The dyeing devices and the color fixing devices are located between the two adjacent carrier rollers. The outer surfaces of the winding rollers are coated with elastic layers. The tensioning shafts are located at the positions adjacent to the winding rollers. Each dyeing device comprises a rotating shaft which is coated with a color absorbing material and is parallel to the corresponding carrier roller, wherein a dye storage groove is arranged below the rotating shaft, the lower portion of the rotating shaft is located in the dye storage groove, the rotating shaft and the corresponding tensioning shaft are connected with a driving motor, the driving motor and the power device are connected with the controller, and the controller is connected with a transmittance measuring instrument. The winding structure is high in cost performance and winding efficiency and easy to apply and popularize.

Owner:CHONGQING KEXIN PLASTIC

Ultralow-twist velvet cotton fabric and weaving and dyeing process thereof

The invention discloses an ultralow-twist velvet cotton fabric. A weaving and dyeing process of the ultralow-twist velvet cotton fabric comprises performing compact and siro spinning on a yarn A composed of 50-100% of long-staple cotton and 0-50% of combed cotton, and a yarn B composed of 0-50% of long-staple cotton and 50-100% of combed cotton to obtain a pure cotton ultralow-twist yarn with a degree of twist of 0-30 twist per inch; weaving the pure cotton ultralow-twist yarn solely or with other yarns into ultralow-twist velvet cotton raw fabric; performing dyeing, aftertreatment, fixation,softening and shaping processes on the ultralow-twist velvet cotton raw fabric to obtain the ultralow-twist velvet cotton fabric. The invention also provides a preparation process of the ultralow-twist velvet cotton fabric. The prepared ultralow-twist velvet cotton fabric achieves the excellent properties of good overall fluffy touch feeling, soft and dry hand feeling, rapid drying after absorbingwater during washing and fabric twist and twilling reduction, and is less prone to losing color, thereby meeting the demands of people on high-grade fabrics.

Owner:盐城福汇纺织有限公司

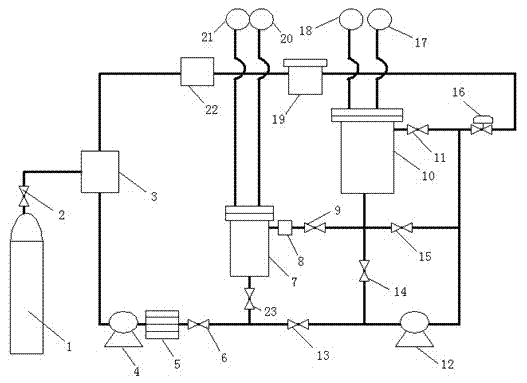

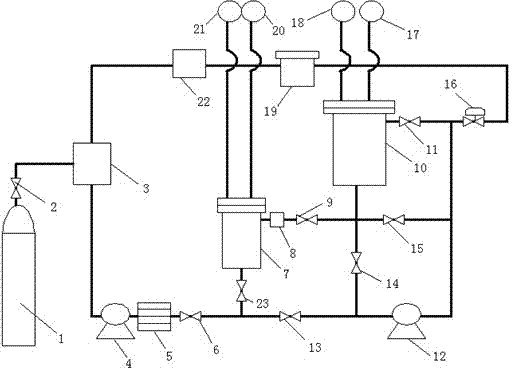

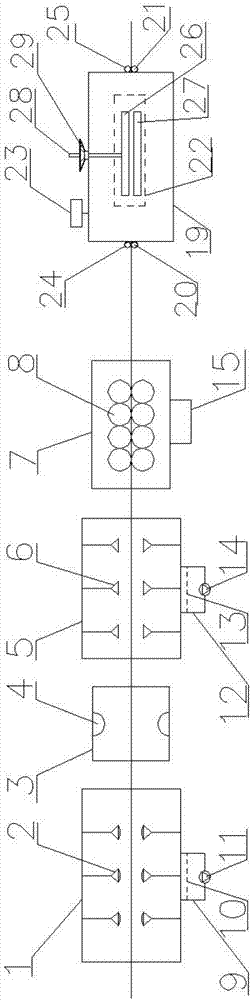

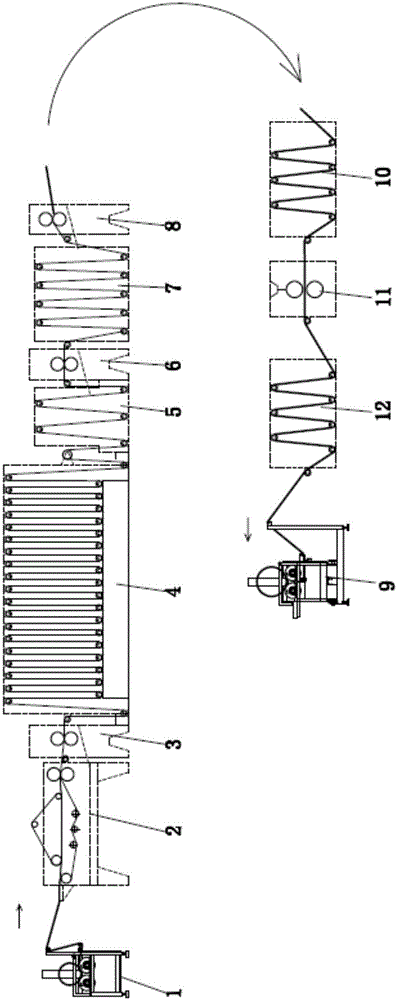

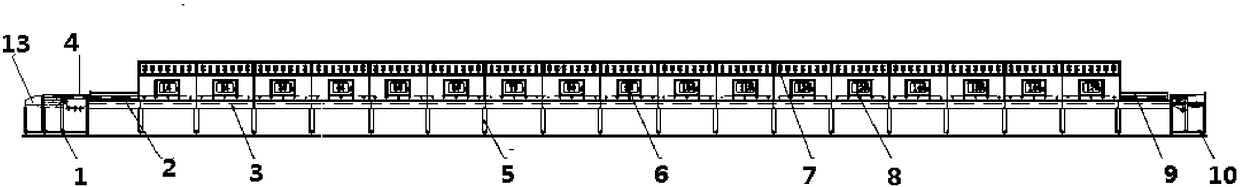

Textile cloth spray-drying system

InactiveCN106995992AGood effectUniform spray holeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersEngineeringUtilization rate

The invention discloses a textile cloth spray-drying system, comprising a dye box (1); a plurality of dye nozzles (2) are arranged in the dye box (1); one end of the dye box (1) is provided with a heating box (3); the other end of the heating box (1) correspond to the dye box (1) is provided with a rinsing box (5); a dye filter (9) is connected below the bottom of the dye box (1); the other end of the rinsing box (5) corresponding to the heating box (3) is provided with a dewatering box (7); the other end of the dewatering box (7) corresponding to the rinsing box (5) is provided with a drying box (19); two cloth feeding rollers (20) and two cloth drawing rollers (21) are connected to two ends of the drying box (19) respectively; an electric heating plate (22) is arranged in the drying box (19); a controller (23) is arranged at the top end of the drying box (19). The textile cloth spray-drying system is good in dyeing uniformity, lower in cost, higher in dye utilization rate, and good in environment-protecting and dyeing effect, and also has the advantages of good cloth-drying effect and zero cloth deformation.

Owner:湖州南浔凯普纺织有限公司

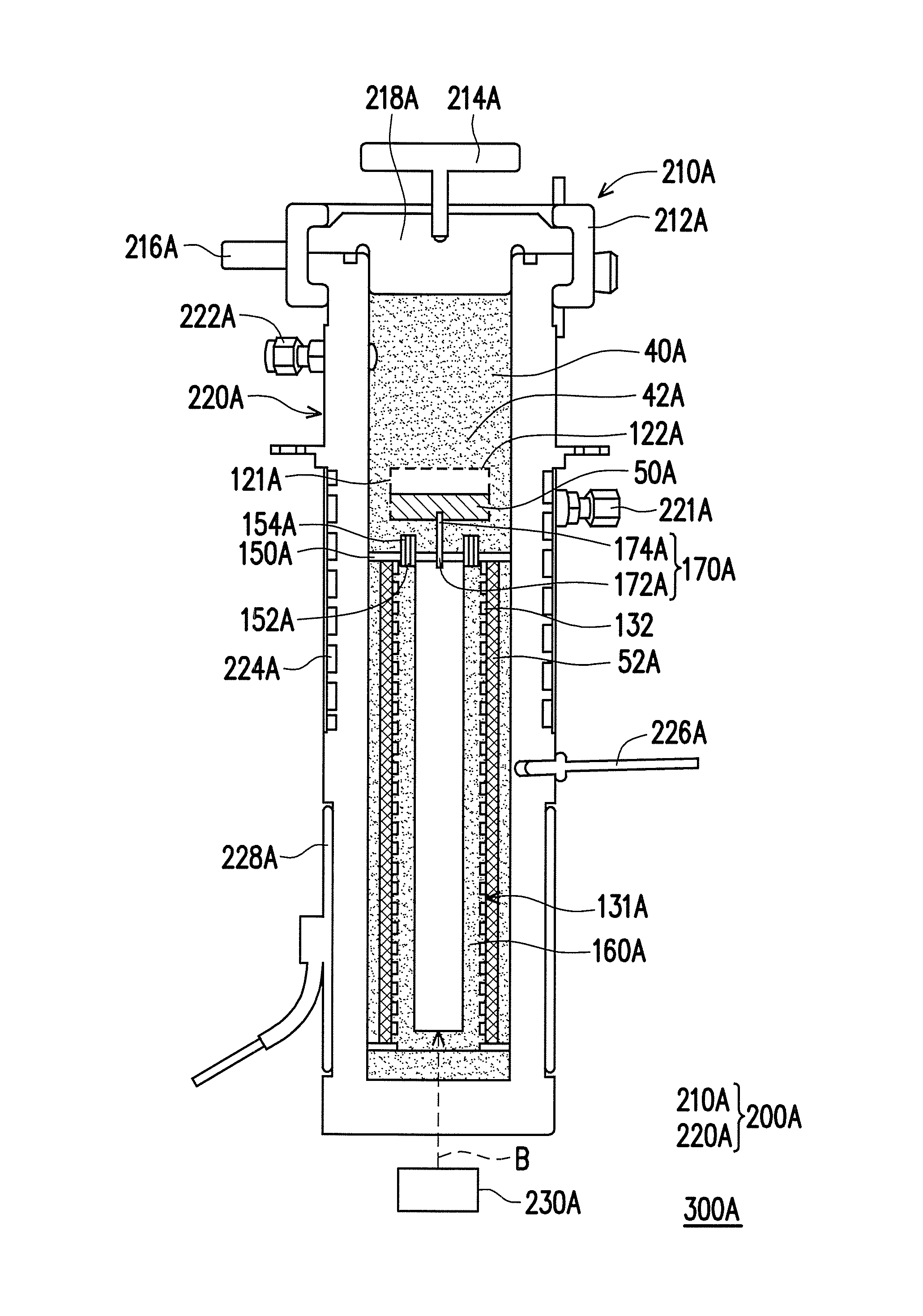

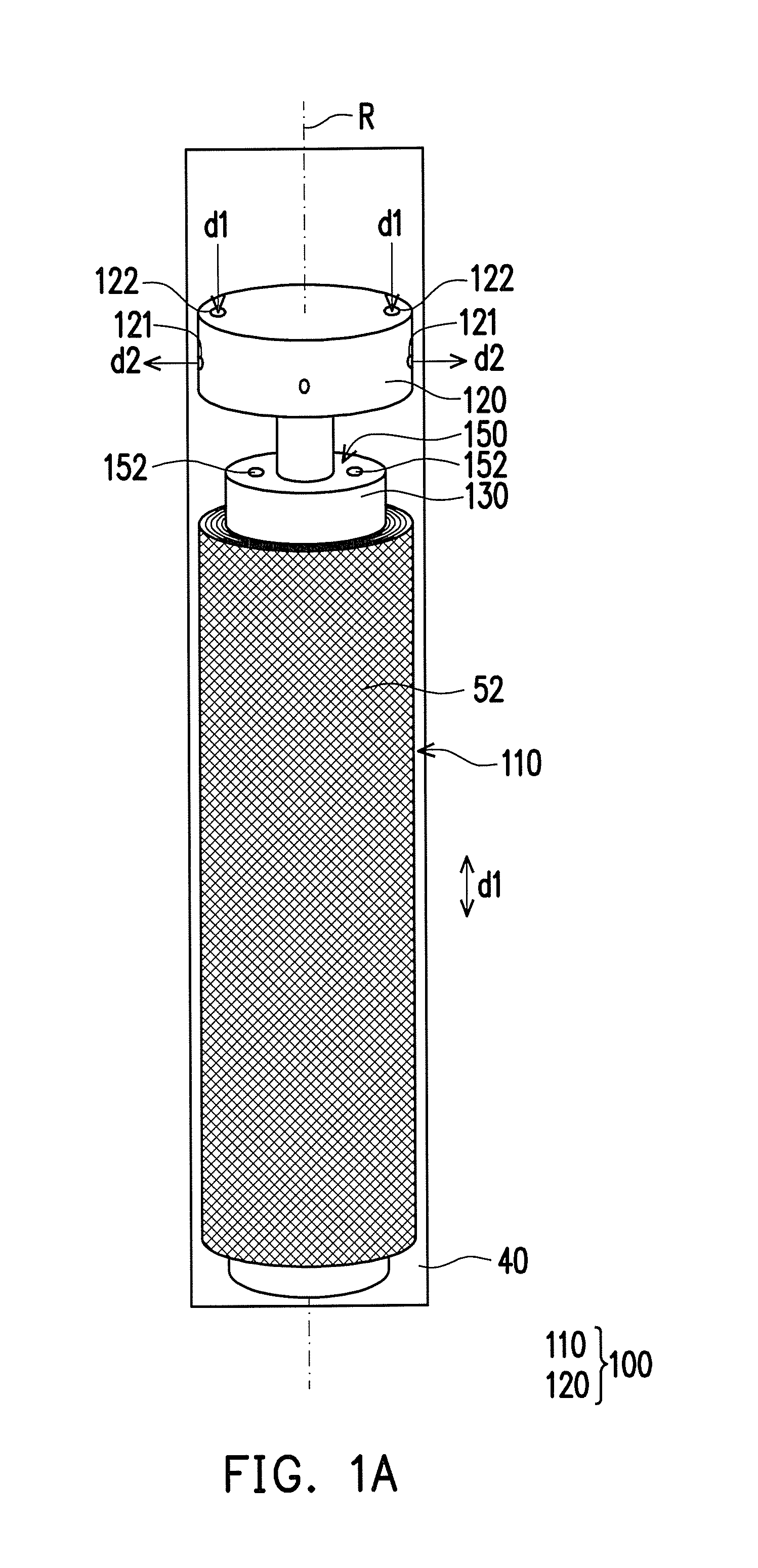

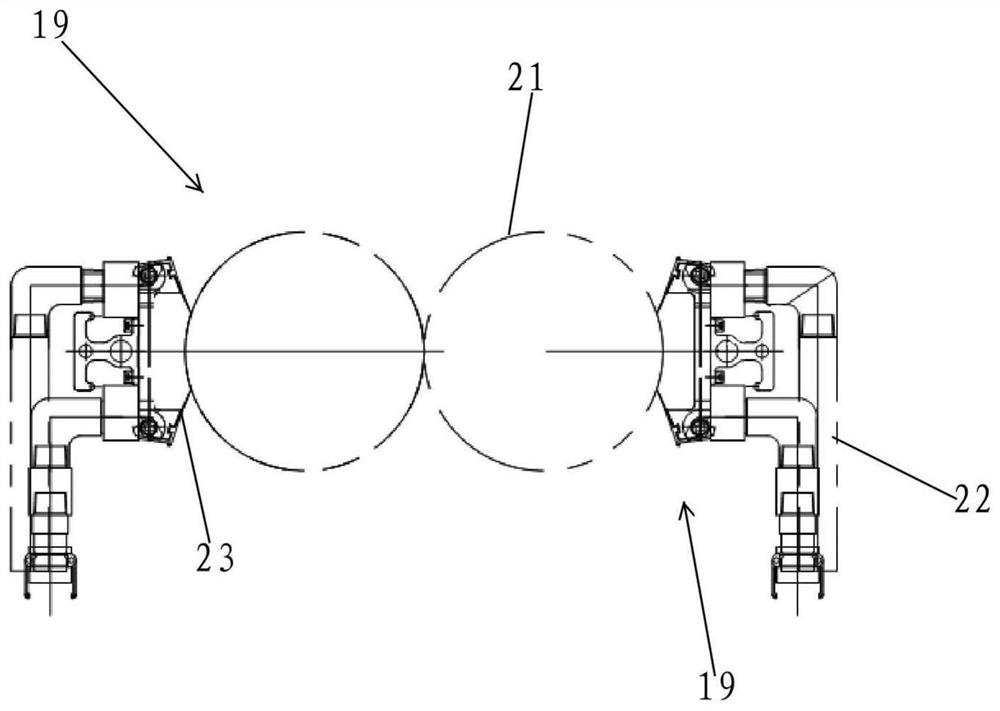

Dyeing device and dyeing apparatus

ActiveUS20160244902A1Improve dyeing effectHigh pressure spaceTextile treatment containersTextile treatment dyeing devicesFiberEngineering

A dyeing device adapted to move in a high pressure space having a fluid is provided. The dyeing device includes a magnetic dyeing shaft and a dye mixing chamber connected to the magnetic dyeing shaft. The magnetic dyeing shaft is configured to make a fiber product wind thereon, and the dye mixing chamber is configured to store dye, and the dye mixing chamber is adapted to let the fluid in the high pressure space flow through. A dyeing apparatus including the dyeing device is also provided.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

