Patents

Literature

261results about "Liquid/gas/vapor treatment of indefinite length materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for mercerized knitted bedding fabric

InactiveCN102433678AMoisturize evenlySoft touchMercerising of indefinite length fabricsSingeingTextile printerPolymer science

The invention discloses a processing method for a mercerized knitted bedding fabric. The processing method mainly adopts a production technology of double-calcination single yarn, first refining and then mercerizing, and grey yarn is sequentially subjected to yarn singeing, yarn steaming, knitting, grey cloth singeing, refining, dewatering, cylinder drying, mercerizing, dyeing, dewatering, scutching, drying, printing, forming and pre-shrinking and finally is checked and stored in a cabin. The mercerized knitted bedding fabric has the advantages of high conformality, low shrinkage, wide width and the like, and can meet the requirement on the knitted bedding fabric; compared with a woven fabric, the mercerized knitted bedding fabric has higher elasticity, water absorption and air permeability, is more smooth and fine in handfeel, and has better comfortableness.

Owner:WUHU SHENGLUO TEXTILE INDAL

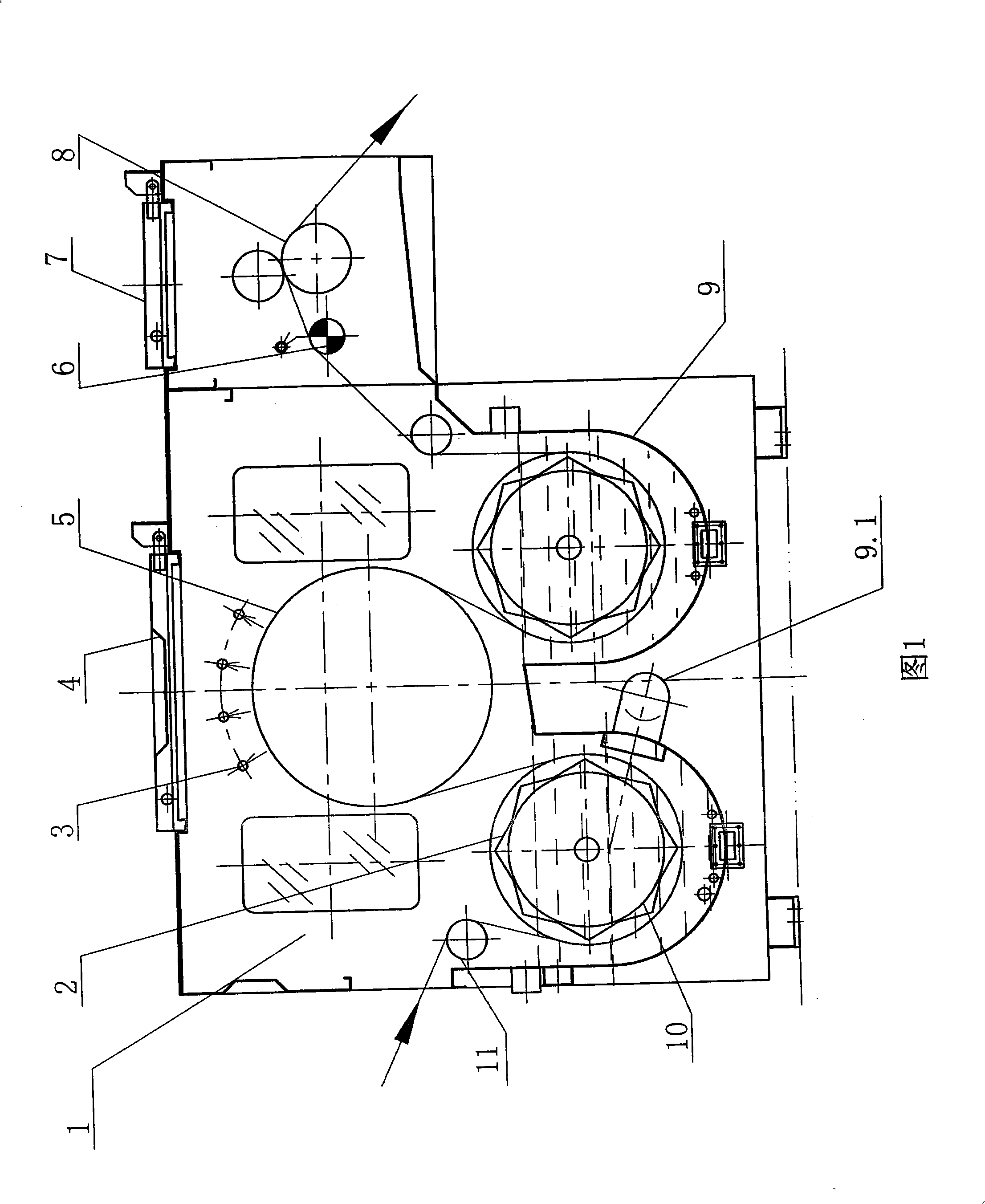

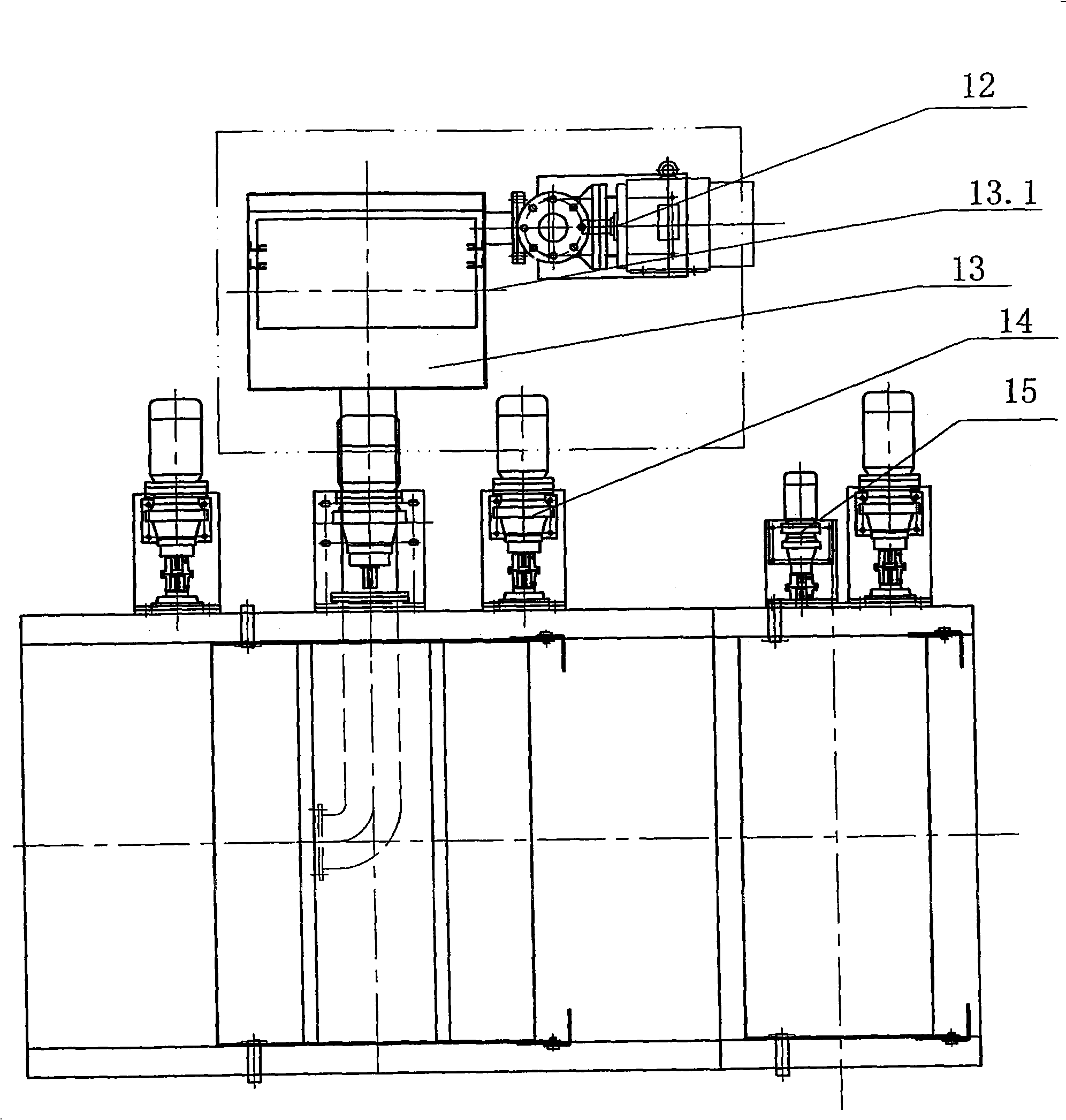

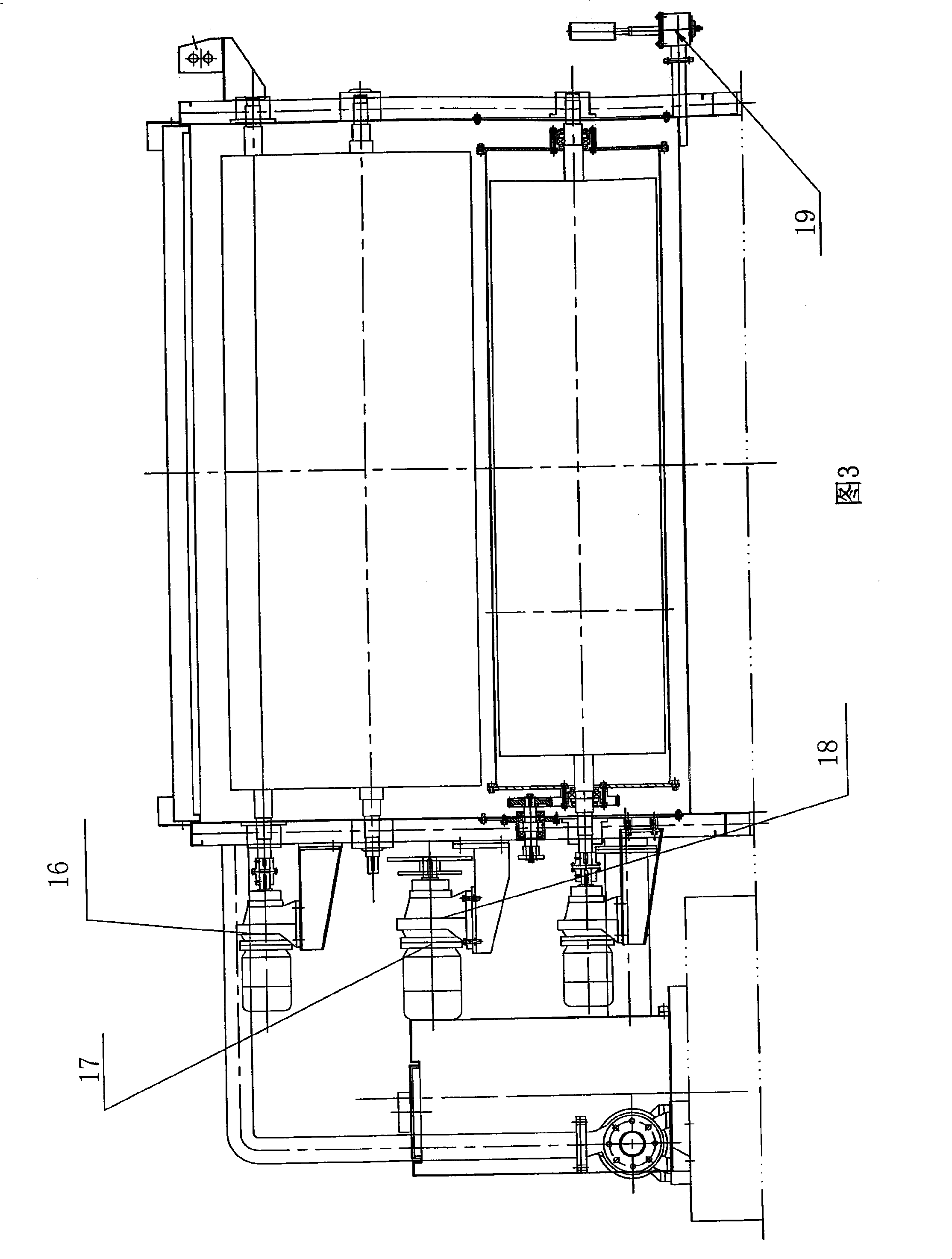

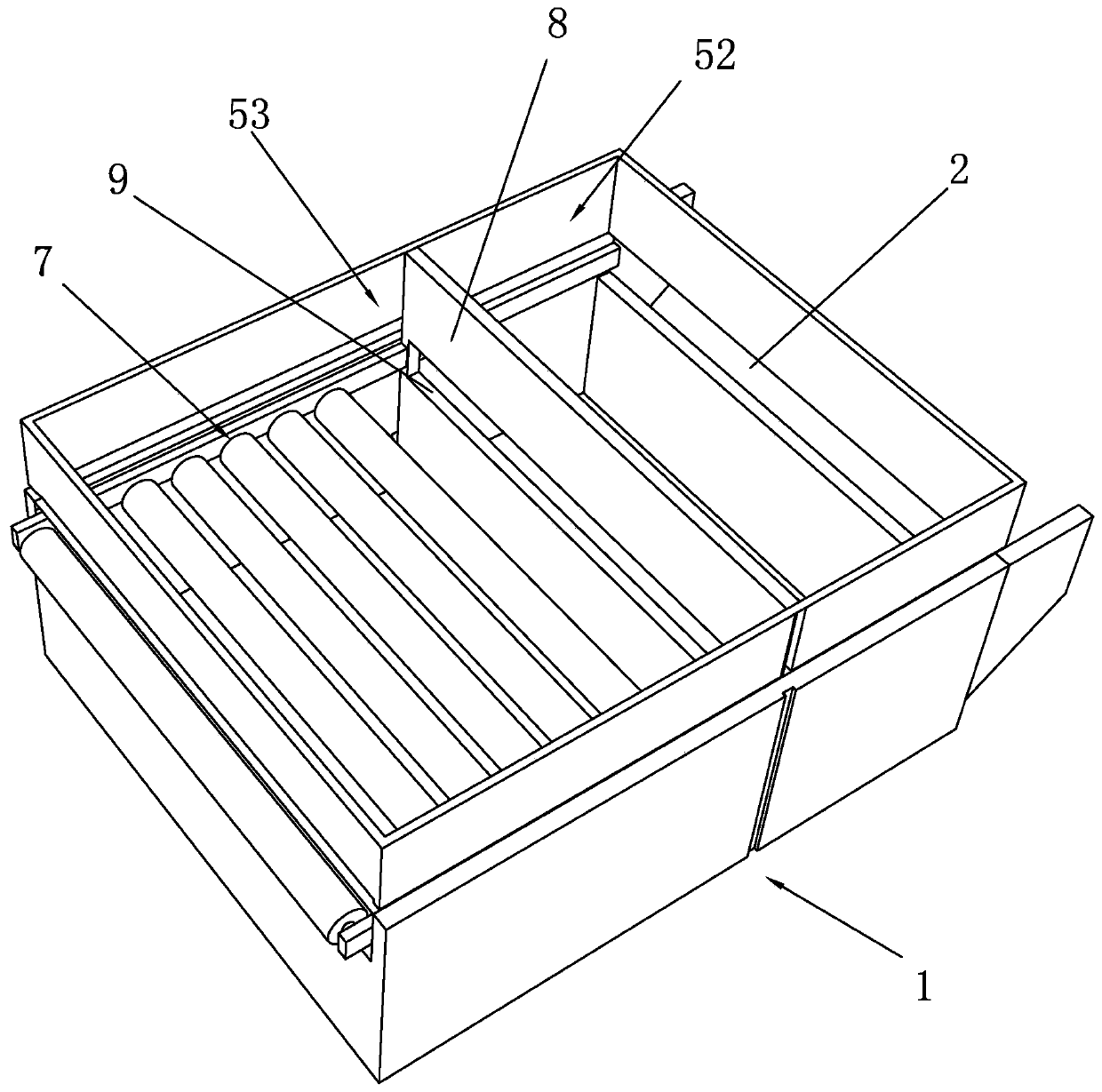

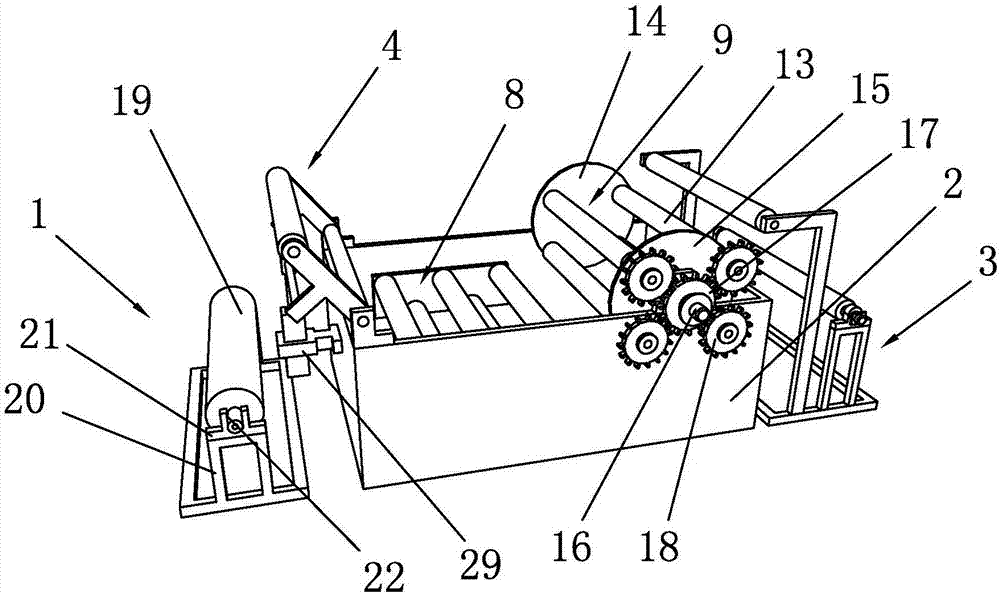

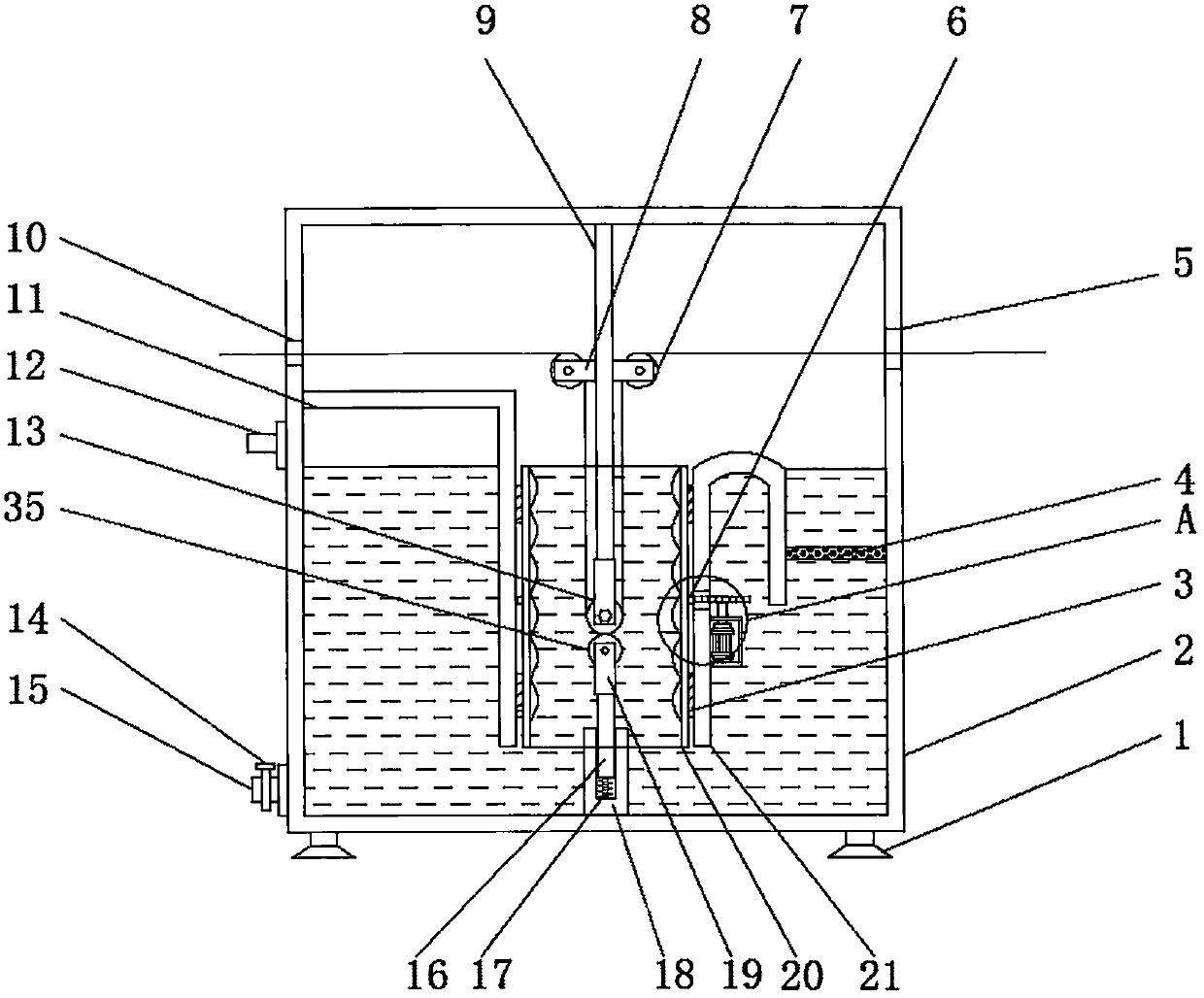

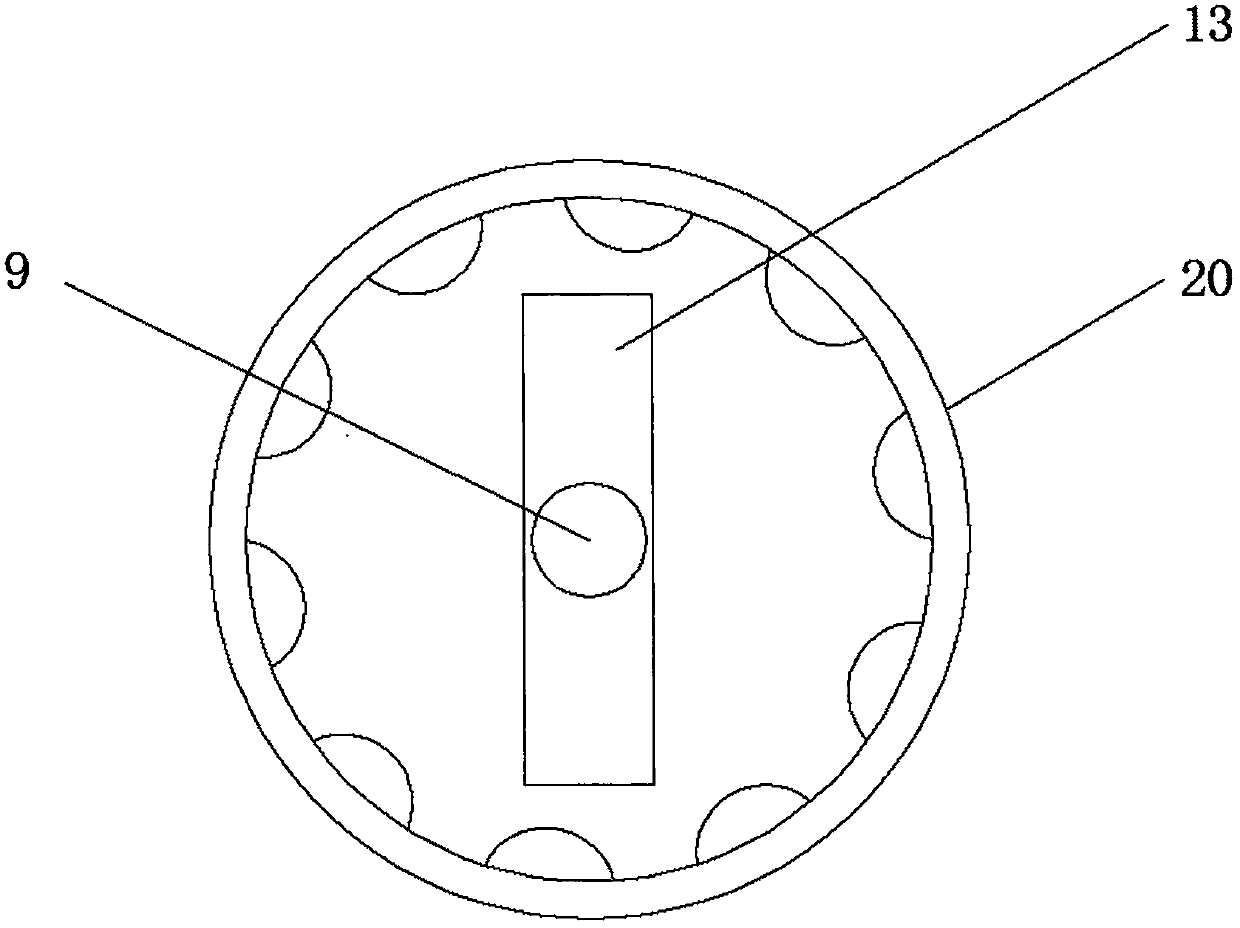

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

Production method of wool/Coolmax/mulberry silk/polyester fiber blended fabric

InactiveCN102560930ATo soften waterSolve the adhesionLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsFiberPolyester

The invention relates to a production method of a wool / Coolmax / mulberry silk / polyester fiber blended fabric, which is characterized in that the blended fabric is made of 60% of Australasian wool, 20% of Coolmax fibers, 15% of polyester fibers, and 5% of mulberry silk by dyeing, recombing, spinning, weaving and dyeing and finishing. The fabric has good color fastness, is non-fading and is breathable.

