Colored spun yarn production device and production method by performing fiber dyeing and blending operation on spinning process

A production device and color mixing technology, which is applied to spinning machines, liquid/gas/steam fiber/sliver/roving processing, textiles and papermaking, etc., and can solve the problems of color spinning production efficiency and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

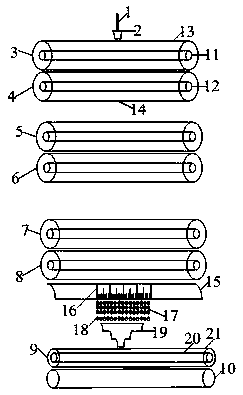

[0024] The present invention will be further described below in conjunction with the accompanying drawings. Depend on figure 1 As shown, a fiber dyeing mixed color spinning production device in the spinning process is spun by a ring spinning frame. The ring spinning frame is composed of 420 spindles or 516 spindles or 1028 spindles with the same structure. Each spindle position includes a drafting system, and the ring spinning frame includes a front deck and a rear deck. The drafting system includes a rear roller drafting pair consisting of the rear bottom roller 4 and the rear top rubber roller 3, and the middle bottom roller 6 and the middle upper rubber roller. The middle roller drafting pair composed of 5, the front roller drafting pair composed of the front bottom roller 8 and the front top rubber roller 7, a roving feeding bell mouth 1 is arranged at the rear of the rear roller drafting pair, and the rear bottom roller Roller 4, middle bottom roller 6, and front bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com