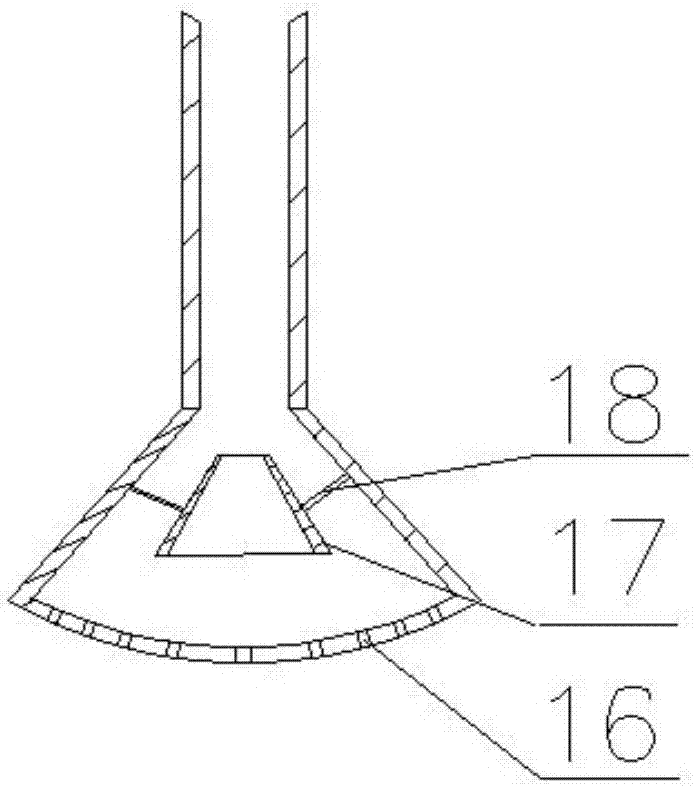

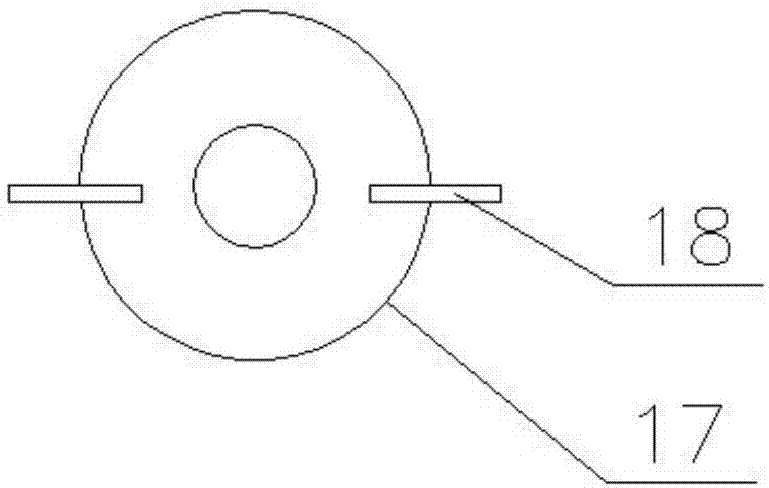

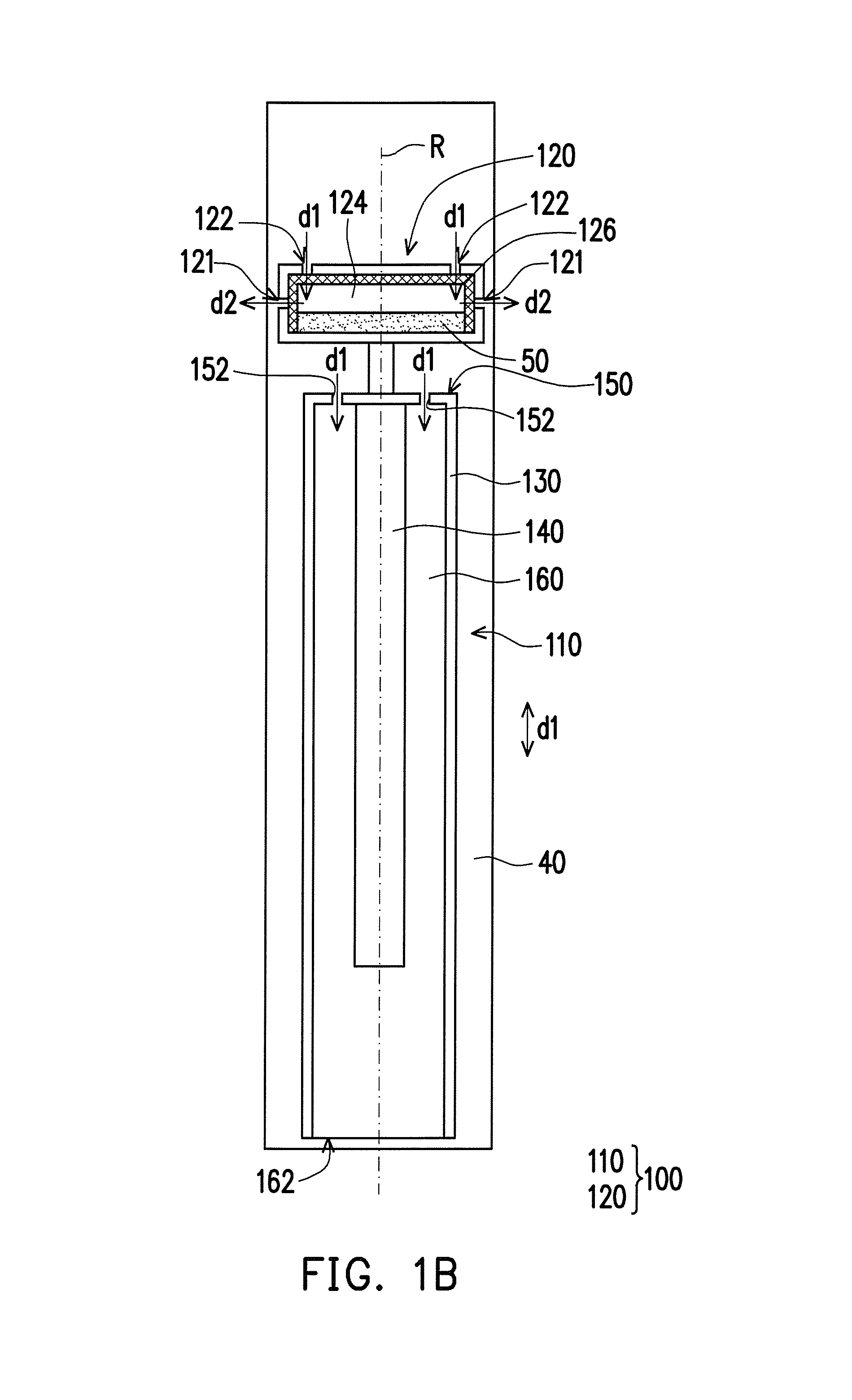

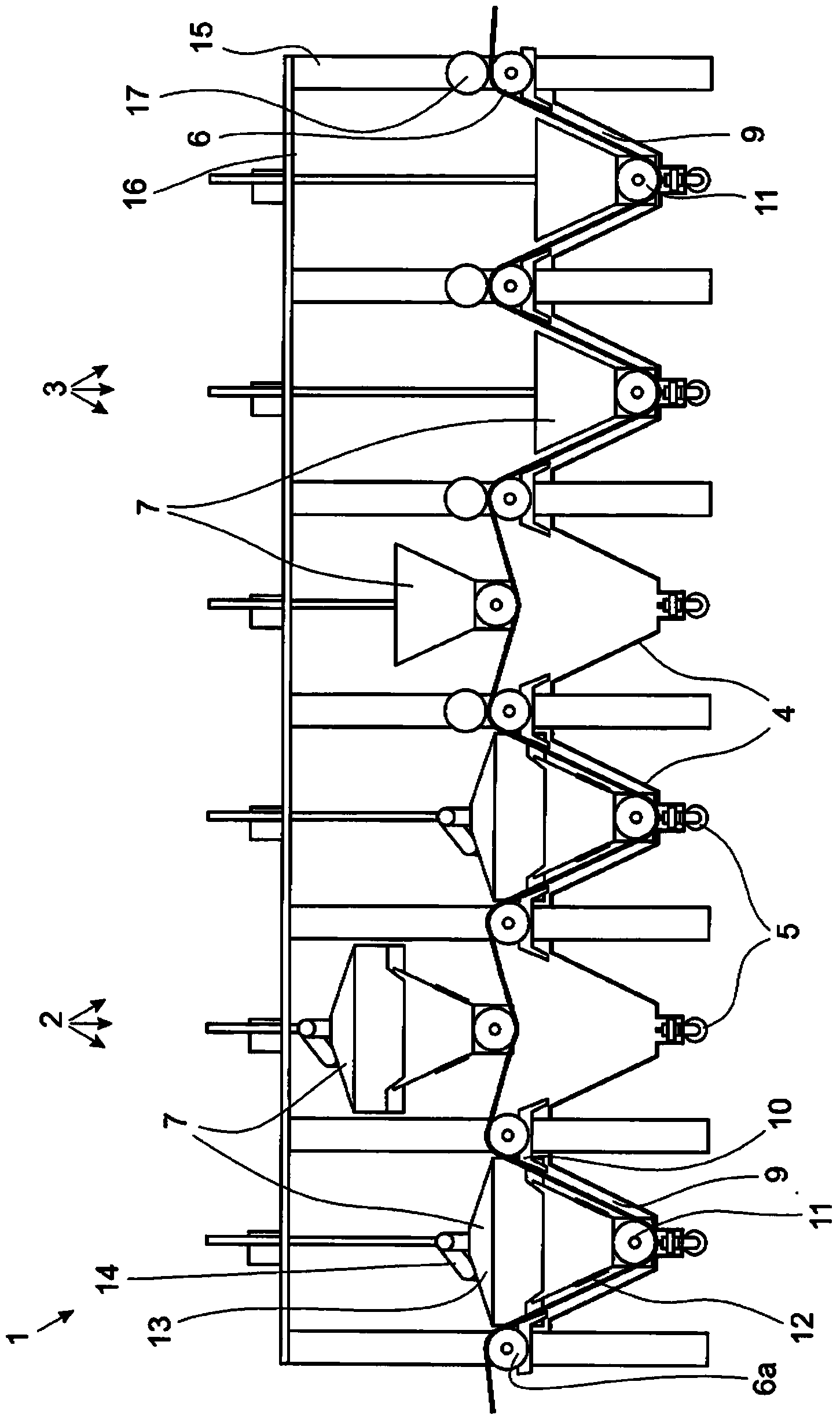

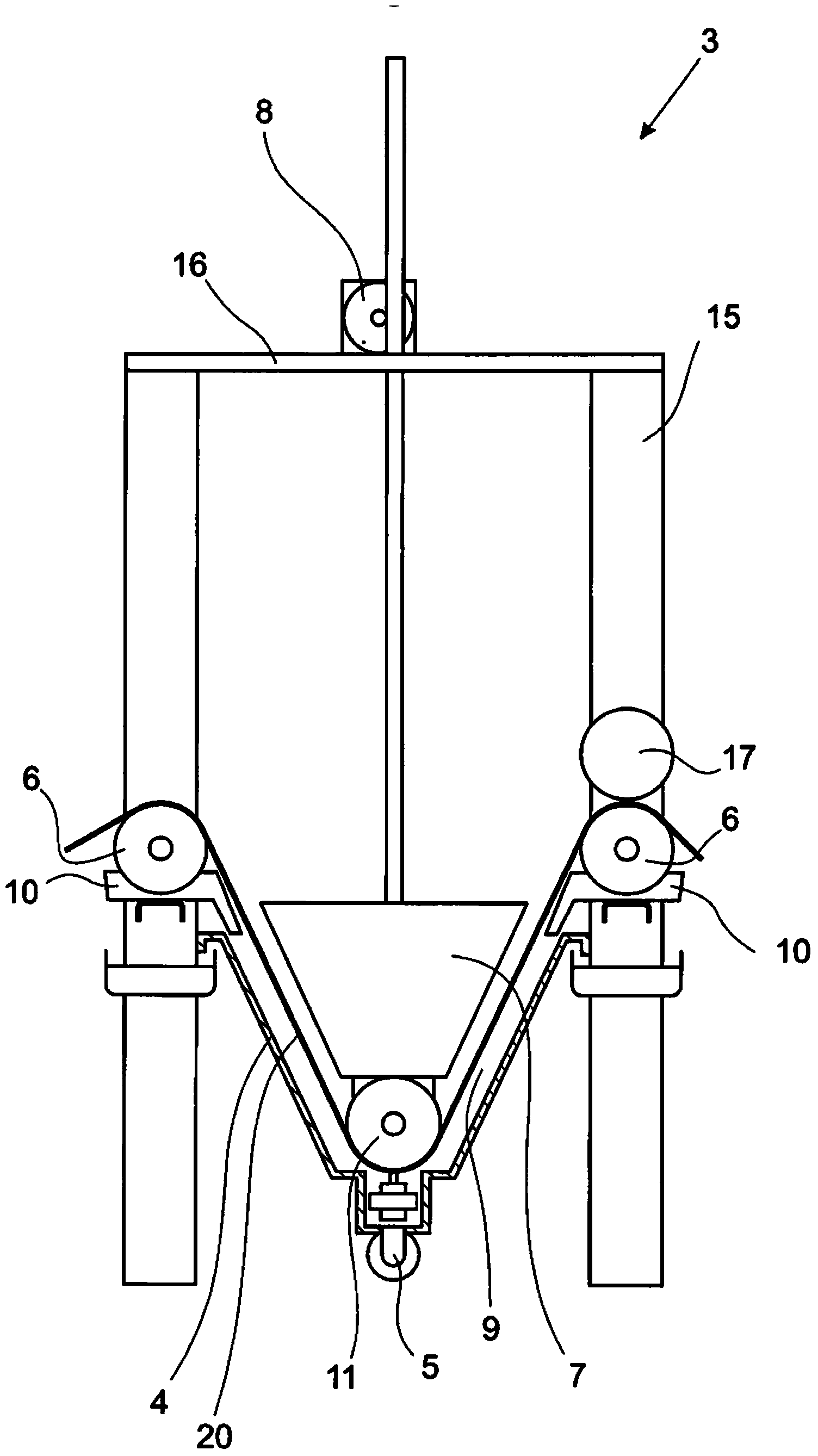

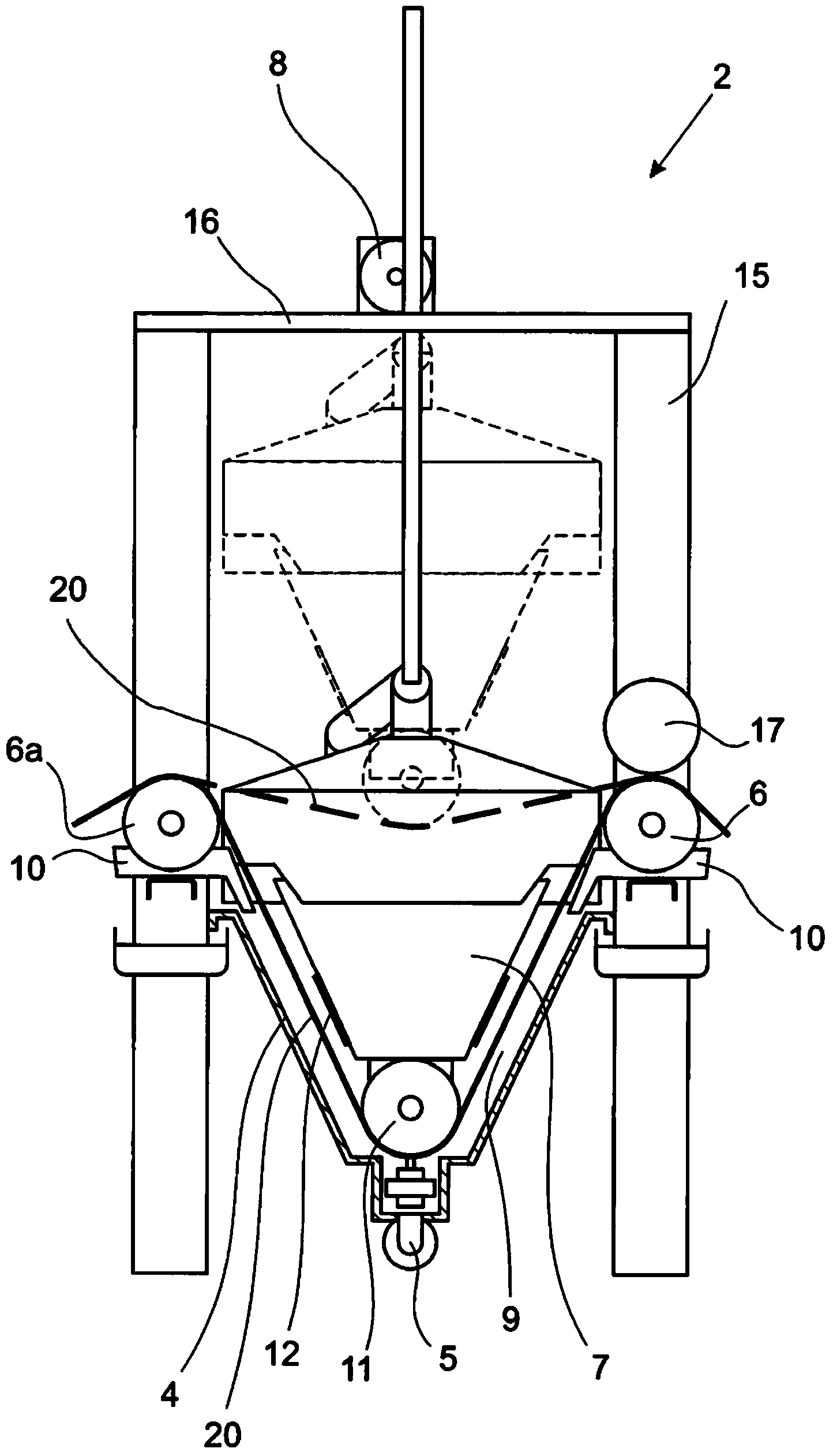

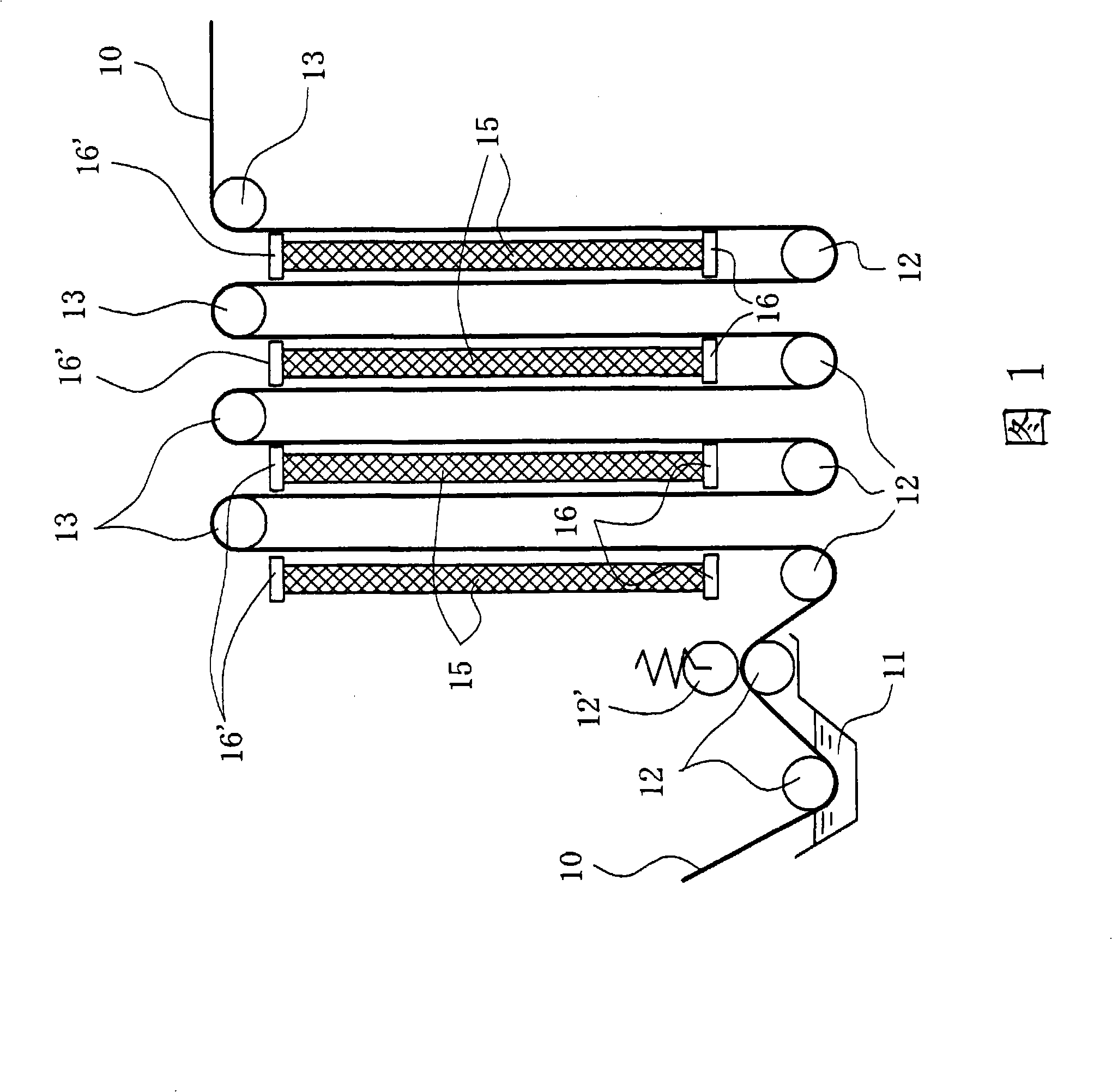

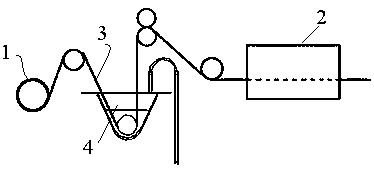

Device and method for the treatment, in particular electrolysis or cleaning, of endless fibers, threads or webs of fabric