Owner:江苏华西村纺织服装有限公司

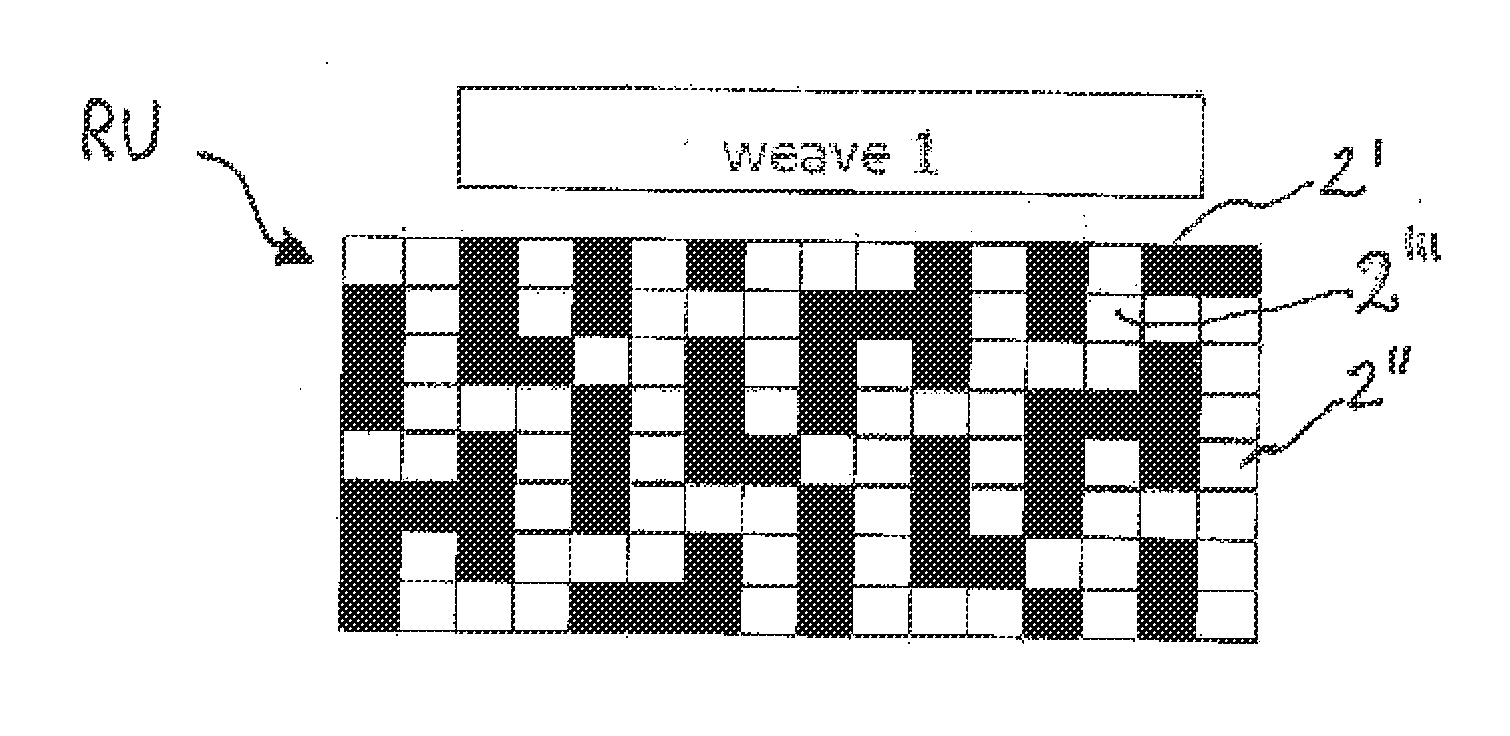

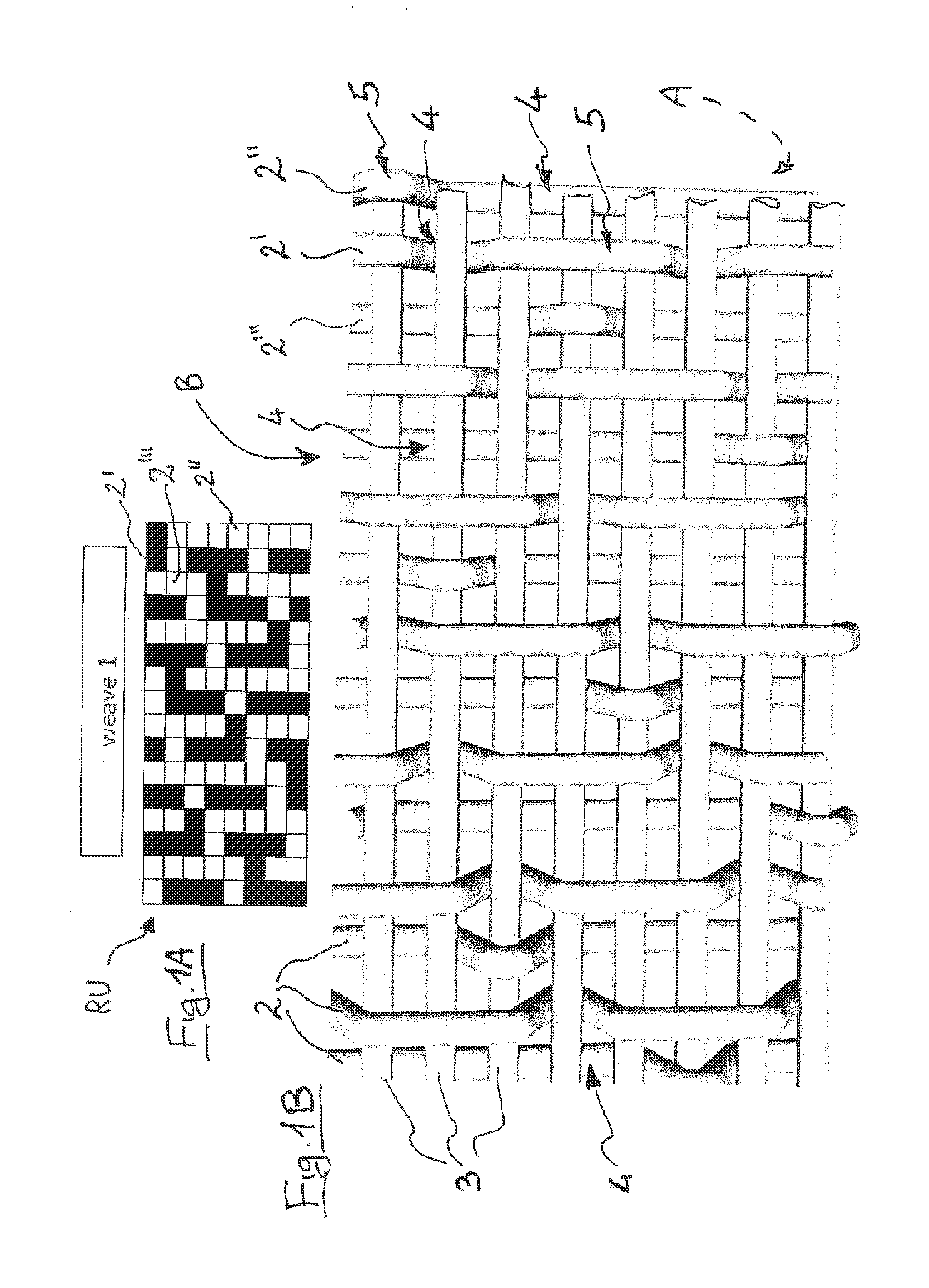

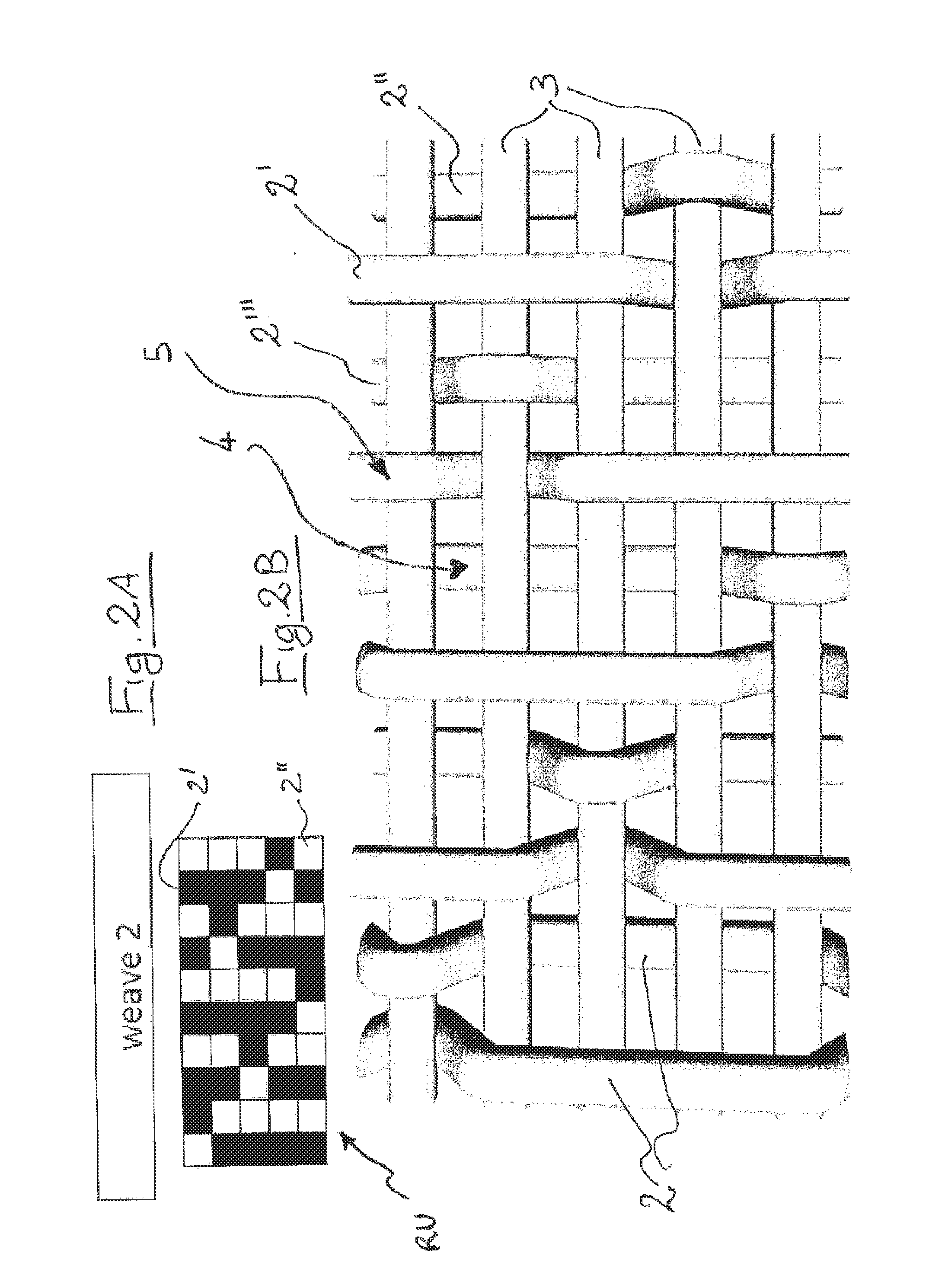

Woven fabric having the aspect of a scuba fabric, and method for producing the same

PendingUS20160083877A1Less-expensive to produceOrnamental textile articlesFibre treatmentNeopreneEngineering

A woven fabric that has the appearance of a neoprene fabric is obtained with a double face fabric in which the warp yarns passes at least three weft yarns on each side of the fabric.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

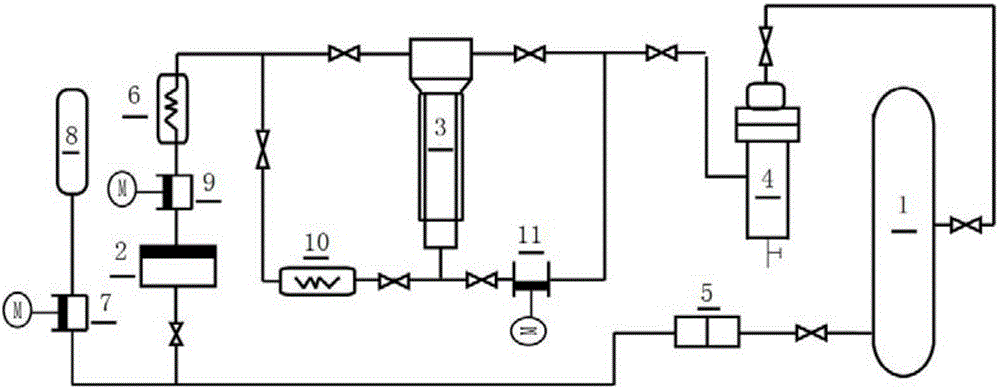

Supercritical fluid spray-dyeing device

InactiveCN101798735ASimple structureOperational securityTextile treatment machine partsSolvent treatment with solvent recoveryDying processesSpray nozzle

Owner:SHANDONG UNIV

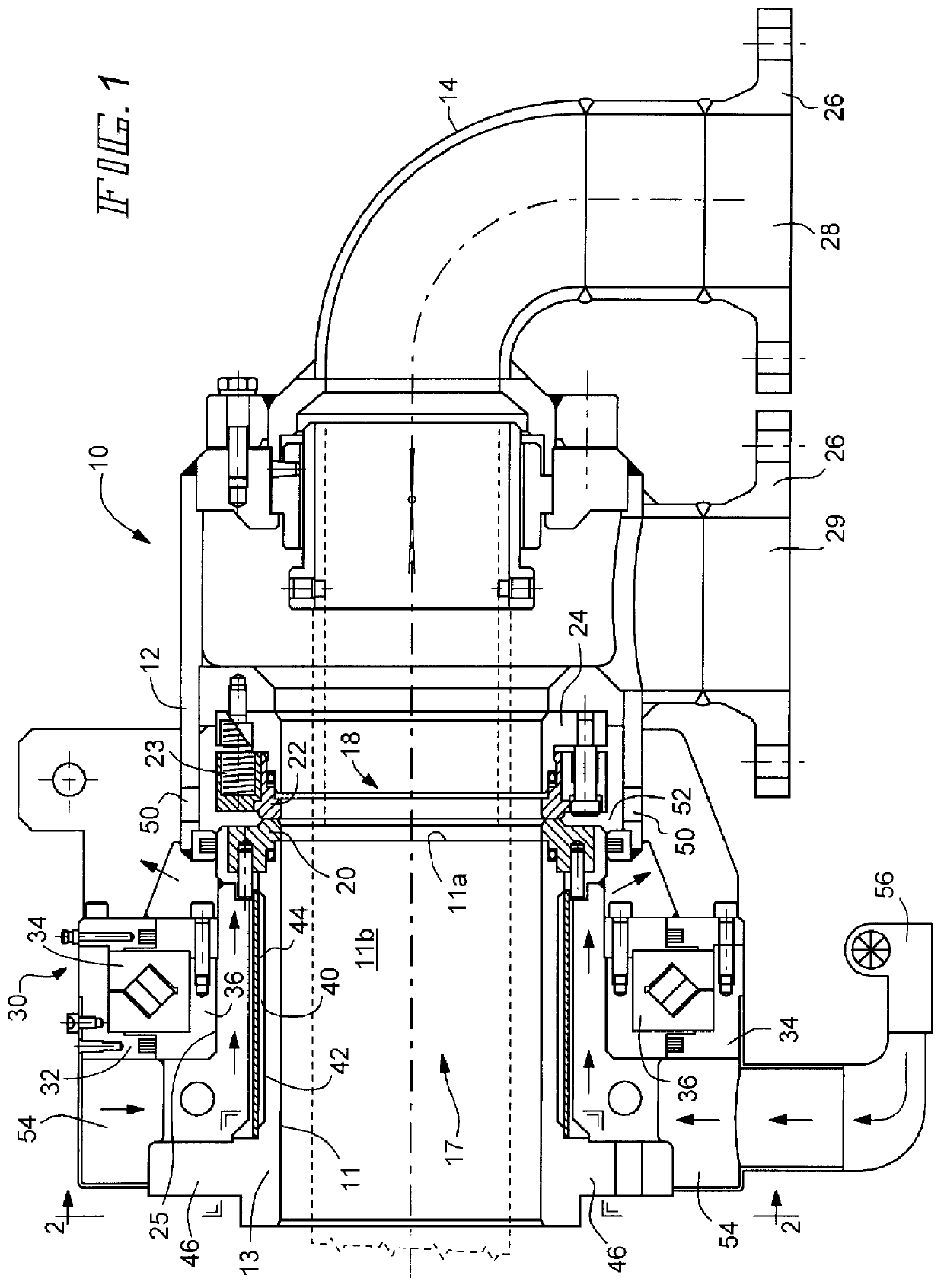

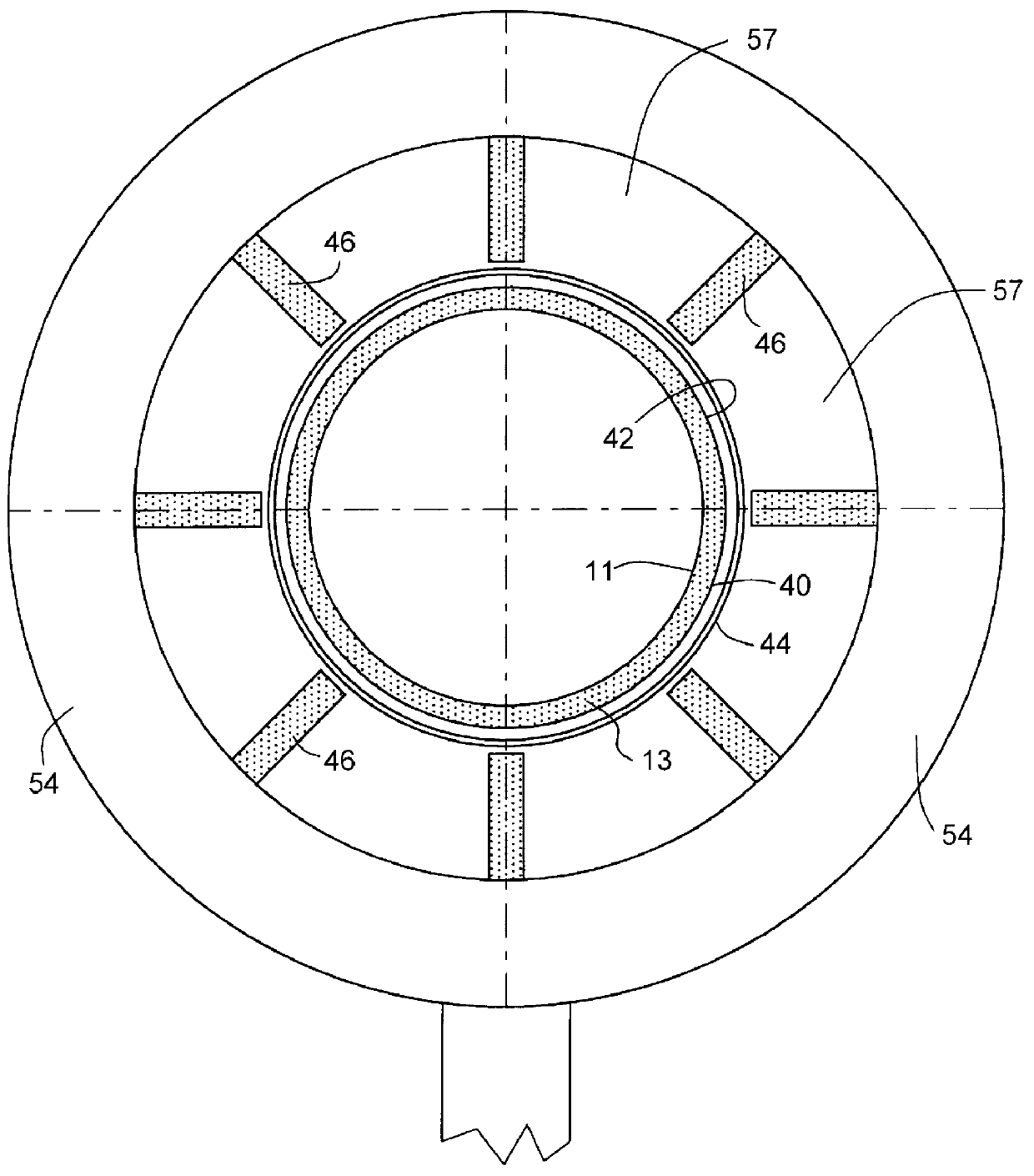

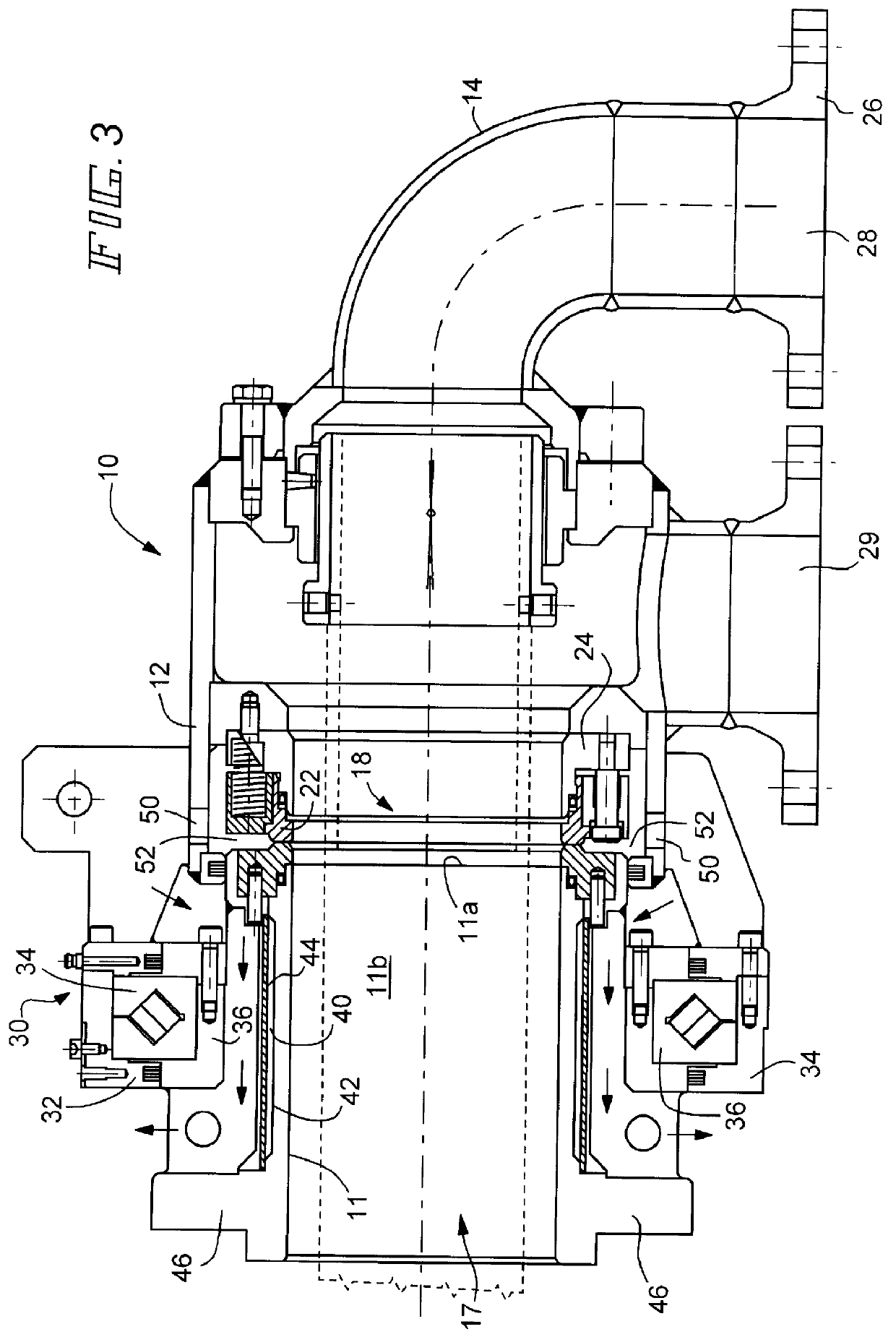

High temperature rotating union

InactiveUS6164316AEasy to assembleIncrease air circulationRoller bearingsBall bearingsAir cycleEngineering

A rotating union has a plurality of fin members spaced about and extending radially outwardly from the rotor to provide an air circulation between the rotor and the bearing assembly to cool the bearing assembly. Additionally, the rotor may include a circumferential annual recess in the rotor outer wall which is enclosed by an annular sealing member to provide an air pocket or gap which insulates the bearing assembly from the hot fluid flowing through the rotating unions.