InactiveCN104169485AReduced external dimensionsExtended stayChemical fixing of textilesHeating/cooling textile fabricsFiberElectrolysis

The invention relates to a bath and a method for treating, in particular electrolyzing or cleaning, endless fibers, threads or webs of fabric. Said bath comprises a bath container (4) which is filled at least in part with a process liquid and which has means for introducing the endless fibers, threads or webs of fabric. The invention is characterized in that said means are arranged in such a way that the endless fibers, threads or webs of fabric are guided through the bath in a V-shape. The invention also relates to a carbonization plant.

Owner:OERLIKON TEXTILE GMBH & CO KG

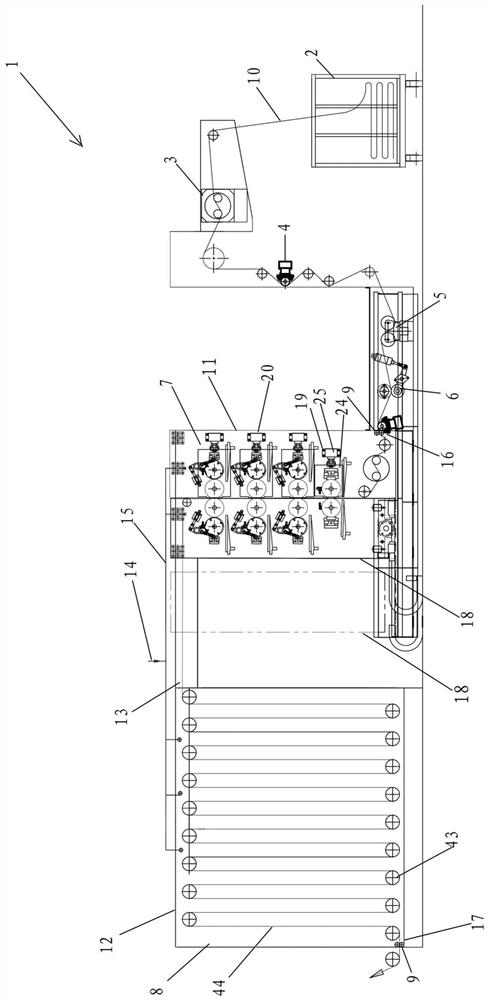

Transfer dyeing equipment

ActiveCN112481865AConsistent circular cross sectionReduce pollutionTextile treatment machine arrangementsTextile treatment carriersPolymer scienceDyeing

The invention discloses transfer dyeing equipment. The transfer dyeing equipment comprises a dyeing box, a dyeing part sleeve device, a permeation box and a penetration device, wherein the dyeing boxis filled with an inert gas; the dyeing part sleeve device is arranged in the dyeing box; the dyeing part sleeve device is configured for dyeing the surface of a fabric with dye; the permeation box isarranged at the downstream of the dyeing box along the movement direction of the fabric, and the permeation box is filled with inert gas; the penetration device is arranged in the penetration box, and the penetration device is used for enabling the dye on the surface of the fabric to penetrate into the fabric, wherein the dyeing box and the penetration box communicate with each other, and the fabric sequentially penetrates through the dyeing box and the penetration box; and the dyeing box is provided with a sealing device at the fabric inlet, and the permeation box is provided with a sealingdevice at the fabric outlet, so that the dyeing box and the permeation box are hermetically sealed relative to the environment.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

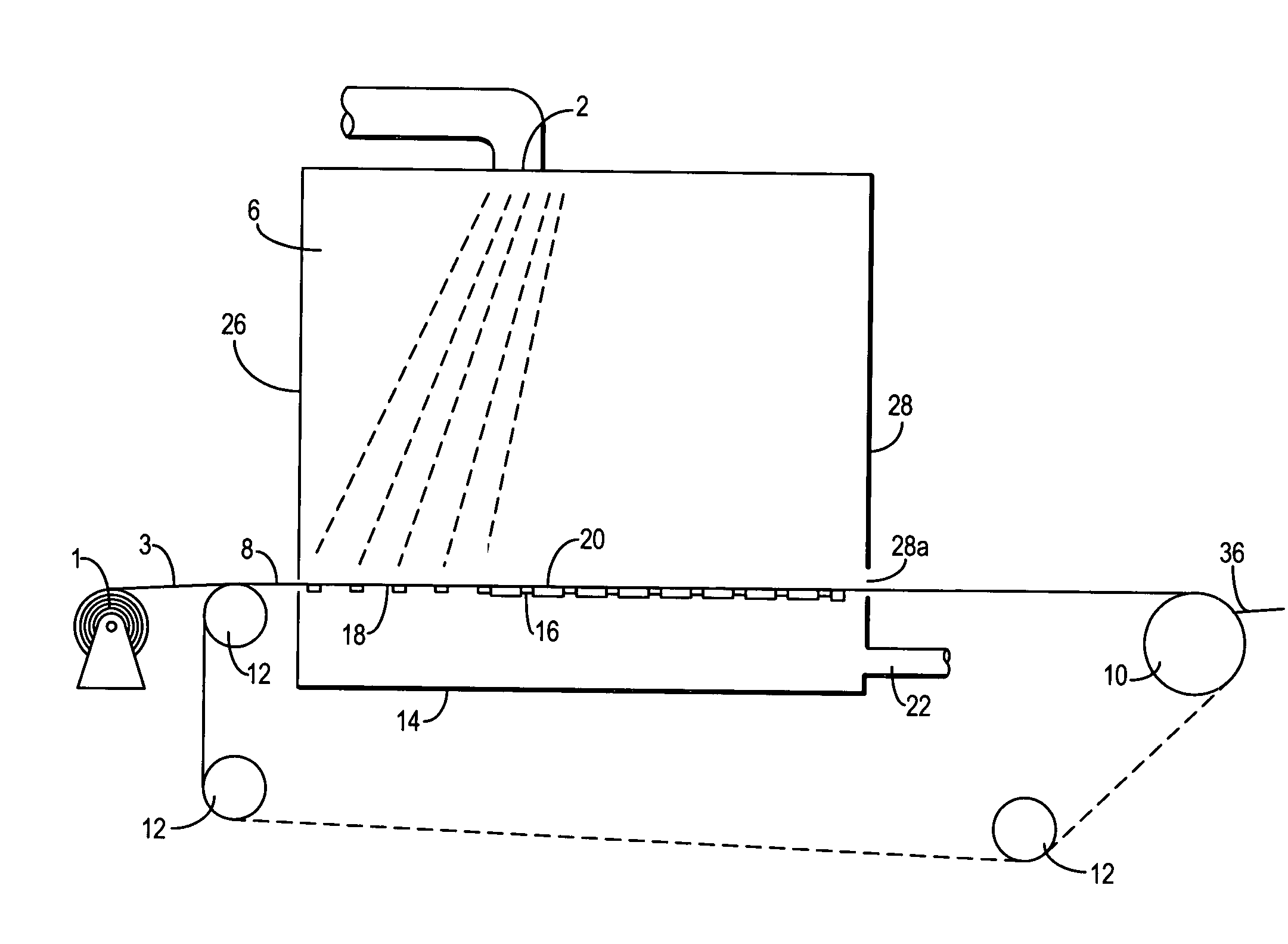

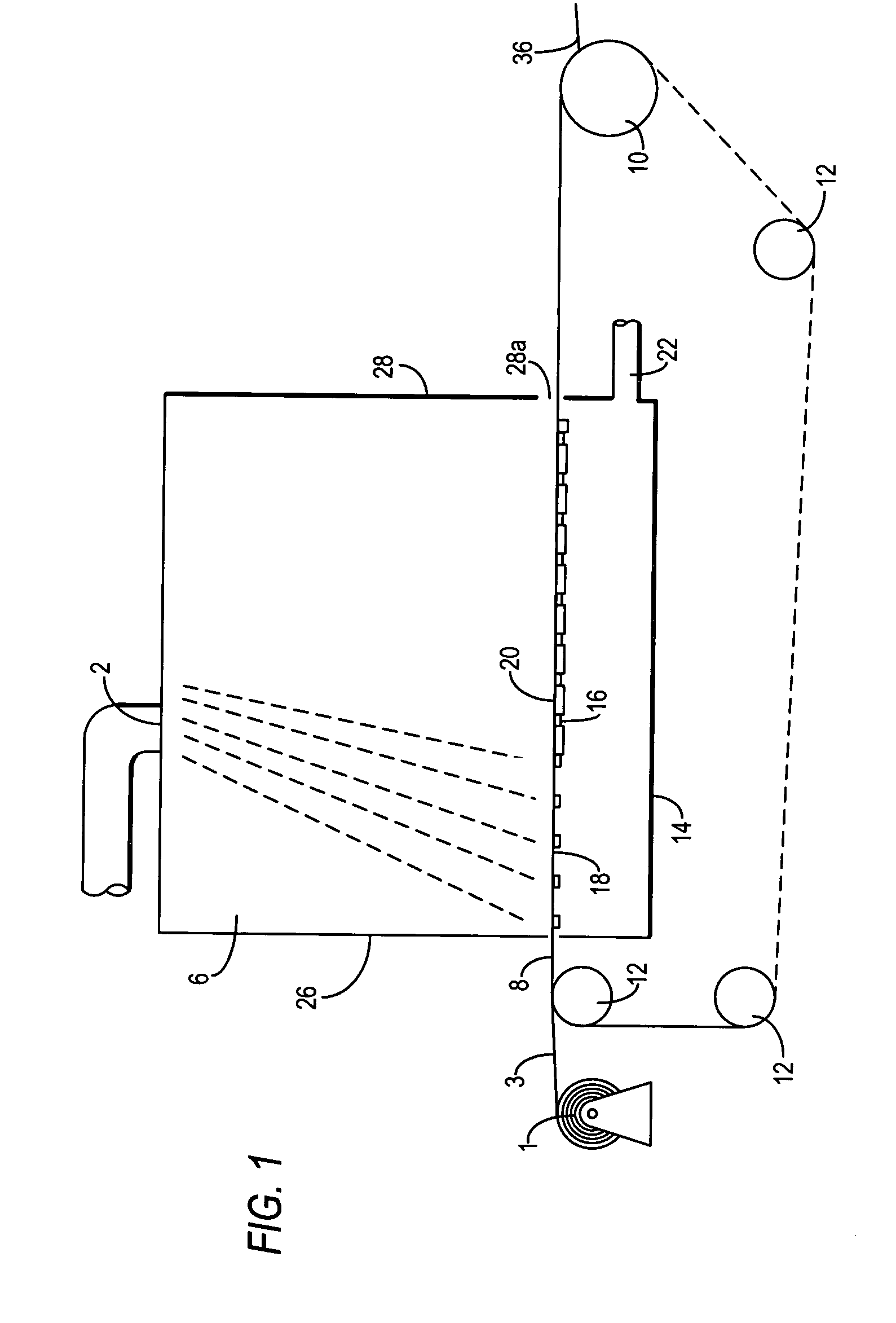

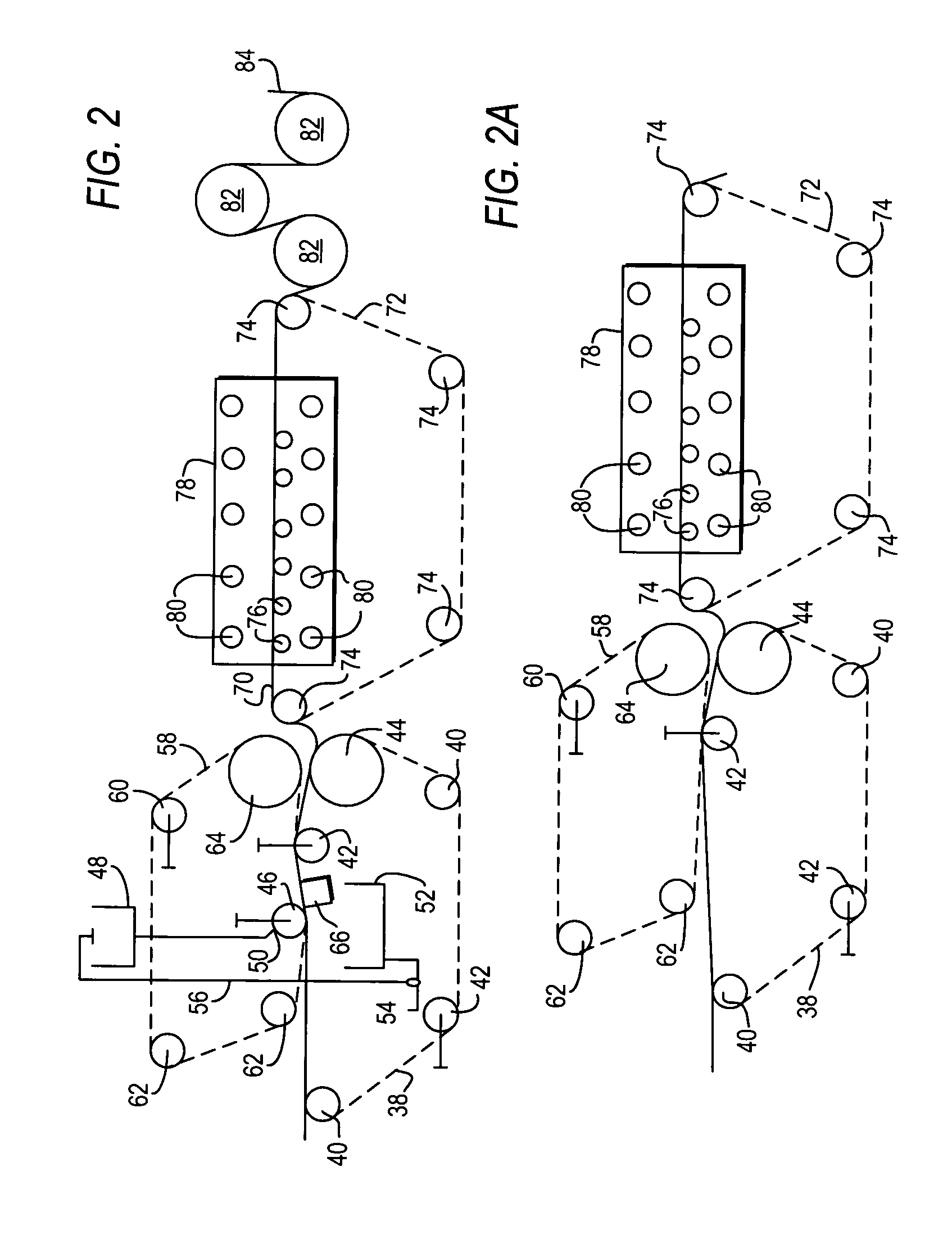

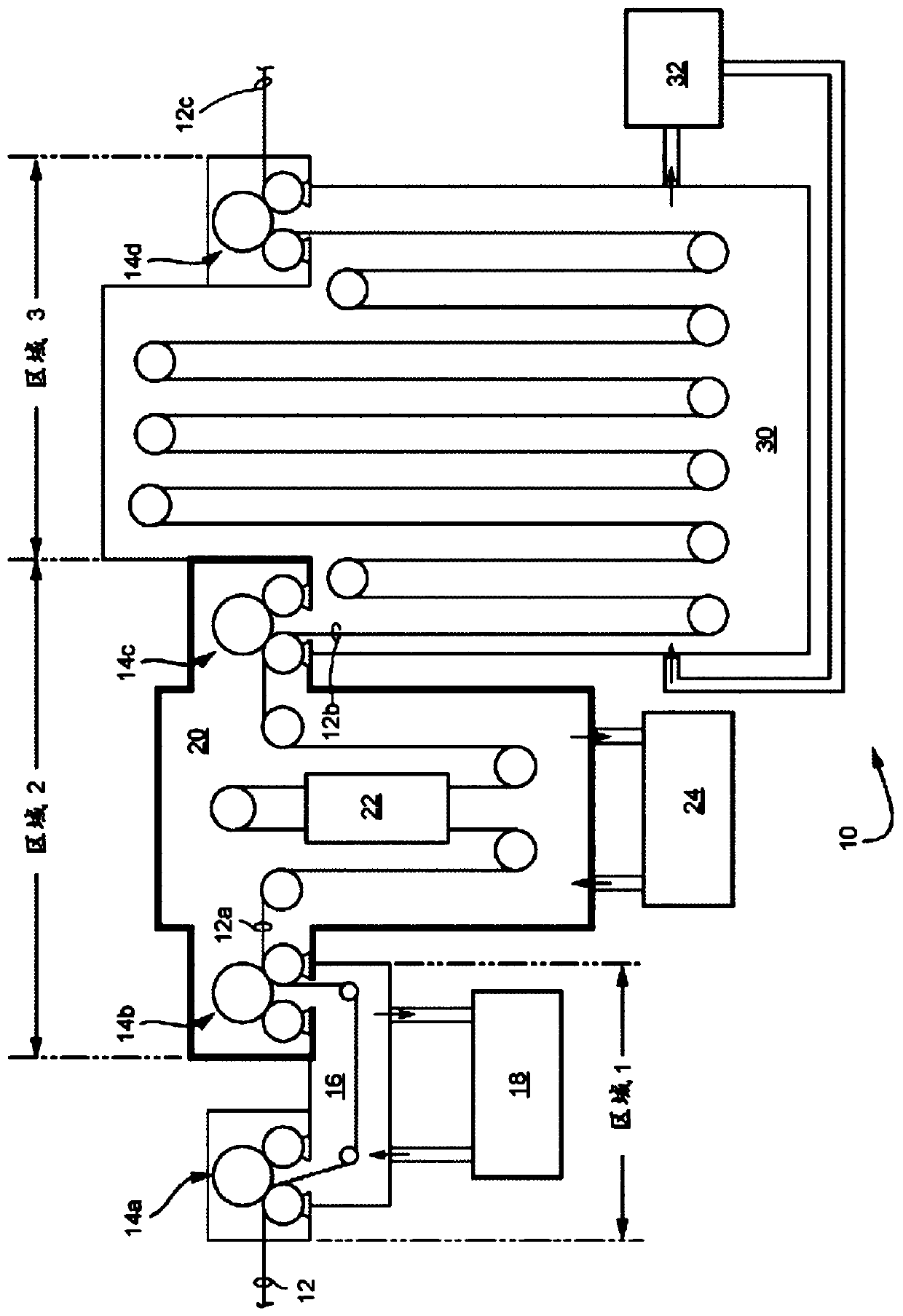

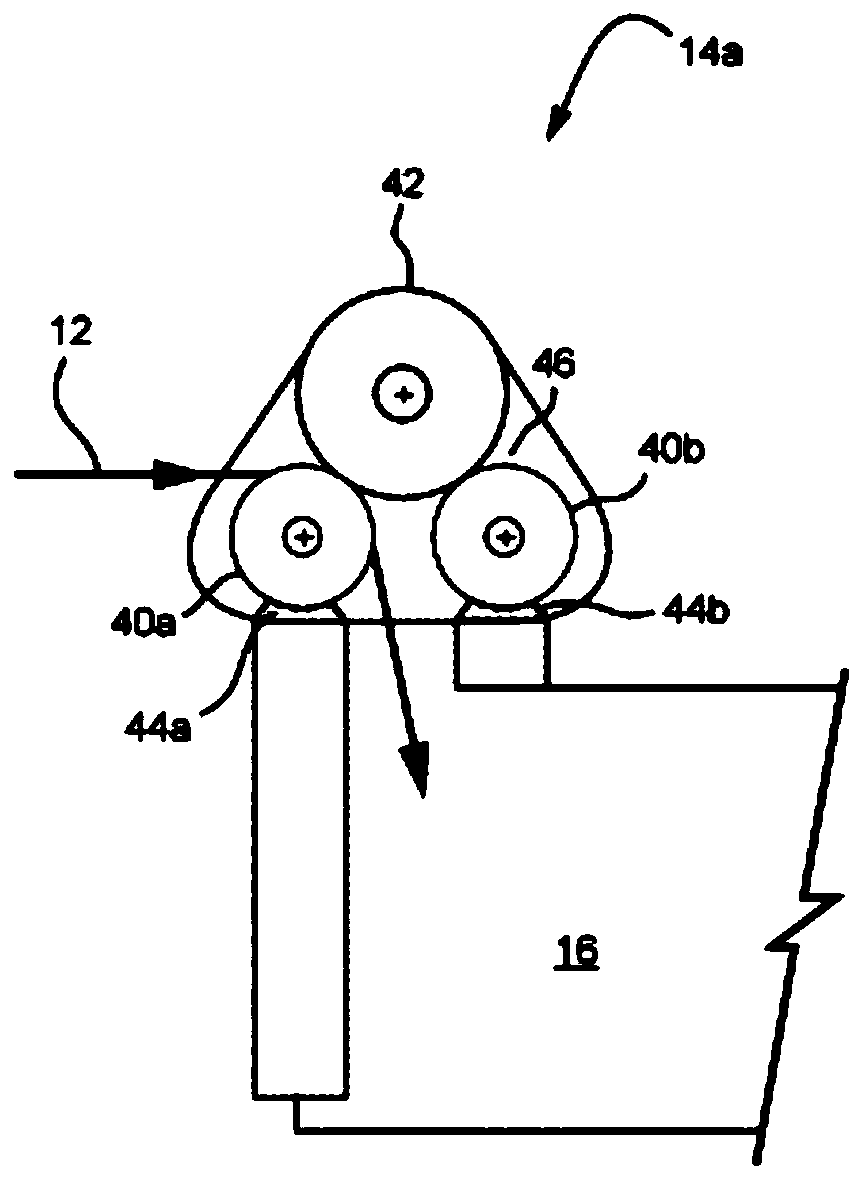

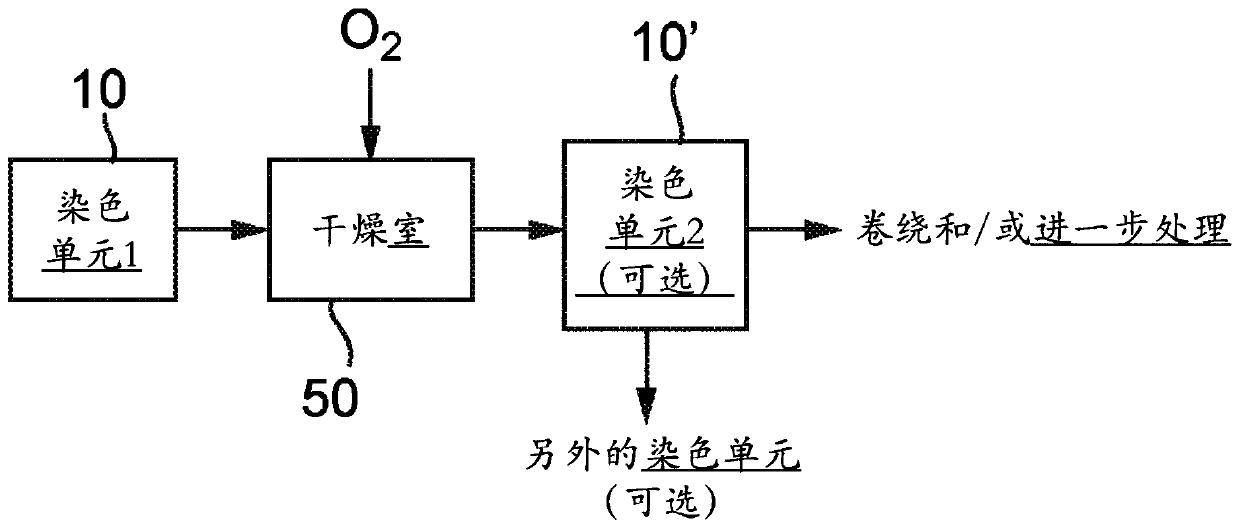

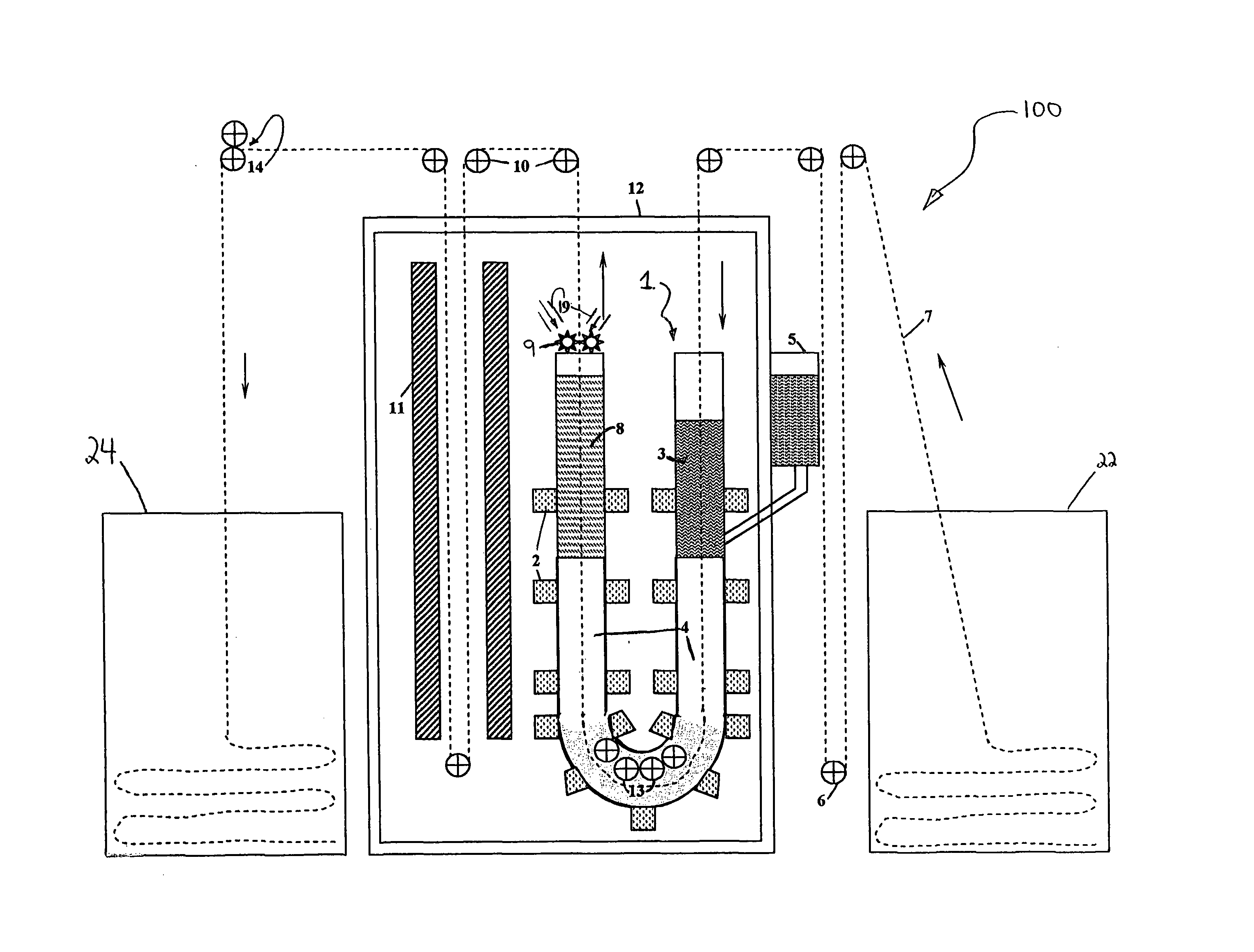

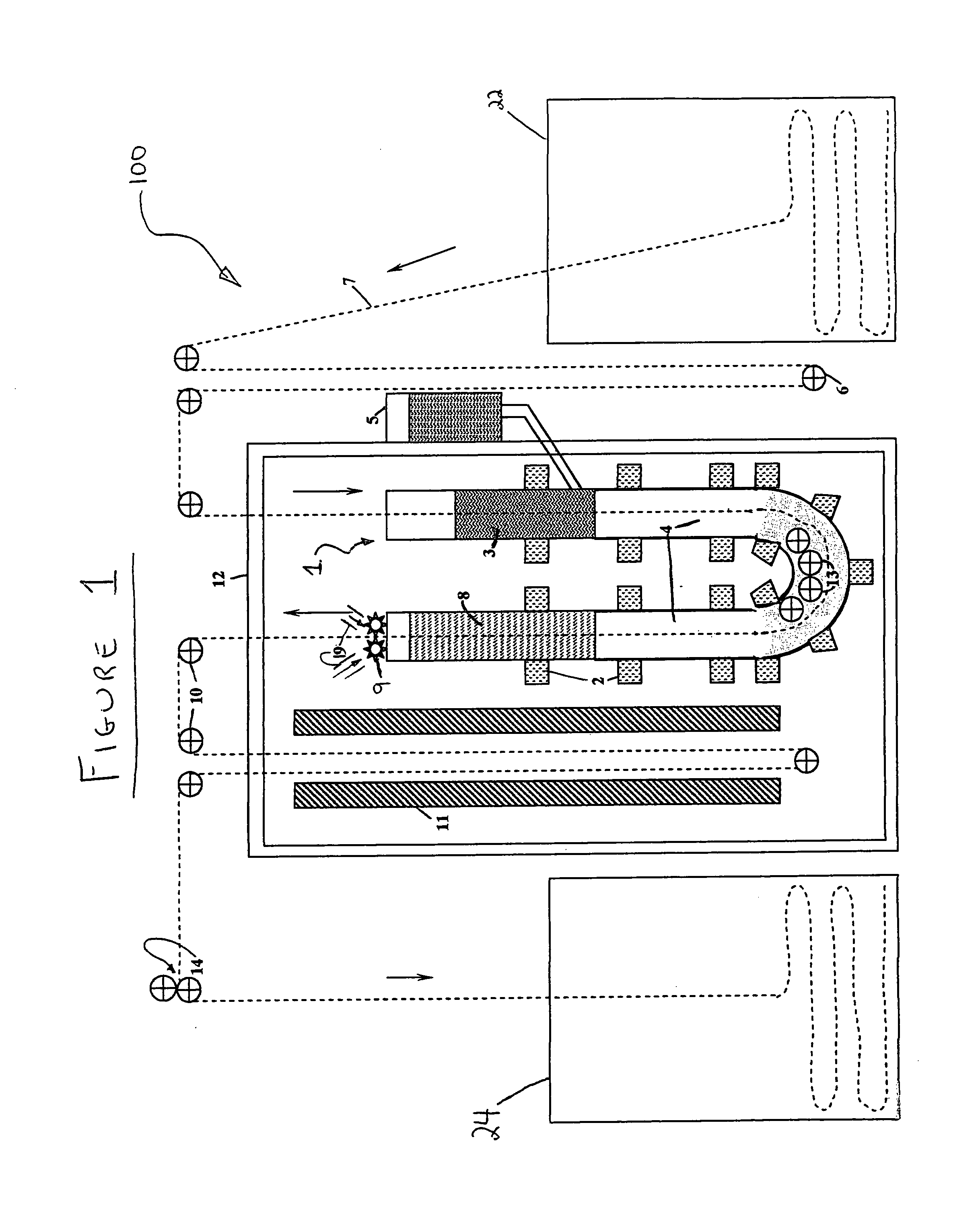

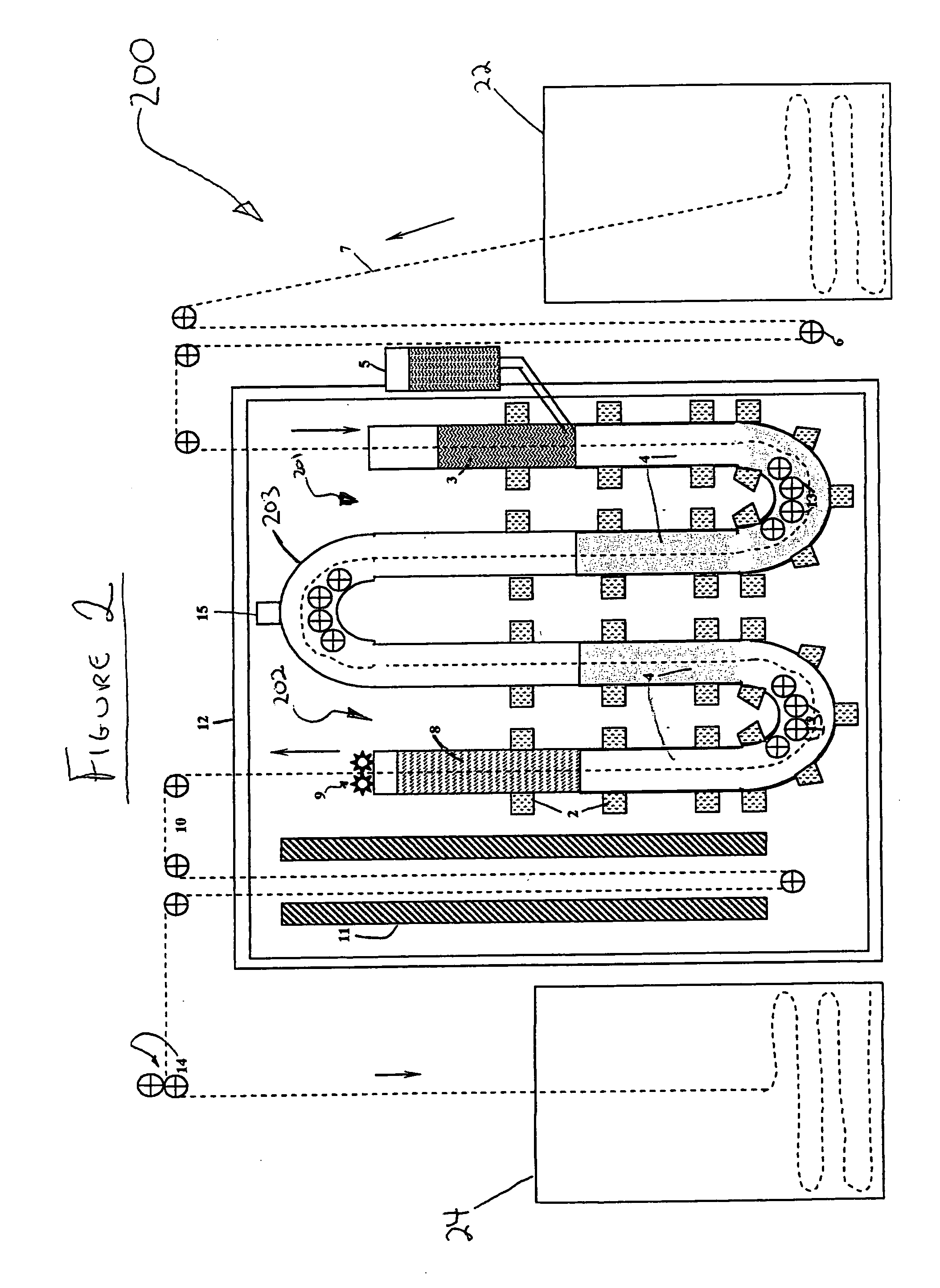

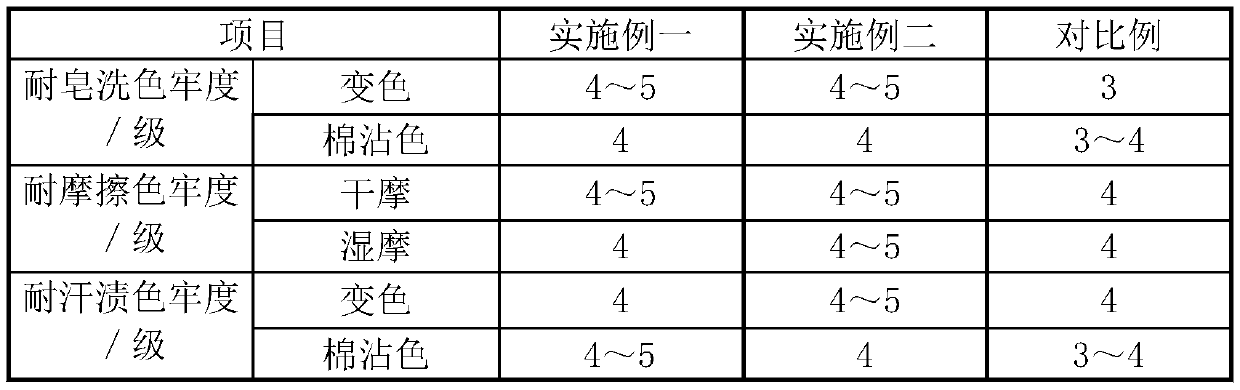

Indigo dyeing process and apparatus and indigo dyed yarns and fabrics made thereby

InactiveCN110036075AHigh color fastnessHigh wet friction valueTextile treatment containersSucessive textile treatmentsYarnColour fastness

Processes and apparatus are disclosed which substantially eliminate the formation of oxidized indigo dye before and during dye application onto a natural fiber yarn or fabric while allowing the leuco-indigo dye molecule to diffuse fully into the natural fibers of the yarn where it can fix to the fibers prior to oxidation (i.e., exposure of the leuco-dyed yarns to oxygen). Indigo dyed textile products (e.g., dyed cotton yarns that may be twill woven to form a denim fabric) exhibit exceptionally high colorfastness as determined by the AATCC Crock Test.