Owner:DEUBLIN

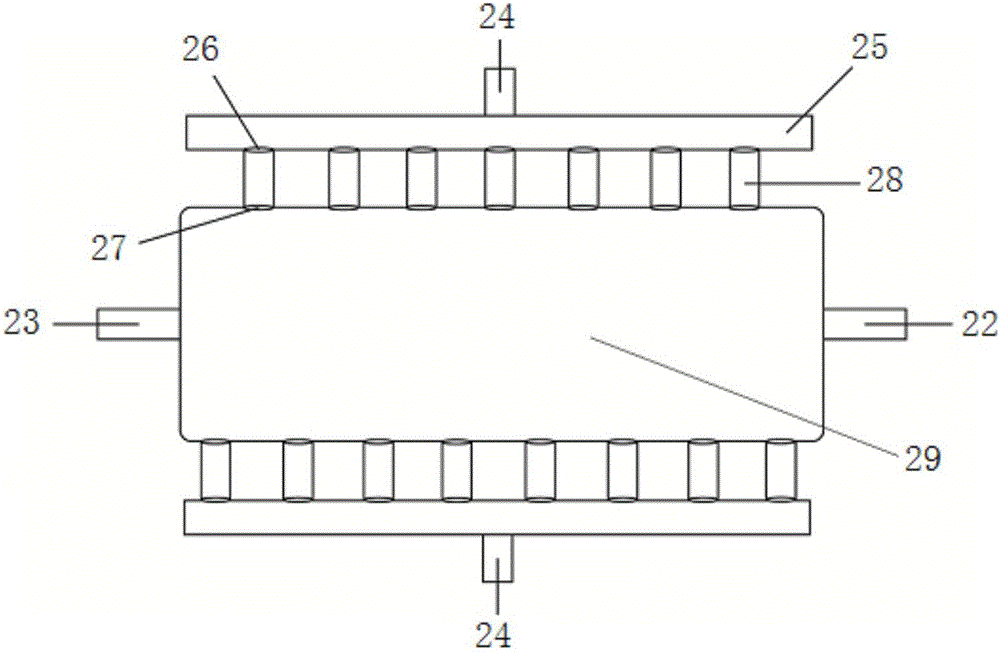

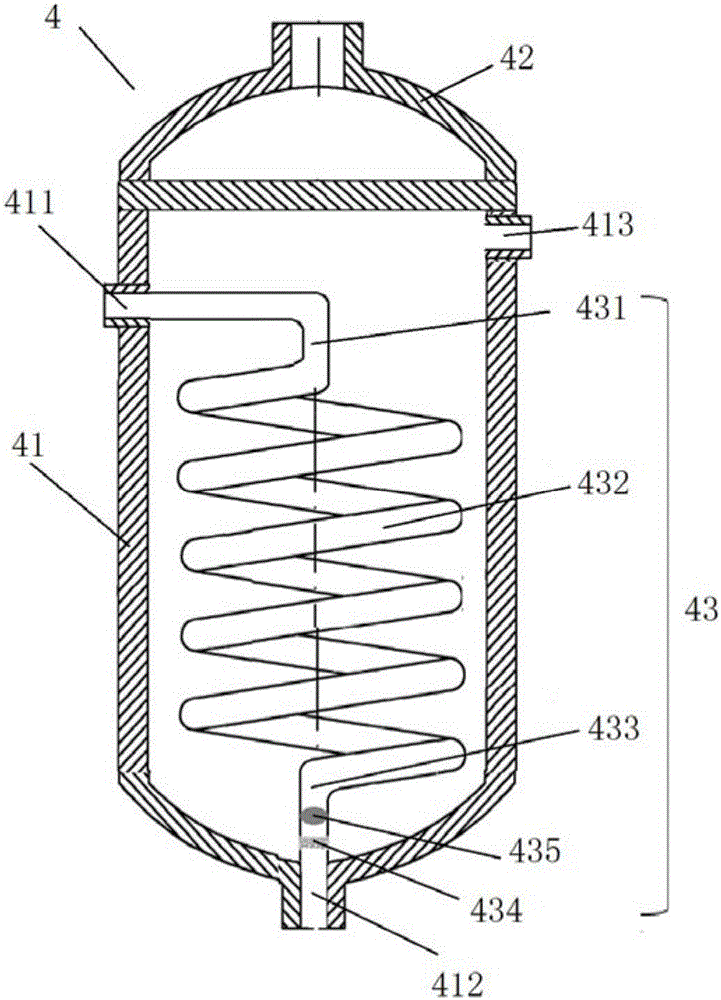

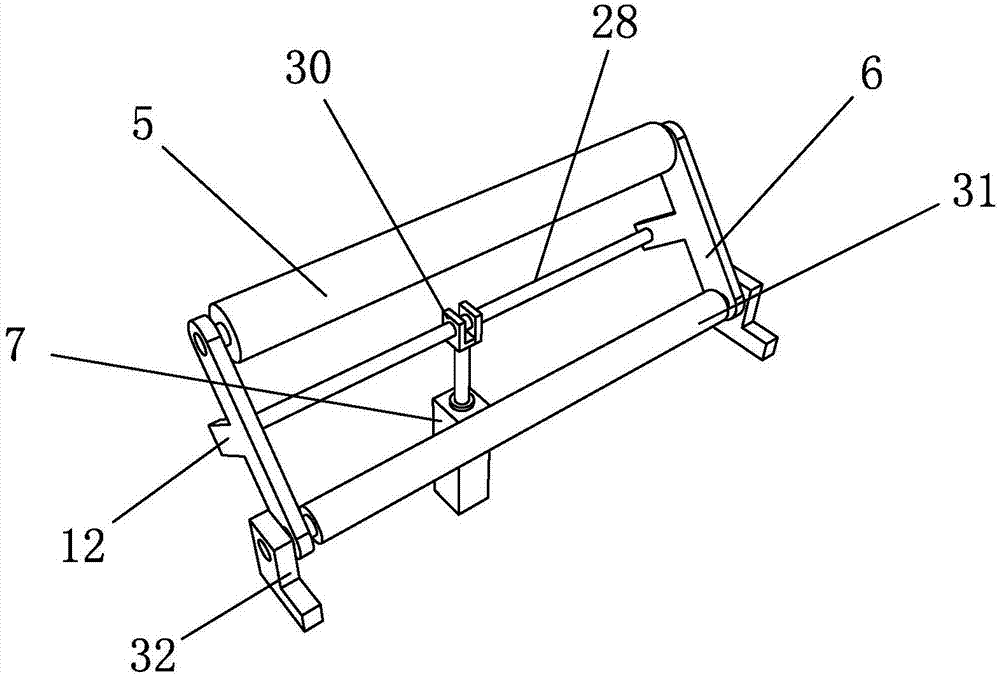

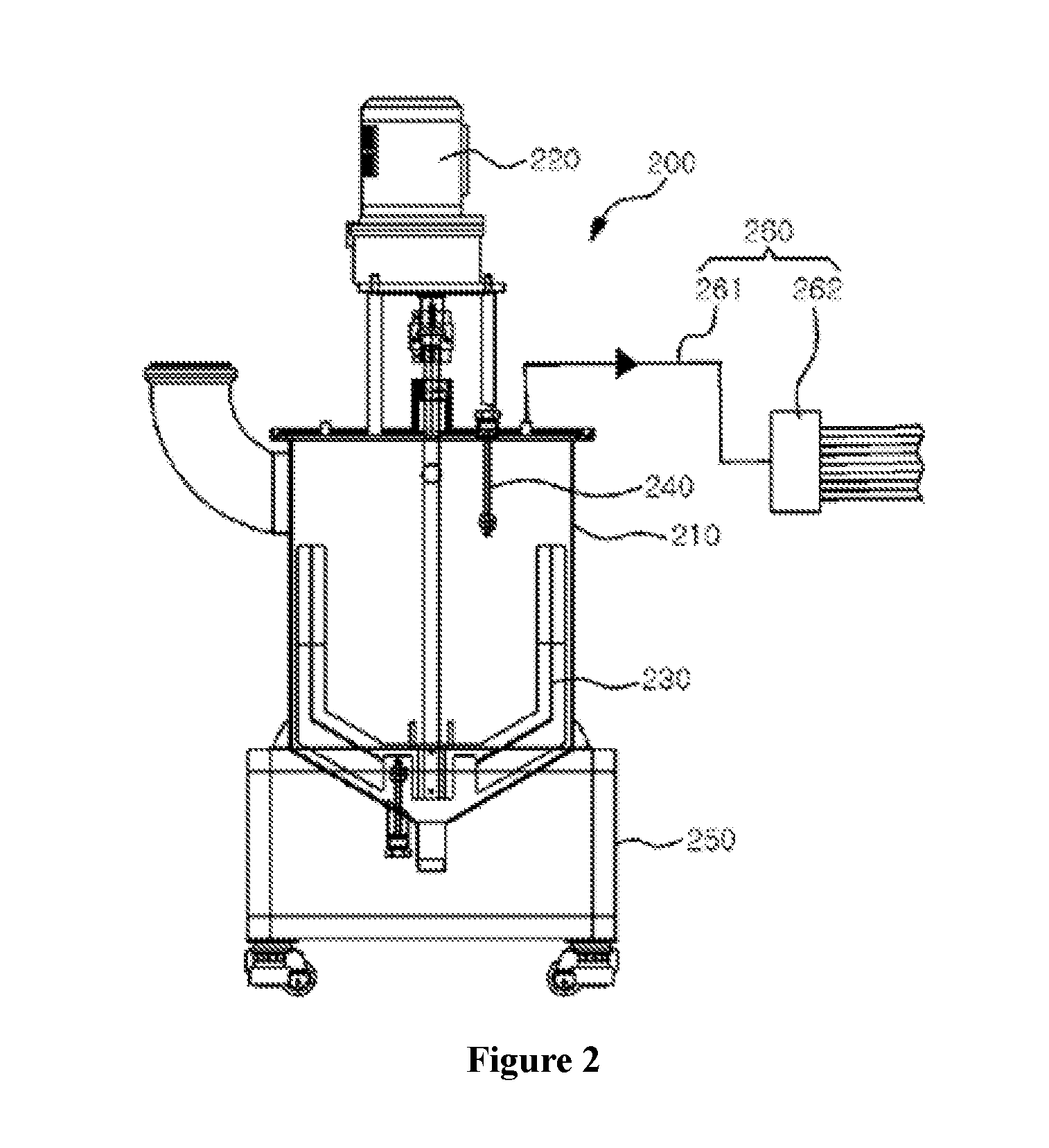

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

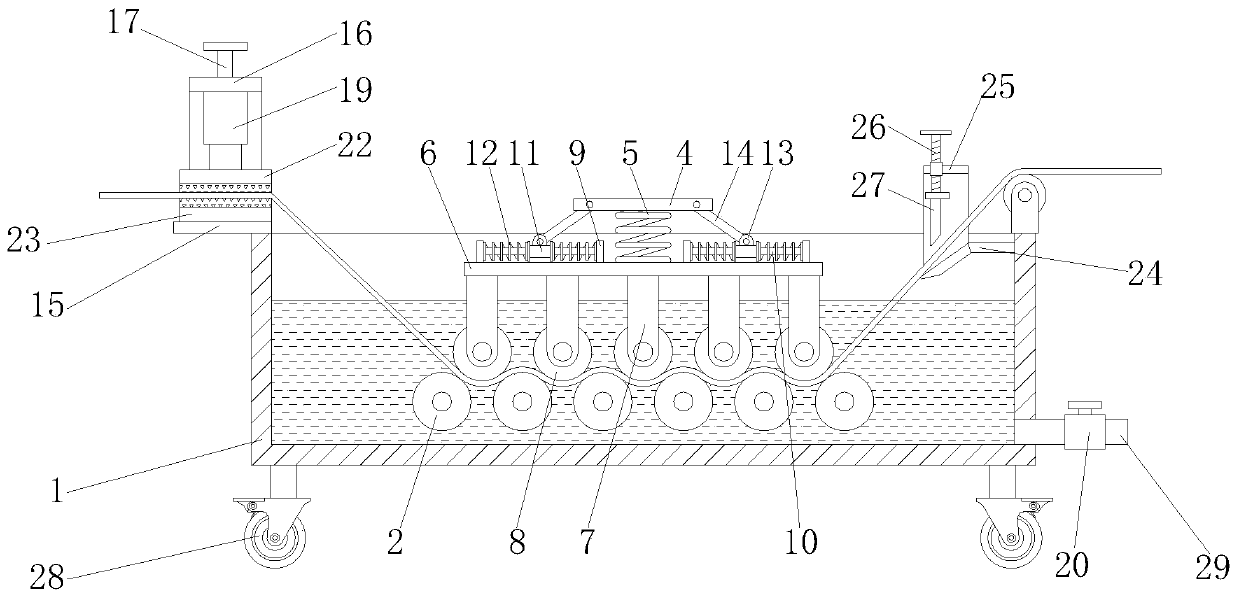

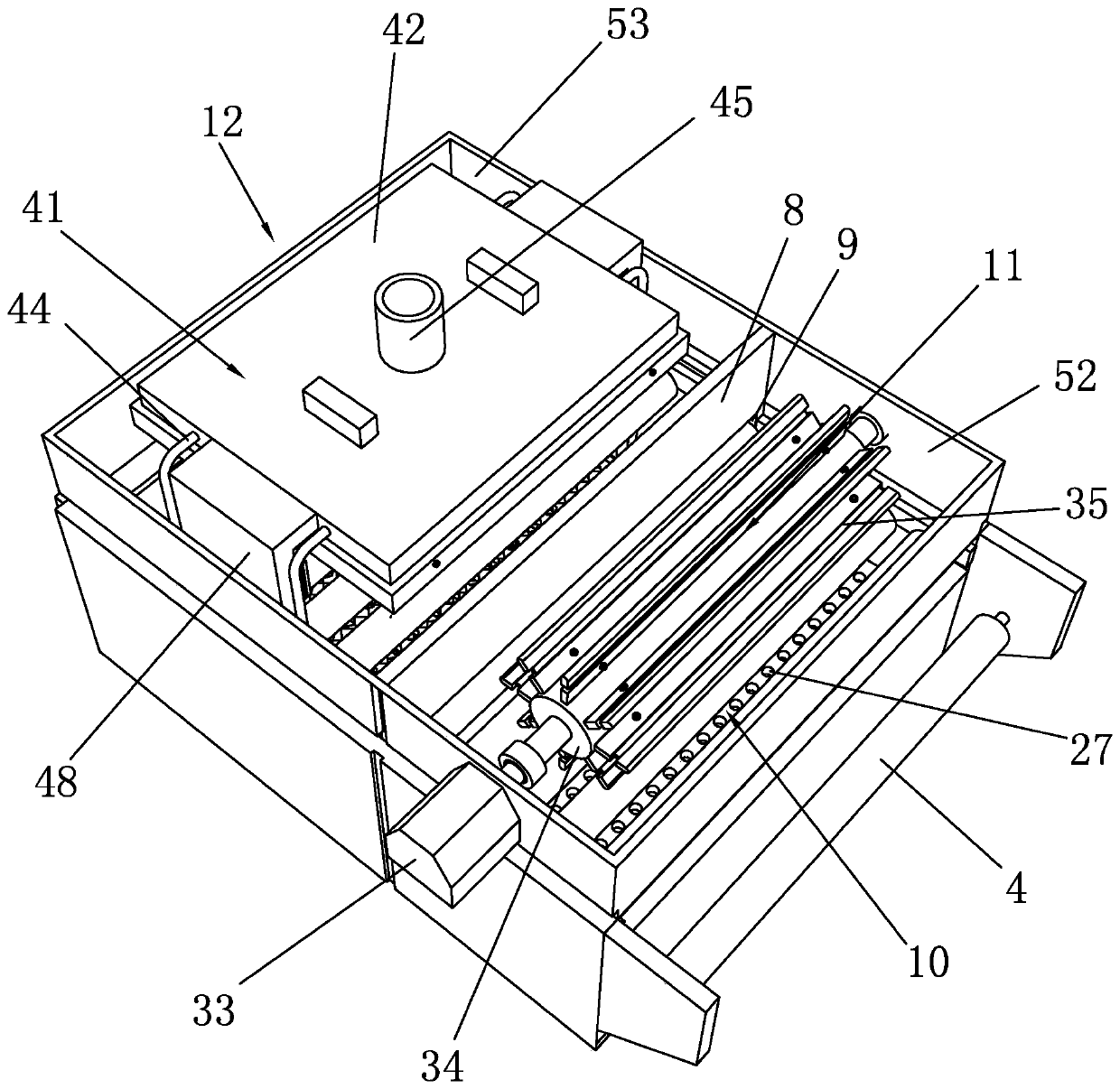

Textile fabric printing and dyeing equipment and printing and dyeing principle

InactiveCN110924015AImprove printing and dyeing qualityEasy to moveMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention discloses textile fabric printing and dyeing equipment and a printing and dyeing principle. The textile fabric printing and dyeing equipment comprises a box body, wherein an inner cavityof the box body is movably connected with a supporting shaft through a rotating shaft; an electric telescopic rod is fixedly connected to each of the front face and the back face of the box body separately; a flat plate is fixedly connected to the tops of the electric telescopic rods; a first spring is fixedly connected to the center of the bottom of the flat plate; the bottom of the first springextends to the inner cavity of the box body and is fixedly connected with a pressing plate; a vertical plate is fixedly connected to each of the front side and the rear side of the bottom of the pressing plate separately; and an extrusion shaft is movably connected to opposite sides of the vertical plates through a rotating shaft. The textile fabric printing and dyeing equipment has the advantages of carrying out pre-dedusting on cloth firstly and then rolling dye on the surface of the cloth, achieving high printing and dyeing quality and capability of scraping and collecting excess dye on the cloth, and solving the problems that the dye and the cloth are not tight in contact, the printing and dyeing quality is poor, scraping and collecting of excess dye on the cloth after printing and dyeing cannot be realized, the dye drips on the ground, and the waste of the dye is caused.

Owner:陈美和

Worsted fabric with function of temperature adjustment and fabrication method thereof

ActiveCN101671901AComfortable to wearIt has two-way temperature adjustment function of warm in winter and cool in summerLiquid/gas/vapor treatment of indefinite length materialsDyeing processFiberWorsted

The invention discloses worsted fabric with the function of temperature adjustment and a fabrication method thereof. The worsted fabric adopts wool strips and air-conditioning fiber cheese as the rawmaterial; as the air-conditioning fiber is formed by combining micro capsules of 2-30 nanometers, paste olefin is injected into the micro capsules; the olefin has the function of energy conversion, can make corresponding reaction on skins to the change of ambient temperature, and adjust the temperature fitting for human bodies through heat absorption, heat storage and heat release and has buffer function on temperature change, so that the worsted fabric made by blending the wool strips and the air-conditioning fiber cheese has the function of bidirectional temperature adjustment so as to trulyachieve the effect of warm in winter and cool in summer; on the other hand, as the air-conditioning fiber cheese is not added with any chemicals and the function of bidirectional temperature adjustment is achieved totally by the self function of the product, the worsted fabric is ecological, environment-friendly and energy-saving, can reduce consumption, and is elegant in quality, smooth in feeling and comfortable in wearing.

Owner:嵊州雅戈尔毛纺织有限公司

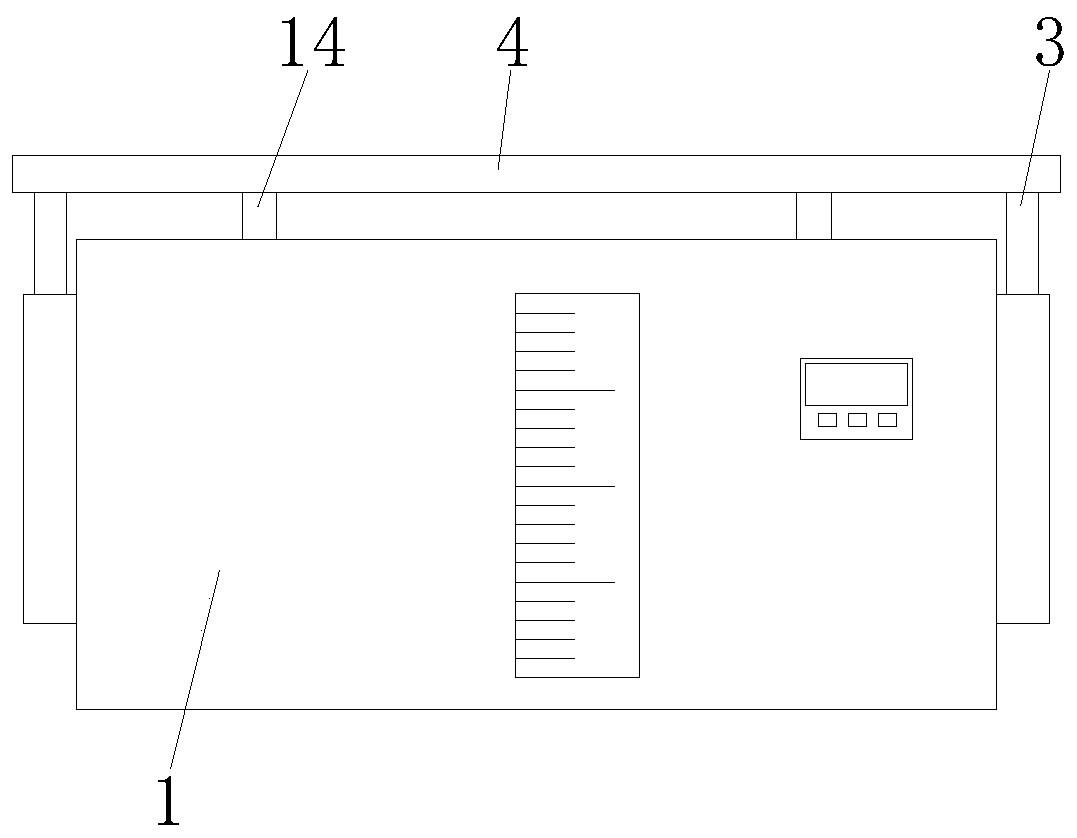

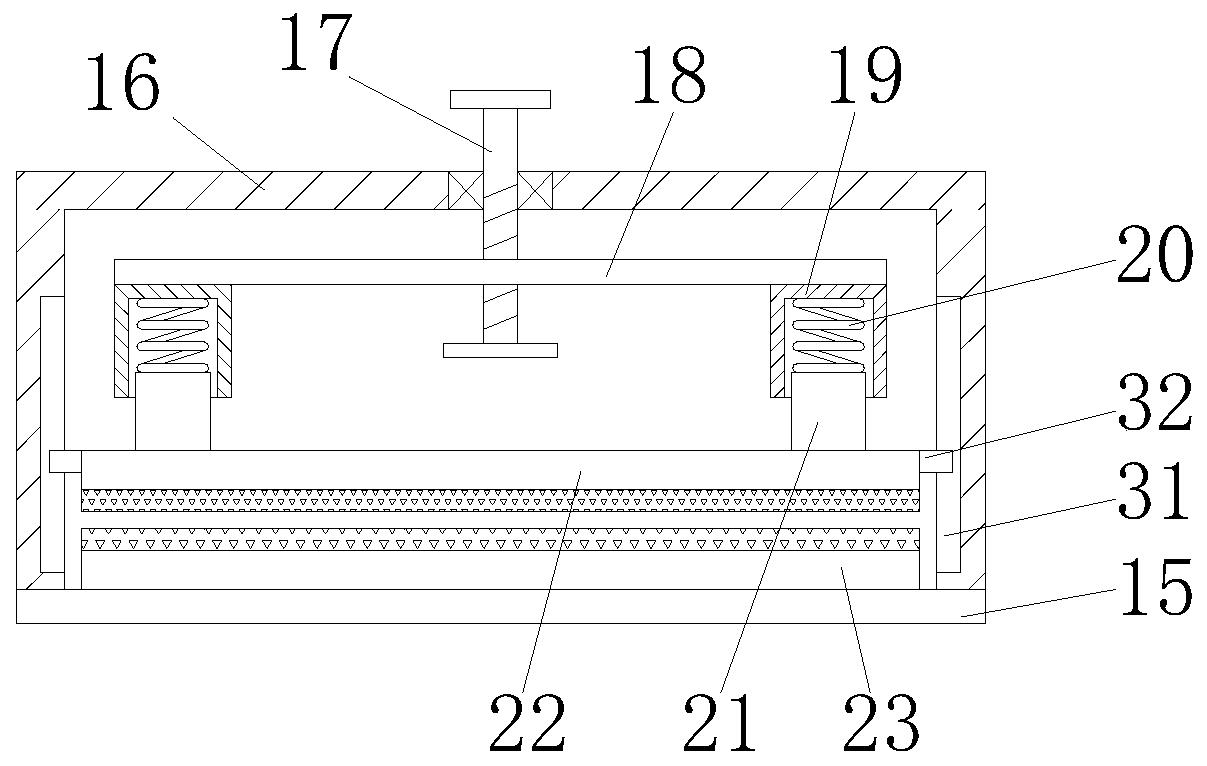

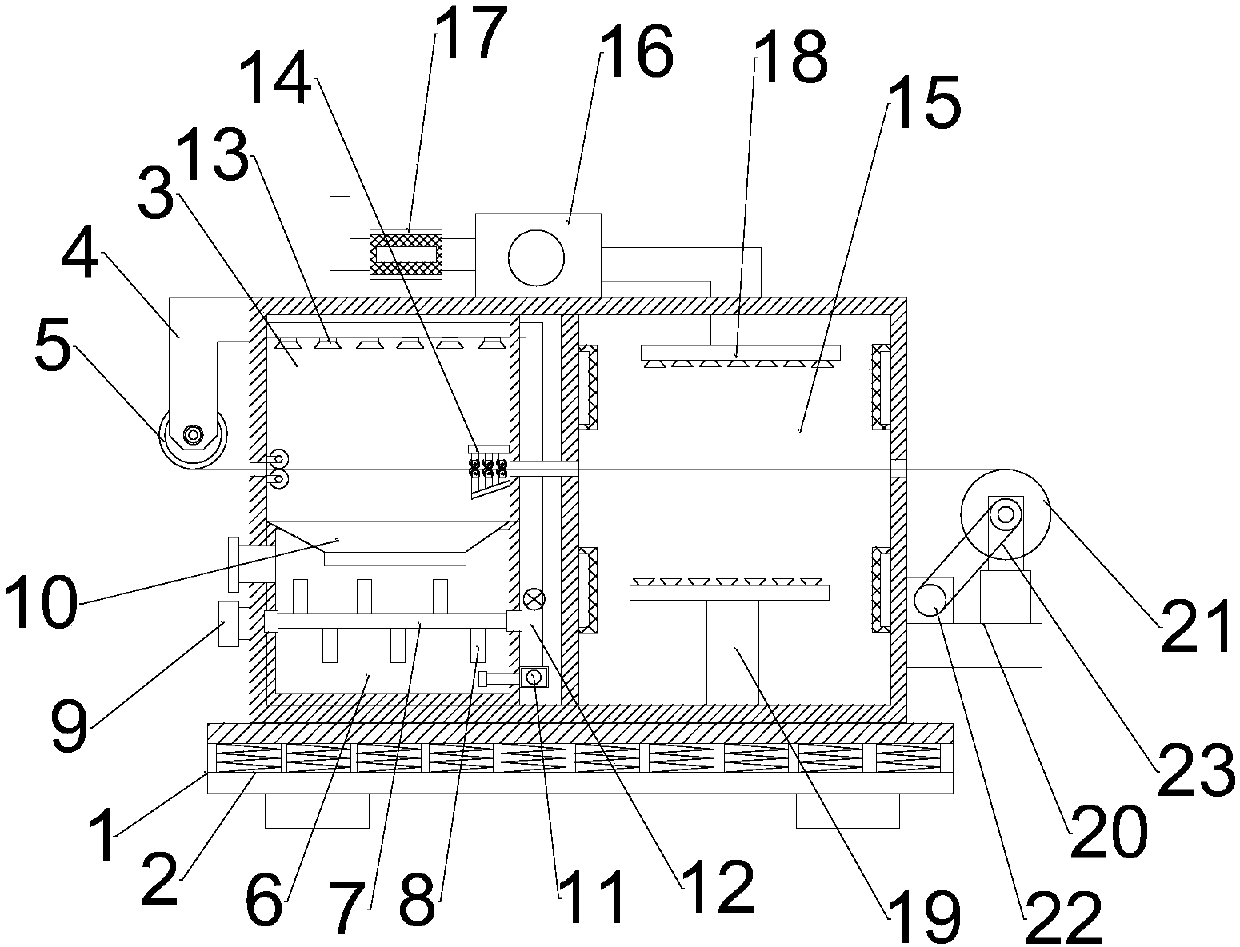

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

Woven materials with incorporated solids and processes for the production thereof