Owner:INDIGO MILL DESIGNS LLC

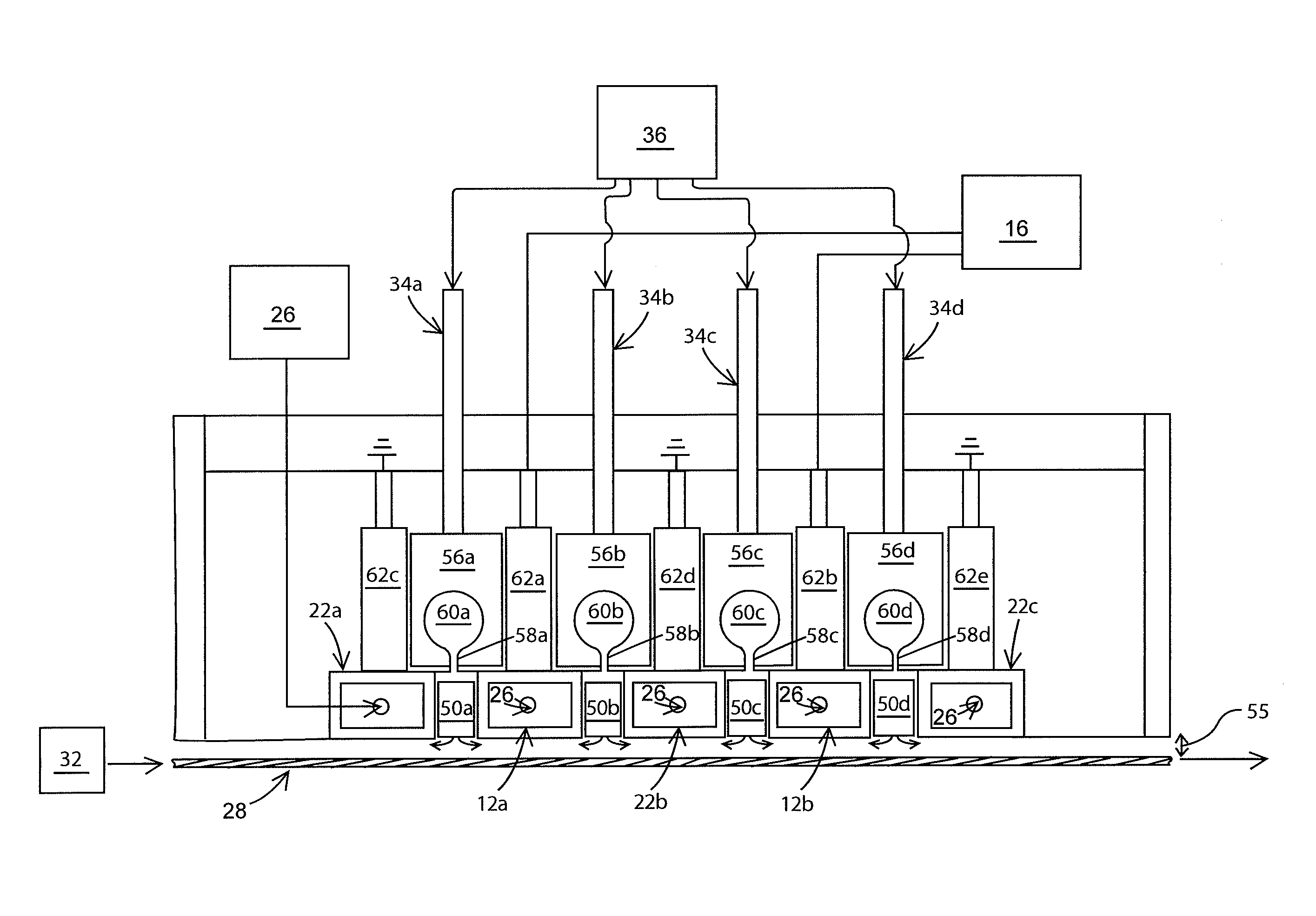

Atmospheric-pressure plasma processing method

InactiveUS20160348292A1Efficient productionMinimum distanceChemical fixing of textilesPlasma welding apparatusEngineeringAtmospheric pressure

Methods for atmospheric pressure plasma discharge processing using powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, are described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

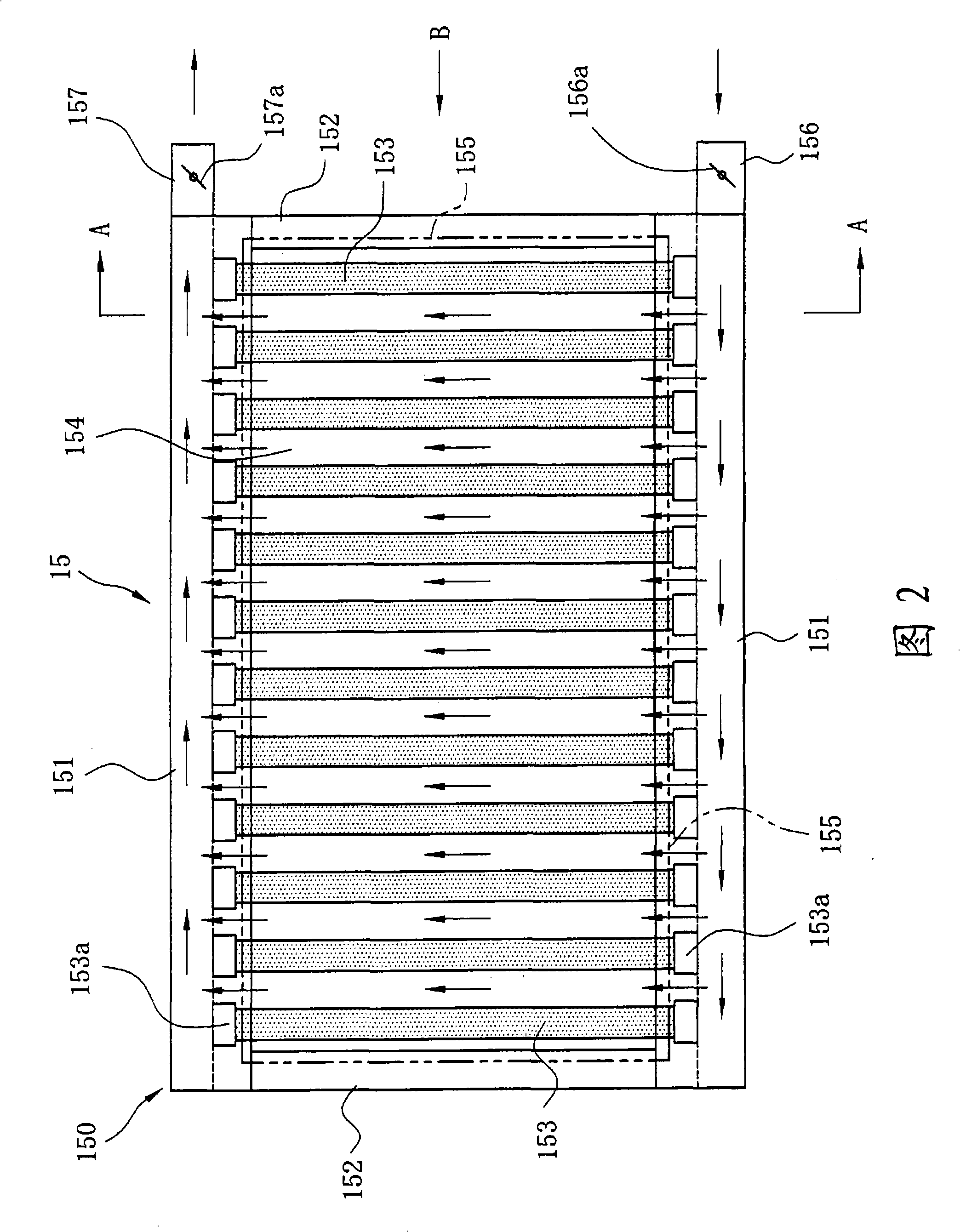

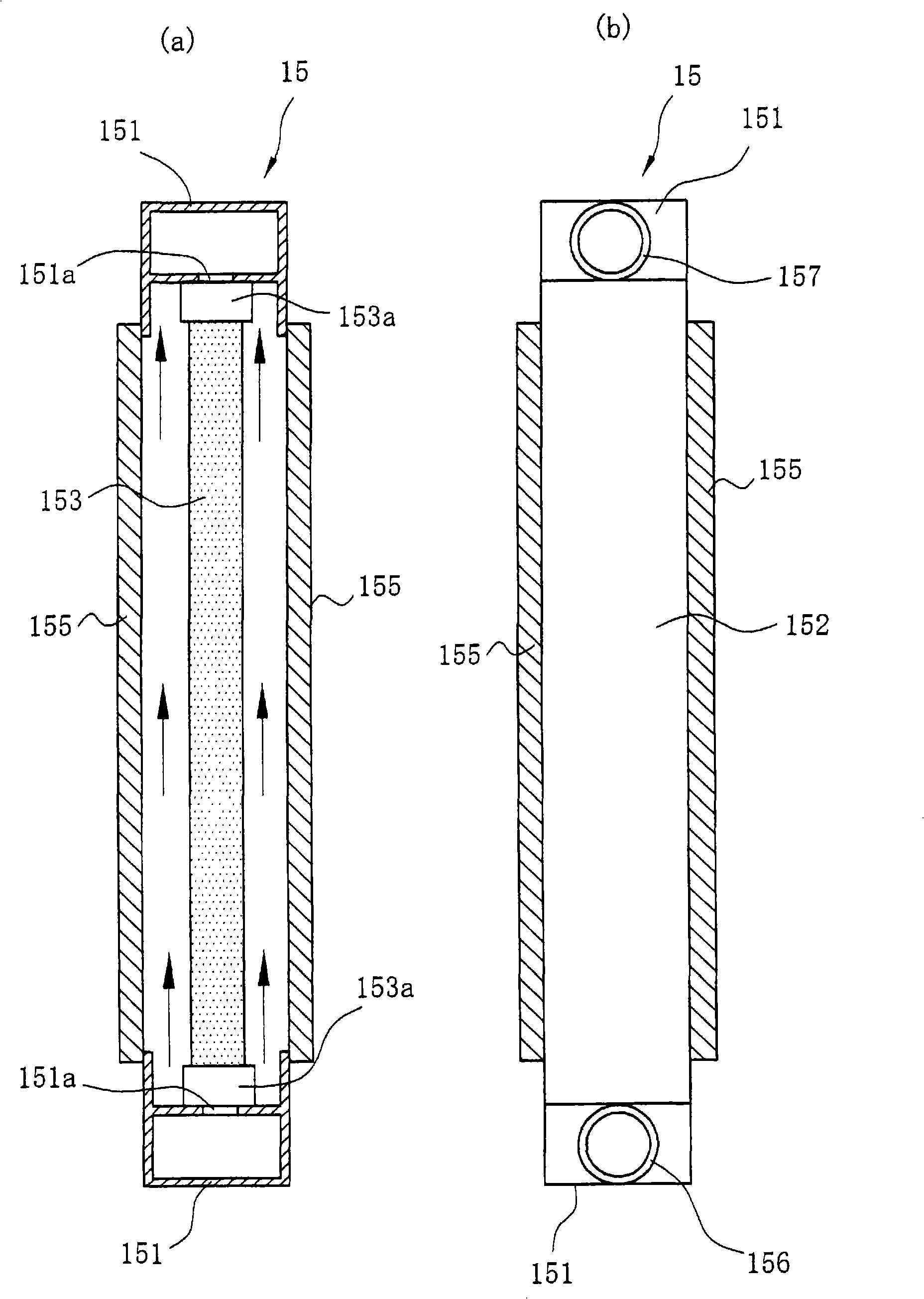

Bleaching/reforming apparatus for fiber and fiber structure

InactiveCN101405451AGood light transmission efficiencyWon't get dirtyChemical fixing of textilesBleaching apparatusUltraviolet lightsEngineering

This invention provides a bleaching / reforming apparatus for a fiber and a fiber structure, comprising applying ultraviolet light and / or visible light from a lamp to a fiber or fiber structure impregnated with a liquid chemical of an oxidizing agent, a reducing agent or the like to bleach / reform the fiber and fiber structure, which apparatus can prevent soiling of the lamp and can enhance the efficiency of operation of the apparatus, and a light source unit for use in the apparatus. The apparatus comprises a light source unit (15) and a support member for detachably supporting the light source unit (15). The light source unit (15) comprises a lamp (153) for applying ultraviolet light and / or visible light, a frame (150) for housing the lamp (153), and a transparent plate (155) mounted onto the frame, for permitting light applied from the lamp (153) to be passed therethrough.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Dyeing apparatus and method therefor

InactiveUS20070056122A1Textile treatment machine partsChemical fixing of textilesHigh densityHydrostatic pressure

A dyeing apparatus and method for continuous dyeing of a fabric article with dye, the apparatus including: (a) a dyeing vessel for containing a high-density liquid; (b) a heating mechanism, thermally associated with the dyeing vessel, for heating a dye fixation zone within the vessel to a temperature above 70° C.; (c) a continuous transport mechanism for continuously transporting the fabric article, through a dye impregnation chamber, and through the dye fixation zone of the dyeing vessel, and (d) a dye-dispensing mechanism for delivering a dye liquor within the dye impregnation chamber, so as to impregnate with the dye, the fabric article passing through the chamber, and wherein the dyeing vessel is dimensioned and configured such that a height of the high-density liquid delivers a hydrostatic pressure of at least 0.1 bar gauge to the dye fixation zone, so as to effect fixation of the dye in the fabric article.

Owner:ZZAKEY TECH

Printing preparation method for improving printing durability

InactiveCN108951203ARealize the continuous process of the whole processEmission reductionChemical fixing of textilesHeating/cooling textile fabricsPolyesterEngineering

The invention provides a printing preparation method for improving the printing durability. The method comprises the steps of printing, drying and fixing, washing, dehydrating in vacuum, and drying for shaping. By adopting the method, the hot melting condition is effectively ensured, the textile has bright color, the tinctorial yield is increased by 5-30 percent, the printing durability is promoted, and the problems that polyester fabrics do not have bright hot molten printing colors or light dyeing, which trouble the printing industry for a long time, can be solved.

Owner:NANTONG WEILI TEXTILE CO LTD

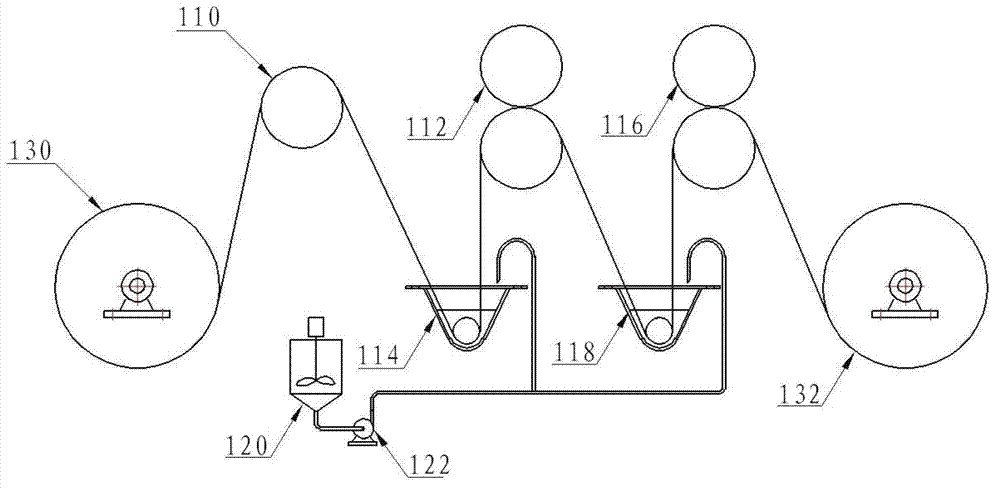

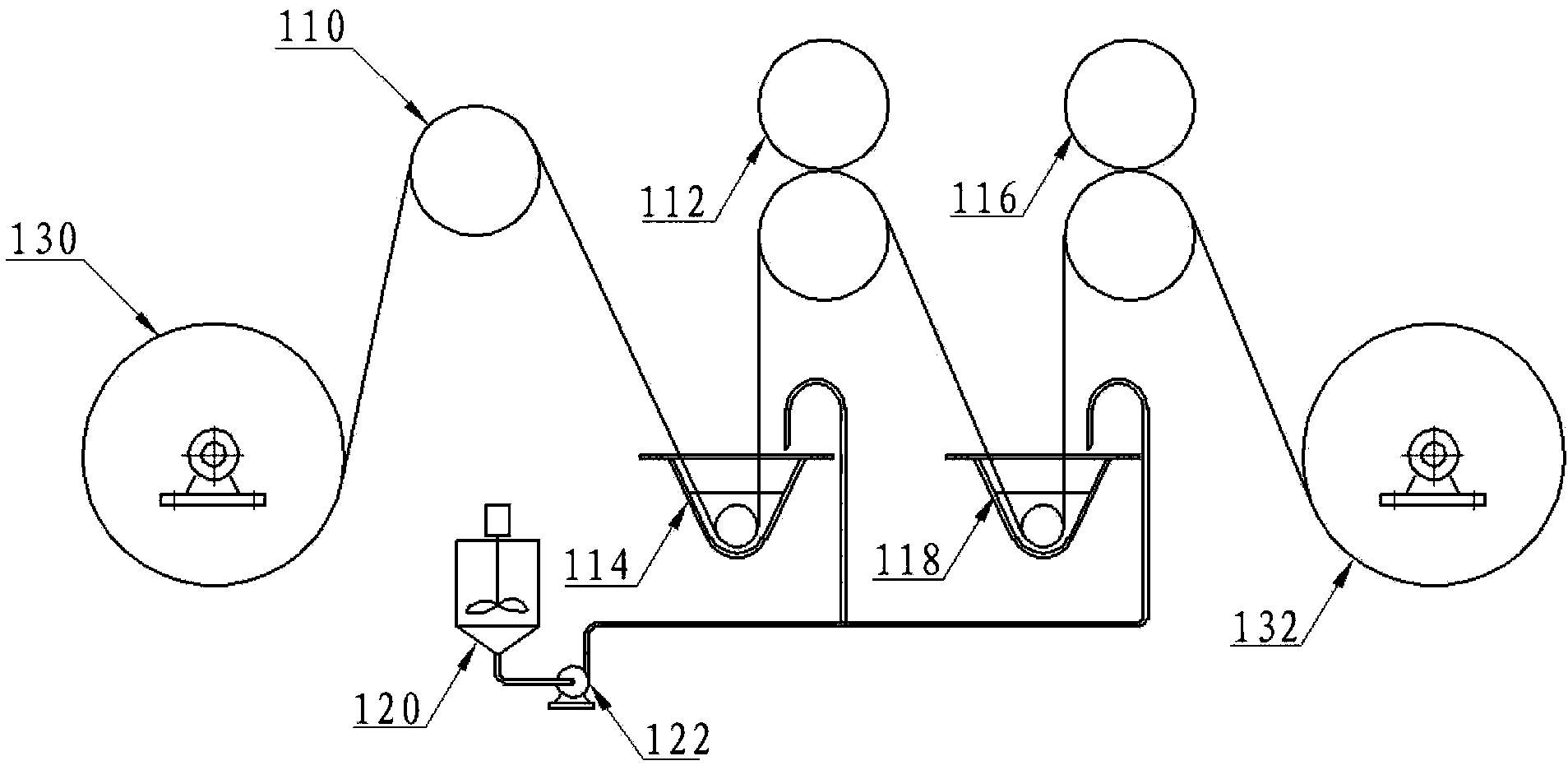

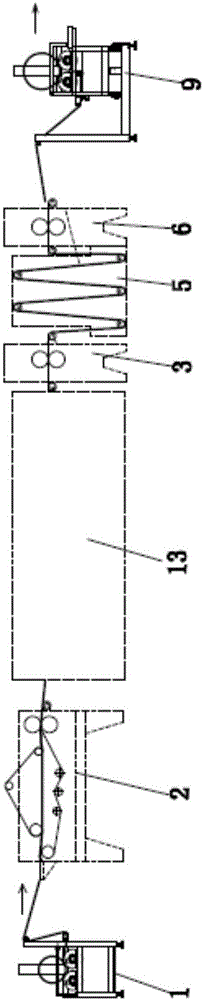

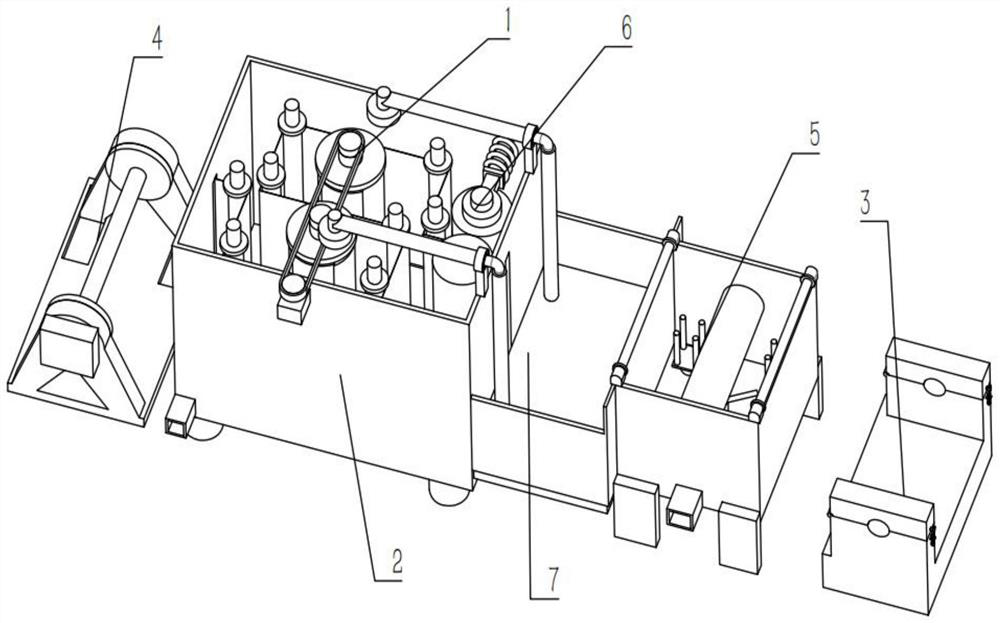

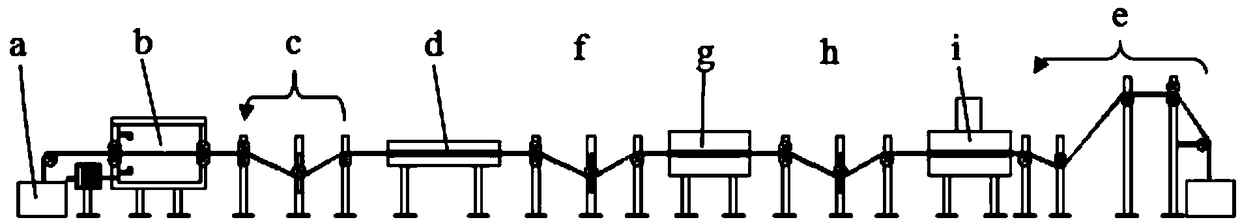

Microfiber dyeing method and production line

InactiveCN105821611ADoes not produce color precipitationReduce water consumptionSucessive textile treatmentsChemical fixing of textilesProduction lineEngineering

The invention discloses a microfiber dyeing production line which comprises an unreeling machine and a reeling machine. The unreeling machine is located at the input end of the production line, and the reeling machine is located at the stop end of the production line; the production line further comprises an ultrasonic dyeing machine arranged behind the unreeling machine in the direction of the production line. The invention further discloses a microfiber dyeing method. The method comprises the steps of unreeling, ultrasonic dyeing and reeling. According to the microfiber dyeing method and production line, the dyeing speed is high, little water is consumed, the color bleeding effect is good, the colors of the front and back batches are same, and color obtained through dyeing is the same that the precious color even though dyeing liquid is added according to the original proportion in the dyeing process.

Owner:肇庆市宝利达机电设备有限公司

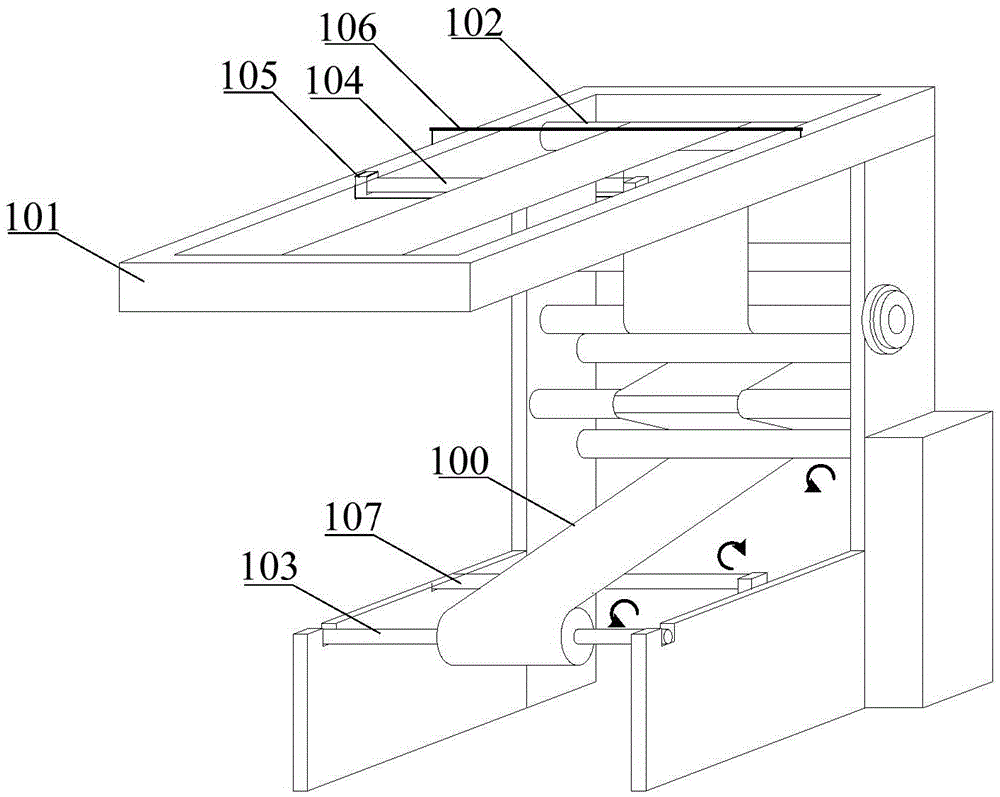

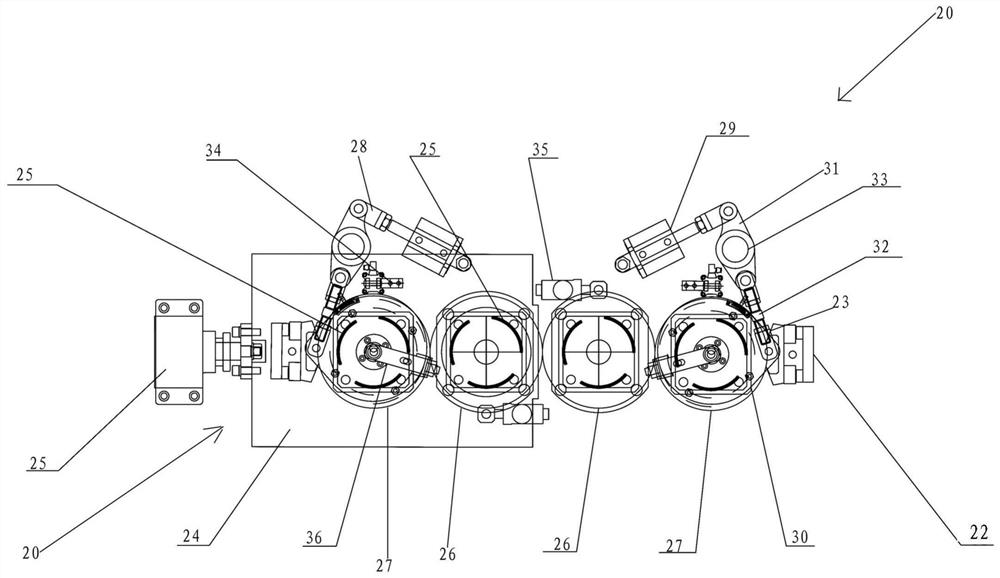

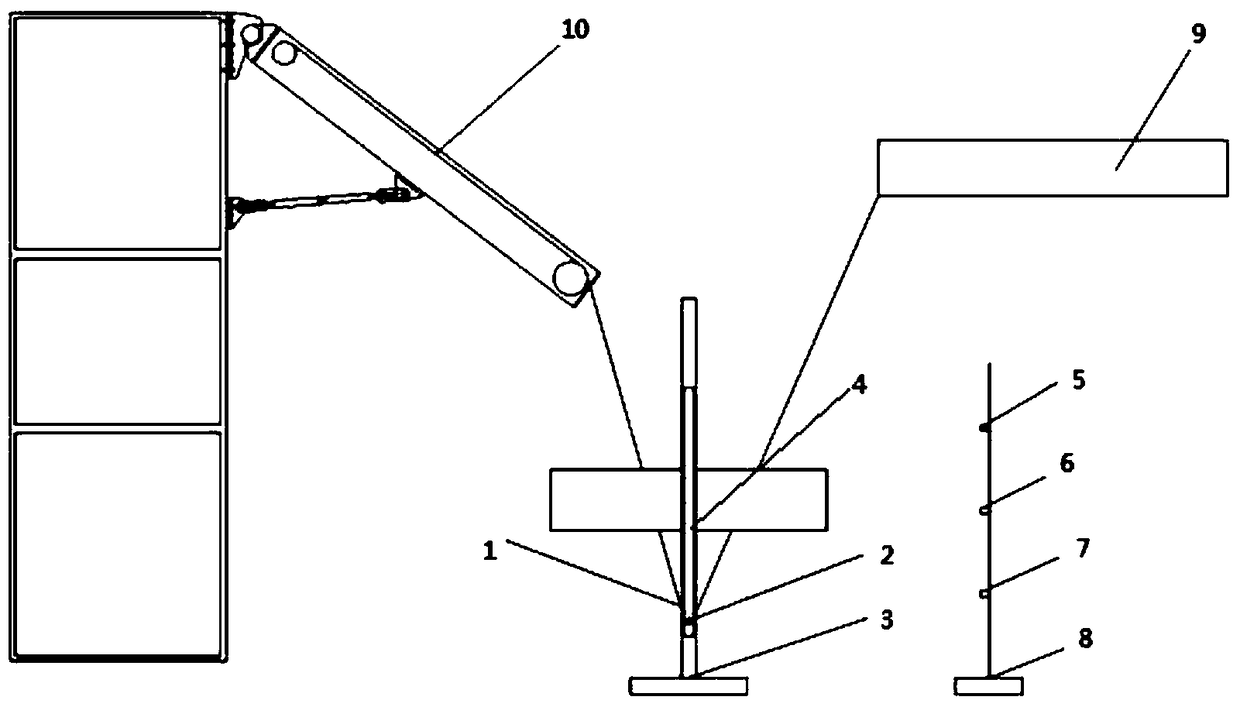

Colored spun yarn production device and production method by performing fiber dyeing and blending operation on spinning process

The invention discloses a colored spun yarn production device and production method by performing fiber dyeing and blending operation on spinning process. The production device is a ring spinning frame comprising a front trolley table surface and a back trolley table surface with the same structure. The front trolley table surface and the back trolley table surface are composed of multiple ingot positions with the same structure. Each ingot position comprises a drawing-off system, the back part of which is connected with a rough yarn feeding bell mouth. The front part of the system is equippedwith a beam splitting piece, the front part of which is equipped with a dyeing system. The front part of the dyeing system is additionally equipped with a color fixation system. The front of the color fixation system is provided with a beam-splitting bell moth and an output roller pair. The front part of the drawing-off system of the ring spinning frame is additionally equipped with the dyeing system and the color fixation system. Fiber dyeing and blending operation are finished on a spinning procedure during production of colored spun yarns. Therefore, production efficiency of colored spun yarns is greatly increased.