Owner:PURIFICATION PRODS +1

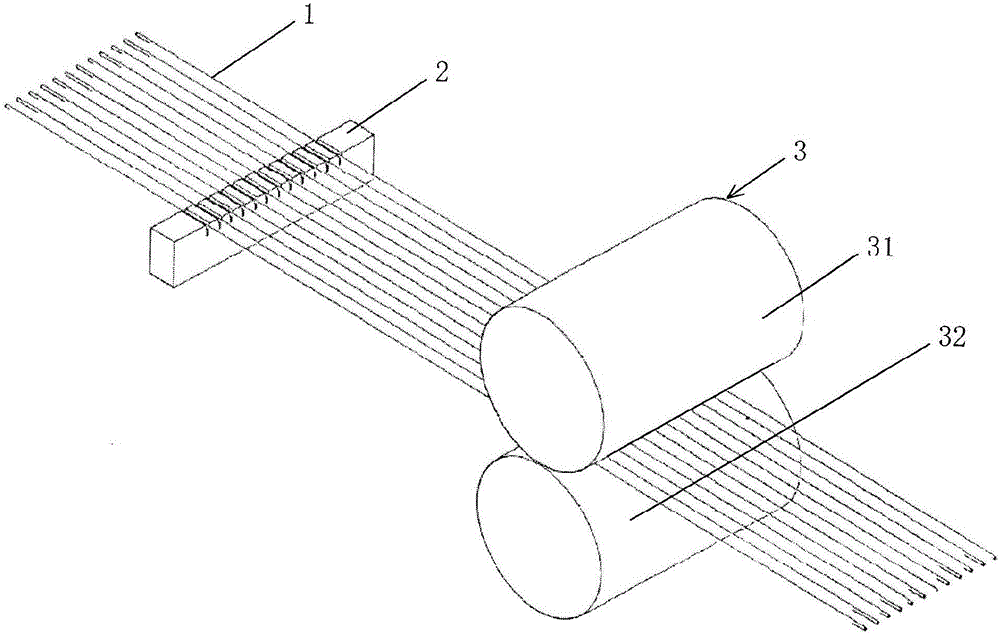

Oiling method for para-aramid fibers

InactiveCN105926203ALiquid/gas/vapor treatment of indefinite length materialsTextile treatment by spraying/projectingFiber bundleAramid

The invention provides an oiling method for para-aramid fibers and belongs to the technical field of artificial fiber preparation. The oiling method comprises steps as follows: oil in an oil tank is heated, para-aramid fiber bundles subjected to spinning, washing, neutralizing and drying sequentially are enabled to pass through an oiling device corresponding to the oil tank and equipped with a plurality of nozzles, each para-aramid fiber bundle corresponds to one nozzle, and each nozzle applies oil to the corresponding para-aramid fiber bundle; the oiled para-aramid fiber bundles are enabled to enter a roll type extrusion device after leaving the oiling device, oil attached to the surfaces of the para-aramid fiber bundles uniformly permeates into fiber texture of the para-aramid fiber bundles, and the oiled para-aramid fibers are obtained. According to the oiling method for the para-aramid fibers, plentiful oil can be obtained by the para-aramid fiber bundles; the oil can permeate into the fibers, so that the oil is uniformly applied to the outsides and the insides of the para-aramid fiber bundles, and quality guarantee is provided for production of follow-up products.

Owner:JIANGSU HENGTONG PRINTING & DYEING GRP CO LTD

Technology for producing base cloth for coated fabric and application thereof

InactiveCN106256941AThe process steps are simpleReduce energy consumptionLiquid/gas/vapor treatment of indefinite length materialsPolyurea/polyurethane coatingsWater basedYarn

The invention discloses a technology for producing base cloth for coated fabric. The technology comprises the steps of 1, beaming and yarn sizing, wherein warp is pulled into a size tank containing water-based environment-friendly resin size to be soaked, and then warp is rolled so that residual size can be removed and subjected to drying solidification for use; 2, weaving, wherein warp obtained in step 1 and weft are interwoven, and semi-finished base cloth is obtained after winding; 3, shaping, wherein the semi-finished base cloth is subjected to dry-shaping, press-polishing and winding, or subjected to drying, shaping, press-polishing, winding, gluing and drying to obtain the finished base cloth. The steps are simple, operability is high, desizing sewage disposal is completely achieved, the problem of shrinkage caused by desizing is solved, energy consumption is reduced, production efficiency is improved greatly, and fabric count consistency and full-width tension consistency of the obtained base cloth are high.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

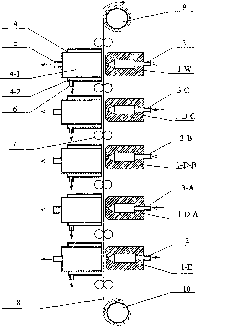

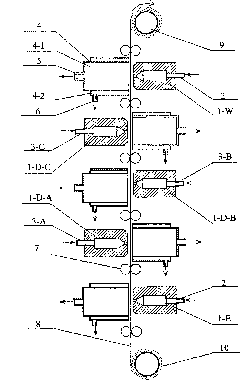

Sizing technology of environment-friendly size on interwoven fabric

InactiveCN103215780AEasy to degradeNo pollution in the processSucessive textile treatmentsLiquid/gas/vapor treatment of indefinite length materialsYarnPolyester

The invention discloses a sizing technology of an environment-friendly size on an interwoven fabric. The interwoven fabric is composed of cotton yarn and polyester network yarn. The sizing technology comprises the following steps: step 1, a beam-warping process, wherein the beam-warping length of the polyester network yarn is 1% longer than the beam-warping length of the cotton yarn; step 2, a size mixing process, wherein the cotton yarn is composed of hydrophilic fibers, the polyester network yarn is composed of hydrophobic fibers, and therefore different size mixing technologies are used; step 3, a slashing process, wherein different size tanks, different squeezing roller pressure and different drying drum temperatures are used for the cotton yarn and the polyester network yarn to carry out the slashing process simultaneously, and the moisture regain of the two types of warp yarn is controlled to be in the range of 4.8% to 5.0%; and step 4, a weaving process, wherein the speed of a weaving machine is 665RPM, and the tensile force of the weaving machine is 3,800N. By means of the sizing technology, the weaving efficiency of the weaving machine can reach 90%, the preparation technology is simple, the fabric cover is flat, smooth and good in style, texture is clear, the size used for the sizing process is easily degradable and cannot cause any pollution to the environment, the purpose that no polyvinyl acetate (PVA) is used in the sizing process is achieved, and a novel concept and a novel method are provided for textile enterprises for environment-friendly production.

Owner:WANG TAI CHINA

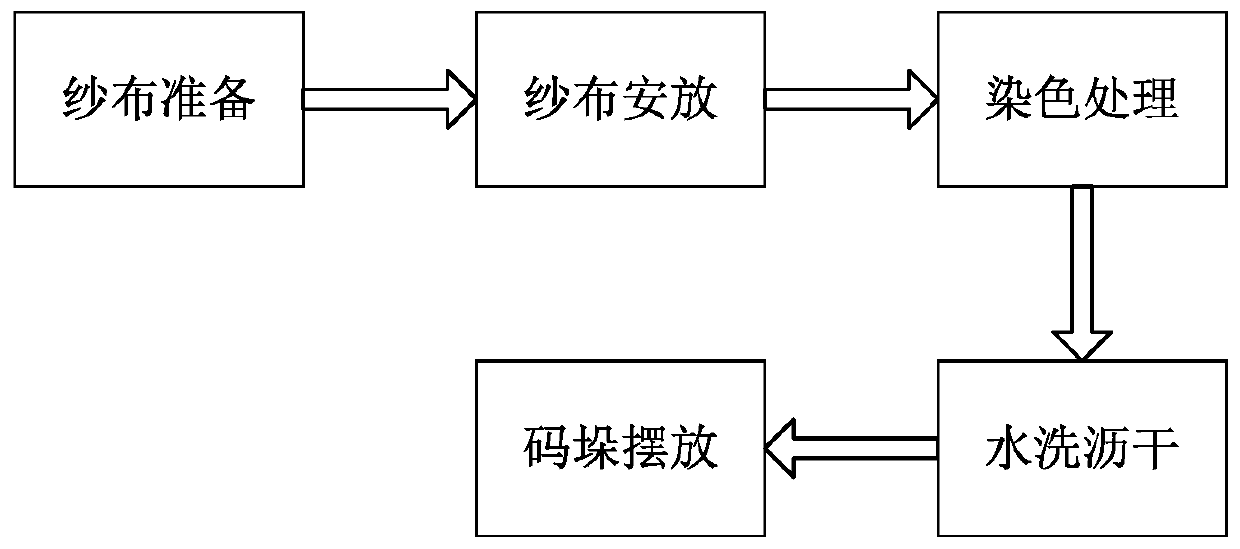

Production technique for colorful cocoon silk cotton

ActiveCN102965871AIncreased softness and bulkinessRelieve stressSolvent-treatmentSucessive textile treatmentsAcetic acidWastewater

The invention discloses a production technique for colorful cocoon silk cotton. The production technique is characterized by comprising the procedures of vacuum infiltration, cocoon cooking, silk cotton production and the like; the degumming and degreasing treatment adopts solution prepared by a ratio of (4.8-5): (980-1020); and the softening and fluffing treatment adopts solution prepared by a ratio of 0.1: (6.1-6.3): (980-1020) amongglacial acetic acid, softening agent and water. The production technique for the colorful cocoon silk cotton, disclosed by the invention, finally prepares the colorful silk cotton products through the innovated procedures of vacuum infiltration, cocoon cooling and silk cotton production; and the soft degree and the fluff degree are largely improved. And at the same time, the color retention of the products is higher, and the products are difficultly faded. Soda ash beneficial to the environment is adopted to replace caustic soda in the traditional technique, so that the waste water treatment pressure is relieved, and the products show the incomparable advantages of the traditional technique in the aspects, such as color and appearance.

Owner:曼居家居科技有限公司

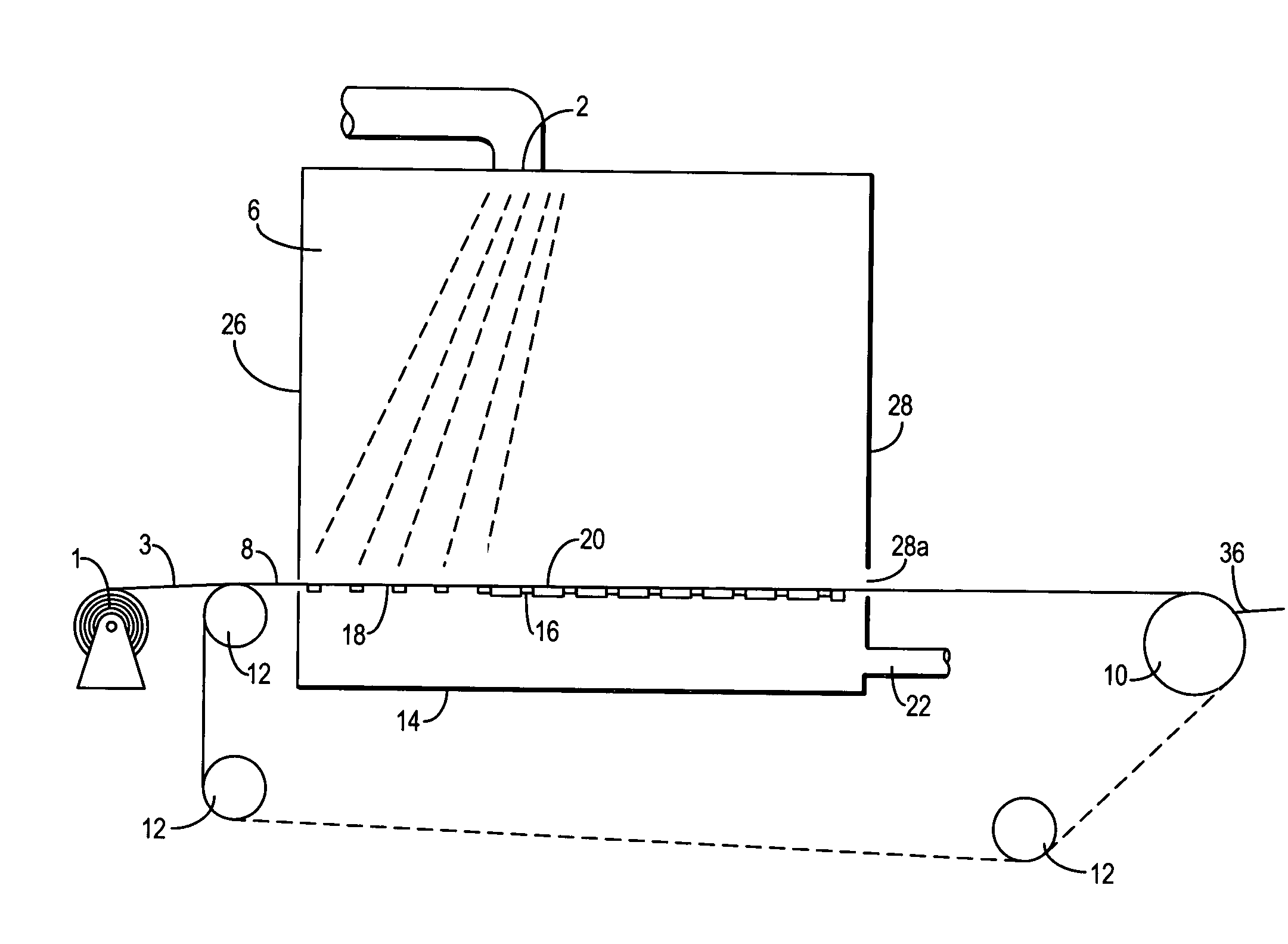

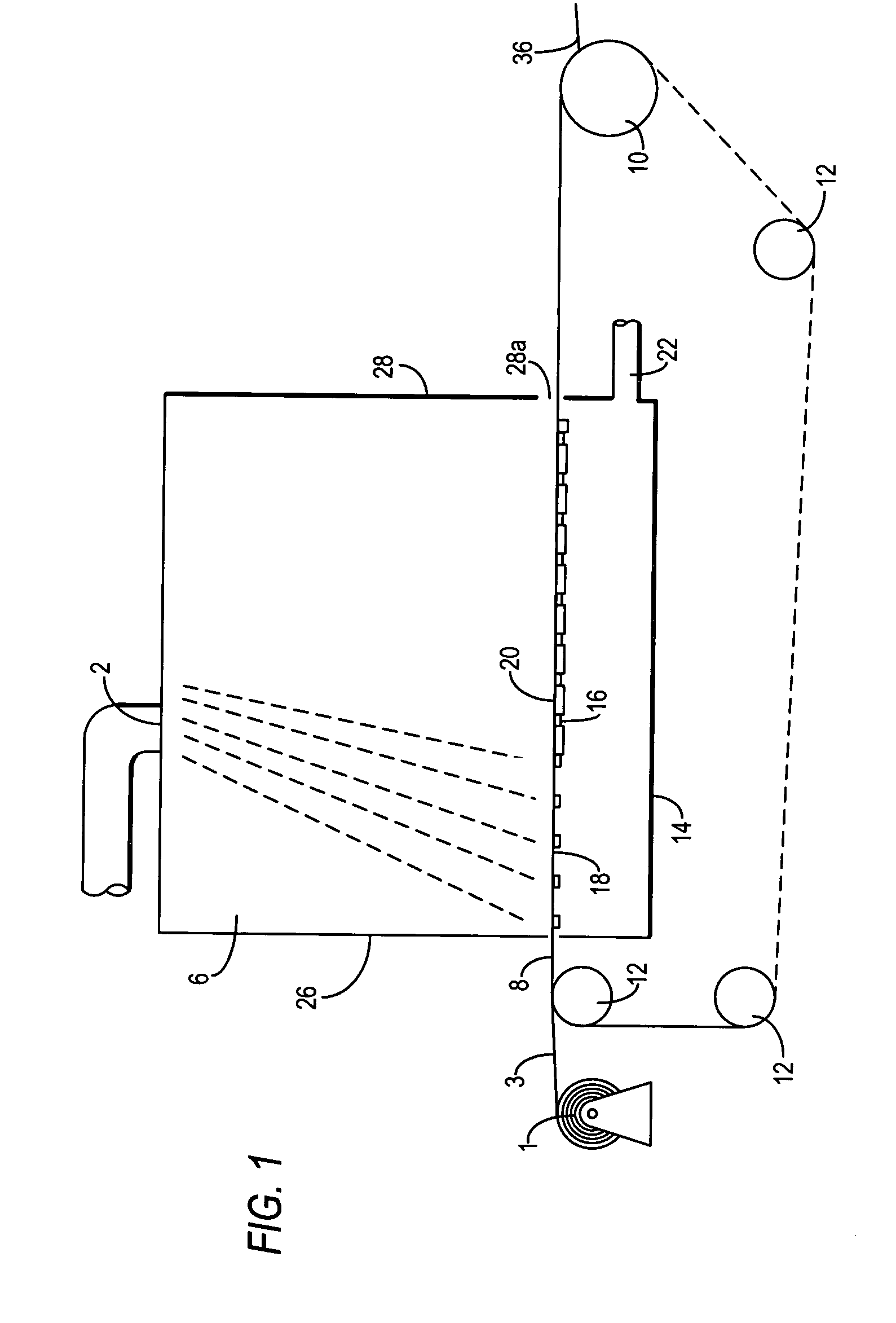

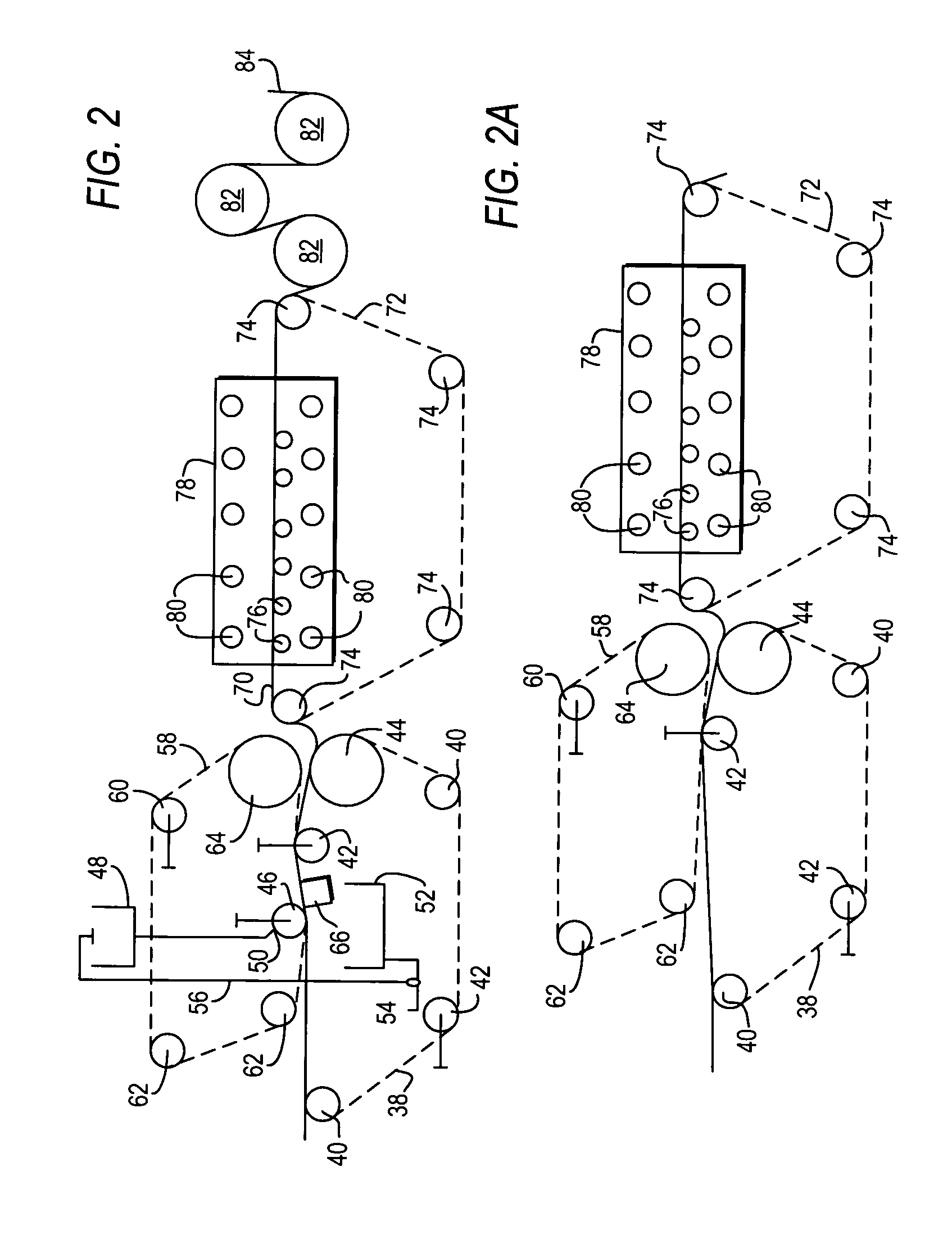

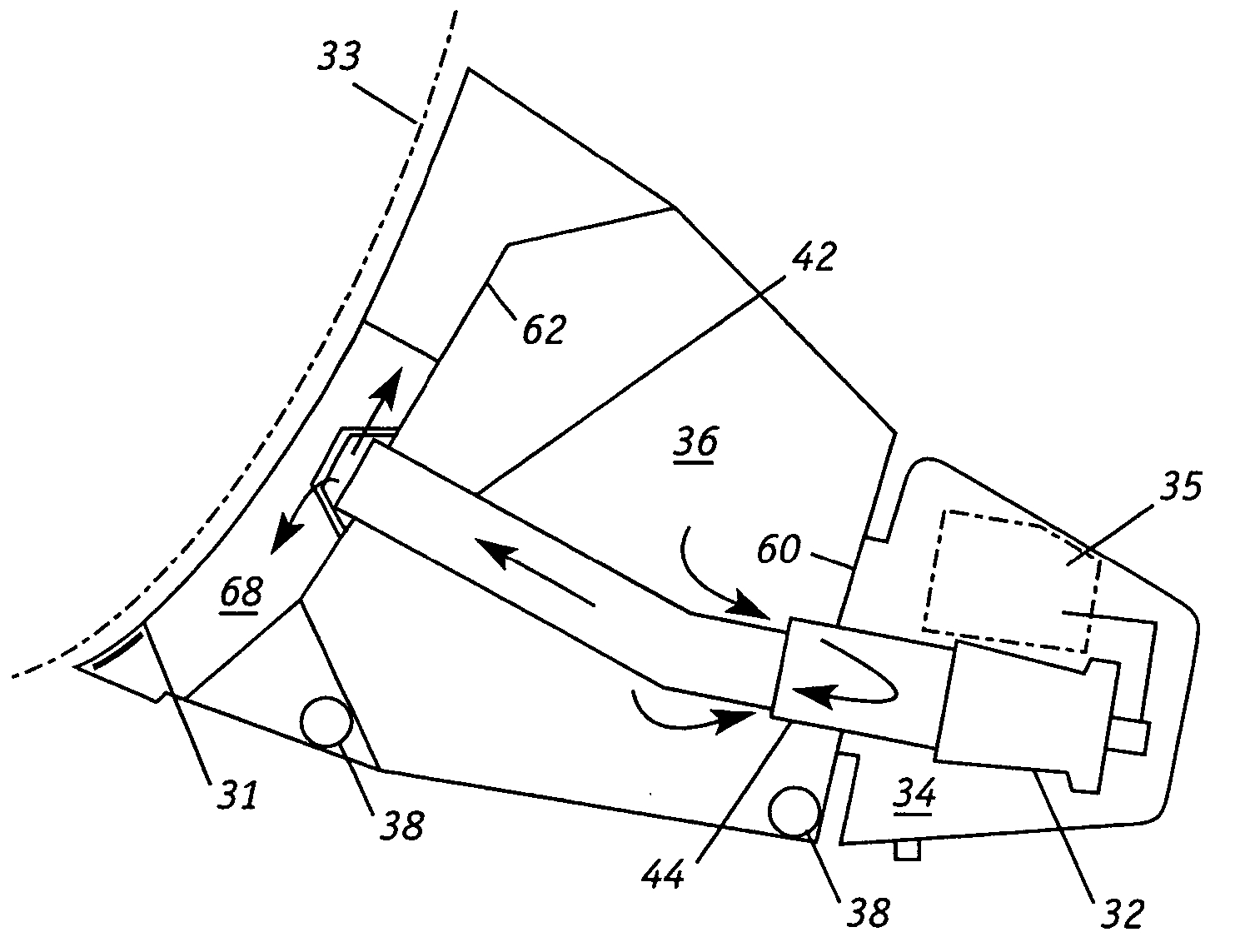

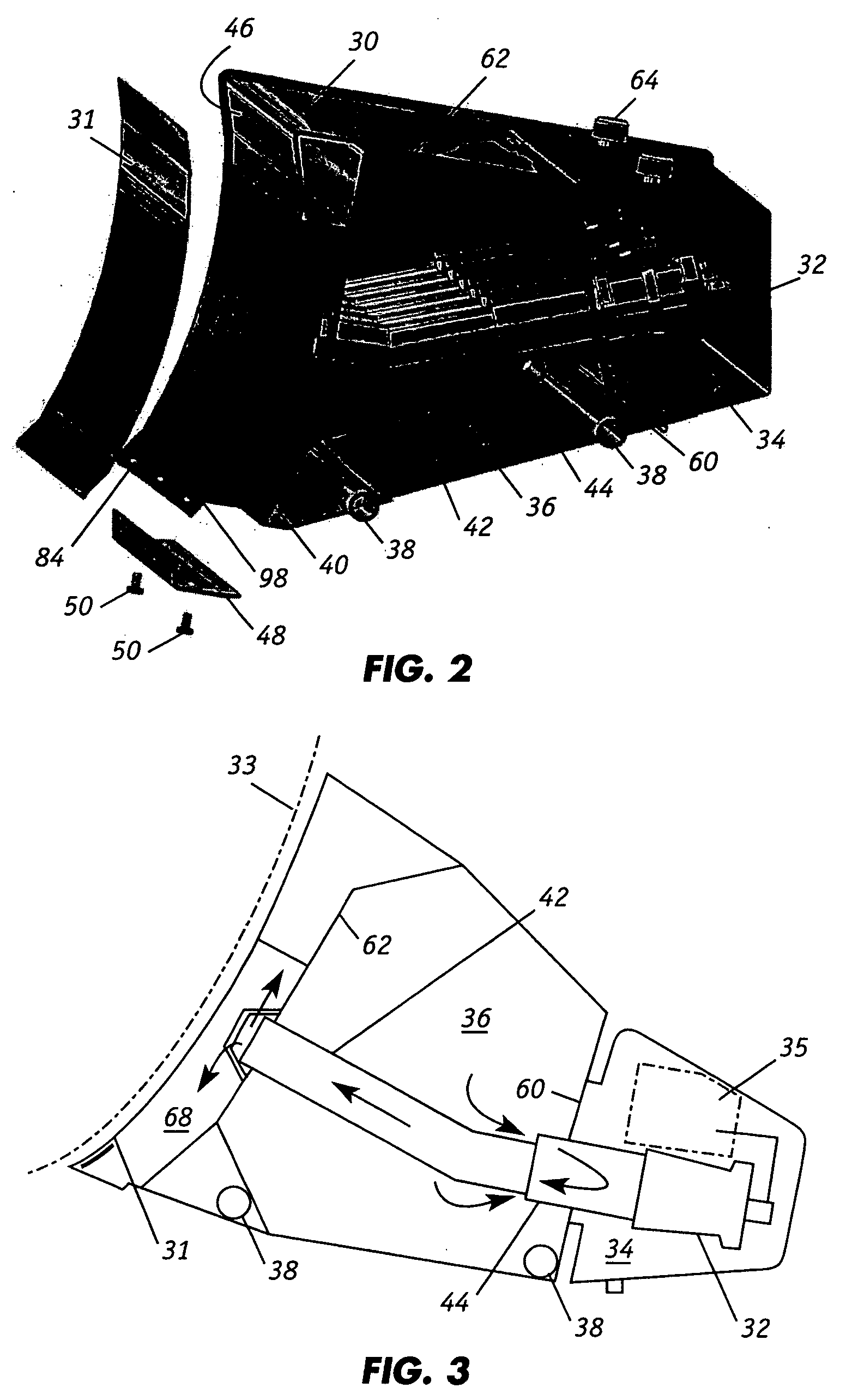

Steam distribution apparatus with removable cover for internal access

ActiveUS20060107704A1Reduce the possibility of damagePrecise alignmentDrying solid materials with heatTextile treatment machine partsEngineeringActuator

Employment of one or more resealable access slots in a steam distributor apparatus affords easy access to the internal chambers of the apparatus for cleaning and maintenance. The access slots can be located on the lower walls of the steam discharge chambers where debris tend to aggregate during operation of the apparatus. The apparatus can have multiple discharge chambers that are separated by spaced-apart partitions or baffle panels. Steam that is supplied from a steam header to each chamber exits each chamber through perforations of a discharge screen plate that is permanently secured onto adjacent partition panels. Actuators can regulate the steam flow from the steam header to the individual discharge chambers thereby creating a steam curtain with uniform or non-uniform cross direction profiles as desired.

Owner:HONEYWELL INTERNAITONL

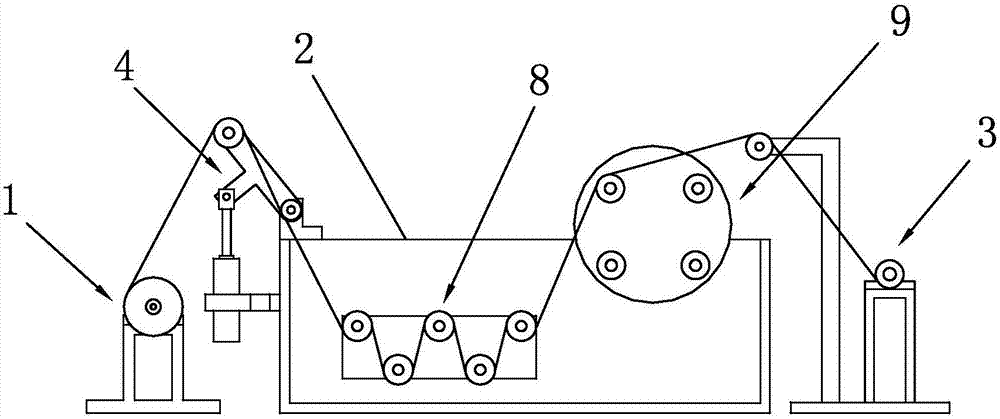

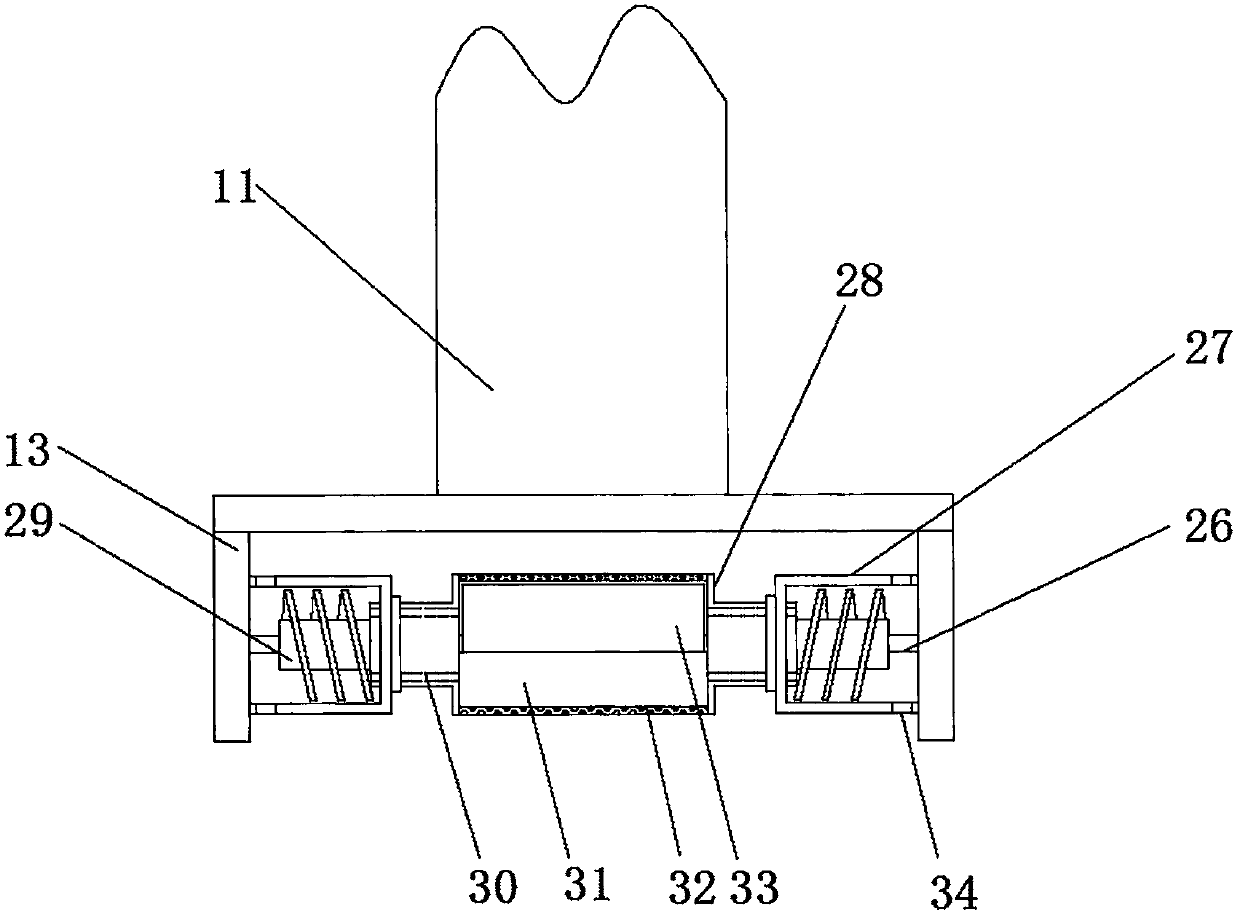

Sizing device for textile fabric

InactiveCN107034605AEasy to installImprove structural stabilityLiquid/gas/vapor treatment of indefinite length materialsTextile treatment carriersYarnSlurry

The invention discloses a sizing device for textile cloth, which comprises a feeding assembly, a slurry tank and a receiving assembly arranged in sequence from left to right, a material guide assembly is arranged at the left end of the slurry tank, and the material guide assembly includes a guide roller, The installation plate and the adjusting cylinder are provided with a sizing assembly and a sizing assembly in the slurry tank. The sizing assembly includes a fixed plate and a sizing roller group. The sizing assembly includes a sizing roller, a fixed plate and a transmission part. The discs are movably connected, and the transmission member includes a rotating shaft, a driving gear and a driven gear. The present invention has strong practicability, reasonable structural design, convenient use and operation, adjusts the transmission angle of the yarn through the material guide assembly, thereby changing the sizing rate of the yarn, and then adjusts the up and down of the cloth through the first sizing roller group and the second sizing roller group. Simultaneous sizing is performed on both sides to speed up the sizing rate. At the same time, the sizing unit is used to beat and press the surface of the sized fabric to improve the sizing uniformity of the fabric.

Owner:嵊州市靖洁纺织机械有限公司

Discharging ink for ink jet printing and process for preparing discharged polyester fiber cloth

InactiveUS20050237369A1Improve securityTake advantage ofMeasurement apparatus componentsInksPolyesterFiber

The present invention provides a discharging ink for ink jet printing, which has excellent discharge properties, is not limited in the dye to be discharged and enables safe and stable processing, in ink jet discharging of a cloth colored in advance, and a process for preparing discharged polyester fiber cloth. The discharging ink for ink jet printing comprises a nonionic surfactant having HLB value of 9 to 16 and ethylene oxide-added mol number of at most 30, guanidine weak acid salt and water. The process for preparing discharged polyester fiber cloth comprises the step of injecting the ink by an ink jet, the step of wet heat treatment or dry heat treatment at 150 to 190° C., and the step of soaping treatment.

Owner:SEIREN CO LTD

Textile cloth dip-dyeing process

InactiveCN111270447AReduce dyeing efficiencyImprove the efficiency of dippingLiquid/gas/vapor treatment of indefinite length materialsLiquid/gas/vapor removal by scrapingPolymer scienceEngineering

The invention relates to a textile cloth dip-dyeing process. A base plate, a bearing frame, a dyeing device and a winding device are included; and the bearing frame is installed at the upper end of the base plate through a base, the dyeing device is arranged on the right side of the bearing frame, the dyeing device is installed on the base plate through a support column, the winding device is arranged on the right side of the dyeing device, and the winding device is installed on the base plate through the base. The textile cloth dip-dyeing process in the invention is capable of solving the problems that the existing equipment is incapable of layering the multi-layer textile cloth during dyeing, such that the middle part of the textile cloth is unable to completely contact with dye, causingthe fact that the middle part cannot be completely dyed, and the dyeing efficiency is reduced; and simultaneously, the redundant dye on the surface of the textile cloth cannot be scraped after the textile cloth is dyed, such that the textile cloth has different surface colors, and the dyeing effect is reduced.

Owner:刘金红

Multiple step dyeing textile with concentrated dye systems

InactiveUS8167958B2Capital costReduce expenditureTextile treatment using short bath ratio liquorLiquid/gas/vapor treatment of indefinite length materialsEngineeringDyeing

The present invention relates to a process for dyeing sheetlike textile materials with a dye, which comprises a concentrated dye system being applied in a total amount of 1% to 25% by weight, based on the textile material, to the textile material in two or more sub-steps and the dye being fixed on the textile material after each and every sub-step.

Owner:DYSTAR COLOURS DISTRIBUTION GMBH

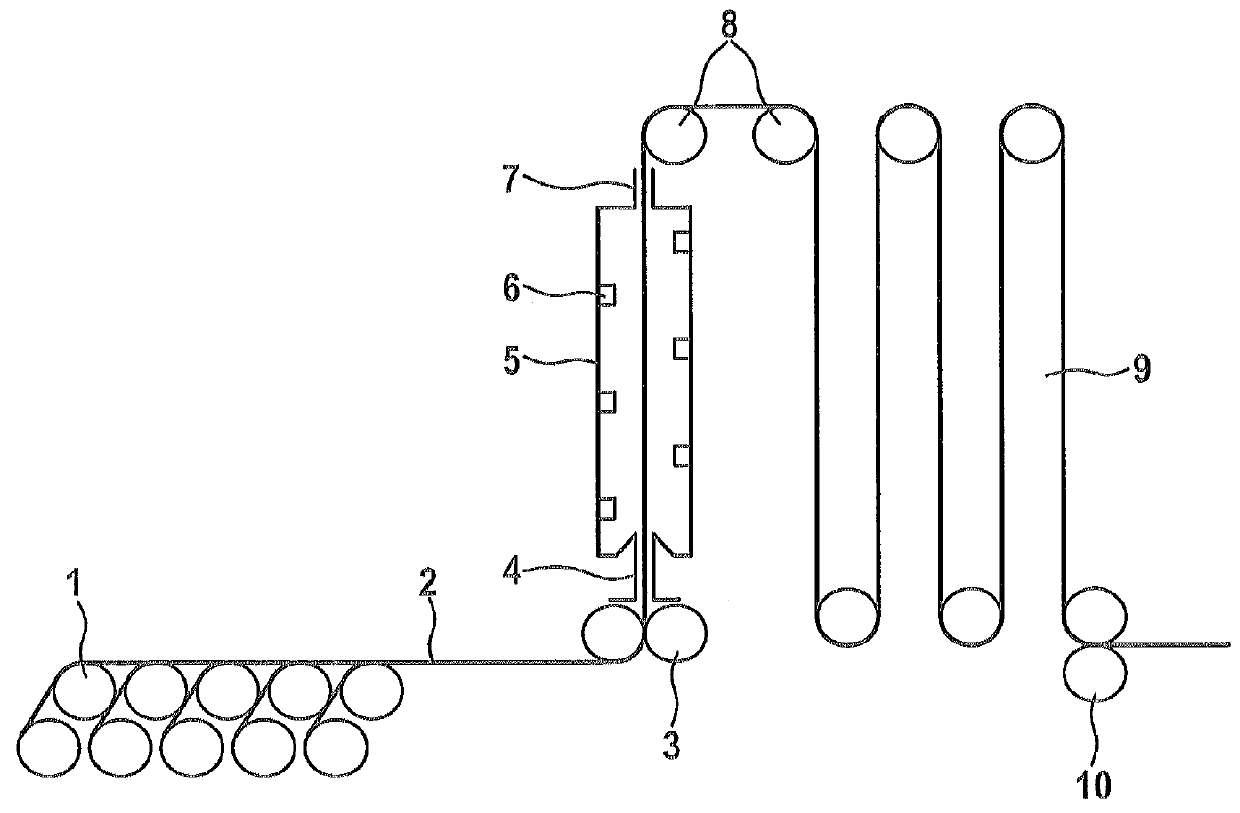

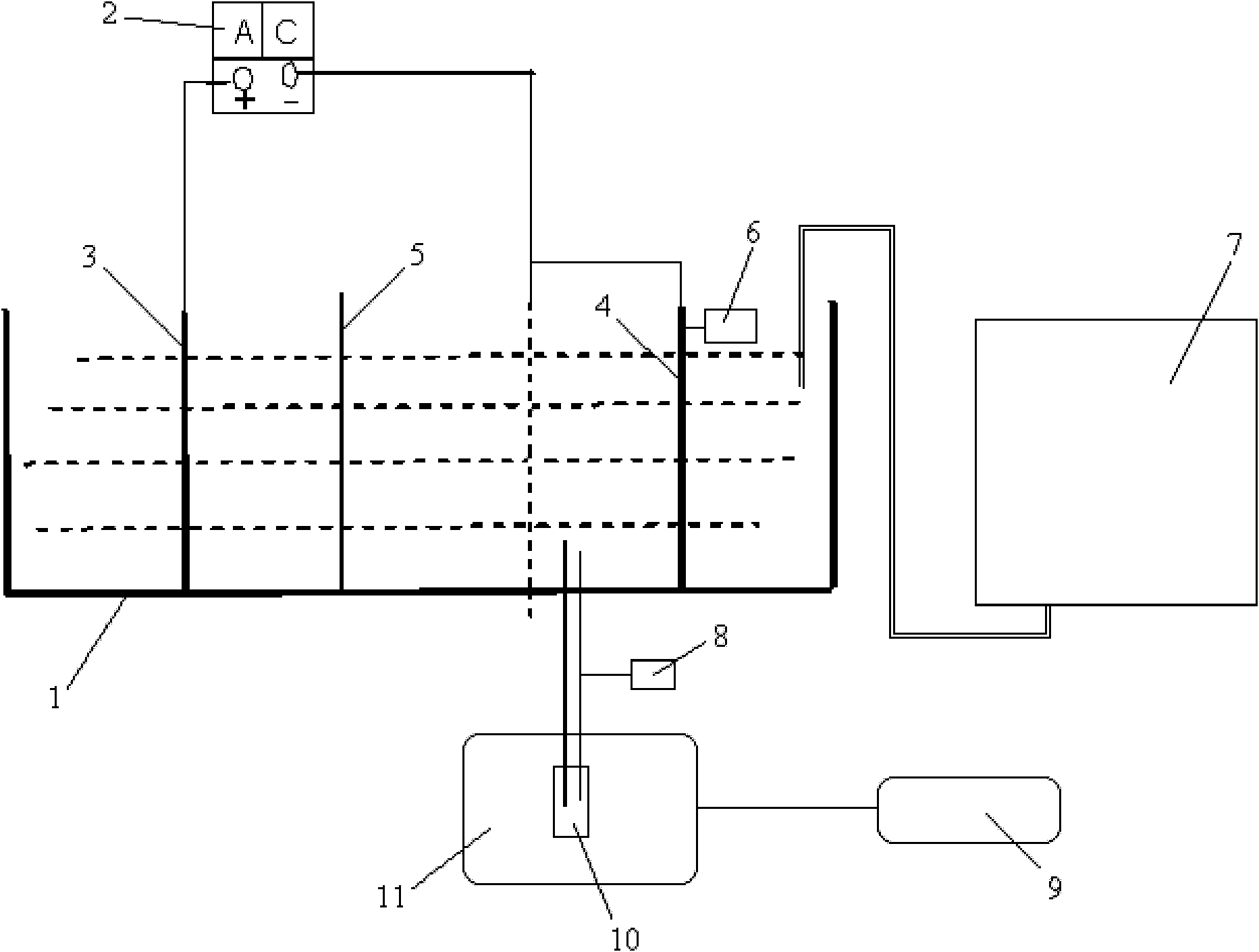

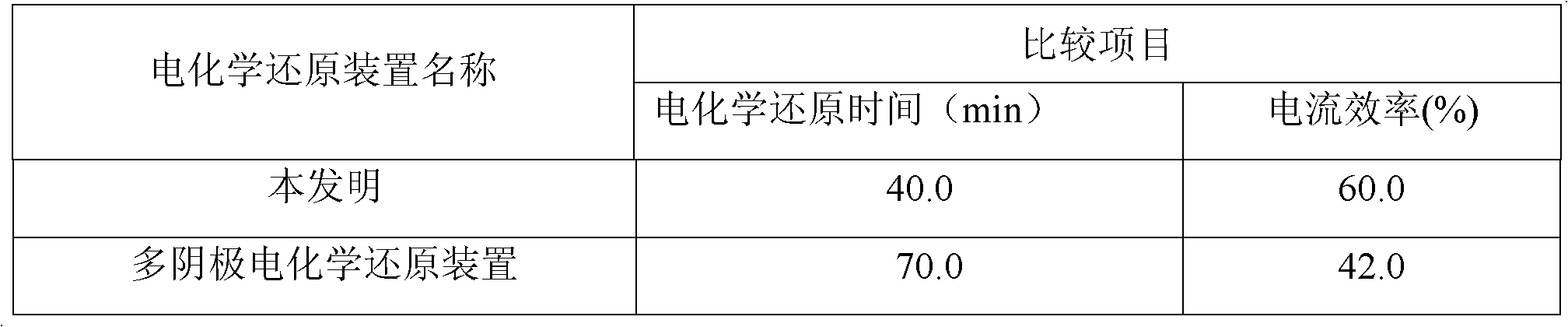

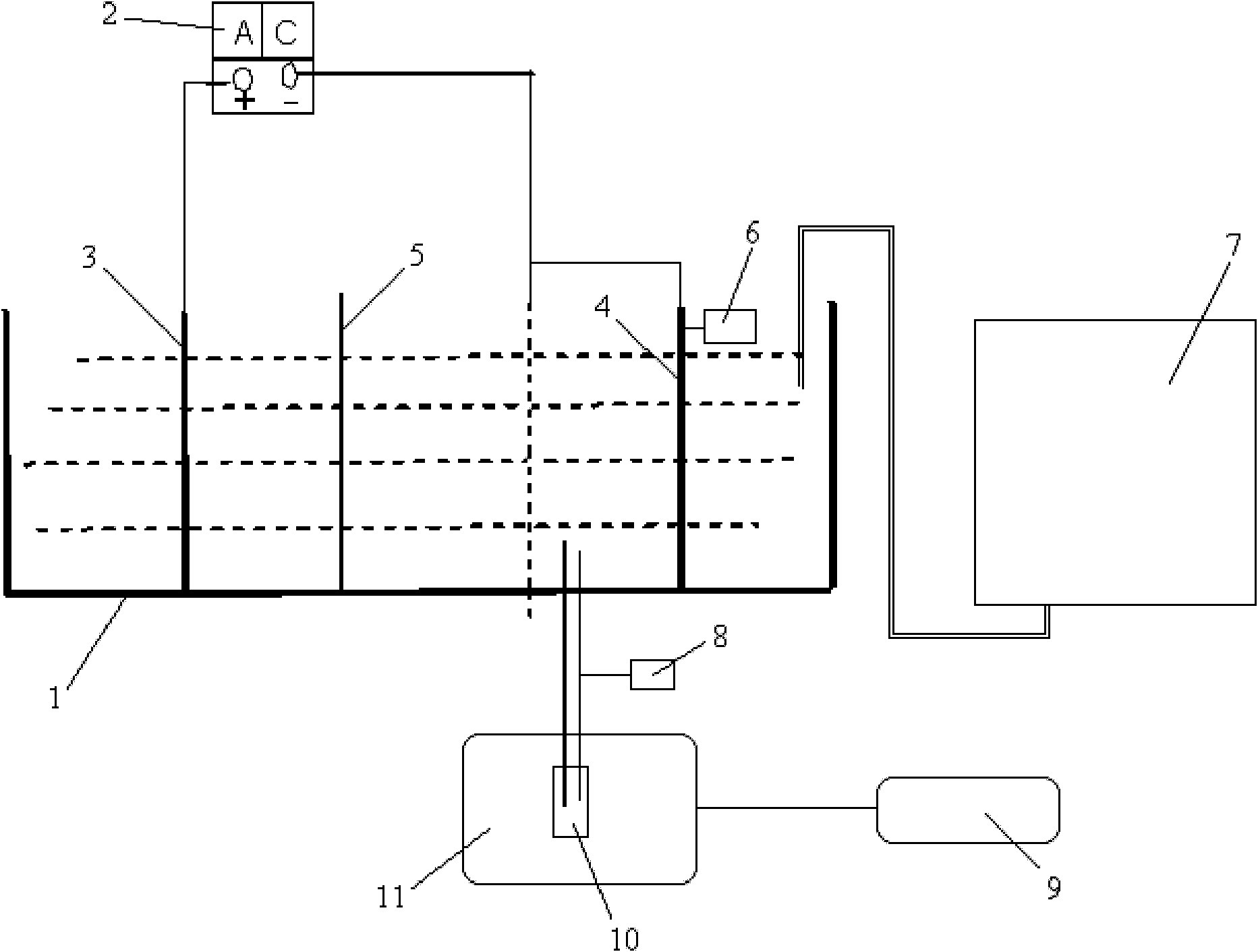

Dyeing apparatus for electrochemical reduction of cotton yarns

InactiveCN102154793AIncrease the chance of mutual contactLess side effectsMaterial analysis by optical meansLiquid/gas/vapor treatment of indefinite length materialsYarnPower flow

The invention relates to a dyeing apparatus for electrochemical reduction of cotton yarns. The dyeing apparatus comprises an electrolytic bath reduction device, a dye concentration on-line monitoring device and a dyeing tank, wherein the electrolytic bath reduction device comprises an electrolytic bath, an anode connected with a positive electrode of a power supply and a cathode connected with a negative electrode of the power supply; an ion exchange isolation membrane is arranged in the electrolytic bath to form an anode region and a cathode region of the electrolytic cell; the anode is arranged in the anode region of the electrolytic bath; the cathode is arranged in the cathode region of the electrolytic bath and is connected with a translation device; the dyeing tank is connected with the cathode region of the electrolytic bath through a first pipeline; and the cathode region of the electrolytic bath is provided with the dye concentration on-line monitoring device in a connecting manner. Through the dyeing apparatus, electrolytic reduction speed of a dye can be increased, and current efficiency can be increased.