Owner:ANHUI HANLIAN TEXTILE CO LTD

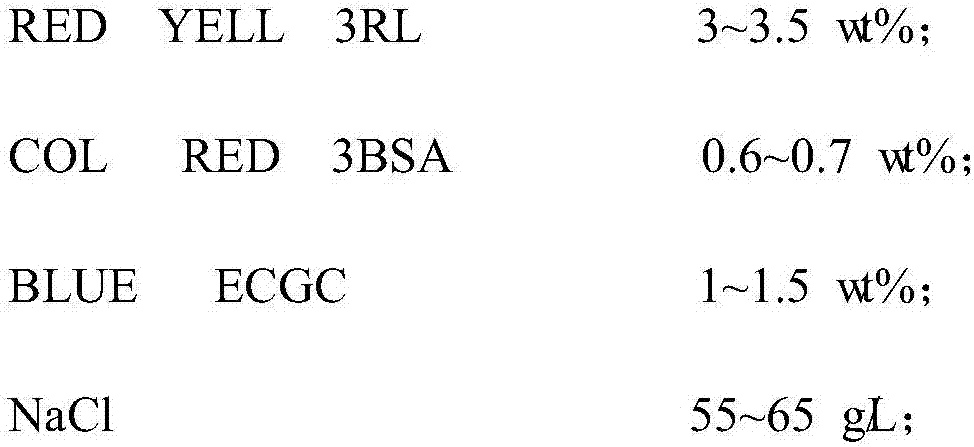

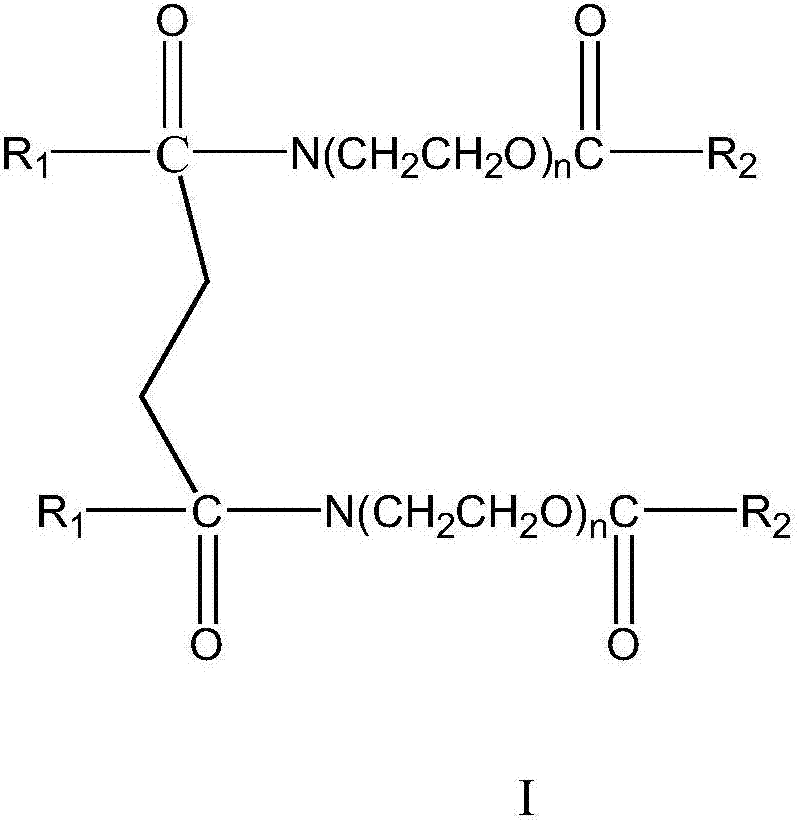

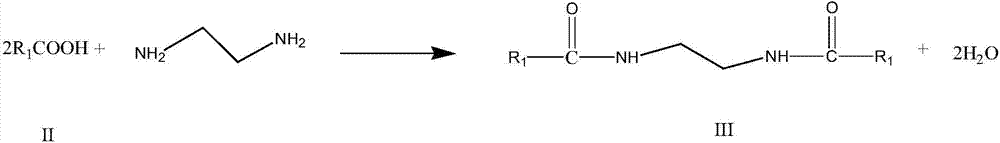

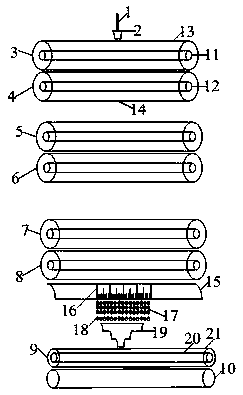

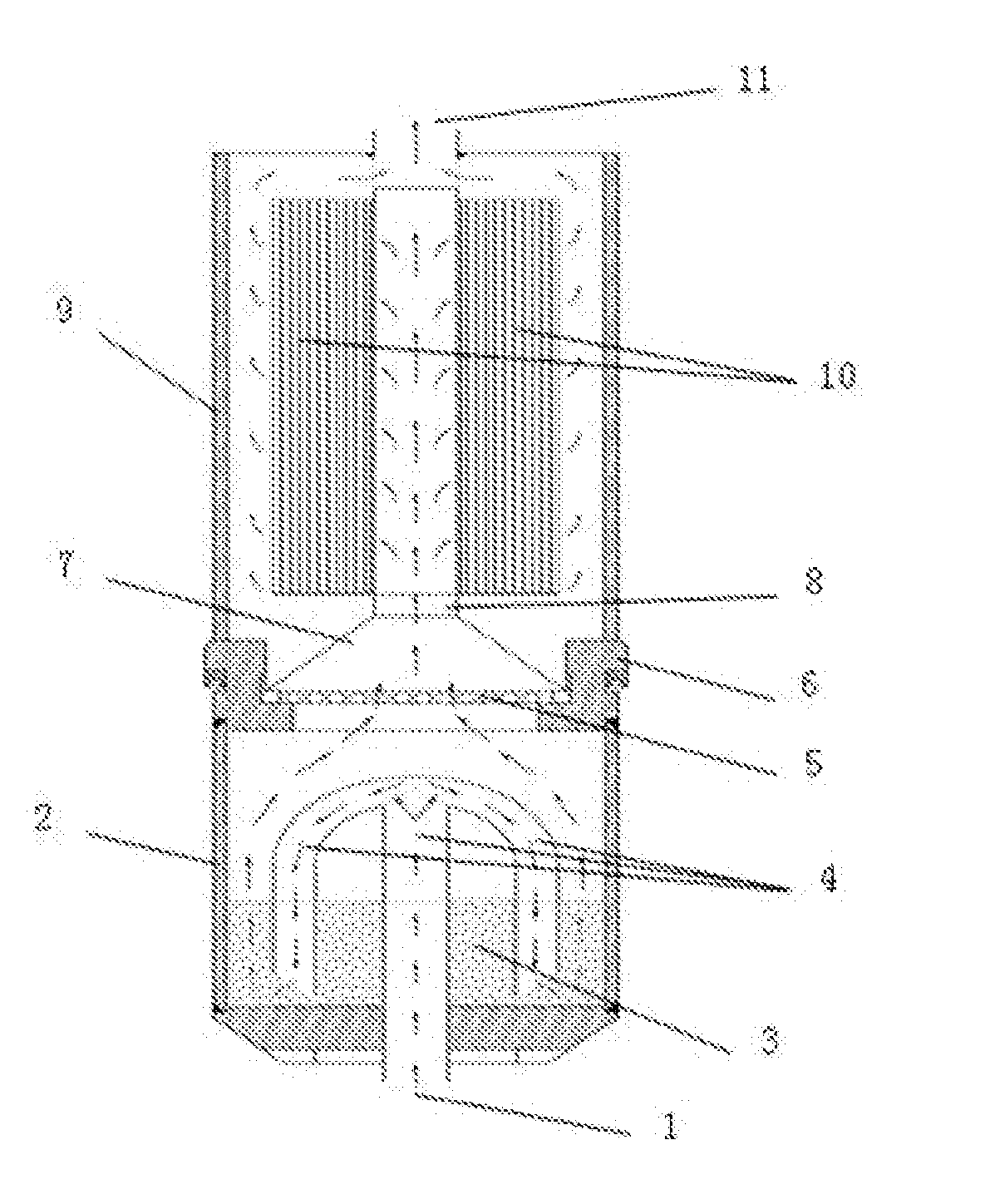

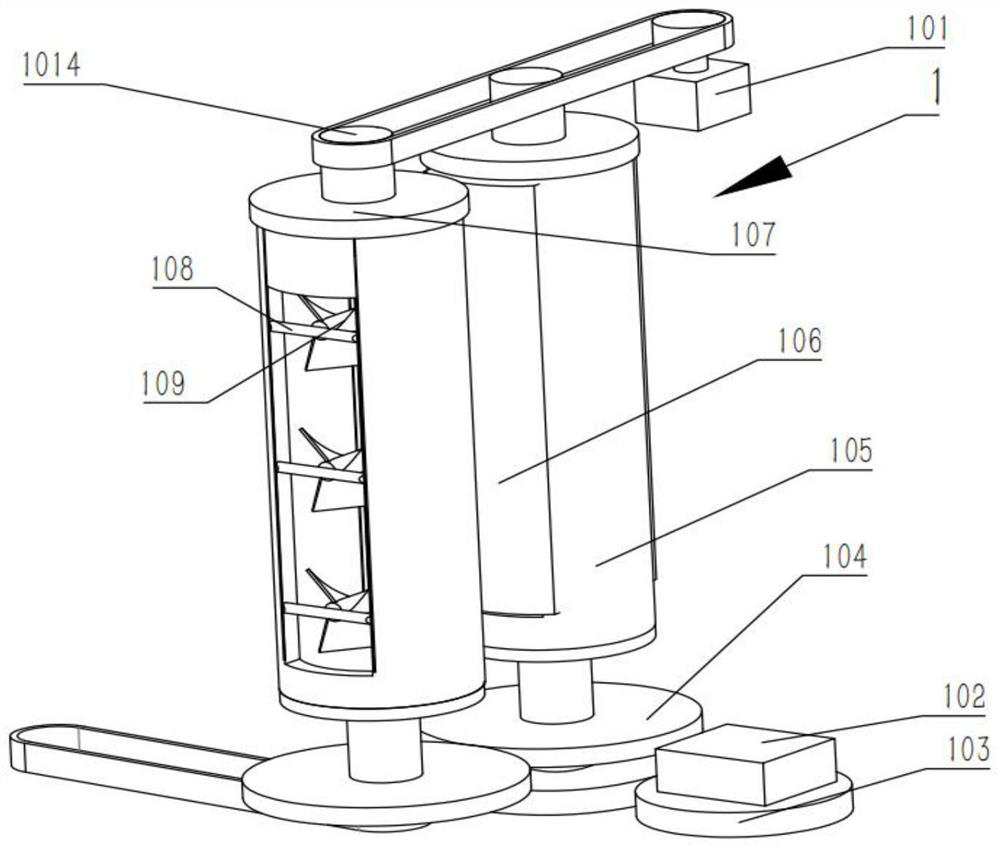

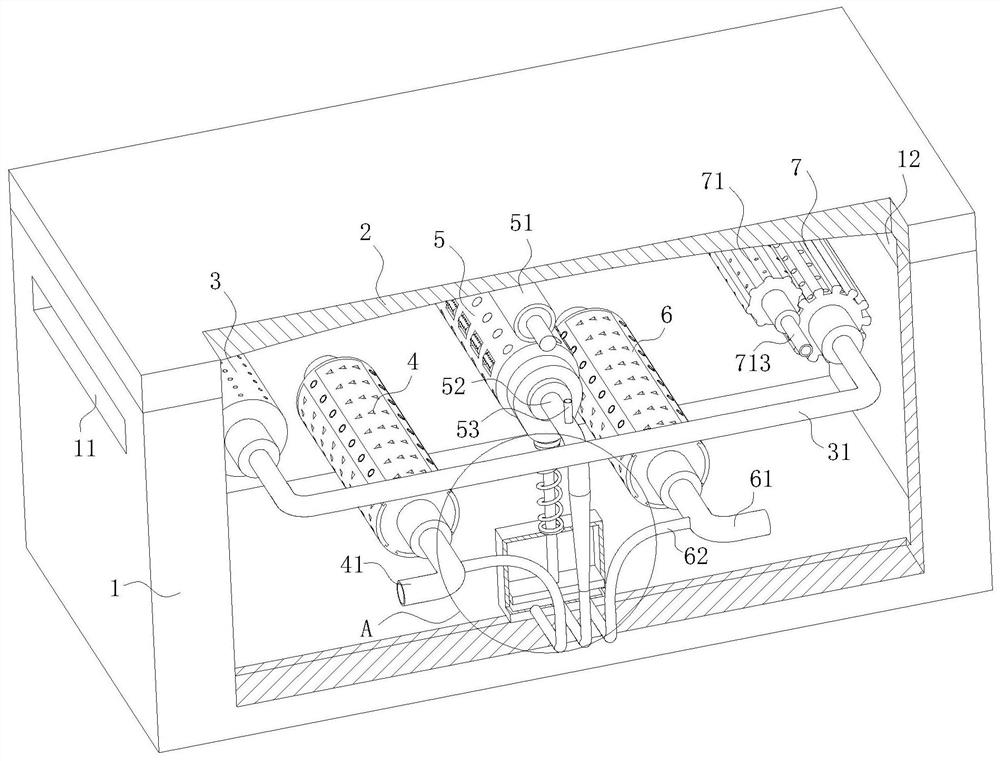

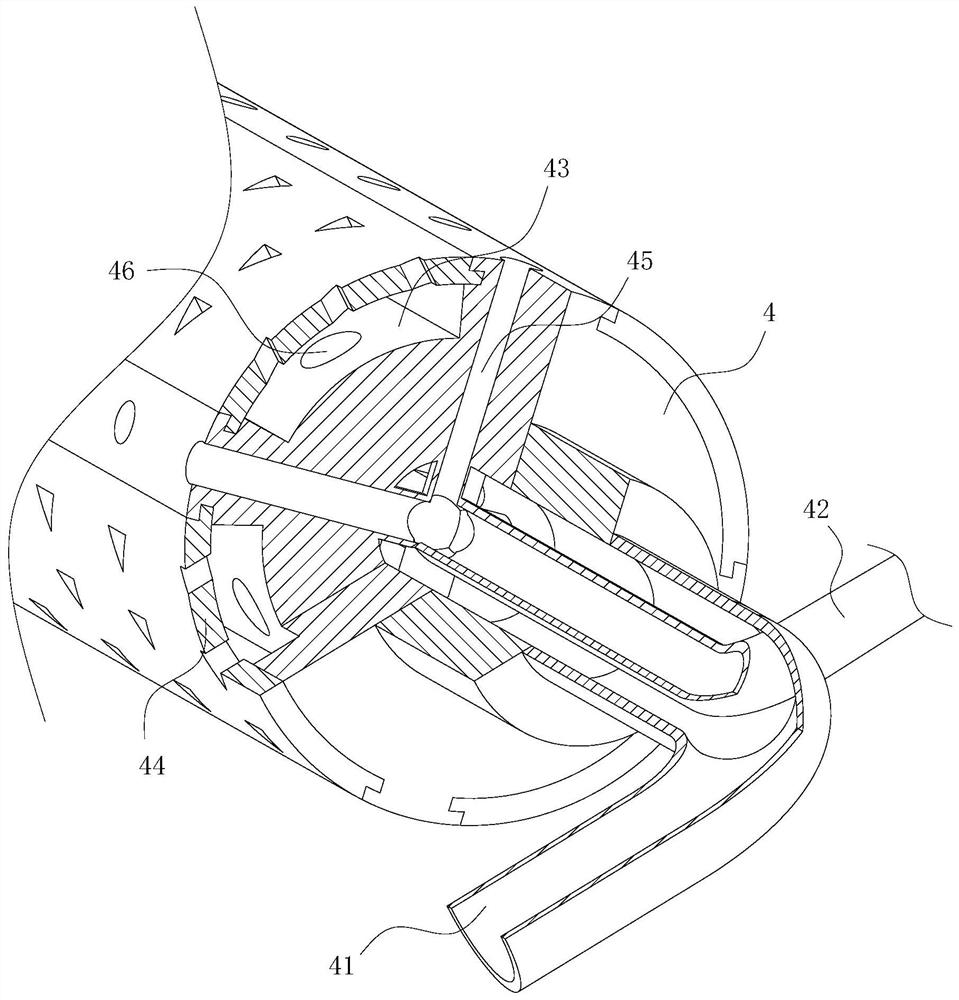

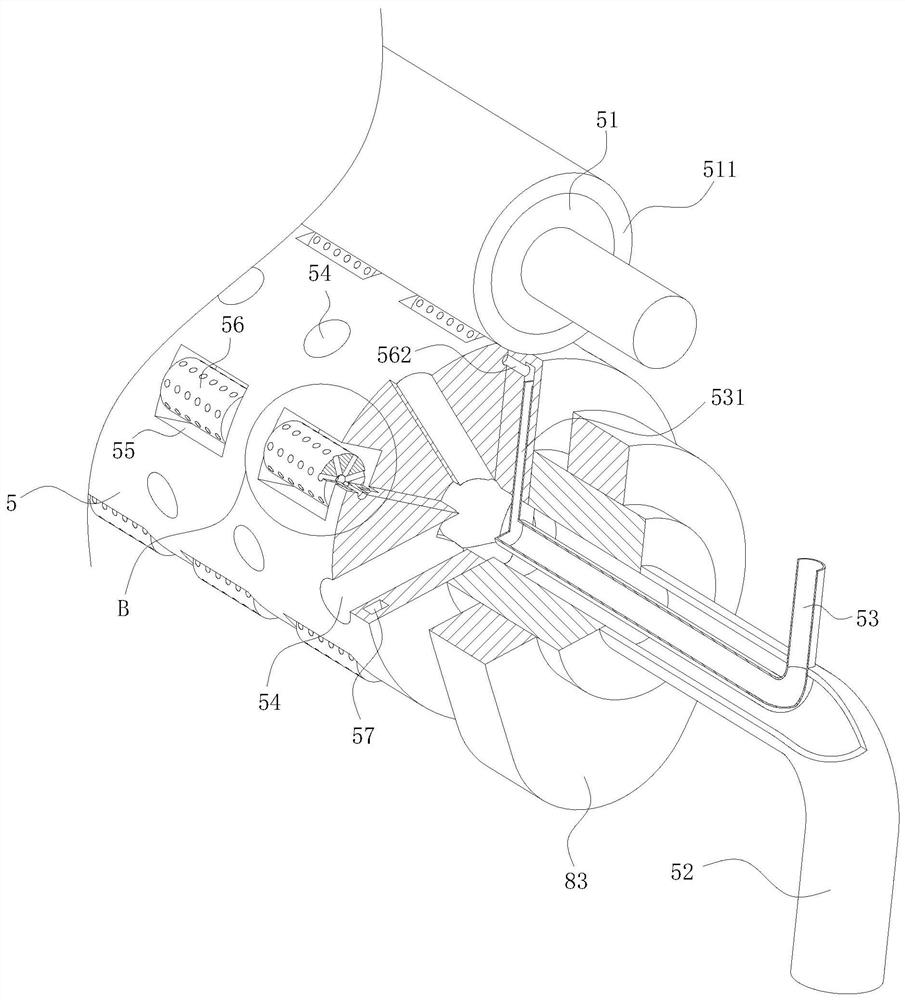

Method for colour-fixing processing of textile and device therefor

ActiveUS20160194825A1Fully contactedImprove responseFibre treatmentChemical fixing of textilesLiquid storage tankDistributor

A device for colour-fixing processing on textiles includes a system of supercritical carbon dioxide fluid, a fixing liquid storage tank (2) and a fixing reactor (9). The fixing liquid storage tank (2) is below the fixing reactor (9) and sealed connected by a connecting device (6). The fixing liquid storage tank (2) has a cylindrical cavity in which a fluid distributor (4) is mounted. The fluid distributor (4) is composed of several interconnected pipes which bending down with the nozzles downward, and one of the pipes is used as circulated fluid inlet (1) connected with the supercritical carbon dioxide fluid system, and the rest pipes are used as circulated fluid outlets.

Owner:SUZHOU UNIV

Production method of blanket with strong color fastness

The invention relates to the technical field of blanket production, in particular to a production method of a blanket with strong color fastness, which comprises the steps of warping weaving, white grey fabric treatment, grey fabric printing and dyeing, drying and fixation, finishing and shaping, finished product preparation and the like, wherein the raw material fiber yarn is polyester fiber yarn, the polyester fiber yarn is mainly prepared from polyethylene terephthalate, polyvinyl chloride resin, polytetrafluoroethylene resin, nano fluorite powder, barium stearate, dicumyl peroxide, zinc oxide and silane coupling agent are compounded, and the used pigment is disperse dye, during the steaming process, a drying and steaming integrated machine is used for uniformly and fully drying and steaming. The production method has the advantages of low energy consumption, low cost and high production efficiency, has good dyeing effect on the blanket, has high color fastness, and can avoid the phenomenon that the blanket is prone to rubbing and fading, and the like. The produced blanket has good luster, smooth grey fabric surface and long use time.