Owner:DONGHUA UNIV

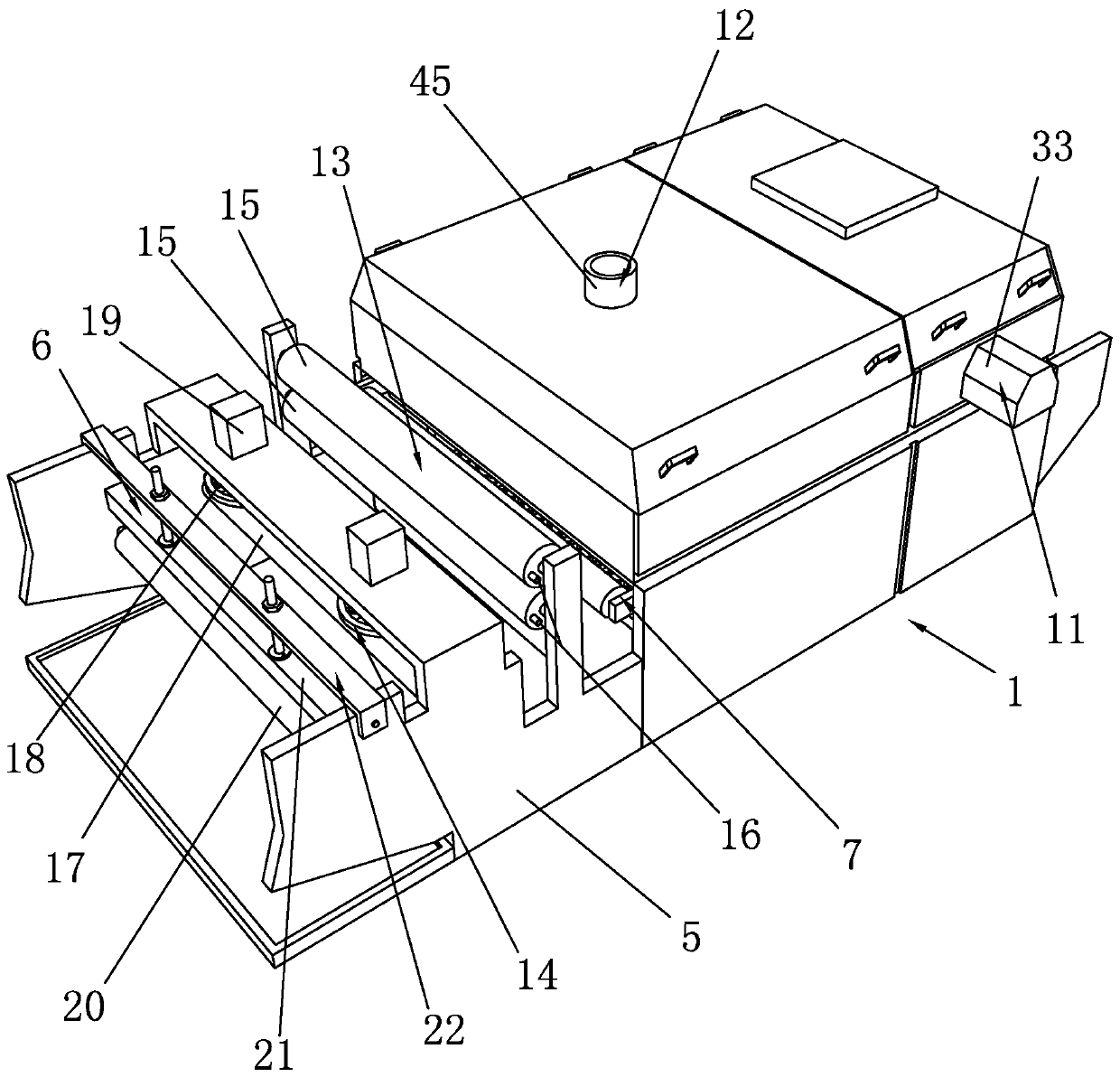

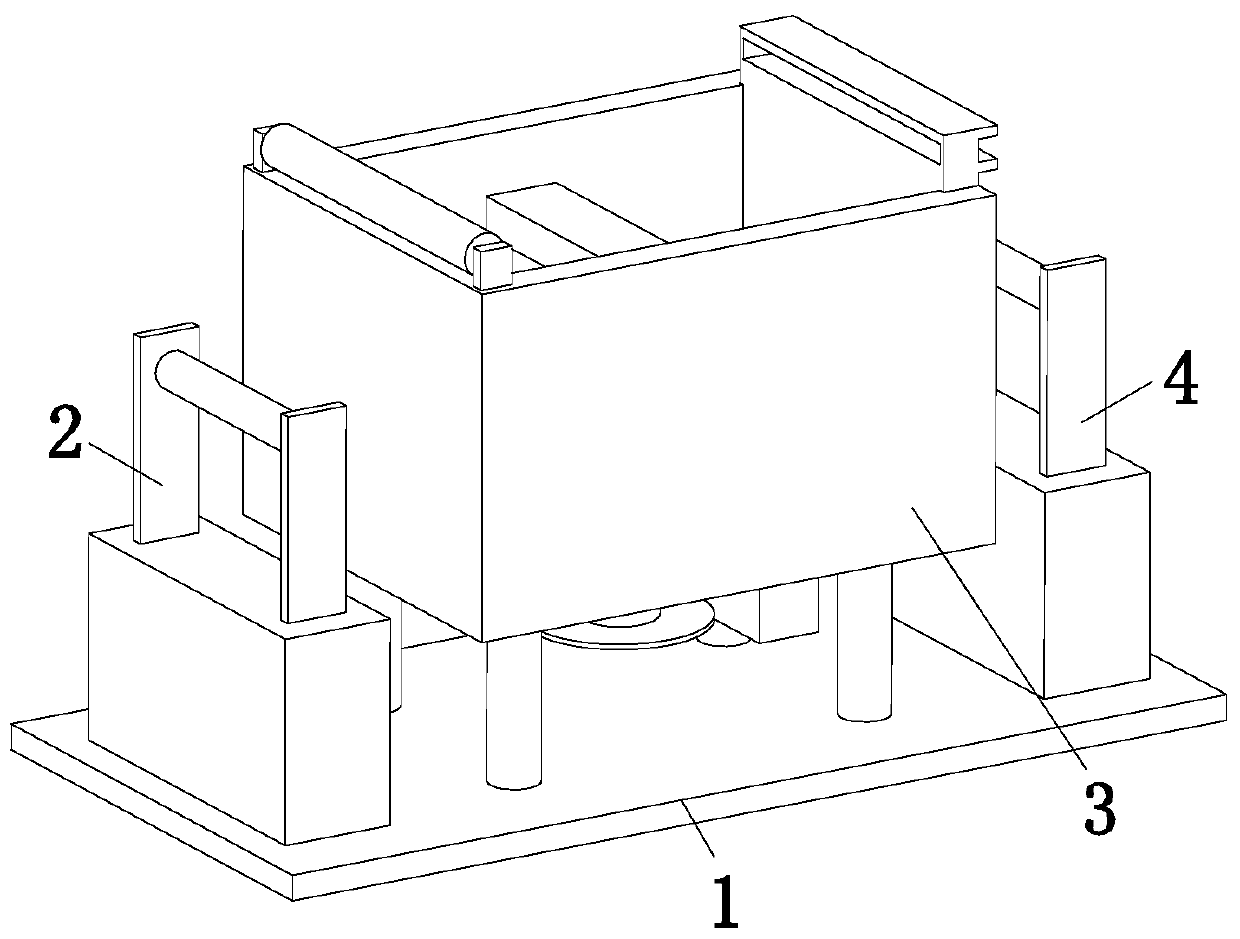

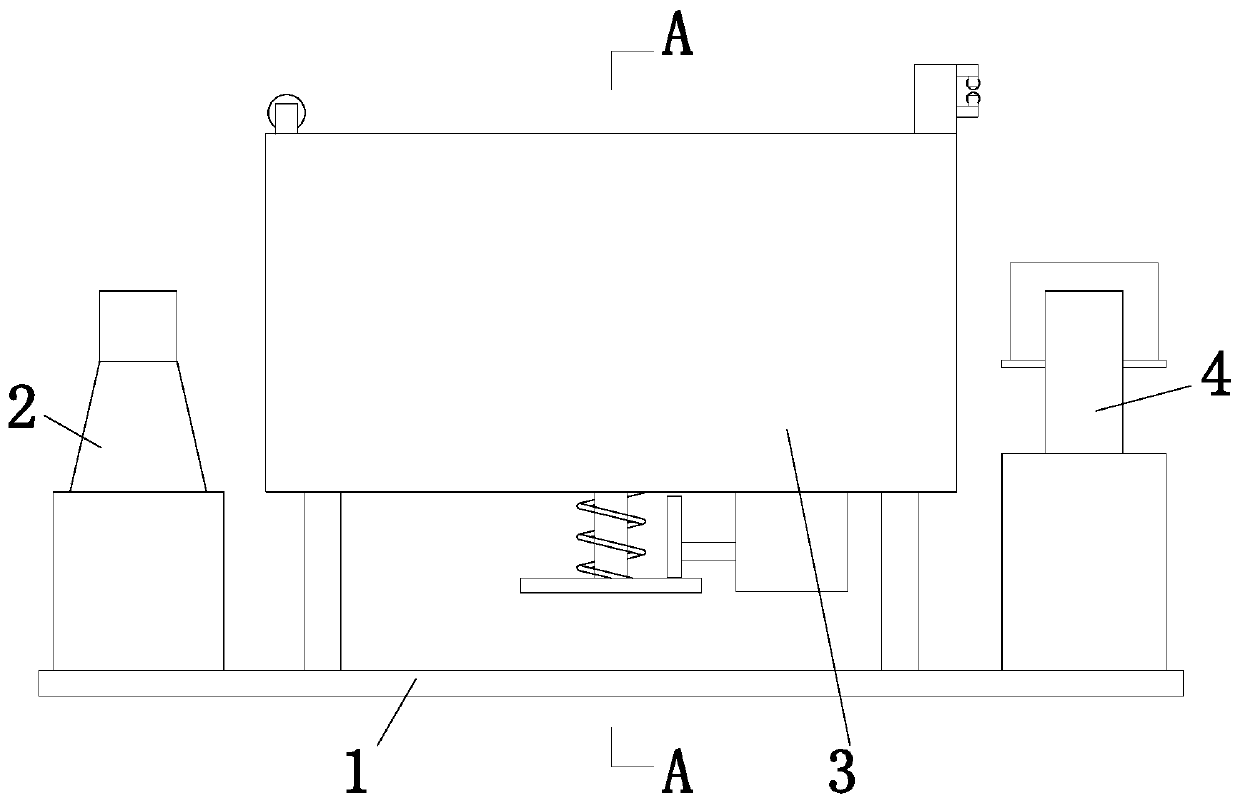

Multifunctional printing-dyeing device for cloth processing

InactiveCN107780078AImprove drying efficiencyImprove printing and dyeing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsEngineeringDyeing

The invention discloses a multifunctional printing-dyeing device for cloth processing. The multifunctional printing-dyeing device comprises a fixed underframe, a damping device and a printing-dyeing chamber, a dye box is arranged at the lower end inside the printing-dyeing chamber, a rotating shaft is arranged in the dye box, a plurality of stirring rods are arranged on the rotating shaft, a stirring motor is arranged at the left end of the rotating shaft, a dye pump is arranged on the right side of the dye box and connected with a feeding pipe which is connected to the upper end inside the printing-dyeing chamber, and a plurality of spraying heads are arranged at the lower end of the feeding pipe inside the dye chamber; a first fixed frame is arranged on the left upper side of the printing-dyeing chamber, an unwinding roller is arranged on the lower side of the first fixed frame, and a dye uniformly-coating device is arranged on the left side wall inside the printing-dyeing chamber and provided with a lower supporting frame and an upper supporting frame. The device combines printing and dyeing with air drying, so that uniformity in printing and dyeing is guaranteed, cloth printingand dyeing efficiency is improved greatly, and quality of cloth after being printed and dyed is ensured.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

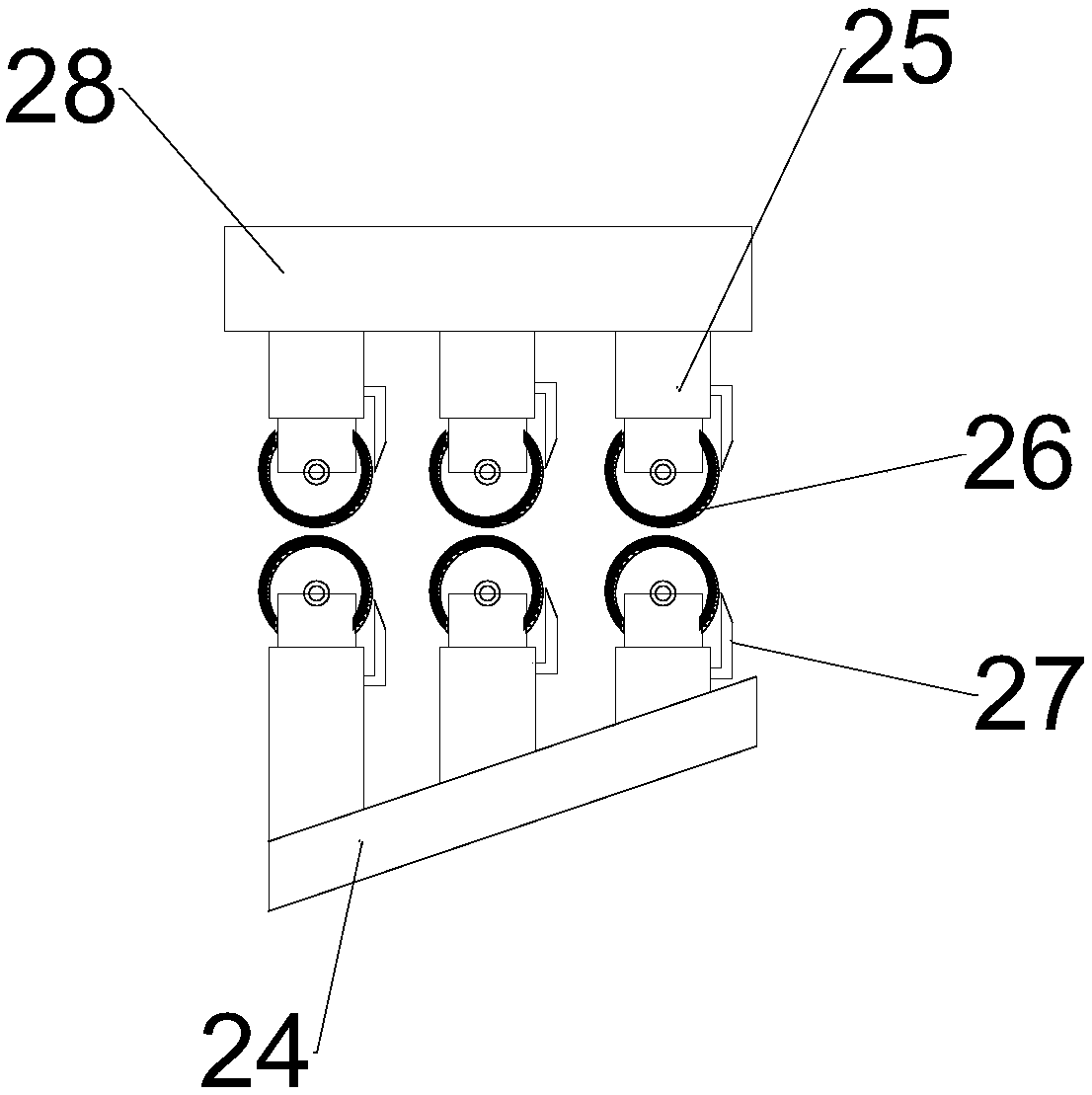

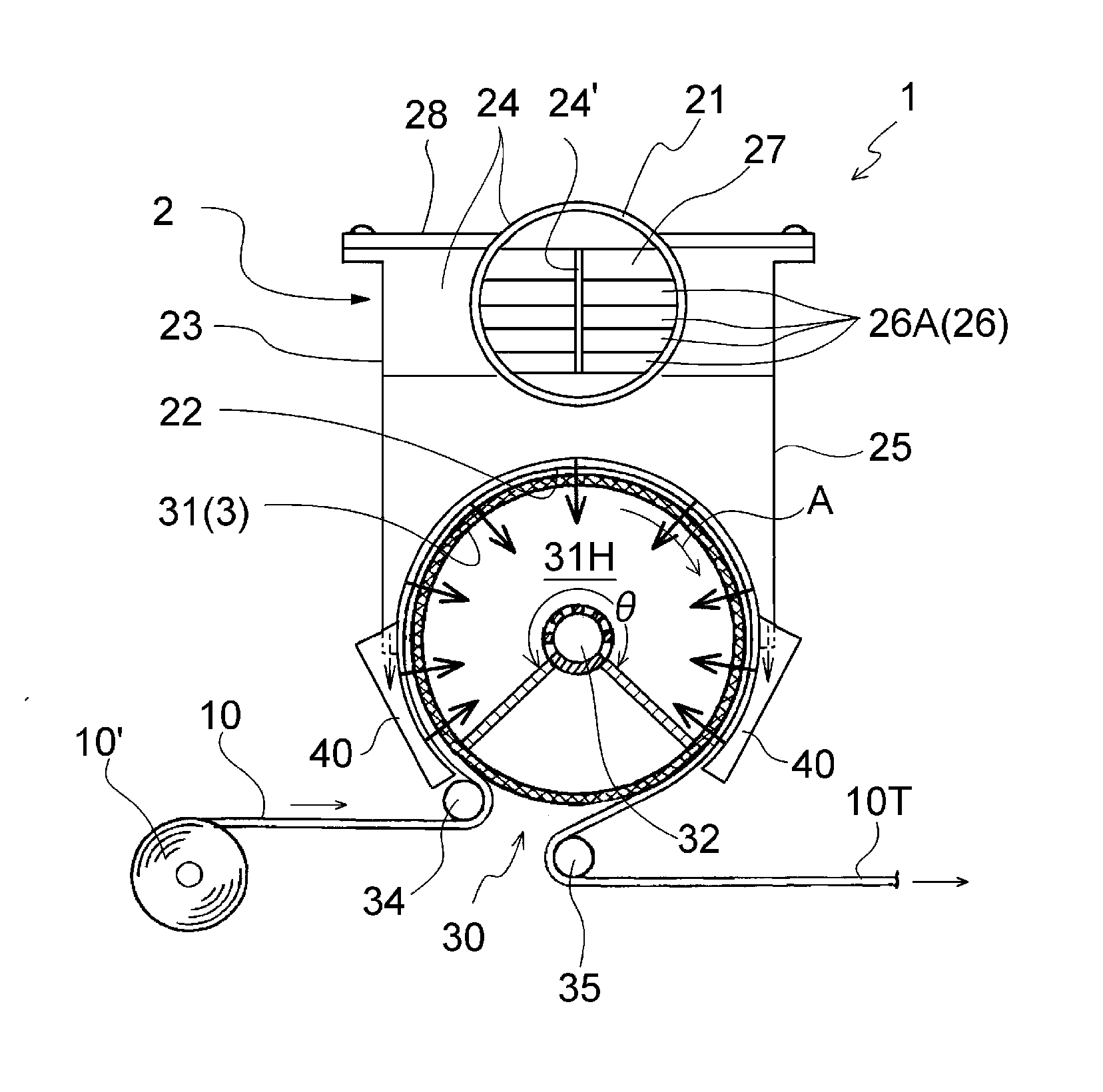

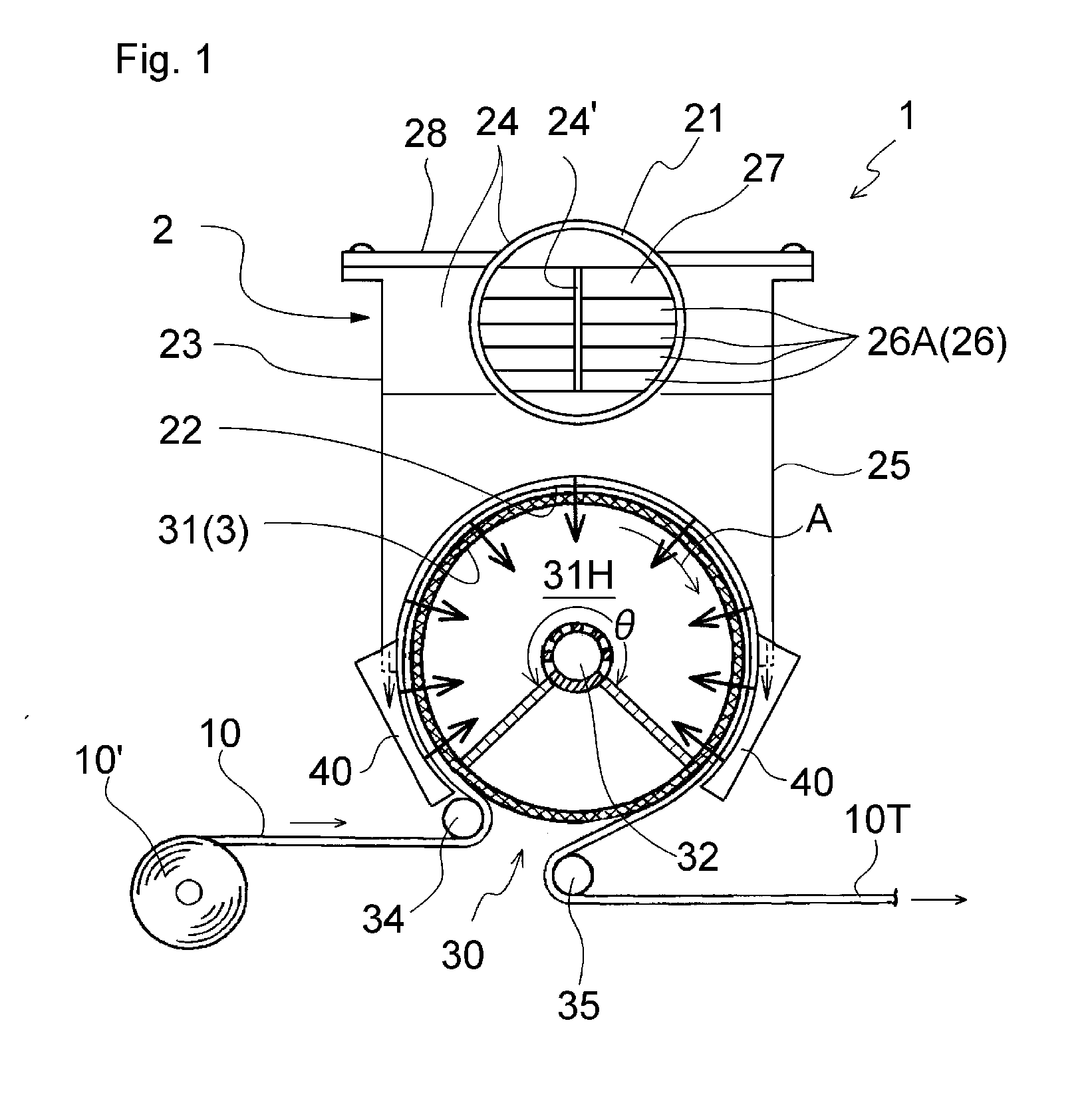

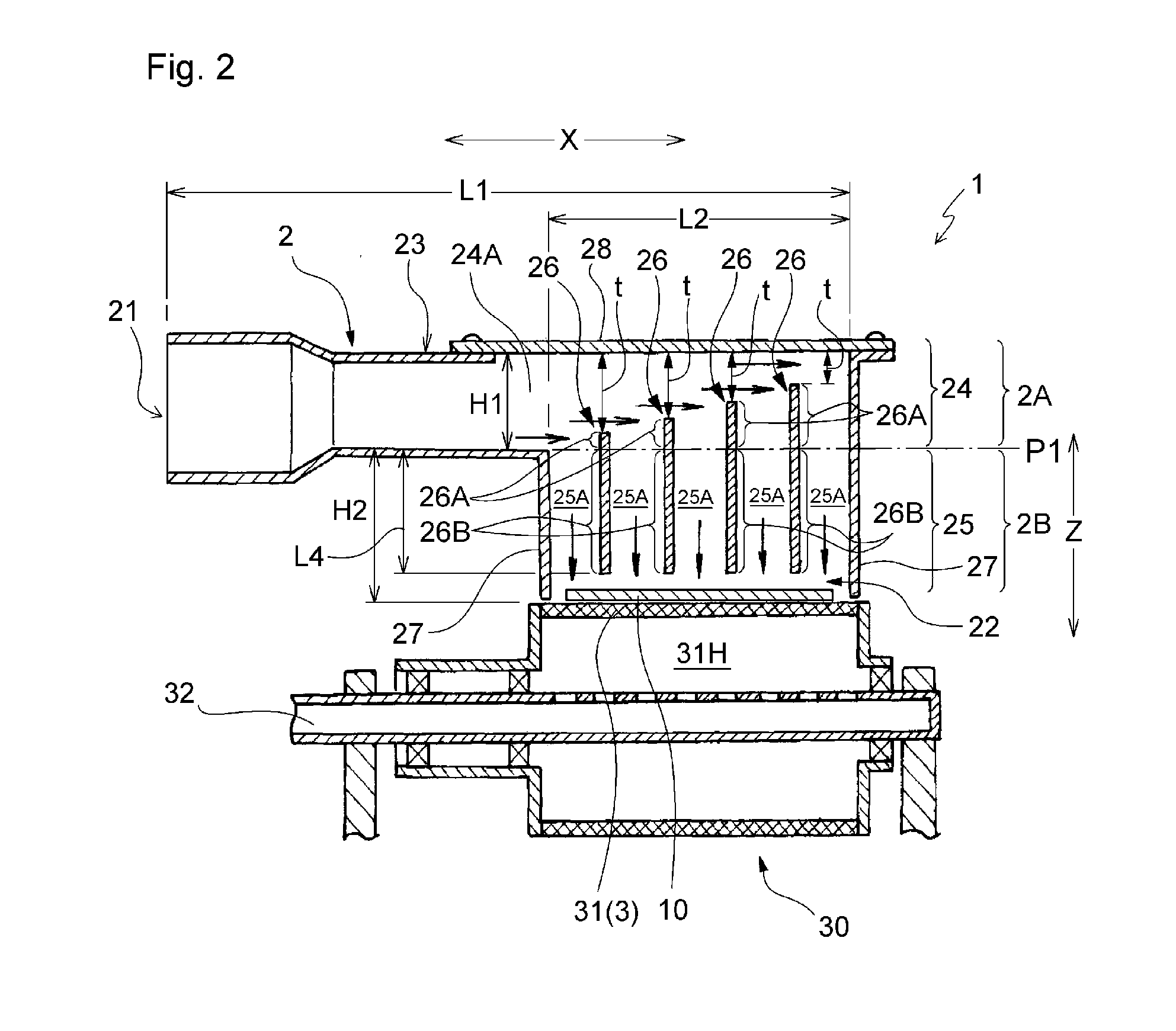

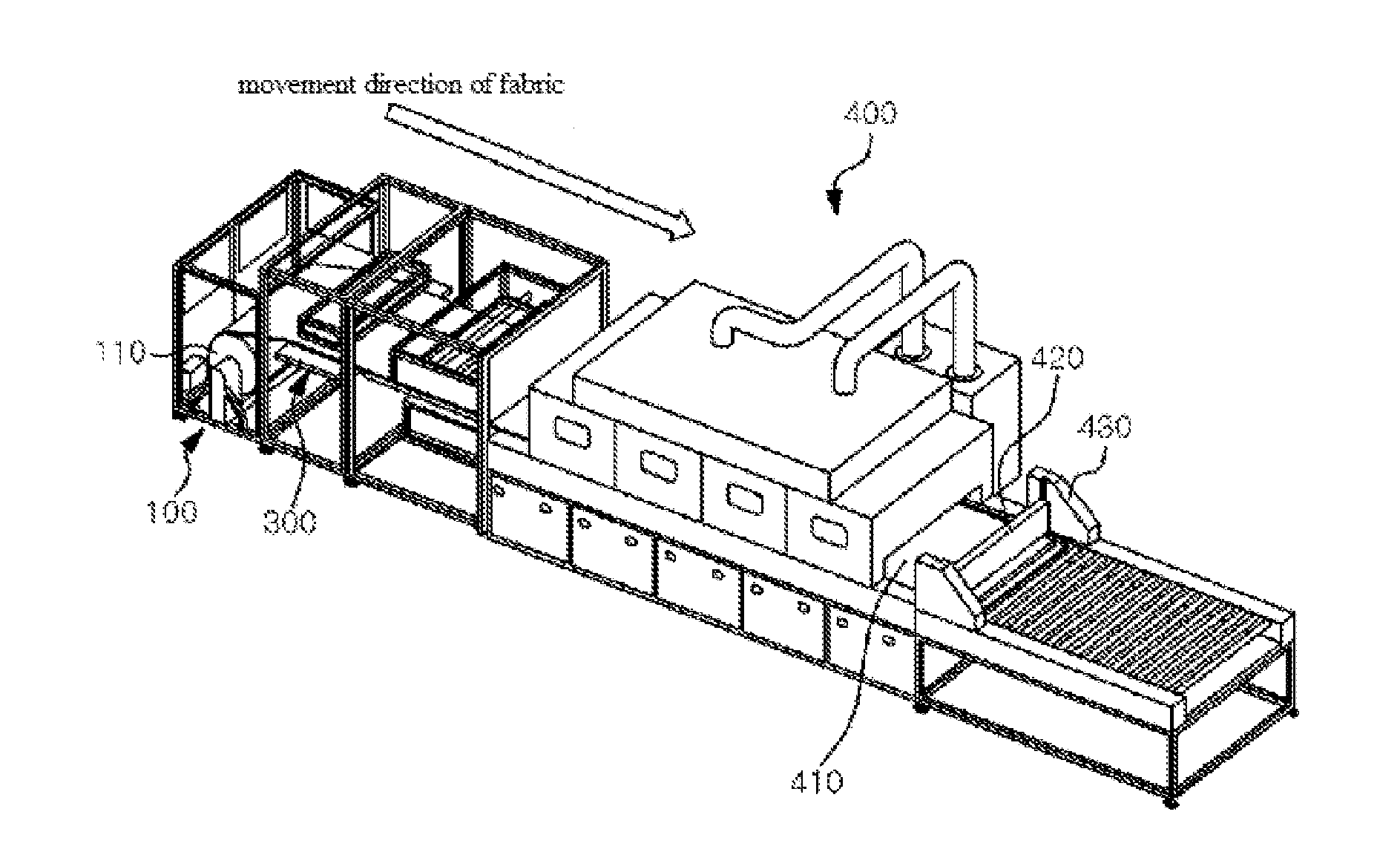

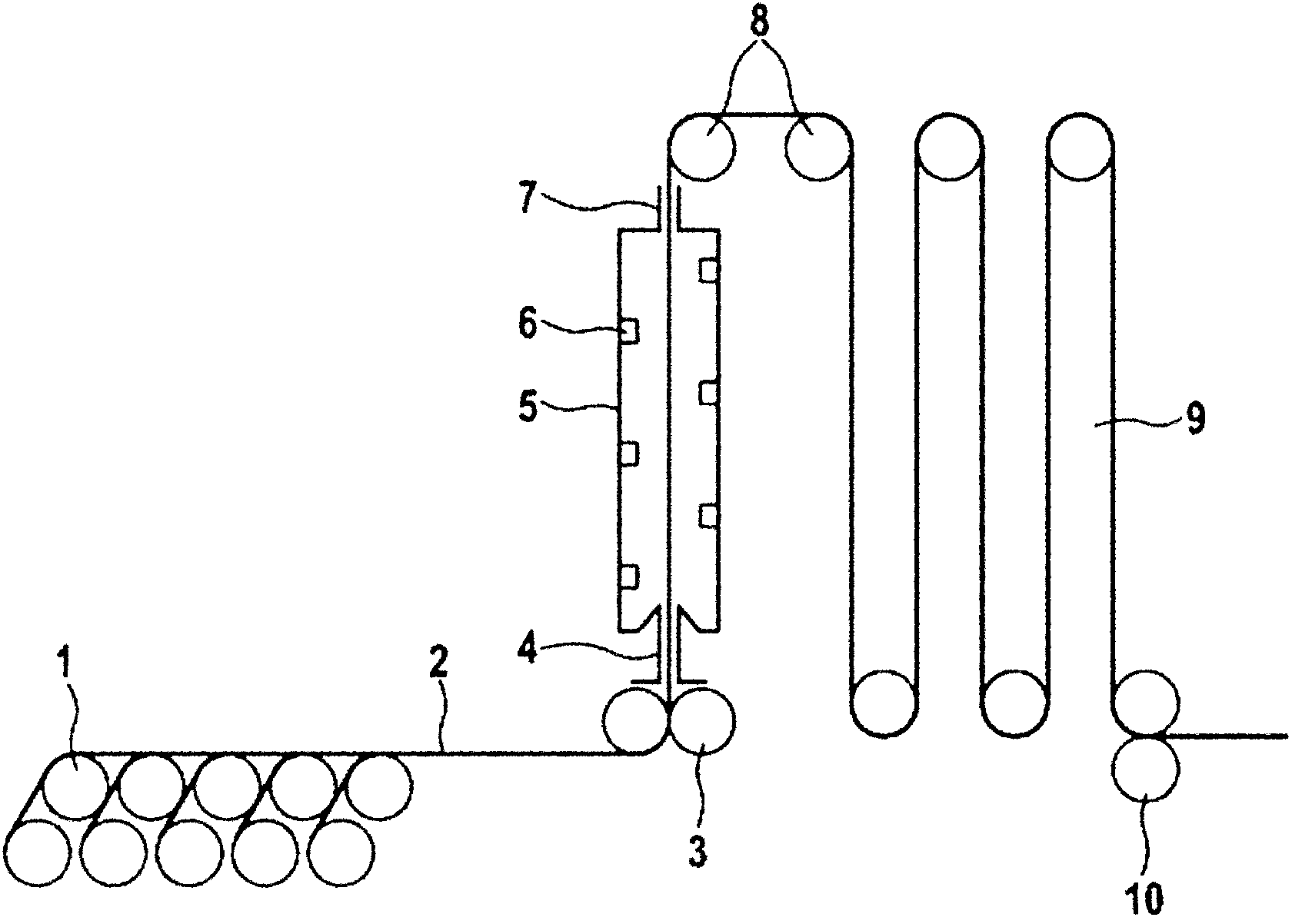

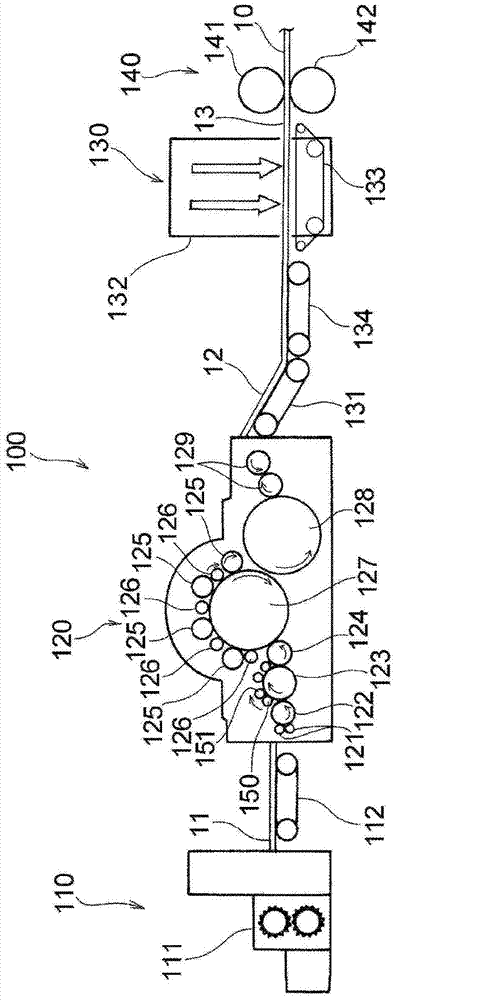

Apparatus for bulking nonwoven fabric

InactiveUS20130174379A1Good precisionSmall sizeHeating/cooling textile fabricsCarding machinesEngineeringNonwoven fabric

A bulking apparatus (1) includes a hot air generator, an air supply duct (2) having an inlet (21) for receiving hot air and an outlet (22) for delivering the hot air to nonwoven fabric, and a sucking part (31) sucking in hot air delivered from the outlet (22) and passed through nonwoven fabric (10) to increase the bulk of the nonwoven fabric being transported. The air supply duct (2) has an inflow portion (24) leading the hot air introduced into the inlet (21) to flow in parallel to the transverse direction of the nonwoven fabric and an outflow portion (25) forming an angle with the inflow portion (24) to lead the hot air flowing through the inflow portion to the outlet (22). The air supply duct (2) has a plurality of baffle plates (26) disposed therein, each baffle plate having a flow-facing part (26A) and a flow-guiding part (26B) located in the inflow portion (24) and the outflow portion (25), respectively. The baffle plates (26) are arranged such that the inflow path (24A) in the inflow portion (24) has a decreasing cross-sectional area with distance from the inlet (21).

Owner:KAO CORP

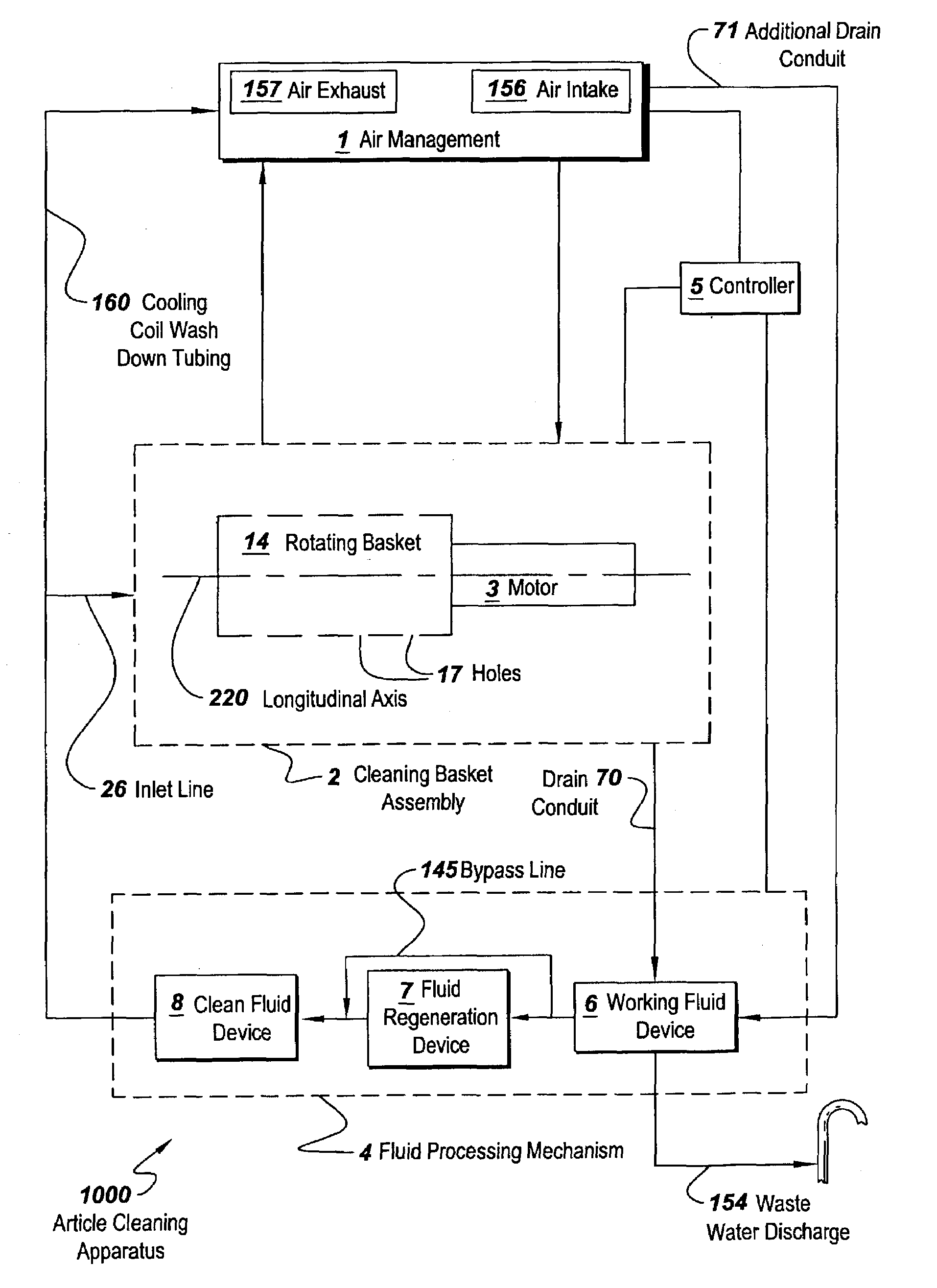

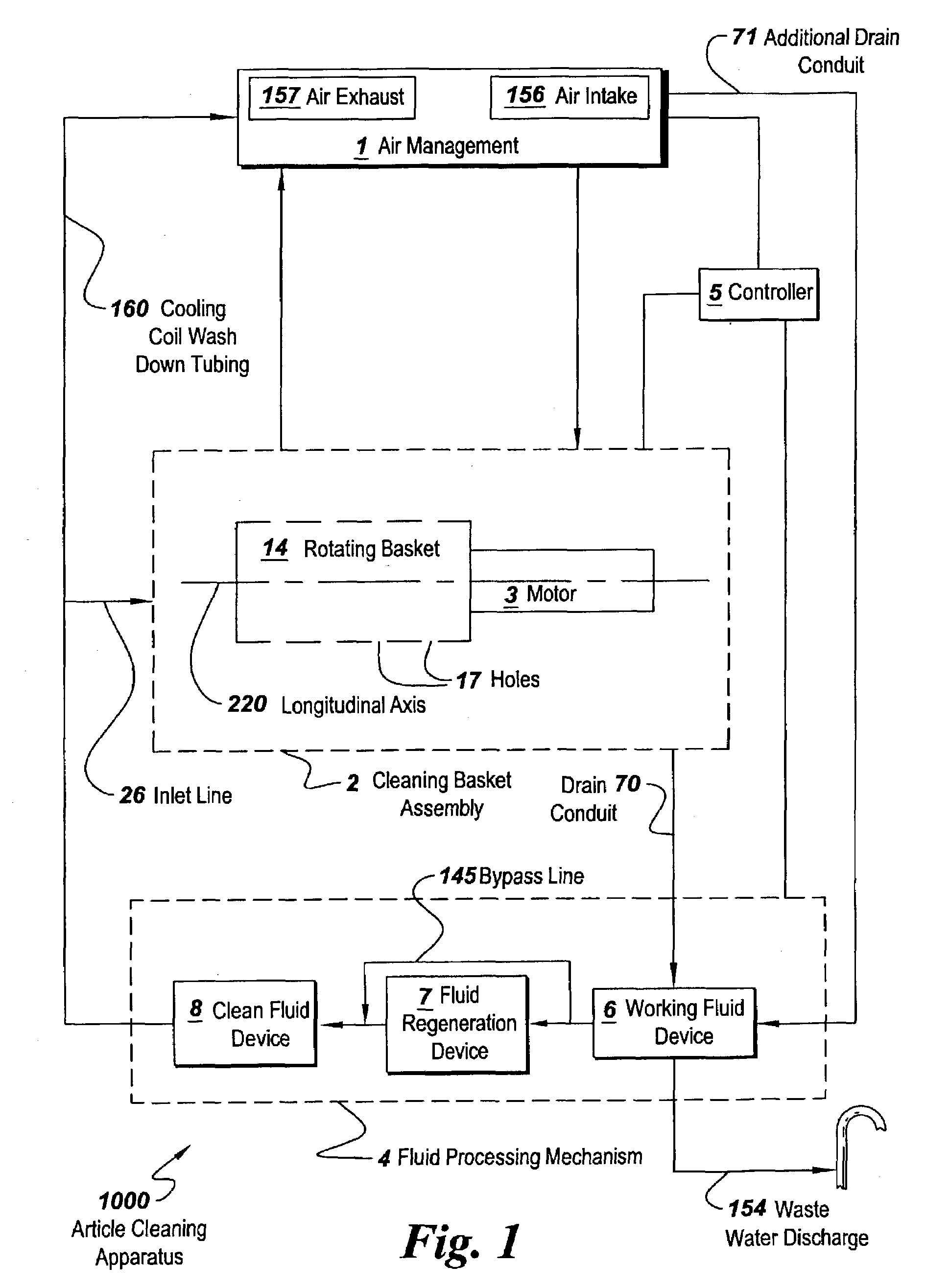

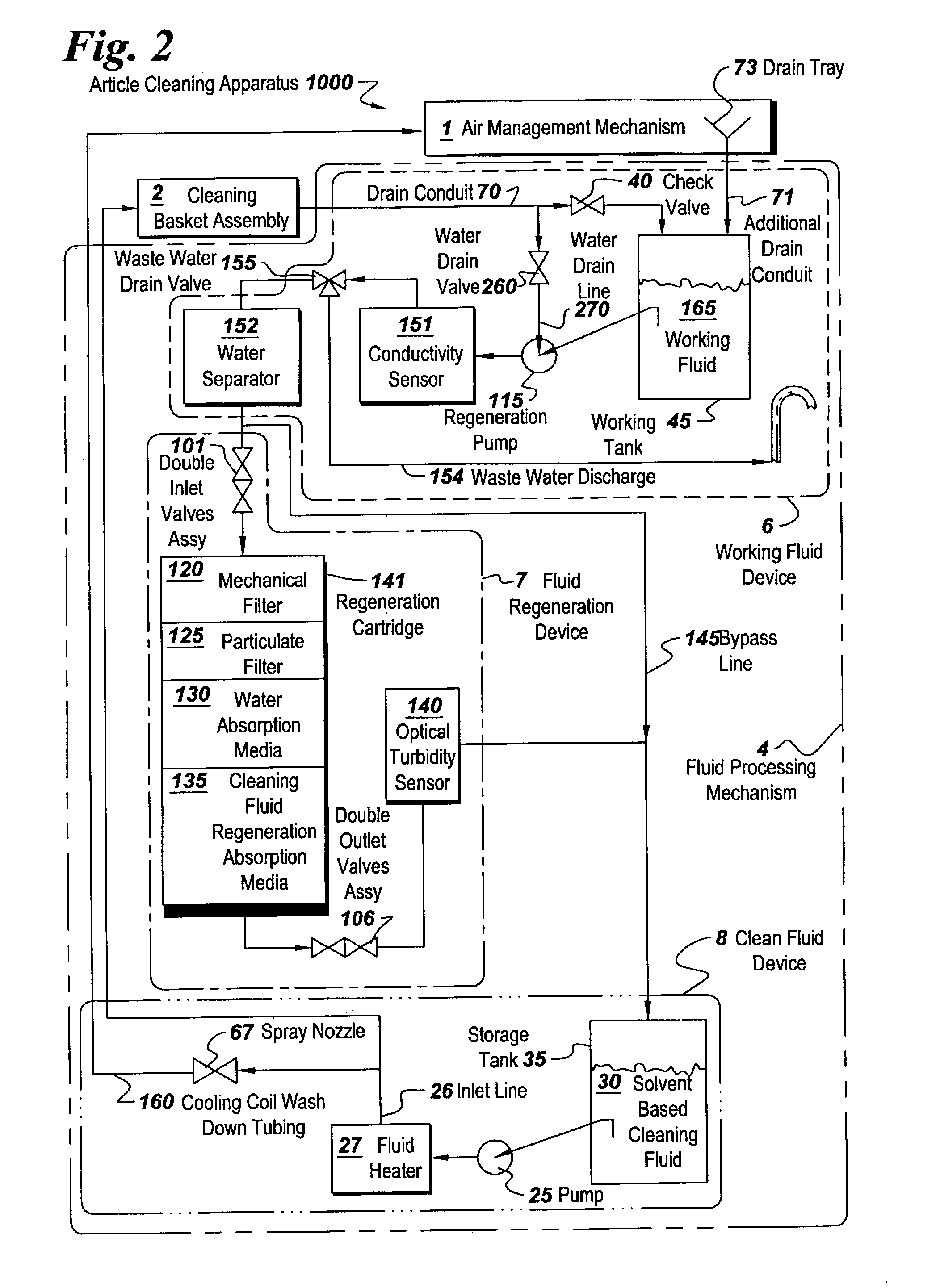

System and method for solvent recovery and purification in a low water or waterless wash

Method and apparatus for recovering and purifying a solvent used in an article cleaning appliance are provided. The method allows passing solvent-based cleaning fluid from a wash basket through a coarse filter configured to remove relatively large particulates from the cleaning fluid. The method further allows passing cleaning fluid from the coarse filter through a particulate filter configured to remove relatively fine particulates from the cleaning fluid. An aqueous phase that may be present in the cleaning fluid is separated by decanting and coalescing through a separator / filter assembly. The cleaning fluid may then be passed through a regeneration cartridge for removing any water that may remain in the cleaning fluid, and for adsorbing organic contaminants that may be present in the cleaning fluid. Recovered solvent may be stored in a tank for subsequent use in a cleaning process performed by the appliance.

Owner:HAIER US APPLIANCE SOLUTIONS INC

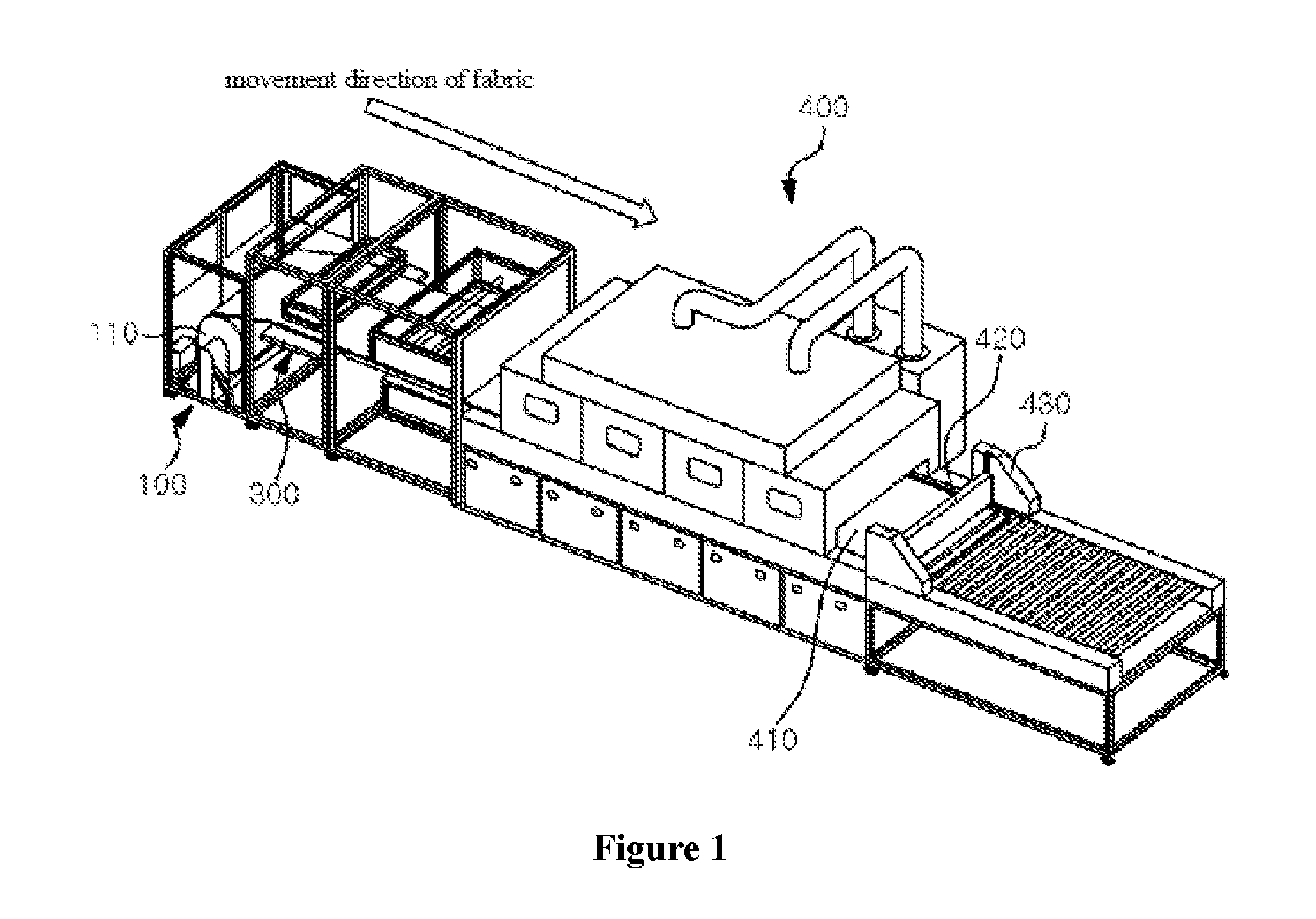

System for injecting functional solution for fabric and method for manufacturing fabric using same

ActiveUS20160130736A1Guaranteed functionMaintenance period can be maximizedLiquid surface applicatorsSolvent-treatmentEngineeringAir blower

Owner:ARMACELL JIOS AEROGELS LTD

Multi-step process for dyeing textile materials with a concentrated dye system

InactiveCN102149867ALow costReduce overheadFibre treatmentTextile treatment using short bath ratio liquorEngineeringTextile

The present invention relates to a process for dyeing sheetlike textile materials with a concentrated dye, which comprises a concentrated dye system being applied in a total amount of 1% to 25% by weight, based on the textile material, to the textile material in two or more sub-steps and the dye being fixed on the textile material after each and every sub-step.