Owner:ZHEJIANG TRUELOVE GROUP

Underwear dyeing and drying system

InactiveCN112267234AAvoid wastingAvoid opening and closingChemical fixing of textilesLiquid/gas/vapor removalEngineeringSprocket

The invention relates to the field of fabric drying, in particular to an underwear dyeing and drying system. The system comprises a drying mechanism and a limiting mechanism, wherein the drying mechanism comprises a motor II, gears, gear shafts, sleeves, heating resistors, fans, a motor III and chain wheel shafts; one gear is fixedly connected to the corresponding gear shaft, and the other gear isfixedly connected to an output shaft of the motor II; the two gears are in meshing transmission; the two gear shafts are fixedly connected to the bottom ends of the two sleeves respectively; the twogear shafts are in meshing transmission; the two sleeves are each provided with the plurality of heating resistors; the fans are fixedly connected to the left ends and the right ends of the multiple chain wheel shafts; the multiple chain wheel shafts are rotationally connected to the interiors of the sleeves; an output shaft of the motor III is in transmission connection with the multiple chain wheel shafts through chains; the motor III is fixedly connected to the interior of the corresponding sleeve; the limiting mechanism comprises rotating rods and limiting plates; and the upper ends and the lower ends of the multiple rotating rods are fixedly connected with the limiting plates.

Owner:史彦龙

Production process for silver ion antibacterial knitted fabric

InactiveCN111472085AHigh fastnessImprove antibacterial propertiesWeft knittingChemical fixing of textilesYarnColour fastness

The embodiment of the invention relates to a production process for a silver ion antibacterial knitted fabric. The production process comprises the following steps that S1, preparation of spun silk card sliver; S2, drawing; S3, roving; S4, preparation of spun silk chinlon filament composite yarn through a Sirofil spinning technology; S5, preparation of the knitted fabric; S6, washing; S7, pretreatment; S8, dyeing; S9, color fixing; and S10, washing and drying. During dyeing, a softening agent and a silver ion antibacterial agent are added, and therefore the fabric can achieve excellent antibacterial performance and can keep the antibacterial performance for a long time. According to the production process for the silver ion antibacterial knitted fabric, the spun silk chinlon filament composite yarn is prepared through the Sirofil spinning technology, the knitted fabric is prepared from the composite yarn and spandex yarn, a proper dyeing and color fixing process is selected, a proper anti-bacterial finishing process is added, and therefore the prepared knitted fabric has excellent color fastness and antibacterial performance, and the fabric can serve as skin-fit clothes.

Owner:浙江华岩针织有限公司

Method for fixing colors of textiles and device thereof

ActiveCN103451884AImprove color fixationPracticalLiquid/gas/vapor open-width material treatmentTextile treatment containersEngineeringNatural fiber

The invention discloses a method for fixing the colors of textiles and a device thereof, and particularly discloses a technology for performing phase transfer catalytic color fixing on natural fiber textiles by adopting dispersed active dyes in a supercritical carbon dioxide fluid. The lower end of a color fixing kettle is connected with a color fixing liquid storing kettle; a fluid distributor is arranged in the color fixing liquid storing kettle; a circulation fluid is fully contacted with color fixing mixed liquid containing a color fixing alkaline accelerant and a phase transfer catalyst when flowing through the fluid distributor; the color fixing alkaline accelerant is transferred onto fibers by using a phase transfer catalyst principle, so that the reaction activity between functional groups on the fibers and dyes is increased, and color fixing of dyes on the fibers is realized. According to the method, a phase transfer catalytic color fixing method and a device thereof with a reasonable structure is adopted, so that the color fixing efficiency of dyes on textiles is increased remarkably; moreover, equipment and a process are simple, and operation is convenient.

Owner:中科首望无水染色智能装备(苏州)有限公司

Textile fabric printing and dyeing method

InactiveCN111845035AInfluence intensityImprove printing and dyeing effectMechanical cleaningPressure cleaningFiberPolymer science

The invention belongs to the technical field of textile fabric processing, and particularly relates to a textile fabric printing and dyeing method. The textile fabric printing and dyeing method comprises the following steps that S1, dust removal treatment is performed on a textile fabric to clear dust and broken fibers attached to the surface of the textile fabric, and then the cleaned fabric is wound around a material roller; and S2, the fabric treated in the step 1 penetrates into a printing and dyeing device, and the fabric after penetrating through the printing and dyeing device directly enters secondary drying equipment to be dried to obtain the finished printed and dyed fabric. According to the textile fabric printing and dyeing method, by repeatedly printing and dyeing the fabric, the printing and dyeing effect of the fabric is improved, meanwhile, the printing and dyeing speed of the fabric is increased, and the printing and dyeing efficiency is improved.

Owner:杜丹

Method of making dispersible wet wipes via patterned binder application

A method of making a dispersible wet wipe includes providing a web of cellulosic fibers. In one embodiment, a first binder is applied to a web surface in a coating that comprises randomly distributed deposits of the first binder. A second binder is applied an intermittent pattern on the web surface to define first regions on the first surface that include first binder but no second binder and to define second regions on the first surface that include both first binder and second binder. In a second embodiment, a first binder is applied to a web surface in a first pattern, and, after applying the first binder, a second binder is applied to the web surface in a second pattern that is different than the first pattern. In a third embodiment, a binder is applied to a web surface in a pattern, the pattern having first regions and second regions, wherein the add-on level of the binder in the first regions is lower than the add-on level of the binder in the second regions.

Owner:KIMBERLY-CLARK WORLDWIDE INC

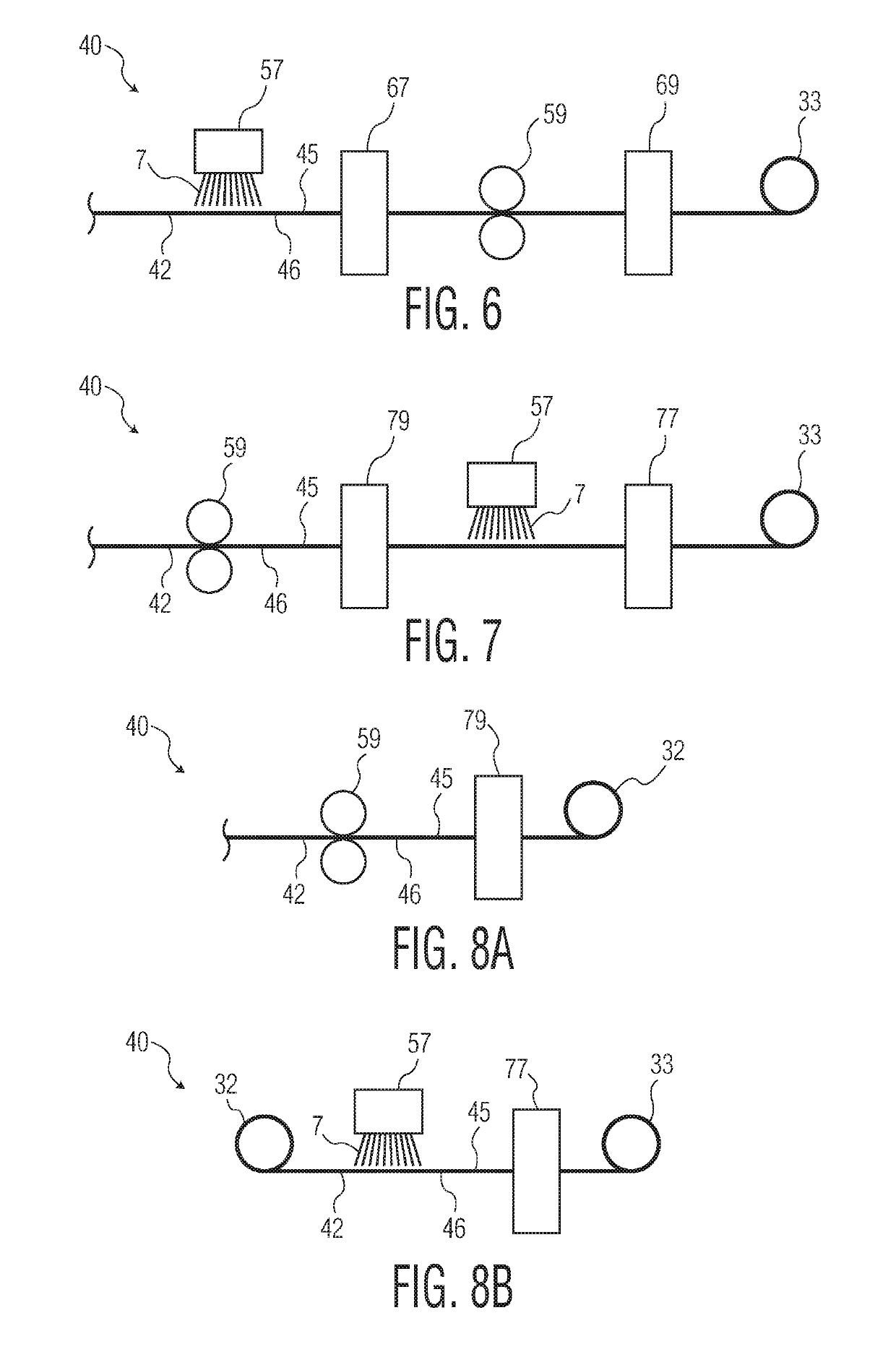

Atomization printing and dyeing production line for cotton tape

InactiveCN108754959ATextile treatment containersSucessive textile treatmentsProduction lineTextile printer

The invention provides an atomization printing and dyeing production line for cotton tape, and relates to the technical field of printing and dyeing equipment. The technical problems that in the priorart, atomization printing and dyeing are conducted in an open environment, and atomized dyeing agents are easily dissipated, so that environmental pollution and the waste of the dyeing agents are caused. The production line comprises a raw material box, an atomization printing and dyeing machine head, a first tension adjusting device, a high-temperature color fixing device and a collecting devicewhich are arranged in sequence, wherein the atomization printing and dyeing machine head adopts a closed atomization printing and dyeing form, and the cotton tape enters the atomization printing anddyeing machine head and then sprayed with atomized dyeing liquid for coloring in the closed environment. The atomization printing and dyeing production line for the cotton tape is used for textile printing and dyeing, the environmental pollution is effectively avoided, and meanwhile the dyestuff is recycled.

Owner:福建荣裕德智能环保机械科技有限公司

Textile dyeing method and device

InactiveCN109306585ASave energyRapid heating and coolingChemical fixing of textilesDyeing processState of artEngineering

The invention provides a textile dyeing method and device. The fixation efficiency is high, and the even dyeing and fixation effect is good. The textile dyeing method comprises the following steps of1, dyeing, wherein textile is subjected to dye / pigment adsorption through a coloring system; 2, heating and fixation through electromagnetic waves, wherein the colored textile in the first step is putinto an electromagnetic wave heating device for heating, heating continues for a period of time, and the dye / pigment diffusion and fixation process for the textile is completed. According to the textile dyeing method, by adopting an electromagnetic wave heating mode, heating is conducted in the dyeing and solidification process of a long machine, through the heating mode, energy is saved, the temperature is increased and decreased quickly, cleanliness is achieved, the penetrability is high, heating is even, and the situation can be avoided that in the prior art, during dyeing and fixation ofthe long machine, due to uneven heating, dye migration of the cloth surface is caused, and accordingly color diffusion is caused.

Owner:QINGDAO JIFA GROUP

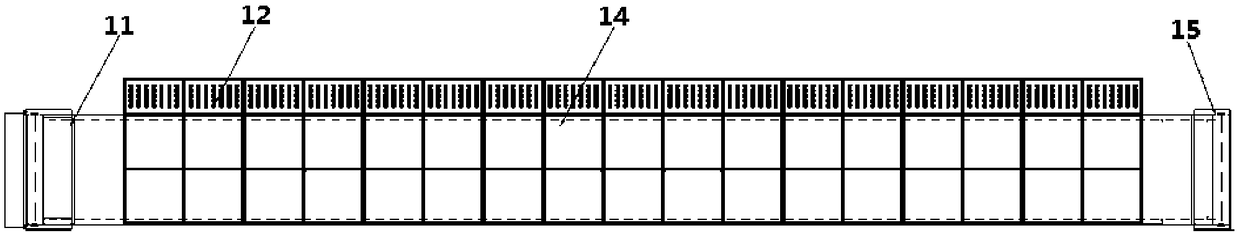

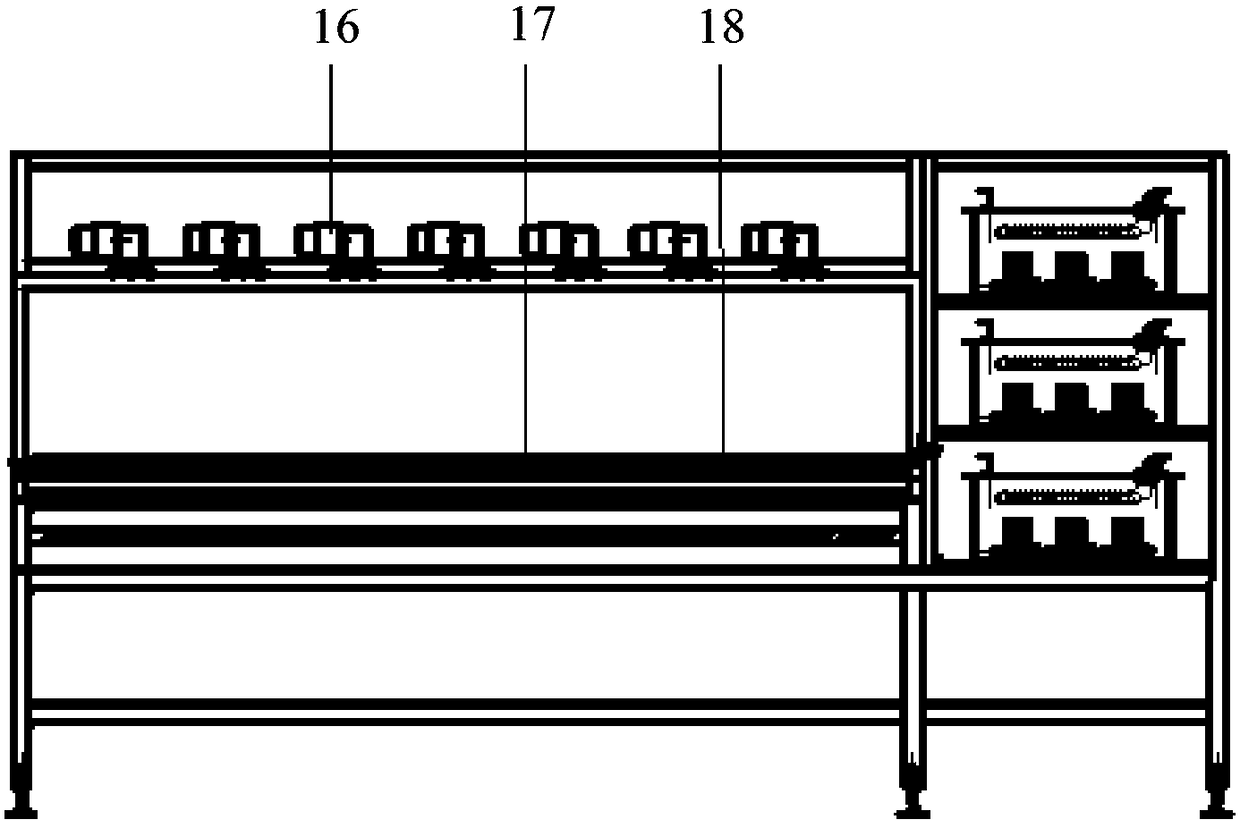

Fixation machine and fixation process

InactiveCN108625073AMaintain effective humidityIncrease high frequency vibrationSucessive textile treatmentsChemical fixing of textilesMicrowaveEngineering

The invention provides a fixation machine. The fixation machine comprises a cloth inlet section, a fixation section and a cloth outlet section. The cloth inlet section, the fixation section and the cloth outlet section are sequentially linked to form a moving channel allowing dyed or printed cloth to advance. The fixation section is sequentially provided with multiple microwave heating boxes in the stretching direction of the moving channel. Each microwave heating box comprises multiple microwave generators, wherein the microwave generators of each microwave heating box are sequentially distributed vertical to the moving channel. The microwave generators are used for heating cloth passing the moving channel. The fixation section is provided with an installing part, the installing part stretches in the stretching direction of the moving channel, moisture absorption cloth is fixed, and the moisture absorption cloth is used for humidifying the cloth advancing on the moving channel. The invention further provides a fixation process. According to the scheme, the problems that existing fixation equipment is high in energy waste, occupies large production sites, and is poor in fixation effect can be solved.

Owner:新乡景弘印染有限公司

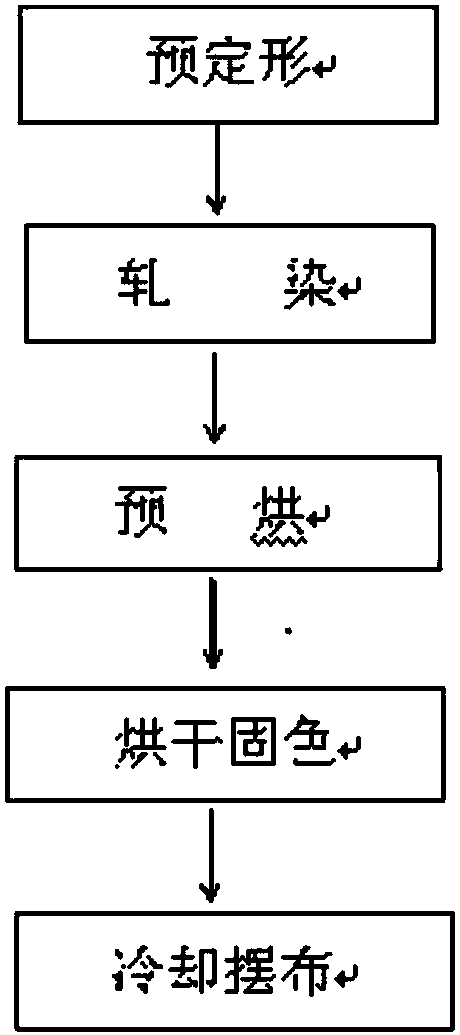

Flash dyeing production method for textiles

ActiveCN109457422AGuaranteed uniformityReduce consumptionChemical fixing of textilesLiquid/gas/vapor removalPulp and paper industryOil water

Disclosed is a flash dyeing production method for textiles. The method comprises the following steps that (1) a preshaping machine removes an oil agent by means of a high temperature method, the shapeof a fabric is stabilized, and the fabric is subjected to dry heating treatment for 10-120 seconds at the temperature of 150-230 DEG C, so that the oil-water content of the fabric is controlled below0.8%; (2) the fabric is dip-dyed through a pad dyeing unit, and the liquid carrying rate of the dyed fabric is controlled at 20-80%; (3) the dyed fabric is subjected to non-contact pre-drying at 150-220 DEG C; (4) the fabric is sent into a drying and color fixing integrated machine for further drying and color fixing; (5) the fabric after being subjected to drying and color fixing enters a cooling unit to be cooled and spread into a finished product. The invention provides the novel high-efficiency continuous flash dyeing production method and complete equipment. The method is low in cost andenergy consumption, free of water washing and sewage discharge and capable of achieving cleaning integration.

Owner:连云港鹰游新立成纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com