Owner:DYSTAR COLOURS DEUTSCHLAND GMBH

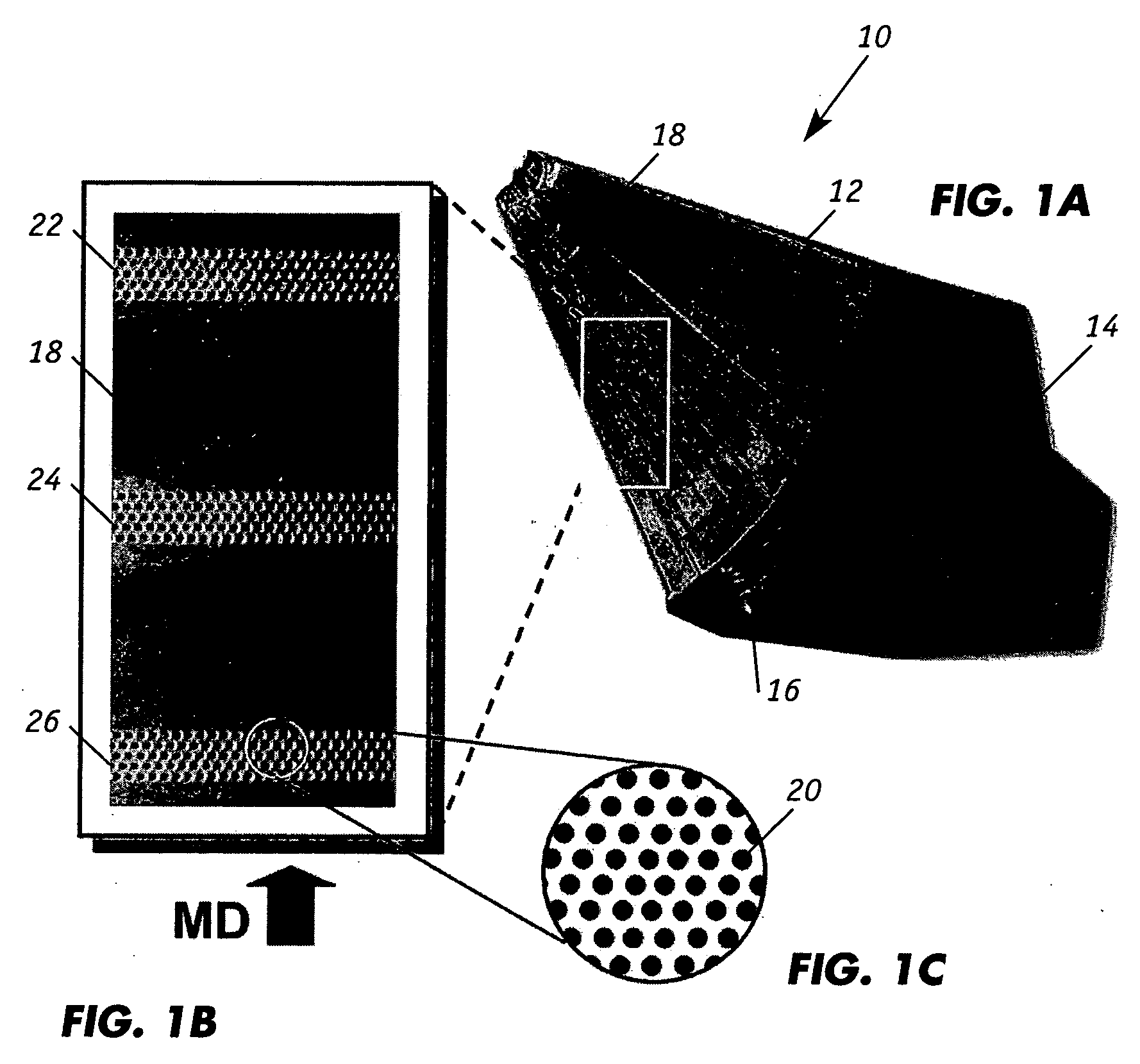

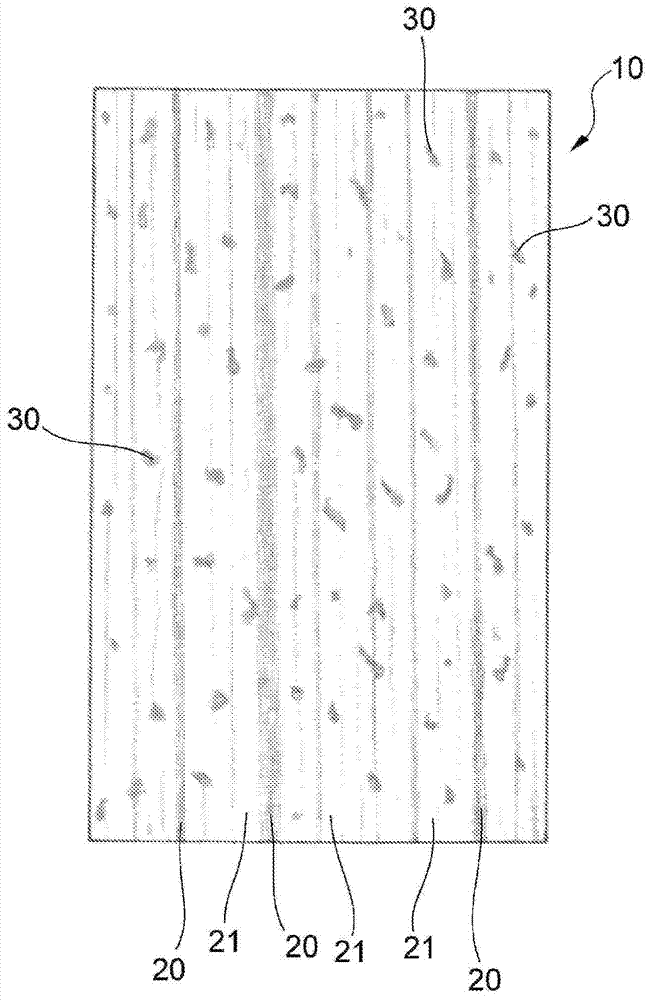

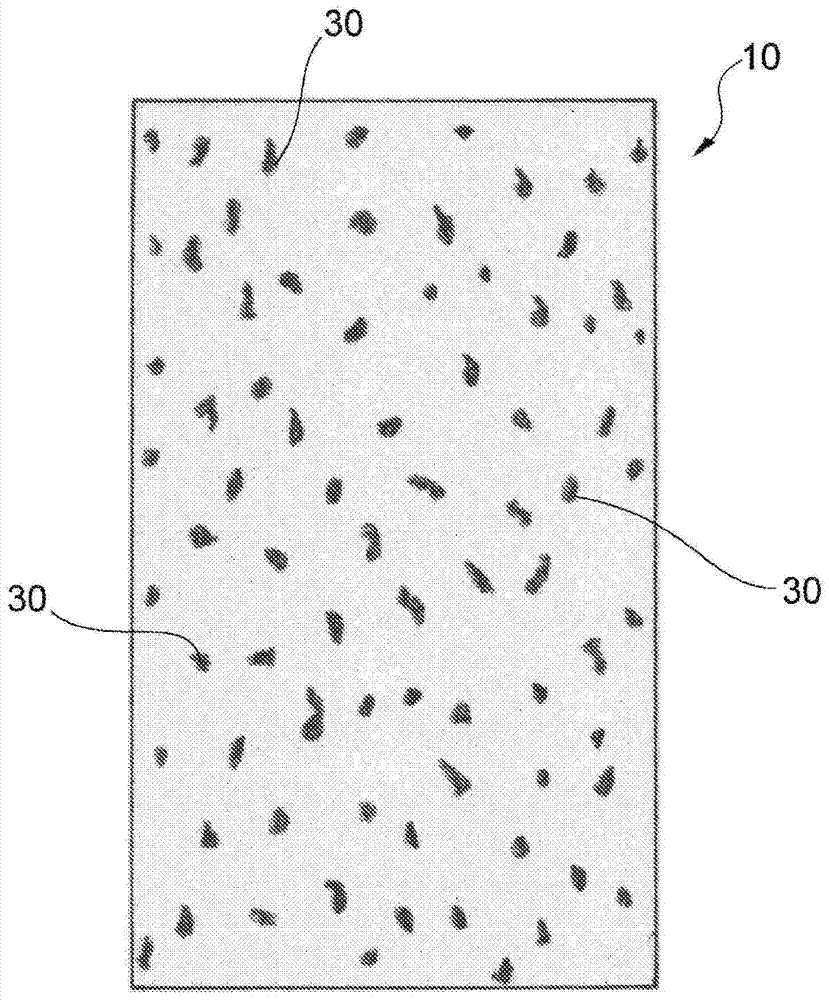

Non-woven fabric and manufacturing process therefor

ActiveCN103946434AHeating/cooling textile fabricsLiquid/gas/vapor treatment of indefinite length materialsEngineeringNonwoven fabric

A non-woven fabric (10) is manufactured by an air-through method. In the non-woven fabric (10), multiple small fiber masses (30) having a color deeper than that of the ground of the non-woven fabric (10) are dispersed and arranged in a disseminated state over the whole of the non-woven fabric (10). Further, the thickness difference (T3) is 1mm or less as defined by the formula: T3 = T1 - T2 [wherein T1 is the thickness of the non-woven fabric (10) as determined under a pressure of 7.64kPa at a position where a small fiber mass (30) is put, while T2 is the thickness thereof as determined under a pressure of 7.64kPa at a position where a small fiber mass (30) is not put].

Owner:KAO CORP

Textile fabric dyeing device with good dyeing uniformity

ActiveCN110878454AIncrease pressureIncrease contact areaTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsPolymer scienceEngineering

The invention discloses a textile cloth dyeing device with good dyeing uniformity, which comprises a housing, a second guide roller support, a sleeve and an inner spiral pipe; a cloth feeding port isarranged at the top of one side of the housing, a cloth discharging port is arranged at the top of the other side of the housing, an L-shaped retainer is arranged on the inner wall of the housing below the cloth feeding port, and an n-shaped retainer is arranged in the housing at one side of the cloth feeding port. The second guide roller is driven to rotate through the transmission of cloth, a dye liquor is pressed into a cavity and is sprayed from a second outlet, the contact area between the cloth and the dye liquor is increased, and the dyeing efficiency is improved; in addition, the dye liquor inside the inner spiral pipe is rotated and surges upward; when the dye liquor rotates, the dye liquor can penetrate the cloth, so that the dyeing efficiency for the cloth is further improved, the cloth is uniformly dyed, and a dye in the dye liquor is prevented from precipitating; when the dye liquor surges upward, impurities floating on the surface of the dye liquor move to the other sideof the n-shaped retainer and are filtered so that the dye liquor is kept clean, the service life of the dye liquor is prolonged, and the cost is reduced.

Owner:JIANGSU SHUANGSHAN GRP

Method for processing health-care type cotton and graphene nylon interwoven silk shirt fabric

ActiveCN106835445AGentrificationRealize healthcareSingeingLiquid/gas/vapor treatment of indefinite length materialsCombingCotton fibre

The invention discloses a method for processing a health-care type cotton and graphene nylon interwoven silk shirt fabric. According to the health-care type cotton and graphene nylon interwoven silk shirt fabric, low-tex combed cotton yarn is interwoven with graphene nylon filaments after being dyed to form greige, and then the high-grade health-care type shirt fabric is obtained after silk-like finishing. The method specifically includes the following steps that the low-tex combed cotton yarn serving as warp yarn is subjected to dyeing, spooling and yarn beam warping in sequence and then is prepared into warp beams by slashing, the warp beams are interwoven with graphene nylon filaments on a gripper loom to produce the greige, and the greige is subjected to fabric finishing, desizing and silk-like finishing in sequence to obtain the finished high-grade health-care type shirt fabric product. The health-care type cotton and graphene nylon interwoven silk shirt fabric prepared by the method is smooth in cloth cover, has multiple health care functions of resisting and inhibiting bacteria, achieving low-temperature far infrared heating, deodorization and adsorption and the like and is easy to clean. The method can give full play to the multiple superior health-care functions of graphene nylon fibers in the aspect of resisting and inhibiting bacteria, achieving low-temperature far infrared heating, deodorization and adsorption and the like, moreover, the good wearing comfortableness of cotton fibers is gave full play to, and the high grade and the health care function of the shirt fabric can be achieved.

Owner:IANGSU COLLEGE OF ENG & TECH

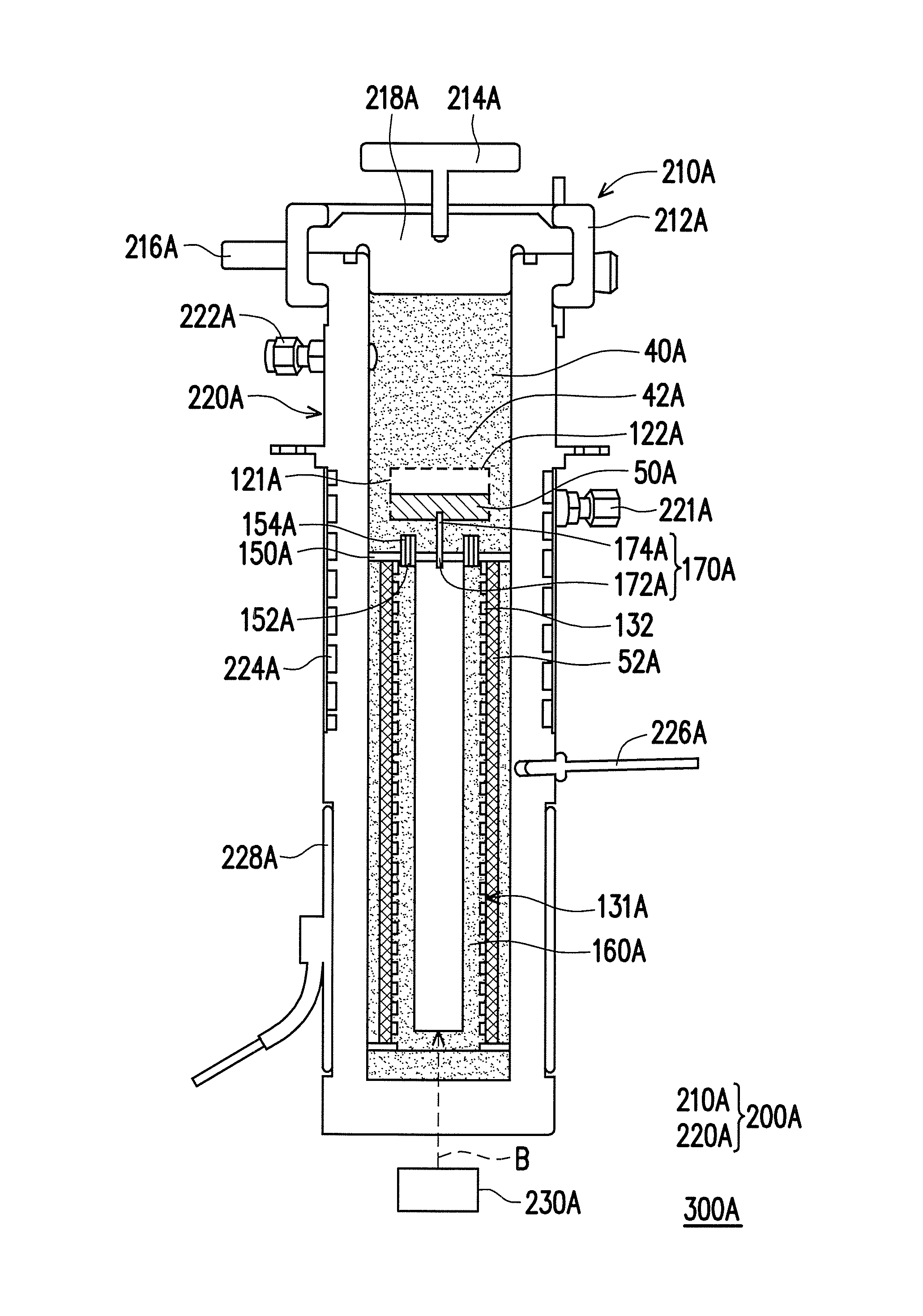

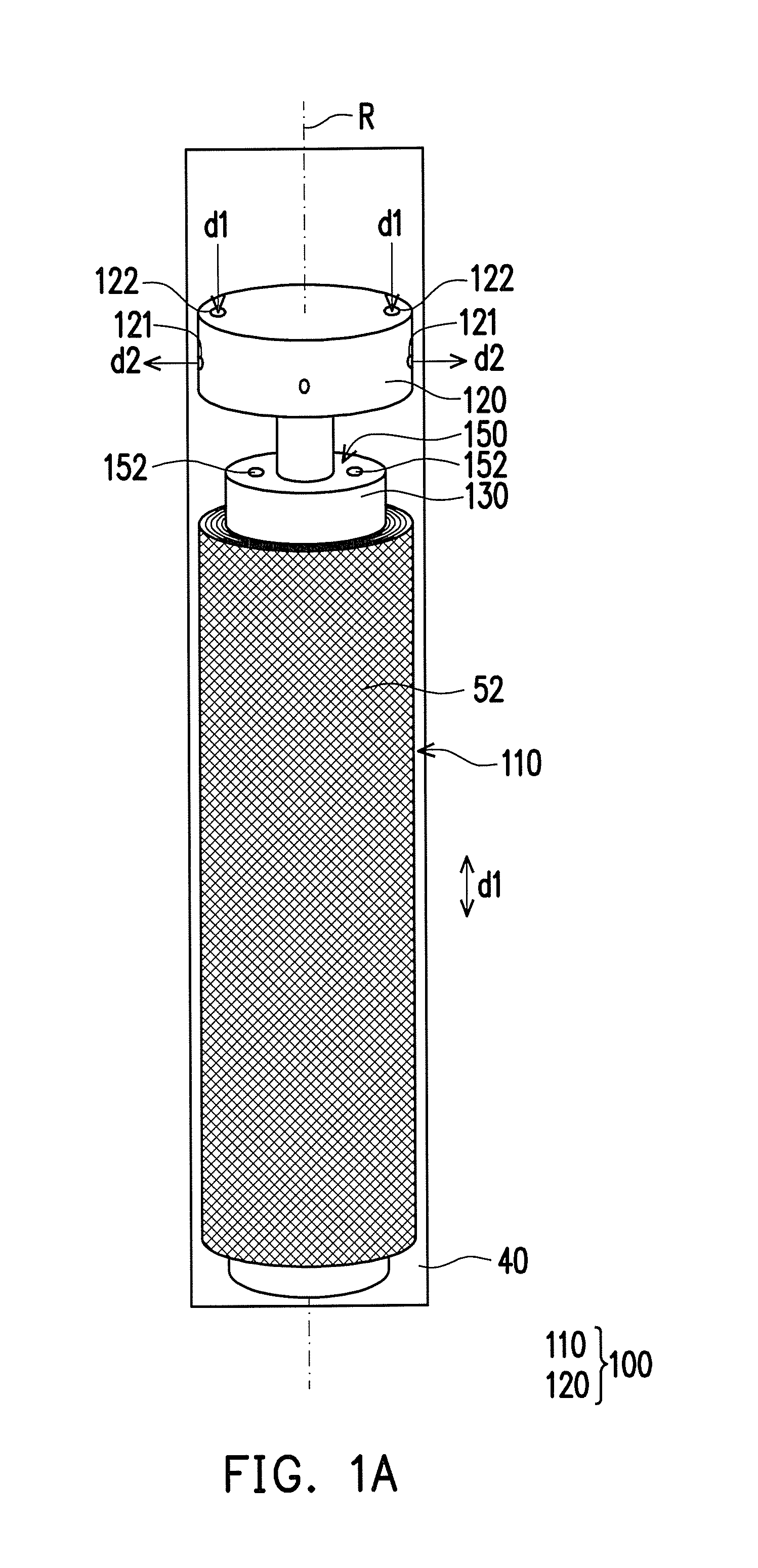

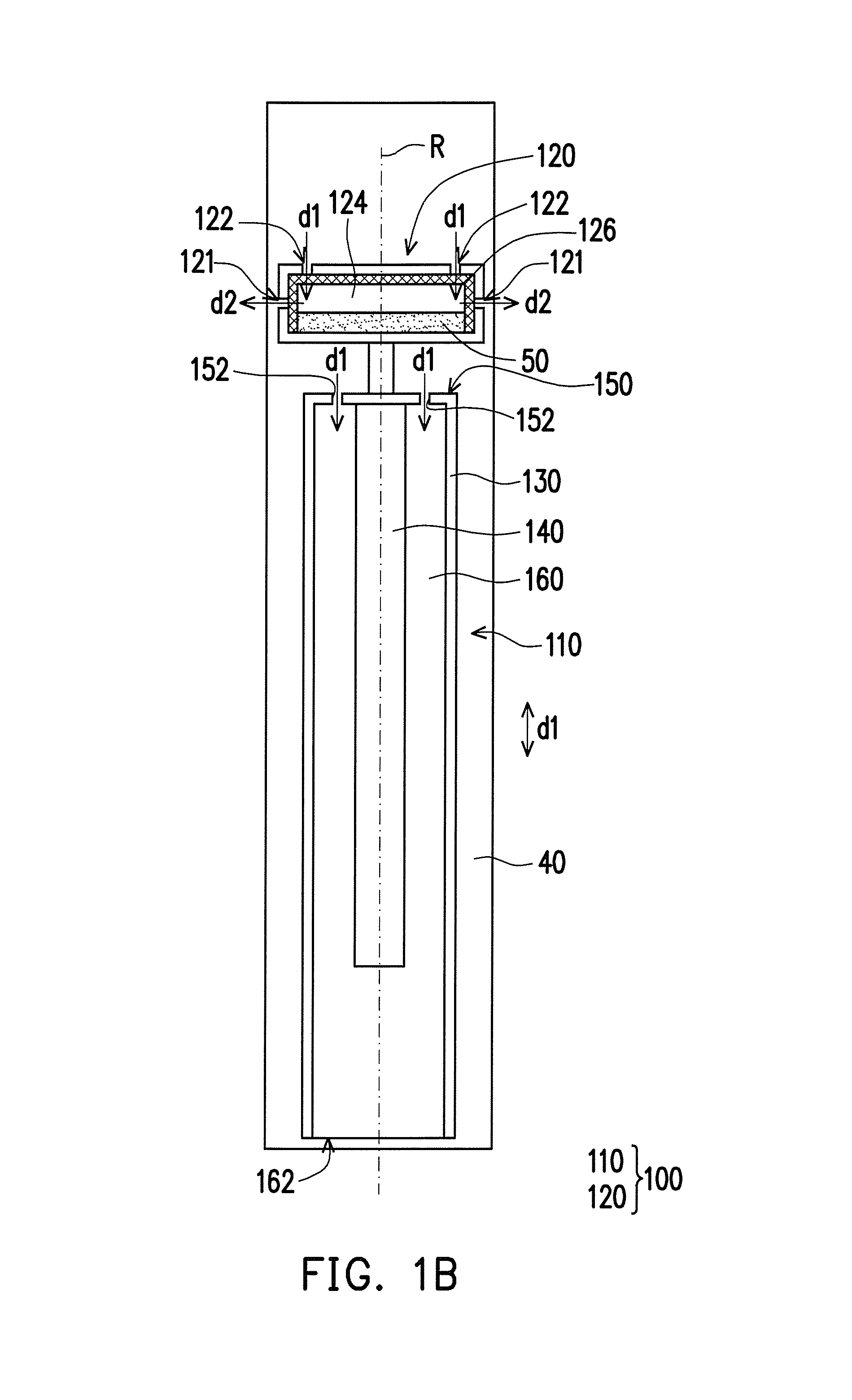

Dyeing device and dyeing apparatus

ActiveUS20160244902A1Improve dyeing effectHigh pressure spaceTextile treatment containersTextile treatment dyeing devicesFiberEngineering

A dyeing device adapted to move in a high pressure space having a fluid is provided. The dyeing device includes a magnetic dyeing shaft and a dye mixing chamber connected to the magnetic dyeing shaft. The magnetic dyeing shaft is configured to make a fiber product wind thereon, and the dye mixing chamber is configured to store dye, and the dye mixing chamber is adapted to let the fluid in the high pressure space flow through. A dyeing apparatus including the dyeing device is also provided.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com